Page 1

STANDARD BULK TRUCK SYSTEMSTANDARD BULK TRUCK SYSTEM

INSTALLATION PROCEDURESINSTALLATION PROCEDURES

LectroCount³

Page 2

Table Of Contents

SECTION page

1. System Overview 3

2. Installation Overview 4

3. Parts Requirements 4

3.1 Liquid Controls Supplied Components 4

3.2 Liquid Controls Supplied Options 4

3.3 Installer Supplied Parts 4

4. Electrical Check 5

5. Truck Cab Computer Installation 6

5.1 General Requirements 6

5.2 Locating Components 6

5.3 Electrical Power Connections 7

5.3.1 Overview 7

5.3.2 Run Battery Cable 7

5.3.3 Installation of Accessory Cable 8

5.4 Truck Seat Grounding 9

5.4.1 Static Electricity and Grounding 9

5.4.2 Installation of Ground Strap Kit 10

6. Supervisory Console Grounding 12

6.1 Grounding Strap Installation 13

7. Lap Pad Connection 14

8. Printer Mounting 14

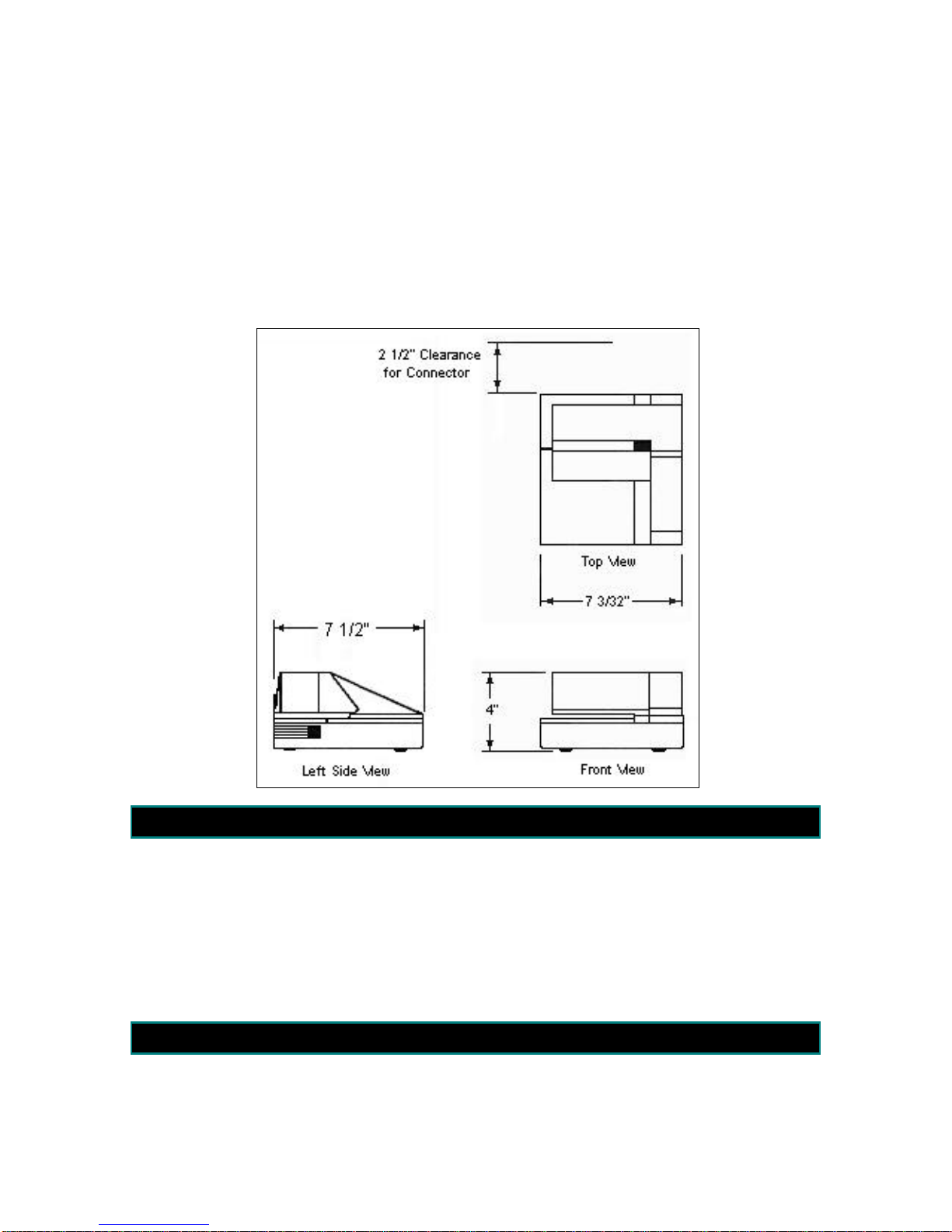

8.1 Printer Connection & Printer Dimensional Drawing 14 & 15

9. Removal of Mechanical Registration Equipment 15

10. Installation of Electronic Temperature Volume Compensator 15

10.1 Installation of Strainer Cover Mounted Thermowells 16 & 17

10.2 Installation of Pipe Mounted Thermowells 18

10.2.1 For Canadian Installations 18

11. Mounting the Remote Supervisory Control Box (RSCB) 19

11.1 Liquid Controls Meters/RSCB with Internal Pulsers 19

11.2 LC Meter with External Pulse Output Device 20

11.3 Neptune Non-Compensated Meter Retrofit Kit 21

11.4 Neptune Temperature Compensated Meter Retrofit Kit 22

11.5 RSCB Mounting Bolt Pattern 23

12. Wiring the RSCB 24

12.1 Wiring of the Valve Solenoids to the RSCB 25

12.1.1 "Diddle" Valve Wiring 26

12.1.2 Liquid Controls Dual Stage Wiring 26

12.1.3 Single Stage Valve and Three Way Solenoid Wiring 26

12.2 Wiring of the RTD Temperature Probe to the RSCB 26

12.3 POD Wiring (Pulse Output Device) 26

12.4 Internal Pulser Wiring 27

12.5 Truck Cab Cable Routing 27

12.6 Connection of the Meter Signal Cable 28

12.6.1 Single Meter Systems 28

12.6.2 Dual Meter Systems 28

13. System Start-Up 28

14. Software Part Numbering System 29

15. Troubleshooting 29 - 37

16. Wiring Diagrams 38

16.1 Mounting Arrangements for Components w/ Brackets 43

Page 3

1. System Overview

The LectroCount3 On-Board Truck

Computer system works in conjunction

with many models of Positive

Displacement Flow Meters. It

accurately measures fuel deliveries,

prints priced receipts, and streamlines

driver record keeping. It can be

equipped with accessories that allow for

temperature volume compensation,

deliveries to be made (net volume), and

delivery information to be exchanged

between the truck computer and an

office computer.

The basic system consists of:

1. Remote Supervisory Control

Box/Remote Electronic Counter

Assembly (RSCB/REC) that is

mounted in place of mechanical

registration equipment on the meter.

2. Supervisory Control Module and

Printer that are mounted in the truck

cab.

3. Lap Pad operator interface.

For trucks equipped with two meters, a

dual meter configuration is available that

allows two RSCB/RECs to be connected

to a single truck computer.

This manual describes the installation of

these components and their

accessories. Read this entire

installation manual before beginning

the installation to make sure that you

understand the total scope of the

project. Specific installation

requirements will vary with the model of

truck. Meter type, configuration of

existing metering equipment, selected

options, and the type of fluid being

metered, all influence installation. Make

sure that the RSCB/REC, Electronic

Temperature Volume Compensation kit

(ETVC), pulser, and valves can be

installed in such a manner so as to not

interfere with routine service of the

meter, the strainer, and the meter

compartment door.

The conduit and wiring for the above

components need to be routed with

similar concerns in mind. If a dual meter

system is being installed, the

RSCB/REC, ETVC, pulser, and valve

work must be duplicated for the second

meter.

NOTE: Power, input and output (I/O) wiring must be in accordance with

Class I, Division 2, wiring methods in Article 501-4(b) of the National

Electrical Code, NFPA 70 and in accordance with the authority having

jurisdiction.

WARNING: Explosion Hazard - Substitution of Components May

WARNING: Explosion Hazard - When in Hazardous Locations, Turn

WARNING: Explosion Hazard - Do NOT Disconnect Equipment

Impair Suitability for Class I, Division 2.

Off Power Before Replacing or Wiring Modules;

Unless Power Has Been Switched Off or the Area is

Known to be Non-hazardous.

3

Page 4

2. Installation Overview

q Ensure that the truck electrical

system meets specifications and

can provide at least 5 Amps for

the LectroCount3 with all truck

accessories operating.

q Electrically ground the truck

seats.

q Mount supervisory control

module and printer in cab.

q Install battery/accessory cables.

q Install odometer kit (optional).

q Remove any existing mechanical

q Remove any existing manual

preset valve.

q Install an electronically controlled

security valve or solenoid kit.

q Mount RSCB / REC

q Install pulser assembly (optional)

q Install Electronic Temperature

Volume Compensation Kit

(optional).

q Route Meter Signal Cable to

truck cab.

registration equipment.

3. Parts Requirements

3.1 LIQUID CONTROLS SUPPLIED COMPONENTS

q RSCB / REC

q Meter Signal Cable (pre-wired to RSCB)

q Battery/Accessory Cable

q Supervisory Control Module

q Lap Pad (driver key pad)

q Ticket Printer with cables

3.2 LIQUID CONTROLS SUPPLIED OPTIONS

q ETVC Kit

q Pulse Output Device (pulser)

q Odometer Pulser

q Dual Meter Switch Box

q RAM Interface Module

q Two Stage Valve or 3-Way Solenoid

3.3 INSTALLER SUPPLIED PARTS

q Protective Sheathing/Conduit for cables

q All Fittings

q Hardware for Truck Computer Mounting Brackets

4

Page 5

4. Electrical Check

Before beginning to install the LectroCount3, it is essential that you complete the

following checklist. If the vehicle electrical system cannot meet the following

requirements, corrective action must be taken before installing the LectroCount3. This

checklist is also included with the system. That copy should be filled out and filed with

the distributor or truck builder. NOTE: Contact the factory if the truck has a positive

ground.

The truck system must meet the following requirements:

q Battery terminals and cables must be in good condition with clean, corrosion free

connections.

q Battery must be charged in accordance with manufacturer’s specifications.

q The alternator must be large enough to meet the total demands of the truck,

including the LectroCount3. LectroCount3 requires 5A minimum for proper

operation. A typical alternator size is 90 amperes.

q If the truck has a history of electrical problems, make sure that these problems

have been corrected before installing the LectroCount3.

q Inspect all truck electrical/electronic equipment for proper installation.

q Determine if the truck is positive or negative ground. (If the system is positive

ground, contact the factory).

q Be sure that the radio antennas were installed in accordance with the

manufacturer’s specifications to prevent RF interference.

To ensure that these requirements are met, check the voltage across the battery

terminals under the following conditions:

LectroCount

3

Vehicle Inspection Check List

With the truck running at low idle, and all accessories off, the voltage should be between

12.6 and 18 VDC.

With all the accessories (lights, heater, radio, and radio mike) on, the voltage must be

between 12.6 and 18 VDC. If the voltage drops significantly when the accessories

are turned on, it may indicate that the alternator will not be able to support the

LectroCount3.

Extend the delivery hose to its full length, engage the hose reel and measure the voltage

as the hose is reeled in. It shouldn’t drop below 10VDC.

With the truck running at high idle, and all accessories off, check the voltage. Again it

should be between 12.6 and 18 VDC.

Repeat the hose reel test with the truck at high idle. Make sure that the voltage does not

drop below 10 VDC.

5

Page 6

5. Truck Cab Computer Installation

5.1 GENERAL REQUIREMENTS

A minimal truck cab computer system

includes:

1. A supervisory control module (SCM)

that is mounted between two right

angle brackets

2. A dot matrix ticket printer

3. A Lap Pad (key pad/display).

Systems equipped with the RAM card

option will have a RAM interface module

mounted atop the supervisory control

module. Dual meter systems will have a

Dual Meter Switch mounted below the

SCM. (See Figure to the right)

The truck computers are shipped with

the components and brackets

assembled. The installer has to bolt the

brackets to the cab floor, ground the

SCM to the truck electrical system, and

route the power and signal cables to the

appropriate connectors on the SCM and

Dual Meter Switch.

Component Configuration

Single Meter/Non-RAM Configuration

Truck Cab

The printer also needs to be mounted in

the truck cab, usually on top of the SCM

“stack”. The Lap Pad is secured in a

holder on the side of one of the

brackets.

5.2 LOCATING COMPONENTS

The SCM bracket should be mounted in

a location where:

q Both the front and back can be

accessed to connect cables

q The Lap Pad and printer will be

accessible to the driver.

q The Supervisory Control Module

fuses can be replaced.

q There is enough room to insert and

remove a RAM card from the RAM

interface module. (RAM systems

only)

Single Meter / RAM Configuration

Dual Meter / RAM System

6

Page 7

5.3 ELECTRICAL POWER CONNECTIONS

5.3.1 Overview

The LectroCount3 is designed to run only

when the ignition switch is in the “on” or

“accessory” position. This prevents the

LectroCount3 from being damaged by

the voltage spikes or electrical noise

that occur when the starter is engaged,

or from draining the truck battery power

when the truck isn’t running.

Voltage from the battery is switched by

a relay that is controlled by the truck’s

accessory circuit. It is vital that the

battery and accessory cables be

properly connected and fused, and that

the SCM is properly grounded.

5.3.2 Run Battery Cable

(Part Number 81232)

The battery cable is supplied with

heavy-duty ring terminals that must be

installed directly to the battery posts.

Make sure that the truck’s electrical

system has been properly checked.

Clean the battery terminals for a

good electrical connection.

q Remove the ATO 7.5 amp fuse from

the battery cable’s black splashproof fuse holder so that the wire is

not live while the cable is routed and

terminated.

q Attach the black cable to the

negative (-) terminal of the battery.

q Connect the orange cable terminal

to the positive (+) terminal of the

battery.

q On truck systems with several

batteries connected in parallel, the

last battery in the system usually has

the least number of connections and

will be the best location to attach the

battery cable.

q Route the cable to the supervisory

control module in the truck cab.

q Seal any holes that you may have

made in the cab wall.

(continued next page)

7

Page 8

q Make sure that you route the cable

in such a manner so as not to

interfere with the operation or

maintenance of the truck.

q The wires will be connected to a

three pin terminal block on the back

of the SCM.

q The block can be removed from the

SCM to ease the process.

q Use a 1/8” screwdriver to back off

the terminal block screws.

q Strip 7/32” of insulation from the

wires.

q Connect the white wire to Pin 2 on

the block and connect the black wire

to Pin 3.

q Make sure that the screws are re-

tightened and that no loose strands

of wire are exposed.

5.3.3 Install Accessory Cable

(Part Number 80747)

The accessory cable consists of a RED and a BLACK conductor in a shielded cable.

The conductors are both connected to the same ring terminal on one end. They are not

terminated on the other end.

The accessory cable must be wired to the truck’s accessory circuit. The power to this

circuit should be:

q OFF when the ignition is off or the engine is cranking,

q ON when the truck is running or the ignition switch is in the “accessory”

position:

Key Switch OFF 0VDC

Key Switch ON 12 VDC (battery voltage)

Key Switch ACCESSORY 12 VDC (battery voltage)

Key Switch or starter button CRANKING 0 VDC

q Check the voltage using an accurate multi-meter.

q Be sure to use a good ground to avoid false readings.

q The voltage should drop momentarily to 0 as the engine is cranked.

If the ignition switch is accessible:

q Connect the ring terminal on the

accessory cable to the accessory

stud on the switch.

q It is usually best to install the ring

terminal over the stud and the nut

that hold the existing accessory

wires in place.

q An additional nut should then be

used to hold the LC accessory cable

on the stud.

8

Page 9

If the ignition switch is not

accessible:

q Install a voltage tap on the

accessory fuse.

q Remove the ring terminal from the

accessory cable.

q Connect both the red and black

conductors in the cable to the fuse

tap.

q Trim back the drain wire and foil

shield at the outer insulation on the

cable.

q Use electrical tape or heat

shrinkable tubing to insulate the

edge of the shield.

q Route the cable to the rear of the

supervisory control module.

5.4 TRUCK SEAT GROUNDING

5.4.1 Static Electricity and Grounding

q Trim the cable to the appropriate

length and strip back the outer

insulation, foil shield, and drain wire.

q Use electrical tape or heat

shrinkable tubing to insulate the

edge of the shield.

q Remove 7/32” of insulation from

both the red and black conductors,

twist the wires together, and insert

them in Pin 1 of the three pin

terminal block.

q Tighten the terminal block screw

using 1/8” flat blade screwdriver.

q Plug the terminal black back into the

SCM.

Static electricity can build up on drivers

and truck seats, especially during cold,

dry weather. Adjustable, shockabsorbing seats add to the problem

because they isolate the seat cushion

from an electrical ground. If the static is

it can cause the truck computer to reset

and/or cause a number of other hard to

trace faults. The discharge can occur

when the driver touches the

LectroCount3 or a part of the truck that

provides a good ground path.

discharged on or near the LectroCount3,

WARNING

To prevent the occurrence of electrostatic discharge (ESD), it is

mandatory that the truck seat(s) be properly grounded. This allows

the static electricity to “bleed off’ the driver and seat before it can

build up to the point where a discharge can interfere with the

operation of the LectroCount3 (or cause an explosion in hazardous

environments!)

9

Page 10

5.4.2 Installation of Ground Strap Kit

q Locate a good ground point near the back of the seat frame. The bottom of the seat

base bracket is usually a good spot.

q Drill a 9/32” hole in the seat frame near the back of the base.

q Attach one end of the ground strap to the bracket using the lock washer, flat washer

and nut provided. The lock washer should penetrate any paint on the bracket to

ensure a good electrical connection.

q Attach the other end of the strap to a metal part of the seat frame at a point where it

contacts the seat cushion. Make sure that there are no intervening pivot points,

guides, adjustment mechanisms, etc., which could interfere with the ground path

between the seat cushion and the ground strap.

q If the seat cushion has a wooden base, use a wood screw and washer to attach the

strap lug to the bottom of the seat at a point where the seat fabric is attached to the

wood. There must be good contact between the seat fabric and ground strap lug.

q Make sure that the strap is positioned so that it doesn’t interfere with the movement

of the seat or is exposed to physical damage.

Checking for a good ground

The resistance should be checked. Use a multi-meter to test the resistance between a

bare spot on the seat frame and PIN 3 on the SCM power connector.

(The ground terminal should be connected directly to the negative terminal of the battery

on a negative ground system)

The test should be done with all accessories, including the dome light, turned OFF. This

will prevent other currents from distorting the measurement.

If the resistance is less than 3 ohms:

The system is grounded sufficiently and no further action is necessary.

If the resistance is greater than 3 ohms:

Locate a better ground on the base of the seat or at some other point in the cab.

“Fan fold” the excess ground strap and tie it with a wire tie to the back of the seat frame.

Make sure that you have left enough slack in the strap to accommodate the seat’s full

range of adjustment.

10

Page 11

A. Air Cushion Type Seat-Adjustable for Height (Bostrom 914 Series Seat or

Equivalent)

B. Air Cushion Type Seat-Adjustable for Height (This includes Dura-Form

Seats or equivalent)

11

Page 12

C. Bench Style Seats-Adjustable for Distance to Steering Wheel (Includes

Manufacturers Standard Production Seats

6. Supervisory Control Module Grounding

The Supervisory Control Module (SCM) case must be grounded to a good chassis

ground on the truck to ensure proper operation. Usually, a good ground path is

established from the SCM case through the mounting brackets and bolts to the chassis.

The ground effectiveness can be reduced over time due to corrosion, dirt, etc., leading to

electrostatic discharge problems.

The ground path should be checked, whenever the LectroCount³ is serviced. This

ensures that the SCM’s case remains properly grounded.

Checking for a good ground:

Resistance should be checked using a multi-meter. Testing should be done with all

accessories, including the dome light, turned OFF to prevent other currents from

distorting the measurement.

Measure the resistance between one of the silver hex head screws on the LectroCount³

mounting bracket and the ground terminal (Pin 3) on the power plug of the SCM.

(The ground terminal should be connected directly to the negative terminal of the battery

on a negative ground system.)

12

Page 13

If the resistance is less than 3 ohms:

The system is grounded sufficiently and no further action is necessary.

If the resistance is greater than 3 ohms:

A grounding strap needs to be attached between the mounting bracket and a

good ground in the cab.

6.1 GROUNDING STRAP INSTALLATION

Mobile Installations

One end of the strap should be attached to the SCM mounting bracket per the following

picture:

Use a star washer between the lug and the bracket. Make sure that the washer

penetrated the paint on the bracket. Attach the other end of the strap to a convenient

ground point in the cab.

The bolt used to ground the seat ground strap on the seat base is usually a good

location. Measure the resistance between the silver hex head screw and (Pin3) again to

make sure that the system is grounded sufficiently.

If the resistance is still greater than 3 ohms:

• Make sure that the proper metal to metal contact is being made on both ends

of the grounding strap. Clean any paint or oxidation that may have

accumulated on the grounding point. Recheck the resistance again.

• Attach the ground strap to another ground point in the cab and repeat the

process.

Fixed Installations

If the LectroCount3 is being installed in a fixed installation, a ground wire should be

connected between one of the silver hex head screws on the SCM chassis and earth

ground on the power supply.

13

Page 14

7. Lap Pad Connection

The “D” connector on the end of the Lap Pad’s coiled

cable should be plugged into the socket labeled “Lap

Pad” on the front of the supervisory console. Tighten

the two captive screws on the connector to hold it in

place.

8. Printer Mounting

8.1 PRINTER CONNECTION

The printer is connected to the

supervisory console via data cable and

a power cable.

The data cable is terminated with a 25

Pin D-connector on the printer end.

The printer is usually mounted on top of the top

module of the SCM bracket assembly. It can

also be mounted on the dash, the passenger

seat, or any other location in the cab that is:

• Level

• Not subject to physical abuse

• Easy for the driver to reach

• Within reach of the printer’s data and

power cables

Industrial strength Velcro (supplied with the

printer) is used to hold the printer in place.

Always place the same type of Velcro (hook or

loop) on the printer to enable easy replacement.

This plugs into the socket labeled “RS232” on the back of the printer, and into

the socket labeled “Printer Signal” on

the supervisory console.

14

Page 15

The power cable is terminated in round,

3 conductor connectors on both ends.

The printer end plugs into the socket

labeled ‘24VDC” on the back of the

printer and the socket labeled “Printer

Power” on the front of the supervisory

console.

E-4900-1 Printer Dimensional Drawing

Avoid placing undue stress on the cable

connectors. (i.e. avoid tight bends,

make sure that the cable is properly

supported independently from the

connector.)

The Sockets labeled “KD” (telephone

style connector) and “FG” on the back of

the printer are NOT used.

9. Removal of Mechanical Registration Equipment

Remove the existing mechanical

register components (if present) by

removing the four bolts that attach the

register “stack” to the meter and lifting

the stack off of the meter.

If you are retrofitting to Neptune Meters,

remove all of the mechanical

10. Install Electronic Temperature Volume Compensator

Nine different ETVC kits are available for use with the LectroCount3 System. Nine of the

kits are designed for installation on common strainers. One is for use on systems where

a strainer cover is not available, or when physical constraints prevent its installation.

components from the meter, leaving just

the star shaped gear and two squareheaded studs.

If the system is equipped with a

mechanical temperature volume

compensation system, remove all of the

mechanical TVC components.

15

Page 16

CAUTION!!!

Be sure to relieve all pressure on the system before installing the ETVC.

10.1 INSTALLATION OF STRAINER COVER MOUNTED THERMOWELLS

q Remove the old cover from

the strainer.

q While the cover is off,

remove the strainer basket,

clean it thoroughly, and then

reinstall it.

Union Fitting

q Lightly coat the new cover

O-ring with grease and place

in position on the strainer.

q Bolt the strainer cover in

place, ensuring that the

weights and measures

thermowell tip points

downwards in the strainer.

q On some cover castings the

designation “this side up” or

an arrow is cast in the cover

to indicate the proper

orientation.

q The weights and measures

thermowell will be filled with

appropriate oil at the time of

inspection. Until then, coat the

supplied 3/8-inch NPT pipe plug with

thread sealant and thread it into the

hole.

Slotted Disk

4 Foam Washers

RTD Probe

Thermowell

RTD PROBE / THERMOWELL

INSTALLATION

16

Page 17

INSTALLATION OF STRAINER COVER MOUNTED THERMOWELLS (CONT.)

q The aluminum thermowell will be

used for the 3-wire platinum RTD

temperature probe.

q Before inserting the probe into the

aluminum thermowell, thoroughly

coat the entire probe length with the

copper, heat transfer grease that is

supplied.

q Insert, then remove, the probe from

the thermowell. Re-coat the end of

the RTD with the heat transfer

grease. Repeat the

insertion/removal process 2 or 3

times. This will provide a uniform

coating inside the thermowell that

ensures the proper heat transfer

from the liquid to the probe inside

the thermowell.

q The kit includes four foam washers

and a slotted metal disc. Slide the

foam washers down the RTD wires

and position them at the tail end of

the RTD.

RTD INSTALLED IN THERMOWELL

q Re-coat the RTD probe and insert it

into the thermowell for the final time.

Position it as far down in the

thermowell as possible.

q The foam washers should “bottom

out” inside the hex nut body of the

thermowell. The disc should be

positioned on top of the foam

washers with the RTD wires running

through its slot.

q Next, feed the RTD wires through

the explosion proof union. Thread

the male ½ NPT side of the union

into the thermowell until the union

contacts the disc and compresses

the foam washers. The number of

washers can be added or subtracted

to provide an optimum fit.

q The slotted disk will prevent the RTD

from being removed from the

thermowell, without removing the

union. After attaching the conduit,

the union should be sealed with the

seal wire kit.

17

Page 18

10.2 INSTALLATION OF PIPE MOUNTED THERMOWELLS

q Re-coat the RTD probe with the

Thermowells can also be installed in half

couplings that are welded in place on

the fluid line.

The two thermowells should be located

within 3” to 6” of each other and within 3

ft. of the meter inlet or outlet.

Avoid placing thermowells directly in

line, or a vortex may form behind the

first thermowell. This could affect the

temperature reading of the second

thermowell.

Both thermowell tips must point to the

center of the pipe.

A ½” NPT half coupling should be used

for the RTD stainless steel ½” NPT

thermowell.

The RTD well must be filled with the

copper, heat transfer grease (supplied).

The RTD must be positioned within 90

degrees of vertical. There must be

enough clearance to allow the RTD and

its electrical conduit to be installed, or

removed for service.

The stainless steel thermowell is used

for the 3-wire platinum RTD temperature

probe. Before inserting the probe into

the thermowell, thoroughly coat the

entire probe length with the copper, heat

transfer grease.

q Insert, then remove the probe from

the thermowell. Re-coat the end of

the RTD with the copper grease and

repeat the inserting/removal process

2 or 3 times. This will help make the

grease coating uniform inside the

thermowell, ensuring the heat

transfers from the liquid to the probe

inside the thermowell.

q The Thermowell Installation kit also

includes four foam washers and a

slotted metal disc.

q Slide the foam washers down the

RTD wires and position them at the

tail end of the RTD.

grease and insert it into the

thermowell for the final time,

positioning it as far down in the

thermowell as possible.

The foam washers should “bottom out”

inside the Hex nut body of the

thermowell.

The disc should be positioned on top of

the foam washers, with the RTD wires

running through its slot.

q Next, feed the RTD wires through

the explosion proof union. Thread

the male ½" NPT side of the union

into the thermowell until the union

contacts the disc and compresses

the foam washers.

The washers can be added or

subtracted to provide an optimum fit.

The slotted disc will prevent the RTD

from being removed from the thermowell

without removing the union.

After attaching the conduit, the union

should be sealed with the seal wire kit.

10.2.1 For Canadian Installations

q A 3/8” NPT half coupling must be

welded in place to accommodate the

brass or stainless 3/8” NPT Weights

and Measures thermowell.

q The thermowell will be filled with a

light oil

q It needs to be positioned with 60

degrees of vertical to allow it to be

filled.

q Make sure that there is enough

clearance (typically 4 to 8 in.) to

allow the weights and measures

temperature probe to be inserted

and remove.

18

Page 19

11. Mounting the Remote Supervisory

Control Box (RSCB)

The RSCB can be mounted directly on,

or near, a liquid flow meter. To

accommodate the variety of different

Specific installation instructions are

available for mounting the RSCB on

the following:

meter styles, the RSCB is available in

two styles:

q Liquid Controls Positive

Displacement Meters

1. With internal pulser.

2. Without internal pulser

Installation kits are available from Liquid

Controls to facilitate the RSCB

installation on many industry standard

meters.

q Neptune Meters

q Neptune Meters w/Temp

Compensator

11.1 LIQUID CONTROLS METERS/RSCB WITH INTERNAL PULSERS

The internal pulser version of the RSCB allows traditional mechanical registration

equipment to be easily replaced with the LectroCount³ electronic register.

(Requires Part Number 81369 Mounting Kit, LC Meter)

q Remove the

mechanical register

components from

the counter bracket

by removing the 4

bolts that attach

them to the meter

flange.

RSCB with an internal pulser mounted on a LC

meter with a two piece cover.

q Remove the adjuster

(and adjuster

mounting plate, if

present) from the

counter bracket.

q Replace the old

meter drive shaft

and bearing with

new drive shaft,

(item#8), and

bearing, (item #9),

using the original

face gear in either

right to left of left to

right positions.

19

Page 20

q Remove the cotter pin from the drive

shaft on the bottom of the RSCB,

taking care not to lose the washer.

Avoid pushing shaft into housing

until drive shaft adapter, item #1, is

pinned onto shaft.

q Place the o-ring; item #3, onto the

pulser drive shaft of the RSCB.

q Place the drive shaft adapter, item

#1, over the pulser drive shaft and o-

ring, lining up the cross-drilled holes.

Make sure that the shaft adapter is

pushed up over the o-ring. Secure

the Drive Shaft Adapter to the Pulser

Drive Shaft, with a cotter pin item

#2.

q Place the RSCB on the counter

bracket, sliding the drive shaft

adapter over the drive shaft of the

meter. Check for shaft engagement.

q Attach RSCB to counter bracket with

4 screws, items #4 and #7, and 4

washers, item #5. (Two of the

screws have been cross drilled to

accommodate a Weights and

Measures seal.)

11.2 LC METER WITH EXTERNAL PULSE OUTPUT DEVICE

The pulse output device replaces the

dynamic seal of a packing gland with a

static seal.

The motion of the meter rotor is

magnetically coupled to the meter when

a POD or other external pulser is used.

The RSCB is not mechanically coupled

to the meter when a POD or other

external pulser is used. The RSCB can

be mounted up to 1000 feet (304.m)

away from the meter. The installer must

provide a suitable bracket to support the

RSCB if it is mounted remotely.

If the RSCB is being mounted directly to

the meter, the RSCB mounting kit is

required.

The POD can only be attached to LC

meters with two piece covers that were

manufactured after 1990.

To install the RSCB mounting kit:

q Attach the short side of the RSCB

mounting bracket to the RSCB using

the four .250-20 x .750” screws and

lock washers provided.

q The right angle bend of the bracket

should be lined up with the front of

the RSCB.

q Attach the bracket and RSCB

assembly to the front meter cover

using the four .250-28 x .750”

screws provided.

q Make sure that the hole in the meter

cover center, lines up with the hole

in the bracket.

q Install the pulse output device

according to the instructions in its

manual (Series E2800”Installation,

Operation, and Parts Manual).

20

Page 21

11.3 NEPTUNE NON-COMPENSATED METER RETROFIT

Field Installation / Replacement of Register Stack With RSCB

Using 81364 Neptune Mounting Kit

q Remove all of the mechanical register components from the meter. Leave just the

star-shaped gear and the two square-headed studs.

q Screw the two cone-tipped clamping screws, (item #7) into sides of adapter bracket,

(item #6), until the conical tip is protruding inside of the bracket.

q Place the bracket onto Neptune meter. Place the square-headed studs through the

holes on the same legs as the cone-tipped screws. Place mounting screws, (item

#4), with washers, (item #3), through the other two holes in the bottom of the

bracket. Screw them into the Neptune meter. Make sure that the bracket is flush

with the meter casting.

q Tighten the cone-tipped clamping screws until the conical tips engage firmly against

the tapered sides of the square-headed studs.

q Remove the cotter pin from the drive shaft on the bottom of the RSCB, taking care

not to lose the washer. Place the driver, (item #5), onto the drive shaft and secure

with the cotter pin, (item #1). Avoid forcing the shaft into the RSCB housing.

q Place RSCB on the adapter bracket. Carefully align the four-pronged driver with the

star-shaped gear. Make sure that all four of the driver’s prongs are properly aligned

with the teeth of the star gear. Fasten the RSCB to the bracket using four screws,

(item #2), and four washers, (item #9).

Correct INCORRECT!

Alignment of Star-Shaped Gear and RSCB Driver

21

Page 22

11.4 NEPTUNE TEMPERATURE COMPENSATED METER RETROFIT KIT

Remove the mechanical registration equipment and the mechanical Temperature

Volume Compensator from the top of the meter.

q Remove the cotter pin from the drive

shaft on the bottom of the RSCB,

taking care not to lose the washer.

q Position the adapter shaft (item #2)

over the pulser shaft. Align the

cross-drilled holes. Secure them in

position with a cotter pin. Remove

the cotter pin from the drive shaft on

the bottom of the RSCB, taking care

not to lose the washer. Place the

driver, (item #5), onto the drive shaft

and secure with a cotter pin (item

#1). Avoid forcing the shaft into the

RSCB housing.

q Position the weather plate

(item #8) on the bottom of the

RSCB.

q Install the Adapter Flange Assembly,

(item #1), on the bottom of the

RSCB. Secure it and the weather

plate with four screws and washers.

q Attach the Neptune Driver Adapter

to the bottom of the adapter shaft

with a cotter pin.

q Position the adapter flange

assembly on top of the meter. Be

sure to center the four arms of the

driver adapter over the meter’s star

gear.

q Fasten the adapter flange to the

meter using 4 screws and washers.

RSCB Mounting Kit for Neptune

Meter with Mechanical

Temperature Compensation

22

Page 23

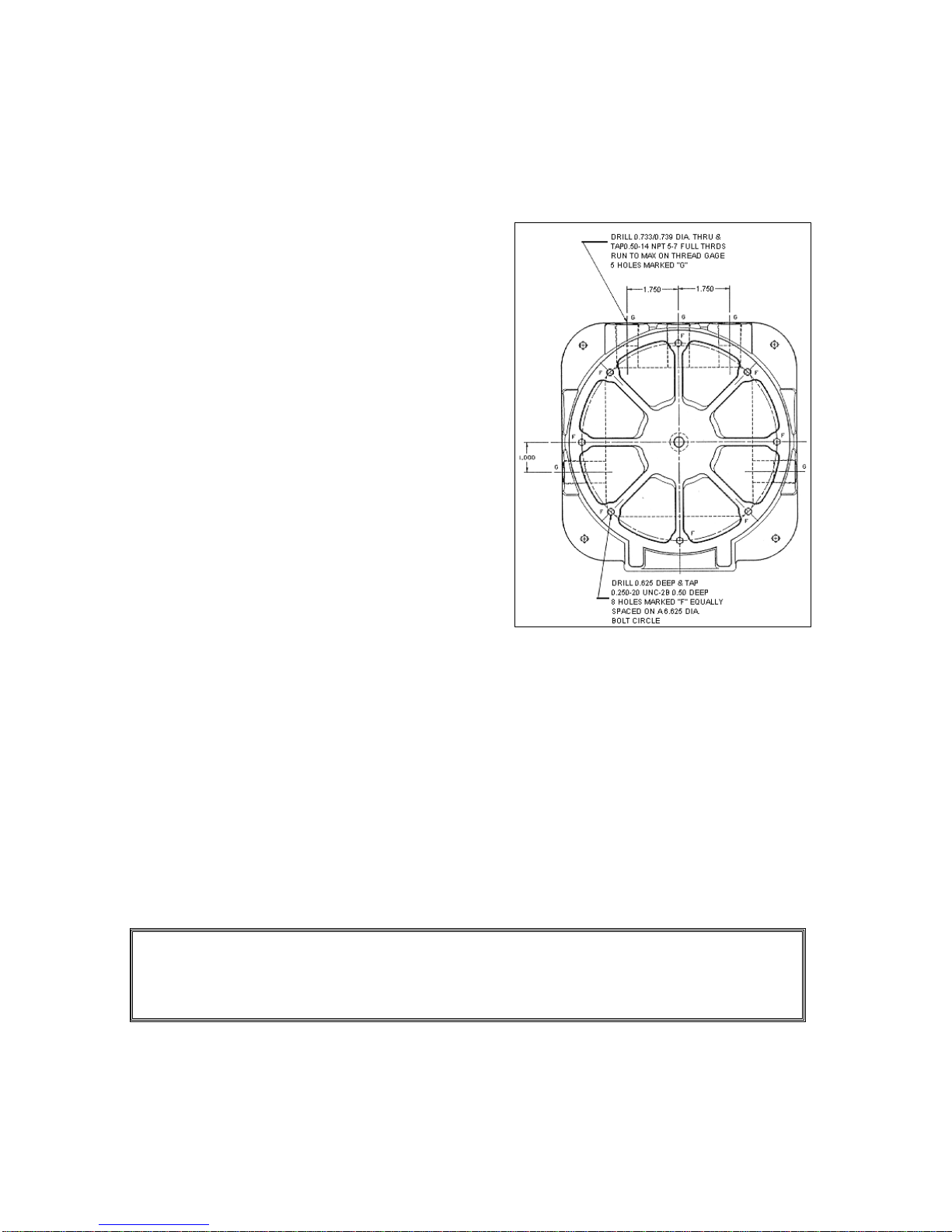

11.5 RSCB MOUNTING BOLT PATTERN

The RSCB base casting contains eight mounting holes in an industry standard bolt

pattern that allow it to be easily attached to a number of common meters. All of the

holes are ½” deep and will require .250-20 screws.

q When mounting the RSCB leave the

cover assembly fastened to the base

to protect the internal components.

q Before securely fastening the RSCB

to the meter or bracket, make sure

that:

§ The remote electronic counter

(REC) is visible.

§ The multi-position switch can be

easily operated.

q If the RSCB will be exposed to the

elements before the installation is

complete, make sure that the cover

gasket is in place and that all (12)

7/16” mounting bolts and washers

are installed.

q Remove all of the pipe plugs from

the RSCB’s seven ½” NPT conduit

hubs. Apply pipe sealant or Teflon

tape to the threads, then re-install

the plugs in the ports.

Refer to the above drawing if you will

need to fabricate a mounting bracket

for the LectroCount

3

RSCB. Brackets

and adapters are available for many

common meters.

NOTE: If the RSCB was not pre-wired from the factory then refer to the wiring diagram in

the back of this manual to assist in field wiring. Terminal block numbers, signal

functions, and wire colors can be found there. Please read the special notes listed on

the drawing.

Liquid Controls will not honor any warranty claims for damage due to

negligence during the installation of the LectroCount3 system.

23

Page 24

12. Wiring the RSCB

Once the control valves, pulser, and ETVC kit (if so equipped) have been mechanically

installed, they need to be wired to the RSCB. The RSCB has seven ½” NPT ports to

accommodate the wires and cables that enter it. Typically, the ports in the back are

used for the signal cables that run to the truck cab and for the optional three-way

solenoid. The installer must choose the ports that best fit the requirements of a particular

installation.

q Remove the 12 bolts that secure the cover of the RSCB.

q Gently lift the cover off of the RSCB until the black coiled wire is accessible.

q Remove the telephone style connector from socket J8 on the RSCB terminal board.

q Place the top cover assembly out of the way.

The wires from the valve, ETVC kit, and pulser need to be routed through suitable

conduit to the RSCB.

The type of conduit used depends on the physical constraints of the installation and the

safety rating required.

Thin wall conduit, Liquid-Tight, and Synflex are among the choices.

The conduit hubs on the RSCB, solenoids, and pulser are all ½ "-14 NPT.

The conduit/cable entrances must be sealed inside and out using appropriate cable

glands to prevent moisture from accumulating in the RSCB.

Avoid chaffing or nicking the cables when pulling them through conduit or compression

fittings.

When routing the conduit, allow ample clearance for service access to the meter and

strainer.

If the system is installed inside a meter box, make sure that there is enough clearance to

close the door.

The RSCB terminal board has six removable terminal blocks (J1-J6) for ease of field

wiring.

Once the wires have been routed into the RSCB, they should be connected to the

appropriate terminal block.

When routing wires to respective terminal block, cut wire to length (always leave 1”-2”

extra length).

When attaching wires to the terminal blocks, remove the terminal block by pulling it

straight up from the circuit board.

q Use a 1/8-inch screwdriver to back off the screw at the desired terminal block

location.

q Strip 7/32” inch of the insulation from the end of the wire and insert the wire into the

desired location on the terminal block.

q Retighten the screw and check to make sure that the wire is fully inserted and that

none of the strands are loose.

q Insert the terminal block onto corresponding mating connector on the RSCB terminal

board.

24

Page 25

Note: The numbers and wires on the wiring blocks face towards the outside of the

box.

12.1 WIRING OF VALVE SOLENOIDS TO RSCB

The solenoid conduit hubs should be

positioned to allow the conduit to be

efficiently routed to the RSCB.

Loosening the 11/8” Hex nut on top of

the solenoid rotates the hubs.

§ Then turn the hub.

§ Loosen the nut a half turn, position

the hub, and then re-tighten.

When wiring the solenoids into the

RSCB junction box, the wires may have

to be spliced in order to reach the

appropriate terminal strip location.

Use stranded 18 GA wire.

It is recommended that red wire be used

for main connections, though black can

be used as a substitute.

Green 18 GA stranded wire should be

used for the case ground.

Use an in-line twist solder splice

(Western Union style splice). Stagger

the splice to make the wires easy to pull.

Leave a small amount of excess wire to

allow for future servicing of the junction

box wiring. Secure the excess wire with

wire ties.

25

Page 26

12.1.1 "Diddle" Valve Wiring

(Part Numbers: A29251 for 2" and A39251 for 3")

One of the solenoids’ green case grounds can be attached to terminal block J5-24 and

the other to J5-25. Solenoid 1 (S1) is on the inlet to the bonnet solenoid. Solenoid 2

(S2) connects the bonnet to the outlet. The wires from S1 connect to terminal block J-4SOL1. The wires from S2 connect to terminal block J-4-SOL2.

12.1.2 Liquid Controls Dual Stage Valve Wiring

(Part Number: A284811 for 2")

Solenoid S1 is hard piped to the top of the differential valve and represents the first

stage of the closure. Solenoid S2 connects the inlet of the differential directly to the

outlet of the differential valve. The second stage and shut-off is controlled here. The

wiring of these solenoids is the same as the "diddle" valve wiring described above in

section 12.1.1.

12.1.3 Single Stage Valve and Three Way Solenoid Wiring

Wire the solenoid to J4-SOL2. Wire the case ground to J5-24 or J5-25.

12.2 WIRING OF RTD TEMPERATURE PROBE TO THE RSCB

Make sure that there is enough slack in

the conduit leading from the RSCB to

the strainer mounted RTD to allow the

strainer cover to be removed.

Feed the cable from the back of the

RTD through the conduit to the RSCB.

Cut the cable on the RSCB end, leaving

enough slack for about two loops of

cable inside the RSCB.

12.3 POD WIRING

Install the pulse output device according

to the instructions in its manual (Series

E2800 “Installation, Operation and Parts

manual).

Wire the POD to terminal block J3 in the

RSCB. The pulser cable is usually best

12.4 INTERNAL PULSER WIRING

Trim back the Teflon sheathing enough

to expose a few inches of the wires

inside.

Strip the insulation from the wires and

connect them to terminal block J2 as

follows:

q 22GA Red Wire J2 - 11

q 22GA Red Wire J2 - 12

q 22GA White Wire J2 - 13

installed with the conduit hub facing

down and the wires routed to one of the

½” NPT conduit hubs on the left side of

the RSCB, using right angle fittings.

It can, however, be wired through any of

the ½” NPT conduit hubs.

If the system is equipped with an internal pulser, the pulser circuit board should already

be connected to the RSCB circuit board through connector J9.

26

Page 27

12.5 TRUCK CAB CABLE ROUTING

We recommend that the following installation practices be followed when

The RSCB is supplied with a cable assembly, consisting of two cables, which connect it

to the truck computer.

The two cables are terminated on the RSCB end with connectors that have been routed

through RSCB hubs and connected to the RSCB circuit board at locations J1 and J6.

On the cab side of the cable assembly, the two cables join in a black 16 pin circular

connector. This connector is supplied with a red plastic cover, which should be kept in

place during the installation. The cable is available in a variety of lengths, ranging from

25 to 500 feet. In most cases, the RSCB is shipped with these two cables attached. If

the cable has not been terminated and connected on the RSCB end, you should connect

the wires to terminal blocks J1 and J6 per the wiring diagram in the back of this manual.

The black cable has a drain wire and a foil shield that must be cut off even with the outer

cable insulation. The edge of the foil must be taped with electrical tape to ensure a

proper floating shield. (The drain wire is connected to pin 16 on the truck computer end,

which in turn is connected to chassis ground.)

q Do not pull the cable too tight in

q Install all exposed cable in ¾”

automotive plastic corrugated loom

(wire tubing).

q Run the cable down the inside edge

of the truck’s frame rail.

q Secure the cable to the frame rail

every 18 to 24 inches with wire ties.

q Install rubber grommets to protect

the cable where it passes through

the cab wall, meter box, etc.

q Keep the cable away from heat

sources such as the engine exhaust

manifold, exhaust pipe, mufflers, etc.

q When routing the cable, avoid

suspension parts, springs, shocks,

rotating shafts, linkages, etc., which

could crush, pinch, or rub the cable.

q Avoid installing the cable where it

will be exposed to excessive flexing.

areas where it will be moved. For

example: in cab-over trucks, leave

enough slack in the cable so that the

cab can be tilted forward without

damaging the cable.

q Leave enough slack in the cable to

allow for easy removal and

installation of the Supervisory

Console and RSBC should they

require servicing.

q In the meter box, avoid leaving the

cable unsecured. Be sure that it

won’t be snagged when tools or

other items are moved. Keep loose

cable from lying on the meter box

floor.

q On some trucks, extra harness cable

can be secured in the frame rail.

Otherwise, coil up extra cable and

securely fasten it to the back wall of

the cab. DO NOT place cable on

the floor of the cab or where it may

be damaged. Also, DO NOT attach

to cable seats that can be moved.

routing the cables to the cab:

27

Page 28

12.6 CONNECT THE METER SIGNAL CABLE

12.6.1 Single Meter Systems

q Remove the cover from the 16 pin

circular connector on the meter

signal cable.

q Insert the connector into the 16-pin

socket on the back of the

supervisory console.

12.6.2 Dual Meter Systems

q Remove the covers from the meter

signal cables.

q Connect the cable that you had

labeled “M1” into the “Meter

1”connector on the back of the dual

meter switch box.

q Connect the cable that you had

labeled “M2” into the “Meter 2”

connector.

The connectors are keyed to ensure that

the pins are properly aligned.

Do Not Force the Connector In!

q After the connector has been

properly inserted, turn the securing

ring clockwise at least ½ turn.

The connectors are keyed to ensure that

the pins are properly aligned.

q After the connector has been

properly inserted, turn the securing

ring clockwise at least ½ turn.

q Each dual meter system is shipped

with a short signal cable connecting

the Dual Meter switch to the

Supervisory Control Module.

Do Not Force the Connector In!

13. System Start Up

q Re-install the in-line ATO 7.5 amp in

the battery cable line.

q Place the ignition switch in the

accessory position. This will initiate

the computer’s start up routine.

q After 15 seconds, the unit will fully

power-up.

The installation is now complete.

Refer to the owner’s manual for instructions

on setting-up and calibrating the system

The dual meter systems also have the

4-pin connector on the switch box wired

to the 10-pin connector on the SCM.

q The “READY” lamp on the SCM will

illuminate.

q The Lap Pad will display:

“NET VOLUME GALLONS"

(Or LITRES).

28

Page 29

14. SOFTWARE PART NUMBERING SYSTEM

Prefix Product

SC 1 LPG 0 Single/Dual Stage 0 Linear/degree F 0 Required 0 single/single Three digit

Dispensed

2 Refined Fuels 1 Diddle Valve 1 Linear/degree C 1 Not Req'd 1 multi-/single e.g. 158

3 Aviation Apps. 2 Selectable in Prover 2 Table 54B/D API 2540 2 multi-/dual

4 NH3 3 Table 54 API 2540 3 single/dual

Security Valve

Type

Temperature

Compensation

4 NH3 Table Canada 4 24 product

5 Mass Flow (No Comp)

6 Table 54B/C &

Methanol

Portable

Ram

# of Products /

# of Meters

Application

15. TROUBLESHOOTING

Troubleshooting Rules

1. Before attempting to troubleshoot the LectroCount3 System, become familiar with the

operation and program of the specific installation.

2. Make sure all electrical connections are secure.

3. Make sure all circuit cards are firmly connected.

4. ALWAYS use a good digital multimeter. Voltage levels are critical to proper system

operation. Use an accurate, reliable multimeter to test for proper voltages at the start

of any service procedures. Voltage requirements are listed under each component.

NOTE: Check for proper operating voltages before changing modules.

5. Enter Mode 7 – diagnostics by pushing M#, 7, and ENTER. Make sure all field

programming entries are accurate, e.g., pulses per unit volume, temperature

coefficient, base temperature, and maximum pulser reversals.

6. NEVER remove a connector with the power on.

7. NEVER install a connector with the power on.

8. NEVER force a connector into a connector receptacle.

9. NEVER exchange or reposition components on circuit boards.

10. In case of a major problem, such as a burned circuit board, evaluate possible causes

before replacing the module and turning on the power.

11. Isolate the problem before changing modules.

12. Be careful when handling ribbon cable. Ribbon cables can be easily damaged.

13. Return all faulty modules with the proper forms, concisely completed.

29

Page 30

There may be several probable causes for a system malfunction. Listed below are

several probable causes to aid in returning the system to operation as quickly as possible.

This list is not all-inclusive and should be only used as a guide.

LectroCount3 Troubleshooting

PROBLEM: Unit will not power-up (no ready light).

PROBABLE CAUSE: No +12VDC to the Supervisory Control Module.

Low Battery voltage.

SOLUTION:

1) Check the 5A fuse for continuity, replace if necessary. (part # 70946)

2) Check battery voltage to the Supervisory Control Module at TB1 # 2 using TB1 #3 as a DC

ground. While LectroCount3 will power-up at 10VDC, it is recommended that the input be at

least +12.6VDC or higher. Refer to the LectroCount3 installation manual and wiring diagram for

more detailed information. If voltage is not present, inspect the battery cable (part # 81232) for

damage.

3) Check the 7.5A in-line fuse (part # 70985) (located near the positive battery terminal) for

continuity and replace if necessary.

4) Check the accessory line voltage at TB1 #1 using TB1 #3 as a DC ground. The DC voltage

should be +12VDC or higher. If the voltage is present, (ignition key in accessory) replace the

power supply board (part # 81213). If voltage is not present, trace the accessory line back to its

source, inspecting any in-line fuses for breaks.

PROBLEM: Unit blows 7.5A fuse.

PROBABLE CAUSE: +12VDC Battery line shorted to ground.

SOLUTION:

1) For safety reasons, Remove the 7.5 Amp in-line fuse from the battery cable (connected to the

positive battery post)

2) Remove the 3-pin power connector (TB1) and inspect for stray wire strands and visible shorts.

3) Inspect the full length of the battery cable, looking for damaged insulation which may cause

shorting between the cable and ground potential (i.e.: truck frame, chassis) If the battery cable

is damaged, replace it. (part #81232)

4) Replace the 7.5 Amp fuse (part # 70985)

PROBLEM: Unit blows 5.0A fuse.

PROBABLE CAUSE: Excessive current on 5A circuit.

SOLUTION:

1) Remove the cable marked PRINTER POWER from the rear panel of the EPSON printer and

replace the 5A fuse. (part # 70946) If the READY light remains on, replace the EPSON

printer.(part # E4900-1) If the 5A fuse blows, replace the printer power cable (part # 81233). If

the 5A fuse continues to blow, replace the power supply board. (part #81213)

30

Page 31

TROUBLESHOOTING

PROBLEM: Unit blows 1.0A fuse / Lap-Pad is blank.

PROBABLE CAUSE: Excessive current on 1 Amp circuit

SOLUTION:

Isolate the problem by disconnecting the following devices until the problem is resolved. After

removing each device, re-install a fresh 1Amp fuse.

1) Lap-Pad: Disconnect the Lap-Pad from the Supervisory Console. Replace the

fuse. If the fuse remains intact, this may indicate a defective Lap-Pad. (part#

E4030-1) Swap the suspect unit with a known working unit for verification.

2) Ram-Card: Remove the Ram-Card from the Ram-Card module. Replace the

fuse. If the fuse remains intact, this may indicate a defective Ram-Card. (part #

E4101-X) Swap the suspect unit with a known working unit for verification. (part

# E4101-X)Verify also that the ribbon cable located on the rear of the RamCard module (part # 81248 ) is not damaged.

3) Odometer Cable: ( if equipped ) (from 10-pin connector on rear of the

Supervisory Console) Replace the fuse. If the fuse remains intact, this may

indicate a defective odometer assembly and cable. (part # 821251) Replace

the assembly with a known-working unit for verification.

4) Pulser Assembly: If after replacing the above units the fuse continues to blow,

it is possible that the pulser assembly is defective. Replace the pulser board

(part # 811521 for internal pulser, part # 81159 for POD type pulsers) with a

known working pulser. Note: For dual-meter systems, it is important to note

which pulser may be causing the problem. Always check the METER 1 and

METER 2 LED indicators on the Dual Meter Switch Box to determine which

pulser may be at fault.

PROBLEM: “Power Loss Stop” appears on Lap-Pad.

PROBABLE CAUSE: Power to LectroCount3 Interrupted during delivery

Static Discharge

SOLUTION:

1) Check battery and accessory cables for damage. Ensure that the Battery, Accessory, and

Ground wires on power connector TB1 (rear of supervisory console) are secure.

2) Turn on all truck accessories. (headlamps, 2-way radio, heater, etc.) Engage the hose reel

and monitor DC voltage at TB1 #2, using TB1 # 3 as a ground. If the voltage drops below +10

VDC, the truck electrical system may not be adequate to handle the current load for the

LectroCount3. It may be necessary to upgrade the electrical system to accommodate the 5

Amp LectroCount³ current requirements.

3) Verify proper grounding of the LectroCount3, including the driver’s seat. Refer to the

LectroCount3 Installation manual for proper grounding procedures.

31

Page 32

PROBLEM: EPSON printer release Light Flashes.

PROBABLE CAUSE: Low voltage to the EPSON printer.

SOLUTION:

1) Check battery voltage for +12.6VDC reading or higher.

2) If voltage is present, replace the LectroCount3 power supply, (part # 81213), located in the

supervisory console.

3) If the release light continues to flash, replace the EPSON printer (part # E49001).

PROBLEM: No power / indicator lights to the EPSON printer.

PROBABLE CAUSE: No power to the EPSON printer.

SOLUTION:

1) Verify that the power switch (located on the left-hand side of the EPSON printer) is in the ON

position.

2) Check the printer power cable ( part # 81233 ) to ensure that it is seated properly. If this does

not correct the problem, replace the power cable (part # 81233), followed by the EPSON

printer (part # E49001).

PROBLEM: “Temperature Over-Range Failure” or “Temperature Under-Range Failure" appears on

Lap-Pad (Single-Meter Configuration)

PROBABLE CAUSE: Open or shorted circuit between RTD probe and Supervisory Control

Module.

SOLUTION:

Check the RTD probe & Signal harness for continuity.

Remove the signal harness (gray / black cable) from the Supervisory Control Module. On the

cable, measure and record the resistance in ohms between the following pins on the cable:

Pin # Pin # Reading

14 to 15 100 Ω ±20

14 to 13 100 Ω ±20

If the readings are not within the above tolerances, replace the RTD probe (part #70229).

If the problem is not corrected, replace the signal harness. (part # 81340)

PROBLEM: “Temperature Over-Range Failure” or “Temperature Under-Range Failure" appears on

Lap-Pad. (Dual-Meter Configuration)

PROBABLE CAUSE: Open or shorted circuit between RTD probe and Supervisory Console.

SOLUTION:

1) Determine which meter is causing the problem. Attempt to make a delivery for

products assigned to both Meter 1 and Meter 2. The Lap-Pad will show a temperature

failure for the suspect meter.

2) Isolate the Dual Meter Switch box. After determining which meter is causing the problem,

(meter #1 or meter # 2) isolate the Dual Meter Switch Box by removing the wiring harness for

32

Page 33

the suspect meter from the METER #1 or METER #2 position. (located on the rear panel of the

Dual Meter Switch Box) Plug the cable directly into the Supervisory Console. To do this, first

remove the 10” signal harness (grey / black cable) with 15-pin connector (part # 81242) from J2

on the rear panel of the Supervisory Console. Attempt to make a delivery. If the problem is

resolved, replace the Dual Meter Switch Box (Part # E2535-1).

Check the RTD probe & Signal harness for continuity.

Remove the Meter #1 or Meter #2 signal harness from the Supervisory Console. On the

cable, measure and record the resistance in ohms between the following pins on the cable:

Pin # Pin # Reading If the readings are not within these tolerances, replace RTD

14 to 15 100 Ω ±20 probe (part#70229). If the problem is not corrected, replace the

14 to 13 100 Ω ±20 signal harness. (part#81340)

PROBLEM: “Temperature Calibration Error” appears on Lap-Pad

PROBABLE CAUSE: Missing temperature calibration information

SOLUTION: Contact the Liquid Controls Service Department @ 1(800) 458-5262

PROBLEM: “Temperature Out Of Table Domain” appears on Lap-Pad

PROBABLE CAUSE: Missing temperature calibration information

SOLUTION: Contact the Liquid Controls Service Department @ 1(800) 458-5262

PROBLEM: REC Counter does not reset / register / counts intermittently

PROBABLE CAUSE: Counter is not receiving pulses during delivery.

SOLUTION:

1) Set up a delivery in Mode #1 and ensure that product flow is registering on the Lap-Pad. If not,

see Product flow does not register on Lap-Pad or REC display

2) Loosen the screws on the REC display cover and gently pull the cover outward to expose the

2 fiber-optic cables. Loosen one of the collars securing the fiber-optic cables to the display

board. Slide the collar away from the fiber-optic cable end approximately ¼” and reseat the

cable. Tighten the collar on the fiber-optic connector ‘finger tight’. Using the same method, reseat the remaining cable. Attempt a delivery and check the rear display to see if it is counting

properly.

3) Remove the (12) 7/16” bolts securing the REC cover. Dis-connect the coiled phone cable and

set it aside. Remove the 2 screws securing the metal ‘L’ bracket to the under-side of the REC

cover. Using the above method, Reset the fiber-optic cables on the I/R driver board. ( part #

81316) Re-install the metal bracket.

4) If the problem persists, replace the following assemblies with known working units until the

problem is resolved:

I / R Driver Bd. ( Part # 81316)

Display Bd. ( Part # 81277)

Coiled Cable (Part #81330)

Signal Harness (Part # 81340)

REC Bd. (Part # 81268)

33

Page 34

Dual Meter Switch Box (if applicable, Part # E2535-1)

PROBLEM: Product flow does not register on Lap-Pad or REC display. (Units with POD type

pulser)

PROBABLE CAUSE: Pulser shaft is not turning with product flow

Pulser Failure

SOLUTION:

1) In Mode # 1, select a product code and initiate a delivery. Do not flow product.

2) Remove the cover from the POD pulser assembly by rotating the cover counter-clockwise.

3) Remove the 3 phillips screws securing the pulser assembly and gently pull the pulser out,

taking care not to damage the attached wiring harness.

4) Manually spin the pulser shaft and monitor the REC display.

5) If the REC display counts, this may indicate a mechanical problem. Contact your local Liquid

Controls Service Center or the Liquid Controls Service Department for additional assistance.

6) If the REC display does not count, see PULSER FAILURE.

PROBLEM: REC Counter display is blank

PROBABLE CAUSE: 9VDC Lithium Battery is low / dead

SOLUTION:

If the display goes blank during the first year of service, replace the display board( LC Part# 81277

) If the display goes blank after more than a year, replace the display board battery (LC Part#

71022)

PROBLEM: “Pulser Failure” appears on Lap-Pad

PROBABLE CAUSE: Missing pulse counts / excessive reversals

SOLUTION:

1) Determine which meter is causing the problem. Attempt to make a delivery for

products assigned to both Meter 1 and Meter 2. The Lap-Pad will show a failure for

the suspect meter.

2) Isolate the Dual Meter Switch box. After determining which meter is causing the

problem, isolate the Dual Meter Switch Box by removing the wiring harness ( grey / black

cable) from either the Meter #1 or Meter #2 position and plug the cable directly into the

Supervisory Console. To do this, first remove the grey / black cable from the back of the

Supervisory Console. Attempt to make a delivery. If the problem is corrected, replace the Dual

Meter Switch Box (Part # E2535-1).

3) Check the pulser output

Select a product code in Mode #1 for the suspect meter. Remove the 12 bolts securing the

REC cover. Lift the cover and remove the coiled phone cable. Set the cover to the side, taking

care not to damage the phone cable connector. Using a reliable voltmeter, measure the

following DC voltages on the REC board (part # 81268)

Terminal # Voltage

J3 #19 +12.6VDC

J3 #18 +6VDC±.5 or 0VDC

J3 #17 +6VDC±.5 or 0VDC

If any of the readings below are observed, check for loose pulser wiring connections. If no loose

connections are found, replace the signal harness. (part # 81340)

34

Page 35

Terminal # Voltage

J3 #19 0VDC

J3 #18 2VDC (or higher)

J3 #17 12VDC (or higher)

Select a product code corresponding to the suspect meter. Insert a ticket into the EPSON printer ,

and begin a delivery. With product flowing through the meter, measure the following DC voltages

on the REC board (part # 81268)

Terminal # Voltage

J3 #19 +12.6VDC

J3 #18 +3VDC± .5VDC

J3 #17 +3VDC± .5VDC

If the following voltages are observed, ensure that the pulser shaft is rotating. Look for any

mechanical problems which may cause either the meter or pulser shaft to lock-up.

Terminal # Voltage

J3 #19 +12.6VDC

J3 #18 +6VDC±.5 or 0VDC

J3 #17 +6VDC±.5 or 0VDC

If the Lap-Pad continues to indicate a pulser failure, replace the pulser board (part # 811521 or

81159 for POD pulsers)

PROBLEM: Valve will not open (single-stage)

PROBABLE CAUSE: Solenoids Inactive / Inoperative

SOLUTION:

1) In Mode # 1, select a product code, insert a delivery ticket into the EPSON printer and start a

delivery.

1) Move the selector switch from ‘RUN’ to the ‘EMERGENCY STOP’ and back to the ‘RUN’

position, listening for an audible ‘clicking’ from the solenoid.

If the solenoid clicks:

This may indicate a mechanical problem with the valve or its associated components. Refer the

problem to a qualified Liquid Controls Service Center.

If the solenoid does not click:

1) Remove the (12) 7/16” bolts securing the REC cover. Lift the cover and remove the coiled

phone cable. Set the cover to the side, taking care not to damage the phone-type cable

connector.

2) Using a reliable voltmeter, measure the following DC voltages on the REC board (part #

81268)

Terminal # Voltage

J4 # 20 1.0VDC ± .5VDC

J4 # 21 12.0VDC ± 1.5VDC

J4 # 22 1.0VDC ± .5VDC

J4 # 23 12.0VDC ± 1.5VDC

35

Page 36

If the above voltages are correct:

This may indicate a mechanical problem with the valve or its associated components. Refer the

problem to a qualified Liquid Controls Service Center.

If the above voltages are NOT correct:

Replace the following components with known-working units until the problem is resolved:

CPU Board* (part # 81204)

Signal Harness (part # 81340)

*Contact your local Liquid Controls Service Center or contact the Liquid Controls Customer Service

Department for assistance.

PROBLEM: Valve will not open (Dual Stage).

PROBABLE CAUSE: Solenoids Inactive / Inoperative.

SOLUTION:

1) Remove the (12) 7/16” bolts securing the REC cover. Lift the cover and remove the coiled

phone cable. Set the cover to the side, taking care not to damage the phone-type cable

connector.

2) Using a reliable voltmeter, measure the following DC voltages on the REC board ( part #

81268)

Terminal # Voltage

J4 # 20 1.0VDC ± .5VDC

J4 # 21 12.0VDC ± 1.5VDC

J4 # 22 1.0VDC ± .5VDC

J4 # 23 12.0VDC ± 1.5VDC

If the above voltages are correct:

This may indicate a mechanical problem with the valve or its associated components. Refer the

problem to a qualified Liquid Controls Service Center.

If the above voltages are not correct:

Replace the following components with known-working units until the problem is resolved:

CPU Board* (part # 81204)

Signal Harness (part # 81340)

*Contact your local Liquid Controls Service Center or contact the Liquid Controls Service center for

assistance.

36

Page 37

PROBLEM: “Ram-Card Disconnected” appears on Lap-Pad

TROUBLESHOOTING

PROBABLE CAUSE: Ram-Card is disconnected from the Supervisory Console

SOLUTION:

Reseat the Ram-Card. If this does not correct the problem, replace the following components until

the problem clears:

Ram-Card ( Part # E4101x )

Ram Module ( Part # E4310-1)

Cable ( Part #81248 )

PROBLEM: “Invalid Ram-Card Status” appears on Lap-Pad

PROBABLE CAUSE: Ram-Card contains invalid account information

SOLUTION:

Refer to the LectroCount3 Owner’s Manual for instructions on clearing the Ram-Card

Due to the complexity of the LectroCount3 system, this trouble-shooting guide cannot cover all

possible situations. Call your local Liquid Controls Service Center or the Liquid Controls Electronic

Customer Service department for any problems which are not covered by this guide.

It may be necessary to break Weights & Measure seals to perform certain trouble-shooting steps in

this guide. Contact your local Weights & Measures authorities for information before breaking any

seals.

Use extreme caution when taking any and all electrical measurements in hazardous environments

to avoid potential electrical shorts and / or sparking.

When taking measurements, always use a reliable digital volt-meter.

37

Page 38

38

P/N 70946

P/N 70945

SINGLE METER TRUCK SYSTEM WIRING DIAGRAM - NEGATIVE GROUND

Page 39

METER #1 REMOTE S.C. CONTROL BOX WIRING

39

Page 40

DUAL METER TRUCK SYSTEM WIRING DIAGRAM – NEGATIVE GROUND

81242 SIGNAL CABLE

40

Page 41

LECTROCOUNT (SHEET 1 OF 2)

E2535 –1 DUAL METER SWITCH ASSEMBLY

81340

81340

89044 NEGATIVE GROUND DUAL METER TRUCK SYSTEM

EO 320 REV. A

1-2-96

41

Page 42

METER #1 REMOTE S.C. CONTROL BOX WIRING

42

Page 43

MOUNTING ARRANGEMENT

FOR SYSTEMS WITH MOUNTING BRACKETS

SINGLE METER SYSTEM

DUAL METER SYSTEM

43

Page 44

SOLD AND SERVICED BY

A NETWORK OF HIGHLY TRAINED

Distributed By:

Backed By Our Worldwide Reputation For

1999 Liquid Controls Printed in U.S.A. (0799) Bulletin #49137C

FULL SERVICE DISTRIBUTORS

Quality, Accuracy and Advanced Design.

Warranty:

Liquid Controls, L.L.C. (“Seller”) products are warranted against

defects in materials or workmanship for a period of one (1) year

from date of installation, provided that the warranty shall not

extend beyond twenty-four (24) months from the date of original

shipment from seller. Seller’s obligations, set forth below, shall

apply only to failure(s) to meet the foregoing obligations

provided that seller is given written notice within (30) days of

any occurrence from which a claim of defect arises. If a warranty

dispute occurs, the purchaser shall be required to provide Seller

with proof of date of sale. The minimum requirement to establish

date of sale shall be a copy of the Seller’s invoice. In the event

that a factory inspection by Seller or its designee(s) supports the

validity of a claim, at the discretion of Seller, repair, replacement

or refund shall be sole remedy for defect

LIQUID

CONTROLS, LLC

CONTROLS

105 Albrecht Drive

Lake Bluff, IL 60044-2242

Telephone: (847) 295-1050

FAX: (847) 295-1057

Website: www.lcmeter.com

and shall be made, free of charge, ex-works factory. In no event

shall Seller be liable for any special, consequential, incidental,

indirect or exemplary damages arising out of warranty, contract,

tort, (including negligence) or otherwise, including but not

limited to, loss of profit or revenue, loss of use of the product or

any associated products and/or equipment, cost of substitute

goods or services, downtime costs or claims of or by Purchaser’s

clients or customers. In any event, the total liability of Seller for

any and all claims arising out of or resulting from the

performance, non-performance or use of the product shall not

exceed the purchase price of the individual product giving rise to

the claim. All other guaranties, warranties, conditions and

representations, either express or implied, whether arising under

any statute, common law, commercial usage or otherwise are

excluded. Electronic Products require

Installation, start-up and servicing by local factory-trained

service representatives. In the absence of installation, start-up and

servicing of Electronic Products by Seller trained service

representatives, this warranty is null and void. Seller’s

obligations as set forth above shall not apply to any product, or,

or any component part thereof, which is not properly installed,

used, maintained or repaired, or which is modified other than

pursuant to Seller’s instructions or approval. NOTE: The above

warranty applies only to products manufactured by Liquid

Controls, Lake Bluff, Illinois. Private label, OEM, and/or

products manufactured by Liquid Controls licensee(s) are

specifically excluded from the above warranty. Consult the

factory for all non-Liquid Controls manufacturers’ warranties.

NO IMPLIED OR STATUATORY WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

Loading...

Loading...