Page 1

Driver'sHandbook

Addendum

Addendum,MackTrucks(ReleaseDate

February2015)

Page 2

Page 3

Foreword

TheinformationinthismanualappliestovehiclesbuiltJanuary2011

andlater.Pleasekeepthisaddenduminthevehicleatalltimes.

TheNationalHighwayTrafcSafetyAdministration(NHTSA)and

MACKTrucksshouldbeinformedimmediatelyifyoubelievethatthe

vehiclehasadefectthatcouldcauseacrash,injuryordeath.

ContactNHTSAbycallingtheAutoSafetyHotlineat1(888)

327-4236,bywritingtoNHTSA,U.S.DepartmentofTransportation,

Washington,DC20590,byTTYat1(800)424-9153,orvisittheir

websiteatwww .nhtsa.dot.gov.

Mack Trucks

Greensboro, NC USA

Order number: PV776-22616311

©2015 Mack Trucks Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced,

stored in retrieval system, or transmitted in any forms by any means,

electronic, mechanical, photocopying, recording or otherwise, without

the prior written permission of

Mack Trucks

Page 4

Page 5

Contents

Addendum......................................................................................................................1

AutomaticTractionControl(A TC)(IfEquipped)...................................................1

TowingInformation.....................................................................................................2

TowingaV ehicleEquippedwithmDRIVETransmission......................................2

Towing.........................................................................................................................6

LiftingTheFrontSuspension..................................................................................6

ABS..........................................................................................................................7

LiftingTheRearSuspension...................................................................................7

Unloading.................................................................................................................7

Max.LoadingDuringLiftingandTowing..............................................................8

Lifting,General........................................................................................................9

LiftingAV ehicleWithLeafSprings.......................................................................9

LiftingAV ehicleWithAirSuspension...................................................................10

TowingCongurations(Rear,Side,andUsingtheT owHooks).................................15

ParkingBrakesandTowingHooks..........................................................................15

TowingBackwardsAndSideways..........................................................................17

TowingBackwards...................................................................................................17

TowingSideways.....................................................................................................17

ReleasingTheBrake....................................................................................................18

ParkingBrake—MechanicalRelease....................................................................18

DiskBrakes..............................................................................................................19

BrakesInWinter......................................................................................................19

JumpStarting...............................................................................................................20

EngineComponents,ServiceSchedules......................................................................22

MP7,MP8andMP10(US2010andNewer)EngineOilChangeIntervals.............22

MP7,MP8andMP10Engines................................................................................22

EngineIntakeAirCleaner.......................................................................................26

EngineComponentMaintenanceIntervals..............................................................27

EngineCoolant.........................................................................................................27

DriveBelts(FanandAccessory).............................................................................29

EngineV alveAdjustments.......................................................................................30

ExhaustAftertreatmentSystem...............................................................................31

RearAxleOilChangeIntervals...............................................................................32

T300SeriesManualTransmissionOilChangeInterval..........................................34

mDRIVETransmissionOilChangeIntervals.........................................................36

PowerSteeringFluid................................................................................................38

Page 6

Page 7

SafetyInformation

IMPORTANT:Beforedrivingthis

vehicle,becertainthatyouhaveread

andthatyoufullyunderstandeachand

everystepofthedrivingandhandling

informationinthismanual.Becertain

thatyoufullyunderstandandfollowall

safetywarnings.

ITISIMPORT ANTTHA TTHE

FOLLOWINGINFORMA TIONBE

READ,UNDERSTOODANDALW A YS

FOLLOWED.

Thefollowingtypesofadvisoriesareused

throughoutthismanual:

DANGER

Dangerindicatesanunsafepracticethat

couldresultinseriouspersonalinjury

ordeath.Adangeradvisorybanneris

inwhitetypeonablackbackground

withablackborder.

WARNING

Warningindicatesanunsafepractice

thatcouldresultinpersonalinjury.A

warningadvisorybannerisinblack

typeonagraybackgroundwithablack

border.

CAUTION

Cautionindicatesanunsafepracticethat

couldresultindamagetotheproduct.

Acautionadvisoryisinblacktypeona

whitebackgroundwithablackborder .

Note:Noteindicatesaprocedure,practice,

orconditionthatmustbefollowedinorder

forthevehicleorcomponenttofunction

inthemannerintended.

Page 8

Page 9

Addendum1

AutomaticTractionControl(ATC)(IfEquipped)

W3089687W3089688

ATCFunctionally

AutomaticTractionControl(A TC)providesimprovedtractiononslipperysurfacesby

reducingwheelspin.Ifadrivewheelstartstospinthesystemoperatesautomatically

asfollows:

ATCappliesairpressuretothebrakeofthespinningwheel.Doingthistransfers

enginetorqueviatheaxledifferentialtothewheelsthathavebettertraction.Brake

controlisactiveatvehiclespeedupto25MPH.

ATClimitsenginetorquewhich,inturn,reduceswheelspintoprovideimproved

traction.Thedrivermayoverridetorquecontrolbyfurtherpressingtheaccelerator

pedal.Enginetorqueisactiveatallvehiclespeeds.

WhenA TCautomaticallybecomesactive,theA TCindicatorlampturnsontoalertthe

operator.Thelampturnsoffwhenthewheel(s)stopsspinning.

ATCOFF(IfEquipped)

ATCmayalsoincludethe“A TCOFF”optionthatisselectabletothedriverviathe

ATCOFFswitchwhichislocatedonthedashboard.

WhenthisfunctionisactivatedwiththeA TCOFFmodeswitchwhichislocatedon

thedashboard,theA TCOFFfunctionwillturnofftheAutomaticTractionControl

(ATC)byallowingtorquetobeappliedtoalldrivewheelasrequiredbythedriverand

willnotreducewheelspinbyapplyingthebrakesorreducingenginetorque.

WhentheoperatorselectstheheavyATCOFFfunction,theA TCindicatorlampbeon

continuouslytoindicatethattheAutomaticTractionControl(A TC)isnotavailable.

TheA TClampwillturnoffwhentheA TCOFFmodeswitchisturnedoff.

HeavyMud/SnowFunction(IfEquipped)

ATCmayalsoincludeaheavymud/snowfunctionwhichallowstheoperatorto

activateA TCwhenadditionaltractionisneeded.

Whenthisfunctionisactivated,withtheA TCMUD/SNOWmodeswitchwhichis

locatedonthedashboard,theheavymud/snowfunctionincreasesavailabletraction

byincreasingpermissiblewheelspin.

Whentheoperatorselectstheheavymud/snowfunction,theA TCindicatorlamp

blinkscontinuously.

TheA TClampstopsblinkingwhentheA TCmodeswitchisturnedoff.

Page 10

2Addendum

TowingInformation

TowingaVehicleEquippedwithmDRIVE

Transmission

VehiclesEquippedwithAMT-D(mDRIVE)withoutTowing

AlternativeProcedure

Note:Refertolabelonthedriverdoorto

checkifvehicleisequippedwithTowing

AlternativeProcedure.

Page 11

Addendum3

W4093877

IfthevehicleisnotequippedwiththeTowingAlternativeProcedure,the

driveshaftmustbedisconnectedtotowthevehicle.

CAUTION

Failuretodisconnectthedriveaxle

shaft(s)orliftthedrivewheelsoffthe

groundbeforetowingorpushingthe

vehiclecancauseserioustransmission

damage.

DANGER

Ifthedriveshafthasbeendisconnected

fortowing,DONOTreusebearing

retainerboltsorstampedstrapbolts,

orstampedstraps.Reuseofbearing

retainerboltsorstampedstrapbolts,

orstampedstrapscancausedriveline

failure,whichcanresultinseparation

ofthedrivelinefromthevehicle.

Aseparateddrivelinecanresultin

propertydamage,seriouspersonal

injuryordeath.

Page 12

4Addendum

VehiclesEquippedwithAMT-D(mDRIVE)andwithTowing

AlternativeProcedure

Note:Thisprocedureisnotintendedtoreplacethestandardtowingprocedures

andmustonlybeusedwhenitisnotpossibletofollowthestandardprocedures.

IfthevehiclecannothavethedriveshaftremovedandisequippedwithTowing

AlternativeProcedure,thevehiclecanbetowedwithouttheremovalofthedriveshaft.

Thisprocedureallowsthevehicletoberemovedfromtoll-ways,bridges,andtunnels

withoutdisconnectingthedriveshaft.

CAUTION

Attheearliestpossibletime,thevehicle

shouldbeconguredforstandard

towingbydisconnectingtheaxleshaft.

Failuretodisconnectthedriveaxle

shaft(s)orliftthedrivewheelsoffthe

groundbeforetowingorpushingthe

vehiclecancauseserioustransmission

damage.

Note:Refertolabelonthedriverdoortocheckifvehicleisequippedwithtowing

alternativeprocedure.Also,somevehicleshavehadthetransmissioncontrolmodule

(TCM)softwareupdatedtoaddthetowingalternativeprocedure.

WhentheTowingAlternativeProcedureisused,3rdgearandHighRangeisengaged

whichenablestheoilpumptorotateduringtowing.T owinggear3HRwillbe

engagedifthefollowingconditionsaremet:

•Transmissioninneutralposition

•Vehiclemovesforwardfasterthanasetlimitforanumberofseconds

•Engineisnotrunning

•Airpressuretothetransmissionmustbegreaterthan700kPa(100psi).Airshould

besuppliedcontinuouslyfromthetowingvehicle.

•IgnitionONandpowerprovidedtotheTCM

•Batteryvoltagemustbe12voltsorhigherforproperTCMfunction

•Notransmissionairpressurediagnostictroublecodes(DTC)

Page 13

Addendum5

CAUTION

Reversetowingisnotallowedwhen

TowingAlternativeProcedureis

used.Reversetowingcandamagethe

transmission.

CAUTION

DonotusetheTowingAlternative

Procedureifthevehiclehasbeeninan

accidentthathascompromisedtheoil

coolinglinesorcoolerorifthevehicle

isbeingtowedfortransmissionfailure.

Usingthisproceduremayresultin

furtherdamagetotheequipment.

ThisprocedureshouldNOTbeusedinthefollowingsituations.

•Vehiclepowerandorairsupplycannotbeveriedtothetransmissionorcannotbe

consistentlysuppliedfromthetowingvehicleifmovinglongerdistances.

•Heavyfrontaldamagetotheradiatorassemblyonvehiclesthathavethe

transmissionoilcoolerinthebottomtankoftheradiator,andthecoolerlines

arecompromised.Towingwithbrokenlineswillpumpalltheoiloutofthe

transmissionandfurtherdamagetheequipment.

•Complaintsinvolvingtransmissionfailurethatrequirestowing.

•ActiveairpressureDTCintheInstrumentClusterforthetransmission.

Page 14

6Addendum

Towing

Note:Duringtowing,themainswitchandparkinglampsshallbelitiftheelectrical

systemofthevehicleisfunctioning.

LiftingTheFrontSuspension

W7001301

Note:Whenthevehicleistowedwiththefrontsuspensionlifted,thesteeringlock

mustbereleased.

CAUTION

Whenthedrivingwheelsarestillin

contactwiththegroundtheaxledrive

shaftmustalwaysberemovedinorder

nottodamagethegearbox.

Ifthehalfshaftshavetoberemoved,iftherearaxlehasbeendamagedforexample,

thehubsmustalwaysbeprovidedwithclosettingcovers.Sandanddirtcould

otherwisendtheirwayinandcauseconsiderabledamage.

T0006670

Disconnectthepropellershaftfromtherearaxleandxitsecurelytothechassis,or

removetheentirepropellershaft.

Page 15

Addendum7

ABS

Note:Duringtowingwiththefrontsuspensionlifted,afaultcodefor“abnormal

sensorsignalfront”issetintheABSsystem.Thisshouldbeconsideredduringthe

nextservice,whentheABSfaultcodesarechecked.

LiftingTheRearSuspension

Note:Whenthevehicleistowedwiththerearsuspensionlifted,thesteeringwheel

mustbelockedwiththesteeringlock,orlashed.

Method:Thismethodispreferredwhentheproperequipmentisnotavailableto

performthewheelliftmethodandisnecessaryforwreckersnotequippedwithan

underliftsystem.

Unloading

Alwaysunloadthevehiclebeforeliftingtherearsuspension,ifcircumstancesallowit.

Thevehicleisunloadedtoreducetheaxleloadingonthetowingvehicle,limitthe

loadingonthevehicle'sliftingpointsandminimizetheriskofdamagetotheload

whichcouldoccurduringtowing.

Ifitisnotpossibletounloadthevehiclewhereitis,itcanbetowedashortdistanceto

asuitableplacewhereunloadingcantakeplace.

Page 16

8Addendum

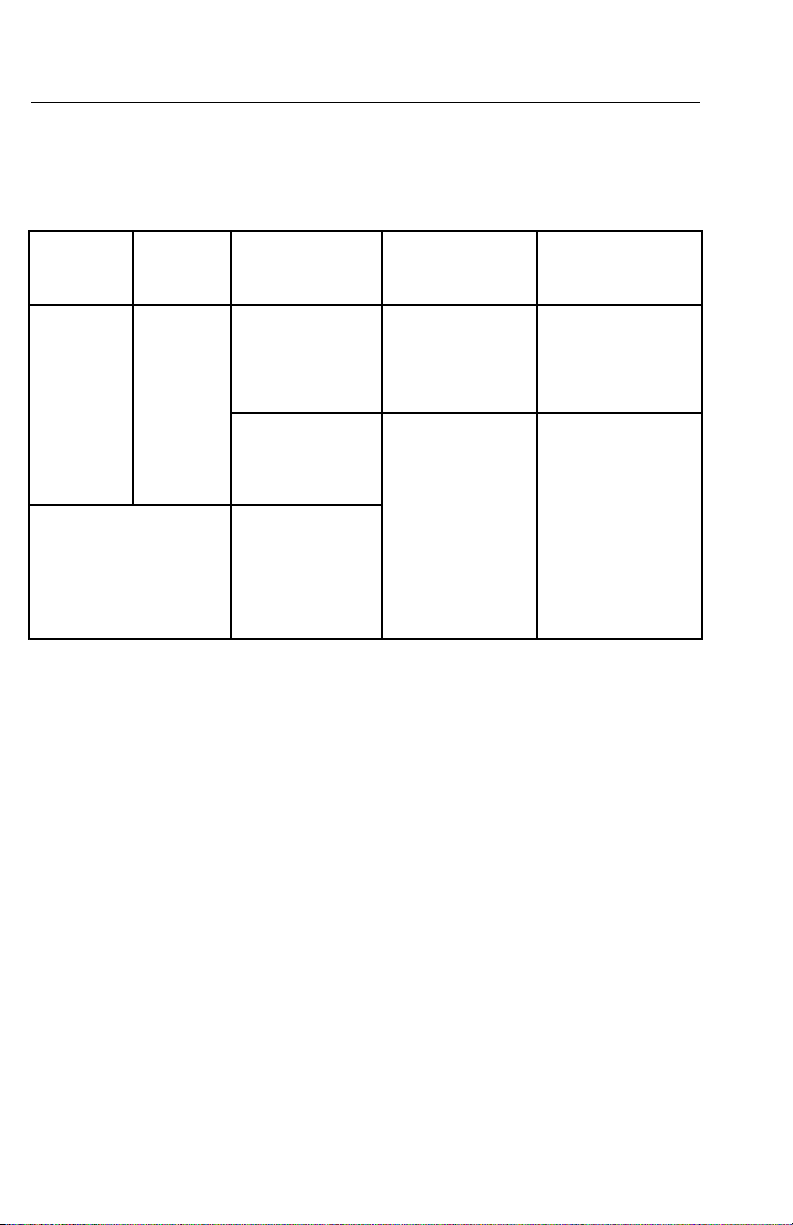

Max.LoadingDuringLiftingandTowing

Thistablespeciestheloadingwhichcanbeappliedtothetowinghook,towinghitch

cross-member,axlesandtorquestayanchorages.

Single

Towing

Hook

Thehook

mustnot

beloaded

bymore

thanthe

vehicle's

gross

weight.

Note:Thetowing

hooksonthevehicle

mustonlybeusedfor

towing.

1max.200mm(7.8inches)fromcenterofmemberweb

Double

Towing

Hooks

Each

hookmust

notbe

loaded

bymore

thanthe

vehicle's

gross

weight.

TowingHitch,

TowingHitch

Cross-Member

Lengthways:Staticloading,

20tons

Vertically(lift):

7tons

Sideways:

17tons

1

Axles,Front

AndRear

lengthwaysand

vertically:

2xaxleloading

Dynamic,e.g.

duringtowing:

1xaxleloading

AirSuspension

Vehicles,Front

TorqueStays

Perside:

max.5tons

Gross:

max.9.5tons

Page 17

Addendum9

Lifting,General

Vehiclesmustonlybeliftedbytheliftingpointsspeciedbelow .Alwaysusesuitable

liftingdevices,suchasclevisesandchassisguards,toavoiddamagingthevehicle.

LiftingAVehicleWithLeafSprings

Seealso“Max.LoadingDuringLiftingandTowing”,page8.

FrontSuspension

Liftbehindthefrontspringanchorageonthechassismember,orbeneaththefrontaxle.

TwinFrontAxles

Liftbeneaththeforwardsfrontaxle,asabove.

Notethatonvehicleswithtwinfrontaxles,agreaterliftheightisneededtogetthe

wheelsontherearwardsfrontaxletoliftfromtheground.

Thewheelsonthefrontaxlescanberemovedtoreducetheliftheight.

RearSuspension

Liftunderneaththetowinghitchcrossmemberintherstinstance.Ifthevehicledoes

nothaveatowinghitchcrossmember,usethechassisendsforlifting.

CAUTION

Remembertoalwaysuseachassis

guardwhenusingacrossmemberfor

lifting.

T0006672

Rearsuspensionliftingpoints,truckwithleafsprings.

Page 18

10Addendum

LiftingAVehicleWithAirSuspension

Ifpossible,“Automaticrideheight”shouldbeactivatedduringtowing.Theignition

lockshouldthenbeinpositionIorll.

If“Manualrideheight”isactivated,settheheighttothesamedriveheightasfor

automaticrideheight.

Thevehiclemustnotbedrivenfasterthan10km/h(6.2mph)iftheairsuspensionis

notactivated

WARNING

Whenyouliftavehiclewithair

suspension,thereisariskthattheair

bellowscouldslideapart.Whenyou

lowerthevehicleagainwhenyouhave

nishedtowing,donotuseyourhands

underanycircumstancestoguide

theairbellowsintoplaceagain.Y ou

riskpinchingyourhands,whichwould

causeseriousinjury .

Page 19

Addendum11

Note:Whenyoulowerthevehicletodriveheightagain,makesurethatthebellows

arelledwithair.When“Automaticrideheight”isactivated,lowerthevehicle

carefullytoensurethatthereisenoughtimeforthebellowstollwithair.

Donotuseyourhandstoguideairbellowsbackintoplaceiftheyhaveslidapart.

W9094924

Page 20

12Addendum

FrontSuspension

Seealso“Max.LoadingDuringLiftingandTowing”,page8.

Method1:WheelLift

Thismethodprovidesthegreatesteasefortowingthevehicle.Liftingatthetireshelps

reducetheriskofpossibledamagetotheaxle,suspension,andenginecomponents

duringtowingoperations.

W9094908

Method2:AxleForkLift

Thisisanalternativeprocedurefortowingthevehicle.Itrequiresstandardtowforks

anddesignatedliftpointsdependingonwhichaxleisequippedonthevehicle.

ForaSteertekNXTequippedvehicle(builtafterJuly2011):

1Useaforkwith3.25”ofclearance,a4.5”openingand2”shank.

2Installtheforkintheboomproperly.

3Thepropertowforklocationiscenteredbetweenthelocknutsontheaxlespring

seats.

ForaSteertekequippedvehicle(builtpriortoJuly2011):

1Installtheforkintheboomproperly.

2Positionthepropertowforksdirectlyundertheaxle,insidetheaxleclampgroups.

3Priortoliftingthevehicle,ensurethatthebottomaxleplateisatinthetowfork

tominimizeanygapbetweenthebottomaxleplatethetowfork.

Page 21

Addendum13

W7001301

Method3:SpringEyeandHangerLiftMethod

Thismethodispermittedforunderliftequippedunits,butcautionmustbetakento

avoiddamagingtheleafspring.

Note:Whenliftingavehiclewiththeunderliftboom,caremustbetakentoavoid

damagingtheengineoilpan.Itmaybenecessarytoremovethefrontfairing.If

necessary,placeablockofwoodbetweenthetopofthebottomandthebottomof

theaxle.

W9094894

Page 22

14Addendum

T0006675

RearSuspension

Ifpossible,avoidliftingtherearofatruckwithairsprings.Theconsequencecouldbe

thattheairbellowsslideapart,unlessyourstsecuretherearaxletothechassis.It

thentakesalotoftimetolineuptheairbellowsagain.

Note:Iftherearaxleisxedtothechassiswithstrapsetc.whenthevehicleis

lowered,thestrapswillburstwhenautomaticrideheightcontrolisactivatedlateron.

Ifyouhavetolifttherearofthevehicleanyway,liftthetowinghitchsupportcross

memberintherstinstance.Ifthevehicledoesnothaveatowinghitchsupportcross

member,liftthechassisends.

Ifyouliftthevehiclebythechassis,thefollowingapplies:

1TheignitionlockmustbeinpositionIorIIandtheairsuspensionin“Automatic

rideheight”mode.

2Liftthechassisuntilthewheelsalmostleavetheground.T akearestuntilthe

airhasdrainedoutoftheairbellows.

3Ifpossible,xtherearaxletothechassissothattheairbellowscannotslideapart.

4Lifttothedesiredheight.

T0006676

Liftingpointsonrearsuspension,truckwithairsprings.

Page 23

Addendum15

TowingCongurations(Rear,Side,andUsingthe

TowHooks)

ParkingBrakesandT owingHooks

WARNING

Thesteeringdoesnothaveanyservo

effectiftheengineisnotrunning.

Theparkingbrakemustbereleasedduringtowing.Tomechanicallyreleasethe

parkingbrake,seeunder

Usethevehicle'stowinghook(s)fortowing.Ifthetruckisequippedwithonetowing

hook,thismayhavethegrossweightofthetruckappliedfromstraightinfront.If

thetruckisequippedwithtwotowinghooks,eachoneofthemmayhavehalfthe

grossweightofthetruckappliedfromstraightinfront.

“ParkingBrake—MechanicalRelease”,page18.

WARNING

thevehicle'stowinghook(s)mustonly

beusedfortowing.Incorrectusecan

leadtopersonalinjuryifthetowing

hookisloadedwithagreaterweight

thanitisdimensionedfor .

1.TowHooks

C0029851

Page 24

16Addendum

C0029852

1.TowHooks

Page 25

Addendum17

TowingBackwardsAndSideways

TowingBackwards

Towfromtherearspringanchorageortrailerhitchhook.

Seealso“Max.LoadingDuringLiftingandTowing”,page8.

T0006679

Towfromtherearspringanchorageortrailerhitchhook.

TowingSideways

Whentowingsideways,selectanattachmentpointclosetotheaxleanchorage,such

asaspringortorquestayanchorage.Inothercases,thechassiscouldbesubjectedto

suchheavyloadingthatitcouldbebent.

Useaspringortorquestayanchoragetotowsideways.

T0006680

Page 26

18Addendum

ReleasingTheBrake

ParkingBrake—MechanicalRelease

Theparkingbrakecanbereleasedmechanicallyifcompressedairisnotavailable.

Note:Sometruckscanhaveparkingbrakecylindersontwoaxles.

WARNING

Alwaysstartbyapplyingchockstothe

wheels,sothatthetruckcannotroll

away.Thisisveryimportant,sinceyou

havetolieunderneaththetrucktocarry

onwiththejob.

•Removethecapontherearoftheparkingbrakecylinder.Unscrewthescrewuntil

thebrakereleases.Usethetoolfromthetoolkit.

Note:Donotremovethesplitpinsfromdesignswhichhaveasplitpin,unscrew

thescrewandnuttogether.

•Remembertoscrewthescrewbacktoitsoriginalplaceagainonceyouhave

nishedtowing,andputtheprotectivecapback.

Parkingbrakecylinder.

T0006682

Page 27

Addendum19

DiskBrakes

Thenewbrakecylindershaveanewreleasemechanismfortheparkingbrakespring,

whichmeansthatthereleaseboltdoesnotcomeoutofthebrakecylinder.

Whenyoustarttoreleasetheparkingbrakemanually,aredplasticplugcomesoutof

thecentreofthenut.Itisentirelyoutafterthreeturns.Atotalofabout45turnsare

neededtofullycompresstheparkingbrakespring.Whentheparkingbrakeisfully

reinstated,(springreleased),theredplasticplugwillreturnintothecentreofthenut.

Note:Alwayslltheparkingbraketankwithairwhenavailable,andreleasethe

parkingbrake,toreducetheamountofturningneededonthereleasemechanism

nut.Thenutshouldonlybereleasedinexceptionalcases,withnoairintheparking

brakesection.

CAUTION

Undernocircumstancesisitpermissible

touseawrenchformanualreleaseor

reinstatementoftheparkingbrake!

Themaximumtorquefortherelease

mechanismnutis47Nm(34.67ft-lbs).

T5011021

Plasticplugforreleasemechanism

BrakesInWinter

Ificeplugsoccurinabrakevalveinthebrakesystem,thebestwaytoxthisisto

heatitwithexhaustgasfromanothervehicle.

Openames(suchasatorch)mustnotbeusedsinceplastichosesandrubbergaskets

cannotwithstandtemperatureshigherthan80°C(176°F).

Page 28

20Addendum

JumpStarting

Ifthebatteriesaredeadforanyreason,youcantakecurrentfromanothervehicle's

batterytogettheenginegoing.

Inordertoavoidanexplosion:

WARNING

Batterieswhicharetobelinkedtogether

mustbeofthesamevoltage(12to12,

24to24).Takecaretoobserveproper

polaritywhenconnectingbatteries.

Batteriesproduceexplosivegases.

Keepsparks,ames,cigarettes,etc.,

awayfrombatteriesatalltimes.Protect

youreyesbywearingsafetygoggles.

BesurevehiclesareNOTtouching

eachother.

WARNING

Rememberthatbatteries,especially

helpstartbatteries,containahydrogen

andoxygenmixture,whichishighly

explosive.Asparkwhichcouldoccur

whenyouapplythejumpercables

incorrectlycouldbeenoughtocausethe

batterytoexplodeandinjureyouand

damagethetruck.Thebatterycontains

sulphuricacid,whichcancauseserious

chemicalburns.Ifyougetanyacidin

youreyes,skinorclothes—rinsewith

largequantitiesofwater.Ifyougetany

splashesinyoureyes,contactadoctor

atonce.

CAUTION

Thebatterycontainsacidwhichis

corrosiveandpoisonous.Itisthus

importantthatthebatteryishandledin

anenvironmentallycompatiblemanner.

WARNING

Alwaysweareyeprotectionwhen

workingaroundbatteriestoprevent

theriskofinjuryduetocontactwith

sulfuricacidoranexplosion.

WARNING

Batteryposts,terminalsandrelated

accessoriescontainleadcompounds,

chemicalsknowntothestateof

Californiatocausecancerand

reproductiveharm.W ashhandsafter

handling.

Note:Yourvehiclemaybeequippedwith

ajump-startconnectorwhichislocatedon

theleftrearsideofthecab.

Page 29

Addendum21

1Theignitionlockinbothtrucksshouldbeinposition0.

2Makesurethatthebatteryinthetruckwhichisgoingtogivestarthelp(A)hasa

totalsystemvoltageof12Vandthatthevehiclesdonottoucheachother.

3

T0006910

AThetruckwhichgivesstarthelp

BThetruckwithadeadbattery

4Connecttheredcablebetweenthepositiveterminals,(1)oneachtruck.

5ConnectoneclampontheblackcabletothenegativeterminalontruckA,(2).

6Connecttheotherclampontheblackcabletoagroundpointashortdistance

fromthebatteryintruckB,(3).

7StarttheengineintruckA.Allowtheenginetorunatasomewhathigherspeed

foraboutaminute,atabout1000rpm.

8StarttheengineintruckB.

WARNING

Checkthattheclampsaresecurelyattached,sothatnosparksoccur.Donotlean

overthebatteryduringthestartattempts.

9Removethecablesinthereverseorderfromattachment.

Page 30

22Addendum

EngineComponents,ServiceSchedules

MP7,MP8andMP10(US2010andNewer)

EngineOilChangeIntervals

Note:FortheMP7,MP8andMP10(US2010andnewer)engines,MACK

stronglyrecommendsusingoilsthatmeetAPICJ-4,VDS-4andEO-OPremium

Plusqualitystandardsatalltimes.

Note:Forinformationaboutoilchangeintervalsfornon-MACKengines,refer

totheappropriateenginemanufacturer'sliterature.

MP7,MP8andMP10Engines

Note:Usetheinformationinthefollowingtabletodeterminetheoperatingcondition

andusageapplicabletoyourvehicle.

EngineOperating

Condition

TotalFuelConsumption

(L/100km)

TotalFuelConsumption

(mpg)

EngineOil&FilterChange

Interval—42L(44quarts)

oilcapacity

EngineOil/FilterChange

Interval—52L(55quarts)

oilcapacity(MP10only)

Note:Ifidletimeisgreaterthan30%,usethenextlowerchangeinterval.

HeavyHaul

>50<50<39

<4.7>4.7>6.0

45000km

(25,000mi)

625hours

60000km

35,000mi

625hours

RegionalHaul

60000km

(35,000mi)

1,000hours

75000km

45,000mi

1,000hours

LongHaul

75000km

(45,000mi)

1,300hours

80000km

50,000mi

1,300hours

Page 31

Addendum23

FuelTankVentilationFilter

Somevehiclesareequippedwithafueltankventilationlter.Anexhaust

stanchion-mountedlterisdesignedforuseinharsh,abrasiveanddirtyenvironments.

Therearealsoafueltank-mountedlter,aframerail-mountedlterandafueltank

bracket-mountedlterfornon-severeenvironments.Thepurposeofthiscomponentis

tolteroutcontaminantsthatcanenterthefueltankfromtheventlines.

Thisltershouldbereplacedinconjunctionwiththevehicleairlter,whenindicated

bytheairrestrictiongaugeortheairlterrestrictorindicatorlightintheinstrument

cluster.Themaximumtimeallowedbeforereplacementis24months.

ExhaustStanchion-MountedFilter

W2069496

Page 32

24Addendum

1–FuelTank-MountedFilter

Page 33

FrameRail-MountedFilter

Addendum25

W2085894

Page 34

26Addendum

EngineIntakeAirCleaner

CAUTION

Theconditionoftheengineintakeair

cleanerismonitoredbytheaircleaner

restrictiongaugemountedoneitherthe

aircleanercanister,theaircleaneroutlet

tube,orinsidethecab(dashmounted

gauge).Continuedoperationwiththe

aircleanergaugeindicatingaclogged

aircleanermaycausedamagetothe

engine.Also,operatingtheenginewith

adamagedaircleanerallowsdustto

passdirectlyintotheengine,causing

damage.Promptlyreplacecloggedor

damagedaircleaners.

Theaircleanergaugeshouldbeinspectedregularlytomonitortheconditionoftheair

cleaner.Replacetheaircleanerwheneithertheaircleanergaugeontheaircleaner

locksintheredorwhenthedash-mountedgaugeshowsanairinletrestrictionof5

kPa(20inH2O).Maximumchangeintervalis24months.

W2055693

Page 35

EngineComponentMaintenanceIntervals

MP7,MP8andMP10

Engines

EngineCoolant

Addendum27

CAUTION

MACKTrucks,Inc.recommendsusing

apropermixtureofapprovedantifreeze

anddeionizedordistilledwaterin

theenginecoolingsystem.MACK

Trucks,Inc.doesNOTrecommend

usingonlyplainwaterasacoolant.

Wateraloneiscorrosiveatengine

operatingtemperaturesanddoesnot

provideadequateboil-overprotection.

Withplainwaterasacoolant,the

boilingpointislowercomparedtoa

properantifreezeandwatermixture,

allowingthecoolingsystemtodevelop

corrosionandcavitationproblemsinthe

engineandradiator .Failuretofollow

MACKTrucks,Inc.'scoolingsystem

care/maintenancerecommendationscan

renderthewarrantyinvalid.

Withamanualtransmission,theenginecoolantsystemcapacityisapproximately

50liters(53USquarts).WithamDRIVEautomatictransmission,thecapacityis

approximately59.5liters(63USquarts).

DANGER

Antifreezeishazardoustohumansand

animalsifingested.Alwaysdisposeof

coolantaccordingtoFederalorlocal

regulations.Disposeofusedcoolantat

arecyclingorwastecollectioncenter.

Note:FullyFormulatedCoolantcanonly

betoppedoffwithpremixed50/50Fully

FormulatedCoolantwhencoolantlevelis

low.

Note:ExtendedLifeCoolantcanonlybe

toppedoffwithpremixed50/50Extended

LifeCoolantwhencoolantlevelislow .

CAUTION

Donottopoffwithwater.Topping

offwithwaterwilldilutethecoolant

additivepackage.Oncedilutedtoo

fartheadditivewillnolongerprovide

sufcientengineprotection,whichcan

leadtoseriousenginedamage.

Page 36

28Addendum

Changethecoolantlterandcoolantaccordingtotheintervalsinthefollowingtable:

Chemical

AdditiveFilter

mustbeusedwith

FullyFormulated

Coo-

Coolant

lant

Filter

LongLifeFilter

withoutadditives

tobeusedwith

ExtendedLife

Coolant

FullyFormulated

Coolant

Coolant

ExtendedLife

Coolant

Note:DoNOTuseextended-lifecoolant

inenginesequippedwithacoolant

conditionerlter.Acoolantlter

HeavyHaul–POC

SandVS

Ateveryengineoilchange.

240000km(150,000mi)or12months,

whichevercomesrst

240000km(150,000

mi)or12months,

whichevercomes

rst

1200000km(750,000mi)or96months,

whichevercomesrst

thatcontainsnosupplementalcoolant

additives(SCA)isavailableforusewhen

extended-lifecoolantisused.

RegionalHaul

–POCH

Long

Haul–

POCM

500000km(300,000mi)or24

months,whichevercomesrst

TypicalCoolantConditionerFilterLocation

W2055694

Page 37

Addendum29

DriveBelts(FanandAccessory)

Allenginedrivebeltshaveautomaticbelttensionersthatautomaticallymaintainthe

correctbelttensionwithouttheneedformanualadjustment.Alldrivebeltsshouldbe

checkedateachservicepointandinspectedforcracksorfrayedmaterial.Replaceany

drivebeltthatdisplayssuchobviouswearordefects.Otherwise,replacethedrive

beltsaccordingtotheintervalsinthefollowingtable:

US2010andNewer

ForNon-V ocational

Applications

ForV ocational

Applications

DriveBeltT ensioners

Replacethedrivebelttensioner(s)every500,000km(300,000mi.)or4000hours,

whichevercomesrst.

500000km(300,000mi)or36months,whichever

comesrst

240000km(150,000mi)or12months,whichever

comesrst

DriveBeltRouting–MP7/MP8

W2055695

Page 38

30Addendum

1.CrankshaftPulley7.IdlerPulley(ifequipped)

2.AutomaticTensioner8.AccessoryDriveBelt

3.IdlerPulley9.AutomaticTensioner

4.WaterPump

5.MainDriveBelt11.A/CCompressor(ifequipped)

6.FanDrive

10.Alternator

W2055696

DriveBeltRouting–MP10

1.CrankshaftPulley6.FanDrive

2.IdlerPulley7.AutomaticTensioner

3.AutomaticTensioner8.Alternator

4.W aterPump

5.MainDriveBelt10.A/CCompressor

9.AccessoryDriveBelt

EngineValveAdjustments

ForUS2010enginesandnewer,adjusttheenginevalvesaccordingtotheintervals

inthefollowingtable:

MP7,MP8

andMP10

Engines

FirstServiceAdjustment:240000km(150,000mi)or12months,

whichevercomesrst

Then,adjustevery500000km(300,000mi)or24months,

whichevercomesrst

Page 39

ExhaustAftertreatmentSystem

TakethevehicletoanauthorizedMACKTruckdealerforservicing.

AftertreatmentDieselParticulateFilter(DPF)

Addendum31

HeavyHaul

Eithercleantheashfrom

theDPForreplacethe

DPFevery400000km

(250,000miles)or4,500

hours,whichevercomes

rst

RegionalHaul

EithercleantheashfromtheDPForreplacethe

DPFevery650000km(400,000miles)or10,000

hours,whichevercomesrst

LongHaul

AftertreatmentHydrocarbonDoser

ForvehiclesbuiltthroughApril2012,CLEANtheaftertreatmenthydrocarbondoser

at240000km(150,000miles)or4,500hours,whicheveroccursrst.

ForvehiclesbuiltMay2012andnewer(engineserialnumbers:MP7-535298,

MP8-961636,MP10-58182),REPLACEtheaftertreatmenthydrocarbondoserat240

000km(150,000miles)or4,500hours,whicheveroccursrst.

AftertreamentDieselExhaustFluid(DEF)T ankFlushing,DEF

PumpFilterandDEFT ankFillerNeckFilter

DrainDEFtank,replaceDEFpumpmainlterandcleanDEFtanknecklterat

thefollowingintervals.

240000km(150,000mi)or4,500hours,whicheveroccursrst.

AftertreatmentDPFIgnitionElectrodeandNozzle

Note:TerraPromodelyear2011to2013areequippedwiththenon-catalyzedthermal

regenerationDPFunit(TRU).

Replacetheaftertreatmentdieselparticulatelter(DPF)ignitionelectrodeandnozzle

(DPFSparkAssistedSystemonly)every240000km(150,000mi)or4,500hours,

whichevercomesrst.

Page 40

32Addendum

RearAxleOilChangeIntervals

GO-J,GO-JPLUSorTO-APlusspecicationgearoil(mineralorsyntheticbase)are

requiredforMACKrearaxlelubrication.Thelengthoftimearearaxlecanoperate

beforeanoilchangeisrequireddependsonthequalityoftheoilusedandtheengine

used.Forsevereserviceoroff-highwayapplications,morefrequentoilchangesmay

benecessary.GO-Jisusedforstandardaxledrainintervals.TO-APlusorGO-JPlus

Syntheticmustbeusedforextendedaxledrainintervals.

PowertrainOperatingConditions(POC)

Trans-

portCy-

cle

GCW

(tonnes)≤36

GCW

(1000lbs)

USand

Canada

Topogra-

phy

POC

LongDistance

36-4

≤80

P-

F

M-

2

,

80-1

P-

H

F

H

2

M

2

>4

8

8

>1

05

05

HHHHVH

-

-

S

VS

2

Distribution

RegionalC-

3

≤

1-36>36

30

6

≤

7-80>80

66

MH

SS

Construction

ity

≤

≤30

30

≤

≤66

66

3

0-4

4

6

7-9

5

H

S

1

4

5-5

>56

6

9

>12

6-1

4

24

V-

VS+

S

1Examplesincludesugarcane,tipper,dumper,swapcarrier,concretemixerand

refusebodies.

2IfthecombinedPTO(atzerovehiclespeed)andidletimeexceeds25%oftotal

operatingtime,movetothenexthigherPOC.

Page 41

Thefollowingtableshowsrecommendedrearaxleoilchangeintervals:

Addendum33

Powertrain

Operating

Conditions

Maximum

FuelCon-

sumption

(litres/100

km)

Maximum

FuelCon-

sumption

(mpg)

OilQuality

GO-JPlus,

TO-APlus

GO-J400000

Forwastecollection,mineoperation,airportservices,etc.,enginehourscanbeused

insteadoffuelconsumption

Medium

(Long

Haul)

≤39≤50≤64≤120

7.0–6.16.0–4.84.7–3.83.7–2.0

DrivingDistancekm(miles)orTime(years/hours)

800000

(500,000)

or3years

(250,000)

or2years

Heavy

(Regional)

800000

(500,000)

or3years

400000

(250,000)

or2years

Severe

(Heavy

Haul)

whichevercomesrst

125000

(80,000)or

1yearor

1200hours

65000

(40,000)or

1yearor

1200hours

Very

Severe

125000

(80,000)or

1yearor

1200hours

65000

(40,000)or

1yearor

1200hours

Very

Severe+

N/A

N/A

6months

6months

Note:TO-APlusorGO-JPlusSynthetic

mustbeusedforextendedaxledrain

intervals.

Page 42

34Addendum

T300SeriesManualTransmissionOilChange

Interval

Thelengthoftimeamanualtransmissioncanoperatebeforeatransmissionoilchange

isrequireddependsonthequalityoftheoilused,thevehicleusage,andengine

size.Forsevereserviceoroff-highwayapplications,morefrequentoilchangesmay

benecessary .

PowertrainOperatingConditions(POC)

Trans-

portCy-

cle

GCW

(tons)≤36

GCW

(1000lbs)

USand

Canada

Topogra-

phy

POC

LongDistance

36-4

>48≤30

8

80-1

≤80

P-

H

F

M-

2

M

2

,

>10

05

5

P-

HHHH

F

-

-

H

S

VS

2

2

Distribution

RegionalC-

3

1-3

6

6

≤66

7-8

0

MH

>3

6

>8

0

SS

Construction

ity

≤3

0

≤6

6

30-4

≤30

67-9

≤66

H

1

4

>5

5-5

4

5

6

6

9

>1

6-1

24

24

V-

H

V-

S

V-

S

S+

1Examplesincludesugarcane,tipper,dumper,swapcarrier,concretemixerand

refusebodies.

2IfthecombinedPTO(atzerovehiclespeed)andidletimeexceeds25%oftotal

operatingtime,movetothenexthigherPOC.

Page 43

Addendum35

Thefollowingtableshowsrecommendedmanualtransmissionoilchangeintervals:

Powertrain

Operating

Conditions

Maximum

FuelCon-

sumption

(litres/100

km)

Maximum

FuelCon-

sumption

(mpg)

OilQuality

GO-JPlus,

TO-APlus

GO-J400000

Forwastecollection,mineoperation,airportservices,etc.,enginehourscanbeused

insteadoffuelconsumption

Medium

(Long

Haul)

≤39≤50≤64≤120

7.0–6.16.0–4.84.7–3.83.7–2.0

DrivingDistancekm(miles)orTime(years/hours)

800000

(500,000)

or3years

(250,000)

or2years

Heavy

(Regional)

800000

(500,000)

or3years

400000

(250,000)

or2years

Severe

(Heavy

Haul)

whichevercomesrst

125000

(80,000)or

1yearor

1200hours

65000

(40,000)or

1yearor

1200hours

Very

Severe

125000

(80,000)or

1yearor

1200hours

65000

(40,000)or

1yearor

1200hours

Very

Severe+

N/A

N/A

6months

6months

Note:Extendedchangeintervalsrequire

theuseofeitherGO-JPlusorTO-APlus

Syntheticspecoil.

Page 44

36Addendum

mDRIVETransmissionOilChangeIntervals

ThelengthoftimeanmDRIVEtransmissioncanoperatebeforeatransmissionoil

changeisrequireddependsonthequalityoftheoilusedandthevehicleapplication.

ThemDRIVEtransmissionoilchangeintervaldependsontheserviceseverity.Always

replacethetransmissionoillterwhenthetransmissionoilischangedandalwaysuse

MACK-approvedsynthetictransmissionoilwhenchangingthetransmissionoil.

PowertrainOperatingConditions(POC)

Trans-

portCy-

cle

GCW

(tons)≤36

GCW

(1000lbs)

USand

Canada

Topogra-

phy

POC

LongDistance

3

6-4

>48

8

8

≤80

P-

H

F

M-

2

M

2

,

>10

0-1

PF

H

2

5

05

HHHHVH

-

-

S

VS

2

Distribution

RegionalC-

3

≤3

1-36>36

0

6

≤6

7-80>80

6

MH

SS

Construction

ity

≤3

≤30

0

≤6

≤66

6

3

0-4

4

6

7-9

5

H

S

1

4

5-5

6

9

6-1

24

V-SV-

>5

6

>1

24

S+

1Examplesincludesugarcane,tipper,dumper,swapcarrier,concretemixerand

refusebodies.

2IfthecombinedPTO(atzerovehiclespeed)andidletimeexceeds25%oftotal

operatingtime,movetothenexthigherPOC.

Page 45

Addendum37

Powertrain

Operating

Conditions

Maximum

FuelCon-

sumption

(litres/100

km)

Maximum

FuelCon-

sumption

(mpg)

OilQuality

97307400000

97315400000

97318800000

97319800000

Medium

(Long

Haul)

≤39≤50≤64≤120

7.0–6.16.0–4.84.7–3.83.7–2.0

DrivingDistancekm(miles)orTime(years/hours)

(250,000)

or3years

(250,000)

or3years

(500,000)

or5years

(500,000)

or5years

Heavy

(Regional)

400000

(250,000)

or3years

400000

(250,000)

or3years

800000

(500,000)

or5years

800000

(500,000)

or5years

Severe

(Heavy

Haul)

whichevercomesrst

N/AN/AN/A

200000

(125,000)

or3years

N/AN/AN/A

400000

(250,000)

or5years

(125,000)

or3years

(250,000)

or5years

Very

Severe

200000

400000

Very

Severe+

N/A

N/A

2500hours

2500hours

Foracompletelistofapprovedoils,contactyourMACKTruckdealer.Also,referto

SB175-61,ApprovedOils,MACKComponents.

Note:Nosamplingisallowed.System

mustbeundisturbeduntiloilandlterare

replaced.

Page 46

38Addendum

PowerSteeringFluid

ThepowersteeringsystemuidreservoirislledwithAutomaticTransmissionFluid

(ATF)Dexron®III.Thereservoircontains1.9liters(4USpints)forsinglegearand

3.8liters(8USpints)fordualgearpowersteeringsystems.

Changethepowersteeringuidandlterevery240000km(150,000mi)or12

months,whichevercomesrst.Rellthepowersteeringsystemwiththesametype

ofuidoriginallyusedinthesystem.Refertothelabelonthesideofthepower

steeringreservoirforthecorrectuid.

Ifthepowersteeringuidhasdarkened,thepowersteeringsystemisrunninghotter

thannormalandtheuidisoverheating.Troubleshootthepowersteeringsystemfor

possibleoverheatingcausesandchangetheuid.

Page 47

Page 48

Page 49

Lastpage

Mack Trucks

http://www.macktrucks.com

PV776-22616311 English 02.2015 © Mack Trucks 2015

Loading...

Loading...