Page 1

CH-9101 Herisau/Switzerland

Tel. +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail sales@metrohm.ch

Internet http://www.metrohm.ch

717 Sample Changer

Instructions for use

8.717.1003

98.03 sn

Page 2

Table of Contents

Page

1 OVERVIEW ___________________________________________ 1

1.1 Side View _______________________________________ 1

1.2 Rear View _______________________________________ 2

1.3 Sensors _________________________________________ 3

1.4 The Sample Changer Models _______________________ 4

2 INSTALLATION ________________________________________ 5

2.1 Setting up the Instrument __________________________ 5

2.2 Safety Considerations _____________________________ 6

2.3 Arranging the Accessories _________________________ 7

2.3.1 Setting up the Rinsing Equipment .................................7

2.3.2 Tubing Fixation ..............................................................8

2.3.3 Magnetic Stirrers ...........................................................8

2.3.4 Sample Racks ...............................................................9

2.3.5 Mounting and Setting up the Titration Heads ..............10

2.4 Remote Connections _____________________________ 11

2.5 External Bus Connections ________________________ 13

3 SAMPLE RACKS ______________________________________14

4 SWING HEAD ________________________________________ 16

4.1 Prerequisites ___________________________________ 16

4.2 Installing the Swing Head _________________________ 16

4.3 Accessories for the Titration Head _________________ 18

5 APPENDIX __________________________________________ 20

5.1 Technical Specifications __________________________ 20

5.1.1 717 Sample Changer ..................................................20

5.1.2 759 Swing Head ..........................................................22

5.2 Servicing and Maintenance _______________________ 23

5.3.1 Servicing ......................................................................23

5.3.2 Maintenance / Attendance ...........................................23

5.3 Warranty and Conformity _________________________ 24

5.3.1 Warranty ......................................................................24

5.3.2 Certificate of Conformity and System Validation

for the 717 Sample Changer ...............................25

5.3.3 Certificate of Conformity and System Validation

for the 759 Swing Head .......................................27

5.4 Accessories ____________________________________ 29

5.5 Index __________________________________________ 34

Page 3

1 Overview

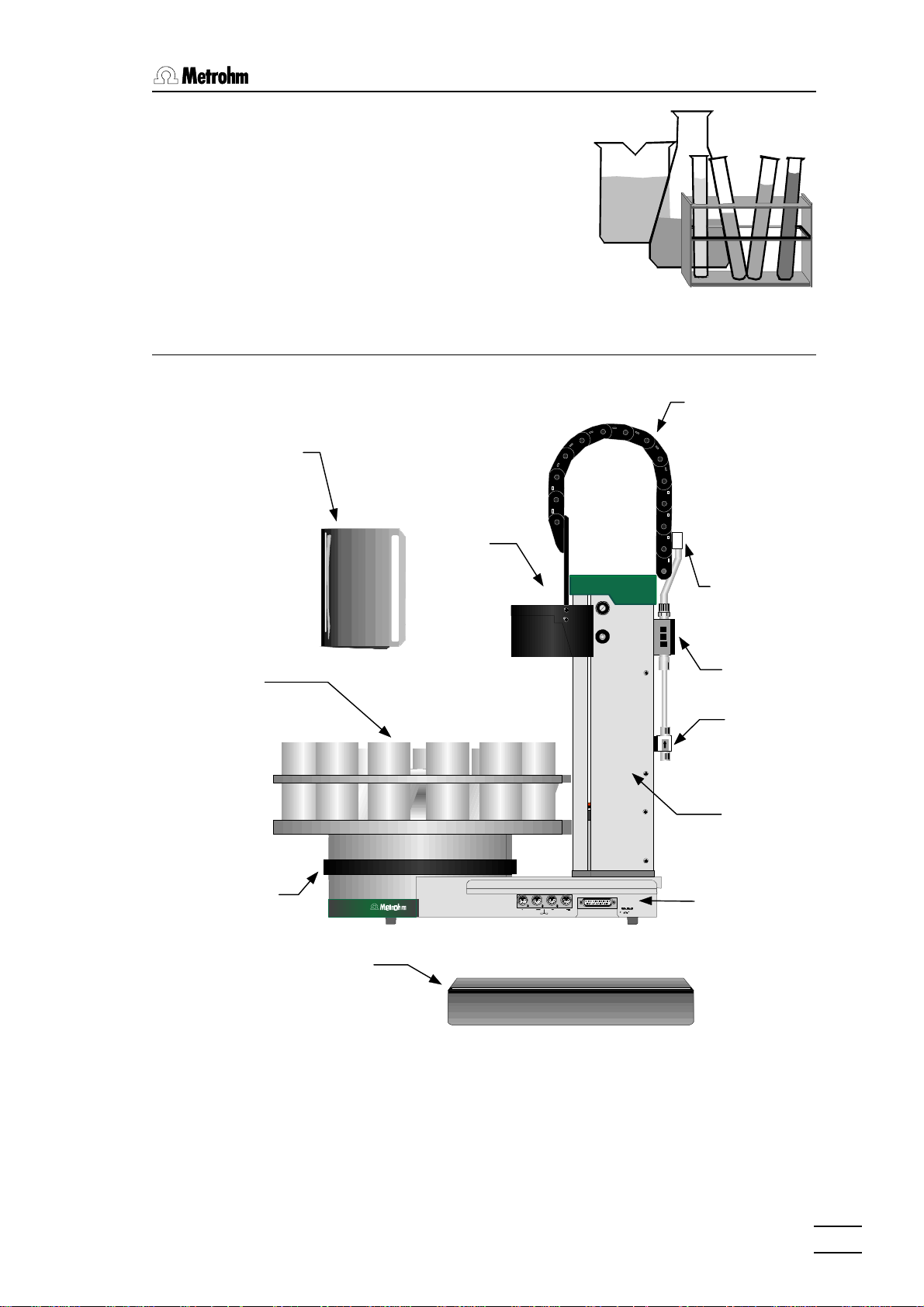

1.1 Side View

1.1 Side View

Splash protection

Rack

Guide chain

Lift

Distribution

head

Pump

Valve

Tower

Stirrer rail

717 Sample Changer, Overview

Connectors

Plug cover

Safety note:

Do not operate the 717 Sample Changer without splash protection

and plug cover being mounted. The plug cover prevents any contamination of the connectors, caused by spilled solvents or chemicals.

1

Page 4

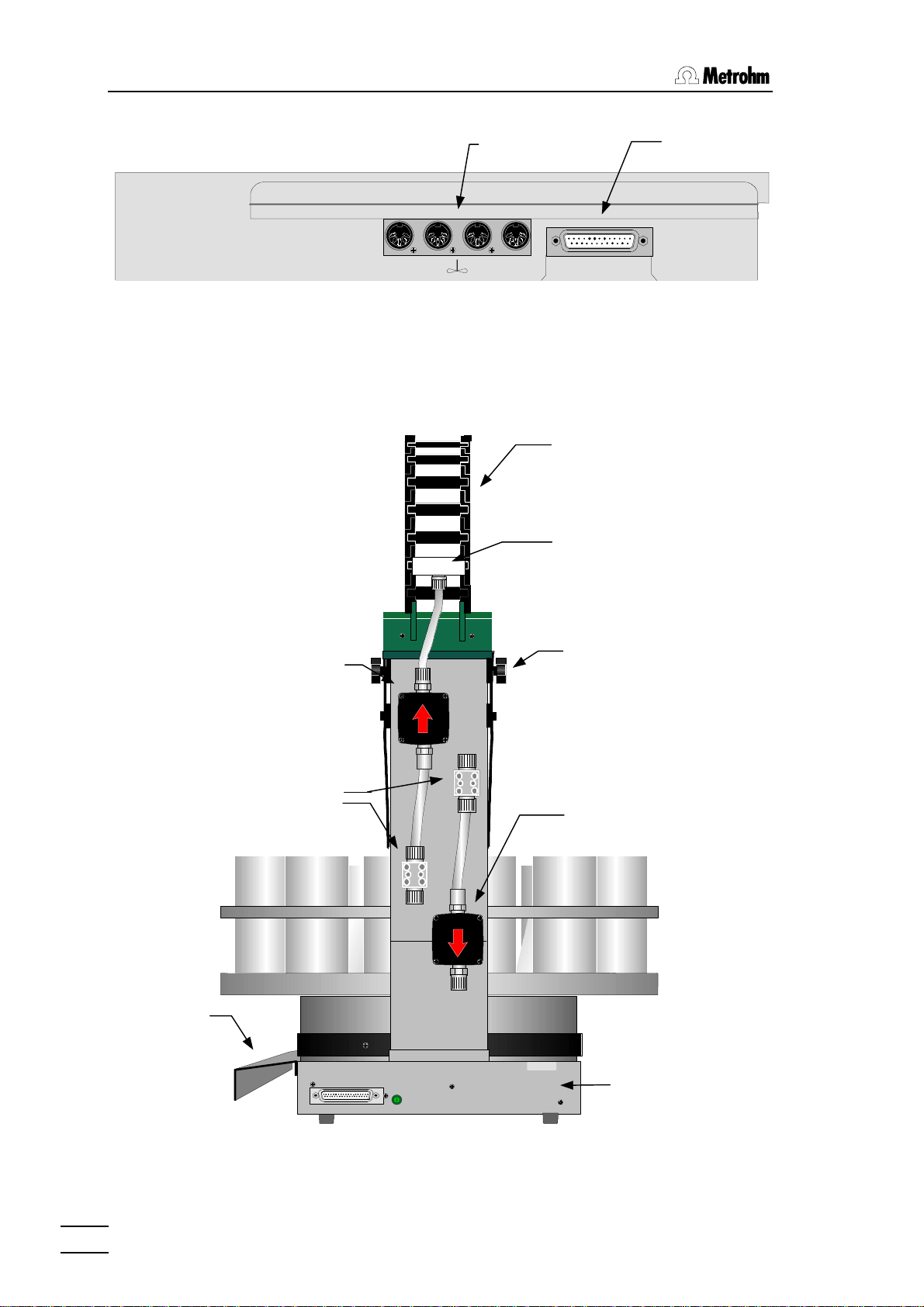

1.2 Rear View

The Connectors (side view):

The remote socket serves the connection of Metrohm- or other

measuring instruments that communicate via a serial cable.

1.2 Rear View

Stirrer

sockets

1 2 3 4

Remote

socket

Remote

Control

Guide chain

Distribution head

Plug cover

Pump 1

Valves

External Bus

Address

0020/02 187

Type 1.717._

Made by Metrohm Herisau Switzerland

Mounting screw

for splash protection

Pump 2

Connectors

2

717 Sample Changer, Overview

Page 5

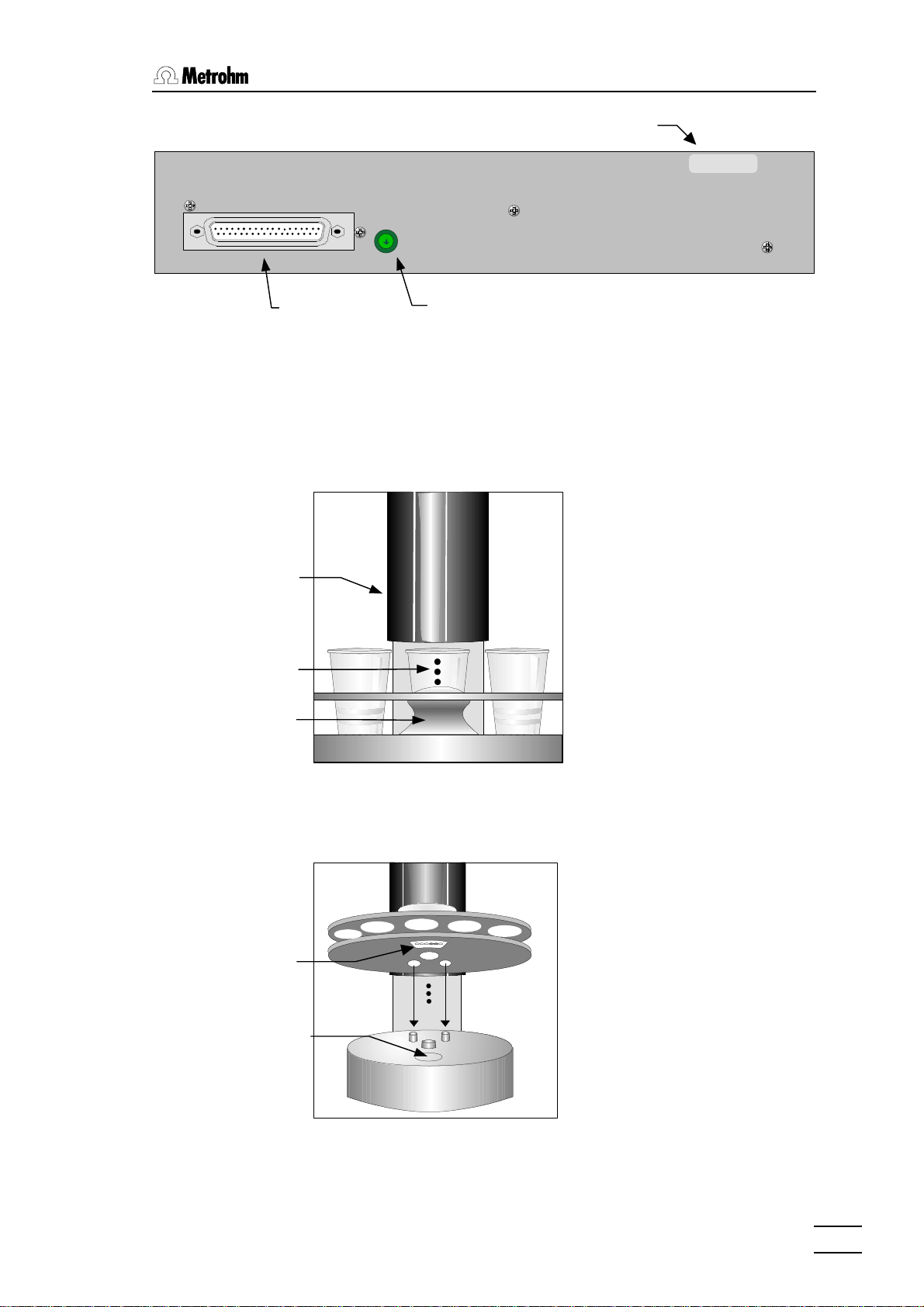

1.3 Sensors

The Connectors (rear):

External Bus

External Bus

socket

1.3 Sensors

Beaker test

Splash protection

Beaker indicator

Address

Manufacturing number

External Bus

address selector

Type 1.717._

Made by Metrohm Herisau

0120/02 187

Each tower of the 717 Sample

Changer is equipped with a

beaker indicator to detect the

presence of a beaker in front

of the particular tower. This

infrared sensor detects many

different materials, if any object is placed in correct position.

Rack

Magnet holder

Magnetic indicator

Front view

Magnetic rack code indicator

The magnetic sensor to detect

the individual rack codes is

mounted below the sample

changer's turntable.

The 717 Sample Changer

should be initialized right after

every rack change, because the

magnetic binary code of the

racks can only be read, if the

rack is in initial position and

therefore the magnet holder is

in accurate position right above

the rack code indicator.

717 Sample Changer, Overview

3

Page 6

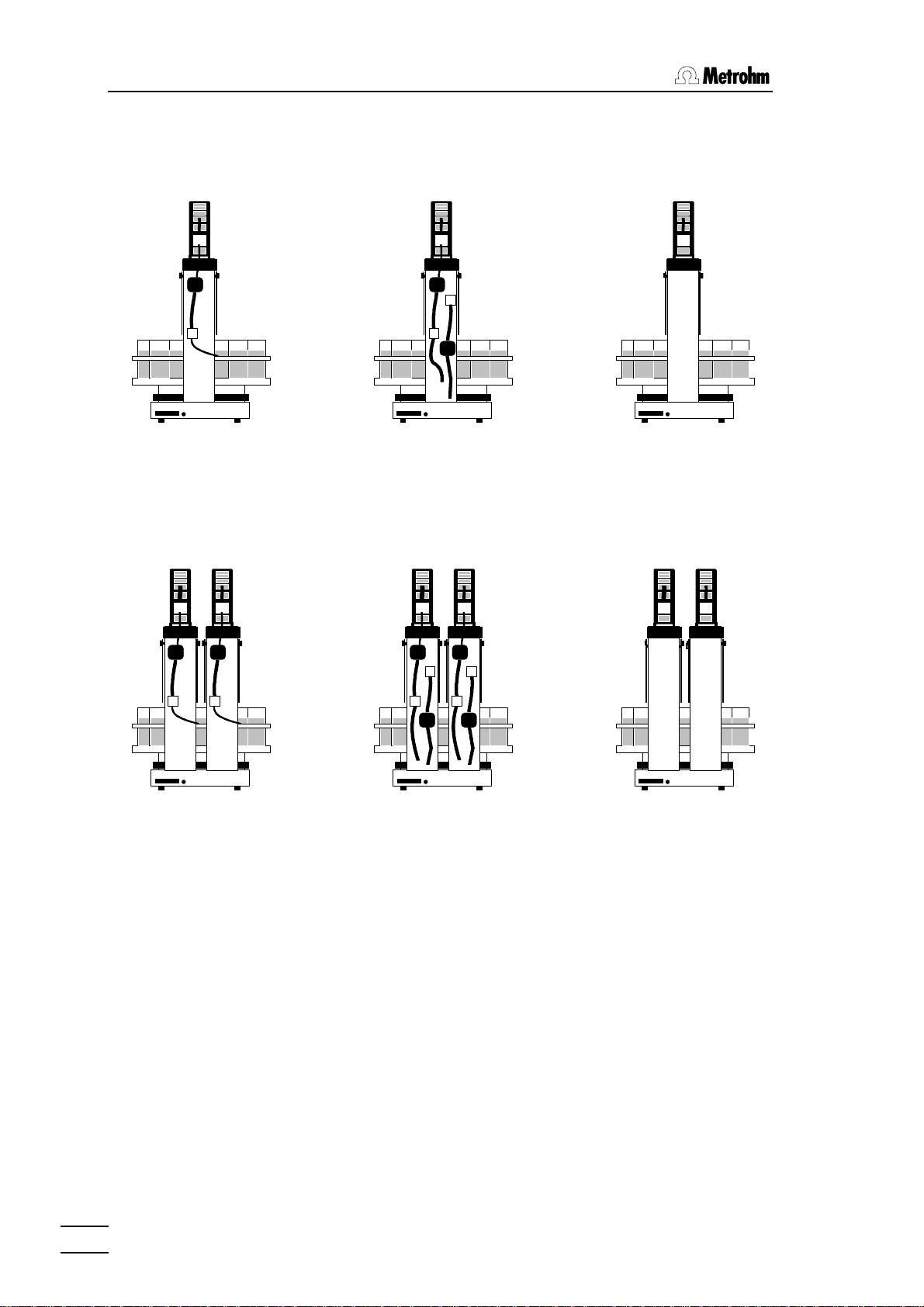

1.4 The Sample Changer Models

11.4 .4 The Sample Changer Models

Model 2.717.0010 Model 2.717.0020 Model 2.717.0030

1 tower, 1 pump 1 tower, 2 pumps 1 tower, no pumps

2 stirrer connections 2 stirrer connections 2 stirrer connections

Tower 1

Tower 2

Tower 1

Tower 2

Tower 1

Model 2.717.0110 Model 2.717.0120 Model 2.717.0130

2 towers, 2 pumps 2 towers, 4 pumps 2 towers, no pumps

4 stirrer connections 4 stirrer connections 4 stirrer connections

Tower 2

4

717 Sample Changer, Overview

Page 7

2 Installation

2.1 Setting up the Instrument

Packaging

The 717 Sample Changer is supplied with the accessories in

separate special packages designed to ensure maximum protection. These contain shock-absorbing foam linings. As only these

special packages guarantee damage-free transport of the instrument, it is essential you store them in a safe place.

Control

Immediately following delivery, check that the consignment is

complete and undamaged (compare with delivery note and accessories list, page 29ff). In case of damage, see "Warranty",

page 24.

2.1 Setting up the Instrument

Setting up

The 717 Sample Changer is a rugged instrument and may be

used in rough environments such as laboratories and manufacturing plants. It must not be exposed to a corrosive atmosphere.

If the sample changer is operated in a rough environment, regular

maintenance is strongly recommended.

717 Sample Changer, Installation

5

Page 8

2.2 Safety Considerations

2.2 Safety Considerations

If failure or malfunctioning occurs during operation of the

717 Sample Changer, the Metrohm Service Department should be

consulted.

If opening the instrument is unavoidable, the following safety precautions are to be strictly adhered to:

Before opening the instrument disconnect it from all electrical sources. Make sure that all main cables have been disconnected.

Only in exceptional cases should the instrument be opened while it

is switched on. Because parts that conduct current are exposed in

this case, this should only be undertaken by an expert who is acquainted with the associated dangers.

Electronic components are sensitive to static electricity and can be

destroyed by discharge. Before touching any components inside

the instrument, both the person and his tools should be grounded

by grasping a grounded object (for example: a metallic part of the

casing of the instrument or a radiator) in order to eliminate any

static electricity.

When peripheral instruments are connected to the 717 Sample

Changer, the sample changer and the instruments to be connected have to be switched off, otherwise all instruments could

suffer damage.

If it becomes apparent that the instrument can no longer be operated safely, it must be put out of operation.

6

717 Sample Changer, Installation

Page 9

2.3 Arranging the Accessories

2.3.1 Setting up the Rinsing Equipment

To mount the PTFE tubings to the pump inlets or outlets enlarge it

carefully using a screwdriver, a pen or another appropriate tool. A

piece of sand paper facilitates grasping of the tubing.

The arrangement of the tubing depends on the rinsing equipment.

Rotating nozzle

Using a changer model with one pump per tower only, the rotating

nozzle (6.2740.000) is recommended for rinsing. The Teflon tubing

is then directly connected to the rinsing pump (pump 1). The distribution head may be dismounted in this case.

2.3 Arranging the Accessories

Place the rotating nozzle vertically in the titration head with the aid

of a SGJ14/12 mm sleeve.

Spray nozzles

When using a changer model with two pumps per tower, spray

nozzles (6.2740.020) may be used in combination with an aspiration tip M8 (6.1543.170). Insert the spray nozzles into the sloped

borings of the titration head. Use Teflon tubings to connect them

to the distribution head. Each of the four outlets of the distribution

head must be plugged. Plug unused outlets with an M6 thread

stopper (6.1446.040) to avoid splashing of liquid during rinsing.

Fix the tubings in the guide chain. Chain links may be removed if

necessary (see below).

Insert the aspiration tip vertically into a boring (SGJ9) of the Macro

Titration head. The Micro Titration head offers also a vertical boring for the placement of the aspiration tip. Connect the tip with the

Teflon 4/6 tubing (6.1805.510) and a screw connector 4/6 mm

(6.1820.030) to pump 2 (valve marked with 'ê'). During the rinsing

procedure, first the sample is sucked off then the electrode is

rinsed in the empty vessel.

717 Sample Changer, Installation

7

Page 10

2.3 Arranging the Accessories

The pump heads of the diaphragm pump, the fittings and the coupling rings are made of PVDF. PVDF is resistant to many chemicals. Acetone, acetanhydride or dimethylformamide (DMF) should

not be used. The diaphragm, and the inner parts of the valves

consist of PTFE and are resistant to most chemicals.

If your samples contain solids (e.g. silver chloride) or sticking substances, you should use the 772 Peristaltic Pump Unit in combination with the 731 Relay Box instead of the diaphragm pump integrated into the changer.

The PE canisters (6.1621.000) are suitable for aqueous solutions.

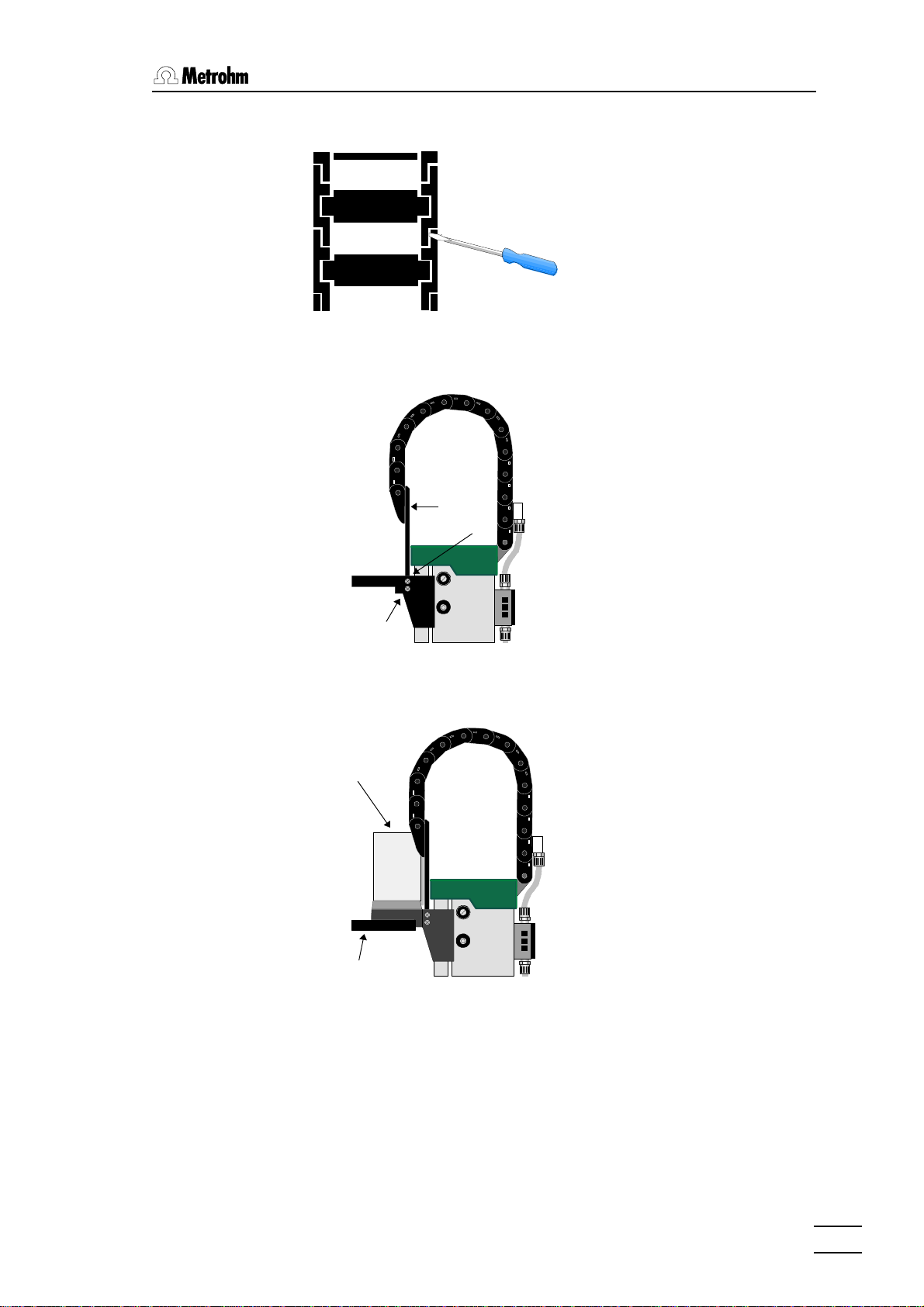

2.3.2 Tubing Fixation

In order to fix the tubing in

the guide chain any chain link

may be opened with a screw

driver or another appropriate

tool.

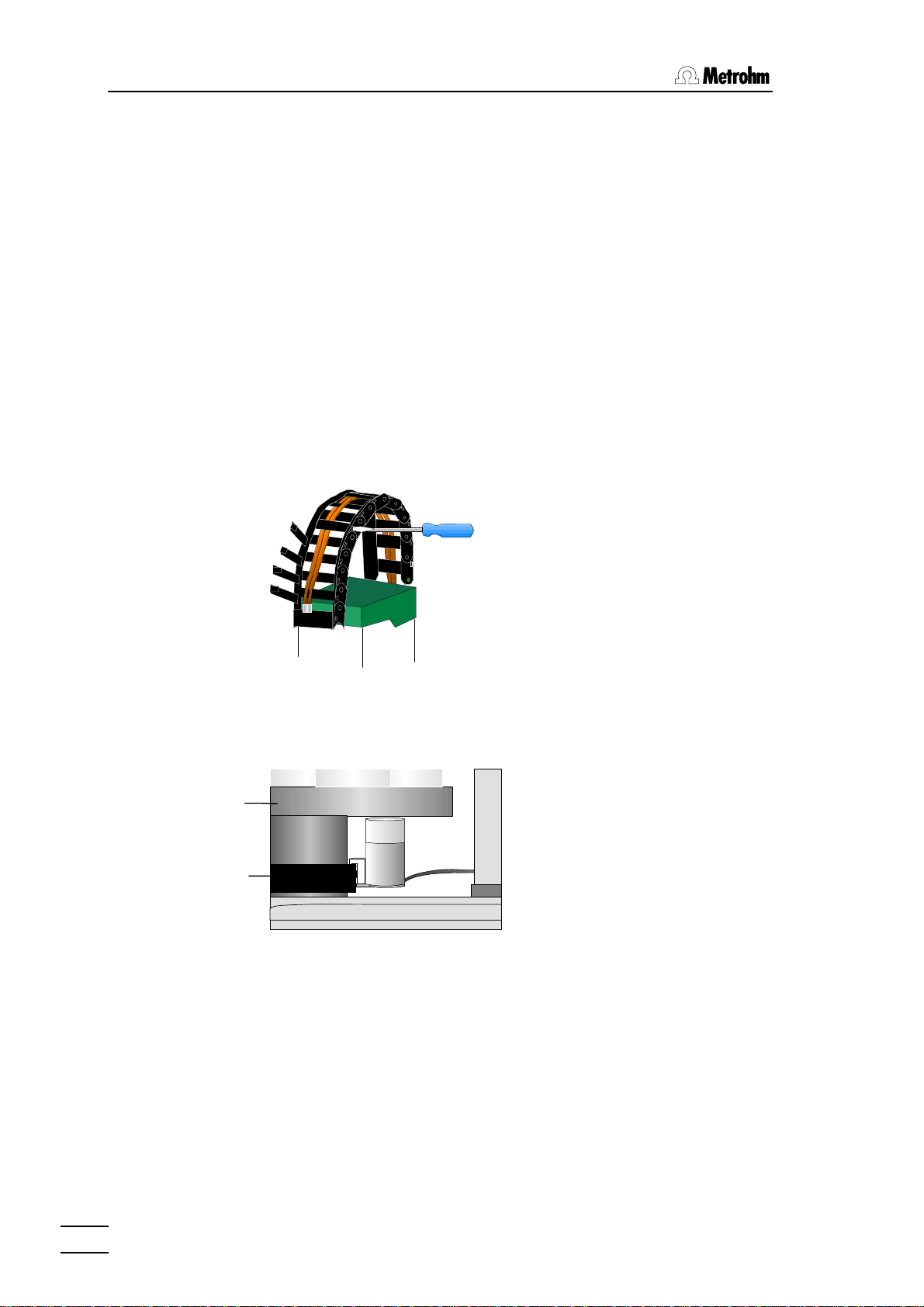

2.3.3 Magnetic Stirrers

Rack

Stirrer rail

Magnetic stirrers 2.741.0010

may be placed in any

position on the stirrer rail

beneath the rack.

8

717 Sample Changer, Installation

Page 11

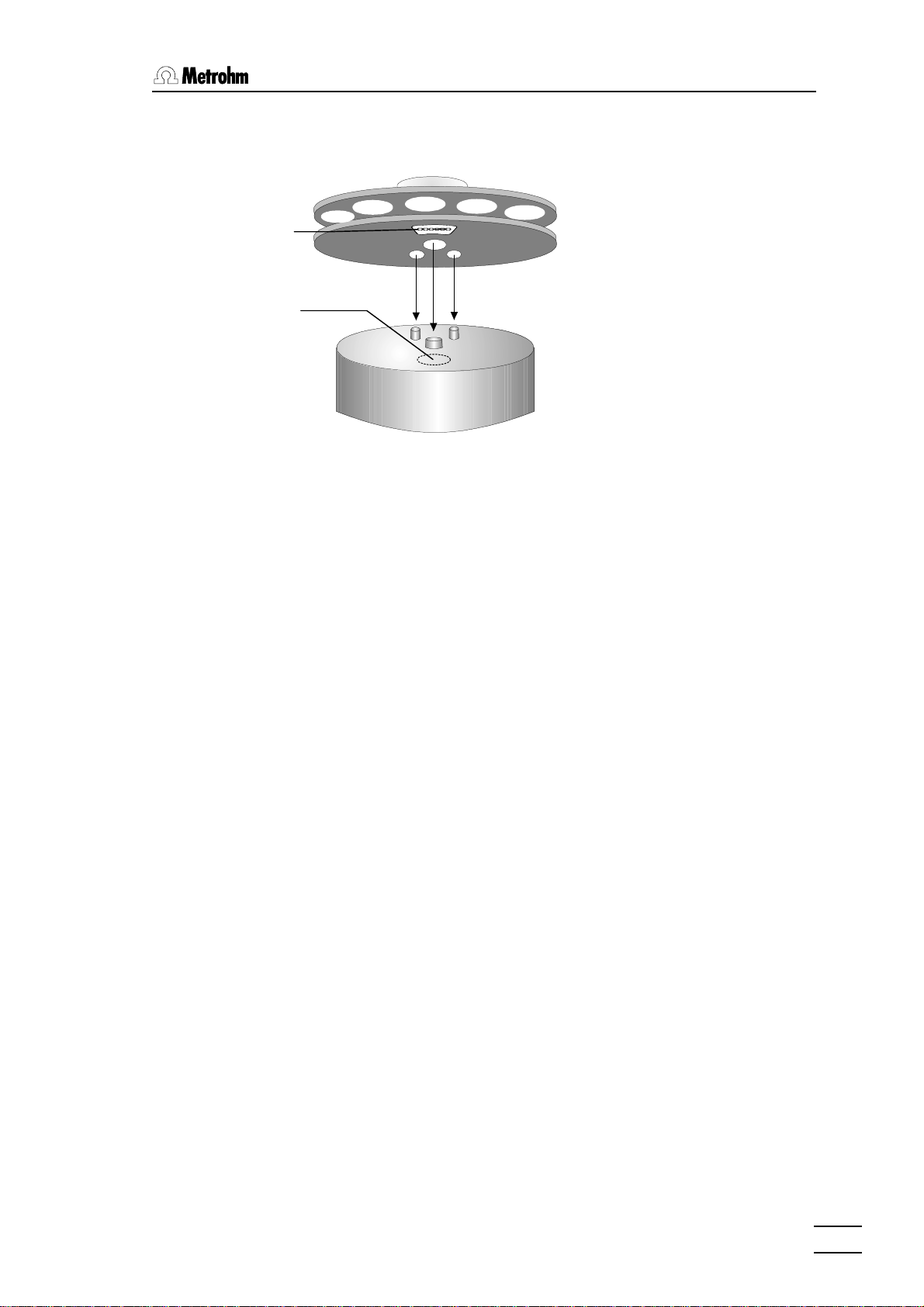

2.3.4 Sample Racks

Magnet holder

Magnetic sensor

2.3 Arranging the Accessories

After placing the rack on the

turntable, the sample

changer must be initialized to

enable the safe reading of

the magnetic rack code.

This can only be done if rack

position 1 is directed to

tower 1.

717 Sample Changer, Installation

9

Page 12

2.3 Arranging the Accessories

2.3.5 Mounting and Setting up the Titration Heads

Macro Titration head

6.1458.010

Micro Titration head

6.1458.020

Mounting screws

Aspiration tip M8

(also for Macro Titration head )

6.1543.170

Electrode

Rotating nozzle

6.2740.000

Burette tip

Rod stirrer

2.722.0020

M6 Spray nozzles

(also for Macro Titration head)

6.2740.020

SGJ14 sleeve

6.1236.020

M8 Thread stopper

4.658.0180

SGJ9 Guide sleeve

6.2709.070

Stirrer propeller

6.1909.020

Use only the designated

Micro electrodes with the

Micro Titration head, see

accessory list, page 33.

Note on Macro Titration head

The arrow sign marks the slightly sloped SGJ boring, which enables to center a rod

stirrer or an electrode in a narrow titration vessel.

10

717 Sample Changer, Installation

Page 13

2.4 Remote Connections

2.4 Remote Connections

665

725

Dosimat

759 Swing Head

711 Liquino

Remote

Valves

Pumps,

e.g. 772

717 Sample Changer

731 Relay Box

Connecting peripheral instruments to the 717 Sample Changer requires Metrohm cables. Otherwise a safe data transmission may

not be guaranteed.

All instruments have to be switched off, before they are connected. Otherwise the instruments could suffer from damage.

14 lines (Output 0–13) are available for the emission of signals.

For receiving signals 8 lines are provided (Input 0–7).

Pin assignment of the Remote socket:

0 Volt

+5 Volt

Output 5

Output 3

Output 1

Output 12

Output 13

Input 0

Input 2

Input 4

Input 6

0 Volt

Output 6

Output 7

Output 4

Output 2

Output 0

Output 8

Output 9

Output 10

Input 1

Input 3

Input 5

Input 7

Output 11

+5V

Inputs

active = low

inactive = high

Outputs

active = low

inactive = high

717 Sample Changer, Installation

The +5 V supply line may by charged with 20 mA maximally.

11

Page 14

2.4 Remote Connections

The required cables are listed in the following table. Details about

the control commands are given in the Instructions for use of the

corresponding instrument.

717 Sample Changer with 759 Swing Head

In order to increase the number of samples, the 759 Swing Head

with a titration head (2.759.0020) or a transfer head (2.759.0010)

can be installed in place of a normal titration head. In this way the

titration head can be moved very accurately to the individual vessels located in several rows on the sample rack. You will find a

more detailed description in the chapter "Swing Head", page 16.

Instrument Cable

665/725 Dosimat 6.2139.000

711 Liquino 6.2141.020

731 Relay Box 6.2125.100

12

730

Connection of further

instruments via the

remote interface

The 759 Swing Head is connected via the remote interface with a

special cable. Using the remote cables for the sample changer,

additional instruments can be connected to the remote socket,

while four lines (Input 7 and Output 11–13) are occupied by the

swing head. These four lines are ignored when the swing head is

switched on in the configuration, they are not continued in the

plug.

717 Sample Changer, Installation

Page 15

2.4.1 External Bus Connections

Via the "External Bus" the 717 Sample Changer is operated by a

control instrument, e.g. the 726 Titroprocessor.

Four dosing instruments (Dosimat 685 or Dosino 700) may be

connected to the "External Bus" interface using a 729 Dosimat

Interface. Up to two Dosimat Interfaces may be connected in line

(daisy chaining) and be assembled with dosing instruments. Each

interface must be addressed correctly.

Before the instruments are connected, all devices have to be

switched off.

2.4 Remote Connections

EBus

Adress 0

Control instrument

Dos. 2

Dos. 1

Dos. 1...4

700685

685

700

717

EBus

Adress 1

Cable 6.2135.000

729

Dos. 3

EBus

Adress 1

Cable 6.2134.000

Dos. 4

729

EBus

Adress 2

Devices such as sample changers which consume a lot of current

should be connected in the first position of the EBus chain behind

the control instrument.

Addresses:

"External Bus"-

Dosing Unit

Address

Control instrument 0 Dos. 1 … Dos. 4

1. 717 Sample Changer 1

2. 717 Sample Changer 2

1. Interface 1 Dos. 1 … Dos. 4

2. Interface 2 Dos. 1 … Dos. 4

717 Sample Changer, Installation

The corresponding EBus address can be set with a screwdriver on

the EBus address selector that is located on the rear panel of the

device (see p. 3).

13

Page 16

3 Sample Racks

3 Sample Racks

A sample rack is a sort of turntable for the positioning of beakers

which are to be placed on the 717 Sample Changer. Because for

titration, various sizes of beakers are common or required, many

kinds of racks can be used and are easily interchangeable. The

rack offers space for various numbers of samples depending on

the diameter of the beakers. Metrohm delivers the following predefined types of standard racks:

Type Number of

beakers

M12-0 12 *) 250 mL Metrohm glass beaker 000001 6.2041.310

M12-0 12 *) 150 mL glass beaker or

M14-0 14 200 mL disposable beaker (Euro) 000011 6.2041.370

M14-0 14 8 oz disposable beaker PP (US) 000101 6.2041.380

M16-0 16 150 mL glass beaker 000010 6.2041.320

M16-0 16 120 mL disposable beaker (US) 100001 6.2041.390

M24-0 24 *) 75 mL Metrohm glass beaker 001000 6.2041.340

M48-1 48 75 mL Metrohm glass beaker 010000 6.2041.350

M128-2 126

2

Type of beaker Predef.

Code

100000 6.2041.360

200 mL disposable beaker (Euro)

15 mL test tubes

250 mL Metrohm glass beaker

*) Parallel titration at two towers possible.

If desired, other user-defined racks can be delivered. Irregular arrangements of beaker positions are also possible.

Every single rack can be identified by a unique magnetic code.

Rod magnets which are attached to the bottom of the rack can be

combined to form a 6-place binary code. The sample changer can

then automatically recognize the mounted rack. This is possible

when the rack is positioned with the first rack position in front of

tower 1. When changing a rack, the sample changer should first

be reset to the normal position. This way the save recognition of a

rack and therefore the correct beaker positioning is made possible. An internal position table containing the unambiguous definition of the turning angles and beaker positions is assigned to each

rack type.

This position table is stored in the control device.

001010 6.2041.400

Order

Number

14

717 Sample Changer, Sample Racks

Page 17

3 Sample Racks

The standard racks provided by Metrohm are already equipped

with a predefined magnetic code for every rack type. If several

racks of the same type are used, the magnet rods can be arranged differently so that a unique identification of a sample rack

is possible, if this is desired.

Format of a magnetic code (example):

000001 i.e. only one magnet is inserted, bit 0

000101 i.e. two magnets are inserted, bit 0 and 2

63 different combinations are possible. The code 000000 stands

for "no code defined".

Magnets inserted

In this example the

code is: 000110

bottom view

717 Sample Changer, Sample Racks

15

Page 18

4.1 Prerequisites

4 Swing Head

To ensure that the individual vessels are approached with precision even when using multiple-row sample racks, a 759 Swing

Head can be installed instead of the normal titration head. The

swing head is fitted with either a titration head (2.759.0020) or a

transfer head (2.759.0010) for pipetting the sample from the sample vessel into a bigger titrating vessel.

4.1 Prerequisites

The 759 Swing Head can be used in combination with the following racks:

Sample rack 759 model Number of

towers

Titration 48 x 75 mL for direct titration

Article No. 6.2041.350

Pipetting 126 x 15 mL and

2 x 150 mL for pipetting

Article No. 6.2041.400

If the two-row sample rack with 48 beakers is used on the 2-tower

model for direct titration, sample beakers cannot be approached

with tower 2. If the rack is used for transferring samples from 126

test tubes into two central measuring/rinsing vessels (special

beakers), all the positions can be approached with tower 1,

whereas tower 2 can only approach the two special beakers.

The swing head cannot be used in combination with other standard rack types.

4.2 Installing the Swing Head

The best procedure for installing the swing head is described below. The swing head will normally be installed by our service personnel.

If a 2-tower sample changer is used, the swing head must always be connected to tower 1 (see page 4)!

Article No.

2.759.0020

Article No.

2.759.0010

1, 2

2

16

With 2-tower sample changers, tower 1 is first moved into a central lift position and tower 2 is moved into the rest position.

Turn off all mains power switches.

Install the new titration head (6.1462.020) or transfer head

(6.1462.010) on the underside of the swing head.

717 Sample Changer, Swing Head

Page 19

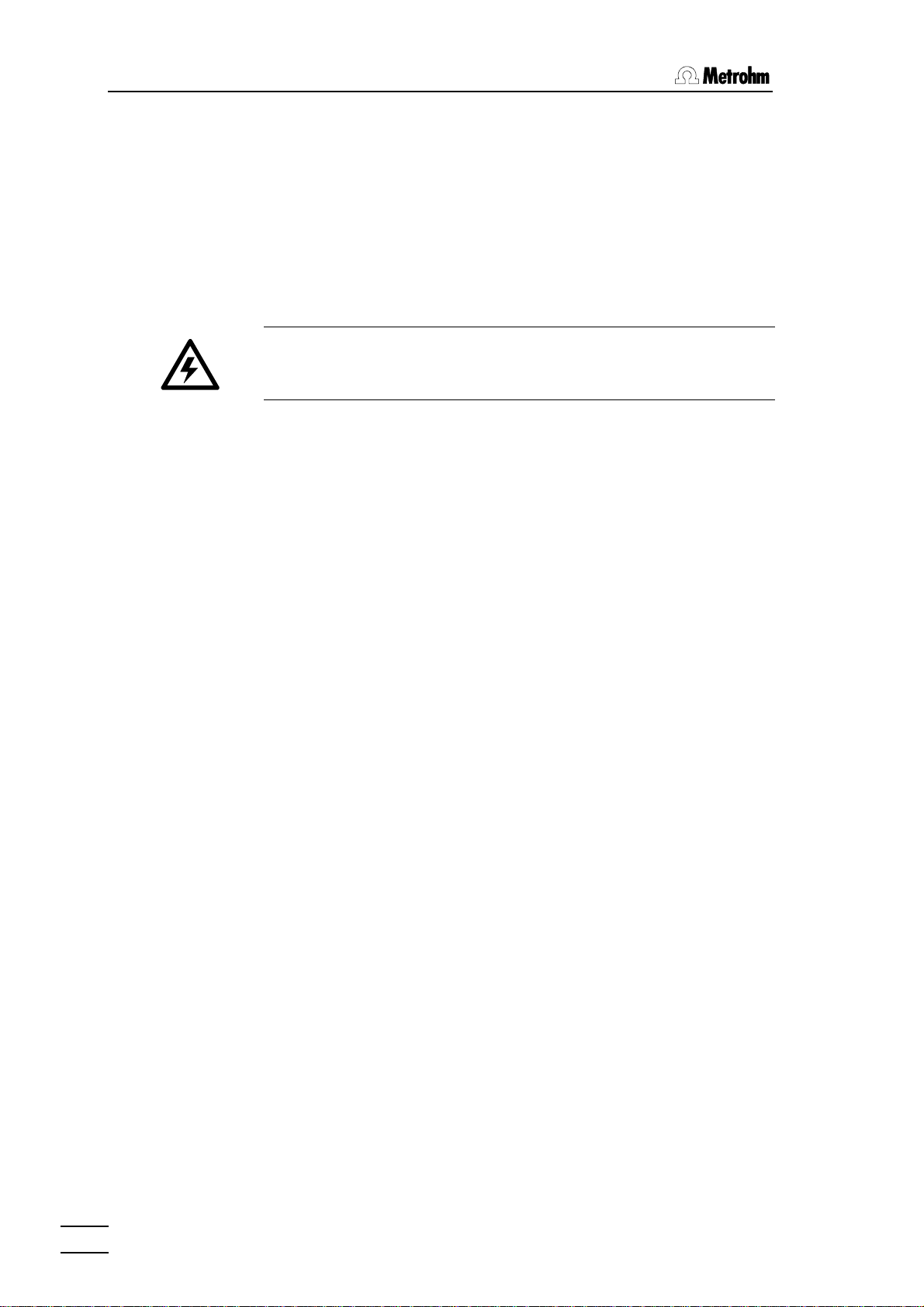

4.2 Installing the Swing Head

Disengage the guide chain

Use a screwdriver to open

the guide chain in-between

two links to facilitate the

process of disassembling the

titration head and installing

the swing head.

Connect the swing head to Tower 1

Loosen screws A on both

sides and remove the titration

head together with the

mounting plate and the

lowest link. Use an angled

C

B

screwdriver for recessedhead screws for 2-tower

sample changers. Then

loosen screws B and C and

connect the new mounting

plate for the swing head

A

(6.2058.000) to the bottom

link (screws C).

Before fixing the swing head to tower 1, rotate screws A a few

times in the appropriate holes to cut a thread into the plastic.

The swing head can now be

759 Swing

head

installed on the mounting

plate (screws B). Ensure that

the lead runs in the guide

chain. After screwing the

swing head and mounting

plate into place on the tower,

the bottom link is re-engaged

Titration or

transfer head

The splash protection supplied with the pipetting swing head

(2.759.0010) is connected to tower 2. The splash shield supplied

with the titration swing head (2.759.0020) is connected to tower 1

when used with the 2-tower model.

717 Sample Changer, Swing Head

17

Page 20

4.3 Accessories for the Titration Head

The 759 swing head can now be connected to the remote socket

of the sample changer (see page 12).

The configuration of the sample changer is carried out in the control instrument.

4.3 Accessories for the Titration Head

The titration head can be

fitted with a 722 Propeller Rod Stirrer, up to two

Micro electrodes, three

burette tips and three

spray nozzles.

722 Rod stirrer

2.722.0020

M6 spray nozzles

6.2740.020

M8 Thread stopper

4.658.0180

for Micro electrode or

burette tip

Micro electrode

Burette tips

M6 spray nozzle

6.2740.020

Stirring propeller

6.1909.030

M8 Aspiration tip

18

717 Sample Changer, Swing Head

Page 21

4.3 Accessories for the Titration Head

Aligning the titration/transfer head

The swing head executes a shift movement as it approaches the

sample vessels. It can adopt any of four fixed positions, depending

on which row is targeted, or whether the lift is in the shift position.

The titration or transfer head should be aligned in order to guarantee that the individual positions are approached with precision.

Place the sample rack that you wish to use on the sample changer

and insert a few sample vessels. Approach one sample position.

Slightly loosen the three screws securing the titration head to the

underside of the swing head and align the titration head so that

electrodes, stirrer, burette tip and tubes are centered in the sample vessel. Retighten the screws. Proceed in exactly the same way

for the transfer head.

717 Sample Changer, Swing Head

19

Page 22

5.1 Technical Specifications

5 AppendixAppendix

5.1 Technical Specifications

5.1.1 717 Sample Changer

Dimensions Height: 0.72 m, Width: 0.28 m, Depth: 0.48 m

Weight 15.5 kg (without accessories, 2-tower model)

10.0 kg (without accessories, 1-tower model)

Material Sample Changer case: metal case, multiple enameling

Lift path 235 mm

Lift Load: approx. 10 N

Stroke speed: adjustable, 3 – 25 mm/s

Turntable Turning speed:

adjustable, 3 – 20 angular degrees/s

Stirrer Stirring speed: adjustable to 15 levels

- Magnet stirrer 180/s – 2600/s

- Rod stirrer 180/s – 3000/s

Pump with Conveying capacity (manometric lift 2m):

Valve 0.33 L/min

20

717 Sample Changer, Appendix

Page 23

5.1 Technical Specifications

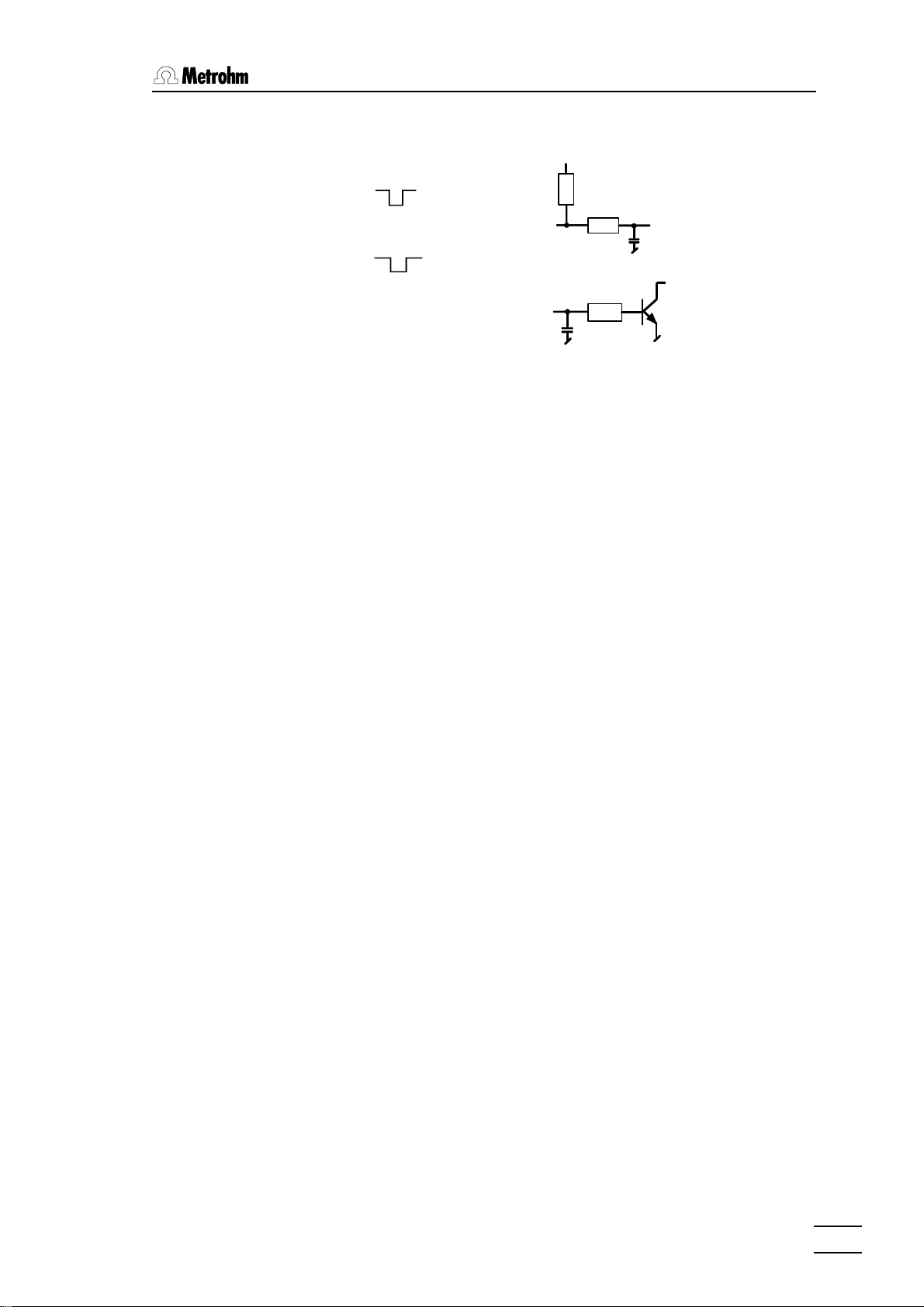

Remote Interface Programmable parallel interface for controlling external

instruments

+5V

t

p

Input:

Output:

t

>20 ms

p

t

p

t

>200 ms

p

V

= 40 V

CEO

active = low

inactive = high

active = low

inactive = high

IC = 20 mA

+5 V: Maximum charge = 20 mA

Temperatures Nominal functional range 5 – 40 °C

Transport and storage: –40 – +70°C

Distribution Connection to the External Bus of a Metrohm control device,

voltage e.g. 726 Titroprocessor, ...

All data are typical values with the exception of those specially marked.

Safety Specifications

Constructed and tested according to IEC 1010 / EN 61010 /

UL 3101-1, Safety Class III

Degree of protection IP 22

The instruction manual contains information and warnings which

the user should follow to guarantee the safe operation of the instrument.

Electromagnetic Compatibility (EMC)

Emitted Interference: The instrument complies with the basic specifications

EN 50081-1/2 1992, EN 55011 (class B), EN 55022

(class B), and NAMUR.

Interference immunity: The basic specifications EN 50082-1 1997, and IEC 801-2 to

IEC 801-4 are adhered to.

717 Sample Changer, Appendix

21

Page 24

5.1 Technical Specifications

5.1.2 759 Swing Head

Dimensions Height: 0.14 m, Width: 0.10 m, Depth: 0.09 m

Weight 0.63 kg

Material Swing Head case: Polybuteneterephthalate (PBTP)

with metallic fiber

Titration Head: Polypropylene

Rotation 4 fix positions

Temperatures Nominal functional range 5 – 40 °C

Transport and storage –40 – +70 °C

Distribution 5 V DC, drawing of current 500 mA

voltage connection to the remote socket of the Metrohm Sample

Changers, e.g. model 717, 730, 760, ...

All data are typical values.

Safety Specifications

Constructed and tested according to IEC 1010 / EN 61010 /

UL 3101-1, Safety Class III

Degree of protection IP 43

Electromagnetic Compatibility (EMC)

Emitted Interference: The instrument complies with the basic specifications

EN 50081-1/2 1992, EN 55011 (class B), EN 55022

(class B), and NAMUR.

Interference immunity: The basic specifications EN 50082-1 1997, and IEC 801-2 to

IEC 801-6 are adhered to.

22

717 Sample Changer, Appendix

Page 25

5.2 Servicing and Maintenance

5.2.1 Servicing

The maintenance of the 717 Sample Changer should include a

yearly service check carried out by a specialist from Metrohm. If

caustic or corrosive chemicals are frequently used, shorter time

intervals between service checks can be necessary.

The Metrohm Service Department can offer technical advice regarding servicing and maintenance of all Metrohm instruments at

any time.

5.2.2 Maintenance / Attendance

Not only do highly sensitive measuring instruments require proper

care, a sample changer also requires this. Serious contaminations

can lead to functional disorders and a shortened life-span of the

rugged mechanics and electronics of the sample changer.

5.2 Servicing and Maintenance

Heavy soiling of the titration heads can influence the results of

measurements. Regular cleaning of exposed parts can prevent

this for the most part.

Chemical or solvent spills should be cleaned up immediately. The

connectors (in particular the power supply) should be protected

from contamination. The sample changer should never be operated without the covering foreseen for this purpose.

If corrosive media has entered the inside of the instrument, the

power plug has to be disconnected immediately to avoid massive

damage to the instruments electronic components. In case of such

damage, the Metrohm service personnel should be notified.

The instrument should not be opened by untrained personnel.

717 Sample Changer, Appendix

23

Page 26

5.3 Warranty and Conformity

5.3 Warranty and ConformityWarranty and Conformity

5.3.1 Warranty

The warranty on our products is limited to defects that are traceable to material, construction or manufacturing error which occur

within 12 months from the day of delivery. In this case, the defects

will be rectified in our workshops free of charge. Transport costs

are to be paid by the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not cov-

ered by the warranty. Checks which are not a result of material or

manufacturing faults are also charged during the warranty period.

For parts of outside manufacture insofar as these constitute an

appreciable part of our instrument, the warranty stipulations of the

manufacturer in question apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as

the absence of guaranteed features, the orderer has no rights or

claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment

or if the goods show signs of transport damage after unpacking,

the carrier must be informed immediately and a written damage

report demanded. lack of an official damage report releases

Metrohm from any liability to pay compensation.

If any instruments and parts have to be returned, the original

packaging should be used if at all possible. This applies above all

to instruments, electrodes, burette cylinders and PTFE pistons.

Before embedment in wood shavings or similar material, the parts

must be packed in a dustproof package (for instruments, use of a

plastic bag is imperative). If open assemblies are enclosed in the

scope of delivery that are sensitive to electromagnetic voltages

(e.g. data interfaces etc.) these must be returned in the associated

original protective packaging (e.g. conductive protective bag).

(Exception: assemblies with built-in voltage source belong in a

non-conductive protective packaging). For damage which arises

as a result of non-compliance with these instructions, no warranty

responsibility whatsoever will be accepted by Metrohm.

24

717 Sample Changer, Appendix

Page 27

5.3 Warranty and Conformity

5.3.2 Certificate of Conformity and System Validation for the

717 Sample Changer

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

Name of commodity: 717 Sample Changer

Name of manufacturer: Metrohm Ltd., Herisau,

Switzerland

Principal technical information: Connection to the External Bus of a

Metrohm control device

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

Electromagnetic compatibility

IEC 801-2 / level 3, IEC 801-3 / level 2, IEC 801-4 / level 3,

EN 55011 / class B, EN 55022 / class B, EN 50081-1/2 1992,

EN 50082-1 1997

Security specifications

IEC 1010, EN 61010, UL 3101-1

It has also been certified by the Swiss Electronical Association (SEV), which is

member of the International Certification Body (CB / IEC).

The technical specifications are documented in the instruction manual.

The system software, stored in Read Only Memories (ROMs) has been validated in connection with standard operating procedures in respect to functionality and performance. The features of the system software are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS certificate of the quality system ISO 9001

for quality assurance in design/development, production, installation and

servicing.

Herisau, March 5, 1998

717 Sample Changer, Appendix

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

25

Page 28

5.3 Warranty and Conformity

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

717 Sample Changer

EU Declaration of Conformity

The Metrohm AG company, Herisau, Switzerland hereby certifies that the instrument:

717 Sample Changer

meets the requirements of EU Directives 89/336/EWG and 73/23/EWG.

Source of specifications:

EN 50081 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of the instrument:

Sample changer for the automation of batch processing of larger sample series, applying titration, dosing and measuring methods in laboratory and industry.

Herisau, March 5, 1998

26

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

717 Sample Changer, Appendix

Page 29

5.3 Warranty and Conformity

5.3.3 Certificate of Conformity and System Validation for the

759 Swing Head

This is to certify the conformity to the standard specifications for electrical appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

Name of commodity: 759 Swing Head

Name of manufacturer: Metrohm Ltd., Herisau,

Switzerland

Principal technical information: Distribution voltage: 5 V DC

Drawing of Currency: 500 mA

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

Electromagnetic compatibility

IEC 801-2 / level 4, IEC 801-3 / level 2, IEC 801-4 / level 3,

IEC 801-5 / level 3, IEC 801-6 / level 2, EN 55011 / class B,

EN 55022 / class B, EN 50081-1/2 1992, EN 50082-1 1997

Security specifications

IEC 1010, EN61010, UL 3101-1

The technical specifications are documented in the instruction manual.

Metrohm Ltd. is holder of the SQS certificate of the quality system ISO 9001

for quality assurance in design/development, production, installation and

servicing.

Herisau, Oct. 23, 1997

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

717 Sample Changer, Appendix

27

Page 30

5.3 Warranty and Conformity

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

759 Swing Head

EU Declaration of Conformity

The Metrohm AG company, Herisau, Switzerland hereby certifies that the instrument:

759 Swing Head

meets the requirements of EU Directives 89/336/EWG and 73/23/EWG.

Source of specifications:

EN 50081 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of the instrument:

The Swing head is an accessory to the Metrohm sample changers 717, 730 and 760

for the automation of batch processing of larger sample series in chemical analytics.

Herisau, Oct. 23, 1997

28

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

717 Sample Changer, Appendix

Page 31

5.4 AccessoriesAccessories

Sample Changer with 1 Tower and 1 Pump 2.717.0010

includes the following accessories:

SGJ14 sleeve 2 6.1236.020

SGJ14 plastic stopper 5 6.1446.000

SGJ9 stopper 3 6.1446.010

M6 thread stopper 6.1446.040

PE canister 10 liter 6.1621.000

FEP tubing connector M6 80 6.1805.110

PTFE tubing 4 meter 4/6 6.1812.000

Guiding shaft 6.1823.000

Connector for canister 6.1828.000

Fixing clip 10x 6.2053.000

Bushing 3 6.2709.070

Rotating nozzle 6.2740.000

Splash protection 6.2751.010

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

5.4 Accessories

Pieces

Sample Changer with 1 Tower and 2 Pumps 2.717.0020

includes the following accessories:

Pieces

SGJ14 sleeve 2 6.1236.020

SGJ14 plastic stopper 5 6.1446.000

SGJ9 stopper 3 6.1446.010

M6 thread stopper 6.1446.040

SGJ14 stopper 6,4 mm 6.1446.160

M8 aspiration tip 6.1543.170

PE canister 10 liter 2 6.1621.000

FEP tubing connector M6 80 6.1805.110

FEP tubing connector M6 48 6.1805.420

PTFE tubing connector M8 60 6.1805.510

PTFE tubing 4 meter 4/6 2 6.1812.000

M8 screw connector 4/6 mm / M8 6.1820.030

Connector for canister 2 6.1828.000

Clip for burette tip 6.2042.020

Fixing clip 10x 6.2053.000

Bushing 3 6.2709.070

M6 spray nozzle 3 6.2740.020

Splash protection 6.2751.010

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

717 Sample Changer, Appendix

29

Page 32

5.4 Accessories

Sample Changer with 1 Tower without Pumps 2.717.0030

includes the following accessories:

Pieces

SGJ14 sleeve 2 6.1236.020

FEP tubing connector M6 80 6.1805.110

Bushing 3 6.2709.070

Splash protection 6.2751.010

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

Sample Changer with 2 Towers and 2 Pumps 2.717.0110

includes following accessories

Pieces

SGJ14 sleeve 4 6.1236.020

SGJ14 plastic stopper 10 6.1446.000

SGJ9 stopper 6 6.1446.010

M6 thread stopper 2 6.1446.040

PE canister 10 liter 2 6.1621.000

FEP tubing connector M6 80 2 6.1805.110

PTFE tubing 4 meter 4/6 2 6.1812.000

Guiding shaft 2 6.1823.000

Connector for canister 2 6.1828.000

Fixing clip 10x 2 6.2053.000

Bushing 6 6.2709.070

Rotating nozzle 2 6.2740.000

Splash protection 6.2751.020

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

30

Sample Changer with 2 Towers and 4 Pumps 2.717.0120

includes the following accessories:

Pieces

SGJ14 sleeve 4 6.1236.020

SGJ14 plastic stopper 10 6.1446.000

SGJ9 stopper 6 6.1446.010

M6 thread stopper 2 6.1446.040

SGJ14 stopper 6,4 mm 2 6.1446.160

M8 aspiration tip 2 6.1543.170

PE canister 10 liter 4 6.1621.000

FEP tubing connector M6 80 2 6.1805.110

FEP tubing connector M6 48 6 6.1805.420

PTFE tubing connector M8 60 2 6.1805.510

PTFE tubing 4 meter 4/6 4 6.1812.000

M8 screw connector 4/6 mm / M8 2 6.1820.030

Connector for canister 4 6.1828.000

717 Sample Changer, Appendix

Page 33

5.4 Accessories

Clip for burette tip 2 6.2042.020

Fixing clip 10x 2 6.2053.000

Bushing 6 6.2709.070

M6 Spray nozzle 6 6.2740.020

Splash protection 6.2751.020

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

Sample Changer with 2 Towers without Pumps 2.717.0130

includes the following accessories:

Pieces

SGJ14 sleeve 4 6.1236.020

FEP tubing connector M6 80 2 6.1805.110

Bushing 6 6.2709.070

Splash protection 6.2751.010

Plug cover 6.2752.010

External Bus cable DB 37-pol 6.2135.000

Instructions for Use for 717 Sample Changer 8.717.1003

Options

Accessories to separate order at additional charge:

722 Rod stirrer for the sample changer

Rod stirrer 2.722.0020

Stirrer propeller PP (104 mm) 6.1909.020

741 Magnetic stirrer

Magnetic stirrer 2.741.0010

Macro Titration head (6x NS14, 3x NS9) 6.1458.010

Micro Titration head (4x M10) 6.1458.020

759 Swing Head with Transfer Head 2.759.0010

includes the following accessories:

Transfer head 6.1462.010

Pipetting tube 10 mL (length 3.8 m, 6.1562.100

inner diameter 2.0 mm)

Guiding shaft for pipetting tube 6.1823.010

Holding plate for the swing head 6.2058.000

Splash protection for tower 2 6.2751.010

717 Sample Changer, Appendix

31

Page 34

5.4 Accessories

759 Swing Head with Titration Head 2.759.0020

includes the following accessories:

Pieces

Titration head 6.1462.020

Stirrer propeller PP (104 mm) for 75 mL vessels 6.1909.030

Clip for burette tip 2 6.2042.030

Holding plate for the swing head 6.2058.000

Splash protection for swing head 6.2751.030

Sample racks and beakers

Rack 12x 250 mL M12-0 *) 6.2041.310

Metrohm glass beaker 250 mL 6.1432.320

Metrohm PP beaker 200 mL 6.1453.220

Metrohm PP beaker 250 mL 6.1453.250

Rack 12x 150 mL M12-0 *) 6.2041.360

for standard glass beaker 150 mL (narrow) or

disposable beaker (Euro) PP 200 mL (1000 pcs.)6.1459.310

Rack14x 200 mL M14-0 6.2041.370

for disposable beaker (Euro) PP 200 mL 6.1459.310

Rack14x 8 oz M14-0 6.2041.380

for disposable beaker (US) PP 8 oz

Rack 16x 150 mL M16-0 6.2041.320

for standard glass beaker (narrow)

Rack 16x 120 mL M16-0 6.2041.390

for disposable beaker (US) 120 mL

Rack 24x 75 mL M24-0 *) 6.2041.340

(with Micro titration head only)

Metrohm glass beaker 75 mL 6.1432.210

32

*) Parallel processing at 2 towers possible

For operation with the 759 Swing Head:

Rack 48x 75 mL M48-1 6.2041.350

for direct titration

Metrohm glass beaker 75 mL 6.1432.210

Rack 126 x 15 mL and 2 x 250 mL M128-2 6.2041.400

for pipetting

for test tubes 15 mL and

Metrohm glass beaker 250 mL 6.1432.320

Metrohm PP beaker 200 mL 6.1453.220

Metrohm PP beaker 250 mL 6.1453.250

717 Sample Changer, Appendix

Page 35

5.4 Accessories

Electrodes for Sample Changer

It is recommended to use Longlife-Electrodes (LL) or titrodes

(without polished glass surface) with the SGJ sleeve SGJ14/12mm

6.1236.040 made of silicon caout-chouc for titrations with the

Macro Titration head.

The following special micro electrodes can be used with the Micro

Titration head and the 759 Swing Head for direct titration.

Comb. micro-pH-electrode (LL) 16 cm 6.0234.110

Micro reference electrode Ag/AgCl 16 cm 6.0736.110

Micro glass electrode 16 cm 6.0134.110

Micro-Ag titrode 16 cm 6.0433.110

Micro-Pt titrode 16 cm 6.0434.110

Micro-Au titrode 16 cm 6.0435.110

Pt 1000 temperature sensor 16 cm 6.1110.110

Dosing Instruments

685 Dosimat 2.685.0010

Exchange Unit with ceramic stopcock 1 mL 6.3013.113

5 mL 6.3013.153

10 mL 6.3013.213

20 mL 6.3013.223

50 mL 6.3013.253

Exchange Unit with PTFE stopcock 1 mL 6.3014.113

5 mL 6.3014.153

10 mL 6.3014.213

20 mL 6.3014.223

50 mL 6.3014.253

700 Dosino 2.700.0010

Dosing unit for Dosino 2 mL 6.3030.120

5 mL 6.3030.150

10 mL 6.3030.210

20 mL 6.3030.220

50 mL 6.3030.250

717 Sample Changer, Appendix

729 Dosimat Interface 2.729.0010

33

Page 36

5.5 Index

5.5 Index

A

Accessories ....................... 7, 29

Address ............................. 3, 13

Aligning .................................. 19

Appendix ................................ 20

Aspiration tip .................... 10, 18

Attendance ............................ 23

B

Beaker ............................. 14, 32

indicator ............................... 3

test ...................................... 3

Burette tip ........................ 10, 18

C

Cables ............................. 11, 12

CE .................................... 26, 28

Certificate ........................ 25, 27

Chemical resistance ................ 8

Code .................................. 3, 14

Conformity ....................... 25, 27

Connections ...... 7, 11,12, 13, 17

Connectors ...................... 1, 2, 3

Control ..................................... 5

D

Diaphragm pump ..................... 8

Distribution head .................. 1, 2

Dosimat ........................... 13, 33

Dosimat Interface ............ 13, 33

Dosing instruments .......... 13, 33

Dosino ............................. 13, 33

E

Electrodes ........................ 10, 33

Electromagnetic compatibility ....

..................................... 21, 22

Emitted interference ........ 21, 22

EU Declaration of Conformity ....

..................................... 26, 28

External Bus

address ......................... 3, 13

connections ....................... 13

socket .................................. 3

F

Failure ...................................... 6

G

Guide chain ........... 1, 2, 7, 8, 17

I

Infrared sensor ........................ 3

Initialize ................................... 3

Input ...................................... 11

Installation ......................... 5, 16

Interference immunity ...... 21, 22

ISO 9001 ......................... 25, 27

L

Lift ............................................ 1

Lines ...................................... 11

M

Magnet holder ......................... 9

Magnetic

code .................... 3, 9, 14, 15

rack code indicator .............. 3

sensor ............................. 3, 9

stirrer ............................. 8, 31

Maintenance .......................... 23

Manufacturing number ............. 3

Micro electrodes ........ 10, 18, 33

Models ......................... 4, 16, 29

Mounting .................. 7, 8, 10, 17

O

Options .................................. 31

Output .................................... 11

Overview ................................. 1

P

Packaging ................................ 5

Peripheral instruments 6, 11, 12

Pin assignment ...................... 11

Pipetting .......................... 16, 31

Plug cover ........................... 1, 2

Position table ......................... 14

Pump ........................... 1, 2, 4, 7

Pump head .............................. 8

R

Rack .......... 1, 3, 8, 9, 14, 16, 32

code .................................... 3

recognition ................ 3, 9, 14

Rear view ............................ 2, 3

Remote connections .............. 11

Remote Interface ......... 2, 11, 14

Rinsing equipment ................... 7

Rod magnets ......................... 14

Rod stirrer .................. 10, 18, 31

Rotating nozzle .................. 7, 10

S

Safety considerations ...........1, 6

Safety specifications ........21, 22

Sample

rack ........1, 3, 8, 9, 14, 16, 32

vessel .....................14, 16, 32

Sensors ....................................3

Servicing .................................23

Setting up .................5, 7, 10, 18

Side view ..............................1, 2

Signals ....................................11

Special beaker ........................16

Splash protection ..................1, 2

Spray nozzles .................7, 8, 18

Stirrer

connections ......................2, 4

propeller .......................10, 18

rail ....................................1, 8

Swing Head.................................

..............12, 16, 22, 27, 31, 32

installation ..........................16

System validation .............25, 27

T

Technical Specifications ...20, 22

Titration head .............................

..........7, 10, 16, 18, 19, 31, 32

vessel .................................16

Titroprocessor ........................13

Tower ...................................1, 4

Transfer head .............16, 19, 31

Tubing ..................................7, 8

Turntable ................................14

V

Valve ....................................1, 2

W

Warranty .................................24

34

717 Sample Changer, Appendix

Loading...

Loading...