LG ffh 8900 Diagram

SERVICING PRECAUTIONS

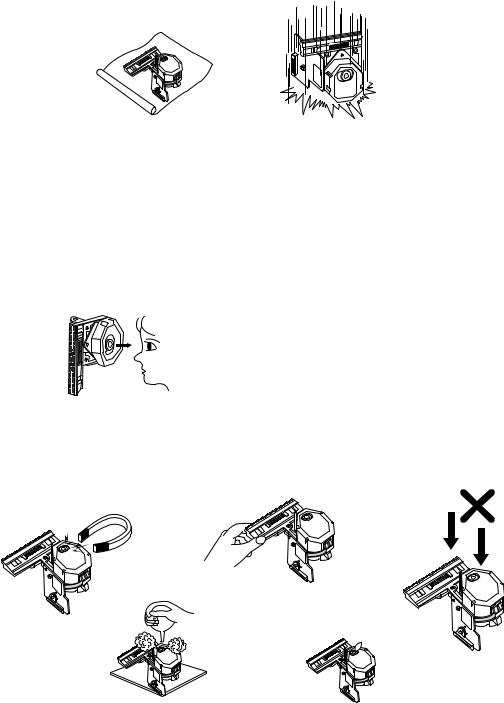

NOTES REGARDING HANDLING OF THE PICK-UP

1.Notes for transport and storage

1)The pick-up should always be left in its conductive bag until immediately prior to use.

2)The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag |

Drop impact |

2.Repair notes

1)The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2)The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or damage to the printed-circuit board.

3)Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason the adjustment point and installation screws should absolutely never be touched.

4)Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don′t let contact fingers or other exposed skin.

5)Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort this.

Pressure

Magnet

Pressure

How to hold the pick-up

Cotton swab

Conductive Sheet

6)Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

-3 -

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1.Preparations

1)Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components can be damaged, and for that reason components should be handled with care.

2)The pick-up is composed of many optical components and other high-precision components. Care must be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong magnetism is present, or where there is excessive dust.

2.Notes for repair

1)Before replacing a component part, first disconnect the power supply lead wire from the unit

2)All equipment, measuring instruments and tools must be grounded.

3)The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is because there is the possibility of damage by static electricity.)

4)To prevent AC leakage, the metal part of the soldering iron should be grounded.

5)Workers should be grounded by an armband (1MΩ )

6)Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent static electricity changes in the clothing to escape from the armband.

7)The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

|

Resistor |

|

Resistor |

(1 Mohm) |

|

Conductive |

||

(1 Mohm) |

||

Sheet |

||

|

CLEARING MALFUNCTION

You can reset your unit to initial status if malfunction occur(button malfunction, display, etc.).

Using a pointed object(such as driver), simply press the RESET button on the inside of the volume knob for more than 3 seconds.

If you reset your unit, you must reenter all its settings(stations, clock, timer)

NOTE: 1. To operate the RESET jump wire, pull the volume rotary knob and release it.

2. If you wish to operate the RESET jump wire, it is necessary to unplug the power cord.

VOLUME

VOLUME KNOB

RESET button

DOWN

- 4 -

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some field-effect transistors and semiconductor chip components. The following techniques should be used to help reduce the incidence of component damage caused by static electricity.

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can generate electrical charges sufficient to damage ESD devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD devices.

6.Do not remove a replacement ESD device from its protective package until immediately before you are ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive materials).

7.Immediately before removing the protective material from the leads of a replacement ESD device, touch the protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER SAFETY PRECAUTIONS.

8.Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

- 5 -

ADJUSTMENTS

This set has been aligned at the factory and normally will not require further adjustment. As a result, it is not recommended that any attempt is made to modificate any circuit. If any parts are replaced or if anyone tampers with the adjustment, realignment may be necessary.

IMPORTANT

1.Check Power-source voltage.

2.Set the function switch to band being aligned.

3.Turn volume control to minimum unless otherwise noted.

4.Connect low side of signal source and output indicator to chassis ground unless otherwise specified.

5.Keep the signal input as low as possible to avoid AGC and AC action.

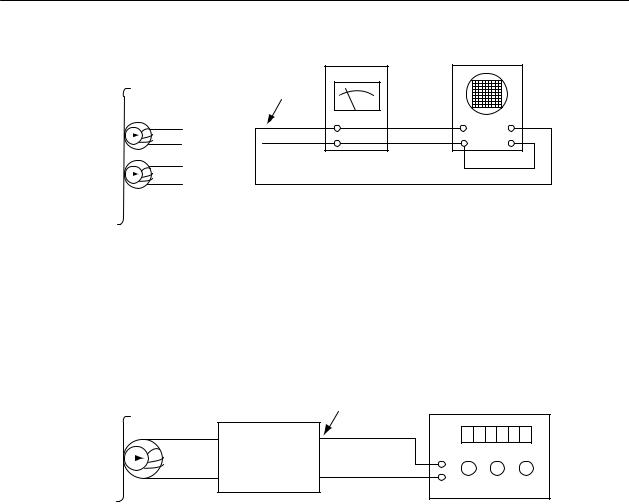

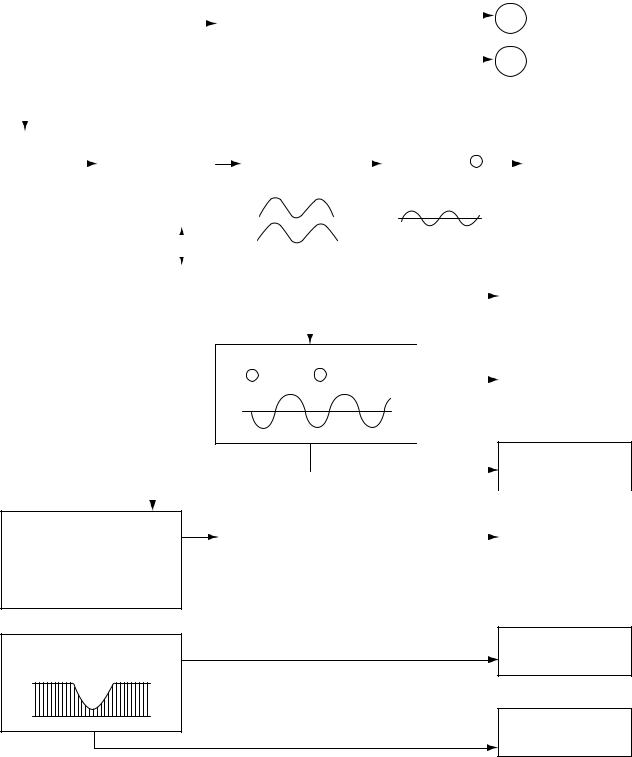

TAPE DECK ADJUSTMENT

1. AZIMUTH ADJUSTMENT

Deck Mode |

|

|

|

Test Tape |

|

|

Test Point |

|

Adjustment |

|

Adjust for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A Deck Playback |

|

|

|

MTT-114 |

|

|

Speaker Out |

|

DECK Screw |

|

Maximum |

|

B Deck Playback |

|

|

|

MTT-114 |

|

|

Speaker Out |

|

Azimuth Screw |

|

Maximum |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electronic |

Dual-trace |

|

||

|

|

|

|

|

|

|

|

Voltmeter |

synchroscope |

|

||

|

Head |

|

Playback Mode |

Speaker Out |

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||

|

|

L ch |

|

|

L out |

|

|

CH1 CH2 |

|

|||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Tape |

|

Unit |

|

|

|

|

|

|

|

|||

MTT-114 |

|

R ch |

|

|

|

|

|

GND |

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

R out |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 1. Azimuth Adjustment Connection Diagram

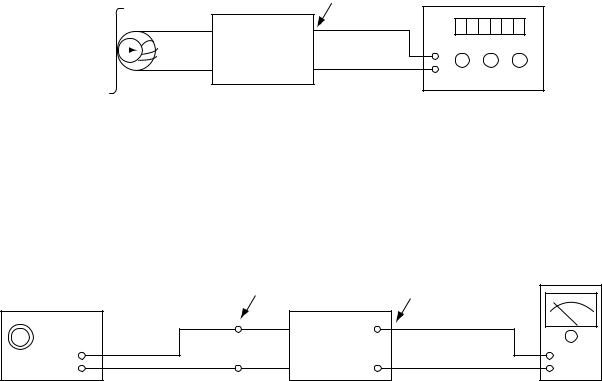

2. MOTOR SPEED ADJUSTMENT

Deck Mode |

|

Test Tape |

|

Test Point |

|

Adjustment |

Adjust for |

Remark |

||

|

|

|

|

|

|

|

|

|

||

Normal Speed |

|

MTT-111 |

|

Speaker Out |

|

VR201 |

3kHz ± 1% |

|

||

|

|

|

|

|

|

|

|

|

||

Hi-Speed |

|

MTT-111 |

|

Speaker Out |

|

more than 5.4kHz |

High-Speed Dubbing Mode |

|||

|

|

|

|

|

|

|

|

|

||

|

|

Head |

|

|

Speaker Out |

Frequency Counter |

||||

|

|

|

|

|

|

Playback Mode |

|

|

||

Test Tape |

|

L out |

|

|

||||||

Unit |

|

|

|

|

||||||

MTT-111 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

||

|

|

|

Record/Playback |

|

R out |

|

|

|||

|

|

|

|

|

GND |

|

|

|||

head

Figure 2. Motor Speed Adjustment Connection Diagram

- 8 -

3. RECORD BIAS ADJUSTMENT

|

Deck Mode |

|

|

Test Tape |

|

Test Point |

|

|

Adjustment |

Adjust for |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Rec/Pause |

|

|

MTT-5511 |

|

ERASE HEAD Wire(PN202) |

|

L203 |

90kHz±5kHz |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Head |

|

Record/Playback |

PN202 |

|

|

Frequency Counter |

||||||

|

|

|

|

and Pause Mode |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Tape |

|

|

|

|

|

Unit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MTT-5511 |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

Record/Playback |

|

GND |

|

|

|||||||

|

|

|

|

head |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Figure 3. Record Bias Adjustment Connection Diagram |

|

|

||||||||

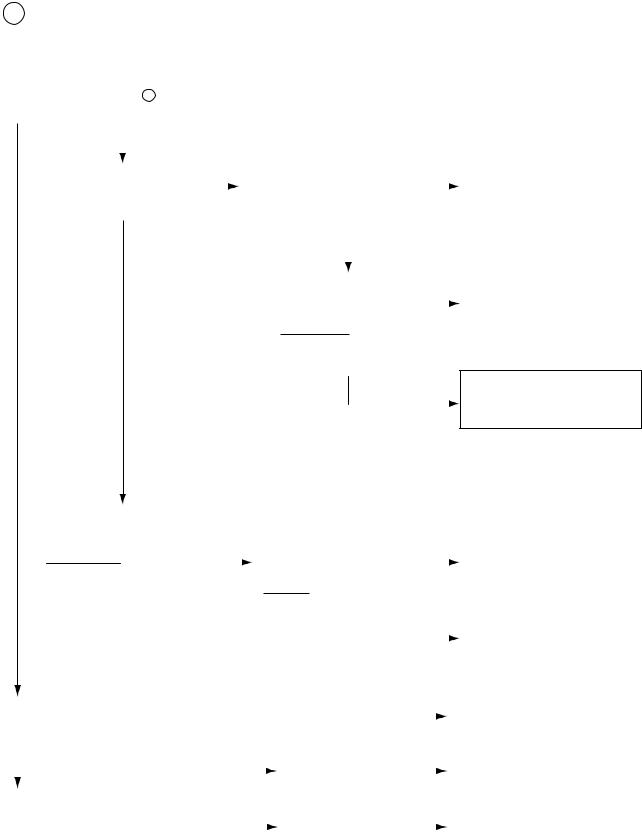

4. TUNER ADJUSTMENT |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Item |

|

|

|

|

Test Point |

|

Adjustment |

|

Adjust for |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

DC Voltage |

|

|

|

Checker Pin TP1, TP2 |

|

|

L106 |

|

0V±50mV |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FM Antenna |

Electronic |

OSCILLOSCOPE |

|

Terminal |

Speake |

Signal Generator |

|

|

Unit |

GND |

|

Figure 4. Tuner(S curve) Adjustment Connection Diagram

- 9 -

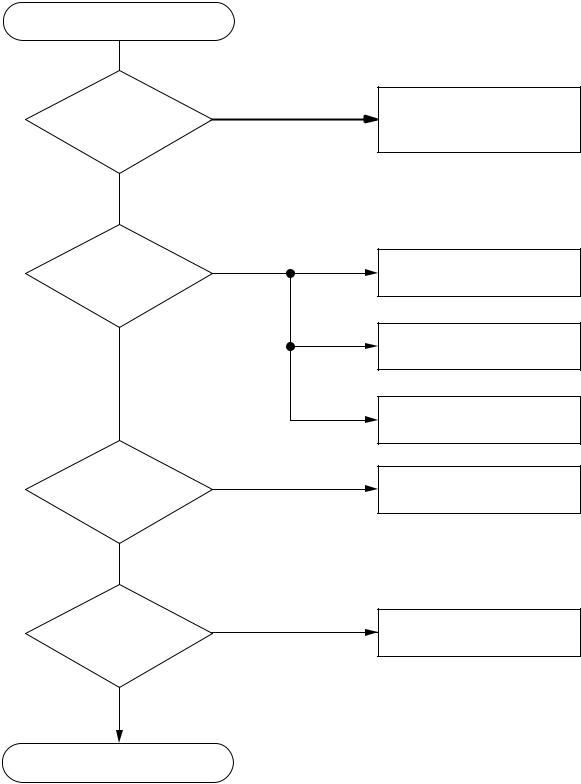

TROUBLESHOOTING

Turn power on.

NO

Is power on?

YES

NO

Does initial read work?

YES

NO

Does it play?

YES

NO

Does it output audio?

YES

OK

Check power supply circuit. (Check PN 701)

Check laser circuit.

Check focus circuit.

Check disc.

Check tracking servo circuit.

Check audio circuit.

- 10 -

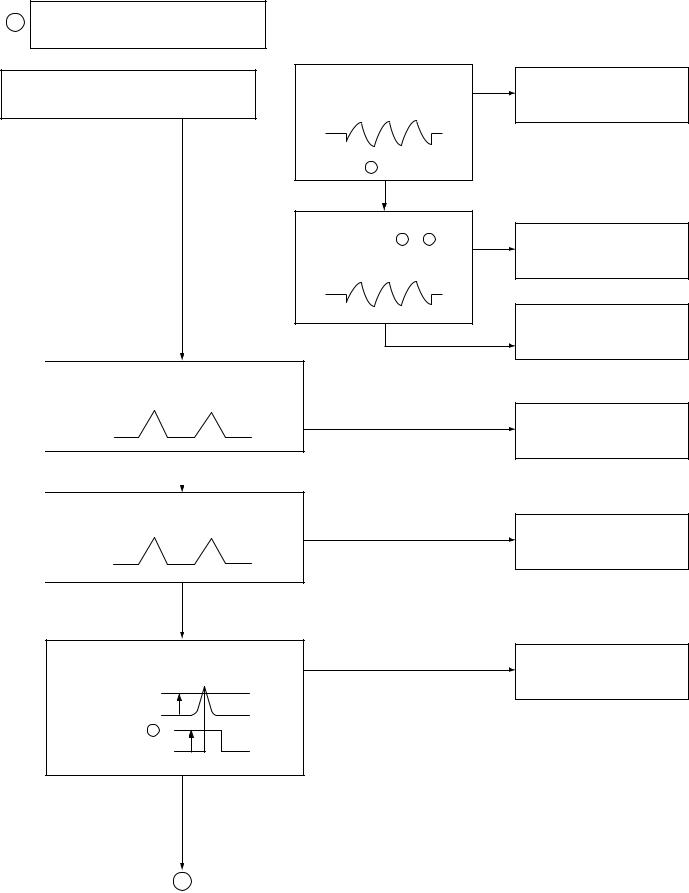

Fails to initial read

|

|

NO |

|

|

|

NO |

|

A |

|

Disc motor turns. |

|

Does laser light? |

|

||||

|

|

|

|

|||||

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

B |

YES |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Does RF |

NO |

Does tracking |

||||||||||||||

waveform |

servo work? |

|||||||||||||||

|

|

|||||||||||||||

appear? |

|

|

Lower envelope |

|||||||||||||

TP 801(RF) |

|

|

of TP801(RF) |

|||||||||||||

|

|

waveform is flat. |

||||||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.3V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Is rotation normal? |

NO |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES

Is there no dropout of RF signal?

YES

NO |

Does signal |

NO |

Does TE2 signal |

|

NO |

|

|

||||||||||||

appear at |

appear at pin 53 |

|

Defective IC |

|

|||||||||||||||

|

TP801(TEO)? |

|

|

of IC801? |

|

|

|

|

|||||||||||

|

|

|

|

|

|

801, pick up |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and/or open |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

wire. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

YES |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Detective pattern. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Does signal appear at IC 803 |

|

|

|

|

|

|

|||||||||||||

NO |

|

Defective IC 801 |

|

||||||||||||||||

Pin 26 and Pin 27 ? |

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

and/or IC 803 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

Defective pick-up |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

and/or connector. |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Does GFS (IC802 pin [) |

NO |

Defective IC 801. |

||||||||||

show as below? |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO

Scratch in disc initial read area.

Defective pick-up adjustment focus offset.

- 11 -

A |

Laser does not light. |

|

|

Is “3.5V” applied to pin 70 of IC 801? |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Did pickup return to |

|

|

Is data transferred from |

|

||||||||

|

|

|

Defective MICOM. |

||||||||||

|

|

|

|

|

|

||||||||

|

|

|

|

||||||||||

|

innermost circular? |

|

|

|

MICOM IC ? |

|

|

||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

YES |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Does voltage appear at IC |

NO |

|

|||||

|

|

|

|

|

|

803 pin , ? |

Defective IC 801, 803 |

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

Defective slide motor and/or |

|

|

connector. |

|

|

|

|

Does it stop at inner pick |

|

|

|

|

Is defect output from LM |

|

|

|

|

|

|

|

|

|||||||||||

|

|

circular after shift? |

|

|

|

|

SW applied to pin of |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

YES |

|

|

PN803? |

|

NO |

|

Defective LMT SW and/or |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connector. |

|

|

|

|

|

|

|

|

|

|

|

OPEN |

CLOSE |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|

|

|

|

|

|

Defective MICOM. |

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NO |

|

|

|

|

|

|

|

|

|||

Is power supplied to laser Q801? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Defective connector. |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

(Q 801 collector: about 1.8V) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

R801 1.0V |

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

Defective Q 801 and/or laser. |

|||||||||

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Does laser current flow? |

|

|

|

|

|

|

|

|

|

|

|

|

YES |

|

|

|

|

|||||||||

|

|

|

|

|

|

R801 1.0V |

|

|

|

Defective laser and/or |

||||||||||||||||

1.0V across R801 |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

connector. |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 12 -

B |

Laser lights. |

NO

Does lens move up/down?

YES

Confirm |

Does TP 801 RF signal appear even in |

|

initial |

low level? |

|

read with |

|

|

disc |

|

|

|

|

|

|

YES |

|

|

|

|

|

Is laser output adjustment correct? |

|

|

||

|

|

|

YES

Does FOK(focus ok) signal appear?

TP801

(RF)

IC801 pin 40 (FOK)

YES

C

Does IC 801 out focus  search signal?

search signal?

IC 801 pin 48 (FEO)

YES

Is focus search signal applied to pin 13 , 16 of CN801?

YES

NO

Defective IC801

NO

Defective IC803

Open activator and/or connector.

NO |

Open connector and/or |

|

defective IC 801. |

NO |

Incorrect turntable height. |

|

Degraded laser diode. |

NO

Defective IC 801.

- 13 -

Loading...

Loading...