Page 1

Service

PD6001

PD6001 /

U1B

Manual

2nd EDITION

This service manual is the revised one.

• 4. ADUSTMENT and 7. BLOCK

DIAGRAM were added.

• A partial revision of the contents.

MENU INPUT/EXITVOLUME

TABLE OF CONTENTS

SECTION PAGE

1. TECHNICAL SPECIFICATIONS ....................................... 1

2. SAFETY INFORMATION .................................................. 2

3. FAILURE DIAGNOSIS ................................................... 20

3.1 FAILURE DIAGNOSIS .............................................................. 20

3.2 FAILURE DIAGNOSIS BY LED ............................................... 70

3.3 RS-232C COMMANDS ............................................................ 75

3.4 POWER ON /OFF FUNCTION FOR THE LARGE-SIGNAL

SYSTEM ................................................................................... 82

3.5 FAN CONTROL ........................................................................ 83

4. ADJUSTMENT .............................................................. 84

4.1 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED

OR REPLACED ........................................................................ 84

4.2 ADJUSTMENT ......................................................................... 86

4.3 BACKUP OF THE EEPROM (DIGITAL ASSY) ..................... 110

4.4 ADJUSTMENTS WHEN THE SERVICE PANEL ASSY IS

REPLACED ............................................................................. 114

4.5 HOW TO CLEAR HISTORY DATA ........................................ 123

4.6 HOW TO BACKUP EEPROM MEMORY (MAIN ASSY) ....... 124

4.7 MENU INFORMATION ........................................................... 127

5. DISASSEMBLY ............................................................ 140

5.1 PCB LOCATION ..................................................................... 140

5.2 DISASSEMBLY ....................................................................... 141

Plasma Monitor

VOLUME

INPUT/EXIT

MENU

ON/STANDBY

SECTION PAGE

6. EXPLODED VIEWS AND PARTS LIST ....................... 154

6.1 PACKING SECTION ............................................................... 154

6.2 EXTERIOR SECTION ............................................................ 155

6.3 FRONT SECTION .................................................................. 156

6.4 CHASSIS SECTION (1/2 ) ...................................................... 157

6.5 CHASSIS SECTION (2/2) ..................................................... 158

6.6 PANEL CHASSIS SECTION .................................................. 159

6.7 MULTI BASE SECTION ......................................................... 160

6.8 PDP SERVICE ASSY 607MX (AWU1231) ............................. 161

6.9 PARTS LIST ........................................................................... 162

7. BLOCK DIAGRAM ....................................................... 178

7.1 OVERALL CONNECTION DIAGR AM .................................... 178

7.2 CONNECTION PIN EXPLANATION ...................................... 180

7.3 GENERAL BLOCK DIAGRAM ............................................... 202

7.4 MAIN BLOCK DIAGRAM ......................................................... 204

7.5 SUB BLOCK DIAGRAM ......................................................... 205

7.6 DD ASSY ................................................................................ 207

7.7 LVDS ASSY ............................................................................ 208

7.8 PDP MODULE BLOCK DIAGRAM .......................................... 209

7.9 60 ADDRESS L and S ASSYS ............................................... 210

7.10 607 SCAN A and B ASSYS .................................................. 211

7.11 60 X DRIVE ASSY ................................................................ 212

7.12 60 Y DRIVE ASSY ................................................................ 214

7.13 60 DIGITAL ASSY ................................................................. 216

7.14 POWER ON SEQUENCE ..................................................... 217

7.15 IC ........................................................................................... 218

ON/STANDBY

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

PD6001

Part no. 90M26AV855020

First Issue 2006.12

MZ

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

CANADA

MARANTZ CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

No.1 JALAN KILANG TIMOR

#08-03 PACIFIC TECH CENTRE

SINGAPORE 159303

PHONE : +65 6376 0338

FAX : +65 6376 0166

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64-9-8451958

FAX :+64-9-8463554

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALING JAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE : +60 - 3 - 7954 8088

FAX :+60-3-79547088

KOREA

MARANTZ KOREA CO., LTD.

ROOM 604, ELECTRO OFFICE, 16-58,

HANGGANG-RO 3GA, YONGSAN-KU,

SEOUL, 140-013, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CHINA

MARANTZ SHANGHAI TRADING LTD.

ROOM.506 SHANGHAI LIGHT INDUSTRY MANSION

1578 NANJING (WEST) ROAD SHANGHAI

CHINA

TEL : 021 - 6248 - 1064

FAX : 021 - 6248 - 3565

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verifi ed before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

060607MZ

Page 3

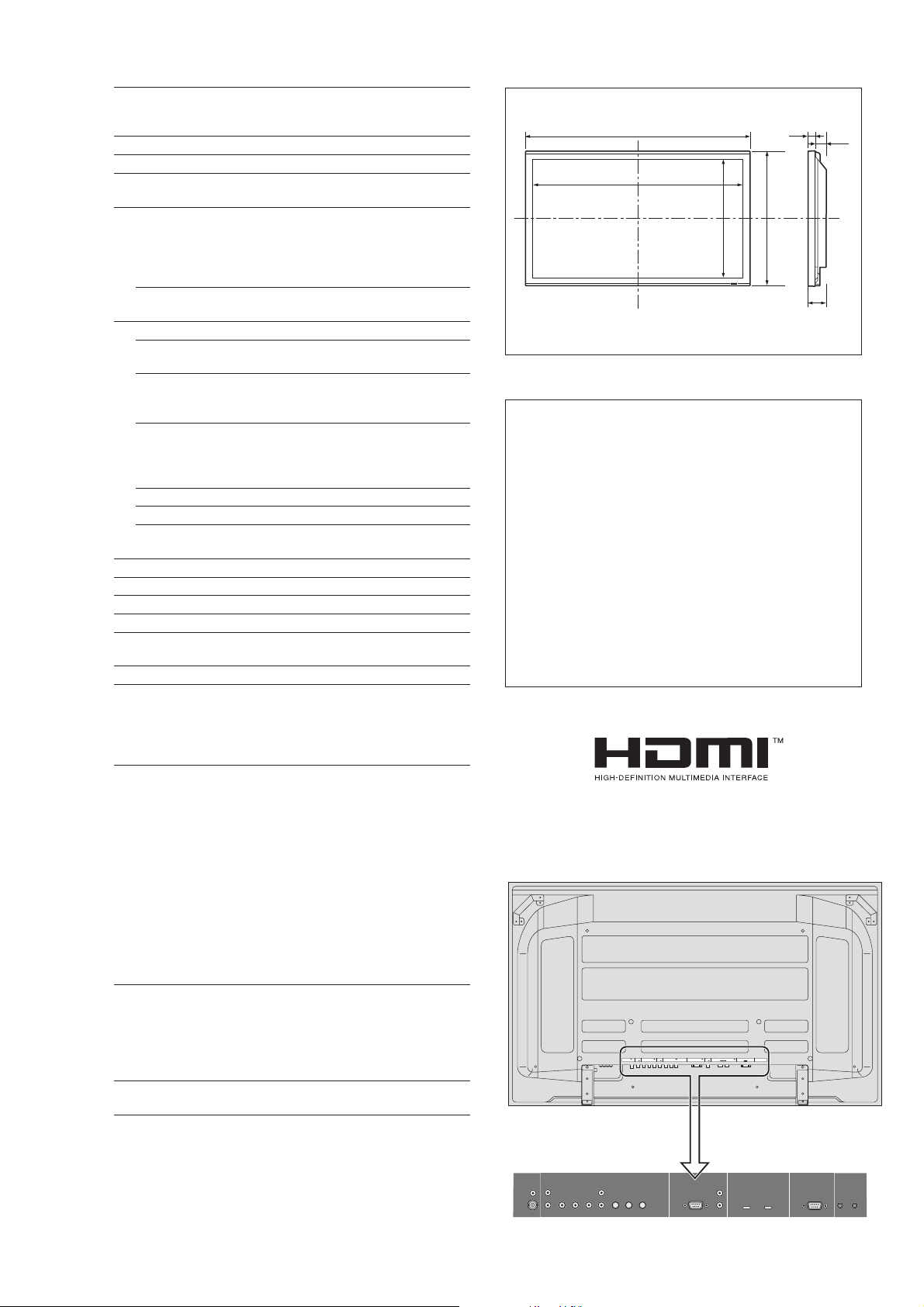

1. TECHNICAL SPECIFICATIONS

Screen Size 51.9 inches(H)⳯29.2 inches(V)

1319 mm(H)⳯742 mm(V)

diagonal 60 inches

Aspect Ratio 16 : 9

Resolution 1365 pixels(H)⳯768 pixels(V)

Pixel Pitch 0.038 inches(H)⳯0.038 inches(V)

0.97 mm(H)⳯0.97 mm(V)

Signals

Synchronization Range Horizontal : 15.5 kHz to 110.0 kHz

(automatic : step scan)

Vertical : 50.0 Hz to 120.0 Hz

(automatic : step scan)

Input Signals RGB, NTSC (3.58/4.43), PAL (B,G,M,N),

PAL60, SECAM, HD*

1

, DVD*

1

Input Terminals

PC/RGB

Visual 1 (Analog) mini D-sub 15-pin⳯1

Video

Visual 1 RCA⳯1

Visual 2 S-Video: DIN 4-pin⳯1

DVD/HD

Visual 1 RCA-pin (Y, Cb/Pb, Cr/Pr)⳯1*

Visual 2 RCA-pin (Y, Cb/Pb, Cr/Pr)⳯1*

HDMI HDMI connector⳯2*

2

1

1

Audio Stereo RCA⳯3 (Selectable)

External Control D-sub 9-pin⳯1 (RS-232C)

Remote In Mini jack⳯1

Remote Out Mini jack⳯1

Sound output 9 W+9 W at 6 ohm

Power Supply AC100 V to 240 V 50 Hz/60 Hz

Current Rating 7.0 A (maximum)

Power Consumption 440 W (typical)

Dimensions 58.1 inches(W)⳯34.7 inches(H)⳯5.0 inches(D)

1476 mm(W)⳯880 mm(H)⳯126 mm(D)

Weight 135.6 lbs / 61.5 kg (without stand)

Environmental Considerations

Operating Temperature 0 °C to 40 °C / 32 °F to 104 °F

Humidity 20 % to 80 % (no condensation)

Storage Temperature -10 °C to 50 °C / 14 °F to 122 °F

Humidity 10 % to 90 % (no condensation)

Other Features Motion compensated 3D Scan Converter (NTSC,

PAL, 480I, 576I, 525I, 625I, 1035I, 1080I), 2-3

pull down Converter (NTSC, 480I, 525I, 1035I,

1080I (60 Hz)), 2-2 pull down Converter (PAL,

576I, 625I, NTSC, 480I, 525I), Digital Zooming

(100 % to 900 % Selectable), Self Diagnosis via

RS232C, PDP Saver (PEAK BRIGHT,

ORBITER, INVERSE, WHITE, SCREEN

WIPER, SOFT FOCUS, etc.), Color Temperature

Select (high/middle/middle low/low, user has 4

memories), Auto Picture Adjust, Input Skip, Color

Tune, Gamma Correction (4 modes), Plug and

play (DDC1, DDC2b, HDMI: E-DDC),

Enhanced Split Screen, etc.

Accessories Power cord (⳯1), Remote control (⳯1), AAA

batteries (⳯2), Manuals (User guide), Ferrite

cores for power cord (⳯2), bands for power

code (⳯2), Cable clampers (⳯3), beads bands

(⳯3), Ferrite core for remote cable (⳯2),

Warranty card

Regulations UL 60065, CAN/CSA-C22.2 No.60065-03,

FCC class B, ICES-003 class B

1.9"

3.0"

58.1" (1476)

(49)

(77)

51.9" (1319)

34.7" (880)

29.2" (742)

5.0"

(126)

Units are in inch

(mm)

The features and specifications may be subject to change without

notice.

*1DVD/HD input signals supported on this system.

480P (60 Hz) 480I (60 Hz) 525P (60 Hz)

525I (60 Hz) 576P (50 Hz) 576I (50 Hz)

625P (50 Hz) 625I (50 Hz) 720P (60 Hz)

720P (50 Hz) 1035I (60 Hz) 1080I (50 Hz)

1080I (60 Hz) 1080P (50 Hz) 1080P (60 Hz)

2

*

HDMI input signals supported on this system.

Supported Signals

• 640ⴒ480P @ 59.94/60 Hz • 1920ⴒ1080I @ 50 Hz

• 1280ⴒ720P @ 59.94/60 Hz • 720ⴒ576P @ 50 Hz

• 1920ⴒ1080I @ 59.94/60 Hz • 1440 (720)ⴒ576I @ 50 Hz

• 720ⴒ480P @ 59.94/60 Hz • 1280ⴒ720P @ 50 Hz

• 1440 (720)ⴒ480I @ 59.94/60 Hz

Note: In some cases a signal on the plasma monitor may not be displayed

properly. The problem may be an inconsistency with standards from

the source equipment (DVD, Set-top box, etc...). If you do experience

such a problem please contact Marantz America, Inc. and also the

manufacturer of the source equipment.

HDMI, the HDMI logo and High-Definition Multimedia Interface are

trademarks or registered trademarks of HDMI Licensing LLC.

DVD/HD3DVD/HD

VIDEO AUDIO

1

AUDIO

DVD/HD1DVD/HD

Cb/Pb Cr/Pr L/R Y Cb/Pb Cr/PrL/R Y

2

2

4

AUDIO

3

PC/RGB

L/R

REMOTE

EXTERNALCONTROL

IN OUT

DVD/HD3DVD/HD

VIDEO AUDIO

1

2

R

(

MONO

L

1

YCb/PbCr/Pr

)

2

AUDIO

DVD/HD

1

DVD/HD

2

R

YCb/PbCr/Pr

(

)

L

MONO

AUDIO

3

PC/RGB

R

(

)

MONO

L

4

HDMI

HDMI

EXTERNALCONTROL

REMOTE

IN

OUT

1

Page 4

2. SAFETY INFORMATION

SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de

de remplacement doivent avoir la même désignation.

type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

Health & Safety Code Section 25249.6 - Proposition 65

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

2

Page 5

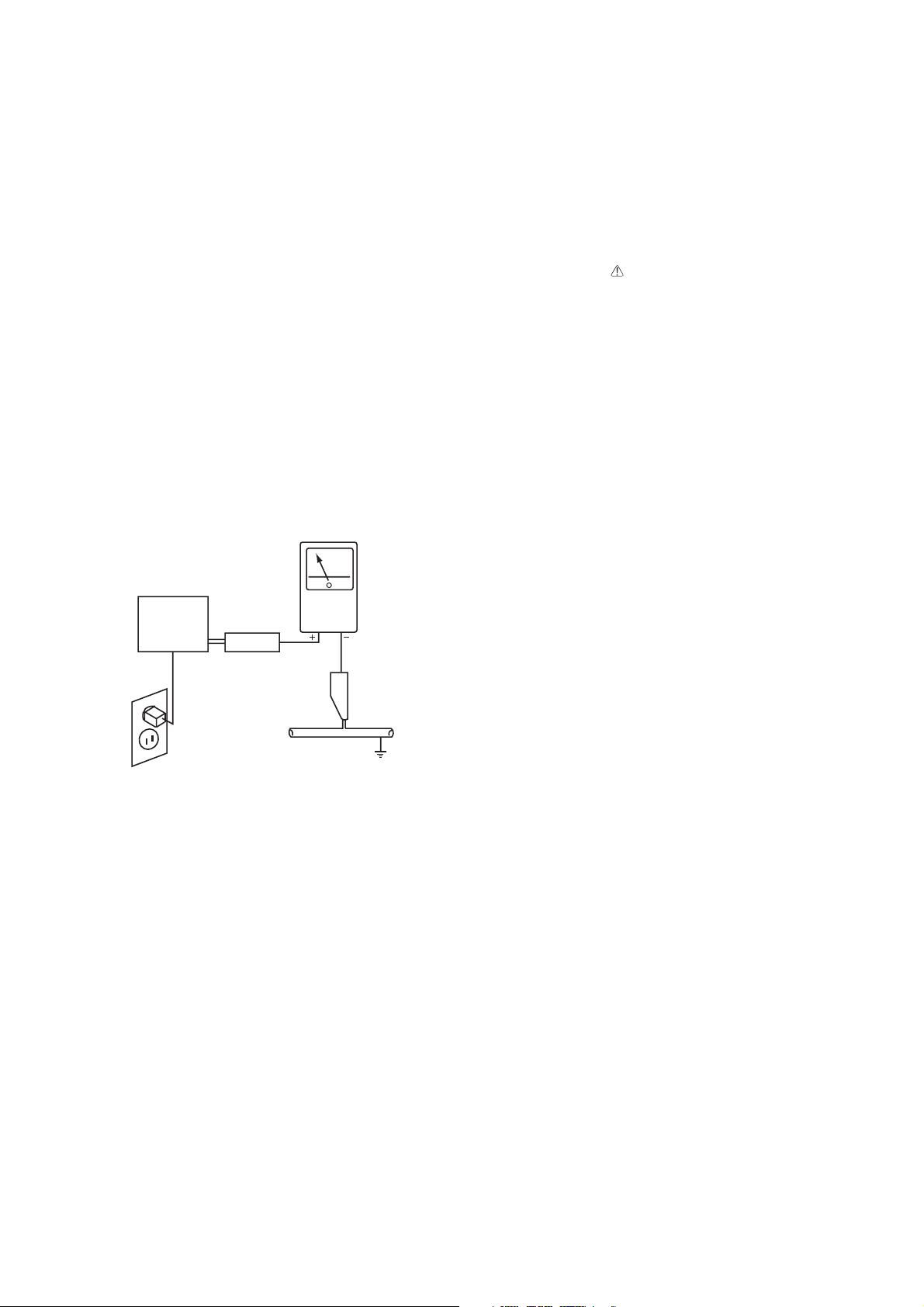

Insulation Resistance Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

( Case of PD6001, AC power is alwayas on. )

(Case of PX-60XR5A, AC power is always on.)

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), The resistance should be greater than 4 MΩ.

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester", measure for current from all

exposed metal parts of the cabinet (input/output terminals,

screwheads, metal overlays, control shaft, etc.), particularly any

exposed metal part having a return path to the chassis, to a known

earth ground (water pipe, etc.). Any current measured must not

exceed 1.0 mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the Set have special

Many electrical and mechanical parts in PIONEER set have

safety related characteristics. These are often not evident

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

have these special safety characteristics are identified in this

Service Manual.

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

Reading should

not be above

1.0 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

3

Page 6

Safety cautions

The matters to be observed without fail are explained below. These matters are indispensable for the

prevention of an accident during the maintenance servicing, the "security of products" after the completion of

servicing work, and the "prevention of the repeated occurrence of similar fault."

(1) The degree of danger and material damage, caused as a result of wrong use by disregarding the contents

of the display" is distinguished and explained in the table below.

If this display is disregarded and equipment is handled

WARNING

CAUTION

(2) Kinds of the matters to be observed are classified and explained in the icons shown below.

This icon indicates a dangerous place where an electric shock is anticipated.

This icon indicates the contents of "caution" that must be borne in mind, without fail.

wrongly, this can be a cause of physical injury and a

fire, thus leading a person to death or serious injury.

If this display is disregarded and equipment is

handled wrongly, this may lead to personal injury or

material damage.

This icon indicates the contents of "caution" that must be practiced, without fail.

WARNING

• Observe the caution matter, without fail.

• In the place where a particular caution is needed during maintenance servicing, such a

caution note is displayed with a label or a stamp that is given to the cabinet, chassis,

PWB, etc. These caution notes and also the caution matters of given in

the instruction manuals, etc., must be observed, without fail.

• Be careful of an electric shock or a burn.

• The power block or the PDP module involves the sections where high voltage or high

temperature is prevalent. When equipment is energized, use working gloves in order to

prevent an electric shock or a burn. At the time of transportation, disassembly,

reassembly, and the replacement of parts, such a servicing job must be done after pulling

out the power plug.

• Modification of equipment is absolutely prohibited. Use the specified parts at all times.

• If any modification is performed, the validity of the manufacturer's warranty is lost at that

moment. The personnel who did this modification is responsible for the physical injury or

the like, if it should occur as a result of the modification. The parts used are given the

safety-based characteristics, such as non-flammability or sufficient withstand voltage. The

parts to be replaced shall be those which are specified in the list of replacement

parts.(Example: The lithium battery (circuit symbol BT9501 in the MAIN PWB) will give

rise to explosion if its polarity is wrongly treated.

WARNING

• The replaced parts and wiring must be arranged in the original conditions.

• For safety reasons, insulation materials like tubes and tapes may be used or some parts

may be mounted clear of the PWB. The internal wiring and the fastening with the

clampers for separation from high-heat and high-voltage parts shall be returned to their

original conditions, without fail.

4

Page 7

CAUTION

• Observe the caution matter, without fail

The caution matters of given in the instruction manuals, etc., must be

•

observed, without fail.

• Do not give shocks and vibration.

The panel surface (display plane) of the filter and the PDP module (include the PDP

•

Service ASSY)

and the scattered glass chips will be a cause of injury.

• Do not put anything.

Do not put anything on the product. Otherwise, this can be a cause of injury as a result

•

of falling down or dropping caused by imbalance.

• Transportation must be done by enough personnel.

The product is heavy. In the case of transportation, unpacking, or packing, more than

•

two persons should do it (three persons for a product of 60-inch or larger) by supporting

the top and the bottom of the product.

is made of glass. If any shocks or vibration is applied, it may be broken

CAUTION

Miscellaneous caution matters

(1) This product uses highly integrated semiconductor parts. Since these parts are fragile to

electrostatic charges, earth bands should be used for handling. The product should be handled

where measures have been taken against electrostatic charges.

(2) If this product is used for the fixed character display or the like as in the case of a character

display board, a phenomenon of burning (not warranted) will occur. Burning is a phenomenon

that the unevenness in the brightness is caused in the display. In such a case, the brightness in

the section where the integrated display time is longer becomes lower than the brightness in

another section where the integrated display time is shorter. This phenomenon is in proportion

to the integrated display time and the brightness. For this reason, to relieve this difficulty during

servicing, do not use any still picture, but use a display by motion pictures of a video or the like.

In addition, use "FULL" for the screen mode and avoid using any display by "NORMAL",

"TRUE", or MULTI SCREEN like side by side etc. If it is necessary to use only a still picture for

unavoidable reasons, use a burning relief function such as "PLE LOCK", "ORBITER",

"SCREEN WIPER", etc.

(3) When a PDP module (include the PDP Service ASSY) is operated after a long time of storage,

it may encounter a difficulty like a failure in displaying a screen or unstability according to the

condition of storage. In such a case, the PDP module (include the PDP Service ASSY) should

be incorporated in the product and aging treatment should be carried out for about two hours

(all screen display).

(4) Sulfides will deteriorate the PDP module (include the PDP Service ASSY) and this is a cause of

malfunction. Therefore, it is absolutely prohibited to put any vulcanized rubber or a material

containing sulfur in the vicinity of the PDP module (include the PDP Service ASSY).

(5) When taking out a PDP module (include the PDP Service ASSY) from the maintenance

5

Page 8

package box, do it slowly so that the panel surface does not get any shock or stress.

If one touches the connector of the flexible cable exposed to the rear side of the PDP module

(6)

(include the PDP Service ASSY), there is danger of causing a poor contact. As such, it must be

handled with utmost care. In addition, the flexible cable is very weak in mechanical strength.

Therefore, this cable must not be touched during handling.

(7) The panel surface of the filter and the PDP module (include the PDP Service ASSY) is easy to

be hurt. These components should be handled very carefully not to press or rub them with a

hard thing. Never put them on a hard thing with the panel surface faced downwards.

When the panel surface of the filter and the PDP module (include the PDP Service ASSY) is

(8)

contaminated, gently wipe off the contaminant with a piece of soft dry cloth. Liquid-state

contamination can be removed by lightly pressing it, without rubbing it. If it is difficult to remove

the contamination, use a piece of cloth soaked with a neutral detergent

water.)

or a rubbing alcohol. The cloth for wiping off should be clean. Never use the same cloth

(Use it, diluting with

repeatedly. If a cleansing detergent or water drops should enter the module interior or be

attached to the module surface other than the display plane at the time of cleaning, this will give

rise to the destruction of the product when the product is energized.

(9) When transporting this product, use the packing materials specified in the list of parts. Once

used, such packing materials should not be used again.

(10) This product is composed of a variety of parts, such as those made of materials like glass,

metal, plastics, etc., and those like a lithium battery (circuit symbol of the MAIN ASSY: BT9501),

etc. Therefore, when abandoning this product, this should be done in accordance with the

relevant law of the nation or an autonomous body.

CAUTION: Risk of Explosion if Battery is replaced by an Incorrect Type. Dispose of Used

Batteries According to above the Instructions.

(11) You should use the following service tools when you replace ICs etc. since solder with free lead is

used in product.

∗ Soldering iron for solder with free lead ; HAKKO SOLDERING IRON 934 (Hakko corporation)

(See the following web address in detail. http://realwww.hkk.idanet.ne.jp/english/index.html)

∗ Solder with free lead ; SN96C 0.3 mm (NIHON SUPERIOR CO., LTD)

(See the following web address in detail. http://www.nihonsuperior.co.jp/english/index.html)

6

Page 9

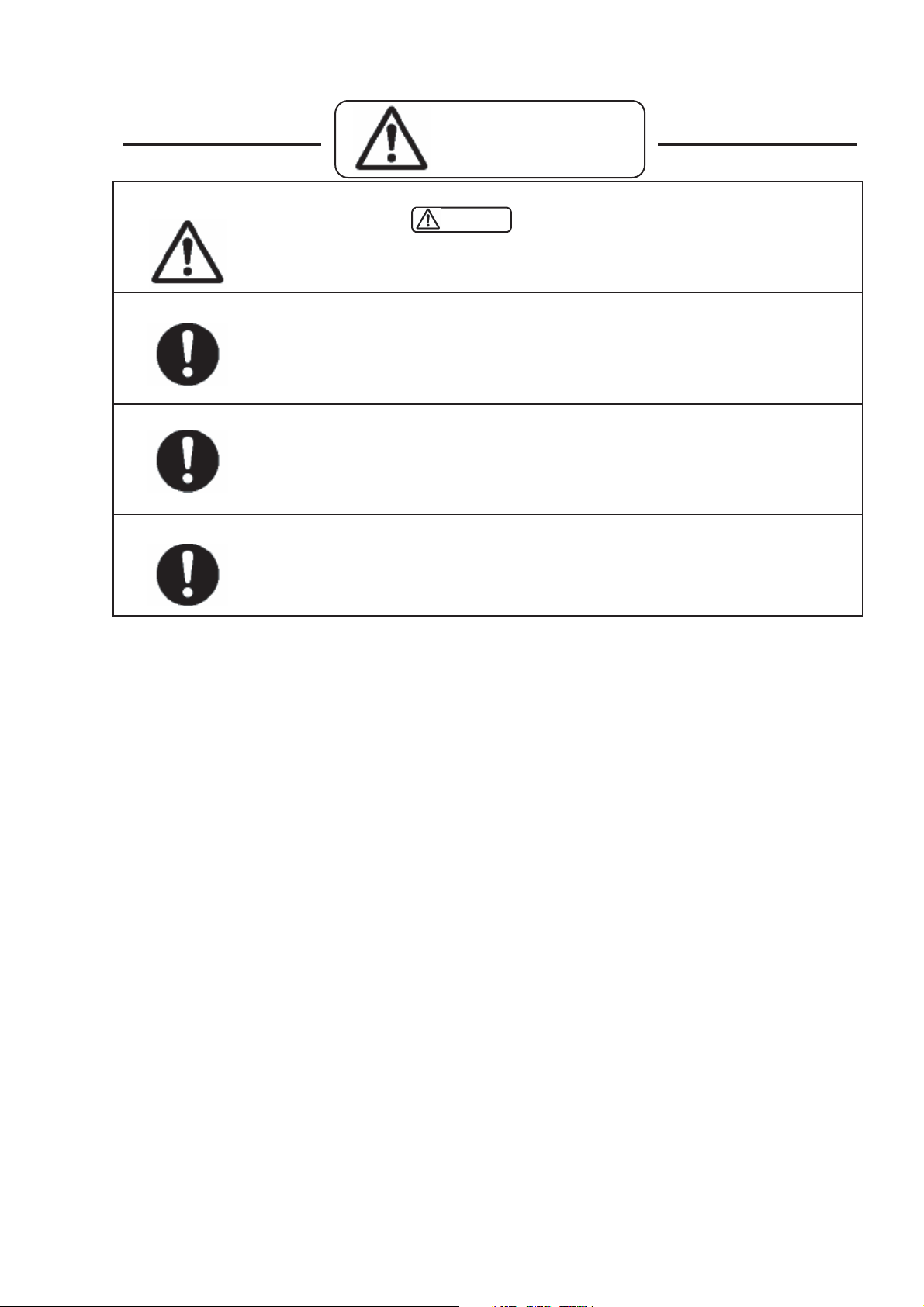

Charged Section

High Voltage Generating Point

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

1. Power cord

2. AC inlet

3. Power switch (S1)

4. Fuse (In the POWER SUPPLY Unit)

5. STB transformer and Converter transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

607 SCAN B Assy

60 Y DRIVE Assy

The places where voltage is 100 V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

The VSUS voltage remains for several minutes after the power to

the unit is turned off. These places must not be touched until

about 10 minutes after the power is turned off, or it is confirmed

with a tester that there is no residual VSUS voltage.

If the procedures described in “3.4 POWER ON/OFF FUNC-

-TION FOR THE LARGE-SIGNAL SYSTEM” are performed

before the power is turned off, the voltage will be discharged in

about 30 seconds.

POWER SUPPLY Unit..................................................(DC205 V)

60 X DRIVE Assy...............................................(–180 V to 205 V)

60 Y DRIVE Assy..............................................(–500 V to 500 V)

607 SCAN A Assy..............................................(–500 V to 500 V)

607 SCAN B Assy..............................................(–500 V to 500 V)

60 X DRIVE Assy Conductive plate XPOWER SUPPLY Unit

607 SCAN A Assy

Power switch (S1)

AC inlet

Fig. High Voltage Generating Point (Rear view)

7

Page 10

High Temperature Section

Caution: Because the places circled ( ) in the photo can be extremely hot, work with care.

8

Page 11

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

9

Page 12

3. FAILURE DIAGNOSIS

3.1 FAILURE DIAGNOSIS

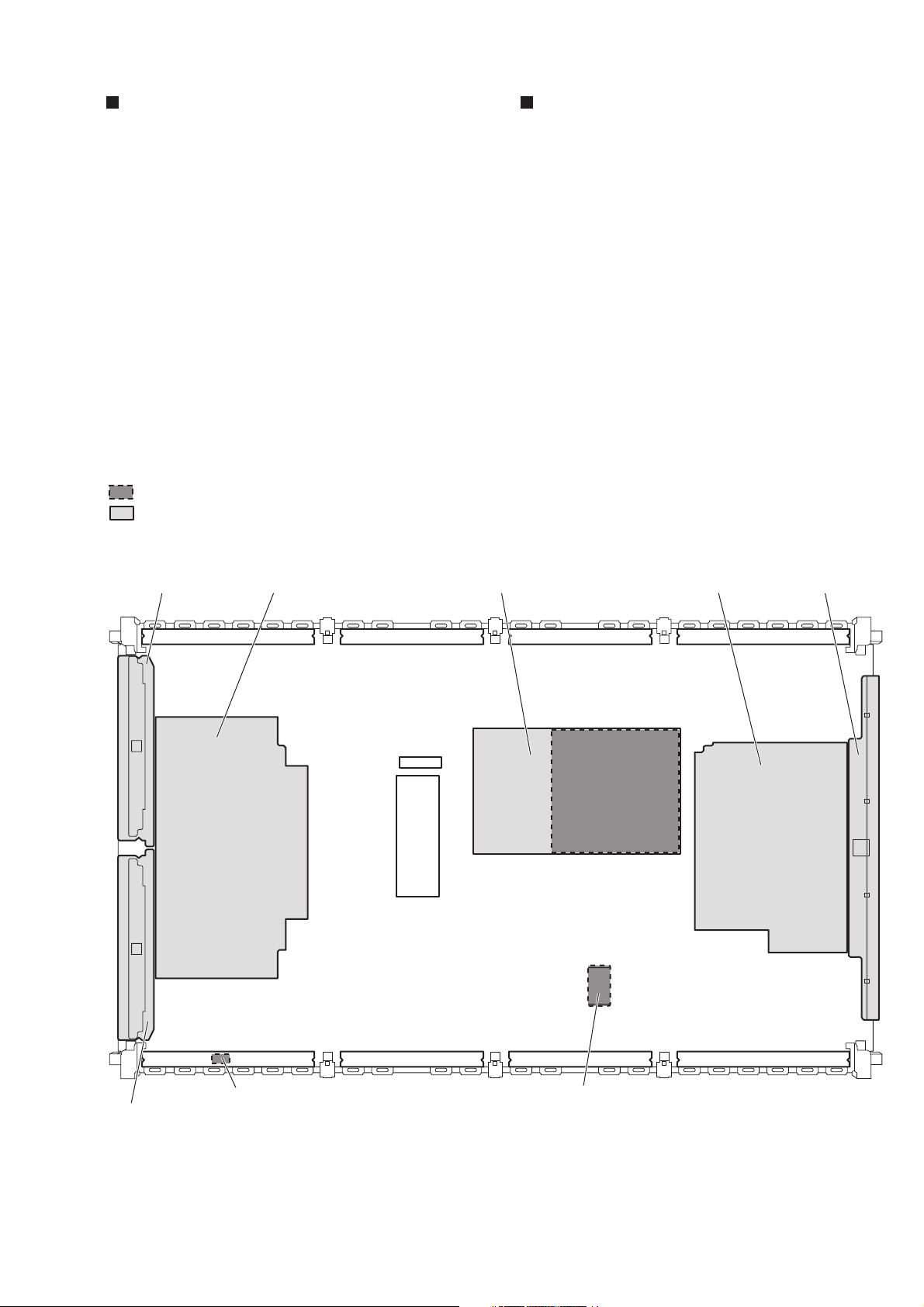

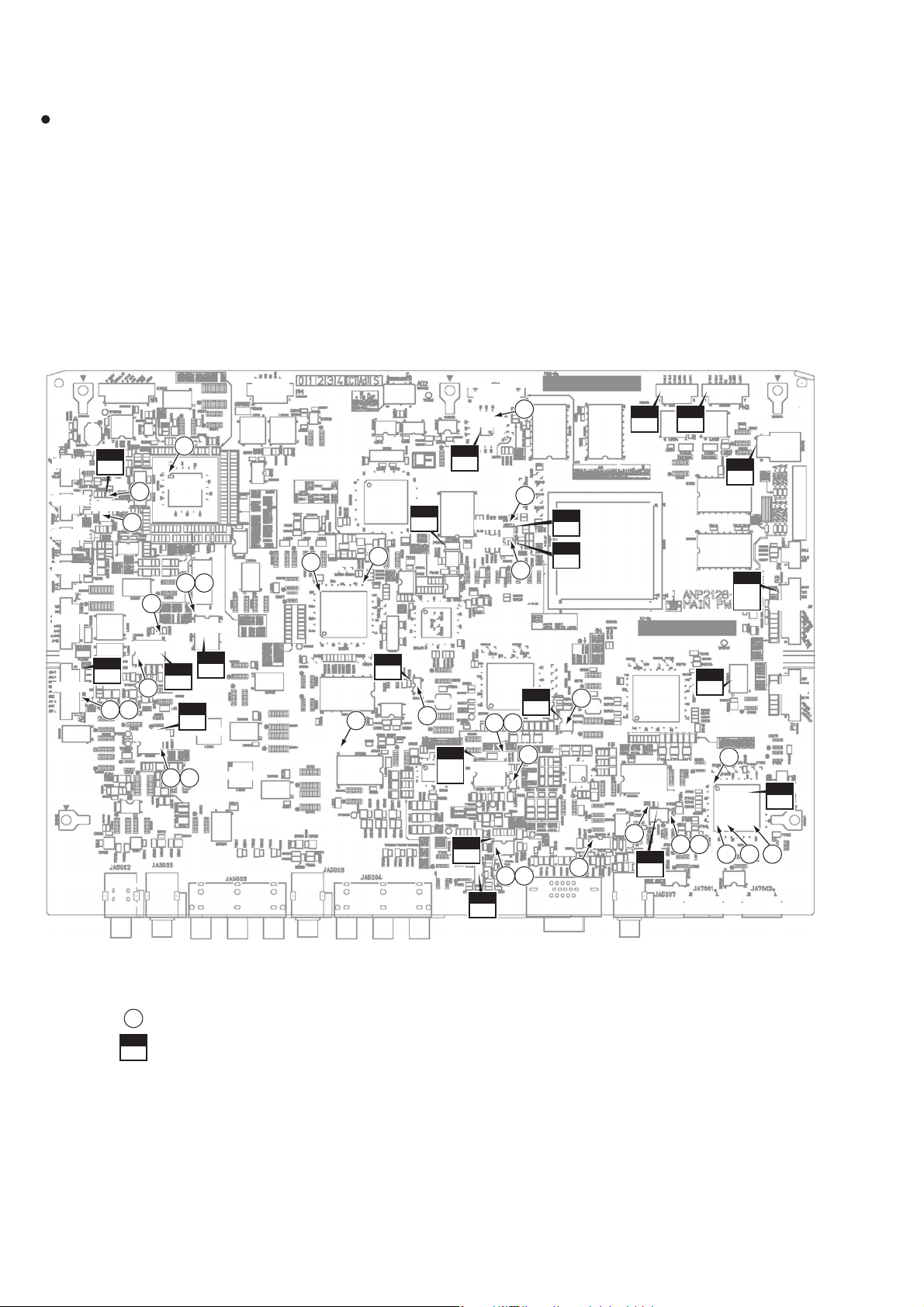

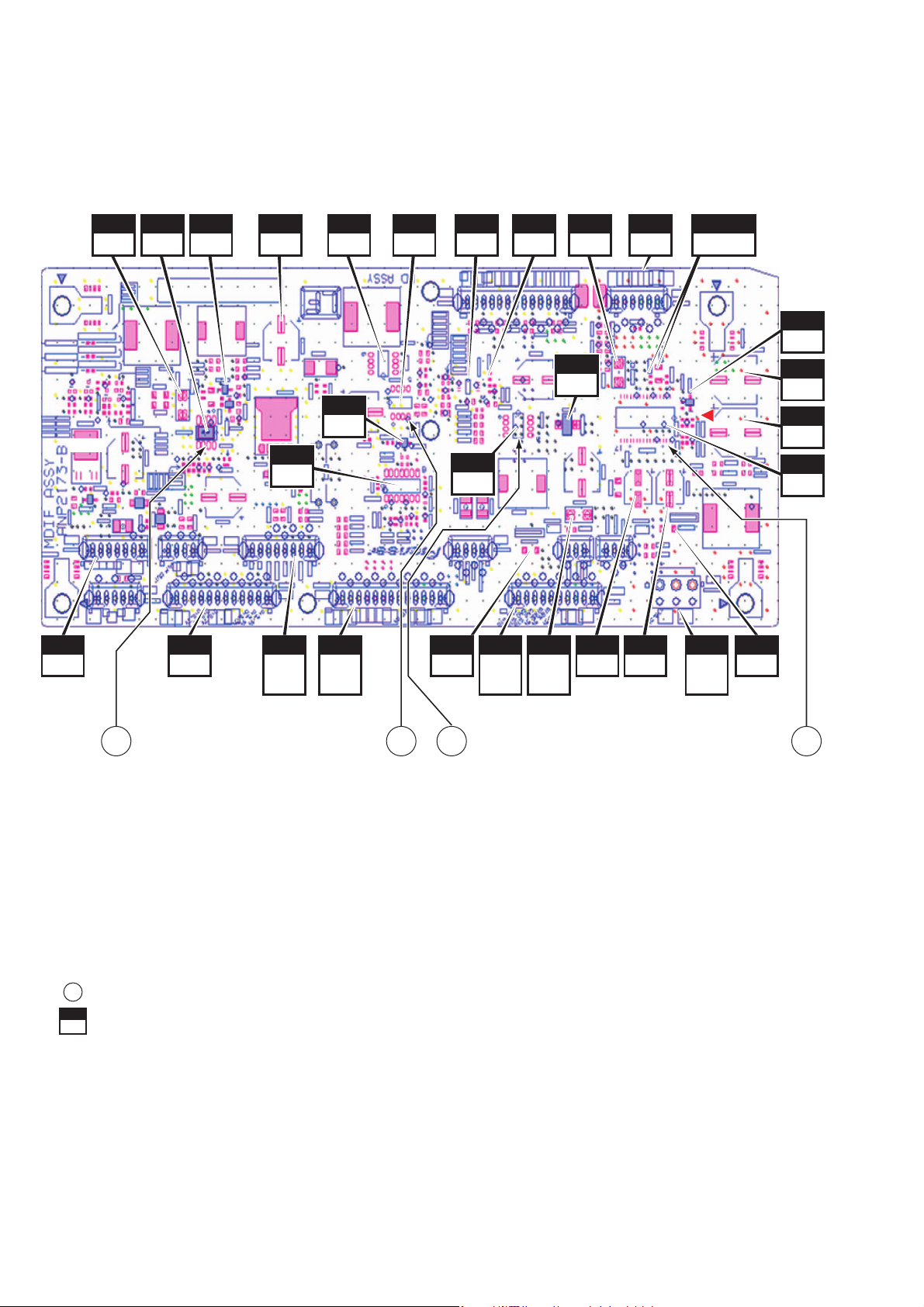

Diagnosis Points of PCB Assy

Note:

If symptoms persist after replacement of parts, such as ICs, following the diagnosis results of this failure-analysis chart, it is

recommended to replace the whole PC board, as short-circuiting or breaking of printed wiring of board patterns is suspected.

MAIN ASSY (XR model)

CN9501

CN9005

CN9004

CN9003

CN9008

CN9001

IC9504

T10

IC9504

CN9001

T31

44 45

15

4

IC5605

IC5302

6

5

3

IC9501

10 12

IC5605

T10

IC5302

T35

45 49

IC5301

IC5301

T11

CN9006

23

IC6201

IC5602

CN8501

IC8501

T22

IC8501

38

PN1

T22

PN2

T22

IC8002

IC8002

T22

39

24

IC8003

T22

X8001

X8002

40

X8001

T22

X8002

T22

CN9010

T40

CN9010

IC6403

T13

2

25

IC5903

T11

T20

13 37

IC5903

IC6501

IC5904

T11

14

11

IC6701

IC7002

IC7004

T21

35

IC7001

CN9009

IC7001

T35

IC5902

T11

IC7003

IC7003

936

8

48

T35

• Legend symbol

45

: Waveform No. on Flowchart.

IC5002

: Broken circuit number on Flowchart, and number of Flowchart that broken parts are written.

T13

20

IC7002

T35

46 47

32

34 33

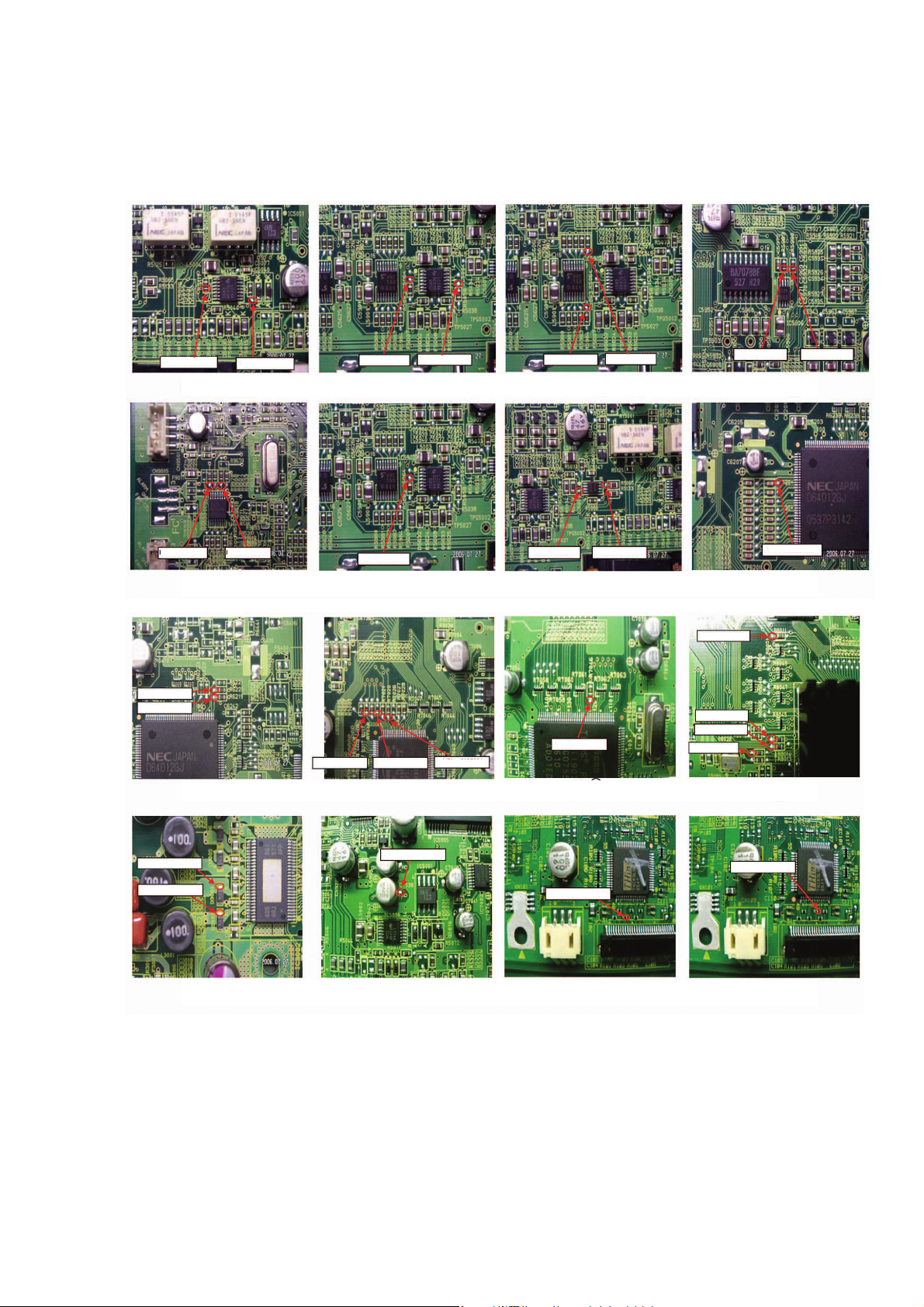

Page 13

Pin4 of IC5006

Pin10 of IC5006

Pin4 of IC5004

Pin10 of IC5004

Pin7 of IC5902

Pin9 of IC5902

Pin6 of IC5906

No. 8 (IC5006) No. 8 (IC5004) No. 9 and ∞ and º No. !

Pin3 of IC5906

Pin74 of IC6201

Pin73 of IC6201

Pin41,43 of IC3002

Pin47,48 of IC3002

Pin3 of IC9504Pin6 of IC9504

Pin4 of IC5004

Pin3 of IC5005

Pin6 of IC5005

Pin119 of IC6201

No. @ No. & No. * No. )

Pin12 of IC8501

Pin57 of IC8501

Pin55 of IC8501

Pin58 of IC8501

Pin48 of IC7001

Pin121 of IC7001

Pin47 of IC7001 Pin44 of IC7001

No. _ No. ¢ No. ª No. ≠

Pin11 of IC7002

Pin55 of IC101

Pin57 of IC101

No. ‹ No. ‚ No. ± No. [

21

Page 14

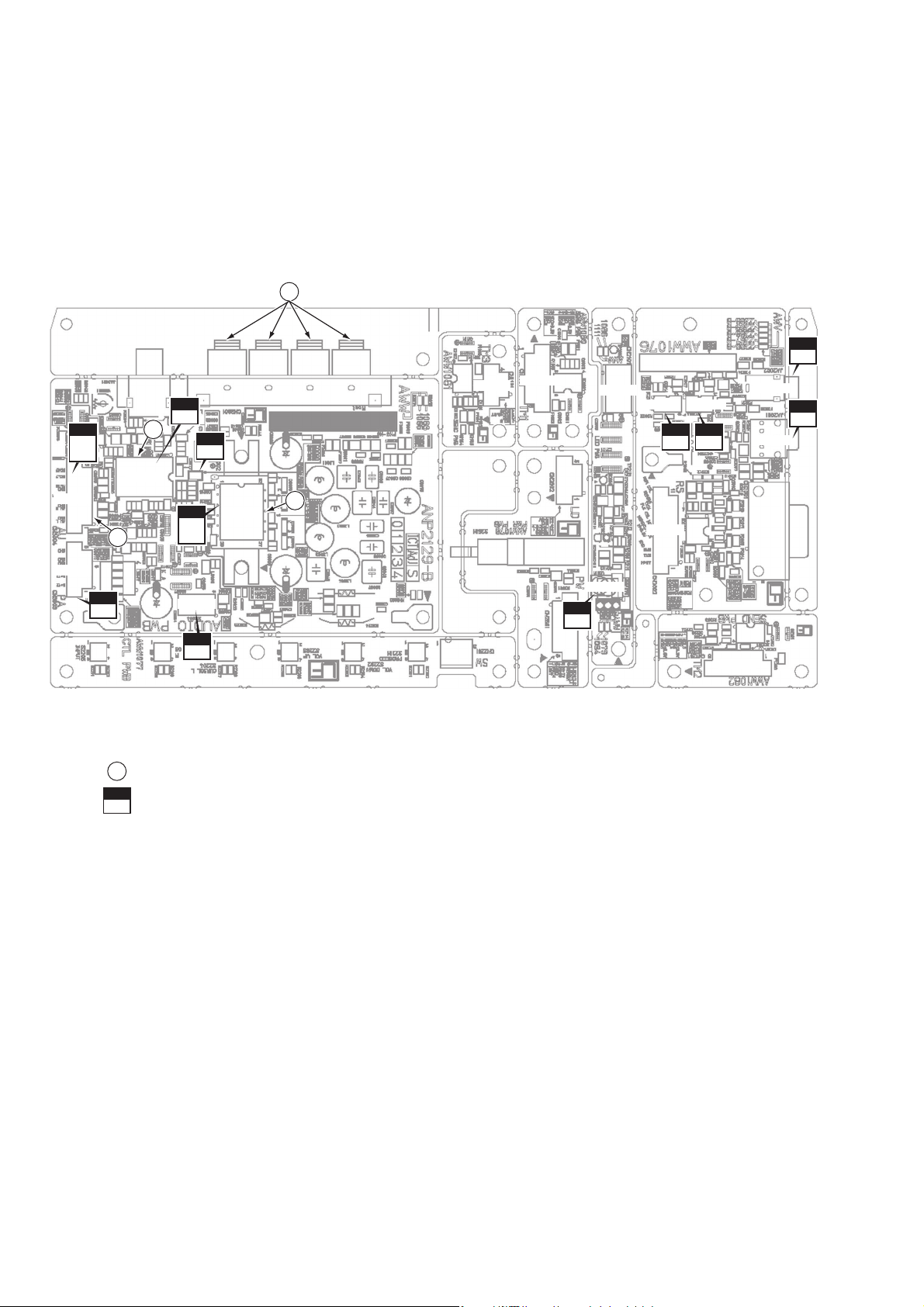

SUB ASSY

CN3004

T30

T33

IC3001

CN3004

44

CN3003

CN3003

T31

13

IC3001

T31

IC3002

T30

T31

IC3004

IC3004

T31

L3005

T31

IC3002

41

CN3001

12

CN1101

CN1001

U2102

T41

CN2101

U2102

IC2002 IC2004

IC2004

IC2002

T40

T40

CN2002

JA2002

T40

JA2002

JA2001

T41

JA2001

CN1201

• Legend symbol

45

: Waveform No. on Flowchart.

IC5002

: Broken circuit number on Flowchart, and number of Flowchart that broken parts are written.

T13

22

Page 15

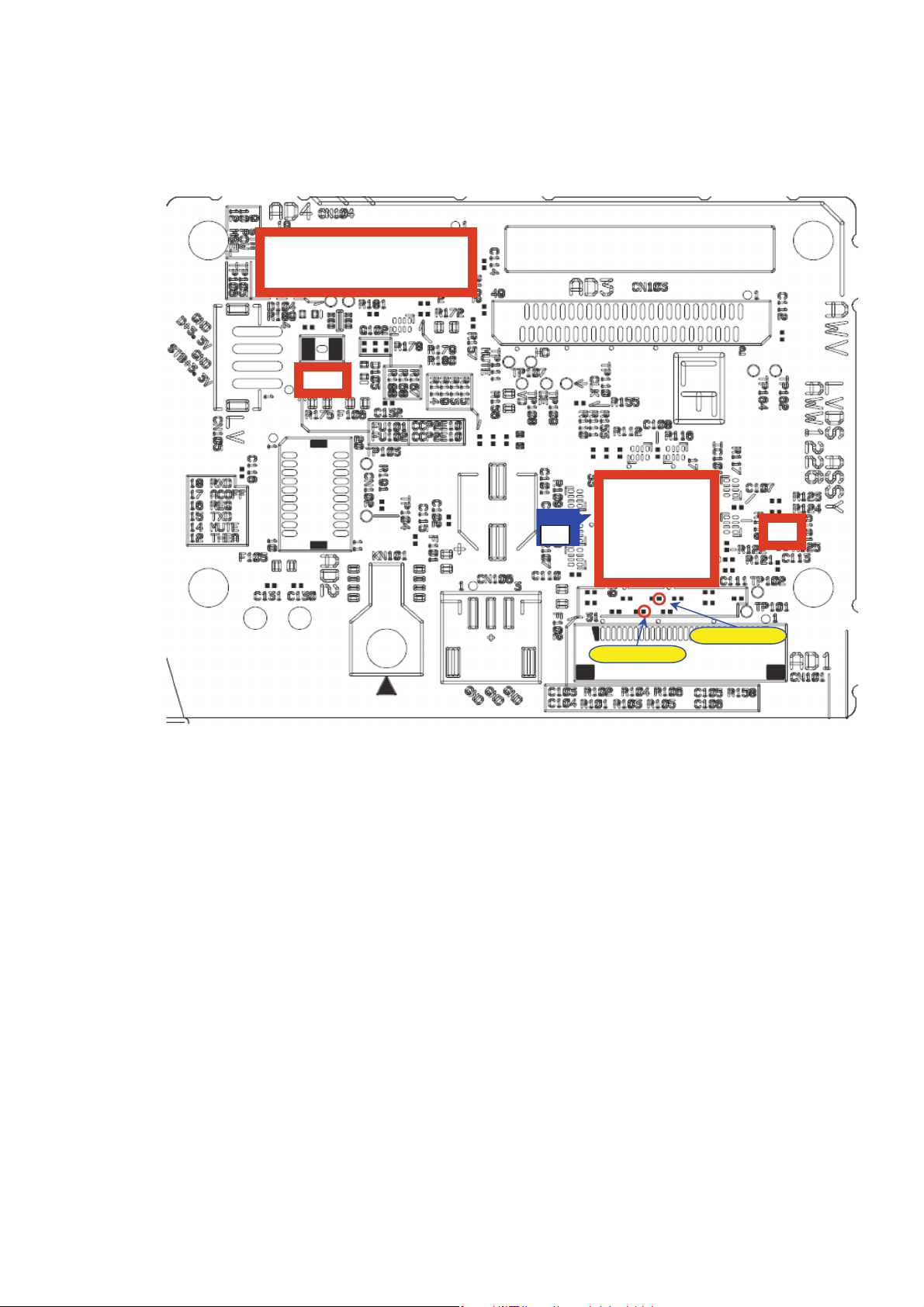

LVDS ASSY

CN104

FU102

IC101

T50

IC101

waveform50

Q101

waveform51

23

Page 16

DD ASSY

IC306

CN305

T61

D303

T63

IC302

T63

D312

T63

CN307

T62

C320

T62

IC303

T62

CN306

T63

T64

Q302

T62

D304

T62

CN302

T62

T64

Q303

T62

Q301

T61

FU301

T61

IC301

T61

CN304

T61

T64

C302

T61

D302

T61

T64

D306

T60

D301

T61

C327

T60

CN309

T60

C328

T60

C326, C337

T60

CN301

T60

T63

D307

T60

C334

T60

C335

T60

IC305

T60

FU302

T60

52

IC302 SW pin (#3)

(= D303 Cathode terminal)

• Legend symbol

52

: Waveform No. on Flowchart.

CN305

: Broken circuit number on Flowchart, and number of Flowchart that broken parts are written.

T61

54 53

Q303 Drain terminal

(#5 - #8)

55

Q301 Drain terminal

(#5 - #8)

IC305 (#11 - #14)

V OUT pin

24

Page 17

H

To LVDS ASSY

F

G

CN3001

To DD ASSY

B

LED

D2102

POLED2

POLED1,

A

C

E

D

CN2101

CN8501

OSD

CN3003

+12V

IC3004

12V to 9V

AUDIO ASSY

CN8502

+3.3V

IC8501

+3.3V

LVDS

Transmitter

U2102

Control

Remote

LED ASSY

S2601

PUSH SW

PWR ASSY

IC1201

SEND ASSY

IC1101

SENC ASSY

IC1001

SENB ASSY

REMIN1

Receiver

CN9008

+6V

REMIN1,

POLED1,

POLED2

POIN, SW7

+3.3V

SCL, SDA

+3.3V

SCL, SDA

+3.3V

SCL, SDA

CN1001 CN1201CN1101 CN2601 CN2602

+12V

+12V

SW7(power on)

LR-in

CN9009

LED-CTL1

(SDA, SCL)

Temp Sens or

CN9004 CN9005CN9003

D9003

Detect.

ALARM

IC9001

FAN Control

IC9505

u-COM

+7V

IC9503

X9501

CN9006

+7V

Power

7V to 3.3 V

+7V

SW7

IC9502

CN9007

7V to 5V

CN9012

+3.3V

+2.5V

+3.3V

LVDS

IC8502

Receiver

+3.3V

IC8105

DSP Controll

+3.3V

+9V

IC3001

IC8101~81 04

Audio

Controller

CN3004

CN9001

SDRAM

+9V

+12V

Audio

IC3002

Amplifier

DC detect

Mute

SCL,

SDL

Audio Control

(Mute, SCL, SDA, ALM)

L/R Audio Signal

ALM

CN7001

Receiver

RGB3

IC8001

Processor

Digital signal

+3.3V

+2.5V

IC8002

2.5V to 1.5V

+5V

IC7002

Audio DAC

+3.3V

HDMI

IC7001

Receiver

JA7001

JA7002

HDMI

DVD/HD3

DVD/HD4

+3.3V

IC8003

+9V

X8001

X8002

3.3V to 1.5V

+9V

SW

Audio

IC5302

IC7003

Audio amp

X7001

IC7004

3.3V to 1.8V

2RCA

2RCA

JA5005

HDMI

JA5006

AUDIO1

XR Model only

Digital V ideo signal , CLK, Sync

TMDS, LVDS

Digital A udio signal

Analog Audio signal

Power Supply

Analog Video signal

Control s ignal

Sync sig nal

2RCA

JA5007

AUDIO2

AUDIO3

+3.3V

CN2002

CN9011 CN9010 CN9501

REMIN1

+5V

TXD1

REMIN2

RXD0/TXD0

+3.3V

232C

IC2001

Receiver

Control

JA2001

CN2001

External

9p D-sub

232C ASSY

CN2201

CTL1

S2202

S2203

S2201

Tac t S W

Tact SW

CTL ASSY

Logic

IC2004

+5V

+5V

Logic

IC2002

IC2003

5V to 3.3 V

+3.3V

JA2002

Remote

Remote In

Tac t S W

Mini jack

Mini jack

CTL2

S2204

S2205

S2206

Tac t S W

Tac t S W

+6V

IC6204

IC6203

6V to 3.3 V

3.3V to 1 .5V

IC6201

Chroma Decoder

+3.3V

+9V

SW

IC5003

BNC

Tac t S W

JA5001

VIDEO1

MAIN ASSY

IC6202

SDRAM

Loop

IC5002

XM Model

only

X6201

XR Model

A/D

IC6501

Converter

LPF

LPF

IC5601

JA5003

SW

Video

3RCA

DVD/HD

+3.3V

+5V

IC5605

+3.3V

IC5004

5BNC

JA5004

Sync sep

IC5603

Buffer

RGB/DVD2

+5V

IC5602

IC5602

+5V

RCA+S

JA5002

VIDEO2

VIDEO3

VIDEO1, VIDEO2(S)

IC5604

/HD2

Sync SW

SW

+3.3V

XM

+5V

+3.3V

A/D

IC6701

Converter

Buffer

IC9504

+5V

+5V

LPF

IC5905

+5V

SW

Video

IC5901

IC5006

Model

only

Loop

RY5001

RY5002

CN5001

XR Model

PC/RGB

+3.3V

SW

IC5904

Buffer

IC5906

+5V

IC5903

Sync sep

+3.3V

IC5902

Sync SW

Buffer

+7V

15p D-sub

+7V

RGB1

DVI

IC7001

IC7006

7V to 5V

TMDS line

IC7006

7V to 5V

XM Model only

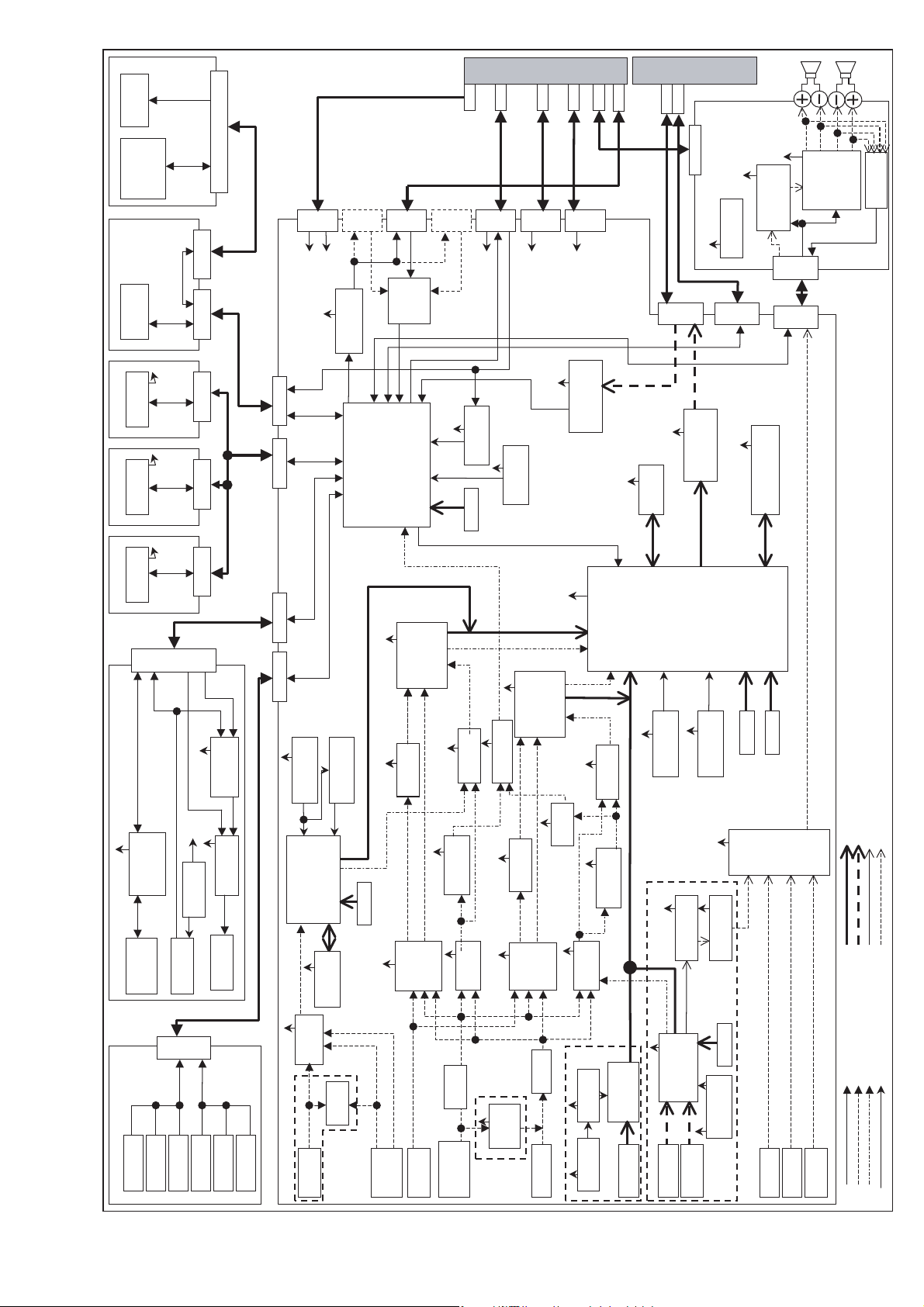

General Block Diagram (1/2)

XR Model : PD5001/PD6001

25

Page 18

LVDS

RECEIVERRECEIVER

DK BLOCKDK BLOCK

IC 1601

60 ADDRESS L

ASSY

AD1

AD2

HOT

60X DRIVE ASSY

X

MASK

MODULE

PLATE

IC1203

X

MASK

MODULE

IC1205

X

DK

MODULE

IC1103

X

DK

MODULE

IC1131

BLOCK

X RESET

60 ADDRESS L

ASSY

AD2AD1

LVDS

DK

BLOCK

RECEIVERRECEIVER

IC 1601

P7

P2

P4

P1 P7 P6P4 P2

LVDS

DK BLOCK

LVDS

DK BLOCK

LVDS

RECEIVER

RECEIVER

IC 1801

60 ADDRESS S

IC 1801

60 ADDRESS S

IC 1601

60 ADDRESS L

ASSY

ASSY

ASSY

+60VP7+60V

+16.5V

IC306

+12 to 7.8V

ALARM

Detect.

AC INLET

P3

CN312CN313

CN315

CN103

To LVDS ASSY

CN104

To LVDS ASSY

P6

P1

P1

Vsus

+6.5V

+16.5V

Power Supply Unit

+16.5V

P12

IC302

+16.5V to 1 2V

DD ASSY

+12V

P2

+16.5V

+12V

+6V

P4

Vsus

+12V

+12V

+6.5V

STB3.3V

EXT_PD

STB3.3V

VSUS_ADJ

M_SW_DET

+6.5V

+12V

+16.5V

+5.1V

P8

CN302(P8)

IC301

IC303

+5.1 to +3. 3V

STB3.3 to +7V

+7V

+3.3V

+2.7V

P6

DRF_B

RELAY

PS_PD

AC DET

PD_TRIG_B

P5

CN(301)CN304(P12)

IC305

+16.5 to + 12V

+12V

AD1

D9

AND

Ext_PD

SQ_SD

SDA

SCL,

DAC

STOP_SQ

SCAN

YSUS

Vofs_ADJ, VYPRST_ADJ

D10

PD

YSUS

&

OVER

Pulse

UNDER

&

OVER

XSUS

PD_MUTE

AND

OR

MASK

Width

YPR-U

DET

VOL

AD2

AD1

AD2

PANEL

SENSOR ASSY

TE1

D21

X3

+12V

Y6

VOLTAGE

CONVERTER

BLOCK

X2X5

DRF

AND

RELAY KDD

Vsus_ADJ

DC-DC

RELAY, PD_TRG_B, AC_DET

V+3V_D

SCL,

SDA

TEMP1

V+3V_EEP

D24

Y4Y5

BLOCK

VOLTAGE

CONVERTER

DRF_B

+12V

PS_PWDN

MODULE

AXY1137-

CONVERTER

V+1V_D

VH_UV_PD, YDRIVE_PD

YRESNC_PD,

YDD_CNV_PD

XSUSTN_PD, XDD_CNV_PD

XDRIVE_PD

IC5V_UV_PD

60Y DRIVE ASSY

VH

DCDC-CON

Y

MASK

MODULE

IC2301

Y

MASK

MODULE

IC2301

Y

MASK

MODULE

IC2302

Y

MASK

MODULE

IC2302

Y

DK

MODULE

IC2103

Y

DK

MODULE

IC2103

Y2

AD2 AD1

VH

SCAN

SCAN

607 SCAN B

ASSY

SCAN

IC2902

IC2901

SCAN

IC2903

CN2902

CN2903

(PSUS)

HOT

PLATE

SCAN

IC2904

SCAN

IC2905

SCAN

IC2906

CN2904

Y

Y

CN2905

UNDER

PD

DRF_B

ADR_PD1

OR

DK

DK

PSUS

VOL

DET

MODULE UCOM

ADR_PD5

MODULE

MODULE

VH

SCAN

SCAN

V+3V_D

XSUS

M30620FCPGP

OR

V+3V_D

IC2151

IC2151

IC2801

CN2802

IC3151

LOGIC

Y SUS MASK

Y SUS -B

BLOCK

Y RESET

Y

Reset

SCAN

IC2802

XSUS MASK

XSUS_U

LOGIC

D18

D17

BLOCK

Y SUS -G

BLOCK

XSUS_D

BLOCK

PHOTO

Y SUS -U

Y SUS -D

Y OFFSET

Y

SCAN

IC2803

XSUS_B

XSUS_G

PHOTO

V+3V_D

V+3V_D

COUPLER

Y PR-U

BLOCK

OFFSET

BLOCK

Y3

CN2801 CN2901

CN2803

XNR-D

COUPLER

X1

D19

&

SUB-FILD CONV.

PATTERN GEN.

XY DRV SEQUENCE

UART

SW

D16

Y1

Y OFS

SCAN CONTROL

PHOTO

COUPLER

SCAN

IC2804

CN2804

LVDS

PEG122C-K

LVDS

V+3V_D

Y8

SCAN

IC2805

IC3401

X6

V+3V_D

D8

H DET

HD

VD

FLASH MEMORY

IC3301

D5

PSUS

SCAN

IC2806

CN2805

AD2AD1

V+3V_D

V+3V_D

AD2AD1

AD2AD1

607 SCAN A

ASSY

BLOCK

DK

LVDS

60 ADDRESS S

ASSY

D7

HD, VD, DCLK, DE

RA, GA, BA

THEATER

LED_R

D6

DK BLOCK

RECEIVER

LVDS

60 ADDRESS S

ASSY

60 ADDRESS L

ASSY

DK BLOCK

RECEIVER

LVDS

IC 1801

60 DIGITAL ASSY

D11

UART

INP_MUTE

V+3VACT

LED_B

MSEL

YOBI

D12

V+3V_D

IC 1801

IC 1601

PDP Module

GF

(1/2)

To MAIN ASSY

CN101 CN102

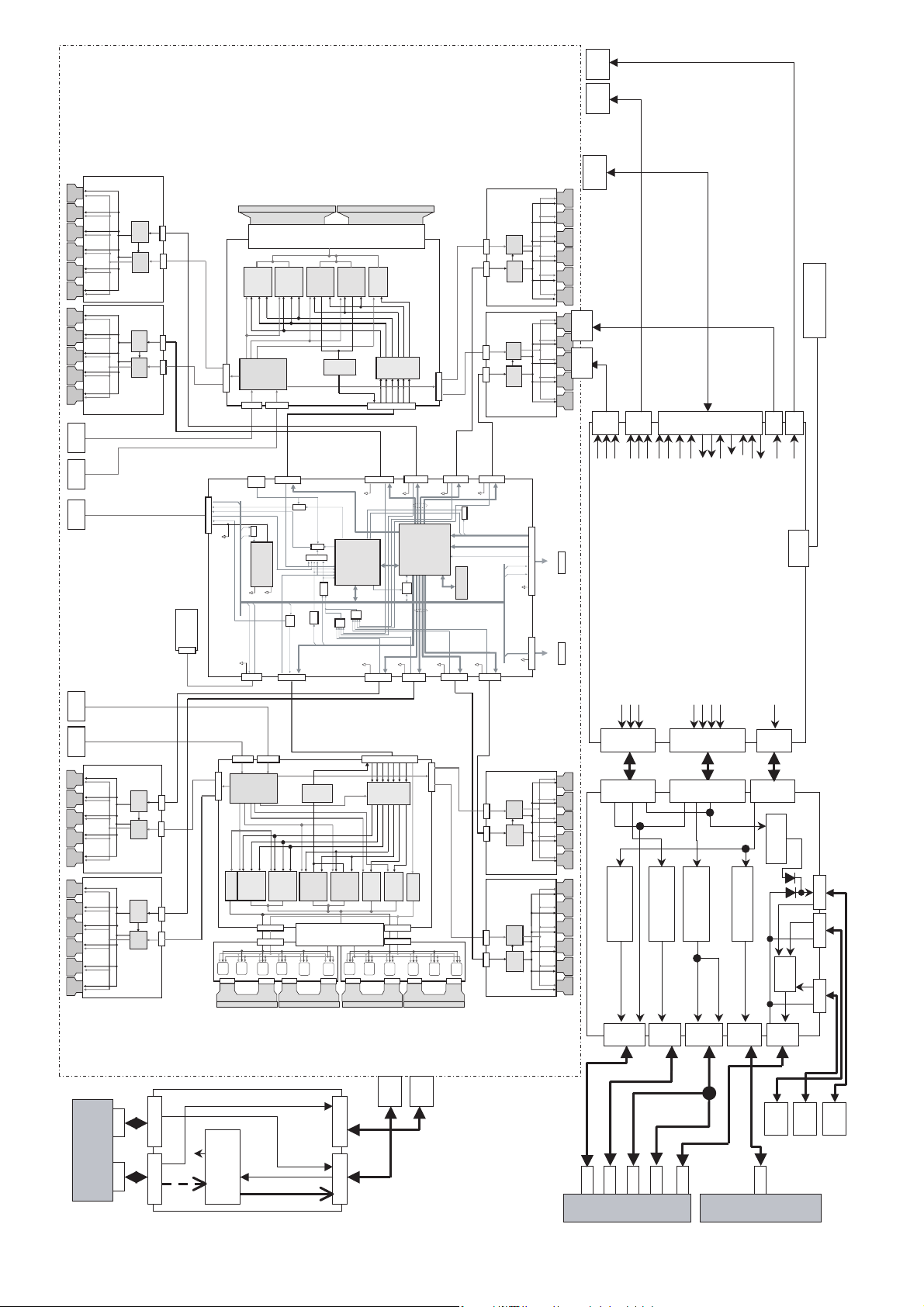

General Block Diagram (2/2)

CN305

CN306

D1

D2

+3.3V

LVDS

IC101

Receiver

LVDS ASSY

CN103 CN104

A

B

C

To MAIN ASSY (1/2)

CN307

D

H

To AUDIO ASSY (1/2)

CN309

CN311

FAN

E

(1)

(3)

(2)

FAN

FAN

26

Page 19

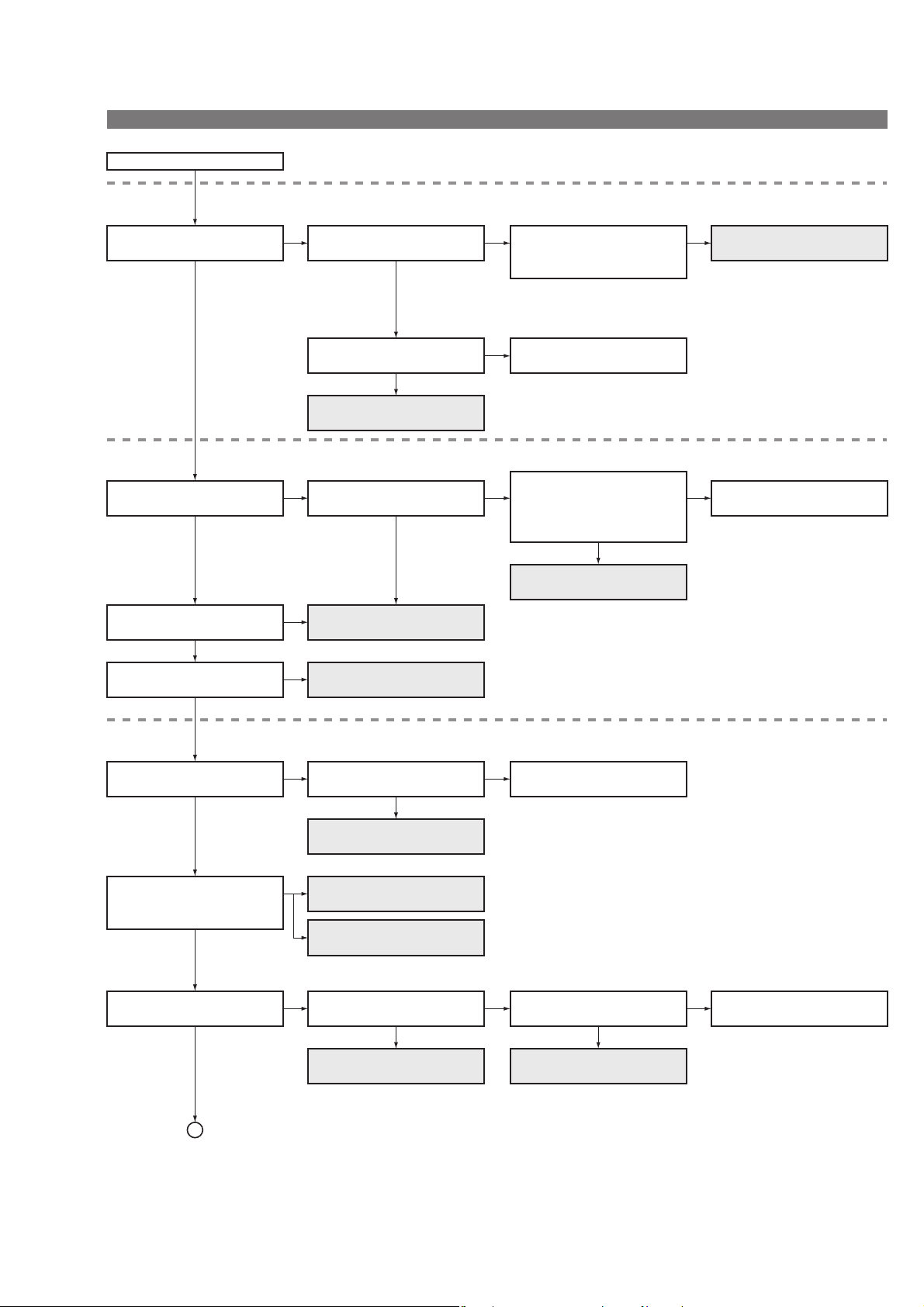

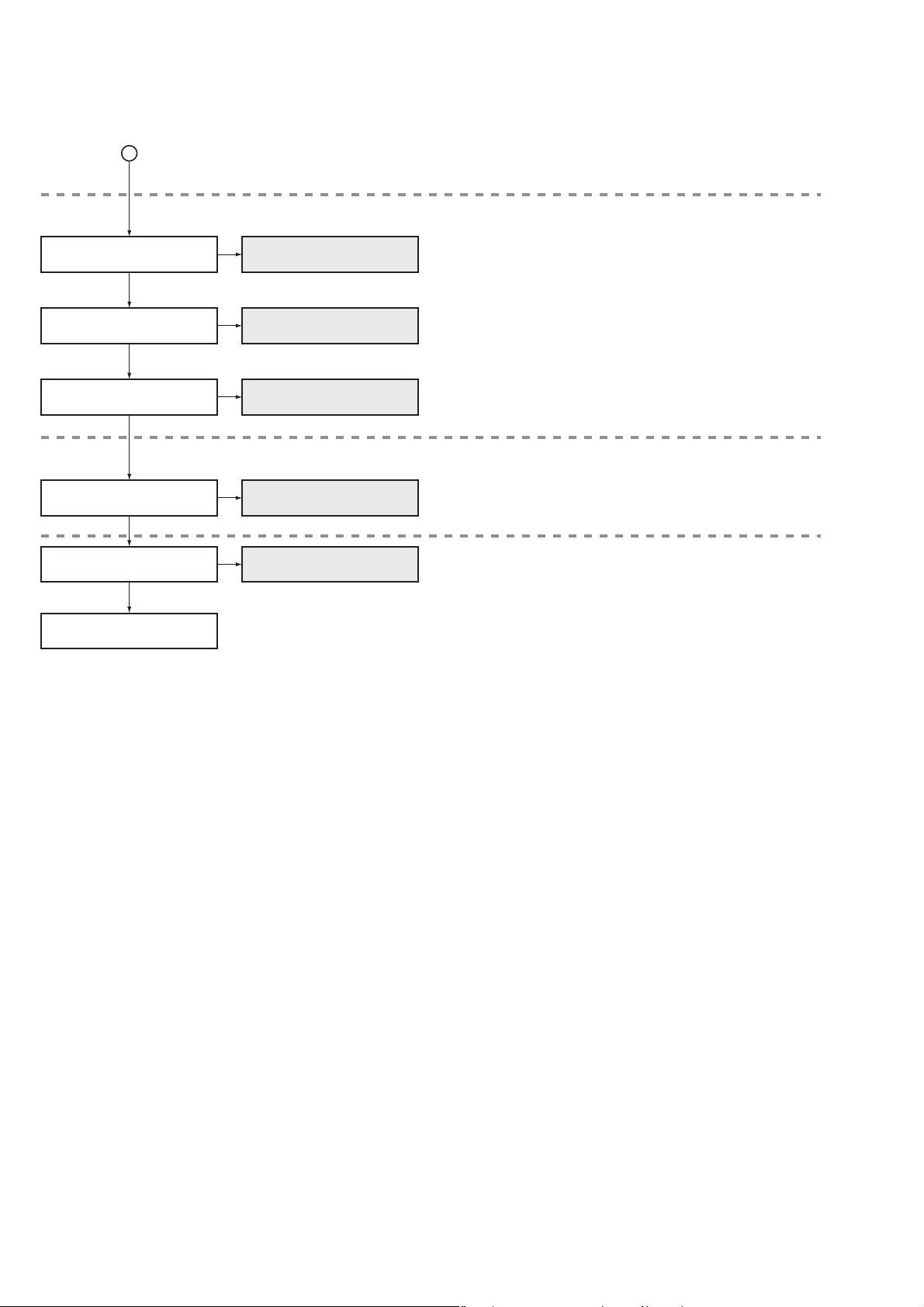

3.1.1 FLOWCHART OF FAILURE ANALYSIS FOR THE WHOLE UNIT

Flowchart of Failure Analysis for The Whole Unit

START

Problems concerning STB status

Is the STB LED lit?

Yes Yes

Problems concerning the power

Can the unit be turned on

(Relay ON)?

Yes

A shutdown occurs.

No

A power-down occurs.

No

Problems concerning lighting of the panel

No

Is STB 3.3 V power supplied?

Is the voltage at AC_DET on the

POWER SUPPLY Unit high?

Yes

Failure analysis for the

MAIN Assy. ⇒ ST1

No

Is the power shutdown?

Yes

Yes

See "Shutdown diagnosis." ⇒ SD

Yes

See "Power-down diagnosis." ⇒ PD

No

Check if the CN304 "P12" cable

that connects the POWER SUPPLY

and DD Assys is firmly connected.

No

Replace the POWER SUPPLY

Unit.

Is the voltage at the RELAY port

No

of the connectors between the

DIGITAL and POWER SUPPLY

Assys H (3.3 V)?

Yes

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS2

A power-down will not be generated if the drive is off.

NG

No

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS1

Replace the MAIN Assy.

Does the screen display reset

lighting?

Yes

Is the panel arbitrary turned on or

off repeatedly? Or do luminescent

spots appear on the screen?

No

Is there any local abnormality

on the screen?

No

A

No

Is the drive off?

Failure analysis for the

drive system ⇒ DR1

Yes

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS3

Failure analysis for the

drive system ⇒ DR2

Yes

Yes

Is the abnormality associated

with one address or one TCP?

Failure analysis for the

drive system ⇒ DR3

No

Yes

Yes

Turn the drive on.

In a case where luminescent spots appear

or the panel is repeatedly turned on or off

In a case where luminescent spots appear

No

Is the abnormality associated

with a single scan line?

Yes

Failure analysis for the

drive system ⇒ DR4

• Check the DRF SW.

• Before turning the drive off with the RS-232C

commands or using the remote control unit,

turn the unit off.

No

Replace the panel chassis.

27

Page 20

A

In the subsequent diagnostic steps, it is most likely that the multi base section is in failure.

Problems concerning video display

Is the panel mask properly

displayed?

Yes

Check with the animated slanting ramp mask. [MKC S03]

Is the on-screen display (OSD)

properly displayed?

Yes

Check on the Factory menu.

Is an external video signal

displayed properly?

Yes

Problems concerning the audio output

Is the audio signal output?

Yes

Do receive a key signal of

a remote control unit?

Yes

No

Failure analysis for the

drive system ⇒ DR2

No

Failure analysis for the

DIGITAL Assy ⇒ DG1

No

Failure analysis for the

MAIN Assy ⇒ MA1

No

Failure analysis for the

audio system ⇒ AU1

No

Failure analysis for the

remote receiver unit ⇒ RM

Specific failure whose cause is

difficult to identify in the initial stage

28

Page 21

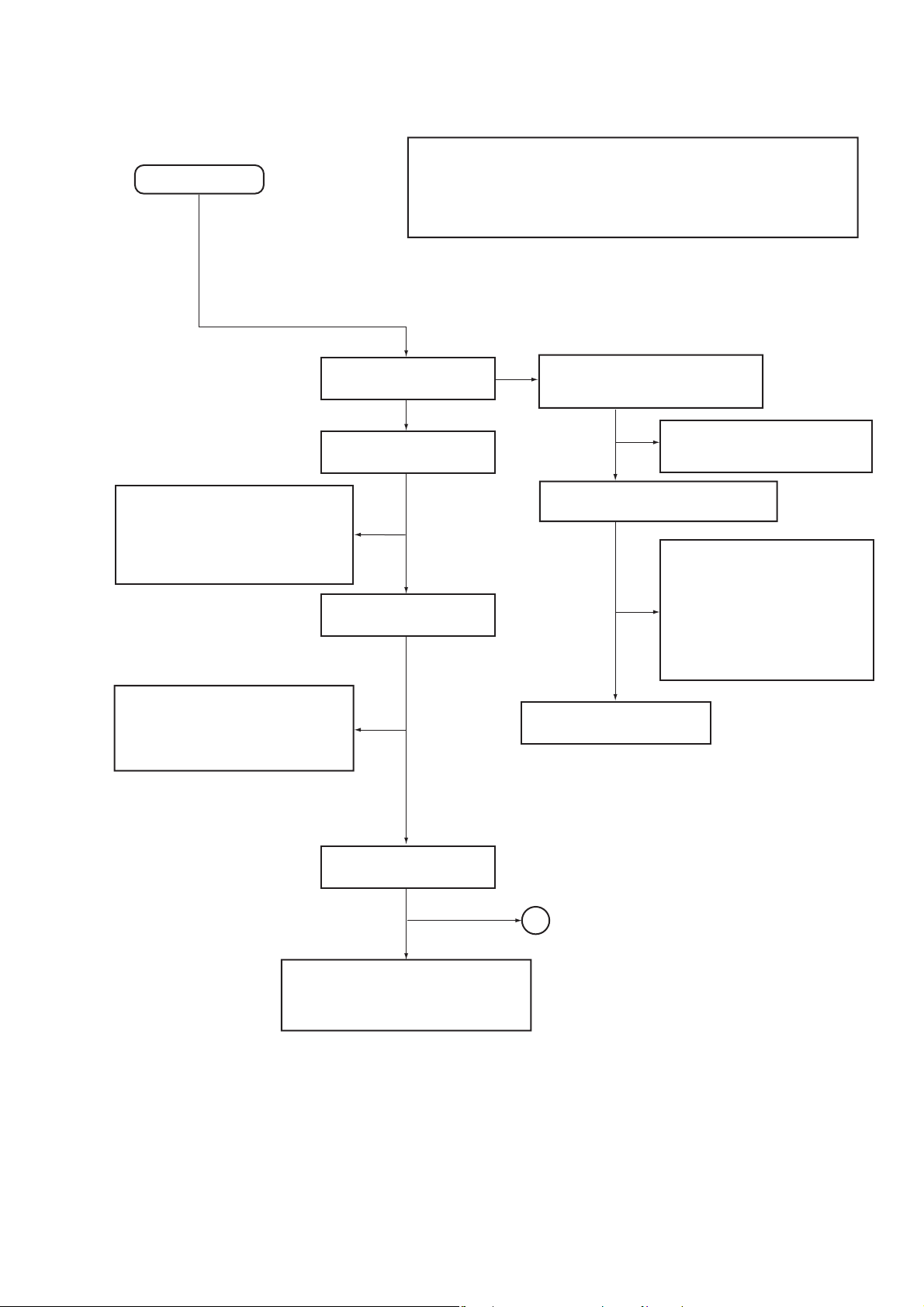

3.1.2 FLOWCHART OF FAILURE ANALYSIS FOR STANDBY STATUS

(1) No power

Note: When an abnormality is detected and indicated by LEDs' flashing or

lighting, all power-supply lines, except for the 7-V DC (M+7 V) and 5-V

ST1

Is 6.8 V DC output from Pin 1

of the CN9006 "PM" connector?

Is 6.8 V DC output from Pin 1

of the CN9009 "PW" connector?

DC (M+5 V) lines, will be automatically shut off after about 10 seconds.

When you are going to check the power-supply lines other than the 7-V

DC (M+7 V) and 5-V DC (M+5 V) lines, place a tester to a measurement

point beforehand then check the line.

NO

Turn the main power on with the cable to

the CN2602 "LD" connector disconnected.

YES

Check if 6.8 V DC is output.

Failure in the CN2602 "LD" connector or

YES

LED Assy (failure in the M5V line at

NO

Pin 5 of the CN2602 "LD" connector)

Failure in the CN9009 "PW" connector or

PWR Assy (failure in S2601 when 6.8 V DC is

applied to the terminal connected to Pin 5 of

the CN9009 "PW" connector but when 6.8 V

DC is not output from the terminal connected

to Pin 1 of the CN9009 "PW" connector)

Is 6.8 V DC output from Pin 6

of the CN9006 "PM" connector?

Failure in the CN9006 "PM" connector or

MAIN Assy (failure in the printed wiring of

board patterns between Pin 1 of the CN9009

"PW" connector and Pin 6 of the CN9006

"PM" connector).

Is 5 V DC output from Pin 4

of the CN9009 "PW" connector?

NO

NO

YES

YES

YES

NO

Disconnect the CN9009 "PW" connector.

Check if 6.8 V DC is output.

Failure in the CN9009 "PW" connector or

PWR Assy (failure in the M5V line at

Pin 5 of the CN2602 "LD" connector,the

SW7 line at Pin 1 of the CN9009 "PW"

YES

connector, the POIN line at Pin 2 of the

CN9009 "PW" connector, the 5-V line at

Pin 4 of the CN9009 "PW" connector or

the M7V line at Pin 5 of the CN9009

NO

Failure in the DD Assy.

(See section T61.)

"PW" connector)

B

Failure in the LED Assy (failure in D2101 or the

CN2602 "LD" connector) or in the MAIN Assy

(failure in the line for the CN9009 "PW"

connector or CN2602 "LD" connector)

29

Page 22

B

Turn the main power on with the cable to

the CN2602 "LD" connector disconnected.

Check if 5 V DC is output.

YES

NO

Turn the main power on with the cable to

the CN9010 "RS" connector disconnected.

Check if 5 V DC is output.

YES

NO

Is 5 V DC output from Pin 5

of IC9502?

YES

Is 3.3 V DC output from Pin 4

of IC9503?

NO (1)

NO (2)

YES

NO

Failure in the CN2602 "LD" connector or LED Assy

(failure in the M5V line at Pin 5 of the CN2602 "LD"

connector)

Failure in the CN9010 "RS" connector or 232C Assy

(failure in the M5V line at Pin 1 of the RS connector)

NO

Is 6.8 V DC input to Pin 1 of IC9502.

YES

Failure in the MAIN Assy.

(failure in IC9502)

Is 6.8 V DC input to Pin 2 of IC9503.

YES

Failure in the MAIN Assy.

(failure in IC9503)

Failure in the MAIN Assy.

(failure in the printed wiring

of board patterns between

Pin 1 of CN9006 "PM" and

pin 1 of IC9502)

NO

Failure in the MAIN Assy.

(failure in the printed wiring

of board patterns between

Pin 2 of IC9503)

Is 0 V DC output from Pin 14

of CN8502 "AD2"?

YES

Failure in the MAIN ASSY (failure in IC9501 or X9501)

Note: If IC9501 is in failure, replace the whole board.

Failure in MAIN Assy

CN2601 "PW" or CN2002 "RS" conector area

NO (4.7V)

Failure in the CN8502 "AD2" connector or MAIN

Assy (failure in IC9501 or X9501)

Note: If IC9501 is in failure, replace the MAIN Assy.

Note :

To check the power supply to the MAIN Assy and AUDIO Assy, follow the procedures described in "DD ASSY

Troubleshooting Chart" (T60 to T64).

For details on statuses of the unit and voltages of each block, see "7.2 CONNECTION PIN EXPLANATION."

30

Page 23

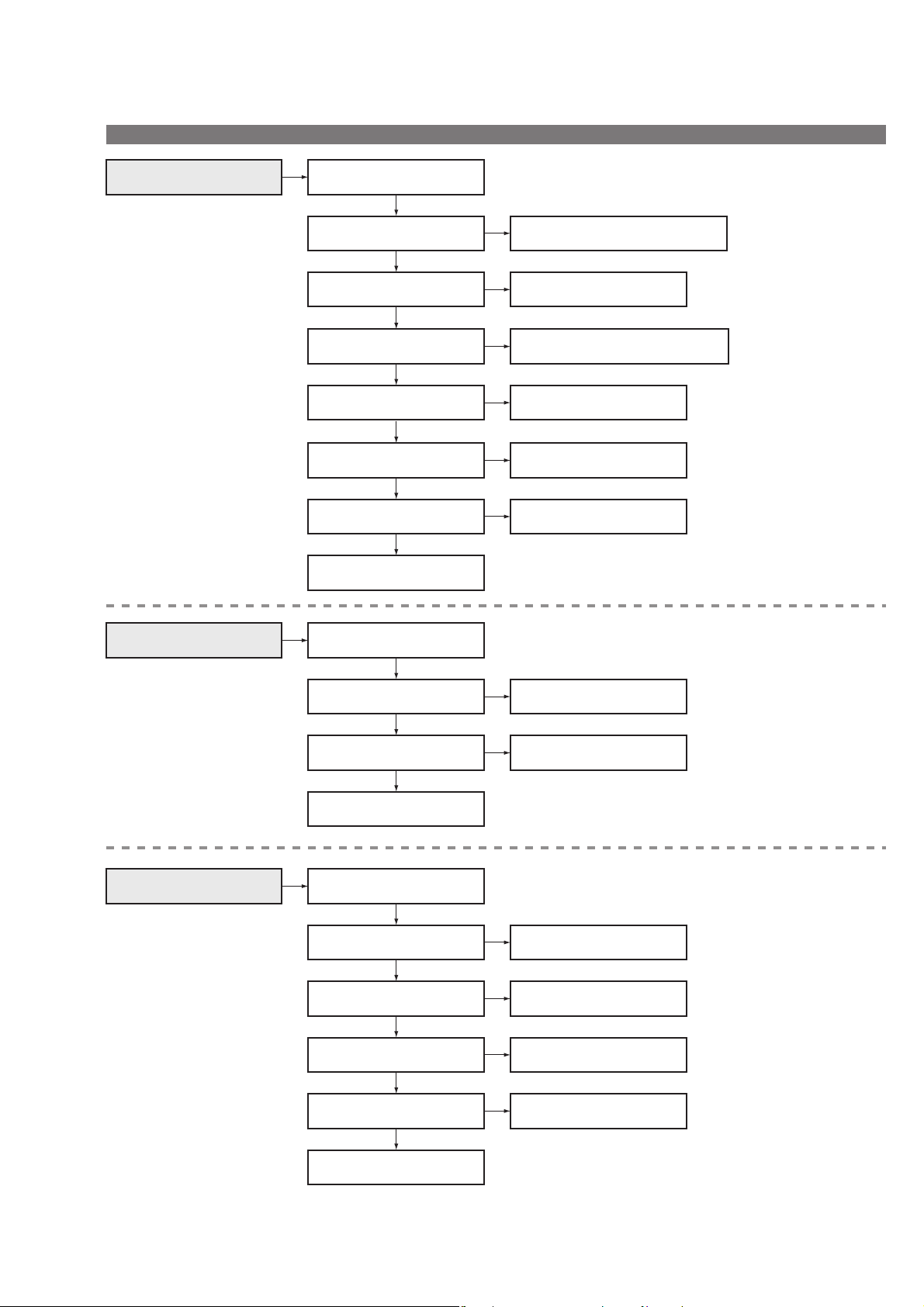

3.1.3 FLOWCHART OF FAILURE ANALYSIS FOR THE POWER SUPPLY UNIT

Flowchart of Failure Analysis for The POWER SUPPLY Unit

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS1

STB 3.3 V power is not output.

Is the cable connected firmly to

the P4 connector?

Yes

Is the cable to the P4 connector

broken?

No

Is the cable connected firmly to

the P12 connector?

Yes

Is the cable to the P12 connector

broken?

No

Is the fuse (F101, F102) blown?

No

Is one of the limiting resistors

(R101/R102) blown?

No

The POWER SUPPLY Unit is

normal.

No

Properly connect the cable between the P4 and

CN3601 "D21" of DIGITAL Assy connectors.

Yes

Replace the defective cable .

No

Properly connect the cable between the P12 and

CN304 "P12" of DD Assy connectors.

Yes

Replace the defective cable.

Yes

Replace the POWER SUPPLY

Unit.

Yes

Replace the POWER SUPPLY

Unit.

Check the voltage at the DIGITAL Assy and

POWER SUPPLY Unit.

Check the voltage at the DD Assy and

POWER SUPPLY Unit.

Check the resistance between F101

and the JW199, using a tester.

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS2

Failure analysis for the

POWER SUPPLY Unit. ⇒ PS3

The power is not on, even though

the RELAY port is active.

Is the relay (RY102) on?

Yes

Is the PFC voltage normal?

Yes

The POWER SUPPLY Unit is

normal.

The cells of the panel do not

light normally.

Is the VADR voltage within the

specified values?

Yes

Is there a fluctuation in the

VADR voltage?

No

Is the VSUS voltage within the

specified range?

Yes

Is there a fluctuation in the

VSUS voltage?

No

The POWER SUPPLY Unit is

normal.

No

Replace the POWER SUPPLY

Unit.

No

Replace the POWER SUPPLY

Unit.

No

Replace the POWER SUPPLY

Unit.

Yes

Replace the POWER SUPPLY

Unit.

No

Replace the POWER SUPPLY

Unit.

Yes

Replace the POWER SUPPLY

Unit.

• Check the relay operation at the terminal

(Pin 11 of P4). (Voltage: 3.3 V)

• Check the relay sound (click).

• Check the voltage between the JW140 (PFC

OUT) and JW180 (Hot_GND) terminal.

• The voltage must be around 390 V

(failure if it is 340 V or less).

Caution: High voltage!

The specified voltage values are between

57 and 63 V.

The ripple must be within 6 V.

The specified voltage values are between

200 and 210 V (VSU: 125/35°C).

The ripple must be within 10 V.

31

Page 24

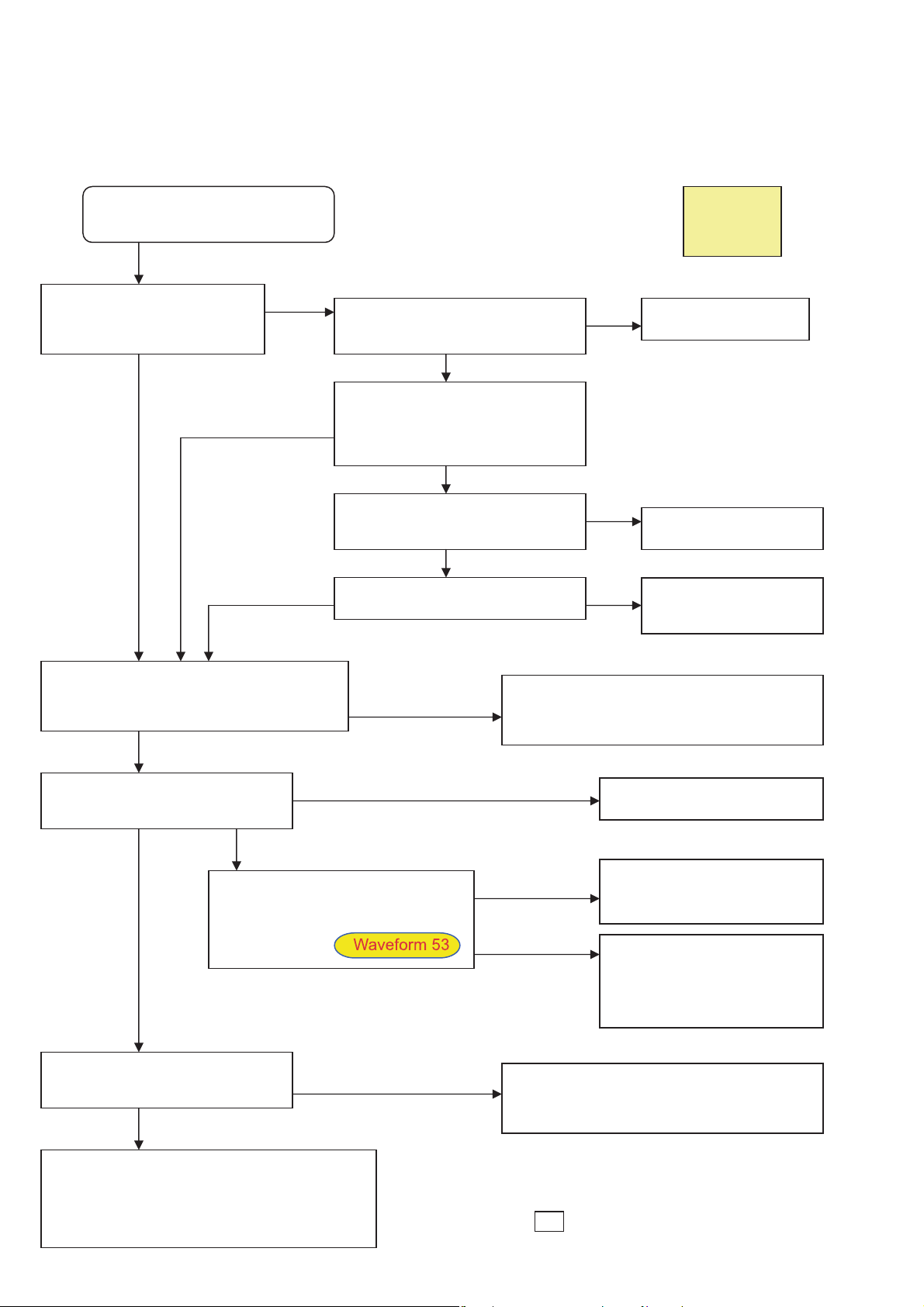

3.1.4 FLOWCHART OF FAILURE ANALYSIS FOR THE DD ASSY

DD ASSY (ANP2173) Trouble Shooting Chart

(1) Trouble Shooting of the "S+12V" output abnormal operation.

Check of S+12V power supply line

Is the S+12V output of CN309

"PA" (#1-3) normally 12.0 V?

Please check the voltage.

YES

NO

NO

NO

Please check the loose contact about

CN309 "PA" connector wire.

Is this contact OK?

YES

After remove the CN309 "PA" connector

wire, please check the S+12V output

line is shorten or not by using the D.M.M.

Is this line shorten?

YES

Please check the C334 and C335

electrolytic capacitors shorten.

Are these capacitors OK?

YES

Is normal voltage output after CN309

"PA" is disconnected?

NO

NO

YES

T60

Please replace the

connector wire.

Please replace these

capacitors.

See "Abnormal in Audio

Trouble shooting".

Is the VCC16.5V input of CN301 "P5" (#1)

normally between 15.7 V and 17.3 V?

Please check this voltage.

Check the S+12V output (CN309 #1 - #3 "PA").

NO

Please check the loose contact about

CN301 "P5" connector wire.

Is this contact OK?

NO

YESYES

Please check the waveform of IC305

#11 - #14 (MD3222N) control IC.

Can you see the same waveform?

Please check the FU302 protector

opened.

Is this protector opened?

NO

YES

YES

In this case, the S+12V P.S. is normally operating.

Please check the AUDIO Assy, speaker units,

speaker cord and audio signal source input.

Please replace the connector wire.

YES

NO

In this case, the S+12V P.S. is normally operating.

Please check the AUDIO Assy, speaker units,

speaker cord and audio signal source input.

In this case, it's possibility of the

AC-DC P.S. unit out of order.

Please replace of the unit.

Please replace IC305 or D306 or

D307.

In this case, any of S+12V power

supply control IC305 or D306 or

D307 or C334 is broken.

Please replace IC305 or C326 or C327 or C328 or

C337.

In this case, S+12V power supply control IC305 or

any of C326, C327, C328, C337 capacitors of the

VCC16.5V input line is broken.

32

• Legend symbol

: This symbol is for directing the broken

T10

parts on "Diagnosis Points of PCB Assy".

Page 25

(2) Trouble Shooting of the "M+7V" output abnormal operation.

Check of M+7V power supply line

Can you hear the power

relay operation sound?

NO

YES

YES

Is the M+7V output of CN305 #1

"PM" normally about 7 V?

Please check the voltage.

NO

YES

NO

YES

Is the STB3.3V input of CN301

"P12" (5-7) normally 3.3 V ?

Please check the voltage.

YES

NO

Please check the loose contact about CN301

"P12" connector wire.

Is this contact OK?

YES

YES

Is this connector wire contact OK?

After remove the CN305 "PM" connector

wire, please check the M+7V output line is

shorten or not by using the D.M.M.

Is this line shorten?

YES

Please check the C302 electrolytic

capacitor and D302 TVS. shorten.

Are these parts OK?

In this case, the M+7V DD Assy part

is normally operating.

Check the MAIN Assy board.

NO

Please replace the connector wire.

NO

NO

T61

Please replace the connector

wire.

Please replace these

capacitor.

Check the Q301 FET (micro PA1725G)

drain terminal (#5 - #8) waveform.

Can you see the same waveform?

Check the Q301 FET (uPA1725G)

gate terminal (#4) waveform.

(3.3 V rectangular pulse)

Can you see the waveform?

Please check the FU301 protector opened.

Is this protector opened?

NO

In this case, it's possibility of the AC-DC

P.S. unit out of order.

Please replace of the unit.

NO

YES

33

YES

NO

YES

In this case, the M+7V DD Assy part

is normally operating.

Check the MAIN Assy board.

In this case, IC301 is broken.

Please replace of this IC.

Please replace Q301 FET, IC301

(LM3478MMX), D301.

In this case, any of IC301 (M+7V

power supply control IC) or Q301 or

D301 is fault.

In this case, Q301 FET is broken.

Please replace Q301 and FU301.

• Legend symbol

: This symbol is for directing the broken

T10

parts on "Diagnosis Points of PCB Assy".

Page 26

(3) Trouble Shooting of the "D+3.3V" output abnormal operation.

Check of D+3.3 power supply line

In this case, the D+3.3 V output is fallen

down. The low voltage alarm on the

MAIN Assy is functioned.

60 inch models

50 inch models

Is the D+3.3V output of CN307 "PN"

(#1-#3) normally 3.3 V?

Please check the voltage.

NO

Is the D+3.3 V output of CN307 "PN"

(#1-#3) normaly 3.3 V?

Please check the voltage.

NO

Is the VCC+3.3V input of CN302

"P8" (#7-#10) normaly 3.3 V?

NO

Failure in the POWER SUPPLY Unit or

loose contact of CN302 "P8" connector

Please check the loose contact

about CN307 "PN", connector wire.

Is this contact OK?

YES

After remove the PN connector wire,

please check the D+3.3V output line

is shorten or not by using the D.M.M.

Is this line shorten?

T62

YES

Failure in the MAIN Assy

YES

Failure in the DD Assy

NO

Please replace the connector

wire.

Please replace C320.

YES

In this case, C320 electrolytic

capacitor is shorten.

YES

Is the VCC5.1V input of CN302 "P8"

(#7-#10) normally between 4.85 V and

5.36 V?

Please check this voltage.

NO

YES

Check the waveform of Q303 FET

drain terminal (#5-#8).

Can you see the same waveform?

NO

Check the Q302 FET (TPC8021-H)

gate terminal (#4) waveform.

(About 8 -10V0-p rectangular pulse)

Can you see the same waveform?

• Legend symbol

: This symbol is for directing the broken

T10

parts on "Diagnosis Points of PCB Assy".

NO

Please check the loose contact about

CN302 "P8" connector wire.

Is this contact OK?

YES

In this case, the MAIN ASSY side is

YES

NO

YES

34

abnormal.

See the LED indicators about trouble

shooting chart or trouble shooting chart

of "Abnormally in image".

In this case, any of the IC303 or FET

Q302 or D304 (bootstrap diode) is

broken.

Please replace IC303 or FET Q302 or

D304.

In this case, any of the IC303 or FET

Q302 or D304 (bootstrap diode) is

broken.

NO

In this case, it's possibility of the

AC-DC P.S. unit out of order.

Please replace of the unit.

Please replace the

connector wire.

Page 27

(4) Trouble Shooting of the "A+12V" output abnormal operation.

This voltage Line is supplied for analog circuit and the fan motors VCC voltage through the variable voltage regulator

on the MAIN ASSY.

The output voltage of the variable voltage regulator is DC 11.6 V or DC 8.8 V or DC 6.0 V.

And, no operation fan motors by acting fan alarm signal is not mentioned on this item.

Check of A+12V power supply line

At first, please check the A+12V output

CN306 "PV" (#1).

Please check the voltage is about

12.2 V.

YES

Is the VCC16.5V input of CN301 "P5"

(#1) normally between 15.7 V and

17.3 V?

Please check this voltage.

YES

NO

Please check the waveform of

IC302 (A+12V control IC;

MPS2367DN) #3 pin.

Can you see the same waveform?

Please check the loose contact

NO

about CN306 "PV", connector wire.

Is this contact OK?

YES

After remove the PV connector wire,

please check the A+12V output line is

shorten or not by using the D.M.M.

Is this line shorten?

YES

Please check the loose contact about

CN301 "P5" connector wire.

Is this contact OK?

NO

T63

NO

Please replace the connector

wire.

Please replace C311, C312

NO

capacitors and D303

(flywheel Diode) shorten.

Please replace the

NO

connector wire.

In this case, it's possibility

YES

of the AC-DC MAIN

POWER unit out of order.

Please replace of the unit.

Please replace IC302 or D312.

In this case, any of IC302

(A+12V control IC; MPS2367DN)

or D312 is broken.

(5) Trouble Shooting of the "A+6.5V" output abnormal operation.

This voltage Line is supplied to MAIN ASSY from MAIN POWER unit via DD ASSY.

Please check board to board connection first if A+6.5V is abnormal.

e.g.) pin contact of connector, short between wire

From MAIN POWER unit

P12 CN304 (#1)

From MAIN POWER unit

P8 CN302 (#1)

To MAIN ASSY

"PV" CN306 (#3, #4)

DD ASSY

35

YES

In this case,the A+12V output of

the MAIN ASSY side is abnormal.

T64

• Legend symbol

: This symbol is for directing the broken

T10

parts on "Diagnosis Points of PCB Assy".

Page 28

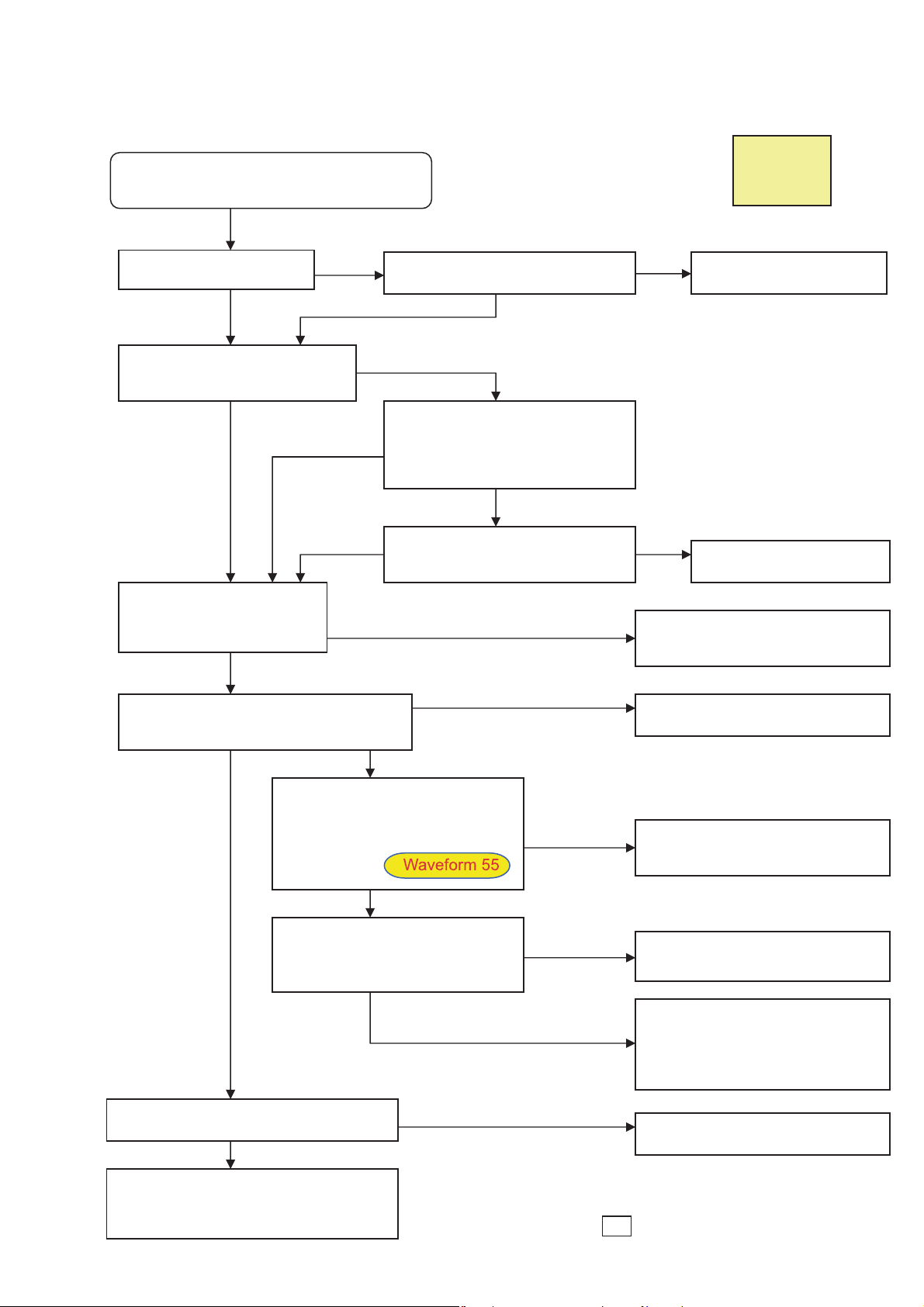

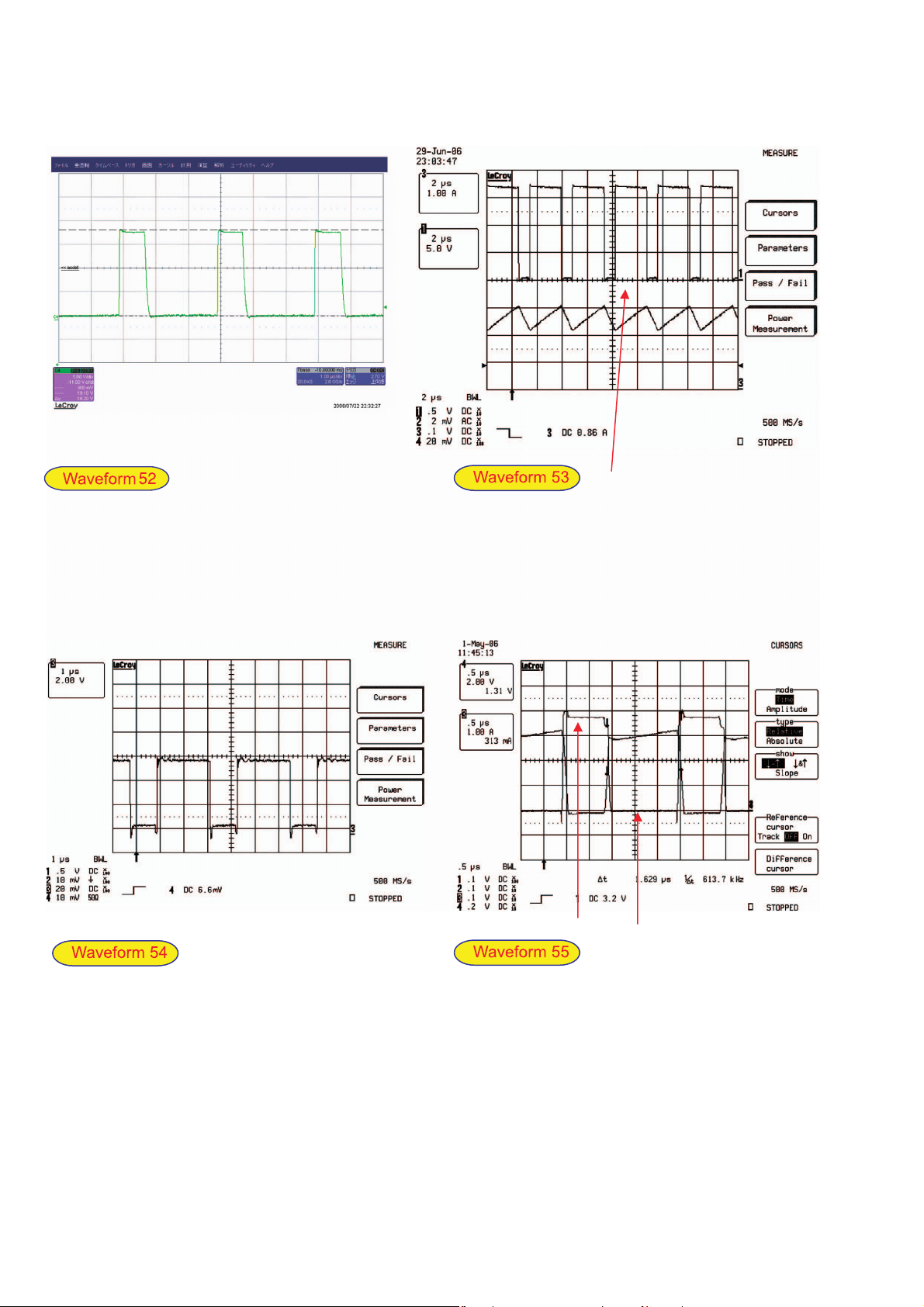

DD ASSY (ANP2173) Waveform (Each 4 Switching Regulators)

A+12V POWER SUPPLY

IC302 #3 voltage waveform.

5 V/div., 1 μs/div.

Normal: 18.2 V0-p, T= 2.95 μs

S+12V POWER SUPPLY

Upper side waveform

IC305 #11-#14 voltage waveform.

5 V/div., 2 μs/div.

Normal: 17.5V0-p, T= 3.3 μs

D+3.3V POWER SUPPLY

Q303 FET Drain terminal (#5-#8)

voltage waveform.

2 V/div., 1 μs/div.

Normal: 6.0 V0-p, T= 3.3 μs

M+7V POWER SUPPLY

Q301 FET Drain terminal (#5-#8)

voltage waveform.

2 V/div., 0.5 μs/div.

Normal: 8.0 V0-p, T= 2.6 μs

36

Page 29

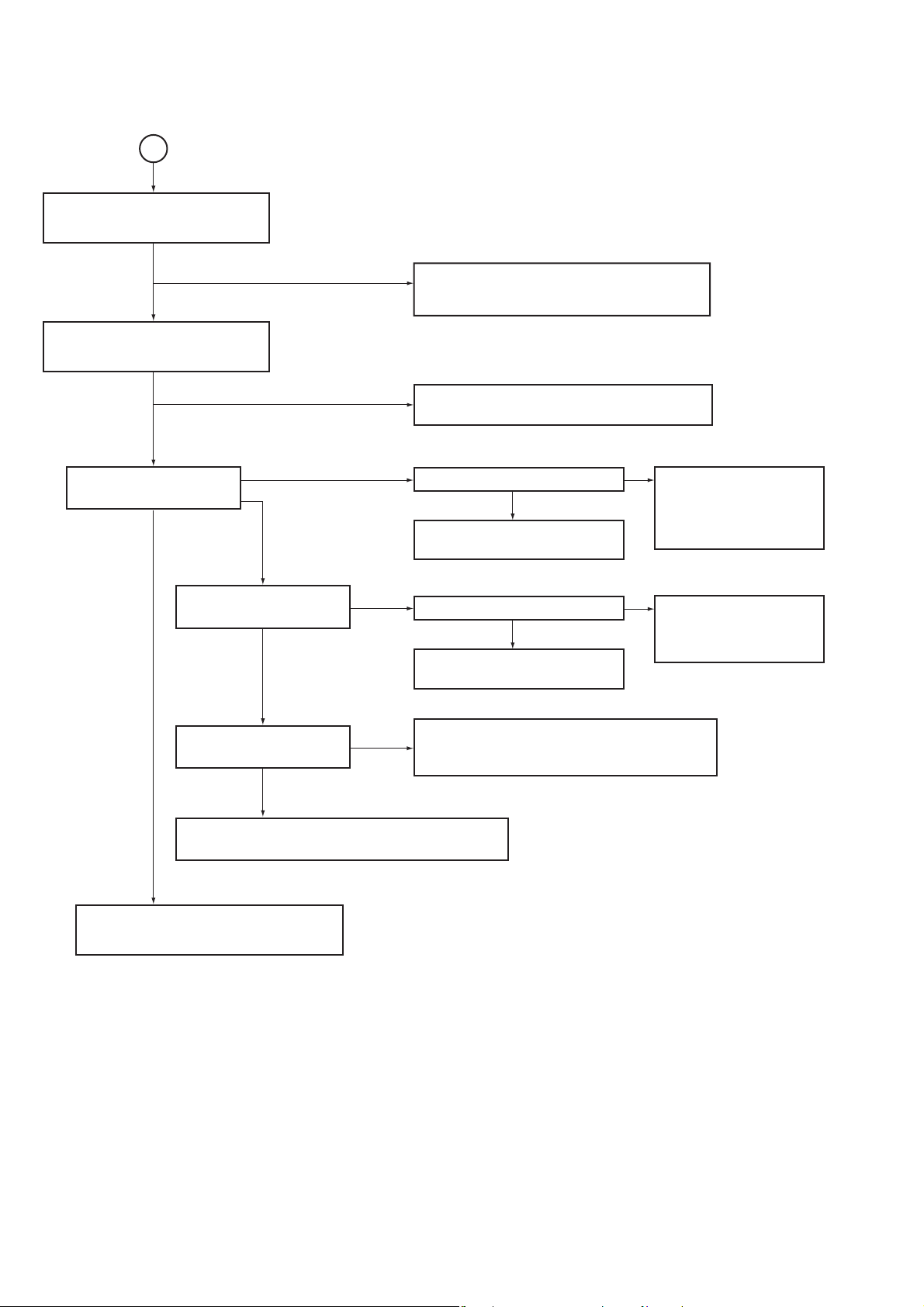

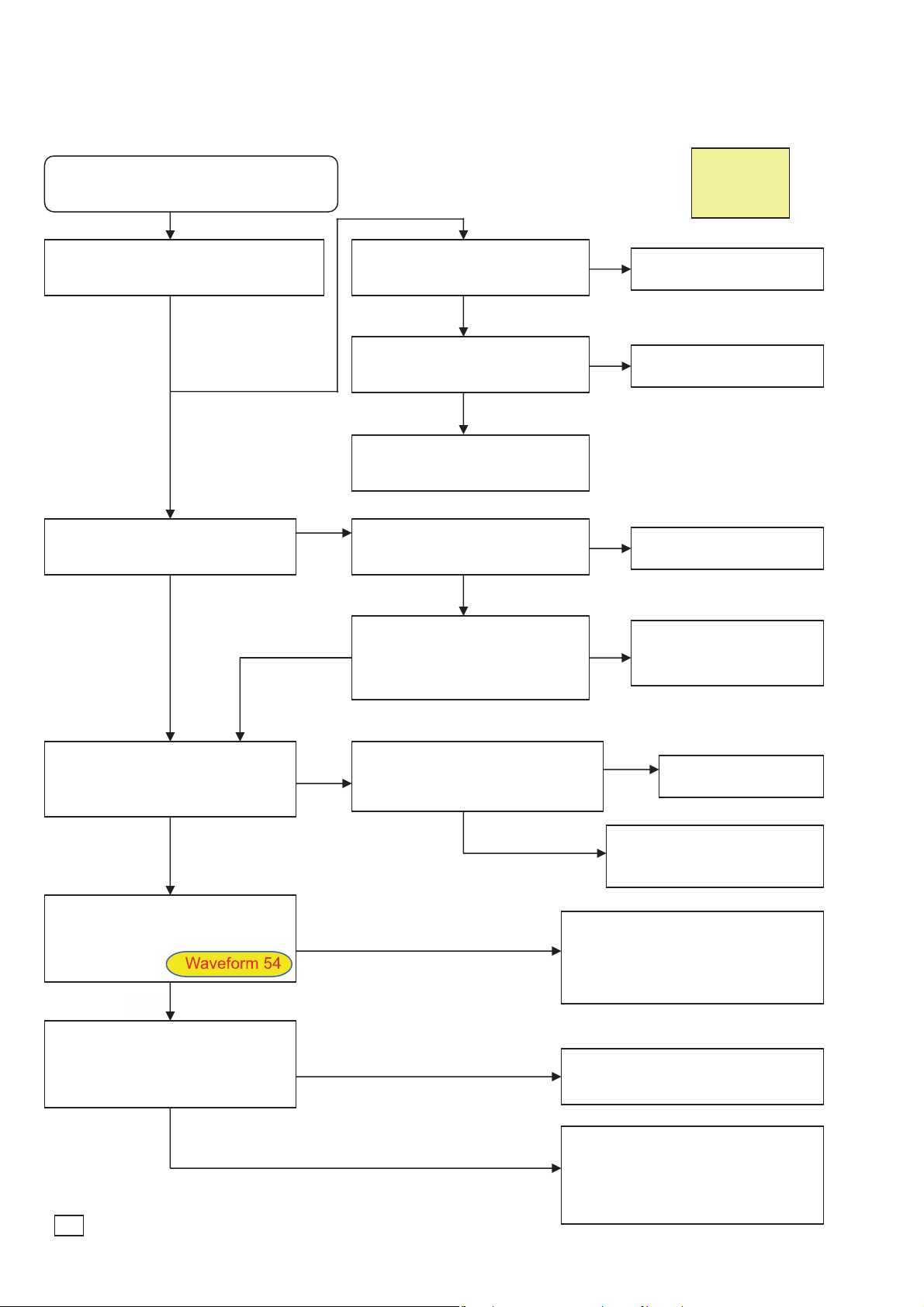

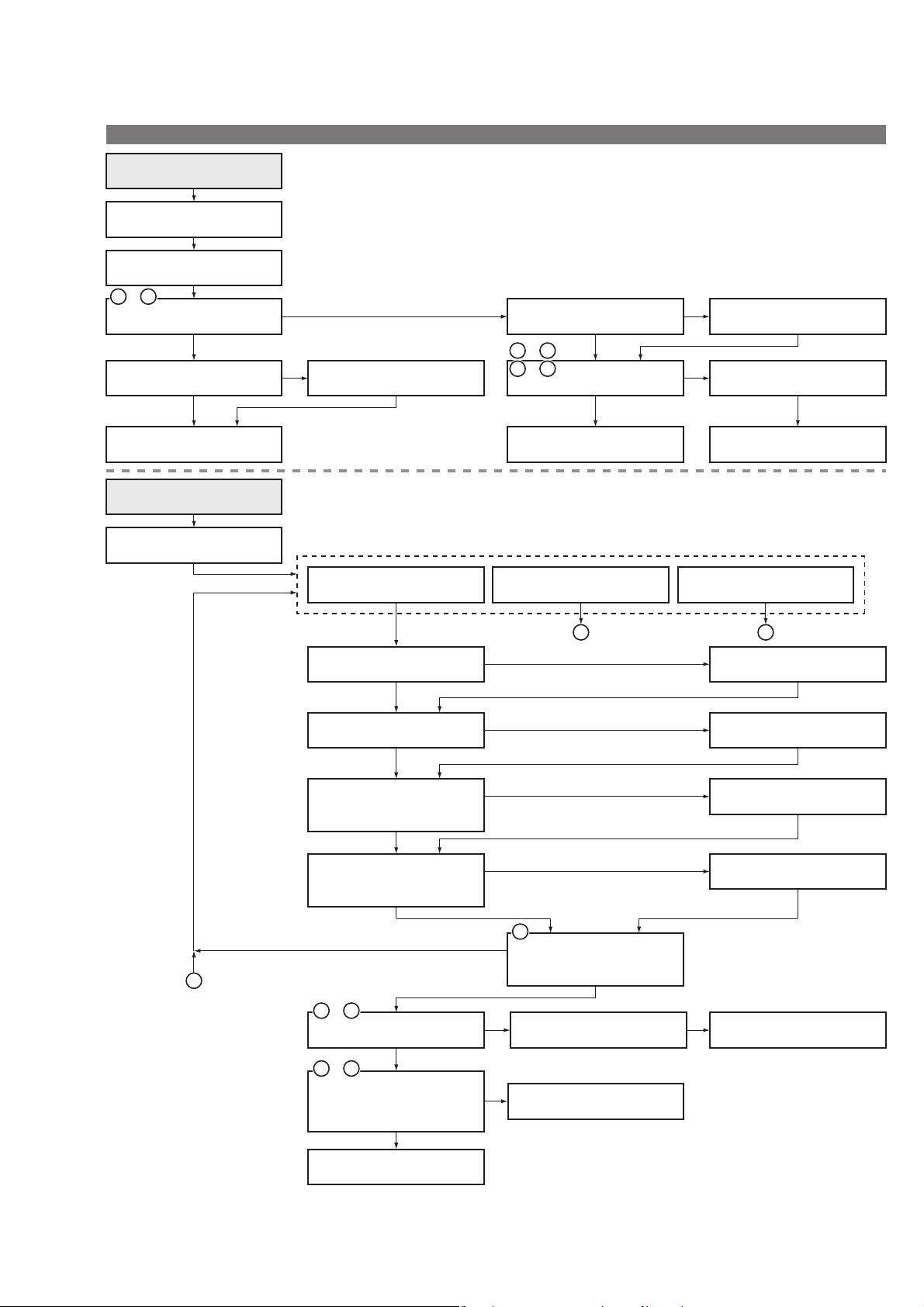

3.1.5 FLOWCHART OF FAILURE ANALYSIS FOR THE DRIVE ASSY

Flowchart of Failure Analysis for The Drive Assy (1)

Failure analysis for the

drive system ⇒ DR1

Reset lighting is not displayed.

X/Y DRIVE Assys

7 9

to

Is the waveform normal when the

voltage is applied to the panel?

Are the panel FFC cables properly

connected to the X/Y DRIVE Assys?

Yes

No

No

Properly connect the panel

FFC cables.

NG

Are the FFC cables properly

connected?

17 24

to

31 35

to

Is the input signal normal?

Yes

Yes

No

Properly connect the FFC cables.

NGYes

No

Replace the FFC cables.

NG

Replace the panel chassis.

Failure analysis for the

drive system ⇒ DR2

Abnormality across the whole

screen, such as luminescent spots

Yes

Another Assy may be in failure.

E

Replace the X/Y DRIVE Assys.

Because it is difficult to identify which drive is in failure, follow the flowchart below to check each Assy.

X DRIVE AssyY DRIVE Assy / SCAN Assy

C

Are all the connectors properly

connected?

Yes

Is the VH set voltage (130 V)

correctly set?

Yes

Is the VOFS set voltage

correctly set (set value: designated

for each panel)?

Yes

Is the VYPRST set voltage correctly

set (set value: designated for

each panel)?

Yes

12 16

to

Is the input signal normal?

(See the oscilloscope photos.)

17 24

to

Is the waveform of the control

signal from the SCAN Assy

normal?

(See the oscilloscope photos.)

Yes

Yes

No

No

No

No

9

Yes

Is the waveform normal when the

voltage is applied to the panel?

(See the oscilloscope photos.)

No

No

Replace the FFC cables. Replace the DIGITAL Assy.

No

Replace the Y DRIVE Assy.

Replace the DIGITAL Assy.

ADDRESS Assy

D

Reconnect the connectors.

Replace the Y DRIVE Assy.

Set the VOFS voltage correctly.

Set the VYPRST voltage correctly.

NG

NG

NG

NG

NG

Replace the SCAN Assy.

37

Page 30

Flowchart of Failure Analysis for The Drive Assy (2)

X DRIVE Assy

C

Are all the connectors properly

connected?

Yes

36

Is the VXNRST set voltage

(-180 V) correctly set?

Yes

E

Another Assy may be in failure.

10 11

to

Is the input signal normal?

(See the oscilloscope photos.)

Yes

Replace the X DRIVE Assy.

Failure analysis for the

drive system ⇒ DR3

The abnormality is associated with

one address or one TCP?

2 6

to

Is the TCP control signal normal?

Yes Yes

Replace the panel chassis.

In most cases of damage on one line,

the panel chassis must be replaced.

No

Reconnect the connectors.

NG

No

Replace the X DRIVE Assy.

7

Yes

Is the waveform normal when the

voltage is applied to the panel?

(See the oscilloscope photos.)

No

No

Replace the FFC cables.

NG

Replace the DIGITAL Assy.

Diagnose the ADDRESS Assy.

No

Are the FFC cables properly

connected?

NG

Replace the DIGITAL Assy.

NG

ADDRESS Assy

D

Are all the connectors properly

connected?

Yes

2 6

to

Is the TCP control signal normal?

(See the oscilloscope photos.)

Yes

Replace the panel chassis.

No

Properly connect the FFC cables.

NG

If the FFC cable that connects the DIGITAL and ADDRESS Assys is in failure,

the abnormality is associated with one address in most cases.

No

Reconnect the connectors.

No

Are the FFC cables properly

connected?

Yes No

Properly connect the FFC cables.

Replace the DIGITAL Assy.

NG

NG

NG

Failure analysis for the

drive system ⇒ DR4

The abnormality is associated

with a single scan line.

9

Is the waveform normal when the

voltage is applied to the panel?

(See the oscilloscope photos.)

Yes

Is the cable connected properly

to the 90-pin connector?

Yes

Replace the SCAN Assy.

Diagnose the SCAN Assy.

No

Is the cable connected properly

to the 15-pin connector?

Yes

17 24

to

Yes

Is the waveform of the SCAN IC

control signal from the Y DRIVE

Assy normal?

No

Connect the cable properly.

NG

No

Connect the cable properly.

NG

No

Replace the Y DRIVE Assy.

Care must be taken that no dirt or dust is attached or gets in.

(The SCAN IC may be damaged.)

38

Page 31

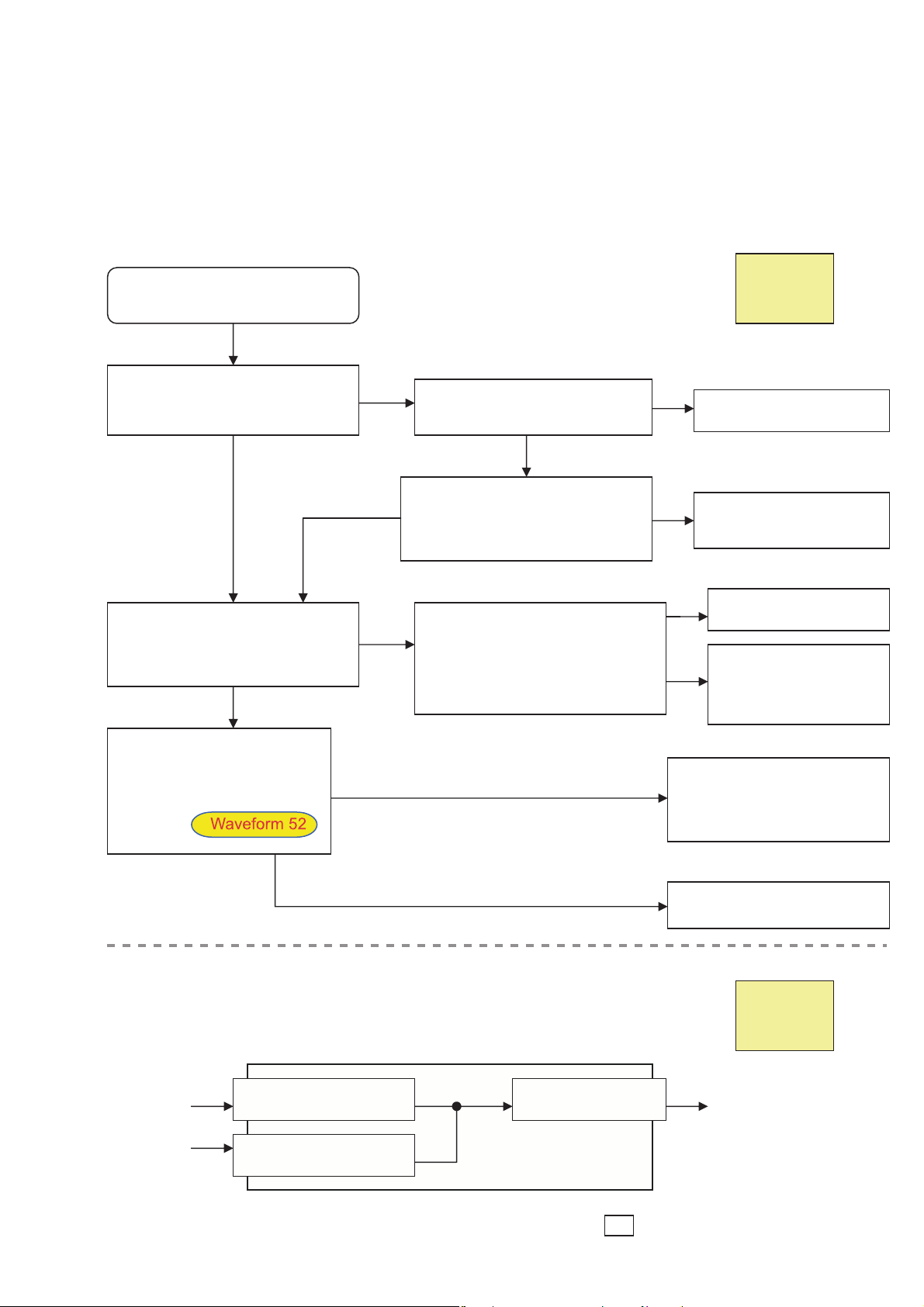

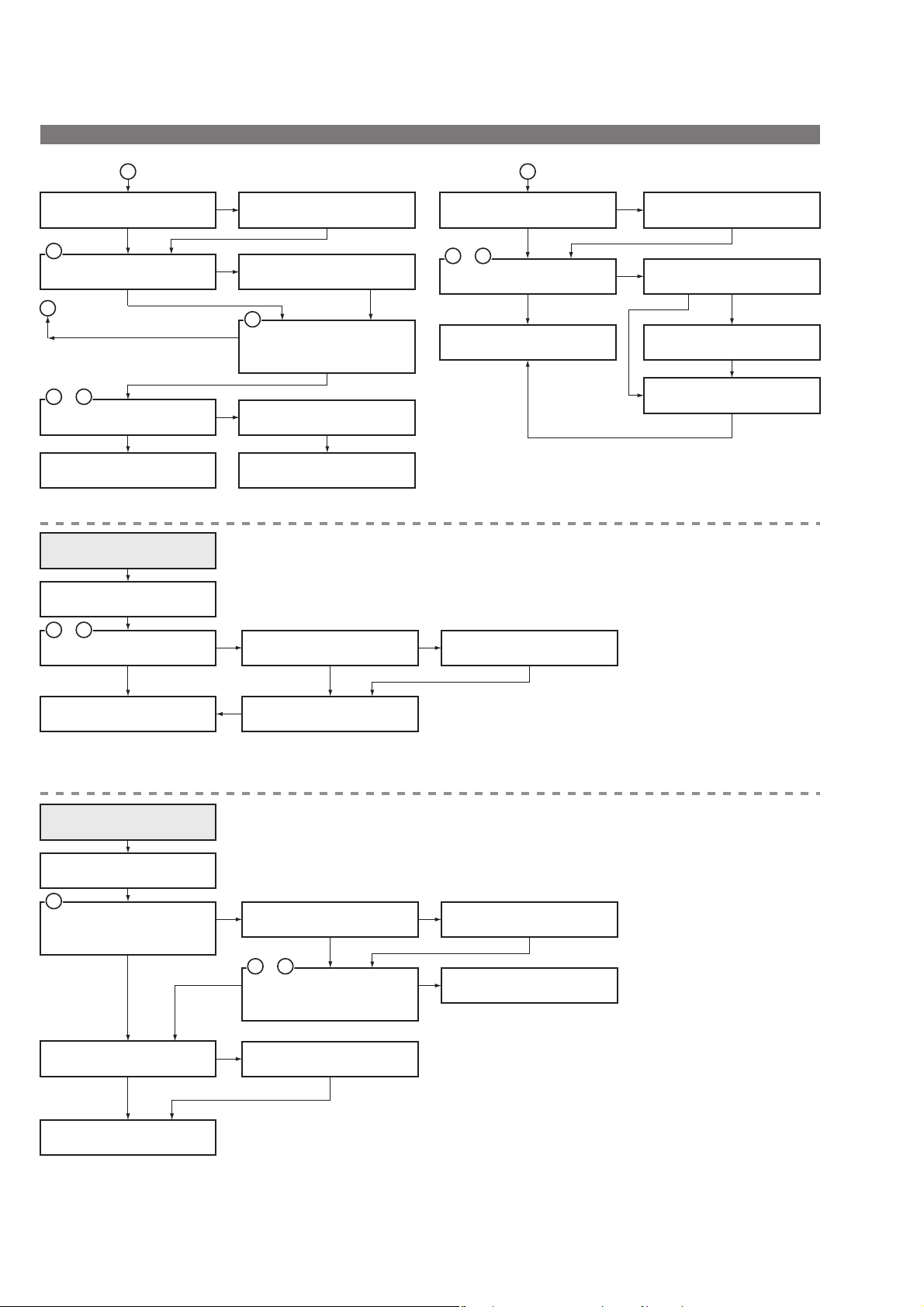

60 ADDRESS ASSY

• ADR LOGIC BLOCK

1) input: VIDEO 60Hz

signal: COLOR BAR (MKSS17)

ch1: L1730 (V+ADR1) (side-A through hole)

1

V: 10 V/div H: 2 mS/div

ch2: IC1601 or IC1801 28 pin (R_E) side-A test plane "R_E"

2

V: 1 V/div H: 2 mS/div

ch3: IC1601 or IC1801 38 pin (CLK) side-A test plane "CLK1"

3

V: 1 V/div H: 2 mS/div

ch4: IC1601 or IC1801 (LE_E) side-A test plane "LE_E"

4

V: 1 V/div H: 2 mS/div

ch5: IC1601 or IC1801 45 pin (HBLK) side-A test plane "HBLK"

5

V: 1 V/div H: 2 mS/div

ch6: IC1601 or IC1801 44 pin (LBLK) side-A test plane "LBLK"

6

V: 1 V/div H: 2 mS/div

2) input: VIDEO 60Hz

signal: Checkered pattern of Black- White (MKSS13)

CH1: L1730 (V+ADR1) (side-A through hole)

1

V: 10 V/div H: 2 mS/div

CH2: IC1601 or IC1801 28 pin (R_E) side-A test plane "R_E"

2

V: 1 V/div H: 2 mS/div

CH3: IC1601 or IC1801 38 pin (CLK) side-A test plane "CLK1"

3

V: 1 V/div H: 2 mS/div

CH4: IC1601 or IC1801 (LE_E) side-A test plane "LE_E"

4

V: 1 V/div H: 2 mS/div

CH5: IC1601 or IC1801 45 pin (HBLK) side-A test plane "HBLK"

5

V: 1 V/div H: 2 mS/div

CH6: IC1601 or IC1801 44 pin (LBLK) side-A test plane "LBLK"

6

V: 1 V/div H: 2 mS/div

ch1

ch2

ch3

ch4

ch5

ch6

• Incoming signals of TCP (1Field)

3) input : VIDEO

signal:Checkered pattern of Black- White (MKSS13)

CH1: L1730 (V+ADR1) (side-A through hole)

1

V: 10 V/div H: 500 nS/div

CH2: IC1601 or IC1801 28 pin (R_E) side-A test plane "R_E"

2

V: 1 V/div H: 500 nS/div

CH3: IC1601 or IC1801 38 pin (CLK) side-A test plane "CLK1"

3

V: 1 V/div H: 500 nS/div