Page 1

Service

PM6004 /

N1SG/N1B/K1B/U1B

Manual

Integrated Amplier

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

PM6004

S0314-0V01DM/DG1108

Copyright 2011 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 1

Page 2

CONTENTS

SAFETY PRECAUTIONS ..........................................................4

NOTE FOR SCHEMATIC DIAGRAM .........................................5

TECHNICAL SPECIFICATIONS ................................................6

DIMENSION ...............................................................................6

CAUTIONS IN SERVICING .......................................................7

Initializing INTEGRATED AMPLIFIER .......................................7

DISASSEMBLY ..........................................................................8

1. FRONT PANEL ASSY ...........................................................9

2. MAIN & VOLUME PWB UNIT .............................................12

3. POWER TRANS ..................................................................13

4. SUB TRANS ........................................................................13

WHEN THE MICROPROCESSOR IS

REPLACED WITH A NEW ONE .............................................14

SERVICE MODE ......................................................................31

ADJUSTMENT .........................................................................32

TROUBLE SHOOTING ............................................................34

1. The power can not be turned on.

(STANDBY LED does not light (STANDBY MODE) .......... 34

2. The power can not be turned on.

(STANDBY LED lights→ash) ........................................... 34

3. STANDBY LED ashes while using unit.

(protection circuit is set) .................................................... 35

4. The power turned on, but a sound does not

output normally. (Both channels) ....................................... 35

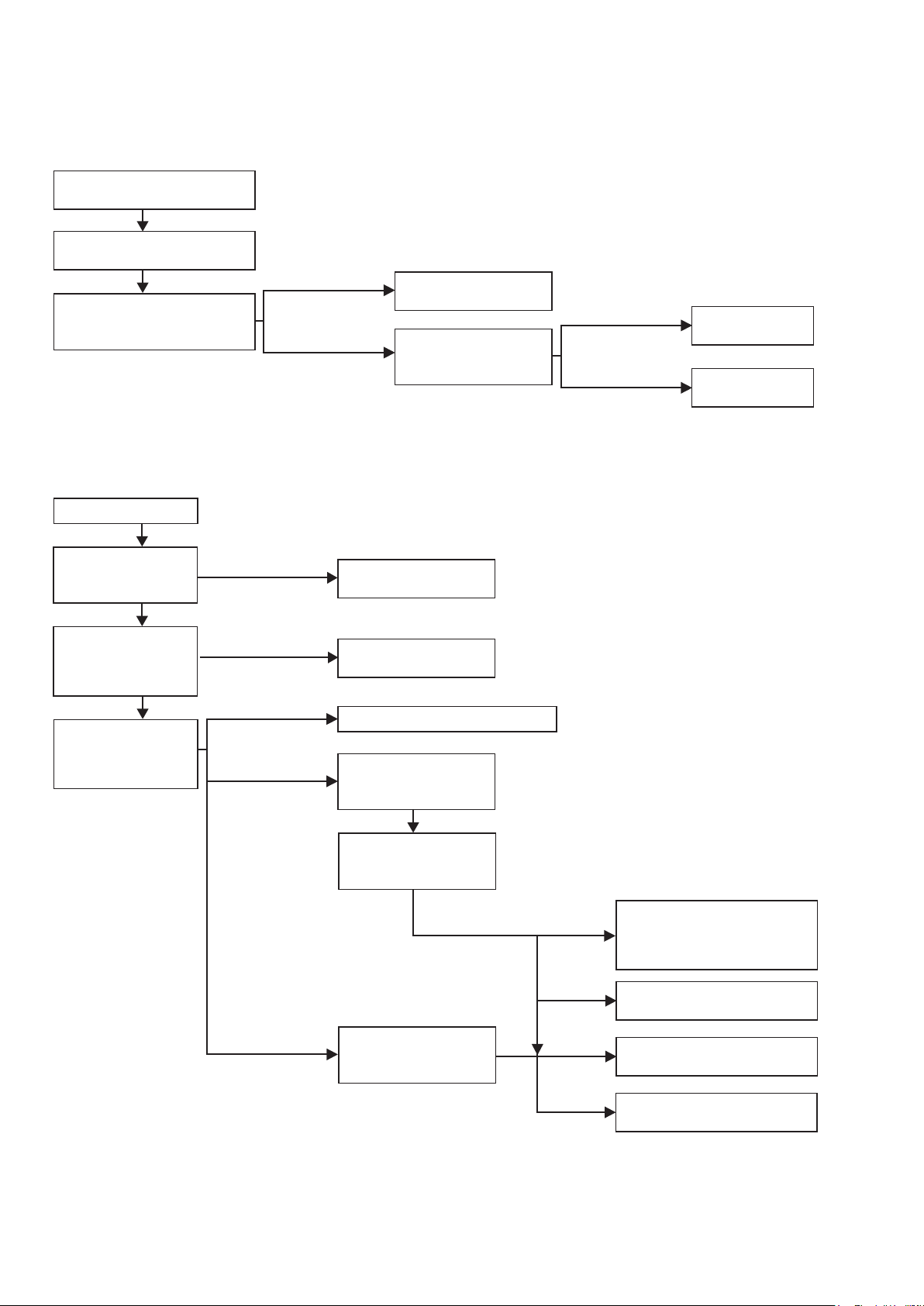

BLOCK DIAGRAM ...................................................................37

POWER SUPPLY BLOCK DIAGRAM .....................................38

LEVEL DIAGRAM ....................................................................39

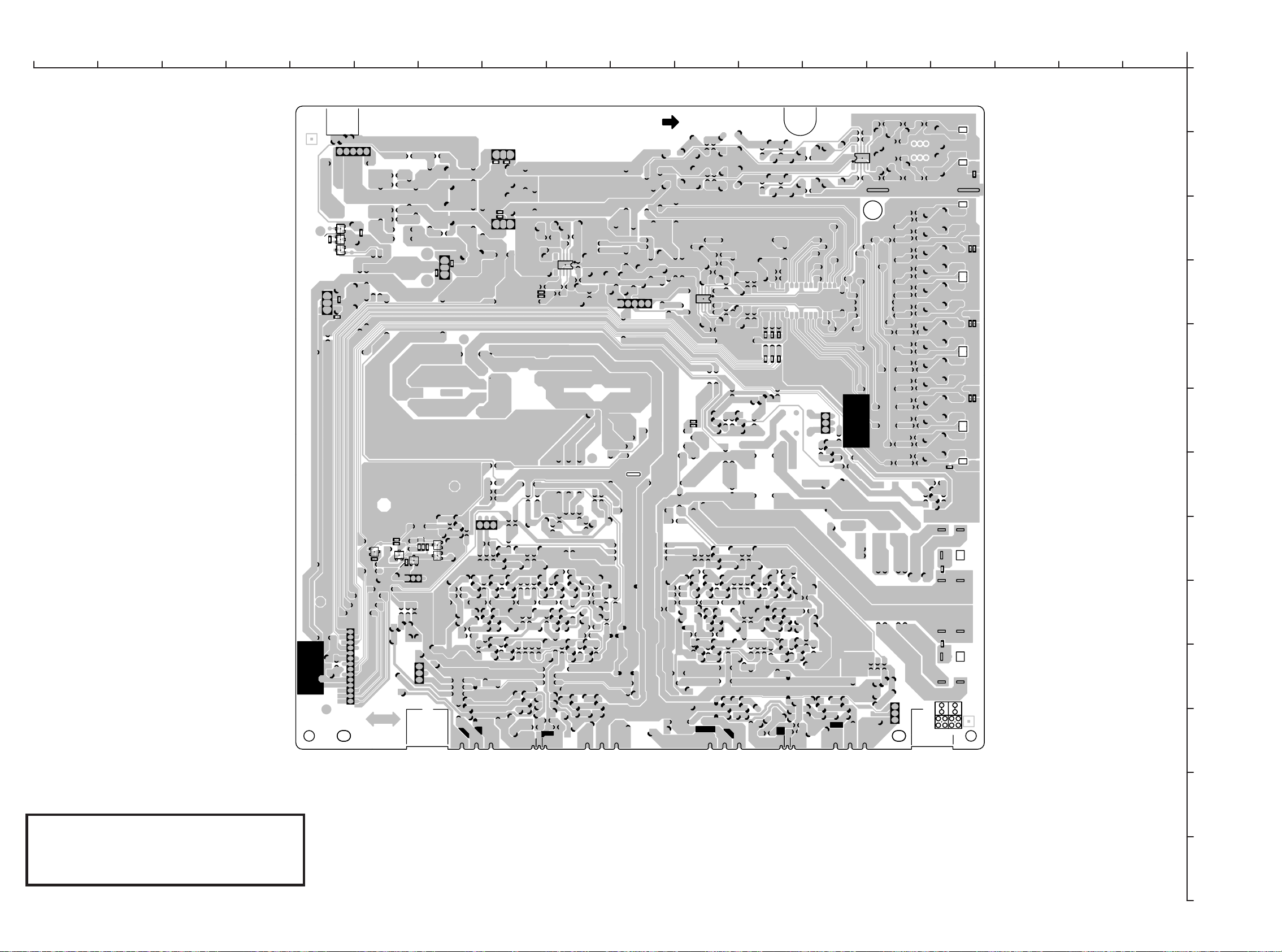

PRINTED WIRING BOARDS ...................................................40

FRONT ....................................................................................40

VOLUME .................................................................................41

STANDBY ................................................................................41

POWER SW ............................................................................42

POSISTER .............................................................................42

HEADPHONE .........................................................................42

TRANS PRI .............................................................................42

TRANS SEC ............................................................................42

MAIN .......................................................................................43

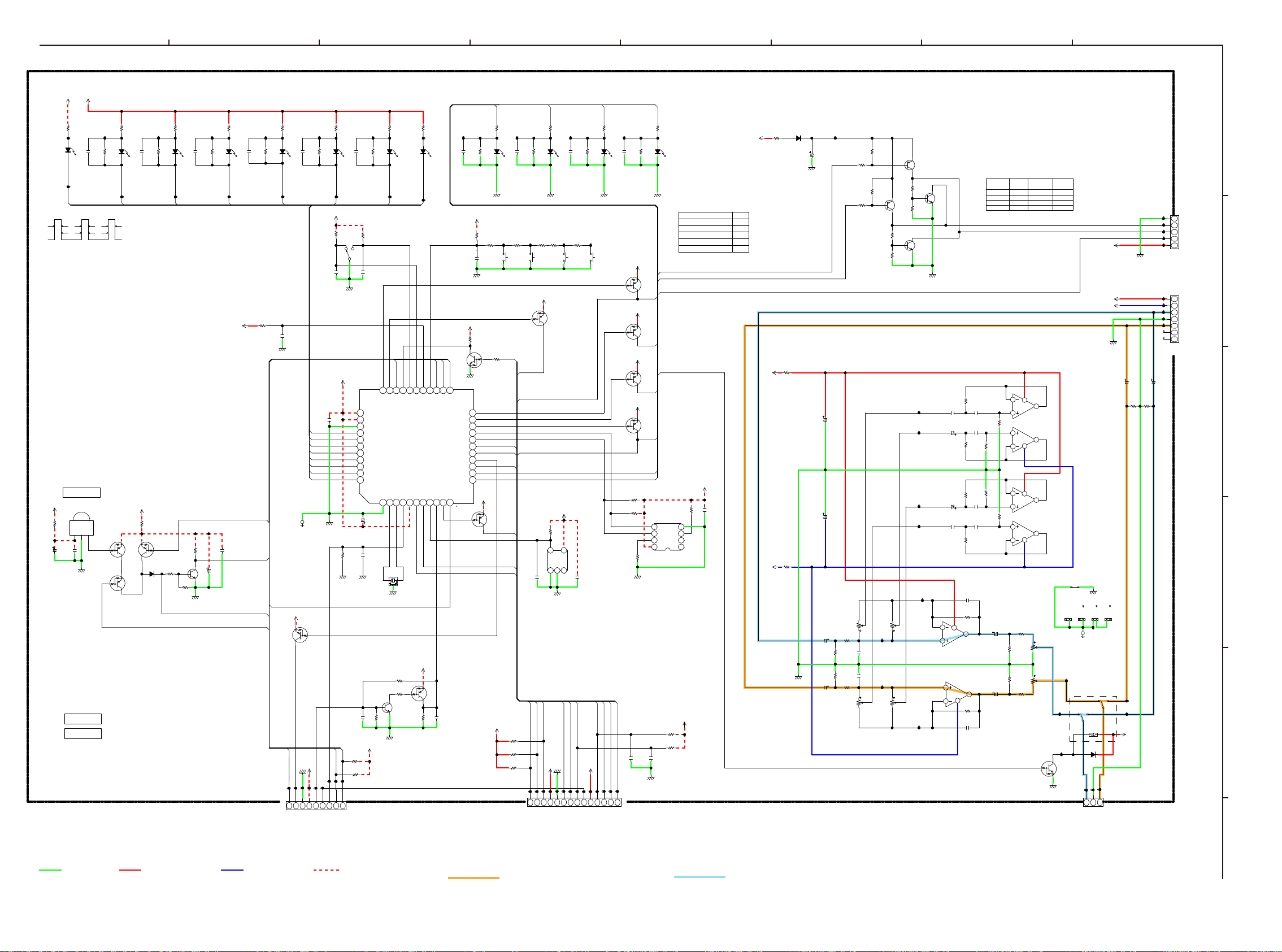

SCHEMATIC DIAGRAMS ........................................................45

MAIN UNIT ..............................................................................45

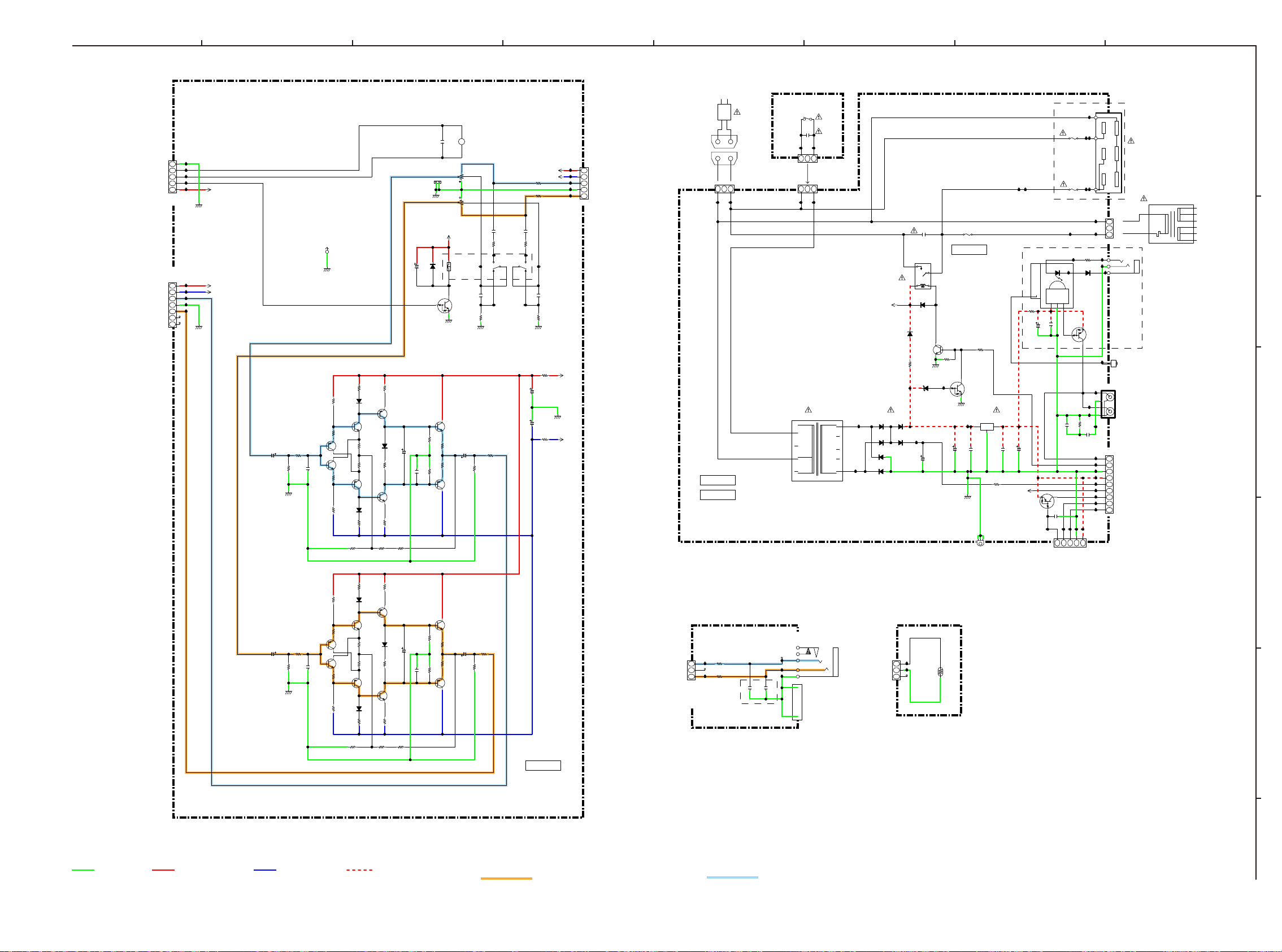

FRONT UNIT ...........................................................................46

VOLUME UNIT ........................................................................47

STANDBY UNIT ......................................................................47

POWER SW UNIT...................................................................47

HEADPHONE UNIT ................................................................47

POSISTER UNIT .....................................................................47

WIRING DIAGRAM ..................................................................48

EXPLODED VIEW ....................................................................49

PARTS LIST OF EXPLODED VIEW ........................................51

PACKING VIEW .......................................................................53

PARTS LIST OF PACKING & ACCESSORIES .......................53

SEMICONDUCTORS ...............................................................55

1. IC's ......................................................................................55

PARTS LIST OF P.C.B. UNIT ..................................................58

8U-110004A MAIN PWB UNIT ASS'Y (N,K model) .................58

8U-110004B MAIN PWB UNIT ASS'Y (U model) ....................58

8U-110005A FRONT PWB UNIT ASS'Y (N,K model) .............63

8U-110005B FRONT PWB UNIT ASS'Y (U model) .................63

2

Page 3

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original MARANTZ parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specications for

company has created the ultimate in stereo sound.

which it is famous.

Parts for your

MARANTZ

equipment are generally available to our National

Marantz

Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

2F,YEON BLDG.,

88-5, BANPO-DONG, SEOCHO-GU,

SEOUL KOREA

PHONE : +82 - 2 - 715 - 9041

FAX : +82 - 2 - 715 - 9040

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol z .

Any other component substitution (other than original type), may increase risk of re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号の部品を使用して下さい。

z

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and veried before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of difculties, do not hesitate to contact the Technical

Department at above mentioned address.

3

091105DM/DG

Page 4

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

ngers are moved across them in some rare cases.

Wear gloves to protect your hands.

◎Use only designated parts!

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphones terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

these properties are difcult to distinguish by sight, and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, res or other dangerous

situations.

4

Page 5

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

5

Page 6

TECHNICAL SPECIFICATIONS

• RMS Power output

(20 Hz – 20 kHz simultaneous drive of both channels): 45 W x 2 (8 Ω load)

• Total harmonic distortion

(20 Hz – 20 kHz simultaneous drive of both channels, 8 Ω load): 0.08 %

• Output band width

(8 Ω load, 0.06 %): 10 Hz – 50 kHz

• Frequency response

(CD, 1 W, 8 Ω load): 10 Hz – 70 kHz +0 dB, -1 dB

• Dumping factor

(8 Ω load, 40 Hz – 20 kHz): 100

• Input sensitivity/Input impedance

PHONO (MM): 2.2 mV/47 kΩ

CD, TUNER, AUX/DVD, RECORDER: 200 mV/20 kΩ

• Maximum allowable PHONO input level (1 kHz)

MM: 100 mV

• RIAA deviation

(20 Hz – 20 kHz): ±1.0 dB

• S/N (IHF-A, 8 Ω load)

PHONO (MM): 83 dB (5 mV input, 1 W output)

CD, TUNER, AUX/DVD, RECORDER: 102 dB (2 V input, Rated output)

• Tone control

Bass (50 Hz): ±10 dB

Treble (15 kHz): ±10 dB

• Power requirement: AC 230 V 50/60 Hz (N)

• Power consumption

(EN60065): 150 W

• Power consumption during standby: 0.2 W

• Weight: 7.4 kg

60 W x 2 (4 Ω load)

AC 220 V 50 Hz (K)

AC 120 V 60 Hz (U)

DIMENSION

370

329 25

440

16

90

104

14

6

Page 7

CAUTIONS IN SERVICING

Initializing INTEGRATED AMPLIFIER

INTEGRATED AMPLIFIER initialization should be performed when the μcom and peripheral parts of μcom were replaced.

1. Turn off the power pressing POWER button.

2. Press POWER button while simultaneously while pressing SOURCE DIRECT buttons.

3. Check the set entered the service mode.(Refer to 31 page "SERVICE MODE".)

POWER

SOURCE DIRECT

7

Page 8

DISASSEMBLY

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

POWER SW PWB UNIT

(Ref. No. of EXPLODED VIEW : 14)

HEADPHONE PWB UNIT

(Ref. No. of EXPLODED VIEW : 15)

FRONT PWB UNIT

(Ref. No. of EXPLODED VIEW : 18)

MAIN & VOLUME PWB UNIT

Refer to "DISASSEMBLY

2. MAIN & VOLUME PWB UNIT"

and "EXPLODED VIEW"

VOLUME PWB UNIT

(Ref. No. of EXPLODED VIEW : 19)

MAIN PWB ASSY

(Ref. No. of EXPLODED VIEW : 25)

POWER TRANS

Refer to "DISASSEMBLY

3. POWER TRANS"

and "EXPLODED VIEW"

POWER TRANS

(Ref. No. of EXPLODED VIEW : 27)

SUB TRANS

Refer to "DISASSEMBLY

4. SUB TRANS"

and "EXPLODED VIEW"

STANDBY PWB UNIT

(Ref. No. of EXPLODED VIEW : 29)

8

Page 9

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction)

Shooting direction: B

[View from the top]

1. FRONT PANEL ASSY

Front side

Shooting direction: DShooting direction: C

Shooting direction: A

Proceeding :

(1) Remove the screws.

View from bottom

View from top

TOP COVER

FRONT PANEL ASSY

→

9

Page 10

(2) Remove the screws.

Shooting direction: C

(3) Cut the wire clamp band.

Shooting direction: D

cut

cut

cut

10

Page 11

(4) Disconnect the connector wire. Remove the screws.

N8101

N8001

N3001

N7501

N6001

N3002

N8504

N8502

Please refer to "EXPLODED VIEW" for the disassembly method of each PWB included in FRONT PANEL ASSY.

11

Page 12

2. MAIN & VOLUME PWB UNIT

Proceeding :

(1) Detach the KNOB AL CAP POINTER. Remove the screws.

Shooting direction: B

(2) Remove the screws.

TOP COVER

MAIN & VOLUME PWB UNIT

→

Shooting of photograph: A

(3) Cut the wire clamp band, then disconnect the connector wire. Remove the screws.

N6001

N8101

N8001

N3001

N7501

N3002

cut

12

Page 13

3. POWER TRANS

Proceeding :

(1) Cut the wire clamp band, then disconnect the connector wire. Remove the screws.

N8101

N8001

TOP COVER

cut

POWER TRANS

→

cut

N8503

4. SUB TRANS

Proceeding :

(1) Remove the screws.

Shooting of photograph: A

(2) Disconnect the connector wire. Remove the screws.

TOP COVER

SUB TRANS

→

N8504

U model only

N8503

N8502

N8501

13

Page 14

WHEN THE MICROPROCESSOR IS REPLACED WITH A NEW ONE

When the U-PRO (Microprocessor) or the Flash ROM is replaced, conrm the following.

PWB Name Ref. No. Description

FRONT U1001 TMP86FH47UG C

After replacing

A : Mask ROM (With software). No need for write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need for write-in of software. But, when the software was updated, you should

write the new software on the microprocessor or ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should write the software on the microprocessor or ash ROM.

Refer to "Update procedure" or "writing procedure", when you write the software.

Necessary Equipment

• Windows PC (OS: Windows 2000 or Windows XP) with Serial port.

• RS-232C Cable straight type (9 Pin female - 9 Pin female)

• Connection JIG (90M-PM11S1JIG)

• Writing Tool and some les (FlashProg.exe, etc... in TM86FH47pass folder)

• Writing data (PM6004_xxxx.h16)

WRITING PROCEDURE

(1) Disconnect the mains cord from the unit.

(2) Connect RS-232C on the connection JIG and Serial Port of windows PC with RS-232C cable.

(3) Connect FPC (upside contact) to the rear panel of the unit from connection JIG.

After

replaced

Remark

(4) Reconnect the mains cord to the unit.

(5) Put the “TM86FH47pass” folder into anywhere on your PC’s hard disc.

14

Page 15

(6) Double click the TM86FH47pass folder.

(7) Double click FlashProg.exe.

15

Page 16

(8) Click Device tab.

(9) Click Apply.

16

Page 17

(10) TMP86FH47 appear in Chosen Device.

(11) Click Object File, and click Browse...

17

Page 18

(12) Choose iHEX Fomat[*.h16,*.h20] in Files of type.

Choose writing data, and click Open.

PM6004_V06.h16

(13) Click Communication tab.

PM6004

18

Page 19

(14) Choose COM port number in COM port.

Choose 9600 in Data Rate.

Click OK.

(15) When Setup window is closed, the tmp folder and FlashProg.ini le are created simultaneously.

Click Yes.

NOTE : These are the original set-up conguration les for that PC. They do not operate, if these les moved to

another PC. When you make it operate with other PC, delete the tmp folder and the FlashProg.ini le and

redo a setup.

19

Page 20

(16) The Flash Programmer is launched.

Click setup icon.

(17) Click Browse....

20

Page 21

(18) Choose FlashProg.ini in TM86FH47pass folder, and click Open.

(19) Click OK.

PM6004

21

Page 22

(20) Press the POWER ON/OFF button, and turn on the unit.

Status indication at lower left in Flash Programming window is changed to "Connected" from "Connecting".

When it did not changed, check the connection of FPC or RS-232C cable.

(21) Select Password in Setup.

22

Page 23

(22) Setup Password opens.

· When writing in a blank microprocessor (Refer to next page).

· When writing (update) in the already written-in microprocessor (Refer to 25 page).

23

Page 24

When writing in a blank microprocessor

Check Single Boot Mode in Address Mode.

Setting in Device Password

· Check Device is BLANK.

· Check Hex in input type.

· Since they are inputted automatically, please do not change text box of "Password", "Password Character Number

Address" and “Password Compare Start Address”.

Setting in Object File Password

· Do not check BLANK password.

· Check Hex in Input Type.

· Type 0102030405060708 into Password.

· Type 0xFF00 into Password Character Number Address.

· Type 0xFF01 into Password Compare Start Address.

Click OK.

24

Page 25

When writing in the already written-in microcomputer (update)

Check Single Boot Mode in Address Mode.

Setting in Device Password

· Check Device is BLANK.

· Check Hex in input type.

· Type 0102030405060708 into Password.

· Type 0xFF00 into Password Character Number Address.

· Type 0xFF01 into Password Compare Start Address.

Setting in Object File Password

· Do not check BLANK password.

· Check Hex in Input Type.

· Type 0102030405060708 into Password.

· Type 0xFF00 into Password Character Number Address.

· Type 0xFF01 into Password Compare Start Address.

Click OK.

25

Page 26

(23) Auto Programming opens.

26

Page 27

(24) Check All Erase, Programming, Verify with SUM and File Compare in Flash Memory Programming.

Check Manual in Recover Process by Programming Error.

Click Start.

27

Page 28

(25) Writing data is written into the microprocessor (U1001).

(26) Click Yes, when writing is successful.

28

Page 29

(27) Click Cancel.

(28) Click Cancel.

29

Page 30

(29) Select the Exit in File, and nish.

(30) Press the POWER ON/OFF button, and turn off the unit.

Disconnect each cable.

(31) Check the software version.

Refer to 31 "SERVICE MODE".

30

Page 31

SERVICE MODE

Microprocessor (U1001) version chseck

(1) Press the POWER button with pressing the SOURCE DIRECT button on the unit.

(2) The rmware version is displayed on the front LED. (Display time is only for 3 seconds.)

CDPHONO TUNER

Version : 16 8 4 2 1

The rmware version is displayed in the lighting position of LED.

Ex. :

Light up RECORDER-2 [1 ], Version : 1

Light up RECORDER-2 [1 ] and AUX/DVD [4 ], Version : 5

Light up RECORDER-2 [1 ] and CD [8 ], Version : 9

(3) Each LED light up then all LED light up.

(4) Turn off the power to quit Service Mode. (The unit to the default status)

RECORDER

MUTE1AUX/DVD 2

31

Page 32

ADJUSTMENT

IDLING CURRENT ALIGNMENT

Adjusting Procedure

Set the power voltage to rated voltage for this adjustment.

(1) Adjust the Idling Current with the variable resistor V6001 and V6002 on the PWB 8U-110004-1.

(2) Turn off the power.

(3) "+" of Connect Digital Voltage is connected to the No. 1 pin and connected "-" to No. 3 pin of N6003.

(4) "+" of Connect Digital Voltage is connected to the No. 1 pin and connected "-" to No. 3 pin of N6004.

(5) Before turning on the power, V6001 and V6002 have been counter clockwise turned with the adjustment driver.

(6) Turn on the power, VOLUME is set as -∞.

(7) After 2 minutes.

With seeing the digital voltage meter turn the variable resister clockwise slowly to adjust the idling current.

Idling adjustment with V6001 (V6002).

•Turn V6001 (V6002) clockwise to increase the idling current.

•The adjustment value of idling current is 10 mV(22.5 mA) ± 0.5 mV(1.1 mA) each.

(8) After 6 minutes.

Repeat the same procedure as 7.

•The adjustment value of idling current is 20 mV(45 mA) ± 0.5 mV(1.1 mA) each.

Adjustment is completed.

(9) Remove connection cable, attach the top cover.

NOTE : Idling current decreases with the temperature rise inside the unit, and it is set to 20 mV (45 mA) of setting value in

about 30 minutes after turn on the power.

32

Page 33

DC OFFSET VOLTAGE ADJUSTMENT

Digital Voltmeter Digital Voltmeter

V

R ch

N6003 V6001

V

L ch

V6003 V6004

N6004

V6002

Adjusting Procedure

DC Offset Voltage Adjustment

(1) Before turning on the power, Insert Digital Voltage Meter between the SPEAKERS SYSTEM A (L CH) "+" and "-".

Insert Digital Voltage Meter between the SPEAKERS SYSTEM A (R CH) "+" and "-".

(2) Adjust the VOLUME to MIN.

(3) Turn on the power. Then turn the SPAKERS SW to A.

Adjustment is started immediately after a speaker relay turns on.

(4) First L CH is adjusted.

The variable resistor V6003 on 8U-110004-1 is turned with adjustment driver, and the Digital Voltage Meter is

adjusted to "0 mV ± 3 mV".

(5) Then, R CH is adjusted.

The variable resistor V6004 on 8U-110004-1 is turned with adjustment driver, and the Digital Voltage Meter is

adjusted to "0 mV ± 3 mV".

NOTE : DC offset voltage drops when turn the semi-xed resistor (V6003 and V6004) clockwise. DC offset voltage rises

when turn the semi-xed resistor un-clockwise. Please turn it slowly, because value of Digital Voltage Meter

changes slowly.

(6) Although after-adjustment DC offset voltage has some change, Please check that the range of DC offset voltage

between L ch (R ch) "+" and L ch (R ch) "-" terminal of SPEAKERS SYSTEM A is "0 mV ± 20 mV". CHART OF

FACTORY MODE.

33

Page 34

TROUBLE SHOOTING

1. The power can not be turned on.

(STANDBY LED does not light (STANDBY MODE)

Checkinsertion of the 8U110005-3 STANDBY PWB UNIT.

Check insertion of the 8U110005-1 FRONT PWB UNIT.

Power not supplied.

Check whether power is being

supplied to the coil of the SUB

TRANS T8501.

Power supplied.

2. The power can not be turned on. (STANDBY LED lights→ash)

Check each connector.

Broken wire in SUB

TRANS T8501

Check whether power

is being supplied to the

D8501-8506

.

.

Power not supplied.

Power supplied.

Malfunction of

D8501-8506

Malfunction of

U8501,U1001.

Check whether power

is being supplied to

the F8510

Check whether power

is being supplied to

the coil of the POWER

TRANS T0001

Check whether power

is being supplied to

the D8001,D81018104,D8201-8202

.

.

Power not supplied.

Power not supplied.

Power not supplied.

Power supplied.

<*1>

Broken wire in STANDBY

F8510

.

Broken wire in POWER

TRANS T0001

Broken D8001,D8101-8104,D8201-8202

STANDBY LED repeats

ON/OFF for 0.5 seconds

each.

Check input level, SPEAKER

connection and SPEAKER

resistance value.

.

.

Damaged DC OFFSET DETECT.

Damaged OVER HEAT DETECT.

Damaged OVER CURRENT

DETECT.

Damaged P_DWN detection

circuit and U1001.

Power supplied.

<*2>

STANDBY LED repeats

ON/OFF for 0.25

seconds each.

34

Damaged power amplier circuit

Damaged power circuit.

Page 35

3. STANDBY LED ashes while using unit. (protection circuit is set)

Check each connector

Refer to <*1><*2> in "The power can not be

turned on. (STANDBY LED lights→ash)"

4. The power turned on, but a sound does not output normally. (Both channels)

4.1 STANDBY LED does not ash (protection mode is not set)

Check each connector

Check whether power is being

supplied to the coil of the

POWER TRANS T0001

4.2 When the volume is turned up, Mute LED ashes. (protection mode is set)

Repeats ON/OFF for 0.5 second each, and automatically returns to normal operation.

Check input level and

each connector

Check SPEAKER connection

and SPEAKER short,

SPEAKER resistance value.

Power not supplied.

Power supplied.

Power supplied.

Broken wire in POWER TRANS

T0001

.

Damaged Selector (U3501)

Mute Circuit (Q6001-6002,L7501-7502).

Damaged Mute circuit, U1001.

When you turn up the volume again after the unit

automatically returns to normal operation and if

the protection circuit is activated, STANDBY LED

will repeat ON/OFF for 0.25 seconds each.

Damaged power amplier

circuit

Malfunction of C7501-7504

35

Page 36

Personal notes:

36

Page 37

BLOCK DIAGRAM

PHONO BLOCK

PHONO AMP

PHONO

PM6004 BLOCK DIAGRAM

TUNER

CD

AUX / DVD

RECORDER-1

IN

RECORDER-2

IN

RECORDER-1

OUT

RIAA

REC OUT SELECTOR

INPUT SERECTOR

REC BUFFER

LOUDNESS

BLOCK

ON

OFF

LOUDNESS

LINE DETECT

PRE AMP BLOCK

VOLUME

M

PRE AMP

NFB

TONE AMP BLOCK

TONE AMP

TREBLE

SOURCE DIRECT

BASS

ON

OFF

BALANCE

MUTE

POWER AMP BLOCK

POWER AMP

NFB

PROTECTION

SPEAKER

RELAY

SPEAKER

RELAY

HEADPHONE

RELAY

SPEAKER-A

(+)

SPEAKER-A

(-)

SPEAKER-B

(+)

SPEAKER-B

(-)

HEADPHONE

RECORDER-2

OUT

REGULATOR BLOCK

USA VERSION ONLY

AC OUTLET

AC IN

FUSE

FUSE

INPUT BLOCK

STANDBY

RELAY

POWER SW

FUSE

LINE DETECT

AMP

MAIN TRANS.

SUB TRANS.

±38V

PROTECTION

±15V

+12V

+5V

+5V

P_OFF DETECT

POWER AMP

PRE AMP

FUNCTION RELAY

FUNCTION LED

MCU

U-COM BLOCK

POWER DETECT

LINE DETECT

PROTECTION

FRONT SW FUNCTION LED

EEPROM

I/R SENSOR

FLASHER IN

USA VERSION ONLY

MCU MOTOR DRIVER

RC5

FLASHER

RELAY DRIVER

MUTE

INPUT SELECTOR

RC5 IN/OUT

37

Page 38

POWER SUPPLY BLOCK DIAGRAM

AC OUTLET

USA VERSION ONLY

K8601

F8610

FUSE

FUSE

AC INLET

J0001

S8501

STANDBY

RELAY

F8510F8620

FUSE

T0001

MAIN

TRANS.

D8001

C8001

A_GND

D8101-D8104

C8101

C8102

D8201

D8202

C8201 C8202 C8203

C8002

PM6004 POWER SUPPLY DIAGRAM

+38V

-38V

U8101

+15V

+15V

C8103

C8104

-15V

-15V

U8102

+12V

U8201 U8202

+12V

+5V

+5V

POWER AMP

PHONO AMP

INPUT SELECTOR, REC BUFFER,

LINE DETECTOR.

PRE AMP

TONE AMP

A_GND

SP RELAY, HP RELAY

SOURDE DIRECT, LOUDNESS RELAY

MOTOR VOLUME DRIVER

FUNCTION LED

S8901 T8501

POWER SW

SUB

TRANS.

D8501-D8504

D_GND

D8505

U8501

C8504 C8506

C8503

D_GND

D8506

+9V

+5V

D_GND

STANDBY RELAY

+5V

MCU, EEPROM, I/R RECEIVER

STANDBY LED, INPUT SELECTOR SW,

FUNCTION SW

+9V

P_OFF DETECTOR

D_GND

FLASHER IN (USA VERSION ONLY)

38

Page 39

LEVEL DIAGRAM

[dB] [dB]

+30

SP out:45W/8Ω +25.56dB(18.97V)

+30

+20

+10

0

-10

-20

-30

-40

-50

-60

PHONO

CD:-13.97dB(200mV)

Phono Amp Gv=39.2dB

MM:-53.15dB(2.2mV)

PHONO AMP

Power Amp Gv=24.1dB

+1.43dB

Pre Amp Gv=15.4dB

-13.97dB

Input Block Pre Amp Block Tone Amp Block Power Amp Block

+20

+10

0

-10

-20

-30

-40

-50

-60

TUNER

CD

AUX / DVD

RECORDER-1

IN

RECORDER-2

IN

RECORDER-1

OUT

RIAA

REC OUT SELECTOR

INPUT SERECTOR

REC BUFFER

LOUDNESS

LINE DETECT

VOLUME

M

PRE AMP

NFB

TONE AMP

TREBLE

BASS

SOURCE DIRECT

BALANCE

MUTE

POWER AMP

NFB

PROTECTION

SPEAKER

RELAY

SPEAKER

RELAY

HEADPHONE

RELAY

SPEAKER-A

(+)

SPEAKER-A

(-)

SPEAKER-B

(+)

SPEAKER-B

(-)

HEADPHONE

RECORDER-2

OUT

LINE DETECT

AMP

39

Page 40

PRINTED WIRING BOARDS

FRONT

(COMPONENT SIDE)

181716151413121110987654321

A

9

Z1603

9:TXD

Z1601

JV1079

JV1052

JV1036

JV1011

JV1060

JV1061

6:P_RELAY

7:ICE4

8:RXD

B1001

15.0

15.0

12.5

1:RC5

2:P_ON

3:D_GND

4:+5VL

5:P_DOWN

12.5

J2001

1

JV1016

JV1048

7.5

7.5

D1501

7.5

JV1037

JV1049

JV1001

JV1006

JV1017

7.5

7.5

STANDBY

7.5

JV1065

JV1044

7.5

7.5

7.5

7.5

JV1045

JV1007

7.5

15.0

JV1066

JV1053

JV1031

12.5

20.0

JV1018

12.5

7.5

JV1026

JV1012

7.5

JV1008

7.5

JV1019

S1411

B1005

C1001

JV1020

7.5

JV1054

JV1073

JV1062

JV1032

JV1057

JV1072

JV1080

X1001

17.5

25.0

B1004

12.5

12.5

15.0

25.0

C2017

R2015

C2011

JV1033

JV1021

R2019

C2015

R2017

R2013

JV1002

JV1027

7.5

JV1067

25.0

JV1081

JV1005

7.5

15.0

JV1058

C2013

1

JV1087

JV1074

JV1038

V2003

BASS

7.5

7.5

JV1050

D1502

PHONO

12.5

7.5

SOURCE

DIRECT

JV1028

JV1003

12.5

D1509

S1401

C2012

JV1014

7

JV1022

JV1034

7.5

JV1046

JV1023

7.5

7.5

JV1055

C2018

D1503

TUNER

JV1047

12.5

JV1039

JV1013

JV1082

C2014

7.5

C2016

R2020

R2016

7.5

JV1063

SPK A

S1403

R2014

R2018

1

CD

1:CE

2:DATA

3:CLK

JV1083

JV1075

JV1035

4:+5VD

5:D-GND

6:F_MUTE

22.5

17.5

JV1068

JV1040

B1002

AUX/DVD

7:A_MUTE

8:PROT_1

9:P_RALAY

10:+12V

11:PROT_2

R2005

R2003

JV1059

17.5

TREBLE

D1504 D1505

D1510

JV1024

22.5

JV1041

LOUDNESS

C2005

C2006

15.0

R1801

REC2/MD/TAPE

D1512

S1402

C2007

C2009

R2009

JV1070

JV1056

C2008

JV1004

R2010

R2012

R2008

14

D1506 D1507

REC1/CD-R

JV1085

JV1009

15.0

12:SPK_A

13:SPK_B

14:DET

D1511

7.5

7.5

SPK B

S1404

7.5

C2003

R2007

C2004

JV1069

JV1076

JV1029

R2004

R2006

JV1084

V2002

7 7

D1801

JV1077

C2010

12.5

JV1064

JV1010

11

1

D1508

MUTE

12.5

12.5

12.5

JV1051

7.5

R2011

BALANCE

B1006

JV1030

7

5

6:NC

7:NC

C2002

12.5

V2001

1:+12V

Q1803

JV1025

C1801

3:TO_L

4:A_GND

5:TO_R

12.5

N1002

C2001

JV1042

2:LOUD

3:MOT+

4:MOT-

1:+15V

2:-15V

5:D-GND

B

E

C

7.5

B

C

Q1802

C2020

JV1078

1

R2002

R2001

JV1015

E

JV1

1

E

C

Q1804

JV1086

R2022

B1003

B

7.5

17.5

R2021

E

C

Q1801

S2001

3

B

7.5

JV1071

C2019

D2001

63101000510AM

8U-110005-1

D1601

FRONT UNIT

1:L

2:A_GND

3:R

C1603

JV1043

U1601

C1601

G

OUT

VCC

B

C

1

D

E

F

FRONT

(FOIL SIDE)

C1604

R1601

R1602

C1602

Q1603

Q1602

Q1601

3

R1605

Q2001

R1603

1

R1804

R1802

Q1604

R1604

G

R1005

C1503

R1518

4

R1505

R1515

C1401

R1401

R1403

5

C1507

R1516

R1402

R1006

R1007

C1005

C1502

R1504

R1503

R1502

C1006

C1501

7

Q1004

R1017

1

R1016

C1002

Q1009

8

1

R1015

33

34

U1001

5

U2002

4

Q1005

C1010

23

44

Q1006

Q1007

22

1

Q1008

12

11

R1013

4

5

1

8

R1012

R1011

C1009

U1003

R1014

R1008

R1009

C1902

R1903

3

U1002

R1010

C1007

Q1003

R1004

C1004

R1001

C1003

1:RC5

2:P_ON

3:D_GND

R1902

Q1002

R1003

5:P_DOWN

6:P_RELAY

4:+5VL

9

R1901

8:RXD

9:TXD

7:ICE4

H

I

1

R1002

Q1010

1

54

C1008

C1412

C1411

R1411

R1412

R1501

Q1001

J

R1808

R1806

R1805

R1809

R1807

1:+15V

3:TO_L

2:-15V

1

3

1

1:L

2:A_GND

3:R

5

R1803

4:A_GND

5:TO_R

6:NC

7:NC

1

1:+12V

2:LOUD

3:MOT+

4:MOT-

5:D-GND

R1513

R1514

R1512

7

7

1

R1521

1

R1522

C1510

8 5

U2001

4

R1511

C1506

R1519

C1509

14

R1520

R1510

C1505

R1509

R1406

7

14:DET

13:SPK_B

11:PROT_2

12:SPK_A

R1405

R1404

R1507

C1504

R1508

10:+12V

9:P_RALAY

7:A_MUTE

8:PROT_1

1

1

3:CLK

4:+5VD

5:D-GND

6:F_MUTE

C1508

R1517

U2003

1:CE

2:DATA

8

1

R1506

K

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

L

M

40

Page 41

181716151413121110987654321

VOLUME

(COMPONENT SIDE)

R5038

R5040

R5037

R5039

JV5001

C5010

JV5007

C5009

B

C

E

B

C

E

R5034

Q5013 Q5014

Q5015

R5033

R5035 R5036

C5008

B

C

E

R5046

C5007

B

C

E

R5045

R5032

Q5016

R5030

C5006

R5031

R5029

C5005

N5002

7

D5006

R5024

12.5

R5023

12.5

R5027 R5028

B

C

E

D5005

B

C

E

R5043

B

C

E

R5022

Q5012

R5044

B

C

E

R5021

R5025 R5026

Q5011

4.A_GND

5.TO_R

R5020

Q5010

JV5012

R5042

R5019

Q5009

D5003 D5004

JV5011

2.-15V

3.TO_L

D5002

R5016

D5001

R5015

R5017 R5018

R5041

1.+15V

1

B

C

E

B

C

E

B

C

E

B

C

E

Q5006Q5007 Q5008

JV5004

Q5005

JV5005

Z5001

R5012

15.0

R5011

15.0

R5010

R5007 R5008

R5013 R5014

R5009

B

C

E

B

C

E

R5004

C5002

JV5008

JV5021

JV5002

B

C

E

B

C

E

R5003

C5001

JV5014

Q5002

Q5001

R5005 R5006

Q5003 Q5004

JV5013

JV5024

C5004

JV5009

7.5

7.5

JV5006

JV5016

12.5

7.5

JV5023

C5003

7.5

7.5

R5047 R5048

C5012

B5002

C5011

V5001

1.+15V

2.-15V

JV5003

7.5

3.IN_L

4.A_GND

1

B5001

5.IN_R

5

8U-110005-2

VOLUME UNIT

JV5017

7.5

JV5018

C2504

R2502

7.5

R5002

R5001

1

C2505

D2501

S2501

C2502

1

7.5

JV5020

N5001

1.+12V

2.LOUD

3.MOT+

C2501

5

4.MOT-

5.D_GND

R2503R2504

R2501

C2503

STANDBY

(COMPONENT SIDE)

R

B8502

L

K8701

JV8512

Z8701

D8702

JV8511

C8701

G

VCC

OUT

K8501

1

2 4

B8501

JV8502

JV8501

Q8501

E

B

C

D8508

1

S8501

3

U8701

Japan/USA: T3.15AL 250V

D8701

Europe/China: T1.6AL 250V

(Sec.)

JV8500

2

C8502

4

F8510

H8512

H8511

(Pri.)

C8506

4

2

17.5

JV8509

F8620

T5.0AL 250V

N8503

4.+5VL

5.P_DOWN

6.P_RELAY

7.ICE4

8.RXD

9.TXD

R8501

C8504

D8507

T8501

JV8504

1

N8501

1

T5.0AL 250V

K8601

1

23

1

JV8510

22.5

1.RC5

2.P_ON

3.D_GND

5 9

F8610

7.5

JV8503

JV8505

2

9

N8504

JV8507

15.0

7.5

7.5

D8505

C8503

D8502

D8503

D8504

1

15.0

D8501

JV8506

D8506

2

N8502

1

JV8514

JV5813

2 4

1

4.RXD

5.ICE4

8U-110005-3

STANDBY UNIT

JV8508

15

5

2.D_GND

1.+5VL

3.TXD

Z8502

1

Z8501

N8505

(Sec.)

(Pri.)

A

B

C

D

E

F

VOLUME

(FOIL SIDE)

1

5

1.+12V

2.LOUD

3.MOT+

4.MOT-

5.D_GND

Q2501

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

2.-15V

3.IN_L

4.A_GND

5.IN_R

5

C5013

8 7 43 216 5

1.+15V

1

1.+15V

2.-15V

3.TO_L

1

4.A_GND

5.TO_R

STANDBY

G

(FOIL SIDE)

9

Q8503

4

5

4.RXD

3.TXD

C8509

5.ICE4

2

1

2

1

2.D_GND

1.+5VL

7

R8503

1

1

(Sec.)

(Pri.)

2 3

2

1

8.RXD

9.TXD

1

3.D_GND

4.+5VL

5.P_DOWN

6.P_RELAY

7.ICE4

678 59

1

2

1.RC5

2.P_ON

U8501

I

C8510

4

2

3

H

G

O

D8509

C8505

R8505

Q8502

R8502

I

2

4

1

3

R8702

Q8701

C8702

J

K

R8701

C8508

R8504

C8507

2

1

4

3

R

L

L

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

M

41

Page 42

181716151413121110987654321

POWER SW

(COMPONENT SIDE)

(Pri.)

1

8U-110005-4

POWER SW

S8901

B8901

2

1

C8901

POSISTER

(COMPONENT SIDE)

POWER SW

(FOIL SIDE)

(Pri.)

POSISTER

(FOIL SIDE)

HEADPHONE

(COMPONENT SIDE)

K9901

Z9901

8U-110005-5

C9901

C9902

H/P UNIT

1

R9901

R9902

3

B9901

1

3.HP_R

2.NC

1.HP_L

2

1

HEADPHONE

(FOIL SIDE)

3

3.HP_R

2.NC

1.HP_L

1

A

B

C

D

E

F

B6501

8U-110005-6

T6501

1

3

1

G

H

I

J

K

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

L

M

42

Page 43

MAIN

(COMPONENT SIDE)

K4001

K3001

K3004

K7501

LOWLOW

UP

UP

LOW

UP

LOW

UP

LOWLOW

UP

UP

MPMP

C4002

C4001

C3010

K3002

K3003

R7505

R7506

7.5

JV46

MKMK

B

C

E

R4002

R4001

Q7504

C7502

12.5

R3002

C3009

R3003

C3012

C3011

C3014

R3012

C3013

C3016

R3016

C3015

C3018

R3020

C3017

R3019

C3020

R3024

C3019

R3023

C3022

R3028

C3021

R3027

S7502

D7502

JV11

L4002

R4005

L4001

R3009

R3011

R3015

C7504

C7503

12.5

R4006

R4004

R4003

R3004

R3001

R3006

R3008

R3005

R3007

R3010

JV189

R3014

R3013

R3018

R3017

R3022

R3021

R3026

R3025

22.5

JV146

R9003

N6003

C4004

C4003

JV53

JV144

7.5

JV93

JV151

JV188

25.0

25.0

JV137

JV154

22.5

C7501

Q9001

R4008

R4007

JV31

JV127

JV29

JV180

JV28

JV69

B

JV19

15.0

17.5

17.5

17.5

17.5

15.0

JV158

15.0

S7501

JV96

JV192

JV167

22.5

R9005

C

25.0

JV89

25.0

JV159

JV16

22.5

R9007

D9001

E

R6093

R9001

C4006

R4010

JV13

C4005

R4009

Z4001

25.0

D7501

E

22.5

17.5

25.0

JV94

3.HP_R

2.NC

1.HP_L

JV179

7.5

JV49

C6011

JV183

17.5

Q6131

C

C4008

C4007

17.5

JV105

R7503

JV112

R6105

Q6111

B

E

B

12.5

B

C

E

Q7503

JV5

U3501

N7501

C6024

C6007

D6005

R6035

R6031

R6083

B

C

E

R6089

JV191

C6022

C6023

C6021

Q6033

R6087

R6069

C4010

R4012

C4009

R4011

JV38

JV109

JV2

JV190

R7504

R6106

R6023

R6057

R6043

R6073

R6077

R6067

Q6031

R3505

D3501

R6019

Q6015

B

C

E

Q6023

B E

C4013

R7508

J6002

D6001

B

C

E

Q6011

B

C

E

R6053

R6081

C4014

7.5

JV54

R7507

B

C

E

JV136

R4014

C4011

JV163

JV40

S7503

B

C

E

Q6007

Q6019

15.0

Q6027

V6001

C4012

R4013

JV62

Q7505

JV98

E

C

B

C6015

JV181

JV135

R6071

R4016

JV141

E

C6003

R6015

Q6003

7.5

R6047

R4015

C3506

B

C

E

R6051

R6079

JV125

22.5

R3502

R3503

R3501

D7503

J6001

R6097

R6039

R6049

JV160

22.5

B

C

E

C3502

R3504

17.5

Q7501

B

C

E

L6002

L6001

R6009

R6011

R6029

C6017

R6041

12.5

C6019

JV86

Q6035

E

C4016

C4018

C4017

C4015

JV78

C3802

22.5

C3501

JV55

JV140

R7501

R9010

JV170

Q6005

JV194

JV85

R6085

Q6132

R3901

R3902

R3802

R7502

7.5

R9009

C6001

R6027

B

C

E

R6099

Q6021

D6007

R6061

Q6029

7.5

7.5

Q6112

C

R3804

R3803

R3801

E

JV47

B

C

E

R6017

B

C

E

B

C

E

B

E

R4018

R4017

JV68

7.5

Q7502

Q6001

B

C

E

Q6009

Q6017

JV145

7.5

B

R4020

R4019

12.5

JV175

JV133

15.0

12.5

C3801

JV198

7.5

25.0

R6005

D6003

Q6013

R6101

E

C

B

R6045

B

C

E

R6055

12.5

C4019

C4020

JV100

JV178

R6003

B

C

E

R6059

Q6025

R6095

JV73

JV7

JV76

C3901

JV193

JV110

22.5

R6001

R4021

R4022

25.0

JV107

JV174

JV67

R6007

R6033

R6037

7.5

JV51

R6075

JV30

R6091

20.0

JV130

JV4

JV81

7.5

JV41

C6013

JV161

15.0

JV115

17.5

25.0

15.0

JV185

C6009

R6021

R6025

R6103

R6109

JV173

DIP

258X241

JV172

17.5

15.0

JV121

JV116

25.0

22.5

25.0

20.0

C3804

JV168

JV164

15.0

20.0

7.5

JV195

20.0

15.0

7.5

15.0

JV142

22.5

22.5

22.5

JV152

JV58

JV35

R6076

JV99

25.0

C3803

JV120

12.5

JV8

JV70

JV15

JV186

JV87

7.5

12.5

7.5

JV6

7.5

JV20

R6096

15.0

JV42

25.0

JV103

R3806

JV92

JV139

JV108

E

JV39

N3001

5.R

4.A_GND

B8001

12.5

JV34

V6003

JV22

JV60

JV23

C6010

R6022

R6110

R6034

JV77

C6014

Q6142

R3805

C8002

R6066

C

2.-15V

1.+15V

3.L

Z4007

R6026

R6104

D6008

Q6122

C3903

R3904

JV18

C3906

R3905

C8001

R6063

R6046

B

C

E

R6060

B

E

R6092

B

IM

15.0

22.5

JV33

JV48

15.0

JV169

D6009

D6011

JV155

Q6014

B

C

E

JV1

R6038

B

C

E

Q6030

R6056

Q6026

R6086

B

C

E

JV118

D3901

R3906

C3904

15.0

17.5

D6004

Q6010

Q6018

B

7.5

C

E

Q6036

R6082

R6080

R6068

D3903

15.0

JV124

D6010

17.5

JV88

B

C

E

R6102

Q6022

JV43

R6062

12.5

Q6032

C3902

R3903

D3902

JV10

D6012

C6004

R6018

JV80

E

C

B

C6020

7.5

JV50

7.5

7.5

12.5

R6070

15.0

B E

V6004

B

C

E

R6100

C6018

D8106

C3907

JV129

7.5

R6064

R6012

Q6006

R6050

JV52

JV37

JV75

B

C

R6088

R6078

R6072

D8105

R6010

R6028

JV32

R6042

R6052

E

JV111

20.0

R6065

JV12

C6002

Q6004

R6030

R6098

R6040

R6048

R6084

Q6034

V6002

1

U8101

O

G

I

O

U8102

J6003

7.5

I

C8103

C8104

G

JV36

12.5

JV24

JV71

12.5

C8201

JV150

D8001

7.5

C8102

JV131

Z4004

C8101

R8002

R9105

I

G

O

U8201

C8003

R8001

R9104

15.0

JV65

63101000410AM

JV61

R9102

R6008

B

C

E

B

C

E

JV44

8U-110004

R9103

R9101

N6001

R6108

Q6002

B

C

E

R6016

Q6008

Q6020

B

C

E

C6016

Q6028

R6054

JV182

B

C

E

B

C

E

15.0

JV3

R6006

JV27

Q6016

Q6024

R6094

E

2.A_GND

1.L

R6002

D6002

Q6012

E

C

B

17.5

R6058

JV9

C

3.R

R6004

E

C

B

15.0

Q6121

Q6141

JV177

JV64

Z4003

B

C

E

C9003

C6012

7.5

7.5

7.5

B

E

B

R6044

Q9003

R6032

R6036

D6006

7.5

JV25

R9011

C6008

R6020

R6024

JV21

JV123

JV165

JV95

C9001

N9001

12

25.0

JV106

Z8201

JV66

7.5

Q9002

R6074

R9106

12.5

JV14

1

3.NC

D9002

12.5

JV196

1.HEAT

2.GND

R9008

R9004

R9002

D8104

D8102

JV199

D8103

D8101

N8001

JV72

R9006

B

C

N6004

D8201

D8202

15.0

JV17

JV45

20.0

E

14.DET

13.SPK_B

12.SPK_A

11.PROT_2

10.+12V

9.P_RELAY

8.PROT_1

7.A_MUTE

6.F_MUTE

5.D_GND

4.+5VD

3.CLK

R6090

JV56

15.0

17.5

17.5

JV83

JV57

7.5

JV26

C9004

12.5

2.DATA

1.CE

N8101

R8102

R8101

C9101

JV79

7.5

12.5

J6005

JV197

12.5

12.5

JV63

25.0

JV59

17.5

C8202

C8203

JV91

25.0

JV162

20.0

JV149

JV114

JV74

D6203

N3002

B8101

Z4005

I

G

O

Z4002

7.5

JV153

R6201

Z4006

181716151413121110987654321

A

B

C

D

U8202

J6004

E

F

G

H

I

J

K

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

L

M

43

Page 44

MAIN

(FOIL SIDE)

181716151413121110987654321

A

DIP

Q9103

Q9102

R9108

Q9101

C8207

C8206

R9107

C8205

C8204

C8105

C8108

C8106

C8107

R3907

C3905

U3901

U3801

R6013

C6005

C3505

C3504

R3507

R3508

C3503

R3506

U4001

C3007

C3001

C3003

C3006

B

C4021

C

C3002

D

C3004

E

C3005

F

Q9008

C9005

R9012

R9013

Q9007

R9014

R9015

C9002

Q9006

R9016

Q9004

Q9005

MK2

MP2

C7506

C7505

MKMK

MP1

G

H

I

J

MK1

MPMP

K

L

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

M

44

Page 45

L4001/L4002:N/K ONLY

87654321

R4001/R4002:N/K 6.8K

C4001/C4002:N/K ONLY

1

L

PHONO IN

K4001

R

L

TUNER IN

R

L

CD IN

R

K3001

L

AUX IN

R

L

REC1 IN

R

K3002

L

REC1 OUT

R

L

REC2 IN

R

K3003

L

REC2 OUT

R

K3004

MAIN PWB

8U-110004-1

3

2

C4021

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

220P

C4001

220P

C4002

0.1Z

C3009-C3022:N/K ONLY

0.1Z

C3001

0.1Z

C3002

0.1Z

C3003

0.1Z

C3004

0.1Z

C3005

0.1Z

C3006

0.1Z

C3007

R4001

6.8K

L4001

BALUN-TRANS

L4002

BALUN-TRANS

R4002

6.8K

220P

C3009

C3010

220P

C3011

C3012

220P

C3013

C3014

220P

C3015

C3016

220P

C3017

C3018

220P

C3019

C3020

220P

C3021

C3022

Z4001

OPEN

OPEN

U SHORT

220P

220P

220P

220P

220P

220P

220P

R3001

R3005

R3009

R3013

R3017

R3021

R3025

C4003

10/50

R4003

R4004

C4004

10/50

220K

220K

220K

220K

220K

220K

220K

330K

330K

220K

R3002

A_GND2

220K

R3006

220K

R3010

220K

R3014

220K

R3018

220K

R3022

220K

R3026

R4005

R4006

R4007

100

56K

56K

R4008

100

R3003

R3004

R3007

R3008

R3011

R3012

R3015

R3016

R3019

R3020

R3023

R3024

R3027

R3028

220

220

220

220

220

220

220

220

560

560

220

220

560

560

C4005

C4006

TU_L

TU_R

CD_L

CD_R

AUX_L

AUX_R

REC1_L

REC1_R

RO1_L

RO1_R

REC2_L

REC2_R

RO2_L

RO2_R

220P

220P

100

R4009

100

R4010

RO2_L

R3506

C4007

220/25

C4008

220/25

RO1_L

R3507

120

U4001

45

120

C4009

678

C4010

REC2_L

C3505

C3504

C3503

R3508

0.039

REC1_L

470P

470P

1000P

120

0.039

123

NJM2068MD

R4012

R4011

82K

AUX_L

82K

CLK

DATA

R4015

R4016

R4014

TU_L

CE

GND POWER + POWER -

R4013

100

100

C4020

C4019

6.8K

6.8K

CD_L

R3501

C3501

R4022

100/25

100/25

C4012

47

10/50

C4011

10

R4021

10

1000P

PH_L

1000P

C4014

R3503

C4013

0.01

LC78212-E

1

L1

2

L2

3

L3

4

LCOM1

5

L4

6

L5

7

l6

8

LCOM2

9

L7

L8

10

LCOM3

11

VEE

12

CE

13

DI

14

CL

15

100K

0.01

C4015

10/50

-15V

+15V

C4016

10/50

U3501

R4019

100

100K

OPEN

C4017

R4017

OPEN

100K

R4018

C4018

R4020

100

PH_R

CD_R

PH_R

TU_R

R1

30

R2

29

R3

28

RCOM1

27

R4

26

R5

25

R6

24

RCOM2

23

R7

22

R8

21

RCOM3

20

VDD

19

RES

18

S

17

VSS

16

R3505

10K

R3504

100K

D3501

1SS133

C3506

4.7/50

STBY POWER

PH_L

AUX_R

C3803

C3804

REC1_R

R3502

C3502

100/25

100/25

47

10/50

REC2_R

U3801

R3805

R3806

RO1_R

8

1

10

10

From Volume PWB B1003

R6001

10

R6002

10

RO2_R

7

6

4 5

3

2

AZ4580MTR

A_GND3R

N6001

1L2

3P-BASE

L_CH

R_CH

220K

R6003

220K

R6004

C3801

R3803

10/50

100K

R3801

100K

R3802

C3802

R3804

10/50

N3001

5P-BASE

From Front PWB B5001

R6108

1K

1K

1

+15V2-15V

R6005

330

R6007

1K

C6005

0.022Z

R6013

1M

R6006

330

R6008

1K

SHORT

KTC2874B

KTC2874B

4

3

L

A_GND

C6011

470/63

C6007

OPEN.

C6001

R6011

100

22/50

FAS

47K

100P

C6003

R6009

Q6001

C6009

OPEN.

C6013

470/63

-15V

C6012

470/63

C6008

OPEN.

C6002

R6012

100

22/50

47K

FAS

100P

C6004

R6010

Q6002

C6010

OPEN.

C6014

470/63

39K

OPEN

C3903

R3904

R3902

10K

R3901

10K

C3902

10/50

100

220P

C3901

R3903

C3907

+15V

-15V

5

R

L ch SIGINAL LINE

D6001

R6015

R6017

D6003

D6002

R6016

R6018

D6004

OPEN

SHORT

R6023

33K

Q6011

R6019

1SS133

22

Q6003

KTA1268GR

Q6005

KTC3200GR

22

1SS133

Q6013

33K

R6021

SHORT

R6025

SHORT

R6024

33K

Q6012

R6020

1SS133

22

Q6004

KTA1268GR

Q6006

KTC3200GR

22

1SS133

Q6014

33K

R6022

SHORT

R6026

C3906

OPEN

D3901

1SS133

U3901

1

8

2

7

3

6

45

AZ4580MTR

OPEN

C3905

KTC3200GR

Q6007

KTC3200GR

22

R6027

22

R6029

KTA1268GR

Q6009

KTA1268GR

R6097

100

KTC3200GR

Q6008

KTC3200GR

22

R6028

22

R6030

KTA1268GR

Q6010

KTA1268GR

R6098

100

D3903

1SS133

100K

R3907

D_GND2

C6015

C6016

47K

R3906

D3902

CLK

DATA

CE

14P-BASE

Q6015

FNS

330P

Q6017

R6099

330

Q6016

FNS

330P

Q6018

R6100

330

C3904

1SS133

N3002

470

R6031

KTA1268GR

1M

R6039

1M

R6041

KTC3200GR

470

R6033

R6101

330

470

R6032

KTA1268GR

1M

R6040

1M

R6042

KTC3200GR

470

R6034

R6102

330

10/63

R3905

DET

1CE2

150

R6043

R6035

4.7K

D6005

1SS133

Q6019

2SA1145

C6017

47/25

Q6021

2SC2705

R6045

D6007

1SS133

4.7K

150

R6037

R6103

390

150

R6044

R6036

4.7K

D6006

1SS133

Q6020

2SA1145

C6018

47/25

Q6022

2SC2705

R6046

D6008

1SS133

4.7K

150

R6038

R6104

390

100K

D_GND

3

4

CLK

DATA

+5VD

From Front PWB B1002

KTC3198GR

22

R6047

KTA1266GR

R6109

KTC3198GR

22

R6048

KTA1266GR

R6110

F_MUTE

5

6

D_GND

F_MUTE7A_MUTE8PROT_1

Q6023

22

R6049

22

R6051

Q6025

390

Q6024

22

R6050

22

R6052

Q6026

390

PROTECT

HEAT

GND

NC

From Posister PWB B6501

9

10

+12V

P_RELAY

R6057

R6053

Q6027

KTA1266GR

Q6029

KTC3198GR

R6055

R6059

C6019

220/25

R6058

R6054

Q6028

KTA1266GR

Q6030

KTC3198GR

R6056

C6020

R6060

220/25

3P-BASE

N9001

1

2

3

DC_DETECT

11

12

SPK_A13SPK_B

PROT_2

z

R6073

22

+12V

Q6110

47K

22

4.7K

R6067

820

R6069

47

R6071

220

V6001

22

47K

R6061

100K

z

R6075

22

R6063

470K

R6064

470K

z

R6074

22

R6077

100

Q6031

R6079

100

2SC3419Y

4.7K

V6003

R6083

R6081

R6085

Q6035

2SC2705

z

47

1K

47

2SA1145

V6004

4.7K

2SA1360/2SC3423_PAIR_OorY

Q6111

R6089

3P-BASE

N6003

220

R6087

R6091

Q6112

D6011

1SS133

D6009

1SS133

D6010

1SS133

D6012

1SS133

00MHK136019C0

Q6033

(C6111+C6112)

2SC3423

10

1

2

3

10

2SA1360

Q6131

2SC4467

R6093

R6095

z

Q6132

2SA1694

R6065

22K

R6066

22K

0.22

0.22

Q6130

21905000200AS

(C6131+C6132)(C6141+C6142)

2SA1694/2SC4467_PAIR

z

R9001

1K

R9009

82K

R9005

22K

R9003

1.5K

D9001

A_GND.

SPK_A

SPK_B

22K

R9007

1SS133

A_MUTE

KTC3198GR

Q9001

L6001

OPEN

J6001

SHORT

R7503

4.7K

R7505

4.7K

R7501

47K

C6021

R6105

R7504

R7506

KTA1266GR

Q7501

R7502

D_GND2

C6023

10

47K

D_GND2

47K

4.7K

Q7502

0.039

Q7503

KTC3198GR

Q7504

KTC3198GR

KRC102M

A

C7501-7504:N/K ONLY

FTR-F4

S7501

2

64

53

1

D7501

1SS133

2

64

53

1

D7502

1SS133

S7502

FTR-F4

C7501

0.01

C7502

0.01

C7503

0.01

C7504

0.01

C7505

0.01

C7506

0.01

K7501

8P_SP_TERMINAL

1

SPEAKER-A

3

9

L_CH

4

SPEAKER-B

2

K7501

8P_SP_TERMINAL

7

SPEAKER-A

5

10

R_CH

6

SPEAKER-B

8

B

D_GND2

Q6120

47K

22

4.7K

R6068

820

R6070

47

R6072

220

V6002

22

47K

R6062

100K

z

R6076

22

Q9008

0.1Z

C9005

22K

R9014

10/63

C9004

R9108

Q9103

KTA1504S

Q9102

KTC3875S

R6078

100

Q6032

2SC3419Y

R6080

100

KRC102S

68K

2SC2705

R6084

47

1K

R6082

R6086

47

Q6036

2SA1145

Q9003

KTA1266GR

22K

R9012

R9013

22K

Q9006

KTC3875S

Q9101

KTC3875S

z

2SA1360/2SC3423_PAIR_OorY

Q6121

R6090

3P-BASE

N6004

220

R6088

R6092

Q6122

6.8K

R9011

R9015

Q9007

KTA1504S

Q9005

KTC3875S

10K

C9101

R9107

00MHK136019C0

Q6034

(C6121+C6122)

D_GND2

D6203

R6201

OPEN

OPEN

A_MUTE

SPK_A

SPK_B

+5VD

14

Z4006

STYLE-PIN

Z4007

OPEN

+12V

OPEN

OPEN

Z4004

Z4005

2SC3423

10

1

2

3

10

2SA1360

C9001

0.47/50

100K

C9002

R9016

47/50

J6004

2SC4467

z

2SA1694

0.1Z

68K

SHORT

Q6141

R6094

R6096

Q6142

Q9004

D_GND2

Q6140

21905000200AS

2SA1694/2SC4467_PAIR

z

R9002

1K

0.22

0.22

R9010

82K

+12V

KTC3875S

+5VD

C8203

J6003

D_GND2

Z4002

OPEN

Z4003

STYLE-PIN

D_GND

47/50

SHORT

J6005

47/50

C9003

U8202

KIA7805API

OUT

0.1Z

C8207

OPEN

R9006

R9004

A_GND.

R9103

22K

1.5K

33K

IN

R9008

D9002

+12V

C8206

22K

1SS133

R9101

R9102

0.1Z

33K

33K

C8202

KTC3198GR

Q9002

L6002

OPEN

J6002

SHORT

Z8202

SCREW

00M51100308M9

47/50

C6022

R6106

+15V

-15V

+12V

OPEN OPEN

10

0.039

C6024

A_GND.

A_GND..

D8105

1N4003

D8106

1N4003

Z8201

HEAT-SINK

00M309V267010

R9106

C8103

C8104

A_MUTE

GND-TERMINAL

22K

KIA7815API

OUT

47/25

C8107

47/25

C8108

KIA7812API

OUT

C8205

R7507

330

D7503

1SS133

R7508

330

Q7505

D_GND2

3

B8001

FG

U8101

0.1Z

0.1Z

OUT

KIA7915PI

U8102

U8201

0.1Z

KRC102M

12

A_GND

IN

C8105

C8106

IN

IN

C8204

16

1

C8001

C8002

R9105

0.1Z

0.1Z

0.1Z

13

z

D8001

KBU804

z

10000/63

z

10000/63

22K

R9104

C8101

C8102

C8201

911

MAIN_GND

22K

470/25

470/25

470/25

4

86

z

D8101

11EQS10

D8102

11EQS10

D8103

11EQS10

D8104

11EQS10

B8101

D8202

1N4003

D8201

1N4003

S7503

BC3/12V

z

R8001

z

0.68UF/4.7ohm

R8101

1(1W)

R8102

1(1W)

R8002

C8003

z

z

3P-BASE

N7501

1

2

3

OPEN

NC

3P-BASE-BOX

HP_L

HP_R

1

2

3

5P-BASE

N8101

1

2

3

4

5

N8001

From HP PWB B9901

AC

GND

AC

From Main Trans

AC

GND

GND

GND

AC

From Main Trans

C

D

E

DET

F

SCHEMATIC DIAGRAMS (1/3)

R ch SIGINAL LINE

SCHEMATIC DIAGRAMS (1/3)

MAIN UNIT

45

Page 46

5VD

87654321

5VL

STANDBY

R1501

D1501

STB

5V

1mS

7mS

0V

IC61 38 pin WAVE FORM at STAND BY mode

CUSHION_IR

R94EV1A

5VL

100

R1601

C1601

100/16

PHONO CDTUNER AUX/DVD REC1/CD-R REC2/MD/TAPE

820

C1501

SLR342VC

0.01

7mS

R1502

1mS1mS

10K

R1503

D1502

PHONO

330

C1502

SELG6E10C-S20

0.01

R1504

10K

R1505

D1503

TUNER

330

C1503

0.01

10K

R1506

R1507

D1504

SELG6E10C-S20

CD

Z1602

Q1601

Q1602

5VL

R1602

D1601

1SS133

100

KRA102S

Q1603

KTC3875S

R1603

47K

Q1604

R1604

18K

R1605

47K

0.1Z

C1604

C1603

100/16

U1601

VCC

3

2

0.1Z

C1602

D-GND

KRA102S

GND

Vout

1

KRA102S