Page 1

Service

PMD351 /N1B/U1B

Manual

TAPE

SECTION PAG E

1. TECHNICAL SPECIFICATIONS ...................................................................................................1

2. SERVICE HINTS AND TOOLS ..................................................................................................... 2

3. TEST EQUIPMENT REQUIRED FOR SERVICING...................................................................... 3

4. ELECTRICAL ADJUSTMENTS .................................................................................................... 3

5. TECHNICAL DESCRIPTION ......................................................................................................10

6. SERVICE PROCEDURE............................................................................................................. 12

7. SERVICE MODE......................................................................................................................... 13

8. WIRING DIAGRAM ..................................................................................................................... 15

9. BLOCK DIAGRAM ...................................................................................................................... 17

10. SCHEMATIC DIAGRAM.............................................................................................................. 19

11. PARTS LOCATION...................................................................................................................... 33

12. MICROPROCESSOR AND IC DATA........................................................................................... 38

13. EXPLODED VIEW AND PARTS LIST......................................................................................... 47

14. ELECTRICAL PARTS LIST ......................................................................................................... 53

Stereo Cassette Deck / Compact Disc Player

HP SELECT

CD

STEREO CASSETTE DECK/COMPACT DISC PLAYER PMD351

QUICK REVERSE

AUTOMATIC TAPE SELECT SYSTEM

DOLBY B-C NR HX PRO

TAPE

PITCH CONT

-

+

CASCADE

CD PITCH CONT.

RESET

MEMO

B

DOLBY NR

REV.MODE

CD-RW PLAYBACK

TIME

0

IR

REC/PAUSE

DUBB.

OFF

C

ON

OFF

ALC

PROGRAM

REPEAT

A-B

EJECT

POWER

TAPE+CD

PHONES

TABLE OF CONTENTS

REC LEVEL

PLAY

PLAY/PAUSE

PLAY PAUSE

STOP

TAPE

PLAY

STOP/EJECT

CD

BALANCE

LR

PMD351

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

PMD351

R

02AT855010 MIT

First Issue 2003.02

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

43-53 Bridge Rd.,

STANMORE NSW 2048

AUSTRALIA

PHONE : +61 - (0)2 - 9519 - 0900

FAX : +61 - (0)2 - 9519 - 0600

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

HONG KONG

Jolly ProAudio Broadcast Engineering Ltd.

UNIT 2, 10F, WAH HUNG CENTRE,

41 HUNG TO ROAD, KWUN TONG, KLN.,

HONG KONG

PHONE : 852 - 21913660

FAX : 852 - 21913990

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

JAPAN

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

Technical

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

SHOCK, FIRE HAZARD SERVICE TEST :

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

130 JOO SENG ROAD

#03-02 OLIVINE BUILDING

SINGAPORE 368357

PHONE : +65 6858 5535 / +65 6381 8621

FAX : +65 6858 6078

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 - 3 - 7954 8088

FAX : +60 - 3 - 7954 7088

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verifi ed before it is return to the user/customer.

Ref. UL Standard No. 1492.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

021216MIT

Page 3

1. TECHNICAL SPECIFICATIONS

TAPE DECK

Track System ............................................4 Track, 2 Channel

Recording/Erasure System.......................... AC 105 kHz Bias

Head System (Rotary type combination)

Rec Play Head........................................ Hard Metal Alloy

Erase Head.............................................Dual Gap Ferrite

Motor System

Capstan ................................. DC Servo Controlled Motor

Reel ...................................................................DC Motor

Wow & Flutter

W RMS.................................................................... 0.14%

Frequency Characterstics

Frequency Response (no Dolby NR)

type I (Normal) ..................................... 30Hz-15kHz ±3dB

type II (High) ........................................30Hz-16kHz ±3dB

type IV (Metal) .....................................30Hz-16kHz ±3dB

Overall S/N (no Dolby NR, IEC-A WTD)

type I (Normal) .......................................................... 53dB

type II (High) .............................................................54dB

type IV (Metal) ..........................................................55dB

Dolby NR effect (B/C, S/N improvement, CCIR-ARM WTD)

............................................................... B 9dB, C 18dB

Output Level/Output Impedance.......................... 500mV/1kΩ

Input Sensitivity/Input Impedance

TAPE IN ....................................................... 100mV/47kΩ

MIC IN........................................................... 0.5mV/10kΩ

COMMON PART

Power Supply

/U ...............................................................120V AC 60Hz

/N ...............................................................230V AC 50Hz

Dimensions

Width.................................................. 19 inches (483mm)

Height .......................................... 5 3/16 inches (133mm)

Depth ......................................... 11 1/32 inches (280mm)

Net Weight.......................................................3.1 lbs. (6.8kg)

CD

Channels .............................................................................. 2

Sampling frequency.................................................. 44.1 kHz

Quantization ...........................................16-bit linear/channel

Error correction system ..................... Cross-interleave Reed-

Solomon code (CIRC)

D/A Conversion ........................................1-bit linear/channel

Wow & Flutter................................... Quartz crystal accuracy

Optical Readout System

Laser.............................................AlGaAs semiconductor

Wavelength ........................................................... 780 nm

Frequency Characterstics (Pitch control off)

Frequency Response........................ 20Hz-20kHz ±0.3dB

Dynamic range......................................................... 90 dB

Signal-to-noise ratio.................................................96 dB

Channel separation.................................................. 90 dB

Total harmonic distortion.......................... 0.005% (1 kHz)

Analog output

Output Level............................................2V RMS stereo

Output

Digital output

Coaxial output............................................. 0.5Vp-p/75Ω

Impedance

.............................................................. <1k

Ω

1

Page 4

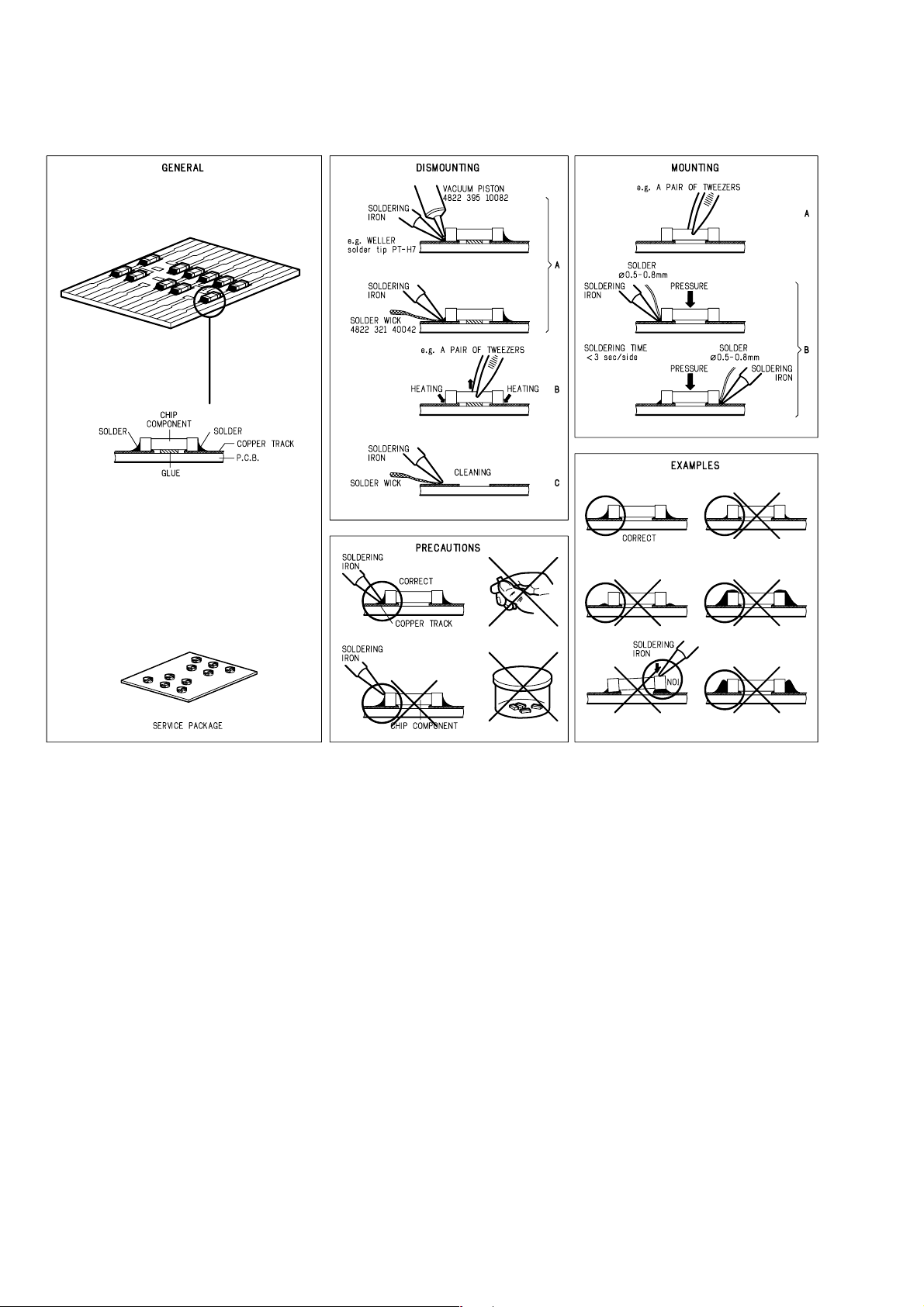

2. SERVICE HINTS AND TOOLS

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

2

Page 5

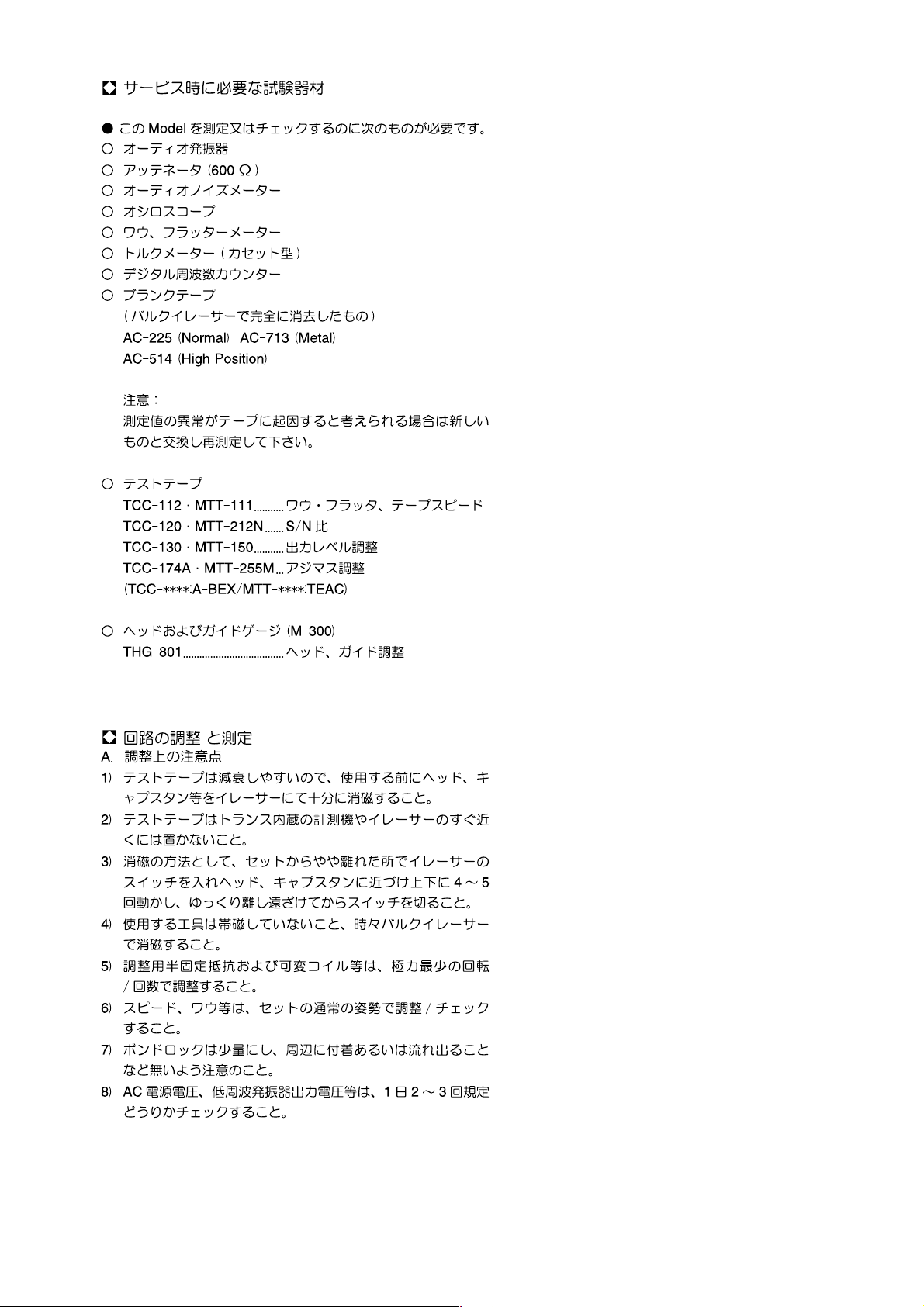

3. TEST EQUIPMENT REQUIRED FOR SERVICING

For measuring or checking a Cassette Deck, the following

instruments and materials are necessary.

• Audio Oscillator (Audio Signal Generator)

• Attenuator (600 ohm)

• Audio Noise Meter

• Oscilloscope

• Wow and Flutter Meter

• Torque Meter (Cassette Type)

• Digital Frequency Counter

• Test Tape

TCC-112/MTT-111 Wow/Flutter, Tape Speed

TCC-120/MTT-212N Signal-to-Noise Ratio

TCC-130/MTT-150 Dolby Level Adjustment

TCC-174A/MTT-255M Azimuth Adjustment

(TCC-

• Blank Tapes (Completely erased with bulk eraser)

AC-225 (Normal)

AC-514 (High Position)

AC-713 (Metal)

NOTE:

If any doubt is noted in a measured value, which is due to a

tape. Re-measurement is necessary by use the new tape.

:A-BEX/MTT-

****

****

:TEAC)

• Mirror cassette 12um padless

TCC-902/MTT-902 Tape fl owing check

• Head guide gauge (M-300)

THG-801

4. ELECTRICAL ADJUSTMENTS

(A) Remark for adjustment

1) Clean and de-magnetize the tape path part before

measurement.

2) Keep cassette tapes away from equipments.

3) De-magnetize tools often.

4) Do not turn adjustment parts by strong force.

5) Keep a cassette deck horizontally while measuring.

6) Keep amount of glue in proper.

7) Confi rm the mains voltage, output level of oscillator and

etc. before adjustment and measurement.

3

Page 6

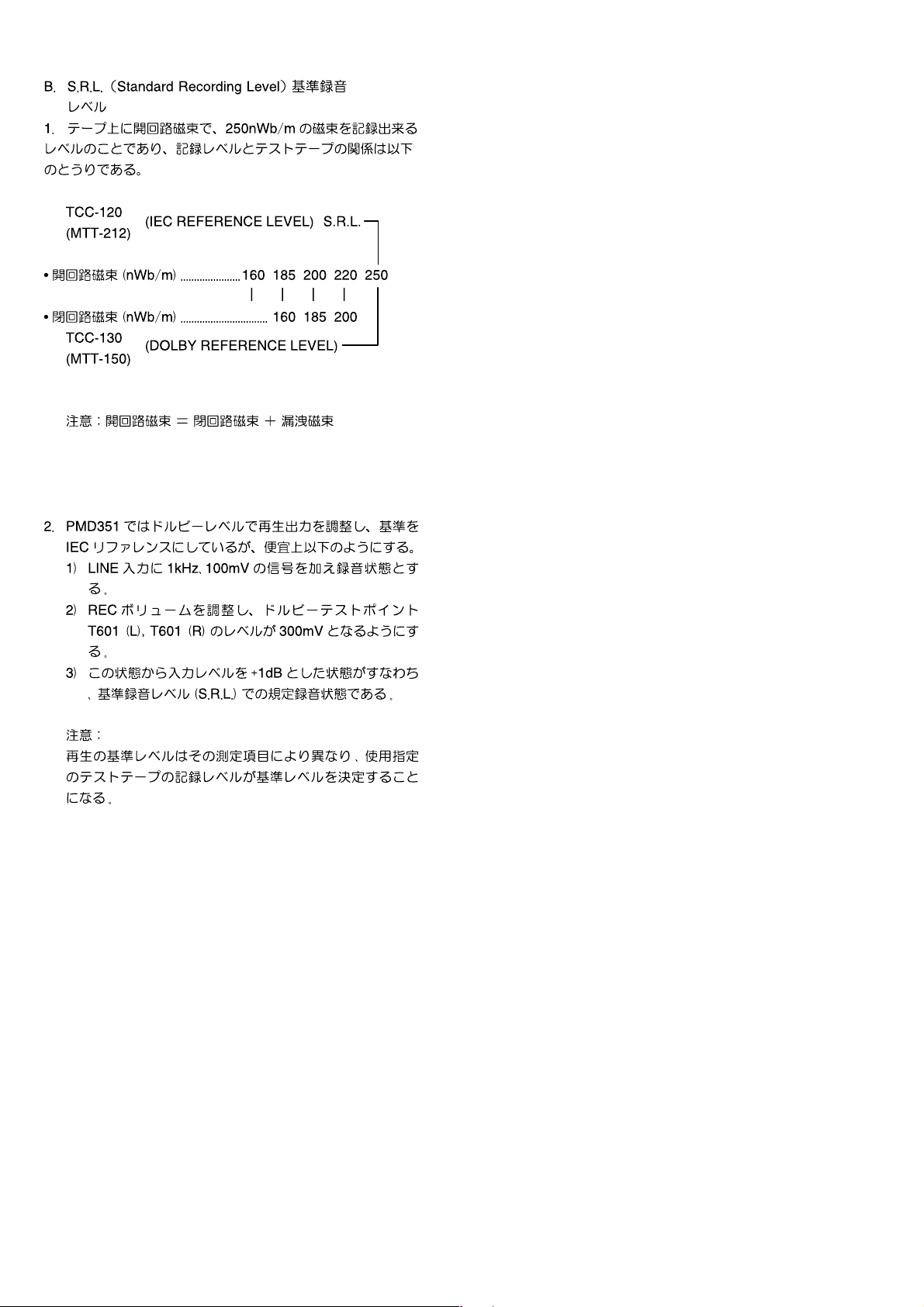

(B) S.R.L. (Standard Recording Level)

1. The Standard Recording Level is a signal of 250nWb/m

on a tape at *OPEN CIRCUIT MAGNETIC FLUX.

The relation between the recording level and a test tape

is as follows.

• OPEN CIRCUIT 160 185 200 220 250

MAGNETIC FLUX

(nWb/m)

• CLOSED CIRCUIT 160 185 200

MAGNETIC FLEX

(nWb/m) **

(*): OPEN CIRCUIT MAGNETIC FLUX = CLOSED

CIRCUIT MAGNETIC FLUX + LEAK

MAGNETIC FLUX.

(**): TCC-130 (DOLBY REFERENCE LEVEL)

(MTT-150)

(***): TCC-120 (IEC REFERENCE LEVEL) (S.R.L.)

(MTT-212N)

2. S.R.L. Setting

1) Apply a 1kHz, 100mV to the LINE INPUT jacks.

2) Put the unit in RECORD mode and adjust the REC

LEVEL control to obtain the following level of signal at

the DOLBY test points T601 (L), T602 (R) 300mV.

3) Adjust the output of the audio oscillator applied to the

LINE INPUT jacks to 112.2mV (+1dB). This is the rated

recording condition for the STANDARD RECORDING

LEVEL.

***

4

Page 7

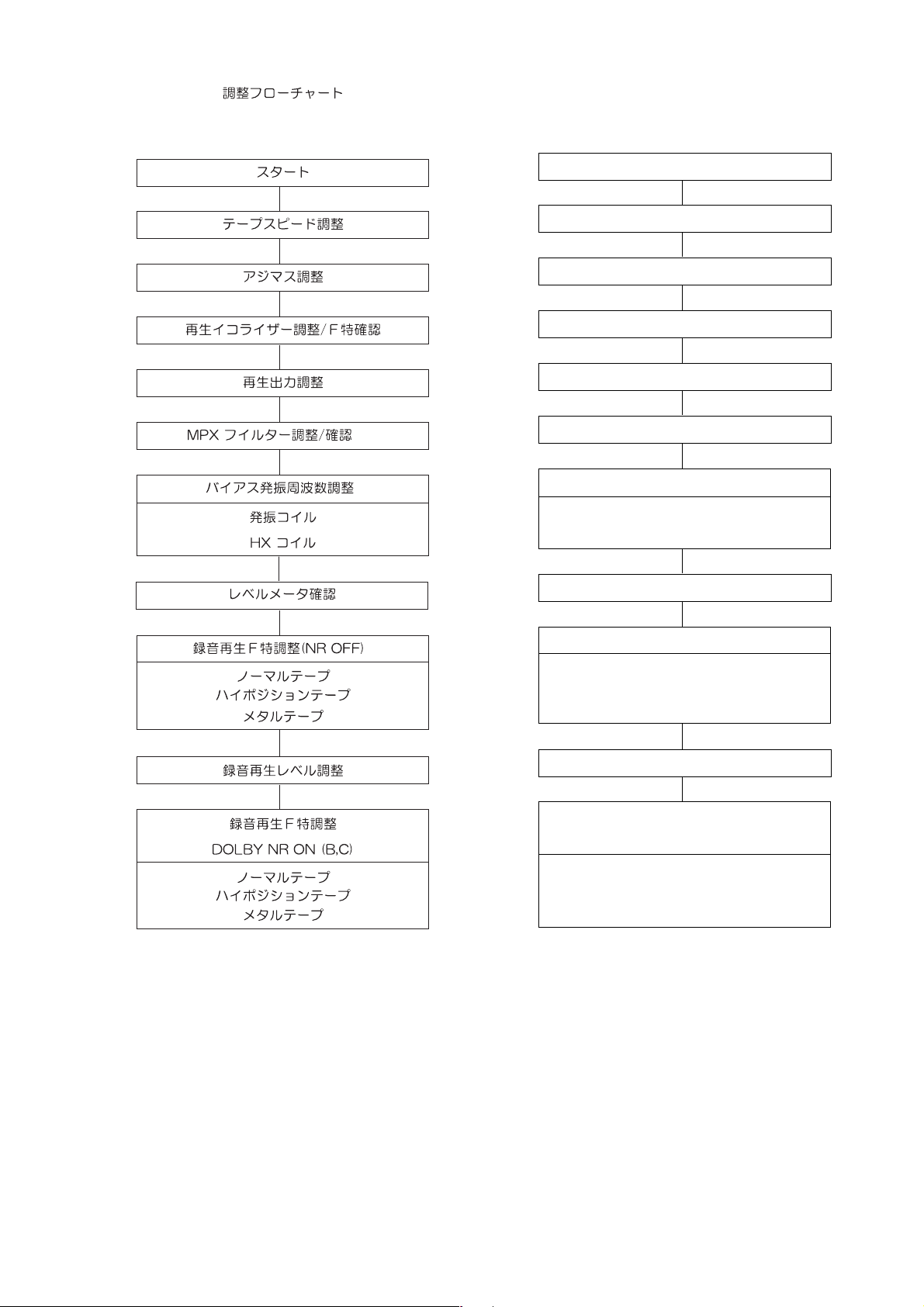

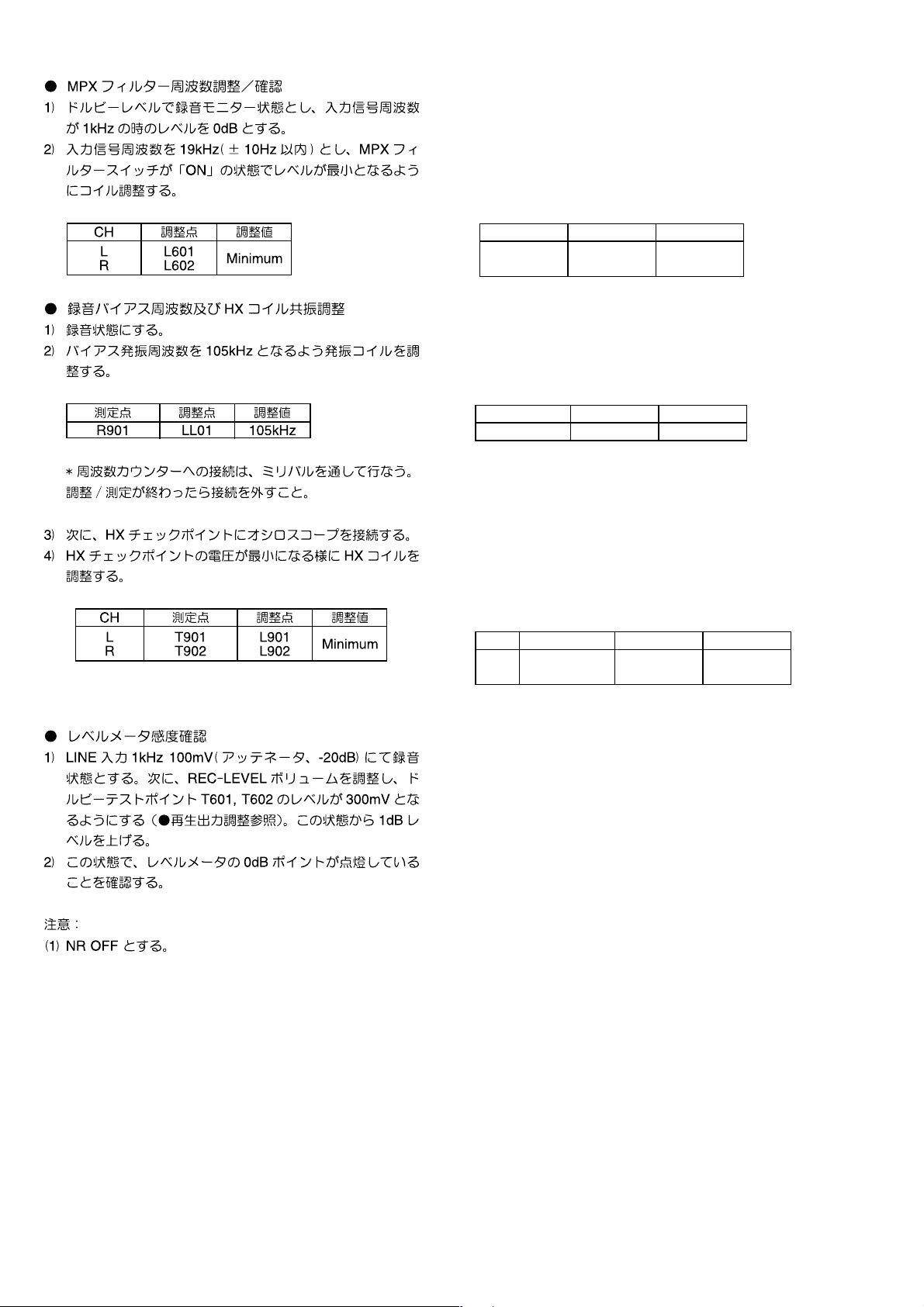

ADJUSTMENT FLOW CHART

Start

TAPE SPEED Adjustment

AZIMUTH Adjustment

PLAY-BACK EQ Adjustment or Check

PLAY-BACK LEVEL Adjustment

MPX Filter Adjustment

BIAS FREQUENCY Adjustment

BIAS OSC Coil

HX Coil

LEVEL METER Sensitivity Check

REC/PB FREQUENCY Response Adjust.

NORMAL Tape

HIGH POSITION Tape

METAL Tape

REC/PB LEVEL Adjustment

REC/PB FREQUENCY Response check

DOLBY NR ON (B,C)

NORMAL Tape

HIGH POSITION Tape

METAL Tape

5

Page 8

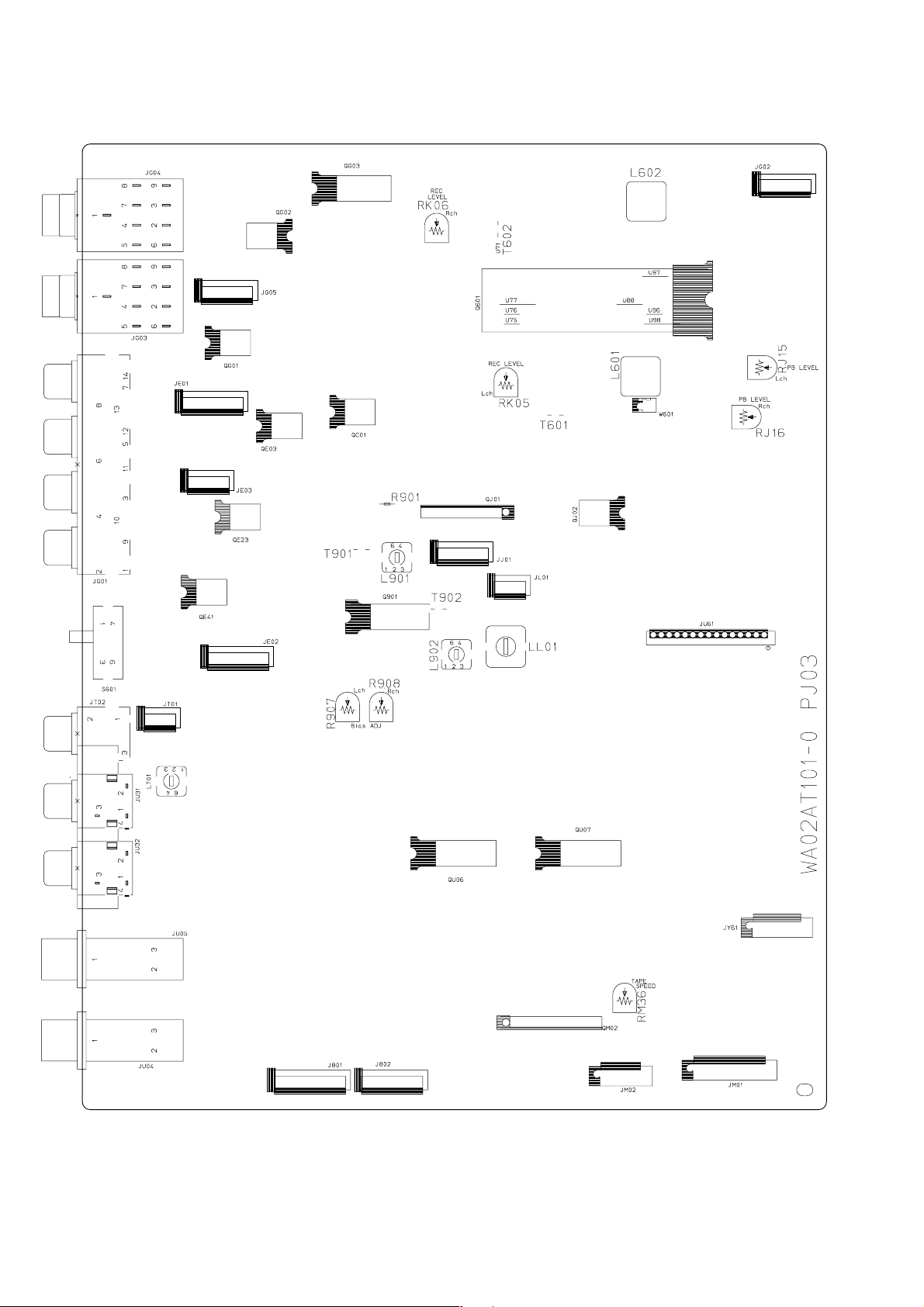

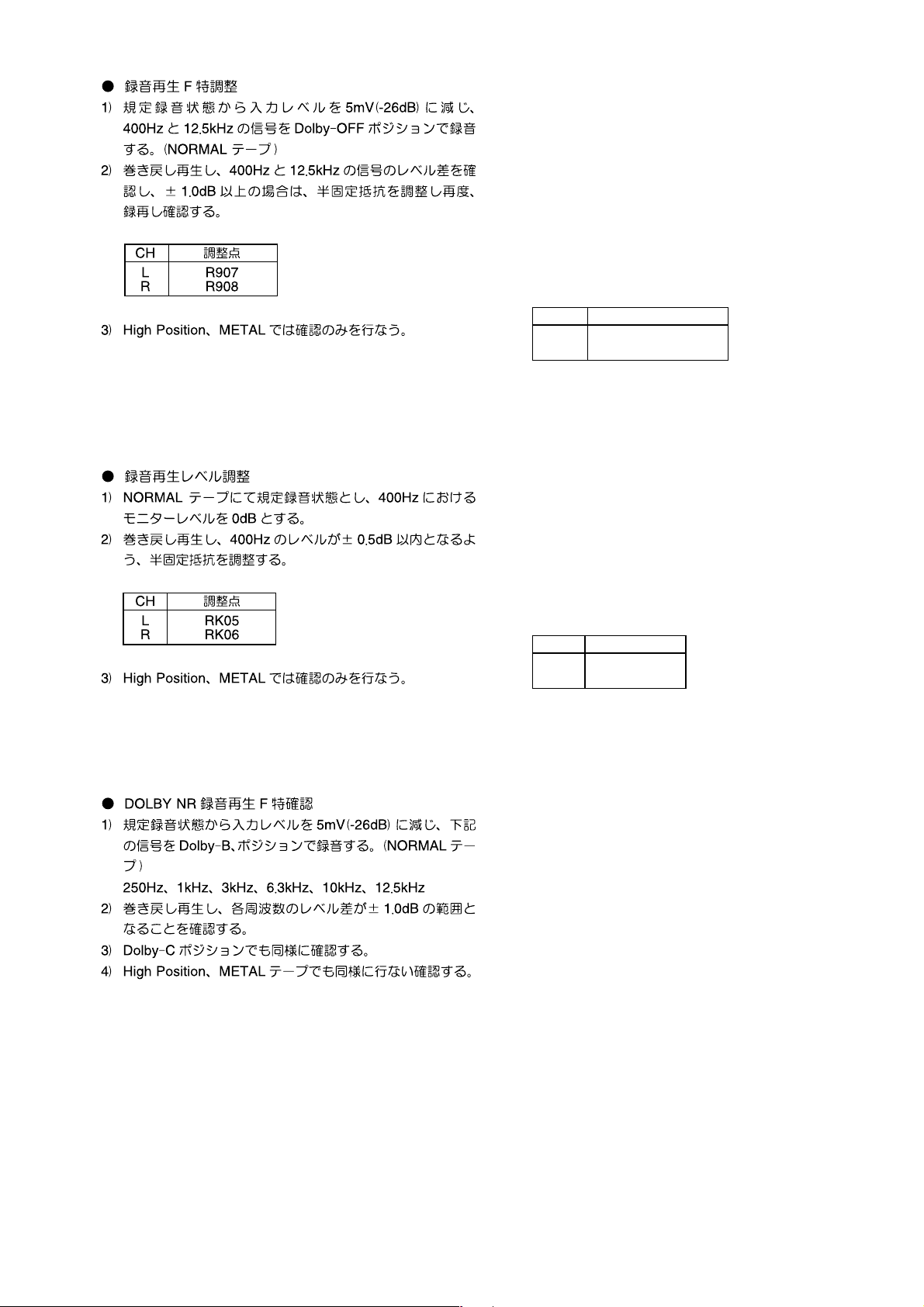

ADJUSTMENT POINT COMPONENT SIDE

6

Page 9

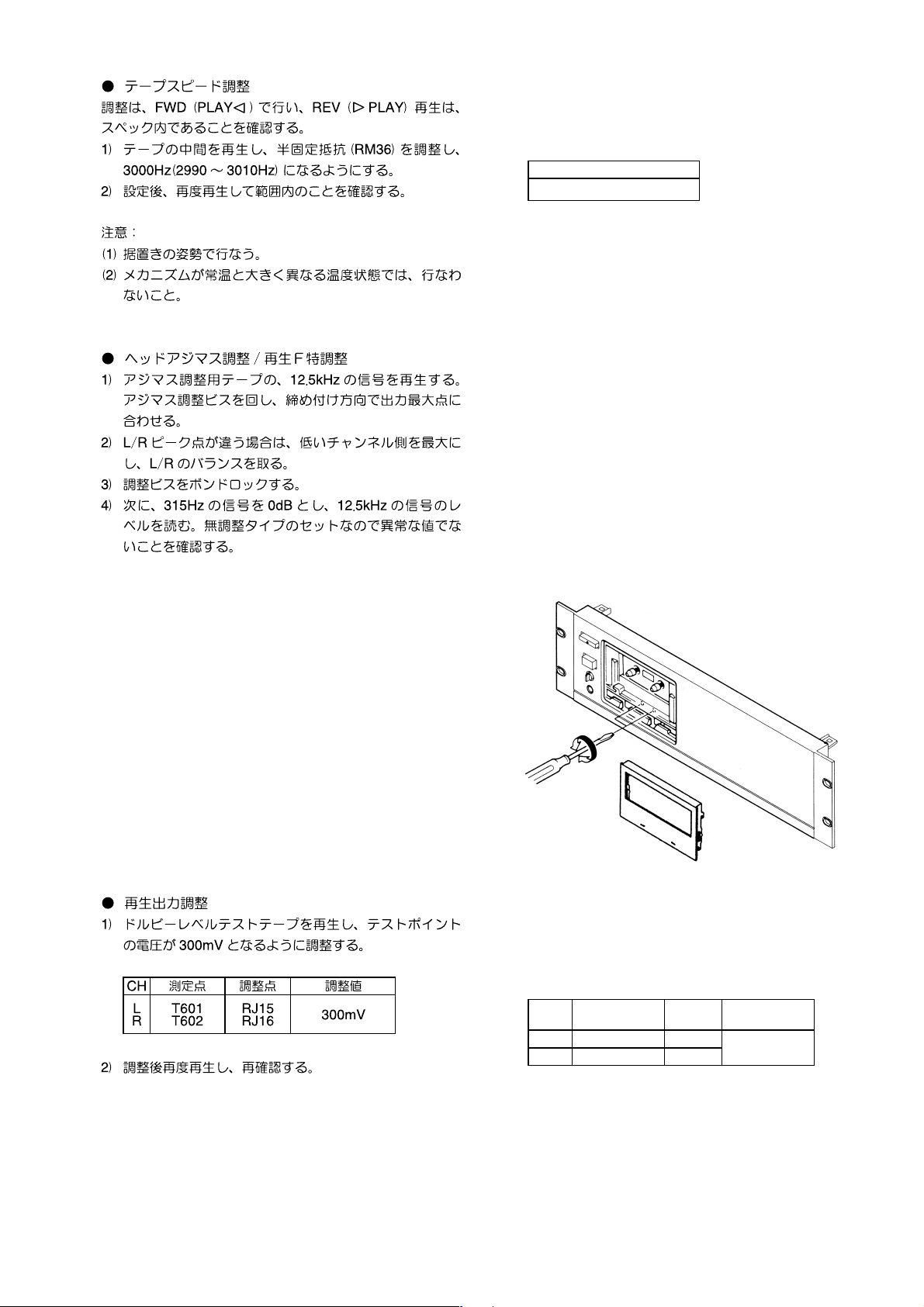

4.1 TAPE SPEED ADJUSTMENT

1) Playback the middle part of the Wow & Flutter test tape.

2) Adjust the variable resistor.

ADJUSTMENT POINT

RM36

for 3000Hz (2990Hz - 3010Hz).

3) Repeat 1) and 2) for both directions.

4.2 HEAD AZIMUTH ADJUSTMENT and

FREQUENCY RESPONSE CHECK

1) Playback the 12.5 kHz part of the Azimuth test tape.

2) Adjust the proper azimuth screw in both directions for

maximum output at the LINE OUTPUT jacks.

3) In case the L/R peak points are different, adjust the

lower channel to the maximum.

4) Lock azimuth screws with glue.

5) Playback the 315 Hz part of the test tape and set a 0 dB

ref., then playback the 12.5 kHz part of the test tape and

confi rm that the output is 0 dB, ±3 dB.

4.3 PLAYBACK LEVEL ADJUSTMENT

1) Playback the DOLBY test tape, adjust the following

variable resistors to the values and the test points

indicated below:

ADJ.

CH TEST POINT

L T601 RJ15

R T602 RJ16

RES.

2) After adjustment, replay and check it again.

Remark:

In case of drifting output during replay, check that the tape

running and the test tape are ok, because they may be

defective.

7

ADJUSTMENT

VALUE

300mV

Page 10

4.4 MPX FILTER ADJUSTMENT

1) Put the unit in REC mode with a S.R.L. input.

2) The MPX fi lter switch ON and change the input

frequency to 19kHz(±10Hz).

3) Adjust L601(L), L602(R) for minimum output at the LINE

OUTPUT jacks.

CH ADJ. POINT ADJ. TO

L

R

L601

L602

Minimum

4.5 RECORDING BIAS FREQUENCY AND HX COIL

ADJUSTMENT

1) Put the unit in REC mode.

2) Adjust the following bias oscillator coil for 105kHz at the

bias frequency.

TEST POINT ADJ. POINT ADJ. TO

R901 LL01 105kHz

Remark:

May have to connect FREQUENCY COUNTER through an

AUDIO VOLT METER.

3) Next, connect the Oscilloscope to the HX test point

(T901, T902).

4) Adjust the HX coils for minimum level.

CH TEST POINT COIL ADJ. TO

L

R

T901

T902

L901

L902

Minimum

4.6 LEVEL METER SENSITIVITY CHECK

1) Put the unit in REC mode with a 1kHz, 100mV signal to

the LINE INPUT jacks.

2) Set the REC LEVEL at the test point T601, T602 as

300mV.

3) Check the VU LEVEL METER indicates 0dB.

Remark:

Dolby switch has to be OFF.

8

Page 11

4.7 REC/PLAYBACK FREQUENCY RESPONSE

ADJUSTMENT

1) Adjust the output level of the audio oscillator to 5.0mV

(-26dB) from the S.R.L. recording condition.

Record 400Hz and 12.5kHz signals with DOLBY OFF.

2) Playback the recorded part and confi rm the level of

differences between 400Hz and 12.5kHz are within ±

1.0dB. If the level difference is out of allowance, adjust

the variable resistor and confi rm the playback level of

rerecording

CH. ADJUSTMENT

L

R

R907

R908

3) Repeat steps #1 and 2 with High Position and METAL

type tapes for confi rmation.

4.8 REC/PLAYBACK LEVEL ADJUSTMENT

1) Input the 400Hz signal and put the unit into record

mode. Measure the output level to set the reference

level of 0dB.

2) Playback the just recorded part and adjust proper

variable resistor, until the REC/PB levels are within

±0.5dB.

CH. ADJUSTMENT

L

R

RK05

RK06

3) Repeat steps #1 and 2 with High Position and METAL

type tapes for confi rmation.

4.9 REC/PLAYBACK FREQUENCY RESPONSE

CHECK DOLBY NR

1) Adjust the output level of the audio oscillator to 5.0mV

(-26dB) from the S.R.L. recording condition.

Record the following signals with DOLBY-B ON and

Normal tape at 250Hz, 1kHz, 3kHz, 6.3kHz, 10kHz and

12.5kHz.

2) Playback the just recorded part and confi rm the

difference of levels are within ±1.0dB.

3) Repeat steps #1 and 2, with High Position and METAL

type tapes.

4) Repeat steps #1 and 2, with Dolby-C ON.

9

Page 12

5. TECHNICAL DESCRIPTION

How to use the RS-232C connector

This input/output connector (D-Sub 9-pin female) is used for

RS-232C external control.

A straight cable available on the market can be connected to

this connector to exercise external control and send status

information.

• Connector pin assignment

1NC

69

51

• RS232C Connection

PMD351 Typical HOST

Transmit Data

Receive Data

Ground

RS in

CS out

2

3

5

7

8

D-Sub 9 Pin

(male)

D-Sub 9 Pin

The wiring requirements for a 9 pin to 9 pin serial

con nec tion, are a male to female straight cable.

• RS-232C physical specifi cations

Cable Straight cable

Baud rate 9600 bps

Data bits 8 bits

Parity bit None

Stop bit 1 bit

Flow control CS/RS Hardware Flow

2TX

3RX

4NC

5 GND

6NC

7RTS

8 CTS

9NC

Rx Data

2

Tx Data

3

5

Ground

7

RTS send

8

CTS receive

(female)

Example

:

Reception Time Command (code

@1

2011

)

[@][1][2][0][1][1][CR]

0x40 0x31 0x32 0x30 0x31 0x31 0x0d

When transmitting commands consecutively, put more

than 100ms blank between commands.

Received command data

Command CD Command TAPE Command

0 "@12000"+CR "@11800"+CR

1 "@12001"+CR "@11801"+CR

2 "@12002"+CR "@11802"+CR

3 "@12003"+CR "@11803"+CR

4 "@12004"+CR "@11804"+CR

5 "@12005"+CR "@11805"+CR

6 "@12006"+CR "@11806"+CR

7 "@12007"+CR "@11807"+CR

8 "@12008"+CR "@11808"+CR

9 "@12009"+CR "@11809"+CR

Time "@12011"+CR

Recall "@12015"+CR

Repeat "@12029"+CR

Next "@12032"+CR "@11832"+CR

Previous "@12033"+CR "@11833"+CR

Pitch Reset "@12037"+CR

Pitch Up Start "@12038"+CR

Pitch Up Stop "@1203801"+CR

Pitch Down Start "@12039"+CR

Pitch Down Stop "@1203901"+CR

Program/Memo "@12041"+CR "@11841"+CR

AMS "@12043"+CR "@11843"+CR

Open/Close "@12045"+CR

Pause "@12048"+CR "@11848"+CR

Clear "@12049"+CR

Fast Backward Start "@12050"+CR "@11850"+CR

Fast Backward Stop "@1205001"+CR

Fast Forward Start "@12052"+CR "@11852"+CR

Fast Forward Stop "@1205201"+CR

Play "@12053"+CR "@11853"+CR

Stop "@12054"+CR "@11854"+CR

A-B "@12059"+CR

Direction "@11847"+CR

REC Mute "@11842"+CR

REC "@11855"+CR

• Command reception

The command packets have a data length of 7 - 10 bytes.

ASCII codes from 0x00 to 0x7f are used to receive serial

data. At the transmission end, therefore, take steps to

convert the ASCII codes into HEX data to set the data in

the data packets. CR (0x0d) is added as the data packet

delimiter.

10

Page 13

• Status confi rmation command

When to confi rmation of the RS232C operations, the

following Status transmitting requirement commands is

transmitted to PMD351, status condition is replies.

• Status transmission

The status packets have a fi xed data length of 8 bytes.

ASCII codes from 0x00 to 0x7f are used to transmit serial

data. For this reason, the ASCII codes are converted

into HEX data before the data is set in the data packets

and transmitted. CR (0x0d) is added as the data packet

delimiter.

Request Command for CD Response from CD

Power "@1?20POWE"+CR

TrayMode "@1?20TRAY"+CR

PlayMode "@1?20PLAY"+CR

Disc "@1?20DISC"+CR

RepeatMode "@1?20RPTM"+CR

TimeMode "@1?20TMOD"+CR

Album "@1?20ALBU"+CR "@120Axxx"+CR

Track "@1?20TRAC"+CR "@120Txxx"+CR

Current Display

Time

Request Command for TAPE Response from TAPE

Power "@1?18POWE"+CR

Cassette "@1?18CASS"+CR

PlayMode "@1?18PLAY"+CR

Current Display

Time

Memo "@1?18MEMO"+CR

"@1?20TIME"+CR "@120xxxx"+CR

"@1?18TIME"+CR "@118xxxx"+CR

Standby "@120POFF"+CR

PowerOn "@120PRON"+CR

Open "@120OPEN"+CR

Close "@120CLOS"+CR

Toc Reading "@120TOCR"+CR

Stop "@120STOP"+CR

Play "@120PLAY"+CR

Pause "@120PASE"+CR

FF "@120FASF"+CR

REW "@120FASR"+CR

NoDisc "@120NODI"+CR

ERROR "@120ERDI"+CR

CDDA "@120CDDI"+CR

MP3 "@120MPDI"+CR

OFF "@120RTOF"+CR

ONE "@120RTON"+CR

ALL "@120RTAL"+CR

A- "@120RTA-"+CR

A-B "@120RTAB"+CR

Track "@120TTRA"+CR

TrackRem "@120TTRE"+CR

TotalRem "@120TREM"+CR

TotalLap "@120TTLA"+CR

Standby "@118POFF"+CR

PowerOn "@118PRON"+CR

IN "@118CAIN"+CR

Eject "@118CAEJ"+CR

Stop "@118STOP"+CR

PlayFW "@118PLFW"+CR

PlayRV "@118PLRV"+CR

Pause "@118PASE"+CR

FF "@118FASF"+CR

REW "@118FASR"+CR

Cue "@118CUE_"+CR

Review "@118REVI"+CR

Rec "@118RECO"+CR

Rec Pause "@118RECP"+CR

OFF "@118MEOF"+CR

ON "@118MEON"+CR

Example

1:

Transmission Power On (code

[@][1][2] [0] [P][R][O][N][CR]

@1

20PRON

0x40 0x31 0x32 0x30 0x50 0x57 0x4f 0x4e 0x0d

Transmitted status data

Category Status from CD

Power

TrayMode

PlayMode

Disc

RepeatMode

TimeMode

Category Status from TAPE

Power

Cassette

PlayMode

Memo

Standby "@120POFF"+CR

PowerOn "@120PRON"+CR

Open "@120OPEN"+CR

Close "@120CLOS"+CR

Toc Reading "@120TOCR"+CR

Stop "@120STOP"+CR

Play "@120PLAY"+CR

Pause "@120PASE"+CR

FF "@120FASF"+CR

REW "@120FASR"+CR

NoDisc "@120NODI"+CR

ERROR "@120ERDI"+CR

CDDA "@120CDDI"+CR

MP3 "@120MPDI"+CR

OFF "@120RTOF"+CR

ONE "@120RTON"+CR

ALL "@120RTAL"+CR

A- "@120RTA-"+CR

A-B "@120RTAB"+CR

Track "@120TTRA"+CR

TrackRem "@120TTRE"+CR

TotalRem "@120TREM"+CR

TotalLap "@120TTLA"+CR

Standby "@118POFF"+CR

PowerOn "@118PRON"+CR

IN "@118CAIN"+CR

Eject "@118CAEJ"+CR

Stop "@118STOP"+CR

PlayFW "@118PLFW"+CR

PlayRV "@118PLRV"+CR

Pause "@118PASE"+CR

FF "@118FASF"+CR

REW "@118FASR"+CR

Cue "@118CUE_"+CR

Review "@118REVI"+CR

Rec "@118RECO"+CR

Rec Pause "@118RECP"+CR

OFF "@118MEOF"+CR

ON "@118MEON"+CR

)

11

Page 14

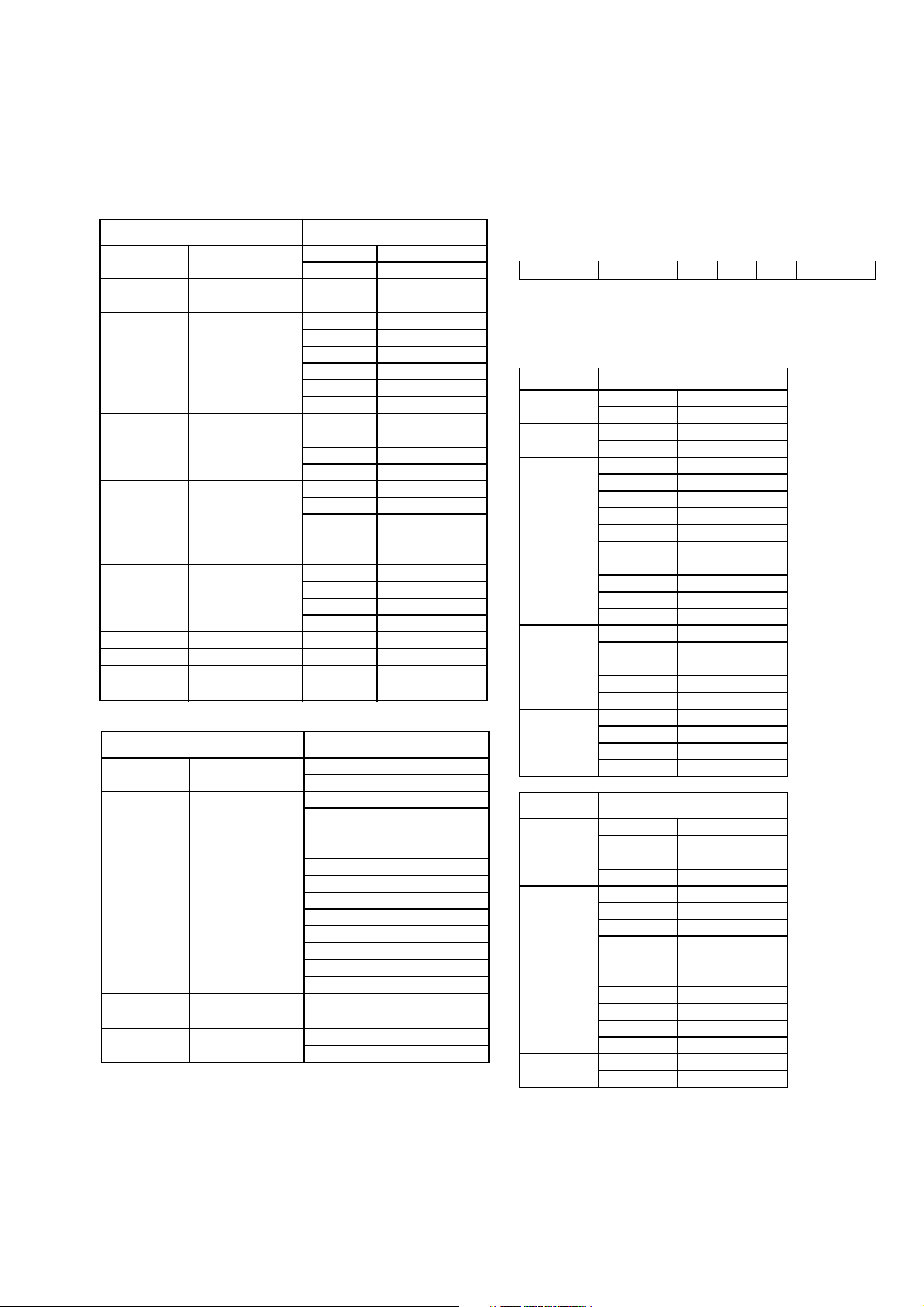

6. SERVICE PROCEDURE

Emergency Eject

1. To open the stucked tray, insert a minus driver into the hole of bottom and push the eject lever.

2. Use a minus driver. (width is about 4 mm)

This picture shows the unit upside down. The eject lever is pointed by the arrow.

The lever is thin so aim the narrow area carefully.

12

Page 15

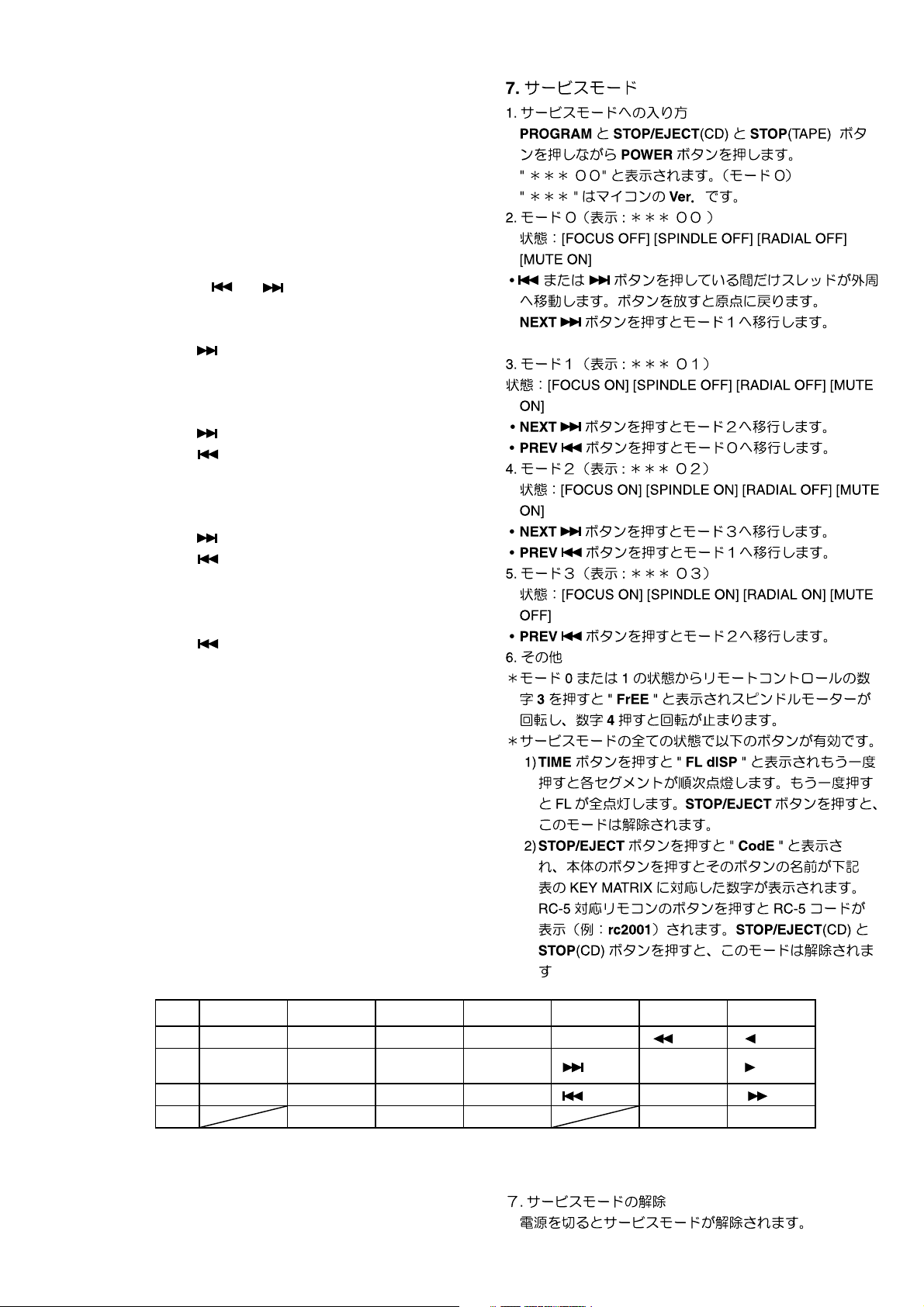

7. SERVICE MODE

1. How to enter into the Service Mode

While pressing PROGRAM, STOP/EJECT(CD) and

STOP(TAPE) buttons, press POWER button.

"

00 " is diaplayed

***

"

" is Version number of the microprocessor.

***

2. Mode0 (Display :

Status: [FOCUS OFF] [SPINDLE OFF] [RADIAL OFF]

[MUTE ON]

• While pressing

toward the outer edge. Release the button makes the

sledge return to the origin.

Press NEXT button to go to Mode 1.

3. Mode 1 (Display :

Status: [FOCUS ON] [SPINDLE OFF] [RADIAL OFF]

[MUTE ON]

• Press NEXT button to go to Mode 2.

• Press PREV button to go to Mode 0.

4. Mode 2 (Display :

Status: [FOCUS ON] [SPINDLE ON] [RADIAL OFF] [MUTE

ON]

• Press NEXT button to go to Mode 3.

• Press PREV button to go to Mode 1.

5. Mode 3 (Display :

Status: [FOCUS ON] [SPINDLE ON] [RADIAL ON] [MUTE

OFF]

• Press PREV button to go to Mode 2.

6. Others

* In the Mode 0 or 1, pressing the number button 3 on the

remote makes the spindle motor rotate and "FrEE" is

displayed. Press the number button 4 to stop rotation.

* In this Service Mode, all of the following button functions

work in any status.

1) Press TIME button, " FL dISP " is displayed. Press

it again then each FL segment lights up one by one.

Press it again then light up all the FL segments. Press

STOP/EJECT button to go to Mode 0

2) Press STOP/EJECT button, " CodE " is displayed.

Then press a button on the unit. The name of the button

is displayed. Pressing a button on the Remote controler

for RC-5 unit display the RC-5 code (Ex. : rc2001) of

the button. Press STOP/EJECT(CD) and STOP(CD)

button to go to Mode 0.

00 )

***

and buttons, the sledge moves

01)

***

02)

***

03)

***

6543210

1 PITCH + TIME One-way mode MEMO STOP/EJECT

2 PITCH 0 REPEAT

3 PITCH - PROGRAM CASCADE ALC ON

4 A-B DOLBY-C DOLBY-B DUBB. REC/PAUSE

Ex.: Press

PITCH +

button,

"1-6"

is displayed.

7. Terminating Service Mode

Turn off power to quit Service Mode.

Continuous

mode

RESET

13

(REW) (PLAY)

(NEXT) STOP (PLAY)

(PREV) PLAY/PAUSE (FF)

Page 16

Personal notes:

14

Page 17

8. WIRING DIAGRAM

TO CD MECHA

TO

CD

MECHA

TO CASSETTE MECHA

15 16

Page 18

9. BLOCK DIAGRAM

AC IN

VAM2202

Mic Input

0.5mV/10K

Line Input

100mV/47K

PT03

Power

Trans.

PS03

Power

Switch

PJ03 MAIN PCB

Q802

Amp

J803

SW

DC

3.3V

15V

12V

8V

CD5V

5V

- 25V

CD Block

RF AMP &

Laser Supply

TZA1024

PG03

REC

VOLUME

Mix

PS01

MP3 Decoder

Control

SAA7324/M2

Cassette Block

EQ AMP

NJM2068

Dolby B/C & REC EQ AMP

HA12155NT (+15V)

uP Block

Micro Processor

uPD784217-8EU

X'TAL

RESET

DAC

CS4338

R/P SWITCH

uPC1330(15V)

16MHz

HXPRO

uPC1297

AUTO REVERSE

R/P HEAD APE MECHANISM

ALPS CMAY2Z3

E-HEAD/

Motor Drive/Ta

pe count ...

Max

PV03

H-Phone

SW/AMP

PP03

RS232C 2Way

01

LT

PY03

IR

FL Driver

uPD16311

Tape Out

(500mV/470Ω)

Mix Out

CD Out

(2Vrms/600Ω)

H-Phone Out

Remote

Digital Out

0.5V

pp/75Ω

Disk/Sled Mtr

Radial/Focus Mtr

CD tray Mtr

TDA7073AT

X3 (8C)

Decoder

Digital Servo

Pitch

Control

BU2630FV

VFD

HQ31207410

PY23

KEY

1817

Page 19

10. SCHEMATIC DIAGRAM

PJ03-1/4

32 1

654

S601

MPX_SW

MICR_IN

ALC_R

RECR_IN

DA

SCK

STB1

MICL_IN

ALC_L

RECL_IN

TAPEL

RECL_IN

RECR_IN

RECL_IN

RECR_IN

LCH

L071 1/2

RCH

H071-2

HEAD

H071-1

HEAD

WO71-1

R/P HEAD

E-HEAD

5

4

3

2

1

WO71

3

2

1

123456789

1

2

3

GND

4

5

JJ01

C908

C902

CJ52

1000P

GND

GND

C901

10p

C916

C907

JL01

3

2

1

CL03

GND

0.012/250V

TO E-HEAD

GND

REC NORMAL=AC22V

DR02 =AC33V

METAL =AC48V

QJ01

UPC1330H

CJ02

470p

GND

RJ22

CJ15

10/16V

L902

105KHZ

L901

105KHZ

LL01

CJ01

470p

RJ02

100k

GND

10k

CJ03

4.7/35V

RJ03

33k

RJ01

100k

RJ21

10k

RJ04

33k

GND

CJ04

4.7/35V

3

2

3

2

C914

0.022

R901

GND

150k

1

2

1

QL01

3

2SD1862

10

RL02

GND

GND

GND

GND

100p/500V

4

560p/250V

61

6

560p/250V

41

100p/500V

4

53

0.1

GND

CL02

+15V

220/10V

CJ14

470/10V

GND

220/10V

2200p

2

CJ16

CJ05

CJ06

RJ08

150k

GND

RJ05

RJ06

68

68

C909

GND

150k

RJ07

1000p

GND

RL01

CL01

ADL

ADR

RECM

TAPER

DUBB

ALC

SCK

STB2

ALC_L

ALC_R

MICL_IN

MICR_IN

DUBB

TAPEL

TAPER

ALC

ADR

ADL

RECM

SCK

DA

STB2

STB1

DA

ALC_L

ALC_R

MICL_IN

MICR_IN

DUBB

TAPEL

TAPER

TO

AUDIO PART

REC

ALC

ADR

ADL

RECM

SCK

DA

STB2

STB1

TO

CPU

CK01

+5VA

R622

LK01

RK11

22MH

10k

CK09

CK07

100p

DM

K 500V

PLAYBACK EQ AMP

+15V

470

100/16V

GND

C912

15k

0.01

1

RL03

CJ09

4.7/35V

QJ03

DTC144ES

GND

CJ10

123456789

181716151413121110

100UH

10k

1

3

GNDGND

4.7/35V

C915

GND

RJ11

3.3k

1

3

RJ12

3.3k

C913

47/16V

GND

100/16V

QL03

DTC114ES

CJ07

0.022

GND

RJ20

10k

CJ08

0.022

R902

150k

C911

0.01

3

33k

CL04

10/16V

1

GND

0.01

C910

1000p

GND

0.047

C904

Q901

UPC1297CA

0.047

C903

RL04

4.7

2

QL04

2SC536

6.8k

RJ09

QJ02

1234

NJM2068DD

8765

CJ13

6.8k

RJ10

T902

R904

15k

0.022

GND

C906

C905

0.022

GND

T901

QL02 LL02

2SD1292

3

2

CL05

10/16V

RJ19

R903

PB_LEVEL ADJ

CJ11

0.022

QJ04

DTC144ES

3

1

2.7k

RJ14

1

32

10k

R907

GND

2

R906

4.7k

RJ15

R905

+15V

RJ13

CJ12

RJ16

2.7k

RJ17

RJ18

0.022

10k

4.7k

32

10k

1

23

1k

GND

2

2

1k

GND

1

32

1

10k

R908

R909

2.7k

1

3

GND

LK02

22MH

CK10

100p

GND

GND

C601

1/50V

CJ17

1000p

C602

1/50V

CJ18

1000p

RK12

10k

CK08

DM

R910

6.8k

1

3

GND

Q902

DTC114ES

Q903

DTC114ES

2

2

C604

1/50V

1/50V

C606

70U

REC

+5V

DM

GND

R621

10k

22k

22k

10p

C635

RU06

CU03

R620

C636

10p

GNDGND

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

1234567891011121314151617181920212223242526272829303132

10k

10k

10k

R619

R618

R617

GND

+15V

R633

10 (1/4)

DOLBY_C

DOLBY

100k

DU09

12

16 15 14 13 12 11 10 9

QU06

74HC4094

12345678

C632

1/50V

C603

1000p

GND

HA12155NT

1/50V

Q601

1/50V

C608

GND GND

C630

100u/16

GND

GND

GND

C605

1/50V

C607

1/50V

C629

R616

GND

10/16V

2

DTC114ES

18k

CU02

1

Q603

3

GND

2

L601

MPX

FIL.

531

GND

2.2k

R601

GND

1

2

R603

W601

5.6k

5.6k

2.2k

3.9k

R604

C642 C641

R615

R602

531

L602

MPX

C633

2

FIL.

1

0.1

2

Q604

3

DTC114ES

GND

16 15 14 13 12 11 10 9

12345678

GND

4.7/35V

R605

C611

C612

R606

4.7/35V

GND

C627

2200p

2200p

22k

C628

4700p

C609

22k

R608 R607

C610

FWB

QU07

DUMMY

C613

2200p

560

560

C614

2200p

4700p

REV

R609

10

R610

10

2

CD=P

74HC4094

2

DTC323TS

2200p

0.1/50V

C615

C617

2200p

0.1/50V

C616

C618

4.7k

R612

GND

QK02

DTC323TS

RECI

QK01

T601

R611

0.1/50V

C619

0.1/50V

C620

GND

GND

RK01

3.3k

4.7k

4.7/35V

C621

4.7/35V

C622

3.3k

RK02

0.47/50V

3

1

1

3

CK02

0.47/50V

RK03

R613

100k

GND

1/50V

C623

1/50V

C624

T602

RK04

3.3k1/50V

C626

3.3k

GND

32

CK03

1/50V

C625

1/50V

CK04

GND

RK06

23

RK08

RU21

GND

10k

1/50V

10k

2.2k

R614

1

2.2k

RK07

1

RK05

10k

RK09

10k

GND

GND

GND

100k

REC LEVEL

RK10

10k

RU22

REC_LEVEL

CK05

4.7/35V

24k

RK13

4.7/35V

CK06

GND

10k

RU23

NORMAL=0V , OTHER=1.2V

CR02=0V , OTHER=1.2V

METAL=0V , OTHER=1.2V

220u/16

C634

GND

10k

GND

WJ01A

GND

RK41

100k

RK42

RK43

82k

RK44

RK45

RK46

100k

RK31

120k

RK21

56k

RK32

68k

RK33

68k

RK34

56k

RK35

56k

RK36

100k

RK22

47k

RK23

33k

RK24

56k

RK25

56k

RK26

150k

82k

47k

56k

19 20

Page 20

MIC_L/MONO

MIC_R

BALANCE INPUT

TAPE IN

RG51

REC

VOL

RG54

123456

PJ03-2/4

RG17 RG19

100

47/16V

NJM2068DD

RG15

10k

RG13

100

GND

BU4066

CG06 RG16RG14

QG02

22k 22k

QG03

CG05

47/16V

10k

1234

8765

GND

RG21 RG25

22k 10k

RG26 CG12

10k 470/10V

GND GND

+15V

JG03

6

5

4

2

3

7

8

9

1

GND

6

5

4

2

3

7

8

9

1

CG07

10/16V

+15V

CG08

10/16V

RG08

100

GND

RG07

100

RG10

10k

RG09

10k

14 13 12 11 10 9 8

1234567

RG18 RG20 RG22

100k 22k 100k

CG04

GND

4.7/35V

RG12

100k

GND

RG11

100k

CG03

4.7/35V

JG04

GND

CG11

0.022

GND

GND

CG14

RG41

2.2k

RG42

2.2k

RG01

CG01

6.8k

GND

CG13

DM

GND

RG02

6.8k

RG03

68k

RG04

68k

4.7/35V

RG05

100k

RG06

100k

CG02

4.7/35V

GND

QG01

NJM2068DD

1234

8765

+15V

DM

JG05

EH

1

2

3

4

5

JG01

7

L

8

14

R

13

ALC_L

ALC_R

ALC

GND

+15V

RG28

10k

RG27

10k

QG05 QG06

DTC144ES DTC144ES

1

3

1

2

3

GND GND

CG09

10/16V

CG10

10/16V

RC04

470

+15V

RC03

470

MICL_IN

CC04

4.7/35V

GND

CC03

4.7/35V

+15V

RC09

100

QC03

C

1

2SC536

B

2

E

3

RC10

GND GND

100

QC04

C

1

2SC536

B

2

E

3

GND

RC06CC06

1M220/10V

DC03

GNDGND

DC02

DC01

QC02

DTC114ES

1

2

DC04

3

GND

MICL_IN

MICR_IN

ALC_L

ALC_R

TAPER

TAPEL

2

MICR_IN

4.7/35V

RE20

4.7k

RE19

4.7k

4.7/35V

8765

QC01

NJM4558DD

1234

DUBB

RECL_IN

RECR_IN

PG03

REC VOL.

DUBB

CE24

4.7/35V

4.7k 4.7k

GND

RE39 RE40

CE23

4.7/35V

CE04

CE03

GND

CG32

47k

RC02

47k

RC01

RG29

10k

+15V

+15V

CG31

RE36

10k

RE35

10k

RE16

10k

RE15

10k

CC05

47/16V

GND

7

RG53

RG52

100k

2

54321

GND

RG30

10k

GNDGND

RECR_IN

10/16V

10/16V

RG33 RG34

10k 10k

GND GND

RE34

4.7k

8765

NJM4558DD

1234

RE33

4.7k

RE14

10k

8765

NJM4558DD

1234

RE13

10k

RC12

10k

RC11

10k

GND

PDM_A

1k

RG31

RG32

QE23

1k

REC

BAL

13

WG01

RECL_IN

CE21

10/16V

QE03

CE01

10/16V

C-M U

12345

123

CD_R

CE26 CE25

10/16V 10/16V

RE22 RE21

150 150

22k

22k

CE22

10/16V

RE32

RE31

GND

CE02

10/16V

RE12

RE11

GND

CC02

4.7/35V

CC01

+15V

4.7/35V

ALC

T-MU

TO J302

(PS01)

GND

47k

47k

47k 47k

RE29 RE30

47k47k

RE10RE09

47k

47k

RC14

10k

RC13

10k

GND

GND

4

CD_L

RE28

10k

RE27

10k

RE08

10k

RE07

10k

JE02

EH

1

GND

1

2

2

3

3

4

4

5

5

6

6

2SC536

QE04

321

EBC

RE53

CE05

100/16V

JE03JG02

EHEH

GND

RE02

1k

RE01

1k

TAPEL

TAPER

JV01

CE43

10k

47/10V

RV15

4.7k

RV16

RV17

RV18

4.7k

EH

RE49RE50

+15V

GNDGND

15k

15k

10k10k

678910

SV01

HP SELECT

+15V

GND

47k 47k

RE42 RE41

12345

RV01

10k

RV03

10k

RV02

RV04

10k

10k

RV13

RV14

10k

QE41

NJM4558DD

RE44

CV05

220/10V

CV06

100/16V

RE43

10k

10k

10k

RV07

10k

RV08

10k

1234

8765

CV01

10/16V

10/16V

CE41

10/16V

10/16V

CV02

CE42

PV03

+15V

PDM_A

HEADPHONE

RV05

18k

QV01

NJM4560D

RV06

18k

T-MU

C-MU

RE51

1k

QE43

DTC323TS

2

2

QE44

DTC323TS

RE52

DTC323TS

2

2

DTC323TS

2

2

LV01

CV03

47/16V

1234

RV09

8765

CV04

47/16V

LV02

1k

QE21

QE22

DTC323TS

QE01

QE02

DTC323TS

WV11

CV07

0.1u

RV11

100

RV10

1k

RV12

100

LV03

JV02

1

2

3

1k

W601A

GND

RE47

470

GND

RE48

470

RE25

470

GND

RE26

470

JG01

1

2

9

JG01

3

4

11

10

L OUT

MIX OUT

R OUT

L OUT

CD OUT

R OUT

1

RE45

47k

3

3

RE46

47k

1

1

RE23

47k

3

3

RE24

47k

1

GND

RE05

470

+15V

GND

RE06

470

GND

JG01

5

6

12

JE01

EH

6

5

4

3

2

1

L OUT

TAPE OUT

R OUT

BALANCE OUT

1

RE03

22k

3

3

RE04

22k

1

PJ03

MAIN PCB

MICL_IN

MICR_IN

ALC_L

ALC_R

TO

DECK MAIN

TAPER

TAPEL

DUBB

RECR_IN

RECL_IN

C-MU

PDM_A

TO

CPU PART

ALC

T-MU

2221

Page 21

DY73

DY71

DY75

DY72

DY74

SY73

FF

SY72

REV

12

SY71

FWD

12

12

SY75

STOP

12

SY74

REW

12

DY53

DY52

DY51

DY77

DY76

DY78

DY79

12

SY76

CD_PLAY

12

12

12

SY53

PITCH+

12

SY52

PITCH0

12

SY51

PITCH-

12

SY77

NEXT

SY79

CD_STOP

SY78

PREV

DY54

DY55

DY56

DY57

CD PLAY

LT3K8B

REV PLAY

SY54

TIME

12

SY55

REPEAT

12

SY56

PROG

12

SY57

A-B

12

DY82DY83

LT3K8B

RY71RY72RY73

150150150

DY81

LT3K8B

FWD PLAY

GNDGNDGND

PY23

TO JY61

(PJ03)

JY71

10

9

8

7

6

5

4

3

2

1

JY51

6

5

4

3

2

1

WY51

JY03

PY03 & PY13

JY01

F2

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

6

5

4

3

2

1

JY02

+5V

SP-F

-30V

SP-V

SP-COM

GNDGND

GND

1

2

4

3

RY51

5k B

PITCH CONT

CD_LED

RPLAY_LED

FPLAY_LED

DGT0

DGT1

DGT2

KEY2

KEY0

KEY1

DGT6

DGT5

KEY0

KEY1

KEY2

KEY3

FLDOUT

FLDIN

FLCLK

FLSTB

RY23

220

E

3

1

C

IR

RY30

RY31

RY32

RY33

220

RY22

CY02

100/10V

GND

QY02 RY21

2

B

FLDIN

FLDOUT

47k

FLCLK

1k

1k

1k

1k

FLSTB

RY28

100K

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

G6

SEG11

G7

SEG12

G8

SEG13

SEG14

SEG15

SEG16

SEG17

SEG18

SEG19

SEG20

G8

G7

G6

G5

G4

G3

G2

G1

G1G2G3G4G5

CD_LED

REC_LED

FPLAY_LED

RPLAY_LED

40

41

42

434445

46

47

484950

51

52

G5

G4

G3

G2

SEG5

LED4

SEG5

LED5

QY01

SEG6

SEG6

DY07

SEG7

OFF

VDD

SEG7

SEG8

DGT3

G1

SEG8

SEG9

SEG9

DY03

SEG10

SEG10

SY03

SEG11

SEG11

SEG12

DGT1

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

DY04

VEE

VDD

G6

G7

G8

1212

SY04

REC/PDUBB

REC PLAY

LT3D8B

DY08

27 28 29 30 31 32 33 34 35 36 37 38 39

CY04

DGT0

0.1

GND

REC_LED

RY01

330

GND

GND

12345678910111213

CY03

0.1

GND

CY06

CY07

CY05

180P

22P

22P

GND

GND

GND

22K

22K

22K

RY24

RY25

GND

3

DY10

1

2

GND

RY26

GND

RY27

22K

GND

GND

DGT2

DGT3

DGT4

DGT5

KEY3

KEY2

KEY1

DY01

SY01

DY02

KEY0

1212

SY02

RESETMEMO

3

GND

9

CASCADE

DGT6

DGT4

5

4

SY05

6

2

1

11

10

12

8

SY05

7

REV MODE

B

C

OFF

DY05

DY06

VSS

SW1

SW2

SW3

SW4

DOUT

DIN

IC

CLK

STB

KEY1

KEY2

KEY3

KEY4

OSC

VDD

SEG1

LED1

SEG2

LED2

SEG3

LED3

UPD16311GC-AB6

FL DRIVER

SEG4

14151617181920212223242526

DY26

DY27

DY25

DY24

DY23

DY22

DY21

SEG1

SEG2

SEG3

DGT1

DGT0

SEG4

12 3

GND

ON

654

SY07

54321

109876

SY06

DOLBY NR

ALC

VY01

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

45

46

47

48

49

50

51

52

54

55

PY33

JY04

KEY0

KEY1

KEY2

PH

KEY3

12345

TO JU53 (PS01)

23 24

FL DISPLAY PANEL

Page 22

0.01

C831

PS03

L831

TO JU54 (PS01)

12345

J802

PJ03-3/4

Q801

NJM7815FA

C803

2200/35V

C833C832

C835

Q803

DTC114ES

GND

GND

PT03

0.1u0.1u

0.1u

2

C810

4.7/35V

R806

10k

1

3

1

3

W831 J801

0.1u

C837

GND GND

C813

10/16V

GND

7

6

5

4

3

2

1

+5V

Q805

DTA144ES

2

D809

D806

R804

10k

D807

RL103E

D801

D3SB20

GND

7

6

5

4

3

2

1

EH

GND

1

3

R803

15k

GND

3

2

C812

1000/16V

GND GND

14

C807

4700/25V

GND

C814

1000/25V

GND

D851D855

RL103E

C851

100/50V

+15V

L001

2

3

1

2

J833

1

2

J832

12

S831

4

22mH x 2

3

J831

2

1

W001

4

5

6

1

2

18

17

16

19

15

14

13

12

1

3

GND

Q807

DTC144ES

2

Q806

DTC114ES

2

R805

4.7k

GND

2

GND

4.7(1/4W)

4.7(1/4W)

Q804

NJM7808AF

GND

2

GND

RL103E

GND

OUTIN

R810

OUTIN

33(1/4W)

R811

10/35V

31

13

R858

C871

R851

GND

100k

C804

100/25V

Q802

NJM7805FA

1k

R852

470

D853

13V

D854

13V

R871

OUTIN

GND

2

GND

Q808

NJM7805AF

OUTIN

GND

2

GND

Q851

2

C

D852

1

B

6.2V

150

R854

2.2k

R872

2

Q872

DTC144EE

31

31

C805

100/10V

2SB1357

3

E

R855

C809

470/10V

GND

GND

15k2.2k

150

2SD2144

1

3

100/10V

Q871

2

10k

C806

GND

R856

R857

GNDGND

R874

10k

C852

47/16V

R873

1

3

PDIN

PDM

3

2

GNDGNDGNDGND GND

6

GND

WJ01B

GND

1

Q873

DTA125TS

TO J303 (PS01)

123

JT01

+5V

CT01 RT01

+15V

+12V

RU09

12k

+5V

+5VA

GNDGND

-5V

-30V

F1

F2

TO CPU

PDIN

TO CPU/MAIN

PDM

PON

0.1 270R

+5V

RU07

22k

RU08

1k

GND

RU10

22k

RU11RU12

1k39k

+5V

+5V

GND

RT02

560R

1

3

GND

1

3

GND

C

E

C

E

RU03

47k

RU17

47k

3

2

QU04

2SC536

2

B

QU02

2SC536

2

B

LT01

PULSE TRANS

3

1

DTA114ES

3

1

DTA114ES

CU09

GND

RU04

47k

GND

RU01

47k

GND

QU08

QU09

0.022

RU05

10k

RU02

10k

3

1

4

61

2

2

DTA144ES

3

1

4700P

GND

GND

GND

QU05

CT02

RCOUT

2

GND

QU03

DTA144ES

RU32

47

GND GND

CT04

0.022

3

2

1

3

2

1

EXC

RCIN

RU31

47

EXRI

2

CT05

CT03

2200P

JU04

JU05

TO CPU

TO CPU

TO CPU

GND

TO CPU

TO CPU

JT02

DM

EXC

RCIN

RCOUT

1

3

2

4

EXRI

EXRO

2

3

1

4

1

2

3

JU31

JU32

CAXL

TAPE FADER

CD FADER

RC5

EXT

2625

Page 23

RS-232C

(D-sub)

CTS

TXD

RTS

RXD

+5VD

DTA144ES

QU62

3

1

5

4

3

2

1

MOT_SW

+5VD

RCOUT

EXRO

RCIN

EXRI

VPP

METAL

FREC

PACK

CRO2

RREC

QS

PR01

9

8

7

6

JR01

+5VD

3

1

2

1

3

GND

GND

RU61

GND

IR

RR39

DM

GND

ADM232AARN

CR36 CR37

22p

GND

DTA144ES

QU64

2

DTC144ES

QU61

2

76

77

78

RU62

DM

79

80

10R

81

82

CU51

100n

83

84

85

GND

86

87

88

89

90

91

92

93

RU63

4k7

94

95

96

97

98

99

100

RU53

47k

+5VD

DU51

1SS301

31

2

CR07

RR35

RR36

QR01

22p

0.1

0

0

8

R2_IN

R2_OUT

9

GND

T2_OUT

T2_IN

10

6V-7

11

T1_IN

CR06

0.1

R1_OUT

12

13

R1_IN

C1-4C2+5C2-

T1_OUT

14

GND

CR05

0.1

2V+3

GND

15

GND

1

16

C1+

VCC

CR04

0.1

CR08

0.1

RR38

RR37

CR10 CR11

220P 220P

GND

GND

GND

PS01-1/3

DTC144ES

QU63

1

2

CDMU

3

GND

4.8V

0V

0V

4.9V

TAPEMU

GND

0V0V4.8V0V0V0V4.2V

LOAD_SW

TRAY_CONT2

IIC_SCL

IIC_SDA

TRAY_CONT1

3.9V

MP_STB

MP_RES

4.8V

4.8V

QU51

UPD784217A

CD_RES

4.8V

5V

0V

3.4V

12345678910111213141516171819202122232425

RU54

+5VD

RU69

10k

RU70

2k2

RU71

10k

QU53

2SC4081

2

0V

+5VD

GND

10R

RCIN

+5VD

1

QU52

BD4742G-TR

3

1

CU54

XU51

3

CSTCC10.0M

GND

RU51

47k

54

5V 4.9V

123

1U

GND

2

GND

RAB

PLL_CS

4.8V0V0.2V

PDIN

MP_RQST

CPU_RES

+5VD

CU55

100n

SCL

SILD

4.5V

4.4V

HFD

MP_RQST

DA_RESET

MP_RQST

SDA

4.2V

REEL1

MP_RES

MP_RES

RU56

REEL2

MP_STB

MP_STB

JR03

100

100

GND

ALC

RECM

10R

GND

+5VD

RU58 RU59RU60

47k DM47k

IIC_SCL

IIC_SDA

IIC_SCL

IIC_SDA

SILD

RM2

51525354555657585960616263646566676869707172737475

SILD

6

5

4

3

2

CPU_RES

1

RM1

CU53

100n

ADR

RAB

RAB

4.2V

0V

4.8V

4.7V

0.1V

1.9V

5V

JR02

9

9

GND

5VD

RXD

TXD

VPP

CTS

RTS

GND

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

JU52

PH9P

GND

+5VD

RXD

TXD

CPU_RES

VPP

CTS

RTS

+5VD

RU78

10k

50

49

48

47

46

45

44

43

42

41

40

39

38

37

RU52

36

10R

35

34

CU52

100n

33

32

31

30

29

28

27

26

GND

RU72

RU73

RU75

RU74

1k

CPM

STB2

STB1

1k

FLCLK

1k

FLDOUT

1k

FLDIN

FLSTB

22k

RU76

+5VD

RU57 RU55

DM DM

RPC

SOL

SCK

RTS

CTS

TXD

RXD

RU77

EXC

ADL

DA

JU53

IR

FLSTB

FLCLK

FLDIN

FLDOUT

1

2

3

TO FRONT PART

4

JY04 (PY13)

5

PJ03-4/4

JU51

PDIN

REEL1

REEL2

QS

ADR

ADL

EXC

STB1

STB2

DA

SCK

CPM

SOL

RPC

RM1

RM2

RECM

TAPEMU

CDMU

RCOUT

EXRO

RCIN

EXRI

METAL

FREC

PACK

22k

CRO2

RREC

ALC ALC

GND GND

30

30

29

29

28

28

27

27

26

26

25

25

24

24

23

23

22

22

21

21

20

20

19

19

18

18

17

17

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

JU61

JU55

PDIN

REEL1

REEL2

QS

ADR

ADL

EXC

STB1

STB2

DA

SCK

CPM

SOL

REC

RPC

RM1

RM2

RECM

TAPEMU

CDMU

RCOUT

EXRO

RM2

RCIN

RM1

EXRI

METAL

FREC

PACK

CRO2

RREC

RPC

SOL

CPM

QS

REEL1

REEL2

METAL

FREC

PACK

CRO2

RREC

C691 W601B

0.1

DU01

DU02

R807

100k

-5V

TAPEMU

CDMU

QM03

LB1641

C-MU

T-MU

12345678910

GND

CM32

0.022

PLAY=4.7V

DM03

4.7V

FF/REW=6.8V

1

3

GND

GND

QM04

DTC144ES

DM02

6.2V

2

(47k,47k)

+5V

RU65

22k

22k

22k

RU66

RU67

RU64

22k

D813

D812

R808

100k

RM33

RU68

22k

CM33

10 1/4W

R809

100k

0.022

+12V

PDM

RM32

2.2k

D872

D871

PDM

1

3

GND

3

GND

STOP=8.6V

QM16

DTC144EE

2

REC=4.7V

STOP=8.6V

2

QM15

DTC144EE

PLAY=0.6V

DTC114EE

DTC114EE

1

TO FRONT PART

JY01 (PY13)

JY62

1234567

JY61

CY61

0.1

F2

+5V

10k

RM39

2

1

3

GND

2

1

3

GND

DM01

RL103E

2

QM02

2SD2144

S/U/V

GND

QM06

QM05

LEADER

TAPE=0V

2

PLAY=2V

0.022

GND

2

0.022

GND

GND

+5V

QM14

DTC144EE

QM12

DTA125TS

STOP=10V

PLAY=0V

1

3

CM35

PLAY=2V

CM34

0.1

RM31

CY62

GND

2.2k

GND

F1

-30V

QM13

DTA125TS

2

1

3

STOP=10.4V

REC=8.4V

1

3

STOP=10.4V

REC=8.4V

PLAY=0.6V

QM07

DTC114EE

1

3

REC=7V

8

SP-V

STB1

STB2

DA

SCK

T-MU

C-MU

ADR

ADL

RECM

ALC

REC

D873

PDM

EXC

SP-COM

SP-F

1

3

PDIN

RCOUT

EXRO

RCIN

PDM

EXRI

D874

PDM_A

STB1

STB2

DA

SCK

T-MU

C-MU

ADR

ADL

RECM

ALC

REC

PDM_A

EXC

PDIN

RCOUT

EXRO

RCIN

PDM

EXRI

PON

TO TAPE / AUDIO

TO POWER SUPPLY

SPEED

10k

RM36

1

23

8.2k

RM35

RM38

220k

STOP=10V

CM31

PLAY=0V

0.022

1

2

QM31

2SD2144

S/U/V

3

GND

JM02

7

7

7

6

6

5

5

4

4

3

3

2

2

1

1

MM02-1

6

5

4

3

2

1

WM02-2

7

6

5

4

3

2

1

2

3.3k

RM34

JM01

GND

+5V

WM01-3

5

5

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

WM01-1

4

3

2

1

6

5

4

3

2

1

WM01-2

4

3

2

1

J074

6

5

4

3

2

1

L071

12

M072

R072

220

R071

470

R073

470

S075

12

12

S073

12

S074

12

S077

12

S076

M071

Q076

1

2

4

3

1

2

4

3

Q071

1

2

4

3

Q072

GND

100M CMAY2Z3

0.022

CJ51

SCL

SDA

PLL_CS

CD_RES

TRAY_CONT2

SDA

SCL

CD_RES

PLL_CS

LOAD_SW

TRAY_CONT1

LOAD_SW

TRAY_CONT1

TRAY_CONT2

HFD

MOT_SW

MOT_SW

HFD

JU54

6

EH

5

+8V

+5VA

+5V

+15V

4

TO J802 (PJ03)

3

2

1

GND

GND

DM: DUMMY

27 28

Page 24

MD

LD

FPC15

TRACKING

FOCUS

SHORT

LAND

1/2VCC

M

SPINDLE MOTOR

M

SLED MOTOR

LIMIT SWITCH

+5VA

J101

D2

D1

D4

VCC

D5

D3

J104

XH6P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

6

5

4

3

2

1

GND

J102

HX4P

4

3

2

1

GND

GND

+5VA

C108

47/10V

R109

10k

R108

DM

PS01-2/3

RAD-

FOC+

FOC-

RAD+

+5VA

SL-

SL+

DM+

DM-

INSW

LOAD_SW

TRAY-

TRAY+

TRAY+

TRAYFOC+

FOCRAD-

RAD+

SL+

SLDM+

DM-

R134C114

220.1

16 15 14 13 12 11 10 9

GND

5.2V

+5VA

4.5V

R126 C117

22

0.1

GND

4.8V

R211

68

R212 R213

5.6 5.6

Q113

2SC4081

5.6k

2.7k

5.6k

R114

R113

R111

Part of Servo Driver

4.9V

Q114

2SC4081

C106

47/10V

R107

15k

C103

0.1

GND

Output from Photo Diode

GND

GND

Part of RF AMP

Q101

TZA1024T/N1

1234567

2.6V

R106

100k

Q102

C112 R133

0.1 22

4.8V

GND

5V

0.8V

0.2V

0.7V

0V

3.8V

0.2V

0.01

4.8V

R104

220k

0V

C118R130

22

0.1

4.6V

C104

4700p

2SC4081

16 15 14 13 12 11 10 9

0V

4.8V

0V

0V

1.9V

0.8V

1.8V

GND

5V

LCD

R110

47

R101

4.7k

148 9 10 11 12 13

GND

GND

C107

47/10V

GND

C101

5p

R102

R103

4.7k

4.7k

R150

R149

10k

C132

R105C105C102

0.1

2.2k47/10V

1.8V

R148

100k

150k

1.2V

R142

2.2k

5V

GND

GND

Part of Loader Cont.

16 15 14 13 12 11 10 9

GND

+5VA

Q112

2SC4081

R146

2.2k

1.2V

Laser H: Laser on

RW H: CD-RW Play

D101

1SS301

R147

C129

2.2k

1000p

3.8V

Q111

0.6V

R144

1k

GND

4.9V

2

31

2SC4081

R141 C131

470 1000p

C130

0.1

GND

4.8V

GND

R138 R145

100k 100

E

4.8V

2

B

4.6V

C

R139

1k

GND

C133

0.1

GND

3

Q110

1

1.9V

R143

100k

2SA1586

R137

100k

2

0.6V

Laser

RW

Radial

FOCUS

HFI

Sledge

VRin

MOTO1

MOT_SW

RW

INSW

Laser

31

D102

1SS301

+5VA

R140

10k

0V

2SC4081

Q109

HFD

D2

D1

D4

D5

D3

HFI

VRin

D2

D3

D4

D5

D1

TRAY_CONT1

TRAY_CONT2

LOAD_SW

HFD

Radial

FOCUS

Sledge

MOTO1

MOT_SW

RW

INSW

Laser

HFI

VRin

D2

D3

D4

D5

D1

TRAY_CONT1

TRAY_CONT2

LOAD_SW

HFD

GND

3

1

DTA114

2

Q106

1

3

Q107

DTC114

2

GND

Q108

DTC114

1

3

2

MOT_SW

Q103 Q105 Q104

TDA7073AT TDA7073AT TDA7073AT

1.7V

1.7V

12345678

C128

0.1

C124

0.1

R129

R136

180k

1k

R135

3.3k

R127

15k

MOTO1

9.8V

C125

0.1

GND

R121 C123

10k 0.1

+8V

R120

12k

Sledge

R124

C122

0.1

1.7V

1.7V

1k

C111 C113

0.1 0.1

GND GND

R151

0

1.7V

1.7V

12345678

R117

1.5k

C126

1000p

R118

18k

Radial

+8V

R122

12k

C120

0.1

R115

R119

15k

GND

12k

9.8V

R116

C121

1000p

FOCUS

1.7V

1k

1.7V

C116C115

1000p1000p

R152

0

+8V

9.8V0V0V

12345678

GND

C119

0.1

C109

47/10V

GND

+REF

TRAY_CONT1

R125

C127

R123

12k

TRAY_CONT2

390

0.1

R220

12k

+REF

C110

100/6.3V

GND

+VR

R131

1k

R132

1k

SYM No. PS01

+REF

+REF

DM: DUMMY

3029

Page 25

Radial

FOCUS

Sledge

MOTO1

RW

INSW

Laser

HFI

VRin

D2

D3

D4

D5

D1

C328 C334

22p 22p

Radial

FOCUS

Sledge

MOTO1

RW

INSW

Laser

HFI

VRin

HFI

D2

D3

D4

D5

D1

VRin

D2

D3

D4

D5

D1

Part of PLL & VCO

+5VPLL

R322

R335

1M

R320

14

X301

8.4672MHz

23

GND

C307 R325

47/10V 10k

+5VPLL

R323

0

C308

10/16V

+5VA

+8V

C342 C343

0.01 0.1

GND GND

+5V

PS01-3/3

+3.3V

R306

10k

R308

10k

R309

10k

R311

10k

R314

10k

C314

180p

GND

10

C331C312

0.0110/16V

GNDGND

16 15 14 13 12 11 10 9

Q303

BU2630FV

100

GND

14 13 12 11 10 9 8

C329

0.01

Q302

L384

BLM11B601

Q304

78L05UA

GND

1

GND

L303

OUTIN

BLM11B601

4.8V2V1V

0V

1234567

GNDGND GND GND

GNDGND

74LS628AF

LCD

0.8Vp-p

C302 R324

1000p 1k

R316

47

R301

470

C301

0.047

GND

10k

R305

10k

R307

10k

R310

10k

R312

10k

R313

10k

R315

C315

220p

180p

C324

R333

680

+5VD

+5VD

C332

0.01

R349

0V

GND

22

4.8V

L383

BLM11B601

C392

2.3V

1.3V

0V

R336

0.1

220

220p

C316

0.9V

+5VPLL

GND

180p

180p

330p

C318

C321

C317

2.1V

5V

2.2V0V2.4V

12345678

0.7V

0V

2V2V0.9V

C323

22p

5V

23

C346C344C345

47/10V0.10.1

GNDGNDGND

Part of CD Decoder

C306

0.022

C313

47/10V

C330

0.1

R302

1M

GND

GND

220p

220p

220p

220p

C322

C319

C320

C325

+3.3V

R346R345R344

4.7k4.7k4.7k

4.3V

4.4V

GND

Q383

2SC4672

1

C

D302

1SS301

R396

100

R395

100

RW

Laser

INSW

C326

1u

C305

47p

R304

1k

1 48

0.01

22k

R317

33k

C311

47/10V

R328

1.4V

2

1.6V

3

1.6V

4

0V

5

3.3V

6

1.2V

7

1.8V

8

1.8V

9

1.8V

10

1.8V

11

1.8V

12

1.8V

13

1.8V

14

0V

15

1.7V

16

1.3V

R319R318

2222

C335

0.1

GND

47R

C337

0.1

GND

R303

C303

GND

GND

R327

1k

R332

1k

R334

1k

C338

2200p

GND

C327

22P

3

E

C393

2

B

100/6.3V

2

GND

31

D301

4.2V

GND

3.4V

3.4V

0V

3.4V

C336

DM DM

GND

L351

BLM11B601

C367

0.1

GND

626364

GND

+3.3V

C368

0V

0V

+3V

0.1

3.4V

C369

100/6.3V

MOTO1

+3.3V

R342

C304

1.9V

C339

10

0.1

Sledge

5758596061

3.4V

Q301

SAA7324H/M2B

3.4V

GND

PLL_CS

Q352

2SC4672

1

C

2

B

R368

3.4V

470

1.7V

0V

SDA

FOCUS

1.9V

1.7V

SCL

3

2.7V

E

Radial

1.8V

1.7V

C351

100/6.3V

1.7V

L302

3.4V

1.7V

1.7V0V0V

+2.7V

R343

5.6

C341

1u

BLM11B252

50515253545556

0V

313029282726252423222120191817

R326

R329

R331

L301

A-GND

TO JT01 (PJ03)

GND

+3.3V

+VR

R347

220

+5VD

10k

10k

10k

R337

R338

GND

R321

R339

R348

100

C340

0.1

10k

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

4932

0V

0.8V

0V

0V

0.1V

2.6V

4.5V

0.1V

4.4V

4.2V

4.8V

C309

22p

GND

GND

100

100

100

BLM11B601

+15V

C391

0.1

C389

10/16V

A-GND

R393

10k

R394

10k

L382

L381

BLM11B252

R391

0

CD_L

1

BLM11B252

J302

R392

0

CD_R

432

TO JE03 (PJ03)

2

C310

82p

10k

R340

A-GNDA-GND

1

A-GND

J303

DM

R341

C390

SILD

RAB

SCL

SDA

CD_RES

SCLK

WCLK

DATA

PLL_CL16

GND

NJM4558M

47/10V

R389

R390

33k

Q382

33k

WCLK

SCLK

DATA

+2.7V

+2.7V

MP_RES

R377

47k

R378

47k

PLL_CL16

+5VD

R379

C388

150p

1234

C387

150P

LMP

R353

10

R364

10

R365

1k

+5VD

220

0.1u

C397

27p

C396

GNDGND GND

Q353

43

0

5

TC7S08F

0.1u

C350

GND

18k

R388

R384

R386

10k

C386

5678

1000P

A-GND

C385

1000P

A-GND

R385

10k

R383

18k

R387

C354

0.1

C352

0.1

C353

0.1

BLM11B601

R397

2

100

R398

1

100

R399

100

10k

10k

IIC_SCL

IIC_SDA

1k

R370

1 48

1.7V

2

1.7V

3

1.7V

4

5

2.7V

6

7

GND

8

9

10

2.6V

11

0V

12

GND

13

14

15

4.2V

16

GND

BLM11B252

L385L386L387

33p

C395

LRCKO

GND

BCKO

SDO

1.6V 3.8V

1k

R371

R367

4.2V

0.5V

470k

2.6V

2.6V

330

R330

R360

100p

C370

0V

1.7V

MP_STB

1k

R372

4.2V

1.7V

R350

330

R361

100p

C371

MP_RQST

1k

R373

R380

R362

100p

C372

R363

10

C355

0.1

10

R358

C358

1U

0V

3.4V

3.4V

Q351

STA016T

0V

3.4V

1.8V

C356

1U

GND

R359

330

10

+3V

R330,R350,R380:BLM11B252

GND

Q381

CS4338

1234

0.1

R381