Page 1

PR 734 PR 744Crawler Tractors

Engine Output (SAE J1349): 150 kW / 201 HP 185 kW / 248 HP

Operating eight:W 20,388 - 24,961 kg 24,605 - 31,669 kg

44,948 - 55,030 lb 54,245 - 69,818 lb

Page 2

PR 734

PR 744

Engine Output (SAE J1349): 150 kW / 201 HP

Operating Weight:

44,948 - 55,030 lb

Blade Capacity: 3.80 - 5.56 m³

4.97 - 7.27 yd³

Hydrostatic travel drive with

electronic control

20,388 - 24,961 kg

Engine utput O (SAE J1349): 185 kW / 248 HP

Operating Weight: 24,605 - 31,669 kg

54,245 - 69,818 lb

Blade Capacity: 4.90 - 7.20 m³

6.41 - 9.42 yd³

Hydrostatic travel drive with

electronic control

PR 734 Litronic PR 744 Litronic

2

Page 3

Performance

Sheer strength and innovative technology – these are the

hallmarks of the generation 4 of Liebherr crawler tractors. The impressive balance between operating weight

and engine output assures maximum productivity under

all conditions. Whether during ripping, dozing or grading,

the PR 734 and the PR 744 excel in any application with

outstanding performance.

Reliability

Strong and robust: In terms of their construction and quality of materials, Liebherr crawler tractors are consistently

designed with longevity in mind. Parts that are subjected

to considerable stress are produced from high-strength

material; critical components are optimally protected. All

this makes Liebherr crawler tractors the benchmark for

reliability and availability.

Economy

Clear economic benefits speak for Liebherr. Like all

Liebherr machines, the PR 734 and the PR 744 boast

an exemplary service concept. This reduces both down

times and maintenance costs. Our latest-generation diesel

engines combine high performance and fuel economy –

guaranteeing exceptional pushing power with low fuel

consumption and the efficient drive system.

Comfort

Generation 4 crawler tractors offer a spacious and comfortable workplace designed according to state-of-the-art

ergonomic standards, giving the operator an excellent

view of the work area and the blade. The intuitive single-joystick enables sensitive and reliable control of the

machine.

PR 734 Litronic PR 744 Litronic

3

Page 4

PR 734 Litronic PR 744 Litronic

4

Liebherr diesel engine

•State-of-the-arttechnology:Pump-line-

nozzle injection system, 4-valve technology, turbocharger with charge-air intercooling and electronic engine management

ensure power reserves in every situation.

•Environmentally-friendlyandeconomical:

Complies with the latest exhaust emissions

standards 2004/26/EC Stage IIIa (EU) and

EPA/CARB Tier 3 (US).

•Extra-deepoilsumppermitstravel

on gradients up to 45°.

Page 5

Performance

Liebherr has over 30 years of experience in the manufacture of hydrostatically

driven tractors. The high-performance generation 4 crawler tractors are the perfect machines for a wide variety of applications.

High productivity

High drawbar pull

The powerful Liebherr diesel engine in combination

with the innovative Liebherr travel drive guarantees

ample power in all situations. The drive system

does not require any gearshifting, which means that

engine power is transferred to the tracks without

interruption – even when cornering.

High dozing and

ripping power

The hydrostatic travel drive enables the operator

to define the optimal travel speed and drawbar pull

with ease - preventing the tracks from slipping and

ensuring that maximum power is transmitted to the

ground at all times.

Optimized blade design

for improved rolling of

the material

The blade contours of the PR 734 and PR 744

machines have been further optimized. Improved

rolling of the material enables the machine to achieve

even higher productivity.

Best levelling

characteristics

The entire front-end superstructure of the machine is

torsionally rigid and robust. In conjunction with the

long track frames, this ensures smooth operation of

the blade at all times.

A diversity of applications

Outstanding

maneuverability

The hydrostatic drive has a further advantage when

working in confined spaces. All travel movements

can be performed quickly and without difficulty,

including counter-rotation.

Liebherr hydrostatic drive

•Automaticspeedandtorqueadjustment

constantly optimizes the machine’s power

flow in the event of load changes.

•Evenatlowspeeds,forexampleindemanding ripping operations, the thermal load of

the hydrostatic travel drive remains low.

The high efficiency of the drive remains

almost unchanged.

Low machine

center of gravity

The layout of the drive components results in an

extremely low machine center of gravity, which permits safe operation during even the most challenging applications on slopes and embankments.

Optimized blade design

•Thebladesaredenedbyuncompromising penetration characteristics and outstanding rolling of the

material. The sloping top corners

of the blade allow the operator to

quickly ascertain blade filling.

•Robustly-builtusingwear-resistant

materials, Liebherr blades excel

under even the most demanding

conditions.

PR 734 Litronic PR 744 Litronic

5

Page 6

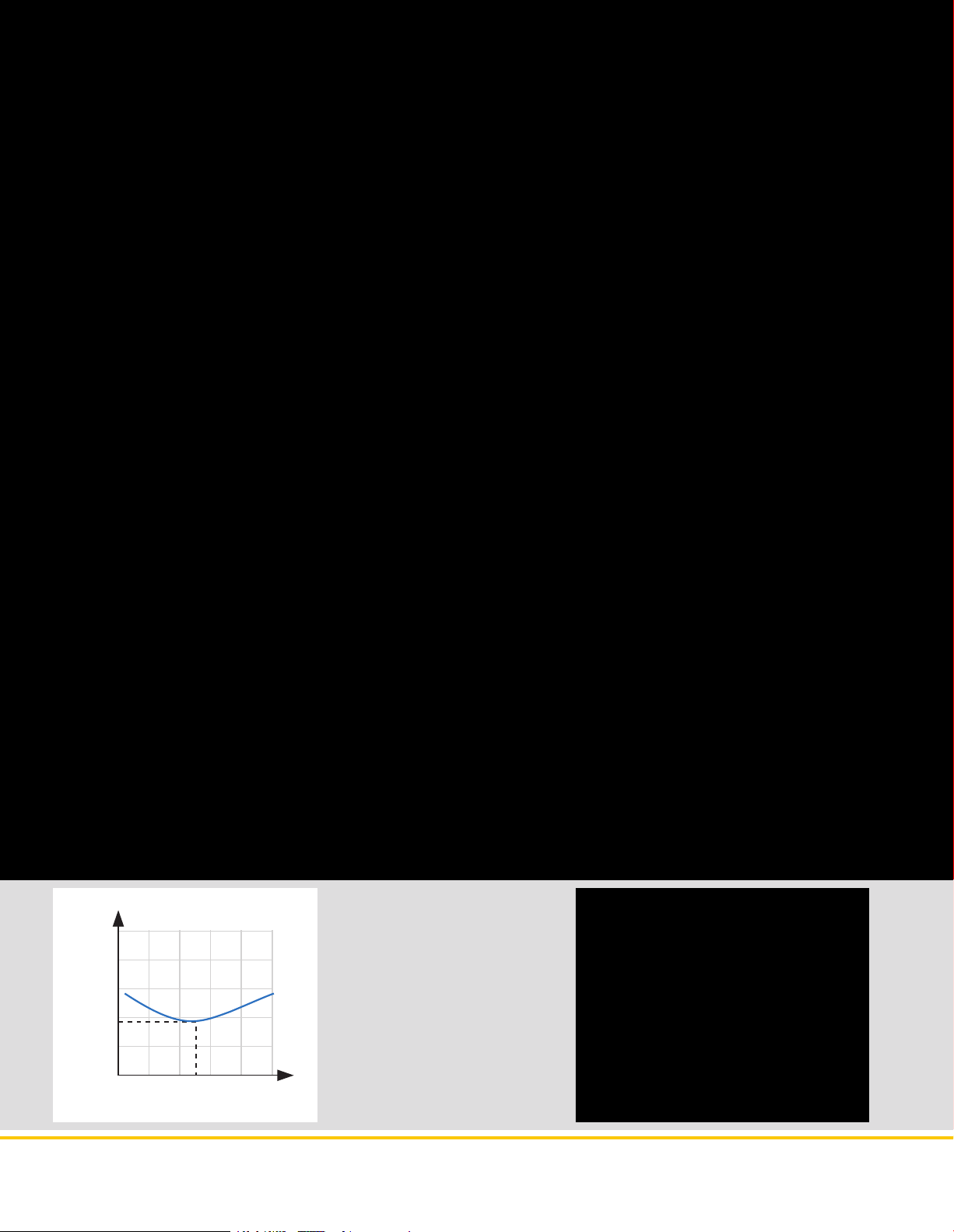

Specific fuel

consumption [g/kWh]

Engine speed [1/min]

PR 734 Litronic PR 744 Litronic

6

Consistent engine speed

for low fuel consumption

•Theratedenginespeedliesinthe

range of lowest specific fuel consumption, thereby ensuring maximum operating efficiency.

Page 7

Economy

Liebherr crawler tractors are consistently designed with cost-effectiveness in

mind, resulting in low fuel consumption, high productivity, long component service lifetimes and low maintenance costs.

Low fuel consumption

Constant engine speed

The Liebherr diesel engine operates at a consistent

speed at all times, regardless of the given travel

speed. The engine is not throttled and re-accelerated, thereby guaranteeing economical fuel consumption.

Low engine speed

The low engine speed results in significantly

enhanced filling of the cylinder chambers and, as a

consequence, more efficient fuel combustion.

Efficient drive system

The hydrostatic travel drive offers excellent efficiency across the entire speed range. The oil temperature remains low even when high power output

is required at low travel speeds (ripping work).

Load-sensing

power hydraulics

This system only uses the energy that is actually

required by the operating equipment. This saves

fuel if the equipment is not being used.

Low maintenance costs

Long maintenance

intervals

Excellent accessibility

The maintenance intervals are optimally geared to the

individual components. For example: maintenancefree bearings are used on exposed dozing frame.

All service points of the diesel engine are accessible from one side of the machine, while the tilting

cab enables access to the components inside the

machine. These measures allow servicing tasks to

be carried out quickly and efficiently.

Tilting cab

•Enablesstraightforward,rapid

access to all components of the

travel drive and power hydraulics.

Easy maintenance

•Allservicepointsarelocatedon

one side of the machine, saving

time and energy during daily

inspection tasks.

Liebherr PR 734 quick-coupler system

•Transportationwidthoflessthan9’10’’:

The hydraulic quick-coupler system

enables the machine to be transported

easily and quickly.

•Shortset-uptimeandstraightforward operation: The time required for

mounting and dismantling the blade is

reduced from several hours to just a few

minutes and this task can be performed

by one person.

PR 734 Litronic PR 744 Litronic

7

Page 8

PR 734 Litronic PR 744 Litronic

8

Key technologies from Liebherr

•Liebherrhasdecadesofexperienceinthe

development, engineering and production

of components.

•Majorkeycomponentssuchasdiesel

engines, transfer gear boxes, hydraulic

cylinders and final drives are Liebherr-built

and represent the highest quality.

Page 9

Reliability

Due to their high quality and excellent engineering, these machines offer maximum

availability. Components developed by Liebherr specifically for use in construction machinery guarantee operational reliability in even the toughest conditions.

Liebherr drive train

Durable engine

Liebherr diesel engines were developed for the most

demanding conditions of use. Their low rated speed

ensures high operational reliability and a long lifetime.

Fewer components

The proven hydrostatic travel drive means that

mechanical components such as a torque converter,

manual gearbox and differential steering or clutches

are not required. Standardized hydraulic pumps and

motors are non-wearing and dependable in operation.

Robust final drive

The large Series 4 final drive is extremely robust and

is engineered to endure the highest loads. A double

gearbox seal with automatic seal monitoring offers

dependable protection.

Robust steel structure

Modular-design

main frame

The main frame is of the proven modular design,

resulting in high torsional rigidity and optimal

absorption of the forces to which it is exposed.

Components subjected to particularly heavy loads

are made of cast steel.

Solutions for a long lifetime

Innovative cooling

system

The electronically controlled suction-type fan controls the operating temperature reliably and regardless of the engine speed. Extra-large radiator fins

ensure good self-cleaning.

Components in life-cycle tests

•FEanalysisisusedduringthedevelopment phase to design the components, thereby ensuring that they

are optimally configured to withstand

heavy-duty use.

•Thecomponentsarethensubjectedto

intensive long-term tests. Only parts

that meet the high quality standard are

used in the machines.

Optimally protected

wiring harness

High-quality material for the protection of the wiring

harness and a well-designed layout ensure the functional reliability of the machine.

State-of-the-art cooling system

•Thehydrostaticallydrivenfanmatchesthe

cooling performance to the cooling requirement, meaning that the engine reaches an

optimal operating temperature more quickly.

•Airistakeninfromdirt-protectedzones,

thereby minimizing contamination caused by

dust particles.

•Optional:Reversiblefanforthequickcleaning

of the radiator in particularly dusty conditions.

PR 734 Litronic PR 744 Litronic

9

Page 10

PR 734 Litronic PR 744 Litronic

10

Intuitive single-joystick control

•Precisioncontrolranges:Thetravel

speed ranges can be pre-selected

and programmed individually using

switches.

Pre-sets:

Setting 1: 0 - 4 km/h / 0 - 2.5 mph

Setting 2: 0 - 6.5 km/h / 0 - 4.0 mph

Setting 3: 0 - 11 km/h / 0 - 6.8 mph

•Memoryfunction:

All programmed settings are retained if

the machine is restarted.

Inching/brake pedal

•Inadditiontothesingle-

joystick control, the operator can use the foot pedal

to control the speed of the

machine and, if necessary,

apply the brakes.

1 Inching function

2 Brake function

Page 11

Comfort

The redesigned workplace offers the operator a remarkable degree of comfort.

Spacious, quiet and designed with ergonomics in mind, Liebherr comfort cabs

offer the ideal conditions for fatigue-free, concentrated work. Excellent visibility

facilitates safe and precise operation.

A top-class cab

Ergonomics

The ergonomically-designed operator’s workplace

offers the ideal environment for relaxed, productive

work. All instruments and operating controls are laid

out comprehensibly and within easy reach.

Low sound values

The sound level in a Liebherr cab is far below the

legal requirements. The PR 734 and the PR 744

boast exemplary noise values thanks to effective cab sound-proofing and state-of-the-art, quiet

diesel engines.

Outstanding visibility

The integrated ROPS/FOPS protection structure

and large-area glazing afford the operator optimum

outward visibility.

Straightforward and precise control

Single-joystick control

Continuously

variable control

Safety in

every situation

All travel movements can be controlled easily and

precisely with only one joystick – including the

“counter-rotation” function.

Speed selection is continuously variable without

gearshifting and therefore without interrupting drawbar pull.

The crawler tractor is driven with positive power

transmission at all times, even on gradients. The

self-locking action of the system (hydrostatic drive)

allows the operator to control braking simply by

reducing joystick movement.

The machine is equipped with an automatic parking

brake that is activated when the machine is stationary.

Instrument panel

•Theinstrumentpanelisideally

positioned in the operator’s

field of vision.

•Automaticmonitoring,display

and warnings in the event of

abnormal operating conditions.

Well-designed details

•Agenerousstoragespace

including a 12V socket for

operating a cooler is standard.

•Theexible,multi-way

adjustable seat with 3-way

adjustable armrests provides

a comfortable workplace.

•Furtherdetailssuchasa

sliding side window, tinted

glazing and a foot rest

enhance the operator’s

comfort.

PR 734 Litronic PR 744 Litronic

11

Page 12

Basic machine

Engine

PR 734 PR 744

Liebherr Diesel engine D 936-L A6 D 936-L A6

Emission regulations according to 97/68/EC,

Rating (ISO 9249) 150 kW / 204 HP 185 kW / 252 HP

Rating (SAE J1349) 150 kW / 201 HP 185 kW / 248 HP

Rated speed 1,800 rpm 1,600 rpm

Displacement 10.5 l / 641 in

Design 6 cylinder in-line engine, water-cooled.

Turbocharged, intercooled

Injection system Direct fuel injection, pump-line-nozzle system,

electronic control

Lubrication Force-feed lubrication, engine lubrication in an

inclined position up to 45°, on all sides

Operating voltage 24 V 24 V

Alternator 80 A 80 A

Starter 7.8 kW / 11 HP 7.8 kW / 11 HP

Batteries 2 x 170 Ah / 12 V 2 x 170 Ah / 12 V

Air cleaner Dry-type air cleaner with safety element,

aspirated pre-cleaner, service gauge in cab

Cooling system Combi radiator, comprising a radiator for water,

hydraulic fluid (PR 734), charge air, fuel.

Hydrostatic fan drive

2004/26/EC stage IIIA and EPA/CARB Tier 3

3

10.5 l / 641 in

3

Travel drive, control

PR 734 PR 744

Transmission system Infinitely variable hydrostatic travel drive,

independent drive for each frame

Travel speed * continuously variable

Speed range 1 (reverse): 0 - 4.0 km/h / 2.5 mph (4.8 km/h / 3.0 mph)

Speed range 2 (reverse): 0 - 6.5 km/h / 4.0 mph (7.8 km/h / 4.8 mph)

Speed range 3 (reverse): 0 -11.0 km/h / 6.8 mph (11.0 km/h / 6.8 mph)

* Pre-adjusted, all speed ranges can be

customized on the travel joystick

Drawbar pull at

1.5 km/h / 0.9 mph 274 kN 365 kN

Electronic control Electronic engine speed sensing control auto-

Steering Hydrostatic

Service brake Wear-free, hydrostatic (dynamic braking)

Automatic park brake Wet multiple-disc brakes, wear-free, auto matically applied with neutral joystick position

Cooling system Hydraulic oil cooler, inte- Separate oil cooler

grated in combi radiator

Filter system Micro cartridge filters

Final drive Heavy-duty combination spur gear with

planetary final drives, double sealed with

electronic seal-integrity indicator

Control Single joystick for all travel and steering

functions

matically adjusts travel speed and drawbar pull

to match changing load conditions

Undercarriage

PR 734 PR 744

L XL LGP L LGP

Mount Via separate pivot shafts and an oscillating

equalizer bar

Chains Sealed and lubricated chains, single-bar

Links 40 44 44 40 44

Track rollers/carrier rollers

Sprocket segments 5 5 5 5 5

Track pads standard 508 mm 508 mm 812 mm 508 mm 812 mm

20” 20” 32” 20” 32”

Track pads optional 560 mm 560 mm 914 mm 560 mm 914 mm

610 mm 610 mm 965 mm 610 mm

710 mm

22”, 24” 22”, 24” 36”, 38” 22”, 24” 36”

28”

grouser pads, track chain tension via grease

tensioner and hydraulic cylinders

7/2 8/2 8/2 7/2 8/2

Operator’s cab

PR 734 PR 744

Cab Resiliently mounted cab with positive pressure

Operator’s seat Fully adjustable suspended seat

Monitoring Combined analog / LC display, automatic

ventilation, can be tilted with hand pump 40°

to the rear. With ROPS Rollover Protective

Structure (ISO 3471) and FOPS Falling Objects

Protective Structure (ISO 3449) integrated

monitoring, display if abnormal operating

conditions

Drawbar pull PR 734/PR 744

Usable drawbar pull will depend on traction and weight of tractor

Noise emissions

PR 734 PR 744

Operator sound exposure L

ISO 6396 (emission at the operator’s position)

Exterior sound pressure

2000/14/EC (emission in the environment)

12 PR 734 Litronic PR 744 Litronic

= 78 dB(A) LpA = 78 dB(A)

pA

LwA = 111 dB(A) LwA = 112 dB(A)

Page 13

Basic machine

Hydraulic equipment

PR 734 PR 744

Hydraulic system Load Sensing proportional pump flow control

Pump type Swash plate variable displacement piston pump

Pump flow max. 209 l/min / 55.2 gpm 260 l/min / 68.6 gpm

Pressure limitation 200 bar / 2,900 PSI 260 bar / 3,770 PSI

Control valve 2 segments, expandable to 4

Filter system Return filter with magnetic rod

Control Single joystick for all blade functions

Dimensions

Refill capacities in US gallons

PR 734 PR 744

Fuel tank 400 l / 105.6 gal 515 l / 136 gal

Cooling system 55 l / 14.5 gal 62 l / 16.4 gal

Engine oil with oil filters 43 l / 11.4 gal 43 l / 11.4 gal

Splitter box 3.1 l / 0.8 gal 6.5 l / 1.7 gal

Hydraulic tank 144 l / 38.0 gal 169 l / 44.6 gal

Final drive L, XL, each 14 l / 3.7 gal 17.5 l / 4.6 gal

Final drive LGP, each 18.5 l / 4.9 gal 19.5 l / 5.1 gal

Dimensions PR 734 L PR 734 XL PR 734 LGP PR 744 L PR 744 LGP

A Height over cab mm 3,258 3,258 3,258 3,434 3,434

ft-in 10’8” 10’8” 10’8” 11’3” 11’3”

B Overall length without attachments mm 4,335 4,335 4,335 4,657 4,692

ft-in 14’3” 14’3” 14’3” 15’3” 15’5”

C Distance idler/sprocket centre mm 2,830 3,240 3,240 2,992 3,316

ft-in 9’3” 10’8” 10’8” 9’10” 10’11”

D Height of grousers mm 65 65 65 71.5 71.5

in 2.56” 2.56” 2.56” 2.81” 2.81”

E Track gauge mm 1,830 1,830 2,180 1,980 2,180

ft-in 6’0” 6’0” 7’2” 6’6” 7’2”

F Total width without trunnions mm 2,381 2,381 2,992 2,541 2,992

(standard shoe width) ft-in 7’10” 7’10” 9’10” 8’4” 9’10”

G Total width over blade-mounting mm 2,724 2,724 3,474 3,000 3,600

trunnions ft-in 8’11” 8’11” 11’5” 9’10” 11’10”

H Ground clearance mm 494 494 494 545 545

in 19” 19” 19” 21” 21”

Tractor shipping weight

lb 38,682 39,890 42,408 46,121 51,324

1

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab and track pads 508 mm/20” (L, XL) and 812 mm/32” (LGP).

PR 734 Litronic PR 744 Litronic 13

1

kg 17,546 18,094 19,236 20,920 23,280

Page 14

Front attachment

Semi-U blade and

PR 734 L PR 734 XL PR 734 LGP PR 744 L PR 744 LGP

Straight blade Semi-U blade Semi-U blade Straight blade Semi-U blade Straight

blade

Blade capacity according to ISO 9246 m3 5.56 5.56 4.10 7.20 6.00

yd

A Height of blade mm 1,400 1,400 1,150 1,545 1,320

ft-in 4’7” 4’7” 3’9” 5’1” 4’4”

B Width of blade mm 3,372 3,372 3,995 3,690 4,520

ft-in 11’1” 11’1” 13’1” 12’1” 14’10”

Width over quick-coupler system

ft-in 9’10” 9’10” 11’6” – –

C Lifting height mm 1,170 1,206 1,215 1,222 1,179

ft-in 3’10” 3’11” 4’0” 4’0” 3’10”

D Depth below ground mm 536 554 559 511 616

ft-in 1’9” 1’10” 1’10” 1’8” 2’0”

E Max. blade pitch 10° 10° 10° 10° 10°

Max. blade tilt mm 780 780 714 930 933

ft-in 2’7” 2’7” 2’4” 3’1” 3’1”

G Width over C-frame mm 3,000 3,000 3,750 3,556 4,034

ft-in 9’10” 9’10” 12’4” 11’8” 13’3”

H Overall length, blade straight mm 5,678 5,948 5,693 6,050 5,935

ft-in 18’8” 19’6” 18’8” 19’10” 19’6”

Operating weight

lb 44,948 46,156 48,771 54,245 60,076

Ground pressure

PSI 10.10 9.10 5.97 11.52 7.11

1

Quick-coupler system optional, LGP version with maximum track pads width 812 mm/32”. When using a quick-coupler system, the installation of

a rear counterweight is recommended.

2

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab, operator, track pads 508 mm/20” (L, XL) and 812 mm/32” (LGP), semi-U/straight blade.

3

The installation of a rear counterweight (2,200kg / 4,850 lb) is recommended.

2

kg 20,388 20,936 22,122 24,605 27,250

2

kg/cm2 0.71 0.64 0.42 0.81 0.50

3

1

mm 2,994 2,994 3,494 – –

7.27 7.27 5.36 9.40 7.90

3

14 PR 734 Litronic PR 744 Litronic

Page 15

Front attachment

Mechanical PR 734 L PR 734 XL PR 744 L

angle blade Angle blade Angle blade Angle blade

Blade capacity according to ISO 9246 m

yd

A Height of blade mm 1,100 1,100 1,200

ft-in 3’7” 3’7” 3’1”

B Width of blade mm 4,240 4,240 4,590

ft-in 13’11” 13’11” 15’1”

B1 Transport width mm 3,850 3,850 4,175

ft-in 12’8” 12’8” 13’8”

C Lifting height mm 1,190 1,203 1,290

ft-in 3’11” 3’11” 4’3”

D Depth below ground mm 617 648 570

ft-in 2’0” 2’2” 1’10”

F Max. blade angle 25° 25° 25°

Max. blade tilt mm 475 475 735

ft-in 1’7” 1’7” 2’5”

G Width over C-frame mm 2,890 2,890 3,200

ft-in 9’6” 9’6” 10’6”

H Overall length, blade straight mm 5,655 5,925 6,215

ft-in 18’7” 19’5” 20’5”

H1 Overall length, blade angled mm 6,458 6,728 7,105

ft-in 21’2” 22’1” 23’4”

Operating weight

lb 45,680 46,888 54,686

Ground pressure

1

Includes coolant, lubricants, 20% fuel, ROPS/FOPS cab, operator, track pads 508 mm/20”, mechanical angle blade

1

kg 20,720 21,268 24,805

1

kg/cm

3

3.80 3.80 4.90

3

4.97 4.97 6.41

2

PSI 10.24 9.24 11.66

0.72 0.65 0.82

PR 734 Litronic PR 744 Litronic 15

Page 16

Rear attachment

Ripper PR 734 PR 744 PR 744

3 shanks with hydraulic

parallelogram Standard Option pitch adjustment

A Ripping depth (max./min.) mm 507 / 357 807 / 357 749 / 449 749 / 449

ft-in 1’8” / 1’2” 2’6” / 1’2” 2’5” / 1’6” 2’5” / 1’6”

B Lifting height (max./min.) mm 681 / 531 681 / 231 755 / 457 759 / 459

ft-in 2’3” / 1’9” 2’3” / 0’9” 2’6” / 1’6” 2’6” / 1’6”

C Additional length, mm 1,199 1,586 1,569

attachment raised ft-in 3’11” 5’2” 5’2”

D Additional length, mm 1,531 1,937 1,937

attachment lowered ft-in 5’00” 6’4” 6’4”

E Toolbar width mm 2,320 2,184 2,184

ft-in 7’7” 7’2” 7’2”

F Distance between teeth mm 1,000 1,000 1,000

ft-in 3’3” 3’3” 3’3”

Weight kg 1,910 3,295 3,305

lb 4,212 7,265 7,286

Max. pitch adjustment – – 25°

Drawbar PR 734 PR 744

A Additonal length mm 498 435

ft-in 1’8” 1’5”

B Socket pin diameter mm 50 50

in 1.97” 1.97”

C Height of jaw mm 510 521

ft-in 1’8” 1’9”

D Ground clearance mm 397 425

ft-in 1’4” 1’5”

Jaw opening mm 95 95

in 3.74” 3.74”

Weight kg 263 345

lb 580 761

PR 734 Litronic PR 744 Litronic 16

rigid

Page 17

Equipment

Basic machine

Tow switch •

Towing hitch rear •

Towing lug front •

Forestry equipment +

Landfill equipment +

Battery compartment, lockable •

Tank guard, complete +

Refueling pump, electric +

Belly pans, heavy-duty •

Diesel particle filter +

Cold start device, heating coil •

Radiator wide-meshed •

Radiator guard, heavy-duty +

Radiator guard, hinged •

Liebherr bio-degradable hydraulic oil +

Liebherr Diesel engine •

Fan, hydraulically driven •

Fan guard •

Engine cover, perforated •

Engine doors, perforated •

Engine doors, hinged, lockable •

Lugs for crane lifting •

Special paint +

Fuel water separator •

Fuel water separator with electric heater

Air filter, dry-type, dual step •

Pre-cleaner with automatic dust ejector •

Toolkit •

Laser/GPS ready kit (2) +

+

Travel drive

Parking brake, automatic •

Function control, automatic •

Control single joystick •

Load limit control, electronic •

Electronic control •

Travel control, 3 speed ranges •

Hydrostatic travel drive •

Inching brake pedal for PR 734 +

Inching brake pedal for PR 744 •

Emergency stop •

Oil cooler •

Final drives planetary gear •

Safety lever •

• = Standard

+ = Option

(1) = only for PR 744

(2) = only for PR 734

Subject to changes.

Undercarriage

Track frame, closed •

Sprocket segments, bolted •

Master link, two-piece •

Track pads with mud hole +

Track guide center part +

Tracks oil-lubricated •

Track guide +

Undercarriage L +

Undercarriage XL (2) +

Undercarriage LGP +

Track frames, oscillating •

Pivot shaft, separate •

Sprocket segments with recesses +

Electrical

system

Starter 7.8 kW •

Working lights front, 4 units •

Working lights rear, 2 units •

Batteries, cold start, 2 units •

Battery main switch, mechanical •

On-board system, 24 V •

Alternator 80 A •

Back-up alarm +

Beacon +

Horn •

Electronic start lock +

Additional lights, rear +

Additional lights, on lift cylinders +

Operator’s cab

Storage compartment •

Armrest 3D adjustable •

Ash tray •

Pressurized air filter •

Operator’s seat, 6-way adjustable •

Operator’s seat, air suspended +

Fire extinguisher •

Dome light •

Coat hook •

Air conditioning +

Cooler +

FM radio +

Radio preinstallation •

ROPS/FOPS •

Rear mirror, inside •

Safety glass, tinted •

Windshield washer system •

Windshield wipers font, rear and on

the doors, with intermittent function •

Sliding window, left •

Sliding window, right +

Protective grids for windows +

Extension, seat back +

Sun visor •

Socket 12 V •

Warm water heating •

Control and

warning lights

Control travel speed range (digital) •

Control engine coolant temperature

(analog) •

Control fuel level (analog) •

Hour meter (analog) •

Warning light battery charging •

Warning light diesel engine •

Warning light electronic travel

control system •

Warning light travel drive seal,

each side •

Warning light parking brake •

Warning light hydraulic oil temperature +

Warning light fuel water separator •

Warning light fan control •

Warning light pump repleneshing

pressure •

Warning light float position blade •

Warning light oil return filter •

Warning light air filter •

Warning light heater Diesel engine •

Main warning light •

Hydraulic

system

Hydraulic control ripper +

Hydraulic control winch +

Variable flow pump, load sensing •

Oil filter with strainer in hydraulic tank •

Blade quick drop •

Control valve for 2 circuits •

Float position blade •

Hydraulic servo control •

Hydraulic tank oil level control +

Attachments

Mounting plate for external tools +

Drawbar rear, rigid +

Drawbar rear, swivelling +

Counterweight, rear 2,000 kg/4,409 lb (2) +

Counterweight, rear 2,200 kg/4,850 lb (1) +

Counterweight, rear with storage

compartment 2,800 kg/6,173 lb (1) +

Counterweight, rear 3,200 kg/7,055 lb (1) +

Ripper 1 shank +

Ripper 3 shanks +

Straight blade +

Semi-U blade +

Angle blade +

Quick-coupler system (2) +

Winch +

Spill plate for blade +

Options and/or special attachments, supplied

by vendors other than Liebherr, are only to be

installed with the knowledge and approval of

Liebherr to retain warranty.

PR 734 Litronic PR 744 Litronic 17

Page 18

The Liebherr Group of Companies

Wide Product Range

The Liebherr Group is one of the largest construction

equipment manufacturers in the world. Liebherr’s highvalue products and services enjoy a high reputation in

many other fields, too. The wide range includes domestic appliances, aerospace and transportation systems,

machine tools and maritime cranes.

Exceptional Customer Benefit

Every product line provides a complete range of models

in many different versions. With both their technical excellence and acknowledged quality, Liebherr products offer

a maximum of customer benefits in practical application.

State-of-the-art Technology

To provide consistent, top quality products, Liebherr

attaches great importance to each product area, its

components and core technologies. Important modules

and components are developed and manufactured inhouse, for instance the entire drive and control technology for construction equipment and mining trucks.

Worldwide and Independent

Hans Liebherr founded the Liebherr family company in

1949. Since that time, the enterprise has steadily grown

to a group of more than 100 companies with over

32,000 employees located on all continents. The corporate

headquarters of the Group is Liebherr-International AG

in Bulle, Switzerland. The Liebherr family is the sole owner

of the company.

www.liebherr.us

Printed in Germany by Typodruck RG-BK-RP LWT/VM 11003720-2-07.10_enUS

Liebherr Construction Equipment Co.

4100 Chestnut Avenue, Newport News, VA 23607, USA

+1 (757) 245 5251, Fax +1 (757) 928 8701

www.liebherr.us, E-Mail: info.lce@liebherr.com

Loading...

Loading...