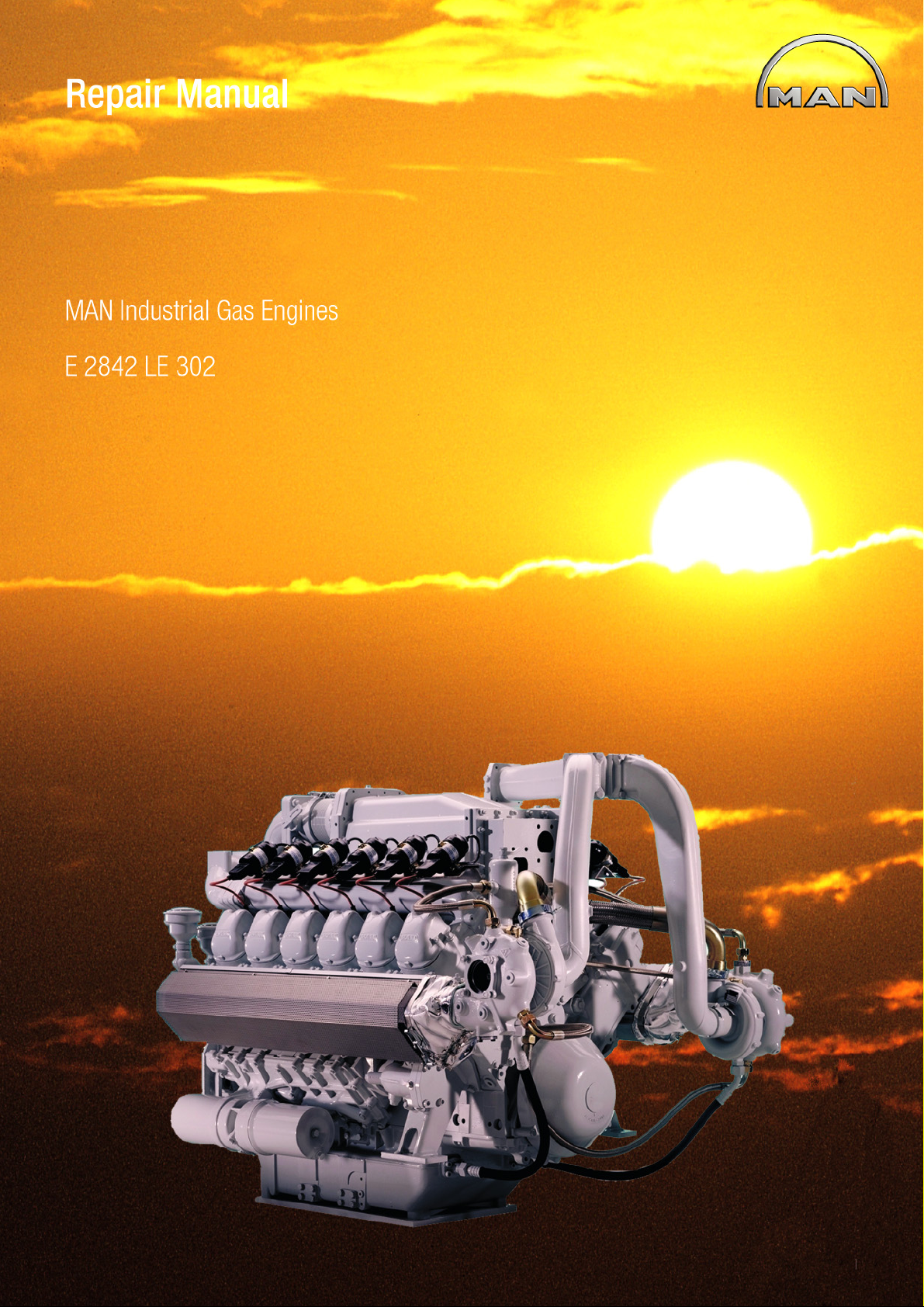

Man E 2942 LE 302 Repair Manual

Instructions

Important instructions which concern technical safety and protection of persons are emphasised as shown

below.

Danger:

This refers to working and operating procedures which must be complied with in order to rule out

the risk to persons.

Caution:

This refers to working and operating procedures which must be complied with in order to prevent

damage to or destruction of material.

Note:

Explanatory descriptions which help in understanding the relevant work or operating procedure to

be carried out.

Assembly of pipes

Danger:

No pipes may be bent.

Risk of breakage!

Fitting flat seals / gaskets

Flat seals / gaskets are often inserted with sealing agents or adhesives to make fitting them easier or to

achieve better sealing. Flat seals may slip in operation due to the “sewing -machine” effect, in particular if

they are used between parts with different rates of linear expansion under heat (e.g. aluminium and cast

iron), and leaks may then occur.

Example:

The cap of the front crankshaft seal. If a sealing agent or an adhesive is used here the flat seal will move

inwards in the course of time as a result of the different expansion rates of the materials. Oil will be lost, for

which the shaft seal may be thought to be responsible.

Flat seals / gaskets can be fitted properly only if the following points are observed:

D Use only genuine MAN seals / gaskets

D The sealing faces must be undamaged and clean

D Do not use any sealing agent or adhesive − as an aid to fitting the seals a little grease can be used if

necessary so that the seal will stick to the part to be fitted

D Tighten bolts evenly to the specified torque

Fitting round sealing rings

D Use only genuine MAN round sealing rings

D The sealing faces must be undamaged and clean

D Always wet round sealing rings with engine oil before fitting them

2

Contents

Preface 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine type classification 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety regulations 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault table 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General notes on engine overhaul 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illustrations of E 2842 LE 302 / E 2842 LE 312 engine 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication schedule 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system schedule 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine management schedule 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition system

Replacing the spark plugs 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition control unit 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking and setting the ignition point 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling system

Draining and filling coolant 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication

Changing the oil filter 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the oil cooler 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the oil pump, servicing 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil injection nozzle 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel / Crankshaft seal

Removing and fitting vibration damper, replacing front crankshaft gasket 35 . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the flywheel, replacing the starter motor toothed wheel 39 . . . . . . . . . . . . . . . . . . .

Removing and installing the crankshaft gasket on flywheel side 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the bearing race 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft gaskets 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake / exhaust system

Removing and installing the intake pipes 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the exhaust pipe 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger, troubleshooting 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking charging pressure 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the turbocharger 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the charge mixture cooler 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dismantling the charge mixture cooler 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head

Removing and installing the cylinder head 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the valve clearance 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dismantling and assembling the rocker arm mechanism 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing valves 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check compression 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve timing

Removing and installing the gear case 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing the camshaft, replacing camshaft bearings 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the valve timing 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Contents

Crankgear, pistons

Removing and installing pistons with conrods 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing pistons from conrod and fitting, checking − replacing conrod 79 . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and installing piston rings 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the cylinder liners 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring piston projection 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attachments

Removing and installing the starter motor 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting impulse sensor 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Data 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankcase 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder liner 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel and starter motor toothed wheel 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conrods 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistons 97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve gear 100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine lubrication 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition system 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition point 104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter motor 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder head bolts 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque guide values 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque guide values 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special tools 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Engine type classification

The type designation, consisting of a sequence of letters and numbers, indicates some characteristics of

each engine, provided you are familiar with the basic terminology.

The system is explained here using the type E 2842 LE 302 / E 2842 LE 312 as an example:

E The “E” at the start of the type designation stands for natural gas (German: Erdgas)

28 The numbers “28” indicate that this is a power unit with 128 mm bore

4 The “4” means 142 mm stroke

2 The “2” indicates the number of cylinders 12

L This letter stands for “charge-air cooling” (German: Ladeluftkühlung)

E The “E” stands for “fitted engine” (German: Einbaumotor) and is intended to distinguish MAN

vehicle engines

302 This is a factory-internal development number.

5

Safety regulations

General

Important safety regulations are summarized in this quick-reference overview and arranged by topic to effectively convey the knowledge necessary to avoid accidents causing injury, damage or environmental hazard. Additional information can be found in the operating instructions of the engine.

Important:

Should an accident occur despite all precautionary measures, particularly one involving contact with corrosive acid, penetration of fuel under the skin, scalding by hot oil, antifreeze splashing into the eyes etc. you

must seek medical assistance immediately.

1. Regulations for the prevention of accidents with personal injury

Inspection, adjustment and repair work may only be performed by authorised and skilled personnel.

D The engine may only be started and operated by authorised personnel.

D When the engine is running, do not get too close to the rotating parts.

Wear close-fitting clothing.

D Do not touch hot engine with bare hands: Risk of burns.

D Keep area surrounding engine, ladders and stairways free of oil and grease. Accidents

caused by slipping can have serious consequences.

D Only work with tools which are in good condition. Worn spanners/wrenches slip: Danger

of injury.

D Persons must not stand under an engine suspended on a crane hook. Keep lifting gear

in order.

D Open the coolant circuit only when the engine has cooled down. If it is unavoidable that

the circuit be opened with the engine at operating temperature, observe the instructions

in the chapter “Maintenance and care” in the operating instructions.

D Do not tighten or undo pipes and hoses under pressure (lubricating oil circuit, coolant

circuit and any downstream hydraulic oil circuits). The fluids which flow out can cause

injury.

6

Loading...

Loading...