McIntosh MR-500 Owners manual

Contents

SERVICE CONTRACT INFORMATION 1

INTRODUCTION 2

INSTALLATION 3, 4

BACK PANEL CONNECTIONS

USING THE FRONT PANEL

HOW THE CIRCUITS WORK 9, 10

PERFORMANCE CHARTS. . . .12, 13

AND CONTROLS 5, 6

CONTROLS 7, 8

PERFORMANCE LIMITS 11

BLOCK DIAGRAM 14

FM STATION LOG 15

The Mclntosh compact Family

TUNER

FM

DIGITAL

MR 500

The MR 500 Digital FM Tuner complements the performance and appearance of all Mclntosh products. It

is specifically designed to match the industry's

leading compacts — the Mclntosh MC 502 Power Amplifier and the Mclntosh C 504 Preamplifier. Separate,

flexibile Mclntosh quality components that are particularly useful where space is limited.

1

The MR 500 FM Tuner is designed to

perform to its specifications for many

years. If you have any questions, please

contact:

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903-9990

Phone: 607-723-3512

Take Advantage of 3 years of

Contract Service...

Fill in the Application NOW.

MclNTOSH THREE YEAR SERVICE CONTRACT

An application for A THREE YEAR SERVICE CONTRACT is included with this manual.

The terms of the contract are:

1. Mclntosh will provide all parts, materials

and labor needed to return the measured

performance of the instrument to the

original performance limits. Because

battery life is dependent on conditions

over which Mclntosh has no control,

they are not covered under the service

contract, nor is any shipping cost to and

from the authorized service agency or

the factory.

2. Any Mclntosh authorized service agency

will repair Mclntosh instruments at nor-

mal service rates. To receive service

under the terms of the SERVICE CONTRACT, the SERVICE CONTRACT CERTIFICATE must be presented when the

instrument is taken to the service agency.

3. Always have service done by a

Mclntosh authorized service agency. If

the instrument is modified or damaged

as a result of unauthorized repair, the

SERVICE CONTRACT will be cancelled.

Damage by improper use or mishandling is not covered by the SERVICE

CONTRACT.

4. The SERVICE CONTRACT is issued to

you as the original purchaser. To pro-

tect you from misrepresentation, this

contract cannot be transferred to a second owner.

5. To receive the SERVICE CONTRACT,

your purchase must be made from a

Mclntosh franchised dealer.

6. Your completely filled in application for

the SERVICE CONTRACT must be postmarked within 30 days of the date of

purchase of the instrument.

7. To receive the SERVICE CONTRACT, all

information on the application must be

filled in. The SERVICE CONTRACT will

be issued when the completely filled in

application is received by Mclntosh

Laboratory Incorporated in Binghamton,

New York.

8. Units in operation outside the United

States and Canada are not covered by

the Mclntosh Service Contract, irrespective of the place of purchase. Nor

are units acquired outside the U.S.A.

and Canada, the purchasers of which

should consult with their dealer to

ascertain what, if any, service contract

or warranty may be available locally.

Copyright 1983 (C) by Mclntosh Laboratory Inc.

2

Installation

any position. The recommended minimum space for

adequate ventilation is 17 inches (43.2 cm) wide, and 4

1/2inches (11.4 cm) high, 15 inches (38.1 cm) deep.

To install the instrument in a Mclntosh cabinet,

follow the instructions that are enclosed with the

cabinet. For any other type of installation follow

these instructions:

1. Unpack from carton

Open the carton and remove the PANLOC brack-

ets, hardware package, and mounting template from

the carton. Remove the MR 500 from its plastic bag

and place it upside down on the shipping pallet;

then unscrew the four plastic feet from the bottom

of the chassis.

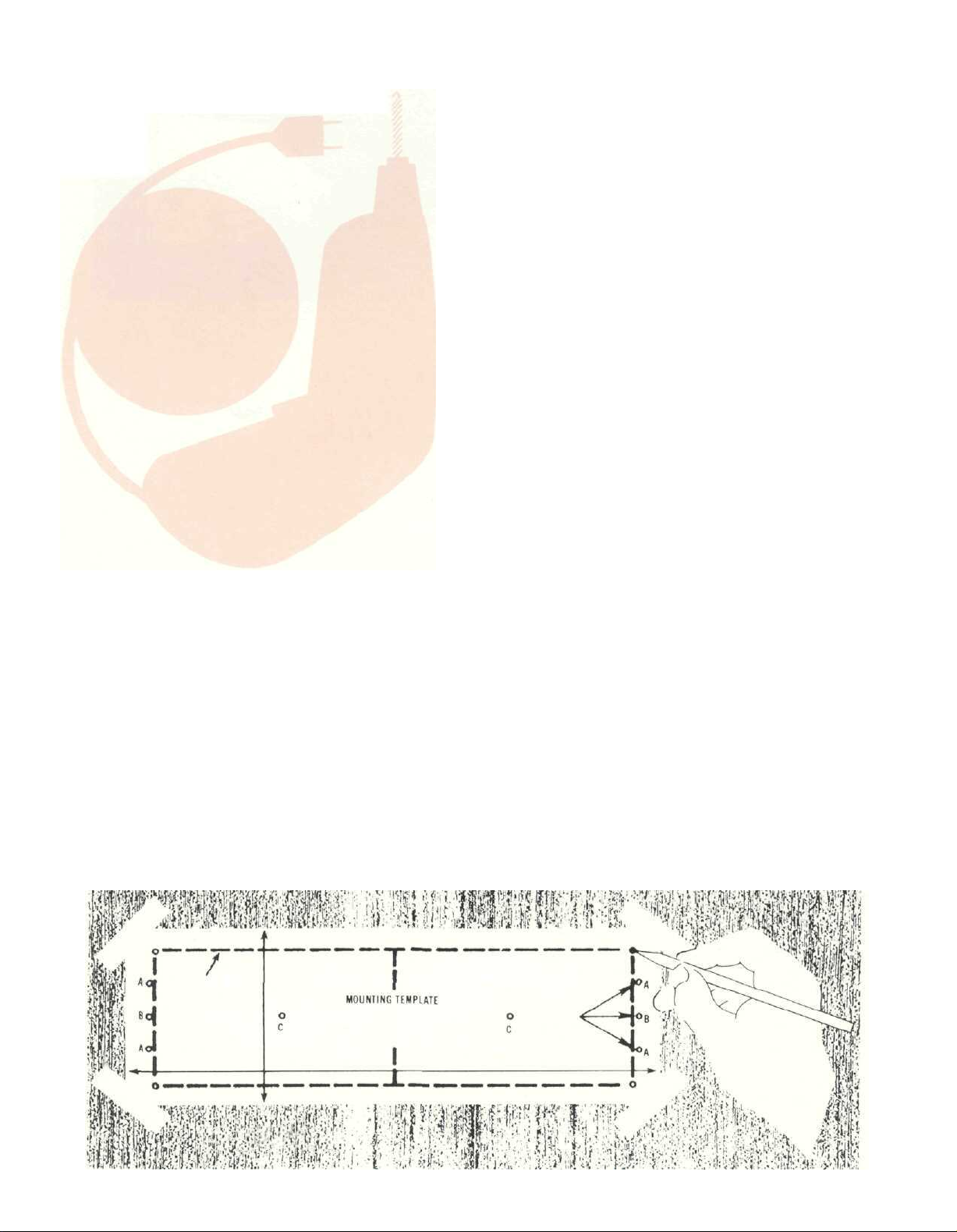

2. Mark the cabinet panel

Place the mounting template in the position on

the cabinet panel where the instrument is to be in-

stalled, and tape it in place. The broken lines that

represent the outline of the rectangular cutout also

represent the outside dimensions of the chassis.

Make sure these lines clear shelves, partitions, or

any equipment. With the template in place, first

mark the six A and B holes and the four small holes

that locate the corners of the cutout. Then, join the

four corner markings with pencil lines, using the

edge of the template as a straigtedge.

The PANLOC system of installing equipment

conveniently and securely is a product of Mclntosh

research. By depressing the two PANLOC buttons on

the front panel, the instrument can be either locked

firmly in place or it can be unlocked so that the

chassis can slide forward, giving you easy access to

the top and rear panels.

The trouble-free life of an electronic instrument is

greatly extended by providing sufficient ventilation to

prevent the build-up of high internal temperatures that

cause deterioration of component parts. You should allow enough clearance so that cool air can enter at the

bottom of the cabinet and be vented from the top. With

adequate ventilation the instrument can be mounted in

3. Drill Holes

Use a drill with a 3/16 inch (5 mm) bit held perpen-

dicular to the panel and drill the six A and B holes.

Then, using a drill bit slightly larger than the tip of

your saw blade, drill one hole at each of two

diagonally opposite corners. The holes should barely touch the inside edge of the penciled outline.

Before taking the next step, make sure that the six A

and B holes have been drilled.

4. Saw the Panel Cutout

Saw carefully on the inside of the penciled lines.

First make the two long cuts and then the two short

cuts. After the rectangular open ing has been cut out,

use a file to square the corners and smooth any

irregularities in the cut edges.

3

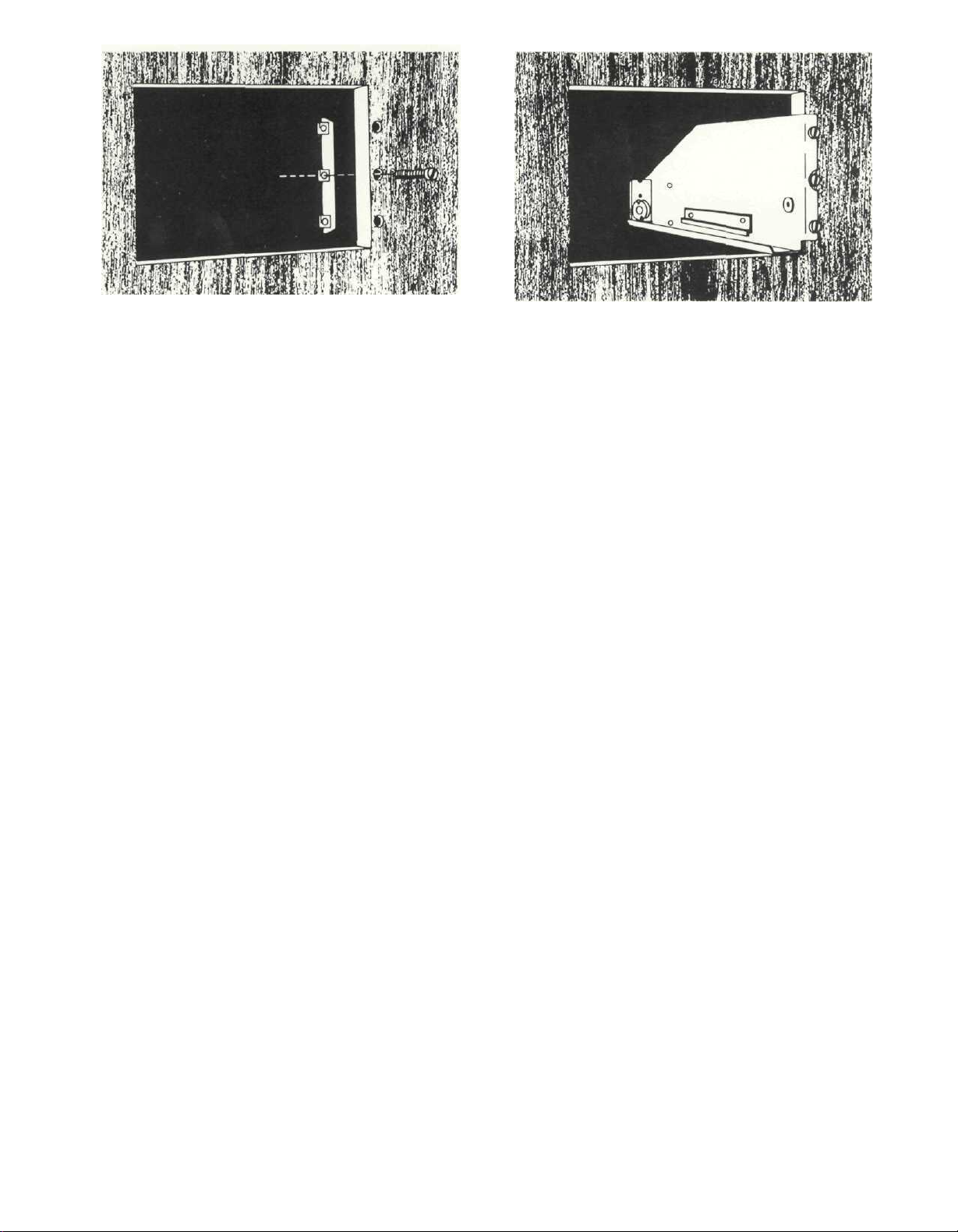

5. Install the Mounting Strips

In the hardware package you will find two mount-

ing strips and two sets of machine screws. For

panels that are less than 1/2 inch (12.7 mm) thick,

use the 3/4 inch (19.1 mm) screws; for panels that are

more than 1/2 inch (12.7 mm) thick, use the 1 1/4 inch

(31,8 mm) screws.

Starting at the right-hand side of the panel, insert

a screw of proper length into the center hole in the

panel, marked B on the template. On the back of the

panel, align a mounting strip with the holes in the

panel and tighten the screw in the center hole until

the screwhead is pulled slightly into the wood.

Repeat this procedure to attach the mounting

strip to the left side of the panel.

6. Attach the PANLOC Brackets

Use two screws of the proper length in the A holes

on each side, attach the PANLOC brackets to the

cabinet panel; the short flange is mounted against

the front (face) of the cabinet panel. The screws

pass through the PANLOC bracket flange, the

cabinet panel, and then through the mounting strips

previously mounted.

7. Install the Instrument

Guide the AC power cord through the panel open-

ing to the back of the cabinet. Then, slide the instru-

ment into the opening, carefully, so that the rails on

the bottom of each side of the chassis engage the

tracks on the mounting brackets. Continue to slide

the instrument into the cabinet until it is stopped by

the adjust position latches. Press the latches inward, this permits the instrument to slide into the

cabinet until its front panel is flush with the cabinet

panel. Depress the PANLOC buttons at the lower left

and right corners of the instrument panel to lock the

unit firmly in the cabinet. Depressing the PANLOC

buttons again will unlock the instrument so that it

can slide to the adjust position; if you press inward

on the adjust position latches then you can remove

the instrument from the cabinet.

4

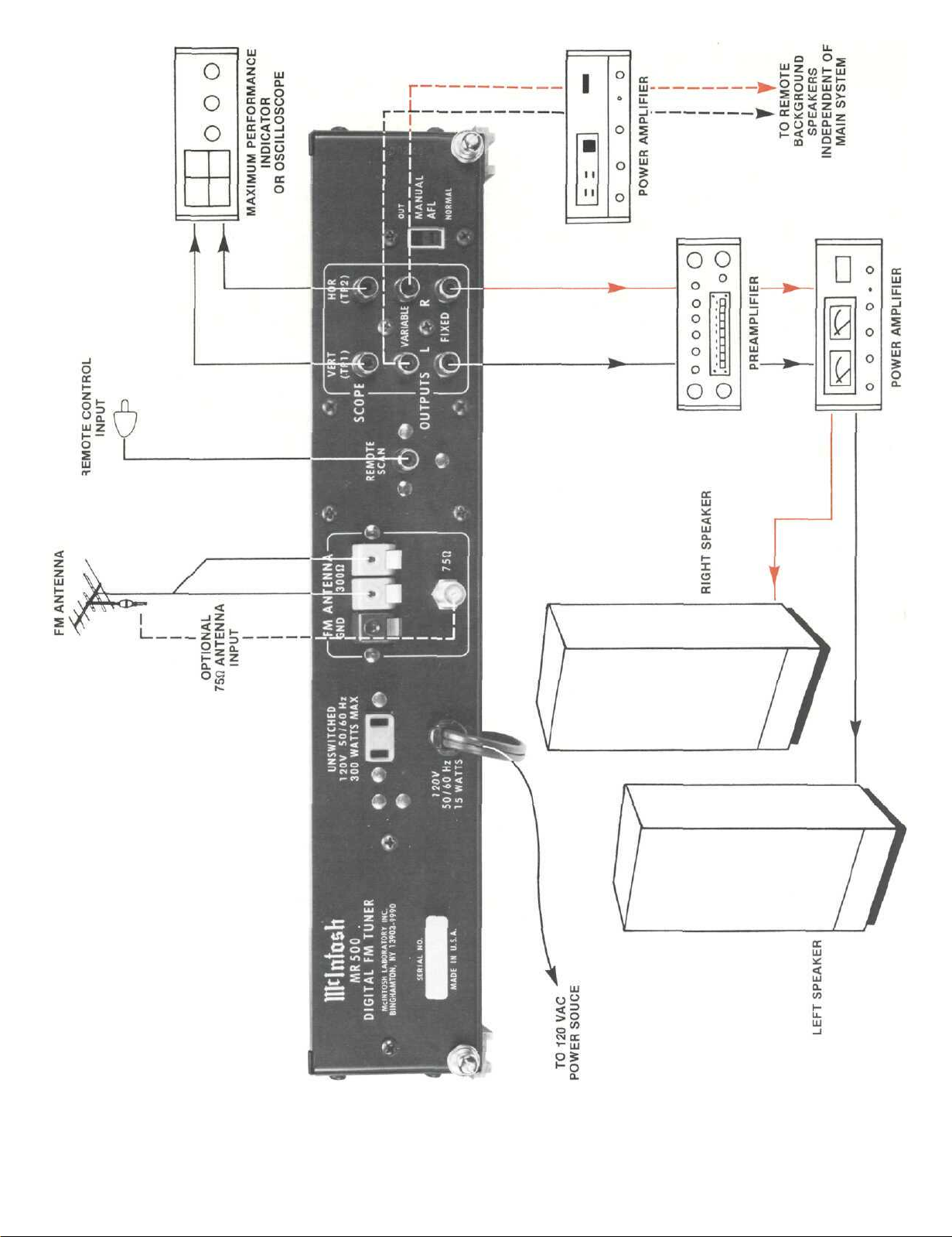

Back Panel Connections and Controls

Use of the back panel connections and controls

will be described from right to left when looking at

the back panel.

MANUAL AFL

Automatic Frequency Lock (AFL) is a Mclntosh

design which assures that the station remains ideal-

ly tuned regardless of any influences that might

cause the station to drift. Because the AFL circuit

does not affect the high quality performance of the

MR 500, the switch should be used in the NORMAL

position. There may be occasions when it would be

desirable to deactivate the AFL circuit for manual

tuning. With the MANUAL AFL switch in the OUT

position, and when using the tuning knob, the AFL

circuit is disabled. The AFL circuit is always active

when the SCAN tuning and the feather touch preset

station selection push buttons are used.

AUDIO OUTPUTS

Use the FIXED OUTPUT jacks on the rear panel to

connect the MR 500 to a stereo control preamplifier

or other equipment which has its own volume control. The position of the VOLUME control does not

affect the loudness of the tuner at the FIXED OUT-

PUT jacks. The output level is 1 volt for 100% FM

modulation.

Use the VARIABLE OUTPUT jacks to connect to

equipment such as a power amplifier or a tape

recorder where control of the volume is to be at the

tuner. With the VOLUME control turned completely

clockwise, the output at the VARIABLE OUTPUT

jacks is 2.5 volts for 100% FM modulation. There is

no difference in the signal quality at either of the

pairs of output jacks; and, both pairs may be used

simultaneously. The output impedance is very low

so that long audio cables can be used without a loss

of high frequencies due to cable capacity.

SCOPE

The vertical and horizontal SCOPE jacks are pro-

vided to connect to a maximum performance indicator or an oscilloscope which can then indicate

FM multipath and signal strength. Connect the ver-

tical jack to the vertical input of the indicator and

the horizontal jack to the horizontal input.

REMOTE SCAN

The REMOTE SCAN jack provides an input for the

cable push button assembly supplied with the

MR 500. Plug the cable into the REMOTE SCAN jack

to provide SCAN tuning at a convenient location

remote from the tuner. If REMOTE SCAN tuning is

not used, leave the jack free of any connection.

CONNECTING AN FM ANTENNA

One of three antenna systems can be used: (1) an

outdoor FM antenna, or (2) a VHF-TV antenna, or (3)

the indoor dipole supplied.

An outdoor antenna is recommended for optimum

performance in all areas. For best results in fringe

(outlying) areas, use a highly directional FM antenna

in conjunction with a rotator. If the antenna uses a

300 ohm down lead, connect it to the ANTENNA

300ohm

reception can be effective. Connect the down lead

from the VHF-TV antenna to the ANTENNA 30012 FM

push connectors.

na connects to the rear panel ANTENNA 75ohm FM

type F coaxial connector.

antenna for use in urban or high strength signal

areas. Connect it to the ANTENNA 300ohm FM push

connector. The flexibility of the twin flat wire

assembly permits it to be placed under a rug, tacked

behind the stereo or placed in any other convenient

location. In some cases, it may be necessary to

"position" the antenna for best signal reception. Do

this before it is permanently located. Avoid locating

the antenna next to other wires or metal objects. Any

indoor antenna may be ineffective in houses having

metal siding or metal foil insulation.

120V AC OUTLET

watts available for additional equipment that has its

own AC power switch. The outlet is not fused.

AC POWER CORD

Hz power line receptacle. The power used by the

MR 500 is 15 watts.

FM

push connectors.

A VHF-TV antenna designed for both FM and TV

The coaxial cable of an unbalanced 75 ohm anten-

Supplied with the tuner is a flexible folded dipole

Provides a 120 volt AC power outlet with up to 300

Connect the AC power cord to a 120 volt, 50 to 60

5

6

Loading...

Loading...