Page 1

Installation & Parts Manual

MA-4 Positive Displacement Meter for

LPG Motor Fuel Dispensers

(Single & Dual Meter Versions)

Installation: M100-11

www.lcmeter.com

Page 2

Table of Contents

Description Page Number

Safety Precautions ..............................................2

How LC Meters Work ..........................................3

Owner’s Information Packet ................................4

Installation Requirements....................................4-5

Installation ...........................................................6-9

Mounting Dimensions - Single Meter......6

Mounting Dimensions - Dual Meter ........7

Operation Requirements ........................8

Meter Installation ....................................8

Meter Start Up & Operation ....................9

Meter Maintenance .............................................10-11

Pulse Output Device 5 (POD5) ...........................12-14

Vapor Eliminator/Strainer Maintenance ...............15-16

Differential Valve Maintenance ............................17

Please have the following information available when you

make inquiries, order replacement parts, or schedule

service. If a specific meter accessory is involved, please

provide the model and serial number of the meter in

question (See Page 4).

Meter Serial Number____________________________

Full Service Distributor___________________________

Full Service Distributor Phone Number______________

Disassembling the Meter.....................................18-19

Removing the Non-Corroded Rotor Gears..........20

Removing Bearing Plates and Rotors .................20

Removing Corroded Rotor Gears........................21

Reassembling the Meter .....................................22-23

Timing the Rotor Gears .......................................24

Torque Chart .......................................................25

Wrench and Socket Size Chart ...........................25

Troubleshooting ................................................... 26

How to Order Replacement Parts .......................27

Meter Assembly Exploded View ..........................28

Strainer Assembly Exploded View.......................29

Differential Valve Exploded View.........................30

Optional Back Check Valve Assembly.................31

Publication Updates & Translations

The most current English versions of all Liquid Controls

publications are available on our website,

www.lcmeter.com. It is the responsibility of the Local

Distributor to provide the most current version of LC

Manuals, Instructions, and Specification Sheets in the

required language of the country, or the language of the

end user to which the products are shipping . If there

are questions about the language of any LC Manuals,

Instructions, or Specification Sheets, please cont act your

Local Distributor.

!!

WARNING WARNING

!

WARNING

!!

WARNING WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and

maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury,

or death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

Safety Procedures

!!

! WARNING

!!

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator ,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

Be Prepared

Make sure that all necessary safety precautions have

been taken. Provide for proper ventilation, temperature

control, fire prevention, evacuation and fire management.

Provide easy access to the appropriate fire extinguishers

for your product. Consult with your local fire department

and state and local codes to make sure that you are

adequately prepared.

Read this manual as well as all the literature provided in

your owner’s packet.

In the Event of a Gas Leak

In the event of a large gas leak: Evacuate the area

and notify the fire department.

In the event of a small, contained gas leak:

1. Stop the leak and prevent accidental ignition.

2. Prevent the entrance of gas into other portions of

the buildings. Some gases, such as LPG , seek lower

levels, while other gases seek higher levels.

3. Evacuate all people from the danger zone.

2

Page 3

How LC Meters Work

4. See that the gas is dispersed before resuming

business and operating motors. If in doubt, notify

your local fire department.

In the Event of a Gas Fire

In the event of large fires or fires that are spreading:

Evacuate the building and notify your local fire

Liquid Controls meters are positive displacement meters.

They are designed for liquid measurement in both

custody transfer and process control applications. They

can be installed in pump or gravity flow systems. Because

of their simple design, they are easy to maintain, and

easy to adapt to a variety of systems.

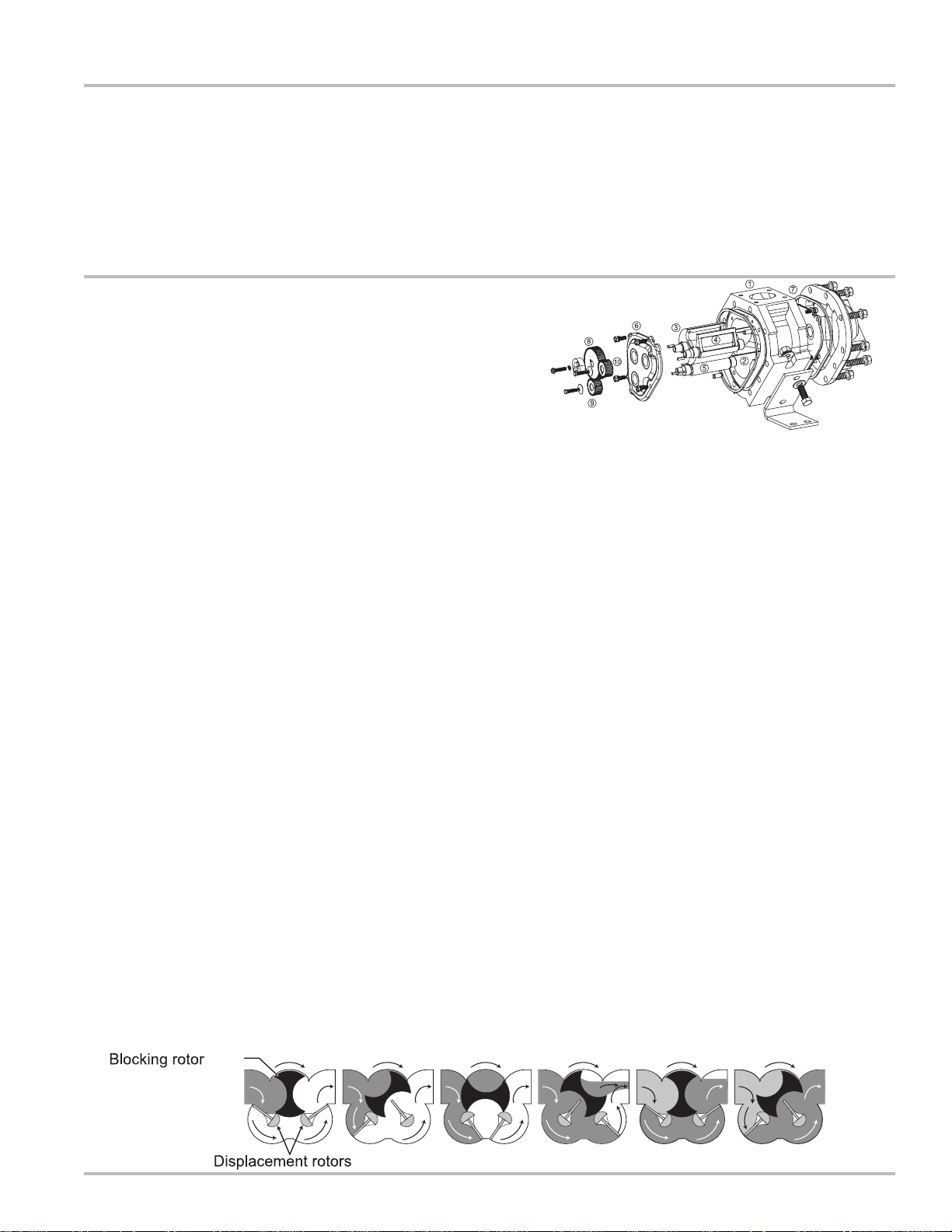

The meter housing (1) is designed with three cylindrical

bores (2). Three rotors, the blocking rotor (3) and two

displacement rotors (4, 5), turn in synchronized

relationship within the bores. The three rotors are

supported by bearing plates (6, 7). The ends of the

rotors protrude through the bearing plates. Blocking rotor

gear (8) is placed on the end of the blocking rotor.

Displacement rotor gears (9, 10) are placed on the ends

of the displacement rotors. These gears create the

synchronized timed relationship between the three rotors.

As fluid moves through the meter housing, the rotor

assembly turns. The liquid is broken into uniform sections

by the turning rotors. Fluid displacement happens

simultaneously. As fluid enters, another portion of the

fluid is being partitioned and measured. At the same

time, the fluid ahead of it is being displaced out of the

meter and into the discharge line. Since the volume of

the bores is known, and the same amount of fluid passes

through the meter during each revolution of the blocking

rotor, the exact volume of liquid that has p assed through

the meter can be accurately determined.

This true rotary motion is transmitted through the packing

gland, the face gear, the adjuster drive shaft, and the

adjuster to the register stack and counter. True rotary

motion output means consistent accuracy since the

register indication is in precise agreement with the actual

volume throughput at any given instant.

At any position in the cycle, the meter body , the blocking

rotor, and at least one of the displacement rotors form a

continuous capillary seal between the un-metered

department. Stop the leakage only if you can safely reach

the equipment.

In the event of small, contained fires that you can

safely control: Stop the leakage if you can safely reach

the equipment. Then use the appropriate extinguisher:

Class B fire extinguisher, water, fog, etc., depending on

the materials. If in doubt, call your local fire department.

Meter Element Exploded View

upstream product and the metered downstream product.

Capillary seals mean no metal-to-metal contact within

the metering element. This means no wear. No wear

means no increase in slippage, and no increase in

slippage means no deterioration in accuracy.

Throughout the metering element, the mating surfaces

are either flat surfaces or cylindrical faces and sections

that are accurately machined. These relatively simple

machining operations, plus the fact that there is no

oscillating or reciprocating motion within the device,

permits extremely close and consistent tolerances within

the LC meter.

The product flowing through the meter exerts a dynamic

force that is at right angles to the faces of the

displacement rotors. The meter is designed so that the

rotor shafts are always in a horizontal plane. These two

facts result in no axial thrust. Therefore, with no need

for thrust washers or thrust bearings, the rotors

automatically seek the center of the stream between the

two bearing plates eliminating wear between the ends

of the rotors and the bearing plates. Once again, no

wear results in no metal fatigue and no friction.

The Liquid Controls meters are made of a variety of

materials to suit a variety of products. Because of our

no-wear design, capillary seals, and unique rotary

metering, LC meters provide unequalled accuracy, long

operating life, and unusual dependability.

3

Page 4

Owner’s Information Packet

Is all your documentation included with your meter? LC

meters come in many variations. The information sent to

you depends on the accessories you have ordered with

your meter. Make an inventory of your Owner’s

Information Packet. First, find your LC packing slip with

the computer printout. Locate the serial number and the

meter model number on this printout. Cross-reference

the packing slip with the actual meter serial numbers.

Included in your Owner’s Information Packet are the

following:

• Installation and Parts Manual

• Bill of Materials

• SCAMP™ Installation and Operation Manual

Record your meter serial number in the space provided

on the inside cover of this manual. The inside cover also

provides a space for your full-service distributor’s name

and telephone number, if applicable. Fill in this

information and keep it handy. Y ou will always need your

meter serial number and model number when calling for

service or parts. See “How to Order Replacement Parts”

on Page 27 in this manual.

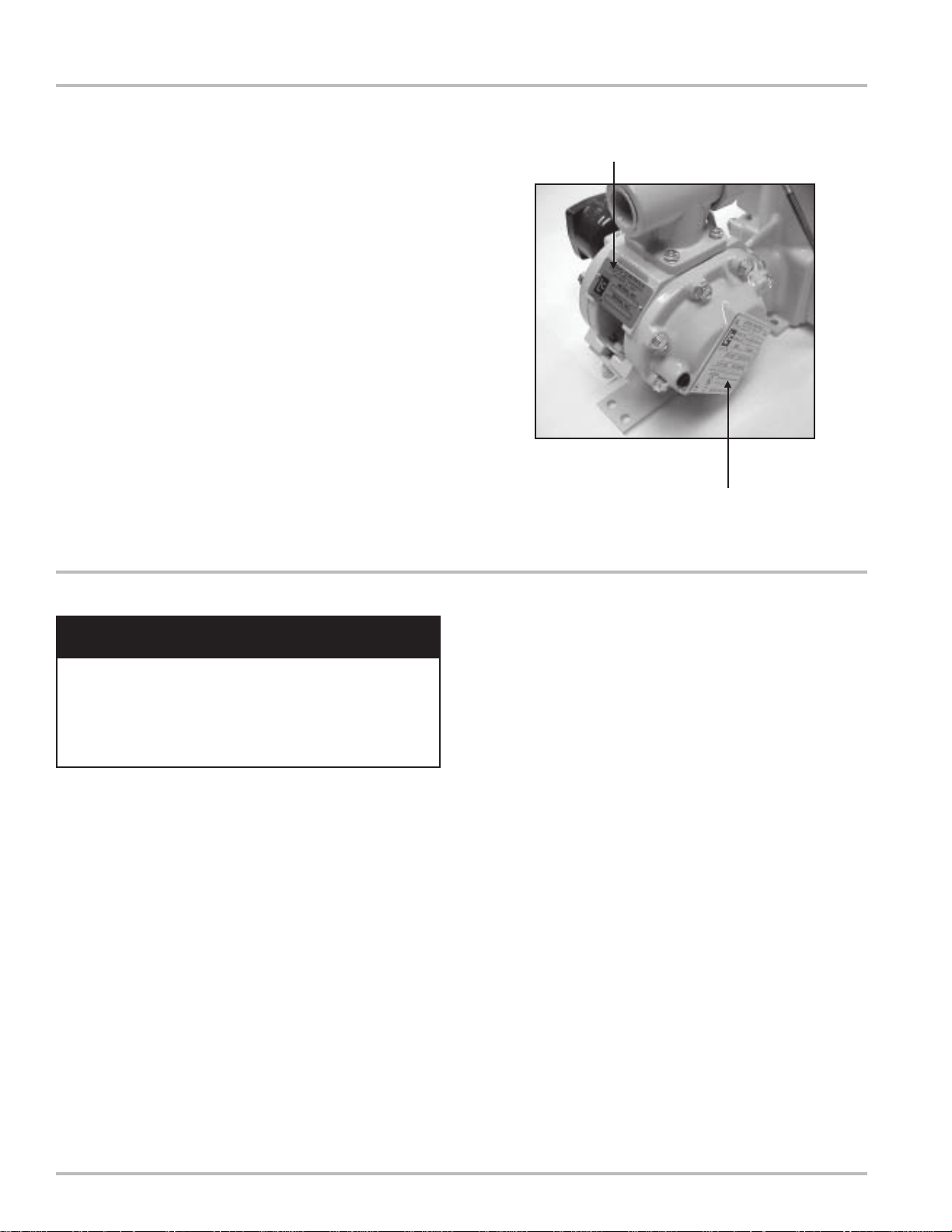

Serial Number Plate (Side)

Serial Number Plate (Rear)

Installation Requirements

!!

! WARNING

!!

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator ,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

• Make sure that all necessary safety precautions

have been taken. Provide for proper ventilation,

temperature control, fire prevention, evacuation,

and fire management.

• Provide easy access to the appropriate fire

extinguishers for your product. Consult with your

local fire department and state and local codes to

make sure that you are adequately prepared.

• Read this manual as well as the literature provided

in your Owner’s Information Packet. If you have any

questions, consult with your full-service distributor

or call the Service Department at Liquid Controls.

• Install the meter and accessories in conformance with

all applicable federal, state, local, construction,

electrical, and safety codes.

• Class 10 meters for LPG must be installed in

accordance with the requirements of ANSI-NFPA 58

in addition to all other state and local codes.

• Under normal operation, do not expose any portion

of the LP-Gas system to pressures in excess of rated

working pressures without an automatic safety valve

to vent the over pressure discharge to a place of

safety away from the operator and other people.

Failure to provide such a safety relief may result in

leakage or rupture of one or more of the components

in the system. This can result in injury or death from

the gas, a fire, or pieces of flying debris from the

rupture.

• Before shipment, protective thread caps were placed

in all meter and accessory openings. They should

remain in place until you are ready to attach piping.

• Prior to meter installation, the entire piping system

should be thoroughly flushed of all debris, with a liquid

that is compatible with the construction of the meter .

• Keep all external surfaces of the meter clean.

• Apply pipe compound to male threads only.

4

Page 5

Installation & Operation Requirements

!!

! WARNING

!!

When a Back Check V alve is used, an automatic safety

valve must be installed to prevent pressure build-up in

excess of rated working pressure in the meter housing.

One automatic safety valve should be installed in each

meter. Remove the pipe plug from the front cover or

rear cover and insert the appropriate automatic safety

valve.

• The meter must always be securely bolted to a

platform or supporting member, regardless of the

mounting position of the meter. Never “hang” a meter

on the connecting pipe.

Operation Requirements

The meter must remain full of product at all times. An

easy way to accomplish this is to put the meter assembly

in the line below the piping center-line (a sump position).

This requires adding elbows and flanges prior to installing

the meter. The meter should be installed in a bypass loop,

below the pipe center-line, with block valves upstream

and downstream. A block valve should be located in the

mainstream, labeled as the bypass valve. A word of

caution: any portion of pipe system that might isolate or

block flow should be provided with a pressure relief to

prevent damage from thermal expansion. There are

excellent benefits to this type of installation. First, the

meter is kept full. Second, this type of installation allows

the meter to be isolated for servicing and calibration while

continuing flow through the bypass valve.

Upstream lines must be maintained full to prevent air

from entering the meter. If the up stream or inlet lines are

constructed in a manner which allows reverse flow, foot

valves or back checks must be installed.

Position the meter with service in mind. Make sure there

is ample work space. Removing the meter covers can

be difficult when ample work space is not available.

Always supply a platform or support for the meter

mounting.

Every meter should be calibrated under actual service

and installation conditions per the API Manual of

Petroleum Measurement Standards:

Chapter 4 - Proving Systems

Chapter 5 - Metering

Chapter 6 - Metering Assemblies

Chapter 11 Section 2.3 - Water Calibration of

Volumetric Provers

Chapter 12 Section 2 - Calculation of Petroleum

Quantities

• Position the meter with service in mind. Provide

ample work space. Removing covers can be difficult

when work space is not available. Always supply a

platform or support for the meter mounting.

• A meter is metallurgically designed to be physically

compatible with a given type of liquid, as originally

specified by the customer, and as indicated on the

Serial Number Plate. A meter should not be used

with a liquid different from the liquid originally

specified, unless the physical characteristics and pH

rating are similar and the application has been

checked with Liquid Controls Sales or Engineering.

These chapters of the API Manual of Petroleum

Measurement Standards supersede the API Standard

1101.

Provide a means of conveniently diverting liquid for

calibration purposes.

Give careful attention to your system’s pumping

equipment and piping because of their influence on liquid

being measured as it enters the meter assembly. Systems

should be made free of conditions that cause or introduce

entrained air or vapor.

Follow the manufacturer’s recommendations fully when

installing pumps. Give particular attention to factors like:

use of foot valves, pipe size to the inlet and conformance

to net positive suction head (NPSH) conditions when

suction pumping is required. Following the manufacturer’s

recommendations will minimize air and vapor elimination

problems.

For liquids such as light hydrocarbons that tend to flash

or vaporize easily at higher ambient temperatures, it is

desirable to use flooded suctions and piping sized larger

than the normal pump size.

Hydraulic shock is harmful to all components of an

operating system including valves, the meter and the

pump. In particular, meters must be afforded protection

from shock because of their need to measure with high

precision. Generally the best protection is prevention,

which can be readily accomplished by adjusting valve

closing rates in such a manner that shock does not occur.

Thermal expansion like hydraulic shock is a phenomenon

that can easily damage meters and systems in general.

Care should be taken in designing the system to include

pressure relief valves in any portion or branch of the

system that might be closed off by closure of operating

valves or block valves.

5

Page 6

Installation

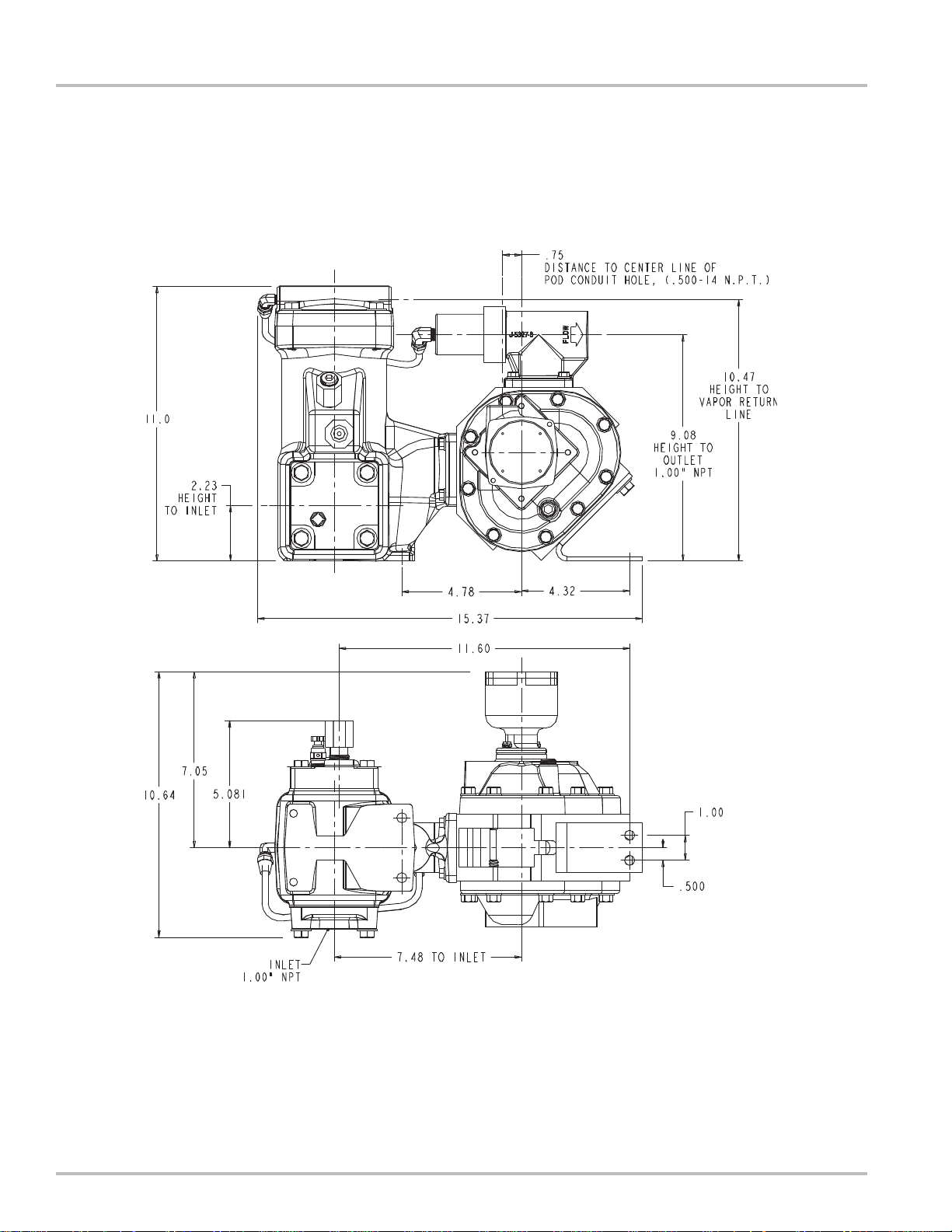

Mounting Dimensions - Single Meter

NOTE: Always request up-to-date engineering approved dimensional drawings before starting any construction. Do

not rely on catalog pictures or drawings, which are for reference only. After receiving the prints, check to see that all

equipment ordered is shown and that any extra pressure taps, plugs, etc. are noted and their size specified.

6

Page 7

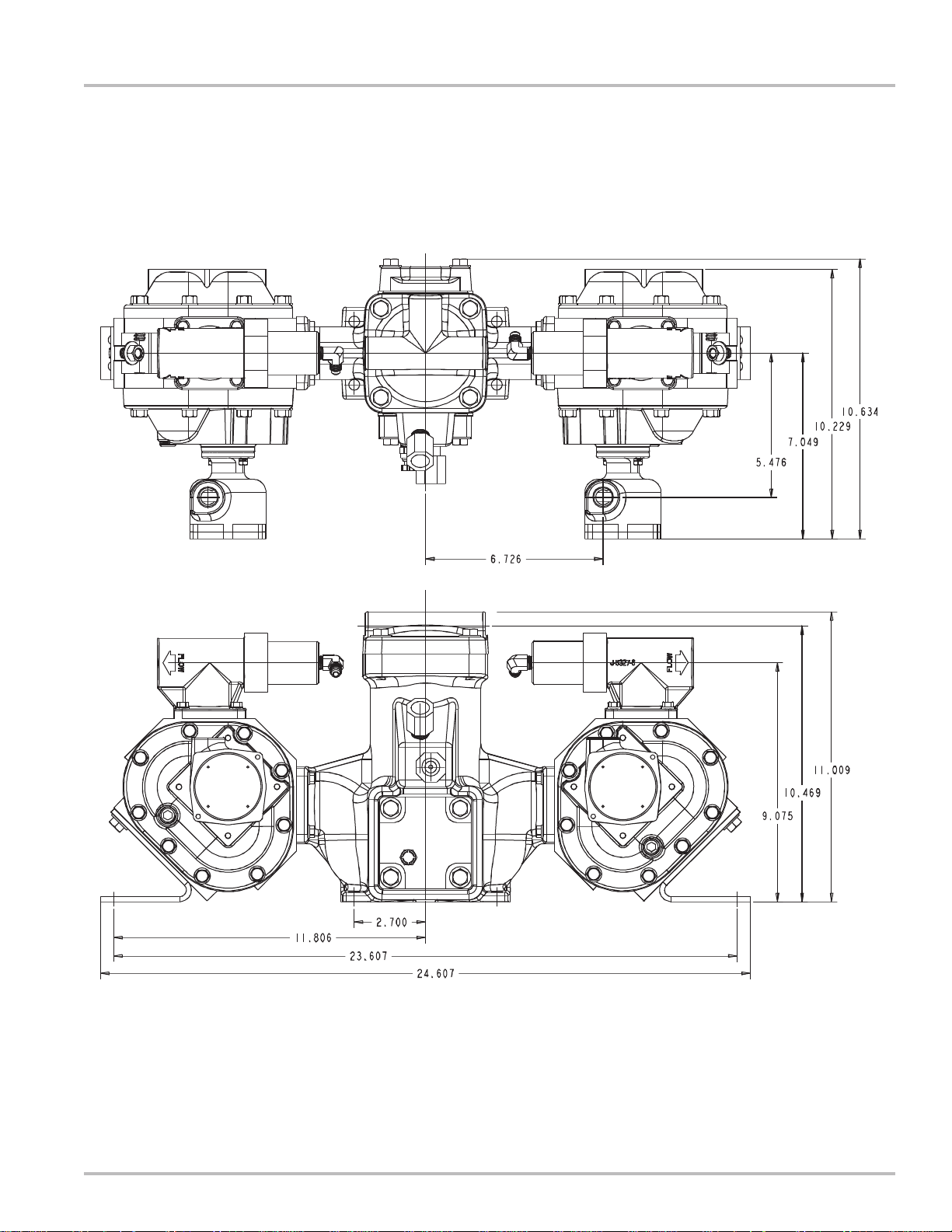

Mounting Dimensions - Dual Meter

Installation

NOTE: Always request up-to-date engineering approved dimensional drawings before starting any construction. Do

not rely on catalog pictures or drawings, which are for reference only. After receiving the prints, check to see that all

equipment ordered is shown and that any extra pressure taps, plugs, etc. are noted and their size specified.

7

Page 8

Installation

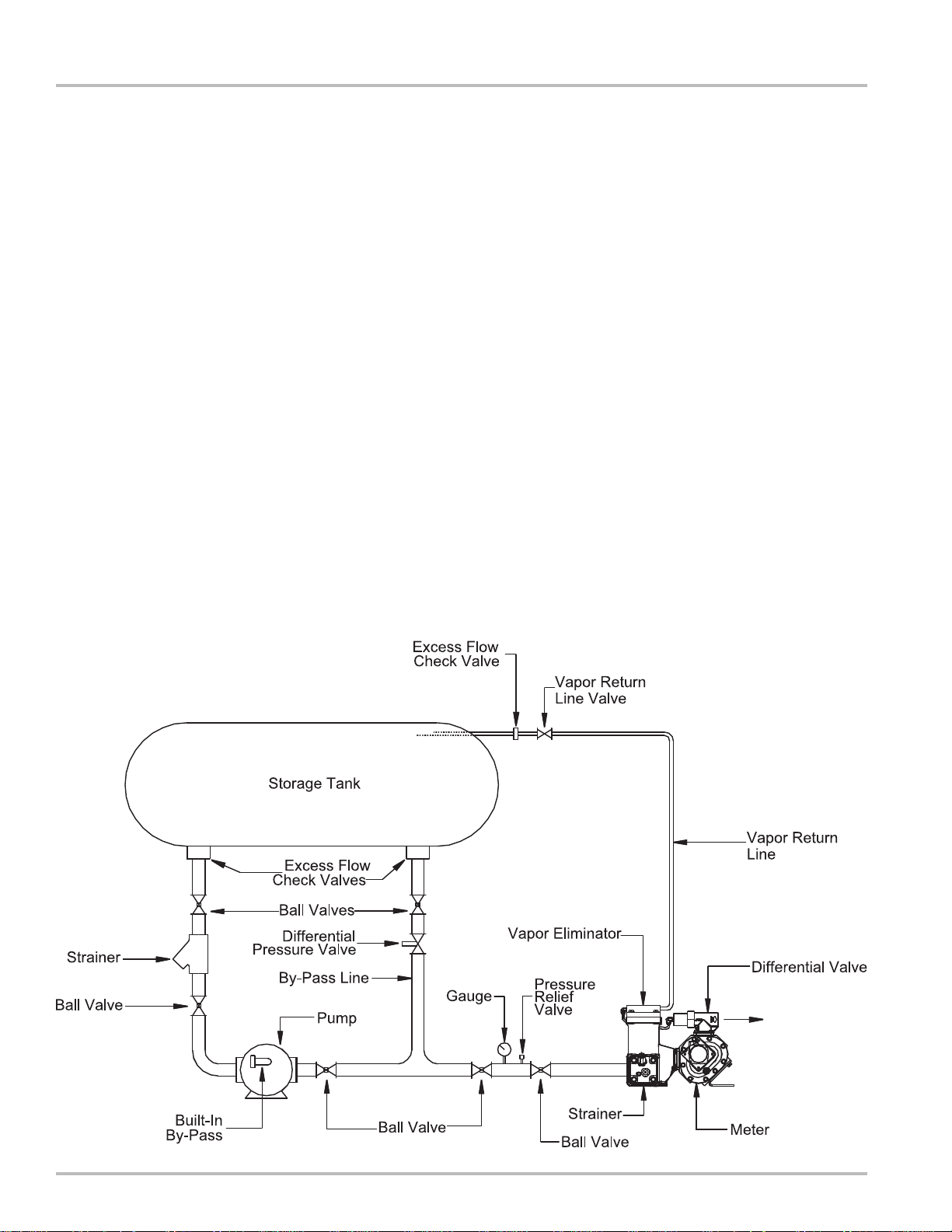

Theory of Operation

The Liquid Controls MA-4 LPG Meter combines a positive

displacement meter, dif ferential valve, strainer, and vapor

eliminator in one assembly.

The Liquid Controls vapor eliminator employs a sleevetype valve that permits a “leak” flow of approximately 0.2

GPM from the vapor vent back to the supply tank. A 200mesh strainer is incorporated in the vapor eliminator

casting and is easily accessible by removing the strainer

cover.

The Liquid Controls differential valve incorporates a

piston-diaphragm type construction, with the piston

moving away from its seat when at least 15 psi pressure

(above product vapor pressure) is maintained at the meter

outlet. The soft seat valve assures measurement

accuracy by requiring 1) pump operation for delivery, 2)

adequate back pressure to prevent product vaporization

during measurement, and 3) blockage of flow when the

vapor eliminator release valve opens.

Meter Installation

Meter:

Install the meter assembly in dispenser cabinet to a

secure base, using the supplied bracket on the meter

housing and the “feet” located on the strainer assembly

base. Make inlet and outlet connections at the flanged

surfaces on the strainer and differential valve,

respectively.

Vent Line:

The vent line from the meter’s vapor vent to the vapor

space on the supply tank should be 1/4 inch minimum

inside diameter tube or pipe. A shut off valve must be

installed in the vapor vent line to allow removal of the

strainer or to service the meter. The vapor release vent

line must be returned to the vapor space of the supply

tank and normally should not be made common with the

other vapor return lines or pump bypass lines. When

properly installed, this line must permit free flow in either

direction. If the valve in the vent line is closed the

meter will not function. These instructions must be

followed to maintain proper function of the differential

valve.

8

Page 9

Meter Start-up and Operation

Prior to meter start up, use extreme caution. Make sure

that:

1. The meter is properly secured

2. All connections are tight

3. All valves are in the closed position

Placing your meter in operation:

Check to determine that all fittings and flanges are tight

and liquid lines are closed.

Open the vapor line to the meter. Using vapor pressure

only, check each joint with a liquid soap solution to see

that no leaks go undetected. When all joints have been

checked, admit liquid SLOWLY to avoid operation on

vapor at speeds greater than the minimum indicated on

the serial number plate and to insure that cover cavities

do not contain vapor which can be compressed. Proper

slow filling can be done by throttling the system with a

valve at the meter OUTLET or by allowing the system to

fill by gravity.

With the valve(s) open between the tank and the meter,

go to the valve located down stream of the meter. Open

the down stream valve slowly until the meter’s register/

counter starts to move. Do not run the meter any faster

than 25% of its maximum rated flow during start-up. Once

the product is flowing out the end of your system, the

outlet valve can be opened all the way provided that the

system is designed not to exceed the flow rate marked

on the meter.

Installation

Never operate the meter or system when partially filled

with liquid, or with pockets of compressed air or vapor

present. If these conditions cannot be avoided, air and

vapor elimination systems may be required. If you cannot

fill the meter slowly by gravity or by using a valve to throttle

back the flow, consult the factory.

Do not operate the meter at a pressure exceeding that

marked on the Serial Number Plate. Under any and all

pressure producing circumstances, for instance, thermal

expansion and hydraulic shock, the working pressure

must not exceed the indicated maximum.

If the meter is operated at a rate greater than the

maximum recommended GPM, excessive wear and

premature failure may occur.

The meter can be calibrated for flows below minimum

ratings if the flow remains constant and varies within

narrow limits or if the product is viscous. A meter should

never be run beyond the maximum flow rate determined

for that class meter and/or liquid measured.

NOTE: If the valves are not manual, consult the valve

manufacturer for slow flow start-up.

Filling the system with a pump:

Consult the pump manufacturer for proper pump priming.

Once the pump is primed with product, proceed.

CAUTION!

Make sure that your pump can operate against a dead

head pressure. If NOT, consult the factory for

assistance.

9

Page 10

Meter Maintenance

!!

! WARNING

!!

Relieving Internal Pressure

All internal pressure must be relieved to zero pressure

before disassembly or inspection of the strainer, air eliminator any valves in the system,

the packing gland, and the front or rear covers.

Serious injury or death from fire or explosion could result from maintenance of an

WARNING

improperly depressurized and evacuated system.

Procedure for Non-LPG Meters

1. Turn off pump pressure to the system.

2. Close valves before and after the meter.

3. Remove pressure by removing the drain plugs and

draining the meter.

Procedure for LPG Meters

1. Close the belly valve of the supply tank.

2. Close the valve on the vapor return line.

3. Close the manual valve in the supply line on the inlet

side of the meter. If no manual valve exists on the

inlet side, consult the truck manufacturer for

procedures to depressurize the system.

Prevent pipe strain or stress from occurring when making

meter or accessory repairs. Pipe strain and stress occur

when the pipes are not supported or are not aligned

correctly to the meter. The weight of the pipes must

always be supported independent of the meter. This

means that the meter and accessories can easily be

removed without affecting the pipes or the pipe alignment.

Never leave any of the pipes hanging.

Seasonal meter storage. If the meter is used for seasonal

work, at the end of each season the meter should be

removed from the system and thoroughly flushed with a

compatible liquid. This includes removing the drain on

the front and rear covers. Then flush the product from

the front and rear covers. If flushing with water is

preferred, extra care should be taken to drain the meter

completely and to dry all internal parts. Immediate refilling

with a compatible liquid (or oil misting) is essential to

prevent corrosion as well as ice damage to parts from

moisture that was overlooked after flushing and drying.

Do not mar or scratch any of the precision machined

surfaces by prying or sanding parts.

4. Slowly open the valve/nozzle at the end of the supply

line.

5. After product has bled off, close the valve/nozzle at

the end of the supply line.

6. Slowly crack the fitting on top of the differential valve

to relieve product pressure in the system. Product

will drain from the meter system.

7. As product is bleeding from the differential valve,

slowly reopen and close the valve/nozzle on the

discharge line. Repeat this step until the product

stops draining from the differential valve and

discharge line valve/nozzle.

8. Leave the discharge line valve/nozzle open while

working on the system.

Torque specifications. All fasteners such as screws and

bolts should be torqued to proper specification. See the

“Torque Chart” on Page 25 of this manual.

Stone the machined surfaces when reassembling the

meter to assure that the machined surfaces are free of

burrs and mars.

Repair pulled threads with threaded insert fasteners.

These can be used in many instances. Contact your

full-service distributor for advice if this occurs.

Coating threads. When removing and replacing bolts

and castings in a meter, always coat the threads with

anti-seize.

Removing flange seals. When removing the flange

assembly , always carefully remove the O-ring seal. Make

sure that the flange surface is clean. Discard and replace

the old O-Ring seal if it is nicked or scratched in any

way. If it is undamaged, it can be reused.

10

Page 11

Meter Maintenance

Examine all fasteners. Make sure fasteners are not bent,

rusted, or have pulled threads. The threads should all

appear evenly placed. If the bolts are bent, check the

housing and cover for flatness. Use a straight edge to

determine flatness.

Look for gaps. When disassembling a meter, use a feeler

gauge to check for gaps between the bearing plate and

housing. If you do find gaps, check the bearing plates for

flatness with a straight edge. Gaps can be caused by

shock problems that must be resolved. Contact your fullservice distributor or the Service Department at Liquid

Controls for assistance if this occurs.

Check the O-Rings. O-Rings should be smooth. Cracked

or worn O-Rings should be replaced. However, a more

serious problem of shock may have occurred if the ORings look nibbled. Shock problems must be verified and

resolved. Contact your full-service distributor or the

Service Department at Liquid Controls for assistance if

this occurs.

Check the bearing plates. Check the bearing plates for

flatness. Use a straight edge. Warped bearing plates can

be caused by shock problems that must be resolved.

Contact your full-service distributor or the Service

Department at Liquid Controls for assistance if this

occurs.

Weights & Measures. Check with the regulatory agency

that governs Weights & Measures in your area. Removing

a seal wire may require Weights & Measures

recalibration.

11

Page 12

Pulse Output Device (POD5)

The Liquid Controls Pulse Output Device (POD) converts

the rotary motion of the Positive Displacement Meter into

electronic pulses making it possible to interface the meter

to electronic monitoring and control equipment. The

POD5 was specifically designed to interface with the MA4 meter and the SCAMP A™ electronics.

The POD5 mounts directly to the front cover of the MA-4

meter. The motion of the meter’s blocking rotor is

magnetically coupled through a stainless steel wall into

the electronics compartment of the POD5. This

eliminates any dynamic seal and isolates the electronics

from the process fluid in the meter.

Inside the POD5 electronics compartment an optical shaft

encoder converts the rotary motion into a high resolution,

two-channel quadrature square wave. Both outputs

switch from 5 volts in the “ON” state to zero volts in the

“OFF” state.

The POD5 electronics compartment also serves as a

conduit junction box. The POD5 has an O-Ring sealed,

threaded cover. The standard wire entrance is a 1/2-14

NPT female hub, which accepts threaded conduit or a

cable gland. A plug-in connector on the encoder

facilitates wiring of the unit. With the wiring entrance

sealed and the cover in place, the housing is

ENCLOSURE TYPE NEMA 4X weatherproof rated. In

addition, the housing is CENELEC rated flameproof, and

UL and Canadian-UL explosion-proof rated when properly

installed with approved conduit.

!!

! WARNING

!!

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator ,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

INSTALLATION:

The POD5 comes factory installed on the meter ready

for wiring with the conduit orientation in the up position.

The hub can be oriented in one of four possible directions;

facing up, down, left, or right. If a different orientation is

required remove the two mounting screws and pull the

POD5 from the front cover. Remove the POD5 O-ring

from the cover.

• After determining the orientation of the conduit

hub, determine which two of the four mounting screw

holes will be used to fasten the POD5 to the front of the

meter cover. It is suggested that the mounting screws

be driven into these holes first to “pre-tap” the threads in

the meter cover. This will make it easier to thread the

screws when the POD5 is in place.

• Position the O-ring on the bottom of the POD5.

• Align the fork driver to the drive mechanism

inside the meter and guide the POD5 into the opening in

the meter cover. When the driver is properly aligned the

POD5 will go in until its mounting flange abuts the meter

cover.

• Rotate the POD5 to the desired orientation and

thread in the mounting screws finger tight. Using a 5/16"

box end wrench, tighten the screws to the appropriate

torque as specified in the “Torque Chart” in this manual.

WIRING:

Wiring into the POD5 must enter through its conduit hub.

For explosion-proof rated installations (Class I, Div. 1)

the wiring must be enclosed in rigid conduit that is rated

for explosion-proof installation. The conduit must be

engaged five (5) full threads into the female hub on the

POD5 to meet explosion-proof standards. When a

Division 2 installation is called for, either rigid conduit,

flexible conduit such as LiquidTight, or no conduit can

be used. When no conduit is used, the instrument cable

must be brought into the conduit hub using a cable gland

to seal the wiring entrance to maintain the ENCLOSURE

TYPE 4X rating. Regardless of the type of conduit/cable

gland used, thread sealant should be applied to prevent

moisture from getting into the POD5 electrical housing.

Removing the cover of the POD5 will expose the plug-in

connector and ground screw.

12

Page 13

Service Information

Due to the simplicity of the POD5, there are few things

that can go wrong with the device. However, as with all

electronic devices, failures can occur making it necessary

to replace failed part(s). There are only three functional

spare parts for the POD5; the hub/magnet assemblyNorth Poles, hub/magnet assembly-South Poles, and the

encoder assembly. The South Pole hub/magnet

assembly operates inside the flowmeter and, therefore,

is exposed to and is wetted by the process fluid. Due to

its materials of construction, this assembly is unlikely to

fail. In the event that it does fail, the POD5 has to be

removed from the meter front cover to access the driver/

lower magnet assembly.

Remove the POD5 from the meter by removing the two

hex head mounting screws and pulling out the POD5.

Remove the two allen head set screws using a 1/16 hex

driver and pull on the driver tang to extract the driver/

lower magnet assembly. Disassemble the hub/magnet

assembly from the drive shaft and attach the new hub/

magnet assembly in its place. Reassemble the unit.

Pulse Output Device (POD5)

It is more likely that if a failure of the POD5 occurs, it can

be repaired by replacing the encoder assembly. Simply

turn off the power to the unit, open the cover , disconnect

the electrical connector, loosen the mounting screws and

pull the encoder assembly out. Remove the hub/magnet

assembly from the old encoder shaft. Reassemble the

new encoder assembly.

Caution: It is important to use the correct hub/magnet

assemblies to maintain the magnetic couple. Use of two

North Pole or two South Pole assemblies will not allow

the driver to function properly.

Encoder Schematic

13

Page 14

Pulse Output Device (POD5)

Specifications

SPECIFICATIONS:

Voltage Supply: ..................................... (V+): 5VDC

Current Supply: ..................................... 26 mA Typical

Output Signal Resolution: ..................... 100 pulses per encoder revolution per channel, upscaled.

Square Wave: ....................................... Dual quadrature channel output.

Pulse Timing: ........................................ Nominal 50% on, 50% off.

Rise/Fall Time of Pulse: ........................ 5 microseconds maximum.

Output: .................................................. Capable of driving one TTL input (0 to 5 volts)

Operating Temperature: ........................ -40ºF to +185ºF (-40ºC to +85ºC)

Humidity Range: ................................... 0-100% non-condensing

Shock: ................................................... 50 G’s for 10 milliseconds

Vibration:............................................... 1 G at 10-150Hz

Electromagnetic Compatibility: .............. (EMI, RFI, etc.) to CE standards

Pulse Transmission Distance:............... Up to 100 feet

14

Page 15

Vapor Eliminator & Strainer Maintenance

Servicing of the vapor eliminator and strainer involves

occasional cleaning of the strainer, or, when required,

replacing a float or sticking valve.

!!

! WARNING

!!

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator ,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

Disassembling and Assembling

1. Disconnect the tubing between the differential valve

and vapor eliminator cover. For the dual meter

system, this may require removal of two segments

of tubing.

2. Remove the four screws on the Vapor Eliminator

cover. Lift the cover to inspect the internal float

assembly . Be careful not to damage the O-Ring seal.

3. If the float is crushed or damaged, remove cotter pin

and replace float.

4. Carefully inspect the sleeve valve for any resistance

to smooth movement of the sleeve on the stem.

Inspect all holes in the sleeve and the stem for foreign

material, which could cause sticking of the valve

and obstruct the flow through the valve. With the float

removed, the sleeve must move on the stem by its

own weight. If defective, replace sleeve and stem

assembly. Note: The vent hole is larger than the

cotter pin hole used to attach the sleeve to the float.

If replacing the sleeve, ensure that the sleeve is in

the correct orientation with the larger hole on top.

15

Page 16

Vapor Eliminator & Strainer Maintenance

5. Inspect the vapor eliminator cover O-Ring and ORing groove. The groove in which the O-Ring is

located must be free of dirt. The flat face against

which the O-Ring seats must be clean and free of

nicks and dents that may allow product to leak past

the O-Ring seal. Replace the O-Ring seal, if

necessary.

6. Remove the four screws on the strainer cover.

Remove the cover and pull the strainer out straight

and level being careful not to drop trapped debris

into the strainer housing.

7. Clean out strainer with compressed air, inspect for

any breaks or other defects, and replace if necessary .

8. Reinstall strainer.

9. Inspect the strainer cover rubber seal and seal

groove. The groove in which the rubber seal seats

must be clean and free of dirt. The flat face against

which the seal seats must be clean and free of nicks

and dents that may allow the product to leak past

the seal.

16

Page 17

Faulty operation of the differential valve may be caused

by defective valve seals, the spring, or the diaphragm.

The diaphragm and the O-Ring valve seat are the only

parts that should require replacement in normal service.

It is not necessary to remove the valve from the line for

disassembly.

Disassembling the Valve

1. Remove connecting tube between differential valve

and vapor eliminator cover. See illustration on Page

15.

2. Unscrew the union nut and remove the spring case,

limit stop, and spring from the body.

Differential Valve Maintenance

3. Remove the diaphragm and piston assembly.

4. The diaphragm can be inspected by unscrewing the

nut and removing the diaphragm head.

5. Inspect the diaphragm for cuts, tears, or pinhole

leaks. Replace if defective. Caution: Do not over

tighten diaphragm retaining nut. Torque

diaphragm retaining nut to 18-20 inch-lbs.

6. Check the O-Ring and replace if necessary.

7. Reinstall piston assembly into body, insert spring,

limit stop, spring case and union nut.

8. Reassemble connecting tube.

17

Page 18

Disassembling the Meter

Tools:

Rotor Gear Wrench or Socket

Bearing Plate Wrench or Socket

Counter Bracket Wrench or Socket

Drain Plug Allen Wrench

Cover Socket or Open End/Box End

NOTE: See Page 25 for the T orque Chart and the Wrench

and Socket Size Chart.

!!

! WARNING

!!

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator ,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

1. Use the cover socket or open end/box end wrench

to remove the bolts holding the front cover to the

outer body . Remove the bolts holding the rear cover .

Spare Displacement Rotor Gear (if unavailable, use a

shop rag between gear teeth)

Plastic or Rubber Mallet

2 Standard Screwdrivers

Emery Cloth, Wire Brush

2. Remove the front and rear covers.

3. Remove the O-Rings from the front and rear of the

housing. Undamaged BUNA O-Rings may be

reused.

18

Page 19

4. Hold a spare displacement rotor gear between the

right displacement rotor gear and the blocking rotor

gear to keep them from turning (if unavailable, use a

shop rag between gear teeth). Use the rotor gear

wrench or socket to remove the right displacement

rotor screw and washer.

Disassembling the Meter

5. Hold the spare gear between the left displacement

rotor gear and blocking rotor gear. Use the rotor gear

wrench or socket to remove the screw and the

packing gland driver held by the screw.

6. Hold the spare gear between the right displacement

rotor gear and the blocking rotor gear. Use the rotor

gear wrench or socket to remove the left

displacement rotor gear screw and washer.

19

Page 20

Removing the Non-Corroded Rotor Gears

7. If the Gears show signs of corrosion, use the

alternative method describe on Page 21, “Removing

Corroded Rotor Gears”. Insert two standard

screwdrivers behind the blocking rotor gear. Gently

pry the gear off its rotor tapered end. If the gear does

not pry off easily, or feels stuck, use the alternative

method described on Page 21, “Removing Corroded

Rotor Gears”.

8. Use the same method to remove the left and the right

rotor gears. Remember, if the gear does not pry off

easily or feels stuck, use the alternative method

described on Page 21, “Removing Corroded Rotor

Gears”.

9. As each gear comes off the rotor , remove the key (1)

from the rotor keyway (2). Save the key to use when

reassembling the meter.

10. Use the bearing plate wrench to remove the bolts

that hold the front bearing plate to the meter housing.

On the back of the meter housing, remove the bolts

that hold the rear bearing plate to the housing. Go to

Step 1, “Removing the Bearing Plates and Rotors”.

Removing the Bearing Plates and

Rotors

1. Insert a screwdriver into each of the two notches near

the dowel pins. Be careful not to mar any of the

surfaces. Gently pry the front bearing plate off the

dowel pins.

2. Remove the front bearing plate and rotor assembly

by pulling a rotor straight out from the housing. Be

careful not to mar any of the surfaces.

3. Remove the remaining bearing plate from the other

side by inserting a screwdriver into each of the two

notches near the dowel pins. Be careful not to mar

any surfaces. Gently pry the rear bearing plate off

the dowel pins.

20

Page 21

1. Replace all three rotor gear screws, without washers,

halfway onto each of the rotor ends.

2. On the back of the meter housing, remove the screws

that hold the rear bearing plate to the housing using

the bearing plate wrench or socket.

3. With a plastic or rubber mallet, tap on the heads of

the screws lightly and equally. As you tap on the

screw heads, the gears are driven off the rotors. As

the rotors are driven in, the rear bearing plate and

the rotor assembly are pushed away from the

housing.

Removing Corroded Rotor Gears

4. Use the bearing plate wrench or socket to remove

the screws that hold the front bearing plate to the

meter housing.

5. Inspect and clean all critical surfaces like gear teeth,

rotors and internal housing faces. Remove any

crystalline formations using a fine emery cloth or a

fine wire brush. Be careful not to mar or alter the

shape of any of the parts. Changing the shape of

parts may interfere with their operation. Remove

nicks and burrs on metal parts with a stone. Remove

all grit and other foreign particles. These may also

damage parts and interfere with proper operation.

Replace all parts that appear worn or damaged.

21

Page 22

Reassembling the Meter

Tools: Cover socket or open end/box end wrench

Spare displacement rotor gear

Rotor gear wrench or socket

Bearing Plate wrench or socket

NOTE: See Page 25 for Torque Chart and Wrench and

Socket Size Chart.

NOTE: The principles of meter disassembly and

reassembly are the same for all the Liquid Controls

Positive Displacement meters. Although your meter may

look slightly different than those pictured, the steps are

the same except as noted.

1. Rotor gears are on the front bearing plate. Install the

non-rotor gear bearing plate using the bearing plate

screws and wrench.

2. Insert the non-tapered ends of the three rotors into

the housing from the opposite side. Place each rotor

into its respective bore in the installed bearing plate.

3. Place the remaining bearing plate over the three

tapered rotor ends and fasten it with the bearing plate

screws. Use the bearing plate wrench.

22

Page 23

4. The rotors should have a small amount of end-play

and be easy to turn. Test each rotor one at a time.

Turn the rotors to make sure that they revolve freely.

Jog the rotors from end to end to check for end-play .

If they do not move easily in both tests, remove the

rotors and check for burrs and corrosion deposits.

Clean them thoroughly. Repeat steps 2,3, & 4.

5. The rotor key is a small wedge of metal. Each rotor

has a notch, or “keyway”, to hold a key. Position a

key into each one of the three rotors. Press the keys

into the rotor keyways with your thumb and forefinger.

Reassembling the Meter

6. Slide the blocking rotor gear on its tapered rotor end.

Slide the right displacement rotor gear on its tapered

rotor end so that the timing marks line up between

the two gears. See “Timing the Rotor Gears” on Page

24.

Hint: Before you place the right displacement rotor

gear on its tapered end, hold the right rotor gear in

position. Turn the blocking rotor gear. Try to line up

the timing marks before you place the right

displacement rotor gear on its tapered rotor end.

7. Position the left displacement rotor gear on its tapered

rotor end so that its timing mark lines up with the

blocking rotor gear. See “Timing the Rotor Gears”

on Page 24.

23

Page 24

Timing the Rotor Gears

Rotor gears are timed by lining up the timing marks

(circled in illustration). The blocking rotor gear has a

tooth directly in front of its timing mark. On the

displacement rotor gears, the timing mark falls in the

space between two gear teeth. Make sure that the tooth

in front of the timing mark on the blocking rotor gear

connects with the space in front of the timing mark on

the displacement rotor gear. You may need to remove

the gears and reposition them several times on their rotor

ends in order to get the timing marks to line up correctly .

For more information, see “Troubleshooting” on Page 26.

1. Position the spare displacement rotor gear between

the left displacement rotor gear and the blocking rotor

gear to prevent the gears from moving. Attach the

right displacement gear washer and screw using the

rotor gear wrench. Tighten the screw to the torque

specification listed in the Torque Chart.

2. Keep the spare displacement rotor gear positioned

by the left displacement rotor gear. Attach the left

displacement gear washer and screw using the rotor

gear wrench. Tighten the screw to the torque

specification listed in the Torque Chart.

3. Position the spare displacement rotor gear between

the right displacement rotor gear and the blocking

rotor gear. Attach the blocking rotor gear with the

packing gland driver and screw using the rotor gear

wrench. Tighten the screw to the torque specification

listed in the Torque Chart.

4. Rotate the gears to make sure that the rotors turn

freely . Burrs, foreign material, or marred surfaces can

restrict the rotor movements. It may be necessary to

remove the gears and rotors and deburr and clean

the surfaces again.

5. Install an O-Ring (1) into the groove (2) on the front

of the meter housing.

6. Fasten the front cover (3) with the cover screws (4)

using the cover socket or open end/box end wrench.

7. Install an O-Ring (8) into the groove (9) on the rear

of the meter housing. Not shown; similar to (2).

8. Fasten the rear cover (10) with the cover screws (1 1)

using the cover socket or open end/box end wrench.

9. Install POD5 Pulse Output Device.

24

Page 25

Torque Chart

Grade 5 Fasteners

Bolt Size

#8 (.164) - 32 UNC-2A 3.5 4.8

#10 (.190) - 24 UNC-2A 5.2 7.1

1/4" (.250) - 20 UNC-2A 7.3 9.9

5/16" (.3125) - 18 UNC-2A 15.3 20.7

Inch-Pounds Newton-Meter

NOMINAL* NOMINAL*

3/8" (.375) - 16 UNC-2A

7/16" (.4375) - 14 UNC-2A

1/2" (.500) - 13 UNC-2A 66 90

5/8" (.625) - 11 UNC-2A 132 179

3/4" (.750) - 10 UNC-2A

NOTE: Torque tolerance is ±10%.

27 37

43 58

233 316

Wrench and Socket Size Chart

Meter

Element

Wrench

Size

NOTE: Prior to installation, apply a small amount of Locquic Primer N764 to each screw. Apply a light coat of Loctite

242 in three even strokes to each screw. The Loctite and Locquic primer are not to be applied to the female connections

in the rotor. Please apply these techniques when repairing meters in the field.

Dust

Cover

Screws

5/16 hex

wrench

Drain

Plug

1/4" Allen

wrench

Meter

Cover

Screws

1/2" hex

wrench/socket

Counter

Bracket

Screws

3/8" hex

wrench/socket

Bearing

Plate

Screws

5/16" hex

wrench/socket

Rotor

Gear

Screws

5/16" hex

wrench/socket

25

Page 26

Troubleshooting

!!

! WARNING

!!

All internal pressures must be relieved before disassembly or inspection of the strainer, air eliminator, any valves in

the system, the packing gland, and the front or rear covers. See “Relieving Internal Pressure” (Page 10).

PROBLEM: Leakage from the cover seal.

PROBABLE CAUSE AND SOLUTION:

Seal has been damaged due to shock pressure or cover bolts have not been tightened sufficiently. Replace seal

and/or re-torque cover bolts.

PROBLEM: Product flows through meter but the register does not operate.

PROBABLE CAUSE AND SOLUTION:

A Check the pulse output device, and gear train. Replace components if required.

B If all meter parts are moving, the problem is in the encoder . The faulty encoder should be checked and rep aired by

trained technician.

PROBLEM: Breaking teeth on timing gears.

PROBABLE CAUSE AND SOLUTION:

A St arting or stopping flow in meter too rapidly. Replace the damaged components. Correct the system operational

practices.

B Pump bypass not adjusted properly. Readjust as necessary.

PROBLEM: Product flows through meter but register does not record properly.

PROBABLE CAUSE AND SOLUTION:

A SCAMP™ is not properly calibrated. Refer to SCAMP™ manual (Bulletin #500184) supplied with meter.

B The vapor release valve is sticking, allowing vapor to pass through meter. Inspect and repair as required.

C The differential valve diaphragm is leaking. Replace the diaphragm.

PROBLEM: No flow through meter.

PROBABLE CAUSE AND SOLUTION:

A Faulty or non-functioning pump.

B The valve is not open or not functioning.

C The meter is “frozen” due to build up of chemical “salts” or foreign material inside metering chamber. To correct,

clean the meter and inspect for damage.

D The vapor vent line valve is shut or there may be an obstruction in vapor vent line between differential valve and

vapor space in tank.

E Blocked strainer.

PROBLEM: Meter runs too slowly.

PROBABLE CAUSE AND SOLUTION:

A The valve’s internal mechanism is faulty. The valve does not open fully.

B The meter gears or rotors are “salted” enough to slow up rotation parts. To correct, clean the meter.

26

Page 27

How to Order Replacement Parts

1. Refer to the exploded view drawings on Pages 28-

31. Find the four digit item number for the part you

want to order. The item numbers are listed on the

exploded drawings.

2. Find the computer printout titled Parts List that has

been inserted in the Owner’s Information Packet

which was shipped with your order. Look up the item

number on the Parts List. The Parts List shows each

item number with a corresponding part number . Find

the corresponding five digit part number for the item

you want to order. The part number represents an

individual piece, a kit, or a complete assembly.

3. Inform your distributor of the part number that you

need. The part number is the only number that allows

the distributor to find the correct component for your

meter.

The Bills of Material are on the LC public website.

Always check the website for the most current

BOM.

27

Page 28

Meter Assembly Exploded View29Strainer Assembly Exploded View

28

Page 29

Single Meter Strainer Assembly

A2694 - Temperature Compensated

A2696 - Non-Compensated

Dual Meter Strainer Assembly

A2697 - Temperature Compensated

NOTE:

• Assembly shown is for systems that use Electronic Temperature Volume Compensation (ETVC). Systems

without ETVC use a 1/2" pipe plug (07223) in place of part numbers 81251, 81255, 80584 and 71375.

• Probe (71375): Class I Division 1 may require installation with conduit per local codes.

Page 30

Differential Valve Exploded View

30

Page 31

Optional Back Check Valve Assembly (PN. 501267)

WARNING:

When a Back Check Valve is used, an automatic safety

valve must be installed to prevent pressure build-up in

excess of rated working pressure in the meter housing.

One automatic safety valve should be installed in each

meter. Remove the pipe plug from the front cover or

rear cover and insert the appropriate automatic safety

valve.

31

Page 32

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2006 Liquid Controls

Pub. No. 500218

(02/06)

Loading...

Loading...