Page 1

Electrolux Outdoor Products

Via Como 72

23868 Valmadrera (Lecco)

ITALIA

Phone +39 0341 203111 - Fax +39 0341 581671

www.electrolux.com/mcculloch - www.electrolux.com/partner

Our policy of continuous improvement means that the specification of products may be altered from time to time without prior notice.

Electrolux Outdoor Products manufacture products for a number of well known brands under various registered patents, designs and

trademarks in several countries.

© Electrolux Outdoor Products Italy

The Electrolux Group. The world’s No. 1 choice

The Electrolux Group is the world’s largest producer of powered appliances for kitchen, cleaning and outdoor use. More than 55 million

Electrolux Group products (such as refrigerators, cookers, washing machines, vacuum cleaners, chain saws and lawn mowers) are sold

PN 249342 REV. 02 (05/04)

each year to a value of approx. USD 14 billion in more than 150 countries around the world.

Page 2

A

14

1

2

16

20

19

7

10

4

3

8

17

15

11

9

12

13

D

1 ltr

10

15

20

5

2 Strokes

Engine totally

sintetyc oil or

Partner oil

50:1

2%

3

20 cm

100

200

300

400

1 ltr

10

20

4

5

McCulloch

oil

40:1

2,5%

25 cm

100

125

250

500

3

E1

18

6

21

B1

B2

B4 B5

B7

B8

5

18

A

22

21

B3

I

H

B6

F1 F3F2

B

B9

10

F4

F5

Page 3

G L1 L2

8T

8"

200 mm

a

d

c

30cc30cc

30cc

30cc30cc

b

H2H1

H3 H4 H5 H6

L3

M1

M2

L4 L5

M3

M4

M5

0,095"

2,4 mm

197"

5000 mm

538249345

249242

228204B

249242

I

N1

N2

O

Page 4

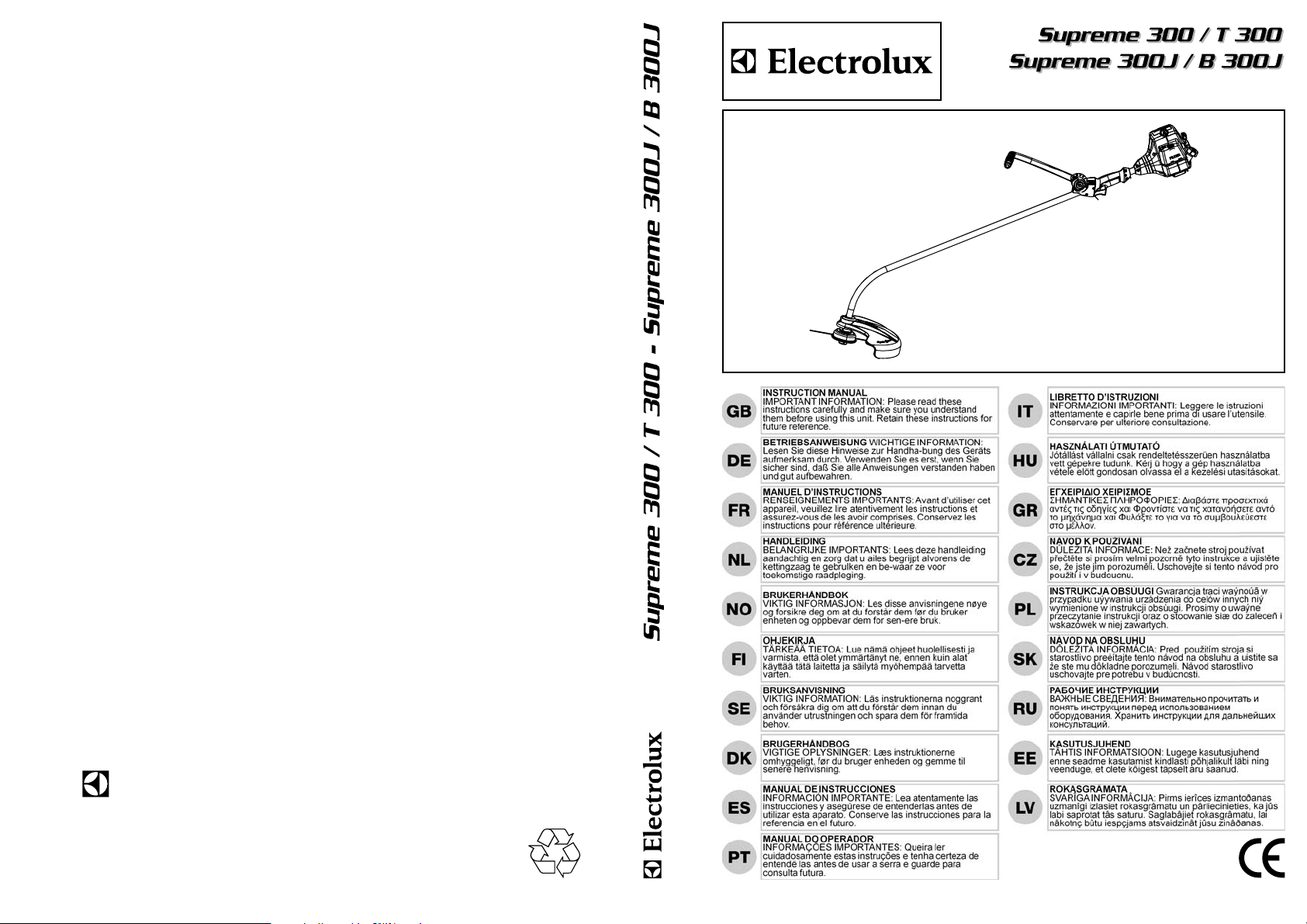

1) ENGINE

2) SHAFT

3) THROTTLE TRIGGER

4) GRIP ADJUSTMENT KNOB

5) BLADE

6) NYLON STRING HEAD

7) STOP SWITCH

8) FUEL ENRICHMENT LEVER

9) STARTER HANDLE

10) HARNESS RING

11) SPARK PLUG

Example of identification label

Meaning of symbols

Warning.

A. General Description

12) AIR FILTER COVER

13) FUEL TANK CAP

14) MUFFLER SHIELD

15) ENGINE/SHAFT JOINT

16) FRONT HANDLE

17) REAR CONTROL GRIP

18) SAFETY GUARD

19) SAFETY LEVER

20) SAFETY POLE GUARD

21) STRING CUTTER BLADE

22) BLADE GUARD

LEGEND:

1) Guaranteed noise level according to

directive 2000/14/EC

2) Manufacturer's name and address

3) Year of manufacture (last two figures; e.g.

03=2003)

4) Product code

5) Serial no.

6) Model/type

7) CE seal of conformity

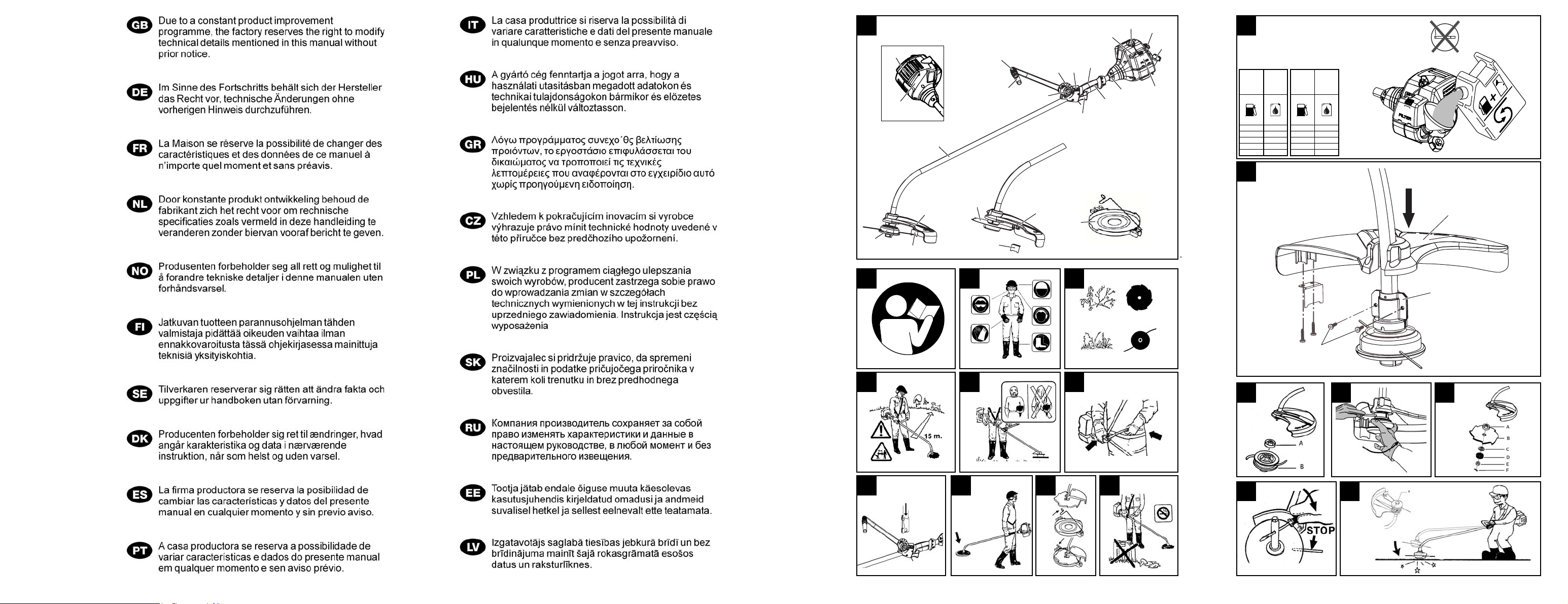

B. Safety precautions

Do not smoke when refueling or

using the machine.

Safety apparel: Approved

protective goggles or visor,

approved hard hat and hearing

protection,

Read the instructions for the user

carefully and make sure you

understand how all the controls

work.

Safety apparel: Approved gloves.

Safety apparel: Approved boots.

15 m

Fuel enrichment (starting aid).

Danger of flying debris.

Minimum safety distance 15m.

Emergency stop.

ENGLISH - 1

Page 5

Maximum shaft speed.

CAUTION!

Danger of serious leg injuries.

Take scrupulous care to follow the

instructions in the manual.

Danger of kickback. The blade is

capable of amputating arms and

legs.

Prior to use

• Do not use this machine for any other purpose

than that for which it was designed, using the

proper cutting devices as indicated in the

instructions.

• B1. Anyone who uses the machine should

have read the entire manual with extreme care.

• Make sure you know how to stop the engine

and blade if necessary (see section entitled

“Starting and stopping the engine”).

• All users should be familiar with the operations

for use of the machine under absolutely safe

conditions as described in this manual, and

should be instructed in the proper cutting

techniques to use, possibly by practical

demonstration.

• Do not use the machine if you are tired, in poor

health or under the effects of alcohol or

medication that could affect your reactions.

• Do not allow children or persons who are not

familiar with these instructions and are not

sufficiently trained to use the brush cutter.

Local regulations may specify an age limit for

users.

• Keep this manual with the machine when

selling or lending it, to enable the future users

to familiarize themselves with the product and

instructions for safe use.

• Always inspect the machine carefully prior to

use: make sure it is correctly assembled and

that there are no loose screws, damaged parts,

fuel leaks.

• Replace any accessories (blades, nylon string

heads, guards) which show damage or cracks

or appear excessively worn. Have your

Authorized Service Center replace any

damaged parts.

• Perform all operations of maintenance and/or

assembly ONLY with the engine off and

wearing gloves.

Apparel

• B2. Dress suitably for the job; wear approved

personal protection gear: a) Close-fitting

clothing (no shorts or loose clothes). b) Safety

boots with non-slip sole, crush-resistant toe

cap and protection against cuts (do not wear

sandals or work barefoot). c) Sturdy gloves

CAUTION!

The cutting parts and muffler may

get very hot and cause burns. Wait

a few minutes before touching

them.

resistant to cuts and vibrations. d) Safety visor

or protective goggles. Remove the protective

film if any. e) Hearing protection. The use of

personal protection gear does not eliminate the

risk of injury but may reduce the effect of the

damage in case of accidents.

• Do not wear loose clothing or jewelry that could

get caught in the moving parts of the machine.

• Watch out for the rotating parts and hot

surfaces of the machine.

Health precautions

CAUTION! Avoid prolonged use.

Noise and vibrations may be

dangerous.

• Prolonged use of the machine or other

equipment expose the operator to vibrations

that can cause the White Finger Syndrome

(Syndrome of Raynaud). This could reduce the

sensitivity of the hands in distinguishing

different temperatures and cause a general

numbness. The operator should therefore

check the conditions of the hands and fingers if

the machine is used continuously or regularly.

If one of the symptoms should appear, consult

a doctor immediately.

• Prolonged use of the machine or other

equipment can cause discomfort, stress,

fatigue, hearing damage. Wear suitable

hearing protection when using the machine.

Correct and scrupulous maintenance can also

help to protect you further from the risk of noise

and vibration.

• Never start or run the engine in a closed or

poorly ventilated place.

CAUTION! The exhaust fumes are

toxic if inhaled, and may cause

asphixiation and even death.

Work zone

• Examine the work area and be careful of any

hazards (such as roads, driveways, power

lines, hanging tree limbs, etc.).

• Before use, remove any rubbish from the work

area such as rocks, broken glass, ropes, metal

parts, cans, bottles and any foreign body that

could become entangled with rotating parts or

2 - ENGLISH

Page 6

be projected dangerously at a distance.

Contact between the blades and any

extraneous objects could cause serious injury

to the operator or other people or animals in

the vicinity, and could also damage the

machine.

• B3. Cut only the material recommended for

each accessory and take care not to let the

blades come into contact with rocks, metal

parts, etc.

• Take special care when working on sloping

terrain.

• B4. Keep any other persons or animals away

from the work zone (minimum distance 15

meters). Since there is a danger when you are

working that the blade or nylon string head

could throw out grass, dirt, rocks or foreign

bodies, when someone approaches switch the

engine off or stop the blade or rotating head

(see section entitled “Starting and stopping the

engine”).

• Take account of possible hazards that may not

be perceived because of the noise of the

machine.

• Make sure there is someone in the vicinity

within safe calling distance in case of accident.

During use

• B5. Fasten your hair above shoulder length.

• B6. Use the machine holding it to the right of

your body so that the exhaust fumes can

escape freely without obstruction from your

clothing. If you have never used a brush cutter

before, practice using it for a while before

actually starting to work with it

• B6. While working, grip the brush cutter firmly

with both hands. Stand in a stable position on

your feet.

• Keep the grips clean and dry.

• Before starting to work, make sure you are

wearing the harness correctly. Adjust the

buckle so that the brush cutter is well balanced

on your right side with the blade or nylon string

head parallel to the ground, from 0 to 30 cm

above it.

• B7. The connection point (B) should be

selected so as to ensure optimum balance of

the machine and in any case as indicated in the

paragraph entitled “Belt strapping”.

• Never try to use the machine with any of its

parts missing or defective, or after any

alterations have been made to it by persons

other than authorized service personnel.

• The operator or user is liable for any accidents

or damages to third parties and property, and

for the dangers to which they may be exposed.

• Do not use the brush cutter while standing on

a ladder or other unstable support. You should

always be able to control your balance.

• Do not use the machine under extreme

weather conditions such as very low

temperatures or in a very hot, damp climate.

• Avoid working in bad weather (fog, rain, wind,

etc.).

• The blade is sharp, so be very careful when

handling it even with the engine off. Wear work

gloves. Switch the engine off and wait for all

rotating parts to come to a complete stop

before performing any operation on the

machine or touching the blade or nylon string

head, especially if you have to remove any

material entangled with those parts.

• Keep all parts of your body and clothing away

from the blades during startup or when the

engine is running.

• During use, keep the work zone in front of you.

Never cut walking backwards as you cannot

see possible hazards.

• Do not put the machine down with the engine

running. Never leave the machine alone.

• Never leave the machine with the engine

running.

CAUTION! In order to ensure proper

operation and safe use of the

machine, make sure to use original

replacements at all times.

Precautions for carrying the machine

• B8. Never carry the brush cutter, even for short

distances, with the engine running. Switch off

the engine and carry it with the blade or nylon

string head facing backward.

• B8. When you transport the brush cutter in a

motor vehicle, place it in a stable fixed position

so that no fuel leaks out. We recommend

emptying the fuel tank whenever you transport

the machine.

B9. CAUTION! For your safety,

during transport and storage, always

protect the blade with the guard

supplied with the machine.

Fire prevention precautions

• B10. Never work with the brush cutter in the

presence of fire or spilled gasoline.

• B10. When filling the fuel tank, dry any spilled

fuel. Do not smoke during this operation. Start

the engine at a distance from the filling site and

far away from any fuel tanks (at least 3

meters). Do not fill the tank with the engine

running.

• Keep the machine clean by removing any

grass cuttings, leaves, excess oil to reduce the

fire hazard.

Kickback

Machines equipped with blades may produce a

violent kickback on contact with solid bodies.

The blade is capable of amputating arms and

ENGLISH - 3

Page 7

legs. The force of the kickback can cause the

operator to lose control of the machine.

Kickback can also occur when cutting with any

type of blade in the hazardous zone (see N1); we

therefore recommend cutting using the

remaining zone.

CAUTION! Always use a sharp blade.

A blade with worn teeth can create

problems in cutting and cause the

blade to kickback.

CAUTION! Do not sharpen a

damaged or worn blade. Replace it

with a new one.

C. Description of the safety devices on the machine,

controls to be made and maintenance of the safety devices

CAUTION! Do not use the machine

for any reason with its safety devices

out of order.

This section describes the safety devices on the

machine, and provides instructions for control

and maintenance to keep them in perfect

working order.

The section “General Description” will help you

to identify the parts described in this section.

The risk of accidents increases considerably if

maintenance is not performed regularly or is not

done professionally. In case of any doubts

contact an authorized service center.

Safety lever

CAUTION! Never use the machine

with its Safety lever pressed with

adhesive tape, string or other.

• This device serves to prevent accidentally

pressing the throttle trigger (fig. A no. 3). In

fact, the trigger (fig. A no. 3), can only be

pressed if the safety lever is pressed at the

same time (fig. A no. 19).

• By means of 2 separate springs, upon

releasing the grip, the throttle trigger (fig. A no.

3) and safety lever (fig. A no. 19) return

automatically to their original positions.

Engine stop device

• Turn the stop button Stop (fig. A no. 7) to O /

STOP to stop the engine.

• To make sure this button works properly, start

the engine and check that it stops when the

Stop button (fig. A no. 7) is turned to the Stop

position.

CAUTION! We recommend the use of

original accessories and

replacements, which can be

purchased from authorized

distributors. The use of other

accessories and replacements

increases the danger of accidents

and in this case the manufacturer

has no liability for damages to

persons and/or property.

Protection for transport

CAUTION! Before applying the guard

switch off the engine and wait for the

cutting device to stop. Use the blade

guard whenever you have to

transport and store the machine.

The guard covers the sharp extremities of the

blade when the machine is in the resting position

for transport or storage (fig. A no. 23).

CAUTION! Never use the machine for

any reason without the specific

safety devices listed below! Though

they do not entirely eliminate all

risks, they greatly reduce the danger.

Safety guard

CAUTION! Never use the machine for

any reason without the

recommended safety guard for the

cutting device in use. The use of an

inadequate or defective guard can

cause serious injuries. Periodically,

check its conditions and replace if

necessary.

• This very important safety device (fig. A no. 18)

prevents any objects that come into contact

with the cutting device, or the grass itself, from

flying up and striking the operator. It should be

checked regularly; check the assembly and

make sure the fastening screws are tight (see

“Assembly of safety guard”).

• If you strike any hard objects that cause

structural damage to the guard on the cutting

device, take the machine to an authorized

service center for replacement of the guard.

4 - ENGLISH

Page 8

Safety pole guard (not supplied with all

models)

CAUTION! Never use a brush cutter

without its safety pole guard

correctly in place.

This device, fastened to the machine, ensures a

minimum distance between the operator and the

cutting device during use, and prevents the

machine from striking and injuring the operator if

the blade hits a hard surface (fig. A no. 20).

Muffler

• The muffler serves to reduce the noise level to

a minimum and to route the exhaust fumes

produced by the combustion engine away from

the operator.

• Follow these procedures for safe use of the

brush cutter.

CAUTION! The muffler can get very

hot during use and should be

allowed to cool for some time after

switching off the engine. Therefore,

take special precautions when, for

any reason, you have to touch the

area around the muffler.

D. Fuel Mixture

CAUTION!

• Do not smoke while refueling!

• Open the cap on the tank by

loosening it slowly.

• Fill the tank outdoor, far from flames

or sparks.

• Never add fuel in the tank when the

engine is running or hot to avoid the

risk of fire (let the engine cool off

before filling the tank).

• Avoid contact of the oil and fuel with

the skin and eyes.

• Fill the tank in a well-ventilated place.

• Do not inhale the toxic fumes of the

fuel mixture.

• Store the fuel mixture in suitable fuel

containers only.

CAUTION! Fire hazard. Never use the

machine with a defective or damaged

muffler.

CAUTION! Engine exhaust fumes are

toxic. For this reason, you should

not use the machine indoors.

CAUTION! Engine exhaust fumes

can get very hot and may contain

sparks. Do not use the machine near

inflammable material.

Harness (not supplied with all models)

CAUTION! It is very important to

familiarize yourself with the release

mechanism. In case of emergency

you need to be able to release the

machine quickly.

The harness is equipped with a fasten-release

mechanism. The harness enables the operator

to support the machine during use (see “Safety

precautions”, B7). Before fastening the machine

to the strapping, adjust the bandolier belt so that

the fasten/release device is about 15 cm above

your waist. Using the blade, fasten the machine

to the buckle (as shown in the figure) using the

hole nearest your body.

Preparation of the mixture

CAUTION! Do not use any other type

of fuel than the type recommended in

this manual. This machine is

equipped with a two-stroke engine

and should therefore be fueled with a

mixture of unleaded gasoline (with a

minimum octane rating = 90) and

fully synthetic oil specific for twospeed engines that use unleaded

gasoline in the proportions indicated

in the table on the cover, fig. (D).

CAUTION! Control the specifications

of the oil shown on the package; the

use of oil lacking the specifications

expressly indicated in this manual

could cause serious damage to the

engine!

• To obtain the best mixture, pour the oil into an

approved container first, followed by the

gasoline, and shake the container well (every

time you take fuel out of it).

• Be careful not to spill the gasoline.

• The characteristics of the mixture tend to

deteriorate in time, so you should only prepare

as much mixture as you are going to need (the

ENGLISH - 5

Page 9

use of deteriorated fuel can seriously damage

the engine).

Filling the tank

CAUTION! The following precautions

should be taken to reduce the fire

hazard:

• Always ensure there is adequate

ventilation.

• Do not smoke or take sources of heat

or sparks near the fuel.

• Refuel with the engine off.

• Open the cap on the tank carefully to

eliminate any excess pressure.

• Do not take the cap off the tank with

the engine running.

• After fueling, close the cap tightly.

• Fill the tank in a well-ventilated place.

• Place the machine on a solid flat surface so

that it cannot tip over, with the cap on the tank

facing upward.

• Clean the area around the fuel cap before

removing it, to prevent any impurities from

contaminating the fuel.

• Take the cap off the fuel container carefully.

Unscrew the cap on the fuel tank and fill it with

the necessary quality, using a funnel.

• Take care not to spill any fuel.

• After filling the tank, screw the cap on tightly.

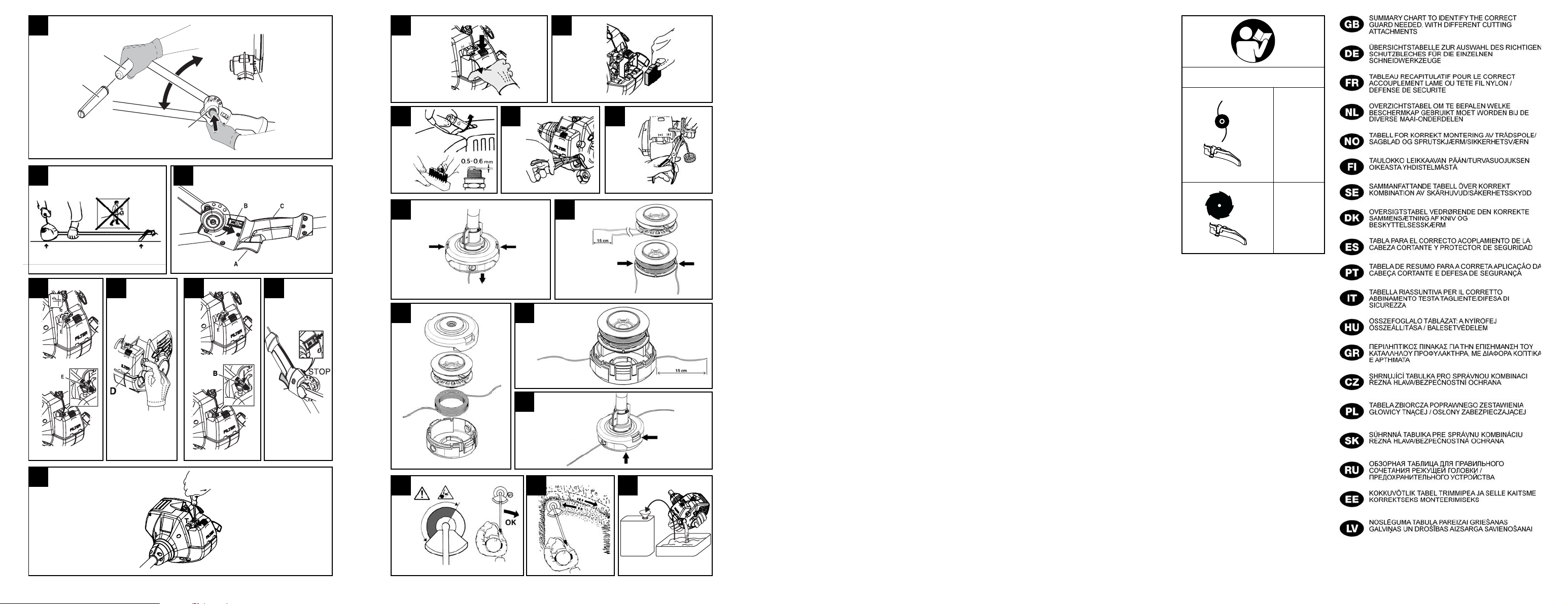

E. Assembly of safety guard

Assembly of safety guard

Mount the shield (A) taking care to match it

correctly to its support (I), insert and tightenthe

F. Usable cutting tools and their installation on the machine

• During use, to prevent problems in starting the

engine again, we strongly recommend that you

avoid letting the fuel run out in the tank.

CAUTION! If you spill any fuel, wipe it

off the machine. If you have spilt it on

yourself, change your clothes at

once. Avoid contact with the skin or

eyes.

CAUTION! The muffler gets very hot

during use and remains hot for some

time after switching off the engine.

This also applies at idle speed. Take

every precaution to reduce the fire

hazard, especially in the presence of

inflammable materials or gas.

Fuel storage

• Gasoline is highly inflammable.

• Before going near any type of fuel, put out your

cigarette, pipe or cigar.

• Store the fuel in a cool, well-ventilated place, in

an approved fuel storage container.

• Never store the engine with fuel in the tank in a

poorly ventilated place where the fumes

produced by the gasoline could propagate and

reach a fire, candle, burner or furnace pilot

light, water heater, dryer, etc.

• The fumes produced by the fuel can cause an

explosion or fire.

• Never store excessive quantities of fuel.

screws (H), mount the string cutter blade as

shown in the figure.

CAUTION! Install the cutting device

only after mounting the shield.

CAUTION! The following are the only

cutting devices that can be installed

on your machine:

a) Nylon string head

b) Grass blade with a maximum of 8

teeth.

Each of these devices requires the

installation of a special guard.

Follow the instructions for correct

assembly carefully. Fasten the

cutting tools correctly with all their

parts in the order indicated so as to

prevent severe injuries to the

operators, other people and animals.

6 - ENGLISH

CAUTION! Use grass blades or nylon

string heads with the MAXIMUM

ROTATION SPEED (stenciled on

them by the manufacturer) of at least

10.500 min

CAUTION! Any operations involving

the cutting devices and their guards

should be done with the engine off.

CAUTION! If you turn the machine

over to facilitate assembly of the

cutting tools, make sure the cap on

the fuel tank is securely fastened and

there are no leaks of fuel.

-1

.

Page 10

CAUTION! WE RECOMMEND THE

USE OF ORIGINAL ACCESSORIES

AND REPLACEMENTS, WHICH CAN

BE PURCHASED FROM

AUTHORIZED DISTRIBUTORS. THE

USE OF OTHER ACCESSORIES AND

REPLACEMENTS INCREASES THE

DANGER OF ACCIDENTS AND IN

THIS CASE THE MANUFACTURER

HAS NO LIABILITY FOR DAMAGES

TO PERSONS AND/OR PROPERTY.

Assembly of nylon string head and blade

Apply the proper guard depending on whether

you plan to use the grass blade or nylon string

head (see chapter: “Application of protective

devices on cutter”).

• F1. Apply the nylon string head as shown in the

illustration: a) Upper plate with blade centering

b) Nylon string head. Tighten by turning

clockwise.

• F2. As you tighten, hold the nylon string head

and plate still and insert the wrench or

screwdriver supplied in the holes in the plate

and gearbox; first turn the plate until the two

holes match.

(only for models equipped with guard and strap)

• F3. Apply the blade as shown in the illustration:

a) Upper plate with blade centering b) Blade

with wording and direction arrow facing upward

c) Lower plate d) Fixed cup e) Blade fastening

nut f) Safety split pin.

• F4. Make sure the hole in the blade is perfectly

coupled with the centering collar on the upper

G. Grip

Bent front grip

(Only for models equipped with guard

and strap)

CAUTION! The grip acts as a guard

when the special extension is

mounted (D). Screw the side safety

guard securely into the threaded

housing on the bent grip as shown in

the figure, whenever you use the

cutting blade.

The bent grip (A) can be adjusted according to

the needs of the operator by folding it forward or

backward. Press the grip adjustment knob (B),

place the grip in one of the positions marked with

the notches (C) in a convenient working position

and release the knob (B).

(Only for models equipped with guard

and strap)

CAUTION! With the blade installed,

use the machine with the grip

adjusted in the position marked with

the first notch only.

plate. Tighten by turning clockwise. As you

tighten, hold the blade-plate assembly still by

inserting the wrench or screwdriver supplied in

the holes provided.

F5. “Tap and go” nylon string head

The nylon string head is used to cut grass and

weeds along borders or in zones with obstacles

like walls, fences or trees. It can operate in a very

narrow or uneven zone. The nylon string cuts the

grass neatly without damaging the bark of the

trees or causing violent impact such as due to

the contact of a rigid blade with a hard surface.

Supply of the nylon string

CAUTION! The string cutting device

fastened on the shield cuts the nylon

cord to the proper length; a string

that is too long reduces the rotation

speed of the engine and interferes

with cutting efficiency, as well as

increasing the risk of injury.

During cutting, the nylon string wears naturally

causing an increase in the speed of the engine

and a reduced cutting capacity. When this

happens, to bring out more string bump the head

against the ground:

release the throttle trigger to reduce the engine

speed to less than 4000 rpm. Tap gently on the

ground with the button (A) as shown in the figure

and the string will come out automatically.

Accelerate again.

If the string does not come out make sure there

is still some left and try again.

CAUTION! Fold the grip parallel to the

machine — in the position of the last

notch (C) — to facilitate transport

and storage of the machine.

ENGLISH - 7

Page 11

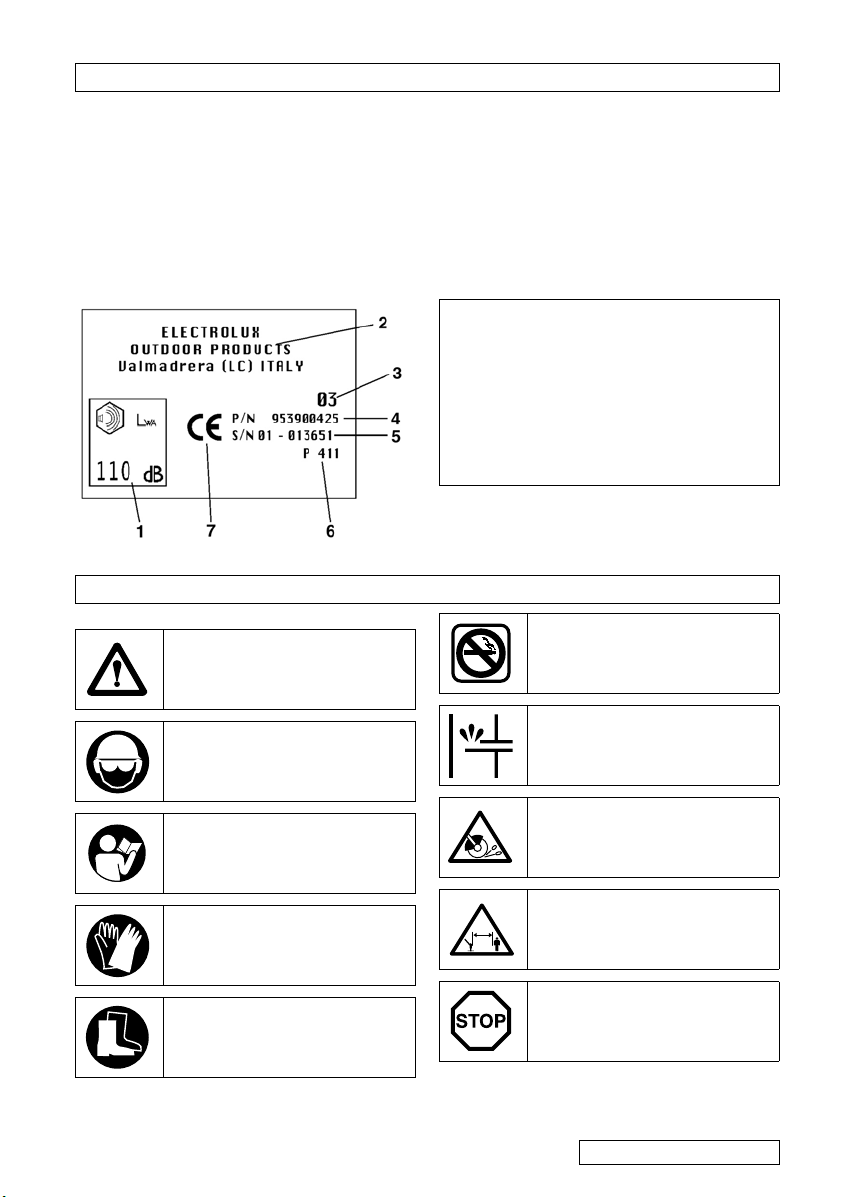

H. Starting and stopping the engine

CAUTION! First read chapter “Safety

Precautions”

H1. CAUTION! Start the brush cutter

in a flat place. During startup stand

in a stable position. Make sure the

blade or nylon string head do not

touch the ground or any obstacles.

CAUTION! Grip the knob of the

starter with one hand and hold the

machine in a stable position with the

other. (Take care not to wind the

starter string around your hand) and

pull slowly until you encounter some

resistance, then pull the cord sharply

and forcefully (to start the engine

when cold or warm follow the

procedures described).

CAUTION! Do not pull the starter

cord all the way and do not release it

abruptly against the machine as this

could damage it.

Startup of cold engine

• H2. Stop switch (A) turned to I opposite the

“STOP” mark.

• H3. Turn the fuel enrichment lever (B) to the

closed position.

• H4. Pump by pressing several times on the

bulb (C) until you see the fuel flow back into the

tank through the tube (D). Pull the starter cord

until the machine starts.

Let the engine run a few seconds holding the

brush cutter still. Grasp the control grip firmly and

accelerate, automatically the enrichment lever

will return to its original position.

CAUTION! The cutting devices are

now rotating.

Startup of warm engine

• H2. STOP switch turned to I (START). Throttle

trigger lever in minimum position (released).

• H5. Enrichment lever (B) in original position.

• H4. Pump by pressing several times on the

bulb (C) until you see the fuel flow back into the

tank through the tube (D). Pull the starter cord.

Stopping the engine

• H6. Turn the stop switch (A) to O (STOP).

CAUTION! After stopping the engine

the rotating parts, blade or nylon

string head, keep spinning by inertia

for a few seconds. Grip the machine

firmly until they stop.

CAUTION! In case of emergency the

above delay can be abbreviated by

scraping the blade supporting cup

parallel on the ground.

I. Carburetor adjustment

Your machine can be equipped with a low

emission carburetor. We recommend that you

have any adjustment of the carburetor made

exclusively by an authorized service center,

which disposes of special equipment for

ensuring the best performance with the lowest

emissions. To adjust the speed to the minimum,

turn the screw marked (T) as shown: With the

engine running and well warmed up, turn the

screw (T) gently clockwise, until the engine

rotates at regular speed (stead noise), without

the cutting devices in motion. If the cutting

devices are moving, turn the screw (T) gently

counterclockwise until you obtain the proper

adjustment. The correct minimum speed is

L. Routine maintenance

Check periodically to see that all the screws in

the machine are securely fastened in place.

Replace damaged, worn, cracked or bent

blades. Always make sure the blade or nylon

string head is correctly installed and the nut

holding the blade is tight.

8 - ENGLISH

shown in the instruction manual in the paragraph

of technical data.

CAUTION! All the above adjustments

should be made with the cutting

devices correctly installed.

CAUTION! Start the brush cutter in a

flat place. During startup stand in a

stable position. Make sure the blade

or nylon string head do not touch the

ground or any obstacles.

The warranty may be invalidated due to

erroneous adjustments made by personnel not

belonging to authorized service centers.

L1. Cleaning the air filter

(At least every 25 hours of work). A clogged filter

causes alteration of the carburetor adjustment,

reducing power and increasing fuel

consumption, as well as causing difficulties in

startup. Open the cover on the filter as shown in

Page 12

the figure by pressing in the point indicated by

the arrow for release. Clean the inside of the filter

housing thoroughly (fig. L2). The filter can be

cleaned using gentle jets of compressed air. For

more thorough cleaning it can be washed in

soapy water.

L3. Gearbox

Every 50 working hours add grease for high

speed gears in the gearbox, through the hole

(C).

L4. Spark plug

Periodically (at least every 50 hours) remove

and clean the spark plug and set the space

between the electrodes (0.5/0.6 mm). Replace it

if excessively encrusted or, in any case, after

100 working hours. In case of excessive

encrustation check the carburetor adjustment,

the percentage of oil in the fuel mixture and

make sure the oil is of excellent quality and

suitable for two-stroke engines.

M. Replacement of nylon string

CAUTION! Use only the

recommended type of nylon string.

Do not use steel wires for any

reason, in order to prevent serious

injury.

M1. String replacement

If, when you bump the nylon string head on the

ground, no more string comes out, it means

there is none left and you have to replace it. To

replace the reel of string, press both the release

pawls indicated by the arrows, remove the empty

reel (fig. M2), unroll any string left and rewind the

new string.

M3. Rewinding the new string

Open the original package of string and insert

the ends of the two strings in the eyelets on the

reel, then wind the strings completely on the reel

in the same direction and fasten the end of each

string in the 2 opposite grooves.

N. Cutting techniques

L5. Fuel filter

To clean or replace the filter, remove the cap on

the tank and take the filter out using a hook or

long-nose pliers. Periodically, every season,

contact your service center for general

maintenance and cleaning of the inside. This will

reduce the possibility of unexpected problems

and will ensure the good performance and long

life of your machine.

CAUTION! Regularly it is important,

in order to prevent the engine from

overheating, to remove the dust and

dirt from the vents, the cylinder

cover and fins on the cylinder, using

a wooden scraper.

CAUTION! In case of prolonged

disuse, empty the fuel tank and run

the engine until it is out of gas. Store

the brush cutter in a dry place.

M4. Reassembly

• Replace the reel in its housing and thread the

ends of the strings in their bushings.

• Pull each string so that about 15 cm comes out

on each side

• Reassemble the nylon string head as shown

(fig. M5).

Start the machine and repeat the procedures

described in the section “Supply of nylon string”.

Replacement of entire string reel

If the reel becomes excessively worn, replace it

with a whole new reel.

Replacement of the complete nylon string

head

If upon visual inspection (and in any case after a

violent bump) the casing on the nylon string

head appears damaged, it should be replaced.

For this operation see “Usable cutting tools and

their installation on the machine”.

CAUTION! Before using the machine

read the following chapters

carefully: “Safety Precautions” and

“Description of safety devices”.

CAUTION! Always wear the

recommended personal protection

gear.

CAUTION! Before using the

machine, make sure all the parts are

properly assembled.

ENGLISH - 9

Page 13

CAUTION! In mounting the cutting

utensils follow the instructions in the

chapter entitled “Usable cutting

tools and their installation on the

machine”. ABSOLUTELY DO NOT

USE THE BRUSH CUTTER IF THE

SPECIFIC SAFETY GUARD FOR THE

CUTTING DEVICE IN USE IS NOT

SECURELY FASTENED (see chapter

“Assembly of safety guards”).

Failure to follow this rule can expose

you to serious danger such as:

a) possible contact with rotating and

cutting parts

b) possible contact with flying

debris.

CAUTION! Do not use worn or

damaged cutting devices.

CAUTION! Try to limit contact and

impact of the cutting devices against

the ground and other objects as

much as possible. Hold the cutting

device away from your body.

CAUTION! Twigs or grass may jam

between the safety guard and the

blade or nylon string head. Never try

to remove this material with the

engine running and the blade

rotating. Always stop the engine

before performing any operations of

cleaning, and wait for the cutting

device to stop in order to prevent

injury.

CAUTION! During use and for a few

minutes after switching off the

machine, the gearbox and zone near

the shaft on which the cutting device

is fastened are very hot. Contact can

cause burns. Do not touch these

parts if they are still hot.

CAUTION! The muffler and its guard

are very hot during use and after the

engine has been switched off, even

with the engine running at minimum

speed. Contact can cause burns. Do

not touch these parts if they are still

hot.

The machine is ideal to complete the work of the

lawnmover. In fact, it can reach places where a

normal lawnmower is unable to go.

During the cutting operations, keep the engine

running at high speed. After every cutting stage,

decelerate the engine to minimum speed as

running it at top speed without a load can

damage the engine severely.

Never raise the brush cutter above knee level

during cutting.

Wait until the engine is running at minimum

speed before moving the machine from one

section to another.

Stop the engine when you change workplace.

Before you start cutting again, make sure your

position is correct and stable.

Cutting and trimming grass borders with the

nylon string head

CAUTION! For nylon string heads,

use only strings made of flexible

material recommended by the

manufacturer. For example, you

should never use metal wire because

it could cause serious injuries to

people, property and animals. An

unsuitable string could break and

turn into a very dangerous missile.

Cutting with the nylon string head is suitable for

light jobs like trimming borders and cutting the

grass around trees.

Mowing

To prevent damage to your lawn or the cutting

mechanism, keep the string parallel to the

ground but avoid contact with the terrain.

Trimming borders

Angle the nylon string head keeping it a short

distance from the ground. Cut using the end of

the string. Do not press the string against the

material to be cut.

Drawing out the string

As you cut, the nylon string wears down

naturally. When this happens, to draw out more

string bump the head against the ground (see

paragraph entitled “Tap and go system for nylon

string head”).

Thinning grass with the grass cutter blade

CAUTION! Always work with a sharp

blade. A blade with worn teeth can

create problems in cutting and can

cause KICKBACK, that is, a violent

thrust on the front of the machine

caused by the impact of the blade

against wood or solid foreign bodies.

This kickback can cause loss of

control of the machine. Never

sharpen a damaged blade: replace

with a new one.

10 - ENGLISH

Page 14

N1. CAUTION! Do not let the blade

cut in the risk sector to prevent

kickback (see paragraph “Safety

precautions”).

Cutting with the blade is recommended for

thinning the grass, especially when tall and

sturdy.

N2. The grass is cut with swinging motions from

side to side, maintaining the blade parallel to the

ground. Cut the grass moving from left to right,

without cutting on the return stroke from right to

left. KICKBACK can occur when cutting is done

with the risk sector of the blade; we recommend

cutting with the rest of the blade. To prevent any

O. Environmental information

This section contains information useful for

maintaining the characteristics of ecocompatibility included in the origin design of the

machine, and as regards proper use and

disposal of oil and fuel.

Design

In the design stage, care was taken to develop

an engine with reduced consumption and low

emissions of noise and pollutant exhaust fumes.

Use of machine

The operations of filling the tank with the fuel

mixture should be carried out in such a way as to

P. Troubleshooting table

recoil of the blade, make sure the supporting cup

does not touch the ground.

N1. CAUTION! WE RECOMMEND

THE USE OF ORIGINAL

ACCESSORIES AND

REPLACEMENTS; THESE CAN BE

FOUND AT YOUR OFFICIAL

DISTRIBUTOR'S. THE USE OF

ACCESSORIES AND

REPLACEMENTS THAT ARE NOT

ORIGINAL INCREASES THE

DANGER OF ACCIDENTS AND IN

THIS CASE THE MANUFACTURER IS

NOT LIABLE FOR ANY DAMAGES

TO PERSONS OR PROPERTY.

avoid spilling fuel and contaminating the soil and

environment.

Periods of prolonged disuse

Always empty the fuel tank with the same

precautions used in filling it (O).

Disposal

Do not dispose inappropriately of the machine

when it is no longer usable. Deliver it to an

authorized organization for proper disposal in

compliance with the regulations in force.

The engine does

not start

Make sure the STOP switch is on I. ●

Make sure that the fuel tank is at least 25%

full.

Make sure the air filter is clean. ●●

Remove the sparkplug, dry and clean it,

then return it to its place. If necessary,

replace it.

Change the fuel filter. Contact your

supplier.

Follow the correct procedure for assembly

of the cutting accessories.

Make sure the metal accessories are sharp,

and contact your supplier if necessary.

The engine continues to have problems: contact your authorized supplier

●●

●●

The engine

stutters or loses

power

●

The machine

starts but does

not cut properly

ENGLISH - 11

●

●

Page 15

Q. Declaration of conformity

The undersigned, authorized by E.O.P., declares that the following products model: type BC020,

BC020J starting from the serial numbers produced from 2003 on, manufactured by E.O.P.,

Valmadrera, Italy, comply with European Directive: 98/37/EEC (Machine Directive), 93/68/EEC

(EEC Marking Directive) & 89/336/EEC (Electromagnetic Compatibility Directive), directive 2000/

14/EEC (Enclosure V).

Valmadrera, 15.12.03

Pino Todero (Technical Manager)

Electrolux Outdoor Products Italy S.p.A.

Via Como 72, 23868 Valmadrera (Lecco)

ITALY

R. Technical data

Displacement (cm3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Bore (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Stroke (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Engine output (kW) (ISO 8893) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8

Maximum shaft rotation frequency (min

Rotation speed (frequency of rotation) of engine at maximum rotation

frequency recommended for shaft (min

Engine speed at max power (min

Minimum speed (min

Maximum speed, no load (min

-1

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2800

-1

Dry weight (kg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4

Fuel tank capacity (cm

3

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Noise pressure (at operator ear) Lpav (dBA) (ISO 7917) . . . . . . . . . . . . . . . . . 99

Measured sound power level Lwav (dBA) (ISO 10884) . . . . . . . . . . . . . . . . . . 113

Guaranteed noise level Lwav (dBA) (ISO 10884). . . . . . . . . . . . . . . . . . . . . . . 114

2

Vibrations on rear grip (m/s

) (ISO 7916) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 - 12

Vibrations on bent front grip (m/s

-1

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10500

-1

) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-1

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8500

10500

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10500

2

) (ISO 7916) . . . . . . . . . . . . . . . . . . . . . . . . 6 - 15

12 - ENGLISH

Loading...

Loading...