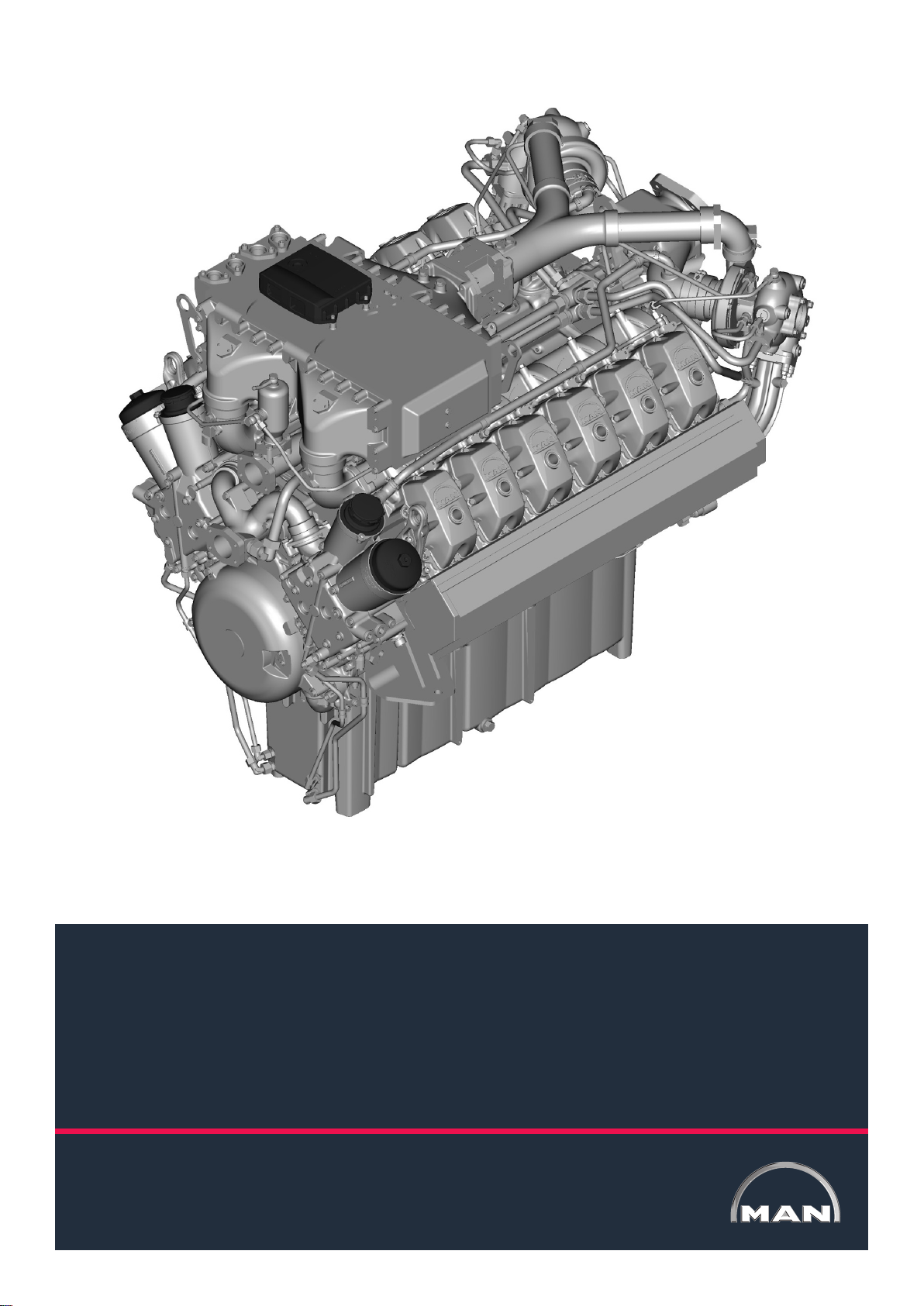

Page 1

Operating Instruction

MAN Industrial Gas Engines

E3268 LE212/222 / E3262 LE202/212

MAN Engines

A Division of MAN Truck & Bus

Page 2

Page 3

Operating Instruction

MAN Industrial Gas Engines

E3268 LE212, E3268 LE222

E3262 LE202, E3262 LE212

51.99587-8006

Version 05

Translation of the original instruction”

“

Page 4

Information and Copyright

Subject to change without notice.

Reprinting, copying or translation, even of extracts, is not allowed without written permission from MAN. All

rights under the copyright law are strictly reserved by MAN.

2016

MAN Truck & Bus AG

Vogelweiherstrasse 33

90441 Nürnberg

Germany

Tel.: +49 911 / 420-1745

Fax: +49 911 / 420-1932

email: Engine-Documentation@man.eu

internet: www.man-engines.com

Technical status: 03.2016

51.99587-8006

Carefully read these Operating Instructions before starting any work!

2

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 5

List of contents

Information and Copyright 2...............................................................

1 Foreword 7.........................................................................

1.1 Information about these instructions 7.............................................

1.1.1 Supplementary publications 7...............................................

1.1.2 Further publications 7......................................................

1.2 Symbol explanation 8...........................................................

1.3 Limitation of liability 9............................................................

1.4 Copyright protection 9...........................................................

1.5 Applicable documents 9.........................................................

1.6 Spare parts 10..................................................................

1.7 Disposal 10.....................................................................

1.8 Warranty provisions 11...........................................................

1.9 Product support 11...............................................................

2 General Safety Instructions 13........................................................

2.1 Intended use 13.................................................................

2.2 Content of the Installation and Operating Instructions 14..............................

2.3 Engine modifications and conversions 14...........................................

2.4 Operator's responsibility 14........................................................

2.5 Personnel requirements 15........................................................

2.5.1 Qualifications 15............................................................

2.5.2 Unauthorised personnel 15..................................................

2.5.3 Instruction 15..............................................................

2.6 Personal protective equipment 16..................................................

2.7 Particular dangers 17.............................................................

2.8 Safety equipment 20.............................................................

2.9 Response to danger and accidents 21..............................................

2.10 Signs 22........................................................................

2.11 Weight data E3268 LE212/LE222 23...............................................

2.12 Environmental protection 24.......................................................

3 Engine model plate 25................................................................

3.1 Explanation of Motor-Nr./Engine No. (engine identification number) 26..................

3.2 Explanation of model designation 26................................................

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

3

Page 6

List of contents

4 Design and function 27...............................................................

4.1 Engine application fields 27.......................................................

4.2 Engine design and engine equipment 27............................................

4.3 Engine views E3262 LE202 29.....................................................

4.3.1 Front left view 29...........................................................

4.3.2 Front right view 30..........................................................

4.4 Engine views E3268 LE212 31.....................................................

4.4.1 Front left view 31...........................................................

4.4.2 Front right view 32..........................................................

5 Transport, packaging and storage 33..................................................

5.1 Requirements 33................................................................

5.2 Safety instructions 33............................................................

5.3 Transport inspection 35...........................................................

5.4 Transport 36....................................................................

5.5 Packaging 40....................................................................

5.6 Storage 40......................................................................

6 Installation and commissioning 41....................................................

6.1 Notes regarding installation and commissioning 41...................................

6.1.1 Requirements 41...........................................................

6.2 Safety instructions 41............................................................

6.3 Engine installation 42.............................................................

6.3.1 Interfaces between engine and plant 42.......................................

6.3.2 Installation Instructions 44...................................................

6.3.3 Installation drawing 44......................................................

6.3.4 Screw and bolt connections 44...............................................

6.4 Completion of the engine and assembly of the drive system 45.........................

6.4.1 Mounting an alternator on the flywheel housing 45..............................

6.4.2 Checking crankshaft axial clearance 46........................................

6.5 Connecting the cooling system 47..................................................

6.5.1 Connecting the engine cooling 47.............................................

6.6 Mounting the gas inlet 48.........................................................

6.7 Mounting the exhaust system 49...................................................

6.7.1 Exhaust gas outlet on engine 49..............................................

6.7.2 Connecting the exhaust system to the engine 50................................

6.8 Connecting the electrical system 51................................................

6.8.1 Starter 51.................................................................

6.9 Torques for screw and bolt connections to Works Standard M 3059 52..................

6.10 First commissioning 53...........................................................

6.11 Commissioning 54...............................................................

6.11.1 Gas system 54.............................................................

6.11.2 Adding coolant 55..........................................................

6.11.3 Filling Engine Oil 56.........................................................

Carefully read these Operating Instructions before starting any work!

4

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 7

List of contents

7 Operation and use 57.................................................................

7.1 Requirements 57................................................................

7.2 Safety instructions 57............................................................

7.3 Preparations prior to operation 58..................................................

7.3.1 Checking the gas quality, opening the gas supply 58............................

7.3.2 Checking the coolant 59.....................................................

7.3.3 Topping up the coolant 59...................................................

7.3.4 Check Engine Oil Level 60...................................................

7.3.5 Topping up the engine oil 61.................................................

7.4 Operation 62....................................................................

7.4.1 Starting 62.................................................................

7.4.2 Operation monitoring system 63..............................................

7.4.3 Emergency shutdown 63....................................................

7.4.4 Stopping 63................................................................

7.4.5 Data storage box 64........................................................

8 Maintenance and care 65..............................................................

8.1 Requirements 65................................................................

8.2 Safety instructions 65............................................................

8.3 Maintenance schedule 66.........................................................

8.3.1 Maintenance schedule for natural-gas operation 67.............................

8.3.2 Maintenance schedule for special gas operation 70.............................

8.4 Maintenance work 75.............................................................

8.4.1 Engine oil change 75........................................................

8.4.2 Changing the coolant 79.....................................................

9 Faults 81............................................................................

9.1 Requirements 81................................................................

9.2 Safety instructions 81............................................................

9.3 Troubleshooting chart 82..........................................................

10 Decommissioning and recommissioning 87............................................

10.1 Requirements 87................................................................

10.2 Safety instructions 87............................................................

10.3 Temporary decommissioning of an engine 88........................................

10.4 Recommissioning of decommissioned engines 89....................................

10.4.1 Commissioning of preserved engines to MAN Works Standard M 3069 89..........

10.4.2 Commissioning of non-preserved engines 89...................................

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

5

Page 8

List of contents

11 Technical data 91....................................................................

11.1 Dimensions and weight 91........................................................

11.1.1 E3268 LE212/LE222 91.....................................................

11.1.2 E3262 LE202/LE212 91.....................................................

11.2 Installation location and space requirements 91......................................

11.3 Engine data 92..................................................................

11.3.1 E3268 LE212/LE222 92.....................................................

11.3.2 E3262 LE202/LE212 94.....................................................

12 Installation drawing 97...............................................................

12.1 Installation drawing E3268 LE212/LE222 97.........................................

12.2 Installation drawing E3262 LE202/LE212 103.........................................

13 Indices 111...........................................................................

13.1 Abbreviations 112.................................................................

13.2 List of keywords 113..............................................................

Carefully read these Operating Instructions before starting any work!

6

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 9

Foreword

1 Foreword

1.1 Information about these instructions

User tip

This provisional version of the instructions reflects the current development state of the engines.

These instructions therefore contain graphic representations of the MAN industrial gas engines on which

these instructions are based.

These instructions provide important information on handling engines. Safe working can only be assured if

all safety instructions and handling instructions are followed.

In addition to this, the local accident prevention regulations and general safety regulations applicable to the

engines' field of application must be followed.

Timely and proper maintenance and care of the engines according to the set maintenance intervals ensure

and maintain the operational safety and the reliable application of these engines.

Only use genuine MAN spare parts and accessories or ones that have been approved by MAN.

Only the genuine spare parts approved by us have been tested by us and therefore meet the requirements

for use of the engine.

A particular concern of MAN is to improve environmental protection.

This begins with the development and design of our engines. We make sure that no environmentally ha

zardous materials are used and, for example, that the emissions fulfil the highest requirements.

Economical operation helps to conserve our resources and our environment.

1.1.1 Supplementary publications

These instructions are supplemented by the following publications:

- Fuels, Lubricants and Coolants for MAN Industrial Gas Engines

Both publications are considered "parts of the product" and should always be kept in the immediate vicinity

of the engine for the personnel.

Carefully read the Installation and Operating Instructions before starting any work! This is especially valid

for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

Failure to follow these instructions and any operating instructions provided by suppliers invalidates the war

ranty.

1.1.2 Further publications

The following publications supplement these instructions:

- Spare Parts Catalogue (included)

For the service personnel

- Repair Instructions

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

7

Page 10

Foreword

1.2 Symbol explanation

Warnings

Warnings are indicated by symbols in these instructions. The warnings are preceded by signal

words which indicate the extent of the danger.

Always heed these warnings and act prudently to prevent accidents, injuries and property damage.

DANGER

Describes an immediately dangerous situation that will lead to serious injury or death if it is not avoided.

WARNING

Describes a possibly dangerous situation that can lead to serious injury or death if it is not avoided.

CAUTION

Describes a possibly dangerous situation that can lead to minor or moderate injury if it is not avoided.

NOTE

Describes a possibly dangerous situation that can lead to damage if it is not avoided.

Tips and Recommendations

User tip

Tips and recommendation as well as information for efficient and trouble-free operation.

ENVIRONMENTAL NOTE

Tips on how to deal with protection of the environment.

General Information

• This symbol indicates a list at the first level.

- This symbol indicates a list at the second level.

1. This symbol indicates a sequence of actions.

1

This symbol indicates a graphic item in the text.

Carefully read these Operating Instructions before starting any work!

8

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 11

Foreword

1.3 Limitation of liability

All of the information in these instructions have been prepared while taking into account the valid standards

and regulations, the state of the art, as well as our many years of experience and knowledge.

MAN is not liable for damages resulting from:

S Failure to follow these instructions

S Improper use

S Use of untrained personnel

S Customer conversions

S Technical modifications

S Use of non-approved spare parts and fuels, fluids and lubricants

The actual scope of delivery for special versions, additional ordering options or technical modifications may

deviate from what is described and illustrated in these instructions.

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of

MAN and the law applicable at the time of contracting arrangements.

1.4 Copyright protection

Treat the Installation and Operating Instructions confidentially. They are aimed solely at persons who deal

with the engine.

The instructions may not be passed to third parties without written approval from MAN.

User tip

The information, texts, drawings, illustrations and other depictions are all protected by copyright and are

subject to industrial property rights.

Any improper use is punishable by law.

1.5 Applicable documents

Supplier components are installed in the engine. Risk assessments have been carried out on these parts

by the suppliers.

The compliance of the design with the existing European and national legislation has been declared by the

respective suppliers of the components.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

9

Page 12

Foreword

1.6 Spare parts

Only use genuine MAN spare parts and accessories or ones that have been approved by MAN.

Only the spare replacement parts approved by us have been tested by us and therefore meet the require

ments for use of the engine.

Spare parts and accessories must either be MAN genuine parts or parts that have been specifically appro

ved by MAN. The reliability, safety and suitability of these parts have been established specifically for the

engines. We cannot assess and vouch for other non-MAN products, despite ongoing market observations.

WARNING

Risk of injury due to incorrect spare parts

Incorrect or faulty spare parts can lead to damage, malfunctions or total failures and interfere with

safety.

For this reason:

S Only use MAN genuine spare parts

User tip

Quote the engine type, engine number and order number in all enquiries and communications,

see page 25.

Order spare parts through authorised dealers or directly from MAN.

For address, see page 2.

1.7 Disposal

Dispose in accordance with national regulations.

If no return or disposal agreement has been made, recycle the disassembled components as follows:

S Sort metals before scrapping.

S Recycle the plastic parts.

S Dispose of all other parts according to their material composition.

10

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 13

Foreword

1.8 Warranty provisions

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of

MAN and the law applicable at the time of contracting arrangements.

Failure to follow these instructions and any operating instructions provided by suppliers invalidates the war

ranty.

The use of non-approved parts leads to the loss of warranty claims.

We recommend to use genuine parts even after the warranty period has expired. This will ensure the conti

nuous performance of the engine.

1.9 Product support

Our MAN product support is available for technical information.

User tip

Quote the engine type, engine number and order number in all enquiries and communications,

see page 25.

Information about contact persons can always be called up by telephone, fax, email or over the Internet.

For addresses see page 2.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

11

Page 14

Foreword

12

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 15

General Safety Instructions

2 General Safety Instructions

This chapter provides information on residual risks and hazards during proper use of the engine.

The generally valid safety instructions to be observed are listed here. They provide optimum protection for

personnel and for the safe and smooth operation of the engine.

In the following, specific, action and situation-related safety information is placed before the corresponding

step, or in the chapter described.

Failure to observe the Operating Instructions and Safety Instructions in this document can result in signifi

cant hazards.

2.1 Intended use

The engine is built exclusively to drive generators or for the coupling of heat exchangers within the limits of

technical data.

Any other use is considered as "non-intended".

MAN is not liable for any damage resulting from non-intended use. The risk is entirely borne by the opera

tor.

Intended use also includes compliance with the country-specific, local environmental regulations.

This in particular concerns the compliance with the applicable legal exhaust emission limits.

Furthermore, the engine operating parameters according to the technical data sheets currently in effect

must also be adhered to.

The mixture generating and control system, as well as - if needed - the exhaust aftertreatment system must

be prepared by the manufacturer of the complete machine to meet these criteria.

Intended use also includes compliance with the prescribed operating, maintenance and repair work.

The engine may only be used, maintained and repaired by persons who are familiar with the engine and

have been informed of the hazards.

Unauthorised modifications to the engine shall void any liability for any resulting property damage and per

sonal injury.

Similarly, tampering with the control system can affect engine performance and emission characteristics.

Compliance with statutory environmental protection requirements is therefore no longer guaranteed.

DANGER

Danger due to non-intended use

Any use that exceeds the intended use and/or any different use of the engine can lead to dangerous

situations which will invalidate the operating permit.

For this reason:

S Use the engine for its intended purpose only.

S Use the engine outside of hazardous areas where there is a risk of explosion.

S Use the engine with an overspeed limiting device installed.

User tip

Observe the following information when operating the engine:

S The safety instructions in these Operating Instructions and the suppliers' instructions.

S The “Technical data" section in these instructions and the suppliers' instructions.

S Country-specific regulations.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

13

Page 16

General Safety Instructions

2.2 Content of the Installation and Operating Instructions

Any person who is instructed to perform work on or with the engine, must have read and understood these

Operating Instructions before starting any work. This also applies if the person has worked with such an

engine or a similar engine, or has already been trained by MAN.

Familiarity with these instructions is therefore essential.

2.3 Engine modifications and conversions

In order to avoid hazards and to ensure optimum performance, no modifications or conversions to the en

gine may be made which are not expressly approved by MAN.

If changes are made without the written consent of MAN, the guarantee or warranty obligation for MAN is

no longer valid for damage and defects which are based on these unauthorised changes. Furthermore

MAN assumes no liability for any damage caused as a result of unauthorised changes.

2.4 Operator's responsibility

The engine operator is subject to the statutory requirements for workplace safety.

In addition to the Safety Instructions in these Operating Instructions, the safety regulations, accident pre

vention regulations and environmental protection regulations valid for the application area of this engine

must also be observed.

In particular:

S The operator must be knowledgeable about the valid occupational health and safety regulations and be

able to assess, in a risk analysis, the dangers that are present in the specific working conditions at the

operating site of the engine. He must then implement these safety regulations in the form of operating

instructions for the operation of the engine.

S During the entire period of operation of the engine the operator must check whether the operating in

structions he created meet the most current standards and regulations and revise them if necessary.

S The operator must clearly define and regulate the responsibilities for installation, operation, maintenance

and cleaning of the product.

S The operator must ensure that all staff who deal with the engine have read and understood the Opera

ting Instructions.

In addition, the operator must periodically train the staff and inform them about hazards.

S The operator must provide the personnel with the necessary protective equipment.

S The operator must limit access to the operating room.

S The operator must ensure proper ventilation of the operating room.

S These operating instructions must be kept in the immediate vicinity of the engine and be readily accessi

ble at any time to those persons working on and with the engine.

The operator is responsible for ensuring that the engine is always operated in perfect working condition and

working order.

In particular:

S Perform maintenance work as described in these instructions in full and at the

specified intervals or have it performed by a MAN Service workshop/authorised MAN partner.

S The operator must have all safety equipment checked regularly for function and integrity.

S The instructions must be followed in full and without restrictions!

14

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 17

General Safety Instructions

2.5 Personnel requirements

2.5.1 Qualifications

WARNING

Risk of injury if personnel is not sufficiently qualified

Improper handling can result in significant personal injury and property damage.

For this reason:

S Specific activities must only be performed by those persons who are named in the respective chapters

in these Operating Instructions.

The following qualifications are specified for various areas of activity in the instructions:

S Instructed Persons

Have been instructed in a briefing about the possible dangers of improper handling in their tasks.

S Qualified Personnel

Due to their technical training, knowledge and experience and knowledge of the relevant regulations

they can properly perform the tasks assigned to them.

S Electric Specialist

Is capable of performing work on electrical systems due to his/her technical education/training, know

ledge and experience as well as knowledge of the respective standards and regulations and can recog

nise and avoid any possible dangers.

The electric specialist is trained for the specific operating site in which he/she works and knows the rele

vant standards and regulations.

Only those people who can perform their work reliably should be considered as authorised personnel. Indi

viduals whose responsiveness is influenced, for example, by alcohol or drugs, are not permitted.

S When selecting personnel, observe the regulations regarding age and profession valid at the operating

site.

2.5.2 Unauthorised personnel

WARNING

Danger to unauthorised personnel

Unauthorised persons who do not fulfil the requirements described here do not realise the dangers that

exist in the working area.

For this reason:

S Keep unauthorised persons out of the working area.

S In case of doubt, address the person and remove him/her from the working area if necessary.

S Interrupt the work until all unauthorised persons are out of the working area.

2.5.3 Instruction

Personnel must be instructed on regular basis and this should be documented in a log to keep better track

of who and when.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

15

Page 18

General Safety Instructions

2.6 Personal protective equipment

Wearing personal protective equipment is necessary to minimise the health risks when working.

S The required personal protective equipment for the relevant job must always be worn while working.

S All signs pertaining to personal protective equipment in the working area must be followed.

Protective Clothing

Close-fitting clothing with low initial tear strength, with narrow sleeves and with no pro

truding parts. It is used primarily to protect against injury, weather and dirt.

No rings, bracelets, necklaces and other jewellery are to be worn while working.

Protective Helmet

To protect against falling and flying parts.

Safety Shoes

To protect against heavy falling parts and slipping on slippery surfaces.

Safety Gloves

To protect the hands from friction, scraping, punctures or deep injuries and to protect

from hot or caustic parts or fluids

To be worn when performing specific types of work

When performing certain types of work, special protective equipment is required. This will be specifically

mentioned in the relevant chapters.

Safety Glasses

To protect the eyes against flying parts and sprayed fluids.

Hearing Protection

To protect the ears from damage by loud noises.

16

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 19

General Safety Instructions

2.7 Particular dangers

The following section describes residual risks which have been identified.

S Observe the safety instructions listed here and the warnings in the other chapters of these instructions

in order to reduce health hazards and avoid dangerous situations.

Electrical Current

DANGER

Danger to life due to electrical voltage

Touching live parts endangers life.

Damaged insulation of components endanger life.

For this reason:

S If the insulation is damaged, immediately switch off the power supply and get the insulation repaired.

S Any work performed on the electrical system may only be made by a qualified electrician.

S When working on the electrical system the power supply must be switched off and then properly

checked to ensure no electrical current is present.

S Before starting any maintenance, cleaning or repair work the power supply must be switched off and

secured from being accidentally switched back on.

S Do not bridge or bypass any fuses. When replacing fuses, ensure to use the correct amperage.

S Keep moisture clear of parts conducting electrical current. This could cause a short-circuit.

Moving Parts

WARNING

Risk of injury due to moving parts

Rotating and/or linear-moving components can cause injuries.

For this reason:

S Do not touch or handle moving parts during operation.

S Do not open the covers during operation.

S Only perform checking and maintenance jobs when the engine is at a standstill.

S Observe the run-on time: before opening any covers ensure that no parts are still moving.

S Wear close-fitting clothing in the hazard area.

Flying components in the event of sudden engine damage

WARNING

Risk of injury due to running engines

In the event of engine damage, components can fly through the engine room at high speed and injure

people in the immediate vicinity.

For this reason:

S Do not remain in the engine room when the engine is running.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

17

Page 20

General Safety Instructions

Exhaust gases

WARNING

Health risk due to leaking exhaust system

Exhaust gases can damage health.

For this reason:

S Immediately stop and repair machines with leaking exhaust systems.

S Ensure sufficient ventilation.

Highly Flammable Substances - Gaseous Fuels, Oils and Grease

WARNING

Risk of injury due to highly inflammable materials

Highly inflammable materials, liquids or gases catch fire easily.

For this reason:

S Smoking, naked flames and sources of ignition are prohibited in the danger zone and immediate sur

roundings.

S Keep fire extinguishers at hand.

S Immediately report any suspicious substances, fluids or gases to the person in charge.

S Repair any leaks.

S In the case of fire, immediately stop working. Leave hazard area until the danger is over.

Coolants - Antifreeze, Anticorrosion Agents

WARNING

Risk of injury caused by coolants that are hazardous to health

Coolant contains substances that are hazardous to health.

For this reason:

S Observe the safety sheets from the manufacturer.

S Always wear protective clothing, chemical-resistant protective gloves and safety glasses.

S Avoid spilling or spraying these substances.

Hot Fluids and Lubricants

WARNING

Risk of burns due to hot fuels, lubricants and coolants

Fuels, lubricants and coolants get hot during operation and cause burns if touched.

For this reason:

S Before handling any fluids and lubricants, check whether they are hot. If necessary, let them cool

down first.

18

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 21

General Safety Instructions

Hot Surfaces

CAUTION

Risk of burns due to hot surfaces

Touching hot components causes burns.

For this reason:

S When performing any work in the vicinity of hot components always wear protective clothing and

protective gloves.

S Before starting any work ensure that all components have cooled down to ambient temperature.

Noise

WARNING

Hearing damage due to noise

The noise level in the working area can cause serious hearing damage.

For this reason:

S Always wear hearing protection when working.

S Do not unnecessarily remain in the hazard area. Leave hazard area when work is finished.

Sharp Edges and Corners

CAUTION

Risk of injury on edges and corners

Sharp edges and corners can cause skin grazes and cuts.

For this reason:

S Always work carefully and with caution in the vicinity of sharp edges and corners.

S In cases of doubt, wear protective gloves.

Dirt and Objects

CAUTION

Risk of tripping due to dirt and discarded objects

Dirt and discarded objects represent a tripping and slipping hazard and can cause serious injuries.

For this reason:

S Always keep the work area clean.

S Remove any objects that are no longer necessary.

S Mark areas where there is a danger of tripping with yellow and black striped tape.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

19

Page 22

General Safety Instructions

2.8 Safety equipment

The operator must have the following safety equipment in place:

Before the engine is placed into operation, install the emergency-off equipment and connect it into the

safety chain of the system.

Connect the emergency-off equipment so that dangerous situations to people and property are avoided in

case the its power supply is interrupted or is turned back on after an interruption.

The emergency-off equipment must always be freely accessible.

WARNING

Danger to life due to non-functioning safety equipment

For this reason:

S Before commencing work, check that all safety equipment is functioning and correctly installed.

S Before starting the engine, check that all safety equipment is functioning and correctly installed.

20

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 23

General Safety Instructions

2.9 Response to danger and accidents

Preventative Measures

S Always be prepared for an accident!

S Keep first aid equipment (first aid kit, blankets, etc.) and fire extinguishers at hand.

S Regularly check first-aid equipment and fire extinguishers for completeness and correct functioning.

S Familiarise the personnel with the emergency, first aid and rescue equipment.

S Instruct the personnel on safety on a regular basis.

S Always keep access lanes for rescue vehicles free of any obstructions.

In the case of an accident: Act accordingly

S Remain calm.

S Immediately shut down engine using the emergency-off button.

S Start first-aid measures.

S Alert rescue services and/or fire department.

S Move people out of the danger zone.

S Clear access lanes for rescue vehicles.

S Inform the person in charge.

CAUTION

Accidents despite preventative measures

Should an accident occur despite all preventative measures, e.g. due to one of the reasons listed below,

call a doctor immediately:

S Contact with caustic acids.

S Penetration of fuel into the skin.

S Scalding by hot oil or coolant.

S Antifreeze sprayed into the eyes, etc..

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

21

Page 24

General Safety Instructions

2.10 Signs

WARNING

Risk of injury due to illegible symbols

Labels and symbols get dirty over time, rendering them illegible.

For this reason:

S Always keep the safety, warning and operational signs in good legible condition.

S Clean or replace illegible safety, warning and operational signs.

The following symbols should be installed in the immediate vicinity of the hazard area.

Access forbidden

Areas displaying this sign must not be entered.

Electric Voltage

Spaces marked with this symbol may only be accessed by qualified electricians.

Unauthorised persons may not enter these spaces.

Hot Surfaces

Hot surfaces such as hot engines and hot fluids may not always be recognisable. Do not

touch these surfaces without protective gloves.

Danger to life due to suspended loads

During lifting operations, loads can swing out and fall down. This can cause serious in

jury and even death.

Risk of injury

Failure to follow the instructions poses a risk of injury.

22

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 25

General Safety Instructions

2.11 Weight data E3268 LE212/LE222

Ensure that suitable lifting gear is used for handling the engine and the engine parts listed in the table.

Part Weight (kg)

Oil pan 95l 27

Crankcase 459

Crankshaft 131

Flywheel housing 30

Flywheel 66

Exhaust turbocharger 1500 rpm 38

Charge mixture cooler E3268 88

Engine carriage 107

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

23

Page 26

General Safety Instructions

2.12 Environmental protection

ENVIRONMENTAL NOTE

Risk of environmental pollution due to incorrect handling of service products

Serious environmental damage can result.

For this reason:

S Follow the safety instructions.

S Take suitable measures immediately if environmentally hazardous substances escape into the envi

ronment.

S Inform the relevant local authorities of the damage.

The following environmentally hazardous substances are used:

Lubricants

Lubricants such as grease and oils contain poisons and environmentally hazardous substances. They must

not be allowed to be released into the environment. Disposal must be performed by a qualified disposal

company.

Coolants

Coolants can contain poisons and environmentally hazardous substances. They must not be allowed to be

released into the environment. Disposal must be performed by a qualified disposal company.

24

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 27

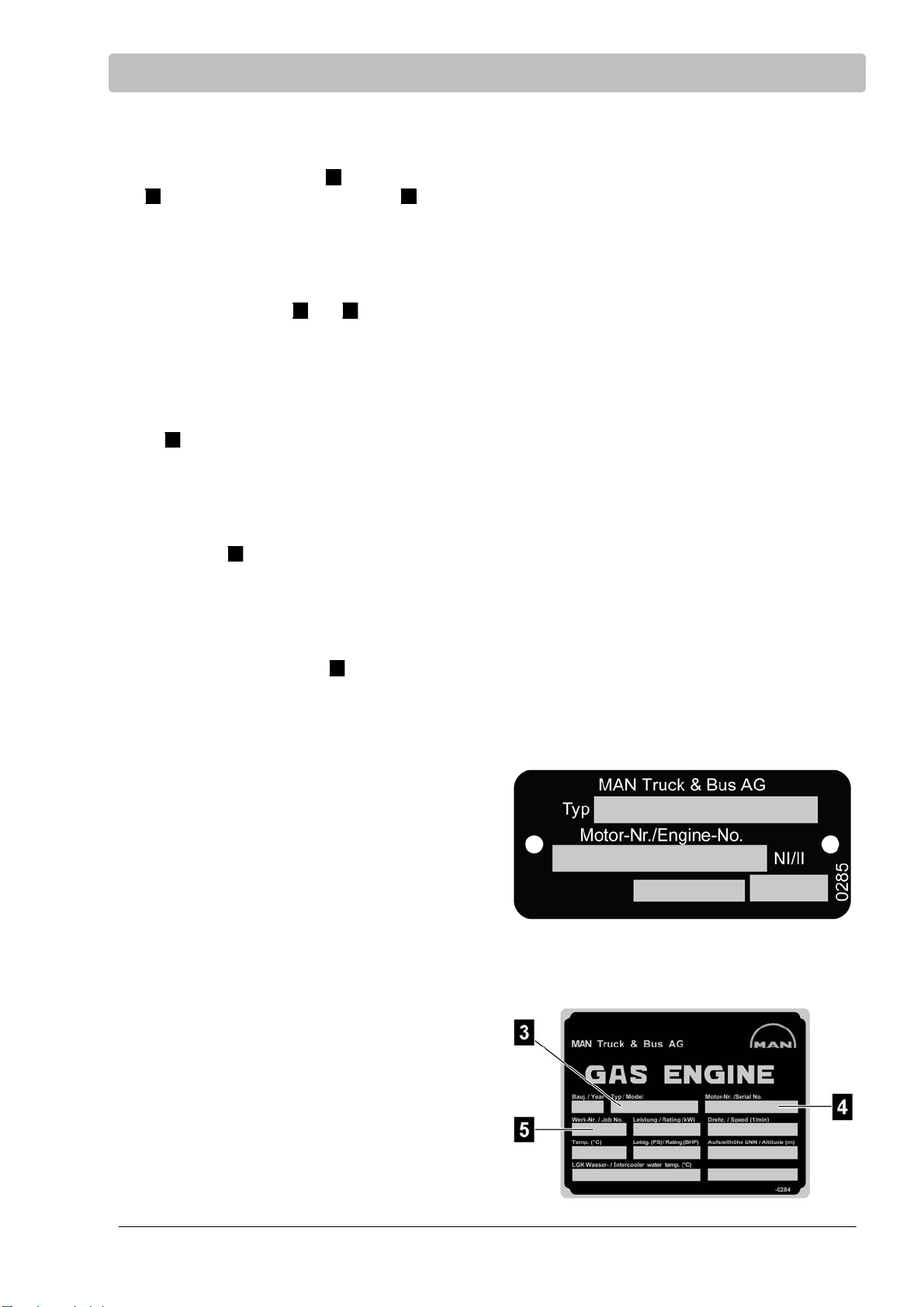

3 Engine model plate

Always quote the engine type 3, engine num

4

ber

and factory number/order number 5 in all

enquiries and communications.

Before the engine is first commissioned, you

should therefore check the relevant data on the

engine model plates and enter it below.

1

The engine model plates

the crankcase.

and 2 are attached to

Engine Model Plate

Model

......................................................................

Engine number

......................................................................

Factory number/order number

......................................................................

3

4

5

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

25

Page 28

Engine Model Plate

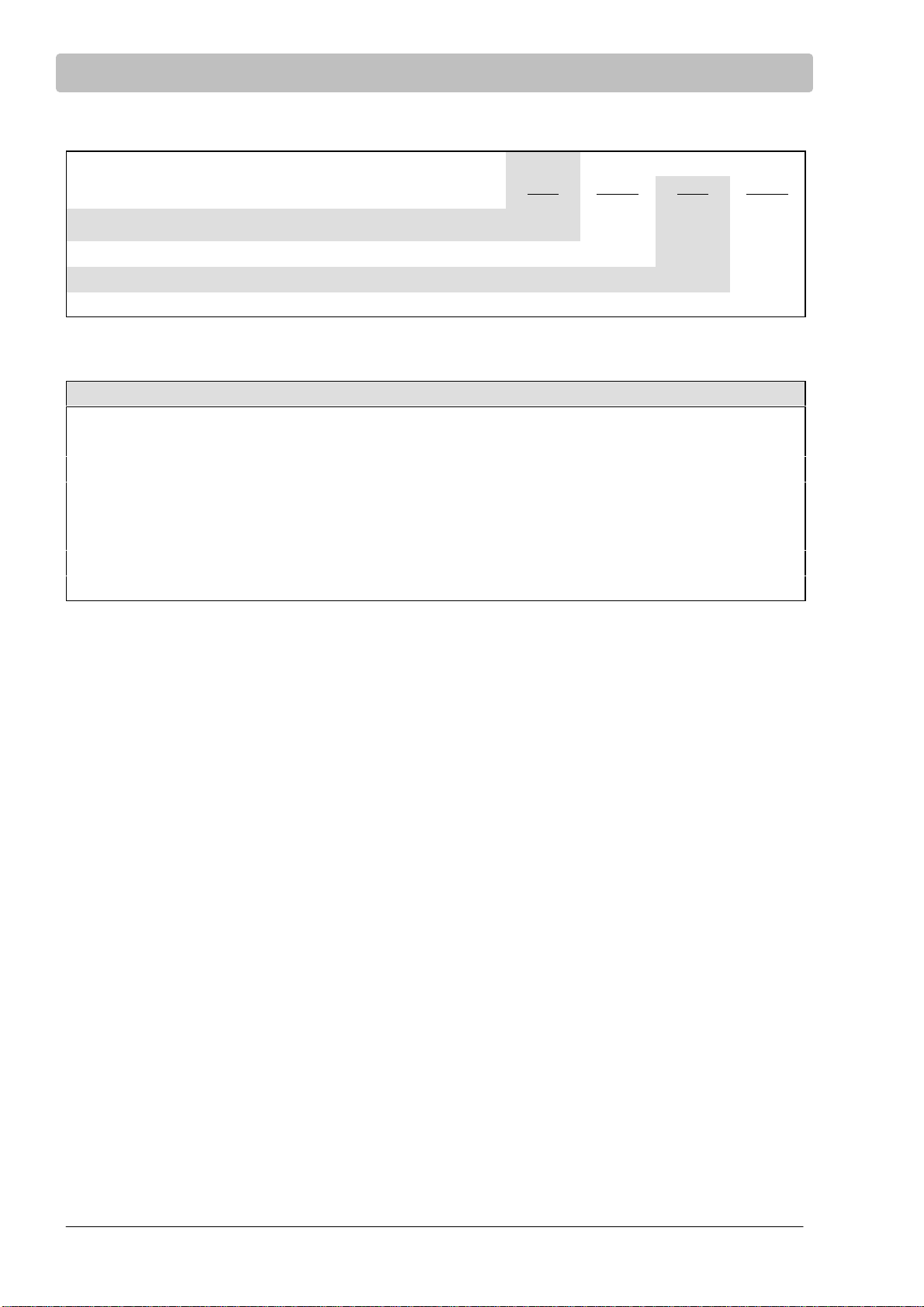

3.1 Explanation of Motor-Nr./Engine No. (engine identification number)

Class identifier (assignment) 1 2 3 4

Motor-Nr./Engine No. XXX XXXX XXX XXXX

1 Model number after model code

2 Day of assembly (determined internally at factory)

3 Assembly sequence (consecutive number on day of assembly)

4 Production- and equipment-specific data

3.2 Explanation of model designation

Model designation Explanation Example

E Fuel type Natural gas/biogas

32 Figure + 100 132 mm bore

6 Stroke figure (rounded) 157 mm stroke

8 / 2 Number of cylinders 8, 12 cylinders

L Charging with charging and

charge mixture cooling

E Engine installation Installation engine

202/212/222 Model designation identification Development number

26

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 29

Design and Function

4 Design and function

4.1 Engine application fields

The 8- and 12-cylinder engines described here are liquid-cooled 4-stroke petrol engines with exhaust gas

turbocharger and mixture cooling.

4.2 Engine design and engine equipment

Engines E3268 LE212, E3268LE222 and E3262 LE202, E3262 LE212 are 8- or 12-cylinder gas engines

with turbocharger and mixture cooling.

Split crankcase, wet cylinder liners made of highly wear-resistant special centrifugal casting, aluminium

piston with cooling duct for piston cooling. Single cylinder heads with shrink-fitted valve seats and pressedin valve guides. 4 valves per cylinder. Valve control via central camshaft, roller tappets, tappet push rods

and rocker arms (OHV).

Charge mixture system

The charge mixture system consists of the charge mixture cooler, the charge mixture manifolds, the throttle

valve and the air distributor pipes.

Gas supply line

The gas supply line - consisting of ball cock, gas filter, solenoid valves, gas pressure regulator, gas mixer

and air filter - is not supplied by MAN.

Engine Lubrication

Force-feed lubrication with two lubrication oil pumps for crankshaft, conrod and camshaft bearings as well

as piston pin sockets, roller tappet and rocker arm.

Oil filtration through oil modules with integrated oil cooler and crankcase breather in main flow. Auxiliary

units such as turbocharger are connected to the engine lubrication oil circuit.

Intake and Exhaust System

Dry exhaust pipes.

For E3268, one exhaust turbocharger; for E3262, two exhaust turbochargers.

The exhaust turbochargers are lubricated via the engine's main flow oil circuit.

The intake air flows through the air filter to the gas mixer and then to the turbocharger(s). The now precom

pressed air/gas mixtures are supplied to the engine after mixture cooling.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

27

Page 30

Design and Function

Flywheel housing and flywheel

The flywheel housing as a connection to SAE1.

Different flywheel versions can be supplied, depending on the type of application.

Starter

The electric starter is of two-pin, insulated design. The starter can be mounted on the left or right of the en

gine.

28

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 31

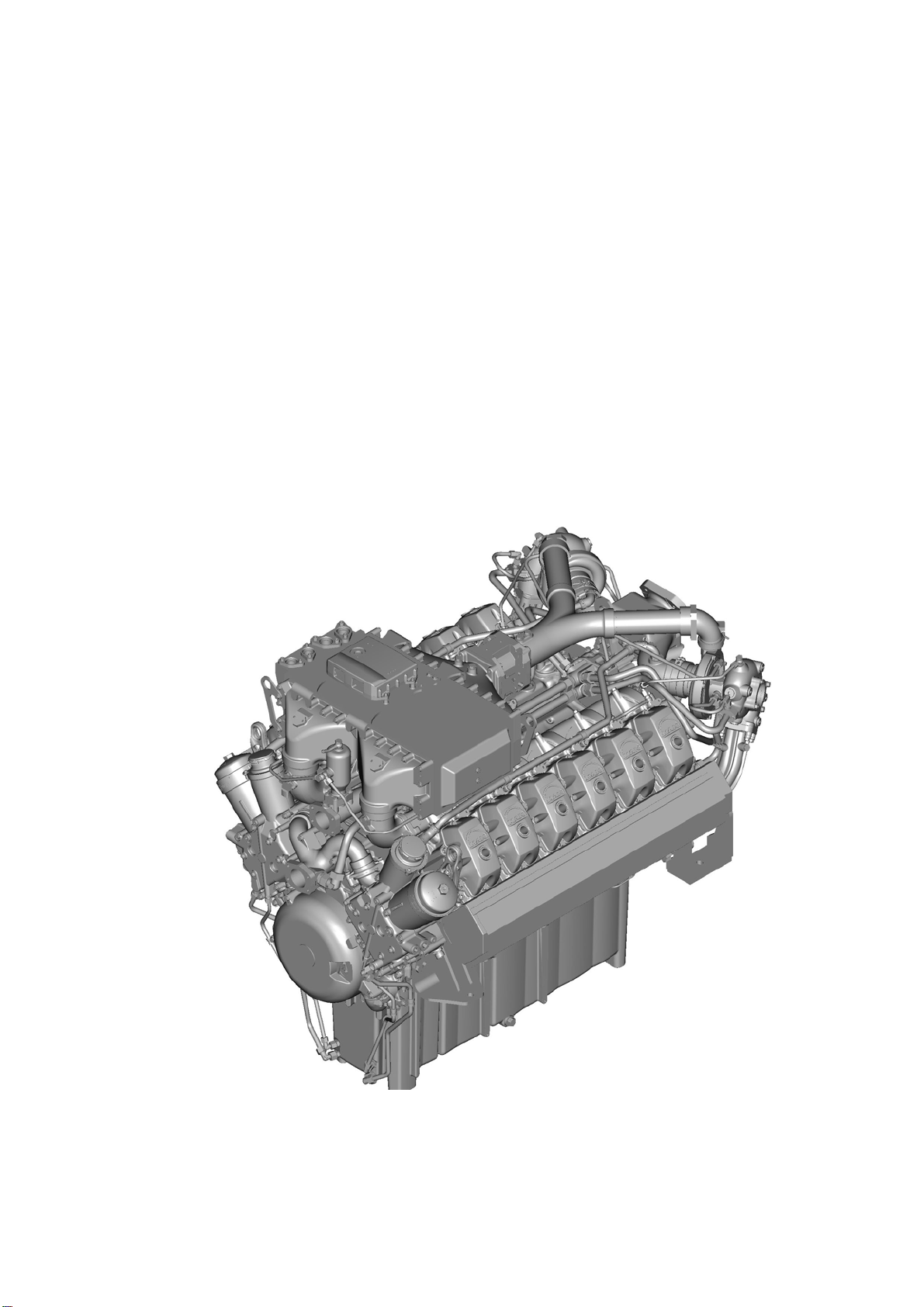

4.3 Engine views E3262 LE202

4.3.1 Front left view

Design and Function

1 Vent housing for coolant

2

Data acquisition

3

Throttle valve

4

Exhaust turbocharger

5

Oil pan

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

6 Oil drain plug

7

Protective cover for crankshaft

and vibration damper

8

Oil filter

9

Oil separator

29

Page 32

Design and Function

4.3.2 Front right view

1

Intake manifold

2

Charge mixture cooler

3

Coolant outlet

4

Coolant inlet

5

Oil drain plug

6

Heat protection cover

7

Oil filler neck

User tip

The gas supply line - consisting of ball cock, gas filter, solenoid valves, gas pressure regulator, gas mi

xer and air filter - is not supplied by MAN.

30

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 33

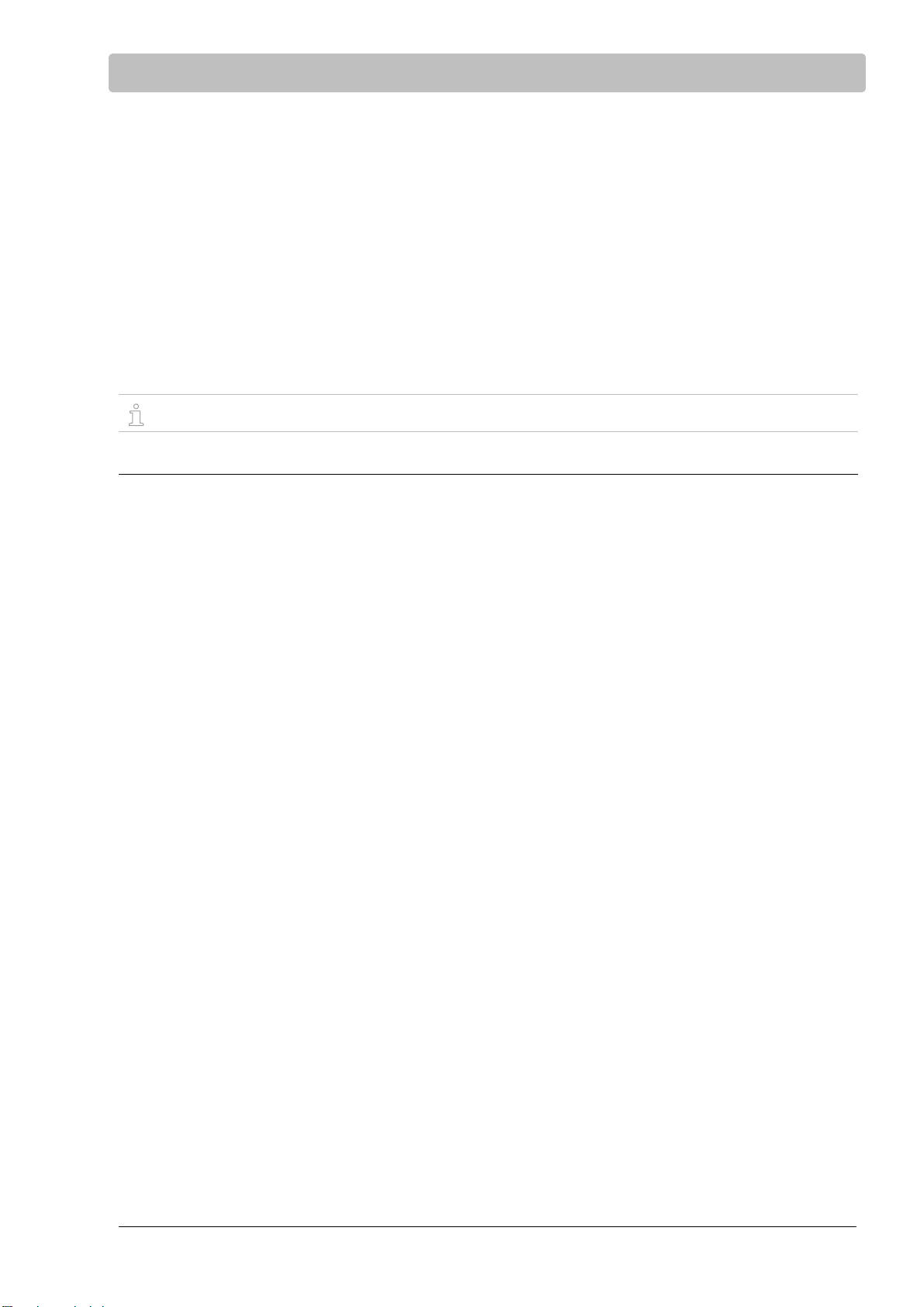

4.4 Engine views E3268 LE212

4.4.1 Front left view

Design and Function

1

Oil separator

2

Vent housing for coolant

3

Data acquisition

4

Throttle valve

5

Exhaust turbocharger

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

6

Oil pan

7

Oil drain plug

8

Protective cover for crankshaft

and vibration damper

9

Oil filter

31

Page 34

Design and Function

4.4.2 Front right view

1

Intake manifold

2

Charge mixture cooler

3

Coolant outlet

4

Coolant inlet

5

Oil drain plug

6

Oil dipstick

7

Oil filler neck

User tip

The gas supply line - consisting of ball cock, gas filter, solenoid valves, gas pressure regulator, gas mi

xer and air filter - is not supplied by MAN.

32

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 35

Transport, Packaging and Storage

5 Transport, packaging and storage

It is absolutely necessary to observe the “Installation Instructions” for the installation and commissioning of

a new or reconditioned engine.

User tip

Installation and commissioning is only to be performed by the employees of the manufacturer of the

entire system or by manufacturer authorised personnel.

5.1 Requirements

Before starting any work read and observe the General Safety Instructions and the safety information in

this chapter.

Strictly observe these instructions and act prudently to avoid accidents, personal injury and property

damage.

Personal Protective Equipment

The following protective equipment must be worn:

S Protective Clothing

S Protective Helmet

S Safety Shoes

S Safety Gloves

5.2 Safety instructions

Heavy Suspended Loads

WARNING

Danger to life due to suspended loads

During lifting, loads can swing out and drop.

For this reason:

S Do not stand under or remain in the swivel range of the suspended load.

S Only move the load under supervision.

S Only use approved lifting equipment and accessories with sufficient load capacity.

S Never use torn or scuffed lifting equipment such as ropes or straps.

S Do not let lifting equipment such as rope or straps come into contact with sharp edges and corners

and do not twist or knot them.

S Before leaving the work area, lower load to ground.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

33

Page 36

Transport, Packaging and Storage

Off-Centre Point of Gravity

WARNING

Danger to life due to incorrect handling of transported item

Transported item can swing out, tilt and/or drop.

For this reason:

S Use the crane hook lugs solely for transporting the engine without attachments (without alternator).

S Observe the information and markings on the package concerning centre of gravity.

S When transporting with a crane, the hook must be placed so that it is directly above the package's

centre of gravity.

S Carefully raise the package and observe its movement. If necessary, change the position of the lifting

equipment.

S Handle transported items carefully and note the symbols and instructions on the packaging.

S Use lifting gear. Diagonal pull not permitted.

Swingout of Packages being Transported

WARNING

Risk of injury due to transported item swinging out

Transported item can cause injury and damage

For this reason:

S Ensure that during the transport of packages, no persons, objects or obstacles are in the swivel range

of the packages being transported.

Unauthorised Transport

NOTE

Risk of damage due to untrained personnel

For this reason:

S Only trained personnel are allowed to unload the transported items.

S Unauthorised transport or attachment/removal of transport aids is not permitted.

S No unauthorised removal of packaging permitted.

Improper Transport

NOTE

Damage due to improper transport

Improper transport can cause packages to fall or tip over. This could cause considerable property

damage.

For this reason:

S Carefully handle the packages when unloading during delivery and when transporting them within the

company. Observe the symbols and instructions on the packages.

S Only use the prescribed lifting points.

34

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 37

Transport, Packaging and Storage

5.3 Transport inspection

Check the delivery for missing items and for damage from transport.

If external signs of transport damage are apparent:

S Do not accept delivery or only accept under written protest.

S List scope of damage on the transport documents or on the transportation company's packaging slip.

S Initiate a claims process.

User tip

Make sure to claim each damage case as soon as it is discovered. Damage claims can only be claimed

within the applicable time limits.

During work on the engine, the engine 1 must not

be accessed!

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

35

Page 38

Transport, Packaging and Storage

5.4 Transport

DANGER

Falling loads (weight 2000kg!) can lead to serious accidents

For this reason:

S Use sufficiently dimensioned crane lifting gear for lifting an engine!

Ropes and chains must exert vertical tension (tolerance 5_) on the crane hooks.

Crane lifting gear, ropes and chains must be in perfect condition.

WARNING

Danger to life due to incorrect handling of transported item

Transported item can swing out, tilt and/or drop.

For this reason:

S Use the crane hook lugs solely for transporting the engine with gearbox.

S Observe the information and markings on the package concerning centre of gravity.

S When transporting with a crane, the hook must be placed so that it is directly above the package's

centre of gravity.

S Carefully raise the package and observe its movement. If necessary, change the position of the lifting

equipment.

S Handle transported items carefully and note the symbols and instructions on the packaging.

S Use lifting gear. Diagonal pull not permitted.

36

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 39

Attachment points E3262 LE202, E3262 LE212

Transport, Packaging and Storage

For lifting the engine, 3 crane hook lugs 1 are attached to the engine.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

37

Page 40

Transport, Packaging and Storage

Attachment points E3268 LE212, E3268 LE222

For lifting the engine, 3 crane hook lugs 1 are attached to the engine.

Carefully read these Operating Instructions before starting any work!

38

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 41

Transport, Packaging and Storage

Transport with Crane

The engine can be transported with a crane under the following conditions.

S The crane and the lifting equipment must be designed for the weight of the engine.

S Ropes and chains must not exert diagonal pull on the crane hooks.

S The operator must be qualified for operating the crane.

1. Attach the ropes, straps or multipoint lifting equipment according to the picture.

2. Ensure that the package is hanging straight or compensate for the off-centre point of gravity.

3. Start the transport.

Transport with Forklift

The engine can be transported with a forklift under the following conditions.

S The forklift must be designed for the weight of the engine.

S The engine must be securely mounted on the pallet.

S The pallet must not be damaged.

S The forklift operator must be qualified and authorised to operate the forklift.

1. Insert the fork of the forklift between or under the pallet's struts.

2. The fork must be inserted into the pallet until it protrudes from the other side.

3. Ensure that the pallet cannot tip over if the centre of gravity of off-centre.

4, Lift the pallet and transport it to the desired location.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

39

Page 42

Transport, Packaging and Storage

5.5 Packaging

Packaging

The individual packages are packed in accordance with the expected conditions of transport.

The purpose of the packaging is to protect the components from transport damage, corrosion and other

damage. For this reason do not unpack components until shortly before they are to be assembled.

Handling Packing Material

Dispose of packing material according to the valid local and statutory regulations.

ENVIRONMENTAL NOTE

Incorrect disposal of packaging materials poses an environmental hazard

• Dispose of packing materials in an environmentally friendly manner.

• Observe the valid local regulations. If necessary, contact a professional disposal company.

5.6 Storage

Storage of packages

Store packages under the following conditions:

S Do not store in the open.

S Store in a dry and dust-free environment.

S Do not expose to damaging chemicals.

S Protect from sunlight.

S Avoid any physical shocks.

S Storage temperature: 15 to 35 °C.

S Relative air humidity: max. 60%.

S If stored for more than 3 months, regularly check the condition of the packaging. If necessary, renew or

replace the preservation.

User tip

Some of the packages may have information printed on them regarding their proper storage. Please

observe this information.

40

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 43

Installation and Commissioning

6 Installation and commissioning

6.1 Notes regarding installation and commissioning

6.1.1 Requirements

Before starting any work read and observe the General Safety Instructions and the safety information in

this chapter.

Strictly observe these instructions and act prudently to avoid accidents, personal injury and property

damage.

Personal Protective Equipment

The following protective equipment must be worn:

S Protective Clothing

S Safety Shoes

S Safety Gloves

6.2 Safety instructions

Personnel

S The installation and commissioning may only be performed by MAN employees or by MAN-trained quali

fied personnel.

WARNING

Danger caused by faulty installation and commissioning!

Installation and commissioning require trained qualified personnel with sufficient experience. Faulty in

stallation can cause life threatening situations and considerable property damage.

For this reason:

S Installation and commissioning may only be performed by expert personnel trained by MAN.

Ground Rules

WARNING

Risk of injury due to improper installation and commissioning

Improper installation and commissioning can cause serious personal injury or considerable property

damage.

For this reason:

S Ensure adequate work space before starting any work.

S Be careful when working with exposed parts with sharp edges.

S Make sure work space is kept clean and orderly!

S Install components in a correct manner.

S Observe the prescribed tightening torques.

S Secure components so that they do not fall or tip over.

S Before commissioning the engine, carefully read the Operating Instructions and familiarise yourself with

the “critical” subjects.

S It is absolutely necessary to observe the “Assembly Instructions” for the installation and commissioning

of a new or reconditioned engine.

S For safety reasons we recommend placing an off limits sign on the door to the engine room and to in

struct the operating personnel that they are responsible for the safety of people who enter the engine

room.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

41

Page 44

Installation and Commissioning

6.3 Engine installation

6.3.1 Interfaces between engine and plant

1

Coolant connections on charge mixture cooler

2

Exhaust turbocharger

3

Intake manifold

4

Exhaust turbocharger

2

and 4 Mount exhaust system, see page 49

3

Mount gas inlet, see page 48

6

and 7 Connect cooling system, see page 47

Carefully read these Operating Instructions before starting any work!

42

This is especially valid for the chapter on General Safety Instructions

5

Engine mounting

6

Coolant inlet

7

Coolant outlet

and the safety instructions in each of the chapters.

Page 45

Installation and Commissioning

1 Exhaust turbocharger

2

Exhaust turbocharger

When installing the engine, perform the following assembly work on the interfaces between engine and

plant:

1

and 2 Mount exhaust system, see Installation Instructions

3

Mount alternator, see page 45

4

Connect gas inlet, see page 48

3 Flywheel

4

Gas inlet

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

43

Page 46

Installation and Commissioning

6.3.2 Installation Instructions

Only general engine installation instructions can be given in this chapter.

More detailed information can be found in the “Installation Instructions for MAN Industrial Gas Engines”.

These instructions can be obtained from MAN, see page 2 for contact address.

6.3.3 Installation drawing

The installation drawing provides information about the type of connections and the connection dimensions.

Depending on the scope of delivery, wiring diagrams, layout diagrams for the resilient engine mounts etc.

may be required. These can be obtained from MAN, see page 2 for contact address.

NOTE

Engine installation is based on the installation instructions and the installation drawing.

For this reason:

S Observe these sources of information for each of the assembly jobs listed hereafter.

6.3.4 Screw and bolt connections

Always tighten screw and bolt connections using a torque wrench.

The assembly tightening torques for all common screw and bolt connections are listed on page 52.

NOTE

Risk of damage due to incorrectly tightened screw and bolt connections

Components get damaged.

For this reason:

S Use impact wrench for pretightening to max. 50% of the specified final torque.

S Always use a torque wrench for final tightening.

44

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 47

Installation and Commissioning

6.4 Completion of the engine and assembly of the drive system

When installing the engine, ensure that there is enough space to perform the regular maintenance work

specified in the maintenance schedule.

6.4.1 Mounting an alternator on the flywheel housing

Flywheel

The connection dimensions of the flywheel 1 are

indicated on the installation drawing.

S Remove oil, grease and preservative from the

flywheel.

Flywheel housing

User tip

For screw and bolt tightening torques, see page

52.

Information regarding the dimensions of the fly

wheel housing 1 and the type of screw and bolt

connections for mounting the alternator can be

found on the installation drawing.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

45

Page 48

Installation and Commissioning

6.4.2 Checking crankshaft axial clearance

NOTE

The engines' crankshaft axial clearance specified in the design must not be reduced under any circum

stances as a result of mounting clutches or other attachments.

For this reason:

S It is essential to determine the crankshaft axial clearance using a dial gauge held on a magnetic stand

before and after flange-mounting any attachments.

S Remove V-belt protection.

S Position the dial gauge holder 1 with dial

gauge 2 on the engine mounting so that the

dial gauge tracer pin is resting on the vibration

damper with a preload.

S Push the crankshaft towards the flywheel hou

sing in axial direction until the stop is reached.

S Zero the dial gauge.

S Pull the crankshaft away from the flywheel hou

sing in axial direction until the stop is reached

S Check the reading on the dial gauge.

If the results of both measurements do not match,

or if the crankshaft springs back after being mo

ved, check the mounting.

Engines Crankshaft axial clea

rance

E3268LE202 /

E3262 LE202

0.20-0.40 mm

46

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 49

6.5 Connecting the cooling system

6.5.1 Connecting the engine cooling

The installation drawing provides information about

the connections.

Installation and Commissioning

S Connect the coolant outlet

S Connect the coolant inlet

1

2

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

47

Page 50

Installation and Commissioning

6.6 Mounting the gas inlet

Both cylinder banks merge into a central gas inlet.

The dimensions of the flange 1 for connecting the

plant-side gas inlet can be found on the installation

drawing, see page 97.

48

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 51

6.7 Mounting the exhaust system

6.7.1 Exhaust gas outlet on engine

The dimensions of the flange 1 for connecting the

plant-side exhaust system can be found on the in

stallation drawing, see page 97.

S Connect the exhaust system to the flange 1 on

the exhaust turbocharger(s).

Installation and Commissioning

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

49

Page 52

Installation and Commissioning

6.7.2 Connecting the exhaust system to the engine

Flexible connecting elements which allow engine

movements due to the flexible engine mounting

and decouple the engine from the exhaust system

in terms of vibration must be installed between the

engine and the exhaust system.

Example: compensator

1

NOTE

Component damage due to forces acting on the turbocharger.

For this reason:

S Exhaust gas lines must be fastened and supported so that no forces act on the turbocharger.

50

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 53

Installation and Commissioning

6.8 Connecting the electrical system

NOTE

Component damage due to corrosion

For this reason:

S The starter battery's negative lead must be fed back to starter terminal 31.

S Connect the engine and all pipe connections from and to the engine with the plant potential using

”ground cables”.

In the case of dual engine plants, independent wiring is required for each engine, i.e. the engines' circuits

must not be linked together.

Batteries

Separate batteries for the starter must be provided for each engine.

6.8.1 Starter

All MAN industrial gas engines have two-pole

starters. The starter battery's positive lead must

therefore be fed back to terminal 30 of the

starter 2, the starter battery's negative lead to

terminal 31 of the starter 1 .

The starter can be mounted either on the left or

the right of the engine.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

51

Page 54

Installation and Commissioning

6.9 Torques for screw and bolt connections to Works Standard M 3059

Screws and bolts / nuts with external‐ or internal hex, head without collar or flange

Thread size

x pitch

for 8.8 / 8 for 10.9 / 10 for 12.9 / 12

M4 2.5 4.0 4.5

M5 5.0 7.5 9.0

M6 9.0 13.0 15.0

M7 14.0 20.0 25.0

M8 22.0 30.0 35.0

M8x1 23.0 35.0 40.0

M10 45.0 65.0 75.0

M10x1.25 45.0 65.0 75.0

M10x1 50.0 70.0 85.0

M12 75.0 105.0 125.0

M12x1.5 75.0 110.0 130.0

M12x1.25 80.0 115.0 135.0

M14 115.0 170.0 200.0

M14x1.5 125.0 185.0 215.0

Strength classes / tightening torques in Nm

M16 180.0 260.0 310.0

M16x1.5 190.0 280.0 330.0

M18 260.0 370.0 430.0

M18x2 270.0 290.0 450.0

M18x1.5 290.0 410.0 480.0

M20 360.0 520.0 600.0

M20x2 380.0 540.0 630.0

M20x1.5 400.0 570.0 670.0

M22 490.0 700.0 820.0

M22x2 510.0 730.0 860.0

M22x1.5 540.0 770.0 900.0

M24 620.0 890.0 1040.0

M24x2 680.0 960.0 1130.0

M24x1.5 740.0 1030.0 1220.0

52

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 55

Installation and Commissioning

6.10 First commissioning

Correct first commissioning is essential for ensuring the operational safety and reliability of the

engines. If commissioning is performed incorrectly, engine damage is inevitable.

The procedure comprises several steps:

S Thorough inspection of the installation

S Filling of the engine with engine oil

S Filling of the engine with coolant, bleeding of the cooling system

S Starting of the engine

S A test run, with measurement and archiving of important data

In order to perform first commissioning, personnel require specific knowledge and skills as well as

special equipment.

First commissioning may therefore only be performed by persons or workshops authorised and certified by

MAN Nuremberg.

NOTE

Incorrectly performed first commissioning results in operating faults that lead to total loss of

the engine.

For this reason:

S Commissioning may only be performed by personnel authorised by MAN Nuremberg.

WARNING

Danger to life due to non-functioning safety equipment

For this reason:

S Before commencing work, check that all safety equipment is functioning and correctly installed.

S Before starting the engine, check that all safety equipment is functioning and correctly installed.

Carefully read these Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

53

Page 56

Installation and Commissioning

6.11 Commissioning

New or reconditioned engines must not be operated during the first operating hours at loads higher than 3/4

power.

After this time period the engine can be slowly brought up to full power.

NOTE

The liability for material defects no longer applies if non-approved fuels, lubricants and coo

lants are used

Liability of material defects is terminated if non-approved fluids and lubricants are used.

For this reason:

S Only use approved fluids and lubricants (see “Fuels, Lubricants and Coolants..." publication).

S The requirements on the quality of gas are specified in “MAN data sheet - Minimum requirement on

the quality of gas for MAN gas engines".

6.11.1 Gas system

User tip

The gas supply line is not included in MAN's scope of delivery. Commissioning, operation, monitoring of

operating conditions, and maintenance of the gas system are all to be performed as described in the

manufacturer's instructions.

Setting for commissioning

For commissioning the engine is to be set for the use of a suitable gas/air mixture. Any deviations from this

will negatively influence the output power, the engine efficiency and the exhaust emissions.

The requirements on the quality of gas are specified in “MAN data sheet - Minimum requirement on the

quality of gas for MAN gas engines".

The operating pressure of the natural gas in the gas line must be at least 20 mbar.

The gas pressure should be steady within this range.

In order to obtain a correct gas/air mixture, the intake air in the engine compartment must be at a tempera

ture of between 10_C and 30_C.