Page 1

L

Manual

Global Drive

System bus (CAN)

for Lenze PLC devices

Page 2

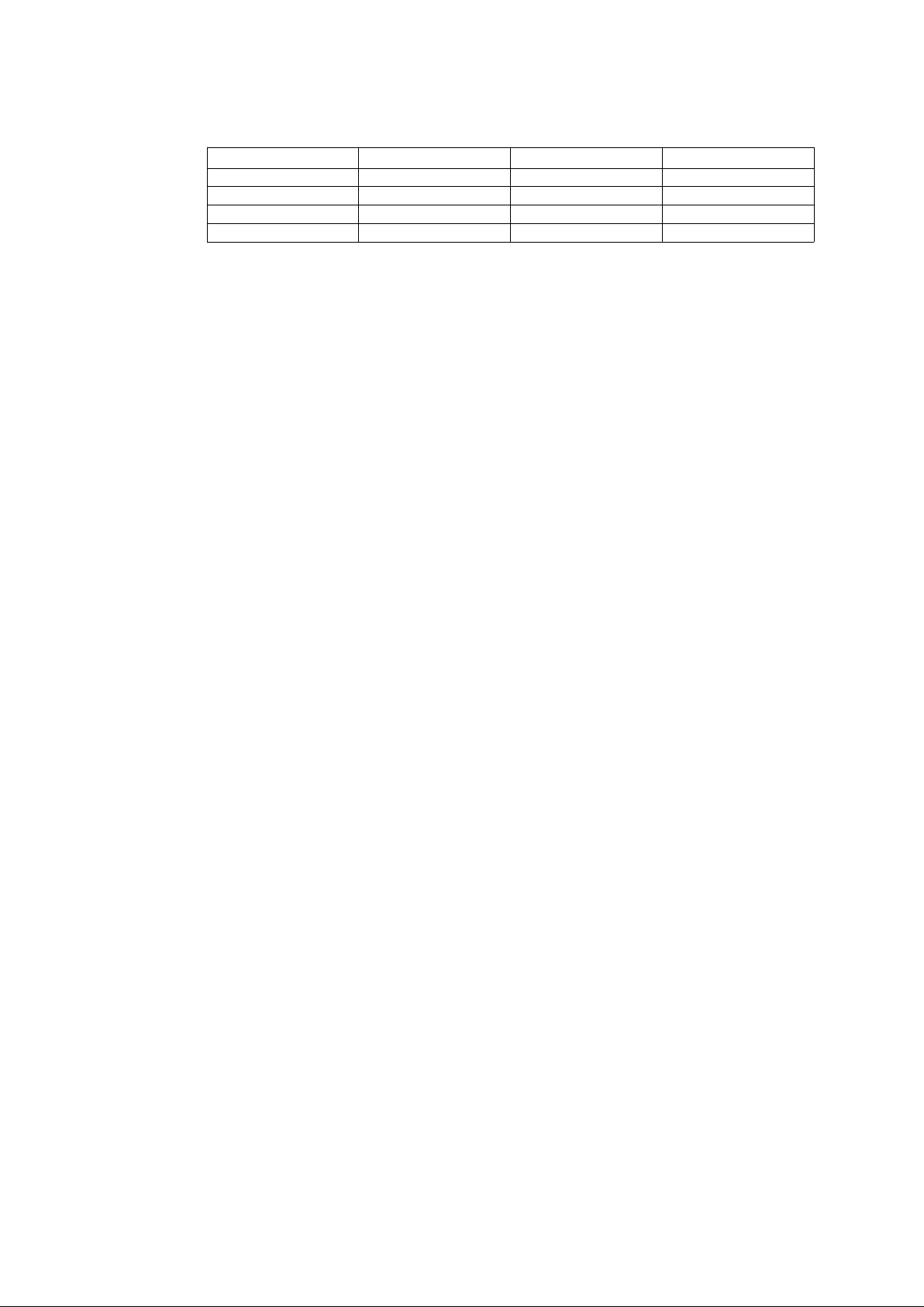

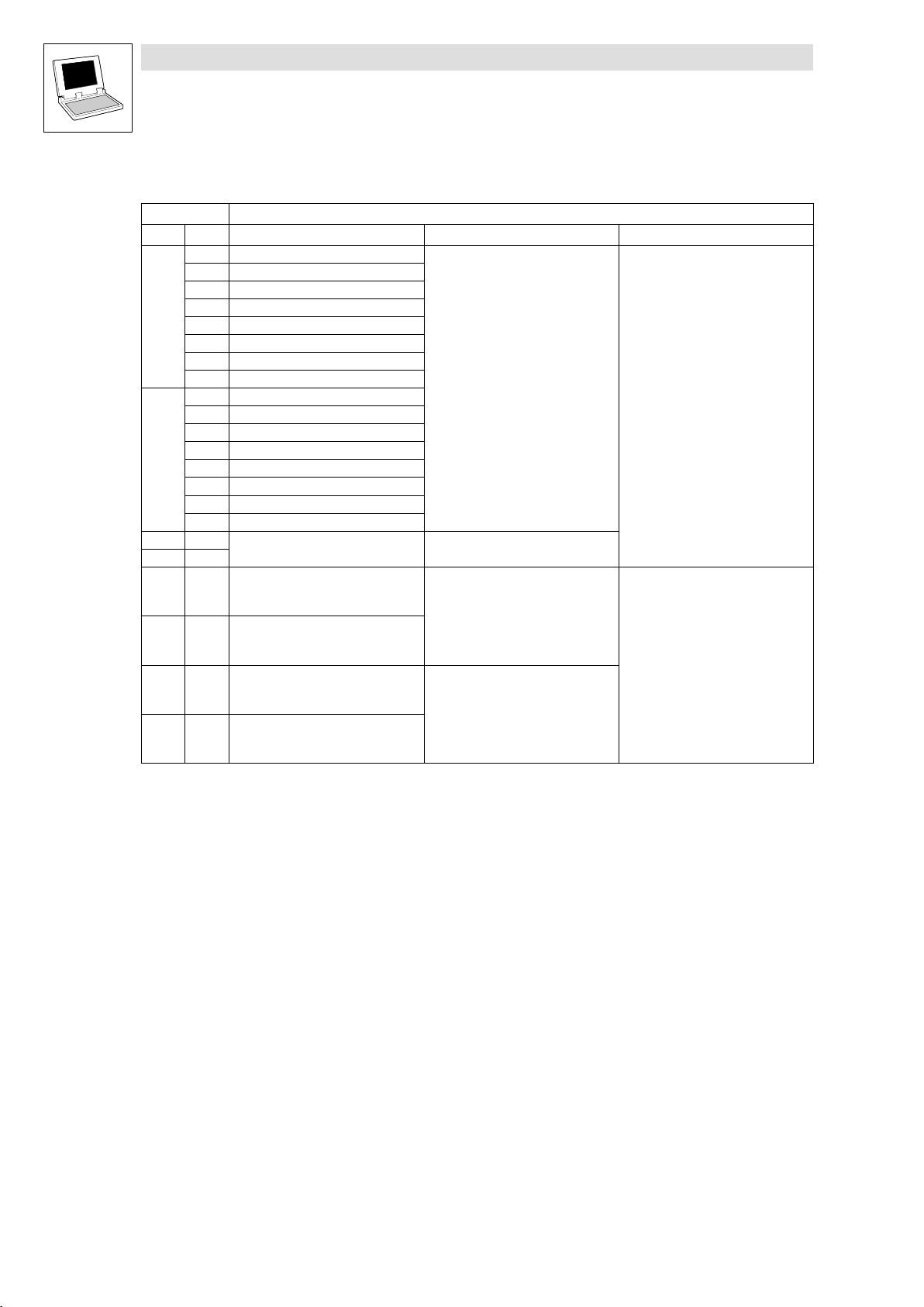

This documentation is valid for the following Lenze PLC devices:

Automation system Type designation As of hardware version As of software version

9300 Servo PLC EVS93XX−xI 2K 2.0

9300 Servo PLC EVS93XX−xT 2K 2.0

Drive PLC EPL10200 Px 2.0

ECSxA ECSxAxxx 1A 6.0

Important note:

The software is supplied to the user as described in this document. Any risks resulting from its quality or use remain the responsibility of the

user. The user must provide all safety measures protecting against possible maloperation.

We do not take any liability for direct or indirect damage, e.g. profit loss, order loss or any loss regarding business.

2006 Lenze Drive Systems GmbH

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze Drive Systems

GmbH.

All information given in these Operating Instructions has been selected carefully and comply with the hardware and software described. Nevertheless, deviations cannot be ruled out. We do not take any responsibility or liability for damages which might possibly occur. Required

corrections will be made in the following editions.

All product names mentioned in this documentation are trademarks of the corresponding owners.

Version 2.0 07/2006 − TD31

Page 3

System bus (CAN) for Lenze PLC devices

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions used in this Manual 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Structure of the description 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Pictographs used in this Manual 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Terminology used 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General information on the system bus (CAN) 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Introduction 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Interfaces of the Lenze PLCs for system bus connection 2−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Identification of the nodes 2−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Structure of the CAN telegram 2−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Identifier 2−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 User data 2−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Network management (NMT) 2−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Transmission of process data 2−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Process data channels 2−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Sync telegram for cyclic process data 2−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Process data telegram 2−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Transmitting parameter data 2−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Parameter data telegram 2−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Writing parameters (example) 2−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Reading a parameter (example) 2−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Free CAN objects 2−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Application recommendations for the different CAN objects 2−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Monitoring mechanisms 2−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 "Heartbeat" 2−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.2 "Node Guarding" 2−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuration (system bus − CAN interface) 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CAN baud rate 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 CAN boot−up 3−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Node address (node ID) 3−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Identifiers of the process data objects 3−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Allocation of individual identifiers 3−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Display of the identifier set 3−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Cycle time (CAN2_OUT/CAN3_OUT) 3−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Delay time (CAN2_OUT/CAN3_OUT) 3−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Synchronisation 3−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 CAN sync response 3−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 CAN sync identifiers 3−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.3 CAN sync Tx transmission cycle 3−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Reset node 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 System bus management 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 Mapping indexes to codes 3−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.1 Functional principle considering as example 3−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L PLC−Systembus EN 2.0

i

Page 4

System bus (CAN) for Lenze PLC devices

Contents

3.11 Remote parameterisation (gateway function) 3−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 Monitoring processes 3−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.1 Time monitoring for CAN1_IN ... CAN3_IN 3−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.2 Bus−off 3−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.3 Time−out when remote parameterisation is activated 3−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.4 Response in the case of system bus fault messages 3−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13 Diagnostics 3−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13.1 Operating status of the CAN interface 3−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13.2 Telegram counter 3−14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.13.3 Bus load by the PLC 3−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Configuration (AIF interface) 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 CAN baud rate 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 CAN boot−up 4−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Node address (node ID) 4−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Identifiers of the process data objects 4−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Allocation of individual identifiers 4−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Display of the identifier set 4−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Cycle time (XCAN1_OUT ... XCAN3_OUT) 4−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Synchronisation 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.1 XCAN sync response 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 XCAN sync identifier 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.3 XCAN sync Tx transmission cycle 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Reset node 4−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Monitoring processes 4−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 Time monitoring for XCAN1_IN ... XCAN3_IN 4−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Bus off 4−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.3 Response for system bus fault messages 4−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Diagnostics 4−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.1 Automation interface (AIF) operating status 4−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Configuration (FIF interface) 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CAN baud rate 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 CAN boot−up 5−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Node address (node ID) 5−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Identifiers of the process data objects 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Allocation of individual identifiers 5−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Display of the identifiers set 5−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Cycle time (FIF_CAN2_OUT/FIF_CAN3_OUT) 5−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Delay time (FIF_CAN2_OUT/FIF_CAN3_OUT) 5−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Synchronisation 5−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 FIF−CAN sync response 5−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 FIF−CAN sync identifier 5−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.3 FIF−CAN sync Tx transmission cycle 5−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Reset node 5−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

PLC−Systembus EN 2.0

L

Page 5

System bus (CAN) for Lenze PLC devices

Contents

5.9 System bus management 5−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Monitoring processes 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.1 Time monitoring for FIF−CAN1_IN ... FIF−CAN3_IN 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.2 Bus−off 5−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.3 Response in the case of system bus fault messages 5−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 Diagnostics 5−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.1 Function interface (FIF) operating status 5−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.2 Telegram counter 5−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.3 Bus load by FIF−CAN 5−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Configuration (CAN−AUX system bus interface) 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 CAN baud rate 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 CAN boot−up 6−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Node address (Node ID) 6−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Identifiers of the process data objects 6−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Allocation of individual identifiers 6−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Display of the identifiers set 6−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Cycle time (CANaux2_OUT/CANaux3_OUT) 6−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Delay time (CANaux2_OUT/CANaux3_OUT) 6−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 Synchronisation 6−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 CANaux sync response 6−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 CANaux sync identifiers 6−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.3 CANaux sync Tx transmission cycle 6−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 Reset node 6−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 System bus management 6−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10 Monitoring processes 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.1 Time monitoring for CANaux1_IN ... CANaux3_IN 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.2 Bus−off 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.3 Response in the case of system bus fault messages 6−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 Diagnostics 6−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.1 Operating status of the CAN−AUX interface 6−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.2 Telegram counter 6−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11.3 Bus load by CAN−AUX 6−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CAN system blocks 7−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 CAN1_IO (node number: 31) − 9300 Servo PLC 7−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Inputs_CAN1 7−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Outputs_CAN1 7−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Process data telegram 7−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Assignment of the user data to variables 7−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 Transferring status and control information of the device control 7−5 . . . . . . . . . . . . . . . . . . . . . . .

7.2 CAN1_IO (node number: 31) − Drive PLC 7−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Inputs_CAN1 7−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Outputs_CAN1 7−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Process data telegram 7−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Assignment of the user data to variables 7−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L PLC−Systembus EN 2.0

iii

Page 6

System bus (CAN) for Lenze PLC devices

Contents

7.3 CAN1_IO (node number: 31) − ECSxA 7−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Inputs_CAN1 7−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Outputs_CAN1 7−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Process data telegram 7−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Assignment of the user data to variables 7−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 CAN2_IO (node number: 32) 7−14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Inputs_CAN2 7−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Outputs_CAN2 7−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.3 Process data telegram 7−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.4 Assignment of the user data to variables 7−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 CAN3_IO (node number: 33) 7−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Inputs_CAN3 7−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Outputs_CAN3 7−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Process data telegram 7−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.4 Assignment of the user data to variables 7−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 CAN_Management (node number: 101) 7−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Inputs_CAN_Management 7−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.2 Outputs_CAN_Management 7−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.3 Activating a reset node 7−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4 Defining the instant of transmission for CAN2_OUT/CAN3_OUT 7−21 . . . . . . . . . . . . . . . . . . . . . . . .

7.6.5 Status messages 7−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 CAN_Synchronization (node number: 102) 7−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 FIF−CAN system blocks (only Drive PLC) 8−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 FIF_CAN1_IO (node number: 34) 8−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 FIF_Inputs_CAN1 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 FIF_Outputs_CAN1 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Process data telegram 8−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Assignment of the user data to variables 8−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 FIF_CAN2_IO (node number: 35) 8−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 FIF_Inputs_CAN2 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 FIF_Outputs_CAN2 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Process data telegram 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Assignment of the user data to variables 8−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 FIF_CAN3_IO (node number: 36) 8−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 FIF_Inputs_CAN3 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 FIF_Outputs_CAN3 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Process data telegram 8−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Assignment of the user data to variables 8−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 FIF_CAN_Management (node number: 111) 8−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 FIF_Inputs_CAN_Management 8−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 FIF_Outputs_CAN_Management 8−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Activating a reset node 8−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.4 Defining the instant of transmission for FIF−CAN2_OUT/FIF−CAN3_OUT 8−5 . . . . . . . . . . . . . . . . . .

8.4.5 Status messages 8−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

PLC−Systembus EN 2.0

L

Page 7

System bus (CAN) for Lenze PLC devices

Contents

9 CAN−AUX system blocks (only ECSxA) 9−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 CANaux1_IO (node number: 34) 9−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Inputs_CANaux1 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2 Outputs_CANaux1 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3 Process data telegram 9−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.4 Assignment of the user data to variables 9−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 CANaux2_IO (node number: 35) 9−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Inputs_CANaux2 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Outputs_CANaux2 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Process data telegram 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.4 Assignment of the user data to variables 9−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 CANaux3_IO (node number: 36) 9−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Inputs_CANaux3 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Outputs_CANaux3 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.3 Process data telegram 9−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.4 Assignment of the user data to variables 9−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 CANaux_Management (node number: 111) 9−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Inputs_CANaux_Management 9−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Outputs_CANaux_Management 9−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Activating a reset node 9−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4 Defining the instant of transmission for CANaux2_OUT/CANaux3_OUT 9−5 . . . . . . . . . . . . . . . . . . .

9.4.5 Status messages 9−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 LenzeCanDrv.lib function library 10−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Overview 10−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Version identifiers of the function library 10−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 L_CanInit − initialising the CAN driver 10−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 L_CanClose − deactivating the CAN driver 10−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 L_CanGetStatus − querying the driver status 10−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 L_CanGetRelocCobId − querying the COB−ID range 10−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 L_CanPdoTransmit − transmitting a CAN object 10−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 L_CanPdoReceive − receiving a CAN object 10−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 LenzeCanDSxDrv.libfunction library 11−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Overview 11−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 Version identifiers of the function library 11−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 L_CanDSxInitIndexCode − Configuration of index mapping 11−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 L_CanDSxOpen − initialising the CanDSx driver 11−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 L_CanDSxClose − deactivating the index mapping 11−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 L_CanDSxOpenHeartBeat − initialising a "Heartbeat" 11−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.7 L_CanDSxHeartBeat − carrying out a "Heartbeat" 11−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8 L_CanDSxCloseHeartBeat − deactivating the "Heartbeat" 11−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.9 L_CanDSxOpenNodeGuarding − initialising the "Node Guarding" 11−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.10 L_CanDSxNodeGuarding − carrying out a "Node guarding" 11−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.11 L_CanDSxCloseNodeGuarding − deactivating the "Node Guarding" 11−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L PLC−Systembus EN 2.0

v

Page 8

System bus (CAN) for Lenze PLC devices

Contents

12 Index 12−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

PLC−Systembus EN 2.0

L

Page 9

System bus (CAN) for Lenze PLC devices

Preface and general information

1.1 About this Manual

1 Preface and general information

1.1 About this Manual

This Manual contains information on the system bus interfaces of the Lenze PLC devices

9300 Servo PLC, Drive PLC and ECSxA.

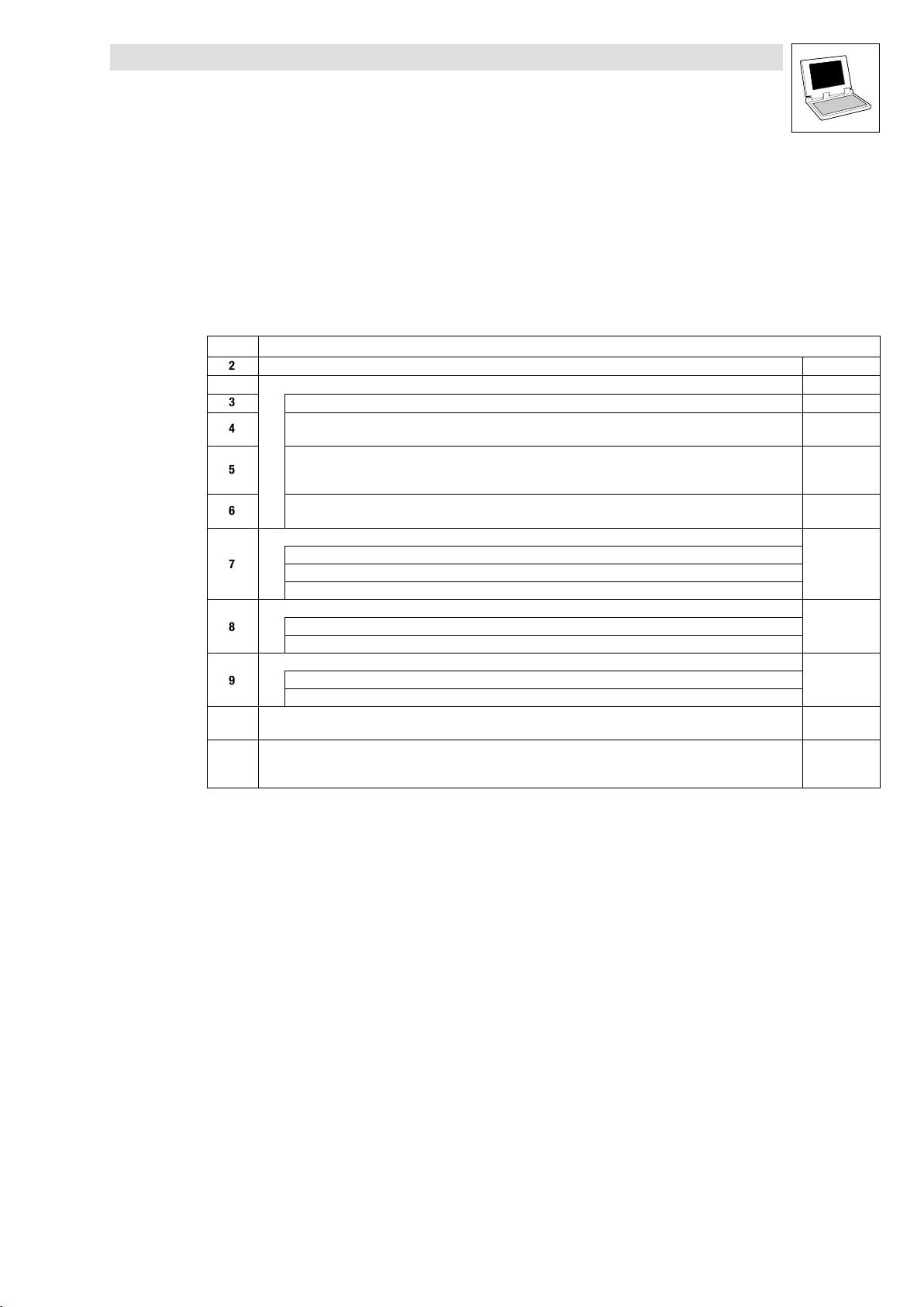

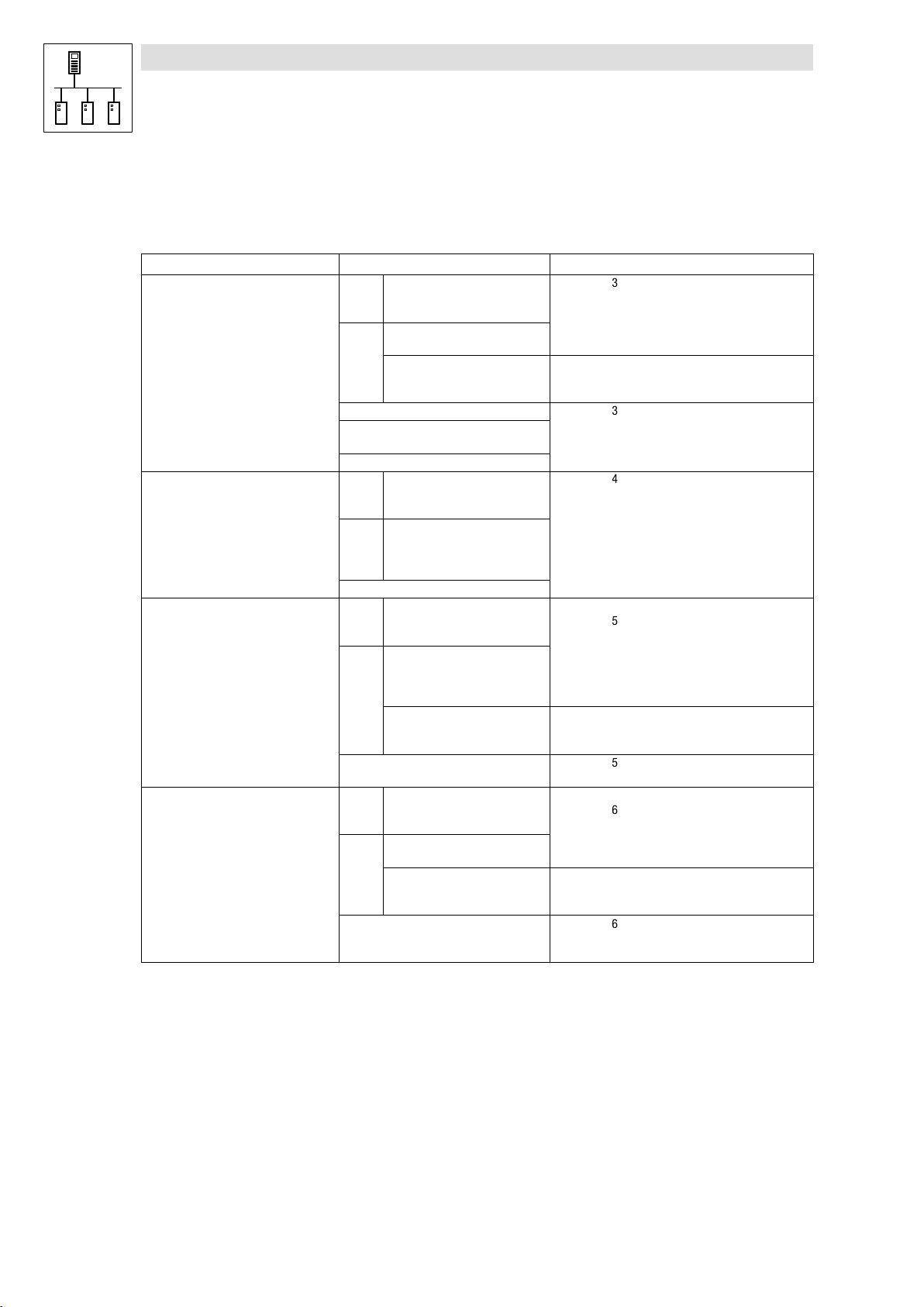

Chapter Content

2 General information on the system bus (CAN) ^ 2−1

Configuration

3

4

5

6

7

8

9

10

11

Integrated "CAN" system bus interface ^ 3−1

Optional system bus interface via automation interface (AIF)

and corresponding fieldbus module (e. g. 2175)

Optional system bus interface via function interface (FIF)

and corresponding function module (e. g. CAN−I/O system bus)

· Only for Drive PLC!

Integrated "CAN−AUX" system bus interface

· Only for ECSxA!

CAN system blocks

CAN objects (CAN1_IO ... CAN3_IO)

CAN synchronisation (CAN_Synchronization)

CAN management (CAN_Management)

FIF−CAN system blocks (only Drive PLC)

CAN objects (FIF_CAN1_IO ... FIF_CAN3_IO)

CAN management (FIF_CAN_Management)

CAN−AUX system blocks (only ECSxA)

CAN objects (CANaux1_IO ... CANaux3_IO)

CAN management (CANaux_Management)

LenzeCanDrv.lib function library

· Free CAN objects

LenzeCanDSxDrv.libfunction library

· Mapping indexes to codes

· "Heartbeat" and "Node Guarding"monitoring mechanisms

^ 4−1

^ 5−1

^ 6−1

^ 7−1

^ 8−1

^ 9−1

^ 10−1

^ 11−1

L

PLC−Systembus EN 2.0

1−1

Page 10

System bus (CAN) for Lenze PLC devices

Preface and general information

1.1 About this Manual

1.1.1 Conventions used in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Variable identifier

... are presented in italics in the explanatory text:

· "Via wDrvNr..."

Tip!

Information about the conventions used for variables of Lenze system blocks, function blocks and

functions can be obtained from the appendix of the DDS online documentation "Introduction into

IEC 61131−3 programming".The conventions ensure universal and uniform labelling and support the

readability of PLC programs.

Lenze functions/function blocks

... can be identified by their designation. They always start with an "L_":

· "The function L_CanInit ..."

· "The L_CanPdoTransmit FB..."

Program listings

... are specified in the "Courier" font, the keywords being printed bold:

· "IF (ReturnValue < 0) THEN..."

1−2

PLC−Systembus EN 2.0

L

Page 11

System bus (CAN) for Lenze PLC devices

Preface and general information

1.1 About this Manual

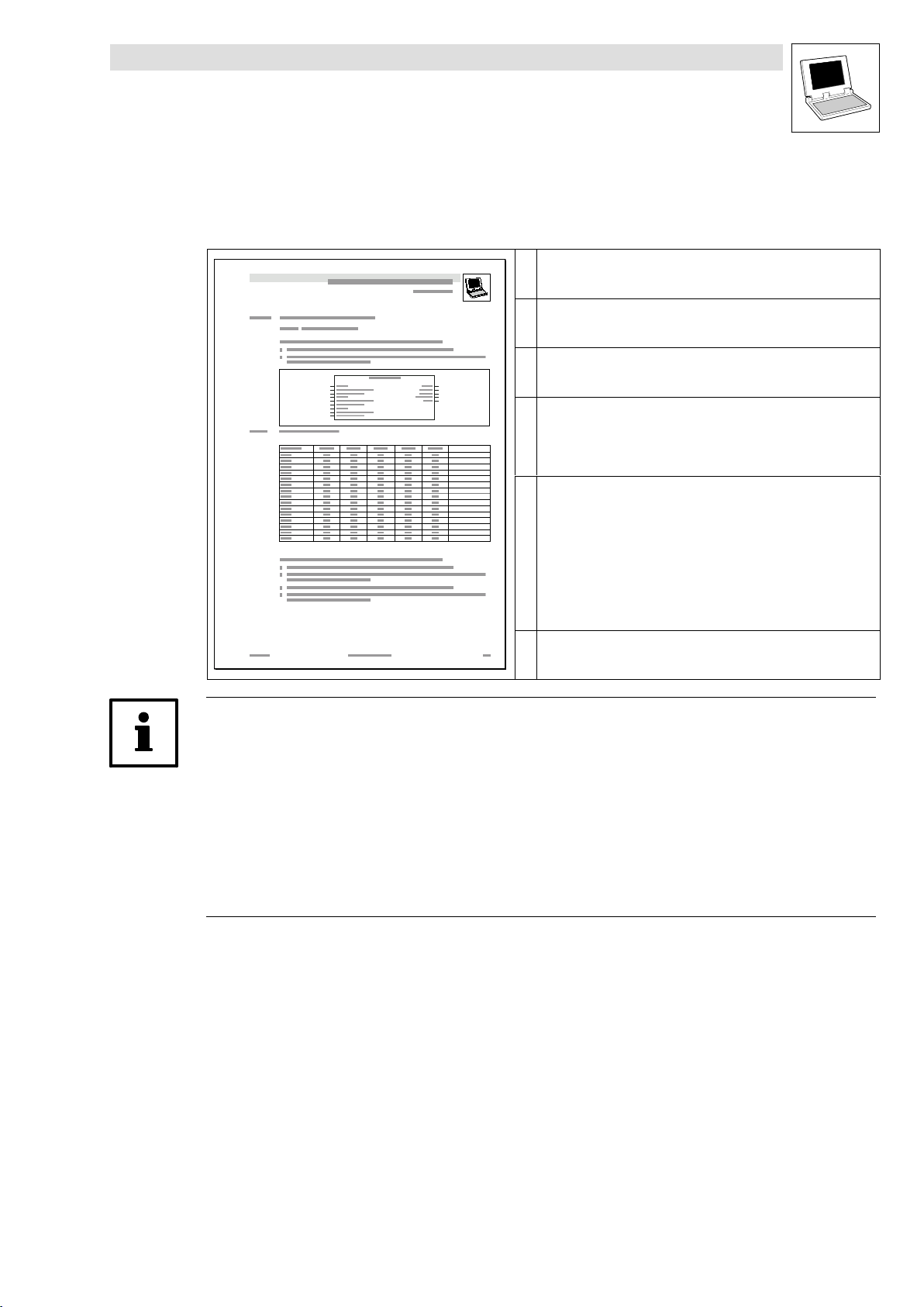

1.1.2 Structure of the description

The descriptions of the individual functions/function blocks as well as of system blocks contained

in this Manual have the same structure:

Headline with SB identifier

SB function and node number

Short description of the SB and its most important features

System block chart including all corresponding variables

· Input variables

· Output variables

Table giving information about input and output variables:

· Identifier

· Data type

· Signal type

· Address

· Display code

· Display format

· Information

Detailed functional description of the SB

Information on return values for a function

If it was not possible to carry out a function faultlessly, a negative return value is sent back,

representing an error number.

· Each error number is assigned to a corresponding error cause in the Meaning column.

· If different error numbers (−1, −2, ...) may apply, a specific digit (1, 2, ...) in the Priority column

additionally is assigned to the error number.

– The smaller this digit, the higher is the priority of the associated error number.

– If several error causes are available at the same time when a function is carried out, always

the error number with the highest priority is returned by the function.

L

PLC−Systembus EN 2.0

1−3

Page 12

System bus (CAN) for Lenze PLC devices

Preface and general information

1.1 About this Manual

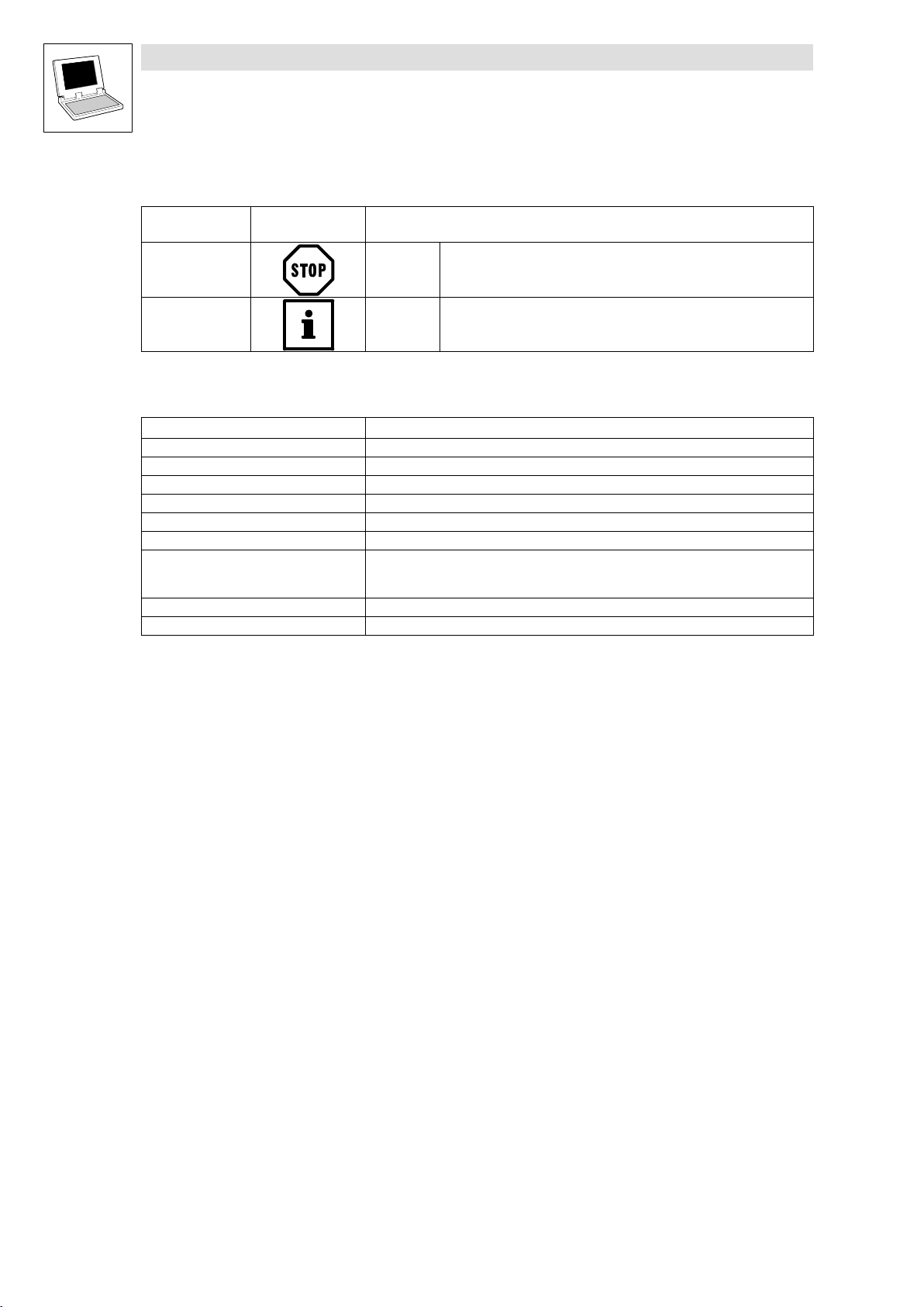

1.1.3 Pictographs used in this Manual

Pictographs

used

Warning of

material damage

More notes Tip!

1.1.4 Terminology used

Term In the following text used for

AIF Automation interface

DDS Drive PLC Developer Studio

FB Function block

FIF Function interface

GDC Global Drive Control (parameterisation program from Lenze)

Parameter codes Codes for setting the function of a function block

PLC · 9300 Servo PLC

SB System block

System bus System bus (CAN): Lenze standard bus system similar to CANopen

Signal words

Stop! Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the controller/drive system or its environment

Indicates a tip or note.

Note!

· Drive PLC

· ECSxA

.

1−4

PLC−Systembus EN 2.0

L

Page 13

System bus (CAN) for Lenze PLC devices

General information

2 General information on the system bus (CAN)

2.1 Introduction

All Lenze drive and automation systems are provided with an integrated system bus interface for the

networking of control components on a field level.

Via the system bus interface, among other things process data and parameter data can be

exchanged between the nodes. Furthermore the interface enables the connection of further

modules, like for example decentralised terminals, operator and input devices, as well as external

controls and host systems.

The system bus interface transfers CAN objects following the CANopen communication profile

(CiA DS301, version 4.01), which was developed under the umbrella association of the CiA (CAN in

Automation), complying with the CAL (CAN Application Layer).

l

PLC−Systembus EN 2.0

2−1

Page 14

System bus (CAN) for Lenze PLC devices

General information

2.2 Interfaces of the Lenze PLCs for system bus connection

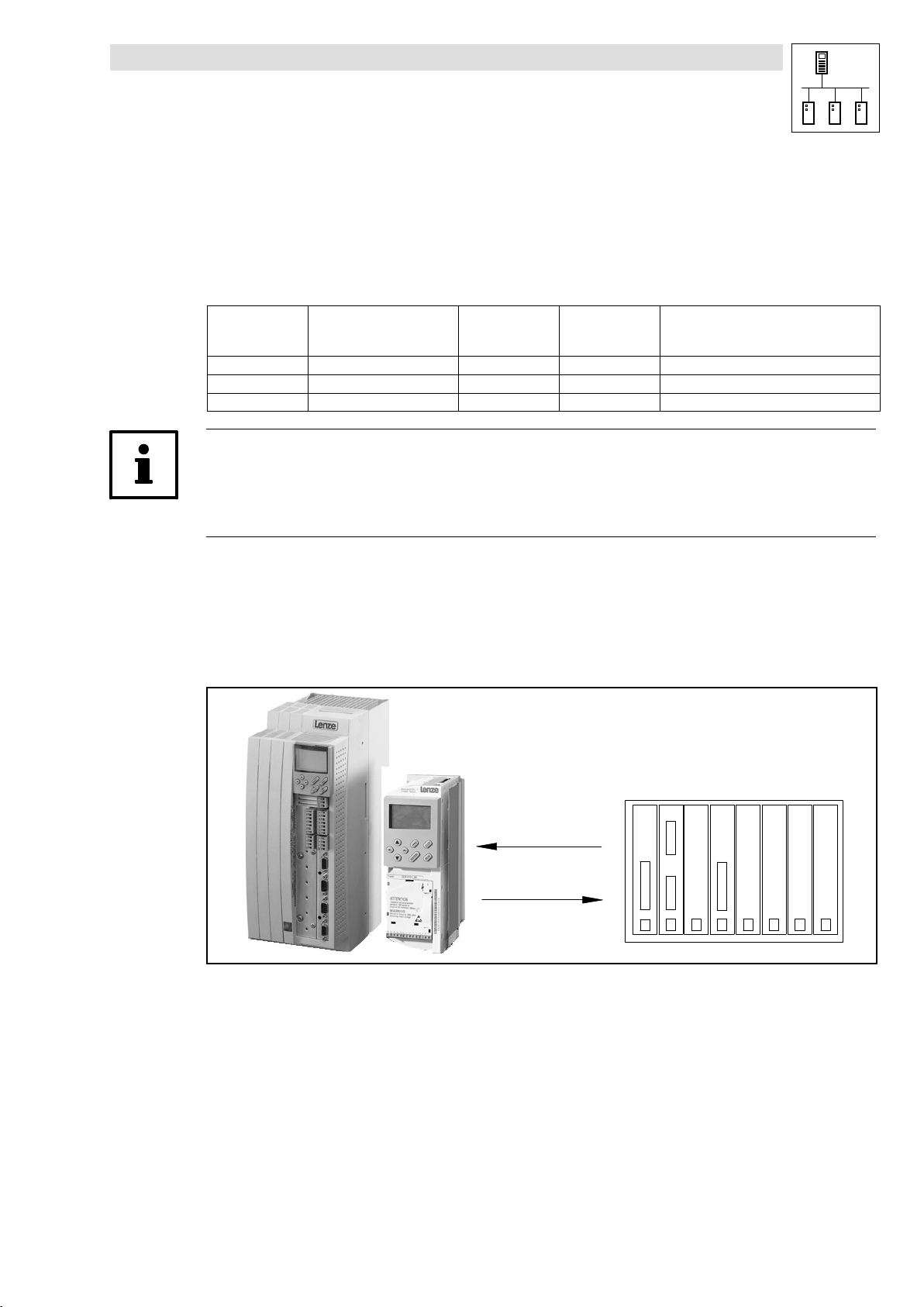

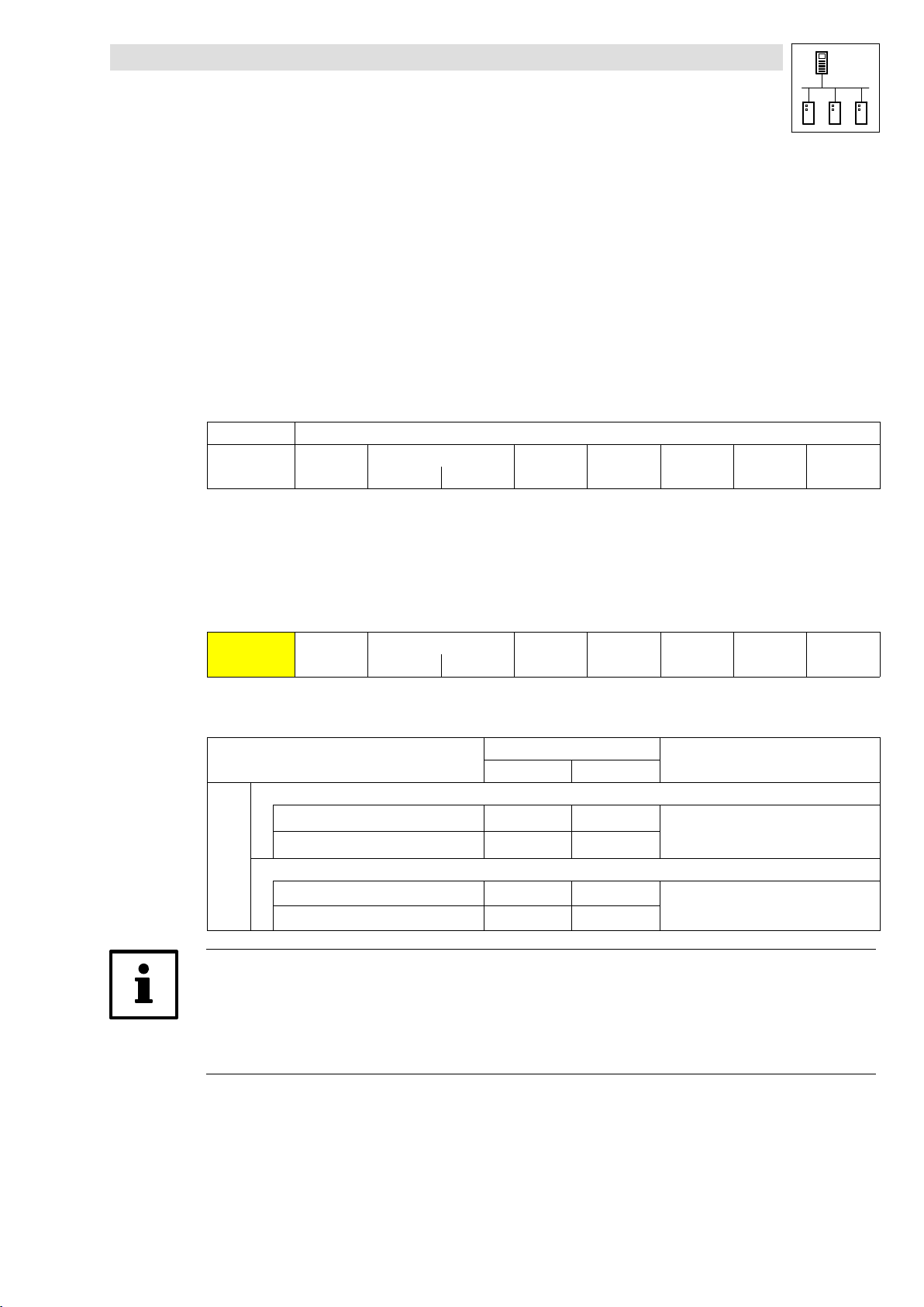

The following table provides an overview of the Lenze PLC system bus interfaces 9300 Servo PLC,

Drive PLC and ECSxA:

CAN objects available Information

System bus interface CAN

Automation interface (AIF)

with corresponding fieldbus module

(e.g. 2175)

Function interface (FIF)

with corresponding function module

(e.g. CAN−I/O system bus)

System bus interface CAN−AUX

PDOs CAN1_IN/CAN1_OUT

CAN2_IN/CAN2_OUT

CAN3_IN/CAN3_OUT

SDOs

SDO1 (parameter data channel 1)

SDO2 (parameter data channel 2)

L_ParRead/L_ParWrite

functionality

Sync telegram

Synchronisation of the internal time basis

by receiving sync telegrams

Free CAN objects

PDOs XCAN1_IN/XCAN1_OUT

XCAN2_IN/XCAN2_OUT

XCAN3_IN/XCAN3_OUT

SDOs XSDO1 (parameter data

channel 1)

XSDO2 (parameter data

channel 2)

XSync telegram

PDOs FIF−CAN1_IN/FIF−CAN1_OUT

FIF−CAN2_IN/FIF−CAN2_OUT

FIF−CAN3_IN/FIF−CAN3_OUT

SDOs

FIF−SDO1 (parameter data

channel 1)

FIF−SDO2 (parameter data

channel 2)

L_ParRead/L_ParWrite

functionality

Sync telegram See chapter 5, "Configuration (FIF interface)".

PDOs CANaux1_IN/CANaux1_OUT

CANaux2_IN/CANaux2_OUT

CANaux3_IN/CANaux3_OUT

SDOs

CAN−AUX−SDO (parameter data

channel)

L_ParRead/L_ParWrite

functionality

Sync telegram See chapter 6, "Configuration (CAN−AUX system bus

See chapter 3, "Configuration (CAN system bus

interface)".

^ 3−1

Reading/writing of codes.

See documentation on the LenzeDrive.lib

function library

See chapter 3, "Configuration (CAN system bus

interface)".

^ 3−1

See chapter 4, "Configuration (AIF interface)".

^ 4−1

For Drive PLC only!

See chapter 5, "Configuration (FIF interface)".

^ 5−1

Reading/writing of codes.

See documentation on the LenzeDrive.lib

function library

^ 5−1

For ECSxA only!

See chapter 6, "Configuration (CAN−AUX system bus

interface)".

^ 6−1

Reading/writing of codes.

See documentation on the function library

LenzeDrive.lib

interface)".

^ 6−1

2−2

PLC−Systembus EN 2.0

l

Page 15

System bus (CAN) for Lenze PLC devices

2.3 Identification of the nodes

Assign a node address − also called Node ID − in the range of 1 to 63 to each node within the system

bus network as a definite identification.

· The same node address may not be assigned more than once within the network.

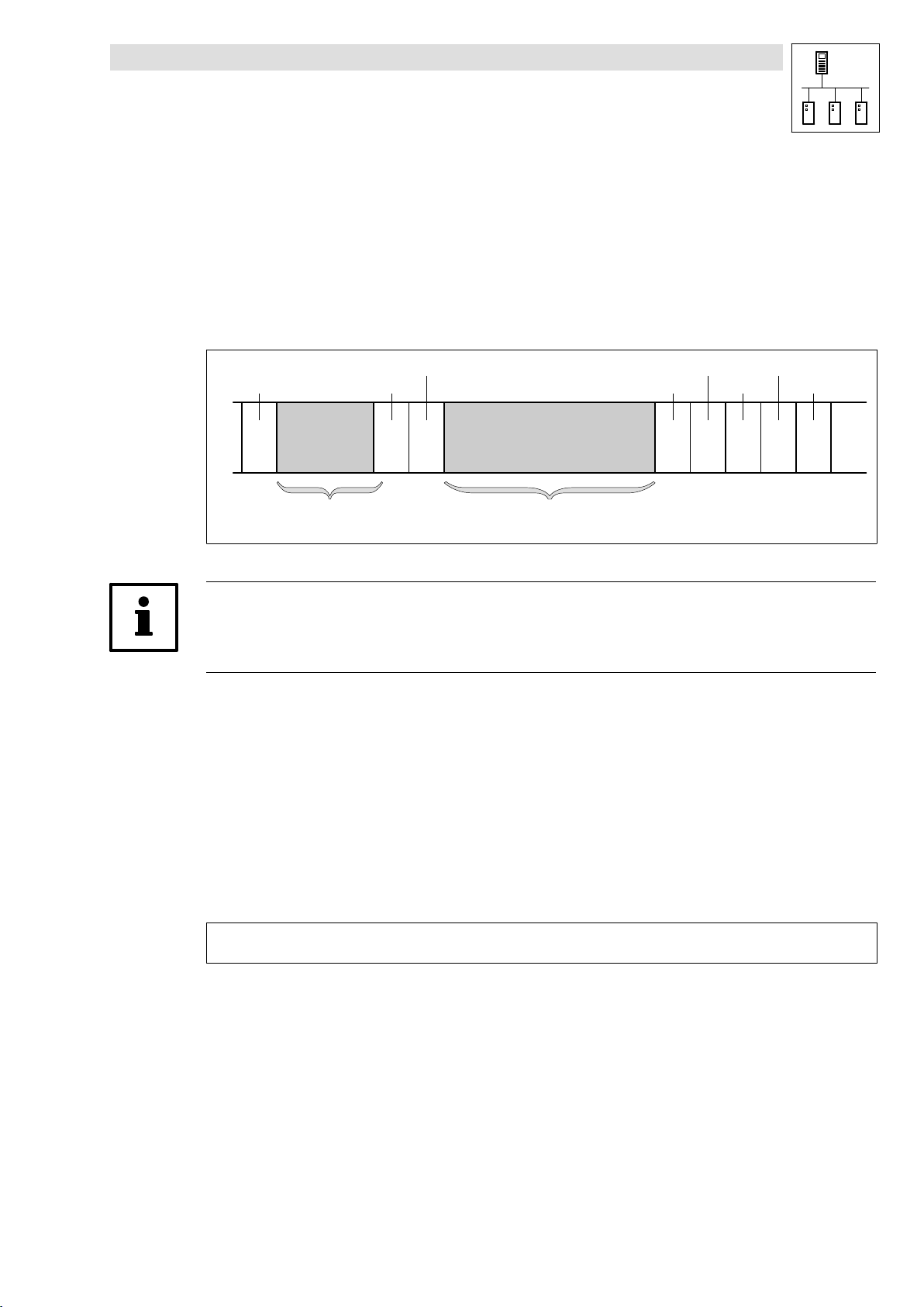

2.4 Structure of the CAN telegram

General information

Start

Identifier

1bit 11bit 1bit 6bit

Description see chapter 2.4.1

Fig. 2−1 Basic structure of a CAN telegram

RTR bit

Tip!

For the user only the identifier and the user data are relevant. All further data of the CAN telegram

are processed by the system.

2.4.1 Identifier

The principle of the CAN communication is based on a message−oriented data exchange between

a transmitter and many receivers. Thereby all nodes practically are able to transmit and receive at the

same time.

The control with regard to the node which is to receive a transmitted message is effected via the

so−called Identifier in the CAN telegram, also called COB−ID (Communication Object Identifier). For

purposes of addressing, the identifier additionally contains information on the priority of the

message, as well as on the type of the user data.

The identifier is composed of a so−called basic identifier and the node address of the node to be

activated:

Control field

User data

0 ... 8 byte

· Network management

· Parameter data

· Process data

Description see chapter 2.4.2

CRC

sequence

15bit

CRC delimit.

1bit 1bit 1bit 7bit

ACK delimit.

ACK slot

End

l

Identifier + basic identifier ) node address

· For Lenze devices, the node address is defined via code C0350. (^ 3−3)

· For the network management and the sync telegram only the basic identifier is required.

PLC−Systembus EN 2.0

2−3

Page 16

System bus (CAN) for Lenze PLC devices

General information

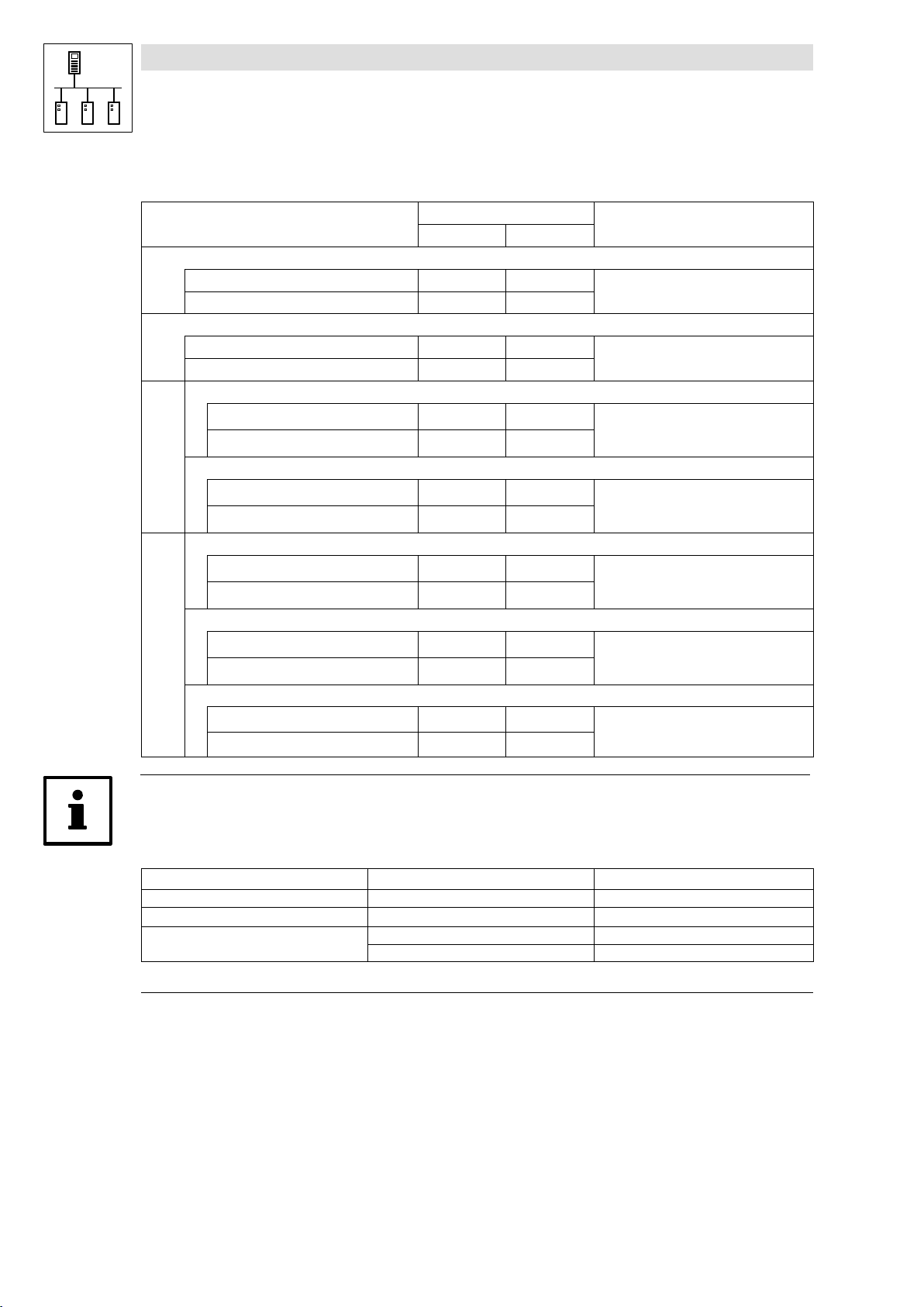

The following table contains the preset basic identifiers of the Lenze devices:

Identifier = basic identifier + node address of the node

dec hex

·Network management

Tx (transmission) 0 0

Rx (reception) 0 0

Sync telegram

Tx (transmission) 128 80

Rx (reception) 128 80

SDOs Parameter data channel 1

Output (transmission) 1536 600

Input (reception) 1408 580

Parameter data channel 2

Output (transmission) 1600 640

Input (reception) 1472 5C0

PDOs CAN1_IO (cyclic process data)

CAN1_IN 512 200

CAN1_OUT 384 180

CAN2_IO (event− or time−controlled process data)

CAN2_IN 640 280

CAN2_OUT 641 281

CAN3_IO (event− or time−controlled process data)

CAN3_IN 768 300

CAN3_OUT 769 301

+ C0350

+ C2350

+ C2450

+ C0350

+ C2350

+ C2450

+ C0350

+ C2350

+ C2450

+ C0350

+ C2350

+ C2450

+ C0350

+ C2350

+ C2450

(CAN)

(XCAN)

(FIF−CAN/CAN−AUX)

(CAN)

(XCAN)

(FIF−CAN/CAN−AUX)

(CAN)

(XCAN)

(FIF−CAN/CAN−AUX)

(CAN)

(XCAN)

(FIF−CAN/CAN−AUX)

(CAN)

(XCAN)

(FIF−CAN/CAN−AUX)

Tip!

For the process data objects you can also set an individual identifier via the following codes, which

is independent of the node address:

Code Interface Information

C0353 / C0354 CAN (system bus interface) ^ 3−4

C2353 / C2354 XCAN (AIF interface) ^ 4−4

C2453 / C2454

FIF−CAN (FIF interface) ^ 5−4

CAN−AUX (system bus interface) ^ 6−4

2−4

PLC−Systembus EN 2.0

l

Page 17

2.4.2 User data

Via the user data area of the CAN telegram, three different types of data are transported:

Data type Information

Network management data Information on the structure of communication via the CAN network. Chapter 2.5(^ 2−6)

Process data Process data are data for control−oriented concerns, e. g. setpoints and actual

system bus interface)

System bus (CAN) for Lenze PLC devices

General information

values.

· Process data are transmitted as so−called PDOs (Process Data Objects) with a

high priority.

· Process data are processed more quickly by the PLC as parameter data.

· The transmission and reception of the process data is effected by the use of

specific system blocks or the free CAN objects:

CAN

(integrated

SB CAN1_IO for cyclic process data (sync−controlled)

9300 Servo PLC:

Drive PLC:

ECSxA:

SB CAN2_IO for event− or time−controlled process data Chapter 7.4(^ 7−14)

SB CAN3_IO for event− or time−controlled process data Chapter 7.5(^ 7−17)

Chapter 2.6(^ 2−7)

Chapter 7.1(^ 7−1)

Chapter 7.2(^ 7−6)

Chapter 7.2(^ 7−6)

(automation interface)

XCAN

FIF−CAN

(function interface,

Drive PLC only!

CAN−AUX

(integrated

system bus interface,

ECSxA only)

Free CAN objects By using the functions/function blocks of the LenzeCanDrv.lib function

Parameter data For Lenze devices, parameter data are the so−called codes.

SB AIF1_IO_AutomationInterface

for cyclic process data (sync−controlled)

SB AIF2_IO_AutomationInterface

for event− or time−controlled process data

SB AIF3_IO_AutomationInterface

for event− or time−controlled process data

SB FIF_CAN1_IO for cyclic process data (sync−controlled) Chapter 8.1(^ 8−1)

SB FIF_CAN2_IO for event− or time−controlled process data Chapter 8.2(^ 8−1)

SB FIF_CAN3_IO for event− or time−controlled process data Chapter 8.3(^ 8−1)

SB CANaux1_IO for cyclic process data (sync−controlled) Chapter 9.1(^ 9−1)

SB CANaux2_IO for event− or time−controlled process data Chapter 9.2(^ 9−1)

SB CANaux3_IO for event− or time−controlled process data Chapter 9.3(^ 9−1)

library, so−called "free CAN objects" additionally can be added to the

fixedly integrated CAN objects.

· Parameter settings for instance are carried out in the case of a one−time

setting of the system during commissioning, or in the case of a material

change of the production machine.

· Parameter data are transferred as so−called SDOs (Service Data Objects) via

the CAN network and are acknowledged by the receiver, i. e. the transmitter

receives a feedback on whether the transmission was successful.

See Manual

· 9300 Servo PLC

· Drive PLC

· ECSxA

Chapter 10(^ 10−1)

Chapter 2.7(^ 2−11)

l

PLC−Systembus EN 2.0

2−5

Page 18

System bus (CAN) for Lenze PLC devices

General information

2.5 Network management (NMT)

The CAN telegram for the network management is structured as follows:

11bit 2 bytes user data

Identifier

00000000000

· By means of this telegram the master can carry out state changes for the entire CAN network.

Byte 1: command

Command Device address

Command

(hex)

01 Operational The PLC can receive parameter and process data.

02 Stopped

80 Pre−operational The PLC can receive parameter data. Process data, however, are ignored.

81

82

Network status

after change

Initialisation

Information

The PLC can receive network management telegrams, parameter and process data, however, cannot be

received.

Reset rode: Changes with regard to the communication−relevant parameters of the system bus (e. g. CAN

address, CAN baud rate, etc.) only are accepted after a reset node.

Byte 2: device address

Device address Information

0 All nodes on the bus are addressed. By this, a state change can be carried out simultaneously for all devices.

1...63 Node address of the node for which a state change is to be effected.

2−6

PLC−Systembus EN 2.0

l

Page 19

System bus (CAN) for Lenze PLC devices

2.6 Transmission of process data

Process data are data for control−oriented concerns, e. g. setpoints and actual values.

· Process data are transferred as so−called PDOs (Process Data Objects) with a high priority via

the system bus.

· Transmitting and receiving the process data is effected by the use of specific system blocks:

General information

CAN

(integrated)

CAN1_IO AIF1_IO_AutomationInterface FIF_CAN1_IO CANaux1_IO Cyclic process data (sync−controlled)

CAN2_IO AIF2_IO_AutomationInterface FIF_CAN2_IO CANaux2_IO Event− or time−controlled process data

CAN3_IO AIF3_IO_AutomationInterface FIF_CAN3_IO CANaux3_IO Event− or time−controlled process data

XCAN

(AIF interface)

Tip!

In the following subchapters you’ll receive further information on the CAN1_IO ... CAN3_IO process

data objects of the CAN interface. This information also applies to the process data objects of the

AIF−, FIF− and CAN−AUX interface!

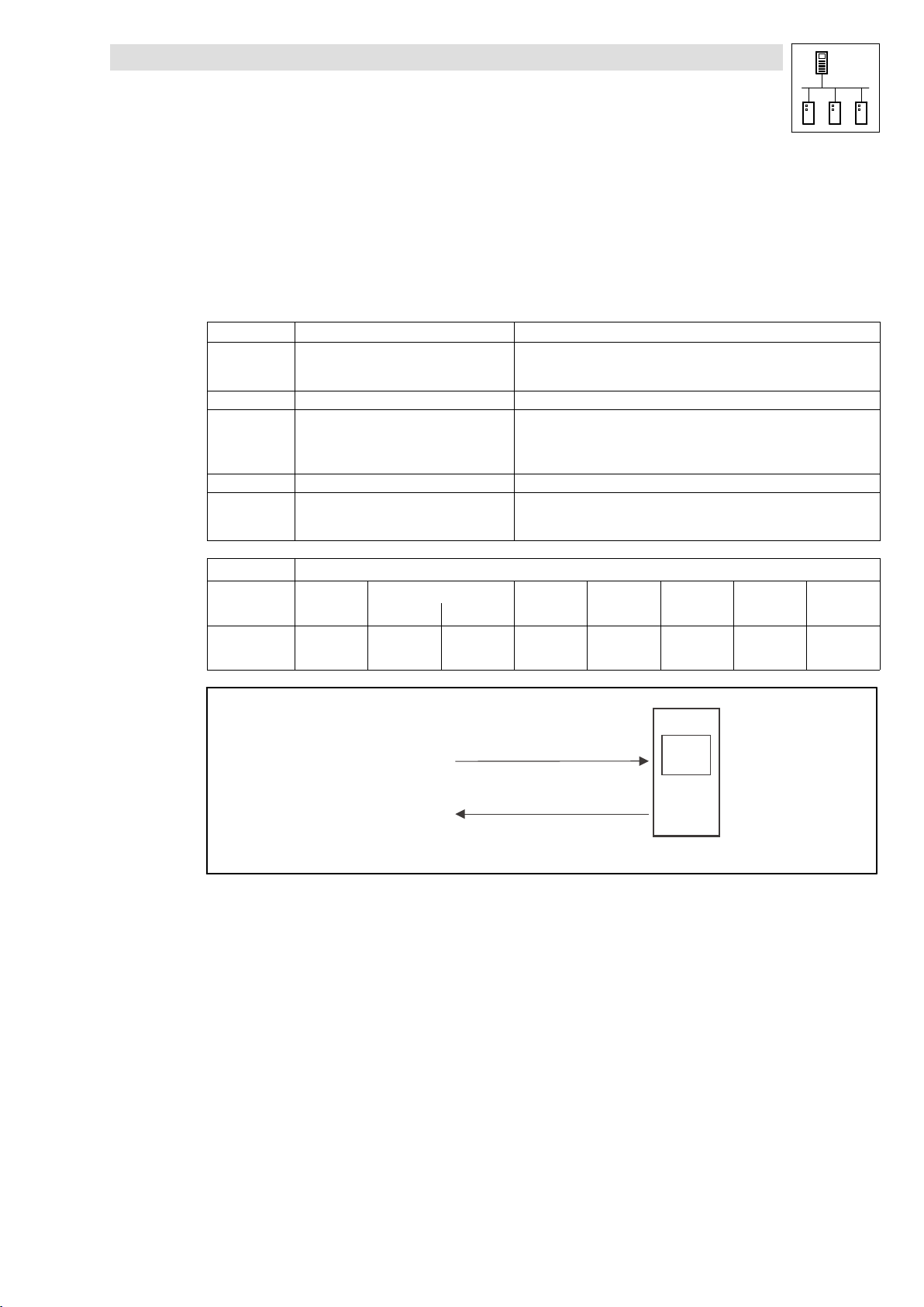

2.6.1 Process data channels

Process data channel 1: CAN1_IO

The CAN1_IO SB can be used for the data exchange of cyclic process data (e. g. setpoints and

actual values) with a higher−level host system.

FIF−CAN

(FIF interface)

For Drive PLC only!

cyclic process data (sync−controlled)

process data channel 1

CANaux

For ECSxA only!

Information

CAN1_IN

CAN1_OUT

Fig. 2−2 Process data channel 1 (CAN1_IO) for the cyclic data exchange

l

PLC−Systembus EN 2.0

Host

2−7

Page 20

System bus (CAN) for Lenze PLC devices

s

General information

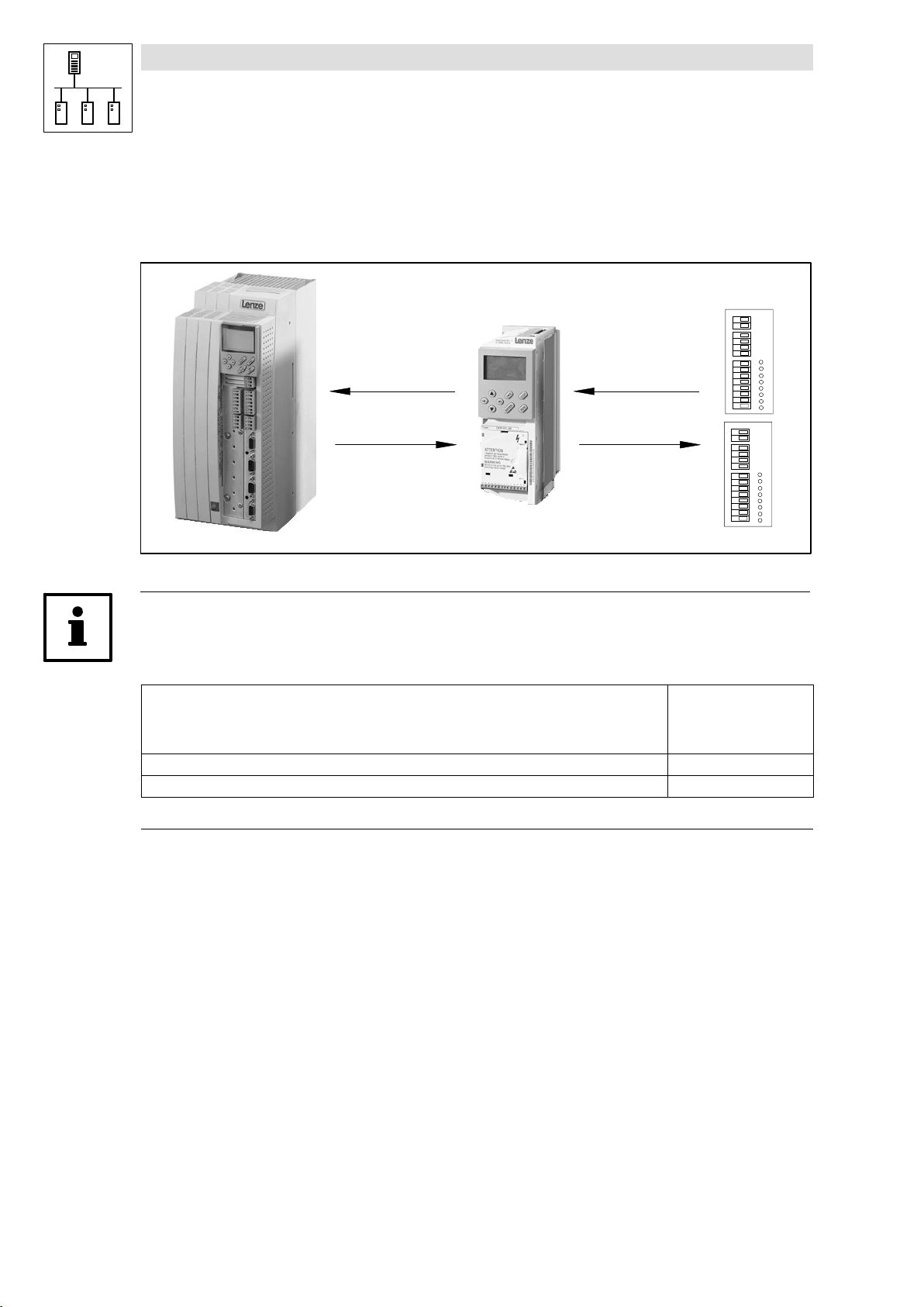

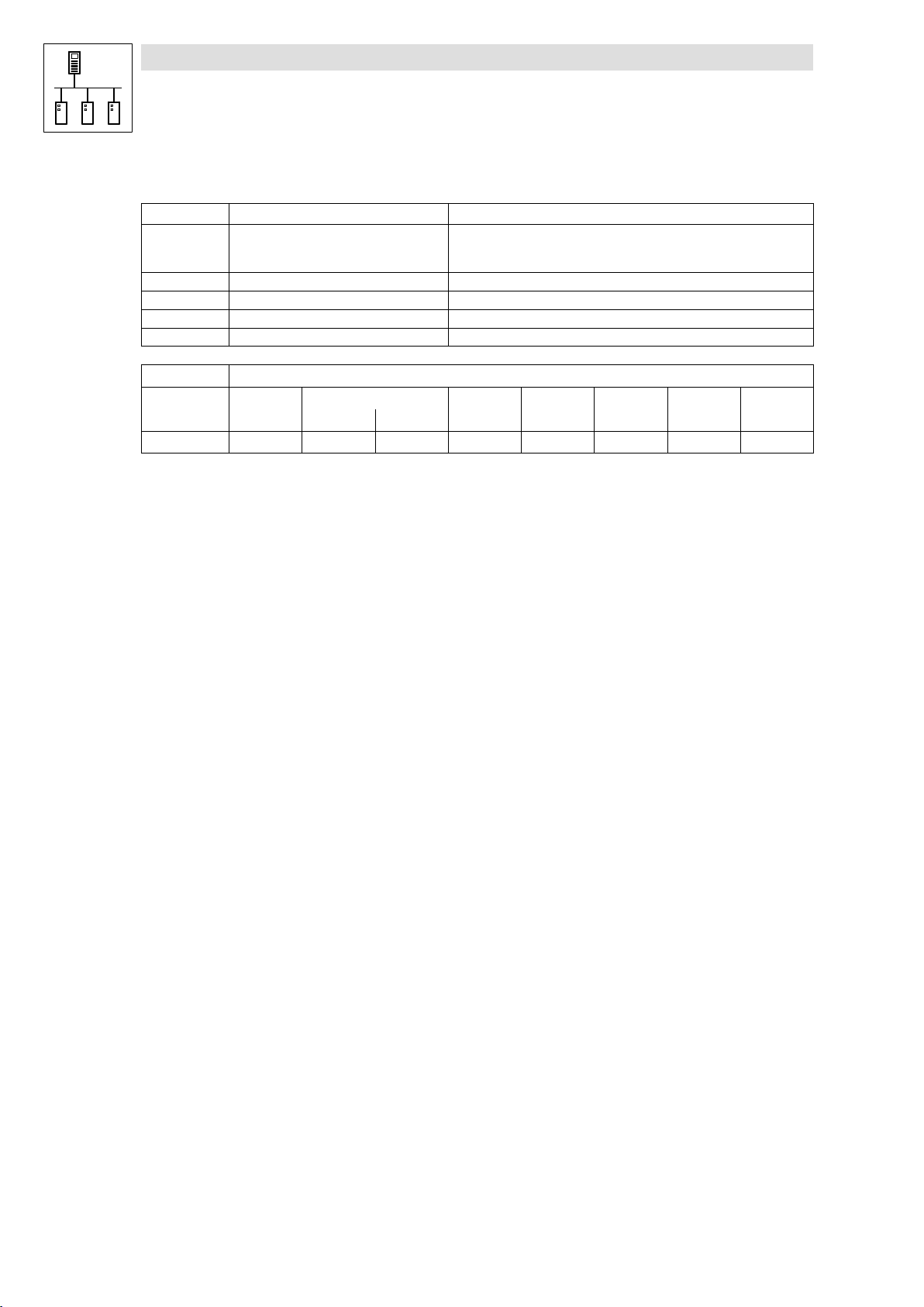

Process data channel 2/3: CAN2_IO/CAN3_IO

The SBs CAN2_IO and CAN3_IO are designed for the data exchange of event− or time−controlled

process data among the devices. These SBs can also be used for the data exchange with

decentralised input/output terminals and higher−level host systems.

event−controlled process data

process data channel 2

CAN2_IN

CAN2_OUT

Fig. 2−3 Process data channels 2 and 3 (CAN2_IO/CAN3_IO) for the event− or time−controlled data exchange

CAN2_OUT

CAN2_IN

event−controlled process data

process data channel 3

CAN3_IN

CAN3_OUT

CAN3_OUT

CAN3_IN

E. g. decentralised terminal

Tip!

Detailed information on the CAN1_IO ... CAN3_IO CAN objects integrated in the PLC can be found

in the chapter 7, "CAN system blocks":

CAN1_IO for cyclic process data (sync−controlled)

CAN2_IO for event− or time−controlled process data Chapter 7.4(^ 7−14)

CAN3_IO for event− or time−controlled process data Chapter 7.5(^ 7−17)

9300 Servo PLC:

Drive PLC:

ECSxA:

Chapter 7.1(^ 7−1)

Chapter 7.2(^ 7−6)

Chapter 7.3(^ 7−10)

2−8

PLC−Systembus EN 2.0

l

Page 21

System bus (CAN) for Lenze PLC devices

General information

2.6.2 Sync telegram for cyclic process data

For the transmission of cyclic process data, a specific telegram − the sync telegram − is required for

the synchronisation.

The sync telegram which has to be generated by a different node initiates the transmission process

for the cyclic process data of the PLC and at the same time is the trigger point for the data acceptance

of the cyclic process data received in the PLC:

Sync telegram Sync telegram

CAN1_OUT CAN1_IN

1. 2. 3. 4.

Fig. 2−4 Synchronisation of the cyclic process data by a sync telegram (without considering the asynchronous data)

1. After a sync telegram has been received, the cyclic process output data (CAN1_OUT) are sent

by the PLC if "respond to sync" has been activated.

2. When the transmission process has been completed, the cyclic process input data (CAN1_IN)

are received by the PLC.

3. The data acceptance in the PLC is effected with the next sync telegram.

4. All further telegrams (e. g. for parameters or event−controlled process data) are accepted in an

asynchronous manner by the PLC after transmission has been completed.

Tip!

The response to a sync telegram is configured via the following codes:

· for CAN1_OUT via C0366. (^ 3−7)

· for XCAN1_OUT ... XCAN3_OUT via C2375. (^ 4−7)

· for FIF−CAN1_OUT via C2466. (^ 5−7)

· for CANaux1_OUT via C2466. (^ 5−7)

Also the telegrams of CAN2_OUT and CAN3_OUT can be transferred after a sync telegram, the

parameterisation of this function is carried out via the CAN_Management SB.

(^ 7−20)

l

PLC−Systembus EN 2.0

2−9

Page 22

System bus (CAN) for Lenze PLC devices

General information

2.6.3 Process data telegram

The process data telegram is structured as follows:

11bit 8 bytes user data

Identifier Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Identifier

Information on the identifier can be found in chapter 2.4.1.

User data

The 8 bytes user data received or to be transmitted respectively can be read or written

simultaneously by several variables of different data types.

Detailed information on the user data can be found in the description to the respective system block:

(^ 2−3)

· CAN system blocks (^ 7−1 ff.)

· FIF−CAN system blocks (^ 8−1 ff.)

· CAN−AUX system blocks (^ 9−1 ff.)

2−10

PLC−Systembus EN 2.0

l

Page 23

System bus (CAN) for Lenze PLC devices

2.7 Transmitting parameter data

For Lenze devices, parameter data are the so−called codes.

· Parameter settings for instance are carried out in the case of a one−time setting of the system

during commissioning, or in the case of a material change of the production machine.

· Parameter data are transferred as so−called SDOs (Service Data Objects) via the system bus

and are acknowledged by the receiver, i. e. the transmitter receives a feedback on whether the

transmission was successful.

2.7.1 Parameter data telegram

The telegram for parameter data is structured as follows:

11bit 8 bytes user data

Identifier

Command

code

· In the following subchapters the different components of the telegram are explained in detail.

· An example for writing a parameter can be found in chapter 2.7.2. (^ 2−15)

· An example for reading a parameter can be found in chapter 2.7.3. (^ 2−17)

Index

Low byte High byte

General information

Subindex Data 1 Data 2 Data 3 Data 4

2.7.1.1 Identifier

Identifier

For the transmission of parameter data, two parameter data channels are provided, which are

addressed via the identifier:

SDOs Parameter data channel 1

Parameter data channel 2

Tip!

Between the identifiers for parameter data channels 1 and 2 there respectively is an offset of 64:

· Output of parameter data channel 1 = 1536

· Output of parameter data channel 2 = 1536 + 64 = 1600

Command

code

Output (transmission) 1536 600

Input (reception) 1408 580

Output (transmission) 1600 640

Input (reception) 1472 5C0

Index

Low byte High byte

Identifier = basic identifier + node address of the node

Subindex Data 1 Data 2 Data 3 Data 4

dec hex

+ C0350

+ C2350

+ C2450

+ C0350

+ C2350

+ C2450

(CAN)

(XCAN)

(FIF−CAN/CANaux)

(CAN)

(XCAN)

(FIF−CAN/CANaux)

l

PLC−Systembus EN 2.0

2−11

Page 24

System bus (CAN) for Lenze PLC devices

General information

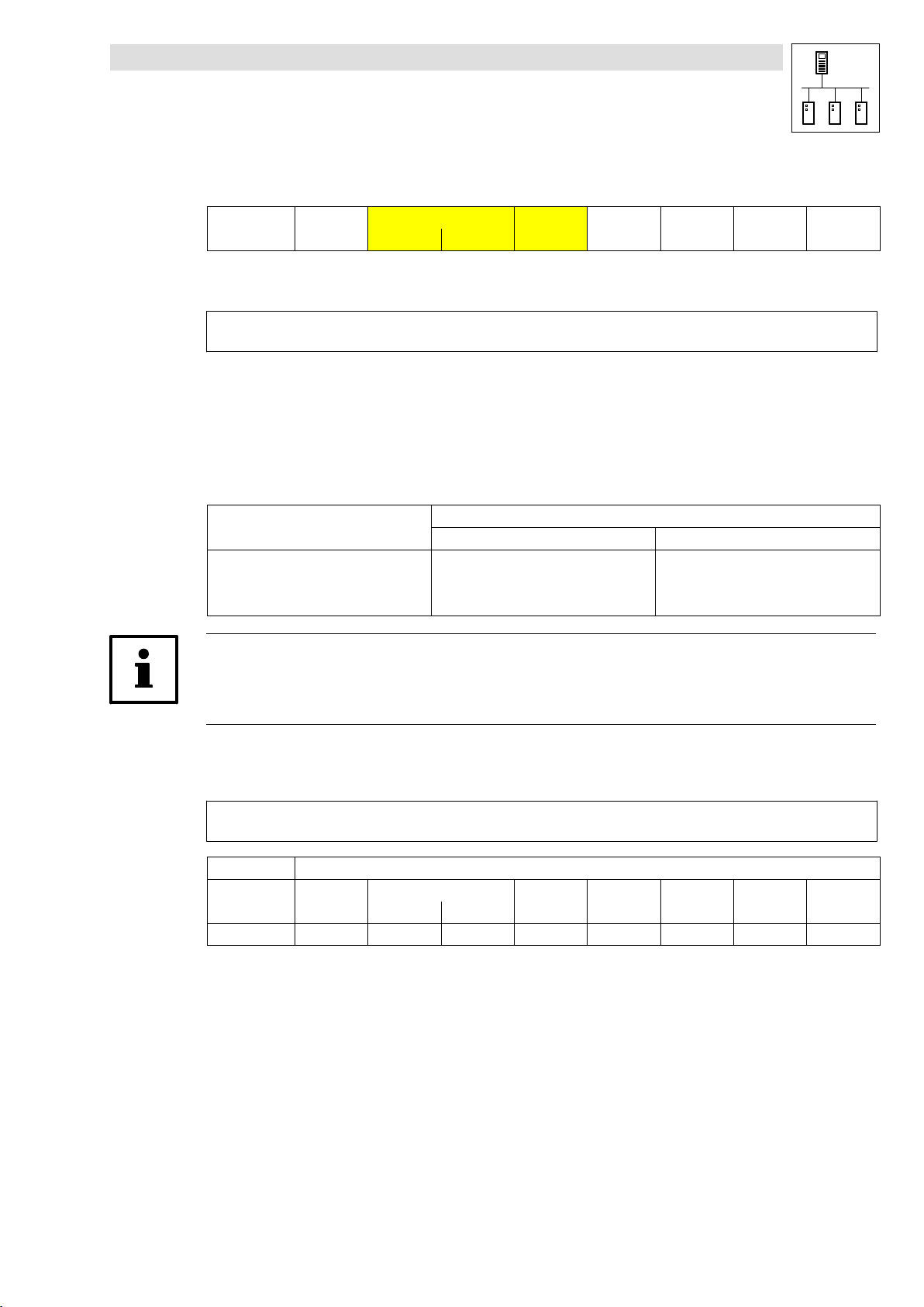

2.7.1.2 Command code

Identifier

Command

code

Index

Low byte High byte

Subindex Data 1 Data 2 Data 3 Data 4

Among other things, the command code contains the command to be carried out as well as

information on the parameter data length, and is structured as follows:

Bit 7 (MSB) Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Command Command Specifier (cs) Length e s

Write request 0 0 1 0

Write response 0 1 1 0 0 0

Read request 0 1 0 0 0 0

Read response 0 1 0 0 1 1

Error Response 1 0 0 0 0 0 0 0

00 = 4 bytes

01 = 3 bytes

10 = 2 bytes

11 = 1 byte

1 1

Command code for parameters with 1, 2, or 4 bytes data length:

4 byte data

(32 bit)

Command hex dec hex dec hex dec Information

Write Request 23 35 2B 43 2F 47 Send parameter to a node

Write Response 60 96 60 64 60 96 Node response to "write request" (acknowledgement)

Read Request 40 64 40 64 40 64 Request for reading a parameter of a node

Read Response 43 67 4B 75 4F 79 Response to the read request with an actual value

Error Response 80 128 80 128 80 128 Node reports an error with regard to communication

2 byte data

(16 bit)

1 byte data

(8 bit)

"Error Response" command

In the case of this error, an "Error Response" is generated by the node that is addressed.

· This telegram in data 4 always contains the value "6", and in data 3 an error code:

Error Response command code Data 3 Data 4 Error message

3

80

hex

C0

hex

5 Incorrect subindex

6 Incorrect index

8

6

Access denied

Job was not edited

(for 8200 vector + FIF module)

2−12

PLC−Systembus EN 2.0

l

Page 25

System bus (CAN) for Lenze PLC devices

2.7.1.3 Addressing the parameter (index/subindex)

General information

Identifier

Command

code

Index

Low byte High byte

Subindex Data 1 Data 2 Data 3 Data 4

The addressing of the parameter or of the Lenze code which is to be read or written is effected via

the index of the telegram:

Index + 24575 * Lenze code number

· The value for the index is to be entered divided into a low and a high byte in the left−justified

Intel format (see example).

· If a subcode is to be addressed, enter the number of the respective subcode in the subindex

of the telegram.

· For codes without subcodes, the subindex always receives the value "0".

· The index for Lenze codes is between 40C0

Lenze code Index

C0000 24575 5FFF

... ... ...

C7999 16576 40C0

(16576) and 5FFF

hex

dec hex

(24575).

hex

Tip!

For converting a code number to the corresponding index, the function L_FUNCodeIndexConv in

the LenzeDrive.lib function library is provided to you.

Example:

Subcode 1 of code C0168 (fault messages) is to be addressed:

Index + 24575 * 168 + 24407 + 5F57

11bit 8 bytes user data

Identifier

Command

code

Index

Low byte High byte

57

hex

5Fhex 1

Subindex Data 1 Data 2 Data 3 Data 4

hex

hex

l

PLC−Systembus EN 2.0

2−13

Page 26

System bus (CAN) for Lenze PLC devices

General information

2.7.1.4 Data of the parameter (data 1 ... data 4)

Identifier

Command

code

Index

Low byte High byte

Subindex Data 1 Data 2 Data 3 Data 4

For the data of the parameter up to 4 bytes (data 1 ... data 4) are provided.

· The data are presented in the left−justified Intel format with data 1 as LSB and data 4 as MSB

(see example).

Example:

For a code in the "Fixed32" data format, the value "20" is to be transmitted.

· "Fixed32" is a fixed point format with 4 decimal positions. Therefore the value has to be

multiplied by 10000:

Data

11bit 8 bytes user data

Identifier

Command

code

+ 20 @ 10000 + 200000 + 00 03 0D 40

1...4

Index

Low byte High byte

Subindex Data 1 Data 2 Data 3 Data 4

hex

40

hex

(LSB) (MSB)

0D

hex

03

hex

00

hex

Tip!

The parameters of the Lenze devices are stored in different formats.

Detailed information on this subject can be found in the Manual for the respective PLC in the chapter

"Appendix − Table of attributes".

2−14

PLC−Systembus EN 2.0

l

Page 27

System bus (CAN) for Lenze PLC devices

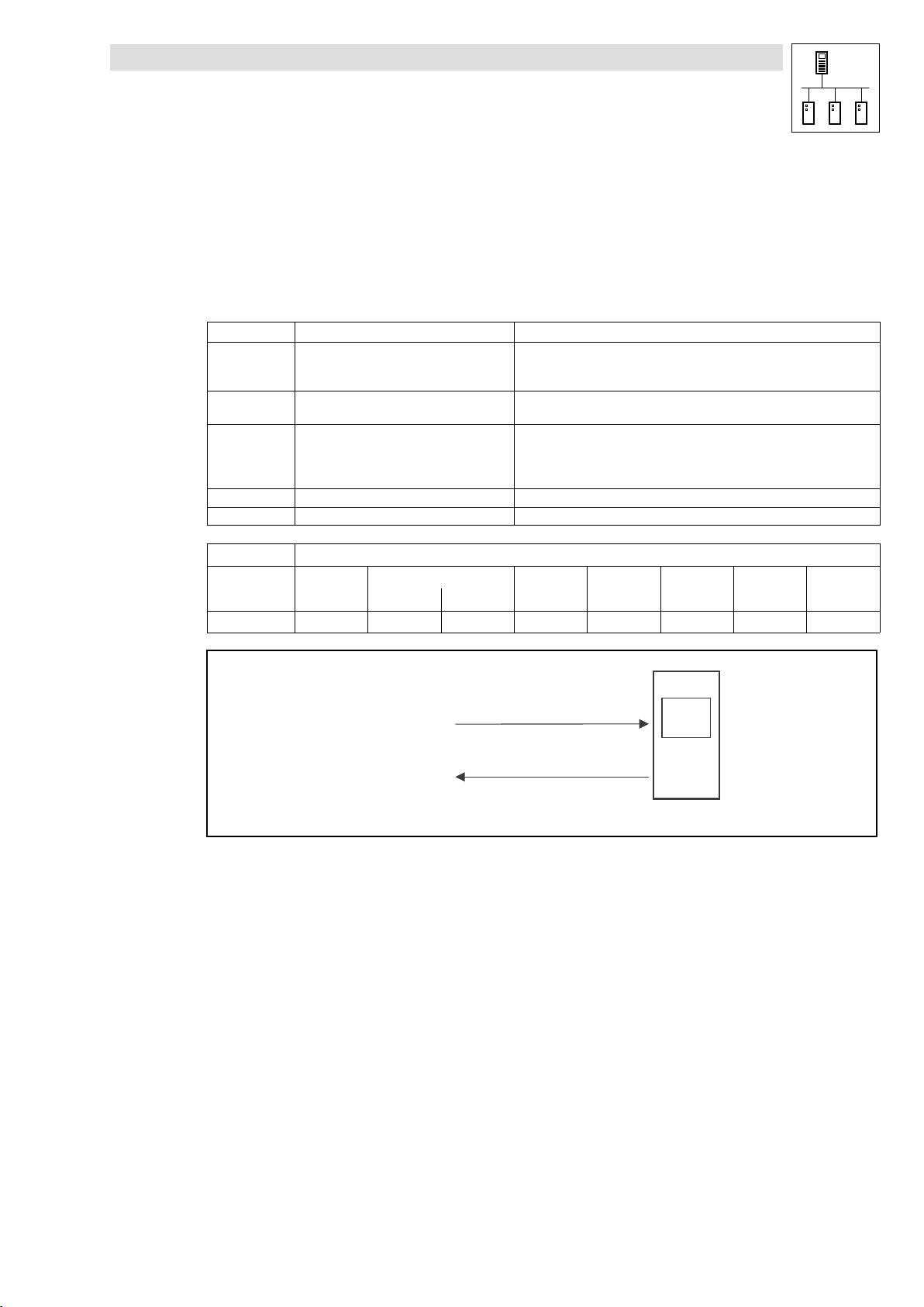

2.7.2 Writing parameters (example)

Task

The acceleration time (C0012) of the controller with the node address 1 is to be set to 20 s via the

parameter data channel 1.

Telegram to the controller

Formula Information

Identifier = basic identifier + node address

Command code = 23

Index = 24575 − number of the Lenze code

Subindex = 0 · Subcode = 0 (no subcode)

Data 1 ... 4 = 20 x 10000

= 1536 + 1

= 1537

hex

= 24575 − 12

= 24563

= 5F F3

hex

= 200000

= 00 03 0D 40

hex

General information

· Basic identifier for parameter data channel 1 (output) = 1536

· Node address of the controller = 1

· Command "Write Request" (send parameter to controller)

· Code = C0012 (acceleration time)

· Value = 20 s

· Fixed32 data format (4 fixed decimal positions); multiply value by 10000

11bit 8 bytes user data

Identifier

1537 23

Fig. 2−5 Writing parameters

Command

code

hex

Index

Low byte High byte

F3

hex

Write Request

(C0012 = 20 s)

Write Response

5F

hex

Subindex Data 1 Data 2 Data 3 Data 4

0 40

hex

(LSB) (MSB)

0D

hex

03

hex

L

Identifier = 1537

Identifier = 1409

SDO 1 / Node-ID 1

00

hex

l

PLC−Systembus EN 2.0

2−15

Page 28

System bus (CAN) for Lenze PLC devices

General information

Telegram from controller (acknowledgement if carried out correctly)

Formula Information

Identifier = basic identifier + node address

Command code = 60

Index = index of the read request

Subindex = subindex of the read request

Data 1 ... 4 = 0 · Acknowledgement only

11bit 8 bytes user data

Identifier

1409 60

= 1408 + 1

= 1409

hex

Command

code

hex

Index

Low byte High byte

F3

hex

5F

· Basic identifier for parameter data channel 1 (input) = 1408

· Node address of the controller = 1

· "Write Response" command (acknowledgement by the controller)

Subindex Data 1 Data 2 Data 3 Data 4

hex

0 0 0 0 0

2−16

PLC−Systembus EN 2.0

l

Page 29

System bus (CAN) for Lenze PLC devices

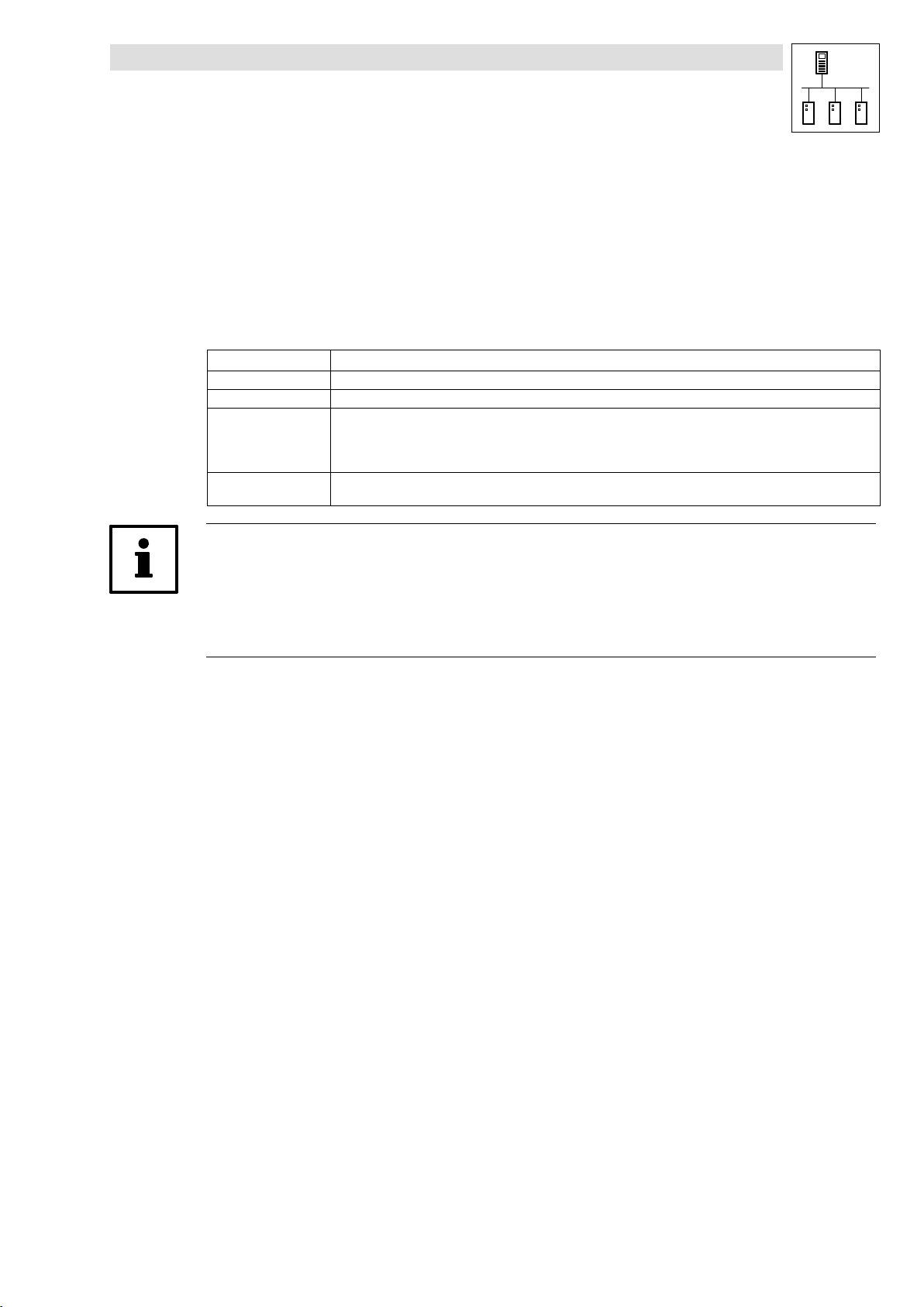

2.7.3 Reading a parameter (example)

Task

The heatsink temperature (C0061) of the controller with the node address 5 is to be read via the

parameter data channel 1.

Telegram to the controller

Formula Information

Identifier = basic identifier + node address

Command code = 40

Index = 24575 − number of the Lenze code

Subindex = 0 · Subcode = 0 (no subcode)

Data 1 ... 4 = 0 · Read request only

= 1536 + 5

= 1541

hex

= 24575 − 61

= 24514

= 5F C2

hex

General information

· Basic identifier for parameter data channel 1 (output) = 1536

· Node address of the controller = 5

· Command "Read Request" (request to read a parameter from the

controller)

· Code = C0061 (heatsink temperature)

11bit 8 bytes user data

Identifier

1541 40

Fig. 2−6 Reading parameters

Command

code

hex

Index

Low byte High byte

C2

hex

Read Request

(C0061 = ???)

Read Response

(C0061 = 43 ºC)

5F

hex

Subindex Data 1 Data 2 Data 3 Data 4

0 0 0 0 0

L

Identifier = 1541

Identifier = 1413

SDO 1 / Node-ID 5

l

PLC−Systembus EN 2.0

2−17

Page 30

System bus (CAN) for Lenze PLC devices

General information

Telegram from the controller (value of the parameter requested)

Formula Information

Identifier = basic identifier + node address

Command code = 43

Index = index of the read request

Subindex = subindex of the read request

Data 1 ... 4 = 43 x 10000

11bit 8 bytes user data

Identifier

1413 43

= 1408 + 5

= 1413

hex

= 430000

= 00 06 8F B0

Command

code

hex

hex

Index

Low byte High byte

C2

hex

5F

· Basic identifier for parameter data channel 1 (input) = 1408

· Node address of the controller = 5

· "Read Response" command (response to the read request with the

current value)

· Assumption: The current heatsink temperature of the controller is 43 ºC,

therefore the value of the parameter to be read is 43

· Fixed32 data format (4 fixed decimal positions); multiply value by 10000

Subindex Data 1 Data 2 Data 3 Data 4

hex

0 B0hex 8Fhex 06

hex

00

hex

(LSB) (MSB)

2−18

PLC−Systembus EN 2.0

l

Page 31

System bus (CAN) for Lenze PLC devices

2.8 Free CAN objects

If many nodes are connected to the system bus (CAN), it may occur that the CAN objects

(CAN1_IO ... CAN3_IO) which are fixedly integrated in the PLC are not sufficient for the

communication intended, and further CAN objects are required.

By using the functions/function blocks of the LenzeCanDrv.lib function library, so−called "free CAN

objects" can be added to the fixedly integrated CAN objects.

Characteristics of the free CAN objects

Free CAN objects

User data per object 1 ... 8 byte

Intended use Transmission of parameter and process data

Transmission modes · Event−controlled transmission

· Time−controlled transmission

· Time−controlled transmission with superimposed event control

· Forced transmission

Range for identifiers Transmission and reception identifiers can be allocated in the range of 0 ... 2047, but they have to differ from the

identifiers of the integrated CAN objects.

General information

(^ 10−2)

Note!

The free CAN objects are processed via a so−called transmit request memory by the operating

system, i. e. the transmission process is not carried out immediately when the L_CanPdoTransmit

FB is called, but is effected in a delayed manner.

The transmission and reception jobs of the free CAN objects are not linked to the process image.

(^ 10−8)

l

PLC−Systembus EN 2.0

2−19

Page 32

System bus (CAN) for Lenze PLC devices

General information

2.9 Application recommendations for the different CAN objects

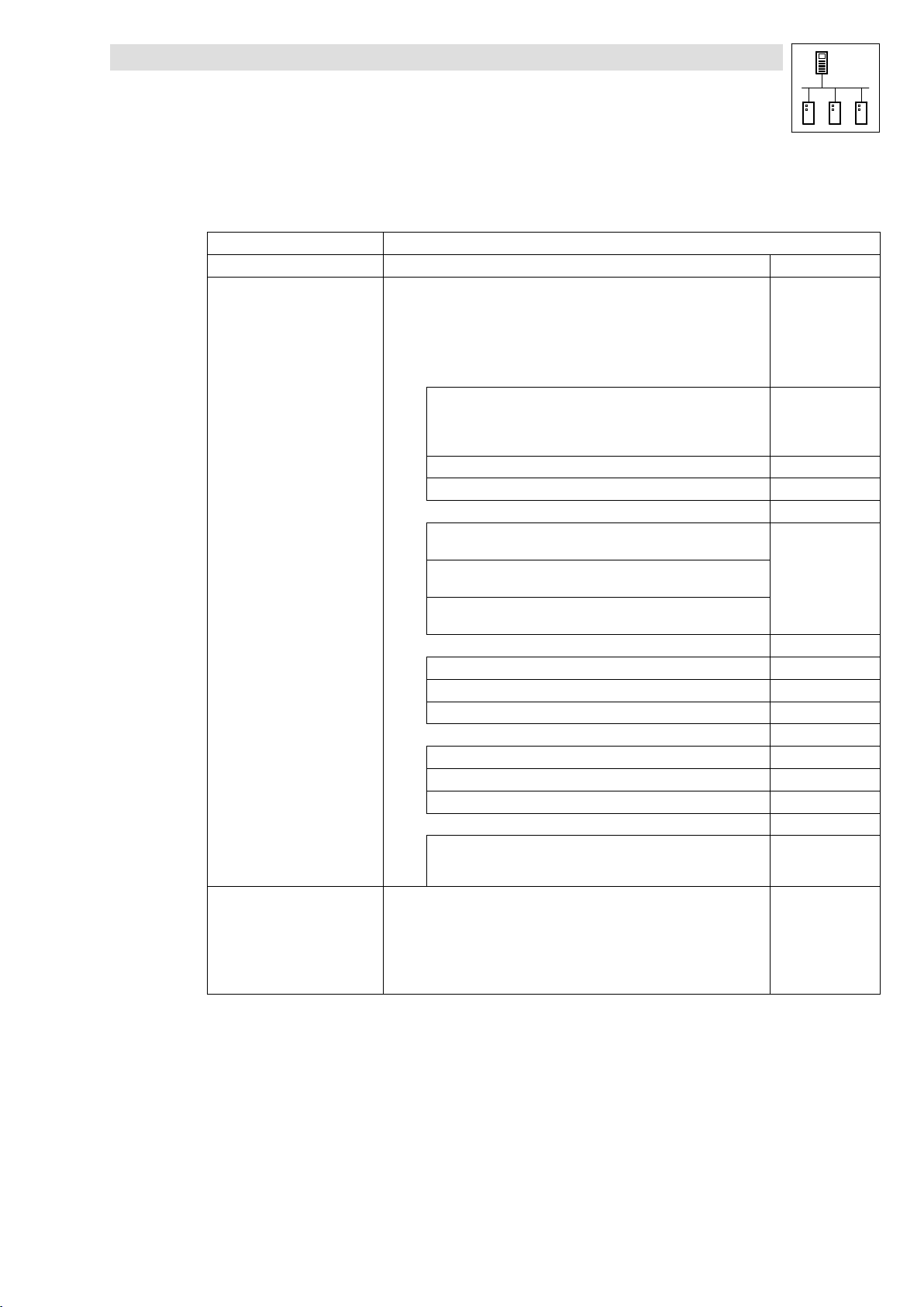

The following table provides a comparison of the different CAN objects and their specific

characteristics:

CAN object Process data

CAN1_IO Þ Þ Þ

CAN2_IO Þ Þ

CAN3_IO Þ Þ

XCAN1_IO Þ Þ Þ

XCAN2_IO Þ Þ

XCAN3_IO Þ Þ

FIF_CAN1_IO Þ Þ Þ

FIF_CAN2_IO Þ Þ

FIF_CAN3_IO Þ Þ

CANaux1_IO Þ Þ Þ

CANaux2_IO Þ Þ

CANaux3_IO Þ Þ

Free CAN objects Þ Data exchange

1)

Sync telegram required for the function of the respective CAN1 object

transmission

Linked to the

process image

Sync telegram

required

1)

Application recommendation

Data exchange

· of position setpoints/actual values

· of speed setpoints for servo applications

· of setpoints/actual values

· with analog terminal I/Os

2−20

PLC−Systembus EN 2.0

l

Page 33

System bus (CAN) for Lenze PLC devices

2.10 Monitoring mechanisms

In the CANopen communication profile (CiA DS301, version 4.01) two optional monitoring

mechanisms for ensuring the function of system bus nodes are specified, "Heartbeat" and "Node

Guarding".

Note!

The "Heartbeat" and "Node Guarding" monitoring mechanisms are supported by the

9300 Servo PLC, Drive, PLC and by the ECSxA axis module as of V6.0.

The initialisation and execution of the monitoring mechanisms is carried out by means of the

functions/function blocks of the LenzeCanDSxDrv.lib function library.

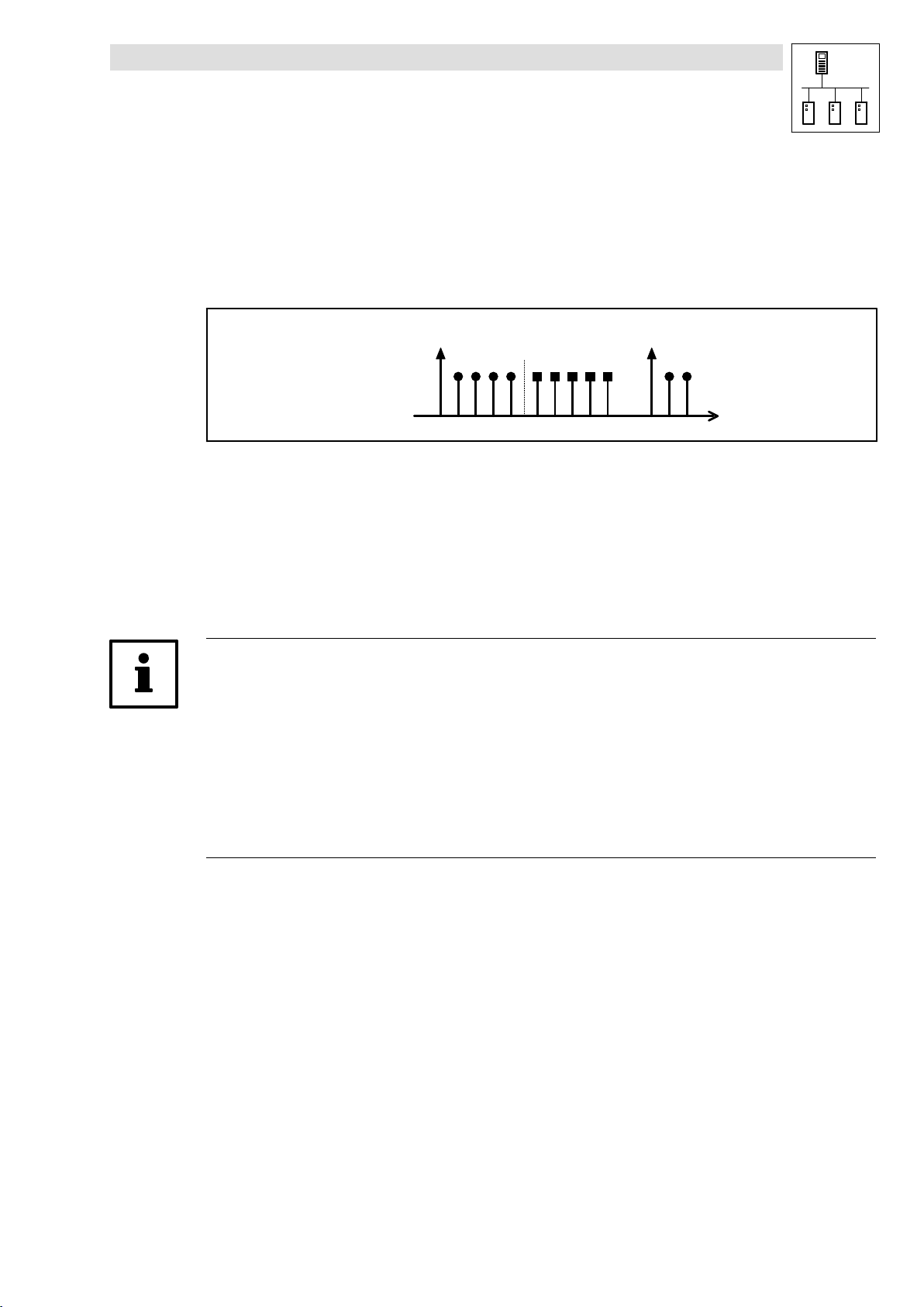

2.10.1 "Heartbeat"

General information

(^ 11−1)

The "Heartbeat" monitoring mechanism is a Producer−Consumer−oriented method which does not

require an enquiry message and where each node is able to monitor the state of all other nodes.

Heartbeat Producer Heartbeat Consumer(s)

s

s

Stopped

Operational

Pre-Operational

Boot-Up Event

Heartbeat

Producer

Time

Request

Request

r

r

r:

reserved

s: State of the heartbeat producer:

4

5

127

0

18

Indication(s)

Heartbeat

Consumer

Time

18

Indication(s)

Heartbeat

Event

Fig. 2−7 "Heartbeat" monitoring mechanism

· A node (Producer) signalises its communication status by cyclically transmitting a so−called

"Heartbeat" message.

· This "Heartbeat" message can be received by one, several, or by all the other nodes

(Consumer), and thus they can monitor the respective node.

· If the responsible, monitoring node (Consumer) does not receive the "Heartbeat" message

from the node to be monitored (Producer) within the set monitoring time

(HeartBeatConsumerTime), a "Heartbeat" event is displayed in its application.

l

PLC−Systembus EN 2.0

2−21

Page 34

System bus (CAN) for Lenze PLC devices

General information

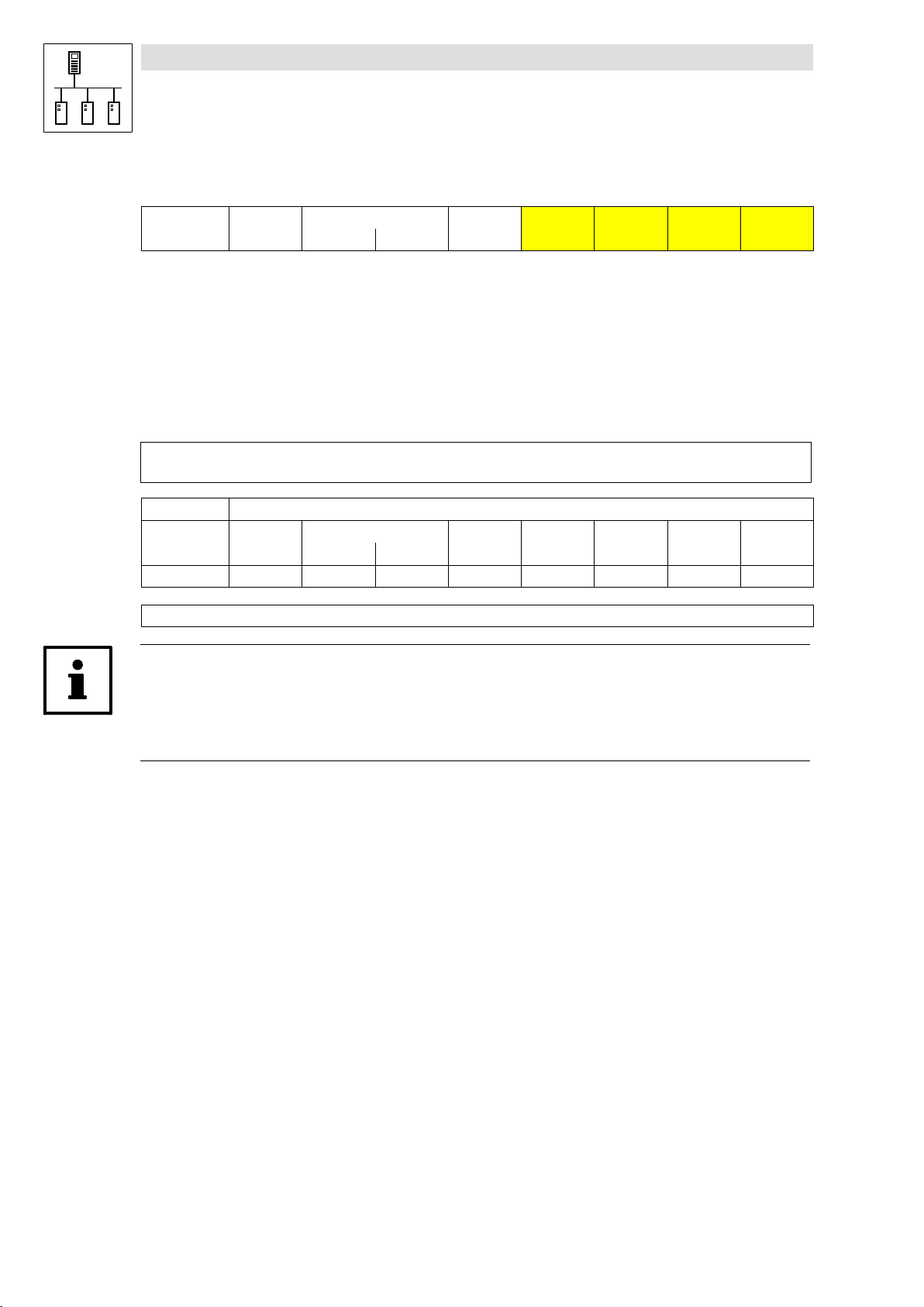

2.10.2 "Node Guarding"

In contrast to the "Heartbeat" monitoring mechanism, for the "Node Guarding" an enquiry message

from the monitoring node (NMT Master) is required.

NMT Master NMT Slave

RTR

Request

Node

Guard

Time

Node

Life

Time

Fig. 2−8 "Node guarding" monitoring mechanism

Confirmation

Request

Confirmation

Node

Guarding

Event

· The NMT master monitors each of the nodes to be monitored (NMT slave) cyclically using a

node−specific "Remote Transmission Request" telegram.

· The NMT slave to be monitored returns its communication status as a response to this

request.

· If the NMT master does not receive the message from the NMT Slave) to be monitored within

the set monitoring time (NodeLifeTime|, a "Node Guarding" event is displayed in its

application.

· For the NMT slave to be monitored, however, a "Life Guarding" event is activated if its status

has not been enquired by the monitoring NMT master for longer than its "Node Life Time".

t

RTR

t

t:

Toggle bit

s: NMT Slave state:

Stopped

4

Operational

5

Pre-Operational

127

Boot-Up Event

0

18

Indication

s

Response

Node

Life

Time

18

Indication

s

Response

Life

Guarding

Event

2−22

PLC−Systembus EN 2.0

l

Page 35

System bus (CAN) for Lenze PLC devices

"CAN" system bus interface configuration

3 Configuration (system bus − CAN interface)

Tip!

Changes with regard to the CAN baud rate, the CAN addresses, and the identifiers for PDOs only

are accepted after a reset node.

A reset node can be effected by

· Reconnection of the mains

· Reset node command via NMT command. (^ 2−6)

· Reset node via C0358 (^ 3−8)

3.1 CAN baud rate

In order to accomplish communication via the system bus, all nodes have to use the same baud rate

for data transmission.

· The configuration of the baud rate is effected via code C0351:

Code LCD

C0351 CAN baud rate 0 0 500 kbit/s

Possible settings

Lenze Selection

1 250 kbit/s

2 125 kbit/s

3 50 kbit/s

4 1000 kbit/s

Information

System bus − baud rate

· Save changes with C0003 = 1.

· Changes are only valid after

reset node!

l

PLC−Systembus EN 2.0

3−1

Page 36

System bus (CAN) for Lenze PLC devices

"CAN" system bus interface configuration

3.2 CAN boot−up

If the initialisation of the system bus and the associated state change from Pre−operational to

Operational is not taken over by a higher−level master system, the PLC or a controller can be

designated as a "quasi" master to accomplish this task.

· The configuration is effected via code C0352:

Code LCD

C0352 CAN mst 0 0 Boot−up not active

Possible settings

Lenze Selection

1 Boot−up active

Information

Device sends system bus boot−up

and thus is the "quasi" master.

Delay time for system bus initialisation (boot−up)

Some nodes (e. g. HMIs) require a specific starting time after mains connection before they can be

transferred to the Operational state via NMT commands by the master.

In order to ensure that even the node with the greatest starting time really is ready to receive NMT

commands, you can set a delay time. When it has expired, NMT commands can only be transmitted

after mains power−up.

· The configuration of this delay time is effected via code C0356/1:

Code LCD

C03561CAN boot−up

Possible settings

Lenze Selection

0 {1 ms} 65000 Delay time after power−on for

3000

Information

initialisation via the "quasi" master

3−2

PLC−Systembus EN 2.0

l

Page 37

System bus (CAN) for Lenze PLC devices

3.3 Node address (node ID)

Assign a node address − also called Node ID − within the range of 1 to 63 to each node within the

system bus network as a definite identification.

· The same node address may not be assigned more than once within the network.

· The configuration of the node address for the PLC is carried out via code C0350:

"CAN" system bus interface configuration

Code LCD

C0350 CAN address 1 1 {1} 63 System bus − node address

Possible settings

Lenze Selection

Allocation of the node address for the data exchange among Lenze devices

If Lenze devices are provided with node addresses in a consistent ascending order, the identifiers

of the event−controlled data objects (CAN2_IO/CAN3_IO) are set in way by the factory which enables

a communication from one device to the other:

L

CAN2_OUT

CAN3_OUT

Node-ID 1

Fig. 3−1 Data exchange among Lenze devices

CAN2_IN

CAN3_IN

L

Node-ID 2

CAN2_OUT

CAN3_OUT

Information

· Save changes with C0003 = 1.

· Changes are only valid after

reset node!

L

CAN2_IN

CAN3_IN

Node-ID 3

l

PLC−Systembus EN 2.0

3−3

Page 38

System bus (CAN) for Lenze PLC devices

"CAN" system bus interface configuration

3.4 Identifiers of the process data objects

The identifiers for the CAN1_IO ... CAN3_IO process data objects are generated by the so−called

basic identifier and the node address set in C0350:

Identifier + basic identifier ) node address

PDOs CAN1_IO (cyclic process data)

CAN2_IO (event− or time−controlled process data)

CAN3_IO (event− or time−controlled process data)

Basic identifiers

dec hex

CAN1_IN 512 200

CAN1_OUT 384 180

CAN2_IN 640 280