Mercedes-Benz AGS, GS7 Service manual

As at 10/03

Trucks • Transmission

Telligent automatic transmission

in ACTROS and ATEGO

Specialist training

Trucks • Transmission <> Telligent

automatic transmission in ACTROS and

This document is intended solely for use in training and is not subject to regular updating.

Printed in Germany

ã 2003 Copyright DaimlerChrysler AG

Publisher: Global Training

This document with all its sections is protected under the laws of copyright. Its use for any purpose whatsoever

requires the prior written consent of DaimlerChrysler AG. This applies in particular to its reproduction, distribution,

modification, translation, recording on microfilm or storage and/or processing in electronic systems, including

databases and on-line services.

1511 5555 02 - 1

st

edition 10.03 124 As at 10/03

Note:

The term »employees« does not imply any preference

of gender and incorporated male and refers to maler

and female employees alike.

Content 29.10.2003

Title Page

Welcome ..................................................................................................................................................................................................................................................1

Training Course Description Code NGAS - MA253..................................................................................................................................................................................3

Overview of shifting systems for ACTROS, AXOR and ATEGO.................................................................................................................................................................4

KontAct network diagram ACTROS models 930 - 934 ............................................................................................................................................................................6

KontAct network diagram for ACTROS models 930-934; exercise .........................................................................................................................................................8

EAS II (Code GE 2) - evolution of control units ........................................................................................................................................................................................9

EAS II - (Code GE2), function diagram ...................................................................................................................................................................................................10

EAS II (Code GE 2), function ..................................................................................................................................................................................................................12

EAS II - (Code GE2), function diagram; exercise ....................................................................................................................................................................................13

Power train networking with EAS II, ACTROS models 930-934; exercise .............................................................................................................................................15

Information exchange on gear shifting EAS ACTROS, models 930-934; exercise ................................................................................................................................17

EAS II - (Code GE2), information exchange and actual values, exercise ...............................................................................................................................................20

EAS II - (Code GE2), components ..........................................................................................................................................................................................................22

EAS II - (Code GE2), control circuit ........................................................................................................................................................................................................25

EAS II - (Code GE2), clutch actuator adjustment, exercise ...................................................................................................................................................................27

EAS II - (Code GE2), clutch actuator - clutch control; exercise .............................................................................................................................................................28

EAS II - (Code GE2), versions, exercise..................................................................................................................................................................................................30

EAS II - (Code GE2), teach-in process; exercise ....................................................................................................................................................................................31

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Content

I

1

EAS II - (Code GE2), teach-in process and teach-in faults; exercise......................................................................................................................................................32

EAS II - (Code GE2), clutch characteristics............................................................................................................................................................................................34

EAS II - (Code GE2), backup mode special features ..............................................................................................................................................................................36

EAS II - (Code GE2), drive control actual values and GS II, exercise .....................................................................................................................................................37

Foot throttle actuator, standard quantity; exercise ...............................................................................................................................................................................39

Foot throttle actuator, onboard teach-in, ACTROS models 930 - 934 ..................................................................................................................................................40

Troubleshooting chart for GS II and EAS II, TIPS procedure and application ........................................................................................................................................41

Carrying out diagnosis with the layer model .........................................................................................................................................................................................43

EAS II - (Code GE2), practical 1; exercise ..............................................................................................................................................................................................50

EAS II - (Code GE2), practical 2; exercise ..............................................................................................................................................................................................54

EAS II - (Code GE2), practical 3; exercise ..............................................................................................................................................................................................56

AGS (Code GE1), functional description ................................................................................................................................................................................................58

AGS (Code GE1), installation survey ......................................................................................................................................................................................................59

Design and features of the G60/85 transmission; exercise .................................................................................................................................................................60

G60/85 transmission transverse shift gate; exercise ...........................................................................................................................................................................63

ATEGO power train networking control units - AGS (Code GE1), exercise............................................................................................................................................64

ATEGO power train networking engine management - AGS (Code GE1); exercise ...............................................................................................................................65

Power train networking - AGS (Code GE1), ATEGO ...............................................................................................................................................................................67

Power train networking - AGS (Code GE1), ATEGO, exercise ................................................................................................................................................................69

AGS (Code GE1), sensor unit operation.................................................................................................................................................................................................71

AGS (Code GE1), sensor unit operation; exercise .................................................................................................................................................................................72

AGS (Code GE1), location of the AGS components on the transmission and their task.......................................................................................................................75

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Content

I

2

AGS (Code GE1), location of the AGS components on the transmission and their task; exercise........................................................................................................81

AGS (Code GE1), assignment and actuation of the solenoid valves; exercise ......................................................................................................................................83

AGS (Code GE1), transmission shift states, exercise ............................................................................................................................................................................86

AGS (Code GE1), sensor analysis, teach-in process and shifting procedure.........................................................................................................................................91

AGS (Code GE1), teach-in process and teach-in faults; exercise ..........................................................................................................................................................93

AGS (Code GE1), clutch sensing............................................................................................................................................................................................................97

AGS (Code GE1), FR and AGS actual values; exercise...........................................................................................................................................................................98

AGS (Code GE1), AGS clutch balancing.............................................................................................................................................................................................. 100

AGS (Code GE1), instructions for testing and repair work ................................................................................................................................................................. 102

AGS (Code GE1), emergency operation characteristics ..................................................................................................................................................................... 103

Transmission diagnosis, practical example template ......................................................................................................................................................................... 104

AGS (Code GE1), practical 1; exercise................................................................................................................................................................................................ 108

AGS (Code GE1), practical 2; exercise................................................................................................................................................................................................ 110

AGS (Code GE1), practical 3; exercise................................................................................................................................................................................................ 112

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Content

I

3

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Content

I

4

Welcome 29.10.2003

Welcome to the NGAS training course. As the training course progresses, it

will become evident how this subject is presented. While it was relatively easy

to have an overview of the shift devices used with the LK and SK, one or two

things have changed since the launch of the ACTROS, ATEGO and AXOR. The first

challenge has no doubt been dealing with the "networking" of the systems.

This will be just one of the hurdles you will have to overcome in the course of

the NGAS training. It will soon become evident that, even with a good

foundational training in electrics, you will only be able to do a proportion of

the tasks set. The other tasks require a good understanding of transmission

mechanics, wiring and different hydraulic systems.

If you have some experience and understanding in the areas of mechanics,

hydraulics and electrics, this will be of great benefit and you will be able to

follow the training course easily. If not, then you have quite some ground to

cover, but we will be happy to help and support you in your efforts.

This is because those who understand the systems are also quick to make a

confident diagnosis. While diagnostic aids, such as DAS and WIS, can

certainly help you in your work, they will rarely actually make the decision for

you as to what ultimately needs repairing.

During the training course you will work with all the named diagnostic aids so

that you will be in a better position afterwards to make a diagnosis on the

shift devices "at home", in your workshop.

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

Welcome

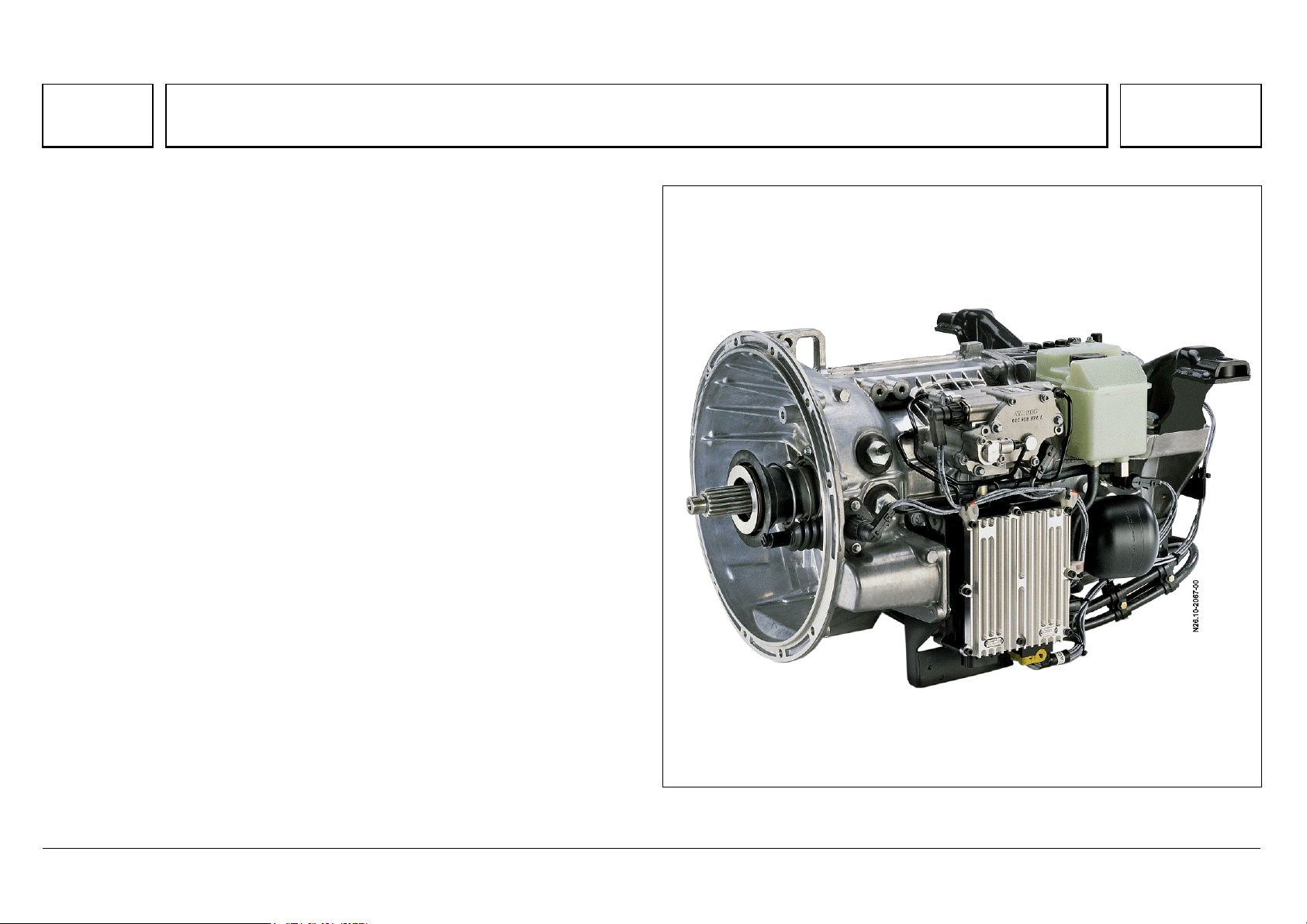

N26.10-2067-00

1

Training sequence

Day 1

Welcome

Overview of gearshift systems and types of gearshift

system

Design and function of the Telligent automatic

transmission II – EAS II gearshift system in the

ACTROS

Networking of the Telligent automatic transmission II

– EAS II gearshift system in the ACTROS

Teach-in processes of the Telligent automatic

transmission II – EAS II gearshift system in the

ACTROS

DAS actual values of the GS II system and drive

control

Practical work on the ACTROS

c

c o

c o

c o

c o

c o

h o

Day 2

Design and function of the Telligent automatic

transmission – AGS gearshift system in the ATEGO

Networking of the Telligent automatic transmission –

AGS gearshift system in the ATEGO

Teach-in processes of the Telligent automatic

transmission – AGS gearshift system in the ATEGO

DAS actual values of the AGS system and drive

control

Practical work on the ATEGO

Troubleshooting aids based on customer complaints

Presentation and feedback in plenary session

c o

h c

c o

c o

h o

o

c o

Troubleshooting aids based on customer complaints

Presentation and feedback in plenary session

Feedback from day 1

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

Welcome

o

c o

o

Final test

Feedback and close of training session

o

o

2

Training Course Description Code NGAS - MA253 29.10.2003

Training course description

Target group

Requirements

Performance level

Methodology

Duration

Objectives

Contents

ACTROS, ATEGO — Telligent® automatic transmission (EAS, AGS) • Specialist training

Mechanics, electricians

The course participants are required to have passed the final test of the NGGG training or have worked through

the preliminary training and passed the initial test. (The knowledge required for this can be acquired from the

CBTs "Telligent gearshift system Parts 1 – 4", "Telligent automatic transmission Parts 1 – 2" and "Wiring

diagrams Parts 1 + 3").

3

50% theory, 50% practical

2 days DCVD, 2-3 days Export

The participant can:

· independently prepare a diagnosis on the Telligent® automatic transmission (ACTROS - EAS; ATEGO - AGS)

· perform testing, adjusting and repair work

· Design and function of the Telligent® automatic transmission vehicle networking

· Drive control on pneumatic (EAS) and hydraulic (AGS) shifting systems

· Diagnosis using current diagnosis systems and fault diagnosis based on case examples

· Carrying out the necessary teach-in processes

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Training Course Description Code NGAS - MA253

3

Overview of shifting systems for ACTROS, AXOR and ATEGO 11.02.03

Since the launch of the ATEGO, AXOR and ACTROS, various other shifting systems have been introduced in addition to the mechanical gearshift system, the MPS

and the EPS, already familiar to us from the SK.

{0>Die verschiedenen Schaltungsarten werden über Verkaufscode dem jeweiligen Getriebetyp und Fahrzeug zugesteuert.<}100{>The various shifting types are

assigned to the respective transmission type and vehicle by way of the sales code.

The respective sales code can be found on the data card.

While no completely new types of gearshift system were introduced with the refinement of the ACTROS model (MPII) in the spring of 2003, existing systems were

nevertheless revised. As a result new sales codes have been issued for better differentiation.

The ATEGO model series is also earmarked for various innovations in 2003. These are also listed below.

The list differentiates between the following shifting systems in the current generation of vehicles:

ACTROS, AXOR, ATEGO Changes to ACTROS models 930 - 934

Sales code GS 1:

· Mechanical shift - MS

· Mechanical-pneumatic shift – MPS

· Mechanical-pneumatic shift with

pneumatic shifting aid - MPS with PSH

Sales code GS 3:

· Hydraulic shift - HS

· Hydraulic-pneumatic shift - HPS

· Hydraulic-pneumatic shift with shift force assist – HPS with SKU

Sales code GS 2: Sales code GS 7:

· Telligent gearshift system – EPS II · Telligent gearshift system II (GSII)

Sales code GE 1: Sales code GE 2:

· Telligent automatic transmission – EAS · Telligent automatic transmission II – EAS II

· Telligent automatic transmission -- AGS

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Overview of shifting systems for ACTROS, AXOR and ATEGO

4

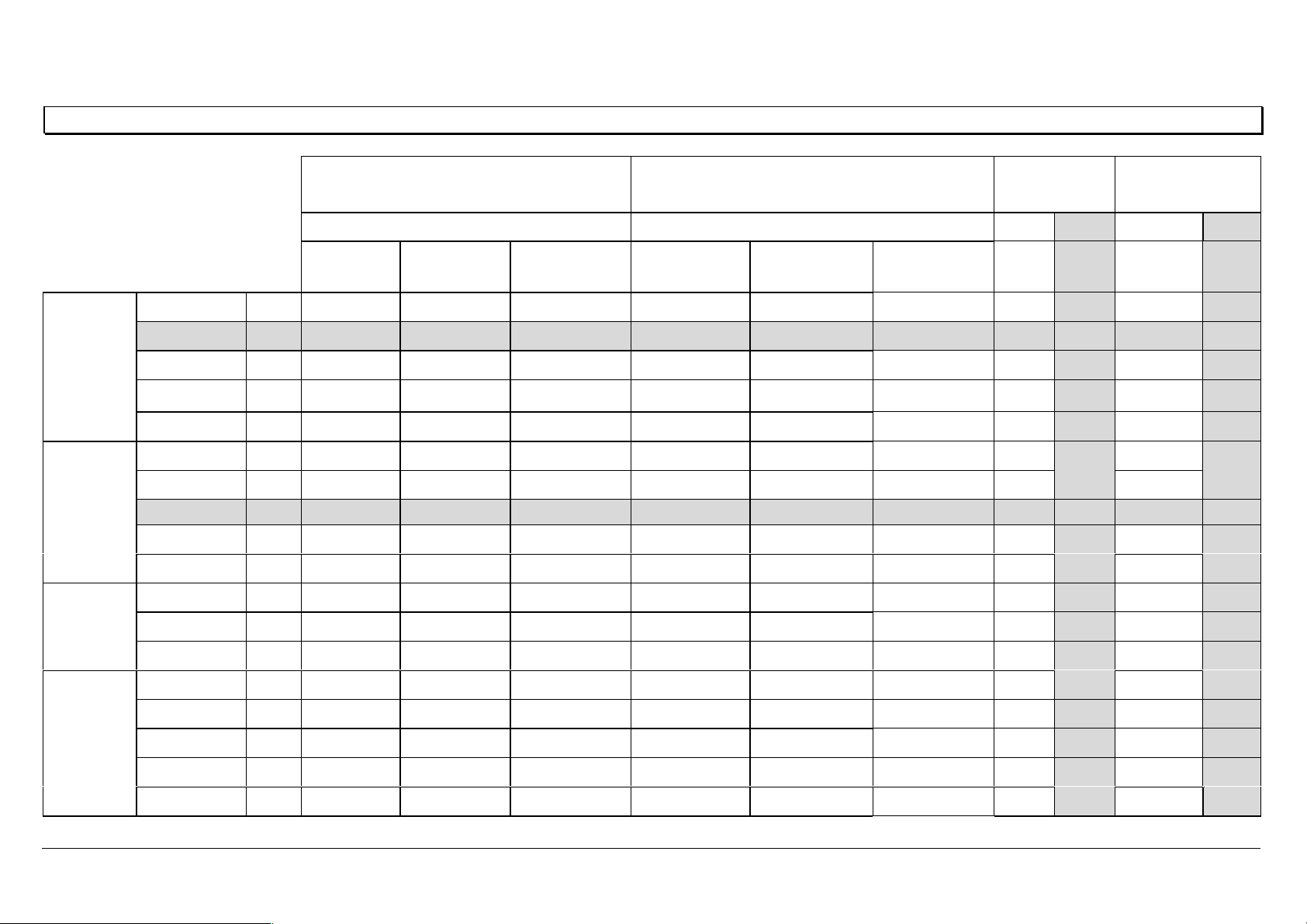

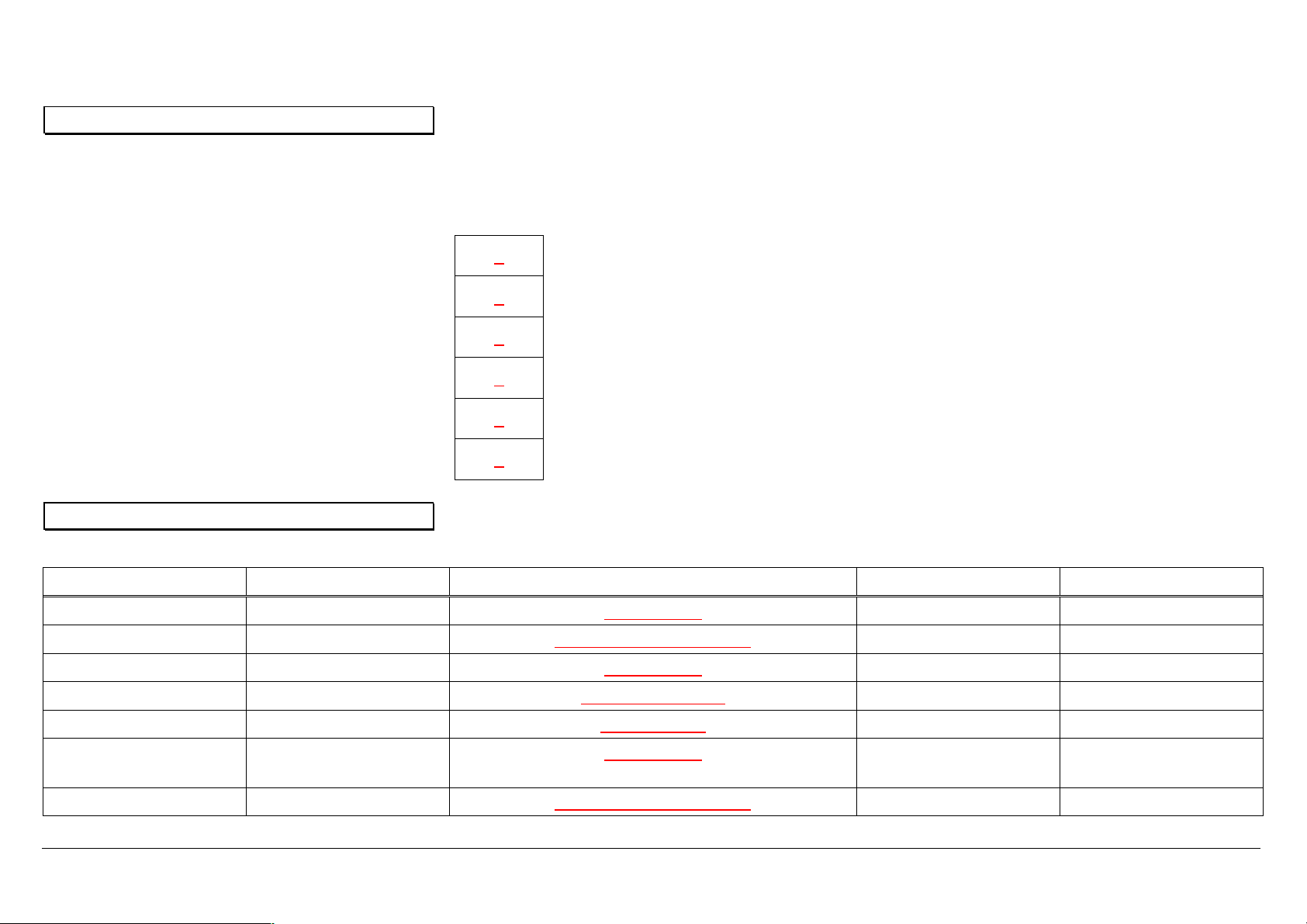

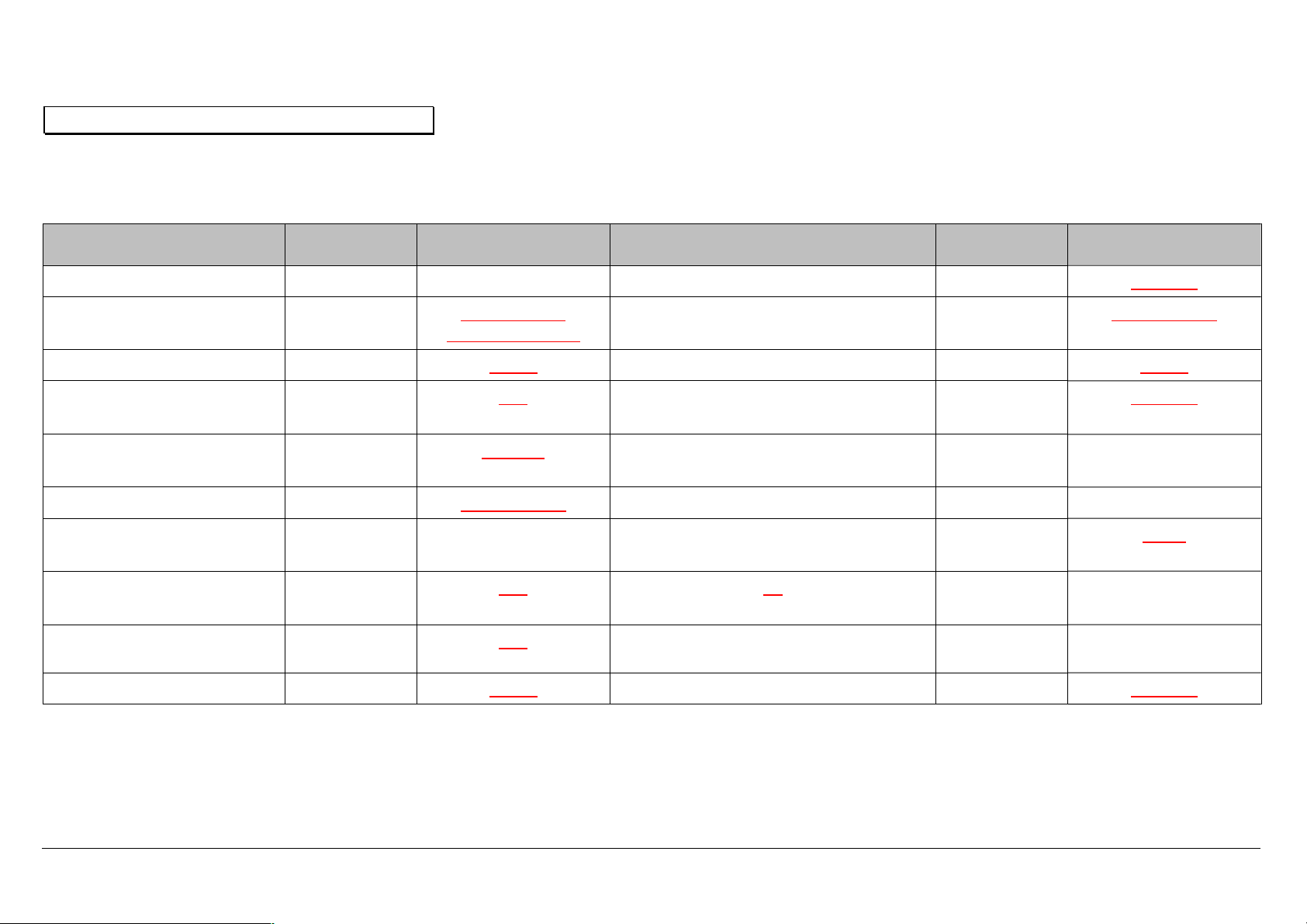

Gearshift system types arranged according to vehicles and transmissions

Mechanical shift Hydraulic shift Telligent Telligent

GS 1 GS 3 GS 2 GS 7 GE 1 GE 2

gearshift syst. aut. transmission

ATEGO

(up to 15t) G 60 - 6 GC 5

ATEGO

(as of 18t) G 100 - 12 GC 7

AXOR

ACTROS

ZF S 5-42 GF 1

G 56 - 6 GC 4

G 85 - 6 GC 6

G 100 - 12 GC 7

G 85 - 6 GC 6

G 131 - 9 GT 1 10/03

G 221 - 9 GD 5

G 211 - 16 GD 3

G 211 - 16 GD 3

G 221 - 9 GD 5

G 240 - 16 GC 2

G 210 - 16 GC 3

G 211 - 16 GD 3

G 231 - 16 GH 6

G 240 - 16 GC 2

G 260 - 16 GC 1

MS MPS MPS with

PSH

!

!

!

!

!

!

!!

!!!!

!!!!

!!!!

HS HPS HPS with

SKU

!

!

!

!!

!!!

!!!

GS GS II EAS/AGS EAS II

10/04

AGS

AGS

AGS

!

EAS

EAS

EAS

EAS

EAS

!

!

!

!

!

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Overview of shifting systems for ACTROS, AXOR and ATEGO

5

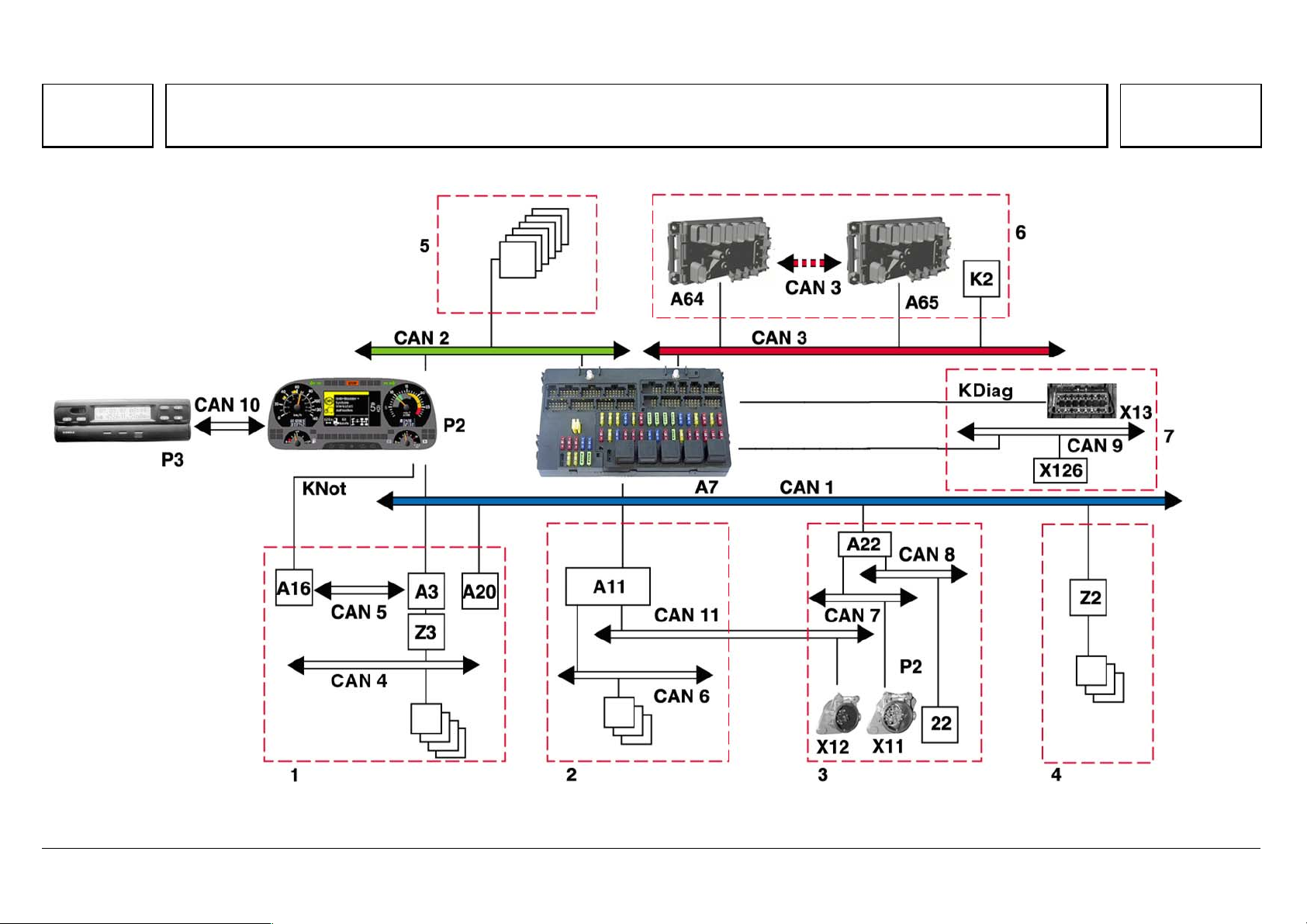

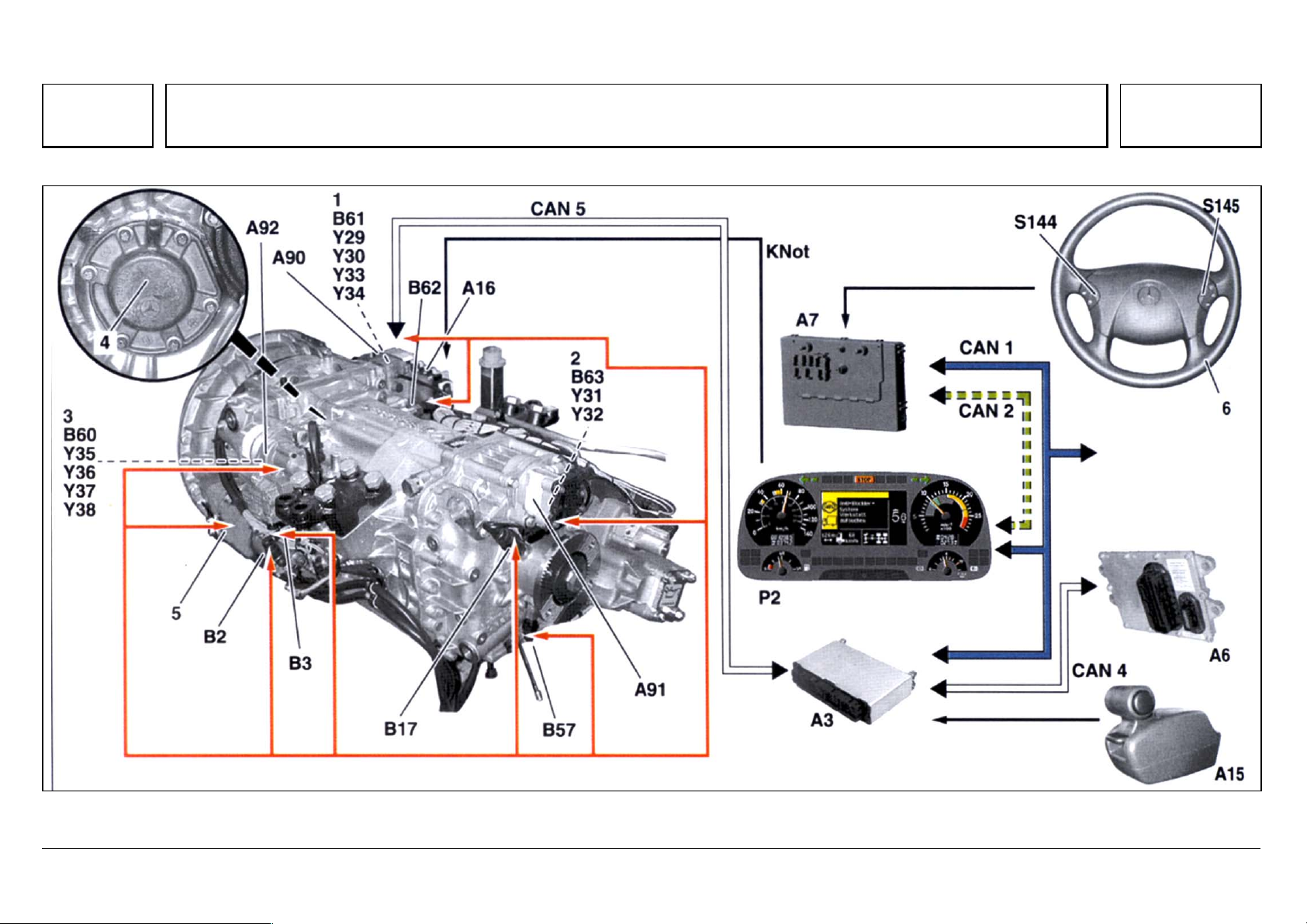

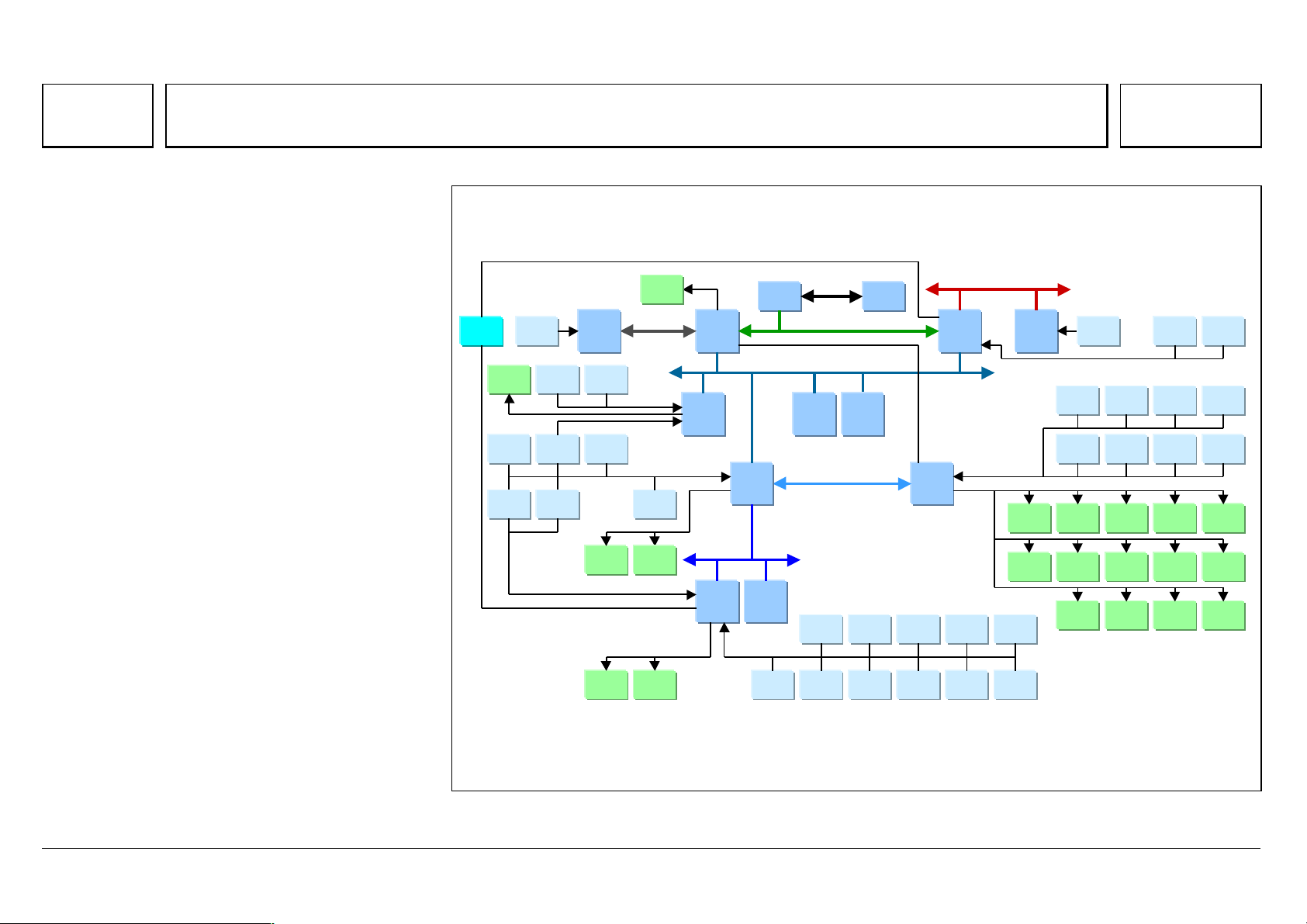

KontAct network diagram ACTROS models 930 - 934 04.02.03

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR KontAct network diagram ACTROS models 930 - 934

W00.19-1011-79

6

1

2

3

4

5

6

7

22

A3 Control unit, drive control (FR) CAN 7 Trailer CAN (PSM) Z2 CAN star point, cab dash support, additional

A7 Base module (GM) CAN 8 Body CAN Z3 CAN star point, additional

A11 Control unit, brake control (BS) CAN 9 Telematics CAN

A16 Control unit, gear control (GS) CAN 10 Speedometer CAN

A20 Control unit, retarder control (RS) CAN 11 Trailer CAN (BS)

Power train components

Brake components

Trailer and body components

Vehicle components CAN 1 Vehicle CAN P2 Instrument (INS)

Cab components CAN 2 Interior CAN P3 Modular tachograph (MTCO)

Frame components CAN 3 Frame CAN X11 15-pin trailer socket

Telematics / diagnosis CAN 4 Engine CAN X12 7-pin ABS trailer socket

Body electronics CAN 5 Transmission CAN X13 Diagnostic socket

A22

A64

A65

CAN 6 Brake CAN X126 Telematics platform (FleetBoard)

Control unit, parameterizable special module (PSM) K2 Battery disconnect switch

Front module (FM)

Rear module (HM)

K

K

Diag K-line diagnosis

Emergency K-line, emergency running mode

Note: For further information see GF 00.19-W-0002 MP "Extended vehicle network KontAct function"

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR KontAct network diagram ACTROS models 930 - 934

7

KontAct network diagram for ACTROS models 930-934; exercise 12.02.03

This exercise is concerned with the new network in the ACTROS. Use the new network diagram to work through the following tasks.

Task

Task

m Enter the CAN BUS designations.

CAN 3

CAN 1

CAN 5

CAN 6

CAN 4

CAN 2

m Which control units are part of the vehicle CAN BUS?

Frame CAN BUS

Vehicle CAN BUS

Transmission CAN BUS

Brakes CAN BUS

Engine CAN BUS

Interior CAN BUS

CAN 10

CAN 11

CAN 7

CAN 9

CAN 8

Tachograph CAN BUS

Trailer CAN (BS)

Trailer CAN (PSM)

Telematics CAN BUS

Body CAN

- Base module (A7), control unit for drive control (A3), control unit for brake control (A11)

- Control unit for retarder control (A20), Parameterizable special module control unit (A22)

- Instrument (P2), CAN star point cab dash support, additional (Z2)

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR KontAct network diagram for ACTROS models 930-934; exercise

8

EAS II (Code GE 2) - evolution of control units 29.10.2003

ACTROS, models 950 -954

Control units

ACTROS, models 930 - 934

Software modules

ACTROS, models 930 - 934

Control units

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II (Code GE 2) - evolution of control units

GT26_00_0014

9

EAS II - (Code GE2), function diagram 29.10.2003

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), function diagram

GT_26_21_0002 (W26.21-1009-79)

10

1 Gate shift cylinder B2 Clutch travel sensor S144 Button group on left of multifunction steering wheel

2 Range shift cylinder B3 Countershaft speed sensor S145 Button group on right of multifunction steering wheel

3 Gear cylindrical actuator B17 Speed sensor

4 Splitter shift cylinder B57 Transmission output speed sensor Y29 Solenoid valve, split 1 (MS1)

5 Clutch actuator B60 Gear sensor (SGG) Y30 Solenoid valve, split 2 (MS2)

6 Multifunction steering wheel B61 Gate sensor (SGE) Y31 Solenoid valve, range 1 (MR1)

B62 Splitter sensor (SSP) Y32 Solenoid valve, range 2 (MR2)

B63 Range sensor (SRA) Y33 Solenoid valve, gate 1 (MG1)

Y34 Solenoid valve, gate 2 (MG2)

A3 Control unit for drive control (FR) with integrated

drive control (FR) software module

A6 Control unit for engine control (MR) CAN2 Interior CAN (redundant) Y36 Even gears air admission solenoid valve (MGB)

A7 Base module (GM) CAN4 Engine CAN Y37 Uneven gears air release solenoid valve (MUE)

A15 Sensor unit for gear control (GS) CAN5 Transmission CAN Y38 Even gears air release solenoid valve (MUE)

A16 Control unit for gear control (GS) with integrated

gear control (GS) software module

A90 Gate module KNot K-line emergency running mode

A91 Range module P2 Instrument (INS)

A92 Gear module

CAN1 Vehicle CAN Y35 Uneven gears air admission solenoid valve (MUB)

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), function diagram

11

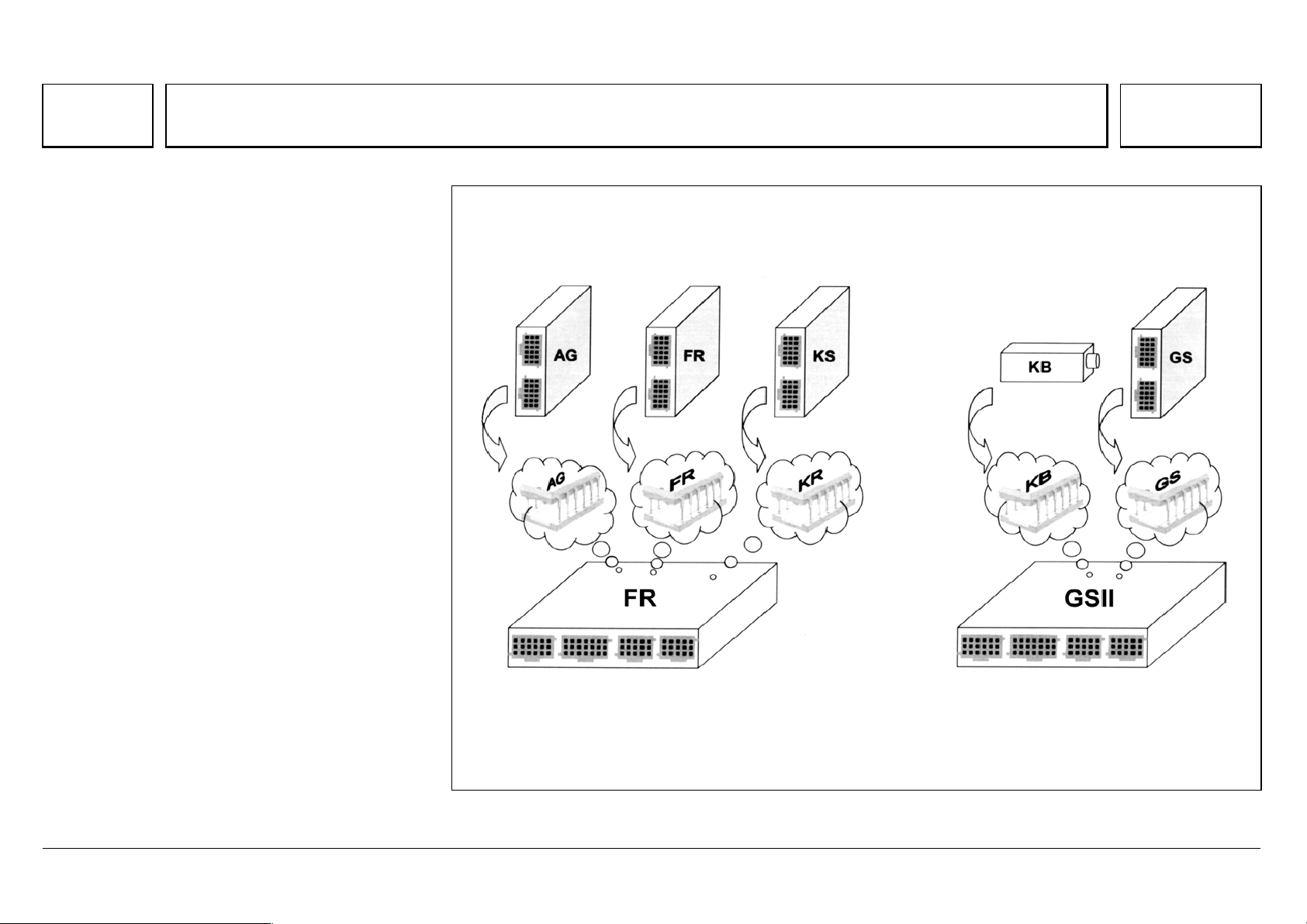

EAS II (Code GE 2), function 29.10.2003

General points:

Based on the gear control II (GS II) shifting system, the Telligent automatic transmission II (EAS II) is a special design with automated clutch.

The design of the Telligent automatic transmission II (EAS II) based on the gear control II (GS II) has been substantially simplified:

The entire clutch hydraulic system used in the first-generation EAS has been replaced by an electropneumatic clutch actuator. This clutch actuator directly

operates the mechanical clutch system.

The old EAS, AG and KS control units are still there but only as virtual control units. The AG is integrated as a drive control software module. The KS control

unit is integrated in the GS control unit as a clutch control software module.

This dispenses with the need for hydraulic lines and maintenance work.

Only the electrical and pneumatic lines are still connected to the clutch actuator.

With the fold-out emergency clutch pedal no longer required, only the accelerator and brake pedals remain.

The option of activating manual or automatic shift mode via a selector switch on the gear control sensor unit has been retained.

Ride comfort has been improved, e.g., the system changes independently from the normal drive mode to a maneuver mode if required. This makes

maneuvering considerably easier.

The Telligent automatic transmission II (EAS II) can be operated in two modes:

· Automatic operation

· Manual operation

The electronic systems for the transmission and the on-board related functions are entirely separate.

Information is exchanged between the electronic systems in the form of CAN messages via the CAN connections

Vehicle CAN (CAN 1),

Interior CAN (CAN 2),

Engine CAN (CAN 4)

Transmission CAN (CAN 5)

and via the

· K line emergency running mode (KNot), in backup drive mode

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II (Code GE 2), function

12

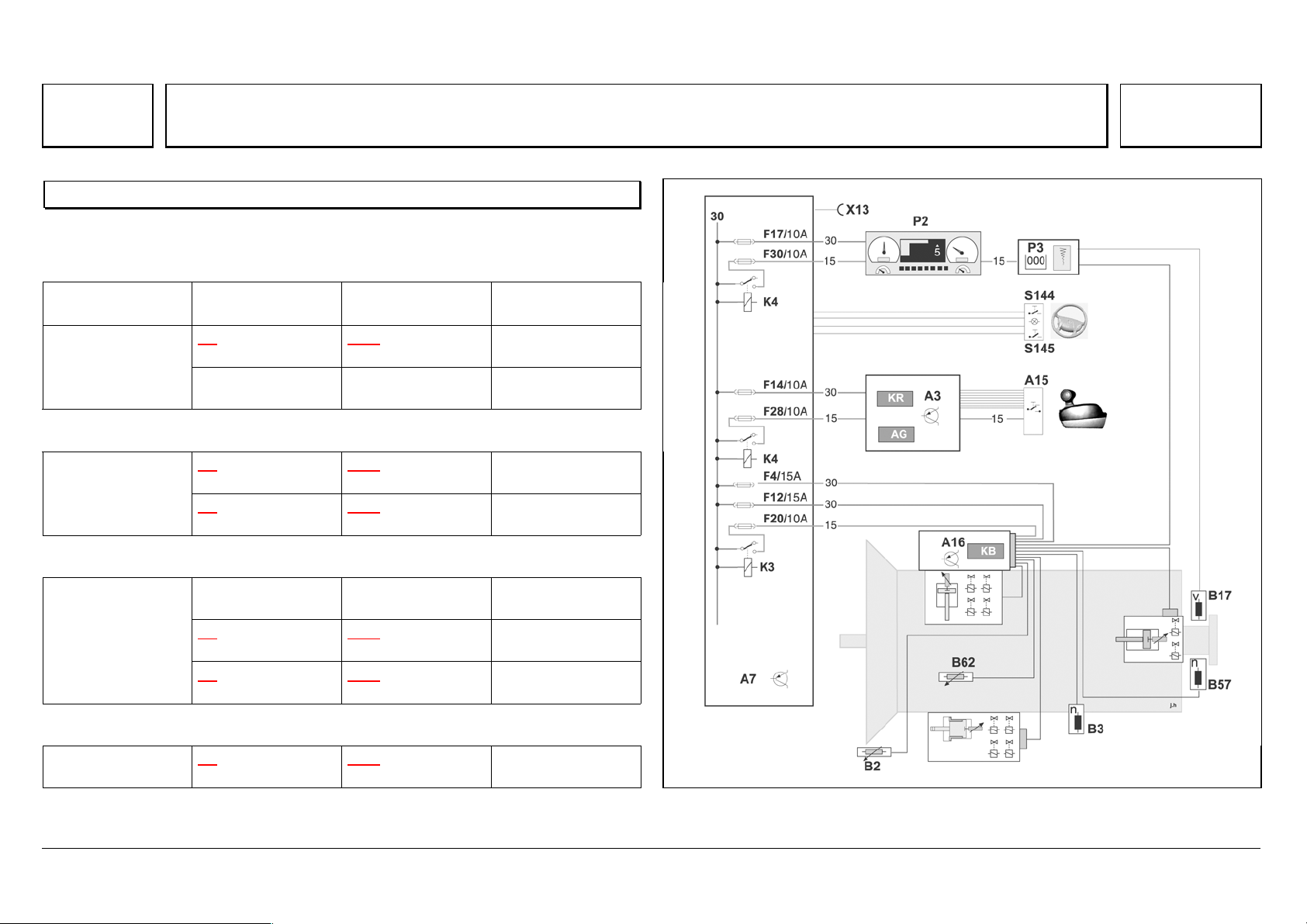

EAS II - (Code GE2), function diagram; exercise 29.10.2003

Task

Using the drawing opposite allocate the following components to the

corresponding terminals, fuses and relays!

Component Terminal Fuse Relay

P2

30 F 17

15 F 30 K4

A3 30 F 14

15 F 28

A16

30 F 4 ----

30 F 12

15 F 20

A 15

15 F 28

----

----

K4

----

K3

K4

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), function diagram; exercise

N26.20-2010-12

13

Task

m Indicate the correct sequence of the signal path during a gear change on the TelligentÒ automatic

transmission in "Manual mode".

Note:

For further information, see GF 26.20-W-0001 MP "Gear control (GS) function" and circuit diagram.

Task

3

2

1

6

5

4

m The TelligentÒ automatic transmission communicates with other components and systems in different

GS control unit

FR control unit

Sensor unit

GS control unit

Gear, gate, range and splitter sensors

Gear, gate, range and splitter solenoid valves

ways. Complete the table.

Component Designation Communication / Connection Designation Component

Sensor unit A15

FR control unit A3

GS control unit A16

Instrument P2

CAN 5 (Transmission CAN)

Electrical line

Electrical line

KNot/CAN1/CAN5

A3 FR control unit

A16 GS control unit

Connected components

A16 GS control unit

Instrument P2

Multifunction steering

S144/S145

CAN1 / CAN2

Electrical line

wheel

Modular tachograph P3

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), function diagram; exercise

CAN 5 (Transmission CAN)

A7 Base module

A7 Base module

A16 GS control unit

14

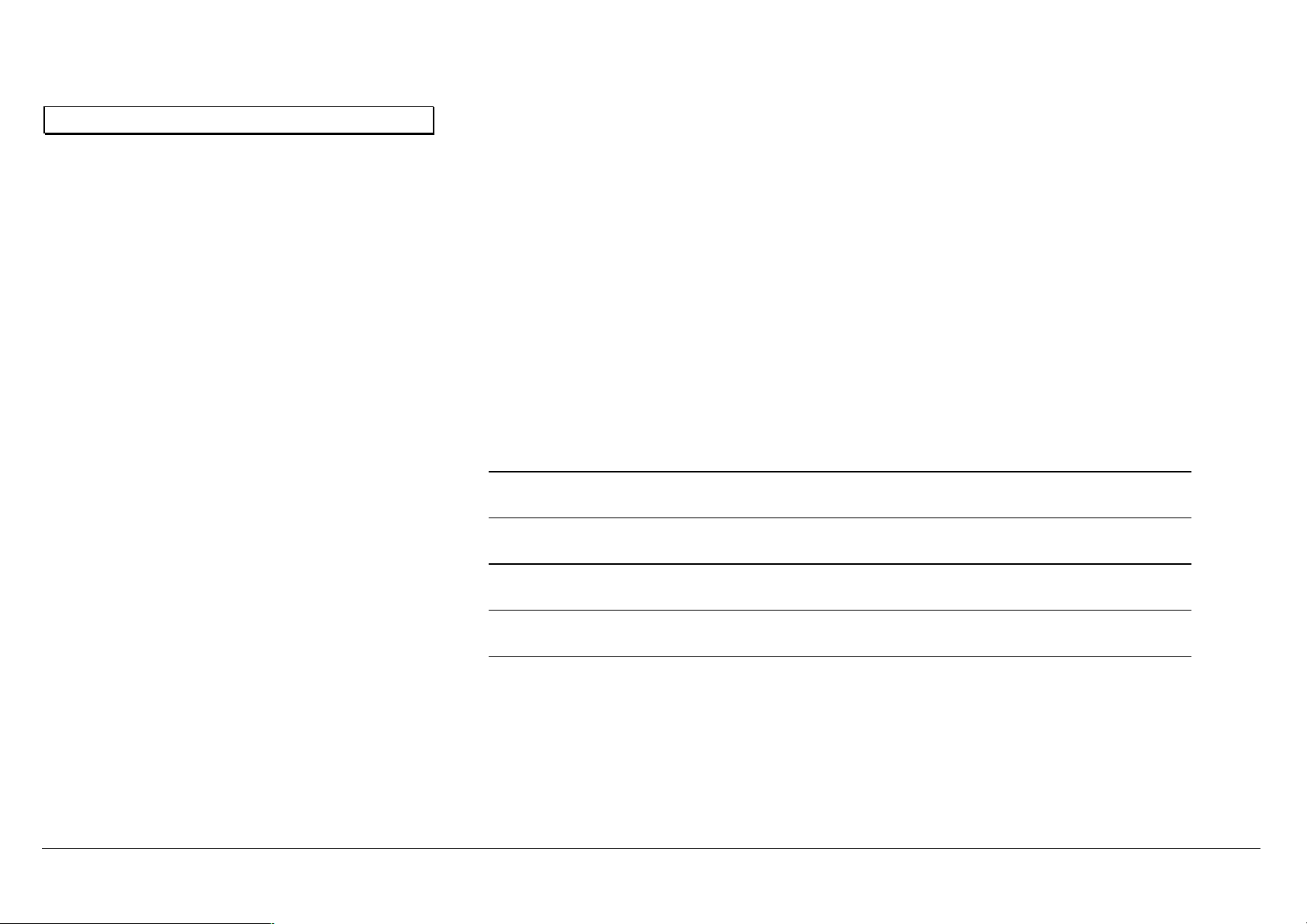

Power train networking with EAS II, ACTROS models 930-934; exercise 02.06.03

X13 B28

CAN 10

B17

Y44

MTCO

P3

B65

B66

INS

P2

RS

A20

G2

S2

S1A42

B1

A15

A68 A82

ASIC

CAN 2

CAN 1

PSM

A22

CAN 5

FR

A3

CAN 4

MR

A6

FLA

A4

BS

A11

Y1

K

GS

A16

Y2

GM

A7

CAN 3

HM

A65

B5

S144 S145

B10 B15 B16 B65 B111

B11 B12 B14

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Power train networking with EAS II, ACTROS models 930-934; exercise

S10 S11 S166

Y6-13 M1

TM Antriebsstrang 1_D.ppt

15

Task

m The diagram shows an all-wheel drive vehicle with retarder control (RS) and EAS II.

Name the missing components.

The following questions may help you to solve the problem.

· How is the clutch actuated?

· Have you also considered clutch sensing?

· Have you thought about all the components required for engaging a gear?

· How is the corresponding gear position determined?

· Have you taken the splitter gearshift system components into consideration?

· How is a driver command transmitted?

Note: Further information on the Telligent automatic transmission II can be found in WIS under

GF 26.21-W-0001 MP "Electronic drive control (EAS) operation".

-

-

-

-

-

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Power train networking with EAS II, ACTROS models 930-934; exercise

16

Information exchange on gear shifting EAS ACTROS, models 930-934; exercise 29.10.2003

Operation Transmitter Receiver What is the reason and the purpose for the part action?

Evaluation of shift logic FR FR Evaluation of CAN messages (influencing variables)

Internal evaluation in the AGF software module

Select: open clutch FR

Reduce engine torque FR

Open clutch

Perform gear change

Adjust engine speed

Current gear position feedback

GS Y39.1/39.2

GS

FR MR

B60, B61, B62,

B63

Display shifted gear

Close clutch

GS

GS Y39.3/39.4

GS

MR

CAN 5 (transmission CAN)

CAN 4

De-energized power train

Energizing of corresponding solenoid valves

Gear can only be changed when clutch open

Corresponding

Energizing of corresponding solenoid valves

solenoid valves

Change in unit pump actuation time and permanent brake actuation, levels 1+2

Reduction of clutch wear

GS

Evaluation of displacement value sensor, energizing of corresponding solenoid valves,

determination of current gear

INS CAN 5, CAN 1

Display of engaged gear

Energizing of corresponding solenoid valves

Establishment of power train frictional connection

Increase engine torque

FR MR

CAN 4, change in unit pump actuation time

Adjustment of specified engine torque setting on FR

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Information exchange on gear shifting EAS ACTROS, models 930-934; exercise

17

Task

m You now know the gear change sequence involved in a gear change. Complete the table below by

determining the detailed information contained in the data exchanged between transmitter and

receiver. If possible, explain why the information is required.

Operation Transmitter Receiver Relevant information Reason

Evaluation of shift logic FR FR Internal data exchange on AGF software

module

Select: open clutch FR GS

Reduce engine torque FR MR

Open clutch request Control of clutch actuator

CAN message (change engine speed and

engine torque)

Open clutch GS Y39.1/39.2 Energizing of clutch actuator solenoid valves,

clutch position, electronic pulse

Perform gear change GS Corresponding

Electronic pulse

solenoid valves

Adjust engine speed MR,

Y6-Y13

FR

Current gear position

feedback

B60, B61, B62,

B63

GS

Display shifted gear GS INS

Change unit pump actuation time and engine

brake actuation

Position of sensors in gear, gate, splitter and

range cylinders

Shifted gear Driver information

Close clutch GS Y39.3/39.4 Energizing of clutch actuator solenoid valves,

clutch position, electronic pulse

Evaluation of relevant CAN messages

(influencing variables)

De-energizing of power train

Open clutch,

Clutch position feedback

Reduction of clutch wear

Evaluation takes place in GS control unit

Close clutch

Increase engine torque FR MR CAN message

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Information exchange on gear shifting EAS ACTROS, models 930-934; exercise

Adjust FR specified torque setting

18

Task

m You now know the information exchange when shifting gear. But how can you still test the pieces of

information?

Complete the table below. Use the DAS simulation and the DAS to help you complete the

corresponding actual values in the respective fields.

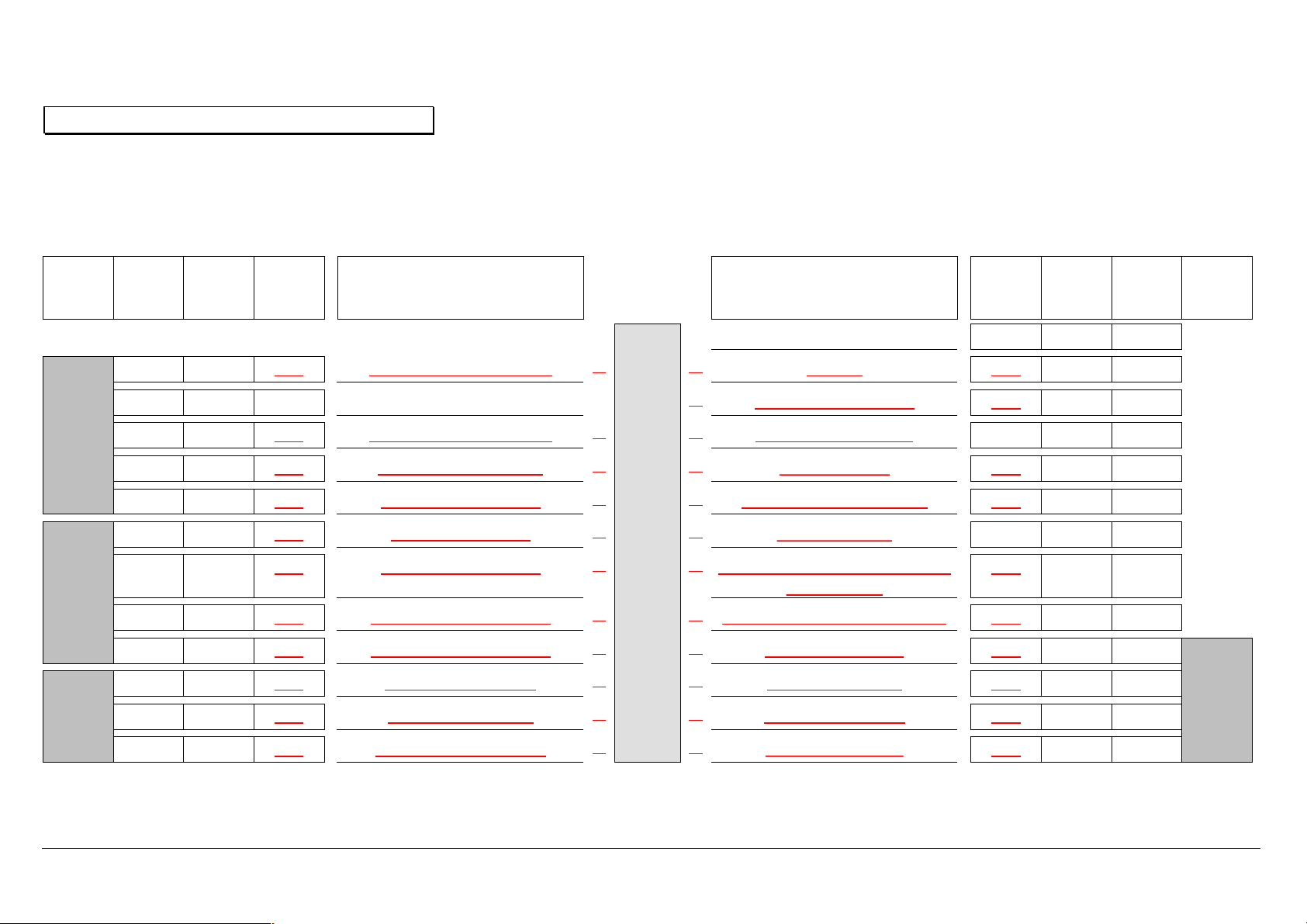

Operation Transmitter Actual values Transmission Receiver Actual values

Evaluation of shift logic FR - - - - - - FR

Select: open clutch FR

16, 82, 83, 86

- - - GS

96, 100, 114, 117

Reduce engine torque FR

Open clutch GS

14, 15

039

- - - MR

- - - Y39.1/Y39.2

B2

Perform gear change GS

288-297

- - - Corresponding

solenoid valves

Adjust engine speed MR

Current gear position

feedback

B60, B61,

B62, B63

Display shifted gear GS

Close clutch GS

004, 006, 034

- - - Y6-Y13 - - -

- - - - - - GS

156 FR

287

- - - Y39.1/Y39.2

INS - - -

B2

Increase engine torque FR

14, 15

- - - MR

113, 114

157, 287, 307

01, 02

221, 223

- - -

35-39

- - -

004, 006

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR Information exchange on gear shifting EAS ACTROS, models 930-934; exercise

19

EAS II - (Code GE2), information exchange and actual values, exercise 29.10.2003

The control units are networked together by a

linear bus structure using the CAN bus network

between the electronic systems of the engine

control and the on-board systems (GS, INS, etc.).

A control unit receives a measured value from a

sensor, from which it generates a data telegram

and puts in on the data bus, where it is available

to all the control units connected to the CAN bus.

The control electronics control and monitor the

entire GS system gear change sequence.

The control electronics receive information from

the system's own sensors and switches (travel

sensors and speed sensors) and also via the CAN

interface of other vehicle systems.

The corresponding solenoid valves are actuated

for shifting the gears. Data are exchanged with

other electronic circuits via the CAN interface.

The shifted and preselected gears and also the

events and text messages are displayed to the

operator in the instrument.

X13

Y44

G2

B17

B65

S2

S1A42

P3

B66

B1

Y1

CAN 10MTCO

B28

A15

Y2

INS

P2

RS

A20

CAN 4

MRA6FLA

A68 A82

FR

A3

A4

ASIC

CAN 2

CAN 1

PSM

A22

CAN 5

B10 B15 B16 B65 B111

BS

A11

K

GS

A16

GM

A7

CAN 3

HM

A65

B2 B3 B57 B99

B60 B61 B62 B63

Y29

Y34 Y35 Y36 Y37 Y38

Y30 Y31 Y32 Y33

Y39.1 Y39.2 Y39.3 Y39.4

S144 S145B5

Y6-13 M1

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), information exchange and actual values, exercise

B11 B12 B14

S10 S11 S166

PPT

20

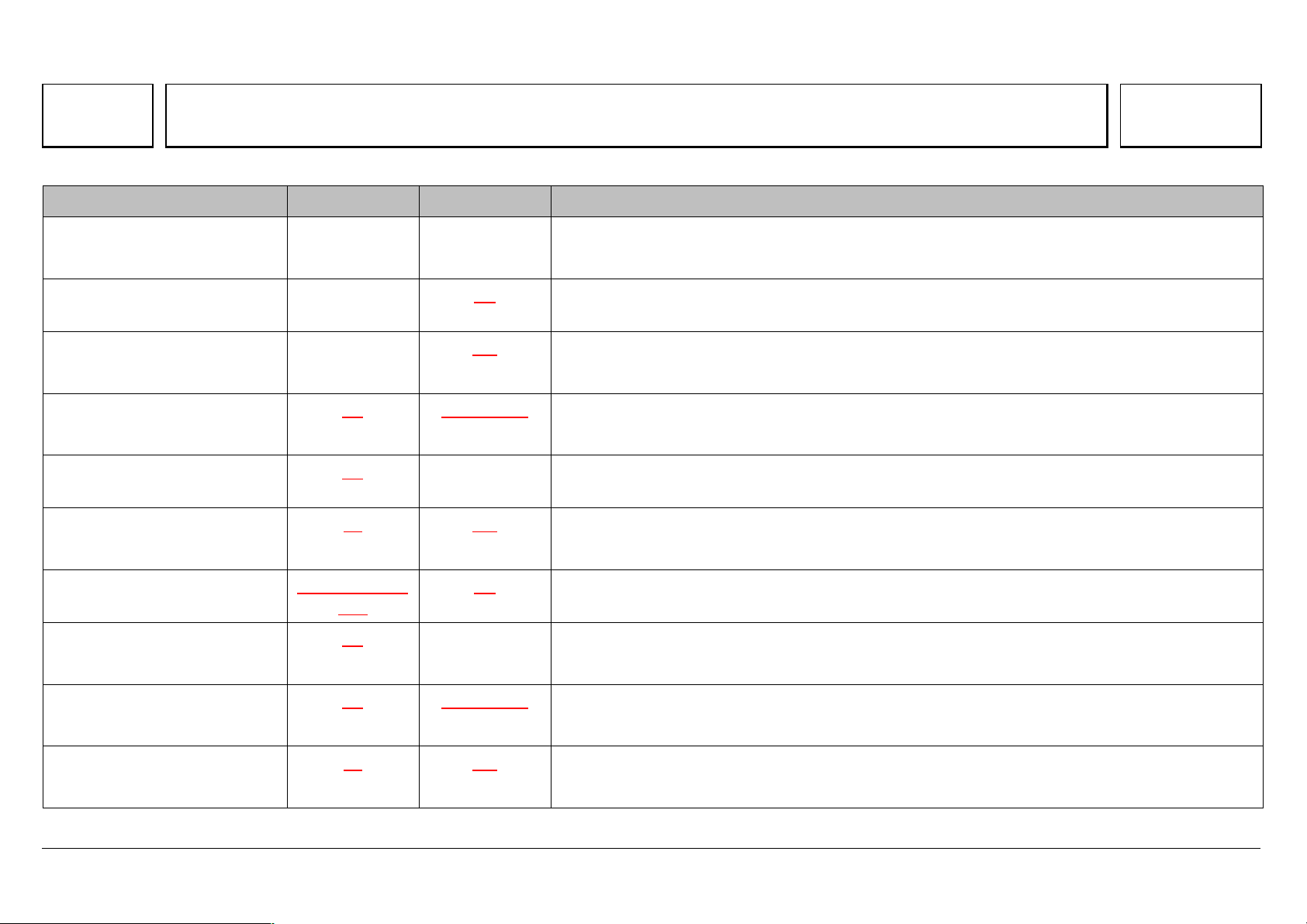

Task

m The diagram shows the GS electronic circuits and those components directly connected. The details

are based on the given vehicle, an Actros with Telligent automatic transmission and all-wheel function.

1. First complete the information exchanged and the direction of information between the relevant

components.

2. Secondly complete the actual value (IW) number that goes with the relevant information.

Use GF 26.20-W-0007MP.

Module IW Information Information IW Pin Com-

ponen

A92

A90

Y35 MUB

290 Actuation of uneven gear

Y37 MUE 291 Actuation of uneven gear

Y36 MGB

Y38 MGE

B60

Y29 MG1

Y30 MG2

292 Actuation of uneven gear

293 Actuation of even gear

036 Gear cylinder position

294 Actuation of gate R

295 Actuation of gate 3/4

ç

ç ç

ç ç

ç ç

ç

A16

è ç

ç

GS

ç ç

ç

ç

Transmission output speed with

GS backup mode 308 P2

V signal 037

Gate cylinder position 035

Split cylinder position

Clutch position 039

Transmission input speed 021

Oil temperature

221

P3

B61

B62

B2

B3

B47

B99

transfer case

è è

è è

ç è

ç è

Detection of direction of travel 281

Open clutch - rapid 298

Open clutch - slow 298

Close clutch - rapid 298

B57

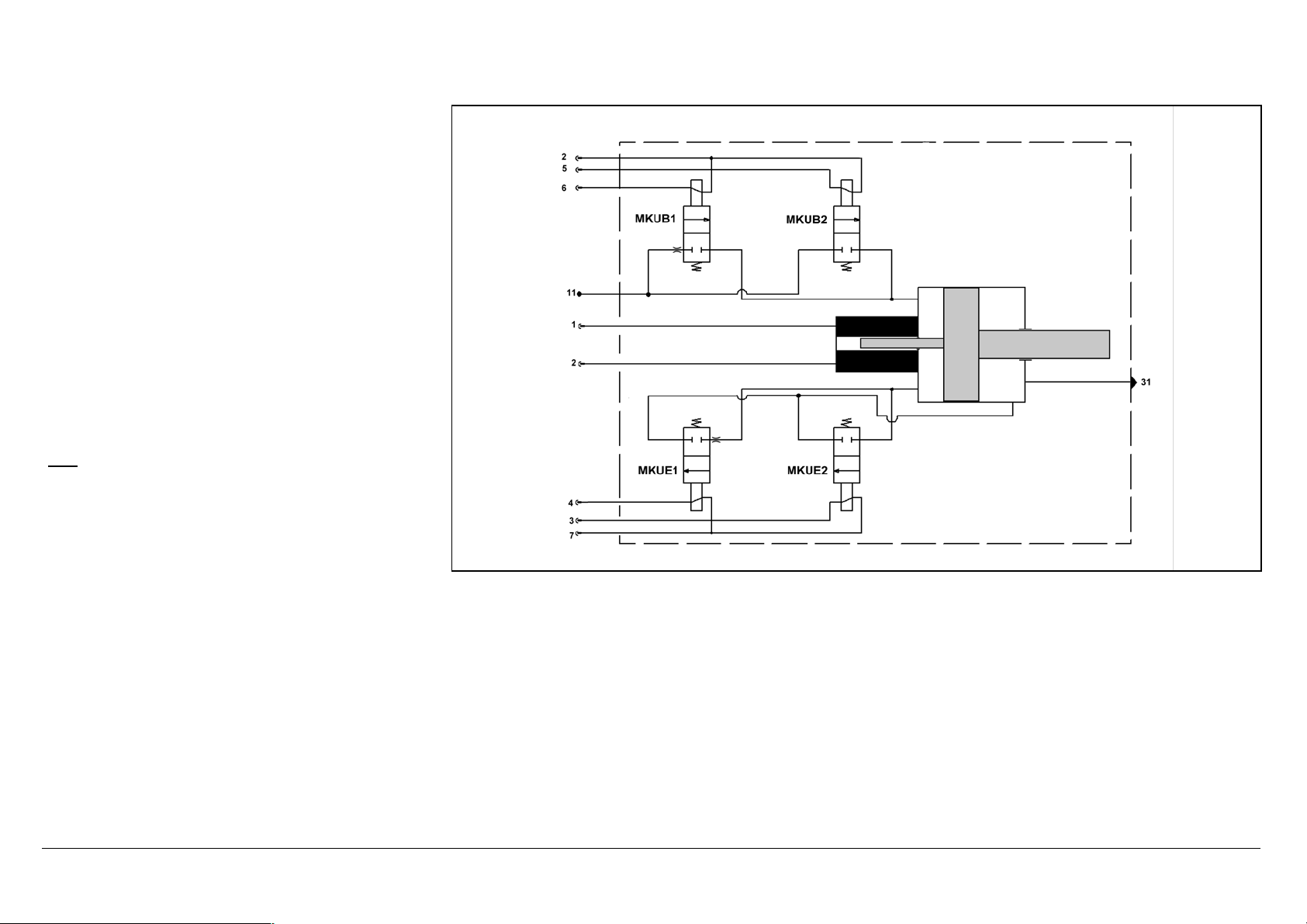

MKUB1 A39.1

MKUB2 A39.2

MKUE1 A39.3

A91

Y33 MS1

Y34 MS2

Y31 MR2

Y32 MR1

288 Actuation of splitter L/H

289 Actuation of splitter L/H

297 Actuation range high

296 Actuation range low

Module

t

A93

B63

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), information exchange and actual values, exercise

038 Range cylinder position

è è

Close clutch - slow 298

MKUE2 A39.4

21

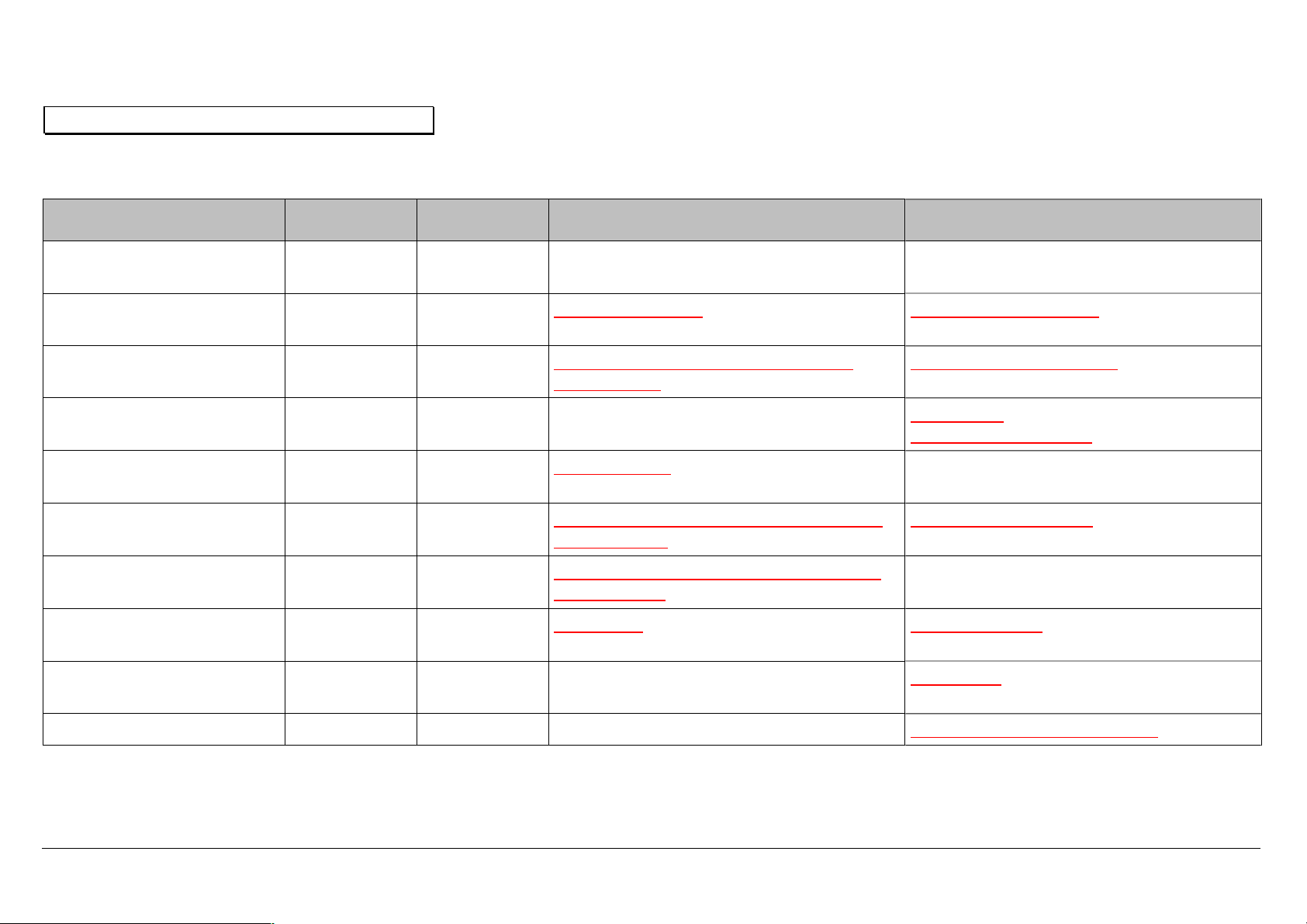

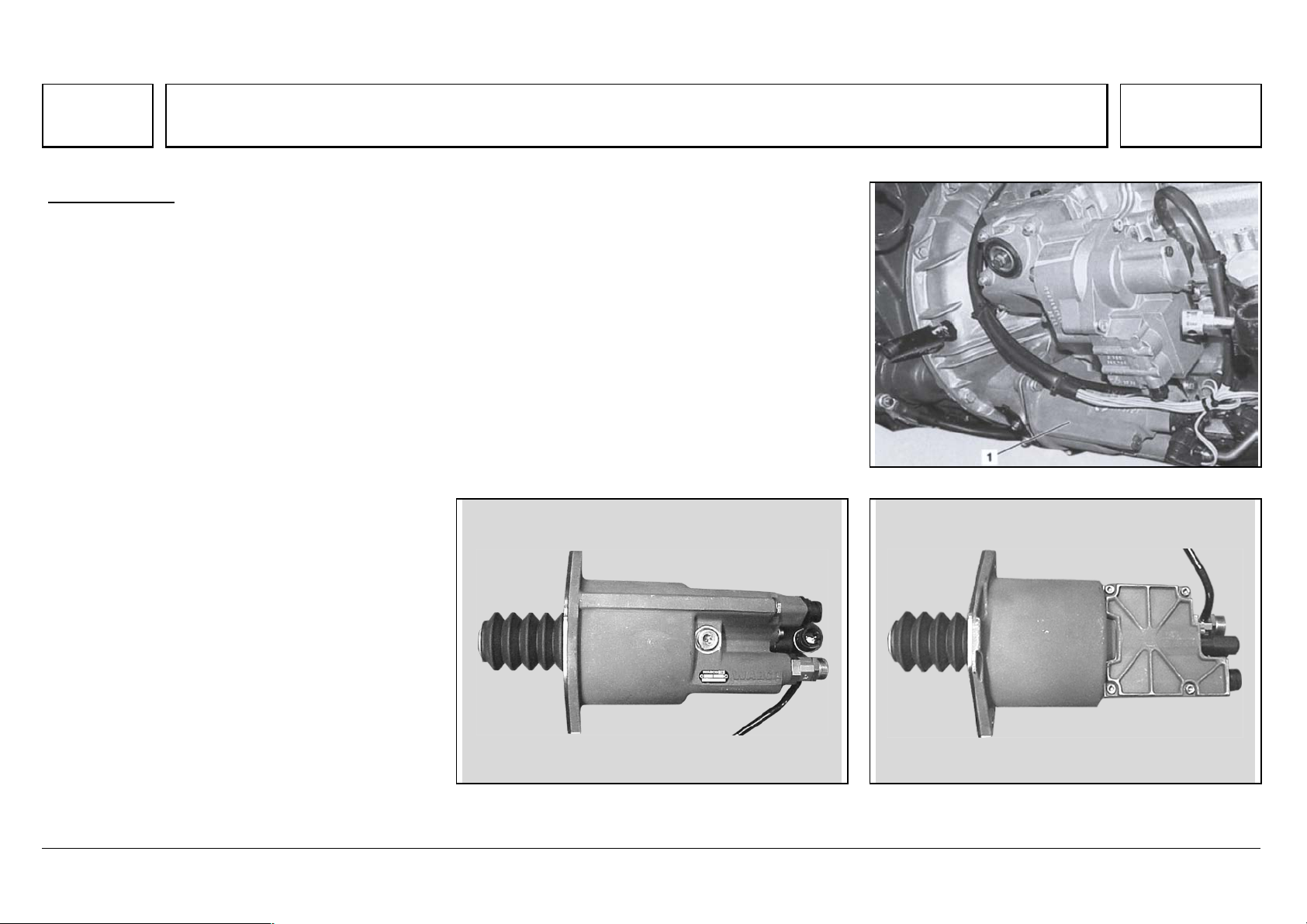

EAS II - (Code GE2), components 29.10.2003

Clutch actuator

The tasks of the clutch actuator are as follows:

· To convert the electrical control signals in the pneumatic control of the actuator cylinder

· To record clutch travel and provide an electrical signal

· To operate the mechanical clutch system

The following components are integrated in the clutch actuator:

· Solenoid valves: Clutch aeration 1, Clutch aeration 2,

Clutch bleeding 1, Clutch bleeding 2

· Clutch travel sensor (B2)

· Actuator cylinder

W25.20-1018-11 (GT_25_20_0010)

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), components

N25.20-2064-01 N25.20-2063-01

22

The clutch actuator directly operates the

mechanical clutch system.

Each of the clutch positions can be moved to and

retained by means of the four solenoid valves.

This basic principle applies:

Cylinder extended ® Clutch open

Cylinder retracted ® Clutch closed

The clutch travel sensor (B2) records the current

position of the clutch actuator.

Key:

MKUB1 Solenoid valve, aerate clutch with throttle

MKUB 2 Solenoid valve, aerate clutch

MKUE 1 Solenoid valve, bleed clutch with throttle

MKUE 2 Solenoid valve, bleed clutch

The four solenoid valves are necessary to properly control the inward and outward flow of compressed air used to move the cylinder.

MKUB2 and MKUE2 have a large air passage and are used to roughly regulate the clutch travel.

MKUB1 and MKUE1 work with a smaller flow area and are used for fine adaptation and very precise positioning during clutch actuation.

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), components

GT25_00_0001

23

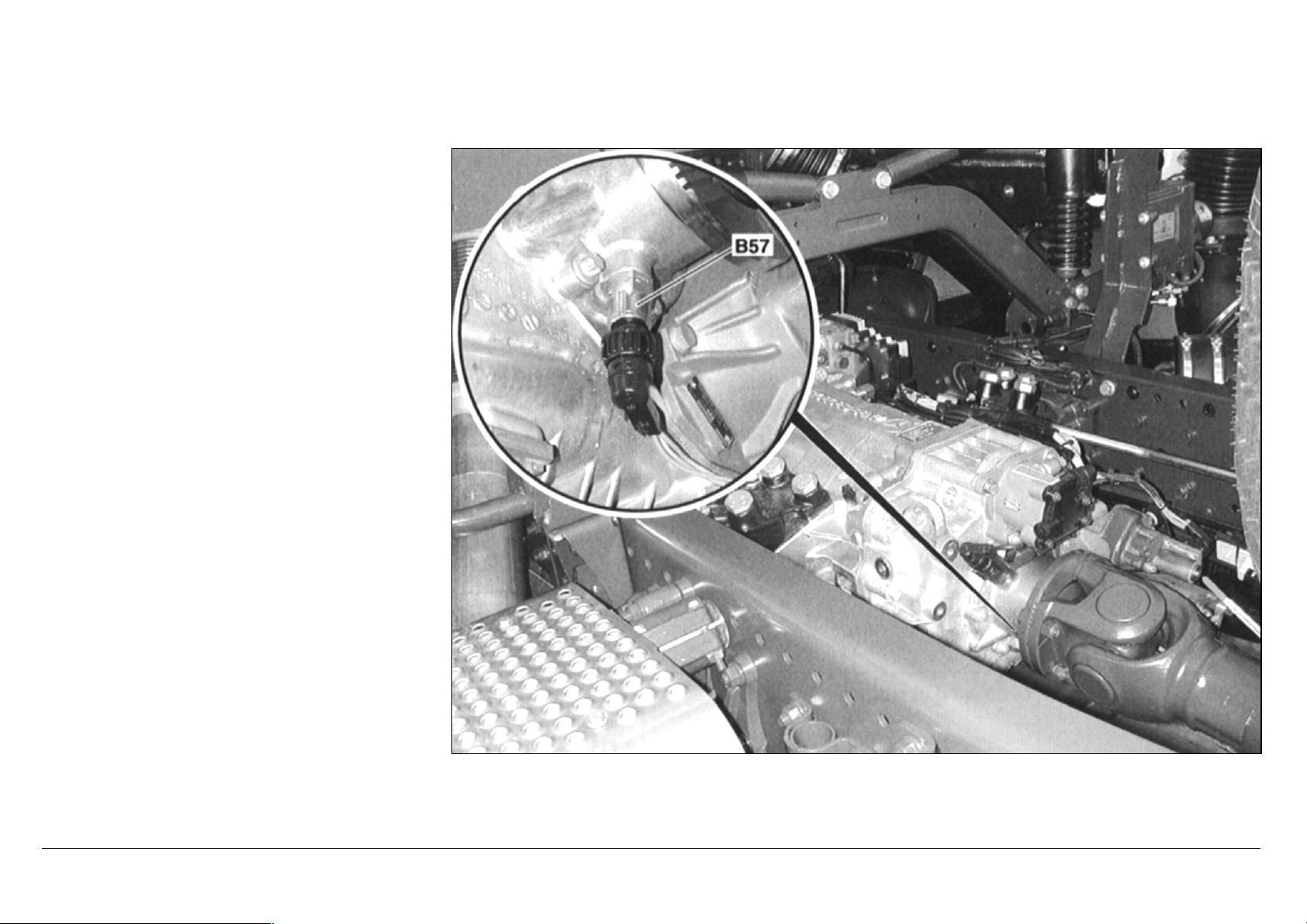

Transmission output speed sensor (B57, B99)

The task of the transmission output speed sensor

is as follows:

· To record the transmission output rpm

DZ1/DZ2

The additional recording of the transmission

output rpm is needed to detect the direction of

rotation.

The transmission output speed sensor (B57) is

installed in all vehicles with Telligent automatic

transmission II.

Vehicles with Telligent automatic transmission II

require direct recording of the transmission

output rpm.

This is because the speed sensor (B17) has been

moved to the transfer case output.

For this reason the transmission output speed

sensor (B99) is only additionally used on vehicles

with Telligent automatic transmission II and allwheel drive.

10/03 Trucks • Transmission <> Telligent automatic transmission in ACTROS and ATEGO <<>> Specialist training

TR EAS II - (Code GE2), components

W26.19-1026-06 (GT_26_20_0019)

24

Loading...

Loading...