B

XTM-XSM POWER UP 2007

ELECTRIC SYSTEM

TROUBLESHOOTING

WORKSHOP MANUALS

B

08.06 3

Introduction

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 1

B - TROUBLESHOOTING

B ELECTRICAL SYSTEM TROUBLESHOOTING

INTRODUCTION............................................................................................................................................... 4

Manual updates................................................................................................................................ 4

Notes for easy consultation .............................................................................................................. 4

Page layout ...................................................................................................................................... 4

Modified pages ................................................................................................................................. 5

Additional pages............................................................................................................................... 5

Editing symbols................................................................................................................................ 5

Abbreviations .................................................................................................................................... 7

TROUBLESHOOTING ...................................................................................................................................... 8

Wiring diagram ................................................................................................................................. 8

Key to general wiring diagram .......................................................................................................... 9

Colour key........................................................................................................................................ 9

Key to electrical components ......................................................................................................... 10

Connector test............................................................................................................................... 1 1

Switch tests .................................................................................................................................. 12

Connection of the switches described in this manual ..................................................................... 12

Key to ignition system................................................................................................................... 13

Troubleshooting ............................................................................................................................. 14

Recharging system key................................................................................................................. 18

Troubleshooting ............................................................................................................................. 19

Lighting system key ...................................................................................................................... 21

Troubleshooting ............................................................................................................................. 22

Lighting system check .................................................................................................................. 24

Signalling system key ................................................................................................................... 29

Troubleshooting ............................................................................................................................. 30

Signalling system check ............................................................................................................... 32

B

4 08.06

Introduction

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 1

B - TROUBLESHOOTING

FIRST EDITION: 08/06

Y Chapter

X Section title

W Page N°

Z Date of issue

•MALAGUTI reserves the right to make any and all changes to its vehicles as it deems fit and appropriate at

any time without prior notice.

•No part of this publication, whether text or illustrations, may be reproduced or circulated. MALAGUTI

reserves all rights over this publication. Reasons must be given for any request for permission (written) thereto.

INTRODUCTION

•This publication describes all necessary steps for troubleshooting concerning the electrical system (of the

models indicated on the front page) and of the possible service operations, which are necessary for their

solution. It supplies the trade technicians (Authorised Service Centres) with the necessary information for

operating in compliance with the modern concepts of “good practice” and “safety at work”

•Further information can be derived from the “Chassis” workshop manual, from the “Engine” workshop

manual and from the Spare Parts catalogue.

•All described operations must be performed by technicians with the necessary skill and experience.

•The steps for the removal of body parts and of electric and mechanical components, to allow access to wiring

or electric components to service, can be taken from the Chassis Workshop Manual.

•We recommend you follow the information given in this publication with care.

•For any further information you may need, refer to the MALAGUTI Service Centre.

MANUAL UPDATES

•Updated pages of this publication will be delivered by us (in a reasonable time) already punched and therefore

ready to be incorporated in the Manual. The superseded sheets should not be removed from the manual as they

remain applicable to the servicing of pre-modified models.

•The table of contents will be duly updated in the event that new pages are inserted, which render the consultation

of the manual difficult.

•IMPORTANT! The Electrical System Troubleshooting Manual is to be considered as an essential tool to be

properly kept up-to-date so as to maintain its “validity” over time.

NOTES FOR EASY CONSULTATION

P AGE LA YOUT

B

08.06 5

Introduction

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 1

B - TROUBLESHOOTING

W

Z

Y

X

MODIFIED PAGES

•Modified pages shall bear the same number as those in the previous edition /pre-modified ones,

followed by the letter M, with the new date of issue appearing in the appropriate box.

•Modified pages may contain new illustrations; in this case, the added illustration (or illustrations) will bear the

number of the illustration on the former page, followed by a letter.

ADDITIONAL P AGES

•Any additional pages shall bear the last number of the section to which they belong, followed by the letter A and

the new date of issue.

EDITING SYMBOLS

•Symbols have been provided for quick and easy reference (see page 6), identifying situations requiring

utmost attention or providing practical suggestions or simple information.

•These symbols may appear next to a text (in which case they refer solely to the text itself), next to a figure

(in which case they refer to the topic illustrated in the figure and to the relative text), or at the top of the page

(in which case they refer to all the topics dealt with in the page).

Note:

The meaning of the symbols should be duly memorised as their scope is to avoid having to repeat basic

technical concepts or safety recommendations. They are therefore to be considered as veritable “memory

tags”. In case of any doubt as to their meaning, consult the page in which they are fully described.

P AGE DX

B

6 08.06

Introduction

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 1

B - TROUBLESHOOTING

R

M

L

H

F

A

B

D

C

I

G

E

A) CAUTION! Recommendations and precautions regarding rider

safety and motor vehicle integrity

.

B) WARNING! Situations entailing the risk of personal injury to

maintenance or repair mechanics, other workshop personnel or

third parties, or damage to environment, vehicle or equipment.

C) FIRE HAZARD

Indicates operations which may constitute a fire hazard.

D) RISK OF EXPLOSION Indicates operations which may

constitute a risk of explosion.

E ) TOXIC FUMES

Indicates a possibility of intoxication or inflammation of the upper

respiratory tract.

F) MECHANICAL MAINTENANCE Operations to be performed only

by an expert mechanic.

G) ELECTRICAL MAINTENANCE

Operations be performed only by an expert electrical/electronic

technician

H) NO! Operations to be absolutely avoided

I) ENGINE SERVICE MANUAL Indicates information which may

be obtained by referring to said manual.

L) SPARE P ARTS CA T ALOGUE

Indicates information which may be obtained by referring to said

catalogue

B

08.06 7

Introduction

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 1

B - TROUBLESHOOTING

F4

A

F Figure

Cs Tightening torque

P Page

Pr Paragraph

S Section

Sc Diagram

T Table

V Screw

ABBREVIATIONS

Note:

the letter V in the illustrations refers to retaining or adjusting screws. The number following this letter refers to

the number of the same type of screw in the unit or component described and illustrated. Letters not followed

by a number indicate a single screw. In case of different screws being referred to in the illustration, the letter

V is followed by a number and a small letter, for instance: (V4a).

Unless otherwise specified, units and components are reassembled by proceeding in the reverse order of

removal.

Before any servicing, make sure that the vehicle is perfectly stable.

The front wheel should preferably be anchored to the equipment (A - F. 4) integral with the lif ting board.

B

8 08.06

CHAPTER

PAGE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Electrical System

SECTION 2

B - TROUBLESHOOTING

EDIZIONE

M

BL

AR

BL

BB

N

M

VR

VL

AR

N

M

VR

VL

GR

N

K A

B

R

+

-

N

LOCK

OFF

ON

VR

GR

VL

M-N

GL-R

GR-R

vuoto

vuoto

vuoto

1

18

LUCI

BL

VR-N

VR

GL

AR

VL-GL

RS

BL-R

BL-R

N

R

VL-GL

GL-R

B

BL-B

B-R

MODE

R

ENGINE

STOP

ON

OFF

ON

OFF

BL

R

10W

ID

SX

VL

10W

ID

DX

N

VR

35W

FARO

10W

ID

SX

N

VL

10W

ID

DX

N

VR

N

21W

STOP

5W

POS

RS

R

AR

HT

1

16

+

ON

OFF

HORN

GR

R

L

VL

M

VR

TURN

N

+

+

N

RS

F 10A

N

GL-R

Vuoto

BL

GR-R

GL-B

AR

B-R

Vuoto

BL-B

GL-VR

BL-N

M-N

RS-N

/ /

BL

R

R-N

N

GR

M-N

B-R

RS-N

B-R

BL-N

GL-VR

B-R

VL-GL

B

R

N

VL-GL

B

R

N

vuoto

vuoto

B-R

BL

VR/N

VR

GL

AR

vuoto

vuoto

R

B

N

B

BL-B

B-R

B-R

N

N

VL-GL

BL-R

B-N

N

VR-N

B-VR

N

GR

M

GR

VR-N

B-VR

B-N

N

BL

BL

BL

Vuoto

BL

B-GL

TPS

B-VL

R-N

B-VL

R-N

R-N

1

2

3

4

5

6 7

8

9

10

11

12

13

14

15

18

19

20

21

22

23

24

25

26

27

28

29

30

31

16

17

WIRING DIAGRAM

B

08.06 9

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Electrical System

SECTION 2

B - TROUBLESHOOTING

KEY TO GENERAL WIRING DIAGRAM

1) BA TTERY

2) 10 A FUSE

3) CONTROL UNIT

4) FL YWHEEL MAGNETO

5) HORN

6) CHASSIS GROUNDING

7) FLASHLIGHT

8) TURN INDICA TOR BUTTON

9) HORN BUTTON

10) FRONT LEFT TURN INDICATO R

11 ) LOW BEAM / HIGH BEAM LIGHT

12) FRONT RIGHT TURN INDICA TOR

13) INSTRUMENT BOARD

14 ) KEY SWITCH

15) “MODE” BUTTON

16) “ENGINE STOP” BUTTON

17) FRONT STOP SWITCH

18) SOLENOID

19) REGULATOR

20) COIL

21 ) MIXER OIL PROBE

22 ) FUEL PROBE

23) REAR RIGHT TURN INDICAT OR

24 ) TAIL AND STOP LIGHT

25) REAR LEFT TURN INDICAT OR

26) GROUND

27 ) SIDE ST AND SWITCH

28 ) REAR STOP SWITCH

29 ) SPEEDOMETER SENSOR

30 ) WA TER TEMPERA TURE SENSOR

31 ) AIR TEMPERA TURE SENSOR

COLOUR KEY

This table lists the abbreviations used to identify the colour of the electrical connection cables on the wiring

diagram.

Abbreviations are given on the diagram, near the component

AR

AZ

B

BL

GL

GR

M

N

R

RS

VL

VR

AZ-B

B-M

B-N

B-R

B-VL

B-VR

BL-B

BL-GL

BL-N

BL-R

GL-B

GL-N

GL-R

GL-VR

GR-R

M-N

R-N

RS-N

VL-GL

VR-N

Orange

Light blue

White

Blue

Yellow

Grey

Brown

Black

Red

Pink

Purple

Green

Light blue White

White Brown

White Black

White Red

White Purple

White Green

Blue White

Blue Y ellow

Blue Black

Blue Red

Y ellow White

Yellow Black

Y ellow Red

Y ellow Green

Grey Red

Brown Black

Red Black

Pink Black

Purple Y ellow

Green Black

B

10 08.06

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Electrical Components

SECTION 2

B - TROUBLESHOOTING

1

2

3

4

5

6

7

8

910111213

14

15

16

17

KEY TO ELECTRICAL COMPONENTS

1) FRONT STOP SWITCH

2) REGULA T OR

3) CONTROL UNIT

4) 10 A FUSE

5) BA TTERY

6) FLASHLIGHT

7) SIDE ST AND SWITCH

8) COIL

9) REAR STOP SWITCH

10 ) MIXER OIL PROBE

1 1 ) SOLENOID

12 ) FUEL PROBE

13) H2O TEMPERATURE SENSOR

14) HORN

15) DIGITAL INSTRUMENT BOARD

16 ) KEY SWITCH

17 ) AIR TEMPERA TURE SENSOR

B

08.06 11

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Checking the Connections

SECTION 2

B - TROUBLESHOOTING

A

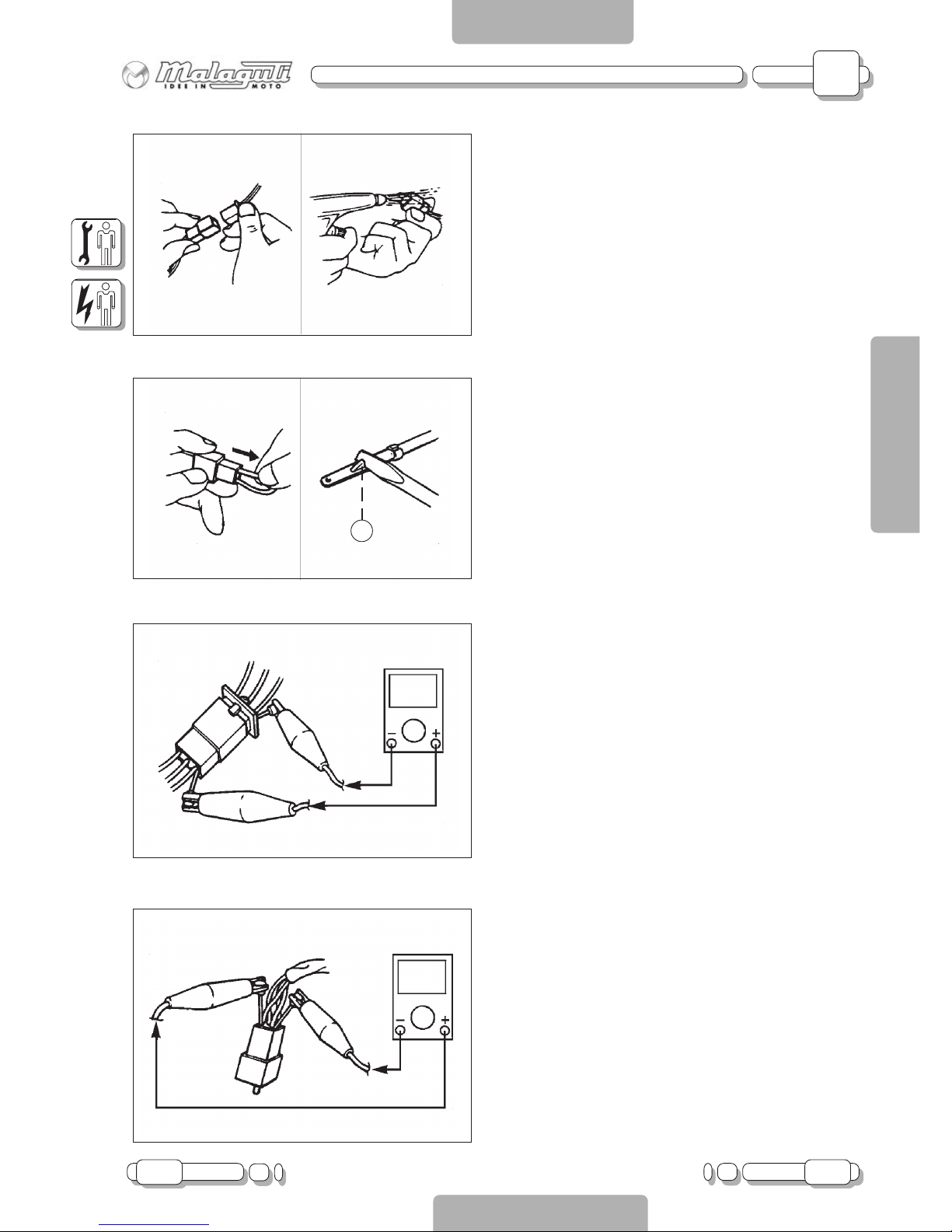

CHECKING CONNECTORS

Check connectors for corrosion and damp.

1. Disconnect

connectors

2. Dry terminals with compressed air .

3. Connect and disconnect connector two or

three times.

4. Pull connector to make sure it is correctly

plugged in.

5. If terminal comes loose, bend stop (A) and

refit terminal in connector.

6. Connect

connectors

NOTE:

The “click” sound means that all

connector parts are correctly assembled.

7. Check continuity with a Tester.

NOTE:

If there is no continuity, clean terminals.

Follow the instructions from step 1 to 7 to

check the electrical equipment.

As a temporary solution, use a contact

cleaner.

Use Tester as shown in the illustration.

B

12 08.06

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Checking the Switches

SECTION 2

B - TROUBLESHOOTING

CHECKING SWITCHES

Use a Tester to check continuity between terminals

and make sure these are correctly connected. If one of

the combinations does not give the requested result,

replace the component.

NOTE:

Operate the “ON-OFF” switch several times.

Put T ester selector on “W”.

Put indicator on “0”.

CONNECTION OF THE SWITCHES

DESCRIBED IN THIS MANUAL

This manual contains connection diagrams, like the one

illustrated on the left, which illustrate how switch

terminals should be connected (key switch, brake

switch, light switch, etc.).

The column on the left indicates the different positions

of the switches; the first line indicates the colours of

the wires connected to the switch terminals.

“•” means that there is continuity between the terminals;

namely a closed circuit in a certain position of the switch.

In this example, there is continuity between “Br” and

“R” when the switch is “ON”.

B

08.06 13

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Ignition System

SECTION 2

B - TROUBLESHOOTING

M

BL

AR

BL

BB

N

M

VR

VL

AR

N

M

VR

VL

GR

N

K

A

B

R

+

-

N

LOCK

OFF

ON

VR

GR

VL

M-N

GL-R

GR-R

vuoto

vuoto

vuoto

1

18

LUCI

BL

VR-N

VR

GL

AR

VL-GL

RS

BL-R

BL-R

N

R

VL-GL

GL-R

B

BL-B

B-R

MODE

R

ENGINE

STOP

ON

OFF

ON

OFF

BL

R

10W

ID

SX

VL

10W

ID

DX

N

VR

35W

FARO

10W

ID

SX

N

VL

10W

ID

DX

N

VR

N

21W

STOP

5W

POS

RS

R

AR

HT

1

16

+

ON

OFF

HORN

GR

R

L

VL

M

VR

TURN

N

+

+

N

RS

F 10A

N

GL-R

Vuoto

BL

GR-R

GL-B

AR

B-R

Vuoto

BL-B

GL-VR

BL-N

M-N

RS-N

//

BL

R

R-N

N

GR

M-N

B-R

RS-N

B-R

BL-N

GL-VR

B-R

VL-GL

B

R

N

VL-GL

B

R

N

vuoto

vuoto

B-R

BL

VR/N

VR

GL

AR

vuoto

vuoto

R

B

N

B

BL-B

B-R

B-R

N

N

VL-GL

BL-R

B-N

N

VR-N

B-VR

N

GR

M

GR

VR-N

B-VR

B-N

N

BL

BL

BL

Vuoto

BL

B-GL

TPS

B-VL

R-N

B-VL

R-N

R-N

Vuoto

3

4

6

14

20

27

16

KEY TO IGNITION SYSTEM

3) CONTROL UNIT

4) FL YWHEEL MAGNETO

6) CHASSIS GROUNDING

14 ) KEY SWITCH

16) “ENGINE STOP” BUTTON

20) COIL

27 ) SIDE ST AND SWITCH

B

14 08.06

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Ignition System

SECTION 2

B - TROUBLESHOOTING

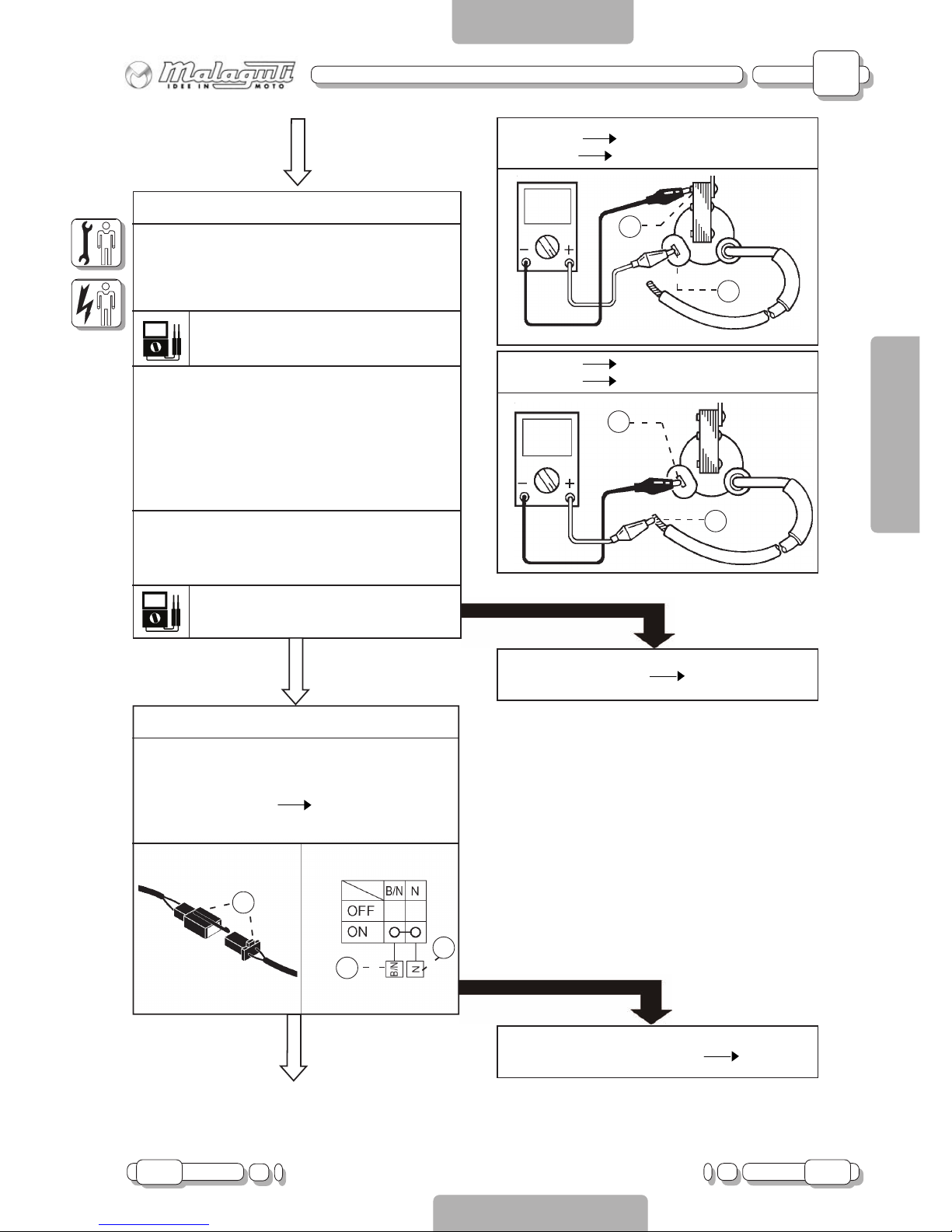

TROUBLESHOOTING

THE IGNITION SYSTEM DOES NOT WORK

(NO SPARKING OR INTERMITTENT SP ARKING)

1. Spark plug

2. Spark plug cap resistance

3. HV coil resistance

4. “ENGINE STOP” button

5. Side stand switch

6. Key switch

7. Pick-up resistance

8. System connections

1. Spark plug

- Check condition of spark plug

- Check type of spark plug

Gap between electrodes:

0.7 mm

COMPLIANT

2. Spark plug cap resistance

- Remove spark plug cap

NOTE

Never pull spark plug cable to remove cap

- Connect the T ester (K

) as shown in the figure

T o remove, turn anti-clockwise

To connect, turn clockwise

- When connecting, check spark plug cable and

if necessary replace it with a new one.

Cap resistance:

5K

± 20% a 20°C

COMPLIANT

Sample spark plug:

NGK BR9ES

Spark plug not in working order Replace or

adjust gap between electrodes

NOT COMPLIANT

T erminal (+) Spark plug side (1)

T erminal (-) Spark plug cable side (2)

2

1

Faulty spark plug cap Replace

NOT COMPLIANT

B

08.06 15

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Ignition System

SECTION 2

B - TROUBLESHOOTING

3. HV coil resistance

- Disconnect orange cable

- Connect T ester “

” to HV coil

- Check resistance of coil’s primary winding

Primary winding resistance:

0,23

± 20% a 20°C

- Connect Tester “

” to HV coil

- Check resistance of coil’s secondary winding

Primary winding resistance:

7,9

± 20% a 20°C

COMPLIANT

1

2

3

4. “Engine Stop” button

- Disconnect four-way connector (1)

- Connect Tester “

” and check continuity

between cables

White-black cable (2) Black cable (3)

See “Checking connectors” on page 1 1

COMPLIANT

T erminal (+) T erminal (1)

T erminal (-) Grounded (2)

1

2

1

2

T erminal (+) Spark plug cable (1)

T erminal (-) T erminal (2)

NOT COMPLIANT

Faulty HV coil Replace

NOT COMPLIANT

Faulty “Engine Stop” button Replace

B

16 08.06

CHAPTER

PAGE ISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Ignition System

SECTION 2

B - TROUBLESHOOTING

5. Side stand switch

- Disconnect two-way connector (1) of side stand

- Connect T ester “

” to connector, as follows:

T erminal (+) T erminal (2)

T erminal (-) T erminal (3)

1

3

2

COMPLIANT

6. Key switch

- Disconnect connector (1) of key switch

- Turn key “ON”

- Connect Tester “

” and check continuity as

follows:

T erminal (+) Orange cable (2)

T erminal (-) Green cable (3)

See “Checking connectors” on page 1 1

1

2

3

COMPLIANT

NOT COMPLIANT

Faulty side stand switch Replace

NOT COMPLIANT

Faulty key switch Replace

B

08.06 17

CHAPTER

PAGEISSUE

ELECTRIC SYSTEM TROUBLESHOOTING

ENGLISH

SECTION 2

Ignition System

SECTION 2

B - TROUBLESHOOTING

7. Pick-up resistance

- Disconnect four-way connector (1) of flywheel

magneto (2)

- Connect T ester “

” to connector, as follows:

T erminal (+) White-Red T erminal (3)

T erminal (-) Blue-White T erminal (4)

- Check pick-up resistance

Pick-up resistance:

350

± 20% a 20°C

COMPLIANT

8. Connections

- Check connections of ignition system

See “Circuit Diagram”.

COMPLIANT

Replace “CDI” control unit

1

4

3

2

NOT COMPLIANT

Replace stator

NOT COMPLIANT

Resume system’s connections

Loading...

Loading...