Page 1

String Trimmer

Owner/Operator Manual

Models

946401 - ST622

Transfer

model &

serial number

label from

product

registration

here.

Coller l’autocollant du

modèle et du numéro de

série dans cet encadré.

Transferir aquí la etiqueta

del modelo y número de

serie del registro del

producto.

ENGLISH

FRANÇAIS

ESPAÑOL

04645100C 2/02

Supercedes 04645100, A-B

Printed in USA

Page 2

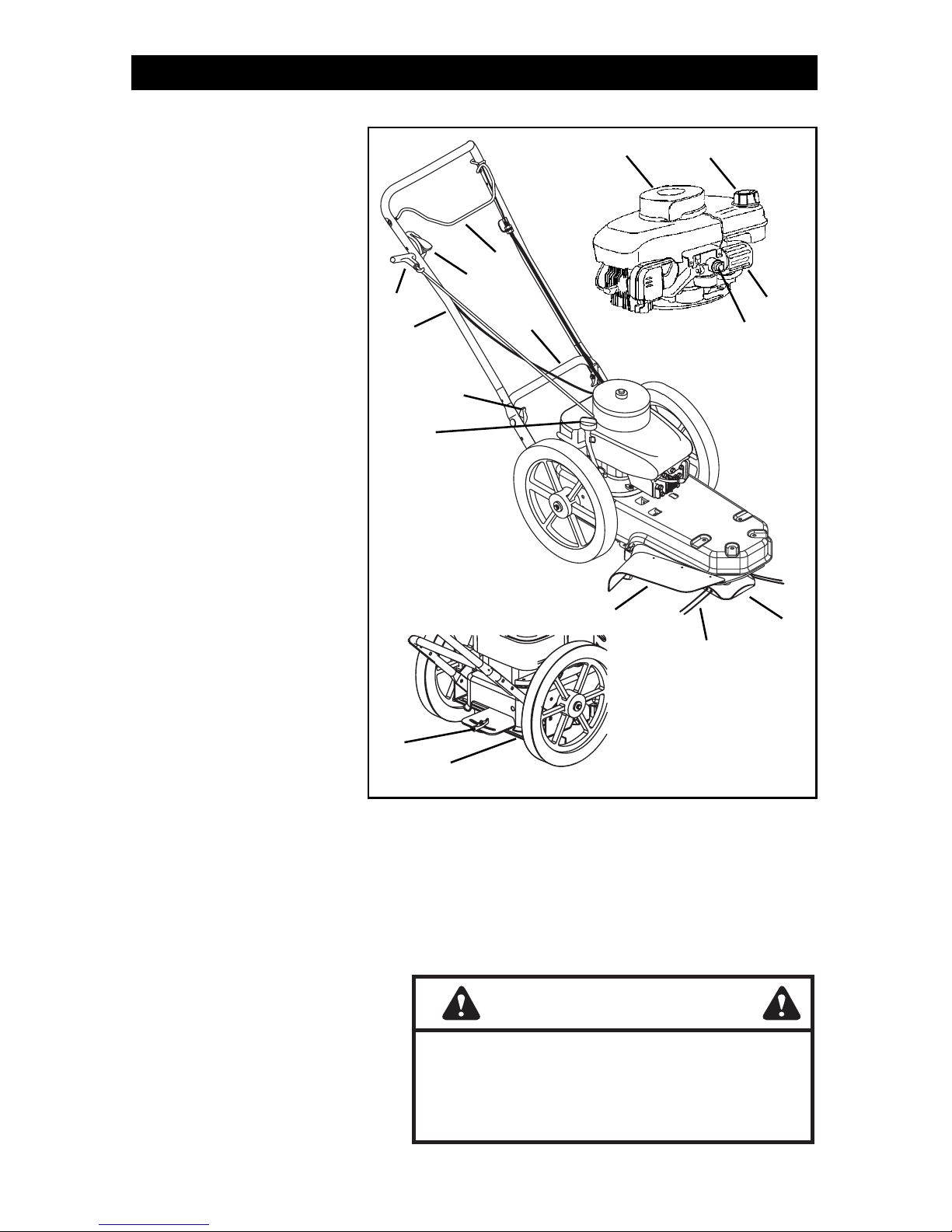

CONTROLS AND FEATURES

ENGLISH

1. Trimmer Head

2. Trimmer Line

3. Upper Handlebar

4. Lower Handlebar

5. Control Bail

6. Throttle Control Lever

7. Recoil Starter Handle

8. Handlebar Wing Knob

9. Oil Dipstick and Cap

10. Fuel Tank and Cap

11. Debris Screen

12. Air Cleaner

13. Primer Bulb

14. Swivel Head Lock

15. Trimmer Shield

16. Trailing Shield

FRANÇAIS

1. Tête de coupe

2. Fil de coupe

3. Guidon supérieur

4. Guidon inférieur

5. Barre de commande

6. Manette des gaz

7. Poignée du démarreur

à cordon

8. Molette de la poignée

9. Jauge à huile et bouchon

10. Réservoir de carburant

et bouchon

11. Crépine anti-débris

12. Filtre à air

13. Poire d’amorçage

14. Verrou de la tête de pivot

15. Garant de coupe

16. Garant de tractage

ESPAÑOL

1. Cabeza recortadora

2. Hilo de recorte

3. Manillar superior

4. Manillar inferior

5. Asidero de control

6. Palanca de control

del acelerador

7. Manilla de arranque

de retroceso

8. Perilla de mariposa

del manillar

9. Varilla medidora de

aceite y tapón

10. Depósito del combustible

y tapón

11. Rejilla de residuos

12. Depurador de aire

13. Perilla de cebado

14. Traba de la cabeza

basculante

5

6

7

3

8

9

14

16

4

15. Protector del recortador

16. Protector de arrastre

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

OX0070

15

11

10

12

13

1

2

OX0201

2

Page 3

TABLE OF CONTENTS

Controls and Features . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . 11

INTRODUCTION

THE MANUAL

Before operation of unit, carefully and

completely read your manuals. The contents

will provide you with an understanding of

safety instructions and controls during normal

operation and maintenance.

All reference to left, right, front, or rear are

given from operator standing in operation

position and facing the direction of forward

travel.

MODEL AND SERIAL NUMBERS

When ordering replacement parts or making

service inquiries, know the Model and Serial

numbers of your unit and engine.

Numbers are located on the product

registration form in the unit literature package.

They are printed on a serial number label,

located on the frame of your unit.

Serial

Number

Label

• Record Engine Model and Serial numbers

here.

PRODUCT REGISTRATION

A warranty registration card must be filled out,

signed, and returned at time of purchase. This

card activates the warranty. Claims meeting

requirements during limited warranty period

will be honored. Return your registration card

to assure warranty service.

OX0070

Service and Adjustments . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . 15

Storage. . . . . . . . . . . . . . . . . . . . . . . . . 16

Service Parts . . . . . . . . . . . . . . . . . . . . 16

Specifications . . . . . . . . . . . . . . . . . . . 16

Warranty. . . . . . . . . . . . . . . . . . . . . . . . 17

UNAUTHORIZED REPLACEMENT

PARTS

Use only Ariens replacement parts. The

replacement of any part on this unit with

anything other than an Ariens authorized

replacement part may adversely affect the

performance, durability, and safety of this unit

and may void the warranty. Ariens disclaims

liability for any claims or damages, whether

warranty, property damage, personal injury or

death arising out of the use of unauthorized

replacement parts.

DELIVERY

Customer Note:

product without complete assembly and

instruction by your retailer, it is your

responsibility to:

• Read and understand all assembly

instructions in this manual. If you do not

understand or have difficulty following the

instructions, contact your nearest Ariens

Dealer for assistance. To locate your

nearest Ariens Dealer, go to

www.ariens.com on the internet or call

1-800-678-5443.

WARNING:

adjustments can cause serious

injury.

• Do not operate the unit unless all controls

function as described in this manual.

Before attempting to operate your

unit:

1. Make sure all assembly has been

properly completed.

2. Understand all Safety Precautions

provided in the manuals.

3. Review control functions and operation of

the unit.

4. Review recommended lubrications,

maintenance and adjustments.

5. Review Limited Warranty Policy.

If you have purchased this

Improper assembly or

GB - 3

© Copyright 2000, 2002

Page 4

6. Fill out Original Purchaser Registration

Card and return the card to Ariens

Company.

DISCLAIMER

Ariens reserves the right to discontinue,

change, and improve its products at any time

without notice or obligation to the purchaser.

SAFETY

The descriptions and specifications contained

in this manual were in effect at printing.

Equipment described within this manual may

be optional. Some illustrations may not be

applicable to your unit.

SAFETY ALERTS

Look for these symbols to point

out important safety precautions.

They mean:

Attention!

Personal Safety Is Involved!

Become Alert!

Obey The Message!

The safety alert symbols above and signal

words below are used on decals and in this

manual.

Read and understand all safety messages.

DANGER:

HAZARDOUS SITUATION! If

not avoided, WILL RESULT in

death or serious injury.

WARNING:

HAZARDOUS SITUATION! If not

avoided, COULD RESULT in death

or serious injury.

IMMINENTLY

POTENTIALLY

PRACTICES AND LAWS

Practice usual and customary safe working

precautions, for the benefit of yourself and

others. Understand and follow all safety

messages. Be alert to unsafe conditions and

the possibility of minor, moderate, or serious

injury or death. Learn applicable rules and

laws in your area.

REQUIRED OPERATOR TRAINING

If unit is to be used by someone other than

original purchaser; loaned, rented or sold,

ALWAYS provide this manual and any needed

safety training before operation.

CAUTION:

HAZARDOUS SITUATION! If not

avoided, MAY RESULT in minor or

moderate injury. It may also be

used to alert against unsafe

practices.

POTENTIALLY

NOTATIONS

NOTE:

proper operation and maintenance practices.

IMPORTANT:

information required to prevent damage to unit

or attachment.

General reference information for

Specific procedures or

GB - 4

Page 5

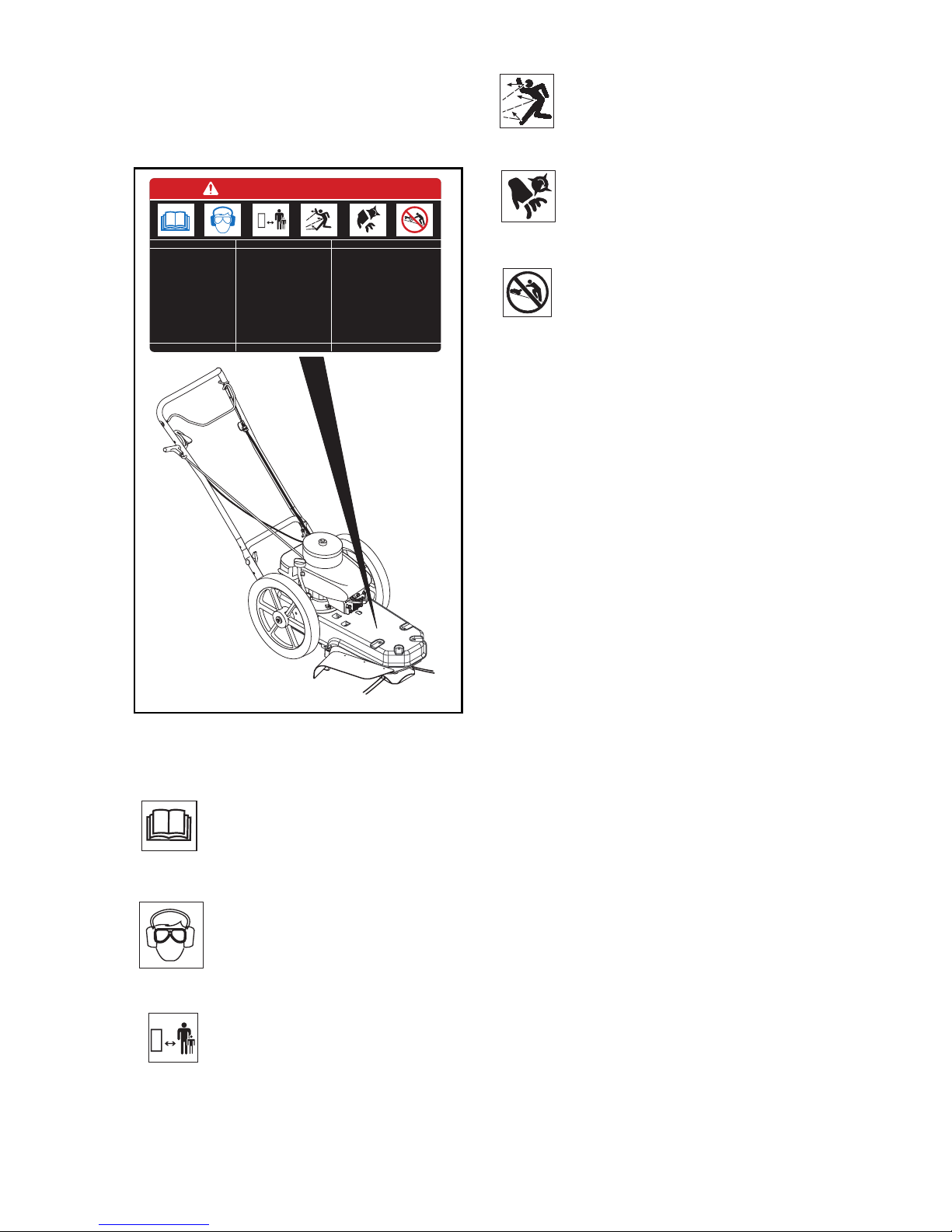

SAFETY DECALS AND

LOCATIONS

ALWAYS replace missing or damaged Safety

Decals. Refer to figure below for Safety Decal

locations.

DANGER / PELIGRO

Remove objects that could

be thrown by the cutter line.

OL0910

Keep body parts away from

rotating cutter line.

TO AVOID SERIOUS INJURY OR DEATH

• Read the Operator’s Manual.

• Always wear protective glasses or

goggles.

• Always wear adequate hearing

protection.

• Do not operate when children or others

are around.

• Remove objects that could be thrown

by the cutter line.

• Keep body parts away from rotating

cutter line.

• Go across slopes, not up and down.

• Keep safety devices (guards, shields,

switches, etc.) in place and working.

• Look down and behind before and

while moving backwards.

• Do not let debris accumulate. Debris

could become a fire hazard or cause

engine to overheat.

Cutter Line Length: 18 inches (46 cm). Longueur de l'unité de coupe : 46 cm (18 in.). Longitud de la línea de corte: 46 cm (18 in.).

POUR ÉVITER DES BLESSURES GRAVES, VOIRE MORTELLES

• Lire le manuel d'entretien.

• Toujours porter des lunettes de protection ou

de sécurité.

• Toujours porter des protège-oreilles appropriés.

• Ne pas utiliser en présence d’enfants ou d'autres

personnes.

• Retirer les objets pouvant être projetés par

l'unité de coupe.

• Se tenir à l’écart de l'unité de coupe rotative.

• Se déplacer travers d'une pente et non pas de

haut en bas.

• Maintenir les dispositifs de sécurité (garants,

protections, boutons de commandes, etc.) en

place et en bon état de fonctionnement.

• Regarder en bas et en arrière, avant et pendant

toute manœuvre de recul.

• Ne pas laisser les débris s'entasser car ils

peuvent provoquer un incendie ou la surchauffe

du moteur.

PARA EVITAR LESIONES SERIAS O LA MUERTE

• Leer el Manual del operador.

• Siempre llevar gafas protectoras o de seguridad.

• Llevar siempre protección para los oídos adecuada.

• No poner en funcionamiento alrededor de niños o

personas ajenas.

• Quitar objetos que puedan ser lanzados por la línea

de corte.

• Mantener las partes del cuerpo alejadas de la línea

de corte giratoria.

• Conducir transversalmente sobre pendientes, no

hacia arriba y abajo.

• Mantener los dispositivos de seguridad (guardas,

protectores, interruptores, etc.) en su lugar y en buen

estado de funcionamiento.

• Mirar hacia abajo y detrás antes y durante el retroceso.

• No permitir la acumulación de residuos. Los residuos

pueden convertirse en un peligro de incendio o causar

el recalentamiento del motor.

1. DANGER! TO AVOID SERIOUS

INJURY OR DEATH

05230800

1

OX0113

OL4620

Go across slopes, not up and

down.

OL4610

• Keep safety devices (guards,

shields, switches, etc.) in place and

working.

• Look down and behind before and

while moving backwards.

• Do not let debris accumulate.

Debris could become a fire hazard

or cause engine to overheat.

ASSEMBLY SAFETY RULES

Read, understand, and follow all safety

practices in Owner/Operator Manual before

beginning assembly. Failure to follow

instructions could result in personal injury and/

or damage to unit.

ALWAYS remove key and/or wire from spark

plug before assembly. Unintentional engine

start up can cause death or serious injury.

OPERATIONAL SAFETY RULES

Read the Operator’s Manual.

OL1801

Always wear protective

glasses, goggles or a face

shield.

Always wear adequate

OL4740

hearing protection.

Do not operate when

children or others are

around.

OL4370

Safety Interlock System

Whenever operator releases control on

handlebar, trimmer head must stop. If feature

fails to operate, disconnect spark plug wire

and adjust or have it repaired before using

unit.

Unit and Work Area Inspection

Inspect unit and work area before operation.

Clear work area of objects which might be

picked up and thrown. Remove all stones,

sticks, wires and other foreign objects. Tall

grass can hide obstacles.

Keep equipment in good condition.

Personal

Only Trained Adults may operate unit. Training

includes actual operation.

GB - 5

Page 6

Wear adequate safety gear, long sleeve shirts,

long pants and protective gloves.

Wear sturdy footwear. DO NOT operate

trimmer when barefoot or when wearing open

sandals or canvas shoes.

Always wear eye protection and appropriate

hearing protection when operating trimmer.

NEVER wear loose clothing, jewelry or long

hair that may get caught in rotating parts.

Protect eyes, face and head from objects that

may be thrown from unit.

Keep children out of work area and under the

watchful care of an adult.

NEVER allow children to operate trimmer.

Turn the trimmer off if children enter the area.

NEVER direct discharge toward bystanders.

The operator is responsible for the safety of

bystanders.

NEVER operate after or during the use of

medication, drugs or alcohol. Complete and

unimpaired attention is required when

operating unit.

ALWAYS stand clear of discharge when

operating unit.

Do not operate trimmer on gravel or on loose

material such as sand. Stop trimmer when

crossing gravel drives, walks, or roads.

Objects may be picked up and thrown, causing

damage or injury.

DO NOT touch parts which are hot. Allow

parts to cool.

Moving parts can cut or amputate fingers or a

hand.

Fumes from the engine exhaust can cause

death or serious injury. DO NOT run engine in

an enclosed area.

Operation

ACCIDENTAL ENGINE START UP or

UNAUTHORIZED USE could result in death or

serious injury.

Take all possible precautions when leaving

unit unattended. Shut off engine. Remove wire

from spark plug and secure it away from spark

plug.

NEVER use wire or wire-rope in place of the

cutting line. It can break off and become a

dangerous projectile. Use only flexible, nonmetallic line recommended by Ariens.

DO NOT pull trimmer backwards unless

absolutely necessary. Look down and back

before and while moving backwards. Keep a

firm footing.

ALWAYS keep trimmer head in contact with

the ground while operating.

Keep the area of operation clear of all persons,

children and pets.

Stop trimmer if anyone enters the area.

Keep safety devices or guards in place and

functioning properly. NEVER modify or remove

safety devices. ALWAYS keep trimmer shield

in place. Keep equipment in good condition.

ALWAYS keep hands and feet away from all

rotating parts during operation.

DO NOT trim at too fast a rate. DO NOT

change engine governor setting or over-speed

the engine.

ALWAYS operate unit when there is good

visibility and light.

Use extra care when approaching blind

corners, shrubs, trees, or other objects which

may obscure vision.

Do not operate trimmer in wet grass. Always

be sure of your footing. Keep a firm hold on

handlebar. Walk, never run.

If equipment vibrates abnormally, stop engine

immediately, wait for moving parts to stop and

remove wire from spark plug. Repair any

damage before restarting unit.

Avoid uneven work areas and any rough

terrain.

Be familiar with area of operation. Stay alert

for holes, rocks, roots, and hidden hazards in

area of operation. Keep away from drop-offs,

ditches or embankments. Operator could lose

footing or balance.

DO NOT operate trimmer unless trimmer

shield and trailing shield are installed. Objects

may be picked up and thrown causing damage

or personal injury.

DO NOT make cutting height adjustments

while the engine is running.

Hazardous Slopes

DO NOT operate on steep slopes. If you feel

uncomfortable on a slope, do not trim it.

NEVER leave unit unattended on a slope.

Chock wheels if parking on a slope.

Trim across the face of slopes, never up and

down. Be especially cautious when changing

direction on slopes.

Spark Arrestor

This product is equipped with an internal

combustion engine. DO NOT use on or near

any unimproved, forest or brush covered land

unless the exhaust system is equipped with a

spark arrestor meeting applicable local, state

or federal laws. A spark arrestor, if used, must

be maintained in effective working order by the

operator. See your Ariens Dealer or engine

manufacturer’s service center.

GB - 6

Page 7

FUEL SAFETY RULES

Fuel is highly flammable and its vapors can

explode. ONLY use approved fuel containers.

• NO Smoking!

• NO Sparks!

• NO Flames!

• Allow engine to cool before filling fuel

tank.

Check fuel supply before starting engine.

DO NOT fill gasoline tank indoors, when

engine is running, or while engine is still hot.

Allow engine to cool several minutes before

removing fuel cap.

Replace gasoline tank cap securely and clean

up any spilled fuel before starting engine.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel it

on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a gasoline

dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lockopen device.

If fuel is spilled on clothing, change clothing

immediately.

MAINTENANCE AND SERVICE

Stop engine, wait for moving parts to stop,

remove ignition wire and secure away from

spark plug before attempting to: repair, adjust,

inspect or clean unit.

Follow engine manufacturer’s safety

instructions when servicing engine.

Keep all nuts, bolts, and screws tight and be

sure equipment is in safe working condition.

Check all hardware at regular intervals,

especially engine and trimmer head

attachment bolts.

Worn out mufflers are more than just a noise

nuisance and should be replaced immediately.

Continued use could result in fire or explosion.

Check components for wear, damage, and/or

deterioration. Replace only with Ariens original

equipment replacement parts.

DO NOT tip the trimmer up or over unless

specifically instructed to do so.

To reduce fire hazard and overheating, keep

equipment free of grass, leaves, debris or

excessive lubricants.

Maintain or replace safety and instruction

labels, as necessary.

Replacement Parts and Accessories

Use only replacement parts and accessories

which have been approved by Ariens and are

properly installed.

STORAGE SAFETY RULES

Allow engine to cool before storing in any

enclosure.

Refer to

unit is to be stored for extended periods.

ALWAYS clean unit before extended storage.

See engine manual for proper storage.

DO NOT store unit with fuel in the fuel tank

inside a building where any ignition sources

are present.

Storage

for important instructions if

WARNING:

and understand

Fuel Safety Rules

proceeding.

AVOID INJURY. Read

Assembly

TOOLS REQUIRED

• Box knife to cut carton

TO REMOVE UNIT FROM CARTON

1. Cut off top of box.

2. Remove packing material.

3. Remove literature pack, safety glasses

and bottle of oil from box.

4. Cut out back of box and pull the unit out.

ASSEMBLY

5. Remove protective packaging materials

from trimming head and around unit.

and

before

GB - 7

Page 8

ASSEMBLY

6

2

3

5

1. Lower Handle

Bar

2. Upper Handle

Bar

3. Carriage Bolt

Engine Crankcase Oil

Fill engine crankcase with proper amount and

viscosity of oil. Refer to Engine Manual for

specific information.

CHECKLIST

Please complete the following checklist before

proceeding:

1

4

OX0012

4. Wing Knobs

5. Bolt Holes

6. Control Bail

• All assembly instructions have been

completed.

• No remaining loose parts in carton.

• Handlebar is adjusted comfortably and

tightened securely.

While learning how to use your unit,

pay extra attention to the following

important items:

• Trimming line is fastened securely in

holder.

• Fuel tank is filled with proper fuel.

• Engine crankcase is filled with oil.

• Become familiar with all controls – their

location and function. Operate them

before you start the engine.

Handlebar Assembly

1. Loosen handlebar wing knobs. Do not

remove them.

2. Unfold handlebar to operating position.

NOTE:

comfortable for the operator. Be sure cable is

clear of pinch points. Refer to

Service and Adjustments.

Adjust handlebar to a height

Handlebars

3. Tighten handlebar wing knobs to secure

upper handlebar.

in

GB - 8

Page 9

OPERATION

CONTROLS AND FEATURES

See Controls and Features on page 3.

WARNING:

and understand

Fuel Safety Rules

proceeding.

Trimmer Head / Trimmer Lines

The trimmer head holds the trimmer line and

provides trimming height adjustment. When

mounted in the trimmer, the trimmer lines

extend about 8 inches (20.3 cm) from the

cutter disk.

Control Bail

• Squeeze the trimmer control bail against

the handlebar to engage trimmer head.

• Release bail to disengage trimmer.

IMPORTANT:

before each use. If control bail moves freely

with no resistance before contacting

handlebar, adjust or repair unit before

operating. See

Check control bail function

Service and Adjustments.

Throttle Control Lever

Fast Slow Stop

Recoil Starter Handle

The recoil starter handle is used to start the

engine.

Primer Bulb

3 x

OX0040

Swivel Head Lock

The swivel head feature is designed to allow

close trimming while walking parallel to fences

or walls.

• Point the front of the unit to the left if

trimming with the left side of the trimmer.

• Point the front of the unit to the right if

trimming with the right side of the trimmer.

To adjust, see

AVOID INJURY. Read

Operational

before

The throttle control

lever controls the

speed of the engine.

OX0210

The settings are

variable between fast

and slow.

For a cold engine, push the

primer bulb three times to

add fuel for easier engine

start. See

Shut Off

Service and Adjustments

Starting and

.

and

.

FILLING FUEL TANK

WARNING: EXPLOSIVE VAPORS

and

FLAMMABLE FUEL

result in serious injury or death.

Handle fuel with care. ALWAYS use

an approved fuel container.

No Smoking! No Lighted Materials!

No Open Flame!

Allow engine to cool before

maintenance.

Never fill tank when engine is

running or is hot from operation.

DO NOT overfill tank. Allow about

1/4" (6.35 mm ) of space at the top

of the filler neck for fuel expansion.

Wipe up any spills and allow

vapors to dissipate before starting

engine. Use approved (Red)

gasoline container.

To add fuel to Fuel Tank:

1. Put unit in open or well-ventilated area.

2. Stop engine and allow to cool.

3. Clean Fuel Cap and surrounding area to

prevent dust, dirt and debris from entering

Fuel Tank.

4. Remove Cap.

IMPORTANT:

gasoline containing alcohol because alcohol

will cause internal parts to deteriorate. See

Engine Manual for correct type and grade of

fuel.

5. Fill fuel tank. (See

capacity.)

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

DO NOT use gasohol or

Specifications

can

for tank

TO STOP IN AN EMERGENCY

To stop in an emergency, release control bail.

When all moving parts have stopped, push

throttle control lever to stop.

TO START AND SHUT OFF

ENGINE

Pre-Start

1. Check engine oil level. See Engine

Manual.

2. Check fuel level.

Starting the Engine

1. Push primer bulb 2 or 3 times for a cold

engine.

2. Set throttle control to Fast.

GB - 9

Page 10

3. Grasp starter handle and pull rope out

slowly until it pulls harder. This is the

compression stroke. Let rope rewind

slowly. Then pull rope with rapid

continuous full arm stroke to start engine.

Allow rope to rewind slowly.

IMPORTANT:

against handlebar.

4. Repeat until engine starts. (If engine does

not start, refer to

DO NOT let starter handle snap

Troubleshooting

.)

Stopping the Engine

1. Release control bail so that trimmer head

stops rotation. Wait until rotating parts

stop completely before leaving operator’s

position.

2. Push throttle control lever to Stop.

3. If leaving unit unattended, disconnect

spark plug wire to prevent accidental

start-up.

TO OPERATE THE TRIMMER

CAUTION:

grass and debris from foam debris

screen and around muffler.

1. Start the engine.

2. Set throttle control to Fast.

3. Hold the control bail against the

handlebar to engage the trimmer head.

4. When trimmer head is rotating at full

speed, move unit forward to trim.

Before every use, clean

TO TRAVEL TO ANOTHER WORK

AREA

When crossing driveways or bare areas,

release the control bail to stop trimmer head

rotation and push down slightly on the

handlebar to lift the trimmer head off the

ground. This prevents premature wear of the

trimmer head.

TRIMMING TIPS

• Operating the trimmer in Fast throttle

provides the best trimming performance.

• In heavy growth, walk slower.

• Do not push the trimmer into heavy

growth too fast.

• Do not trim on extremely steep slopes. Do

not trim on slopes when the ground is wet

or slippery. If you do not feel comfortable

on a slope, do not trim it.

• Keep the trimmer clear of dirt and grass

build-up.

• Install a new trimmer line when line is

worn to less than 4 inches (10.2 cm). See

Service and Adjustments

.

TO TRANSPORT UNIT

ALWAYS turn engine off when transporting on

truck or trailer. Tie unit down securely. Do not

tie down by linkages, guards, cables or other

parts that may be damaged.

GB - 10

Page 11

MAINTENANCE

WARNING: AVOID INJURY. Read

and understand Fuel and

Maintenance and Service Safety

Rules before proceeding.

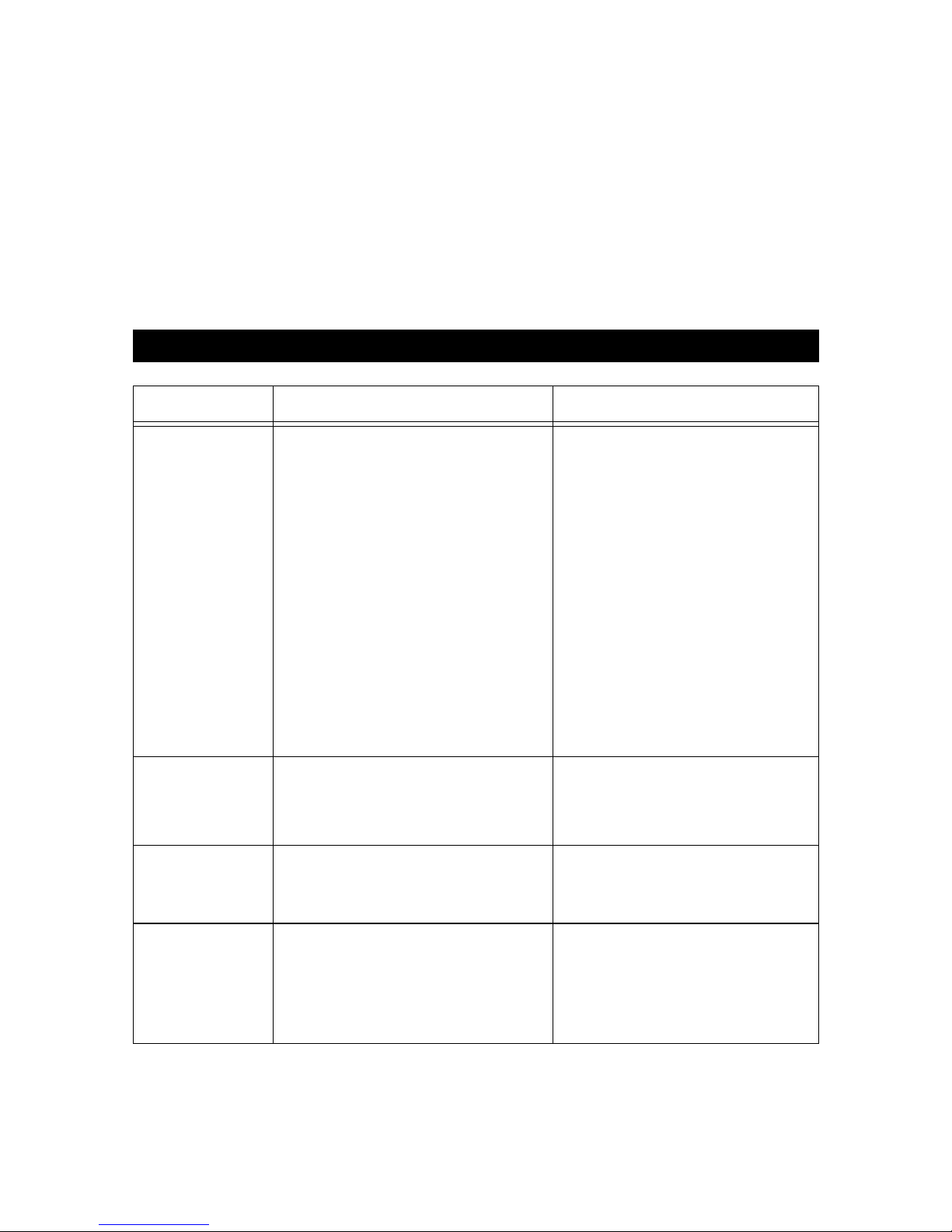

MAINTENANCE SCHEDULE

Service Performed Intervals (Hours)

Each

Use

Check Fasteners •

Check Trimmer Lines •

Check Control Bail

Operation

Check Engine Oil •

Clean Debris Screen •

Clean Unit •

Check Air Cleaner •1

Check Spark Plug •

Change Engine Oil •2 •1

Clean Engine Cooling Fins •1

1. More often under extremely dusty or dirty

conditions.

2. Change engine oil after first 2 hours of

use, then every 25 hours or every

season, whichever comes first.

SERVICE POSITION

1. Remove the gas cap and place a piece of

plastic (a plastic garbage bag works well)

over the tank opening. Reinstall the cap.

This keeps gasoline from spilling out the

tank.

2. Set the unit swivel in the center position.

3. Loosen the two wing nuts on the lower

handlebar.

4. Tip the unit up onto its back to rest on the

lower handlebar. A 4" x 4" (10.2 x 10.2

cm) wood block under the swivel bracket

helps steady the unit by tilting it farther

back.

5. When service is complete, place unit in its

normal operating position.

6. Align handlebars and tighten wing nuts.

7. Be sure to remove the plastic from the gas

tank opening.

25 50

•

Wood Block

OX0231

CHECK FASTENERS

Make sure all hardware is tightened properly.

Pay special attention to handlebar, guards,

shields, and trimmer head mounting hardware.

CHECK TRIMMER LINES

Make sure trimmer line is securely fastened in

holder. Replace trimmer line when it is worn to

less than 4 inches (10.2 cm) . See

Adjustments

for specific instructions.

Service and

CHECK CONTROL BAIL

OPERATION

The trimmer head must disengage completely

when the bail handle is released. Adjust bail

travel if necessary. See

Adjustments

.

CHECK ENGINE OIL

See Engine Manual for specific information on

checking engine oil.

CLEAN DEBRIS SCREEN

Remove all grass and debris from debris

screen on top of engine. A clogged screen will

cause the engine to overheat.

CLEAN UNIT

Clean unit thoroughly. Brush dirt and debris off

with a brush or cloth. Apply paint or spray

lubricant to exposed metal surfaces.Do not

use abrasives, solvents, or harsh cleaners.

IMPORTANT:

store unit outdoors. Store trimmer in a cool,

dry, protected location.

NEVER spray unit with water or

CHECK AIR CLEANER

See Engine Manual for specific information on

checking and servicing the air cleaner.

CHECK SPARK PLUG

See Engine Manual for specific information on

checking, cleaning, and changing the spark

plug.

GB - 11

Page 12

CHANGE ENGINE OIL

Change the engine oil after the first 2 hours of

use, then every 25 hours or every season,

whichever comes first. Oil should be changed

when engine is warm.

1. Disconnect spark plug wire.

2. Clean area around oil cap.

3. Tip the string trimmer on its right side.

CAUTION: Before tipping unit,

remove enough fuel so no spillage

will occur. A piece of plastic bag

may be used to seal fuel tank when

tipping unit. To seal, remove fuel

tank cap, cover fuel tank opening

with plastic, replace and tighten

cap securely before attempting to

tip unit. Be sure to remove plastic

before operating unit.

SERVICE AND ADJUSTMENTS

WARNING: AVOID INJURY. Read

and understand Fuel and

Maintenance and Service Safety

Rules before proceeding.

REPLACING TRIMMER LINE

Replace the trimmer line when it extends less

than 4 inches (10.2 cm) from cutter disk. For

best results, use only genuine Ariens

replacement trimmer line.

1. Stop the engine and wait for all moving

parts to stop. Disconnect the spark plug

wire and place it securely away from the

spark plug.

2. Remove the worn trimmer line from the

cutter disk.

3. Thread the two ends of the trimmer line

up from the bottom, through the two holes

in the cutter disk.

4. Cross the line and thread the ends of the

line through the two holes on the side of

the cutter disk.

OX0063

5. Make sure the ends of the line extend

through the cutter disk at the same length.

Uneven trimmer lines cause the trimmer

head to be out of balance, which results in

excessive vibration.

4. Place a container for the oil under the oil

cap.

5. Remove oil cap and let the oil drain. Tip

the unit more to drain all the oil from the

engine if necessary.

6. Place the unit upright.

7. Refill the engine with oil recommended in

the Engine Manual.

8. Replace and tighten oil cap.

9. Clean up any spilled oil.

10.Reconnect the spark plug wire.

CLEAN ENGINE COOLING FINS

Remove grass, dirt and debris from engine

cooling fins every 25 hours to prevent damage

caused by overheating.

6. Pull trimmer line tight.

7. If necessary, cut the ends of the trimmer

line to the same length.

HANDLEBAR HEIGHT

ADJUSTMENT

1. Loosen and remove both wing knobs from

handlebar.

2. Remove carriage bolts, taking care to

support handlebar.

3. Set handlebar to desired height.

4. Line up holes in upper handlebar with

holes in lower handlebar. Be sure to use

the same holes on each side.

5. Reinstall carriage bolts and wing knobs.

Tighten securely.

OX0080

CUTTING HEIGHT ADJUSTMENT

The standard cutting height is adjustable from

1-3/16" to 4-3/8" (3 to 11.1 cm). To raise the

cutting height, place more spacers (up to 4)

below the cutter disk. Spacers not used under

the cutter disk must be assembled above the

cutter disk. For example, if you place two

spacers under the cutter disk, the other two

spacers must be in place above the cutter

disk.

NOTE: There must always be at least one

spacer between the cutter disk and the height

guide.

GB - 12

Page 13

1

2

3

1. Hex Shaft

2. Spacers

3. Cutter Disk

4. Height Guide

5. Washer

6. Lock Washer

7. Cap Screw

4

5

6

7

OX0090

2

1 spacer = 1-3/16"

(3 cm)

2 spacers = 2-3/4"

(7 cm)

3 spacers = 3-5/8"

(9.2 cm)

4 spacers = 4-3/8"

(11.1 cm)

1. Raise the cutter head off the ground.

2. Loosen and remove capscrew, lock

washer and washer.

3. Remove height guide and bottom spacer.

4. Remove cutter disk and any of the

remaining spacers required to achieve the

desired cutting height.

5. Reinstall the cutter disk.

6. Reinstall the spacers required to achieve

the desired cutting height.

7. Reinstall height guide on the hex shaft.

NOTE: Be sure the hex shaft and the hex hole

in the height guide are correctly aligned.

8. Reinstall washer, lock washer and

capscrew. Tighten securely.

NOTE: The minimum cutting height may be

lowered to 1-3/16" (3 cm) by using one spacer

below the cutter disk and installing the cutter

disk upside down on the hex shaft.

HEIGHT GUIDE REPLACEMENT

The height guide requires periodic

replacement. When used on hard surfaces,

such as concrete, it may need to be replaced

more frequently. If height guide is damaged or

worn, it must be replaced.

1. Raise the cutter head off the ground.

2. Loosen and remove capscrew, lock

washer and washer.

3. Remove worn height guide.

4. Install new height guide.

5. Reinstall hardware and tighten securely.

Wing Knob

OX0070

3. Rotate the back of the unit in the opposite

direction of the side you wish to cut with.

4. Tighten wing knob securely.

CONTROL BAIL TRAVEL

ADJUSTMENT

Control Bail must disengage trimmer head as

control is released. There should be a slight

amount of slack in the control cable wire when

bail is fully released. If the trimmer head does

not disengage completely when the control

bail is released, increase the amount of slack

in the control cable wire as follows:

1. Loosen the bottom cable nut.

2. Push the cable conduit upward toward the

control bail.

3. Tighten the upper cable nut onto the

mounting bracket to lock the conduit in

place.

4. Turn nuts against mount to lock in

position.

3

5

1. Control Cable

2. Control Cable

Wire

3. Control Bail

4. Handlebar

5. Cable Nuts

6. Cable Conduit

4

2

6

1

OX0120

SWIVEL HEAD ADJUSTMENT

1. Stop the engine and wait for all moving

parts to stop. Disconnect the spark plug

wire and place it securely away from the

spark plug.

2. Loosen the wing knob on the bracket at

the rear of the unit.

GB - 13

Page 14

DRIVE BELT REPLACEMENT

13

1

8

12

11

5

2

1. Six hex washer

head screws

2. Trimmer shield

3. Four hex

washer head

screws

4. Trimmer frame

5. Jackshaft

assembly

6. Jackshaft

spacers

7. Jackshaft

pulley belt

fingers

10

6

7

9

4

1

1

8. V-belt

9. Jackshaft

pulley

10.Engine sheave

11.Capscrew

12.Lock washer

13.Engine sheave

belt fingers

3

OX0020

7

6

5

4

1. Engine sheave

belt fingers

2. Engine sheave

3. Idler

4. Idler belt finger

6. Jackshaft

pulley belt

fingers

7. Jackshaft

pulley

3

OX0100

5. V-belt

To remove the old belt:

1. Stop the engine and wait for all moving

parts to stop. Disconnect the spark plug

wire and place it securely away from the

spark plug.

2. Place unit in service position (see

Maintenance section).

CAUTION: Before tipping unit,

remove enough fuel so no spillage

will occur. A piece of plastic bag

may be used to seal fuel tank when

tipping unit. To seal, remove fuel

tank cap, cover fuel tank opening

with plastic, replace and tighten

cap securely before attempting to

tip unit. Be sure to remove plastic

before operating unit.

2

1

3. Remove the six (6) hex washer head

screws and the trimmer shield.

4. Remove the four (4) hex washer head

screws on the top side of the frame. The

jackshaft assembly, belt fingers and

jackshaft spacers will now be loose.

GB - 14

Page 15

5. Remove the v-belt from the jackshaft

pulley.

6. Remove the capscrew and lock washer

from the engine sheave.

7. Lower the engine sheave past the belt

fingers and remove the belt.

To install the new belt:

1. Slide the new belt over the groove in the

engine sheave and slide the sheave

against the engine. Make sure the belt is

in the groove and is inside the belt fingers.

2. Install the capscrew and lock washer.

Tighten securely.

3. Slide the belt between the idler and belt

finger on the idler bracket.

4. Install the four tapping screws in the holes

in the frame, from the top side of the

frame.

5. Install the four jackshaft spacers on the

tapping screws.

6. Install the belt finger. Make sure the bent

tabs are facing up and are to the sides

and front of the unit.

7. Install the belt in the groove of the

jackshaft pulley.

8. Attach the jackshaft assembly to the

frame with the four tapping screws.

Fasten securely.

9. Reinstall the trimmer shield with the six

tapping screws.

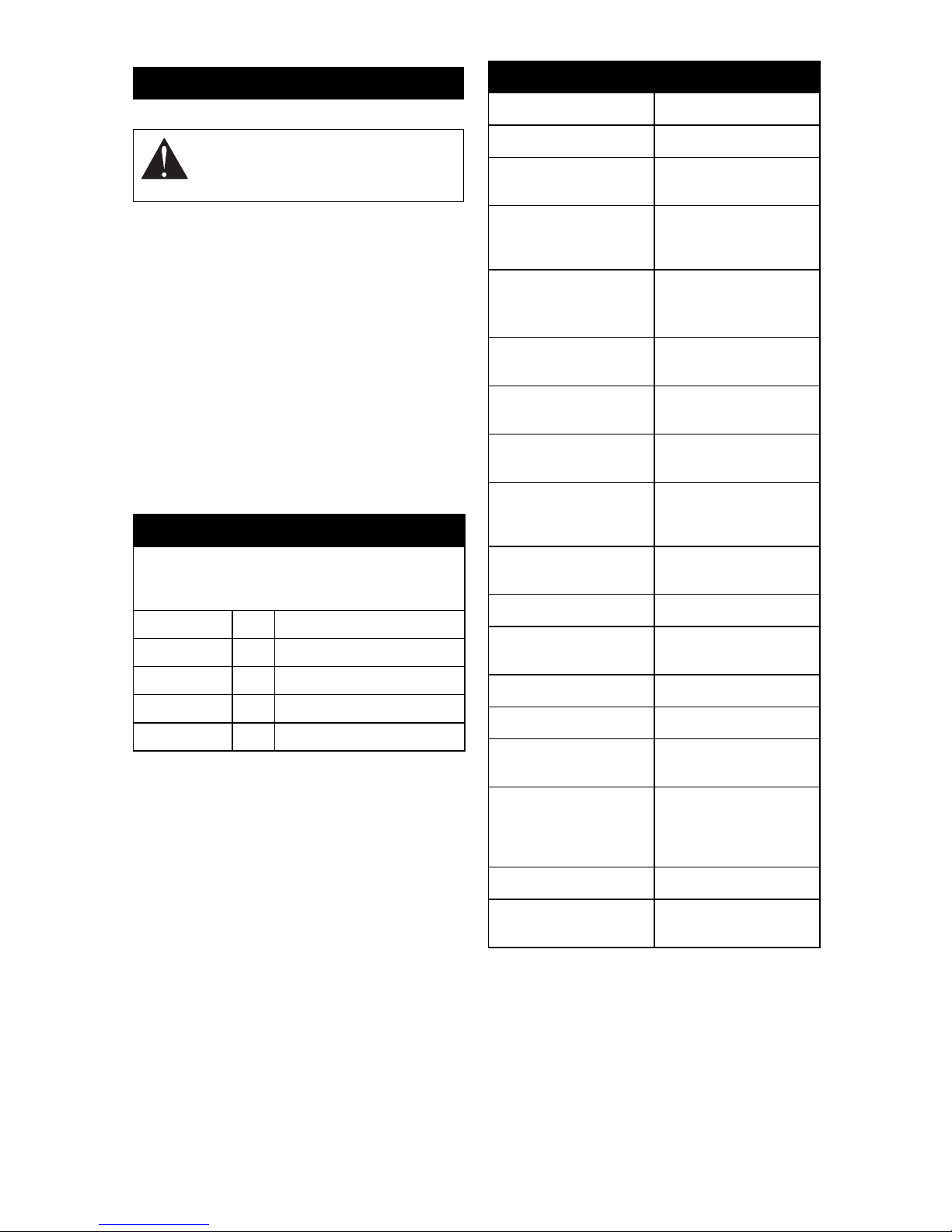

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE CORRECTION

Engine will

not start or

runs poorly

Engine

overheats

Poor

trimming

performance

1. Spark plug wire disconnected.

2. Engine not primed

3. Fuel tank empty.

4. Throttle control lever not in

correct position.

5. Engine is flooded.

6. Defective or incorrectly gapped

spark plug.

7. Stale or contaminated gasoline.

8. Engine cooling system

overloaded with debris.

9. Dirty carburetor or fuel line.

10.Dirty air filter or precleaner.

11.Carburetor out of adjustment.

1. Engine cooling system

overloaded with debris.

2. Carburetor out of adjustment.

1. Engine not set at Fast speed. 1. Set engine throttle to Fast

1. Connect spark plug wire.

2. Prime engine.

3. Add fuel to the fuel tank.

4. See Engine Manual.

5. Wait several minutes before

attempting to start.

6. Replace or regap spark plug.

7. Drain fuel tank and refill with

fresh gasoline.

8. Clean debris screen and

cooling fins.

9. Clean carburetor or fuel line.

See Engine Manual.

10.Replace air filter or

precleaner.

11.See Engine Manual or

contact your dealer.

1. Clean engine screen and

cooling fins.

2. See Engine Manual or

contact your dealer.

position.

Trimmer

vibrates

1. Cutter line lengths are too

uneven.

2. Loose hardware.

1. Trim or adjust cutter line to

equal lengths. Replace if

necessary.

2. Check all bolts and nuts,

including engine mounting

hardware, for tightness.

GB - 15

Page 16

STORAGE

SPECIFICATIONS

Model Number 946401

WARNING: AVOID INJURY. Read

and understand Fuel and Storage

Safety Rules before proceeding.

If the trimmer is to be stored for more than 30

days, follow these steps to prepare your unit.

1. Run the engine until it stops from running

out of gasoline. See Engine Manual for

specific instructions on preparing the

engine for storage.

2. Clean all dirt and debris from the trimmer.

Refer to Maintenance for cleaning

instructions.

3. Inspect unit for signs of wear, breakage or

damage. Order any parts required and

make necessary repairs to avoid delays

when beginning use again.

4. Keep all nuts, bolts and screws properly

tightened and know unit is in safe working

condition.

SERVICE PARTS

Be sure to always use genuine Ariens parts

to keep your String Trimmer running like

new.

Part no. Qty Description

07236900 1 Drive Belt

04641800 1 Trimmer Line (Pkg of 6)

04641100 1 Height Guide

04645000 1 Long Life Height Guide

Description ST622

Engine Power - HP

(KW)

Engine Operating

Fast Idle Speed RPM

Engine

Displacement

- cu. in. (cc)

Fuel See Engine Manual

Fuel Tank Capacity qt (Liters)

Cutting Width - in

(cm)

Handlebars Max.

Extended Height - in

(cm)

Minimum Folded

Height - in (cm)

Length - in (cm) 57.88 (147.02)

Minimum Folded

Length - in (cm)

Width - in (cm) 22 (55.88)

Weight - lbs (Kg) 83 (37.65)

Cutter Head Speed RPM

6 (4.48)

3600

12.06 (197.6)

for type and grade

1.25 (1.18)

22 (55.88)

41.38 (105.11)

19.38 (49,23)

37.25 (94.62)

3600

GB - 16

Drive Belt 4L Section, Single

“V” Construction,

Raw Edge Kevlar

Cord

Wheel Size - in (cm) 14 (35.56)

Replacement Line

Length - in. (cm)

18 (46)

Page 17

2 Year Limited Warranty

Ariens Company warrants to the original purchaser that consumer products manufactured

by Ariens Company will be free from defects in material and workmanship for a period

of two (2) years after the date of purchase, and will repair any defect in material or

Ariens Company

655 West Ryan Street

P.O. Box 157

Brillion, WI 54110-0157

1-866-622-5633

Fax 920-756-2407

www.ariens.com

This warranty is subject to the following conditions, limitations, and exclusions:

This warranty is valid only if the following conditions are

met:

• The warranty registration card must be completed and

returned to Ariens Company.

• The purchaser must perform maintenance and minor

adjustments explained in the owner’s manual.

• The purchaser must promptly notify Ariens Company or an

authorized Ariens service representative of the need for

warranty service.

This warranty is subject to the following limitations:

• The purchaser must transport the product to and from the

place of warranty service.

• Warranty service must be performed by an authorized Ariens

service representative. (To find an authorized Ariens service

representative, contact Ariens Company at the number or

address above.)

• Batteries are warranted only for a period of twelve (12)

months after date of purchase, on a prorated basis. For the

first ninety (90) days of the warranty period, a defective

battery will be replaced free of charge. If the applicable

warranty period is more than 90 days, Ariens Company will

cover the prorated cost of any defective battery, for up to

twelve(12) months after the date of purchase.

workmanship, and repair or replace any defective part, subject to the conditions, limitations

and exclusions set forth herein.

The two year duration of this warranty applies only if the product is put to ordinary,

reasonable, and usual personal, family, or household uses. If the product is put to any

business, commercial, or industrial use such as, but not limited to, commercial landscaping,

mowing or snow removal services, or golf course or park maintenance, or agricultural

or farmstead use, then the duration of this warranty is ninety (90) days after the date

of purchase, or one (1) year after the date of purchase if the product is labeled as a

Professional/Commercial Product. If any product is rented or leased, then the duration

of this warranty is ninety (90) days after the date of purchase.

The following items are not covered by this warranty:

• Engines and engine accessories are covered only by the

warranty made by the engine manufacturer, and are not

covered by this warranty.

• If the product is equipped with a Peerless gearbox and/or

transmission, the gearbox and/or transmission are covered

only by the warranty made by Peerless, and are not covered

by this warranty.

• Parts that are not genuine Ariens service parts are not

covered by this warranty.

• Shoes, runners, scraper blades, shear bolts, string trimmer

height guide, mower blades, mower vanes, trimmer line,

headlights, light bulbs, are not covered by this warranty.

• Any defect which is the result of misuse, alteration, improper

assembly, improper adjustment, neglect, or accident, is not

covered by this warranty.

• Products which were not purchased in the United States,

Puerto Rico, or Canada are not covered by this warranty. In

all other countries, contact place of purchase.

LIMITATION OF REMEDY AND DAMAGES

Ariens Company’s liability under this warranty, and under any

implied warranty that may exist, is limited to repair of any

defect in workmanship, and repair or replacement of any

defective part. Ariens Company shall not be liable for incidental,

special, or consequential damages (including lost profits).

Some states do not allow the exclusion of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

DISCLAIMER OF FURTHER WARRANTY

Ariens Company makes no warranty, express

or implied, other than what is expressly made

in this warranty. If the law of your state provides

that an implied warranty of merchantability, or

an implied warranty of fitness for particular

purpose, or any other implied warranty, applies

to Ariens Company, then any such implied

warranty is limited to the duration of this

warranty. Some states do not allow limitations

on how long an implied warranty lasts, so the

above limitation may not apply to you.

Form: MLW2-121300

GB - 17

Loading...

Loading...