Page 1

L

Show/Hide Bookmarks

Manual

Global Drive

PLC Developer Studio

Global Drive

9300 Servo PLC

Page 2

This documentation is valid for the following Lenze PLC devices:

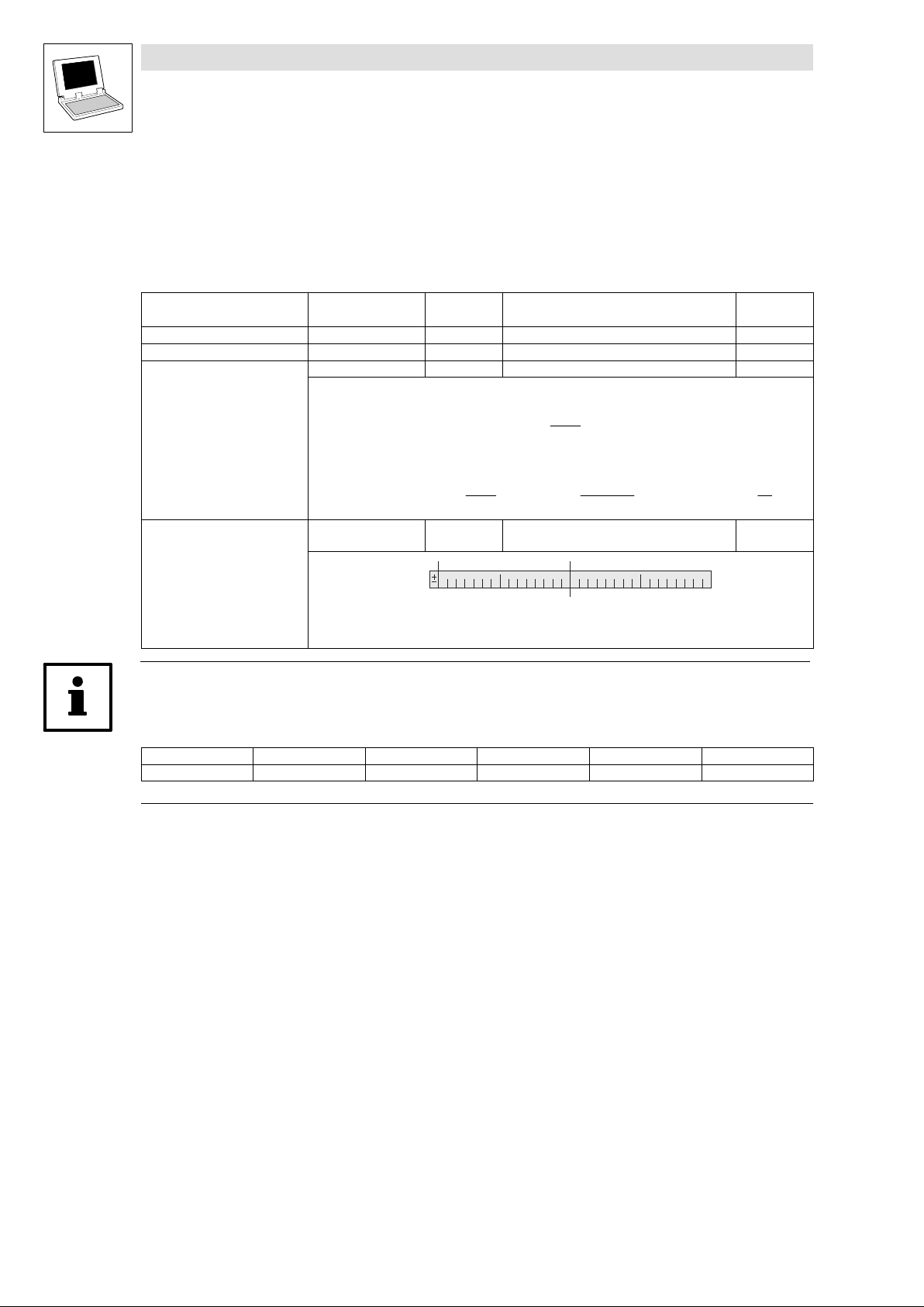

Type designation As of hardware version As of software version

9300 Servo PLC EVS93XX−xl 7A 8.0

9300 Servo PLC EVS93XX−xT 7A 8.0

What’s new?

Version Changes

1.4 07/2000 Revised edition for the 9300 Servo PLC as of software version V1.0

2.0 07/2001 Revised edition for the 9300 Servo PLC as of software version V2.0

3.0 01/2003 Revised edition for the 9300 Servo PLC as of software version V6.0

4.0/4.1 08/2006 Revised edition for the 9300 Servo PLC as of software version V7.0

5.0 10/2010 Revised edition for the 9300 Servo PLC as of software version V8.0

5.1 09/2013 General corrections

Important note:

The software is supplied to the user as described in this document. Any risks resulting from its quality or use remain the responsibility of the

user. The user must provide all safety measures protecting against possible maloperation.

We do not take any liability for direct or indirect damage, e.g. profit loss, order loss or any loss regarding business.

2013 Lenze Automation GmbH

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze Automation GmbH.

All information given in this documentation has been carefully selected and tested for compliance with the hardware and software described.

Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility or liability for any damage that may occur. Required

correction will be included in updates of this documentation.

All product names mentioned in this documentation are trademarks of the corresponding owners.

Version 5.1 09/2013

Page 3

9300 Servo PLC

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions used in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 System block descriptions 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Pictographs in this Manual 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Terminology used 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 System block introduction 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 System block principle 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Node numbers 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Access via system variables 1−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Access via absolute addresses 1−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.5 Definition of inputs/outputs 1−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.6 Linking of system blocks with DDS 1−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.7 Signal types and scalings 1−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 System blocks 2−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 AIF1_IO_AutomationInterface (node number 41) 2−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Inputs_AIF1 2−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Outputs_AIF1 2−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 AIF2_IO_AutomationInterface (node number 42) 2−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Inputs_AIF2 2−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Outputs_AIF2 2−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 AIF3_IO_AutomationInterface (node number 43) 2−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Inputs_AIF3 2−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Outputs_AIF3 2−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 AIF_IO_Management (node number 161) 2−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Inputs_AIF_Management 2−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Outputs_AIF_Management 2−25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 ANALOG1_IO (node number 11) 2−26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Inputs_ANALOG1 (analog input) 2−26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Outputs_ANALOG1 (analog output) 2−27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 ANALOG2_IO (node number 12) 2−28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Inputs_ANALOG2 (analog input) 2−28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Outputs_ANALOG2 (analog output) 2−28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN1_IO (node number 31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN2_IO (node number 32) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN3_IO (node number 33) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN_Management (node number 101) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAN_Synchronization (node number 102) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L

See "System bus (CAN) for Lenze PLCs" Manual.

9300 Servo PLC EN 5.1

i

Page 4

9300 Servo PLC

Contents

2.7 DCTRL_DriveControl (node number 121) 2−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Inputs_DCTRL 2−30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Outputs_DCTRL 2−30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Quick stop (QSP) 2−31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Operation disabled (DISABLE) 2−31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.5 Controller inhibit (CINH) 2−32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.6 Setting TRIP (TRIP−SET) 2−32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.7 Resetting TRIP (TRIP−RESET) 2−33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.8 Output of digital status signals 2−33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.9 Transfer of status/control word via AIF 2−35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 DFIN_IO_DigitalFrequency (node number 21) 2−36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Inputs_DFIN 2−36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 DFOUT_IO_DigitalFrequency (node number 22) 2−43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 Inputs_DFOUT / Outputs_DFOUT 2−43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 DIGITAL_IO (node number 1) 2−47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 Inputs_DIGITAL (digital inputs) 2−47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.2 Outputs_DIGITAL (digital outputs) 2−48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 FCODE_FreeCode (node number 141) 2−49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 MCTRL_MotorControl (node number 131) 2−52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.1 Inputs_MCTRL 2−53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.2 Outputs_MCTRL 2−55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.3 Current controller 2−56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.4 Torque setpoint / additional torque setpoint 2−57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.5 Torque limitation 2−58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.6 Maximum speed 2−59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.7 Speed controller 2−60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.8 Torque control with speed limitation 2−61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.9 Speed setpoint limitation 2−62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.10 Phase controller 2−62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.11 Quick stop (QSP) 2−63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.12 Field weakening 2−64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.13 Switching frequency changeover 2−64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.14 Feedback systems 2−65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.15 Touch probe (TP) 2−66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.16 Manual adaptation of motor data 2−68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.17 Monitoring 2−70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.17.7 LP1 − monitoring of the motor phases 2−83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.17.17 PL − monitoring of the rotor position adjustment 2−92 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 MCTRL_AUX_HighResFeedback (node number 181) 2−95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.1 Inputs_MCTRL_AUX_HighResFeedback 2−95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.2 Outputs_MCTRL_AUX_HighResFeedback 2−95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 STATEBUS_IO (node number 51) 2−96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 SYSTEM_FLAGS (system flags, node number 151) 2−97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.1 Inputs SYSTEM_FLAGS 2−97 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.2 Outputs SYSTEM_FLAGS 2−98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

9300 Servo PLC EN 5.1

L

Page 5

9300 Servo PLC

Contents

3 Appendix 3−99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 PLC functionality 3−99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Extendability/networking 3−100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Memories 3−101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Retain memory 3−102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Persistent memory 3−103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Downloading data 3−104 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 System POUs 3−105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 System error messages 3−106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Overview of system error messages, error sources and reactions 3−107 . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Response and its effects on the drive 3−110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 System error message reset 3−110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Causes and remedies 3−111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Fault analysis via the fault memory 3−116 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 Fault analysis via the LED display of the PLC 3−118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.7 Fault analysis via the 9371BB keypad 3−118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.8 Fault analysis via the LECOM status word C0150 3−118 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Code table 3−119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Temporary codes 3−150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 RAM access via codes 3−150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Attribute table 3−153 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Index 4−159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L

9300 Servo PLC EN 5.1

iii

Page 6

9300 Servo PLC

Contents

iv

9300 Servo PLC EN 5.1

L

Page 7

Preface and general information

1 Preface and general information

1.1 About this Manual

This Manual describes the system block functions which can be selected and parameterised in the

control configuration of the Drive PLC Developer Studio (DDS) for 9300 Servo PLC.

1.1.1 Conventions used in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Information type Distinction (in text) Example

System block name bold The SB DIGITAL_IO...

System (block) variable identifier italics The input DIGIN_bIn1_b...

9300 Servo PLC

Tip!

Information about the conventions used for variable names of Lenze system blocks, function blocks

and functions can be obtained from the appendix of the DDS online documentation "Introduction

into IEC 61131−3 programming". The conventions ensure universal and uniform naming and support

the readability of PLC programs.

1.1.2 System block descriptions

All system block descriptions given in this Manual have the same structure:

Headline with SB identifier

SB function and node number

Short description of the SB and its most important features

System block chart including all corresponding variables

Input variables

Output variables

Table giving information about input and output variables:

Identifier

Data type

Signal type

Address

Display code

Display format

Info

l

Detailed SB description

9300 Servo PLC EN 5.1

1−1

Page 8

9300 Servo PLC

Preface and general information

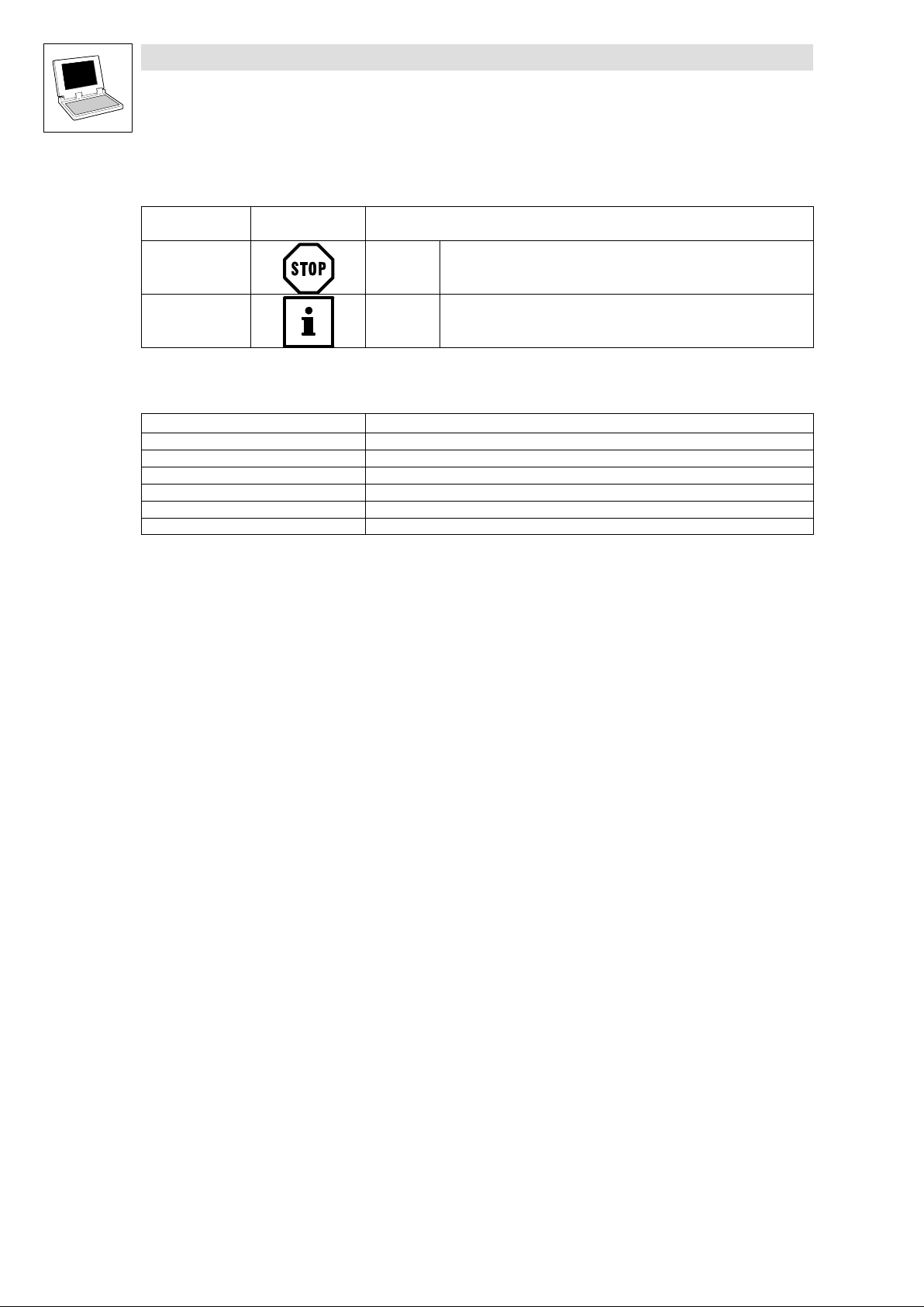

1.1.3 Pictographs in this Manual

Pictographs

used

Warning of material

damage

More notes Tip!

1.1.4 Terminology used

Term In this Manual used for

AIF Automation interface

DDS Drive PLC Developer Studio

FIF Function interface

GDC Global Drive Control (parameter setting program from Lenze)

SB System block

System bus System bus (CAN): Lenze standard bus system similar to CANopen

Signal words

Stop! Warns of potential damage to material.

Note!

Possible consequences if disregarded:

Damage of the PLC or its environment

Indicates a tip or note.

.

1−2

9300 Servo PLC EN 5.1

l

Page 9

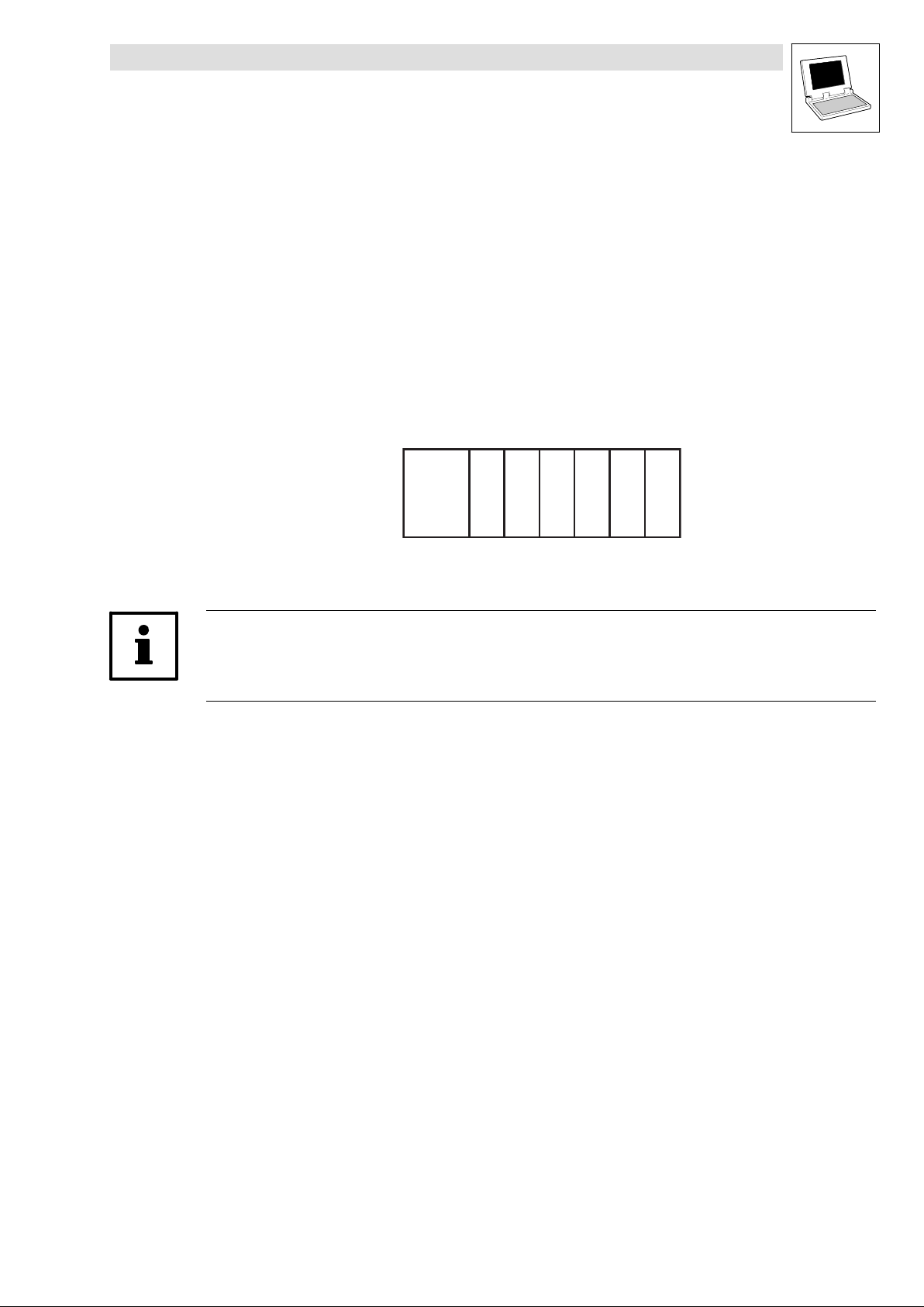

1.2 System block introduction

For a long time, Lenze has followed the principle of describing controller functions with the aid of

function blocks (FBs). This principle can also be found in the IEC 61131−3 standard.

Functions which can be used as software functions in projects are stored in function libraries

as function blocks or functions.

In addition, quasi−hardware functions are available as system blocks (SBs).

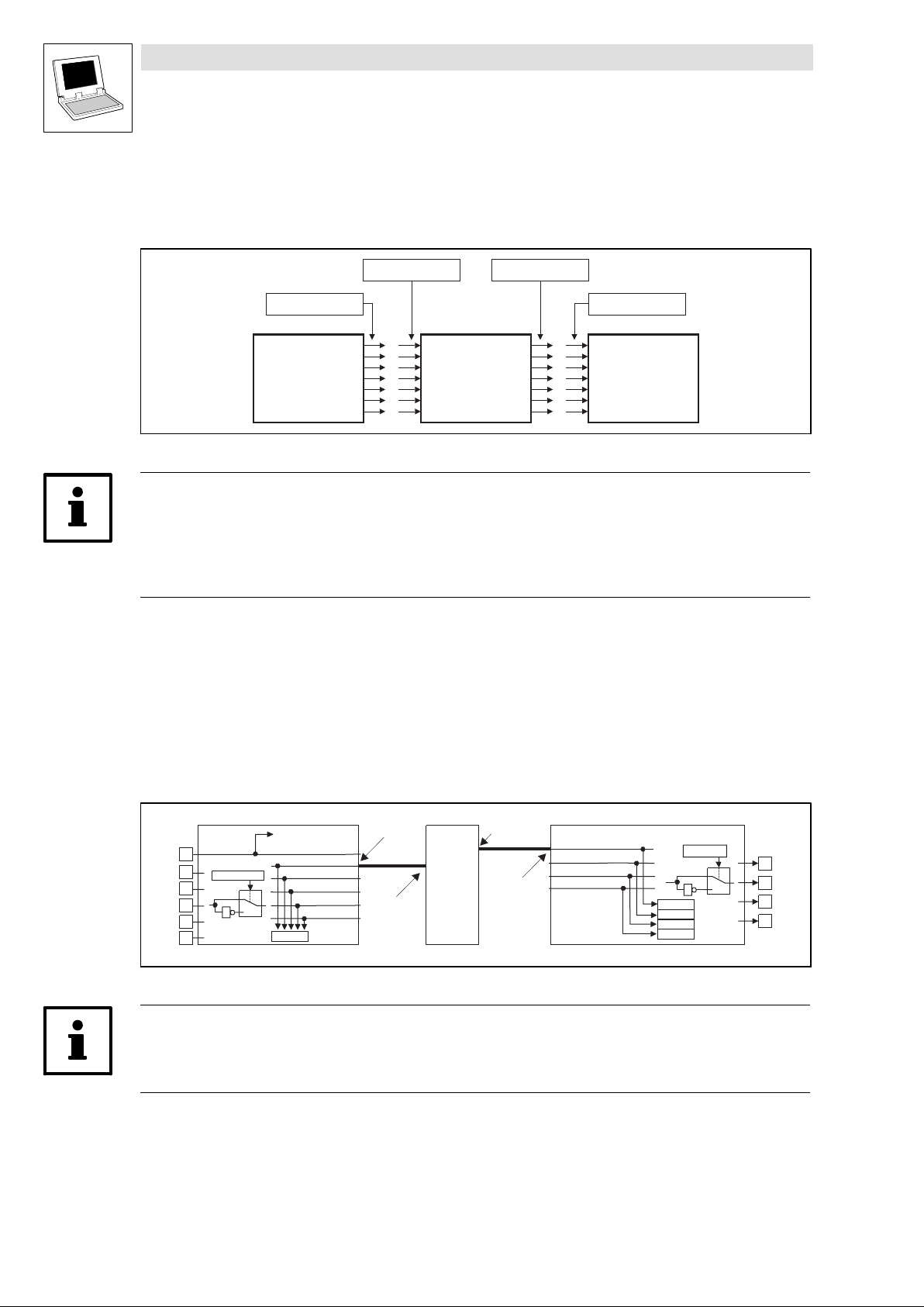

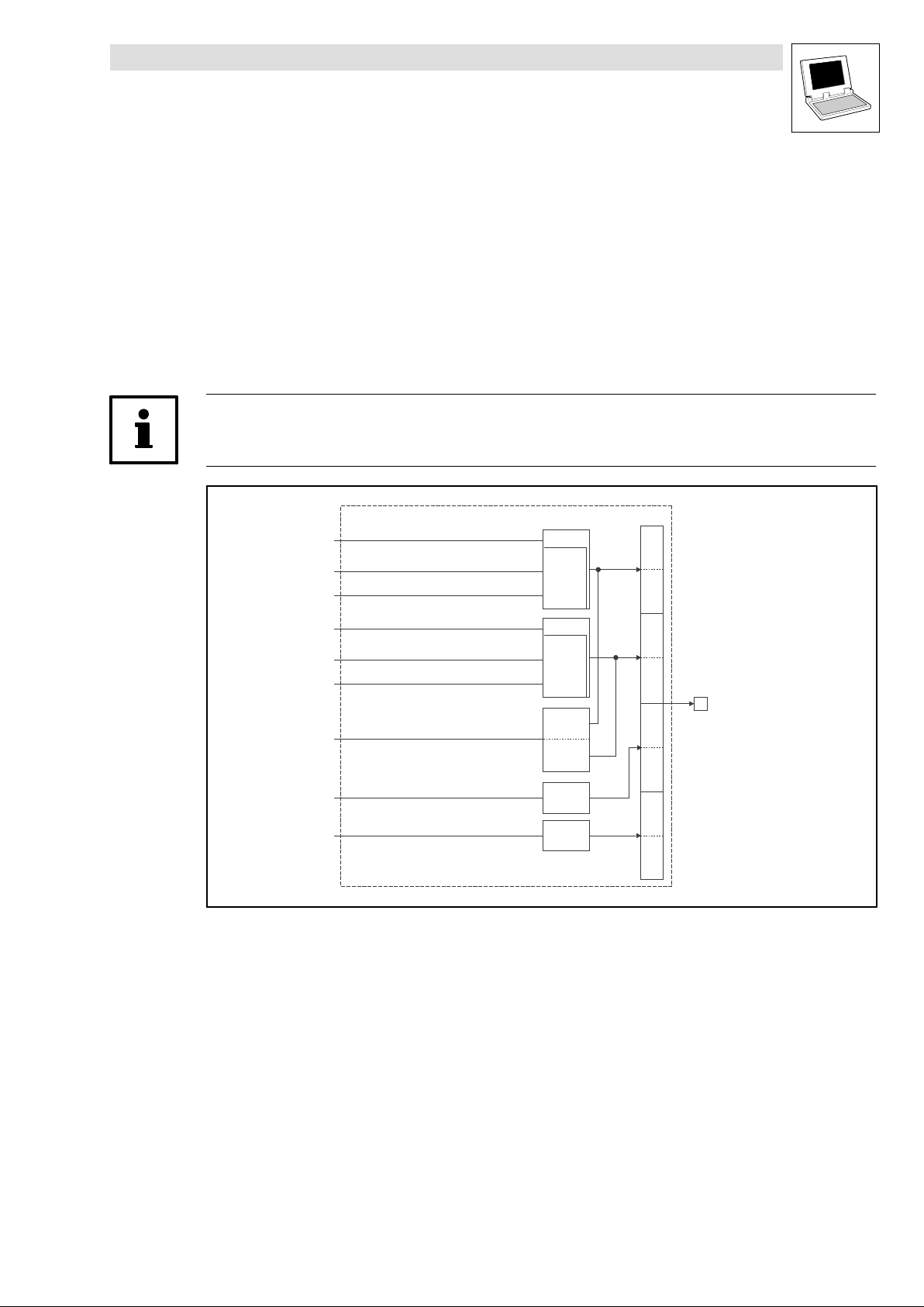

1.2.1 System block principle

The system−block principle can be explained by means of a PLC system in a rack:

The rack contains the CPU, digital I/Os, analog I/Os, counter card, positioning card, etc. as

additional cards:

9300 Servo PLC

Preface and general information

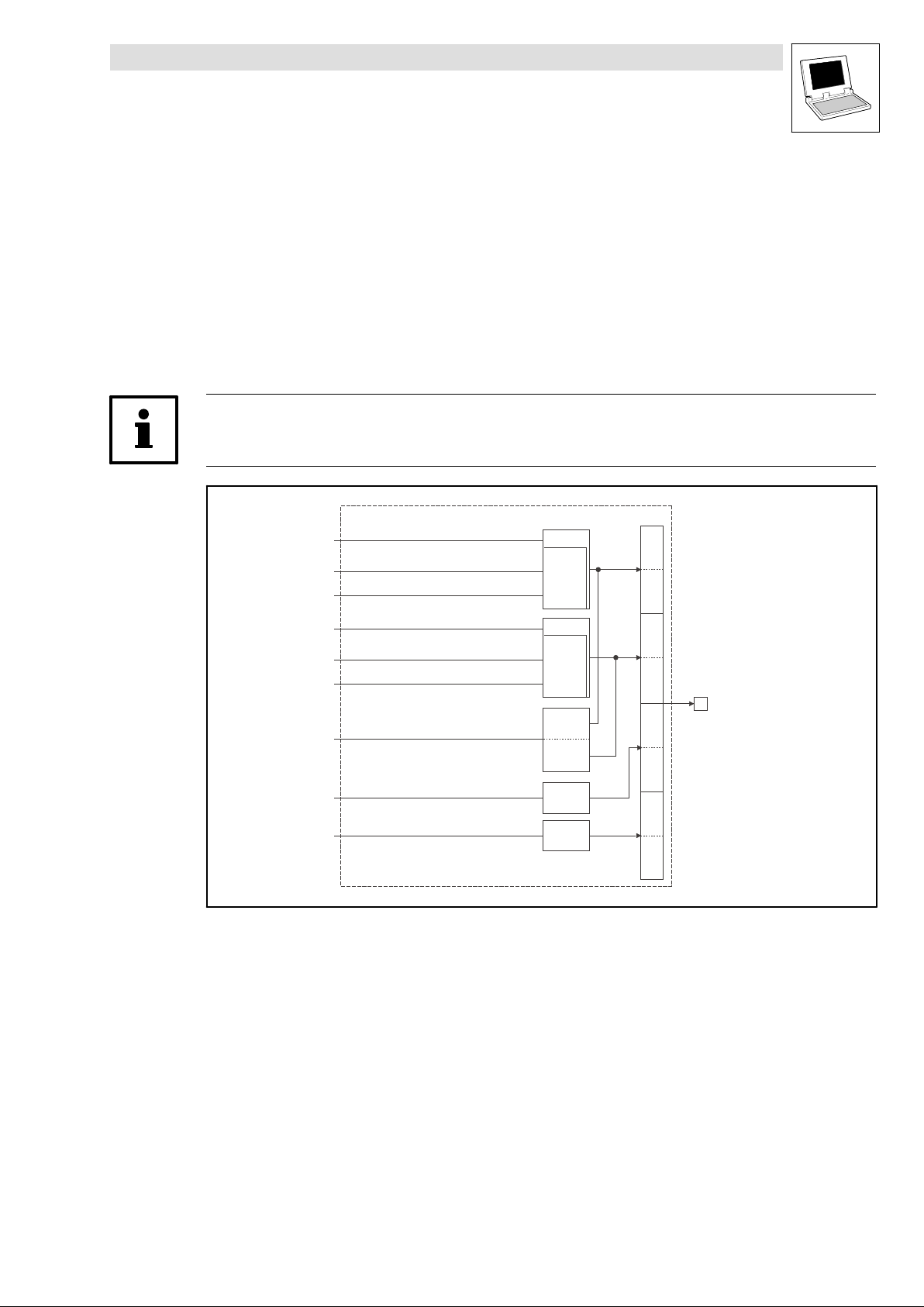

CPU

The CPU can directly access the additional cards and process the resulting information.

Additional cards have fixed addresses for access.

With Lenze PLC controllers, system blocks can be compared with these additional cards!

System blocks are special (hardware) function blocks permanently integrated into the

run−time system of the PLC.

SBs can address real hardware.

SBs are assigned/identified through so−called node numbers. (^ 1−4)

SB inputs and outputs are accessed via system variables or absolute memory addresses.

(^ 1−5)

Inputs/outputs are always classified from the program’s point of view. (^ 1−6)

Required SBs must be explicitly linked to the project via the control configuration of DDS.

(^ 1−7)

xxxxxx

x = Additional cards

l

9300 Servo PLC EN 5.1

1−3

Page 10

9300 Servo PLC

Preface and general information

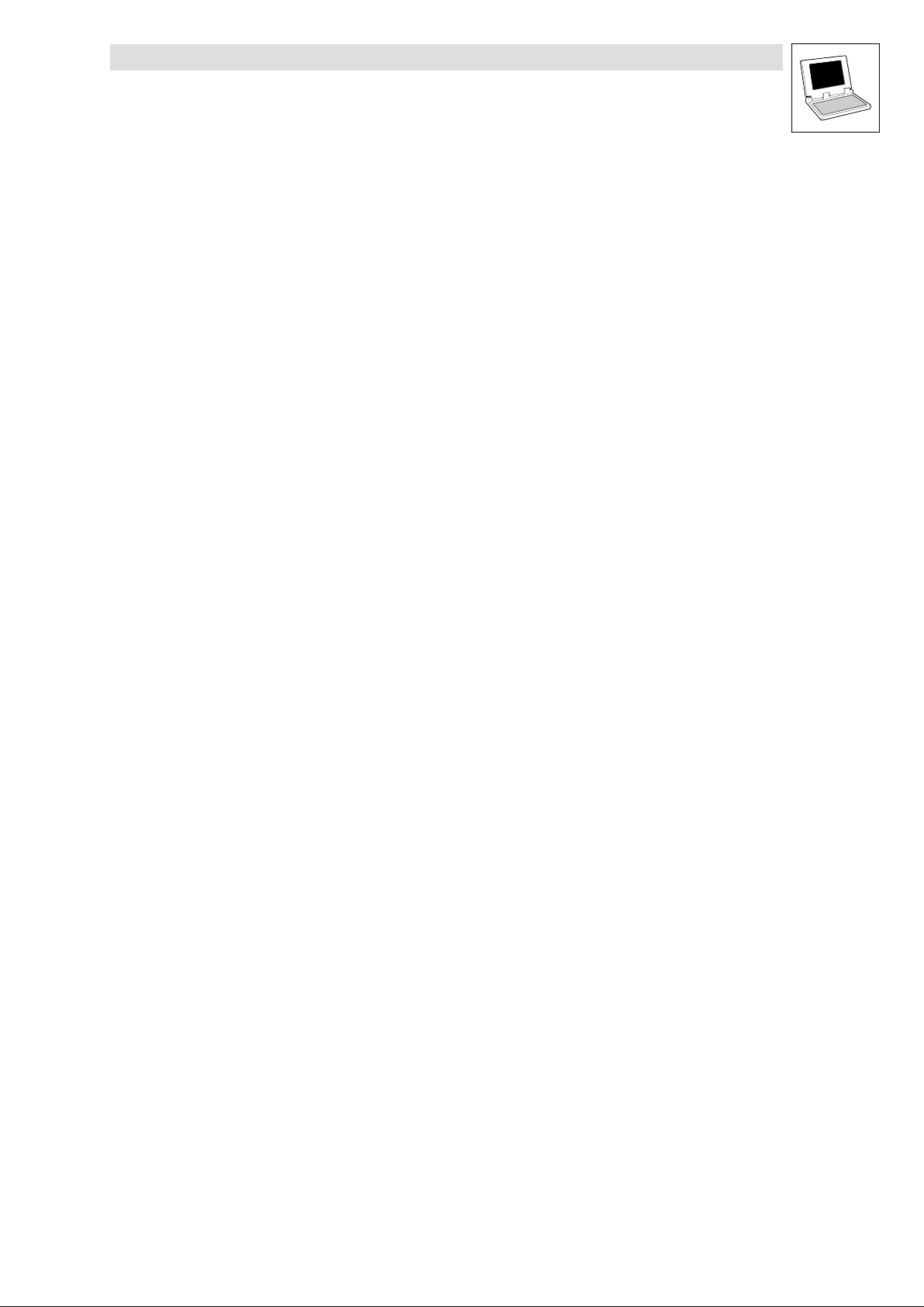

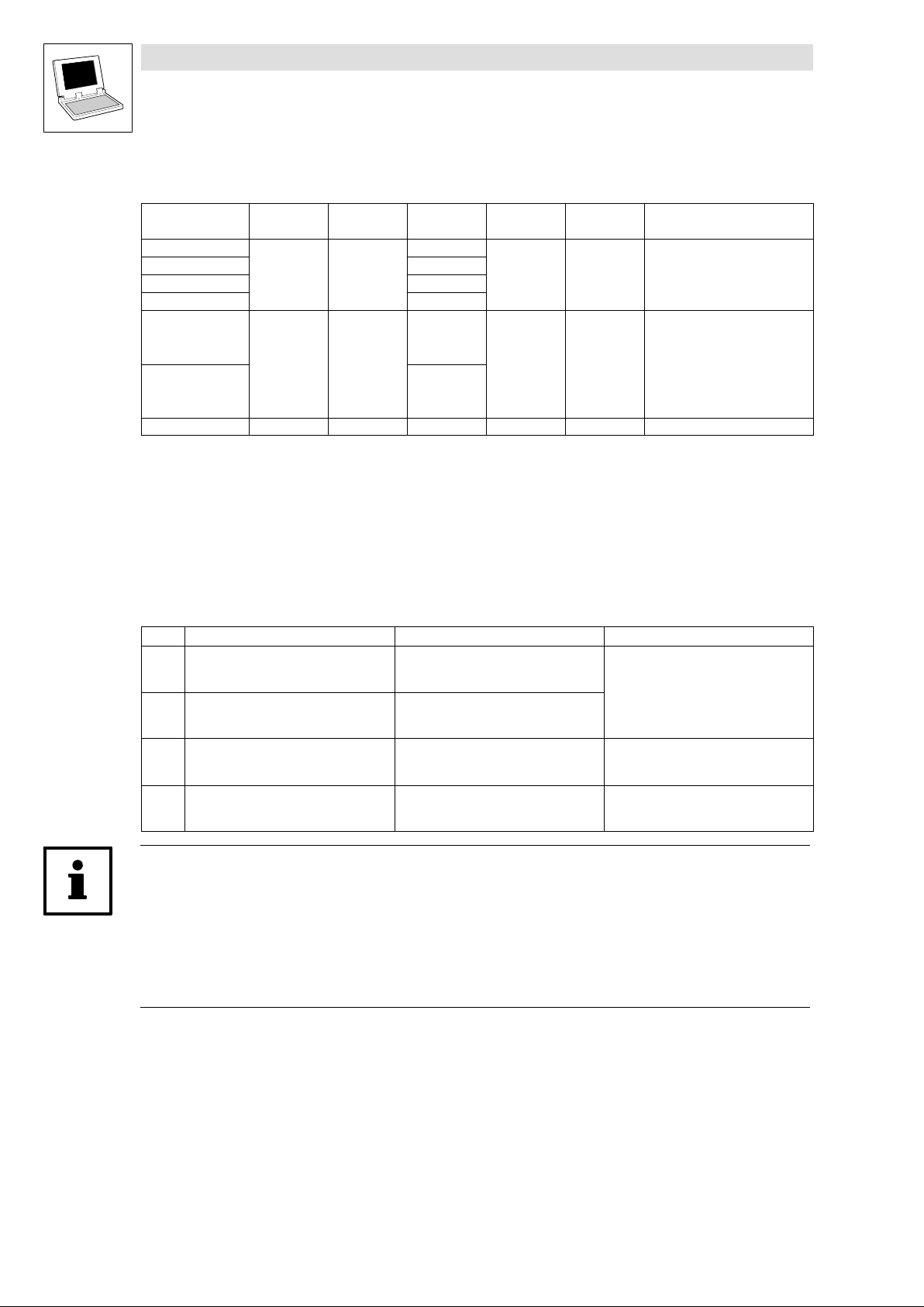

1.2.2 Node numbers

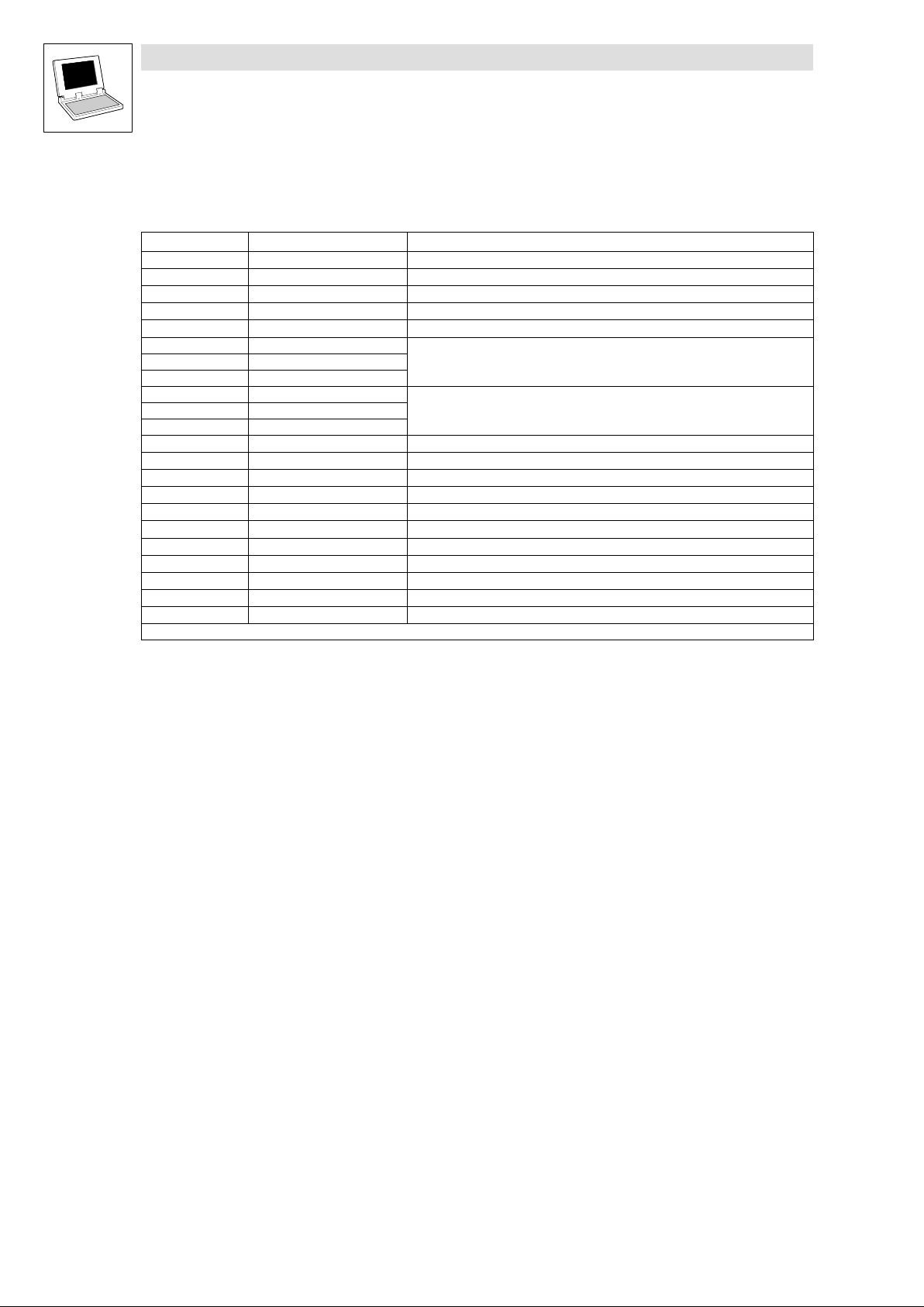

The system blocks of the 9300 Servo PLC carry the following node numbers:

Node number System block Notes

1 DIGITAL_IO Digital inputs/outputs

11 ANALOG1_IO Analog inputs/outputs 1

12 ANALOG2_IO Analog inputs/outputs 2

21 DFIN_IO_DigitalFrequency Digital frequency input

22 DFOUT_IO_DigitalFrequency Digital frequency output

31 CAN1_IO

32 CAN2_IO

33 CAN3_IO

41 AIF1_IO_AutomationInterface

42 AIF2_IO_AutomationInterface

43 AIF3_IO_AutomationInterface

51 STATEBUS_IO State bus

60 OSC_Oscilloscope Oscilloscope function

101 CAN_Management System bus (CAN) management

102 CAN_Syncronization System bus (CAN) synchronisation

121 DCTRL_DriveControl Device control

131 MCTRL_MotorControl Motor control

141 FCODE_FreeCodes Free codes

151 SYSTEM_FLAGS System flags

161 AIF_IO_Management Automation interface management

171 VAR_PERSISTENT Persistent variables

1

SBs for system bus (CAN) are described in the "System bus (CAN) for Lenze PLC devices" manual.

The node number is part of the absolute SB address (see chapter 2). (^ 1−5)

181 MCTRL_AUX_HighResFeedback High−resolution encoder signal

System bus (CAN)

Automation interface

1

1

1

1−4

9300 Servo PLC EN 5.1

l

Page 11

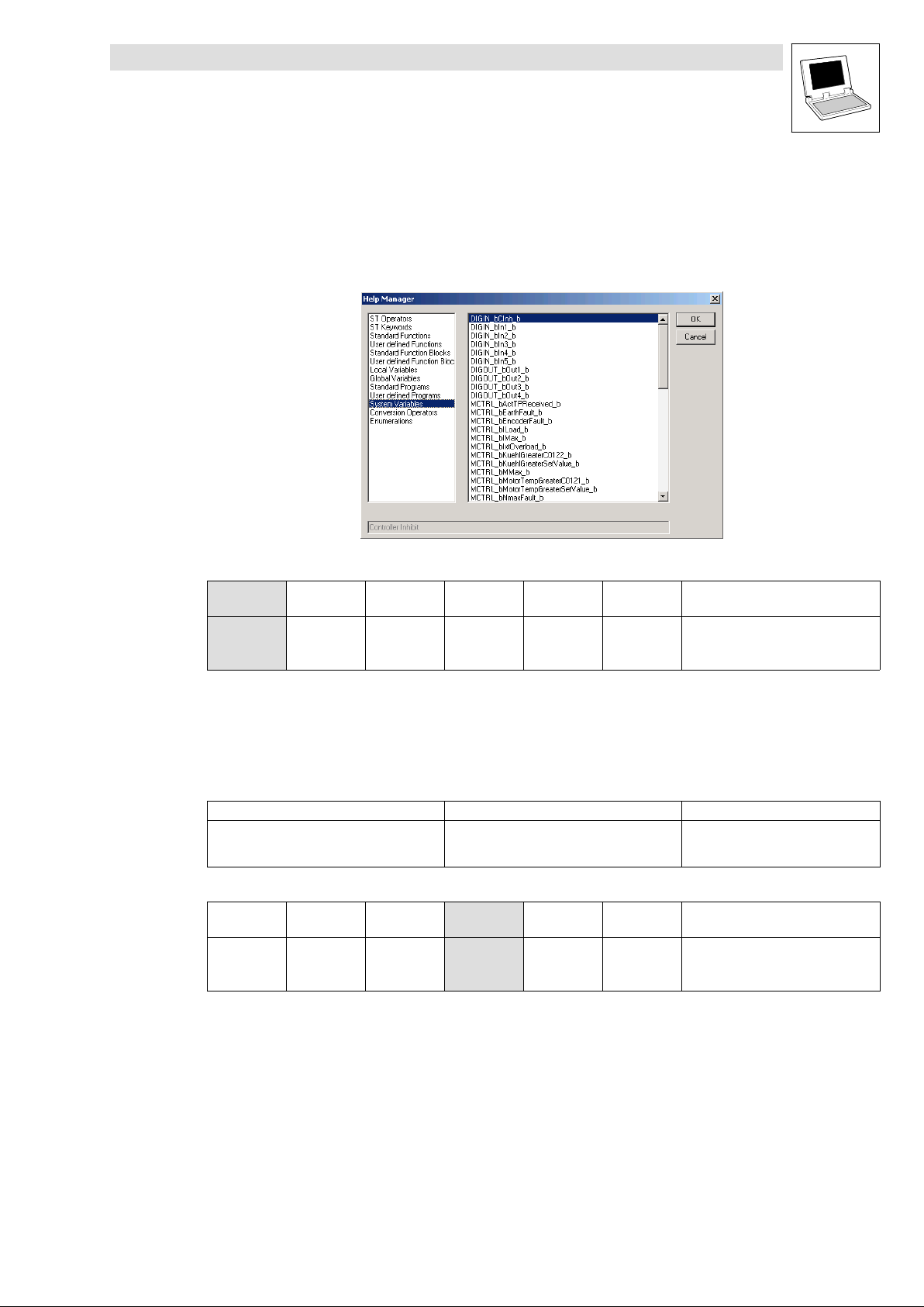

1.2.3 Access via system variables

You can use the system variables of a system block in your project after the system block has been

integrated into the control configuration of the DDS.

Open the input assistance in the DDS editors via <F2> to get a listing of all available system

variables:

9300 Servo PLC

Preface and general information

This Manual lists the system variables in the table for the corresponding system block:

Variable Data type Signal type Address Display

DIGIN_bIn1_b

... ... ...

DIGIN_bIn8_b %IX1.0.7 C0443/8

Example: Table with SB DIGITAL_IO inputs of the Drive PLC

Bool Binary

%IX1.0.0 C0443/1

1.2.4 Access via absolute addresses

System block inputs and outputs can also be accessed via absolute addresses according to the

IEC61131−3 standard:

For inputs use: For outputs use:

%IXa.b.c %QXa.b.c

This Manual lists the absolute addresses in the table for the corresponding system block:

Variable Data type Signal type Address Display

DIGIN_bIn1_b

... ... ...

DIGIN_bIn8_b %IX1.0.7 C0443/8

Example: Table with SB DIGITAL_IO inputs of the Drive PLC

Bool Binary

%IX1.0.0 C0443/1

code

code

Display

format

bin

Display

format

bin

Note

a = node number

b = word address

c = bit address

Note

l

9300 Servo PLC EN 5.1

1−5

Page 12

9300 Servo PLC

Preface and general information

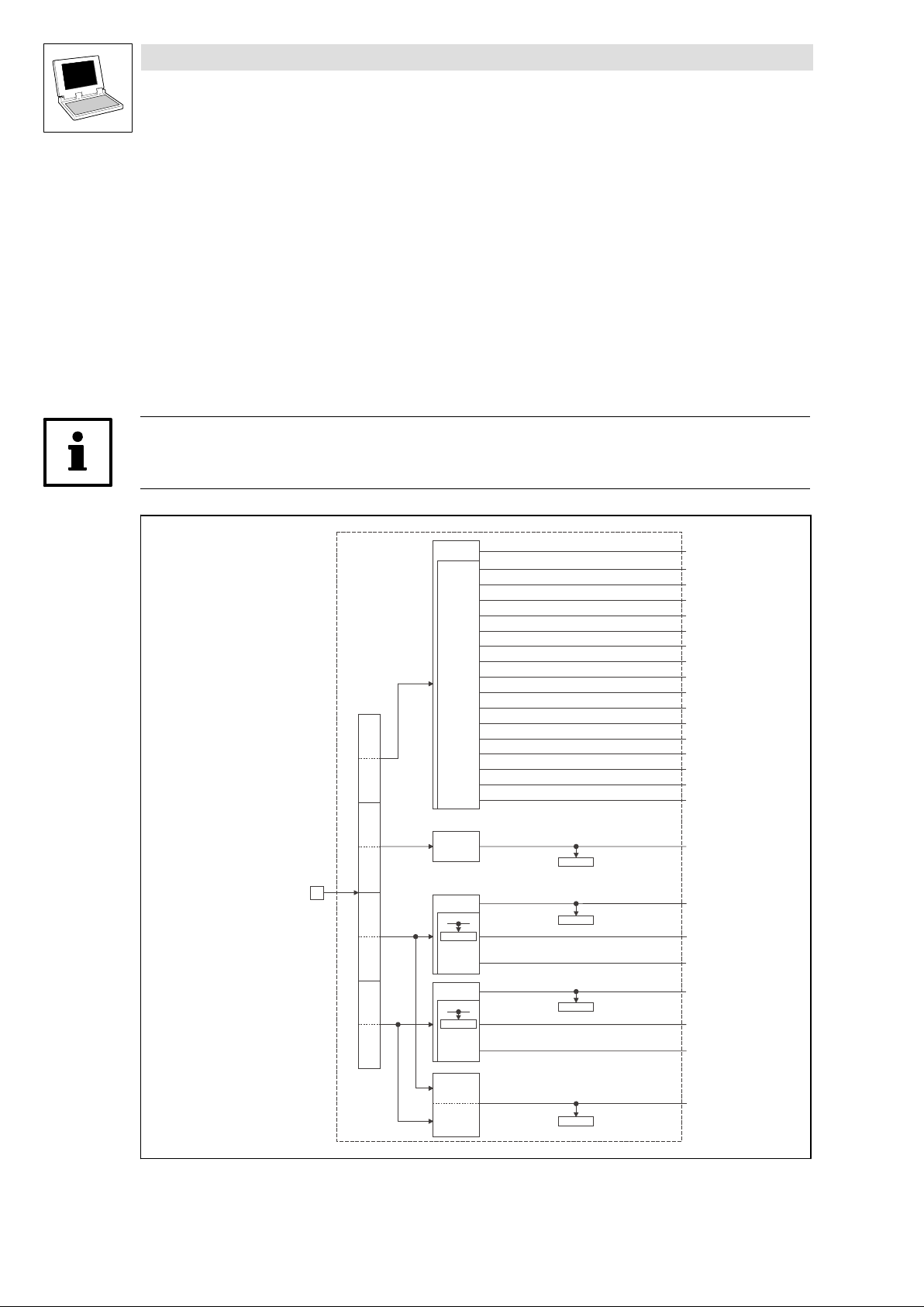

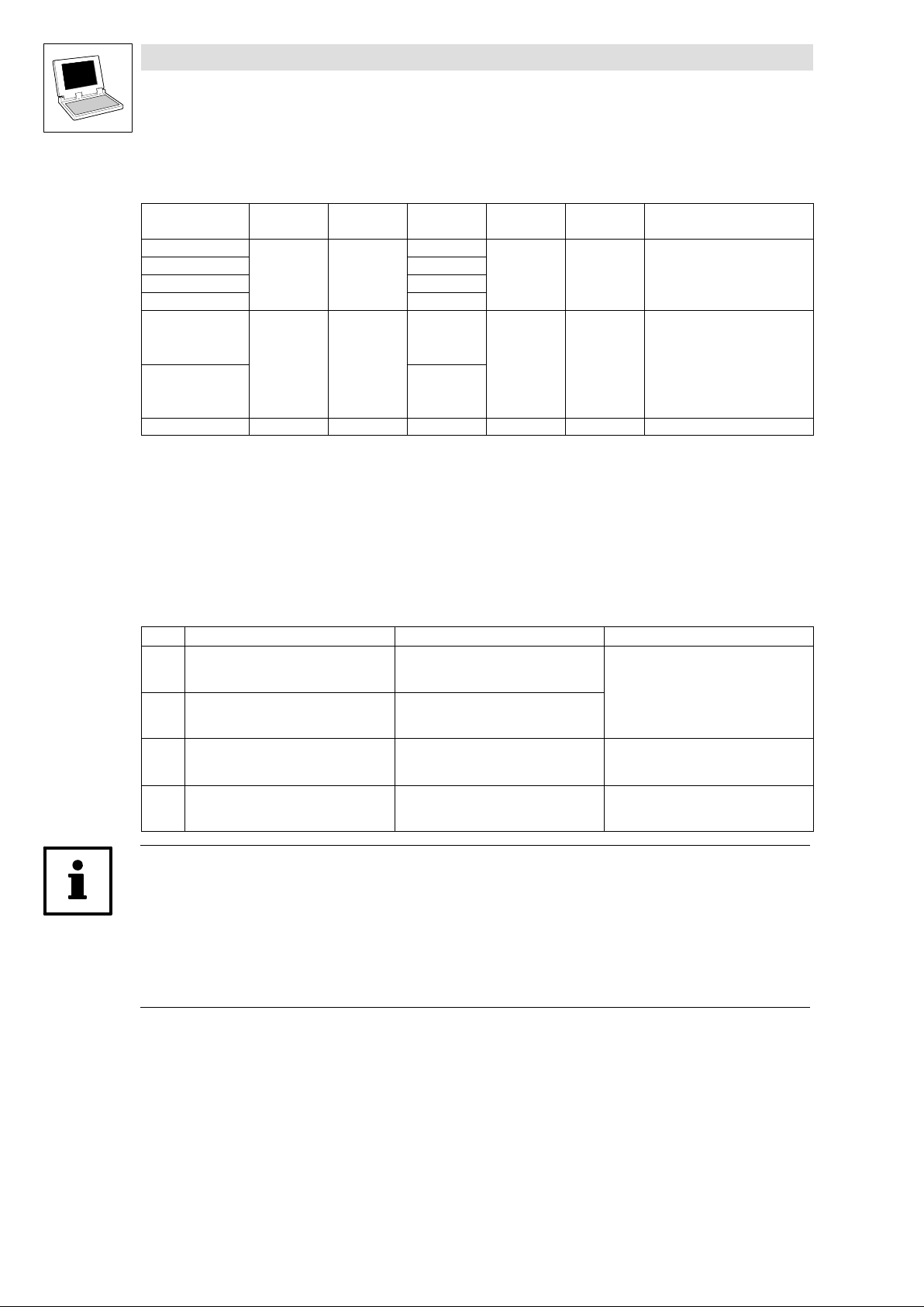

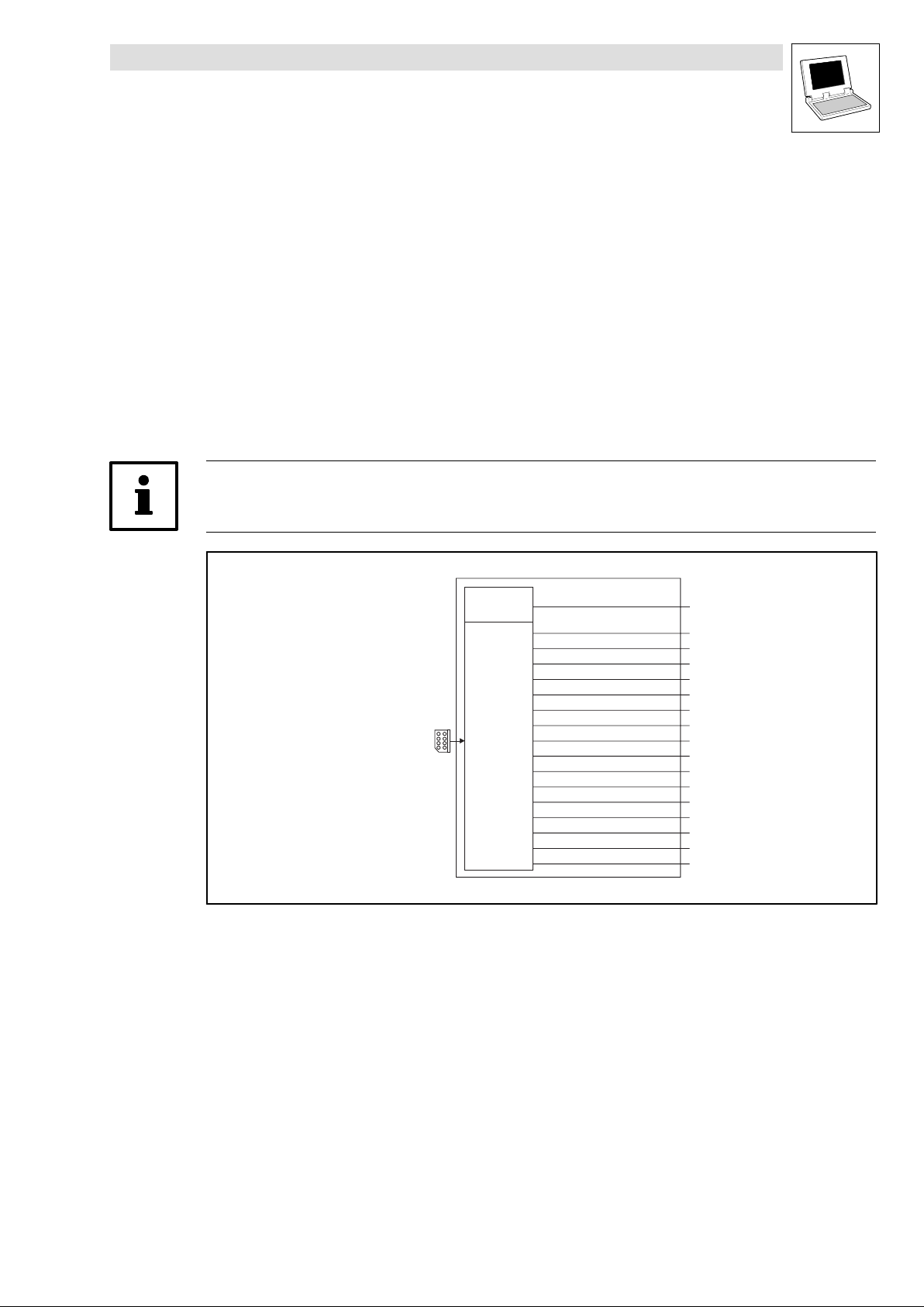

1.2.5 Definition of inputs/outputs

The application program is connected with the hardware by linking system blocks with program

organisation units (POUs):

SB-Output SB-Input

POU-Input POU-Output

SB

POU

Fig. 1−1 Principle: Linking of system blocks with a program organisation unit (POU)

Tip!

Inputs and outputs are always classified from the program’s point of view.

Logic SB inputs are hardware outputs of the PLC.

Logic SB outputs are hardware inputs of the PLC.

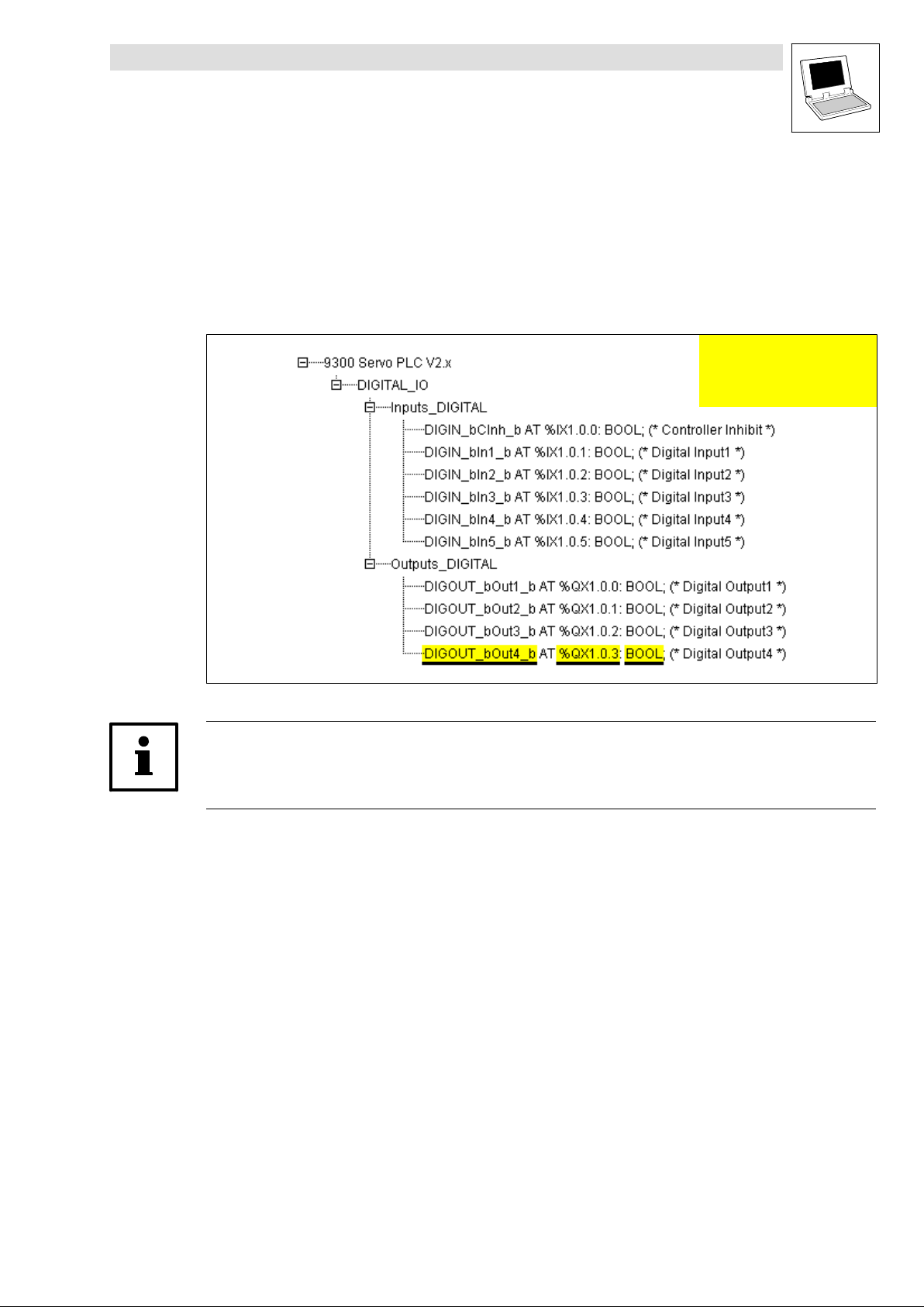

Example: System block DIGITAL_IO of the 9300 Servo PLC

If you want to use the digital input 1 and the digital output 1 of the 9300 Servo PLC, proceed as

follows:

1. Link the SB DIGITAL_IO explicitly with the DDS control configuration.

2. Access to digital input 1:

Assign the system variable DIGIN_bIn1_b to a POU input.

3. Access to digital output 1:

Assign the system variable DIGOUT_bOut1_b to a POU output.

POU

POU-OUT

SB-IN

SB-OUT

POU-IN

0

1

DCTRL -X5/28

DIGIN_bCInh_b

DIGIN_bIn1_b

DIGIN_bIn2_b

DIGIN_bIn3_b

DIGIN_bIn4_b

DIGIN_bIn5_b

C0443

DIGIN

X5

28

E1

C0114/1...5

E2

E3

1

E4

E5

DIGOUT_bOut1_b

DIGOUT_bOut2_b

DIGOUT_bOut3_b

DIGOUT_bOut4_b

SB

(^ 1−7)

C0444/1

C0444/2

C0444/3

C0444/4

DIGOUT

C0118/1...4

0

1

1

X5

A1

A2

A3

A4

Fig. 1−2 Principle: Linking of the 9300 Servo PLC system block DIGITAL_IO with a POU

Tip!

According to the IEC61131−3 standard, only one copy of the digital input 1 and the digital output 1

may be transferred.

1−6

9300 Servo PLC EN 5.1

l

Page 13

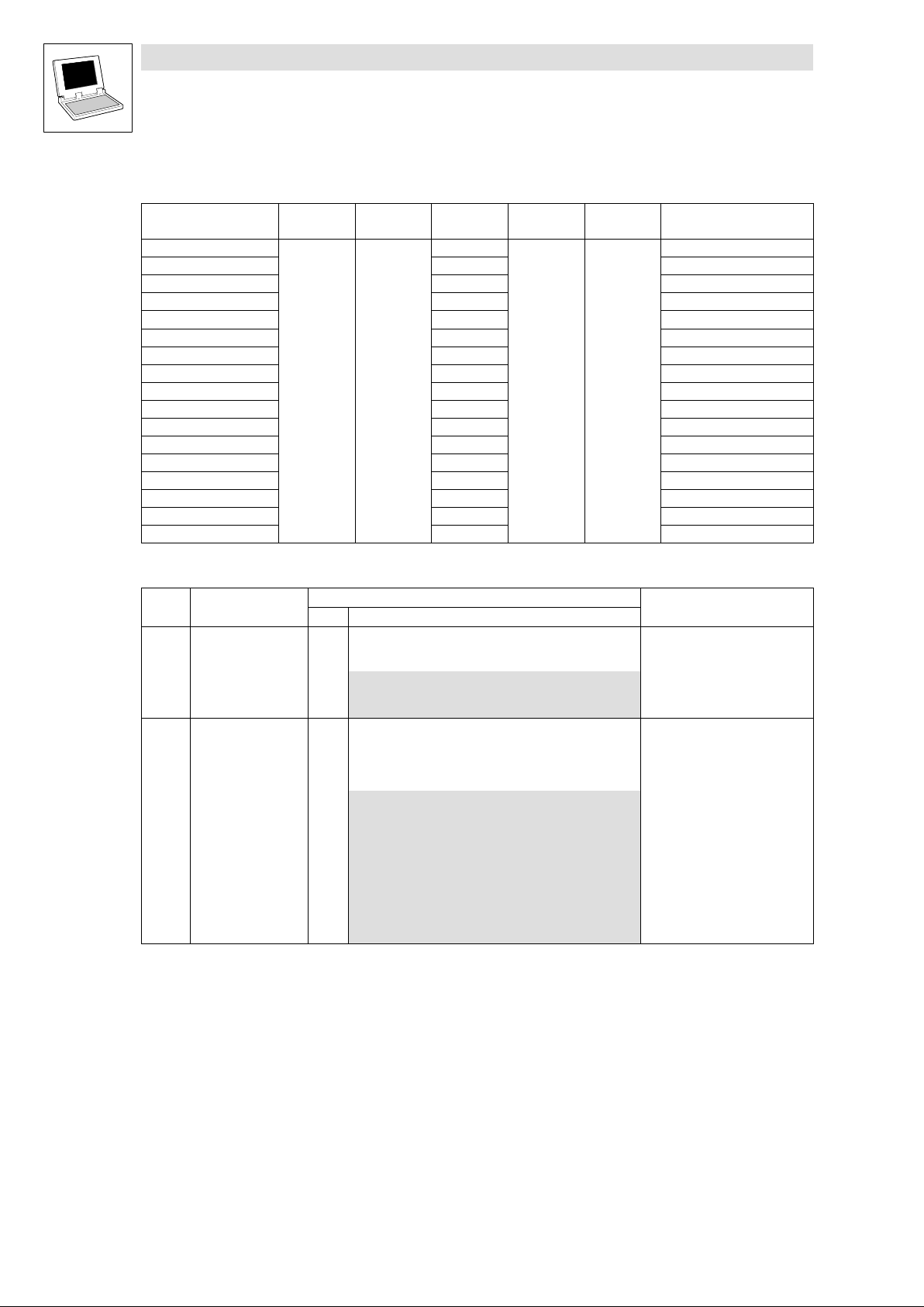

1.2.6 Linking of system blocks with DDS

The system blocks required must be explicitly linked to the project via the control configuration of the

DDS.

The control configuration is placed as an object in the Resources tab in the Object organiser.

The control configuration lists all inputs and outputs including the identifiers of the

corresponding I/O variable, the absolute address and the data type of the I/O variable for

every linked SB.

9300 Servo PLC

Preface and general information

Identifier of the I/O variable

Absolute address

Data type of the I/O variable

Fig. 1−3 Example: Control configuration for 9300 Servo PLC with linked SB DIGITAL_IO

Tip!

The control configuration provides a context menu for adding and deleting SBs which can be

activated via the right mouse key.

l

9300 Servo PLC EN 5.1

1−7

Page 14

9300 Servo PLC

Preface and general information

1.2.7 Signal types and scalings

Most inputs and outputs of Lenze function blocks/system blocks can be assigned to a certain signal

type. We distinguish between digital, analog, position and speed signals.

The identifier of the corresponding input/output variable has an ending (starting with an underscore).

It indicates the signal type.

Signal type Ending Memory

Analog _a (analog) 16 bits 100 % 16384 H

Digital _b (binary) 8 bits 0 FALSE; 1 TRUE G

Phase difference or speed

Phase−angle or position _p (position) 32 bits 1 motor revolution 65536 E

_v (velocity) 16 bits 15000 rpm 16384 F

Phase difference/speed ref. to 1 ms

Scaling example:

Speed (on motor side) + 15000 [rpm] +

1 motor revolution + 65536 [inc]

Variable value (..._v) +

space

Direction (0 clockwise rotation; 1 counter−clockwise rotation)

No. of motor revolutions (0 ... 32767)

Phase angle or position (0 ... 65535)

Scaling

(external value º internal value)

15000

60 [s]

15000

@ 65536 [inc] +

60 [s]

High Word Low Word 031

15000

60000 [ms]

@ 65536 [inc] + 16384

Previous

identification

inc

ƪ

ƫ

ms

Note!

Due to their scaling, analog signals have an asymmetrical resolution range (−200 % ... +199.99 %):

External value: −200 % −100 % 0 +100 % +199.99 %

Internal value: −32768 −16384 0 +16384 +32767

1−8

9300 Servo PLC EN 5.1

l

Page 15

2 System blocks

The following sections inform about the system blocks of the basic unit.

9300 Servo PLC

System blocks

L

9300 Servo PLC EN 5.1

2−9

Page 16

9300 Servo PLC

System blocks

2.1 AIF1_IO_AutomationInterface (node number 41)

2.1 AIF1_IO_AutomationInterface (node number 41)

2.1.1 Inputs_AIF1

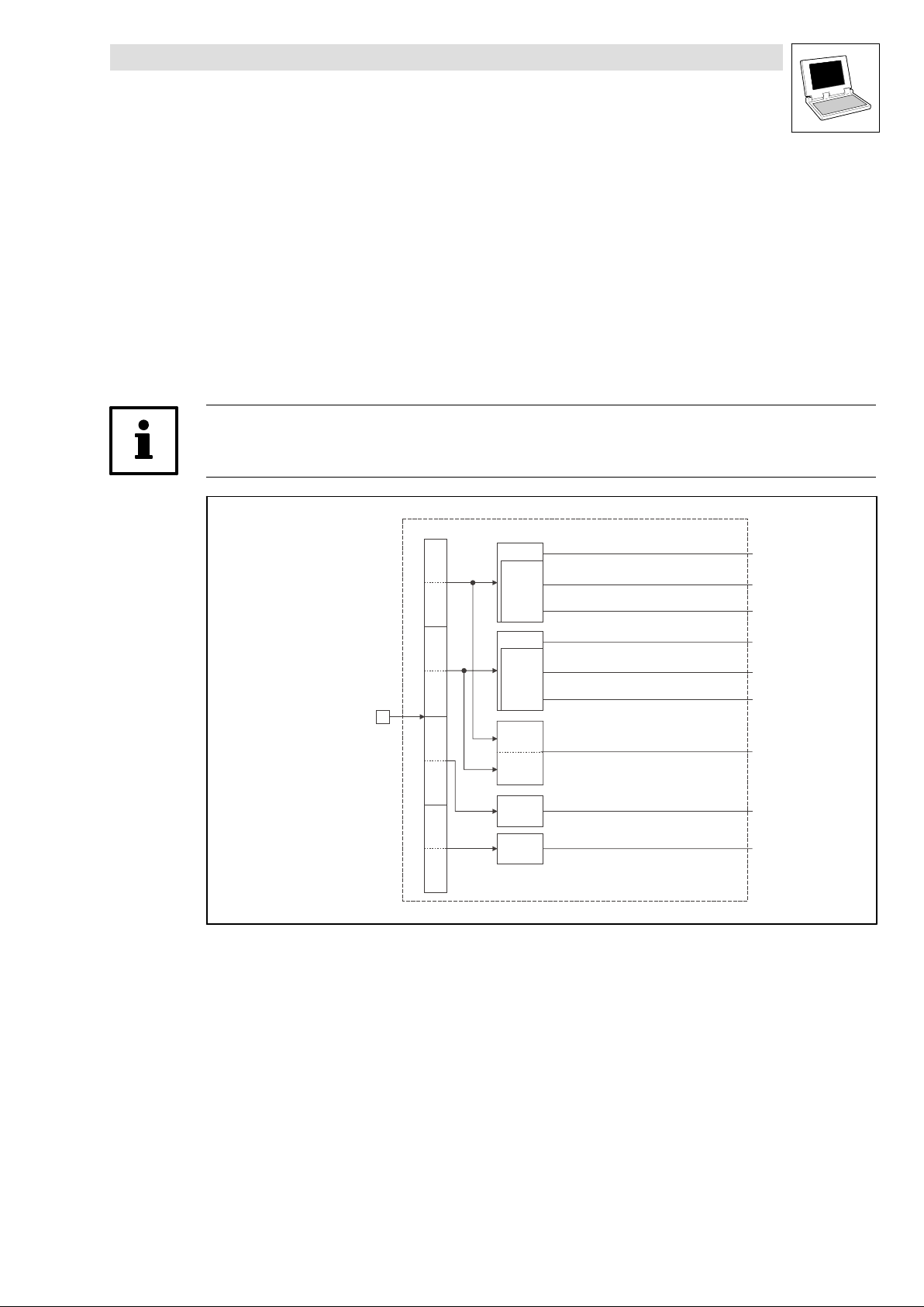

This SB is used as an interface for input signals (e.g. setpoints/actual values) from attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

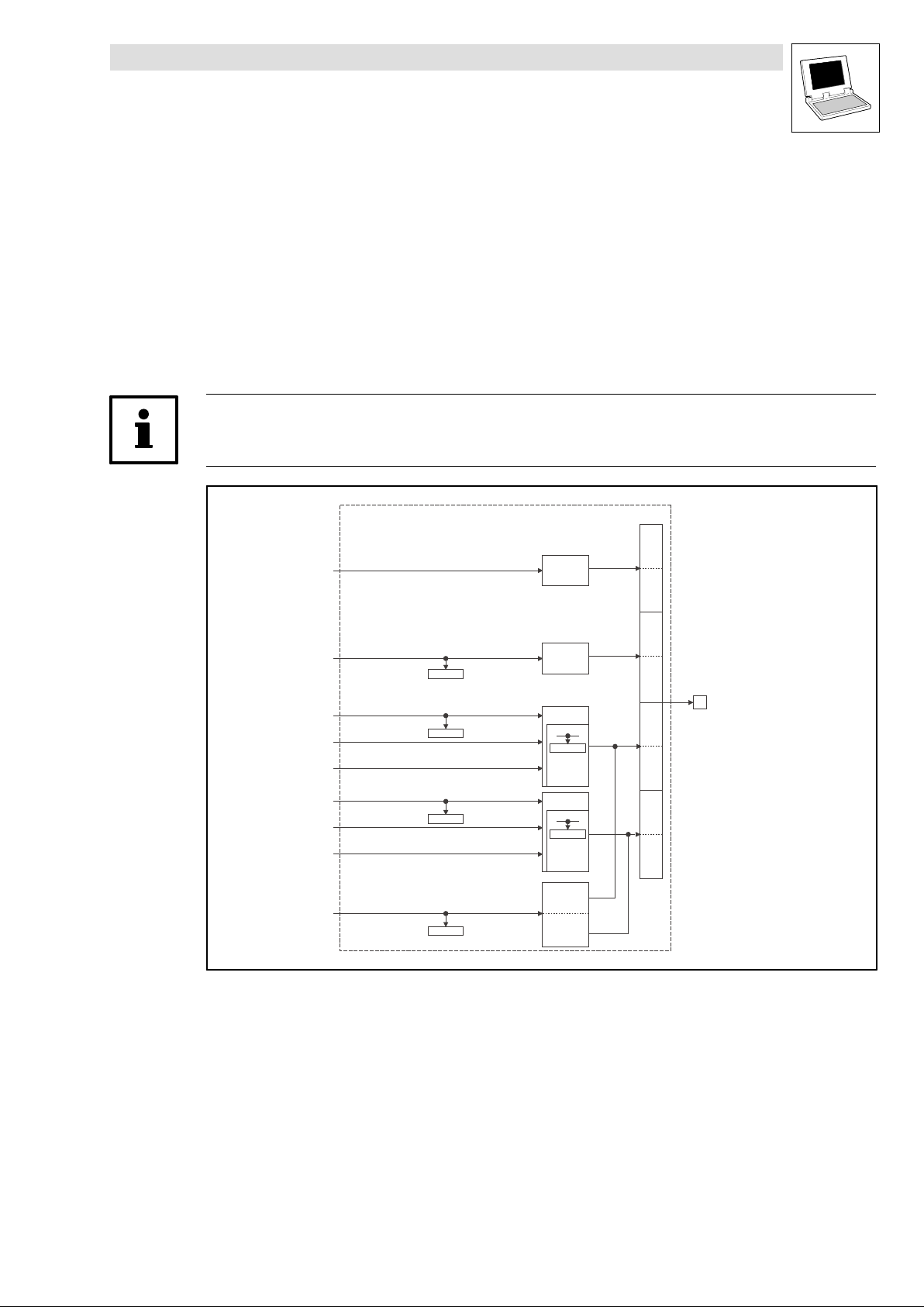

Automation

Interface

Inputs_AIF1

Byte

1

Controlword

Byte

2

Byte

3

Byte

4

Byte

5

Byte

6

Byte

7

Byte

8

16 Bit

16 binary

signals

16 Bit

16 Bit

C0855/1

16 binary

signals

16 Bit

C0855/2

16 binary

signals

C0856/1

C0856/2

C0856/3

AIF1_wDctrlCtrl

AIF1_bCtrlB0_b

AIF1_bCtrlB1_b

AIF1_bCtrlB2_b

AIF1_bCtrlQuickstop_b

AIF1_bCtrlB4_b

AIF1_bCtrlB5_b

AIF1_bCtrlB6_b

AIF1_bCtrlB7_b

AIF1_bCtrlDisable_b

AIF1_bCtrlCInhibit_b

AIF1_bCtrlTripSet_b

AIF1_bCtrlTripReset_b

AIF1_bCtrlB12_b

AIF1_bCtrlB13_b

AIF1_bCtrlB14_b

AIF1_bCtrlB15_b

AIF1_nInW1_a

AIF1_nInW2_a

AIF1_bInB0_b

…

AIF1_bInB15_b

AIF1_nInW3_a

AIF1_bIn16_b

…

AIF1_bIn31_b

Fig. 2−1 Inputs_AIF1

2−10

16 Bit

LowWord

16 Bit

HighWord

9300 Servo PLC EN 5.1

AIF1_dnInD1_p

C0857

L

Page 17

9300 Servo PLC

System blocks

2.1 AIF1_IO_AutomationInterface (node number 41)

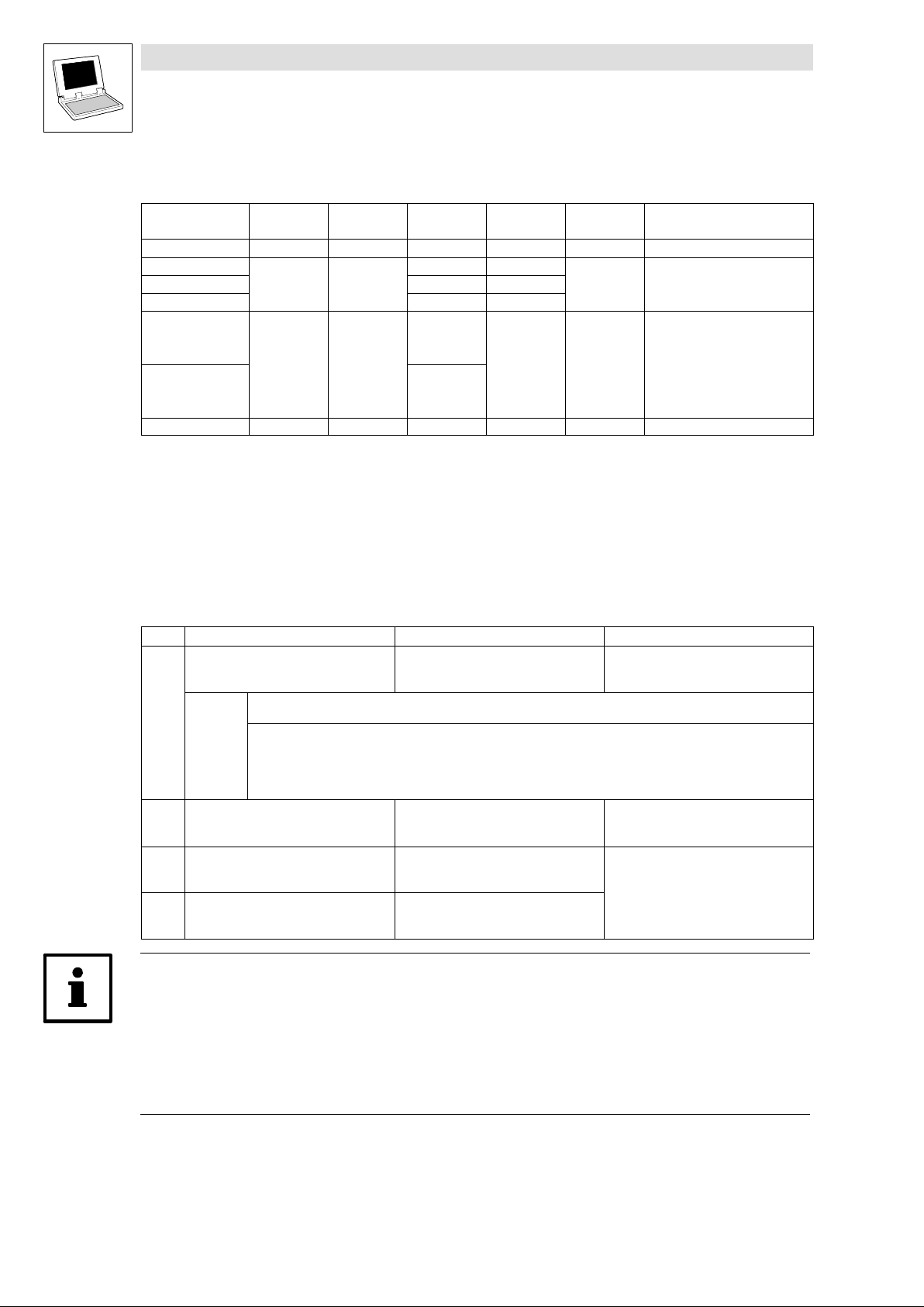

System variables

Variable Data type Signal type Address Display

AIF1_wDctrlCtrl Word − %IX41.0 C0136/3 hex

AIF1_bCtrlB0_b

AIF1_bCtrlB1_b

AIF1_bCtrlB2_b

AIF1_bCtrlQuickstop_b

AIF1_bCtrlB4_b

AIF1_bCtrlB5_b

AIF1_bCtrlB6_b

AIF1_bCtrlB7_b

AIF1_bCtrlDisable_b

AIF1_bCtrlCInhibit_b

AIF1_bCtrlTripSet_b

AIF1_bCtrlTripReset_b

AIF1_bCtrlB12_b

AIF1_bCtrlB13_b

AIF1_bCtrlB14_b

AIF1_bCtrlB15_b

AIF1_nInW1_a

AIF1_nInW2_a

AIF1_nInW3_a

AIF1_bInB0_b

...

AIF1_bInB15_b

AIF1_bInB16_b

...

AIF1_bInB31_b

AIF1_dnInD1_p Double integer Position %ID41.1 C0857 dec [inc]

Bool Binary

Integer Analog

Bool Binary

%IX41.0.0

%IX41.0.1

%IX41.0.2

%IX41.0.3

%IX41.0.4

%IX41.0.5

%IX41.0.6

%IX41.0.7

%IX41.0.8

%IX41.0.9

%IX41.0.10

%IX41.0.11

%IX41.0.12

%IX41.0.13

%IX41.0.14

%IX41.0.15

%IW41.1 C0856/1

%IW41.2 C0856/2

%IW41.3 C0856/3

%IX41.2.0

...

%IX41.2.15

%IX41.3.0

...

%IX41.3.15

code

C0136/3 bin

C0855/1

C0855/2

Display

format

dec [%]

hex

Note

L

9300 Servo PLC EN 5.1

2−11

Page 18

9300 Servo PLC

System blocks

2.1 AIF1_IO_AutomationInterface (node number 41)

User data

The received 8 bytes of user data are assigned to several variables of different data types

simultaneously. Thus the data can be evaluated in the PLC program as

binary information (1 bit)

control word/quasi−analog value (16 bits)

phase information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2

Notes:

3, 4

AIF1_bInB0_b

AIF1_bInB1_b

AIF1_bInB2_b

AIF1_bCtrlQuickstop_b

AIF1_bInB4_b

...

AIF1_bInB7_b

AIF1_bCtrlDisable_b

AIF1_bCtrlCInhibit_b

AIF1_bCtrlTripSet_b

AIF1_bCtrlTripReset_b

AIF1_bInB12_b

...

AIF1_bInB15_b

Drive PLC:

All variables assigned to byte 1/2 can be freely used in the PLC program.

9300 Servo PLC:

The assignment of the controller−internal control word to byte 1/2 is not a fixed assignment.

Byte 1/2 can, however, be used to write the signals for the quick stop (QSP), DISABLE, CINH, TRIP−SET and

TRIP−RESET functions to the SB DCTRL_DriveControl.

– To do this, connect the variable AIF1_wDctrlCtrl with the variable DCTRL_wAIF1Ctrl of the SB

DCTRL_DriveControl.

The signals can also be read and processed via the following variables:

– AIF1_bCtrlQuickstop_b

– AIF1_bCtrlDisable_b

– AIF1_bCtrlCInhibit_b

– AIF1_bCtrlTripSet_b

– AIF1_bCtrlTripReset_b

AIF1_wDctrlCtrl

AIF1_nInW1_a

2−12

5, 6 AIF1_bInB0_b

...

AIF1_bInB15_b

7, 8 AIF1_bInB16_b

...

AIF1_bInB31_b

AIF1_nInW2_a

AIF1_nInW3_a

9300 Servo PLC EN 5.1

AIF1_dnInD1_p

L

Page 19

9300 Servo PLC

System blocks

2.1 AIF1_IO_AutomationInterface (node number 41)

2.1.2 Outputs_AIF1

This SB is used as an interface for output signals (e.g. setpoints/actual values) to attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

Outputs_AIF1

Fig. 2−2 Outputs_AIF1

AIF1_wDctrlStat

AIF1_nOutW1_a

AIF1_nOutW2__a

AIF1_bFDO0_b

…

AIF1_bFDO15_b

AIF1_nOutW3_a

AIF1_bFDO16_b

…

AIF1_bFDO31_b

AIF1_dnOutD1_p

C0858/1

C0858/2

C0858/3

C0859

16 Bit

16 Bit

16 Bit

C0151/4

16 binary

signals

16 Bit

C0151/4

16 binary

signals

16 Bit

LowWord

16 Bit

HighWord

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Byte

1

2

3

4

5

6

7

8

Automation

Interface

L

9300 Servo PLC EN 5.1

2−13

Page 20

9300 Servo PLC

System blocks

2.1 AIF1_IO_AutomationInterface (node number 41)

System variables

Variable Data type Signal type Address Display

AIF1_wDctrlStat Word − %QW41.0 − −

AIF1_nOutW1_a

AIF1_nOutW2_a %QW41.2 C0858/2

AIF1_nOutW3_a %QW41.3 C0858/3

AIF1_bFDO0_b

.. ...

AIF1_bFDO15_b %QX41.2.15

AIF1_bFDO16_b %QX41.3.0

.. ...

AIF1_bFDO31_b %QX41.3.15

AIF1_dnOutD1_p Double integer Position %QD41.1 C0859 dec [inc]

Integer Analog

Bool Binary

%QW41.1 C0858/1

%QX41.2.0

code

C0151/4 hex

Display

format

dec [%]

Note

Display code in hex

as double word

User data

The 8 bytes of user data to be sent can be written to via several variables of different data types

simultaneously. Thus the data can be transferred by the PLC program as

binary information (1 bit)

status word/quasi−analog value (16 bits)

phase information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2

AIF1_wDctrlStat

Notes:

Drive PLC:

All variables assigned to byte 1/2 can be written to by the PLC program.

9300 Servo PLC:

Bytes 1 and 2 can be used to transfer the status word from the SB DCTRL_DriveControl.

To do this, connect the variable DCTRL_wStat of the SB DCTRL_DriveControl with the variable AIF1_wDctrlStat.

In addition to signals such as IMP and CINH, the SB DCTRL_DriveControl status word contains some freely

assignable signals which can be written to via the variables DCTRL_bStateB.._b of the SB DCTRL_DriveControl.

3, 4

5, 6 AIF1_bFDO0_b

...

AIF1_bFDO15_b

7, 8 AIF1_bFDO16_b

...

AIF1_bFDO31_b

AIF1_nOutW1_a

AIF1_nOutW2_a

AIF1_dnOutD1_p

AIF1_nOutW3_a

Tip!

Avoid simultaneous overwriting via different variable types to ensure data consistency.

Thus bytes 5 and 6 should only be written to

– by the variable AIF1_dnOutD1_p,

– by the variable AIF1_nOutW2_a or

– by the variables AIF1_bFDO0_b ... AIF1_bFDO15_b.

2−14

9300 Servo PLC EN 5.1

L

Page 21

9300 Servo PLC

System blocks

2.2 AIF2_IO_AutomationInterface (node number 42)

2.2 AIF2_IO_AutomationInterface (node number 42)

2.2.1 Inputs_AIF2

Automation interface (node number 42)

This SB is used as an interface for input signals (e.g. setpoints/actual values) from attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

Fig. 2−3 Inputs_AIF2

Automation

Interface

Inputs_AIF2

Byte

1

Byte

2

Byte

3

Byte

4

Byte

5

Byte

6

Byte

7

Byte

8

16 Bit

16 binary

signals

16 Bit

16 binary

signals

16 Bit

LowWord

16 Bit

HighWord

16 Bit

16 Bit

AIF2_nInW1_a

AIF2_bInB0_b

...

AIF2_bInB15_b

AIF2_nInW2_a

AIF2_bInB16_b

...

AIF2_bInB31_b

AIF2_dnInD1_p

AIF2_nInW3_a

AIF2_nInW4_a

L

9300 Servo PLC EN 5.1

2−15

Page 22

9300 Servo PLC

System blocks

2.2 AIF2_IO_AutomationInterface (node number 42)

System variables

Variable Data type Signal type Address Display code Display

AIF2_nInW1_a

AIF2_nInW2_a %IW42.1

AIF2_nInW3_a %IW42.2

AIF2_nInW4_a %IW42.3

AIF2_bInB0_b

... ...

AIF2_bInB15_b %IX42.0.15

AIF2_bInB16_b %IX42.1.0

... ...

AIF2_bInB31_b %IX42.1.15

AIF2_dnInD1_p Double integer Position %ID42.0

Integer Analog

Bool Binary

%IW42.0

%IX42.0.0

format

Note

User data

The 4 first bytes of the received 8 bytes of user data are assigned to several variables of different data

types simultaneously. Thus the data can be evaluated in the PLC program as

binary information (1 bit)

quasi−analog value (16 bits)

angle information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2 AIF2_bInB0_b

...

AIF2_bInB15_b

3, 4 AIF2_bInB16_b

...

AIF2_bInB31_b

5, 6

AIF2_nInW1_a

AIF2_dnInD1_p

AIF2_nInW2_a

AIF2_nInW3_a

7, 8

AIF2_nInW4_a

2−16

9300 Servo PLC EN 5.1

L

Page 23

9300 Servo PLC

System blocks

2.2 AIF2_IO_AutomationInterface (node number 42)

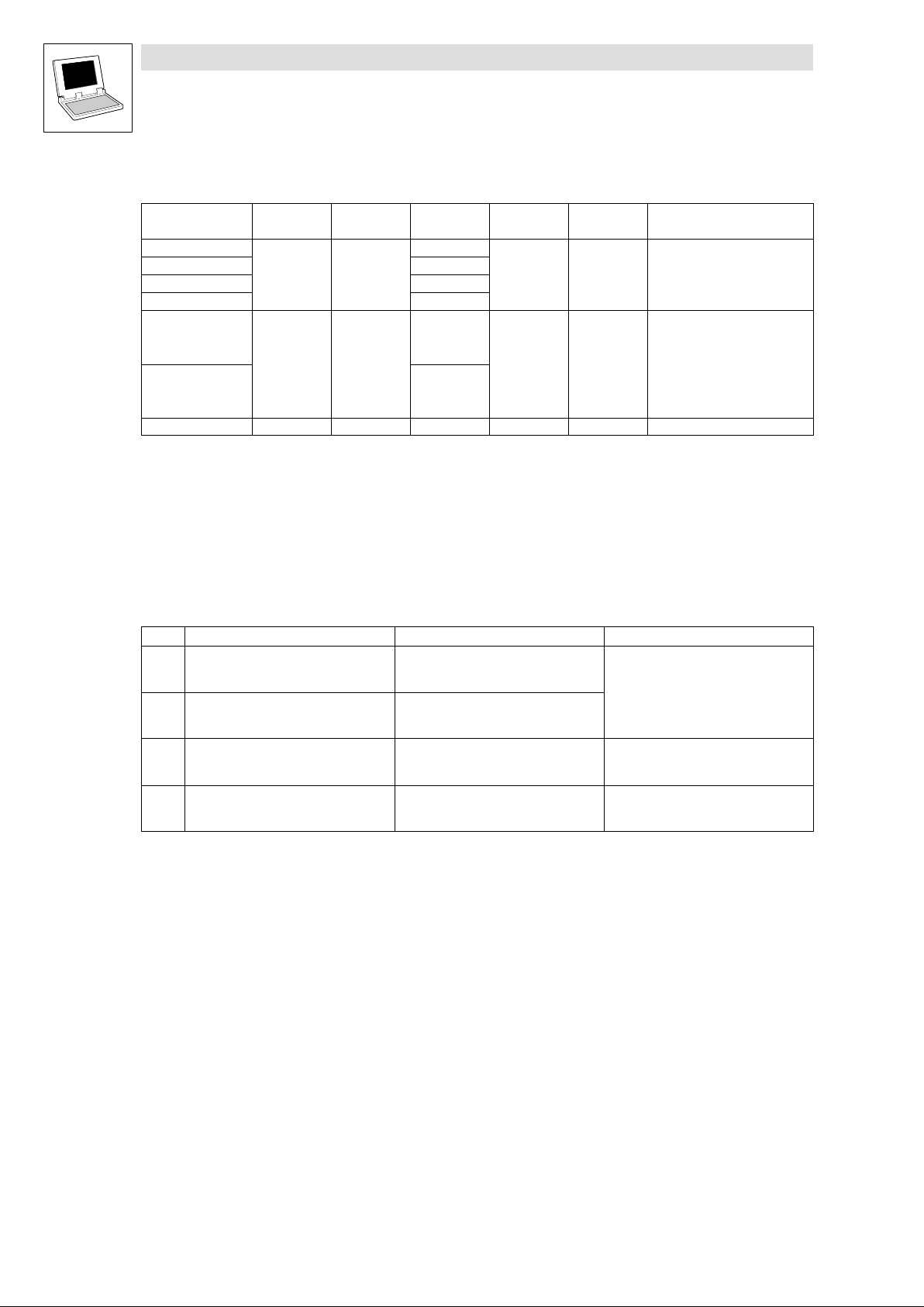

2.2.2 Outputs_AIF2

This SB is used as an interface for output signals (e.g. setpoints/actual values) to attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

Outputs_AIF2

AIF2_nOutW1_a

AIF2_bFDO0_b

...

AIF2_bFDO15_b

AIF2_nOutW2_a

AIF2_bFDO16_b

...

AIF2_bFDO31_b

AIF2_dnOutD1_p

AIF2_nOutW3_a

AIF2_nOutW4_a

16 Bit

16 binary

signals

16 Bit

16 binary

signals

16 Bit

LowWord

16 Bit

HighWord

16 Bit

16 Bit

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Byte

1

2

3

4

5

6

7

8

Automation

Interface

Fig. 2−4 Outputs_AIF2

L

9300 Servo PLC EN 5.1

2−17

Page 24

9300 Servo PLC

System blocks

2.2 AIF2_IO_AutomationInterface (node number 42)

System variables

Variable Data type Signal type Address Display code Display

AIF2_nOutW1_a

AIF2_nOutW2_a %QW42.1

AIF2_nOutW3_a %QW42.2

AIF2_nOutW4_a %QW42.3

AIF2_bFDO0_b

... ...

AIF2_bFDO15_b %QX42.0.15

AIF2_bFDO16_b %QX42.1.0

... ...

AIF2_bFDO31_b %QX42.1.15

AIF2_dnOutD1_p Double integer Position %QD42.0

Integer Analog

Bool Binary

%QW42.0

%QX42.0.0

format

Note

User data

The first 4 bytes of the 8 bytes of user data to be sent can be written to via several variables of different

data types at the same time. Data can therefore be transferred by the PLC program as

binary information (1 bit)

quasi−analog value (16 bits)

angle information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2 AIF2_bFDO0_b

...

AIF2_bFDO15_b

3, 4 AIF2_bFDO16_b

...

AIF2_bFDO31_b

5, 6

AIF2_nOutW1_a

AIF2_dnOutD1_p

AIF2_nOutW2_a

AIF2_nOutW3_a

7, 8

AIF2_nOutW4_a

Tip!

Avoid simultaneous overwriting via different variable types to ensure data consistency.

Thus bytes 1 and 2 should only be written to

– by the variable AIF2_dnOutD1_p,

– by the variable AIF2_nOutW1_a or

– by the variables AIF2_bFDO0_b ... AIF2_bFDO15_b.

2−18

9300 Servo PLC EN 5.1

L

Page 25

9300 Servo PLC

System blocks

2.3 AIF3_IO_AutomationInterface (node number 43)

2.3 AIF3_IO_AutomationInterface (node number 43)

2.3.1 Inputs_AIF3

This SB is used as an interface for input signals (e.g. setpoints/actual values) from attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

Fig. 2−5 Inputs_AIF3

Automation

Interface

Inputs_AIF3

Byte

1

Byte

2

Byte

3

Byte

4

Byte

5

Byte

6

Byte

7

Byte

8

16 Bit

16 binary

signals

16 Bit

16 binary

signals

16 Bit

LowWord

16 Bit

HighWord

16 Bit

16 Bit

AIF3_nInW1_a

AIF3_bInB0_b

...

AIF3_bInB15_b

AIF3_nInW2_a

AIF3_bInB16_b

...

AIF3_bInB31_b

AIF3_dnInD1_p

AIF3_nInW3_a

AIF3_nInW4_a

L

9300 Servo PLC EN 5.1

2−19

Page 26

9300 Servo PLC

System blocks

2.3 AIF3_IO_AutomationInterface (node number 43)

System variables

Variable Data type Signal type Address Display code Display

AIF3_nInW1_a

AIF3_nInW2_a %IW43.1

AIF3_nInW3_a %IW43.2

AIF3_nInW4_a %IW43.3

AIF3_bInB0_b

... ...

AIF3_bInB15_b %IX43.0.15

AIF3_bInB16_b %IX43.1.0

... ...

AIF3_bInB31_b %IX43.1.15

AIF3_dnInD1_p Double integer Position %ID43.0

Integer Analog

Bool Binary

%IW43.0

%IX43.0.0

format

Note

User data

The 4 first bytes of the received 8 bytes of user data are assigned to several variables of different data

types simultaneously. Thus the data can be evaluated in the PLC program as

binary information (1 bit)

quasi−analog value (16 bits)

angle information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2 AIF3_bInB0_b

...

AIF3_bInB15_b

3, 4 AIF3_bInB16_b

...

AIF3_bInB31_b

5, 6

AIF3_nInW1_a

AIF3_dnInD1_p

AIF3_nInW2_a

AIF3_nInW3_a

7, 8

AIF3_nInW4_a

2−20

9300 Servo PLC EN 5.1

L

Page 27

9300 Servo PLC

System blocks

2.3 AIF3_IO_AutomationInterface (node number 43)

2.3.2 Outputs_AIF3

This SB is used as an interface for output signals (e.g. setpoints/actual values) to attached fieldbus

modules (e.g. INTERBUS, PROFIBUS−DP).

The process image is

– created in the cyclic task in a fixed time interval of 10 ms.

– created in an interval task within the time set for this task.

– read at the beginning of the task and written at its end.

Tip!

Please observe the Operating Instructions for the attached fieldbus module.

Outputs_AIF3

AIF3_nOutW1_a

AIF3_bFDO0_b

...

AIF3_bFDO15_b

AIF3_nOutW2_a

AIF3_bFDO16_b

...

AIF3_bFDO31_b

AIF3_dnOutD1_p

AIF3_nOutW3_a

AIF3_nOutW4_a

16 Bit

16 binary

signals

16 Bit

16 binary

signals

16 Bit

LowWord

16 Bit

HighWord

16 Bit

16 Bit

Byte

Byte

Byte

Byte

Byte

Byte

Byte

Byte

1

2

3

4

5

6

7

8

Automation

Interface

Fig. 2−6 Outputs_AIF3

L

9300 Servo PLC EN 5.1

2−21

Page 28

9300 Servo PLC

System blocks

2.3 AIF3_IO_AutomationInterface (node number 43)

System variables

Variable Data type Signal type Address Display code Display

AIF3_nOutW1_a

AIF3_nOutW2_a %QW43.1

AIF3_nOutW3_a %QW43.2

AIF3_nOutW4_a %QW43.3

AIF3_bFDO0_b

... ...

AIF3_bFDO15_b %QX43.0.15

AIF3_bFDO16_b %QX43.1.0

... ...

AIF3_bFDO31_b %QX43.1.15

AIF3_dnOutD1_p Double integer Position %QD43.0

Integer Analog

Bool Binary

%QW43.0

%QX43.0.0

format

Note

User data

The first 4 bytes of the 8 bytes of user data to be sent can be written to via several variables of different

data types at the same time. Data can therefore be transferred by the PLC program as

binary information (1 bit)

quasi−analog value (16 bits)

angle information (32 bits)

according to the requirements.

Byte Variable (1 bit) Variable (16 bits) Variable (32 bits)

1, 2 AIF3_bFDO0_b

...

AIF3_bFDO15_b

3, 4 AIF3_bFDO16_b

...

AIF3_bFDO31_b

5, 6

AIF3_nOutW1_a

AIF3_dnOutD1_p

AIF3_nOutW2_a

AIF3_nOutW3_a

7, 8

AIF3_nOutW4_a

Tip!

Avoid simultaneous overwriting via different variable types to ensure data consistency.

Thus bytes 1 and 2 should only be written to

– by the variable AIF3_dnOutD1_p,

– by the variable AIF3_nOutW1_a or

– by the variables AIF3_bFDO0_b ... AIF3_bFDO15_b.

2−22

9300 Servo PLC EN 5.1

L

Page 29

9300 Servo PLC

System blocks

2.4 AIF_IO_Management (node number 161)

2.4 AIF_IO_Management (node number 161)

2.4.1 Inputs_AIF_Management

This SB monitors the communication of a communication module connected to the automation

interface (AIF).

In the event of an error, AIF_bCe0CommErr_b is set to TRUE and the communication error

"CE0" (LECOM no. 61) is set. The response to this can be configured under C0126 (Lenze

setting: off).

New AIF communication modules (e.g. 2133 and 2175) also use

AIF_bFieldBusStateBit0_b ... AIF_bFieldBusStateBit15_b to transfer an error number from the

communication module.

C2121 displays the status.

Tip!

Please observe the documentation for the attached communication module.

Automation

interface

Fig. 2−7 System block "Inputs_AIF_Management"

AIF

Communication

Error

AIF

Fieldbus State

Inputs_AIF_Management

AIF_bCe0CommErr_b

AIF_bFieldBusStateBit0_b

AIF_bFieldBusStateBit1_b

AIF_bFieldBusStateBit2_b

AIF_bFieldBusStateBit3_b

AIF_bFieldBusStateBit4_b

AIF_bFieldBusStateBit5_b

AIF_bFieldBusStateBit6_b

AIF_bFieldBusStateBit7_b

AIF_bFieldBusStateBit8_b

AIF_bFieldBusStateBit9_b

AIF_bFieldBusStateBit10_b

AIF_bFieldBusStateBit11_b

AIF_bFieldBusStateBit12_b

AIF_bFieldBusStateBit13_b

AIF_bFieldBusStateBit14_b

AIF_bFieldBusStateBit15_b

L

9300 Servo PLC EN 5.1

2−23

Page 30

9300 Servo PLC

System blocks

2.4 AIF_IO_Management (node number 161)

System variables

Variable Data type Signal type Address Display code Display

AIF_bCe0CommErr_b

AIF_bFieldBusStateBit0_b %IX161.1.0 Error number − bit 0

AIF_bFieldBusStateBit1_b %IX161.1.1 Error number − bit 1

AIF_bFieldBusStateBit2_b %IX161.1.2 Error number − bit 2

AIF_bFieldBusStateBit3_b %IX161.1.3 Error number − bit 3

AIF_bFieldBusStateBit4_b %IX161.1.4 Error number − bit 4

AIF_bFieldBusStateBit5_b %IX161.1.5 Error number − bit 5

AIF_bFieldBusStateBit6_b %IX161.1.6 Error number − bit 6

AIF_bFieldBusStateBit7_b %IX161.1.7 Error number − bit 7

AIF_bFieldBusStateBit8_b %IX161.1.8 Error number − bit 8

AIF_bFieldBusStateBit9_b %IX161.1.9 Error number − bit 9

AIF_bFieldBusStateBit10_b %IX161.1.10 Error number − bit 10

AIF_bFieldBusStateBit11_b %IX161.1.11 Error number − bit 11

AIF_bFieldBusStateBit12_b %IX161.1.12 Error number − bit 12

AIF_bFieldBusStateBit13_b %IX161.1.13 Error number − bit 13

AIF_bFieldBusStateBit14_b %IX161.1.14 Error number − bit 14

AIF_bFieldBusStateBit15_b %IX161.1.15 Error number − bit 15

Bool binary

%IX161.0.0 Communication error "CE0"

format

Notes

Codes

Code LCD

C0126 MONIT CE0 3

C2121 AIF: state

Possible settings

Lenze Selection

0 TRIP

2 Warning

3 Off

G

0 {dec} 255

Decimal value is bit−coded:

Bit 0 XCAN1_IN monitoring time

Bit 1 XCAN2_IN monitoring time

Bit 2 XCAN3_IN monitoring time

Bit 3 XCAN bus−off

Bit 4 XCAN operational

Bit 5 XCAN pre−operational

Bit 6 XCAN warning

Bit 7 Internally assigned

Info

Configuration for communication

error "CE0" with automation

interface

AIF−CAN: Status

Detailed information can be

found in the documentation for

the corresponding

communication module.

2−24

9300 Servo PLC EN 5.1

L

Page 31

9300 Servo PLC

System blocks

2.4 AIF_IO_Management (node number 161)

2.4.2 Outputs_AIF_Management

This SB transfers commands and messages to a fieldbus module connected to an automation

interface (AIF).

For this purpose C2120 provides a control word. The commands are specified as numbers. Some

command numbers are universally applicable for all fieldbus modules, others apply only for special

modules. The total number of commands available can amount to up to 16.

Tip!

Read the documentation for the attached fieldbus module.

Outputs_AIF_Management

AIF control word

Bit 8 … 15

AIF_wControl

Fig. 2−8 System block "Outputs_AIF_Management"

System variables

Variable Data type Signal type Address Display code Display

AIF_wControl Word %QX161.0 C2120

Codes

Code LCD

C2120 AIF: Control

Possible settings

Lenze Selection

0 No command

1 Read CAN codes + reinitialisation

2 Read XCAN codes

10 Read XCAN C2356/1 ... 4

11 Read XCAN C2357

12 Read XCAN C2375

13 Read XCAN C2376 ... C2378

14 Read XCAN C2382

255 Not assigned

Bit 7

Toggle-Bit (MSB)

Bit0…6

C2120

Note

format

Info

AIF command

L

9300 Servo PLC EN 5.1

2−25

Page 32

9300 Servo PLC

System blocks

2.5 ANALOG1_IO (node number 11)

2.5 ANALOG1_IO (node number 11)

2.5.1 Inputs_ANALOG1 (analog input)

The input is the interface for differential analog signals between terminals X6/1, 2. It can be used as

a setpoint input or as an actual value input.

X6

1

2

Fig. 2−9 Inputs_ANALOG1

System variables

C0034

Inputs_ANALOG1

AIN1_nIn_a

C0400

AIN1_bError_b

Variable Data type Signal type Address Display

code

AIN1_nIn_a Integer Analog %IW11.0 C0400 dec [%] Analog input 1

AIN1_bError_b Bool Binary %IX11.1.0 − − Only when C0034 = 1:

Display

format

Note

TRUE if I < 2 mA

Selection of master voltage/master current

C0034 can be used to set whether the input is to be used for a master voltage or a master

current:

Code LCD

C0034 Mst current 0 Selection: Master voltage/master

Possible settings

Lenze Selection

0 −10 V ... + 10 V (master voltage)

1 +4 mA ... +20 mA (master current)

2 −20 mA ... +20 mA

Info

current

Please also observe the jumper position X3 at the front of the 9300 Servo PLC in this

connection (see terminal assignment).

Use as a 4 ... 20 mA master current input

If the input is used as a master current input (C0034 =1), then AIN1_bError_b = TRUE as long

as the absolute value of the master current is < 2 mA, otherwise it is FALSE.

C0598 can be used to set the response for the case that the absolute value of the master

current is < 2 mA:

2−26

Code LCD

C0598 MONIT SD5 3 Monitoring configuration:

Possible settings

Lenze Selection

0 TRIP

2 Warning

3 Off

Info

Absolute master current value across

X6/1, 2 < 2 mA

9300 Servo PLC EN 5.1

L

Page 33

9300 Servo PLC

System blocks

2.5 ANALOG1_IO (node number 11)

Terminal assignment

Set via C0034 whether the input is to be used for a master voltage or a master current.

Set jumper bar X3 according to setting in C0034:

Stop!

Do not plug the jumper on 3−4! The PLC cannot be initialised in this case.

Terminal Use Jumper X3 Measuring range

X6/1, 2

Differential input for

master voltage

Differential input for

master current

6

4

2

6

4

2

5

3

1

5

3

1

C0034 = 0

Level:

Resolution:

Scaling:

C0034 = 1

Level:

Resolution:

Scaling:

C0034 = 2

Level:

Resolution:

Scaling:

−10 V ... +10 V

5 mV (11 bits + sign)

10 V 16384 100 %

+4 mA ... +20 mA

20 A (10 bits without sign)

+4 mA 0 0 %

+20 mA +16384 +100 %

−20 mA ... +20 mA

20 A (10 bits + sign)

20 mA 16384 100 %

2.5.2 Outputs_ANALOG1 (analog output)

The output can be used as a monitor output. Internal analog signals can be output as voltage signals

via terminal X6/62 and used, for instance, as display values or setpoints for slave drives.

AOUT1_nOut_a

Fig. 2−10 Outputs_ANALOG1

System variables

Variable Data type Signal type Address Display

AOUT1_nOut_a Integer Analog %QW11.0 C0434 dec [%] Analog output 1

Terminal assignment

Terminal Use Measuring range

X6/62 Analog output 1 (monitor 1) Level:

X6/7 Internal ground, GND −

Outputs_ANALOG1

C0434

code

Resolution:

Scaling:

X6

62

Display

format

−10 V ... +10 V (max. 2 mA)

20 mV (9 bits + sign)

10 V 16384 100 %

Note

L

9300 Servo PLC EN 5.1

2−27

Page 34

9300 Servo PLC

3

4

System blocks

2.6 ANALOG2_IO (node number 12)

2.6 ANALOG2_IO (node number 12)

2.6.1 Inputs_ANALOG2 (analog input)

The input is the interface for differential analog signals between terminals X6/3, 4.

X6

Fig. 2−11 Inputs_ANALOG2

System variables

Variable Data type Signal type Address Display

AIN2_nIn_a Integer Analog %IW12.0 C0405 dec [%] Analog input 2

Terminal assignment

Terminal Use Measuring range

X6/3, 4 Differential input for master voltage

(no effect of jumper X3)

2.6.2 Outputs_ANALOG2 (analog output)

The output can be used as a monitor output. Internal analog signals can be output as voltage signals

via terminal X6/63 and used, for instance, as display values or setpoints for slave drives.

AOUT2_nOut_a

Inputs_ANALOG2

AIN2_nIn_a

C0405

code

Level:

Resolution:

Scaling:

Outputs_ANALOG2

C0439

Display

format

−10 V ... +10 V

5 mV (11 bits + sign)

10 V 16384 100 %

X6

63

Note

Fig. 2−12 Outputs_ANALOG2

System variables

AOUT2_nOut_a Integer Analog %QW12.0 C0439 dec [%] Analog output 2

Terminal assignment

Terminal Use Measuring range

X6/63 Analog output 2 (monitor 2) Level:

X6/7 Internal ground, GND −

2−28

Variable Data type Signal type Address Display

code

Resolution:

Scaling:

9300 Servo PLC EN 5.1

Display

format

−10 V ... +10 V (max. 2 mA)

20 mV (9 bits + sign)

10 V 16384 100 %

Note

L

Page 35

9300 Servo PLC

System blocks

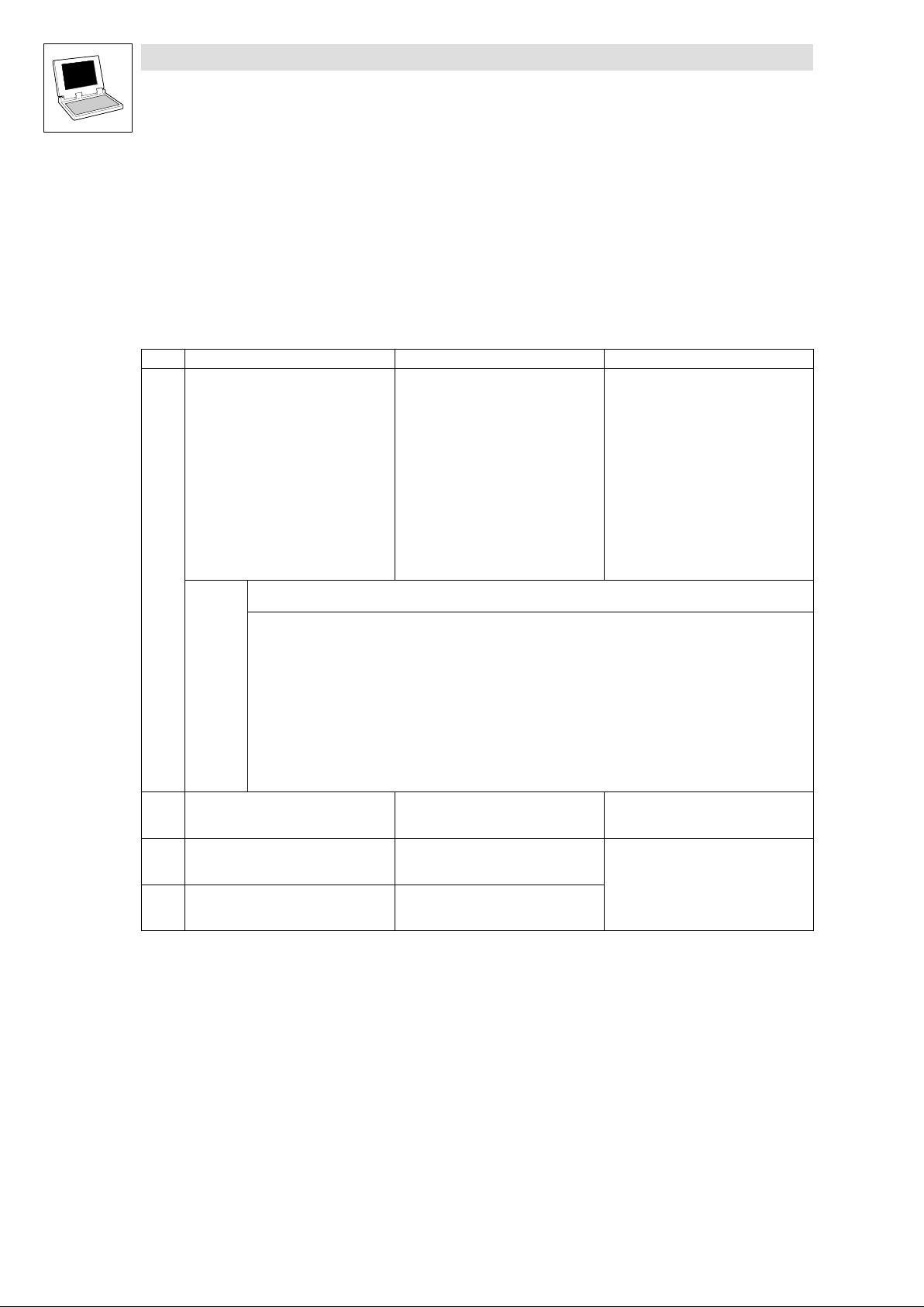

2.7 DCTRL_DriveControl (node number 121)

2.7 DCTRL_DriveControl (node number 121)

This SB controls the transition of the 9300 Servo PLC to certain states (e.g. TRIP, TRIP−RESET, quick

stop (QSP) or controller inhibit (CINH)).

The process image is created in the course of a fixed system task (interval: 2 ms).

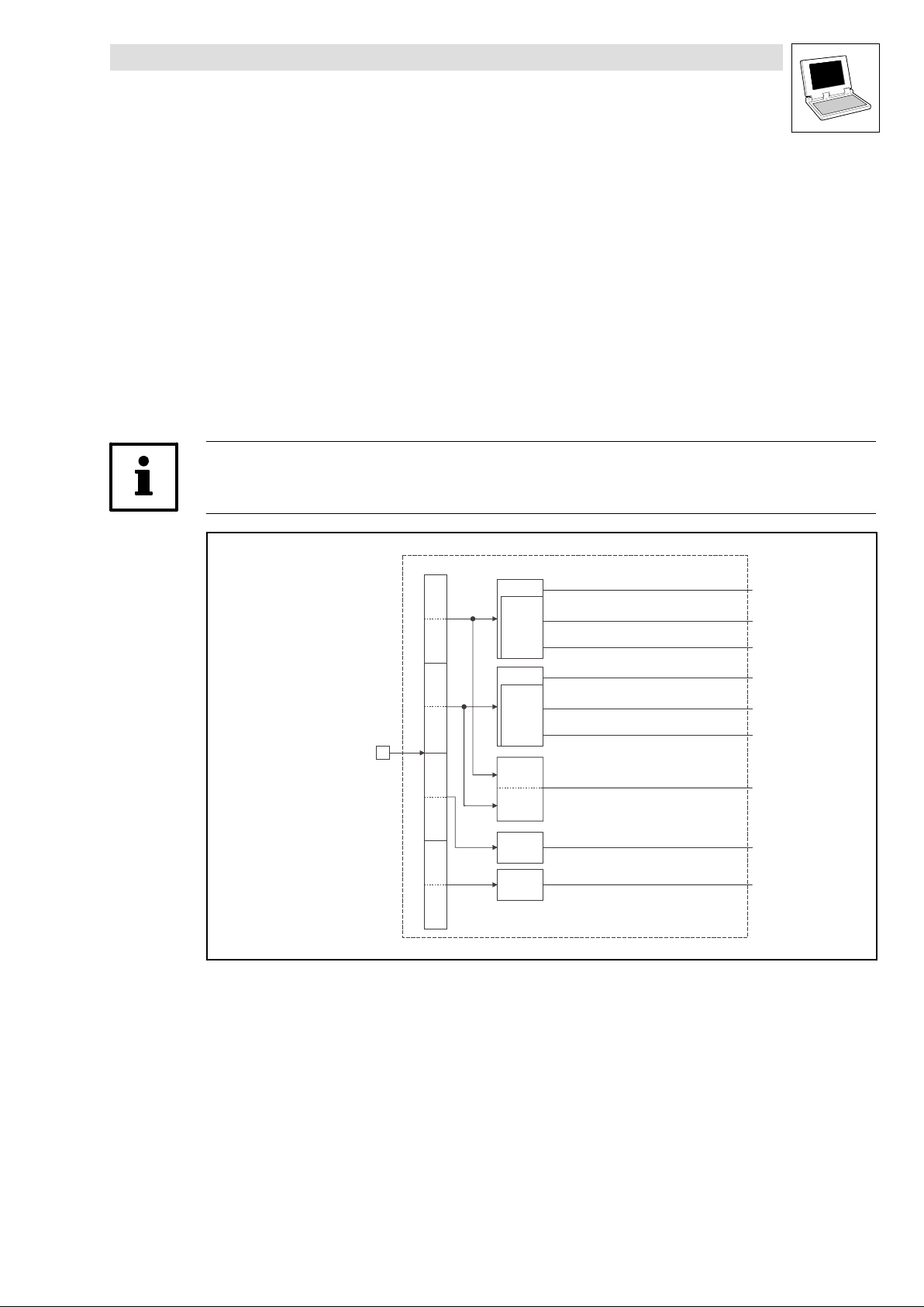

DCTRL_wCAN1Ctrl

DCTRL_wAIF1Ctrl

DCTRL_bCInh1_b

DCTRL_bCInh2_b

DCTRL_bTripSet_b

DCTRL_bTripReset_b

DCTRL_bStateB0_b

DCTRL_bStateB2_b

DCTRL_b _bStateB3

DCTRL_b _bStateB4

DCTRL_bStateB5_b

DCTRL_bStateB14_b

DCTRL_bStateB15_b

C0878/1

C0878/2

C0878/3

C0878/4

16 Bit

16 Bit

C0135

C0136/1

16

C135.B3

C135.B8

C135.B9

X5/28

Bit10

Bit10

C135.B10

Bit11

Bit11

C135.B11

DCTRL_bImp_b

DCTRL_bNActEq0_b

DCTRL_bCInh_b

DCTRL_bStat1_b

DCTRL_bStat2_b

DCTRL_bStat4_b

DCTRL_bStat8_b

DCTRL_bWarn_b

DCTRL_bMess_b

Bit3

Bit3

Bit8

Bit8

Bit9

Bit9

DCTRL_DriveControl

QSP

>

1

DISABLE

>

1

>

1

CINH

TRIP-SET

>

1

TRIP-

>

1

RESET

>

1

STAT

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

DCTRL_bFail_b

DCTRL_bImp_b

DCTRL_bTrip_b

DCTRL_bQspIn_b

DCTRL_bRdy_b

DCTRL_bCwCCw_b

DCTRL_bNActEq0_b

DCTRL_bCInh_b

DCTRL_bStat1_b

DCTRL_bStat2_b

DCTRL_bStat4_b

DCTRL_bStat8_b

DCTRL_bWarn_b

DCTRL_bMess_b

DCTRL_bInit_b

DCTRL_bExternalFault_b

DCTRL_wFaultNumber

DCTRL_wStat

C0150

Fig. 2−13 DCTRL_DriveControl

Tip!

The SB DCTRL_DriveControl only affects the motor control and drive control of the

9300 Servo PLC, i.e. motor control/drive control and application program of the PLC are completely

independent of each other as long as the signals are not queried in the application program.

If, for instance, the motor control initiates a TRIP, the application program will not be stopped!

If, however, a TRIP is caused by a task overflow, the application program of the PLC will be

stopped as well!

L

9300 Servo PLC EN 5.1

2−29

Page 36

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

2.7.1 Inputs_DCTRL

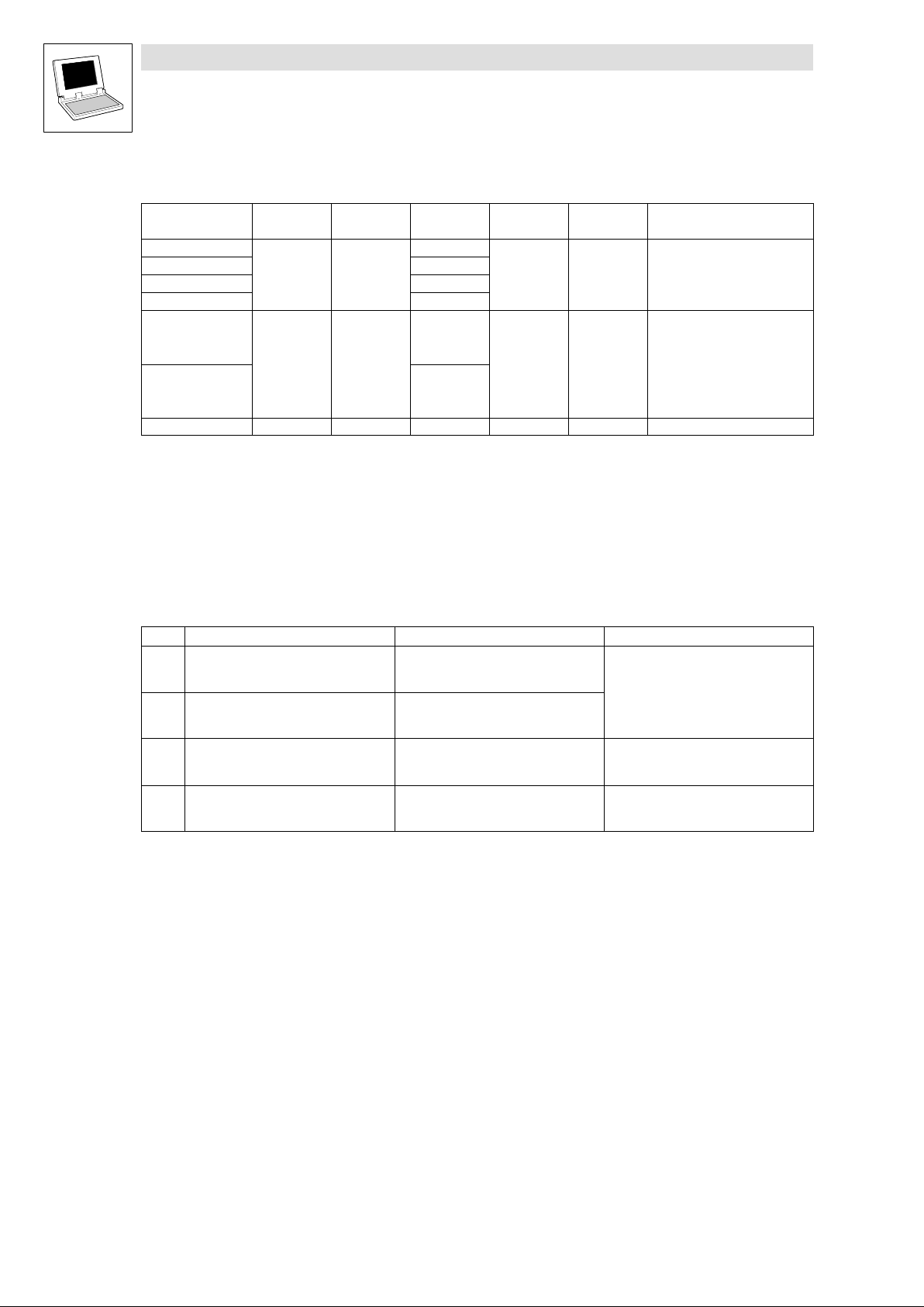

System variables

Variables Data type Signal type Address Display

DCTRL_bFail_b

DCTRL_bImp_b %IX121.0.1 TRUE = power output stages with high

DCTRL_bTrip_b %IX121.0.2 TRUE = active fault

DCTRL_bQspIn_b %IX121.0.3 TRUE = quick stop (QSP) ^ 2−31

DCTRL_bRdy_b %IX121.0.4 TRUE = ready for operation

DCTRL_bCwCcw_b %IX121.0.5 FALSE = CW, TRUE = CCW

DCTRL_bNActEq0_b %IX121.0.6 TRUE = motor speed < C0019

DCTRL_bCInh_b %IX121.0.7 TRUE = RSP ^ 2−32

DCTRL_bStat1_b

DCTRL_bStat2_b

DCTRL_bStat4_b

DCTRL_bStat8_b

DCTRL_bWarn_b

DCTRL_bMess_b %IX121.0.13 TRUE = active message

DCTRL_bInit_b %IX121.0.14 TRUE = initialisation phase

DCTRL_bExternalFault_b %IX121.0.15 TRUE = external error ^ 2−34

DCTRL_wStat

DCTRL_wFaultNumber %IW121.2 C0168 Current error number ^

2.7.2 Outputs_DCTRL

System variables

Bool Binary

Bool Binary

Bool Binary

Word −

Code

%IX121.0.0 TRUE = active error

%IX121.0.8

%IX121.0.9

%IX121.0.10

%IX121.0.11

%IX121.0.12 TRUE = active warning

%IW121.1 C0150

Display

Format

resistance

Status signals ^ 2−33

Status word ^ 2−33

hex

Note

3−106

Variable Data type Signal type Address Display

DCTRL_wCAN1Ctrl

DCTRL_wAIF1Ctrl %QW121.2 AIF control word

DCTRL_bCInh1_b

DCTRL_bCInh2_b

DCTRL_bTripSet_b

DCTRL_bTripReset_b

DCTRL_bStatB0_b

DCTRL_bStatB2_b

DCTRL_bStatB3_b

DCTRL_bStatB4_b

DCTRL_bStatB5_b

DCTRL_bStatB14_b

DCTRL_bStatB15_b

Word

Bool Binary

Bool Binary

%QW121.3 CAN control word

%QX121.0.1 C0878/1

%QX121.0.2 C0878/2

%QX121.0.3 C0878/3

%QX121.0.4 C0878/4

%QX121.1.0

%QX121.1.2

%QX121.1.3

%QX121.1.4

%QX121.1.5

%QX121.1.14

%QX121.1.15

Code

Display

Format

bin

Controller inhibit (CINH) ^ 2−31

TRIP−SET ^ 2−32

TRIP−RESET ^ 2−33

Status signals ^ 2−33

Note

2−30

9300 Servo PLC EN 5.1

L

Page 37

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

2.7.3 Quick stop (QSP)

The QSP function is used to stop the drive independently of the selected setpoint within an adjustable

time interval.

Note!

Quick stop (QSP) will only be set if DCTRL_bQspIn_b is connected to MCTRL_bQspOut_b of

SB MCTRL_MotorControl:

DCTRL_bQspIn_b

Any Variable

OR

MCTRL_bQspOut_b

MCTRL_nHiMLim_a

MCTRL_nLoMLim_a

MCTRL_bNMSwt_b

C0907/3

C0906/4

C0906/3

C0907/2

The function can be controlled via the following 3 inputs (OR−linked):

– Control word CAN1_wDctrlCtrl of SB CAN1_IN

– Control word AIF_wDctrlCtrl of SB AIF1_IN

– Control word C0135, bit 3

C0136/1 indicates the control word C0135:

Code LCD

C0136 CTRLWORD

1 DCTRL_DriveControl

Possible settings

Lenze Selection

g

0 {hex} FFFF

Info

Control word

Hexadecimal value is bit−coded.

Speed is reduced to 0 within the deceleration time set under C0105:

Code LCD

C0105 QSP Tif 0.000 Deceleration time for quick stop (QSP)

Possible settings

Lenze Selection

0.000 {0.001 s} 999.900

Info

Referred to speed change

... 0

n

max

.

2.7.4 Operation disabled (DISABLE)

This function sets "Operation disabled (DISABLE)" in the drive, i.e. the power output stages are

inhibited and all speed/current/position controllers are reset. With "Operation disabled", the drive

cannot be started with the "Controller enable" command.

The function can be controlled via the following 3 inputs (OR−linked):

– Control word CAN1_wDctrlCtr of SB CAN1_IN

– Control word AIF_wDctrlCtrl of SB AIF1_IN

– Control word C0135, bit 8

C0136/1 indicates the control word C0135. (^ 2−31)

L

9300 Servo PLC EN 5.1

2−31

Page 38

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

2.7.5 Controller inhibit (CINH)

This function sets "Controller inhibit (CINH)" in the drive, i.e. the power output stages are inhibited

and all speed/current/position controllers are reset.

The function can be controlled via the following 6 inputs (OR−linked):

– Terminal X5/28 (FALSE = controller inhibit active)

– Control word CAN1_wDctrlCtr of SB CAN1_IN

– Control word AIF_wDctrlCtrl of SB AIF1_IN

– Control word C0135, bit 9

– System variable DCTRL_bCInh1_b (TRUE = set controller inhibit)

– System variable DCTRL_bCInh2_b (TRUE = set controller inhibit)

C0136/1 indicates the control word C0135. (^ 2−31)

2.7.6 Setting TRIP (TRIP−SET)

This function sets "TRIP" in the drive and signals an "external error" (error message "EEr").

The function can be controlled via the following 4 inputs (OR−linked):

– Control word CAN1_wDctrlCtr of SB CAN1_IN

– Control word AIF_wDctrlCtrl of SB AIF1_IN

– Control word C0135, bit 10

– System variable DCTRL_bTripSet_b (TRUE = set TRIP)

C0136/1 indicates the control word C0135. (^ 2−31)

The response to TRIP can be set under C0581:

Code LCD

C0581 MONIT Eer 0 Monitoring configuration:

Possible settings

Lenze Selection

0 TRIP

1 Message

2 Warning

3 Off

Info

External error

2−32

9300 Servo PLC EN 5.1

L

Page 39

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

2.7.7 Resetting TRIP (TRIP−RESET)

This function resets an active TRIP provided that the cause of malfunction is eliminated. If the cause

of malfunction is still active, there is no response.

The function can be controlled via the following 4 inputs (OR’d):

– Control word CAN1_wDctrlCtr of SB CAN1_IN

– Control word AIF_wDctrlCtrl of SB AIF1_IN

– Control word C0135, bit 11

– System variable DCTRL_bTripReset_b

Note!

The function can only be performed by the FALSE−TRUE edge of the signal resulting from the OR

operation!

A FALSE−TRUE edge cannot occur if one of the inputs is TRUE!

C0136/1 indicates the control word C0135. (^ 2−31)

2.7.8 Output of digital status signals

Via DCTRL_wStat a status word is output which consists of the signals generated from the SB

DCTRL_DriveControl and of signals from freely configurable SB inputs:

DCTRL_bStateB0_b

DCTRL_bStateB2_b

DCTRL_b _bStateB3

DCTRL_b _bStateB4

DCTRL_bStateB5_b

DCTRL_bStateB14_b

DCTRL_bStateB15_b

Fig. 2−14 Output of the status word DCTRL_wStat

With C0150 you can display the status word:

DCTRL_bImp_b

DCTRL_bNActEq0_b

DCTRL_bCInh_b

DCTRL_bStat1_b

DCTRL_bStat2_b

DCTRL_bStat4_b

DCTRL_bStat8_b

DCTRL_bWarn_b

DCTRL_bMess_b

DCTRL_DriveControl

STAT

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

DCTRL_wStat

C0150

L

9300 Servo PLC EN 5.1

2−33

Page 40

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

Code LCD

C0150 Status word

Possible settings

Lenze Selection

g

Info

Status word DCTRL_wStat

FCODE_bC150Bit0_b ...

FCODE_bC150Bit15_b

0 {1} 65535

Decimal value is bit−coded:

Bit 00 Freely configurable 0

Bit 01 IMP (DCTRL_bImp_b)

Bit 02 Freely configurable 2

Bit 03 Freely configurable 3

Bit 04 Freely configurable 4

Bit 05 Freely configurable 5

Bit 06 n = 0 (DCTRL_bNActEq0_b)

Bit 07 RSP (DCTRL_bCInh_b)

Bit 08 Status (DCTRL_bStat1_b)

Bit 09 Status (DCTRL_bStat2_b)

Bit 10 Status (DCTRL_bStat4_b)

Bit 11 Status (DCTRL_bStat5_b)

Bit 12 Warning (DCTRL_bWarn_b)

Bit 13 Message (DCTRL_bMess_b)

Bit 14 Freely configurable 14

Bit 15 Freely configurable 15

DCTRL_bStateB0_b

DCTRL_bStateB2_b

DCTRL_bStateB3_b

DCTRL_bStateB4_b

DCTRL_bStateB5_b

DCTRL_bStateB14_b

DCTRL_bStateB15_b

The system variables DCTRL_bStat1_b ... DCTRL_bStat8_b display the status of the drive in

binary−coded form:

DCTRL_bStat8_b DCTRL_bStat4_b DCTRL_bStat2_b DCTRL_bStat1_b Status

0 0 0 0 Initialisation after connection of the supply voltage

0 0 0 1 Protection against unexpected start−up active (C0142 = 0)

0 0 1 1 Drive inhibited (controller inhibit)

0 1 1 0 Drive enabled

0 1 1 1 The triggering of a monitoring function resulted in a "message"

1 0 0 0 The triggering of a monitoring function resulted in a TRIP

1 0 1 0 The triggering of a monitoring function resulted in a FailQSP

0 = FALSE 1 = TRUE

2.7.8.1 TRIP status (DCTRL_bExternalFault_b)

If a "TRIP" is initiated in the drive (e.g. via the system variable DCTRL_bTripSet_b, C0135/bit 10 or

keypad), the system variable DCTRL_bExternalFault_b is set to TRUE.

DCTRL_bExternalFault_b is reset to FALSE as soon as the error source is reset.

2−34

9300 Servo PLC EN 5.1

L

Page 41

9300 Servo PLC

System blocks

2.7 DCTRL_DriveControl (node number 121)

2.7.9 Transfer of status/control word via AIF

If the control and/or status word of SB DCTRL_DriveControl is to be assigned to SB AIF1_IO, the

following program in the IEC1131−3 programming language IL can, for instance, be used:

LD DCTRL_wStat

ST AIF1_wDctrlStat /* writing the status word */

LD AIF1_wDctrlCtrl

ST DCTRL_wAIF1Ctrl /* writing the control word */

Tip!

The assignment of the status/control word depends on the communication module used and on the

transmission profile set (e.g. DRIVECOM).

L

9300 Servo PLC EN 5.1

2−35

Page 42

9300 Servo PLC

System blocks

2.8 DFIN_IO_DigitalFrequency (node number 21)

2.8 DFIN_IO_DigitalFrequency (node number 21)

2.8.1 Inputs_DFIN

This SB can convert a pulse current at the digital frequency input X9 into a speed value and scale it.

The transmission is very precise without offset and gain errors.

In addition, this SB provides the phase correction value DFIN_dnIncLastScan_p which is

required within the calling task for phase processing of touch probe processes.

(^ 2−41)

Fig. 2−15 DFIN_IO_DigitalFrequency

System variables

Variable Data type Signal type Address Display

DFIN_nIn_v Integer Velocity %IW21.0 C0426 dec [rpm] Value in inc/ms

DFIN_bEncFaultCable_b Bool Binary %IX21.1.0 − − TRUE = Monitoring

DFIN_bTPReceived_b Bool Binary %IX21.1.2 − − Receive touch probe (TP)

DFIN_dnIncLastScan_p Double integer Position %ID21.1 − − inc between TP and task start

X9

E5

C0427

C0425

4V

(X9/8) MONIT_SD3

MP

C0431

0

1

C0428 C0429

0

1

DFIN_IO_DigitalFrequency

C0426

DFIN_bEncFaultCable_b

TP/MP

-Ctrl

DFIN_bTPReceived_b

DFIN_dnIncLastScan_p

Code

DFIN_nIn_v

Display

Format

Note

"FaultEncCable" has been

triggered because X9/8 is not

supplied with voltage and the

digital frequency coupling is thus

interrupted.

2−36

Stop!

The digital frequency input X9 cannot be used if

you use the digital frequency output X10 (C0540 = 0, 1, 2) and

an incremental encoder/sin−cos encoder!

9300 Servo PLC EN 5.1

L

Page 43

9300 Servo PLC

System blocks

2.8 DFIN_IO_DigitalFrequency (node number 21)

Tip!

The process image is newly created for every task the SB is used in.

If DFIN_nIn_v, DFIN_dnIncLastScan_p and DFIN_bTPReceived_b are used in several tasks,

each task creates its own SB process image.

This process is different from the previous process image creation principle!

The digital frequency input X9 is dimensioned for TTL−level signals.

The input of a zero track is optional.

Configuration of the number of increments

The drive can be adapted to the connected encoder or upstream controller with digital

frequency cascade or digital frequency bus under C0425.

Code LCD

C0425 DFIN const 3 Number of increments of the encoder

Possible settings

Lenze Selection

0 256increments per revolution

1 512increments per revolution

2 1024increments per revolution

3 2048increments per revolution

4 4096increments per revolution

5 8192increments per revolution

6 16384increments per revolution

Info

input

L

9300 Servo PLC EN 5.1

2−37

Page 44

9300 Servo PLC

System blocks

2.8 DFIN_IO_DigitalFrequency (node number 21)

Configuration of the digital frequency input signal

The type of the digital frequency input signal is configured under C0427:

Code LCD

Possible settings

Info

Lenze Selection

C0427 DFIN function 0 Type of the digital frequency signal

0 2 phases

1 A = Speed / B = Direction

2 A or B = Speed or direction

C0427 = 0 (2 phases)

A

A

B

B

Z

Z

Track CW rotation CCW rotation

A leads track B by 90º

(DFIN_nIn_v = positive value)

lags behind track B by 90º

(DFIN_nIn_v = negative value)

B − −

Signal sequence with phase shift (CW rotation)

C0427 = 1 (A = Speed / B = Direction)

A

A

B

B

Z

Z

Track CW rotation CCW rotation

A transmits the speed transmits the speed

B = FALSE

(DFIN_nIn_v = positive value)

= TRUE

(DFIN_nIn_v = negative value)

Control of the direction of rotation via track B

C0427 = 2 (A or B = speed or direction)

A

A

B

B

Z

Z

Track CW rotation CCW rotation

A transmits the speed and the direction

= FALSE

of rotation

(DFIN_nIn_v = positive value)

B = FALSE transmits the speed and the direction

of rotation

(DFIN_nIn_v = negative value)

Control of the speed and the direction of rotation

via track A or track B

2−38

9300 Servo PLC EN 5.1

L

Page 45

9300 Servo PLC

System blocks

2.8 DFIN_IO_DigitalFrequency (node number 21)

Transmission function

DFIN_nIn_v + f[Hz] @

60

IncrementsfromC0425

@

15000

14

2

Example:

Input frequency = 200 kHz

C0425 = 3, this corresponds to 2048 increments/rev.

DFIN_nIn_v[rpm] + 200000Hz @

Signal adaptation

Finer resolutions can be achieved by adding a downstream FB (e.g. L_CONV from the

LenzeDrive.lib):

X9

(X9/8)

4V

MONIT_SD3

C0427

C0425

DF_IN

DFIN_nIn_v

C0426

DFIN_bEncFaultCable_b

60

+ 5859rpm

2048

nIn_a nOut_a

NNumerator

Ndenominator

L_CONV

0

TP/MP

1

E5

Fig. 2−16 Digital frequency input (DFIN_IO_DigitalFrequency) with downstream FB L_CONV for scaling

nOut_a + f[Hz] @

-Ctrl

C0428 C0429

IncrementsfromC0425

DFIN_bTPReceived_b

DFIN_dnIncLastScan_p

60

nNumerator

@

nDenominator

@

15000

14

2

L

9300 Servo PLC EN 5.1

2−39

Page 46

9300 Servo PLC

System blocks

2.8 DFIN_IO_DigitalFrequency (node number 21)

2.8.1.1 Technical data for the connection of X9

B

B

A

A

Z

Z

l = max. 50 m

Lamp control

GND

B

B

A

A

Z

Z

X9