Page 1

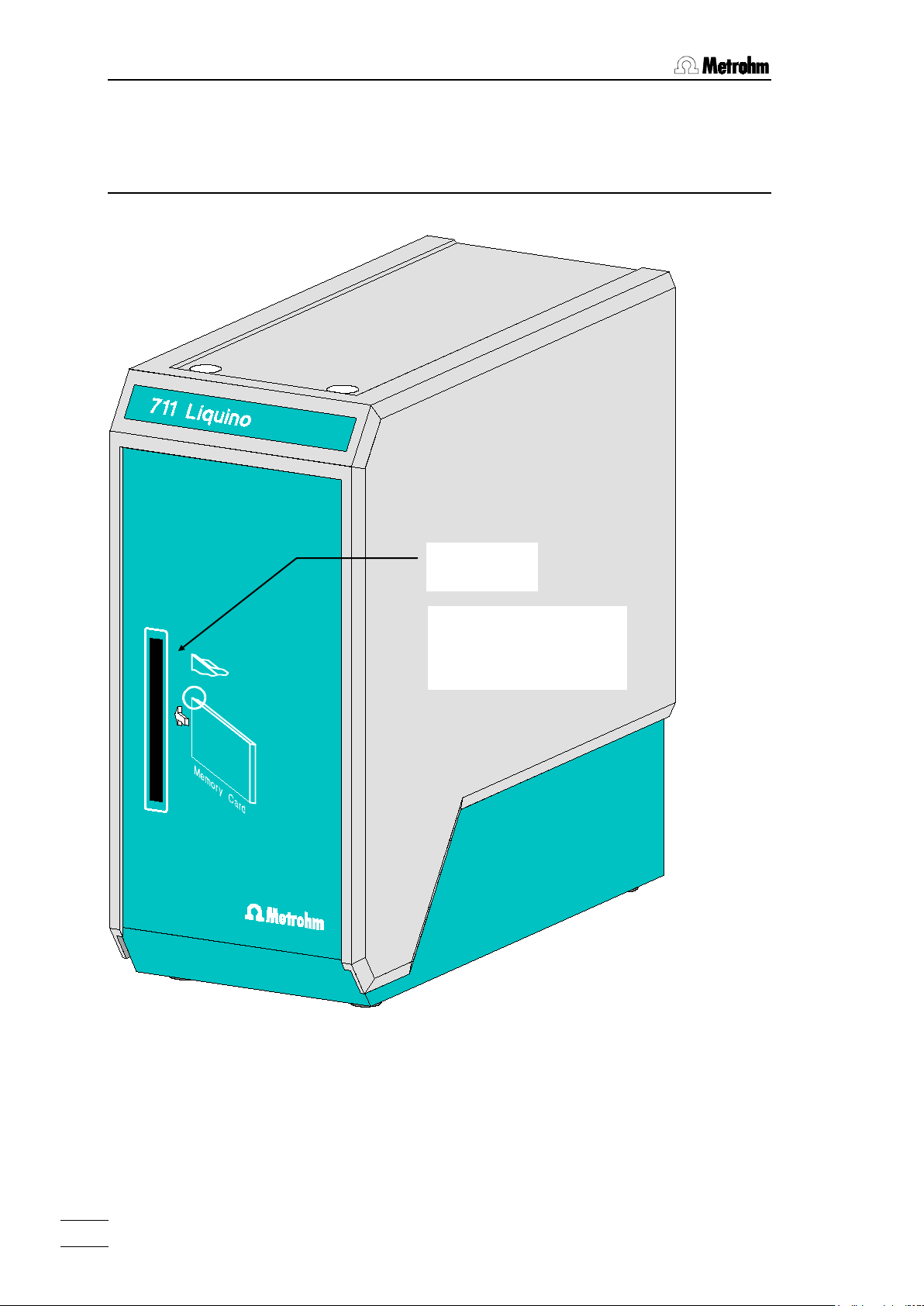

711 Liquino

Manual

8.711.1023

Page 2

Page 3

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

711 Liquino

Manual

8.711.1023 02.99 dm

Page 4

Teachware

Metrohm AG

CH-9101 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://products.metrohm.com under Literature/Technical documenta-

tion.

Page 5

Table of content

page

1 Overview 1

1.1 Application range __________________________________________1

1.2 Application possibilities ____________________________________1

1.3 Instrument description ______________________________________2

1.3.1 Front view ......................................................................................... 2

1.3.2 Rear view .......................................................................................... 3

2 Installation 4

2.1 Instrument setup __________________________________________4

2.1.1 Mains connection ............................................................................. 4

2.2 Safety information _________________________________________5

2.3 Setup ____________________________________________________7

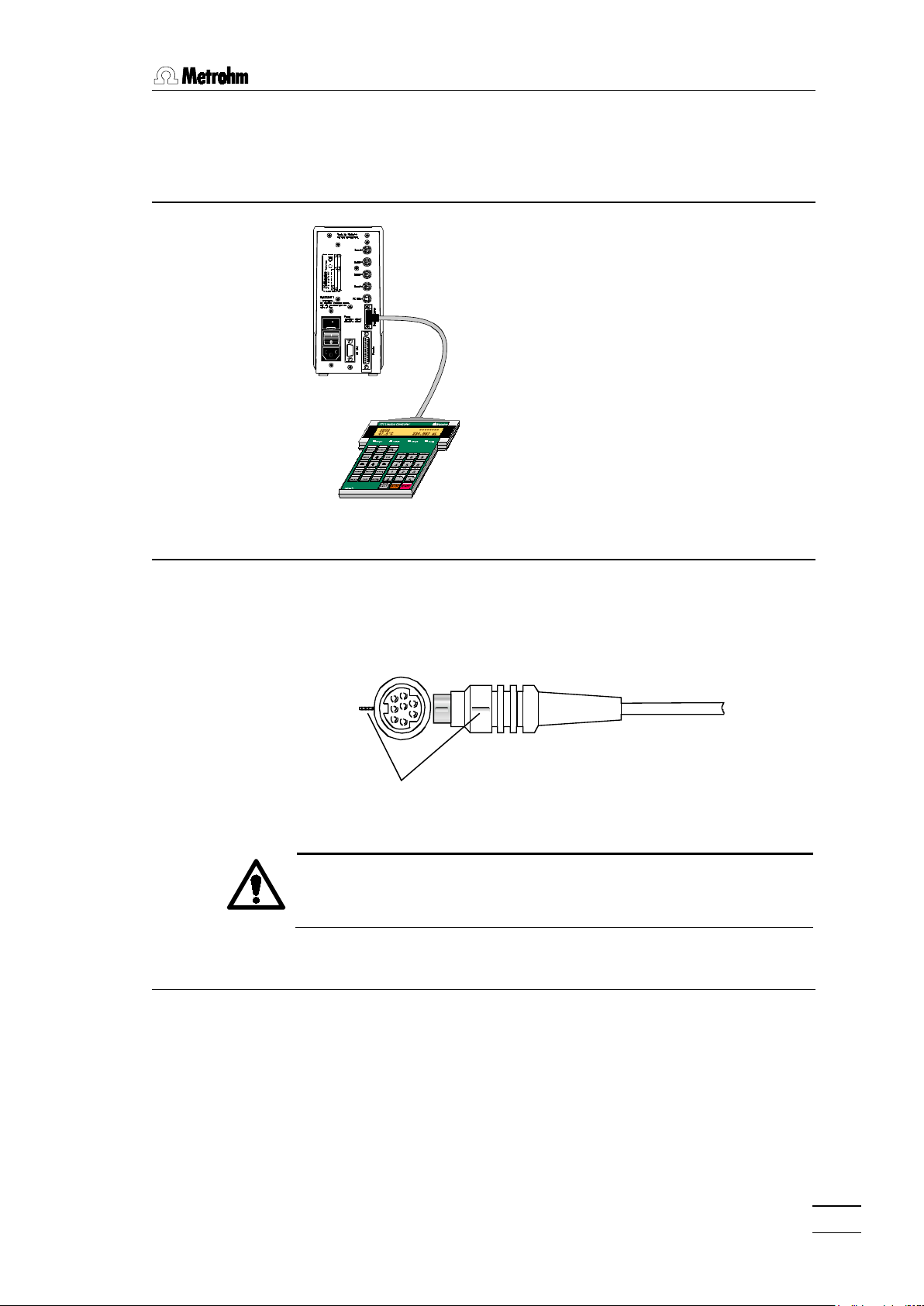

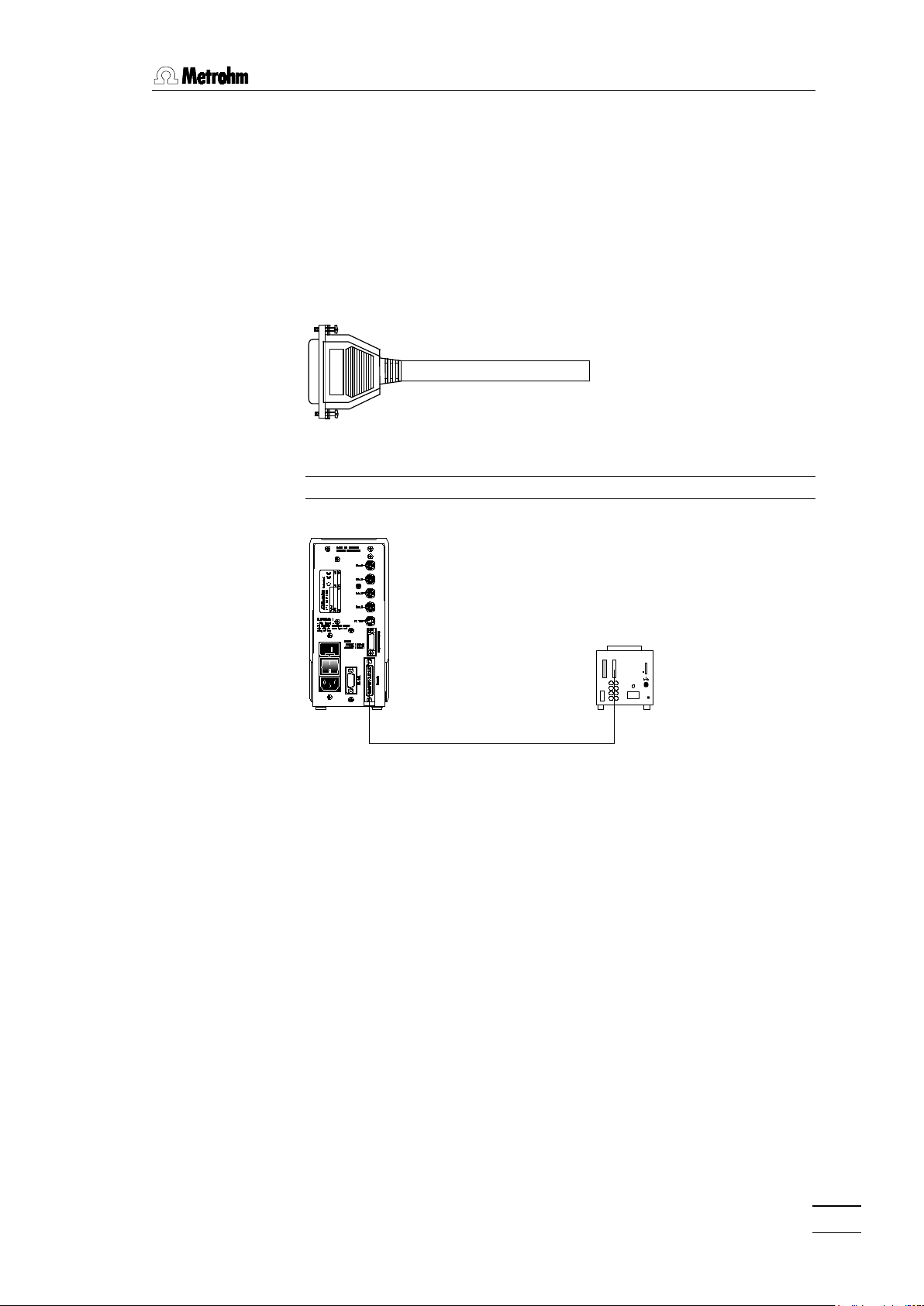

2.3.1 Connecting the keyboard ................................................................. 7

2.3.2 Connecting the Dosinos ................................................................... 7

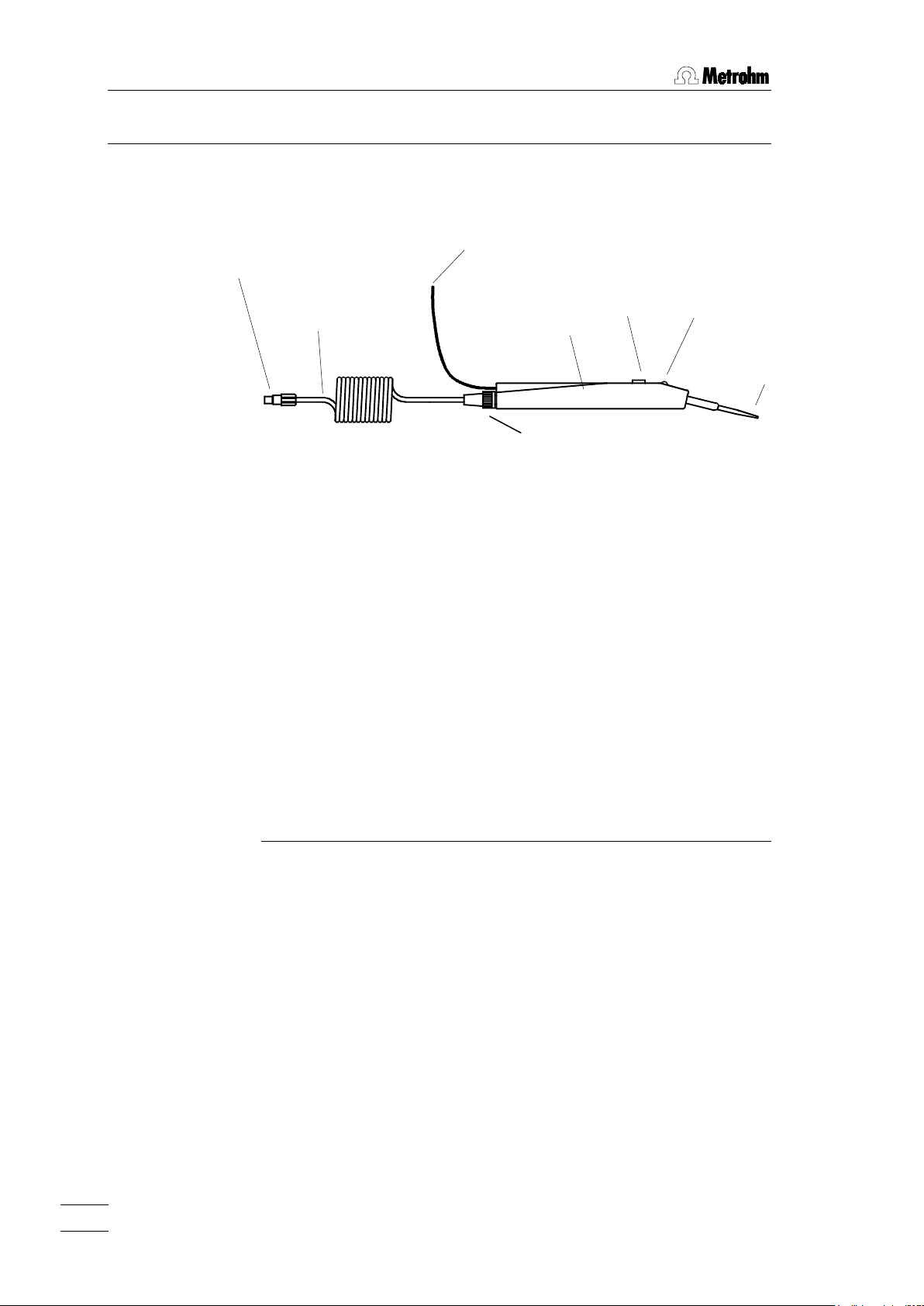

2.3.3 Connecting a Pt100 temperature sensor ......................................... 7

2.3.4 Installing the pipetting attachment ................................................... 8

2.4 Memory card ______________________________________________8

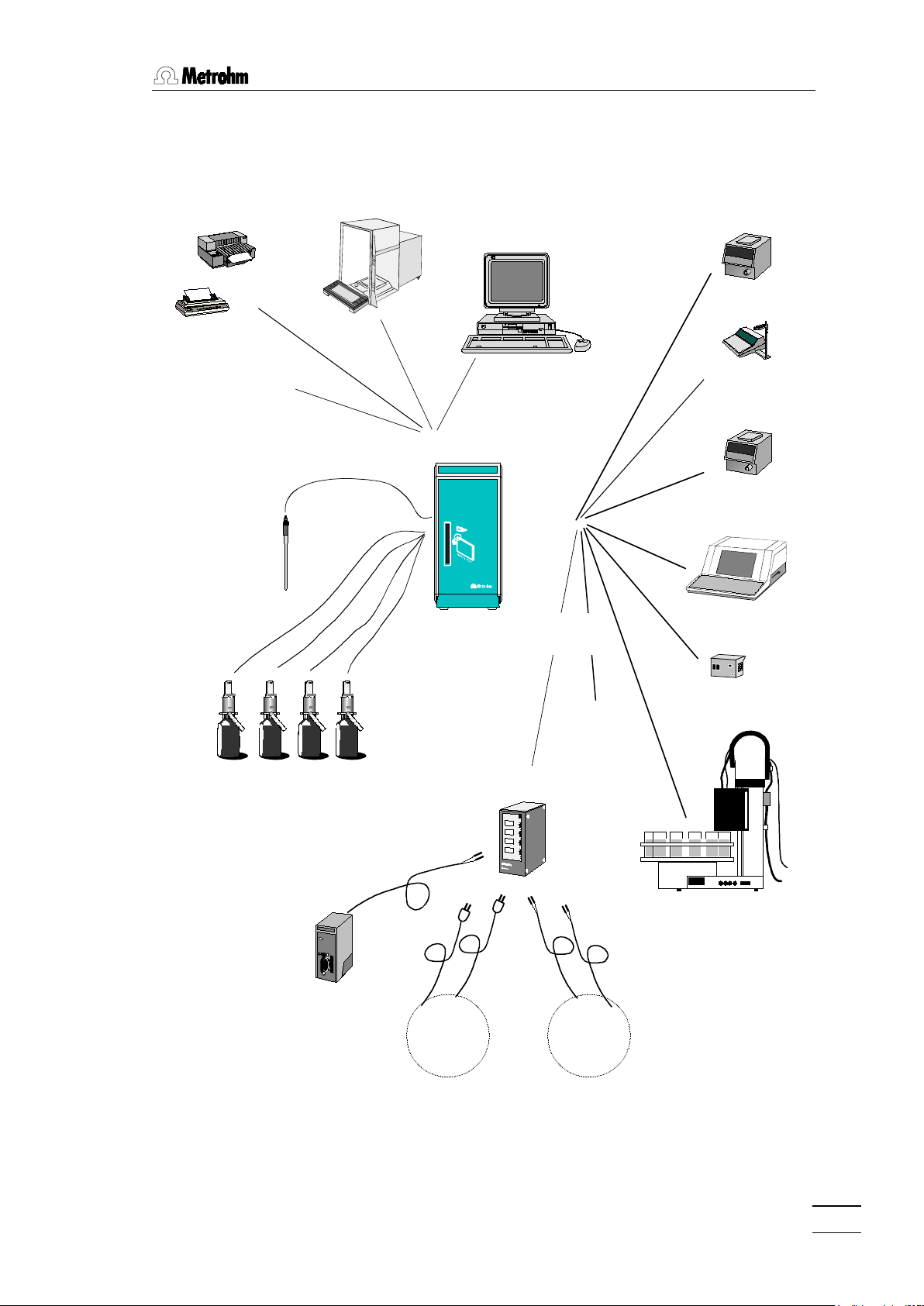

2.5 Connections ______________________________________________9

2.5.1 Remote connections ...................................................................... 10

2.5.2 Serial connections .......................................................................... 16

2.5.3 Connecting a printer ....................................................................... 17

2.5.4 Connecting a balance .................................................................... 19

3 Introduction 20

3.1 The Liquino concept ______________________________________20

3.2 Tutorial _________________________________________________21

3.2.1 Basic configuration ......................................................................... 21

3.2.2 Defining dosing units ...................................................................... 22

3.2.3 Dosing and dispensing .................................................................. 24

3.2.4 Changing the dosing unit ............................................................... 28

3.2.5 Temperature measurement ............................................................ 29

3.2.6 PIP – precise pipetting/diluting ....................................................... 30

3.2.7 SMPL – fully automatic sampling ................................................... 33

3.2.8 CONT – the automatic volumetric flask .......................................... 40

3.2.9 XDOS – the electronic dropping funnel .......................................... 43

3.2.10 XDOS – temperature-controlled addition ..................................... 46

3.2.11 SEQ – complex procedures under control ................................... 51

3.2.12 GLP – automatic validation ........................................................... 57

4 Detailed description 61

4.1 The keyboard ____________________________________________61

4.1.1 Menu keys ...................................................................................... 62

4.1.2 Action keys ..................................................................................... 62

4.1.3 Editing and navigating keys ........................................................... 62

4.1.4 Manual functions and other keys ................................................... 63

4.2 Editing __________________________________________________65

4.2.1 Navigating in menus ....................................................................... 65

4.2.2 Data input ....................................................................................... 65

4.2.3 Text input ........................................................................................ 66

4.3 Configuration ____________________________________________68

4.3.1 Defining the dosing units ................................................................ 68

4.3.2 The configuration menu .................................................................. 69

4.3.3 Keyboard and graphics options ..................................................... 71

711 Liquino, Instructions for use

Page 6

Table of content

page

4.4 XDOS mode - controlled dosing ____________________________ 74

4.4.1 XDOS mode parameters ................................................................ 77

4.4.2 Examples of reports - XDOS mode ................................................ 81

4.5 SEQ mode - complex processes ____________________________ 83

4.5.1 Commands ..................................................................................... 84

4.5.2 SEQ mode parameters .................................................................. 89

4.5.3 Commands in a sequence ............................................................. 91

4.5.4 Example of a report - SEQ mode ................................................... 93

4.6 CONT mode - preparation of solutions ______________________ 94

4.6.1 Preparation of solutions ................................................................. 94

4.6.2 Standard solutions / Dilutions ........................................................ 95

4.6.3 CONT mode parameters ................................................................ 96

4.6.4 Example of a report - CONT mode ................................................ 99

4.7 PIP mode - precise pipetting and diluting ___________________ 100

4.7.1 PIP mode parameters .................................................................. 103

4.7.2 Example of a report - PIP mode ................................................... 105

4.8 SMPL mode - fully automatic sampling _____________________ 106

4.8.1 Sampling process in detail ........................................................... 110

4.8.2 SMPL mode parameters .............................................................. 113

4.8.3 Example of report - SMPL mode .................................................. 118

4.9 GLP mode - validation ___________________________________ 120

4.9.1 GLP mode parameters ................................................................. 123

4.9.2 Example of report - GLP mode .................................................... 125

4.10 Storing and loading methods ____________________________ 128

4.10.1 Internal method memory ............................................................ 128

4.10.2 Memory card .............................................................................. 129

5 The 711 Liquino in synthesis laboratories 133

5.1 The advantages of the 711 Liquino _________________________ 133

5.2 Please note … __________________________________________ 135

6 Appendix 139

6.1 Dosing units and Dosinos ________________________________ 139

6.1.1 Preparing and emptying the dosing units .................................... 141

6.1.2 Defining dosing units ................................................................... 143

6.2 Error messages _________________________________________ 144

6.3 Service and maintenance _________________________________ 148

6.3.1 Service .......................................................................................... 148

6.3.2 Maintenance / Care ...................................................................... 148

6.4 Validation / GLP ________________________________________ 149

6.5 Diagnosis ______________________________________________ 150

6.6 Initialize data memory ___________________________________ 160

6.7 Technical specifications _________________________________ 162

6.8 Warranty and certificates _________________________________ 164

6.8.1 Warranty ....................................................................................... 164

6.9 EC Declaration of conformity _____________________________ 165

6.9.1 Certificate of Conformity and System Validation .......................... 166

6.10 Accessories ___________________________________________ 167

7 Index 171

711 Liquino, Instructions for use

Page 7

1. Overview

1

1 Overview

1.1 Application range

The Metrohm 711 Liquino is a very versatile laboratory instrument which can

be used everywhere that liquid handling is to be simplified and automated.

This is the case in both analytical laboratories and in synthesis laboratories.

It is equally suitable for both the preparation of complicated formulations in

filling plants and also for simple delivery and pumping tasks involving toxic

or aggressive media.

Owing to the freely programmable process sequences and versatile communication interfaces (RS232 or remote connection) it can be integrated into complex automated systems to undertake demanding dosing and monitoring functions, which otherwise would only be capable of realization with a

considerably greater expenditure.

1.2 Application possibilities

The 711 Liquino can be used for the whole range of applications which fall

under the general heading of 'Liquid Handling'.

In analytical laboratories

• manual, highly accurate liquid dosing.

• complex, process-controlled dosing tasks with freely selectable specifi-

cations, e.g. a certain volume in a given period, constant dosing speed

during a preselected time interval, a certain volume with constant dosing

speed. In addition this can also be temperature-controlled, i.e. if a certain temperature limit is exceeded or undercut during the dosing process

then the dosing process can be interrupted and a predefined action triggered, e.g. switching on a cooling bath.

• automated preparation of defined solutions (e.g. standard solutions) or

mixtures of liquids (e.g. mobile phases for HPLC or IC). It is possible to

connect a balance without any problems.

• highly accurate pipetting and diluting even small volumes of liquid.

• automated sampling and sample preparation for a range of analytical

methods (e.g. titrations, pH measurements, etc.) with and without a

sample changer.

• preparation of complex formulations in automated filling plant.

In synthesis laboratories

• manual, highly accurate liquid dosing.

• complex, process-controlled dosing tasks with freely selectable specifi-

cations, e.g. a certain volume in a given period, constant dosing speed

during a preselected time interval, a certain volume with constant dosing

speed. In addition this can also be temperature-controlled, i.e. if a certain temperature limit is exceeded or undercut during the dosing process

then the dosing process can be interrupted and a predefined action triggered, e.g. switching on a cooling bath.

711 Liquino, Instructions for use

Page 8

1.3 Instrument description

2

Slot for memory

Always insert the card so that

1.3 Instrument description

1.3.1 Front view

card

the upper edge of the card

with the label faces right.

711 Liquino, Instructions for use

Page 9

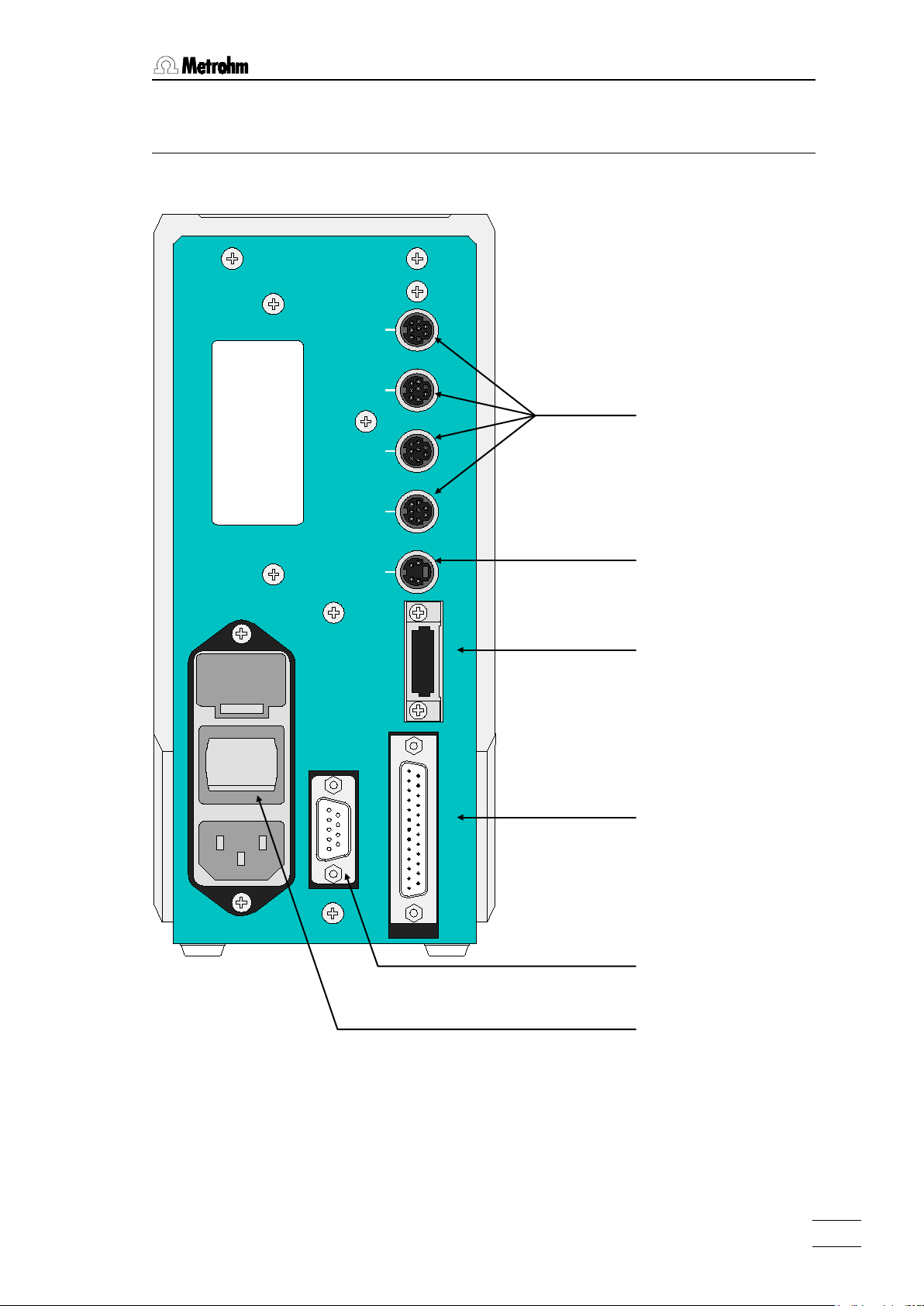

1. Overview

3

- Fire Hazard For continued pr ot ection replace

only with the same type and

rating of fuse

Fuse:

100/115V : 315mAT

230/240V : 160mAT

Keyboard/Display

Rem ot e

RS 232

Pt 100

Dos.4

Dos.3

Dos.2

Dos.1

Made by Metrohm

Herisau Switzerland

WARNING !

Connections for

Connection for

Keyboard connection

Remote

Serial RS 232

Fuses, mains switch

Name plate

1.3.2 Rear view

4 Dosinos

Pt100 temperature sensor

interface

interface

and mains connection

711 Liquino, Instructions for use

Page 10

2.1 Instrument setup

4

Follow the ins

supply. If the instrument is operated with the mains voltage incorrectly set

and/or the wrong mains fuse there may be a fire risk!

2 Installation

2.1 Instrument setup

Packaging

The 711 Liquino is supplied in packaging which provides excellent protection. This includes a shock-absorbing plastic foam lining. Please store this

packaging as it is the only way to guarantee damage-free transport of the

instrument.

Checks

Please check immediately on receipt whether the shipment is complete and

undamaged.

Location

The 711 Liquino is a robust instrument and can therefore be used even under rough conditions in laboratories and factories.

However, care must be taken that it is not exposed to a corrosive atmosphere. Regular care of the instrument is essential if it is used in rough surroundings.

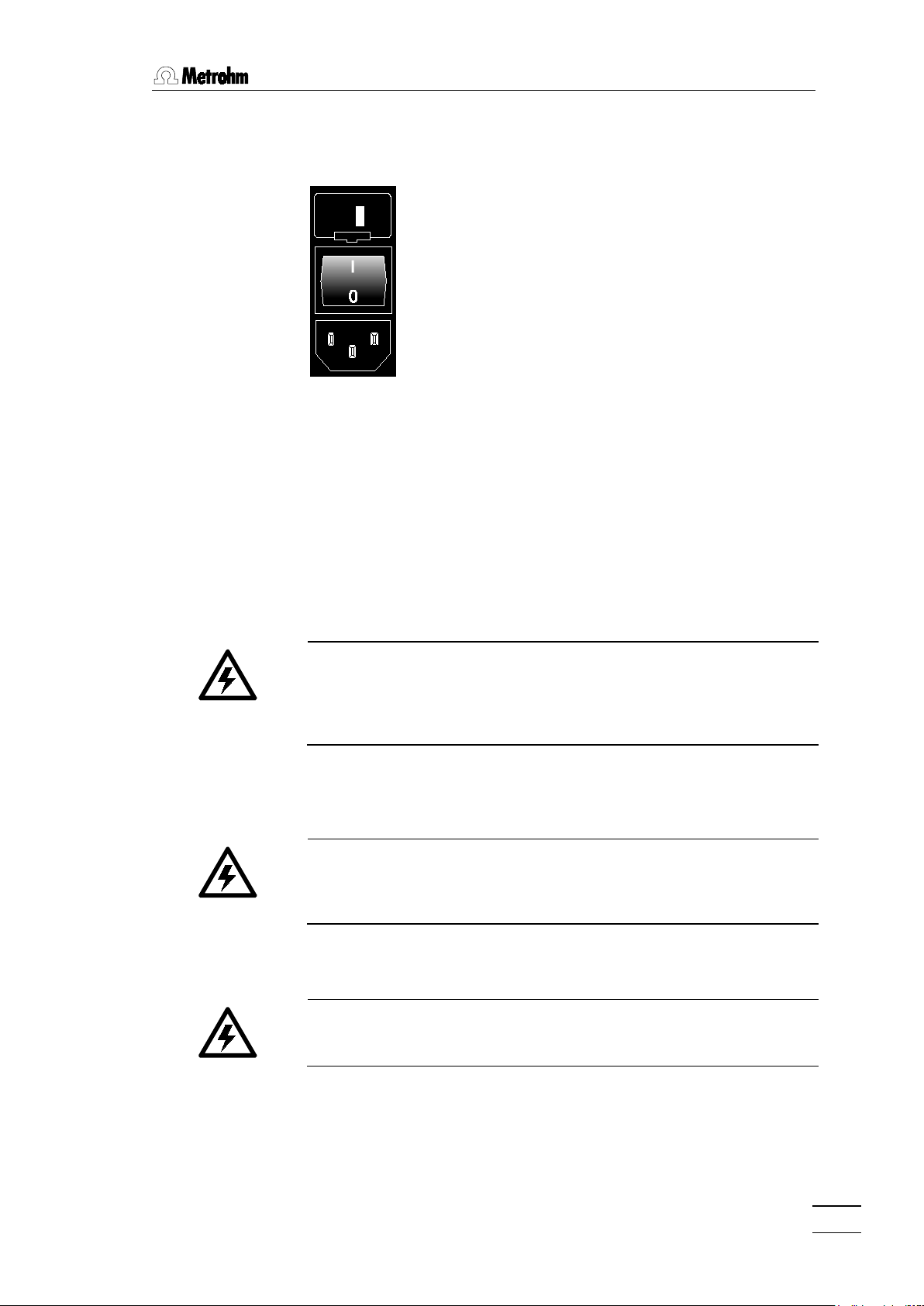

2.1.1 Mains connection

Setting the mains supply

Before switching on the 711 Liquino for the first time check that the mains

voltage set on the instrument (see illustration on following page) corresponds to the local mains voltage. If this is not the case then the correct

mains voltage must be set as follows:

• Pull out mains cable

Remove the mains cable from the mains connector of the 711 Liquino.

• Remove fuse holder

Use a screwdriver to loosen the fuse holder beside the mains connector

and remove completely.

• Check and replace fuses

Remove the built-in fuses for the required mains voltage from the fuse

holder and check their specifications:

100…120 V 0.315 A (slow-blow) Metrohm no. U.600.0011

220…240 V 0.16 A (slow-blow) Metrohm no. U.600.0008

tructions given below to connect the instrument to the mains

• Insert fuses

Exchange fuses if necessary and replace them in the fuse holder.

• Set mains voltage

Remove the white fuse block from the fuse holder and reinsert it so that

the correct mains voltage is visible through the window in the fuse holder.

711 Liquino, Instructions for use

Page 11

2. Installation

5

230

Mains switch

Mains connection

socket

Fuse holder with

window

• Insert fuse holder

Insert fuse holder and press it until it clicks into place.

2.2 Safety information

General

This instrument left our factory in perfect condition from a safety point of

view. The following information must be carefully observed in order to maintain this condition and to ensure hazard-free operation.

Mains connection

The mains cables supplied with the instrument are three-core and are fitted

with an earthing pin. If a different plug must be used then the yellow/green

lead must be connected to the protective earth.

WARNING!

Any break in the earth conductor inside or outside the instrument can represent a source of danger to the operator. Making a break in the earth conductor is forbidden.

Before connecting the plug to the mains supply a check must be made that

the instrument is set to the local mains voltage and that the appropriate fuses are inserted.

WARNING!

When changing a fuse and when setting a different mains voltage the mains

cable must be disconnected from the mains supply.

When replacing fuses care must be taken that voltage, current and type

have been selected correctly (see Technical data, fuses, page 162).

WARNING!

Short-circuiting fuses or the temporary use of incorrect fuses is forbidden.

Repair and maintenance:

If faults or malfunctions occur during the operation of the 711 Liquino it is

recommended that the cable connections with the peripheral units are

checked first for proper functioning (see page 9ff). It may be possible to lo-

711 Liquino, Instructions for use

Page 12

2.2 Safety information

6

out.

cate the source of the fault with the aid of the diagnosis functions. If the

cause of the malfunction cannot be found please contact the Metrohm service department.

The instrument should only be opened when switched on under exceptional

circumstances. As this exposes electrically live components it should only

be carried out by an expert who is familiar with the risks involved.

The instrument must be separated from all electricity sources before it is opened. Make sure that the mains plug has been pulled

Condensers in the instrument may still be charged even when the instrument is no longer connected to the mains supply.

Changing the battery

The connecting wires of the old battery must be cut before desoldering so

that any residual charge which may still be present cannot be shortcircuited. The polarity of the new battery must be taken into account when it

is fitted.

Lithium batteries cannot be recharged and should not be short-circuited or

exposed to temperatures above 70 °C under any circumstances.

Old batteries must be disposed of in an environmentally acceptable way

and must not be burnt.

Static electricity:

The circuit contains components which could be destroyed by electrostatic

charges or whose functions could be affected by them. Work on an open

instrument should only be carried out in ESD-protected surroundings.

Suitable measures:

1. A conductive mat on the work surface connected to the earth conductor

via a resistor of approx. 1 MΩ.

2. Earthed soldering iron.

3. Persons working with components must have their wrists connected to

the earth conductor via a resistor of approx. 1 MΩ.

4. Components and assembled PCBs should only be stored and transported in conductive packaging or foam.

5. New components should be stored in their original packaging until re-

quired.

If it becomes apparent that the instrument can no longer be operated safely

then it should not be used at all.

711 Liquino, Instructions for use

Page 13

2. Installation

7

The keyboard is connected to the keyboard

Dos.1

The notch on the plug must coincide with the

marking on the panel.

2.3 Setup

2.3.1 Connecting the keyboard

socket provided for it on the rear panel of the

instrument.

2.3.2 Connecting the Dosinos

The Dosinos are connected to the sockets ”DOS1” to ”DOS4” on the rear

panel of the 711 Liquino. Press each Dosino plug into the socket until it

clicks into place!

A Dosino should only be connected when the instrument is switched off!

The 711 Liquino only recognizes Dosinos which are already plugged in

when it is switched on.

2.3.3 Connecting a Pt100 temperature sensor

711 Liquino, Instructions for use

The Pt100 temperature sensor 6.1111.030 with 4-wire technology can be

used with the 711 Liquino. It is connected to the socket marked with ”Pt100”

on the rear panel of the instrument.

Page 14

2.4 Memory card

8

Pipet tip

Green pilot lamp

6.1562.040

Black start

button

6.1562.050

Pipetting tubing

Connection to dosing port 1

of the Dosino 700

Connection cable to 711 Liquino (remote

connection)

Screw nipple

2.3.4 Installing the pipetting attachment

The pipetting attachment available as an option is suitable for automatic pipetting functions with a Dosino 700.

Pipet handle

To install the pipetting attachment proceed as follows:

• Loosen the screw nipple on the pipet handle and push it over the pipet

tubing.

• Guide the pipet tubing into the handle and fix the tubing with the screw

nipple.

• Mount the pipet tubing on dosing port 1 of the Dosino dosing unit.

• Insert in the 25-pin connection cable plug into the remote socket of the

Liquino. The second connection cable plug is used to connect another

peripheral unit to the Liquino.

• As soon as the pipet handle is connected the green pilot lamp lights up

to indicate that it is ready for work.

• The angle between the tubing guide and the handle can be adjusted for

strain-free work.

Important: the pipet tubing must always be clean and kink-free!

Pipetting accessories:

Pipet handle 6.1562.040

with spiral pipet tubing, 3 mL 6.1562.050

Pipet tubing, 10 mL 6.1562.100

Pipet tubing, 3 mL 6.1829.020

Pipet tubing, 0.7 mL 6.1562.010

Pipet tips for pipet tubing 0.7 mL, 10 pieces 6.1562.030

Pipet tip holder 6.2052.010

2.4 Memory card

The memory card (e.g. 6.2245.010) must be inserted in the slot on the front

panel of the 711 Liquino so that the front of the memory card (with the type

name) faces to the right. A little pressure is necessary to push the memory

card completely into the slot. Never remove the memory card from the instrument when it is being accessed by the instrument.

711 Liquino, Instructions for use

Page 15

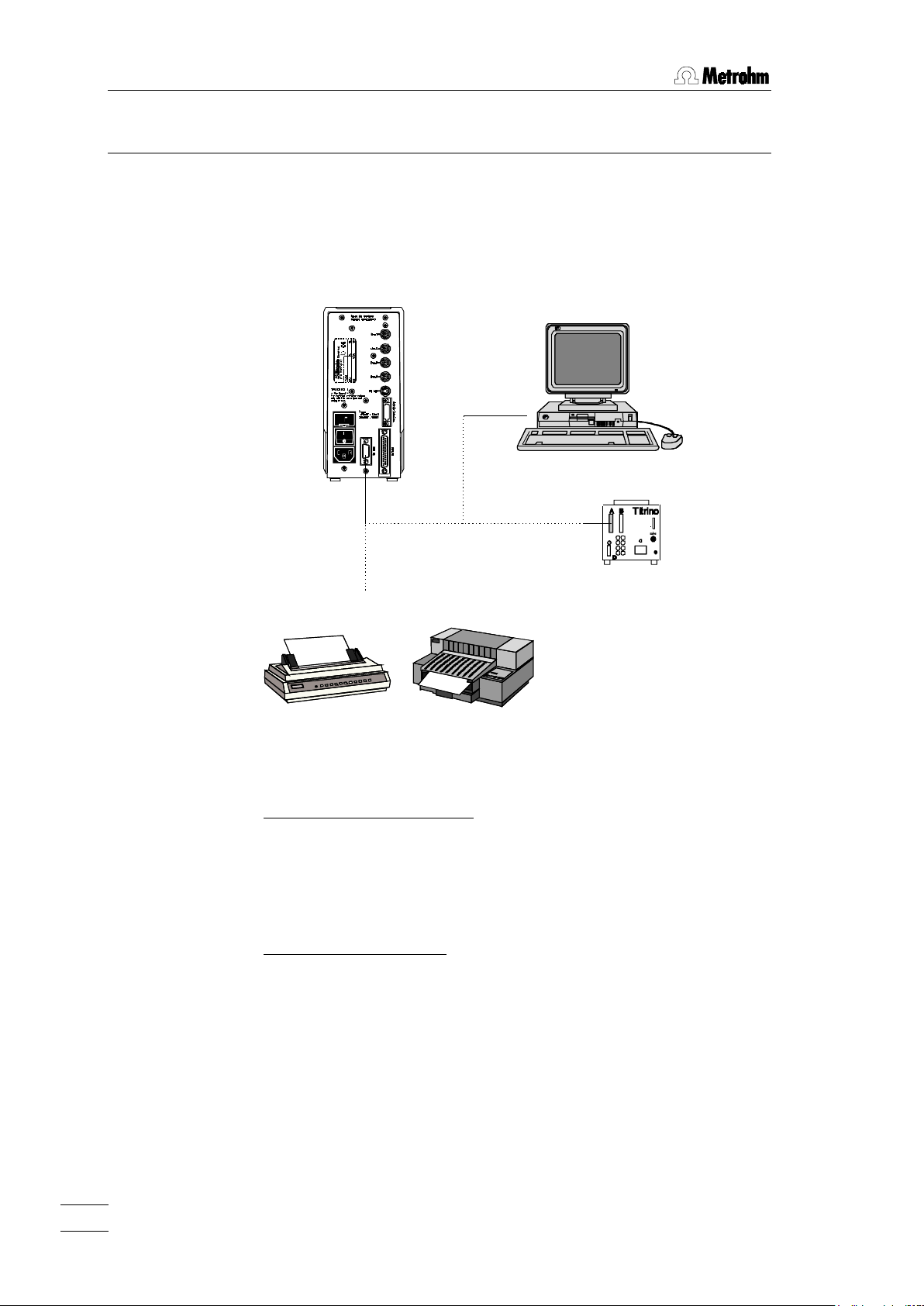

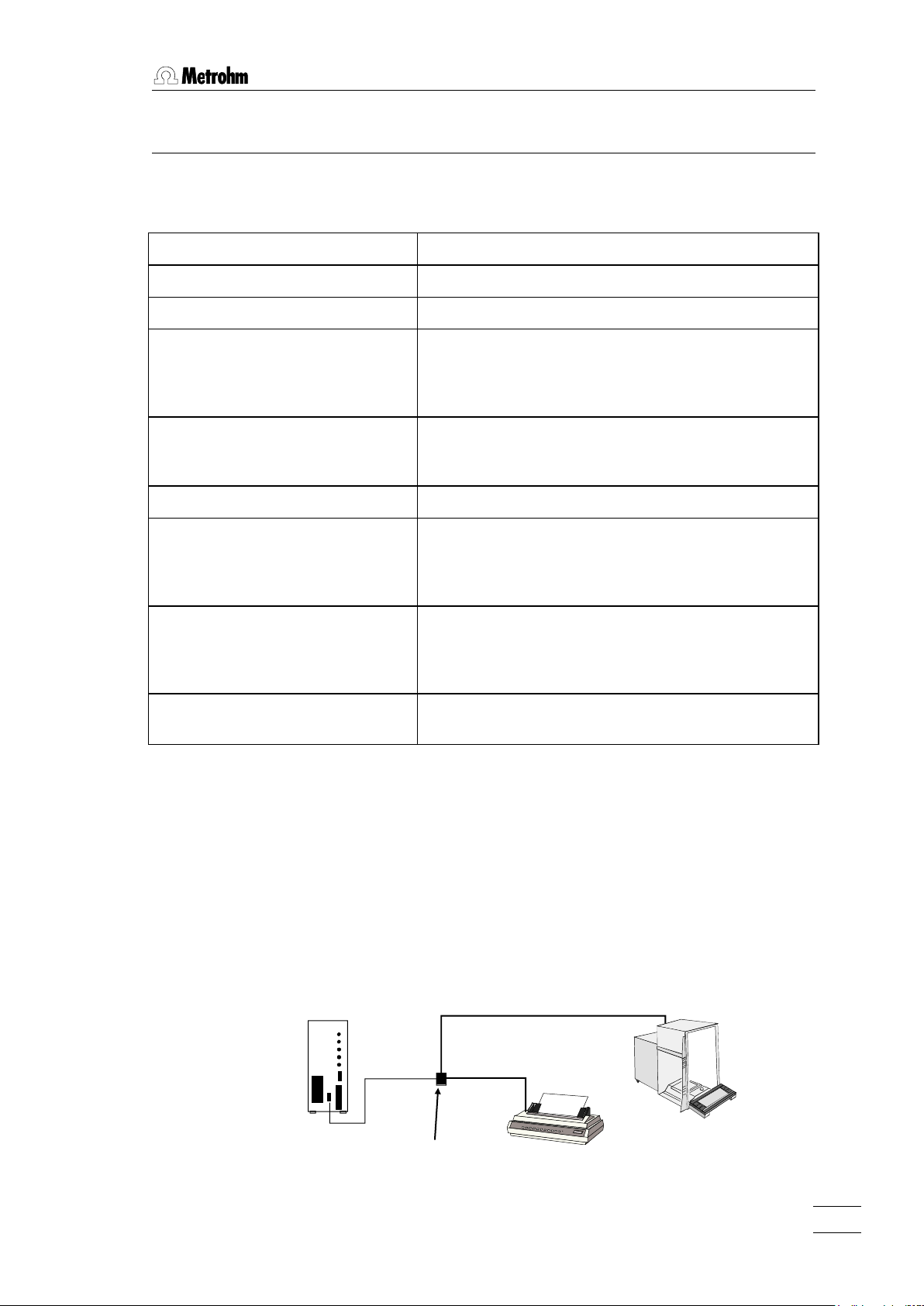

9

RS 232

Remote

Dosimats

pH Meter /

Conductometer

Titrino family

726 Titroprocessor

730 Sample changer

665

..

691

692

712

713

702

751

Seiko

Citizen

Epson

HP

IBM

other devices

e. g. thermostat

730

711 Liquino

726

700 Dosinos

Pt100

Printer

Balance

pumps

heating bath

etc.

AC

DC

731 Relay box

other

devices

Dos.1-4

772 Pump unit

683 Pump

711 Liquino

pumps

heating bath

etc.

...

776

Personal computer

2. Installation

2.5 Connections

Metrohm automated systems with the 711 Liquino

711 Liquino, Instructions for use

Page 16

2.5 Connections

10

Input 0

21

START

Input 1

9

STOP

Input 2

22

HOLD / CONTINUE

Input 3

10

External ready

Input 4

23

Sample Changer ready

Input 5

11

not used

Input 6

24

PIP continue

Input 7

12

not used

Output 0

5

Ready

Output 1

18

Upper limit

Output 2

4

Lower limit

Output 3

17

EOD (End of Determination)

Output 4

3

Activate 1

Output 5

16

Activate 2

Output 6

1

External start

Output 7

2

Start Sample Changer

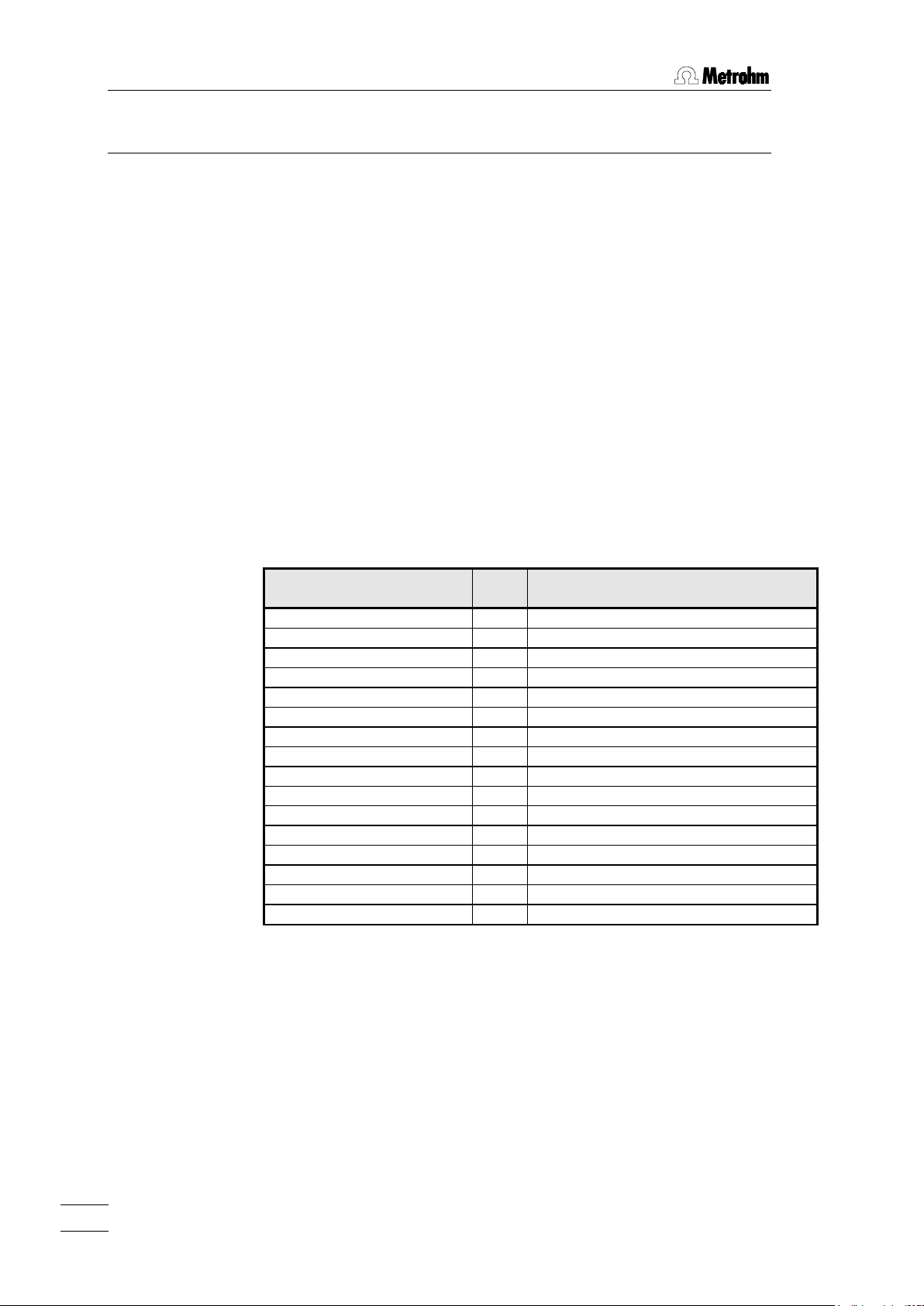

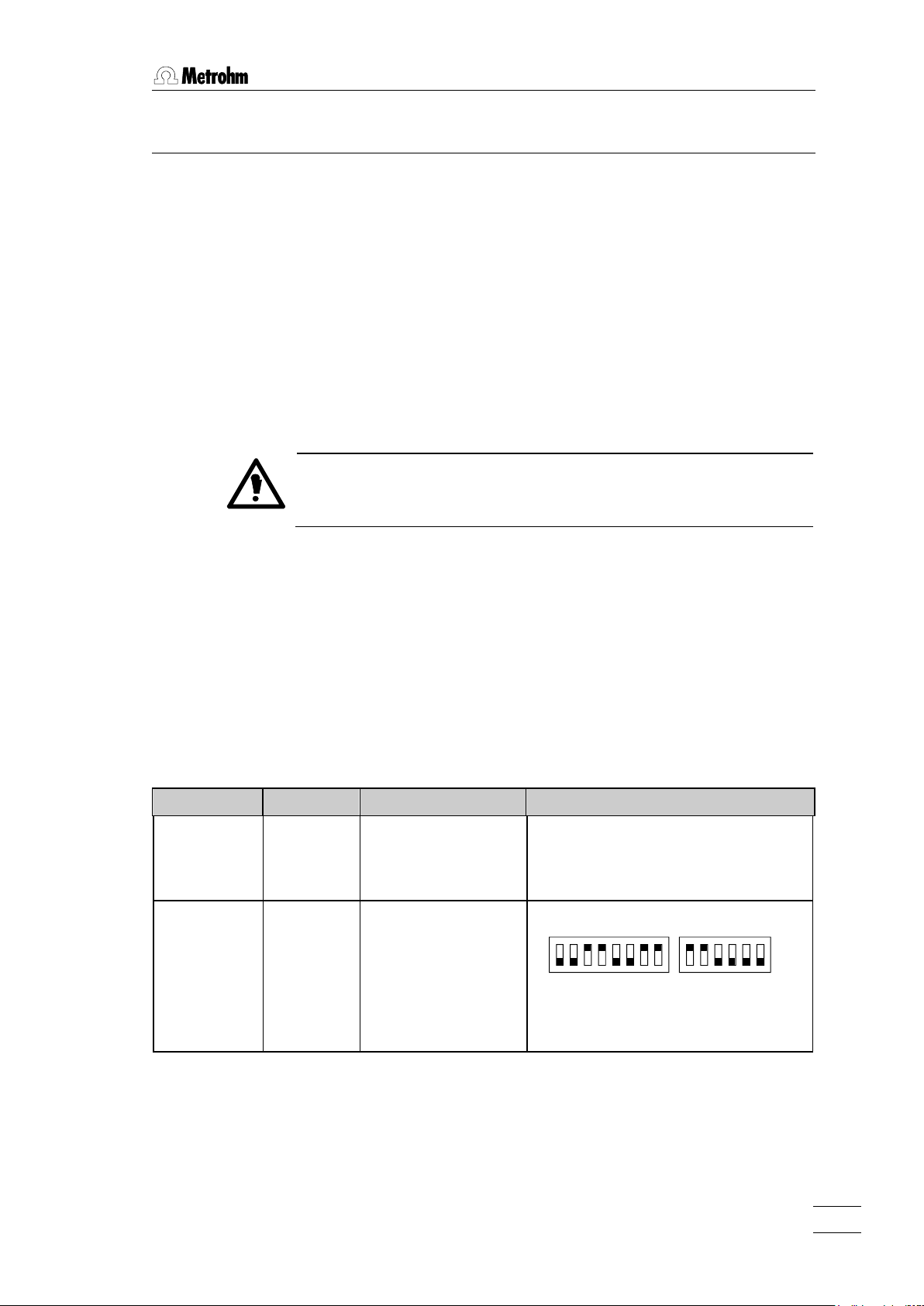

2.5.1 Remote connections

The remote control of instruments within a Metrohm automated system can

(apart from data communication via RS232 interfaces) be carried out in a

simple manner with the help of parallel-switched signal leads, the remote

lines (or I/O lines). Signals can be set statically or transmitted as a signal

pulse (usually approx. 200 ms duration); see SCAN and CONTROL commands, (page 91ff). The signal level is +5 volt (TTL-level) in each case.

The functions which can be used for remote control or monitoring tasks

each occupy a particular remote lead. The remote socket of a Metrohm instrument has input leads (Input0…7, for the control of certain functions, e.g.

START or STOP) and output leads (Output0…8, to display instrument conditions, e.g. 'ready' or 'End of Determination').

The remote connection is normally a 25-pin socket. Different connection cables are available for different types of instrument. The suitable remote cable

is listed in the ‘Instructions for use’ of the corresponding instrument. Special

connection cables can also be made according to the customers’ particular

requirements.

Remote lead occupancy for 711 Liquino:

Remote lead Pin Function

Output leads 8…13 cannot be used.

In the SEQ mode remote leads Input3…7 and Output4…7 can be freely

used with the commands SCAN and CONTROL (see page 91ff).

711 Liquino, Instructions for use

Page 17

2. Installation

11

Note:

B

A

Titrino

C

D

230

cable 6.2141.090

Connection cables

Only Metrohm cables should be used to connect the 711 Liquino to other

instruments as these are the only ones with which interference-free data

transmission can be guaranteed.

Remote cables for the 711 Liquino always have a name on the end of the

cable to indicate the instrument with which the particular plug is intended to

be used and which connection it should be plugged in to.

Example:

Titrino B

692 / 712 / 71 3

Liquino — Titrino

Cable 6.2141.090 is used in the SMPL mode. Details can be found on page

106ff.

Control commands can also be used in an SEQ method, for example:

>SEQ sequence st ep 4 ( CONTROL command)

pat t er n * 1* * ----

starts Titrino (start pulse)

>SEQ sequence st ep 5 ( Pause command)

pause 00: 00: 01

>SEQ sequence st ep 6 ( CONTROL command)

pat t ern *0**----

wait 1 s

reset remote interface

(end pulse)

>SEQ sequence st ep 7 ( SCAN command)

pattern ****1---

wait for ready message from Titrino

711 Liquino, Instructions for use

Page 18

2.5 Connections

12

711

B

A

Titrino

C

D

230

683 Pump Unit

I

0

683 Pump Unit

I

0

730

cable 6.2141.100

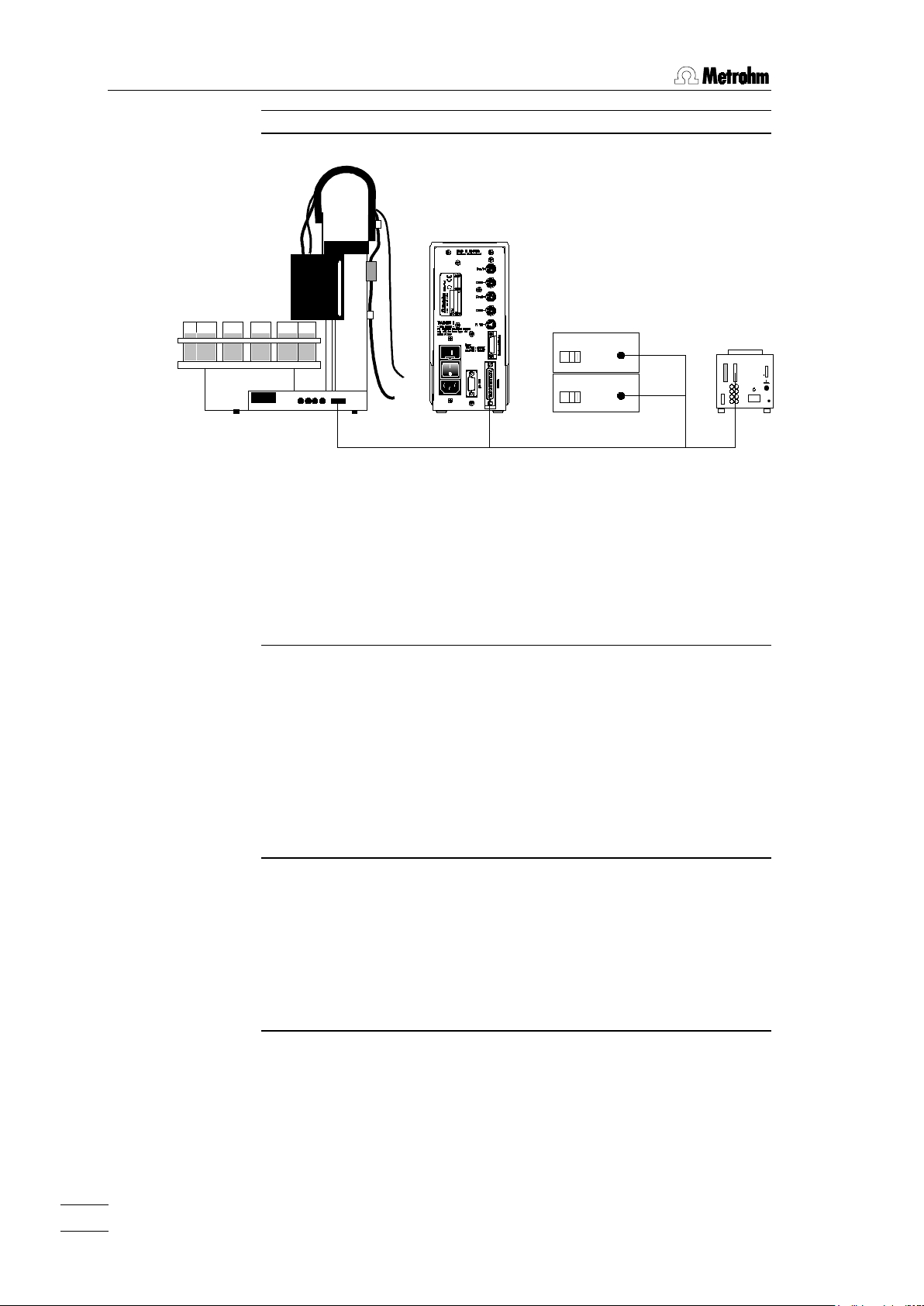

Liquino — Titrino — 683 Pump — 730 Sample Changer

Cable 6.2141.100 is used for the SMPL mode if aspiration and rinsing the titration vessel are to be carried out as quickly as possible (with 2 x Pump

683). The sample changer connection can be left open if no sample chang-

er is required.

The Titrino, the pumps and the sample changer can also be addressed with

the control commands of a SEQ method, for example:

Start Titrino

>SEQ sequence st ep 4 ( CONTROL command)

pat t er n * 1* * ---- starts Titrino (starts pulse)

>SEQ sequence st ep 5 ( Pause command)

pause 00: 00: 01

>SEQ sequence st ep 6 ( CONTROL command)

pat t er n * 0* * ----

wait 1 s

starts Titrino (ends pulse)

>SEQ sequence st ep 7 ( SCAN command)

pattern ****1---

wait for ready message from Titrino

Run pump 1 for 10 s

>SEQ sequence st ep 8 ( CONTROL command)

pattern ***1---- switches on 1st 683 pump

>SEQ sequence st ep 9 ( Pause command)

pause 00: 00: 10

wait 10 s

>SEQ sequence st ep 10 ( CONTROL command)

pattern ***0----

switches off 1st pump 683 again

Run pump 2 for 1 min 5 s

>SEQ sequence st ep 11 ( CONTROL command)

pat t er n * * 1* ---- switches on 2nd pump 683

>SEQ sequence st ep 12 ( Pause command)

pause 00: 01: 05

wait 1 min 5 s

>SEQ sequence st ep 13 ( CONTROL command)

pat t er n * * 0* ----

switches off 2nd pump 683 again

711 Liquino, Instructions for use

Page 19

2. Installation

13

711

B

A

Titr

ino

C

D

7

30

cable 6.9921.165

Command to

730 Sample Changer

SCN:Rm: ready1 ←

CTL:Rm: START device1→

Switch sample changer to next sample

>SEQ sequence st ep 14 ( CONTROL command)

pat t er n 1* * * ---- switches sample changer 1 sample further

*)

(start pulse)

>SEQ sequence st ep 15 ( Pause command)

pause 00: 00: 01

>SEQ sequence st ep 16 ( CONTROL command)

pat t er n 0* * * ----

wait 1 s

resets remote interface

(end pulse)

>SEQ sequence st ep 17 ( SCAN command)

pattern ***1*---

wait for ready message from sample

changer

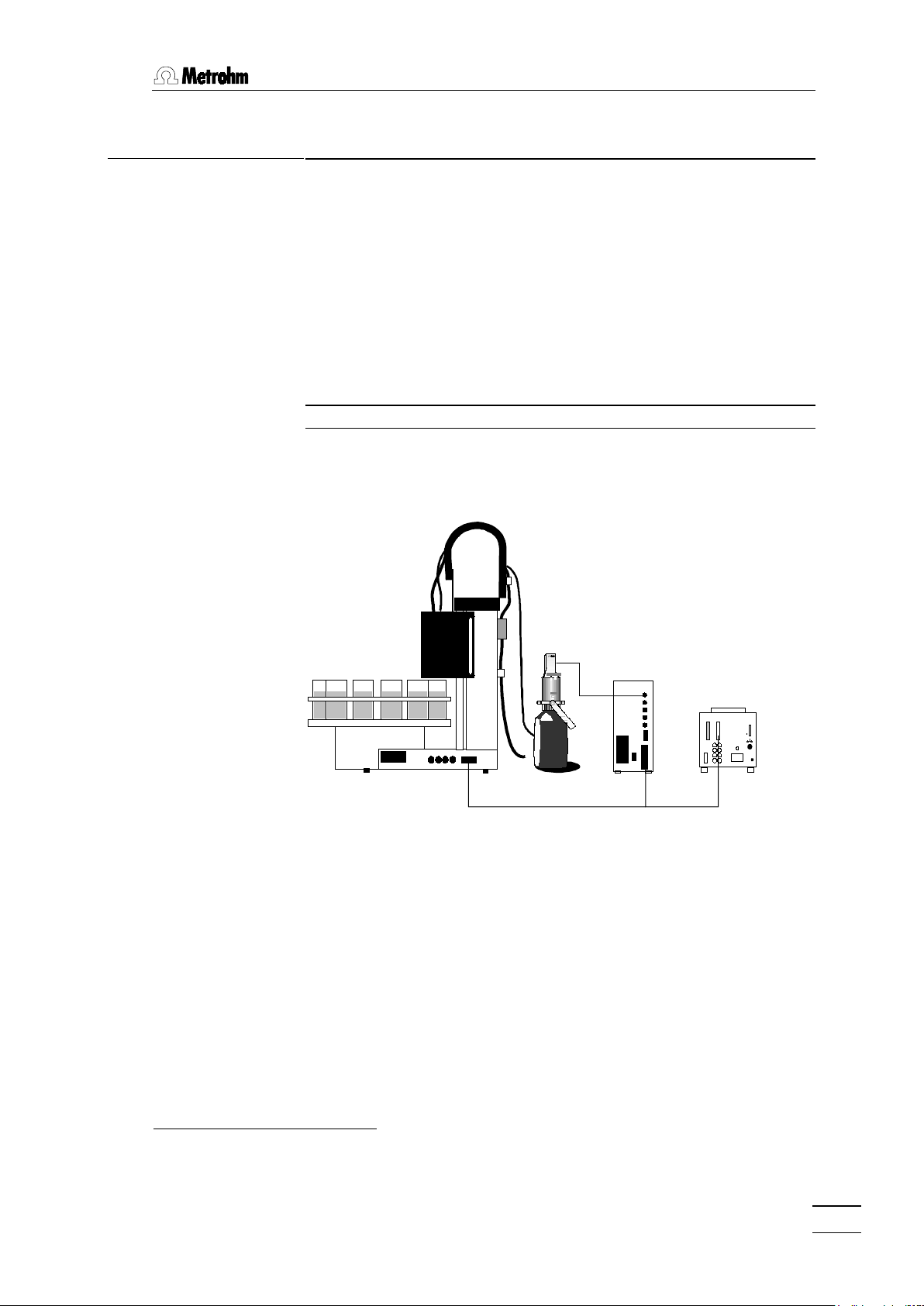

711 Liquino – 730 Sample Changer – Titrino

730 Sample Changer with Titrino and 711 Liquino for automated pipetting of

different samples on the sample changer into a special beaker on the sample rack.

The 711 Liquino can be used in any automated system for pipetting tasks

(PIP mode). In this case the 730 Sample Changer controls the working process. The 711 Liquino is used in the PIP mode. The determination of the

samples is carried out by the Titrino which, like the Liquino, is started from

the sample changer.

This arrangement of instruments requires a special remote cable

(6.9921.165). Other special cables for similar instrument combinations are

available on request.

*)

For this function the sample changer must be appropriately programmed with Scan and Control com-

mands!

711 Liquino, Instructions for use

Page 20

2.5 Connections

14

>st ar t sequence

3 Lift: 1: shift mm

1 Lift: 1: shift mm

711

731

772

cable

6.2125.100

Dosinos

heating bath

mains cable

Example of a sample changer method:

1 CTL: Rm: INIT

>sampl e sequence

1 CTL: Rm: START devi ce1

2 SCN: Rm: r eady1

4 CTL: Rm: *********1****

5 Wai t 1 s

6 CTL: Rm: *********0****

7 Mov e: 1: sampl e

8 Li f t : 1: wor k mm

9 CTL: Rm: *********1****

10 Wai t 1 s

11 CTL: Rm: *********0****

12 SCN: Rm: r eady1

13 Mov e: 1: spec. 1

14 Li f t : 1: wor k mm

15 CTL: Rm: *********1****

16 Wai t 1 s

17 CTL: Rm: *********0****

18 SCN: Rm: end1

19 St i r : 1: ON s

20 CTL: Rm: START devi ce2

2 1 SCN: Rm: e nd2

22 St i r : 1: OFF s

23 Pump: 1. 1: 12 s

24 Pump: 1. * : 10 s

25 Pump: 1. 1: 12 s

28 NOP

>f i nal sequence

2 NOP

← Initialize remote interface

← Start Liquino (PIP mode)

← Wait for pipetting step

← Lift out of sample vessel

← Switch pipetting further (corresponds to

<ENTER>)

— separating bubble is aspirated —

← Reset remote interface

← Position sample beaker

← Immerse pipet tubing in sample

← Switch pipetting further (corresponds to

<ENTER>)

← Reset remote interface

← Wait for next pipetting step

← Move to titrating beaker

← Pipet tubing in titrating beaker

← Switch pipetting further (corresponds to

<ENTER>)

← Reset remote interface

← Wait for end of PIP mode

← Stirrer on

← Start Titrino

← Wait for end of determination

← Switch off stirrer

← Aspirate titration beaker

← Rinse titration beaker

← Aspirate titration beaker

— sample is aspirated —

— sample is ejected —

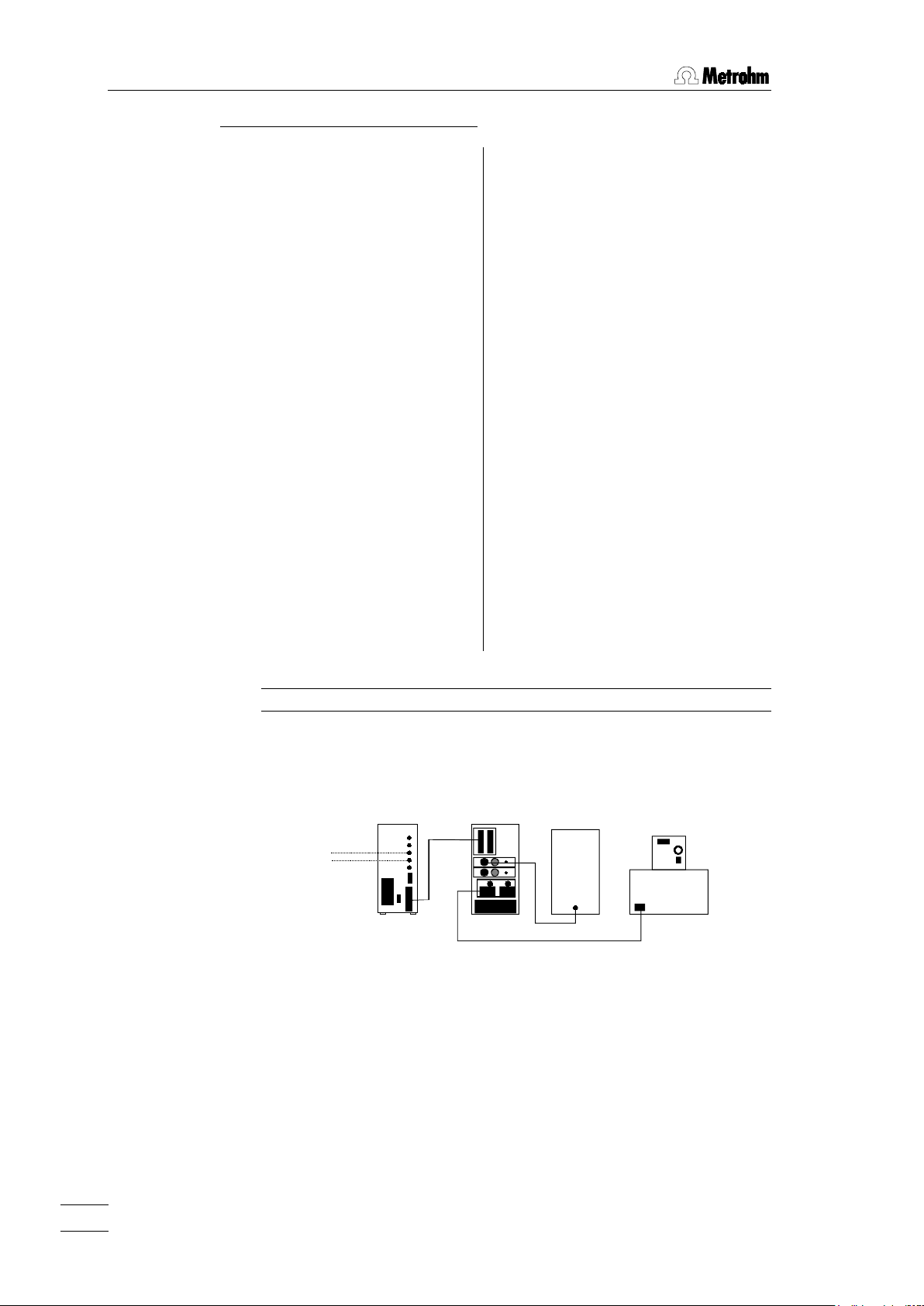

711 Liquino – 731 Relay Box – 772 Pump Unit – Heating Bath

Liquino with 772 Pump Unit as delivery or aspiration pump and a heating

bath.

With the aid of a Metrohm 731 Relay Box the output leads of the 711 Liquino

can be monitored and, according to their line conditions, two low-voltage

d.c. voltage outputs and two mains voltage outputs can be switched.

In this way the heating bath can be switched automatically via the temperature monitoring function. If the measured temperature falls below a certain

value the bath is heated up.

A connected pump (e.g. the Metrohm 772 Pump Unit) can be selectively

switched on or off during the method procedure.

711 Liquino, Instructions for use

Page 21

2. Installation

15

731 Relay Box settings:

Connect 772 Pump Unit to DC1 (or DC2)

Output voltage: 18 or 24 volt

Remote address selection disk DC1: 7 (=Output 7)

Connect heating bath to AC1 (or AC2,

mains voltage)

Remote address selection disk AC1: 2 (=Output 2)

711 Liquino settings

Temperature monitoring

XDOS mode (contained in SEQ mode):

Par amet er s

>XDOS moni t or i ng

t emperat ur e: on

low limit xx°C

upper limit ...

action: ...

al ar m pi ns: under

Control commands for the pump

SEQ mode

Switch on pump:

command: CONTROL

i nt er f ace: Remot e

pat t er n 1* * * ---- (Output 7)

(switch off with

0***----)

711 Liquino, Instructions for use

Page 22

2.5 Connections

16

cable 6.2134.040 (9-pin/9-pin)

or 6.2134.050 (9

printer cables: see page 17f

711

2.5.2 Serial connections

A wide range of possible connections can be made at the RS232 interface.

As well as all Metrohm instruments which are equipped with the Metrohm

remote control language, a printer (requirement: serial interface or parallel/serial converter) or a personal computer (PC) can also be connected.

Any instrument from another manufacturer which is equipped with a serial

RS232 interface can also be connected.

-pin/25-pin)

A requirement for correct data transmission is that the transmission parameters are correctly set; these must coincide with the interface settings of the

connected instrument (see following page).

Control commands (examples):

>SEQ sequence st ep 4 (Control command)

st r i ng &M; $G

starts Metrohm instrument

>SEQ sequence st ep 6 (Control command)

st r i ng &M; $S

stops Metrohm instrument

Input data query (example):

>SEQ sequence st ep 5 (Scan command)

st r i ng * R"

wait for ready message from

Metrohm instrument

The following section provides information about the settings and cables

necessary to connect a printer.

711 Liquino, Instructions for use

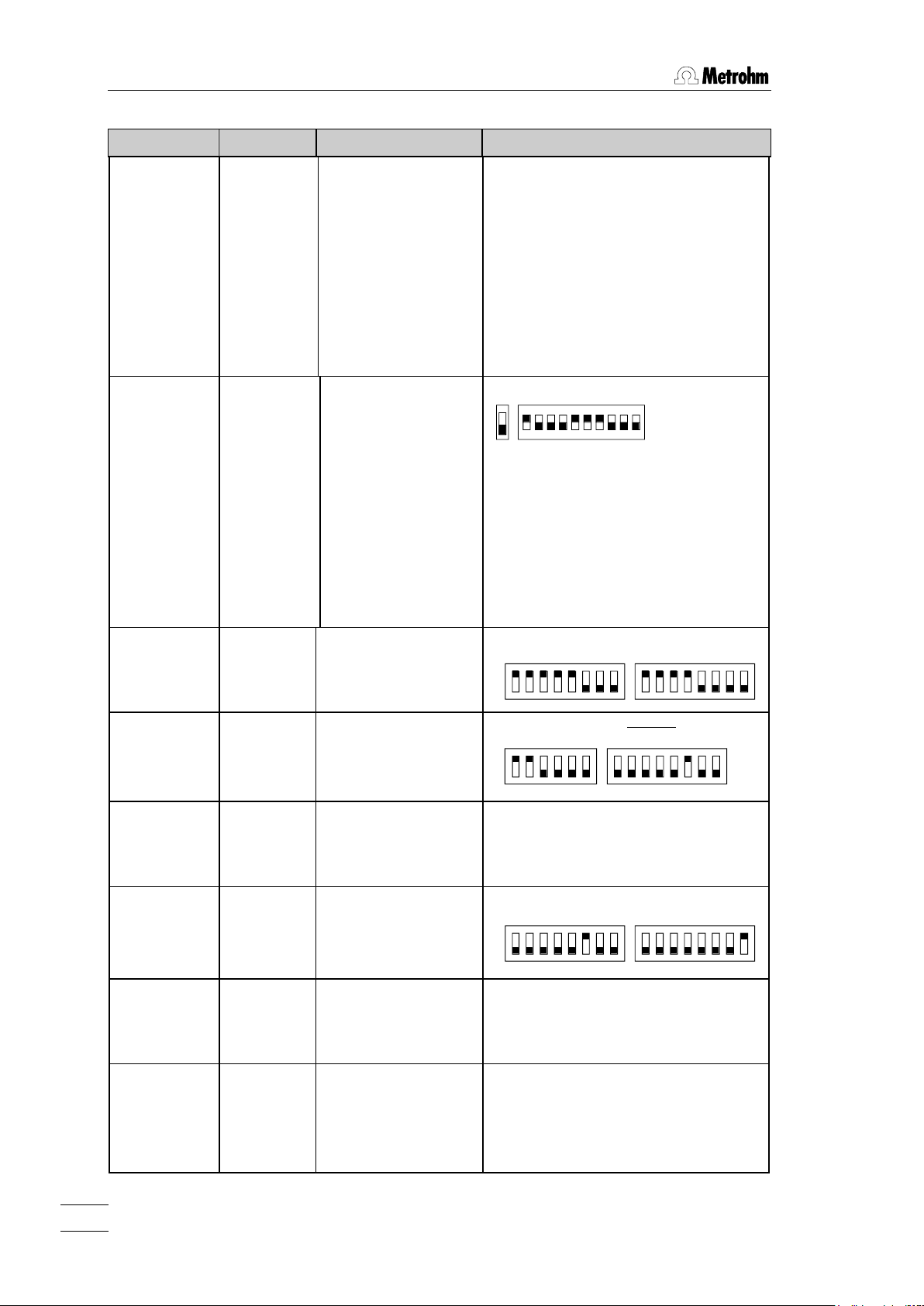

Page 23

2. Installation

17

The Liquino must be switched off before a printer is connected to the RS232

interface!

Printer

Cable

RS232 settings

Settings on printer

IBM Proprinter

6.2125.050

+

6.2125.010

baud rate: 9600

data bit: 8

stop bit: 1

Parity: none

handshake: Hardware

send to: IBM

see printer manual

Seiko

DPU-411

6.2125.020

+

6.2125.010

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Seiko

DIP switch settings:

DIP01 DIP02

on

off

1 2 3 4 5 6 7 8 1 2 3 4 5 6

Depending on the set dialog language, the

adjustable 7-bit ASCII character set of the

printer will be set automatically to the national character set.

2.5.3 Connecting a printer

Printers with the following printer drivers can be connected:

IBM IBM Proprinter and printers with IBM emulation

Epson Epson printers and printers with Epson emulation

Seiko Seiko printer DPU-411 or DPU-414

Citizen Citizen printer IDP560 RS

HP HP printers and printers with HP PCL3 emulation

If you wish to connect a different printer then ensure that this can emulate

one of the printer modes supported by the 711 Liquino.

Most printers with a serial interface are connected with cable 6.2134.050.

Printers with a parallel interface require a serial/parallel converter (e.g.

2.145.0300) and cable 6.2125.020 + adapter cable 6.2125.010.

The interface parameters are entered in the configuration menu under

‘>RS232 settings’. The printer type must also be entered in the configura-

tion menu under ‘>Peripheral units’ and ‘send to:’

If you use an A4 printer and the graphics do not cover the whole width of the

page then you can proceed as follows:

When the instrument is switched on keep the <CONFIG> key pressed

down. In this way you access the setup menu. Press the <> key and

<ENTER>. You can now alter the relative width and height of the graphics.

In each case press <ENTER> after the entry.

The following table provides information about the connection of several selected printers.

711 Liquino, Instructions for use

Page 24

2.5 Connections

18

Printer

Cable

RS232 settings

Settings on printer

Seiko

DPU-414

6.2125.130

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Seiko

Recommended DIP switch settings:

Dip SW-1 Dip SW-2 Dip SW-3

1 OFF ON ON

2 ON OFF ON

3 ON ON ON

4 OFF ON ON

5 ON ON OFF

6 OFF ON ON

7 ON OFF ON

8 ON OFF ON

Depending on the set dialog language, the

adjustable 7-bit ASCII character set of the

printer will be set automatically to the national character set.

Citizen

IDP562-RS

6.2125.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Citizen

DIP switch settings:

1 2 3 4 5 6 7 8 9

10

ON

SSW1

The adjustable 7-bit ASCII character set of

the printer can only be set to the national

character set by switching DIP switches 4

and 5 in the printer:

4 5 Character set

OFF OFF USA

ON ON United Kingdom

ON OFF France

OFF ON Germany

No special Spanish character set is available (it is best to select French).

Epson

with 6-pin

round plug

6.2125.040

+

6.2125.010

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Epson

DIP switch settings:

SW1 SW2

on

off

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

Epson

with additional

serial interface

#8148

6.2134.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Epson

DIP switch settings at interface:

SW1 SW2

on

off

1 2 3 4 5 6 7 81 2 3 4 5 6

Epson LX-300

6.2134.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: Epson

see printer manual

HP Deskjet

with serial interface

6.2134.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: HP

DIP switch settings:

A B

on

off

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

HP Laserjet

with serial interface

6.2134.050

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: HP

see printer manual *

HP Deskjet/

Laserjet

with parallel

interface

6.2125.020

+6.2125.01

0

+ serial/

parallel converter

2.145.0300

baud rate: 9600

data bit: 8

stop bit: 1

parity: none

handshake: Hardware

send to: HP

see printer manual *

* The printer must be set to the PC-8 character set. PCL3 command:

esc(10U

711 Liquino, Instructions for use

Page 25

2. Installation

19

Balance

Cable

Sartorius MP8, MC1

6.2134.060

Mettler AB, AG (LC-RS25)

supplied with balance

Mettler AM, PM

from Mettler: ME 33995: green wire to Pin 2, brown wire to

Pin 3, white wire to Pin 7, yellow wire to Pin 20 of the 25-pin

plug

+ 6.2125.010 25-pin/9-pin adapter

Mettler interface 016

cable supplied with interface 016: red wire to Pin 3, white

wire to Pin 7 of the 25-pin plug

+ 6.2125.010 25-pin/9-pin adapter

Mettler interface 011 or 012

6.2125.020 + 6.2125.010

Mettler AT

from Mettler: ME 33995: green wire to Pin 2, brown wire to

Pin 3, white wire to Pin 7, yellow wire to Pin 20 of the 25-pin

plug

+ 6.2125.010 25-pin/9-pin adapter

AND models ER-60, 120, 180, 182

models FR-200, 300

models FX-200, 300, 320

with RS232 interface (OP-03)

6.2125.020 + 6.2125.010

Precisa, balances with RS232C interface

6.2125.080 + 6.2125.010

711

6.2125.010

printer cable

balance cable

6.2125.030

2.5.4 Connecting a balance

The following balances can be connected to the RS232 output of the

711 Liquino:

The balance type must be preselected on the 711 Liquino with the

<CONFIG> key under ‘>Peripheral units’.

The weight will be transmitted as a number with up to 6 places, together

with sign and decimal point. Units and control characters sent by the balance will not be transmitted.

For the simultaneous connection of printer and balance the adapter cable

6.2125.010 + with junction plug 6.2125.030 are required.

If the balance only works with 7 bit and the printer only works with 8 bit then

the balance parity must be set to "space" while the 711 Liquino and printer

run with 8 bit, "no parity".

711 Liquino, Instructions for use

Page 26

3.1 The Liquino concept

20

3 Introduction

3.1 The Liquino concept

The 711 Liquino is designed so that, together with one or more 700

Dosinos, it can automate a wide range of tasks in the laboratory. Everything

which falls under the general heading of 'liquid handling', i.e. the transport of

liquids in any form, belongs to its range of applications. Its functions can be

divided up into three steps.

• Simple manual dosing and dispensing with up to four dosing devices.

• Automated procedures for frequently reoccurring and defined tasks. The

preset modes in the instrument are used for this. When they are appropriately set they can be stored as methods in the Liquino itself or on a

memory card and can be reloaded at any time.

• Complex process sequences, which can be made up from several indi-

vidual methods or modes with additional auxiliary commands as required. In this way a large number of instruments can be controlled for

use in demanding analytical or synthesis units.

The practical 700 Dosinos are used as dosing instruments; they can be

conveniently operated with the functions and commands of the 711 Liquino.

Special functions (PREP, EMPTY) are available for preparatory work (i.e.

bubble-free filling and rinsing of the tubing) and emptying dosing units

when a reagent needs to be changed. In order to carry out these procedures in as comfortable and reagent-saving manner as possible you can

define different types of dosing unit. As the length and diameter of the tubing used can be defined the 711 Liquino is able to calculate and then use

the optimal volumes for the above-mentioned functions.

With the help of the special GLP mode the 711 Liquino can be used to validate all your dosing units, i.e. to determine their accuracy. In this way GLPconform work can be ensured and also documented.

The dosing procedures in the GLP mode have been optimized and realized

for the 700 Dosino in such a way that meaningful characteristic values can

be determined; these allow detailed information about the accuracy of the

dosing cylinder to be obtained.

You can adapt the necessary limits for the assessment of the reliability of

the dosing accuracy yourself to suit your requirements. The limits recommended by Metrohm are set as standard. We recommend that you use

these limits.

711 Liquino, Instructions for use

Page 27

3 Introduction

21

CONFIG

A

The dialog language, date and time can be set in the configuration menu.

J

ENTER

YES

• and then <> and <ENTER>.

DOS NR

SELECT

P

•

• With <ENTER> the entry ‘dialog: english’ can be accepted.

CLEAR

Q

• The number keys are used to enter the current date in the format year-

lete the entry. (The date is “year 2000 safe“!)

•

• Enter the current time and confirm it with <ENTER>.

QUIT

NO

•

3.2 Tutorial

This tutorial will introduce you step by step to the operation of the Metrohm 711

Liquino. It is arranged so that you can work through it from the beginning to the

end and in this way become familiar with the most important functions of the instrument. You will be guided through each section step by step so that you will

be able to carry out the simplest settings. You can also carry out further fine adjustments. The necessary information for this can be found in section 4.

3.2.1 Basic configuration

The most important basic settings are carried out as follows:

• Press <CONFIG>

Di s pl ay : conf i gur at i on

>per i pher al uni t s

Di s pl ay : >auxi l i ar i es

di al og: engl i sh

The colon in this menu entry indicates that parameters can be selected

from a list here. Press the <SELECT> key several times in order to

view the different selection possibilities and become familiar with this

operating mode.

Di s pl ay : >auxi l i ar i es

di al og: deut sch

Di s pl ay : >auxi l i ar i es

dat e: 90- 01- 01

month-date. If a mistake is made then <CLEAR> can be used to de-

The entry is accepted with <ENTER>.

Di s pl ay : >auxi l i ar i es

t i me: 01: 00: 00

Di s pl ay : >auxi l i ar i es

device l abel ********

Press <QUIT> 2x in order to exit the configuration menu.

711 Liquino, Instructions for use

Page 28

3.2 Tutorial

22

Except for the "Sampling dosing unit" in the SMPL mode the standard port

occupancy for all modes is as follows:

Port 1: dosing unit output

Port 2 (bottle): refilling opening

CONFIG

A

• Press <CONFIG> and then 3x <>.

ENTER

YES

•

DOS NR

SELECT

P

• One of the ten configurable dosing units can be selected with the

Di s pl ay : >dosi ng uni t s 1

3.2.2 Defining dosing units

In order for the complete tubing system of a Dosino to be fully filled with the

reagent solution without any air bubbles the 711 Liquino must know the dimensions of the connected tubing. For this reason a dosing unit can be de-

*)

fined in the configuration menu and then selected for the method.

Di s pl ay : conf i gur at i on

>dosi ng uni t s

Access the submenu ‘dosing units’ with <ENTER>.

Di s pl ay : > dosi ng uni t s

dos. uni t : D1

<SELECT> key. Press <ENTER> to access the settings for the corresponding dosing unit. The index for the dosing unit is located in the top

right-hand corner of the display.

Di s pl ay : >dosi ng uni t s 1

I D D1

• Enter an identification text for the dosing unit or leave the preset entry

as it is. Text input is explained on page 63.

• Accept the entry with <ENTER>.

Di s pl ay : >dosi ng uni t s 1

l engt h t ube1 400 mm

• Now enter the length of tubing at Dosino port 1 (for tandem dosing

including the tubing length up to the T-piece) and accept the entry with

<ENTER>.

Di s pl ay : >dosi ng uni t s 1

di am. t ube1 2. 0 mm

• The inner diameter of the tubing at Dosino port 1 can be entered here

and confirmed with <ENTER>.

Di s pl ay : >dosi ng uni t s 1

l engt h t ube2 250 mm

• Now enter the length of the tubing at Dosino port 2 (bottle) and accept

the entry with <ENTER>.

*)

In a single method ‘standard’ can also be selected for the dosing unit used. For the modes XDOS, CONT

and GLP ‘standard’ means:

Port1 (dosing port): L = 40cm, D = 2mm

Port2 (bottle): L = 25cm, D = 2mm.

For PIP ‘standard’ means: Port1 (pipetting tubing): L = 150cm, D = 2mm

Port2 (bottle): L = 25cm, D = 2mm.

For SMPL ‘standard’ means: Port1 (sample tubing): L = 40cm, D = 2mm

Port2 (measuring cell): L = 16cm, D = 2mm

Port3 (rinsing agent): L = 50cm, D = 2mm.

711 Liquino, Instructions for use

Page 29

3 Introduction

23

di am. t ube2 2. 0 mm

QUIT

NO

• The dosing unit has now been defined. Press <QUIT> 2x to exit the

• The inner diameter of the tubing at Dosino port 2 can be entered here

and confirmed with <ENTER>.

Di s pl ay : >dosi ng uni t s 1

l engt h t ube3 0 mm

• As no tubing is connected to Dosino ports 3 and 4 the tubing lengths

must be set to 0 mm. Check this for port 3, press <ENTER> and

check the value for port 4 (the diameter is not requested if the length

has been set to 0 mm). Press <ENTER> again.

Di s pl ay : >dosi ng uni t s 2

I D D2

configuration menu.

711 Liquino, Instructions for use

Page 30

3.2 Tutorial

24

MANUAL

MAN OFF

D

DOS NR

SELECT

P

• Now use the <DOS NR / SELECT> key to select the connected dosing

PREP

4

L

•

DOSING

7

G

START

Z

• If you now press the <START> key and hold it down then dosing will take

3.2.3 Dosing and dispensing

This is where you learn the simplest functions of the Liquino: manual dosing

and dispensing.

Fit a reagent bottle with a dosing unit and a Dosino and connect the Dosino

to the Liquino. Select, e.g. connection socket 'Dos. 1' or 'Dos. 2' for this.

Now switch the 711 Liquino briefly off and then on again. In this way the instrument recognizes the connected Dosino.

Details about setting up dosing units can be found in section 6.1.2, page

143.

Now immerse the dosing tip, which must be connected to Dosino Port 1 by

tubing, in a rinsing beaker.

• Switch the Liquino to the manual operating mode. Press the <MANUAL>

key.

Di spl ay: manual

r eady 0. 000 mL

device. On the 711 Liquino keyboard there are four LEDs. If you have connected the Dosino to socket '

SELECT> key once so that the LED '

Dos. 2' then press the <DOS NR /

DOS 1' lights up.

<1>

• Prepare the dosing unit by pressing the <PREP> key.

The PREP function is used to rinse the tubing and fill the dosing cylinder

free from bubbles.

Di s p l ay: wast e por t :

tip(1) or flask(2)?

• Now select whether the rinsing volume of the reagent solution should be

discharged via the dosing tip (connected to Dosino Port 1) or returned to

the storage bottle (via filling Port 2 of the Dosino). Press <

1>.

Di spl ay: manual

PREP r unni ng. . .

• The tubing is now automatically rinsed with the required volume of

reagent. Excess reagent solution is discharged into the rinsing beaker.

Wait until the Liquino reports 'ready'.

Now exchange the rinsing beaker for the vessel into which you wish to

carry out dosing.

• Press the <DOSING> key.

Di spl ay: man u a l DOSI NG

r eady 0. 000 mL

place when the Dosino has switched the stopcock. You will notice that the

dosing speed increases slowly. If you release the <START> key and then

press it down again it will again start dosing at a slow speed which is

gradually increased.

This behavior can be very useful when you need to dose accurately, e.g.

to fill a volumetric flask up to the mark.

711 Liquino, Instructions for use

Page 31

3 Introduction

25

•

J

<ENTER>

• Press the <CONFIG> key and the <> key twice.

•

START

Z

• Start dosing again by pressing the <START> key; you will see that the

FILL

5

M

•

If you do not want the dosing speed to increase or you require a quicker

increase in the dosing speed then you can set this in the configuration.

A

CONFIG

2x

<ENTER>

<ENTER>

<SELECT>

<ENTER>

Di spl ay: conf i gur at i on

>manual

• Here you will find the submenu with the settings which are effective for

manual functions.

Di spl ay: >manua l DOS1 ← dosing connection

dos. uni t : def aul t

• In the first line, above right, the address of the dosing connection to

which the particular setting applies is shown. You can make different

settings for each of the four dosing connections. The settings for the

other dosing connections DOS2 to DOS4 are also found in this submenu. Now press the <ENTER> key three times.

Di spl ay: >manual DOS1

>>dosi ng

• If you want to alter the dosing behavior of dosing device 1 you will find

this in the second submenu '>>Dosing' after pressing the <ENTER>

key as given above. If your Dosino is connected to 'Dos. 2' then press

the <ENTER> key six times.

Di spl ay: >>dosi ng DOS1

r at e t ype: i ncr easi ng

• By pressing the <SELECT> key and confirming with <ENTER> you

can switch to a constant dosing speed. You should, however, leave the

setting with increasing speed alone and press <ENTER>.

Di spl ay: >>dosi ng DOS1

sl ope 4

• Enter the highest value '10' for the slope of the increase of the dosing

speed. Confirm the entry with <ENTER>.

By pressing the <QUIT> key twice you will return to the display for dosing.

Di spl ay: man u a l DOSI NG

r eady 3. 349 mL

dosing speed increases more rapidly and that the highest dosing speed is

reached very quickly.

When the max. cylinder volume has been reached the dosing unit will be

filled automatically. Filling the dosing cylinder can also be triggered manu-

711 Liquino, Instructions for use

ally by pressing the <FILL> key.

Page 32

3.2 Tutorial

26

MANUAL

MAN OFF

D

• Operating the <MAN. OFF / MANUAL> key switches manual operation off

MANUAL

MAN OFF

D

• Switch the Liquino to the manual operating mode by pressing the

DOS NR

SELECT

P

•

PREP

4

L

• Prepare the dosing unit again by pressing the <PREP> key. Accustom

DISPENSE

8

H

• When you have prepared the dosing unit press the <DISPENSE> key.

CLEAR

Q

<ENTER>

START

Z

•

START

Z

• If you press the <START> key the required reagent volume will be dosed.

FILL

5

M

•

again. The Liquino is again in the basic condition.

If you want to dose a particular volume several times then select the 'Dispense' function. Proceed in a similar manner to dosing.

<MANUAL> key.

Di spl ay: manual

r eady 0. 000 mL

Use the <DOS NR / SELECT> key to select the connected dosing device.

yourself to rinsing the dosing units with which you want to work by means

of the 'PREP' function before you use them. This is an absolute necessity

when you change the reagent. Other things which must be taken into account when a reagent is changed are mentioned below.

Di spl ay: manual DI S

vol ume? 1. 0 mL

• Enter the required volume. If you do not want to dose a particular volume

or if you want to correct a faulty entry press the <CLEAR> key.

Di spl ay: manual DI S

vol ume? i nf i ni t e mL

• You can enter a new value or confirm the value 'infinite'. In this case dosing

or dispensing will be carried out automatically until you press the

<STOP> key.

After you have entered a value and confirmed it with <ENTER> you can

start to dispense with the <START> key. You also have the possibility of

first altering the dosing speed. This is set to the maximum dosing speed

as standard.

Di spl ay: manual DI S

r at e? max mL/ mi n

The maximum dosing speed depends on the dosing unit used and the

cylinder volume. For example, for a 10 mL cylinder it is 33.33 mL/min, for a

50 mL cylinder 166.66 mL/min. The same values apply to the filling speed

of the dosing unit.

• For viscous reagent solutions you should select a lower dosing speed as

otherwise a large counterpressure could build up in the tubing during rapid dispensing.

This can be carried out several times. The 'DISPENSE' function is repetitive.

Filling the dosing cylinder can be triggered with the <FILL> key.

711 Liquino, Instructions for use

Page 33

27

•

A

J

• Press the <CONFIG> key and the <> key twice.

DOS NR

SELECT

P

• Press the <SELECT> key in order to switch on automatic filling of the

QUIT

NO

• Exit the configuration menu by pressing <QUIT> twice.

START

Z

• Now dispense again by pressing the <START> key and you will see that

MANUAL

MAN OFF

D

CONFIG

<ENTER>

3 Introduction

If you want, you can configure your Liquino so that after each dispensing

process the dosing cylinder is refilled automatically.

2x

Di spl ay: conf i gur at i on

>manual

• Here you will find the submenu with the settings which are effective for

manual functions.

Di spl ay: >manua l DOS1 ← dosing connection

dos. uni t : de f a ul t

• In the first line, above right, the address of the dosing connection to

which the particular setting applies is shown. You can make different

settings for each of the four dosing connections. The settings for the

other dosing connections DOS2 to DOS4 are also found in this submenu. Now press the <ENTER> key twice.

Di spl ay: >manual DOS1

auto fill: off

• The colon after the word 'fill' shows that a list of entries is available for

this menu item. In this case there are only two possibilities: 'on' and

'off'.

dosing unit. Confirm the entry with <ENTER>.

<ENTER>

2x

the dosing cylinder is automatically refilled after each dosing process.

• Pressing the <MAN. OFF / MANUAL> key switches manual operation off

again. The Liquino is again in the basic condition.

711 Liquino, Instructions for use

Page 34

3.2 Tutorial

28

Warning!

EXCH

6

N

• Always press the <EXCH> key first. Only in this way will the stopcock

MANUAL

MAN OFF

D

EMPTY

3

T

EXCH

6

N

• Check whether the dosing tip is immersed in a waste beaker. Use the

3.2.4 Changing the dosing unit

A dosing device consists of a dosing unit (the green part) with a dosing cylinder (2, 5, 10, 20 or 50 mL) and the dosing drive, the Dosino 700. If you are

working with different reagents then you do not need a separate dosing

drive for each reagent bottle. Fit the individual reagent bottles with a dosing

unit (the actual buret) and simply mount the dosing drive connected to the

Liquino or dosing unit on a different reagent bottle as it is required.

Incorrect disassembly of the dosing drive can damage the dosing unit

and/or the Dosino.

of the dosing unit be moved to the safe, so-called 'exchange' position.

You can then loosen the dosing drive without any risk by carefully turning it counterclockwise and lifting it off. Observe the lines marked on

the front of the dosing unit when doing this.

If you do not use a dosing unit for a long time or want to change the reagent

we recommend that the dosing unit or the dosing cylinder and the tubing

are completely emptied. This can be carried out simply and conveniently by

means of the 'EMPTY' function.

<MANUAL> key to switch to manual operation. Then press

<EMPTY>.

<1>, <2>

Di spl ay: empt y t o por t :

tip(1) or flask(2)?

• You can now select whether the cylinder contents of the dosing unit are to

be pumped back into the reagent bottle or discharged into a waste beaker

via the dosing tip. Select <1> or <2>.

• The contents of the dosing cylinder are now discharged and the tubing

emptied. Please remember that the contents of the dosing tubing at Port 1

will always be discharged via the dosing tip.

• To terminate the 'EMPTY' function the dosing cylinder is filled with air. After

pressing the <EXCH> key the dosing unit can now be carefully removed.

711 Liquino, Instructions for use

Page 35

3 Introduction

29

MANUAL

MAN OFF

D

TEMP

9

I

MANUAL

MAN OFF

D

• Connect a Pt100 temperature sensor. The connection socket is on the

3.2.5 Temperature measurement

The 711 Liquino is equipped with a Pt100 temperature measuring input.

Apart from temperature-controlled dosing this means that simple manual temperature measurements can also be carried out.

rear panel of the 711 Liquino. Use the <MANUAL> key to switch to

manual operation. Then press <TEMP>.

Di spl ay: manual

21. 5° C

• The measured temperature in degrees Celsius is shown immediately. The

measurement can be switched off by pressing the <MANUAL> key again.

711 Liquino, Instructions for use

Page 36

3.2 Tutorial

30

*

MODE

-

X

DOS NR

SELECT

P

• The PIP mode must first be activated. This sets all method parameters

ENTER

YES

• Press <ENTER>. The instrument is now in the PIP mode.

PARAM

B

QUIT

NO

• In the submenu ‘PIP parameters’ no further entries are necessary.

J

• The next submenu is accessed with <>.

Di s pl ay : >PI P dosi ng uni t

3.2.6 PIP – precise pipetting/diluting

Example: Pipet 1mL and dilute with 9mL. Distilled water is used as the

"hydraulic“ liquid.

Preconditions / Preparation

The easiest and most accurate means of pipetting is with pipetting attachment 6.1562.040. The keyboard can be used to proceed from step to step.

Define a dosing unit which corresponds to the tubing of the Dosino used.

This procedure is described on page 22. (This is not necessary if the pipet-

Method editing

ting attachment is used as this corresponds to the standard settings.)

to standard values. Press the <MODE> key and then <SELECT> until

‘PIP’ appears in the display:

Di s pl ay : mode sel ect : PI P

Di s pl ay : PIP ********

r eady 0. 000 mL

• The <PARAM> key is used to access the parameter menu, where all

the possible settings for a PIP method can be found.

Di s pl ay : par amet er s

>PI P par amet er s

• The submenu ‘PIP parameters’ contains the main settings for a PIP

method. Press <ENTER> to open the submenu.

Di s pl ay : >PI P par amet er s

pi pet t i ng vol . 1. 000 mL

• Enter the required pipetting volume (1 mL) and press <ENTER> to

accept the entry.

Di s pl ay : >PI P par amet er s

di l ut i ng vol . 9. 000 mL

• Enter the 9 mL used as diluting volume in the example and press

<ENTER>

Press the <QUIT> key to exit the submenu.

Di s pl ay : par amet er s

>PI P par amet er s

<ENTER>

Di s pl ay : par amet er s

>PI P dosi ng uni t

• The submenu ‘PIP dosing unit’ is opened with <ENTER>.

711 Liquino, Instructions for use

Page 37

3 Introduction

31

dr i ve uni t : DOS1

START

Z

•

ENTER

YES

• Before the Dosino is used for the first time in the new configuration the

<SELECT>

<ENTER>

<SELECT>

<ENTER>

<QUIT>

• The Dosino which is to be used can be selected here with <SELECT>

(DOSx refers to the connection number on the 711 Liquino). Accept

with <ENTER>.

Di s pl ay : >PI P dosi ng uni t

dos. uni t : def aul t

• In this menu item the 711 Liquino is informed about the tubing of the

Dosino. Press <SELECT> until the dosing unit defined in the above

preparation step appears. (If the pipetting attachment is used this setting can be left as ‘standard’). Confirm with <ENTER>.

Di s pl ay : par amet er s

>PI P r a t e s

• As the ‘PIP dosing unit’ submenu contains no further menu items, an

automatic return is made to the submenu selection. All necessary parameters have now been entered! The parameter menu is exited with

<QUIT>.

Di s pl ay : PIP ********

r eady 0. 000 mL

If an inquiry is always to be made about the pipetting volume at the start of

the method then enter the value under ‘parameters/>PIP preselections/query pip. vol.’.

Various PIP methods can also be edited and then stored in the method

memory. Each of these methods can then be reloaded by pressing a few

keys. The method memory is described on page 128.

Carrying out the method

When <START> is now pressed the display shows

Di s pl ay : Not pr epar ed yet !

Run PREP now?

Dosino cylinder and the complete tubing system must be filled bubblefree with reagent solution. Press <YES>.

Di s pl ay : wast e por t :

t i p( 1) or f l ask ( 2) ?

<1> , <2>

• Press <1> to empty the cylinder contents through the dosing tip, or

<2> to return them to the bottle. Take care that the tip of the dosing

tubing is located in a vessel. Wait until the 711 Liquino has ended the

preparation (PREP). The instrument then returns to its normal state.

711 Liquino, Instructions for use

Page 38

3.2 Tutorial

32

START

Z

follow the instructions shown on the display.

• From now on when <START> is pressed the method will be run im-

mediately.

*)

<ENTER>

• The pipetting process consists of several steps. For each step instruc-

tions are shown on the display. If the pipetting attachment is used then

the key built into the handle can be used to switch from one step to the

next. The pipetting process can also be started with it. Whenever the

LED on the handle lights up the 711 Liquino is ready for the next step.

Without the pipetting attachment <ENTER> must be pressed in order

to carry out the next step.

• In the first step a separatory bubble is formed, which is located be-

tween the "hydraulic“ liquid (in this case water) and the sample. Just

*)

The warning about the preparation of the tubing system appears each time the mode is changed and after

the instrument has been switched off and on again. If it is certain that the Dosinos used have already been

prepared then press <NO> (<QUIT> key) to acknowledge the warning. The method can now be run in the

normal manner by pressing <START>.

711 Liquino, Instructions for use

Page 39

3 Introduction

33

3.2.7 SMPL – fully automatic sampling

The capabilities and possible uses of an SMPL method will be demonstrated by means of a complexometric titration of Ni

Liquino and Titrino 716.

Chemistry

2+

The Ni

ed with Na-EDTA. The detection mechanism with the Cu-ISE electrode is

based on the following equilibrium equation:

ion is buffered to pH 10, complexed with Cu-EDTA and then titrat-

2+

with the help of the 711

Procedure

Cu-EDTA Cu

2+

+ EDTA

2-

2+

The presence of the Ni

ion displaces the equilibrium to the right:

2+

+ Cu-EDTA Cu

Ni

2+

+ Ni-EDTA

2+

The concentration of the Cu

depends on the stability of the Ni-EDTA complex.

ion (to which the Cu-ISE electrode reacts)

The SMPL mode of the Liquino offers a fully automated sample transfer,

perfect preparation of the titration cell between the individual titrations (for

multiple determinations) and complete control of the Titrino. However, a corresponding method must first be created or selected in the Titrino.

The Dosino at connection 1 carries out the "sampling“ processes, for which

its four ports have fixed definitions.

1. Through port 1 the Liquino draws in the required amount of sample and

transfers it to the titration vessel through the cylinder and port 2.

2. Solvent is drawn in through port 3 and transferred to the titration vessel

for rinsing/diluting (the amount can be freely selected) – in this case H

O

2

is used.

3. The second Dosino adds the buffer (pH 10).

4. The third Dosino adds the complexing agent Cu-EDTA.

5. 30 s is allowed to elapse (this possibility exists after each reagent addition) in order to allow the complexing ion to be completely bound and to

2+

release the Cu

ions.

6. The Titrino is started via the remote lead and the sample is titrated with

Na-EDTA.

At the end of the titration the "sampling“ Dosino removes the contents of the

titration vessel through port 2 and transfers them to a waste container via

port 4.

711 Liquino, Instructions for use

Page 40

3.2 Tutorial

34

Waste

Port 4

Solvent

Port 3

Titration vessel

Port 2

Sample

Port 1

A new titration can now be carried out. The number of determinations and

the number of times the cell is to be rinsed out can be entered.

The Liquino offers the possibility of carrying out titrations comfortably and

confidently. Even if the titration cell is only rinsed out once the variations only amount to 0.01 to 0.02%.

Multiple determinations at defined time intervals are also possible (e.g. periodic sampling of a sample flow).

Preconditions / Preparation

Tubing connections of the "sampling“ Dosino

The determination of the NI2+ ion by potentiometric endpoint indication can

be carried out with the help of the Cu-ISE electrode. For an elegant automation of the analysis the following items are required:

• the new 711 Liquino

• 3 Dosino 700s with dosing unit 710: 20 mL and 2x 10 mL glass cylin-

ders. (20mL cylinder for "sampling“ dosing unit).

• any Titrino available (e.g. 716)

• Liquino - Titrino connection cable 6.2141.090

• one Cu-ISE electrode 6.0605.02 with electrode cable 6.2104.020

• one reference electrode 6.0726.100 (KNO

sat.) with electrode cable

3

6.2106.020

• one magnetic stirrer 728

• sampling mode equipment 6.5614.010.

711 Liquino, Instructions for use

Page 41

3 Introduction

35

*

MODE

-

X

DOS NR

SELECT

P

• The SMPL mode must first be activated. This sets all method parame-

ENTER

YES

• Press <ENTER>. The instrument is now in the SMPL mode.

PARAM

B

Method editing

The dosing units which correspond to the tubing used for the Dosinos must

be defined. This process is described on page 16.

ters to standard values. Press the <MODE> key and then <SELECT>

until ‘SMPL’ appears in the display:

Di s pl ay : mode sel ect : SMPL

<ENTER>

<ENTER>

<ENTER>

<ENTER>

<ENTER>

<ENTER>

Di s pl ay : SMPL ********

r eady 0. 000 mL

• The <PARAM> key is used to access the parameter menu, where all

the possible settings for an SMPL method can be found.

Di s pl ay : par amet er s

>SMPL par amet er s

• The submenu ‘SMPL parameters’ contains the main settings for an

SMPL method. Press <ENTER> to open the submenu.

Di s pl ay : >SMPL par amet er s

sampl e c ount 1

• Enter the number of samplings (or titrations), which are to be carried

out after each other automatically. Accept the value with <ENTER>.

Di s pl ay : >SMPL par amet er s

sampl i ng mode: manual

• If a multiple determination on the same sample is to be carried out then

<SELECT> can be used to choose the entry ‘auto’. However, if a different sample is to be transferred each time then ‘manual’ should be

selected. In this case the process requires the sample tubing to be

immersed in the new sample each time. Press <ENTER>.

Di s pl ay : >SMPL par amet er s

t i me i nt er val 00: 05: 00

• This parameter determines the time interval between successive sam-

ples. For a multiple determination this value should be set to 00:00:00.

In this way the next sample will be transferred at the end of the titration.

Press <ENTER> to accept the value.

Di s pl ay : par amet er s

>SMPL sampl i ng oper at i on

• As the ‘SMPL parameters’ submenu contains no further menu items,

an automatic return is made to the submenu selection. The submenu

‘SMPL sampling operation' contains the parameters for sample transfer. Press <ENTER> to open it.

Di s pl ay : >SMPL sampl i ng oper at i on

sampl e v ol ume 3 mL

• Enter the volume of the sample to be transferred to the measuring cell

(in this case 3 mL). Press <ENTER> to accept the value.

Di s pl ay : >SMPL sampl i ng oper at i on

711 Liquino, Instructions for use

Page 42

3.2 Tutorial

36

di l ut i on vol . 3 mL

QUIT

NO

• As the remaining parameters in this submenu can be left at their preset

J

<ENTER>

•

<ENTER>

<ENTER>

<ENTER>

• The dilution volume is the amount of solvent to be added to the meas-

uring cell after the sample has been transferred there (in the example 3

mL). Press <ENTER> to accept the value.

Di s pl ay : >SMPL sampl i ng oper at i on

sampl e r i nse vol . 3 mL

• Before the actual sample transfer the Dosino cylinder is rinsed with the

sample. This rinsing volume should be about the same as the transfer

amount (in the example 3 mL). For a multiple determination, in which

the same sample is always used, this volume can also be smaller.

Press <ENTER> to accept the value.

Di s pl ay : >SMPL sampl i ng oper at i on

sampl e r i nse r ep. 1

• Enter how often the cylinder is to be rinsed with the sample. If samples

are being transferred which do not greatly differ from one another 1

rinse is sufficient. Press <ENTER> to accept the value.

values it can be exited with the <QUIT> key.

Di s pl ay : par amet er s

>SMPL sampl i ng oper at i on

The next submenu is accessed with <>.

Di s pl ay : par amet er s

>SMPL meas. c el l r i ns i ng

• Press <ENTER> to open the submenu ‘SMPL meas.cell rinsing.

<ENTER>

<ENTER>

<ENTER>

<ENTER>

Di s pl ay : >SMPL meas. cel l r i nsi ng

ext er nal Pump: of f

• The cell can also be rinsed with external pumps. However, the same

Dosino is to be used here. Press <ENTER> to accept the default value ‘off’.

Di s pl ay : >SMPL meas. cel l r i nsi ng

r i nsi ng r epet i t i ons 1

• Enter the number of times that the measuring cell is to be rinsed. As

this process takes a considerable time this value should be kept as low

as possible. In this example 1 rinse is sufficient. Press <ENTER> to

accept the value.

Di s pl ay : >SMPL meas. cel l r i nsi ng

aspi r . vol ume 40 mL

• The suction volume corresponds to the sample volume + dilution vol-

ume (solvent) + titrant consumption. The value must be so large that

the measuring cell is completely emptied after the titration. In this case

the total volume amounts to 40 mL. Press <ENTER> to accept the

value.

Di s pl ay : >SMPL meas. cel l r i nsi ng

aspi r . r at e max mL/ mi n

• This setting is left at ‘max’. It only requires alteration for viscous liquids.

Press <ENTER>.

711 Liquino, Instructions for use

Page 43

37

before

after

after

3 Introduction

<ENTER>

<ENTER>

<ENTER>

<SELECT>

<ENTER>

<ENTER>

<ENTER>

<SELECT>

<ENTER>

<SELECT>

<ENTER>

Di s pl ay : >SMPL meas. cel l r i nsi ng

r i nsi ng vol ume 30. 0 mL

• The amount of solvent to be used to rinse the measuring cell is entered

here. In this example 30 mL are sufficient. Press <ENTER> to accept

the value.

Di s pl ay : >SMPL meas. c el l r i nsi ng

r i ns. r at e max mL/ mi n

• The measuring cell should be rinsed as rapidly as possible, so that the

rate can be left at ‘max’. Press <ENTER>.

Di s pl ay : par amet er s

>SMPL dosi ng uni t s

• As the ‘SMPL meas. cell rinsing’ submenu contains no further menu

items, an automatic return is made to the submenu selection. The

submenu ‘SMPL dosing units' contains the parameters for the auxiliary

dosing units and the tubing of the "sampling“ dosing unit. The addition

of the pH 10 buffer and the Cu-EDTA are defined here. The submenu is

opened with <ENTER>.

Di s pl ay : >SMPL dosi ng uni t s

dos. uni t 1: def aul t