LG GBB530***Q Series, GBB530***P Series, GBB539 Series, GBF539 Series, GBB530***M Series Service Manual

...

http://biz.lgs ervice.com

R E FR IG E R ATOR

SER VIC E MANUA L

C AUT ION

B E FOR E S E R V IC ING T HE UNIT, R E AD T HE " S A FE TY

P R E CA U T IONS " IN T HIS MA NUA L .

GBB532****

GBB530****

MODE L :

R ef. No .R ef. No .

GBB531****

GBB539****

Ref. No.

GBF539****

Re f. N o.

GBF530 *** *

C OL OR :

C ONT E NTS

S AF E TY P R E C A UTIO NS ......................................................................................................... ... ........................................... 2

S E R VIC ING P R E C AU TION S ................................................................................................................................................... 3

S PE CIF ICA T IO NS ............................................................................................................. ...................................................4-7

P A RT S IDE NT IFIC ATION .......................................................................................................... .........................................8-12

INS TR UC TION S F OR R E V E R S ING DOO R S WING ......................................................................................... ...............13-15

DIS AS S E MB LY ................................................................................................................... .............................................. 16-17

DO OR .......................................................................................................................... ......................................................16

DO OR S WIT CH ................................................................................................................... ..............................................16

F AN AND F AN MO T OR ............................................................................................................. ........................................16

DE F ROS T C ONTR OL AS S E MBLY ...................................................................................................... .............................17

F R E E ZE R HE AT E R, S HE ATH ..................................................................................................... ... ..................................17

D JU S T ME NT .................................................................................................................... ............................................. 18-19

A

C O MPRESS OR (A + + and A s ) ledoM + ..................................................................................... .................................. ..18

P T C- STA RTE R (A++ a nd A+ Mo del s) .................................................................................... .. . ..................................18

O LP (O VER L OAD PRO T EC TOR ) (A++ a nd A + Mo del s ) ...................................................... . . ..................................19

C OMP R ES S OR ................................................................................................................. ................................................20-28

INVE R TE R L IN E AR COMP R E SSOR . ................................................................................................... .......................20-28

HE A VY R E PAIR ME TH OD OF R E FR IG E RA T O R B Y AP PL IC AT ION OF R E

OUT LINE ..................................................................................................................... .. .....................................................29

HE AVY R E P AIR S V C ME T HOD ....................................................................................................... .......................... .30-34

C IR CUIT DIA GR AM ............................................................................................................... ...........................................35-4

TR OU BL ES HO OTING (ME C HA NIC AL P AR T) ............................................................................................. ....................4-49

COMPRESS OR AND ELECTRIC COMPONENTS ........................................................................................ . ....................... ..4

PTC AN D OLP .............................................................................................................................. .............. .........................4

ANOTHE R E LE C T RIC C OMP ONE NTS ................................................................................................... .........................4

S E R VIC E DIAG NOS IS C HAR T ....................................................................................................... ...............................

R E FR IG E R ATING CY CL E ........................................................................................................ ... ............................... .4-

MIC OM F UN C TION & PC B C IR C UIT E XP L ANA T IO N ...................................................................................... ..............5-5

MIC OM E R R OR C ODE ..............................................................................................................

P C B P IC TUR E ................................................................................................................ ... .............................................. .5-6

TR OU BL ES HO OTING WIT H E R R OR DIS PLAY ............................................................................................ .................6-7

TR OU BL ES HO OTING WIT HOUT E R R OR DIS P L AY ......................................................................................... .............7-8

R E FE R E NC E ..................................................................................................................... ................................................8-8

E XP LODE D V IE W &R E PL AC EME NT P AR T S L IS T ......................................................................................... ...............8-

F R IG ER ANT ................................... ...... ..29-34

.. .4

.......................................5-5

S AF E T Y P R E C A UT IONS

P lea se read the following instructions before servicing your

refrigerator.

1. Check the s et for electric los ses.

2. Unplug prior to s ervicing to prevent electric s hock.

3. Whenever testing with power on, wear rubber gloves to

preve nt electric s hock.

4. If you use any kind of applianc e, check regular current,

voltage a nd capacity.

5. Don't touch meta l products in the fre ez er with we t

hands . This ma y ca us e fros tbite.

6. Prevent water from following onto electric eleme nts in

the me cha nical par

7. Whe n s tan ding up a fter ha ving c hecked the lowe r

s ection of the refrige ra tor with the uppe r door open,

move with care to avoid hitting the upper door.

ts.

8. When tilting the s et, remove any materials on the set,

es pecially the thin plates(ex. Glas s s helf or books.)

9. When s ervicing the e vaporator, wear cotton gloves.

10. L eave the disas s embly of the refrigerating cycle to a

s pecialized servic e ce nter. T he ga s ins ide the circuit

may pollute the environment.

11. W hen you discharge the refrigerant, wea r the protective

safety glasses or goggle for eye s afety.

12. W hen you repair the c yc le sys tem in refrige ra tor, the

work area is well ventilated.

E specially if the refrigerant is R 600

hea t s ources . (No s moking)

- 2 -

S E R VIC ING P R E C A UT IONS

F eature s of refrigerant (R 600a)

• Achromatic and odor less gas.

• Flamma ble gas and the ignition (explos ion) a t 494°C .

• Upper/lowe r explos ion limit: 1.8% ~8.4% /V ol.

F eature s of the R 600a refrigerato r

• C harging of 60% refrigerant compared with a R134a model.

• The s uction pre ssure is below 1bar (abs) during the operation.

• Becaus e of its low suction pressure, the external air may ow

in the cyc le s ystem when the refrigera nt lea k, and it causes

malfunc tion in the compressor.

• The dis placement of compressor using R 600a mus t be at

least 1. 7 times la rger than that of R 134a.

• Any type of drye r is applicable (X H-5, 7, 9).

• The E VAP OR AT OR or any other cycle part that has welding

joint is hidde n in the foam. ( If not hidden inside, the whole

ele ctric parts mus t be tes ted with the LE AK AG E T E S T

according to the IE C S ta ndard.)

• The compressor ha s label of the refrigerant R 600a.

• Only the S VC ma n must have an access to the system

.

Ins tallation place

• Mus t be well ventilated.

• Mus t be 20 m

• Mus t be no-s moking area.

• No ignitable fa ctors must be pres ent.

3

or la rger.

Utilities

• R efrigerant cylinder (MAX NE T 300g)

• Ma nometer

• V acuum pump (600

• P iercing C lamp

• Quick coupler

• Hoses (5m-1E A, 1m-3E A)

• LOKR IN

• P orta ble Leakage detector (3g/year

• Nitrogen cylinder (for leakage tes t)

• C oncentration gauge

G

ℓ /min)

)

After the refrigerant (R 600a) is completely discharged,

repair any defective parts a nd replace the drye r. At any

case you must us e the LOK R ING for connecting or replac ing

any part in the cycle (No F ire, N o W elding). C harge the N2

gas in order to check for leakage from welding points and the

LOK R ING . If lea kages are found, repair the defects again.

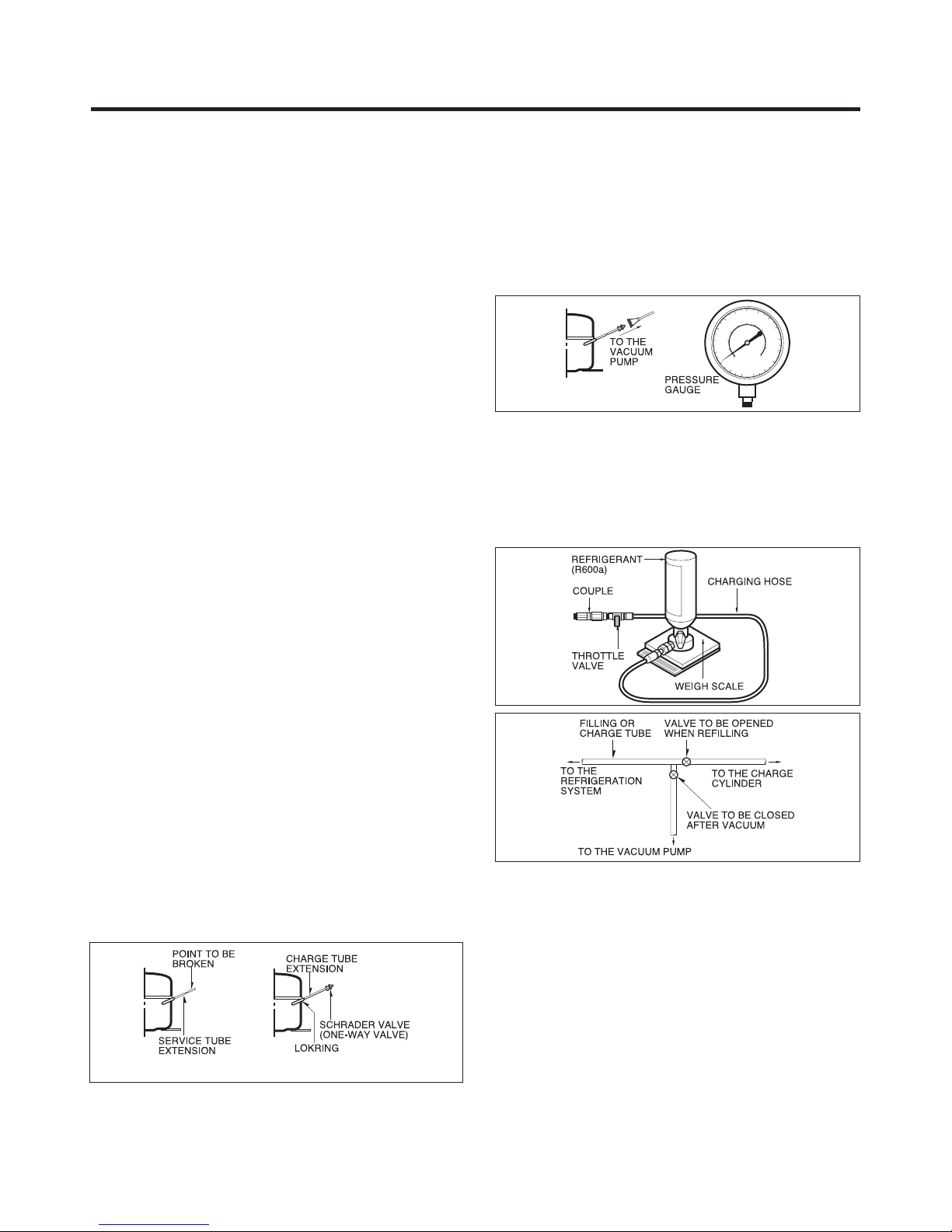

C onnect the S chra der va lve to pump with the couple

then turn the pump on for vacuum s tate (Figure 3). L et the

pump run until the low pressure ga uge indica tes the vacuum

(gauge pressure -1a tm or -760mmHg, absolute pressure 0 ).

R ecommended vacuum time is 30 min.

r. And

F igur e 3

After the sys tem is co mpletely va cuume d, ll it with the

re frige ra nt R 600a up to what has been specie d a t y our

refrige rator Na me P late. T he amount of refrige rant (R 600a)

mus t be precis ely me as ure d within the error

electron s cale ( F igure 4).

If you use the manifold connected with both the refrige rant

(R 600a) cylinder and the vacuum pump s imultaneous ly, make

sure the pump valve is closed (F igure 5).

of ±2g by an

Make s ure before Servic ing

• R efrigerant

C onrm the refrigerant by checking Name P late and the label

on the compressor, after opening the C OVE R ASSE MB LY ,

B AC K -M/C .

• If the refrigerant is R 600a, you mus t not weld or apply a heat

source.

Air R echa rging in C ompressor

B efore relling the refrige rant, you mus t perform the te st

according to C hapter 5 (T R OU BL ES HOOT ING C HAR T). When

the de fects are found, yo u mu s t dis cha rge the re s idua l

re frig e ra nt ( R 600a ) in the ou tdoor. F or di s cha rg in g the

refrigerant R 600a, break the narrow portion of tube extens ion

by hand or with a pipe cutte r as shown in Figure 1. Lea ve it for

30min in outside to s tabilize the pressure with ambient. The n,

chec k the pressure by pie rcing the drye r part with pierci

pliers. If the refrigerant is not completely dis cha rged, let the

refrigerator alone for more 30min in outside.

F igur e 1 F igur e 2

Atta ch the service tube installed with a S chra der valve (oneway valve) by using the LOK R ING (F igure 2). T hen, conne ct

the S chr a der v alve (one-wa y v a lve ) to the pump tha t is

connected to the dis charging hos e leading to the outside .

When dis cha rging the residual refrigerant, repeat 3 cycle that

includes 3min of the pump running->pump o->30s ec

compressor running.

ng

of the

F igur e 4

C onne c t the c ha rgin g hos e (tha t is c onne cte d to the

refrige rant (R 600a) cylinder) to the S chra der valve ins talled

on the service tube. Then, charge the refrigerant (R 600a) by

controlling the T hrottle va lve. W hen you

open the Throttle valve because it may make damage to the

compressor. Gra dua lly cha rge the refrige rant (R 600a ) by

cha nging open and close the Throttle Valve (5g a t ea ch time).

The cha rging hose must use a one-wa y valve to prevent the

refrigerant reuence. C lose the S chrader valve cap after the

refrigerant ( R 600a) is completely re cha rged.

Afte r you completely re ch a rge the re frige ra nt (R 600a ),

perform the leakage test by using a porta b

or s oa py wa ter. T es t the low pre ssure (s uc tion) pa rts in

compre ssor o time and high pressure parts in compressor

on time. If the leakages are found, resta rt from the refrigera nt

(R 600a) disc harging process and repa irs de fects of leaks.

After the leakage test, che ck the tempe rature of e ach pa rts of

the cycle . C heck with ha nds if the C ON DE NS E R a nd the

ca se (H O T -LINE pipe) that is contacted to the door gasket

are warm. C onrm that fros t is unif

surface of the EVAP OR ATOR .

do s o, do not fully

le leakage detector

orm dis tributed on the

- 3 -

F igur e 5

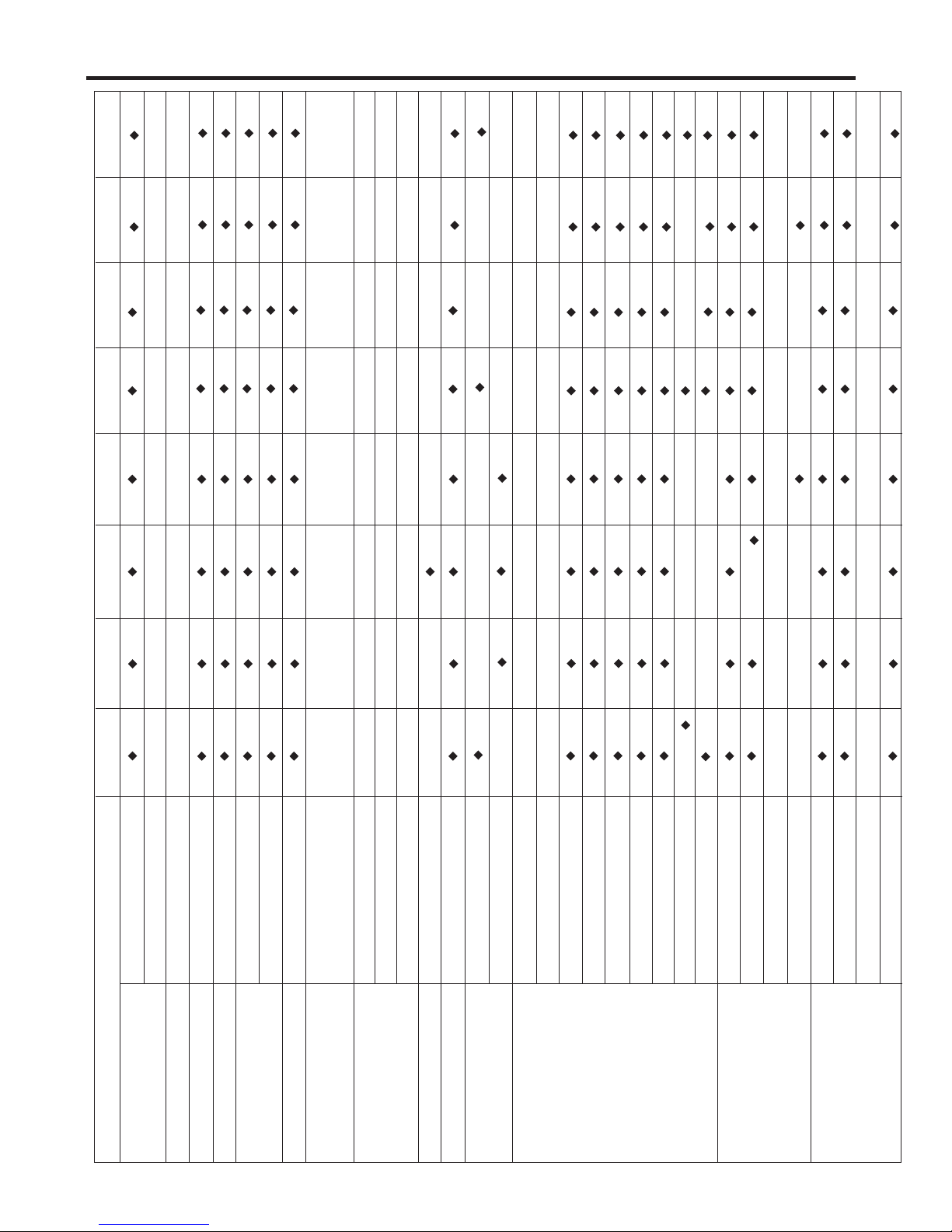

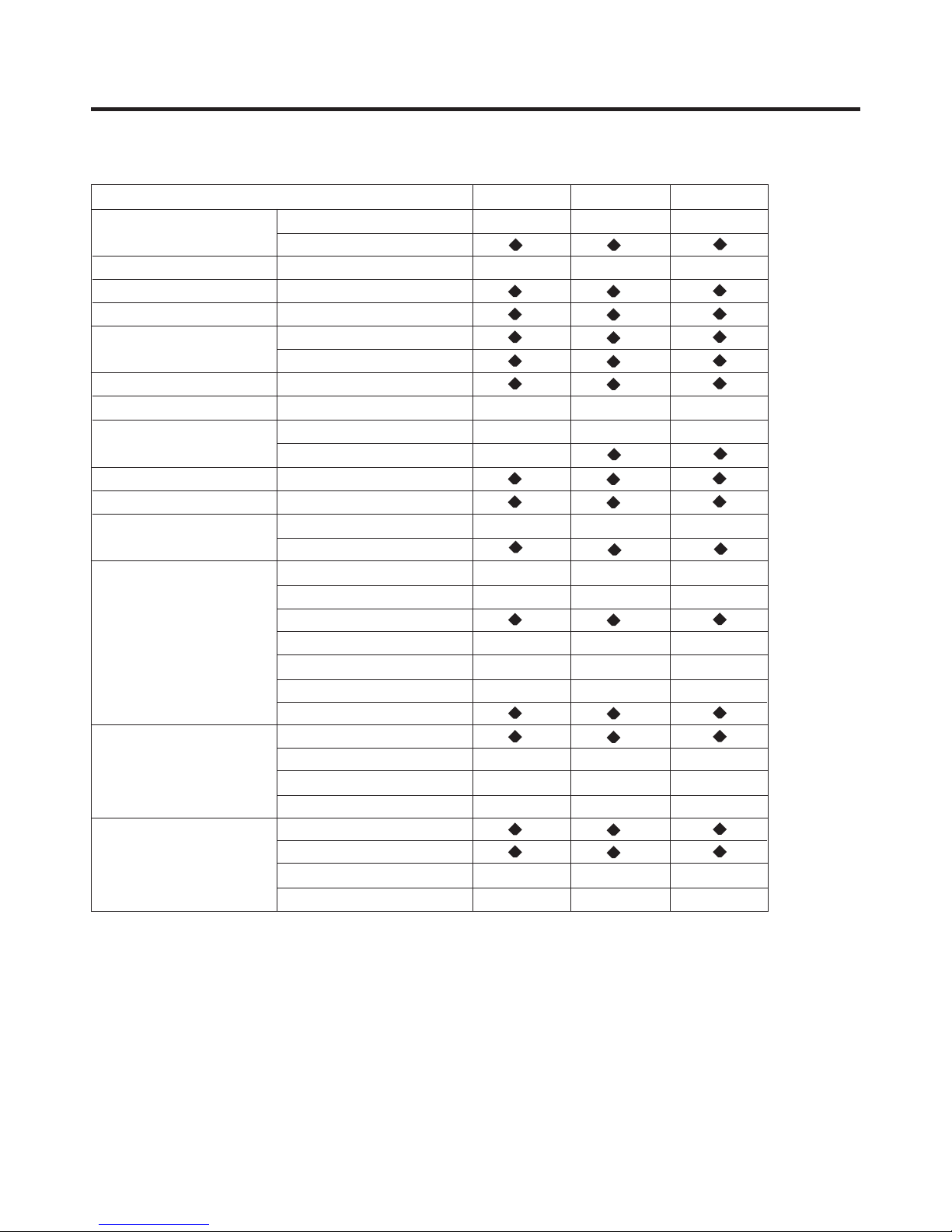

S P E C IFIC ATIONS

•

G B B530***Q*

•

G B F530***Z*

•

G B B530***Z*

•

G B B530***X*

•

530*** P*

G B F

•

G B B 530***W*

•

•

•

•

-

-

•

•

-

-

•

-

-

•

-

-

•

-

-

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

67g

67g (FLA102)

61g (BMG089)

67g (FLA102)

61g (BMG089)

67g

67g (FLA102)

61g (BMG089)

63g (CMA089)

-

180cc(FLA102)

180cc(FLA102)

-

180cc(FLA102)

150cc(CMA089)

-

-

175cc(FLB124)

-

-

170cc(BMG089)

-

-

170cc(BMG089)

-

175cc(FLB124)

- -

Yes(CMA089)

170cc(BMG089)

No (FLA102/BMG089)

•

•

•

•

•

•

2E A

-

-

-

-

3E A

3E A

•

-

•

3E A 2E A

•

•

•

•

-

•

-

-

- -

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-

•

•

•

•••

•••

•

•

•

3E A

3E A

3E A

•

3E A

•

3E A

•

•

-

-

•

•

•

•

-

•

•

•

•

•

-

•

•

•••

•

-

•

-

•

-

•

-

-

•

•

•

•

•

•

-

-

•

-

57g (BMG089)

61g (CMA089)

•

150ccCMA089)

170cc(BMG089)

-

•

•

-

•

3E A(option 2)

•

•

•

- -

•

•

(option )

-

•

•

- -

4E A

•

-

G B B 530***P*

G B B 530*** F*

IT EMS

•

•

-

-

•••••••

•

67g (FLA102)

61g (BMG089)

63g (CMA089)

180cc(FLA102)

150cc(CMA089)

170cc(BMG089)

-

Yes(CMA089)

No (FLA102/BMG089)

•

-

-

3E A

-

- -

•

•••

-

3E A

-

•

•

•

•

-

•

•

-

67g (FLB124)

65g (FMA102)

-

175cc(FLB124)

-

-

120cc(FMA102)

•

•

-

•••••••••

-

3E A(option 2)

•

•

(option )

-

•••

-

3E A

•

-

(2E A)

5 HFP

P T C S tarting T ype

P in Tube Type

S piral C ondenser

Wire C ondenser

R emovable G la s s S helf

Vita, L E D(1E A)

C over, T V (L )

C over, T V (U )

F res h 0 Zone

Magic C risper (1E A)

Vegetable Drawer (1E A)

Foldin g S h e lf

F an C ooling

Micom Control

F ull Automatic

Heater Defros t

Heater, S heath

R 600a

H T S 55 MT

595(W) X 2010(H) X 650(D)

595(W) X 1900(H) X 650(D)

S5 H FP

Bottl e Rac k

E gg T ray

Da iry C orner

B asket

Water T ank

Tray Drawer (3E A)

Tray Ice

Ice B ox

Wire S helf

DE F ROS TING S YS TE M

NE T WE IGHT

C OOLING S YS T E M

1. R ef. No: G B B530*****, G B F530*****

DIME NS IONS (mm)

TE MP E R AT UR E C ONT R OL

DE F ROS TING DE V IC E

C OMP R ES S OR

E VA P OR AT OR

R E FR IG E R ANT WE IGHT

LUB R ICAT ION OIL

C ONDE NS E R

R E FR IG E R AT OR

C OMP AR TME NT

DO OR B AS KE T

FR E E ZE R

C OMP AR TME NT

- 4 -

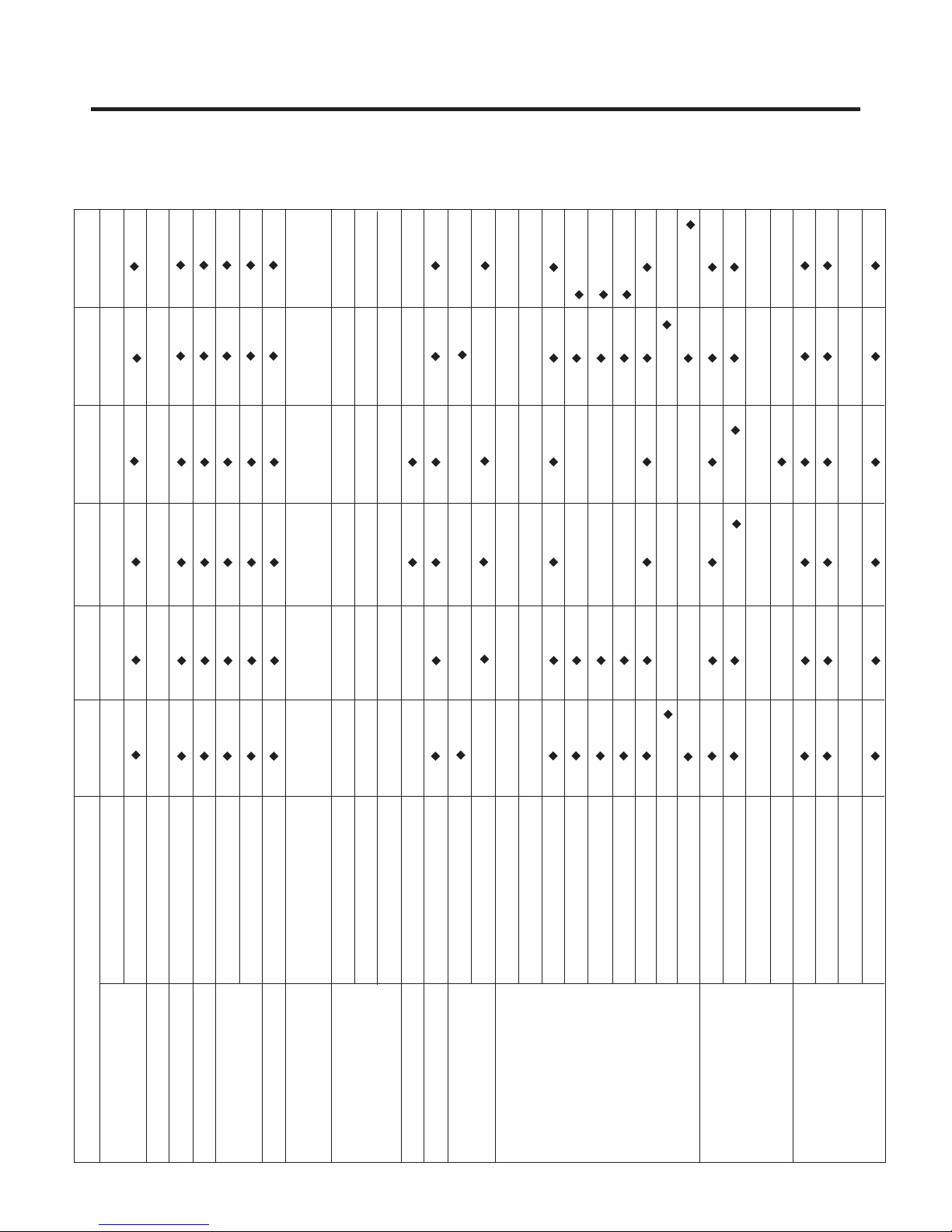

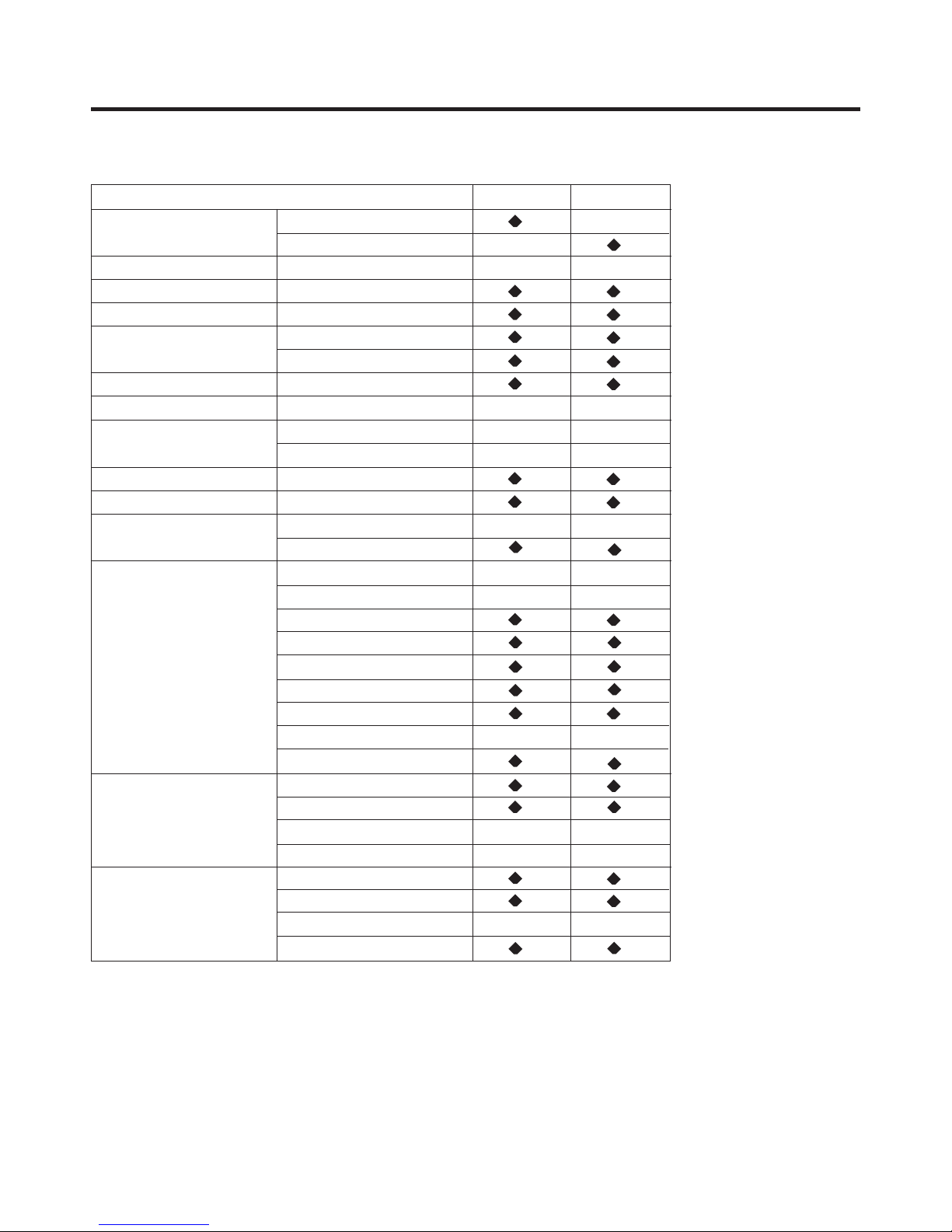

S P E CIFIC ATIONS

-

•

G B B539***Z*

-

G B B539***F*

•

-

539*** W*

G B F

-

G B B 539***W*

-

G B B 539***P*

-

•

•

•

•

-

•

67g (FLA102)

61g (BMG089)

180cc(FLA102)

-

170cc(BMG089)

-

•

•

2E A (option 1)

•

(option - )

•

•

(option - )

(option - )

•

•

•••

(option )

-

•

-

2E A

•

•

-

•

•

•

•

•

•

-

•

67g (FLB124)

65g (FMA102)

-

175cc(FLB124)

-

120cc(FMA102)

•

•

-

•

•

•

•

-

•

•

•

(option )

2E A

-

•

•

•

2E A

-

•

•

-

•

-

(option 1) (option 1)

-

57g (BMG089)

61g (CMA089)

-

170cc(BMG089)

•

•

-

•

•

•

•

-

•

2E A

-

•

-

• •

3E A

(option )

-

•••

-

•

•

•

•

-

-

•

•

•••••••

•

•

•

•

63g (CMA089)

57g (BMG089)

61g (CMA089)

67g (FLA102)

61g (BMG089)

-

170cc(BMG089)

180cc(FLA102)

150cc(CMA089)

170cc(BMG089)

•

150ccCMA089) 150ccCMA089)

- -

Yes(CMA089)

-

•

•

No (FLA102/BMG089)

•

-

-

•

-

-

(option 1)

-

2E A

•

-

2E A

- -

•

•

•

(option )

-

-

- -

•••

•

•

- -

3E A

-

2E A

•

-

-

•

•

•

•

-

•

•

-

67g (FLB124)

65g (FMA102)

G B B 539***F*

F an C ooling

Micom C ontrol

F ull Automatic

He ater Defros t

He ater, S heath

595(W ) X 2010(H) X 650(D)

IT EMS

1. R ef. No: G B B539*****, G B F539*****

595(W ) X 1900(H) X 650(D)

DIME NS IONS (mm)

TE MP E R AT UR E C ONT R OL

NE T WE IGHT

C OOLING S Y S TE M

DE F ROS TING S YS TE M

R 600a

DE F ROS TING DE VIC E

R E FR IG E RAN T WE IGHT

-

175cc(FLB124)

H T S 55 MT

S 5 H FP

LUB R ICAT ION OIL

-

-

120cc(FMA102)

5HFP

P T C S tarting T ype

C OMP R ES S OR

•

•

-

-

(option 1)

2E A

•••••••••

•

•

(option )

-

•••

-

2E A

•

-

A)

(2E

P in Tube Type

S piral C ondens er

Wire C ondenser

R emovable G la s s S helf

Vita, L E D(1E A)

C over, T V (L )

C over, T V (U )

F res h 0 Zone

Magic C risper (1E A)

Vegetable Drawer (1E A)

Foldi ng S h e lf

Bottle R ack

E gg T ray

Da iry C orner

B asket

Water T ank

Tray Drawer (3E A)

Tray Ice

Ice B ox

Wire S helf

E VA P OR AT OR

C ONDE NS E R

R E FR IG E RAT OR

C OMP AR TME NT

DO OR B AS KE T

FR E E ZE R

C OMP AR TME NT

- 5 -

S P E C IFIC AT IONS

1. R ef. No: G B B539*****, G B F539*****

DIME NS IO NS (mm)

NE T WE IG HT

C OOLING S YS T E M

TE MP E R AT UR E C ONTR OL

DE F ROS TING S YS TE M

DE F ROS TING DE VICE

R E FR IG E R AN T WE IGHT

LUB R ICAT ION OIL

C OMP R ES S O R

E VA P OR AT OR

C ONDE NS E R

R E FR IG E R AT OR

C OMP AR TME NT

DO OR B AS KE T

F R EEZE R

C OMP AR TME NT

IT EMS

595(W ) X 2010(H) X 650(D)

595(W ) X 1900(H) X 650(D)

F an C ooling

Micom C ontrol

F ull Automatic

He ater Defros t

He ater, S heath

R 600a

5HFP

S 5 HF P

P T C S tarting T ype

P in Tube Type

S piral C ondens er

Wire C ondenser

R emovable G la ss S helf

Vita, LE D(1E A)

C over, T V (L )

C over, T V (U )

F res h 0 Zone

Magic C risper (1E A)

Vegetable Drawer (1E A)

E gg T ray

Da iry C orner

B asket

Water T ank

Tray D rawer (3E A)

Tray Ice

Ice B ox

Wire S helf (2E A)

G B B539**HW*

-

•

-

•

•

•

•

•

57g (BMG089)

61g (CMA089)

170cc(BMG089)

150cc(CMA089)

•

•

-

•

3E A

-

•

-

-

-

•

•

- -

3E A

-

•

•

-

- -

G

BB539**HP*

-

•

-

•

•

•

•

•

63g

-

•

•

•

-

•

3E A

-

•

-

-

-

•

•

3E A

-

•

•

-

GBB539**HZ*

-

•

-

•

•

•

•

•

67g

-

•

•

•

-

•

3E A

-

•

-

-

-

•

•

-

3E A

-

•

•

-

-

- 6 -

S P E C IFIC AT IONS

1. R ef. No: G B B530***M*, GB F539***M*

DIME NS IO NS (mm)

NE T WE IGHT

C OOLING S YS T E M

TE MP E R AT UR E C ONTR OL

DE F ROS TING S YS TE M

DE F ROS TING DE VICE

R E FR IG E R AN T WE IGHT

LUB R ICAT ION OIL

C OMP R ES S OR

E VA P OR AT OR

C ONDE NS E R

R E FR IG E R AT OR

C OMP AR TME NT

DO OR B AS KE T

F R E E ZE R

C OMP AR TME NT

IT EMS

595(W ) X 2010(H) X 650(D)

595(W ) X 1900(H) X 650(D)

F an C ooling

Micom C ontrol

F ull Automatic

He ater Defros t

He ater, S heath

R 600a

HTS 55M T

S 5 H FP (5CST)

P T C S tarting T ype

P in Tube Type

S piral C ondens er

Wire C ondenser

R emovable G la s s S helf

Vita, L E D(1E A)

C over, T V (L )

C over, T V (U )

F res h 0 Zone

Magic C risper (1E A)

Vegetable Drawer (1E A)

Folding Shelf

Bottel Rack

E gg T ray

Da iry C orner

B asket

Water T ank

Tray D rawer (3E A)

Tray Ice

Ice B ox

Wire S helf (2E A)

G B B530**QM*

•

-

-

•

•

•

•

•

61g

- -

170cc 170cc

•

•

-

•

3E A

-

•

• •

•

•

•

-

•

•

• •

3E A

-

•

•

-

•

G B B 539**QM*

-

•

-

•

•

•

•

•

61g

•

•

-

•

2E A

-

•

•

•

•

-

•

•

2E A

-

•

•

-

•

- 7 -

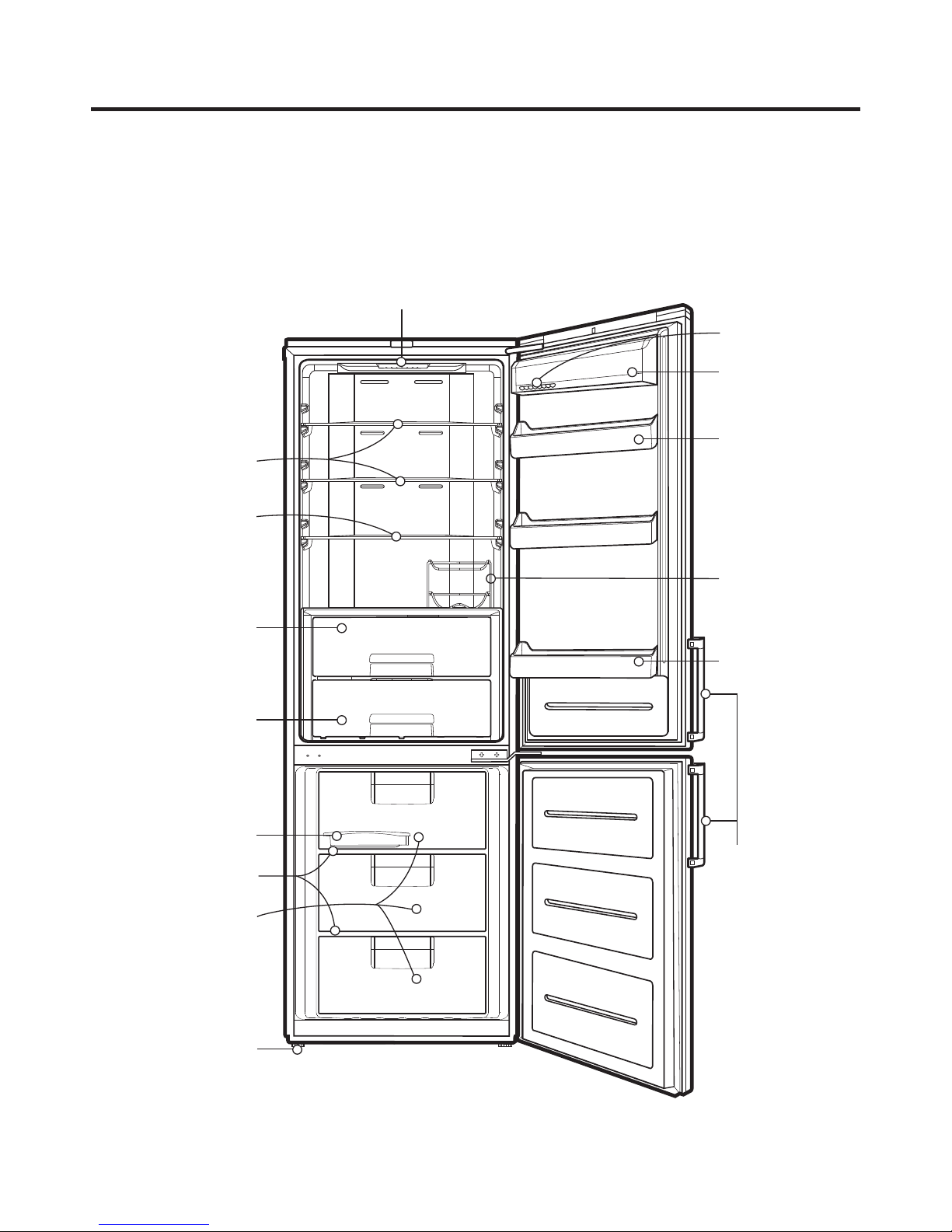

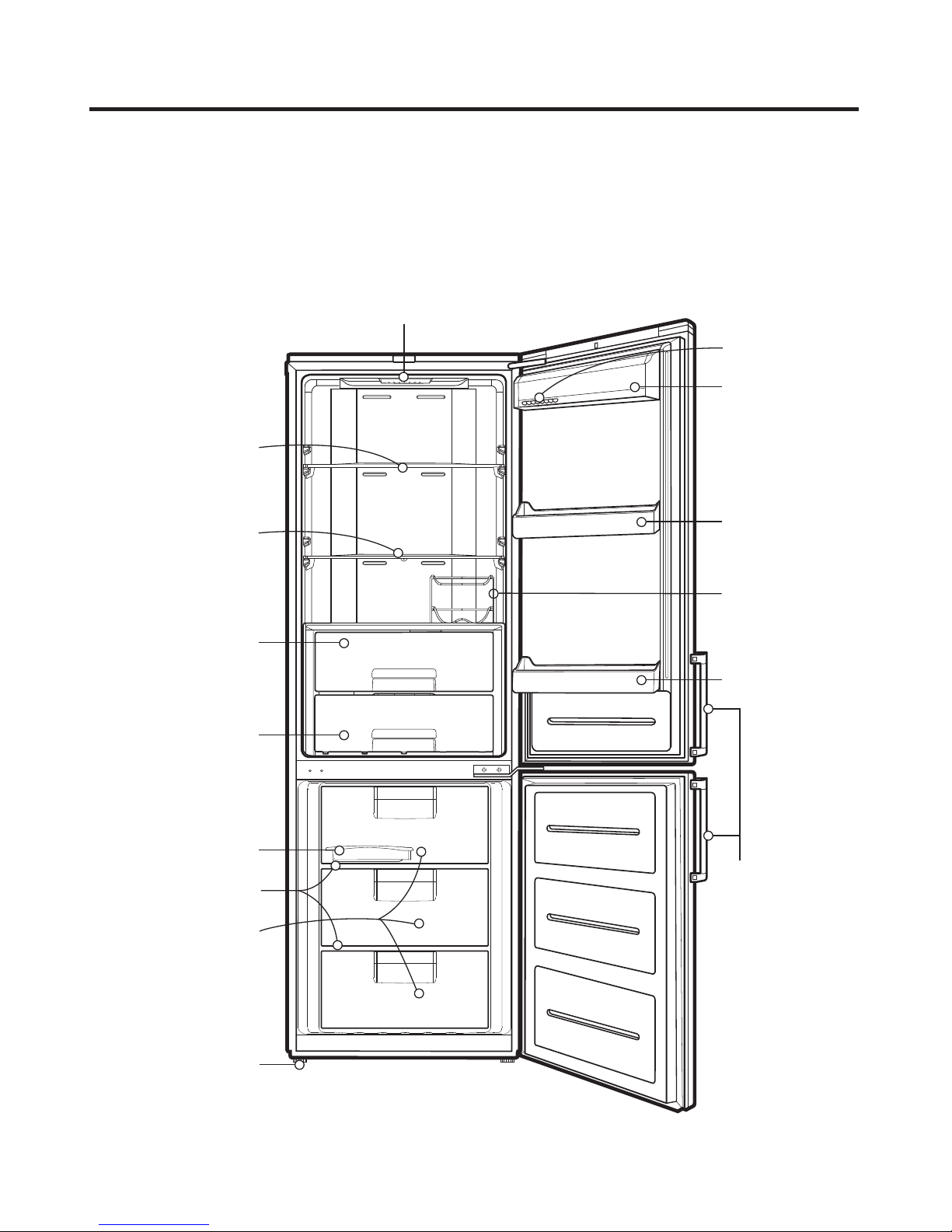

P A RTS I D E N T I F ICA T I O N

G B B530****

Model Name : GBB530**Q**, GBB530**C**

Lamp

Removable

Glass Shelf

Removable

Glass Shelf

(Folding shelf

Optional)

Egg Tray (Optional)

Dairy Corner

(Optional)

Basket Door

Bottle Rack

(Optional)

Vegetable

Drawer (Used to

keep fruits and

vegetables etc.

fresh and crisper)

Fresh '0' Zone

(Optional)

Ice Tray

Wire Shelf

Freezer

Compartment

Leveling Screw

Basket Door

EZ Open

Handle

(Optional)

- 8 -

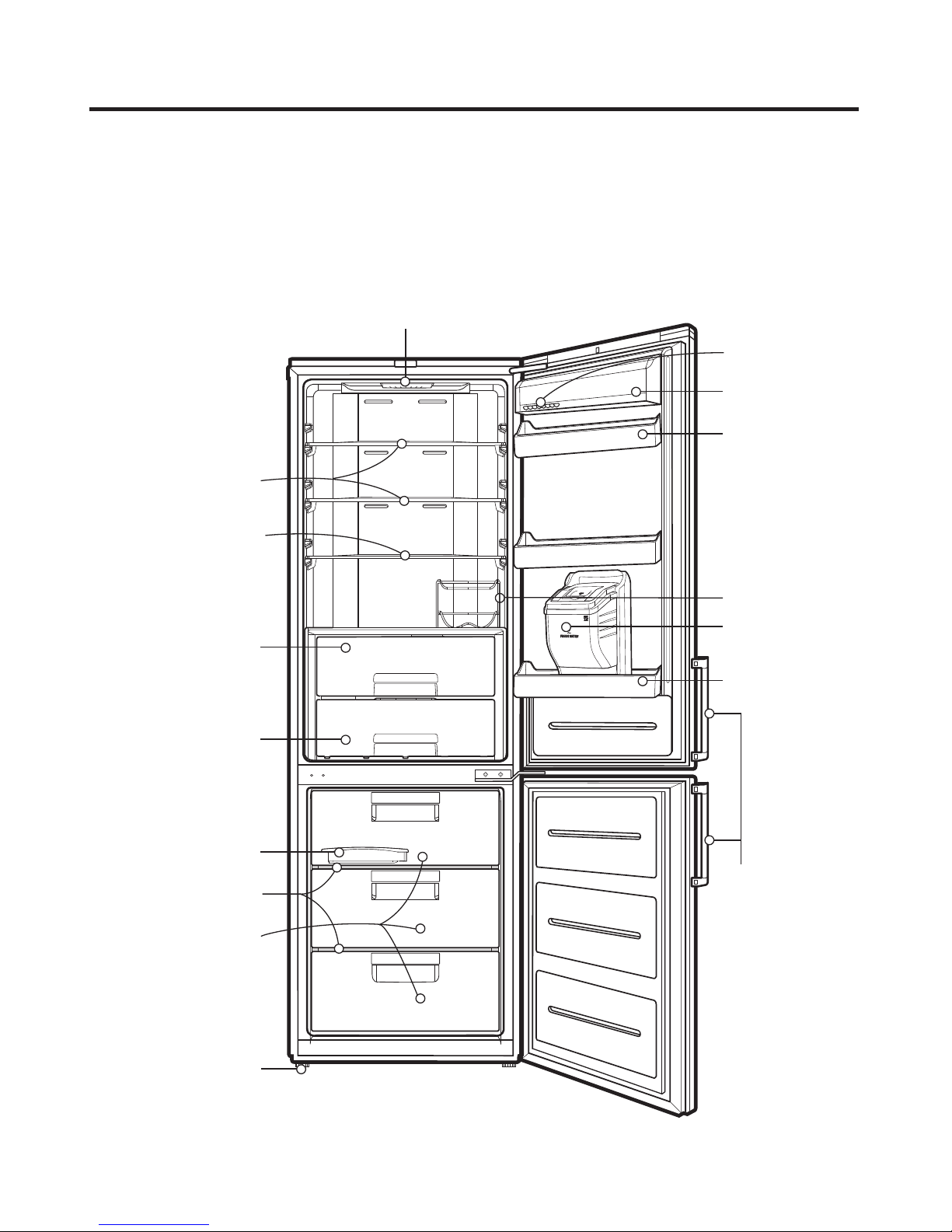

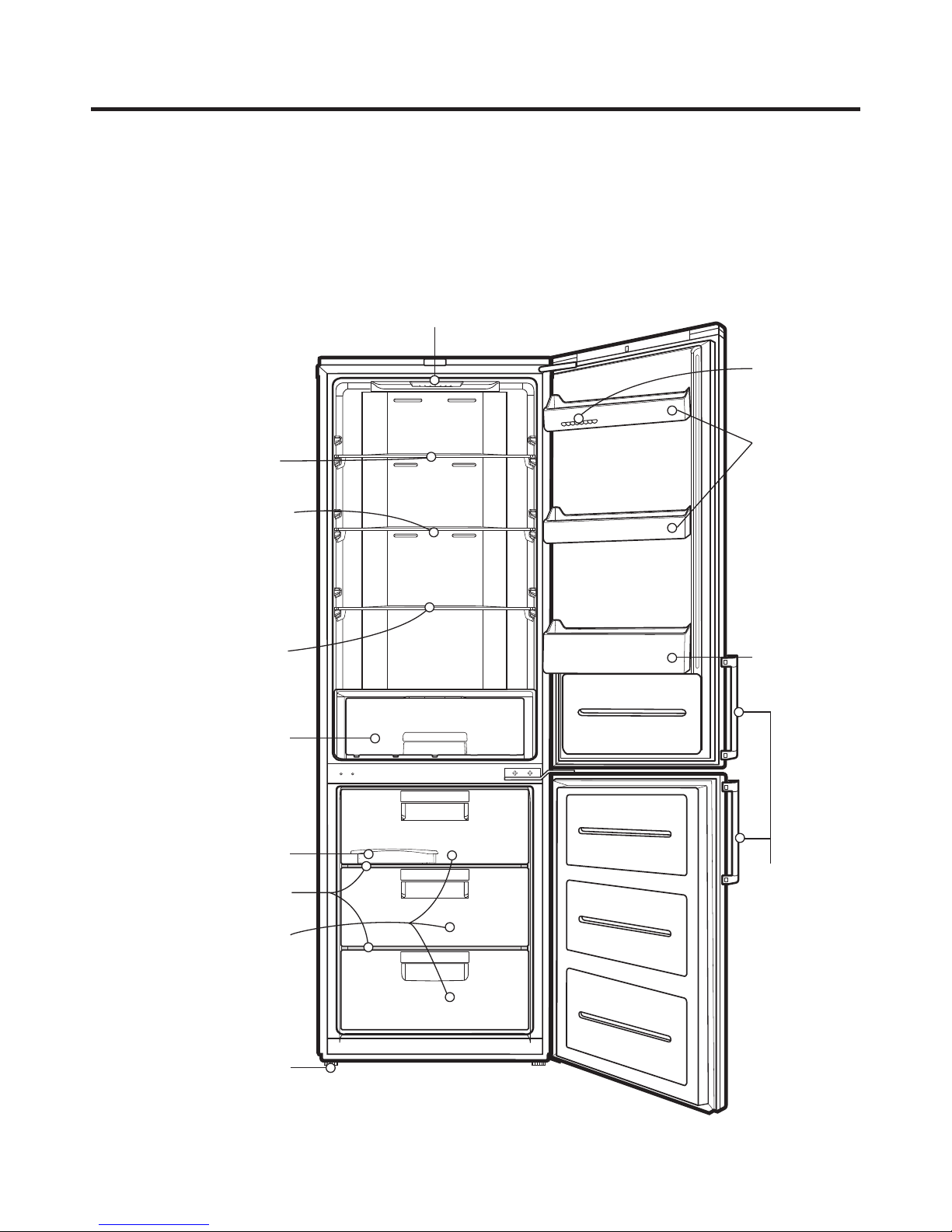

P A R T S I D E N T I F I C ATIO N

G B B530*****

Model Name : GBF530**Q**

Lamp

Removable

Glass Shelf

Removable

Glass Shelf

(Folding shelf

Optional)

Vegetable

Drawer (Used to

keep fruits and

vegetables etc.

fresh and crisper)

Fresh '0' Zone

(Optional)

Egg Tray (Optional)

Dairy Corner

(Optional)

Basket Door

Bottle Rack

(Optional)

Water Tank

(Optional)

Basket Door

Ice Tray

Wire Shelf

Freezer

Compartment

Leveling Screw

EZ Open

Handle

(Optional)

- 9 -

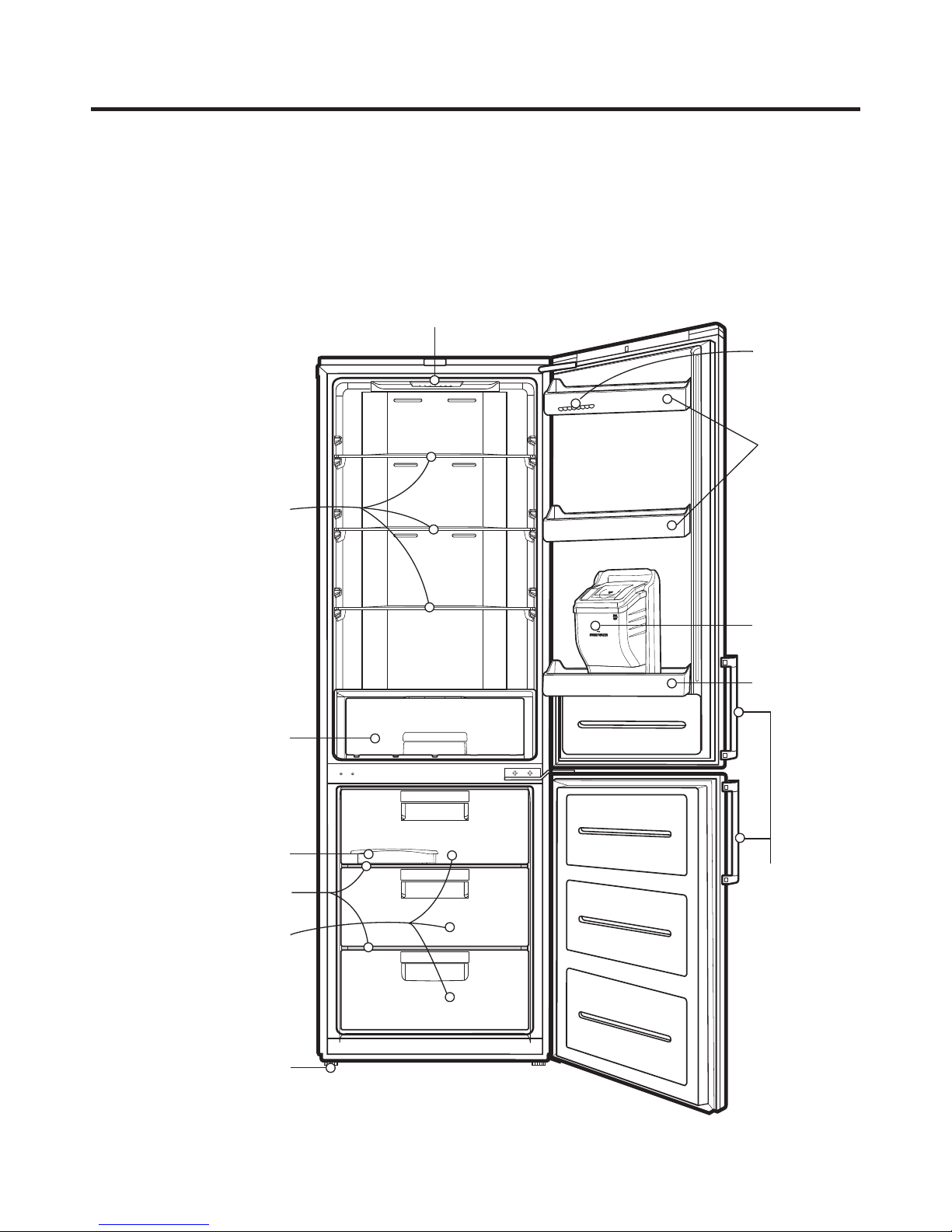

P A R T S ID E NTI F I C A T I O N

G B B539*****

Model Name : GBB539**QF*, GBB539**QP*, GBB539**CF*, GBB539**CP*, GBB539**CZ*, GBB539**QZ*

Lamp

Egg Tray (Optional)

Dairy Corner

(Optional)

Removable

Glass Shelf

Removable

Glass Shelf

(Folding shelf

Optional)

Vegetable

Drawer (Used to

keep fruits and

vegetables etc.

fresh and crisper)

Fresh '0' Zone

(Optional)

Ice Tray

Wire Shelf

Freezer

Compartment

Basket Door

Bottle Rack

(Optional)

Basket Door

EZ Open

Handle

(Optional)

Leveling Screw

- 10 -

P A R T S ID E NTI F I C A T I O N

G B B539****

Model Name : GBB539**QW*, GBB539**HW*

Lamp

Egg Tray (Optional)

Removable

Glass Shelf

Removable

Glass Shelf

(Folding shelf

Optional)

Removable

Glass Shelf

Vegetable

Drawer (Used to

keep fruits and

vegetables etc.

fresh and crisper)

Ice Tray

Wire Shelf

(Optional)

Freezer

Compartment

Basket Door

Basket Door

EZ Open

Handle

(Optional)

Leveling Screw

- 11 -

P A R T S I D E NTI F I C A TIO N

G B B539****

Model Name : GBF539***W*

Lamp

Removable

Glass Shelf

Egg Tray (Optional)

Basket Door

Vegetable

Drawer (Used to

keep fruits and

vegetables etc.

fresh and crisper)

Ice Tray

Wire Shelf

Freezer

Compartment

Leveling Screw

Water Tank

(Optional)

Basket Door

EZ Open

Handle

(Optional)

- 12 -

INS TR UC TIONS F OR R E VE R S ING DOOR S WING

This re frigera tor a llows the owner to change the door s wing if desired. T he hinging of the doors ca n be changed

to the opposite s ide anytime you wish.

When revers ing the door s wing :

R ead the instructions all the way through before starting.

·

Ha ndle pa rts carefully to avoid s cratching paint.

·

S et s crews down by their related parts to avoid using them in the wrong places .

·

P rovide a non-s cratching work surface for the doors .

IMPO R TA NT

Once you begin, do not move the ca binet until door-swing revers al is completed.

Thes e instructions are for changing the hinges from the right side to the left s ide-if you ever want to cha nge the hinges back

to the right s ide, follow thes e s ame ins tructions and re verse all reference s to left and right.

B efor R emoving the Doors , empty a nd R emove a ll the Door Bas kets of both R efrigerator/Freezer D oors , including the B ank

Da iry. C lose both door

Warning E lec tric S hoc k Hazar d

Dis connect electrical s upply to refrigera tor before installing. F ailure to do so could re s ult in death or serious injury.

s before removing hinge pins .

C a ution :

Do not let either door drop to the oor. Doing s o could dama ge the Door S top.

- 13 -

INS TR UC TIONS F OR R E VE R S ING DOOR S WING

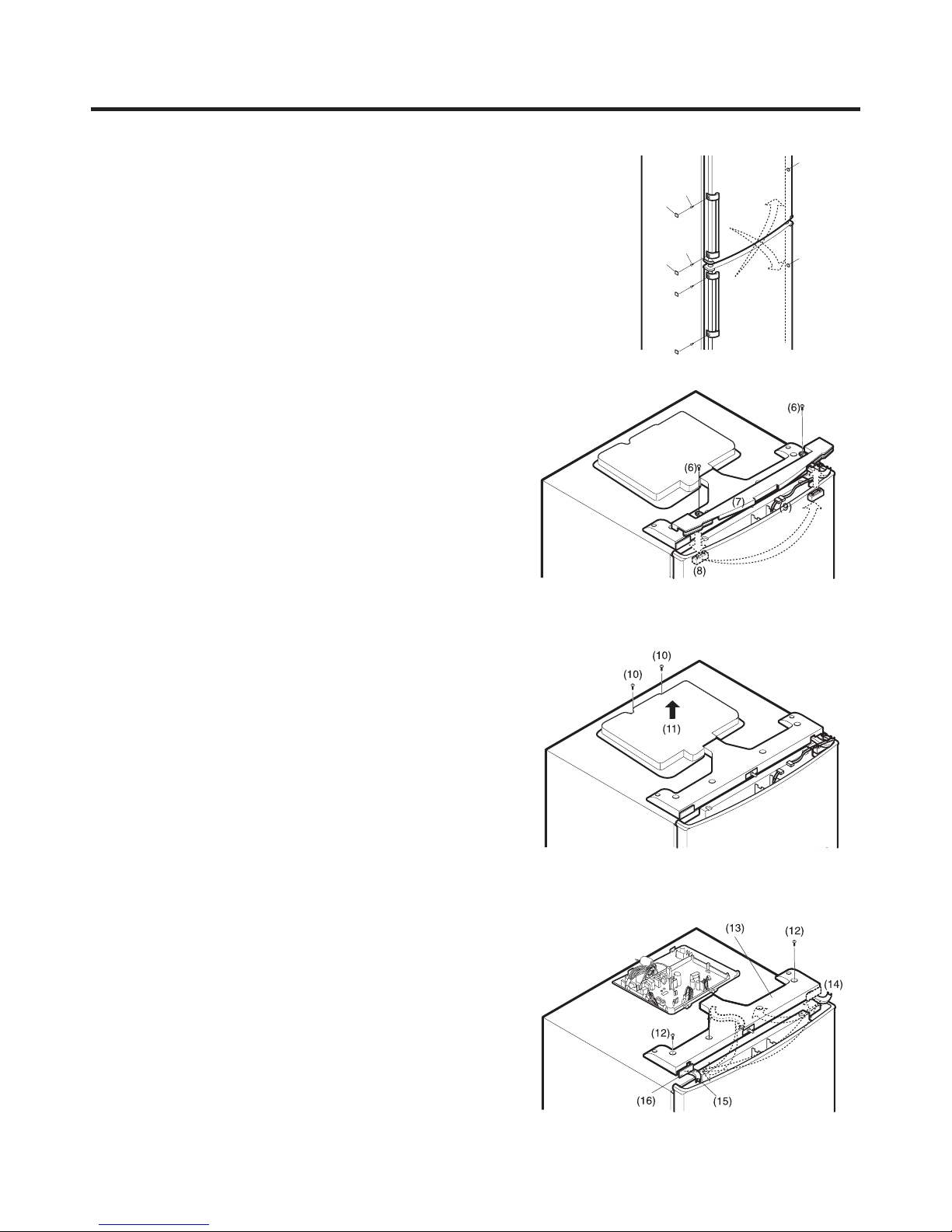

1) R emove screws(3) after removing a C AP(2) from the s ide

of the refrigerator room HANDLE (1).

The freezer room HAND LE (5) ma y be also dis assembled in

a same may as the refrigera tor room H ANDLE (1).

2) R emove the s crews (6) in the DE CO C OVE R (7).

R emove the DE CO CO VE R (7) and move the C OV ER

HING E (8) to s ide of DE C O C OV E R (7). Disassemble the

Housing C onnector(9) ins ide of the DE CO C OV E R (7).

(2)

(2)

(4)

(3)

(1)

(3)

(4)

(5)

3) R emove the s crews (10) in the C OV E R -P W B (11), a nd

remove the C OVE R -P WB(11).

4) R emove the s crews (12) in the T OP C O V E R F R ONT (13)

and remove the TOP C OV E R F RONT (13) .

5) R emove the H OLDE R C OR D (14) placed in right a nd ins ert

it to ce nter. And then move COVE R F R ONT (16).

Take out the HOL DE R C OR D(spare) (15) and to pl

ac e in

the center of TOP C OV E R F RONT (13), and insert to the

left s ide.

- 14 -

INS TR UC TIONS F OR R E VE R S ING DOOR S WING

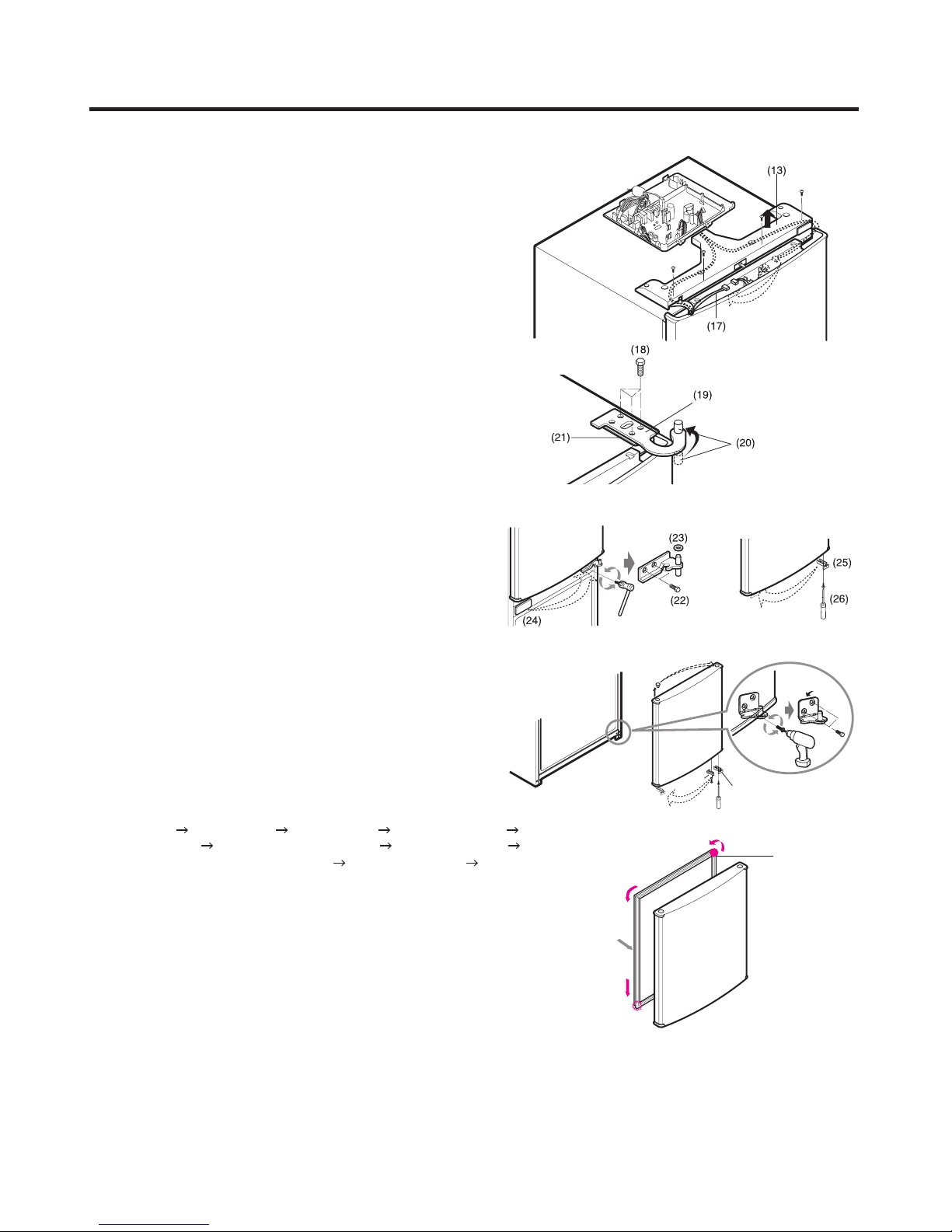

6) Take out the LEAD WIRE(17) assembly from the TOP

COVER FRONT(13) and assemble it on the left side.

7) Remove bolts(18) securing HINGE-U(19).

Uns crew of the hinge pin(20).

Place HINGE-U and seat hinge upside down and apply

them to left side of the refrigerator.

NOTE:

Seat hinge to be placed under the HINGEU(19).

8) Remove bolts(22) securing HINGEC(23) and then remove

HINGE-C(23).

Remove the freezer door. Move in left side of the

refrigerator CAP(24). Move to left side of the refrigerator

door BRACKET DOOR (25) and screw (26).

9) Remove Bolts(27), HINGE-L (28), STOPPER (29), (30) and

Lavel(31).

Use the new HINGE-L in Drawer and attach a label to a

screw Hole.

10) Assemble:

HING E -L F reezer Door HIN G E -C (23) R efrigerator Door

HING E -U(19) TO P C OV ER F R O NT(13) C OVE R P WB (11)

Connect the H ous ing C onnector(9) DE C O C OV E R (7) HAN DLE (1) (5)

11) Remove Freezer and Refrigerator Door Gaskets and turn them 180˚.

Assemble them again and put some lubricant onto their surface.

NOTE:

Reversing the doors is not covered by the warranty.

LUBRICANT

(29 )

(32 )

(27 )

(30 )

G AS KE T

- 15 -

DI S A SSEMBL Y

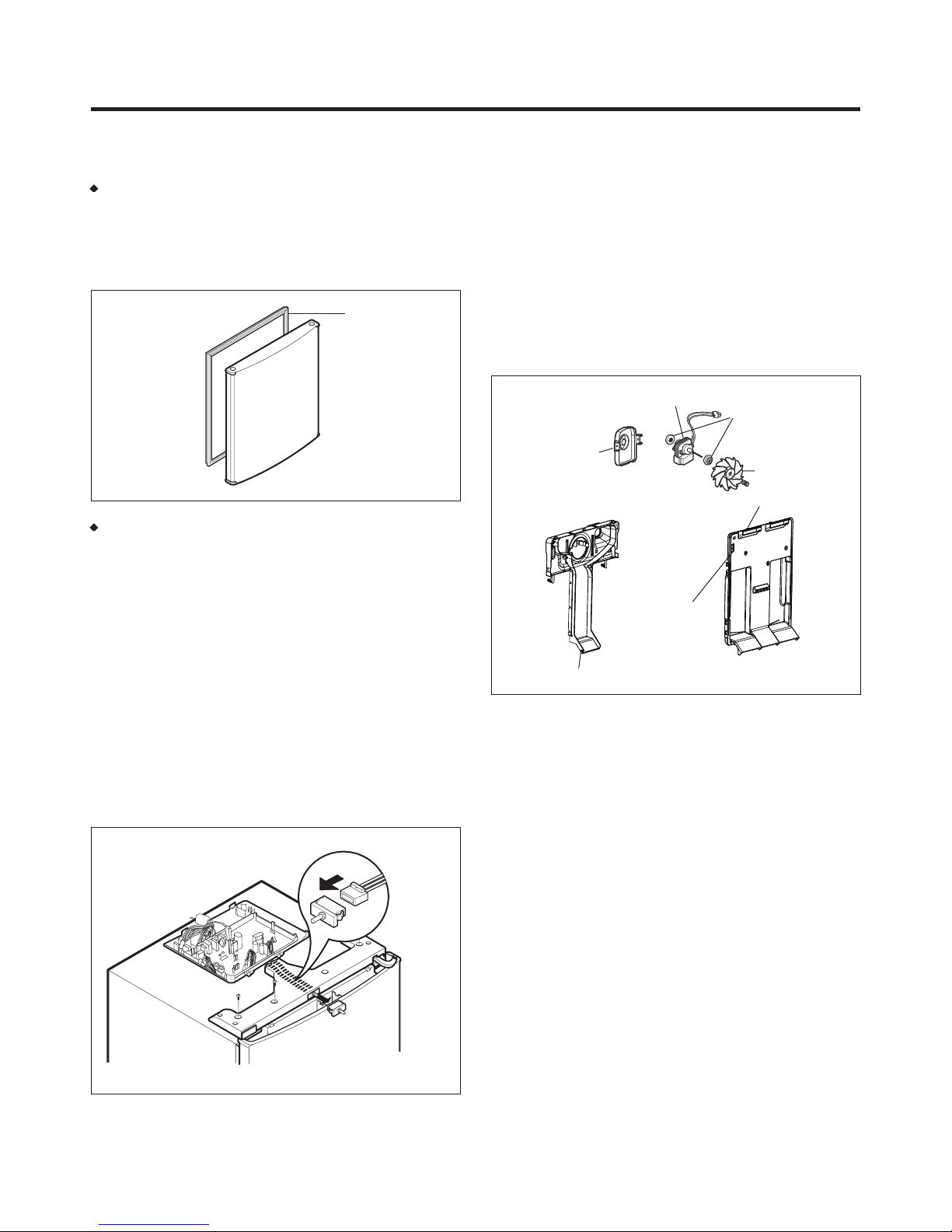

1. DOOR

•

Freezer Door

1) Refer to previous chapter "Instruction for Reversing

Door Swing".

2) P ull out Door Gasket to remover from the Door

Foam Assembly, F .

G AS KE T

•

Refrigerator Door

1) Refer to previous chapter "Instruction for Reversing

Door Swing".

2) Pull out the Door Gasket to remove from the Door

Foam Assembly, R .

F igur e 7

3. FAN AND FAN MOTOR

1) Remove all of the freezer compartment,

(Involved wire shelf, ice maker)

2) Pull out the Grille Fan and Shroud F.

3) Disconnect the Housing of lead wire.

4) Remove three screws in Grille Fan.

5) Separate Shroud, F to the Grille Fan.

6) Loose three screws xed to the Bracket.

7) Pull out Bracket and then remove the Fan Motor

Assembly.

* Fan Motor Assembly can’t separate.

MOTOR

BRACKET,

MOTOR

SENSOR

DAMPER

FAN

GRILLE, FAN

2. DOOR SWITCH

1) Unplug the power cord from the outlet.

2) Loosen s ix screws in upper part and disconnect Top

Cover Front.

3) Disconnect Lead Wire from switch.

4) Disengage hook behind the switch by pressing it with

hands.

F igur e 9

SHROUD

Figure 11

- 16 -

DI S A SSE M B L Y

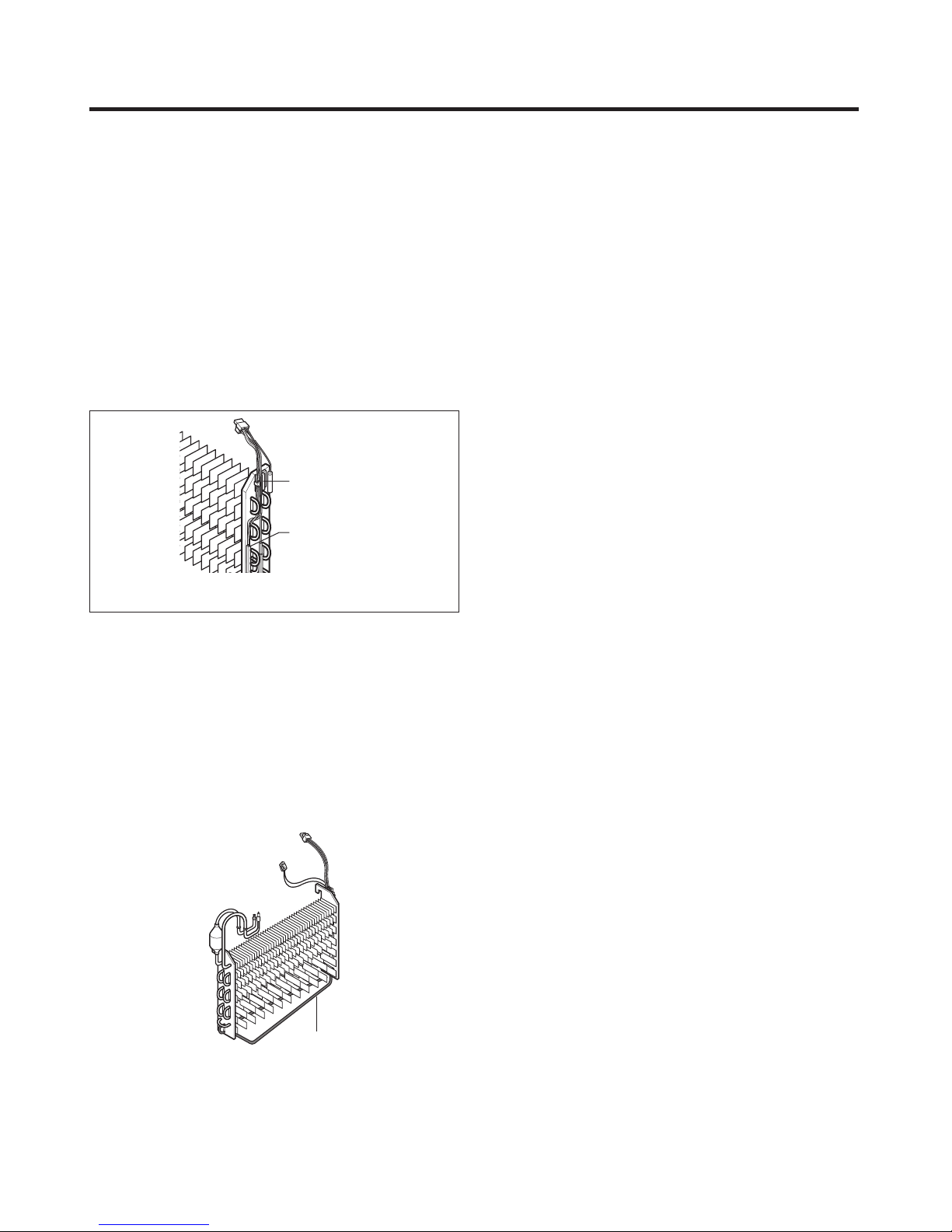

4. DE F R OS T C ONT R OL A SSE MB LY

Defrost C ontrol Assembly cons is ts of T hermistor and F use,

Melting. Thermis tor functions to defros t automatically a nd it

is a ttached to metal side of the E vapora tor and s enses

tempera ture.

F us e, Melting is a kind of s afety device for preventing

overheating of the Hea ter when defros ting.

At the temperature of 77˚C, it s tops the emission of heat

from the Hea ter.

1) P ull out the S hroud, F after removing the G rille .

- Freezer

P ull out the G rille. - Fridge

arate the connector connec ted with the D efrost

2) S ep

C ontrol Assembly a nd replace new one .

Thermistor

F us e, Melting

F igur e 12

5. FR EEZE R HE AT E R , S HE AT H

In this refrigerator, H eater, S heath is us ed for defros ting

hea ter. D uring heating, the temperature of heater rise s

about 300~350˚C . T herefore, be careful not to burn while

servicing.

1) After removing the G rille and S hroud, s epara te the

He ater, S hea th by disconnecting the conne ctors.

2) E xcha nged Hea ter, S heath and connected the hous ing.

He ater, S hea th

F igur e 13

- 17 -

ADJUSTMENT

1. COMPRESSOR (In A++ and A+ Models)

1) Role

The compres s or intakes low tempera ture and low pressure

gas evapora ted from E vaporator of the R efrigerator, and

condenses this gas to high tempera ture and high pres s ure

gas , and then plays delivering role to C ondenser.

2) Composition

The C ompressor is C ompose d of C ompres s or Apparatus

compressing ga s , C ompres sor Motor moving C ompressor

Apparatus and C as e protecting C ompre s s or Apparatus

and Motor. T here is R elay Ass embly (one set of

P T CS tarter and O ver L oad Protector (OLP )) in

C ompre s s or. O n the other ha nd, becaus e the C ompre s s or

cons ists of 1/1000mm processing precis ion components

and is sealed after production in abs ence of dust or

humidity, dea l and repair w

ith ca re.

3) Note for Usage

(1) Be ca reful not to a llow over-voltage a nd over-current.

(2) No S trike

If applying forcible power or strike (dropping or care les s

dea ling), poor ope ration and nois e may occur.

(3) Us e proper e lectric components appropriate to the

C ompre s s or.

(4) Note to K eep C ompre s s or.

If C ompressor gets wet in the rain and rus t in the pin of

He rmetic T erminal, the res ult may be poor operat

and poor contac t may caus e.

ssor ins ide in replacing the

C ompre s s

noise.

ion

2. PTC-STARTER (In A++ and A+ Models)

1) Composition of PTC-Starter

semiconductor s ta rting device which us es cera mic

material and this material cons ists of B aTiO

(2) The higher the temperature is , the higher becomes the

res istance value. Thes e features are used as s tarting

device for the Motor.

2) Role of PTC-Starter

(1) PT C is a ttached to Hermetic C ompres s or used for

R efrigera tor, S how C as e a nd starts Motor.

(2) C ompres sor for household refrigerator applies to

single-phase induction Motor.

F or normal operation of the single-phase induction

and s ub-coil. After the starting is over, the current in

the a bove roles . S o, PT C is us ed a s a motor s tarting

device.

3.

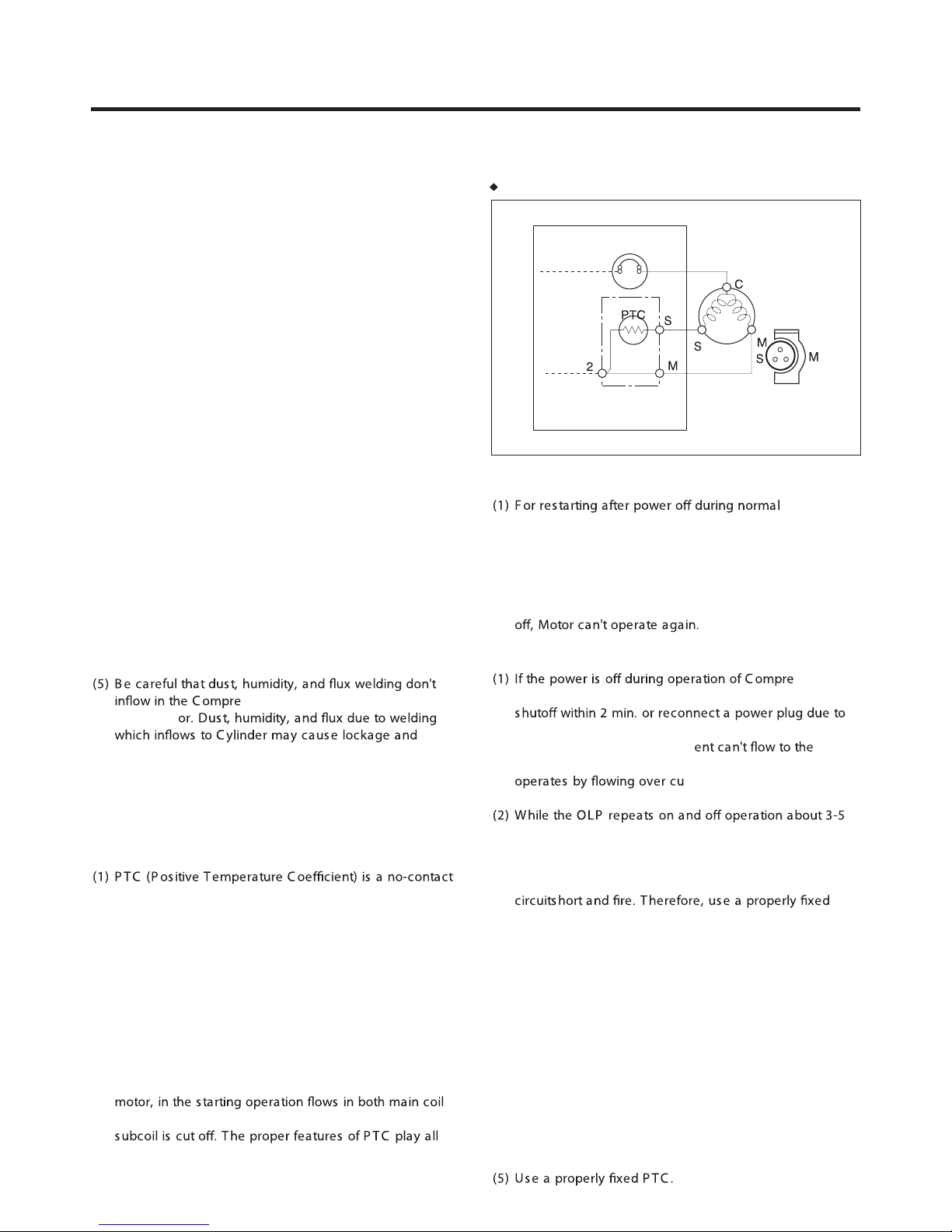

3) PTC-Applied Circuit Diagram

•

According to S ta rting Method for the Motor

OV E R LOA D

P ROT E CT OR (O .L.P )

C OMP R E SS O R

MOTOR

P TC S TAR TE R

R S IR

R E LAY AS SE MBL Y

HE R ME TIC

TE R MINAL

Figure 9

4) Motor Restarting and PTC Cooling

C ompre s s or Motor operation, plug the power cord after

5 min. for pres s ure ba lance of R efrigera ting C ycle a nd

P T C cooling.

(2) During normal opera tion of the C ompres sor Motor, P TC

elements genera te heat continuously. T herefore, if P TC

isn't cooled for a while after the power has been s hut

5) Relation of PTC-Starter and OLP

ssor a nd

the power is on before the P TC is cooled, (instant

misconnecting), the P TC is n't cooled a nd a res istance

value grows. As a res ult, curr

subcoil and the Motor can't operate a nd the O LP

rrent in only in the

main-coil.

times, P TC is cooled a nd C ompres sor Motor performs

normal operation.

If OLP doesn't opera te when P T C is not cooled,

C ompre s s or Motor is worn a way and ca us es

OLP without fail.

6) Note to Use PTC-Starter

(1) Be ca reful not to a llow over-voltage a nd over-current.

(2) No S trike

Don't apply a forcible power or s trike .

(3) Keep a part from a ny liquid.

If liquid such as oil or water away enter the P TC , P TC

materials it may break due to insulation breakdown of

the ma terial its elf.

(4) Don't change P T C at your convenience.

Don't disa s s emble PT C and mold. If the exterior to the

P T C-starter is damaged, res istance value is a ltered

and it may caus e poor starting of the compres sor mo

may cause.

tor

- 18 -

ADJUSTMENT

3. OLP (OVER LOAD PROTECTOR)

(In A++ and A+ Models)

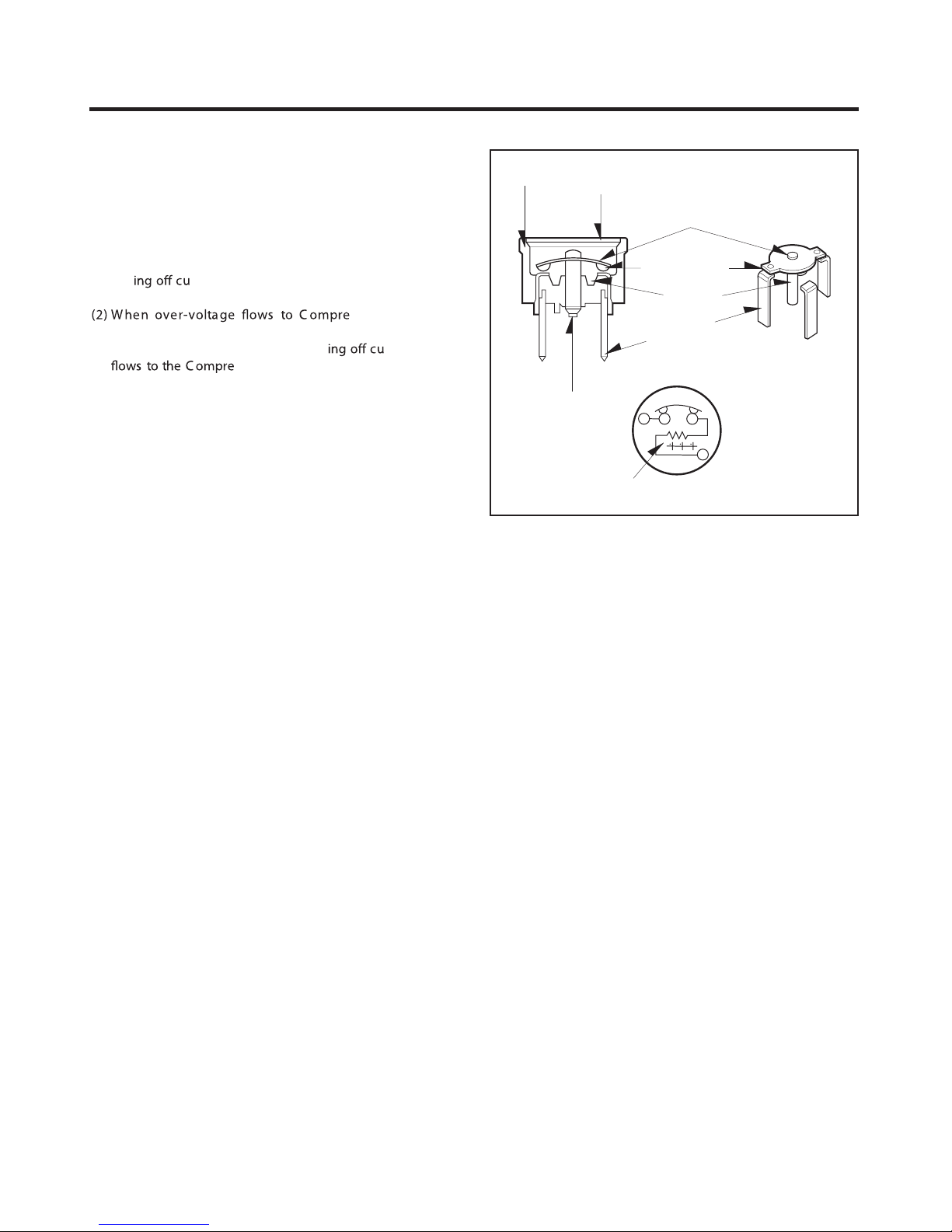

1) Denition of OLP

(1) O LP (OVE R LO AD P R OT E CTOR ) is atta ched to the

H e rme tic C ompre s s or a nd prote c ts the Mo tor by

cutt

rising temperature by B imetal in the O LP .

B imetal works by hea ting the heater inside the OL P,

and the OLP prote cts Motor by cutt

2) Role of the OLP

(1) T he OL P is attached to the Hermetic C ompres sor used

for the R efrigerator and S how Ca se and prevents the

Motor C oil from being started in the C ompres sor.

(2) Do not turn the Adjus t S crew of the O LP in any way for

normal operation of the OL P.

(C omposition and connection Dia gram of OLP)

rrent in C ompres s or Motor in ca se of over-

s s or motor, the

rrent which

ssor Motor.

C ONT AC TING

P OINT

ADJ US T

S CR E W

C OV E R

HE ATE R

B IME T AL

C ONT AC TING

P OINT

HE ATE R

TE R MINALS

B IME T AL

Figure 20

- 19 -

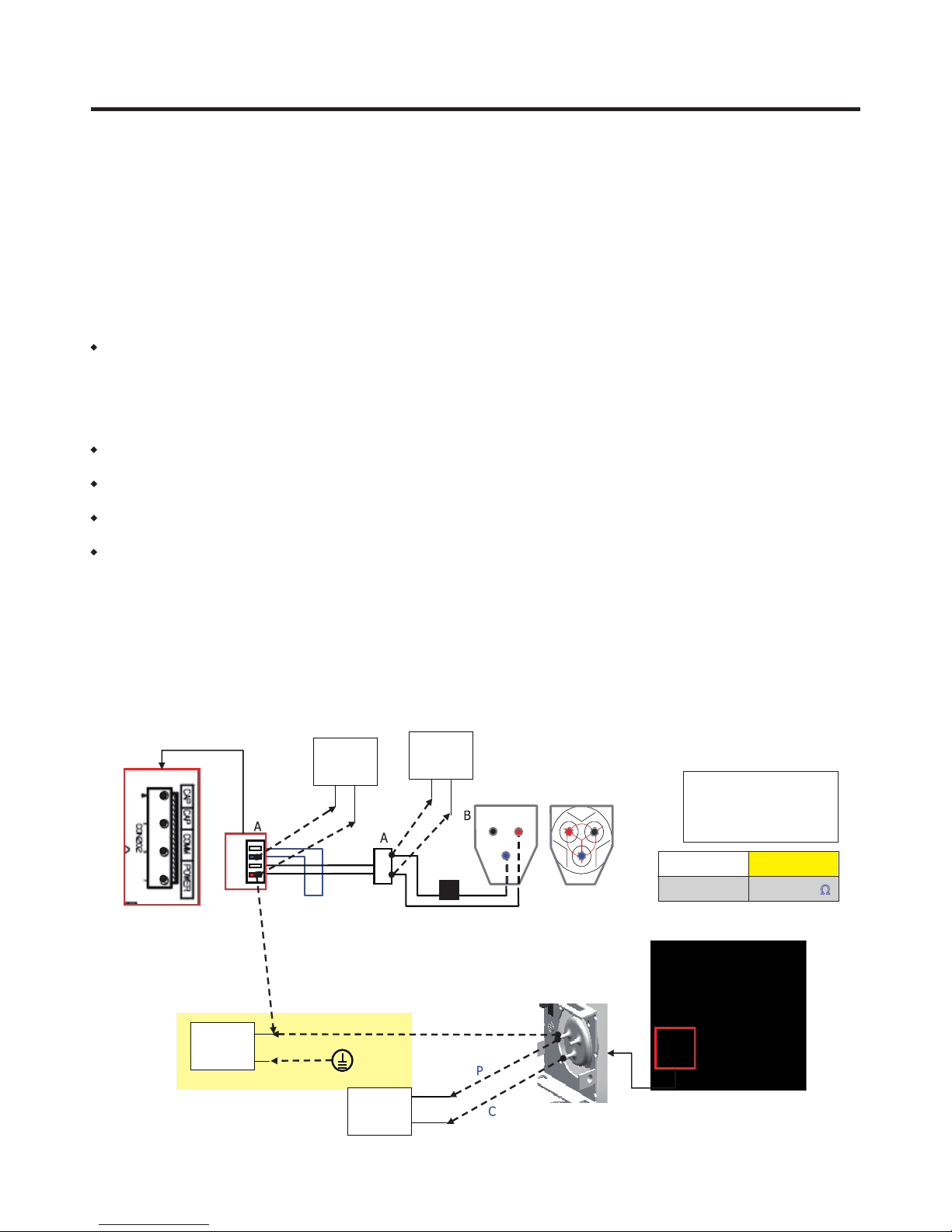

COMPRESSOR

1. Inverter Linear Compressor

Check for defect of the inverter linear compressor in following orders:

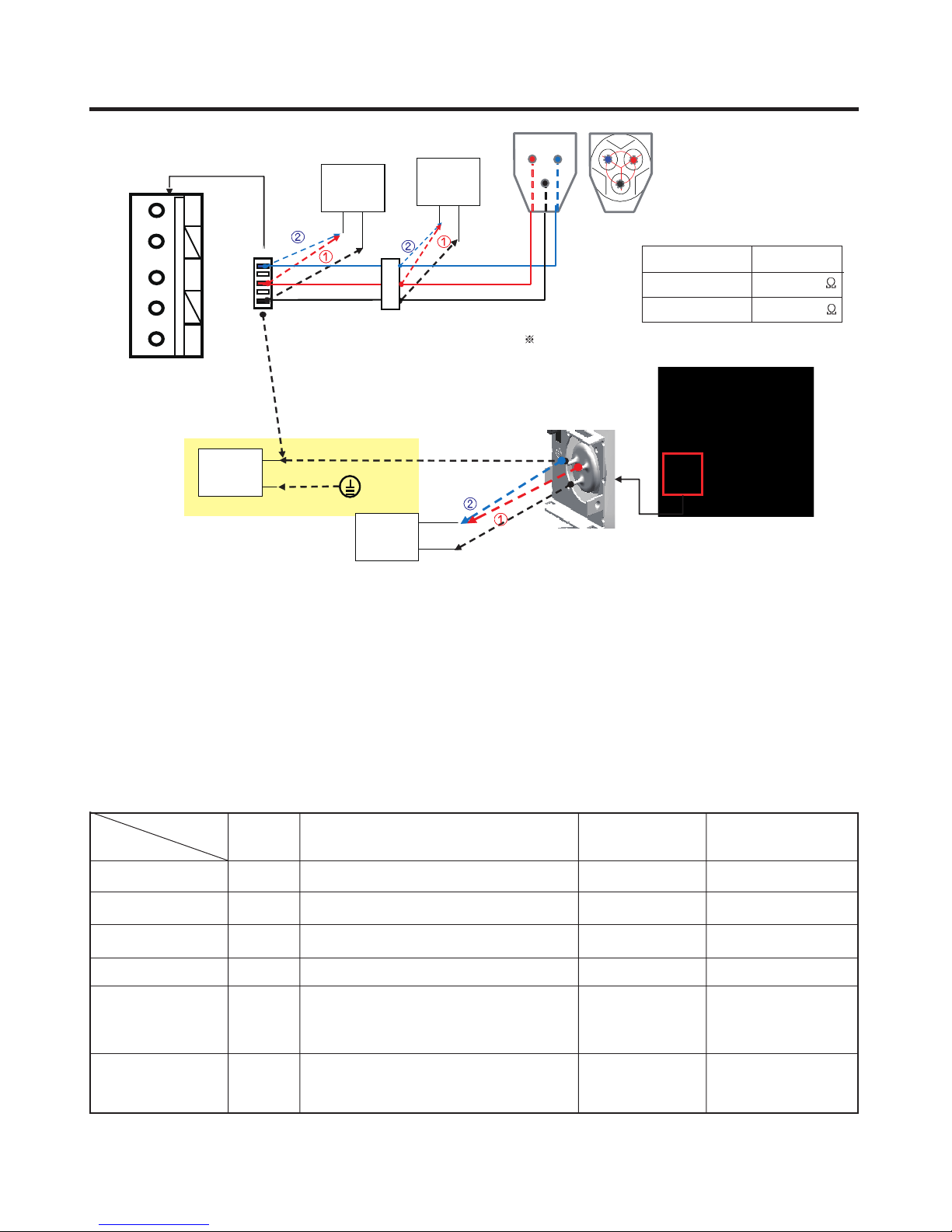

1) Method to Measure Compressor Winding Resistance

Normal Determination Criteria.

The compressor winding resistance can be determined as normal if resistance values show the values as described in

below gure when measuring resistance values of the harness (connected with compressor) to connect.

Connect201(CON201) of the main PWB as shown in below gure.

Defect Determination Criteria

•

Check connection status of the Compressor Connection Harness-P(Lead Wire) which is located at the M/C room where

resistance values measured at the CON201 Housing are shown as innite or several hundred MΩ . Separate connecting

wires of the M/C room (A-point in Figure) and then measure resistance values at the connecting wires again. The

compressor can be determined as normal if resistance values are shown as standard resistance value. Check connection

status of a harness.

Defect at M/C room connection contact or CON201 Housing contact, short-circuit of harness)

•

Where resistance values measured at A-point are also shown as innite or several hundred MΩ , disassemble a cover PTC

of the compressor terminal and check the terminal connecting status at the B-point in Figure.

•

Where there is no failure in the wiring status and resistance values are shown as innite or several hundred MΩ , it may be

determined as defect of compressor.

•

Since if there is no failure in resistance values of the compressor, it may be defective Main PWB, replace the Main PCB

and check for normal operation of the compressor.

•

When determining any defect through resistance measuring, it can be determined as normal if resistance values show as

descried in the below gure by measuring ① power and ③ common terminal or ② full power and ③ common terminal.

However, resistance values are measured when measuring ① power and ② full but measuring is meaningless since they

cannot become criteria for determining defect (measuring not required).

Caution

1. Be sure to powering o the refrigerator and measure after several minutes has passed.

2. If not accurately measuring resistance, wrong determination may be guided. (Dierence of resistance value of several W

or so may occur.)

CON201

Multi

Tester

Multi

Tester

Earth

Multi

Tester

OLP

Po N/C

Co

Because of ambient temperature or operating situations;

the values shown can have a slight devlation.

Po : Power

Co : Common

N/C : Open terminal

FLA102NAMA

Resistance

10 ~ 12

Ω

Dead Short Check

Multi

Tester

Hermetic terminal

- 20 -

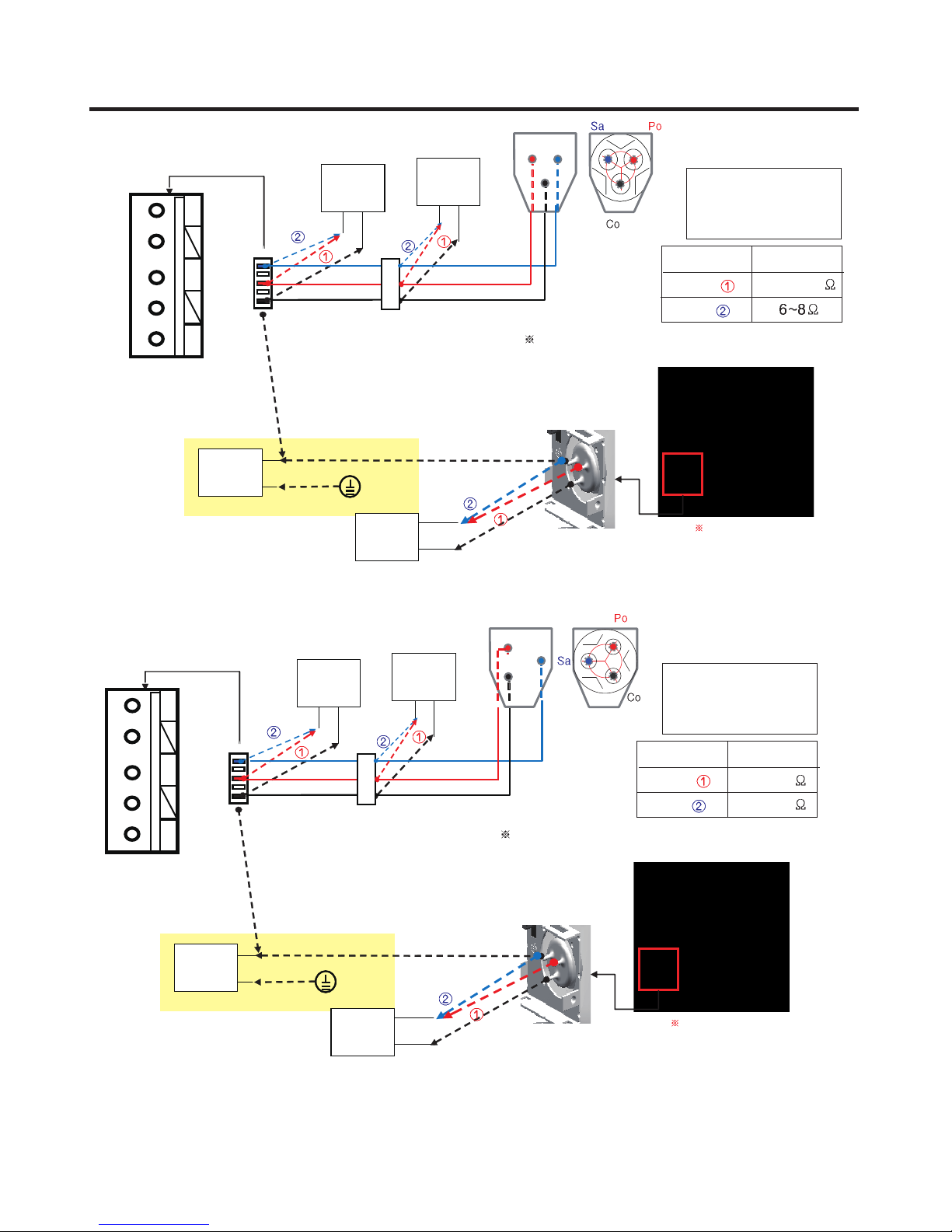

COMPRESSOR

Point D

Power SaveComon

Point A

Multi

Tester

Dead Short Check

Multi

Tester

Earth

Point B

Multi

Tester

Multi

Tester

Sa : Save

Po : Power

Co : Comon

Mode

Power (

Save (

Because of ambient temperature or operating situations;

the values shown can have a slight devlation.

Hermetic terminal

)

)

FLB124NAMA

Point D

Resistance

10.5~12.5

Power SaveComon

Point A

Multi

Tester

Dead Short Check

Multi

Tester

Earth

Point B

Multi

Tester

Multi

Tester

Sa : Save

Po : Power

Co : Comon

)

)

Resistance

16.2~18.6

11.6~15.1

Mode

Power (

Save (

Because of ambient temperature or operating situations;

the values shown can have a slight devlation.

Hermetic terminal

FMA102NAMA

- 21 -

COMPRESSOR

Point D V U

Multi

Tester

W

Mode

BMG089NAMV

BMG089NHMV

Because of ambient temperature or operating situations;

the values shown can have a slight devlation.

Hermetic terminal

Resistance

12.3~15.1

12.6~15.4

Power SaveComon

Point A

Multi

Tester

Dead Short Check

Multi

Tester

Point B

Earth

Multi

Tester

2) Method to Determine Defect of Inverter Linear Drive

Determination of Comp Operation

Separate the back cover at the rear of refrigerator and determine for possible operation while touching the compressor with

the hands with insulation gloves worn.

Comp Operation

- Determine possible trip by checking operation status if cold air comes out after opening the doors of the R-Room.

Protective Logic (Trip)

- To protect the compressor from abnormal operation, this logic is used to temporally stop the refrigerator when abnormal

operation occurs and to re-operate it after abnormal signal disappears.

Compressor protection Logic Table

App.

FCT0 Trip

Stroke Trip

Locked Piston Trip

Current Trip

IPM Fault

Communication

Error

* If LED of PCB is blinking, Refer to next page.

A-Inv.

A-Inv.

A-Inv.

A-Inv.

A-Inv.

A-Inv.

Initial, Motor sensing Voltage > 2.5V+20%

Piston overruns the designed range.

Piston is locked.

Current overruns the designed range

IPM pin 14 output voltage = low (IPM Short,

High current input, or low voltage input)

Checksum error

Requirement Waiting Time

30”

1’00”

2’30”

6’00”

20”

-

- 22 -

The number of LED

blinking

1

2

5

6

7

8

COMPRESSOR

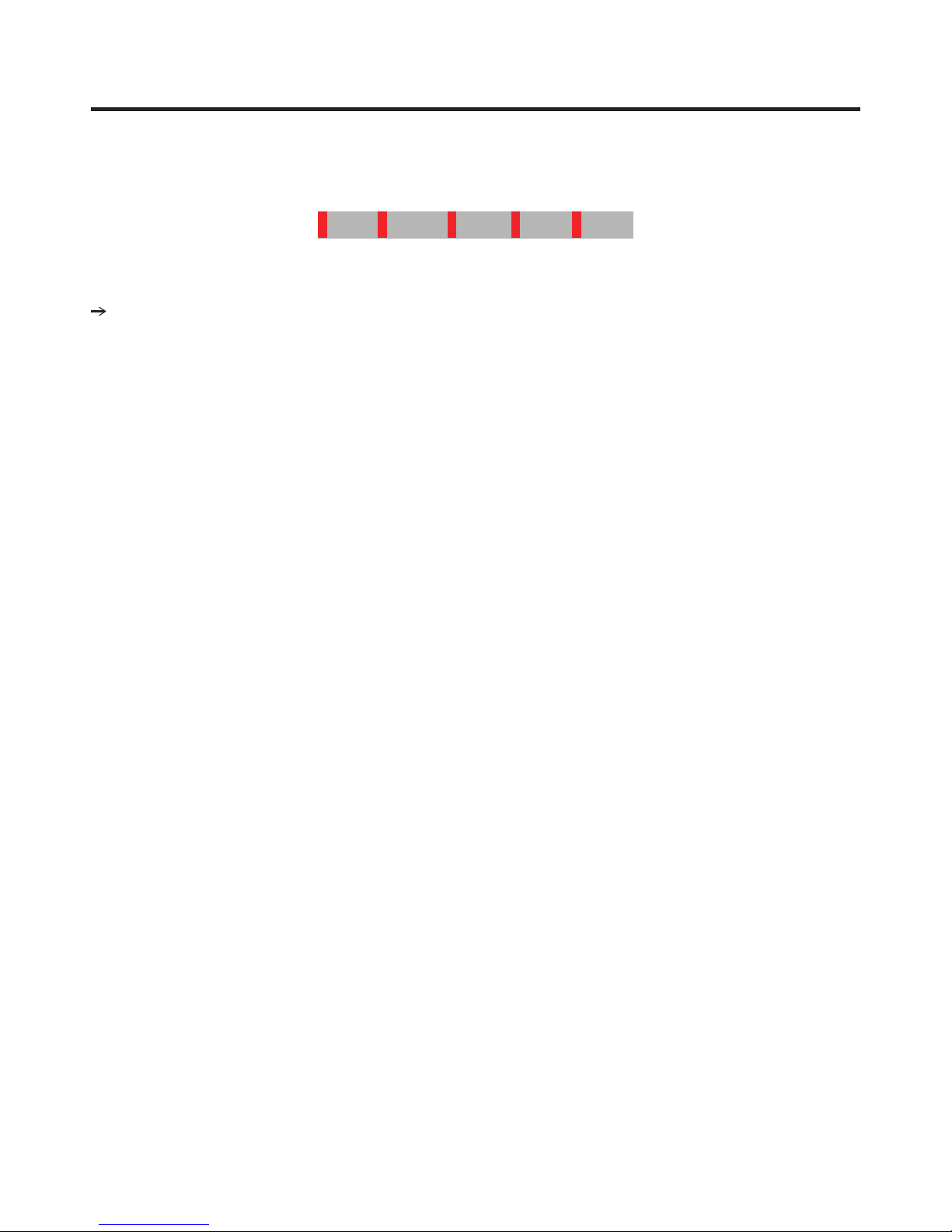

3) LED blinks one time, then repeats (FCTO Trip)

Blink BlinkOFF OFF

• FCT0 : When same trip occurs after power reset, change PCB.

Because it is occurred by overvoltage (more than 2.5V) at voltage and

current sensing parts, PCB has to be changed.

- 23 -

COMPRESSOR

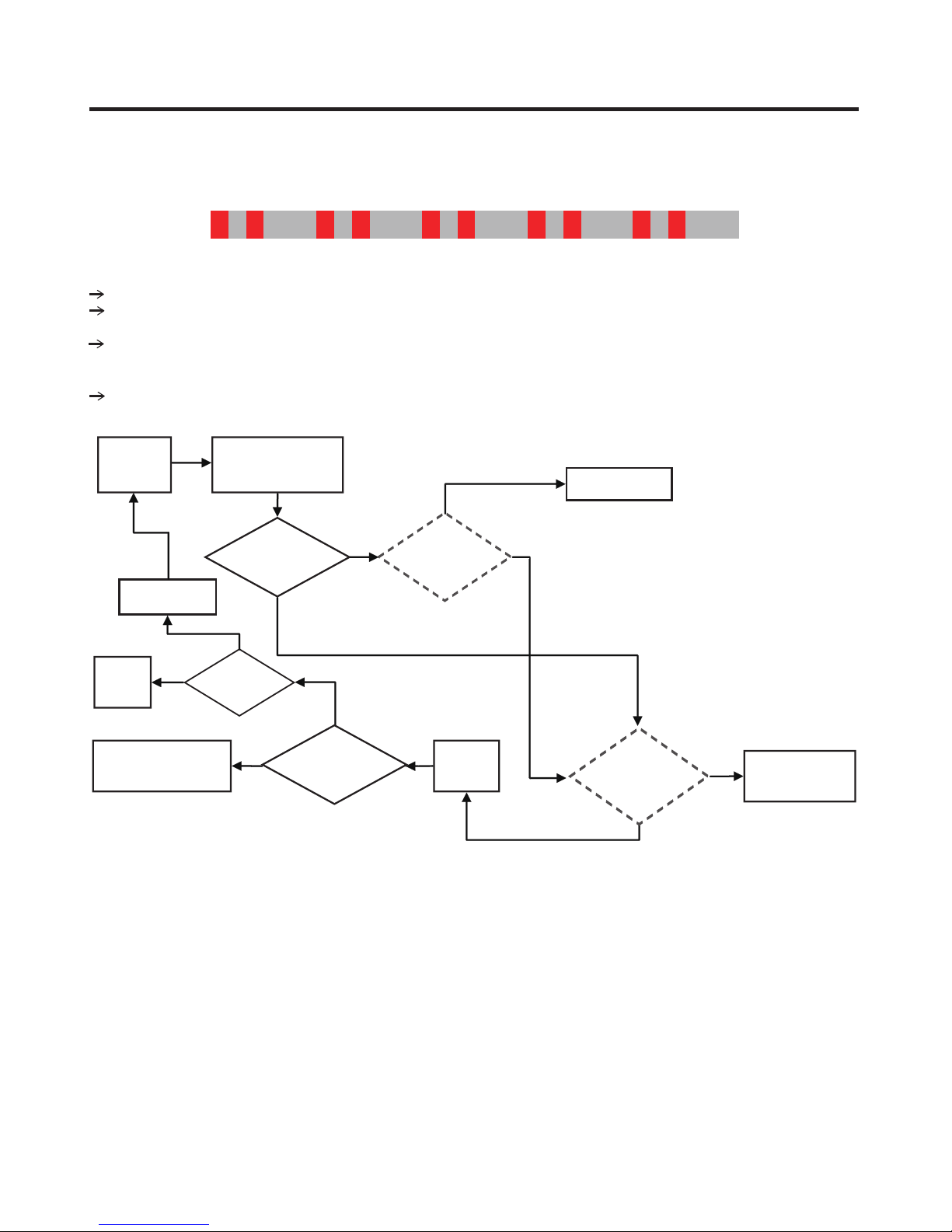

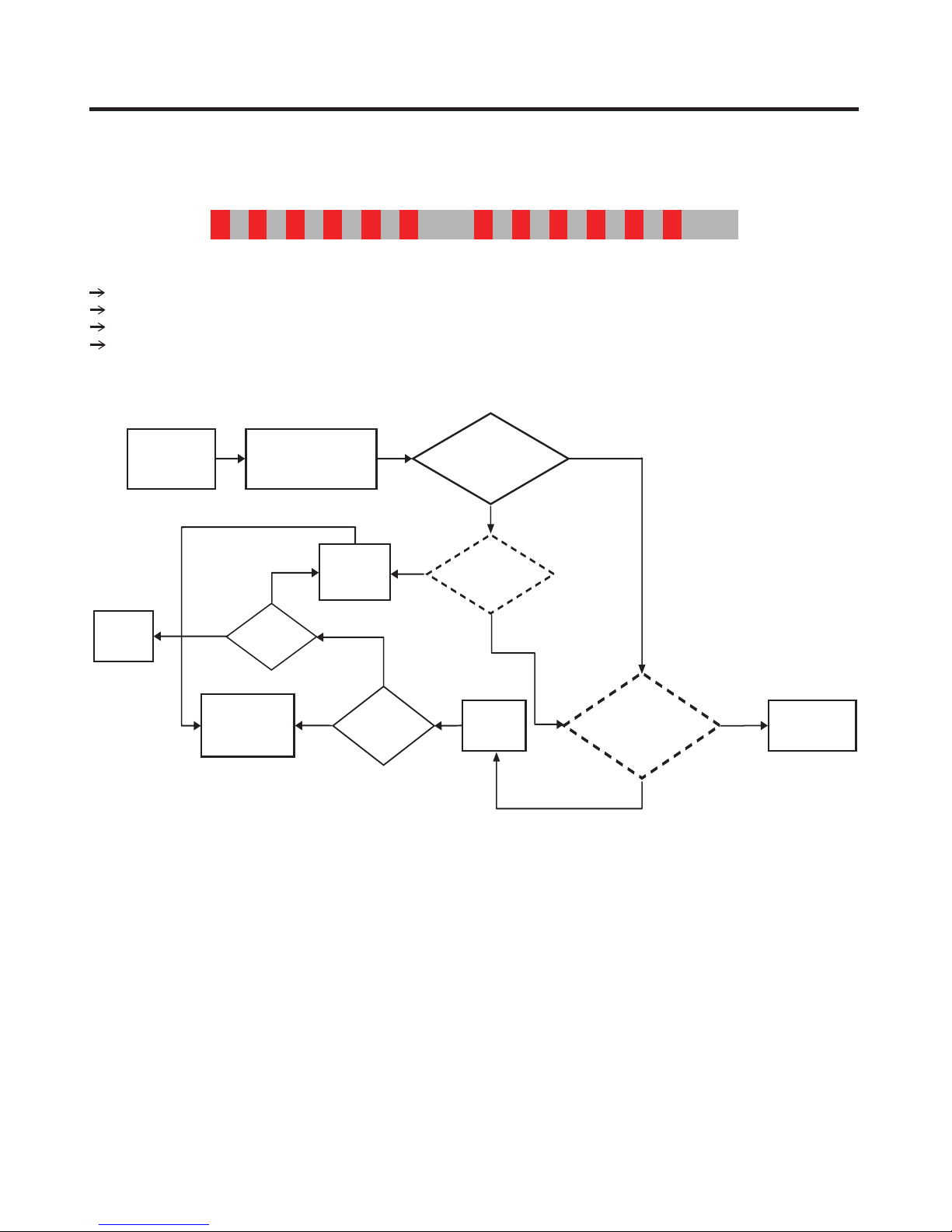

4) LED blinks two times, then repeats (Stroke Trip)

Blink BlinkBlink Blink

Purpose: Prevent abnormally long piston strokes.

Case 1. If compressor doesn’t work and LED blinks

- Cause: Possibly harness from compressor to PCB might be defective.

Case 2. If compressor works intermittently and LED blinks

- Cause: Condenser Fan or Freezer Fan is not running. Sealed system problem such as moisture restriction, restriction at

capillary tube or refrigerant leak.

Logic: Compressor is forced to o and then tries to restart after 1 minute.

Protection

logic

Check B

Replace

Driver PCB

Fix

Cycle

OK

NG

Blink 2 times

(Stroke Trip)

Check B2

Compressor

Doesn ’ t work

Cycle

Check E

N

Y

FFO FFOFFO

N

Y

Harness

Connecting

Check C

Y

Fix Harness

Repeat

Check Procedure

N

Stroke Trip

Occur?

Reset

Power

- 24 -

Compressor

Damage

Check C

Y

N

Replace

Compressor

COMPRESSOR

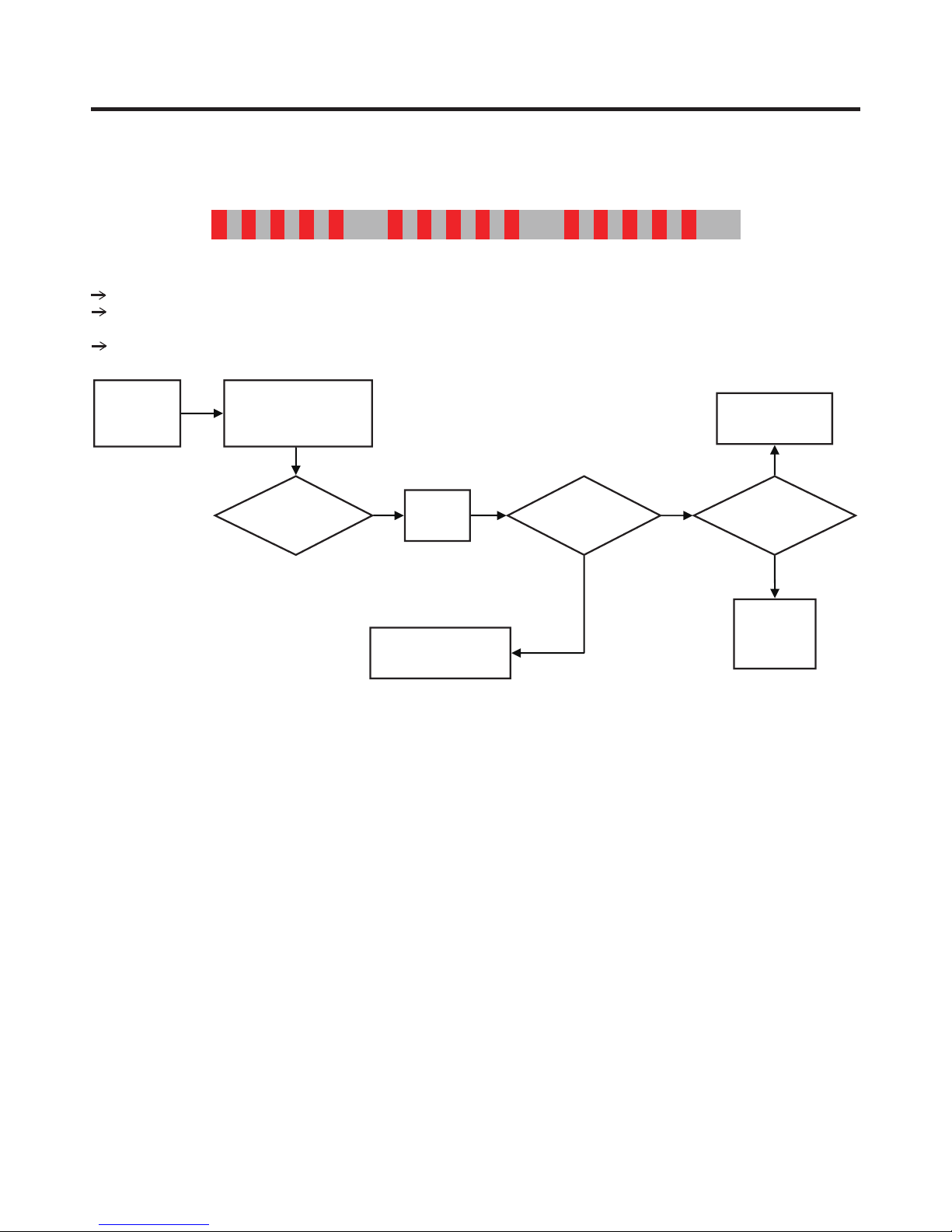

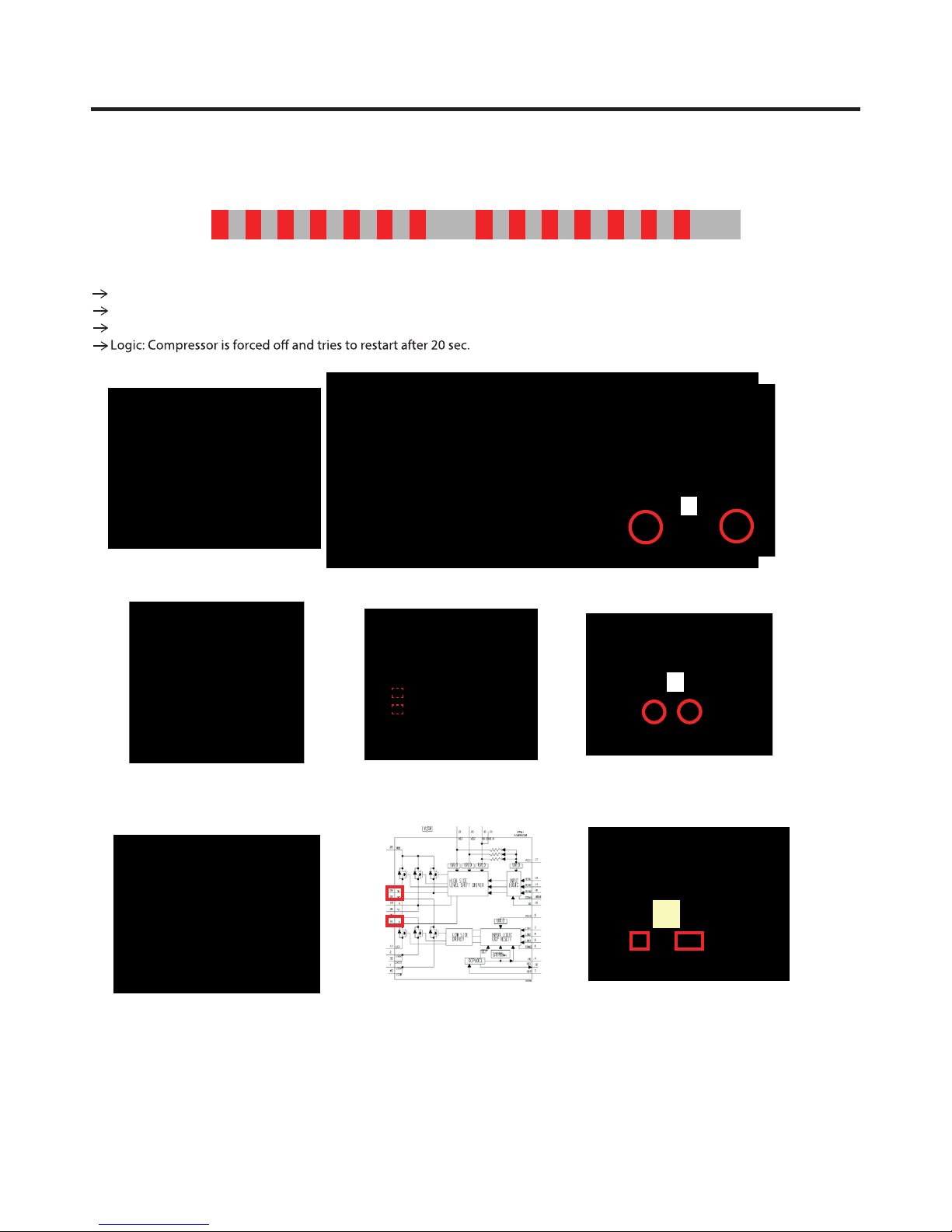

5) LED blinks ve times, then repeats (Locked Piston)

Blink Blink Blink Blink Blink OFF

Purpose: To detect locked piston

Cause: Lack of oil to the cylinder, cylinder or piston damaged and or restricted discharge.

A Locked Piston can also be caused by foreign materials inside the compressor.

Logic: Compressor is forced o and tries to restart within 2.5 minutes.

Protection

logic

Check B

Blink 5 times

(Lock Piston Trip)

Check B3

Compressor

Doesn’t work

Reset

Power

Repeat

Check Procedure

Compressor

Doesn’t work

N

Replace

Compressor

N

Y

Hi side

restriction

Y

Sealed

system

Repair

- 25 -

COMPRESSOR

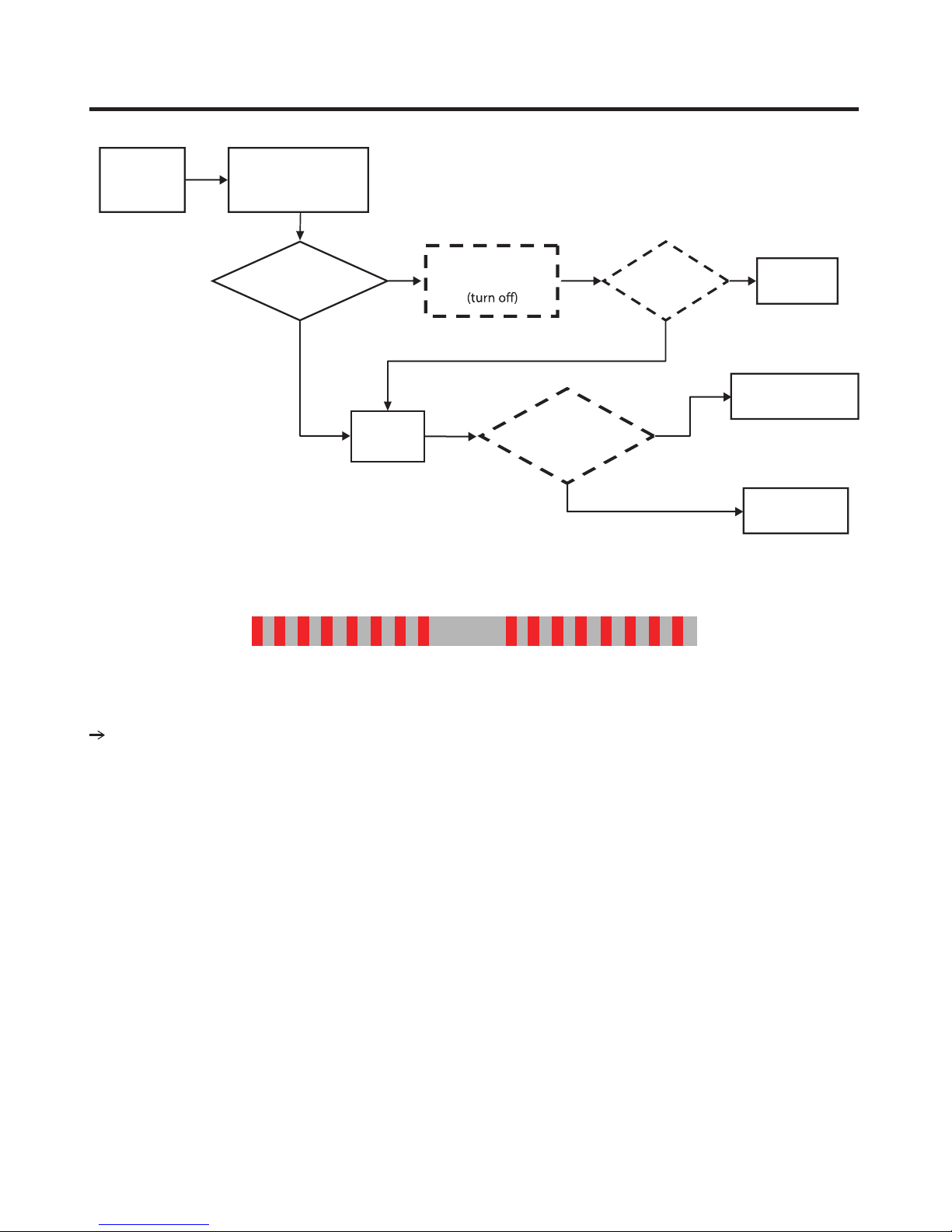

6) LED blinks six times, then repeats (Current Trip)

Blink Blink Blink Blink Blink Blink

Purpose: Prevent over-current (overload protect)

Cause: Ambient temperature is high (over 43˚C) and/or refrigerator’s condenser air movement is restricted.

Condenser Fan is stopped, restricted discharge line, compressor is damaged, or IPM device is defective.

Logic: Compressor is forced o and tries to restart after 6 min.

Protection

logic

Check B

Fix

Cycle

Blink 6 time

(Current Trip)

Check B4

Y

Cycle

Check E

Replace

Driver

PCB

Y

NG

OFF

Compressor

Intermittently

works

IPM

Check B5

Y

N

Y

Repeat

Check

Procedure

N

Current trip

Occur?

Reset

Power

Compressor

Damage

Check C3

Y

NG

Replace

Compressor

- 26 -

COMPRESSOR

7) LED blinks seven times, then repeats (IPM Fault)

Purpose: Prevent high current due to IPM Short

Cause: Damaged IPM (Dead Short)

Test for a dead short at Point A with a VOM.

230 V

OFFBlink Blink Blink Blink Blink Blink Blink

A

100 V EBR789107

230V EBR805254

A

A

- 27 -

COMPRESSOR

Protection

logic

Check B

Blink 7 times

(Lock Piston Trip)

Check B5

Compressor

Doesn’t work

N

Power

Reset

Y

Check IPM

visual inspection

8) LED blinks eight times, then repeats (Communication Error)

Blink

Blink

Blink

Blink

Compressor

Damage

Check C3

NG

Short

Test

Point A

Y

Y

N

Replace

Drive PCB

Repeat

Check Procedure

Replace

Compressor

Blink

• Communication Error : When same trip occurs after power reset,

change PCB.

Because Program is not matching in MICOM, program has to be

rewritten or PCB has to be changed.

Blink

Blink OFF

Blink

- 28 -

Loading...

Loading...