Maxdata 7200IRM5 user manual

MAXDATA PLATINUM 7200 IR M5

User’s Manual

2 3MAXDATA PLATINUM 7200 IR M5Contents

Contents

1 Safety Information 7

Safety Warnings and Cautions ................................................................................................................7

Intended Application Uses ......................................................................................................................7

General Warnings ....................................................................................................................................8

Place Battery Marking ........................................................................................................................8

Site Selection ..........................................................................................................................................9

Equipment Handling Practices ................................................................................................................9

Power Cord Warnings ...........................................................................................................................10

System Access Warnings .....................................................................................................................10

Rack Mount Warnings ...........................................................................................................................11

Electrostatic Discharge (ESD) ................................................................................................................11

Other Hazards .......................................................................................................................................11

Battery Replacement ........................................................................................................................11

Cooling and Airflow ..........................................................................................................................11

Laser Peripherals or Devices ............................................................................................................ 12

2 Platform Description 13

Platform Features ..................................................................................................................................14

Platform Front .......................................................................................................................................15

Standard Control Panel ..........................................................................................................................16

Local Control Panel ................................................................................................................................18

Platform Rear ........................................................................................................................................20

Processors .............................................................................................................................................21

Plug-in Voltage Regulator Module (VRM) Converters ...........................................................................21

System Memory ....................................................................................................................................21

Available Memory Configurations ....................................................................................................22

Power Subsystem .................................................................................................................................24

Power Supply Modules ....................................................................................................................24

Cooling Subsystem ...............................................................................................................................26

Hot-swap PCI Slots ...............................................................................................................................26

Peripherals .............................................................................................................................................27

Hot-Swap SCSI Hard Disk Drive Support .........................................................................................27

Removable Media Drive Bay Support ..............................................................................................27

5 ¼-inch Half-height Drive Bay .........................................................................................................27

Platform Board Set ................................................................................................................................28

Main Board ............................................................................................................................................ 29

RAID Support ........................................................................................................................................31

Memory Board ......................................................................................................................................32

3 Starting Up and Shutting Down the Server 33

Plugging the Server into AC Power .......................................................................................................33

Powering On the Server ........................................................................................................................33

Shutting Down the Server .....................................................................................................................34

4 Server Platform Utilities 35

BIOS Setup Utility .................................................................................................................................35

BIOS Setup Utility Page Layout .............................................................................................................35

Keyboard Commands ............................................................................................................................ 36

Console Redirection ..............................................................................................................................37

Serial Configuration Settings .................................................................................................................37

Keystroke Mappings ..............................................................................................................................38

Setup Alias Keys ....................................................................................................................................38

Limitations .............................................................................................................................................38

Interface to Server Management ..........................................................................................................38

Sample Setup for Console Redirection .................................................................................................38

Server Configuration .........................................................................................................................38

Console Configuration ......................................................................................................................39

LSI Logic MPT SCSI Utility ....................................................................................................................40

System Configuration Wizard (SCW) .....................................................................................................42

Starting the System Configuration Wizard ............................................................................................43

Using the Server Configuration Wizard Option .....................................................................................43

Configuring Channels ............................................................................................................................45

LAN Channel Configuration Screen 1 - LAN IP Setup ...........................................................................45

LAN Channel Configuration Screen 2 - Server Management and Serial Over LAN Setup ....................47

LAN Channel Configuration Screen 3 - LAN Alerting Setup ..................................................................48

Configuring the Serial/Modem Channel ................................................................................................49

Serial/Modem Configuration Screen 1 - Modem Setup ........................................................................49

Serial/Modem Configuration Screen 2 -

Configuring Remote Server Management Options for a Serial / Modem Connection ..........................50

Serial/Modem Configuration Screen 3 - Configuring Alerting over a Serial/Modem Connection ..........51

Select Users to Configure Screen .........................................................................................................52

Configure Users Screen ........................................................................................................................52

Configuring the Advanced Features ......................................................................................................54

Advanced Features Configuration Screen 1: SNMP, KVM, Telnet ........................................................54

SNMP Settings ................................................................................................................................. 54

KVM Settings ...................................................................................................................................54

Telnet Settings .................................................................................................................................54

Advanced Features Configuration Screen 2: HTTP Settings .................................................................55

Advanced Features Configuration Screen 3: SMTP Alert Settings .......................................................55

Saving the Configuration to a Disk ........................................................................................................56

Saving the Configuration to the Server .................................................................................................56

5 User Serviceable Platform Components 57

Tools and Supplies Needed ...................................................................................................................57

Removing and Installing the Top Cover .................................................................................................57

Removing the Top Cover ..................................................................................................................58

Installing the Top Cover ....................................................................................................................58

Hot-swapping a System Fan Assembly .................................................................................................59

Hot-swapping Hard Disk Drives ............................................................................................................60

Determining Drive Status .................................................................................................................60

Removing a Hard Disk Drive ............................................................................................................61

Mounting a Hard Disk Drive in a Carrier ...........................................................................................61

Installing a Hard Disk Drive Assembly ..............................................................................................61

Hot-swapping Power Supplies ..............................................................................................................62

Removing a Power Supply ...............................................................................................................62

Installing a Power Supply .................................................................................................................62

Installing and Removing PCI Cards .......................................................................................................63

Removing Hot-plug PCI Card with Operating System Hot-Plug Interface ........................................63

Removing Hot-plug PCI Card with Hardware Hot-Plug Interface ..................................................... 64

Installing a Hot-plug PCI Add-in Card ................................................................................................65

Removing a Non-Hot-Plug PCI Card .................................................................................................66

Installing a Non-Hot-Plug PCI Card ...................................................................................................66

Installing and Removing the Fibre Channel Module ..............................................................................67

Removing the Fibre Channel Module ............................................................................................... 67

Installing the Fibre Channel Module ................................................................................................. 68

4 5MAXDATA PLATINUM 7200 IR M5Contents

Installing and Removing Memory Boards .............................................................................................68

Removing Memory Board Air Baffle ................................................................................................69

Installing Memory Board Air Baffle ..................................................................................................69

Hot Removal of a Memory Board .....................................................................................................70

Hot Insertion of a Memory Board .....................................................................................................71

Cold Removal of Memory Board ......................................................................................................71

Cold Insertion of a Memory Board ...................................................................................................71

Installing and Removing DIMMs ...........................................................................................................72

Rules for Adding Memory ................................................................................................................72

Installing DIMMs ..............................................................................................................................73

Removing DIMMs ............................................................................................................................74

6 Replacing the CMOS Battery 75

7 Regulatory and Integration Information 77

Product Regulatory Compliance ............................................................................................................77

Product Safety Compliance ..............................................................................................................77

Product EMC Compliance .....................................................................................................................77

Product Regulatory Compliance Markings ............................................................................................77

Electromagnetic Compatibility Notices .................................................................................................77

Europe (CE Declaration of Conformity) ............................................................................................77

Figures

1. PLATINUM 7200 IR Server Front View ...........................................................................................13

2. Front Components ..........................................................................................................................15

3. Front Panel Controls and Indicators ................................................................................................16

4. Local Control Panel .........................................................................................................................18

5. Rear Platform Features ...................................................................................................................20

6. Power Supply Indicators ..................................................................................................................25

7. Hard Disk Drive Carrier .................................................................................................................... 27

8. Main Board Component Locations .................................................................................................. 29

9. Hot-Plug Memory Board LEDs and Buttons ....................................................................................32

10. Removing the Top Cover ................................................................................................................58

11. System Fan Location and Removal .................................................................................................59

12. Hard Disk Drive Carrier ....................................................................................................................60

13. Removing the Battery .....................................................................................................................76

Tables

1. Safety Warnings and Cautions ..........................................................................................................7

2. Chassis Feature Summary ..............................................................................................................14

3. Front Components ..........................................................................................................................15

4. Front Panel Controls and Indicators ................................................................................................16

5. Local Control Panel .........................................................................................................................18

6. Rear Platform Features ...................................................................................................................20

7. Power Supply Indicators ..................................................................................................................25

8. Power Indicator ...............................................................................................................................26

9. Attention Indicator ........................................................................................................................... 26

10. Hard Disk Drive Carrier ....................................................................................................................27

11. Main Board Component Locations ..................................................................................................30

12. Hot-Plug Memory Board LEDs and Buttons ....................................................................................32

13. BIOS Setup Utility Page Layout .......................................................................................................35

14. BIOS Setup: Keyboard Commands .................................................................................................36

15. Hard Disk Drive Carrier ....................................................................................................................60

16. Product Certification Markings ........................................................................................................77

6 MFMAXDATA PLATINUM 7200 IR M5Contents

1 Safety Information

This document applies to MAXDATA PLATINUM Server Boards, MAXDATA PLATINUM Server Chassis

(pedestal and rack-mount) and installed peripherals. To reduce the risk of bodily injury, electrical shock,

fire, and equipment damage, read this document and observe all warnings and precautions in this

guide before installing or maintaining your MAXDATA PLATINUM server product.

In the event of a conflict between the information in this document and information provided with the

product or on the website for a particular product, the product documentation takes precedence.

Your server should be integrated and serviced only by technically qualified persons.

You must adhere to the guidelines in this guide and the assembly instructions in your server manuals

to ensure and maintain compliance with existing product certifications and approvals. Use only the

described, regulated components specified in this guide. Use of other products/components will void

the UL Listing and other regulatory approvals of the product, and may result in noncompliance with

product regulations in the region(s) in which the product is sold.

Safety Warnings and Cautions

To avoid personal injury or property damage, before you begin installing the product, read, observe,

and adhere to all of the following safety instructions and information. The following safety symbols

may be used throughout the documentation and may be marked on the product and/or the product

packaging.

Table 1. Safety Warnings and Cautions

Indicates potential hazard if indicated information is ignored

Indicates shock hazard that results in serious injury or death if safety

instructions are not followed

Indicates hot components and surfaces

Indicates electrostatic discharge cautions

Indicates do not touch fan blades, may result in injury

Indicates to unplug all AC power cord(s) to disconnect AC power

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be installed in

offices, schools, computer rooms, and similar commercial type locations. The suitability of this product

for other product categories and environments (such as medical, industrial, residential, alarm systems,

and test equipment), other than an ITE application, may require further evaluation.

7MAXDATA PLATINUM 7200 IR M5

General Warnings

The power supply in this product contains no user-serviceable parts. There may be

more than one supply in this product. Refer servicing only to qualified personnel.

Do not attempt to modify or use the supplied AC power cord if it is not the exact type

required. A product with more than one power supply will have a separate AC cord

for each supply.

The DC push-button on/off switch on the front panel does not turn off system AC

power. To remove power from the system, you must unplug each AC power cord

from the wall outlet or power supply.

Ensure that the system is disconnected from its power source and from all telecommunication links, networks, and modem lines whenever the chassis cover is to be

removed. This may require disconnecting multiple power cords. Do not operate the

system with the cover removed.

A microprocessor and heat sink may be hot if the system has been running. Also,

there may be sharp pins and edges on some board and chassis parts. Contact should

be made with care. Consider wearing protective gloves.

Danger of explosion if the battery is incorrectly replaced. Replace only with the same

or equivalent type recommended by the equipment manufacturer. Discard used

batteries according to manufacturer’s instructions.

Depending on the weight of the product, two people together should lift it.

The system is designed to operate in a typical office environment. Choose a site that

is:

• Clean and free of airborne particles (other than normal room dust).

• Well ventilated and away from sources of heat including direct sunlight.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields produced by electrical devices.

• In regions that are susceptible to electrical storms, we recommend you plug your

system into a surge suppresser and disconnect telecommunication lines to your

modem during an electrical storm.

• Provided with a properly grounded wall outlet.

• Provided with sufficient space to access the power supply cords, because they

serve as the product’s main power disconnect.

Place Battery Marking

There is insufficient space on this server board to provide instructions for replacing and disposing of

the battery. For system safety certification, the following statement or equivalent statement may be

required to be placed permanently and legibly on the chassis near the battery.

CAUTION

Risk of explosion if battery is incorrectly replaced.

Replace with only the same or equivalent type recommended by the manufacturer. Dispose of used

batteries according to the manufacturer’s instructions.

8 Safety Information

Site Selection

The system is designed to operate in a typical office environment. Choose a site that is:

• Clean, dry, and free of airborne particles (other than normal room dust).

• Well-ventilated and away from sources of heat including direct sunlight and radiators.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields produced by electrical devices.

• In regions that are susceptible to electrical storms, we recommend you plug your system

into a surge suppresser and disconnect telecommunication lines to your modem during an

electrical storm.

• Provided with a properly grounded wall outlet.

• Provided with sufficient space to access the power supply cord(s), because they serve as the

product’s main power disconnect.

Equipment Handling Practices

Reduce the risk of personal injury or equipment damage:

• Conform to local occupational health and safety requirements when moving and lifting

equipment.

• Use mechanical assistance or other suitable assistance when moving and lifting equipment.

• To reduce the weight for easier handling, remove any easily detachable components.

CAUTION

The power button, indicated by the stand-by power marking, DOES NOT completely turn off the system

AC power, 5 V standby power is active whenever the system is plugged in. To remove power from

system, you must unplug the AC power cord from the wall outlet. Your system may use more than

one AC power cord. Make sure all AC power cords are unplugged. Make sure the AC power cord(s)

is/are unplugged before you open the chassis, or add or remove any non hot-plug components.

Do not attempt to modify or use an AC power cord if it is not the exact type required. A separate AC

cord is required for each system power supply.

Some power supplies in MAXDATA PLATINUM Servers use Neutral Pole Fusing. To avoid risk of

shock use CAUTION when working with power supplies that use Neutral Pole Fusing.

The power supply in this product contains no user-serviceable parts. Do not open the power supply.

Hazardous voltage, current and energy levels are present inside the power supply. Return to

manufacturer for servicing.

When replacing a hot-plug power supply, unplug the power cord to the power supply being replaced

before removing it from the server.

To avoid risk of electric shock, turn off the server and disconnect the power cord, telecommunications

systems, networks, and modems attached to the server before opening it.

9MAXDATA PLATINUM 7200 IR M5

Power Cord Warnings

If an AC power cord was not provided with your product, purchase one that is approved for use in

your country.

CAUTION

To avoid electrical shock or fire, check the power cord(s) that will be used with the product as

follows:

• Do not attempt to modify or use the AC power cord(s) if they are not the exact type required to

fit into the grounded electrical outlets

• The power cord(s) must meet the following criteria:

- The power cord must have an electrical rating that is greater than that of the electrical

current rating marked on the product.

- The power cord must have safety ground pin or contact that is suitable for the electrical

outlet.

• The power supply cord(s) is/are the main disconnect device to AC power. The socket outlet(s)

must be near the equipment and readily accessible for disconnection.

• The power supply cord(s) must be plugged into socket-outlet(s) that is /are provided with a

suitable earth ground.

System Access Warnings

CAUTION

To avoid personal injury or property damage, the following safety instructions apply whenever accessing

the inside of the product:

• Turn off all peripheral devices connected to this product.

• Turn off the system by pressing the power button to off.

• Disconnect the AC power by unplugging all AC power cords from the system or wall outlet.

• Disconnect all cables and telecommunication lines that are connected to the system.

• Retain all screws or other fasteners when removing access cover(s). Upon completion of

accessing inside the product, refasten access cover with original screws or fasteners.

• Do not access the inside of the power supply. There are no serviceable parts in the power

supply. Return to manufacturer for servicing.

• Power down the server and disconnect all power cords before adding or replacing any non hotplug component.

• When replacing a hot-plug power supply, unplug the power cord to the power supply being

replaced before removing the power supply from the server.

CAUTION

If the server has been running, any installed processor(s) and heat sink(s) may be hot. Unless you

are adding or removing a hot-plug component, allow the system to cool before opening the covers.

To avoid the possibility of coming into contact with hot component(s) during a hot-plug installation,

be careful when removing or installing the hot-plug component(s).

CAUTION

To avoid injury do not contact moving fan blades. If your system is supplied with a guard over the

fan, do not operate the system without the fan guard in place.

10 Safety Information

Rack Mount Warnings

The equipment rack must be anchored to an unmovable support to prevent it from tipping when a

server or piece of equipment is extended from it. The equipment rack must be installed according to

the rack manufacturer’s instructions.

Install equipment in the rack from the bottom up, with the heaviest equipment at the bottom of the

rack.

Extend only one piece of equipment from the rack at a time.

You are responsible for installing a main power disconnect for the entire rack unit. This main disconnect

must be readily accessible, and it must be labeled as controlling power to the entire unit, not just to

the server(s).

To avoid risk of potential electric shock, a proper safety ground must be implemented for the rack

and each piece of equipment installed in it.

Electrostatic Discharge (ESD)

CAUTION

ESD can damage disk drives, boards, and other parts. We recommend that you perform all procedures

at an ESD workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground - any unpainted metal surface - on your server when handling

parts.

Always handle boards carefully. They can be extremely sensitive to ESD. Hold boards only by their

edges. After removing a board from its protective wrapper or from the server, place the board

component side up on a grounded, static free surface. Use a conductive foam pad if available but

not the board wrapper. Do not slide board over any surface

Other Hazards

Battery Replacement

CAUTION

There is the danger of explosion if the battery is incorrectly replaced. When replacing the battery, use

only the battery recommended by the equipment manufacturer.

Dispose of batteries according to local ordinances and regulations.

Do not attempt to recharge a battery.

Do not attempt to disassemble, puncture, or otherwise damage a battery.

Cooling and Airflow

CAUTION

Carefully route cables as directed to minimize airflow blockage and cooling problems. For proper

cooling and airflow, operate the system only with the chassis covers installed. Operating the system

without the covers in place can damage system parts. To install the covers:

1. Check first to make sure you have not left loose tools or parts inside the system.

2. Check that cables, add-in boards, and other components are properly installed.

3. Attach the covers to the chassis according to the product instructions.

11MAXDATA PLATINUM 7200 IR M5

Laser Peripherals or Devices

CAUTION

To avoid risk of radiation exposure and/or personal injury:

• Do not open the enclosure of any laser peripheral or device.

• Laser peripherals or devices are not user serviceable.

• Return to manufacturer for servicing.

12 Safety Information

2 Platform Description

The PLATINUM 7200 IR Server is a compact, high-density, rack-mount system with support for one

to four Intel® Xeon™ processors and 64 GB of DDR2 400 MHz SDRAM memory. The system is based

on the PLATINUM 7200 IR Server Board using the Intel® E8501 chipset. The platform supports hot

plug PCI-X and PCI-Express add-in cards; hot-swap, redundant power supply modules; hot swap,

redundant cooling fans, hot-plug memory with RAS features, and hot-swap hard disk drives. The

server platform is shown below.

Figure 1. PLATINUM 7200 IR Server Front View

Platform Features

The platform features are outlined in the following table.

Table 2. Chassis Feature Summary

Feature Description

Dimensions (4U rackmount platform)

Clearance

requirements

Configuration

flexibility/Scaleability

Serviceability • Front access to hot-swap hard disk drives

Availability • Four hot-plug PCI-Express slots

Manageability • Server Management support through the Management Module - Profes

Front control panel • System power button and LED

Height: 6.8 inches (173 mm)

Width: 17.6 inches (447 mm)

Depth: 27.8 inches (706 mm)

Weight of fully configured system: 90 lbs (40 kg)

• Front clearance: 3 inches (76 mm)

• Side clearance: 1 inch (25 mm)

• Rear clearance: 6 inches (152 mm)

• Support for one to four processors

• Support for at least two generations of processors

• Support for up to five Ultra 320 SCSI hard disk drives

• Support for up to seven PCI adapters

• Support for up to 64 GB Double Data Rate-2 (DDR-2) 400 MHz Synchro

nous Dynamic Random Access Memory (SDRAM) memory support

• Option for front control panel with or without a LCD

• Option for 2 Gbps Fibre Channel Module

• Choose either Management Module - Professional or Management

Module - Advanced

• Front access to hot-swap fans

• Rear access to hot-swap power supplies

• System power and system status LEDs

• System ID buttons and LEDs on front panel and rear of system

• Memory configuration and status LEDs

• Processor failure LEDs

• Color-coded parts to identify hot-swap and non-hot-swap serviceable

components

• One hot-plug PCI-X 133 MHz slot

• Two PCI-X 100 MHz slots (not hot-swap)

• Two 1470 W power supplies in a redundant (1+1) configuration

• Dual power cords (1+1) when two power supplies are installed

• Four hot-swap system fans in a redundant (2+2) configuration

• Five hot-swap 1-inch Ultra-320 SCSI hard disk drives

• Four hot-plug Memory Boards (operating system support required)

• RAID on MotherBoard (ROMB) with a battery-backed DDR2 400 MHz

DIMM for disk cache

sional or Management Module - Advanced

• Remote management

• Emergency Management Port (EMP)

• Intelligent Platform Management Interface (IPMI) 1.5 compliant, partial

IPMI 2.0 compliance

• Wired For Management (WfM) 2.0 compliant

• Remote diagnostics support

• System reset button

• NMI button

• System ID button and LED

• Optional LCD

• System status LED

• Hard drive status LED

• LAN1 and LAN2 status LEDs

• Video connector

• Three USB 2.0 ports

-

-

14 15MAXDATA PLATINUM 7200 IR M5Platform Description

Platform Front

A

B

C ED

F F

G

Table 3. Front Components

Figure 2. Front Components

Item Description

A. CD-ROM / DVD-ROM drive bay

B.

C. Video connector

D. USB 2.0 ports

E. Front control panel. Standard control panel shown.

F. Hot-swap fan modules

G. Hot-swap disk drives

5 ¼ peripheral bay

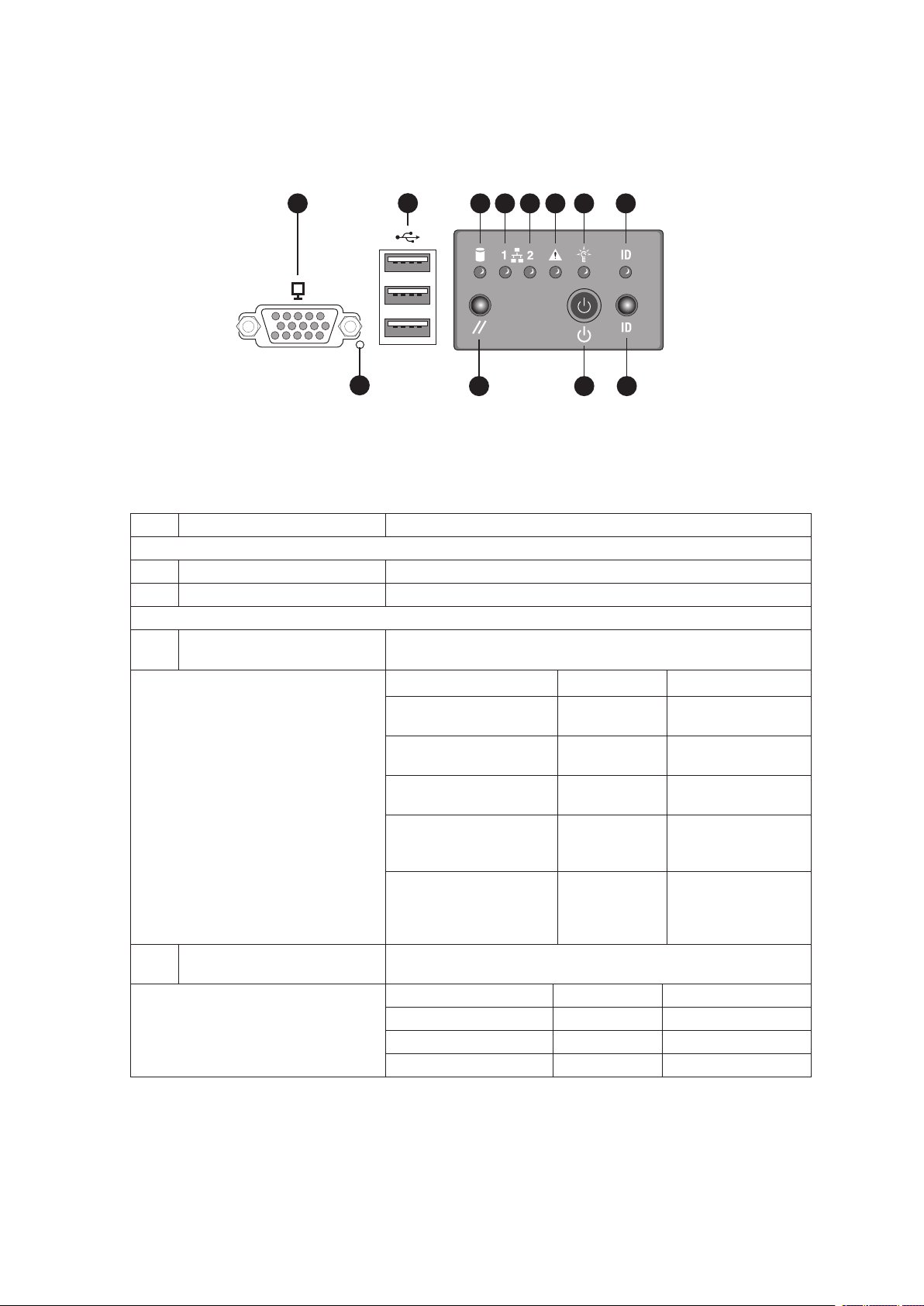

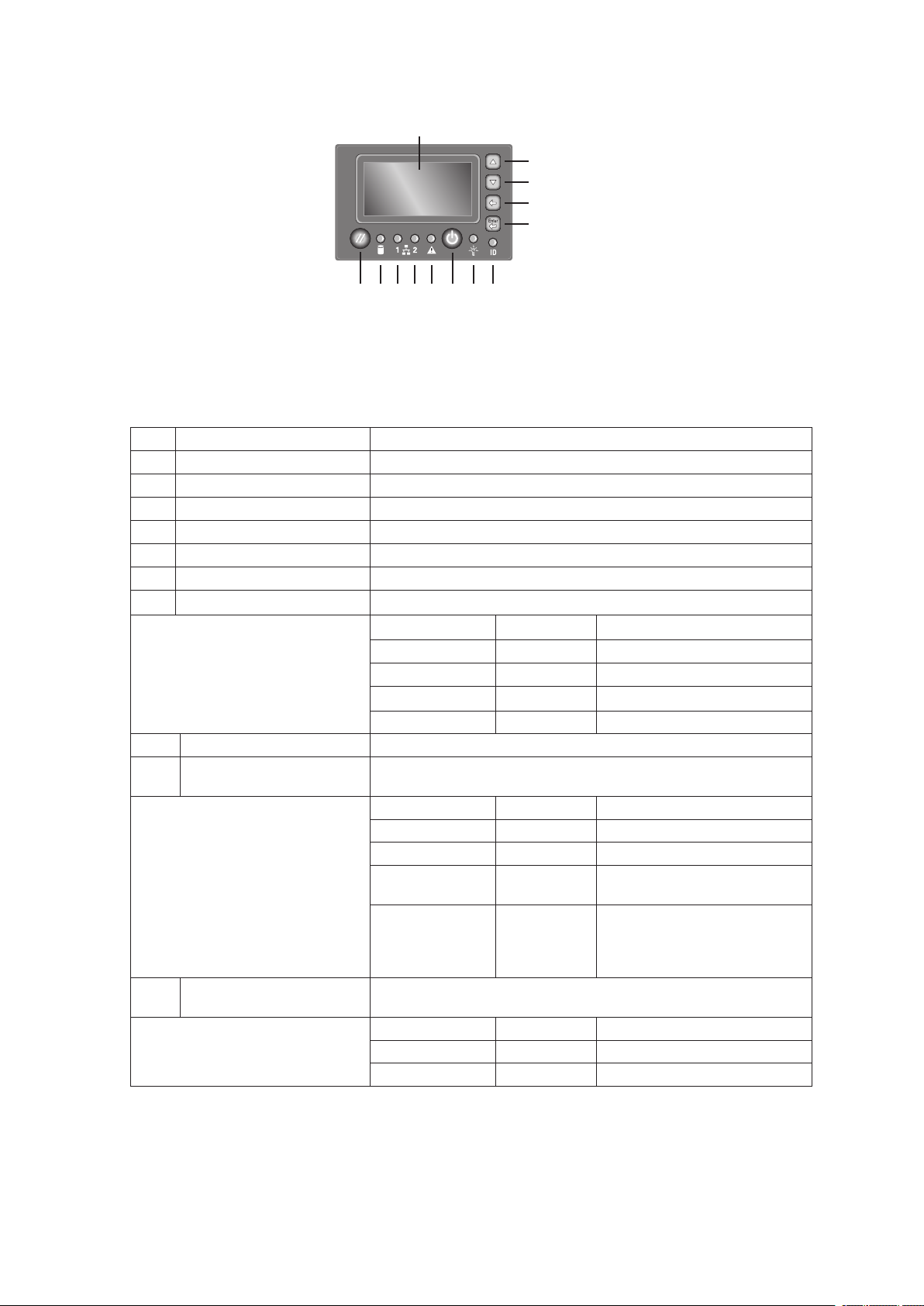

Standard Control Panel

A

B

J L

K

C ED

F

H

G

I

The standard control panel provides a user interface for system management via switches and status

LEDs. The control panel also contains the speaker. Figure 3 shows the location of the buttons and

status LEDs on the standard control panel.

Figure 3. Front Panel Controls and Indicators

Table 4. Front Panel Controls and Indicators

Item Feature Description

Front Panel Connectors

A Video connector Video port, standard VGA compatible, 15-pin connector

B Three USB connectors Three USB 2.0 ports, 4-pin connectors

Front Panel Buttons and LED Indicators

C Hard Drive Activity LED

(Green/Amber)

D,

E

LAN1, LAN2 Status LEDs

(Green)

Indicates hard drive activity and fault status.

LED State Description

Green, On A hard drive is

being initialized.

Green, Blinking A hard drive is

active.

Amber, On Hard drive/slot

failure.

Amber, Slow Blinking

(~1 Hz)

Amber, Fast Blinking

(~2.5 Hz)

Indicates LAN activity status

LED State Description

Off

On Inactive No Access

Blinking Active Access

Idle

A predictive hard

drive/slot failure or

rebuild in process.

Hard drive rebuild

interrupted or

rebuild on empty

slot.

16 17MAXDATA PLATINUM 7200 IR M5Platform Description

Item Feature Description

F System Status/Fault LED

(Green/Amber)

G System Power LED

(Green)

H System ID LED (Blue) Identifies the system via server management or locally.

I NMI button Asserts NMI.

J System Reset button Press to reset the system.

K System Power button Press to turn the system power on or off.

L System ID button Press to turn the System ID LED on or off.

Indicates system status.

LED State Description

Off

Green, On Ready System booted

Green, Blinking Degraded CPU or DIMM

Amber, On Critical Alarm Critical Power

Amber, Blinking

Indicates system power status.

LED State ACPI

Off Power off

On Power on No

Off

Blinking S1 Yes

On S0 Yes

Not ready AC Power Off,

POST error

and ready

disabled

Supply, Blower,

Voltage, or

Temperature

failure

Non-Critical

Alarm

S4/S5 Yes

Redundant Power

Supply or Blower

failure. NonCritical Blower,

Voltage, and

Temperature

failure.

No

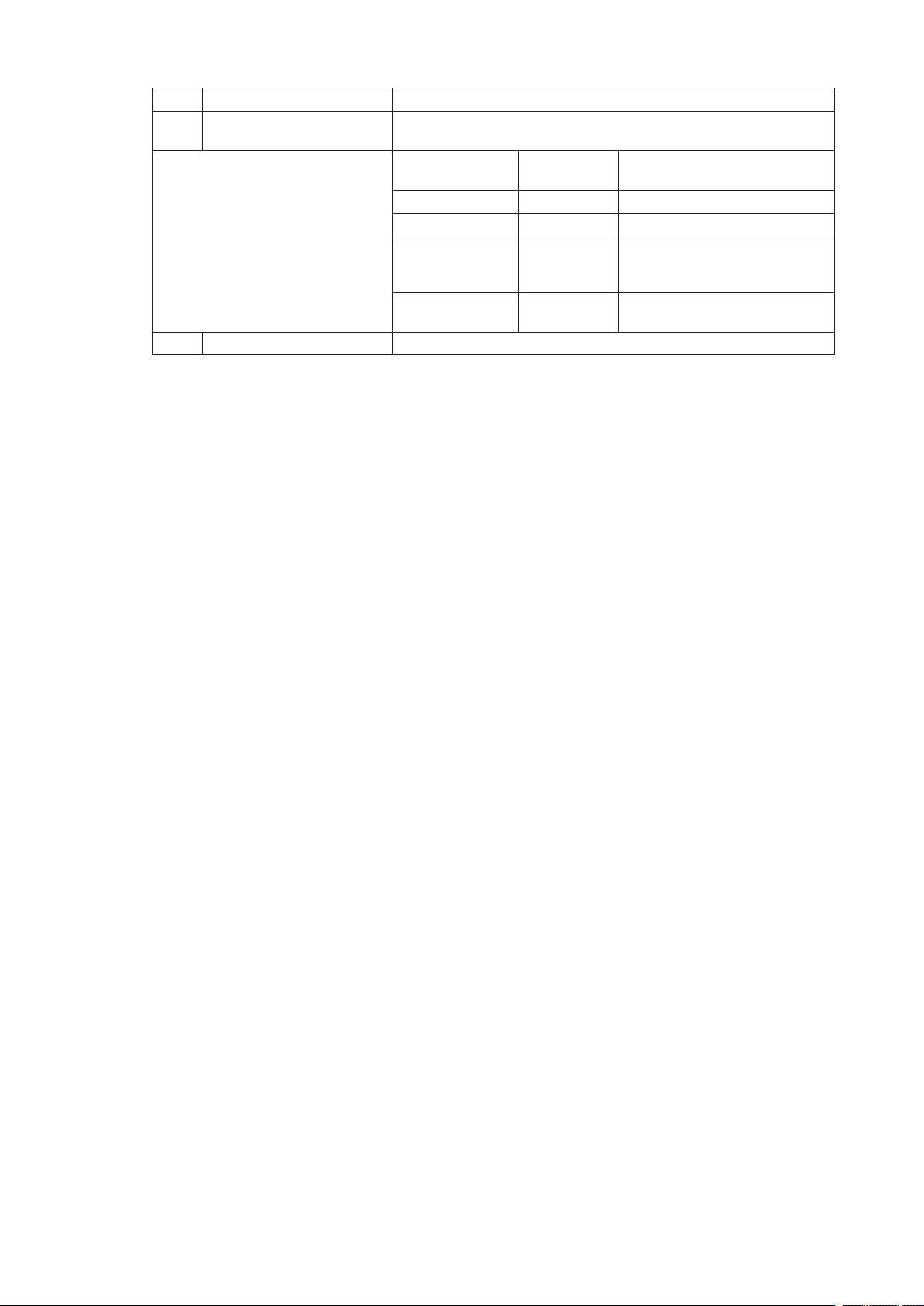

Local Control Panel

A

B

C

D

E

M L K J I GH F

Table 5. Local Control Panel

Item Feature Description

A LCD display Video display

B Scroll up button Press to scroll up on the LCD.

C Scroll down button Press to scroll down on the LCD.

D Back button Press to move to the previous LCD screen.

E Select button Press to enter a command or select an option on the LCD.

F System ID LED (Blue) Helps identify the system via server management.

G System Power LED (Green) Indicates system power status.

H System Power button Toggles system power

I System Status/Fault LED

(Green/Amber)

J,K

LAN1, LAN2 Status LEDs

(Green)

Figure 4. Local Control Panel

Off Power off ACPI: No

Off Power on ACPI: No

Off

Blinking S1 ACPI: Yes

On S0 ACPI: Yes

Indicates system status.

Off

Green, On Ready System booted and ready

Green, Blinking Degraded Processor or DIMM disabled

Amber, On

Amber, Blinking

Indicates LAN activity status.

Off

On Inactive No access

Blinking Active Access

S4 / S5 ACPI: Yes

Not ready AC power off, POST error

Critical

Alarm

Non-Critical

Alarm

Idle

Critical power supply, blower,

voltage, or temperature failure

Redundant power supply or

blower failure.

Non-critical blower, voltage, or

temperature failure.

18 19MAXDATA PLATINUM 7200 IR M5Platform Description

Item Feature Description

L Hard Drive Status LED

(Green/Amber)

M System Reset button Resets the system.

Indicates hard drive activity and fault status.

Green On A hard drive is being

Green Blinking A hard drive is active.

Amber On Hard drive/slot failure.

Amber Slow

Amber Fast Blinking

Blinking

(~1 Hz)

(~2.5 Hz)

initialized.

A predictive hard drive/slot

failure or rebuild in process.

Hard drive rebuild interrupted

or rebuild on empty slot.

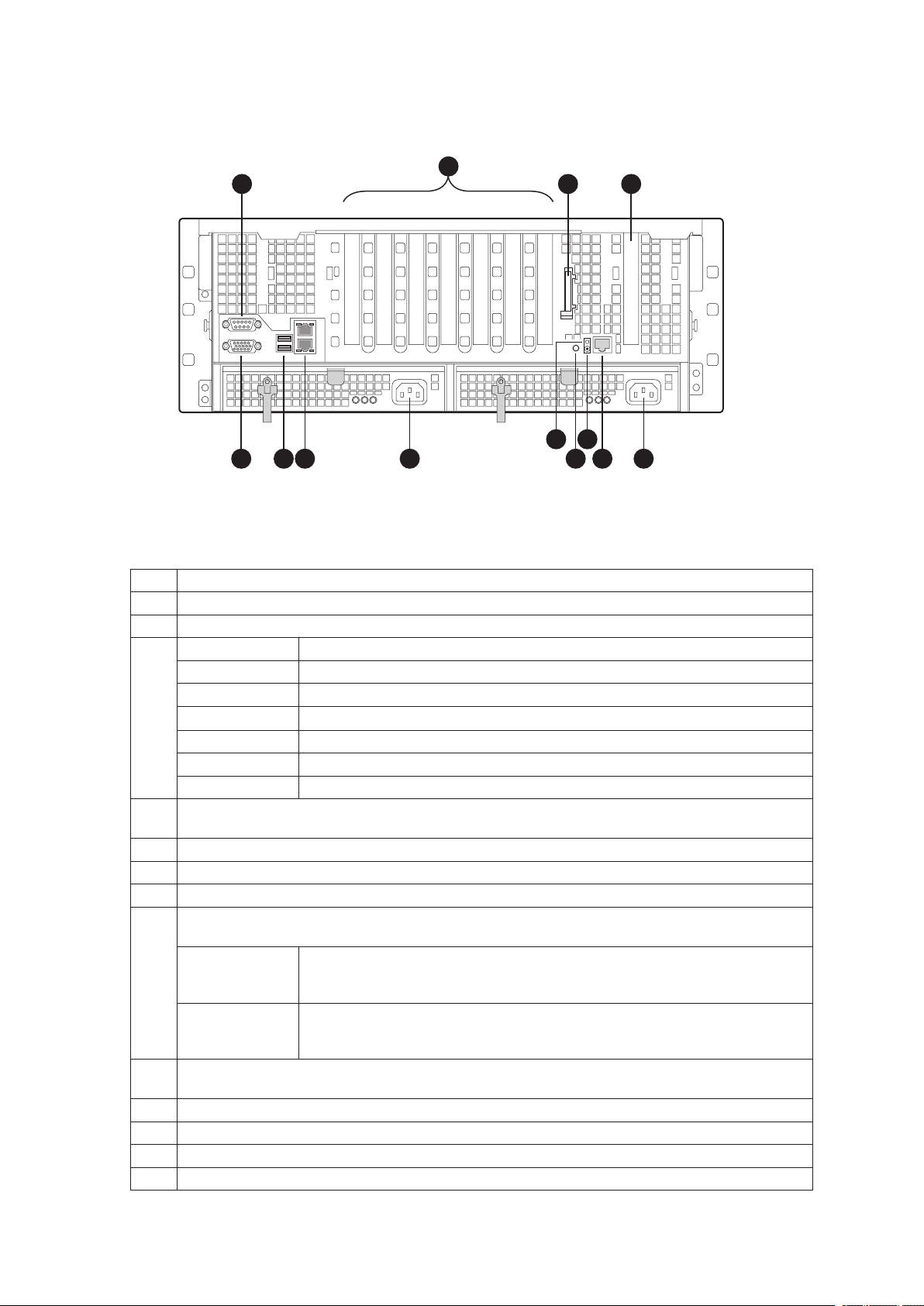

Platform Rear

A

C D

1 7

432 5 6

B

E

F

G

H1

JH2L

K

I

Figure 5 shows the features on the chassis back panel.

Figure 5. Rear Platform Features

Table 6. Rear Platform Features

Item Description

A Serial port connector. Emergency Management Port access is provided through the serial port.

B PCI Slots

Slot 1 PCI-Express x8 (hot-plug)

Slot 2 PCI-X 133 MHz, 64-bit (hot-plug)

Slot 3 PCI-Express x4 (hot-plug)

Slot 4 PCI-Express x4 (hot-plug)

Slot 5 PCI-Express x4 (hot-plug)

Slot 6 PCI-X 100 MHz, 64-bit (not hot-plug)

Slot 7 PCI-X 100 MHz, 64-bit (not hot-plug)

C External SCSI connector. The external SCSI bus supports both LVDS and SE signals through

the external SCSI connector.

D Fibre Channel Module Slot

E Video port, standard VGA compatible, 15-pin connector

F Two USB 2.0 ports

G Two LAN ports, RJ45 connector (LAN1 on top, management features, LAN2 on bottom)

LAN port LEDs:

Status LED

(Green)

Speed LED

(Green/Amber

dual color)

AC input power connectors

H1,

H2

I System ID button

J System ID LED (blue)

K DC jack (not used)

L Server Management RJ-45 connector (GCM) (Advanced Management Module only)

On: ethernet link is detected

Off: no ethernet connection

Blinking: ethernet link is active

Off: 10 Mbps

Green On: 100 Mbps

Amber On: 1000 Mbps

20 21MAXDATA PLATINUM 7200 IR M5Platform Description

Processors

The PLATINUM 7200 IR Server supports from one to four 64-bit Intel® Xeon™ Processor MP with 1 MB

L2 Cache or one to four 64-bit Intel® Xeon™ Processor MP with 8 MB L3 Cache. These processors

are targeted for multiprocessor servers. Several architectural and microarchitectural enhancements

have been added to this processor, including an increased L2 cache size and an integrated L3 cache

(64-bit Intel® Xeon™ Processor MP with 8 MB L3 Cache).

Plug-in Voltage Regulator Module (VRM) Converters

Two types of plug-in voltage regulator module (VRM) converters are used in the system:

• VRM 9.1

• VRM 10.2

Input power to the Main Board is 12 V and 3.3 V Standby (VSB). All other voltages must be generated

on the board set including 3.3 V and 5 V. There are numerous VRDs used to generate the required

voltage levels. Processor core voltage to processors 1 and 2 is generated by embedded VRDs.

Processors 3 and 4 require one plug-in 10.2 VRM each to provide the core voltage. A plug-in VRM

9.1 is required when using more than 2 processors with iL3 cache.

System Memory

The Memory Boards connect to the Main Board through x16 PCI Express connectors. Between one

and four Memory Boards can be installed. Each Memory Board has four DIMM sockets and supports

two DDR2 channels with two DIMMs per channel. The Memory Boards support both single-rank and

double-rank registered DIMMs.

The DIMMs on each Memory Board must be installed in pairs. Each pair is referred to as a bank.

A bank may consist of one rank (a pair of single-sided DIMMs) or two ranks (a pair of double-sided

DIMMs). The BIOS executes a memory test prior to configuring the memory in POST and when a

Memory Board is inserted into the system during a hot plug operation.

A DIMM bank will be disabled if any of the following occur:

• Uncorrectable errors are found during a memory test

• An uncorrectable ECC error occurred during runtime

• The DIMM rank correctable error count passes the error sparing threshold on a Memory Board

where sparing is enabled

• A Memory Board fails

If a DIMM fails the memory test, an LED will light on the Memory Board to identify the location of the

bad DIMM and the DIMM bank will be disabled. The failing DIMM event is logged to the System Event

Log (SEL) and the BIOS disables the memory DIMM and/or the Memory Board. Upon subsequent

reboots, this memory is not initialized unless the BIOS setup option “Retest all system memory” or

“Retest board memory” is selected.

Available Memory Configurations

Four memory configurations are available in the BIOS Setup utility.

• Maximum Performance: Maximum Performance is the default configuration in BIOS setup.

With this configuration, the BIOS first attempts to configure the Memory Boards as fourway interleaved. If four-way interleaving cannot be accomplished, it will attempt to two-way

interleave. It will then use one-way interleaving if any remaining memory cannot be fourway or two-way interleaved. This interleaving process configures the memory for maximum

performance. This configuration cannot be used if you want hot-add or hot-replace memory.

• Maximum Compatibility: Maximum Compatibility provides the most flexibility with DIMMs

and Memory Boards. This option allows memory to be hot-added and hot-replaced. Server

performance will be reduced due to one-way interleaving.

• Memory Mirroring: The Memory Mirroring feature provides redundancy. It uses either two

or four Memory Boards, paired as sets of two. Memory Boards in slots A and B form one set.

Memory Boards in slots C and D form the second set. One board within a set of Memory

Boards duplicates the second board in the set. Each Memory Board in a set must have the

same amount of memory installed.

When a hardware or DIMM error is detected on a primary Memory Board, the second board

becomes the primary board and remains primary until the failing board or DIMM is replaced.

Memory Mirroring uses board-level redundancy, allowing for hot-replacement. The hot-add is

supported by adding two addition mirrored Memory Boards.

The BIOS turns on the mirror LED on each Memory Board when the system is configured for

mirroring.

• Memory RAID: If the server contains four Memory Boards with equal memory capacity, the

system can be configured for Memory RAID. Data is written to three of the Memory Boards

while one is reserved for redundant parity information. This reduces the total overall available

memory by one-fourth. The RAID LED on the Memory Board will indicate that the Memory

Board is in a RAID configuration.

When a DIMM rank or board fails, the system will continue to operate with the remaining

three boards by recreating the data from the failed board. The system loses its redundancy at

this point, and will remain in this non-redundant state until the failing board and/or memory is

replaced.

This configuration allows for hot-replacement of failing Memory Boards and hot-add and hot-

replacement of memory DIMMs.

22 23MAXDATA PLATINUM 7200 IR M5Platform Description

The server BIOS also includes two additional memory reliability, accessibility, and serviceability (RAS)

features:

• Memory Sparing: A rank on each Memory Board can be reserved as a “spare” and can

only be used as a backup for other ranks on the same Memory Board. The memory rank that

is configured as spare is held in reserve and cannot be used by the operating system. Hot

removal cannot be performed when in a Memory Sparing configuration.

When the error rate for a failing rank exceeds an established threshold, the contents of that

rank are copied to the spare rank. At the completion of the copy, the failing rank is disabled

and the spare is used in its place. This is called Memory Sparing. By enabling memory sparing,

the total memory of each Memory Board is reduced by the largest DIMM rank installed on the

Memory Board. This ensures that any failing rank will fit on the spare rank.

When the failing rank switches to the spare, the BIOS will turn on the Memory Board LED to

indicate the bad rank. The failing DIMM rank is then disabled on subsequent system boots.

• Memory Hot Plug: This memory RAS feature provides the ability to hot-replace and hot-add

Memory Boards while the system is running. This feature can be used to perform:

- Memory Hot Replace: While the system is in operation, you can remove a failed Memory

Board, provided it is in a RAID or Mirror configuration, and replace it with a board of the

same memory capacity. The system will test, initialize, and rebuild the data on the Memory

Board and then include this board in the system memory configuration. The activity is

transparent to the operating system,

- Memory Hot Add: You can increase the memory capacity of the system while the

operating system is active. In a RAID configuration, you can remove one Memory Board

at a time to upgrade the memory or replace the Memory Board. In a Mirror configuration

you can add an addition two mirrored Memory Boards. In a Maximum Compatibility

configuration, a new Memory Board can be added to an empty slot. When the initialization

is complete, the operating system is informed of the new memory.

NOTE

Memory Hot Add must be supported by the operating system in order to perform this function. Check

for any operating system restrictions.

Power Subsystem

The power subsystem consists of the following:

• Power supply modules

• Plug-in VRM converters

• The Power Distribution Board

The power subsystem can be configured with two power supply modules installed for 1+1 redundancy

at 220 VAC.

Power Supply Modules

The output rating of the power supply is 1470 W when operated between 170 VAC and 264 VAC. It

is a current-sharing power supply with auto-ranging input. The power supply is approximately 7.75

inches wide by 13.5 inches deep by 1.4 inches high. The power supply modules have universal AC

input with Power Factor Correction (PFC) Distributed Power Supplies (DPS). The AC input receptacle

is an IEC-320 C14.

The power supply has two DC outputs: 12 V and 3.3 VSB. The 12 V main power is distributed

through the server and is converted locally at the point-of-load using either embedded or plug-in VRM

converters. The power supply is capable of power-safe monitoring.

In an N+1 configuration, the 12 VDC outputs have active (forced) current sharing. The two externally

enabled outputs have the following maximum ratings:

• +12 VDC: 121 A

• +3.3 VDCSB: 5 A

Each power supply module requires one power cord to supply AC power to the system. When two

power supply modules and two power cords are installed, the system supports (1+1) power cord

redundancy. This feature allows the system to be powered by two separate AC sources. In the 1+1

configuration, the system continues to operate, without interruption, if one of the AC sources fails.

24 25MAXDATA PLATINUM 7200 IR M5Platform Description

Loading...

Loading...