Page 1

INSTALLATION & O PERATION

MANUAL

MO D EL IT3 7 5

FIELD MOUNTED RATE INDICATOR AND TOTALIZER

February 2002

Page 2

Sponsler, Inc.

Model IT375

Contents

Pg. 2

CONTENTS

1. Introduction 3

1.1 Model Number Designation 4

1.2 Intrinsic Safety Considerations 4,5

2. Specification 6

3. Operation 7

3.1 Display 7

3.2 Test Mode 7

3.3 Filtering 8

3.4 Calculation of Rate and Total 9

3.5 Total Conversion 9

3.6 Frequency Cutoff 10

3.7 Linearizer 10

4. Programming 11

4.1 Program Steps 12,13

4.1 Flow Chart 14,15

5. Example 16

6. Versions 17

6.1 Battery Powered Version 17

6.2 DC Power Version 18

6.3 Relay and 4-20mA Output Version 19

7. Fl owmeter Inp ut 20,21,22

8. Intrinsic Safety Connections 23

8.1 Coils 23

8.2 Simple Apparatus 23

8.3 Namur Proximity Switches 23,24

8.4 Alarm Outputs 25

9. Installation 26

9.1 Wall Mounting 26

9.2 Panel Mount Version 26

9.3 Removing the Front Panel 27

9.4 The Main Electronics 27

9.5 Wiring 28

9.6 Terminal Designations 28

Index 29

Page 3

Sponsler, Inc.

Model IT375

Introduction

Pg. 3

1. INTRODUCT ION

The Model IT375 Rate Totalizer is a microprocessor-based instrument that accepts a sinewave or pulse input from

Sponsler Company, Inc. Precision Turbine Flowmeters. The instrument displays 5 digits of Flowrate, 7 digits of

Resettable Total and an Accumulated Total. The displayed rate and total values can be in different engineering units.

The instrument is compatible with a wide range of flowmeters. Links on the input board enable the circuit to be

configured for millivolt signals, reed switches, pulse trains and most other signal types.

Although three different versions of the Model IT375 are available, No.3 is the standard.

1. A Battery Powered Version with no outputs.

2. A DC Powered Version with either:

i. high and low flow alarms or

ii. a low flow alarm and pulse output.

3. A Loop Powered Version with 4-20mA output and alarms as above.

The instrument is fully programmable from the front panel; the user can program timebase, K-factors, alarm and 4-20mA

setpoints, decimal placements and filter constants.

The Model IT375 features many improvements, a few are listed below:

The output board can have both ALARMS and a 4-20mA OUTPUT.

The voltage drop across the alarm outputs is only 0.8 VOLTS.

The voltage supply for the DC and loop powered versions can go AS LOW AS 9 VOLTS.

Overall lower current consumption with an improved battery life - 5 YEARS BATTERY LIFE is typical

regardless of the duration of totalizing activity

4-20mA output ACCURACY is 0.05% of span and the LINEARITY is 0.05% of span at 25°C.

The millivolt input can accept signals AS LOW AS 15mVp-p.

Wide input frequency range - 0.01Hz to 10kHz.

Wide Kfactor range - Kfactors from 0.000001 to 999,999 can be programmed.

Available in a PANEL MOUNT version.

The Model IT375 Rate Indicator and Totalizer conforms to the EMC-Directive of the Council of European Communities

89/336/EEC and the following standards:

Generic Emission Standard EN 50081-1 Residential, Commercial & Light Industry Environment.

Generic Emission Standard EN 50081-2 Industrial Environment.

Generic Immunity Standard EN 50082-1 Residential, Commercial & Light Industry Environment.

Generic Immunity Standard EN 50082-2 Industrial Environment.

In order to comply with these standards, the wiring instructions in Section 9.5 must be adhered to.

Page 4

Sponsler, Inc.

Model IT375

Introduction

Pg. 4

Versions:

Mounting Options:

Intr insical ly Safe

Linearized

Model IT375i . 4 0 L

1.1 MODEL NUMBER DESIGNATION

The Model Number of the IT375 describes the power & output options installed and the mounting options.

SR = Strain relief cable entry

PM = Panel Mount

WM = Wall mount

4 = Turbine Adaptor(standard)

XP = Explosion proof

0 = Battery Powered Version

3 = DC powered with battery backup and

alarm outputs

4 = Loop powered with 4-20mA output,

alarm outputs and back up batteries

The above sample part number is the standard IT375 unit.

1.2 INTRINSIC SAFETY CONSIDERATIONS

The Model IT375i is certified for use in hazardous areas and has both CENELEC and CSA NRTL/C approvals.

The Model IT375i certification details are:

CENELEC Approval: Kema.

Type of Protection: Ex ia.

Group: IIB.

Temperature Class: T4 at ambient temperature of 60°C.

CSA NRTL/C Approval

File Number: LR 104 840-5.

Type: Class 1, Groups C and D.

When installing in hazardous areas, the instrument must be installed according to the guidelines in Section 8 and in

accordance with standards for wiring and installation in hazardous areas.

4-20mA/DC Power:

The input can be connected to IS circuits with the following maximum values:

Ui = 28V

Ii = 93mA

Pi = 653mW

The internal capacitance and inductance seen on these terminals is 0.1uF and 0mH.

Relay Outputs:

The outputs can be connected to IS circuits with the following maximum values:

Ui = 28V

Ii = 93mA

Pi = 653mW

The internal capacitance and inductance seen on these terminals is 0.1uF and 0mH.

Page 5

Sponsler, Inc.

Model IT375

Introduction

Pg. 5

Fl owmeter Inp ut:

Entity parameters on the flowmeter enable connection to a wide range of approved sensors.

Input parameters are:

Ui = 24V

Ii = 20mA

Pi = 320mW

The internal capacitance and inductance seen on these terminals is 0.002uF and 0mH.

Output parameters are:

Uo = 10.0V

Io = 9.0mA

Maximum allowed external capacitance is 60µF.

Maximum allowed external inductance is 1.5H.

Page 6

Sponsler, Inc.

Model IT375

Specifications

Pg. 6

2. SPECIFICATION

General:

Display: LCD which is continuously powered.

Resettable Total: 7 digits with 10mm (0.4") high digits. Resettable from front panel.

Accumulat ed Total : Displayed when the ACCUM TOTAL button is depressed.

Rate: 5 digits with 8.5mm (0.33") high digits.

K-factor: The pulses per unit of measure (eg. pulses/gallon) is programmable in the range 0.000001

to 999,999.

Decimal Points: Decimal point positions are fully programmable for both rate and total.

Timebase: Rate can be displayed in units per second, minute, hour or day.

Frequency Range: 0.01Hz to 10kHz.

Signal Type: Link settable for sinewave (15mV P-P minimum), open collector, reed switch, pulse or

Namur proximity switch.

Battery Powered Version:

Type: Two lithium battery packs.

Batt ery Life: 5 years typical.

Loop Powered 4-20mA Output Version:

Scale: The 4mA and 20mA points are programmable.

Resolution and Linearity: 0.05% of span.

Accuracy: 0.05% of span at 25°C.

0.1% (typ) of span, full temperature range.

Update Time: 0.5 second.

Connection: Two-wire.

Loop Power Supply: 9-28 Volts.

Supply Backup: Lithium battery

DC Power/Alarm Version:

Outputs: Two optically isolated open collector outputs suitable for driving DC solenoids or

external relays. The outputs can be programmed to provide high and low flow alarms or

pulse output and low flow alarm.

Saturation: .8Volts

Switching Power: 200mA. 30VDC maximum.

DC Power Input: 9-28 Volt at 4mA maximum.

Supply Backup: Lithium battery.

Output Pulse Frequency: 500Hz Maximum

Output Pulse Duration: 1ms if CAL0 = 2 (unscaled pulse output).

If CAL0 = 1 (scaled pulse output) the duration of the pulse automatically adjusts to the

output frequency:

a. 1ms if output > 50Hz.

b. 10ms if output = 5...50Hz.

c. 100ms if output < 5Hz.

Physical:

Temperature: Operating temperature: -20°C to 60°C.

Dimensions: 97mm (3.8") high x 150mm (5.9") wide x 41mm (1.6") deep (cable glands not included).

Protection: Sealed to Nema 4X or IP67 standards.

Cable Entry: By cable glands.

Turbine Meter Adaptor: An optional mounting stem is available for mounting the Model IT375 directly on turbine

flowmeters which have a 1" NPT boss or 1" BSP boss.

Optional Mounting:

Wall: Universal mounting bracket supplied as standard.

Pipe: A galvanized metal bracket is available which enables the Model IT375 to be attached to

a 2" vertical or horizontal pipe.

Panel: Supplied with mounting brackets. Terminals accessible from rear.

The panel mount version is not watertight.

Cutout: 141mm (5.6") wide x 87mm (3.4" high).

Page 7

Sponsler, Inc.

Model IT375

Operation

Pg. 7

ACCUM

3. OPERATION

The Model IT375 Rate Indicator and Totalizer accepts a sinewave or pulse input from a wide range of flowmeters. The

instrument is fully programmable with all operating parameters and calculation constants programmable from the front

panel. The setup parameters are stored in a non-volatile memory and are retained for at least 40 years in the event of a

power loss.

3.1 DISPLAY

The Model IT375 displays:

Rate

Resettable Total

Accumulated Total

Both the Rate and Resettable Total are displayed continuously. The Accumulated Total is displayed only when the

ACCUM TOTAL key is depressed.

The keys on the front of the IT375 have the following functions:

Depressing this key will display the

TOT AL

Ac cu mulated Total .

RESET

Depressing this key resets the Resettable Total

at any time.

Depressing this key advances the Program Mode scroll

PROGRAM

3.2 TEST MODE

The IT375 has a Test Mode which can be entered by simultaneously depressing all 3 front panel keys. The tests and

results are as follows:

Low Test Depressing the ACCUM TOTAL key, the low alarm output (if installed) will go low. If

a 4-20mA option is installed, the output will go to 4mA.

High Test Depressing the RESET key, and depending on the programmed pulse output mode, the

high alarm output (if installed):

a. will go low if CAL0 = 0 (low and high alarms)

b. will output 100ms pulses every 0.5 sec if CAL0 = 1 (scaled pulse output).

c. will output 1ms pulses every 0.5 sec if CAL0 = 2 (unscaled pulse output).

If a 4-20mA option is installed, the output will go to 20mA.

Display Test Depressing the PROGRAM key, all segments of the display will flash.

To exit the Test Mode, simultaneously depress all three front panel keys.

Page 8

Sponsler, Inc.

Model IT375

Operation

Pg. 8

Filter Factor vs Time to Reach New Reading

(for a step change in input signal)

0

20

40

60

80

100

120

0 10 20 30 40 50 60 70 80 90 100

Filter Factor

Time to Reach % of

New Reading (seconds)

90% of New Reading 99% of New Reading

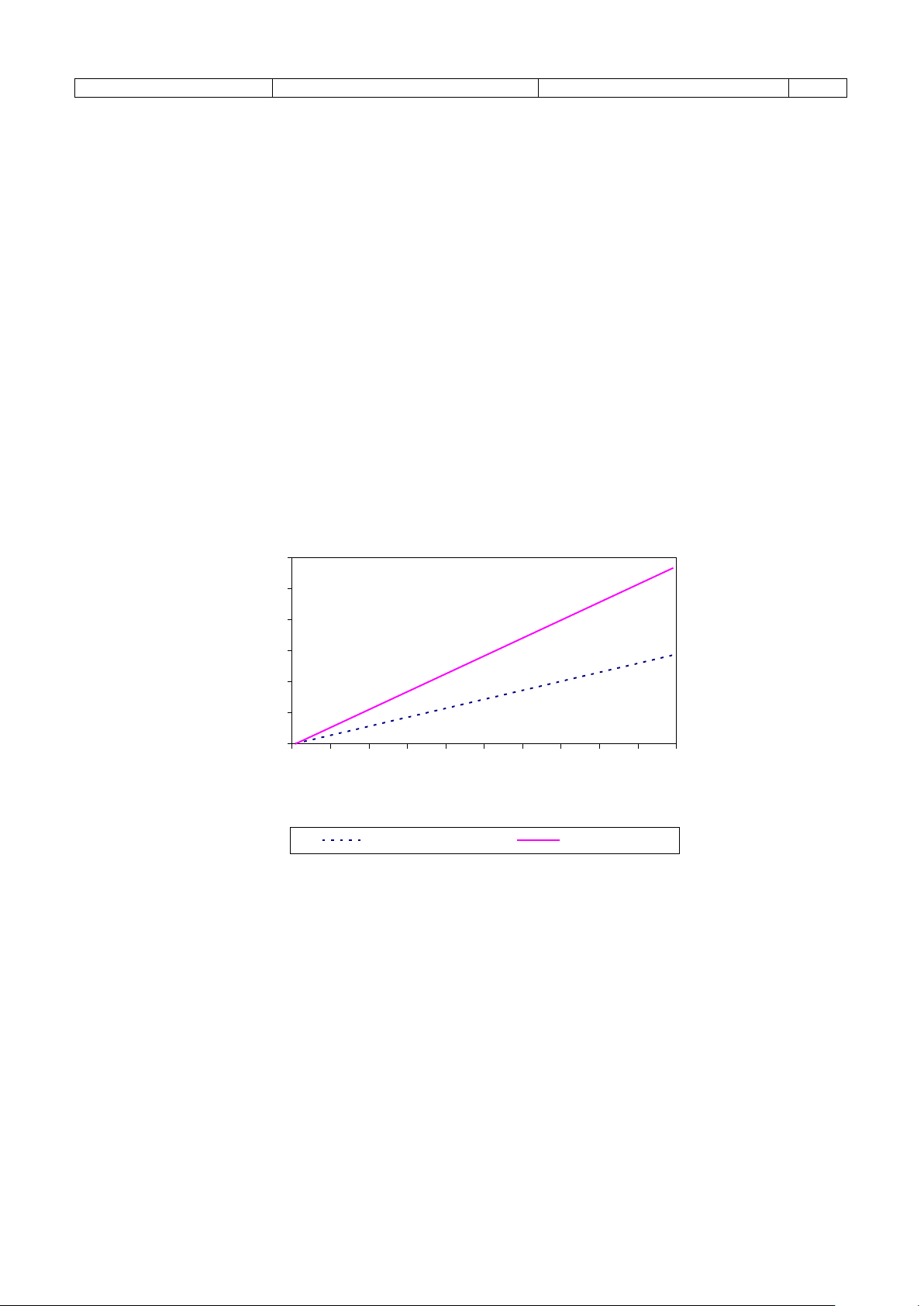

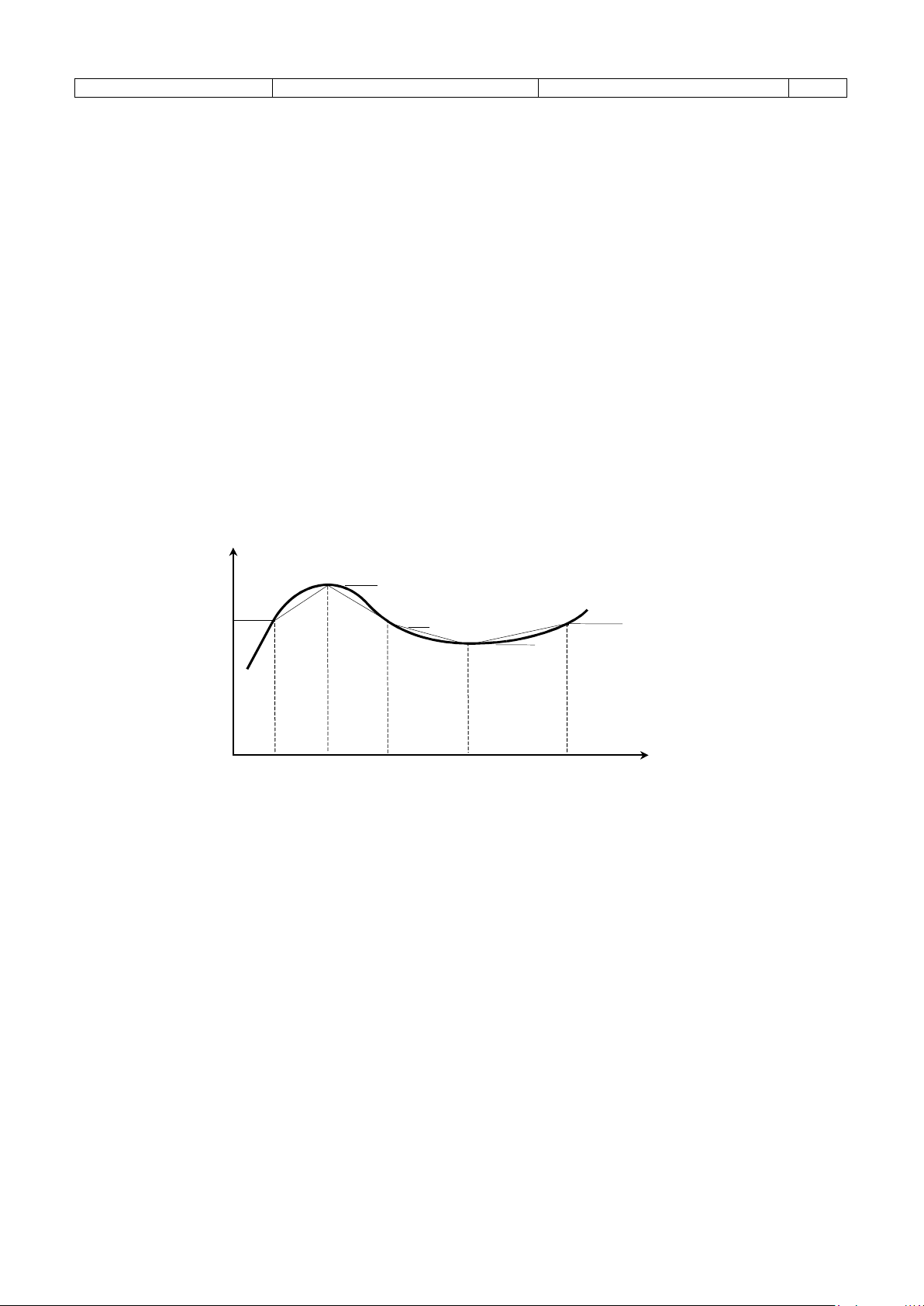

3.3 FILTERING

Frequency fluctuations caused by pulsating flow through a flowmeter can interfere with the precision of the displayed

rate. For this reason, the Model IT375 has a programmable digital filter which will average out these fluctuations and

enable accurate, stable readings.

The degree of filtering of the input signal can be adjusted depending on the magnitude of fluctuation and the particular

application. Values from 1 to 99 can be programmed where 1 corresponds to no filtering and 99 corresponds to

heavy filtering. Such flexibility in filtering allows each application to be addressed on it’s merits.

When programming the degree of filtering, it is advisable to start with no filtering (the factor equals 1) and gradually

increase until a steady reading is obtained. It is important that the filtering is not too heavy because this will cause an

overdamped (slow) response to changes in the flowrate.

The following graph shows the time to reach 90% and 99% of a new reading for a step change in input signal.

Page 9

Sponsler, Inc.

Model IT375

Operation

Pg. 9

3.4 CALCULATION OF RATE

The flow rate, R, is calculated as follows:

f x H

R=

K

where f is the input frequency in Hz (pulses/second).

H is the timebase of rate and is 1 for seconds, 60 for minutes, 3600 for hours and 86,400 for days.

K is the Kfactor (pulses/unit volume).

The Kfactor is flowmeter dependent and is supplied with the flowmeter. It will be either on a calibration certificate or

stamped on the body of the meter.

The user programs the Kfactor and selects the timebase during the programming procedure.

3.5 TOTAL CONVERSION

The Total Conversion Factor is programmed to enable the rate to be displayed in one engineering unit and the totals to

be displayed in another. For example, the rate can be displayed in gallons/minute and the totals in barrels.

The Total Conversion Factor is a division factor which is used to convert the totals to a different engineering unit than

the rate unit. Therefore, it only affects the totals (both resettable and accumulated).

Example:

If the Rate is required in gallons/minute:

1. The Kfactor would be programmed as pulses per gallon.

2. The Timebase would be programmed as minutes.

If the Totals are required in barrels:

1. The Total Conversion Factor is programmed as 42 because there are 42 gallons in a barrel. All totals will now

totalize in barrels.

Below is a table containing common units and their corresponding Total Conversion constants:

Rate/Unit Time Totals

Gallons (US)/Unit Time

Litres/Unit Time Kilolitres 1000

Litres/Unit Time m3 1000

ml/Unit Time Litres 1000

Mgallons/Unit Time Acre-feet 0.32587

Equivalency ≤ 1 rate unit ÷ equivalency

Equivalency ≥ 1 rate unit ÷ reciprocal of equivalency (1/equivalency)

Barrels (oil) 42.000

Total Conversion Factor

Page 10

Sponsler, Inc.

Model IT375

Operation

Pg. 10

Scaling Factor

Out 1

Out 2

Out 3

Out 4

Out 5

Frequency

0

Inp 1

Inp 2

Inp 3

Inp 4

Inp 5

3.6 FREQUENCY CUTOFF

A frequency cutoff can be programmed below which flow rate is not registered.

Input frequencies at or below the cutoff are totalized, however, the rate is displayed as zero.

The frequency cutoff has a default value of 0.25Hz. The cutoff should be left as 0.25Hz unless the flowmeter in use has

a lower frequency.

Note that the lower a cutoff frequency the correspondingly longer response time for flow rate to update. For example, if

the cutoff is set to 0.01Hz the Model IT375 will continue to display the flow rate for 100 seconds even if the signal

stops. This is because a cutoff frequency of 0.01Hz means that the time interval between signals is 100 seconds (period

= 1/frequency), therefore, the Model IT375 must wait 100 seconds before it can determine that the flow has actually

stopped.

3.7 LINEARIZATION

The following dia gram graphs the change in K-factor with frequency for a hypot hetical flowmeter. The heavy

black line re presents t he actual K-fac tor of t he flowmete r, while the light black line is the a pproximat ion

used i n the instrument.

Up to 10 frequencies and K-factors can be programmed. Frequencies must be programmed in ascending

orde r. L inea r Int er pola tion i s use d be t ween poi nt s. If an i nput fre que nc y is l ess t han t he f irst (l owest) o r

greater than the last (highest) pr ogr ammed frequency, the K-factor will remain a constant value.

Note: Display update time increases to 1sec if the linearizer is enabled in the battery powered version

of the Mod el IT375.

Page 11

Sponsler, Inc.

Model IT375

Programming

Pg. 11

4. PROGR AMMI NG

The Model IT375 is fully programmable with all parameters being stored in non-volatile memory.

The Program Mode can be entered in one of two ways:

1. By removing the lower cover strip (ie. the dark grey strip along the bottom of the enclosure) and reversing it’s left

– right orientation. This brings a small magnet on the inside of the cover strip in contact with a reed switch inside

the instrument.

2. By removing the front section of the enclosure which contains the main processor board and batteries.

The PROGRAM key is used to step through the program (CAL sequences) and the ACCUM TOTAL and RESET keys

on the front panel are used to change and increment the flashing digits.

Note that only flashing digits can be changed.

Up to eighteen CAL steps are accessible depending on which options are installed. The CAL number is displayed in the

lower right display and the parameter is displayed above it.

Parameters in Program Mode that consist of whole numbers and digits after the decimal point are restricted to a

maximum of 6 digits combined. Therefore, the number of significant digits entered as whole numbers will determine the

number of available digits after the decimal point.

Example:

The entry of 1, 100 and 10,000

000001 in the whole numbers leaves 5 digits available after the decimal point

000100 in the whole numbers leaves 3 digits available after the decimal point

010000 in the whole numbers leaves 1 digit available after the decimal point

Page 12

Sponsler, Inc.

Model IT375

Programming

Pg. 12

Step

Comment

CAL 00

Pulse Output (applies to DC Power/Alarm version only).

0 = No pulse output, low and high alarms.

CAL 01

Kfactor - whole numbers.

CAL 02

Kfactor - digits after the decimal point.

The Kfactor is the pulses per unit of measure (eg. pulses/litre,

CAL 03

Cutoff Frequency.

This determines the cutoff frequency in the range of 0.01 -

ken when programming this value

CAL 04

Decimal Point for Rate Display.

The flow rate can be displayed with 0, 1, 2 or 3 places after the

CAL 05

Timebase for Rate.

The rate can be displayed in units per second, minute, hour or

CAL 06

Filter.

The filter constant for filtering the input signal.

CAL 07

Decimal Point for Total Display.

The totals can be displayed with 0, 1, 2 or 3 places after the

CAL 08

Total Conversion Factor - whole numbers.

CAL 09

Total Conversion Factor - digits after the decimal point.

CAL 10

Low Alarm - whole numbers.

CAL 11

Low Alarm - digits after the decimal point.

4.1 PROGRAM STEPS

1 = Scaled pulse output and low alarm.

2 = Unscaled pulse output and low alarm.

pulses/gallon, etc). The Kfactor can be programmed in the

range of 0.000001 - 999,999.

See Section 3.4.

0.99Hz. The default setting is 0.25HZ.

Note that care must be ta

because a low value may cause a slow update time.

decimal point.

day.

0 = second

1 = minute

2 = hour

3 = day

1 No filtering.

to

99 Very heavy filtering.

decimal point.

Page 13

Sponsler, Inc.

Model IT375

Programming

Pg. 13

Step

Comment

CAL 10 & 11 program the flow rate below which the low

CAL 12

High Alarm or Pulse Output Factor - whole numbers.

CAL 13

High Alarm or Pulse Output Factor - digits after the decimal

CAL 12 & 13 program the flow rate above which the high

CAL 14

4mA Setpoint- whole numbers.

CAL 15

4mA Setpoint- digits after the decimal point.

CAL 14 to CAL 15 represent the flow rate at which 4mA will

CAL 16

20mA Setpoint- whole numbers.

CAL 17

20mA Setpoint- digits after the decimal point.

CAL 16 & 17 represent the flow rate at which 20mA will be

CAL 18

Number of linearization points.

00 = linearizer disabled

INP 01

Point #1 Frequency – whole numbers.

Input points must be programmed in ascending frequency

INP.01

Point #1 Frequency – digits after the decicmal

OUT 01

Point #1 Kfactor – whole numbers.

Kfactors can never be zero

OUT.01

Point #1 Kfactor – digits after the decimal.

SOFT

Software Version.

alarm relay will close. The value can be programmed in the

range 0 to 999,999.

point.

alarm relay will close. The value can be programmed in the

range 0 to 999,999.

If the scaled pulse output is selected (CAL0 = 1), then the

value will represent the total per pulse, eg. 5 liters per pulse.

be output. If the 4-20mA output is not installed, these

parameters can be ignored.

output. If the 4-20mA output is not installed, these parameters

can be ignored.

xx = number of points

order

Page 14

Sponsler, Inc.

Model IT375

Programming

Pg. 14

0 = SECOND, 1 = MINUTE, 2 = HOUR, 3 = DAY

RATE TIMEBASE

0

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

0

3

TOT AL D I SPLAY

PRESS KEY TO INCREMENT FLASHING DIGIT

0

3

K-FACTOR

PROGRAMMING

1468523

0

K-FACTOR

PROGRAM

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

0-999999

CUTOFF

000

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

.0.01 - .99 HZ DEFAULT @2.5 HZ

RATE DISPLAY

PROGRAM

0

3

FILTER

1

TOTAL CONVERSION

PRESS KEY TO INCREMENT FLASHING DIGIT

0 - 999999

PROGRAM

.000001 - .999999

PRESS KEY TO INCREMENT FLASHING DIGIT

0 - 999999

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

.000001 - .999999

LOW ALARM

FLASHING DIGIT

1 - 999999

.000001 - .999999

INITIATE – REMOVE & REVERSE BOTTOM STRIP

EXIT – REPEAT ABOVE STEP

TOTAL

RATE 79.4

0 =

PULSE OUTPUT

WHOLE NUMBERS

DIGITS AFTER DECIMAL

FREQUENCY

PLACES AFTER DECIMAL

1

2

0

CAL 00

000000

CAL 01

000000

CAL 02

PROGRAM

CAL 03

1

2

1

2

99

PROGRAM

0

CAL 04

CAL 05

01

CAL 06

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

SOFT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

0 = NO OUT PUTS

1 = SCALED PULSE OUTPUT & LOW ALARM

2 = UNSCALED PULSE OUTPUT & LOW ALARM

.000001 - .999999

COMBINATION

CAN’T EXCEED

6 D IGITS

PLACES AFTER DECIM AL

TOTAL CONVERSION

FACTOR WHOLE NUMBERS

DIGITS AFTER DECIMAL

LOW ALARM

WHOLE NUMBERS

DIGITS AFTER DECIMAL

CAL 07

000000

CAL 08

000000

CAL 09

000000

CAL 10

000000

CAL 11

0

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT D IGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

1

2

PROGRAM

PROGRAM

PROGRAM

CONTINUED ON NEXT PAGE

COMBINATION

CAN’T EXCEED

6 D IGITS

COMBINATION

CAN’T EXCEED

6 D IGITS

Page 15

Sponsler, Inc.

Model IT375

Programming

Pg. 15

FLASHING DIGIT

CONTINUED FROM PREVIOUS PAGE

HIGH ALARM OR

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

.000001 - .999999

COMBINATION

4mA SETPOINT

PROGRAM

4mA SETPOINT

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

20mA SETPOI NT

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

00

LINEARIZATION

00

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

POINT #1 FREQUENCY

COMBINATION

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

0 - 999999

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

.000001 - .999999

COMBINATION

PROGRAM

PRESS KEY TO INCREMENT FLASHING DIGIT

.000001 - .999999

POINT #1 K-FACTOR

POINT #1 K-FACTOR

COMBINATION

0 - 999999

.000001 - .999999

0-999999

.000001 - .999999

COMBINATION

000000

00 = LINEARIZED DISABLED

SOFT

PROGRAM

SOFTWARE VERSION

CAL 00

PULSE OUTPUT F ACTOR

WHOLE NUMBERS

HIGH ALARM OR

PULSE OUTPUT F ACTOR

DIGITS AFTER DECIMAL

WHOLE NUMBERS

DIGITS AFTER DECIMAL

WHOLE NUMBERS

0 =

CAL 12

000000

000000

CAL 13

PROGRAM

000000

CAL 14

000000

CAL 15

CAL 16

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT D IGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

0-999999

CAN’T EXCEED

6 D IGITS

CAN’T EXCEED

6 D IGITS

CAN’T EXCEED

6 D IGITS

20mA SETPOI NT

DIGITS AFTER DECIMAL

POINTS

WHOLE NUM BERS

POINT #1 FREQUENCY

DIGITS AFTER DECIMAL

WHOLE NUMBERS

DIGITS AFTER DECIMAL

000000

CAL 17

PROGRAM

10

XX

CAL 18

00

000000

INP 01

000000

INPUT 01

000000

OUT 01

000000

OUT 01

PROGRAM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO INCREMENT FLASHING DIGIT

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

PRESS KEY TO ADVANCE TO NEXT DIGIT

PRESS PROGRAM TO ADVANCE TO NEXT MENU ITEM

XX = NUMBER O F POINTS

0 - 999999

CAN’T EXCEED

6 D IGITS

CAN’T EXCEED

6 D IGITS

202d3.2L

Page 16

Sponsler, Inc.

Model IT375

Example

Pg. 16

Value of

CAL00

0

No Pulse Output

CAL01

000148

Kfactor (whole numbers)

CAL02

914

Kfactor (decimals)

CAL03

0.25

Cutoff Frequency

CAL04

1

Rate decimal position

CAL05

1

Timebase

CAL06

01

Filter disabled

CAL07

0

Total decimal position

CAL08

000000

Total Conversion (whole numbers)

CAL09

264201

Total Conversion (decimals) (1/3.785)

CAL10

000015

Low Alarm (whole numbers)

CAL11

0000

Low Alarm (decimals)

CAL12

000225

High Al arm (whole numbers)

CAL13

000

Hi gh Ala rm (de c imals)

CAL14

000015

4mA Output (whole numbers)

CAL15

0000

4mA Output (decimals)

CAL16

000225

20mA Output (whole numbers)

CAL17

000

20mA Output (decimals)

CAL18

3

3 point linearization

INP 01

000037

Point #01 frequency (whole numbers)

INP.01

0746

Point #01 frequency (decimals)

OUT 01

000148

Point #01 Kfactor (whole numbers)

OUT.01

085

Point #01 Kfactor (decimals)

INP 02

000268

Point #02 frequency (whole numbers)

INP.02

338

Point #02 frequency (decimals)

OUT 02

000148

Point #02 Kfactor (whole numbers)

OUT.02

073

Point #02 Kfactor (decimals)

INP 03

000563

Point #03 frequency (whole numbers)

INP.03

061

Point #03 frequency (decimals)

OUT 03

000148

Point #03 Kfactor (whole numbers)

OUT.03

080

Point #03 Kfactor (decimals)

SOFT

202d3.2L

Software Version

5. EXAMPLE

A typical 2 inch liquid flowmeter has an operating range of 15 – 225 gpm and produces 148.914 pulses per gallon with a

maximum output frequenc y of 563Hz. 3 points of linearization is required. The flow rate is displayed in gallons/ min

with 1 decimal point and the total i n liters wi th no decimals. A 4-20mA output is installed and 4mA is to represent 15

gallons/min and 20mA is to represent 225 gallons/min The instrument is then programmed as follows:

Calibration mode i s entered by removing the lower cover strip (ie. the dark grey strip along the bottom of the enclosure)

and reversing it’s left right orientation.

The following values are then entered:

Step

Parameter

Description

Page 17

Sponsler, Inc.

Model IT375

Versions

Pg. 17

6. VER SIONS

This table summarizes features of each of the different Model IT375 versions:

Model Number IT375i.X0L IT375i.X3L IT375i.X4L

Version

Power

Output

Supply Backup

The standard unit is intrinsically safe (i), turbine mounted (4), battery powered (0) and linearized (L)

X denotes the mounting options, insert the corresponding number for the preferred option:

SR Strain relief cable entry

PM Panel mount

WM Wall mount (standard)

4 Turbine adaptor

EX Explosion proof

Battery powered DC powered Loop powered

DC powered;

Lithium batteries

None

None Lithium batteries Lithium batteries

9-28Volts at

4mA maximum

Alarms - two open collector outputs

Pulse output and low flow alarm

IT375i.40L

Loop powered;

9-28 Volts with

4-20mA out

OR

6.1 BATTERY POWERED VERSION

The battery powered version of the Model IT375 is designed for operation in the field without external power sources.

Lithium batteries provide sufficient power to operate the instrument for up to 5 years and the operator is warned of a low

power condition by a message on the LCD display.

New batteries can be purchased via Sponsler Company, Inc. or our distributors and replaced in the field without

compromising the IS approvals. There are two battery packs in each instrument and care must be taken to replace

only one pack at a time so that there is always power connected to the memory. Failure to do this may result in

loss of totals.

Page 18

Sponsler, Inc.

Model IT375

Versions

Pg. 18

Power/4-20mA Loop

Low

Alarm

Opto-

Isolated

Outputs

High

Alarm

4 +

3 -

6 +

5 -

2 +

1 -

A

-

+

mA Me t er

+

-

RL

For

Pulse

Low Alarm

<<

<<

<<

<<

High Alar m

9 - 28 VDC

4-20mA

6.2 DC POWER VERSION

The DC power version will operate from an external power source between 9-28VDC and draws no more than 4mA.

This enables the instrument to be powered from AC mains with DC adaptors and eliminates the need to run separate DC

voltages in the field.

The instrument uses lithium batteries for backup if the DC power is interrupted. However, alarms and/or pulse outputs

are disabled if the DC power is interrupted.

Open collector outputs are also provided for high and low flow rate alarms. If a pulse output is programmed, terminals

5(-) and 6(+) will act as a pulse out. The output can sink up to 200mA and can be used to control external relays, lights

or audible alarms. The outputs are internally protected against inductive voltage spikes caused by relay coils etc. Both

outputs are independent and optically isolated.

The alarm setpoints can be programmed. The low flow alarm will switch on whenever the flow rate drops below the

programmed low flow rate setpoint. Similarly, the high alarm switches on whenever the flow exceeds the high flow rate

setpoint.

If a scaled pulse output is programmed, a pulse will be output every preset value of the total. For example, if the total is

in liters, then programming 5 will output one pulse every 5 liters. If an unscaled pulse output is programmed, output

pulses will occur at the flowmeter input frequency.

Specification for Alarm Outputs

Maximum Current): 200mA. (sink)

Maximum Voltage: 30Vdc.

Saturation Voltage: 0.8Vdc across outputs when in the "on" state.

Isolation: Both outputs are separately isolated.

Pulse Frequency: 500Hz maxi mum.

Pulse Duration: 1ms if CAL0 = 2 (unscaled pulse output).

If CAL0 = 1 (scaled pulse output) the duration of the pulse automat ically adjusts to the

output frequency:

a. 1ms if output > 50Hz.

b. 10ms if output = 5...50Hz.

c. 100ms if output < 5Hz.

Page 19

Sponsler, Inc.

Model IT375

Versions

Pg. 19

6.3 RELAY AND 4-2 0 mA OUTP UT VERSION

This version combines features of the DC powered with a 4-20mA output.

The 4-20mA output provides a two-wire retransmission of the flow rate. Both the 4mA and 20mA setpoints are fully

programmable so that the output can span either the entire operating range or only a portion.

The instrument draws its operating power from the 4-20mA loop and uses the internal lithium batteries for backup if the

4-20mA loop is interrupted. The alarm/pulse outputs are disabled if the 4-20mA loop is interrupted.

Specifications:

Resolution and Linearity: 0.05% of span.

Accuracy: 0.05% of span at 25°C.

0.1% (typ) of span, full temperature range.

Response (4-20mA): 0.5 second.

Loop Power Supply: 9-28 Volts.

Since the 4-20mA output is designed to provide power to the Model IT375, it is not isolated from the input. Hence, all

sensors must be self-powering (such as reed switches and coils). If external power is required to power the sensor (eg.

Namur switches, Hall effect sensors or opto-sensors), the power supply delivering the external power must be isolated

from the 4-20mA loop supply.

Typical Connection

Connection to a Sensor requiring External Power

Page 20

Sponsler, Inc.

Model IT375

Fl owmeter Inp ut

Pg. 20

7. FLOWMETER INPUT

The Model IT375 has an input conditioning circuit which will accept signals from most sinewave or pulse producing

flowmeters. Links on the rear panel enable the input circuit to be configured for different signal types.

The input will interface directly to:

Turbine flowmeters.

Open collector outputs.

Reed switches.

Logic signals.

Two-wire proximity switches.

The following pages give examples of interfacing to various signal inputs. A circuit diagram of the input is also

provided.

For pulse or logic type signals, the input switching threshold is 1.3 volts. That is, the input signal must have a "low"

voltage of less than 1.2 volts and a "high" voltage of greater than 1.4 volts.

For flowmeters with reluctance type coils, the minimum input voltage is 15mVp-p

All inputs are protected for overvoltage up to 28 volts.

Page 21

Sponsler, Inc.

Model IT375

Fl owmeter Inp ut

Pg. 21

Link 3

COIL PULSE

NPS

Switching threshold voltage is 1.3 volts.

Link Settings

Link 1

Link 2

DBL DBH

NPS

Link 1

Link 2

COIL PULSE

DBL DBH

eg. Positive displa c eme nt flowmeters

Link 1

Link 2

COIL PULSE

DBL DBH

NPS

1. Squarewave, CMOS or Pulse

Link Settings

Link 1

Link 2

DB DBH

2. Open Collector

With 15µA/150µA i nternal pull up current

COIL PULSE

Link 3

3. Reed Switch - Battery Powered

With 15µA internal pull up current

Link Settings

Link 3

NPS

with reed switc h outputs.

Note: For a s witch or reed input with co ntact bounce li nk DBL ca n be switc hed "on". T his will elimi nate the effect o f switch bounce while

limiting the input frequency to 200Hz.

4. Reed Switch - External DC Power

With 150µA internal pull up current

Link Settings

Link 3

Note: For a switch or reed input with contact bounce link DBH can be switched "on". This will eliminate the effect of switch bounce while

limiting the input frequency to 200Hz.

Page 22

Sponsler, Inc.

Model IT375

Fl owmeter Inp ut

Pg. 22

COIL PULSE

DB DBH

NPS

825R inpu t impe dance

Link Settings

Link 1

Link 2

DBL DBH

NPS

Link Settings

Link 1

Link 2

Link 3

COIL PULSE

NPS

825R input impedance

Link Settings

Link 3

COIL PULSE

NPS

825R input impeda nc e

8+

7-

+12 Volt s

0 V

5. Coils

Link Settings

Link 1

Link 2

Link 3

eg. Millivolt signal from paddlewheel

or turbine (15mV P-P minimum).

Note: I f the input has a very high impe danc e ,

the follow ing link setti ngs should be use d:

COIL PULSE

Link 3

6. Namur Proximity Switch

DBL DBH

Note: If a 4-20mA output is installe d, t he suppl y to the proximity switch must be isolated.

For IS connections of Namur switches

see Section 8.

7. Namur Proximity Swith – External DC Power

Note: Use this connection for battery or loop powered versions of the Model IT375.

If a 4-20mA output is installed, the supply to the proximity s witch must be isolated.

Link 1

Link 2

DBL DBH

For IS connections of Namur switches

see Section 8.

Page 23

Sponsler, Inc.

Model IT375

Intrinsic Safety

Pg. 23

8. INTRINSIC SAFETY CONNECTIONS

When installing the Model IT375 in hazardous areas, the wiring and installation must comply with appropriate

installation standards.

The approval uses entity parameters on the input for connections to the flowmeter and associated apparatus type approval

for the 4-20 mA output. The 4-20mA output must, therefore, only be connected to barriers with the specified safety

parameters as shown on the following page.

8.1 COILS

The Model IT375 will connect directly to a turbine flowmeter or paddlewheel with a certified Intrinsically Safe (IS) coil

or other certified IS sensor which produce a pulse input provided they do not exceed the following input parameters:

Ui = 24V

Ii = 20mA

Pi = 320mW

The maximum allowed capacitance and inductance of the pulse or coil including the cabling is:

Cext = 60µF

Lext = 1.5H

The interna l capa cit ance and i nduct ance of the Model IT375 seen on the input are negligibly small with Ci = 0.002uF

and Li = 0mH. The maximum voltage and current produced by the Model IT375 on its inputs (terminals 1 to 4) are:

Uo = 10.0V (open circuit)

Io = 9.0mA (short circuit)

8.2 SIMPLE APPARATUS

Devices such as reed switches which can be classed as "simple apparatus", as defined in the CENELEC standards

EN50020, can be connected to the Model IT375 without certification.

8.3 NAMUR PROXIMITY SWITCHES

Connection to certified Namur proximity switches is permitted as shown on the following page with the following

maximum input parameters:

Ui = 24V

Ii = 20mA

Pi = 320mW

Page 24

Sponsler, Inc.

Model IT375

Intrinsic Safety

Pg. 24

MODEL IT375

+ - 2+

1-

8+

7-

IS BARRIER

Input Parameters

ENTITY PARAMETERS FOR INPUT

Ui = 24 V

Uo = 10.0 V

SAFE AREA

HAZARDOUS AREA

+ - I

Namur Proximity Detector

IS CERTIFIED BARRIER

A Namur Switch Input

MODEL IT375

SAFE AREA

HAZARDOUS AREA

Link Setti ngs

Link 1

Link 2

Link 3

COIL

PULSE

DBL DBH

NPS

8+

7-

IS Barrie r

Ro = 3 00 ohm

Uo = 28 V maximum

Io = 9 3 m A maximum

Po = 0.653 W maximum

L/R < specified for selected barrier

EXAMPLES BARRIERS

MTL 187’ 787, 787SP, 3041, 3042,

2441, 2442, 4041, 4045

Pepperl & Fuchs

Z248/Ex, Z488/Ex, Z488/Ex-R,

KHD3-ICR/E X 13 0 20 0, ZG 31/EX

Cable length < 5 km

Rate Totalizer

TER M INALS 7 & 8

Ii = 20 mA

Pi = 320 mW

Ci = 0.002 uF

Li = 0.0

Io = 9.0 mA

Cext = 60 uF

Lext = 1.5 H

Uo = 24 V maximum

Io = 2 0 m A maximum

Po = 320 mW maximum

L/R < specified for selected barrier

And 4-20mA Retransmission

IS Certified

INPUT

Page 25

Sponsler, Inc.

Model IT375

Intrinsic Safety

Pg. 25

IS CERTIFIED BARRIER

SAFE AREA

HAZARDOUS AREA

4 or 6

3 or 5

MODEL IT375

IS Certified Device

8.4 ALARM OUTPUTS

The low alarm and high alarm/pulse output can be connected to suitably certified devices provided the circuit is protected

with a barrier with the maximum safety parameters:

Uo = 28V

Io = 93mA

Pmax = 0.653W

The input capacitance on these terminals is 0.1uF max and the inductance is negligible.

Note: The two alar m outputs must be kept as independent IS circuits and each protected with their own barrier. It i s not

permissible to connect these circuits via a common barrier.

Uo = 28 V maximum

Io = 9 3 m A maximum

Po = 653 mW maximum

Such as an Alarm Lamp

Or IS Solenoid

Page 26

Sponsler, Inc.

Model IT375

Installation

Pg. 26

MODEL IT375

SIGNAL

HIGH

LOW

9-28v

9. INSTALLATION

9.1 WALL MOUNTING

A wall mounting bracket is supplied with each instrument. Round head screws should be used to attach the bracket to the

wall (countersunk screws should not be used). The bracket is mounted first with the tray section at the bottom. The

instrument is then mounted on the bracket with two screws as shown below.

9.2 PANEL MOUNT VERSION

The panel mount version of the Model IT375 is supplied with two panel mount brackets and plug-in terminals which are

accessible from the rear of the instrument.

A diagram of the rear panel is shown below:

ALARM

RELAY 2

ALARM

(PULSE)

INP UT

(INPUT )

RELAY !

POWER/4-20 !mA OUTPUT LOOP

Rear View of IT375 Panel Mount Case

The cutout for the panel mount version is 141mm (5.55") wide x 87mm (3.43") high.

Page 27

Sponsler, Inc.

Model IT375

Installation

Pg. 27

9.3 REMOVING THE FRON T PANEL

The front panel should be removed as follows:

1. Remove the top and bottom cover strips (ie. the dark plastic strip) by levering a screwdriver under one end.

2. Undo the screws retaining the front. Do not remove the screws, they are retained by O-rings.

3. Remove the front panel from the housing.

To replace the front cover, reverse the above procedure. Ensure that the front panel is aligned at connector points before

tightening the screws.

9.4 THE MAIN ELECTRONICS

The front section of the housing contains the microprocessor and display. It is possible to adjust the display contrast via

a small potentiometer on the board. The Display Contrast is shown below and this can be adjusted for optimum contrast

and clarity.

Adjacent to this control is a RESET switch which can be used to reset the microprocessor.

Note: Depressing the RESET switch will reset all totals to zero.

Page 28

Sponsler, Inc.

Model IT375

Installation

Pg. 28

152mm (6.0")

98mm (3.9")

141mm (5.6")

87mm (3.5"

43mm (1.7")

16mm (0.6")

REAR VIEW

SIDE VIEW

Terminal Descriptions

Dimensional Dr awing

All Versions

No.

7

8

Signal Input (-)

Signal Input (+)

4-20mA (-) or OVdc In

11

4-20mA (+) or +9-28Vdc In

2

4-20mA or DC Versions

No.

3

4

Low Alarm (-)

Low Alarm (+)

5

6

High Alarm (-) or Pulse (-)

High Alarm (+) or Pulse (+)

9.5 WIRING

When connecting the IT375 it is good practice to use shielded cable. The shield should be connected to earth at one end

of the cable. The other end of the shield should not be connected.

This wiring practice is mandatory in order to comply with the requirements for Electromagnetic Compatibility as per

EMC-Directive 89/336/EEC of the Council of the European Community

.

9.6 TERMINAL DESIGNATIONS

All versions

8 Pulse (+) / Coil Input

7 Pulse (-) / Coil Input

4-20mA and DC Versions

6 High Alarm (+) or Pulse Output (+)

5 Hi gh Ala rm (-) or Pulse Output (-)

4 Low Alarm (+)

3 Lo w Al arm (-)

4-20mA Output Version

2 4-20mA (+)

1 4-20mA (-)

DC Power Version

2 DC Power (+) +9 to 28V

1 DC Power (-) 0V

Page 29

Sponsler, Inc.

Model IT375

Installation

Pg. 29

Index

4-20mA Output, 19

A

Accumulated Total, 9

Operating

Temperature, 6

Operation, 7

P

Panel Mount, 6,26

Programming, 11

Protection, 6

Pulse Output, 12

B

Battery Powered, 17

C

CAL Sequences, 12

Cutoff Frequency, 11

D

DC Power, 18

Decimal Point, 12

Display, 7

Display Test, 7

F

Filtering, 8

Flow Chart, 14,15

Flow Rate, 9

Frequency Cutoff, 10

H

High Alarm, 13

High Test, 7

R

Rate, 9

Removing the Front Panel, 27

Resettable Total, 7

S

Specification, 6

T

Temperature, 6

Terminal

Designations, 26, 28

Test Mode, 7

Timebase, 12

Total Conversion, 9

W

Wall Mounting, 26

I

Input Signal, 18

Installation, 26

Intrinsic Safety, 5, 23

K

Kfactor, 9,12

L

Link Settings, 19

Low Alarm, 12

Low Test, 7

M

Model Number, 4

O

Page 30

Sponsler Company, Inc.

Model IT375

Index

Pg. 30

Page 31

Sponsler Company, Inc.

Model IT375

Index

Pg. 31

Page 32

© 20 09

Pub. No. MN-IT375

(9/2009)

Loading...

Loading...