Page 1

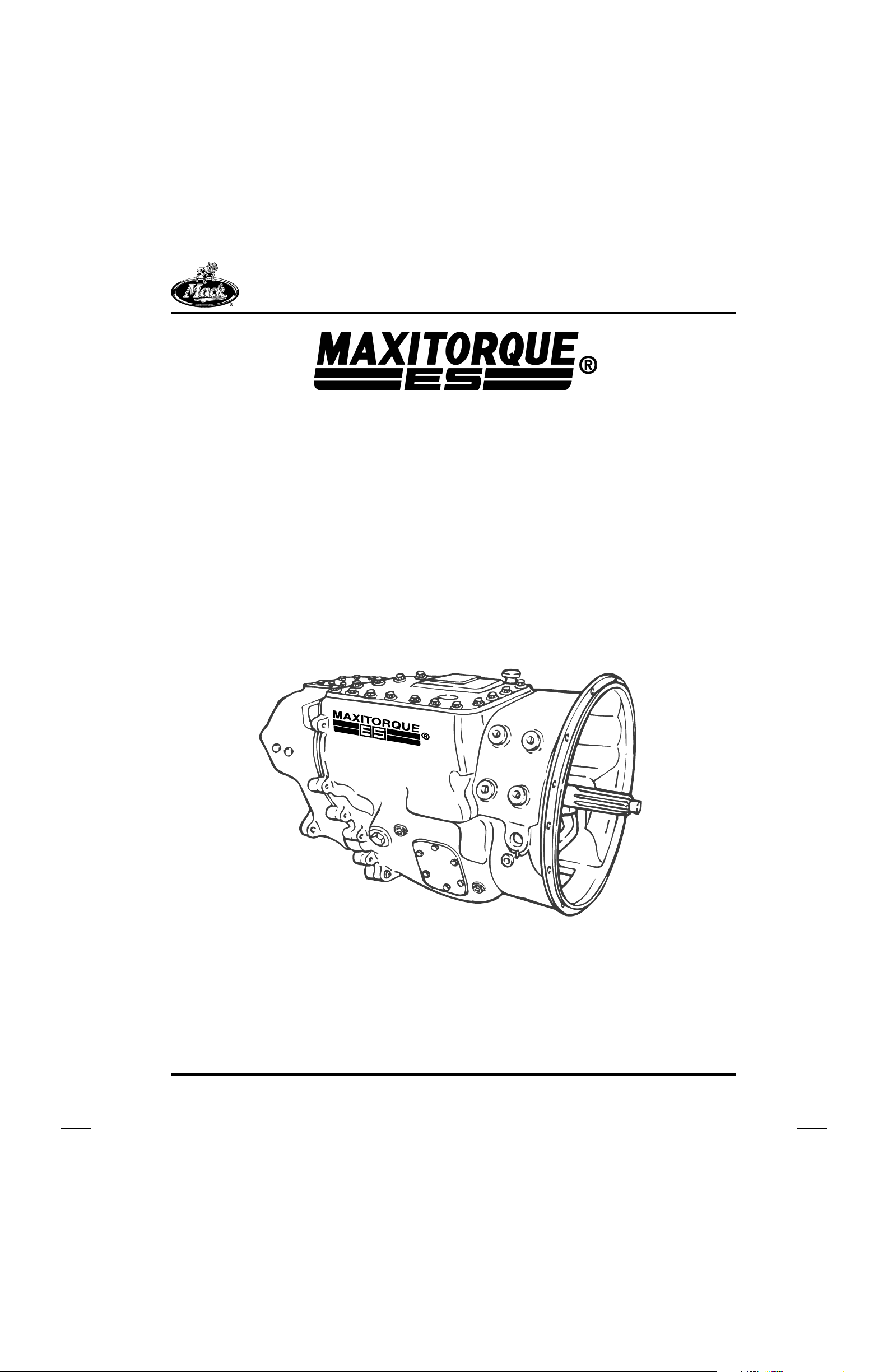

TRANSMISSION

T310

SERVICE MANUAL

APRIL 2003

(NEW ISSUE)

10-126

Page 2

front.fm Page -ii Thursday, December 19, 2002 10:54 AM

-ii

Page 3

newknow.fm Page 1 Thursday, May 21, 1998 2:23 PM

Manual: _______________________________ Publication Number: _______

Vehicle Model: _________________________ Model Year: ______________

Do you find procedures properly organized and easy to follow? m Yes m No

If not, please explain: ____________________________________ __________

___________________________________ ____________________________

PLEASE LET US KNOW!

Your comments and suggestions will help

us improve this manual!

Please complete and mail this form or FAX

your comments to: (610) 709-3800.

___________________________________ ____________________________

Manual page numbers: _____________________________________________

Are there any important procedures or other information presently not in this

manual that you would like to see included? m Yes m No

If yes, please describe: _____________________________ ________________

___________________________________ ____________________________

___________________________________ ____________________________

Did you find any errors in the procedures or illustrations? m Yes m No

If yes, what pages? _______________________________ ________________

Please explain: ___________________________________________________

_______________________________________________________________

Please include a copy of each page in question and mark your comments and

suggestions.

Name: ________________________________ Phone: (_____) _____-_______

Company: _______________________________________________________

Address: ________________________________________________________

City: _________________________________ State: _______ Zip: _______

Position Title: ____________________________________ ________________

Thank You For Your Assistance

Mack Trucks, Inc.

(ATTENTION: RTS STAFF, 6S3)

DO NOT STAPLE — USE TRANSPARENT T A PE

Page 4

Busreply.fm Page 1 Thursday, May 21, 1998 2:24 PM

FOLD ALONG THIS LINE • DO NOT STAPLE • USE TRANSPARENT TAPE

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO. 1602 ALLENTOWN, PA

POSTAGE WILL BE PAID BY ADDRE SS EE

SERVICE PUBLICATIONS (RTS), 6S3

MACK TRUCKS INC

WORLD HEADQUARTERS

PO BOX M

ALLENTOWN PA 18105-9972

FOLD ALONG THIS LINE

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

Page 5

TRANSMISSION

T310

SERVICE MANUAL

APRIL 2003

(NEW ISSUE)

© MACK TRUCKS, INC. 2003

10-126

Page 6

front.fm Page ii Thursday, December 19, 2002 10:54 AM

ATTENTION

The information in this manual is not all inclusive and

cannot take into account all unique situations. Note that

some illustrations are typical and may not reflect the

exact arrangement of every component installed on a

specific chassis.

The information, specifications, and illustrations in this

publication are based on information that was current at

the time of publication.

No part of this publication may be reproduced, stored in a

retrieval system, or be transmitted in any form by any

means including (but not limited to) electronic,

mechanical, photocopying, recording, or otherwise

without prior written permission of Mack Trucks, Inc.

ii

Page 7

front.fm Page iii Thursday, December 19, 2002 10:54 AM

TABLE OF CONTENTS

TABLE OF CONTENTS

iii

Page 8

front.fm Page iv Thursday, December 19, 2002 10:54 AM

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Advisory Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Service Procedures and Tool Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

EXPLANATION OF NUMERICAL CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CONVERSION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VISUAL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TRANSMISSION IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unit Identification Stamping Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DESCRIPTION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DESCRIPTION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

T310 Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

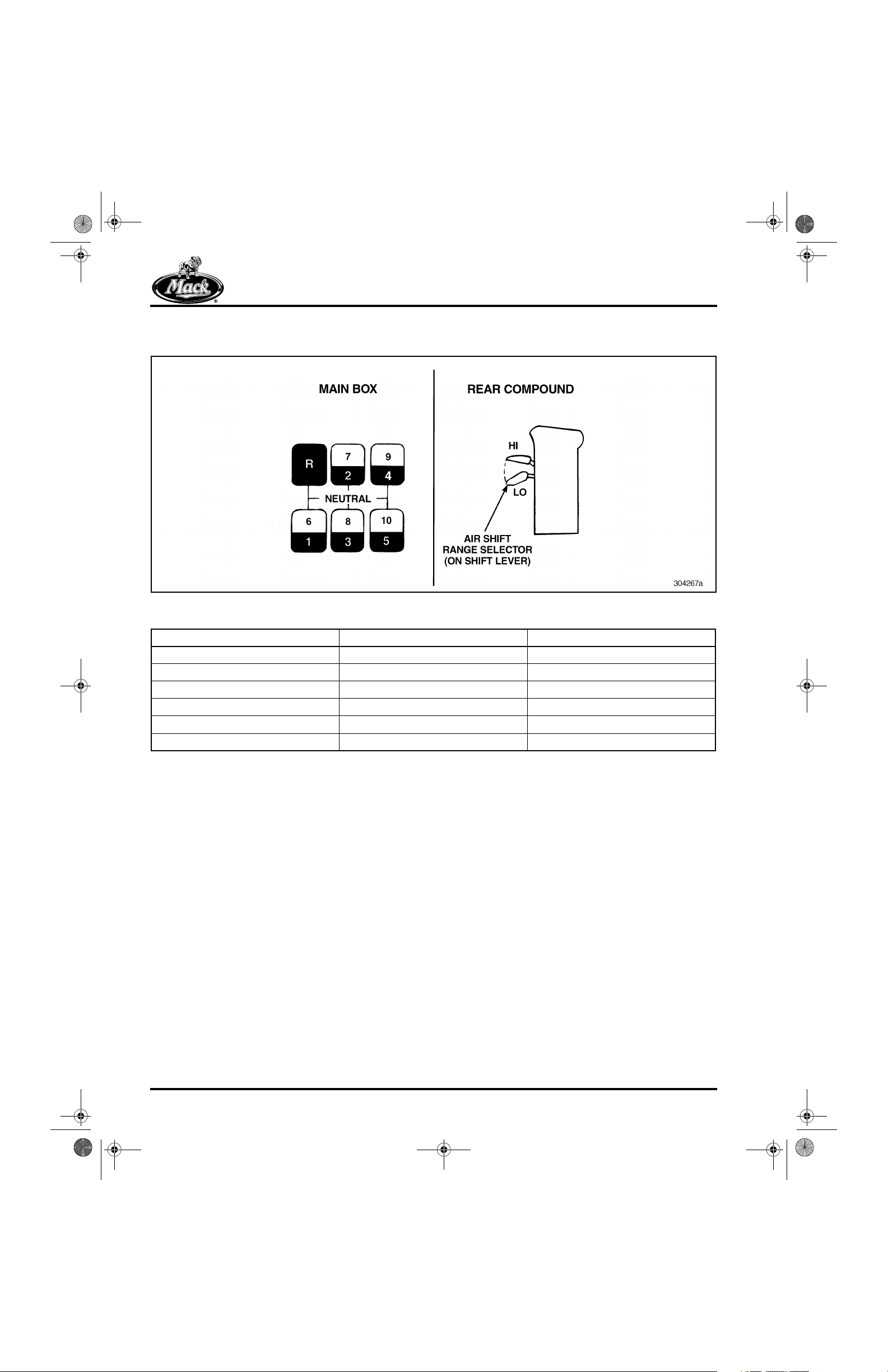

Gear Ratios and Shift Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

T310 Shifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COMPONENT LOCATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

COMPONENT LOCATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

TROUBLESHOOTING CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

TRANSMISSION MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Changing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Change Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Draining Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Oil Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Magnetic Oil Filter Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Air Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

TRANSMISSION DISASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

TRANSMISSION COMPONENT DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Main Case Shift Cover Disassembly [323] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Two-Position Range Shift Cylinder Disassembly [324] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Range Shift Valve [323] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Main Drive Pinion Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Front Mainshaft Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

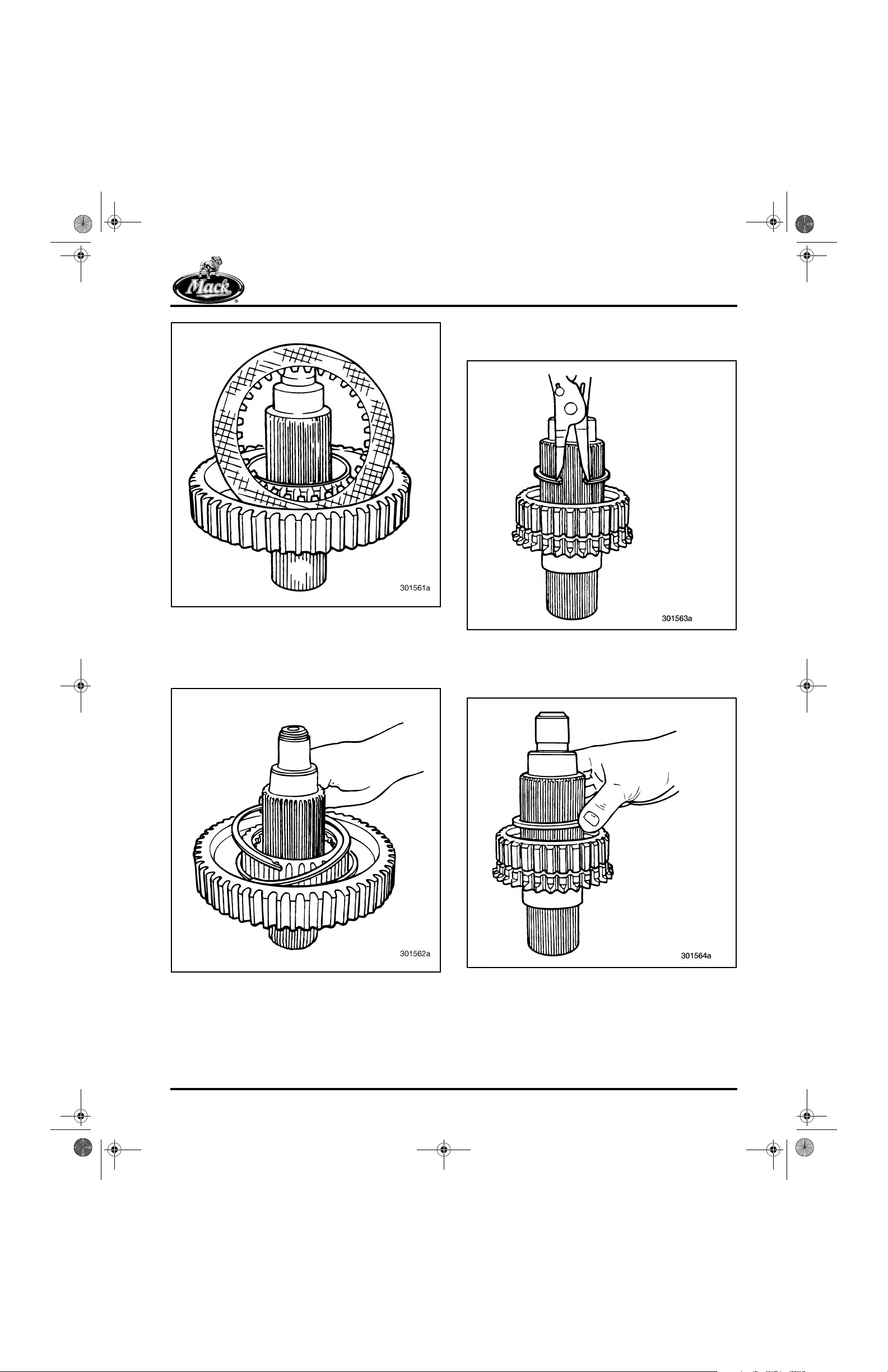

Rear Mainshaft and Synchronizer Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Synchronizer Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

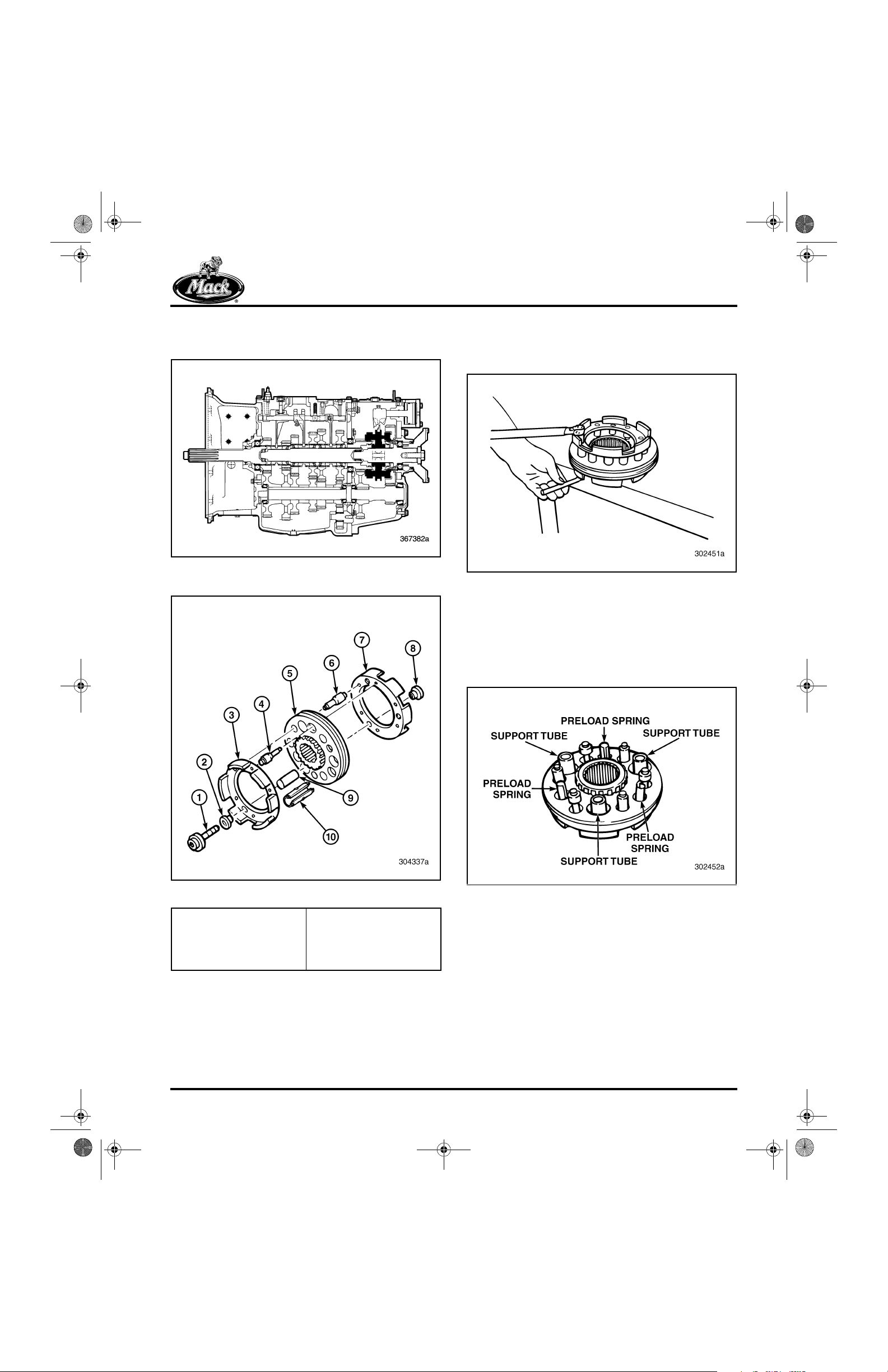

Rear Mainshaft Bearing Cover Disassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Compound Main Drive Gear Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Front Countershaft Front Bearing Cover Disassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

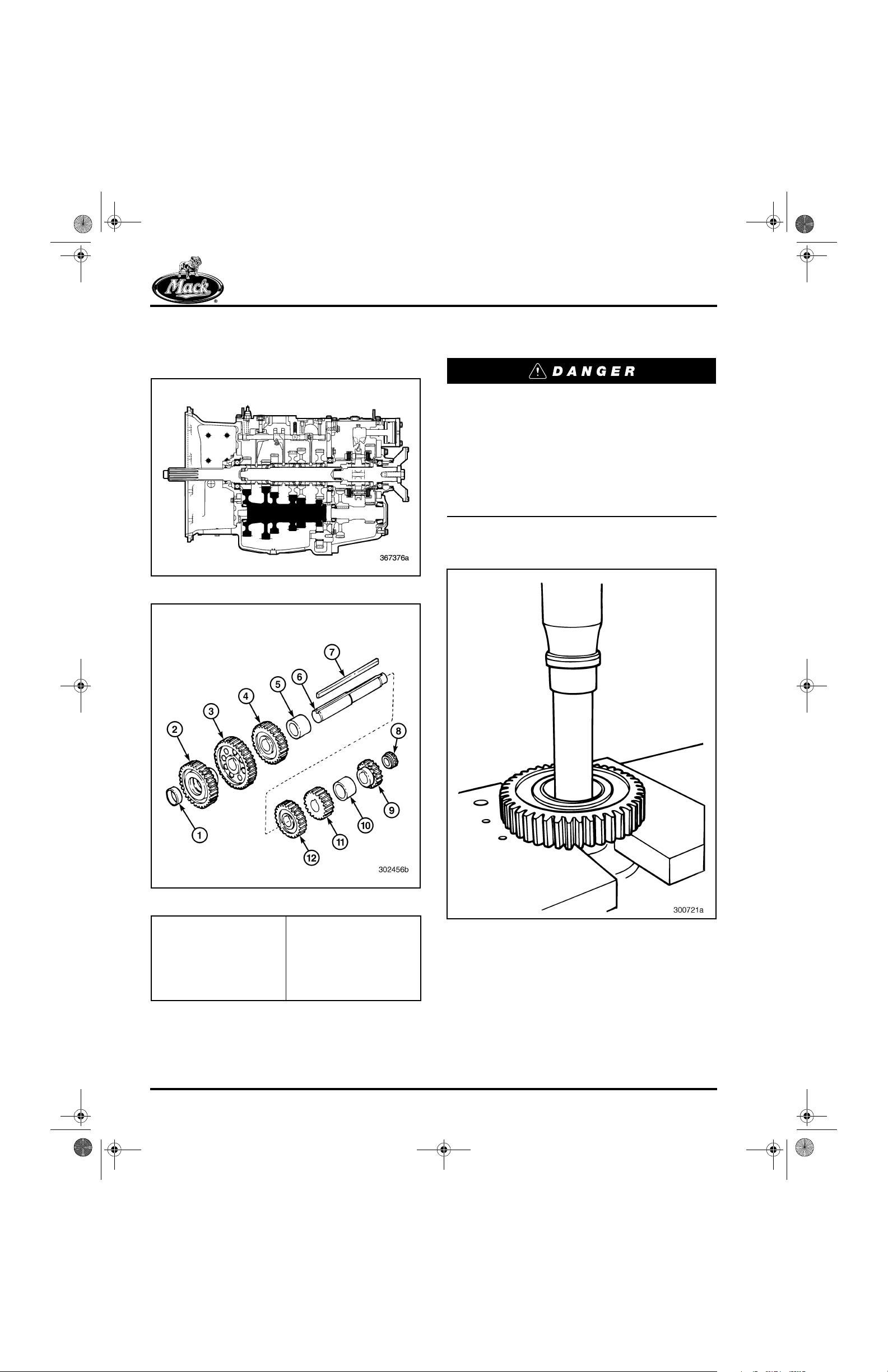

Front Countershaft Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Front Countershaft Rear Bearing Cover Disassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Rear Countershaft Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Rear Countershaft Bearing Cover Disassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Reverse Idler Gear Disassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

iv

Page 9

front.fm Page v Thursday, December 19, 2002 10:54 AM

INSPECTION OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Bearings [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Gears [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Shifter Forks, Sliding Clutches and Shift Rails [323] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Oil Seals [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

General Reassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

TRANSMISSION COMPONENT REASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Reverse Idler Gear Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Rear Countershaft Bearing Cover Reassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Rear Countershaft Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Front Countershaft Rear Bearing Cover Reassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Front Countershaft Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Front Countershaft Front Bearing Cover Reassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . 105

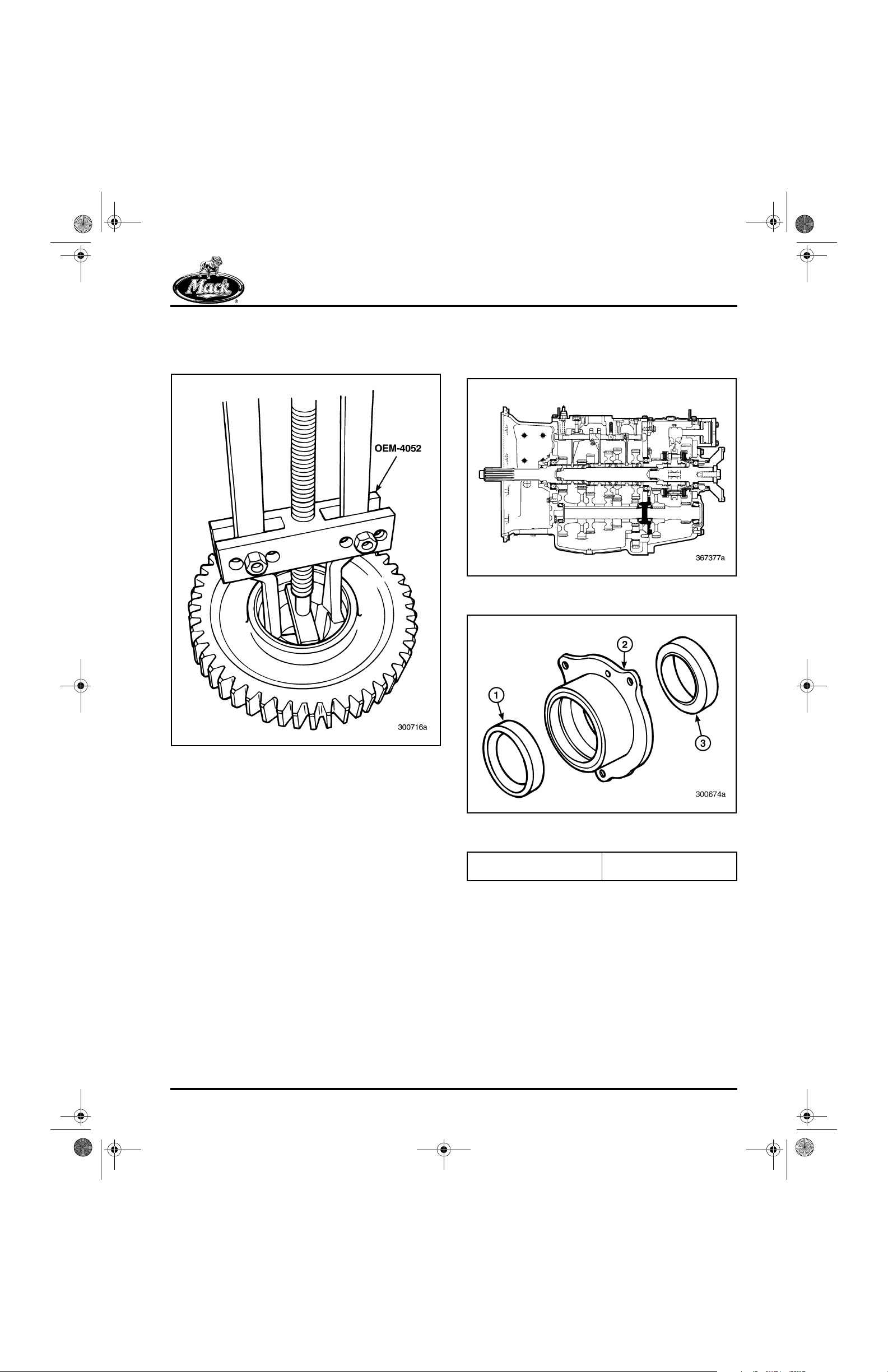

Compound Main Drive Gear Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Rear Mainshaft Bearing Cover Reassembly [321] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Synchronizer Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Rear Mainshaft Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Front Mainshaft Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Main Drive Pinion Reassembly [322] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Range Shift Valve [323] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Two-Position Range Shift Cylinder Reassembly [324] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Main Case Shift Cover Reassembly [323] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

TRANSMISSION REASSEMBLY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Gear Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Fits and Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

General Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Transmission Specifications and Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

SCHEMATIC & ROUTING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

SCHEMATIC DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Air Piping Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Air Control Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

SPECIAL TOOLS & EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

SPECIAL TOOLS AND EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

DISASSEMBLED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

DISASSEMBLED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

v

Page 10

front.fm Page vi Thursday, December 19, 2002 10:54 AM

NOTES

vi

Page 11

10-126.bk Page 1 Thursday, December 19, 2002 10:55 AM

INTRODUCTION

INTRODUCTION

Page 1

Page 12

10-126.bk Page 2 Thursday, December 19, 2002 10:55 AM

INTRODUCTION

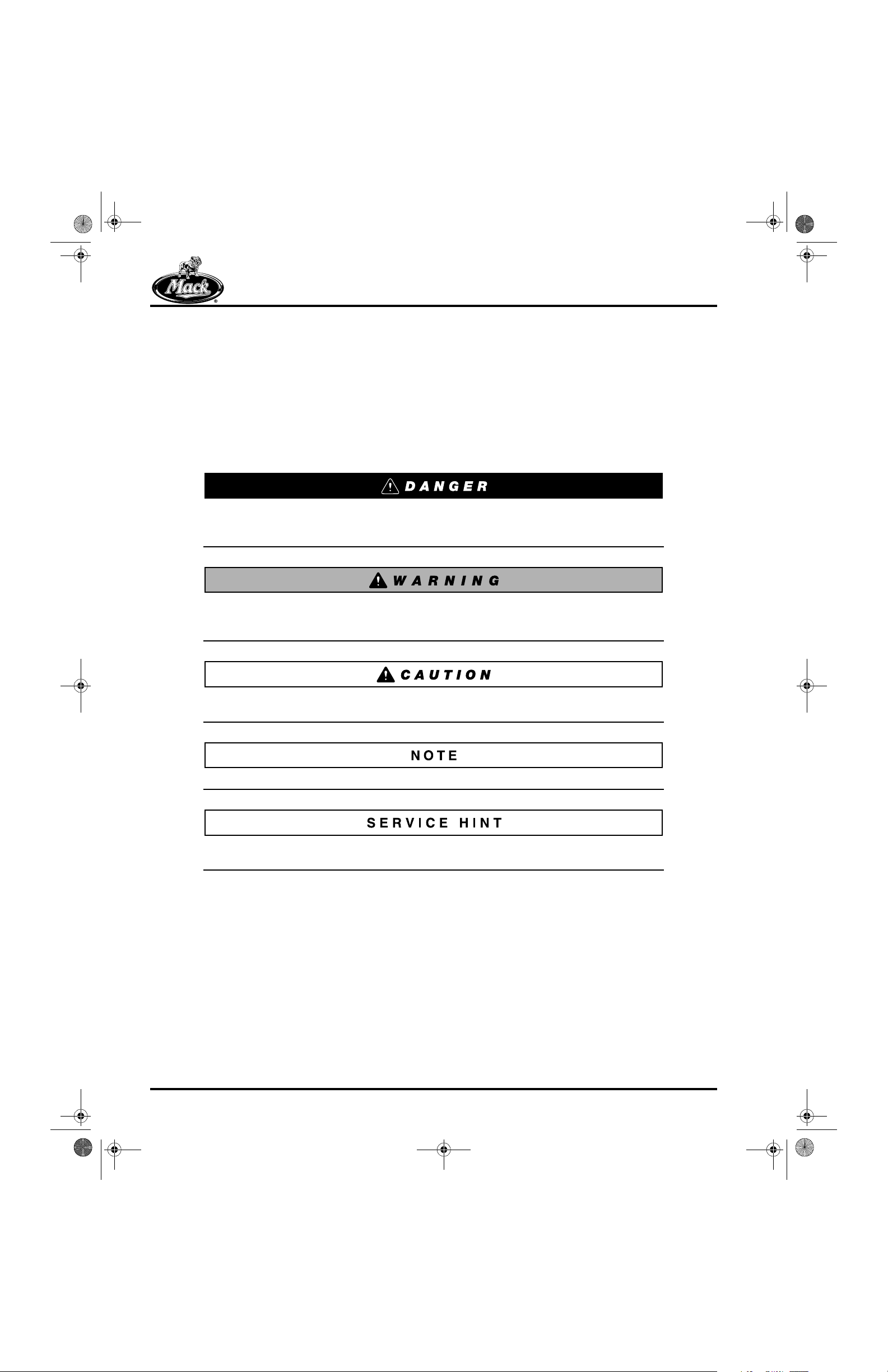

SAFETY INFORMATION

Advisory Labels

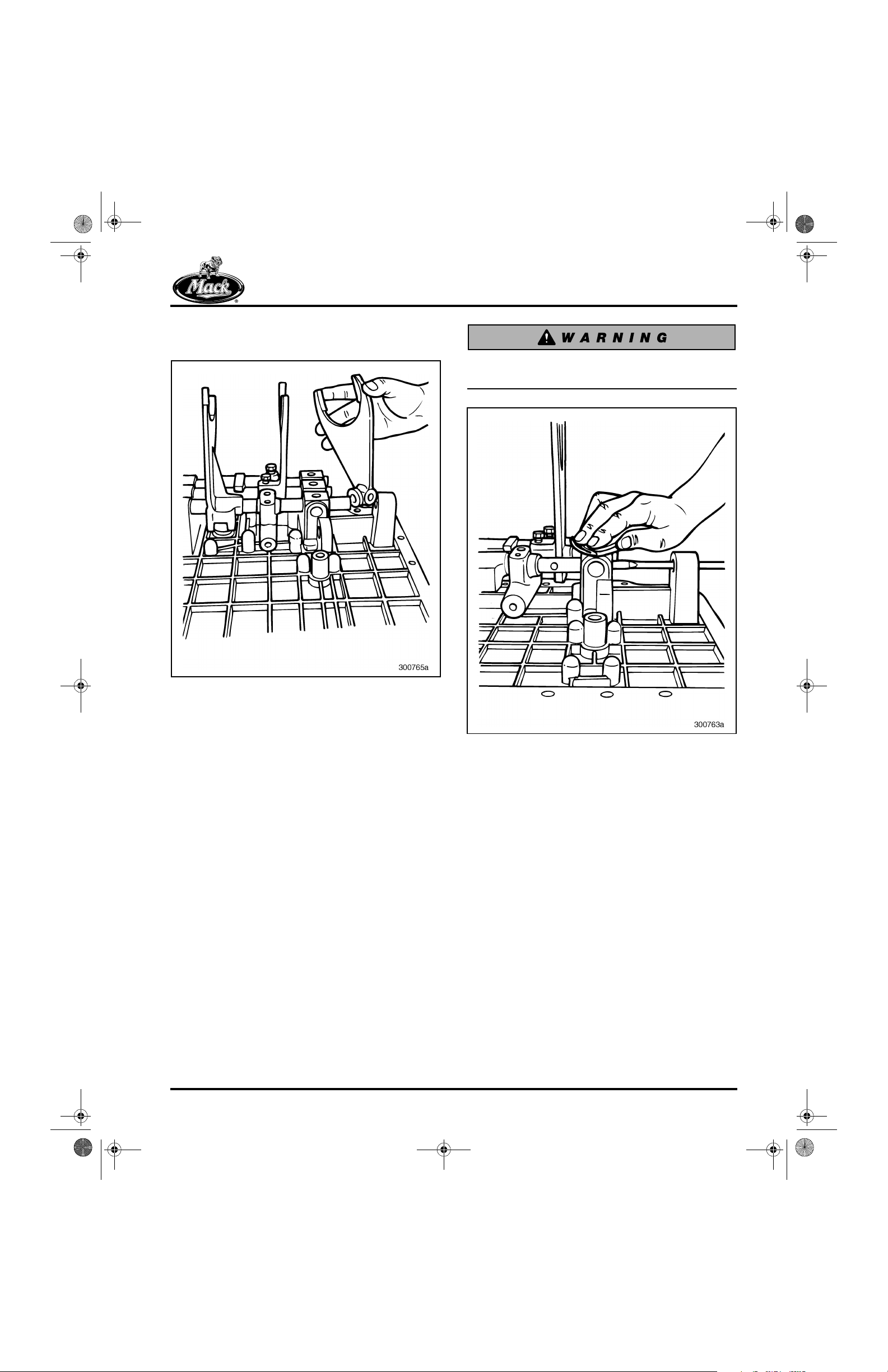

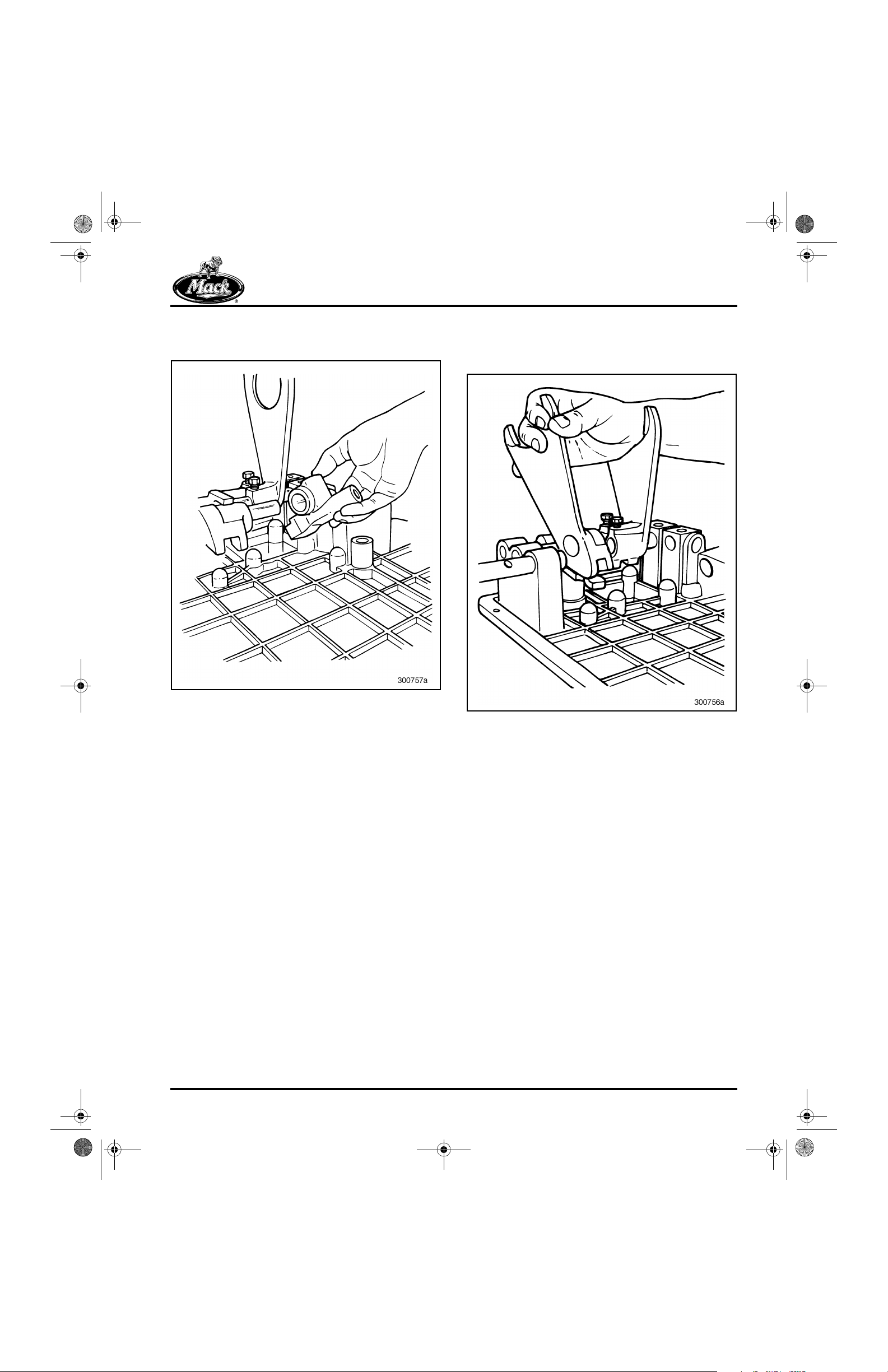

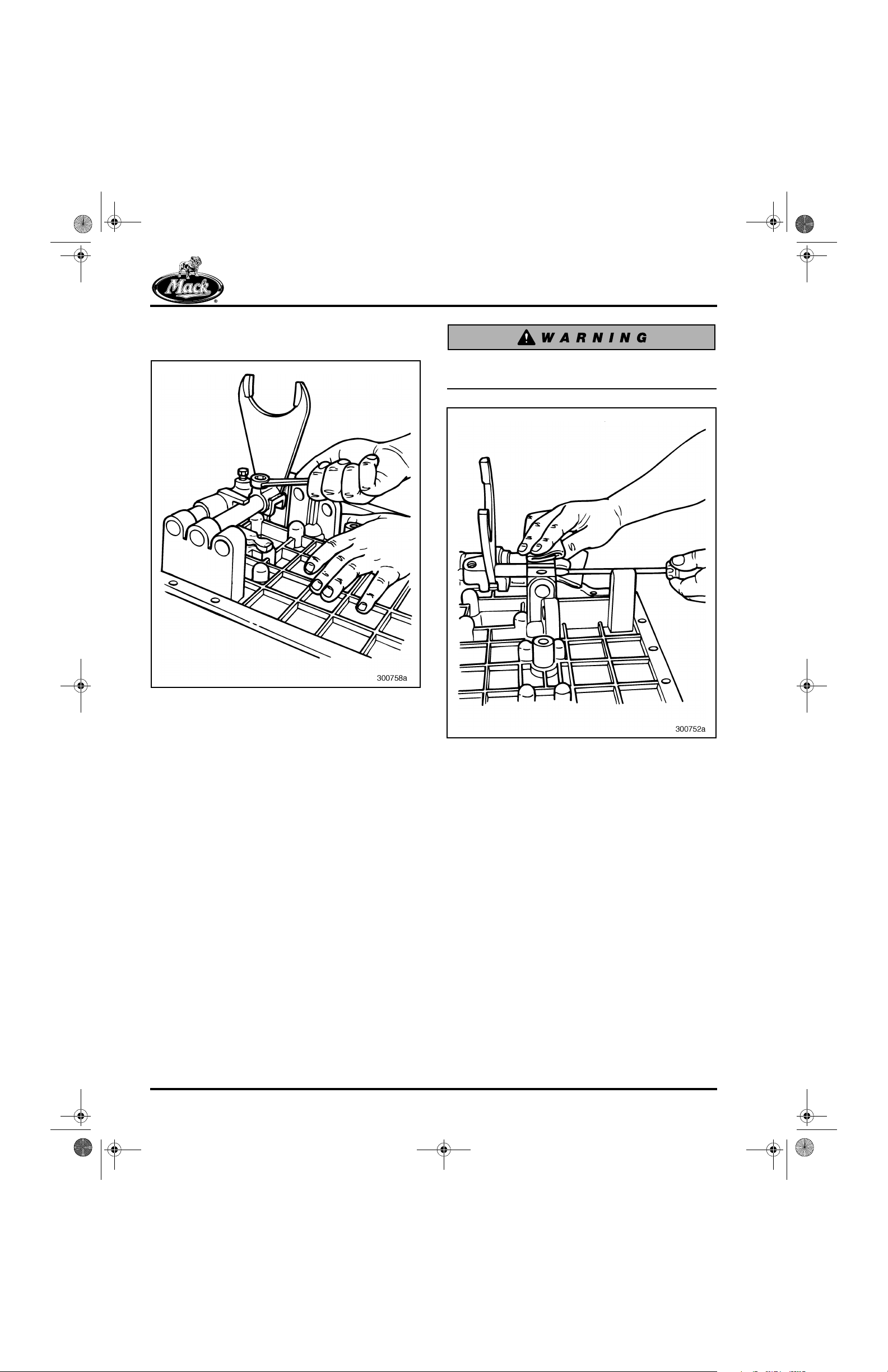

Cautionary signal words (Danger-Warning-Caution) may appear in various locations throughout this

manual. Information accented by one of these signal words must be observed to minimize the risk of

personal injury to service personnel, or the possibility of improper service methods which may damage

the vehicle or cause it to be unsafe. Additional Notes and Service Hints are used to emphasize areas of

procedural importance and provide suggestions for ease of repair. The following definitions indicate the

use of these advisory labels as they appear throughout the manual:

Activities associated with Danger indicate that death or serious personal

injury may result from failing to heed the advisory. Serious personal injury

may be equated to career-ending injury.

Activities associated with Warning indicate that personal injury may result

from failing to heed the advisory. In this case, personal injury is not equated to

career-ending injury, but results in possible change in quality of life.

Activities associated with Caution indicate that product damage may result from

failing to heed the advisory. Caution is not used for personal injury.

A procedure, practice, or condition that is essential to emphasize.

A helpful suggestion that will make it quicker and/or easier to perform a procedure,

while possibly reducing service cost.

Page 2

Page 13

10-126.bk Page 3 Thursday, December 19, 2002 10:55 AM

Service Procedures and Tool Usage

Anyone using a service procedure or tool not recommended in this manual must first satisfy himself

thoroughly that neither his safety nor vehicle safety will be jeopardized by the service method he selects.

Individuals deviating in any manner from the instructions provided assume all risks of consequential

personal injury or damage to equipment involved.

Also note that particular service procedures may require the use of a special tool(s) designed for a

specific purpose. These special tools must be used in the manner described, whenever specified in the

instructions.

1. Before starting a vehicle, always be seated in the driver’s seat, place the

transmission in neutral, be sure that parking brakes are set, and

disengage the clutch.

INTRODUCTION

2. Before working on a vehicle, place the transmission in neutral, set the

parking brakes, and block the wheels.

3. Before towing the vehicle, place the transmission in neutral and lift the

rear wheels off the ground, or disconnect the driveline to avoid damage to

the transmission during towing.

Engine-driven components such as Power Take-Off (PTO) units, fans and fan

belts, driveshafts and other related rotating assemblies, can be very

dangerous. Do not work on or service engine-driven components unless the

engine is shut down. Always keep body parts and loose clothing out of range

of these powerful components to prevent serious personal injury. Be aware of

PTO engagement or nonengagement status. Always disengage the PTO when

not in use.

REMEMBER,

SAFETY. . .IS NO ACCIDENT!

Page 3

Page 14

10-126.bk Page 4 Thursday, December 19, 2002 10:55 AM

INTRODUCTION

Mack Trucks, Inc. cannot anticipate every

possible occurrence that may involve a potential

hazard. Accidents can be avoided by recognizing

potentially hazardous situations and taking

necessary precautions. Performing service

procedures correctly is critical to technician safety

and safe, reliable vehicle operation.

The following list of general shop safety practices

can help technicians avoid potentially hazardous

situations and reduce the risk of personal injury.

DO NOT perform any services, maintenance

procedures or lubrications until this manual has

been read and understood.

r Perform all service work on a flat, level

surface. Block wheels to prevent vehicle

from rolling.

r DO NOT wear loose-fitting or torn clothing.

Remove any jewelry before servicing

vehicle.

r ALWAYS wear safety glasses and protective

shoes. Avoid injury by being aware of sharp

corners and jagged edges.

r Use hoists or jacks to lift or move heavy

objects.

r NEVER run engine indoors unless exhaust

fumes are adequately vented to the outside.

r Be aware of hot surfaces. Allow engine to

cool sufficiently before performing any

service or tests in the vicinity of the engine.

r Keep work area clean and orderly. Clean up

any spilled oil, grease, fuel, hydraulic fluid,

etc.

r Only use tools that are in good condition,

and always use accurately calibrated torque

wrenches to tighten all fasteners to specified

torques. In instances where procedures

require the use of special tools which are

designed for a specific purpose, use only in

the manner described in the instructions.

r Do not store natural gas powered vehicles

indoors for an extended period of time

(overnight) without first removing the fuel.

r Never smoke around a natural gas powered

vehicle.

Page 4

Page 15

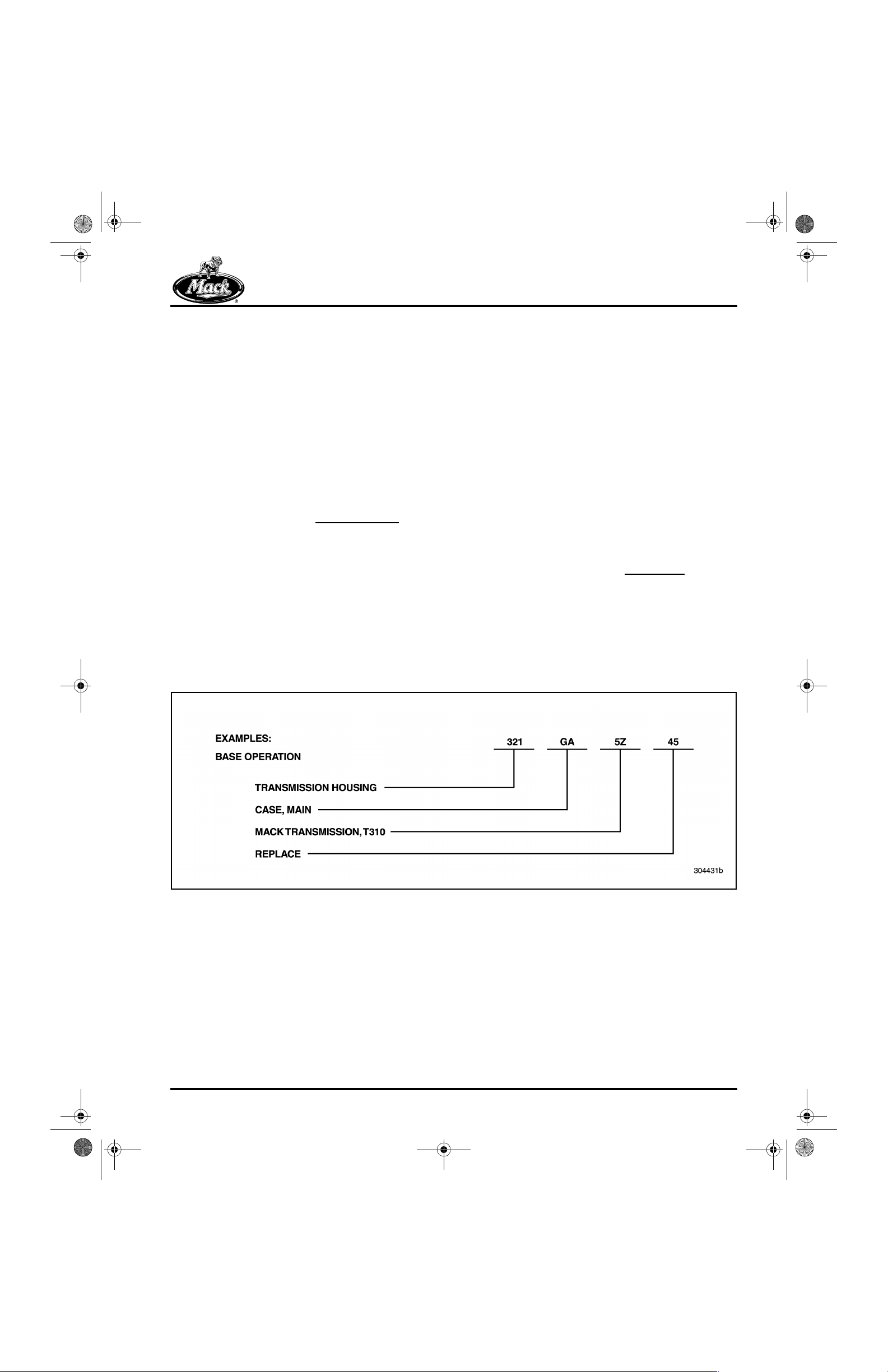

10-126.bk Page 5 Thursday, December 19, 2002 10:55 AM

INTRODUCTION

EXPLANATION OF NUMERICAL

CODE

The organization of MACK service manuals has

been upgraded to standardize manual content

according to a reference system based on

component identification. The reference system

helps link the information contained in this

publication with related information included in

other MACK service-warranty publications, such

as associated service bulletins, warranty

manuals, and MACK Service Labor Time

Standards.

The system is based on a numerical code

first digit of which identifies the general

component grouping as listed here:

GROUP 000 — GENERAL DATA

GROUP 100 — CHASSIS

GROUP 200 — ENGINE

GROUP 300 — CLUTCH, TRANSMISSION,

TRANSFER CASE AND PTO

, the

GROUP 400 — STEERING, AXLES, WHEELS

AND TIRES, DRIVELINE

GROUP 500 — BRAKES, AUXILIARY

SYSTEMS

GROUP 600 — CAB, TRUCK BODY

GROUP 700 — ELECTRICAL

The second two digits of the 3-digit code are used

to identify the system, assembly or

subassembly, as appropriate, within each of the

groupings. The codes applicable to this

publication are shown at the beginning of each

procedure, as necessary, to guide you to specific

component information.

Additionally, a two-character alpha code

[GA] CASE, MAIN) may be shown with each

operation. This alpha code, in combination with

the three-digit Group number, identifies the

specific assembly, subassembly or part, and

directly relates to the first five positions of the

operation code listed in the MACK Service Labor

Time Standards.

(i.e.,

Example of Numerical Code

Page 5

Page 16

10-126.bk Page 6 Thursday, December 19, 2002 10:55 AM

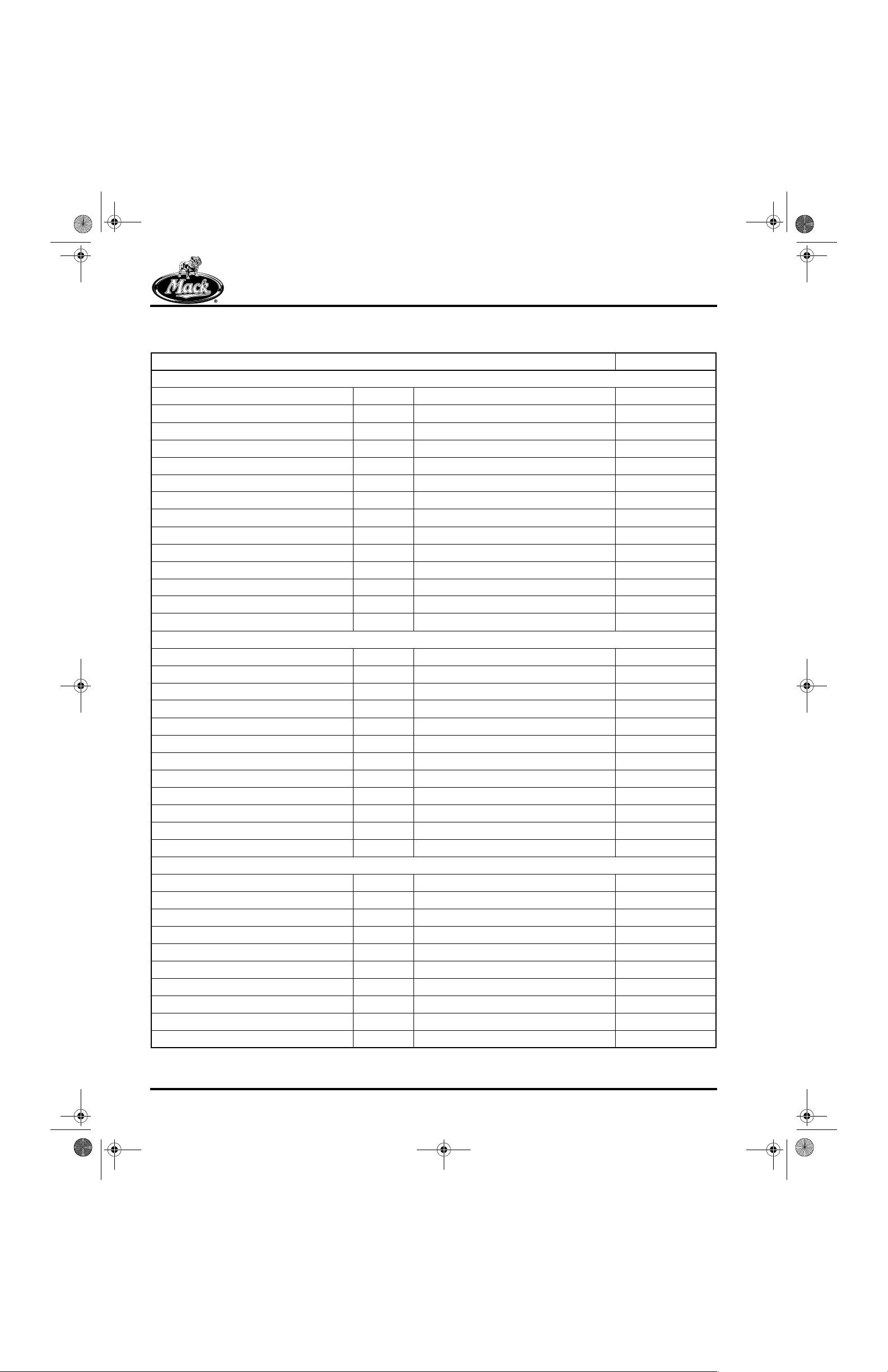

INTRODUCTION

CONVERSION CHART

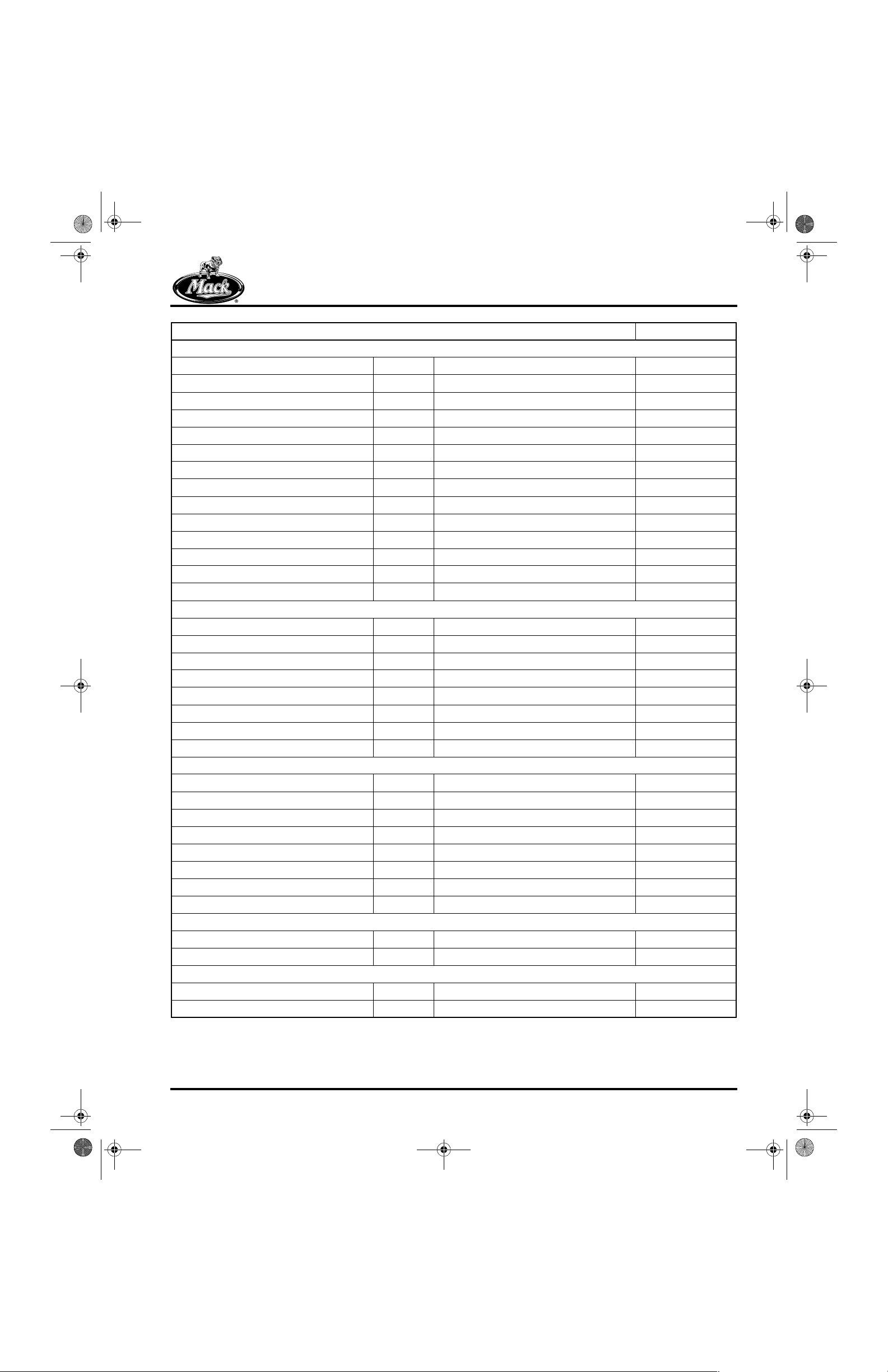

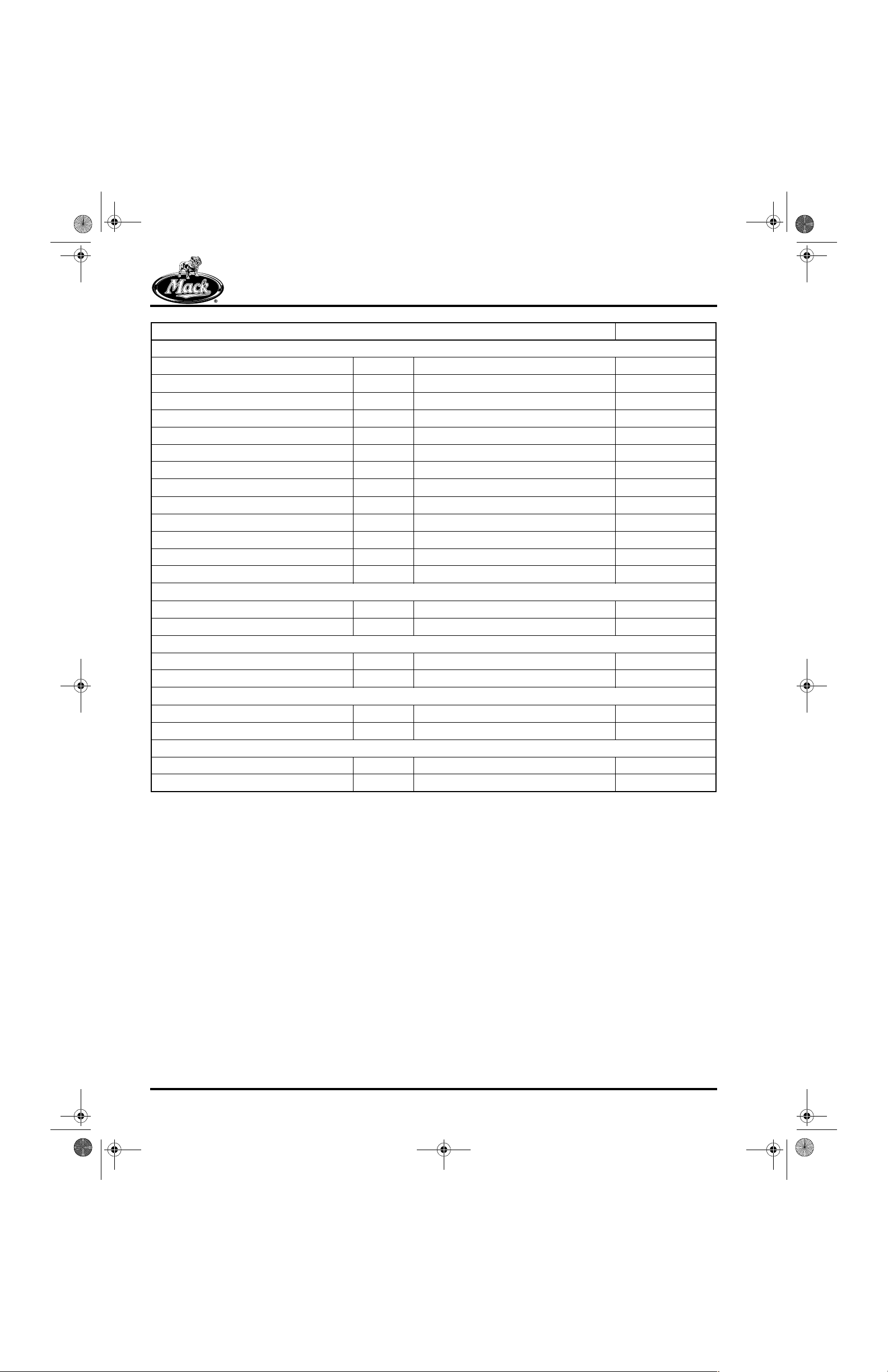

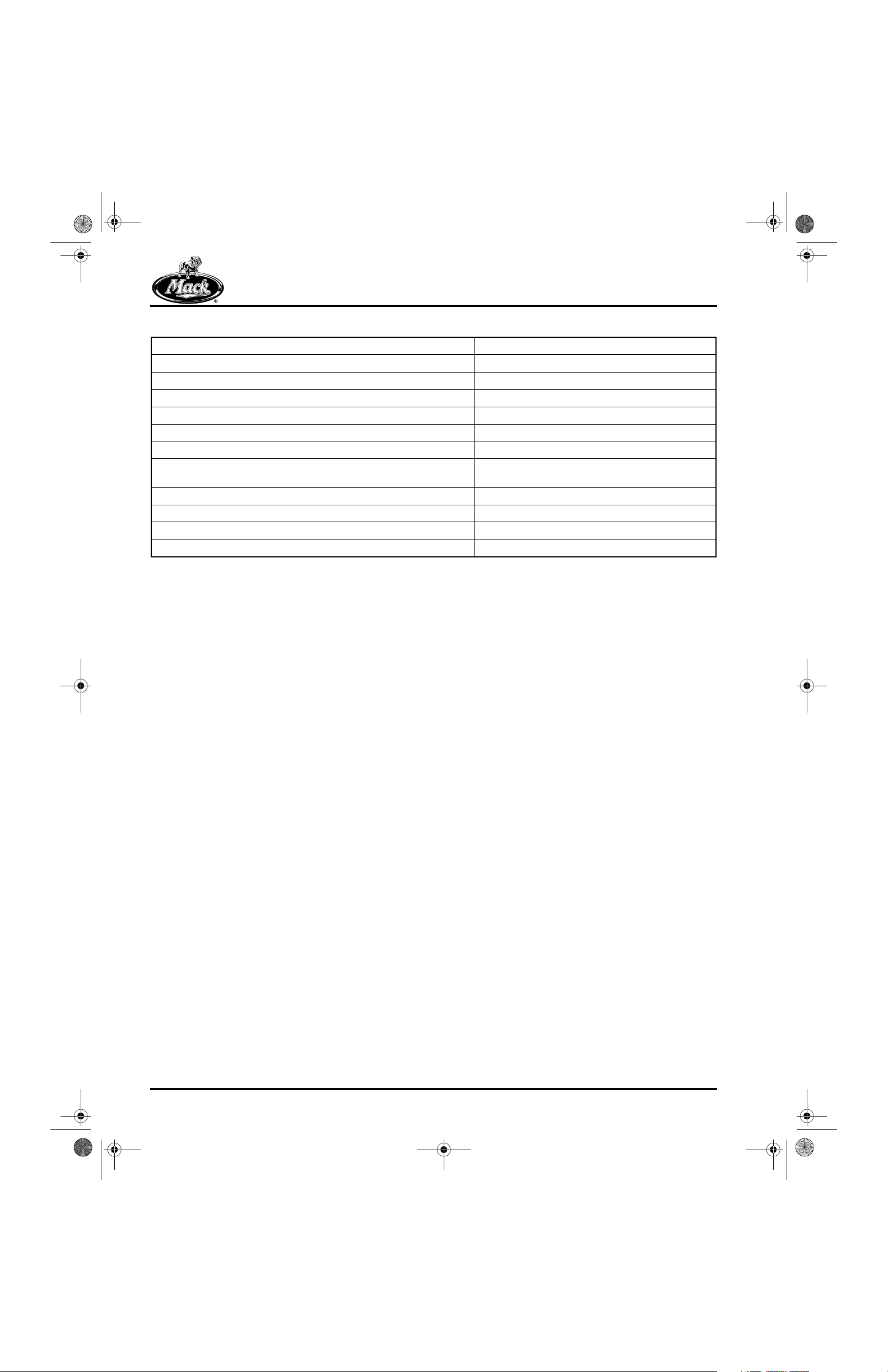

Conversion Units Multiply By:

Length Calculations

Inches (in) to Millimeters (mm) 25.40

Inches (in) to Centimeters (cm) 2.540

Feet (ft) to Centimeters (cm) 30.48

Feet (ft) to Meters (m) 0.3048

Yards (yd) to Centimeters (cm) 91.44

Yards (yd) to Meters (m) 0.9144

Miles to Kilometers (km) 1.609

Millimeters (mm) to Inches (in) 0.03937

Centimeters (cm) to Inches (in) 0.3937

Centimeters (cm) to Feet (ft) 0.0328

Centimeters (cm) to Yards (yd) 0.0109

Meters (m) to Feet (ft) 3.281

Meters (m) to Yards (yd) 1.094

Kilometers (km) to Miles 0.6214

Area Calculations

Square Inches (sq-in) to Square Millimeters (sq-mm) 645.2

Square Inches (sq-in) to Square Centimeters (sq-cm) 6.452

Square Feet (sq-ft) to Square Centimeters (sq-cm) 929.0

Square Feet (sq-ft) to Square Meters (sq-m) 0.0929

Square Yards (sq-yd) to Square Meters (sq-m) 0.8361

Square Miles (sq-miles) to Square Kilometers (sq-km) 2.590

Square Millimeters (sq-mm) to Square Inches (sq-in) 0.00155

Square Centimeters (sq-cm) to Square Inches (sq-in) 0.155

Square Centimeters (sq-cm) to Square Feet (sq-ft) 0.001076

Square Meters (sq-m) to Square Feet (sq-ft) 10.76

Square Meters (sq-m) to Square Yards (sq-yd) 1.196

Square Kilometers (sq-km) to Square Miles (sq-miles) 0.3861

Volume Calculations

Cubic Inches (cu-in) to Cubic Centimeters (cu-cm) 16.387

Cubic Inches (cu-in) to Liters (L) 0.01639

Quarts (qt) to Liters (L) 0.9464

Gallons (gal) to Liters (L) 3.7854

Cubic Yards (cu-yd) to Cubic Meters (cu-m) 0.7646

Cubic Centimeters (cu-cm) to Cubic Inches (cu-in) 0.06102

Liters (L) to Cubic Inches (cu-in) 61.024

Liters (L) to Quarts (qt) 1.0567

Liters (L) to Gallons (gal) 0.2642

Cubic Meters (cu-m) to Cubic Yards (cu-yd) 1.308

Page 6

Page 17

10-126.bk Page 7 Thursday, December 19, 2002 10:55 AM

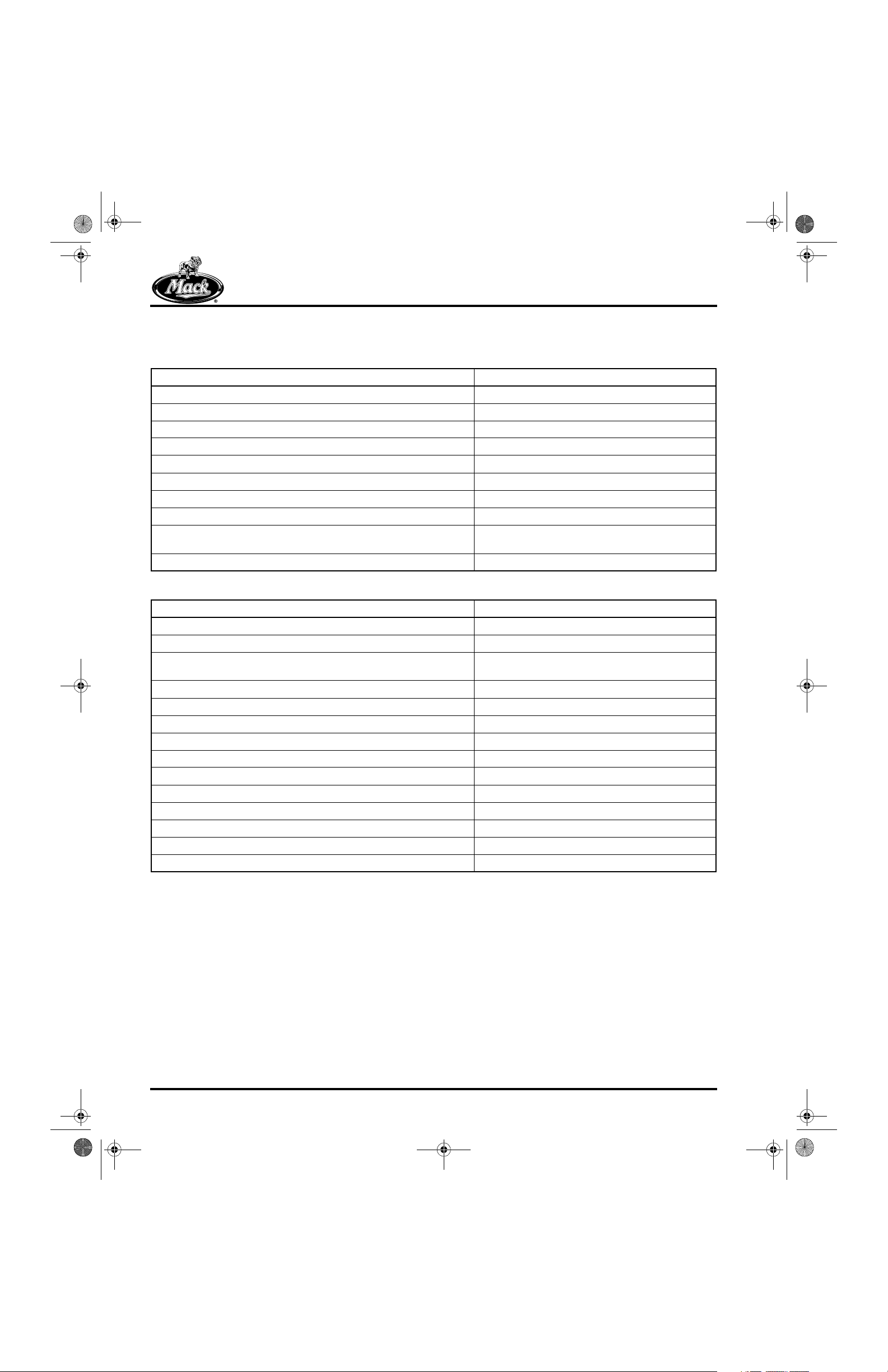

Weight Calculations

Ounces (oz) to Grams (g) 28.5714

Pounds (lb) to Kilograms (kg) 0.4536

Pounds (lb) to Short Tons (US tons) 0.0005

Pounds (lb) to Metric Tons (t) 0.00045

Short Tons (US tons) to Pounds (lb) 2000

Short Tons (US tons) to Kilograms (kg) 907.18486

Short Tons (US tons) to Metric Tons (t) 0.90718

Grams (g) to Ounces (oz) 0.035

Kilograms (kg) to Pounds (lb) 2.205

Kilograms (kg) to Short Tons (US tons) 0.001102

Kilograms (kg) to Metric Tons (t) 0.001

Metric Tons (t) to Pounds (lb) 2205

Metric Tons (t) to Short Tons (US tons) 1.1023

Metric Tons (t) to Kilograms (kg) 1000

Force Calculations

Ounces Force (ozf) to Newtons (N) 0.2780

Pounds Force (lbf) to Newtons (N) 4.448

Pounds Force (lbf) to Kilograms Force (kgf) 0.456

Kilograms Force (kgf) to Pounds Force (lbf) 2.2046

Kilograms Force (kgf) to Newtons (N) 9.807

Newtons (N) to Kilograms Force (kgf) 0.10196

Newtons (N) to Ounces Force (ozf) 3.597

Newtons (N) to Pounds Force (lbf) 0.2248

Torque Calculations

Pound Inches (lb-in) to Newton Meters (N·m) 0.11298

Pound Feet (lb-ft) to Newton Meters (N·m) 1.3558

Pound Feet (lb-ft) to Kilograms Force per Meter (kgfm) 0.13825

Newton Meters (N·m) to Pound Inches (lb-in) 8.851

Newton Meters (N·m) to Pound Feet (lb-ft) 0.7376

Newton Meters (N·m) to Kilograms Force per Meter (kgfm) 0.10197

Kilograms Force per Meter (kgfm) to Pound Feet (lb-ft) 7.233

Kilograms Force per Meter (kgfm) to Newton Meters (N·m) 9.807

Radiator Specific Heat Dissipation Calculations

British Thermal Unit per Hour (BTU/hr) to Kilowatt per Degree Celsius (kW/°C) 0.000293

Kilowatt per Degree Celsius (kW/°C) to British Thermal Unit per Hour (BTU/hr) 3414.43

Temperature Calculations

Degrees Fahrenheit (°F) to Degrees Celsius (°C) (°F32) 0.556

Degrees Celsius (°C) to Degrees Fahrenheit (°F) (1.8 x °C) + 32

INTRODUCTION

Conversion Units Multiply By:

Page 7

Page 18

10-126.bk Page 8 Thursday, December 19, 2002 10:55 AM

INTRODUCTION

Conversion Units Multiply By:

Pressure Calculations

Atmospheres (atm) to Bars (bar) 1.01325

Atmospheres (atm) to Kilopascals (kPa) 101.325

Bars (bar) to Atmospheres (atm) 0.98692

Bars (bar) to Kilopascals (kPa) 100

Bar (bar) to Pounds per Square Inch (psi) 14.5037

Inches of Mercury (in Hg) to Kilopascals (kPa) 3.377

Inches of Water (in H

Pounds per Square Inch (psi) to Kilopascals (kPa) 6.895

Pounds per Square Inch (psi) to Bar (bar) 0.06895

Kilopascals (kPa) to Atmospheres (atm) 0.00987

Kilopascals (kPa) to Inches of Mercury (in Hg) 0.29612

Kilopascals (kPa) to Inches of Water (in H

Kilopascals (kPa) to Pounds per Square Inch (psi) 0.145

Power Calculations

Horsepower (hp) to Kilowatts (kW) 0.74627

Kilowatts (kW) to Horsepower (hp) 1.34

Fuel Performance Calculations

Miles per Gallon (mile/gal) to Kilometers per Liter (km/L) 0.4251

Kilometers per Liter (km/L) to Miles per Gallon (mile/gal) 2.352

Velocity Calculations

Miles per Hour (mile/hr) to Kilometers per Hour (km/hr) 1.609

Kilometers per Hour (km/hr) to Miles per Hour (mile/hr) 0.6214

Volume Flow Calculations

Cubic Feet per Minute (cu-ft/min) to Liters per Minute (L/min) 28.32

Liters per Minute (L/min) to Cubic Feet per Minute (cu-ft/min) 0.03531

O) to Kilopascals (kPa) 0.2491

2

O) 4.01445

2

Page 8

Page 19

10-126.bk Page 9 Thursday, December 19, 2002 10:55 AM

VISUAL IDENTIFICATION

VISUAL IDENTIFICATION

Page 9

Page 20

10-126.bk Page 10 Thursday, December 19, 2002 10:55 AM

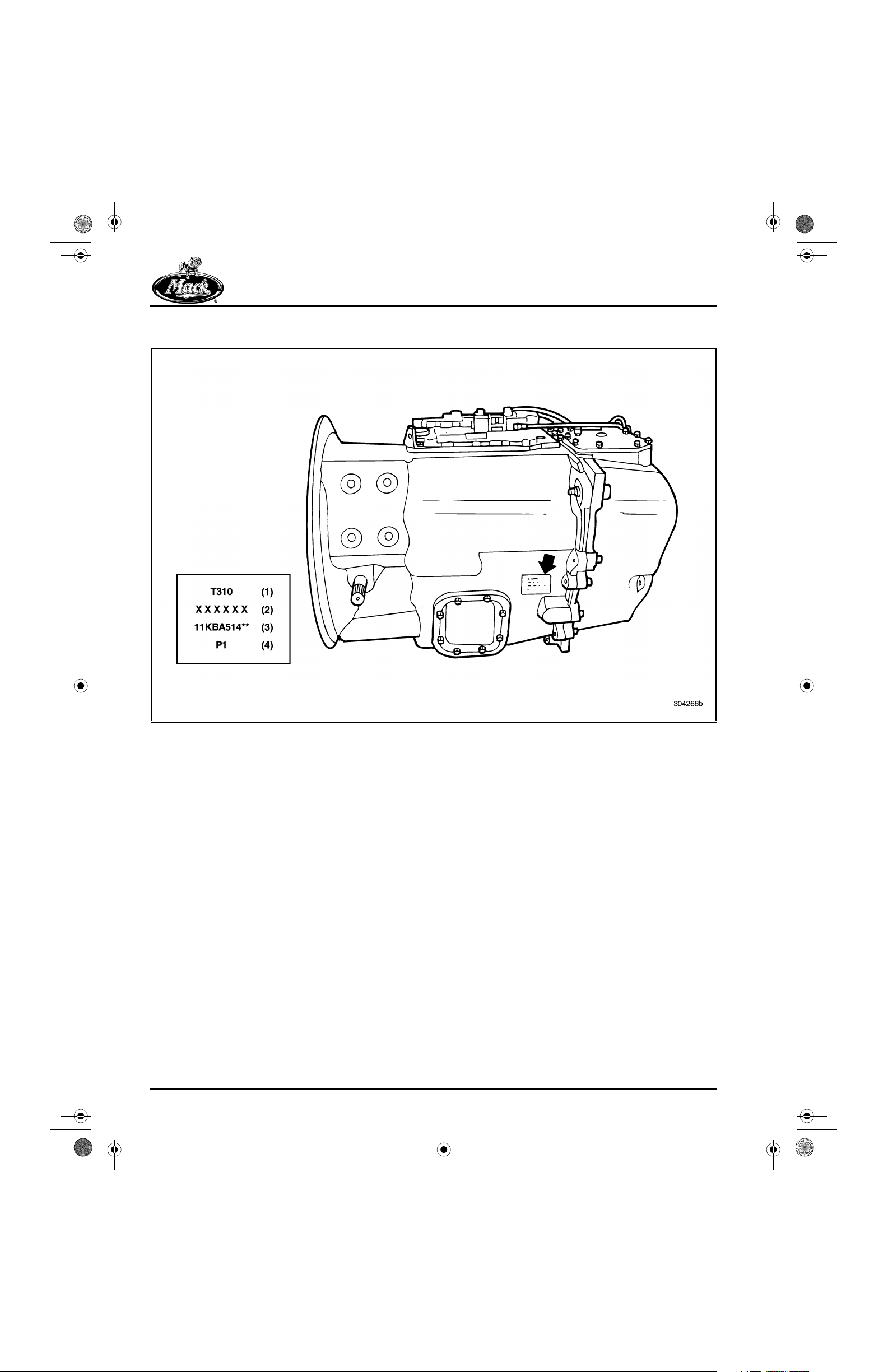

VISUAL IDENTIFICATION

TRANSMISSION IDENTIFICATION

1

Figure 1 — Location of Identification Stamping on Left Side of Main Case

Unit Identification Stamping

Location

The following model code information is stamped

on the left side of the transmission, toward the

rear of the main case. Refer to Figure 1.

1. Unit Symbol Identification

T = transmission

3 = 300 series

10 = useable forward speeds

2. Transmission Serial No.

3. Transmission Assembly (Part) No.

* = digits may vary

4. Specific variant of the base assembly

number (variant to item No. 3)

Page 10

Page 21

10-126.bk Page 11 Thursday, December 19, 2002 10:55 AM

2

VISUAL IDENTIFICATION

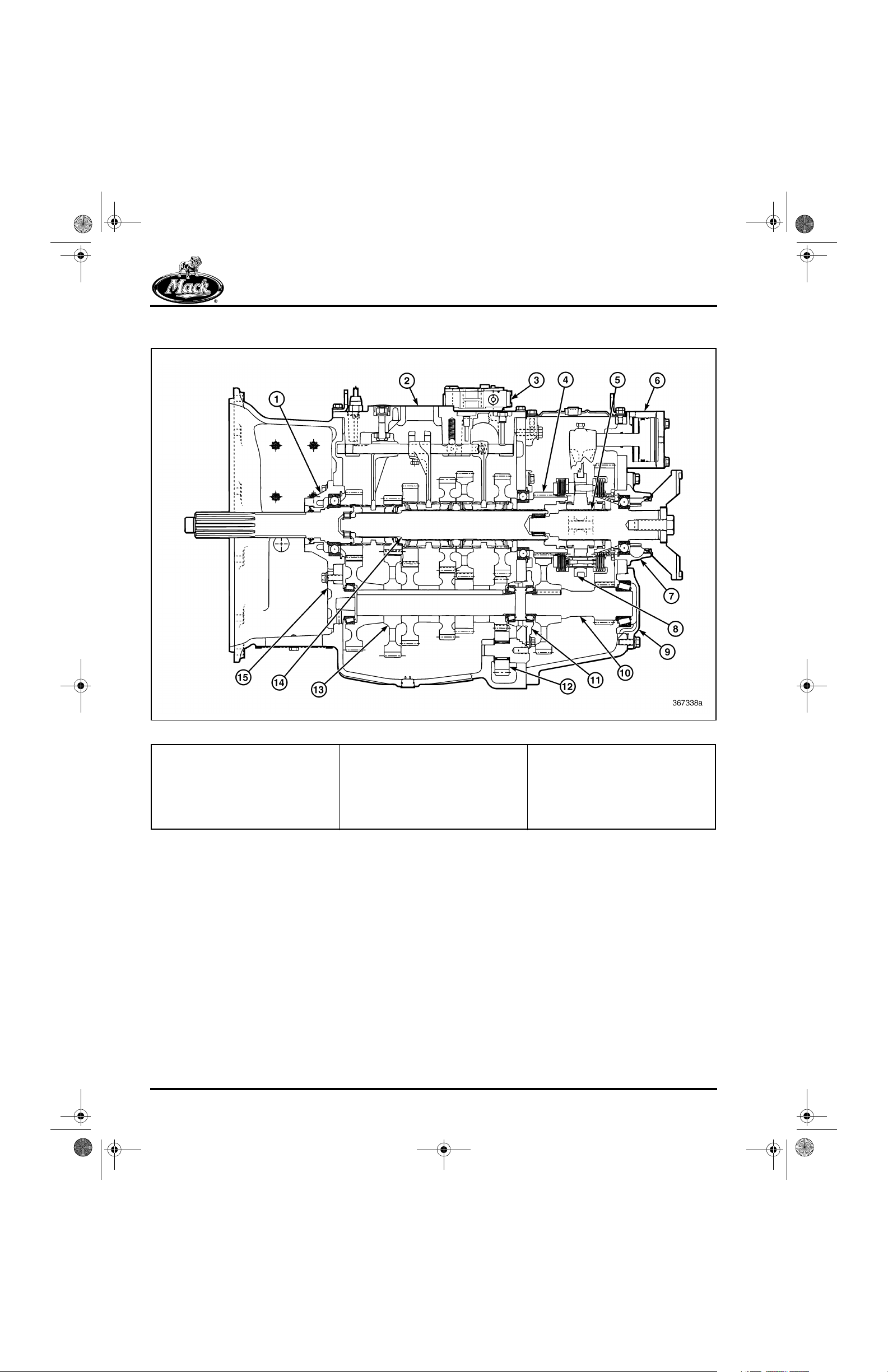

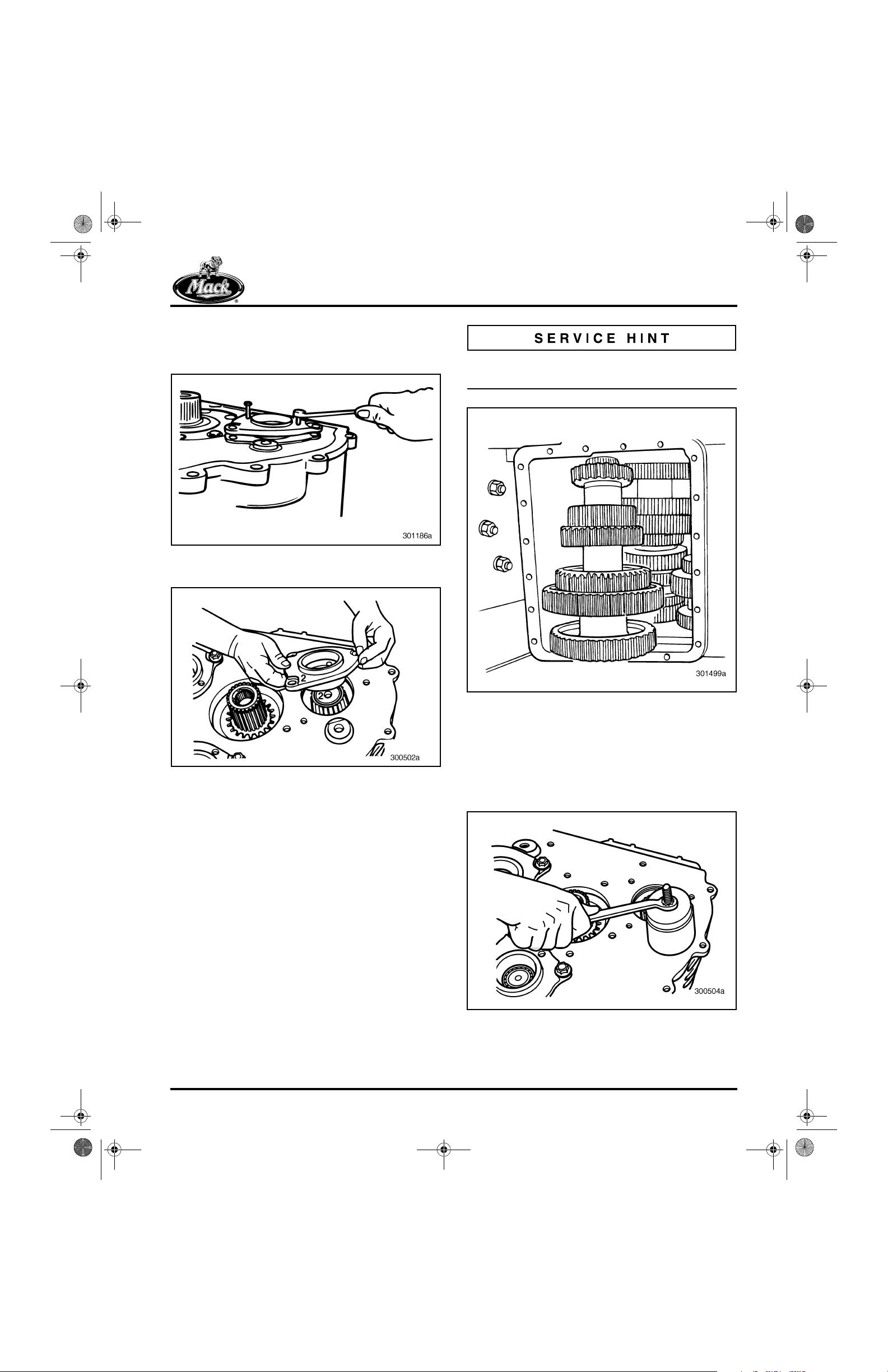

Figure 2 — Cutaway View of T310 Transmission

Page 11

Page 22

10-126.bk Page 12 Thursday, December 19, 2002 10:55 AM

NOTES

Page 12

Page 23

10-126.bk Page 13 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

DESCRIPTION AND OPERATION

Page 13

Page 24

10-126.bk Page 14 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

DESCRIPTION AND

OPERATION

T310 Transmissions

DESCRIPTION

The T310 transmission is a member of a new

family of MACK transmissions designated as

MAXITORQUE

These transmissions are the next evolution of the

durable triple-countershaft transmission. New

features and product enhancements have been

engineered into these transmissions to provide a

wide range of advantages which include the

following:

r New and revised gear ratios for greater

overall range and versatility

r Lower “LOs” in forward and reverse for

superior site maneuvering

r Improved shift quality through the use of a

new sliding clutch with a fine-pitch tooth

design versus the coarse-pitch tooth design

of previous transmissions

r Enhanced durability

r Weight reduction versus the previous series

transmissions

The T310 transmissions are triple-countershaft

units. They consist of a compact main box which

houses five non-synchronized forward-speed

gear sets plus a reverse gear set. The rear case

of the T310 transmission is also a triplecountershaft unit. The rear case consists of Lorange and Hi-range gear sets which are air

controlled by an air shift selector located on the

main shift lever.

®

ES (T300) Series transmissions.

All gears are of the spur-type design and are in

constant mesh with mating gears. All shifting is

done by forks and sliding clutches. The shift rails

and forks are integral with the shift cover for the

main case.

A single gear shift lever is used to shift through a

standard “H” pattern. An air shift range selector,

mounted on the gear shift lever, is also used for

shifting the T310. The range selector directs air

pressure to the compound air shift cylinder.

Operating the selector causes a shift between Hi

range or Lo range in the compound.

The T310 has 10 forward speeds and two reverse

speeds. Each of the five forward speeds in the

main case is used once with the compound in Lo

range (first, second, third, fourth and fifth), and

once more with the compound in Hi range (sixth,

seventh, eighth, ninth and tenth). Reverse may

be used in either Lo range or Hi range. See

Figure 7.

The compound range shift is accomplished using

a plate-type synchronizer, shifted by a range shift

cylinder and a shift fork.

The six countershafts, three in the main case and

three in the rear case, are equally spaced around

the mainshafts. This design distributes the load

equally among the countershafts, thus keeping

normal deflection and gear tooth loading to a

minimum.

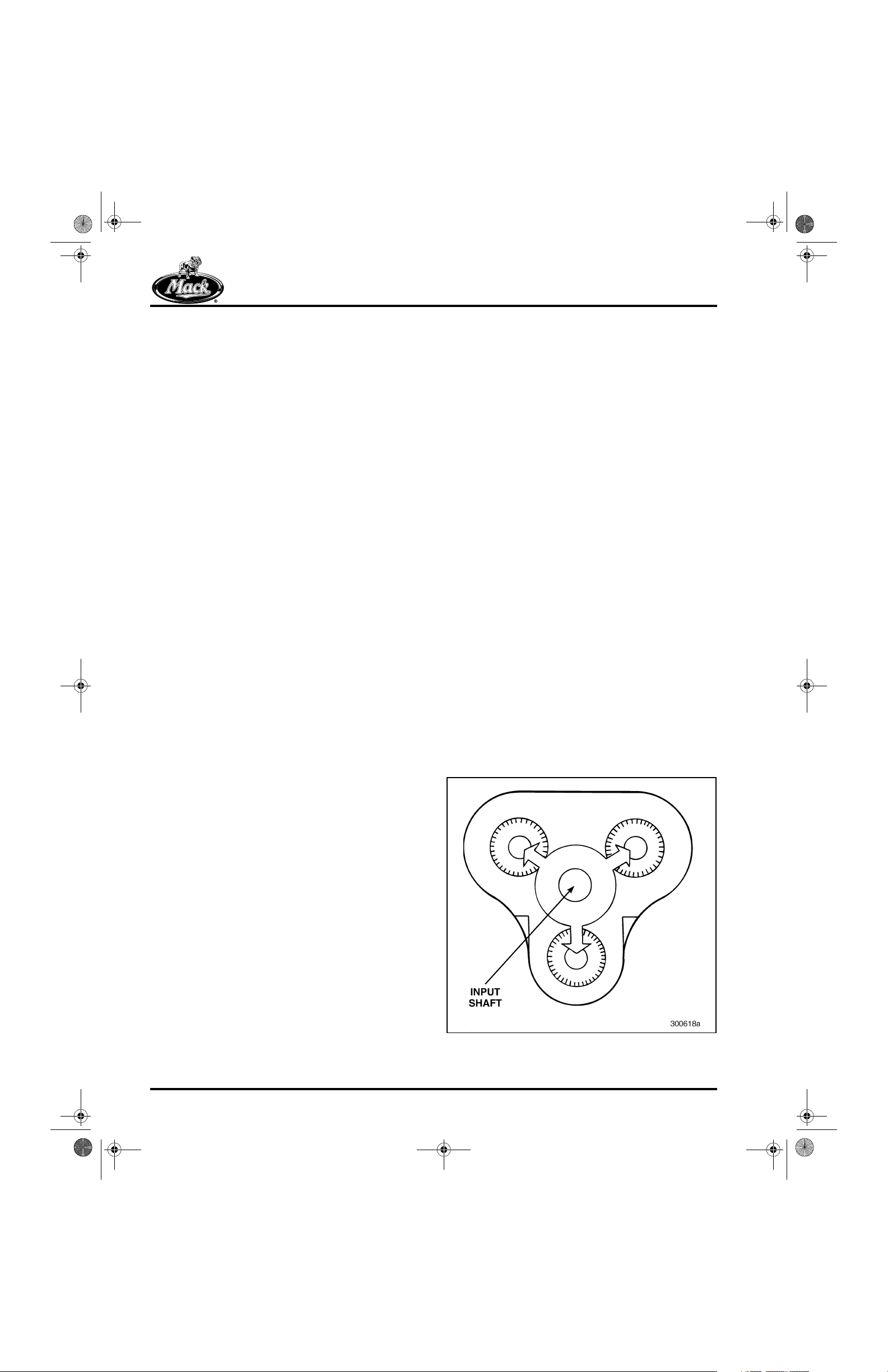

3

The main case and the bell housing are a onepiece casting, made from aluminum and heattreated for strength.

The main case also has 6- and 8-bolt openings

that allow for the addition of Power Take-Off

(PTO) units. PTO operation is off the (53 tooth)

countershaft fifth (10th) speed gear.

The bearings are housed in cast-iron bearing

retainers (covers). Tapered roller bearings are

used at each end of all transmission

countershafts.

Page 14

Figure 3 — Equal Torque Distribution

Page 25

10-126.bk Page 15 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

Lubrication

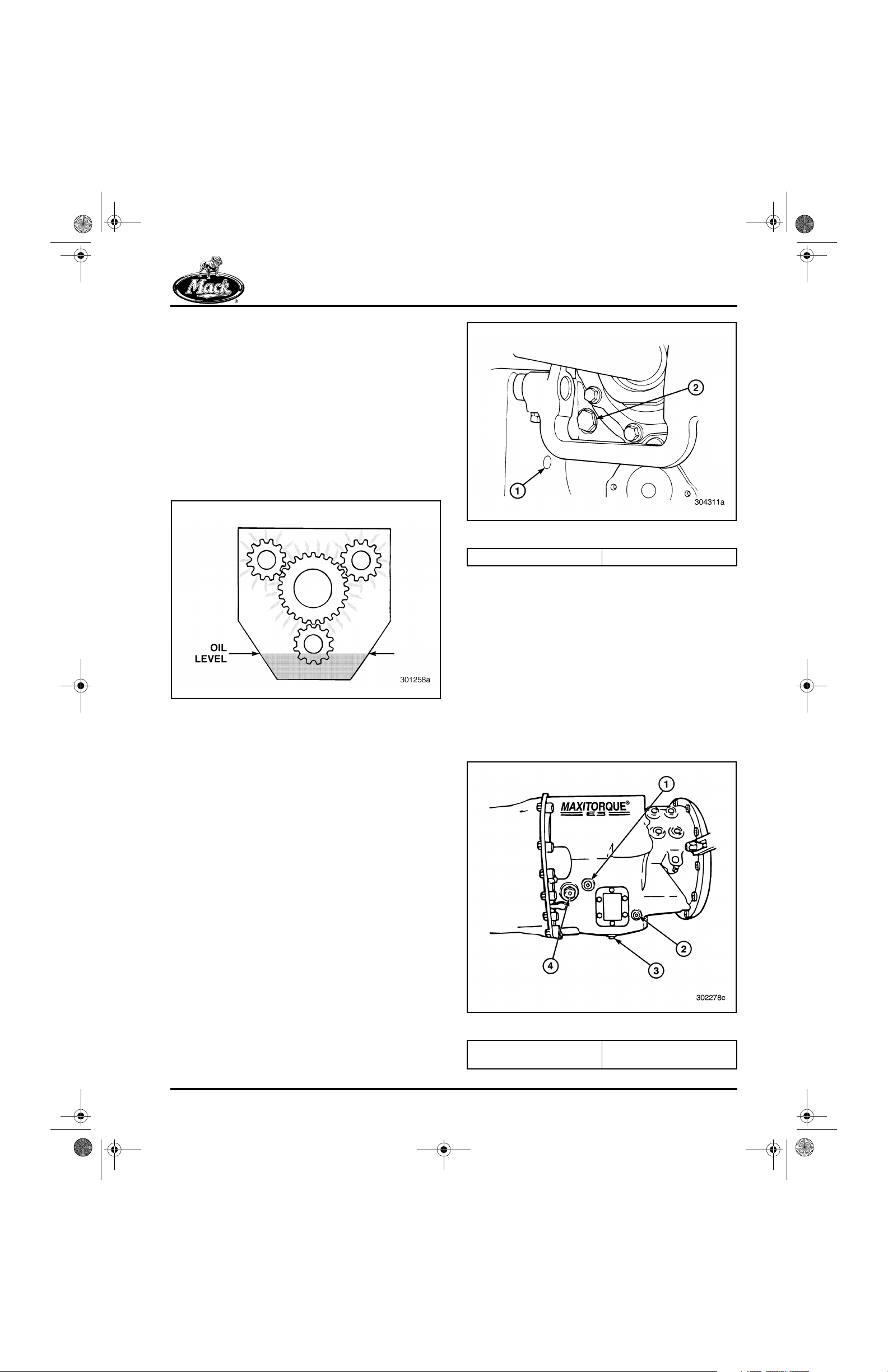

SPLASH LUBRICATION

All parts inside the transmission are lubricated by

a splash-and-gravity system. To minimize

churning, only the lower countershaft dips into the

lubrication oil. As the gears on that countershaft

spin, a constant spray of oil is directed to all

internal parts of the transmission. The oil cools as

it circulates over the aluminum case. Troughs and

passages, cast into the inside of the case,

capture and direct oil to the bearings.

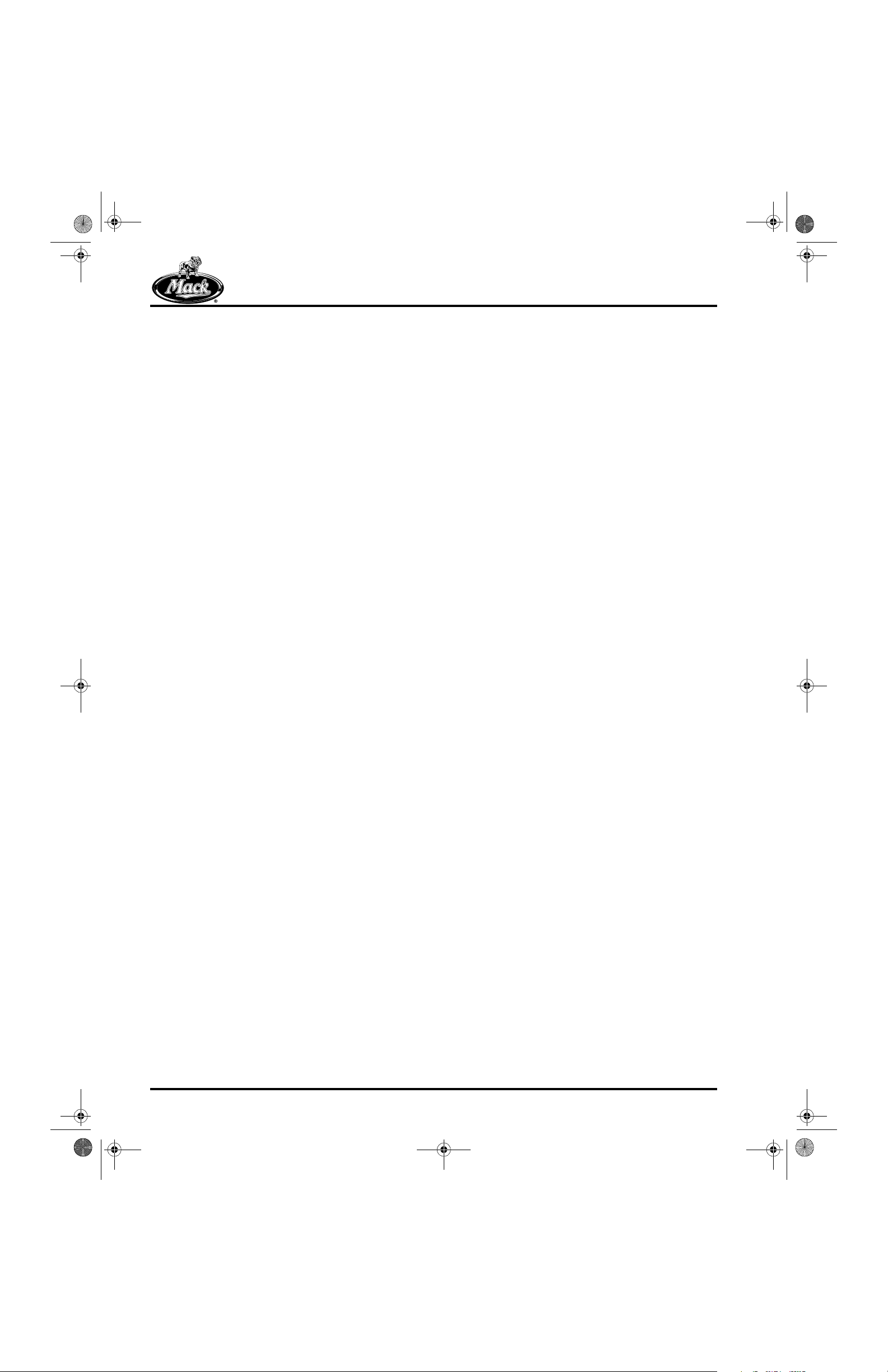

4

Figure 4 — Splash Lubrication

TRANSMISSION CASE OIL COOLER LINE

PLUGS

5

Figure 5 — Transmission Case Oil Cooler Line Plugs

1. Outlet Plastic Cap 2. Suction Tube Plug

MAGNETIC OIL FILTER

A magnetic oil filter assembly is built into the right

side of the main case. It consists of a magnetic

plug which removes ferrous metallic particles

from the passing oil. After passing the magnetic

plug, the oil is channelled upward to an outlet,

where it returns (by gravity) down into the

transmission case sump. The magnetic plug is

removable from the outside of the transmission,

without the necessity of draining the oil since this

plug is above the oil level. The drain plug at the

bottom of the case is also magnetic.

6

An integral oil cooler pump system has been

developed for MACK T300 series transmissions.

The oil cooler is optional for engine ratings under

400 hp and chassis ratings under 80,000 GVW.

The oil cooler system is required when the

engine rating is equal to or exceeds 400 hp, or

the chassis rating is greater than 80,000 GVW.

On T310 transmissions that are not built with oil

cooler pump systems, the tube line openings are

plugged or capped. The main suction tube area

contains a metal plug and the outlet fitting area

receives a plastic cap.

Figure 6 — Plug Locations

1. Magnetic Filter Plug

2. Oil Temperature Sensor

3. Oil Drain Plug

4. Oil Fill and Level Plug

Page 15

Page 26

10-126.bk Page 16 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

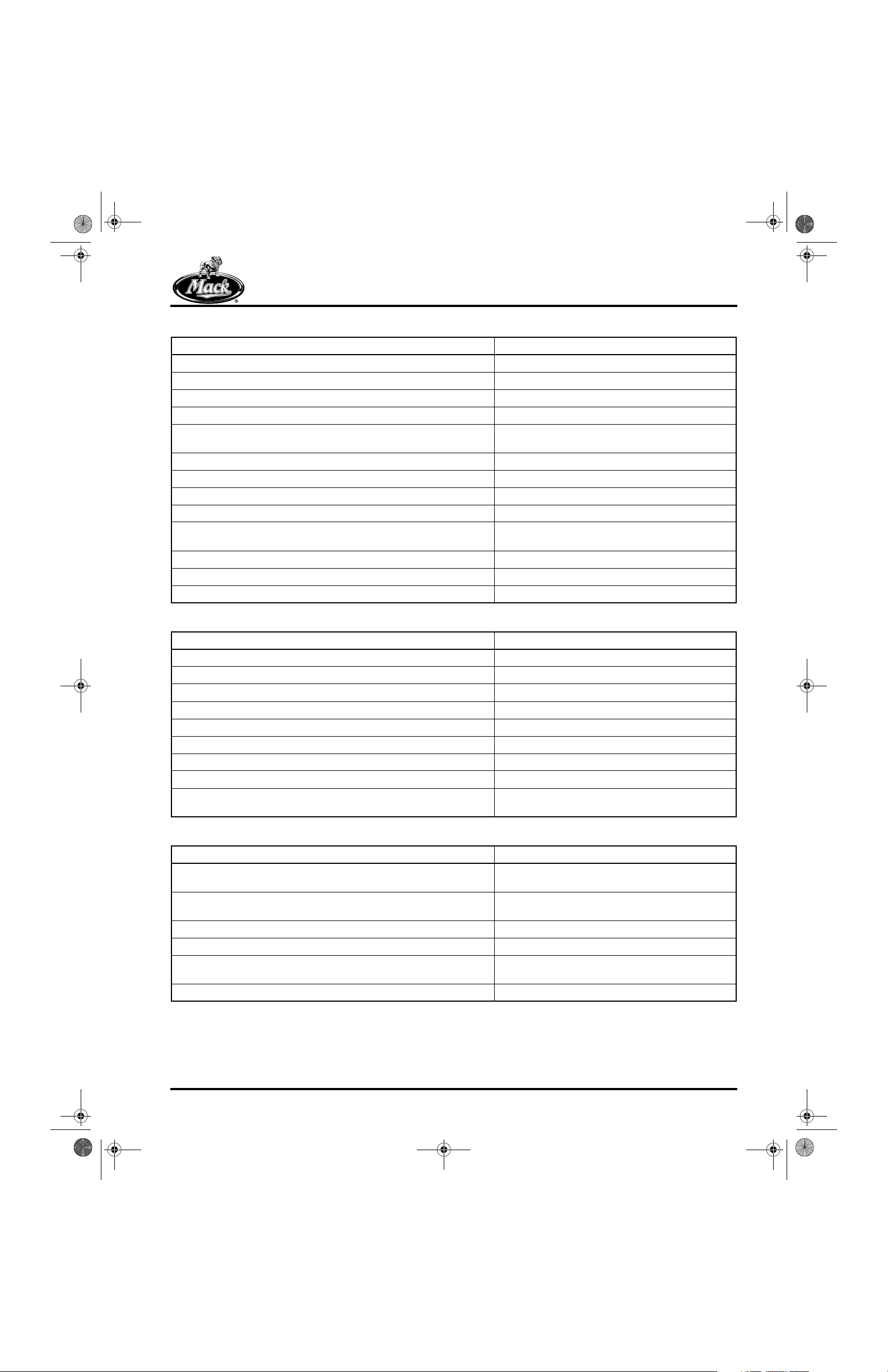

Gear Ratios and Shift Pattern

7

Figure 7 — T310 Gear Ratios and Shift Pattern

Gear Position (Main Box) Lo-Range Ratios Hi-Range Ratios

1/6 13.81 2.67

2/7 10.05 1.94

3/8 7.18 1.39

4/9 5.17 1.00

5/10 3.75 0.73

R/R 14.73 2.75

Page 16

Page 27

10-126.bk Page 17 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

T310 Shifting Instructions

Make sure air pressure is at least 100 psi and unit

is warmed before making range shifts. Always

start in Lo range. This also applies to

dynamometer testing. When the truck is

stationary, do NOT shift into Hi range and then

start moving the truck. Otherwise, damage to the

synchronizer may result. To avoid transmission

damage, do not change range while in reverse.

The T310 unit is a range-shifted transmission

which has 10 forward “highway” speeds. This

transmission features a Lo and Hi auxiliary

compound section controlled by an air shift range

selector located on the shift lever. The compound

section is equipped with a synchronizer to

facilitate Lo-/Hi-range shifting.

The Lo range provides five low ratios. Never

attempt to move the vehicle from a stopped

position in any gear higher than fifth speed gear.

Depending on load, grade, or road conditions, it

may be necessary to start in first, second, third or

fourth speed gears. In Hi range there are five

forward gears that can be shifted in the standard

manner. Always remember, however, to double

clutch whether moving up or down through these

gears. Reverse gear can be used in Lo range or

Hi range.

UPSHIFTING (NORMAL HIGHWAY)

DOWNSHIFTING (NORMAL HIGHWAY)

Shift from 10th speed gear down through the Hi

range (9-8-7-6), double clutching through each

gear. While still in sixth speed gear, flip the air

shift range selector down to Lo range (preselect).

Then move the shift lever through neutral to fifth

speed gear. As the shift lever passes through

neutral, the transmission is placed into Lo range.

Then, shift down to fourth, third, second and first

speed gears, double clutching between all gears.

r Always start in Lo range according to shift

marker plate instructions. Never start in a

gear higher than fifth speed gear, even when

dynamometer testing.

r When the truck is stationary, do not shift into

Hi range and then start moving the truck.

Damage to the synchronizer can result.

r Be careful not to overspeed the engine

during downshifting. Damage to powertrain

components may result.

r To avoid transmission damage, do not

change range while moving in reverse gear.

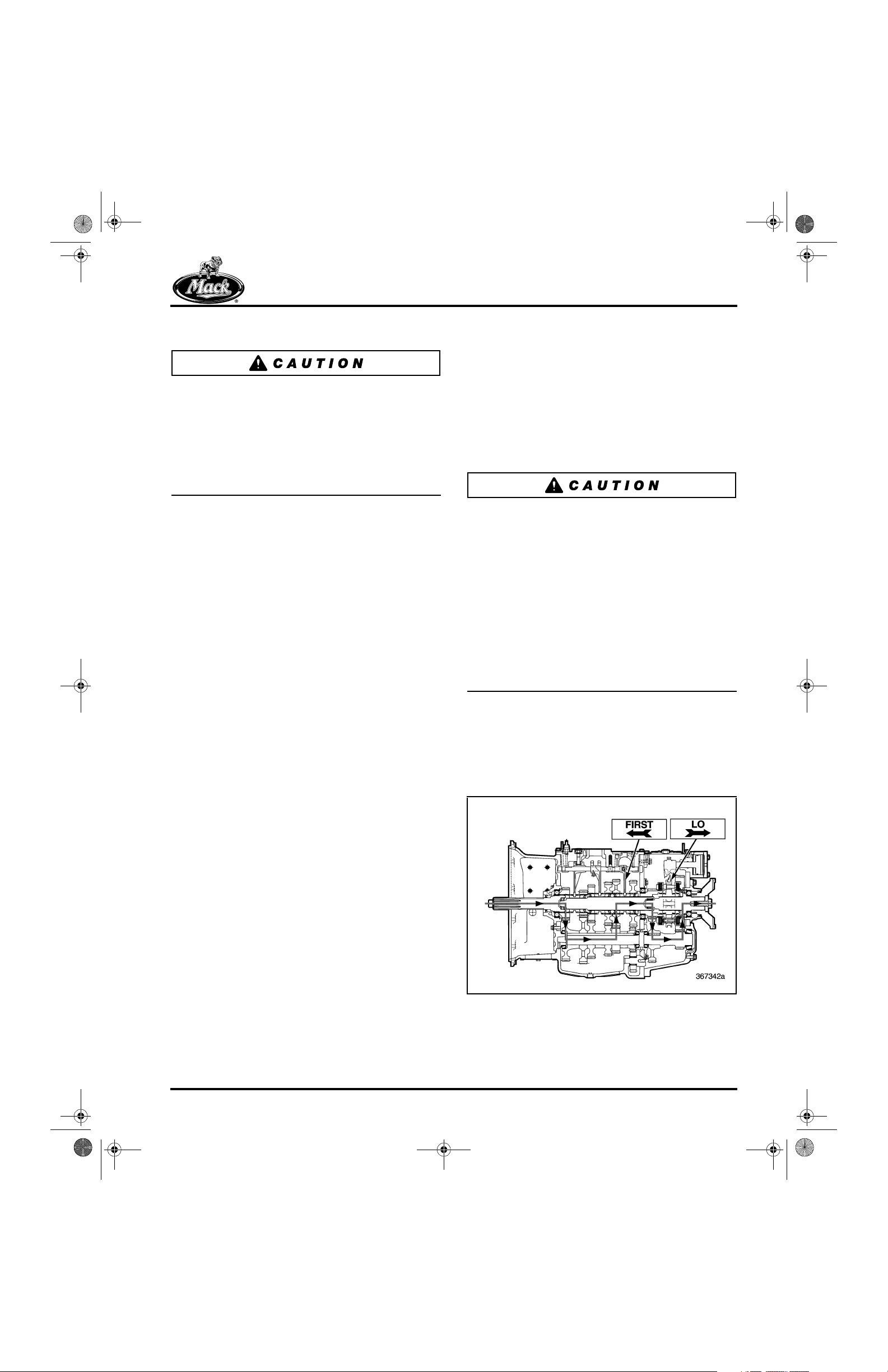

Power Flow Diagrams

The following illustrations show power flow

through the T310 transmission in each gear

range.

8

With the shift lever in neutral, flip the air shift

range selector down to Lo range. Then shift the

transmission into first gear. Shift up to second,

third, fourth and fifth speed gears, double

clutching between the gears. When maximum

engine RPM has been reached in fifth gear, flip

the air shift range selector up to Hi range

(preselect). Then move the shift lever through

neutral to sixth gear. As the shift lever passes

through neutral, the transmission is placed into Hi

range. Continue following the normal sequence

(7-8-9-10), being sure to double clutch from one

gear to the next.

Figure 8 — First Speed

Page 17

Page 28

10-126.bk Page 18 Thursday, December 19, 2002 10:55 AM

DESCRIPTION AND OPERATION

9

Figure 9 — Second Speed

10

12

Figure 12 — Fifth Speed

13

11

14

Figure 11 — Fourth Speed

Figure 10 — Third Speed

Figure 13 — Sixth Speed

Figure 14 — Seventh Speed

Page 18

Page 29

10-126.bk Page 19 Thursday, December 19, 2002 10:55 AM

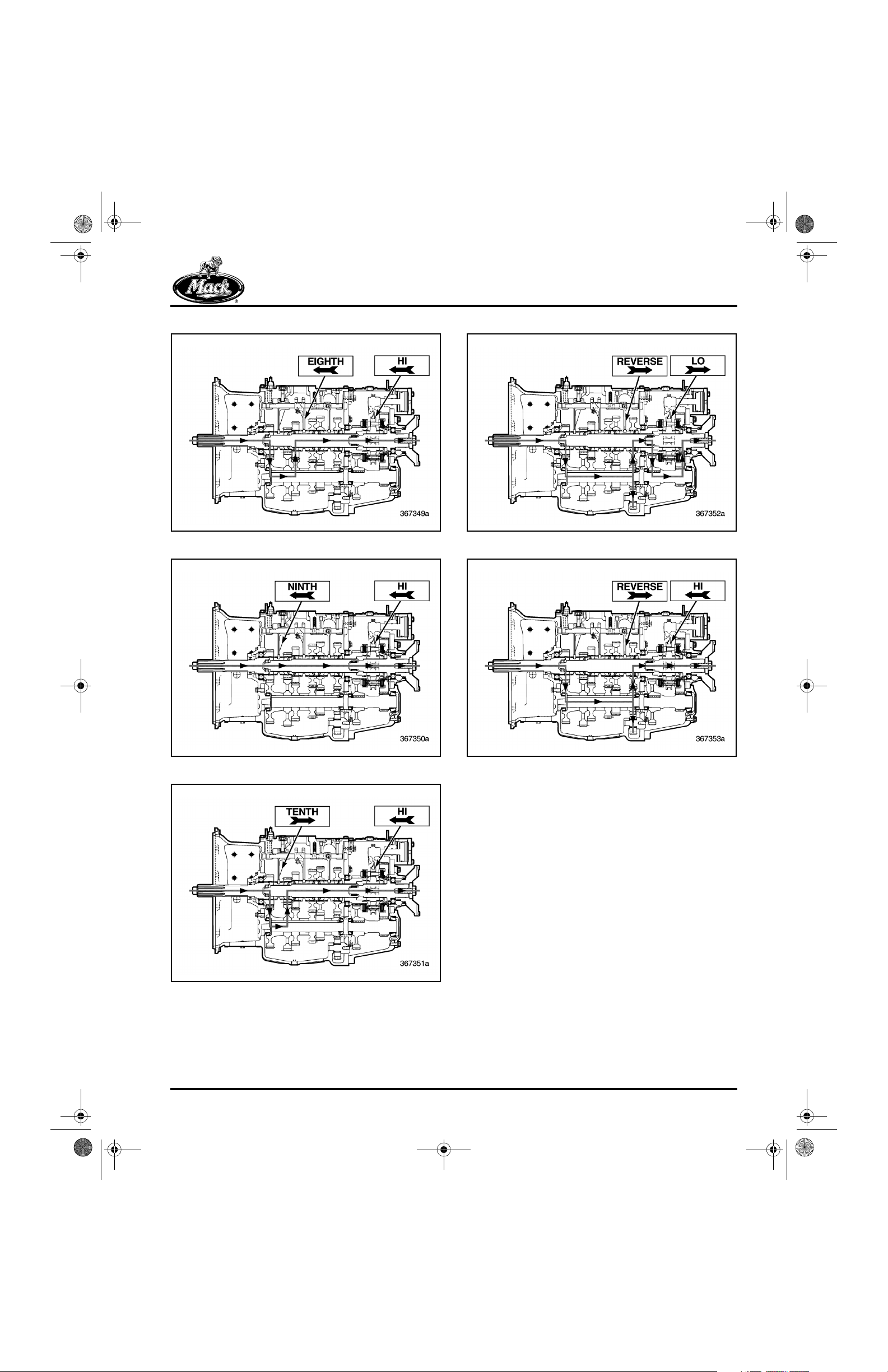

DESCRIPTION AND OPERATION

15

Figure 15 — Eighth Speed

16

18

Figure 18 — Reverse Speed (Lo)

19

17

Figure 16 — Ninth Speed

Figure 19 — Reverse Speed (Hi)

Figure 17 — Tenth Speed

Page 19

Page 30

10-126.bk Page 20 Thursday, December 19, 2002 10:55 AM

NOTES

Page 20

Page 31

10-126.bk Page 21 Thursday, December 19, 2002 10:55 AM

COMPONENT LOCATOR

COMPONENT LOCATOR

Page 21

Page 32

10-126.bk Page 22 Thursday, December 19, 2002 10:55 AM

COMPONENT LOCATOR

COMPONENT LOCATOR

20

Figure 20 — Major Component Locations for T310 Transmission

1. Main Drive Pinion Assembly

2. Main Case Shift Cover Assembly

3. Range Shift Valve Assembly

4. Compound Main Drive Gear

5. Rear Mainshaft and Synchronizer

Assembly

6. Range Shift Cylinder

7. Rear Mainshaft Bearing Cover

8. Synchronizer Assembly

9. Rear Countershaft Bearing Cover

10. Rear Countershaft Assembly

11. Front Countershaft Rear Bearing

Cover

12. Reverse Idler Gear

13. Front Countershaft Assembly

14. Front Mainshaft Assembly

15. Front Countershaft Front Bearing

Cover

Page 22

Page 33

10-126.bk Page 23 Thursday, December 19, 2002 10:55 AM

TROUBLESHOOTING

TROUBLESHOOTING

Page 23

Page 34

10-126.bk Page 24 Thursday, December 19, 2002 10:55 AM

TROUBLESHOOTING

TROUBLESHOOTING CHARTS

NOISY TRANSMISSION

Probable Cause Remedy

a. Low oil level a. Fill to correct level.

b. Wrong oil used b. Drain and refill with correct oil.

c. Side-mounted PTO installed too tight or too loose c. Reinstall PTO correctly.

d. Loose bell housing-to-flywheel housing capscrews d. Install new capscrews, using Loctite

e. Incorrect clutch-driven discs used e. Install correct clutch-driven discs.

f. Gears worn, chipped, rough, cracked f. Replace gears.

g. Bearings worn, cracked, corroded, galled, etc. g. Replace bearings.

h. Mismatched carrier ratios h. Install correct matched gearing.

i. Resonating (ringing) driveshaft i. Install suitable dampening material, then high-

speed balance driveshaft.

j. Driveline angles (air bags deflated) j. Correct driveline angles (allow air bags to fill).

®

.

HARD SHIFTING

Probable Cause Remedy

a. Incorrect driving practices a. Train driver in correct driving practices.

b. Low oil level b. Fill to correct level.

c. Improperly adjusted clutch, clutch linkage, clutch brake or shift

linkage

d. Wrong oil used d. Drain and refill with correct oil.

e. Remote shift linkage not lubricated e. Clean and lubricate.

f. Shift lever binding or has interference f. Relieve binding or interference.

g. Poppet balls binding in their holes g. Clean holes and balls.

h. Loose setscrews in shifters or shift forks h. Tighten to correct torque.

i. Worn spigot bearing i. Replace bearing.

j. Clutch brake ears broken j. Replace clutch brake.

k. Clutch discs worn into main drive pinion k. Replace clutch discs and main drive pinion.

l. Mainshaft snap ring or thrust washer failure l. Replace snap rings or thrust washers.

m. Improperly adjusted fourth/fifth eccentric pin m. Adjust properly.

n. PTO engaged n. Disengage PTO.

c. Adjust properly.

Page 24

Page 35

10-126.bk Page 25 Thursday, December 19, 2002 10:55 AM

Probable Cause Remedy

a. Excessive length and/or weight of gear shift lever and/or knob a. Replace with standard lever and/or knob.

b. Shift lever interference b. Remove interference.

c. Improperly adjusted remote control linkage c. Adjust properly.

d. Worn or loose mounting insulators d. Replace insulators.

e. Loose, broken or missing capscrews between clutch housing and

flywheel housing

f. Weak or broken shift rail poppet springs f. Replace springs.

g. Bent or worn shift forks g. Replace forks.

h. Broken snap rings h. Replace snap rings.

i. Shift rail bent or poppet notches worn i. Replace shift rail.

j. Worn taper or chipped teeth on sliding clutch teeth j. Replace sliding clutch and mating gear if clutch

k. Worn or damaged spigot bearing k. Replace bearing.

l. Engine flywheel housing misalignment l. Realign properly.

m. Chassis resonant ride m. Correct resonance.

TROUBLESHOOTING

GEAR DISENGAGEMENT (JUMPING OUT OF GEAR)

e. Replace capscrews, check threads in case.

teeth are damaged.

OIL LEAKS

Probable Cause Remedy

a. Oil level too high a. Drain to correct level.

b. Fill plug loose or O-ring defective or missing b. Tighten plug or correct O-ring condition.

c. Drain plug or magnetic plug loose c. Tighten plug.

d. Loose or missing capscrews d. Tighten or replace.

e. Improper lubricant used e. Drain and refill with correct oil.

f. Clogged breather f. Clean or replace.

g. Gaskets or O-rings broken, shifted or squeezed out of position g. Replace gaskets or O-rings.

h. Worn oil seals h. Replace seals.

i. O-rings or seals in air shift cylinder leaking air pressure into

transmission

BEARING FAILURE

Probable Cause Remedy

a. Dirt in system a. Clean system, replace bearings as needed,

b. Wrong grade of oil or contaminated oil b. Clean system, replace bearings as needed,

c. Excessive vibrations c. Eliminate vibrations, replace bearings.

d. Binding or seized propeller shaft slip yoke d. Clean and replace as needed.

e. Improper bearing clamping e. Replace bearings and reclamp using correct

f. Improper bearing installation (preloads, etc.) f. Replace using correct procedures.

i. Replace O-rings or seals.

flush and refill with clean oil.

flush and refill with clean oil.

procedures.

Page 25

Page 36

10-126.bk Page 26 Thursday, December 19, 2002 10:55 AM

TROUBLESHOOTING

AIR SHIFT MALFUNCTIONS

Probable Cause Remedy

a. Low system air pressure a. Wait for pressure to build back up to normal.

b. Restricted or clogged air filter in range shift valve b. Replace air filter.

c. Restricted air line (bent, squeezed, twisted, etc.) c. Re-route and/or replace air lines

d. Air lines too small d. Replace with correct size air lines.

e. Defective O-rings in air shift cylinder e. Replace O-rings.

f. Scored air shift cylinder or piston f. Repair or replace cylinder or piston.

g. Defective range shift valve and/or air shift selector valve (on shift

lever)

h. Defective synchronizer h. Repair or replace as needed.

i. Incorrect driving practices (not preselecting) i. Train driver in correct driving practices.

j. Range synchronizer friction discs worn or burned j. Replace synchronizer discs as needed.

k. Intermixed synchronizer parts k. Install matched parts.

g. Repair or replace cylinder or piston.

Page 26

Page 37

10-126.bk Page 27 Thursday, December 19, 2002 10:55 AM

MAINTENANCE

MAINTENANCE

Page 27

Page 38

maintenance.fm Page 28 Thursday, January 2, 2003 7:57 AM

MAINTENANCE

TRANSMISSION

MAINTENANCE

Checking Oil Level

Perform oil level check when the oil is at

operating temperature. The vehicle must be in a

level position, both front-to-rear and side-to-side.

r Check the transmission oil level at the

intervals specified in the Maintenance and

Lubrication Manual (TS494).

r To check the oil level in the transmission,

first remove the filler plug (2) from the right

side of the main case.

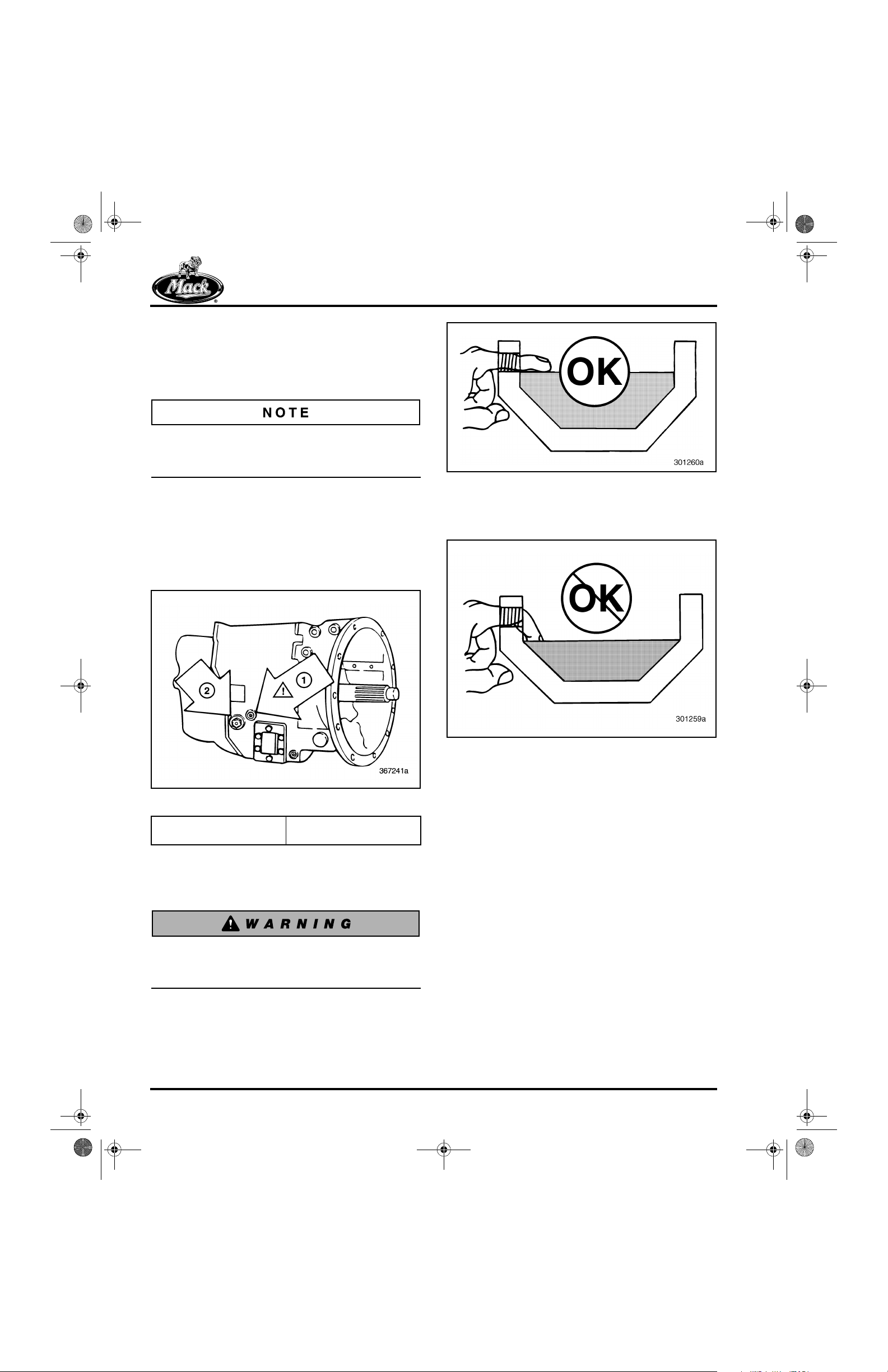

21

22

Figure 22 — Correct Oil Level

r If oil can only be felt by reaching the finger

down into the unit, the oil level is too low.

23

Figure 21 — Oil Filler and Check Plug

1. Magnetic Filter Plug (Not

for Level Check)

2. Oil Filler and Check Plug

r The oil must be level with the bottom of the

filler plug hole as determined by feel or by

visual inspection.

Be careful not to burn your finger in hot gear

oil when checking the oil level in the

transmission.

Figure 23 — Incorrect Oil Level

r Add specified make-up oil, if needed, until

the oil is level with the bottom of the filler

plug hole. Do NOT overfill. Use oil of the

proper specification. MACK-approved gear

oils can be found on the internet at

www.macktrucks.com.

r Reinstall and tighten the oil filler plug

(Figure 21) as follows:

1. Check that the O-ring on the plug is not

cut or damaged. Replace as necessary.

2. Install the plug and tighten to 35–50 lb-ft

(47–68 N•m) torque.

Page 28

Page 39

maintenance.fm Page 29 Thursday, January 2, 2003 7:57 AM

MAINTENANCE

Changing Oil

Preserve the environment! Drained gear oil is

classified as a hazardous toxic material which

must be recovered, handled, stored and disposed

of according to applicable State or Federal

guidelines.

Change Interval

r Change the oil at intervals specified in the

Maintenance and Lubrication Manual

(TS494).

Draining Oil

r Before draining oil from the transmission,

the oil should be at normal operating

temperature.

r Remove the magnetic drain plug from the

bottom of the transmission main case and

drain the hot oil into an industry-approved

recovery container.

Oil Fill

r Remove the oil filler plug (2) (Figure 25),

then fill the transmission using specified oil

until the oil is level with the bottom of the

filler plug hole (also see Figure 22). Do NOT

overfill.

MACK-approved lubricants can be found on the

internet at www.macktrucks.com

the Parts and Service category.

r Reinstall and tighten the oil filler plug as

follows:

1. Check that the O-ring on the plug is not

cut or damaged. Replace as necessary.

2. Install the plug and tighten to 35–50 lb-ft

(47–68 N•m) torque.

25

, then click on

r Clean and replace the magnetic drain plug,

then torque the plug to 25–30 lb-ft

(34–41 N•m).

24

Figure 24 — Plug Locations

Figure 25 — Oil Filler and Check Plug

1. Magnetic Filter Plug (Not

for Level Check)

2. Oil Filler and Level Plug

Be sure to add oil to the transmission through the

filler hole, NOT the magnetic filter plug hole.

Damage to the transmission and seals can occur

due to overfilling. The magnetic oil filter hole is

higher on the transmission case than the filler

hole.

1. Magnetic Filter Plug

2. Oil Temperature Sensor

3. Oil Drain Plug

4. Oil Fill and Level Plug

Page 29

Page 40

maintenance.fm Page 30 Thursday, January 2, 2003 7:57 AM

MAINTENANCE

Magnetic Oil Filter Plug

Remove the magnetic oil filter plug and clean the

magnet in the plug every time the oil is changed.

Reinstall the magnetic plug. Tighten the plug to

20–23 lb-ft (27–31 N•m) torque.

Air Breather

The T310 has one air breather located on the

main case shift cover. The air breather should be

removed and cleaned with a suitable solvent

every time the oil is changed. Also check to be

sure that airflow through the breather is

unobstructed. Reinstall breather into the main

case shift cover and tighten until snug.

Page 30

Page 41

10-126.bk Page 31 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

REPAIR INSTRUCTIONS

Page 31

Page 42

10-126.bk Page 32 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

TRANSMISSION

DISASSEMBLY PROCEDURES

[320]

Unless a complete overhaul is necessary, remove

only those parts required to gain access to faulty

parts. Do not disturb parts with a heavy press fit

(interference fit) unless replacement is

necessary. When replacement is necessary, use

proper press setups and pullers to protect usable

parts from damage.

External inspection of the unit before cleaning

and disassembly often reveals information about

existing operating conditions. This may help

when diagnosing problems.

1. Clean the transmission externally and mount

it in an overhaul stand. Drain the lubricant

and plug any air line openings to prevent dirt

from entering.

Lift and move the transmission with a hoist, using

the two lifting brackets provided.

2. Disconnect the air lines attached to the

range shift valve and the range shift cylinder.

Air lines are installed using a push/pull type

fitting and are best removed using tool kit

9032-1800trk which can be obtained through

the MACK parts system. Disconnect the air

lines using the following procedure:

a. Select the appropriate size release tool

from kit 9032-1800trk.

26

During disassembly, remember the sequence in

which components and individual parts are

removed from the transmission. It is good

practice to keep related parts together in groups

when removed. Small parts such as shims and

spacers can be wired to the larger pieces with

which they belong. Groups of parts can be kept

together in boxes.

Keep parts such as shim packs, bearing cones,

bearing retainers (covers), bearing cups and

gears with the original countershaft from which

they are removed. Mark each countershaft and

bearing cover before removal. Mark the upper left

front and rear countershafts and bearing covers

(viewed from rear) as number 1. Mark the upper

right front and rear countershafts and bearing

covers (viewed from rear) as number 2. Mark the

lower front and rear countershafts and bearing

covers as number 3.

Figure 26 — Air Line Release Tools

Page 32

Page 43

10-126.bk Page 33 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

b. Insert the tool over the air line and

release the lines from the fittings by

pushing in toward the fitting and at the

same time, pulling on the hose.

27

5. Remove the range shift valve, interlock

sleeve, spring, pin and O-ring from the main

case shift cover.

29

Figure 27 — Removing Air Lines

1. Air Line Removal Tool

9032-1800trk

2. Air Hose Fitting Release

Ferrule

3. Label all disconnected air lines for proper

reassembly.

4. Using the appropriate tools, remove the

range shift valve 5/32 Allen-head screws

(outer) and capscrews (inner).

28

Figure 29 — Removing Range Shift Components

1. Range Shift Valve

2. O-Ring

3. Interlock Sleeve

4. Interlock Spring

5. Interlock Pin

6. Shift Cover

Figure 28 — Removing Range Shift Valve Allen-Head

Screws

Page 33

Page 44

10-126.bk Page 34 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

6. Remove the clutch release bearing

assembly, shafts, yoke and clutch brake (if

equipped).

7. With transmission in neutral, remove the

main case shift cover capscrews.

30

Figure 30 — Removing Main Case Shift Cover

Capscrews

8. Remove the main case shift cover assembly

and cover gasket.

31

9. Remove the rear case top cover capscrews.

32

Figure 32 — Removing Rear Case Top Cover Capscrews

10. Remove the rear case top cover. Carefully

scrape RTV sealant from around top cover

opening.

33

Figure 31 — Removing Main Case Shift Cover

Page 34

Figure 33 — Removing Rear Case Top Cover

Page 45

10-126.bk Page 35 Thursday, December 19, 2002 10:55 AM

To remove the drive yoke bolt, place at least two

gears in both the main case and the rear case

into engagement. This will lock the transmission

gearing and prevent it from rotating while

removing the yoke bolt.

11. Reach through the rear case top opening

and verify that the synchronizer assembly

sliding clutch is engaged.

12. Reach into the main case top opening and

move at least two sliding clutches into

engagement. This locks two different gears

to the mainshaft and prevents the gears and

shaft of the transmission from rotating.

REPAIR INSTRUCTIONS

14. Remove the drive yoke, using a suitable

puller such as J 07804-A or equivalent.

35

13. Remove the drive yoke or drive flange by

separating the capscrew and clamp plate.

34

Figure 35 — Removing Drive Yoke

15. Shift the transmission gears into neutral.

Verify that the transmission is in neutral.

16. If not already done, disconnect the air lines

from the range shift cylinder. Label air lines

for correct installation during assembly.

Figure 34 — Removing Clamp Plate and Capscrew

Page 35

Page 46

10-126.bk Page 36 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

17. Remove the shift fork locking bolt.

36

Figure 36 — Removing Shift Fork Locking Bolt

18. Remove the four bolts that secure the shift

cylinder to the rear case.

37

19. Remove the shift cylinder cover and O-ring.

38

Figure 38 — Removing Shift Cylinder Cover

20. While holding the shift fork, slide the shift

cylinder from the rear of the transmission.

Remove the shift cylinder-to-rear case

gasket.

Figure 37 — Removing Shift Cylinder Bolts

To help remove the shift cylinder, use a plastic

mallet to lightly tap on the piston to loosen the

shift rail from the fork.

39

Figure 39 — Removing Shift Cylinder

Page 36

Page 47

10-126.bk Page 37 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

21. Remove the range shift cylinder gasket and

discard.

40

Figure 40 — Removing Range Shift Cylinder Gasket

22. Number the front countershaft front bearing

covers and the rear countershaft rear

bearing covers, using a grease pencil. Write

number 1 on the upper right front cover

(viewed from front), number 2 on the upper

left front cover (viewed from front) and

number 3 on the lower front cover. Write

number 1 on the upper left rear cover

(viewed from rear), number 2 on the upper

right rear cover (viewed from rear) and

number 3 on the lower rear cover.

41

42

Figure 42 — Mark Rear Countershaft Bearing Covers for

Placement

23. Remove all of the rear countershaft bearing

cover capscrews.

43

Figure 41 — Mark Front Countershaft Front Bearing

Covers for Placement

Figure 43 — Removing Rear Countershaft Bearing

Cover Capscrews

Page 37

Page 48

10-126.bk Page 38 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

24. Remove the jackscrew plugs from the

covers.

44

Figure 44 — Removing Jackscrew Plugs

Pry the plugs loose using a thin knife-edge or

similar tool. Do not cut through plugs during

removal. Save for reuse, or replace if necessary.

26. Mark the rear countershafts as shown in

Figure 46 so they can be installed in the

same position during reassembly. Refer to

Figure 42 for number locations.

46

Figure 46 — Marking Rear Countershafts

27. Remove the rear mainshaft bearing cover

capscrews. Remove the jackscrew plugs

from the cover.

47

25. Remove the rear countershaft bearing

covers, shims and O-rings. Jackscrew holes

are provided to assist removal.

45

Figure 45 — Removing Bearing Cover

Figure 47 — Removing Rear Mainshaft Bearing Cover

Capscrews

Page 38

Page 49

10-126.bk Page 39 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

28. Remove the rear mainshaft bearing cover.

Jackscrew holes are provided to assist in

removal.

48

Figure 48 — Removing Rear Mainshaft Bearing Cover

Using Jackscrews

49

29. With the transmission in a vertical position

(rear case upward), remove the two

capscrews located inside the rear case.

50

Figure 50 — Removing Outer Rear Case-to-Main Case

Capscrews

30. Remove the remaining capscrews and

dowel bolts holding the rear case to the main

case.

Figure 49 — Rear Mainshaft Bearing Cover Removed

When separating the rear case from the front

case, make sure the transmission is in the

vertical position. The rear countershafts are

not supported when the case is removed.

They can fall out and cause damage or

personal injury.

Tap dowel bolts out of the rear case using a brass

hammer or a combination of a brass hammer and

a steel hammer, as long as contact is made with

the brass hammer only.

51

Figure 51 — Removing Dowel Bolts

Page 39

Page 50

10-126.bk Page 40 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

52

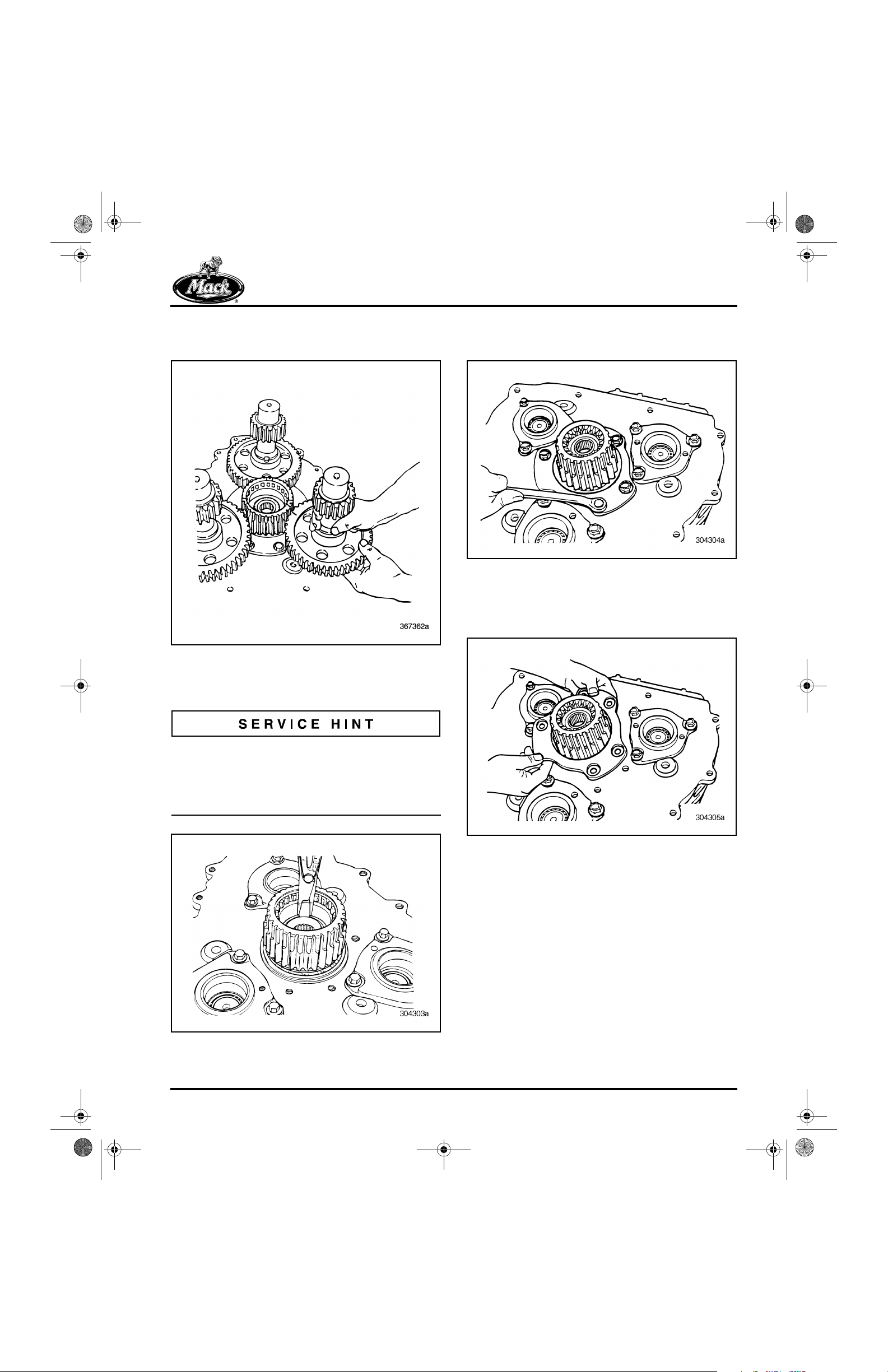

Due to the relatively small size of the rear

countershaft Lo gear, it is necessary to first

remove each rear countershaft rear bearing cone

to allow removal of the rear mainshaft. The rear

countershaft bearings overhang the rear

mainshaft Lo gear as shown in Figure 54. This

bearing overhang prevents mainshaft removal if

the bearings are not removed first.

54

Figure 52 — Removing Inner Rear Case-to-Main Case

Capscrews

31. Lift the rear case from the front case. Lift

only the case, not the compound gear set or

output shaft. Tap on the output shaft to

loosen it if necessary.

Be sure unit is vertical, so that the

countershafts will not fall out when the case

is removed.

53

Figure 54 — Rear Countershaft Bearing Overhang

Page 40

Figure 53 — Removing Rear Case

Page 51

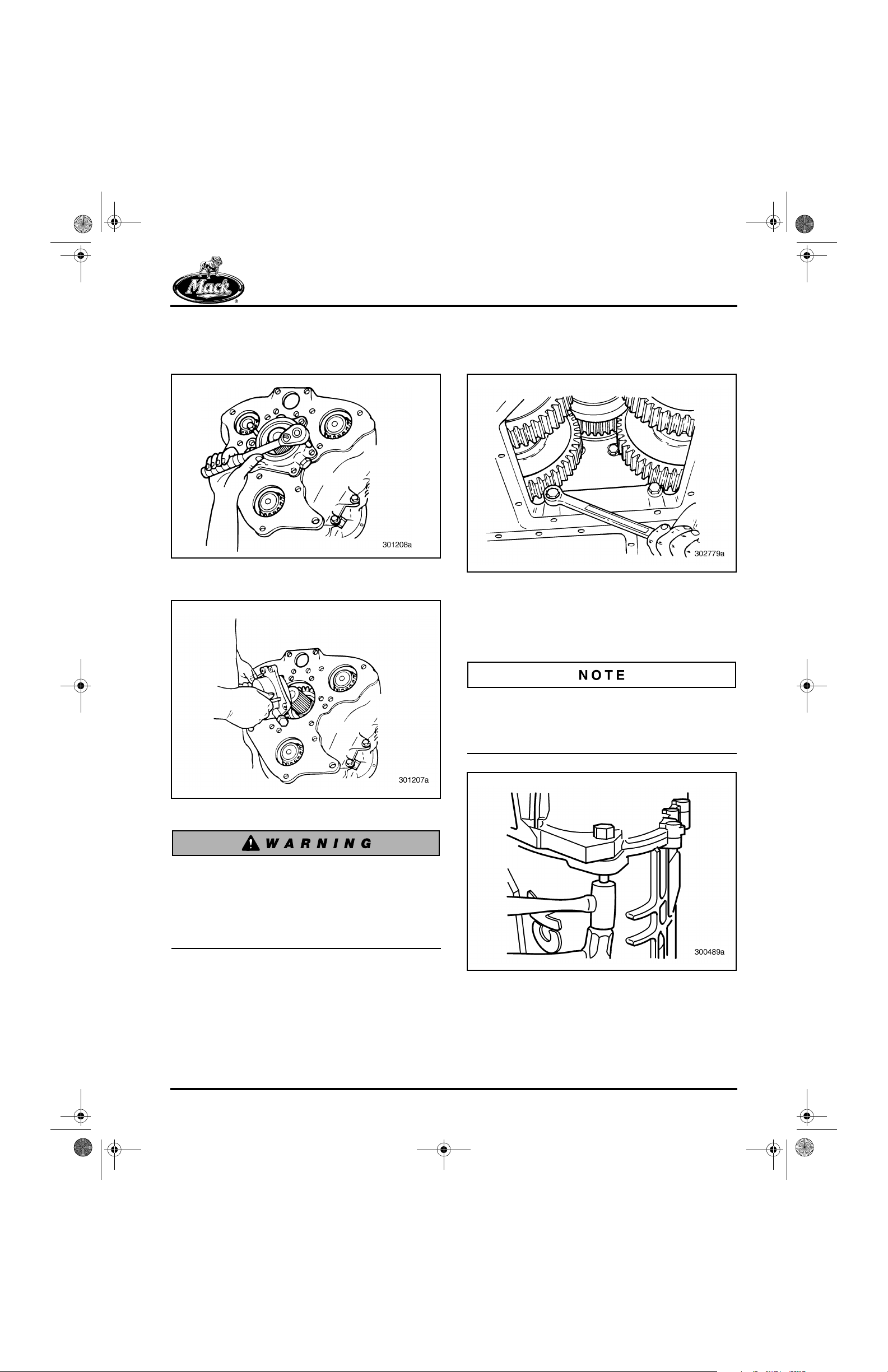

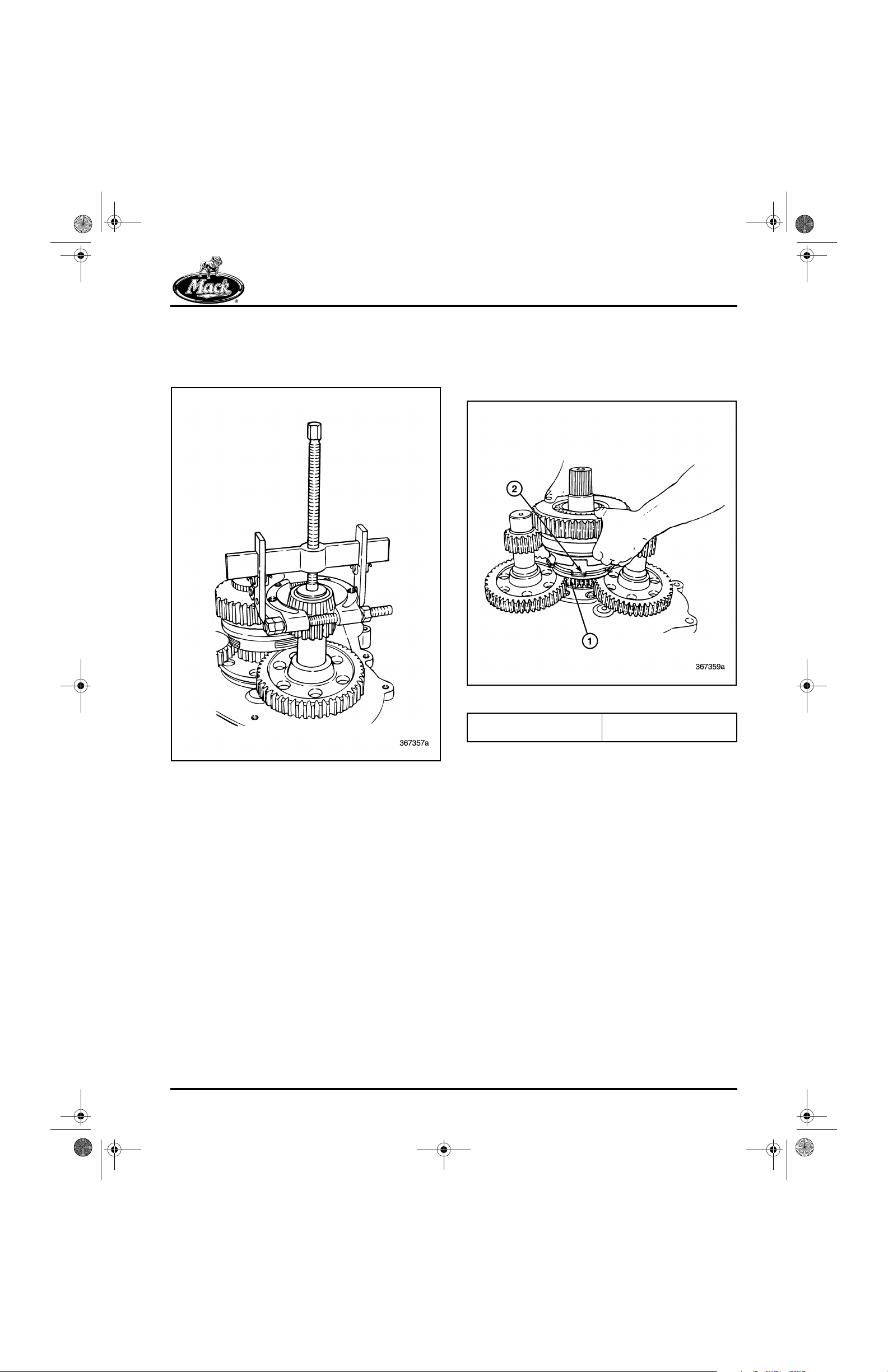

10-126.bk Page 41 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

32. Using a suitable puller arrangement, such as

two jaw puller J 21834-4A and bearing

separator J 8176 or equivalent, remove all

three rear countershaft rear bearing cones.

55

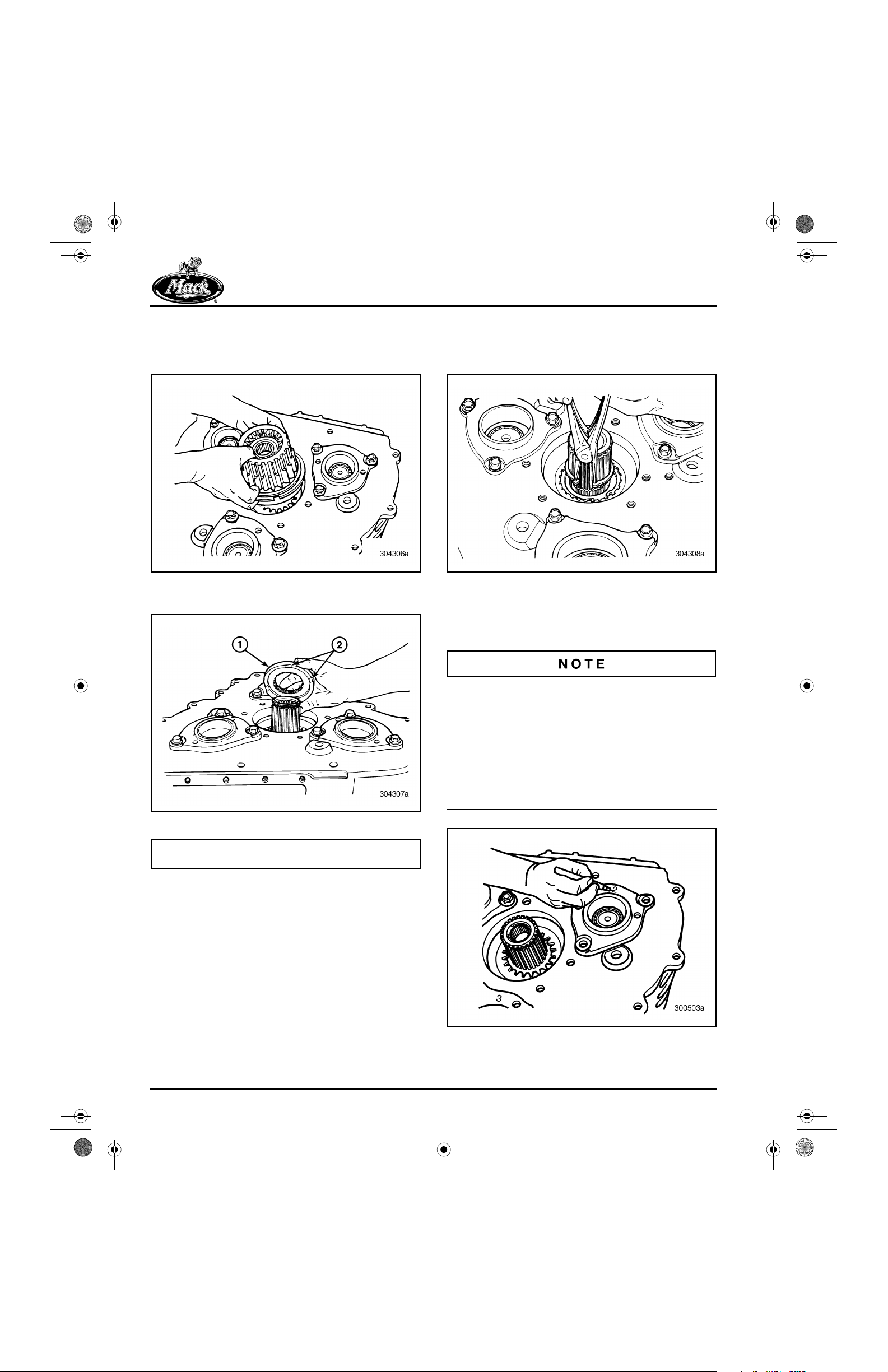

33. Remove the synchronizer and rear

mainshaft assembly from the main drive

gear. Allow the Hi-range (forward)

synchronizer plates and backing plate to

remain on the main drive gear.

56

Figure 55 — Removing Rear Countershaft Rear Bearing

Cone

Figure 56 — Removing Synchronizer and Output Shaft

1. Main Drive Gear Backing

Plate

2. Hi-Range Synchronizer

Plates

Page 41

Page 52

10-126.bk Page 42 Thursday, December 19, 2002 10:55 AM

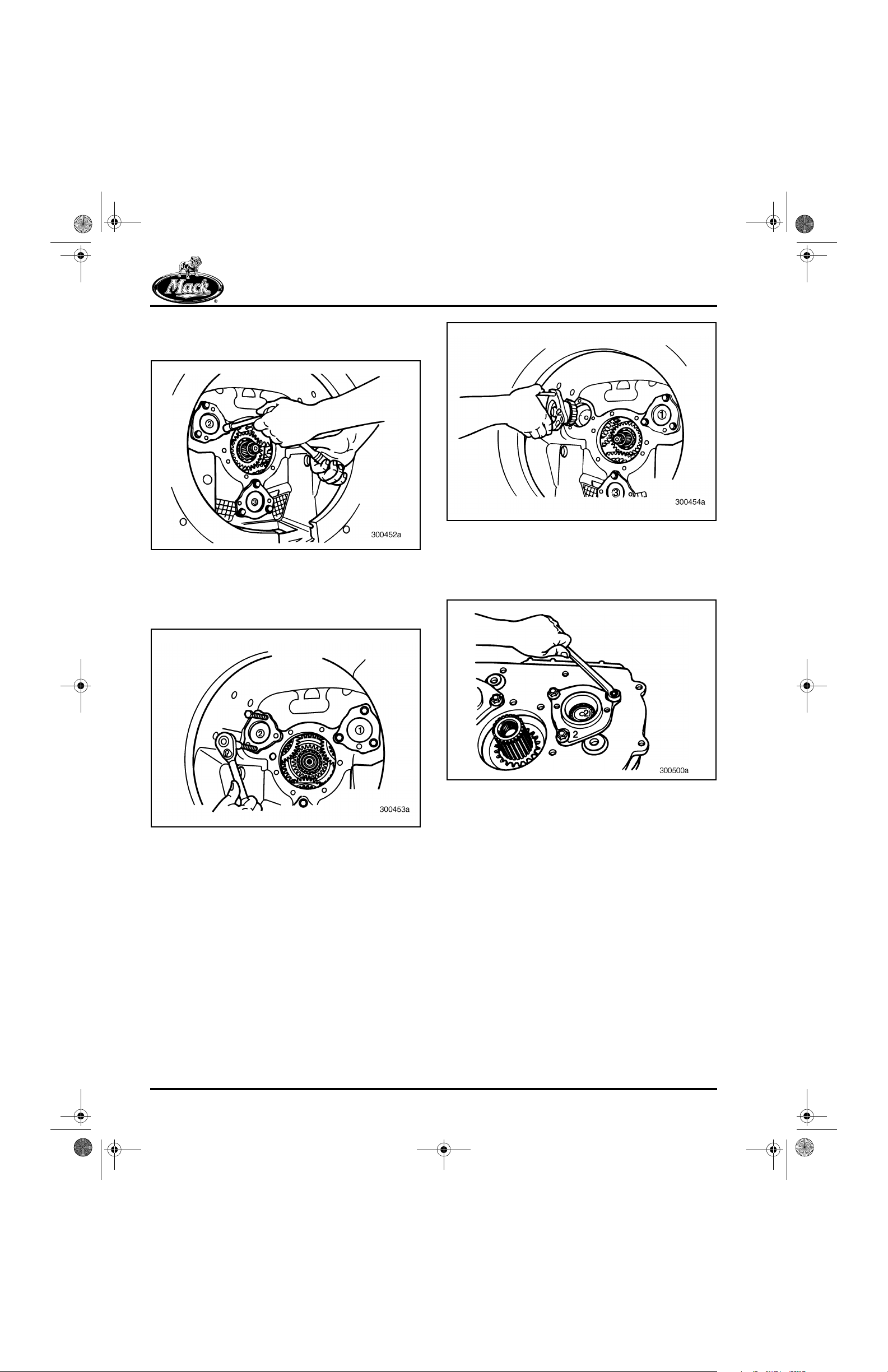

REPAIR INSTRUCTIONS

34. Remove the Hi-range synchronizer plates,

and the main drive gear backing plate.

57

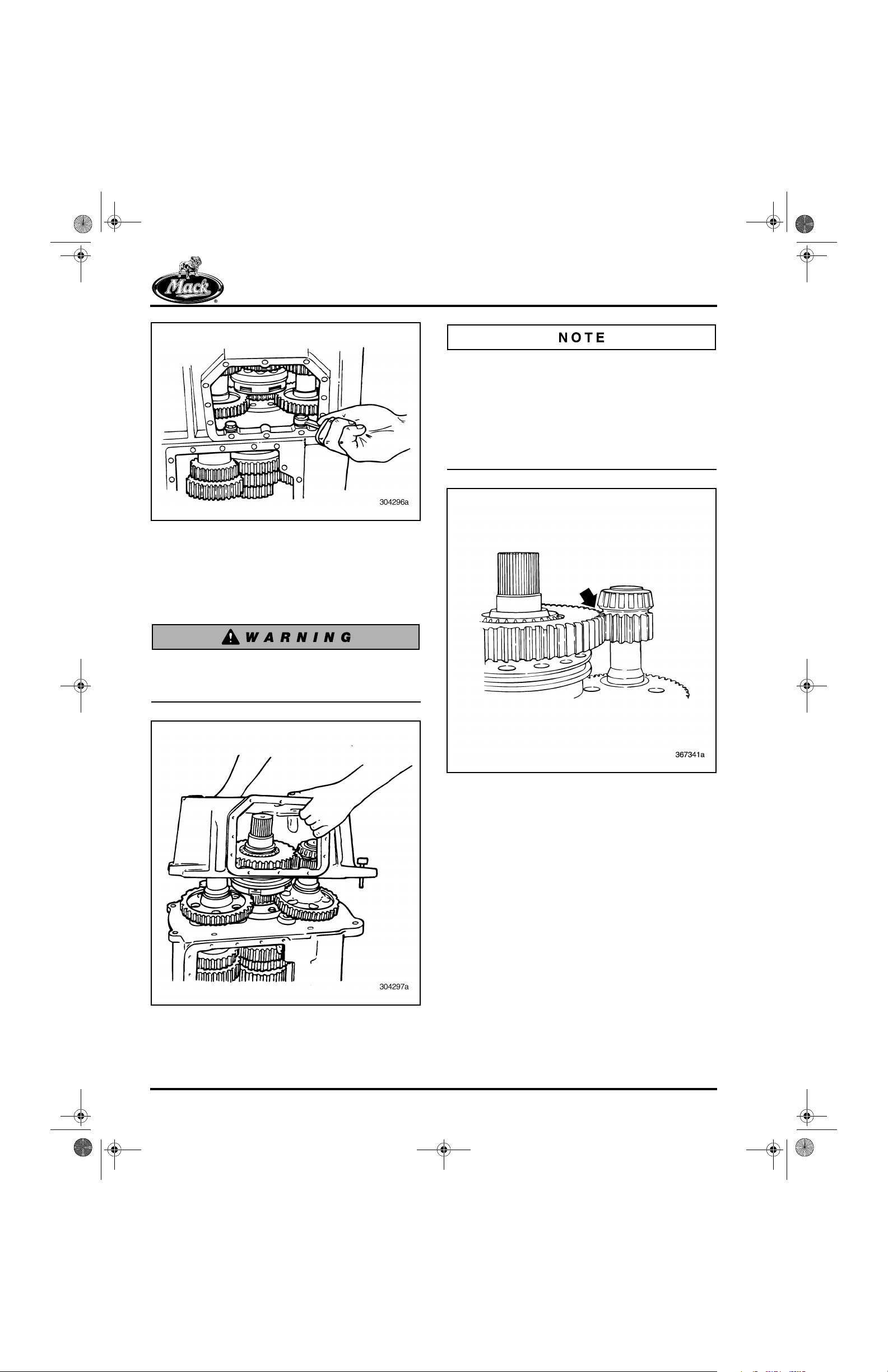

35. Mark the rear countershafts (if not already

done) so that they can be installed in the

same location during installation.

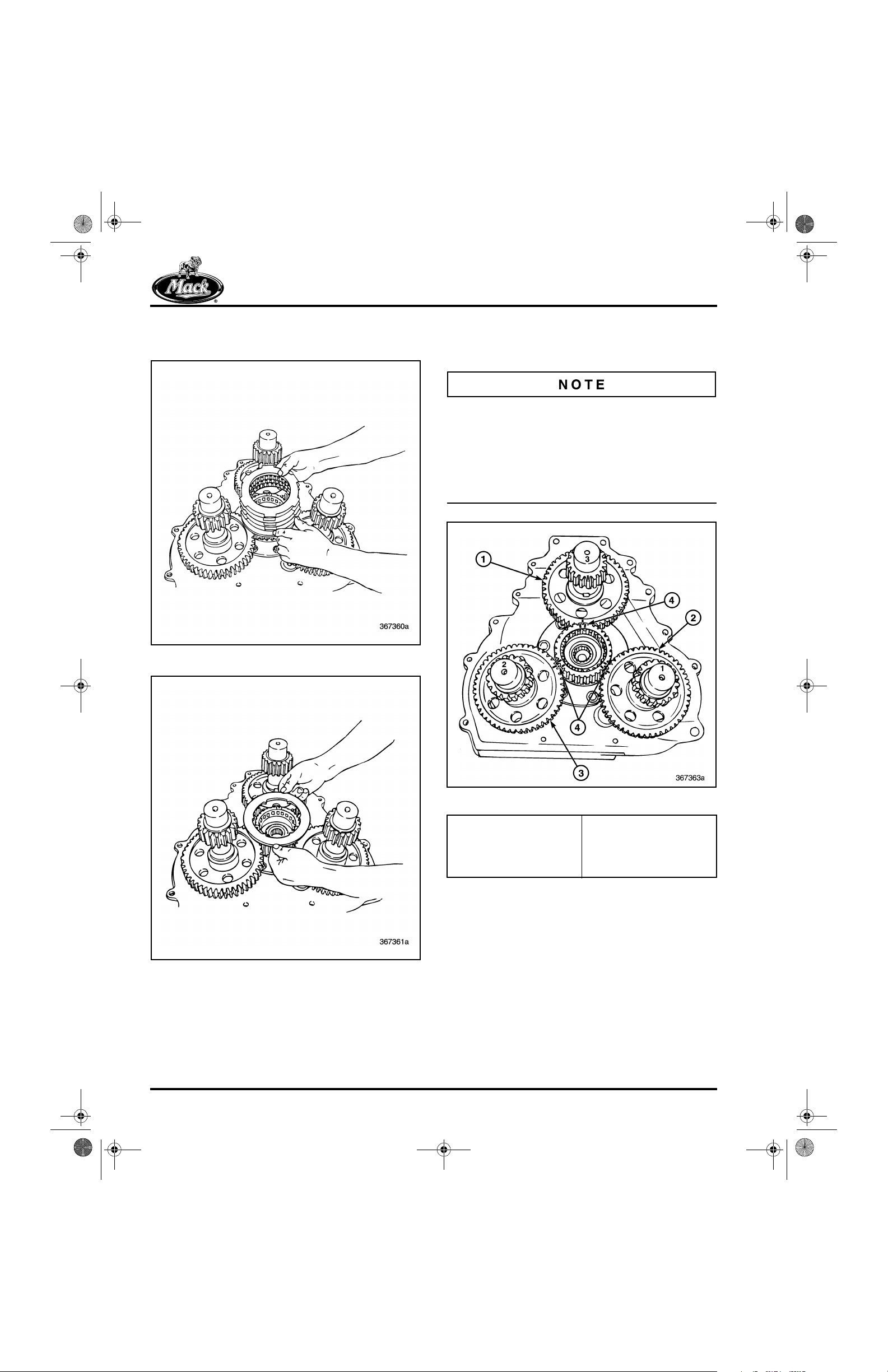

Notice the gear timing marks. If no timing marks

are present, use white paint to mark the gears in

three equally spaced marks on the mainshaft.

The countershaft mating gear teeth must be

marked in alignment with the shaft keyway. Mark

the mainshaft main drive gear-to-countershaft

gears.

59

Figure 57 — Removing Hi-Range Synchronizer Plates

58

Figure 58 — Removing Main Drive Gear Backing Plate

Figure 59 — Main Drive Gear-to-Countershaft Timing

1. Lower Countershaft

(No. 3)

2. Upper Left Countershaft

(No. 1)

3. Upper Right Countershaft

(No. 2)

4. Main Drive Gear-toCountershaft Timing

Marks

Page 42

Page 53

10-126.bk Page 43 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

36. Remove the three rear countershafts from

the rear of the transmission.

60

38. Remove the compound main drive gear

retaining plate capscrews.

62

Figure 62 — Removing Compound Main Drive Gear

Retaining Plate Capscrews

39. Remove the compound main drive gear

retaining plate.

63

Figure 60 — Removing Rear Case Countershafts

37. Remove the snap ring from inside the

compound main drive gear.

To help in removing the compound main drive

gear snap ring, use a pry bar to slightly lift the

front mainshaft during removal. This allows more

clearance and frees the snap ring from the snap

ring groove.

61

Figure 63 — Removing Compound Main Drive Gear

Retaining Plate

Figure 61 — Removing Main Drive Gear Snap Ring

Page 43

Page 54

10-126.bk Page 44 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

40. Remove the compound main drive gear

(with ball bearing) and the spacer from the

front mainshaft.

64

Figure 64 — Removing Main Drive Gear from Front

Mainshaft

65

41. Using suitable snap ring pliers, remove the

mainshaft snap ring directly behind the

previously removed spacer.

66

Figure 66 — Spacer Mainshaft Snap Ring

42. Mark the front countershaft rear bearing

covers and front countershafts for correct

placement during reassembly.

Figure 65 — Removing Spacer from Front Mainshaft

1. Spacer 2. Spacer Lubrication

Grooves

If not already done, use a grease pencil to

number the front countershaft rear bearing

covers. Write number 1 on the upper left rear

cover (viewed from rear), number 2 on the upper

right rear cover (viewed from rear), and number 3

on the lower rear cover. Also, mark the front

countershafts (use the same numbers and

locations indicated above) so that they can be

installed in the same position during reassembly.

67

Page 44

Figure 67 — Mark Front Countershafts and Front

Countershaft Rear Bearing Covers

Page 55

10-126.bk Page 45 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

43. Position the transmission case horizontally.

Remove the main drive pinion bearing cover

capscrews.

68

Figure 68 — Removing Pinion Bearing Cover Capscrews

44. Remove the main drive pinion bearing

assembly. Jackscrew holes are provided to

assist in removal.

69

45. Remove main drive pinion bearing assembly

from the case.

70

Figure 70 — Removing Main Drive Pinion Assembly

46. Remove the exposed sliding clutch.

71

Figure 69 — Use Jackscrews to Remove Main Drive

Pinion Assembly

Figure 71 — Removing Sliding Clutch

Page 45

Page 56

10-126.bk Page 46 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

47. Remove the No. 2 (upper left) front

countershaft front bearing cover capscrews.

72

Figure 72 — Removing No. 2 Front Countershaft Front

Bearing Cover Capscrews

48. Using jackscrews, remove the No. 2 (upper

left) front countershaft front bearing cover.

73

74

Figure 74 — No. 2 Front Countershaft Front Bearing

Cover Removed

49. Remove the No. 2 (upper right) front

countershaft rear bearing cover capscrews.

75

Figure 73 — Removing No. 2 Front Countershaft Front

Bearing Cover

Page 46

Figure 75 — Removing No. 2 Front Countershaft Rear

Bearing Cover Capscrews

Page 57

10-126.bk Page 47 Thursday, December 19, 2002 10:55 AM

50. Remove the No. 2 (upper right) front

countershaft rear bearing cover, using

jackscrews. Remove shim with cover.

76

REPAIR INSTRUCTIONS

Removal is easier if the transmission is in the

vertical position.

78

Figure 76 — Removing No. 2 Front Countershaft Rear

Bearing Cover

77

Figure 77 — No. 2 Front Countershaft Rear Bearing

Cover Removed

51. Using a pry bar, move the mainshaft

rearward in the case to relieve pressure on

the snap rings and free mainshaft gears

from countershaft gears.

52. Remove the No. 2 countershaft (upper right,

as viewed from rear) from the case.

Figure 78 — Removing No. 2 Countershaft from

Transmission Case

53. Using tool J 34630 or a slide hammer,

remove the upper right reverse idler shaft

(next to No. 2 countershaft location). To

prevent damage to the reverse idler gear,

catch the gear as it separates from the shaft.

79

Figure 79 — Using Tool J 34630 to Remove Reverse Idler

Shaft

Page 47

Page 58

10-126.bk Page 48 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

80

Figure 80 — Removing Reverse Idler Gear and Shaft

81

82

Figure 82 — Removing Snap Ring from Inside Reverse

Speed Gear

58. Remove the external-toothed and internaltoothed thrust washers from inside the

reverse speed gear.

83

Figure 81 — Reverse Idler Gear and Shaft Removed

54. Remove the No. 1 (upper left) front

countershaft rear bearing cover capscrews.

55. Using jackscrews, remove the No. 1 (upper

left) front countershaft rear bearing cover.

Remove shims with cover.

56. Using tool J 34630 or a slide hammer,

remove the upper left reverse idler shaft

(next to No. 1 countershaft). To prevent

damage to the reverse idler gear, catch the

gear as it separates from the shaft.

57. Remove the snap ring from inside the

reverse speed gear.

Figure 83 — Removing External-Toothed Thrust Washer

84

Figure 84 — Removing Internal-Toothed Thrust Washer

Page 48

Page 59

10-126.bk Page 49 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

59. Remove the reverse gear mainshaft snap

ring.

85

Figure 85 — Removing Reverse Gear Mainshaft Snap

Ring

1. Snap Ring 2. Reverse Gear

60. From top of case, slide the reverse gear and

reverse/first sliding clutch forward.

86

61. Using a pry bar, move the rear end of the

No. 1 (upper left) countershaft away from the

mainshaft as far as possible without

damaging the bearing. Block the

countershaft in this position, using wadding

made from rags.

87

Figure 87 — Moving and Blocking No. 1 (Upper Left)

Countershaft Away from Mainshaft

62. Tip the front end of the mainshaft outward

and remove it from the case.

Figure 86 — Sliding Reverse Gear and Reverse/First

Clutch Forward

The reverse gear is free on the mainshaft and

can fall off when handling the mainshaft

assembly.

88

Figure 88 — Removing the Mainshaft

Page 49

Page 60

10-126.bk Page 50 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

63. Remove the No. 3 (lower) front countershaft

rear bearing cover capscrews.

64. Using jackscrews, remove the No. 3 (lower)

front countershaft rear bearing cover.

Remove shims with cover.

65. Using tool J 34630 or a slide hammer,

remove the lower reverse idler shaft (next to

No. 3 countershaft). To prevent damage to

the reverse idler gear, catch the gear as it

separates from the shaft.

66. Remove the No. 1 (upper left) front

countershaft by pulling and tilting the front

end of the shaft upward.

89

67. Remove the No. 3 (lower) countershaft by

pulling and tilting the front end of the shaft

upward.

90

Figure 90 — Removing No. 3 Lower Countershaft

68. Remove the remaining No. 1 (upper right,

viewed from front) and No. 3 (lower) front

countershaft front bearing cover capscrews

and bearing covers. Use jackscrews to

remove the covers.

91

Figure 89 — Removing No. 1 Upper Left Countershaft

Figure 91 — Remaining No. 1 and No. 3 Front

Countershaft Bearing Covers

Page 50

Page 61

10-126.bk Page 51 Thursday, December 19, 2002 10:55 AM

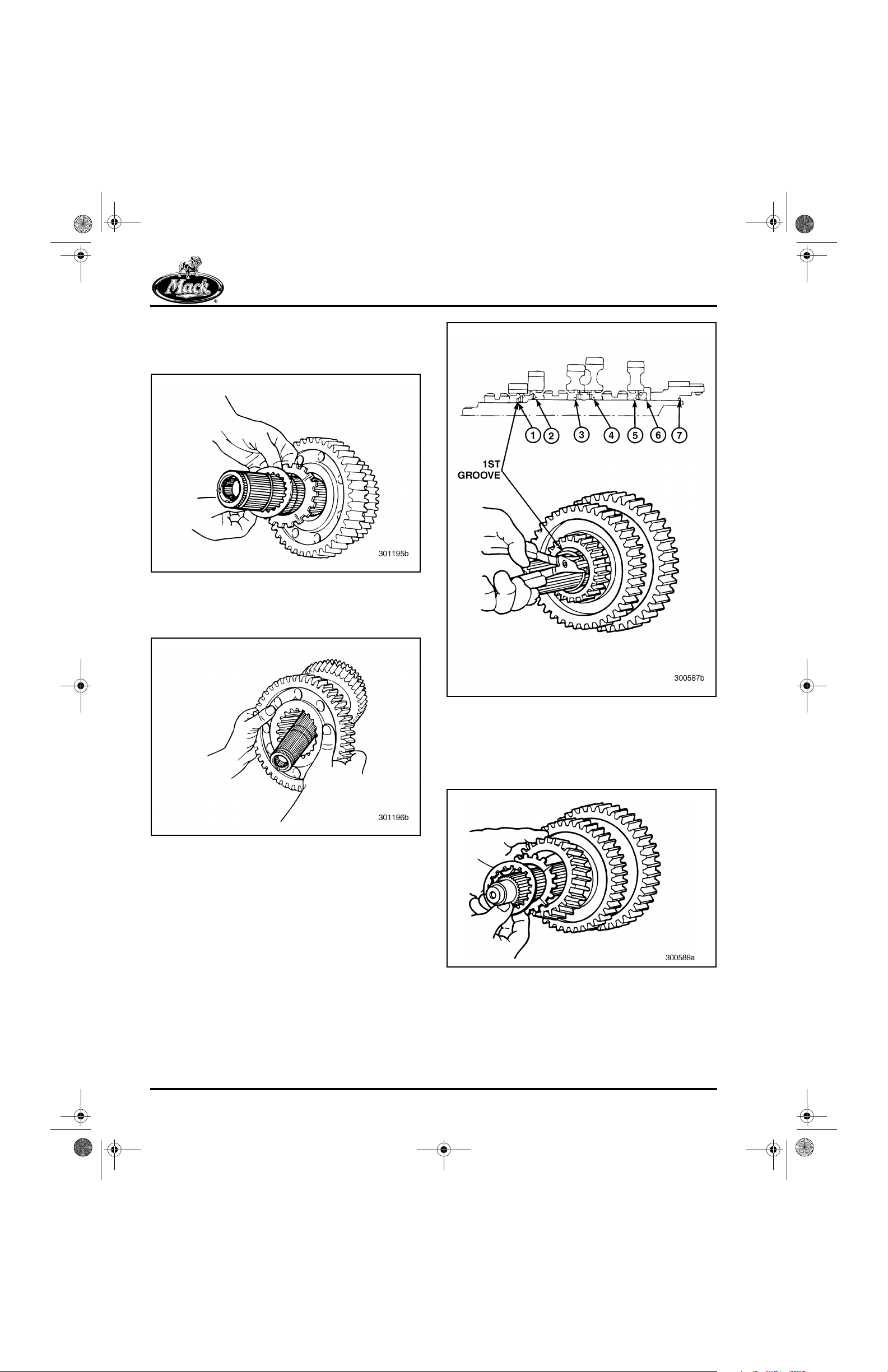

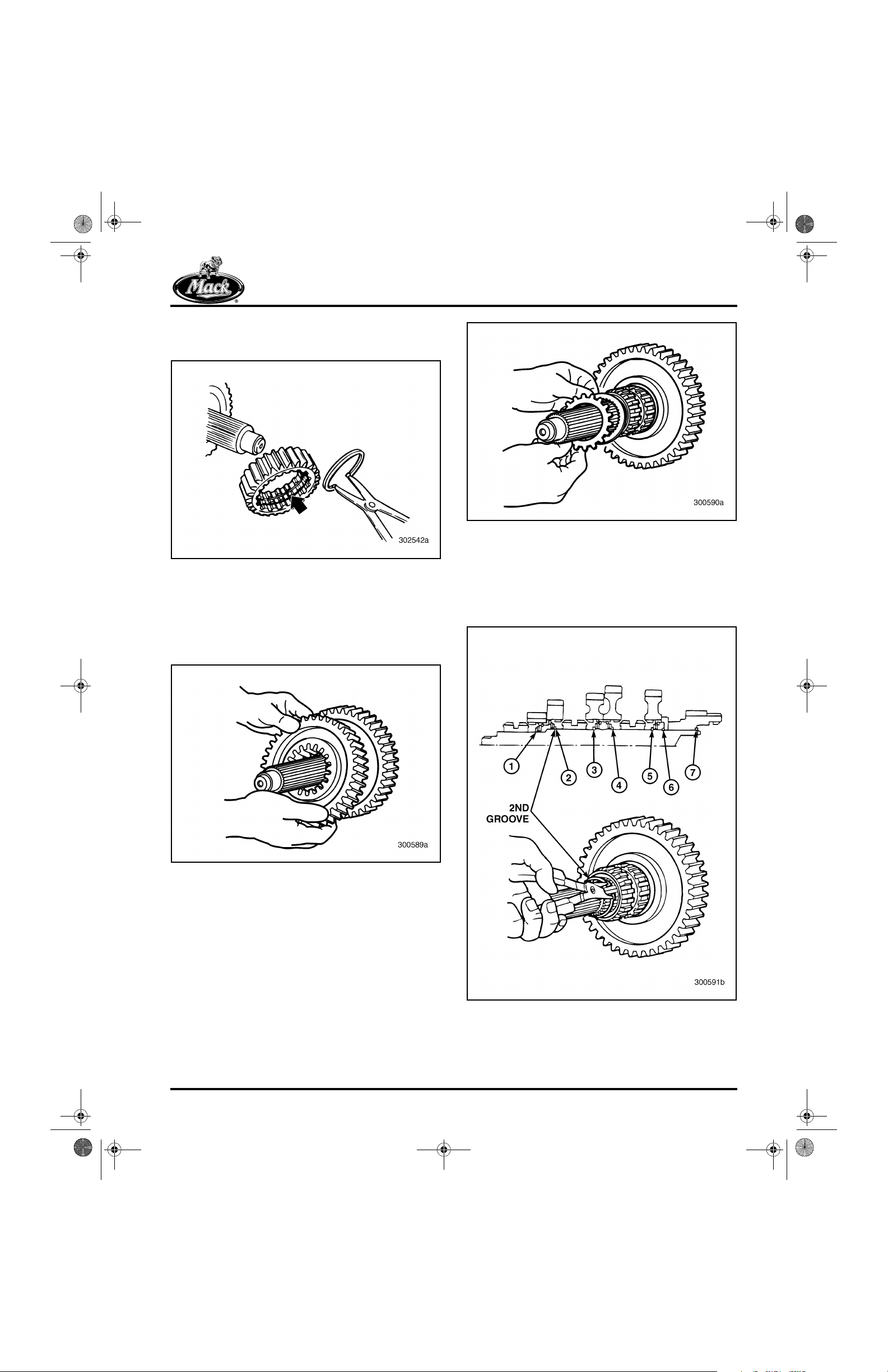

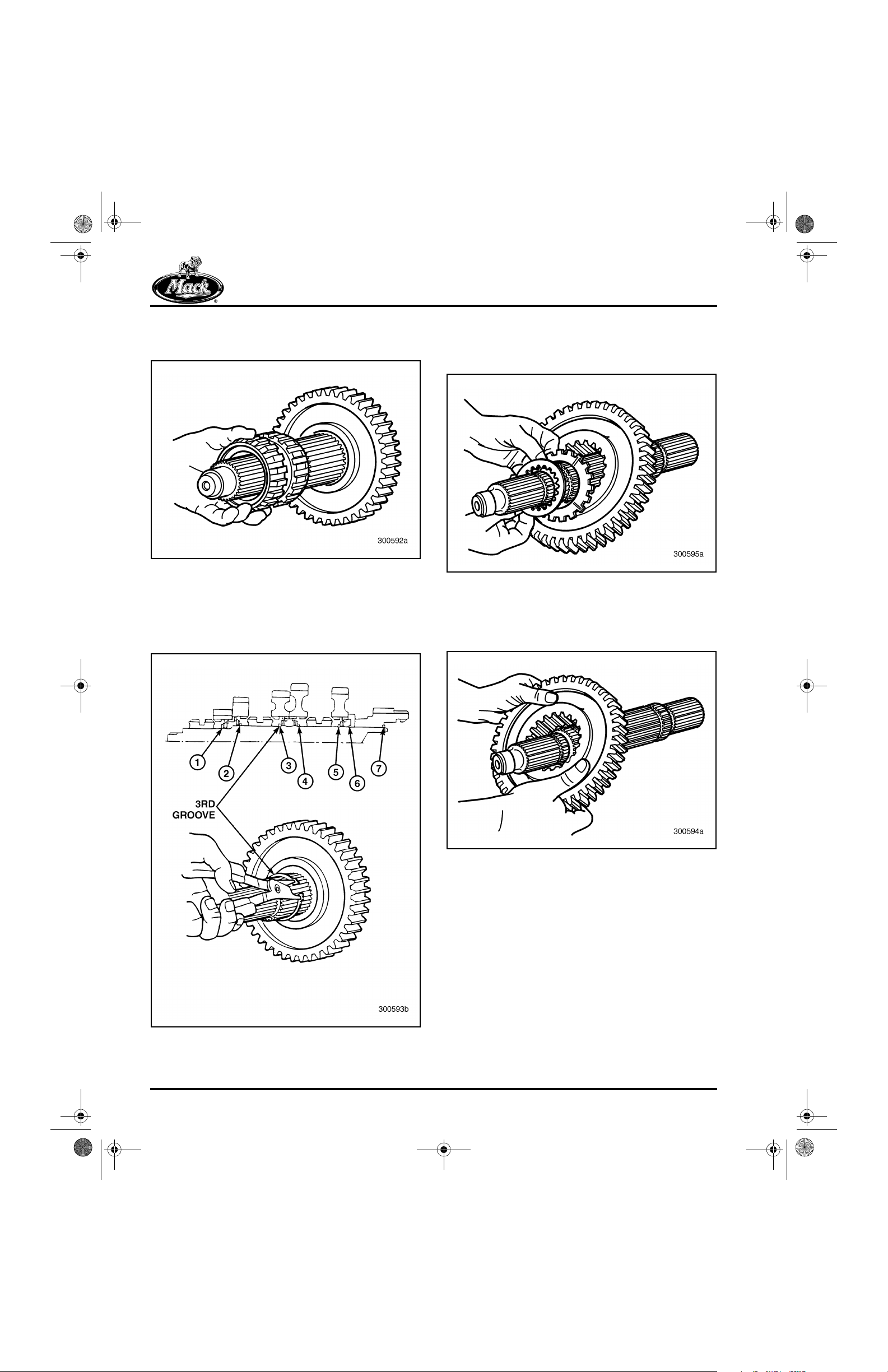

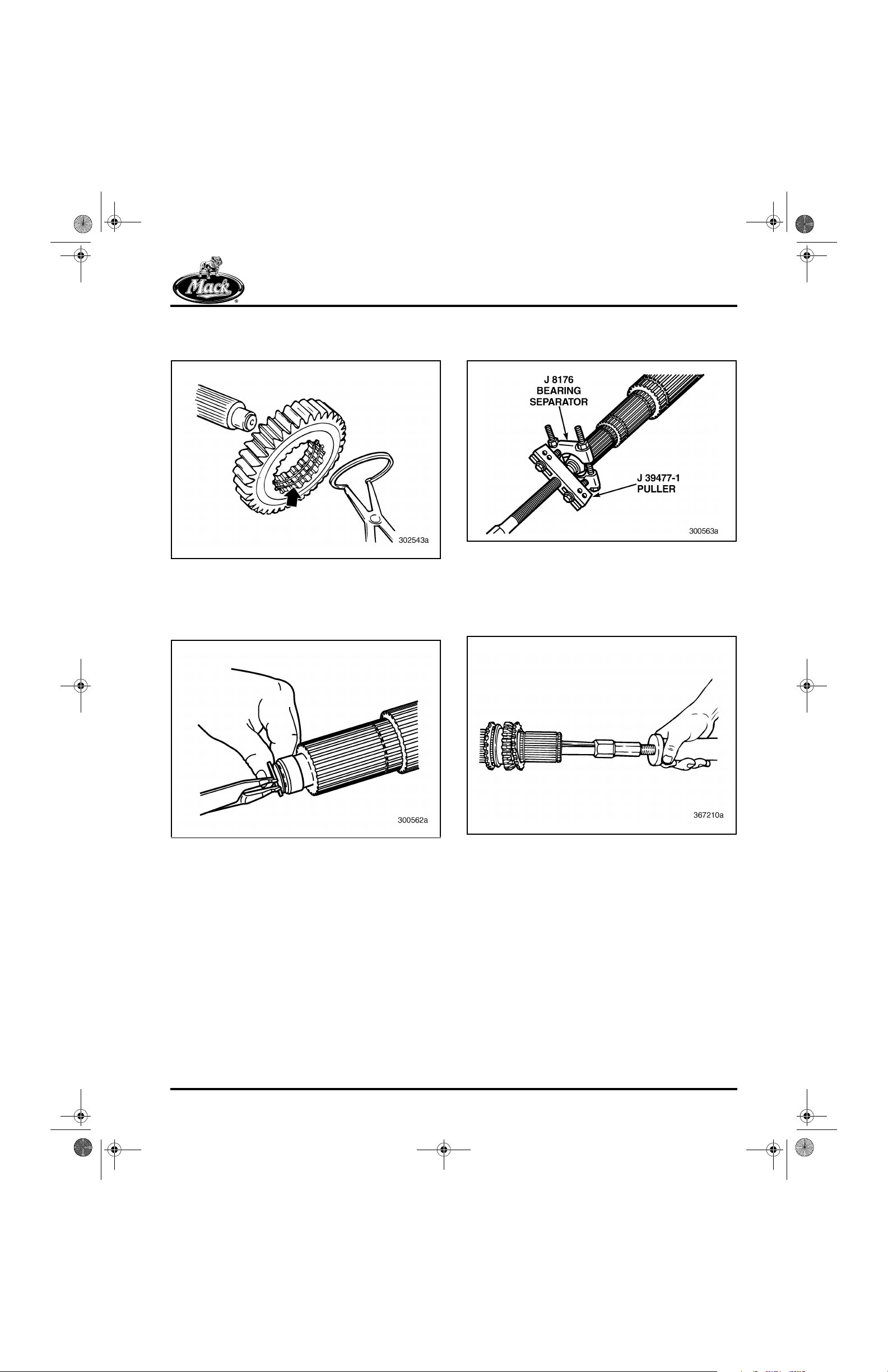

REPAIR INSTRUCTIONS

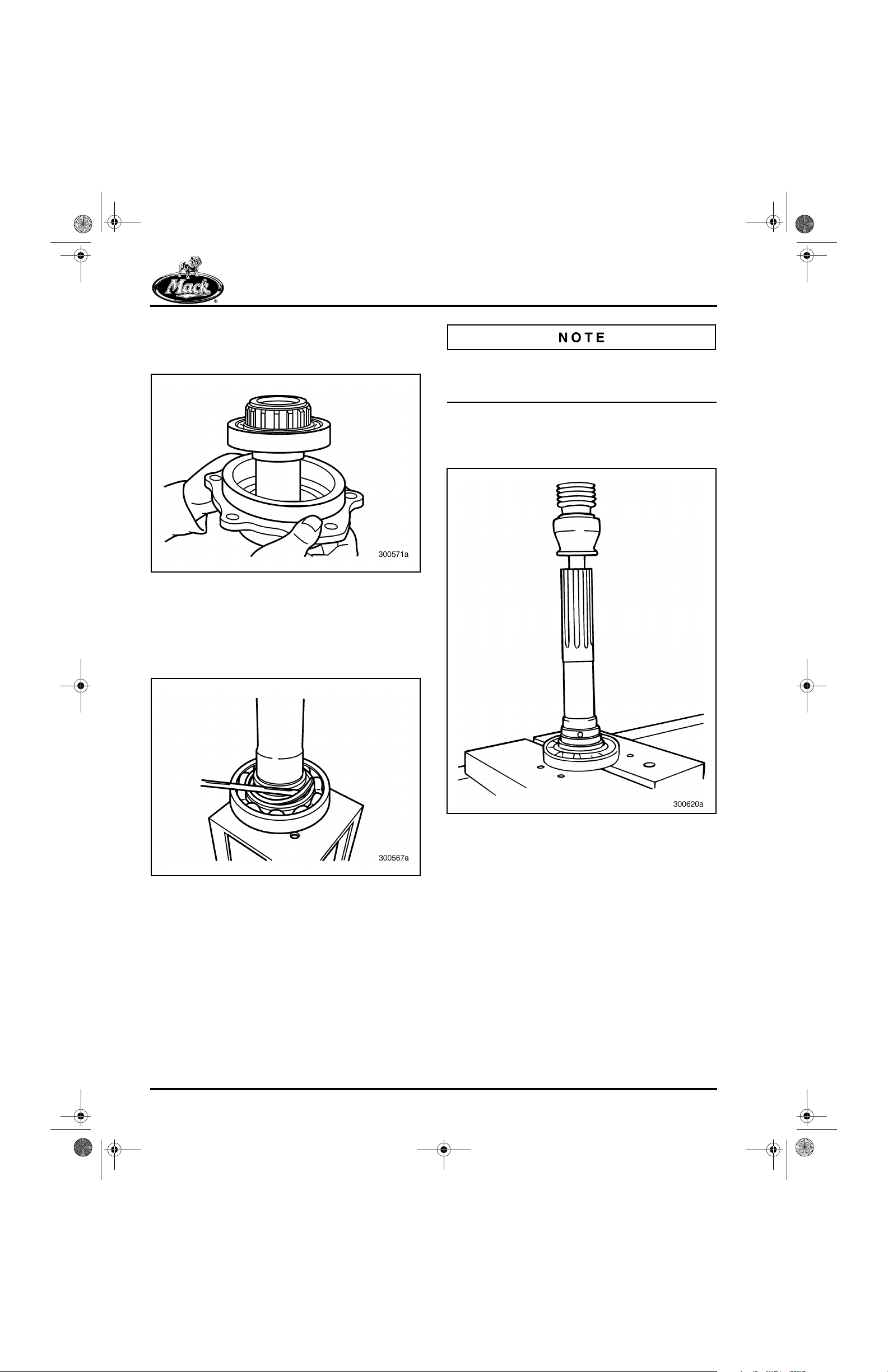

TRANSMISSION COMPONENT

DISASSEMBLY

[320]

Unless a complete overhaul is necessary, remove

only the parts that are required to repair the

assembly. Do not disturb parts that have a heavy

press fit (interference fit) unless replacement of

the part is necessary. When replacement is

necessary, use proper pullers and press setups

to prevent damage to usable parts.

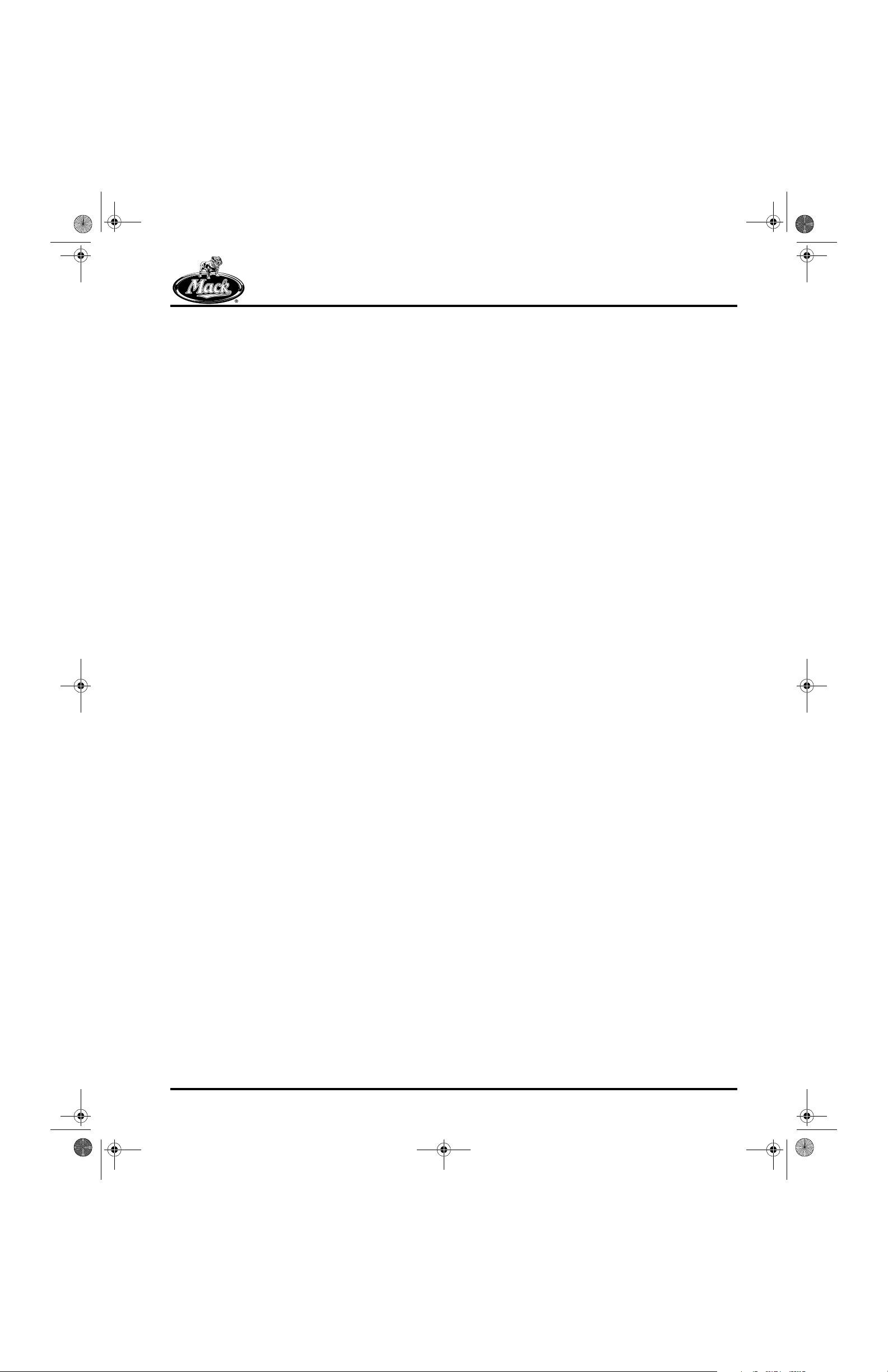

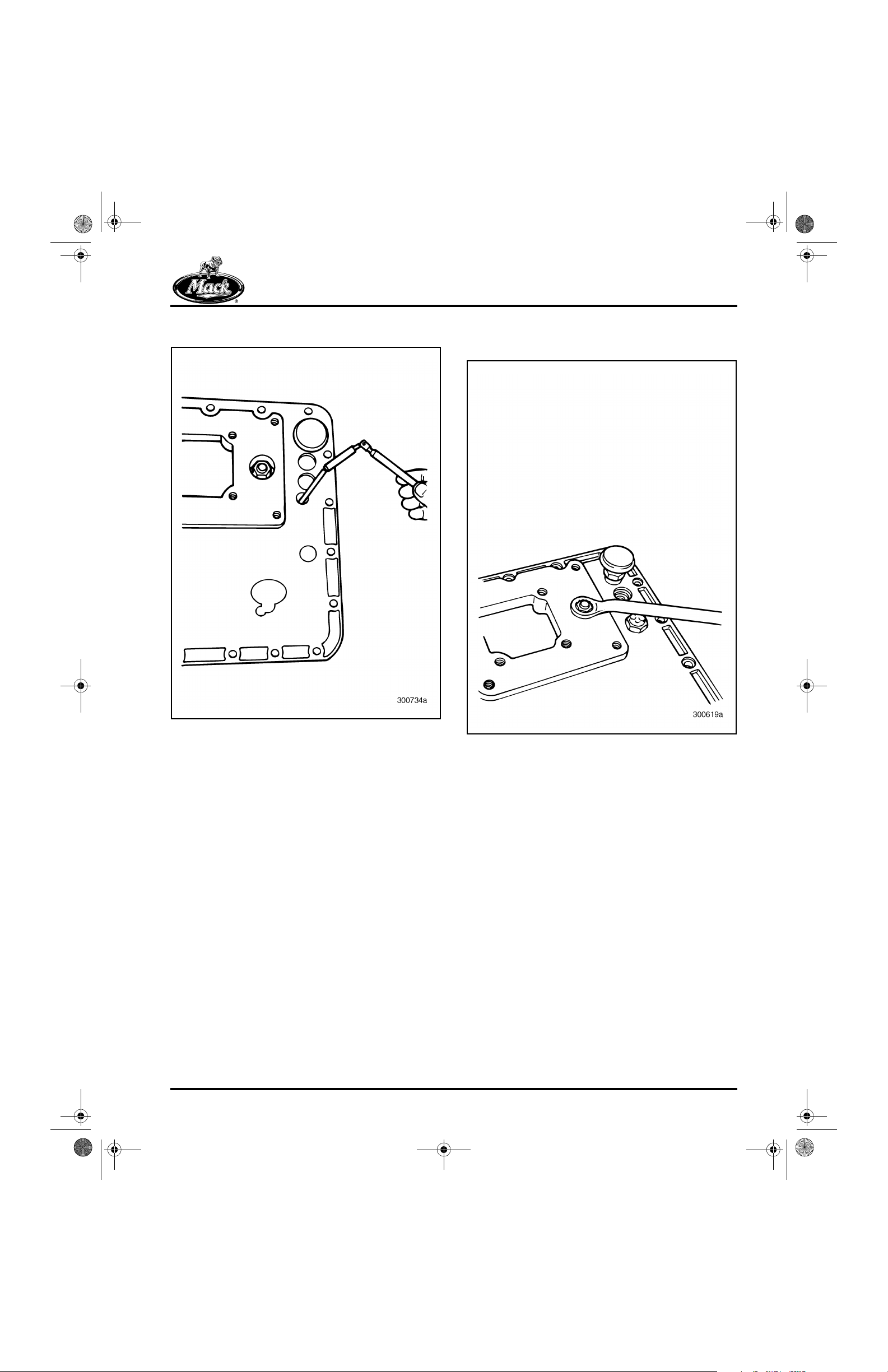

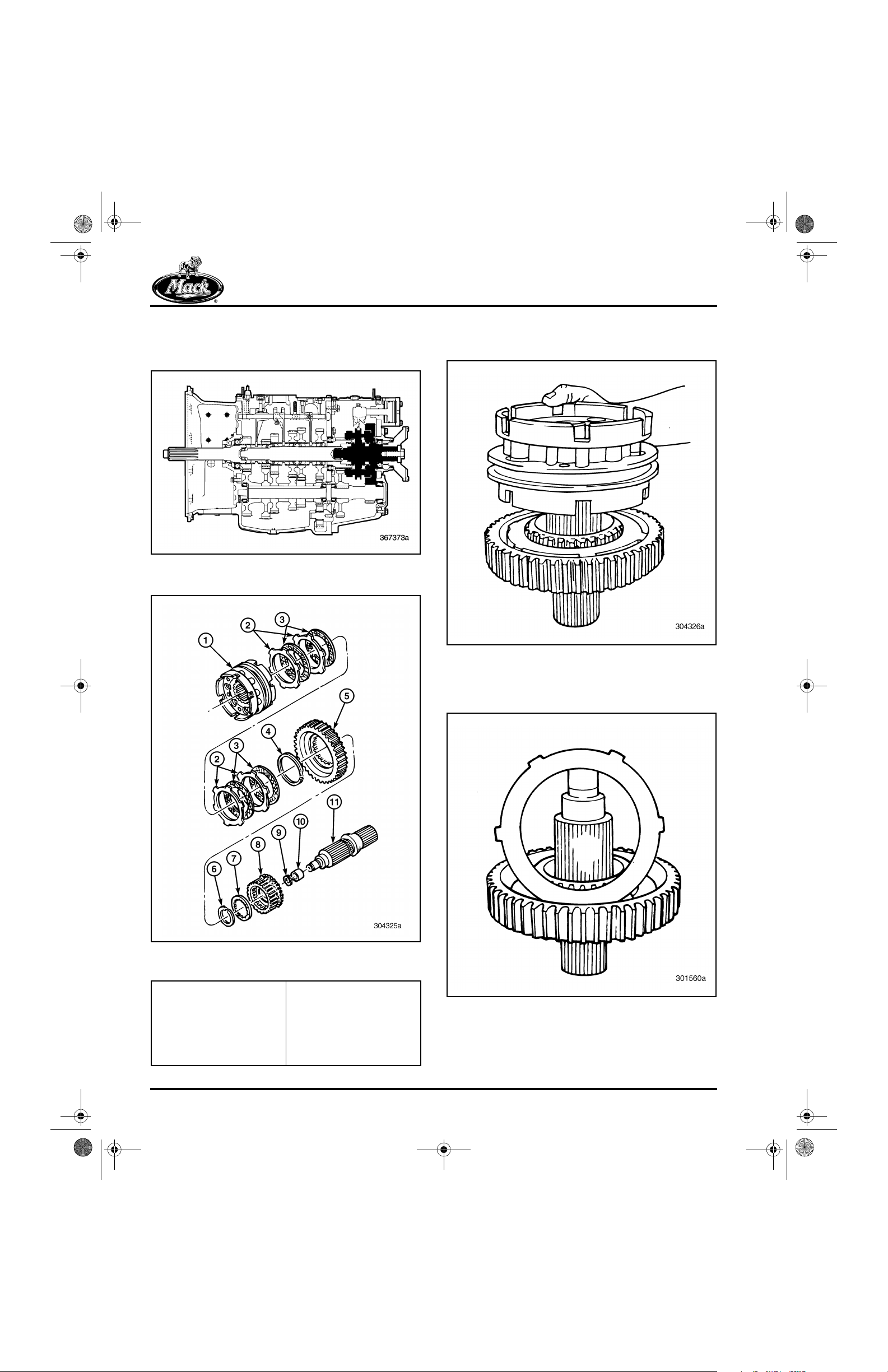

Main Case Shift Cover

Disassembly [323]

92

93

Figure 93 — Shift Cover Assembly

Figure 92 — Main Case Shift Cover Component Locator

Page 51

Page 62

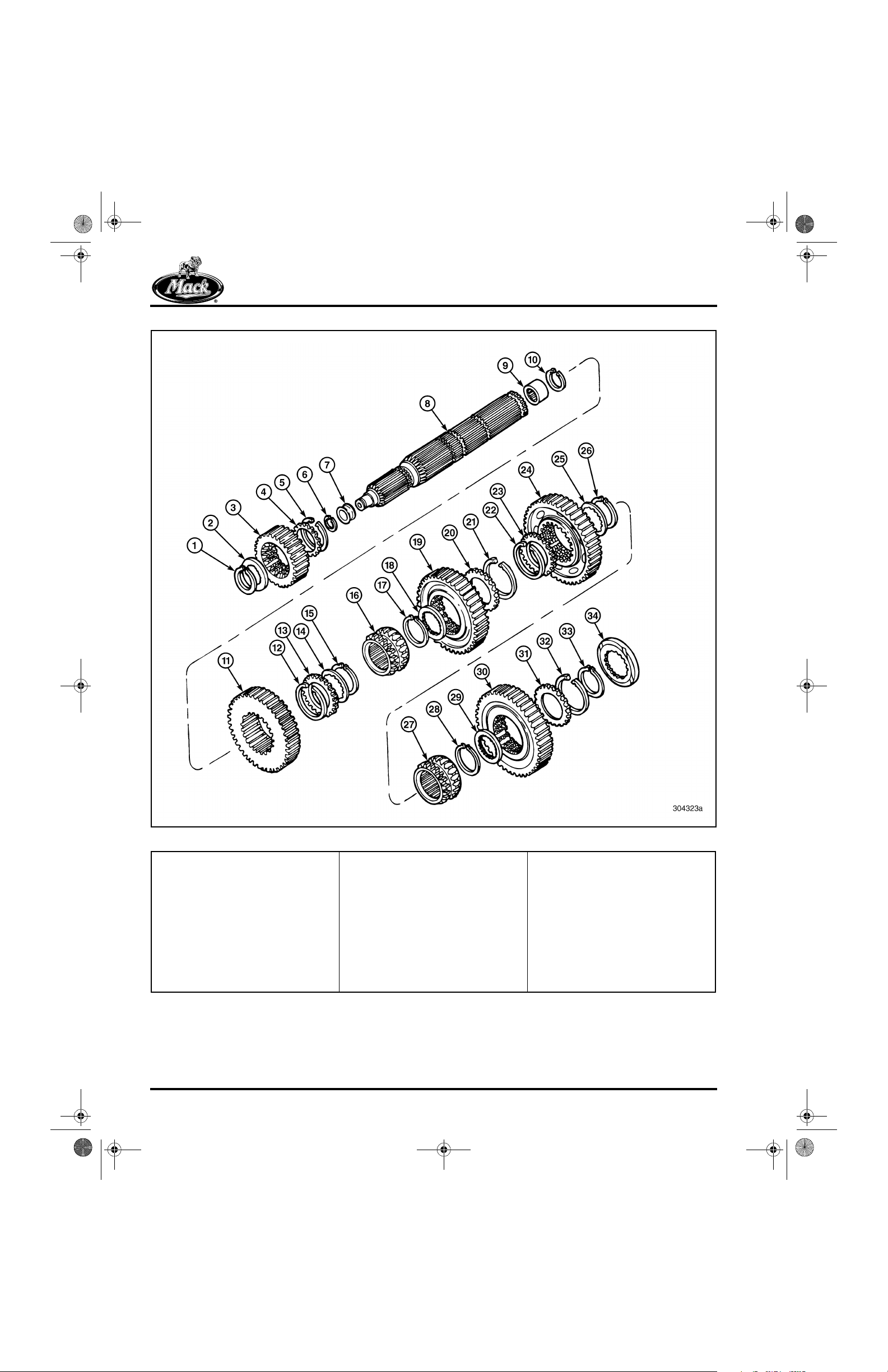

10-126.bk Page 52 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

94

1. 4th/5th Shift Fork

2. 2nd/3rd Shift Fork

3. 1st/Reverse Shifter

4. Shifter Body Spring (Interlock)

5. Shifter Body Plunger (Interlock)

6. 1st/Reverse Shift Fork

7. 4th/5th Shifter

8. 4th/5th Rocker Pin

9. Washer

10. 4th/5th Rocker Arm

11. B ushin g

Page 52

Figure 94 — Exploded View of Main Case Shift Cover

12. Washer

13. Interlock Pin

14. Poppet Ball

15. Poppet Ball Spring

16. Interlock Rocker Hardware

17. Interlock Sleeve and O-Ring

18. Interlock Spring

19. 4th/5th Rocker Pin Hardware

20. Interlock Rocker

21. Interlock Rocker Bolt

22. Pipe Plug

23. Breather

24. Interlock Pin

25. Interlock Ball

26. 1st/Reverse Shift Rail

27. 2nd/3rd Shift Rail

28. Interlock Ball

29. Interlock Pin

30. Interlock Ball

31. 4th/5th Shift Rail

32. 1st/Reverse Shifter Ball

33. 1st/Reverse Shifter Spring

Page 63

10-126.bk Page 53 Thursday, December 19, 2002 10:55 AM

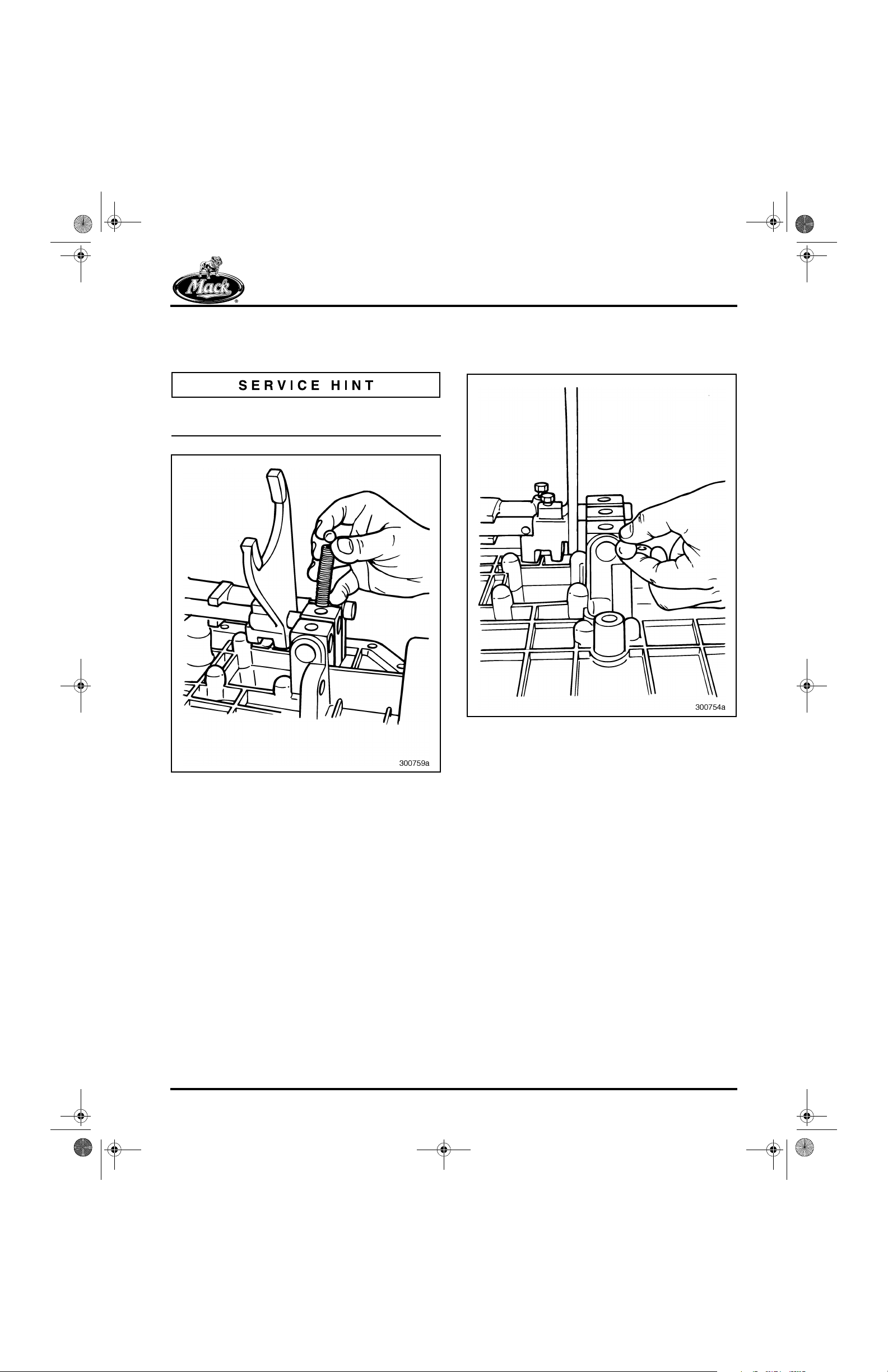

REPAIR INSTRUCTIONS

1. Remove the nut and washers from the

interlock rocker bolt.

95

Figure 95 — Remove Nut and Washers

2. Remove the interlock rocker and bolt from

the cover.

96

97

Figure 97 — Remove Interlock Ball from Cover

4. Remove the setscrew from the first/reverse

shift fork.

98

Figure 96 — Remove Interlock Rocker and Bolt

3. Remove the interlock ball from the cover.

Figure 98 — Removing Setscrew from First/Reverse

Shift Fork

Page 53

Page 64

10-126.bk Page 54 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

5. Remove the setscrew from the first/reverse

shifter.

99

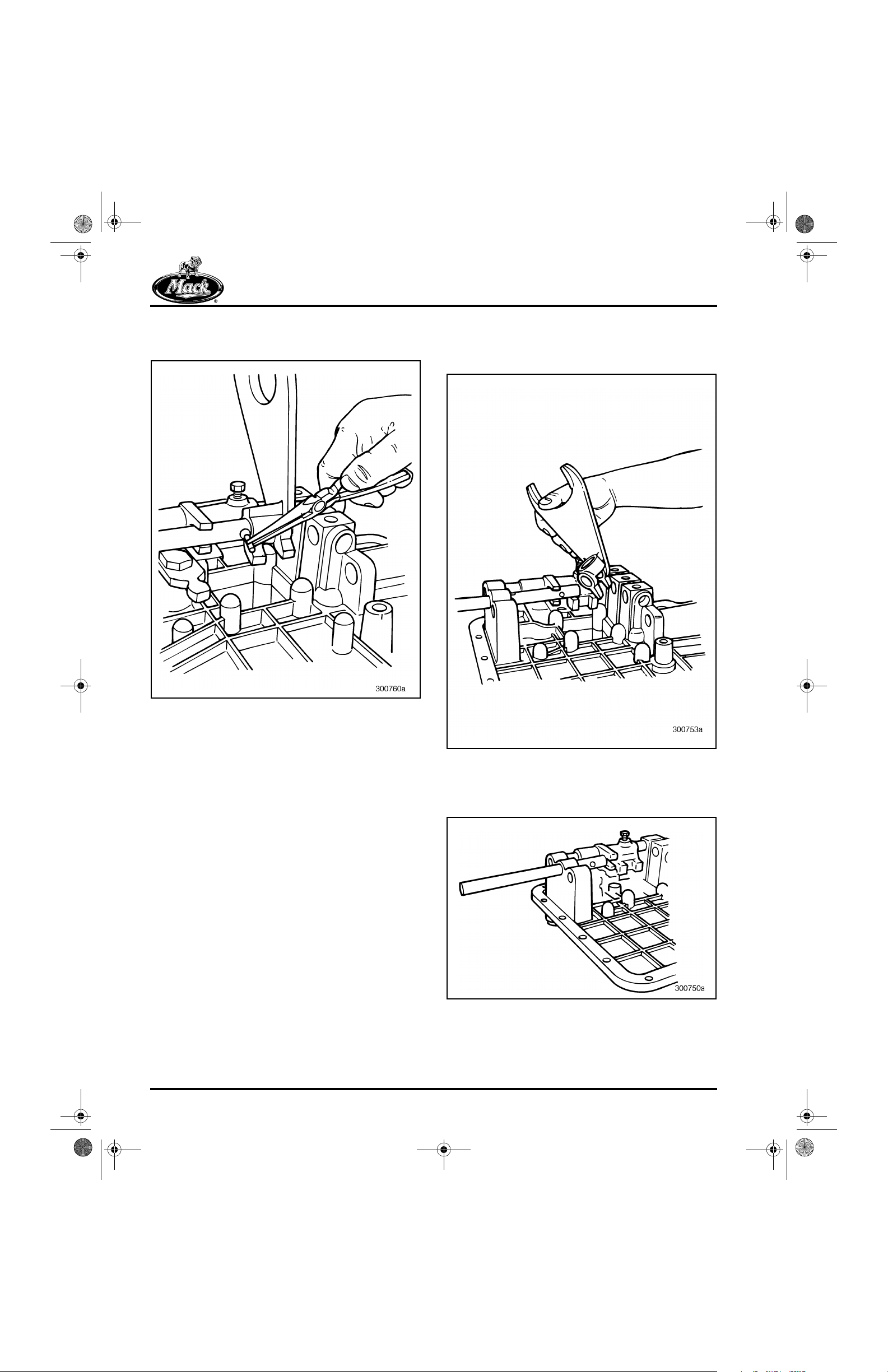

6. Slide the first/reverse shift rail to the left and

remove the interlock pin.

100

Figure 99 — Removing Setscrew from First/Reverse

Shifter

Figure 100 — Sliding First/Reverse Shift Rail

Page 54

Page 65

10-126.bk Page 55 Thursday, December 19, 2002 10:55 AM

7. Remove the first/reverse shift fork from the

cover.

101

REPAIR INSTRUCTIONS

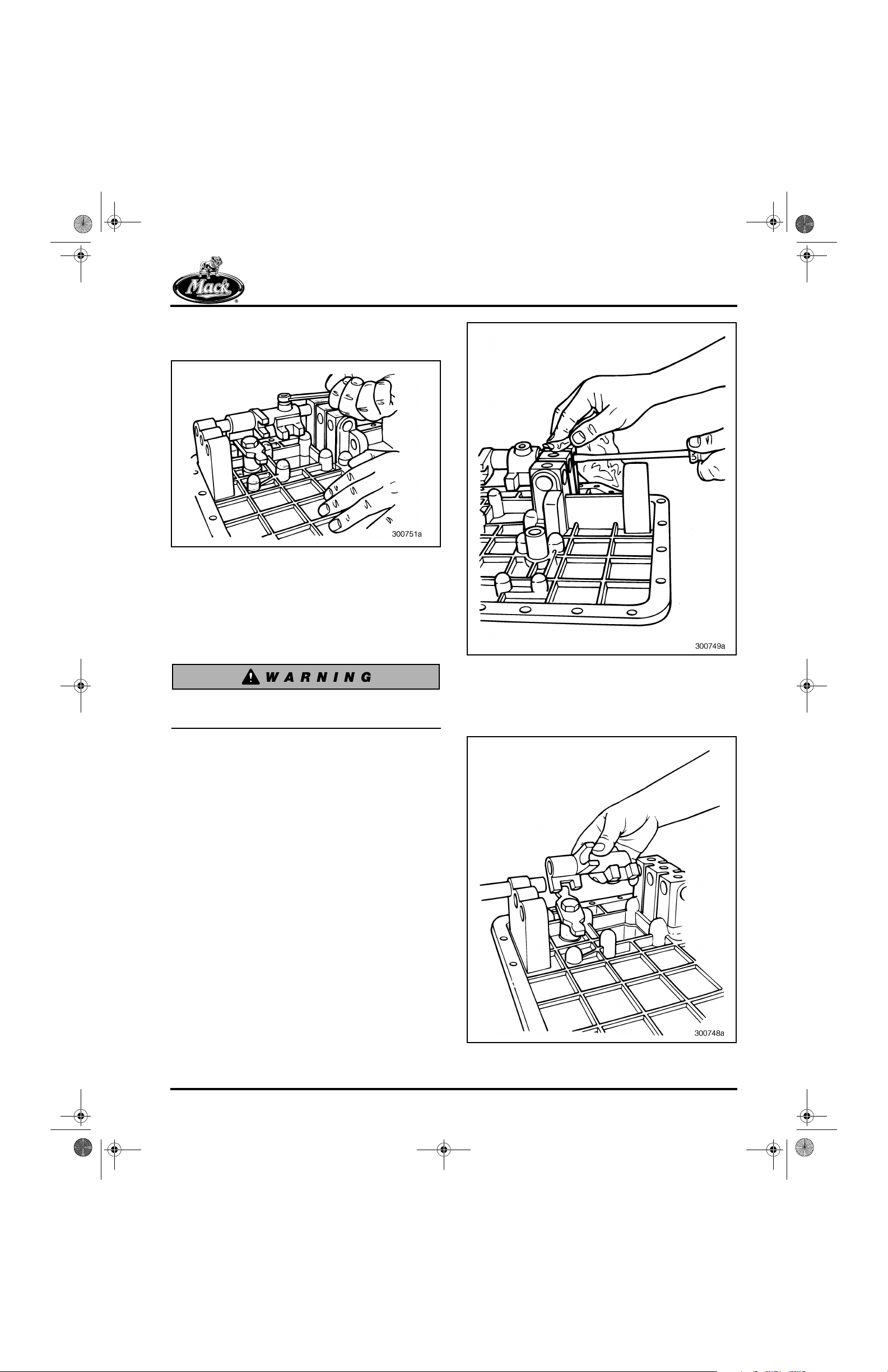

Poppet balls are spring loaded and may cause

injury when released.

102

Figure 101 — Removing First/Reverse Shift Fork

8. Push the first/reverse shift rail forward, using

a metal bar or large screwdriver. Hold a

shop towel over the top opening. The shop

towel prevents the spring and ball under the

rail from popping out and becoming lost.

Figure 102 — Pushing First/Reverse Shift Rail Forward

Page 55

Page 66

10-126.bk Page 56 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

9. Remove the poppet ball and spring from the

first/reverse shift rail vertical pocket in line

with the rail.

A magnet is helpful in removing the poppet ball

and spring.

103

10. Remove the interlock ball from the horizontal

pocket between the first/reverse shift rail

and the second/third shift rail.

104

Figure 103 — Removing Poppet Ball and Spring

Figure 104 — Removing Interlock Ball

Page 56

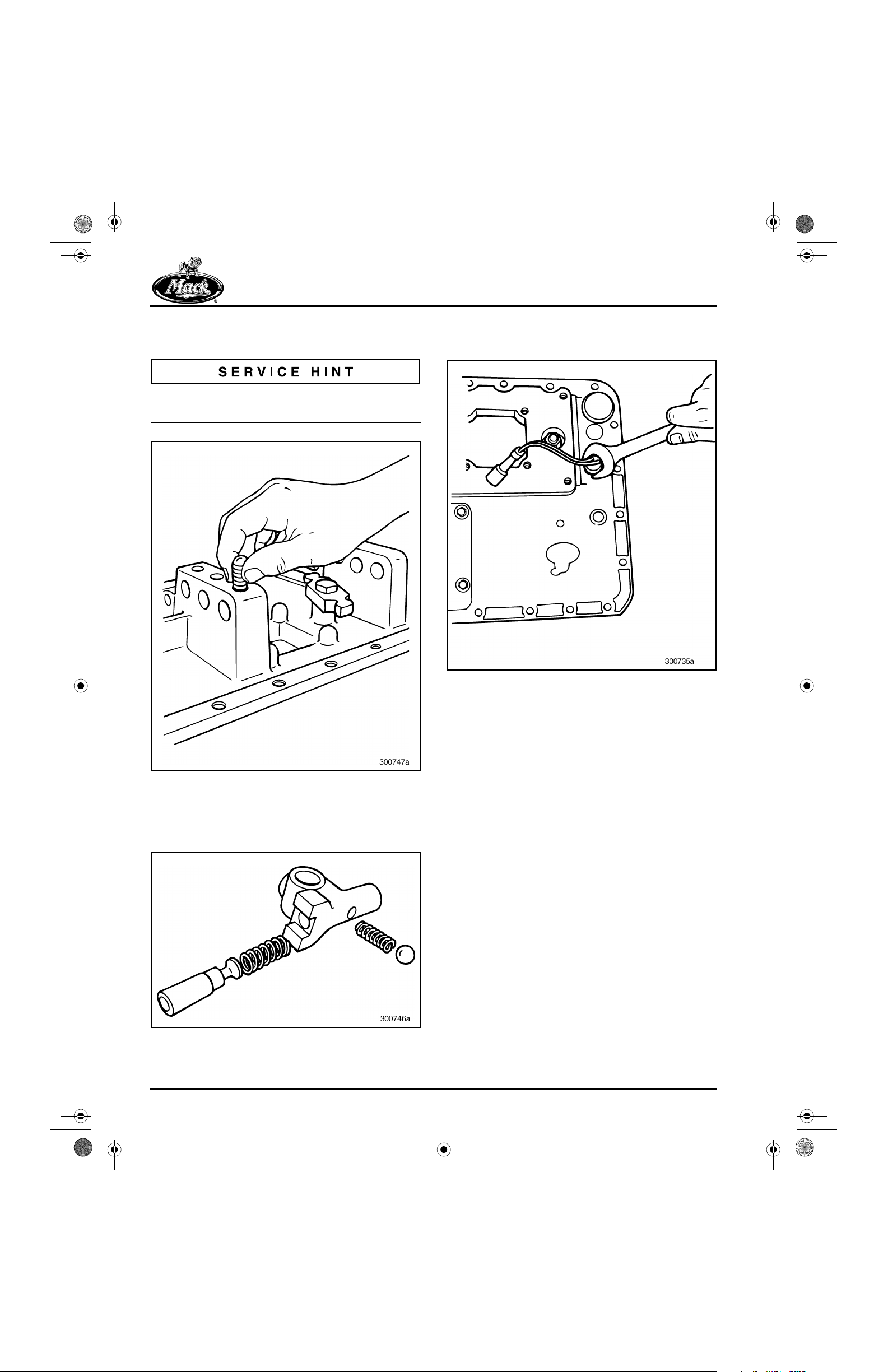

Page 67

10-126.bk Page 57 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

11. Continue sliding the first/reverse shift rail

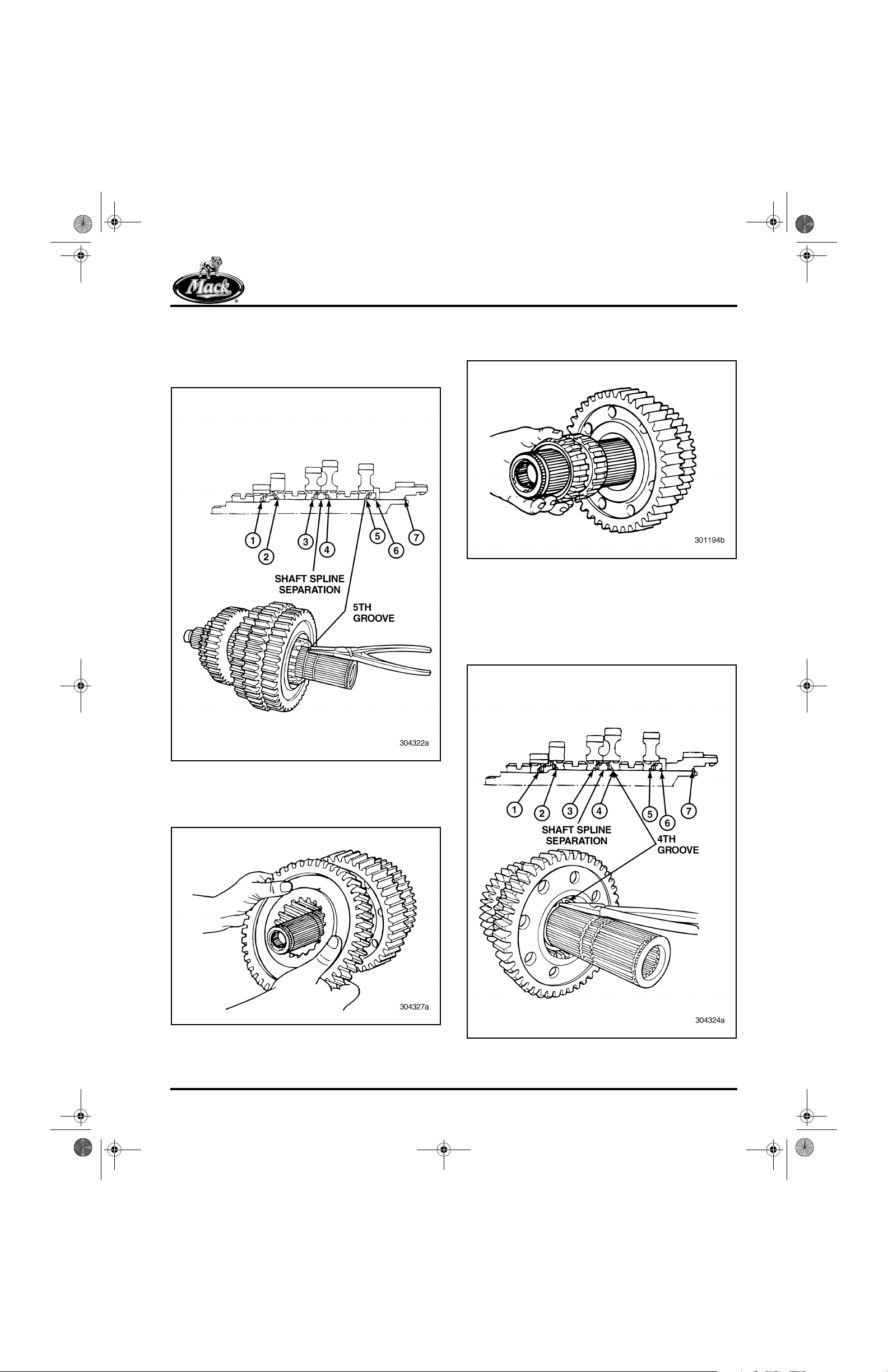

forward to remove the first/reverse shifter.

105

12. Slide the first/reverse shift rail from the shift

cover and at the same time, remove the

fourth/fifth shift fork.

106

Figure 105 — Removing First/Reverse Shifter

Figure 106 — Removing Fourth/Fifth Shift Fork

Page 57

Page 68

10-126.bk Page 58 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS

13. Remove the setscrew from the second/third

shift fork.

107

Poppet balls are spring loaded and can cause

injury when they are released.

108

Figure 107 — Removing Setscrew from Second/Third

Shift Fork

14. Push the second/third shift rail forward,

using a metal bar or large screwdriver. Hold

a shop towel over the top opening. The shop

towel prevents the spring and ball under the

rail from popping out and becoming lost.

Figure 108 — Pushing Second/Third Shift Rail Forward

Page 58

Page 69

10-126.bk Page 59 Thursday, December 19, 2002 10:55 AM

REPAIR INSTRUCTIONS