Page 1

7010 TOC ANALYZER - USER MANUAL

Version: 1.12

Prepared: DC

Verified : FG

Checked: FS

Approved: DM

Issued: 28/09/2015

1

Page 2

I N D E X

7010 TOC ANALYZER - USER MANUAL

1 SAFETY PRECAUTIONS AND HAZARDS

1.1 General informations

1.2 List of warnings and potential dangers

1.3 Vent waste gas

1.4 Sample

1.5 UV lamps disposal

1.6 Analyzer general hazards

1.6.1 Electrical precautions and hazards

1.6.2 Operating precautions and hazards

1.6.3 Chemical and waste gas hazards

2 INTRODUCTION

2.1 Analyzer description

2.2 Applications

2.3 Fast Loop Reservoir

2.4 Liquid enclosure components

2.4.1 Peristaltic pumps

6

6

7

9

9

9

10

10

11

12

13

14

16

19

20

21

2.4.2 Scrubber

2.4.3 UV reactor (UVR) + UV Scrubber

2.4.4 U-Tube

2.4.5 Glass condenser

2.4.6 Dryer

2.4.7 By-pass Valve

2.5 Electrical enclosure components

2.5.1 Copper filter

2.5.2 Sodalime filter

2

22

22

23

23

24

24

25

26

26

Page 3

7010 TOC ANALYZER - USER MANUAL

2.5.3 Pump motor

2.5.4 Air compressors

2.5.5 Pressure regulator , capillary and flowmeter

2.5.6 NDIR

2.5.7 User connections

3 INSTALLATION

3.0 Unpacking and inspecting

3.1 Analyser moving

3.2 Location and mounting instruction

3.3 PRECOMMISSIONING

3.4 Electrical connections

3.4.1 AC Power connections

3.4.2 Analog output

connections

3.4.4 Relay A/B

3.4.5 Digital input/output

27

28

28

29

29

30

31

31

31

32

33

34

34

35

36

3.4.6 Levels

3.4.7 External dilu to r supply

3.4.8 Fuses

4 USER INTERFACE

4.0 User instructions

4.1 Main Page

4.2 Main page + process values

4.3 Calibration page

3

37

37

37

40

41

42

45

46

Page 4

7010 TOC ANALYZER - USER MANUAL

4.3.1 Zerogas

4.3.2 Liquid Zero

4.3.3 Manual Calibration

4.3.4 Run autocal

4.4 Timing page

4.5 General setup page

4.6 Datalogger pag

4.7 Dual stream configuration

4.8 Dual range option

5 MAINTENANCE

5.1 Pump tubing replacement

5.2 Copper wool replacement

5.3 Sodalime replacement in sodalime filter

5.4 UVR tubing's connection replacement

5.5 UV lamps replacements

5.6 Fuses replacement

47

48

49

50

51

52

53

55

56

59

61

63

64

65

66

67

6 PREPARATION OF THE CHEMICALS

6.1 Preparation of the TOC standard solution

6.2 Preparation of the COD standard solution

6.3 Preparation of the Persulphate solution

6.4 Preparation of the Acid solution

6.5 Preparation of reducing solution

6.6 Preparation of the Cleaning solution

6.7 Preparation of TC Reagent solution

7 ANALYZER SHUT DOWN

APPENDIX Optional Configurations

4

68

69

70

71

72

73

74

75

76

Page 5

55

Page 6

1.0 SAFETY PRECAUTIONS AND HAZARDS

1.1 General informations

7010 TOC ANALYZER - USER MANUAL

Metrohm Applikon

operators of analyzer must be sure to read and observe the following instructions and to apply all national or local regulations and laws regarding

health and safety of the workfare.

Use, maintenan ce and service of this analyser are allowed only by qualified personnel fully trained on the analyzer’s operation.

This personnel should be physically and mentally fit and not under the effect of alcohol or/and drugs.

When the analyzer is not used it should be protected from intentional or unintentional powering on, using a proper circuit breaker.

Before to proceed with analyzer installation, please read through and fully understand this instruction manual to ensure proper operation. Pay

attention to all caution and dangers labels present on the analyzer and all caution and danger statements written in this manual. For analyzer

installation and use, please refer carefully to all information and recommendations present in this manual.

Failure to do so and non-observance of hazard or danger warnings could result in death or serious inju ry to the operators or damage to the

analyzer.

Before to use the analyser is necessary to check visually for damage of safety devices and report to your reference head even if they don’t cause

analyzer stop or malfunction.

All analyzer components are installed inside two metallic enclosures with doors equipped with a special key for opening, only endowed qualified

maintenance personnel. (ref. section 3.3). Opening the door for visual inspection is possible while the analyser is in normal operation, but only if all

the safet y precautions and hazard and danger labels have been strictly observed.

shall not be liable for errors contained herein and/or for any incorrect use of the analyser. The department head and the

6

Page 7

7010 TOC ANALYZER - USER MANUAL

1.2 List of warnings and potential dangers

The table below is a list of hazard and danger warning labels that is possible to find on the analyzer and/or in this manual.

In the case of these labels, becoming damaged or unreadable they should be replaced with new ones by the analyzer owner.

7

Page 8

Tab. 1-1: List of hazards and dangers

Hazard of eletrical shock

This symbol is used to warn of a hazard of severe electric shock or electrocution. All controls and maintenance on electrical

devices labelled with this symbol should be made by qualified personnel in accordance with national or local regulations.

Qualified personnel means a person who has been fully trained and has professional experience to avoid electrical hazards

and dangers. To avoid potential fatal electrical shock and/or analyzer damage always disconnect input power to analyzer before

servicing.

Hazard of chemical burns

This symbol is used t o warn of a hazard of severe burns and seroius injury from dangerous chemicals. All handling and

manipulations during operation and maintenance of chemicals labelled with this symbol should be made by qualified personnel

in accordance with national or local regulations. Qualified personnel means a person who has been fully trained and has

professional experience to avoid chemical hazards and dangers. Before to proceed with the handling of chemicals or

operations read the material safety data sheets supplied with each chemical to ensure all the necessary precautions are taken.

Hazard of UV radiation

This symbol is used to warn of an hazard of ultraviolet radiation. It is obligatory to wear eye protection to operate with the UV

lamps labelled with this symbol.

Never look directly at a lighted UV lamp. UV radiation exposure can cause severe and permanent damage to skin and eyes.

Concerned parts:

Fans

Air compressors

UV power supplies

Main power supply

UV lamps

Pump motors

Input terminal

Corcerned parts:

Liquids enclosure

Reagents containers

Concerned parts:

UV lamps

Hazard of thermic shock and burns

This symbol is used to warn of an hazard of t hermic shock and burns. Some parts of the analyzer become extremely hot during

analyzer normal operations. Avoid skin contact with these surfaces and if necessary to service these parts be sure to

sufficiently enough to avoid burning. Always disconnect input power to analyzer before servicing these parts.

Warning of general hazard

This symbol means that is necessary read this manual before proceeding with any service operation to know exactly how to

operate in a proper way. Only qualified personnel or personnel fully trained on analyzer use and maintenance is allowed to

proceed with service operations on the unit.

Corcerned parts:

UV lamps

Pump motors

Air compressor

Concerned parts:

TOC analyzer

8

Page 9

7010 TOC ANALYZER - USER MANUAL

1.3 Vent waste gas

Waste gases coming from analyzer oxidation process depend on th e user’s sample composition. They are labelled on the external side of the

cabinet as VENT outlets. It is necessary to connect an extension tubing or to provi de for safe venting to the atmosphere or to a classified safe

area.

1.4 Sample

Take appropriate precautions to avoid direct contact with sample stream.

It is responsability of the user to be aware of and take all precautions

regarding physical, chemical, radiation and/or biological hazards and

dangers coming from sample stream and/or sample vapours. It is also

responsibility of the user to be aware of potential hazards regarding the

chemical and physical compat ibi lit y of sample stream with the analyzer

materials.

1.5 UV lamps disposal

Used or replaced UV lamps contain a small quantity of mercury and they

must be disposed according with national or local environmental

regulations regardin g hazardous and poisonus materials.

Table 1-2 : List of materials used in 7010 TOC Analyzer

Pump tubings

Fittings

Connection tu bings

GLS,U Tube,

Scrubber, Condenser

Halogens and sodalime filter body

Filter cont ent s

UV lamps

Bypass valve

IR cell

Gas dryer tubing

Norprene,Tygon

Polypropylene

PFA

Glass

PVC, p olycarbon at e

Copper wool (halogens filter),

Sodalime (CO2 filter)

Quartz

Noryl, viton

Stainless st eel

Nafion

9

Page 10

1.6 ANALYZER GENERAL HAZARDS

1.6.1 Electrical precautions and hazards

7010 TOC ANALYZER - USER MANUAL

In all electrical devices that are 230 VAC (or 115 VAC opt.) powered present hazards of

electrical shock or electrocution.

To protect all the personnel involved in analyzer use and maintenance, the doors of the two

analyser enclosures are equipped with a special key for opening.

If necessary to operate inside the electrical enclosure with the analyzer powered on, please

consider th at this operation must be made only by qualified personnel in accordance with

national or local regulations. Qualified personnel means a person who has been fully trained

and has professional experience to avoid electricity hazards and dangers.

Service qualif ied personnel will receive the special key to open the electrical enclosure.

Before to service the analyzer or parts of that electrically powered, turn off all power to avoid risk

of electrocut ion.

To turn off power from an electrical device is necessary to interrupt the power line using a circuit

breaker or an isolating switch to be sure that there is no power in the area being serviced.

Users and qualified maintenance personnels must proceed as follows:

pay attent ion to electrical shock and/or electrocutions labels placed on the analyser

always isolate power before servicing the analyser

In case of loss of power the analyser stops and will automaticall y restart as soon as power is

restored.

WARNING: UV lamp power supply

reaches an ignition voltage up to 3000

volts; do not operate any service

activity without removing the

instrument power cord

Analyser’s control circuitry is powered 24

Vdc and 12 Vdc. Inside the electrical

enclosure the lower level of protection

against direct contacts is IP2X. Analyzer

enclosures are IP54 (because of air fans

holes).

Protection against indirect contacts is

guaranteed by efficient grounding of all

isolated metal masses.

Grounding bar is located inside the

electrical enclosure, in upper left position

below the protection cover.

It will be user’s responsability to

check and garantee periodically the

perfect efficiency of analyzer’s

grounding.

.

10

Page 11

1.6.2 Operating precautions and hazards

7010 TOC ANALYZER - USER MANUAL

HAZARD:

PREVENTIVE ACTIONS:

HAZARD:

PREVENTIVE ACTIONS:

HAZARD:

PREVENTIVE ACTIONS:

Mechanical hazards caused by moving parts such as fans, pumps, motors and air compressors

To avoid risks the analyzer’s moving parts have been designed, built and located in a closed enclosure with a

special opening key. Where present inside the enclosures, these parts have protection covers to avoid any contact

and physical injury to users.

Hazards of burns caused by hot parts of UV lamps, motors and air compressors

To avoid risks, the analyser’s parts that become very hot to the touch have been designed, built and located in

closed enclosure with a special opening key. When present inside the enclosures, these parts have protection

covers and warning labels to avoid any contact and physical injury to users.

Hazard of poisoning caused by waste gas coming out from VENT line

Install t he analyser in location of adequate dimensions and well ventilated.

HAZARD:

PREVENTIVE ACTIONS:

11

Hazards of UV radiation exposure caused by UV lamps

To avoid risks, the analyser’s parts that produce UV radiation emissions have been designed, built and located in

closed enclosure with a special opening key. When present inside the enclosures, these parts have protection

covers and warning labels to avoid any contact and/or exposure and/or physical injury to users.

Page 12

7010 TOC ANALYZER - USER MANUAL

HAZARD:

PREVENTIVE ACTIONS:

HAZARD:

PREVENTIVE ACTIONS:

Hazard of electric shock and/or electrocution in the

electrical enclosure

The analyser’s electric equipment complies with

EN 60204

To avoid risks, the analyser’s parts that can cause

hazard of electric shock and/or electrocution have

been designed, built and located in a closed

enclosure with a special opening key. When

present inside the enclosures, these parts have

protection covers and warning labels to avoid any

contact and serious injury or death to users.

Hazard of burns and poisoning caused by contact with dangerous chemicals

To avoid risks, the analyser ’s parts that can cause contact wit h chemicals have been designed, built and locat ed in

closed enclosure with a special opening key. Before to service the liquids enclosure, read the material safety data

sheets supplied with each chemical to t ake all the necessary precautions when handling. Wear eye protections,

gloves, mask and protective clothing if necessary.

requirements.

Electrical equipments of input power and grounding must

comply the national or local regulations and laws.

Check that the source voltage to be used corresponds

with that requested by the analyser.

Check periodically the power cord as well as the analyser

grounding.

WARNING:

voltage up to 3000 Volts; do not undertake any service

activity without removing the instrument power cord.

NOTE :

UV lamp power supply reaches an ignition

1.6.3 Chemical and waste gas hazards

The analyser has been designed, built and equipped to avoid risks caused by physical and chemical factors as noise, vibrations, radiations, dust,

waste gas etc.

12

Page 13

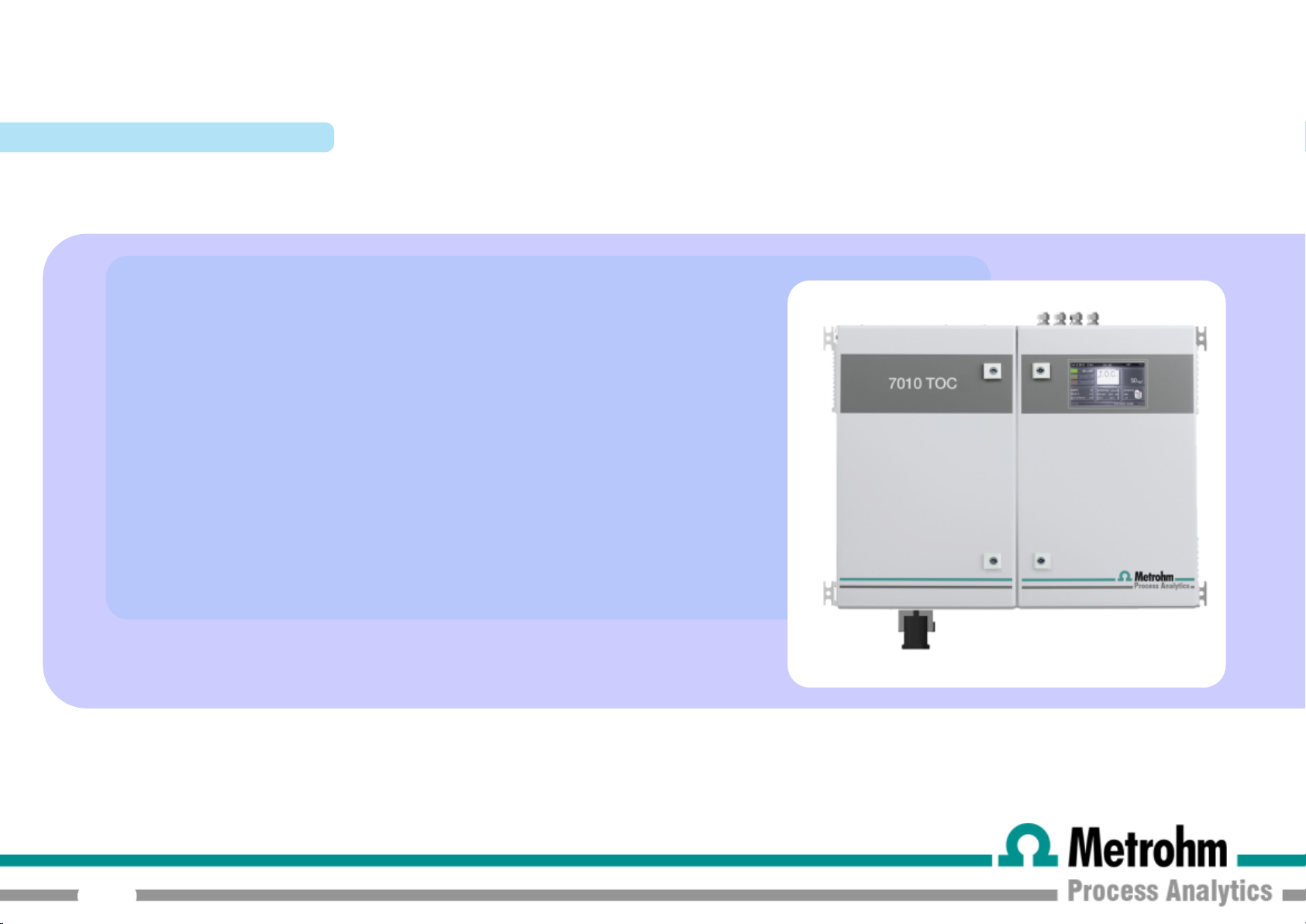

2.0 ANALYZER DESCRIPTION

This manual provides general information regarding the principle of

operation and proper installation and operation of the 7010 TOC A nal yser .

The analyser measures Total Organic Carbon in liquid samples using the

EPA approved method based on UV persulfate oxidation and detection of

generated carbon dioxide using a Non Dispersive Infrared analyser. This

method meets also the requirements of European ISO/CEN guidelines. The

analyser provides this measurements on liquid samples ranging from 0-5

7010 TOC ANALYZER - USER MANUAL

mg/l to 0-20000 mg/l.

The analyser conforms to EPA, DIN, CE, AST M and NAMUR regulations.

13

Page 14

2.1 APPLICATIONS

The

701 0 TOC

(TOC) in water.

It has been designed for the following applications:

Industrial wast e water

Condensate and cooling water

Drinking and river water

analyser continuously measures Total Organic Carbon

7010 TOC ANALYZER - USER MANUAL

Industrial wat er treatment plant inlet/outlet

For different applications or different aqueous matrices it is recommended

to contact your Metrohm distributor to verify your application with our

specialists.

14

Page 15

7010 TOC ANALYZER - USER MANUAL

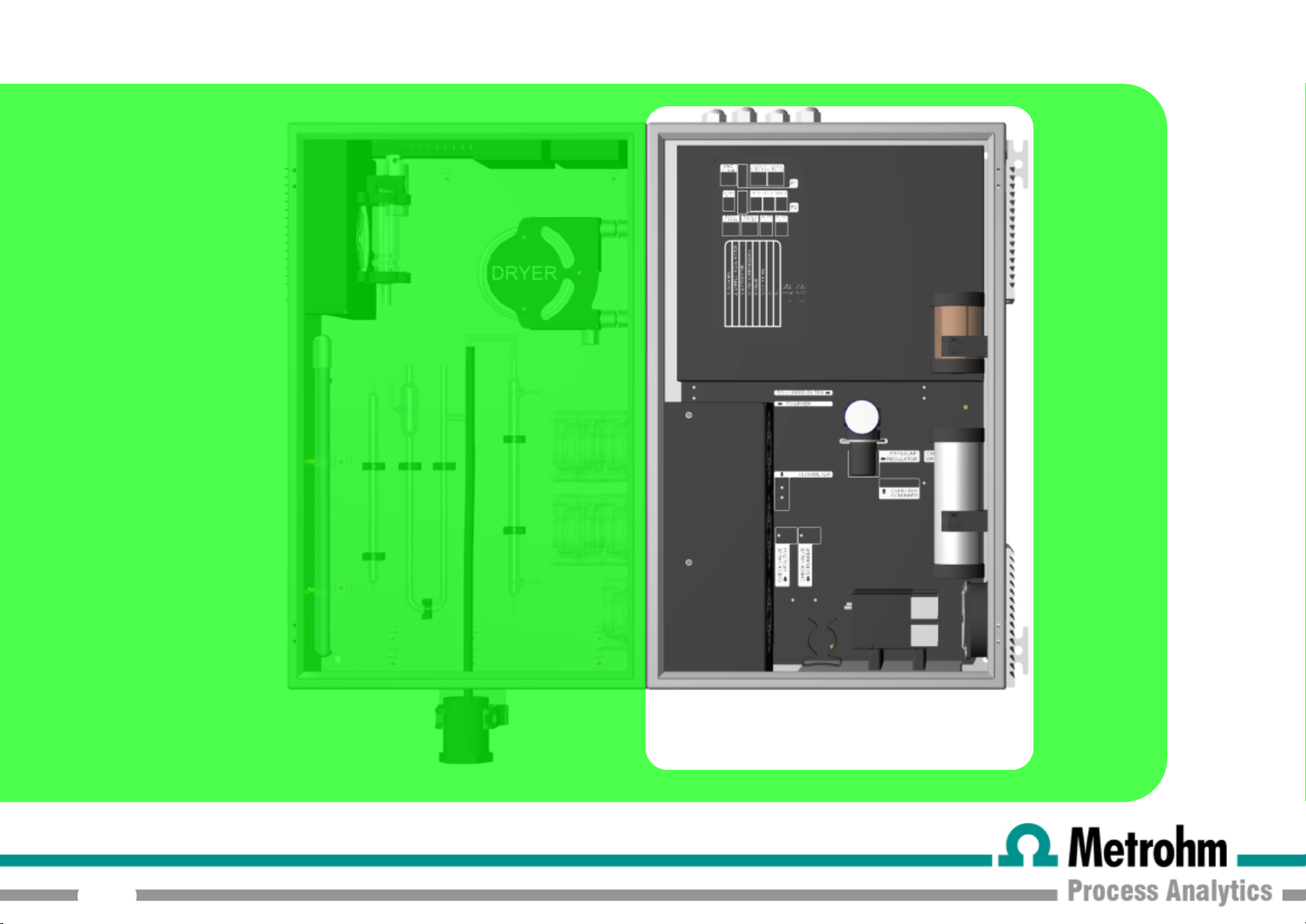

The analyser is assembled in two separated enclosures. The first one, called

LIQUIDS enclosure

, includes all the components involved in sample and reagent flows as well as

their mixing in sparging and oxidation stages. This enclosure is properly vented by a fan to allow good air refreshment inside the cabinet. The second one, called

enclosure

, includes the main power supply, the carrier gas generation and flow adjustment devices, the controlleing PCB assembly and the infrared detector.

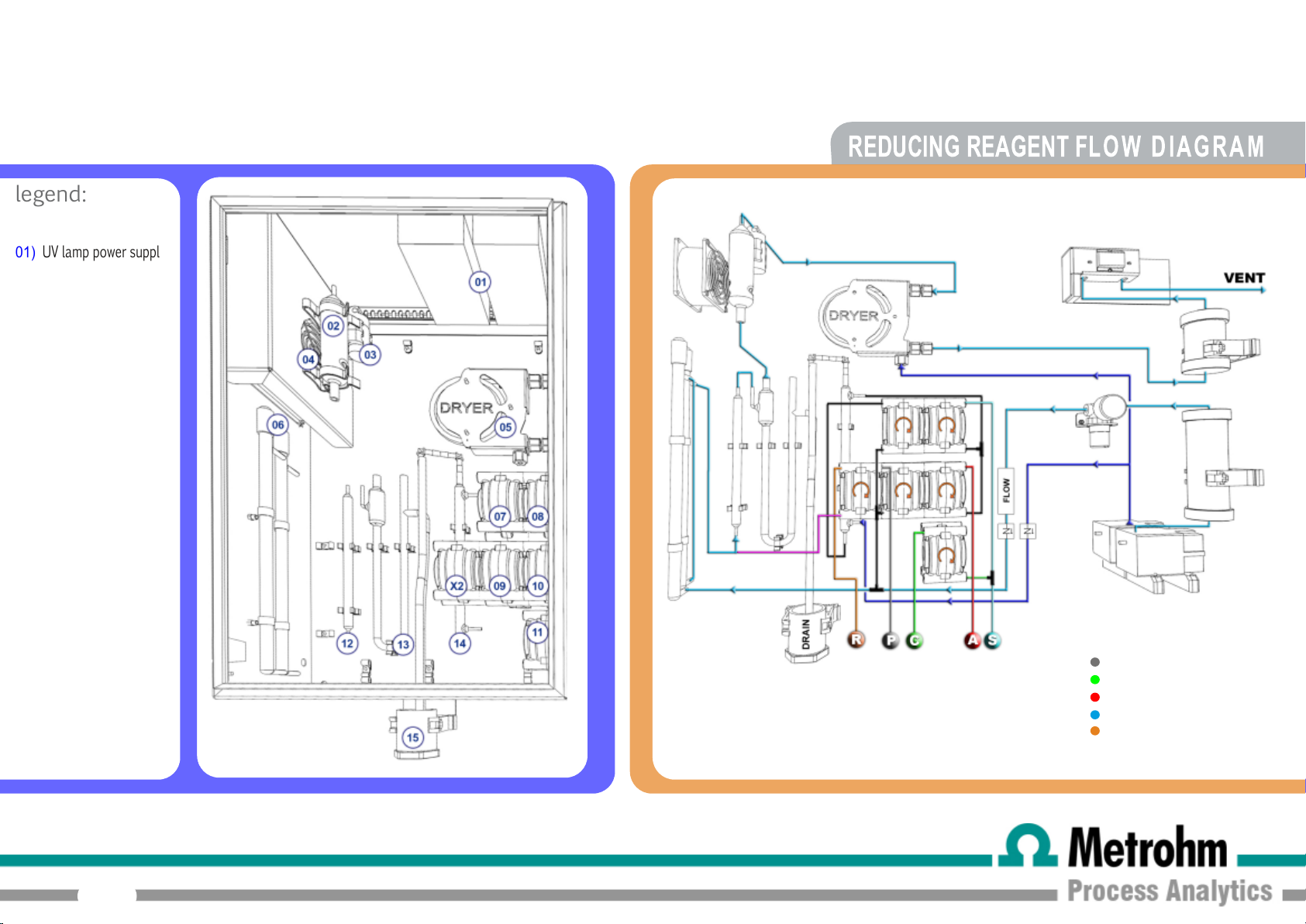

legend:

01)

UV lamp power supplies

02) glass condenser

03) by-pass valve

04) condenser fan

05) dryer tubing

06) UV reactor

07) resample pump

08) sample pump

09) persulfate pump

10)

phosphoric acid pump

11) auto pump

12) UV scrubber

13) U-tube

14) scrubber

15) drain

ELECTRICAL

legend:

01) user connections

02) copper filter

03) pumps motor

04) pressure regulator +

flow capillary

05) sodalime filter

06) dryer + scrubber

capillary

07) flowmeter

08) check valve

09)

carrier gas compressor

10) scrubber gas

compressor

11) fan

12) air filter

13) NDIR

15

Page 16

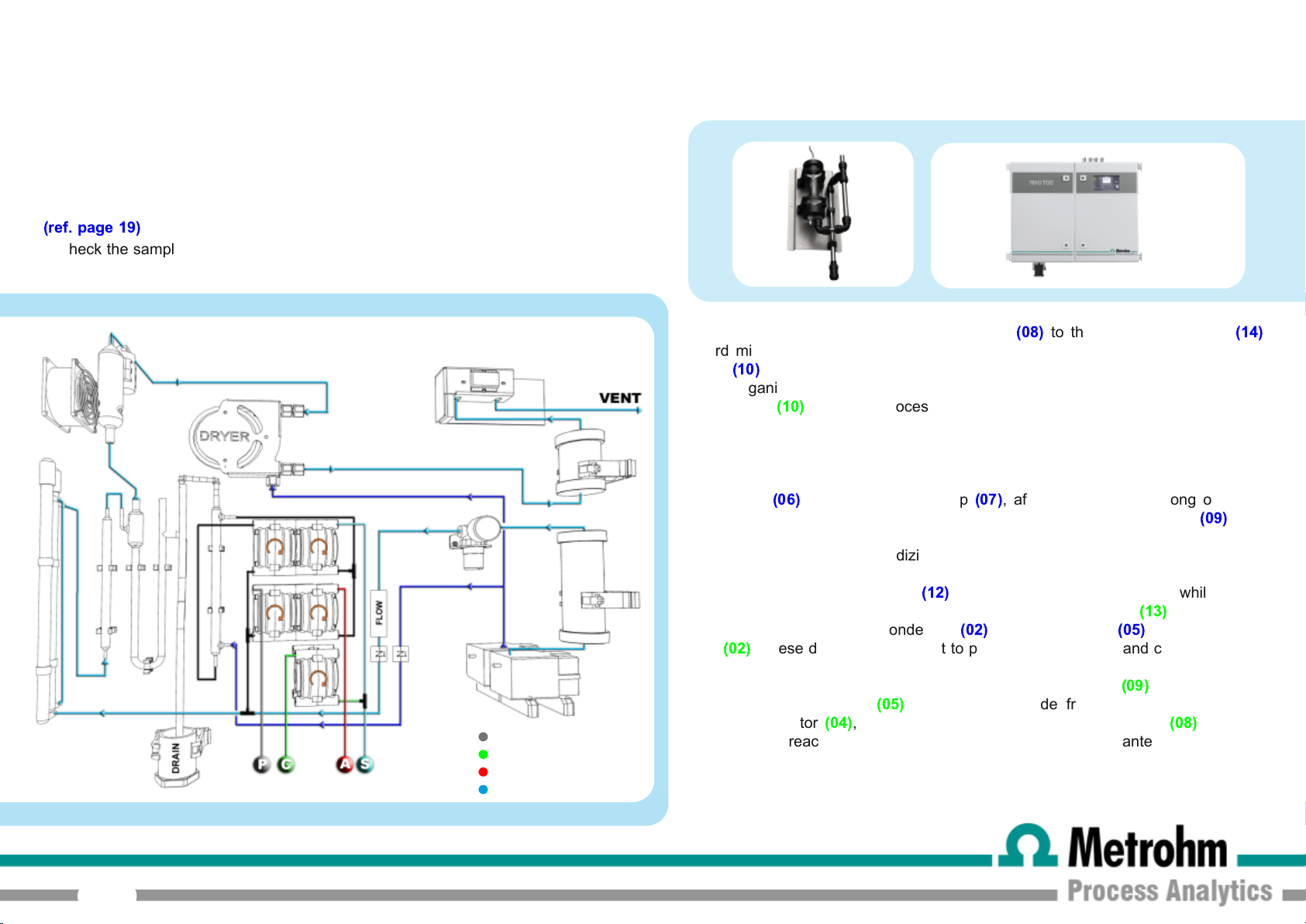

2.2 OPERATING PRINCIPLE

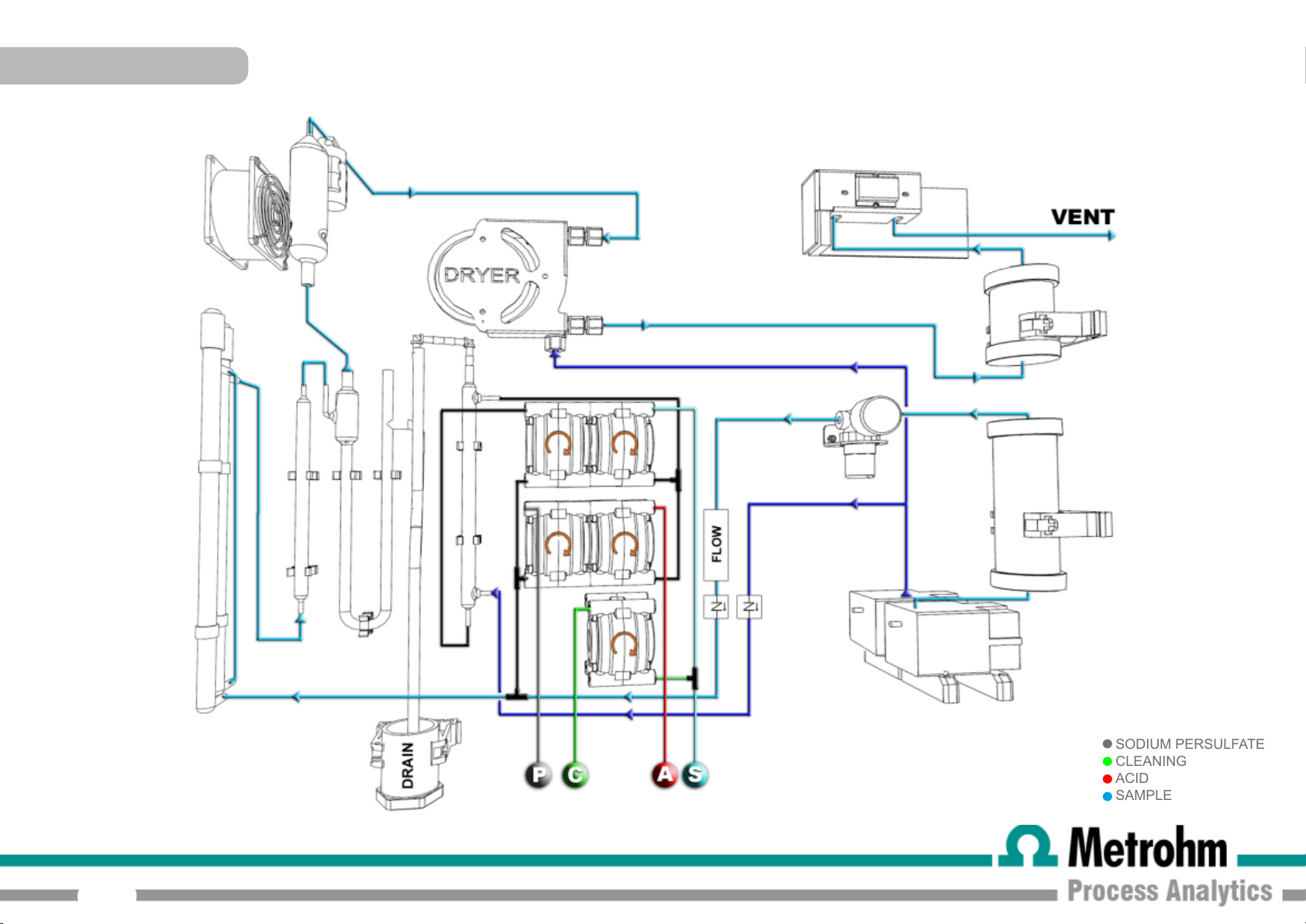

SODIUM PERSULFATE

CLEANING

ACID

SAMPLE

The water from the sample source (directly from the sampling point or through the optional

filtration unit) is fed to a sampling device mounted on the external left side of the analyzer

(ref. page 1 9)

to check the sample presence. This device allows a good sample refreshment and will put

the analyzer in stand-by condition in case of loss of sample.

. This device drains the sample excess and is equipped with a level sensor

7010 TOC ANALYZER - USER MANUAL

The sample is pumped by a peristaltic pump

afterd mixing with acid (usually phosphoric acid) pumped by a second peristaltic

pump

(1 0)

.

The inorganic removal is performed using ambient air provided by an internal air

compressor

carbon carbonates to carbon dioxide. The carbon dioxide dissolved in water is then

driven out by the sample to the vent using compressed air.

The acidified and sparged sample is then pumped from the scrubber bottom to the

UV reactor

agent (usually sodium persulfate) pumped by a dedicated peristaltic pump

The presence of a strong oxidizing agent combined with high level UV radiation

causes the oxidation of organic compounds. The produced carbon dioxide is

driven to the gas-liquid separator

that containing carbon dioxide goes to the infrared analyser

sequence through a glass condenser

filter

(02)

the stainless cell of the IR. The carrier gas used for the oxidation and detection

stages is generated by a second internal a ir compressor

through a sodalime filter

pressure regulat or

finally the UV reactor. All these devices are necessary to guarantee high precision

and stability of carrier gas flow as well as to control and be able to display the flow.

(1 0)

. This first process lowers the pH of the sample and convert the

(06)

by the resample pump

(1 2)

. The liquid sample is drained off while the air

(02)

. These devices are present to prevent condensation and corrosion inside

(05)

. The carbon dioxide free gas passes through a

(04)

, a capillary tubing and a digital flowmeter

(08)

to the inorganic scrubber

(07)

, after mixing with a strong oxidizing

(1 3)

, passing in

, gas drier tubing

(05)

and a halogens

(09)

and is passed

(08)

(1 4)

(09)

.

to reach

16

Page 17

SODIUM PERSULFATE

CLEANING

ACID

SAMPLE

TOC FLOW DIAGRAM

7010 TOC ANALYZER - USER MANUAL

17

Page 18

legend:

01)

UV lamp power supplies

02) glass condenser

03)by-pass valve

04) condenser fan

05) dryer tubing

06) UV reactor

07) resample pump

08) sample pump

7010 TOC ANALYZER - USER MANUAL

REDUCING REAGENT FLOW D I AGRAM

09) persulfate pump

10)

phosphoric acid pump

11) auto pump

12) UV scrubber

13) U-tube

14) scrubber

15) drain

X2)

reducing reagent pump

18

SODIUM PERSULFATE

CLEANING

ACID

SAMPLE

REDUCING REAGENT

Page 19

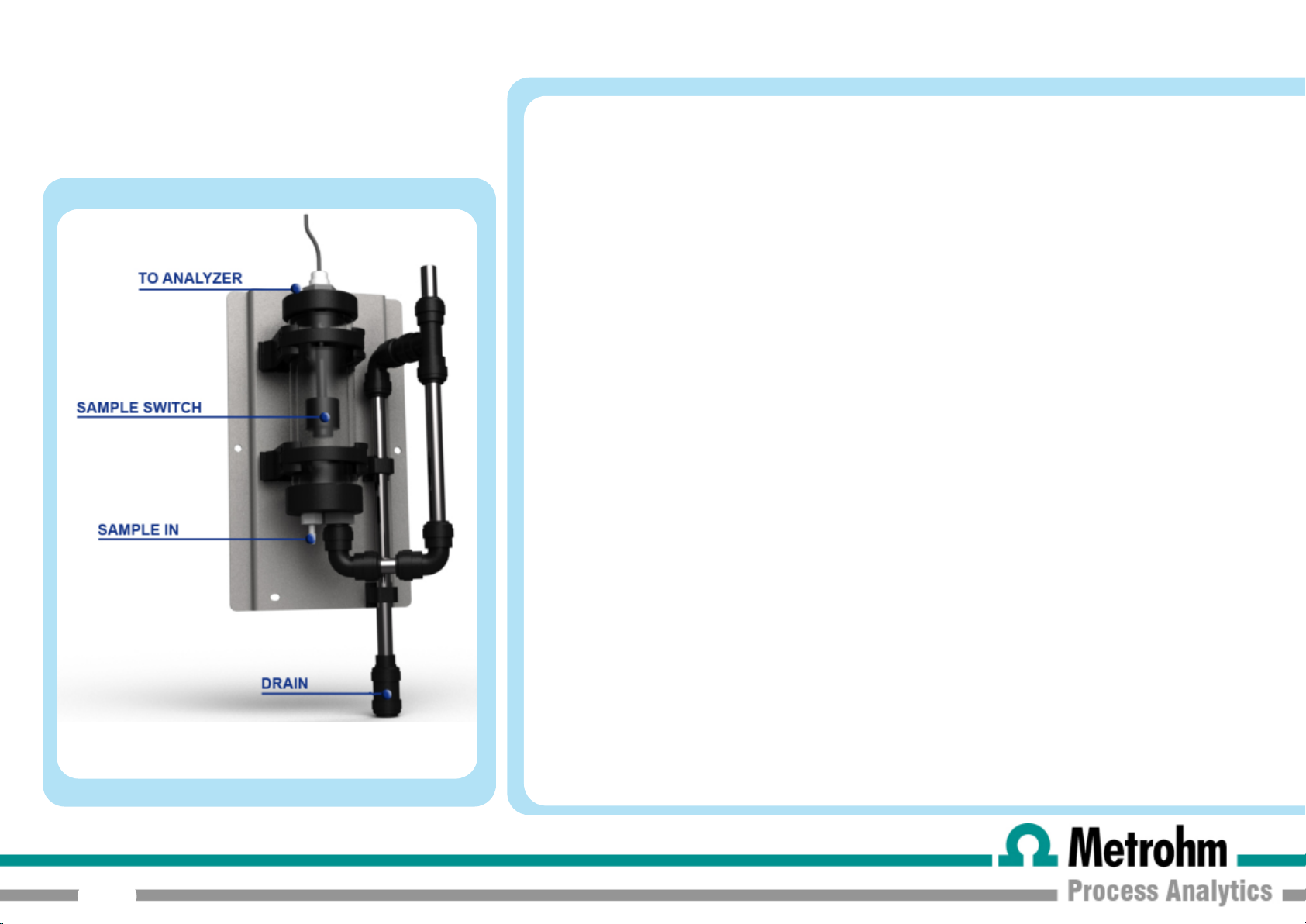

2.3 FAST LOOP RESERVOIR

7010 TOC ANALYZER - USER MANUAL

The external reservoir allows a fast circulation of the sample coming f rom the sampling point or from the

optional filtration unit.

Inside the fast-loop reservoir the sample is at atmospheric pressure and this allows the sample pump to

function with a constant delivery and no overpressure.In addition, the fast-loop reservoir is a usef ul extra

quantity of sample to avoid wrong alarms in case of a short loss of sample as well as eliminating air

bubbles coming from the sample line or from t he cleaning cycle of the optional filtration unit.

The stainless steel drain tubing keeps a constant water level inside the container and allows a proper

sample circulation to avoid suspended solids accumulation.

The sample flow should be adjusted to have a constant sample overflow through the stainless steel tube.

Up to 3 level switches can be connected to the analyzer, e.g. Stream A,Stream B and dilution water. Two

of the switches are normally connected to the terminals that are foun d at the left hand side of the

analyzer. For a dual stream analyzer where dilution water is also required for one or both streams, the

third level switch is connected to the user connection inside the analyzer (see page 37).

19

For a single stream analyzer, in the even t of a missing sample or dilution water stream for a period longer

than a preset time (normally set on installation to 30 s), an ala rm - LOSS OF SAMPLE - is triggered and

the analyzer switches to Standby. When the missing sample or dilution water stream is reestablished, the

analyzer restartsautomatically with a conditioning cycle.

In the case of a dual stream configuration, if no Stream A is present then the analyzer will continue to

work only on Stream B until Stream A is reestablished, and vice-versa. If both streams are not present

then again the alarm LOSS OF SAMPLE is triggered and the analyzer switches to Standby.

If either or both streams are being diluted and the dilution water stream is missing, then jumpers found

alongside the internal Level 3 terminal can be used to make the analyzer work only on the undiluted

stream or switch to Standby if both streams are diluted, again giving the alarm LOSS OF SAMPLE.

Page 20

7010 TOC ANALYZER - USER MANUAL

20

LIQUID ENCLOSURE

Page 21

7010 TOC ANALYZER - USER MANUAL

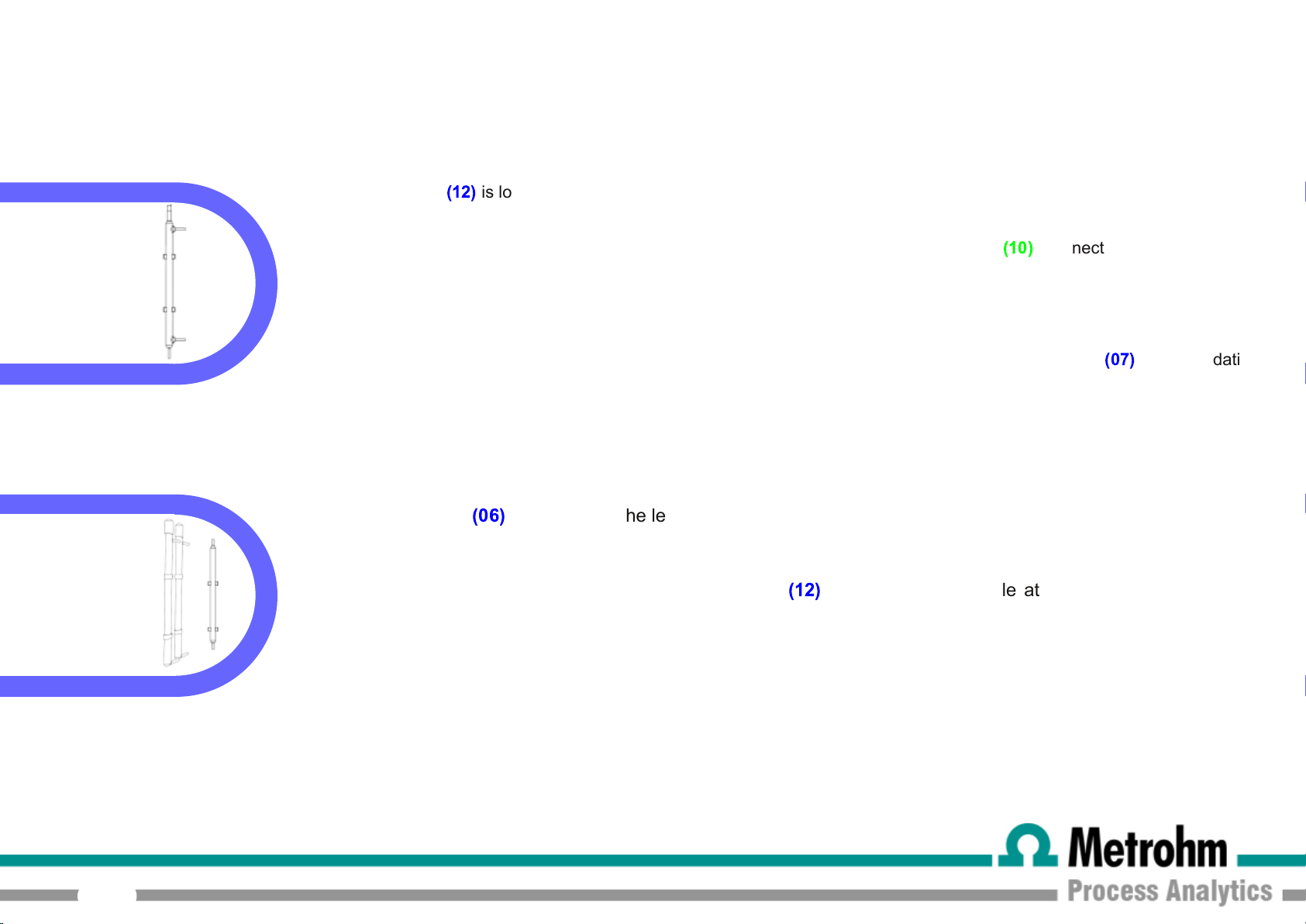

2.4.1 PERISTALTIC PUMPS

In normal on-line conditions t he 7010 TOC analyser uses two pump motors with two pump heads driven by each motor.

An extra pump head driven by a specific motor is used just in autocalibration, autovalidation or autocleaning cycles.

The sample pump head shown in flow diagram as

closest to the motor. It pumps the sample from the external reservoir to the T fitting connected on the other side to

the phosphoric acid pump head. Optimizing the sample pump flowrate is important to have a representative sample and

to reduce the analyser response time.

The phosphoric acid pump head

It pumps phosphoric acid from the phosphoric acid container to the T fitting connected to sample pump head

acid addition to the sample is necessary to lower the sample pH and to remove the inorganic carbon (IC) by gas

sparging.

The resample pump head

the acidified and sparged sample from the bottom of the scrubber

gas coming from the air compressor

The persulfate pump head

sodium persulfate from the persulfate container to the UV reactor

coming from the resample pump

(1 0)

is driven by the M2 motor and is located in the middle position,closest to the motor.

(07)

is driven by the M1 motor and is located in the upper position, UV lamps side. It pumps

(09)

and directed to UV reactor

(09)

is driver by the M2 motor and is located in the middle position, UV lamps side. It pumps

(07)

and after is directed to UV reactor

(08)

is driven by the M1 motor and is located in the upper position,

(1 4)

to the T connection where it mixes with the carrier

(06)

.

(06)

, adding it to the mixture of sample and carrier gas

(06)

.

(08)

(1 0)

. The

21

The auto pump head shown in flow diagram as

standard solution or the cleaning solution from its container to the analysis circuit when requested by the user or when

programmed as autocal/val/clean cycle. The auto pump flowrate is higher than sample pump flowrate. This means that in

case of an autocleaning cycle a portion of the cleaning solution will be driven towards the sample inlet, cleaning the

sampling point.

(11 )

is driven by the M3 motor. It pumps the calibration/validation

Page 22

2.4.2 SCRUBBER

7010 TOC ANALYZER - USER MANUAL

The scrubber

It is a glass cylinder with the acidified sample inlet in upper right position. The acidified sample passes down by gravity

through the scrubber and it’s sparged by the carrier gas coming from air compressor

position.

The carbon dioxide coming from the inorganic carbon present in the sample is sparged by the carrier gas flow and

removed from the sample through the vent/drain tubing connected to the straight upper position of the scrubber.

As a result, the sample at the scrubber bottom is IC free and it can be pumped by resample pump

stage.

2.4.3 UV REACTOR + UV SCRUBBER

The UV reactor

The reaction of oxidation is catalyzed by UV radiat ion with decomposition of sodium persulfate and creation of

strongly oxidizing radicals. These conditions ensure the best recovery of organics present in the sample.

The second UV lamp is connected to UV scrubber

inside this device.

(1 2)

is located in a vertical position near the peristaltic pumps.

(06)

is located on the left side of liquids enclosure. It consists of two high energy UV lamps.

(1 2)

. The oxidized sample at the UV lamps is sparged

(1 0)

, connected in the lower right

(07)

to the oxidation

22

Page 23

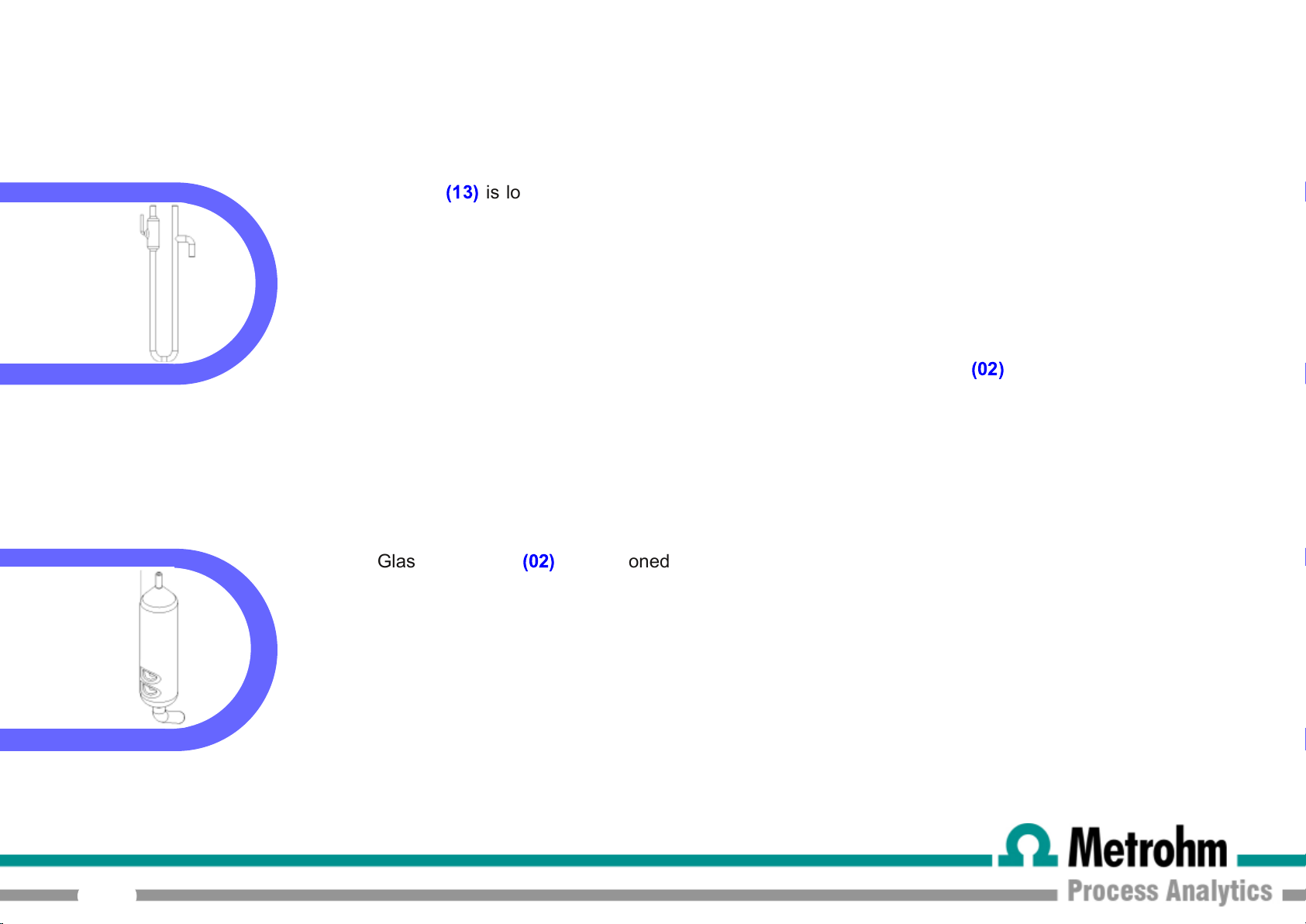

2.4.4 U-TUBE

7010 TOC ANALYZER - USER MANUAL

2.4.5 GLASS CONDENSER

The U-Tube

inlet and two outlet points.

It separates the analyzed liquid part of the sample coming from UV reactor from the gaseous stream direct ed

to the infrared analyser. It also drains the exausted sample and vents the sparging gas coming from the top of

the scrubber.

The gas mixture coming from the oxidation stage is driven by the carrier gas to the drying devices through the

upper right outlet of the gas-liquid separator, towards to the glass condenser

The Glass condenser

temperature difference between its glass body, cooled by a fan, and the hot treated sample coming from UV

reactor.

(1 3)

is located in the middle position of liquids enclosure. It is a U shaped glass device, with two

(02)

.

(02)

is positioned between U tube and the by-pass valve. The glass condenser uses the

23

Page 24

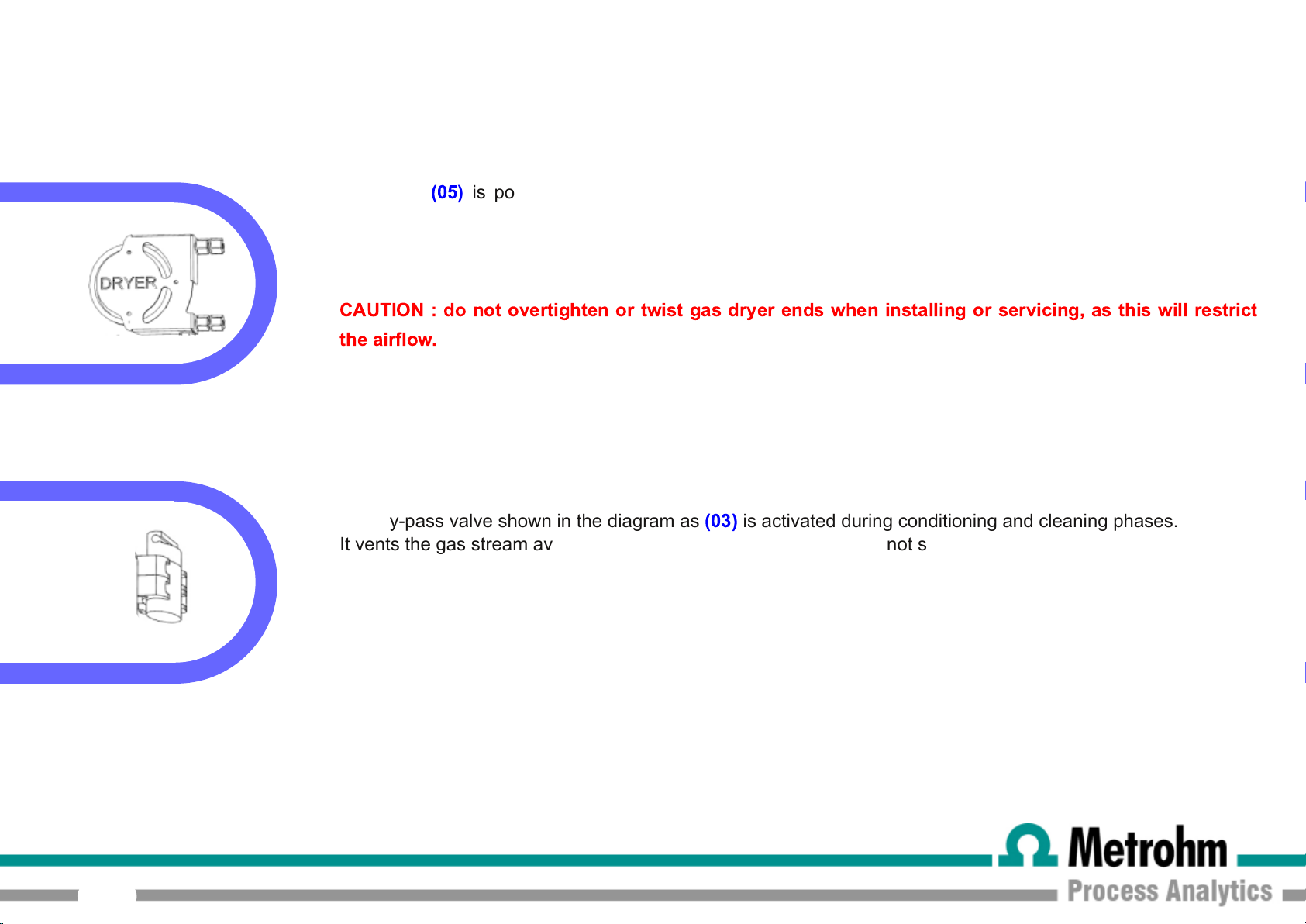

2.4.6 DRYER

7010 TOC ANALYZER - USER MANUAL

2.4.7 BY-PASS VALVE

The dryer

concentric tubes. In the internal tubing flows the gas stream to dry. This tubing is water vapour permeable so

that the humidity passes to the external tubing. In the external tubing there is a counter-current purge gas flow

that removes the water vapour. The dryer prevents water condensation inside the IR cell

CAUTION : do not overtighten or twist gas dryer ends when installing or servicing, as this will restrict

the airflow.

The By-pass valve shown in the diagram as

It vents the gas stream avoiding it to flow through the IR cell when not strictly necessary.

(05)

is positioned between the BY-PASS VALVE and the IR detector. It consists of a coil of two

(03)

is activated during conditioning and cleaning phases.

24

Page 25

7010 TOC ANALYZER - USER MANUAL

25

ELECTRICAL ENCLOSURE

Page 26

2.5.1 COPPER FILTER

7010 TOC ANALYZER - USER MANUAL

2.5.2 SODALIME FILTER

The copper filter

plastic container filled with copper wool. The gas leaving the dryer tubing is forced to go through this device to

prevent corrosive effects due to gases like chlorine or chlorine dioxide that could be generated in the oxidation

stage.

The sodalime filter

and it absorbs the carbon dioxide from atmospheric air providing the analyzer with CO2 free air for its

processes.

(02)

is located in the electrical enclosure immediately before the IR detector inlet. It is a

(05)

is located on the left side of electrical enclosure. It’s a plastic container full of sodalime

26

Page 27

M1

M2

M3

2.5.3 PUMP MOTOR

7010 TOC ANALYZER - USER MANUAL

The pump motors

M1,M2

and

M3

are positioned in the

electrical enclosure, on the left side.

They drive multiple pump heads that move the sample and

reagents throug h the different analyser t reat ment stages.

Depending on the configurations there will be from three to six

pump heads.

Motor rev/min Position Driven pumps

M1 05-06 rpm upper sample

M2 1 rpm middle acid

Pump Head mL/rotation

14 0,21

16 0,8

15 1,7

24 2,8

resample

persulfate

27

optional reducing reagent

M3 10-12 rpm lower calibration

validation

cleaning

Page 28

2.5.4 AIR COMPRESSORS

7010 TOC ANALYZER - USER MANUAL

2.5.5 PRESSURE REGULATOR

CAPILLARY AND FLOWMETER

The air compressors

provides the sparging gas used in the scrubber and the counterflow gas in the dryer.The second compressor

(09)

provides the carrier gas for oxidation and detection stages. They eliminate the need for an external air

treatment system and for compressed air as a requested utility, this saving cost.

These devices

the front and are used to they allow for a highly precise and reliable adjustment for the carrier gas flow.

(04)

(09)

and

and

(1 0)

are located on the lower side of the electrical enclosure. Compressor

(07)

are located in the central part of the electrical enclosure with a pressure gauge on

(1 0)

28

Page 29

2.5.6 NDIR

7010 TOC ANALYZER - USER MANUAL

2.5.7 USER CONNECTIONS

The infrared analyser

board fitted with a stainless steel cylinder (the IR cell). It’s a Non-Dispensive Infrared analyser (NDIR) with high

stability and reliability. The measuring scale of IR is related to the range of

701 0 TOC

analyzer provides:

1 4-20 mA output (A01). (A second 4-20 mA output (A02) is available on dual channels analyzers).

2 relays (RELAY A - programmable and RELAY B - fault)

1 24 Vdc

1 digital input

(1 3)

is located in the higher part of the electrical enclosure, on the right side. It is a PCB

701 0 TOC

29

1 digital output

1 level 3 - additional contact

RS485

Page 30

7010 TOC ANALYZER - USER MANUAL

30

INSTALLATION

Page 31

3.0 UNPACKING AND INSPECTING

The

701 0 TOC

performances di rect ly in our facilities and it’s delivered inside a wooden

box. Before to proceed with analyser installation, it is recommended to

check carefully that box and analyzer have not been damaged during

transportation. Take extreme care during analyzer unpacking and

moving.

analyzer is assembled and fully tested for proper

3.1 ANALYZER MOVING

Take extreme care when lifting or moving the analyzer, its weight is about

37 kg. Before t o move the analyzer it is recommended to empty

manually the glass p art s of liquids enclosure using an appropriate plastic

syringe and tubing.

7010 TOC ANALYZER - USER MANUAL

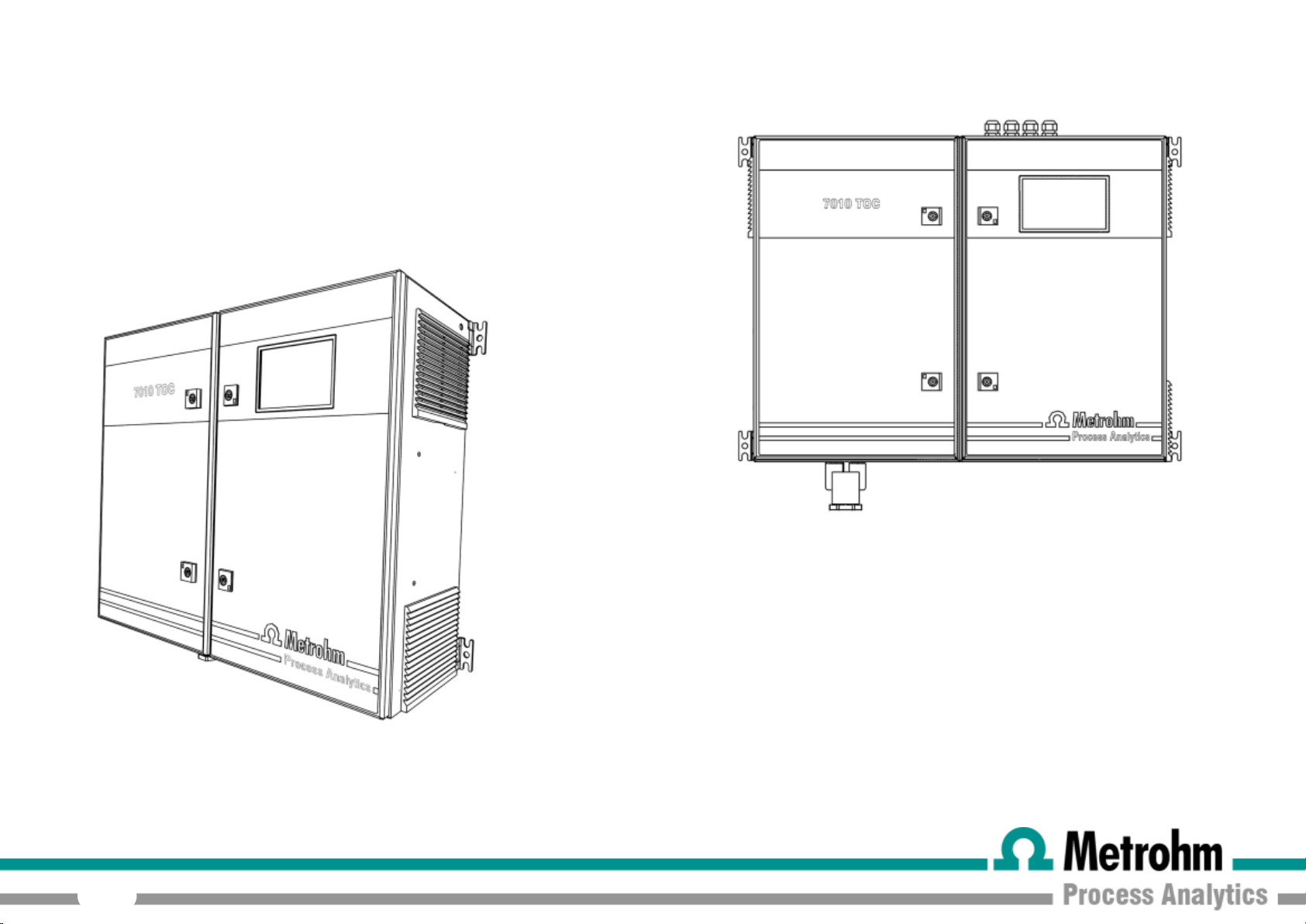

3.2 LOCATION AND MOUNTING INSTRUCTION

It is recommended to install the analyzer in a suitable position. The

location must be clean, covered and properly enclosed to provide the

analyser with good ventilation and low dust concentration. Operating

environmental conditions are: temperature between 5 and 40° C at max

80% relative humidity.

Due of chemicals and waste gases it is absolutely necessary to choose a

well ventilat ed location for the analyzer.

31

The

701 0 TOC

wall or stainless steel support rack installation. Use 4 screws M8 to

fix the analyzer.

The analyser should be mounted with the display at eye level for

easier operation and access.

analyzer is supplied with four mounting brackets for

Page 32

3.3 PRECOMMISSIONING

Liated below are key points that must be followed in order to have

an ideal installation:

the installation site should be as near to the sampling point

as possible to reduce delay in response time

the drain line should be properly dimensioned and positioned

with downward slope to allow the draining of analysed

sample and the overflow coming from the external fast-loop

reservoir. ( If the optional filtration unit is present, the drain

pipe should be dimensioned to drain also the sample coming

out from filtration system fast-loop).

Clearance requirements for the analyzer should be 20 cm on

either side and 100 cm on the front

7010 TOC ANALYZER - USER MANUAL

Sufficient space for two 10 liter containers and one 5 liter

container should be provided beneath the ana lyzer; if

necessary, the reagents containers should be positioned in

a suitable receptacle in case of spills

Dedicated waste gas line should be provided for safe venting

to the atmosphere unless installed in a well ventiled area of

adequate dimensions.

ATTENTION: depending on the sample chemical composition,

its oxidation can generate hazardous gases. In these cases it’s

strictly necessary to provide a safety system to allow waste

gases vent to the atmosphere

32

WARNING: the sample drain of the analyzer must be at

ambient pressure with no restriction or counterpressure.

Please verify that this condition has been strictly respected

during installation.

Page 33

3.4 ELECTRICAL CONNECTIONS

All electrical connections should be made by qualified personnel in accordance

with nationa l or local codes and regulations.

Qualified Personnel means a person who has been fully trained and has

professional experien ce to avoid electrical hazards and dangers.

Service qualified personnel will receive the special key to open the electrical

enclosure.

A circuit breaker must be installed near the analyzer to allow easy isolation of

power in case of electrical problems and every time it is necessary to service the

analyzer.

7010 TOC ANALYZER - USER MANUAL

It will be user’s task to check and guarantee periodically the perfect functionality

of the analyzer’s grounding.

To avoid potential fatal electrical shock and/or analyzer

damage always disconnect input power to analyzer before

servicing (disconnecting the 115 VAC - 230 VAC plug)

ALWAYS ISOLATE POWER BEFORE SERVICING

33

Page 34

3.4.1 AC POWER CONNECTION

The

701 0 TOC

Hz power. I t is provided with 2 meter long power cord and European

Schuko plug (ref. CEE 7/ VII re gulat ion). Optional configuration with 115

Vac power supply and US plug. The analyzer is delivered with the power

cord wires are already connected to terminals AC section of

CONNECTIONS

AC power enters on the top side of the electrical compartments through

the supplied power cord.

All the connections must be made in accordance with national or local

regulations. It is recommended that the analyzer has its own dedicated

circuit with a circuit breaker or an isolating switch installed near the unit.

analyser is designed fo r operation with 230VAC, 50/60

USER

.

7010 TOC ANALYZER - USER MANUAL

3.4.2 ANALOG OUTPUT CONNECTIONS

The

701 0 TOC

outputs for analysis value. Wiring connections use a twisted-pair signal

cable with shield connected to the A/01 or A/02 located right on top of

electrical enclosure.

34

analyzer provides 2 optically isolated 4-20 mA analog

Page 35

3.4.3 RELAY A/B

NO ALARM: C NC / ACTIVE ALARM: C NO

RELAY A function is programmable in the general setup page.

Here below the list of the possible functions:

online (relay activated when analyzer is online)

offline (relay activated when analyzer is offline)

loss of sample (relay activated in case of loss of sample alarm)

result alarm (re lay activated in case of result higher than the

programmed value)

validation alarm (relay activated in case of validation alarm)

reagent alarm (relay activated in case of reagent's alarm)

calibration alarm (relay activated in case of calibration alarm)

7010 TOC ANALYZER - USER MANUAL

RELAY B is activated in case of fault alarm

Fault alarms occur if certain conditions arise that risk the analyzer giving

incorrect results. T hey are as follows:

carrier gas flow too low

reagent levels too low

zero gas too high

emergency stop activated

35

Page 36

3.4.4 RS 485

MODBUS RTU CONNECTION GUIDE 7010 Toc

Baud Rate 9600

Data bits 8

Parity E

Stop bit 1

Slave I.D. 1

Address format alias

150 32-bits float (CD-AB) result CH1

152 32-bits float (CD-AB) result CH2

154 16-bit unsigned analyser status

7010 TOC ANALYZER - USER MANUAL

RS 485 SETTINGS

PROTOCOL

VALUES

STATUS VALUES

Stand by 0

Conditioning (to drain) 3

Conditioning (purge detector) 4

Online 5

Zerogas 6

Zerogas 7

Auto Function 1

Stopped 8

36

Page 37

3.4.5 DIGITAL INPUT/EXTRA RELAY

Digital input is a remote function available for the following features:

Start / Stop

Digital input ' s function is selectable by the user.

Extra Relay is used for external operations. (24V DC available) for

powering external devices. This output may be configured for separate

ON and pause periods. The ON period is configurable between 1 and 99

seconds, the pause period is configurable between 1 and 999 minutes.

3.4.6 LEVELS

Level switch terminals - level 1 and level 2 works with same logic as

level switches left side connectors. Additional level 3 can be configured

with jumpers in order to be associated to 1, 2 or 1 & 2.

C is the common terminal.

7010 TOC ANALYZER - USER MANUAL

3.4.7 EXTERNAL DILUTOR SUPPLY

230/115 Vac for supplying power to the external dilutor. Functions when

the analyzer is in Conditioning and On-line mode.

3.4.8 FUSES

The analyzer has 2 fuses.

Fuse F1 power supply fuse 3.15 A for 230 V version

4 A for the 115 V version

Fuse F2 IR detector/digital flowmeter 1.25 A

37

Page 38

Before to proceed with analyzer start-up it is absolutely necessary to check that all the operations for a proper

installation and reagents preparation have been properly carried out.

Please verify that all the suggestions and recommendations has been respected.

After t his double check, please proceed as follows:

Connect the sample line inlet tubing (or filtered sample outlet coming from optional filtration system) to the fast-loop reservoir installed on

the left side of the 7010 TOC analyzer

Connect the drain fitting of the fast-loop reservoir to the waste line

Put the acid inlet tubing (red label) in the phosphoric acid container beneath the analyzer and check that it is correct by position at the

bottom of the container

7010 TOC ANALYZER - USER MANUAL

Put the persulfate inlet tubing (white label) in the sodium persulfate container beneath the analyzer and checkthat it is correct by position

at the bottom of the container

Put the cleaning (or calibration or validation) solution inlet tubing (green label) in the cleaning (or calibration or validation) solution

container placed beneath the analyzer and check that it is correct by position at the bottom of the container

Connect the funnel beneath the analyzer is connected to the waste DRAIN line

Check sample presence in fast-loop reservoir and adjust the sample flowrate (suggested 100-500 ml / min)

Switch on power to the analyzer. External fans, microprocessor and infrared analyzer will start.

38

Page 39

The analyzer will proceed as follows:

7010 TOC ANALYZER - USER MANUAL

if the analyzer has been previously shut off in

operation but measurement and output signal are not still valid until the conditioni ng delay has expired.

if the analyzer has been previously shut off in

press

operation but measurement and output signal are not still valid until the conditi oning delay has expired.

In the next few following minutes it is necessary to check:

sample presence in the scrubber, sample presence in the gas-liquid separator.

free draining waste with no restriction of gas-liquid separator drain outlet. The drain tube must not be submerged and the exhausted sample

must be carried out by gravity.

It is not recommended to proceed with a

IMPORTANT NOTE:

During analyzer’s initial start-up it is necessary to decide to confirm cleaning as the automatic option (programmed as default option)

or change to validation or calibration.

ONLINE

button on the display. This forces t he analyzer to start immediately with a conditioning cycle. The analyzer is totally in

zerogas cycle

ONLINE

STANDBY

and a

calibration cycle

status, it will start immediately with a conditioning cycle. The analyzer is totally in

status, it will stay in

before leaving the analyzer in online status for 4/6 hours .

STANDBY

mode; to start the analyser it is necessary to

This selection depends on the user’s sample composition and characteristics. For dirty samples it is highly recommended to use the default

selection to avoid dirt accumulation inside the analyzer.

This change of selection can only be made by

When one option between cleaning, calibration and validation is selected as desidered automatic function the remaining two will be automatically

disabled.

Forex. : ifautocleaning is the automatic function enabled, autocalibration and autovalidation will be automatically disabled.

39

Metrohm Applikon

qualified personne l.

Page 40

40

USER INTERFACE

Page 41

7010 TOC ANALYZER - USER MANUAL

4.0 USER INSTRUCTIONS

The user interface consists of a touchscreen located on the front panel of the analyzer enclosure. All the

output/input data, information, alarms and fault conditions are shown on the display while all the commands

and settings may be entered into to the analyzer simply by pressing the touchscreen buttons.

41

Page 42

4.1 MAIN PAGE

The main screen displays:

Date and time

Analyzer's st at us (on-line, conditioning, stopped, loss of sample...)

Login **** window (two levels of password)

On Line / standby buttons

7010 TOC ANALYZER - USER MANUAL

these commands

to online operations or to stop the analyzer in stand-by condition.

Stopped but t on

displays the status of the analyzer when it is stopped (reading

only), it is possible to escape from Stopped pressing Online or

Standby but t ons

The trend of analysis

It displays graphically the analyzer's value trend during time.

The name of the analysis

(for example TOC, TC, COD,...); read only

The value of analysis.

If the value is below 20, one decimal place will be displayed.

(min. press 2 secs)

(min. pres. 2 secs)

allows to force the analyzer

.

42

Page 43

The main screen displays:

A result record is written every 3 min into the notepad that can be

opened by touching the central result graph. In the notepad data

from the current day is shown.

In the case of an alarm being generated by the analyzer details will

appear as a moving message at the bottom of the screen.

The message will identify the type of the alarm and the time the

alarm was activated.

7010 TOC ANALYZER - USER MANUAL

The message remains visible until the cause has been resolved

43

Page 44

Pressing on Login the user select:

BASIC

ADVANCED

SERVICE

Pressing on **** the user can enter the 4 number passwords

BASIC

7010 TOC ANALYZER - USER MANUAL

ADVANCED password: 1111

(access to calibration, timing and datalogger pages)

SERVICE

Pressing on ****

password: available from

technicians/distributors

(access to calibration, timing pages,general setup pages

and datalogger)

44

Metrohm Applikon

Page 45

4.2 MAIN PAGE + PROCESS VALUES

Simply by pressing on the main page it is possible to display the following information:

SAMPLE (OK / NO):

displays th e normal or lack of presence of sample in the

fast-loop reservoir

RELAY A (OFF / ON):

displays the status of the relay A

OUT EXTRA RLY (OFF / ON):

displays the status of the external operation relay

(refer to timing page for activation and programmation)

7010 TOC ANALYZER - USER MANUAL

CARRIER flow :

displays the carrier gas flow value through the digital

flowmeter in cc/min

CO2 conc:

displays the carbon dioxide value in ppm detected by the

infrared analyzer

VALIDATION:

displays the value of last validation against the last stored

calibration value (in percentage %).

45

REAGENT TANKS LEVEL:

allows to reset the counter to 100%. This operation should be done

when the reagent container is refilled.

In order to reset the counter simply press the reagent tank.

A new button will appear: PRESS 3 sec TO FILL REAGENTS

Pressing the button, the counter will be reset to 100%.

Page 46

4.3 CALIBRATION PAGE

Service password Press

7010 TOC ANALYZER - USER MANUAL

In the right side the current calibration parameters stored in

the analyser are displayed only.

ppm zerogas:

expressed in ppm generated by carrier gas (ambient air

filtered by sodalime filter) as detected by the infrared

analyzer

ppm liq. zero:

ppm generated by reagents and distilled water as detected

by the infrared analyzer

ppm baseline

mg/l standard:

solution used for calibration

ppm span gas:

ppm generated by the standard solution as detected by the

infrared analyzer

the residual CO2 concentration value

the CO2 concentration value expressed in

= ppm zerogas + ppm liq. zero

displays the value in mg/l of the standard

the CO2 concentration value expressed in

to go back to MAIN PAGE Press

46

Page 47

4.3.1 ZEROGAS

To exit Zerogas simply press

Starts a zerogas cycle.

This value is typically lower than 200 ppm

The

ZEROGAS

stored in the analyzer database.

A

ZEROGAS

programmed in the timing menu or by manually pressing for few

seconds the button

During a zerogas cycle the pumps and UV lamps are switched off.

In these conditions the carrier gas goes through all the fluidics to

reach the

detected by the infrared analyzer decreases so that after the

programmed delay time it will be stable and equal to the

generated by carrier gas only. This value is stored and shown as

ZEROGAS

NDIR

.

value expressed as

cycle starts automatically at the time and interval

ZEROGAS

. The

CO2

on the calibration page.

concentration value expressed in ppm

CO2

ppm is automatically

CO2

7010 TOC ANALYZER - USER MANUAL

A graphic of the trend of the ppm of

NDIR

programmed for the zerogas cycle, the value of ppm of

measured and the last zerogas value.

Refreshing frequently this value is extremely important because

the sodalime loses its capacity to adsorb

If the

high” will be activated and the analyzer will display this alarm

message.

is shown together with a counter of the seconds

ZEROGAS

47

exceed a certain preset limit, the alarm “Zero too

CO2

value detected by the

CO2

from ambient air.

CO2

Page 48

4.3.2 LIQUID ZERO

7010 TOC ANALYZER - USER MANUAL

Allows to store the zero

procedure, perfo rmed with distilled water.

This calibration should be made manually every time the

reagents are replaced and every time it is intended to perform

a manual calibration.

The

LIQUID ZERO

inlet tubing of the sample pump from the external fast-loop

reservoir and connecting it to a distilled water container, using

an extension tube if necessary.

With these conditions the distilled water is pumped through all

the fluidics until the operator decides that the

concentration value expressed in ppm detected by the infrared

analyzer is stable.

cycle is performed manually taking out the

CO2

value of liquid zero calibration

CO2

Press

stable reading then press the

seconds. The page closes and the ppm of

infrared analyzer is then stored in the instrument.

LIQUID ZERO

48

button. Wait for at least 30 minutes for a

PRESS TO CAL

CO2

button for few

detected by the

Page 49

4.3.3 MANUAL CALIBRATION

7010 TOC ANALYZER - USER MANUAL

Allows for storing the span

calibration procedure , performed with a standard solution.

Suggested standard solution value to be used for calibration

should be equal to at least 50% of analyzer full scale.

The

CALIBRATION

inlet tubing of the sample pump from the external fast loop

reservoir and connecting it to the selected standard solution

container, using an extension tube if necessary.

Press

it possible to set the value in mg/l of the standard solution used

for calibration .

With these conditions the standard solution is pumped through all

the fluidics. Once the operator decides that the

concentration value expressed in ppm as detected by the

infrared analyzer and the Value expressed in mg/l is stable, press

the

the last stored baseline value is subtracted and the ppm span

gas value is stored.

MANUAL CAL

PRESS TO CAL

cycle is performed manually taking out the

button by pressing the standard number is

button for few seconds. The page closes,

CO2

value from the liquid span

CO2

If the

infrared analyzer during the manual calibration is out of the

tolerance range, the a nalyzer will abort the calibration showing

an error message “Calibration error” in the main page.

CO2

concentration value expressed in ppm detected by the

49

Page 50

4.3.4 RUN AUTOCAL

Allows to run an autocalibration cycle.

The standard value to be used should be the one displayed in Manual

Cal.

An

AUTOCAL

programmed on timing menu if autocalibration is enabled as auto mati c

option.

If autocalibration is the selected automatic option, at the time

programmed on timing menu the calibration pump

With these conditions the standard solution is pumped from a container

placed beneath the analyzer through all the fluidics for the number of

minutes programmed on timing menu.

cycle starts automatically at the time and interval

(11 )

is switched on.

7010 TOC ANALYZER - USER MANUAL

The

CO2

concentration value expressed in ppm detected by the

infrared analyzer will increases until after the programmed delay time

when it will be stable and equal to the

standard solution.

After subtracting the last stored baseline value, it will stored and shown

as ppm span gas.

The trend of analysis values is displayed during autocalibration cycle

together with ppm of

and carrier flow.

CO2

measured by

CO2

generated by the applied

NDIR

, last calibration stored

50

To exit RUN AUTOCAL press

Page 51

4.4 TIMING PAGE

Service password Press

7010 TOC ANALYZER - USER MANUAL

ZeroGas time

Using the sliding switch it is possible to enable

automatic zero gas.

Zerogas hours: allows to set the time for automatic zero calibration (hour,

minutes) of the infrared analyzer

Zerogas days of the week: allows to set the zero automatic calibratio n

interval of the infrared analyzer simply by selecting one or more days of the

week

Extra Relay

Using the switch it is possible to enable

It is possible also to set the frequency (min) and the running time (sec).

When ON a 24 Vdc will be available on the terminal of the user

connections.

COND delay min

Allows to set the number of minutes that analyzer reconditions with sample

before on-line operation after an autocal/val/clean or when switched on

after a standby or a stop.

ZGas period sec

Allows to set the number of seconds that zerogas cycle is active before

storing the CO2 ppm value corresponding to zerogas.

Clean (autocal / autoval / autoclean) delay min

Allows to set the number of minutes that the auto pump is swit ched on

during an autocalibration / autovalidation / autocleaning cycle

(ON)

(ON)

or disable

or disable

(OFF) Extra Relay

(OFF)

.

to go to MAIN PAGE Press

51

AUTO time

Using the switch it is possible to enable

function

AUTO hour : allows to set the time (hour, minutes) of automatic function

AUTO days of the week: allows to set the enabled automatic option interval

of the analyzer simply by selecting one or more day of the week

(ON)

or disable

(OFF)

automatic

Page 52

7010 TOC ANALYZER - USER MANUAL

4.5 GENERAL SETUP PAGE

Admin password Press

DATE :

press current date to set the date

(day, month, year

)

ALARMS

FLOW MIN

If the value of the carrier gas flow decreases b elow this value, the carrier

flow alarm switches on.

ZEROGAS MAX

to the zero gas. If exceeded it switches on the zerogas alarm.

VAL TOLERANCE

ALARM mg/l

value alarm contact (in mg/l)

: allows to set the alarm of the carrier gas flow.

.: allows to set the maximum value of CO2 corresponding

: allows to set a tolerance acceptable for validation.

: allows to set the value that if exceeded switches on the

GENERAL SETTINGS

Analyzer mg/l

CO2 ppm

installed. There are three options: 1000, 5000 and 10000 ppm.

Range

Factor

: allows setting of the range of the analogue output

: factor to be applied if dilution is used and/or as a con version

factor to report results as another parameter i.e. COD.

: allows setting of the range in mg/l of the analyzer

: allows setting of the range in ppm of the IR detector

OUTPUTS

Relay A

(ONLINE, OFFLINE , LOSS OF SAMPLE, RESULT ALARM, VALID ALARM, REAG ALARM,

CALIB ERROR)

Relay B

4-20 mA TES T: allows to test the 4-20 mA output

Using the switch it is possible to enable

the 4-20 mA output.

Set the percentage of the scale and connect a multimeter to the analogic

output terminal of the user connections.

0% corresponds to 4 mA

50% corresponds to 12 mA

100% corresponds to 20 mA

: allows to set the function of the relay A

: FAULT (only read window)

(ON)

or disable

(OFF)

the test of

to go to MAIN PAGE Press

52

TIME :

press current time to set the time

(in hours/minutes 24 hours format)

MANUAL CALIBRATION SETTING

ZEROGAS ppm

ZEROLIQ ppm

SPAN VALUE ppm

: allows to set manually zerogas value in ppm of CO2

: allows to set manually zero liquid value in ppm of CO2

: allows to set manually span value in ppm of CO2

Page 53

4.6 DATA LOGGER PAGE

Service password Press

7010 TOC ANALYZER - USER MANUAL

The Result Notepad that is accessible from the Main screen shows

results for the current day. Records for a longer time are stored on

the instrument and can down loaded onto a USB stick.

Here results are recorded every 15 min for up to 30 calendar days.

Once 30 days data has been collected then the files are overwritten

on a FIFO basis.

To download result s stored in the data logger you first need to insert

a USB key.

Open the door of the electronic enclosure and insert a USB key into

the port that is positioned on the cover behind the door.

Go to the data logger menu (violet USB logo) and press on the

button, keeping it pressed until the software automatically

exits back to the main screen. On the USB key there will now be a

to go to MAIN PAGE Press

53

folder named ‘datalog’, inside which there is another folder named

‘’TOC’’, where you will find one csv file for each day's data.

Additional buttons are available on t he data logger screen.

CLEAR FIRST DAY

logger memory.

CLEAR ALL

DTLG ON/OFF

ALARM LOG

– deletes all data in the data logger memory.

- Alarm Log - It allows to access to the Alarm log

– deletes the earliest day's data in the data

– switches on and off the data logger.

page.

Page 54

4.7 ALARM LOG PAGE

Service password Press Press

TIME

- Alarm occurring time

7010 TOC ANALYZER - USER MANUAL

to go to MAIN PAGE Press

54

EVENT

RESET TIME

- kind ofalarm

- time when the alarm resets

Page 55

4.7 DUAL STREAM CONFIGURATION - OPTION

If the analyzer is configured as a dual channel instrument, the extra relay is used to

control an external valve.

On the Main page the current results for streams A and B are displayed.

On the Timing page the user is able to select the length of time each stream will be

measured. A conditioning period as set in the Timings page will take place between each

change of stream.

On the Settings page there is the possibility to set two different full scale values for the

two analogue outputs. In addition two independent Factor settings for each stream can be

entered for correct calculation according to the dilution used or as a conversion factor to

report results as another parameter i.e. COD. Similarly two independent Alarm settings

can be entered.

7010 TOC ANALYZER - USER MANUAL

55

Page 56

4.8 DUAL RANGE OPTION

It the analyser is confi gured as dual range instrument, the

extra relay is used to control an external dilutor.

When the result exceeds the programmed threshold the

analyser will switch from range L (low) to range H (high) and

the extra rel ay will be activated.

Every time the analyzer is turned ONLINE or after an OFF LINE

7010 TOC ANALYZER - USER MANUAL

operation ( ZERO GAS, AUTOFUNCTION, LOSS OF SAMPLE) ,

it starts from the high range condition (diluted sample).

A conditioning period will divide the two statuses during

which no results will be displayed.

56

Page 57

After t he conditioning period the result according to range H (high)

is shown

7010 TOC ANALYZER - USER MANUAL

57

When the DUAL RANGE option is selected, the TIMING PAGE allows

to set the thresholds where the instrument will switch between high

and low ranges.

Page 58

Only the analog output referring to the current range is active while

the other is forced down to 0 (4 mA).

External dilu ti on factor determines the range H (high) result

calculation

The A relay can be used to report the range L (low) or H (high)

status.

7010 TOC ANALYZER - USER MANUAL

58

Page 59

7010 TOC ANALYZER - USER MANUAL

59

MAINTENANCE

Page 60

7010 TOC ANALYZER - USER MANUAL

Regular maintenance will ensure excellent analyzer performance over a number of years.

It is important to follow a scheduled maintenance program to make certain the analyzer is kept clean and in good condition.

OPERATION FREQUENCY

daily weekly monthly 4 monthly annual

Visual check of FAULT alarms

Visual check of Liquids Enclosure

Visual check of halogens filter

Visually inspect the scrubber and

UV scrubber for normal bubble flow

Sample fast loop reservoir cleaning*

Refill reagent containers

Scrubber and gas liquid separator cleaning*

Soda lime replacement in soda lime filter**

Copper wool replacement in halogens filter*

Pumps tubing replacement*

UV lamps check for leakages and tubing connection replacement

Maintenance visit by qualified service engineer

* Frequency of cleaning/replacement dependant on sample quality

** Frequency of replacement dependant on ambient air quality

60

Page 61

7010 TOC ANALYZER - USER MANUAL

5.1 PUMP TUBING REPLACEMENT

The peristalt ic pump heads are located in the Liquids Enclosure.

Before proceeding to replace the tubing, please read carefully Section 1 of this manual on hazards and dangers. It is recommended to wear

appropriate clot hing, gloves and eyes protection. Phosphoric acid, sodium persulfate and cleaning solut ions should be handled with extreme care.

Proceed as follows:

A)

With the analyzer in normal online operation, disconnect all solution and sample lines

from their containers and reconnect them to a distilled water source. Leave the analyzer

running in this way for at least an hour.

B)

Put the analyzer in Standby. Pumps and UV lamps will be switched off.

C)

Using the key, open the Liquids Enclosure.

D)

Disconnect each pump tubing from their inlet and outlet fittings, taking care to note which

fitting will be needed to reconnect to which pump.

E)

Undo the four wings nuts on the mounting screws that supports pump heads.

F)

Slide the pump heads to left and remove them from the mounting screws.

G)

Carefully separate the two halves, avoiding dropping the rotor and then removing the

used tubing.

H)

Place the pump half containing the rotor in one hand and move the rollers in the 2, 6 and

10 o’ clock positions. Place tubing in the outer port and against the two rollers as shown,

keeping your thumb on the tubing to hold it in place. Insert the tubing loading key on the

back of the rotor shaft and push the rotor in as far as possi ble. The tubing should now be

positioned deep into the pump head body. Wit h the key firmly pressed against the rotor, turn

counter-clockwise, while pushing down until tubing is fully in place around the rotor.

61

Page 62

I)

With the tubing is now on place, remove the key and position the other pump half onto the rotor shaft

and snap shut, being careful not to pinch the tubing between the plastic pump halves.

J)

Check if the pump turns correctly using the key.

K)

Holding the two parts of the pump head tightly together, slide it into the mounting screws moving the

rotor block with the key or with a screwdriver until the shaft aligns with the motor drive.

L)

Replace the four wing nuts, tightening them to finger tight so to have a firm mounting of the pump

head.

M)

Repeat the steps fromDtoLfor each additional pump head for which it is necessary to replace the

tubing.

N)

Reconnect the acid and persulfate intake tubing to their containers, run online t he analyser.

7010 TOC ANALYZER - USER MANUAL

O)

The analyser will start the conditioning cycle, with status indicator flashing with green light, until the

conditioning t ime will be expired. After the conditioning time of 30 minutes, the analyser will start

regular on line measurements.

62

Page 63

5.2 COPPER WOOL REPLACEMENT

The halogens filter is located into the electrical enclosure ( please read the hazards and dangers list

in section 1). This operation should be made by qualified personnel who have been fully trained and

has professional experience to avoid electricity hazards and dangers.

A)

put the analyser in stand-by and open the analyzer electrical enclosure

B)

disconnect the inlet and outlet tubing of the filter from their fittings

C)

remove the filter plastic body from its support clamp

7010 TOC ANALYZER - USER MANUAL

D)

unscrew top and bottom caps from filter body

E)

with extreme care, using a proper tool, pull out the used wool from ther plastic cylinder

F)

replace the used wool with new wool and press it into place to form a compact pod.

G)

screw back on the top and bottom caps

H)

put the filter in the clamp, connect fittings and turn on line the analyzer

63

Page 64

5.3 SODALIME REPLACEMENT

The sodalime filter is located inside the electrical enclosure

(refer section 1 for hazard warnings).

All handling and manipulations operations on chemicals

labelled with symbol should be made by qualified personnel in

accordance with national or local regulations.

Qualified Personnel means a person who has been fully

trained and has prof essional experience to avoid chemical

hazards and dangers.

Warning: Sodalime (granules) is a strong oxidizer and

should be handled with extreme care.

Irritating to eyes, respiratory system and skin.

It causes burns.

Avoid contact with skin.

Do not breathe dust.

Wear suitable gloves, face mask, clothes protection and

operate in an adequate environment.

Before to proceed to sodalime replacement in sodalime filter,

read with care the material safety data sheets supplied with

this chemical to take all the necessary precautions when

handling.

7010 TOC ANALYZER - USER MANUAL

A)

put the analyser in

stand-by and open the

analyzer’s electrical

enclosure

B)

disconnect the inlet and

outlet tubing of the filter

from their fittings

C)

remove the filter plastic

body from its support clamp

D)

unscrew filter upper cap,

pull out the wool disc and

pour the used sodalime into

a proper container for

disposal, taking all

precautions its handling

E)

fill the plastic body with

new sodalime granules,

insert the wool disc and

screw the upper cap

F)

install the filter on its

support clamp and

reconnect inlet and outlet

tubings, put the analyser on

line

64

Used sodalime must be disposed according with national or

local environment al regulations regarding hazardous and

poisonous materials.

Page 65

5.4 UVR TUBING'S CONNECTION REPLACEMENT

WARNING – UV lamps may be hot if recently powered. Handle with

suitable gloves.

A)

Put the analyzer in standby mode

B)

Open the analyzer Liquid Enclosure

C)

Dismount the UV lamps from their supports

D)

Cut the plastic clamp and the norprene tubing's connection and replace

them with new ones

E)

The Teflon tubing should be inserted inside the quartz inlets/outlets of

the UV lamps, taking care not to impede the liquid flow (see adjacent

diagram)

F)

The norprene tubing should cover the Teflon tubing and the arm of the

quartz inlets/outlets of the UV lamps

7010 TOC ANALYZER - USER MANUAL

G)

Use the black clamps supplied to fix the norprene tubing to the Teflon

tubing

H)

Check the clamp has been correctly positioned (that there are no

leakages) using a syringe with DI water connected at the same point used

to drain the lamps.

I)

If no leakages are found, then remount the UV lamps on their supports

and switch on the analyzer

J)

Once the analyzer has been running for two hours check again for leaks

at the connection to the UV lamps.

65

Page 66

5.5 UV LAMP REPLACEMENT

The UV lamps are located in the Liquids Enclosure.

WARNING – UV lamps may be hot if recently powered. Handle with

suitable gloves.

A)

With the analyzer in normal online operation, disconnect all solution and

sample lines from their containers and reconnect them to a distilled water

source. Leave the analyzer running in this way for at least an hour.

B)

Put the analyzer in Standby. Switch off the power.

C)

Using the key, open the Liquids Enclosure. Using a syringe remove the

remaining liquid from the UV lamps (see adjacent figure). Reconnect the

tubing to the ‘T’ afterwards.

7010 TOC ANALYZER - USER MANUAL

D)

Remove the wires from the cable guide in the top of the Liquid

Enclosure.

E)

Disconnect the UV lamp wires from the rear of the UV lamp power supplies, after first cutting the g ain protecting the connection.

F)

Remove the four screws supporting the lamps using a 3 mm Allen key or driver.

G)

Cut the black clamp holding the tubing to the top and bottom of the lamps.

H)

Connect the replacement lamps to the UV lamp power supply. First slip the supplied thermo–retractable gain over the end of the UV lamp wire.

Reconnect the wires with the UV lamp power supply and position the gains over t he connections. Apply heat to contract the gain. The gain is required

to protect the connection from humidi ty.

I)

Reinsert the wires into the cable guide.

J)

Reconnect the tubing to the top and bottom of the UV lamps following the instructions in Section 5.4.

66

Page 67

5.6 FUSES REPLACEMENT

The fuses are located inside the analyzer electrical enclosure (refer to section 1 for

hazards and dangers warnings) .

All operations within the electrical enclosure should be made by qualified personnel

in accordance with national or local codes and regulations.

Qualified Personnel means a person who has been fully trained and has

professional experien ce to avoid electricity hazards and dangers.

The

701 0 TOC

labelled as F1 and F2. Before to proceed to service operations on the electrical

enclosure, read carefully all the information written in this manual regarding this

matter.

analyzer h as two fuses located inside the USER CONNECTIONS

7010 TOC ANALYZER - USER MANUAL

To avoid any risk, turn off the analyzer main power before servicing the electrical

enclosure.

A)

turn off main power

B)

open the electrical enclosure

C)

remove the protection cover

D)

remove the small protection cover of the fuse assembly

E)

remove the fuse

F)

check the fuse and if broken replace it with a new one.

67

Page 68

6 PREPARATION OF THE CHEMICALS

7010 TOC ANALYZER - USER MANUAL

The chemica l solutions used with

online standard operation are :

phosphoric acid, 10% solution v/v and sodium

persulfate solu ti on, 1M as reagents

standard soluti on, used in different concent rat ion

depending on analyser range to calibrate or validate

the TOC

cleaning solution

optional reducing reagent solution for applications

with high content of chlorides

Before to proceed to these solutions preparation, read the

material safety data sheets supplied with each chemical to

take all the necessary precautions when handling.

Chemicals must be handled by qualified personnel trained

on hazards and dangers to avoid accidents.

701 0 TOC

analyser in

Metrohm Applikon

TOC operation as solutions or predosed packs.

68

supplies all the chemicals used for

Page 69

7010 TOC ANALYZER - USER MANUAL

6.1 PREPARATION OF TOC STANDARD SOLUTION

Use distilled water reagent grade for preparation of TOC standa rd solutions and for analyser zero calibration.

Organic compounds usually used as TOC standards are potassium hydrogen phthalate (KHP) reagent grade and

ethylene glycol reagent grade.

The table 4.1 is shows a list of other calibration solution compounds that have been approved for this use.

Before to proceed to prepare the chosen solution, read with attention its material safety data and use all precautions

recommended when handling.

Always use suitable wears, gloves, and eyes protection.

For use of powdered chemicals, wear a protective face mask or suitable respirator.

69

For standard solution preparation, prepare a stock solution by adding the quantity shown in table 4.1 (according to

chosen compound and concentration in grams or ml) into a 1000 ml class A volumetric flask.

Dilute to volume with reagent water. If other concentrations are required, dilute accordingly or measure an appropriate

ratio of chemical.

Tab. 4-1: Amount (g or ml) for preparation of 1 liter TOC standard solution 1000 mg/l

Organic compound Amount

Ethylene glyco l 2,33 ml

Potassium hydrog en phthalate (KHP) 2,12 g

Acetic acid 2,50 g

Sucrose 2,38 g

Page 70

7010 TOC ANALYZER - USER MANUAL

6.2 PREPARATION OF COD STANDARD SOLUTION

Use distilled water reagent grade for preparation of COD standard solutions and for analyzer zero calibration.

Before to proceed to prepare the solution, verify eventual toxicity of used chemical and read with attention its material

safety dat a and use all precautions when handling.

Always use suitable wears, gloves, and eyes protection.

For use of powdered chemicals, wear a protective face mask or suitable respirator.

For 1000 mg/l standard solution preparation, prepare a stock solution by adding 0,85 g of potassium hydrogen

phthalate (K HP ) into a 1000 ml class A volumetric flask.

70

Dilute to volume w it h reagent water. If other concentrations are required, dilute accordingly or take an appropriate ratio

of KHP.

Page 71

7010 TOC ANALYZER - USER MANUAL

6.3 PREPARATION OF PERSULPHATE SOLUTION

Sodium persulphate is a strong oxidizer and should be handled with ext reme care.

Contact with combustible material may cause fire.

Irritating to eyes, respiratory system and skin.