Page 1

L

Manual

Global Drive

PLC Developer Studio

Global Drive

Function library

LenzeDrive.lib

Page 2

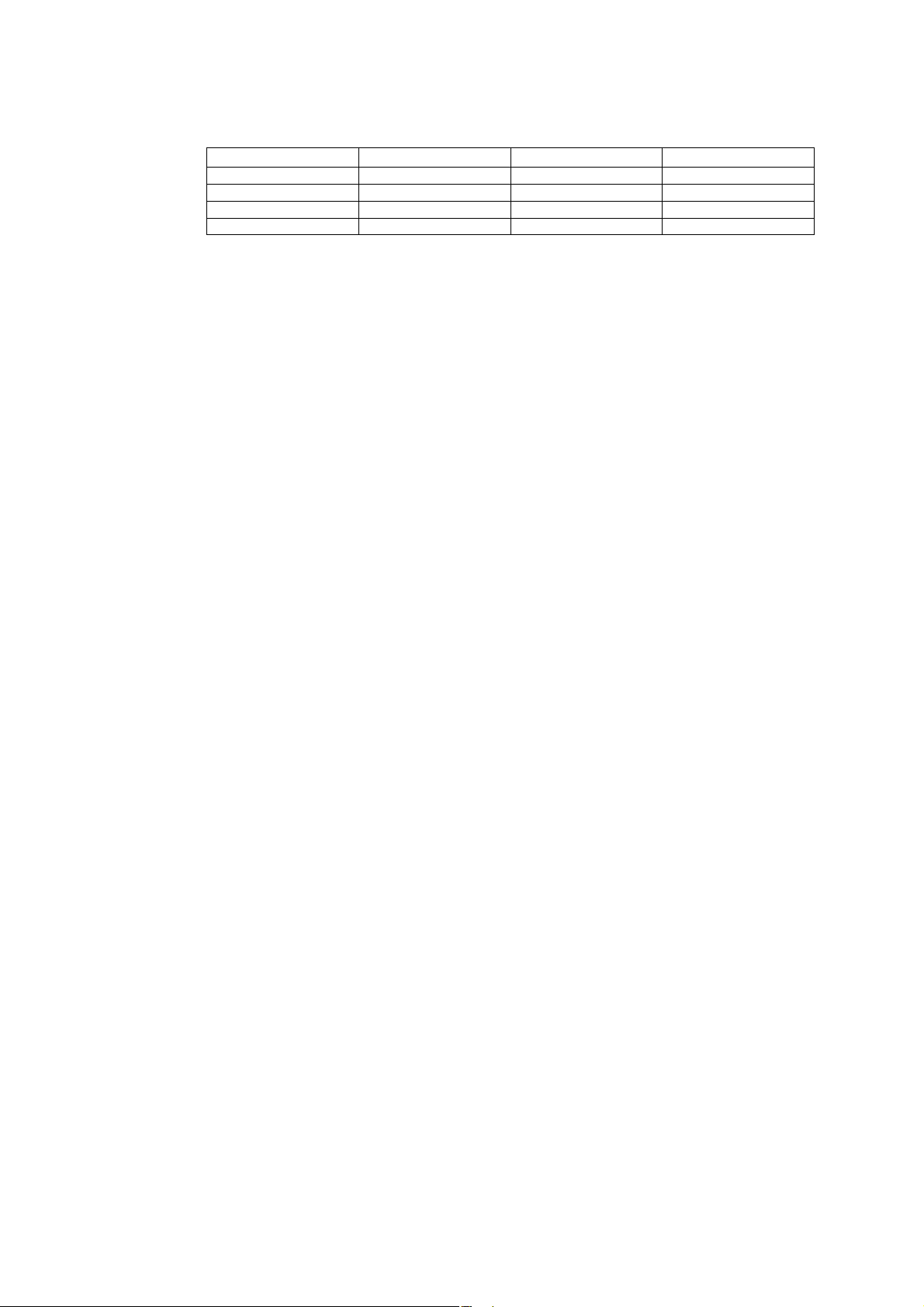

The function library LenzeDrive.lib can be used for the following Lenze PLC devices:

Type as of hardware version as of software version

9300 Servo PLC EVS93XX−xI 2K 1.0

9300 Servo PLC EVS93XX−xT 2K 1.0

Drive PLC EPL10200 VA 1.0

ECSxA ECSxAxxx 1C 7.0

Important note:

The software is supplied to the user as described in this document. Any risks resulting from its quality or use remain the responsibility

of the user. The user must provide all safety measures protecting against possible maloperation.

We do not take any liability for direct or indirect damage, e.g. profit loss, order loss or any loss regarding business.

2006 Lenze Drive Systems GmbH

No part of this documentation may be copied or made available to third parties without the explicit written approval of Lenze Drive

Systems GmbH.

All information given in this documentation has been carefully selected and tested for compliance with the hardware and software

described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility or liability for any damage that may

occur. Required corrections will be included in updates of this documentation.

All product names mentioned in this documentation are trademarks of the corresponding owners.

Version 1.7 07/2006

Page 3

Function library LenzeDrive.lib

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions used in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Description layout 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Pictographs used in this Manual 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Terminology used 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Lenze software guidelines for variable names 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Hungarian Notation 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.1 Recommendation for designating variable types 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.2 Designation of the signal type in the variable name 1−5 . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.3 Special handling of system variables 1−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Version identifiers of the function library 1−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Function blocks 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General signal processing 2−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Programming fixed setpoints (L_FIXSET) 2−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Analog signal processing 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Absolute value generation (L_ABS) 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Addition (L_ADD) 2−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Input gain and offset (L_AIN) 2−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Inversion (L_ANEG) 2−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Output gain and offset (L_AOUT) 2−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Arithmetic (L_ARIT) 2−11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.7 Changeover (L_ASW) 2−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.8 Comparison (L_CMP) 2−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.9 Curve function (L_CURVE) 2−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.10 Dead−band (L_DB) 2−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.11 Differentiation (L_DT1_) 2−21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.12 Limiting (L_LIM) 2−22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.13 Delay (L_PT1_) 2−23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.14 Ramp generator (L_RFG) 2−24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.15 Sample & Hold (L_SH) 2−26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.16 S−ramp generator (L_SRFG) 2−27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Digital signal processing 2−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Logical AND (L_AND) 2−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Delay (L_DIGDEL) 2−30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Up/down counter (L_FCNT) 2−32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Flip−flop (L_FLIP) 2−33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Logical NOT (L_NOT) 2−34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 Logical OR (L_OR) 2−35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.7 Edge evaluation (L_TRANS) 2−36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Processing of phase−angle signals 2−38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Arithmetic (L_ARITPH) 2−38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Addition (L_PHADD) 2−39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Comparison (L_PHCMP) 2−40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 Difference (L_PHDIFF) 2−41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Division (L_PHDIV) 2−42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 Integration (L_PHINT) 2−43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.7 Integration (L_PHINTK) 2−45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

LenzeDrive.lib EN 1.7

i

Page 4

Function library LenzeDrive.lib

Contents

2.5 Signal conversion 2−49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Normalization (L_CONV) 2−49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Conversion of phase−angle to analog (L_CONVPA) 2−50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Conversion of a phase−angle signal (L_CONVPP) 2−51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Conversion (L_CONVVV) 2−52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Normalization with limiting (L_CONVX) 2−53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Communication 2−54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Type conversion (L_ByteArrayToDint) 2−54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Type conversion (L_DintToByteArray) 2−54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Code index (L_FUNCodeIndexConv) 2−54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Read codes (L_ParRead) 2−55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.5 Write codes (L_ParWrite) 2−59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Special functions 2−63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Transparent mode with keypad 9371BB/9371BC (L_Display9371BB) 2−63 . . . . . . . . . . . . . . . . . . . .

2.7.2 Fault trigger (L_FWM) 2−68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Motor potentiometer (L_MPOT) 2−70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Speed preconditioning (L_NSET) 2−73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.5 Process controller (L_PCTRL) 2−79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.6 Right/Left/Quickstop (L_RLQ) 2−83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Appendix 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Code table 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Index 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

LenzeDrive.lib EN 1.7

l

Page 5

Function library LenzeDrive.lib

Preface and general information

1.1 About this Manual

1 Preface and general information

1.1 About this Manual

This Manual contains information on the function blocks that are included in the function library

LenzeDrive.lib for the Drive PLC Developer Studio.

These function blocks can be used in the 9300 Servo PLC, Drive PLC and ECSxA

automation system.

The function blocks are based on the functions that are available in the 9300 servo inverter

(V2.0).

In the Drive PLC Developer Studio (DDS) you make the basic settings for your drive application

offline by using variables (in accordance with the IEC61131−3 standard) as aids for parameterizing

the appropriate function blocks.

Via Global Drive Control (GDC) or the keypad you can then set the parameters for the required

functionality of your drive application online by accessing the codes of the function block instances.

1.1.1 Conventions used in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Variable names

are written in italics in the explanation:

"The signal at nIn_a ..."

Lenze functions/function blocks

can be recognized by their names. They always begin with an "L_":

"The FB L_ARIT can ..."

Program listings

are written in "Courier", keywords are printed in bold:

"IF (ReturnValue < 0) THEN..."

Instances

For function blocks that have one or more first instances there are tables that describe the

corresponding codes:

Variable name L_ARIT1 L_ARIT2 Setting range Lenze

byFunction C0338 C0600 0 ... 5 1

You can access these codes online with Global Drive Control (GDC) or keypad.

L

Tip!

You can use the Parameter Manager to assign the same codes to these instances that are assigned

in the 9300 servo inverter (V2.0).

LenzeDrive.lib EN 1.7

1−1

Page 6

Function library LenzeDrive.lib

Preface and general information

1.1 About this Manual

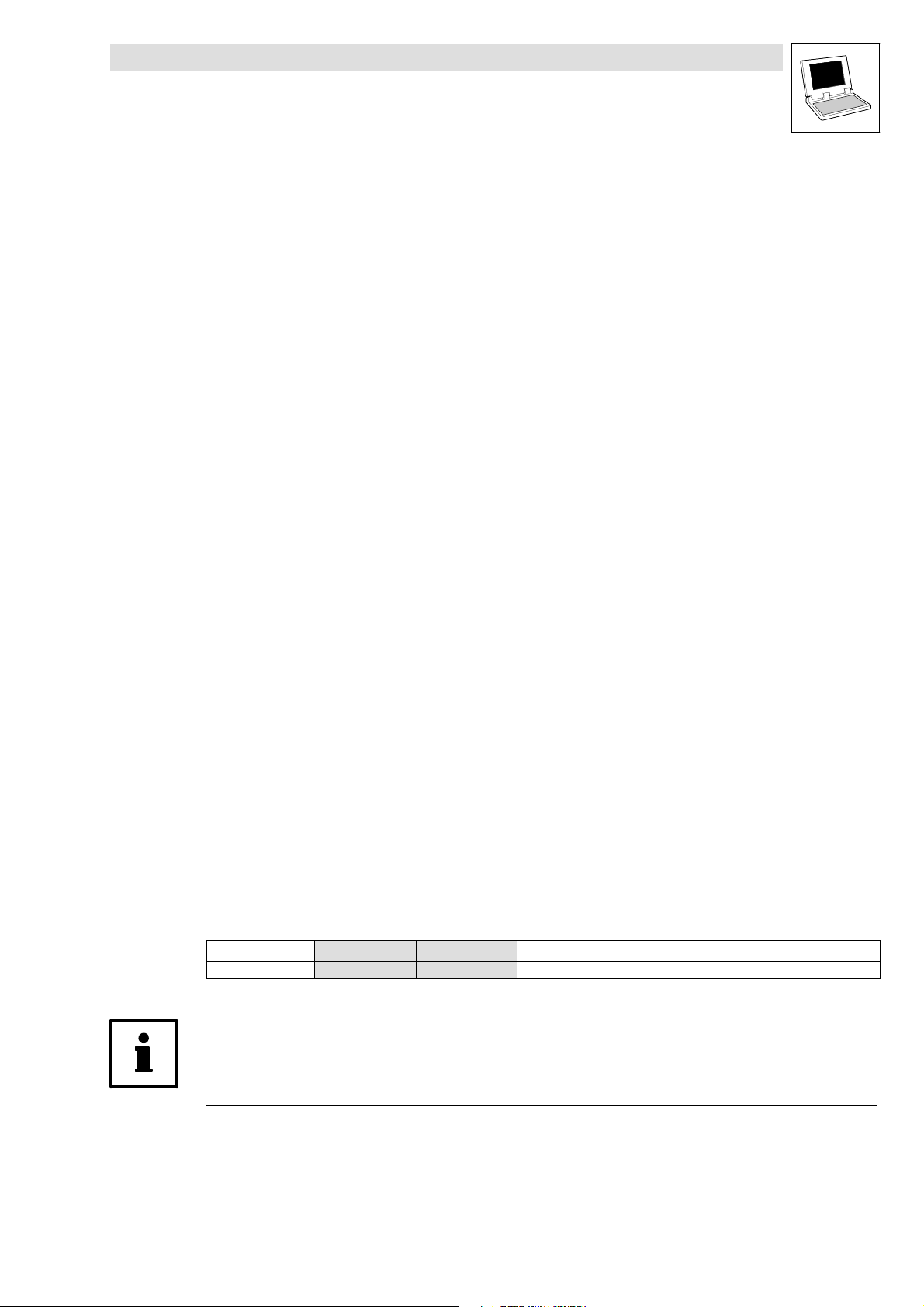

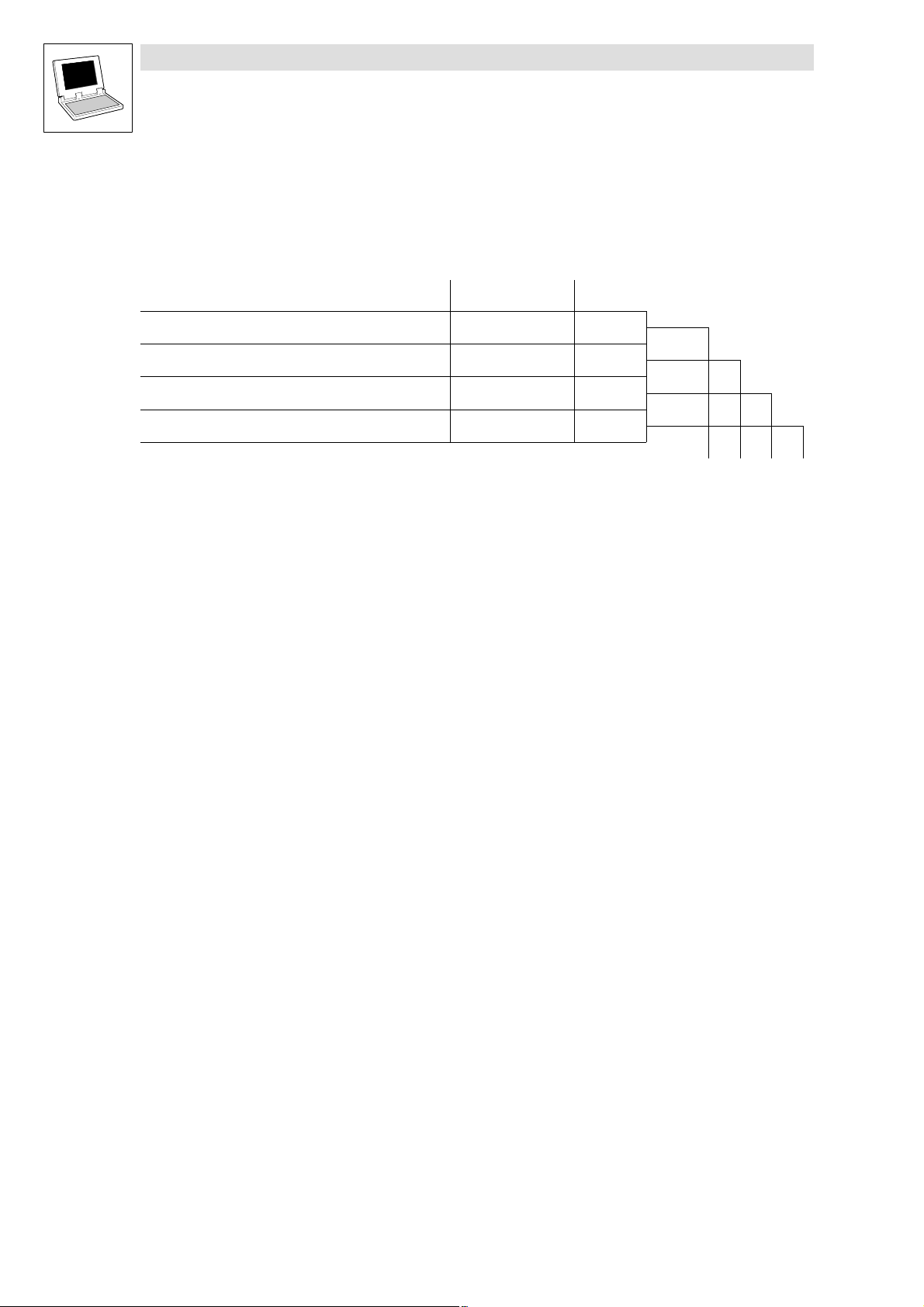

1.1.2 Description layout

All function/function block and system block descriptions contained in this Manual have the same

structure:

Function Function block (FB)/

Heading stating function and function identifier

Declaration of the function:

Data type of the return value

Function identifier

List of transfer parameters

Short description of the most important properties

Function chart including all

associated variables

Transfer parameters

Return value

Table giving information about the

transfer parameters:

Identifiers

Data type

Possible settings

Info

Table giving information about the

return value:

Data type of the return value

Possible return values and their

meaning

Additional information

(Notes, tips, application examples, etc.)

system block (SB)

−

FB/SB chart including all

associated variables

Input variables

Output variables

Table giving information about the

input and output variables:

Identifiers

Data type

Variable type

Possible settings

Info

−

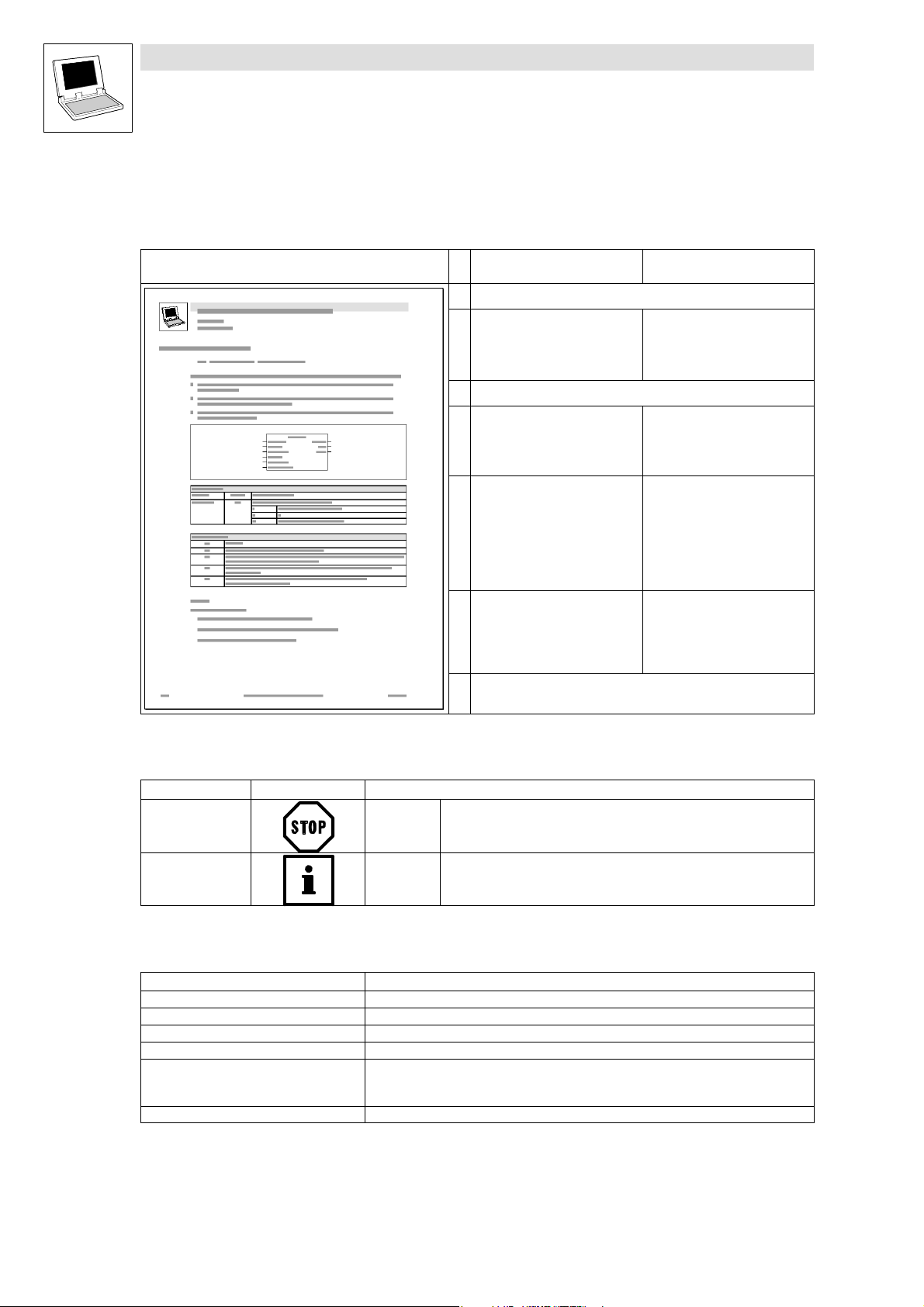

1.1.3 Pictographs used in this Manual

Pictographs used Signal words

Warning of material

damage

Other notes Tip!

Stop! Warns of potential damage to material.

Note!

1.1.4 Terminology used

Term In the following text used for

DDS Drive PLC Developer Studio

FB Function block

GDC Global Drive Control (parameterization program from Lenze)

Parameter codes Codes for setting the functionality of a function block

PLC 9300 Servo PLC

SB System block

Drive PLC

ECSxA "Application" axis module

Possible consequences if disregarded:

Damage to the controller/drive system or its environment.

Indicates a tip or note.

1−2

LenzeDrive.lib EN 1.7

L

Page 7

Function library LenzeDrive.lib

Preface and general information

1.2 Lenze software guidelines for variable names

1.2 Lenze software guidelines for variable names

The previous concepts for Lenze controllers were based on codes that represented the input and

output signals, and the parameters of function blocks.

For the sake of clarity, names were defined for the codes in the documentation.

In addition, the signal types were defined by graphical symbols.

The user could see at a glance which kind of signal (analog, phase−angle etc.) had to be present at

the particular interface.

The concept for the new automation system does not use direct codes in the

programming. The IEC 61131−3 standard is used instead.

This standard is based on a structure of variable names.

If the user applies variables in his project, then he can name the variables as he chooses.

In order to avoid the growth of a multitude of different conventions for naming variables in existing

and future projects and function libraries that are programmed by Lenze personnel, we have set up

software guidelines that must be followed by all Lenze staff.

In this convention for creating variable names, Lenze keeps to the Hungarian Notation that has been

specifically expanded by Lenze.

If you make use of Lenze−specific functions or function blocks, you will immediately be able to see,

for instance, which data type you must transfer to a function block, and which type of data you will

receive as an output value.

1.2.1 Hungarian Notation

These conventions are used so that the most significant characteristics of a program variable can

instantly be recognized from its name.

Variable names

consist of

a prefix (optional)

a data−type entry

and an identifier

The prefix and data−type entry are usually formed by one or two characters. The identifier (the

"proper" name) should indicate the application, and is therefore usually somewhat longer.

Prefix examples

prefix Meaning

a Array (combined type), field

p Pointer

L

LenzeDrive.lib EN 1.7

1−3

Page 8

Function library LenzeDrive.lib

Preface and general information

1.2 Lenze software guidelines for variable names

Examples of the data−type entry

Examples of a data−type Meaning

b Bool

by Byte

n Integer

w Word

dn Double integer

dw Double word

s String

f Real (float)

sn Short integer

t Time

un Unsigned integer

udn Unsigned double integer

usn Unsigned short integer

Identifier (the proper variable name)

An identifier begins with a capital letter.

If an identifier is assembled from several "words", then each "word" must start with a capital

letter.

All other letters are written in lower case.

Examples:

Array of integers anJogValue[10] ;

Bool bIsEmpty ;

Word wNumberOfValues ;

Integer nLoop ;

Byte byCurrentSelectedJogValue ;

1.2.1.1 Recommendation for designating variable types

In order to be able to recognize the type of variable in a program according to the name, it makes

sense to use the following designations, which are placed in front of the proper variable name and

separated from it by an underline stroke:

I_<Variablename> VAR_INPUT

Q_<Variablename> VAR_OUTPUT

IQ_<Variablename> VAR_IN_OUT

R_<Variablename> VAR RETAIN

C_<Variablename> VAR CONSTANT

CR_<Variablename> VAR CONSTANT RETAIN

g_<Variablename> VAR_GLOBAL

gR_<Variablename> VAR_GLOBAL RETAIN

gC_<Variablename> VAR_GLOBAL CONSTANT

gCR_<Variablename> VAR_GLOBAL CONSTANT RETAIN

1−4

Example

for a global array of type integer that includes fixed setpoints (analog) for a speed setting:

g_anFixSetSpeedValue_a

LenzeDrive.lib EN 1.7

L

Page 9

Function library LenzeDrive.lib

Preface and general information

1.2 Lenze software guidelines for variable names

1.2.1.2 Designation of the signal type in the variable name

The inputs and outputs of the Lenze function blocks each have a specific signal type assigned. These

may be: digital, analog, position, or speed signals.

For this reason, each variable name has an ending attached that provides information on the type of

signal.

Signal type Ending Previous designation

analog _a (analog)

digital _b (binary)

Phase−angle difference or speed _v (velocity)

Phase−angle or position _p (position)

Tip!

Normalizing to signal type phase−angle difference/speed: 16384 (INT) ¢ 15000 rpm

Normalizing to signal type analog: 16384 ¢ 100 % ¢ value under [C0011] = n

Normalizing to signal type angle or position: 65536 ¢ 1 motor revolution

H

G

F

E

max

Examples:

Variable name Signal type Type of variable

nIn_a Analog input value Integer

dnPhiSet_p Phase signals Double integer

bLoad_b Binary value (TRUE/FALSE) Bool

nDigitalFrequencyIn_v Speed input value Integer

1.2.1.3 Special handling of system variables

System variables require special handling, since the system functions are only available for the user

as I/O connections in the control configuration.

In order to be able to access a system variable quickly during programming, the variable name must

include a label for the system function.

For this reason, the name of the corresponding system block is placed before the name of the

variable.

Examples:

AIN1_nIn_a

CAN1_bCtrlTripSet_b

DIGIN_bIn3_b

L

LenzeDrive.lib EN 1.7

1−5

Page 10

Function library LenzeDrive.lib

Preface and general information

1.3 Version identifiers of the function library

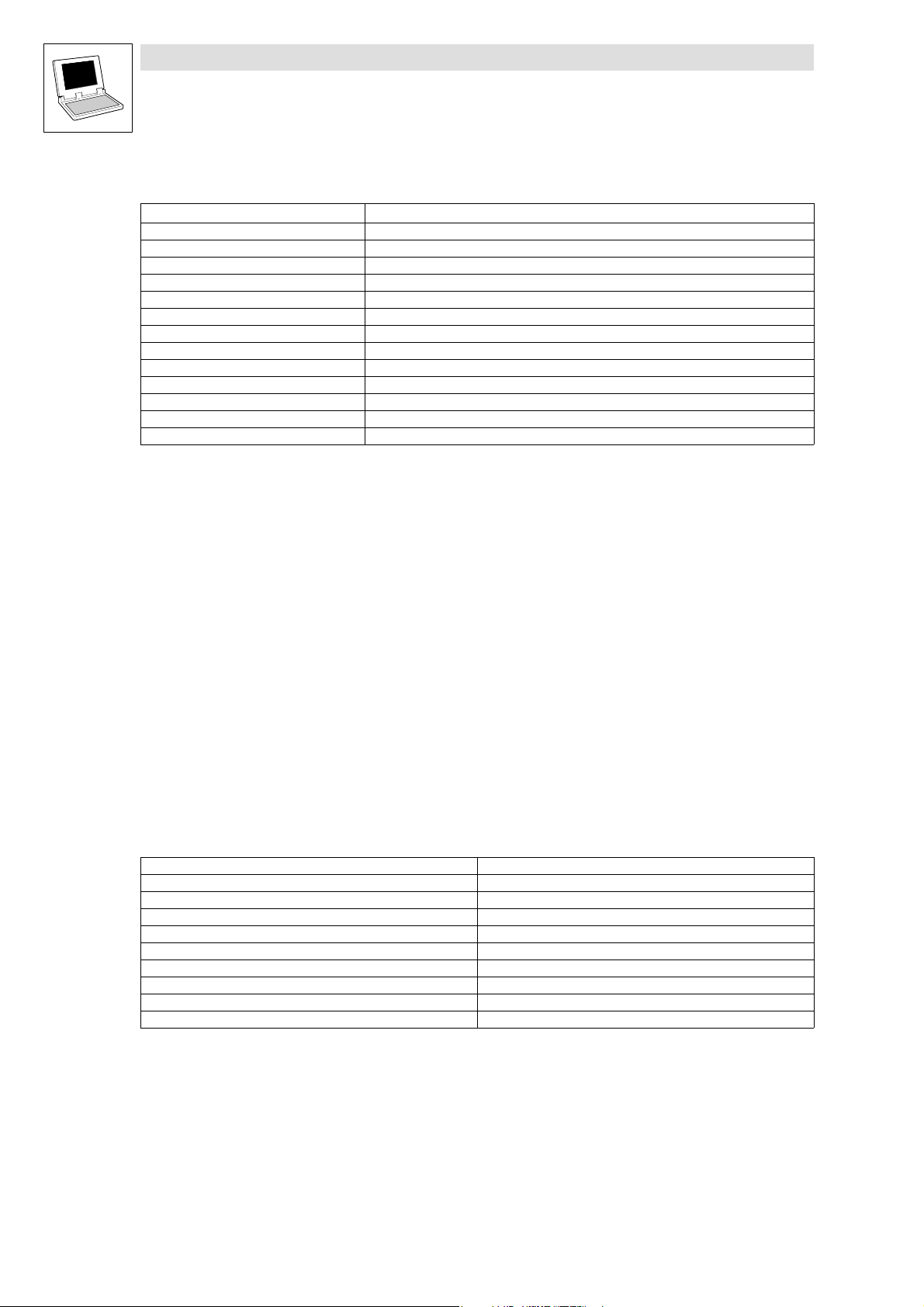

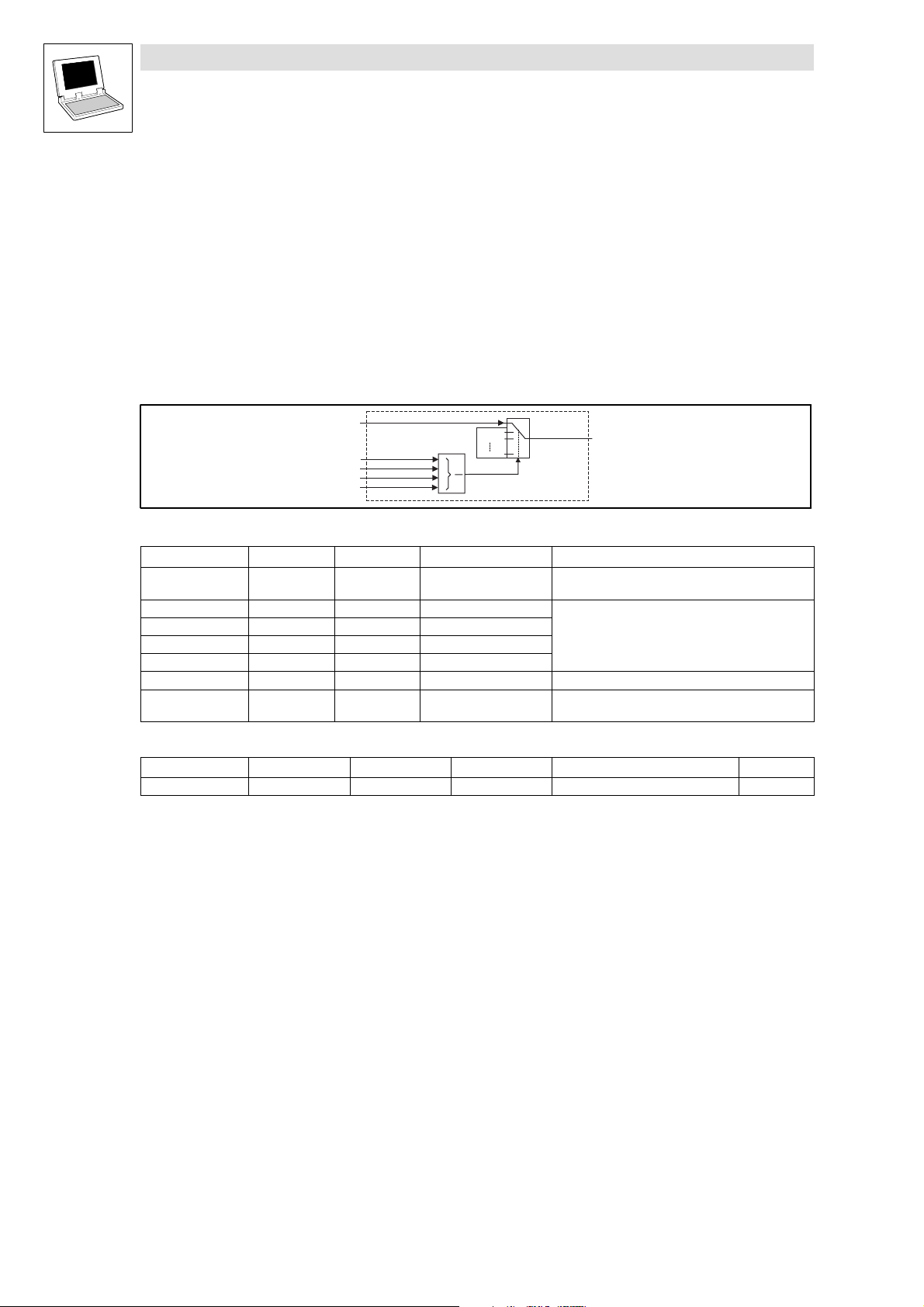

1.3 Version identifiers of the function library

The version of the function library can be found under the global constant

C_w[Function library name]Version .

Version identifiers as of PLC software version 7.x:

Constant Meaning

C_w[FunctionLibraryName]VersionER External Release 01

C_w[FunctionLibraryName]VersionEL External Level 05

C_w[FunctionLibraryName]VersionIR Internal Release 00

C_w[FunctionLibraryName]VersionBN Build No. 00

The value of this constant is a hexadecimal code.

In the example, "01050000" stands for version "1.05".

Example

value

Version: 01 05 00 00

1−6

LenzeDrive.lib EN 1.7

L

Page 11

2 Function blocks

Note!

Due to their internal structure, the below function blocks have to be called in a time−equidistant task

(e.g. in a 5−ms task):

L_DIGDEL

L_DT1_

L_MPOT

L_NSET

L_ParRead

L_ParWrite

L_PCTRL

L_PHDIFF

L_PHINT

L_PHINTK

L_PT1_

L_RFG

L_SRFG

L_TRANS

Caution: The cyclic task PLC_PRG is not time−equidistant!

Function library LenzeDrive.lib

Function blocks

l

LenzeDrive.lib EN 1.7

2−1

Page 12

Function library LenzeDrive.lib

General signal processing

2.1.1 Programming fixed setpoints (L_FIXSET)

2.1 General signal processing

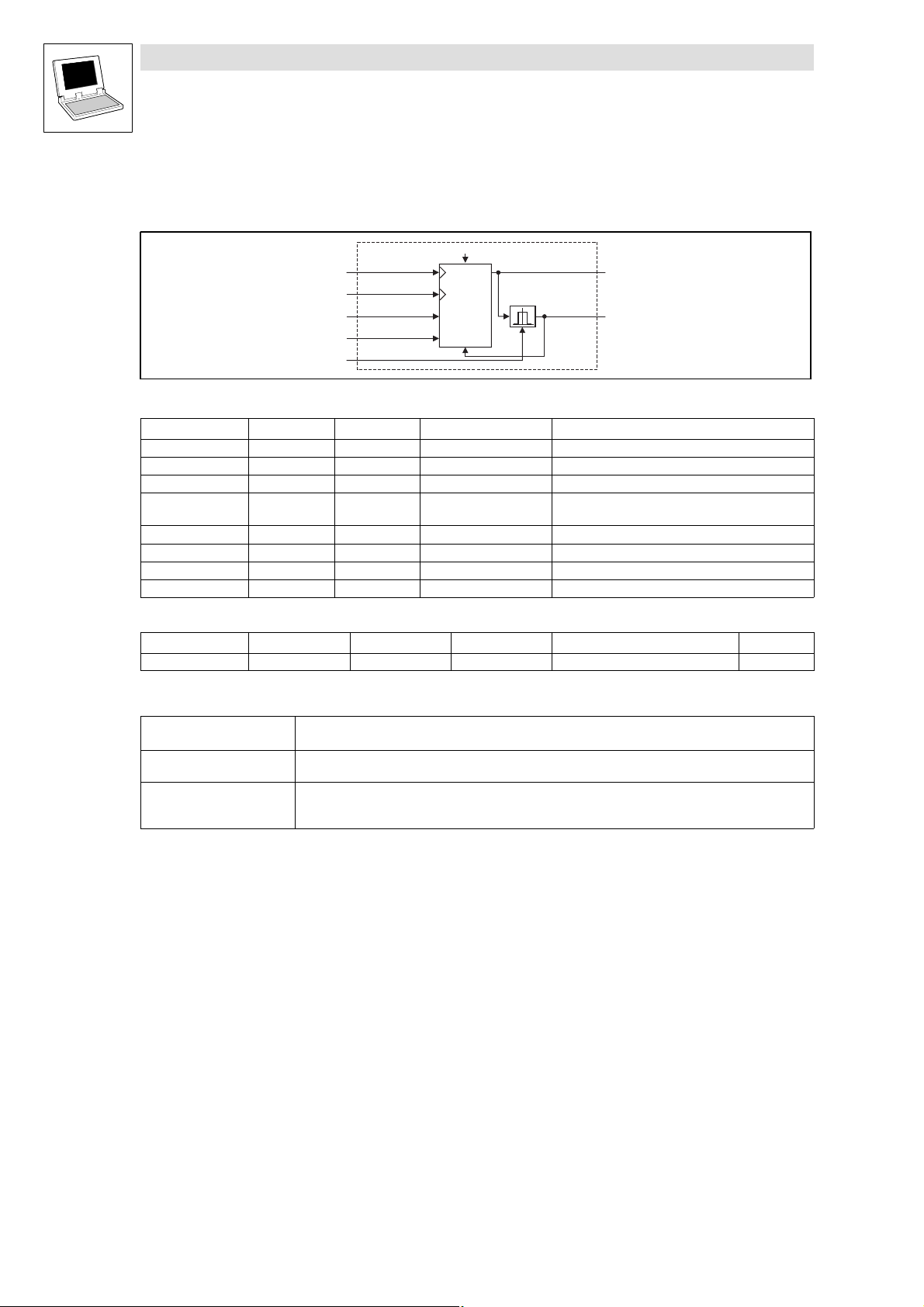

2.1.1 Programming fixed setpoints (L_FIXSET)

You can program up to 15 fixed setpoints with this FB. The addressing of the setpoint that is to be

output is made through the boolean (logic) inputs.

Fixed setpoints can be used, for example, for:

Different set dancer positions in a dancer position control

Different stretch ratios (gearbox factor) when using a speed ratio control with digital frequency

coupling

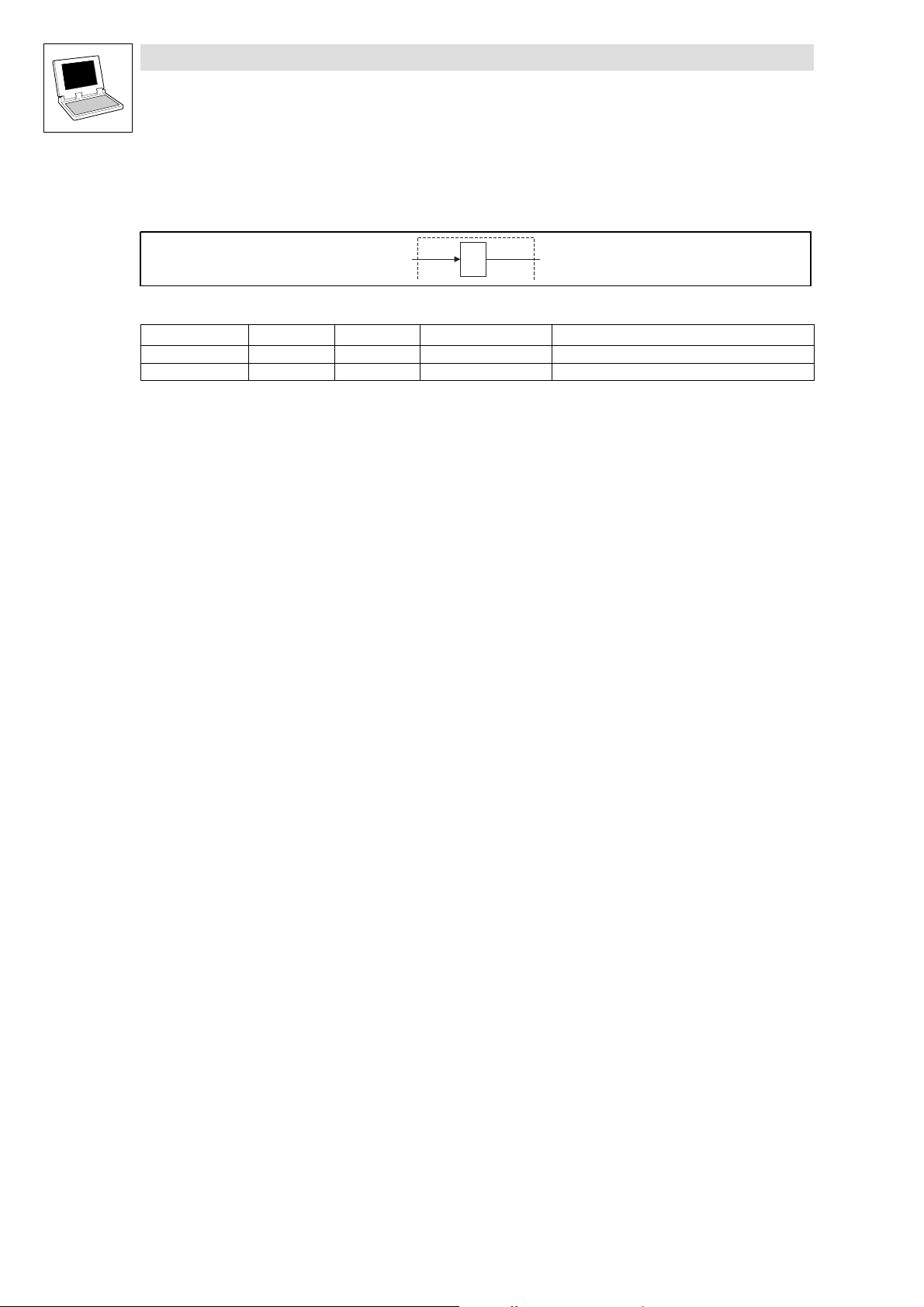

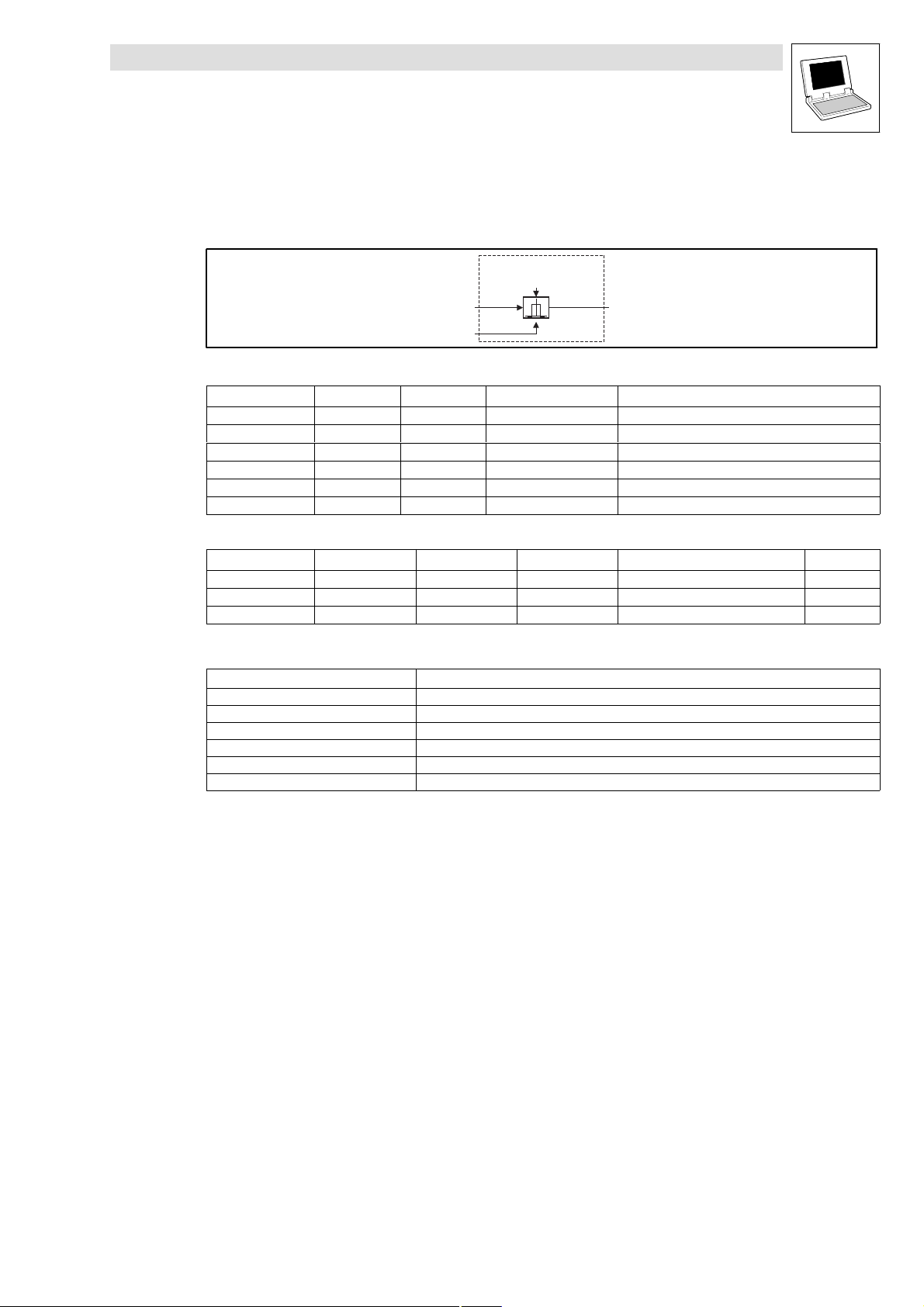

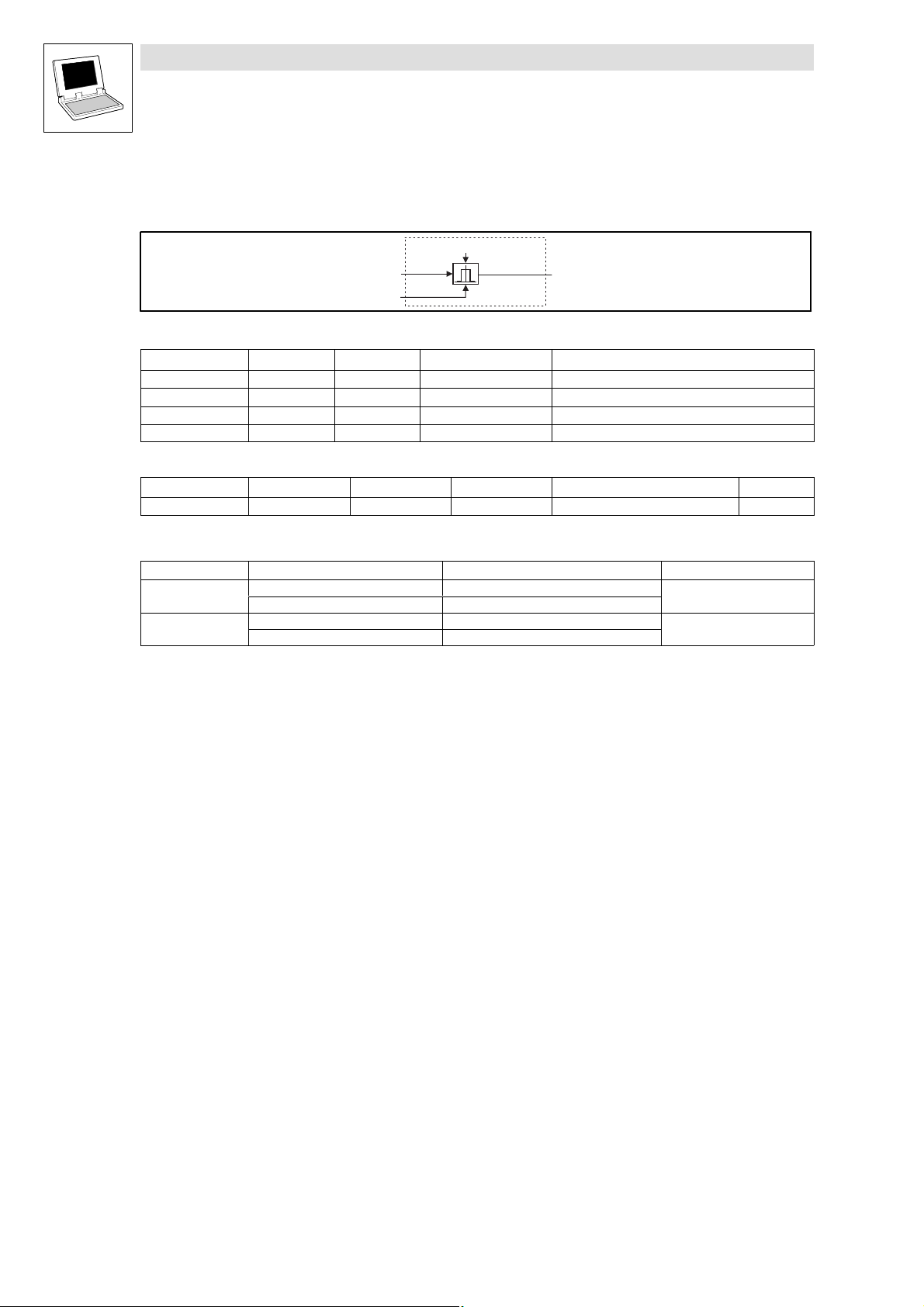

Fig. 2−1 Programming fixed setpoints (L_FIXSET)

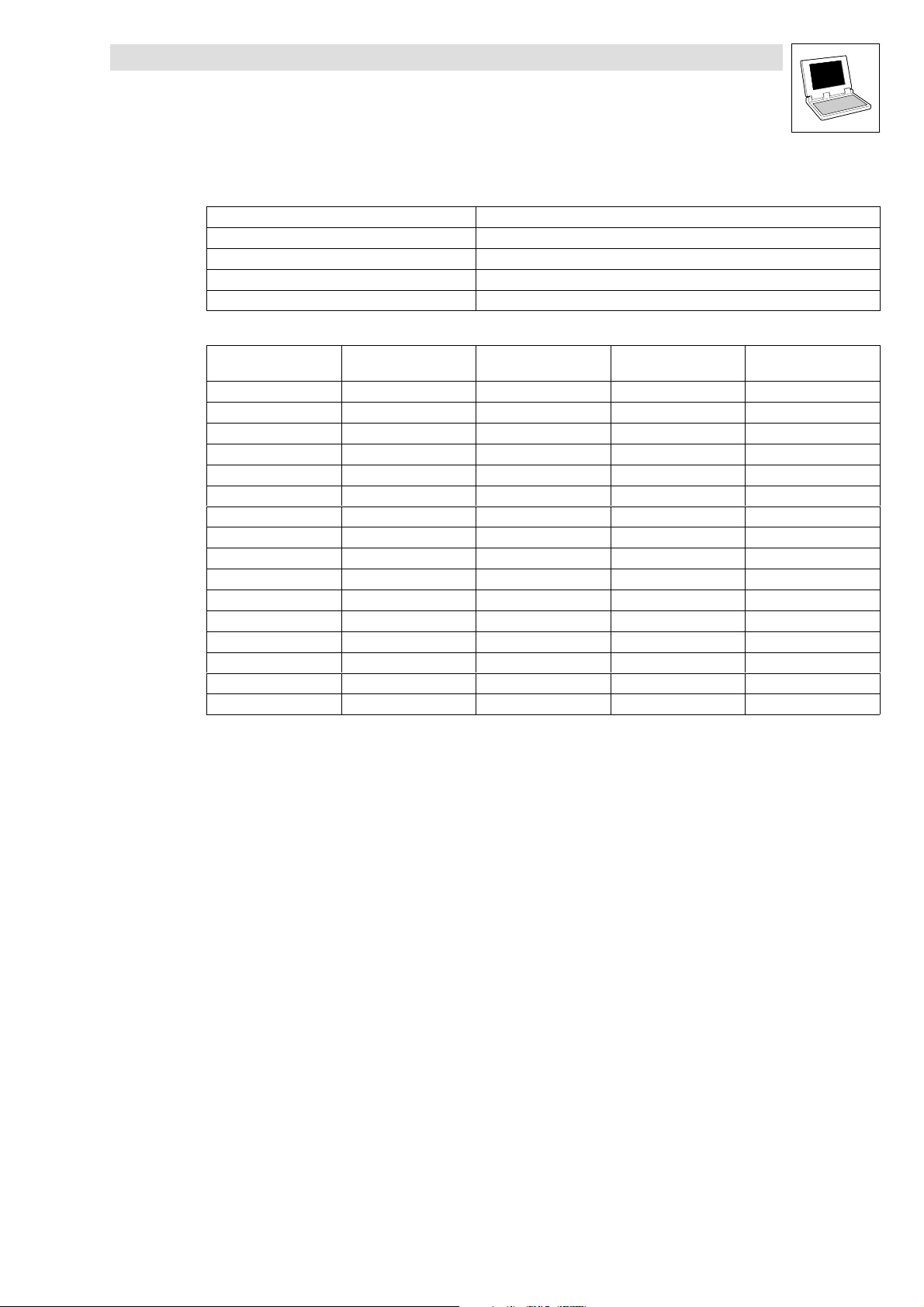

VariableName DataType SignalType VariableType Note

nAin_a Integer analog VAR_INPUT nAin_a is connected to nOut_a , if (bIn1_b ... bIn4_b)

bIn1_b Bool binary VAR_INPUT

bIn2_b Bool binary VAR_INPUT

bIn3_b Bool binary VAR_INPUT

bIn4_b Bool binary VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

anSollW[1...15] Array of integers VAR CONSTANT RETAIN Variable that can have fixed setpoints assigned to

Parameter codes of the instances

VariableName L_FIXSET1 SettingRange Lenze

anSollW[1...15] C0560/1 ... 15 −199.99 ... 199.99 % 0.00

Function

nOut_a can be used as a setpoint source (signal source) for another FB (e.g. process controller,

arithmetic block, etc.). The parameterization and handling is the same as for JOG, but it is

independent of JOG. (^ 2−73: L_NSET)

Parameterization of the fixed setpoints

– The individual fixed setpoints can be parameterized through anSollW1 ... anSollW15.

Output of the selected fixed setpoint:

– If the binary inputs are triggered with a HIGH signal, a fixed setpoint from the table is

switched to nOut_a . (^ 2−3)

Range:

– You can enter values from −199.99% ... 199.99% (100 % corresponds to 16384).

nAin_a

bIn1_b

bIn2_b

bIn3_b

bIn4_b

DMUX

0

3

FIXSET1...15

0

15

anSollW1

anSollW2

anSollW15

L_FIXSET

nOut_a

FALSE is on all the selection inputs.

The number of inputs to be assigned depends on the

number of required fixed setpoints.

them.

2−2

LenzeDrive.lib EN 1.7

L

Page 13

Function library LenzeDrive.lib

General signal processing

2.1.1 Programming fixed setpoints (L_FIXSET)

2.1.1.1 Enable of the fixed setpoints

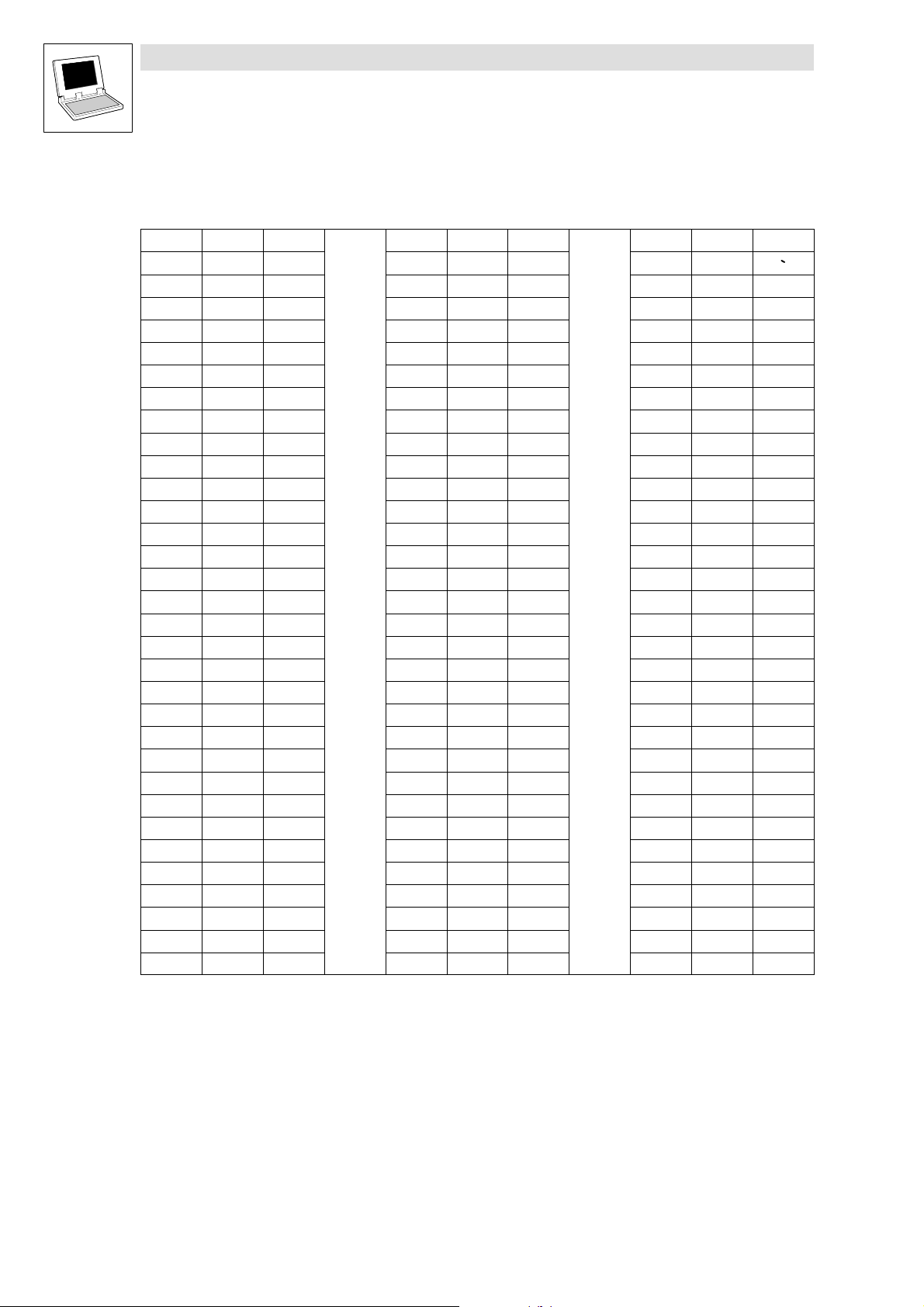

Number of required fixed setpoints Number of the inputs to be assigned

1 at least 1

1 ... 3 at least 2

4 ... 7 at least 3

8 ... 15 4

Decoding table of the binary input signals:

Output signal

nOut_a =

nAin_a 0 0 0 0

anSollW1 1 0 0 0

anSollW2 0 1 0 0

anSollW3 1 1 0 0

anSollW4 0 0 1 0

anSollW5 1 0 1 0

anSollW6 0 1 1 0

anSollW7 1 1 1 0

anSollW8 0 0 0 1

anSollW9 1 0 0 1

anSollW10 0 1 0 1

anSollW11 1 1 0 1

anSollW12 0 0 1 1

anSollW13 1 0 1 1

anSollW14 0 1 1 1

anSollW15 1 1 1 1

0 = FALSE

1 = TRUE

1st input

bIn1_b

2nd input

bIn2_b

3rd input

bIn3_b

4th input

bIn4_b

L

LenzeDrive.lib EN 1.7

2−3

Page 14

Function library LenzeDrive.lib

Analog signal processing

2.2.1 Absolute value generation (L_ABS)

2.2 Analog signal processing

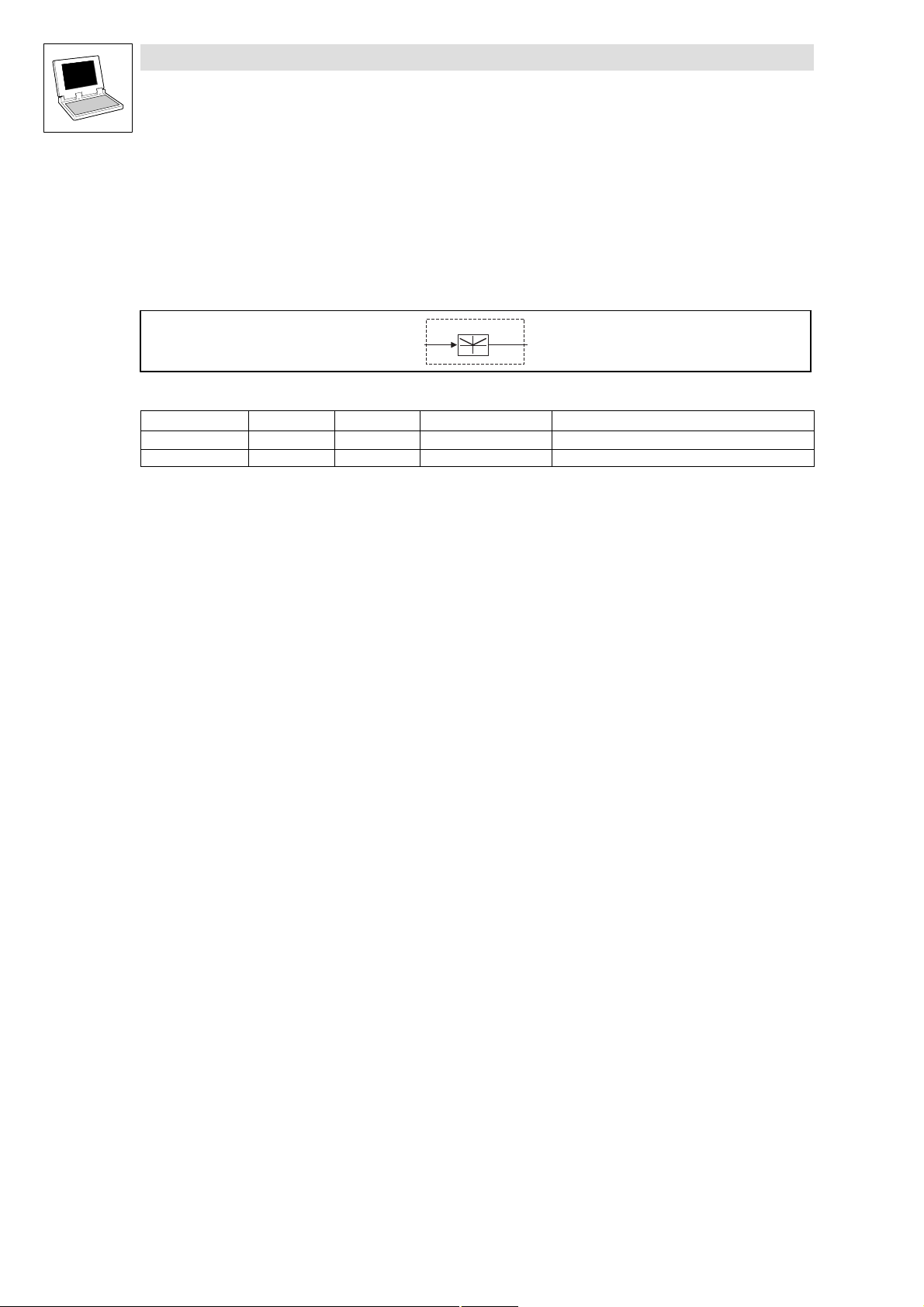

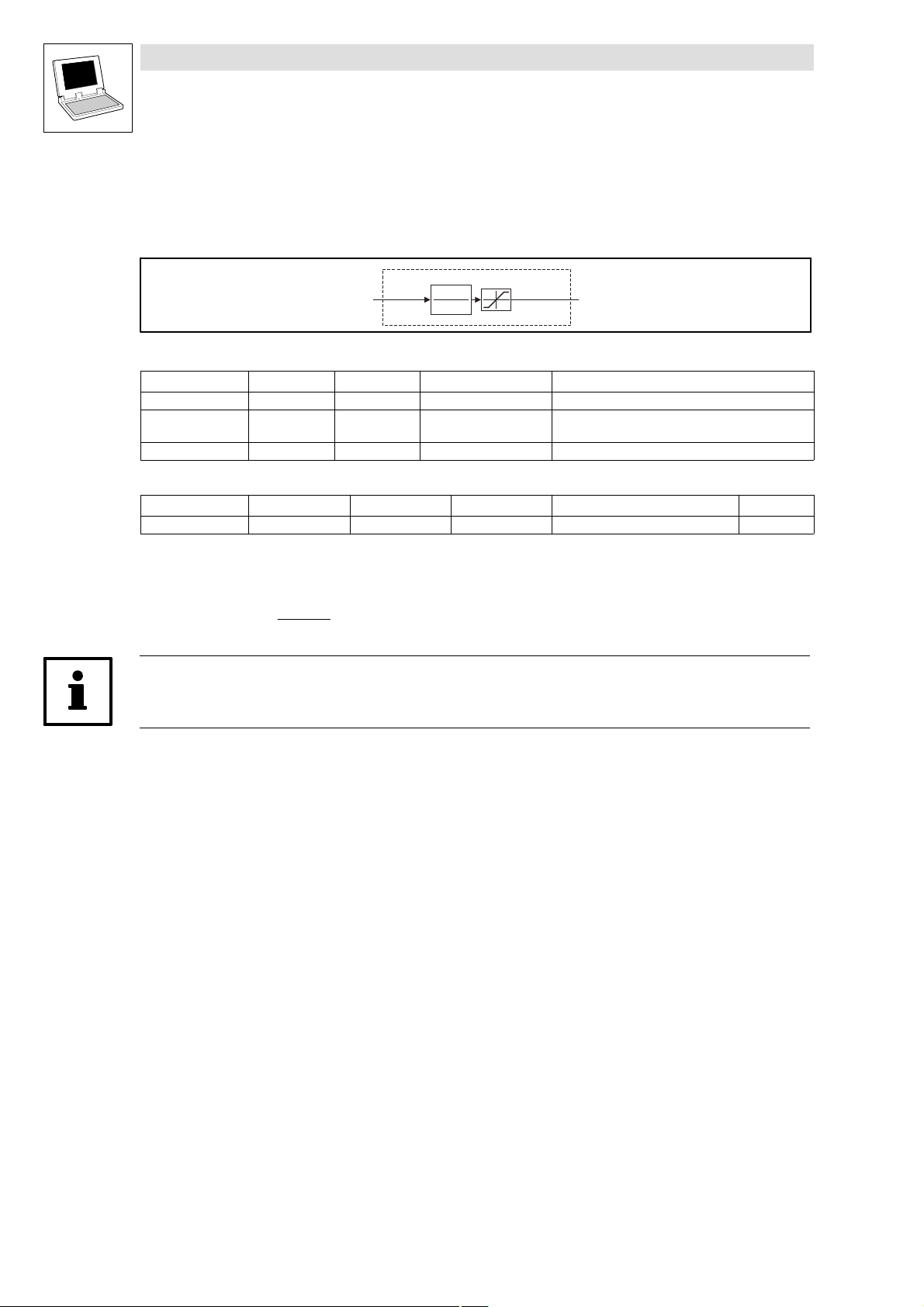

2.2.1 Absolute value generation (L_ABS)

This FB converts bipolar values into unipolar values. It calculates the absolute value of the input

signal.

Fig. 2−2 Absolute value generation (L_ABS)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

n I n _ a

L _ A B S

n O u t _ a

2−4

LenzeDrive.lib EN 1.7

L

Page 15

Function library LenzeDrive.lib

Analog signal processing

2.2.2 Addition (L_ADD)

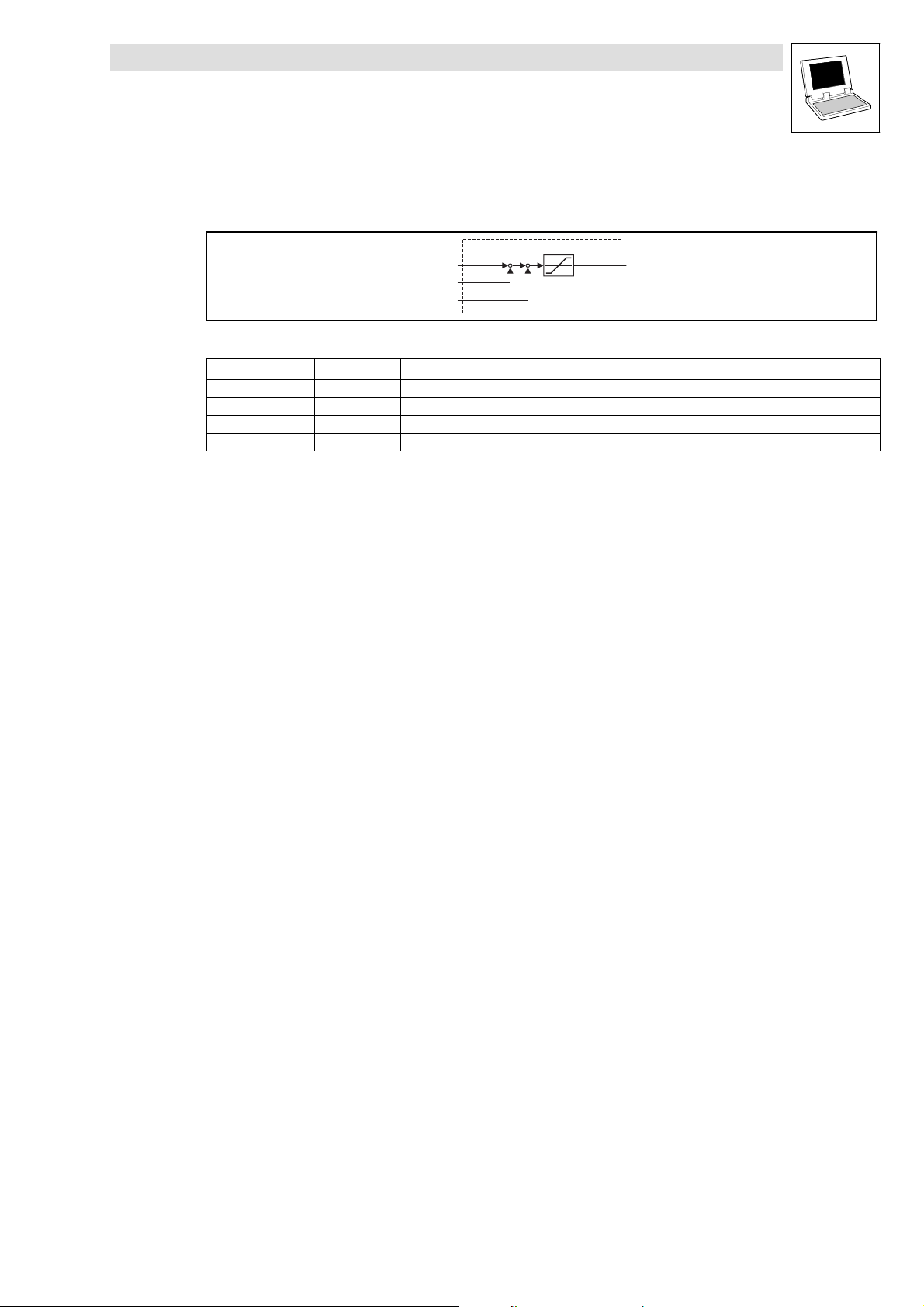

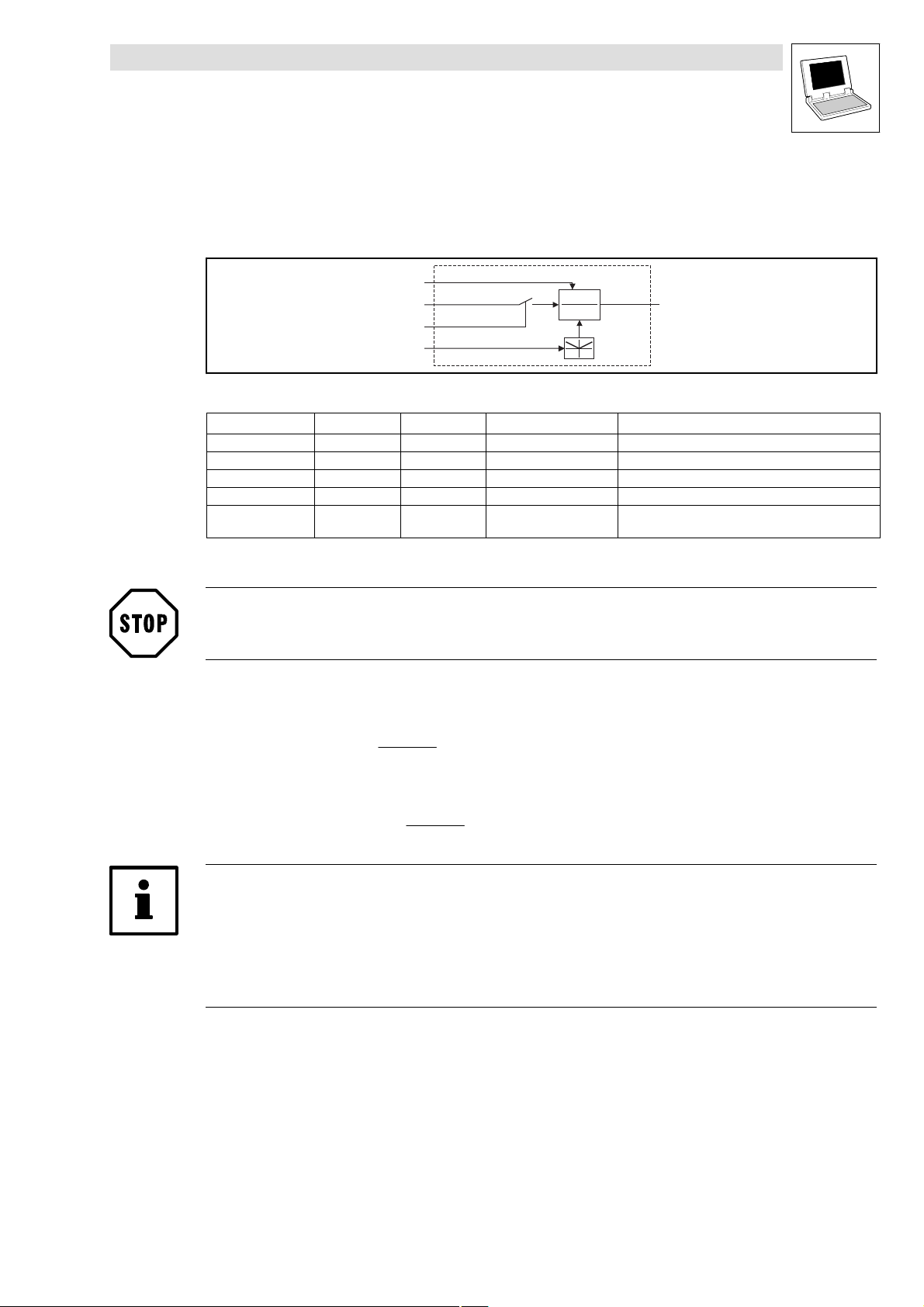

2.2.2 Addition (L_ADD)

This FB adds or subtracts input values, depending on the input that is used.

L _ A D D

± 3 2 7 6 7

Fig. 2−3 Addition (L_ADD)

VariableName DataType SignalType VariableType Note

nIn1_a Integer analog VAR_INPUT Addition input

nIn2_a Integer analog VAR_INPUT Addition input

nIn3_a Integer analog VAR_INPUT Subtraction input

nOut_a Integer analog VAR_OUTPUT Signal is limited to ±32767.

Functional sequence

1. The value at nIn1_a is added to the value of nIn2_a.

2. The value of nIn3_a is subtracted from the calculated result.

3. The result of the substraction is then limited to ±32767.

n I n 1 _ a

n I n 2 _ a

n I n 3 _ a

+

-+

n O u t _ a

L

LenzeDrive.lib EN 1.7

2−5

Page 16

Function library LenzeDrive.lib

Analog signal processing

2.2.3 Input gain and offset (L_AIN)

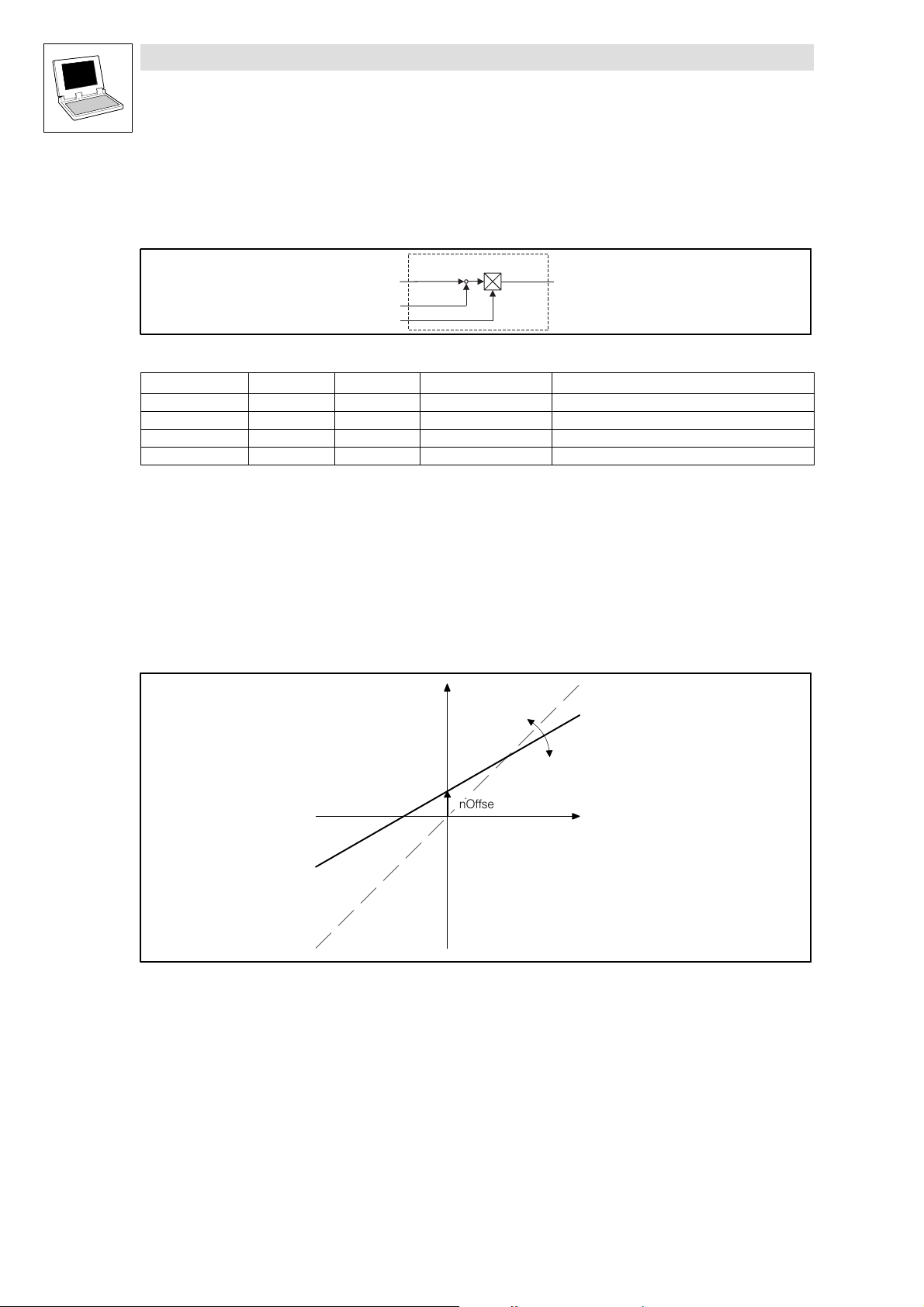

2.2.3 Input gain and offset (L_AIN)

This FB is preferentially used for addition circuitry at the analog input terminals, to adjust the gain and

offset.

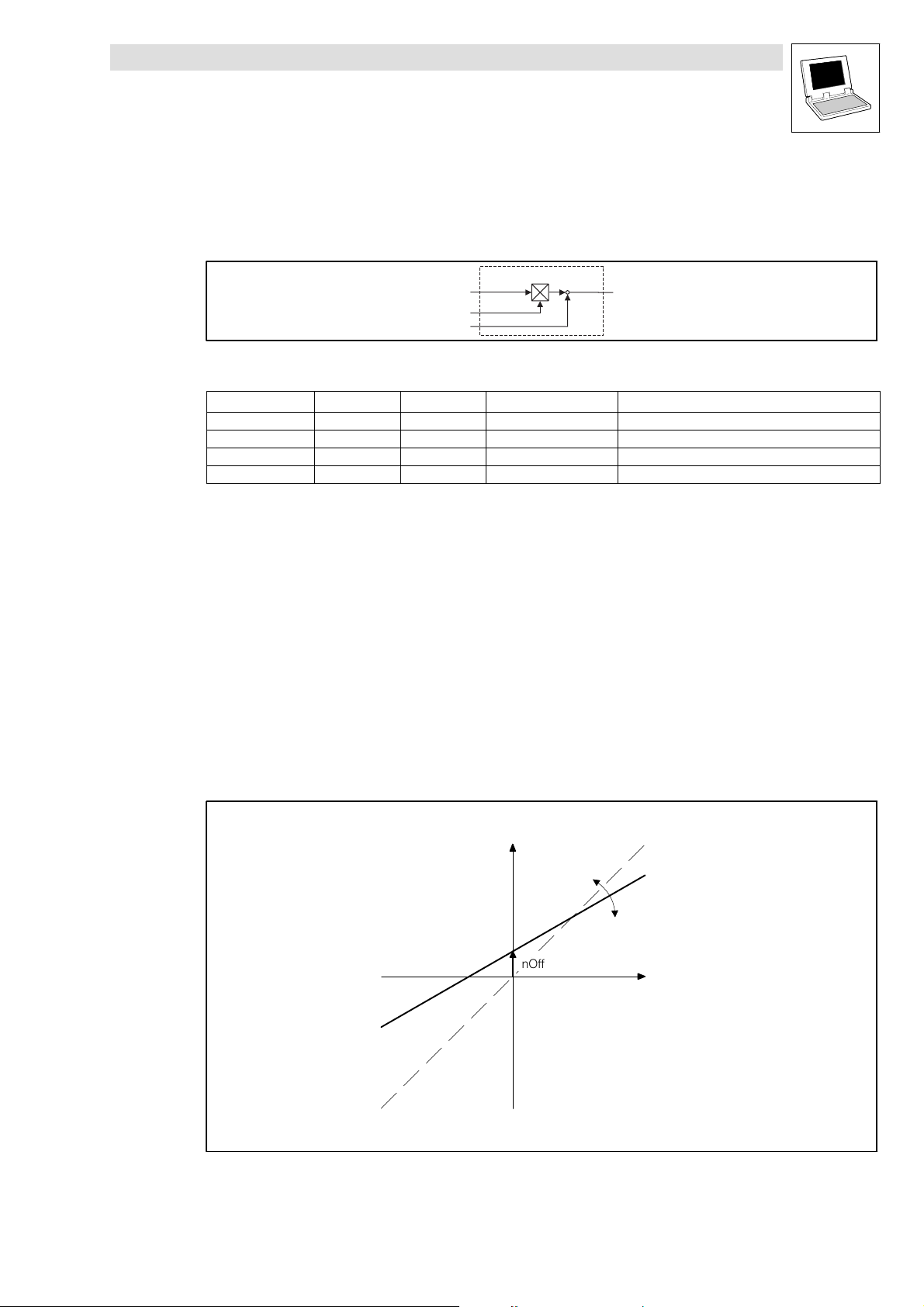

Fig. 2−4 Input gain and offset (L_AIN)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT Input signal

nOffset_a Integer analog VAR_INPUT Offset of the input signal

nGain_a Integer analog VAR_INPUT Gain of the input signal

nOut_a Integer analog VAR_OUTPUT

Function

Offset

– The value at nOffset_a is added to the value of nIn_a

– The result of the addition is limited to ±32767.

Gain

– The limited value (after the offset) is multiplied by the value at nGain_a .

– Next, the signal is limited to ±32767.

The signal is given out at nOut_a .

nOut_a

nIn_a

nOffset_a

nGain_a

+

+

L_AIN

nOut_a

Fig. 2−5 Offset and gain of the analog input

nGain_a

nOffset_a

nIn_a

2−6

LenzeDrive.lib EN 1.7

L

Page 17

Function library LenzeDrive.lib

Analog signal processing

2.2.3 Input gain and offset (L_AIN)

Funtion in IL

LD nIn_a

INT_TO_DINT

ADD (nOffset_a

INT_TO_DINT

)

LIMIT −32767,32767

MUL (nGain_a

INT_TO_DINT

)

DIV 16384

LIMIT −32767,32767

DINT_TO_INT

ST nOut_a

L

LenzeDrive.lib EN 1.7

2−7

Page 18

Function library LenzeDrive.lib

Analog signal processing

2.2.4 Inversion (L_ANEG)

2.2.4 Inversion (L_ANEG)

This FB inverts the sign of an input value. The input value is multiplied by −1 and then output.

Fig. 2−6 Inversion (L_ANEG)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

n I n _ a

* ( - 1 )

L _ A N E G

n O u t _ a

2−8

LenzeDrive.lib EN 1.7

L

Page 19

Function library LenzeDrive.lib

Analog signal processing

2.2.5 Output gain and offset (L_AOUT)

2.2.5 Output gain and offset (L_AOUT)

This FB is preferentially used for additional circuitry at analog output terminals, to adjust the gain and

offset.

L_AOUT

+

nIn_a

nGain_a

nOffset_a

Fig. 2−7 Output gain and offset (L_AOUT)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT Input signal

nGain_a Integer analog VAR_INPUT Gain of the input signal

nOffset_a Integer analog VAR_INPUT Offset of the input signal

nOut_a Integer analog VAR_OUTPUT

Function

nOut_a

+

Gain

– The value at nIn_a is multiplied by the value at nGain_a .

– The multiplication is performed according to the formula:

16384 @ 16384 @ 2

*14

+ 16384

– The result of the multiplication is limited to ±2

[100% @ 100% + 100%]

14

Offset

– The limited value (after amplification) is added to the value at nOffset_a

– The result of the addition is limited to ±2

Next, the signal is limited to ±2

14

and output to nOut_a .

nOut_a

14

nGain_a

nOffset_a

nIn_a

Fig. 2−8 Offset and gain of the analog output

L

LenzeDrive.lib EN 1.7

2−9

Page 20

Function library LenzeDrive.lib

Analog signal processing

2.2.5 Output gain and offset (L_AOUT)

Function in IL

LD nIn_a

INT_TO_DINT

MUL (nGain_a

INT_TO_DINT

)

DIV −32767,32767

ADD (nOffset_a

INT_TO_DINT

)

LIMIT −32767,32767

DINT_TO_INT

ST nOut_a

2−10

LenzeDrive.lib EN 1.7

L

Page 21

Function library LenzeDrive.lib

Analog signal processing

2.2.6 Arithmetic (L_ARIT)

2.2.6 Arithmetic (L_ARIT)

This FB can arithmetically combine two analog signals.

Fig. 2−9 Arithmetic (L_ARIT)

VariableName DataType SignalType VariableType Note

nIn1_a Integer analog VAR_INPUT

nIn2_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT The signal is limited to ±32767.

byFunction Byte VAR CONSTANT RETAIN Selection of the function

Parameter codes of the instances

VariableName L_ARIT1 L_ARIT2 SettingRange Lenze

byFunction C0338 C0600 0 ... 5 1

Function

Selection of the function Arithmetic function Notes

byFunction = 0 nOut_a = nIn1_a

byFunction = 1 nOut_a = nIn1_a + nIn2_a

byFunction = 2 nOut_a = nIn1_a − nIn2_a

byFunction = 3

byFunction = 4

byFunction = 5

nOut_a +

nOut_a +

nOut_a +

nIn1_a

nIn2_a

byFunction

x

+

y

(nIn1_a) @ (nIn2_a)

16384

nIn1_a

@ 164

|

|

nIn2 a

nIn1_a

16384 * nIn2_a

L_ARIT

±32767

*

x/(1-y)/

nOut_a

If the denominator = 0,

the denominator is set = 1.

@ 16384

Function in ST

CASE byFunktion OF

0: nOut_a:=nIn1_a;

1: nOut_a:= DINT_TO_INT ( LIMIT (−32767,( INT_TO_DINT (nIn1_a)+ INT_TO_DINT (nIn2_a)),32767));

2: nOut_a:= DINT_TO_INT ( LIMIT (−32767,( INT_TO_DINT (nIn1_a)− INT_TO_DINT (nIn2_a)),32767));

3: nOut_a:= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)* INT_TO_DINT (nIn2_a))/16384),32767));

4: IF (nIN2_a=0) THEN

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*164)),32767));

ELSE

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*164)/ ABS (nIn2_a)),32767));

END_IF

5: IF (16384− INT_TO_DINT (nIn2_a)=0) THEN

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*16384),32767));

ELSIF (16384− INT_TO_DINT (nIn2_a)>32767) THEN

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*16384/32767),32767));

ELSIF (16384− INT_TO_DINT (nIn2_a)<−32767) THEN

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*16384/−32767),32767));

ELSE

nOut_a= DINT_TO_INT ( LIMIT (−32767,(( INT_TO_DINT (nIn1_a)*16384)/(16384− INT_TO_DINT (nIn2_a)))

END_IF

END_CASE ;

L

LenzeDrive.lib EN 1.7

2−11

Page 22

Function library LenzeDrive.lib

Analog signal processing

2.2.7 Changeover (L_ASW)

2.2.7 Changeover (L_ASW)

This FB switches between two integer values. So it is, for example, possible to change between an

initial diameter and a calculated diameter during winding.

Fig. 2−10 Changeover (L_ASW)

VariableName DataType SignalType VariableType Note

nIn1_a Integer analog VAR_INPUT

nIn2_a Integer analog VAR_INPUT

bSet_b Bool binary VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

Function

Control signal Output signal

bSet_b = TRUE nOut_a = nIn2_a

bSet_b = FALSE nOut_a = nIn1_a

n I n 1 _ a

n I n 2 _ a

b S e t _ b

L _ A S W

0

n O u t _ a

1

2−12

LenzeDrive.lib EN 1.7

L

Page 23

Function library LenzeDrive.lib

Analog signal processing

2.2.8 Comparison (L_CMP)

2.2.8 Comparison (L_CMP)

This FB compares two integer values with each other. You can use comparators to implement

threshold switches.

Fig. 2−11 Comparison (L_CMP)

VariableName DataType SignalType VariableType Note

nIn1_a Integer analog VAR_INPUT

nIn2_a Integer analog VAR_INPUT

bOut_b Bool binary VAR_OUTPUT

byFunction Byte VAR CONSTANT RETAIN Comparison function for the inputs

nHysteresis Integer VAR CONSTANT RETAIN Hysteresis function

nWindow Integer VAR CONSTANT RETAIN Window function

Parameter codes of the instances

VariableName L_CMP1 L_CMP2 L_CMP3 SettingRange Lenze

byFunction C0680 C0685 C0690 1 ... 6 6

nHysteresis C0681 C0686 C0691 0.00 ... 100.00 % 1.00

nWindow C0682 C0687 C0692 0.00 ... 100.00 % 1.00

Function

Selection of the function Comparison function

byFunction = 1 nIn1_a = nIn2_a

byFunction = 2 nIn1_a > nIn2_a

byFunction = 3 nIn1_a < nIn2_a

byFunction = 4 nIn1_a = nIn2_a

byFunction = 5 nIn1_a > nIn2_a

byFunction = 6 nIn1_a < nIn2_a

b y F u n c t i o n

n H y s t e r e s i s

n I n 1 _ a b O u t _ b

n I n 2 _ a

L _ C M P

n W i n d o w

L

LenzeDrive.lib EN 1.7

2−13

Page 24

Function library LenzeDrive.lib

Analog signal processing

2.2.8 Comparison (L_CMP)

2.2.8.1 Function 1: nIn1_a = nIn2_a

Selection: byFunction = 1

This function compares two signals for equality. For instance, you can make the V comparison

"actual speed is equal to set speed" (n

The exact function can be seen in the diagram. (^Fig. 2−12)

nWindow

nHysteresis

1

nWindow

act

nHysteresis

= n

set

).

0

nIn1_a

nHysteresis

nWindow

nIn2_a

nWindow

nHysteresis

bOut_b

Fig. 2−12 Equality of signals (nIn1_a = nIn2_a)

Use nWindow to set the window within which the equality is valid.

Use nHysteresis to set a hysteresis, if the input signals are not stable and the output oscillates.

nIn2_a

nIn1_a

t

t

2−14

Note!

With this function, you must use the FB in a fast task, to achieve optimum sampling of the signals.

LenzeDrive.lib EN 1.7

L

Page 25

Function library LenzeDrive.lib

Analog signal processing

2.2.8 Comparison (L_CMP)

2.2.8.2 Function 2: nIn1_a > nIn2_a

Selection: byFunction = 2

With this function, you can make the comparison "actual speed is above a limit" (n

one direction of rotation.

nIn1_a

nIn2_a

nHysteresis

bOut_b

nHysteresis

1

bOut_b

> nx ) for

act

t

0

Fig. 2−13 Signal values exceeded (nIn1_a > nIn2_a)

Functional sequence

1. If the value at nIn1_a is below the value at nIn2_a, then bOut_b changes from FALSE to TRUE.

2. Only when the signal at nIn1_a is above the value of nIn2_a − nHysteresis again, will bOut_b

change from TRUE to FALSE.

2.2.8.3 Function 3: nIn1_a < nIn2_a

Selection: byFunction = 3

With this function, for instance, you can make the comparison "actual speed is below a limit"

(n

< nx ) for one direction of rotation.

act

bOut_b

nHysteresis

1

nIn1_anIn2_a

nIn1_a

nHysteresis

nIn2_a

bOutb_b

t

t

0

nIn2_a

Fig. 2−14 Gone below signal values (nIn1_a < nIn2_a)

nIn1_a

Functional sequence

1. If the value at nIn1_a is below the value at nIn2_a, then bOut_b changes from FALSE to TRUE.

2. Only when the signal at nIn1_a is above the value of nIn2_a − nHysteresis again, will bOut_b

change from TRUE to FALSE.

L

LenzeDrive.lib EN 1.7

t

2−15

Page 26

Function library LenzeDrive.lib

Analog signal processing

2.2.8 Comparison (L_CMP)

2.2.8.4 Function 4: |nIn1_a| = |nIn2_a|

Selection: byFunction = 4

With this function, for instance, you can make the comparison "n

This function is the same as function 1. (^ 2−14)

– However, the absolute value of the input signals (without sign) is generated here before the

signal processing.

2.2.8.5 Function 5: |nIn1_a| > |nIn2_a|

Selection: byFunction = 5

With this function, for instance, you can make the comparison "n

the direction of rotation.

This function is the same as function 2. (^ 2−15)

– However, the absolute value of the input signals (without sign) is generated here before the

signal processing.

= 0".

act

| > |nx |" independently of

act

2.2.8.6 Function 6: |nIn1_a| < |nIn2_a|

Selection: byFunction = 6

With this function, you can make the comparison "n

of rotation.

This function is the same as function 3. (^ 2−15)

– However, the absolute value of the input signals (without sign) is generated here before the

signal processing.

| < |nx |" independently of the direction

act

2−16

LenzeDrive.lib EN 1.7

L

Page 27

Function library LenzeDrive.lib

Analog signal processing

2.2.9 Curve function (L_CURVE)

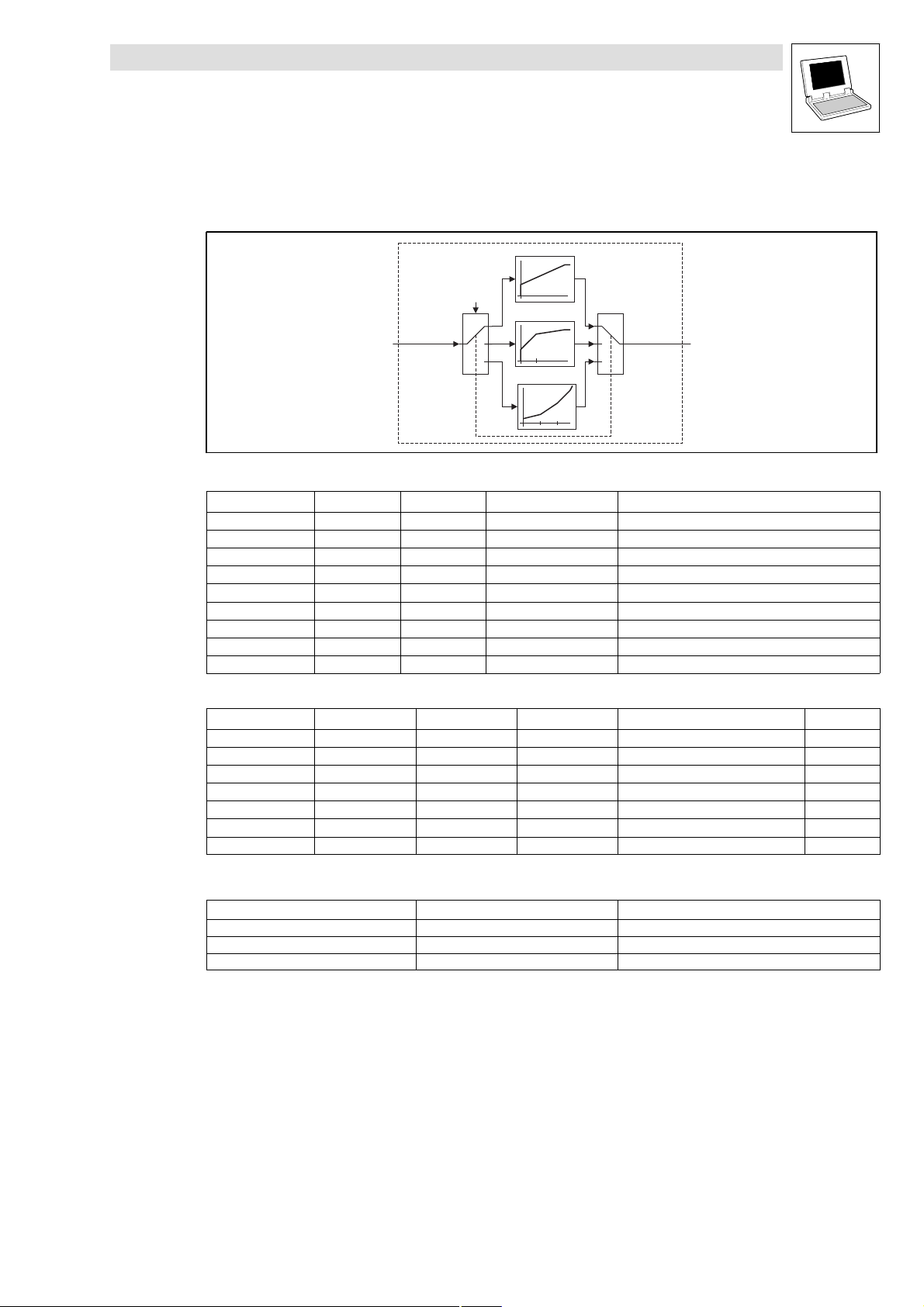

2.2.9 Curve function (L_CURVE)

This FB converts an analog signal into a characteristic curve.

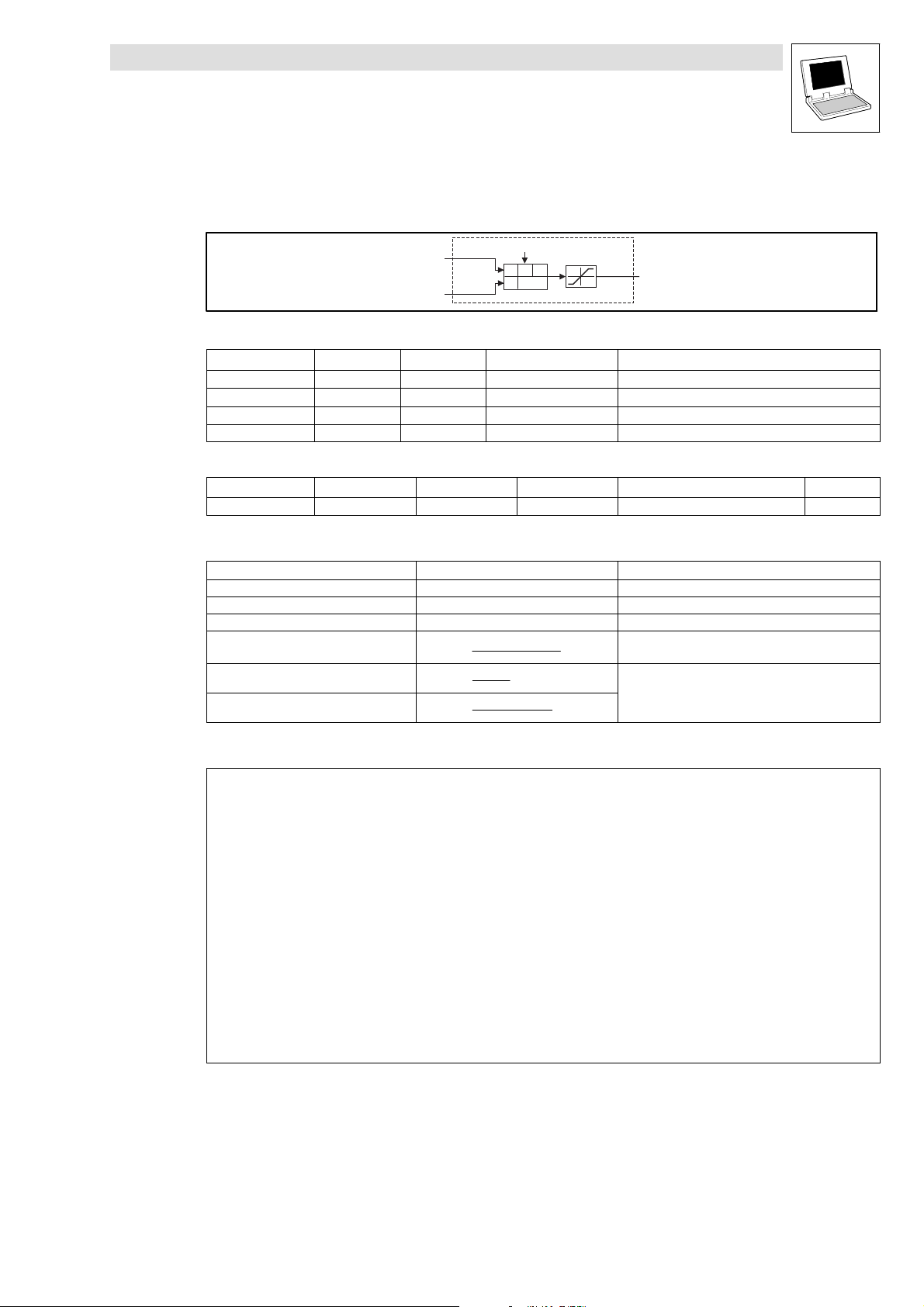

Fig. 2−15 Curve function (L_CURVE)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

byFunction Byte VAR CONSTANT RETAIN Selection of the characteristic/curve function

nY0 Integer VAR CONSTANT RETAIN Entry of Y0 from vector (0, Y0)

nY1 Integer VAR CONSTANT RETAIN Entry of Y1 from vector (X1, Y1)

nY2 Integer VAR CONSTANT RETAIN Entry of Y2 from vector (X2, Y2)

nY100 Integer VAR CONSTANT RETAIN Entry of Y100 from vector (16384, Y100)

nX1 Integer VAR CONSTANT RETAIN Entry of X1 from vector (X1, Y1)

nX2 Integer VAR CONSTANT RETAIN Entry of X2 from vector (X2, Y2)

Parameter codes of the instances

nIn_a

Y0 = nY0

Y1 = nY1

Y2 = nY2

Y100 = nY100

X1 = nX1

X2 = nX2

byFunction

1

2

3

Characteristic 1

y

y100

y0

Characteristic 2

y

y100

y1

y0

x1

Characteristic 3

y

y100

y2

y1

y0

x1 x2

L_CURVE

x

1

2

3

x

x

nOut_a

VariableName L_CURVE1 SettingRange Lenze

byFunction C0960 1 ... 3 1

nY0 C0961 0 ... 199.99 % 0.00

nY1 C0962 0 ... 199.99 % 50.00

nY2 C0963 0 ... 199.99 % 75.00

nY100 C0964 0 ... 199.99 % 100.00

nX1 C0965 0.01 ... 99.99 % 50.00

nX2 C0966 0.01 ... 99.99 % 75.00

Function

Selection of the function Curve function Informationen for entry of the interpolation points

byFunction = 1 Characteristic with two co−ordinates ^ Fig. 2−16

byFunction = 2 Characteristic with three co−ordinates ^ Fig. 2−17

byFunction = 3 Characteristic with four interpolatio points ^ Fig. 2−18

100% corresponds to 16384.

A linear interpolation is carried out between the co−ordinates.

For negative values at nIn_a the settings of the interpolation points are processed inversely

(see line diagrams).

– If this is not required, insert an FB L_ABS or an FB L_LIM before or after the FB L_CURVE.

L

LenzeDrive.lib EN 1.7

2−17

Page 28

Function library LenzeDrive.lib

a

Analog signal processing

2.2.9 Curve function (L_CURVE)

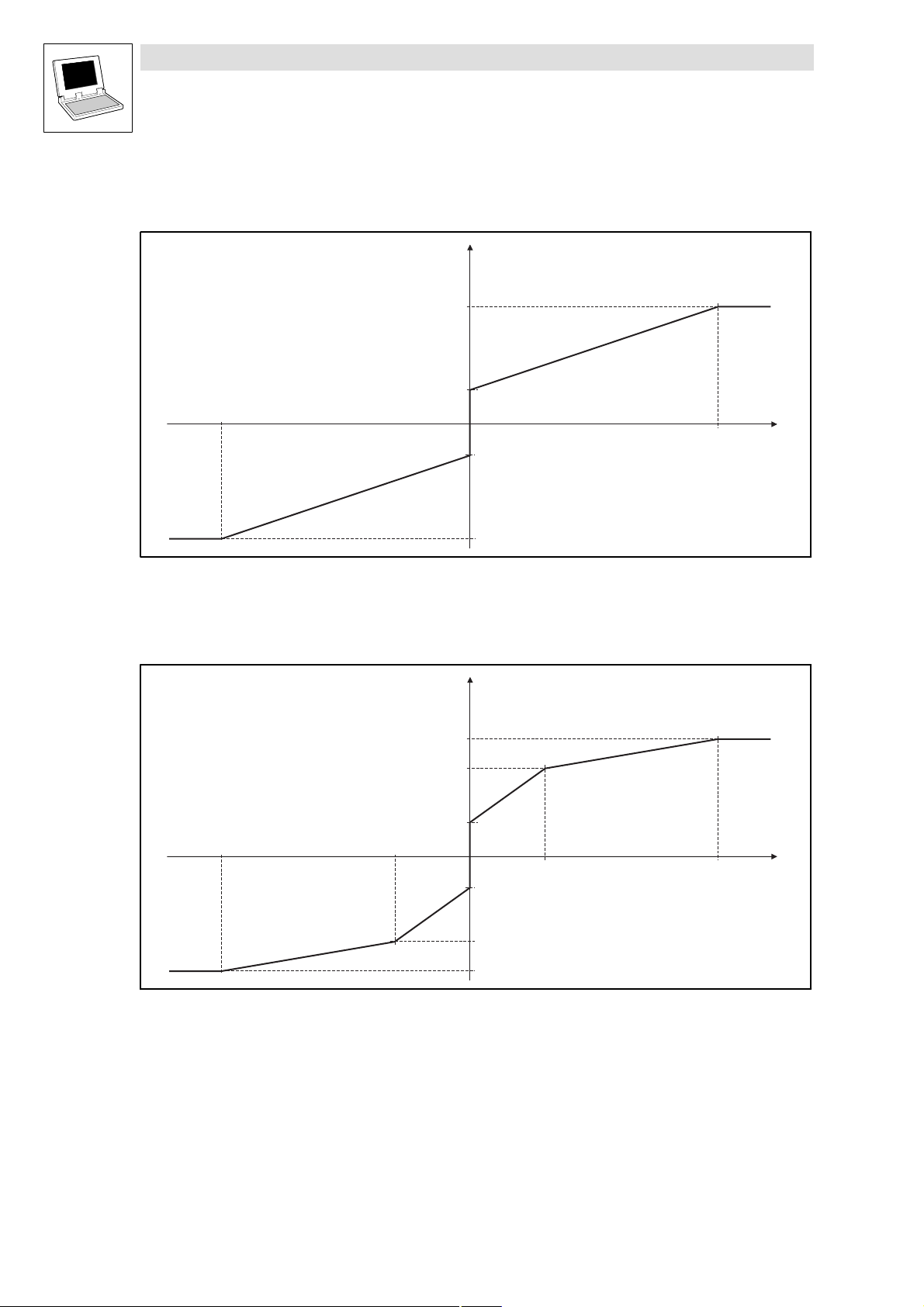

2.2.9.1 Characteristic with two co−ordinates

byFunction = 1

y

n O u t _ a

n Y 1 0 0

n Y 0

- 1 0 0 %

Fig. 2−16 Line diagram with 2 co−ordinates

2.2.9.2 Characteristic with three co−ordinates

byFunction = 2

y

n O u t _ a

n Y 1 0 0

n Y 1

y 0

- n Y 0

- n Y 1 0 0

y 1 0 0

1 0 0 %

y 1 0 0

y 1

x

n I n _

- 1 0 0 %

Fig. 2−17 Line diagram with 3 co−ordinates

2−18

n Y 0

y 0

- n X 1

- Y 0

- n Y 1

- n Y 1 0 0

LenzeDrive.lib EN 1.7

x 1

n X 2 1 0 0 %

x

n I n _ a

L

Page 29

Function library LenzeDrive.lib

a

Analog signal processing

2.2.9 Curve function (L_CURVE)

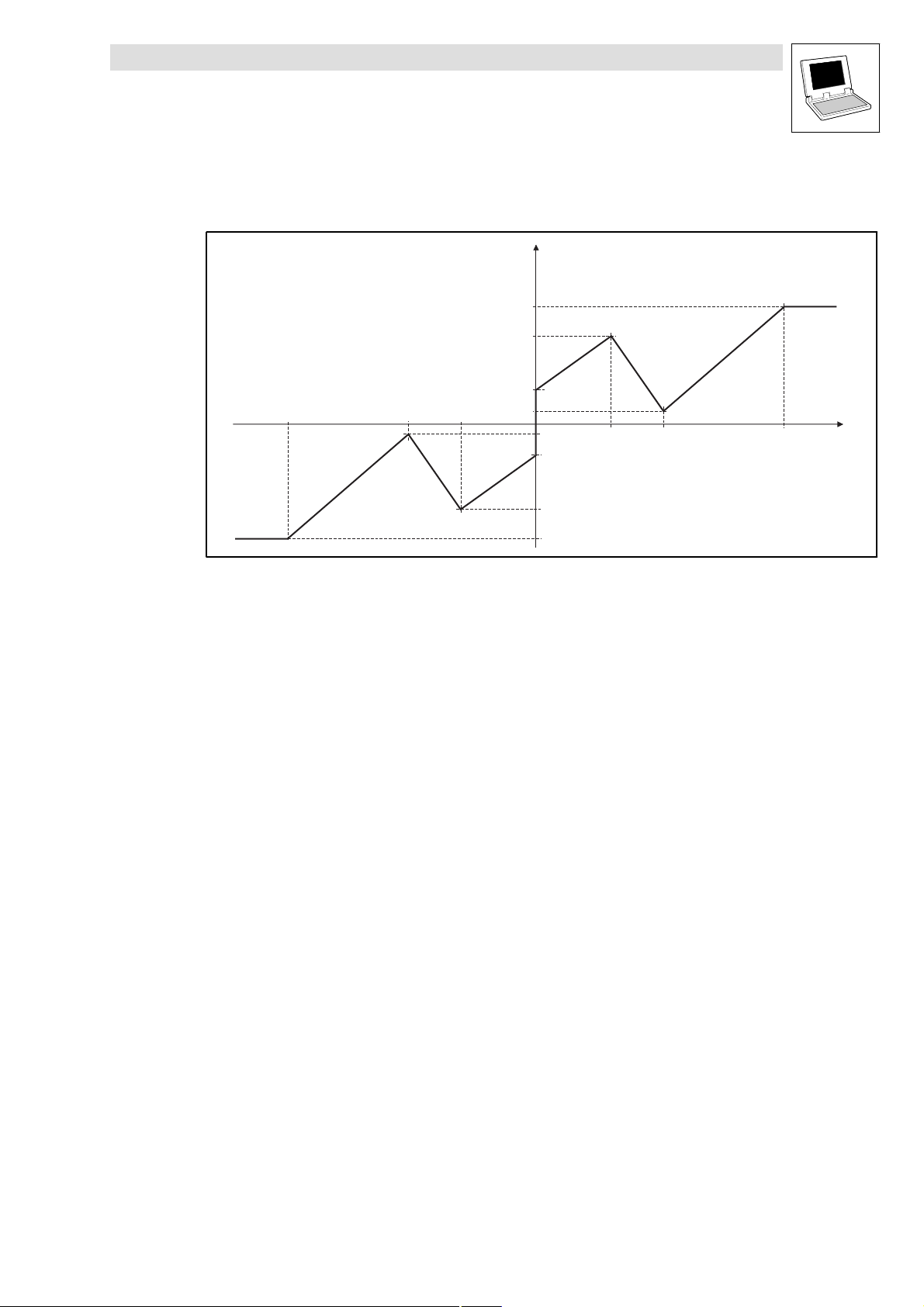

2.2.9.3 Characteristic with four co−ordinates

byFunction = 3

y

n O u t _ a

- 1 0 0 %

Fig. 2−18 Line diagram characteristic with 4 co−ordinates

- n X 1- n X 2

n Y 1 0 0

n Y 1

n Y 0

n Y 2

y 0

- n Y 2

- n Y 0

- n Y 1

- n Y 1 0 0

y 1 0 0

y 1

y 2

x 1 x 2

n X 1 n X 2 1 0 0 %

x

n I n _

L

LenzeDrive.lib EN 1.7

2−19

Page 30

Function library LenzeDrive.lib

Analog signal processing

2.2.10 Dead−band (L_DB)

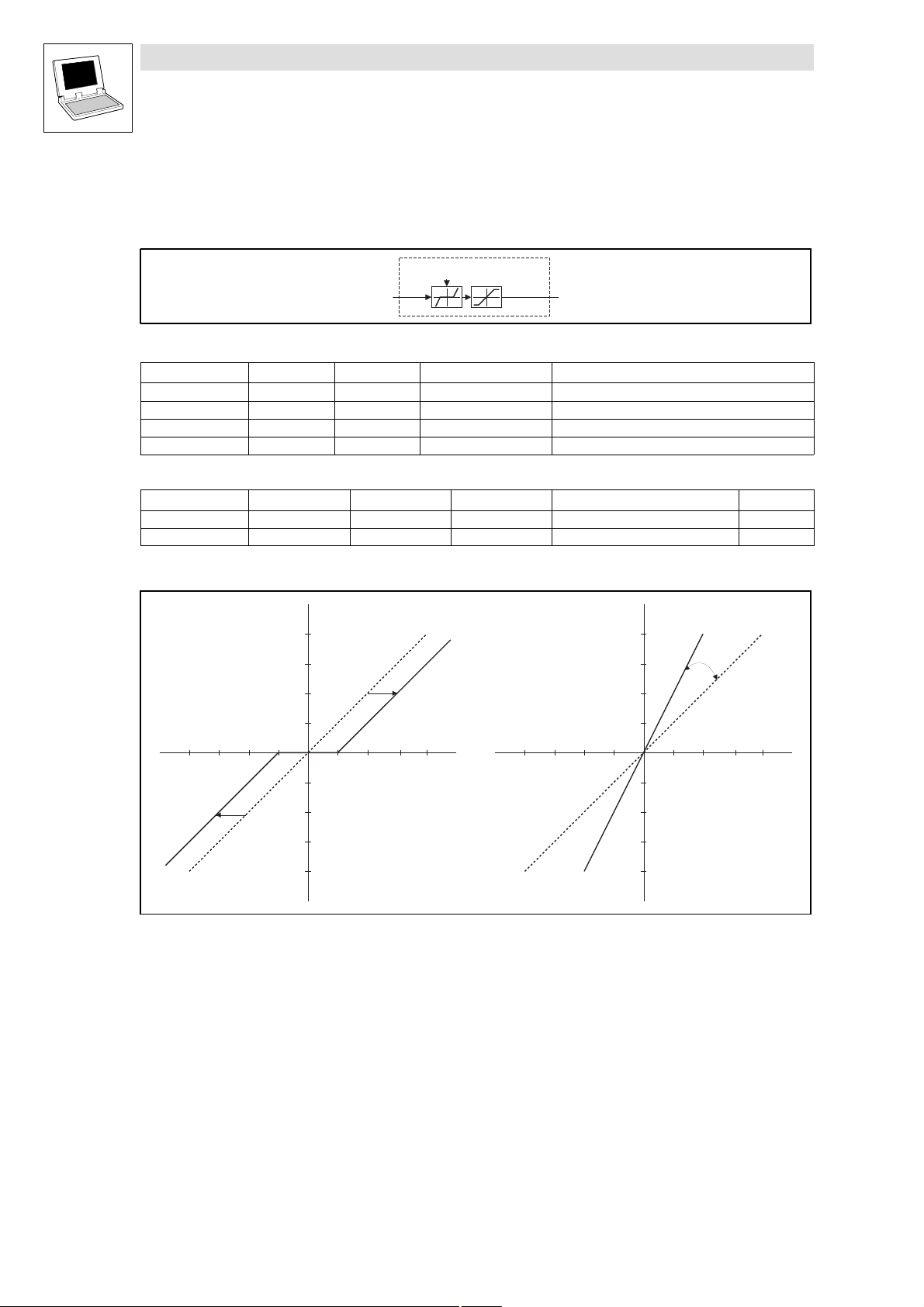

2.2.10 Dead−band (L_DB)

This FB eliminates disturbances around the zero point (e.g. interfering influences on analog input

voltages).

Fig. 2−19 Dead band (L_DB)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT The signal is limited to ±32767.

nGain Integer − VAR CONSTANT RETAIN Gain

nDeadBand Integer − VAR CONSTANT RETAIN Dead band

Parameter codes of the instances

VariableName L_DB1 SettingRange Lenze

nGain C0620 −10.00 ... 10.00 1.00

nDeadBand C0621 0 ... 100.00 % 1.00

Function

n G a i n = 1 , 0 0

n D e a d B a n d = 6 , 1 0 % = 1 0 0 0

n O u t _ a

n D e a d B a n d

nIn_a

nGain

nDeadBand

±32767

L_DB

nOut_a

n G a i n = 2 , 0 0

n D e a d B a n d = 0 %

n O u t _ a

n G a i n

n D e a d B a n d

Fig. 2−20 Dead band and gain

In nDeadBand you can set the parameters for the dead band.

In nGain you can alter the gain.

100 % corresponds to 16384.

n I n _ a

n I n _ a

2−20

LenzeDrive.lib EN 1.7

L

Page 31

Function library LenzeDrive.lib

Analog signal processing

2.2.11 Differentiation (L_DT1_)

2.2.11 Differentiation (L_DT1_)

This FB differentiates signals. You can use it, for instance, for the acceleration injection (dv/dt).

Fig. 2−21 Differentiation (L_DT1_)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT The signal is limited to ±32767.

nGain Integer VAR CONSTANT RETAIN Gain K

nDelayTime Integer VAR CONSTANT RETAIN Delay time T

bySensibility Byte VAR CONSTANT RETAIN Input sensitivity of nIn_a

Parameter codes of the instances

VariableName L_DT1_1 SettingRange Lenze

nGain C0650 −320.00 ... 320.00 1.00

nDelayTime C0651 0.005 ... 5.000 s 1.000

bySensibility C0653 1 ... 7 1

Function

Selection of the function Function

bySensibility = 1 15 Bit

bySensibility = 2 14 Bit

bySensibility = 3 13 Bit

bySensibility = 4 12 Bit

bySensibility = 5 11 Bit

bySensibility = 6 10 bit

bySensibility = 7 9 Bit

nIn_a

bySensibility

nGain

nDelayTime

±32767

L_DT1_

nOut_a

loss

The FB only evaluates the specified most significant

bits, according to the setting.

Fig. 2−22 Delay time T

L

K

of the 1st order differential section

loss

LenzeDrive.lib EN 1.7

T

loss

t

2−21

Page 32

Function library LenzeDrive.lib

Analog signal processing

2.2.12 Limiting (L_LIM)

2.2.12 Limiting (L_LIM)

This FB limits signals to preset ranges of values. You can fix the range of values by defining an upper

and a lower limit.

Fig. 2−23 Limiting (L_LIM)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog/velocity VAR_INPUT

nOut_a Integer analog/velocity VAR_OUTPUT

nMaxLimit Integer VAR CONSTANT RETAIN Defines the upper limit. (100 % 16384)

nMinLimit Integer VAR CONSTANT RETAIN Defines the lower limit. (100 % 16384)

Parameter codes of the instances

VariableName L_LIM1 SettingRange Lenze

nMaxLimit C0630 −199.99 ... 199.99 % 100.00

nMinLimit C0631 −199.99 ... 199.99 % −100.00

Note!

The lower limit must always be set lower than the upper limit.

Otherwise nOut_a is set = 0.

n I n _ a

n M a x L i m i t

n M i n L i m i t

L _ L I M

n O u t _ a

2−22

LenzeDrive.lib EN 1.7

L

Page 33

Function library LenzeDrive.lib

Analog signal processing

2.2.13 Delay (L_PT1_)

2.2.13 Delay (L_PT1_)

This FB filters and delays analog signals.

Fig. 2−24 Delay (L_PT1_)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT

nOut_a Integer analog VAR_OUTPUT

nDelayTime Integer VAR CONSTANT RETAIN Time constant

Parameter codes of the instances

VariableName L_PT1_1 SettingRange Lenze

nDelayTime C0640 0.01 ... 50.00 20.00

Function

K=1

nDelayTime

nIn_a

T

L_PT1_

nOut_a

t

Fig. 2−25 Delay T of the first−order delay element

Use the constant nDelayTime to set the delay time.

The proportional value is fixed at K = 1 .

L

LenzeDrive.lib EN 1.7

2−23

Page 34

Function library LenzeDrive.lib

Analog signal processing

2.2.14 Ramp generator (L_RFG)

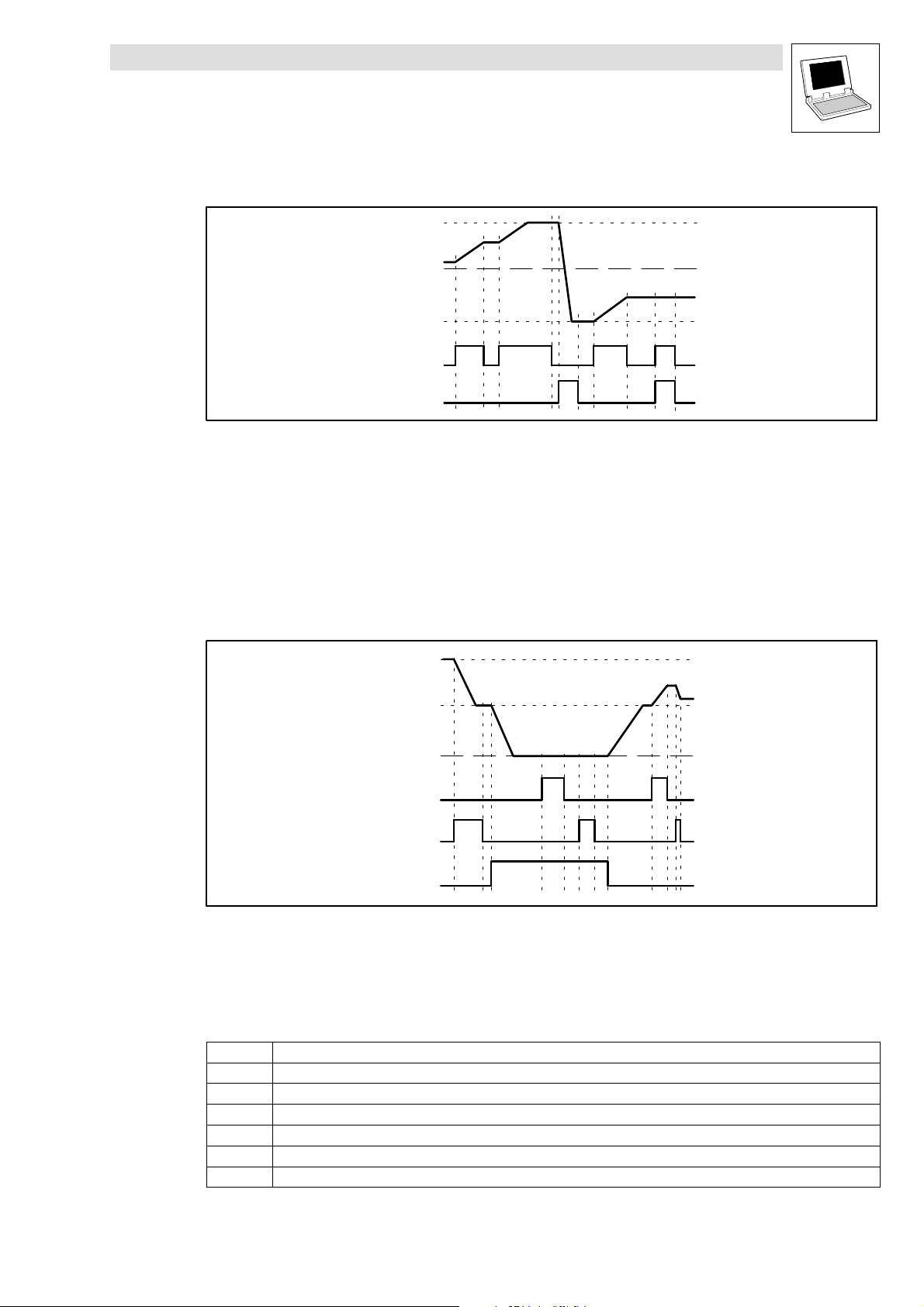

2.2.14 Ramp generator (L_RFG)

This FB functions as a ramp generator to control the rate of rise of signals.

Fig. 2−26 Ramp generator (L_RFG)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog/velocity VAR_INPUT

nSet_a Integer analog/velocity VAR_INPUT

bLoad_b Boo binary VAR_INPUT

nOut_a Integer analog/velocity VAR_OUTPUT

dnTir Double Integer VAR CONSTANT RETAIN Acceleration time T

dnTif Double Integer VAR CONSTANT RETAIN Deceleration time T

Parameter codes of the instances

n I n _ a

n S e t _ a

b L o a d _ b

d n T i r

L _ R F G

d n T i f

n O u t _ a

0

1

ir

if

Variable name L_RFG1 SettingRange Lenze

dnTir C0671 0.000 ... 999.999 s 0.000

dnTif C0672 0.000 ... 999.999 s 0.000

Range of functions

Calculation and setting of the acceleration and deceleration times

Loading of the ramp generator

2−24

LenzeDrive.lib EN 1.7

L

Page 35

Function library LenzeDrive.lib

Analog signal processing

2.2.14 Ramp generator (L_RFG)

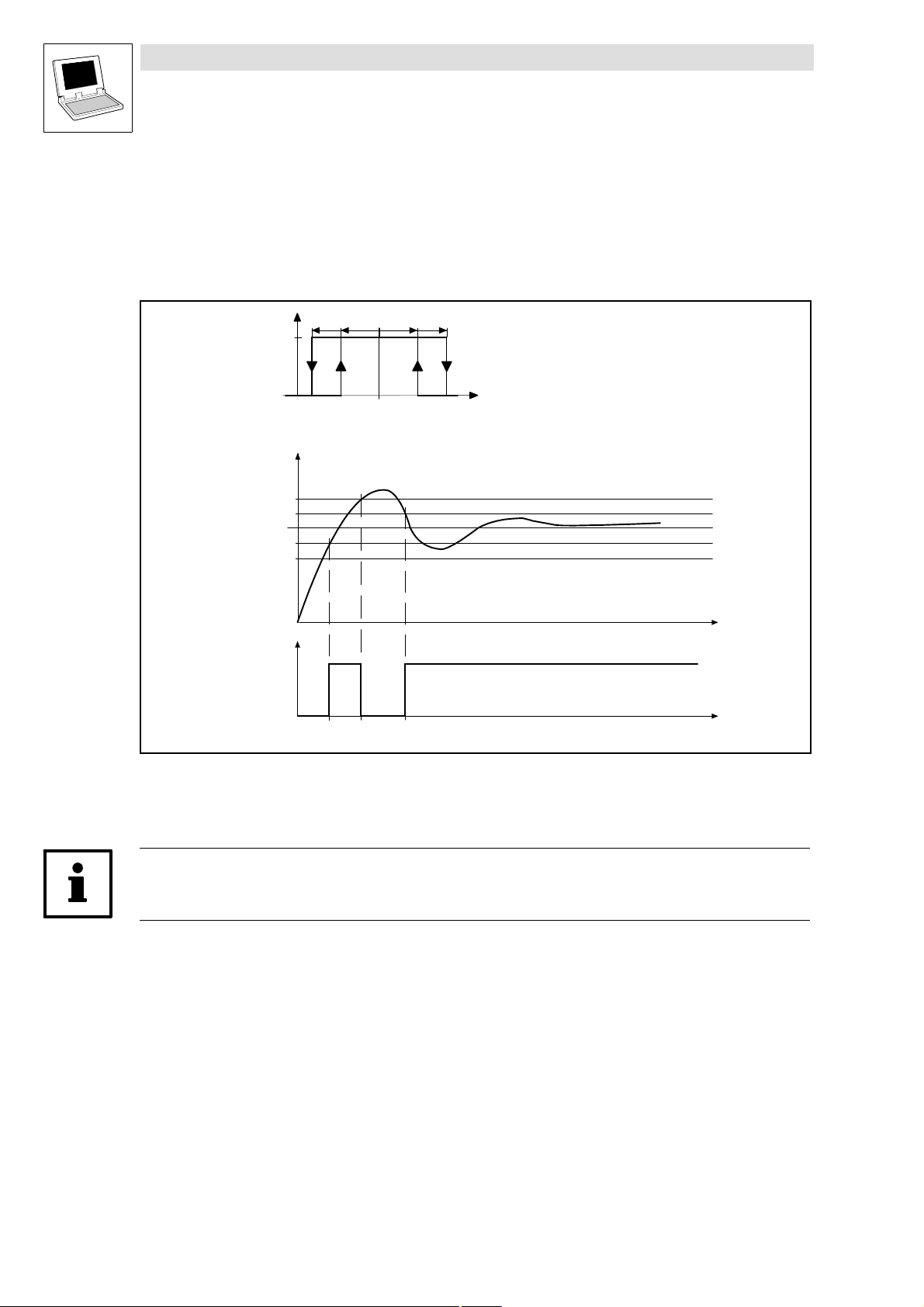

2.2.14.1 Calculation and setting of the acceleration and deceleration times

The acceleration time and deceleration times refer to a change of the output value from 0 to 100 %

(100% = 16384). The times to be set: Tir and Tif can be calculated from the formula in Fig. 2−27:

[%]

nOut_a

100%

w2

w1

0

t

ir

T

ir

t

if

T

if

t

Tir+ t

Fig. 2−27 Acceleration and deceleration times of L_RFG

w1, w2 Change of the main setpoint, depending on tir resp. t

100%

ir

w2 * w1

Here tir and tif are the required times for the change between w1 and w2. The calculated values T

and Tif are entered under dnTir and dnTif.

2.2.14.2 Loading of the ramp generator

By using nSet_a and bLoad_b you can initialize the ramp generator with defined values.

As long as bLoad_b = TRUE, the signal at nSet_a is output to nOut_a.

If bLoad_b is set = FALSE, then the ramp generator runs with the preset T

loaded value through nSet_a to the value at nIn_a.

Note!

16384 100 % C0011 (n

max

)

Tif+ t

if

100%

if

w2 * w1

−times from the

i

ir

L

LenzeDrive.lib EN 1.7

2−25

Page 36

Function library LenzeDrive.lib

Analog signal processing

2.2.15 Sample & Hold (L_SH)

2.2.15 Sample & Hold (L_SH)

This FB can store analog signals. The stored value is also available after mains disconnection.

Fig. 2−28 Sample & Hold (L_SH)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog/velocity VAR_INPUT

bLoad_b Bool binary VAR_INPUT FALSE = store

nOut_a Integer analog/velocity VAR_OUTPUT

nCurValRetain Integer VAR_GLOBAL RETAIN

Function

By using bLoad_b = TRUE the signal at nIn_a is switched to nOut_a.

By using bLoad_b = FALSE the last valid value is stored and output at nOut_a. A signal change

at nIn_a does not produce any change at nOut_a.

Storing in the case of mains disconnection:

– Set bLoad_b = FALSE, when the supply voltage is switched off (either mains/line supply,

DC−bus, or voltage supply of the control terminals).

– Set bLoad_b = FALSE, when the supply voltage is switched on again (either mains/line

supply, DC−bus, or voltage supply of the control terminals).

n I n _ a

b L o a d _ b

S & H

n C u r V a l R e t a i n

L _ S H

n O u t _ a

Store the present output value after power interruption

L _ S H

S & H

n C u r V a l R e t a i n

n O u t _ a

n I n _ a

b L o a d _ b

[ V A R _ G L O B A L R E T A I N ]

Fig. 2−29 Programming to store the present output value after a supply interruption

Inorder to store the latest value at nOut_a after a supply interruption, you must declare a global

variable of type RETAIN (VAR_GLOBAL RETAIN). Link this variable as shown in Fig. 2−29.

In this variable, the present value is always stored at nOut_a The variable will hold the value

after a supply interruption.

When the supply is switched on again, the stored value is read into the FB L_SH from the

variable and applied as the starting value.

[ V A R _ G L O B A L R E T A I N ]

2−26

LenzeDrive.lib EN 1.7

L

Page 37

Function library LenzeDrive.lib

Analog signal processing

2.2.16 S−ramp generator (L_SRFG)

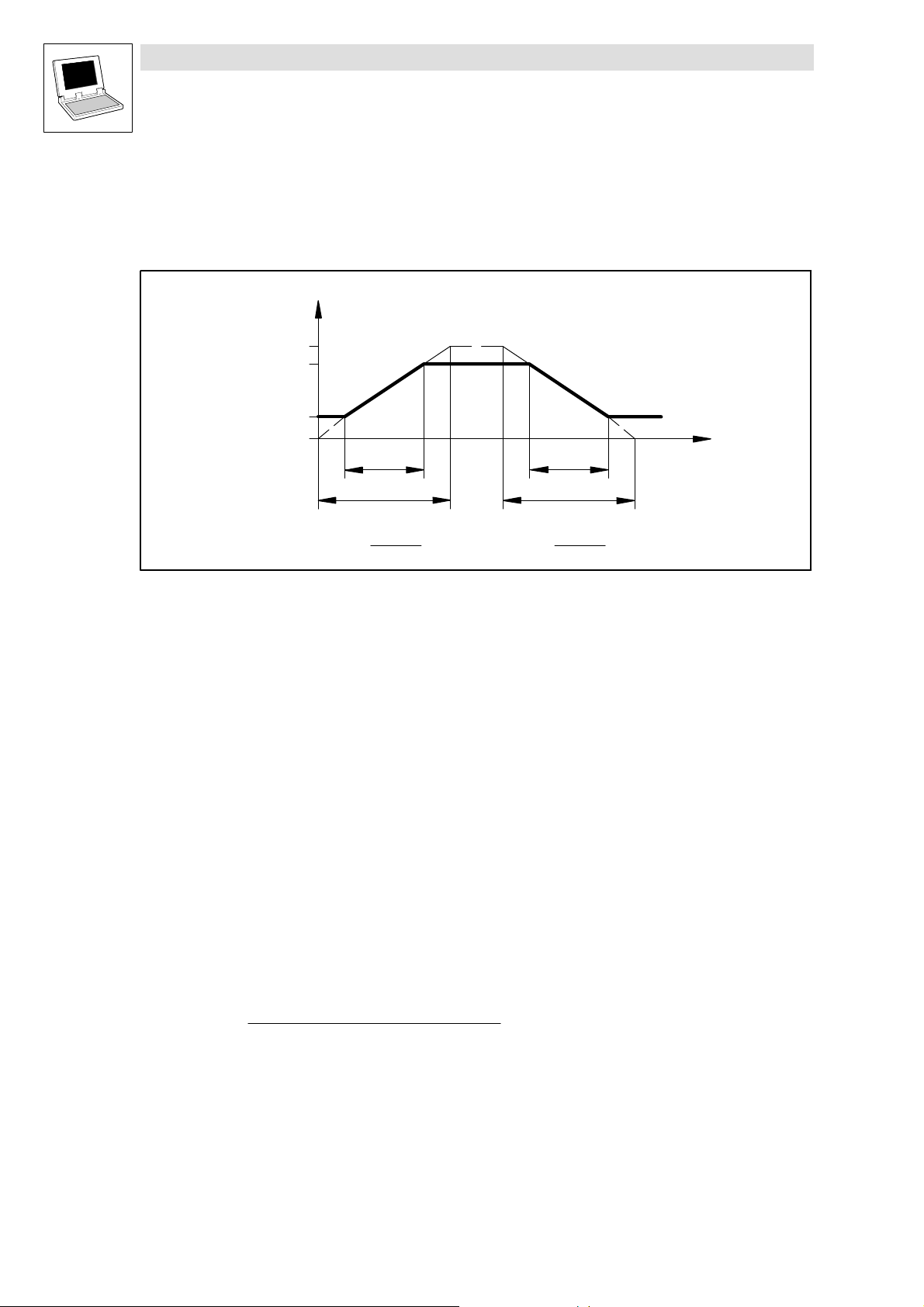

2.2.16 S−ramp generator (L_SRFG)

This FB conditions a setpoint through an S−curve (sin2−curve).

Fig. 2−30 S−ramp generator (L_SRFG)

VariableName DataType SignalType VariableType Note

nIn_a Integer analog VAR_INPUT Input

nSet_a Integer analog VAR_INPUT Start value for the ramp generator. The ramp is

bLoad_b Bool binary VAR_INPUT TRUE = takes the value at nSet_a and outputs this at

nOut_a Integer analog VAR_OUTPUT The signal is limited to ±100 %. (100 % = 16384)

nDeltaOut_a Integer analog VAR_OUTPUT Provides the acceleration of the ramp generator.

dwTi Unsigned Long VAR CONSTANT RETAIN Acceleration in [%] (100 % = 16384)

dwJerk Unsigned Long VAR CONSTANT RETAIN Jerk

Parameter codes of the instances

VariableName L_SRFG1 SettingRange Lenze

dwTi C1040 0.001 ... 5000.000 % 100.000

dwJerk C1041 0.001 ... 999.999 s 0.200

nIn_a

nSet_a

bLoad_b

0

1

dwTi

dwJerk

L_SRFG

nOut_a

nDeltaOut_a

initiated by bLoad_b = TRUE.

nOut_a; nDeltaOut_a remains at 0 %.

The signal is limited to ±100 %.

Note!

16384 100 % C0011 (n

max

)

L

LenzeDrive.lib EN 1.7

2−27

Page 38

Function library LenzeDrive.lib

n

Analog signal processing

2.2.16 S−ramp generator (L_SRFG)

Function

Load ramp generator

By using bLoad_b = TRUE loads the ramp generator with the signal at nSet_a.

This value is instantly accepted and output to nOut_a. No ramp−up or ramp−down through an

S−curve takes place.

As long as bLoad_b remains = TRUE, the ramp generator is disabled.

Acceleration and jerk

The maximum acceleration and the jerk can be adjusted separately.

n O u t _ a

n I n _ a

t

Fig. 2−31 Line diagram

Acceleration

Jerk

Max. acceleration:

– By using dwTi you set the positive as well as the negative acceleration.

– The setting is calculated according to the formula:

1s @ 100%

Jerk:

– By using dwJerk you set up a jerk−free acceleration of the drive.

– The jerk is entered in [s] until the ramp generator operates with maximum acceleration (see

Fig. 2−31).

dwTi

D e l t a O u t _ a

t

Q

d w J e r k

R

d w T i

t

d w T i

t

2−28

LenzeDrive.lib EN 1.7

L

Page 39

Function library LenzeDrive.lib

Digital signal processing

2.3.1 Logical AND (L_AND)

2.3 Digital signal processing

2.3.1 Logical AND (L_AND)

This FB implements the logical AND combination of binary signals. These operations can be used

for the control of functions or the generation of status information.

Fig. 2−32 Logical AND (L_AND)

VariableName DataType SignalType VariableType Note

bIn1_b Bool binary VAR_INPUT

bIn2_b Bool binary VAR_INPUT

bIn3_b Bool binary VAR_INPUT

bOut_b Bool binary VAR_OUTPUT

Truth table

bIn1_b bIn2_b bIn3_b bOut_b

0 0 0 0

1 0 0 0

0 1 0 0

1 1 0 0

0 0 1 0

1 0 1 0

0 1 1 0

1 1 1 1

0 = FALSE

1 = TRUE

The function corresponds to a series connection of normally−open contacts in a contactor control.

bIn1_b

bIn2_b

bIn3_b

&

L_AND

bOut_b

bIn1_b

bIn2_b

bIn3_b

Fig. 2−33 AND function as a series connection of normally−open contacts

Note!

Use the inputs bIn1_b and bIn2_b if you only need two inputs. Fix input bIn3_b to TRUE.

L

LenzeDrive.lib EN 1.7

bOut_b

2−29

Page 40

Function library LenzeDrive.lib

Digital signal processing

2.3.2 Delay (L_DIGDEL)

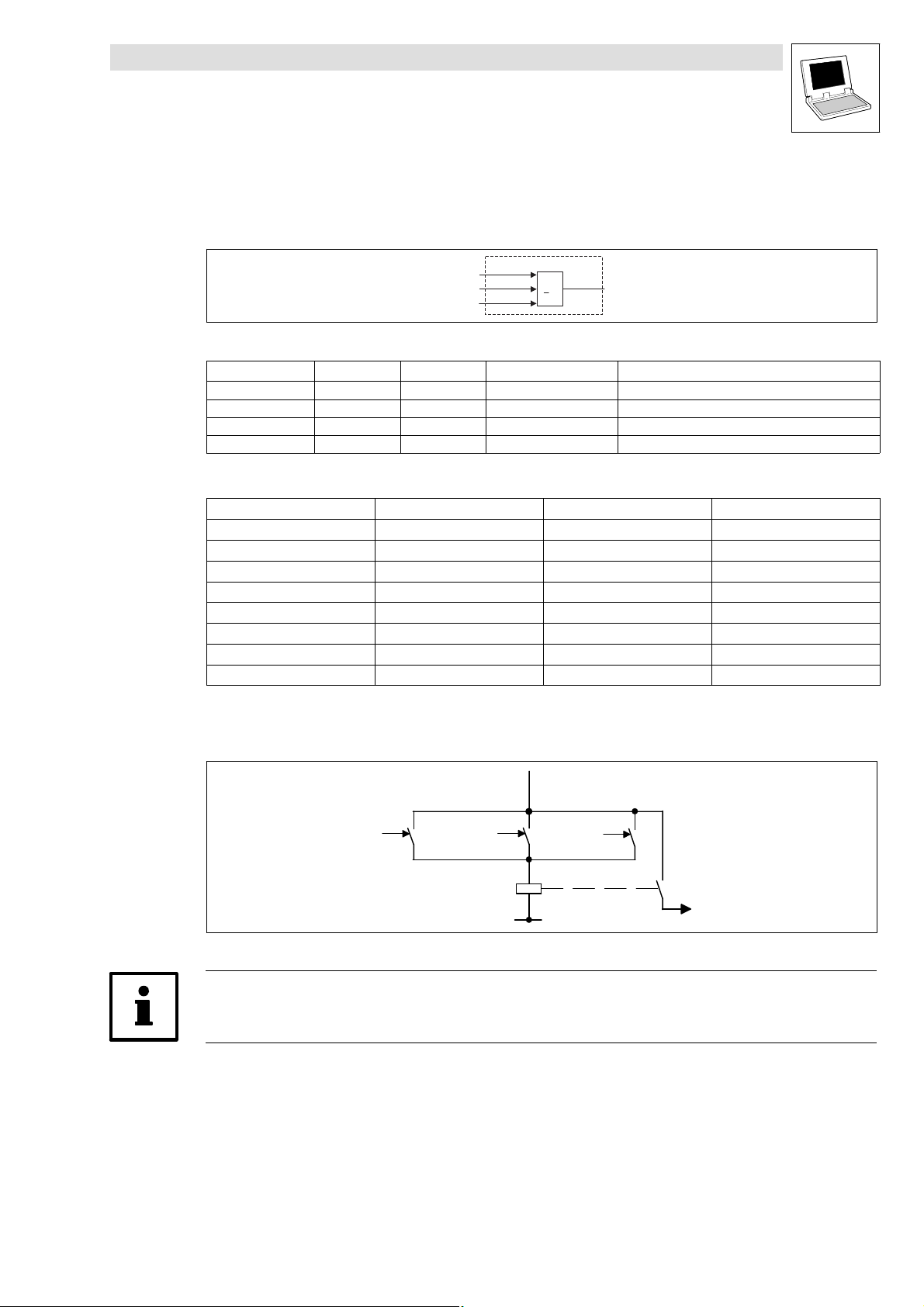

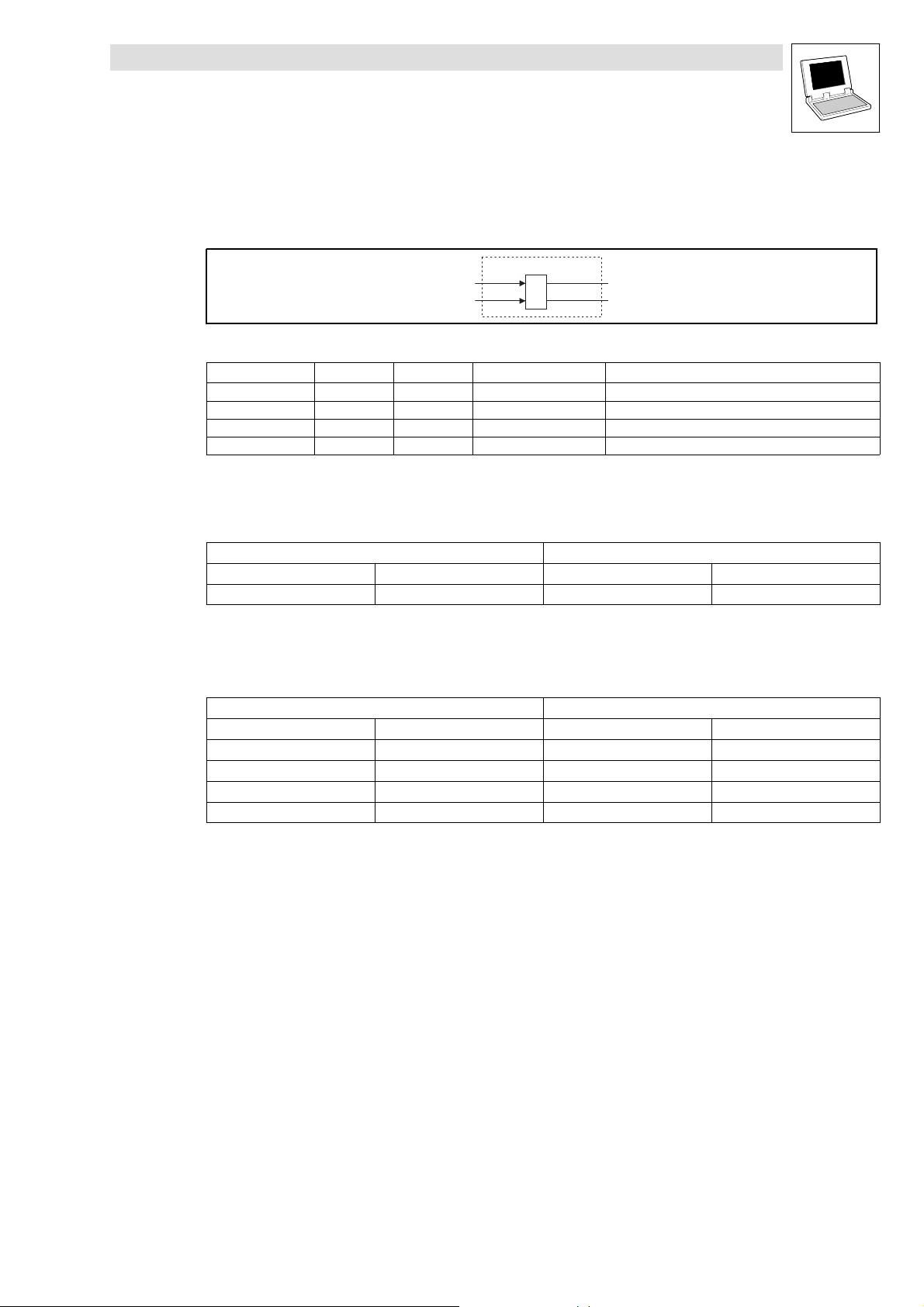

2.3.2 Delay (L_DIGDEL)

This FB delays binary signals.

Fig. 2−34 Delay element (L_DIGDEL)

VariableName DataType SignalType VariableType Note

bIn_b Bool binary VAR_INPUT

bOut_b Bool binary VAR_OUTPUT

byFunction Byte VAR CONSTANT RETAIN Selection of the function

wDelayTime Word VAR CONSTANT RETAIN Delay time

Parameter codes of the instances

VariableName L_DIGDEL1 L_DIGDEL2 SettingRange Lenze

byFunction

wDelayTime C0721 C0726 0.001 ... 60.000 s 1.000

C0720

L_DIGDEL

byFunction

wDelayTime

bIn_b

0t

C0725 0

bOut_b

0 ... 2

2

Range of functions

On−delay

Dropout delay

General delay

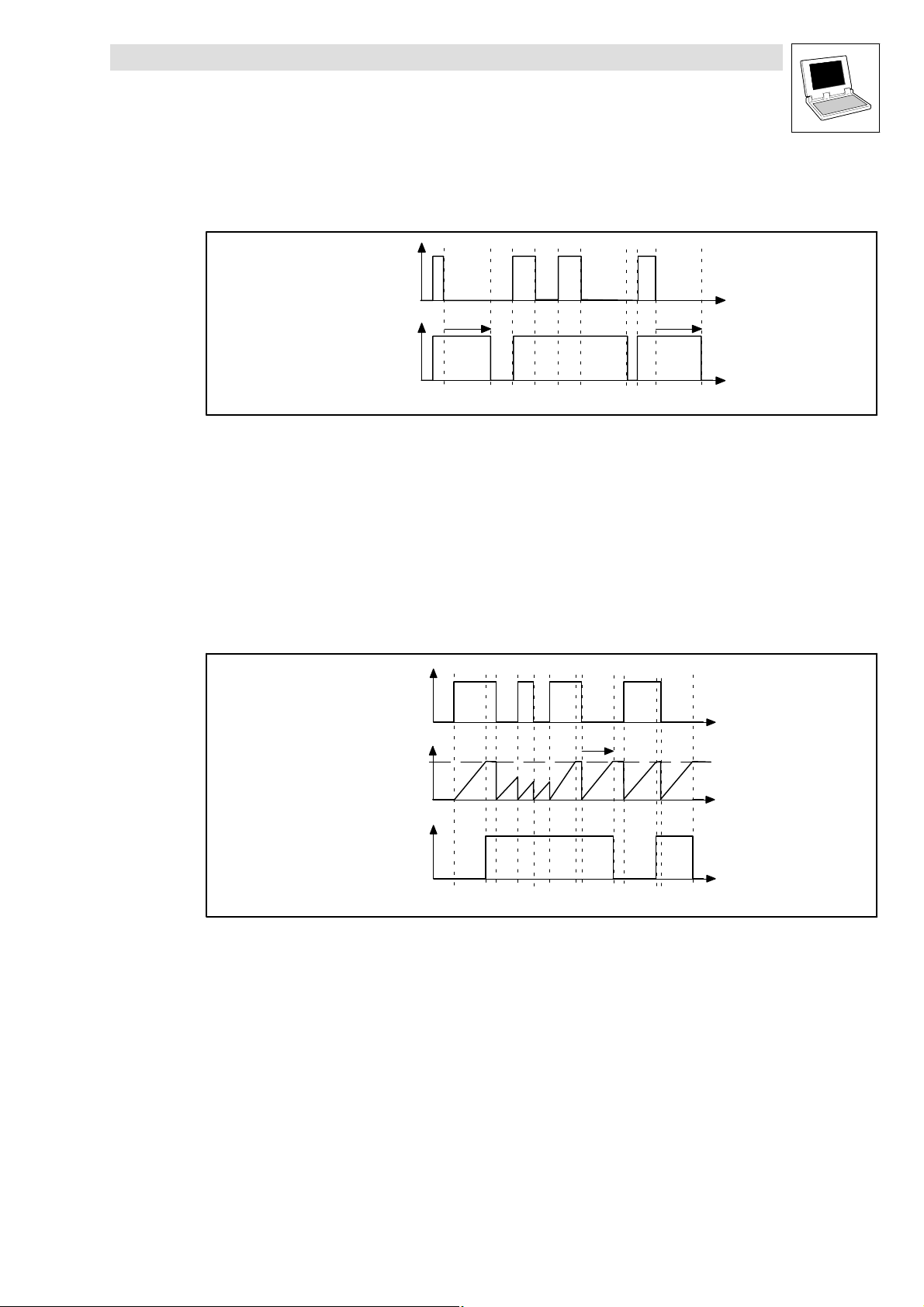

2.3.2.1 On−delay

byFunction = 0

Fig. 2−35 On−delay

The FB L_DIGDEL operates like a retriggerable monostable circuit.

bIn_b

bOut_b

wDelayTime

wDelayTime

t

t

2−30

Functional sequence

1. A FALSE−TRUE transition at nIn_b starts the timer element.

2. If the delay time has elapsed, that is set by wDelayTim has elapsed, bOut_b switches

immediately = TRUE.

3. A TRUE−FALSE edge at nIn_b resets the timer element, and switches bOut_b = FALSE,

immediately.

LenzeDrive.lib EN 1.7

L

Page 41

Function library LenzeDrive.lib

Digital signal processing

2.3.2 Delay (L_DIGDEL)

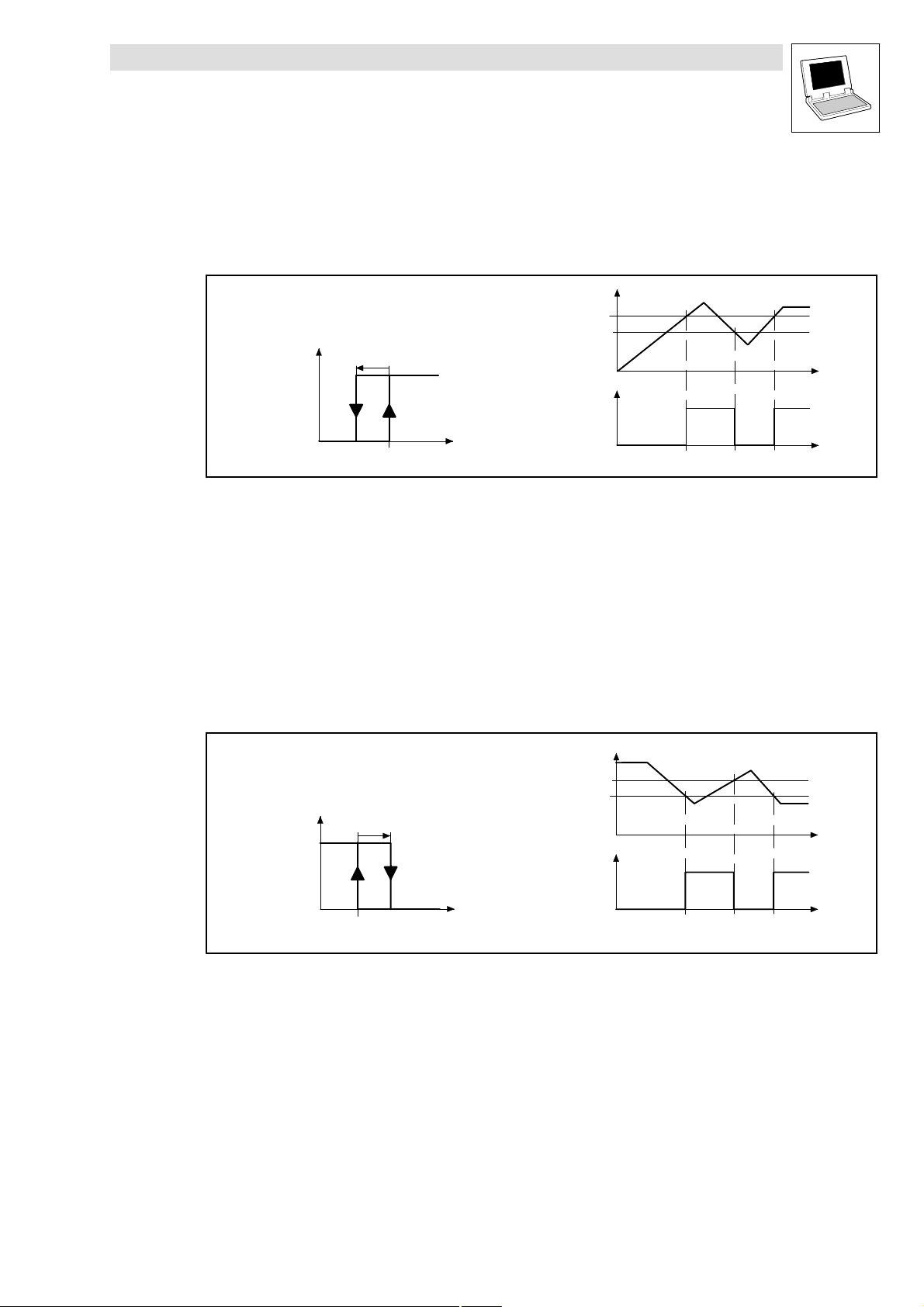

2.3.2.2 Dropout delay

byFunction = 1

bIn_b

Fig. 2−36 Dropout delay

Functional sequence

1. A FALSE−TRUE transition at nIn_b switches bOut_b = TRUE and resets the timer element.

2. A TRUE−FALSE edge at nIn_b starts the timer element.

3. If the delay time has elapsed, that is set by wDelayTime has elapsed, bOut_b = FALSE,

immediately.

2.3.2.3 General delay

byFunction = 2

bOut_b

bIn_b

wDelayTime

wDelay

Time

wDelayTime

t

t

t

Fig. 2−37 General delay

Functional sequence

1. Any edge/transition at nIn_b resets the timer element, and starts it.

2. After the delay time, that is set by wDelayTime has elapsed, bOut_b = nIn_b.

L

bOut_b

LenzeDrive.lib EN 1.7

t

t

2−31

Page 42

Function library LenzeDrive.lib

Digital signal processing

2.3.3 Up/down counter (L_FCNT)

2.3.3 Up/down counter (L_FCNT)

This FB is a digital up/down counter, that is limited to the value nCmpVal_a.

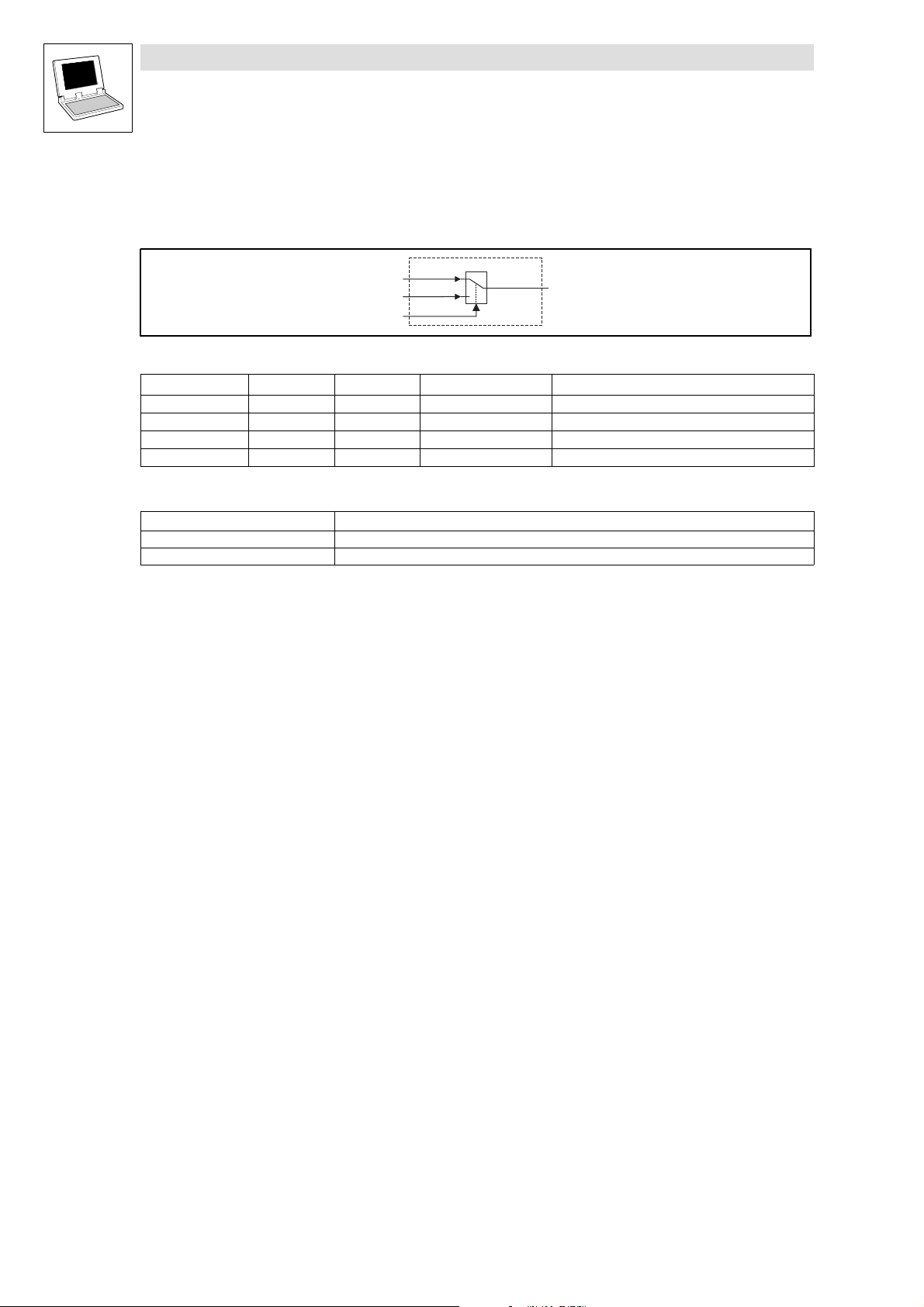

Fig. 2−38 Up/down counter (L_FCNT)

VariableName DataType SignalType VariableType Note

bClkUp_b Bool binary VAR_INPUT FALSE−TRUE edge = counts up by 1.

bClkDwn_b Bool binary VAR_INPUT FALSE−TRUE edge = counts down by 1.

nLdVal_a Integer analog VAR_INPUT Start value

bLoad_b Bool binary VAR_INPUT TRUE = accept start value

nCmpVal_a Integer analog VAR_INPUT Comparison value

nOut_a Integer analog VAR_OUTPUT The count value is limited to ±32767.

bEqual_b Bool binary VAR_OUTPUT TRUE = comparison value reached.

byFunction Byte VAR CONSTANT RETAIN Selection of the function

Parameter codes of the instances

VariableName L_FCNT1 SettingRange Lenze

byFunction C1100 1 ... 2 1

Function

bClkUp_b

bClkDown_b

nLdVal_a

bLoad_b

nCmpVal_a

byFunction

CTRL

L_FCNT

nOut_a

bEqual_b

The input has the highest priority.

Selection of the

Function

byFunction = 1 If the count value nCmpVal_a , the output bEqual_b is set to TRUE. At the next clock cyle, the

byFunction = 2 If the count value = nCmpVal_a , the counter stops( bClkUp_b / bClkDwn_b are ignored).

Description

counter is reset to the value nLdVal_a and the output bEqual_b is set to FALSE.

bLoad_b = TRUE sets the counter to the value at nLdVal_a and responds to bClkUp_b / bClkDwn_b

again.

2−32

LenzeDrive.lib EN 1.7

L

Page 43

Function library LenzeDrive.lib

Digital signal processing

2.3.4 Flip−flop (L_FLIP)

2.3.4 Flip−flop (L_FLIP)

This FB is implemented as a D flip−flop. You can use this function to evaluate and store digital signal

transitions (edges).

Fig. 2−39 Flipflop (L_FLIP)

VariableName DataType SignalType VariableType Note

bD_b Bool binary VAR_INPUT

bClk_b Bool binary VAR_INPUT Evaluates FALSE−TRUE edges only

bClr_b Bool binary VAR_INPUT Evaluates the input level only; input has highest

bOut_b Bool binary VAR_OUTPUT

Functional sequence

bD_b

bClk_b

bOut_b

bD_b

bClk_b

bClr_b

D

CLR

Q

L_FLIP

bOut_b

(edge−triggered).

priority (reset input).

t

t

Fig. 2−40 Sequence of a flip−flop

bClr_b always has priority.

1. If bClr_b = TRUE, then bOut_b switches = FALSE. This state is held as long as bClr_b = TRUE.

2. A FALSE−TRUE edge at bClk_b switches bD_b = bOut_b. This state is stored until

– another FALSE−TRUE edge occurs at bClk_b or

– bClr_b switches = TRUE.

t

L

LenzeDrive.lib EN 1.7

2−33

Page 44

Function library LenzeDrive.lib

Digital signal processing

2.3.5 Logical NOT (L_NOT)

2.3.5 Logical NOT (L_NOT)

This FB enables the logical inversion of digital signals. You can use this FB for the control of functions

or the generation of status information.

Fig. 2−41 Logical NOT (L_NOT)

VariableName DataType SignalType VariableType Note

bIn_b Bool binary VAR_INPUT

bOut_b Bool binary VAR_OUTPUT

Truth table

0 = FALSE

1 = TRUE

The function corresponds to a change from a normally−open contact to a normally−closed contact

in a control with contactors.

bIn_b

bIn_b bOut_b

0 1

1 0

bIn_b

L_NOT

bOut_b

1

bOut_b

Fig. 2−42 Function of L_NOT as a change from a normally−open to a normally−closed contact

2−34

LenzeDrive.lib EN 1.7

L

Page 45

Function library LenzeDrive.lib

Digital signal processing

2.3.6 Logical OR (L_OR)

2.3.6 Logical OR (L_OR)

This FB enables the logical OR combination of digital signals. You can use this combination for the

control of functions or the generation of status information.

Fig. 2−43 Logical OR (L_OR

VariableName DataType SignalType VariableType Note

bIn1_b Bool binary VAR_INPUT

bIn2_b Bool binary VAR_INPUT

bIn3_b Bool binary VAR_INPUT

bOut_b Bool binary VAR_OUTPUT

Truth table

bIn1_b bIn2_b bIn3_b bOut_b

0 0 0 0

1 0 0 1

0 1 0 1

1 1 0 1

0 0 1 1

1 0 1 1

0 1 1 1

1 1 1 1

0 = FALSE

1 = TRUE

The function corresponds to a parallel connection of normally−open contacts in a contactor control.

bIn1_b

bIn2_b

bIn3_b

L_OR

bOut_b

>1

bIn1_b

Fig. 2−44 Function of L_OR as a parallel connection of normally−open contacts

bIn2_b

bIn3_b

Note!

If you only need 2 inputs, use the inputs bIn1_b and bIn2_b. Fix the input bIn3_b to FALSE.

L

LenzeDrive.lib EN 1.7

bOut_b

2−35

Page 46

Function library LenzeDrive.lib

Digital signal processing

2.3.7 Edge evaluation (L_TRANS)

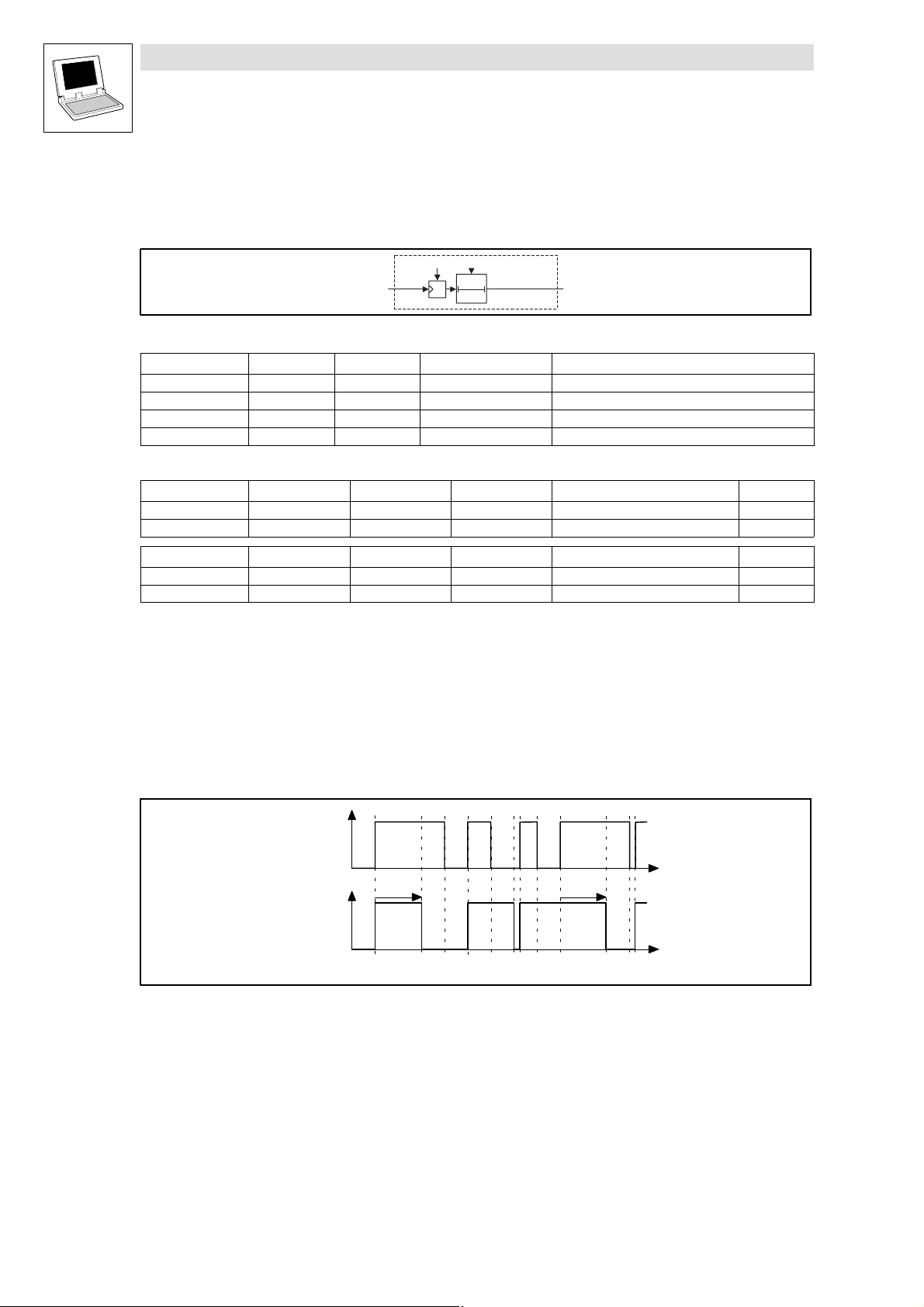

2.3.7 Edge evaluation (L_TRANS)

This FB is a post−triggered edge detector. You can use this function to detect digital signal transitions

(edges) and turn them into defined pulses.

Fig. 2−45 Edge evaluation (L_TRANS)

VariableName DataType SignalType VariableType Note

bIn_b Bool binary VAR_INPUT

bOut_b Bool binary VAR_OUTPUT (retriggerable)

byFunction Byte − VAR CONSTANT RETAIN Selection of the function

wPulseTime Word − VAR CONSTANT RETAIN Pulse duration of the output signal

Parameter codes of the instances

VariableName L_TRANS1 L_TRANS2 L_TRANS3 SettingRange Lenze

byFunction C0710 C0715 C1140 0 ... 2 0

wPulseTime C0711 C0716 C1141 0.001 ... 60.000 s 0.001

bIn_b

byFunction

wPulseTime

0t

L_TRANS

bOut_b

VariableName L_TRANS4 SettingRange Lenze

byFunction C1145 0 ... 2 0

wPulseTime C1146 0.001 ... 60.000 s 0.001

Range of functions

Evaluate rising edges

Evaluate falling edges

Evaluate rising and falling edges

2.3.7.1 Evaluate rising edges

byFunction = 0

bIn_b

bOut_b

Fig. 2−46 Evaluation of FALSE−TRUE transitions

wPulseTime wPulseTime

t

t

2−36

Functional sequence

1. If a TRUE−FALSE or a FALS−TRUE transition occurs at nIn_b, then bOut_b switches = TRUE.

2. After the time defined as wPulseTime has elapsed, then bOut_b switches = FALSE, provided

no further FALSE−TRUE transition has occurred at nIn_b.

LenzeDrive.lib EN 1.7

L

Page 47

Function library LenzeDrive.lib

Digital signal processing

2.3.7 Edge evaluation (L_TRANS)

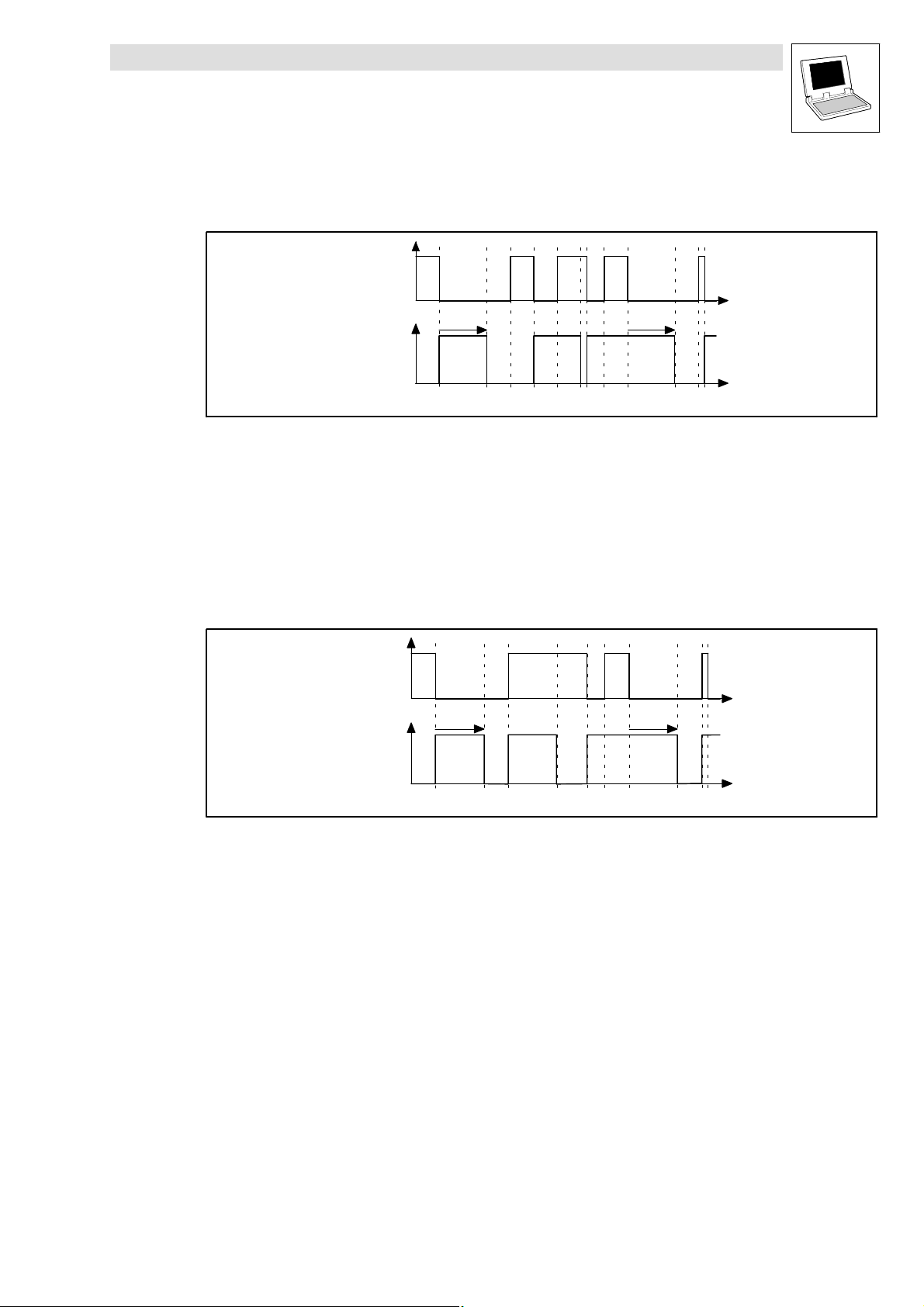

2.3.7.2 Evaluate falling edges

byFunction = 1

bIn−b

wPulseTime wPulseTime

bOut_b

Fig. 2−47 Evaluation of TRUE−FALSE transitions

Functional sequence

1. If a TRUE−FALSE or a FALSE−TRUE transition occurs at nIn_b, then bOut_b switches = TRUE.

2. After the time defined as wPulseTime has elapsed, then bOut_b switches = FALSE, provided

no further TRUE−FALSE transition has occurred at nIn_b.

2.3.7.3 Evaluate rising and falling edges

byFunction = 2

bIn_b

wPulsTime wPulsTime

bOut_b

t

t

t

Fig. 2−48 Evaluation of both transitions

Functional sequence

1. If a TRUE−FALSE or a FALS−TRUE transition occurs at nIn_b, then bOut_b switches = TRUE.

2. After the time defined as wPulseTime has elapsed, then bOut_b switches = FALSE, provided

no further TRUE−FALSE or FALSE−TRUE transition has occurred at nIn_b.

t

L

LenzeDrive.lib EN 1.7

2−37

Page 48

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.1 Arithmetic (L_ARITPH)

2.4 Processing of phase−angle signals

2.4.1 Arithmetic (L_ARITPH)

This FB calculates a phase output signal from two phase input signals.

Fig. 2−49 Arithmetic (L_ARITPH)

VariableName DataType SignalType VariableType Note

dnIn1_p Double Integer position VAR_INPUT

dnIn2_p Double Integer position VAR_INPUT

dnOut_p Double Integer position VAR_OUTPUT The signal is limited to ±230.

byFunction Byte VAR CONSTANT RETAIN Selection of the function

Parameter codes of the instances

VariableName L_ARITPH1 SettingRange Lenze

byFunction C1010 0 ... 3, 14, 21, 22 1

Function

Selection of the function Arithmetic function Limiting of the

byFunction = 0 dnOut_p = dnIn1_p without dnOut_p is not limited.

byFunction = 1 dnOut_p = dnIn1_p + dnIn2_p 2

byFunction = 2 dnOut_p = dnIn1_p − dnIn2_p 2

byFunction = 3 dnOut_p = (dnIn1_p dnIn2_p) / 2

byFunction = 14 dnOut_p = dnIn1_p / dnIn2_p 2

byFunction = 21 dnOut_p = dnIn1_p + dnIn2_p without with overflow

byFunction = 22 dnOut_p = dnIn1_p − dnIn2_p without with overflow

byFunction = 21/22:

Please note, that an overflow may occur, and then the numerical value of dnOut_p does not

match the result.

byFunction = 14:

If the denominator = 0, then dnOut_p = 230 The sign depends on the sign of dnIn1_p.

d n I n 1 _ p

d n I n 2 _ p

b y F u n c t i o n

x

y

L _ A R I T P H

3 0

± 2

+

*

-

/

d n O u t _ p

result

30

30

30

30

2

30

Note

(remainder not considered)

(remainder not considered)

2−38

LenzeDrive.lib EN 1.7

L

Page 49

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.2 Addition (L_PHADD)

2.4.2 Addition (L_PHADD)

This FB adds or subtracts phase signals, depending on the input that is used.

3 1

L _ P H A D D

Fig. 2−50 Addition (L_PHADD)

VariableName DataType SignalType VariableType Note

dnIn1_p Double−integer position VAR_INPUT Addition input

dnIn2_p Double−integer position VAR_INPUT Addition input

dnIn3_p Double−integer position VAR_INPUT Subtraction input

dnOut_p Double−integer position VAR_OUTPUT The signal is limited to ±2147483647

dnOut2_p Double−integer position VAR_OUTPUT Signal without limiting / with overflow

Functional sequence

d n I n 1 _ p

d n I n 2 _ p

d n I n 3 _ p

+

-

+

± 2 - 1

d n O u t _ p

d n O u t 2 _ p

1. The signal at dnIn1_p is added to the signal at dnIn2_p

2. The signal at dnIn3_p is subtracted from the calculated result.

3. The result of the subtraction is then limited to ±2147483647 and output to dnOut_p and output

as unlimited to dnOut2_p.

Please observe, that at dnOut2_p there may be an overflow, thus producing a false value.

L

LenzeDrive.lib EN 1.7

2−39

Page 50

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.3 Comparison (L_PHCMP)

2.4.3 Comparison (L_PHCMP)

This FB compares two phase signals (paths) with each other.

Fig. 2−51 Comparison (L_PHCMP)

VariableName DataType SignalType VariableType Note

dnIn1_p Double−integer position VAR_INPUT Signal to be compared

dnIn2_p Double−integer position VAR_INPUT Comparison value

bOut_b Bool binary VAR_OUTPUT

byFunction Byte VAR CONSTANT RETAIN Selection of the function

Parameter codes of the instances

VariableName L_PHCMP1 L_PHCMP2 L_PHCMP3 SettingRange Lenze

byFunction C0695 C1207 C1272 1 ... 2 2

Function

Selection Comparison function If the comparison condition is fulfilled Note

byFunction = 1

byFunction = 2

dnIn1_p < dnIn2_p bOut_b = HIGH

dnIn1_p dnIn2_p bOut_b = LOW

dnIn1_p<dnIn2_p bOut_b = HIGH

dnIn1_pdnIn2_p bOut_b = LOW

dnIn1_p

dnIn2_p

byFunction

L_PHCMP

bOut_b

Compares the absolute value

of the inputs.

2−40

LenzeDrive.lib EN 1.7

L

Page 51

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.4 Difference (L_PHDIFF)

2.4.4 Difference (L_PHDIFF)

This FB adds a phase−angle signal to the phase setpoint. A setpoint/actual value comparison is also

possible.

L _ P H D I F F

d n O u t _ p

+

-

Fig. 2−52 Difference (L_PHDIFF)

d n S e t _ p

d n A d d _ p

b E n _ b

n I n _ v

b R e s e t _ b

I n t e r v a l T i m e

T A S K

VariableName

dnSet_p Double−integer position VAR_INPUT Provision of a position setpoint

dnAdd_p Double−integer position VAR_INPUT Adaptive position value for an actual position

bEn_b Bool binary VAR_INPUT TRUE = Adaptive position value is added on.

nIn_v Integer velocity VAR_INPUT Provision of the actual speed for conversion/calculation

bReset_b Bool binary VAR_INPUT TRUE = Actual phase−angle integrator is set to 0.

dnOut_p Double−integer position VAR_OUTPUT Signal is not limited.

DataType SignalType VariableType Note

of the position value

Functional sequence

If bEn_b = TRUE :

1. The speed (rpm) signal at nIn_v is integrated by the phase−angle integrator.

2. The phase−angle signal at dnAdd_p is added to the integrated speed signal in each task cycle.

3. The result of the phase−angle integrator is subtracted from the phase−angle signal at dnSet_p

and then output at dnOut_p.

If bEn_b = FALSE

1. The speed (rpm) signal at nIn_v is integrated by the phase−angle integrator.

2. The result of the phase−angle integrator is subtracted from the phase−angle signal at dnSet_p

and then output at dnOut_p.

Note!

The phase−angle integrator derives a position from a speed.

In nIn_v the speed can be defined (16384 15000 rpm ).

(INT)65536 corresponds to one encoder turn.

L

LenzeDrive.lib EN 1.7

2−41

Page 52

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.5 Division (L_PHDIV)

2.4.5 Division (L_PHDIV)

This FB divides or multiplies phase−angle signals in binary−exponent format.

Fig. 2−53 Division (L_PHDIV)

VariableName DataType SignalType VariableType Note

dnIn_p Double integer position VAR_INPUT

dnOut_p Double integer position VAR_OUTPUT 65536 inc = 1 encoder revlution

byDivision Short Integer VAR CONSTANT RETAIN Exponent of the divisor

Parameter codes of the instances

VariableName L_PHDIV1 SettingRange Lenze

byDivision C0995 −31 ... 31 0

Function

d n I n _ p

2

1

b y D iv i s i o n

± 2

R e v o lu ti o n

3 1

L _ P H D I V

d n O u t _ p

You can calculate the result of the arithmetical function according to the formula:

dnOut_p +

dnIn_p

byDivision

2

Positive values in byDivision result in a division.

Negative values in byDivision result in a multiplication.

The output signal is limited to ±2

– The output signal cannot exceed this limit value.

31

−1 encoder turns.

2−42

LenzeDrive.lib EN 1.7

L

Page 53

Function library LenzeDrive.lib

t

Processing of phase−angle signals

2.4.6 Integration (L_PHINT)

2.4.6 Integration (L_PHINT)

This FB can integrate a speed or a velocity to a phase−angle (path/distance). The integrator can

accept max. ±32000 encoder revolutions.

L _ P H I N T

± 3 2 0 0 0

R e v o lu ti o n

d n O u t _ p

b F a i l _ b

bFail_b = FALSE .

Fig. 2−54 Integration (L_PHINT)

VariableName DataType SignalType VariableType Note

nIn_v Integer velocity VAR_INPUT Actual speed value: 16384 15000 rpm

bReset_b Bool binary VAR_INPUT TRUE sets the phase−angle integrator = 0 and

dnOut_p Double−integer position VAR_OUTPUT 65536 inc = 1 encoder revolution (Overflow is possible.)

bFail_b Bool binary VAR_OUTPUT TRUE = Overflow occurred.

Range of functions

I n t e r v a l T i m e

T A S K

n I n _ v

b R e s e t _ b

Constant input value

Calculation of the output signal

2.4.6.1 Constant input value

Fig. 2−55 Function of L_PHINT with constant input value

A positive signal at nIn_v is incremented (the counter value is increased at every call of the

function).

dnOut_p

+32767 revolutions

+32000 revolutions

t

-32000 revolutions

-32767 revolutions

bFail_b

L

A negative signal at nIn_v is decremented (the counter value is decreased at every call of the

function).

dnOut_p produces the count value of the bipolar integrator.

If the count exceeds the value of +32000 encoder revolutions, then

bFail_b switches = TRUE.

If the count exceeds the value of +32767 encoder revolutions (corresponds to +2147483647

inc.) there is an overflow, and the count procedure continues from a value of −32768 encoder

turns.

LenzeDrive.lib EN 1.7

2−43

Page 54

Function library LenzeDrive.lib

Processing of phase−angle signals

2.4.6 Integration (L_PHINT)

If the count falls below the value of −32000 encoder revolutions, then

bFail_b switches= TRUE.

If the count falls below the value of −32768 encoder revolutions (corresponds to −2147483648

inc.) there is an overflow, and the count procedure continues from a value of +32767 encoder

turns.

bReset_b = TRUE:

– the integrator switches to 0.

– sets dnOut_p to 0, as long as nIn_v has a positive signal applied.

– switches bFail_b = FALSE .

2.4.6.2 Calculation of the output signal

The output value at dnOut_p can be derived from the formula:

dnOut_p[inc] + nIn_v[rpm] @ t[s] @ 65536[incńUmdr.]

(t = integration time, 16384 15000 rpm, 1 inc. = 1)

Example:

You want to determine the count of the integrator with a certain speed at the input and a certain

integration time t.

Given values:

– nIn_v = 1000 rpm (INT)1092

– t = 10 s

– Start value of the integrator is 0.

Solution:

– Conversion of the input signal nIn_v:

1000rpm +

– Calculation of the output signal

dnOut_p +

1000rev.

60s

1000rev.

60s

@ 10s @