Page 1

L

Manual

Global Drive

PLC Developer Studio

Global Drive

Function library

LenzeIOSystem.lib

Page 2

The LenzeIOSystem.lib and LenzeIOSystemVxxxx.lib function libraries can be used for

the following Lenze PLC devices:

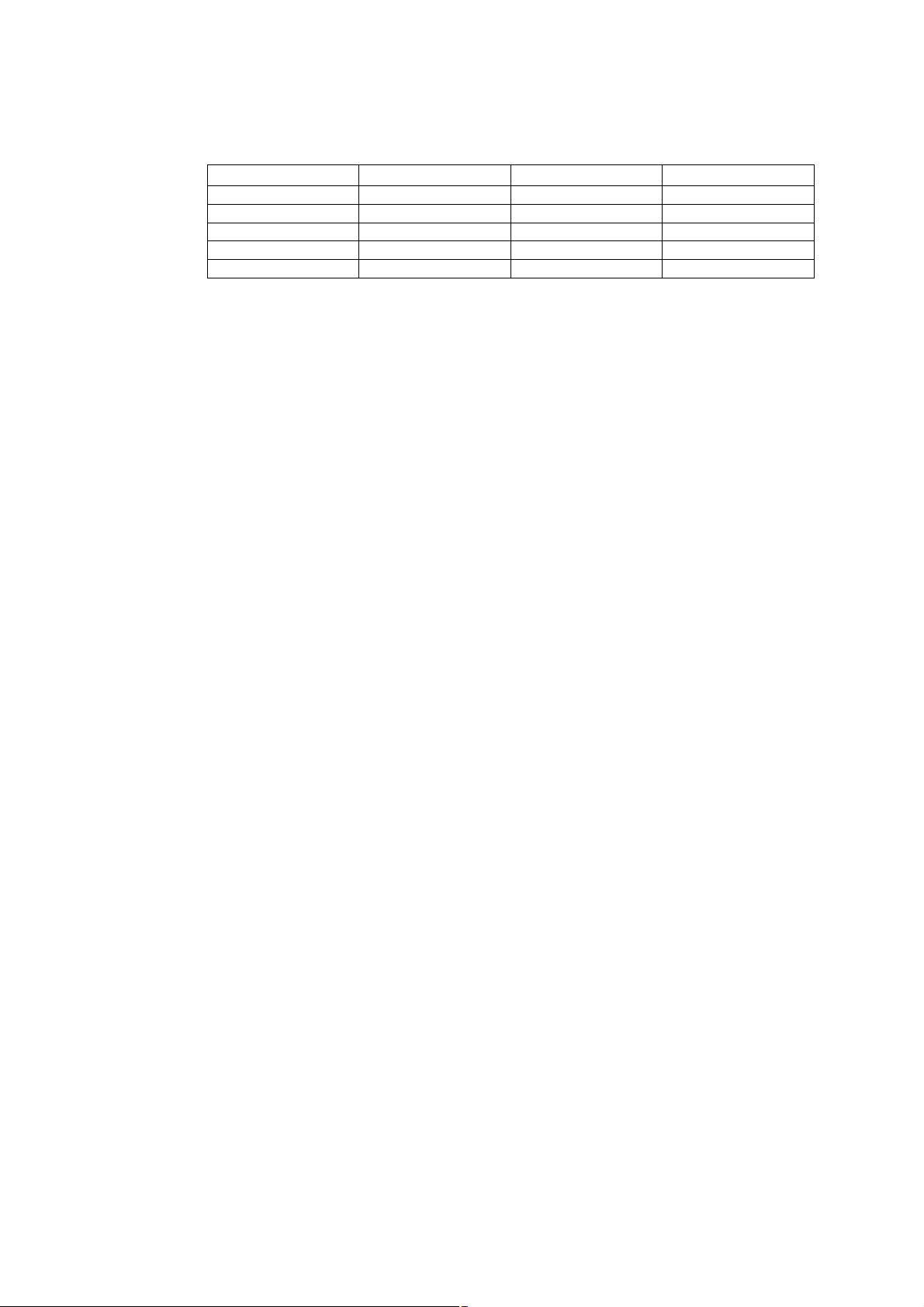

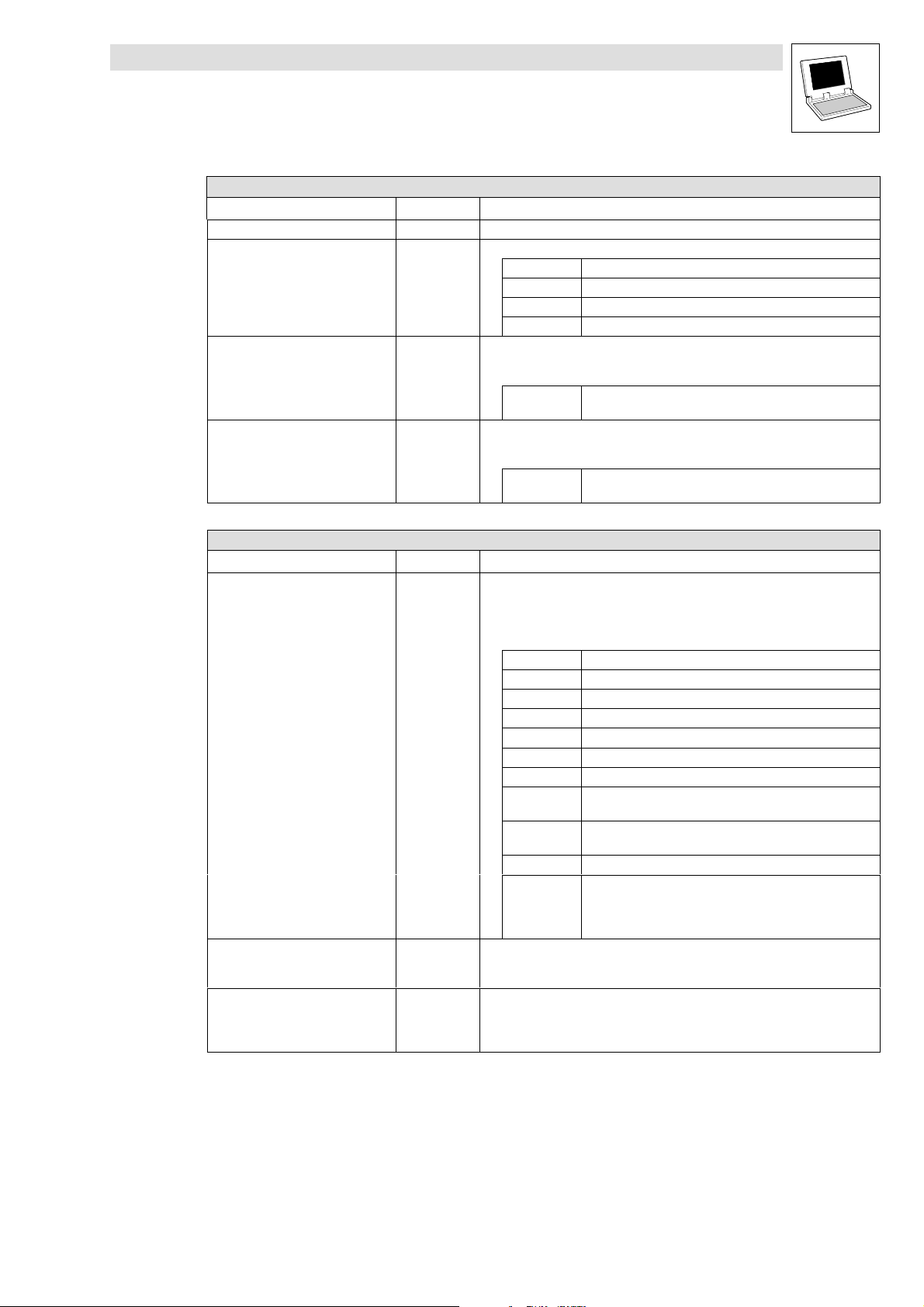

Type As of hardware version As of software version

Drive PLC EPL10200_xI VC 2.x

Drive PLC EPL10200_xT VC 2.x

9300 Servo PLC EVS93xx_xI 2K 2.x

9300 Servo PLC EVS93xx_xT 2K 2.x

ECSxA ECSxAxxx 1C 7.0

Important note:

The software is supplied to the user as described in this document. Any risks resulting from its quality or use remain the responsibility

of the user. The user must provide all safety measures protecting against possible maloperation.

We do not take any liability for direct or indirect damage, e.g. profit loss, order loss or any loss regarding business.

ã 2006 Lenze Drive Systems GmbH

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze Drive

Systems GmbH.

All information given in this documentation has been carefully selected and tested for compliance with the hardware and software

described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility or liability for any damage that may

occur. Required corrections will be included in updates of this documentation.

All product names mentioned in this documentation are trademarks of the corresponding owners.

Version 1.7 11/2006

Page 3

Function library LenzeIOSystem.lib

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions used in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Structure of the descriptions 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Pictographs used in this Manual 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Terminology used 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Version identifiers of the function library 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Introduction 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Introduction 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Design concept 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Minimum configuration 2−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Application examples 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Modular decentralised I/O system 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Compact decentralised I/O system 3−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Function blocks for parameterisation 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 L_IOParComGuarding − Monitoring function 4−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 L_IOParAlnModule − Parameterisation function 4−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 L_IOParAOutModule − Parameterisation function 4−7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 L_IOParAlAOModule − Parameterisation function 4−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 L_IOParSSIModule − Parameterisation function 4−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 L_IOParCounterModule − Counter function 4−14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 L_IOParCounterDIModule − Counter function 4−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 L_IOParPDO15 − Parameterisation function 4−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 L_IOParPDO610 − Parameterisation function 4−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 L_IOParCompactModule − Parameterisation function 4−26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Function blocks for process data processing 5−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 L_IOData15 − Coordinate data 5−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 L_IOData610 − Coordinate data 5−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 L_IOCompactModule − Coordinate data 5−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 L_IOCounterDataToIO − Counter function 5−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 L_IOCounterDataFromIO − Counter function 5−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 L_IOCounterDIModuleDataToIO − Counter function 5−14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 L_IOCounterDIModuleDataFromIO − Counter function 5−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 L_IOSSIDataToIO − Counter function 5−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 L_IOSSIDataFromIO − Counter function 5−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 L_IOConvByteToByteArray − Conversion function 5−18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 L_IOConvByteArrayToByte − Conversion function 5−19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 L_IODInModule − Bit conversion 5−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 L_IODOutModule − Bit conversion 5−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 L_IOAInModule − Signal conversion 5−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.15 L_IOAOutModule − Signal conversion 5−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

LenzeIOSystem.lib EN 1.7

i

Page 4

Function library LenzeIOSystem.lib

Contents

6 Appendix 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Signal functions for analog inputs EPM−T310 6−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Signal functions for analog outputs EPM−T320 6−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Signal functions for analog inputs and outputs EPM−T330 6−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Measured value scaling 6−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Selecting the counter modes EPM−T410 6−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Index 7−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

LenzeIOSystem.lib EN 1.7

l

Page 5

Function library LenzeIOSystem.lib

Preface and general information

1.1 About this Manual

1 Preface and general information

1.1 About this Manual

This Manual contains information on the LenzeIOSystem.lib and LenzeIOSystemVxxxx function

libraries for the Drive PLC Developer Studio.

1.1.1 Conventions used in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Variable identifiers

are printed in italics in the explanatory text:

· "By means of bReset..."

Tip!

Information about the conventions used for variables of Lenze system blocks, function blocks and

functions can be obtained from the appendix of the DDS online documentation "Introduction into

IEC 61131−3 programming". The conventions ensure universal and uniform labelling and support

the readability of PLC programs.

Lenze functions/function blocks

can be identified by the name. They always begin with an "L_":

· "By means of the L_IOPar..."FB

Program listings

are itemised in the "Courier" font, the keywords being printed bold:

· "IF (ReturnValue < 0) THEN..."

L

LenzeIOSystem.lib EN 1.7

1−1

Page 6

Function library LenzeIOSystem.lib

Preface and general information

1.1 About this Manual

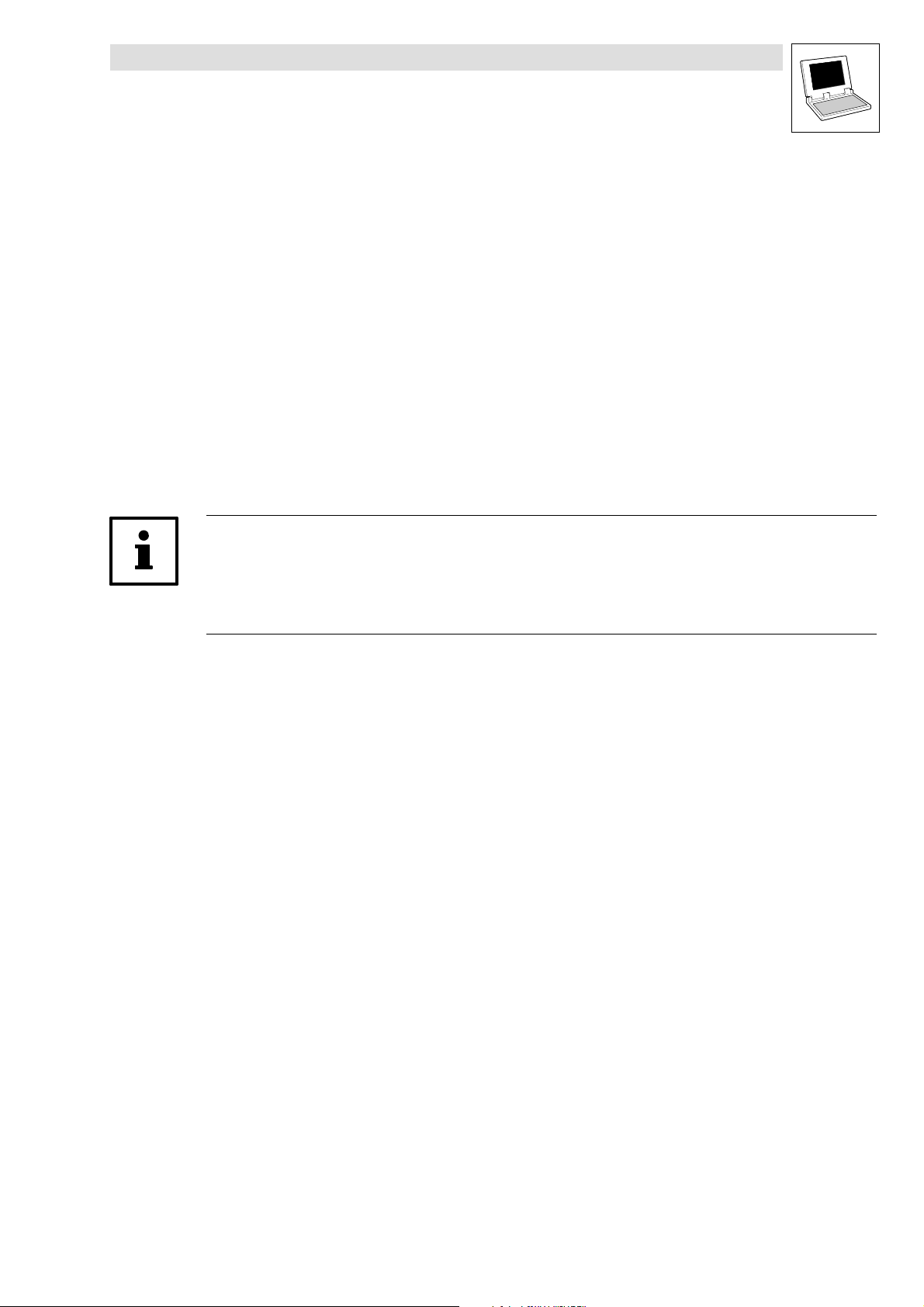

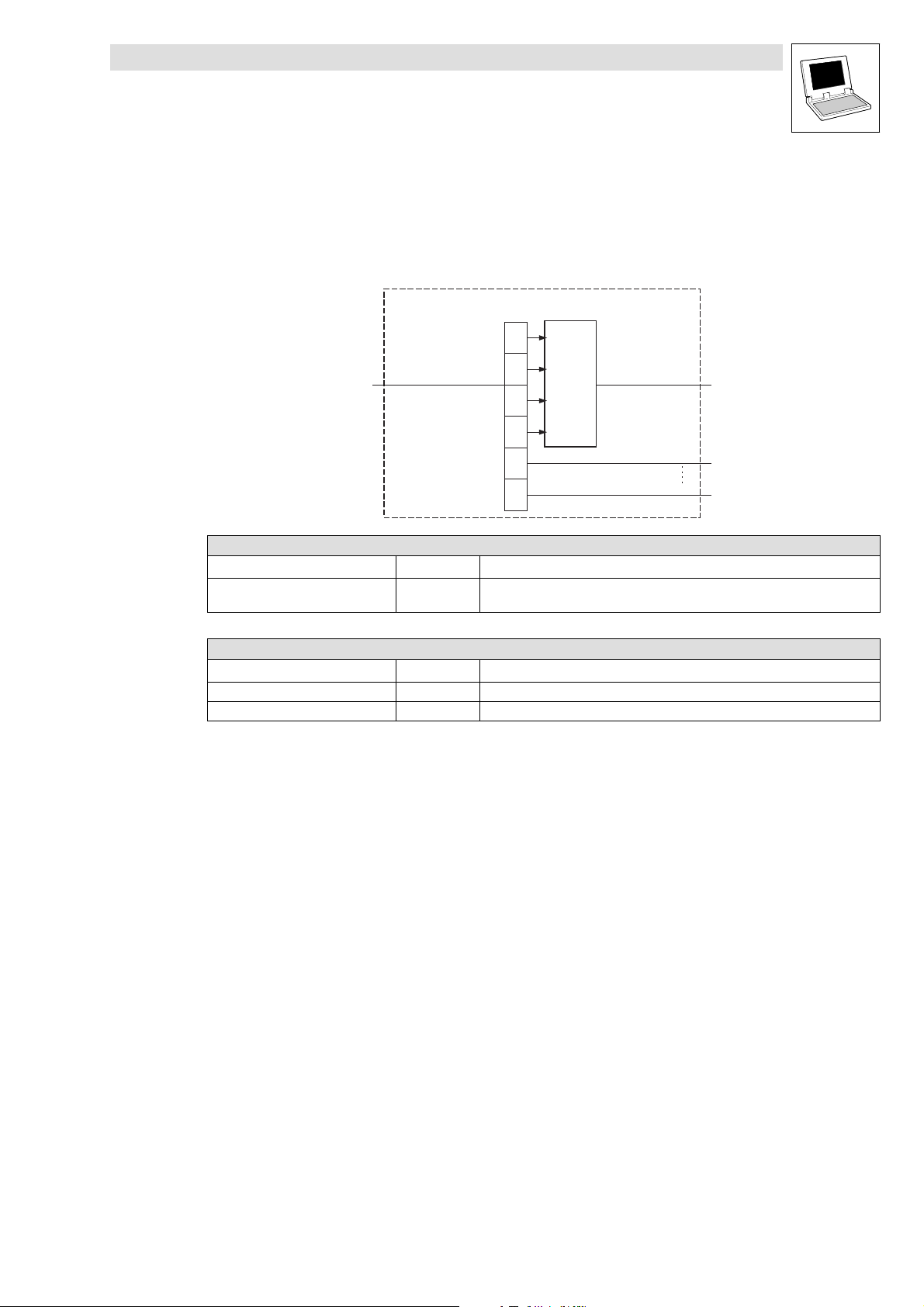

1.1.2 Structure of the descriptions

The descriptions of the individual functions/function blocks as well as system blocks in this Manual

are structured in a standardised manner according to the following pattern:

Function Function block (FB)/

Headline with function and identifier

Declaration of the function:

· Data type of the return value

· Function identifier

· List of the transfer parameters

Short description with the most important features

Graph showing the function

including all corresponding

variables

· Transfer parameters

· Return value

Table giving information on the

transfer parameters:

· Identifiers

· Data type

· Possible settings

· Information

Table giving information on the

return value:

· Data type of the return value

· Possible return values and their

meaning

Further information

(comments, tips, application examples, etc.)

system block (SB)

−

System block/function block chart

including all corresponding

variables

· Input variables

· Output variables

Table giving information about

input and output variables:

· Identifiers

· Data type

· Variable type

· Possible settings

· Information

−

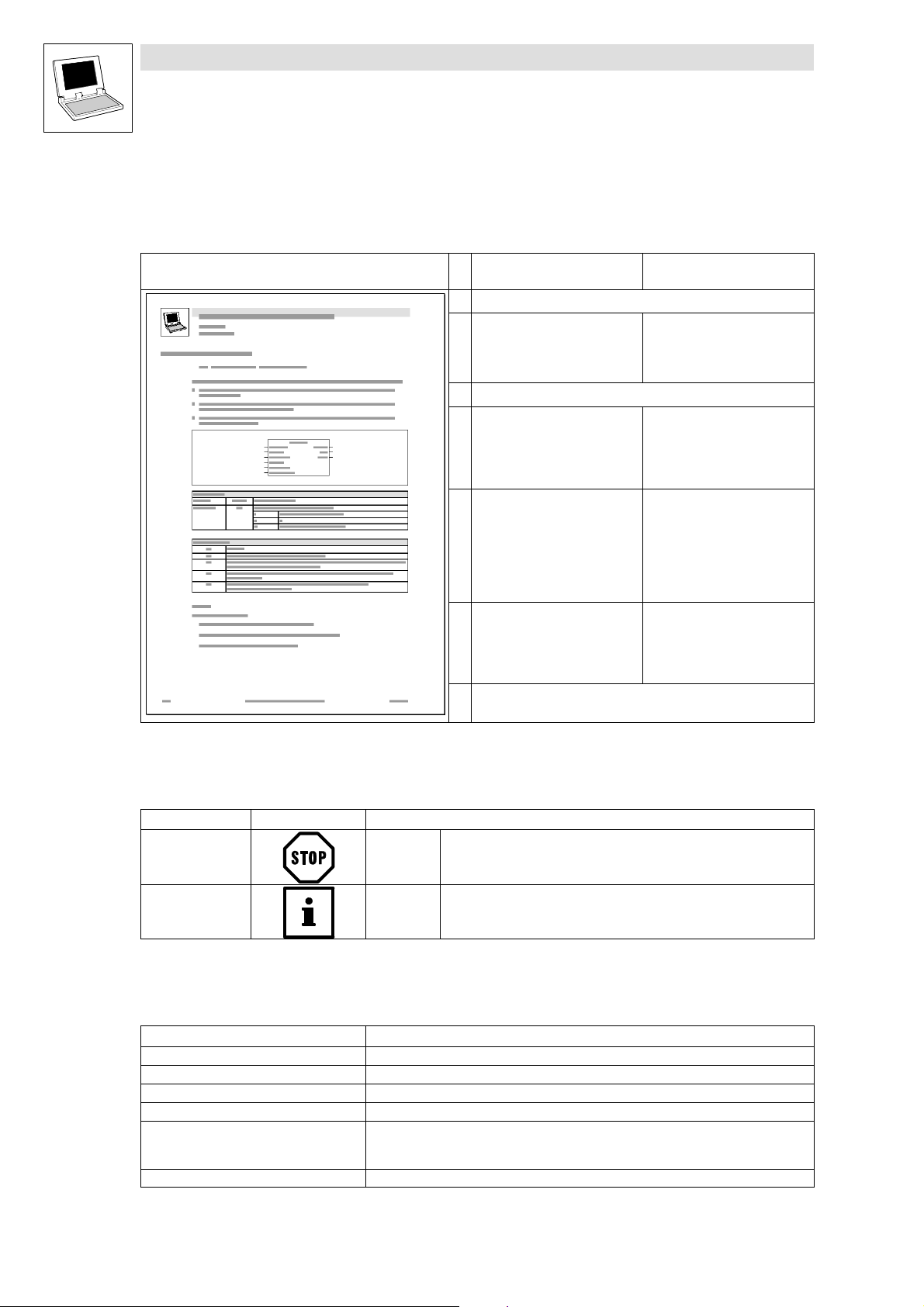

1.1.3 Pictographs used in this Manual

Pictohraphs used Signal words

Warning of

material damage

More notes Tip!

Stop! Warns of potential damage to material.

Note!

1.1.4 Terminology used

Term In this Manual used for

DDS Drive PLC Developer Studio

FB Function block

GDC Global Drive Control (parameter setting program from Lenze)

Parameter codes Codes for setting the function of a function block

PLC · 9300 servo PLC

SB System block

· Drive PLC

· ECSxA "Application" axis module

Possible consequences if disregarded:

Damage of the controller/drive system or its environment.

Indicates a tip or note.

1−2

LenzeIOSystem.lib EN 1.7

L

Page 7

Function library LenzeIOSystem.lib

Preface and general information

1.2 Version identifiers of the function library

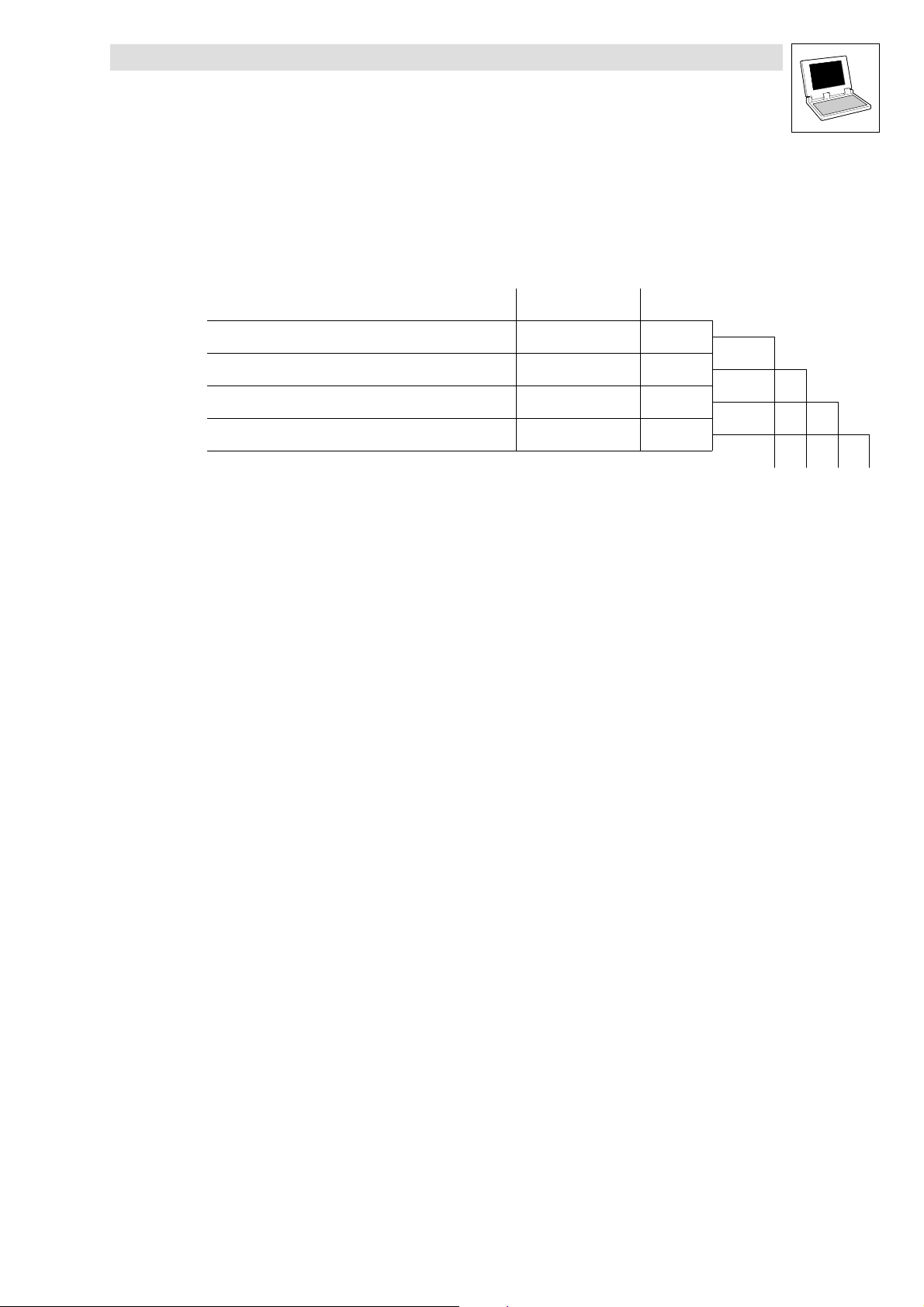

1.2 Version identifiers of the function library

The version of the function library can be found under the global constant

C_w[Function library name]Version .

Version identifiers as of PLC software version 7.x:

Constant Meaning

C_w[FunctionLibraryName]VersionER External Release 01

C_w[FunctionLibraryName]VersionEL External Level 05

C_w[FunctionLibraryName]VersionIR Internal Release 00

C_w[FunctionLibraryName]VersionBN Build No. 00

The value of this constant is a hexadecimal code.

· In the example, "01050000" stands for version "1.05".

Example

value

Version: 01 05 00 00

L

LenzeIOSystem.lib EN 1.7

1−3

Page 8

Function library LenzeIOSystem.lib

Preface and general information

1−4

LenzeIOSystem.lib EN 1.7

L

Page 9

Function library LenzeIOSystem.lib

Introduction

2.1 Introduction

2 Introduction

2.1 Introduction

The user is offered suitable function blocks in function libraries to enable decentralised I/O system

support by Lenze PLC products.

These function blocks are integrated in an IEC 61131 program and assist in the parameterisation of

the I/O system as well as in process data processing. Furthermore, they provide digital and analog

I/O system input and output information.

LenzeI/OSystem.lib

This library provides all setting options. User configuration via user codes is not required.

2.2 Design concept

The function libraries contain two types of function blocks.

· Parameter data blocks

· Process data blocks

Parameter data blocks

These function blocks allow the modification of index information in the decentralised I/O system and

the transmission of specified data. These data are transmitted only once to the I/O system during the

initialisation phase.

· Parameterising communication

– These blocks parameterise communication relationships

(Identifier assignment for PDO communication, transmission method, transmission period,

etc.) between PLC and I/O system.

– These settings are mandatory for data exchange.

· Parameterising modules and monitoring functions

– The function blocks are required for

individual parameterisation of analog modules,

individual parameterisation of counter modules,

communication monitoring

Process data blocks

These function blocks provide assistance for evaluating and further processing the current process

data information from the I/O system inputs in the PLC program.

Information and data can be transferred into the process via the output modules.

· Process data blocks to transmit and receive I/O data between PLC and I/O system.

· Process data blocks for I/O signal conversion.

L

LenzeIOSystem.lib EN 1.7

2−1

Page 10

Function library LenzeIOSystem.lib

Introduction

2.3 Minimum configuration

2.3 Minimum configuration

A minimum configuration must be established to integrate the I/O system, consisting of one

parameter data block L_IOParPDO15 to parameterise communication relationships and one

process data block L_IOData15 to evaluate the input/output information.

The information of the parameter block is transmitted to the I/O system and the function block for

PLC I/O system process data exchange.

Data exchange between the output of the parameter block and the input of the process data block

is possible with the help of a global variable.

Note!

The function libraries for the decentralised I/O system are based on unassigned CAN objects, so that

the CAN driver must be initialised via block L_CANInit.

The block L_CANInit is located in the Lenze library LenzeCanDrv.lib.

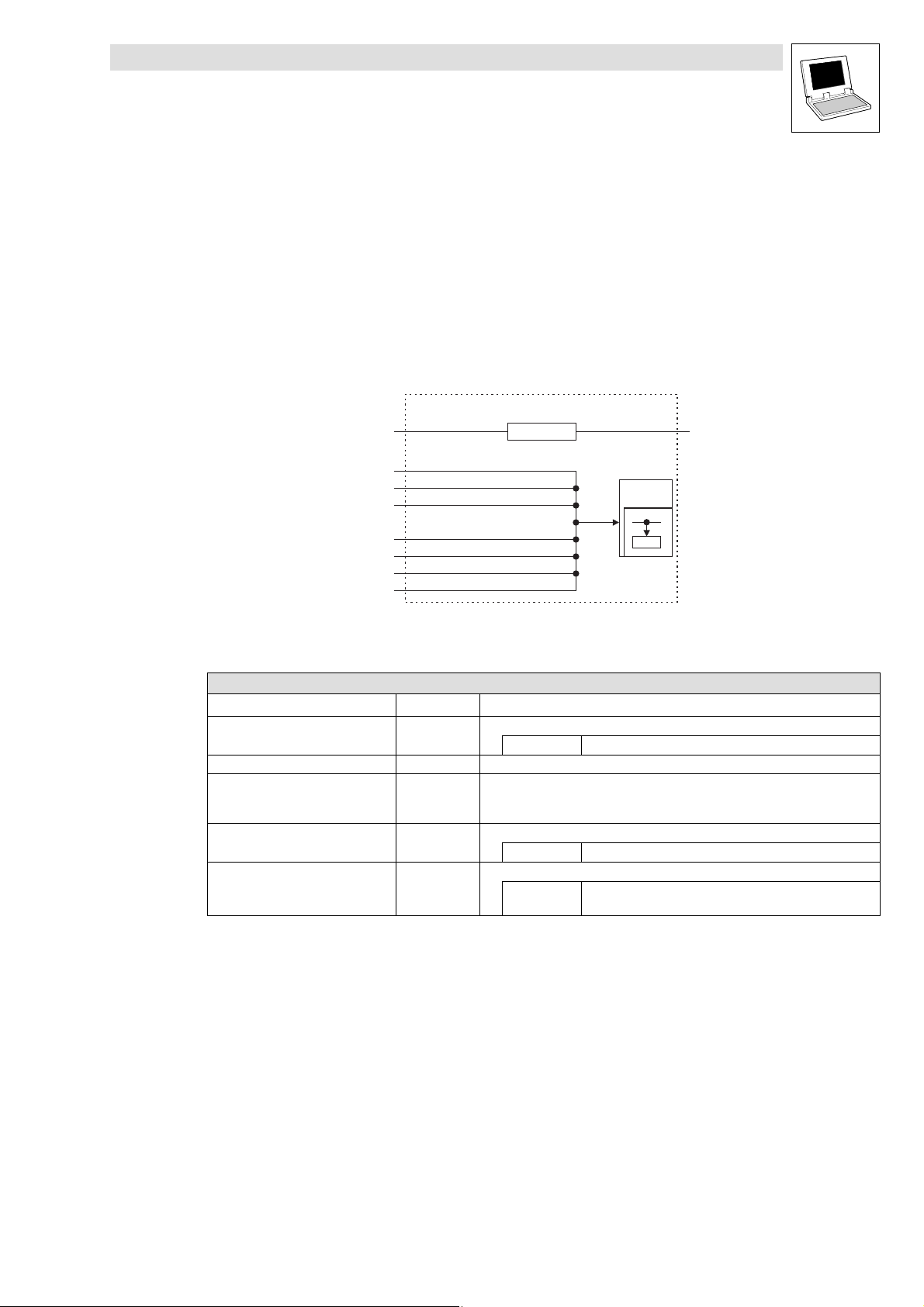

wDrvNr

10

dwRelocCobld

0

L_CanInit

L_CanInit

CTRL

10 = System bus

0 = ID range 832..895 (Servo PLC only)

Note!

The identifier range is limited in the case of the 9300 Servo PLC.

Use of function blocks L_IOParPDO15 and L_IOParPDO610 requires adjustment of the

Cob IDs from PDO4 onwards.

2−2

LenzeIOSystem.lib EN 1.7

L

Page 11

Function library LenzeIOSystem.lib

Application examples

3.1 Modular decentralised I/O system

3 Application examples

The examples were generated with DDS version 2.0. Examples concerning the I/O system are given

in the directory C:\Programme\Lenze\DDS_P_2_20\Projects\IOSystem\Samples

3.1 Modular decentralised I/O system

The modular decentralised I/O system with eight digital inputs and outputs is integrated into a PLC

program with the help of LenzeIOSystem.lib.

During this process, the following steps must be carried out in the given order:

1. Initialise the CAN driver

2. Parameterise the communication conditions

3. Program the process data exchange between PLC and I/O system

4. Initialise the codes

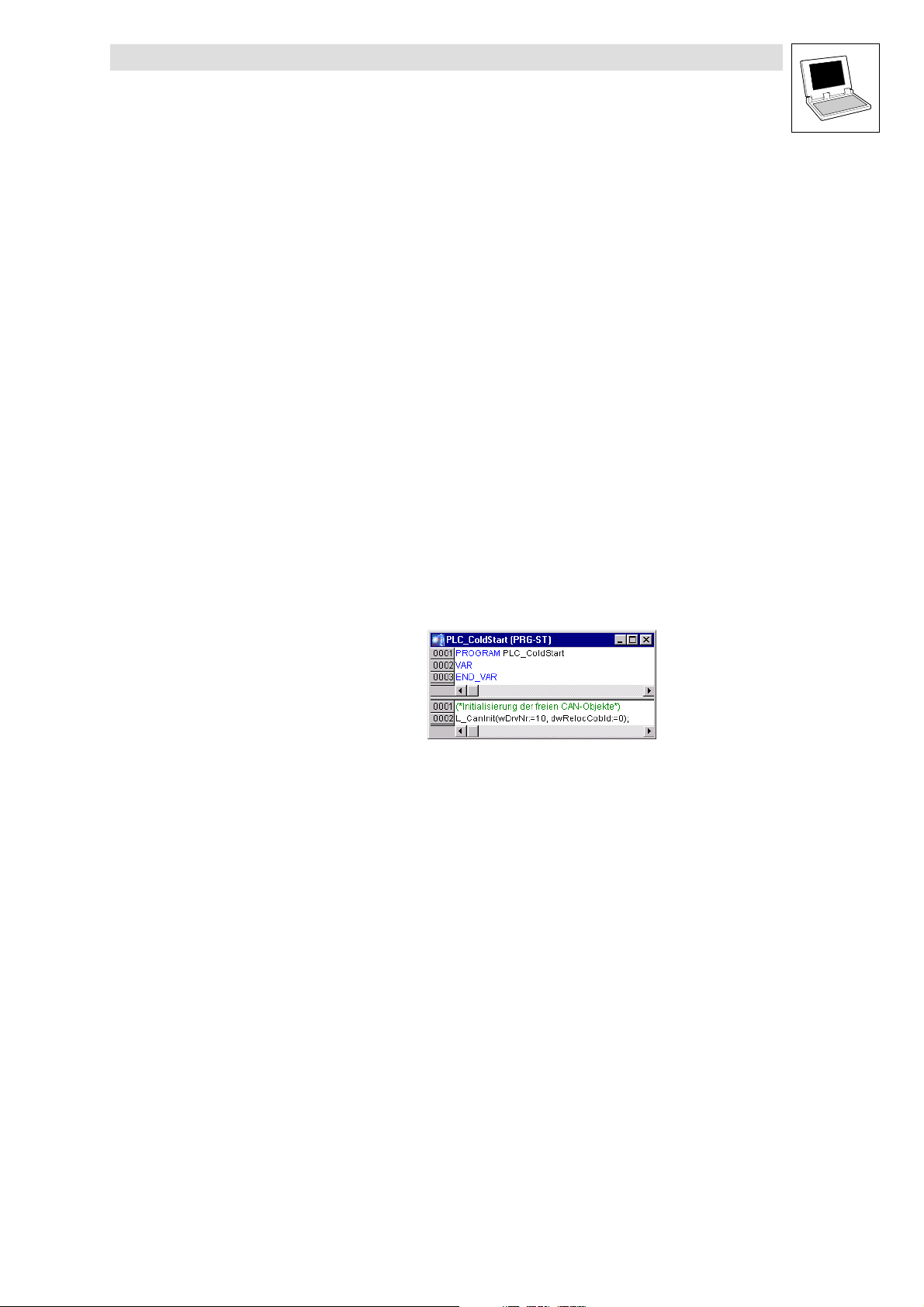

Initialising the CAN driver

Communication between the PLC and the I/O system is based on "unassigned CAN objects"

(control, alarm, diagnostics...). These objects are available in DDS from version 2.x onwards.

To initialise the unassigned CAN objects, the function L_CANInit must be requested once only in the

system POU PLC_ColdStart.

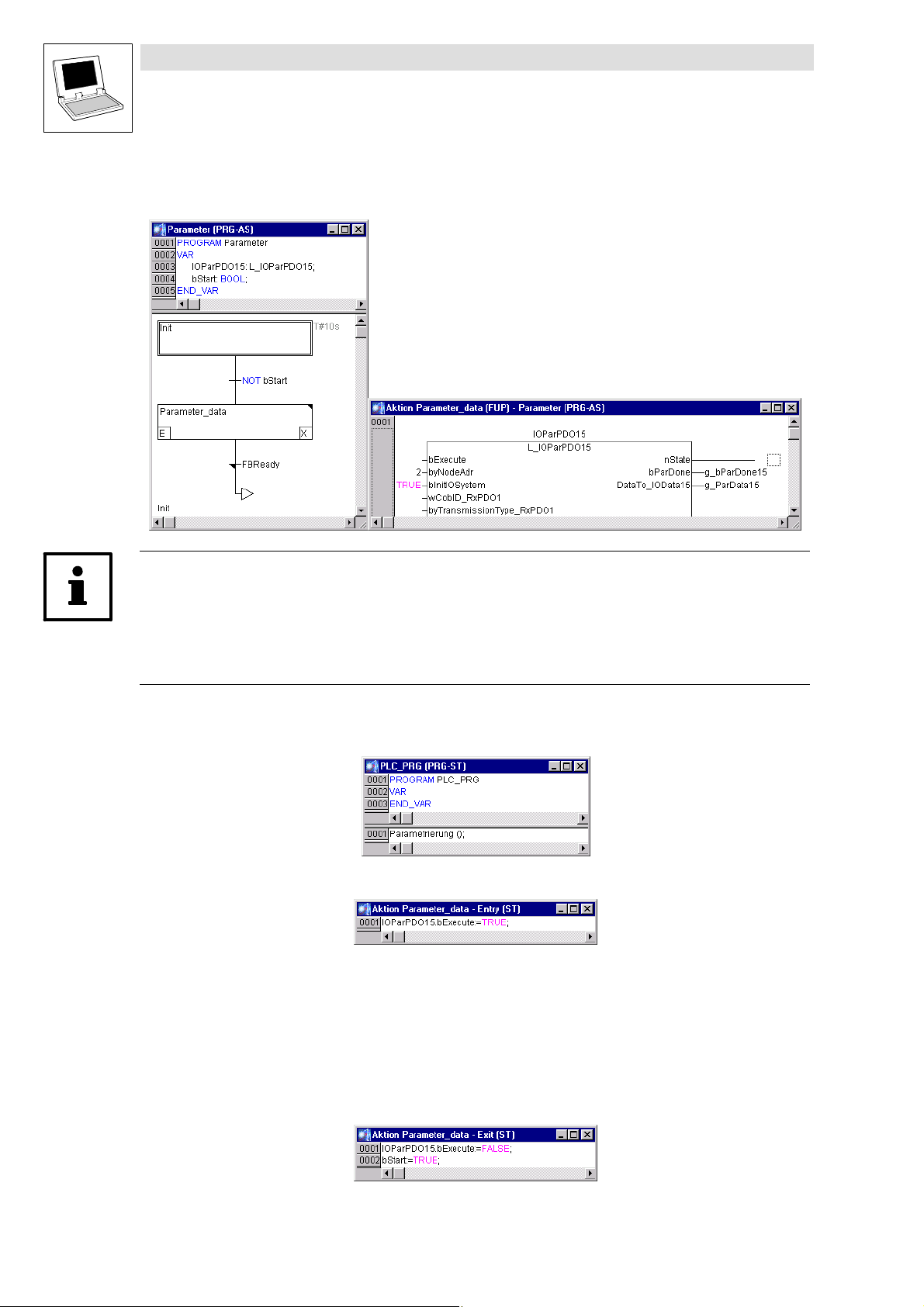

Parameterising the communication conditions

Function block L_IOParPDO15 for parameterising the communication conditions of PDO1−PDO5 is

integrated into the SFC editor and necessarily is to be used in every project. This function block

specifies the communication parameters in the I/O system.

The values are transferred to the process data block L_IOData15 as a structure (STRUCT) in order

to match the communication parameters of the devices (controller and I/O system).

On program execution, this step is executed only once at the beginning.

L

LenzeIOSystem.lib EN 1.7

3−1

Page 12

Function library LenzeIOSystem.lib

Application examples

3.1 Modular decentralised I/O system

Then the Parameter program that must be generated in the SFC editor follows. With the invocation

of the function block instance, the step Parameter_data has the action generated in the FBD editor.

Note!

· Enter a minimum time of ten seconds for step Init via the menu command ExtrasÞStep

attibutes.... Correct entry: T#10s

Make sure that step Parameter_data is not executed before the initialisation phase of the I/O system

is complete. This is achieved with a minimum time of ten seconds.

As this POU must be processed cyclically, the program is invoked in the PLC_PRG (main program).

The sequential function chart ensures a cyclic task.

The parameterisation process is started via the initial action in step Parameter_data.

Once the parameterisation is complete, the final action in step Parameter_data sets input bExecute

to FALSE and variable bStart to TRUE.

Variable bStart ensures that step Parameter_data is executed

· on switching on

· on reset and subsequent starting.

When the parameterisation is complete, the PLC_PRG (main program) stops in step Init. It does not

impose an extra burden on the target system during subsequent program operation.

3−2

LenzeIOSystem.lib EN 1.7

L

Page 13

Function library LenzeIOSystem.lib

Application examples

3.1 Modular decentralised I/O system

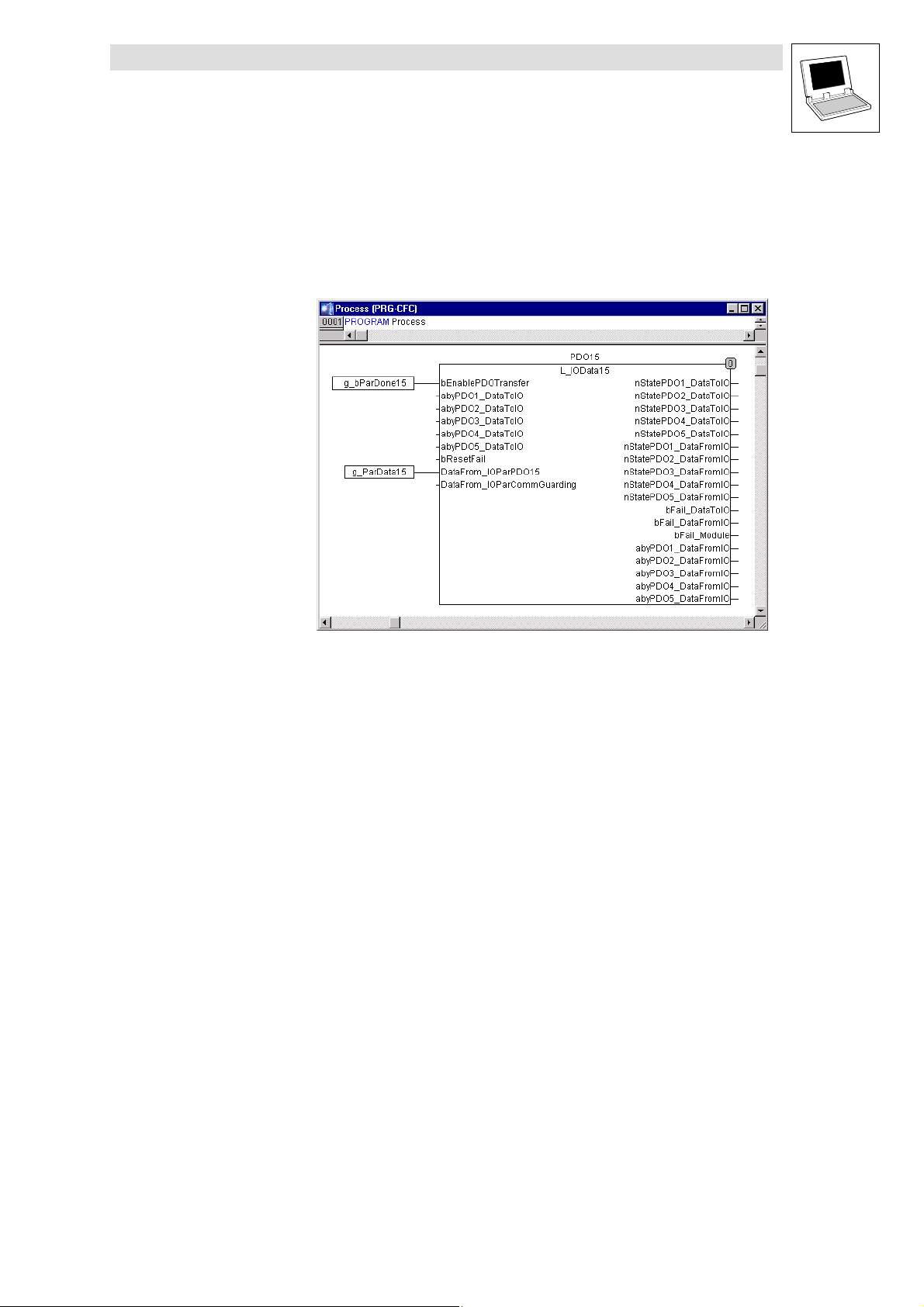

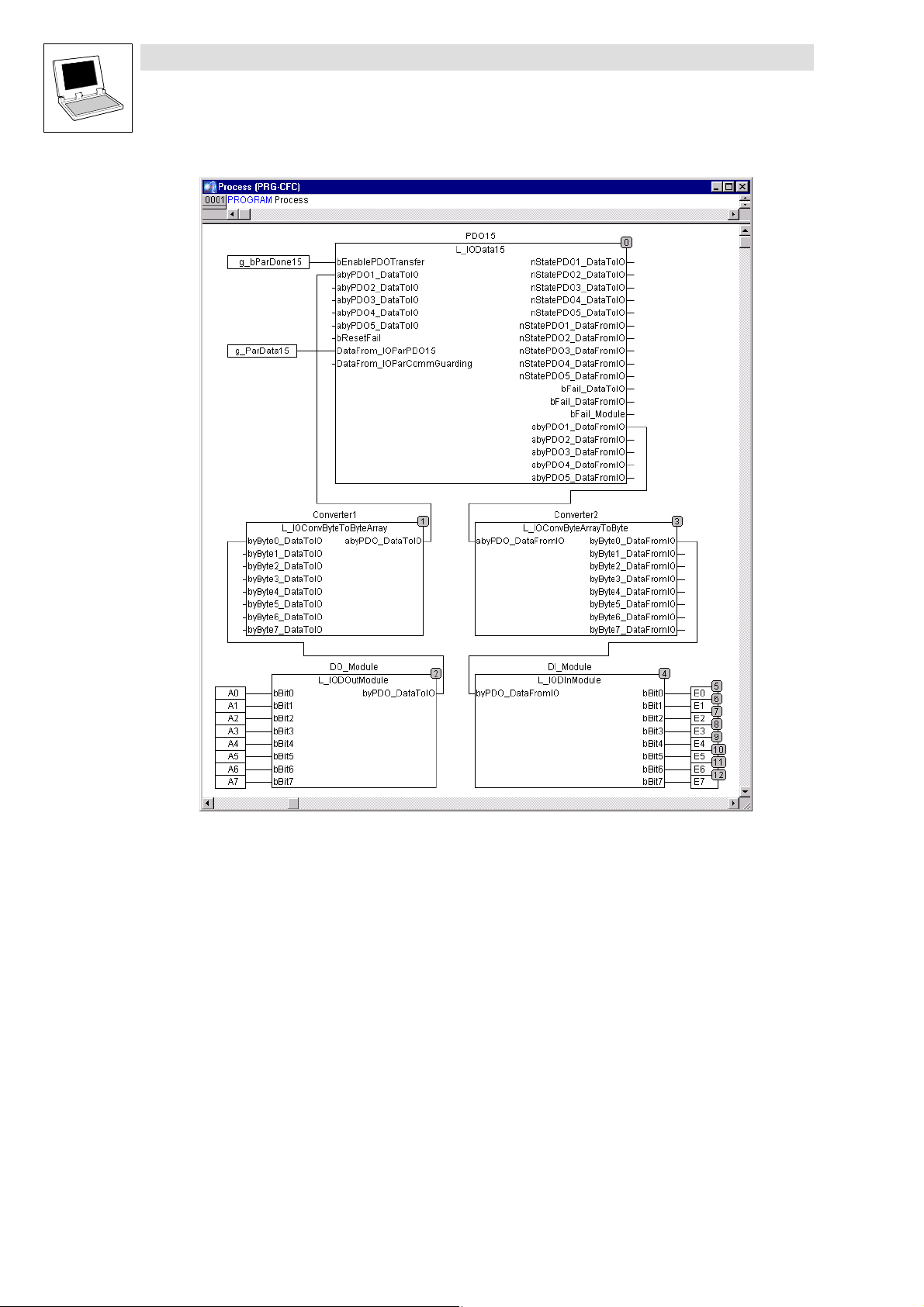

Programming the process data exchange between PLC and I/O system

The CFC editor is used to generate a program named Process.

· Declare an instance of function block L_IOData15 in Process.

· Generate two inputs in the CFC editor, assign names g_bParDone15 and g_ParData15 and

attach these to the corresponding inputs of function block L_IOData15 as shown in the figure.

Several conversion blocks are available to evaluate input data and to transfer output data.

Function block L_IOData15 transmits output data to the I/O system and receives input data from

there.

At input DataFrom_IOParPDO15, CAN communication relationships between PLC and I/O system

are transmitted from parameterisation block L_IOParPDO15 to process data block L_IOData15.

Process data transmission is started after parameterisation via a High signal at input

bEnablePDOTransfer.

Data conversion for evaluating individual channels

The program Process can be extended as follows:

· Use the menu command ExtrasÞOrder to indicate the sequence.

· Drag the individual function blocks to their positions in order to make the program sequence

comprehensible.

L

LenzeIOSystem.lib EN 1.7

3−3

Page 14

Function library LenzeIOSystem.lib

Application examples

3.1 Modular decentralised I/O system

3−4

Function block L_IOData15 supplies the transmit and receive data as 8 byte information via the CAN

telegram.

The two converters convert the information into individual bytes.

A digital input and output module maps the individual bits.

Initialising the codes

Initialise the following codes in the PLC

· Code C0352

Subcode 0 = 1

Defines PLC as a CAN master so that the configuration enters the Operational state.

· Code C0356

Subcode 1 = 10000

Increases the boot−up time to10s

· Code C2104

Subcode 0 = 1

Starts the PLC program automatically after switching on the mains

LenzeIOSystem.lib EN 1.7

L

Page 15

Function library LenzeIOSystem.lib

Application examples

3.2 Compact decentralised I/O system

3.2 Compact decentralised I/O system

The compact module EPM − T832 with 24 digital inputs and 8 digital outputs is integrated into a PLC

program with the help of LenzeIOSystem.lib.

During this process, the following steps must be carried out in the given order:

1. Initialise the CAN driver

2. Parameterise the communication conditions

3. Program the process data exchange between PLC and I/O system

4. Initialise the codes

Initialising the CAN driver

Communication between the PLC and the I/O system is based on "unassigned CAN objects"

(control, alarm, diagnostics...). These objects are available in DDS from version 2.x onwards.

To initialise the unassigned CAN objects, the function L_CANInit must be requested once only in the

system POU PLC_ColdStart.

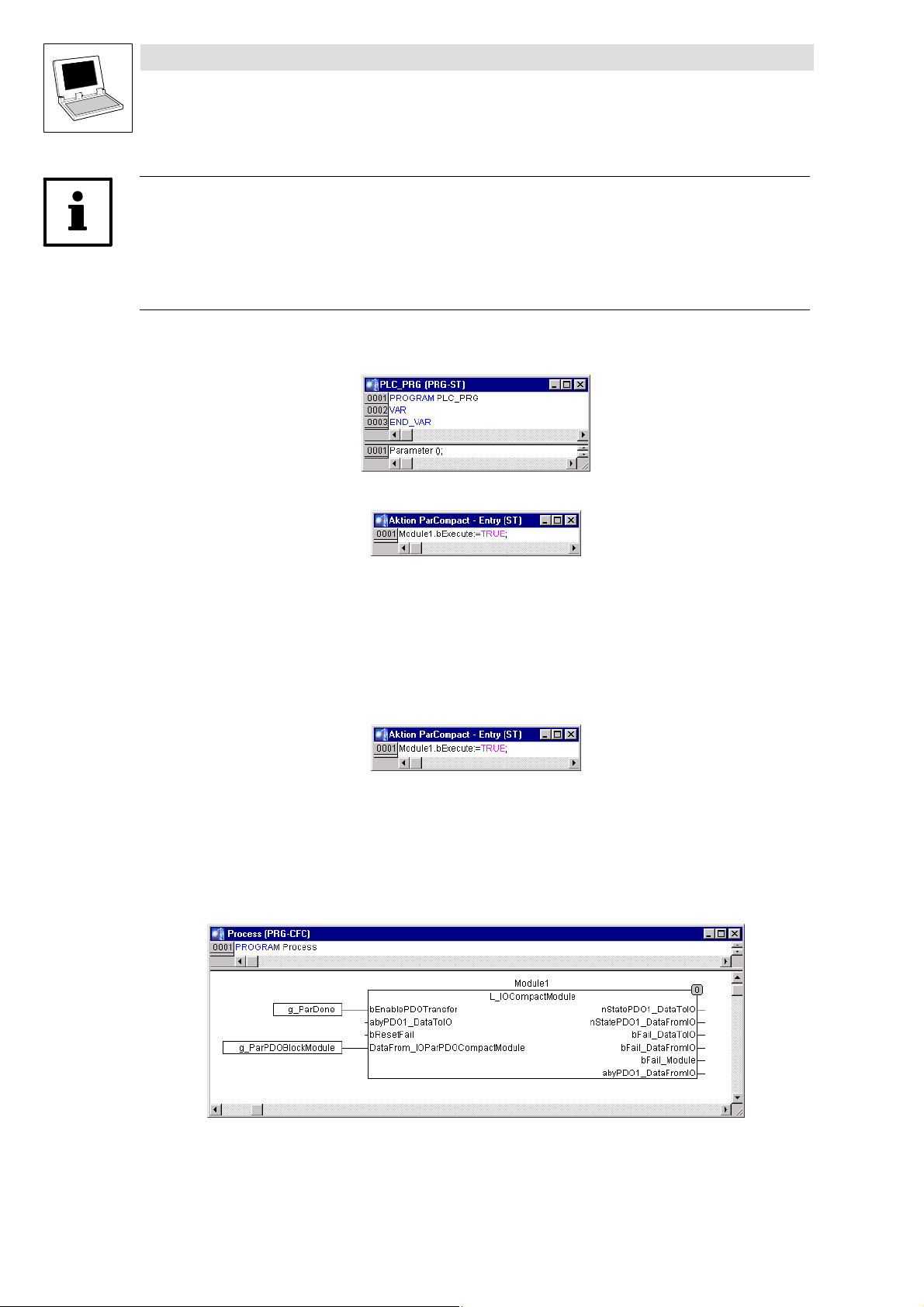

Parameterising the communication conditions

Function block L_IOParCompactModule for parameterising the communication conditions is

integrated into the SFC editor and necessarily is to be used in every project. This function block

specifies the communication parameters in the I/O system.

The values are transferred to the process data block L_IOCompactModule as a structure (STRUCT)

in order to match the communication parameters of the devices (controller and I/O system).

On program execution, this step is executed once only at the beginning.

Then the Parameter program that must be generated in the SFC editor follows. With the invocation

of the function block instance, the step ParCompact has the action generated in the FBD editor.

L

LenzeIOSystem.lib EN 1.7

3−5

Page 16

Function library LenzeIOSystem.lib

Application examples

3.2 Compact decentralised I/O system

Note!

· Enter a minimum time of ten seconds for step Init via the menu command ExtrasÞStep

attributes.... Correct entry: T#10s

Make sure that step Parameter_data is not executed before the initialisation phase of the I/O system

is complete. This is achieved with a minimum time of ten seconds.

As this POU must be processed cyclically, the program is invoked in the PLC_PRG (main program).

The sequential function chart ensures a cyclic task.

The parameterisation process is started via the initial action in step ParCompact.

Once the parameterisation is complete, the final action in step ParCompact sets input bExecute to

FALSE and variable bStart to TRUE.

Variable bStart ensures that step ParCompact is executed

· on switching on

· on reset and subsequent starting.

When the parameterisation is complete, the PLC_PRG (main program) stops in step Init. It does not

impose an extra burden on the target system during subsequent program operation.

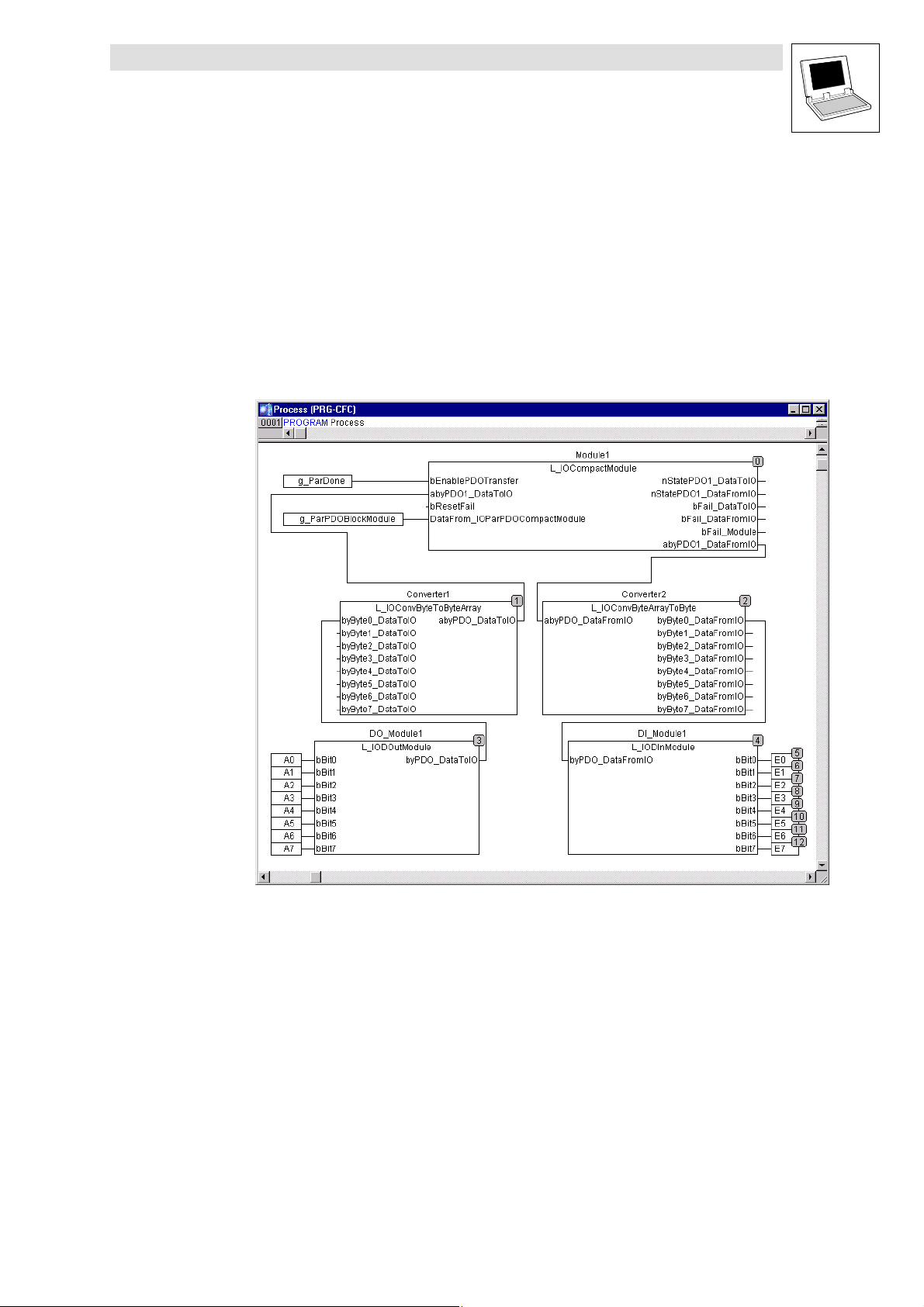

Programming the process data exchange between PLC and I/O system

The CFC editor is used to generate a program named Process.

· Declare an instance of function block L_IOCompactModule in Process.

· Generate two inputs in the CFC editor, assign names g_bParDone15 and g_ParData15 and

attach these to the corresponding inputs of function block L_IOCompactModule as shown in

the figure.

3−6

Several conversion blocks are available to evaluate input data and to transfer output data.

Function block L_IOCompactModule transmits output data to the I/O system and receives input

data from there.

LenzeIOSystem.lib EN 1.7

L

Page 17

Function library LenzeIOSystem.lib

Application examples

3.2 Compact decentralised I/O system

At input DataFrom_IOParPDO15, CAN communication relationships between PLC and I/O system

are transmitted from parameterisation block L_IOParCompactModule to process data block

L_IOCompactModule.

Process data transmission is started after parameterisation via a High signal at input

bEnablePDOTransfer.

Data conversion for evaluating individual channels

The program Process can be extended as follows:

· Use the menu command ExtrasÞOrder to indicate the sequence.

· Drag the individual function blocks to their positions in order to make the program sequence

comprehensible.

L

Function block L_IOCompactModule supplies the transmit and receive data as 8*8 byte information

via the CAN telegram.

The two converters convert the information into individual bits.

A digital input and output module maps the individual bits.

If the example for eight inputs / outputs is to be extended to 24 inputs, two further function blocks

L_IODInModule must be generated and linked via converter L_IOConvByteArrayToByte.

LenzeIOSystem.lib EN 1.7

3−7

Page 18

Function library LenzeIOSystem.lib

Application examples

3.2 Compact decentralised I/O system

Initialising the codes

Initialise the following codes in the PLC

· Code C0352

Subcode 0 = 1

Defines PLC as a CAN master so that the configuration enters the Operational state.

· Code C0356

Subcode 1 = 10000

Increases the boot−up time to10s

· Code C2104

Subcode 0 = 1

Starts the PLC program automatically after switching on the mains

3−8

LenzeIOSystem.lib EN 1.7

L

Page 19

Function library LenzeIOSystem.lib

4 Function blocks for parameterisation

This chapter contains information on function blocks for parameterisation.

The following functions and modules are parameterised:

· Monitoring function

· Analog input modules

· Analog output modules

· Counter modules

· Link between PLC control and I/O system

· Link between PLC control and compact module

Function blocks

L

LenzeIOSystem.lib EN 1.7

4−1

Page 20

Function library LenzeIOSystem.lib

Function blocks

4.1 L_IOParComGuarding − Monitoring function

4.1 L_IOParComGuarding − Monitoring function

This function block parameterises, via the input setting, the monitoring functions provided by the I/O

system.

Included are

· NodeGuarding, Heartbeat and a Lenze−specific monitoring function,

· setting the output channels’ switching behaviour in the case of an error via input

byErrorBehavior.

The function block output indicates the transmission status.

L_IOParComGuarding

bExecute

byNodeAdr

tGuardTime

byLifeTimeFactor

tHeartbeatConsumerTime

byHearbeatConsumerAdr

tHeartbeatProducerTime

byErrorBehavior

tTimeOutPDO1_DataToIO

CTRL

EPM-T110

EPM-T111

Ixxxh

nState

tTimeOutPDO10_DataToIO

tTimeOutPDO1_DataFromIO

tTimeOutPDO10_DataFromIO

DataTo_IOData15

DataTo_IOData610

Note!

Use the FBs of LenzeCanDSxDrv.lib for evaluating the functions NodeGuarding and Heartbeat.

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

tGuardTime Time Nodeguarding: Time interval.

byLifeTimeFactor Byte Lifeguarding:

tHeartbeatConsumerTime Time Heartbeat: Monitoring interval.

byHeartbeatConsumerAdr Byte Node ID of the device to be monitored. (HeartbeatProducer Node ID)

An NMT master must poll the I/O system within the guard time period.

Default t = 0 ms

t = 0 − 65535 ms

Life Time Factor x Guard Time = Life Time.

Once this period has expired, the I/O system is switched into a predefined status.

The I/O system is switched into a predefined status if no telegram is received from

the Heartbeat Producer within this interval.

t = 0 − 65535 ms

4−2

LenzeIOSystem.lib EN 1.7

L

Page 21

Function library LenzeIOSystem.lib

Function blocks

4.1 L_IOParComGuarding − Monitoring function

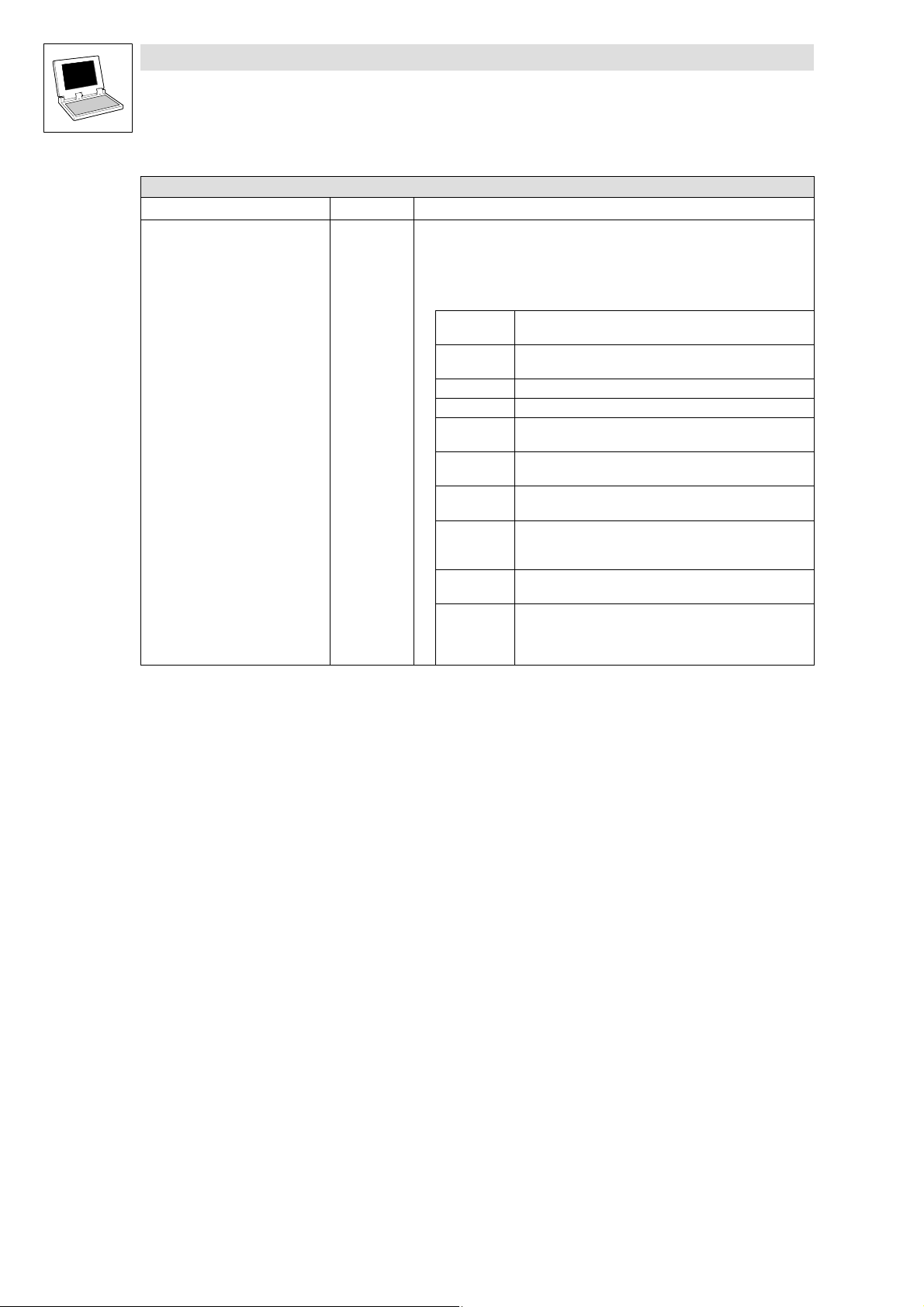

(Variable type: VAR_INPUT)ð Inputs

Variable name Information/possible settingsData type

tHeartbeatProducerTime Time Set the transmission time for one heartbeat telegram t = 0 − 65535ms

byErrorBehavior Byte Set the bus status / behaviour on critical device error

0 Pre−Operational (default)

1 No status change

2 Stop

3 Reset after 2 seconds

tTimeOutPDO1_DataToIO

...

tTimeOutPDO10_DataToIO

tTimeOutPDO1_DataFromIO

...

tTimeOutPDO10_DataFromIO

Time Monitoring period for process input data (Lenze−specific).

If no data are received at the selected PDO within the monitoring period, the I/O

system assumes the status set under byErrorBehavior.

Default t = 0 ms

t = 0 − 65535 ms

Time Monitoring period for process output data.

If no data are transmitted from the I/O system to the PLC at the selected PDO within

the monitoring period, function block L_IODataXXX signals a time monitoring error.

Default t = 0 ms

t = 0 − 65535 ms

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer States

DataTO_IOData15 Struct Structure for process data block L_IOData15.

DataTO_IOData610 Struct Structure for process data block L_IOData610

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on program restart.

0 Transmit command is executed.

1 Transmit command sent − processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied − wrong target system: Subindex does not exist

2005 Access denied − wrong target system: Index does not exist

2013 Access denied − wrong target system: Invalid value range

2111 Access denied − wrong target system: More than 4 digits

specified after comma, or no fixed−comma−format index

2117 Communication channel does not exist − also refer Set byCom

channel

2120 Too many modules connected − parameter transfer aborted

−10xx Incorrect value at function block input.

XX := Number of faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

Transfer process output data monitoring periods to process data block L_IOData15.

Global struct−type variable

Transfer process output data monitoring periods to process data block

L_IOData610.

Global struct−type variable

L

LenzeIOSystem.lib EN 1.7

4−3

Page 22

Function library LenzeIOSystem.lib

Function blocks

4.2 L_IOParAlnModule − Parameterisation function

4.2 L_IOParAlnModule − Parameterisation function

By means of the L_IOParAInModule function block, the analog input modules (EPM−T310 / 311 /

T312) are parameterised. Parameterisation is started by a high edge on the input bExecute.

Each module has four channels, whereby each channel can be set individually.

The following is provided:

· Voltage measurement

· Current measurement

· Resistance measurement

· Temperature measurement

On the output of the function block, the transmission status and the information on the connected

modules are displayed.

L_IOParAInModule

bExecute

CTRL

nState

byNodeAdr

byAnalogModuleNo

BEnableDiagnosticAlarm *

bEnableAnalogInterrupt

byFunctionInput_CH1

BySampleRate_CH1 *

BySelectionFcn_CH1 *

ByHysteresis_CH1 *

ByTriggerSelection_CH1 *

ByTriggerValue_CH1 *

byFunctionInput_CH4

BySampleRate_CH4 *

BySelectionFcn_CH4 *

ByHysteresis_CH4 *

ByTriggerSelection_CH4 *

ByTriggerValue_CH4 *

*

Input/function is exclusively supported by type EPM−T310.

EPM-T110

EPM-T111

Ixxxh

4−4

LenzeIOSystem.lib EN 1.7

L

Page 23

Function library LenzeIOSystem.lib

Function blocks

4.2 L_IOParAlnModule − Parameterisation function

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute BOOL Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

bEnableDiagnosticAlarm BOOL

bEnableAnalogInterrupt BOOL

byFunctionInput_CH1

...

byFunctionInput_CH4

bySampleRate_CH1

...

bySampleRate_CH4

bySelectionFcn_CH1

...

bySelectionFcn_CH4

byHysterese_CH1

...

byHysterese_CH4

byTriggerSelection_CH1

...

byTriggerSelection_CH4

byTriggerValue_CH1

...

byTriggerValue_CH4

Byte

Byte

Byte

Byte

Byte

DWORD

· The analog module that is mounted first has the slot number 1.

· Maximally 16 analog modules can be attached.

Enable diagnostics alarm

TRUE Diagnostics alarm is enabled

Enable analog data transmission

TRUE Data transmission is enabled

Parameterise function

Default ±10V function code = 3B

^ 6−1

Select number of conversions per second

0 15 conversions

1 30 conversions

2 60 conversions

3 123 conversions

4 168 conversions

5 202 conversions

6 3.7 conversions

7 7.5 conversions

Selection

0 Selection deactivated

1 Use 2 of 3 values

2 Use 4 of 6 values

Hysteresis

0 Hysteresis deactivated

1 Hysteresis ±8

2 Hysteresis ±16

Transmission result

0 Use default settings

1 Upper limit value exceeded

2 Lower limit value not reached

3 Input value has changed by a defined value.

Value selection for a transmission event

2 Default

h

L

LenzeIOSystem.lib EN 1.7

4−5

Page 24

Function library LenzeIOSystem.lib

Function blocks

4.2 L_IOParAlnModule − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifiers Data type Value/meaning

nState Integer

States

If a transmission error occurs during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit request is executed.

The module is parameterised.

1 Transmit request dropped

Processing is running

2001 Error occurred during bus transfer

2002 Transmit request timed out

2004 Access denied

Incorrect target system: index does not exist

2005 Access denied

Incorrect target system: subindex does not exist

2013 Access denied

Incorrect target system: invalid value range

2111 Access denied

Incorrect target system: more than 4 decimal positions

specified or no fixed point format index

2117 Communication channel does not exist

byCom−Channelsetting

−10xx Incorrect value at function block input.

XX := number of the faulty input (counting direction

downwards), parameterisation impossible.

Remedy: change input value, restart data transmission

4−6

LenzeIOSystem.lib EN 1.7

L

Page 25

Function library LenzeIOSystem.lib

Function blocks

4.3 L_IOParAOutModule − Parameterisation function

4.3 L_IOParAOutModule − Parameterisation function

By means of the L_IOParAOutModule function block, the analog output modules (EPM−T320 /

T321 / T322) are parameterised. Parameterisation is started by a high edge on the input bExecute.

Each module has four channels, whereby each channel can be set individually.

The following is provided:

· Voltage measurement

· Current measurement

The function block output indicates the transmission status.

L_IOParAOutModule

bExecute

byNodeAdr

byAnalogModuleNo

BEnableDiagnosticAlarm *

CTRL

nState

EPM-T110

EPM-T111

byFunctionOutput_CH1

byFunctionOutput_CH2

byFunctionOutput_CH3

byFunctionOutput_CH4

*

Input/function is exclusively supported by type EPM−T320.

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute BOOL

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

Execute write request

FALSE ä TRUE Write request is executed

· The analog module that is mounted first has the slot number 1.

· Maximally 16 analog modules can be attached.

bEnableDiagnosticAlarm BOOL

byFunctionOutput_CH1

...

byFunctionOutput_CH4

Byte

Enable diagnostics alarm

TRUE Diagnostics alarm is enabled

Parameterise function

Default ±10V function code = 01

^ 6−4

Ixxxh

h

L

LenzeIOSystem.lib EN 1.7

4−7

Page 26

Function library LenzeIOSystem.lib

Function blocks

4.3 L_IOParAOutModule − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifiers Data type Value/meaning

nState Integer

States

If a transmission error occurs during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit request is executed.

The module is parameterised.

1 Transmit request dropped

Processing is running

2001 Error occurred during bus transfer

2002 Transmit request timed out

2004 Access denied

Incorrect target system: subindex does not exist

2005 Access denied

Incorrect target system: index does not exist

2013 Access denied

Incorrect target system: invalid value range

2111 Access denied

Incorrect target system: more than 4 decimal positions

specified or no fixed point format index

2117 Communication channel does not exist

byCom−Channelsetting

−10xx Incorrect value at function block input.

XX := number of faulty input (counting direction down),

parameterisation impossible.

Remedy: change input variable, restart data transmission

4−8

LenzeIOSystem.lib EN 1.7

L

Page 27

Function library LenzeIOSystem.lib

Function blocks

4.4 L_IOParAlAOModule − Parameterisation function

4.4 L_IOParAlAOModule − Parameterisation function

Function block L_IOParAIAOModule parameterises the analog input and output modules

EPM−T330, a High edge at input bExecute starting the parameterisation process.

Every module has four channels that can each be set individually. Two analog inputs and two analog

outputs are available.

The following functions can be set:

· Voltage measuring

· Current measuring

· Voltage output

· Current output

The function block output indicates the transmission status and information on linked modules.

L_IOParAIAOModule

bExecute

CTRL

nState

byNodeAdr

byAnalogModuleNo

bEnableDiagnosticAlarm

bEnableAnalogInterrupt

byFunctionInput_CH1

bySampleRate_CH1

byFunctionInput_CH2

bySampleRate_CH2

byFunctionOutput_CH3

byFunctionOutput_CH4

EPM-T110

EPM-T111

Ixxxh

L

LenzeIOSystem.lib EN 1.7

4−9

Page 28

Function library LenzeIOSystem.lib

Function blocks

4.4 L_IOParAlAOModule − Parameterisation function

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

bEnableDiagnosticAlarm Bool

bEnableAnalogInterrupt Bool

byFunctionInput_CH1

...

byFunctionInput_CH2

bySampleRate_CH1

...

bySampleRate_CH2

byFunctionOutput_CH3

...

byFunctionOutput_CH4

Byte

Byte

Byte

Execute write request

FALSE ä TRUE Write request is executed

· The first analog module installed is assigned slot number 1.

· A maximum of 16 analog modules may be plugged.

Enable diagnostic alarm

Enable analog data transmission

Parameterise function

Select number of conversions per second

Parameterise function

TRUE Diagnostic alarm is enabled

TRUE Data transmission is enabled

Default ±10V function parameter = 01

^ 6−6

0 15 conversions

1 30 conversions

2 60 conversions

3 123 conversions

4 168 conversions

5 202 conversions

6 3.7 conversions

7 7.5 conversions

Default ±10V function code = 01

^ 6−6

h

h

4−10

LenzeIOSystem.lib EN 1.7

L

Page 29

Function library LenzeIOSystem.lib

Function blocks

4.4 L_IOParAlAOModule − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer

States

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit command is executed.

The module is parameterised.

1 Transmit command sent

Processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied

Wrong target system: Index does not exist

2005 Access denied

Wrong target system: Subindex does not exist

2013 Access denied

Wrong target system: Invalid value range

2111 Access denied

Wrong target system: More than 4 digits specified after

comma, or no fixed−comma−format index

2117 Communication channel does not exist

Set byCom channel

−10xx Incorrect value at function block input.

XX := Number of the faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

L

LenzeIOSystem.lib EN 1.7

4−11

Page 30

Function library LenzeIOSystem.lib

Function blocks

4.5 L_IOParSSIModule − Parameterisation function

4.5 L_IOParSSIModule − Parameterisation function

The SSI interface (SSI = Synchronous Serial Interface) is a synchronously clocked interface.

Function block L_IOParSSIModule converts the serial information of the measured values into

parallel information that is subsequently supplied to the control system.

L_IOParSSIModule

bExecute

byNodeAdr

byAnalogModuleNo

byFunction_Baudrate

bFunction_Code

bFunction_Hold

bFunction_SetDigitalOut

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool Execute write request

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

CTRL

FALSE ä TRUE Write request is executed

· The first analog module installed is assigned slot number 1.

· A maximum of 9 modules may be plugged.

byFunction_Baudrate

bFunction_Code Bool Coding

bFunction_Hold Bool Hold function

bFunction_SetDigitalOut Bool Digital outputs

Byte Baud rate setting

0 300 kbps

1 100 kbps

2 300 kbps

3 600 kbps

4 300 kbps

Default 0 Binary code

1 Gray code

0 Not active

1 Active

0 Not active

1 Active

nState

EPM-T110

Ixxxh

4−12

LenzeIOSystem.lib EN 1.7

L

Page 31

Function library LenzeIOSystem.lib

Function blocks

4.5 L_IOParSSIModule − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer States

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit command is executed.

The module is parameterised.

1 Transmit command sent

Processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied

Wrong target system: Subindex does not exist

2005 Access denied

Wrong target system: Index does not exist

2013 Access denied

Wrong target system: Invalid value range

2111 Access denied

Wrong target system: More than 4 digits specified after

comma, or no fixed−comma−format index

2117 Communication channel does not exist

Set byCom channel

−10xx Incorrect value at function block input.

XX := Number of faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

L

LenzeIOSystem.lib EN 1.7

4−13

Page 32

Function library LenzeIOSystem.lib

Function blocks

4.6 L_IOParCounterModule − Counter function

4.6 L_IOParCounterModule − Counter function

The counter modules are parameterised via function block L_IOParCounterModule.

· The counter function is specified via inputs byFunction_CH1 and byFunction_CH2.

L_IOParCounterModule

bExecute

CTRL

nState

byNodeAdr

byAnalogModuleNr

byFunction_CH1

byFunction_CH2

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

· The first analog module installed is assigned slot number 1.

· A maximum of 16 analog modules may be plugged.

byFunction_CH1 Byte Parameterise function

Default (2 * 32 bit counters) function code 00

^ 6−10

byFunction_CH2 Byte Parameterise function

Default (2 * 32 bit counters) function code 00

^ 6−10

EPM-T110

Ixxxh

h

h

4−14

LenzeIOSystem.lib EN 1.7

L

Page 33

Function library LenzeIOSystem.lib

Function blocks

4.6 L_IOParCounterModule − Counter function

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer States

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit command is executed.

The module is parameterised.

1 Transmit command sent

Processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied

Wrong target system: Subindex does not exist

2005 Access denied

Wrong target system: Index does not exist

2013 Access denied

Wrong target system: Invalid value range

2111 Access denied

Wrong target system: More than 4 digits specified after

comma, or no fixed−comma−format index

2117 Communication channel does not exist

Set byCom channel

−10xx Incorrect value at function block input.

XX := Number of faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

L

LenzeIOSystem.lib EN 1.7

4−15

Page 34

Function library LenzeIOSystem.lib

Function blocks

4.7 L_IOParCounterDIModule − Counter function

4.7 L_IOParCounterDIModule − Counter function

The counter function of module EPM−T430 is parameterised via function block

L_IOParCounterDIModule.

· The counter function is specified via inputs byFunction_CH1.

L_IOParCounterDIModule

bExecute

CTRL

nState

byNodeAdr

byAnalogModuleNr

byFunction_CH1

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

byAnalogModuleNo Byte Slot number

· The first analog module installed is assigned slot number 1

· A maximum of 16 analog modules may be plugged.

byFunction_CH1 Byte Counter function

0 Fourfold pulse evaluation

1 Pulse and direction evaluation

2 Counter upwards / downwards

3 Frequency measuring

4 Period measuring

EPM-T110

Ixxxh

4−16

LenzeIOSystem.lib EN 1.7

L

Page 35

Function library LenzeIOSystem.lib

Function blocks

4.7 L_IOParCounterDIModule − Counter function

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer States

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit command is executed.

The module is parameterised.

1 Transmit command sent

Processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied

Wrong target system: Subindex does not exist

2005 Access denied

Wrong target system: Index does not exist

2013 Access denied

Wrong target system: Invalid value range

2111 Access denied

Wrong target system: More than 4 digits specified after

comma, or no fixed−comma−format index

2117 Communication channel does not exist

Set byCom channel

−10xx Incorrect value at function block input.

XX := Number of faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

L

LenzeIOSystem.lib EN 1.7

4−17

Page 36

Function library LenzeIOSystem.lib

Function blocks

4.8 L_IOParPDO15 − Parameterisation function

4.8 L_IOParPDO15 − Parameterisation function

This function block serves to set communication−relevant parameters between the PLC control and

the I/O system for PDO 1 − 5.

· Via 3 or 4 input values, a transmission/reception object is parameterised.

· The output nState displays the parameterisation status.

· Via the output DataTo_IOData15 , information is transferred to the L_IOData15 process data

block in a fixed structure.

L_IOParPDO15

bExecute_b

CTRL

byNodeAdr

bInitIOSystem

wCoID_RxPDO1

byTransmissionType_RxPDO1

tCycleTime_RxPDO1

nState

bParDone

wCoID_RxPDO5

byTransmissionType_RxPDO5

tCycleTime_RxPDO5

wCoID_TxPDO1

byTransmissionType_TxPDO1

tinhibitTime_TxPDO1

tCycleTime_RxPDO1

wCoID_TxPDO5

byTransmissionType_TxPDO5

tinhibitTime_TxPDO5

tCycleTime_RxPDO5

DataTo_IOData15

Internal function

bExecute_b = TRUE

Parameter data are transferred to the I/O system

bInitIOSystem = TRUE bInitIOSystem = FALSE

· Index 2358

initialisation of the I/O system.

· Waiting time 10s until initialisation has been completed.

If the boot−up time is >10s, the waiting time corresponds to the

boot−up time

.

is written for purposes of value acceptance or

hex

· Index 2358

initialisation of the I/O system.

hex

· Waiting time 10s until initialisation has been completed.

If the boot−up time is >10s, the waiting time corresponds to

the boot−up time

.

EPM-T110

EPM-T111

Ixxxh

is written for purposes of value acceptance or

4−18

State change of the I/O system by NMT telegram from the

controller:

Pre−operational ä Operational

LenzeIOSystem.lib EN 1.7

Parameterisation completed

L

Page 37

Function library LenzeIOSystem.lib

Function blocks

4.8 L_IOParPDO15 − Parameterisation function

Note!

Features and use of the L_IOParPDO15 FB.

· Use the L_IOParPDO15 FB last in a sequencer consisting of several FBs for parameterisation.

By means of the L_IOParPDO15 FB, parameterisation of the I/O system is carried out.

· For sending the NMT telegram, the controller has to be in the Operational CAN status,

therefore parameterise the controller as master. After the boot−up time has expired, the state

change from Pre−operational to Operational is automatically effected.

· If several IO systems (stations) are parameterised with standard values via the

L_IOParPDO15 FB on the system bus, an identifier collision between the individual PDOs of

these stations can occur. Therefore check the identifiers used.

After changing to the Operational CAN status, the current process image of the I/O system is sent.

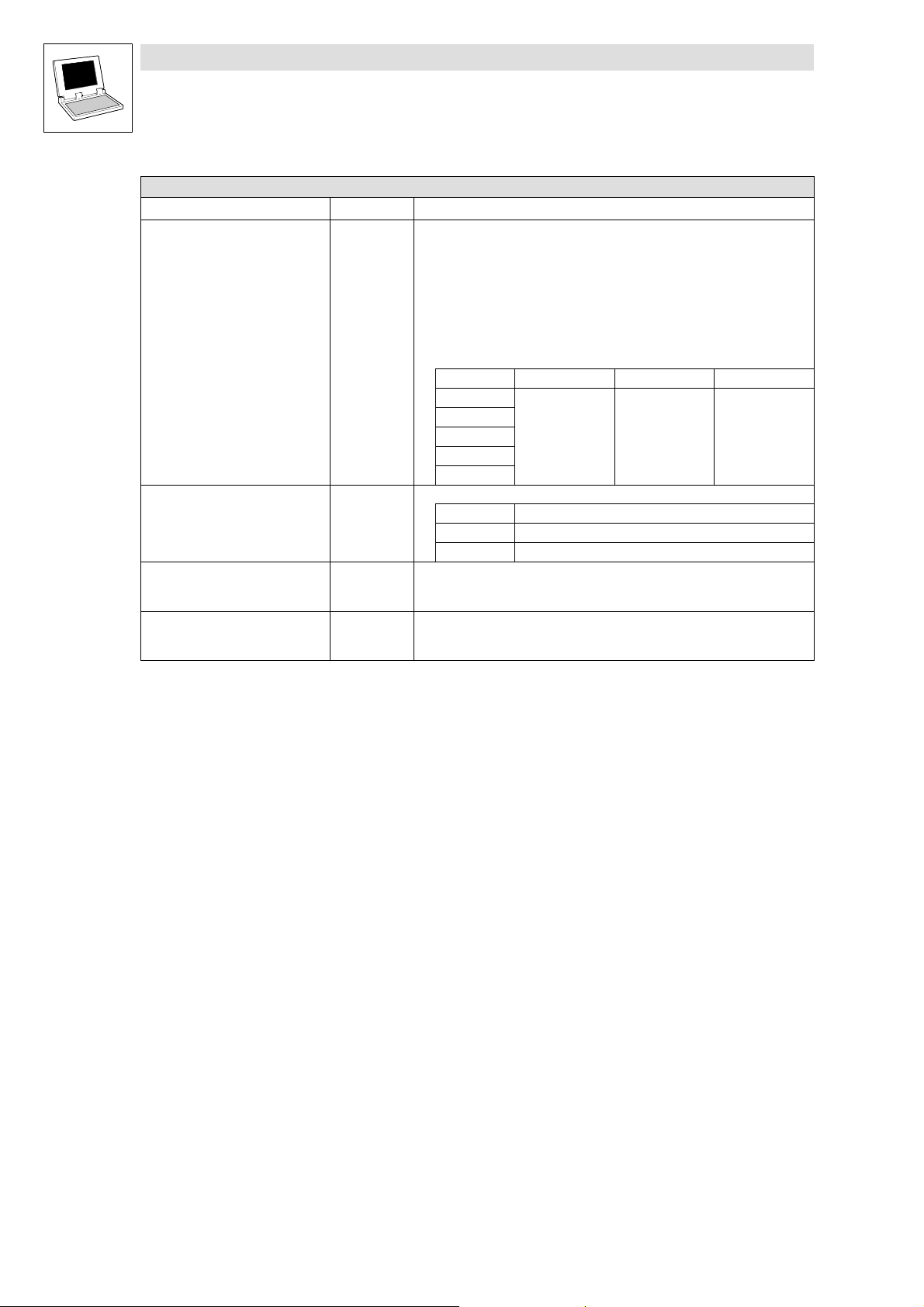

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute BOOL

byNodeAdr Byte Device address: 1 − 63

bInitIOSystem BOOL

wCobID_RxPDO1

...

wCobID_RxPDO5

byTransmissionType_RxPDO1

...

byTransmissionType_RxPDO5

tCycleTime_RxPDO1

...

tCycleTime_RxPDO5

WORD

Byte

Time Cycle time: t = 0 − 65535 ms

Execute write request

FALSE ä TRUE Write request is executed

Initialise I/O system after parameterisation

TRUE · Value acceptance by reset node

· I/O system is re−initialised, state change to Operational

FALSE · No value acceptance

· I/O system is not initialised

Setting identifiers

Default values: input wiring = 0

RxPDO = receive identifiers from the I/O system

Identifiers can be optionally set by value selection.

If the input wiring is "0", the identifiers are composed as follows.

Note!

The basic identifiers are not settled in the pre−assigned area of the standard system

bus.

ID range: 384−831

By this, crossovers of the ID with the free CAN objects which the IO−lib is based on

are avoided.

RxPDOX Identifier = Basic ID + Node address

RxPDO1 837 835 2

RxPDO2 840

RxPDO3 845

RxPDO4 850

RxPDO5 855

Transmission mode

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

L

LenzeIOSystem.lib EN 1.7

4−19

Page 38

Function library LenzeIOSystem.lib

Function blocks

4.8 L_IOParPDO15 − Parameterisation function

(Variable type: VAR_INPUT)ð Inputs

Variable name Information/possible settingsData type

wCobID_TxPDO1

...

wCobID_TxPDO5

byTransmissionType_TxPDO1

...

byTransmissionType_TxPDO5

tinhibitTime_TxPDO1

...

tinhibitTime_TxPDO5

tCycleTime_TxPDO1

...

tCycleTime_TxPDO5

WORD

Byte

Time Inhibit time: t = 0 − 65535 ms

Time Cycle time: t = 0 − 65535 ms

Setting identifiers

Default values: input wiring = 0

TxPDO = receive identifiers from the I/O system

Identifiers can be optionally set by value selection.

If the input wiring is "0", the identifiers are composed as follows.

Note!

The basic identifiers are not settled in the pre−assigned area of the standard system

bus.

ID range: 384−831

By this, crossovers of the ID with the free CAN objects which the IO−lib is based on

are avoided.

TxPDOX Identifier = Basic ID + Node address

TxPDO1 838 836 2

TxPDO2 841

TxPDO3 846

TxPDO4 851

TxPDO5 856

Transmission mode

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

4−20

LenzeIOSystem.lib EN 1.7

L

Page 39

Function library LenzeIOSystem.lib

Function blocks

4.8 L_IOParPDO15 − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifiers Data type Value/meaning

nState Integer

nState Integer

bParDone BOOL

DataTO_IOData15 Struct Structure for the L_IOData15

States

If a transmission error occurs during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit request is executed.

The module is parameterised.

1 Transmit request dropped

Processing is running

2001 Error occurred during bus transfer

2002 Transmit request timed out

2004 Access denied

Incorrect target system: index does not exist

2005 Access denied

Incorrect target system: subindex does not exist

2013 Access denied

Incorrect target system: invalid value range

2111 Access denied

Incorrect target system: More than 4 decimal positions

specified or no fixed point format index

2117 Communication channel does not exist

byCom−Channelsetting

−10xx Incorrect value at function block input.

XX := number of faulty input (counting direction down),

parameterisation impossible.

Remedy: change input variable, restart data transmission

States

If a transmission errors occur during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

−150 Can bus is not in the "Operational" status.

−121 Incorrect driver number

−120 CAN driver for free CAN objects at present is not initialised.

−119 The transmit request memory is full.

The transmit request could not be entered anymore.

−118 No free CAN channel available.

−12 Message identifier is beyond the permissible range.

−11 pIOAddress pointer does not point to PLC−RAM.

0 Transmit or reception request has been carried out.

1 Request has not yet been completed and still is available in

the request memory.

10 Telegram length is greater than 8 bytes.

Telegram length is limited to 8 bytes.

200 Data in the reception memory have been overwritten.

Parameterisation

TRUE Parameterisation completed

process data block

Global variable of the "Struct" type

L

LenzeIOSystem.lib EN 1.7

4−21

Page 40

Function library LenzeIOSystem.lib

Function blocks

4.9 L_IOParPDO610 − Parameterisation function

4.9 L_IOParPDO610 − Parameterisation function

This function block serves to set communication−relevant parameters between the PLC control and

the I/O system for PDO 6 − 10.

· Via 3 or 4 input values, a transmission/reception object is parameterised.

· The output nState display the parameterisation status.

· Via the output DataTo_IOData610, information is transferred to the L_IOData610 process data

block in a fixed structure.

L_IOParPDO610

bExecute_b

CTRL

byNodeAdr

bInitIOSystem

wCobID_RxPDO6

byTransmissionType_RxPDO6

tCycleTime_RxPDO6

nState

bParDone

wCobID_RxPDO10

byTransmissionType_RxPDO10

tCycleTime_RxPDO10

wCobID_TxPDO6

byTransmissionType_TxPDO6

tinhibitTime_TxPDO6

tCycleTime_RxPDO6

wCobID_TxPDO10

byTransmissionType_TxPDO10

tinhibitTime_TxPDO10

tCycleTime_RxPDO10

DataTo_IOData610

Internal function

bExecute_b = TRUE

Parameter data is transferred to the I/O system

bInitIOSystem = TRUE bInitIOSystem = FALSE

· Index 2358

is written for purposes of value acceptance or initialisation of

the I/O system.

· Waiting time 10s until initialisation has been completed.

If the boot−up time is >10s, the waiting time corresponds to the

boot−up time

.

hex

· Index 2358

initialisation of the I/O system.

hex

· Waiting time 10s until initialisation has been completed.

If the boot−up time is >10s, the waiting time corresponds to

the boot−up time

.

EPM-T110

EPM-T111

Ixxxh

is written for purposes of value acceptance or

4−22

State change of the I/O system by NMT telegram from the

controller:

Pre−operational ä Operational

LenzeIOSystem.lib EN 1.7

Parameterisation completed

L

Page 41

Function library LenzeIOSystem.lib

Function blocks

4.9 L_IOParPDO610 − Parameterisation function

Note!

Features and use of the L_IOParPDLO610 FB.

· Use the L_IOParPDO610 FB last in a sequencer consisting of several FBs for

parameterisation. By means of the L_IOParPDO610 FB, parameterisation of the I/O system is

carried out.

· Parameterise the controller as master.

After the boot−up time has expired, for the master the change from the Pre−operational to the

Operational status is effected automatically.

· For sending the NMT telegram, the controller has to be in the Operational CAN status.

· If several IO systems (stations) are parameterised with standard values via the

L_IOParPDO610 FB on the system bus, an identifier collision between the individual PDOs of

these stations can occur. Therefore check the identifiers used.

After changing to the Operational CAN status, the current process image of the I/O system is sent.

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute BOOL Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

bInitIOSystem BOOL

wCobID_RxPDO6

...

wCobID_RxPDO10

byTransmissionType_RxPDO6

...

byTransmissionType_RxPDO10

tCyceTime_RxPDO6

...

tCyceTime_RxPDO10

WORD

Byte

Time Cycle time: t = 0 − 65535 ms

Initialise I/O system after parameterisation

TRUE · Value acceptance by reset node

FALSE · No value acceptance

· I/O system is not initialised

Setting identifiers

Default values: input wiring = 0

RxPDO = receive identifiers from the I/O system

Identifiers can be optionally set by value selection.

If the input wiring is "0", the identifiers are composed as follows.

Note: The basic identifiers are not settled in the pre−assigned area of the standard

system bus.

ID range: 384−831

By this, crossovers of the ID with the free CAN objects which the IO−lib is based on

are avoided.

RxPDOX Identifier = Basic ID + Node address

RxPDO6 862 860 2

RxPDO7 865

RxPDO8 870

RxPDO9 875

RxPDO10 880

Transmission mode

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

L

LenzeIOSystem.lib EN 1.7

4−23

Page 42

Function library LenzeIOSystem.lib

Function blocks

4.9 L_IOParPDO610 − Parameterisation function

(Variable type: VAR_INPUT)ð Inputs

Variable name Information/possible settingsData type

wCobID_TxPDO6

...

wCobID_TxPDO10

byTransmissionType_TxPDO6

...

byTransmissionType_TxPDO10

tinhibitTime_TxPDO6

...

tinhibitTime_TxPDO10

tCyceTime_TxPDO6

...

tCyceTime_TxPDO10

WORD

Byte

Time Inhibit time: t = 0 − 65535 ms

Time Cycle time: t = 0 − 65535 ms

Setting identifiers

Default values: input wiring = 0

TxPDO = receive identifiers from the I/O system

Identifiers can be optionally set by value selection.

If the input wiring is "0", the identifiers are composed as follows.

Note: The basic identifiers are not settled in the pre−assigned area of the standard

system bus.

ID range: 384−831

By this, crossovers of the ID with the free CAN objects which the IO−lib is based on

are avoided.

Transmission mode

TxPDOX Identifier = Basic ID + Node address

TxPDO6 863 861 2

TxPDO7 866

TxPDO8 871

TxPDO9 876

TxPDO10 881

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

4−24

LenzeIOSystem.lib EN 1.7

L

Page 43

Function library LenzeIOSystem.lib

Function blocks

4.9 L_IOParPDO610 − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifiers Data type Value/meaning

nState integer

nState integer

bParDone BOOL

DataTO_IOData610 Struct Structure for the L_IOData610

States

If a transmission error occurs during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

0 Transmit request is executed.

The module is parameterised.

1 Transmit request dropped

Processing is running

2001 Error occurred during bus transfer

2002 Transmit request timed out

2004 Access denied

Incorrect target system: index does not exist

2005 Access denied

Incorrect target system: subindex does not exist

2013 Access denied

Incorrect target system: invalid value range

2111 Access denied

Incorrect target system: More than 4 decimal positions

specified or no fixed point format index

2117 Communication channel does not exist

byCom−Channelsetting

−10xx Incorrect value at function block input.

XX := number of faulty input (counting direction down),

parameterisation impossible.

Remedy: change input variable, restart data transmission

States

If a transmission error occurs during the parameterisation process or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Errors are reset via an edge reversal at input bExecute or on

program restart.

−150 Can bus is not in the "Operational" status.

−121 Incorrect driver number

−120 CAN driver for free CAN objects at present is not initialised.

−119 The transmit request memory is full.

The transmit request could not be entered anymore.

−118 No free CAN channel available.

−12 Message identifier is beyond the permissible range.

−11 pIOAddress pointer does not point to PLC−RAM.

0 Transmit or reception request has been carried out.

1 Request has not yet been completed and still is available in

the request memory.

10 Telegram length is greater than 8 bytes.

Telegram length is limited to 8 bytes.

200 Data in the reception memory have been overwritten.

Parameterisation

TRUE Parameterisation completed

process data block

Global variable of the "Struct" type

L

LenzeIOSystem.lib EN 1.7

4−25

Page 44

Function library LenzeIOSystem.lib

Function blocks

4.10 L_IOParCompactModule − Parameterisation function

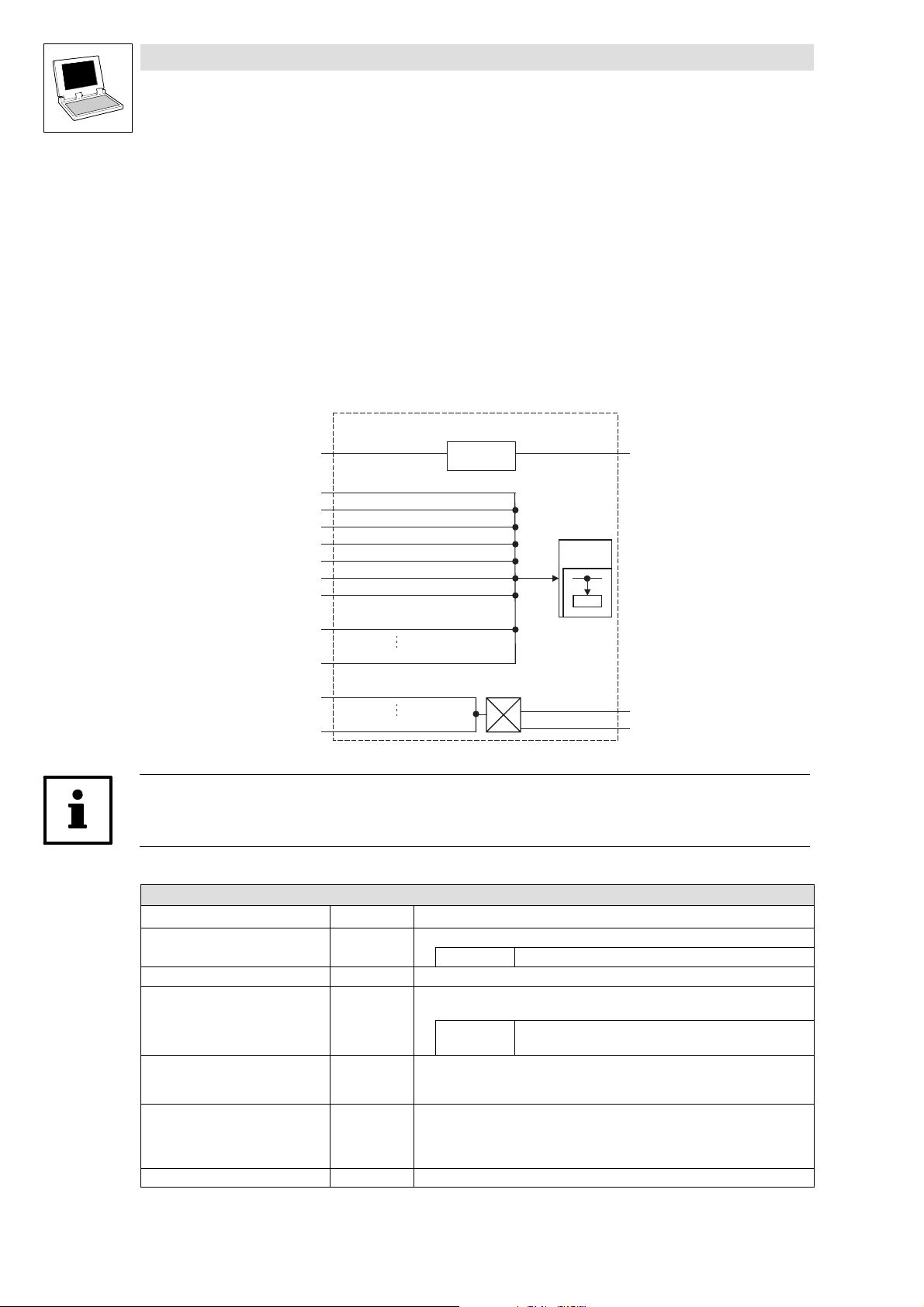

4.10 L_IOParCompactModule − Parameterisation function

This function block assists in the setting of parameters relevant to PLC control compact module

communication.

· Parameterising a function for process data exchange time monitoring.

· Output nState indicates the parameterisation process status.

· Use output DataTo_IODataBlockModule to transfer fixed−structure information to process data

block L_IOCompactModule.

L_IOParCompactModule

bExecute_b

CTRL

nState

bParDone

byNodeAdr

bInitIOSystem

byErrorBehavior

tTimeOutPDO1_DataToIO

tTimeOutPDO1_DataFromIO

wCobID_RxPDO1

byTransmissionType_RxPDO1

tCycleTime_RxPDO1

wCobID_TxPDO1

byTransmissionType_TxPDO1

tinhibitTime_TxPDO1

tCycleTime_RxPDO1

ð Inputs (Variable type: VAR_INPUT)

Variable name Data type Information/possible settings

bExecute Bool Execute write request

FALSE ä TRUE Write request is executed

byNodeAdr Byte Device address: 1 − 63

bInitIOSystem Bool Initialise I/O system after parameterisation

DataTo_IODataBlockModule

EPM-T8xx

Ixxxh

TRUE · Value accepted via Reset Node

· I/O system is reinitialised, status changes to OPERATIONAL

FALSE · No value accepted

· I/O system is not initialised

byErrorBehavior Byte Set the bus states

tTimeOutPDO1_DataToIO Time Monitoring period for process input data (Lenze−specific).

tTimeOutPDO1_DataFromIO Time Monitoring period for process output data.

Behaviour during a critical device error

0 Pre−Operational

1 No status change

2 Stop

3 Reset after 2 seconds

If no data are received at the selected PDO within the monitoring period, the I/O

system assumes the state set under byErrorBehavior.

Default t = 0 ms (monitoring off)

t = 0 − 65535 ms

If no data are transmitted from the I/O system to the PLC at the selected PDO within

the monitoring period, function block l_IODataXXX signals a time monitoring error.

Default t = 0 ms (monitoring off)

t = 0 − 65535 ms

4−26

LenzeIOSystem.lib EN 1.7

L

Page 45

Function library LenzeIOSystem.lib

Function blocks

4.10 L_IOParCompactModule − Parameterisation function

(Variable type: VAR_INPUT)ð Inputs

Variable name Information/possible settingsData type

wCobID_RxPDO1 Word Set identifiers

byTransmissionType_RxPDO1

tCyceTime_TxPDO6

...

tCyceTime_TxPDO10

wCobID_TxPDO1 Word Set identifiers

byTransmissionType_TxPDO1

tInhibitTime_TxPDO6

...

tInhibitTime_TxPDO10

tCyceTime_TxPDO6

...

tCyceTime_TxPDO10

Byte Transmission method

Time Cycle time t = 0 − 65535 ms

Byte Transmission method

Time Inhibit time t = 0 − 65535 ms

Time Cycle time t = 0 − 65535 ms

Default values: Input setting = 0

RxPDO = I/O system receive identifiers

Identifiers can be given any setting with a specified value.

The identifiers are composed as follows if the input setting = 0.

Note!

The basic identifiers are outside the preassigned standard system bus range.

ID range: 384−831

This prevents IDs from coinciding with unassigned CAN objects on which the IO−lib is

based.

RxPDOX Identifier = Basic ID + Node address

RxPDO1 837 835 2

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

Default values: Input setting = 0

TxPDO = I/O system receive identifiers

Identifiers can be given any setting with a specified value.

The identifiers are composed as follows if the input setting = 0.

The basic identifiers are outside the preassigned standard system bus range.

ID range: 384−831

This prevents IDs from coinciding with unassigned CAN objects on which the IO−lib is

based.

TxPDOX Identifier = Basic ID + Node address

TxPDO1 838 836 2

0 Event−controlled

1 Time−controlled

2 Event−controlled with superimposed cycle time

L

LenzeIOSystem.lib EN 1.7

4−27

Page 46

Function library LenzeIOSystem.lib

Function blocks

4.10 L_IOParCompactModule − Parameterisation function

Outputs ð (Variable type: VAR_OUTPUT)

Identifier Data type Value/meaning

nState Integer States

nState

bParDone Byte Parameterisation status

DataTO_IODataCompactmodule Struct Structure for process data block L_IOCompactModule

Integer States

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

If a transmission error occurs during the parameterisation process, or the input data

are incorrect, the parameterisation process is aborted and an error number is

indicated at output nState.

Any errors are reset via an edge reversal at input bExecute or on

program restart.

Global struct−type variable

0 Transmit command is executed.

The module is parameterised.

1 Transmit command sent

Processing in process

2001 Error occurred during bus transfer

2002 Transmit command timed out

2004 Access denied

Wrong target system: Index does not exist

2005 Access denied

Wrong target system: Subindex does not exist

2013 Access denied

Wrong target system: Invalid value range

2111 Access denied

Wrong target system: More than 4 digits specified after

comma, or no fixed−comma−format index

2117 Communication channel does not exist

Set byCom channel

−10xx Incorrect value at function block input.

XX := Number of faulty input (counting direction down),

parameterisation impossible.

Remedy: Change input value, restart data transmission

−150 CAN bus not in Operational status.

−121 Wrong driver number

−120 CAN driver for unassigned CAN objects currently not initialised.

−119 Transmit command memory is full.

Transmit command could not be entered.

−118 No free CAN channel available.

−12 Message identifier outside permissible range.

−11 pIOAddress pointer does not point at PLC RAM.

0 Transmit and/or receive command is executed.

1 Command has not yet been completed and is still in the

command memory.

10 Telegram longer than 8 bytes.

Telegram length limited to 8 bytes.

200 Data in receive memory have been overwritten.

TRUE Parameterisation executed

4−28

LenzeIOSystem.lib EN 1.7

L

Page 47

Function library LenzeIOSystem.lib

Function blocks

5 Function blocks for process data processing

This chapter contains information on function blocks for coordination, support and conversion.

The following functions and modules are coordinated:

· Digital and analog input and output data

The following functions and modules are supported:

· Analog input modules

· Analog output modules

· Counter modules

· Link between PLC control and I/O system

· Link between PLC control and compact module

L

LenzeIOSystem.lib EN 1.7

5−1

Page 48

Function library LenzeIOSystem.lib

Function blocks

5.1 L_IOData15 − Coordinate data

5.1 L_IOData15 − Coordinate data

Function block L_IOData15 coordinates digital and analog input and/or output data.