Page 1

Installation Manual

Electromagnetic Flowmeters

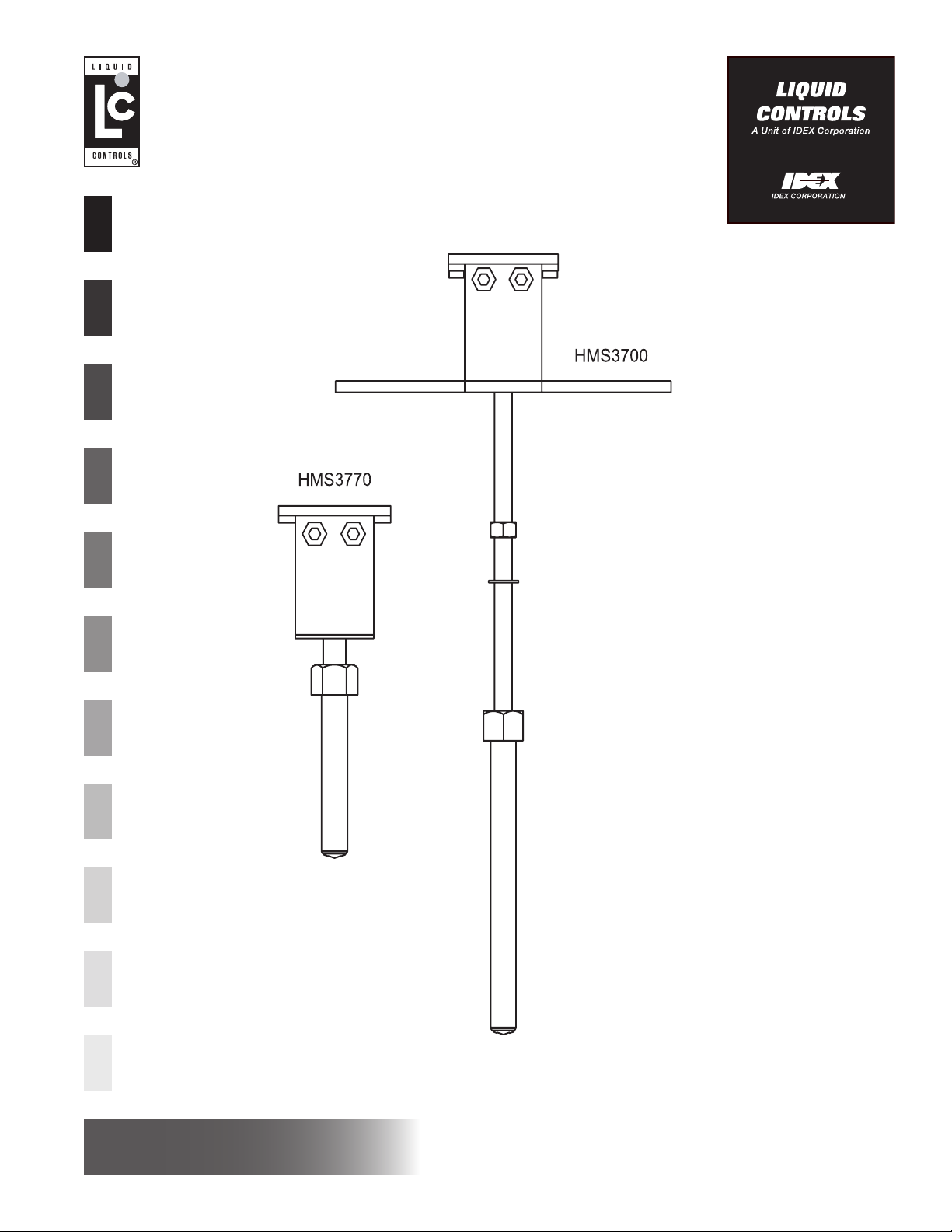

Models HMS3700 & HMS3770 Insertion Sensors

Installation

www.lcmeter.com

Page 2

Table of Contents

Description Page Number

Introduction .................................................................................. 2-3

General ........................................................................... 3

Applications ..................................................................... 3

Basic Components .......................................................... 3

Safety Legend ................................................................. 3

Unpacking ....................................................................... 3

Transportation and Handling ........................................... 3

Start up and Maintenance ............................................... 3

Installation .................................................................................... 4-7

Operating Temperature Range ....................................... 4

Dimensions ..................................................................... 4

Sensor Installation Guidelines ........................................ 5

Grounding Instructions .................................................... 5

Model 3770 (installation in non-pressurized systems. .... 6

Model 3700 (installation in pressurized systems) ........... 7

Publication Updates and Translations

The most current English versions of all Liquid Controls publications are available on our website, www.lcmeter.com.

It is the responsibility of the Local Distributor to provide the most current version of LC Manuals, Instructions, and

Specification Sheets in the required language of the country, or the language of the end user to which the products are

shipping . If there are questions about the language of any LC Manuals, Instructions, or Specification Sheets, please

contact your Local Distributor.

!!

WARNING WARNING

!

WARNING

!!

WARNING WARNING

• Before using this product, read and understand the instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of equipment and/or systems in accordance with all applicable codes and ordinances.

• Failure to follow the instructions set forth in this publication could result in property damage, personal injury,

or death from fire and/or explosion, or other hazards that may be associated with this type of equipment.

Introduction

• This manual is an integral part of the product. Carefully read and understand all the instructions contained in this

publication since it contains important information regarding safety, operation, and maintenance of the instrument.

• The product and technical information contained in this manual may be changed without notice.

• This flow meter must be used only in the applications for which it has been designed. The improper use, tampering

with the instrument, or substitutions of any components immediately voids the product warranty.

• The manufacturer is considered responsible only if the instrument is used in its original configuration.

• Reproduction of this manual or of software supplied with this instrument is expressly forbidden.

2

Page 3

Introduction

General

This manual contains information concerning the application, installation, and operation of the HMS3700 and

HMS3770 insertion flow meters. Keep a copy of this

manual with the flow meter for future reference.

Applications

LCMag electromagnetic flow meters are designed for liquid flow measurement in most industries including water

& waste water, food & beverage, pharmaceutical, chemical, and more. These meters are not suitable for measurement of petroleum products, and other liquid media

with low electrical conductivity. Minimum electrical conductivity of measured liquids is 5µS.

Basic Components

An LCMag electromagnetic flow meter system consists

of two basic components: the flow meter, and the converter. The flow meter is the tube which inserts through

the wall of the pipe and into the liquid flow for measurement. The converter is the electronic control that provides power to the flowmeter and provides signal processing, flow calculation, and display outputs for the user.

The wetted parts of the flow meter (liner and electrodes)

must be selected for compatibility with the liquid being

measured.

Unpacking

Always inspect the instrument for damage from shipping

upon receipt. File a damage claim with the carrier if damage is discovered.

Transportation and Handling

Do not lift the instrument from the carton by the converter head. Use lifting eyes where provided for larger

meters, or lift by the sensor body.

When transporting, never use forks of a forklift, chains,

wire slings, or any other object in the flow tube of the

meter. Serious damage to the instrument will result.

Start up and Maintenance

• Before starting up the instrument, always make sure

that there is a suitable connection to ground as described on Page 5 of this manual.

• Periodically verify the following: the integrity of the

power supply cables, the proper tightening of the

sealing elements (cable glands, covers, etc.), the mechanical attachment of the instrument to the pipe or

to the wall stand.

The converter must be selected for compatibility with the

environment in which it will operate.

Safety Legend

Before using the instrument, always establish a reliable electrical connection to ground.

Avoid any attempt to repair the instrument. If the instrument is not functioning properly, please call

the nearest authorized representative.

Pay maximum attention during operation.

Caution.

Danger.

3

Page 4

Installation

Flow Direction

Before installing the sensor, confirm the direction of the

liquid flow in the piping. The sign of the flow rate is posi-

tive when the flow direction is from - to + as printed on

the nameplate on the sensor body.

If flow direction is reversed after the installation, it is sufficient to reverse the sign of the KA coefficient in the

converter (refer to converter installation manual).

Operating Temperature Range

PTFE Wetted Parts

Liquid Temp. Ambient Temp.

Min. Max. Min. Max.

°F -4 302 14 140

°C -20 150 -10 60

Dimensions

HMS3700 HMS3770

Size Nominal Pipe Diameter L

1 3" to 20" 19"

2 3" to 40" 24.5"

3 3" to 80" 34.5"

Size Nominal Pipe Diameter L

1 3" to 20" 7"

2 3" to 40" 9.5"

3 3" to 80" 18"

4

Page 5

Sensor Installation Guidelines

NO YES

Installation

For vertical installations

with descending flow

direction contact the

manufacturer.

Avoid operation of the

system with the pipe

partially empty.

Avoid installation of this

instrument near bends

in the piping or accessories such as valves.

If the system is under

pressure, opening the

ball valve before tightening the fixing nut

could result in the

sensor being propelled

from the pipe line.

Never open the ball

valve unless the fixing

nut is properly tightened.

For vertical installations,

use ascending flow

conditions only.

During normal operation

of the instrument, the

pipe must be completely

full of liquid, or completely empty.

Install the sensor away

from bends in the pipe

and accessories such

as valves.

Lock the center bushing

before opening the ball

valve.

Grounding Instructions

For correct operation of the meter, it is essential that the

sensor and the liquid be at the same electrical potential.

Always connect the sensor and the converter to ground.

For grounding with a cathode protection pipe, contact

the manufacturer.

5

Page 6

Installation

Model 3770 (installation in a non-pressurized system)

Step 1

Step 2

Cut the jacket (1"

diameter) to the proper

length “Z”.

Z = L - S - 1/

NOTE: Refer to Step 6

for L dimension.

D - 1.26"

8

Step 4

Tighten the lock nut with

a wrench.

Step 5

Line up the connector

box longitudinally with

pipe line axis.

Tighten the lock nut with

wrench, maintaining the

alignment. Ensure that

the lock nut is tight

enough to create a

proper seal with the

gasket.

Step 3

Recommended dimension of 1" thread.

Weld the jacket to the

pipe line.

Place the gasket on the

sensor.

Place the sensor in the

jacket.

Step 6

Sensor installed

Size Nominal Diameter Range L

Size 1 3" up to 20" 7"

Size 2 3" up to 40" 9.5"

Size 3 3" up to 80" 18"

6

Page 7

Model 3700 (installation in pressurized systems)

Installation

Step 1

Step 2

Step 3

Weld a 1" pipe to the

pipeline.

NOTE: Verify “X”

dimension (Step 2).

X

= 5.5"

MAX

Step 5

Open the valve.

Screw the sensor up to

the “Z” dimension.

Verify the alignment.

Tighten the block nut

maintaining alignment.

Step 4

Screw the 1" jacket to

the valve.

NOTE: The O-Ring in

the jacket must be

placed underside (near

valve).

Insert the sensor with

valve closed.

Tighten the lock nut with

wrench.

Step 6

Size Nominal Diameter Range L

Size 1 3" up to 20" 19"

Size 2 3" up to 40" 24.5"

Size 3 3" up to 80" 34.5"

Length Z = L - S - 1/

D

8

7

Page 8

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.5262 • 847.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2005 Liquid Controls

Pub. No. 500339

(3/31/05)

Loading...

Loading...