Page 1

INSTALLATION & OPERATION

MANUAL

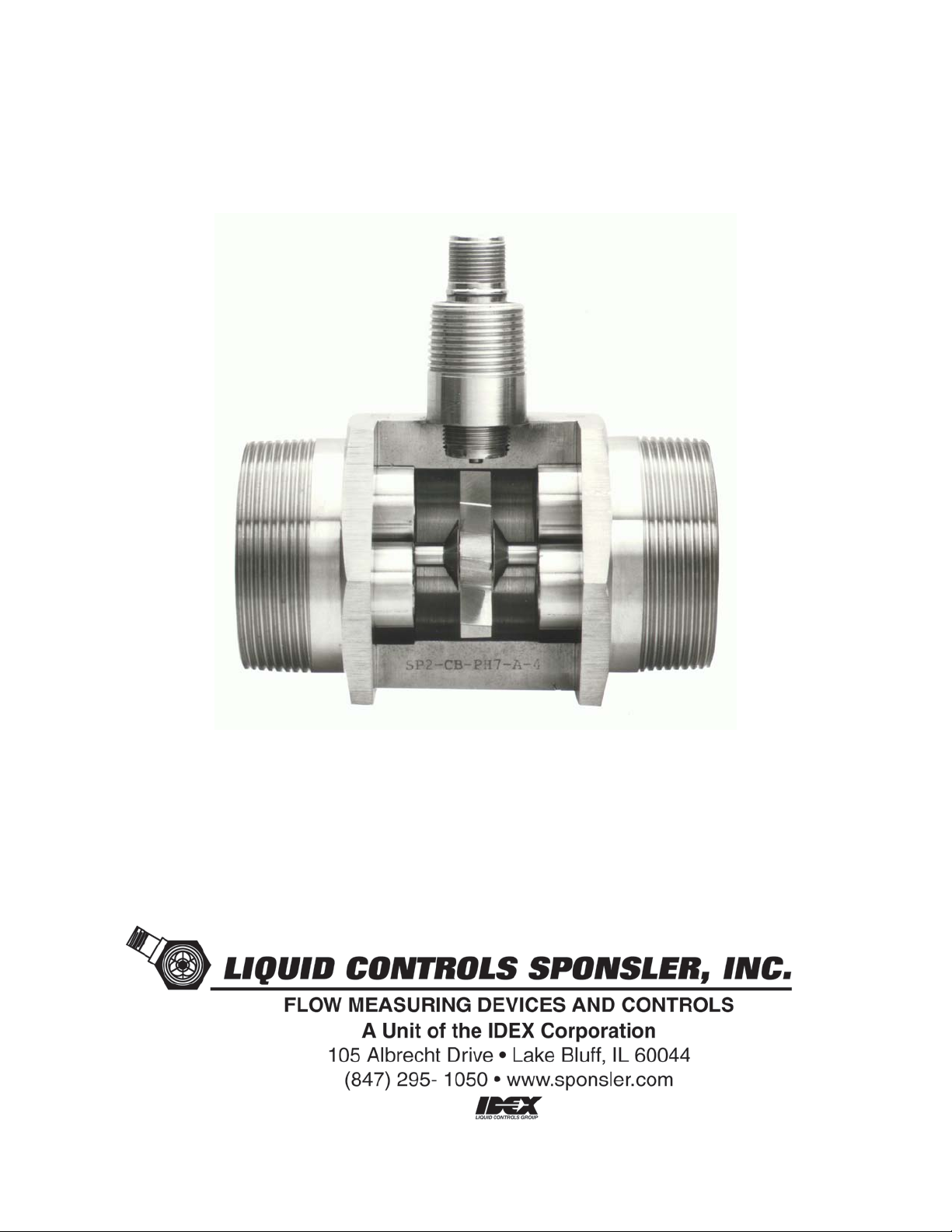

Precision Turbine Flowmeters

Page 2

TABLE OF CONTENTS

PAGE #

DESCRIPTION

1

Forward

4

3 Typical Meter Runs

7

FIGURE 2: 1/2” and Larger Assembly Procedure

10

FIGURE 5: Corrosive Meter Assembly Procedure

2

3

5

6

8

9

11

Pre-Installation Inspection, Installation

Installation (continued)

Typical Flowstraightener Section

FIGURE 1: 1/4” Assembly Procedure

FIGURE 3: MF20-90 Assembly Procedure

FIGURE 4: MF100-175 Assembly Procedure

FIGURE 6: 3A Sanitary Meter Assembly Procedure

Page 3

FORWARD

Pg.1

A. PRINCIPLE OF OPERATION

1. The precision turbine flowmeter is a volumetric flow measuring device.

2. The flowing fluid engages the vaned rotor causing it to rotate at an angular velocity proportional to the flowrate.

3. The angular velocity of the rotor results in the generation of an electrical signal (AC sine wave type). Summation

of the pulsing electrical signal relates directly to the flow rate.

4. The differential pressures developed across the turbine flowmeter balances out normal downstream thrust

loads, thus eliminating the need for thrust bearings over the rated range of the meter.

5. The vaned rotor is the only moving part of the flowmeter.

B. PHYSICAL DESCRIPTION

Refer to Assembly procedures in this manual for the identification of major parts of a typical SPONSLER PRECISION

TURBINE FLOWMETER.

C. ELECTRICAL DESCRIPTION

The pickup coil furnished with each SPONSLER PRECISION TURBINE FLOWMETER is a sensing device that

converts the change of magnetic flux from a permanent magnet, produced by the revolving rotor, into an AC sine wave.

Signal amplitude and frequency are directly proportional to flow rate.

1. Pickup Coil Types (a) Variable Reluctance- Generating pickups contain a permanent magnet and associated wire-wound coil. The

movement of the ferrous material of the rotor blade past the coil tip disrupts a magnetic field producing an AC

signal within the coil winding.

(b) Inductance-Generating pickups contain a wire-wound coil suitably fixed within a hermetically sealed housing.

The movement of a permanent magnet embedded in a rotor produces an AC signal within the coil winding.

2. Pickup Coil Output- The generated AC sinewave is transmitted via 2 wire shielded cable that minimizes external

interference.

3. Your Pickup Coil- Has been selected to best suit your particular application. The reluctance coil provides the

highest full scale frequency and a lesser signal/noise ratio. The inductance coil has a higher signal/noise ratio

and a lower full scale frequency.

Page 4

PRE-INSTALLATION INSPECTION

Pg.2

Your SPONSLER PRECISION TURBINE FLOWMETER is a measuring instrument capable of providing you with

high precision performance over a long period. It should be treated with care and not subjected to rough handling.

1. Unpack carefully and verify the information contained on the packing slip for proper MODEL Number, SERIAL

Number, and CALIBRATION Data.

2. Remove the instrument from the plastic packaging and remove the endfitting protectors from the flowmeter

housing.

3. Visually inspect the entire unit. Any visible damage should be reported to the manufacturer immediately.

4. Replace the endfitting protectors and return the Flowmeter to its plastic packaging. The unit may thus be stored

indefinitely until installation.

INSTALLATION

A. GENERAL PROCEDURE

1. Meter Position- FLOWMETERS are normally calibrated in a horizontal attitude. Best correlation of calibration,

therefore, occurs when installed and operated in this position. Meters may, however, be operated satisfactorily in

any position.

2. Flow Direction- ALL SPONSLER PRECISION TURBINE FLOW METERS are marked “IN” and “OUT” and have

an arrow to indicate the proper direction of the flow. (Bi-Directional flowmeters excluded)

3. Meter Location A. Relative- When it is expected that flow will be intermittent, the meter should not be mounted at a low point in

the piping system. Solids that settle or congeal in the meter may affect the meter’s performance.

B. Tolerance to Mechanical Vibration- Although the SPONSLER PRECISION TURBINE FLOWMETER is

designed for rugged service, the meter life may be increased by location in a minimum vibration area.

C. Tolerance to Electrical Interference- In order to achieve optimum electrical signal output from the

flowmeter, consideration must be given to its isolation from ambient electrical interference such as nearby

motors, transformers, and solenoids. (Section IV Maintenance Electrical)

4. System Pressure A. Minimum Operation Pressure- A minimum operating pressure should be maintained to preclude a change in

the calibration factor due to various types of two phase phenomena. The minimum operating pressure is a

function of the vapor pressure of the fluid and the presence of other dissolved gases. Maintenance of the

system back pressure serves to avoid cavitation or fluid separation.

Calculation of the back pressure is by the following formula:

BP = (meter ∆P x 2) + (VP x 1.25)

Where:

BP = Back pressure required

∆P = Flowmeter pressure drop @ maximum flow

VP = Product vapor pressure at maximum temperature (psig)

B. Maximum Meter Pressure- Safe working pressure for the flowmeter is determined by the size and type of

connecting fittings used and the materials of construction. Consult the factory for specifications for your

particular model.

Page 5

B. PIPING

Pg.3

1. General Piping Considerations- As explained in the FORWARD, the fluid moving through the flowmeter engages

the angled blades of the turbine rotor. Thus the rotational velocity of the rotor is a function of the fluid velocity and

the blade angle engagement. Swirl present in the fluid ahead of the meter can change the effective angle of

engagement and, therefore, cause a deviation from the supplied calibration (done under controlled flow

conditions). Proper installation of the Flowmeter minimizes the harmful effects of fluid swirl.

2. The Meter Location- That section of the pipe immediately preceding, including, and following the flowmeter is

known as “THE METERING LOCATION”. Three typical metering arrangements are described in the following

section of this manual. Each is designed to minimize fluid swirl. A flowstraightener is also shown and should be

used where installation does not allow the otherwise straight run of pipe upstream of the meter. PLEASE NOTE:

The required lengths of pipe are given in pipe diameters and represent the minimum distances between piping

components that are recommended to eliminate flow disturbances.

3. Meter-By-Pass- Where possible, such as in a new piping system, it is advisable to include a valved by-pass around

the flowmeter. However, the by-pass connections are not to be placed within the recommended metering run.

4. Line Purge- In a newly installed piping system or one in which fittings have been disturbed, the line should be

flushed thoroughly prior to installing the instrument to minimize possible damage to the flowmeter from foreign

materials.

C. ELECTRICAL CONNECTION

The standard SPONSLER PRECISION TURBINE FLOWMETER pickup coil is designed to mate with an

MS310610SL-4S connector. A two-wire shielded cable should be used to lead from the connector to the electronic

instrument in use. The cable shield is connected (grounded) to the appropriate connector on the display unit ONLY,

in order to minimize ground-loop and interface difficulties. The connection cable should be located away from power

lines whenever possible.

Precautions should be taken when removing or installing the pickup coil. Any physical damage such as bent

threads or twisted leads are not covered by SPONSLER CO., INC warranty.

D. ASSEMBLY NOTES

1. Removal of internals should be performed in a clean area.

2. Ensure that internals are clean and dry before reassembling.

Page 6

3 TYPICAL METERING RUNS

5D

*10D

FLOW

5D

5D

2D

3D

STRAIGHTENER

FLOW

20D

FLOW

5D

Pg.4

UPSTREAM

Pipe fitting immediately

preceding metering location

Wide open valve (gate or plug)

or

Sharp right angle bend

(mitered elbow)

or

straight run of pipe

Long radius bends

or

smooth elbows

or

two elbows

or

partially open valves

of any type

METERING LOCATION

DOWNSTREAM

Pipe fitting immediately

following metering

location.

Any fitting, valve or pipe

run

Any fitting, valve or pipe

run

*Minimum lengths of

straight pipe required

expressed in nominal pipe

diameters.

Page 7

TYPICAL FLOWSTRAIGHTENER SECTION

1/5 DIAMETER

2 DIAMETERS

Pg.5

Flowstraightener- A full cluster of thin wall tubes fixed within a section of pipe.

The length of the internal tubes is equal to 2 diameters of outer pipe.

The diameter of internal tubes is equal to approximately 1/5 the inside diameter of outer pipe. This

requires 18 to 20 such tubes.

Page 8

FIGURE 1: 1/4” PRECISION TURBINE FLOWMETER

HOUSING: AN, NPT, FLANGED

5

3

2

1

6

DOW NSTREAM

UPSTREAM

8

5

7

4

ENDVIEW

4

DISASSEMBLY FOR 1/4” METERS

REASSEMBLY FOR 1/4” METERS

ITEM

DESCRIPTION

QTY

1

HOUSING

1

2

ROTOR

1

3

BEARING

2

4

CONE 2 5

HANGER

2

6

SHAFT

1

7

RETAINING RING

1

8

PICKUP COIL

1

Pg.6

1. Remove retaining ring; Lift out carefully by placing a small flathead screw driver under the

radius notch.

2. Remove internals from housing.

3. Review all parts for damage. STOP: If any part appears damaged DO NOT

REASSEMBLE call factory for instructions.

4. Clean parts thoroughly before reassembling.

NOTE: Internals must go back together the exact way that they come out.

1. Insert cones in hangers, and bearings in rotor.

2. Assemble internals as illustrated.

3. Slide internals in housing, (position hangers as illustrated in endview).

4. Install retaining ring - Make sure it seats in groove.

5. Observe that hangers do not turn.

6. Observe that rotor spins freely.

Page 9

FIGURE 2: 1/2” & LARGER PRECISION TURBINE FLOWMETER

F

ABCDE

END VIEW

1B

1C

FIT TO ROTOR

L

DISASSEMBLY FOR 1/2” AND LARGER METERS

REASSEMBLY FOR 1/2” AND LARGER METERS

FOR BALL BEARING

FOR SLEEVED BEARING

FOR BALL BEARING

FOR SLEEVED BEARING

1. Remove lock nut from shaft end marked

Before beginning: Assembly must go back

NOTE: If any part appears damaged “DO

assembly. DO NOT OVER TIGHTEN.

ITEM

DESCRIPTION

QTY

ITEM

DESCRIPTION

QTY

A

BEARING

2

1A

CARBIDE SLV.

1

C

CONE 2 1C

GRAPHITAR SLV

1 D CLIP ASSY.

2 2 CARBIDE JRNL

1 E LOCK NUT

2 F

SHAFT

1

Pg.7

B ROTOR 1 1B TEFLON SLV. 1

2 CARBIDE ONLY

FIT TO SHAFT

DO NOT REMOVE

PICKUP COIL

HOUSING: AN, NPT, FLANGE

(AN shown)

1A

DO NOT REMOVE

C

“IN”.

2. Insert extraction hook into “IN” clip

assembly and extract with a parallel

pulling motion.

3. Remove cone, bearings and rotor.

4. Remove “OUT” clip assembly with

extraction hook as directed in step 2. DO

NOT remove lock nut. Leave clip, cone,

shaft and nut assembled.

(Refer to diagram)

together the exact way it comes out.

1. Remove lock nut from shaft end marked

“IN”.

2. Insert extraction hook into “IN” clip

assembly and extract with a parallel

pulling motion.

3. Remove cone and rotor. DO NOT attempt

to remove bearing from rotor.

4. Remove “OUT” clip assembly with

extraction hook as directed in step 2. DO

NOT remove lock nut. Leave clip, cone,

shaft and nut assembled.

(Refer to diagram)

NOT REASSEMBLE”. Call factory for

instructions

1. Place meter on table vertically, “OUT” side

upward.

2. Insert “OUT” clip/cone/shaft/nut assembly

into housing as illustrated in endview

diagram, push down as far as it will go

(seating against step in housing)

Clip bundle diameter may need to be

clamped for easier insertion.

3. Flip meter around and insert bearing,

rotor, bearing , then cone.

Be sure the “IN” marking on the rotor

coincides with the “IN” marking on the

housing.

4. Insert “IN” clip assembly.

5. Screw on lock nut snug against “IN” clip

assembly. DO NOT OVER TIGHTEN.

NOTE: If any part appears damaged DO

NOT REASSEMBLE. Call factory for

instructions

1. Place meter on table vertically, “OUT” side

upward.

2. Insert “OUT” clip/cone/shaft/nut assembly

into housing as illustrated in endview

diagram, push down as far as it will go

(seating against step in housing)

Clip bundle diameter may need to be

clamped for easier insertion.

3. Flip meter around and insert rotor with

bearing , then cone.

Be sure the “IN” marking on the rotor

coincides with the “IN” marking on the

housing.

4. Insert “IN” clip assembly.

5. Screw on lock nut snug against “IN” clip

Page 10

FIGURE 3: MF20-90 LO-FLO SERIES FLOWMETER

G

F

D-1

C-1

K

B

C-2

D-2

E

H

I

J

A

AN FLARE SHOWN

INTERNAL ASSEMBLY IS

TYPICAL FOR NPT, TUBE FIT TING

HIGH PRESSURE, FNPT, & FLANGED

STANDARD LO-FLO SERIES

.

SLEEVED BEARING INTERNALS

1

1

1

1

1

1

1

1

PICKUP COIL

ORIFICE LOCK SCREW

ORIFICE

SHAFT

RETAINER

SCREW PLUG

HOUSING

J

I

H

E

B

A

QTY

DESCRIPTION

DESIGNATOR

ROTOR/BEARING ASSY.

D-2

C-2

K

O-RING****

1

**** CONSULT FACTORY FOR O-RING MATERIALS

AND INSTALLATION

1

O-RING****

K

C-1

D-1

ROTOR/SHAFT ASSY.

1

1

1

1

2

1

1

1

1

BALL BEARING INTERNALS

PICKUP COIL

ORIFICE LOCK SCREW

ORIFICE

BEARING CUP

BEARING

RETAINER

SCREW PLUG

HOUSING

J

I

H

G

F

B

A

QTY

DESCRIPTION

DESIGNATOR

This assembly r eferences al l Model Number s

with Graphitar (GS), Teflon (TS), Carbide (CS),

This assembly r eferences al l Model Number s

with Teflon Ball (TB), Metal Ball (MB) and

and Flu orosint (F S) sleeved bear ing designat ors

Cryo Bal l (CB) bear ing design ators.

DISASSEMBLY PROCEDURE

REASSEMBLY PROCEDURE

FOR BALL BEARING

FOR SLEEVED BEARING

FOR BALL BEARING

FOR SLEEVED BEARING

Pg.8

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove bearings and rotor/shaft

assembly.

4. Review all parts for damage.

A. Check bearings thoroughly.

B. Check o-ring for cracks/nicks.

Replace if evident.

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove rotor/bearing assembly.

4. Review all parts for damage.

A. Check bearing faces and bore

thoroughly.

B. Check o-ring for cracks/nicks

Replace if evident

NOTE: If any part appears damaged, DO

NOT REASSEMBLE, call factory for

instructions.

1. Insert bearing into bearing cup.

2. Insert rotor/shaft assembly and bearing.

3. Insert retainer (with o-ring) and remove

4-40 screw.

4. Screw in screw plug.

NOTE: If any part appears damaged, DO

NOT REASSEMBLE, call factory for

instructions.

1. Place rotor/bearing assembly on shaft.

2. Insert retainer (with o-ring) and remove

4-40 screw.

3. Screw in screw plug.

For liquid applications: Internals work best

when wet.

Page 11

FIGURE 4: MF100-175 LO-FLO SERIES FLOWMETER

SLEEVED BEARING INTERNALS

1

1

1

1

1

1

PICKUP COIL

RETAINER

SCREW PLUG

HOUSING

H

B

A

QTY

DESCRIPTION

DESIGNATOR

ROTOR/BEARING ASSY

.

C-2

O-RING****

A

AN FLARE SHOWN

D-1

C-1

B

C-2

E

D-1

SHAFT

1

G

F-2

H

D

F-1

F-2

G

**** CONSULT FACTORY FOR O-RING MATERIALS

AND INSTALLATION.

F-1

C-1

SHAFT

E

D

O-RING****

1

1

1

2

1

1

1

1

BALL BEARING INTERNALS

PICKUP COIL

BEARING

ROTOR

RETAINER

SCREW PLUG

HOUSING

H

G

B

A

QTY

DESCRIPTION

DESIGNATOR

This assembly referenc es all Model Numbers

and Fluorosint (FS) sleev ed bearing designator.

Cryo Ball (CB) bearing des ignator.

INTERNAL ASSEMBLY IS

TYPICAL FOR NPT, TUBE FITTING,

HIGH PRESSURE, FNPT & FLANGED

STD. LO-FLO SERIES.

DISASSEMBLY PROCEDURE

REASSEMBLY PROCEDURE

FOR BALL BEARING

FOR SLEEVED BEARING

FOR BALL BEARING

FOR SLEEVED BEARING

Replace if evident

Pg.9

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove bearings and rotor. It is not

necessary to remove shaft.

4. Review all parts for damage.

A. Check bearings thoroughly.

B. Check o-ring for cracks/nicks.

Replace if evident.

1. With a large screw driver, remove screw

plug.

2. Insert 4-40 screw into either of the tapped

holes on the face of the retainer and

extract from housing.

3. Remove rotor/bearing assembly. It is not

necessary to remove shaft.

4. Review all parts for damage.

NOTE: If any part appears damaged, DO

NOT REASSEMBLE, call factory for

instructions.

1. Insert bearings into rotor and insert in

housing on shaft.

3. Insert retainer (with o-ring) and remove

4-40 screw.

4. Screw in screw plug.

A. Check bearing faces and bore

thoroughly.

B. Check o-ring for cracks/nicks

NOTE: If any part appears damaged, DO

NOT REASSEMBLE, call factory for

instructions.

1. Place rotor/bearing assembly on shaft in

housing.

2. Insert retainer (with o-ring) and remove

4-40 screw.

3. Screw in screw plug.

For liquid applications: Internals work best

when wet.

Page 12

FIGURE 5: CORROSIVE SERIES FLOWMETER

CORROSIVE SERIES HOUSING

ASSEMBLY.

DIRECTION OF RE-

5

432

1

PICKUP COIL

NOTE: HAND TIGHTEN

DO NOT USE FORCE

FLOW

DISASSEMBLY FOR CORROSIVE METERS

REASSEMBLY FOR CORROSIVE METERS

for instructions.

ITEM

DESCRIPTION

QTY

4

SLEEVE 1 5

DOWNSTREAM HANGER

1

Pg.10

1 END NUT 1

2 UPSTREAM HANGER 1

3 ROTOR/PIVOT ASSEMBLY 1

1. Unscrew end nut from housing.

2. Retract upstream hanger from housing.

3. Remove rotor. NOTE: Pivot is pressed into rotor DO NOT ATTEMPT

TO REMOVE.

4. From opposite end of housing, push sleeve and downstream hanger

through upstream end of housing.

5. Review all parts for damage. Be sure the bearings in the end of the

hangers are still intact. Clean off all debris before reassembling.

NOTE: If any part appears damaged DO NOT REASSEMBLE, call factory

1. Assemble internals as illustrated.

2. From upstream end of housing, insert internals into housing.

It may be necessary to tilt the meter housing slightly for easier insertion

of the internals.

3. Screw in end nut and tighten.

NOTE: For proper operation, internals must be housed.

For liquid applications: internals work best when wet.

Page 13

DISASSEMBLY FOR 3A SANITARY METERS

REASSEMBLY FOR 3A SANITARY METERS

ITEM

DESCRIPTION

QTY

1

HOUSING

1 2 ROTOR

1 3 CONE 2 4

HANGER

2 5 O-RING

1 6 SHAFT (Carbide or Teflon)

1

Pg.11

FIGURE 6: 3A SANITARY TURBINE FLOWMETER

1. Remove O-ring.

2. Push entire assembly out through the O-ring side of the meter.

3. Review all parts for damage

NOTE: If any part appears damaged, DO NOT REASSEMBLE. Call the factory for instructions.

• Check bearings thoroughly

• Check O-rings for cracks and nicks

NOTE: Internals must go back together the exact way that they come out.

1. Assemble the internal assembly as illustrated.

2. Push the assembly into the housing on the O-ring side.

3. Butt clip hanger up against the step inside the housing

4. Reinstall the O-ring.

5. Make sure the rotor spins freely and the clip hangers do not turn at all.

Page 14

Page 15

Page 16

© 2009

Pub. No. MN-PTF-IOMr1

(6/2010)

Loading...

Loading...