Page 1

Supplementary instruction manual Leica SP2600

To be used only in conjunction

with instruction manual Leica SM2500 .

V1.2 English 07/2002

Always keep this manual near the instrument.

Read carefully prior to operating the instrument.

Leica SP2600

Ultramilling attachment

Page 2

Page 3

NOTE

The information, numerical data, notes and value

judgments contained in this manual represent the

current state of scientific knowledge and stateof-the-art technology as we understand it following thorough investigation in this field.

We are under no obligation to update the present

manual according to the latest technical developments, nor to provide our customers with additional copies, updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations etc. contained in this manual we exclude liability as far as permissible according to

the national legal system applicable in each individual case. In particular, no liability whatsoever

is accepted for any financial loss or consequential damage caused by or related to compliance

with statements or other information in this manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the present manual are not to be considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it possible to continuously improve the technology and

manufacturing techniques used in our products.

This document is protected under copyright laws.

Any copyrights of this document are retained by

Leica Microsystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods including any electronic systems and media requires

express prior permission in writing by Leica Microsystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the name plate at

the back of the instrument.

© Leica Microsystems Nussloch GmbH

Published by:

Leica Microsystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Telephone: +49 (0)6224 143-0

Facsimile: +49 (0)6224 143-200

Internet: http://www.histo-solutions.com

Leica SP2600 Ultramilling attachment

3

Page 4

Table of contents

1. Important information................................................................................................................6

1.1 Symbols in the text and their meaning ................................................................................................ 6

1.2 Designated use........................................................................................................................................ 6

1.3 Information on this instruction manual................................................................................................ 7

2. Safety ............................................................................................................................................ 8

2.1 Safety regulations ................................................................................................................................... 8

2.2 Built-in safety devices............................................................................................................................ 9

2.3 Safety instructions ................................................................................................................................ 10

3. Technical Data ......................................................................................................................... 13

4. Installation................................................................................................................................. 14

4.1 Overview - Leica SP2600 Ultramilling attachment / basic instrument Leica SM2500

- instrument parts / functions .............................................................................................................. 14

4.2 Leica SP2600 standard delivery.......................................................................................................... 15

4.3 Site requirements.................................................................................................................................. 15

4.4 Unpacking, transport, installation ...................................................................................................... 15

4.5 Installing the Leica SP2600 ultramilling attachment........................................................................ 16

4.6 Connecting the vacuum cleaner......................................................................................................... 17

4.7 Installing additional accessories........................................................................................................ 18

5. Operation ..................................................................................................................................... 19

5.1 Overview of chapter 5 Operation...................................................................................................... 19

5.2 Adjusting the pre-millers in the calibrating device..........................................................................20

5.3 Adjusting the finishing millers in the calibrating device ................................................................. 25

5.4 Specimen holder systems - how to combine individual components .......................................... 29

5.5 Clamping specimen .............................................................................................................................. 30

5.5.1 Installing the base plates in the basic instrument ........................................................................... 30

5.5.2 Clamping the specimen holders in the base plate with dove tail guide ....................................... 30

5.5.3 Clamping the vacuum stages on/in the base plates........................................................................ 31

5.5.4 Connecting the vacuum pump / placing specimens onto the vacuum stages ............................ 32

5.6 Preparatory steps prior to the milling procedure ............................................................................ 34

5.7 Pre-milling .............................................................................................................................................. 36

5.7.1 Perspective view of the pre-milling procedure................................................................................ 38

5.8 Finishing milling ..................................................................................................................................... 40

5.8.1 Perspective view of the finishing milling procedure ....................................................................... 42

5.9 Switching the instrument off (switching off the control unit .......................................................... 43

4

Supplementary instruction manual V 1.2 07/2002

Page 5

Important information

6. Troubleshooting ....................................................................................................................... 44

7. Cleaning, disinfection and maintenance ............................................................................ 45

7.1 Cleaning and disinfection .................................................................................................................... 45

7.2 Maintenance.......................................................................................................................................... 46

7.2.1 Resharpening the millers ..................................................................................................................... 46

7.2.2 Replacing the light bulb in the calibration device............................................................................ 47

8. Overview - accessories .......................................................................................................... 48

8.1 Miller holders and millers .................................................................................................................... 48

8.2 Base plates for specimen holders and vacuum stage adapters ................................................... 48

8.3 Specimen holders ................................................................................................................................. 48

8.4 Vacuum stage adapters ....................................................................................................................... 48

8.5 Vacuum stages and matching lids / perforated specimen holders .............................................. 49

8.6 Vacuum pumps ...................................................................................................................................... 49

8.7 Additional accessories ........................................................................................................................ 50

9. Warranty and service ................................................................................................................ 51

Leica SP 2600 Ultramilling attachment

5

Page 6

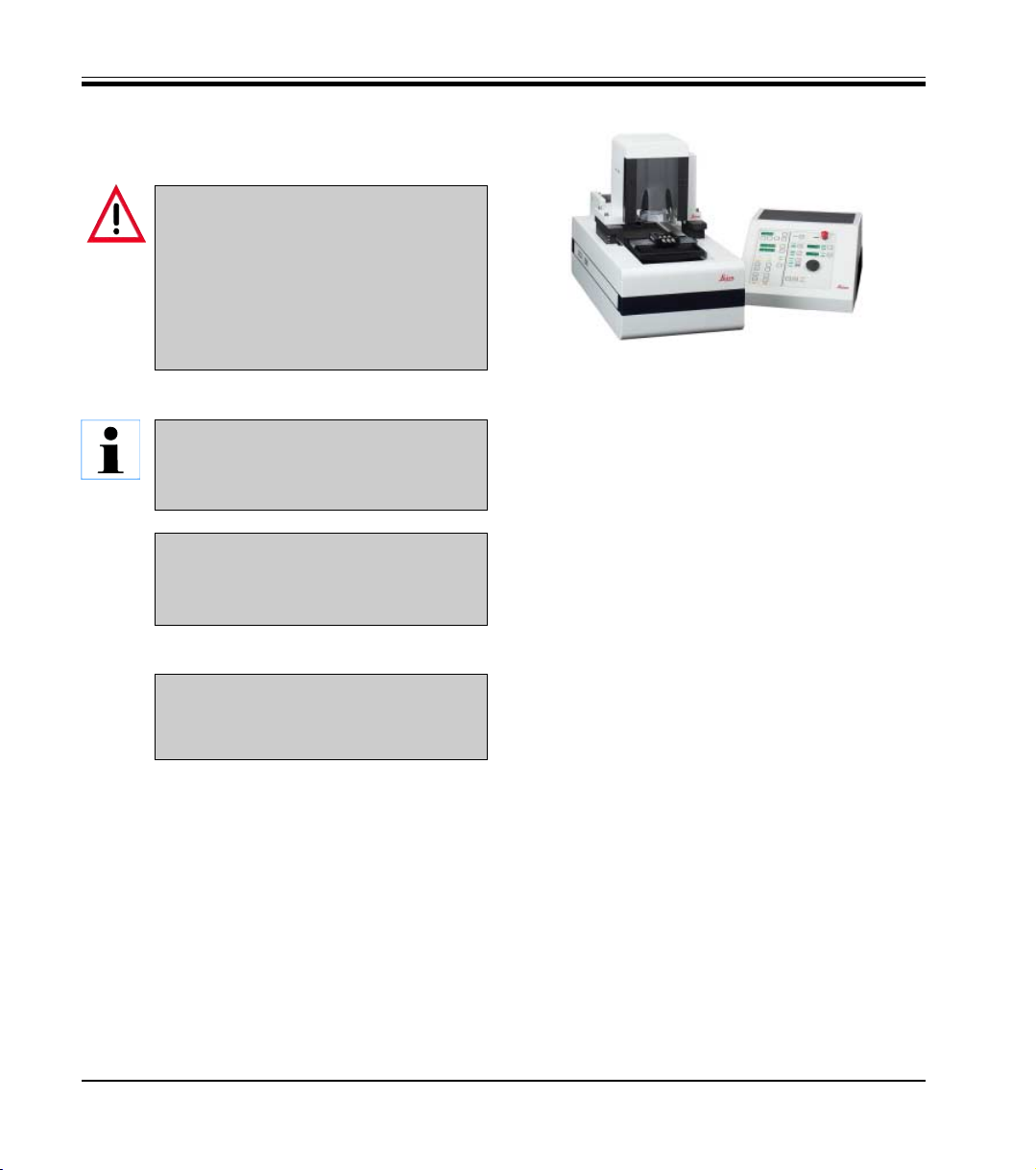

1. Important information

1.1 Symbols in the text and their meaning

Warnings and cautions appear in a

grey box and are marked by a warning

triangle.

Failure to comply with these warnings/

cautions can lead to accidents, bodily

injury and damage to instrument and/

or accessories.

Notes, i.e. important information for the

user, appear in a grey box and are

marked by an information sign.

Figures in brackets refer to item num-

(5)

bers in illustrations or to the illustrations themselves.

1.2 Designated use

Fig. 1.1

The Leica SP2600 is designated to prepare milled

surfaces and thin slices of specimen materials

such as plastics and metals as well as of organic

materials (such as bones, teeth) in medicine, biology and industry.

The Leica SP2600 ultramilling attachment is an

accessory which cannot be operated as a standalone device but must be used in conjunction

with the Leica SM2500 sliding microtome described in a separate instruction manual.

ENTER

6

Function keys that need to be pressed

Fig. 5.23

on the control unit are printed in bold

and capital letters.

Specimen surfaces are milled with a rotating

spindle, equipped with either a pre- or a finishing

miller.

With each sledge stroke, the micrometer feed

mechanism of the Leica SM2500 lowers the miller towards the specimen by the feed setting selected.

The Leica SP2600 may be used only in conjunction with accessories and supplementary instruments made by Leica.

If the instrument is used for any other than

the designated application, this will be

considered an improper use of the product!

Supplementary instruction manual V 1.2 07/2002

Page 7

1.3 Information on this instruction manual

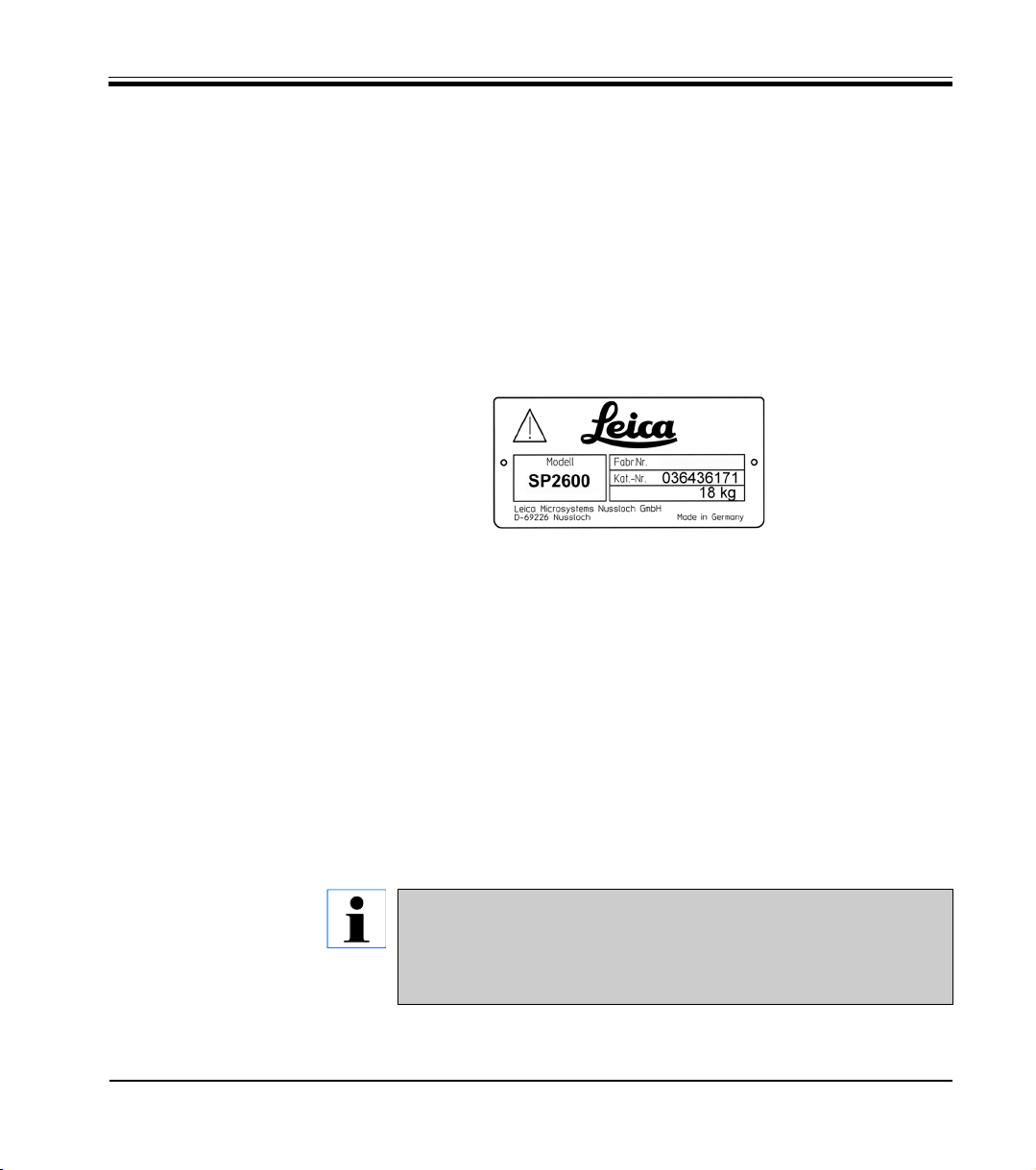

Instrument type

This supplementary instruction manual must be used together with the Leica

SM2500 sliding microtome instruction manual describing the basic instrument Leica SM2500, which is needed to operate the Leica SP2600 ultramilling attachment.

All information provided in this supplementary instruction manual applies

only to the instrument type indicated on the title page.

A name plate indicating the instrument type and serial number is attached to

the rear of the Leica SP2600 ultramilling device.

Fig. 1.2

Working with this instruction manual

This supplementary instruction manual contains important instructions and

information related to the operating safety and maintenance of the Leica

SP2600 ultramilling attachment.

It is an important part of the Leica SP2600 ultramilling attachment.

Prior to setting up and operating the Leica SP2600 together with the Leica

SM2500 be sure to read carefully both this supplementary instruction

manual as well as the Leica SM2500 instruction manual, with the exception

of chapters 5.5.6 - 5.7 of the Leica SM2500 manual. These chapters describe

installation of knife holders / knives and sectioning with the Leica SM2500

and are not of importance for operating the Leica SP2600 ultramilling attachment.

1. Important information

Leica SP 2600 Ultramilling attachment

If additional requirements on accident prevention and environmental protection exist in the country of operation, this supplementary

instruction manual must be supplemented by additional appropriate instructions to ensure compliance with such requirements.

7

Page 8

2. Safety

2.1 Safety regulations

This instrument has been built and tested in accordance with the same directives and standards as the Leica SM2500.

For a complete list of the directives and standards applied please refer to

chapter 2.1, page 8 of the Leica SM2500 instruction manual.

In order to maintain the SP2600 in a condition compliant with the above directives and standards and to ensure safe operation, the operator must observe the instructions and warnings contained in this supplementary instruction manual as well as in the Leica SM2500 instruction manual.

The Leica SP2600 ultramilling may be operated only in conjunction

with the Leica SM2500 sliding microtome!

8

Supplementary instruction manual V 1.2 07/2002

Page 9

2.2 Built-in safety devices

The instrument is equipped with the following safety devices:

1

Plexiglass protective cover

The miller is equipped with a protective cover made of plexiglass (1).

When the cover is moved to the upper limit position (1, Fig. 2.1) the miller

is automatically blocked and cannot be started.

For any manipulations in the milling area (such as inserting millers, fine

adjustment of specimen height etc.) the protective cover (1, Fig. 2.1) must

be in the upper limit position.

Fig. 2.1

1

To be able to start the miller, the protective cover must be lowered (1,

Fig. 2.2).

2. Safety

Never touch the milling spindle while the plexiglass cover is shut,

no matter whether the spindle is rotating or not.

Fig. 2.2

Important note on the safety devices built in by the manufacturer:

The safety devices provided by the manufacturer constitute only a basis for

accident prevention.

Major responsibility for accident prevention during the use of the instrument

rests with the employer who has the operating authority for the instrument

and, in addition, with the persons, designated by him, who operate, service

and repair the instrument.

To ensure safe and trouble-free operation of the instrument, be sure to

comply with all instructions, warning and cautions in this supplementary

instruction manual as well as in the Leica SM2500 instruction manual!

Leica SP 2600 Ultramilling attachment

9

Page 10

2. Safety

2.3 Safety instructions

Be sure to read and comply with the

safety instructions, warnings and cautions in this chapter as well as in

chapter 2 of the Leica SM2500 instruction manual, even if you are already familiar with the operation and use of

other Leica products.

Safety instructions - general

The Leica SP2600 ultramilling attachment may only be operated in conjunction with the Leica SM2500 sliding microtome.

Prior to working with the Leica SP2600

ultramilling attachment, be sure to

read the following instruction manuals:

The entire Leica SM2500 instruction

manual except chapters 5.5.6

through 5.7.

This supplementary instruction

manual Leica SP2600.

The Leica SP2600 ultramilling attachment may only be operated by skilled

laboratory personnel. It may only be

used for the designated application

and operated in accordance with the

instructions contained in this supplementary instruction manual and in the

Leica SM2500 instruction manual!

Safety instructions - transport and installation

Be sure to follow the unpacking instructions (attached to the outside of

the instrument shipping crate)!

Never remove or modify any of the

safety devices installed on the instrument and/or accessories!

Before mounting the ultramilling attachment, make sure the bearing

blocks of the microtome supporting the

milling attachment and the bearing

surfaces of the milling attachment are

clean.

Two people are required to place the

milling attachment on the bearing

blocks from above.

Do not slide the milling attachment

onto the bearing blocks to prevent the

bearing surfaces of the microtome and

milling attachment from getting

scratched!

The bearing surfaces must not become

damaged under any circumstances!

Caution:

When releasing the lid of the milling

attachment (can be lifted and used as

a handle) be careful not to get your fingers caught between the lid and the

body of the milling attachment!

10

Supplementary instruction manual V 1.2 07/2002

Page 11

2. Safety

Safety instructions - transport and installation

Caution!

Only the vacuum cleaner offered by

Leica or other vacuum cleaner brands

rated at 230 V/ 50 Hz and a maximum

power draw of 4 A can be connected

directly to the SM2500 control unit (see

page 17), and this only in countries

where the mains supply is 230 V / 50

Hz!

Otherwise, the vacuum cleaner must

be connected directly to mains and operated via the on/off switch of the

vacuum cleaner.

Safety instructions - inserting the millers into the

holders / working with the calibrating device

Twisted or deformed springs for the

miller holders must be exchanged!

When the millers are inserted into the

holders the letter V (pre-millers) or F

(finishing miller) must be visible for the

milling edge to point into the right direction.

Caution:

The gauge contact plate must never hit

the milling edge.

This could damage the surface of the

contact plate, leading to incorrect

measuring results.

Be very careful when drawing the contact plate close to the milling edge.

Always use the magnifier.

Safety instructions working with the instrument

Never remove or modify any of the

safety devices installed on the instrument and/or accessories!

Never touch the milling spindle while

the plexiglass cover is shut, no matter

whether the spindle is rotating or not.

Always slide the plexiglass cover to

the upper position prior to attaching

the miller holders to the milling

spindle!

Wear protective gloves when working

with potentially infectious material!

Always slide the plexiglass cover to

the upper position prior to checking

the distance between milling edge

and specimen surface! - Risk of injury!

Always check the distance between

miller cutting edge and specimen surface thoroughly prior to milling!

Under no circumstances may the

miller cutting edge be positioned more

than a few microns (= selected milling

thickness) below the specimen surface when starting the milling procedure.

When spraying alcohol to moisten the

specimen surface, remove excess liquid as soon as it starts accumulating.

Do not operate near open flames or

near other sources of ignition!

No liquids may enter the interior of the

instrument during operation!

Leica SP2600 Ultramilling attachment

11

Page 12

2. Safety

Safety instructions working with the instrument

Do not exceed a milling thickness setting of 5 µm with the following materials: brittle, very ductile materials such

as titanium or fiberglass and compound samples containing such materials (such as printed circuit boards).

During milling:

switch on the vacuum cleaner,

wear appropriate safety goggles,

wear appropriate mask (type of

mask depends on the material being

milled / size of the chips that form

during milling).

Goggles and mask prevent milling

chips and microdust from entering

your eyes and from being inhaled.

Caution - rotating miller:

After switching off the milling spindle

(button (37) - chapter. 5.4.11, p. 34 - instruction manual Leica SM2500) the

miller continues to rotate for a little

while.

When switching off the mains switch

on the control unit (see chapter 5.2, p.

21 - Instruction manual Leica SM2500)

the milling spindle will rotate briefly.

Therefore, never switch off the control

unit, while one of your hands is in the

rotation zone of the miller.

- Risk of injury!

Never touch the milling spindle while

it is rotating and/or while the plexiglass cover is shut, no matter whether

the spindle is rotating or not.

Safety instructions cleaning disinfection and maintenance

Only authorized service technicians

may access the internal components of

the instrument for service and repair!

Cleaning detergents appropriate for

the ultramilling attachment.

Varnished surfaces:

mild laboratory detergents (slightly

moistened cloth)!

Non-varnished metal parts:

mild laboratory detergents,

xylene substitutes (slightly

moistened cloth)

alcohol (slightly moistened cloth).

For disinfection of the instrument and

accessories use Leica Cryofect or

other commercial disinfectants. - Use

all disinfectants according to the

manufacturers instructions.

When disinfecting, wear appropriate

goggles and mask as well as protective gloves.

Dispose of potentially infectious

specimen material as per the laboratory regulations applicable in the

country of operation.

No liquids may enter the interior of the

instrument during cleaning, disinfection or maintenance!

12

Supplementary instruction manual V 1.2 07/2002

Page 13

3. Technical Data

Ultramilling attachment

Milling spindle (special design)......................................................................................... type TSAV 60 x 160

Motor, rotation speed selectable in 100-rpm steps ............................................................ 500 to 3.000 rpm

Protective class ................................................................................................................................................... I

Pollution degree.................................................................................................................................................. 2

Dimensions and weight - ultramilling attachment

Dimensions (H x W x D) ..................................................................................................... 300 x 315 x 240 mm

Weight ........................................................................................................................................................... 18 kg

Vacuum cleaner Fakir S20

Nominal voltage ........................................................................................................................................... 230 V

Nominal frequency ......................................................................................................................................50 Hz

Power draw ............................................................................................................................................ max. 4 A

These specifications are supplemented by the specifications contained in the Leica SM2500 instruction manual.

Leica SP 2600 Ultramilling attachment

13

Page 14

4. Installation

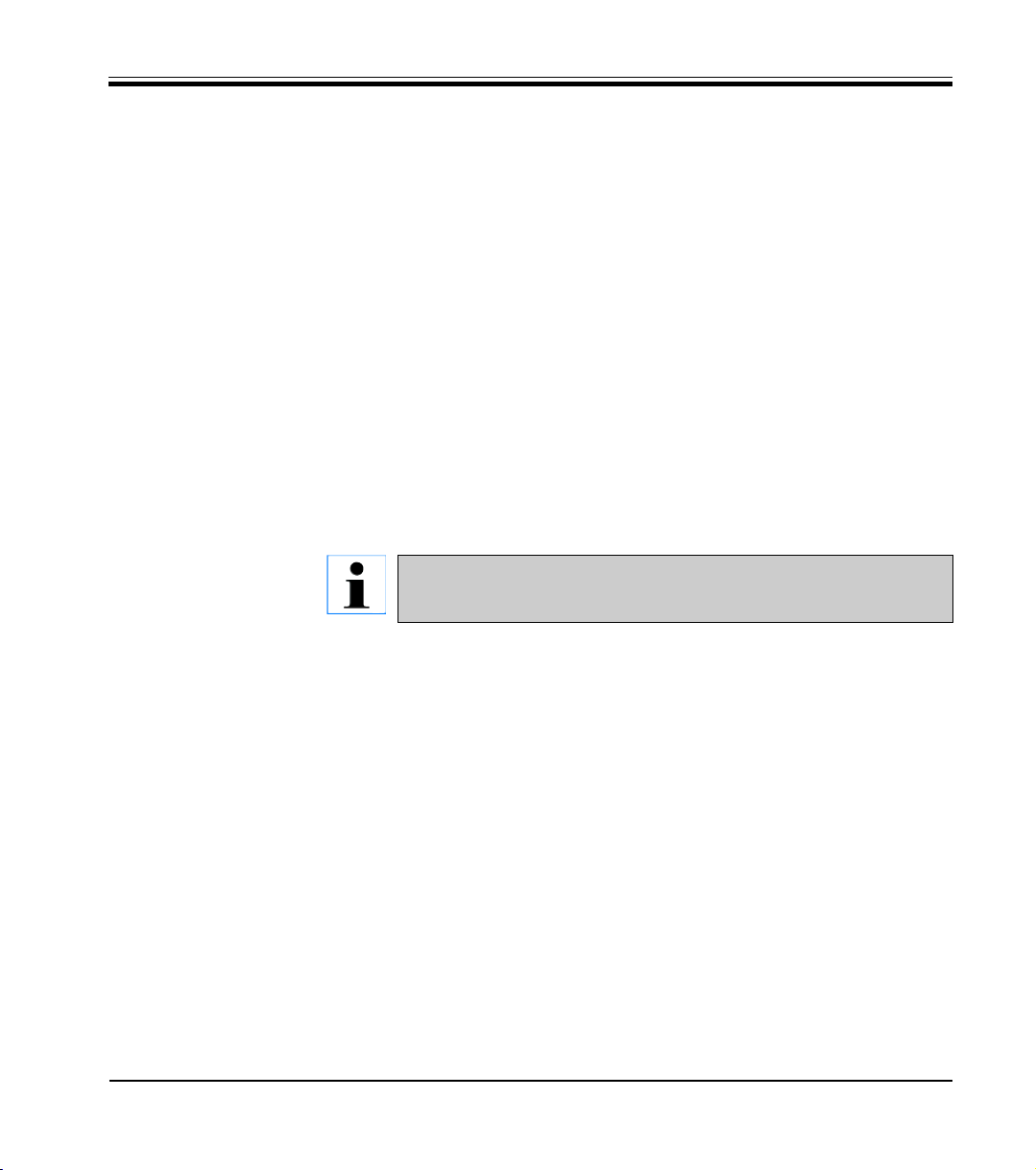

4.1 Overview - Leica SP2600 Ultramilling attachment / basic instrument Leica SM2500

- instrument parts / functions

1.4

1.2

1.5

Fig. 4.1 1

1.1

2

2.1 2.2

1.3

1. Leica SM2500 - basic instrument (sliding microtome)

1.1 Leica SP2600 - ultramilling attachment

1.2 Carrier for ultramilling attachment SP2600 (when not in use)

1.3 Specimen holder system (not part of standard delivery)

1.4 Carrying handle, black, rear (extendible - not visible in Fig. 4.1)

1.5 Carrying handle, black, front (extendible)

2. Leica SM2500 - control unit

2.1 Control panel

2.2 Emergency stop button

3. Foot switch (not shown in Fig. 4.1 - for details on the foot switch please

refer to p. 18, chapter 4.6 of this supplementary instruction manual and to

p. 18, chapter 4.5.2 and p. 24, chapter 5.4.1 of the Leica SM2500 manual).

14

Supplementary instruction manual V 1.2 07/2002

Page 15

4. Installation

4.2 Leica SP2600 standard delivery

Standard delivery includes:

1 Basic instrument Leica SP2600 (Ultramilling

attachment)

1 Calibrating device with dial gauge for miller

adjustment

3 Holders, each with two springs, for pre- and

finishing millers, one holder delivered attached

to the instrument.

1 Carrier for Leica SP2600 Ultramilling device

when not in use

1 Tool set:

1 Allen key, size 2.5, with handle

1 Allen key, size 4.0

1 Allen key, size 4.0 with handle

1 Allen key, size 5.0 with handle

1 Allen key, size, 8.0

1 Power cord type KN 2/5 7,5 V

1 Box level

1 Plexiglass block, 19 x 33 x 53 mm

1 Balance weight, installed in one of the miller

holders

1 Flat belt

1 Dust cover

1 Supplementary instruction manual for Leica

SP2600, to be used in conjunction with the

Leica SM2500 instruction manual

- German

- English

Millers and specimen holders are not

included in the instrument standard

delivery but have to be ordered separately, in accordance with each users

specific application(s).

Mounting instructions for all accessories and/or references to the corresponding chapters of the instruction

manual Leica SM2500 can be found in

chapter 5.6 of this instruction manual.

4.3 Site requirements

For site requirements, please refer to chapter 4.2

of the Leica SM2500 instruction manual.

4.4 Unpacking, transport, installation

Be sure to follow the unpacking instructions (attached to the outside of

the instrument shipping crate)!

Never remove or modify any of the

safety devices installed on the instrument and/or accessories!

The Leica SP2600 ultramilling attachment is supplied only in conjunction

with the Leica SM2500 microtome

(Leica SM2500 microtomes already installed at a customers site must be returned to the manufacturer for upgrading with a Leica SP2600 ultramilling

attachment).

For instructions on how to install / set up the Leica SM2500 please refer to chapter 4 of the Leica

SM2500 instruction manual.

Leica SP2600 Ultramilling attachment

15

Page 16

4. Installation

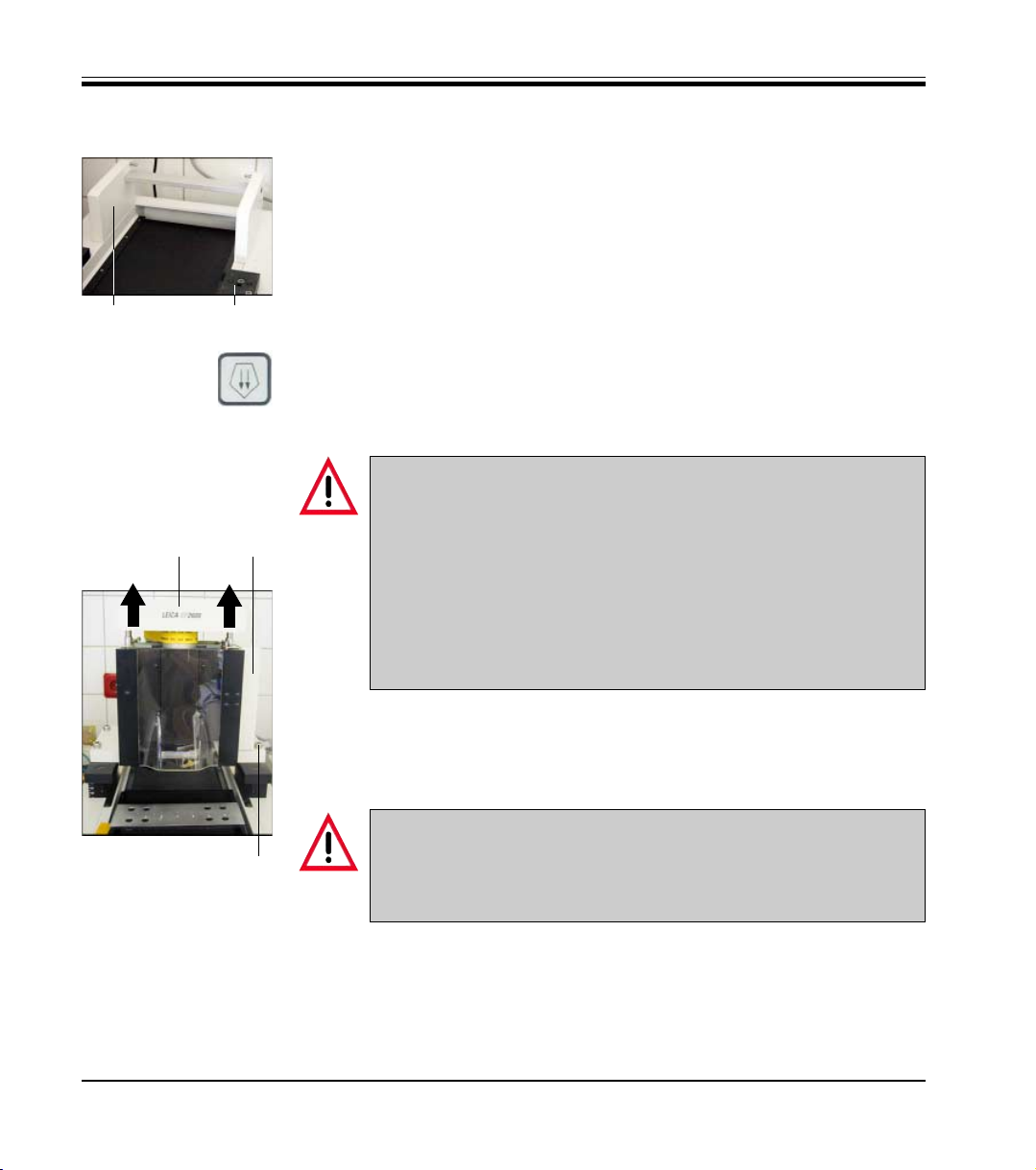

4.5 Installing the Leica SP2600 ultramilling attachment

Place the carrier (1, Fig. 4.2) for the ultramilling attachment (3, Fig. 4.3) on

the rear part of the Leica SM2500 microtome fitting the two pins of the

carrier into the corresponding bores in the Leica SM2500 microtome.

1 2

Fig. 4.2

Lower the bearing blocks (2) of the microtome as far as they will go (use

button (51), chapter 5.4.13, p. 36 - Leica SM2500 manual).

Prior to placing the ultramilling attachment onto the microtome:

Make sure the bearing blocks of the microtome supporting the

milling attachment and the bearing surfaces of the milling attach-

34

ment are clean.

Two people are required to place the milling attachment on the

bearing blocks from above.

Do not slide the milling attachment onto the bearing blocks to prevent the bearing surfaces from getting scratched!

The bearing surfaces must not become damaged under any circumstances!

Fig. 4.3

16

Place ultramilling device (3) onto the microtome bearing blocks (two

people!).

Lift lid (4) of the milling attachment (serves as a handle - see Fig. 4.3).

Caution:

When releasing the lid of the milling attachment (can be lifted and

5

used as a handle) be careful not to get your fingers caught between the lid and the body of the milling attachment!

Fasten the ultramilling attachment to the microtome with four screws (5)

using a size 8 Allen key.

Connect the connecting cable of the milling attachment to the control

unit (see chapter 4.5.2, page 18 of the Leica SM2500 manual).

Supplementary instruction manual V 1.2 07/2002

Page 17

4.6 Connecting the vacuum cleaner

Milling dust is extracted by a vacuum cleaner, through a nozzle (1) located in

the milling area.

230 V / 50 Hz Vacuum cleaners with a power draw of maximum 4 A

can be connected directly to the SM2500 control unit and thus be

switched on/off via the vacuum cleaner button on the SM2500 con-

Fig. 4.4

1

Installing vacuum cleaners rated at 230 V/ 50 Hz / max. power draw 4 A

Insert the connection piece of the vacuum cleaner hose into nozzle (1) at

the rear of the ultramilling attachment.

Connect any one of the two adapter cables (both cables are identical)

supplied as part of the Leica SM2500 standard delivery into the vacuum

cleaner socket at the control unit (see chapter 4.5.2, p. 18 of the Leica

SM2500 manual).

Connect the vacuum cleaner power cord to the socket of the adapter

cable.

Switch on the on/off switch of the vacuum cleaner.

The vacuum cleaner can now be switched on/off via the vacuum cleaner

button on the control unit (button (35), chapter 5.4.11, p. 34 of the Leica

SM2500 manual).

trol unit.

4. Installation

Leica SP 2600 Ultrafräse

Caution!

Only the vacuum cleaner offered by Leica or other vacuum cleaner

brands rated at 230 V/ 50 Hz and a maximum power draw of 4 A can

be connected directly to the SM2500 control unit, and this only in

countries where the mains supply is 230 V / 50 Hz!

Otherwise, the vacuum cleaner must be connected directly to

mains and operated via the on/off switch of the vacuum cleaner.

Installing other vacuum cleaners:

Insert the connection piece of the vacuum cleaner hose into nozzle (1) at

the rear of the ultramilling attachment.

Connect the power cord of the vacuum cleaner to mains.

Operate the vacuum cleaner via the vacuum cleaner on/off switch.

17

Page 18

4. Installation

4.7 Installing additional accessories

Install further accessories as described in chapters 4.5.2 and 4.5.3, pages

18 and 19 of the Leica SM2500 instruction manual.

Connect the foot switch.

The foot switch must be connected - otherwise the instrument will

not be operational. --> For details on the foot switch, see chapter

4.5.2, p. 18 and chapter 5.4.1, p. 24 of the Leica SM2500 instruction

manual.

If working with vacuum stages, also a vacuum pump must be installed - --> see page 33, chapter 5.6.4 of this supplementary instruction manual.

18

Supplementary instruction manual V 1.2 07/2002

Page 19

5.1 Overview of chapter 5 Operation

Prior to working with the Leica SP2600 ultramilling attachment, be

sure to read the following instruction manuals:

The entire Leica SM2500 instruction manual except chapters

5.5.6 through 5.7.

This supplementary instruction manual Leica SP2600.

Chapter 5 of this supplementary instruction manual Leica SP2600 includes

the following subchapters:

5.1 Overview - chapter 5.

5.2 Adjusting the pre-millers in the calibrating device

5.3 Adjusting the finishing millers in the calibrating device

5.4 Specimen holder systems - how to combine individual components

5.5 Clamping specimens

5.5.1 Installing the base plates in the basic instrument

5.5.2 Clamping the specimen holders in the base plate with dovetail guide

5.5.3 Clamping the vacuum stages on/in the base plates

5.5.4 Connecting the vacuum pump/placing specimens onto the vacuum

stages

5.6 Preparatory steps prior to the milling procedure

5.7 Pre-milling

5.7.1 Perspective view of the pre-milling procedure

5.8 Finishing milling

5.8.1 Perspective view of the finishing milling procedure

5.9 Switching the instrument off (switching off the control unit).

5. Operation

Initial operation:

The first time you operate the instrument, we recommend you work through

the above subchapters, in numerical order as listed.

Pay particular attention to the safety instructions..

Leica SP 2600 Ultramilling attachment

19

Page 20

5. Operation

5.2 Adjusting the pre-millers in the calibrating device

Preparatory steps

Connect mains power supply (20) to miller cali-

bration device (18).

Connect mains power supply (20) to mains: the

light bulb is switched on.

20

18

16

1

Place magnifier (16) onto calibration device.

Loosen regulating screws (6), (7) and (11) in

miller holder (2) until they are flush with the

inner surfaces of the miller holder.

If the screws protrude from the inner surfaces

of the miller holder (2), spring (1) and miller (3)

cannot be inserted into the correct position.

Twisted or deformed springs for the

miller holders must be exchanged!

Fig. 5.1

4

Fig. 5.2

20

Inserting the miller into the miller holder

Insert spring (1) straight from above into miller

holder (2) - the two upper edges of the spring

must be flush with the upper surface of the

6

11

miller holder.

Carefully insert miller (3) from the front - the

letter V must be visible.

6

When the miller is inserted into the

holder the letter V must be visible. That way, the milling edge is pointing

into the right direction.

Insert the miller (3) completely - it must fit

3

7

5

2

against the rear and lower inner surface of the

miller holder (2) and be flush with spring (1).

Insert screw (4) and washer (5) and tighten

slightly to fasten miller (3) .

Supplementary instruction manual V 1.2 07/2002

Page 21

5. Operation

Z

Fig. 5.3

Y

Adjusting the miller

The miller (3) is adjusted in the holder (2) along

6

three different axis (x, y and z - see Fig. 5.3, left).

Adjustment along the x-axis is done outside the

6

calibration device (18, Fig. 5.1).

X

For adjustment along the z- and y-axis, the miller

holder (2) with miller (3) has to be fastened in the

calibration device.

Adjustment along the x-axis

Adjust miller (3) as shown in Fig. (5.4a / 5.4b).

Along the entire length of both sides of the

miller, there must be a uniform distance between miller (3) and miller holder (2) / spring

(1) (see Fig. 5.4b).

The miller is adjusted along the x-axis via the

two regulating screws (6) (Allen key, size 2.5).

Tighten (clockwise) and/or loosen (counter-

2

3

clockwise) screws (6, Fig. 5.3) alternately un-

til the miller is adjusted to a parallel position

as shown in Fig. 5.4b.

132

Fig. 5.4a: WRONG Fig. 5.4b: CORRECT

Leica SP2600 Ultramilling attachment

Do not tighten screws (6) too much. If

screws (6) are too tight, screw (7, Fig.

5.2) (for adjustment along the y-axis)

can no longer be moved.

21

Page 22

5. Operation

12

(12)

18

Adjustment along the z-axis

1. Pull lever (12) at the left of calibration device

(18) forward as far as it will go, thus moving

contact plate (17) backwards to its rear limit

position. This prevents the contact plate from

hitting the milling edge during the adjustment

procedure.

2. Once miller (3) has been correctly adjusted

along the x-axis, place miller holder (2) with

16

10

17

miller (3) next to block (8) into the calibration

device.

3. Fit the clamping device (9) (with the semicir-

cular recess pointing in your direction) against

the miller holder (2) and fasten with two

knurled screws (10) (turn screws clockwise).

9

2 38

Fig. 5.5

4. Rotate magnifier (16) forward to a position

above the miller.

5. With lever (12), bring contact plate (17) close

to the miller (move lever backwards) until just

a very small gap remains (see Fig. 5.6).

Caution:

The gauge contact plate must never hit

the milling edge.

This could damage the surface of the

contact plate, leading to incorrect

measuring results.

Be very careful when bringing the contact plate close to the milling edge.

Always use the magnifier.

Fig. 5.6

22

17

Supplementary instruction manual V 1.2 07/2002

Page 23

5. Operation

6. Insert the size-5 Allen key into regulating

11

3

screw (4) insert size-2.5 Allen key into regulating screw (11) (Fig. 5.7).

The arrows in Fig. 5.7 indicate clockwise sense of rotation.

Fig. 5.7 4

Fig. 5.8 a - CORRECT

Fig. 5.8 b - WRONG

7

90°

7. Tighten/loosen screws (11) and (4) alternately

to adjust miller (3) along the z-axis. The miller

edge is adjusted correctly when the outer

edge of the miller is at right angles to the front

surface of the contact plate (see Fig. 5.8a).

The miller MUST NOT be positioned as shown

in Fig. 5.8b and 5.8c!

Tightening either regulating screw (4,

11) (= clockwise rotation in the sense

of the arrow) brings the corresponding

side of the miller closer to the contact

plate.

8. If one of the two screws (4, 11) has been tightened as far as it will go, slightly release the

opposite screw. This slackens the screw that

had been completely tightened .

Do not tighten screws (4, 11) too much.

If screws (4, 11) are too tight, screw (7,

Fig. 5.2) (for adjustment along the yaxis) can no longer be moved.

Fig. 5.8 c - WRONG

Leica SP2600 Ultramilling attachment

Caution:

Be very careful when bringing the

contact plate close to the milling

edge.

Always use the magnifier.

Make sure the milling edge does not

hit the contact plate!

23

Page 24

5. Operation

12

Fig. 5.9 a

Adjustment along the y-axis

1. Select reference value 1.

14

13

17

3

The reference value will be needed

later on to adjust the finishing miller to

the same milling level as the premiller.

Any reference value can be selected.

Experience, however, shows that 1 is

the best value for new millers (i.e. millers not yet resharpened).

2. To select the reference value, move lever (12),

setting the dial of the inner (smaller) scale (13)

to a position just below 1 and the dial of the

outer scale (14) to approximately 70 (approx.

7

10 oclock) (Fig. 5.9a).

3. Rotate regulating screw (7) clockwise, bringing the milling edge (3) close to the contact

plate (17).

4. Slowly continue to turn screw (7) clockwise

until the dial of scale (14) starts to move (i.e.

14

until the milling edge touches the contact

plate).

5. Keep rotating screw (7) very carefully and

13

slowly until the dial of scale (14) is in the upper 0 position and the dial of scale (13) is located exactly at 1 (Fig. 5.9b).

Fig. 5.9 b

24

Caution:

Be very careful when bringing the contact plate close to the milling edge.

Always use the magnifier.

Make sure the milling edge does not

hit the contact plate!

7

Supplementary instruction manual V 1.2 07/2002

Page 25

5. Operation

5.3 Adjusting the finishing millers in the

calibrating device

Carry out preparatory steps as per chapter 5.2,

page 20 (Adjusting the pre-millers in the calibrating device).

Twisted or deformed springs for the

miller holders must be exchanged!

Insert spring and finishing miller as described

in chapter 5.2, page 20 (Inserting the miller into

the miller holder).

When the finishing miller is inserted

into the holder, the letter F must be

visible. - That way, the milling edge is

pointing into the right direction.

Fig. 5.10

Leica SP2600 Ultramilling attachment

25

Page 26

5. Operation

12

Adjusting the finishing miller

Just like the pre-miller, the finishing miller is adjusted in the miller holder along three different

axis (see page 21).

Adjustment along the x-axis

As described for the pre-miller - see page 21.

Adjustment along the z-axis

Carry out steps 1 - 4 as described on page 22

(Fig. 5.5) for the pre-miller.

Next:

5. With lever (12), bring contact plate (17) close

to the miller (turn lever backwards) so that only

a small gap remains (see Fig. 5.11).

Caution:

The gauge contact plate must never hit

the milling edge.

This could damage the surface of the

contact plate, leading to incorrect

measuring results.

Be very careful when bringing the contact plate close to the milling edge.

Always use the magnifier.

Fig. 5.11

26

17

Supplementary instruction manual V 1.2 07/2002

Page 27

5. Operation

6 Insert size-5 Allen key into regulating screw

11

3

(4) insert size-2.5 Allen key into regulating

screw (11) (Fig. 5.12) .

The arrows in Fig. 5.12 indicate clockwise sense of rotation.

Fig. 5.12 4

a

Fig. 5.13 a - CORRECT: angle a = angle b

Fig. 5.13 b - WRONG

7

b

7 Tighten/loosen screws (11) and (4) alternately

to adjust miller (3) along the z-axis. The miller

is adjusted correctly when angle a equals

angle b, i.e. when the distance between each

end of the milling edge and the contact plate

is the same: in Fig. 5.13a the finishing miller

correctly adjusted.

The miller MUST NOT be positioned as shown

in Fig. 5.13b and 5.13c!

Tightening either regulating screw (4,

11) (= clockwise rotation in the sense

of the arrow) moves the corresponding

side of the miller towards the contact

plate.

8. If one of the two screws has been tightened

as far as it will go, slightly release the opposite screw . This slackens the screw that had

been completely tightened.

Do not tighten screws (4, 11) too much.

If screws (4, 11) are too tight, screw (7)

(for adjustment along the y-axis) can

no longer be moved.

Fig. 5.13 c - WRONG

Leica SP2600 Ultramilling attachment

Caution:

Be very careful when bringing the

contact plate close to the milling edge.

Always use the magnifier.

Make sure the milling edge does not

hit the contact plate!

27

Page 28

5. Operation

12

Fig. 5.14 a

Adjustment along the y-axis

1 Select the same reference value as was set

for the pre-miller.

14

13

17

3

7

2 To select the reference value, move lever (12),

setting the dial of the inner (smaller) scale (13)

Pre-miller and finishing miller used for

milling a specific sample must be adjusted using the same reference value.

This ensures that both milling edges

hit the sample at exactly the same

height.

Minor differences in height can still be

adjusted via the height adjustment button on the control unit, once the miller

holder has been attached to the milling

spindle (see chapter 5.4.13, p. 36 the

Leica SM2500 manual).

to a position just below 1 and the dial of the

outer scale (14) to approximately 70 (approx.

10 oclock) (Fig. 5.14a).

3 Rotate regulating screw (7) clockwise, bring-

ing the milling edge (3) close to the contact

plate (17).

14

4 Slowly continue to turn screw (7) clockwise

until the dial of scale (14) starts to move (i.e.

13

until the milling edge touches the contact

plate).

5 Keep rotating screw (7) very carefully and

slowly until the dial of scale (14) is in the upper 0 position and the dial of scale (13) is located exactly at 1 (Fig. 5.14b).

Fig. 5.14 b

28

Caution:

Be very careful when bringing the contact plate close to the milling edge.

Always use the magnifier.

Make sure the milling edge does not

7

Supplementary instruction manual V 1.2 07/2002

hit the contact plate!

Page 29

5.4 Specimen holder systems - how to combine individual components

5. Operation

Base plate

with vise

0383 09267

Base plate with

dovetail guide

0383 09422

Vacuum stage

adapter for base

plate with vise

0383 60407

Vacuum stage

adapter for base

plate with

dovetail guide

0383 20351

Specimen clamp

44 x 58 mm, for

base plate with

dovetail guide

0383 09415

Round specimen

holder,

for base plate

with dovetail

guide

0383 08992

Vacuum stage

55 x 100 mm

0364 09011

Vacuum stage

for lids

30 - 50 mm

0364 09001

Vacuum stage

76 x 25 mm,

for perforated

specimen holders

0364 18199

Vacuum stage

with variable

surface:

76 x 25, 76 x 65

and 100 x 65 mm,

for perforated

specimen holders

0364 18197

SPECIMEN

SPECIMEN

SPECIMEN

Lid, 30 mm

0364 09005

Lid, 40 mm

0364 09007

Lid, 50 mm

0364 09009

Specimen holder,

perforated,

in 9 different sizes:

5 x 5 perforations

0364 26808

5 x 10 perforations

0364 26809

10 x 10 perforations

0364 26810

10 x 15 perforations

0364 26811

15 x 15 perforations

0364 26812

20 x 10 perforations

0364 26813

20 x 15 perforations

0364 26814

25 x 15 perforations

0364 26815

30 x 15 perforations

0364 26816

SPECIMEN

SPECIMEN

Configurations:

1. Base plate with dovetail guide (0383 09422) and holder for round specimens (0383 08992)

= order no. 0383 08993

2. Base plate with dovetail guide (0383 09422) and specimen clamp 44 x 58 mm (0383 09415) with eccentric ring (0383 09425)

= order no. 0383 20212

3. Vacuum stage 76 x 25 mm with vacuum stage adapter (0383 60407) for base plate with vise (0383 09267)

= order no. 0364 18200

Leica SP 2600 Ultramilling attachment

29

Page 30

5. Operation

5.5 Clamping specimen

For a detailed overview of the clamping systems available, please

refer to chapter, 5.4, page 29.

5.5.1 Installing the base plates in the basic instrument

For detailed instructions on how to install the base plates in the

basic instrument, please refer to chapters 5.5/5.5.1, pages 38/39 of

the Leica SM2500 instruction manual.

When working with the Leica SP2600 ultramilling attachment, always insert the eccentric ring prior to installing the base plates.

The eccentric ring blocks the specimen orientation mechanism

thus providing enhanced stability during milling.

For details on how to insert the eccentric ring, please refer to

chapter 5.5/5.5.1, page 39 of the Leica SM2500 instruction manual.

5.5.2 Clamping the specimen holders in the base plate with dove tail guide

30

For detailed instructions on how to clamp the specimen clamp 44 x

58 mm and/or the round specimen holder in the base plate with

dovetail guide as well as on how to clamp specimens in these

specimen holders, please refer to chapter 5.5.4 Mounting specimen holders onto the base plate with dovetail guide, pages 42 - 44

of the Leica SM2500 instruction manual.

Supplementary instruction manual V 1.2 07/2002

Page 31

Fig. 5.15

5. Operation

5.5.3 Clamping the vacuum stages on/in the base plates

Clamping the vacuum stages in the base plate

with vise (Fig. 5.15)

Fasten the vacuum stage on the vacuum stage

adapter for the base plate with vise (with 4

Allen screws (1) / Allen key size 4).

The 4 size-four Allen screws are part of the

Vacuum stage adapter standard delivery, the

size-four Allen key comes as part of the Leica

SP2600 standard delivery.

Clamp the vacuum stage in the base plate with

vise.

For detailed instructions on how to do this,

please refer to chapter 5.5.2, page 41 Clamping specimen stages of the Leica SM2500 instruction manual: the vacuum stage is

clamped the same way as the specimen

1

stages described there.

Fig. 5.16

Leica SP2600 Ultramilling attachment

Clamping the vacuum stages in the base plate

with dovetail guide (Fig. 5.16)

Fasten the vacuum stage on the vacuum stage

adapter for the base plate with dovetail guide

(with 4 Allen screws (1) / Allen key size 3).

The 4 size-three Allen screws are part of the

Vacuum stage adapter standard delivery, the

size-three Allen key comes as part of the Leica

SM2500 standard delivery.

Clamp the vacuum stage in the base plate with

dovetail guide.

For detailed instructions on how to do this,

please refer to chapter 5.5.4, page 44 Clamping the round specimen holder of the Leica

SM2500 instruction manual: the vacuum stage

is clamped the same way as the round specimen holder.

31

Page 32

5. Operation

5.5.4 Connecting the vacuum pump / placing specimens onto the vacuum stages

IMPORTANT:

Prior to first use, every vacuum table

surface must be milled once, just like

a specimen surface. This ensures that

the surface of the specimens milled on

the table later on will be perfectly

even.

To mill a table surface, carry out one

entire pre- and finishing milling cycle

as per chapters 5.6 - 5.8, pages 34 - 43

of this manual.

Fig. 5.17

Fig. 5.18

12

Connecting the vacuum pump

Place vacuum pump (make sure the voltage

rating of the vacuum pump is appropriate for

the mains supply in your laboratory!) on the

floor underneath the microtome bench.

Connect vacuum pump to mains.

Slide connecting hose (1) (part of standard

delivery of Leica vacuum pumps) onto the

nozzle on vacuum pump (2).

Connect the other end of connecting hose (1)

to the nozzle (3) of the vacuum stage.

Place the specimen onto the vacuum stage.

There are different types of vacuum

stages for different specimen sizes see next page.

32

Supplementary instruction manual V 1.2 07/2002

Page 33

5. Operation

Placing specimens onto vacuum stage for 30 -

50-mm lids

Fasten a lid suited to the size of the specimen

to be milled onto the vacuum stage (slotted

screws are part of standard delivery of

vacuum stage lids - use slotted screwdriver).

Place the specimen (1) onto the sintered sur-

face (2) of the lid.

Switch on the vacuum pump.

Fig. 5.19 12

Fig. 5.20 3

Fig. 5.21 4

Placing specimens onto vacuum stages for per-

forated specimen holders

Fasten a perforated specimen holder (3) suited

to the size of the specimen on the vacuum

stage 76 x 25 mm (4) or onto the vacuum stage

with variable surface (not shown here).

Place specimen on the perforated area of the

vacuum stage

Switch on the vacuum pump.

The following is recommended for all

vacuum stages, no matter of which

type and size:

If the specimen is smaller than the sintered or perforated stage surface, the

entire stage surface not covered by the

specimen should be covered with

autoadhesive plastic film.

Placing specimens onto vacuum stage 55 x 100

mm

Place the specimen directly on the sintered

surface area of the vacuum stage.

(Vacuum stage 55 x 100 mm not shown here).

Leica SP2600 Ultramilling attachment

33

Page 34

5. Operation

5.6 Preparatory steps prior to the milling procedure

For a detailed description of all control elements located on the

control unit, please refer to chapters 5.3 (Overview - control

panel) and 5.4 (Description of each individual control element) of

the Leica SM2500 instruction manual.

Select manual mode of operation MAN (button (5) - chapter 5.4.3, page

26, Leica SM2500 instruction manual).

In MAN mode, carry out the following preparatory steps:

Move the milling spindle to the upper limit position (button (48), chapter

5.4.13, p. 36, Leica SM2500 manual) and open the plexiglass cover.

Attached the miller holder (1) (containing the adjusted pre-miller) to the

milling spindle (use Allen screws size 5 (2) / Allen key size 5 - part of

SP2600 standard delivery).

Always slide plexiglass cover to upper position prior to attaching

the miller holders to the milling spindle!

34

1

2

Fig. 5.22

Supplementary instruction manual V 1.2 07/2002

Page 35

5. Operation

Insert the specimen (see chapters 5.5.2 and 5.5.4, pages 30 and 33 of this

manual) or - if you need to mill a vacuum table prior to first use - see

chapter 5.5.3, page 31 of this manual).

Wear protective gloves when working with potentially infectious

specimen material!

or

or

Move the specimen sledge underneath the miller (buttons (56) or (57),

chapter 5.4.14, page 37, Leica SM2500 instruction manual).

Set the milling window (button (61) and others - see chapter 5.4.14, page

37, Leica SM2500 instruction manual).

Press button (51) (chapter 5.4.13, page 36, Leica SM2500 manual) to bring

the cutting edge of the miller close to the specimen surface (coarse adjustment - small gap must still remain).

Always slide the plexiglass cover to the upper position prior to the

distance check milling edge / specimen surface! - Risk of injury!

Next, use buttons (50) and/or (49) (see chapter 5.4.13, page 36, Leica

SM2500 instruction manual) for fine adjustment of the distance between

milling edge and specimen surface.

Check the remaining distance in three different zones of the specimen

surface (beginning/center/end) moving the specimen sledge via buttons

(56) - (59), see chapter 5.4.14, page 37, Leica SM2500 manual) - the cutting edge of the miller should just about touch the specimen surface.

Caution:

Always check the distance between miller cutting edge and

specimen surface thoroughly prior to milling!

Under no circumstances may the miller cutting edge be positioned

more than a few microns (= selected milling thickness) below the

specimen surface when starting the milling procedure.

Leica SP 2600 Ultramilling attachment

If the surface height of the specimen is uneven, the cutting edge

should just about touch the highest point of the specimen. - Then

mill the specimen until the surface is completely level.

35

Page 36

5. Operation

5.7 Pre-milling

or

+

+

Select automatic mode of operation AUTO (button (5) - chapter 5.4.3, page

26 Leica SM 2500 instruction manual).

In AUTO mode, set the milling parameters for the pre-milling procedure:

Select STOP or PHOTO position (buttons (23) or (26) chapter 5.4.8, page

31 - Leica SM2500 instruction manual).

Select milling thickness (button (10) / rotary selector switch (9) - see

chapters 5.4.4 and 5.4.5, pages 27/28 - Leica SM2500 instruction manual).

(--> see following page for recommended settings).

Activate retraction (button (10) / rotary selector switch (9) - see chapters

5.4.4 and 5.4.5, pages 27/28 - Leica SM2500 instruction manual).

Select milling and return stroke speed.

(button (19) / rotary selector switch (9) - see chapter 5.4.4, page 27 and

chapter 5.4.7, page 30 - Leica SM2500 instruction manual).

(see next page for recommended settings).

36

or

Close plexiglass protective cover.

Start miller rotation (button (37) - chapter 5.4.11, page 34 - Leica SM2500

instruction manual).

Select rotational speed of miller (buttons (39), (40) - chapter 5.4.11, page

34 - Leica SM2500 instruction manual).

Select desired milling mode (button (15) - chapter 5.4.6. page 29 - Leica

SM2500 instruction manual).

Individual parameter settings depend on specimen material and

size. Please refer to the following page for a list of recommended

settings.

Supplementary instruction manual V 1.2 07/2002

Page 37

5. Operation

Recommended milling thickness settings for pre-milling

10 µm - keep milling until surface is completely level.

5 µm - three entire sledge strokes (milling and return stroke).

3 µm - three entire sledge strokes (milling and return stroke).

Do not exceed a milling thickness setting of 5 µm with the following materials: brittle, very ductile materials such as titanium or fiberglass and compound samples containing such materials (such

as printed circuit boards).

Recommended sledge speed settings for pre-milling

Milling stroke: 1.5 mm/s

Return stroke: any speed

Recommended rotational speed of miller for pre-milling

2,000- 3,000 rpm (depending on specimen type)

Recommended mode of operation for pre-milling

Select continuous mode of operation.

Starting the milling procedure

Switch on the vacuum cleaner (via button (35) on the control unit - see

chapter 5.4.11, page 34 of Leica SM2500 instruction manual) or via the

on/off switch of the vacuum cleaner itself.

Start sledge stroke (buttons (29), (30) - chapter 5.4.10, p. 33 - Leica

+

SM2500 instruction manual).

Carry out the milling steps as per above recommendation.

--> See next page for a perspective view of the pre-milling procedure.

Leica SP 2600 Ultramilling attachment

During milling:

switch on the vacuum cleaner,

wear appropriate safety goggles,

wear appropriate mask (type of mask depends on the material

being milled / size of the chips that form during milling).

Goggles and mask prevent milling chips and microdust from entering your eyes and from being inhaled.

37

Page 38

5. Operation

5.7.1 Perspective view of the pre-milling procedure

1

2

38

Fig. 5.23

Pre-milling procedure

The milling spindle carrying the pre-miller rotates clockwise (circular arrow

(1)) while the specimen sledge passes underneath the miller in the direction

of arrow (2).

The pre-miller leaves a serrated surface texture which is then in a second

milling procedure milled to a mirrorlike, even surface by the finishing miller

(see Fig 5.24 p. 42).

Supplementary instruction manual V 1.2 07/2002

Page 39

5. Operation

Ending the pre-milling procedure

or

Press RUN STOP or RUN ENABLE to stop the sledge (buttons (29), (30) -

Chapter 5.4.10, page 33 - Leica SM2500 manual) - or, when working in

PROG mode of operation, wait for the programmed number of strokes to

be finished (see chapter 5.4.3, page 26, Leica SM2500 manual).

If the specimen sledge has not stopped in the front limit position, activate

manual mode of operation MAN (button (5) - chapter 5.4.3, page 26,

Leica SM2500 manual) and move the specimen to the front limit position

(via buttons (58) or (59) - chapter 5.4.14, page 37- SM2500 manual) .

Stop miller rotation (button (37) - chapter 5.4.11, page 34 - Leica SM2500).

After switching off the milling spindle (button (37) - chapter. 5.4.11,

p. 34 - instruction manual Leica SM2500) the miller continues to

rotate for a little while!

Risk of injury!

Slide plexiglass protective cover to upper position.

Never touch the milling spindle while it is rotating and/or while

the plexiglass cover is shut, no matter whether the spindle is rotating or not.

Remove the miller holder containing the pre-miller.

Leica SP 2600 Ultramilling attachment

39

Page 40

5. Operation

5.8 Finishing milling

Attach the miller holder containing the finishing miller to the milling

spindle (Allen screws / Allen key size 5) - see Fig. 5.21, page 34).

Always slide the plexiglass cover to the upper limit position prior

to attaching the miller holders to the milling spindle!

Bring the cutting edge of the miller close to the specimen surface and

thoroughly check the distance between miller cutting edge and specimen surface as described for the pre-miller on page 35.

If necessary, adjust the milling window (button (61) and others - see

chapter 5.4.14, page 37 of Leica SM2500 instruction manual).

Setting the milling parameters for the finishing milling procedure

Once again activate automatic mode of operation AUTO and set the

milling parameters using the same control unit buttons as described for

the pre-miller on page 36.

Individual parameter settings depend on specimen material and

size. Please refer to the recommendations below and on the following page.

40

Recommended milling thickness settings for finishing milling

5 µm - keep milling until surface is completely level.

3 µm - three entire sledge strokes (milling and return stroke).

2 µm - three entire sledge strokes (milling and return stroke).

1 µm - three entire sledge strokes (milling and return stroke).

Do not exceed a milling thickness setting of 5 µm with the following materials: brittle, very ductile materials such as titanium or fiberglass and compound samples containing such materials (such

as printed circuit boards).

Supplementary instruction manual V 1.2 07/2002

Page 41

5. Operation

Recommended sledge speed settings for finishing milling

Milling stroke: 0.5 mm/s to 1.0 mm/s

Return stroke: any speed

Recommended rotational speed of miller for finishing milling

< 2.000 rpm

Recommended mode of operation for finishing milling

Select continuous mode of operation.

Starting the milling procedure

During milling:

switch on the vacuum cleaner,

wear appropriate safety goggles,

wear appropriate mask (type of mask depends on the material

being milled / size of the chips that form during milling).

Goggles and mask prevent milling chips and microdust from entering your eyes and from being inhaled.

Switch on the vacuum cleaner (via button (35) on the control unit - see

chapter 5.4.11, page 34 of Leica SM2500 instruction manual) or via the

on/off switch of the vacuum cleaner itself.

Start sledge stroke (buttons (29), (30) - chapter 5.4.10, p. 33 - Leica

+

SM2500 instruction manual).

Carry out the milling steps as per above recommendation.

--> See following page for a perspective view of the finishing milling procedure.

Leica SP 2600 Ultramilling attachment

Important note:

If you need to mill several specimens with identical results (e.g.

for examining a specimen layer located at a certain level), completely identical parameters have to be selected for each specimen (for pre-milling as well as for the finishing milling procedure).

41

Page 42

5. Operation

5.8.1 Perspective view of the finishing milling procedure

1

42

2

Fig. 5.24

Finishing milling procedure

The milling spindle carrying the finishing miller rotates clockwise (circular

arrow (1)) while the specimen sledge passes underneath the miller in the direction of arrow (2).

The serrated surface structure created by the pre-miller (see Fig 5.23 p. 38)

is converted by the finishing miller into a mirrorlike, completely even surface.

Supplementary instruction manual V 1.2 07/2002

Page 43

Ending the finishing milling procedure

5. Operation

or

Press RUN STOP or RUN ENABLE to stop the sledge (buttons (29), (30) -

chapter 5.4.10, page 33 - Leica SM2500 manual) - or, when working in

PROG mode of operation, wait for the programmed number of strokes to

be finished (see chapter 5.4.3, page 26, Leica SM2500 manual)

If the specimen sledge has not stopped in the front limit position, activate

manual mode of operation MAN (button (5) - chapter 5.4.3, page 26, Leica

SM2500 manual) and move the specimen to the front limit position (via

buttons (58) or (59) - chapter 5.4.14, page 37- SM2500 manual) .

Stop miller rotation (button (37) - chapter 5.4.11, page 34 - Leica SM2500).

After switching off the milling spindle (button (37) - chapter. 5.4.11,

p. 34 - instruction manual Leica SM2500) the miller continues to

rotate for a little while!

Risk of injury!

Remove the specimen for subsequent microscopic examination.

Slide plexiglass protective cover to upper position.

Never touch the milling spindle while it is rotating and/or while

the plexiglass cover is shut, no matter whether the spindle is rotating or not.

Remove the finishing miller.

5.9 Switching the instrument off (switching off the control unit)

Once all milling procedures have been completed or at the end of your

workday, switch off the mains switch at the rear of the control unit.

When switching off the mains switch on the control unit (see

chapter 5.2, p. 21 - Instruction manual Leica SM2500) the milling

spindle will rotate briefly.

Therefore, never switch off the control unit, while one of your

hands is in the rotation zone of the miller.

- Risk of injury!.

Leica SP 2600 Ultramilling attachment

43

Page 44

6. Troubleshooting

6. Troubleshooting

For all instructions on error detection and trouble shooting, please refer to

chapter 6, page 64 of the Leica SM2500 instruction manual .

44

Supplementary instruction manual V 1.2 07/2002

Page 45

7.1 Cleaning and disinfection

Cleaning

Clean the basic instrument Leica SM2500 as per the instructions in chap-

ter 7.1, pages 65 - 67 of the Leica SM2500 instruction manual.

Clean the Leica SP2600 with a soft, slightly moistened cloth using one of

the detergents listed above.

Clean diamond millers with a soft cloth moistened with alcohol.

7. Cleaning, disinfection and maintenance

Only authorized service technicians may access the internal components of the instrument for service and repair!

Cleaning detergents appropriate for the ultramilling attachment varnished surfaces:

mild laboratory detergents (slightly moistened cloth)!

non-varnished metal parts:

mild laboratory detergents,

xylene substitutes (slightly moistened cloth)

alcohol (slightly moistened cloth).

No liquids may enter the interior of the instrument during cleaning!

Disinfection

Remove potentially infectious milling waste / remaining samples and dis-

pose of as per the regulations applicable.

Disinfect instrument and accessories as per the instructions of the disin-

fectant manufacturer.

Leica SP 2600 Ultramilling attachment

For disinfection of the instrument and accessories use Leica Cryofect or other commercial disinfectants. - Use all disinfectants according to the manufacturers instructions!

No liquids may enter the interior of the instrument during disinfection!

When disinfecting, wear appropriate goggles and mask as well as

protective gloves!

Dispose of potentially infectious specimen material as per the

laboratory regulations applicable in the country of operation!

45

Page 46

7. Cleaning, disinfection and maintenance

7.2 Maintenance

Only authorized service technicians may access the internal components of the instrument for service and repair!

No liquids may enter the interior of the instrument during maintenance!

Carry out the maintenance steps to be done by the user as per the in-

structions in chapter 7.2, pages 67 - 70 of the Leica SM2500 instruction

manual.

In addition to the maintenance steps listed in the Leica SM2500 manual,

the following maintenance work is required for the Leica SP2600:

chapter 7.2.1 - Resharpening the millers.

chapter 7.2.2 - Replacing the light bulb in the calibration device.

7.2.1 Resharpening the millers

The millers need to be resharpened as soon as the milled specimen sur-

faces no longer have a smooth, mirrorlike appearance and/or when milling residues / residues of a grimy appearance start to accumulate on the

specimen surface.

46

Supplementary instruction manual V 1.2 07/2002

Page 47

7. Cleaning, disinfection and maintenance

7.2.2 Replacing the light bulb in the calibration device

Remove base cover (2) of calibration device (1) (unscrew 4 slotted

screws (3)).

Loosen light bulb holder (5) (metal bridge with lamp socket) (unscrew 2

slotted screws (4)).

Take replacement light bulb (8) out of sponge rubber cube (7).

Remove broken light bulb (6) from lamp socket and replace with new

light bulb (8).

Place another replacement bulb (8) into the sponge rubber cube (7).

Put light bulb holder (5) back in place.

Place ring with cable (9) onto bore (10) in the light bulb holder.

Fasten light bulb holder with two screws (4).

Put sponge rubber cube (7) with new replacement light bulb (8) back into

the calibration device.

Put base cover (2) back in place and fasten with 4 screws (3).

7

1

Fig. 7.1

Leica SP 2600 Ultramilling attachment

8

5

6

10

9

2

4

3

47

Page 48

8. Overview - accessories

8.1 Miller holders and millers

Miller holder

Holder for pre- and finishing miller

Pre-miller

Pre-miller D - with diamond edge, cutting angle -1°, clearance angle +3°

Finishing miller

Finishing miller D - with diamond edge, cutting angle +3°, clearance

angle +4°, for milling plastics

Finishing miller D - with diamond edge, cutting angle -8°, clearance angle

+1.5°, for milling precious and nonferrous heavy metals

Finishing miller D - with diamond edge, cutting angle -1°, clearance angle

+1.5°, for milling light metals

Finishing miller D - with diamond edge, cutting angle -5°, clearance angle

+1.5°, for milling light metals

Counterbalance insert - for Leica SP2600 - to be used instead of a pre- or

finishing miller

8.2 Base plates for specimen holders and vacuum stage adapters

Base plate with vise

Base plate with dovetail guide

8.3 Specimen holders

Specimen clamp 44 x 58 mm,

for base plate with dovetail guide

Round specimen holder, for base plate with dovetail guide

8.4 Vacuum stage adapters

Vacuum stage adapter for base plate with vise

Vacuum stage adapter for base plate with dovetail guide

48

Supplementary instruction manual V 1.2 07/2002

Page 49

8. Overview - accessories

8.5 Vacuum stages and matching lids / perforated specimen holders

Vacuum stage for Leica SP2600 - basic body for lids 30 - 50 mm

Lid, 30 mm, for Leica SP2600 vacuum stage

Lid, 40 mm, for Leica SP2600 vacuum stage

Lid, 50 mm, for Leica SP2600 vacuum stage

Vacuum stage for Leica SP2600 - 55 x 100 mm

Vacuum stage, 76 x 25 mm

Available either configured (with vacuum stage adapter for base plate

with vise) or without vacuum stage adapter.

To be used with several different perforated specimen holders:

specimen holder, 5 x 5 perforations

specimen holder, 5 x 10 perforations

specimen holder, 10 x 10 perforations

specimen holder, 10 x 15 perforations

specimen holder, 15 x 15 perforations

specimen holder, 20 x 10 perforations

specimen holder, 20 x 15 perforations

specimen holder, 25 x 15 perforations

specimen holder, 30 x 15 perforations

Vacuum stage, with variable surface: 76 x 25 mm, 76 x 56 mm

and 100 x 65 mm.

To be used with the same perforated specimen holders as vacuum stage

76 x 25 mm.

8.6 Vacuum pumps

Vacuum pump, 230 V, 50 Hz

Vacuum pump, 120 V, 60 Hz

Leica SP 2600 Ultramilling attachment

49

Page 50

8 Overview - accessories

8.7 Additional accessories

Vacuum cleaner and vacuum cleaner accessories

Vacuum cleaner Fakir S20, with connection hose

230 V / 50 Hz only

Set of vacuum cleaner bags for Fakir S 20

Illumination

Halogen spotlight illumination

230 V/50 Hz only

50

Supplementary instruction manual V 1.2 07/2002

Page 51

9. Warranty and service

For all information on warranty and service, please refer to chapter 9, pages

74 - 76 of the Leica SM2500 instruction manual.

9. Warranty and service

Leica SP 2600 Ultramilling attachment

51

Loading...

Loading...