Page 1

Page 2

1 02/08

MALAGUTI S.p.A.

Via Emilia 498, 40068 - San Lazzaro di Savena (BO) - ITALY

Tel. 051.62.24.811 - F ax 051.69.47.782

e-mail: info@malaguti.com - http: // www .malaguti.com

FOREWORD

• The present manual specifically addresses to specialised technical personnel (MALAGUTI authorised service centres and single motor mechanics) and contains all the

service interventions indicated by the Manufacturer until the publishing of this document.

• Some basic technical information has been intentionally omitted as it is considered to be common knowledge.

• Additional information is available in the SPARE P ARTS CAT ALOGUES of each model.

• It is important to read all the general information before going through the manual to the specific topics and the maintenance operations to be carried out on the motor-bike in

order to make sure the topics, the technical and safety concepts are clearly understood and the manual can be used as a sure reference text.

• All checks, maintenance, repairs or replacements of spare parts in our motor-bikes are to be performed by skilled and e xpert technical personnel with specific experience

in state-of-the-art technology and full knowledge of the quickest and most rational procedures, technical characteristics, setting values , tightening torques and information as

to which may only be properly and exhaustively pro vided by the manufacturer.

• It is important to adhere strictly to the following instructions. Any oper ation carried out carelessly or not carried out at all may lead to personal injury , damage to the motorcycle

or simply to complaints.

MALAGUTI S.p.A. reserves the right to make any changes and modifications hereto it deems necessary without prior notice.

For further information and details, please contact MALAGUTI S.p .A. Servicing or Engineering Division.

Page 3

2 02/08

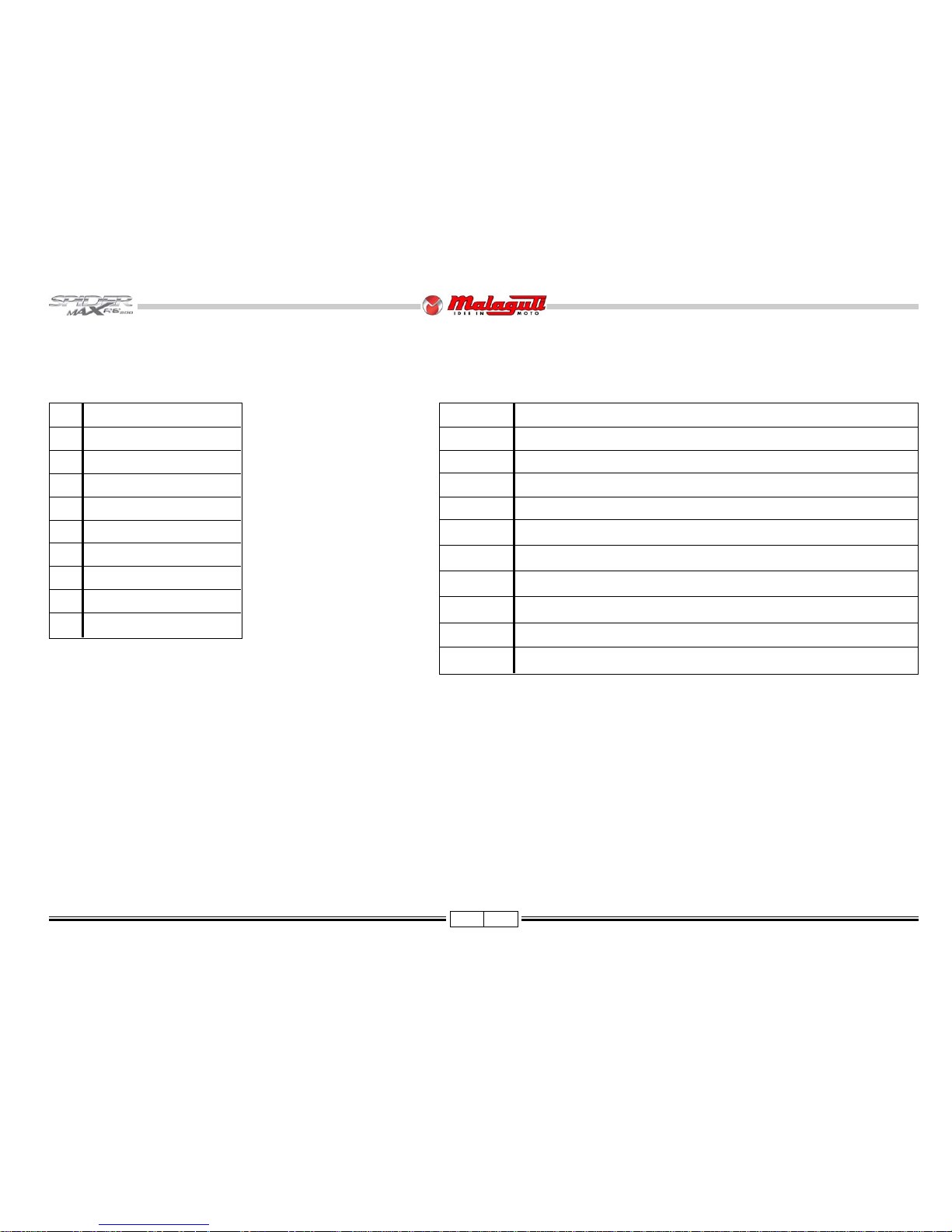

NOTES FOR EASY CONSULTATION

ABBREVIATIONS

EDITING SYMBOLS:

• Symbols have been provided for quick and easy reference, identifying situations requiring utmost attention or providing practical suggestions or simple information.

• These symbols may appear next to a text (in which case they refer solely to the text itself), next to a figure (in which case they refer to the topic illustrated in the figure and

to the relative text), or at the top of the page (in which case they refer to all the topics dealt with in the page).

NOTE - The meaning of the symbols should be duly memorised as their scope is to avoid having to repeat basic technical concepts or safety recommendations.

Cs T orque wrench setting

D Nut

Dx Right

F Picture

G Gasket

P Page

R Washer

Sx Left

T Table

V Screw

TECHNICAL DICTIONARY

V = (DC) Direct current (battery supply)

V ~ (A C) Alternating current (flywheel supply)

A : Ampere Unit of measurement of the electrical current

W : Watt Unit of measurement of the electrical power (product of V olts and Amperes; A x V = W)

ΩΩ

ΩΩ

Ω : OHM Unit of measurement of the electrical resistance

< Lower

≤≤

≤≤

≤ Lower or equal

> Higher

≥≥

≥≥

≥ Higher or equal

bar Unit of measurement of pressure

N * m Newton/metre Unit of measurement of the tightening torque

Page 4

3 02/08

M

R

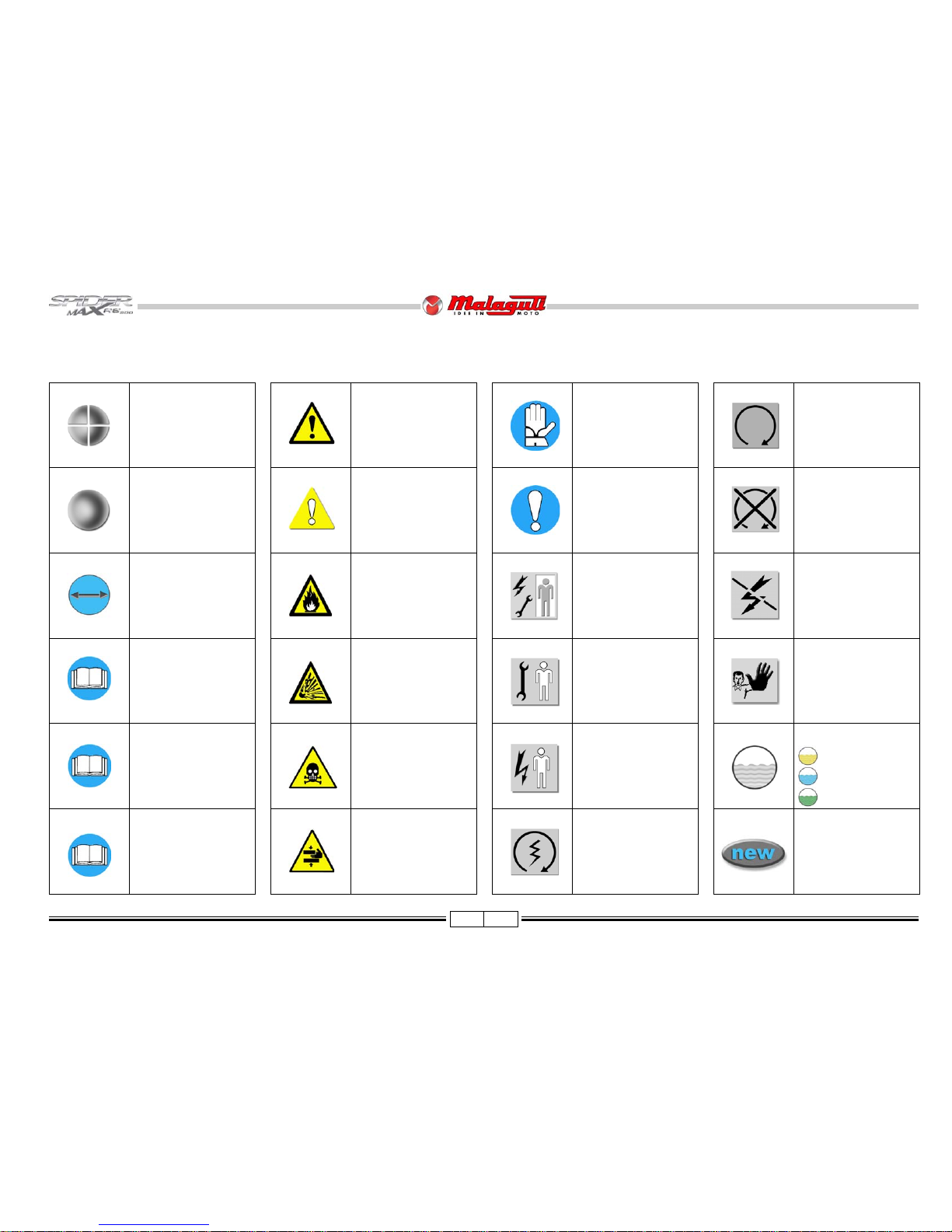

SYMBOL LIST

CAUTION!

Recommendations and

precautions regarding rider

safety and motor vehicle

integrity.

WARNING! Situations entailing

the risk of personal injury to

maintenance or repair

mechanics, other workshop

personnel or third parties, or

damage to environment,

vehicle or equipment

FIRE HAZARD.

Indicates operations which

may constitute a fire

hazard

RISK OF

EXPLOSION

Indicates operations

which may constitute a

risk of explosion

TOXIC FUMES

Indicates a possibility of

intoxication or inflammation

of the upper respiratory

tract

WARNING!

Danger of crashing

arms

SAFETY GLOVES

These operations require

the use of safety gloves

IMPORTANT

This topic requires special

attention

GENERAL SERVICE

PERSONNEL

Skilled electronic or

mechanical technician.

MECHANICAL

MAINTENANCE

Operations to be performed

only by an expert mechanic

ELECTRICAL

MAINTENANCE

Operations be performed

only by an expert electrical/

electronic technician

IGNITION KEY ON

(ON position)

PRESENT MANUAL

Information on the

present manual

“ENGINE” SERVICE

MANUAL

Indicates information which

may be obtained by

referring to said catalogue

SP ARE PARTS

CATALOGUE

Indicates information which

may be obtained by

referring to said catalogue

DISASSEMBL Y

OPERATIONS

ASSEMBL Y

OPERATIONS

SYMMETRICAL

OPERATIONS

Operations that must be

carried out also on the other

side of the unit or

component.

EMPTY THE CIRCUIT

REPLACE WITH NEW,

ORIGINAL SPARE

PARTS

IDLING ENGINE

Switch on the engine, at

idling speed, to perfom

these interventions.

ENGINE OFF

Indicates operations to

be performed with

engine off

POWER OFF

Indicates that negative

pole is to be disconnected

from the battery before

performing the operation

NO!

Operations to be

absolutely avoided

OIL

COOLANT

FUEL

Page 5

4 02/08

Before any servicing, make sure that the vehicle is perfectly stable.

The front wheel should preferably be anchored to fixture, which is integral with the lift platform.

GENERAL WORK PROCEDURES

• The recommendations given hereafter are aimed at ensuring maximum work safety as well as at considerably reducing the risk of accidents, personal injury, equipment

damage and idle times, and should therefore be strictly adhered to.

• Always listen with attention to the customer’ s opinion and complaints about the motor-bike operation, asking specific questions in order to ha ve a complete understanding of

all the symptoms and identify with good approximation the real causes of the trouble. The present man ual provides the technical information and the basic indications on the

intervention procedures but these have to be integrated with the personal e xpertise.

• We suggest planning the service interventions in order to avoid any waste of time or downtime. Try to reduce as much as possible the operations necessary to reach the

components that needs repairing.

• Prepare the components that are likely to be replaced and all the original spare parts you may need.

• Use only the original spare parts.

• Mark the components that may be mis-placed during re-assembly operations.

• Only use quality tools and equipment.

• Only use equipment conforming to EU Directives for lifting the vehicle.

• During operations, always keep tools and equipment at hand, possibly laying them out according to the sequence in which they are to be used. Absolutely avoid putting them on the

vehicle itself, out-of-sight or in poorly accessible places.

• Always keep the work area neat and clean.

• When tightening screws or nuts, start with the larger diameter or inner fasteners, and tighten them in progressive “pulls” using a “criss-cross” pattern.

• The torque settings specified in the manual refer to the “final torque”, which must be attained progressively by steps.

• Preferably use open-end box wrenches by “pulling” and not “pushing”.

Page 6

5 02/08

• Before carrying out any operation, wait f or all parts to cool down.

• For operations requiring two mechanics, make sure that the various steps to be performed by each of them are clearly defined and co-ordinated beforehand.

• Make sure that each component has been properly mounted before proceeding with assembling the next one.

• Always replace gaskets, O-rings, circlips and split pins at every refitting.

• Only use screwdrivers with sizes suitable to the screws to be loosened or tightened.

Never use open flames for any reason.

Never leave open containers or containers not suitable for holding fuel in passageways, close to heat sources, etc.

Never use petrol to clean the vehicle or the floor of the workshop. Always use low flash point solvents to clean the vehicle components.

When welding, make sure that there are no flammable liquids in the vicinity.

Never suck from or blow into the fuel pipe.

Never leave the engine running in closed or poorly ventilated areas.

Do not use fuses with a higher rated capacity than indicated: this may cause se v ere damages to the electrical system and burn a fire as a conse-quence of short circuit.

• Make sure that the vehicle is stable and not to have to take on awkward working positions.

• Never reuse old gaskets or circlips.

• Never use a screwdriver as a lever or chisel.

• Never use pincers to loosen or tighten screws or nuts because, in addition to not providing a sufficient clamping force, they may also damage the screw head or nut hexagon.

• Never tap the wrench with a hammer or other similar tool to loosen or tighten screws and nuts.

• Never attempt to increase the lever arm by fitting a tube into the wrench.

Page 7

6 02/08

CONTENTS

DESCRIPTION P.

RIGHT RADIA T OR - LEFT RADIA T OR 38

ELECTRICAL FAN RADIA TOR - EXP ANSION RESER VOIR - THERMAL EXP ANSION VAL VE 39

KEY SWITCH - DASHBO ARD P ANEL 40

LEG PROTECTOR 41

UPPER HANDLEBAR COVER - ACCESSES 43

FRONT AND REAR HANDLEBAR COVER - ACCESSES 44

HANDLEBAR - BRAKE MASTER CYLINDERS 45

DRIVER SEAT - ACCESSES 46

P ASSANGER SEA T - CUSHION DRIVER SEA T - GRAB HANDLE 47

HELMET COMP ARTMENT 48

ACCESSES - DIRECTION INDICA TORS AND T AIL LIGHTS 48

REAR FAIRING 49

TAIL LIGHTS 50

SIDE REACH - VOL T A GE RECTIFIER 51

COOLANT PUMP - COIL 51

RELA Y HOLDER 52

ACCESSES - ELECTRONIC INJECTION ECU THRO TTLE BODY 53

BA TTERY COMP AR TMENT - ACCESSES 54

FUEL TANK 55

AIRBOX 57

FRONT MUDGUARD - FRONT WHEEL - WHEEL SPINDLE 58

(FRONT BRAKE) DISCS - FRONT WHEEL - REASSEMBLY 59

BRAKE CALLIPERS - FRONT CALLIPER REPLACEMENT AND DISASSEMBL Y 60

LOWER F AIRING MUDGU ARD - FORK 63

ST ANCHION GROUP - STANCHION DISASSEMBL Y - CHECK THE OIL LEVEL IN THE ST ANCHION 63

FRONT FORK OIL REPLACEMENT 64

COMPLETE FORK 64

EXHAUST - EXHA UST MANIFOLD 65

LAMBDA SENSOR - REMOV AL - REASSEMBLING 66

REAR SHOCK ABSORBERS 67

REAR ARM - SHOCK ABSORBER SUPPORTING PLA TE 68

REAR CALLIPER - REAR CALLIPER DISASSEMBL Y 69

REAR WHEEL - (REAR BRAKE) DISC ENGINE 71

ENGINE REASSEMBL Y - ENGINE MOUNT 72

ANTI-VIBRATION CONNECTING RODS - ENGINE MOUNT 73

SUBFRAME 74

UPPER SUBFRAME - SIDE SUBFRAMES - CENTRAL ALUMINIUM FRAME 75

FRAME DIMENSION CHECK 76

CABLE POSITIONING, “PIPE SYSTEM” AND ANCHORING TIES 77

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

23

4

DESCRIPTION P.

SPECIFICATIONS 7

IDENTIFICATION D A T A: FRAME N° / ENGINE N° - TYRES 8

MAINTENANCE TABLE 9

LUBRICANT TABLE 10

FUEL TANK - COOLANT T ANK 11

BLEEDING, COOLING CIRCUIT 12

BLEEDING OF THE LEFT SIDE - BLEEDING OF THE RIGHT SIDE 12

ENGINE OIL 13

CHECK THE OIL LEVEL - TOPPING UP 13

CHANGE ENGINE OIL 14

TRANSMISSION OIL - CHECK THE LEVEL - RENEW 15

BRAKE OIL - CHECK - CHANGE 16

BRAKING SYSTEM BLEEDING - INTEGRAL SYSTEM 17

CHECK THE LEVEL OF THE BRAKE LIQUID - FR ONT LEFT CALLIPER 17

CHECKING BRAKE PADS AND DISCS - BRAKE P ADS 18

REPLACING THE BRAKE P ADS - DISCS 18

FORK - CHECK THE OIL LEVEL IN THE ST ANCHION 19

FRONT FORK OIL REPLACEMENT 19

REAR SHOCK ABSORBER ADJUSTMENT - STEERING 2 0

HANDLEBAR ADJUSTMENT 2 0

LOCATION OF THE MAIN ELECTRICAL ELEMENTS 21

INSTRUMENT BOARD 23

KEY SWITCH - HANDLEBAR LOCK 24

LOCKING - DISENGAGING 24

STAR TING THE ENGINE 24

LIGHTING SYSTEM - LAMPS 25

ADJUSTING THE BEAM LIGHT 26

FUSES - GENERAL PROTECTION FUSE AND CHARGE PROTECTION FUSE 27

BA TTERY ASSEMBLY - CHARGE BA TTERY 28

SP ARK PLUG - REMPLACE 29

PROCEDURES FOR DISMANTLING AND REMOVING COMPONENTS 30

REASSEMBL Y NOTE - CENTRAL F AIRING - REAR VIEW MIRRORS 30

FRONT DIRECTION INDICA TORS (BULB CHANGE) 30

ACCESSES - REPLACING THE FRONT PARKING LIGHT 31

DASHBOARD - BRAKING DISTRIB UTOR - HORN 32

AIR GRID - WINDSCREEN - FRONT F AIRING 33

ACCESSES - IMMOBILIZER ECU 35

SIDE STAND SWITCH - FUEL SUPPLY PUMP 36

RADIATORS 37

Page 8

7 02/08

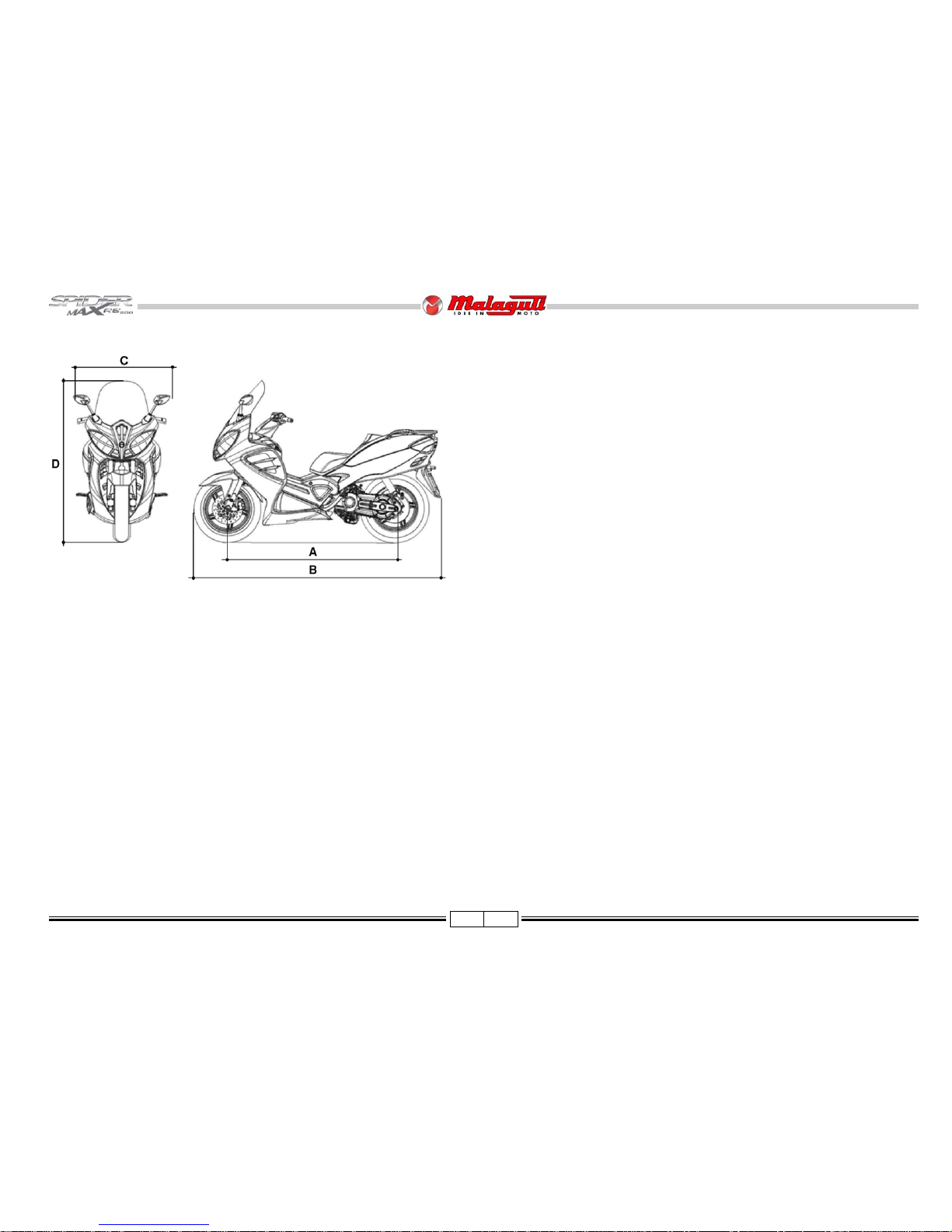

DIMENSIONS

Wheel base (A) m .......................................................................................1,490

Max. length (B) m........................................................................................2,200

Max. width (C) m.........................................................................................0,930

Max. height (D) m........................................................................................1,470

Kerb weight kg ...............................................................................................230

Max. load with rider , passenger and luggage kg..............................................180

CAP ACITY

Engine oil cm3 ........................................................................................... 1700*

T ransmission oil cm3 ................................................................................... 250*

Fuel tank (total).............................................................................................. 14 *

ENGINE: single-cylinder , f our-valve

Valves type............................................................................. PIAGGIO M34CM

n° Cylinders ...................................................................................................... 1

Bore x stroke mm .................................................................................. Ø 94x71

Capacity cm3.................................................................................................493

Compression ratio ............................................................................... 10.5 ± 0.5

Cooling........................................................................................................ liquid

Starting system ............................................................................electric starter

Greasing system.................................................................................. wet sump

SP ARK PLUGS

Type.............................................................................................. NGK CR7EKB

TRANSMISSION

Automatic speed variator with expandab le pulleys, V-belt, automatic

dry centrifuge clutch, reduction gear and transmission

compartment with forced circulation cooling system.

FUEL SYSTEM

Electronic injection with electrical fuel pump.

Fuel: unleaded petrol.

ELECTRONIC IGNITION

High efficiency , inductive type coupled with the injection system,

variable advance and separate HV coil.

BRAKES

The braking system is hydraulically operated and features double front disc (2

discs with a diam. of 270 mm) and rear disc (260 mm diam. disc) with braking

distribution system. The brak es are operated as follows:

Left lever: rear lever + front lever (right hand side of the vehicle)

Right lever: front brake (left hand side of the vehicle)

CHASSIS

“V-Bo x” type, composed of a double pressure die cast shell made of aluminium,

coupled, on the front and rear sides, to a steel pipe frame.

SUSPENSIONS

Fr o n t: hydraulically controlled fork with two Ø 41 mm rods.

Stroke: 120 mm

Rear: 2 hydraulic shock absorbers with adjustable preloading spring.

BA TTER Y

12V , 14Ah, maintenance-free.

TIRES

Fr on t: 120/80 - 16 60 S

Rear: 150/70 - 16 68 S

*

Indicative V alue

SPECIFICATIONS

F. 1

Page 9

8 02/08

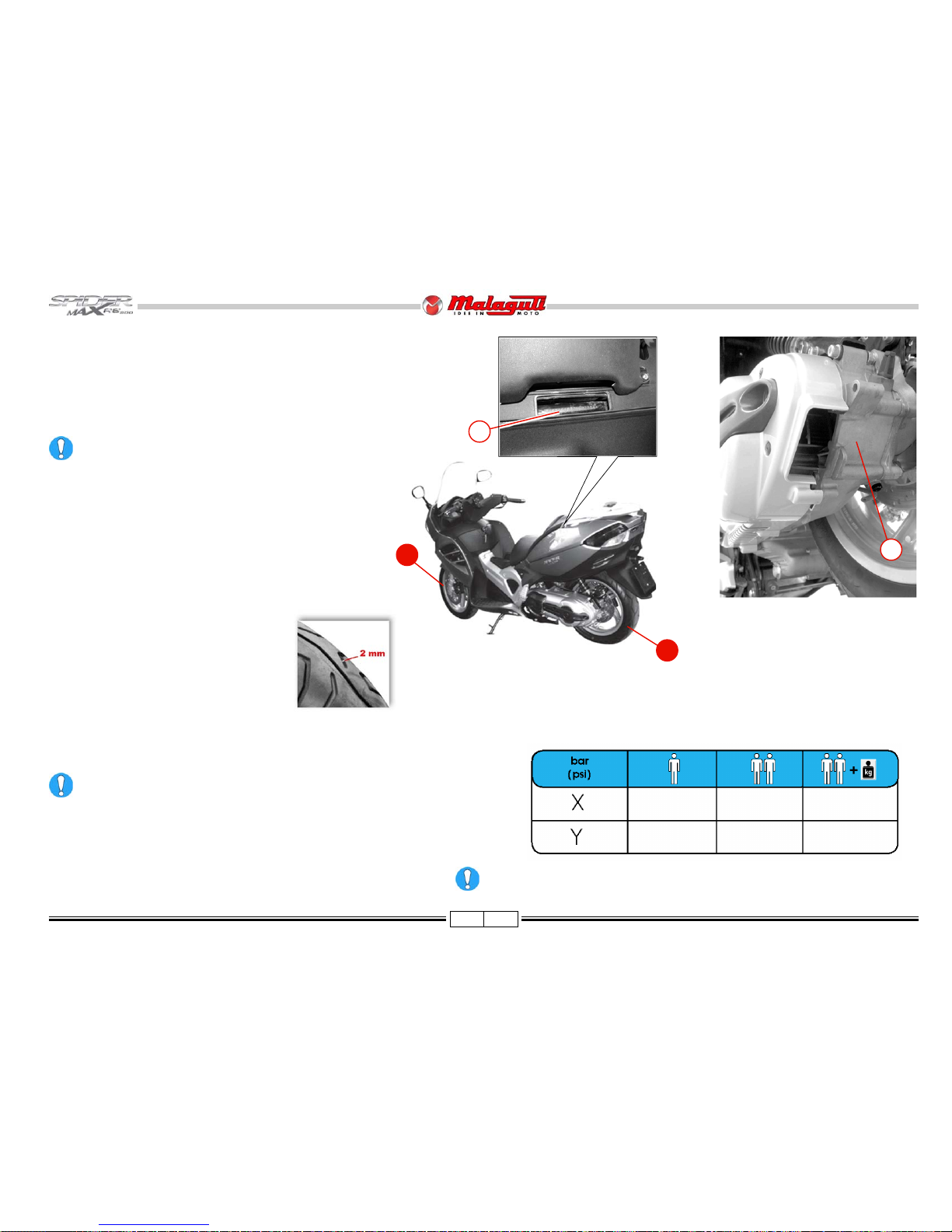

TYRES

Type: T ubeless (without inner tube)

It is possible to use tyres with load and speed indexes that are higher

than or identical to those indicated.

It is however necessary for speed indexes to be identical for both

tyres. Use only tyres with the relevant type approval.

Tyre inflation pressure must be adjusted while the tyre is at ambient

temperature.

150/70 - 16” - 68S

120/80 - 16” - 60S

2.3 2.3 2.3

(33.4) (33.4) (33.4)

2.3 2.3 2.3

(33.4) (33.4) (33.4)

B

F. 2

F. 3

A

• To read the vehicle’s identification number (VIN) (A) lift the saddle

and remove the cover located in front of the helmet compartment.

• Engine identification data are located on the left-hand engine crankcase (B).

Any alteration to the vehicle identification data is pursued

by the Law.

Minimum tread depth is 2 mm.

• There are T.W.I. marks all around the tyre

sides. These correspond to tyre wear

indicators situated in the tyre’s tread; if

there is no difference between the

thickness of the tyre wear indicators and

the tread depth, the tyre must be replaced.

F. 4

X

Y

IDENTIFICATION DATA: FRAME N° / ENGINE N°

Page 10

9 02/08

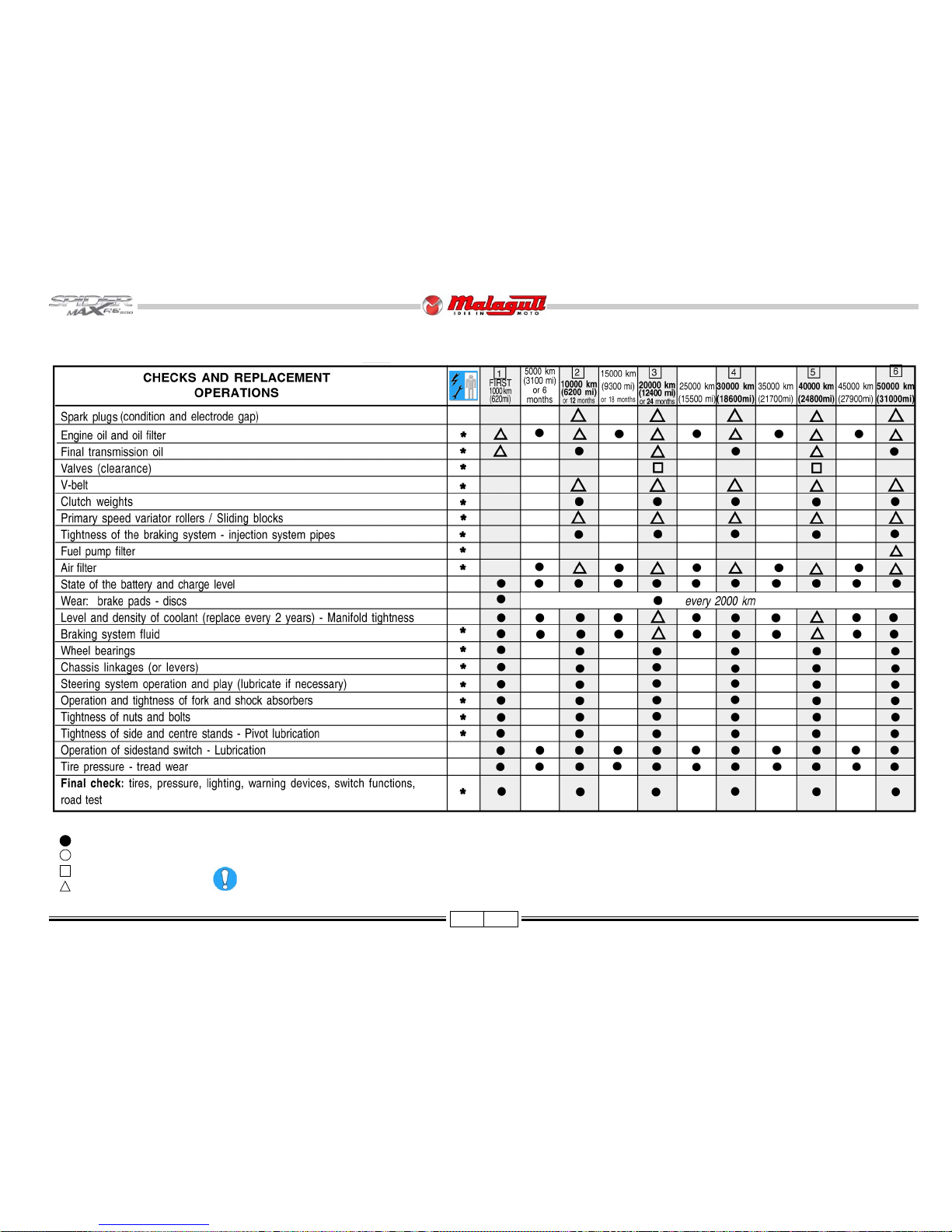

MAINTENANCE TABLE

NOTE - Maintenance operations should be performed more frequently if the vehicle is used in rainy weather, in dusty places or on rough

terrain.

Due to their simplicity, checks with no asterisk CAN also be carried out b y technicians not authorised by MALA GUTI, b ut under

their direct responsibility.

Nr. : coupon

: check

: clean

: adjust

: replace

Page 11

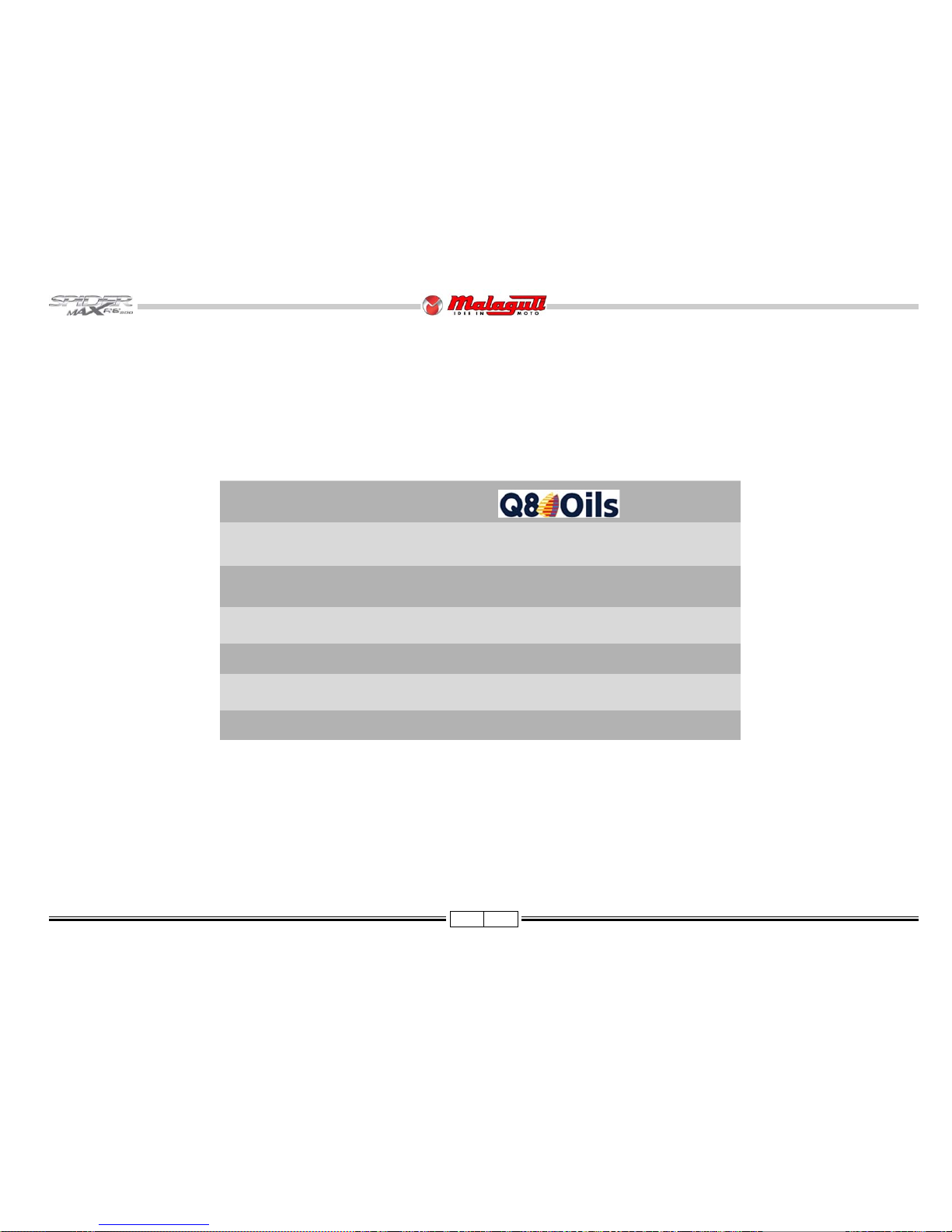

10 02/08

LUBRICANT TABLE

NOTE - Use only recommended products.

LUBRICANTS

ENGINE OIL (4-STROKE TYPE) FORMULA EXCEL SAE 5W40

ENGINE TRANSMISSION OIL ZC 90

AIR FILTER LUBRICANT AIR FILTER OIL

RADIATOR FLUID Q8 LONG-LIFE RED

BRAKE CIRCUIT FLUID BRAKE FLUID DOT 4

FORK ROD OIL FORK OIL

Page 12

11 02/08

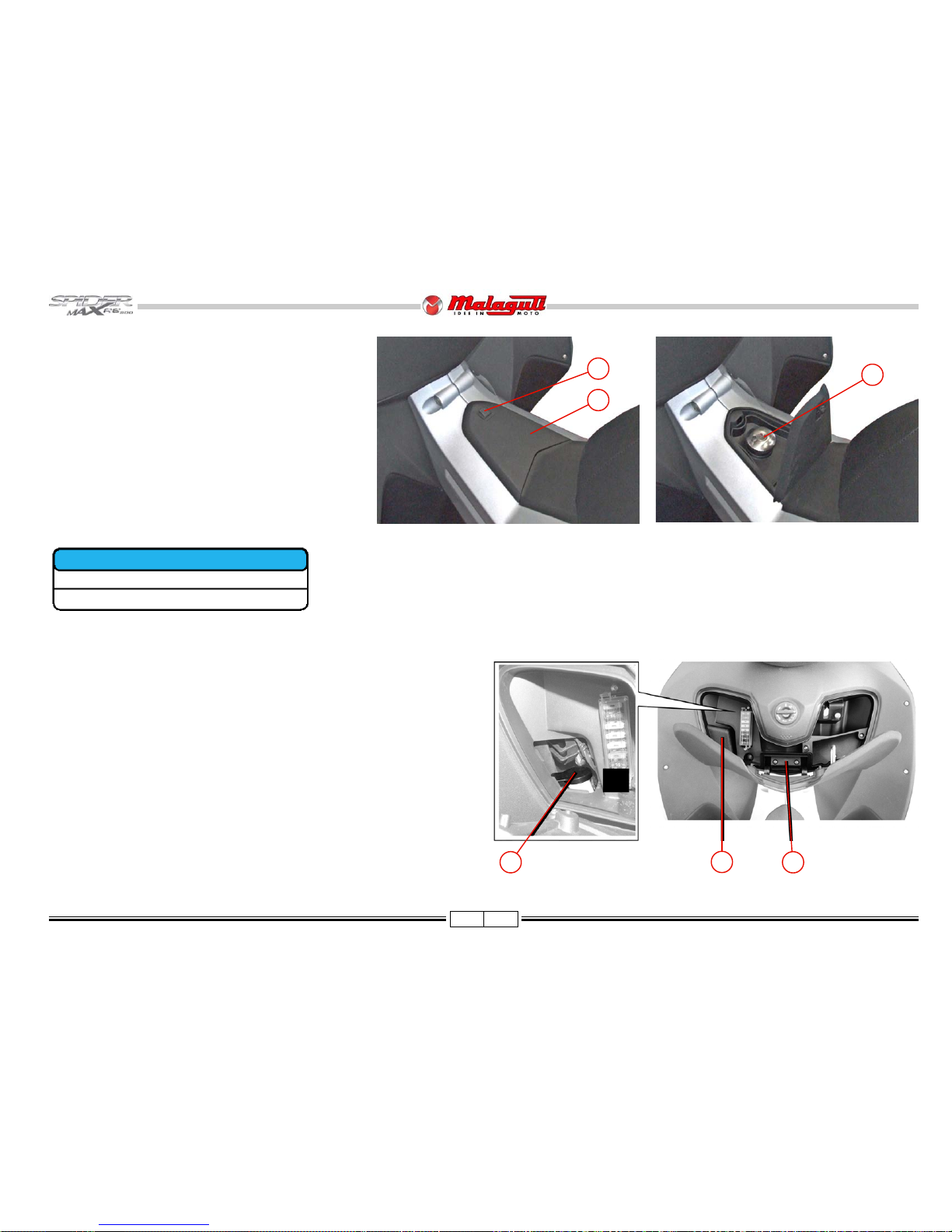

FUEL TANK

To access the fuel tank, proceed as follows:

• Place the vehicle on the centre stand.

• Remove the ignition key from the ignition block.

• Open the door (A) in front of the seat, by acting on the lever

(B).

• Insert the ignition key, remove the cap (B) and refuel the

tank.

• After refuelling, immediately remove any possible traces

of fuel from the vehicle body, since fuel may deteriorate

the vehicle’s outer surfaces.

Use UNLEADED PETROL.

F. 5

F. 7

COOLANT TANK

• T o access the engine coolant tank, open the glov e compartment (A) located at the

centre of the lower fairing and remove the plastic co ver (B). Owing to the particular

position of the tank, the level of coolant, with respect to the minimum and maximum

level marks, can be checked through the grid under the upper fairing, on the front

side of the vehicle. Use the coolant prescribed in this manual - or one having

identical characteristics - for any topping up. Never unscrew the tank cap (T) when

the engine is warm, so as to avoid burnings. Do not top up with water, except in

emergency situations and in this case, have the entire contents of the tank replaced

by a suitable product as soon as possible.

A

*

Indicative V alue

B

T

14*

3*

F. 6

A

B

C

FUEL TANK Litres

TOTAL TANK CAPACITY

RESERVE

Page 13

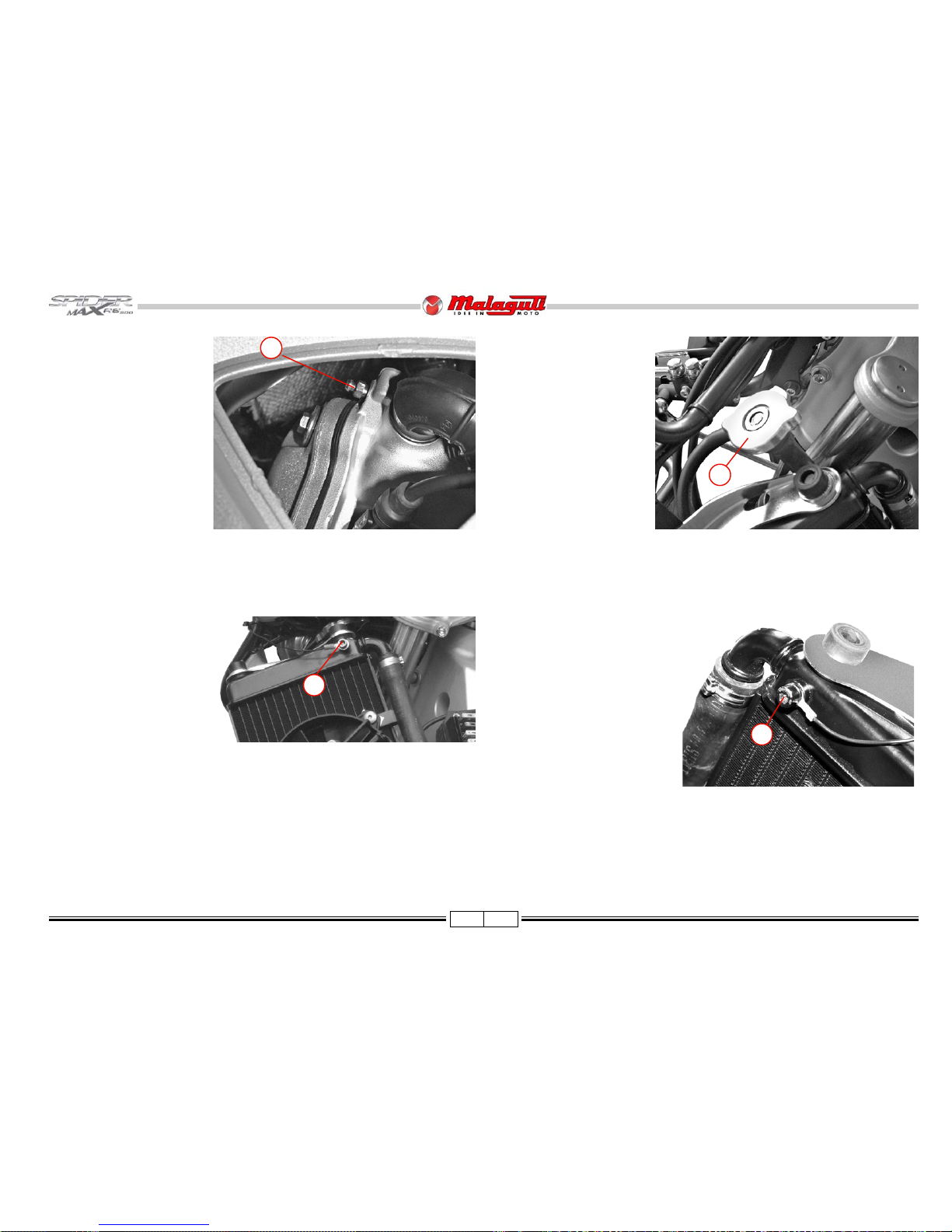

12 02/08

BLEEDING, COOLING

CIRCUIT

T o bleed the air , with the

circuit completely drained

from the coolant, proceed as

follows:

BLEEDING OF THE LEFT

SIDE

• Remove the cap on the

bleeding coupling (A).

• Fit a tube in the coupling

(A) of the bleed nipple on

the cylinder head.

• Refill the expansion reser-

voir with coolant, as described: (P. 11).

• Release and remove the

filler (B).

• Pour some coolant in the

main radiator (left).

• Slacken the coupling (A)

and go on refilling the main

radiator until some liquid

would drip off the tube (with

regular flow).

• Now, close the b leed nipple

(coupling - A) and fill in up

to the rim of the main

radiator.

• Slacken the bleed screw (C),

until some liquid drips off with

regular flow.

• Close the screw and top up

the liquid.

• Open the bleed nipple on the

cylinder head and check the

tubes for liquid dripping,

showing that the bleeding

has been correctly carried

out.

• Close the coupling (A) back.

F . 7/a

F . 7/c

BLEEDING OF THE RIGHT

SIDE

• Slacken the bleed screw (D),

until some liquid drips off with

regular flow.

• Close the screw and top up the

liquid in the main radiator.

• With the help of an assistant,

slightly tilt the vehicle on the right side and, keeping it in this

position, slightly slacken the

screw (D), to let any remaining

air out of the right radiator.

• Tighten the bleed screw (D),

F . 90/a

which act as the ground screw .

• Open the bleed nipple on the cylinder head and check the tubes for liquid dripping,

showing that the bleeding has been correctly carried out.

• Close the coupling (A), remove the tube and fit the cap.

• Check the main radiator is completely refilled with coolant; top up and refit the filler

(B), if necessary.

F . 7/d

F . 7/b

C

A

B

D

Page 14

13 02/08

ENGINE OIL

• As far as four-stroke engines are concerned, engine oil is used to lubricate distribution components, base bearings

and thermal unit. An insufficient amount of oil can seriously damage the engine.

• In all four-stroke engines, deterioration of the oil and a certain consumption are to be considered normal.

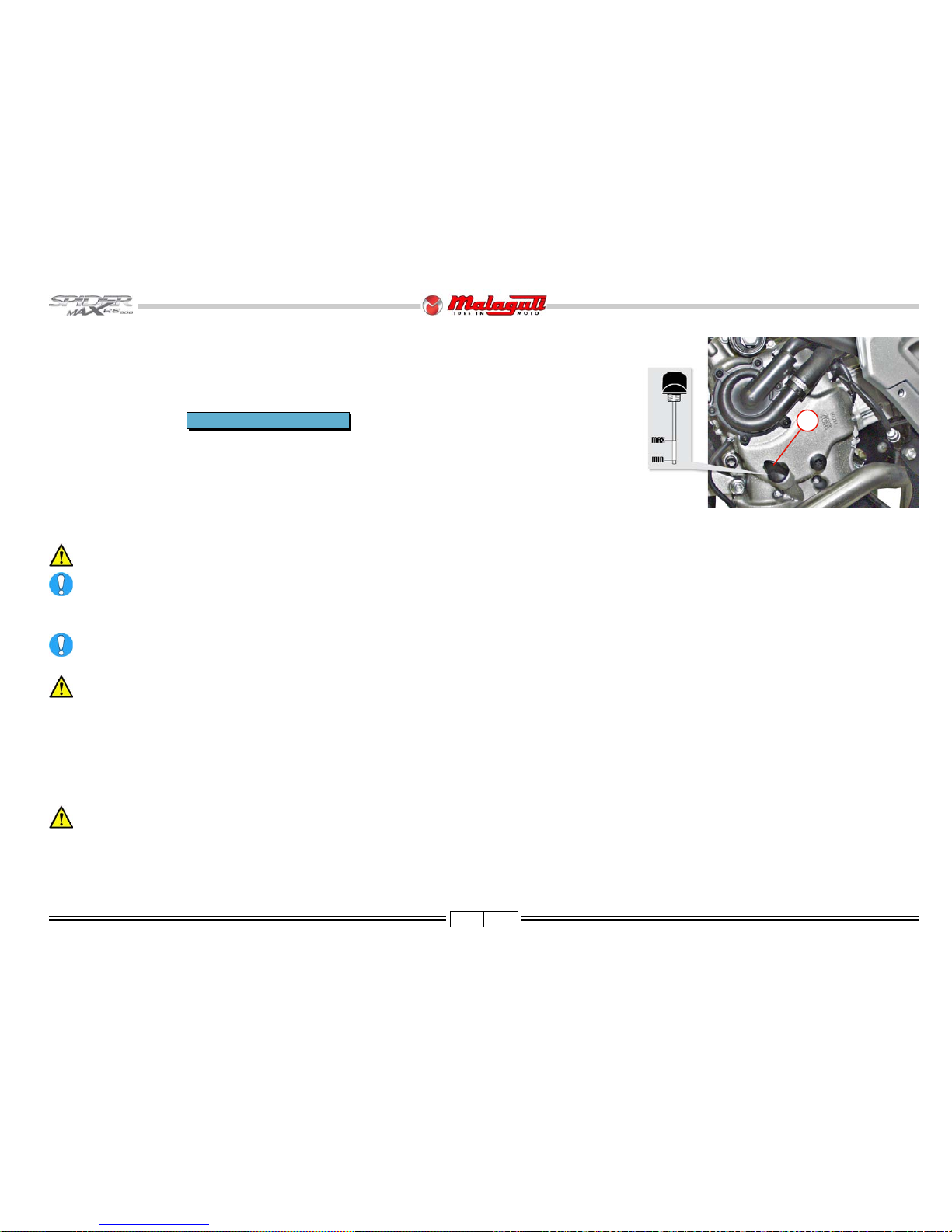

CHECK THE OIL LEVEL

This check should be performed when the engine is cold, as described below:

1) Park the vehicle on flat ground and put it on its centre stand (e v en a slight inclination ma y alter results).

2) Unscrew the cap/dipstick (A), dry it with a clean cloth and refit it, wrenching it firmly in place.

3) Remove the cap/dipstick and make sure the le vel falls betwe en the MAX and MIN notches; if necessary, top up

with Q8 FORMULA EXCEL SAE 5W40 oil.

The MAX level notch corresponds to quantity of about 1700 cm3 of oil in the engine.

If you need to check the level when the engine is warm, remember that the level line will be lo wer . It is best to wait at least 10 minutes fr om stopping the

engine in order to have a correct reading.

The vehicle features a control system that activates the “LO W OIL PRESSURE” alarm signal of the digital instrument boar d in the event of trouble.

TOPPING UP

Before topping up, check the oil level and in no case allow the level to rise above the MAX notch.

• T opping up to le v el falling betw een the MIN and MAX marks means using about 400 cm3 of oil.

Never allow the level to rise above the MAX mark! This may seriously damage the engine, due to excessive internal pressure.

• Every 3000 km, it is recommended to have the engine oil checked.

ALARM MESSAGE (LO W OIL PRESSURE)

The digital instrument board features a control system displaying a “LOW OIL PRESSURE” message (B - § 3.11.6). The message appears when the vehicle is turned on to

signal that the check function is working. The message disappears automatically after a f e w seconds . It will only reappear during vehicle use if there is actually a low oil

pressure problem.

If the message appears when you are braking, when the engine is idling or when curving, stop the vehicle, check the oil le vel and top up if necessary .

Every 3,000 km, the message OIL is displayed on the digital instrument board. This warning light indicates that it is time to change the engine oil. This

warning light is displayed on the instrument board until the indicated operation is carried out.

Waste oil is toxic f or the environment, therefore we suggest you contact an A uthorised Service Centre for disposal according to the rules in for ce.

every 3000 km or 6 months

F. 8

A

Page 15

14 02/08

every 6000 km or 12 months

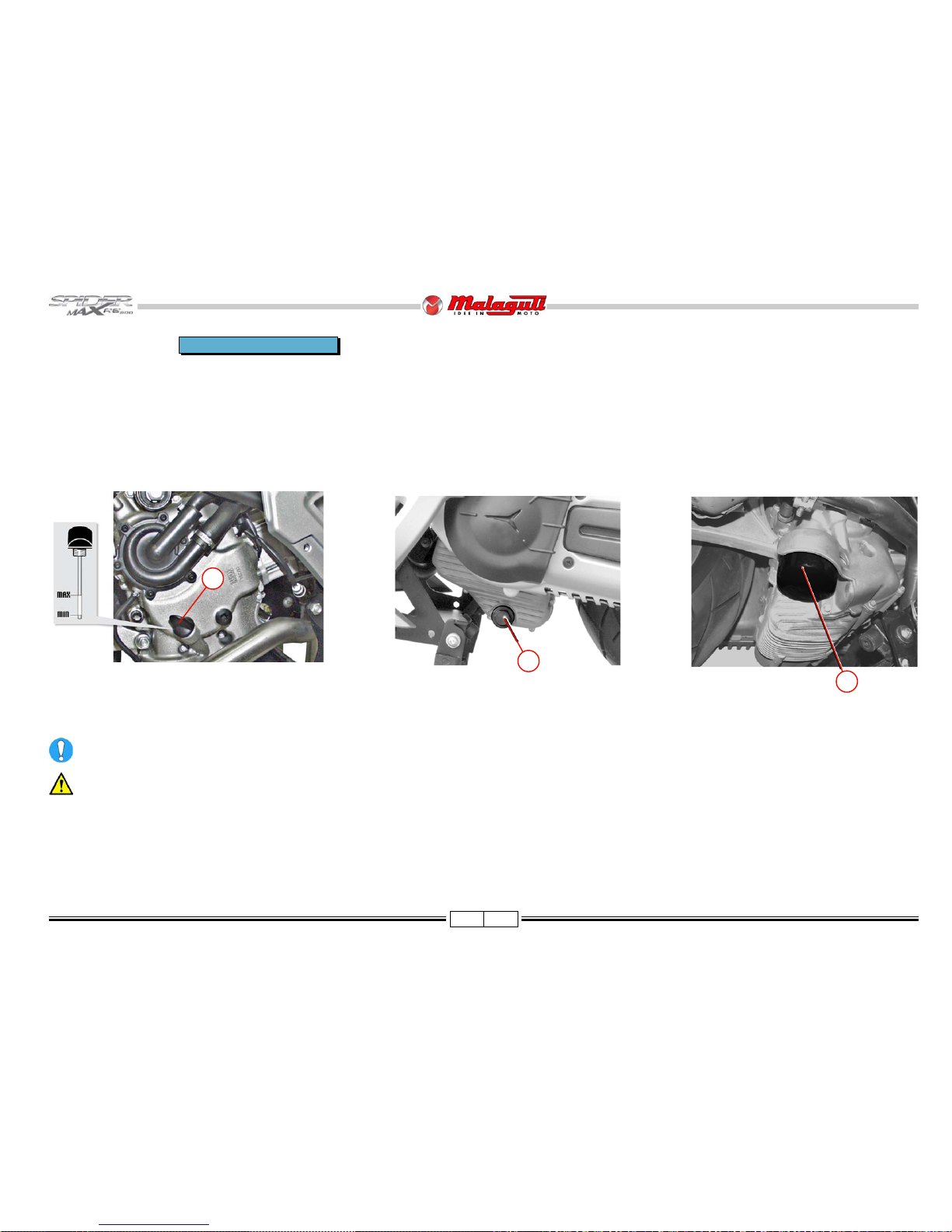

CHANGE ENGINE OIL

• The engine must be emptied by letting the oil flow from the drainage cap (B) of the filter beside the transmission. To facilitate drainage, loosen the cap/dipstick (A F. 8/a).

• Unscrew the cartridge filter (C) and remove it. Fit a ne w filter , and lubricate the O-rings with engine oil. Since a certain amount of oil remains in the circuit, fill through the cap

(A) using about 1500 cm3 of oil. Start the vehicle, let it run for a few minutes and turn it off: after 5 minutes, check the level and top up b ut never above the MAX mark.

F. 9

B

F . 9/a

C

The cartridge filter must be replaced every time the oil is changed. For topping up and replacement use Q8 FORMULA EXCEL SAE 5W40 oil.

Letting the engine run with an insufficient amount of lubricant or with the wrong types of lubricant causes wear to moving parts and can in the long run

cause serious damage.

Waste oil contains polluting substances. Ha ve oil replaced by an Authorised Service Centre that will also dispose of waste oil in accordance to the la w.

F . 8/a

A

Page 16

15 02/08

Max

Min

TRANSMISSION OIL

CHECK THE LEVEL

1) Place the vehicle on a level surface on its centre stand.

2) Unscrew the dipstick (A), clean it and refit it, wrenching it tightly.

3) Pull it out again and check that the oil level is between the MIN and MAX notches.

4) If the level is insufficient, top up until you almost reach the MAX notch.

5) Fill the crankcase with this type of oil: Q8 ZC 90

Crankcase capacity approx.: 250 cm3

RENEW

• Carry out the operations described above at points 1-2, without refitting the dipstick; then put a container under the

engine crankcase and unscrew the drainage screw (B), paying attention to the gasket.

• Let oil flow into the container (pay attention to avoid scorching).

• Refit the drain plug with gasket and fill with approximately 250 cm3 of new oil (Q8 ZC 90), then refit the cap and

dipstick (A).

• Now repeat checks 3-4-5. If the drainage screw gasket is damaged, replace it.

Regularly check for oil leakages near the drain plug at the rear wheel.

every 6000 km or 12 months

after the first 1,000 km and every 24,000 km

F. 1 0

F. 1 1

A

B

Page 17

16 02/08

MIN

S

CHANGE

If the fluid features traces of dirt, debris or water, it m ust be replaced. A soft and spongy feeling in the brake le ver can indicate the presence of air in the

circuit.

CHECK

• The visual check should be made through the sight glass (S) of the tanks: front

brake (A) and rear brake (B), when the vehicle is on level ground and perfectly

upright.

• The oil should be at 3 mm from the bottom edge of the sight glass.

BRAKE OIL

When topping up, never use more than one oil.

F. 1 2

every 30 days

every 12.000 Km or 24 months

A

B

MIN

S

F. 1 3

Page 18

17 02/08

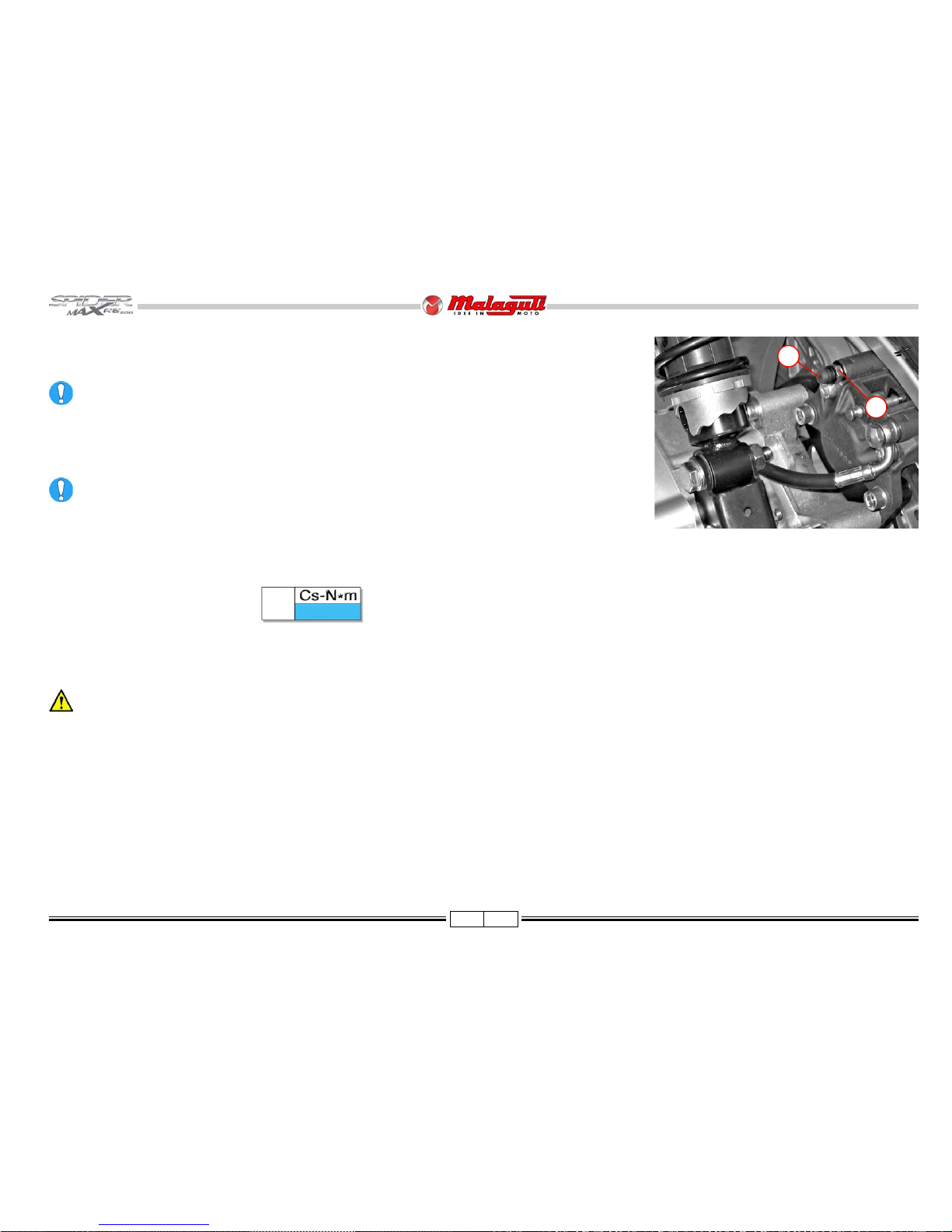

BRAKING SYSTEM BLEEDING

INTEGRAL SYSTEM

Put the vehicle on firm and level ground.

• Remove the cover of the oil pump tank (left-hand side), releasing the two screws, so as to top up the liquid.

NOTE - The left brake lever allows the front right brake calliper and the rear brake calliper to be controlled interlockedly

at the same time.

To b leed the circuit of the integral system, fir st bleed the rear brake calliper .

• Fill in the left brake liquid tank up to the maximum level.

• Remove the rubber cap (A) from the bleed screw (B) and fit the rubber hose to collect the brake liquid.

• Operating the left brake lever , charge and pressurise.

• Keeping the left brake le ver oper ating, slack en the bleed scre w to let the air out. Then, tighten the bleed screw (B).

• Repeat the operation until only brake liquid is let out of rubber hose.

• These operations should be repeated for the front right calliper.

• Restore the level of the brake liquid in the sump.

During the bleeding, av oid the contact between the brake liquid and the bodywork, to avoid dama ges. Moreover , during the bleeding of the brake callipers,

avoid the contact between the liquid and the brake discs or the brake pads. Failure to observe this rule may affect the functions and the efficiency of the

braking system. If, during the bleeding, more air would come out, check all of the couplings: if they do not show any malfunctioning, look for the entrance

of the air in the different seals of the pump and in the pistons of the calliper.

During this operation, oil may leak from the bleed screw on the calliper and on the disc: if so, carefully dry the calliper and degrease the disc.

CHECK THE LEVEL OF THE BRAKE LIQUID (P. 16)

FRONT LEFT CALLIPER

• T o bleed the front left calliper, operate the right brake lever.

F. 1 4

B

A

B

12 ÷ 16

Page 19

18 02/08

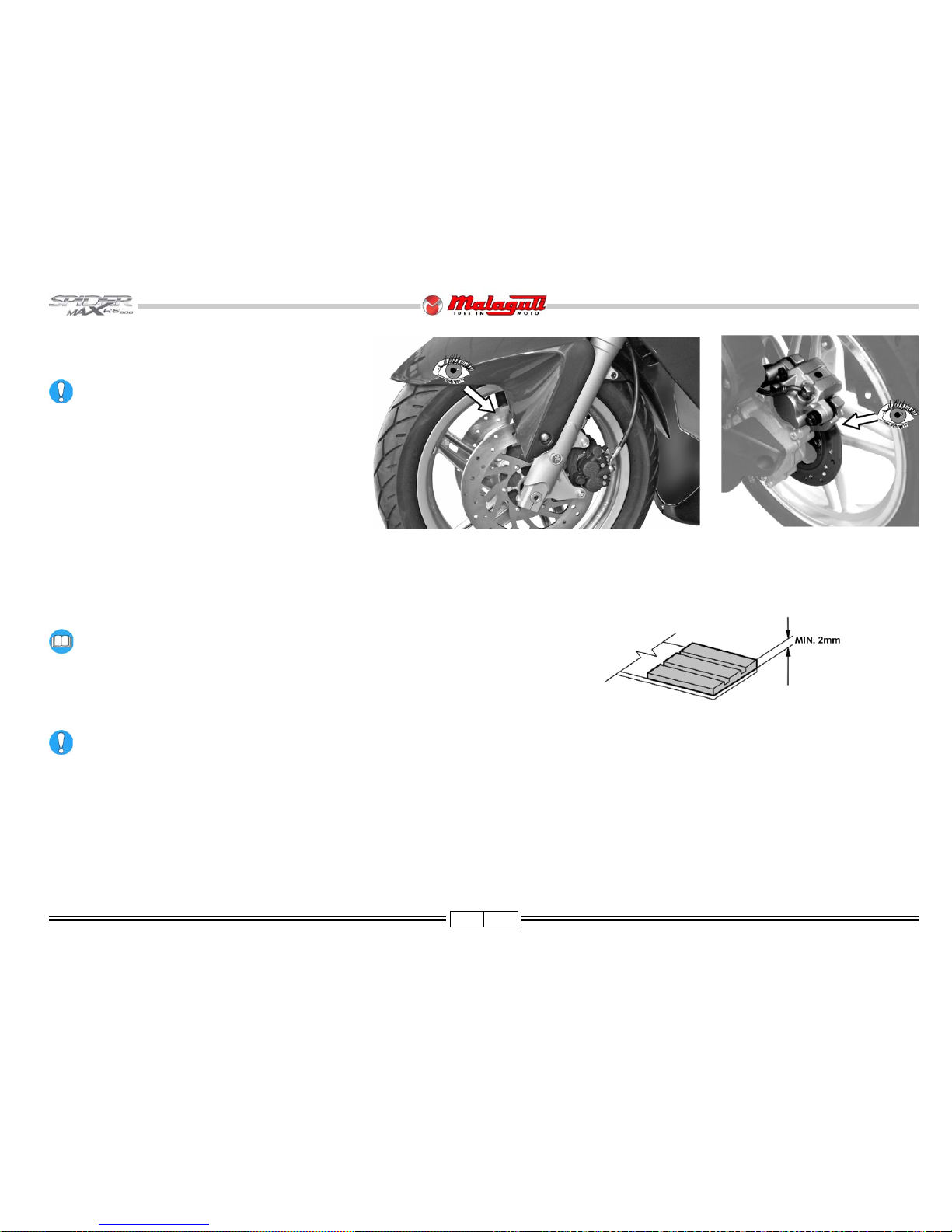

CHECKING BRAKE PADS AND DISCS

BRAKE P ADS

Check front and rear brake pads and discs for wear

every 2,000 Km.

• Visually check the thickness of the brake pads as shown

in the picture.

The minimum thickness of the brake pad lining should

not be thinner than 2 mm.

• Replace the brake pads in case their thickness is below

the allowed limit or they are damaged.

REPLACING THE BRAKE PADS

F. 17

F. 1 5

F. 16

DISCS

Check the discs for wear and replace if necessary (service limit 4.5 mm).

In case of abnormal wear or signs of scoring, carry out grinding.

For instructions on how replacing the front and rear brake pads please refer

to pages 60 and 61.

Page 20

19 02/08

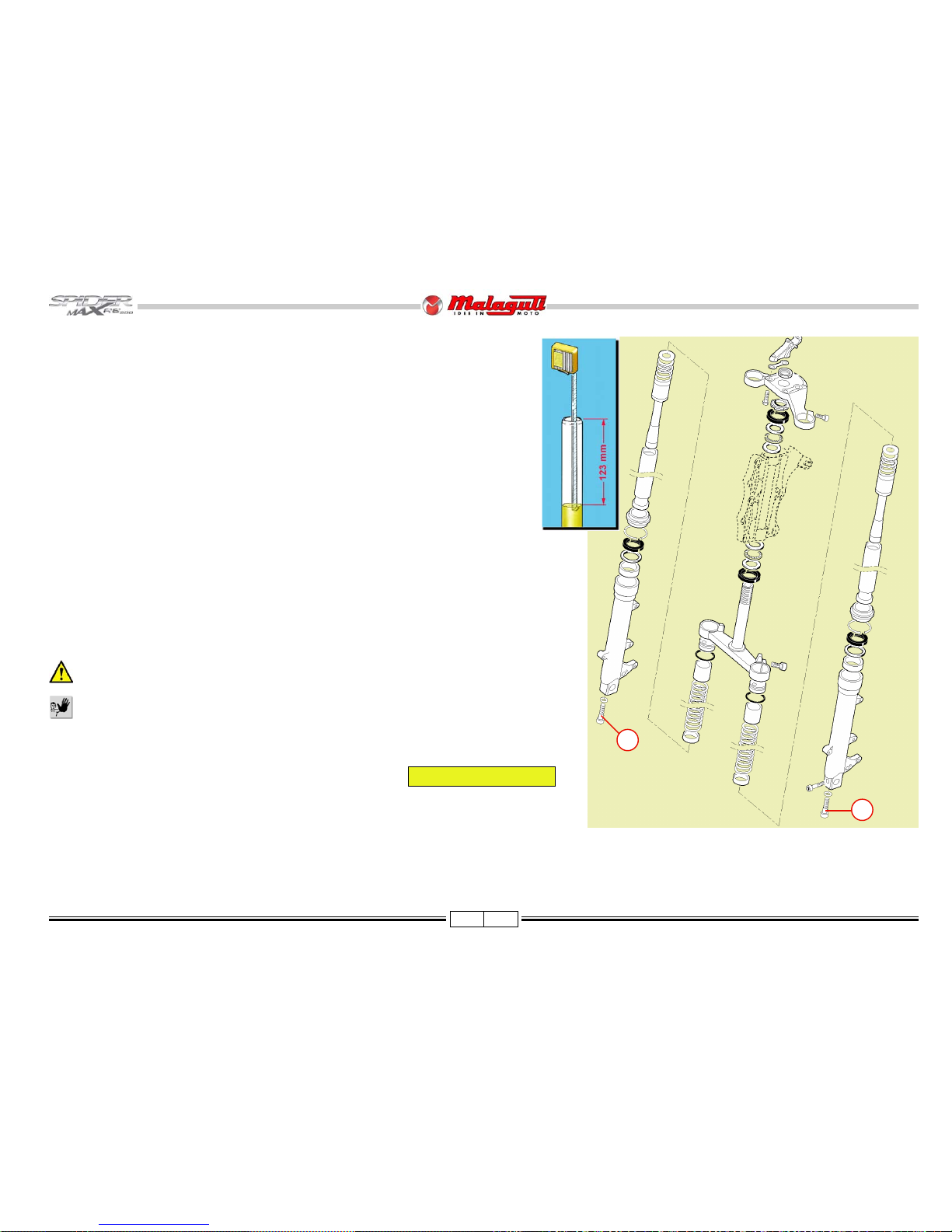

FORK

CHECK THE OIL LEVEL IN THE STANCHION

• In there case if the “limit switch” of the front fork or irregular noise, check the oil

level inside the fork stems by removing the stems, as shown in the picture, and

follow the instructions at page 63.

• Bring to the limit (downwards) the leg, keeping it in perfect vertical position.

• Using a meter or the stick of a gauge, check the proper oil level, which should be at

mm 123 from the upper edge of the leg.

• If necessary, top up with oil: Q8 FORK OIL

F. 1 8

V

V

FRONT FORK OIL REPLACEMENT

• Place a suitable container under the stanchion and remove the screw (V).

• Allow as much oil as possible to drain out.

• Disassemble the stanchions, as previously described.

• T urn ov er the stanchion, to let the remaining oil drain out.

The hydraulic oil is corrosive and may cause personal damages.

Do not dispose of spent oil in the environment.

• Refit the drain screw (V).

• Carefully pour the new oil in the leg.Carefully pour the new oil in the leg.

• Check the oil level, as previously described.

• Refit the components of the legs and the legs themselves on the motorcycle.

Quantity per leg 385 cc.

Page 21

20 02/08

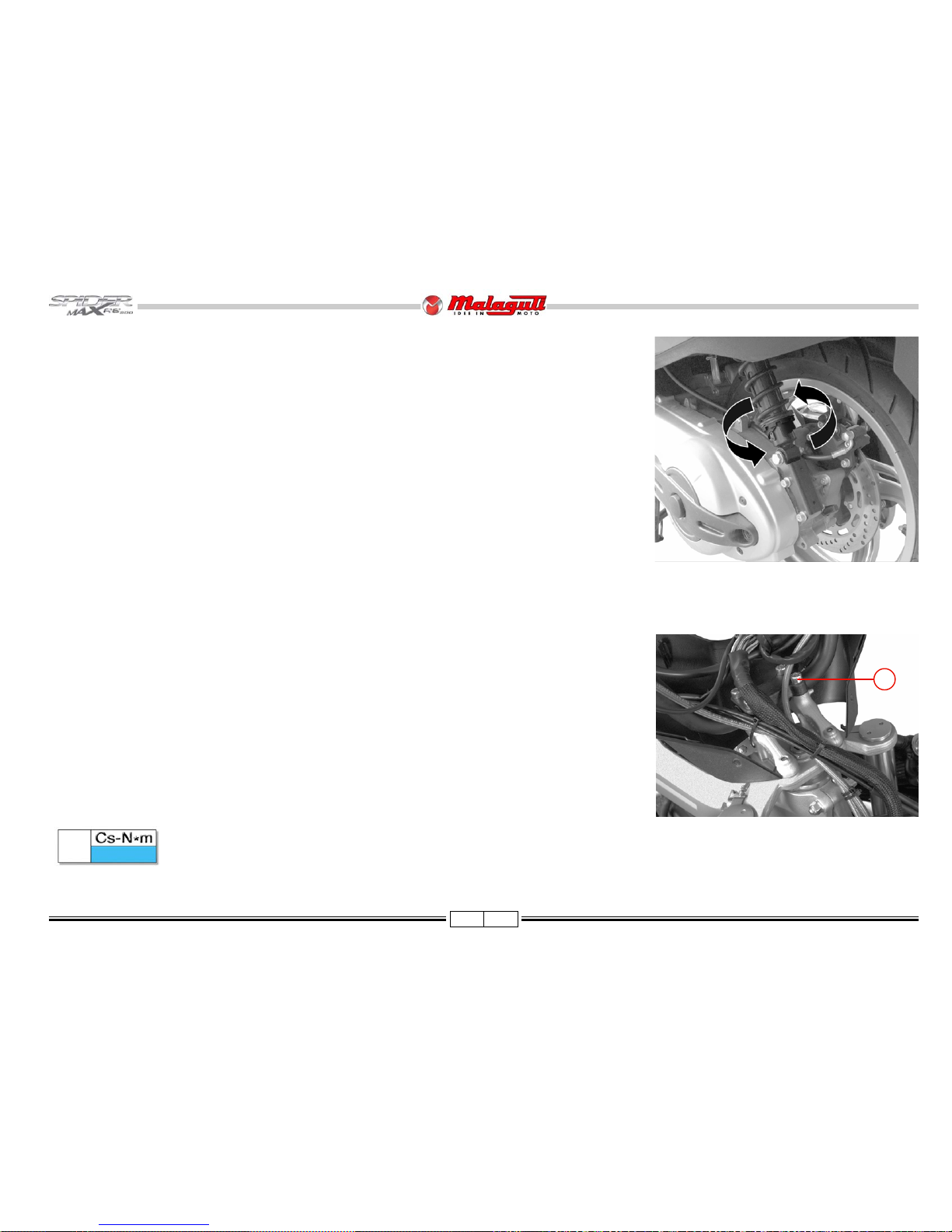

REAR SHOCK ABSORBER ADJUSTMENT

• The rear shock absorbers can be adjusted on the spring pre-load allowing to adapt the motorcycle behaviour

according to the load, the type of ride and the road.

• Use the supplied wrench on the ring nut placed in the shock absorber lower part; rotating it counterc lockwise to

increase the spring power.

• In case of an exceeding friction, use force tube and the shock absorber wrench.

Four adjustments are possible:

1) Driver only

2) Driver and luggage compartment

3) Driver and passenger

4) Driver, passenger and luggage compartment

F. 1 9

F. 2 0

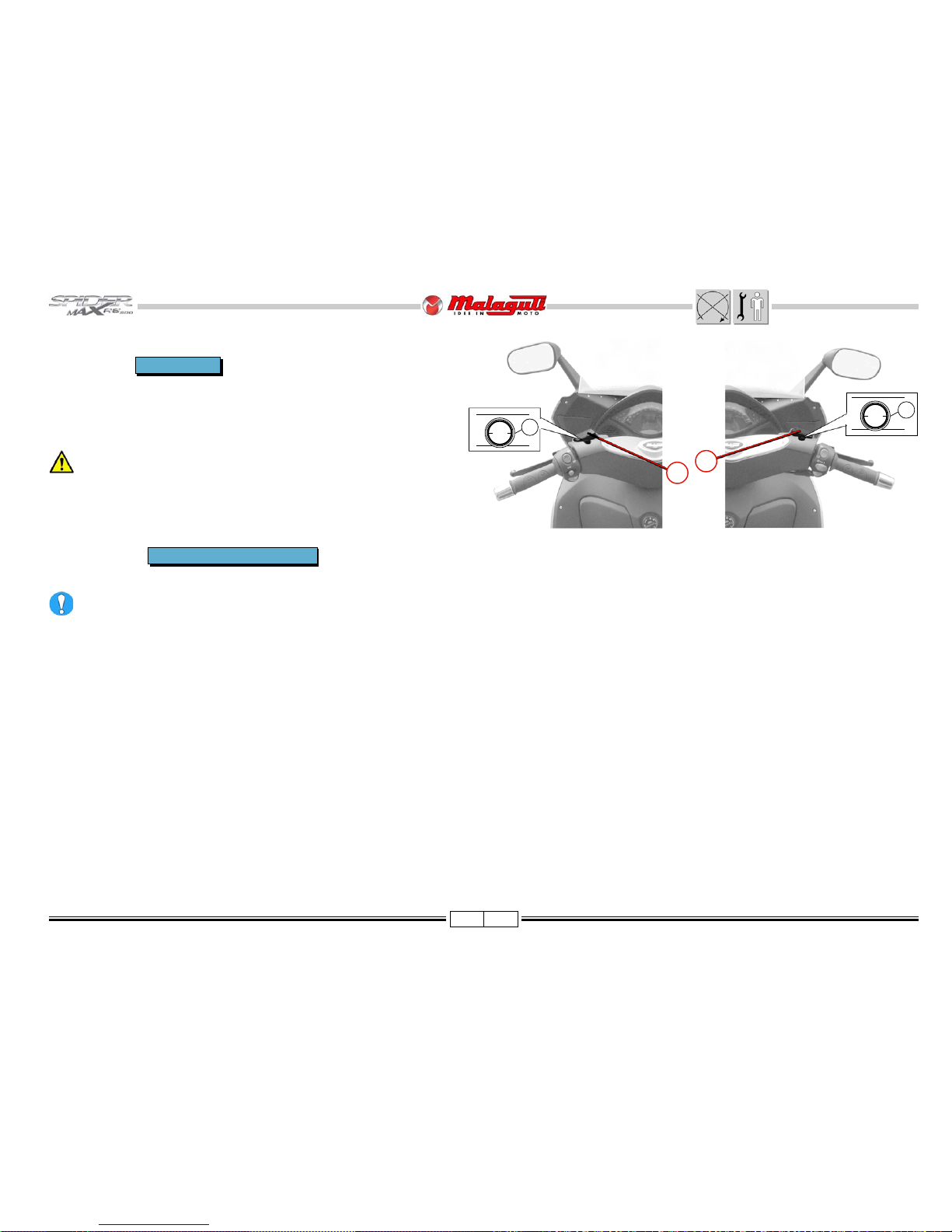

STEERING

PLA Y CHECK

• Place the motorcycle on the central stand.

• Rotate the handlebar repeatedly in both directions, to check that the ball bearings can slide smoothly .

• In case of (a light) friction during rotation or exceeding smooth sliding, adjust it by means of the appropriate wrench.

HANDLEBAR ADJUSTMENT

T o adjust the handlebar , proceed as follows:

• Remove the handlebar upper cover .

• Slacken moderately the screws (V4).

• Adjust the handlebar position, lifting or lowering it with both hands.

• After finding the right adjustment tighten the screws (V4), in a criss-cross pattern, until reaching the specified

torque.

V4

30 ± 20%

V4

Page 22

21 02/08

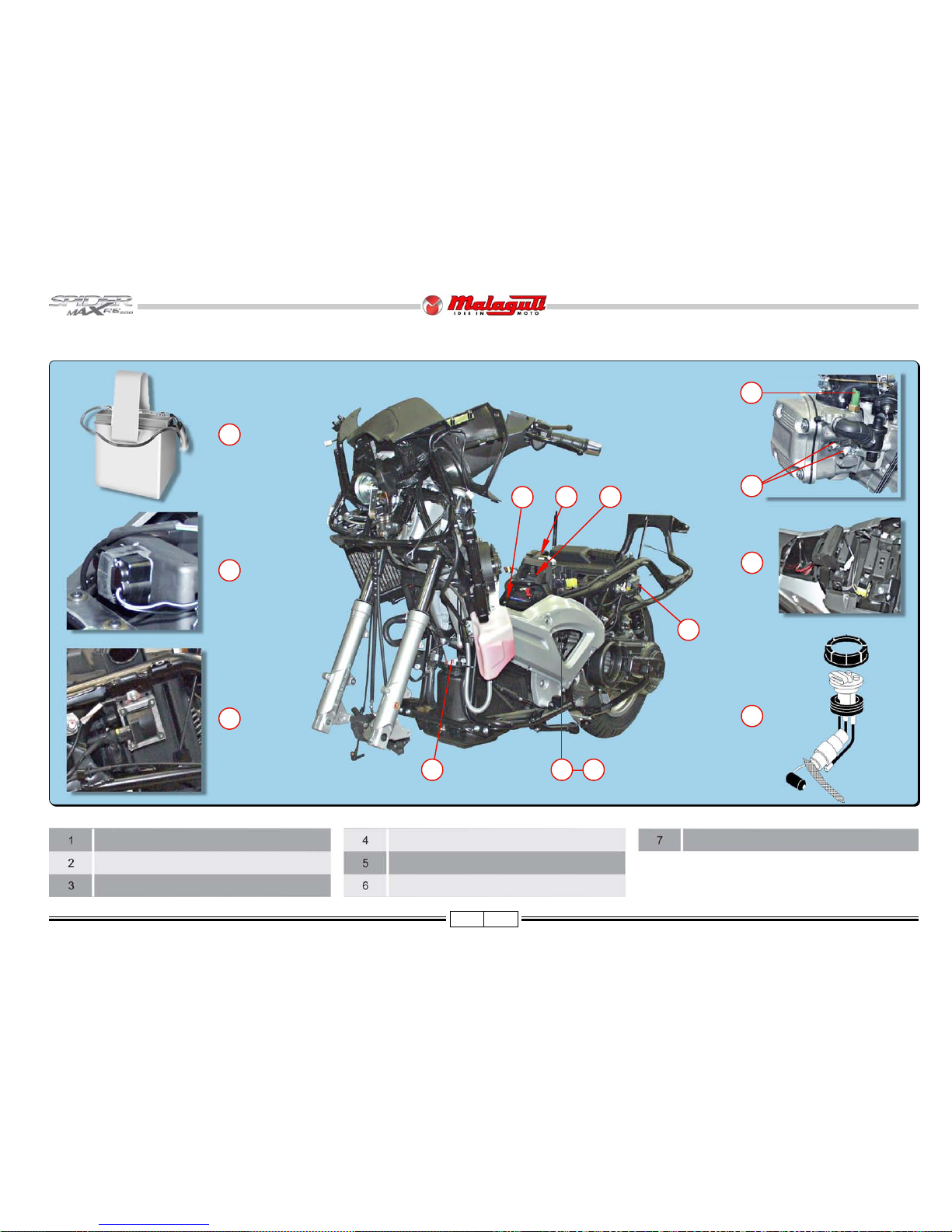

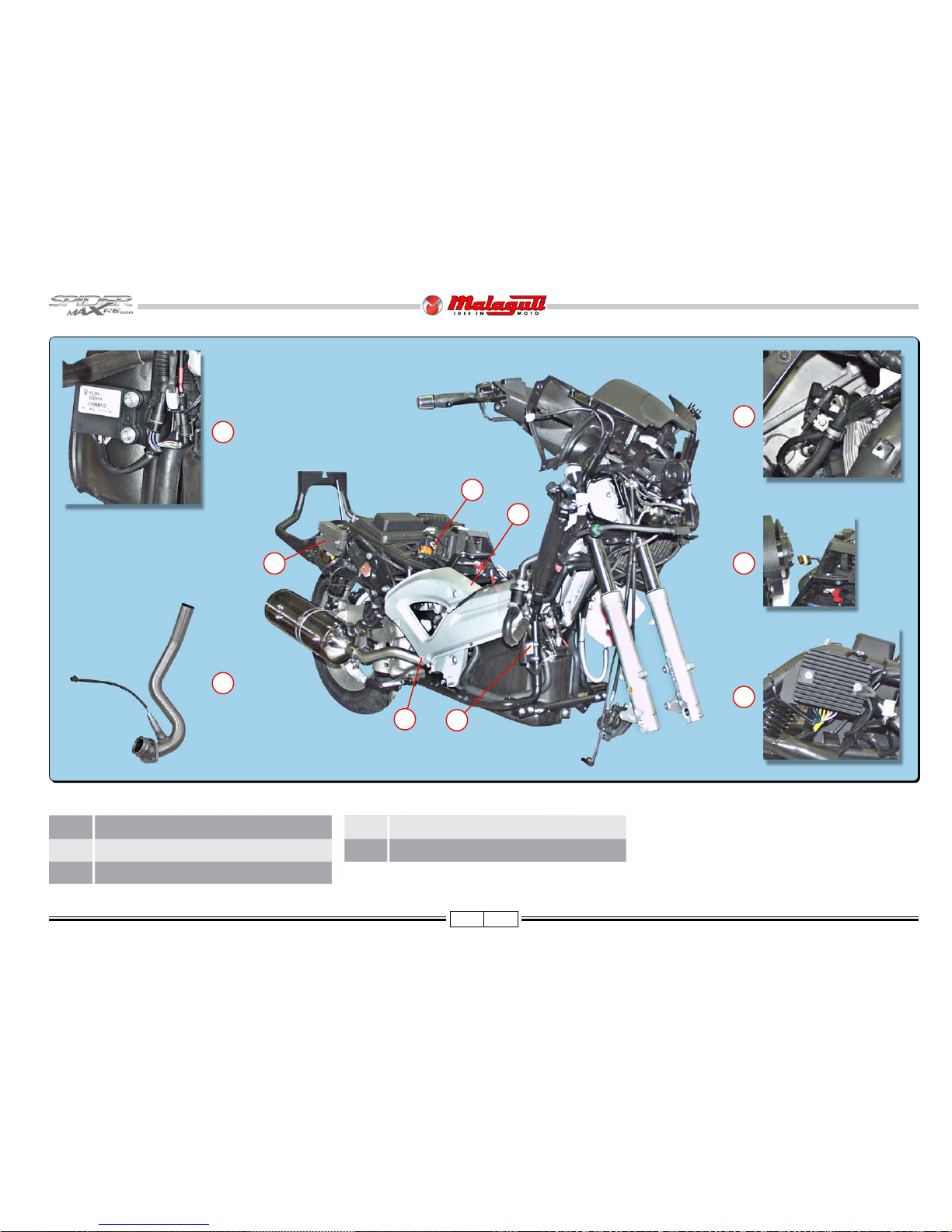

LOCATION OF THE MAIN ELECTRICAL ELEMENTS

F. 21

Battery

Rollover sensor

Ignition coil

Spark plugs

Temperature sensor

Relays and flasher

Fuel pump

1

3

1

2

3

6

7

26

7 4 5

5

4

Page 23

22 02/08

F. 22

8 Immobilizer control unit

9 Lambda sensor

10 Fuel injector

11 Regulator

8

9

10

11

11

8

10

9

12 Diagnostic plug

12

12

Page 24

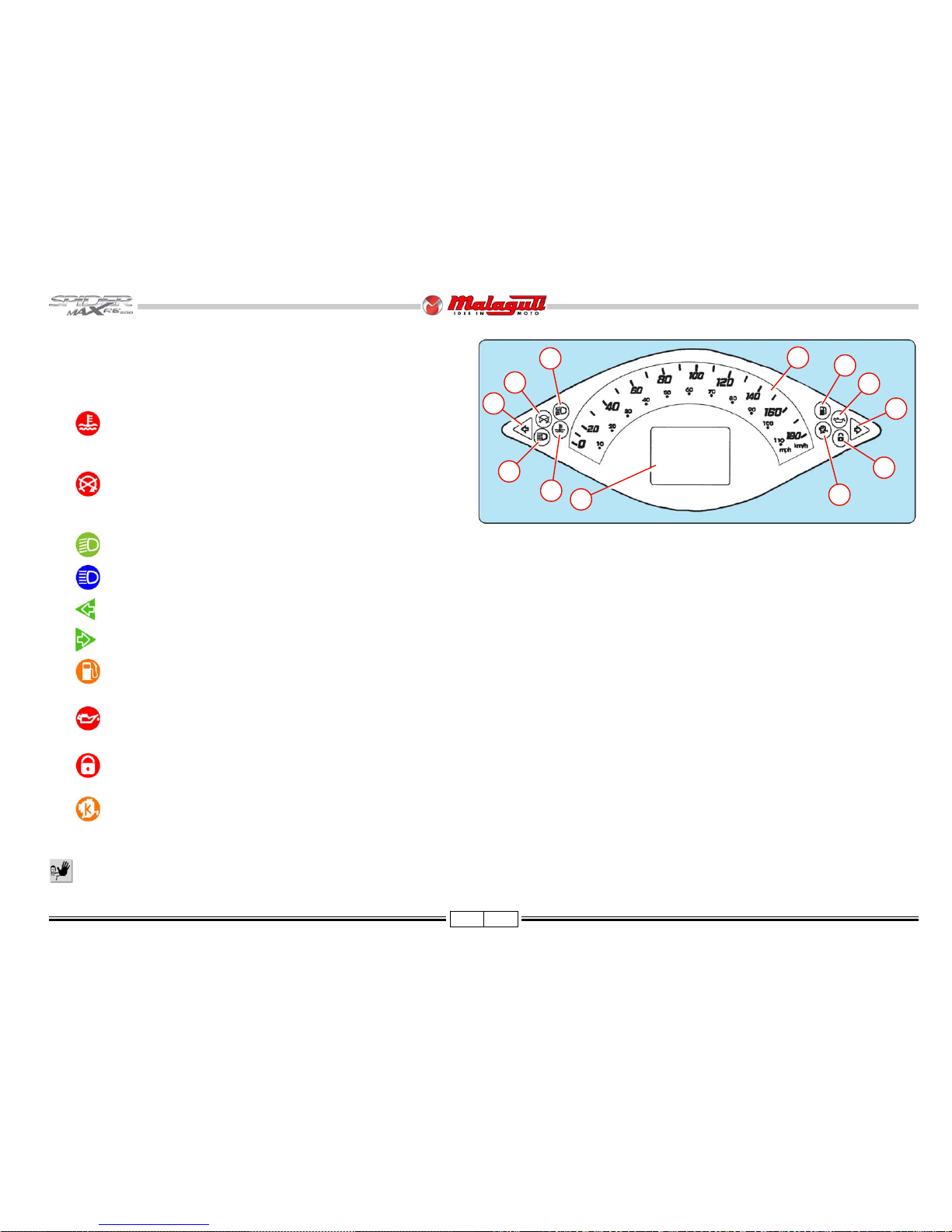

23 02/08

F. 2 3

INSTRUMENT BOARD

1) Multifunction digital instrument board

2) Analogue instruments, Speedometer

This indicates the current speed in km/h or mph.

3) Coolant temperature

The warning light comes on to indicate that the coolant temperature is

too high.

4) Sidestand / engine stop

This light comes on to indicate that the sidestand is down and that the

“Engine Stop” button is OFF.

5) Low beam

6) High beam

7) Left hand turn

8) Right hand turn

9) Fuel level

The warning light comes on to indicate that the reserve amount has been reached.

10) Oil

This light comes on while the engine is running to indicate that engine oil pressure is insufficient.

11) Immobilizer

After about 20 days, the light stops flashing in order not to discharge the battery. However the immobiliz er function is still active.

12) Injection

This light comes on while the engine is running to indicate that the injection system is not functioning correctly; contact an Authorised MALAGUTI Service Centre.

Avoid cleaning the instruments with pressurised c leaning systems in order to prevent any dama ge.

9

10

11

12

5

6

7

8

1

2

3

4

Page 25

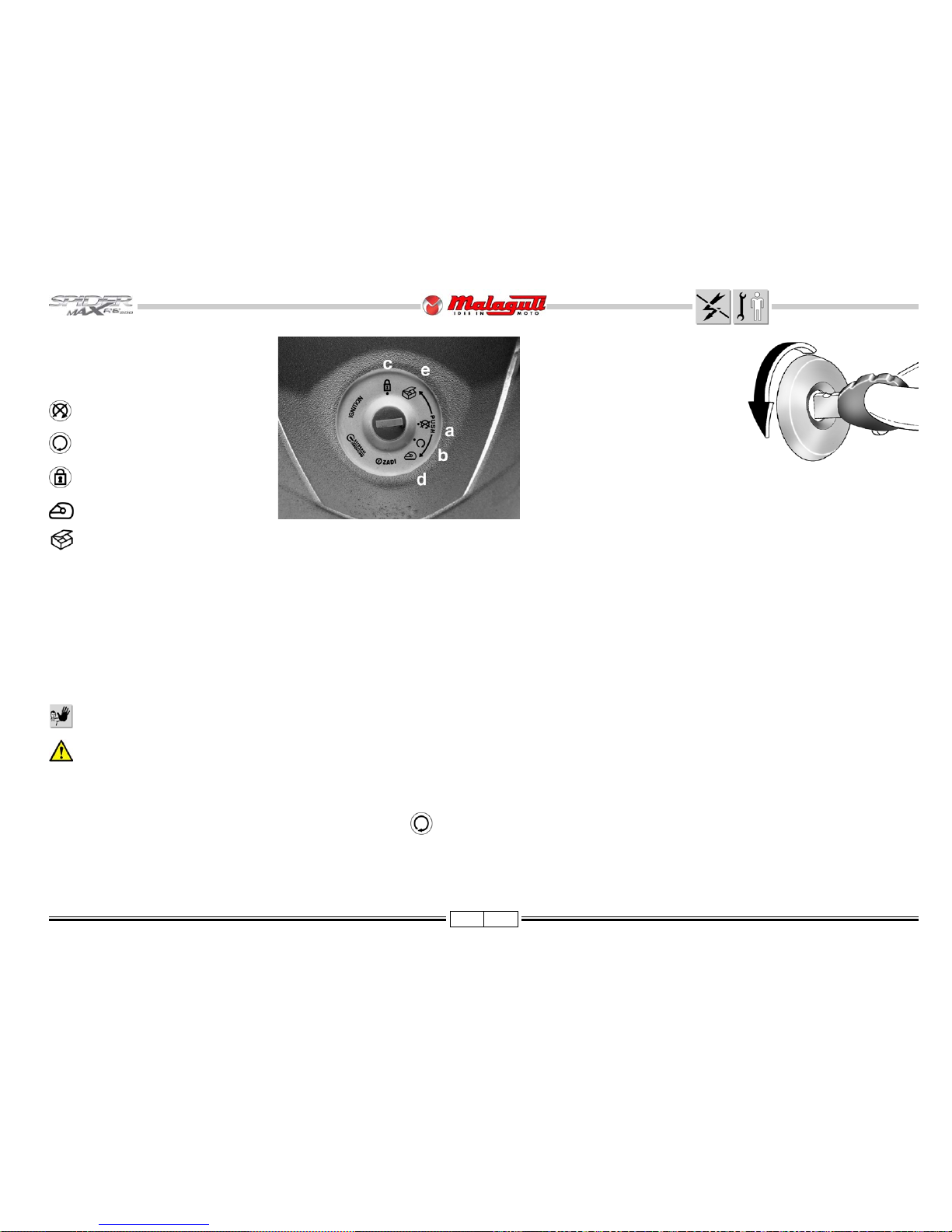

24 02/08

KEY SWITCH

• This switch controls the ignition circuit and

the handlebar lock.

Ignition disabled (the key can be

removed).

Ready to start’ position (the key

cannot be emoved).

Handlebar lock activated (ignition is

disabled. The ke y can be remov ed)

Helmet compartment opening position

Glove compartment opening position

HANDLEBAR LOCK

LOCKING

Turn the handlebar all the way to

the right or left, push the key in

and turn it counter-clockwise (F. 8).

DISENGAGING

Turn the key clockwise.

NOTE - The motor-bike is not

equipped with kick starter.

F. 24

F. 25

NOTE - The vehicle is supplied with two keys. If you lose both ke ys, you will have to replace the entire key block and ‘Immobilizer’ system.

ST AR TING THE ENGINE

• The engine cannot be started if the sidestand is down or if the emergency stop button is turned OFF.

• Before pressing the ignition button, pull the front or rear brake le ver and keep it pulled to start the engine, since this lever acts on a special ignition consent switch.

If the tank is empty, do not operate the «START» button and do not turn the key «ON» as this would damage the injection system.

If the engine does not turn on, release the ignition switch, wait a few seconds, then try again. Do not operate the ignition system for more than 10 seconds

at each attempt.

CHECKING THE WARNING LIGHT OF THE ENGINE OIL PRESSURE SENSOR (AUT OMA TIC)

• When turning the ignition key inserted in the ignition block to position ( ), without starting the vehicle, the displa y should show the message LOW OIL PRESSURE f or

about 8 seconds, to signal that the engine oil pressure sensor is working; the LOW OIL PRESSURE message must disappear when the vehicle sets off. Should the message

not appear on the display, check the engine oil level before starting the vehicle.

Page 26

25 02/08

C

B

A

B

C

D

E

G

F

G

F

E

F. 2 6

LIGHTING SYSTEM

LAMPS

Functions Specifications Replacing (page)

A (F ront) parking light 12V - 5W (W5W) 31

B Low beams/high beams 12V - 35/35W (HS1) 35

C Front direction indicators 12V - 21W (PY21) 30

D Number plate light 12V - 5W (W5W) -

E Rear direction indicators 12V - 16W (W16W) 48

F (Rear) parking lights 12V - 5W (R5W) 50

G (Rear) parking and stop lights 12V - 21/5W (P21/5W) 50

Always replace burnt bulbs by ne w, identical ones

and test them before reassembling all the

components previously removed.

Page 27

26 02/08

ADJUSTING THE BEAM LIGHT

• The adjusting knobs (A) of the two headlamp beam light are located inside the central shield,

as indicated in the picture. To adjust the beam light it is not necessary to remov e the central

shield.

To c heck/adjust the beam, proceed as follows:

• Put the vehicle in running conditions at 10 metres from a wall.

• T urn on the low beam headlights and keep the vehicle balanced without

a stand (lean it against a wall for instance).

• Turn the adjustment knobs of the two projectors (A) one at a time,

bearing in mind that turning clockwise lowers the beam, and anticlockwise raises it.

Adjust the beam so that its bottom line projected on the wall is at

about 78 cm from the floor .

F. 2 7

F. 2 8

A

Page 28

27 02/08

FUSES

• The electrical wiring includes eight fuses,

protecting the main components from

possible malfunctioning and are placed

in the luggage compartment.

A - 15 A Lights

B - 7.5 A Stop + Direction

indicators

C - 5 A ECU under the panel

D - 5 A Relay

E - 25 A Main fuse

F - 10 A Coil - Pump fuel -

Injector

G - 7.5 A Electrical fan

H - 3 A ECU supply support

GENERAL PROTECTION FUSE

NOTE - Inside the battery compartment,

is located the general protection

fuse (A) (30 A).

CHARGE PROTECTION FUSE

• Remove the battery holder to access the charge protection fuse (30 Amp.).

Do not replace the fuses with ones having higher capacities, since that may seriously damage the

electrical system and set on fire the vehicle, in case of short circuit.

F. 2 9

F. 3 0

• To replace one or more fuses, simply

open the central door of the leg protector

and extract the burnt out fuse, replacing

it with one having the same specifications.

F. 3 1

Page 29

28 02/08

BATTERY ASSEMBLY

• The battery is placed in the central tunnel.

• To access the battery compartment, first remove the seat (P. 46).

• After suitably charging the battery, apply some adhesiv e tape, taking off the two protection films placed on the edges

on the adhesive part (P).

• Extract from the battery compartment the wiring with the red cables (+) and the two black cables (-).

• Connect the wiring cable ends to the battery terminals.

Never invert the cables connection.

• Fit the battery inside the compartment.

• Place properly the wiring cables.

Before refitting the removed parts, we suggest to test the “control panel” in order to chec k the connections are

properly fitted.

• Refit:

- Battery compartment cover

- Dripproofing protection (fuel) and drain hose.

- Fuel filler cap

- Seat

The original battery, supplied by “Malaguti”, is a hermetic type (12V - 14A). If replaced, install a battery having the same specifications. In fact, the battery

compartment cannot host a battery with a drain hose.

While checking, servicing, repairing the vehicle, absolutely avoid starting the engine with the electrical system connected (even if only temporarily or for

ignition) to a battery having specifications different from those indicated by “Malaguti”.

CHARGE BA TTERY

To carry out this operation, we suggest to remove the battery from its compartment and disconnect the cables.

It is advisable to use gloves and protectiv e ey ew ear , when the battery must be remov ed from its housing; f or e xample, when it needs to be recharged.

• We recommend recharging with an amperage of 1/10 of the power of the charged battery.

• Refit the battery, taking care to connect the positive cable to the positive pole and the negative cables to the negative pole.

It is important to keep the battery always completely charged; therefore, in winter or when the v ehicle is not used, it should be recharged at least once a month.

Danger of explosion! Do not use open flames (lighters, matchsticks, etc.).

The battery contains highly toxic sulphuric acid. Av oid contact with the e y es , skin, and clothes. Keep the battery out of reach from children.

F. 3 2

P

Page 30

29 02/08

SPARK PLUG

REMPLACE

The spark plug is an essential component: NGK CR7EKB

Spark plugs with a heat degree different from the

recommended one may seriously damage the engine.

• The SpiderMax engine features an ignition system with a doub le spark

plug (C).

• For maintenance, remove the side partition (P), carefully remove the

cap by turning it clockwise and anticlockwise alternatively . Now , unscrew

the spark plug using the special wrench supplied with the vehicle.

Remove the spark plug when the engine is cold.

• Examine the spark plug conditions after a reasonably long drive (10-15

km) and after letting the engine cool down (at least 10-15 minutes),

since the sediments and the colour of the insulator can provide useful

information about the heat degree of the spark plug, carburetion,

lubrication and general conditions of the engine. If the insulator is

light brown around the central electrode, it indicates good working

order.

• Black, dry (to touch), sooty and tarnished deposits show that the

functioning temperature is too low (the heat rating of the spark plug is

too high), carburetion too rich or faulty ignition.

every 10.000 km

• Whitish insulating material shows an “e xtremely light” mixture or the heat rating of the spark plug too low (spark plug

too “hot”).

Check and clean every 6.000 km.

• After disassembling the spark plug, carefully clean the electrodes and the insulating material, using a metal brush. Adjust

the distance between the electrodes (operating only on the ground electrode), using a gauged shim: the distance should be

0.7 : 0.9 mm.

• Blow out energetically , to prev ent possible residues from entering the engine and refit it by tightening it by hand all the wa y

in; then, tighten it to the prescribed torque.

F . 33/a

12 ÷ 14

F. 3 3

Page 31

30 02/08

• Release the screws lower

(V3).

• Carefully remove the

central shield, paying

special attention in order

not to damage the locking

teeth.

• Disconnect the connector

(B) (parking light).

• Release the cable from the

bracket (C) and remove the

shield completely .

V2

A

V

V3

B

C

CENTRAL

FAIRING

• Release the screw upper (V)

PROCEDURES FOR DISMANTLING AND

REMOVING COMPONENTS

REASSEMBLY NOTE

REAR VIEW

MIRRORS

• Lift the rubber part (A) and

release the fastening screws

of the rear view mirror (V).

• Remove the rear view

mirror, complete.

V2

10 ± 20%

V3

1,5 ± 15%

V

1,5 ± 15%

F. 3 4

F. 3 5

F. 3 6 F. 3 7

FRONT DIRECTION

INDICA T ORS

(BULB CHANGE)

• The bulb holders of the front

direction indicators are integrated in the front headlights.

• To access the bulbs of the

front direction indicators, remove the inserted side covers (A).

A

Page 32

31 02/08

ACCESSES

(after removng the

central shield)

A) Control panel

B) Antilock

bracking

system

C) Beam light

adjusting

knobs

D) Horn

NOTE - The parking light bulb

is located inside the

central shield

• Remove the bulb and

replace by another of the

same type.

Reconnect the

connectors to test

the new bulb before

reassembling all

components.

• Remove the bulb

holder.

F. 3 8

F. 4 0 F. 4 1

REPLACING THE FRONT PARKING LIGHT

• Release the screws (V5).

• Release the screws (V2).

• Remove the cover (A).

D

C

B

A

F. 3 9

A

V2

V5

Page 33

32 02/08

F. 42

DASHBOARD

• Undo the screws (V4) and remove the control

panel carefully .

HORN

• Disconnect the two clamps (B).

• Release the screw (V) and remove the horn.

F. 43

V2

10 ± 20%

1,5 ± 15%

BRAKING DISTRIBUTOR

NOTE - To access the braking distributor (A),

remove the central fairing (P. 30).

Drain completely the circuit.

• Release the screws (V2).

V

10 ± 20%

• Undo the connectors (B).

• Remove pipes (C) and

gaskets (D).

B

20 ± 10%

F. 4 4

B

V

While reassembling, take care not to in vert the fitting of the Faston connectors. Blue

cable (+)lower terminal - Orange cable (-) upper terminal.

V2

A

C

B

D D

C

B

C

D

Page 34

33 02/08

AIR GRID

• After removing the cover of

the front parking light bulb,

you can remove the air grid

in order to clean it.

F. 4 5

WINDSCREEN

• Remove the central fairing

(p. 30).

• Release the screws(V3)

and remove the windscreen.

FRONT

FAIRING

NOTE - The front fairing is

made of two parts,

one right and one

left. The following

instructions apply

to the whole

fairing.

• Release the screws (V2).

• Release and remove the

lower screw (V1) and its

washer.

F. 47

V2

F. 4 6

F. 4 8

V3

V

V1

V1

1,5 ± 15%

• Release the screws (V4).

V4

1,5 ± 15%

V3

1,5 ± 15%

V2

1,5 ± 15%

• Release the central upper

screew (V).

V

5 ± 20%

Page 35

34 02/08

• Release the screws (V2)

and remove the passenger

footpeg.

• Remove the rubber mat.

V2

40 ± 15%

F. 5 0

F. 5 2

F. 4 9

F. 5 1

V2

• Release the screws

(V8).

• Release the half-fairing

upper part from the mirror mount, opening it up

carefully.

V8

1,5 ± 15%

Page 36

35 02/08

• Disconnect the two connectors (A) (direction

indicators).

• Disconnect the connector

(B) (front headlight).

• Remove the fairing.

ACCESSES

(after removing the two

front half-fairings)

Right half-fairing:

A) Immobilizer ECU

B) Side stand switch

connector

C) Fuel pump

- Right radiator

- Key switch

F. 5 3

F. 54

B

A

C

A

B

H

V2

Left half-fairing:

D) Expansion reservoir

E) Left radiator

F) Radiator fan

F. 5 5

E

F

D

IMMOBILIZER ECU

• Disconnect the three connectors (H).

• Release the screws (V2).

• Remove the Immobilizer ECU (A).

V2

10 ± 20%

If the Immobilizer ECU is replaced, store two or more ignition keys.

(please refer: DIA GNOSTICS MANUAL of the ELECTRICAL SYSTEM AND

EMS INJECTION SYSTEM, chapter “Immobilizer”).

Before refitting the different connectors, make sure if the inside sealing

rubbers (yellow) are worn out, and if the external ones are in the right

place. If these checks are not observed, in case of rain, the dashboard

may indicate improper warnings.

Page 37

36 02/08

SIDE STAND

SWITCH

• Release the screws (V2).

• Remove the switch (A).

• Open the front fairing.

• Disconnect the connector (B)

and detach the whole wiring

(if necessary), after releasing

its clips.

NOTE - While assembling a

new complete wiring,

refit new clips, placed

and fixed as before.

F. 5 7

F. 5 6

V2

V2

A

V2

5 ± 20%

B

C

F. 5 8

FUEL SUPPLY PUMP

• Disconnect the connector

(C - F. 57)

• The procedure to remove the

fuel supply pump (A) and its

float (B), can be understood

from the picture on the side.

• Check the conditions of the

gasket (C) and replace it, if

necessary.

• Carefully clean the mesh filter

(D).

NOTE - All of the inf ormation

on the pump can be

deducted by reading

the Manual “Injection”.

A

C

D

B

Page 38

37 02/08

F. 6 2

F. 5 9

F. 6 0

F. 6 1

RADIATORS

(including lines

and expansion

reservoir)

• Wait for the engine to cool

down completely .

• Put a suitable container

under the coolant pump (A).

• Remove the clip (B).

• Detach the tube (C) and fit

it in the container.

• Remove the cap (D - F. 60)

from the expansion

reservoir.

• In case radiators have to be

removed together with

lines, slacken the clip (B1)

and detach the tube (C1).

• Let the liquid completely drain into the container. Pour the spent

liquid in a container

suitable for its ecological disposal.

The coolant is

potentially polluting,

therefore it should

not be released in the

environment.

• Disconnect the connector of

the electrical fan wiring.

Release the bleed

screws (V) on both

the radiators,

releasing both

ground cable ends

(M).

• Cut all the clips securing the

lines composing the cooling

system circuit.

V

M

In case the pump (A) has to be removed, release the screws (V6).

• Cut the clip (E) securing the electrical fan wiring.

After refitting any of the components of the cooling system, fix the lines with new clips, in the same position as before, and fix the ground cable end

(M - F . 62) again, both to the right radiator as well as to the left radiator .

D

V6 CBA

B1

C1

E

Page 39

38 02/08

• Release and remove the

screws (V2) and their

washers.

• Remove the right

radiator.

RIGHT RADIATOR

• Release the lower securing

screw (V) of the right radiator (A).

• While reassembling,

first fit the radiators

on the upper silent

blocks.

NOTE - The radiators are fit-

ted on Silent blocks

(B); first release them

from the lower ones,

and then extract them

from above.

• Release and remove the

screws (V2) and their

washers.

F. 6 6

• Remove the left radiator ,

including the electrical fan.

LEFT RADIATOR (including

the electrical fan)

F. 6 3

F. 6 5

F. 64

V

10 ± 20%

V2

10 ± 20%

V2

10 ± 20%

B

B

A

V

V2

B

V2

Page 40

39 02/08

F. 6 7

F. 6 9

EXPANSION

RESERVOIR

Drain the coolant from

the circuit, as previously

described.

• Disconnect the tube (C) from the

expansion reservoir.

• Release the screws (V2).

THERMAL

EXPANSION VALVE

NOTE - The cooling system

includes two thermal

expansion valves:

A - Thermal expansion

valve for the right

radiator

adjustment

• To remove it, release it

from the clips (F) and slide

it from the support (S).

ELECTRICAL FAN

RADIATOR

• Release the screw (V) and

remove the expansion

reservoir.

V2

10 ± 20%

V

10 ± 20%

V2

C

F. 6 8

V

A

S

F

F. 70

B - Thermal expansion valve on the engine

• T o remove it, release it from the clips of the rubber hoses and slide it from the support

(S).

S B

Page 41

40 02/08

F. 7 1

KEY

SWITCH

• Disconnect the seat opening

transmission cable (A).

• Disconnect the helmet compartment opening transmission cable (B).

• The key switch (C) is fitted

by two nuts (D) and two “antitampering” screws (V2), that

can be accessed from the

lower part of the switch body .

To disassemb le the

key switch, use the

special insert: “T orks

t 30” for special

screws.

cod. 08606600

F. 7 2

Take care not to

damage the cables

during the operation.

Squeezing or cuts of

some of the fibres of

the cables imply their

complete

replacement.

• Disconnect the two-way connector connected to the Immobilizer.

DASHBOARD

PANEL

• Release the screws (V2).

• Remove the dashboard

panel (A), releasing it from

the locking tabs.

F. 7 3

V2

V2

B

A

V2

C

D

V2

If the key switch is replaced, or all of the stored keys are lost, replace the

Immobilizer ECU as well, and store new keys. To store a third key, use the

“Master key” (cod. 09007000) (please ref er: DIAGNOSTICS MANU AL of the

ELECTRICAL SYSTEM AND EMS INJECTION SYSTEM).

Page 42

41 02/08

F. 7 4 F. 7 5

F. 7 6 F. 7 7

LEG

PROTECTOR

• Remove the key switch ring

nut (A) rotating it counterclockwise.

• Release the retaining

screws (V2) of the fusebox.

• Remove the transparent

cover.

• Push forward the fusebox

• Release the screw (V).

• Release the three screws

(V) inside the luggage

compartment.

• Release the screw underneath (V1).

V1

5 ± 20%

V

5 ± 20%

V

V1

V

V2

Page 43

42 02/08

F. 7 8 F. 7 9

F. 8 0

V3

5 ± 20%

F. 8 1

• Release the screws (V3). • Unlock the luggage compartment closing transmission cable from its seat (A).

• Open slightly the footpeg

until the plastic locking tabs

are released.

• Extract the leg protector

assembly , together with the

footpegs.

V3

Page 44

43 02/08

• Remove the footpeg if

necessary, release the

screws (V2).

ACCESSES

(after removing the upper

handlebar cover)

B) Main wiring end

V4) Handlebar inclination

adjusting screws.

V2

1,5 ± 15%

V2

1,5 ± 15%

F. 8 4

F. 8 2 F. 8 3

UPPER HANDLEBAR

COVER

• Release the screws (V2) and remove

the upper handlebar cover (A).

F. 8 5

V2

V2

A

B

V4

Page 45

44 02/08

F. 8 6

F. 8 8

• Release the outside screws

(B2) and remove the front

handlebar cover (A).

• Release the remaining four

inside screws and remove

the rear handlebar cover

(P).

FRONT AND REAR

HANDLEBAR

COVER

• Release the upper screws

(V2).

ACCESSES

• Removing the front handlebar

cover allows to reach the two

brake liquid pumps (A) and

the two stop switches (B).

V2

V2

1,5 ± 15%

B2

1,5 ± 15%

F. 8 7

P

B2

A

B

A

B

A

Page 46

45 02/08

BRAKE MASTER

CYLINDERS

Empty the hydraulic

system and dispose of

the liquid in compliance

with the law in force.

Ensure that there are

no leaks or splashes

of brake liquid, as it is

corrosive and may

cause personal injury

or damage the

motorcycle painted

parts.

• Release the screws (V2) and

remove the clamp (D).

• Remove the pump unit (E).

• In order to reassemble the

unit lock (by means of a long

T-wrench) the lower screw,

without tightening it, and then

the upper screw; finally tighten both of them to the

specified torque.

NOTE- After reassembling the hydraulic pump, always refill the system with new

liquid.

V2

28 ± 15%

A

20 ± 10%

F. 9 1

• Release and extract the coupling (A).

• Remove the tube (B) and the gaskets (C).

• Disconnect the Stop switch (S).

NOTE - Repeat the same procedure for both brake pumps.

S

B

A

C

HANDLEBAR

To remo ve the handlebar:

• Remove the handlebar cover: upper, front and rear

(P. 4 4).

• Cut the clips securing wiring, tubes, and cables.

• Remove the (right and left) brake master cylinders.

• Release the transmissions from the accelerator con-

trol (B).

• Release the two counterweights (P).

• Detach the two twistgrips (M).

• Release the two switches (D).

• Release the screws (V4).

• Remove the plate securing the handlebar (A).

• Remove the handlebar (C).

Tighten in a criss-cross pattern.

V4

30 ± 20%

After assembling the

(front/rear) brake

master cylinder, fit

the tube (B) between

two new gaskets (C)

And tighten the

coupling A to the

specified torque.

F. 9 2

V2

E

A

B

D

C

F. 8 9

V4

F. 9 0

B

P

M

D

P

M

D

A

V4

C

Page 47

46 02/08

F. 9 3

F. 9 4

DRIVER

SEAT

• Release the screws (V2) on

the rear part.

• Remove the driver seat (A),

releasing it form the locking

tab (B).

V2

5 ± 20%

V2 A

ACCESSES

• Removing the driver seat,

allows reaching the following

electronic components:

A) Relay (black) - Starter

B) Relay (yellow) - Electric

fan

C) Relay (red) - Injection

system

D) Tilt sensor connector

E) Tilt sensor

F) Flasher

B

NOTE - In order to access the

tilt sensor (E) it is necessary

to remove the rubber protection (G).

When reassembling the

sensor, make sure that

the cable (H) is facing

downwards.

F. 9 6

G

A

B

F. 9 5

E

F

CD

H

Page 48

47 02/08

F. 97

F. 9 8

PASSANGER

SEAT

(including

movable support)

• Remove the Benzing ring (C)

and release the passenger

seat shock absorbers.

• Release the screws (V2)

from the front supports.

• Remove the seat together

with the grab handle and

movable support.

• In order to release the

passenger seat (F . 49) from

the movable support, first

release the screws (V6).

CUSHION DRIVER SEAT

• Release the screws (V2).

Slackening the screws (V2) allows adjusting

the cushion travel according to the user’ s

requirements.

GRAB HANDLE

• Release the screws (V5) and remove the grab handle

(D).

D

C

V2

V5

30 ± 15%

V2

10 ± 20%

V6

10 ± 20%

V5

V2

V5

V6

F. 9 9

Page 49

48 02/08

F. 100

F. 1 01

F. 102

F. x x

• Disconnect the 12V plug cable from the back of the helmet compartment.

HELMET

COMPARTMENT

• Extract (without any tool) the

compartment inside coating.

• Release the screws (V).

• Release the screws (V2a).

V2a

F. 1 03

DIRECTION INDICATORS AND TAIL LIGHTS (BULB CHANGE)

• Lift the seat.

• Removing the inserted side covers (A), allows reaching the rear direction indicator

bulbs.

• Removing the inserted rear covers (B), allows reaching the tail light bulbs.

V2

5 ± 15%

V4

10 ± 20%

V2a

5 ± 15%

• Release and extract carefully the helmet compartment without removing it

completely.

V2a

• Release the screws (V2).

• Release the screws (V4).

V2

V4

V4

B

A

V

1,5 ± 15%

V

Page 50

49 02/08

REAR

FAIRING

• Release the two screws (V2).

• Release the screw (V).

F. 104

• Lift the helmet compartment,

disconnect the connector (A)

and release the cable from

the clamp (B).

• Remove the helmet compartment completely .

F. 105

V

5 ± 15%

V2

5 ± 15%

Page 51

50 02/08

F. 106

F. 1 07

F. 108 F. 109

• Release the screws (V4). • Extract the entire fairing to-

gether with the tail lights.

TAIL LIGHTS

• Tail lights can be accessed by

removing the helmet compartment and the rear fairing.

• Disconnect the wiring.

• Release the screws (V3).

• Remove the cable clamps (A).

• Remove the headlight

concerned.

While reassembling,

refit the cable clamps

as before.

The tail lights glass

cannot be replaced.

If it is broken, replace

the whole headlight.

A

V3

V4

1,5 ± 15%

• Keep the rear fairing

components far from heat

sources, in a clean place

where they cannot be

accidentally damaged.

V4V4

Page 52

51 02/08

SIDE REACH (after

removing the rear

fairing)

• Removing the rear fairing

allows reaching the following

components:

Right-hand side

A) Voltage regulator

B) Coolant pump

C) (T ree-phase) stator

connector

D) Ground ends

F. 110

Left side

A) Coil

B) Ground ends

F. 1 11

C

B

A

B

C

V4

VOLTAGE REGULATOR

• Release the screws (V2).

• Remove the wiring cable ends from the right

screw.

• Remove the voltage rectifier (A).

• Disconnect the flywheel connector (C) and the

connector (F) located underneath the wiring

protection sheaths

COIL

• Disconnect the connector (C).

• Release the screws (V4).

• Remove the coil (A).

COOLANT PUMP

See Service Manual (Section “C”).

M

DA V2

F

Page 53

52 02/08

• Disconnect the connector of the

anti-tilting device.

F. 112

• Release the rear screw (V1).

F. 1 13

• Release the two front screws (V2).

V2

RELAY HOLDER

• Extract the starting relay (C), including the

30A fuse (battery recharge protection).

If the starting relay is replaced, take

special care to the assembly of the

red and blue cable (Please refer:

DIAGNOSTICS MANU AL of the

ELECTRICAL SYSTEM AND EMS

INJECTION SYSTEM).

F. 114

V1

V2

C

F. 1 15

C

Page 54

53 02/08

ACCESSES

A) Injection ECU

B) Injector

C) Motor temperature sensor

NOTE - All of the information concerning these com-

ponents can be deducted by reading the DIAGNOSTICS MANUAL of the ELECTRICAL

SYSTEM AND EMS INJECTION SYSTEM.

ELECTRONIC

INJECTION ECU

THROTTLE BODY

• T o remo v e the ECU see the Electric

System Diagnostics Manual

(Section“B”).

F. 116

B

C

1

A

•After disconnecting all

connectors, remove the relay

holder (1) on one side or

remove it completely.

F. 1 17

Page 55

54 02/08

BATTERY

COMPARTMENT

• Remove the fuel filler cap

(A).

• Release the screws (V2).

• Extract the dripproofing

protection (B) and the drain

hose.

• Remove the battery compartment cover.

• Release the screw (V) at the bottom of the battery compartment and remove the

compartment, extracting the battery cables and fusebox.

ACCESSES

• Removing the battery compartment, allows reaching the starting relay and the

corresponding 30 A fuse (recharge protection).

F. 118

F. 121

F. 120

NOTE - Inside the battery com-

partment, is located

the general protection

fuse (F) (30 A).

• Release the battery cables.

• Extract the battery.

F. 1 19

V

10 ± 20%

F

B

A V2

V

Page 56

55 02/08

F. 1 25F. 124

• Release the screws (V4).

To remo ve the tank,

proceed as follows:

• Remove the battery and the

whole compartment (P. 54).

• Remove the cap (A).

• Extract the dripproofing protection (B) and its tube (C).

• Refit the original cap on the

fuel filler, to prev ent dirt from

entering the fuel tank, during

the frame removal operations.

FUEL TANK

NOTE - To access the fuel tank, first remove the front fairing (P. 33).

Fuel fumes are highly toxic, and therefore harmful to your health. V entilate

the room before proceeding and, if necessary , wear a protection mask.

Do not remove the tank, unless the latter has been previously emptied.

Do not smoke, nor use bare flames. Do not carry out any the operation while

working and producing sparks (such as welding, grinding, etc.).

• Remove the connector (1)

from the fuel pump,

pressing by two fingers at

the base of the connector.

F. 1 23

F. 122

T V4

V

A

C

B

To drain the tank, w ait

for the engine to cool

down completely and

use a manual pump.

1

V4

10 ± 20%

Page 57

56 02/08

• Disconnect the tube (C).

• After extracting the tank, release the screw (V), releasing

it from the support (T).

• Extract the tank, sliding it

from the front side of the

frame, downwards.

• Disconnect the connector (A)

of the fuel pump.

• The fuel tank is blocked, in

its rear side, by the two

Silent Blocks (B).

A

T

V

C

F. 126

F. 128

F. 1 27

F. 129

C

B

Page 58

57 02/08

AIRBOX

• Release the screws (V8) and

remove the cover (A).

• Release the hose (B) from

the throttle body .

• Extract the airbox.

• Release the gas recovery

hose (C).

F. 130

F. 1 31

F. 132

A

V8

C

C

B

Page 59

58 02/08

WHEEL SPINDLE

• Slacken the screw (V1)

from the wheel spindle

clamp.

• Release the wheel spindle

(B) and extract it, taking

care not to damage spacer

(C) and the spacer (B1).

FRONT WHEEL

REMOVAL

Before removing the

front wheel, check for

the perfect stability of

the motorcycle. If necessary, place one suitable support under

the engine.

FRONT

MUDGUARD

• Release the screws

(Va)

• Release the screws

(Vb) and corresponding

nuts (A).

F. 133

Vb

3,5 ± 10%

Va

3,5 ± 10%

F. 1 34

F. 135 F. 136

Do not actuate the

brake levers without

the wheel, as the pads

would close.

• Release the screws (V2) and release the entire callipers.

• Release the screw (V) and extract the odometer sprocket (A).

B1

B

C

V1

B

Va

A

Vb

Va

V

V2

A

V2

30 ± 20%

Vb

Page 60

59 02/08

FRONT WHEEL

REASSEMBLY

When reassembling the wheel, observe

rotation direction, which can be determined

by the position of the spokes of the rim (see

previous pictures).

T o reassemble the wheel, proceed as f ollows:

• Insert the wheel in the fork (in the proper direction).

• Insert the wheel spindle (B) and the spacer (B1).

• Insert the spacer (C).

Do not exchange the spacer (B1) with the

spacer (C).

Tighten the spindle (B) to the specified torque.

(FRONT BRAKE)

DISCS

• T o separate the discs (D) from the front wheel,

release and remove the screws (V6) and the

washers (E).

Check the discs (D) for wear and replace if

necessary (service limit 4.5 mm). In case of

abnormal wear or signs of scoring, carry out

grinding.

When reassembling the (right and left

brake) discs observe disc rotation

direction, which can be determined by

the position of the slots.

B

45 ± 15%

V6

11 ± 10 %

F. 137

D

V6

E

E

V6

D

• Tighten the screw

(V1) of the wheel

spindle clamp.

F. 141

• Refit the odometer

sprocket (pick-up)

(A) and secure it by

means of the screw

(V).

V

10 ± 15%

V1

20 ± 15%

F. 138

F. 140

B1

B

C

F. 139

A

V

V1

Page 61

60 02/08

BRAKE

CALLIPERS

An abnormal resistance

or an excessive travel

of the brake levers may

indicate the braking

system malfunctioning.

• Open up the clamp (F).

• Undo the screws (V2) in order

to release the fork clipper.

FRONT CALLIPER

REPLACEMENT

NOTE - The front callipers

have the same technical

specifications but are one

right and one left.

• After removing the front

brake callipers, release

the screw/coupling (V) and

extract the swinging

coupling (A) and the

gaskets (B).

Do not use the brake lever after removing the callipers: the piston may

jump off, causing brake liquid leaks. The liquid is corrosive and may

cause serious personal damage.

After removing the callipers from their housing, place a container

underneath in order to let the liquid drain from the hydraulic system and

dispose of it in compliance to the law in force.

V2

30 ± 20%

FRONT CALLIPER

DISASSEMBLY

In order to extract the pads:

• Release and remove the

screw (V).

• Shift downward the stop

plate (A), in order to release

the pins (B) and extract

them from the other side of

the calliper unit.

V

20 ± 10%

F. 142

V

F. 144 F. 145

A

B

F. 1 43

A

V

B

B

V2

F

V

A

Page 62

61 02/08

• Remove the stop plate. • Extract the pins (B).

• Extract the pads.

NOTE - It is possible to

remove and replace

the pads without

removing the brake

callipers from the

vehicle.

• Release the nut (D - F. 146).

• Remove the floating support (S) from the calliper

body , including the two

slide pins.

During reassembly ,

lubricate the slide pins

must rubber gasket

grease.

D

20 ± 20%

F. 1 47

F. 146

F. 148

F. 1 49

D

S

B

B

Page 63

62 02/08

• Check the dust seals (P - P1)

for wear. In case of signs of

(even light) wear or damage,

replace them.

• Open by means of a screwdriver (or any other similar tool),

the bracket (B) fins (A). Remember to wear safety gloves.

• Release the screws (V2).

• Remove the plate (C).

After refitting the plate

(C) and the bracket

and tightening the

screws (V2) to the

specified torque, lean

the fins (A) as before

(Please refer: F. 144).

• Blow with a small compressed air flow to extract the

two pistons from the

calliper body .

An excessive pressure may cause

the two pistons (E) to jump off

violently .

After servicing the braking system, always check that:

• The brake liquid tubes are not damaged, squeezed or twisted.

• The brake discs and pads are not soiled with oil or grease;

• All the screws and couplings are properly tightened.

• There are no leaks from the couplings.

• Remove the dust seal (A) and the seal ring (B) from both the

pistons.

During this operation, take care not to damage the dust

seal and seal ring housing.

• Make sure there are no signs of scoring on the pistons and their

housing.

• Clean carefully and wash only with alcohol.

Always use new dust seals and seal rings.

Refit the pistons, the seal rings (B) and the dust seals (A),

greasing with brake liquid.

Complete the check, clean, replace and refit all the

components repeating the disassembly operations in the

reverse order .

F. 1 53F. 152

F. 150

F. 1 51

B

A

C

A

P

V2

P1

E

E

Page 64

63 02/08

V

30 ± 25%

FORK

STANCHION GR OUP

Make sure that the motorcycle is really stable; in case, put a suitable support

under the engine. The front wheel will ha ve to protrude over the runawa y

edge of the lift.

ST ANCHION DISASSEMBL Y

Lock the stanchion

group in a suitable

vice, carefully

protecting the slider

side with soft jaws, as

to avoid squeezing or

scoring.

• Release the upper screw (V2).

• Detach downwards the fork leg

(A), rotating it in the two directions.

NOTE - To remove one or both of the legs

of the front fork, completed with

stanchion, first remove:

• front fairing

• (front/rear) handlebar cover

• (right-hand side) odometer sprocket

• Front wheel

• brake callipers

• front mudguard

• Release the screw (V).

NOTE - The disassemb ly of the

stanchion can be deducted