MAXDATA PLATINUM 7200 IR

User’s Manual

2 3MAXDATA PLATINUM 7200 IR M7Contents

Contents

1 Safety Information 7

Safety Warnings and Cautions ................................................................................................................7

Intended Application Uses ......................................................................................................................7

General Warnings ....................................................................................................................................8

Place Battery Marking ........................................................................................................................8

Site Selection ..........................................................................................................................................9

Equipment Handling Practices ................................................................................................................9

Power Cord Warnings ...........................................................................................................................10

System Access Warnings .....................................................................................................................10

Rack Mount Warnings ...........................................................................................................................11

Electrostatic Discharge (ESD) ................................................................................................................11

Other Hazards .......................................................................................................................................11

Battery Replacement ........................................................................................................................11

Cooling and Airflow ..........................................................................................................................11

Laser Peripherals or Devices ............................................................................................................ 12

2 Platform Description 13

Platform Features ..................................................................................................................................14

Platform Front .......................................................................................................................................15

Standard Control Panel ..........................................................................................................................16

Platform Rear ........................................................................................................................................18

Processors .............................................................................................................................................19

System Memory ....................................................................................................................................19

Available Memory Configurations ....................................................................................................20

Power Subsystem .................................................................................................................................21

Power Supply Modules ....................................................................................................................21

Cooling Subsystem ...............................................................................................................................23

Hot-swap PCI Slots ...............................................................................................................................24

Peripherals .............................................................................................................................................25

Hot-Swap Hard Drive ........................................................................................................................25

Removable Media Drive Bay Support ..............................................................................................25

5 ¼-inch Half-height Drive Bay .........................................................................................................25

System Board Set .................................................................................................................................26

Main Board ............................................................................................................................................ 26

Video Support ........................................................................................................................................29

Ethernet Support ................................................................................................................................... 29

Memory Board ......................................................................................................................................30

I/O Riser Board (optional) ......................................................................................................................31

SAS Riser Board (optional) ....................................................................................................................32

3 Starting Up and Shutting Down the Server 33

Powering On the Server ........................................................................................................................33

Shutting Down the Server .....................................................................................................................33

4 Server Platform Utilities 35

BIOS Setup Utility .................................................................................................................................35

BIOS Setup Utility Page Layout .............................................................................................................35

Keyboard Commands ............................................................................................................................ 36

Console Redirection ..............................................................................................................................37

Serial Configuration Settings ............................................................................................................37

Keystroke Mappings .........................................................................................................................38

Setup Alias Keys ...............................................................................................................................38

Limitations ........................................................................................................................................ 38

Interface to Server Management .....................................................................................................38

Sample Setup for Console Redirection ............................................................................................38

Extensible Firmware Interface (EFI) Shell .............................................................................................39

5 User Serviceable Platform Components 43

Tools and Supplies Needed ...................................................................................................................43

Removing and Installing the Top Cover .................................................................................................43

Removing the Top Cover ..................................................................................................................44

Installing the Top Cover ....................................................................................................................44

Hot-swapping a Front System Fan ........................................................................................................45

Hot-swapping a Rear System Fan .........................................................................................................45

Hot-swapping Hard Disk Drives ............................................................................................................47

Determining Drive Status .................................................................................................................47

Removing a Hard Disk Drive ............................................................................................................48

Mounting a Hard Disk Drive in a Carrier ...........................................................................................48

Installing a Hard Disk Drive Assembly ..............................................................................................48

Hot-swapping Power Supplies ..............................................................................................................49

Removing a Power Supply ...............................................................................................................49

Installing a Power Supply .................................................................................................................49

Installing and Removing PCI Cards .......................................................................................................50

Removing Hot-plug PCI Card with Operating System Hot-Plug Interface ........................................50

Removing Hot-plug PCI Card with Hardware Hot-Plug Interface ..................................................... 51

Installing a Hot-plug PCI Add-in Card ................................................................................................52

Removing a Non-Hot-Plug PCI Card .................................................................................................53

Installing a Non-Hot-Plug PCI Card ...................................................................................................53

Installing and Removing Memory Boards .............................................................................................54

Removing a Memory Board .............................................................................................................54

Installing a Memory Board ...............................................................................................................55

Installing and Removing DIMMs ...........................................................................................................55

Memory Population Rules ................................................................................................................55

Installing DIMMs ..............................................................................................................................57

Removing DIMMs ............................................................................................................................58

4 5MAXDATA PLATINUM 7200 IR M7Contents

6 Replacing the CMOS Battery 59

7 Regulatory and Integration Information 6

Product Regulatory Compliance ............................................................................................................61

Product Safety Compliance ..............................................................................................................61

Product RoHS Compliance ....................................................................................................................61

Product EMC Compliance .....................................................................................................................61

Product Regulatory Compliance Markings ............................................................................................61

Electromagnetic Compatibility Notices .................................................................................................61

Europe (CE Declaration of Conformity) ............................................................................................61

Appendix A: POST Codes 63

POST Progress Codes and Messages ..................................................................................................64

POST Error Messages and Handling .....................................................................................................67

POST Error Beep Codes ........................................................................................................................78

1

Figures

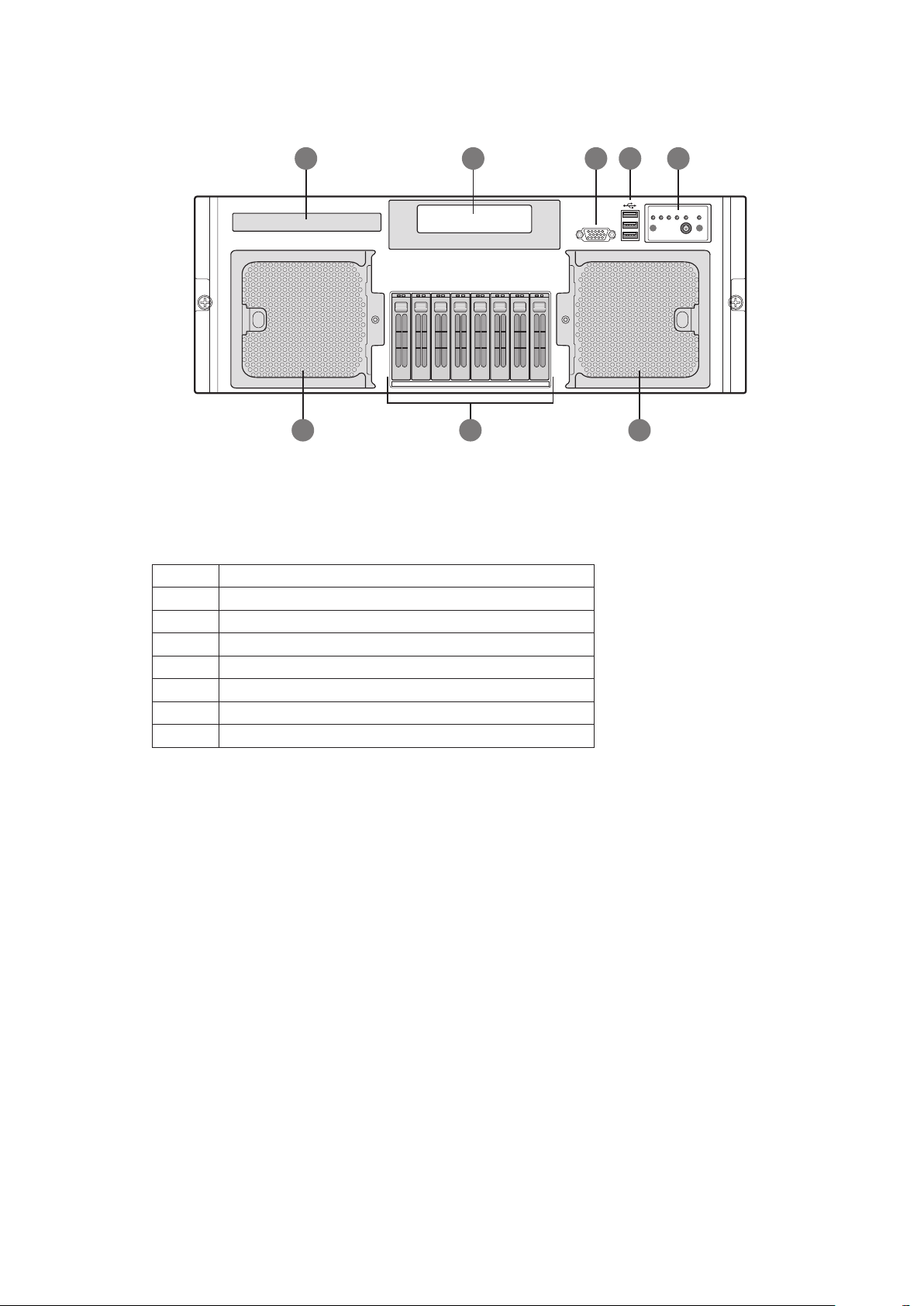

1. PLATINUM 7200 IR Server Front View ...........................................................................................13

2. Front Components ..........................................................................................................................15

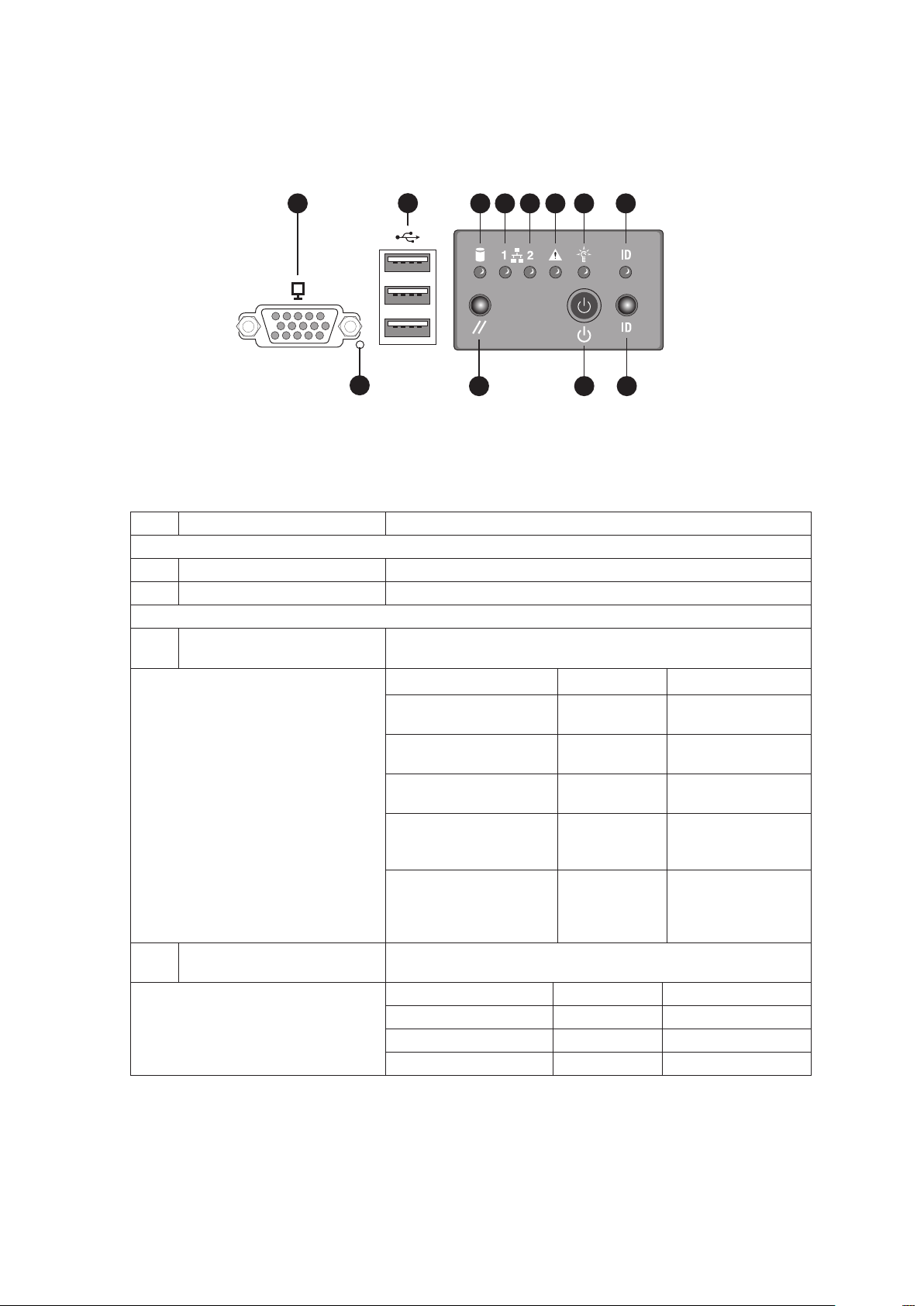

3. Front Panel Controls and Indicators ................................................................................................16

4. Rear Platform Features ...................................................................................................................18

5. Memory Boards...............................................................................................................................19

6. Power Supply Indicators ..................................................................................................................22

7. Rear Fan Locations ..........................................................................................................................23

8. Hard Drive Carrier ............................................................................................................................ 25

9. Main Board Component Locations .................................................................................................. 27

10. Main Board Jumpers .......................................................................................................................28

11. Memory Board LEDs and Connectors .............................................................................................30

12. I/O Riser Board Connectors .............................................................................................................31

13. SAS Riser Connectors .....................................................................................................................32

14. Removing the Top Cover.................................................................................................................44

15. System Fan Location and Removal .................................................................................................45

16. Removing a Rear System Fan .........................................................................................................46

17. Hard Disk Drive Carrier ....................................................................................................................47

18. Attaching the Hard Drive to the Carrier ...........................................................................................48

19. PCI Slot Attention Button ................................................................................................................51

20. Opening Memory Board Latches ....................................................................................................54

21. Removing a Memory Board ............................................................................................................54

22. Minimum Memory Population .........................................................................................................55

23. Memory Board A and B Population .................................................................................................56

24. Memory Board A, B, C, D Population ..............................................................................................56

25. Remove Memory Board DIMM Cover ............................................................................................57

26. Install DIMMs ..................................................................................................................................58

27. Removing the Battery .....................................................................................................................60

Tables

1. Safety Warnings and Cautions ..........................................................................................................7

2. Chassis Feature Summary ..............................................................................................................14

3. Front Components ..........................................................................................................................15

4. Front Panel Controls and Indicators ................................................................................................16

5. Rear Platform Features ...................................................................................................................18

6. Power Supply Indicators ..................................................................................................................22

7. Power Indicator ...............................................................................................................................24

8. Attention Indicator ........................................................................................................................... 24

9. Hard Disk Drive Carrier .................................................................................................................... 25

10. Main Board Component Locations ..................................................................................................27

11. Hot-Plug Memory Board LEDs and Buttons ....................................................................................30

12. BIOS Setup Utility Page Layout .......................................................................................................35

13. BIOS Setup: Keyboard Commands .................................................................................................36

14. EFI Shell Commands ....................................................................................................................... 40

15. Hard Disk Drive Carrier ....................................................................................................................47

16. Product Certification Markings ........................................................................................................61

17. Port 80 POST Code LEDs ................................................................................................................63

18. POST Progress Codes and Messages ............................................................................................64

19. POST Error Manager Messages and Handling ................................................................................68

20. Beep Codes .....................................................................................................................................78

6 PBMAXDATA PLATINUM 7200 IR M7Contents

1 Safety Information

This document applies to MAXDATA PLATINUM Server Boards, MAXDATA PLATINUM Server Chassis

(pedestal and rack-mount) and installed peripherals. To reduce the risk of bodily injury, electrical shock,

fire, and equipment damage, read this document and observe all warnings and precautions in this

guide before installing or maintaining your MAXDATA PLATINUM server product.

In the event of a conflict between the information in this document and information provided with the

product or on the website for a particular product, the product documentation takes precedence.

Your server should be integrated and serviced only by technically qualified persons.

You must adhere to the guidelines in this guide and the assembly instructions in your server manuals

to ensure and maintain compliance with existing product certifications and approvals. Use only the

described, regulated components specified in this guide. Use of other products/components will void

the UL Listing and other regulatory approvals of the product, and may result in noncompliance with

product regulations in the region(s) in which the product is sold.

Safety Warnings and Cautions

To avoid personal injury or property damage, before you begin installing the product, read, observe,

and adhere to all of the following safety instructions and information. The following safety symbols

may be used throughout the documentation and may be marked on the product and/or the product

packaging.

Table 1. Safety Warnings and Cautions

Indicates potential hazard if indicated information is ignored

Indicates shock hazard that results in serious injury or death if safety

instructions are not followed

Indicates hot components and surfaces

Indicates electrostatic discharge cautions

Indicates do not touch fan blades, may result in injury

Indicates to unplug all AC power cord(s) to disconnect AC power

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be installed in

offices, schools, computer rooms, and similar commercial type locations. The suitability of this product

for other product categories and environments (such as medical, industrial, residential, alarm systems,

and test equipment), other than an ITE application, may require further evaluation.

7 MAXDATA PLATINUM 7200 IR M7

8 Safety Information

General Warnings

The power supply in this product contains no user-serviceable parts. There may be

more than one supply in this product. Refer servicing only to qualified personnel.

Do not attempt to modify or use the supplied AC power cord if it is not the exact type

required. A product with more than one power supply will have a separate AC cord

for each supply.

The DC push-button on/off switch on the front panel does not turn off system AC

power. To remove power from the system, you must unplug each AC power cord

from the wall outlet or power supply.

Ensure that the system is disconnected from its power source and from all telecommunication links, networks, and modem lines whenever the chassis cover is to be

removed. This may require disconnecting multiple power cords. Do not operate the

system with the cover removed.

A microprocessor and heat sink may be hot if the system has been running. Also,

there may be sharp pins and edges on some board and chassis parts. Contact should

be made with care. Consider wearing protective gloves.

Danger of explosion if the battery is incorrectly replaced. Replace only with the same

or equivalent type recommended by the equipment manufacturer. Discard used

batteries according to manufacturer’s instructions.

Depending on the weight of the product, two people together should lift it.

The system is designed to operate in a typical office environment. Choose a site that

is:

• Clean and free of airborne particles (other than normal room dust).

• Well ventilated and away from sources of heat including direct sunlight.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields produced by electrical devices.

• In regions that are susceptible to electrical storms, we recommend you plug your

system into a surge suppresser and disconnect telecommunication lines to your

modem during an electrical storm.

• Provided with a properly grounded wall outlet.

• Provided with sufficient space to access the power supply cords, because they

serve as the product’s main power disconnect.

Place Battery Marking

There is insufficient space on this server board to provide instructions for replacing and disposing of

the battery. For system safety certification, the following statement or equivalent statement may be

required to be placed permanently and legibly on the chassis near the battery.

CAUTION

Risk of explosion if battery is incorrectly replaced.

Replace with only the same or equivalent type recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

Site Selection

The system is designed to operate in a typical office environment. Choose a site that is:

• Clean, dry, and free of airborne particles (other than normal room dust).

• Well-ventilated and away from sources of heat including direct sunlight and radiators.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields produced by electrical devices.

• In regions that are susceptible to electrical storms, we recommend you plug your system

into a surge suppresser and disconnect telecommunication lines to your modem during an

electrical storm.

• Provided with a properly grounded wall outlet.

• Provided with sufficient space to access the power supply cord(s), because they serve as the

product’s main power disconnect.

Equipment Handling Practices

Reduce the risk of personal injury or equipment damage:

• Conform to local occupational health and safety requirements when moving and lifting

equipment.

• Use mechanical assistance or other suitable assistance when moving and lifting equipment.

• To reduce the weight for easier handling, remove any easily detachable components.

CAUTION

The power button, indicated by the stand-by power marking, DOES NOT completely turn off the system

AC power, 5 V standby power is active whenever the system is plugged in. To remove power from

system, you must unplug the AC power cord from the wall outlet. Your system may use more than

one AC power cord. Make sure all AC power cords are unplugged. Make sure the AC power cord(s)

is/are unplugged before you open the chassis, or add or remove any non hot-plug components.

Do not attempt to modify or use an AC power cord if it is not the exact type required. A separate AC

cord is required for each system power supply.

Some power supplies in MAXDATA PLATINUM Servers use Neutral Pole Fusing. To avoid risk of

shock use CAUTION when working with power supplies that use Neutral Pole Fusing.

The power supply in this product contains no user-serviceable parts. Do not open the power supply.

Hazardous voltage, current and energy levels are present inside the power supply. Return to

manufacturer for servicing.

When replacing a hot-plug power supply, unplug the power cord to the power supply being replaced

before removing it from the server.

To avoid risk of electric shock, turn off the server and disconnect the power cord, telecommunications

systems, networks, and modems attached to the server before opening it.

9 MAXDATA PLATINUM 7200 IR M7

10 Safety Information

Power Cord Warnings

If an AC power cord was not provided with your product, purchase one that is approved for use in

your country.

CAUTION

To avoid electrical shock or fire, check the power cord(s) that will be used with the product as

follows:

• Do not attempt to modify or use the AC power cord(s) if they are not the exact type required to

fit into the grounded electrical outlets

• The power cord(s) must meet the following criteria:

- The power cord must have an electrical rating that is greater than that of the electrical

current rating marked on the product.

- The power cord must have safety ground pin or contact that is suitable for the electrical

outlet.

• The power supply cord(s) is/are the main disconnect device to AC power. The socket outlet(s)

must be near the equipment and readily accessible for disconnection.

• The power supply cord(s) must be plugged into socket-outlet(s) that is /are provided with a

suitable earth ground.

System Access Warnings

CAUTION

To avoid personal injury or property damage, the following safety instructions apply whenever accessing

the inside of the product:

• Turn off all peripheral devices connected to this product.

• Turn off the system by pressing the power button to off.

• Disconnect the AC power by unplugging all AC power cords from the system or wall outlet.

• Disconnect all cables and telecommunication lines that are connected to the system.

• Retain all screws or other fasteners when removing access cover(s). Upon completion of

accessing inside the product, refasten access cover with original screws or fasteners.

• Do not access the inside of the power supply. There are no serviceable parts in the power

supply. Return to manufacturer for servicing.

• Power down the server and disconnect all power cords before adding or replacing any non hotplug component.

• When replacing a hot-plug power supply, unplug the power cord to the power supply being

replaced before removing the power supply from the server.

CAUTION

If the server has been running, any installed processor(s) and heat sink(s) may be hot. Unless you

are adding or removing a hot-plug component, allow the system to cool before opening the covers.

To avoid the possibility of coming into contact with hot component(s) during a hot-plug installation,

be careful when removing or installing the hot-plug component(s).

CAUTION

To avoid injury do not contact moving fan blades. If your system is supplied with a guard over the

fan, do not operate the system without the fan guard in place.

Rack Mount Warnings

The equipment rack must be anchored to an unmovable support to prevent it from tipping when a

server or piece of equipment is extended from it. The equipment rack must be installed according to

the rack manufacturer’s instructions.

Install equipment in the rack from the bottom up, with the heaviest equipment at the bottom of the

rack.

Extend only one piece of equipment from the rack at a time.

You are responsible for installing a main power disconnect for the entire rack unit. This main disconnect

must be readily accessible, and it must be labeled as controlling power to the entire unit, not just to

the server(s).

To avoid risk of potential electric shock, a proper safety ground must be implemented for the rack

and each piece of equipment installed in it.

Electrostatic Discharge (ESD)

CAUTION

ESD can damage disk drives, boards, and other parts. We recommend that you perform all procedures

at an ESD workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground - any unpainted metal surface - on your server when handling

parts.

Always handle boards carefully. They can be extremely sensitive to ESD. Hold boards only by their

edges. After removing a board from its protective wrapper or from the server, place the board

component side up on a grounded, static free surface. Use a conductive foam pad if available but

not the board wrapper. Do not slide board over any surface

Other Hazards

Battery Replacement

CAUTION

There is the danger of explosion if the battery is incorrectly replaced. When replacing the battery, use

only the battery recommended by the equipment manufacturer.

Dispose of batteries according to local ordinances and regulations.

Do not attempt to recharge a battery.

Do not attempt to disassemble, puncture, or otherwise damage a battery.

Cooling and Airflow

CAUTION

Carefully route cables as directed to minimize airflow blockage and cooling problems. For proper

cooling and airflow, operate the system only with the chassis covers installed. Operating the system

without the covers in place can damage system parts. To install the covers:

1. Check first to make sure you have not left loose tools or parts inside the system.

2. Check that cables, add-in boards, and other components are properly installed.

3. Attach the covers to the chassis according to the product instructions.

11 MAXDATA PLATINUM 7200 IR M7

Laser Peripherals or Devices

CAUTION

To avoid risk of radiation exposure and/or personal injury:

• Do not open the enclosure of any laser peripheral or device.

• Laser peripherals or devices are not user serviceable.

• Return to manufacturer for servicing.

12 Safety Information

2 Platform Description

The PLATINUM 7200 IR Server is a compact, high-density, rack-mount system with support for one

to four Intel® Xeon™ MP processors and 256 GB of 533 MHz / 667 MHz FBDIMM memory. The

platform supports hot plug PCI-Express add-in cards; hot-swap, redundant power supply modules;

hot swap, redundant cooling fans; memory with RAS features; and hot-swap hard disk drives. The

server platform is shown below.

Figure 1. PLATINUM 7200 IR Server Front View

Platform Features

The platform features are outlined in the following table.

Table 2. Chassis Feature Summary

Feature Description

Dimensions Height: 6.8 inches (173 mm)

Width: 17.6 inches (447 mm)

Depth: 27.8 inches (706 mm)

Weight of fully configured system: 90 lbs (40 kg)

Clearance

requirements

Configuration

flexibility/

Scaleability

Serviceability • Front access to hot-swap hard disk drives

Availability • Two hot-plug PCI Express slots

Manageability • Remote management

Front control panel • System power button and LED

• Front clearance: 3 inches (76 mm)

• Side clearance: 1 inch (25 mm)

• Rear clearance: 6 inches (152 mm)

• Support for one to four processors

• Support for at least two generations of processors

• Support for up to four 2.5-inch SATA hard drives, or eight 2.5-inch SAS hard

drives with optional SAS riser board

• Support for up to seven PCI-Express adapters:

- Four x8 slots

- Three x4 slots

• Support for up to 256 GB Fully Buffered DIMM (FBD) Double Data Rate-2

(DDR2) 533 or 667 MHz memory

• Support for two integrated gigabit LAN ports, or four integrated gigabit LAN

ports with optional I/O riser board

• Front access to hot-swap fans

• Rear access to hot-swap power supplies

• System power and system status LEDs

• System ID buttons and LEDs on front panel and rear of system

• Memory status LEDs

• Processor failure LEDs

• Color-coded parts to identify hot-swap and non-hot-swap serviceable

components

• Up to two 1570-watt power supplies in a redundant (1+1) configuration; the

second power supply is optional

• Dual power cords (1+1) when two power supplies are installed

• Up to eight hot-swap system fans in a redundant (7+1) configuration; two

rear fans are optional; four rear fans are required for redundancy

• Eight hot-swap 2.5-inch SAS hard drives

•

SAS RAID riser board (optional) with a battery-backed DDR2 DIMM for disk cache

• Emergency Management Port (EMP)

• Intelligent Platform Management Interface (IPMI) 1.5 compliant, partial IPMI

2.0 compliance

• Wired For Management (WfM) 2.0 compliant

• Remote diagnostics support

• Optional Intel® Remote Management Module 2 provides remote KVM and

media features (requires optional I/O riser)

• System reset button

• NMI button

• System ID button and LED

• System status LED

• Hard drive status LED

• LAN1 and LAN2 status LEDs

• Video connector

• Three USB 2.0 ports

14 15MAXDATA PLATINUM 7200 IR M7Platform Description

Platform Front

A

B

C

E

D

G

FF

Table 3. Front Components

Figure 2. Front Components

Item Description

A. CD-ROM / DVD-ROM drive bay

B. 5 ¼ peripheral bay

C. Video connector

D. USB 2.0 ports

E. Front control panel

F. Hot-swap fan modules (2)

G. Hot-swap disk drives (0-7, from left to right)

Standard Control Panel

A

B

J L

K

C ED

F

H

G

I

The standard control panel provides a user interface for system management via switches and status

LEDs. The control panel also contains the speaker. Figure 3 shows the location of the buttons and

status LEDs on the standard control panel.

Figure 3. Front Panel Controls and Indicators

Table 4. Front Panel Controls and Indicators

Item Feature Description

Front Panel Connectors

A Video connector Video port, standard VGA compatible, 15-pin connector

B Three USB connectors Three USB 2.0 ports, 4-pin connectors

Front Panel Buttons and LED Indicators

C Hard Drive Activity LED

(Green/Amber)

D,

E

LAN1, LAN2 Status LEDs

(Green)

Indicates hard drive activity and fault status.

LED State Description

Green, On A hard drive is

being initialized.

Green, Blinking A hard drive is

active.

Amber, On Hard drive/slot

failure.

Amber, Slow Blinking

(~1 Hz)

Amber, Fast Blinking

(~2.5 Hz)

Indicates LAN activity status

LED State Description

Off Idle

On Inactive No Access

Blinking Active Access

A predictive hard

drive/slot failure or

rebuild in process.

Hard drive rebuild

interrupted or

rebuild on empty

slot.

16 17MAXDATA PLATINUM 7200 IR M7Platform Description

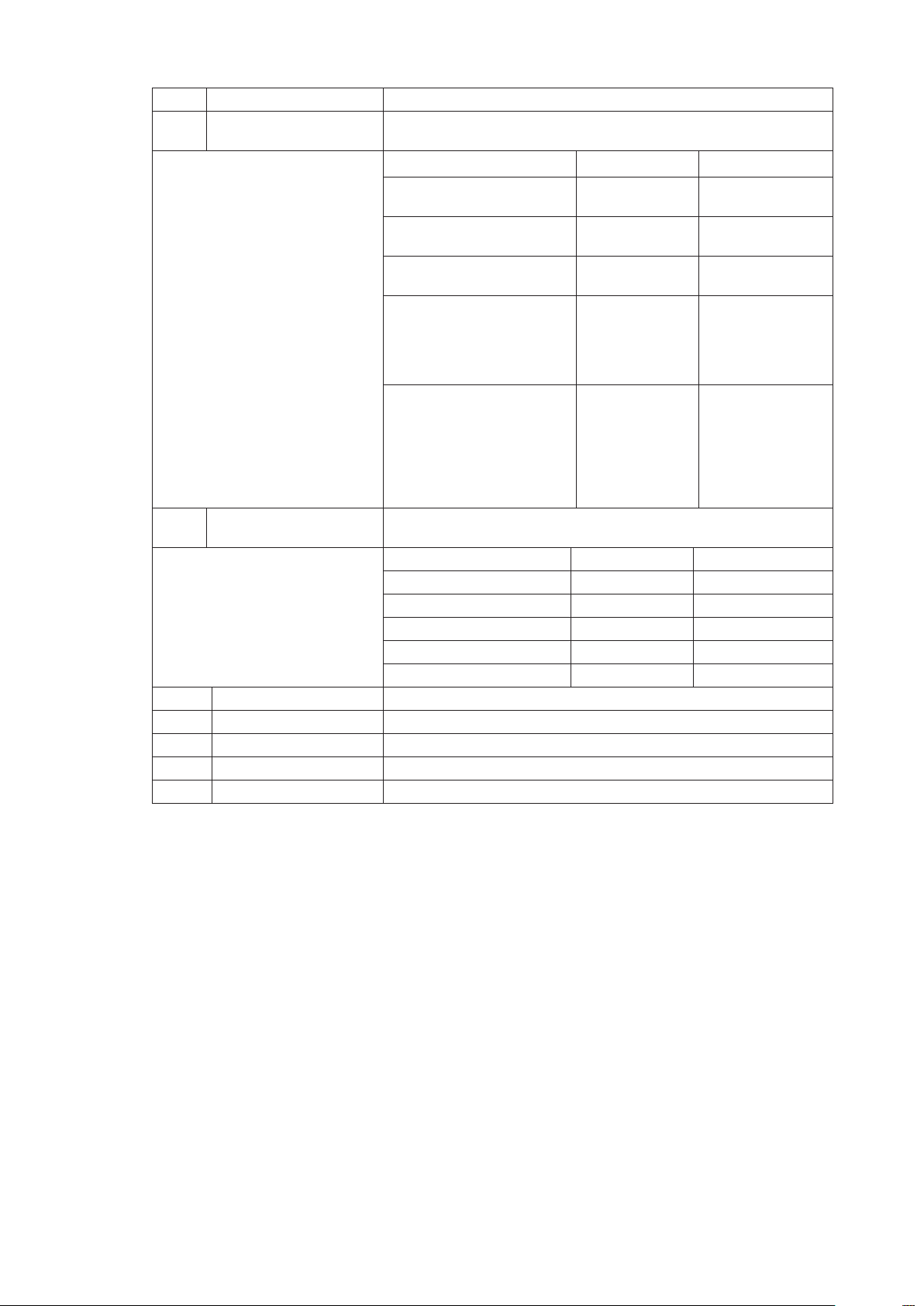

Item Feature Description

F System Status/Fault LED

(Green/Amber)

G System Power LED

(Green)

H System ID LED (Blue) Identifies the system via server management or locally.

I NMI button Asserts NMI.

J System Reset button Press to reset the system.

K System Power button Press to turn the system power on or off.

L System ID button Press to turn the System ID LED on or off.

Indicates system status.

LED State Description

Off Not ready AC Power Off,

POST error

Green, On Ready System booted

and ready

Green, Blinking Degraded CPU or DIMM

disabled

Amber, On Critical Alarm Critical Power

Supply, Blower,

Voltage, or

Temperature

failure

Amber, Blinking Non-Critical

Alarm

Indicates system power status.

LED State ACPI

Off Power off No

On Power on No

Off S4/S5 Yes

Blinking S1 Yes

On S0 Yes

Redundant Power

Supply or Blower

failure. NonCritical Blower,

Voltage, and

Temperature

failure.

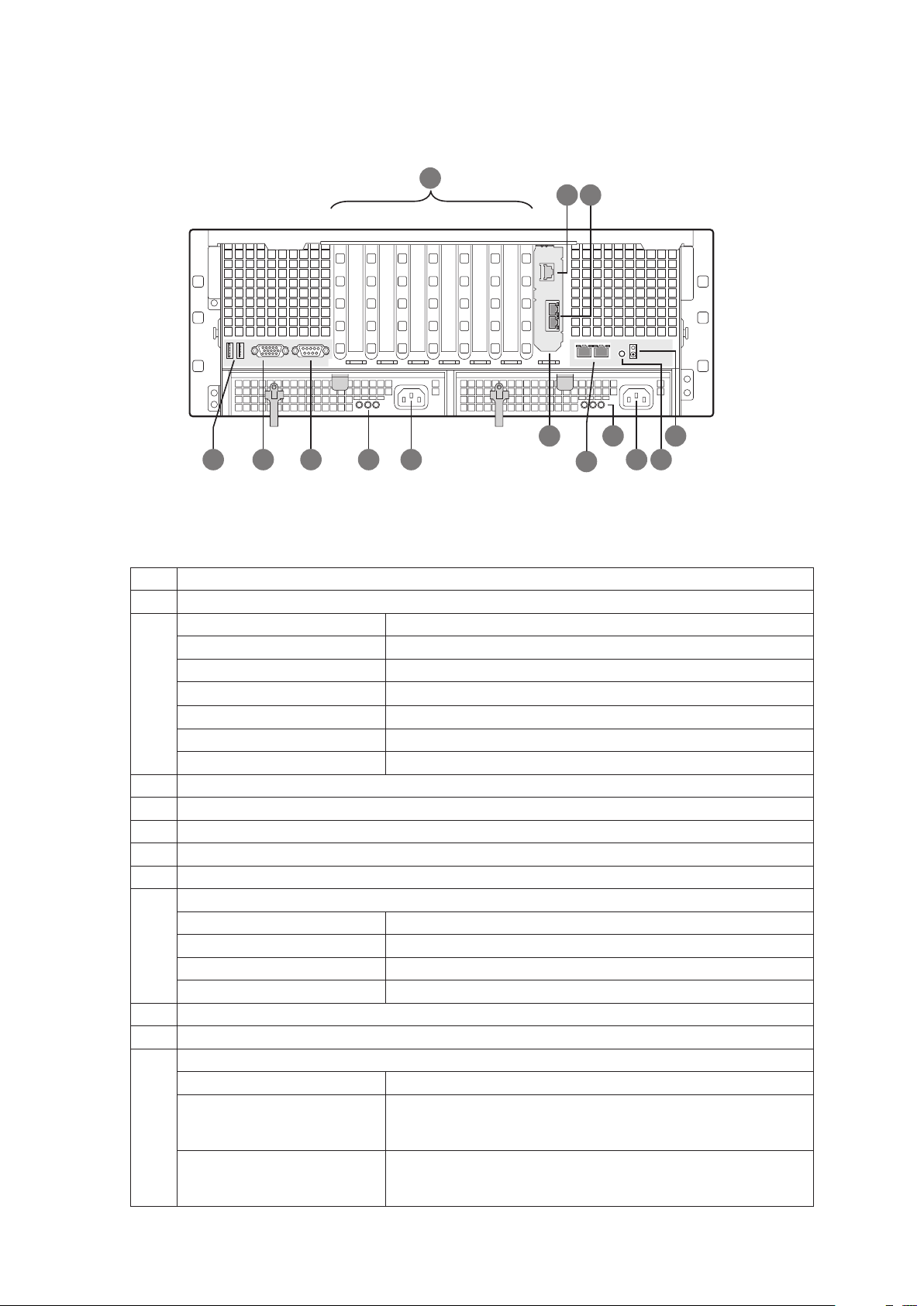

Platform Rear

B C

1 7432 5 6

A

D

F

G

K

H

L

M

J

I N

E

This diagram shows the system with the optional I/O panel installed.

Figure 4. Rear Platform Features

Table 5. Rear Platform Features

Item Description

A PCI Slots

Slot 1 PCI Express x8, hot-plug

Slot 2 PCI Express x8, hot-plug

Slot 3 PCI Express x8, not hot-plug

Slot 4 PCI Express x8, not hot-plug

Slot 5 PCI Express x4, not hot-plug

Slot 6 PCI Express x4, not hot-plug

Slot 7 PCI Express x4, not hot-plug

B Intel® Remote Management Module 2 (RMM2) NIC

C I/O riser Ethernet ports (two)

D USB ports (two)

E Standard VGA-compatible video port with 15-pin connector

F Serial port B connector

G Power supply LEDs

Power Supply LED Power Supply Status

Left: Power good (green) Power supply is on

Center: Fault (amber) Power supply failure

Right: AC OK (green) Power supply is connected to AC

H AC input power connector

I I/O riser card (optional)

J LAN 1 (left), LAN 2 (right) RJ45 Ethernet connectors

LAN Port LED LAN Status

Status LED (green) Off: No Ethernet connected

Speed LED (green / amber) Off: 10 Mbps

On: Ethernet link detected

Blink: Ethernet link active

Green: 100 Mbps

Amber: 1000 Mbps

18 19MAXDATA PLATINUM 7200 IR M7Platform Description

Item Description

K Power supply LEDs

Power Supply LED Power Supply Status

Left: Power good (green) Power supply is on

Center: Fault (amber) Power supply failure

Right: AC OK (green) Power supply is connected to AC

L AC input power connector

M System ID button

N Blue system ID LED to identify the system from among many systems

Processors

The PLATINUM 7200 IR Server supports from one to four 64-bit Intel® Xeon™ processors MP (7x00

sequence).

System Memory

The memory boards connect to the main board through x16 PCI Express connectors. One to four

memory boards can be installed, two on each side of the system. Memory board baffles are not needed

for empty memory board slots, but DIMM blanks are required for each socket on each memory board

in which a DIMM is not installed.

Figure 5. Memory Boards

Each memory board has these features:

• Supports up to eight FBD Generation-1 DIMMs

• Supports FBD speeds of 533MT/s (4-4-4, 5-5-5 latencies) and 667MT/s (5-5-5 latency)

• Supports FBDIMM configurations of x8, x4, single, dual-rank DDR2 DRAMs

• Supports DDR2 DRAM technologies of 512 Mbit, 1 Gbit, and 2 Gbit

• Supports Closed Loop Thermal Throttling with FBDIMM AMB temperature sensors

• LED fault indicators for each DIMM

• One field replaceable unit (FRU) EEPROM

• Supports memory mirroring and memory sparing

See “Memory Board” for additional information.

Available Memory Configurations

The BIOS configures the system memory into the best possible configuration after comparing the

current FBDIMM population with the desired memory configuration selected by the user in BIOS

Setup. Possible configurations are:

Dual-channel Mode (Maximum Performance Mode): The default setting providing the

•

highest system performance and increased FBD bandwidth. This requires each lock-stepped

pair of FBDIMMs on a branch to be identical. A lock-stepped FBDIMM pair is defined as the

FBDIMMs installed in identically numbered FBDIMM sockets on both memory riser boards

(channels) on a given Memory Branch.

•

Single-channel Mode: A failsafe mode when the installed memory configuration is

incompatible with dual-channel operation. In single-channel mode, only Branch 0, Channel 0 is

operational with all other FBDIMMs disabled automatically.

•

DIMM Sparing Mode: Only supported in a lock-stepped (dual-channel) configuration. DIMM

Sparing is the use of a lock-stepped FBDIMM rank on a memory branch to provide a backup

in case any other lock-stepped FBDIMM rank on the same branch exceeds a user-selectable

Memory ECC Correctable Error threshold in a fixed time period. This failure prediction

mechanism allows the system to automatically:

- Copy the contents of a failing FBDIMM rank to a backup or spare FBDIMM rank

- Disable the failing FBDIMM rank

These actions are completed before the FBDIMM rank begins to generate more serious

memory ECC uncorrectable errors that would bring down the system by corrupting memory.

•

Memory Mirroring Mode: Memory Mirroring is a high availability mode providing a redundant

image of the system memory. This image allows the system to continue operating if memory

ECC uncorrectable errors would otherwise bring down the system in another memory

configuration.

20 21MAXDATA PLATINUM 7200 IR M7Platform Description

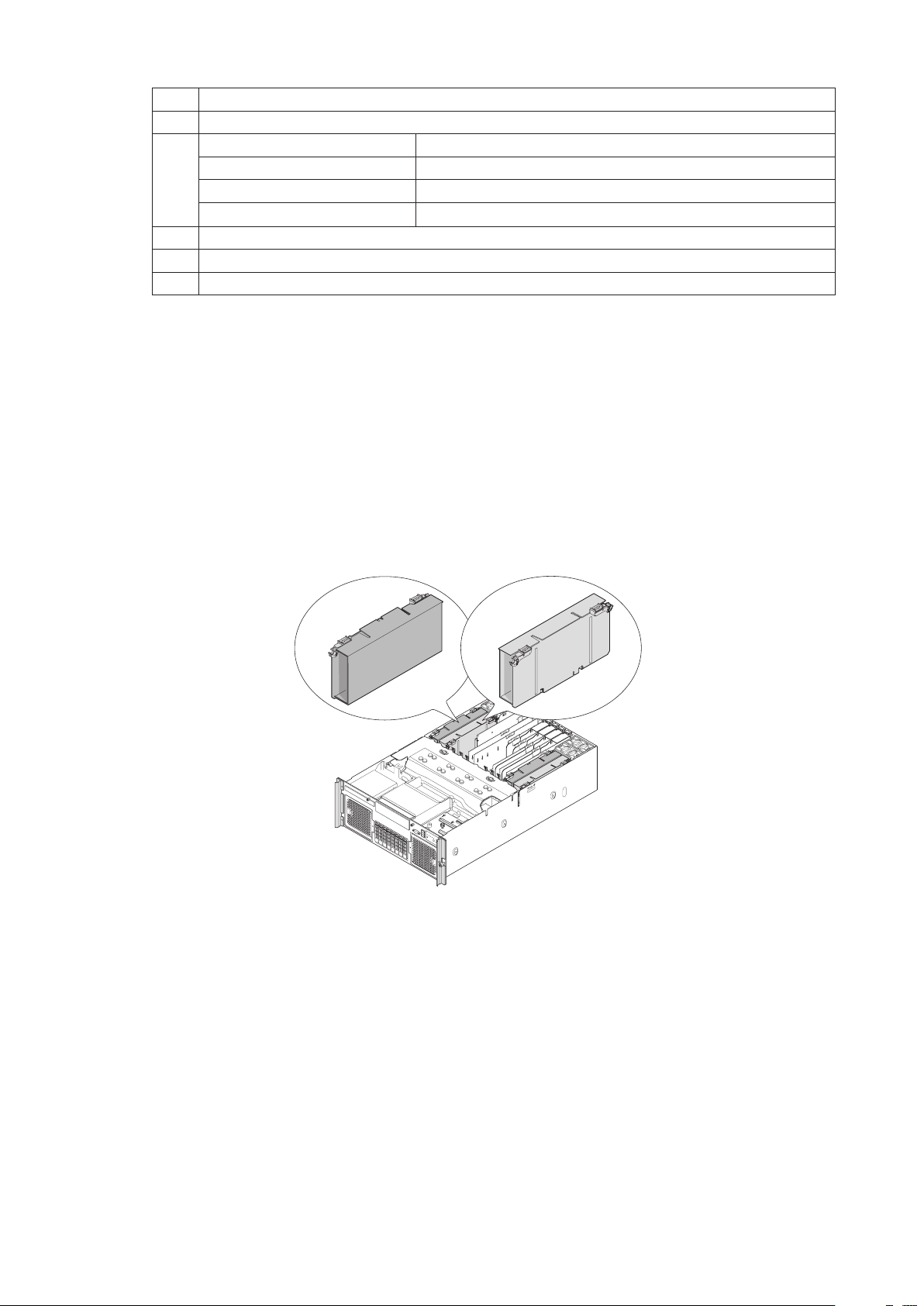

Power Subsystem

The power subsystem consists of the following:

• Power supply modules

• The Power Distribution Board

The power subsystem can be configured with two power supply modules installed for 1+1 redundancy

at 220 VAC.

Power Supply Modules

The output rating of the power supply is 1570 W when operated between 180 VAC and 264 VAC. It

is a current-sharing power supply with auto-ranging input. The power supply is approximately 7.75

inches wide by 14.5 inches deep by 1.47 inches high. The power supply modules have universal AC

input with Power Factor Correction (PFC) Distributed Power Supplies (DPS). The AC input receptacle

is an IEC-320 C14.

The power supply has two DC outputs: 12 V and 3.3 VSB. The 12 V main power is distributed through

the server and is converted locally at the point-of-load using embedded VRM converters. The power

supply is capable of power-safe monitoring.

In an N+1 configuration, the 12 VDC outputs have active (forced) current sharing. The two externally

enabled outputs have the following maximum ratings:

• +12 VDC: 121 A

• +3.3 VDCSB: 5 A

Each power supply module requires one power cord to supply AC power to the system. When two

power supply modules and two power cords are installed, the system supports (1+1) power cord

redundancy. This feature allows the system to be powered by two separate AC sources. In the 1+1

configuration, the system continues to operate, without interruption, if one of the AC sources fails.

Each power supply module has three status LEDs. These are located next to the input connector,

A

B

C

as shown by the following figure.

Figure 6. Power Supply Indicators

Table 6. Power Supply Indicators

Location Purpose Description

A (left) Power Good LED (green) This green LED is driven by internal circuitry and is lit

whenever the power is turned on.

B (center) Fault LED (amber) This amber LED is driven by internal circuitry and is

lit when a power rail has failed. The LED is lit even if

the power supply is in a latched state. The only time

(during a fault) when it is not lit is if the +3.3 VSB is

lost.

The LED is not lit when the power supply is turned off

by powering down the platform.

C (right) AC OK LED (green) This green LED is driven by internal circuitry and is lit

whenever the AC power cord is plugged in to an active

AC power source.

22 23MAXDATA PLATINUM 7200 IR M7Platform Description

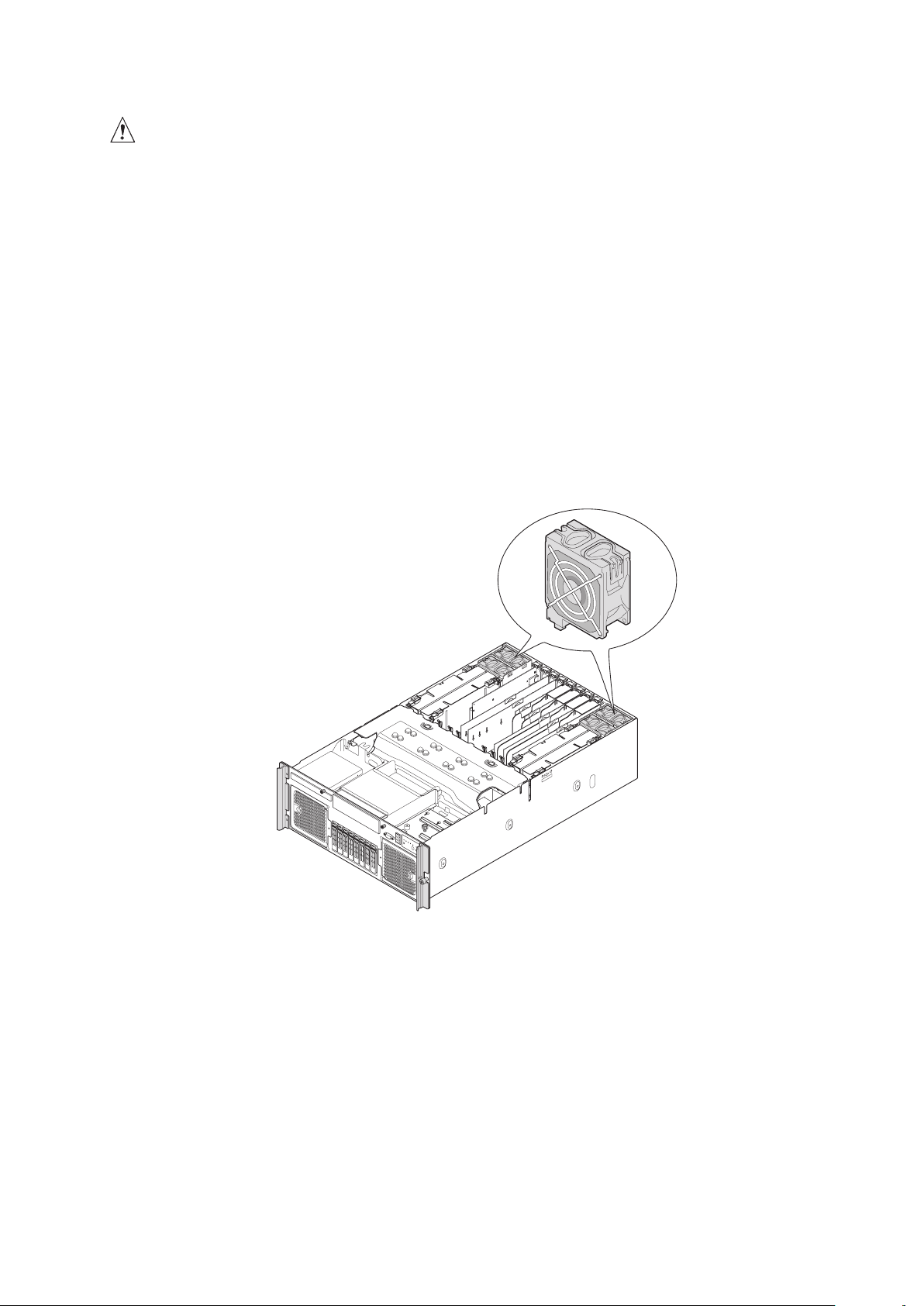

Cooling Subsystem

CAUTION

The chassis top cover must be installed for proper system cooling. Cooling components must be hotswapped within two minutes. This time period applies only to the time that the cooling component

is physically removed, not from the time of failure.

The cooling subsystem consists of hot-swap, redundant (7+1) fans. In a redundant configuration, the

system supports one fault at a time, either one fan fault or one power supply fault, and it supports

hot-swapping one component at a time. If a cooling component fails, the system cooling is maintained

and the system continues to operate while the component is hot-swapped.

Each front fan assembly has one status LED. The LED is off when both fans are operating normally.

The LED illuminate amber if one or both of the fans fails. Failed front fans can be hot-swapped from

the front of the system.

Each rear fan has one status LED. The LED is off when the fan is operating normally and illuminates

amber if the fan fails. Failed rear fans can be replaced from the top of the system when the top cover

is removed.

Figure 7. Rear Fan Locations

For proper processor cooling, the processor duct must always be in place. Systems that are configured

with fewer than four processors should have processor blanks installed to maintain proper cooling.

Hot-swap PCI Slots

The two hot plug PCI slots have power and attention LEDs. The attention button is used to invoke a

hot-plug sequence to remove or add an adapter without having to use the software interface. They

are identified by the green arrow on the PCI divider label. The status of the LEDs is shown in Table

7 and Table 8.

Table 7. Power Indicator

Green Power LED State Definition

Off Power off: Power has been removed from the slot. A card can be

inserted or removed.

On Power on: The slot is powered on. A card cannot be inserted or

removed.

Blinking Power transition: The slot is in the process of powering up or down. A

card cannot be inserted or removed.

Table 8. Attention Indicator

Amber Attention LED State Definition

Off Normal: Normal operation

On Attention: Power fault or operational problem has occurred with this

slot.

Blinking Locate: The slot is being identified at the user’s request.

/ NOTE

If you hot-remove a PCI card without following the proper procedure, power will automatically be

turned off to the slot.

24 25MAXDATA PLATINUM 7200 IR M7Platform Description

Peripherals

C

B

A

Hot-Swap Hard Drive

The hot-swap hard drive carrier and SAS backplane board accommodate 2.5-inch SAS or SATA hard

drives.

Figure 8. Hard Drive Carrier

Table 9. Hard Disk Drive Carrier

Item Description

A Latch

B Green LED

Green on SAS drive is installed and working correctly

Green blink Hard drive is active

C Amber LED

Amber on Hard drive or slot failure

Amber slow blink (~1 Hz) Predictive hard drive / slot failure or rebuild is in process

Amber fast blink (~2.5 Hz) Hard drive rebuild interrupted or rebuild on empty slot

Removable Media Drive Bay Support

The DVD-ROM/CD-ROM drive is installed in a sheetmetal carrier and is inserted from the front of the

chassis. The tape back-up drive is also installed from the front of the chassis. You must power down

the platform and remove the top cover to remove or install these devices.

5 ¼-inch Half-height Drive Bay

The system supports one 5 ¼-inch, half-height device mounted at the front of the system. A USB

or SATA tape backup device can be cabled to the internal USB or SATA port located on the main

board. Alternatively, a SCSI or SAS tape backup device can be cabled to a PCI Express add-in card

(not included).

System Board Set

The board set consists of the following boards:

• Main board

• Memory boards

• I/O riser board (optional)

• SAS riser board (optional)

• Front panel board

• SAS backplane board

• Power distribution board

• SATA-to-IDE adapter board

Main Board

The main board contains:

• Chipset north and south bridge components

• Processor sockets

• Four memory board connectors

• Video components

• Trusted Platform Module

• Seven PCI Express slots

• Back panel I/O connectors

26 27MAXDATA PLATINUM 7200 IR M7Platform Description

A

B C E F G

H

I

J

M

L

K

U

T S R

Z

Y

V

X

CC

Q

P

O

N

D

BB

W

AA

Figure 9. Main Board Component Locations

Table 10. Main Board Component Locations

Item Description Item Description

A Dual Ethernet ports P Front panel connector

B I/O riser slot Q Power distribution board connectors (3)

C PCI Express x4 (slot 7) R Processor socket 1

D Serial Port A S Processor socket 2

E PCI Express x4 (slot 6) T Processor socket 3

F PCI Express x4 (slot 5) U Processor socket 4

G PCI Express x8 (slot 4) V SAS riser slot

H PCI Express x8 (slot 3) W Chassis intrusion

I PCI Express x8 hot-plug (slot 2) X 4-port SATA connector

J PCI Express x8 hot-plug (slot 1) Y Internal USB port

K Serial port B Z Memory board (slot C)

L Video port AA Single port SATA connectors

M USB 1 (top), USB 2 (bottom) BB Memory board (slot D)

N Memory board (slot A) CC Real-time clock battery

O Memory board (slot B)

C D

E

B

A

F

Figure 10. Main Board Jumpers

Label Name Function Location

A Rolling BIOS 1 - 2 = Force other bank

*2 - 3 = Normal mode

B Password disable or clear *1 - 2 = Password protect

2 - 3 = Password disabled / cleared

C Clear CMOS / NVRAM *1 - 2 = Normal

2 - 3 = Forced CMOS / NVRAM clear

D BMC force update *1 - 2 = Disable BMC force update

2 - 3 = Enable BMC force update

E BMC flash write protect *1 - 2 = Disable flash write protect

2 - 3 = Enable flash write protect

F Circuit breaker 1 - 2 = 20A/110V (USA)

*2 - 3 = 15A/100V (Japan)

*Default Jumper Setting

J3D1

J3C2

J3C3

J5C1

J6D1

J6F1

28 29MAXDATA PLATINUM 7200 IR M7Platform Description

Video Support

The main board uses the ATI RN50 Embedded Video Controller with 32 MB of video RAM. The RN50

provides these features:

• 2D/3D video accelerator

• Dual DAC for simultaneous port support (front / rear video support)

• Resolutions from VGA up to UXGA (1600 x 1200)

• Digital Video Input/Output (DVI/DVO) interface routed to the Intel

Module 2 (RMM) for KVM support up to 165 MHZ

• 3.3 V 32-bit / 33 MHz PCI host interface

The main board has a standard DB5 video connector.

®

Remote Management

Ethernet Support

1000/100/10 Ethernet capability is supported by the ESB2 MAC and 82563EB PHY (Physical Layer).

The 82563EB PHY outputs two Gbit LAN ports and connects to a 1x2 RJ45 Gbit connector that is

accessible at the rear of the system.

Memory Board

IHG

F

E

D

C

A

B

Q

P

O

N

M

L

K

J

One, two, or four memory boards can be installed. Each memory board has eight DIMM sockets

that support x4 or x8, single- or dual-rank FBD DDR2 DIMMs. FBD speeds of 533 MT/s (4-4-4, 5-5-5

latencies) and 667 MT/s (5-5-5 latency) are supported. DDR2 DRAM technologies of 512 Mbit, 1 Gbit,

and 2 Gbit are supported. The memory boards connect to the main board through x16 PCI Express

connectors. The memory boards have LEDs that indicate the status of the memory board power and

the status of each DIMM.

Figure 11. Memory Board LEDs and Connectors

Table 11. Hot-Plug Memory Board LEDs and Buttons

Item Description

A Power Good LED (green). The memory board power is good

B DIMM1 Fault LED (amber). DIMM1 had an error and needs to be replaced

C DIMM2 Fault LED (amber). DIMM2 had an error and needs to be replaced

D DIMM3 Fault LED (amber). DIMM3 had an error and needs to be replaced

E DIMM4 Fault LED (amber). DIMM4 had an error and needs to be replaced

F DIMM5 Fault LED (amber). DIMM5 had an error and needs to be replaced

G DIMM6 Fault LED (amber). DIMM6 had an error and needs to be replaced

H DIMM7 Fault LED (amber). DIMM7 had an error and needs to be replaced

I DIMM8 Fault LED (amber). DIMM8 had an error and needs to be replaced

J DIMM1 Socket

K DIMM2 Socket

L DIMM3 Socket

M DIMM4 Socket

N DIMM5 Socket

O DIMM6 Socket

P DIMM7 Socket

Q DIMM8 Socket

30 31MAXDATA PLATINUM 7200 IR M7Platform Description

I/O Riser Board (optional)

B

A

D

C

The I/O riser board is a vertical riser that provides advanced server management with a dedicated

maintenance Ethernet port, and additional dual-gigabit Ethernet ports.

The Remote Management Module 2 (RMM2) and RMM2 NIC plug into the I/O riser board to provide an

upgrade path to advanced server management capabilities. When the optional RMM2 is installed, the

original set of server management features continue to work and additional functionality is available.

This functionality seamlessly integrates into the server, with respect to configuration functions and

software support.

The RMM2 supports keyboard, mouse, video redirect, and media redirect functionality, which lets

the user use the remote system to control the host server.

The Intel 82575EB PCI Express-based Ethernet controller provides advanced networking control and

capability with dual-gigabit Ethernet ports. This controller hosts the Intel® I/O Acceleration Technology

II (Intel® I/OAT2) capability that provides optimization of the TCP flow. The Intel® I/O riser provides an

option to disable Gbit port A and / or port B in the BIOS. Server management traffic over these ports

is not supported. For management traffic, use the main board LAN ports.

Figure 12. I/O Riser Board Connectors

Item Description Item Description

A RMM2 NIC C Dual gigabit LAN Ethernet ports

B RMM2 NIC connector D Remote Management Module 2 connector

SAS Riser Board (optional)

C

B

D

E

A

The SAS riser board works with the SAS backplane board to support eight SAS hard drives. The

SAS riser uses a dedicated slot at the front of the system to make cabling to the SAS backplane

convenient.

The SAS riser board uses the LSI1078 SAS controller to provide eight SAS channels at up to 3Gb/s.

The riser natively supports Integrated RAID levels 0, 1, and 1E.

If the optional RAID Activation Key and DDR2-667 registered DIMM are installed, hardware RAID

levels 0, 1, 5, 6, 10, 50, and 60 are enabled. The optional RAID smart battery can be installed to provide

DDR2 DIMM refresh support during a power failure.

Figure 13. SAS Riser Connectors

Item Description Item Description

A SES Connector D RAID Activation Key

B SAS x4 Port A E RAID DIMM Connector

C SAS x4 Port B

32 PBMAXDATA PLATINUM 7200 IR M7Platform Description

3 Starting Up and Shutting Down the Server

Powering On the Server

Press the power button on the front control panel. The fans start and POST begins.

/ NOTE

It might take three minutes or longer for video to be displayed, depending on the amount of memory

installed.

The server attempts to boot from the first device on the list of available devices in the boot manager.

If this device is not available, it will move to the second device. It continues down the list until it

reaches the first available device.

Press F2 during POST to enter the BIOS setup utility. This utility also contains a boot manager that

allows to select a boot device for immediate boot.

Shutting Down the Server

1. Exit the operating system (if applicable)

2. Press and hold the power button until the server shuts down.

CAUTION

Powering down the server with the power button does not remove all power from the system. The

+3.3 V standby power is still available to the system even when it is not running. To remove standby

power from the system, unplug all power cords from the system and unplug the power supplies. If

you do not unplug the power supplies, standby power may be held up by the integrated capacitors

for more than 10 minutes.

34 PBMAXDATA PLATINUM 7200 IR M7

4 Server Platform Utilities

BIOS Setup Utility

The BIOS Setup Utility is a text-based utility that allows you to configure the system and view and

change device settings and view environmental information for the platform. The BIOS Setup Utility

interface consists of several screens, called pages. Each page contains information or links to other

pages. The first page in Setup displays links for general categories. These links lead to pages containing

specific configuration settings.

The BIOS Setup Utility is functional through console redirection over various terminal emulation

standards. This may limit some functionality due to compatibility. For example, colors, some keys or

key sequences, and mouse support may be limited.

To enter the BIOS Setup Utility, press <F2> when prompted during POST to access the Systems

Options Menu.

BIOS Setup Utility Page Layout

The BIOS Setup Utility page layout is sectioned into functional areas. The following table lists and

describes the functional areas and their position on the screen.

Table 12. BIOS Setup Utility Page Layout

Functional Area Description

Menu Selection Bar The Menu Selection Bar is located at the top of the screen. It displays the

major menu selections available.

Setup Item List The Setup Item List is a set of configurable and informational items. The

left column shows the setup item. The right column shows the corresponding option. The option contains an informational value or possible

settings for the setup item.

Item Specific Help Area The Item Specific Help area is located on the right side of the screen

and contains help text for the highlighted Setup Item. Help information

includes the meaning and usage of the item, allowable values, and the

affects of the options.

Keyboard Command

Area

Status Bar The Status Bar is on the bottom line of the screen. The status value “NV”

The Keyboard Command Bar is located at the bottom of the screen and

displays help for keyboard special keys and navigation keys. The keyboard

command bar is context-sensitive. It displays keys relevant to the current

page and mode.

indicates you have made changes to Setup that have not been saved.

Keyboard Commands

The bottom right portion of the Setup screen provides a list of commands that are used to navigate

through the BIOS Setup Utility. These commands are context sensitive.

The Keyboard Command Bar supports the following key presses:

Table 13. BIOS Setup: Keyboard Commands

Key Option Description

<Enter> Execute Command The <Enter> key is used to activate sub-menus when the

selected feature is a sub-menu, or to display a pick list if

a selected option has a value field, or to select a sub-field

for multi-valued features like time and date. If a pick list is

displayed, the <Enter> key will select the currently highlighted

item, undo the pick list, and return the focus to the parent

menu.

<Esc> Exit The <Esc> key provides a mechanism for backing out of any

field. This key will undo the pressing of the <Enter> key. When

the <Esc> key is pressed while editing any field or selecting

features of a menu, the parent menu is re-entered.

When the <Esc> key is pressed in any sub-menu, the parent

menu is re-entered. When the <Esc> key is pressed in any

major menu, the exit confirmation window is displayed and

you are asked whether changes can be discarded. If “No” is

selected and the <Enter> key is pressed, or if the <Esc> key

is pressed, you are returned to where you were before <Esc>

was pressed without affecting any existing any settings. If

“Yes” is selected and the <Enter> key is pressed, setup is

exited and the BIOS continues with POST.

Up Arrow Select Item The up arrow is used to select the previous value in a pick

list, or the previous option in a menu item‘s option list. The

selected item must then be activated by pressing the <Enter>

key.

Down arrow Select Item The down arrow is used to select the next value in a menu

item’s option list, or a value field’s pick list. The selected item

must then be activated by pressing the <Enter> key.

Left and Right

Arrow

<Tab> Select Field The <Tab> key is used to move between fields. For example,

<-> Change Value The minus key on the keypad is used to change the value of

<+> Change Value The plus key on the keypad is used to change the value of the

Select Menu The left and right arrow keys are used to move between the

major menu pages. The keys have no affect if a sub-menu or

pick list is displayed.

<Tab> can be used to move from hours to minutes in the time

item in the main menu.

the current item to the previous value. This key scrolls through

the values in the associated pick list without displaying the full

list. This key only works for date and time.

current menu item to the next value. This key scrolls through

the values in the associated pick list without displaying the

full list. On 106-key Japanese keyboards, the plus key has a

different scan code than the plus key on the other keyboard,

but will have the same effect. This key only works for date and

time.

36 37MAXDATA PLATINUM 7200 IR M7Server Platform Utilities

Key Option Description

<F9> Setup Defaults Pressing <F9> causes the following to appear:

Load default configuration now? (Y/N)

If the “Y” key is pressed, all Setup fields are set to their

default values. If the “N” key is pressed, or if the <Esc> key is

pressed, you are returned to where you were before <F9> was

pressed without affecting any existing field values

<F10> Save and Exit Pressing <F10> causes the following message to appear:

Save Configuration changes and exit now? (Y/N)

If the “Y” key is pressed, all changes are saved and Setup is

exited. If the “N” key is pressed, or the <Esc> key is pressed,

you are returned to where you were before <F10> was pressed

without affecting any existing values.

Each Setup Utility menu page contains a number of features. Some features are used for informative

purposes only, and other features are associated with a value field that you can configure. Depending

on the security option chosen and in effect, a menu feature’s value may be changeable. If a value

cannot be changed, the feature’s value field is inaccessible.

Console Redirection

The BIOS supports redirection of both video and keyboard through a serial link (COM port). When

console redirection is enabled, local (host server) keyboard input and video output are passed both

to the local keyboard and video connections and to the remote console via the serial link. Keyboard

inputs from both sources are considered valid and video is displayed to both outputs. With console

redirection, the system can be operated without a host keyboard or monitor attached to the system

and run entirely via the remote console. Setup and any other text-based utilities can be accessed via

console redirection.

Serial Configuration Settings

When redirecting through a modem (as opposed to a null modem cable), the modem needs to be

configured with the following:

• Auto-answer (for example, ATS0=2, to answer after two rings).

• Modem reaction to DTR set to return to command state (e.g., AT&D1).

Failure to provide the second item will result in the modem either dropping the link when the server

reboots (as in AT&D0) or becoming unresponsive to server baud rate changes (as in AT&D2).

The option for handshaking must be set to RTS/CTS + CD for optimum performance. The CD refers

to carrier detect. If EMP is sharing the COM port with serial redirection, the handshaking must be

set to Xon/Xoff + CD. In selecting this form of handshaking, the server is prevented from sending

video updates to a modem that is not connected to a remote modem. If this is not selected, video

update data being sent to the modem inhibits many modems from answering an incoming call. An

EMP option utilizing CD should not be used if a modem is not used and the CD is not connected.

Both EMP and console redirection require N, 8, 1 mode (no parity, 8-bit data, 1 stop bit).

The BIOS does not require that the splash logo be turned off for console redirection to function. The

BIOS supports multiple consoles, some of which are in graphics mode and some in text mode. The

graphics consoles can display the logo while the text consoles receive the redirected text.

The console redirection ends at the beginning of the Legacy OS boot (INT 19h).

Keystroke Mappings

During console redirection, the remote terminal (which may be a dumb terminal or a system with a

modem running a communication program) sends keystrokes to the local server. The local server

passes video back over this same link. The keystroke mappings follow VT-UTF8 format with the

following extensions.

Setup Alias Keys

The <Del> and <Ctrl>-<function key> combinations are synonyms for the <F2> or “Setup” key. These

are not prompted for in screen messages. These hotkeys are defined only for Console Redirection

support, and are not used on locally attached keyboards.

Limitations

BIOS Console redirection terminates after an EFI-aware operating system calls EFI Boot Service

ExitBootServices. The operating system is responsible for continuing the Console Redirection after

that point. BIOS console redirection is a text console and any graphical data such as a logo are not

redirected.

Interface to Server Management

If BIOS determines that console redirection is enabled, it passes the baud rate through the Intelligent

Platform Management Bus (IPMB) to the appropriate management controller.

Sample Setup for Console Redirection

Below is an example of how to configure the console/host and server for console redirection. In

this example, the console is running under Microsoft® Windows®. The console and server is directly

connected through the serial ports of both systems using a serial null modem cable:

Server Configuration

1. Power on the server.

2. When prompted, press the <F2> key to enter BIOS Setup.

3. The BIOS Setup menu displays the Main menu. Use the arrow keys move to the Server

Management menu.

4. At the Server Management menu, select Console Redirection.

5. Select Serial B Console Redirection.

6. Set Console Redirect to “Enabled”.

7. Set the Bit Rate to “115.2K”.

8. Set the Flow Control to “RTS/CTS”.

9. Set the Terminal Type to “PC-ANSI”.

10. Press the <F10> key.

11. At the prompt to save changes and exit BIOS Setup, select “Yes” and press the <Enter> key.

12. The server reboots and console redirection is enabled.

13. Power down the server and configure the console.

38 39MAXDATA PLATINUM 7200 IR M7Server Platform Utilities

Console Configuration

1. Boot the console into the operating system.

2. Click the Start button in the task bar.

3. Select Programs > Accessories > Communications and click “Hyperterminal”.

4. At the Connection Description window, enter “guest” for the name and click “Ok”.

5. At the Connect To window, select the COM port of the console that the Null modem is

connected. In this example, it is COM1.

6. At the COM1 Properties window, select “115200” in the Bits per second (Baud rate) box to

match what was configured on the server.

7. Select “Hardware” for the Flow Control to match what was configured in the BIOS Setup

(CTS/RTS is the hardware flow control).

8. Leave the default settings for the other boxes. Click “Ok” to accept the settings and enter the

Hyperterminal screen.

9. Power on the server. The console starts displaying the redirection once the video synchronizes

on the server.

Extensible Firmware Interface (EFI) Shell

The EFI shell application allows other EFI applications to be launched, EFI device drivers to be loaded,

and operating systems to be booted. The combination of the EFI firmware and the EFI Shell provides

an environment that can be modified and adapted to many hardware configurations.

The EFI shell provides a set of basic commands to manage files and EFI NVRAM shell and boot

variables. A list of these basic commands is in Table 14.

Extensive information is available on the EFI website at http://developer.intel.com/technology/efi.

Table 14. EFI Shell Commands

Command Description

<drive_name>: Change drives. For example, entering fs0: and pressing the <Enter>

key changes the drive to the LS-240 drive

alias [-bdv] [sname] [value] Sets or gets alias settings

attrib [-b] [+/- rhs] [file] Views or sets file attributes

bcfg -? Configures boot driver and load options in EFI NVRAM

botmaint Launches the Boot Maintenance Manager

break Executes a breakpoint

cd [path] Changes the directory

cls [background color] Clears the screen

comp file1 file2 Compares two files

connect [-r] [-c] Handle#

½DeviceHandle#

DriverHandle#

cp [-r] file [file] ... [dest] Copies files and directories, [-r] = recursive

date [mm/dd/yyyy] Gets or sets the date

dblk device [Lba] [Blocks] Performs a hex dump of BlkIo Devices

devices [-b] [-1XXX] Displays devices

devtree [-b] [-d] Displays device tree

dh [-b] [-p prot_id] | [handle] Dumps handle information

disconnect DeviceHandle#

[DriverHandle#

[ChildHandle#]

dmem {address] [size] [;MMIO] Displays the contents of memory

dmpstore Dumps the variable store

drivers [-b] [-lXXX] Displays drivers

drvcfg [-c] [-lXXX] [-f] [-v] [-s] Invokes the driver configuration protocol

drvdiag [-c] [-lXXX] [-s] [-e] [m] Invokes the driver diagnostics protocol

echo [[-on | -off] | [text] Echoes text to the standard output device or toggles script echo

edit [filename] Opens the text editor allowing you to create or edit a file

eficompress infile outfile Compresses an EFI file

Efidecompress infile outfile Decompresses an EFI file

endfor Provides a delimiter for loop constructs (scripts only)

endif Provides a delimiter for IF THEN constructs (scripts only)

for var in <set>

goto label Makes batch file execution jump to another label

guid [-b] [sname] Dumps known guide ids

help [-b] [internal_command] Displays help information

hexedit [[-f]FileName|[-d

DiskName Offset Size]|[-m

Offset Size]]

if [not] condition then Provides conditional constructs (scripts only)

load driver_name Loads a driver

loadbmp [-c] [-t] [-i[UGA

Instance]] file

loadpcirom romfile Loads a PCI option ROM

Binds the EFI driver to a device and starts the driver

Disconnects device from driver

Edits in HEX mode

Displays a bitmap file on the screen

40 41MAXDATA PLATINUM 7200 IR M7Server Platform Utilities

Table 14. EFI Shell Commands (continued)

Command Description

ls [-b] [dir] [dir] ... Obtains directory listings

map [-bdvr] [sname[:]] [handle] Maps sname to device path

mem [address] [size] [;MMIO] Dumps Memory or Memory Mapped IO

memmap [-b] Dumps memory map

mkdir dir [dir] Creates a new directory

mm address [Width] [;Type] [n] Memory Modify: type = Mem, MMIO, IO, PCI, [n] for non interactive

mode when inside a .nsh file

mode [col row] Sets or gets the current graphics mode

mount BlkDevice [sname[:]] Mounts a file system on a block device

mv [src…] [dst] Move one or more files/directories to destination

pause Prompts to quit or continue (scripts only)

pci [bus_dev] [func] Displays PCI device information

rconnect DeviceHandle#

[DriverHandle#

[ChildHandle#]] | [-r]

reset [reset_string] Performs a cold reset

rm file/dir [file/dir] Removes files or directories

setsize file Sets size of a new file

stall microseconds Delays for the specified number of microseconds

time [hh:mm:ss] Gets or sets the time

type [-a] [-u] [-b] file Displays the contents of a file

ver Displays version information

vol fs [volume_label] Sets or displays a volume label

Reconnects one or more drivers from a device

42 PBMAXDATA PLATINUM 7200 IR M7

5 User Serviceable Platform Components

Tools and Supplies Needed

• Phillips #2 screwdriver

• Flat head screwdriver

• Antistatic wrist strap (recommended)

Removing and Installing the Top Cover

WARNING

Make sure the rack is anchored securely so it will not tilt forward when the server chassis is

extended. A crush hazard exists should the rack tilt forward. This could cause serious injury.

CAUTIONS

For proper cooling and airflow, do not operate the server with the cover removed. Do not leave the

chassis cover open or a system fan removed any longer than necessary; system cooling could be

reduced.

The server comes with a removable top cover that allows the PCI cards, Memory Boards, and the

system fans to be hot-swapped, and the system components to be serviced.

With the exception of the components described in this chapter, all servicing must be done

by a qualified service technician.

Removing the Top Cover

A

B

To remove the top cover, follow these instructions:

1. Observe the safety precautions, warnings, and cautions described in “Safety Information”.

2. If the chassis is rack-mounted, slide the chassis out far enough to expose the entire top cover.

3. Unscrew the two captive screws on the faceplate of the chassis.

4. Slide the top cover toward the back of the chassis until the tabs on the cover disengage with

the slots in the chassis.

5. Lift the cover to remove it.

Figure 14. Removing the Top Cover