Page 1

THE BIG SOLDER JOINT

Sometimes in our high fidelity

industry it seems like if you want

to attract attention to a product or

a listening experience, the best

way to do it is to concoct a new bit

of technical jargon or say that

"the listening panel" decided this

or that. Contractions and

acronyms run rampant. One

begins to feel like an outsider if he

doesn't know what CD, DAD, THD.

SID, TIM, AFC, LSI, VHP, MPX,

RF, or some other combination of

the alphabet means. Confusion

reigns for many if not all.

On the other hand, once in a

while a statement is made that

makes one stop short and think

about how the statement compares with practical experience.

One such statement recently overheard was made by a well respected and experienced recording engineer. He stated that

loudspeaker leads must not be

spliced by soldering two sections

of lead together. He stated

"soldered connections produce

distortion". Further, "anyone" can

hear the difference between a

"soldered connection" and a mechanically "clamped connection".

At first though one might prefer

to pooh-pooh the statement. After

all, how many solder connections

are there in the electronics between the microphone to recorder,

and from the playback device

through the amplifier to the

speaker. Amplifiers have tens, hun-

dreds, perhaps even thousands of

solder connections. Power transistors have their chips soldered

to their heat sinks internally.

Loudspeakers have the voice coil

leads soldered to other leads.

Crossover networks have soldered

connections. So why worry about

soldered connections?

On the other hand, speaker

leads might be special. Some feel

the bigger the better, so maybe a

little solder might introduce some

kind of "impedance" or some such

thing. Let's think about it.

First, to make a good solder

joint, one is suppose to make a

IF,

good mechanical connection. The

wires to be joined are to be clean

so solder can adhere. The wires

are then soldered. Solder, made of

tin and lead, has a much higher

resistance than copper wire. The

resistance is about 9 times as

much for the same cross sections

and length. It is hard to say how

thick the solder is in a well made

solder joint, but you can easily

estimate that it most certainly is

less than say three times the

thickness of the paper this is written on, which would be 1/100th of

an inch. Therefore, the resistance

of a solder joint joining two copper

wires would be no more than the

resistance of adding an additional

lenght of copper wire 9/100th of an

inch long to the circuit. This

sounds negligible.

But some might say, well, solder

isn't like copper. The resistance

might be non-linear, and this will

cause distortion. We decided to

test for non-linearity in solder.

There might be all kinds of

solder joints, some bigger than

others. We decided to make a

solder joint that really had a lot of

solder. We made the joint real

long. Verrrrrry loooooong. We

determined that 6 feet of #20 wire

gauge Ersin 63/37 multicore wire

solder measures 0.5 ohm.

Therefore, we selected a length

sixteen times as long, or 96 feet, to

form an 8 ohm solder test resistor.

This was used to represent a

ridiculously huge "solder joint".

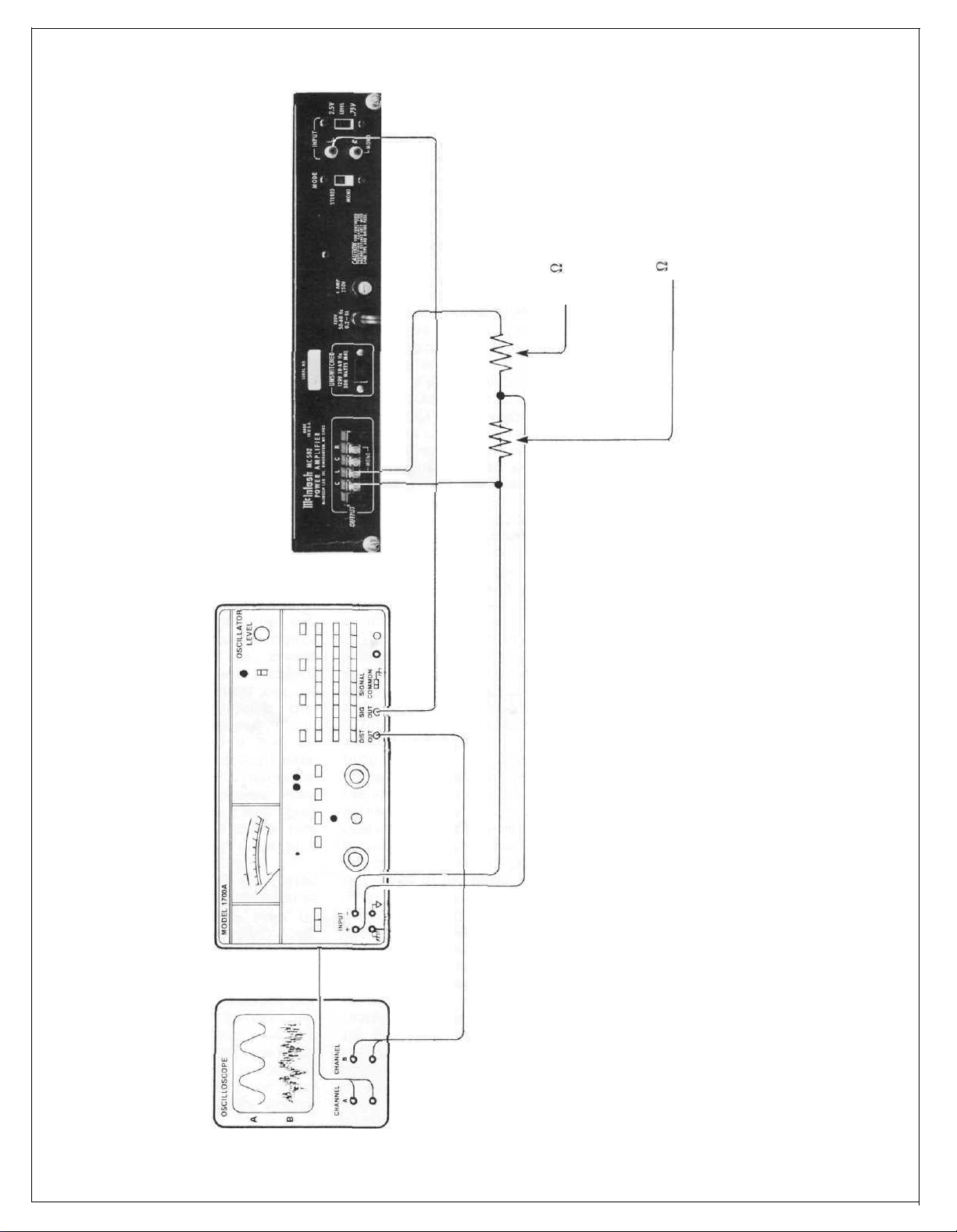

How do you test a "solder joint"?

We used a Mclntosh MC-502 power

amplifier and Sound Technology

1700A Distortion Analyzer. First we

tested the Sound Tech 1700A,

oscillator output to analyzer input.

The total harmonic distortion (THD)

measured 0.0016% at 1 kHz, the

residual limit for the instrument.

Next, we fed the test signal through

the MC-502 to an 8 ohm non-

inductive dummy load. The THD

measured the same, 0.0016%. We

also tested the MC-502 into an open

circuit and into 16 ohms with the

same result, 0.0016%.

Next, we made a voltage divider

of the 8 ohm "solder joint" 96 foot

length of solder and the 8 ohm noninductive load resistor. We fed the

MC-502 into the divider, which gave

a 16 ohm load to the amplifier, and

placed the distortion analyzer

across the 8 ohm non-inductive

resistor. The output to the analyzer

was attenuated to 1/2 (or by 6 dB)

by the divider, so the analyzer had

to be readjusted for "set level".

Surprise of surprises, the

analyzer indicated 0.1% distortion! Someone is correct, solder is

no good! But wait, what kind of

distortion is it? An oscilloscope

across the analyzer output might

show. Viewing the scope quickly

indicated the trouble. The "distortion" was our local AM station at

680 kHz being picked up by 96 feet

of solder spread out about the lab

bench.

To revise the "solder joint" we

wound the 96 feet of solder on a

plastic bobbin. Solder is bare so it

was necessary to insulate the

turns which was easily done by

winding an insulated copper wire

simultaneously with the solder,

making a bifilar winding. The

layers were insulated using mask-

ing tape. The finished coil looked a

bit like a toroid coil 3 inches in

diameter and 2 inches wide. The

copper wire was connected to the

end of the solder wire so that the

current flowing in the solder was

moving in the opposite direction to

the current moving in the copper

wire right next to it. This, of course,

has the effect of cancelling the

magnetic fields and cancelling the

susceptibility of the coil to any

radiated fields, such as that from

the AM radio station. The new coiled "solder joint" was tested. This

time, lo and behold, we measured

0.0016%.

If we had stopped with the first

test, we might have concluded that

the world is wrong and that solder

is a "no-no". Testing further

proves to us that solder is perfectly

OK and suggests we must be

careful how we view what we hear.

Page 2

JOINT"

GAUGE SOLDER

"SOLDER

8

96' OF 20

INDUCTIVE

NON

LOAD RESISTOR

8

SET UP

MEASURING TEST

DISTORTION

Loading...

Loading...