Page 1

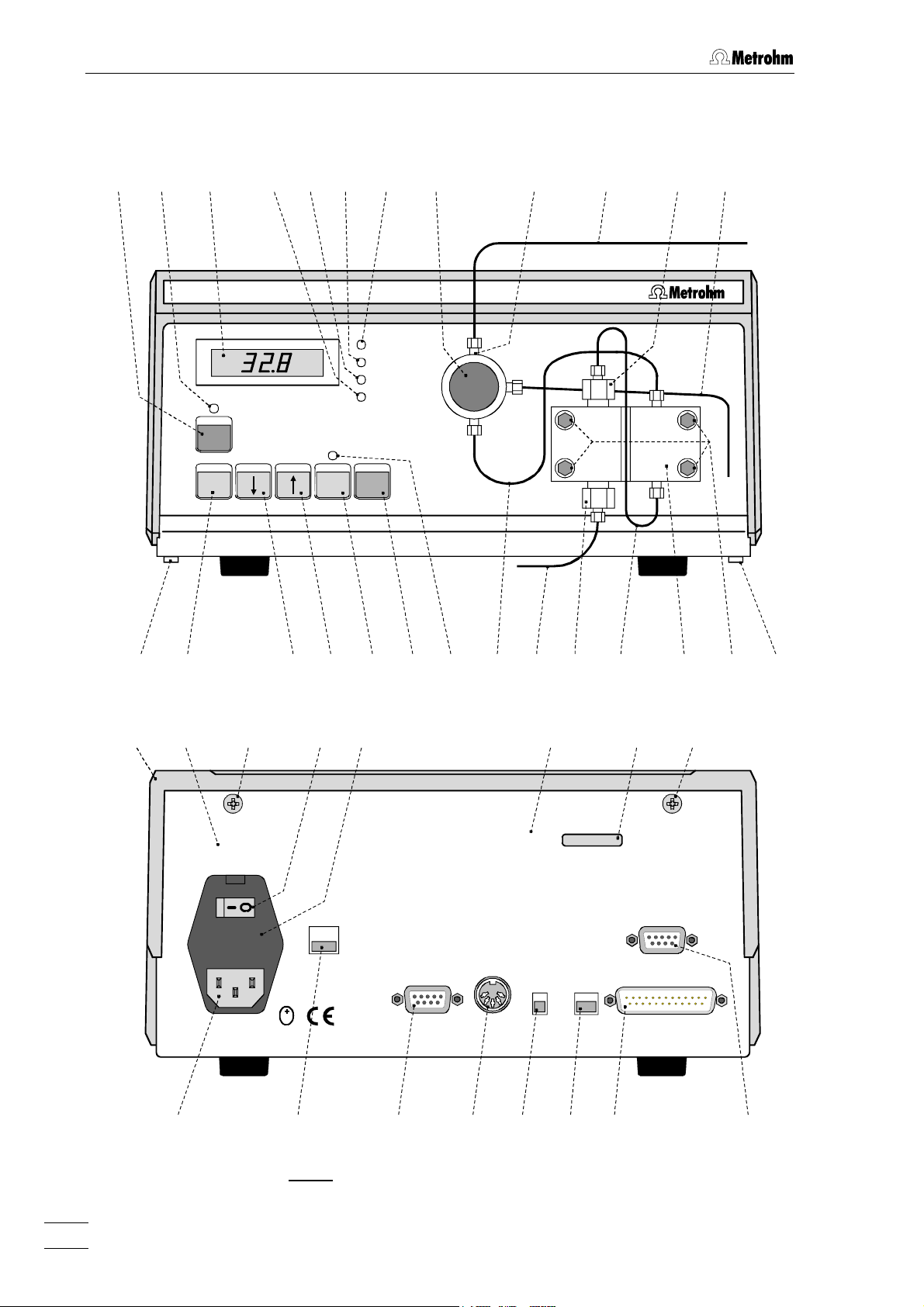

709 IC Pump

IC Pump709

FLOW

P

min

P

max

P

actual

R/S

SELECT EXT. PURGE

METROHM Ltd.

CH-9101 Herisau

Instructions for Use

8.709.1033

Page 2

Page 3

CH-9101 Herisau/Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

CompuServe 100031,3703

Internet http://www.metrohm.com

E-Mail sales@metrohm.ch

709 IC Pump

IC Pump709

FLOW

P

min

P

max

P

actual

R/S

SELECT EXT. PURGE

8.709.1033 Instructions for Use

16.10.2003 / chs

Page 4

Page 5

Table of contents

Table of contents

1 Introduction ..................................................................................... 1

1.1 Instrument description.................................................................... 1

1.2 Parts and controls ........................................................................... 2

1.3 Information about the Instructions for Use.................................. 4

1.3.1 Organization........................................................................... 4

1.3.2 Notation and pictograms ....................................................... 5

1.4 Safety notes...................................................................................... 6

1.4.1 Electrical safety ......................................................................6

1.4.2 General safety rules ............................................................... 6

2 Installation........................................................................................ 7

2.1 Setting up the 709 IC Pump .......................................................... 7

2.1.1 Packaging .............................................................................. 7

2.1.2 Check ..................................................................................... 7

2.1.3 Location.................................................................................. 7

2.1.4 Arrangement of the instruments............................................. 7

2.2 Mounting the pump head ...............................................................8

2.3 Attaching the accessories.............................................................. 9

2.3.1 Capillaries............................................................................... 9

2.3.2 PEEK connectors ...................................................................9

2.3.3 Steel connectors .................................................................. 10

2.3.4 Pulsation dampener ............................................................. 10

2.3.5 Filter unit PEEK..................................................................... 11

2.3.6 Filter unit Manufit.................................................................. 12

2.4 Connecting the tubing ..................................................................13

2.4.1 Connection to injection valve with PEEK capillaries ............ 13

2.4.2 Connection to injection valve with steel capillaries .............. 14

2.4.3 Connection to eluent container ............................................ 15

2.5 Electrical connection ....................................................................15

709 IC Pump

2.6 Mains connection ..........................................................................16

2.6.1 Setting the mains voltage..................................................... 16

2.6.2 Fuses.................................................................................... 16

2.6.3 Mains cable and mains connection ..................................... 17

2.6.4 On/off switching of the instrument ....................................... 17

2.7 Deaerating the pump..................................................................... 18

I

Page 6

Table of contents

3 Operation ........................................................................................ 19

3.1 Sequence of operations ............................................................... 19

3.2 Flussrate......................................................................................... 20

3.3 Flow correction.............................................................................. 20

3.4 Pressure limit values for safety shutdown ................................ 21

3.4.1 Minimum pressure limit........................................................ 21

3.4.2 Maximum pressure limit....................................................... 22

3.5 Switching the pump drive on and off ......................................... 22

3.6 On/off switching of the external control .................................... 23

3.7 Inquiry of the current pressure ................................................... 23

3.8 Overview of the key functions..................................................... 23

4 Notes – Maintenance – Faults...................................... 25

4.1 Practical notes............................................................................... 25

4.1.1 Protection against foreign particles ..................................... 25

4.1.2 Pulsation dampener............................................................. 25

4.1.3 Eluents ................................................................................. 25

4.2 Maintenance and servicing.......................................................... 26

4.2.1 General information ............................................................. 26

4.2.2 Maintenance work at the pump head .................................. 27

4.3 Faults and malfunctions............................................................... 31

4.4 Diagnosis........................................................................................ 32

4.4.1 General information ............................................................. 32

4.4.2 Entry of diagnostics with automatic display test.................. 33

4.4.3 Keyboard test....................................................................... 33

4.4.4 RS232 Test........................................................................... 34

4.4.5 Initialize and test RAM.......................................................... 35

4.5 Validation / GLP............................................................................. 36

5 Interfaces ....................................................................................... 37

5.1 RS232 interface ............................................................................. 37

5.1.1 General rules for remote control .......................................... 37

5.1.2 Call-up of objects................................................................. 38

5.1.3 Trigger.................................................................................. 39

5.1.4 Status messages ................................................................. 40

5.1.5 Error messages.................................................................... 41

5.1.6 RS232 error rectification....................................................... 41

5.1.7 Remote control commands ................................................. 42

5.1.8 Data transmission protocol.................................................. 43

709 IC Pump

II

Page 7

Table of contents

5.1.9 Handshake ........................................................................... 43

5.1.10 Pin assignment................................................................... 44

5.1.11 Setting the baud rate.......................................................... 45

5.2 Control interface............................................................................ 46

5.2.1 Functions.............................................................................. 46

5.2.2 Settings for the control interface ..........................................46

5.2.3 Control inputs and outputs................................................... 47

6 Appendix ..........................................................................................49

6.1 Technical specifications............................................................... 49

6.2 Scope of delivery...........................................................................52

6.3 Optional accessories .................................................................... 54

6.4 Warranty and conformity .............................................................. 57

6.4.1 Warranty ............................................................................... 57

6.4.2 EU Declaration of conformity ...............................................58

6.4.3 Certificate of conformity and system validation ................... 59

6.5 Index................................................................................................ 60

List of figures

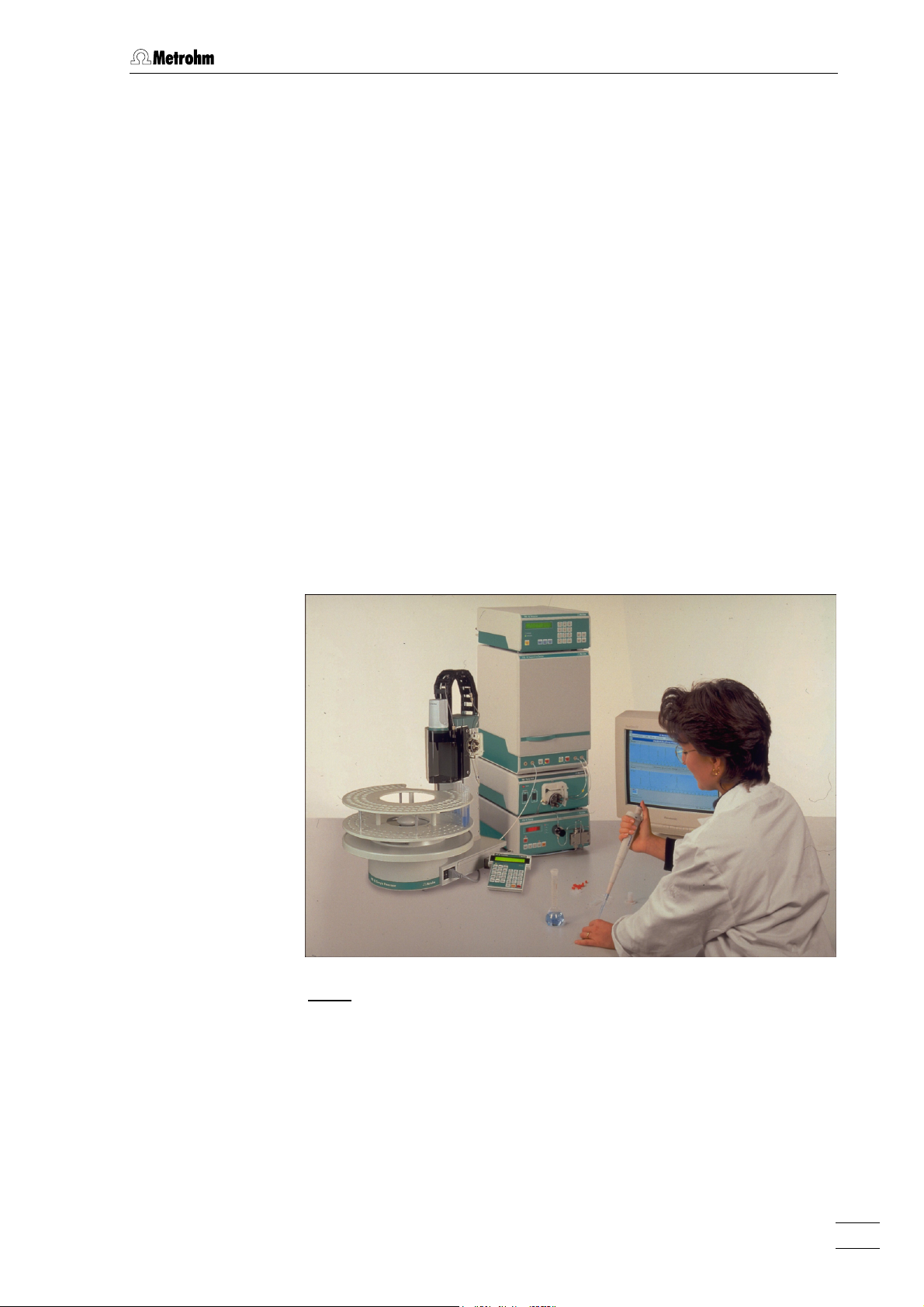

Fig. 1: IC system with 732 IC Detector, 733 IC Separation Center

and 766 IC Sample Processor .............................................................. 1

Fig. 2

: Front and rear of 709 IC Pump .............................................................2

Fig. 3

: Connectors for capillaries ..................................................................... 9

Fig. 4

: Filter unit PEEK (6.2821.100) .............................................................. 11

Fig. 5

: Filter unit Manufit (6.2821.000) ........................................................... 12

Fig. 6

: Connection to injection valve with PEEK capillaries ........................... 13

709 IC Pump

Fig. 7

: Connection to injection valve with steel capillaries............................. 14

Fig. 8

: Connection at 732 IC Detector............................................................ 15

Fig. 9

: Components of the pump head.......................................................... 28

Fig. 10

Fig. 11

: Replacement of the piston seal 67 ..................................................... 28

: Components of inlet valve 68 and outlet valve 69.............................. 30

III

Page 8

Table of contents

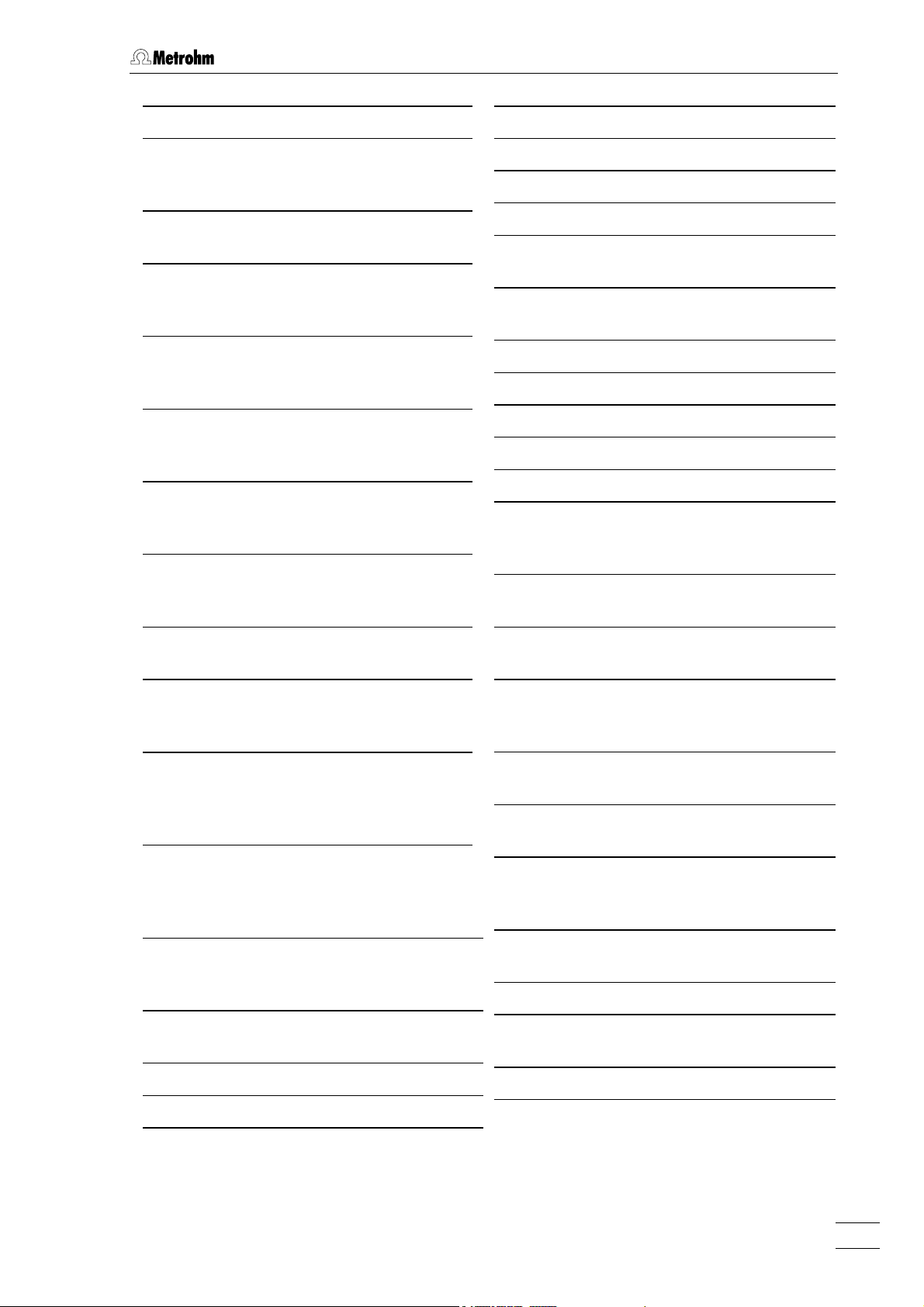

List of numbered parts and controls

1 Display .......................................... 2

2 LED "R/S"....................................... 2

3 Key <R/S> ................................... 2

4 Key <SELECT> ........................... 2

5 Key < ↓ >..................................... 2

6 Key < ↑ >..................................... 2

7 LED "Ext." ...................................... 2

8 Key <EXT.> ................................. 2

9 Key <PURGE> ............................ 2

10 LED "FLOW" .................................. 2

11 LED "P

12 LED "P

13 LED "P

"....................................... 2

min

" ...................................... 2

max

" .................................... 2

actual

14 Connection capillary ..................... 2

15 Aspirating capillary........................ 2

16 Inlet valve screw connection......... 2

17 Connection capillary ..................... 2

18 Pump head .............................. 2,28

19 Fastening screws .......................... 2

20 Outlet capillary .............................. 2

21 Outlet valve screw connection ...... 2

22 Connection capillary ................ 2,13

23 Connection.................................... 2

24 Purge valve ................................... 2

25 Screw ............................................ 2

26 Screw ............................................ 2

27 Housing cover............................... 2

28 Fuse data ...................................... 2

29 Mains switch ................................. 2

30 Fuse cover .................................... 2

31 Mains connection plug ................. 2

32 Mains voltage selectors ................ 2

33 Control interface............................ 2

34 Recorder output socket ................ 2

35 Sliding switch ................................ 2

36 Sliding switch ................................ 2

37 RS232 interface............................. 2

38 Current Loop interface .................. 2

39 Manufacturing number.................. 2

40 Instrument data ............................. 2

41 Ferrule........................................... 9

42 Pressure screw ............................. 9

43 Capillary ......................... 9,11,13,14

44 Compression fitting .................. 9,11

45 Connector ................................... 11

46 Housing for filter unit ................... 11

47 Connector ................................... 11

48 Inlet capillary .......................... 12,14

49 Manufit pressure screw............... 12

50 Counterpart end .......................... 12

51 PTFE gasket ................................ 12

52 Steel meshes .............................. 12

53 Steel mesh holding end .............. 12

54 Manufit housing .......................... 12

55 Outlet capillary ....................... 12,14

56 Filter unit PEEK ...................... 11,13

57 Pulsation dampener ............... 13,14

58 Filter unit Manufit.................... 12,14

59 Coupling...................................... 14

60 Screw .......................................... 28

61 Piston .......................................... 28

62 Spring retainer............................. 28

63 Spring.......................................... 28

64 Piston cartridge ........................... 28

65 Piston guide sleeve..................... 28

66 Sapphire supporting ring ............ 28

67 Piston guide sleeve ..................... 28

68 Piston seal................................... 28

69 Inlet valve ............................... 28,30

70 Outlet valve ............................ 28,30

71 Screw holder ............................... 28

72 Special tool ................................. 28

73 Special tool ................................. 28

74 Valve housing.............................. 30

75 Sealing ring ................................. 30

76 Sleeve.......................................... 30

77 Sapphire sleeve .......................... 30

78 Sapphire sphere.......................... 30

79 Ceramic holder............................ 30

80 Seal .............................................30

709 IC Pump

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 709 IC Pump is a serial dual piston pump especially developed for

ion chromatography and optimized for use with Metrohm ion chromatographic instruments (e.g. 732 IC Detector and 733 IC Separation Center). The 709 IC Pump operates with minimal residual pulsation and has

an excellent flow constancy. In addition to the 2.709.0010 Standard

version with parts made of sapphire, ruby, ceramics, Kel-F, Teflon or

stainless steel, the totally metal free 2.709.0110 version is available.

All functions can be set simply at the front of the unit. The current and

entered data are indicated on the LED display. To assure optimum operational reliability, both lower and upper pressure limit values can be

set. If such a limit is reached, the pump switches itself off automatically.

An additional purge valve allows rapid removal of air from the pump

system.

709 IC Pump

Fig. 1

: IC system with 732 IC Detector, 733 IC Separation Center

and 766 IC Sample Processor

1

Page 10

1 Introduction

1.2 Parts and controls

3 1 13 24

2 12 11 10 23 22 21 20

IC Pump709

FLOW

P

min

P

max

P

actual

R/S

SELECT EXT. PURGE

45

28

Made by Metrohm Herisau Switzerland

26 2627

FUSE

230 V: 0,25 AT

115 V: 0,5 AT

S

6 8 9 7 14 15 1918171625 25

29

30 3940

WARNING - Risk of olectric shock - disconnect equ ipment from supply before opening.

230V

CONTROL

REC.

Type 1.709.

f=50-60 Hz

S=50 VA

TIME

CONST.

HIGH

LOW

CURRENT

LOOP

RS 232

CURRENT

LOOP

RS 232

31 32 33 34 38

Fig. 2

: Front and rear of 709 IC Pump

709 IC Pump

2

35 36 37

Page 11

1.2 Parts and controls

1 Display (LED)

2 LED "R/S"

Lights up when pump drive switched

on

3 Key <R/S> (Run/Stop)

On/off switching of the pump drive

4 Key <SELECT>

Switching display 1 to "Flow", "P

"P

max

" or "P

actual

"

5 Key < ↓ >

Continuous decrement of the displayed digital values

6 Key < ↑ >

Continuous increment of the displayed

digital values

7 LED "Ext."

Lights up when external control is

switched on

8 Key <EXT.>

On/off switching of external control via

RS232 or current loop interface

min

",

18 Pump head (6.2824.040/6.2824.100)

19 Fastening screws for pump head 18

20 Outlet capillary of purge valve

21 Outlet valve screw connection

22 Connection capillary to 733 IC

Separation Center

23 Attachment for connection capillary to

733 IC Separation Center

24 Purge valve

25 Screw for housing cover

26 Screw for housing cover

27 Housing cover

28 Fuse data

29 Mains switch

Switch for on/off switching of the unit:

I = ON 0 = OFF

30 Fuse cover

Changing the fuses, see section 2.6.2

9 Key <PURGE>

Deaeration of pump

10 LED "FLOW"

Lights up when flow rate is shown in

display 1

11 LED "P

min

"

Lights up when lower pressure limit

value for automatic shutoff of the

pump is shown in display 1

12 LED "P

max

"

Lights up when upper pressure limit

value for automatic shutoff of the

pump is shown in display 1

13 LED "P

actual

"

Lights up when current pressure is

shown in display 1

14 Connection capillary between purge

valve and pump head

15 Aspirating capillary

31 Mains connection plug

Mains connection see section 2.6

32 Mains voltage selector

115V: 100...120 V ± 10%

230V: 220...240 V ± 10%

33 Control interface

see section 5.2

34 Recorder output socket

Recorder output: 1 mV/MPa

35 Sliding switch "Time Constant"

Time constant for the recorder output:

HIGH ≈ 1 s; LOW ≈ 20 ms

36 Sliding switch for external control:

RS232 / Current Loop

37 RS232 interface

38 "Current Loop" interface

(details on request)

39 Manufacturing number

16 Inlet valve screw connection

17 Connection capillary

in pump head (integral)

709 IC Pump

40 Instrument data

Type number, mains frequency, power

consumption

3

Page 12

1 Introduction

1.3 Information about the Instructions for Use

Please read through these Instructions for Use carefully before

operating the 709 IC Pump. The Instructions for Use contain information and warnings to which the user must pay attention in order to

assure safe operation of the instrument.

1.3.1 Organization

These 8.709.1033 Instructions for Use for the 709 IC Pump provide a

comprehensive overview of the installation, startup procedure, operation, fault rectification and technical specifications of this instrument.

The Instructions for Use are organized as follows:

Section 1 Introduction

Description of the instrument, parts and controls,

safety notes

Section 2 Installation

Mounting the pump head, electrical connections,

tubing connections, mains connection

Section 3 Operation

Detailed description of operation,

explanation of all key functions

Section 4 Notes – Maintenance – Faults

Practical notes, maintenance, fault rectification,

diagnosis, validation

Section 5 Interfaces

Description of RS232 interface,

remote control language, control interface

Section 6 Appendix

Technical data, standard equipment, options,

warranty, declaration of conformity, index

To find the information you require about the instrument please use either the Table of contents or the Index at the back.

As a supplement to the Instructions for Use, the Metrohm Monograph

8.732.2003 "Ion chromatography" is also supplied. This provides an

introduction to the theoretical fundamentals and general information on

separating columns and sample pretreatment. You will find detailed information on the separating columns available from Metrohm and on

special IC applications in the relevant "Application Bulletins", which

are available on request free of charge from your Metrohm agency.

709 IC Pump

4

Page 13

1.3 Information about the Instructions for Use

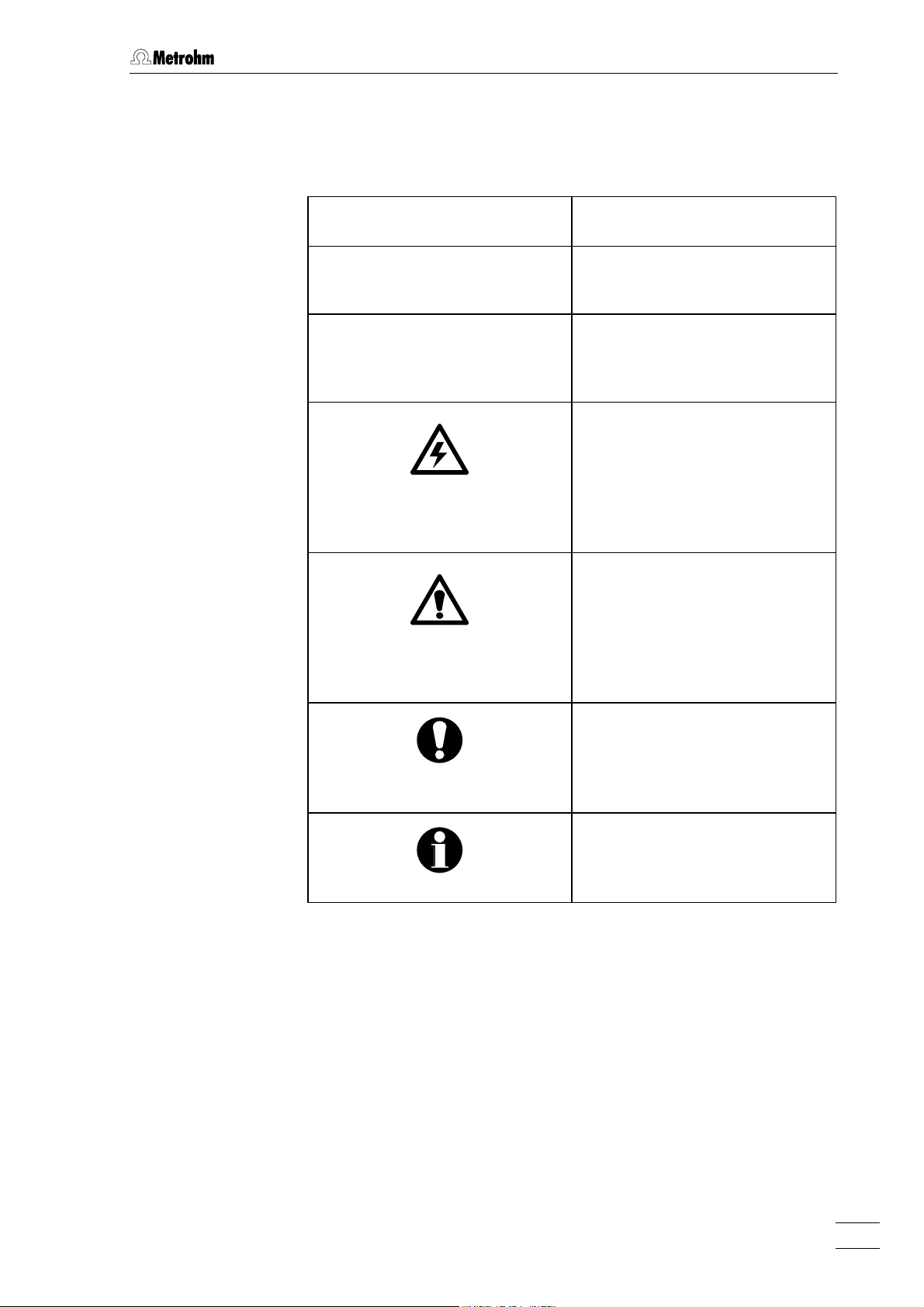

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

<SELECT> Key

"0.0" Entry value

25 Part or control

(see section 1.2)

Hazard

This symbol draws attention to

a possible danger to life or

injury if the associated

directions are not followed

correctly.

Warning

This symbol draws attention to

possible damage to instruments or instrument parts if the

associated directions are not

followed correctly.

Caution

This symbol marks important

information. Read these directions before continuing.

Comment

This symbol marks additional

information and tips.

709 IC Pump

5

Page 14

1 Introduction

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 709 IC Pump is assured in

the context of the specifications IEC 1010-1 (protection class 1, degree

of protection IP40), the following points should be noted:

• Mains connection

Set the mains voltage and check the mains fuse and mains

connection in accordance with the instructions in section 2.6.

• Opening the 709 IC Pump

To avoid all danger of coming into contact with live components do

not open the instrument or remove any parts when the 709 IC Pump is

connected to the power supply. Always disconnect the instrument

from all voltage sources before you open it and ensure that the mains

cable is disconnected from mains connection plug 31 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 709 IC Pump, you should earth yourself and any tools you

are using by touching an earthed object (e.g. housing of the instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General safety rules

• Handling of solvents

Check the pump tubing and all input and output leads periodically for

possible leaks. Follow the relevant instructions regarding the handling

of flammable and/or toxic solvents and their disposal.

709 IC Pump

6

Page 15

2.1 Setting up the 709 IC Pump

2 Installation

2.1 Setting up the 709 IC Pump

2.1.1 Packaging

The 709 IC Pump is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The actual instrument

is packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instruments free from damage.

2.1.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 6.2). In the case of transport damage, see

instructions in section 6.4.1 "Warranty".

2.1.3 Location

Position the 709 IC Pump in the laboratory at a location convenient for

operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the pump and eluent reservoir must be protected

against direct sunlight.

2.1.4 Arrangement of the instruments

In one-channel operation, the 709 IC Pump, 733 IC Separation Center

and 732 IC Detector are best stacked on top of one another in this order.

709 IC Pump

In two-channel operation (733.0X20 IC Separation Center), the optimum

arrangement (1, 2 or 3 towers) depends on the laboratory space available. However, the 709 IC Pumps should be set up at the very bottom

and the 732 IC Detectors at the very top.

7

Page 16

2 Installation

2.2 Mounting the pump head

To ensure that the pump drive is not damaged during transport a black

plastic block is mounted in place of the pump head on the right side of

the 709 IC Pump front panel. This transport safeguard block has to be

removed after undoing the four screws.

To avoid any damage to the pump head, the protective block must be

remounted if the pump has to be moved any great distance.

Next, the 6.2824.040 Pump Head 18 (6.2824.040 or 6.2824.100) with integrated piston units is unpacked and fixed in place of the transport

safeguard block with the four hexagon screws 19 as shown in Fig. 2.

To ensure that the pump head is not positioned wrongly, the holes at

the rear for the clamping bolts have different depths, i.e. 1 clamping

bolt is longer than the rest. The deepest hole must naturally accommodate the longest bolt. If this is not the case, the pump will not

function properly.

The connection capillary 14 fastened to purge valve 24 is screwed onto

pump head 18 as shown in Fig. 2.

The 2.709.0110 IC Pump MF (metal-free version) should only be

…

operated in the pressure range of 0

higher pressure, the 6.2824.100 PEEK pump head can be damaged.

So make sure that the maximum shutoff pressure

always set to

≤

25.0 MPa (see section 3.4.2).

25.0 MPa (0…250 bar). With

P

of the pump is

max

709 IC Pump

8

Page 17

2.3 Attaching the accessories

2.3 Attaching the accessories

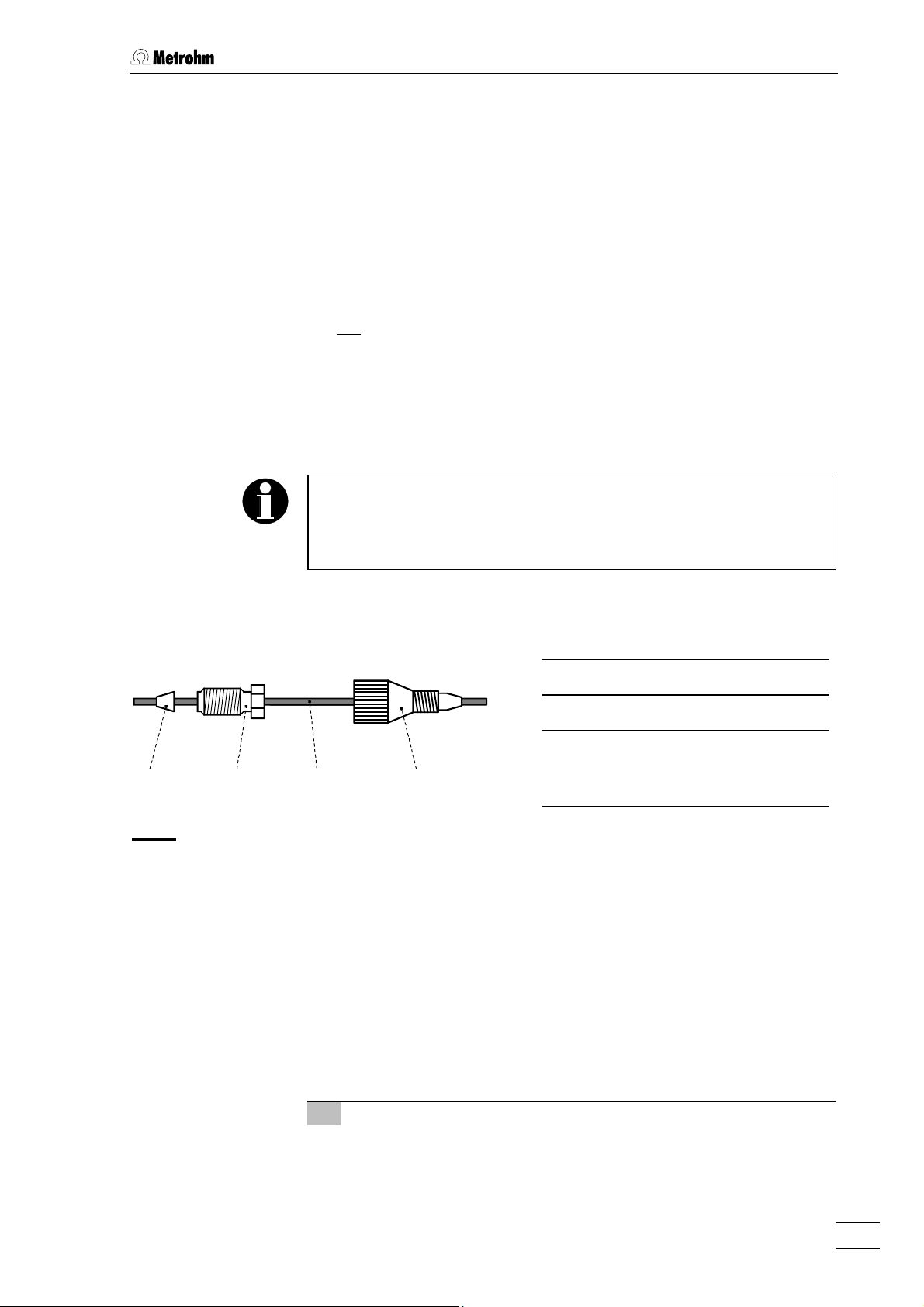

2.3.1 Capillaries

Some of the connections under high pressure between the 709 IC

Pump and the IC system must be set up by the user. For the pressure

range 0…25 MPa (0…250 bar) the 6.1831.010 PEEK capillary

1

(i.d. = 0.25 mm, e.d. =

of the 709 IC Pump can be used for both pump versions. For the pressure range 25…50 MPa (250…500 bar), which is permissible only for

the not

(i.d. = 0.25 mm, e.d. =

With PEEK capillaries the connection is made preferably with the

6.2744.010 PEEK connectors (see section 2.3.2), with steel capillaries,

the 6.2620.000 and 6.2620.010 steel connectors should be used (see

section 2.3.3).

metal-free 2.709.0010 version, the 6.2620.020 Steel capillary

Capillaries fitted with new connectors must have a perfectly flat cut

surface. For PEEK capillaries it is best to use the 6.2621.080 Capil-

lary tubing cutter, for steel capillaries the 6.2621.040 Capillary

tubing cutter.

/16", length = 3 m) supplied in the accessories

1

/16", length = 3 m) must be used.

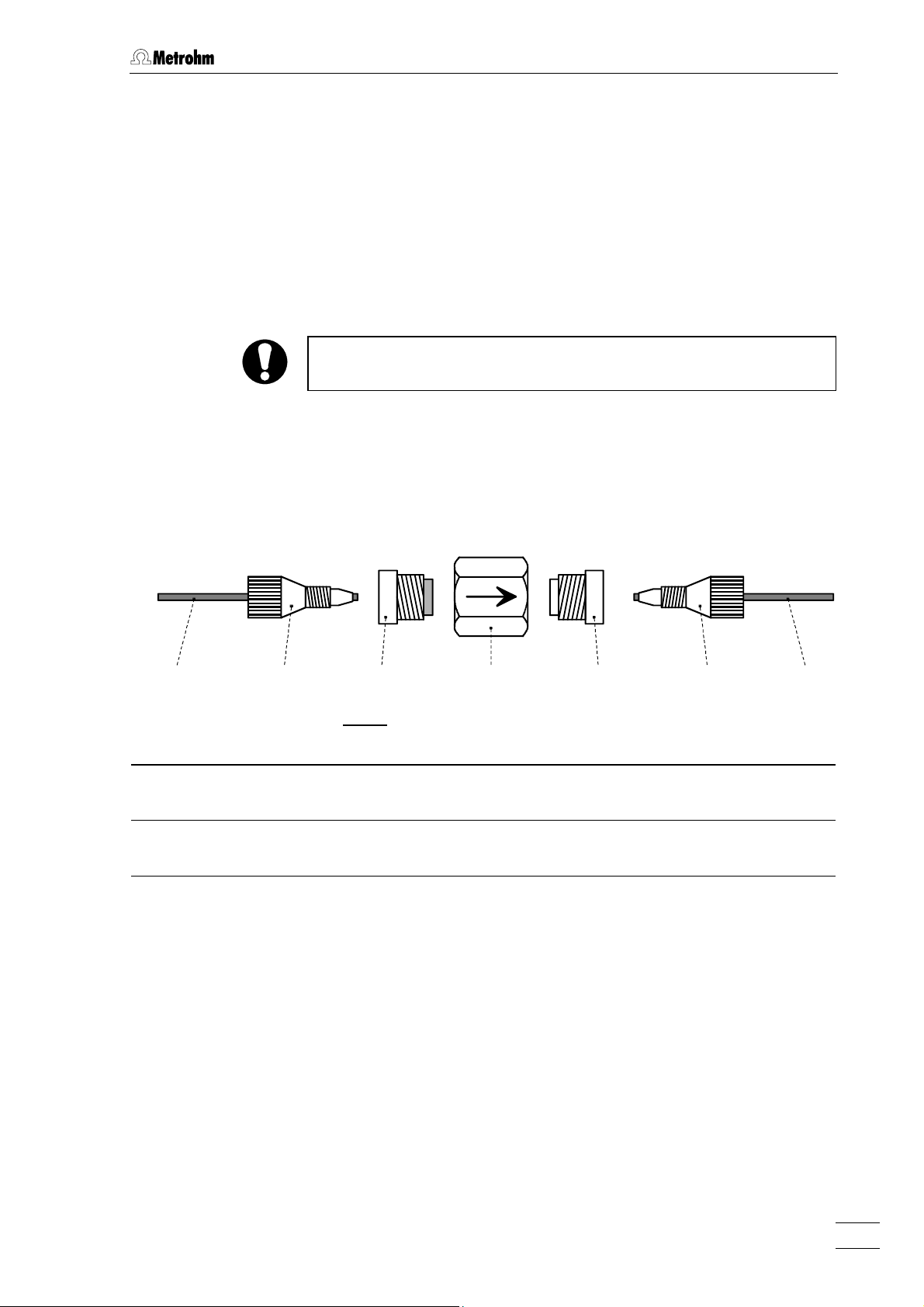

4241 43 44

: Connectors for capillaries

Fig. 3

2.3.2 PEEK connectors

41 Ferrule (6.2620.010)

42 Pressure screw (6.2620.000)

43 Capillary

6.2620.020 Steel capillary or

6.1831.010 PEEK capillary

44 Compression fitting

(6.2744.010)

709 IC Pump

For the connection of 6.1831.010 PEEK capillaries or of 6.1822.010

PTFE Microcapillaries (i.d. = 0.3 mm), the supplied 6.2744.010 PEEK

Compression fittings are used. It is best to proceed as follows:

1 Mount compression fitting

Slide a compression fitting 44 (6.2744.010) over the end of the

capillary 43 to be fastened as shown in Fig. 3.

9

Page 18

2 Installation

2 Insert capillary in connection

Push capillary end in the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten compression fitting

Tighten compression fitting 44 by hand (never use tools).

2.3.3 Steel connectors

For the connection of steel capillaries, the steel connectors 6.2620.010

Ferrule and 6.2620.000 Pressure screw available as an option are

used. Proceed as follows:

1 Mount connectors

Slide a pressure screw 42 (6.2620.000) and a ferrule 41

(6.2620.010) over the end of the capillary 43 to be fastened as

shown in Fig. 3.

2 Insert capillary in connection

Push capillary end into the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten pressure screw

Tighten pressure screw 42 with the open-end spanner 1/4"

(6.2621.010) supplied.

2.3.4 Pulsation dampener

To protect the column material against pressure drops caused by the

injector, the use of a pulsation dampener connected between the pump

and the injection valve of the 733 IC Separation Center is recommended. The optional 6.2620.150 Pulsation dampener MF is very

well suited to this purpose (see section 6.3).

The metal-free 6.2620.150 Pulsation dampener is supplied fully assembled and has two connections for capillaries, for which the connectors

supplied or two 6.2744.010 PEEK compression fittings can be used.

The flow direction is arbitrary. The pulsation dampener is positioned in

the interior of the 733 IC Separation Center on the base below the injection valve (see 732/733 Instructions for Use).

709 IC Pump

10

Page 19

2.3 Attaching the accessories

2.3.5 Filter unit PEEK

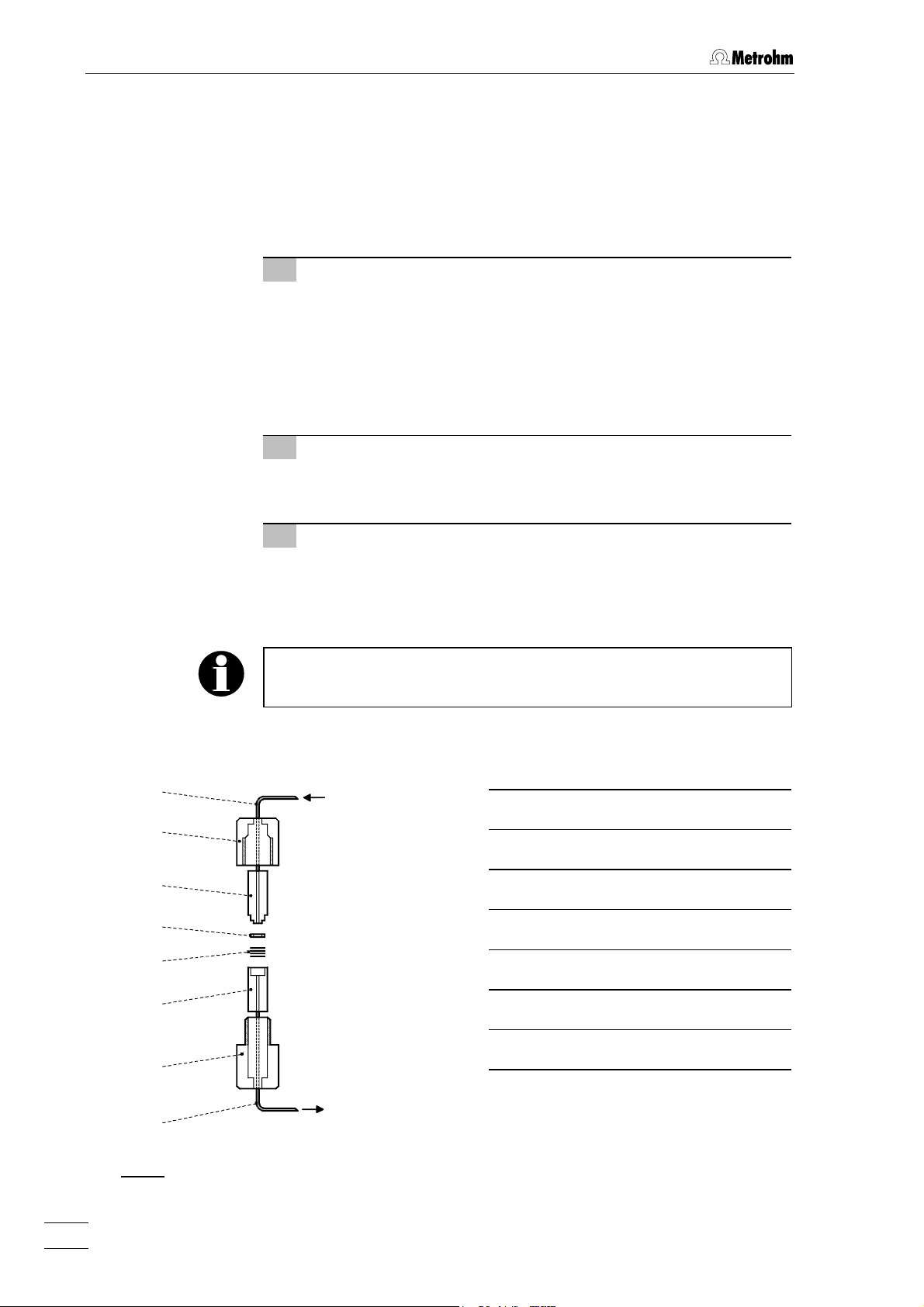

The 6.2821.100 Filter unit PEEK supplied (see Fig. 4) serves to avoid

contamination of the piston seals by abrasive particles and can be used

in the pressure range 0…25 MPa (0…250 bar). The filter unit consists of

the housing 46 and the two connectors 45 (with filter) and 47 (without

filter) to be screwed into the housing 46. For the connection of capillaries 43, PEEK compression fittings 44 (6.2744.010) must be used.

New connectors 45 with filter are available as an option with the ordering number 6.2821.110 (10 pieces).

For the connection of the filter unit, please note the flow direction

arrow printed on the housing.

43 44 45 46 47 44 43

Fig. 4

: Filter unit PEEK (6.2821.100)

43 Capillary

6.1831.010 PEEK capillary

44 Compression fitting (6.2744.010) 47 Connector without filter

45 Connector with filter (6.2824.110)

Part of 6.2824.100 Filter unit

46 Housing for filter unit

Part of 6.2824.100 Filter unit

Part of 6.2824.100 Filter unit

709 IC Pump

11

Page 20

2 Installation

2.3.6 Filter unit Manufit

The 6.2821.000 Filter unit Manufit available as an option (see section 6.3) serves to avoid contamination of the piston seals by abrasive

particles and can be used in the pressure range 0…50 MPa

(0…500 bar) together with steel capillaries. It is installed as follows (see

Fig. 5):

1 Prepare Manufit housing

• Insert outlet capillary 55 with steel mesh holding end 53 into

Manufit housing 54.

• Insert the 4 steel meshes 52 provided into the steel mesh

holding end 53.

• Press the PTFE gasket 51 into the steel mesh holding end

53.

2 Prepare Manufit pressure screw

• Insert inlet capillary 48 with counterpart end 50 into Manufit

pressure screw 49.

3 Assembly

• Fit the two capillary end pieces 50 and 53 together.

• Screw Manufit pressure screw 49 and Manufit housing 54

firmly together.

To replace contaminated steel meshes, proceed in the reverse order.

48

IC Pump

709

48 Inlet capillary

49

49 Manufit pressure screw

50

51

52

50 Counterpart end

51 PTFE gasket (6.2821.010)

52 4 Steel meshes (6.2821.020)

53

53 Steel mesh holding end

54 Manufit housing

54

IC Separation

55

Fig. 5

: Filter unit Manufit (6.2821.000)

709 IC Pump

12

Center 733

55 Outlet capillary

Page 21

2.4 Connecting the tubing

2.4 Connecting the tubing

2.4.1 Connection to injection valve with PEEK capillaries

For the pressure range 0…25 MPa (0…250 bar), it is recommended to

use 6.1831.010 PEEK capillaries, a 6.2620.150 Pulsation dampener

(see section 2.3.4), and a Filter unit PEEK (see section 2.3.5) to connect

the 709 IC Pump to the injection valve of the 733 IC Separation Center.

Proceed as follows:

1 Connection to 709 IC Pump

• Cut connection capillary 22 (6.1831.010 PEEK capillary) to

the required length and equip it with connectors.

• Attach connection capillary 22 to connection 23 of the 709 IC

Pump (see Fig. 2).

2 Connection of filter unit PEEK

• Attach the other end of connection capillary 22 at the connec-

tor 45 (with filter) of the filter unit 56 (see Fig. 6).

• Connect a PEEK capillary 43 cut to the required length and

equipped with connectors to the connector 47 of the filter unit

56.

3 Installation of the capillary in the IC Separation

Center

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

4 Connection of the pulsation dampener

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

5 Connection to the injection valve

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

22 56 43

709

Fig. 6

: Connection to injection valve with PEEK capillaries

57 43

733

22 Connection capillary

6.1831.010 PEEK capillary

43 PEEK capillary (6.1831.010) 57 Pulsation dampener (6.2620.150)

709 IC Pump

56 Filter unit PEEK (6.2821.100)

13

Page 22

2 Installation

2.4.2 Connection to injection valve with steel capillaries

For the pressure range 25…50 MPa (250…500 bar), it is recommended

to use 6.2620.020 steel capillaries, a 6.2620.150 Pulsation dampener

(see section 2.3.4), and a Filter unit Manufit (see section 2.3.6) to connect the not metal-free

733 IC Separation Center. Proceed as follows:

1 Connection of filter unit Manufit

• Attach inlet capillary 48 of the filter unit Manufit 58 to connec-

tion 23 of the 709 IC Pump (see Fig. 2).

• Attach outlet capillary 55 of the filter unit Manufit 58 using a

coupling 59 to a steel capillary 43 cut to the required length

and equipped with connectors (see Fig. 7).

2 Installation of the capillary in the IC Separation

Center

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

2.709.0010 IC Pump to the injection valve of the

43 Capillary

6.2620.020 Steel capillary

3 Connection of the pulsation dampener

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

4 Connection to the injection valve

• Procedure, see 732/733 Instructions for Use, section 2.6.5.

45 59 43

709

Fig. 7

: Connection to injection valve with steel capillaries

57 4358 52

733

57 Pulsation dampener (6.2620.150)

48 Inlet capillary

58 Filter unit Manufit (6.2824.000)

of filter unit Manufit 58

55 Outlet capillary

59 Coupling (6.2620.060)

of filter unit Manufit 58

709 IC Pump

14

Page 23

2.5 Electrical connection

2.4.3 Connection to eluent container

The 6.1834.000 Aspirating tubing (i.d. = 1.5 mm, e.d. = 2.5 mm, length

= 1.2 m) supplied is slid over the aspirating capillary 15. The

6.2821.090 Aspirating filter supplied is screwed onto the other end of

the tubing. The end of the tubing with the aspirating filter is then introduced in the eluent container.

Only degassed (with N

, He or vacuum) and microfiltered (0.45 µm

2

filter) eluents may be used!

It must be ensured that the eluent used is freely miscible with any

residual solvent in the pump head (the pump head is filled with

isopropanol or methanol/water in the factory). If this is not the case,

the pump must first be rinsed with a solvent that is miscible with both

the previous and subsequent eluent (e.g. acetone).

If you use the optional available 6.5324.000 Bottle rack, the

6.1834.010 Aspirating tubing (accessory of the bottle rack, length =

2.5 m) must be installed instead of the 6.1834.000 Aspirating tubing.

The end of the tubing with the screwed-on 6.2821.090 aspirating filter

is then fixed in the eluent vessel according to the instructions on the

leaflet supplied with the bottle rack.

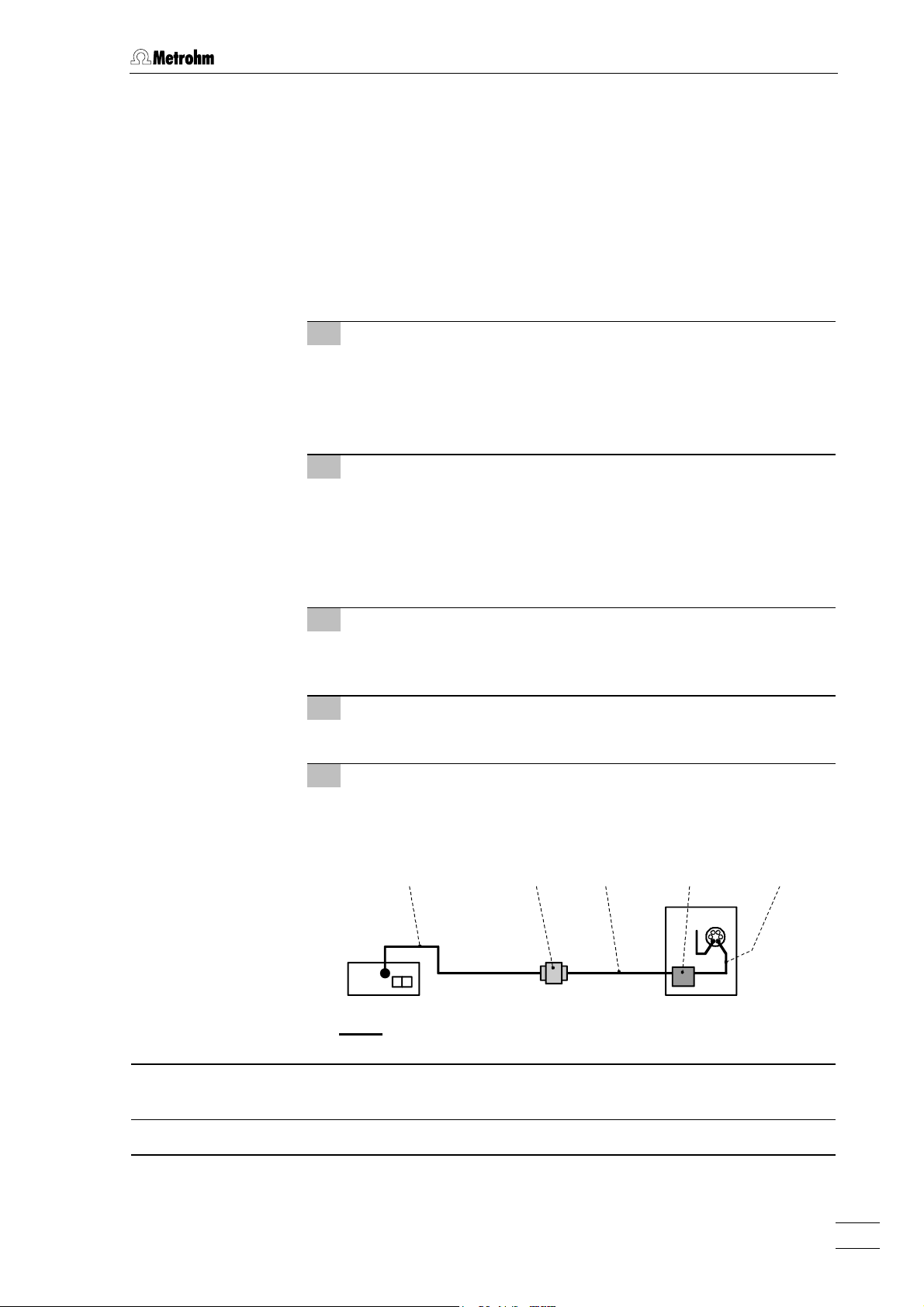

2.5 Electrical connection

The connection of the 709 IC Pump at the 732 IC Detector is made

acc. to Fig. 8 using the 6.2125.060 cable or another RS cable specified

as a "null modem" cable. To ensure proper functioning of the communication between the 732 IC Detector and 709 IC Pump, the sliding switch

36 on the IC pump must be set to "RS 232" and the external control

switched on with <EXT.> key 8 (see section 3.6).

732

709

Fig. 8

: Connection at 732 IC Detector

6.2125.060

709 IC Pump

15

Page 24

2 Installation

2.6 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.6.1 Setting the mains voltage

Before switching on the 709 IC Pump for the first time, check whether

the mains voltage set on the instrument (can be read in the mains voltage selector 32) matches the local mains voltage. If this is not the case,

you must switch the mains voltage by pushing the mains voltage selector 32 with a screwdriver:

Position of the mains

voltage selector 32:

230V

115V

230V: 220…240 V ± 10%

115V: 110…120 V ± 10%

2.6.2 Fuses

The 709 IC Pump contains two fuses built in as standard, either of type

0.25 AT (for 230 V: 0.25 A, slow-blow, Metrohm ordering number

U.600.0010) or 0.5 AT (for 110 V: 0.5 A, slow-blow, Metrohm ordering

number U.600.0013). Ensure that the two fuses correspond to the fuse

type specified for the local mains voltage (see fuse data 28). To change

wrong or blown fuses, proceed as follows:

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 31 of the

709 IC Pump.

2 Remove fuse cover

Using a screwdriver, lever out fuse cover 30 forwards until it

opens.

3 Check and change fuses if necessary

Carefully take the fuses installed for the desired mains voltage

out of the fuse holder and check its specifications:

100…120 V 0.5 A (slow-blow) Metrohm No. U.600.0013

220…240 V 0.25 A (slow-blow) Metrohm No. U.600.0010

Change fuse if necessary and reinsert in fuse holder.

709 IC Pump

16

Page 25

2.6 Mains connection

4 Install fuse holder

Reinsert fuse holders in the instrument (the arrows printed on the

holders must point in the same direction as the arrows on the

inside of fuse cover 30).

5 Install fuse cover

Push in fuse cover 30 firmly until it clicks into place.

6 Connect mains cable

Plug mains cable into mains connection plug 31.

2.6.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables:

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 31 (see Fig. 2).

2.6.4 On/off switching of the instrument

The 709 IC Pump is switched on and off using mains switch 29. When

the instrument is switched on, all segments of display 1 and all LEDs

light up for a few seconds. The instrument is then in the standby mode

("ready" status).

709 IC Pump

17

Page 26

2 Installation

2.7 Deaerating the pump

The purge valve 24 is opened by turning anticlockwise and the pump

can now be deaerated by pressing the <PURGE> key 9.

The solvent bottle should be located somewhat above the pump, but at

least at the same level as the pump head 18 (never below the pump).

When the <PURGE> key is pressed the pump operates at the maximum flow rate (5 mL/min).

9

For safety reasons the <PURGE> key

mode of the pump, i.e. the <PURGE> key is disabled when the pump

is running in normal operation.

Should the pump not prime by itself, the 6.2816.020 syringe supplied is

used to siphon off solvent via the outlet capillary 20 with opened purge

valve through the pump head until there are no more bubbles in the

solvent entering the syringe. The pump can then again be purged

briefly by pressing the <PURGE> key 9.

functions only in the stop

On completion of this procedure, the purge valve 24 is closed by turning clockwise. The pump is now ready for operation.

709 IC Pump

18

Page 27

3.1 Sequence of operations

3 Operation

3.1 Sequence of operations

Installation

1. Setting up the pump Section 2.1

2. Mounting the pump head Section 2.2

3. Attaching the accessories Section 2.3

4. Tubing connections Section 2.4

5. Electrical connection Section 2.5

6. Mains connection Section 2.6

Startup procedure

1. Switching on the pump Section 2.6

2. Deaerating the pump Section 2.7

Settings

1. Setting the flow rate Section 3.2

2. Flow correction (option) Section 3.3

3. Setting the pressure limit

values Section 3.4

Switching on the pump drive

Switching off the pump drive

Section 3.5

Section 3.5

Standby mode

709 IC Pump

Switching off the pump

Section 2.6

19

Page 28

3 Operation

3.2 Flow rate

The flow rate can be set in the range of 0.05…5.00 mL/min with the

pump drive switched on or off as follows:

1 Select "FLOW"

Press <SELECT> key 4 until the "FLOW" LED 10 lights up.

2 Set flow rate

Press < ↓ > key 5 or < ↑ > key 6 until the desired flow rate (in

mL/min) appears in display 1.

3 Store flow rate

Release < ↓ > key 5 or < ↑ > key 6: the value shown in display

1 at the time of release will be stored.

3.3 Flow correction

Since the difference between displayed and actual flow rate can be

maximum 3 % owing to unavoidable tolerances in the manufacture of

mechanical parts, there is a possibility to adjust the 709 IC Pump after

installation of a new pump head. For this, a correction factor of 0.9…1.1

can be entered in the 709 IC Pump.

The correction factor is determined by measurement of the actual flow

rate with the aid of a measuring cylinder:

Correction factor =

In the entry of the correction factor, proceed as follows:

1 Select flow correction

Press <SELECT> key 4 for ca. 3 s until all LEDs (10...13) go out

and the correction factor appears in display 1.

2 Set flow correction

Press < ↓ > key 5 or < ↑ > key 6 until the desired flow correction appears in display 1.

Displayed flow rate (in mL/min)

Measured flow rate (in mL/min)

3 Store flow correction

Release < ↓ > key 5 or < ↑ > key 6: the value shown in display

1 at the time of release will be stored.

4 Return to standby mode

Press <SELECT> key 4 briefly, the pump is again in the

standby mode.

709 IC Pump

20

Page 29

3.4 Pressure limit values for safety shutdown

3.4 Pressure limit values for safety shutdown

3.4.1 Minimum pressure limit

The minimum shutoff pressure of the pump can be set in steps of

0.1 MPa from 0.1…50 MPa with the pump drive switched on or off. Proceed as follows:

1 Select "P

Press <SELECT> key 4 until the "P

min

"

" LED 11 lights up.

min

2 Set shutoff pressure

Press < ↓ > key 5 or < ↑ > key 6 until the desired minimum

shutoff pressure (in MPa) appears in display 1.

3 Store shutoff pressure

Release < ↓ > key 5 or < ↑ > key 6: the value shown in display

1 at the time of release will be stored.

Entry of the value "0.0" switches off the lower pressure limit monitoring.

The set limit value should lie far enough below the particular operating

pressure. If the pump pressure falls below this preset lower limit during

operation, the microprocessor checks whether this violation persists for

several revolutions of the cam or whether it was a temporary drop in

pressure due to an air bubble or a brief leak in the valves. If the cause is

a temporary loss of pressure, the pump is not switched off. In the case

of a pressure drop due to leaks or interrupted inflow of the eluent, the

pump drive is switched off and disabled.

If the pump has been shut off by the minimum pressure monitoring, the

LED 11 flashes, the shutoff pressure can be requested in the display

" (see section 3.7). The safety shutdown is not active during the

"P

actual

first two minutes after the pump drive has been switched on with the

<R/S> key 3.

709 IC Pump

Pressing the <R/S> key 3 re-enables the pump drive, the LED 11 no

longer flashes and the pump is in the standby mode. Pressing the

<R/S> key 3 again puts the pump back into operation.

21

Page 30

3 Operation

3.4.2 Maximum pressure limit

The maximum shutoff pressure of the pump can be set in steps of

0.1 MPa from 0.1…50 MPa with the pump drive switched on or off. Proceed as follows:

1 Select "P

Press <SELECT> key 4 until the "P

max

"

" LED 12 lights up.

max

2 Set shutoff pressure

Press < ↓ > key 5 or < ↑ > key 6 until the desired shutoff

pressure (in MPa) appears in display 1.

3 Store shutoff pressure

Release < ↓ > key 5 or < ↑ > key 6: the value shown in display

1 at the time of release will be stored.

The set limit value should lie between 5.0 and 10.0 MPa above the particular operating pressure or the maximum admissible operating pressure of the column. If the pump exceeds the preset limit value during

operation, the pump drive is switched off within 1 pump cycle and disabled. If the pump has been switched off by the maximum pressure

limit monitoring, the LED 12 flashes, the shutoff pressure can be requested in the display "P

" (see section. 3.7).

actual

Pressing the <R/S> key 3 re-enables the pump drive, LED 12 no

longer flashes and the pump is in the standby mode. Pressing the

<R/S> key 3 again puts the pump back into operation.

The 2.709.0110 IC Pump MF (metal-free version) should only be

…

operated in the pressure range of 0

higher pressure, the 6.2824.100 PEEK pump head can be damaged.

So make sure that the maximum shutoff pressure

≤

always set to

25.0 MPa.

25.0 MPa (0…250 bar). With

P

max

3.5 Switching the pump drive on and off

Switching on Pressing the <R/S> key 3 switches on the pump drive.

While the pump drive is running, LED 2 above the

<R/S> key 3 lights up.

Switching off To switch off the pump drive, press the <R/S> key 3

again. LED 2 goes out.

of the pump is

709 IC Pump

22

Page 31

3.6 On/off switching of the external control

3.6 On/off switching of the external control

Switching on Pressing the <EXT.> key 8 switches on the external

control. The interface (RS232, see section 5.1 or "Cur-

rent Loop", details on request) is selected with sliding

switch 36. With active external control the LED 7 above

the <EXT.> key 8 lights up. All keys with the exception

of <SELECT> 4 (selection of display function) are

blocked.

Switching off To switch off the external control, the <EXT.> key 8 is

pressed again. The LED 7 goes out and all functions

are once more accessible manually via the keypad.

3.7 Inquiry of the current pressure

The current pressure of the pump can be queried at any time when the

pump drive is switched on. Proceed as follows:

1 Select "P

Press <SELECT> key 4 until the "P

actual

"

actual

2 Read pressure

The current pressure (in MPa) is shown in display 1.

3.8 Overview of the key functions

On/off switching of the pump drive

R/S

When the pump drive is switched on, the LED above

the key is on.

" LED 13 lights up.

709 IC Pump

SELECT

Selecting the display function

FLOW Current flow rate in mL/min

Minimum shutoff pressure for automatic

P

min

Range: 0.01...5.00 mL/min

shutdown of the pump drive

Range: 0.1... 50 MPa (1...500 bar)

(P

min

< P

max

)

0.0: no shutoff

23

Page 32

3 Operation

Maximum shutoff pressure for automatic

P

max

shutdown of the pump drive

Range: 0.1...50 MPa (1...500 bar)

(P

P

Current pressure

actual

max

> P

min

)

NX Correction factor for flow rate (see

section 3.2). The <SELECT> key must

be pressed for ca. 3 s.

Range: 0.90 ... 1.10

Input key for continuous lowering of the value selected with the <SELECT> key. When the key is

released the current value is stored.

Pressing this key briefly changes the displayed value

by one digit, if the key is pressed longer the value is

changed continuously and increasingly faster.

PURGE

EXT.

Input key for continuous raising of the value selected

with the <SELECT> key. When the key is released

the current value is stored.

Pressing this key briefly changes the displayed value

by one digit, if the key is pressed longer the value is

changed continuously and increasingly faster.

On/off switching of the external control of the pump

via RS232 or current loop interface.

On/off switching of the maximum delivery rate

(5 mL/min) to purge the pump.

This key is active only in the standby mode.

709 IC Pump

24

Page 33

4.1 Practical notes

4 Notes – Maintenance – Faults

4.1 Practical notes

4.1.1 Protection against foreign particles

To protect the column against foreign particles which could have an

adverse influence on the separation efficiency, we advise you to subject

both the eluents and all samples to microfiltration (0.45 µm filter) and

to siphon the eluent through the 6.2821.090 Aspirating filter.

To avoid contamination by abrasive particles arising from piston seals

of the 709 IC Pump, it is advantageous to install an in-line filter between the pump and the 733 IC Separation Center. We recommend to

use either the 6.2821.100 Filter unit PEEK for the standard operation

with PEEK capillaries (see section 2.3.5) or the 6.2821.000 Filter unit

Manufit for the operation in the pressure range > 25.0 MPa

(> 250 bar) with steel capillaries (option, see section 2.3.6).

4.1.2 Pulsation dampener

To protect the column material against pressure shocks caused by injection we recommend to use a pulsation dampener between the 709

IC Pump and the 733 IC Separation Center. The optional 6.2620.150

Pulsation dampener MF (see section 2.3.4) is eminently suitable for

this purpose.

4.1.3 Eluents

Treatment

For the preparation of the eluents one should use chemicals of a purity

degree of at least "p.a.". For dilution please use only high purity water.

Fresh eluents should always be microfiltered (0.45 µm filter) and de-

gassed (with N

stirred with a magnetic stirrer, particularly when the recycling proce-

dure is employed or when alkaline eluents are used. For alkaline eluents and eluents with low buffering capacity one should preferably use

absorbers.

CO

2

, He or vacuum). The eluent should be continuously

2

709 IC Pump

The supply vessel containing the eluent must be closed as tightly as

possible to avoid excessive evaporation. This is primarily important with

eluents containing organic solvents (e.g. acetone), the evaporation of

which can lead to drifts in the long term. If work is performed in a very

sensitive range, even if one drop of condensate falls back in the eluent

this can cause a noticeable change in the background conductivity.

25

Page 34

4 Notes – Maintenance – Faults

Precipitates

Salt crystals between the piston and the seal are the cause of abrasive

particles, which can enter the eluent. These lead to contaminated

valves, pressure rise and in extreme cases to scratched pistons. It is

thus essential to ensure that no precipitates can appear, e.g. when

the eluent is changed. Solutions used in direct succession must therefore be miscible. If the system has to be rinsed with an organic solution,

several solvents with increasing or decreasing lipophilic character may

possibly have to be used (e.g. water ↔ acetone ↔ chloroform).

4.2 Maintenance and servicing

4.2.1 General information

Care

The 709 IC Pump requires proper care and attention. Excessive contamination of the instrument could possibly lead to malfunctions and a

shorter service life of the inherently rugged mechanical and electronic

parts.

Spilled chemicals and solvents should be wiped up immediately. It is

especially important to protect the plug connections at the rear of the

instrument (particular the mains plug) against contamination.

Although constructional measures have been designed to virtually

eliminate such a situation, should corrosive media penetrate the

interior of the instrument the mains plug of the 709 IC Pump must be

immediately disconnected to prevent extensive damage to the

instrument electronics. Inform Metrohm service if your instrument has

been damaged in such a way.

The instrument must not be opened by untrained personnel. Please

comply with the safety notes in section 1.4.1.

Maintenance by Metrohm service

Maintenance of the 709 IC Pump is best done as part of an annual service performed by specialists from the Metrohm company. If work is

frequently performed with caustic and corrosive chemicals, it may be

necessary to shorten the interval between servicing.

The Metrohm service department is always willing to offer expert advice

on the maintenance and servicing of all Metrohm instruments.

709 IC Pump

26

Page 35

4.2 Maintenance and servicing

4.2.2 Maintenance work at the pump head

In many cases, an unstable baseline (pulsation, flow fluctuations) can

be traced to contaminated valves or faulty, leaky piston seals. For

cleaning contaminated valves and/or replacement of wear parts such

as pistons, piston seals and valves, proceed as follows:

1 Detach pump head

Unscrew connection capillary 14 from the pump head 18 with

the aid of the ¼" wrench (see Fig. 2). Then remove the pump

head 18 from the pump housing by loosening the 4 hexagon

screws 19 using the 6.2621.030 hexagon key. The main piston is

on the left (when viewed from front), the auxiliary piston on the

right.

2 Disassemble pump head

Strip down pump head 18 in accordance with Fig. 9. Main and

auxiliary pistons are identical with the following exceptions:

• The spring 63 of the auxiliary piston (right piston) is more

powerful (longer) than that of the main piston (left piston).

• Inlet and outlet valve are not present in the secondary

cylinder.

61

To prevent the piston

64

, the screw 60 must be undone very carefully by hand.

suddenly jumping out of the piston cartridge

3 Cleaning/replacement of piston 61

Pistons contaminated by abrasive particles or deposits are

cleaned with scouring powder and rinsed free of any particles

with dist. water. Relatively badly contaminated or scratched

pistons must be replaced (spare part: 6.2824.070 Zircon piston).

4 Replacement of piston seal 68

To remove damaged piston seals 68 the special tool 72 is used.

This is screwed into the seal 68, which can then be pulled out

(see Fig.10A).

72

When the special tool

completely destroyed!

If you use only aqueous eluents the 6.2741.000 piston seal can be

replaced by the 6.2741.010 PE piston seal available as an option.

is screwed into the piston seal 68 the latter is

709 IC Pump

27

Page 36

4 Notes – Maintenance – Faults

71

18

70

60 61 62 63 64 65 66 68 69

67

70

: Components of the pump head

Fig. 9

A

18

72

73

68

68

B

73

C

72

Fig. 10

: Replacement of the piston seal

68

18 Pump head (6.2824.040/6.2824.100) 67 Piston guide sleeve (4.709.4370)

60 Screw for piston cartridge 64 68 Piston seal (6.2741.000/6.2741.020)

61 Piston with piston shaft (6.2824.070 zircon

piston or 6.2824.000 sapphire piston)

62 Spring retainer 70 Outlet valve (6.2824.010/6.2824.080)

63 Spring (6.2824.050) for main piston or

Spring (6.2824.060) for auxiliary piston

64 Piston cartridge (4.709.0760) 72 Special tool (6.2617.010) to remove the

65 Piston guide sleeve (4.709.4380) 73 Special tool (6.2617.010) to install the

66 Sapphire supporting ring (6.2824.030)

709 IC Pump

28

69 Inlet valve (6.2824.020/6.2824.090)

71 Screw holder for valve

piston seal 68

piston seal 68

Page 37

4.2 Maintenance and servicing

To install a new piston seal

68 the special tool 73 is used:

• First the new seal is inserted firmly in the recess of tool

73 by

hand (see Fig. 10B). The seal spring must be located on the

outside.

• The tool

head

with the aid of tool

73 together with the seal is then inserted in the pump

18 and the seal pressed into the pump head recess

72 (see Fig. 10C).

The seal surface in the pump head

contact with tool)!

18

must not be damaged (avoid

5 Cleaning/replacement of inlet valve 69 and outlet

valve 70

Different valves are used depending on the pump version. In the

2.709.0010 IC Pump, the 6.2824.020 Inlet valve and the 6.2824.010

Outlet valve are built-in, in the metal-free 2.709.0110 IC Pump, the

6.2824.090 Inlet valve and the 6.2824.080 Outlet valve are built-in..

Contaminated or blocked valves are cleaned by rinsing with dist.

water, RBS solution or acetone. The rinsing effect can be

reinforced by brief treatment in an ultrasonic bath (max. 20 s; if

longer the sapphire sphere of the valve can be damaged).

If this does not have the desired effect, the valves can be

disassembled as shown in Fig. 11. The valve components are

pushed out with the aid of a syringe needle inserted through the

upper opening in the valve housing

74. The individual compo-

nents are rinsed with dist. water and/or acetone, and the sapphire sphere cleaned with a paper towel. The valve is then

reassembled in accordance with Fig. 11. The components of the

inlet and outlet valves are identical, they are distinguished only

by the positioning of the sapphire sleeve

holder

79 (see Fig. 11).

77 and the ceramic

Valves that fail to function faultlessly after such cleaning must be

replaced.

In the reinstallation of the inlet valve

69 or the outlet valve 70 on

no account must the two outwardly identical valves be interchanged. To determine which valve is which, note that the liquid

flows through the pump head from the bottom up. The flow

direction of the valves can be checked simply by blowing

through the clean valve. Both valves are installed with the black

face in the direction of the pump head (see Fig. 9).

709 IC Pump

29

Page 38

4 Notes – Maintenance – Faults

69

If by mistake an inlet valve

an extreme pressure buildup occurs within the working cylinder, which

is not detected by the pressure transducer and will destroy the piston

68

seal

6 Mounting the pump head

Inlet valveOutlet valve

6.2824.020/ 6.2824.010/

6.2824.090 6.2824.080

!

The components of the pump head 18 are reassembled as

shown in Fig. 9. The screw

be tightened only by hand. On the other hand, the two valve

screw holders

then remounted on the pump (see section 3.2).

71 are tightened with a wrench. The pump head is

is installed instead of the outlet valve 70,

60 and the piston cartridge 64 may

74

75

76

77

78

79

80

Fig. 11

: Components of inlet valve

outlet valve

70

74

75

76

79

78

77

80

69 and

74 Valve housing

75 Sealing ring (black)

76 Sleeve

77 Sapphire sleeve

The bright side must point towards

the sapphire sphere

78 Sapphire sphere

79 Ceramic holder for sapphire

sphere

The large recess must point in the

direction of the sapphire sphere

80 Seal

The larger opening must point

outwards

709 IC Pump

30

Page 39

4.3 Faults and malfunctions

4.3 Faults and malfunctions

If difficulties appear with the IC system during analyses, their causes

are best investigated in the order separating column → 709 IC Pump

→ eluent → 732/733 IC System (see 732/733 Instructions for Use,

section 5.3.2). Several of the malfunctions which may appear with the

709 IC Pump are listed in the following table with details of possible

causes and countermeasures.

Malfunction Cause Rectification

• Dark or undefined

display

• Pump does not

respond to keystroke

• Pump drive is

switched on automatically after

switching on the

instrument without

keystroke

Baseline with high

noise level, pulsation

Drift of the baseline • Thermal equilibrium

• Battery of Zero Power

RAM discharged

• Contaminated pump

values

• Faulty piston seals

• Quality of the pump

does not suffice for the

selected sensitivity

not yet reached

• Leak in system

• Evaporation of organic

solvent in eluent

• Inform Metrohm

service

• Clean the valves (see

section 4.2.2)

• Replace the piston

seals (see sec-

tion 4.2.2)

• Use pulsation

dampener, use more

powerful pump or

lower the sensitivity

• Condition system with

heating switched on

• Check connections

and make leakproof

• Ensure better closure

of eluent supply vessel

709 IC Pump

Considerable pressure

drop

Considerable pressure

rise

Error message "E01" in

the display

Error message "E02" in

the display

Error message "E03" or

"E05" in the display

• Leak in system • Check connections

and make leakproof

• Contamination of the

filter in the 6.2821.000

Filter unit Manufit

• Contamination of the

filter in the 6.2821.100

Filter unit PEEK

• RS232 receive error • Inform Metrohm

• ROM test error • Inform Metrohm

• RAM test error • Inform Metrohm

• Clean or replace

6.2821.020 Steel

mesh(es)

• Replace 6.2821.110

connector with filter

service

service

service

31

Page 40

4 Notes – Maintenance – Faults

4.4 Diagnosis

4.4.1 General information

The 709 IC Pump is a very precise and reliable instrument. Thanks to its

rugged construction it is virtually impossible for external mechanical or

electrical influences to have an adverse effect on its functions.

Although the occasional fault in the instrument can not be excluded

completely, it is certainly much more likely that malfunctions are caused

by wrong operation or handling or through improper connections and

operation with non-Metrohm instruments.

It is thus advisable in each case to isolate the fault with the rapid and

easy to perform diagnostic tests. The customer thus need not call

Metrohm service until there is a true fault in the instrument. In addition,

with the aid of the numbering in the diagnostic program he can provide

the service engineer with much more accurate information.

In inquiries always quote the manufacturing number 39 of the 709 IC

Pump (see Fig. 2), program version (see section 4.4.2) and specify

possible error messages.

Procedure

The diagnostic steps must be performed in sequence and compared

with the reactions of the 709 IC Pump (indented). In the "yes" case, continue with the next instruction.

If the instrument does not show the expected reaction ("no" case), the

appropriate diagnostic step must be repeated to exclude an operating

error. With repeated wrong reactions, however, there is a strong possibility that a malfunction exists.

Equipment needed

3.496.8480 Test plug (Necessary only if external required functions

(RS 232) should also be checked).

709 IC Pump

32

Page 41

4.4 Diagnosis

4.4.2 Entry of diagnostics with automatic display test

1. Power off.

2. Disconnect all external connections (cables at rear) except mains

cable.

3. Press and hold <R/S> key 3 (keep pressed) and power on.

The display 1 shows for about 3 s the switch-on test pattern and all 6 LEDs are switched on for visually checking.

8.8.8.8.8

The display 1 shows for about 3 s the number of the installed program version.

7 0 9.1 0

4. Release <R/S> key 3.

4.4.3 Keyboard test

1. Press <R/S> 3.

2. Press <SELECT> 4.

3. Press <

4. Press <

5. Press <EXT> 8.

6. Press <PURGE> 9.

1 1

1 2

↓ > 5.

1 3

↑ > 6.

1 4

1 5

709 IC Pump

1 6

2 x x

(x x) = not relevant

33

Page 42

4 Notes – Maintenance – Faults

4.4.4 RS232 Test

This test is meaningful only if the 709 IC Pump

is used interconnected with other instruments

via RS 232 connection. In addition, a

3.496.8480 Test plug normally used in the repair service is required for this test. However,

this plug can also be purchased by customers

under the above number.

For the sake of completeness, the procedure

is described here.

(If a diagnostic test of the RS232 interface is

not required, continue with section 4.4.5)

1. Power off.

2. Insert 3.496.8480 plug in port "RS232" 37.

3. Sliding switch 36 on rear panel to setting "RS232".

4. Press and hold <SELECT> key 4 (keep pressed) and power on.

2

5. Release <SELECT> key 4.

Connections in the

3.496.8480 plug

TxD

RxD

DCD

DTR

DSR

RTS

CTS

2 . .

2 0 0

The test runs automatically and checks several functions in

succession. If one of these functions is faulty, the display

"2 0 0" does not appear directly but some value is shown

briefly. If, e.g., no test plug is plugged in, the following appears:

2 . .

2 0 8

2 0 0

6. Power off.

7. Remove test plug.

709 IC Pump

34

Page 43

4.4 Diagnosis

4.4.5 Initialize and test RAM

On the odd occasion large disturbing signals (e.g. mains spikes, lightning, etc.) can have an adverse effect on the processor functions and

hence lead to a system crash. After such a crash the RAM area must be

initialized. Although the basic instrument data remain stored, the RAM

initialization should be performed only when necessary since the stored

, P

user data (flow rate, P

1. Power off.

min

etc.) are cleared as a result.

max

2. Press and hold <

3

3. Release <

↓ > key 5.

3

RAM is tested and initialized.

↓ > key 5 (keep pressed) and power on.

3 0 0

8.8.8.8.8

2.5 x

4. The lost data of the user must now be reentered.

The "FLOW" LED

lights up.

709 IC Pump

35

Page 44

4 Notes – Maintenance – Faults

4.5 Validation / GLP

The requirements of GLP (Good Laboratory Practice) include a peri-

odic check of analytical measuring instruments with regard to their reproducibility and accuracy using Standard Operating Procedures,

SOP).

The 709 IC Pump as part of the complete ion chromatography system,

whose most important components also include separating column,

732 IC Detector, 733 IC Separation Center, and evaluation system,

must be incorporated in its comprehensive validation.

Testing of the electronic and mechanical function groups of Metrohm

instruments can and should be performed as part of a regular service

by trained personnel of the manufacturing company (see section 4.2.1).

All Metrohm instruments are equipped with start-up-test routines which

check for perfect functioning of the relevant assemblies when the instrument is switched on. If no error message is displayed, it may be assumed the instrument is operating without faults.

The Metrohm company also supplies its instruments with an integrated

diagnostic program (see section 4.4) which, in the case of possible

malfunctions or faulty behavior, allows the user to check the functioning

of certain assemblies and localize the fault. Diagnostic programs can

also be integrated in a validation procedure.

709 IC Pump

36

Page 45

5.1 RS232 interface

5 Interfaces

5.1 RS232 interface

5.1.1 General rules for remote control

The 709 IC Pump is equipped with the comprehensive Metrohm remote

control language, which allows full control over the instrument via an

RS232 interface, i.e. the 709 IC Pump can receive data from an external

device or send data to an external device. The 709 IC Pump sends

and LF as the terminator of a requested data block. In contrast,

2×C

R

and LF are used as the terminator of a data line. On receipt of data

C

R

from an external device, this must always close its commands with C

and L

as a delimiter between the individual commands.

The data are grouped logically and readily understandable. For example, to select the flow rate the command

. If more than one command is sent on a line, ‘;’ must be used

F

R

&Parameter.A.Flow"1.5"

must be sent with entry of the boldface characters sufficing, in other

words

&Pa.A.F"1.5"

All quantities of the 709 IC Pump are collected in groups. The entries

for the parameters, for example, are located in the group

&Parameter

The ‘Parameter’ group contains sub-groups, e.g. for setting the parameter for the Metrohm pump head

&Parameter.A

This subgroup in turn contains the individual inquiries for the settings,

e.g. the inquiry regarding the flow rate

&Parameter.A.Flow

or regarding the setting of the minimum shutoff pressure

&Parameter.A.Pmin

The data have a hierarchical structure (tree structure). The quantities

which appear in this tree are called objects in what follows. The flow

rate is that object which is called up with the command

709 IC Pump

&Parameter.A.Flow

Once you are at the desired location in the tree, you can request the

value of the object:

&Parameter.A.Flow $Q Q for Query

37

Page 46

5 Interfaces

The inquiry ‘$Q’ initiates the output of the value on the instrument, in

other words the value output is triggered. Entries which begin with the

character ‘

$’ always trigger something and are hence referred to as

triggers in what follows.

However, values of objects can not only be requested, they can also be

modified. Values are always inputted in inverted commas, e.g.

&Parameter.A.Flow"1.5"

5.1.2 Call-up of objects

A section from the object tree is shown below:

Node 3

Node 2

Node 1

Flow NX

A

Parameter

M

Pump

Node 0

&

Root

The following rules apply to the call-up of objects:

Rules Examples

The root of the tree is designated by ‘&’.

For the call-up of an object, the nodes (levels) of the tree are

marked by a point (.).

For the call-up of the objects, as many characters as

necessary to allow unambiguous allocation of the object

suffice. If the call-up is not unambiguous, the first object in

the series is identified.

Call up of the minimum shutoff

pressure:

&Parameter.A.Pmin

or

&Pa.A.Pmi

Uppercase and lowercase letters can be used. &PA.A.PMI or &pa.a.pmi

A value can be assigned to an object. Values are marked at

both their beginning and end by inverted commas ("). They

can contain maximum 8 ASCII characters. Numeric values

can contain up to 3 digits and a decimal point. Numbers with

more than 3 digits are not accepted. With numbers <1,

leading zeros must be entered.

709 IC Pump

38

Entry of "1.5" for the flow rate:

&Parameter.A.Flow

Correct numeric entries:

"38.5", "0.97"

Incorrect numeric entries:

"1,5" or "+3" or ".13"

"1.5"

Page 47

5.1 RS232 interface

Rules Examples

Until a new object is called up, the old object remains in

force.

New objects can be addressed relative to the old object:

A leading point leads one node forwards in the tree.

More than one leading point leads one node backwards

in the tree. n nodes backwards require n+1 leading points.

To return to the root, enter a leading '&'. Jump from the node 'M' via the

5.1.3 Trigger

Triggers initiate an action at the 709 IC Pump, e.g. starting of a mode or

sending of data. Triggers are marked by the introducer

The following triggers are possible:

From the root to the node 'A':

&Pa.A

Forwards from the node 'A' to

'Flow': .F

Jump from Flow onto the node

'A' and selection of a new object

'NX' at this node: ..NX

root into the node 'Pump': &Pu

'$'.

$G Go Starts processes, e.g. starting the pump

$S Stop Stops processes

$Q Query Used to request all information from the current

node in the tree forwards up to and including the

values

$Q.P Path Used to request the path from the root of the tree

up to the current node

$Q.H Highest

Index

$Q.N"i" Name Used to request the name of the daughter node

$D Detail-Info Used to request detailed status information

Used to request the number of daughter nodes of

the current node

with index i, i = 1...n

The triggers

'$G' and '$S' are linked to particular objects, see Over-

view table in section 5.1.5.

All other triggers can always be used at all locations in the data tree.

Examples

Inquiry of the value of the pressure:

:

&Info.Actual.Pressure $Q