Page 1

BA 11.5032−EN

.=<Q

Ä.=<Qä

Operating Instructions

Gearbox

DISCO−Variable speed drive

l

Page 2

Product key

DISCO variable speed drive with rear−mounted gearbox − D −

Lengend for the product key

Gearbox type GST

GKS

GSS

Helical gearbox

Helical−bevel gearbox

Helical−worm gearbox

Gearbox size

Number of stages

Disco variable speed drive

Output design

A

R

Drive size Motor frame size

V

H

S

B

C

K

l

motor design

DISCO size

Solid shaft

Hollow shaft

Hollow shaft with shrink disk

Foot mounting, with centring

Foot mountin, without centring

Without foot, with centring

Without flange

With flange (through holes)

With flange (threaded holes)

2

l

BA 11.5032−EN 3.0

Page 3

DISCO variable speed drive without rear−mounted gearbox 11. 7 0 0 0.

Lengend for the product key

Product group

Product family 1

DISCO size

Free output shaft 1

0

no data

with motor

with free drive shaft

without motor

Standard

BA 11.5032−EN 3.0

l

3

Page 4

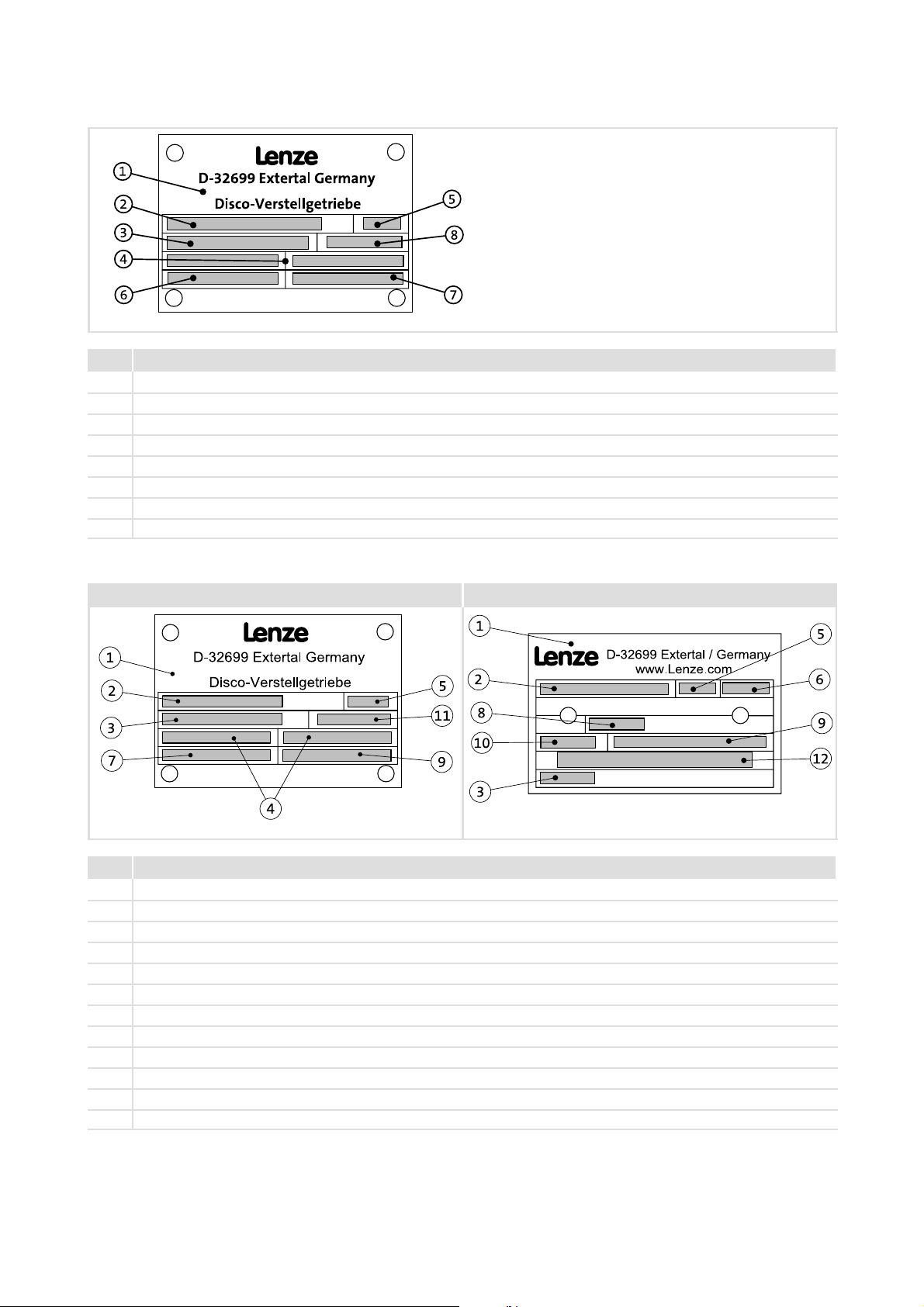

Nameplate

DISCO variable speed drive without rear−mounted gearbox

Pos. Contents

1 Production location / Name of product

2 Gearbox type

3 Order number

4 Rated speed:drive | output

5 Year of manufacture/ week of manufacture

6 Rated torque

7 Material number

8 Power

GT−DISCO−002.iso

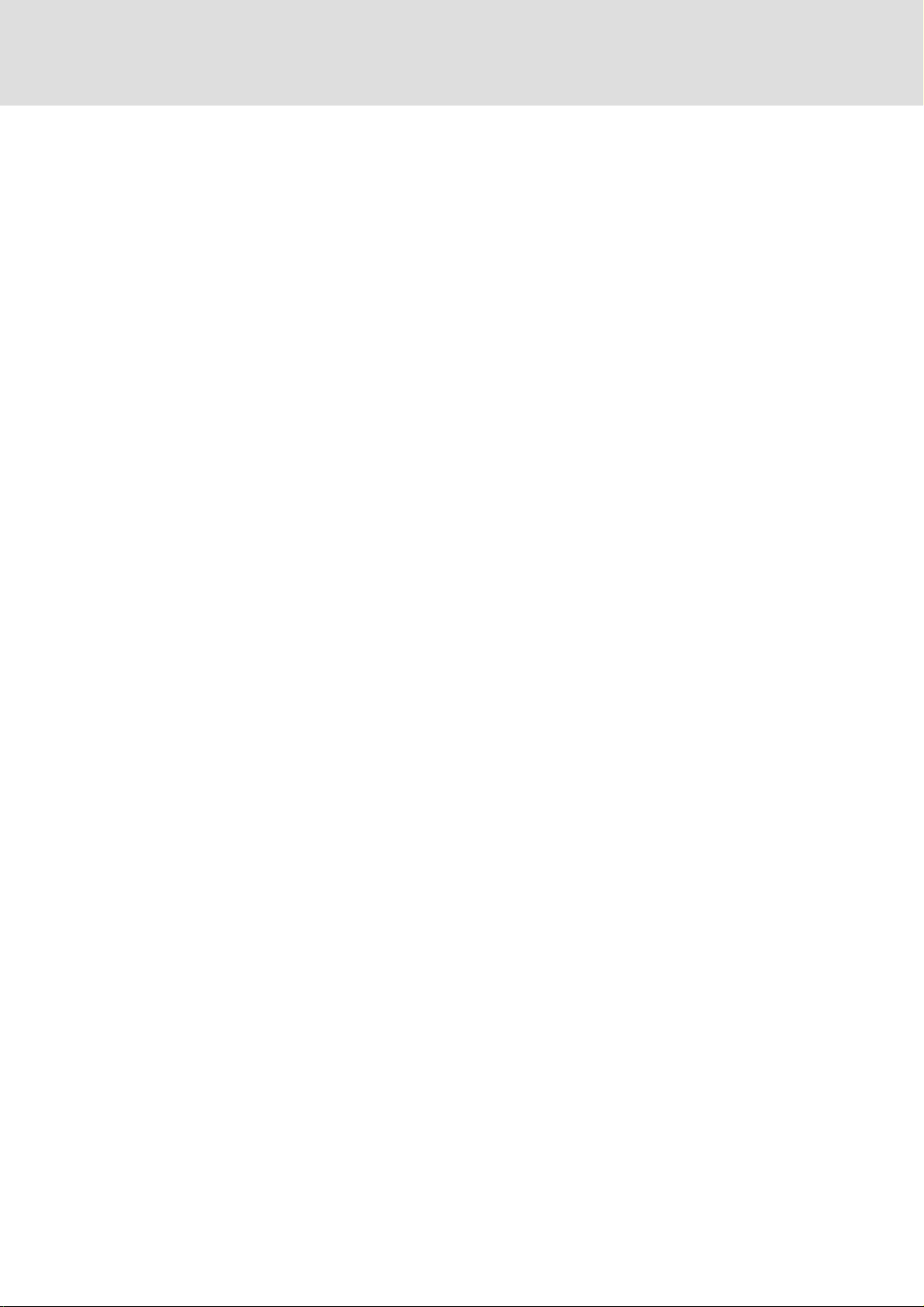

DISCO variable speed drive with rear−mounted gearbox

DISCO nameplate Nameplate of rear−mounted gearbox

GT−DISCO−001.iso GT−DISCO−006.iso

Pos. Contents

1 Production location / Name of product

2 Gearbox type

3 Order number

4 Rated speed:drive | output

5 Year of manufacture/ week of manufacture

6 Mounting position / position of the system modules

7 Rated torque

8 Lubricant

9 Material number / serial number

10 Ratio

11 Power

12 Bar code

4

l

BA 11.5032−EN 3.0

Page 5

Document history

Material number Version Description

410700 1.0 09/1999 TD09 Completely revised

483298 1.1 12/2003 TD09 Revised description of the mounting position and position of the system blocks

13251318 2.0 10/2007 TD09 New nameplate: Compact unit and DISCO version

Table of oil grades and new representation of the positions of ventilation, oil

filler plug and oil drain plug

.=<Q 3.0 12/2008 TD09 New edition due to reorganisation of the company

0Fig. 0Tab. 0

BA 11.5032−EN 3.0

l

5

Page 6

Mounting position (A−F) and position of system modules (1−6)

DISCO variable speed drive with helical gearbox

GST − 1D VDR (foot on variable speed drive)

Terminal box: 2, 3, 4, 5Spindle housing: 2, 3, 4, 5 Handwheel/adjusting device: 2, 3, 4, 5

A B

C D

E F

6

l

BA 11.5032−EN 3.0

Page 7

GST − D

Terminal box: 2, 3, 4, 5Spindle housing: 2, 3, 4, 5 Handwheel/adjusting device: 2, 3, 4, 5

A B

C D

E F

BA 11.5032−EN 3.0

l

7

Page 8

DISCO variable speed drive with helical−bevel gearbox and helical−worm gearbox

GKS − D / GSS − D

Solid shaft: 2, 3, 8 (3+5) Hollow shaft: 0 Hollow shaft with shrink disc: 3, 5

Flange: 2, 3, 8 (3+5) Without flange: 0

Terminal box: 2, 3, 4, 5 Spindle housing: 2, 3, 4, 5 Handwheel/adjusting device: 2, 3, 4, 5

A B

C D

E F

8

l

BA 11.5032−EN 3.0

Page 9

DISCO variable speed drive without rear−mounted gearbox

11.70

Terminal box: 2, 3, 4, 5Handwheel/adjusting device: 2, 3, 4, 5

A B

C D

E F

BA 11.5032−EN 3.0

l

9

Page 10

Contentsi

1 Preface and general information 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About these Operating Instructions 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Terminology used 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Scope of supply 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Lenze drive systems 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Labelling 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Legal regulations 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Personnel responsible for safety 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 General safety information 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Definition of notes used 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Product features 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Transport weights 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Operating conditions 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Temperatures 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Ambient conditions 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Storage 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Installation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Connection of main motor 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical adjusting device 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Operational check 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning and operation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 During operation 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Maintenance 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Oil filling quantities for DISCO gearboxes 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Oil grades for DISCO variable speed drives 25 . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Breather position, oil filling screw and drain plug 26 . . . . . . . . . . . . . . . . . .

7.2 Maintenance intervals 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Maintenance operations 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Replacing the lubricant 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Spare parts list 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Repair 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 10

BA 11.5032−EN 3.0

Page 11

Contents i

8 Troubleshooting and fault elimination 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Disposal 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Appendix 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Spare−parts list 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.1 DISCO variable speed drive size 02 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.2 DISCO variable speed drive size 03 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.3 DISCO variable speed drive size 04−07 34 . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.4 DISCO variable speed drive size 08−18 36 . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1.5 Speed adjustment mechanism, size 02−07 38 . . . . . . . . . . . . . . . . . . . . . . . .

10.1.6 Speed adjustment mechanisms, size 08−18 40 . . . . . . . . . . . . . . . . . . . . . . .

BA 11.5032−EN 3.0

l 11

Page 12

1

Preface and general information

About these Operating Instructions

1 Preface and general information

1.1 About these Operating Instructions

ƒ These Operating Instructions provide information about safety−relevant work on

and with DISCO variable speed drives. They contain safety instructions which must

be observed.

ƒ All personnel working on and with DISCO variable speed drives must have these

Operating Instructions available and observe the information and notes relevant for

them.

ƒ The Operating Instructions must always be in a complete and perfectly readable

state.

1.2 Terminology used

Term In the following text used for

DISCO Disco variable speed drive

Drive system Drive systems with DISCO variable speed drives and other drive

1.3 Scope of supply

ƒ The drive systems are combined individually according to a modular design. The

scope of supply can be obtained from the pertinent papers.

ƒ After receipt of the supply, check immediately whether it corresponds with the

accompanying papers. Lenze does not grant any warranty for subsequent claims.

Claim for

– visible transport damages immediately to the forwarder.

– visible deficiencies / incompleteness immediately to the responsible Lenze

subsidiary / agency.

components

12

l

BA 11.5032−EN 3.0

Page 13

1.4 Lenze drive systems

1.4.1 Labelling

Lenze drive systems are uniquely designated by the content of their nameplates.

Manufacturer

Lenze Drives GmbH

Postfach 10 13 52

D−31763 Hameln

Application as directed

ƒ Lenze drive systems

– are intended for use in machinery and plant,

– must only be used for the purposes ordered and confirmed,

– must only be operated under the ambient conditions prescribed in these

Operating Instructions,

– must not be operated beyond their corresponding power limits.

Preface and general information

Lenze drive systems

Labelling

1

Any other use shall be deemed inappropriate!

1.5 Legal regulations

Liability

ƒ The information, data, and notes in the Operating Instructions were state of the art

at the time of printing. Claims referring to drive systems which have already been

supplied cannot be derived from the information, illustrations, and descriptions.

ƒ We do not accept any liability for damage and operating interference caused by:

– inappropriate use,

– unauthorised modifications to the drive system,

– improper working on and with the drive system,

– operating faults,

– disregarding the Operating Instructions.

Warranty

ƒ Conditions of warranty: see terms of sale and delivery of Lenze Drive Systems

GmbH.

BA 11.5032−EN 3.0

ƒ Warranty claims must be made to Lenze immediately after detecting the deficiency

or fault.

ƒ The warranty is void where liability claims cannot be made.

l

13

Page 14

2

Safety instructions

Personnel responsible for safety

2 Safety instructions

2.1 Personnel responsible for safety

Operator

ƒ An operator is any natural or legal person who uses the drive system or on behalf of

whom the drive system is used.

ƒ The operator or his safety officer must ensure

– that all relevant regulations, instructions and legislation are observed.

– that only qualified personnel work with and on the drive system.

– that the personnel have the Operating Instructions available for all corresponding

operations.

– that non−qualified personnel are prohibited from working with and on the drive

system.

Skilled personnel

Skilled personnel are persons who − because of their education, experience, instructions,

and knowledge about corresponding standards and regulations, rules for the prevention

of accidents, and operating conditions − are authorised by the person responsible for the

safety of the plant to perform the required actions and who are able to recognise potential

hazards.

(See IEC 364, definition of skilled personnel)

2.2 General safety information

ƒ This safety information does not claimed to be complete. In case of questions and

problems, please contact your Lenze representative.

ƒ At the time of delivery the drive system meets the state of the art and ensures safe

basic operation.

ƒ The drive system is a source of danger for persons, for the drive system itself, and for

other material assets of the operator, if

– unqualified personnel works with and on the drive system,

– the drive system is used inappropriately.

14

ƒ The drive systems must be designed such that they perform their functions after

proper installation and with application as directed in fault−free operation and that

they do not cause hazards for persons. This also applies for their interaction with the

complete plant.

ƒ Be sure to take appropriate measures in the case of drive system failure so that no

material damage occurs.

ƒ Operate the drive system only when it is in a proper state.

ƒ Retrofittings, modifications, or redesigns of the drive system are basically

prohibited. Lenze must be contacted in all cases.

l

BA 11.5032−EN 3.0

Page 15

Safety instructions

Definition of notes used

2

2.3 Definition of notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property damage

if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

BA 11.5032−EN 3.0

l

15

Page 16

3

Technical data

Product features

3 Technical data

ƒ The most important technical data are provided on the nameplate (layout and

contents ^ page 4).

ƒ The product catalogues contain further technical data.

3.1 Product features

GT−DISCO−005.iso

Fig. 1 Layout of the DISCO variable speed drive

1 Pinion shaft 8 Clutch thrust collar

2 Left inner sun 9 Clutch collar

3 Right inner sun 10 Ball retainer ring

4 Disk spring 11 Pinion cage

5 Planet 13 Spindle

6 Slide block 14 Guide part

7 Thrust collar 15 Ball headed pin

The DISCO variable speed drive is a planetary gearbox, where all the functional parts run

in an oil bath. The planets, located in the pinion cage, rotate around the driving inner

sun. The speed and the force flow are transmitted from the drive shaft to the inner sun.

The flat, double−coned planets are driven by the inner sun, simultaneously rolling along

the outer rings which are fixed in the housing. So the planets don’t only rotate about

their own axes but also about the inner sun. They thus move the pinion cage with them,

which has a fixed connection with the output shaft.

The speed setting is altered by means of an adjustment spindle through rotating one of the

three outer rings on the housing. This moves the planets to a different radius of rotation,

depending on the size of the air gap between the outer rings. In this way, steplessly

adjustable output speeds are achieved. Supplementary gearboxes, in the form of single or

16

l

BA 11.5032−EN 3.0

Page 17

Technical data

Product features

multi−stage helical, conical or worm gearboxes, can be used to adjust output speed to the

requirements of the application.

( Stop!

The DISCO must only be changed to a fasterspeed while it is running!

Otherwise, the DISCO could be damaged!

Changing to a slowerspeed is allowed while the DISCO is standing still.

3

BA 11.5032−EN 3.0

l

17

Page 18

3

Technical data

Transport weights

3.2 Transport weights

DISCO with GST helical gearbox

Gearbox size

071−1 02 071−3 03 080−3 04 090−3 05 100−32 06 112−22 07 132−12 18 132−22 08

GST 04 < 18

GST 05 < 25 < 32 < 43

GST 06 < 36 < 40 < 51 < 67

GST 07 < 56 < 64 < 75 < 83 < 120 < 130

GST 09 < 99 < 110 < 127 < 150 < 161 < 223 < 230

GST 11 < 168 < 185 < 221 < 232 < 272 < 279

GST 14 < 296 < 333 < 343 < 406 < 413

Drive size

DISCO with GKS helical−bevel gearbox

Gearbox size

071−1 02 071−3 03 080−3 04 090−3 05 100−32 06 112−22 07 132−12 18 132−22 08

GKS 04 < 28

GKS 05 < 41 < 49 < 59

GKS 06 < 64 < 69 < 79 < 96

GKS 07 < 104 < 113 < 123 < 131 < 168 < 178

GKS 09 < 191 < 202 < 218 < 242 < 252 < 315 < 322

GKS 11 < 329 < 346 < 382 < 392 < 433 < 440

GKS 14 < 574 < 607 < 621 < 684 < 709

Drive size

DISCO with GSS helical−worm gearbox

Gearbox size

071−1 02 071−3 03 080−3 04 090−3 05 100−32 06 112−22 07

GSS 04 < 28

GSS 05 < 41 < 48 < 59

GSS 06 < 62 < 56 < 77 < 94

GSS 07 < 101 < 109 < 120 < 128 < 165 < 175

Drive size

DISCO type 11.700 / 11.710

DISCO

size

02 < 10 < 5

03 < 19 < 13

04 < 27 < 28 < 21

05 < 42 < 45 < 35

06 < 74 < 78 < 58

07 < 89 < 58

09 < 151 < 88

11 < 158 < 85

071−1 071−3 080−1 080−3 090−1 090−3 100−1 100−3 112−22 132−12 132−22

Weight in [kg] with oil filling, for mounting position A, all values are aproximate

Type 11.700 with motor size

Type

11.700

18

l

BA 11.5032−EN 3.0

Page 19

3.3 Operating conditions

3.3.1 Temperatures

ƒ DISCO: permissible ambient temperature −15 bis +40°C

ƒ Rear−mounted gearbox (see Operating Instructions for the gearbox)

ƒ Motor (see temperature class for the motor)

The operating temperature is determined by the power loss, the ambient temperature and

the cooling system!

3.3.2 Ambient conditions

ƒ DISCO variable speed drives are dust and hose−proof.

ƒ Motors corresponding to their degree of protection (s. nameplate and/or operating

instructions of the motor).

Technical data

Operating conditions

Temperatures

3

ƒ Ambient media − especially chemically aggressive − can damage shaft sealing rings

and lacquers (plastics in general). Abrasive media may damage the shaft sealing

rings.

BA 11.5032−EN 3.0

l

19

Page 20

4

Mechanical installation

Storage

4 Mechanical installation

} Danger!

Only transport the drive with transport equipment or hoists which are suitable

for this load (see transport weights, chapter 3.2). Ensure a safe fixing. Avoid

shocks!

The motors attached to the gearbox are partially equipped with eyebolts.

These are exclusively determined for motor/gearbox mounting and

dismounting and must not be used for the complete geared motor!

4.1 Storage

If you do not install the DISCO at once, please ensure proper storage conditions.

ƒ Up to one year:

– Without special measures in dry, dust−free enclosed rooms without direct sunlight.

– Store DISCO with ventilation in a manner that the breather screw is at the top.

– Shafts and bright surfaces are delivered with protection against corrosion.

ƒ Over one year:

– Please consult the factory.

4.2 Installation

Mount the drive systems on an even surface, free from distortion. If they are mounted on

a baseplate, then the baseplate must also be mounted without distortion. If this is not

done, then stresses appear in the gearbox housing and have a bad effect on the parallel

alignment of the shafts and thus on the bearing and tooth alignment.

The output shaft of the drive system must be well aligned with the machine shaft that is

to be driven. Small inaccuracies can be compensated by using a flexible coupling.

Couplings, gear wheels, sprockets etc. must only be fixed by screwing to the shaft ends of

the drive system. Driving them on can damage the ball bearings.

20

l

BA 11.5032−EN 3.0

Page 21

5 Electrical installation

{ Danger!

Electrical connections must only be carried out by skilled personnel!

{ Danger!

Always earth the drive!

If it is not possible to earth it via attached items (e.g. the motor) then the

gearbox must be earthed!

5.1 Connection of main motor

Electrical installation

Electrical adjusting device

5

To connect the motor correctly, you must follow:

ƒ the notes in the terminal box of the motor

ƒ the notes in the operating instructions of the motor

ƒ the technical data on the motor nameplate.

5.2 Electrical adjusting device

( Stop!

The DISCO must only be changed to a fasterspeed while it is running!

Otherwise, the DISCO could be damaged!

Changing to a slowerspeed is allowed while the DISCO is standing still.

1. Connect the electrical adjustment device as shown in the circuit diagram (Fig. 2).

Ensure the right polarity of the adjustment motor!

2. It is vital to carry out a functional check in order to avoid damages to the DISCO.

– Check the positions of the adjustment motor and the limit−switch box, see page 6

Position of system blocks".

5.2.1 Operational check

Adjustment motor in position 5 / limit−switch box in position 3

1. Switch on the DISCO.

2. Increase the speed: counter−clockwise rotation of the actuator in the limit−switch

housing.

3. While the speed is increased activate the limit−switch S4 with an insulated

screwdriver.

BA 11.5032−EN 3.0

l

21

Page 22

5

Electrical installation

Electrical adjusting device

Operational check

4. The adjustment motor and actuator must stop.

5. If the actuator and adjustment motor do not stop, reverse the polarity of the

adjustment motor.

Adjustment motor in position 3 / limit−switch box in position 5

1. Switch on the DISCO.

2. Increase the speed: clockwise rotation of the actuator in the limit−switch housing.

3. While the speed is increased, activate the limit−switch S3 with an insulated

screwdriver.

4. The adjustment motor and actuator must stop.

5. If the actuator and adjustment motor do not stop, reverse the polarity of the

adjustment motor.

Adjustment motor in position 5 / limit−switch in position 3 Adjustment motor in position 3 / limit−switch in position 5

22

GT−DISCO−003.iso GT−DISCO−004.iso

Fig. 2 Circuit plan of the servo adjustment mechanism with potentiometer indicator

0 Driving motor 3 Actuator (the long lever activates S3)

1 Adjustable 4 Long lever

2 Auxiliary supply L1, N=230 V~ 5 Short lever

A1 Indicator 0...100V =/ 1000 W/V

(option)

F1, F2, F3 Fuses* Q2 Motor protection switch*

K1, K2 Reversing contactors* S1, S2 Pushbutton switches*

M1 Adjustment motor S3, S4 Limit switches

* not included in the scope of supply

Q1 Main switch*

l

BA 11.5032−EN 3.0

Page 23

Commissioning and operation

6 Commissioning and operation

( Stop!

Commissioning of the drive only by qualified staff!

6.1 Before switching on

Check:

ƒ Is the mechanical fixing o.k.?

ƒ Are the electrical connections o.k.?

ƒ Are all rotating parts and surfaces that may become hot protected against contact?

ƒ For gearboxes with breathing:

– Is the plug removed from the breather screw?

6

Before switching on

) Note!

Rear−mounted gearboxes must have separate ventilation, ^ Operating

Instruction of the gearbox!

6.2 During operation

( Stop!

During running−in, raised temperatures may occur over a period of 2 − 8 hours.

ƒ During operation, check the drive periodically and take special care of:

– unusual noises or temperatures,

– leakages,

– loose fixing elements,

– the condition of the electrical cables.

ƒ If any interference should occur, proceed according to the troubleshooting list in

chapter 8. If the interference cannot be eliminated, please contact the Lenze Service.

BA 11.5032−EN 3.0

l

23

Page 24

7

Maintenance

Oil filling quantities for DISCO gearboxes

7 Maintenance

The DISCO drives are supplied with oil filling.

) Note!

ƒ Lubricating instructions for rear−mounted gearboxes, see Operating

Instructions of the gearbox.

ƒ We recommend to check the oil level regularly!

ƒ If you use an oil not listed in Tab. 2, we recommend lubricants with the

following technical values:

– Viscosity: 32mm

– Flash point: ~ 210°C

– Pourpoint: ~ −30°C

– FZG test A8.3/90: damage force stage ³10

– Air release property: 5min. at 50°C

– Foam volume after air inlet at 25/95/25°C: 230/10/290 ml

2

/s ±10% at 40°C

7.1 Oil filling quantities for DISCO gearboxes

DISCO size

horizontal vertical

Spindle housing Output shaft

above side below below above

size 02

02 0,4 0,3 0,4 0,4 0,4

03 0,4 0,5 0,8 0,6 0,6

04 0,5 0,5 1,0 1,0 1,0

05 0,7 1,0 2,0 2,0 1,5

06/07 1,5 2,0 3,0 3,5 2,5

08 2,5 4,0 3,5 6,0 5,0

09 3,0 6,0 4,5 9,5 7,0

10/11 6,0 10,0 4,5 14,0 11,0

Tab. 1 Oil quantities − guide values

Mounting positions

size 02

size 03

sizes 03/04 K

sizes

02/03

GT−DISCO−008.iso

24

Oil sight glass Oil drain plug

K

Oil control plug Ventilation

Oil filler plug

l

BA 11.5032−EN 3.0

Page 25

Oil filling quantities for DISCO gearboxes

Oil grades for DISCO variable speed drives

7.1.1 Oil grades for DISCO variable speed drives

Maintenance

7

Manufacturer

Shell

Oil types

DISCO lifetime oil

Shell Tegula V 32

Astron HLP 32 / Pentran 32

LAMORA HLP 32

RENOLIN MR 10 VG 32 / RENOFLUID TF 1500

Degol GB 32

OSO 32 / BLASIA 32

Energol HL−XP 32 / Energol HLP−HM 32

Hyspin AWS 32 / Hyspin SP 32

TORQUE FLUID N 45

Wiolan HF 32

Rando Oil HD A−32

Tab. 2 Recommended oil grades for DISCO variable speed drives

BA 11.5032−EN 3.0

l

25

Page 26

7

Maintenance

Oil filling quantities for DISCO gearboxes

Breather position, oil filling screw and drain plug

7.1.2 Breather position, oil filling screw and drain plug

GT−DISCO−007.cdr

Oil filling for gearboxes without ventilation Ventilation / oil filler plug

Oil drain plug Oil control plug

1) Facing the housing

2) In case of a position of the handle different from the shown one, the positions are facing the housing respectively

26

l

BA 11.5032−EN 3.0

Page 27

7.2 Maintenance intervals

ƒ The mechanical power transmission system is maintenance−free.

ƒ No oil change when DISCO lifetime oil is used.

If other oils are used, an oil change is necessary after every 2000 hours of operation.

ƒ Shaft seal rings:

– The operating life depends on the conditions of use.

– Replace leaking shaft seals to prevent further damage.

( Stop!

For drive systems: Also observe the maintenance intervals for the other drive

components!

7.3 Maintenance operations

Maintenance

Maintenance intervals

7

7.3.1 Replacing the lubricant

ƒ DISCO should be warm.

ƒ Secure the drive system and machinery against unintended movement or mains

power−up.

( Stop!

Rear−mounted gearboxes have separate lubrication; see the Operating

Instructions for gearboxes!

1. Drain lubricant through the outlet (^ Abb. in Tab. 1).

2. Insert oil drain plug with new seal.

3. Fill in lubricant through the inlet.

4. Fit the oil filler plug.

5. Dispose of the used oil according to current regulations.

7.3.2 Spare parts list

You find the spare parts list in the10appendix

7.4 Repair

Lenze recommends that repairs are carried out by the Lenze Service.

BA 11.5032−EN 3.0

l

27

Page 28

Troubleshooting and fault elimination8

8 Troubleshooting and fault elimination

Fault Possible cause Remedy

Drive does not start

Motor runs, gearbox does not

Unusual running noise

Excessive temperature

Loose fixing elements Vibrations Avoid vibrations

Voltage supply interrupted

Faulty electrical connection Check that supply voltage matches

Excessive load Reduce load

Coupling components are missing or

defective

Gearbox is defective Inform Lenze Service

Overload Reduce load

Damage to the gearbox or motor Inform Lenze Service

Overload Reduce load

Inadequate heat dissipation Improve cooling air flow

Lack of lubricant Top up lubricant according to regulations

Check connection

nameplate data

Check drive−machine assignment

Check mounting

Check drive−machine assignment

Check drive−machine assignment

Clean gearbox/motor

28

l

BA 11.5032−EN 3.0

Page 29

9 Disposal

Protect the environment! Valuable materials can be recycled.

What? Where?

Transport material Pallets Return to the manufacturer or

Lubricants Oil, grease Dispose according to current

Components Housing:

Disposal 9

forwarder

Packaging material Cardboard box to waste paper

Plastics to plastics recycling or

residual waste

Reuse or dispose of wood wool

regulations

Bearings, shafts, gear wheels:

Seals:

Cast iron

Steel

Hazardous waste

Separate different types of

material and dispose

BA 11.5032−EN 3.0

l

29

Page 30

10

Appendix

Spare−parts list

DISCO variable speed drive size 02

10 Appendix

10.1 Spare−parts list

10.1.1 DISCO variable speed drive size 02

4401

4420

4410

201

4421

220

221

1.07

1.03

4471

1.08

4424

4423

4425

30

l

BA 11.5032−EN 3.0

Page 31

Appendix 10

Pos. Name

0.25 Seal

0.26 Seal

0.28 Hexagon head cap screw

0.29

Locking washer for sizes 02−03

Spring washer for sizes 04−07

0.30 Cheese head screw

0.31 Spring washer

0.40 Oil sight glass

0.41 Locking screw

0.42 Angled breather tube

2.01 Cover

2.02 Shaft

2.04 Housing

2.05 Flange

2.06 Fan cover

2.07 Socket

2.08 Three−phase AC motor

2.09 Fan

2.10 Starting coupling

2.11 Flexible coupling

2.15 Deep−groove ball bearing

2.16 Deep−groove ball bearing

2.17 Inner ring

2.18 Shaft sealing ring

2.19 Circlip

2.20 Circlip

2.21 Circlip

2.22 Featherkey

2.23 Featherkey

2.24 Featherkey

2.25 Shim ring

2.27 Seal

2.28 Set screw

2.29 Set screw

2.30 Hexagon head cap screw

2.31

Locking washer for sizes 02−03

Spring washer for sizes 04−07

2.32 Cheese head screw

2.33 Seal

2.34 Cheese head screw

2.35 Spring washer

2.36 Hexagon head cap screw

2.37 Hexagon nut

2.38 Spring washer

3.01 Cover

3.03 Flange

3.05 Shaft

3.08 Hub

3.09 Pinion cage

3.10 Slide block

3.11 Socket

3.12 Washer

3.14 Clutch collar

3.15 Ball retainer ring

3.16 Clutch thrust collar

3.17 Flange

Pos. Name

3.19 Socket

3.26 Socket

3.27 Pressure spring

3.28 Deep−groove ball bearing

3.29 Deep−groove ball bearing

3.32 Deep−groove ball bearing

3.36 Shaft sealing ring

3.38 Circlip

3.39 Circlip

3.40 Circlip

3.41 Circlip

3.51 Circlip

3.52 Dowel pin

3.53 Hexagon head cap screw

3.56 Dowel pin

3.57 Dowel pin

3.58 Dowel pin

3.59 Cheese head screw

3.60 Spring washer

3.62 Cheese head screw

3.73 Set screw

3.76 Featherkey

3.78 Circlip

3.80 Seal

4.00 Spindle housing assembly

4.01 Spindle housing

4.02 Housing

4.03 Spindle

4.04 Guide part

4.05 Shaft

4.06 Ball headed pin

4.08 Socket

4.09 Adapter

4.10 Small worm−geared motor

4.12 Handwheel

4.13 Rotation−direction indicator

4.14 Setting indicator

4.15 Bevel

4.16 Bevel

4.17 Worm

4.20 Deep−groove ball bearing

4.21 Socket

4.22 Flange sleeve

4.23 Shaft sealing ring

4.24 Shaft sealing ring

4.25 Seal

4.26 Seal

4.27 Sealing ring

4.28 Circlip

4.29 Locking ring

4.31 Shim ring

4.32 Seeger ring

4.33 Dowel pin

4.34 Dowel pin

4.35 Dowel pin

4.36 Dowel pin

Pos. Name

4.37 Dowel pin

4.38 Dowel pin

4.39 Set screw

4.40 Set screw

4.41 Set screw

4.42 Conical plug

4.43 Protection cover

4.44

Hexagon head cap screw

Cheese head screw

4.45

Hexagon head cap screw

Cheese head screw

4.46 Spring washer

4.47 Cheese head screw

4.48 Circlip

4.51 Cover

4.52 Cheese head screw

4.53 Spring washer

4.55 Hub

4.56 Bell housing

4.57 Handle

4.58 Hexagon head cap screw

6.00 Inner sun assembly

6.01 Left inner sun

6.02 Right inner sun

6.03 Planet

6.04 Pressure disc

6.05 Disk spring

6.06 Circlip

201 Pinion

220 O−ring

221 Hexagon head cap screw

4401 Flange

4410 Shaft

4420 Deep−groove ball bearing

4421 Shaft sealing ring

4422 Circlip

4423 Deep−groove ball bearing

4424 Adapter disc

4425 Circlip

4471 Hexagon head cap screw

BA 11.5032−EN 3.0

l

31

Page 32

10

Appendix

DISCO variable speed drive size 03

10.1.2 DISCO variable speed drive size 03

4401

4410

201

4420

4421

220

221

4471

1.08

4422

4423

4425

32

l

BA 11.5032−EN 3.0

Page 33

Appendix 10

Pos. Name

0.25 Seal

0.26 Seal

0.28 Hexagon head cap screw

0.29

Locking washer for sizes 02−03

Spring washer for sizes 04−07

0.30 Cheese head screw

0.31 Spring washer

0.40 Oil sight glass

0.41 Locking screw

0.42 Angled breather tube

1.01 Housing

1.02 Thrust collar

1.03 Foot

1.04 Set screw

1.05 Seal−Lock hexagon nut

1.06 Dowel pin

1.07 Cheese head screw

1.08 Oil sight glass

2.01 Cover

2.02 Shaft

2.04 Housing

2.05 Flange

2.06 Fan cover

2.07 Socket

2.08 Three−phase AC motor

2.09 Fan

2.10 Starting coupling

2.11 Flexible coupling

2.15 Deep−groove ball bearing

2.16 Deep−groove ball bearing

2.17 Inner ring

2.18 Shaft sealing ring

2.19 Circlip

2.20 Circlip

2.21 Circlip

2.22 Featherkey

2.23 Featherkey

2.24 Featherkey

2.25 Shim ring

2.27 Seal

2.28 Set screw

2.29 Set screw

2.30 Hexagon head cap screw

2.31

Locking washer for sizes 02−03

Spring washer for sizes 04−07

2.32 Cheese head screw

2.33 Seal

2.34 Cheese head screw

2.35 Spring washer

2.36 Hexagon head cap screw

2.37 Hexagon nut

2.38 Spring washer

3.01 Cover

3.03 Flange

3.05 Shaft

3.08 Hub

Pos. Name

3.09 Pinion cage

3.10 Slide block

3.11 Socket

3.12 Washer

3.14 Clutch collar

3.15 Ball retainer ring

3.16 Clutch thrust collar

3.17 Flange

3.19 Socket

3.26 Socket

3.27 Pressure spring

3.28 Deep−groove ball bearing

3.29 Deep−groove ball bearing

3.32 Deep−groove ball bearing

3.36 Shaft sealing ring

3.38 Circlip

3.39 Circlip

3.40 Circlip

3.41 Circlip

3.51 Circlip

3.52 Dowel pin

3.53 Hexagon head cap screw

3.56 Dowel pin

3.57 Dowel pin

3.58 Dowel pin

3.59 Cheese head screw

3.60 Spring washer

3.62 Cheese head screw

3.73 Set screw

3.76 Featherkey

3.78 Circlip

3.80 Seal

4.00 Spindle housing assembly

4.01 Spindle housing

4.02 Housing

4.03 Spindle

4.04 Guide part

4.05 Shaft

4.06 Ball headed pin

4.08 Socket

4.09 Adapter

4.10 Small worm−geared motor

4.12 Handwheel

4.13 Rotation−direction indicator

4.14 Setting indicator

4.15 Bevel

4.16 Bevel

4.17 Worm

4.20 Deep−groove ball bearing

4.21 Socket

4.22 Flange sleeve

4.23 Shaft sealing ring

4.24 Shaft sealing ring

4.25 Seal

4.26 Seal

4.27 Sealing ring

Pos. Name

4.28 Circlip

4.29 Locking ring

4.31 Shim ring

4.32 Seeger ring

4.33 Dowel pin

4.34 Dowel pin

4.35 Dowel pin

4.36 Dowel pin

4.37 Dowel pin

4.38 Dowel pin

4.39 Set screw

4.40 Set screw

4.41 Set screw

4.42 Conical plug

4.43 Protection cover

4.44

Hexagon head cap screw

Cheese head screw

4.45

Hexagon head cap screw

Cheese head screw

4.46 Spring washer

4.47 Cheese head screw

4.48 Circlip

4.51 Cover

4.52 Cheese head screw

4.53 Spring washer

4.55 Hub

4.56 Bell housing

4.57 Handle

4.58 Hexagon head cap screw

201 Pinion

220 O−ring

221 Hexagon head cap screw

4401 Flange

4410 Shaft

4420 Deep−groove ball bearing

4421 Shaft sealing ring

4422 Circlip

4423 Deep−groove ball bearing

4424 Adapter disc

4425 Circlip

4471 Hexagon head cap screw

BA 11.5032−EN 3.0

l

33

Page 34

10

10.1.3 DISCO variable speed drive size 04−07

Appendix

DISCO variable speed drive size 04−07

4401

4421

4410

201

4420

220

221

4471

1.08

4425 4423 4422

34

l

BA 11.5032−EN 3.0

Page 35

Appendix 10

Pos. Name

0.25 Seal

0.26 Seal

0.28 Hexagon head cap screw

0.29

Locking washer for sizes 02−03

Spring washer for sizes 04−07

0.30 Cheese head screw

0.31 Spring washer

0.40 Oil sight glass

0.41 Locking screw

0.42 Angled breather tube

1.01 Housing

1.02 Thrust collar

1.03 Foot

1.04 Set screw

1.05 Seal−Lock hexagon nut

1.06 Dowel pin

1.07 Cheese head screw

1.08 Oil sight glass

2.01 Cover

2.02 Shaft

2.04 Housing

2.05 Flange

2.06 Fan cover

2.07 Socket

2.08 Three−phase AC motor

2.09 Fan

2.10 Starting coupling

2.11 Flexible coupling

2.15 Deep−groove ball bearing

2.16 Deep−groove ball bearing

2.17 Inner ring

2.18 Shaft sealing ring

2.19 Circlip

2.20 Circlip

2.21 Circlip

2.22 Featherkey

2.23 Featherkey

2.24 Featherkey

2.25 Shim ring

2.27 Seal

2.28 Set screw

2.29 Set screw

2.30 Hexagon head cap screw

2.31

Locking washer for sizes 02−03

Spring washer for sizes 04−07

2.32 Cheese head screw

2.33 Seal

2.34 Cheese head screw

2.35 Spring washer

2.36 Hexagon head cap screw

2.37 Hexagon nut

2.38 Spring washer

3.01 Cover

3.03 Flange

3.05 Shaft

3.08 Hub

Pos. Name

3.09 Pinion cage

3.10 Slide block

3.11 Socket

3.12 Washer

3.14 Clutch collar

3.15 Ball retainer ring

3.16 Clutch thrust collar

3.17 Flange

3.19 Socket

3.26 Socket

3.27 Pressure spring

3.28 Deep−groove ball bearing

3.29 Deep−groove ball bearing

3.32 Deep−groove ball bearing

3.36 Shaft sealing ring

3.38 Circlip

3.39 Circlip

3.40 Circlip

3.41 Circlip

3.51 Circlip

3.52 Dowel pin

3.53 Hexagon head cap screw

3.56 Dowel pin

3.57 Dowel pin

3.58 Dowel pin

3.59 Cheese head screw

3.60 Spring washer

3.62 Cheese head screw

3.73 Set screw

3.76 Featherkey

3.78 Circlip

3.80 Seal

4.00 Spindle housing assembly

4.01 Spindle housing

4.02 Housing

4.03 Spindle

4.04 Guide part

4.05 Shaft

4.06 Ball headed pin

4.08 Socket

4.09 Adapter

4.10 Small worm−geared motor

4.12 Handwheel

4.13 Rotation−direction indicator

4.14 Setting indicator

4.15 Bevel

4.16 Bevel

4.17 Worm

4.20 Deep−groove ball bearing

4.21 Socket

4.22 Flange sleeve

4.23 Shaft sealing ring

4.24 Shaft sealing ring

4.25 Seal

4.26 Seal

4.27 Sealing ring

Pos. Name

4.28 Circlip

4.29 Locking ring

4.31 Shim ring

4.32 Seeger ring

4.33 Dowel pin

4.34 Dowel pin

4.35 Dowel pin

4.36 Dowel pin

4.37 Dowel pin

4.38 Dowel pin

4.39 Set screw

4.40 Set screw

4.41 Set screw

4.42 Conical plug

4.43 Protection cover

4.44

Hexagon head cap screw

Cheese head screw

4.45

Hexagon head cap screw

Cheese head screw

4.46 Spring washer

4.47 Cheese head screw

4.48 Circlip

4.51 Cover

4.52 Cheese head screw

4.53 Spring washer

4.55 Hub

4.56 Bell housing

4.57 Handle

4.58 Hexagon head cap screw

6.00 Inner sun assembly

6.01 Left inner sun

6.02 Right inner sun

6.03 Planet

6.04 Pressure disc

6.05 Disk spring

6.06 Circlip

201 Pinion

220 O−ring

221 Hexagon head cap screw

4401 Flange

4410 Shaft

4420 Deep−groove ball bearing

4421 Shaft sealing ring

4422 Circlip

4423 Deep−groove ball bearing

4424 Adapter disc

4425 Circlip

4471 Hexagon head cap screw

BA 11.5032−EN 3.0

l

35

Page 36

10

Appendix

DISCO variable speed drive size 08−18

10.1.4 DISCO variable speed drive size 08−18

4401 4471

4421

4410

201

4420

220

221

4422 4423

4424

1.08

4425

36

l

BA 11.5032−EN 3.0

Page 37

Appendix 10

Pos. Name

0.25 Seal

0.26 Seal

0.28 Hexagon head cap screw

0.29

Locking washer for sizes 02−03

Spring washer for sizes 04−07

0.30 Cheese head screw

0.31 Spring washer

0.40 Oil sight glass

0.41 Locking screw

0.42 Angled breather tube

1.01 Housing

1.02 Thrust collar

1.03 Foot

1.04 Set screw

1.05 Seal−Lock hexagon nut

1.06 Dowel pin

1.07 Cheese head screw

1.08 Oil sight glass

2.01 Cover

2.02 Shaft

2.04 Housing

2.05 Flange

2.06 Fan cover

2.07 Socket

2.08 Three−phase AC motor

2.09 Fan

2.10 Starting coupling

2.11 Flexible coupling

2.15 Deep−groove ball bearing

2.16 Deep−groove ball bearing

2.17 Inner ring

2.18 Shaft sealing ring

2.19 Circlip

2.20 Circlip

2.21 Circlip

2.22 Featherkey

2.23 Featherkey

2.24 Featherkey

2.25 Shim ring

2.27 Seal

2.28 Set screw

2.29 Set screw

2.30 Hexagon head cap screw

2.31

Locking washer for sizes 02−03

Spring washer for sizes 04−07

2.32 Cheese head screw

2.33 Seal

2.34 Cheese head screw

2.35 Spring washer

2.36 Hexagon head cap screw

2.37 Hexagon nut

2.38 Spring washer

Pos. Name

3.01 Cover

3.03 Flange

3.05 Shaft

3.08 Hub

3.09 Pinion cage

3.10 Slide block

3.11 Socket

3.12 Washer

3.14 Clutch collar

3.15 Ball retainer ring

3.16 Clutch thrust collar

3.17 Flange

3.19 Socket

3.26 Socket

3.27 Pressure spring

3.28 Deep−groove ball bearing

3.29 Deep−groove ball bearing

3.32 Deep−groove ball bearing

3.36 Shaft sealing ring

3.38 Circlip

3.39 Circlip

3.40 Circlip

3.41 Circlip

3.51 Circlip

3.52 Dowel pin

3.53 Hexagon head cap screw

3.56 Dowel pin

3.57 Dowel pin

3.58 Dowel pin

3.59 Cheese head screw

3.60 Spring washer

3.62 Cheese head screw

3.73 Set screw

3.76 Featherkey

3.78 Circlip

3.80 Seal

6.00 Inner sun assembly

6.01 Left inner sun

6.02 Right inner sun

6.03 Planet

6.04 Pressure disc

6.05 Disk spring

6.06 Circlip

201 Pinion

220 O−ring

221 Hexagon head cap screw

Pos. Name

4401 Flange

4410 Shaft

4420 Deep−groove ball bearing

4421 Shaft sealing ring

4422 Circlip

4423 Deep−groove ball bearing

4424 Adapter disc

4425 Circlip

4471 Hexagon head cap screw

BA 11.5032−EN 3.0

l

37

Page 38

10

10.1.5 Speed adjustment mechanism, size 02−07

Appendix

Speed adjustment mechanism, size 02−07

38

l

BA 11.5032−EN 3.0

Page 39

Appendix 10

Pos. Name

4.00 Spindle housing assembly

4.01 Spindle housing

4.02 Housing

4.03 Spindle

4.04 Guide part

4.05 Shaft

4.06 Ball headed pin

4.08 Socket

4.09 Adapter

4.10 Small worm−geared motor

4.12 Handwheel

4.13 Rotation−direction indicator

4.14 Setting indicator

4.15 Bevel

4.16 Bevel

4.17 Worm

4.20 Deep−groove ball bearing

4.21 Socket

4.22 Flange sleeve

4.23 Shaft sealing ring

4.24 Shaft sealing ring

4.25 Seal

4.26 Seal

4.27 Sealing ring

4.28 Circlip

4.29 Locking ring

4.31 Shim ring

4.32 Seeger ring

4.33 Dowel pin

4.34 Dowel pin

4.35 Dowel pin

4.36 Dowel pin

4.37 Dowel pin

4.38 Dowel pin

4.39 Set screw

4.40 Set screw

4.41 Set screw

4.42 Conical plug

4.43 Protection cover

4.44

Hexagon head cap screw

Cheese head screw

4.45

Hexagon head cap screw

Cheese head screw

4.46 Spring washer

4.47 Cheese head screw

4.48 Circlip

4.51 Cover

4.52 Cheese head screw

4.53 Spring washer

4.55 Hub

4.56 Bell housing

4.57 Handle

4.58 Hexagon head cap screw

Pos. Name

5.00 Limit−switch assembly

5.01 Housing

5.02 Housing

5.03 Actuator

5.04 Board assembly

5.05 Plate

5.06 Microswitch

5.07 Potentiometer

5.08 Worm

5.09 Screw joint

5.10 Screw joint

5.11 Set screw

5.12 Cheese head screw

5.13 Screw

5.14 Set screw

5.15 Set screw

5.16 Adapter

5.18 Circlip

5.19 Seal

5.20 O−ring

5.21 O−ring

7.00 Spindle housing assembly

7.01 Spindle housing

7.03 Spindle

7.04 Guide part

7.23 O−ring

7.25 Seal

7.29 Keeper plate

7.31 Shim ring

7.75 Flange sleeve

BA 11.5032−EN 3.0

l

39

Page 40

10

10.1.6 Speed adjustment mechanisms, size 08−18

Appendix

Speed adjustment mechanisms, size 08−18

40

l

BA 11.5032−EN 3.0

Page 41

Appendix 10

Pos. Name

1.01 Housing

1.02 Thrust collar

1.03 Foot

1.04 Set screw

1.05 Seal−Lock hexagon nut

1.06 Dowel pin

1.07 Cheese head screw

1.08 Oil sight glass

4.00 Spindle housing assembly

4.01 Spindle housing

4.02 Housing

4.03 Spindle

4.04 Guide part

4.05 Shaft

4.06 Ball headed pin

4.08 Socket

4.09 Adapter

4.10 Small worm−geared motor

4.12 Handwheel

4.13 Rotation−direction indicator

4.14 Setting indicator

4.15 Bevel

4.16 Bevel

4.17 Worm

4.20 Deep−groove ball bearing

4.21 Socket

4.22 Flange sleeve

4.23 Shaft sealing ring

4.24 Shaft sealing ring

4.25 Seal

4.26 Seal

4.27 Sealing ring

4.28 Circlip

4.29 Locking ring

4.31 Shim ring

4.32 Seeger ring

4.33 Dowel pin

4.34 Dowel pin

4.35 Dowel pin

4.36 Dowel pin

4.37 Dowel pin

4.38 Dowel pin

4.39 Set screw

4.40 Set screw

4.41 Set screw

4.42 Conical plug

4.43 Protection cover

4.44

Hexagon head cap screw

Cheese head screw

4.45

Hexagon head cap screw

Cheese head screw

4.46 Spring washer

4.47 Cheese head screw

4.48 Circlip

4.51 Cover

4.52 Cheese head screw

Pos. Name

4.53 Spring washer

4.55 Hub

4.56 Bell housing

4.57 Handle

4.58 Hexagon head cap screw

5.00 Limit−switch assembly

5.01 Housing

5.02 Housing

5.03 Actuator

5.04 Board assembly

5.05 Plate

5.06 Microswitch

5.07 Potentiometer

5.08 Worm

5.09 Screw joint

5.10 Screw joint

5.11 Set screw

5.12 Cheese head screw

5.13 Screw

5.14 Set screw

5.15 Set screw

5.16 Adapter

5.18 Circlip

5.19 Seal

5.20 O−ring

5.21 O−ring

BA 11.5032−EN 3.0

l

41

Page 42

Notes!

42

l

BA 11.5032−EN 3.0

Page 43

Notes !

BA 11.5032−EN 3.0

l

43

Page 44

Q

Lenze Drives GmbH

Postfach 10 13 52

D−31763 Hameln

Germany

(

( Service

Ê Service

E−Mail Lenze@Lenze.de

Internet www.Lenze.com

+49(0)5154/ 82−0

008000/ 2446877 (24 h helpline)

+49(0)5154/ 82−28 00

BA 11.5032−EN 3.0 12/2008

© 2008

TD09

10987654321

Loading...

Loading...