Page 1

EM2650UH/EM2651UH/EM2650LH/EM2651LH

GB Petrol Brushcutter

F Débroussailleuse thermique

D Motorsense

I Decespugliatore a benzina

NL Benzinebosmaaier

E Desbrozadora

P Roçadeira a gasolina

DK Benzindrevet buskrydder

GR Βενζινοκίνητο Θαμνοκοπτικό

INSTRUCTION MANUAL

MANUEL D’INSTRUCTIONS

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

GEBRUIKSAANWIJZING

MANUAL DE INSTRUCCIONES

MANUAL DE INSTRUÇÕES

BRUGSANVISNING

ΟΔΗΓΙΕΣ ΧΡΗΣΗΣ

EM2650UH

EM2651UH

EM2650LH

EM2651LH

Page 2

Important:

Read this instruction manual carefully before putting the Petrol Brushcutter into operation and strictly observe

the safety regulations!

Preserve instruction manual carefully!

Important :

Veuillez lire attentivement ce manuel d’instructions avant d’utiliser la débroussailleuse thermique, et observez

strictement les consignes de sécurité !

Veillez à conservez ce manuel d’instructions !

Wichtig:

Lesen Sie vor Verwendung der Motorsense diese Bedienungsanleitung aufmerksam durch und halten Sie

die Sicherheitsregeln strikt ein!

Bewahren Sie diese Bedienungsanleitung sorgfältig auf!

Importante:

Leggere attentamente il presente manuale di istruzioni prima di mettere in funzione il decespugliatore a

benzina e rispettare rigorosamente le normative sulla sicurezza.

Conservare con cura il manuale di istruzioni.

Belangrijk:

Lees deze gebruiksaanwijzing aandachtig door voordat u de benzinebosmaaier in gebruik neemt en houdt u

te allen tijde aan de veiligheidsinstructies!

Bewaar deze gebruiksaanwijzing zorgvuldig!

Importante:

Lea atentamente este manual de instrucciones antes de utilizar la desbrozadora y cumpla estrictamente la

normativa de seguridad.

Conserve el manual de instrucciones con cuidado.

Importante:

Leia cuidadosamente este manual de instruções antes de utilizar a roçadeira a gasolina e cumpra todas as

normas de segurança!

Guarde este manual de instruções num local seguro!

Vigtigt:

Læs denne brugsanvisning omhyggeligt igennem inden du anvender den benzindrevne buskrydder og

overhold sikkerhedsregulativerne til mindste detalje!

Gem denne brugsanvisning omhyggeligt!

Σημαντικό:

Διαβάστε αυτό το εγχειρίδιο οδηγιών προσεκτικά πριν θέσετε σε λειτουργία το Βενζινοκίνητο Θαμνοκοπτικό

και να τηρείτε με ακρίβεια τους κανονισμούς ασφαλείας!

Διατηρήστε με προσοχή το εγχειρίδιο οδηγιών!

2

Page 3

English

(Original instructions)

Thank you very much for purchasing the MAKITA Petrol Brushcutter. We are

pleased to recommend to you the MAKITA Petrol Brushcutter which is the

result of a long development programme and many years of knowledge and

experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your MAKITA Petrol Brushcutter.

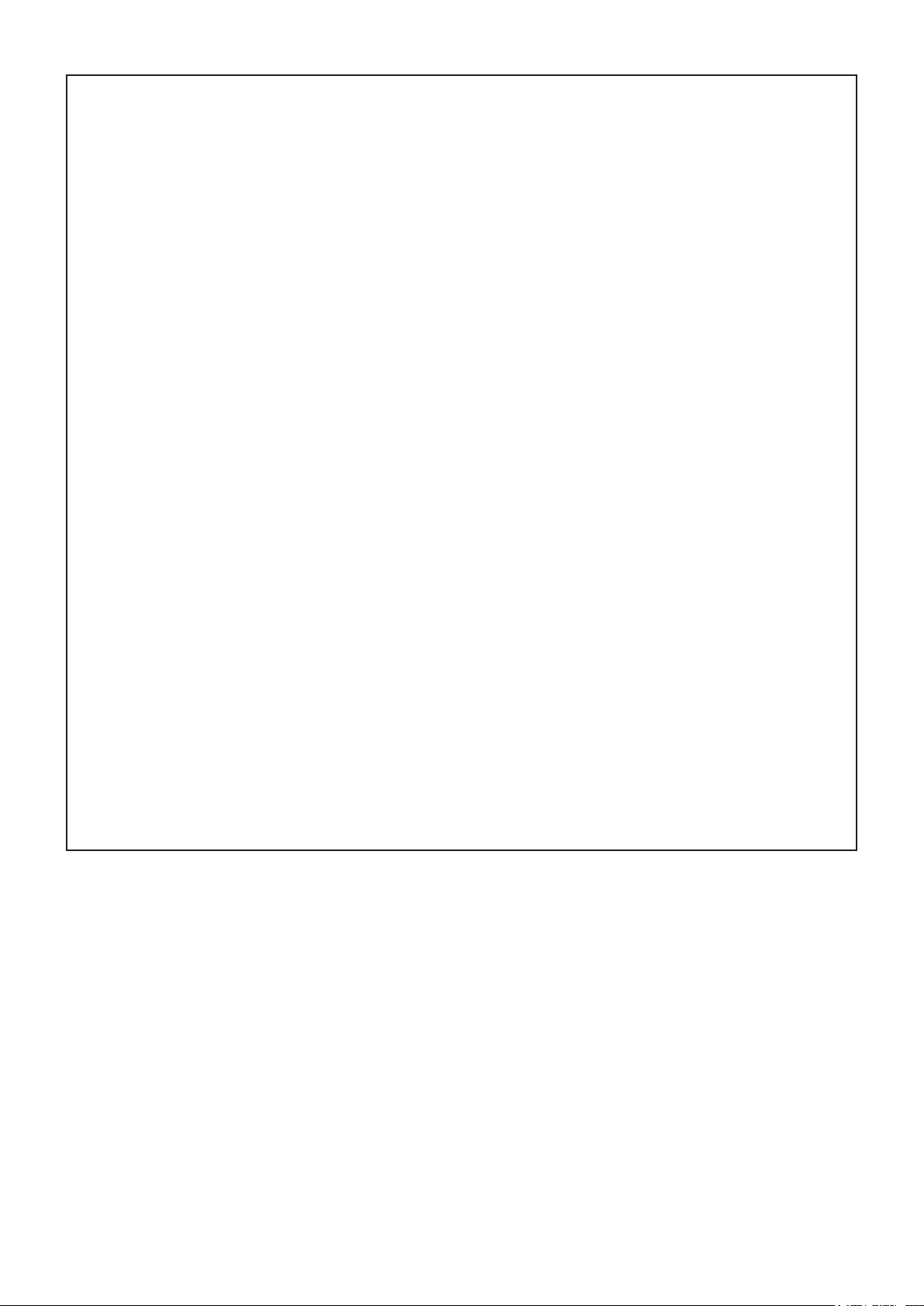

SYMBOLS

You will note the following symbols when reading the instructions manual.

Read instruction manual and follow

the warnings and safety precautions!

Table of Contents Page

Symbols .........................................................................3

Safety instructions .........................................................4

Technical data................................................................8

Designation of parts.....................................................10

Mounting of handle ...................................................... 11

Mounting of protector...................................................12

Mounting of cutter blade or nylon cutting head............13

Before start of operation ..............................................14

Correct handling of machine........................................16

Points in operation and how to stop ............................16

Resharpening the cutting tool ......................................18

Servicing instructions...................................................20

Storage ........................................................................23

Wear protective helmet, eye and ear

protection!

Take Particular care and attention!

Forbidden!

Keep distance!

Flying object hazard!

No smoking!

No open ame!

Protective gloves must be worn!

Top permissible tool speed

Fuel (Gasoline)

Engine-manual start

Emergency stop

First Aid

Recycling

ON/START

OFF/STOP

Wear sturdy boots with nonslip soles.

Steeltoed safety boots are recommended!

Kickback!

Keep the area of operation clear of all

persons and pets!

3

Page 4

SAFETY INSTRUCTIONS

General Instructions

– To ensure correct operation, user has to read this instruction manual to make

himself familiar with the handling of the Petrol Brushcutter. Users insufciently

informed will risk danger to themselves as well as others due to improper

handling.

– It is recommended only to lend the Petrol Brushcutter to people who have

proven to be experienced with Petrol Brushcutters.

Always hand over the instruction manual.

– First users should ask the dealer for basic instructions to familiarize oneself

with the handling of an engine powered cutter.

– Children and young persons aged under 18 years must not be allowed

to operate the Petrol Brushcutter. Persons over the age of 16 years may

however use the device for the purpose of being trained only whilst under

supervision of a qualied trainer.

– Use Petrol Brushcutters with the utmost care and attention.

– Operate the Petrol Brushcutter only if you are in good physical condition.

Perform all work calmly and carefully. The user has to accept liability for

others.

– Never use the Petrol Brushcutter after consumption of alcohol or drugs, or if

feeling tired or ill.

– National regulation can restrict the use of the machine.

Intended use of the machine

– The Petrol Brushcutter is only intended for cutter grass, weeds, Bushes,

undergrowth it should not be used for any other purpose such as Edging or

hedge cutting as this may cause injury.

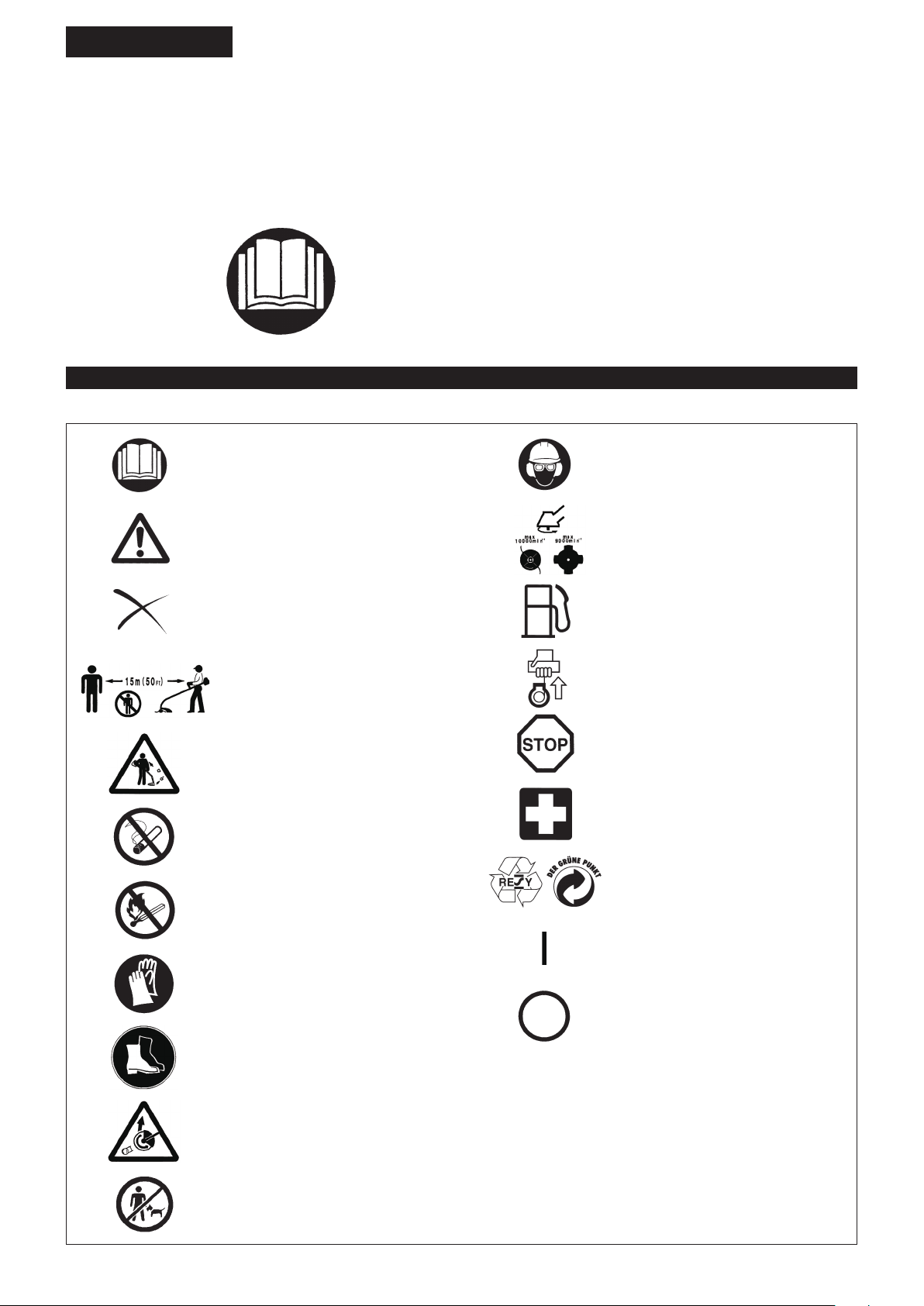

Personal protective equipment

– The clothing worn should be functional and appropriate, i.e. it should be tight-

tting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

– In order to avoid either head-, eye-, hand-or foot injuries as well as to protect

your hearing the following protective equipment and protective clothing must

be used during operation of the Petrol Brushcutter.

– Always wear a helmet where there is a risk of falling objects. The protective

helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

– The visor (2) of the helmet (or alternatively goggles) protects the face from

ying debris and stones. During operation of the Petrol Brushcutter always

wear goggles, or a visor to prevent eye injuries.

– Wear adequate noise protection equipment to avoid hearing impairment (ear

muffs (3), ear plugs etc.).

– The work overalls (4) protect against ying stones and debris.

We strongly recommend that the user wears work overalls.

– Special gloves (5) made of thick leather are part of the prescribed equipment

and must always be worn during operation of the Petrol Brushcutter.

– When using the Petrol Brushcutter, always wear sturdy shoes (6) with a non-

slip sole. This protects against injuries and ensures a good footing.

Starting up the Petrol Brushcutter

– Please make sure that there are no children or other people within a working

range of 15 meters (50 ft), also pay attention to any animals in the working

vicinity.

– Before use always check that the Petrol Brushcutter is safe for operation:

Check the security of the cutting tool, the control lever for easy action and

check for proper functioning of the control lever lock.

– Rotation of the cutting tool during idling speed is not allowed. Check with your

dealer for adjustment if in doubt. Check for clean and dry handles and test

the function of the start/stop switch.

Diagrammatic gure

15 Meters

4

Page 5

Start the Petrol Brushcutter only in accordance with the instructions.

– Do not use any other methods for starting the engine!

– Use the Petrol Brushcutter and the tools only for such applications as

specied.

– Only start the Petrol Brushcutter engine, after the entire assembly is done.

Operation of the device is only permitted after all the appropriate accessories

are attached!

– Before starting make sure that the cutting tool has no contact with hard

objects such as branches, stones etc. as the cutting tool will revolve when

starting.

– The engine is to be switched off immediately in case of any engine problems.

– Should the cutting tool hit stones or other hard objects, immediately switch off

the engine and inspect the cutting tool.

– Inspect the cutting tool at short regular intervals for damage (detection of

hairline cracks by means of tapping-noise test).

– Operate the Petrol Brushcutter only with the shoulder strap attached which is

to be suitably adjusted before putting the Petrol Brushcutter into operation. It

is essential to adjust the shoulder strap according to the user size to prevent

fatigue occurring during use. Never hold the cutter with one hand during use.

– During operation always hold the Petrol Brushcutter with both hands.

Always ensure a safe footing.

– Operate the Petrol Brushcutter in such a manner as to avoid inhalation of

the exhaust gases. Never run the engine in enclosed rooms (risk of gas

poisoning). Carbon monoxide is an odorless gas.

– Switch off the engine when resting and when leaving the Petrol Brushcutter

unattended, and place it in a safe location to prevent danger to others or

damage to the machine.

– Never put the hot Petrol Brushcutter onto dry grass or onto any combustible

materials.

– The cutting tool has to be equipped with it appropriate guard.

Never run the cutter without this guard!

– All protective installations and guards supplied with the machine must be

used during operation.

– Never operate the engine with faulty exhaust mufer.

– Shut off the engine during transport.

– During transport over long distances the tool protection included with the

equipment must always be used.

– Ensure safe position of the Petrol Brushcutter during car transportation to

avoid fuel leakage.

– When transporting the Petrol Brushcutter, ensure that the fuel tank is

completely empty.

–

When unloading the Petrol Brushcutter from the truck, never drop the Engine

to the ground or this may severely damage the fuel tank.

–

Except in case of emergency, never drop or cast the Petrol Brushcutter to the

ground or this may severely damage the Petrol Brushcutter.

– Remember to lift the entire equipment from the ground when moving the

equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing re.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool replacement

Refuelling

– Shut off the engine during refuelling, keep away from open ames and do not

smoke.

– Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always

wear protective gloves during refuelling. Change and clean protective clothing

at regular intervals.

– Take care not to spill either fuel or oil in order to prevent soil contamination

(environmental protection). Clean the Petrol Brushcutter immediately after

fuel has been spilt.

– Avoid any fuel contact with your clothing. Change your clothing instantly if

fuel has been spilt on it (to prevent clothing catching re).

– Inspect the fuel cap at regular intervals making sure that it can be securely

fastened and does not leak.

– Carefully tighten the fuel tank cap. Change location to start the engine (at

least 3 meters away from the place of refuelling).

– Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of

explosions).

– Only transport and store fuel in approved containers. Make sure the fuel

stored is not accessible to children.

5

3 meters

Page 6

Method of operation

– Only use the Petrol Brushcutter in good light and visibility. During the winter

season beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

– Never cut above waist height.

– Never stand on a ladder and run the Petrol Brushcutter.

– Never climb up into trees to perform cutting operation with the Petrol

Brushcutter.

– Never work on unstable surfaces.

– Remove sand, stones, nails etc. found within the working range.

Foreign particles may damage the cutting tool and can cause dangerous

kick-backs.

– Before commencing cutting, the cutting tool must have reached full working

speed.

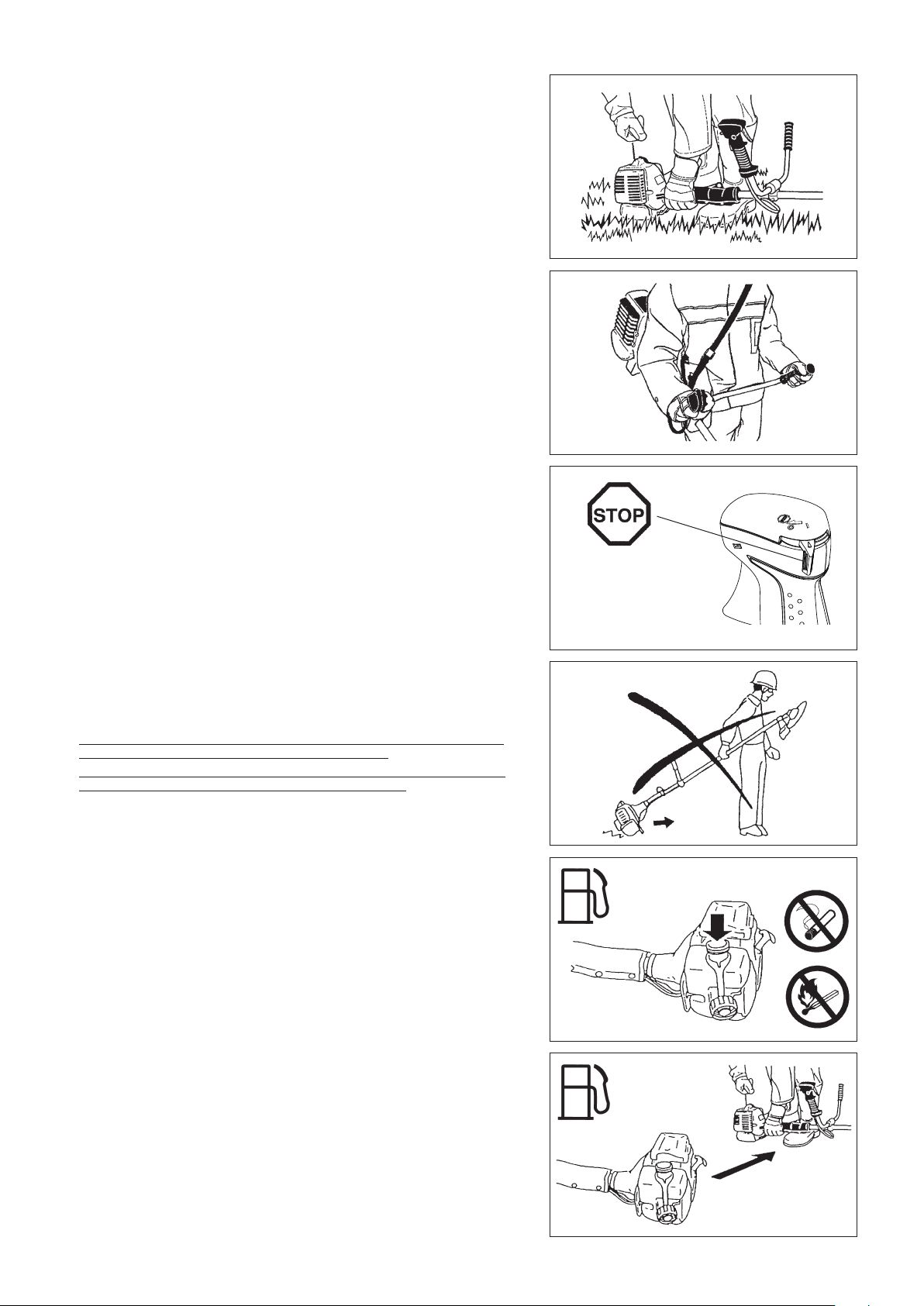

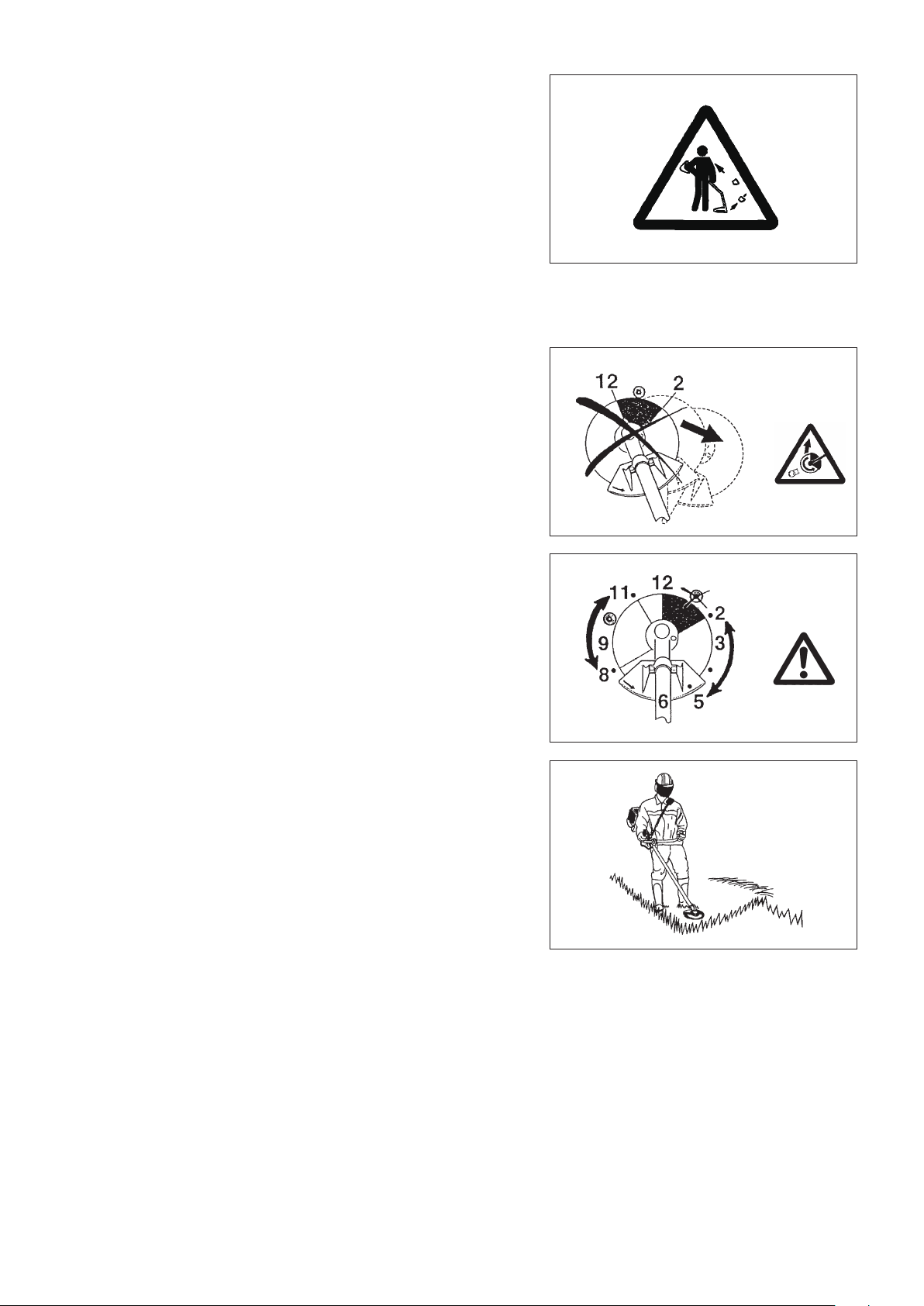

Kickback

– When operating the Petrol Brushcutter, uncontrolled kickback may occur.

– This is particularly the case when attempting to cut within a blade segment

between 12 and 2 o’clock.

– Never apply the Petrol Brushcutter within a segment between 12 and 2

o’clock.

– Never apply this segment of the Petrol Brushcutter blade to solids, such as

bushes and trees, etc., having a diameter in excess of 3 cm or the Petrol

Brushcutter will be deected at great force with the risk of injuries.

Kickback prevention

To avoid kickbacks, observe the following:

– Operation within a blade segment between 12 and 2 o’clock presents positive

hazards, especially when using metal cutting tools.

– Cutting operations within a blade segment between 11 and 12 o’clock, and

between 2 and 5 o’clock, must only be performed by trained and experienced

operators, and then only at their own risk.

Easy cutting with almost no kickback is possible within a blade segment

between 8 and 11 o’clock.

Cutting Tools

Employ only the correct cutting tool for the job in hand.

Caution:

Kickback

Diagrammatic

gure

Diagrammatic

gure

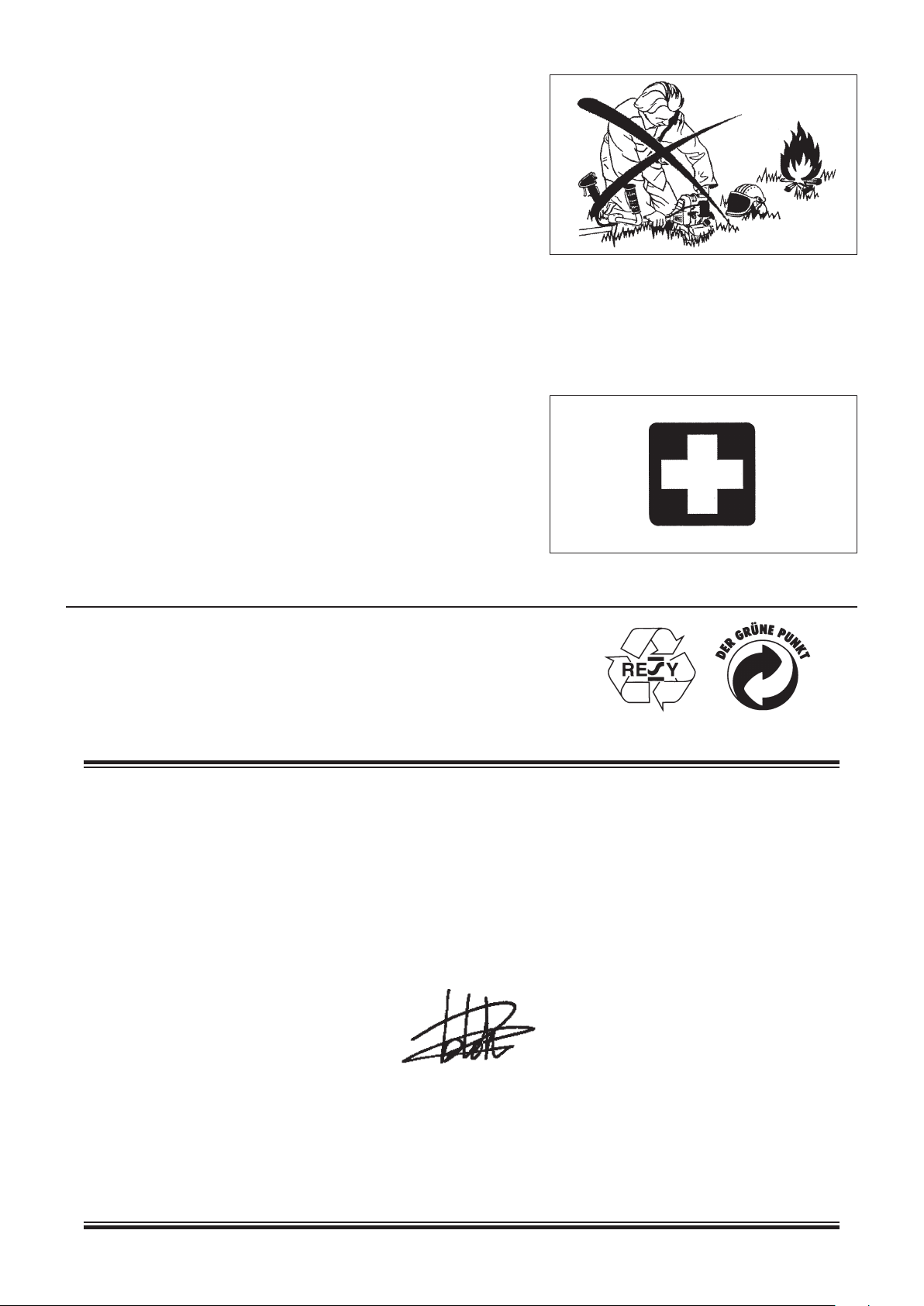

EM2650UH, EM2651UH, EM2650LH, EM2651LH with cutter blade, Nylon

cutting head

For cutting thick materials, such as weed, high grass, bushes, shrubs,

underwood, thicket etc. (max. 2 cm dia. thickness). Perform this cutting work by

swinging the Petrol Brushcutter evenly in half-circles from right to left (similar to

using a scythe).

Maintenance instructions

– The condition of the cutter, in particular of the cutting tool of the protective

devices and also of the shoulder strap must be checked before commencing

work. Particular attention is to be paid to the cutting blades which must be

correctly sharpened.

– Turn off the engine and remove spark plug connector when replacing or

sharpening cutting tools, and also when cleaning the cutter or cutting tool.

6

Page 7

Never straighten or weld damaged cutting tools.

– Operate the Petrol Brushcutter with as little noise and contamination as

possible. In particular check the correct setting of the carburetor.

– Clean the Petrol Brushcutter at regular intervals and check that all screws

and nuts are well tightened.

– Never service or store the Petrol Brushcutter in the vicinity of naked ames.

– Always store the Petrol Brushcutter in locked rooms and with an emptied fuel

tank.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modications on the Petrol Brushcutter as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by MAKITA.

Use of non-approved accessories and tools means increased risk of accidents.

MAKITA will not accept any liability for accidents or damage caused by the use of non-approved cutting tools and xing devices of cutting tools,

or accessories.

First Aid

In case of accident make sure that a rst-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the rst aid box.

When asking for help, please give the following

information:

– Place of accident

– What happened

– Number of injured persons

– Kind of injuries

– Your name

Packaging

The MAKITA Petrol Brushcutter will be delivered in two protective cardboard

boxes to prevent transport damage. Cardboard is a basic raw material and

is therefore consequently reusable or suitable for recycling (waste paper

recycling).

EC-DECLARATION OF CONFORMITY

Petrol Brushcutter: model EM2650UH, EM2651UH, EM2650LH, EM2651LH

(See TECHNICAL DATA for the specications)

We declare under our sole responsibility that this product is in compliance with the following Directives, 2000/14/EC, 2006/42/EC.

The most important standards applied to properly meet the requirements of the above Directives were: EN11806.

Measured Sound Power: 108.5 dB (A)

Guarantee Sound Power: 111 dB (A)

These sound power levels wear measured in accordance with Council Directive, 2000/14/EC.

Conformity assessment procedure: Annex V.

27. NOV. 2009

Tomoyasu Kato

Director

Responsible Manufacturer:

Makita Corporation.

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Authorized Representative in Europe:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15 8JD, ENGLAND

7

Page 8

TECHNICAL DATA EM2650UH, EM2650LH

Model

EM2650UH EM2650LH

Bike handle Loop handle

Dimensions: length x width x height (without cutting blade) mm

Mass (without plastic guard and cutting blade) kg

Volume (fuel tank) L

Volume (oil tank) L

Engine displacement cm

3

1,765 x 620 x 474 1,765 x 330 x 264

5.5 5.1

0.6

0.08

25.4

Maximum engine performance kw 0.77 at 7,000 min

Engine speed at recommended max. spindle speed min

Maximum spindle speed (corresponding) min

Maximum fuel consumption kg/h

Maximum specic fuel consumption g/kwh

Idling speed min

Clutch engagement speed min

Carburetor type

-1

-1

8,500

6,500

0.33

408

-1

-1

3,000

3,900

WALBRO WYL

Ignition system type Solid state ignition

Spark plug type

NGK CMR4A

Electrode gap mm 0.7 - 0.8

Right handle

Vibration per

ISO 22867

(Rear grip)

Left handle

(Front grip)

Sound pressure level average to

ISO 22868

Sound power level average to

ISO 22868

a

hv eq

Uncertainty K

a

hv eq

Uncertainty K

L

PA eq

Uncertainty K

L

WA eq

Uncertainty K

2

m/s

m/s

m/s

m/s

2

2

2

2.6 5.1

0.8 0.2

2.3 4.1

0.5 0.4

dBA 96.6

dBA 0.9

dBA 105.5

dBA 1.3

Fuel Automobile gasoline

Engine Oil

SAE 10W-30 oil of API Ciassication,

Class SF or higher (4-stroke engine for automobile)

Cutting tools (cutter blade dia.) mm 230

Gear ratio 14/19

-1

8

Page 9

TECHNICAL DATA EM2651UH, EM2651LH

Model

EM2651UH EM2651LH

Bike handle Loop handle

Dimensions: length x width x height (without cutting blade) mm

Mass (without plastic guard and cutting blade) kg

Volume (fuel tank) L

1,765 x 620 x 474 1,765 x 330 x 264

5.6 5.2

0.6

Volume (oil tank) L 0.08

Engine displacement cm

3

25.4

Maximum engine performance kw 0.77 at 7,000 min

Engine speed at recommended max. spindle speed min

Maximum spindle speed (corresponding) min

Maximum fuel consumption kg/h

Maximum specic fuel consumption g/kwh

Idling speed min

Clutch engagement speed min

Carburetor type

-1

-1

8,500

6,500

0.33

408

-1

-1

3,000

3,900

WALBRO WYL

Ignition system type Solid state ignition

Spark plug type

NGK CMR4A

Electrode gap mm 0.7 - 0.8

Right handle

Vibration per

ISO 22867

(Rear grip)

Left handle

(Front grip)

Sound pressure level average to

ISO 22868

Sound power level average to

ISO 22868

a

hv eq

Uncertainty K

a

hv eq

Uncertainty K

L

PA eq

Uncertainty K

L

WA eq

Uncertainty K

2

m/s

m/s

m/s

m/s

2

2

2

2.5 5.5

0.5 1.0

2.4 4.4

0.2 0.4

dBA 96.6

dBA 0.9

dBA 105.5

dBA 1.3

Fuel Automobile gasoline

Engine Oil

SAE 10W-30 oil of API Ciassication,

Class SF or higher (4-stroke engine for automobile)

Cutting tools (cutter blade dia.) mm 230

Gear ratio 14/19

-1

9

Page 10

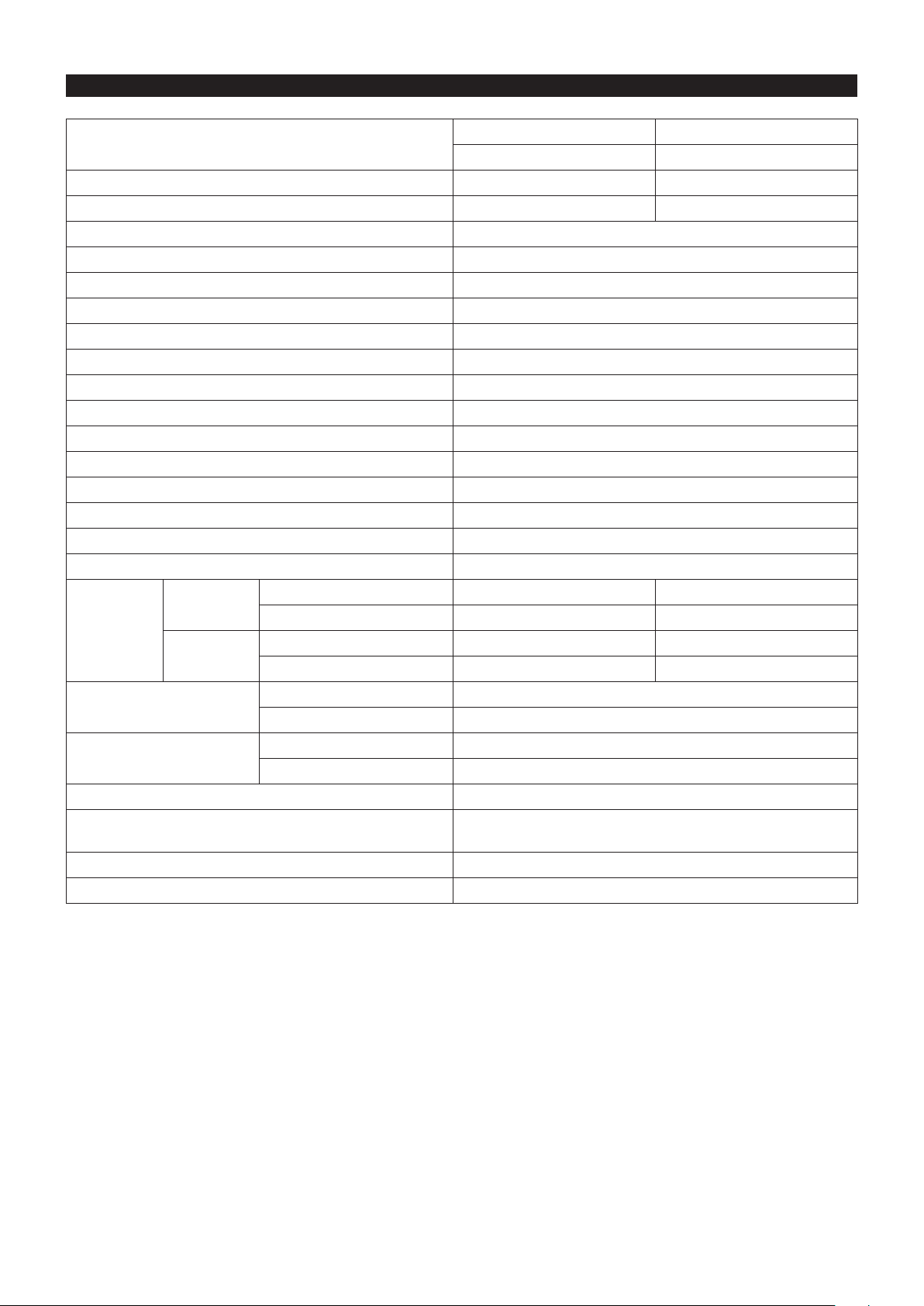

DESIGNATION OF PARTS

EM2650UH

EM2651UH

⑪

⑬

⑯

④

⑫

⑨

⑤

⑩

EM2650LH

EM2651LH

⑦

⑩

⑬

⑨

⑤

⑫

④

⑦

⑧

⑪

⑮

⑰

⑳

③

⑲

⑭

②

⑮

⑱

⑥

①

⑭

GB DESIGNATION OF PARTS

1 Fuel tank

2 Rewind starter

3 Air cleaner

4 I-O switch (on/off)

5 Spark plug

6 Exhaust mufer

7 Clutch case

8 Rear grip

21

22

9 Hanger

10 Handle

11 Control lever

12 Control cable

13 Shaft

14 Protector

15 Gear Case/Head case

16 Handle holder

17 Cutter blade

18 Nylon cutting head

19 Fuel ller cap

20 Starter knob

21 Exhaust pipe

22 Oil gauge

10

Page 11

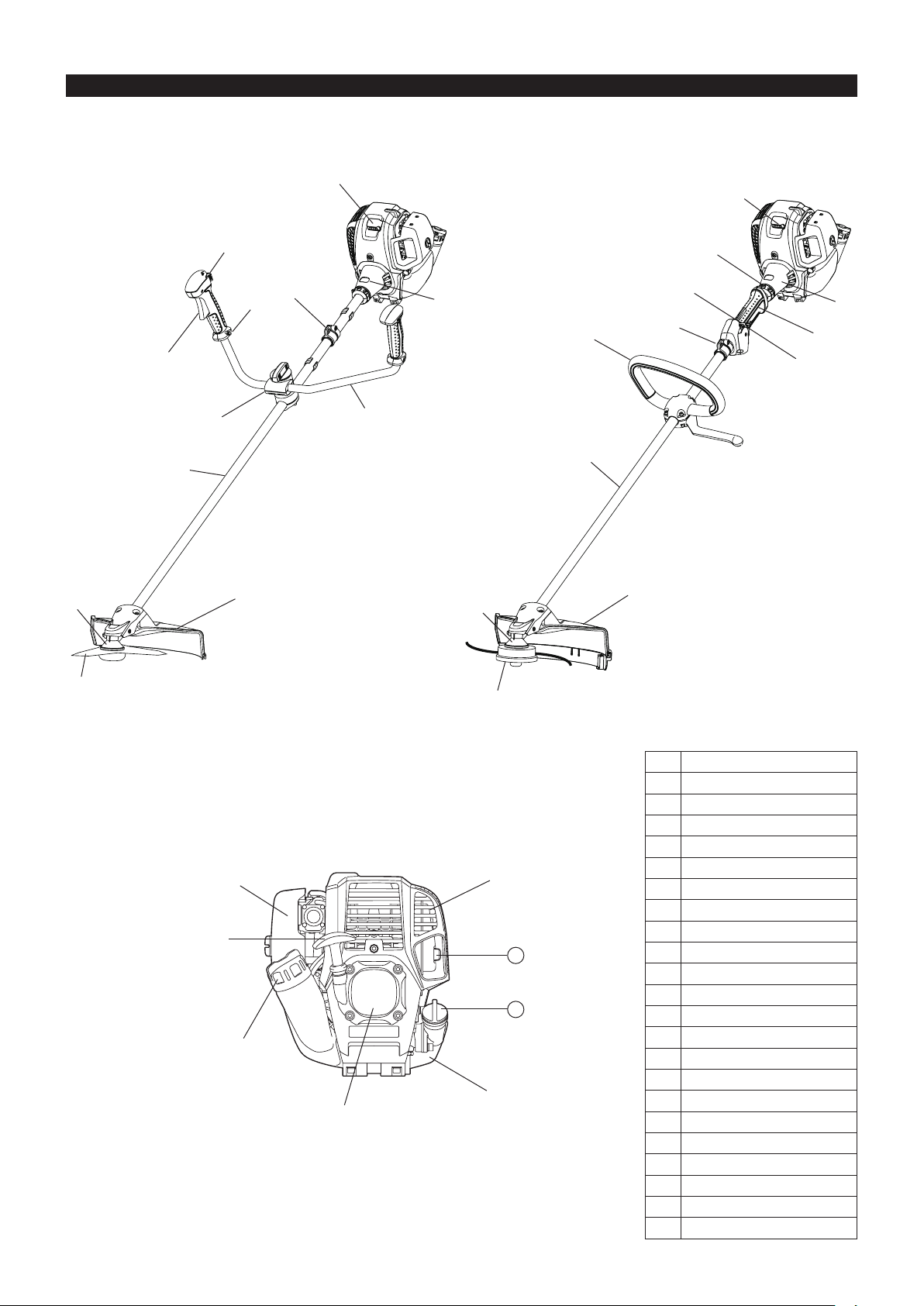

MOUNTING OF HANDLE

(1)

(2)

(3)

(4)

(5)

CAUTION: Before doing any work on the Petrol Brushcutter, always stop the

engine and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the Petrol Brushcutter only after having assembled it

completely.

For machines with bike handle models

– Loosen knob (1).

– Place handle (4) between handle clamp (2) and handle holder (3).

– Adjust handle (4) to an angle that provides a comfortable working position

and then secure by rmly hand-tightening knob (1).

CAUTION: Do not forget to mount spring (5).

For machines with loop handle

– Fix a barrier to the left side of the machine together with the handle for

operator protection.

– Do not adjust position of the loop handle too close to the control grip. Keep

not less than 250 mm distance between the handle and the grip.

(a distance collar is provided for this purpose.)

Engine

Engine

11

Page 12

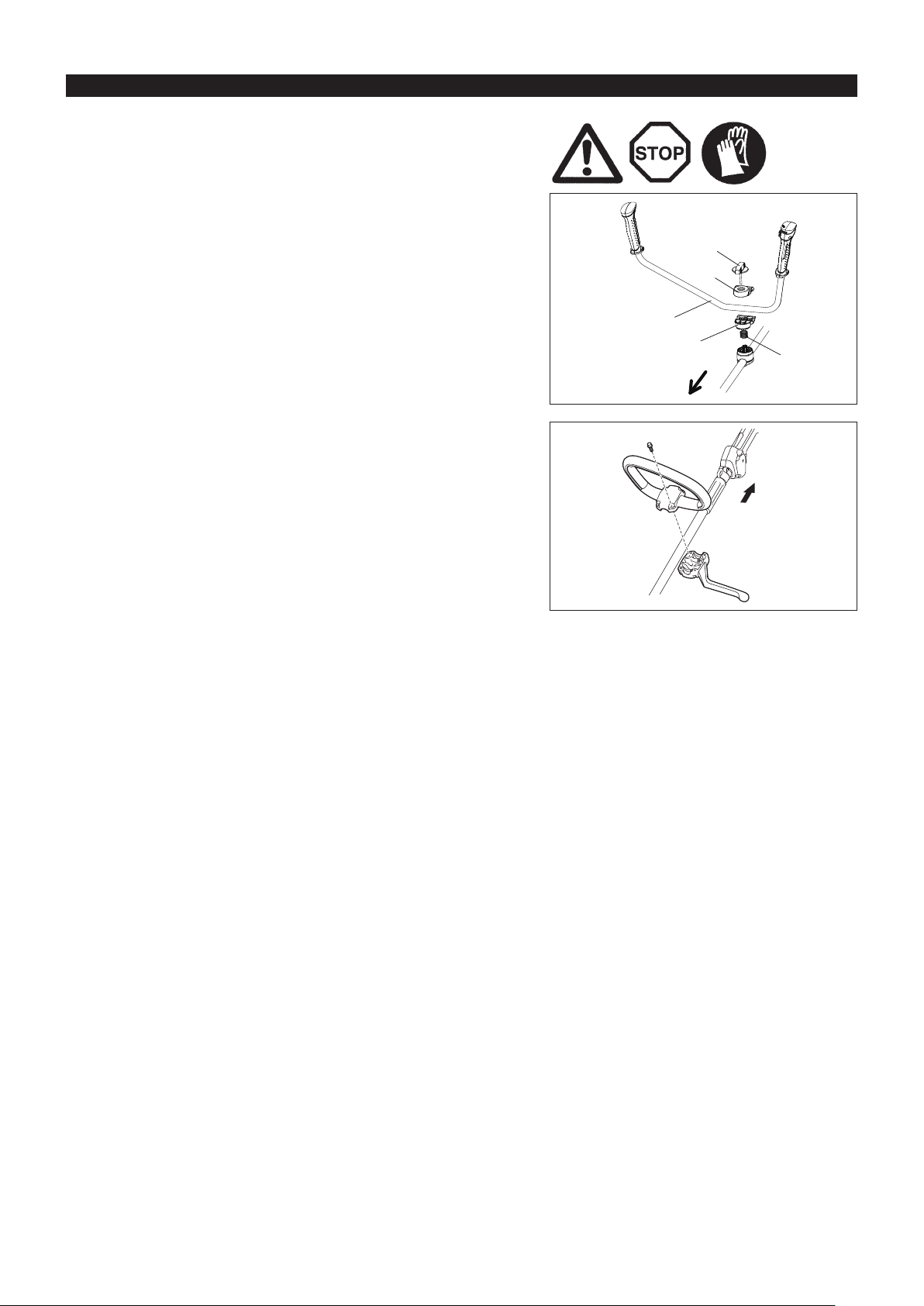

MOUNTING OF PROTECTOR

To meet the applicable safety provisions, only the tool/

protector combinations as indicated in the table must be used.

Be sure to use genuine MAKITA cutter blades or

nylon cutting head.

– The cutter blade must be well polished, free of cracks or

breakage. If the cutter blade hits against a stone during

operation, stop the engine and check the blade immediately.

– Polish or replace the cutter blade every three hours of operation.

– If the nylon cutting head hits against a stone during operation,

stop the engine and check the nylon cutting head immediately.

Metal blade

Protector for metal blades

CAUTION: The appropriate protector must always be installed, for

your own safety and in order to comply with accidentprevention regulations.

Operation of the equipment without the guard being in

place is not permitted.

The outside diameter of the cutter blade must be

230 mm (9 - 1/16”). Never use any blades surpassing

230 mm (9 - 1/16”) in outside diameter.

– In use of the metal blade, x the protector (3) to the clamp (2) with two bolts

M6 x 30 (1).

NOTE: Tighten the right and left bolts evenly so that the gap between the clamp

(2) and the protector (3) will be constant.

Otherwise, the protector sometimes may not function as specied.

Nylon cutting head

(3)

Protector for

nylon cutting head

(1)

(2)

– In cases where the nylon cord cutter is to be used, be sure to mount the

nylon cord cutter protector (4) onto the metal blade protector (3).

– Mount the nylon cord cutter protector (4) by sliding it into place from the ank

of the metal blade protector (3) as shown.

– Remove tape adhered to cutter, which cuts nylon cord, on nylon cord cutter

protector (4).

CAUTION: Be sure to push in nylon cord cutter protector (4) until it is fully

inserted.

Take care not to injure yourself on the cutter for cutting the nylon

cord.

– To remove the nylon cord cutter protector (4), apply a hex wrench into the

notch on the metal blade protector (3), push it in and meanwhile slide the

nylon cord cutter protector (4).

(3)

(4)

Hex wrench

12

Page 13

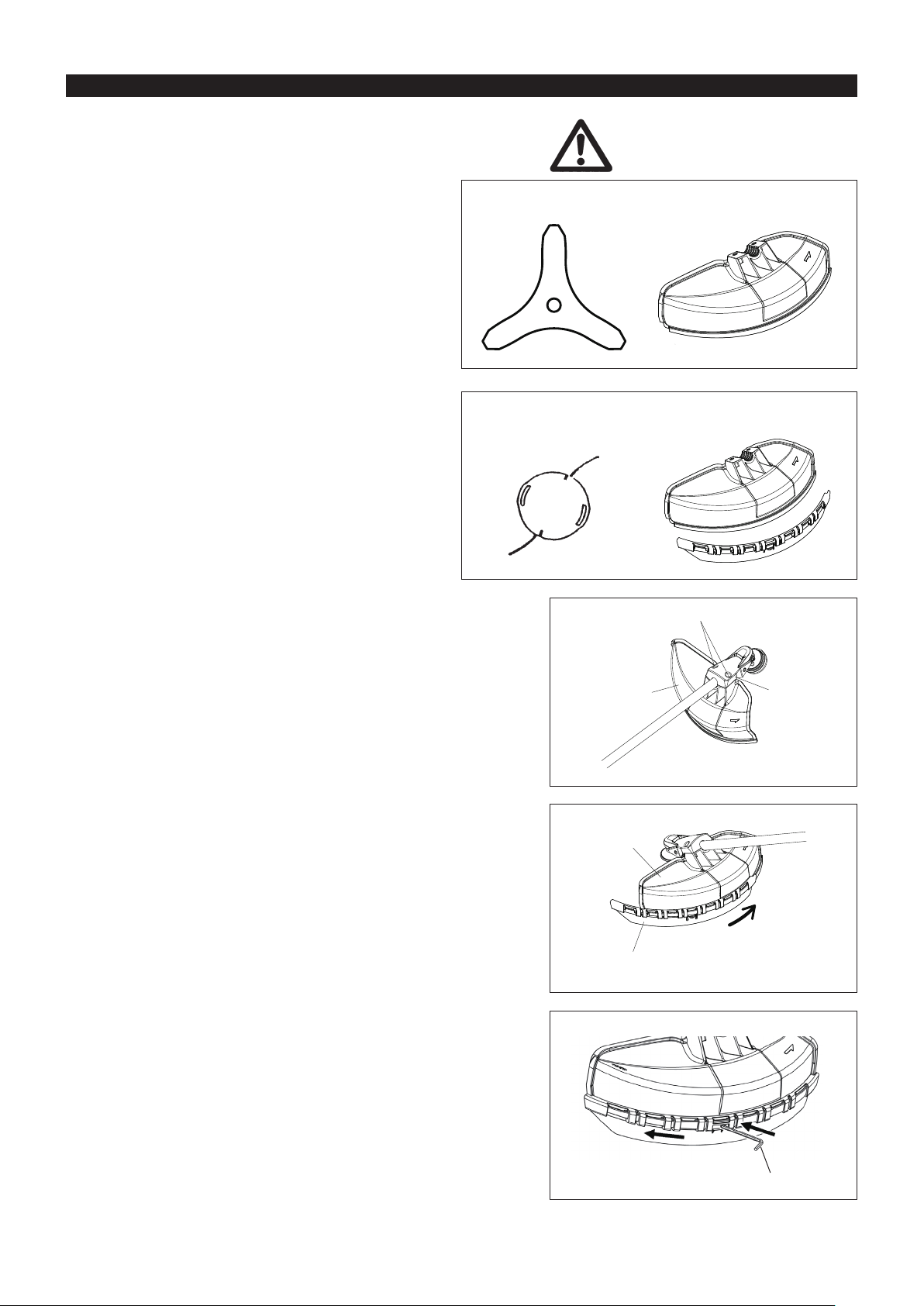

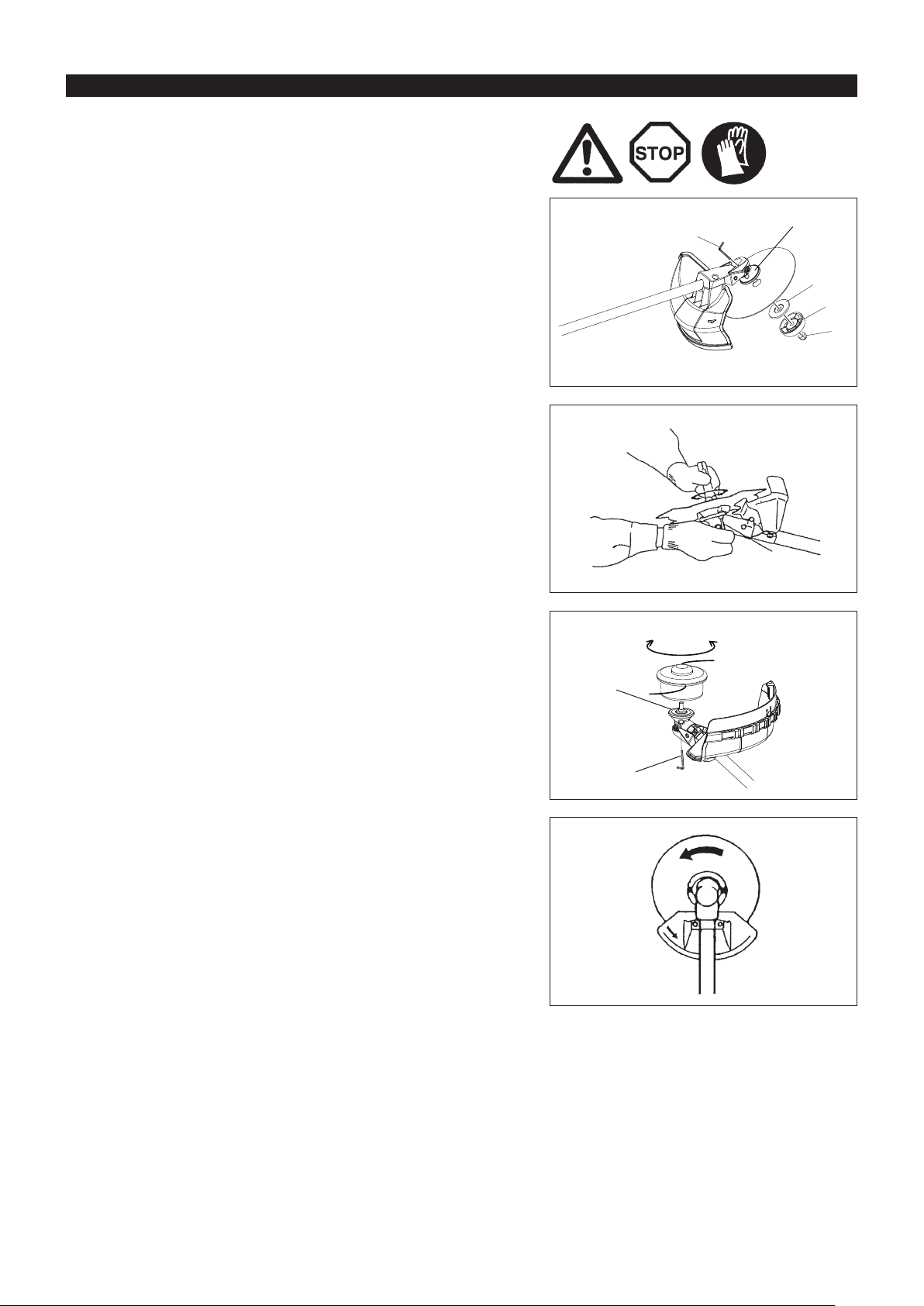

MOUNTING OF CUTTER BLADE OR NYLON CUTTING HEAD

Turn the machine upside down, and you can replace the cutter blade or nylon

cutting head easily.

– Insert the hex wrench through the hole in the gear case and rotate the

receiver washer (4) until it is locked with the hex wrench.

– Loosen the nut (1) (left-hand thread) with the socket wrench and remove the

nut (1), cup (2), and clamp washer (3).

Mounting of cutterblade with the hex wrench still in place

– Mount the cutter blade onto the shaft so that the guide of the receiver washer

(4) ts in the arbor hole in the cutter blade. Install the clamp washer (3), cup

(2), and secure the cutter blade with the nut (1).

[Tightening torque: 13 - 23 N-m]

NOTE: Always wear gloves when handling the cutter blade.

NOTE: The cutter blade-fastening nut (with spring washer) is a consumable

part. If there appears any wear or deformation on the spring washer,

replace the nut.

Hex wrench

(4)

(3)

(2)

(1)

Hex wrench

Mounting of nylon cutting head

– The clamp washer (3), cup (2), and nut (1) are not necessary for mounting

the nylon cutting head. The nylon cutting head should go on top of the

receiver washer (4).

– Insert the hex wrench through the hole in the gear case and rotate the

receiver washer (4) until it is locked with the hex wrench.

– Then screw the nylon cutting head onto the shaft by turning it counter-

clockwise.

– Remove the hex wrench.

– Make sure that the blade is the left way up.

(4)

Hex wrench

Rotation

Loosen

Tighten

13

Page 14

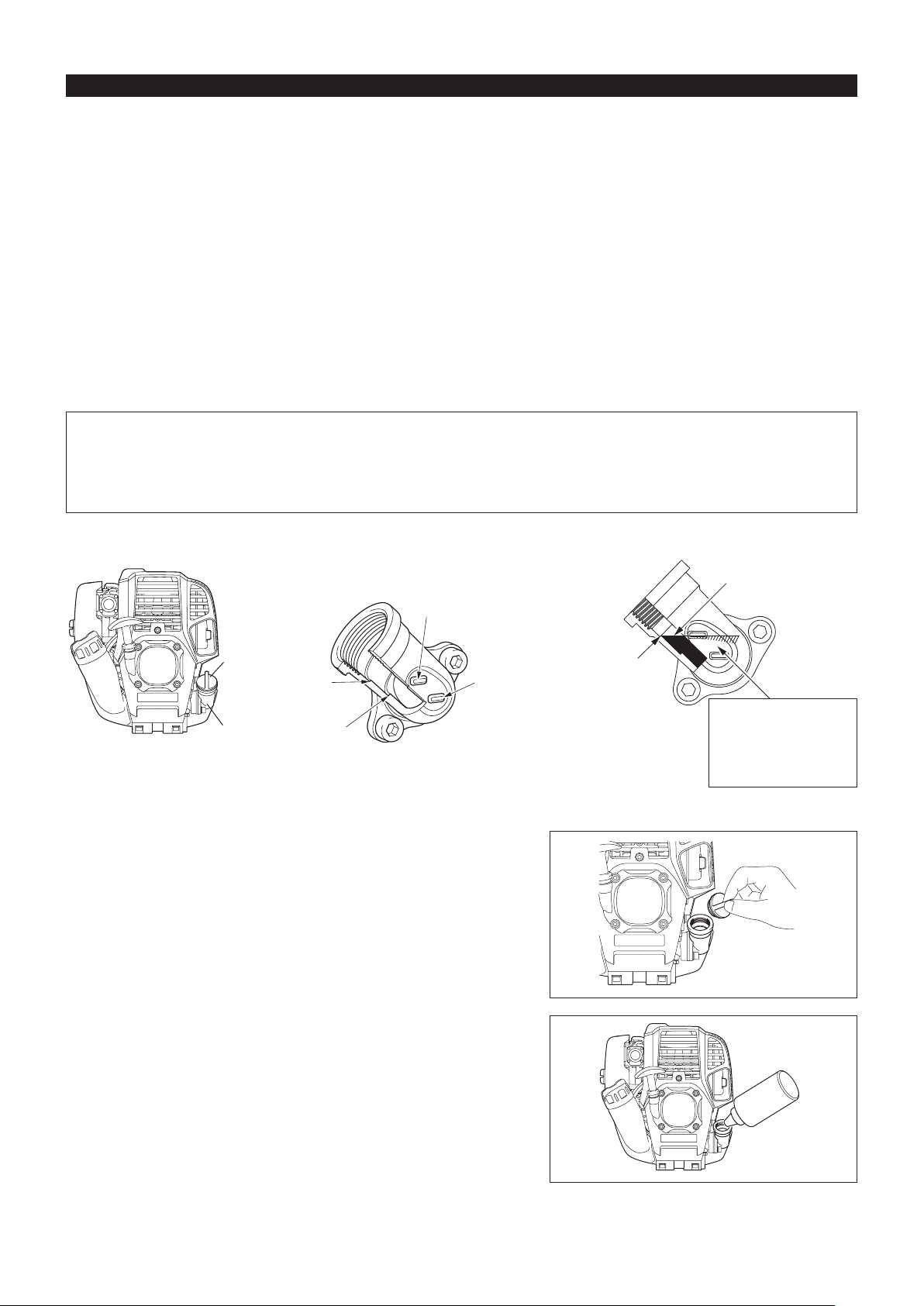

BEFORE START OF OPERATION

Inspection and rell of engine oil

– Perform the following procedure, with the engine cooled down.

– Set the engine level, remove oil cap (Fig. 1), and check to see whether or not there is oil in the range between the upper limit and lower limit

marks of the oil pipe (Fig. 2).

– Top up with oil to upper limit mark if oil is insufcient (oil level is close to lower limit mark) (Fig. 3).

– The area surrounding the external marks is transparent, so the amount of oil inside can be checked without having to remove the oil cap.

However, if oil pipe becomes extremely dirty, visibility may be lost, and oil level will have to be checked against stepped section on inside of

oil pipe.

– For reference, the oil rell time is about 10h (10 times or 10 tanks of oil rell).

If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P 20)

Recommended oil: SAE 10W-30 oil of API Classication, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08L

Note: If the engine is not kept upright, oil may go into around the engine, and may be relled excessively.

If the oil is lled above the limit, the oil may be contaminated or may catch re with white smoke.

Point 1 in Replacement of oil: “Oil gauge”

– Remove dust or dirt near the oil rell port, and detach the oil gauge.

– Keep the detached oil gauge free of sand or dust. Otherwise, any sand or dust adhering to the oil gauge may cause irregular oil

circulation or wear on the engine parts, which will result in troubles.

Oil cap

Internal stepped

section (upper

limit)

Oil pipe

Fig. 1

(1) Keep the engine level, and detach the oil cap.

Internal stepped

section (lower

limit)

External mark

(upper limit)

External mark

(lower limit)

Fig. 2 Oil pipe Fig. 3

Top up with oil until

oil level reaches

internal stepped

section (upper

limit).

Oil

The area between the

external upper and lower

limits is transparent, so

oil level can be checked

externally against these

marks.

(2) Fill with oil to upper limit mark. (see Fig. 3)

Use oil bottle when lling.

(3) Securely tighten the oil cap. Insufcient tightening may cause oil leakage.

14

Page 15

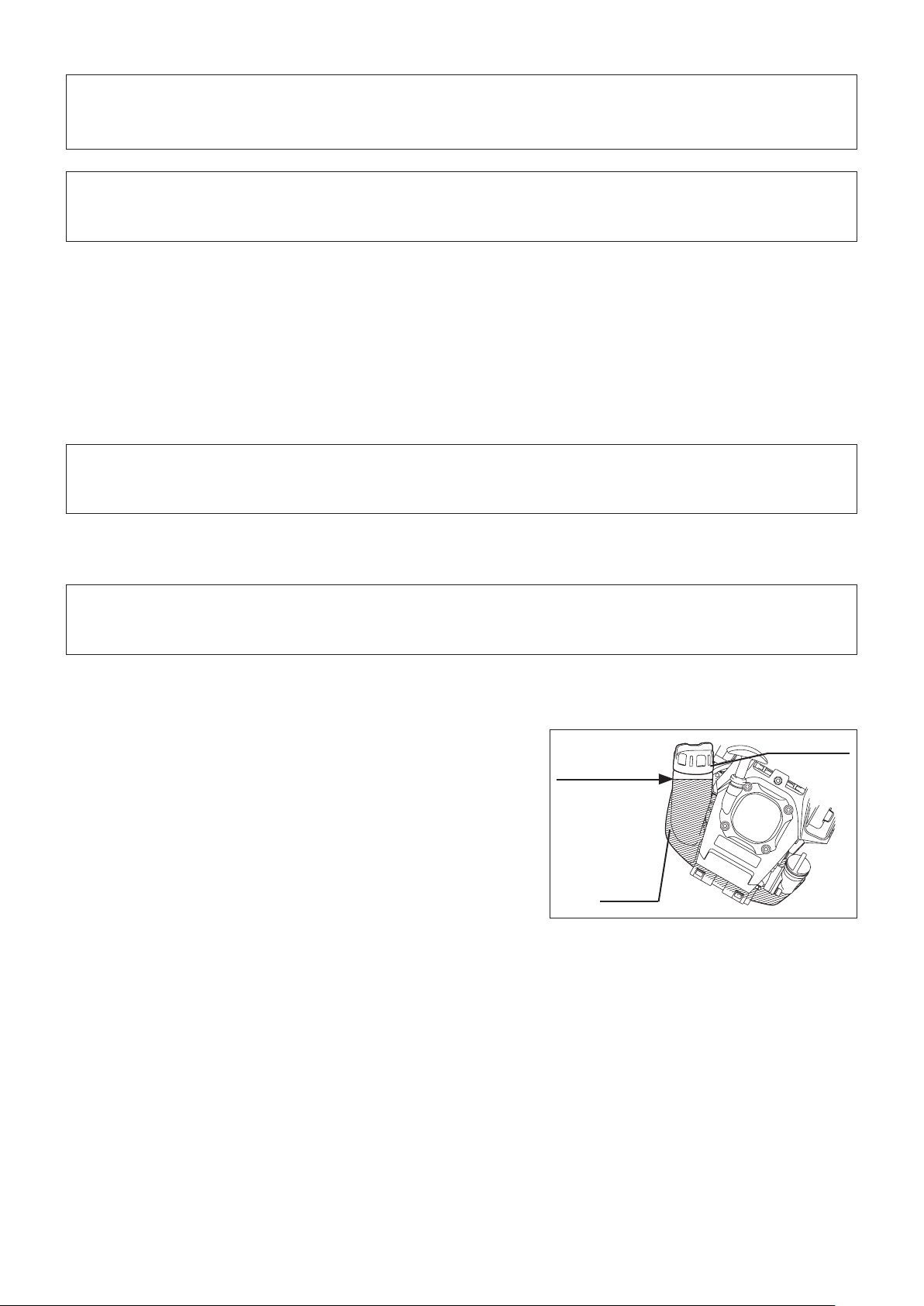

Note

● Do not replace oil with the engine in a tilted position.

● Filling with oil while engine is tilted leads to overlling which causes oil contamination and/or white smoke.

Point 2 in Replacement of oil: “If oil spills out”

– If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will

contaminate the engine. Be sure to wipe out spilt oil before start of operation.

REFUELING

Handling of fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refueling must be performed in a sufciently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the

skin becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains still

irritated, consult your doctor.

Storage period of fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

– Keep the machine and tank at a cool place free from direct sunshine.

– Never keep the fuel in the cabin or trunk.

Fuel

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for fuel

– Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

– Use of deteriorated oil will cause irregular startup.

Refueling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Gasoline used: Automobile gasoline (unleaded gasoline)

– Loosen the tank cap a little so that there will be no difference in atmospheric

pressure.

– Detach the tank cap, and refuel, discharging air by tilting the fuel tank so

that the refuel port will be oriented upward. (Never rell fuel full to the oil rell

port.)

– Wipe well the periphery of the tank cap to prevent foreign matter from

entering into the fuel tank.

– After refueling, securely tighten the tank cap.

● If there is any aw or damage on the tank cap, replace it.

● The tank cap is consumable, and therefore should be renewed every two to

three years.

Fuel upper limit

Fuel tank

Fuel tank cap

15

Page 16

CORRECT HANDLING OF MACHINE

Attachment of shoulder strap

– Adjust the strap length so that the cutter blade will be

kept parallel with the ground.

For EM2650UH, EM2651UH

NOTE: Be careful not to trap clothing, etc., in the buckle.

Detachment

For EM2650LH, EM2651LH

– In an emergency, push the notches (1) at both sides, and you can detach the

machine from you.

Be extremely careful to maintain control of the machine at this time. Do not

allow the machine to be deected toward you or anyone in the work vicinity.

WARNING: Failure to maintain complete control of the machine at all could

result in serious bodily injury or DEATH.

Buckle

EM2650UH

EM2651UH

(1)

Hanger

For EM2650UH, EM2651UH

– In an emergency, push the notches (2) at both sides, and

you can detach the machine from you.

Be extremely careful to maintain control of the machine

at this time. Do not allow the machine to be deected

toward you or anyone in the work vicinity.

WARNING: Failure to maintain complete control of the

machine at all could result in serious bodily

injury or DEATH.

(2)

POINTS IN OPERATION AND HOW TO STOP

Observe the applicable accident prevention regulations!

STARTING

Move at least 3 m away from the place of refuelling. Place the Petrol Brushcutter on a clean piece of ground taking care that the cutting tool

does not come into contact with the ground or any other objects.

A: Cold start

1) Set this machine on a at space.

2) Set the I-O switch (1) to OPERATION.

OPERATION

Lock-off lever

STOP

Throttle lever

High speed

Low speed

Throttle lever

Low speed

High speed

STOP

(1)

OPERATION

Lock-off lever

(1)

16

EM2650LH

EM2651LH

EM2650UH

EM2651UH

Page 17

3) Primer pump

Continue to push the primer pump until fuel enters into the primer pump. (In

general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

4) Recoil starter

Pull the start knob gently until it is hard to pull (compression point). Then,

return the start knob, and pull it strongly.

Never pull the rope to the full. Once the start knob is pulled, never release

your hand immediately. Hold the start knob until it returns to its original

point.

5) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

Note: In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the electrode

section of the spark plug.

Primer Pump

Carburetor

Caution during operation:

If the throttle lever is opened fully in a no-load operation, the engine rotation is increased to 10,000 min-1 or more. Never operate the engine at a

higher speed than required and at an approximate speed of 6,000 - 8,500 min-1.

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difcult to start the engine, open the throttle by about 1/3.

Pay attention to the cutter blade which may rotate.

At times, such as winter, when starting the engine

CLOSE

is difcult

Operate choke lever with the following procedure when starting engine.

● After implementing startup steps 1) to 3), set choke lever to the CLOSE

position.

● Implement startup step 4) and start engine.

● Once engine starts, set choke lever to the OPEN position.

● Implement startup step 5) and complete warm up.

CAUTION: If a bang (explosive sound) is heard and the engine stops, or the

CAUTION: If the choke lever is left in the CLOSE position, and the starter knob

just-started engine stalls before the choke lever is operated, return

the choke lever to the OPEN position, and pull the starter knob a

few times again to start the engine.

merely pulled repeatedly, to much fuel will be sucked in, and the

engine will become difcult to start.

17

OPEN

Page 18

STOPPING

1) Release the throttle lever (2) fully, and when the

engine rpm has lowered, set the I-O switch to

STOP the engine will now stop.

2) Be aware that the cutting head may not stop

immediately and allow it to slow down fully.

STOP

(2)

(2)

STOP

(1)

(1)

EM2650LH

EM2651LH

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw.

CHECKUP OF LOW-SPEED ROTATION

– Set the low-speed rotation to 3,000 min-1.

If it is necessary to change the rotation speed, regulate the adjusting screw

(illustrated on the right), with Phillips screwdriver.

– Turn the adjusting screw to the right, and the engine rotation will increase.

Turn the adjusting screw to the left, and the engine rotation will drop.

– The carburetor is generally adjusted before shipment. If it is necessary to

readjust it, please contact Authorized Service Agent.

Carburetor

Adjusting

screw

RESHARPENING THE CUTTING TOOL

CAUTION: The cutting tools mentioned below must only be resharpened by an

– cutter blade

An expert resharpening and balancing service is provided by Authorized

Service Agents.

authorized facility. Manual resharpening will result in imbalances of

the cutting tool causing vibrations and damage to the equipment.

EM2650UH

EM2651UH

NOTE: To increase the service life of the cutter blade it may be turned over

once, until both cutting edges have become blunt.

NYLON CUTTING HEAD

The nylon cutting head is a dual string trimmer head capable of both automatic

and bump & feed mechanisms.

The nylon cutting head will automatically feed out the proper length of nylon

cord by the changes in centrifugal force caused by increasing or decreasing

rpms. However, to cut soft grass more efciently, bump the nylon cutting head

against the ground to feed out extra cord as indicated under operation section.

Operation

– Increase the nylon cutting head speed to approx. 6,000 min-1.

Low speed (under 4,800 min-1) is not suitable, the nylon cord will not feed out

properly at low speed.

– The most effective cutting area is shown by the shaded area.

If the nylon cord does not feed out automatically proceed as follows:

1. Release the throttle lever to run the engine idle and then squeeze the

throttle lever fully. Repeat this procedure until the nylon cord feeds out to

the proper length.

2. If the nylon cord is too short to feed out automatically with the above

procedure, bump the knob of the nylon cutting head against the ground to

feed out the nylon cord.

3. If the nylon cord does not feed out with procedure 2, rewind/replace the

nylon cord by following the procedures described under “Replacing the

nylon cord.”

18

Most effective cutting area

Idle speed

Knob

Full speed

Page 19

Replacing the nylon cord

– First, stop the engine.

– Press on the housing latches inward to lift off the cover, then remove the

spool.

Cover

Latches

– Hook the center of new nylon cord into the notch in the center of the spool,

with one end of the cord extending about 80 mm (3 - 1/8”) more than the

other.

Then wind both ends rmly around the spool in the direction of the head

rotation (left-hand direction indicated by LH and right-hand direction by RH on

the side of the spool).

– Wind all but about 100 mm (3 - 15/16”) of the cords, leaving the ends

temporarily hooked through a notch on the side of the spool.

Press

Spool

Press

80 mm (3 - 1/8”)

For left hand rotation

Spool

100 mm (3 - 15/16”)

Notches

– Mount the spool in the housing so that the grooves and protrusions on the

spool match up with those in the housing. Keep the side with letters on

the spool visible on the top. Now, unhook the ends of the cord from their

temporary position and feed the cords through the eyelets to come out of the

housing.

– Align the protrusion on the underside of the cover with the slots of the

eyelets.

Then push cover rmly onto the housing to secure it.

Eyelets

Cover

Protrusion

Slot of eyelet

19

Page 20

SERVICING INSTRUCTIONS

CAUTION: Before doing any work on the Petrol Brushcutter, always stop the engine and pull the plug cap off the spark plug (see “checking the

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

spark plug”).

Always wear protective gloves!

Daily checkup and maintenance

– Before operation, check the machine for loose screws or missing parts. Pay particular attention to the tightness of the cutter blade or nylon

cutting head.

– Before operation, always check for clogging of the cooling air passage and the cylinder ns.

Clean them if necessary.

– Perform the following work daily after use:

• Clean the Petrol Brushcutter externally and inspect for damage.

• Clean the air lter. When working under extremely dusty conditions, clean the lter the severall times a day.

• Check the blade or the nylon cutting head for damage and make sure it is rmly mounted.

• Check that there is sufcient difference between idling and engagement speed to ensure that the cutting tool is at a standstill while the

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

– Check the functioning of the I-O switch, the lock-off lever, the control lever, and the look button.

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

conrm that the engine main unit and engine oil are sufciently cooled down. Otherwise, there may remain a risk of

scald.

Note: If the oil lled above the limit, it may be contaminated or may catch re with white smoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classication SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

1) Conrm that the fuel tank cap is tightened securely.

2) Place large container (pan, etc.) under drain hole.

Fuel tank cap

3) Remove drain bolt and then remove oil cap to drain out oil from drain hole.

At this time, be sure not to mislay drain bolt’s gasket, or to dirty any of the

removed components.

4) Once all the oil has been drained, combine gasket and drain bolt, and tightly

secure drain bolt, so that it will not loosen and cause leaks.

* Use cloth to fully wipe off any oil attached to bolt and equipment.

Oil cap

Oil cap

Drain hole

Gasket

Drain bolt

Alternative draining method

Remove oil cap, tilt Petrol Brushcutter toward oil ller hole, and drain out oil.

Collect oil in container.

20

Page 21

5) Set the engine level, and gradually ll up to upper limit mark with new oil.

6) After lling, tightly secure oil cap, so that it will not loosen and cause leaks.

If oil cap is not tightly secured, it may leak.

Internal stepped

section (upper

limit)

Internal stepped

section (lower

limit)

Upper limit mark

Oil

External mark

(upper limit)

External mark

(lower limit)

POINTS ON OIL

– Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the

relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

– Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6

months).

CLEANING OF AIR CLEANER

DANGER: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

– Turn the choke lever to the full close side, and keep the carburetor off from

dust or dirt.

– Loosen air cleaner cover mounting bolt.

– Pull the cover and detach the air cleaner cover.

– If oil adheres to the element (sponge), squeeze it rmly.

– For heavy contamination:

1) Remove the element (sponge), immerse it in warm water or in waterdiluted neutral detergent, and dry it completely.

2) Clean the element (felt) with gasoline, and dry it completely.

– Before attaching the element, be sure to dry it completely. Insufcient drying

of the element may lead to difcult startup.

– Wipe out with waste cloth, oil adhering around the air cleaner cover and plate

breather part.

– Immediately after cleaning is nished, attach the cleaner cover and tighten it

with xing bolts. (In remounting, rst place the upper claw, and then the lower

claw.)

Points in Handling Air Cleaner Element

– Clean the element several times a day, if excessive dust adheres to it.

– If operation continues with the element remaining not cleared of oil, oil

in the air cleaner may fall outside, resulting in oil contamination.

Element (sponge)

Air cleaner cover

Pick this part and

remove the element

(felt).

Plate

Choke

lever

Breather Part

Element (felt)

Fixing bolt

21

Page 22

CHECKING THE SPARK PLUG

– Only use the supplied universal wrench to remove or to install the spark plug.

– The gap between the two electrodes of the spark plug should be 0.7 - 0.8 mm

(0.028” - 0.032”). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged or contaminated, clean it thoroughly or replace it.

CAUTION: Never touch the spark plug connector while the engine is running

(danger of high voltage electric shock).

SUPPLY OF GREASE TO GEAR CASE

– Supply grease (Shell Alvania 2 or equivalent) to the gear case through the

grease hole every 30 hours. (Genuine MAKITA grease may be purchased

from your MAKITA dealer.)

CLEANING OF FUEL FILTER

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

– The fuel lter (1) of the suction head is used to lter the fuel required by the

carburetor.

– A periodical visual inspection of the fuel lter is to be conducted. For that

purpose open the tank cap, use a wire hook and pull out the suction head

through the tank opening. Filters found to have hardened, been polluted or

clogged up are to be replaced.

– Insufcient fuel supply can result in the admissible maximum speed being

exceeded. It is therefore important to replace the fuel lter at least quarterly to

ensure satisfactory fuel supply to the carburetor.

0.7 mm - 0.8 mm

(0.028” - 0.032”)

Gear case

Grease hole

Fuel pipe

Hose clamp

Fuel lter (1)

REPLACEMENT OF FUEL PIPE

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe every year, regardless of operating frequency. Fuel

leakage may lead to re.

If any leakage is detected during inspection, replace the oil pipe immediately.

Fuel pipe

INSPECTION OF BOLTS, NUTS AND SCREWS

– Retighten loose bolts, nuts, etc.

– Check for fuel and oil leakage.

– Replace damaged parts with new ones for safety operation.

CLEANING OF PARTS

– Keep the engine always clean.

– Keep the cylinder ns free of dust or dirt. Dust or dirt adhering to the ns will

cause piston seizure.

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

22

Page 23

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and conrm that the engine cools

down.

Just after stopping the engine, it may still hot with possibility of burns, inammability and re.

ATTENTION: When the machine is kept out of operation for a long time, drain up all fuel from the

fuel tank and carburetor, and keep it at a dry and clean place.

– Drain up fuel from the fuel tank and carburetor according to the following

procedure:

1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove it

completely.

2) Pull out the fuel lter from the rell port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the lter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

– Remove the spark plug, and drip several drops of engine oil through the

spark plug hole.

– Gently pull the starter handle so that engine oil will spread over the engine,

and attach the spark plug.

– Attach the cover to the cutter blade.

– During storage, keep the rod horizontal or keep the machine upright with the

blade edge oriented upward. (In this case, pay full attention to prevent the

machine from falling.)

Never store the machine with the cutter blade edge oriented downward.

Lubricating oil may spill out.

– Keep the drained fuel in a special container in a well-ventilated shade.

Drain fuel

Humidity

Attention after long-time storage

– Before startup after long-time shutdown, be sure to replace oil (refer to P 20). Oil will deteriorate while the machine is kept out of

operation.

Fault location

Fault System Observation Cause

Engine not starting or with

difculty

Warm start problems Tank lled ignition spark

Engine starts but dies Fuel supply Tank lled Incorrect idling adjustment, carburetor contaminated

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank lled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty

Compression No compression when

pulled over

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

existing

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Insufcient performance Several systems may

simultaneously be

affected

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Engine idling poor Air lter contaminated, carburetor contaminated, mufer

clogged, exhaust duct in the cylinder clogged

23

Page 24

Item

Operating time

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

Shutdown/

rest

Corres-

ponding P

Engine oil

Tightening parts

(bolt, nut)

Replace *

Inspect 22

1

20

Clean/inspect —

Inspect/clean 14

Fuel tank

Drain fuel *

3

23

Throttle lever Check function —

Stop switch Check function 18

Cutting blade Inspect 12

Low-speed rotation Inspect/adjust 18

Air cleaner Clean 21

Ignition plug Inspect 22

Cooling air duct Clean/inspect 22

Inspect 22

Fuel pipe

Replace *

2

—

Gear-case grease Rell 22

Fuel lter Clean/replace 22

Clearance between air intake

valve and air discharge valve

Adjust *

Engine overhaul *

Carburetor Drain fuel *

2

2

3

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

—

—

23

24

Page 25

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description

of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times

Low pulling speed of starter rope Pull strongly

Lack of fuel Feed fuel

Clogged fuel lter Clean

Broken fuel tube Straighten fuel tube

Deteriorated fuel Deteriorated fuel makes starting more difcult.

Replace with new one. (Recommended

replacement: 1 month)

Excessive suction of fuel Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. Once engine starts, cutter blade

Engine does not start

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufcient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although

engine is warmed up.

Engine stops soon

Engine speed does not increase

Cutter blade does not rotate Loosened cutter blade-tightening nut Tighten securely

Stop engine immediately

Main unit vibrates abnormally Broken, bent or worn cutter blade Replace cutter blade

Stop engine immediately

Cutter blade does not stop immediately High idling rotation Adjust

Stop engine immediately

Engine does not stop Detached connector Attach securely

Run engine at idling, and set choke lever

to CLOSE

Clogged fuel lter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Twigs caught by cutter blade or dispersionpreventing cover.

Abnormal drive system Make request for inspection and maintenance.

Loosened cutter blade-tightening nut Tighten securely

Shifted convex part of cutter blade and cutter

blade support tting.

Abnormal drive system Make request for inspection and maintenance.

Detached throttle wire Attach securely

Abnormal drive system Make request for inspection and maintenance.

Abnormal electric system Make request for inspection and maintenance.

starts rotating. Pay full attention to cutter

blade.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specied.

Set to “OPEN”

Remove foreign matter

Attach securely

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

25

Page 26

Nederlands

(Originele instructies)

Hartelijk dank voor uw aankoop van deze benzinebosmaaier van MAKITA.

Met trots bevelen wij u deze benzinebosmaaier van MAKITA van harte aan als

resultaat van een langdurig ontwikkelingsprogramma en jarenlange kennis en

ervaring.

Lees deze handleiding met daarin nauwkeurige beschrijvingen van de diverse

punten die zijn hoogstaande prestaties demonstreren. Hierdoor bent u in staat

de best mogelijke resultaten te behalen die de benzinebosmaaier van MAKITA

u kan bieden.

SYMBOLEN

Let op de volgende symbolen wanneer u de gebruiksaanwijzing leest.

Lees de gebruiksaanwijzing en

volg de waarschuwingen en

veiligheidsvoorzorgsmaatregelen op!

Inhoud Pagina

Symbolen.....................................................................95

Veiligheidsinstructies ...................................................96

Technische gegevens ................................................100

Namen van onderdelen .............................................102

De handgreep monteren............................................103

De beschermkap monteren .......................................104

Het snijgarnituur monteren ........................................105

Vóór het begin van het werk ......................................106

Correcte hantering .....................................................108

Tips voor gebruik en procedure voor stoppen ...........108

Het snijgarnituur slijpen .............................................110

Onderhoudsinstructies............................................... 112

Opslag .......................................................................115

Draag een veiligheidshelm, gezichts- en

gehoorbescherming!

Besteed bijzondere zorg en aandacht!

Verboden!

Houd afstand!

Gevaar voor rondvliegende voorwerpen!

Verboden te roken!

Geen open vuur!

Veiligheidshandschoenen vereist!

Toegestaan maximumtoerental

Brandstof (benzine)

Motor handmatig starten

Noodstop

EHBO

Recyclen

AAN/START

UIT/STOP

Draag stevige schoenen met antislipzolen.

Veiligheidsschoenen met stalen neuzen

worden aanbevolen.

Terugslag!

Houd mensen en huisdieren weg van het

werkgebied!

95

Page 27

VEILIGHEIDSINSTRUCTIES

Algemene instructies

– Voor een correcte gebruik dient de gebruiker deze gebruiksaanwijzing te

lezen om zichzelf bekend te maken met de juiste manier van omgaan met de

benzinebosmaaier. Gebruikers die onvoldoende geïnformeerd zijn, lopen de

kans zichzelf en anderen in gevaar te brengen als gevolg van onjuist omgaan

met de benzinebosmaaier.

– Het verdient aanbeveling de benzinebosmaaier uitsluitend uit te lenen

aan mensen die bewezen hebben ervaren te zijn met het gebruik van een

benzinebosmaaier.

Geef altijd de gebruiksaanwijzing mee.

– Allereerst dienen gebruikers de dealer te vragen om basisinstructies om

zichzelf bekend te maken met het omgaan met een motoraangedreven

maaier.

– Laat geen kinderen of jonge mensen die jonger zijn dan 18 jaar met de

benzinebosmaaier werken. Jongeren die ouder zijn dan 16 jaar mogen echter

het gereedschap gebruiken om te oefenen, maar alleen onder toezicht van

een gekwaliceerde begeleider.

– Gebruik de benzinebosmaaiers met de hoogst mogelijke zorg en aandacht.

– Gebruik de benzinebosmaaier alleen als u in goede lichamelijke conditie

bent. Werk altijd rustig en voorzichtig. De gebruiker is aansprakelijk ten

opzichte van anderen.

– Gebruik nooit de benzinebosmaaier nadat u alcohol of geneesmiddelen hebt

gebruikt of als u zich moe of ziek voelt.

– Door nationale regelgeving kan de functionaliteit van de machine zijn beperkt.

Bedoeld gebruik van het gereedschap

– De benzinebosmaaier is alleen bedoeld voor het maaien van gras, onkruid,

struiken en ondergroei. Hij mag niet worden gebruikt voor andere doeleinden

zoals het snoeien van heggen en hagen, anders kan dit letsels veroorzaken.

Persoonlijke-veiligheidsuitrusting

– De te dragen kleding dient functioneel en geschikt te zijn, d.w.z. nauwsluitend

zonder te hinderen. Draag geen juwelen of kleding die in de struiken kunnen

verstrikt raken.

– Om tijdens het gebruik letsels aan hoofd, ogen, handen of voeten

te voorkomen en uw gehoor te beschermen, moeten de volgende

veiligheidsuitrusting en beschermende kleding worden gebruikt terwijl u met

de benzinebosmaaier werkt.

– Draag altijd een helm wanneer het risico bestaat op vallende objecten. U

moet de veiligheidshelm (1) regelmatig controleren op schade en uiterlijk na 5

jaar worden vervangen. Gebruik alleen goedgekeurde veiligheidshelmen.

– Het spatscherm (2) van de helm (of de veiligheidsbril) beschermt het gezicht

tegen rondvliegend afval en stenen. Draag altijd een veiligheidsbril of een

spatscherm wanneer u de benzinebosmaaier gebruikt om oogletsel te

voorkomen.

– Draag geschikte uitrusting om u te beschermen tegen het lawaai en

gehoorbeschadiging te voorkomen (oorbeschermers (3), oordopjes, enz.).

– Een werkoverall (4) beschermt tegen rondvliegend afval en opspringende

stenen.

Wij raden u sterk aan een werkoverall te dragen.

– Speciale handschoenen (5) van dik leer maken deel uit van de

voorgeschreven uitrusting en moeten altijd worden gedragen tijdens het

gebruik van de benzinebosmaaier.

– Draag altijd stevige schoenen (6) met een antislipzool wanneer u de

benzinebosmaaier gebruikt. Dit beschermt u tegen letsel en garandeert dat u

stevig staat.

De benzinebosmaaier starten

– Controleer of er geen kinderen of andere mensen aanwezig zijn binnen

een werkbereik van 15 meter (50 feet) en let ook of er geen dieren in de

werkomgeving zijn.

– Controleer vóór het gebruik altijd of de benzinebosmaaier veilig is voor

gebruik:

Controleer de bevestiging van de snijgarnituur, controleer of de gashendel

gemakkelijk kan worden bediend, en controleer of de uit-vergrendelhendel

goed werkt.

– Het snijgarnituur mag niet draaien bij stationair motortoerental. Neem bij

twijfel contact op met uw dealer voor afstelling. Controleer of de handgrepen

schoon en droog zijn en test de werking van de stopschakelaar.

Schematische

voorstelling

15 meters

96

Page 28

Start de benzinebosmaaier alleen in overeenstemming met de instructies.

– Gebruik geen enkele andere methode om de motor te starten!

– Gebruik de benzinebosmaaier en de gereedschappen uitsluitend voor de

beschreven toepassingen.

– Start de motor van de benzinebosmaaier alleen nadat deze volledig is

gemonteerd. Het gereedschap mag uitsluitend worden gebruikt nadat alle

toepasselijke toebehoren zijn gemonteerd!

– Controleer vóór het starten of het snijgereedschap geen contact heeft met

harde voorwerpen, zoals takken, stenen, enz., omdat het snijgereedschap

gaat ronddraaien tijdens het starten.

– De motor moet onmiddellijk uitgeschakeld worden in geval van enige

motorstoring.

– Als het snijblad of de maaikop stenen of andere harde voorwerpen raakt, moet

u de motor onmiddellijk uitschakelen en het snijgarnituur controleren.

– Controleer het snijgarnituur regelmatig op beschadiging (inspecteren op

haarscheurtjes met de klopgeluidentest).

– Gebruik de benzinebosmaaier alleen wanneer de schouderriem is bevestigd,

die goed moet worden afgesteld voordat de benzinebosmaaier wordt

gebruikt. Het is belangrijk de schouderriem af te stellen overeenkomstig

de lichaamsgrootte van de gebruiker om vermoeidheid tijdens gebruik te

voorkomen. Houd de maaier nooit met slechts één hand vast tijdens het

gebruik.

– Houd de benzinebosmaaier altijd met beide handen vast tijdens het gebruik.

Zorg er altijd voor dat u stevig staat.

– Gebruik de benzinebosmaaier zo, dat u geen uitlaatgassen kunt inademen.

Laat de motor nooit draaien in een gesloten vertrek (kans op gasverstikking).

Koolmonoxide is een geurloos gas.

– Schakel de motor uit tijdens pauzes en wanneer u de benzinebosmaaier

onbeheerd achterlaat, en leg hem op een veilige plaats om gevaar voor

anderen en beschadiging van het gereedschap te voorkomen.

– Leg nooit een warme benzinebosmaaier op droog gras of enige andere

ontvlambare materialen.

– Het snijblad moet zijn uitgerust met zijn bijbehorende beschermkap.

Gebruik de maaier nooit zonder zijn beschermkap!

– De hele veiligheidsuitrusting en alle beschermkappen die bij het gereedschap

zijn geleverd, moeten tijdens het werk worden gebruikt.

– Gebruik het gereedschap nooit met een defecte uitlaatdemper.

– Schakel de motor uit tijdens het vervoer.

– Tijdens vervoer over lange afstanden moeten altijd de beschermingsdelen die

bij het gereedschap werden geleverd worden gebruikt.

– Leg tijdens vervoer per auto de benzinebosmaaier op een veilige plaats om te

voorkomen dat er brandstof uit lekt.

– Wanneer u de benzinebosmaaier vervoert, moet u ervoor zorgen dat de

brandstoftank volledig leeg is.

–

Let erop dat bij het uitladen van de benzinebosmaaier uit de auto de motor

niet op de grond valt omdat hierdoor de brandstoftank ernstig kan worden

beschadigd.

–

Behalve in noodgevallen mag u de benzinebosmaaier nooit laten vallen of

op de grond gooien omdat dit ernstige schade aan de benzinebosmaaier kan

veroorzaken.

– Let erop dat u het volledige gereedschap van de grond tilt wanneer u het

verplaatst. Het is bijzonder gevaarlijk de brandstoftank over de grond te slepen

en dit zal beschadiging en lekkage veroorzaken die kan leiden tot brand.

Brandstof bijvullen

– Schakel de motor uit tijdens het bijvullen van brandstof, houd het gereedschap

uit de buurt van open vuur en rook niet.

– Vermijd huidcontact met minerale-olieproducten. Adem brandstofdampen niet

in. Draag altijd veiligheidshandschoenen tijdens het bijvullen van de brandstof.

Zorg dat u de beschermende kleding regelmatig vervangt en reinigt.

– Wees voorzichtig geen brandstof of olie te morsen om bodemverontreiniging

te voorkomen (milieubescherming). Reinig de benzinebosmaaier onmiddellijk

nadat brandstof erop is gemorst.

– Vermijd dat brandstof in aanraking komt met uw kleding. Kleed u onmiddellijk

om als brandstof op uw kleding is gemorst (om te voorkomen dat de kleding

vlam vat).

– Inspecteer de brandstofvuldop regelmatig om zeker te zijn dat de dop stevig

kan worden aangedraaid en niet lekt.

– Draai de dop van de brandstoftank stevig vast. Verplaats de maaier voordat

u de motor start (tenminste 3 meters afstand tot de plaats waar brandstof is

bijgevuld.)

– Vul nooit brandstof bij in een gesloten vertrek. Brandstofdampen verzamelen

zich vlak boven de vloer (kan op explosie).

– Vervoer en bewaar brandstof alleen in goedgekeurde tanks. Zorg dat de

opgeslagen brandstof niet toegankelijk is voor kinderen.

• Pauzeren

• Vervoeren

• Brandstof bijvullen

• Onderhouden

• Onderdelen vervangen

3 meters

97

Page 29

Gebruiksmethode

– Gebruik de benzinebosmaaier alleen bij een goede verlichting en

zichtbaarheid. Wees in de winter bedacht op gladde of natte plaatsen, ijs en

sneeuw (gevaar voor uitglijden). Zorg er altijd voor dat u stevig staat.

– Maai nooit boven heuphoogte.

– Sta nooit op een ladder terwijl u de benzinebosmaaier gebruikt.

– Klim nooit in een boom om daar de benzinebosmaaier te gebruiken.

– Werk nooit op een instabiele ondergrond.

– Verwijder zand, stenen, spijkers, enz., die u binnen uw werkbereik vindt.

Vreemde voorwerpen kunnen het snijgarnituur beschadigen en gevaarlijke

terugslagen veroorzaken.

– Voordat u begint te maaien, moet het snijgarnituur op maximaal toerental

draaien.

Terugslag

– Wanneer u de benzinebosmaaier gebruikt, kan een ongecontroleerde

terugslag optreden.

– Dit is met name het geval wanneer u begint met maaien binnen het

snijbladsegment van de benzinebosmaaier tussen 12 en 2 uur.

– Begin nooit met maaien binnen het segment tussen 12 en 2 uur op het

snijblad van de benzinebosmaaier.

– Zorg ervoor dat dit snijbladsegment van de benzinebosmaaier nooit in

aanraking komt met harde voorwerpen, zoals stuiken, bomen, enz., met een

diameter van 3 cm of meer omdat anders de benzinebosmaaier met grote

kracht wordt teruggeslagen met kans op letsel.

Terugslag voorkomen

Houd rekening met het volgende om terugslag te voorkomen:

– Maaien binnen het snijbladsegment tussen 12 en 2 uur levert risico op, met

name bij gebruik van metalen snijgarnituur.

– Maaien binnen het snijbladsegment tussen 11 en 12 uur of tussen 2 en 5 uur

mag alleen worden uitgevoerd door opgeleide en ervaren gebruikers, en dit

alleen op eigen risico.

Gemakkelijk maaien met nagenoeg geen kans op terugslag is mogelijk

binnen het snijbladsegment tussen 8 en 11 uur.

Snijgarnituren

Gebruik uitsluitend het juiste snijgarnituur voor de geplande werkzaamheden.

Let op:

Terugslag

Schematische

voorstelling

Schematische

voorstelling

EM2650UH, EM2651UH, EM2650LH, EM2651LH met metalen snijblad of

nylondraad-maaikop

Voor het maaien van dik materiaal, zoals onkruid, hoog gras, struiken, heesters,

kreupelhout, ondergroei, enz. (max. 2 cm diameter). U kunt maaien door de

benzinebosmaaier gelijkmatig in halve cirkels van rechts naar links te zwaaien

(op de manier waarop u een zeis gebruikt).

Onderhoudsinstructies

– De toestand van de maaier, met name van het snijgarnituur en de

veiligheidsuitrusting, naast de schouderriem, moeten worden gecontroleerd

voor aanvang van de werkzaamheden. Besteed bijzondere aandacht aan de

snijbladen die correct moeten worden geslepen.

– Schakel de motor uit en trek de bougiekap eraf wanneer u het snijgarnituur

vervangt of slijpt, en wanneer u de maaier of het snijgarnituur schoonmaakt.

98

Page 30

Probeer nooit beschadigde snijgarnituren recht te trekken

of te lassen.

– Gebruik de benzinebosmaaier met zo weinig mogelijk lawaai en vervuiling.

Controleer met name de carburator op een verkeerde afstelling.

– Maak de benzinebosmaaier regelmatig schoon en controleer of alle bouten

en moeren stevig zijn vastgedraaid.

– Onderhoud of bewaar de benzinebosmaaier niet in de buurt van open vuur.

– Bewaar de benzinebosmaaier altijd in een afgesloten ruimte en met een

leeggemaakte brandstoftank.

Volg de relevante instructies voor het voorkomen van ongevallen die door de relevante beroepsverenigingen en verzekeringsmaatschappijen

zijn uitgegeven.

Breng geen wijzigingen aan de benzinebosmaaier aan, omdat u op die manier uw veiligheid in gevaar brengt.

Het uitvoeren van onderhoud of reparaties door de gebruiker is beperkt tot de activiteiten die in de gebruiksaanwijzing zijn beschreven. Alle

andere werkzaamheden moet worden uitgevoerd door een erkend servicecentrum. Gebruik uitsluitend originele vervangingsonderdelen en

accessoires die zijn vervaardigd en geleverd door MAKITA.

Het gebruik van niet-goedgekeurde accessoires en gereedschappen leidt tot een verhoogde kans op ongevallen.

MAKITA aanvaardt geen enkele aansprakelijkheid voor ongevallen of schade veroorzaakt door het gebruik van niet-goedgekeurde

snijgarnituren, bevestigingsmiddelen voor snijgarnituren of accessoires.

EHBO

Zorg dat er altijd een EHBO-doos beschikbaar is in de buurt waar er wordt

gemaaid om eerste hulp te bieden bij eventuele ongevallen. Vervang

onmiddellijk elk item dat uit de EHBO-doos is genomen.

Geef de volgende informatie wanneer u hulp inroept:

– Plaats van het ongeval

– Beschrijving van het ongeval

– Aantal gewonden

– Soort letsels

– Uw naam

Verpakking

De benzinebosmaaier van MAKITA wordt geleverd in twee beschermende

kartonnen dozen om schade tijdens het transport te voorkomen. Karton is een

ruw basismateriaal en kan daarom opnieuw worden gebruikt en is geschikt om

te recyclen (recyclen papierafval).

EC-VERKLARING VAN CONFORMITEIT

Benzinebosmaaier: modellen EM2650UH, EM2651UH, EM2650LH en EM2651LH

(Zie TECHNISCHE GEGEVENS voor de specicaties)

Wij verklaren onder eigen verantwoordelijkheid dat dit product voldoet aan de normen van de richtlijnen 2000/14/EC en 2006/42/EC.

De meest belangrijke normen die zijn toegepast om te voldoen aan de bovenvermelde richtlijnen zijn: EN11806.

Gemeten geluidsvermogen: 108,5 dB (A)

Garantie geluidsvermogen: 111 dB (A)

Deze geluidsvermogenniveaus zijn gemeten volgens Richtlijn van de Raad, 2000/14/EC.

Procedure conformiteitsbeoordeling: Bijlage V.

27 nov. 2009

Tomoyasu Kato

Directeur

Verantwoordelijke fabrikant:

Makita Corporation.

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Erkende vertegenwoordiger in Europa:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15 8JD, ENGELAND

99

Page 31

TECHNISCHE GEGEVENS VAN EM2650UH EN EM2650LH

Model

EM2650UH EM2650LH

Fietsstuurhandgreep Beugelhandgreep

Afmetingen: lengte x breedte x hoogte (zonder snijblad) mm

Gewicht (zonder kunststofbeschermkap en snijblad) kg

Volume (brandstoftank) l

Volume (olietank) l

Cilinderinhoud cm

3

1.765 x 620 x 474 1.765 x 330 x 264

5,5 5,1

0,6

0,08

25,4

Maximaal motorvermogen kW 0,77 bij 7.000 min

Motortoerental bij aanbevolen maximaal astoerental min

Maximaal astoerental (bijbehorend) min

Maximaal brandstofverbruik kg/u

Maximaal speciek brandstofverbruik g/kwh

Stationair toerental min

Toerental op aangrijppunt van koppeling min

Carburator type

-1

-1

8.500

6.500

0,33

408

-1

-1

3.000

3.900

WALBRO WYL

Ontstekingssysteem type Transistorontsteking

Bougie type

NGK CMR4A

Elektrodenafstand mm 0,7 - 0,8

Rechterhandgreep

Trillingen volgens

ISO 22867

(Achterste handvat)

Linkerhandgreep

(Voorste handvat)

Gemiddeld geluidsdrukniveau volgens

ISO 22868

Gemiddeld geluidsvermogenniveau volgens ISO 22868

a

hv eq

Onzekerheid K m/s

a

hv eq

Onzekerheid K m/s

L

PA eq

Onzekerheid K dB (A) 0,9

L

WA eq

Onzekerheid K dB (A) 1,3

2

m/s

m/s

2

2

2

2,6 5,1

0,8 0,2

2,3 4,1

0,5 0,4

dB (A) 96,6

dB (A) 105,5

Brandstof Benzine voor auto’s

Motorolie

SAE 10W-30 olie volgens API-classicatie,

SF-klasse of beter (4-taktmotorolie voor auto’s)

Snijgarnituren (diameter snijblad) mm 230

Overbrengingsverhouding van tandwielen 14/19

-1

100

Page 32

TECHNISCHE GEGEVENS VAN EM2651UH EN EM2651LH

Model

EM2651UH EM2651LH

Fietsstuurhandgreep Beugelhandgreep

Afmetingen: lengte x breedte x hoogte (zonder snijblad) mm

Gewicht (zonder kunststofbeschermkap en snijblad) kg

Volume (brandstoftank) l

1.765 x 620 x 474 1.765 x 330 x 264

5,6 5,2

0,6

Volume (olietank) l 0,08

Cilinderinhoud cm

3

25,4

Maximaal motorvermogen kW 0,77 bij 7.000 min