Page 1

Installation & Parts Manual

Gear Plate Selection Guide

Installation: M100-30

www.lcmeter.com

Page 2

Table of Contents

Description Page Number

Gear Plate Selection Guide....................................................3

General Meter Data ..................................................... 3

Packing Gland Ratio...............................................................4

Pattern Codes..............................................................4

Gears .....................................................................................5

Gear Limitations ..........................................................5

Available Gears ........................................................... 5

Register St ack Components ........................................5

Units per Revolution ....................................................5

Formulas for Computing Gear Plate Ratios............................6-7

Gear Plate Assembly Drawings.............................................. 8-11

Pattern 10 Long Shaft..................................................8

Pattern 10 Short Shaft ................................................. 9

Pattern 20, 30, 40, & 50 Long Shaft ............................10

Pattern 20, 30, 40, & 50 Short Shaft............................ 11

Parts List ................................................................................12

Gear Plate Assemblies: Patterns 10, 20, 30, 40, & 50.12

Gear Plate Assemblies: Patterns 20, 30, 40, & 50.......12

Basic Gear Plate Part Numbers for Pattern Styles ......12

Change Gear Part Numbers........................................ 12

Swing Arm Assembly Drawings.............................................. 13-14

Gear Plates by Meter Size & Unit of Measure........................ 15

M-5 Gear Plate Listing............................................................16-17

M-7 & M-10 Gear Plate Listing ...............................................17-19

M-15 & M-25 Gear Plate Listing .............................................20

M-30 & M-40 Gear Plate Listing .............................................21-22

M-60, MS-75 & M-120 Gear Plate Listing...............................23

2

Page 3

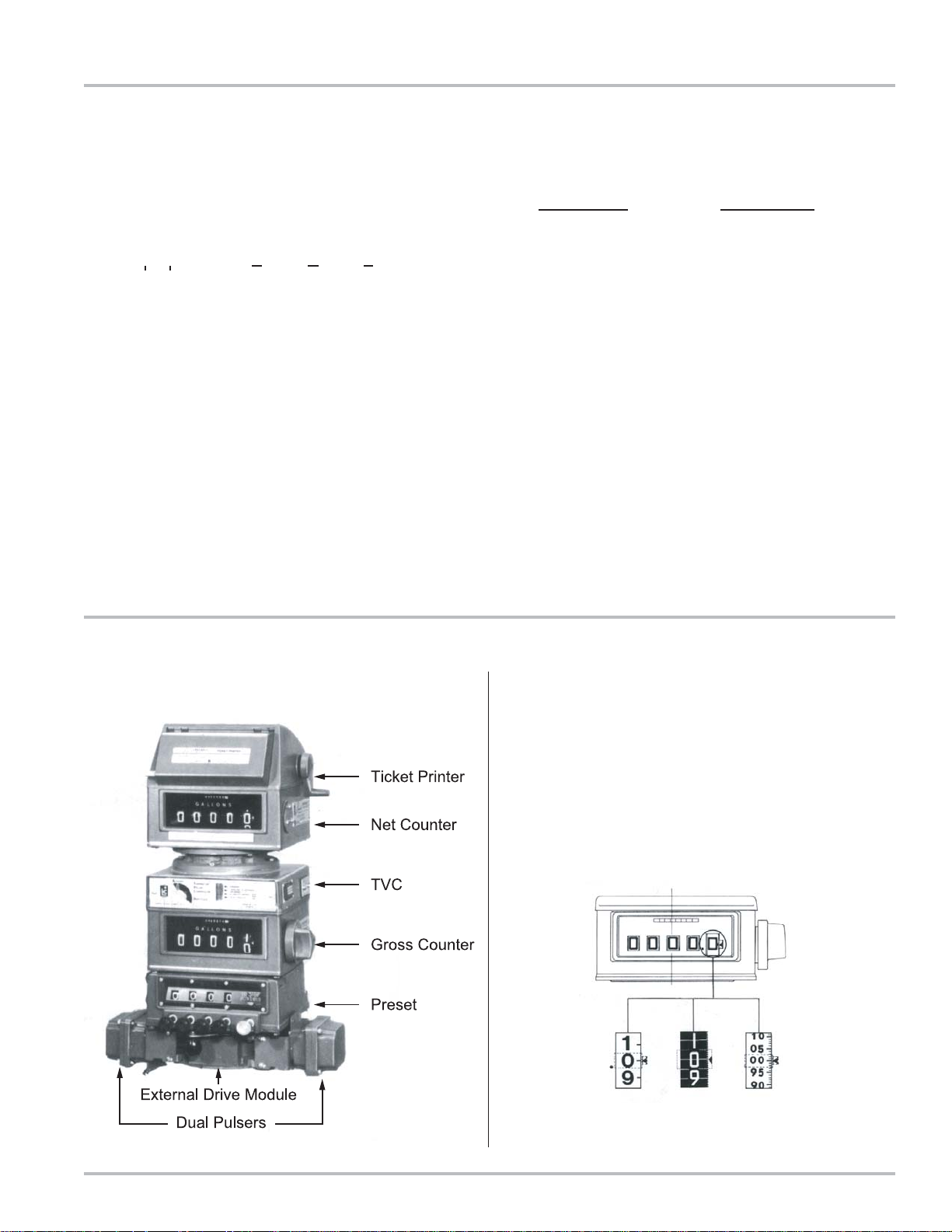

Gear Plate Selection Guide

Gear plates are used to convert a meter’s output to the desired unit of measure; for example, 1/10 or whole US

gallons, 1/10 or whole imperial gallons, liters, cubic meters, barrels, pounds, etc. To facilitate the changing of the unit

of measure desired, the gear plate is attached to the base of the large numeral counter with two screws. To make

proper gear plate selection, you will need to know:

1. Meter size

2. Unit of measure required

3. Packing gland ratio

4. Meter register stack components (preset, TVC, counter, ticket printer, etc.)

General Meter Data

• M-5, M-7, and M-10 meters supplied standard with 1/10 gallon, Pattern 10 gear plates.

• M-15 and M-25 meters supplied standard with 1/10 gallon, Pattern 20 gear plates.

• M-25, M-30, M-40, M-60, and M-80 meters supplied standard with Whole Gallon, Pattern 10 gear plates.

• When deviating from above standards, see appropriate meter price list for correct pricing.

• Any meter model incorporating a T emperature V olume Compensator requires an even centered gear plate (Pattern

10, 30, or 50).

• Meter models supplied with Class 10 and 12 construction are configured using a Pattern 30 gear plate.

• Consult Customer Support Department at the factory for gear plate ratios not listed on pages 15 through 23.

Meter Size Revolutions per

gallon of the

blocking rotor

M-5 (New Style)--------------------- 4.0790

M-5 (Old Style) ---------------------12.2370

M-7 ------------------------------------- 5.555

M-10 ----------------------------------- 5.555

M-15 ----------------------------------- 2.058

M-20* ---------------------------------- 2.058

M-25 ----------------------------------- 2.058

M-30 ----------------------------------- 0.742

M-40 ----------------------------------- 0.742

M-60 (New Style) ------------------- 0.3983

M-60 (Old Style)--------------------- 0.2545

M-70 ----------------------------------- 0.4024

M-80 ----------------------------------- 0.3983

M-120---------------------------------- 0.1579

*M-20 meter uses only 2:1 packing glands. Consult Customer Service Department at the factory for proper gear plates.

Meter Size Revolutions per

gallon of the

blocking rotor

MS-5 ------------------------------------ 12.2370

MS-7 -------------------------------------- 5.555

MS-15 ------------------------------------2.058

MS-25 ------------------------------------2.058

MS-30 ------------------------------------0.742

MS-40 ------------------------------------0.742

MS-75 ------------------------------------0.2545

MS-120----------------------------------- 0.1579

3

Page 4

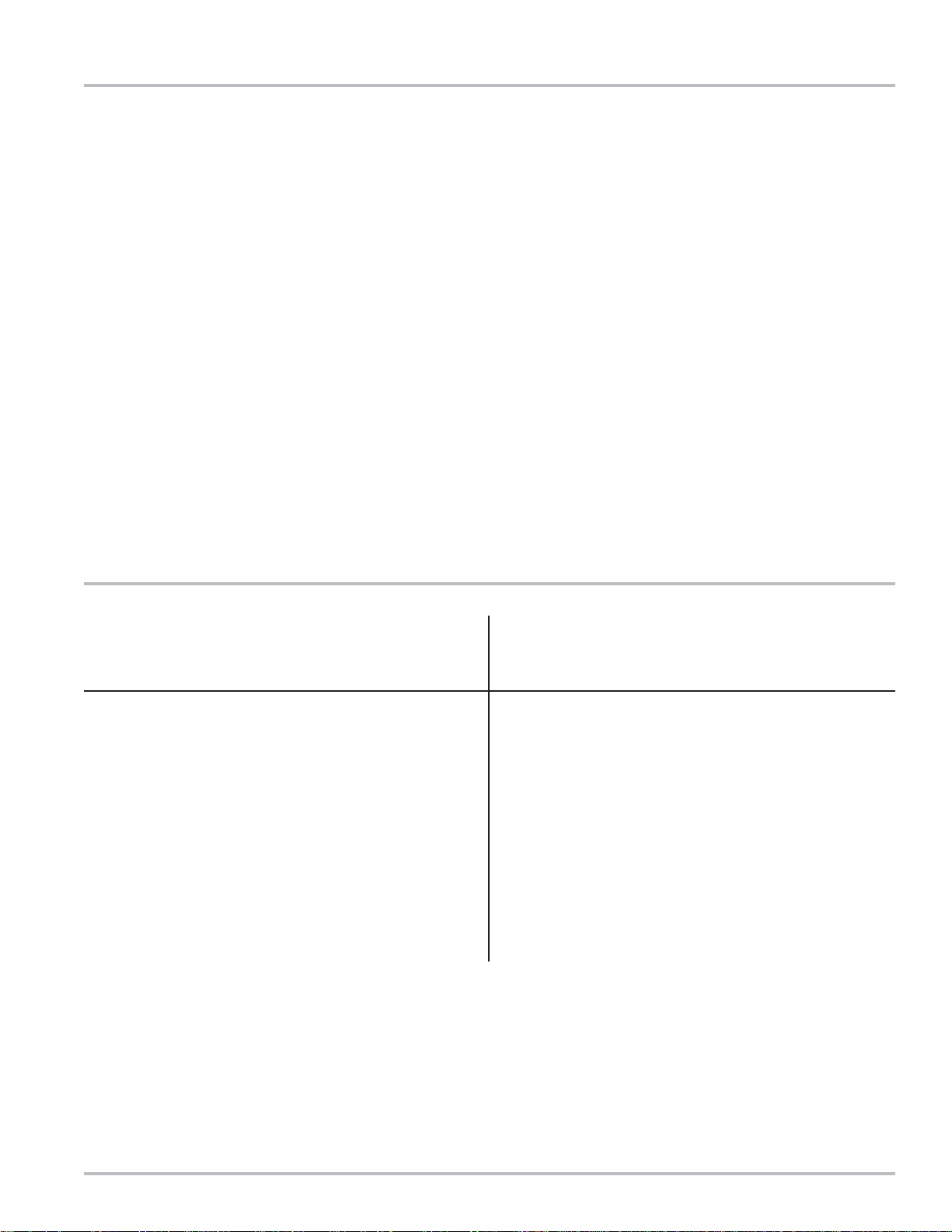

Packing Gland Ratio

Three packing gland ratios are available to permit achieving the proper RPM of the register unit wheel (right hand wheel).

Pattern Codes

The Pattern Code number diagram shows five general gear assembly configurations that can be constructed using the

basic gear plate and swing arm assemblies. Patterns 10, 30, and 50 can be used with a mechanical temperature

compensator.

Dr=Driving gear, Dn=Driven gear, I=Idler gear

Pattern 10 - shows the simplest gear plate form with a driver and a driven gear. Tot al teeth of gear A

plus gear B must equal 118. (A=Dr, B=Dn)

Pattern 20 - shows the simple gear plate form with an idler gear added to reverse output

rotation. Do not use when a mechanical temperature compensator is used.

(A=Dr, B=I, C=Dn)

Pattern 30 - shows a plate with dual idler gears. This pattern is used when a

T emperature V olume Compensator (TVC) is part of the register stack. When the register

stack includes a TVC, you must have an even number of centers in the gear plate.

When looking down on the Adjuster, rotation should be counterclockwise. (A=Dr, B=I,

C=I, D=Dn)

Pattern 40 - shows a plate with a compound gear set (B/C). Do not use when a mechanical

temperature compensator is used.

Pattern 50 - shows a plate with dual compound gears (B/C) and (D/E). This gear

plate configuration is used:

1. When a TVC is part of the register stack, when the register stack includes a

TVC, you must have an even number of centers in the gear plate; when looking

down on the Adjuster, rotation should be counterclockwise.

2. When you cannot obtain the desired ratio with only two sets of gears.

4

Page 5

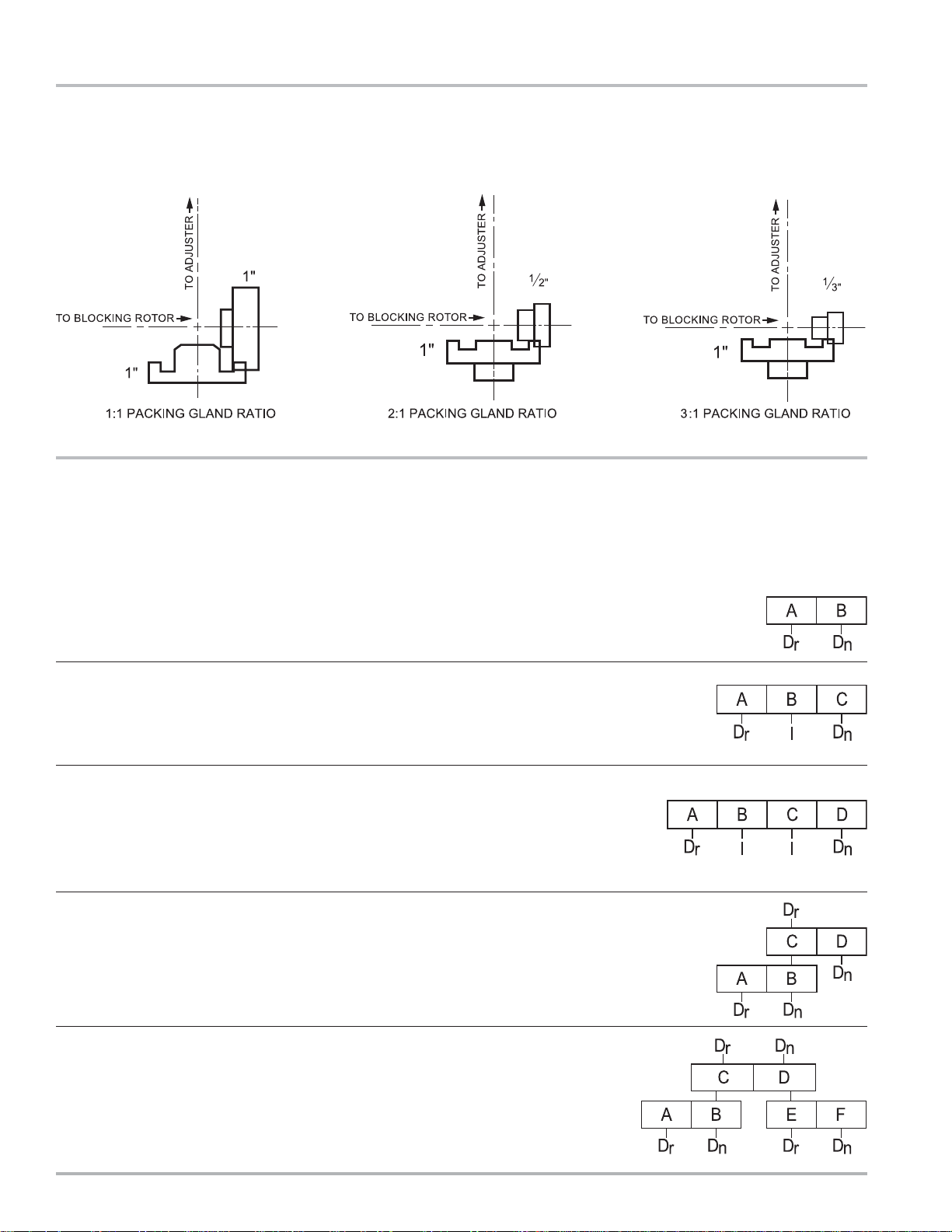

Gear Limitations Available Gears

• Adjuster Reduction: 3.997:1 at 25% setting.

• Two Gear Ratio Capacity: Pattern 10 must equal 1 18

total teeth.

• Idler Arm Capacity: Patterns 20, 30, 40, & 50: 114

teeth maximum, 72 teeth minimum.

C - D

A - B E - F A C E

Typical Six Gear Ratio - Pattern 50

A+B equal to or greater than 72 teeth.

A+B equal to or less than 114 teeth.

E+F equal to or greater than 72 teeth.

E+F equal to or less than 114 teeth.

B+E+5 teeth equal to or less than C+D.

C+26 teeth equal to or less than A+B.

D+26 teeth equal to or less than E+F.

A+F equal to or less than 113 teeth.

A+F equal to 118 teeth on two gear ratio.

B D F

X X = Ratio

Standard gears range from 30 to 69 teeth inclusive. Other

gears available are listed below.

No. of Teeth Part Number

19 --------------------------- V-2324

20 --------------------------- V-6180

26 --------------------------- V-6190

28 --------------------------- V-2328

29 --------------------------- V-2332

59 --------------------------- V-2452

59 (60T. P.D.) ------------ V-2454

69 --------------------------- V-2492

69 (70T. P.D.) ------------ V-4572

70 --------------------------- V-2496

72 --------------------------- V-2500

75 --------------------------- V-2504

76 --------------------------- V-2508

78 --------------------------- V-2512

80 --------------------------- V-2516

84 --------------------------- V-2520

90 --------------------------- V-2524

Gears

Register Stack Components

Units per Revolution

The right hand wheel of the register determines the unit

of measure.

NOTE: the right hand register wheel (units wheel) must

not exceed 250 revolutions per minute (RPM) or 125 RPM

when the meter is equipped with a preset. There are

three packing glands available to achieve the proper

RPM. 1:1, 2:1, or 3:1.

1/10 Units Wheel

or 1 Unit/Rev. with

Decimal Point

Whole Unit Wheel

or 10 Units/Rev.

No Decimal Point

1 Barrel Wheel

or 1 Unit/Rev.

or 100 Units/Rev.

5

Page 6

Formulas for Computing Gear Plate Ratios

Nb x R

Pg x W x R

1. Nb = Revolutions per gallon of the blocking rotor.

Meter Model Nb Value

M-5 (old style) ------------- 4.0790

M-5 (new style)---------- 12.2370

MS-5 ----------------------- 12.2370

M-7 --------------------------- 5.555

MS-7 ------------------------- 5.555

M-10 ------------------------- 5.555

M-15 ------------------------- 2.058

MS-15 ----------------------- 2.058

*M-20 ------------------------ 2.058

M-25 ------------------------- 2.058

M-30 ------------------------- 0.742

MS-30 ----------------------- 0.742

M-40 ------------------------- 0.742

M-60 (new style)---------- 0.3983

M-60 (old style) ----------- 0.2545

M-70 ------------------------- 0.4024

MS-75 ----------------------- 0.2545

M-120------------------------ 0.1579

MS-120---------------------- 0.1579

*M-20 uses only 2:1 packing glands. Consult the

Customer Service Department at the factory for proper

gear plate selection.

c

= R1 R2=

a

D

n

D

r

7. R2 = Dn divided by Dr, which is the actual ratio.

8. Dn = Driven gear.

9. Dr = Driving gear

10. For 20% correction, multiply the gear plate ratio, R1,

by .98 as in the following example:

Nb x Rc x .98

11. The % difference of the actual ratio (R2) cannot be

greater than or less than 1% of the desired ratio.

100 (R1-R2)

∆R = = % difference in ratios

NOTE: To convert specific gravity to pounds, use the

following example.

For a specific gravity of 0.893:

R

1

= R

1

2. Rc = Number of units per revolution of the right-hand

wheel of the counter. For a counter to read in 10th

gallons, the unit per revolution of the right-hand wheel

is 1 gallon. For a counter to read in pounds, the unit

per revolution of the right-hand wheel is 10 pounds.

Refer to the units per revolution on page 5.

3. Pg = Packing gland ratio; 1:1, 2:1, or 3:1.

4. W = Units per gallon. For example; pounds per gallon

or kilograms per gallon. If the counter reads in

gallons, this value is 1.

5. Ra = Adjuster ratio = 3.997.

6. R1 = Gear plate ration desired.

0.893 x 8.3453 = 7.452 pounds per gallon.

Water weighs 8.3453 pounds per gallon and has a

specific gravity of 1.000.

6

Page 7

Formulas for Computing Gear Plate Ratios

Examples

Example 1: Find a gear plate ratio for 7.50 pounds per

gallon.

Example 2: Find a gear plate ratio for Imperial Gallons

at 2% correction.

Meter Model:------------- M7-A

Unit of Measure: -------- pounds per gallon

Packing Gland Ratio:-- 2:1

Units per Gallons: ------ 7.50

Adjuster Ratio: ---------- 3.997

Nb x R

Pg x W x R

5.555 x 10

2 x 7.50 x 3.997

c

R2 = = = .9344

= R1 R2 =

a

D

n

D

r61

61 57

D

r

= R1 = .9265

57

D

n

D

D

Meter Model:------------- M7-A

Unit of Measure: -------- whole imperial gallons

Correction Factor------- (2%) .98

Packing Gland Ratio:-- 2:1

Units per Gallons: ------ .83267 Imperial Gallons per US

Gallon

n

r

Adjuster Ratio: ---------- 3.997

Nb x Rc x .98 D

Pg x W x R

5.555 x 10 x .98

2 x .83267 x 3.997

R2 = x x

= R1 R2 =

a

= R1 = 8.1785

D

D

D

n

D

r

n

D

r

D

n

r

n

D

r

100 (R1-R2)

∆R = = = .85%

R

1

100 (.9265 - .9344)

.9265

60 67 75

R2 = x x = 8.1707

30 41 30

100 (R1-R2)

∆R = = = .095%

R

1

30 60

D

r

100 (8.1785-8.1707)

8.1785

D

r

41 67

D

n

D

n

30 75

D

r

D

n

7

Page 8

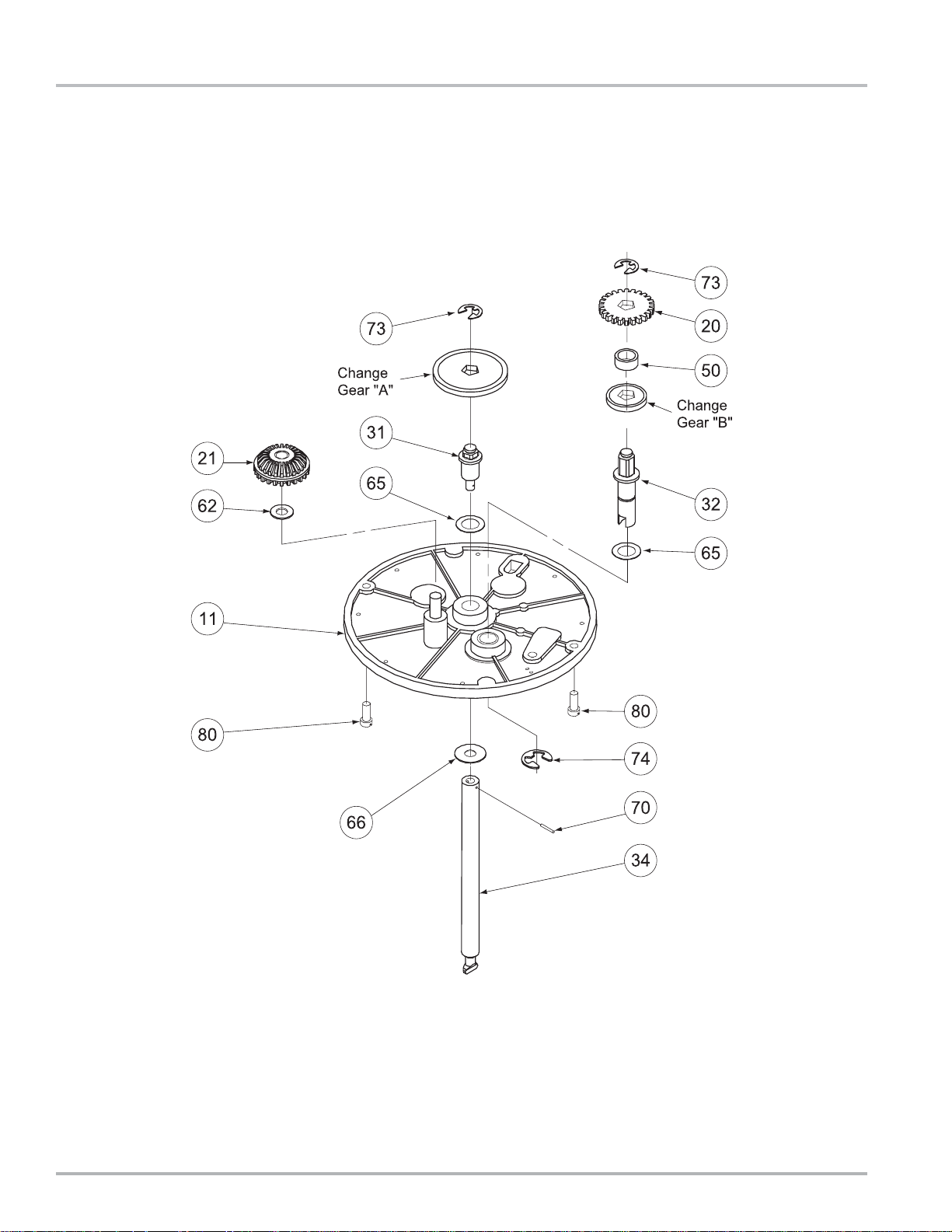

Gear Plate Assemblies

Pattern 10, Long Shaft (LC Preset)

8

Page 9

Pattern 10, Short Shaft

Gear Plate Assemblies

9

Page 10

Gear Plate Assemblies

Patterns 20, 30, 40, & 50 Long Shaft (LC Preset)

10

Page 11

Patterns 20, 30, 40, & 50 Short Shaft

Gear Plate Assemblies

11

Page 12

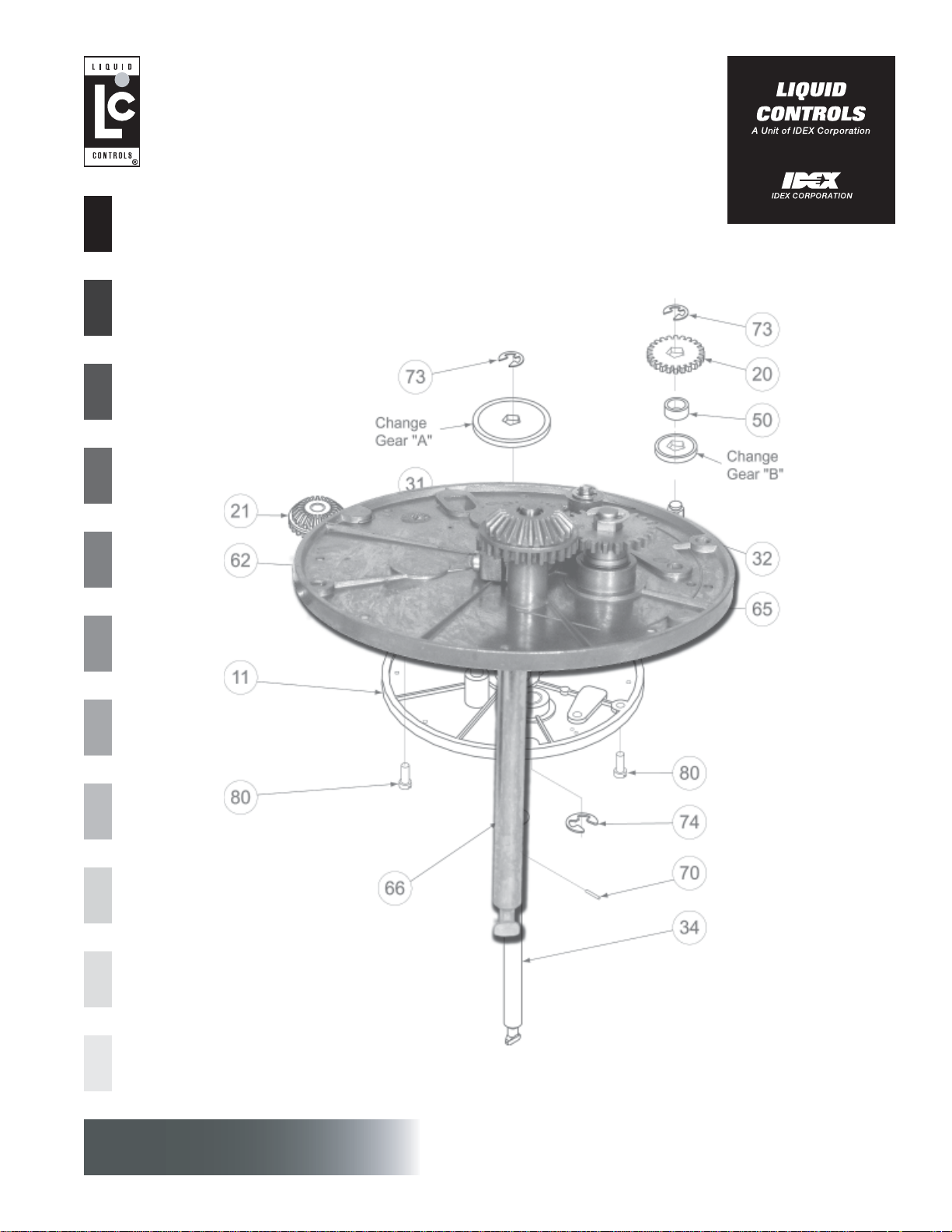

Parts List

Gear Plate Assemblies:

Patterns 10, 20, 30, 40, & 50

Item No. Description Part No.

10 Gear Plate, Short Shaft

11 Gear Plate, Long Shaft

20 25 Tooth Gear V-4176

21 25 Tooth Bevel Gear V-4180G

31 Drive Shaft V-4000

32 Preset Drive Coupling 40175

33 Register Drive Coupling 43762

(short shaft)

34 Register Drive Coupling 73763

w/Preset (long shaft)

41 Bushing V-2548

50 Spacer V-1315

60 Washer V-1025

62 Washer V-1095

65 Washer V-1165

66 Washer V-1175

70 Groove Pin 6915

72 E-Ring V7475

73 E-ring SP-4377

80 Screw 960152

Change Gear “A” A/R

Change Gear “B” A/R

Change Gear “C” A/R

Change Gear “D” A/R

Change Gear “E” A/R

Change Gear “F” A/R

Gear Plate Assemblies:

Pattern 20, 30, 40, & 50

Item No. Description Part No.

12 Swing Arm Assy V25365

30 Stud 6979

40 Bushing V-2544

60 Washer V-1025

61 Washer V-1040

62 Washer V-1050

63 Washer (.045) V-1065

72 E-ring V-7475

71 Nut V-7450

Basic Gear Plate Part Numbers

for Pattern Styles:

Pattern

Number

10

20

30

40

50

Basic Gear Plate

for Register

41225

41226

49912

41229

44456

Basic Gear Plate for

Preset and Register

41227

41227

49913

41224

44455

Change Gear Part Numbers:

No. Part No.

19 V-2324

20 V-6180

26 V-6190

28 V-2328

30 V-2336

31 V-2340

32 V-2344

33 V-2348

34 V-2352

35 V-2356

36 V-2360

37 V-2364

38 V-2368

39 V-2372

40 V-2376

41 V-2380

42 V-2384

43 V-2388

44 V-2392

45 V-2396

46 V-2400

47 V-2404

48 V-2408

49 V-2412

50 V-2416

51 V-2420

52 V-2424

No. Part No.

53 V-2428

54 V-2432

55 V-2436

56 V-2440

57 V-2444

58 V-2448

59 V-2452

59 V-2454

(expanded)

60 V-2456

61 V-2460

62 V-2464

63 V-2468

64 V-2472

65 V-2476

66 V-2480

67 V-2484

68 V-2488

69 V-2492

69 V-4572

(expanded)

70 V-2496

72 V-2500

75 V-2504

76 V-2508

78 V-2512

80 V-2516

84 V-2520

90 V-2524

12

Page 13

Pattern 20 & 40 (1 Swing Arm)

Swing Arm Assemblies

Bevel Gear

13

Page 14

Swing Arm Assemblies

Pattern 30 & 50 (2 Swing Arms)

Bevel Gear

14

Page 15

Gear Plates by Meter Size & Unit of Measure

(

)

(

)

Meter Model Unit of Measure Gear Plate Number P/G ratio

M5

MA4

MA5

M7

MS7

MA7

M15

MS15

MA15

M25

M30

MS30

M40

US Gallon G1103 2:1

1/10 US Gallon G1125-59 tooth expanded 3:1

Imp. Gallon G1150 2:1

1/10 Imp. Gallon G1165 3:1

Liters/Gallons G1620 2:1

1/10 US Gallon G1127 1:1

US Gallon G2112 2:1

1/10 US Gallon G2132-69 tooth expanded 2:1

Liters/Gallons G2681 2:1

Imp. Gallon G2156 2:1

1/10 Imp. Gallon G2166 2:1

1/10 US Gallon G2146 1:1

US Gallon G3126 2:1

1/10 US Gallon G3161 1:1

Liters/Gallons G3517 1:1

Imp. Gallon G3214 2:1

Barrels G3646 2:1

US Gallon G4121 2:1

Imp. Gallon G4211 2:1

Liters/Gallon G4410 1:1

Dekaliters G4470 2:1

42 Gallon Barrel G4510 2:1

M60

M80

M60

MS75

MS120

NEW

OLD

US Gallon G6120 1:1

Imp. Gallon G6220 1:1

Dekaliters G6410 1:1

US Gallon G5110 1:1

Imp. Gallon G5211 1:1

Dekaliters G5411 1:1

42 Gallon Barrel G5510 1:1

US Gallon G7110 1:1

Imp. Gallon G7210 1:1

Dekaliters G7270 1:1

42 Gallon Barrel G7300 1:1

15

Page 16

M-5 Gear Plate Listing

Part #

G1101 US Gal 10 Preset/TVC 5.0988 Class 8 ONLY 2:1 5.0479 5.1497 0.1961 50 31-70-55-55-31-70

G1102 US Gal 10 TVC 5.0988 Class 8 ONLY 2:1 5.0479 5.1497 0.1961 50 31-70-55-55-31-70

G1103 US Gal 10 5.0988 Class 8 ONLY 2:1 5.0479 5.1497 0.1961 40 31-70-31-70

G1104 US Gal 10 Preset 5.0988 Class 8 ONLY 2:1 5.0479 5.1497 0.1961 40 31-70-31-70

G1106 US Gal 10 4.9805 2% - Class 8 ONLY 2:1 4.9307 5.0303 0.2008 40 32-68-32-75

G1107 US Gal 10 Preset 4.9805 2% - Class 8 ONLY 2:1 4.9307 5.0303 0.2008 40 32-68-32-75

G1113 US Gal 10 TVC 15.3198 Direct Drive ONLY 2:1 15.1666 15.4729 0.0653 50 28-59-28-75-28-76

G1114 US Gal 10 Preset/TVC 15.3198 Direct Drive ONLY 2:1 15.1666 15.4729 0.0653 50 28-59-28-75-28-76

G1115 US Gal 10 TVC 15.0000 2% - Direct Drive ONLY 2:1 14.8500 15.1500 0.0667 50 28-76-38-70-26-78

G1116 US Gal 10 Preset/TVC 15.0000 2% - Direct Drive ONLY 2:1 14.8500 15.1500 0.0667 50 28-76-38-70-26-78

G1124 1/10 US Gal 1 Preset/TVC 1.0172 3:1* 1.0071 1.0273 0.9831 10 58-59

G1125 1/10 US Gal 1 TVC 1.0172 3:1* 1.0071 1.0273 0.9831 10 58-59

G1126 1/10 US Gal 1 Preset/TVC 1.0000 2% 3:1* 0.9900 1.0100 1.0000 10 59-59

G1127 1/10 US Gal 1 TVC 1.0000 2% 3:1* 0.9900 1.0100 1.0000 10 59-59

G1150 IMP Gal 10 6.1290 Class 8 ONLY 2:1 6.0678 6.1902 0.1631 40 30-75-31-76

G1152 IMP Gal 10 6.0067 2% - Class 8 ONLY 2:1 5.9467 6.0667 0.1665 40 28-69-32-78

G1153 IMP Gal 10 TVC 18.3933 Direct Drive ONLY 2:1 18.2093 18.5772 0.0544 50 28-72-34-64-20-76

G1154 IMP Gal 10 TVC 18.0000 2% - Direct Drive ONLY 2:1 17.8200 18.1800 0.0556 50 30-60-26-78-26-78

G1164 1/10 IMP Gal 1 TVC 1.2264 3:1* 1.2142 1.2386 0.8154 10 53-65

G1166 1/10 IMP Gal 1 1.2000 2% 3:1* 1.1800 1.2120 0.8333 20 40-40-48

G1167 1/10 IMP Gal 1 TVC 1.2000 2% 3:1* 1.1800 1.2120 0.8333 30 40-40-40-48

G1172 1/10 IMP Gal 1 Preset/TVC 1.2264 3:1* 1.2142 1.2386 0.8154 10 53-65

G1173 1/10 IMP Gal 1 Preset 1.2000 2% 3:1* 1.1800 1.2120 0.8333 20 40-40-48

G1174 1/10 IMP Gal 1 Preset/TVC 1.2000 2% 3:1* 1.1800 1.2120 0.8333 30 40-40-40-48

G1281 KG/Gal 10 3.823 3.748 Preset 1.3191 2% - Class 8 ONLY 2:1 1.3060 1.3322 0.7581 20 47-40-62

G1282 KG/Gal 10 3.823 3.748 1.3191 2% - Class 8 ONLY 2:1 1.3060 1.3322 0.7581 20 47-40-62

G1287 KG/Gal 10 4.816 4.720 TVC 1.0702 Class 8 ONLY 2:1 1.0595 1.0809 0.9344 10 57-61

G1288 KG/Gal 10 3.82 3.75 3.9600 2% - Direct Drive ONLY 2:1 3.9204 3.9996 0.2525 40 30-63-35-66

G1289 KG/Gal 10 3.82 3.75 Preset 3.9600 2% - Direct Drive ONLY 2:1 3.9204 3.9996 0.2525 40 30-63-35-66

Units of

Measure

Units

per

Rev

Range

High Low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G1348 LBS/Gal 10 7.191 7.049 1.4333 3:1* 1.4190 1.4476 0.6977 20 30-45-43

G1350 LBS/Gal 10 7.330 7.184 1.4063 3:1* 1.3923 1.4203 0.7111 20 32-45-45

G1357 LBS/Gal 10 7.549 7.400 1.3652 3:1* 1.3516 1.3788 0.7324 20 41-50-56

G1362 LBS/Gal 10 7.575 7.425 TVC 1.3600 3:1* 0.3464 1.3736 0.7353 10 50-68

G1365 LBS/Gal 10 7.682 7.530 1.3417 3:1* 1.3283 1 3551 0.7453 20 41-41-55

G1366 LBS/Gal 10 7.724 7.574 TVC 1.3340 3:1* 1.3207 1.3473 0.7500 10 51-68

G1373 LBS/Gal 10 7.828 7.673 1.3191 3:1* 1.3060 1.3322 0.7581 20 47-40-62

G1379 LBS/Gal 10 7.878 7.722 TVC 1.3137 3:1* 1.3006 1.3268 0.7612 10 51-67

G1382 LBS/Gal 10 7.908 7.752 TVC 1.2885 3:1* 1.2757 1.3013 0.7761 10 52-67

G1419 LBS/Gal 10 8.413 8.247 TVC 1.2264 3:1* 1.2142 1.2386 0.8154 10 53-65

G1421 LBS/Gal 10 8.423 8.257 1.2000 2% 3:1* 1.1880 1.2120 0.8333 20 40-40-48

G1425 LBS/Gal 10 8.698 8.525 TVC 1.1852 3:1* 1.1734 1.1970 0.8438 10 54-64

G1427 LBS/Gal 10 8.423 8.257 Preset 1.2000 3:1* 1.1880 1.2120 0.8333 20 40-40-48

G1446 LBS/Gal 10 8.893 8.716 1.1591 3:1* 1.1476 1.1706 0.8620 20 44-40-51

G1491 LBS/Gal 10 7.270 7.130 2.1250 Direct Drive ONLY 2:1 2.1037 2.1462 0.0471 20 32-40-68

G1492 LBS/Gal 10 10.450 10.250 Preset 1.4783 Direct Drive ONLY 2:1 1.4635 1.4930 0.6765 20 46-45-68

G1507 LBS/Gal 10 10.807 10.593 0.9583 3:1* 0.9488 0.9678 1.0435 20 48-46-46

G1525 LBS/Gal 10 11.031 10.812 Preset/TVC 0.9344 3:1* 0.9251 0.9437 1.0702 10 61-57

G1530 LBS/Gal 10 11.312 11.088 Preset 0.9111 3:1* 0.9019 0.9202 1.0975 20 45-40-41

G1532 LBS/Gal 10 11.244 11.022 0.9167 3:1* 0.9076 0.9258 1.0909 20 48-40-44

G1535 LBS/Gal 10 11.452 11.226 0.9000 3:1* 0.8910 0.9090 1.1111 20 50-40-45

G1538 LBS/Gal 10 11.663 11.432 0.8837 3:1* 0.8749 0.8925 1.1316 20 43-40-38

G1541 LBS/Gal 10 11.893 11.657 0.8667 3:1* 0.8581 0.8753 1.1538 20 45-40-39

G1554 LBS/Gal 10 12.884 12.629 0.8000 3:1* 0.7920 0.8080 1.2500 20 50-40-40

G1618 LITRES/Gal 10 Preset 1.3191 2% - Class 8 ONLY 2:1 1.3059 1.3323 0.7581 20 47-40-62

G1619 LITRES/Gal 10 Preset/TVC 1.3478 Class 8 ONLY 2:1 1.3343 1.3612 0.7419 30 46-40-40-62

G1620 LITRES/Gal 10 1.3478 Class 8 ONLY 2:1 1.3343 1.3612 0.7419 20 46-40-62

G1621 LITRES/Gal 10 TVC 1.3478 Class 8 ONLY 2:1 1.3343 1.3612 0.7419 30 46-40-40-62

G1622 LITRES/Gal 10 1.3191 2% - Class 8 ONLY 2:1 1.3059 1.3323 0.7581 20 47-40-62

G1623 LITRES/Gal 10 TVC 1.3191 2% - Class 8 ONLY 2:1 1.3059 1.3323 0.7581 30 47-40-40-62

G1633 LITRES/Gal 10 Preset 1.3478 Class 8 ONLY 2:1 1.3343 1.3612 0.7419 20 46-40-62

* 3:1 packing gland ratio for direct drive M-5 and 1:1 for M-5 with internal gearing.

16

Page 17

M-5 Gear Plate Listing (continued)

Part #

G1638 LITRES/Gal 10 Preset/TVC 2.6406 2% 3:1* 2.6142 2.667 0.3787 50 40-65-56-56-40-65

G1643 LITRES/Gal 10 4.0408 Direct Drive ONLY 2:1 4.0004 4.0812 0.2475 40 35-66-35-75

G1644 LITRES/Gal 10 Preset 4.0408 Direct Drive ONLY 2:1 4.0004 4.0812 0.2475 40 35-66-35-75

G1645 LITRES/Gal 10 TVC 4.0408 Direct Drive ONLY 2:1 4.0004 4.0812 0.2475 50 35-66-54-54-35-75

G1646 LITRES/Gal 10 Preset/TVC 4.0408 Direct Drive ONLY 2:1 4.0004 4.0812 0.2475 50 35-66-54-54-35-75

G1647 LITRES/Gal 10 3.9600 2% - Direct Drive ONLY 2:1 3.9204 3.9996 0.2525 40 30-63-35-66

G1648 LITRES/Gal 10 Preset 3.9600 2% - Direct Drive ONLY 2:1 3.9204 3.9996 0.2525 40 30-63-35-66

G1649 LITRES/Gal 10 TVC 3.9600 2% - Direct Drive ONLY 2:1 3.9204 3.9996 0.2525 50 30-63-54-54-35-66

Units of

Measure

Units

per

Rev

Range

High Low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

* 3:1 packing gland ratio for direct drive M-5 and 1:1 for M-5 with internal gearing.

M-7 & M-10 Gear Plate Listing

Part #

G2102 US GAL 10 6.7857 2% 2:1 6.7179 6.8535 0.1474 50 28-76-56-56-30-75

G2103 US GAL 10 PRESET 6.7857 2% 2:1 6.7179 6.8535 0.1474 40 28-76-30-75

G2106 US GAL 10 TVC 6.9643 2:1 6.8947 7.0339 0.1436 50 28-75-56-56-30-78

G2109 US GAL 10 PRESET 6.9643 2:1 6.8947 7.0339 0.1436 40 28-75-30-78

G2112 US GAL 10 6.9643 2:1 6.8947 7.0339 0.1436 40 28-75-30-78

G2123 1/10 US GAL 1 PRESET 0.6857 2% 2:1 0.6789 0.6925 1.4583 10 70-48

G2126 1/10 US GAL 1 0.6857 2% 2:1 0.6789 0.6925 1.4583 10 70-48

G2129 1/10 US GAL 1 PRESENT 0.6956 2:1 0.6887 0.7025 1.4375 10 69-48

G2132 1/10 US GAL 1 0.6956 2:1 0.6887 0.7025 1.4375 10 69-48

G2146 1/10 US GAL 1 1.36 2% 1:1 1.3464 1.3736 0.7353 10 50-68

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G2152 IMP GAL 10 8.1707 2% 2:1 8.089 8.2524 0.1224 50 30-60-41-67-30-75

G2155 IMP GAL 10 PRESET 8.3483 2:1 8.2649 8.4317 0.1198 50 34-69-37-75 34-69

G2156 IMP GAL 10 8.3483 2:1 8.2649 8.4317 0.1198 50 34-69-37-75-34-69

G2160 1/10 IMP GAL 1 PRESET 0.8154 2% 2:1 0.8073 0.8235 1.2264 10 65-53

G2162 1/10 IMP GAL 1 0.8154 2% 2:1 0.8073 0.8235 1.2264 10 65-53

G2165 1/10 IMP GAL 1 PRESET 0.8308 2:1 0.8225 0.8391 1.2037 10 65-54

G2166 1/10 IMP GAL 1 0.8308 2:1 0.8225 0.8391 1.2037 10 65-54

G2174 KG/GAL 10 2.947 2.889 TVC 2.3333 2% 2:1 2.3100 2.3566 0.4286 50 39-52-48-48-32-56

G2176 KG/GAL 10 3.023 2.963 TVC 2.3214 2:1 2.2982 2.3446 0.4307 30 28-48-48-65

G2177 KG/GAL 10 3.023 2.963 2.3214 2:1 2.2982 2.3446 0.4307 20 28-48-65

G2179 KG/GAL 10 3.066 3.005 TVC 2.2907 2:1 2.2678 2.3136 0.4365 50 37-56-48-48-37-56

G2182 KG/GAL 10 3.249 3.185 TVC 2.1613 2:1 2.1397 2.1829 0.4627 30 31-48-48-67

G2184 KG/GAL 10 3.276 3.211 TVC 2.1429 2:1 2.1215 2.1643 0.4667 30 35-40-40-75

G2185 KG/GAL 10 3.334 3.268 TVC 2.1071 2:1 2.0861 2.1281 0.4746 30 28-48-48-59

G2187 KG/GAL 10 3.402 3.335 TVC 2.0645 2:1 2.0439 2.0851 0.4844 30 31-48-48-64

G2188 KG/GAL 10 3.509 3.439 2.0000 2:1 1.9800 2.0200 0.5000 20 30-48-60

G2189 KG/GAL 10 3.582 3.511 TVC 1.9643 2:1 1.9447 1.9839 0.5091 30 28-48-48-55

G2190 KG/GAL 10 3.617 3.545 TVC 1.9429 2:1 1.9235 1.9623 0.5147 30 35-40-40-68

G2191 KG/GAL 10 3.704 3.631 TVC 1.8929 2:1 1.874 1.9118 0.5283 30 28-48-48-53

G2192 KG/GAL 10 3.754 3.68 TVC 1.8667 2:1 1.8481 1.8853 0.5357 30 30-45-45-56

G2193 KG/GAL 10 3.88 3.803 TVC 1.8095 2:1 1.7915 1.8275 0.5526 10 42-76

G2194 KG/GAL 10 3.940 3.862 1.7813 2:1 1.7635 1.7991 0.5614 20 32-45-57

G2195 KG/GAL 10 4.018 3.938 1.7442 2:1 1.7268 1.7616 0.5733 10 43-75

G2199 KG/GAL 10 4.679 4.586 1.5000 2:1 1.485 1.515 0.6667 20 30-48-45

G2201 KG/GAL 10 4.902 4.805 1.4318 2:1 1.4175 1.4461 0.6984 20 44-30-63

G2202 KG/GAL 10 4.925 4.828 1.4250 2:1 1.4108 1.4392 0.7018 20 40-45-57

G2203 KG/GAL 10 5.082 4.981 1.3809 2:1 1.3671 1.3947 0.7240 20 42-40-58

G2205 KG/GAL 10 5.342 5.236 1.3137 2:1 1.3006 1.3268 0.7612 10 51-67

G2206 KG/GAL 10 5.350 5.244 2.6238 1:1 2.5976 2.6500 0.3811 40 30-57-42-58

G2207 KG/GAL 10 5.420 5.320 1.2941 2:1 1.2812 1.3070 0.7700 20 34-44-44

G2209 KG/GAL 10 5.771 5.656 1.2162 2:1 1.2041 1.2283 0.8222 40 37-40-40-45

G2210 KG/GAL 10 5.824 5.708 1.2051 2:1 1.1931 1.2171 0.8298 20 39-40-47

G2225 KG/GAL 10 7.684 7.532 0.9131 2:1 0.9040 0.9222 1.0952 40 46-40-40-42

G2226 KG/GAL 10 7.852 7.696 0.8929 2:1 0.8840 0.9018 1.1200 20 56-36-50

G2292 KG/GAL 10 16.283 15.96 0.8621 1:1 0.8535 0.8707 1.16 20 58-40-50

G2294 KG/GAL 10 16.556 16.228 0.8478 1:1 0.8394 0.8562 1.1795 20 46-40-39

G2299 KG/GAL 100 17.064 16.727 4.1129 2:1 4.0718 4.1540 0.2431 40 31-51-30-75

17

Page 18

M-7 & M-10 Gear Plate Listing (continued)

Part #

G2304 LBS/GAL 10 2.527 2.477 2.7778 2:1 2.7501 2.8055 0.3600 40 39-65-39-65

G2309 LBS/GAL 10 3.407 3.340 TVC 2.0186 2% 2:1 1.9985 2.0387 4.0954 50 45-62-60-60-43-63

G2313 LBS/GAL 10 3.820 3.740 PRESET 1.8387 2:1 1.8204 1.8570 0.5438 20 31-46-57

G2314 LBS/GAL 10 3.820 3.740 1.8387 2:1 1.8204 1.8570 0.5438 20 31-46-57 41349

G2317 LBS/GAL 10 4.235 4.151 1.6579 2:1 1.6414 1.6744 0.6032 20 38-40-63

G2320 LBS/GAL 10 4.780 4.690 PRESET 1.4687 2:1 1.4541 1.4833 0.6808 20 32-48-47

G2321 LBS/GAL 10 4.780 4.690 1.4687 2:1 1.4541 1.4833 0.6808 20 32-48-47

G2322 LBS/GAL 10 5.188 5.085 TVCNH3 1.3529 2:1 1.3394 1.3664 0.7391 30 34-40-40-46

G2324 LBS/GAL 10 6.015 5.896 TVC 1.1666 2:1 1.155 1.1782 0.8571 30 48-48-48-56

G2327 LBS/GAL 10 6.34 6.21 PRESET 1.1071 2:1 1.0961 1.1181 0.9032 10 56-62

G2328 LBS/GAL 10 6.34 6.21 1.1071 2:1 1.0961 1.1181 0.9032 10 56-62

G2329 LBS/GAL 100 6.417 6.29 TVC 10.918 2:1 10.8098 11.0271 0.0915 50 30-70-34-75-33-70

G2330 LBS/GAL 10 6.408 6.281 1.0952 2:1 1.0843 1.1061 0.913 20 42-40-46

G2331 LBS/GAL 10 6.534 6.404 2.1053 2% 1:1 2.0843 2.1263 0.475 10 38-80

G2334 LBS/GAL 10 6.551 6.421 2.1429 1:1 2.1215 2.1643 0.4667 20 35-40-75

G2337 LBS/GAL 10 6.628 6.497 1.0588 2:1 1.0483 1.0693 0.9444 20 51-40-54

G2340 LBS/GAL 10 6.78 6.65 PRESET 1.0345 2:1 1.0242 1.0448 0.9667 10 58-60

G2341 LBS/GAL 10 6.78 6.65 1.0345 2:1 1.0242 1.0448 0.9667 10 58-60

G2344 LBS/GAL 10 6.917 6.78 2.0294 1:1 2.0092 2.0496 0.493 20 34-40-69

G2346 LBS/GAL 10 6.997 6.858 0.9831 2% 2:1 0.9733 0.9929 1.0172 10 59-58

G2347 LBS/GAL 10 7.006 6.868 1 2:1 0.99 1.01 1 10 59-59

G2349 LBS/GAL 100 7.085 6.944 9.9064 2:1 9.8074 10.0050 4.1009 50 33-63-34-65-28-76

G2350 LBS/GAL 10 7.12 6.979 TVC 1.9714 1:1 1.9517 1.9911 0.5072 30 35-40-40-69

G2357 LBS/GAL 10 7.39 7.24 PRESET 1.9 1:1 1.881 1.919 0.5263 20 30-48-57

G2358 LBS/GAL 10 7.39 7.24 1.9000 1:1 1.881 1.919 0.5263 20 30-48-57

G2365 LBS/GAL 10 7.589 7.439 1.8125 2% 1:1 1.7944 1.8306 0.5517 20 32-40-58

G2368 LBS/GAL 10 7.62 7.469 1.8421 1:1 1.8237 1.8605 0.543 20 38-40-70

G2371 LBS/GAL 10 7.637 7.486 1.8378 1:1 1.8195 1.8561 0.5441 20 37-40-68

G2374 LBS/GAL 10 7.67 7.52 1.7941 2% 1:1 1.7762 1.8120 0.5574 20 34-40-61

G2377 LBS/GAL 10 7.76 7.6 PRESET 1.8095 1:1 1.7915 1.8275 0.5526 10 42-76

G2378 LBS/GAL 10 7.76 7.6 1.8095 1:1 1.7915 1.8275 0.5526 10 42-76 41967

G2387 LBS/GAL 10 7.96 7.8 1.7632 1:1 1.7456 1.7808 0.5672 20 38-40-67

G2393 LBS/GAL 10 8.05 7.89 PRESET 1.7442 1:1 1.7268 1.7616 0.5733 10 43-75

G2394 LBS/GAL 10 8.05 7.89 1.7442 1:1 1.7268 1.7616 0.5733 10 43-75

G2398 LBS/GAL 10 8.188 8.026 1.7142 1:1 1.6971 1.7313 0.5830 20 28-50-48

G2401 LBS/GAL 10 8.19 8.03 1.7143 1:1 1.6972 1.7314 0.5833 20 35-40-60

G2405 LBS/GAL 10 8.257 8.093 1.7000 1:1 1.6830 1.7170 0.5882 20 40-40-68

G2411 LBS/GAL 10 8.284 8.12 1.6944 1:1 1.6775 1.7113 0.5901 20 36-48-61

G2414 LBS/GAL 10 8.29 8.130 1.6585 2% 1:1 1.642 1.675 0.6029 20 41-48-68

G2418 LBS/GAL 10 8.324 8.16 0.8269 2% 2:1 0.8187 0.8351 1.2093 20 52-43-43

G2428 LBS/GAL 100 8.586 8.416 8.1738 2:1 8.0921 8.2555 0.1223 50 37-67-36-65-30-75

G2429 LBS/GAL 10 8.605 8.435 1.6315 1:1 1.6152 1.6478 0.6129 20 38-40-62

G2433 LBS/GAL 10 8.736 8.563 1.575 2% 1:1 1.5593 1.5907 0.6349 20 40-40-63

G2435 LBS/GAL 10 8.740 8.567 TVC 1.6061 1:1 1.5901 1.6221 0.6226 30 33-40-40-53

G2438 LBS/GAL 10 8.747 8.574 1.6046 1:1 1.5886 1.6206 0.623 20 43-43-69

G2442 LBS/GAL 100 8.805 8.630 7.9714 2:1 7.8917 8.0511 0.125 50 35-62-35-63-30-75

G2445 LBS/GAL 10 8.890 8.710 PRESET 1.5790 1:1 1.5633 1.5947 0.6333 20 38-48-60

G2446 LBS/GAL 10 8.890 8.710 1.5790 1:1 1.5633 1.5947 0.6333 20 38-48-60

G2451 LBS/GAL 10 8.992 8.814 1.5609 1:1 1.5453 1.5765 0.6406 20 41-40-64

G2455 LBS/GAL 10 9.173 8.991 PRESET 1.5313 1:1 1.5160 1.5466 0.6531 20 32-48-49

G2458 LBS/GAL 10 9.200 9.020 1.5250 1:1 1.5098 1.5402 0.6557 20 40-40-61

G2461 LBS/GAL 10 9.260 9.080 TVC 1.5152 1:1 1.5001 1.5303 0.6600 30 33-40-40-50

G2467 LBS/GAL 10 9.360 9.170 PRESET 1.5000 1:1 1.4850 1.5150 0.6667 20 30-43-45

G2468 LBS/GAL 10 9.360 9.170 1.5000 1:1 1.4850 1.5150 0.6667 20 30-43-45

G2471 LBS/GAL 10 9.502 9.314 1.4773 1:1 1.4626 1.4920 0.6769 20 44-44-65

G2477 LBS/GAL 10 9.508 9.320 1.4762 1:1 1.4615 1.4909 0.6770 20 42-40-62

G2480 LBS/GAL 10 9.7 9.5 1.4474 1:1 1.433 1.4618 0.6909 20 38-40-55

G2483 LBS/GAL 10 9.800 9.610 1.4318 1:1 1.4175 1.4461 0.6984 20 44-30-63

G2486 LBS’GAL 10 9.800 9.610 PRESET 1.4318 1:1 1.4175 1.4461 0.6984 20 44-30-63

G2489 LBS/GAL 10 9.933 9.737 1.4130 1:1 1.3989 1.4271 0.7077 20 46-46-65

G2492 LBS/GAL 10 9.960 9.770 1.4081 1:1 1.3941 1.4221 0.7100 10 49-69

G2495 LBS/GAL 10 10.120 9.920 1.3846 1:1 1.3708 1.3984 0.7222 20 39-40-54 41972

G2496 LBS/GAL 10 10.120 9.920 PRESET 1.3846 1:1 1.3708 1.3984 0.7222 20 39-40-54

G2501 LBS/GAL 10 10.321 10.117 1.3600 1:1 1.3464 1.3736 0.7353 10 50-68

G2502 LBS/GAL 10 10.249 10.046 1.3695 1:1 1.3559 1.3831 0.7301 20 46-46-63

G2507 LBS/GAL 10 10.332 10.127 1.3571 1:1 1.3436 1.3706 0.7368 20 42-40-57

G2510 LBS/GAL 10 10.350 10.150 1.3555 1:1 1.3400 1.3690 0.7377 20 45-40-61

G2513 LBS/GAL 10 10.53 10.32 PRESET 1.3333 1:1 1.32 1.3466 0.75 10 51-68

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

18

Page 19

M-7 & M-10 Gear Plate Listing (continued)

Part #

G2514 LBS/GAL 10 10.53 10.32 1.3333 1:1 1.32 1.3466 0.75 10 51-68

G2520 LBS/GAL 10 10.684 10.473 1.3137 2% 1:1 1.3006 1.3268 0.7612 10 51-67

G2523 LBS/GAL 10 10.9 10.68 PRESET 1.2885 1:1 1.2757 1.3013 0.7761 10 52-67

G2524 LBS/GAL 10 10.9 10.68 1.2885 1:1 1.2757 1.3013 0.7761 10 52-67

G2530 LBS/GAL 10 11.168 10.73 1.2692 1:1 1.2566 1.2818 0.7879 10 52-66

G2533 LBS/GAL 10 11.18 10.96 PRESET 1.2553 1:1 1.2428 1.2678 0.7966 20 47-30-59

G2534 LBS/GAL 10 11.18 10.96 1.2553 1:1 1.2428 1.2678 0.7966 20 47-30-59

G2536 LBS/GAL 10 11.251 11.029 1.2264 2% 1:1 1.2142 1.2386 0.8154 10 53-65

G2537 LBS/GAL 10 11.3 11.1 1.2400 1:1 1.2276 1.2524 0.806 20 50-40-62

G2543 LBS/GAL 10 11.45 11.22 PRESET 1.2264 1:1 1.2142 1.2386 0.8154 10 53-65

G2544 LBS/GAL 10 11.45 11.22 1.2264 1:1 1.2142 1.2386 0.8154 10 53-65

G2547 LBS/GAL 10 11.66 11.43 PRESET 1.2037 1:1 1.1917 1.2157 0.8307 10 54-65

G2548 LBS/GAL 10 11.66 11.43 1.2037 1:1 1.1917 1.2157 0.8307 10 54-65

G2551 LBS/GAL 10 11.79 11.56 1.1666 2% 1:1 1.1550 1.1782 0.8571 20 42-42-49

G2554 LBS/GAL 10 11.84 11.61 PRESET 1.1852 1:1 1.1734 1.1970 0.8438 10 54-64

G2555 LBS/GAL 10 11.84 11.61 1.1852 1:1 1.1734 1.197 0.8438 10 54-64

G2561 LBS/GAL 10 11.931 11.695 1.1765 1:1 1.1648 1.1882 0.85 20 34-40-40

G2564 LBS/GAL 10 12.07 11.83 PRESET 1.1636 1:1 1.152 1.1752 0.8593 10 55-64

G2565 LBS/GAL 10 12.07 11.83 1.1636 1:1 1.152 1.1752 0.8593 10 55-64

G2567 LBS/GAL 10 12.231 11.989 1.1454 1:1 1.1340 1.1568 0.8730 10 55-63

G2568 LBS/GAL 10 12.254 12.012 1.1454 1:1 1.1340 1.1568 0.8730 10 55-63

G2571 LBS/GAL 10 12.43 12.18 PRESET 1.1316 1:1 1.1203 1.1429 0.8837 20 38-40-43

G2572 LBS/GAL 10 12.43 12.18 1.1316 1:1 1.1203 1.1429 0.8837 20 38-40-43

G2575 LBS/GAL 10 12.501 12.234 TVC 1.1228 1:1 1.1116 1.1340 0.8906 30 49-40-40-55

G2578 LBS/GAL 10 12.678 12.427 1.1071 1:1 1.0961 1.1181 0.9032 10 56-62

G2581 LBS/GAL 10 12.891 12.636 1.0889 1:1 1.0781 1.0997 0.9184 20 45-40-49

G2584 LBS/GAL 10 13.12 12.86 1.0702 1:1 1.0595 1.0809 0.9344 10 57-61

G2587 LBS/GAL 10 13.332 13.068 1.0526 1:1 1.0421 1.0631 0.9500 20 38-40-40

G2589 LBS/GAL 10 14.037 13.759 1.0000 1:1 0.9900 1.0100 1.0000 10 59-59

G2590 LBS/GAL 10 14.1 13.82 0.9756 1:1 0.9659 0.9853 1.0250 20 41-40-40

G2596 LBS/GAL 10 14.35 14.070 0.9777 1:1 0.968 0.9874 1.0227 20 45-45-44

G2599 LBS/GAL 10 14.647 14.357 0.9583 1:1 0.9488 0.9678 1.0435 20 48-46-46

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G2673 LITERS/GAL 10 TVC 1.8000 2% 2:1 1.782 1.818 0.5555 30 35-45-45-63

G2674 LITERS/GAL 10 1.8 2% 2:1 1.7820 1.8180 0.5555 20 30-48-54

G2680 LITERS/GAL 10 PRESET 1.8387 2:1 1.8204 1.857 0.5438 20 31-46-57 40449

G2681 LITERS/GAL 10 1.8387 2:1 1.8204 1.857 0.5438 20 31-46-57 41349

G2690 DEKALITERS/GAL 10 18.3933 2:1 18.2094 18.5772 0.0544 50 28-72-34-64-20-76

G2870 WHOLE PINTS 10 1.7368 1:1 1.7195 1.7541 0.5758 20 38-45-66

G2877 WHOLE QUARTS 10 1.7370 2:1 1.7197 1.7543 0.5758 20 38-45-66

G288 1/10 CUBIC FT 1 5.1935 2:1 5.1416 5.2454 0.1925 50 30-69-58-58-31-70

19

Page 20

M-15 & M-25 Gear Plate Listing

Part #

G3114 US GAL 10 PRESET 2.5161 2% 2:1 2.491 2.5412 0.3974 20 31-45-78

G3115 US GAL 10 2.5161 2% 2:1 2.491 2.5412 0.3974 20 31-45-78

G3116 US GAL 10 TVC 2.5161 2% 2:1 2.491 2.5412 0.3974 30 31-41-41-78

G3123 US GAL 10 TVC 2.5714 2:1 2.5457 2.5971 0.3888 30 28-46-46-72

G3124 US GAL 10 TVC 2.5714 2:1 2.5457 2.5971 0.3888 30 28-46-46-72

G3125 US GAL 10 PRESET 2.5714 2:1 2.5457 2.5971 0.3888 20 28-48-72

G3126 US GAL 10 2.5714 2:1 2.5457 2.5971 0.3888 20 28-48-72

G3160 1/10 US GAL 1 PRESET 0.5147 1:1 0.5096 0.5198 1.9428 20 68-40-35

G3161 1/10 US GAL 1 0.5147 1:1 0.5096 0.5198 1.9428 20 68-40-35

G3200 IMP GAL 10 3.0891 2:1 3.0583 3.1199 0.3237 40 33-58-33-58

G3201 IMP GAL 10 TVC 3.0891 2:1 3.0583 3.1199 0.3237 50 33-58-49-49-33-58

G3202 IMP GAL 10 3.0303 2% 2:1 3 3.0606 0.33 40 33-50-30-60

G3203 IMP GAL 10 TVC 3.0303 2% 2:1 3 3.0606 0.33 50 30-60-49-49-33-50

G3215 1/10 IMP GAL 1 0.6182 1:1 0.6121 0.6243 1.6176 20 55-48-34

G3216 1/10 IMP/GAL 1 TVC 0.6182 1:1 0.6121 0.6243 1.6176 30 55-40-40-34

G3217 1/10 IMP GAL 1 0.6065 2% 1:1 0.6005 0.6125 1.6486 20 61-40-37

G3218 1/10 IMP GAL 1 TVC 0.6065 2% 1:1 0.6005 0.6125 1.6486 30 61-40-40-37

G3229 KG/GAL 10 TVC 1.5111 1:1 1.496 1.5262 0.6618 30 45-40-40-68

G3230 KG/GAL 10 3.436 3.368 1.5135 1:1 1.4984 1.5286 0.6607 20 37-40-56

G3235 KG/GAL 100 3.44 3.372 TVC 15.1182 1:1 14.9671 15.2693 0.0660 50 28-59-28-75-28-75

G3305 LBS/GAL 10 6.562 6.432 0.7925 1:1 0.7846 0.8004 1.2619 20 53-40-42

G3307 LBS/GAL 10 6.706 6.574 0.7755 1:1 0.7678 0.7832 1.2895 20 49-49-38

G3310 LBS/GAL 10 6.932 6.795 0.7353 2% 1:1 0.7280 0.7426 1.3600 10 68-50

G3320 LBS/GAL 100 7.079 6.939 TVC 3.6736 2:1 3.6369 3.7103 0.2722 50 36-69-56-56-36-69

G3326 LBS/GAL 100 7.204 7.061 3.6100 2:1 3.5739 3.6461 0.2770 40 30-57-30-57

G3328 LBS/GAL 10 7.222 7.079 0.7200 1:1 0.7128 0.7272 1.3888 20 50-40-36

G3329 LBS/GAL 10 7.342 7.196 TVC 0.7083 1:1 0.7013 0.7153 1.4118 30 48-40-40-34

G3330 LBS/GAL 100 7.508 7.359 3.4637 2:1 3.4291 3.4983 0.2890 40 36-67-36-67

G3335 LBS/GAL 10 7.584 7.434 0.6857 1:1 0.6789 0.6925 1.4583 10 70-48

G3338 LBS/GAL 100 7.59 7.44 TVC 3.4261 2:1 3.3919 3.4603 0.2900 50 44-63-49-49-28-67

G3342 LBS/GAL 10 7.676 7.524 0.6774 1:1 0.6707 0.6841 1.4762 20 62-40 42

G3343 LBS/GAL 10 7.676 7.524 TVC 0.6774 1:1 0.6707 0.6841 1.4762 30 62-40-40-42

G3344 LBS/GAL 100 7.74 7.59 TVC 3.3564 2:1 3.3229 3.3899 0.298 50 30-57-44-60-44-57

G3346 LBS/GAL 10 7.801 7.647 0.6667 1:1 0.6601 0.6733 1.5 20 57-38-38

G3347 LBS/GAL 10 7.801 7.647 TVC 0.6667 1:1 0.6601 0.6733 1.5 30 57-38-38-38

G3349 LBS/GAL 10 8.244 8.081 0.6308 1:1 0.6245 0.6371 1.5854 20 65-40-41

G3350 LBS/GAL 10 8.581 8.411 0.6061 1:1 0.6001 0.6121 1.65 20 66-40-40

G3353 LBS/GAL 100 8.429 8.268 3.0232 2:1 2.993 3.0534 0.3307 40 43-65-30-60

G3356 LBS/GAL 10 8.450 8.280 PRESET 0.6168 1:1 0.617 0.6229 1.6200 20 60-40-37

G3357 LBS/GAL 10 8.450 8.280 0.6168 1:1 0.617 0.6229 1.6200 20 60-40-37

G3358 LBS/GAL 10 8.409 8.242 0.6061 2% 1:1 0.6001 0.6121 1.6500 20 66-40-40

G3359 LBS/GAL 100 8.488 8.319 TVC/PST 3.0625 2:1 3.0319 3.0931 0.3265 50 32-49-48-48-30-60

G3360 LBS/GAL 100 8.691 8.520 PRESET 2.9920 2:1 2.9621 3.0219 0.3340 40 37-64-37-64

G3361 LBS/GAL 10 8.841 8.666 0.5882 1:1 0.5824 0.5940 1.7000 20 68-40-40

G3362 LBS/GAL 10 8.959 8.781 0.5689 2% 1:1 0.5633 0.5745 1.7576 20 58-40-33

G3363 LBS/GAL 100 9.242 9.059 PRESET 2.8137 2:1 2.7856 2.8418 0.3342 40 31-52-31-52

G3369 LBS/GAL 100 9.262 9.078 2.8079 2:1 2.7799 2.8359 0.3560 40 37-62-37-62

G3373 LBS/GAL 100 9.417 9.230 TVC/PST 2.7600 2:1 2.7324 2.7876 0.3623 40 50-60-50-50-30-69

G3374 LBS/GAL 10 9.696 9.504 0.5362 1:1 0.5309 0.5415 1.8649 20 69-40-37

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G3510 LITERS/GAL 10 1.3333 2% 1:1 1.3200 1.3466 0.7500 20 48-48-64 41973

G3516 LITERS/GAL 10 PRESET 1.3600 1:1 1.3464 1.3736 0.7353 10 50-68 41353

G3517 LITERS/GAL 10 1.3600 1:1 1.3464 1.3736 0.7353 10 50-68 41980

G3550 DEKALITERS/GAL 10 6.7857 2:1 6.7179 6.8535 0.1474 40 28-70-28-76 41981

G3555 DEKALITERS/GAL 10 6.6597 2% 2:1 6.5932 6.7262 0.1501 40 31-80-31-80

G3560 DEKALITERS/GAL 10 PRESET 6.7857 2:1 6.7179 6.8535 0.1474 40 28-70-28-76

G3644 42 GAL/BARREL 1 PRESET 10.8333 2:1 10.7250 10.9416 0.0923 50 30-52-30-75-30-75

G3645 42 GAL/BARREL 1 10.8333 2:1 10.7250 10.9416 0.0923 50 30-52-30-75-30-75

G3646 42 GAL/BARREL 1 10.5903 2% 2:1 10.4844 10.6962 0.0944 50 36-61-30-75-30-75

G3650 1/10 CUBIC FT 1 1.8857 2% 2:1 1.8669 1.9045 0.5303 20 35-40-66

G3651 1/10 CUBIC FT 1 1.9231 2:1 1.9039 1.9423 0.52 20 39-39-75

20

Page 21

M-30 & M-40 Gear Plate Listing

Part #

G4110 US GAL 10 0.9091 2% 2:1 0.9001 0.9181 1.1 20 55-40-50

G4111 US GAL 10 TVC 0.9091 2% 2:1 0.9001 0.9181 1.1 30 55-40-40-50

G4115 US GAL 10 1.8571 1:1 1.8386 1.8756 0.5385 20 35-40-65

G4116 US GAL 10 TVC 1.8571 1:1 1.8386 1.8756 0.5385 30 35-40-40-65

G4118 US GAL 10 TVC 1.8182 2% 1:1 1.8001 1.8363 0.55 30 33-48-48-60

G4120 US GAL 10 PRESET 0.9344 2:1 0.9251 0.9437 1.0702 10 61-57

G4121 US GAL 10 0.9344 2:1 0.9251 0.9437 1.0702 10 61-57

G4132 US GAL 100 9.2857 2:1 9.1929 9.3785 0.1077 50 28-60-31-65-30-62

G4134 US GAL 100 9.0909 2:1 9.0000 9.1818 0.11 50 30-60-33-75-35-70

G4150 IMP GAL 10 1.1071 2:1 1.0961 1.1181 0.9032 10 56-62

G4151 IMP GAL 10 PRESET 1.1071 2:1 1.0961 1.1181 0.9032 10 56-62

G4153 IMP GAL 10 1.0926 2% 2:1 1.0817 1.1035 0.9153 20 54-30-59

G4154 IMP GAL 10 TVC 1.0926 2% 2:1 1.0817 1.1035 0.9153 30 54-30-30-59

G4219 LBS/GAL 100 3.473 3.405 Z 2.699 2:1 2.6721 2.7259 0.3705 40 42-69-42-69

G4221 LBS/GAL 100 3.544 3.474 Z 2.6453 2:1 2.6189 2.6717 0.378 40 40-70-43-65

G4223 LBS/GAL 100 3.612 3.54 Z 2.5957 2:1 2.5698 2.6216 0.3853 40 36-58-36-58

G4225 LBS/GAL 100 3.684 3.611 Z 2.5448 2:1 2.5194 2.5702 0.393 40 42-67-42-67

G4227 LBS/GAL 100 3.75 3.676 Z 2.5000 2:1 2.4750 2.5250 0.4000 20 30-45-75

G4229 LBS/GAL 100 3.82 3.744 Z 2.4544 2:1 2.4299 2.4789 0.4074 40 30-47-30-47

G4231 LBS/GAL 100 3.889 3.812 Z 2.4107 2:1 2.3866 2.4348 0.4148 40 38-59-38-59

G4233 LBS/GAL 100 3.966 3.888 Z 2.3636 2:1 2.3400 2.3872 0.4231 20 33-40-78

G4236 LBS/GAL 100 4.043 3.963 Z 2.3187 2:1 2.2956 2.3418 0.4313 40 44-67-44-67

G4239 LBS/GAL 100 4.125 4.043 Z 2.2727 2:1 2.2500 2.2954 0.4400 20 33-40-75

G4242 LBS/GAL 100 4.207 4.123 Z 2.2286 2:1 2.2064 2.2508 0.4487 20 35-40-78

G4245 LBS/GAL 100 4.286 4.201 Z 2.1875 2:1 2.1657 2.2093 0.4571 20 32-40-70

G4248 LBS/GAL 100 4.367 4.281 Z 2.1466 2:1 2.1252 2.1680 0.4659 40 43-63-43-63

G4252 LBS/GAL 100 4.453 4.365 Z 2.1053 2:1 2.0843 2.1263 0.4750 10 38-80

G4255 LBS/GAL 100 4.536 4.446 Z 2.0667 2:1 2.0461 2.0873 0.4839 20 30-45-62

G4258 LBS/GAL 100 4.615 4.524 Z 2.0313 2:1 2.011 2.0516 0.4923 20 32-45-65

G4261 LBS/GAL 100 4.704 4.611 Z 1.9931 2:1 1.9732 2.013 0.5017 40 34-48-34-48

G4264 LBS/GAL 100 4.799 4.704 Z 1.9535 2:1 1.934 1.973 0.5119 40 43-60-35-49

G4267 LBS/GAL 100 4.884 4.787 Z 1.9196 2:1 1.9005 1.9387 0.5209 40 39-54-44-61

G4270 LBS/GAL 100 4.971 4.873 Z 1.8857 2:1 1.8669 1.9045 0.5303 20 35-40-66

G4273 LBS/GAL 100 5.072 4.971 Z 1.8485 2:1 1.8301 1.8669 0.541 20 33-45-61

G4276 LBS/GAL 100 5.172 5.070 Z 1.8125 2:1 1.7944 1.8306 0.5517 20 32-50-58

G4279 LBS/GAL 100 5.263 5.159 Z 1.7813 2:1 1.7635 1.7991 0.5614 20 32-50-57

G4282 LBS/GAL 100 5.357 5.251 Z 1.7500 2:1 1.7325 1.7675 0.5714 20 40-40-70

G4285 LBS/GAL 100 5.454 5.346 Z 1.7188 2:1 1.7017 1.7359 0.5818 20 32-45-55

G4288 LBS/GAL 100 5.561 5.451 Z 1.6857 2:1 1.6689 1.7025 0.5932 20 35-40-59

G4291 LBS/GAL 100 5.671 5.559 Z 1.6531 2:1 1.6366 1.6696 0.6049 40 35-45-35-45

G4294 LBS/GAL 100 5.781 5.667 Z 1.6216 2:1 1.6054 1.6378 0.6167 20 37-40-60

G4297 LBS/GAL 100 5.897 5.780 Z 1.5897 2:1 1.5739 1.6055 0.6290 20 39-40-62

G4300 LBS/GAL 100 5.999 5.881 Z 1.5625 2:1 1.5469 1.5781 0.6400 20 32-50-50

G4303 LBS/GAL 100 6.108 5.987 Z 1.5349 2:1 1.5196 1.5502 0.6515 20 43-40-66

G4306 LBS/GAL 100 6.224 6.101 Z 1.5062 2:1 1.4912 1.5212 0.6639 40 44-54-44-54

G4309 LBS/GAL 100 6.346 6.220 Z 1.4773 2:1 1.4626 1.4920 0.6769 20 44-40-65

G4312 LBS/GAL 100 6.477 6.349 Z 1.4474 2:1 1.433 1.4618 0.6909 20 38-40-55

G4315 LBS/GAL 100 6.592 6.461 Z 1.4222 2:1 1.4080 1.4364 0.7031 20 45-40-64

G4318 LBS/GAL 100 6.719 6.586 Z 1.3953 2:1 1.3814 1.4092 0.7167 20 43-40-60

G4321 LBS/GAL 100 6.836 6.700 Z 1.3714 2:1 1.3577 1.3851 0.7292 20 35-40-48

G4324 LBS/GAL 100 6.967 6.829 Z 1.3456 2:1 1.3322 1.3590 0.7432 40 50-58-50-58

G4327 LBS/GAL 100 7.088 6.948 Z 1.3226 2:1 1.3094 1.3358 0.7561 20 31-45-41

G4330 LBS/GAL 100 7.237 7.092 Z 1.2955 2:1 1.2826 1.3084 0.7719 20 44-40-57

G4333 LBS/GAL 100 7.377 7.231 Z 1.2708 2:1 1.2581 1.2835 0.7869 20 48-40-61

G4336 LBS/GAL 100 7.531 7.380 Z 1.2449 2:1 1.2325 1.2573 0.8033 20 49-35-61

G4339 LBS/GAL 100 7.670 7.518 Z 1.2222 2:1 1.2100 1.2344 0.8182 20 45-40-55

G4342 LBS/GAL 100 7.828 7.673 Z 1.1976 2:1 1.1857 1.2095 0.8350 40 53-58-53-58

G4345 LBS/GAL 100 7.969 7.811 Z 1.1765 2:1 1.1648 1.1882 0.85 20 34-40-40

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

21

Page 22

M-30 & M-40 Gear Plate Listing (continued)

Part #

G4348 LBS/GAL 100 8.125 7.964 Z 1.1538 2:1 1.1423 1.1653 0.8667 20 52-40-60

G4351 LBS/GAL 100 8.272 8.108 Z 1.1333 2:1 1.122 1.1446 0.8824 20 45-40-51

G4354 LBS/GAL 100 8.437 8.27 Z 1.1111 2:1 1.1 1.1222 0.9 20 36-40-40

G4357 LBS/GAL 100 8.609 8.439 Z 1.0889 2:1 1.0781 1.0997 0.9184 20 45-40-49

G4358 LBS/GAL 100 8.606 8.436 Z 1.0893 2:1 1.0785 1.1001 0.918 20 56-40-61

G4360 LBS/GAL 100 8.75 8.577 Z 1.0714 2:1 1.0607 1.0821 0.9333 20 42-40-45

G4363 LBS/GAL 100 8.928 8.752 Z 1.05 2:1 1.0395 1.0605 0.9524 20 40-40-42

G4366 LBS/GAL 100 9.114 8.934 Z 1.0286 2:1 1.0184 1.0388 0.9722 20 35-40-36

G4367 LBS/GAL 100 9.291 9.107 Z 1.0090 2:1 0.9990 1.0190 0.9911 40 37-56-57-38

G4370 LBS/GAL 100 9.473 9.285 Z 0.9897 2:1 0.9799 0.9995 1.0104 40 37-53-55-38

G4372 LBS/GAL 100 9.663 9.472 Z 0.9705 2:1 0.9608 0.9802 1.0303 20 34-40-33

G4374 LBS/GAL 100 9.858 9.66 Z 0.9512 2:1 0.9417 0.9607 1.0513 20 41-40-39

G4376 LBS/GAL 100 10.061 9.86 Z 0.9318 2:1 0.9225 0.9411 1.0732 20 44-40-41

G4378 LBS/GAL 100 10.259 10.056 Z 0.9138 2:1 0.9047 0.9229 1.0943 20 58-40-53

G4380 LBS/GAL 100 10.44 10.233 Z 0.8980 2:1 0.8891 0.9069 1.1136 20 49-40-44

G4382 LBS/GAL 100 10.653 10.442 Z 0.88 2:1 0.8712 0.8888 1.1364 20 50-40-44

G4384 LBS/GAL 100 10.866 10.651 Z 0.8627 2:1 0.8541 0.8713 1.1591 20 51-40-44

G4386 LBS/GAL 100 11.079 10.86 Z 0.8462 2:1 0.8378 0.8546 1.1818 20 39-40-33

G4388 LBS/GAL 100 11.298 11.074 Z 0.8298 2:1 0.8216 0.838 1.2051 20 47-40-39

G4390 LBS/GAL 100 11.518 11.29 Z 0.8140 2:1 0.8059 0.8221 1.2286 20 43-40-35

G4392 LBS/GAL 10 11.898 11.662 X 0.3152 1:2 0.3121 0.3183 3.1729 40 57-32-57-32

G4393 LBS/GAL 100 11.953 11.716 Z 0.7843 2:1 0.7765 0.7921 1.2750 20 51-40-40

G4394 LBS/GAL 100 12.187 11.946 Z 0.7692 2:1 0.7616 0.7768 1.3000 20 52-40-40

G4395 LBS/GAL 100 12.427 12.181 Z 0.7544 2:1 0.7469 0.7619 1.3256 20 57-40-43

G4397 LBS/GAL 100 12.922 12.666 Z 0.7255 2:1 0.7183 0.7327 1.3784 20 51-35 37

G4398 LBS/GAL 100 13.183 12.922 Z 0.7111 2:1 0.7040 0.7182 1.4063 20 45-40-32

G4400 LBS/GAL 100 13.702 13.43 Z 0.6842 2:1 0.6774 0.6910 1.4615 20 57-35-39

G4401 LBS/GAL 100 13.948 13.672 Z 0.6712 2:1 0.6654 0.6788 1.4878 20 61-40-41

G4402 LBS/GAL 100 14.213 13.932 Z 0.6596 2:1 0.6531 0.6661 1.5161 20 47-45-31

G4403 LBS/GAL 100 14.488 14.201 Z 0.6471 2:1 0.6407 0.6535 1.5454 20 68-40-44

G4404 LBS/GAL 100 14.765 14.473 Z 0.6349 2:1 0.6286 0.6412 1.575 20 63-40-40

G4405 LBS/GAL 100 15.056 14.758 Z 0.6226 2:1 0.6164 0.6288 1.6061 20 53-40-33

G4406 LBS/GAL 100 15.364 15.059 Z 0.6102 2:1 0.6041 0.6163 1.6389 20 59-40-36

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G4409 LITERS/GAL 10 0.4828 2% 1:1 .4780 0.4876 2.0714 20 58-48-28

G4410 LITERS/GAL 10 0.4912 1:1 0.4863 0.4961 2.0358 20 57-48-28

G4450 CUBIC METERS 1 24.4653 2:1 24.2207 24.7099 0.0408 50 30-46-19-72-19-80

G4470 DEKALITERS/GAL 10 2.4516 2:1 2.4271 2.4761 0.4079 20 31-45-76

G4471 DEKALITERS/GAL 10 PRESET 2.4516 2:1 2.4271 2.4761 0.4079 20 31-45-76

G4473 DEKALITERS/GAL 10 2.4040 2% 2:1 2.3800 2.4280 0.4160 40 33-51-36-56

G4474 DEKALITERS/GAL 10 TVC 2.4040 2% 2:1 2.3800 2.4280 0.4160 50 33-51-50-50-36-56

G4510 42 GAL/BARREL 1 3.8158 2% 2:1 3.7777 3.8539 0.2620 50 30-58-60-60-38-75

G4515 42 GAL/BARREL 1 3.8954 2:1 3.8565 3.9343 0.2567 50 38-75-60-60-38-75

G4516 42 GAL/BARREL 1 PRESET 3.8954 2:1 3.8565 3.9343 0.2567 40 38-75-38-75

G4550 35 IMP GAL/BAR 1 TVC 3.8954 2:1 3.8565 3.9343 0.2567 50 38-75-60-60-38-75

22

Page 23

M-60, MS-75, M-80 & MS-120 Gear Plate Listing

M-60 (old style) & MS-75

Part #

G5110 US GAL 10 0.6389 1:1 0.6326 0.6452 1.5652 10 72-46

G5115 US GAL 10 PRESET 0.6389 1:1 0.6326 0.6452 1.5652 10 72-46

G5117 US GAL 10 TVC 0.625 2% 1:1 0.6188 0.6312 1.6 30 64-35-35-40

G5140 US GAL 10 1/1 ADJ 2.5436 1:1 2.5182 2.569 0.3931 40 35-56-39-62

G5210 IMP GAL 10 PRESET 0.7612 1:1 0.7536 0.7688 1.3137 10 67-51

G5211 IMP GAL 10 0.7612 1:1 0.7536 0.7688 1.3137 10 67-51

G5212 IMP GAL 10 0.75 2% 1:1 0.7425 0.7575 1.3333 20 60-40-45

G5410 DEKALITERS/GAL 10 PRESET 1.6829 1:1 1.6661 1.6997 0.5942 20 41-48-69

G5411 DEKALITERS/GAL 10 1.6829 1:1 1.6661 1.6997 0.5942 20 41-48-69

G5412 DEKALITERS/GAL 10 1.6486 2% 1:1 1.6322 1.665 0.6066 20 37-40-61

G5453 CUBIC METERS 1 8.4180 2:1 8.3339 8.5021 0.1188 50 30-61-35-63-30-69

G5454 CUBIC METERS 1 8.2432 2% 2:1 8.1608 8.3256 0.1213 50 30-60-37-61-30-75

G5510 42 GAL/BARREL 1 2.6777 1:1 2.651 2.7044 0.3735 40 33-54-33-54

Units of

Measure

Units

per

Rev

M-60 (new style) & M-80

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

Part #

G6120 US GAL 10 1.0000 1:1 0.9900 1.0100 1.0000 10 59-59

G6122 US GAL 1 0.9830 2% 1:1 0.9732 0.9928 1.0172 10 59-58

G6211 IMP GAL 10 1.1852 1:1 1.1734 1.1970 0.8438 10 54-64

G6222 IMP GAL 10 1.1750 2% 1:1 1.1633 1.1867 0.8510 20 40-47-47

G6312 CUBIC METERS 1 13.2944 2:1 13.1615 13.4273 0.0752 50 34-63-28-75-28-75

G6410 DEKALITERS/GAL 10 2.6667 1:1 2.6401 2.6933 0.375 40 37-60-37-60

G6512 42 GAL/BARREL 1 4.1800 1:1 4.1382 4.2218 2.3924 40 30-57-30-66

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

MS-120

Part #

G7110 US GAL 10 0.3947 1:1 0.3908 0.3986 2.5333 20 76-43-30

G7111 US GAL 10 TVC 0.3947 1:1 0.3908 0.3986 2.5333 30 76-43-43-30

G7112 US GAL 10 0.3866 2% 1:1 0.3828 0.3904 2.5866 20 75-29-29

G7113 US GAL 10 TVC 0.3866 2% 1:1 0.3828 0.3904 2.5866 30 75-29-29-29

G7210 IMP GAL 10 0.4746 1:1 0.4699 0.4793 2.1070 20 59-28-28

G7211 IMP GAL 10 TVC 0.4746 1:1 0.4699 0.4793 2.1070 30 59-44-44-28

G7213 IMP GAL 10 0.4638 2% 1:1 0.4592 0.4684 2.1563 20 69-40-32

G7214 IMP GAL 10 TVC 0.4638 2% 1:1 0.4592 0.4684 2.1563 30 69-40-40-32

Units of

Measure

Units

per

Rev

Range

High low Min Max

Used

With

Ratio

Special

Notes

P/G

Ratio

Ratio

Recip

Check

Pat #

Gear & POS #

A-B-C-D-E-F

G7242 CUBIC METERS 1 5.2232 2:1 5.171 5.2754 0.1915 40 35-75-32-78

G7243 CUBIC METERS 10 5.1188 2% 2:1 5.0677 5.1699 0.1954 40 30-63-32-78

G7270 DEKALITERS/GAL 10 1.0435 1:1 1.0331 1.0539 0.9583 20 46-50-48

G7271 DEKALITERS/GAL 10 1.0227 2% 1:1 1.0125 1.0329 0.9778 20 44-40-45

G7300 42 GAL/BARREL 1 1.6579 1:1 1.6414 1.6744 0.6032 20 38-45-63

23

Page 24

A Unit of IDEX Corporation

105 Albrecht Drive

Lake Bluff, IL 60044-2242

1.800.458.52628 • 47.295.1050

Fax: 847.295.1057

www.lcmeter.com

© 2004 Liquid Controls

Pub. No. 49030

(06/04)

Loading...

Loading...