Page 1

BODY BUILDER INSTRUCTIONS

Mack Trucks

Electrical Wiring and Connections

CHU, CXU, GU, TD, MRU, LR

Introduction

This information provides design and function, specification and procedure details for

Electrical Wiring and Connections for MACK vehicles.

Note: For information on mDrive PTO installation and wiring see Section 9 PTO

Installation, mDrive.

Note: For information on PTO parameter programming see Section 9 PTO Parameter

Programming.

Unless stated otherwise, following a recommendation listed in this manual does not

automatically guarantee compliance with applicable government regulations. Compliance

with applicable government regulations is your responsibility as the party making the

additions/modifications.

Please be advised that the MACK Trucks, Inc. vehicle warranty does not apply to any

MACK vehicle that has been modified in any way, which in MACK's judgment might affect

the vehicles stability or reliability.

Section 3

Contents

• “Abbreviations”, page 3

• “General Wiring Definitions”, page 4

• “Routing and Clipping Guidelines”, page 5

• “Body Builder Connectors, Schematic Examples”, page 17

• “Remote Start n Stop”, page 23

• “Remote Engine Stop”, page 24

• “Adding Auxiliary Accelerator Pedal”, page 25

• “BodyLink III”, page 26

• “Auxiliary Switch Locations (Cab)”, page 30

• “Power Connections”, page 31

• “Control Link II”, page 37

• “LR Workbrake”, page 50

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Page 1 (94)

All Rights Reserved

Page 2

• “Wiring J1939”, page 52

• “9-pin Diagnostic Connector”, page 54

• “16-pin Diagnostic Connector”, page 55

• “Termination Resistor”, page 60

• “Parameter List”, page 61

• “Multiplexing Body Builder J1939 CAN ”, page 77

• “Support Inbound and Outbound J-1939 Message Information ”, page 85

CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Release 01

Page 2 (94)

Page 3

Abbreviations

• ACC Adaptive Cruise Control

• BOC Back of Cab

• CAN Controller Area Network

• CDS Custom Defined Statement (replaced by DCL)

• DCL DataMax Control Language

• ECM Engine Control Module

• EHT Electronic Hand Throttle

• EMS Engine Management System

• ESC Engine Speed Control

• FMI Failure Mode Identification

• GMT Greenwich Mean Time

• MID Message Identifier (J1587 source)

• PGN Parameter Group Number (J1939 message ID)

• PID Parameter Identification (J1587)

• PID Product Identification (order code)

• PTO Power Take Off

• PTT2 Premium Tech Tool 2

• SA Source Address (J1939 unit identifier)

• SID Subsystem Identification (J1587)

• SPN Suspect Parameter Number (J1939 parameter)

• SSC Single Speed Control

• TCM Transmission Control Module

• VDA Vehicle Data Administration (OEM database)

• VECU Vehicle Electronic Control Unit

• V-MAC Vehicle Management And Control (Mack brand electronics name)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 3 (94)

All Rights Reserved

Page 4

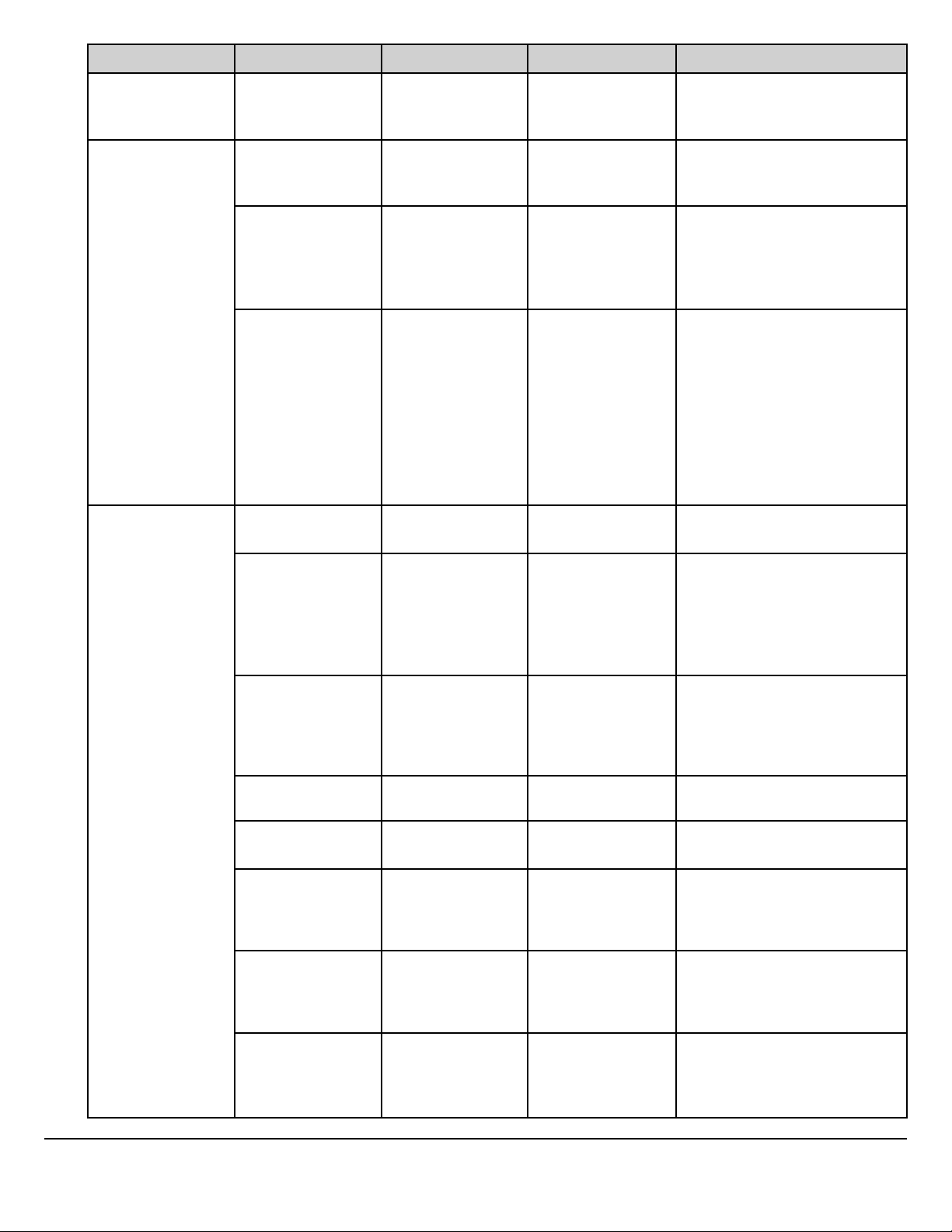

General Wiring Definitions

The general wiring definitions provides a standardized list of terminology used in running wires, hoses, and cables throughout the vehicle.

Abrasive Surface

AWG

Bundled With

Cable Tie

Chafing To wear away by rubbing

Contacts

Crimped A routed commodity that is bent or pressed into ridges

Damaged An item that differs from its original condition

Drooping Routed items hanging downward which are detrimental to safe vehicle operation

Dual Fall

High Current

Electrical Cables

High Nut Extended clamp length

Kinked

Items capable of causing damage to the routed commodity in a rubbing condition during vehicle

operation

American Wire Gauge

A number of items tied, wrapped, or otherwise held together

A nylon plastic self-sizing strap, UV resistant, capable of bundling specified load(s) during vehicle

operation

Items touching each other.

(Pertaining to the Compressor Discharge Line) A high point in the routing of the Compressor Dis-

charge Line (located on the engine) whereby any collected moisture is allowed to fall in two different di-

rections where it is either dissipated by heat or is purged

Wire sizes 13 mm sq. (0.5 inches sq.) (6 AWG) and larger

A tight bend, curl, or twist in the routed commodity causing flow to be restricted

Low Current Elec-

trical Cables

Low Nut

Material Grade 30

Material Grade 50

May

Not Secured

Plastic Conduit

Puncture Small hole or wound

Routed With

Rubbing Items that contact each other and have independent movement

Shall

Sharp Edge A surface capable of cutting or piercing the routed commodity during vehicle operation

Should

Verb typically used in a statement of practice that is a permissive condition and carries no requirement

or recommendation. It can be included to alter statements of mandate or recommendation

Corrugated or smooth wall tubing used to protect hoses, harnesses, cables, tubing, pipes, etc.

Items taking the same path but not attached to each other (i.e., parallel but separate)

Verb typically used in a statement of required, mandatory or specifically prohibitive practice regarding

Verb typically used in a statement of recommended, but not mandatory, practice in typical situations

with deviations allowed if Engineering judgement or Engineering study indicates the deviation is

Wire sizes 8 mm sq. (0.3 inches sq) (8 AWG) and smaller

Standard clamp length

Minimum yield strength of 30,000 psi

Minimum yield strength of 50,000 psi

Items not fastened, bundled or tied

routing and clipping

appropriate

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 4 (94)

All Rights Reserved

Page 5

Twisted

Distorted from the routed commodities’ original shape about it’s cross-sectional center line

Touch Items that contact each other but do not have relative movement

Routing and Clipping Guidelines

1 Brackets used in routing and clipping should be Material Grade 50 or better to ensure sufficient clamp load when sharing

joint connections with cross members or other structural members. This applies only to joint connections using a low nut.

Brackets of Material Grade 30 are acceptable provided the shared joint is using a high nut. The area of the clip bracket

under the bolt head must be a least as large as the bolt head itself.

2 Clips that scratch exterior mounting surfaces shall not be used (i.e., barbed/spring type) unless the material is non-corrod-

ing (i.e., plastic). Clips must have rust protection.

3 Clip sizes should adequately secure the bundle without restricting flow, causing collapse, or preventing relative

movement.

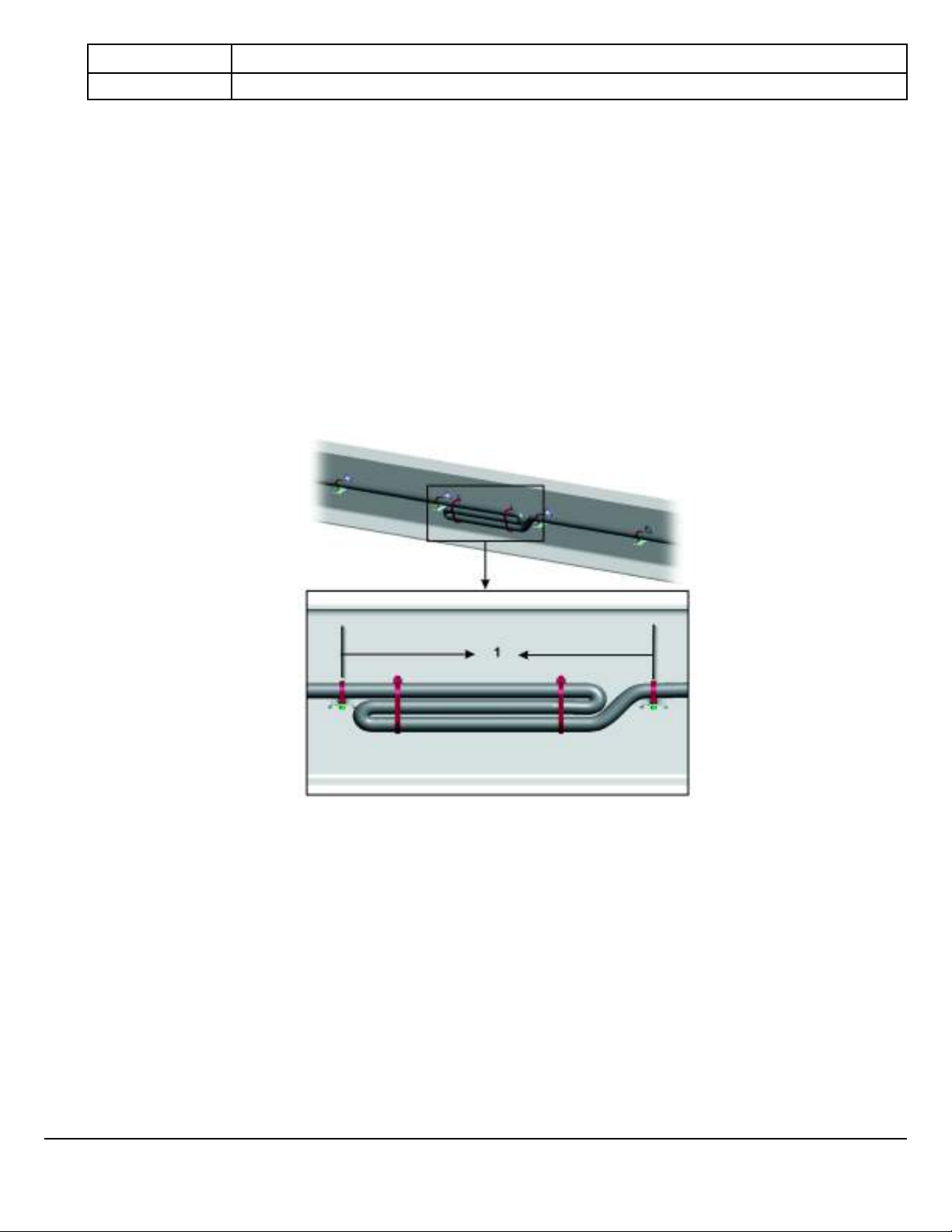

4 Bundles shall be supported at 24 inches (600 mm) maximum intervals, a cable tie should be used between clip points on

bundles with the exception of electrical wiring harness which shall have a maximum support distance of 18 inches (450

mm) and a cable tie on bundles between clip points. When air and electrical lines are bundled together, the commodity

with the greater cross sectional area may determine the support spacing. A minimum of two cable ties shall be used between clip points to bundle electrical lines when the larger interval is used.

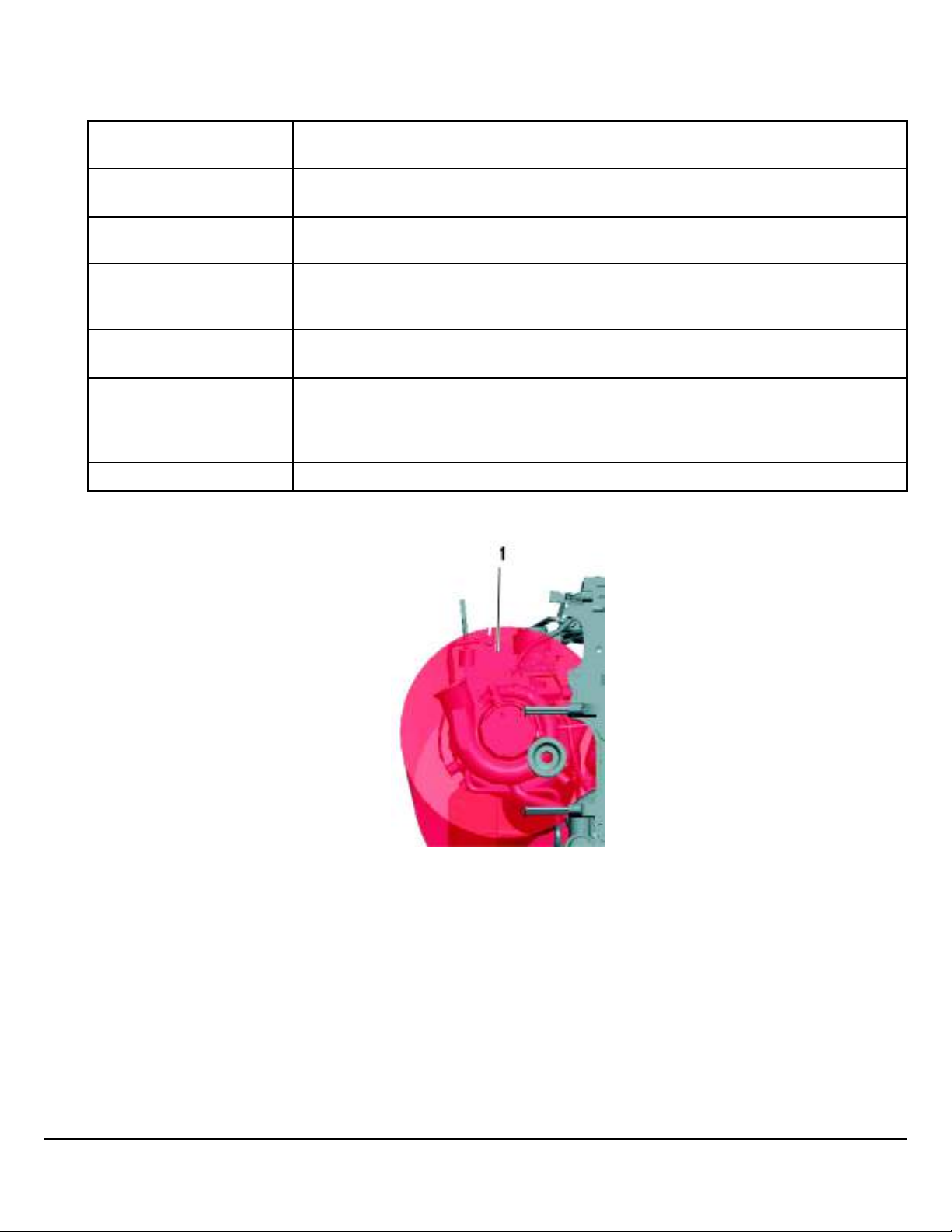

W3104131

1 Support electrical cables every 18 inches (450 mm)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 5 (94)

All Rights Reserved

Page 6

Support Distances, Continued

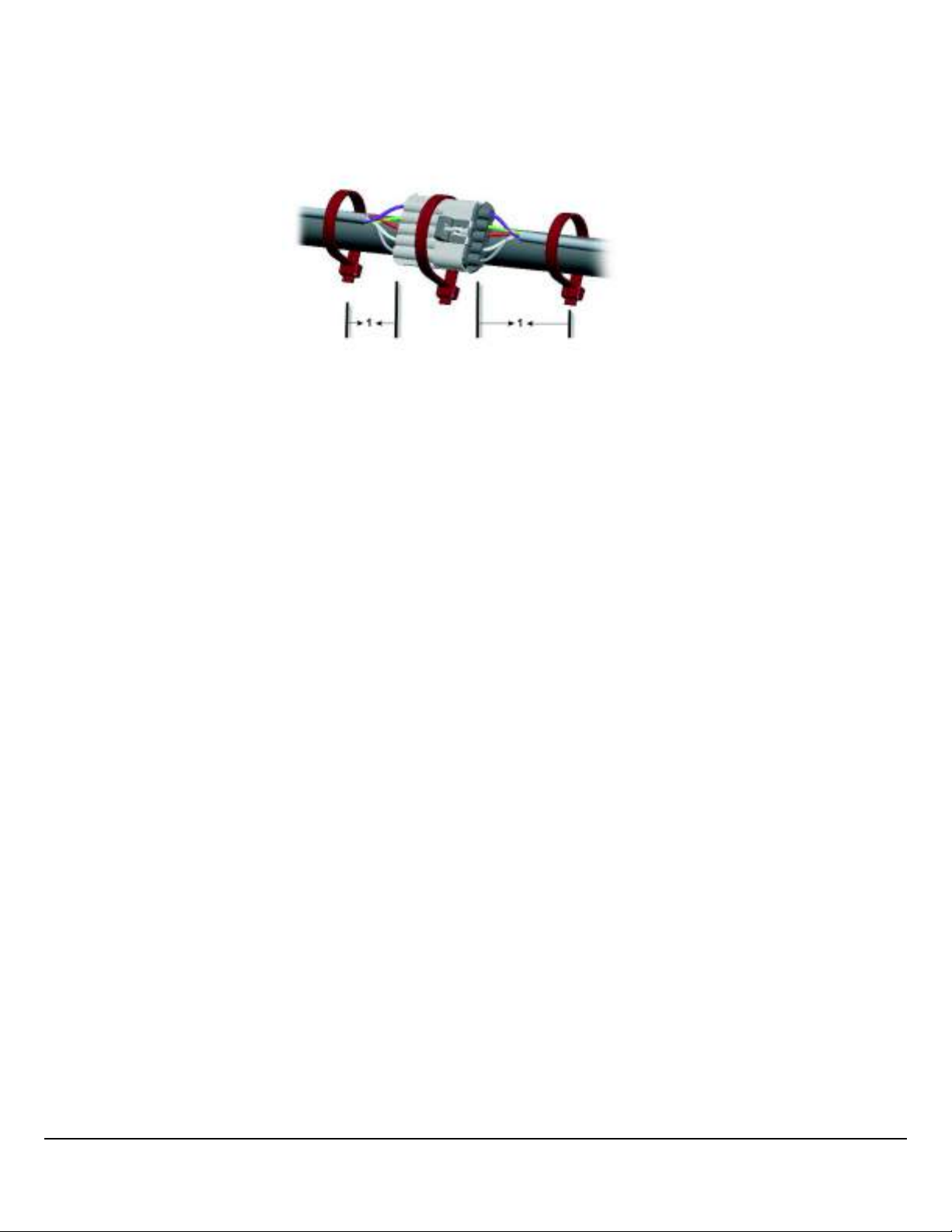

1 Support cables near connectors every 4 inches (100 mm)

W3104144

1 Electrical cables and wiring harnesses are to be secured 4 inches (100 mm) from the wire insertion end of the connector

or clipped to the body.

2 Routing and clipping on purchased components (i.e., engine/transmission) should not include removing or replacing a

bolt(s), nut(s) or screw(s) installed by the manufacturer. In such cases where this is unavoidable, the bolt(s), nut(s) or

screw(s) shall be re-installed to the manufacturer’s specifications.

3 Bundles should not contact sharp edges of cross members. Contact may occur if it is against a smooth surface, a smooth

radiused edge or a coined edge and the bundle is secured to prevent independent movement.

4 Hoses, tubing, pipes and electrical conduits shall not rub each other but may touch.

5 The fabric braided portion of the compressor discharge hose is compatible to be bundled with all routed air lines.

6 The compressor discharge pipe shall be routed independent of all other routing.

7 Electric cables/harnesses must not be bundled with fuel or hydraulic lines. The electrical cables/harnesses may be routed

parallel with fuel or hydraulic lines, however must remain separated by approved clipping materials. When design control

is possible, electrical cables/harnesses will be routed above fuel or hydraulic lines. If fuel or hydraulic lines must route

above circuit protected electrical cables /harnesses, the fuel or hydraulic lines will have no fittings or potential leak points

above electrical cables/harnesses and shall be minimized to the shortest distance possible over low current electrical cables/harnesses.

8 All associated markings on air and electrical harnesses should have a corresponding clipping apparatus.

9 Critical clipping locations shall be designated on the component to insure proper placement in the vehicle (i.e., tape).

10 Maximum support distance for compressor discharge rigid pipe, 30 inches (762 mm). Pipe to be isolated from support

brackets (i.e. rubber isolator).

11 Maximum support distance for compressor discharge flex hose, 24 inches (600 mm).

12 Compressor discharge line should have a constant fall from compressor to air dryer. A dual fall is allowable provided it oc-

curs on the engine and within 24 inches (600 mm) of the compressor.

13 Maximum allowable dip in compressor discharge pipe/hose is one half the outer diameter of the pipe/hose. Preferred rout-

ing should have no dips in any of the routing. This is to avoid line blockage due to water collecting and freezing in the line.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 6 (94)

All Rights Reserved

Page 7

Heating Specifications

In order to maintain the integrity of the cables and hoses, observe the following specifications for routing near a heat source.

Cable, hose, or harness

type

Electrical cables and wiring

harnesses

Unprotected hoses, tubing,

harnesses, and cables

5 inches (130 mm) in all directions from turbocharger, exhaust components, and other high

6 inches (150 mm) above, 5 inches (130 mm) beside and 4 inches (100 mm) below

Specification

heat components

Hoses, tubing, harnesses,

and cables protected by re-

3 inches (76 mm) above, 2 ½ inches (63,5 mm) beside and 2 inches (51 mm) below

flective heat sheathing

Silicone transmission coolant

hoses

2 inches (51 mm) from exhaust manifold and turbo (with reflective heat sleeving), 1 inch (25

mm) from exhaust pipe

Hoses, tubing, harnesses,

and cables protected by a

heat shield (no reflective

3/8 inch (10 mm) between the component and the heat shield. (Not valid for fuel lines)

sheathing)

Refrigerant suction hoses 8 inches (200 mm)

W3109897

1 Heat Radius from the Turbocharger, Front: 5 inches (130 mm)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 7 (94)

All Rights Reserved

Page 8

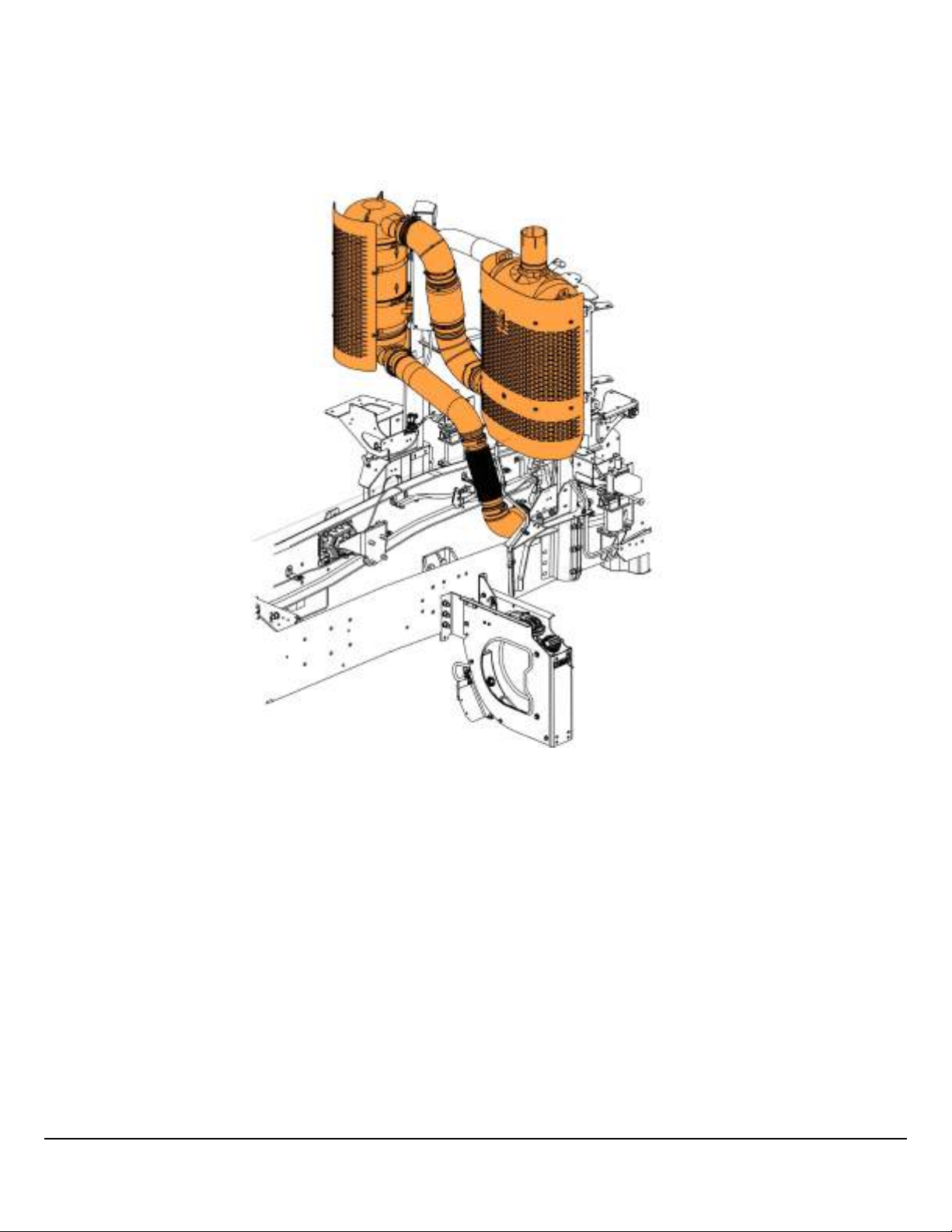

W2106268

The SCR, DPF, and exhaust piping generate substantial heat. Keep electrical cables away from these components.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 8 (94)

All Rights Reserved

Page 9

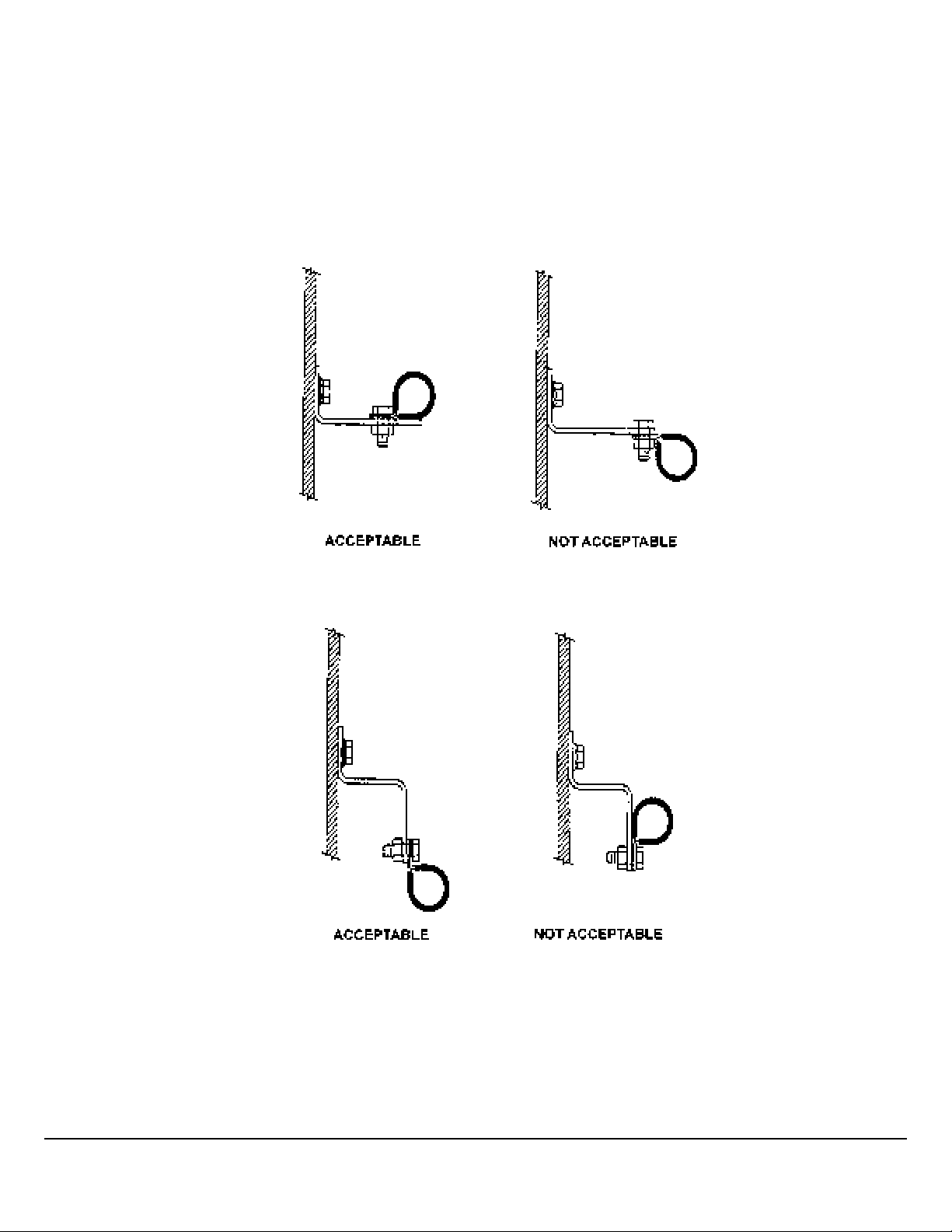

Clipping Guidelines

Clipping brackets should be designed and mounted to adequately support the bundle. Clips should be mounted in a hanging

position or supported along three-quarters of the horizontal mounting surface. Orientations that do not conform to the illustrations shall be tested.

1 When hoses, wires, and cables cross one another, secure them with a clamp. This prevents the sawing motion that could

abrade them.

2 When routing flex hoses that are bent in two planes, clip them to prevent twisting. Clamp the hose at the point where the

hose changes planes. The clamp has the effect of dividing the hose into two assemblies. If the section of the hose is bent

in the same plane as the movement, the bend will absorb the movement and the hose will not twist.

W3103550

W3103553

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 9 (94)

All Rights Reserved

Page 10

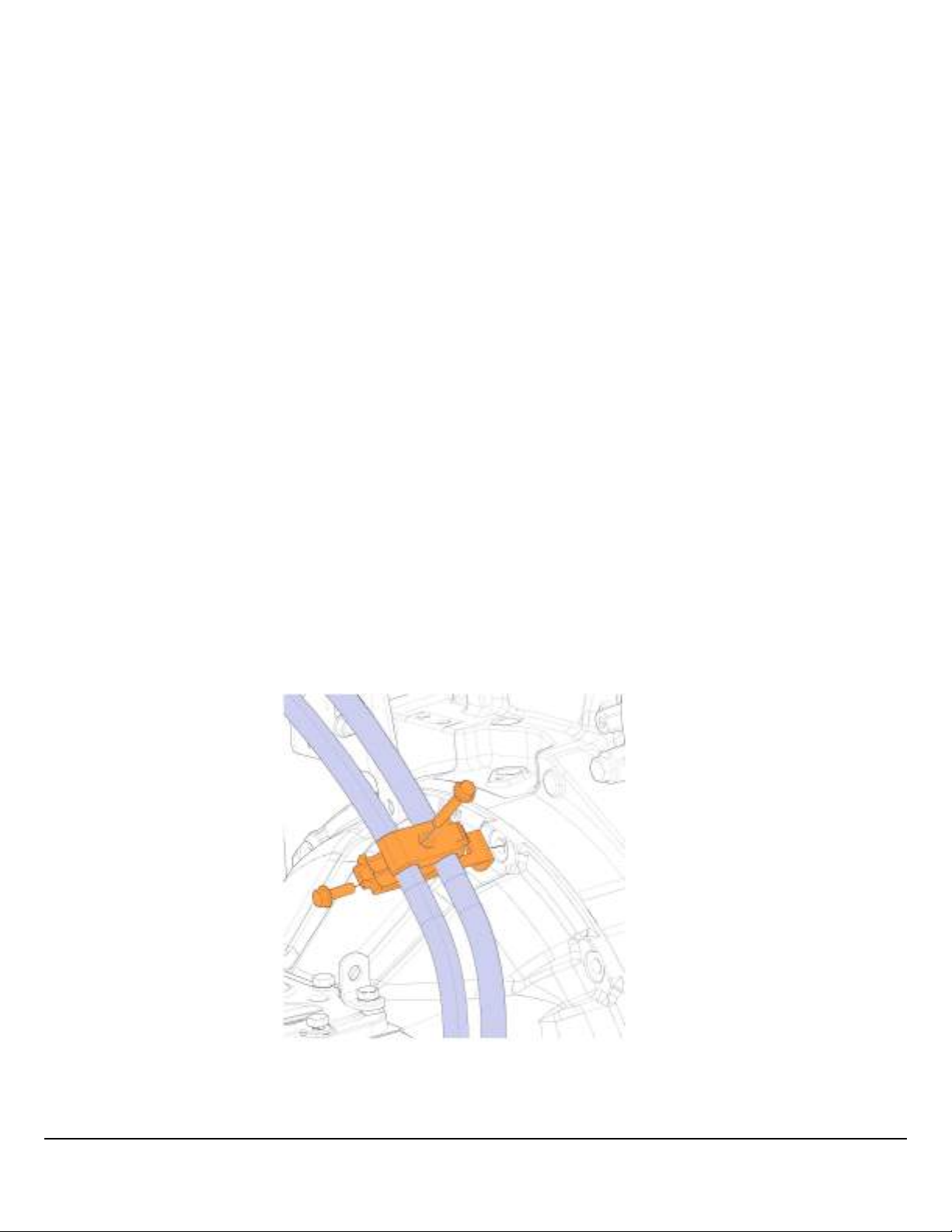

When routing connectors with cable ties, ensure the cable ties do not contact the connector locking tab. Cable ties should also not contact the bare wire.

W3104148

W3104149

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 10 (94)

All Rights Reserved

Page 11

Battery Cable Guidelines

The battery cable guidelines prevent electrical interference that can occur from improperly routed cables. In addition, the

guidelines prevent cable damage through abrasion.

1 Battery cables with standard SAE stranding shall be supported at 16 inches (400 mm) maximum intervals. A separator

type cable tie or an independent separator with cable tie may be used between clip points. No relative movement may occur between cables. If two (2) cable separators are used, they are to be installed equidistant from each other and arranged on a straight line, a maximum span between clip points of 24 inches (600 mm) may be used.

2 Strain relief clipping shall be provided for the battery and starter motor terminals. The strain relief clip shall be located with

no relative motion to the terminals. The strain relief clip should be located close to these terminals and shall be within 20

inch (500 mm) cable length to the starter terminals.

3 Grommets shall be installed at points where cables pass through sheet metal or frames.

4 Routing shall avoid exposed edges of frame members, abrasive surfaces, and all sharp edges. When routing inside the

frame, ensure that no contact with the frame is made with uncovered cables. Uncovered battery cables, external of the

battery box, shall be routed independent of all other conduits. Covered cables may be bundled with other similarly covered

conduits and air piping with a secured separator. Do not route with/under fuel lines.

5 Cables should be clipped as close as possible to all cable bends.

6 Battery cables shall not be located within 5 inches (130 mm) of engine exhaust related components or other heat sources

without heat coverings or heat shielding. Testing shall be performed to determine effects of closer allowances and the use

of heat shields. Battery cables should not be installed in any area directly above engine exhaust related components.

7 Where cables flex between moving parts, the last supporting clip shall be securely mounted such that relative movement

does not promote chaffing.

8 Battery cables shall not support any mechanical loads other than their own mass.

9 Minimum bend radii of battery cables should be 3 times the cable diameter for standard SAE strand cable.

W3104133

1 Tube Diameter

2 Circle Diameter ( 3 x Tube Diameter)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 11 (94)

All Rights Reserved

Page 12

Battery Guidelines, Continued

1 Star washers shall not be used on current path connections including grounds.

2 Asphalt type loom shall not be used for battery cable protection applications.

3 Battery cables shall not rub each other or surrounding items, but may touch when all items have no independent move-

ment. Uncovered battery cables may not touch each other outside the battery box.

4 All exposed exterior to cab circuit ends shall be coated with a dielectric protective coating. Thickness to be 0.13 – 0.3 in-

ches (3.5 – 7 mm) wet, full coverage, 3 inches (76.2 mm) diameter, or shall be completely covered with required inhibitor.

5 Clip orientations should be per illustration or installation drawings utilizing compression or heavy duty clip.

6 Plastic conduit may be bundled and cable tied with covered battery cables when all items have no independent movement

with each other. Battery cables may touch each other, plastic conduit or the battery, inside the battery box.

7 Covered battery cables may be securely tied or clamped to each other if no independent movement exists. Cables at-

tached to the same terminal stud may be tied or clamped to each other.

8 Battery cable ends at the starter motor posts should be installed and positioned first with the engine harness terminals as-

sembled after. Starter terminals that come with the starter may be first on the starter studs. Terminals shall not be re-configured or bent.

9 Frame bolt placement, adjacent to the battery box, should have the bolt or screw threaded end facing away from the bat-

tery box and any related cables. Wrench grip type bolts should not be used in the frame at the battery box area. Nonwrench grip type bolt or screw threaded ends may face toward the battery box only if clip bracketing or shielding shall be

provided to prevent any possible cable contact with frame mounted hardware. Bolts that mount the battery box to the

frame may be oriented toward the battery box.

10 Added abrasion protection should be used where the cable contacts other routed commodities or surfaces with no inde-

pendent movement such as frame rail surfaces or transmission and engine castings. Polyethylene, polypropylene, nylon

conduit and thick wall heat shrink tubing may be used for added abrasion protection.

11 Cables should be located to afford protection from road splash, stones, abrasion, grease, oil and fuel. Cables exposed to

such conditions should be further protected by either, or a combination of, the use of heavy wall thermoplastic insulated

cable, additional tape application, plastic sleeve or conduit.

12 Anytime an existing fastener is used to secure a clipping bracket (or any similar device), the fastener shall be re-torqued

to the value specified in the original documentation given for the fastener.

13 Each exposed exterior circuit end must be coated with a dielectric protective coating. Thickness to be 0.13 – 0.3 inches

(3.5 – 7 mm) wet, full coverage, 3 inches (76.2 mm) diameter.

14 Do not use box clamps to secure battery cables.

15 In addition to berringer clamps, use double-head tie clamps.

W3077595

Berringer clamps are recommended for securing battery cables to each other.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 12 (94)

All Rights Reserved

Page 13

W3105372

Box Clamps (shown above) are NOT to be used for securing battery cables to each other.

W3105374

Double-head tie clamps may be used to route battery cables.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 13 (94)

All Rights Reserved

Page 14

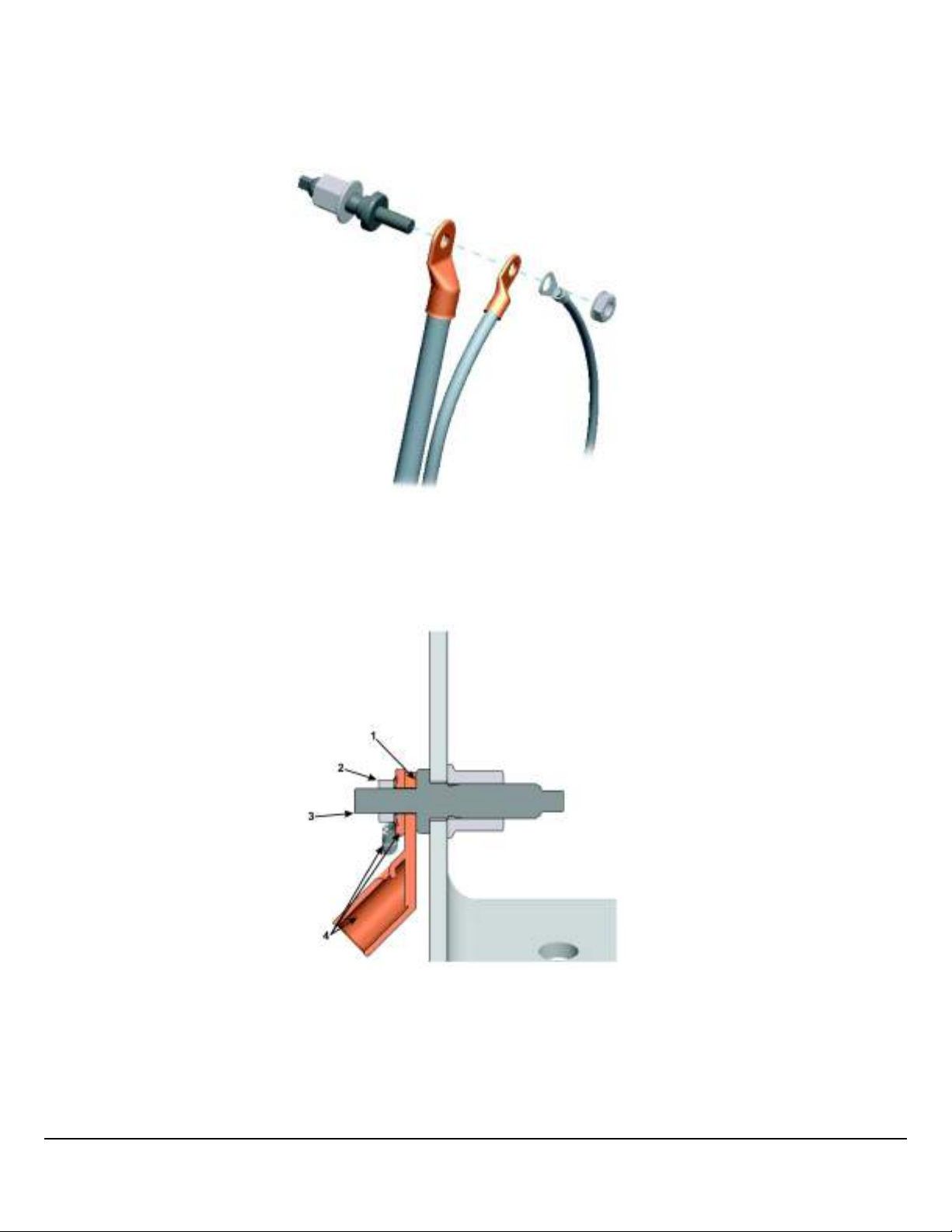

Ring Terminal Assembly

Assemble terminal carrying the highest current (largest gauge wire) first, then graduate to the smallest gauge up to the fastener. Use a maximum of three (3) terminals per stud (unless otherwise specified on an illustration drawing).

W3104152

When attaching ring terminals with a fastener, tighten the fastener to appropriate torque so that the contact area will touch

the terminal at any point, in a full circle that is part of the terminal.

W3104153

1 Contact Area

2 Fastener

3 Stud

4 Terminals

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 14 (94)

All Rights Reserved

Page 15

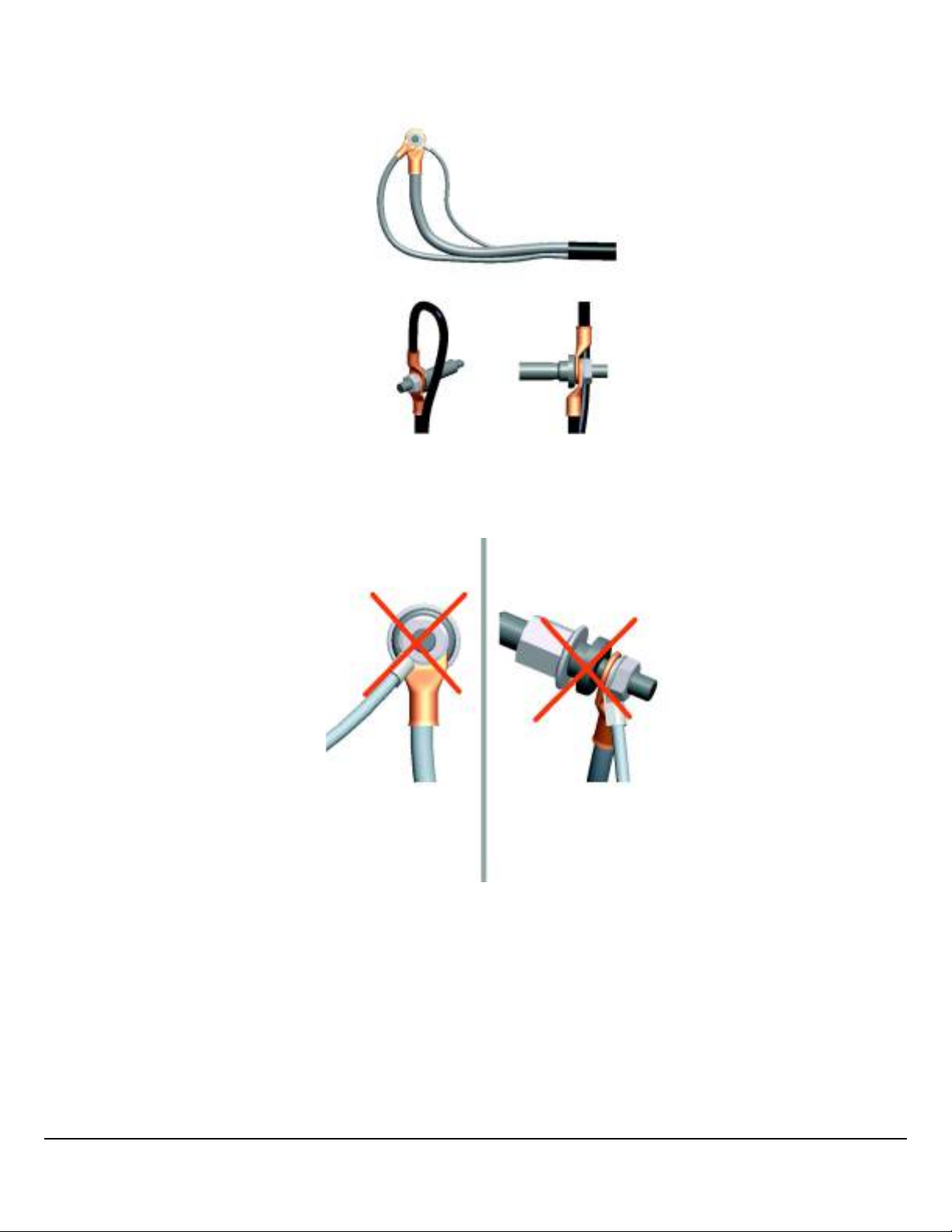

When attaching multiple terminals, position the terminals at an angle to allow maximum contact of the terminal surface. Terminals are not allowed to bend other than their natural form. Terminals may be stacked back to back.

W3104154

Improperly fanned terminals result in unacceptable bends.

W3104155

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 15 (94)

All Rights Reserved

Page 16

NOx Sensor Routing

The NOx sensor requires unique routing considerations. The NOx sensor harness must not be bundled with other wiring harnesses. However, it may be routed with other harnesses as long as they are not high voltage cables. The sensor harness is

a set length and no altering or modifying of the NOx sensor harness is allowed.

W3104156

Conventional

W3109892

Cabover

Note: DO NOT splice into a V-MAC, ABS/ATC or any other electronic control unit harness.

Do not cut or tap into the J1939 green/yellow twisted wires or any other wire or harness used on this vehicle. Use the provided connectors, and only add approved J1939 components with validated software. Failure to comply may result in personal injury or equipment damage. Any cutting, splicing, alteration or modification to the wiring will Void the Mack Trucks

Warranty on the Electrical System.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 16 (94)

All Rights Reserved

Page 17

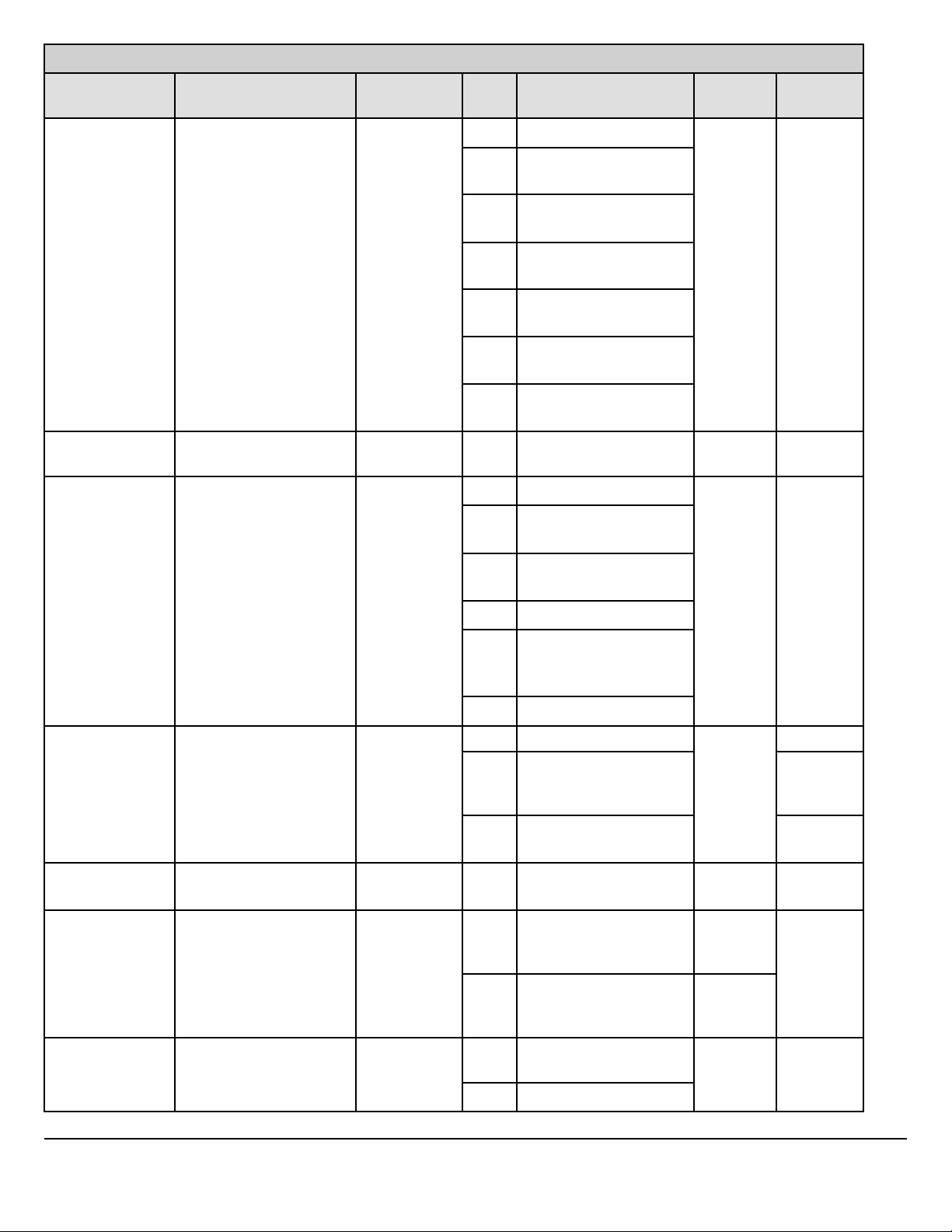

Body Builder Connectors, Schematic Examples

Third party devices are often installed on MACK trucks. These devices need information (vehicle speed, gear, etc.) to operate safely and efficiently. However these devices are not quality controlled as far as MACK is concerned, and are not part of

the main control databus. Therefore, MACK provides an external connector to supply a body device with the necessary information it needs to function properly.

MACK trucks do not use an external body builder module (BBM). In MACK trucks, the functions of the BBM are managed by

the Vehicle Electrical Control Unit (VECU) and are transmitted to the body device via an SAE J1939 connector. SAE J1939

is a communications link between standalone vehicle modules. This data link is commonly referred to as the “Control Data

link”. It is used primarily to transmit control signals that are shared between other standalone modules. The information on

the SAE J1939 control link is used for control functions. Fault messages or diagnostic information also transmits across this

link. These control signals may be for engine, transmission, brakes or a number of other vehicle control needs. The J1939

operates at 250,000 bits per second, which is approximately 26 times faster than the J1708/1587 data link. This higher speed

allows the system to operate at a faster sampling rate and higher resolution, thus enabling better control of vehicle functions.

Terminating Resistors

Terminating resistors are wired to each end of the SAE J1939 data link to prevent signal reflections. They must remain connected for the data link to function properly. The resistance value of each termination resistor is 110–130 Ω. When properly

installed in the data link, their combined resistance is 50–70 Ω since they are connected in parallel.

The termination resistor at one end of the SAE J1939 data link is located in the fuse/relay center (FRC) near the vehicle electronic control unit (VECU) and the other near the engine control module (ECM). On vehicles equipped with MACK engines,

the termination resistor at the engine end is located inside the ECM. On vehicles equipped with Cummins engine, the termination resistor is located in the harness area just outside of the ECM.

A SAE J1939 data link connection is located at the transmission area in the chassis harness. On vehicles equipped with an

electronically controlled transmission (Allison/Autoshift II/Meritor Freedom Line), the connection to the transmission is located at the chassis harness. On vehicles equipped with a manual non-electronically controlled transmission - the connector

stub will have an un-terminated blanking plug installed.

Only two termination resistors are used in each data link. Never install more than two terminator resistors in one data link. If

more than two resistors exist in the SAE J1939 data link circuit, incorrect or absent signals may occur. You can easily check

to see if you have two resistors by measuring the resistance between pin C and D for the 9-pin diagnostic connector, or pin 3

and 11 for the 16-pin diagnostic connector, with the ignition key in OFF position. The correct resistance is 50 – 70 Ω. The termination resistors should each have a resistance of 110 – 130 Ω when tested individually.

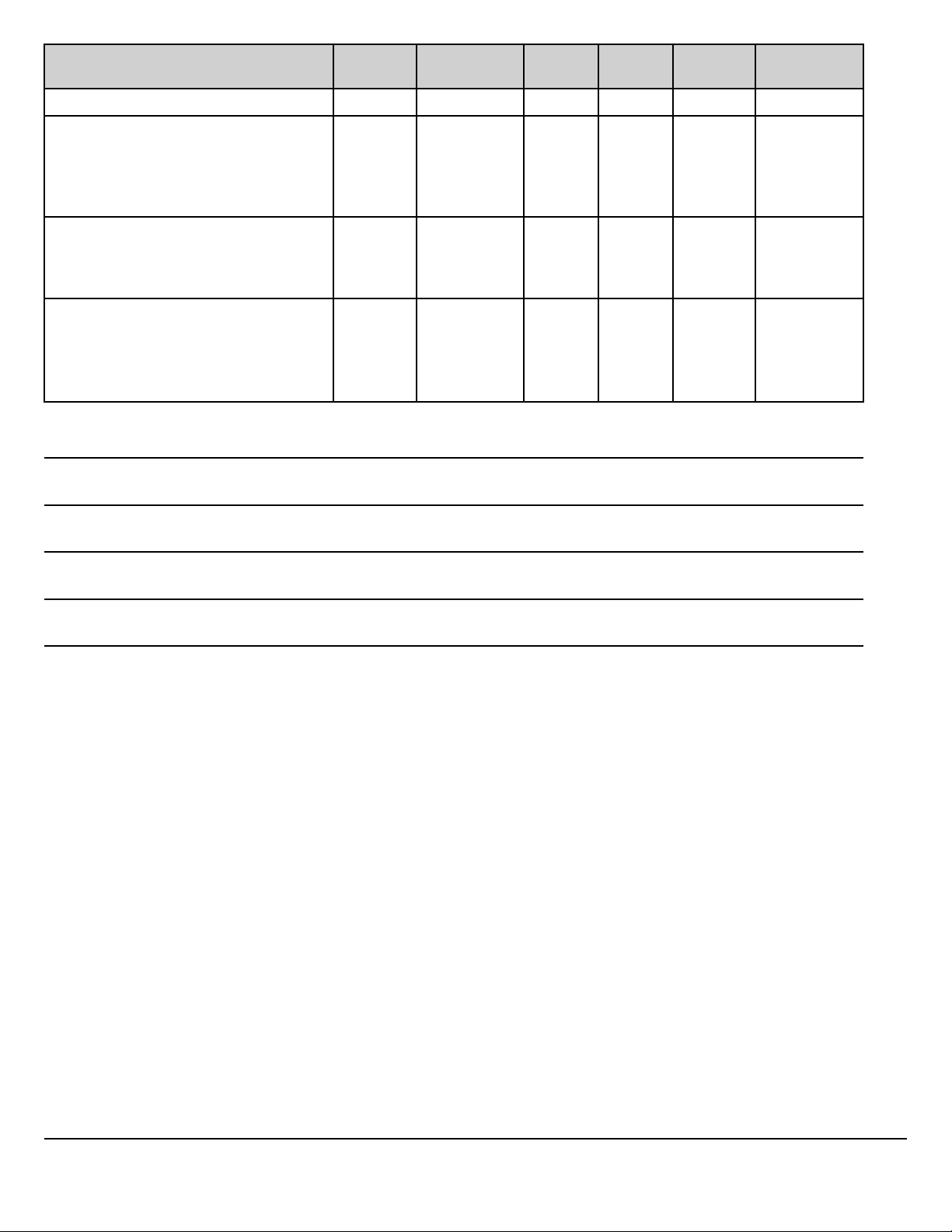

Notes

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 17 (94)

All Rights Reserved

Page 18

Electrical Wiring and Connections

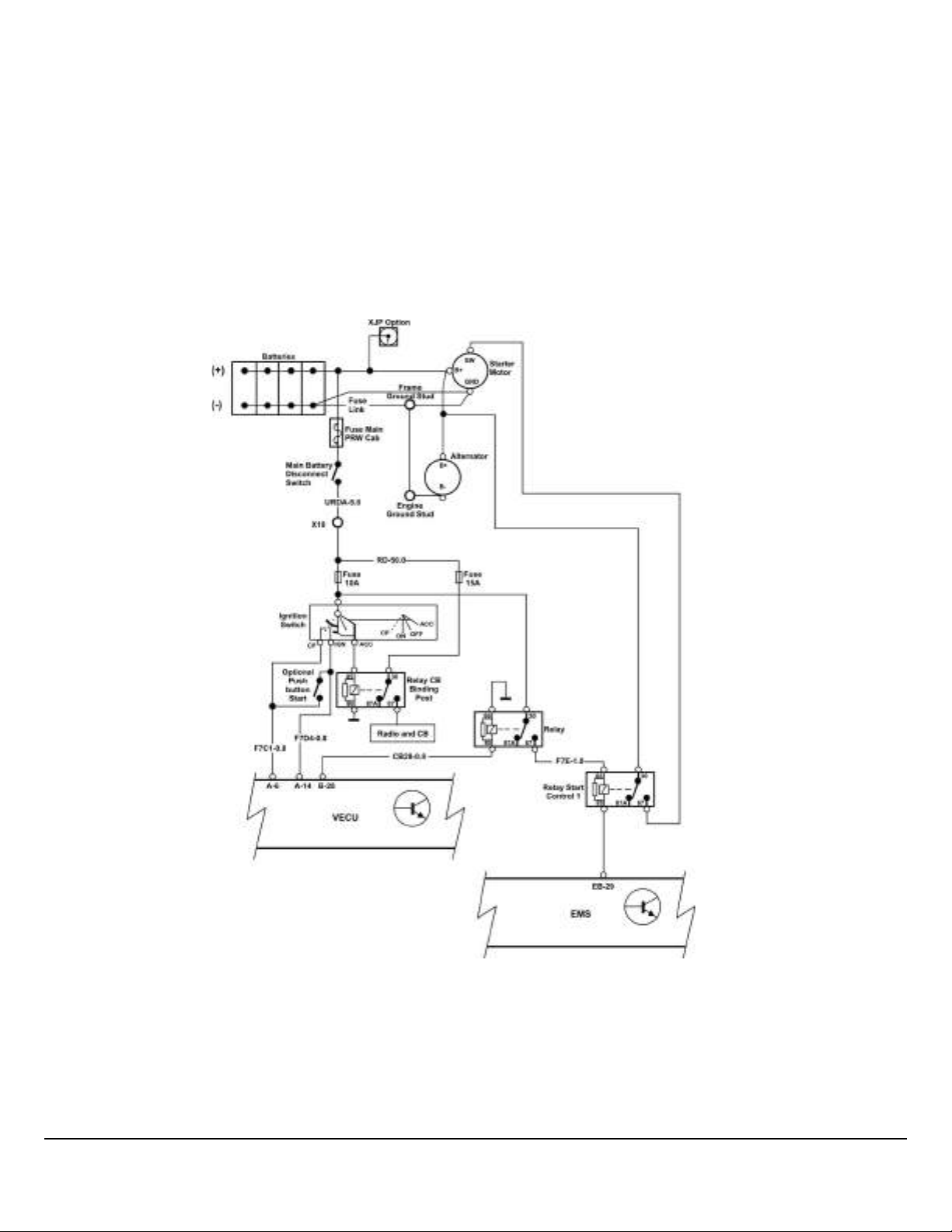

Main Power and Starting Circuits

Figure 1 shows the starter circuits. Note that the EMS and VECU directly control the starter relay. The EMS inhibits starter

for engine running, starter overheat and PTO. The VECU inhibits the starter mainly for transmission in gear.

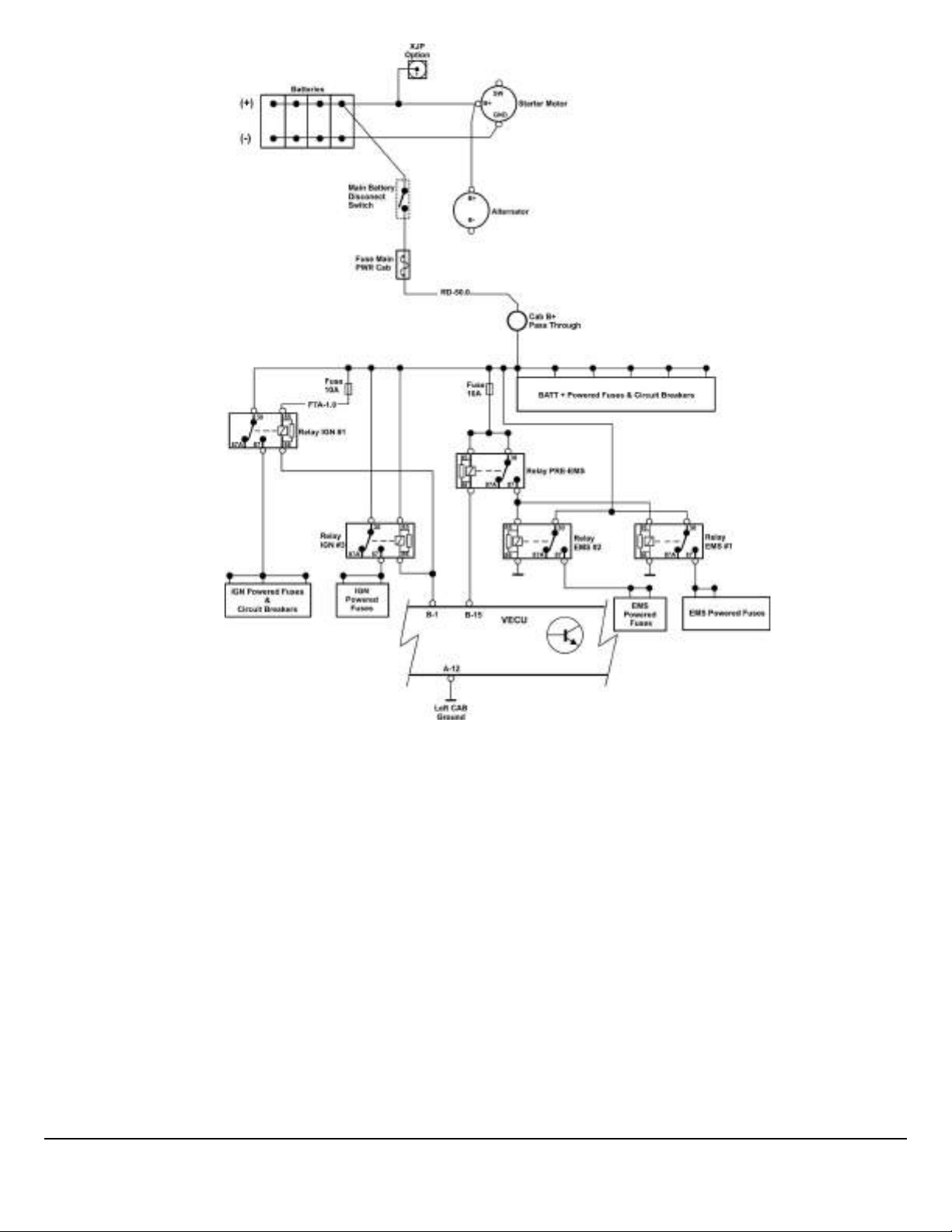

Figure 2 shows the main power circuits. Ignition and “EMS” power are controlled by the VECU through relays. “EMS” power

is connected after the key is turned on and remains on during crank and for some seconds after key off, mainly to service the

Engine Management System. Ignition power is similar, but is disconnected during crank and supplies items not necessary

for engine start. MACK conventional trucks actually have a second set of ignition circuits for items not normally needed for

driving (e.g. Sleeper) which also supplies one of the Granite BodyLink III power pins indicated in Figure 7. The first and second power relays are also shut off at low voltage. The first relay powers off at a lower threshold than the second.

W3113939

Fig. 1 Main Power and Starting Circuit

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 18 (94)

All Rights Reserved

Page 19

W0113940

Fig. 2 Battery & Ignition - Switched Supplies - Conventional Trucks

“IGN” circuits will be disconnected at LOW VOLTAGE and during STARTING.

“EMS” circuits remain powered while at key ON or CRANK and may remain powered at key OFF.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 19 (94)

All Rights Reserved

Page 20

Vehicle Control Unit (VECU) Connections

Fig. 3 Vehicle Control Unit (VECU) Connectors

Notes

W3088359

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 20 (94)

All Rights Reserved

Page 21

Description of VECU Pin Layout

VECU Connector A (Green)

Pin Number Type Mack Name

PA-1 DI-H Cruise Control: Set/Decel

PA-2 DI-H Cruise Control: Resume/Accel

PA-3 DI-H Cruise Control: On/Off

PA-4 DI-H A/C On

PA-5 DI-H Service Brake

PA-6 DI-H Key Switch Crank

PA-7 DI-H

PA-8 DI-H Clutch

PA-9 DI-H Neutral

PA-10 DI-H Air Suspension Interlock

PA-11 DO-L (1A) DRL Control

PA-12

PA-13

PA-14 DI-H Key Switch Ignition

PA-15

PA-16

PA-17 DI-H CDS 2 switch / PTO 4

PA-18 DI-H IVS2 used for Volvo Automatic gearbox

PA-19 DI-H Fan Override

PA-20 DI-H Engine brake 2

PA-21 DI-H Engine brake 1

PA-22 DI-H EOL

PA-23 DI-H IVS 1

PA-24 DI-L

PA-25 DI-L Interwheel Lock

PA-26 DI-L 5th Wheel Slide Switch

PA-27 DI-L Remote Engine Shutdown

–

–

–

–

Battery ( + after PWR )

—

Ground

J1939 + BBM

J1939 – BBM

—

PA-28 DI-L Hood Tilt Switch

PA-29 DI-H PTO1

PA-30 DI-H DRL Override

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 21 (94)

All Rights Reserved

Page 22

VECU Connector B (Blue)

Pin Number

PB-1 DO-L (1A) Power Relay #1 (load shedding)

PB-2 DO-L (1A) Power Relay #2 (load shedding)

PB-3 DO-L (1A) Interwheel Diff Lock

PB-4 DO-L (1A) 5th Wheel Slide Interlock /Regen Inhibited

PB-5 (12 v, 50 mA) Output Supply 4

PB-6 Frequency Input Vehicle Speed Sensor +

PB-7 DI-H PTO 2

PB-8 AI (4K) Throttle Pedal Signal

PB-9 AI (2 - 10K) Spare

PB-10 (5V, 10 mA) Output Supply 1, (T.P.)

PB-11 DI-L Parking Brake

PB-12 DI-L EB Steering wheel 1

PB-13 DI-L RH Operation

PB-14 AI (1.5-4K) Spare

PB-15 DO – L (0.2A) EMS Relay

Type

Mack Name

PB-16 DO-L (1A) Aux Fan

PB-17 DO – H (10 mA) Buffered IVS 1 (Only EMS)

PB-18 DO-L (1A) PTO output

PB-19 (12V, 70mA) Output Supply 3

PB-20 Frequency Input Vehicle Speed Sensor -

PB-21 DI-H CDS 1 / PTO 3

PB-22

PB-23

PB-24 AI (2 - 10K)

PB-25 (6.5-9V, 15mA) Output Supply 5

PB-26 (5V, 10 mA) Output Supply 2

PB-27 AI Spare

PB-28 DO – H ( 2A) Starter Control (ASSIST or starter protection)

PB-29 DI-L Door Switch

PB-30 DI-H Shut Down Override

—

—

Analog Ground

Analog Ground

—

VECU Connector C (Green)

Pin Number Mack Name

PC-1 J1587 B

PC-2 J1587 A

PC-3

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 22 (94)

—

All Rights Reserved

Page 23

Pin Number Mack Name

PC-4 J1939 H

PC-5 J1939 L

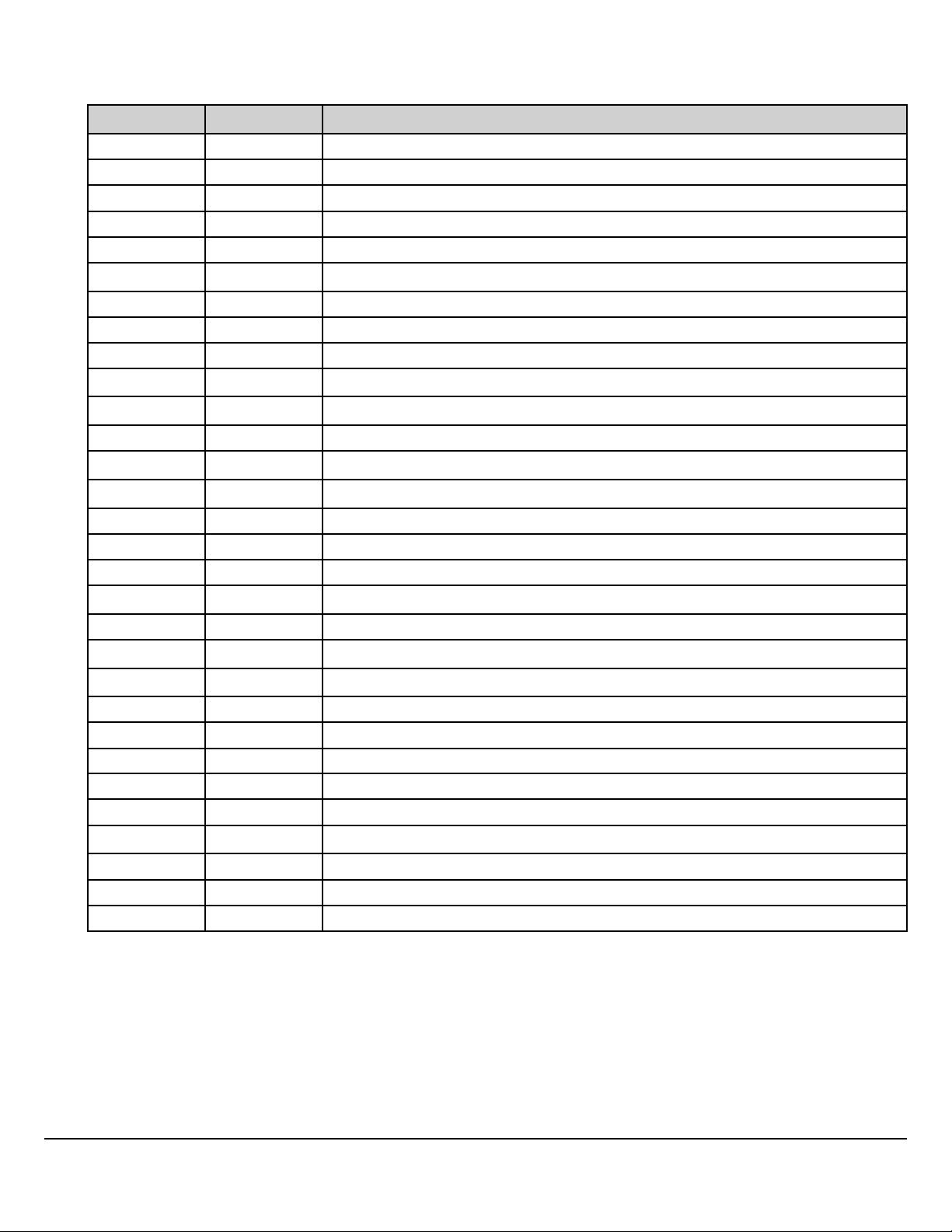

Remote Start n Stop

Note: This is only a suggestion for a body builder installed system.

W3121912

Fig. 4 Remote Start N Stop V-MAC IV

Note: Refer to “Remote Start N Stop V-MAC IV, Schematic Components” table for descriptions and part

numbers.

Remote Start N Stop V-MAC IV, Schematic Components

Description Part Number

Relay 25171095

Relay Connector 20865681

Terminal Female 925AM22

Terminal Male 20865699

Secondary Lock 25154889

Switch Drive Position 25153559

Switch Drive Position Connector 21402299

Terminal Drive Position Switch 25091569

Park Brake Switch 25171211

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 23 (94)

All Rights Reserved

Page 24

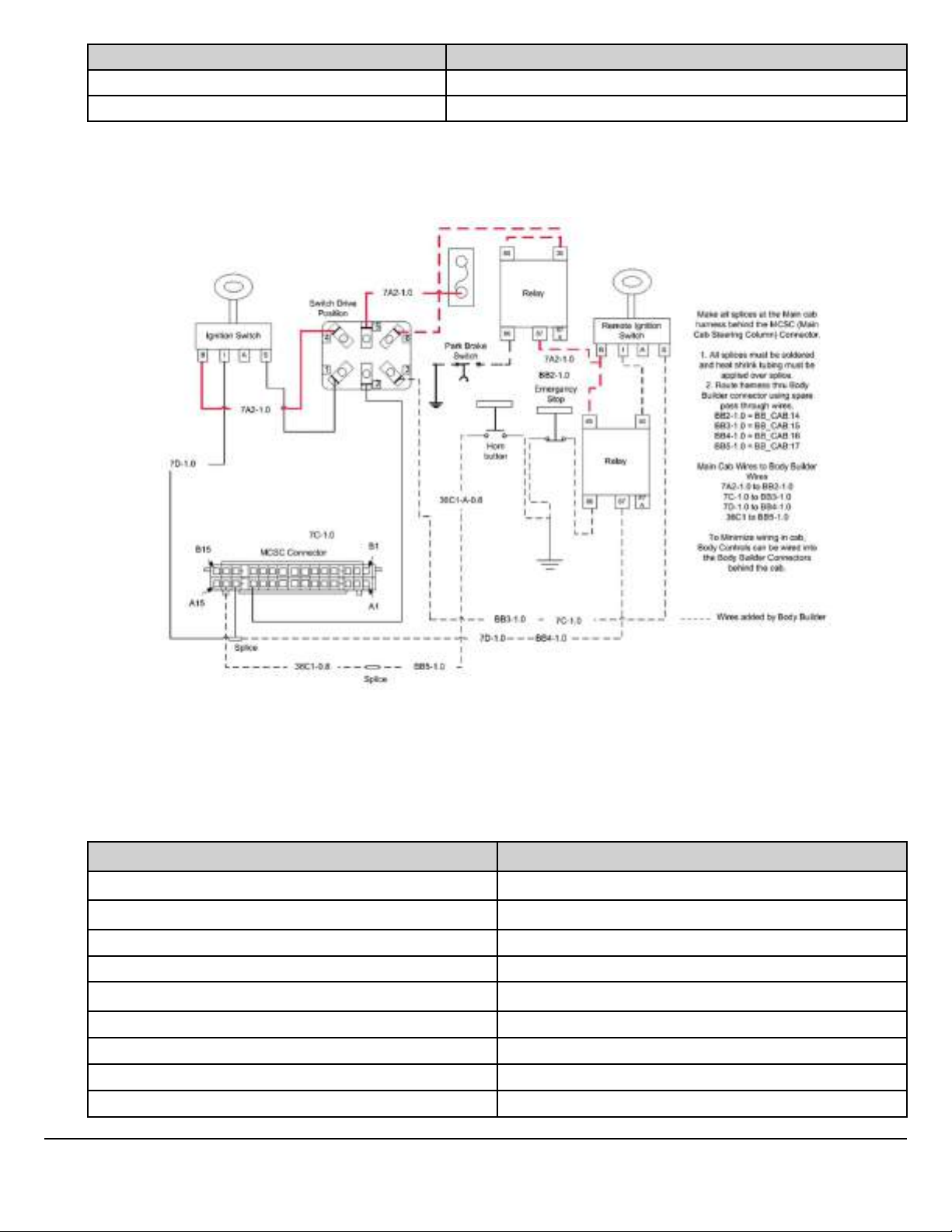

Remote Engine Stop

If a chassis was ordered with “Remote Engine Stop”, a relay is pre-installed in the harness. Installation of the push button

switch is all that is required.

If installing “Remote Engine Stop” to a chassis (MRU / LR and Conventional Chassis’), relay P/N 25082390 must be installed

in addition to installing the push button switch. Only MRU and LR models are pre-wired for the Remote Engine Stop.

Note: For Remote Engine Stop to work you must run an accessory kit and P/N 85137397 reprogram the VECU (Can only be

done by a Dealer) and parameters need to be programmed. See “Remote Engine Stop” in the Body Builder, Parameter Programming service bulletin.

Note: The input to the VECU pin A27 (Green 30-way connector on VECU) is an active low digital input that must be attached

to an isolated signal ground.

DO NOT switch chassis/cab ground to pin A27 of the VECU. Interference from other components on the chassis/cab

ground could cause an engine shutdown when not requested by the body builder.

Note: The switching of ground to an input that carries a very low current requires special switching equipment. It is recommended using a switch with gold contacts, or a relay to switch the signal ground to Pin A27 of the VECU.

Gold resists corrosion on the contacts and relays have enough ‘swiping’ motion on the contacts to help keep them clean.

W3113955

Fig. 5 Remote Engine Stop

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 24 (94)

All Rights Reserved

Page 25

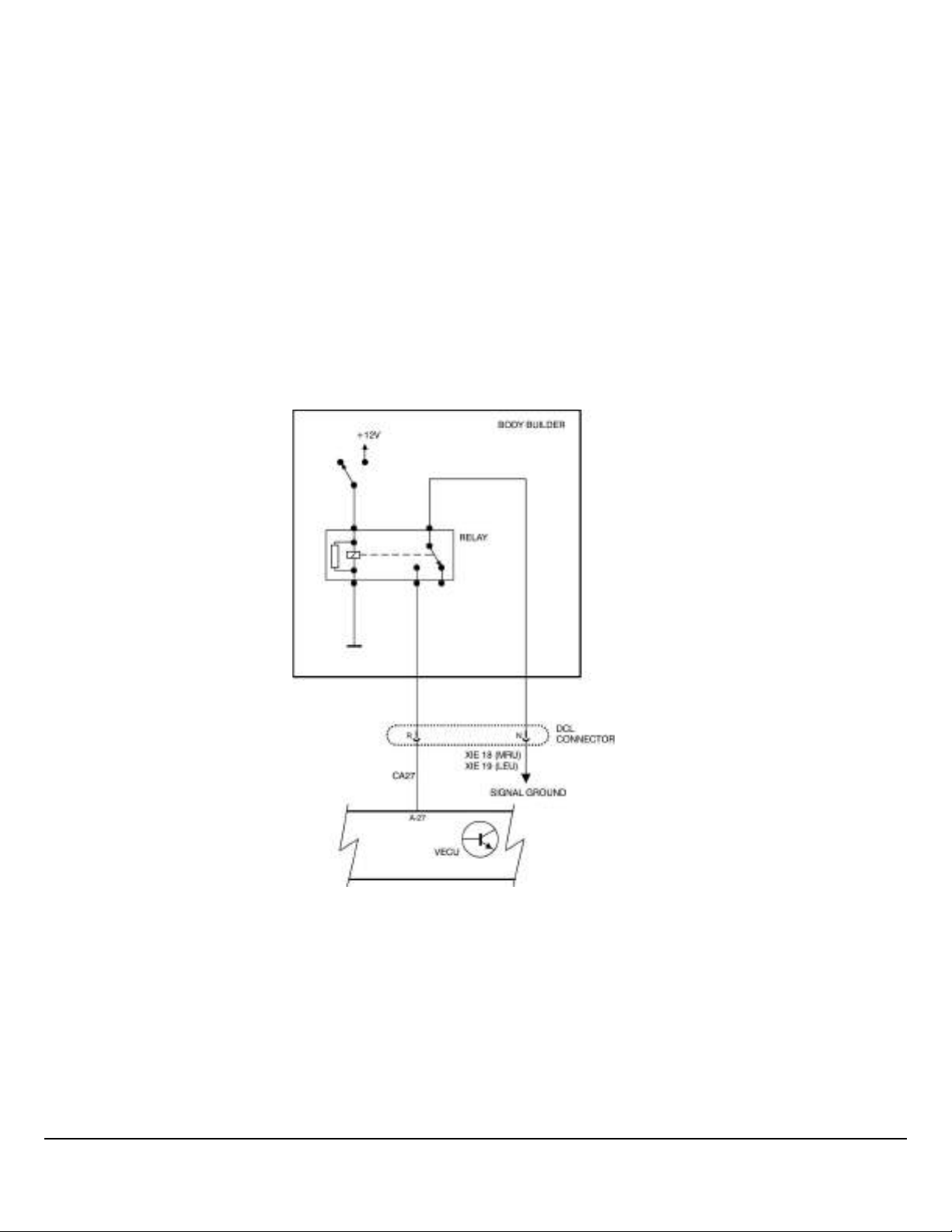

Adding Auxiliary Accelerator Pedal

Below is a suggestion for adding an auxiliary accelerator pedal, based on the Mack LR dual steering solution.

The pedal is wired in parallel using a multi-pin selector switch. If the signal is not switched between the two accelerator pedals, a fault code may be generated due to high current at the throttle pedal signal input line (VECU B-8).

Note: See data link system before using such a device.

Note: An identical pedal is needed for the auxiliary sensor accelerator pedal because it requires an IVS signal. A substitute

type pedal may cause a fault code and is not recommended.

Fig. 6 Auxiliary Acceleration Pedal Signal

Note: Refer to “Auxiliary Acceleration Pedal Signal, Schematic Components” table for component ID(s) and

descriptions.

Notes

W3113956

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 25 (94)

All Rights Reserved

Page 26

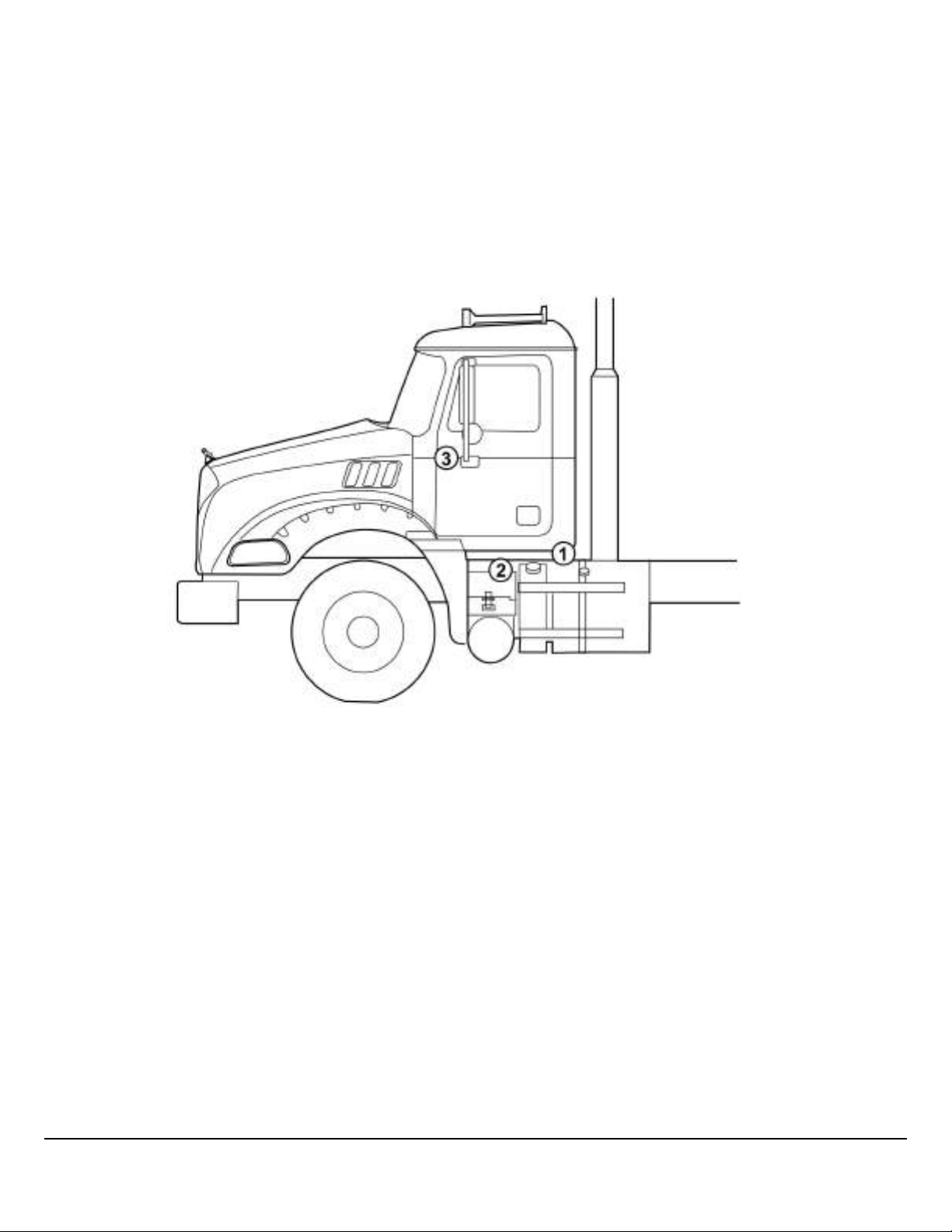

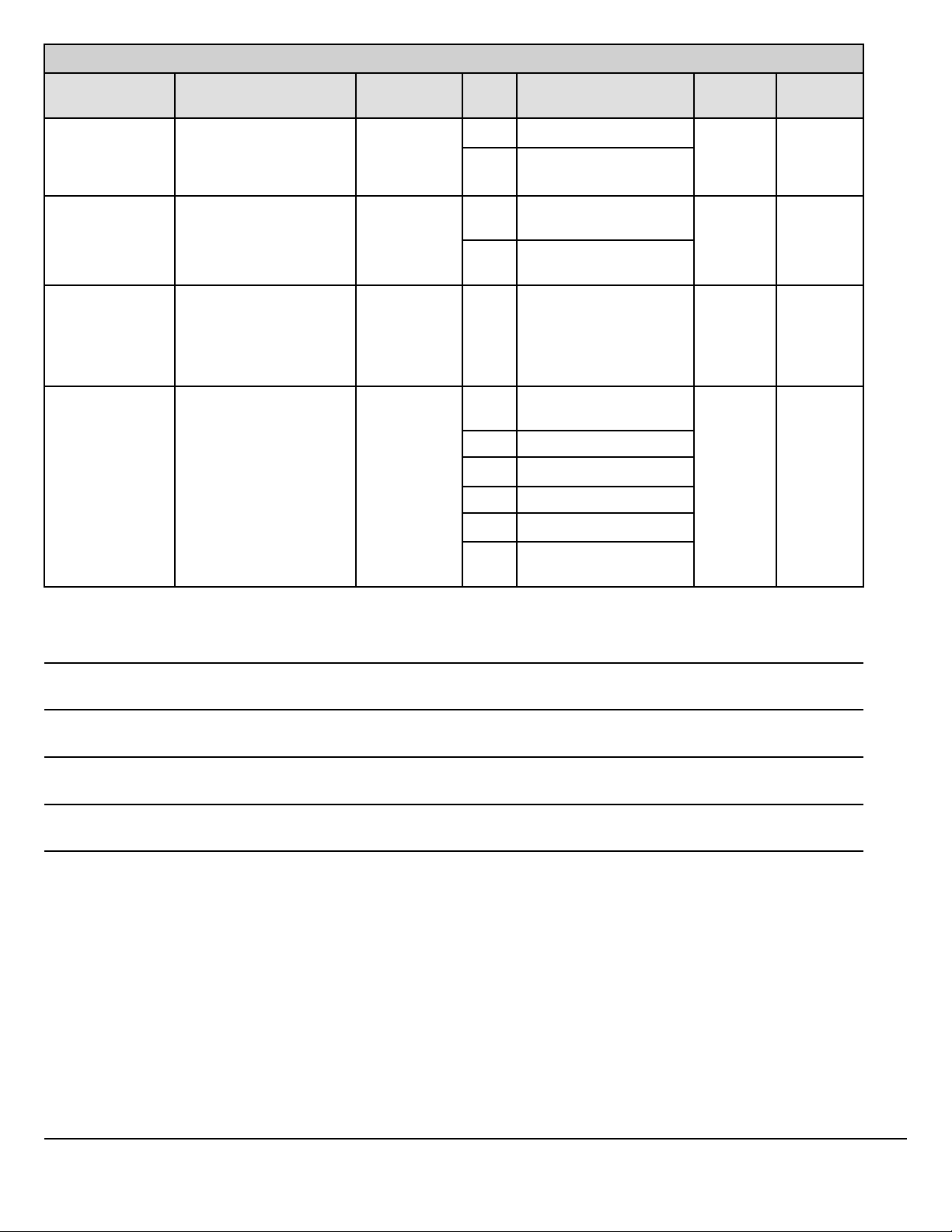

BodyLink III

BodyLink III is the standard Mack Granite straight truck body builder electrical interface. It consists of a 29-pin electrical

quick-connector and grounding stud mounted just under the rear of the cab (near BOC). BodyLink III includes an electrical

pin-out label. Also available with BodyLink III is a cab pass-thru between the seats. Note that the carpeting or floor mate is

not cut at the factory to avoid unnecessary noise if not used. Also available is a ‘BodyLamp’ dash light to indicate typically

when the dump body is elevated. This lamp is activated via pin #17 when grounded. Also available with BodyLink III are assignable (can be labeled) dash switches. These switches output via pins 8 to 14 on the BodyLink III connector. A female connector and pins are included with BodyLink III, typically supplied in the cab with the sales and service literature packets.

Note: The BodyLink III BOC connector is supplied with the mating connector housing and terminal pins from the factory. If

additional pins or connectors are required they can be purchased from your local Mack Dealer. The connector housing is

25177195 and the terminal kit is 21750652.

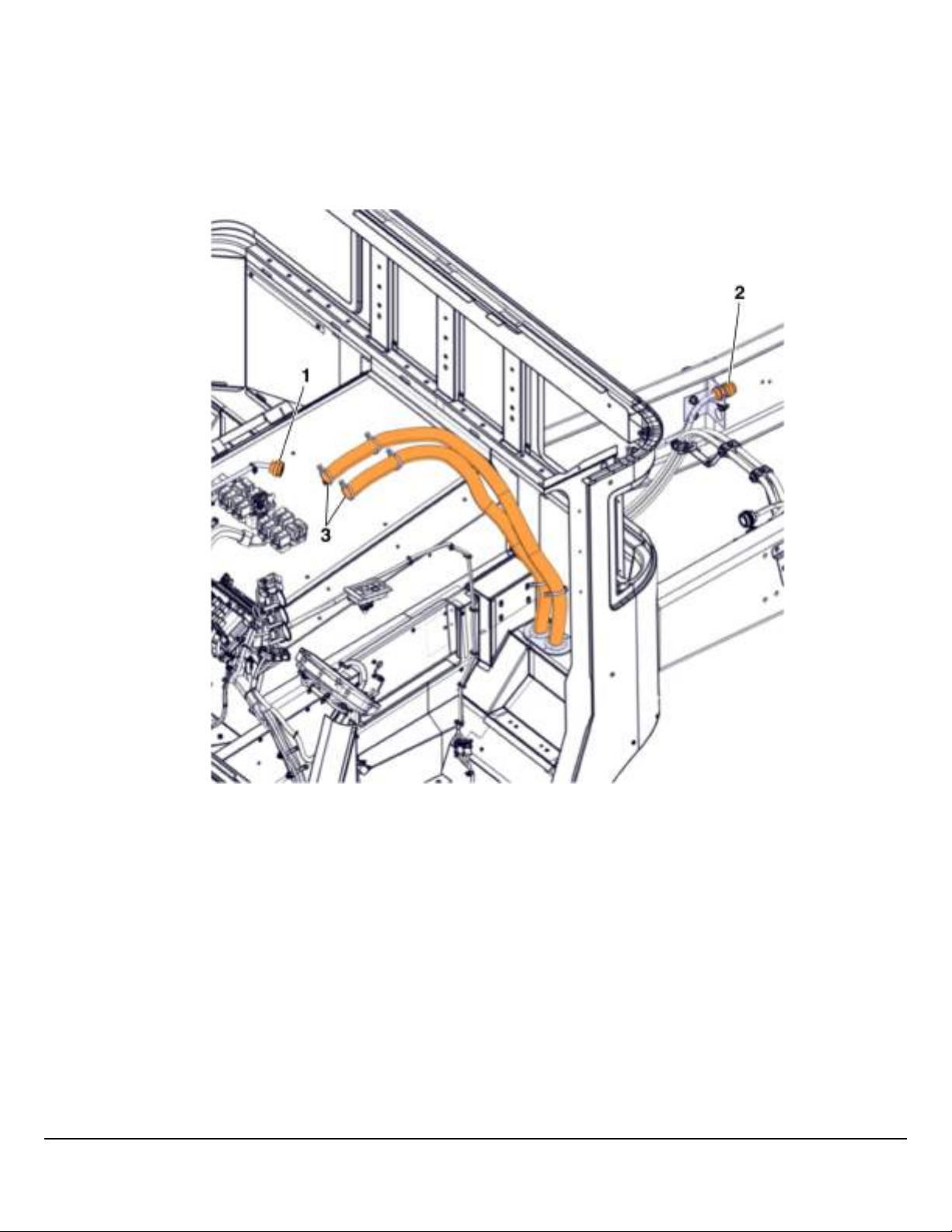

W3084959

Fig. 7 Granite BodyLink III Components

1 BodyLink III Connector

2 Pass-Thru

3 Switch

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 26 (94)

All Rights Reserved

Page 27

Order Codes for Body Connections (Granite BodyLink III)

Item Sales Code Model Status Description

BodyLink III w/Cab

Pass-Thru

BodyLink III w/o Cab

Pass-Thru

BodyLamp

Six (6) Assignable

Switches

Notes

B83 0025

B83 0026

B66 0002

164 0012

GU7, GU8

GU7, GU8

GU7, GU8

GU7, GU8

Standard

(Straight)

No cost option

Optional

Optional

29-pin under-cab connector, la-

bel, female connector, cab pass-

thru.

Same as above without pass-

thru.

9-pin back-of-cab power & light-

ing only

Six (6) assignable dash rocker

switches w/ labels (5 on-off, 1

momentary)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 27 (94)

All Rights Reserved

Page 28

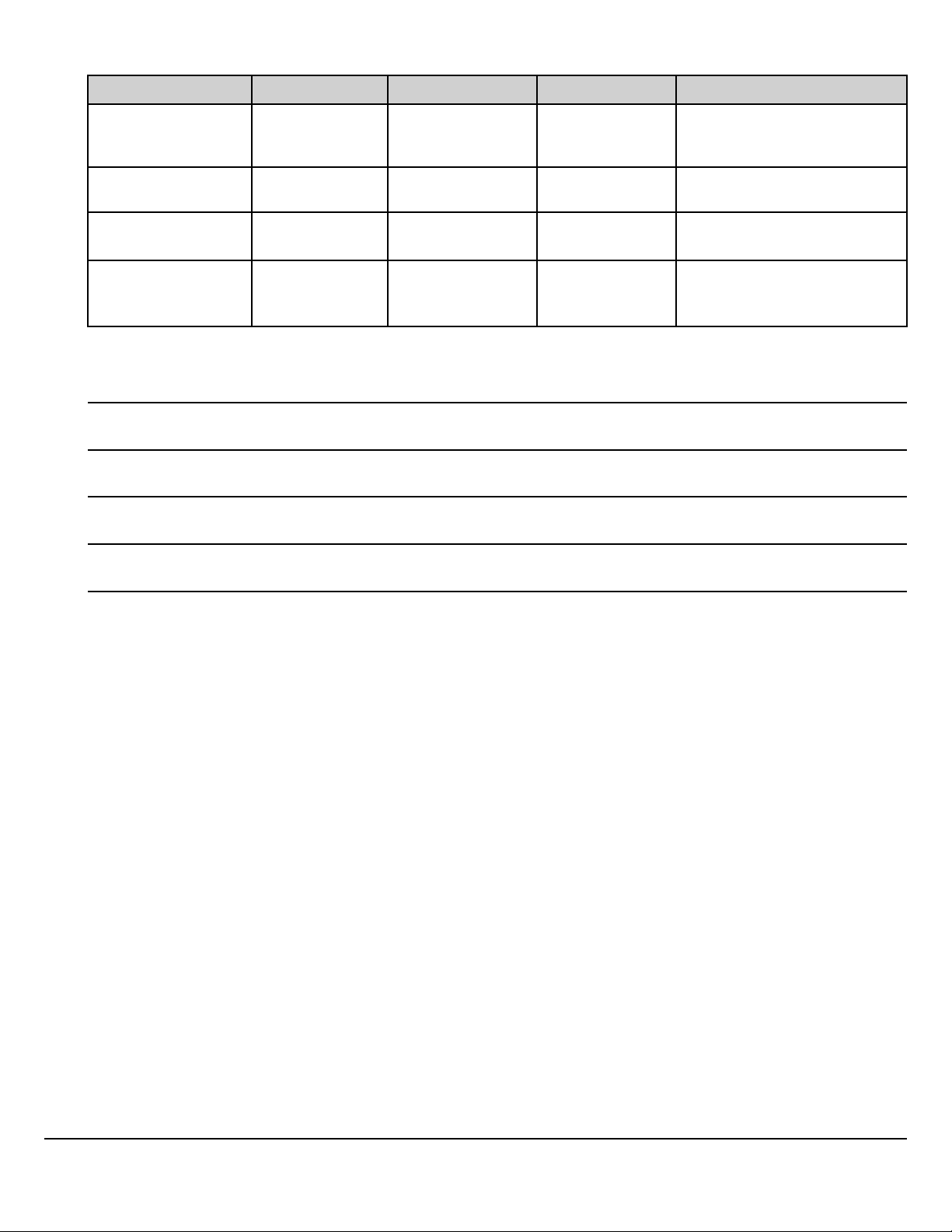

Fig. 8 Granite BodyLink III Routing Beneath Driver Seat

1 Rubber Adhesive Tape

W3092527

W3092528

Fig. 9 Granite BodyLink III Cab Pass Through and Connector

1 Body Builder Harness

2 Gasket

3 Spacer

4 Nut, Panel

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 28 (94)

All Rights Reserved

Page 29

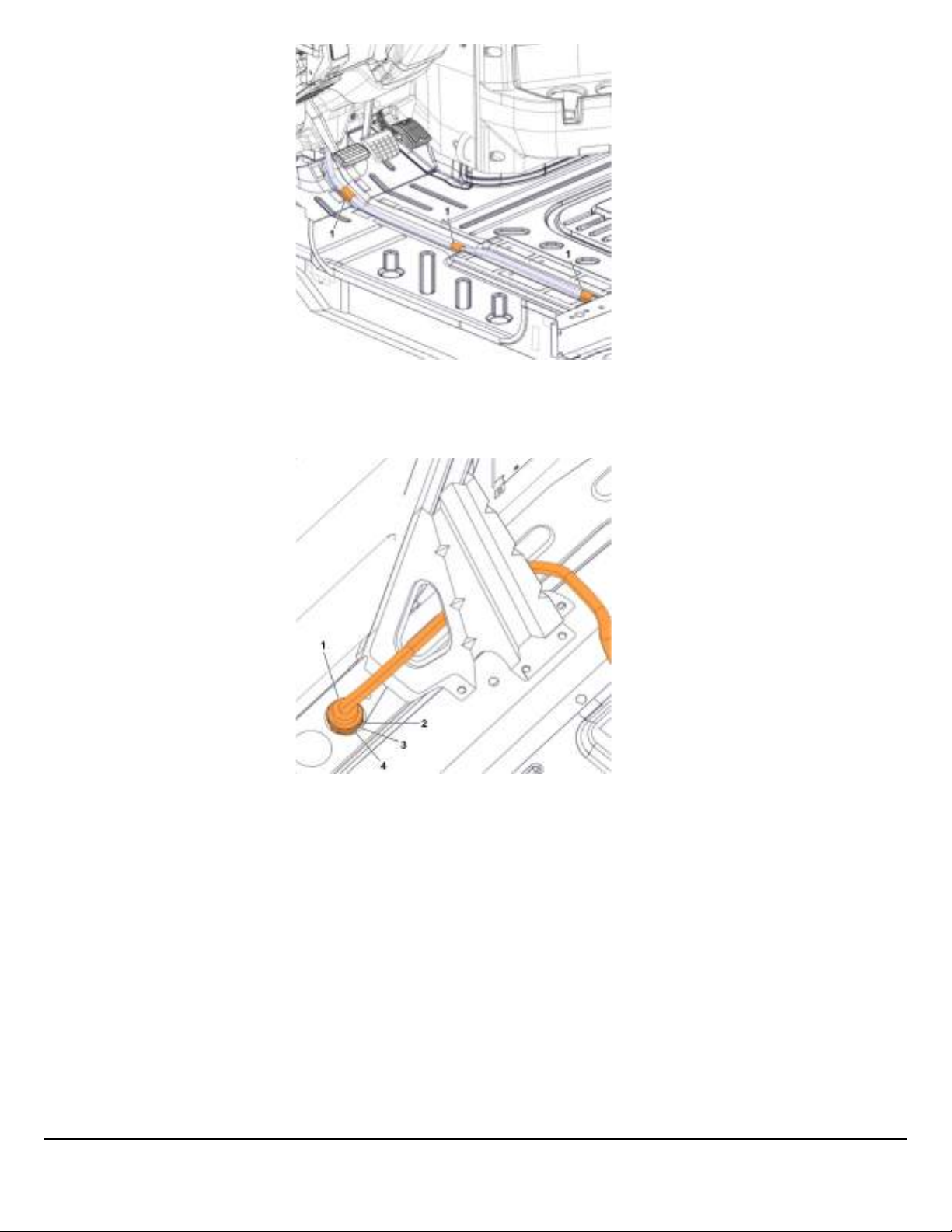

Fig. 10 Granite BodyLink III 29-pin Connector, Wire Insertion Side of Connector.

Pin Chart for Granite BodyLink III 29-pin Connector

Pole Description

1 BATTERY POWER (30A)

2 IGNITION POWER (30A)

3 STOP LAMP

4 TAIL LAMP

5

6 LH TURN

7 RH TURN

8 AUX SWITCH #1 (IGN)

9 AUX SWITCH #2 (BATT)

10 AUX SWITCH #3 (IGN)

11 AUX SWITCH #4 (IGN)

12 AUX SWITCH #5 (IGN)

W3064928

REVERSE SIGNAL

13 AUX SWITCH #6 (DOWN)

14 AUX SWITCH #6 (UP)

15 PARK BRAKE

16 NEUTRAL SIGNAL

17 INDICATOR SWITCH (BODY LAMP)

18 (12v positive) PTO #1 – CA29

19 (12v positive) PTO #2 – CB7

20 (12v positive) SPEED CONTROL ON/OFF

21 BB J1939 +

22 BB J1939 -

23 (12v positive) SPEED CONTROL SET / DECEL

24 (12v positive) SPEED CONTROL RESUME / ACCEL

25 and 26

-

27 LH TURN/STOP

28

-

29 RH TURN STOP

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 29 (94)

All Rights Reserved

Page 30

Auxiliary Switch Locations (Cab)

W3099971

Connector

1 IGN_SP11

2

Wire ID Description

1

Spare Ignition, Switch 4

- -

3 ILLUM_OPT Optional Illumination Connector

4 S026B Switch 3, Ignition

5

S026C Switch 4, Ignition

6 S026D Switch 5, Ignition

7

S027B Switch 6, Battery

8 ING_SP12 Spare Ignition, Switch 3

9 BAT_SP3 Spare Ignition, Switch 6

10 IGN_SP10 or BB_LP

11 BB_LP_6SW_PLUG

2

Spare Ignition, Switch 5

-

12 MISC_2 Output, Switch 3

13 MISC_3 Output, Switch 4

14 MISC_4 Output, Switch 5

15 MISC_5 Output, Switch 6

16 MISC_6

3

Output, Switch 6

1 If body builder wiring is specified, attach body builder wiring as follows: MISC_2 to BBSP_2, MISC_3 to BBSP_3, MISC_4 to BBSP_4, MISC_5 to BBSP_5,

MISC_6 to BBSP_6. Otherwise, band all MISC connectors behind ABC panel.

2 If body builder wiring is specified, attach body builder wiring as follows: MISC_2 to BBSP_2, MISC_3 to BBSP_3, MISC_4 to BBSP_4, MISC_5 to BBSP_5,

MISC_6 to BBSP_6. Otherwise, band all MISC connectors behind ABC panel.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 30 (94)

All Rights Reserved

Page 31

3 Connect spare ignition and battery connector to main cab harness as follows: IGN_SP12 to IGN_SP1 or IGN_SP9, IGN_SP11 to BAT_SP4, IGN_SP10 to IGN_

SP8 or BB_LP_PLUG, and BAT_SP3 to IGN_SP3.

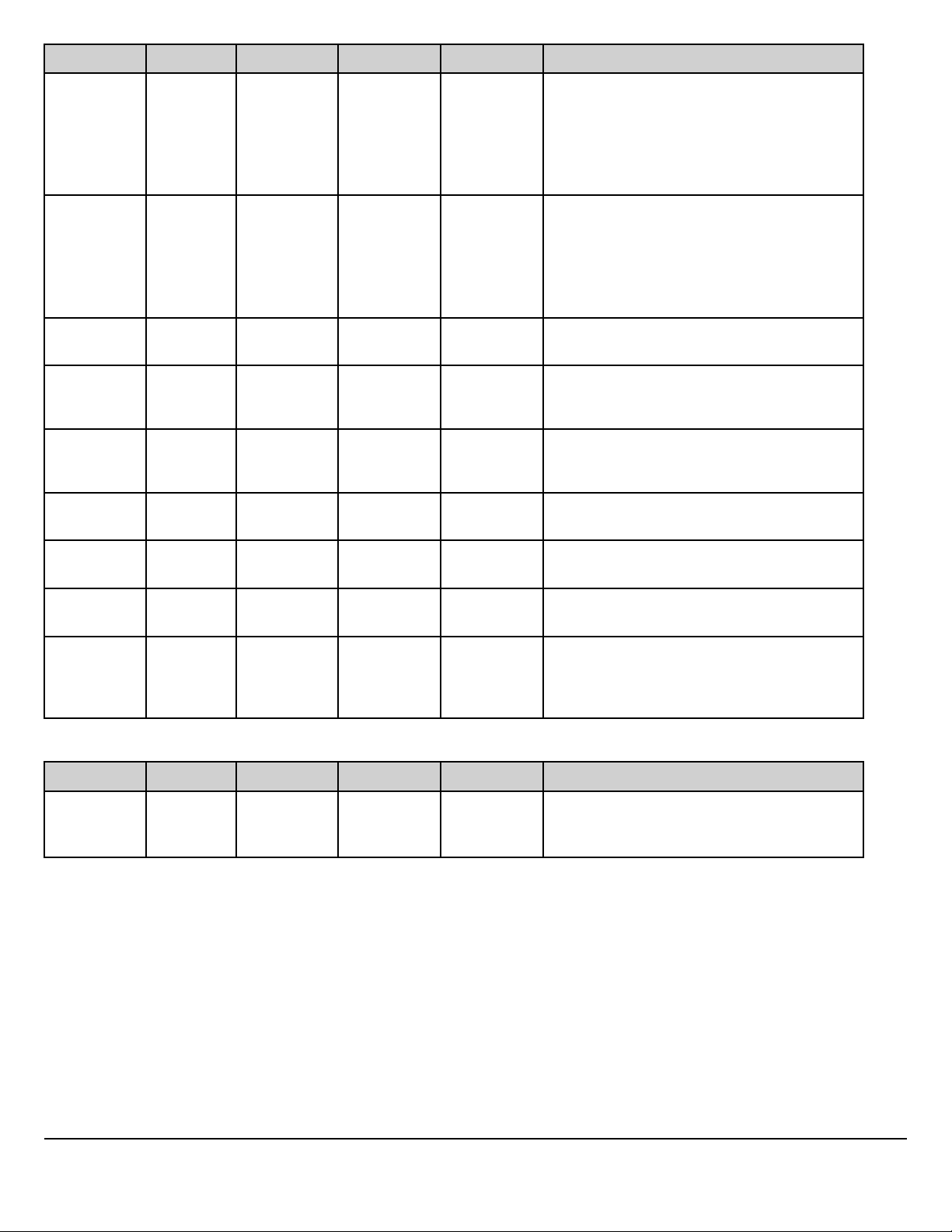

Power Connections

Some judgement must be made for powering body equipment with the following trade-offs:

Ignition power – Will power off during engine crank which may cause faults or other effects if power supplies inputs used by

ECU’s on EMS power. May also be disconnected for low voltage disconnect.

EMS Connections – Available with key off but may effect starter performance or be affected by starter power fluctuations.

Battery Connections – Always available but will contribute to key off battery drain as well as effect, and be affected by, starter

as above.

W3113941

Fig. 11 Power Connections

Interrupted at ENGINE CRANK and LOW VOLTAGE DISCONNECT.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 31 (94)

All Rights Reserved

Page 32

Fig. 12 DCL Conventional

Locations for the DCL Conventional are:

LR – Driver side of Main Cab Wiring Harness near Fuse and Relay center

MRU – Mounted in the center electrical panel between the seats.

Conventional – Mounted under the ABS module taped to main harness.

DCL Conventional

PIN Circuit Number Circuit Function

A CA17 PTO 4/ CDS 2

B CB21 PTO 3 / CDS 1

C

CB7;CB7B

W3085103

PTO 2

D CB16

E CB18

F F17A18

Spare Relay Control 2 (Controlled by

VECU) CDS 2 out PTO 4

Spare Relay Control 1 (Controlled by

VECU) CDS 1 out PTO 3

Ignition Bus Feed

G F18A EMS Power 1

H F17C3 Cruise SET/DECEL

J F17D3 Cruise RESUME/ACCEL

K N/A Not Used

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 32 (94)

All Rights Reserved

Page 33

Notes

W3113946

Fig. 20 Conventional DCL Connections

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 33 (94)

All Rights Reserved

Page 34

W3113945

Fig. 13 PTO & Engine Speed Control Connections

Note: Shaded area mDrive Dual PTO only.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 34 (94)

All Rights Reserved

Page 35

Conventional Auxiliary Switches

Conventional Trucks have the option to place dash switches connected to outputs in the outside body connector.

Fig. 14 Conventional Auxiliary Switches

Notes

W3113948

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 35 (94)

All Rights Reserved

Page 36

W3113952

Fig. 15 Conventional — Reverse & Neutral Power

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 36 (94)

All Rights Reserved

Page 37

Control Link II

MRU and LR feature standard “Control Link II” body builder electrical connections. Control Link II consists of two Deutsch

HP-20 connectors, a 9-pin lighting connector along the frame rail, and a 29-pin electrical/electronic connector in-cab, typically located above the engine tunnel body-in-white”.

Fig. 16 Control Link II Components

1 Body Builder Cab Pass-Thru

2 29-pin Electrical/Electronic Connector

3 Refuse Body Builder Control Outputs

4 9-pin Lighting Connector

5 Body Builder Console (MRU Only)

Order Codes for Body Connections (LCF Control Link II)

Item Sales Code Model Status Description

Control Link II Refuse

System

Body Builder Console

Body Power Only

B830030

M110003 MRU Included

B831018 MRU

No Connectors B830000 MRU

Concrete Pumper

Connectors

B831004/5/6/7 MRU

MRU, LR

Standard

Optional

Delete Option

Optional

W3084958

29-pin Cab & 9-pin

BOC Connections

Console Included w/

Control Link II

9-pin Back-of-Cab

Power & Lighting Only

Without Body Builder

Quick Connections

Contact Sales

Engineering

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 37 (94)

All Rights Reserved

Page 38

Fig. 17 Body Builder Pass Through Area from Cab to Under Cab

1 Wiring Harness

2 Bracket

3 Cable Ties

4 Grommets

5 Screw

6 Electrical Gasket

W3092642

W3092641

Fig. 18 Body Builder Pass Through Area from Cab to Under Cab

1 Clamps

2 Clamps

3 Chassis Clean Power

4 Chassis Body Builder

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 38 (94)

All Rights Reserved

Page 39

Body Builder Connections

LR Control Link II

The body builder connector can be accessed by removing the panels on the center console. The suggested routing path for

upfitters is not a physical component provided with the vehicle. It’s purpose in the illustration is to indicate the suggested wiring routes for upfitter harnesses. For convenience, MACK provides a pair of rubber grommets located behind the driver seat.

This is the pass-through area which leads beneath the cab.

W9096945

1 29-pin Body Builder Connector

2 9-pin Lighting Connector

3 Suggested Harness Routing for Upfitters

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 39 (94)

All Rights Reserved

Page 40

Fig. 19 Control Link II, 9-pin Lighting Connector, Wire Insertion Side of Connector

Pin Chart for Control Link II 9-pin Lighting Connector

Pole Wire ID Description

T F37B-3.0 Tail Lamp

Z F4D3–3.0 RH Turn

Y F33B-3.0 Stop Lamp

X F4C3–3.0 LH Turn

W F35B1–3.0 Clearance Lamp

V F34C-3.0 Neutral Power

U F34B2–5.0 Reverse Power

R XM1–13.0 Clean Ground

S F73A2–5.0 Clean Ground

Notes

W3064929

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 40 (94)

All Rights Reserved

Page 41

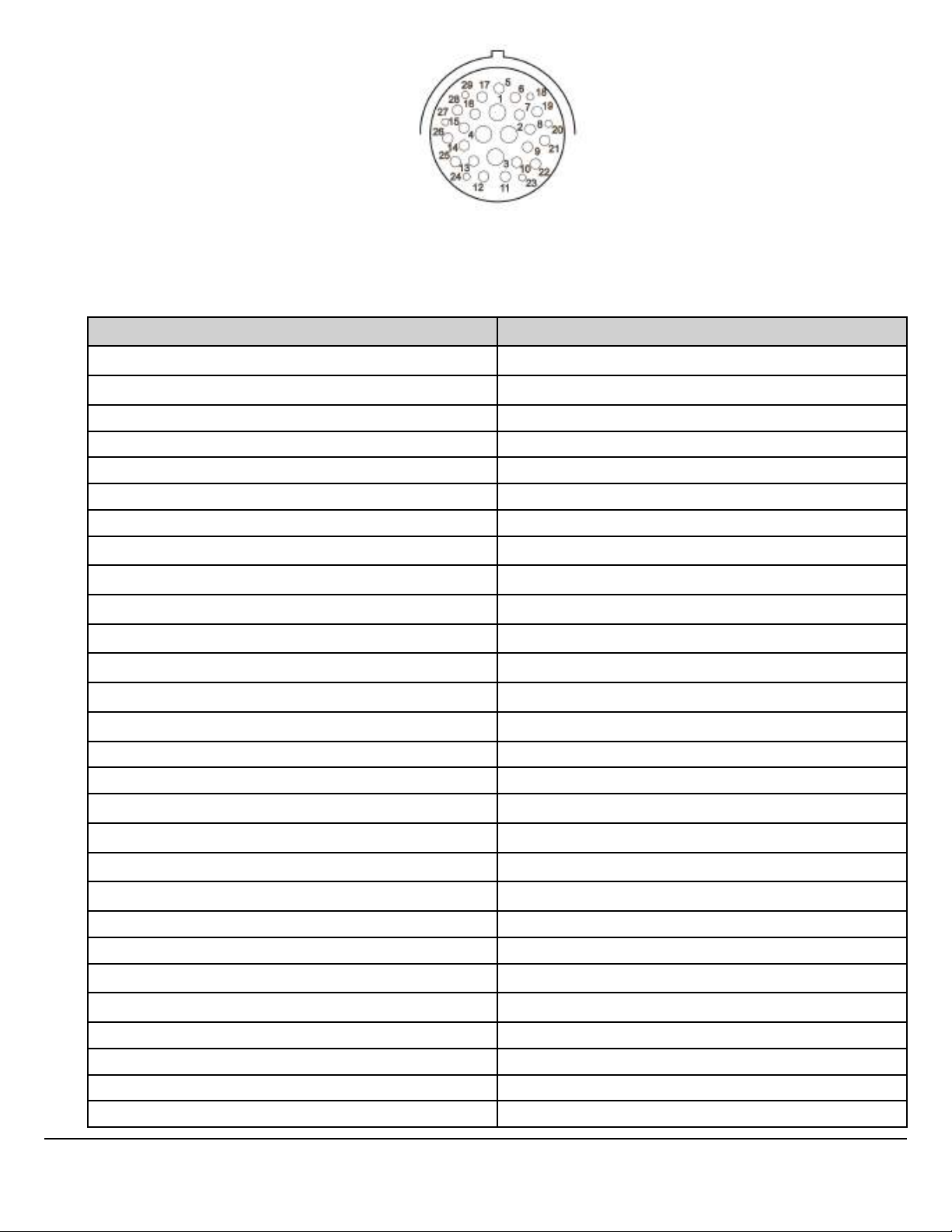

W3064928

Fig. 20 MRU/LR/LEU Control Link II 29-pin Connector, Wire Insertion Side of Connector

Pin Assignments for MRU/LR/LEU Control Link II 29-pin Body Builder Connector

Pole Wire ID Description

1 F39B–5.0 IGNITION POWER (30A)

2 FABA-5.0 BATTERY POWER (30A)

3 F40B1–3.0 IGNITION POWER (25A)

4 XABA-5.0 CLEAN GROUND

5 F42B1–1.0 REVERSE SIGNAL

6–11

- -

12 CA29–1.0 VMAC PTO# 2

13 CB7–1.0 VMAC PTO# 1

14 HA23–1.0 ENGINE RPM SIGNAL

15 N164–0.8

TRANSMISSION TEMPERATURE

SIGNAL

16 NA16–1.0 ECU GROUND

17 F18A1–1.0 IGNITION SIGNAL

18 N145NO-0.8 ALLISON #145 (12V)

19 X2A113–2.0 CAB GROUND

20 N143–0.8 ALLISON #143

21 DL5HB1–0.8 BBM J1939 (H)

22 DL5LB1–0.8 BBM J1939 (L)

23 N130NO-0.8 ALLISON # 130

24 N162–0.8 ALLISON # 162

25 N105-0.8 ALLISON # 105

26 N145B–0.8 ALLISON # 145

27 N103A-0.8 ALLISON # 103

28 N142A-0.8 ALLISON # 142

29 N117A-0.8 ALLISON # 117

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 41 (94)

All Rights Reserved

Page 42

Fig. 21 Body Builder Power & Ground LR Control Link II

Notes

W3114392

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 42 (94)

All Rights Reserved

Page 43

DCL Connector (LR/MRU) or Connector X21A (LR)

PIN Description

A Cruise ON/OFF Switch

B Spare SW.3 / PTO 3

C PTO 2

D VECU SW. Input

E Cruise ON/OFF Switch

F PTO 1

G Decel

H Accel

J EMS Power 1 CB18

K Spare Relay 2 / PTO 4

L Spare SW.2 / PTO 4

W3100110

M

N

Spare Relay 1 / CDS 1 OUT / PTO 3 (MRU Only; unused on

LR)

Signal Ground

P Ground

R Engine Stop/Spare Switch

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 43 (94)

All Rights Reserved

Page 44

MRU/LR DCL Connections

Figures 18 and 21 show DCL connections which are available on all Conventional models. Figures 16 and 22 show DCL connections for MRU/LR. The availability of these is limited as they are used for mDrive, ACC, Aux Fan and other options. However, when available they can be used for more complicated controls such as secondary enable of engine speed control or

as configurable PTO output.

W3113947

Fig. 22 DCL Connector

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 44 (94)

All Rights Reserved

Page 45

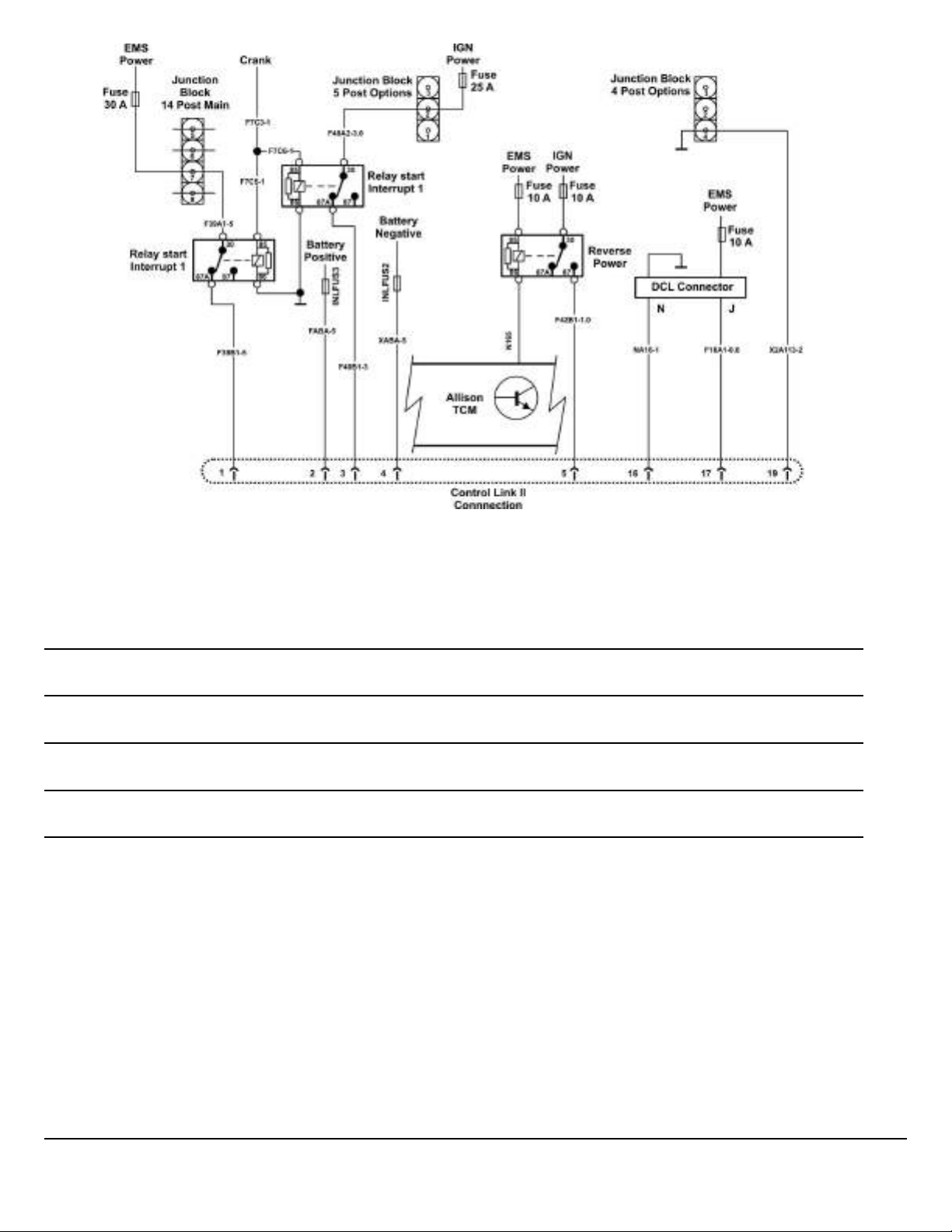

Allison Connections

MRU/LR Control Link II has many Allison connections included. Conventional BodyLink does not. However, all trucks with Allison Transmissions include a connector (X06D) to access Allison functions directly.

Fig. 23 Allison Connections — MRU, LR Control Link II

Note: * Shaded section on MRU / LR only

Notes

W3113943

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 45 (94)

All Rights Reserved

Page 46

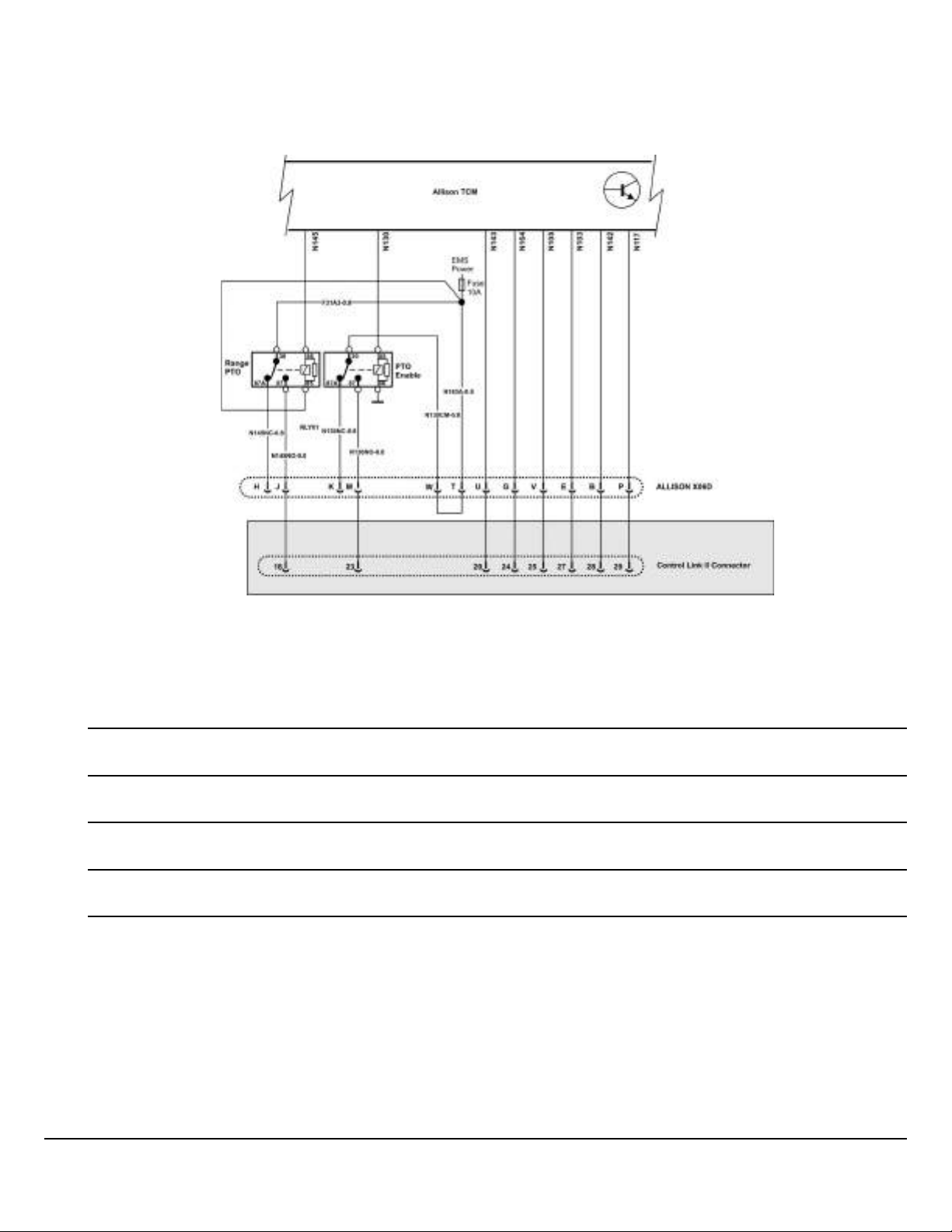

PTO and Engine Speed Control Connections

MRU and LR have several specific wiring options for PTO that don’t necessarily affect engine speed control. However the

Control link II connection offers access to inputs to affect engine speed control based on PTO activation or other equipment

inputs.

W3113944

Fig. 24 PTO & Engine Speed Control Connections

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 46 (94)

All Rights Reserved

Page 47

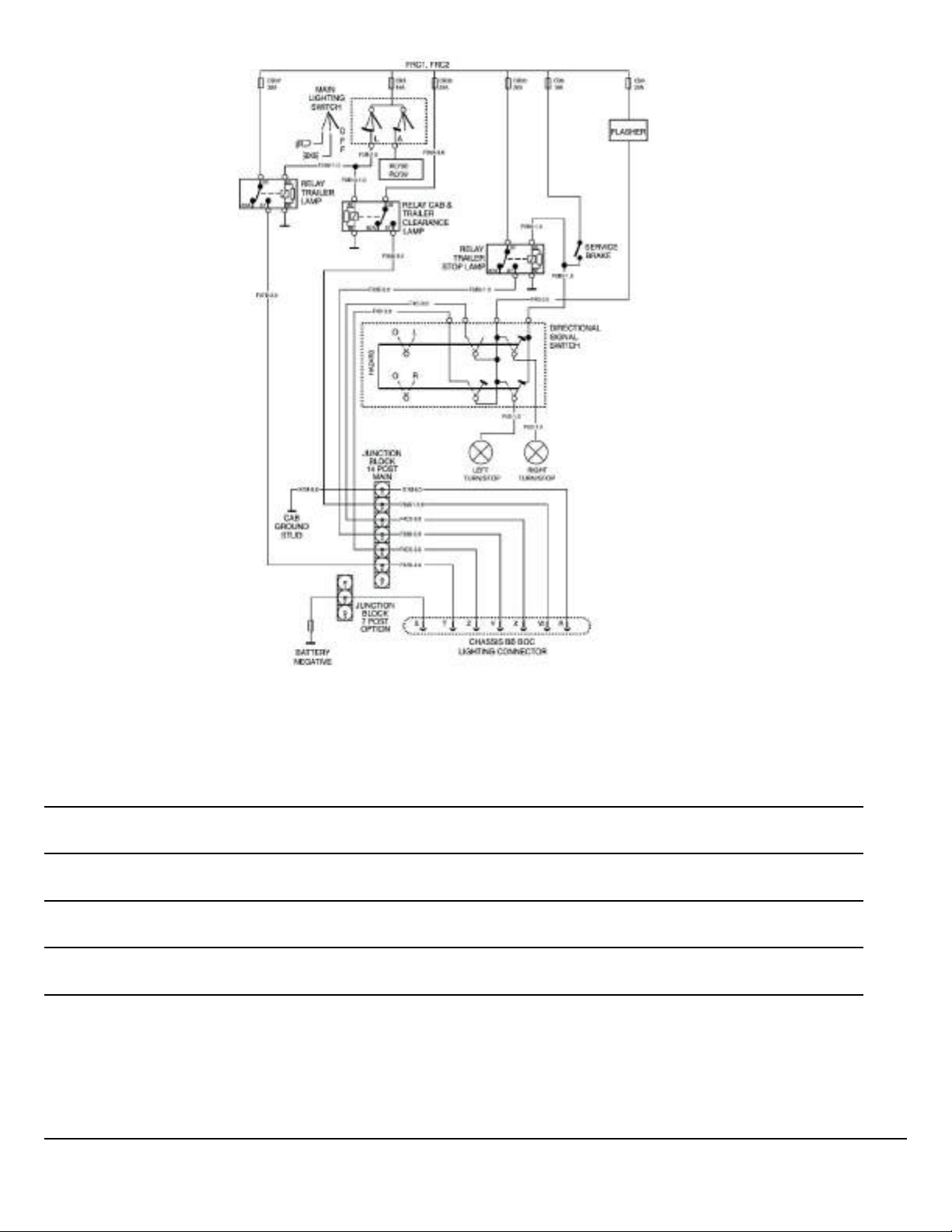

Lighting Connections

MRU/LR Control Link II has lighting connections in a separate BOC connector whereas Conventional has lighting connections in the Body Link connector which is also BOC. These are nominally lighting outputs but can also be used for control.

Note than Neutral and Reverse are also in the MRU/LR Control Link II Connector.

Fig. 25 Conventional Lighting Connections

Notes

W3114099

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 47 (94)

All Rights Reserved

Page 48

Fig. 26 MRU/LR Lighting Connections

Notes

W3116272

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 48 (94)

All Rights Reserved

Page 49

W3113951

Fig. 27 MRU/LR Lighting Connections – Reverse and Neutral

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 49 (94)

All Rights Reserved

Page 50

LR Workbrake

The Mack has a workbrake which operates pneumatically like a service brake. It is also tied into Allison inputs to effect a

forced neutral. The Allison also has some conditions to allow switching driving positions so that loss of throttle and transmission control don’t happen while moving.

Fig. 28 LR Workbrake

Notes

W3113953

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 50 (94)

All Rights Reserved

Page 51

Summary

Figure 31 shows examples of what the control pins could be used for in an application. The PTO inputs are programmable

and can affect a conditional output, engine ramp, engine limits, etc. See programming section for details. Note that full safety

evaluation of the system should be carried out. I.E., adequate interlocks should be programmed or wired, so that the engine

will not accelerate in unintended situations. Interlocks can be done by powering switches using switched power (for example

neutral power) or by software parameters or both. For example, most applications should only have the engine ramp using

body controls when the park brake is on and the transmission is in neutral. Exceptions should be carefully considered..

Fig. 29 Example MRU showing Body Builder supplied wiring for Controls

Notes

W3113957

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 51 (94)

All Rights Reserved

Page 52

General

Wiring J1939

Mack doesn’t necessarily recommend or condone tapping into the J1939 databus. This is the main control buss and even devices only listening can improperly load the line and cause communication problems. The signals are fast enough that they

are affected by the physics of the electrical charges traveling through the lines. So it matters how the device is designed and

where it is placed in relation to other devices. However this method can save wiring and gives the body builder more flexibility

and control in developing applications. To that end the following information is provided. However, it is recommended applications be implemented with sufficient field testing to uncover any problems.

Here are two ways to properly connect to J1939 without damaging the cab harness.

1. Connect at the diagnostic connector.

The diagnostic port contains J1939 lines mainly for temporary connection for diagnostic tools. Since it also contains power

and ground for diagnostic tools, it is a convenient choice for connection of control and monitoring devices. However, note that

J1939 specifies one device per node. So, it would be incorrect to place two devices there.

2. Add the device at the terminating resistor.

The terminating resistor for the main CAN bus is found in the dash. This method effectively lengthens the “backbone” of the

main can line and adds a node. To do this the body builder would make a “T” harness to insert between the terminating resistor and it’s connector (see figure). Theoretically, more than one node could be placed this way. However, some trucks are already at or near the theoretical limit

Mack follows SAE J1939-15 meaning it uses an unshielded, twisted pair and is theoretically limited to 10 devices.

W3083536

Fig. 30 Adding a Node at the Terminating Resistor

* To Truck

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 52 (94)

All Rights Reserved

Page 53

The following parts can be used in the above “T” harness. Critical is that only two terminating resistor remain on the network

(one is in the ECM). It may also be possible to have one terminating resistor in the aftermarket device if it is replacing the terminating resistor.

T Harness Part Numbers

T Harness

Abbreviation Connector Part Number (New) Part Number (Old)

MACK # Delphi # MACK # Deutsch #

Cab Harness Ter-

CHTRC

minating Resistor

21430472 13510085 3187784 DTM04-2P

Connector

Notes

Cab Harness Ter-

CHTR

minating Resistor

21430457 15429045 25171700

120 Ω

Connection to Cab

harness

20500398 13510099 3187782 DTM06-2S

AD Aftermarket Device N/A N/A N/A

MC

BBI

Mating Connector

Body Builder

Installed

N/A N/A N/A

N/A N/A N/A

DTM06-2S-

P006

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 53 (94)

All Rights Reserved

Page 54

Another more convenient way to connect to J1939 (or J1587) is through the diagnostic connector.

9-pin Diagnostic Connector

W9000628

Fig. 31 9-pin Diagnostic Connector

Note: Export Engines Only

9-pin Diagnostic Connector

9-pin Diagnostic Connector

PIN Definition

A Ground

B Battery

C CAN H (J1939 H-Yellow)

D CAN L (J1939 L-Green)

E Not used (Shield)

F J1587 +

G J1587 –

H Not Used

J Ignition + (Key Switch)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 54 (94)

All Rights Reserved

Page 55

16-pin Diagnostic Connector

Fig. 32 16-pin Diagnostic Connector (OBD 13)

16-pin Diagnostic Connector (OBD 13) Pin Allocation

16-pin Diagnostic Connector (OBD 13 SAE J1962-Type A Connector)

PIN Definition

W3085011

1

OEM discretionary (assigned as: Key switch – ignition signal for

AM tool)

2 (Not Used)

3 OEM discretionary (assigned as: SAE J1939-15_CAN_H)

4 Chassis ground

5

Chassis ground

6 CAN_H line of ISO

7

(Not Used)

8 (Not Used)

9 (Not Used)

10 (Not Used)

11 OEM discretionary (assigned as: SAE J1939-15_CAN_L)

12 OEM discretionary (assigned as: SAE J1587 positive)

13 OEM discretionary (assigned as: SAE J1587 negative)

14 CAN_L line of ISO

15 (Not Used)

16 Battery positive voltage

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 55 (94)

All Rights Reserved

Page 56

Serial Communications and Programming Abbreviations

Acronym Description

ACM Aftertreatment Control Module

BBM Body Builder Module

CAN Controller Area Network

CDS Customer Defined Statement

DCL DataMax Control Language

ECC/MCC Electronic Climate Control/ Manual Climate Control

ECM Engine Control Module

EHT Electronic Hand Throttle

ECS Electronic Speed Control

FMI Failure Mode Identifier

GSECU Gear Selector ECU

LCM Light Control Module

NOx Nitrogen Oxide

PGN Parameter Group Number (J1939)

PID Parameter Identification (J1587)

PTO Power Take-Off

SA Source Address (J1939 Sender)

SCU Satellite Control Unit (Qualcomm)

SID Subsystem Identification (J1587)

SPN Suspect Parameter Number (J1939)

SRS Supplemental Restraint System

SSC Single Speed Control

TCM Transmission Control Module

TPM Tire Pressure Monitor

VCADS Vehicle Computer Aided Diagnostic System (service tool)

VDA Vehicle Data Administration (OEM database)

VECU Vehicle ECU

V-MAC

Vehicle Management and Control (Mack’s electrical

architecture)

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 56 (94)

All Rights Reserved

Page 57

Data Link System

This section provides information on the design and function of the vehicle communications data links. These communication

links are based on SAE J1587, J1708 and J1939 Recommended Practices and the ISO 14229 Standard. For more specific

information about the ISO 14229 Standard, please refer to the ISO website (www.iso.org).

The data links are used to relay shared vehicle information between control modules and diagnostic, service and (in the case

of onboard diagnostic (OBD) information) scan tools. The three datalink types used are SAE J1939, SAE J1587/J1708 and

ISO 14229.

SAE J1939

SAE J1939 is a communications link between stand alone vehicle modules. This data link is commonly referred to as the

“Control Data link”.

It is used primarily to transmit control signals that are shared between other stand alone modules. The information on the

SAE J1939 control link is used for control functions. Fault messages or diagnostic information also transmits across this link.

These control signals may be for, engine, transmission, brakes or a number of other vehicle control needs.

The J1939 operates at 250,000 bits per second which is approximately 26 times faster then the J1708/1587 data link. This

higher speed allows the system to operate at a faster sampling rate and higher resolution, thus being more capable of providing better control of vehicle functions.

The J1939 data link consists of a pair of 18 gauge unshielded twisted wires. The designations of the networks are CAN_H

and CAN_L. The designation of the individual wires are DL1H which is yellow and DL1L which is green. The nominal rate of

twist required is 0.89 twists per 25.4 mm (1 inch) or 33 twists per meter (3.28 feet). This twist helps protect against electrical

interference.

The J1939 data link is electrically terminated at each end with a load resistor, which is commonly referred to as a termination

resistor. Each J1939 network has two termination resistors associated with it. Only two termination resistors are allowed within a network. The termination resistor can be located external as part of the wiring harness, or integrated internally in the

ECM. Any ECM that does not contain the termination resistor is referred to as a Type I, and an ECM that contains the termination resistor is referred to as a TYPE II. The correct number of termination resistors can be easily checked by measuring

the resistance across cavities C and D of the 9-pin diagnostic connector or across cavities 3 and 11 for the 16-pin diagnostic

connector. The correct resistance is 50 – 70 ohms. The terminating resistors should each have a resistance of 110 – 130

ohms when tested individually.

Note: It is important to remember which control units the vehicle is equipped with and which fault codes are stored in each

control unit.

Do not splice into a V-MAC, ABS/ATC or any other electronic control unit harness.

Note: Do not cut or tap into the J1939 green/yellow twisted wires or any other wire or harness used on this vehicle.

Use the provided connectors, and only add approved J1939 components with validated software. Failure to comply

may result in personal injury or equipment damage. Any cutting. splicing, alteration or modification to the wiring

will Void the Mack Trucks Warranty on the Electrical System.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 57 (94)

All Rights Reserved

Page 58

ISO 14229

Note: ISO 14229 only applies to vehicles with MACK engines.

ISO 14229 is the Powertrain control link. The ISO is used for programming between the ECM, ACM and TCM. It is used primarily to transmit control signals that are shared between other stand alone modules. The information on the ISO 14229 control link is used for control functions. Fault messages or diagnostic information also transmits across this link. These control

signals may be for engine, transmission and aftertreatment ECUs.

The ISO 14229 operates at 500,000 bits per second. This higher speed allows the system to operate at a faster sampling

rate and higher resolution, thus being more capable of providing better control of vehicle functions.

The ISO 14229 data link consists of a pair of 18 gauge unshielded twisted wires. The designations of the networks are CAN_

H and CAN_L . The designations of the individual wires are DL2H and DL2L which are both white with orange stripes. The

nominal rate of twist required is 40 twists per meter (3.28 feet). This twist helps protect against electrical interference.

The ISO 14229 data link is electrically terminated at each end with a load resistor, which is commonly referred to as a termination resistor. Each ISO 14229 network has two termination resistors associated with it. Only two termination resistors are

allowed within a network. The termination resistor can be located external as part of the wiring harness, or integrated internally in the ECU/ECM. Any ECU/ECM that does not contain the termination resistor is referred to as a Type I, and an ECU/

ECM that contains the termination resistor is referred to as a TYPE II. The correct number of termination resistors can be

easily checked by measuring the resistance across cavities 3 and 11 for the 16-pin diagnostic connector. The correct resistance is 50 – 70 ohms. The terminating resistors should each have a resistance of 110 – 130 ohms when tested individually.

Note: It is important to remember which control units the vehicle is equipped with and which fault codes are stored in each

control unit.

SAE J1708/1587

Note: MACK engines and mDrive transmissions do not include the J1587 / J1708 datalink.

SAE J1708/1587 is a communications link between stand alone vehicle modules. This data link is commonly referred to as

the “Information Data link”. It is used primarily to transmit shared information between these stand alone modules. Fault messages or diagnostic information also transmits across this link. The J1708/1587 exchanges information with a data bus speed

of 9600 bits per second. The J1708 defines parameters that relate primarily to hardware and basic software compatibility.

The J1587 defines the actual data to be transmitted by particular modules. The J1587/1708 data link consists of a pair of 18

gauge twisted wires. The nominal rate of twist required is 1 twist per 25.4 mm (1 inch) or 40 twists per meter (3.28 feet). This

twist helps protect against electrical interference. A fault in this data link can affect the transfer of information, and can make

it difficult to communicate with the source in order to carry out tests using VCADS (found in the Premium Tech Tool or PTT).

An indication that there is a problem with SAE J1708/1587 can be that faults from a certain control unit can not be corrected,

erased or reset.

Data Link Faults

W3005017

Whenever a data link fault is present, refer to Guided Diagnostics found in the manufacturer's scan tool (Premium Tech Tool

or PTT) for diagnostic information.

Note: The ISO 14229 does not have FMIs. Instead this data link has failure type bytes (FTBs).

• The type of FMI/FTB that an individual electronic control unit (ECU) can monitor is dependent on the software in the ECU.

All FMIs/FTBs cannot be recognized by all ECUs.

• The ECU reporting the diagnostic trouble code (DTC) may not be the ECU that is involved at the site of the specific failure.

For example, The engine control module (ECM) may report a data link fault that is actually at the vehicle electronic control

unit (VECU). The VECU would not be able to report if the data link is broken between the VECU and data link backbone.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 58 (94)

All Rights Reserved

Page 59

Datalink Topology

US2010 Emissions Engine plus OBD2013

Acronym Description

ECM Engine Control Module

ACM Aftertreatment Control Module

NOx Nitrogen Oxide

GSECU Gear Selector ECU

TCM Transmission Control Module

DEF Diesel Exhaust Fluid

ACC Active Cruise Control

VECU Vehicle ECU

ABS Anti-Lock Braking System

BBM Body Builder Module

SCU Satellite Control Unit (Qualcomm)

W3084851

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 59 (94)

All Rights Reserved

Page 60

Termination Resistor

W3005518

Termination Resistor, 2–pin

Termination Resistor – J1939

Termination resistors are wired to each end of the SAE J1939 data link to prevent signal reflections. They must remain connected for the data link to function properly. The resistance value of each termination resistor is 110–130 Ω. When properly

installed in the data link, their combined resistance is 50–70 Ω since they are connected in parallel.

The termination resistor at one end of the SAE J1939 data link is located in the fuse/relay center (FRC) near the vehicle electronic control unit (VECU) and the other near the engine control module (ECM). On vehicles equipped with MACK engines,

the termination resistor at the engine end is located inside the ECM. On vehicles equipped with Cummins engine, the termination resistor is located in the harness area just outside of the ECM.

A SAE J1939 data link connection is located at the transmission area in the chassis harness. On vehicles equipped with an

electronically controlled transmission (Allison/Autoshift II/Meritor Freedom Line), the connection to the transmission is located at the chassis harness. On vehicles equipped with a manual non-electronically controlled transmission - the connector

stub will have an un-terminated blanking plug installed.

Only two termination resistors are used in each data link. Never install more than two terminator resistors in one data link. If

more than two resistors exist in the SAE J1939 data link circuit, incorrect or absent signals may occur. You can easily check

to see if you have two resistors by measuring the resistance between pin C and D for the 9-pin diagnostic connector, or pin 3

and 11 for the 16-pin diagnostic connector, with the ignition key in OFF position. The correct resistance is 50 – 70 Ω. The termination resistors should each have a resistance of 110 – 130 Ω when tested individually.

Termination Resistor – ISO 14229

Termination resistors are also wired for the ISO 14229 data link. One resistor is located in the engine control module (ECM).

The other is a two pin resistor located in the dash close to the diagnostic connector. The diagnostic connector is located on

the driver’s side lower dash panel. Termination resistors must remain connected for the data link to function properly. The resistance value of each termination resistor is 110–130 Ω. When properly installed in the data link, their combined resistance

is 50 – 70 Ω since they are connected in parallel

The termination resistor at one end of the ISO 14229 data link is located in the fuse/relay center (FRC) near the vehicle electronic control unit (VECU) and the other near the engine control module (ECM). On vehicles equipped with MACK engines,

the termination resistor at the engine end is located inside the ECM.

A ISO 14229 data link connection is located at the transmission area in the chassis harness. On vehicles equipped with an

electronically controlled transmission (Allison/Autoshift II/Meritor Freedom Line), the connection to the transmission is located at the chassis harness. On vehicles equipped with a manual non-electronically controlled transmission - the connector

stub will have an un-terminated blanking plug installed.

Only two termination resistors are used in each data link. Never install more than two terminator resistors in one data link. If

more than two resistors exist in the ISO 14229 data link circuit, incorrect or absent signals may occur. You can easily check

to see if you have two resistors by measuring the resistance between pin 3 and 11 for the 16-pin diagnostic connector, with

the ignition key in OFF position. The correct resistance is 50 – 70 Ω. The termination resistors should each have a resistance

of 110 – 130 Ω when tested individually.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 60 (94)

All Rights Reserved

Page 61

0802013 Electrical System Version 3 Parameters

Parameter List

Group DOID Parameter Caption Description

Cruise Control AI AI Cruise Control Max

Speed

Engine Fan

Controls

Engine Governor P1I03 AZQ High Idle Governor

Engine Idle

Settings

P1I2F FTX Fan Enable With

Engine Brake

For HiIgh Gears

P1I04 AZO High Idle Enable

Flag For Low Gears

P1I05 AZR High Idle Gear Ratio

For Low Gears

P1I18 AZS High Idle Ratio For

High gears

P1F9W YA Engine Idle, Target

Speed

The maximum speed that can be

set in the cruise control.

This flag will enable the fan with

the engine brake. 0 = Disabled, 1

= Enabled

Engine speed where the governor output crosses the max tor-

que curve. Used for high gear

ratios.

If this flag is set to TRUE, it is

possible to use a higher end gov-

ernor engine speed for low

gears.

Gear ratio for the gear P1I03 set-

ting should be used. For higher

gears the end governor speed is

used.

Gear ratio for the gear where end

governor engine speed is used.

For lower gears the P1I03 setting

should be used.

Target engine speed at idle.

Engine Protection P1I19 FVS Customer Shut

Down For Oil

Pressure

P1I17 FVU Customer Shutdown

For Coolant Level

P1I2B FVY Customer Shutdown

For Transmission

Temperature

P1I2A GHA Customer Shutdown

For Oil Temperature

P1I18 FVW Customer Shutdown

For Coolant

Temperature

Engine Speed

Limit

P1ANA AU Max Engine Speed

Stationary

Customer shut down status, 0 =

No action, 1 = Forced idle, 2 =

Shut off engine

Customer shut down status, 0 =

No action, 1 = Forced idle, 2 =

Shut off engine

Customer shut down status, 0 =

No action, 1 = Forced idle, 2 =

Shut off engine

Customer shut down status, 0 =

No action, 1 = Forced idle, 2 =

Shut off engine

Customer shut down status, 0 =

No action, 1 = Forced idle, 2 =

Shut off engine

Maximum engine speed allowed

when the vehicle is stationary.

The maximum engine speed

varies between approximately

1200 - 2600 rpm depending on

engine type.

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 61 (94)

All Rights Reserved

Page 62

Group DOID Parameter Caption Description

P1I04 AZO High Idle Enable

Flag For Low Gears

P1IDB BNQ Max Engine Speed

with a Vehicle

Speed Error

Engine Torque

Limit

P1JED JAA PTO Through Drive-

shaft, Enables

Injection Control P1AM4 ATJ Injector Cylinder 1,

Calibration

P1AM5 ATK Injector Cylinder 2,

Calibration

P1AM6 ATL Injector Cylinder 3,

Calibration

P1AM7 ATM Injector Cylinder 4,

Calibration

P1AM8 ATN Injector Cylinder 5,

Calibration

P1AM9 ATO Injector Cylinder 6,

Calibration

If this flag is set to TRUE, it is

possible to use a higher end gov-

ernor engine speed for low

gears.

Specifies the max engine speed

when a vehicle speed error is

active.

Configures if PTO is enabled

through driveshaft. If set to 1, tor-

que limit for low vehicle speed is

deactivated. 0 = Disable ,

1 = Enable

The new trim code must be pro-

grammed after replacing the unit

injector. The trim code (T/C) is

shown on the injector label and

consists of up to 9 characters.

Miscellaneous

Engine Settings

P1G3E IVT & JAN Injector Perform-

ance Log

P1I15 AIZ Fuel Consumption,

Calibration In

Percent

P1AOF DX Gust Data, Engine

ECU Password

P1IEA JZF Smart Torque,

Enable

P1IRK MYD Accelerator Limiter,

Enable

P1I07 9G Diff RSL, Transmis-

sion Ratio Highest

Gear

Reset has to be done after injec-

tor change, by using the routine

control: R1AFI - Reset of Target

Torque Reference Value

A percentage correction value to

compensate any deviation be-

tween the calculated fuel con-

sumption shown in the Driver

Information Display and the fuel

consumption according to the

customer's fuel protocol.

Password to allow changing of

parameter values on this vehicle.

If a password is in place, correct

entry of the password will be re-

quired when changing parameter

values.

Enables the Smart Torque

function

Enables the Accelerator Limiter

function. 0 = Disabled, 1 =

Enabled

The gearbox ratio in the highest

gear. The ratio can be found in

the gearbox specifications. The

Mack Body Builder Instructions CHU, CXU, GU, TD, MRU, LR

USA139388593 Date 7.2017 Electrical Wiring and Connections Page 62 (94)

All Rights Reserved

Page 63

Group DOID Parameter Caption Description

ratio must be entered in order for

the control module to calculate

which gear is selected.

Miscellaneous

Engine Settings

Miscellaneous

Vehicle Settings

P1I08 9H Diff RSL, Transmis-

sion Ratio Next

Gearbox ratio second highest

gear.

Highest Gear

P1AOD DV Diff RSL, Max

VSPD Next Highest

Gear

Speed limitation when the second highest gear is selected. The

value must be lower than param-

eter P1AOC. Do not use with

AMT gearboxes.

P1AL0 AJ Diff RSL, Enable /

Disable

Activating different speed limitations when driving in the highest

or second highest gear. This

function is used if the maximum