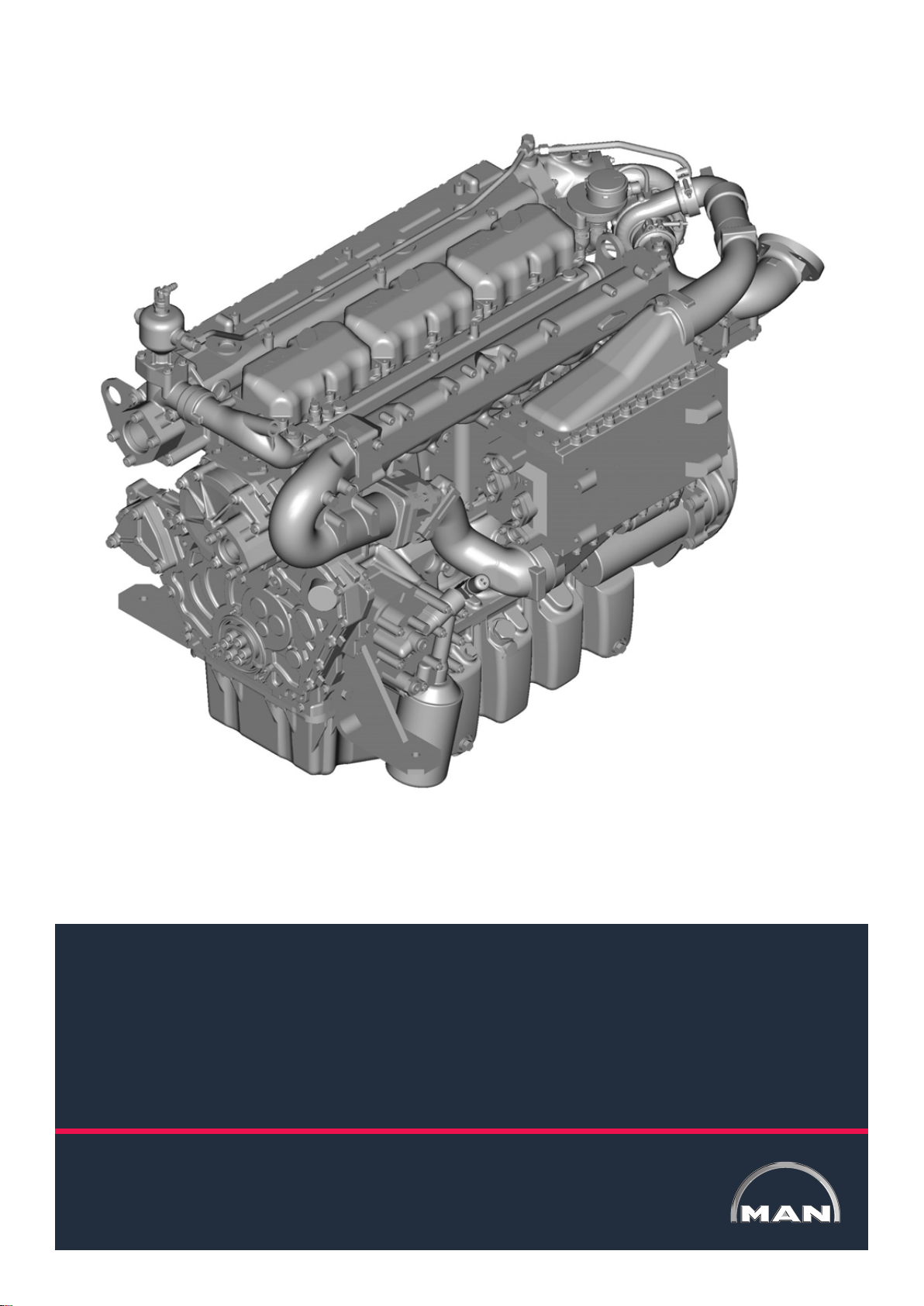

Man E0834 LE302, E0834 LE312, E0834 LE322, E0836 LE202, E0836 LE302 Operating Instructions Manual

Page 1

Operating Instruction

MAN Industrial Gas Engines

834 LE302/312/322 / E0836 LE202/302

E0

MAN Engines

A Division of MAN Truck & Bus

Page 2

Page 3

Operating Instructions

MAN Industrial Gas Engines

E0834 LE302 / 312/ 322

E0836 LE202/ 302

51.99493-8538 “Translation of the original operating instructions”

Version 07

Page 4

Page 5

MAN-Industrial Gas Engines E0834 LE302 ; E0836LE202/302

Information and Copyright

Subject to change.

The information, text, drawings, pictures and other illustrations that it contains are protected by copyright

and are subject to industrial property rights. Any misuse is punishable by law.

It is not permitted to change the contents of this document. The same applies to changes to the context of

individual chapters and/or the whole document. MAN Truck & Bus AG assumes no liability for any

damages arising from non-compliance with the above provisions.

Reprinting, copying or translation, even of extracts, is not allowed without written permission from MAN. All

rights under the copyright law are strictly reserved by MAN.

2018

MAN Truck & Bus AG

Vogelweiherstraße 33

90441 Nuremberg

Germany

Tel.: +49 911 / 420-1745

Fax: +49 911 / 420-1932

Email: Engine-Documentation@man.eu

Internet: www.man-engines.com

Technical status: 08.2018

51.99493-8538

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

3

Page 6

Table of Contents

1 Preface 8...........................................................................

1.1 Information about Operating Instructions 8.........................................

1.1.1 Publications belonging to the Operating Instructions 8..........................

1.1.2 Additional Publications for the Engines 8.....................................

1.2 Key to Symbols 9...............................................................

1.3 Limitation of Liability 10...........................................................

1.4 Copyright 10....................................................................

1.5 Other Applicable Documents 10...................................................

1.6 Spare Parts 11..................................................................

1.7 Disposal 11.....................................................................

1.8 Warranty Terms 12..............................................................

1.9 Service 12......................................................................

2 General Safety Instructions 13........................................................

2.1 Intended Use 13.................................................................

2.2 Contents of the Operating Instructions 14...........................................

2.3 Modifications and Conversions to the Engine 14.....................................

2.4 Responsibility of the Operator 14...................................................

2.5 Personnel Requirements 15.......................................................

2.5.1 Qualifications 15...........................................................

2.5.2 Unauthorised Persons 15....................................................

2.5.3 Instructions 15.............................................................

2.6 Personal Protective Equipment 16.................................................

2.7 Specific Dangers 17..............................................................

2.8 Safety Equipment 21.............................................................

2.9 Conduct in Dangerous Situations and When Accidents Occur 22.......................

2.10 Signs 23........................................................................

2.11 Environmental Protection 24.......................................................

3 Engine Model Plate 25................................................................

3.1 Explanation of the Motor-Nr./Engine-No. (Engine Identification Number) 26..............

3.2 Explanation of Model Designation 26...............................................

4 Design and Function 27..............................................................

4.1 Engine, General 27..............................................................

4.2 Engine Views E0834 LE302/ 312/ 322 28...........................................

4.2.1 Front Left View 28..........................................................

4.2.2 Front Right View 29........................................................

4.3 Engine Views E0836 LE202 30....................................................

4.3.1 Front Left View 30..........................................................

4.3.2 Front Right View 31........................................................

4.4 Engine Views E0836 LE302 32....................................................

4.4.1 Front Left View 32..........................................................

4.4.2 Front Right View 33........................................................

Carefully read the Operating Instructions before starting any work!

4

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 7

Table of Contents

5 Transport, Packaging and Storage 36..................................................

5.1 Prerequisite 36..................................................................

5.2 Safety Instructions 36............................................................

5.3 Transport Inspection 38...........................................................

5.4 Transport 39....................................................................

5.5 Packaging 41....................................................................

5.6 Storage 41......................................................................

6 Installation and Commissioning 42....................................................

6.1 Prerequisite 42..................................................................

6.2 Safety Instructions 42............................................................

6.3 Installation - Engine 43...........................................................

6.3.1 Safety Equipment 43.......................................................

6.3.2 Engine Model Plate Data 43.................................................

6.4 Commissioning 44...............................................................

6.4.1 Gas System 44............................................................

6.4.2 Filling Coolant 45...........................................................

6.4.3 Filling Engine Oil 46........................................................

7 Operation 48.........................................................................

7.1 Prerequisite 48..................................................................

7.2 Safety Instructions 48............................................................

7.3 Preparations before Operation 49..................................................

7.3.1 Check Gas Quality, Open Gas Supply 49......................................

7.3.2 Checking Coolant 49........................................................

7.3.3 Refilling Coolant 50.........................................................

7.3.4 Checking Engine Oil Level 51................................................

7.3.5 Refilling Engine Oil 52......................................................

7.4 Operation 53....................................................................

7.4.1 Starting Engine 53..........................................................

7.4.2 Monitoring Operation 54.....................................................

7.4.3 Stopping in an Emergency 54................................................

7.4.4 Engine Shut Off 54.........................................................

8 Maintenance and Care 55.............................................................

8.1 Maintenance instructions 55.......................................................

8.2 Maintenance Schedule 55.........................................................

8.3 Repair instructions 55............................................................

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

5

Page 8

Table of Contents

9 Faults 57............................................................................

9.1 Prerequisite 57..................................................................

9.2 Safety Instructions 57............................................................

9.3 Fault Table 58...................................................................

10 Decommissioning and Recommissioning 63...........................................

10.1 Prerequisite 63..................................................................

10.2 Safety Instructions 63............................................................

10.3 Temporary Decommissioning of Engines 64.........................................

10.4 Recommissioning of Decommissioned Engines 65...................................

10.4.1Commissioning of Preserved Engines according to MAN-Werknorm M 3059 65.....

10.4.2Commissioning of Non-Preserved Engines 65..................................

11 Technical Data 67....................................................................

11.1 Dimensions and Weights 67.......................................................

11.1.1E0834 LE302 67...........................................................

11.1.2E0836 LE202 67...........................................................

11.1.2E0836 LE302 67...........................................................

11.2 Installation Location and Space Requirements 67....................................

11.3 Engine Data 68..................................................................

11.3.1E0834 LE302 68...........................................................

11.3.1E0834 LE312 70...........................................................

11.3.1E0834 LE322 72...........................................................

11.3.2E0836 LE202 74...........................................................

11.3.2E0836 LE202 76...........................................................

Carefully read the Operating Instructions before starting any work!

6

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 9

Table of Contents

12 Indices 79..............................................................................

12.1 Abbreviations 80.................................................................

12.2 Technical Terms 81..............................................................

12.3 Index 82........................................................................

13 Notes 84.............................................................................

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

7

Page 10

Foreword

1 Preface

1.1 Information about Operating Instructions

These Operating Instructions provide important information on dealing with engines. Prerequisite for safe

operation is the compliance with all safety and handling instructions.

Furthermore, the local accident prevention regulations valid for the engine's area of application and the

general safety regulations must be observed.

Timely and proper maintenance and care of the engines according to the set maintenance intervals ensure

and maintain the operational safety and the reliable application of these engines.

Use only genuine MAN spare parts and accessories or those approved by MAN.

Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines.

A particular concern of MAN is to improve environmental protection. This begins with the development and

design of our engines. We make sure that no environmentally hazardous materials are used and, for ex

ample, that the emissions fulfil the highest requirements.

Economical operation helps to conserve our resources and our environment.

1.1.1 Publications belonging to the Operating Instructions

The following publications belong to the Operating Instructions

- Fluids and Lubricants for MAN Gas Engines

- Assembly Instructions

Both publications are considered "parts of the product" and should always be kept in the immediate vicinity

of the engine for the personnel.

Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on

General Safety Instructions and the safety instructions in each of the chapters.

Failure to observe these Operating Instructions and any accompanying supplier operating instructions

leads to the loss of warranty claims.

1.1.2 Additional Publications for the Engines

The following instructions supplement the Operating Instructions for the engines:

For the operator, maintenance and service personnel

- Spare Parts Catalogue (included)

For the service personnel

- Repair Instructions

Carefully read the Operating Instructions before starting any work!

8

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 11

Foreword

1.2 Key to Symbols

Warnings

Warnings are identified in these Operating Instructions with symbols. These warnings are pre

ceded by signal words that express the magnitude of the risk.

Always heed these warnings and act prudently to prevent accidents, injuries and property damage.

DANGER!

... indicates an imminently hazardous situation, which leads to death or serious injuries if

not avoided.

WARNING!

... indicates a possible hazardous situation, which can lead to death or serious injuries if not

avoided.

CAUTION!

... indicates a possible hazardous situation, which can lead to minor or light injuries if not

avoided.

IMPORTANT!

indicates a possible dangerous situation that can lead to property damage if it is not

avoided.

Tips and Recommendations

NOTE!

highlights useful tips and recommendations as well as information for efficient and smooth

operation.

General Information

• This symbol indicates a list at the first level.

- This symbol indicates a list at the second level.

1. This symbol indicates a sequence of actions.

(1) In the text, this symbol indicates a position in a graphic.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

9

Page 12

Foreword

1.3 Limitation of Liability

All of the information in these instructions have been prepared while taking into account the valid standards

and regulations, the state of the art, as well as our many years of experience and knowledge.

MAN is not liable for damages resulting from:

SFailure to follow these instructions

S Improper use

S Use of untrained personnel

S Customer conversions

S Technical modifications

S Use of non-approved spare parts and fluids and lubricants

The actual scope of delivery for special versions, additional ordering options or technical modifications may

deviate from what is described and illustrated in these instructions.

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of

MAN and the law applicable at the time of contracting arrangements.

1.4 Copyright

Please handle these Operating Instructions as confidential. They are only to be used by the persons work

ing with the engine. Transfer to a third party without explicit written permission from MAN is strictly prohib

ited.

NOTE!

The information, texts, drawings, illustrations and other depictions are all protected by copy

right and are subject to industrial property rights. Any improper use is punishable by law.

1.5 Other Applicable Documents

Supplier components are installed in the engine. Risk assessments have been carried out on these parts

by the suppliers.

The compliance of construction with the existing European and national legislation has been declared by

the respective suppliers of the components.

10

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 13

Foreword

1.6 Spare Parts

Use only genuine MAN spare parts and accessories or those approved by MAN.

Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines.

Spare parts and accessories must either be MAN genuine parts or parts that have been specifically ap

proved by MAN. The reliability, safety and suitability of these parts have been established specifically for

the engines. We cannot assess and vouch for other non-MAN products, despite ongoing market observa

tions.

WARNING!

Risk of injury from incorrect spare parts!

Incorrect or faulty spare parts can lead to damage, malfunctions or total failures and inter

fere with safety.

For this reason:

S Only use MAN genuine parts

NOTE!

Please always specify the engine model, engine number and order number when corres

ponding with MAN, see page 25.

Order spare parts through an authorised dealer or directly from MAN.

For addresses, see page 3.

1.7 Disposal

Dispose in accordance with national regulations.

If no return or disposal agreement has been made, recycle the disassembled components as follows:

S Sort metals before scrapping.

S Recycle the plastic parts.

S Dispose of all other parts according to their material composition.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

11

Page 14

Foreword

1.8 Warranty Terms

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of

MAN and the law applicable at the time of contracting arrangements.

Failure to observe these Operating Instructions and any accompanying supplier operating instructions

leads to the loss of warranty claims.

The use of non-approved parts leads to the loss of warranty claims.

We recommend to use genuine parts even after the warranty period has passed. This will ensure the con

tinuous performance of the engine.

1.9 Service

Our MAN product support is available for technical information.

NOTE!

Please always specify the engine model, engine number and order number when corres

ponding with MAN, see page 25.

Information about contact persons can always be called up by telephone, fax, email or over the Internet.

For addresses see page 3.

12

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 15

General Safety Instructions

2 General Safety Instructions

This chapter provides information on residual risks and hazards during proper use of the engine. The gen

erally valid safety instructions to be observed are listed here. They provide optimum protection for person

nel and for the safe and smooth operation of the engine.

In the following, specific, action and situation-related safety information is placed before the corresponding

step, or in the chapter described.

Failure to observe the Operating Instructions and Safety Instructions in this document can result in signific

ant hazards.

2.1 Intended Use

The engine is built exclusively to drive generators or for the coupling of heat exchangers within the limits of

technical data

Any other use is considered as "not intended".

MAN is not liable for any damage resulting from use that is not intended. The risk is entirely borne by the

operator.

Intended use also includes compliance with the country-specific, local environmental regulations.

This in particular concerns the compliance with the applicable legal exhaust emission limits.

Furthermore, the engine operating parameters according to the technical data sheets currently in effect

must also be adhered to.

The mixture generating and control system, as well as - if needed - the exhaust aftertreatment system must

be prepared by the manufacturer of the complete machine to meet these criteria.

Intended use also includes compliance with the prescribed operating, maintenance and repair work.

The engine may only be used, maintained and repaired by persons who are familiar with the engine and

have been informed of the hazards.

Unauthorised modifications to the engine shall void any liability for any resulting property damage and per

sonal injury.

Likewise, the manipulation of the control system could affect the performance and emission characteristics

of the engine. Compliance with the statutory environmental requirements can therefore no longer be guar

anteed.

DANGER!

Danger from not using the product as intended!

Any use that exceeds the intended use and/or any different use of the engine can lead to

dangerous situations which will invalidate the operating permit.

For this reason:

S Use the engine for its intended purpose only.

S Use the engine outside of hazardous areas where there is a risk of explosion.

S Use the engine with an overspeed limiting device installed.

NOTE!

Observe the following information when operating the engine:

S The safety information in these Operating Instructions and in the supplier's operating in

structions.

S The “Technical Data" chapter in these Operating Instructions and in the supplier's operat

ing instructions.

S Country-specific regulations.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

13

Page 16

General Safety Instructions

2.2 Contents of the Operating Instructions

Any person who is instructed to perform work on or with the engine, must have read and understood these

Operating Instructions before starting any work. This also applies if the person has worked with such an

engine or a similar engine, or has already been trained by MAN.

Reading and understanding the Operating Instructions is thus mandatory.

2.3 Modifications and Conversions to the Engine

In order to avoid hazards and to ensure optimum performance, no modifications or conversions to the en

gine may be made which are not expressly approved by MAN.

If changes are made without the written consent of MAN, the guarantee or warranty obligation for MAN is

not longer valid for damage and defects, which are based on these unauthorised changes. Furthermore

MAN assumes no liability for any damage caused as a result of unauthorised changes.

2.4 Responsibility of the Operator

The operator of the motor is subject to the statutory requirements for workplace safety.

In addition to the Safety Instructions in these Operating Instructions, the safety regulations, accident pre

vention regulations and environmental protection regulations valid for the application area of this engine

must also be observed.

In particular:

S The operator must be knowledgeable about the valid occupational health and safety regulations and be

able to assess, in a risk analysis, the dangers that are present in the specific working conditions at the

operating site of the engine. He must then implement these safety regulations in the form of operating

instructions for the operation of the engine.

S During the entire period of operation of the engine the operator must check whether the operating in

structions he created meet the most current standards for regulations and revise them if necessary.

S The operator must clearly define and regulate the responsibilities for installation, operation, maintenance

and cleaning of the product.

S The operator must ensure that all staff who deal with the engine have read and understood the Operat

ing Instructions.

In addition, the operator must periodically train the staff and inform them about hazards.

S The operator must provide the personnel with the necessary protective equipment.

S The operator must limit access to the operating room.

S The operator must ensure proper ventilation of the operating room.

S These operating instructions must be kept in the immediate vicinity of the engine and be readily access

ible at any time to those persons working on and with the engine.

The operator is responsible for ensuring that the engine is always operated in perfect working condition and

working order.

In particular:

S Maintenance work such as that described in the Maintenance Instructions are to be completely per

formed within the prescribed time intervals or are to be performed by a MAN service workshop/MAN

contract partner.

S The operator must have all safety equipment checked regularly for function and integrity.

S The instructions in the Operating Instructions are to be followed completely and fully!

14

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 17

General Safety Instructions

2.5 Personnel Requirements

2.5.1 Qualifications

WARNING!

Risk of injury caused by insufficient qualifications!

Improper handling can result in significant personal injury and property damage

For this reason:

S Specific activities must only be performed by those persons who are named in the re

spective chapters in these Operating Instructions.

The following qualifications will be designated in the Operating Instructions for various task areas.

S Instructed Persons

Have been instructed in a briefing about the possible dangers of improper handling in their tasks.

S Qualified Personnel

Due to their technical training, knowledge and experience and knowledge of the relevant regulations

they can properly perform the tasks assigned to them.

S Electric Specialist

Is capable of performing work on electrical systems due to his/her technical education/training, know

ledge and experiences as well as knowledge of the respective standards and regulations and can recog

nise and avoid any possible dangers.

The electric specialist is trained for the specific operating site in which he/she works and knows the rel

evant standards and regulations.

Only those people who can perform their work reliably should be considered as authorised personnel. Indi

viduals whose responsiveness is influenced, for example, by alcohol or drugs, are not permitted.

S When selecting personnel, observe the regulations regarding age and profession valid at the operating

site.

2.5.2 Unauthorised Persons

WARNING!

Danger for unauthorised persons!

Unauthorised persons who do not fulfil the requirements described here do not realise the

dangers that exist in the working area.

For this reason:

S Keep unauthorised persons out of the working area.

S In case of doubt, address the person and remove him/her from the working area if neces

sary.

S Interrupt the work until all unauthorised persons are out of the working area.

2.5.3 Instructions

Personnel must be instructed on regular basis and this should be documented in a log to keep better track

of who and when.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

15

Page 18

General Safety Instructions

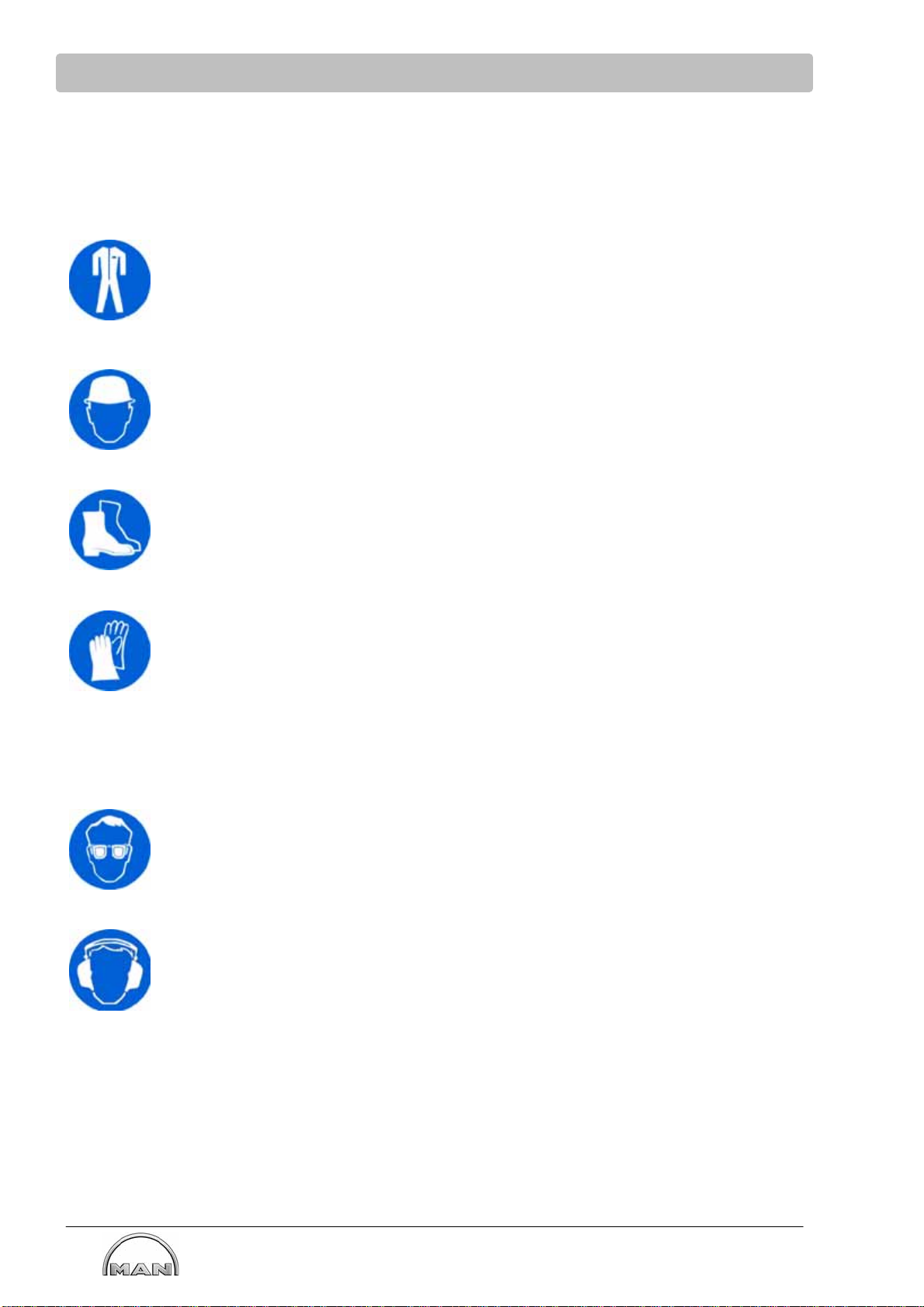

2.6 Personal Protective Equipment

Wearing personal protective equipment is necessary to minimise the health risks when working.

S The required personal protective equipment for the relevant job must always be worn while working.

S All signs pertaining to personal protective equipment in the working area must be followed.

Protective Clothing

Close-fitting clothing with low initial tear strength, with narrow sleeves and with no pro

truding parts. It is used primarily to protect against injury, weather and dirt.

No rings, bracelets, necklaces and other jewellery are to be worn while working.

Protective Helmet

To protect the head from falling or flying objects.

Safety Shoes

To protect the feet from heavy falling objects and from slipping on slick surfaces.

Safety Gloves

To protect the hands from friction, scraping, punctures or deep injuries and to protect

from hot or caustic parts or fluids

To be worn when performing specific types of work

When performing certain types of work, special protective equipment is required. These will be specifically

mentioned in the relevant chapters.

Safety Glasses

To protect the eyes from flying objects and spraying fluids.

Hearing Protection

To protect the ears from damage by loud noises.

16

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 19

General Safety Instructions

2.7 Specific Dangers

The following section describes residual risks which have been identified.

S Observe the safety instructions listed here and the warnings in the other chapters of these instructions

in order to reduce health hazards and avoid dangerous situations.

Electrical Current

DANGER!

Risk of death caused by electrical current!

There is a risk of death when coming into contact with parts conducting electrical currents.

Damaged insulation or components can be life threatening.

For this reason:

S If the insulation is damaged, immediately switch off the power supply and get the insula

tion repaired.

S Any work performed on the electrical system may only be made by a qualified electrician.

S When working on the electrical system the power supply must be switched off and then

properly checked to ensure no electrical current is present.

S Before starting any maintenance, cleaning or repair work the power supply must be

switched off and secured from being accidentally switched back on.

S Do not bridge or bypass any fuses. When replacing fuses, ensure to use the correct am

perage.

S Keep moisture clear of parts conducting electrical current. This could cause a short-cir

cuit.

Moving Parts

DANGER!

Risk of death caused by electrical current!

Do not touch or pull on the following parts of the ignition system when the engine is in oper

ation:

S Ignition coils and caps

S Wires of the high voltage circuit

S Wires of the low voltage circuit

S Connectors of the output and input wires

WARNING!

Risk of injury caused by moving parts!

Rotating or linear moving parts can cause serious injuries.

For this reason:

S During operation do not reach into or tamper with moving parts.

S Do not open the covers during operation.

S Observe the run-on time: before opening any covers ensure that no parts are still moving.

S Wear close-fitting clothing in the hazard area.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

17

Page 20

General Safety Instructions

Multi-engine plants

WARNING!

Risk of injury caused by engines!

Persons in the operating room are at a risk if engine damage occurs.

For this reason:

S Limit the time spent in the operating room to the absolute minimum.

S Set up protective partitions to isolate running engines.

S Access to the operating room may only be made when engine is running at a light load.

Exhaust gases

WARNING!

Risk of health hazard caused by exhaust gases!

Leaks in the exhaust system can cause dangerous exhaust gases to leak into the engine

room.

For this reason:

S Ensure sufficient ventilation.

S Immediately shut down engines with exhaust leaks.

Highly Flammable Substances - Gaseous Fuels, Oils and Grease

WARNING!

Fire hazard caused by gaseous fuels!

For this reason:

S No smoking and no open flames.

S The regulations for gas installations must to be observed.

S Leaks in the gas supply system are an explosion hazard and are to be rectified

immediately.

Conduct when gas leaks

S Close shutoff valve for gas supply

S Switch off master switch for electrical system

S Block off the hazard area. Keep all uninvolved persons out of the hazard area

S If gas leaks, immediately notify those responsible and start repairs

Conduct in case of fires

S Alert fire department

S Administer first aid to the injured and, if necessary, notify the paramedics

S When gas leaks from a system and catches fire, the flames cannot be easily

extinguished. Try to cool the burning object (e.g. by reducing the surrounding oxygen:

close doors and windows).

Burning gas = Controlled gas!

S Prevent the flames from spreading to the surroundings

S If the flames spread to the surroundings, fight resulting fires using fire extinguishers

S Keep calm!

18

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 21

WARNING!

Risk of fire caused by highly flammable substances!

Highly flammable materials (lubricating oils, greases) can catch fire and cause serious to

deadly injuries.

For this reason:

S Do not smoke in the hazard area or in the vicinity.

No open fires or sources of ignition.

S Keep fire extinguishers at hand.

S Immediately report any suspicious substances, fluids or gases to the person in charge.

S In the case of fire, immediately stop working. Leave hazard area until the danger is over.

Coolants - Antifreeze, Anticorrosion Agents

WARNING!

Risk of injury caused by coolants that are hazardous to health

Coolants contain substances that are hazardous to your health. Contact with these sub

stances can lead to serious poisoning, allergies, skin irritations and damage to eyes.

For this reason:

S Observe the safety sheets from the manufacturer.

S Always wear protective clothing, chemical-resistant protective gloves and safety glasses.

S Avoid spilling or spraying these substances.

General Safety Instructions

Hot Fluids and Lubricants

WARNING!

Risk of burns caused by hot fluids and lubricants!

Fluids and lubricants can reach high temperature while in operation and cause burns when

coming into contact with them.

For this reason:

S Before handling any fluids and lubricants, check whether they are hot. If necessary, let

them cool down first.

Hot Surfaces

CAUTION!

Risk of burns caused by hot surfaces!

Contact with hot components can cause burns.

For this reason:

S When performing any work in the vicinity of hot components always wear protective cloth

ing and protective gloves.

S Before starting any work ensure that all components have cooled down to ambient tem

perature.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

19

Page 22

General Safety Instructions

Noise

WARNING!

Risk of hearing damage caused by noise!

The level of noise occurring in the working area can cause serious damage to hearing.

For this reason:

S Always wear hearing protection when working.

S Do not unnecessarily remain in the hazard area. Leave hazard area when work is fin

ished.

Sharp Edges and Corners

CAUTION!

Risk of injury cause by sharp edges and corners!

Sharp edges and corners can cause cuts and scrapes to the skin.

For this reason:

S Always work carefully and with caution in the vicinity of sharp edges and corners.

S In cases of doubt, wear protective gloves.

Dirt and Objects

CAUTION!

Risk of tripping caused by dirt and objects!

Dirt and objects can cause a person to slip or trip which can cause considerable injuries.

For this reason:

S Always keep the work area clean.

S Remove any objects that are no longer necessary.

S Mark areas where there is a danger of tripping with yellow and black striped tape.

Strong magnetic fields

WARNING!

Risk of death caused by strong magnetic fields!

Strong magnetic fields can cause serious injuries and death as well as considerable prop

erty damage.

For this reason:

S Persons with cardiac pacemaker must not remain in the vicinity of the engine.

The operation of the cardiac pacemaker could be negatively affected.

S Persons with metal implants must not remain in the vicinity of the engine. Metal implants

could heat up or be attracted to the magnetic source.

S Keep ferromagnetic materials and electromagnets away from magnetic sources. These

materials can be magnetically attracted and can fly through the room and injure people or

cause death. Keep a minimum distance of 3 m.

S Take off all metal objects (jewellery, watches, pens, etc.) before starting any maintenance

work.

S Do not take any electronic devices near the magnetic source. They could be damaged.

S Dot not take any memory devices, credit cards, etc. near the magnetic source. Data could

be erased.

20

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 23

General Safety Instructions

2.8 Safety Equipment

The operator must have the following safety equipment in place:

Before the engine is placed into operation, install the emergency-off equipment and connect it into the

safety chain of the system.

Connect the emergency-off equipment so that dangerous situations to people and property are avoided in

case the its power supply is interrupted or is turned back on after an interruption.

The emergency-off equipment must always be freely accessible.

WARNING!

Risk of death caused by non-operational safety equipment!

Safety equipment ensures maximum safety during operation. Even if they may make work

ing more complicated, they must not be overridden. Safety can only be guaranteed if the

safety equipment is intact and operational.

For this reason:

S Before starting any work, check whether all of the safety equipment is correctly installed

and in good operating order.

S Before starting the engine, check whether all of the safety equipment is correctly installed

and in good operating order.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

21

Page 24

General Safety Instructions

2.9 Conduct in Dangerous Situations and When Accidents Occur

Preventative Measures

S Always be prepared for an accident!

S Keep first aid equipment (first aid kit, blankets, etc.) and fire extinguishers at hand.

S Check first aid equipment and fire extinguishers regularly for completeness and proper operation.

S Familiarise the personnel with the emergency, first aid and rescue equipment.

S Instruct the personnel on safety on a regular basis.

S Always keep access lanes for rescue vehicles free of any obstructions.

In the case of an accident: Act accordingly

S Remain calm.

S Immediately shut down engine using the emergency-off button.

S Start first aid measures.

S Alert rescue services and/or fire department.

S Move people out of the danger zone.

S Clear access lanes for rescue vehicles.

S Inform the person in charge.

CAUTION!

Accidents despite preventative measures

If an accident occurs, e.g. from one of the listed points below, despite all of the preventative

measures, contact a physician immediately.

S Contact with caustic acids.

S Penetration of fuel into the skin.

S Scalding by hot oil or coolant.

S Antifreeze sprayed into the eyes, etc..

22

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 25

General Safety Instructions

2.10 Signs

The following symbols should be installed in the immediate vicinity of the hazard area.

WARNING!

Risk of injury caused by illegible symbols!

Stickers and symbols can become dirty or made otherwise illegible in the course of time!

For this reason:

S Always keep the safety, warning and operational signs in good legible condition.

S Clean or replace illegible safety, warning and operational signs.

Electric Voltage

Rooms marked with this symbol may only be accessed by qualified electricians.

Unauthorised persons may not enter these rooms.

Hot Surfaces

Hot surfaces such as hot engines and hot fluids may not always be recognisable. Do not

touch these surfaces without protective gloves.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

23

Page 26

General Safety Instructions

2.11 Environmental Protection

CAUTION!

Environmental hazard caused by incorrect handling!

Incorrect handling of environmentally hazardous substances, especially when incorrectly

disposed of, can cause considerable damage to the environment.

For this reason:

S Always heed the information below.

S If environmentally hazardous substances are accidentally released into the environment,

immediately take suitable measures to minimise this. If in doubt, inform the responsible

local authorities.

The following environmentally hazardous substances are used:

Lubricants

Lubricants such as grease and oils contain poisons and environmentally hazardous substances. They must

not be allowed to be released into the environment. Disposal must be performed by a qualified disposal

company.

Coolants

Coolants can contain poisons and environmentally hazardous substances. They must not be allowed to be

released into the environment. Disposal must be performed by a qualified disposal company.

24

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 27

3 Engine Model Plate

Always specify the engine typeand engine number

when sending messages and making queries.

For this reason before the engine is commis

sioned, read off and enter in the data from the en

gine model plates below.

Engine model plate (1) is installed on the crankcase.

Engine Model Plate

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

25

Page 28

Engine Model Plate

3.1 Explanation of the Motor-Nr./Engine-No. (Engine Identification Number)

Motor-Nr./Engine-No. Class identifier (assignment)

711 Model number according to index of model codes

1234 Day of assembly (plant internal)

547 Assembly order (sequence number on day of assembly)

3.2 Explanation of Model Designation

Model designation Explanation Example

E Fuel type Natural gas (or biogas)

08 Figure + 100 108 mm bore

3 Stroke figure (rounded) 125 mm stroke

4 / 6 Number of cylinders 4, 6 cylinders

L Charging with charger and

charge air cooling

E Engine installation Installation engine for power

generation plants

202 / 302 Model designation identification 202 = Development number

302 = Development number

26

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 29

Design and Function

4 Design and Function

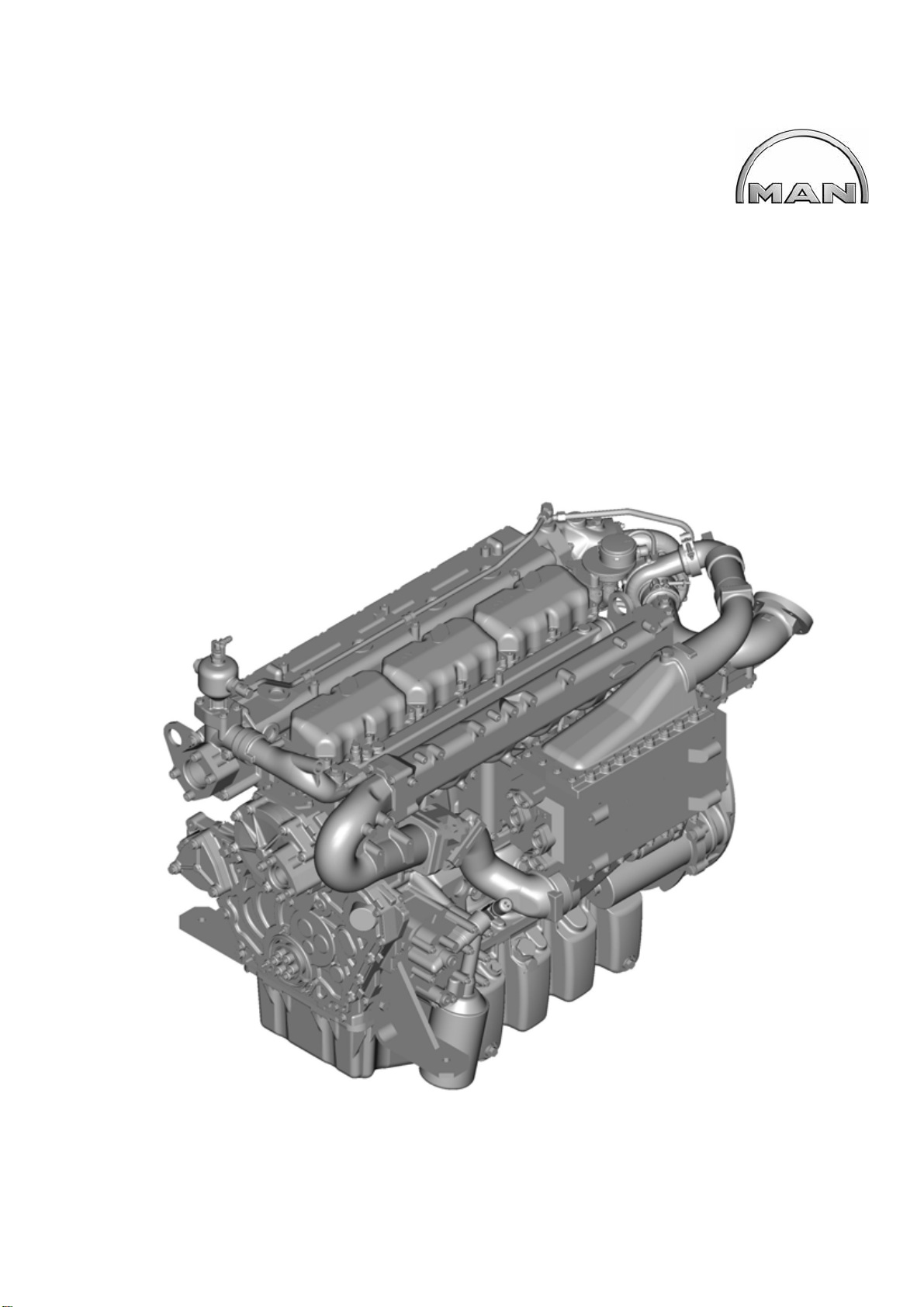

4.1 Engine, General

The 4 and 6 cylinder engines described here is liquid-cooled 4-cycle spark ignition engine with turbochar

ging and intercooling.

Engine Monitoring

Monitoring of the engine is made through various sensors. The sensors are designed, for example, as rpm

and temperature sensors, which report the various operating conditions of the engine to the engine control

unit. The engine control unit operates according to the EVA principle:

E = Eingang (Input)

V = Verarbeitung (Processing)

A = Ausgang (Output)

The engine control units process the information received from the sensors and control the output signals

which are sent to the actuators. The actuators convert the signals into mechanical factors.

Engine Lubrication

Pressure feed lubrication with one lube-oil pump for the bearings of the crankshaft, connecting rods and

camshafts as well as piston pin sockets, roller tappets and rocker arms.

Oil is filtered through a filter module with an integrated oil cooler and a crankcase breather in the main flow.

Ancillary assemblies such as turbocharger and PTOs are connected to the engine oil circuit.

Intake and Exhaust System

The dry exhaust pipes are mounted to the cylinder heads. From the high-pressure stage the exhaust is

guided through the turbochargers.

The turbochargers are lubricated by the engine's main-flow oil circuit connected to the pressure connec

tions onthe turbochargers.

The intake air is routed through the air filter to the turbochargers. The pre-compressed charge air isthen

routed to the engine.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

27

Page 30

Design and Function

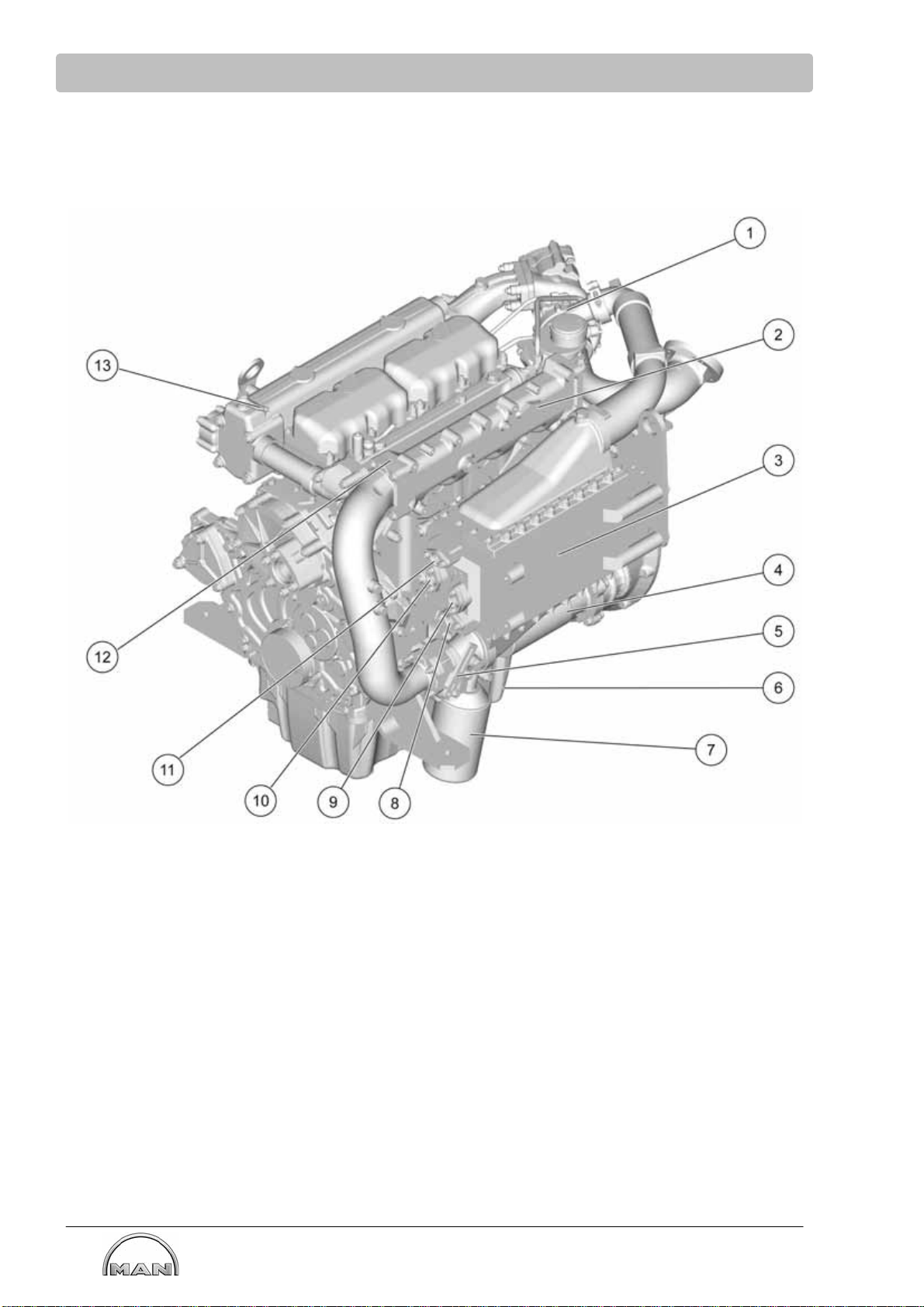

4.2 Engine Views E0834 LE302/ 312/ 322

4.2.1 Front Left View

(1) Turbocharger

(2) Intake manifold

(3) Charge mixture cooler

(4) Starter

(5) Throttle valve

(6) Oil drain screw

(7) Oil filter

(8) Coolant inlet, low‐temperature stage

(9) Coolant outlet, low‐temperature stage

(10) Coolant inlet, high‐temperature stage

(11) Coolant outlet, high‐temperature stage

(12) Flame protection filter

(13) Ventilation connection for coolant to separate ventilation reservoir

Carefully read the Operating Instructions before starting any work!

28

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 31

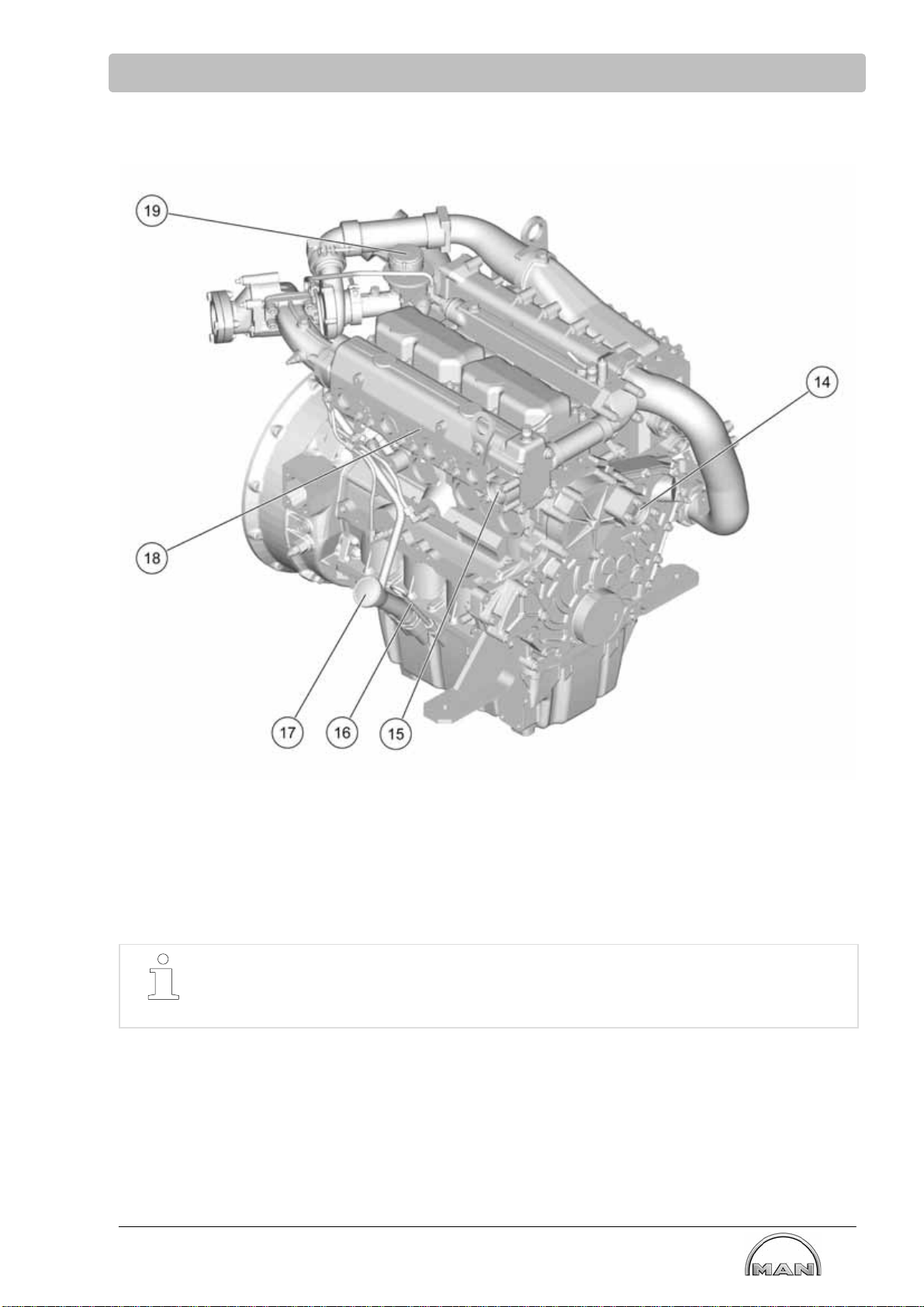

4.2.2 Front Right View

Design and Function

(14) Coolant inlet

(15) Coolant outlet

(16) Oil dipstick

(17) Oil filler neck

(18) Exhaust pipe

(19) Crankcase ventilation

NOTE!

The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure

regulator, gas mixer and air filter are not included in the MAN scope of delivery.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

29

Page 32

Design and Function

4.3 Engine Views E0836 LE202

4.3.1 Front Left View

(1) Turbocharger

(2) Intake manifold

(3) Charge mixture cooler

(4) Starter

(5) Throttle valve

(6) Oil drain screw

(7) Oil filter

(8) Oil cooler

(9) Flame protection filter

(10) Ventilation connection for coolant to separate ventilation reservoir

Carefully read the Operating Instructions before starting any work!

30

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 33

4.3.2 Front Right View

Design and Function

(5) Oil drain screw

(11) Coolant outlet

(12) Coolant inlet

(13) Oil dipstick

(14) Exhaust pipe

(15) Crankcase ventilation

NOTE!

The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure

regulator, gas mixer and air filter are not included in the MAN scope of delivery.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

31

Page 34

Design and Function

4.4 Engine Views E0836 LE302

4.4.1 Front Left View

(1) Turbocharger

(2) Intake manifold

(3) Charge mixture cooler

(4) Starter

(5) Throttle valve

(6) Oil drain screw

(7) Oil filter

(8) Oil cooler

(9) Flame protection filter

(10) Ventilation connection

32

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 35

4.4.2 Front Right View

Design and Function

(11) Coolant inlet

(12) Coolant outlet

(13) Oil filler neck

(14) Oil dipstick

(15) Oil separator

(16) Bleeder line

NOTE!

The gas supply line consisting of the ball valve, gas filter, solenoid valves, gas pressure

regulator, gas mixer and air filter are not included in the MAN scope of delivery.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

33

Page 36

Design and Function

34

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 37

Design and Function

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

35

Page 38

Transport, Packaging and Storage

5 Transport, Packaging and Storage

It is absolutely necessary to observe the “Assembly Instructions” for the installation and commissioning of a

new or reconditioned engine.

NOTE!

Installation and commissioning is only to be made by the employees of the manufacturer of

the entire system or by manufacturer authorised personnel.

Nevertheless, as part of the installation and the use of the engine, situations will occur

where the operator or his maintenance personnel will have to be familiar with the handling

of packages. In these situations it is absolutely necessary to observe the following informa

tion.

5.1 Prerequisite

Before starting any work read and observe the General Safety Instructions and the safety information in this

chapter.

Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage.

Personal Protective Equipment

The following protective equipment must be worn:

S Protective Clothing

S Protective Helmet

S Safety Shoes

S Safety Gloves

5.2 Safety Instructions

Heavy Suspended Loads

WARNING!

Risk of death caused by heavy suspended loads!

During lifting operations, loads can swing out and fall down. This can cause serious injury

and even death.

For this reason:

S Do not stand under or remain in the swivel range of the suspended load.

S Only move the load under supervision.

S Only use approved lifting equipment and accessories with sufficient load capacity.

S Never use torn or scuffed lifting equipment such as ropes or straps.

S Do not let lifting equipment such as rope or straps come into contact with sharp edges

and corners and do not twist or knot them.

S Before leaving the work area, lower load to ground.

36

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 39

Off-Centre Point of Gravity

WARNING!

Risk of injury caused by falling or tipping packages!

Packages can have a centre of gravity that is off-centre. If the lifting equipment is not hoo

ked up properly, these packages could tip over and fall causing serious injuries.

For this reason:

S Observe the information and markings on the package concerning centre of gravity.

S When transporting with a crane, the hook must be placed so that it is directly above the

package's centre of gravity.

S Carefully raise the package and observe its movement. If necessary, change the position

of the lifting equipment.

Swingout of Packages being Transported

WARNING!

Risk of injury caused by packages swing out during transportation!

When transporting the packages with a crane, the packages can swing out and cause

serious injuries and significant property damage.

Transport, Packaging and Storage

For this reason:

S Ensure that during the transport of packages, no persons, objects or obstacles are in the

swivel range of the packages being transported.

Unauthorised Transport

IMPORTANT!

Risk of property damage if packages are transported by untrained personnel!

Unauthorised transport by untrained personnel can cause packages to fall or tip over. This

could cause considerable property damage.

For this reason:

S Unloading of packages during delivery and their in-house transport are only to be per

formed by trained personnel under the supervision of the manufacturer's employees.

S Refrain from any unauthorised transportation or removal of the transportation aids.

S No unauthorised removal of packaging permitted.

Improper Transport

IMPORTANT!

Risk of property damage caused by improper transport!

Improper transport can cause packages to fall or tip over. This could cause considerable

property damage.

For this reason:

S Carefully handle the packages when unloading during delivery and when transporting

them within the company. Observe the symbols and instructions on the packages.

S Only use the prescribed lifting points.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

37

Page 40

Transport, Packaging and Storage

5.3 Transport Inspection

Check the delivery for missing items and for damage from transport.

If external signs of transport damage are apparent:

S Do not accept delivery or only accept under written protest.

S List scope of damage on the transport documents or on the transportation company's packaging slip.

S Initiate a claims process.

S Get engine checked by an expert before it is placed into commission.

NOTE!

Make sure to claim each damage case as soon as it is discovered. Damage claims can only

be claimed within the applicable time limits.

38

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 41

5.4 Transport

Lifting Points

Transport, Packaging and Storage

There are 2 lifting lugs (1) and (2) for the crane installed on the engine.

WARNING!

Risk of death caused by the load falling!

During lifting operations, loads can fall down. This can cause serious injury and even death.

For this reason:

S The „crane lifting lugs“ are only to be used to transport the engine with no ancillary

assemblies attached.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

39

Page 42

Transport, Packaging and Storage

Transport with Crane

The engine can be transported with a crane under the following conditions.

S The crane and the lifting equipment must be designed for the weight of the engine.

S The operator must be qualified for operating the crane.

1. Attach the ropes, straps or multipoint lifting equipment according to the picture.

2. Ensure that the package is hanging straight or compensate for the off-centre point of gravity.

3. Start the transport.

Transport with Forklift

The engine can be transported with a forklift under the following conditions.

S The forklift must be designed for the weight of the engine.

S The engine must be securely mounted to the pallet.

S The pallet must not be damaged.

S The forklift operator must be qualified and authorised to operate the forklift.

1. Insert the fork of the forklift between or under the pallet's struts.

2. The fork must be inserted into the pallet until it protrudes from the other side.

3. Ensure that the pallet cannot tip over if the centre of gravity of off-centre.

4, Lift the pallet and transport it to the desired location.

40

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 43

Transport, Packaging and Storage

5.5 Packaging

Packaging

The individual packages are packed in accordance with the expected conditions of transport.

The purpose of the packaging is to protect the components from transport damage, corrosion and other

damage. For this reason do not unpack components until shortly before they are to be assembled.

Handling Packing Material

Dispose of packing material according to the valid local and statutory regulations.

IMPORTANT!

Risk of hazard to the environment caused by incorrect disposal!

Packaging materials are valuable raw materials and can in many cases continue to be used

or can be processed and recycled. Incorrect disposal of packaging materials may cause an

environmental hazard.

For this reason:

S Dispose of packing materials in an environmentally friendly manner.

S Observe the valid local regulations. If necessary, contact a professional disposal com

pany.

5.6 Storage

Storage of packages

Store packages under the following conditions:

S Do not store in the open.

S Store in a dry and dust-free environment.

S Do not expose to damaging chemicals.

S Protect from sun light.

S Avoid any physical shocks.

S Storage temperature: 15 to 35 °C.

S Relative humidity: max. 60 %.

S If stored for more than 3 months, regularly check the condition of the packaging. If necessary, renew or

replace the preservation.

NOTE!

Some of the packages may have information printed on them regarding their proper sto

rage. Please observe this information.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

41

Page 44

Installation and Commissioning

6 Installation and Commissioning

6.1 Prerequisite

Before starting any work read and observe the General Safety Instructions and the safety information in this

chapter.

Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage.

Personal Protective Equipment

The following protective equipment must be worn:

S Protective Clothing

S Safety Shoes

S Safety Gloves

6.2 Safety Instructions

Personnel

S The installation and commissioning may only be performed by MAN employees or by MAN-trained quali

fied personnel.

Ground Rules

WARNING!

Danger caused by faulty installation and commissioning!

Installation and commissioning require trained qualified personnel with sufficient experi

ence. Faulty installation can cause life threatening situations and considerable property

damage.

For this reason:

S Installation and commissioning are only to be performed by MAN employees.

S Installation and commissioning by MAN trained qualified personnel may only be per

formed with approval from MAN.

WARNING!

Risk of injury caused by improper installation and commissioning!

Improper installation and commissioning can cause serious personal injury or considerable

property damage.

For this reason:

S Ensure adequate work space before starting any work.

S Be careful when working with exposed parts with sharp edges.

S Make sure work space is kept clean and orderly!

S Install components in a correct manner.

S Observe the prescribed tightening torques.

S Secure components so that they do not fall or tip over.

S Before commissioning the engine, carefully read the Operating Instructions and familiarise yourself with

the “critical” subjects.

S It is absolutely necessary to observe the “Assembly Instructions” for the installation and commissioning

of a new or reconditioned engine.

Carefully read the Operating Instructions before starting any work!

42

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 45

Installation and Commissioning

S For safety reasons we recommend placing an off limits sign on the door to the engine room and to in

struct the operating personnel that they are responsible for the safety of people who enter the engine

room.

6.3 Installation - Engine

The installation of the engine, i.e. connection to the power supply, connection of the cooling system, are to

be performed in accordance with the manufacturer's instructions for the entire system and with the help of

the “Assembly Instructions”.

6.3.1 Safety Equipment

WARNING!

Risk of death caused by the absence of safety equipment!

An emergency-off button, for shutting down the system or engine in an emergency, must be

installed for each engine.

For this reason:

S Install an emergency stop button to shut down the system in an emergency.

S Check whether all of the safety equipment is correctly installed and in good operating or

der.

WARNING!

Risk of death caused by faulty operation!

At excessive loads or if malfunctions occur the engine can overheat and suddenly seize.

For this reason:

S The sensors which monitor the engine parameters must be connected to and evaluated

by the module manufacturer's monitoring equipment.

S If sensor values go outside the permissible limits or if there is a power loss, the engine

must be able to be immediately shut off by the monitoring equipment.

The following sensors are installed in the engine:

S Exhaust temperature

S Oil pressure

S Coolant temperature

6.3.2 Engine Model Plate Data

Please always specify the engine model, engine number and order number when corresponding with MAN,

see page .

For this reason, before commissioning the engine, read off the data from the engine model plate and enter

it into the Engine Model Plate chapter, see page 25.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

43

Page 46

Installation and Commissioning

6.4 Commissioning

New or reconditioned engines must not be operated during the first operating hours at loads higher than

3/4 power.

After this time period the engine can be slowly brought up to full power.

IMPORTANT!

Termination of liability for material defects by use of non-approved fluids and lubric

ants!

Liability of material defects is terminated if non-approved fluids and lubricants are used.

For this reason:

S Only use approved fluids and lubricants (see “Fluids and Lubricants ..." publication).

S The requirements on the quality of gas are specified in “MAN data sheet - Minimum re

quirement on the quality of gas for MAN gas engines"

6.4.1 Gas System

NOTE!

The gas supply line is not included in MAN's scope of delivery. Commissioning, operation,

monitoring of operating conditions, and maintenance of the gas system are all to be per

formed as described in the manufacturer's instructions.

Setting for commissioning

For commissioning the engine is to be set for the use of a suitable gas/air mixture. Any deviations from this

will negatively influence the output power, the engine efficiency and the exhaust emissions.

The requirements on the quality of gas are specified in ”MAN data sheet - Minimum requirement on the qu

ality of gas for MAN gas engines".

The operating pressure of the natural gas in the gas line must be at least 20 mbar.

The gas pressure should be steady within this range.

To get a correct gas/air mixture the air in the engine room must have a temperature of between 10_

and 30_C.

The gas must not contain any condensation when it enters the gas mixer, see “MAN data sheet - Minimum

requirement on the quality of gas for MAN gas engines".

Faults

We urgently recommend that you have faults rectified only at an authorised specialist workshop.

Air filter

The maximum pressure differential up and downstream of the filter may not exceed the following:

New w 10 hPA

Dirty x 30 hPA

The filter element must therefore be changed as stated in the maintenance instructions.

Gas filter

The gas filter must filter grain size x 6 mm.

Carefully read the Operating Instructions before starting any work!

44

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 47

Installation and Commissioning

6.4.2 Filling Coolant

NOTE!

Do not let coolant drip or leak out while filling. Do not let coolant leak out onto the ground or

into bodies of water. Otherwise, the environment will be damaged.

The engine's cooling system is to be filled with a mixture of tap water and antifreeze (ethylene glycol or an

ticorrosion agent). Coolant must be filled according to the filling specifications of the BHKW (combined heat

and power plant) manufacturer.

For suitable antifreeze agents see approved Fuels, Lubricants and Coolants according to MAN 324 NF and

MAN 248.

Coolant may only be filled at the filler neck.

S Remove cap.

S Slowly fill coolant.

S Close expansion reservoir.

S Run engine for approx. 15 minutes at rated speed.

S Shut off engine and carefully unscrew cap with safety valve to the first stop to release pressure, then

carefully open. Add coolant if necessary.

S When adding coolant, do not add cold coolant to a warmed-up engine. Ensure that the proper mixing

ratio of “water/antifreeze" is met.

S Check coolant before the next commissioning (with engine cold). Add coolant if necessary.

S Repeat this procedure until coolant can no longer be added.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

45

Page 48

Installation and Commissioning

6.4.3 Filling Engine Oil

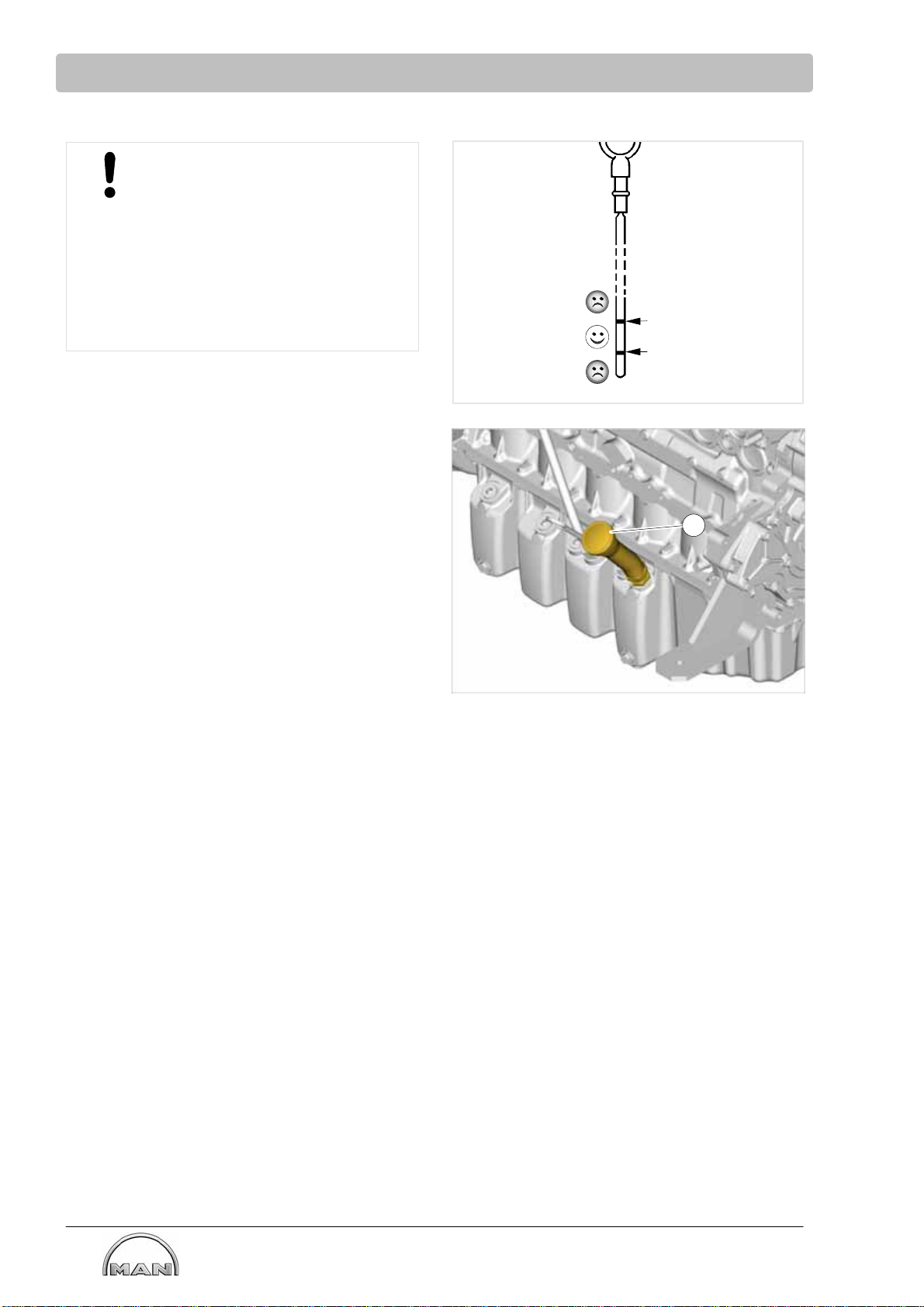

IMPORTANT!

Component damage caused by

over filling!

Engine damage can occur if engine

oil is filled to above the max. mark

on the oil dipstick.

For this reason:

S Do not fill engine oil above the

max. mark on the oil dipstick

1. Remove cap.

2. Slowly fill engine oil into the filler neck.

For oil filling capacity, see “Technical Data”

page 68.

MAX

MIN

3. Reinstall cap.

46

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 49

Installation and Commissioning

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

47

Page 50

Operation

7 Operation

7.1 Prerequisite

Before starting any work read and observe the General Safety Instructions and the safety information in this

chapter.

Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage.

Personal Protective Equipment

The following protective equipment must be worn:

S Protective Clothing

S Safety Shoes

S Safety Gloves

7.2 Safety Instructions

Personnel

S Operation of the engine may only be performed by instructed personnel or bytrained qualified personnel.

Ground Rules

WARNING!

Danger caused by faulty operation!

Improper operation can cause serious personal injury or considerable property damage.

For this reason:

S Perform all operating steps in accordance with the instructions in these Operating Instruc

tions.

S Before starting any work ensure that all covers and protective equipment have been in

stalled and are operating properly.

S Never shut off any safety equipment while in operation.

S Make sure work space is kept clean and orderly! Any unused parts or components lying

around are potential sources of accidents.

WARNING!

Risk of injury caused by vapours!

In the first operating hours of the engine the paint on hot engine parts will burn off produ

cing vapours that are hazardous to health.

For this reason:

S Ensure sufficient ventilation.

S Limit time spent in the engine area to the absolute minimum.

48

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 51

7.3 Preparations before Operation

DANGER!

Danger caused by damaged engines!

Damaged engines can be dangerous to persons.

For this reason:

S Check engine for damage and leaks before each operation.

S Do not operate engine if damage is found.

Before each operation check the engine's coolant and oil level.

If necessary add coolant and engine oil.

IMPORTANT!

Termination of liability for material defects by use of non-approved fluids and lubric

ants!

Liability of material defects is terminated if non-approved fluids and lubricants are used.

For this reason:

S Only use approved fluids and lubricants (see “Fluids and Lubricants ..." publication).

Operation

7.3.1 Check Gas Quality, Open Gas Supply

WARNING!

Risk of fire caused by highly flammable substances!

Highly flammable substances, fluids or gases can catch on fire and cause serious or deadly

injuries.

For this reason:

S Do not smoke in the hazard area or in the vicinity.

No open fires or sources of ignition.

S Keep fire extinguishers at hand.

S Immediately report any suspicious substances, fluids or gases to the person in charge.

S In the case of fire, immediately stop working. Leave hazard area until the danger is over.

1. Check the quality of the gas, see “MAN data sheet - Minimum requirement on the quality of gas for

MAN gas engines".

2. Open gas supply.

7.3.2 Checking Coolant

WARNING!

Risk of scalding!

The cooling system is under pressure and the coolant is hot.

For this reason:

S Let engine cool down.

NOTE!

The cooling system is not included in MAN's scope of delivery.

Check the coolant level according to the manufacturer's operating manual.

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

49

Page 52

Operation

7.3.3 Refilling Coolant

NOTE!

Do not let coolant drip or leak out while refilling. Do not let coolant leak out onto the ground

or into bodies of water otherwise this will cause damage to the environment.

IMPORTANT!

Engine damage caused by excessive temperature difference!

When refilling with cold coolant in an engine at operating temperature there is a risk of en

gine damage caused by excessive temperature difference.

For this reason:

S Do not fill with cold coolant.

Fill the cooling system of the engine with a mixture of tap water and ethylene glycol antifreeze agent or an

ticorrosion agent.

NOTE!

The cooling system is not included in MAN's scope of delivery.

Add coolant according to the manufacturer's operating manual.

50

Carefully read the Operating Instructions before starting any work!

This is especially valid for the chapter on General Safety Instructions

and the safety instructions in each of the chapters.

Page 53

7.3.4 Checking Engine Oil Level

NOTE!

Check the oil level when the engine is horizontal and only after at least 20 minutes have

passed since the engine was switched off.

1. Pull out oil dipstick (1).

2. Wipe off oil dipstick (1) with a lint-free, clean

cloth.

3. Reinsert the oil dipstick (1) all the way.

4. Pull out oil dipstick (1) again and check oil level.

The oil level should be between both of the marks

on the dipstick and should never drop below the

lower mark.

5. Reinsert the oil dipstick (1) all the way.

If the oil level is too low, refill with new oil.

Operation

1

MAX