Page 1

Instruction Manual

Leica CM3050 S – Cryostat

English V1.2– 11/2006

Always keep this manual near the instrument.

Read carefully prior to operating the instrument.

Leica CM3050 S

Cryostat

Page 2

Page 3

Important note

Serial No.: .............. ......................................................

Year of Manufacture: ...............................................

Country of Origin: Federal Republic of Germany

The information contained in this document

represents state-of-the-art technology as well as

the current state of knowledge.

Leica will not assume liability for errors that might

be contained in this manual, nor for accidental

damage or damage arising from the delivery,

performance or use of this manual.

Therefore, no claims can be made based on the

text and illustrations in this instruction manual.

Leica Microsystems Nussloch GmbH reserves the

right to change technical specifications

without notice since each of our products is

subject to a policy of continuous improvement.

This document is protected under copyright laws.

Leica Microsystems Nussloch GmbH

retains all rights related to this documentation.

Any reproduction of text and illustrations - or any

parts thereof - in form of printing, photocopying,

microfiches, or other methods, including

electronic systems, requires the prior written

permission of Leica Microsystems Nussloch

GmbH.

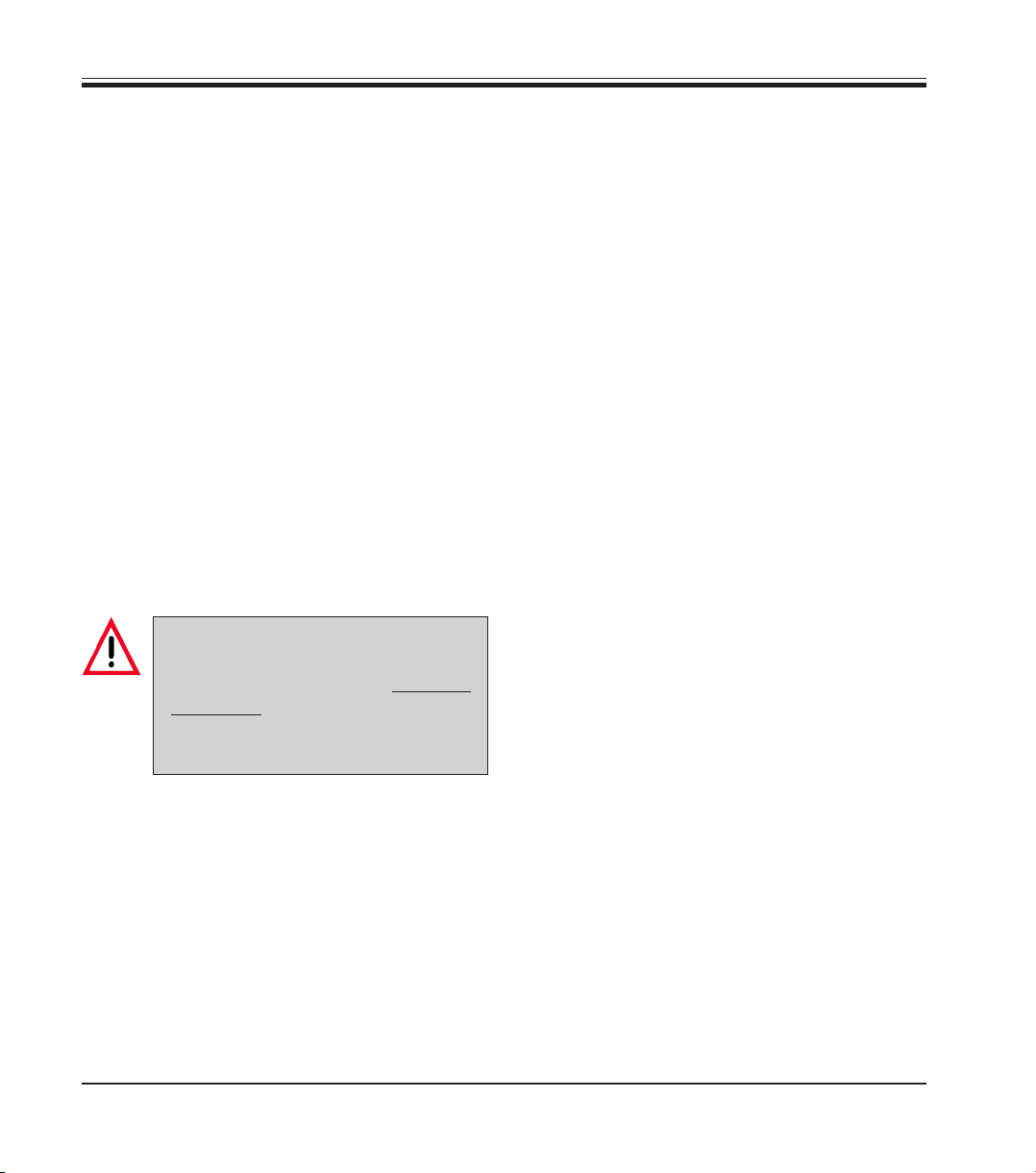

The serial number and the year of manufacture

are specified on the nameplate at the back of the

instrument.

Issued by:

Leica Microsystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 6224 143-0

Fax: +49 6224 143-200

Internet: http://www.histo-solutions.com

Leica CM 3050 S – Cryostat

© Leica Microsystems Nussloch GmbH

3

Page 4

Table of Contents

1. Important information ................................................................................................................ 7

1.1 Symbols used in this manual and .................................................................................................... 7

1.2 Designated use ................................................................................................................................... 8

1.3 Qualification of personnel .......................................................................................................... 8

2. Sicherheit .................................................................................................................................... 9

2.1 General information on instrument design and safe handling .................................................... 9

2.2 Integrated safety devices ................................................................................................................. 9

2.2.1 Locking the handwheel ................................................................................................................... 10

2.2.2 Centering the handwheel grip ........................................................................................................ 10

2.2.3 Emergency stop function (instruments with sectioningmotor only) ........................................ 11

2.2.4 Knife guard ........................................................................................................................................ 11

2.3 Safety instructions: handling and operation of the instrument................................................. 12

2.3.1 Transport ........................................................................................................................................... 12

2.3.2 Site requirements ............................................................................................................................. 12

2.3.3 Electrical connections ..................................................................................................................... 12

2.3.4 Handling microtome knives/blades ............................................................................................... 13

2.3.5 Knife guard/handwheel lock........................................................................................................... 13

2.3.6 Motorized sectioning ....................................................................................................................... 13

2.3.7 Defrosting/Handling frozen tissue ................................................................................................. 13

2.3.8 Frozen parts of the instrument and frozen accessories ............................................................ 13

2.3.9 Infectious/radioactive material ...................................................................................................... 14

2.3.10 Disinfection and cleaning ............................................................................................................... 14

2.3.11 Removing/reinstalling the microtome ........................................................................................... 15

2.3.12 Display message ‘Dry microtome’ ................................................................................................. 15

2.3.13 Maintenance .............................................................................................................................. 15

3. Installation................................................................................................................................. 16

3.1 Site requirements ............................................................................................................................. 16

3.1.1 General site requirements .............................................................................................................. 16

3.1.2 Electrical connections ..................................................................................................................... 16

3.2 Unpacking and installation ............................................................................................................. 16

3.2.1 Repacking .......................................................................................................................................... 16

3.3 Standard delivery ............................................................................................................................. 17

3.4 Installing/inserting accessories ..................................................................................................... 19

3.4.1 Installing the handwheel ................................................................................................................. 19

3.4.2 Inserting the accessories ............................................................................................................... 19

3.4.3 The footswitch .................................................................................................................................. 20

3.5 Prior to switching on the instrument ........................................................................................ 20

4

Instruction Manual V1.2 - 11/2006

Page 5

Table of Contents

4. Instrument Properties .............................................................................................................. 21

4.1 Overview ............................................................................................................................................ 21

4.2 Technical Data........................................................................................................................... 23

5. Operation ................................................................................................................................... 25

5.1 Operating the instrument for the first time ................................................................................... 25

5.2 Switching on/fuses ........................................................................................................................... 26

5.3 Control panel 1 .................................................................................................................................. 27

5.3.1 Key functions in control panel 1..................................................................................................... 27

5.3.2 Display functions in control panel 1 .............................................................................................. 27

5.3.3 Display indications when switching on ........................................................................................ 28

5.3.4 Menu functions: setting parameters of refrigeration, time and preset counter .................... 29

5.3.5 Status display .................................................................................................................................... 32

5.3.6 Indication of refrigeration state, section thickness setting and counters .............................. 33

5.4 Control panel 2 .................................................................................................................................. 34

5.4.1 Selecting a sectioning mode / ........................................................................................................ 35

5.4.2 Setting the sectioning window ....................................................................................................... 36

5.4.3 Selecting sectioning speed ............................................................................................................ 37

5.4.4 Emergency stop ................................................................................................................................ 37

5.4.5 Coarse feed keys .............................................................................................................................. 38

5.4.6 Trimming and sectioning functions ............................................................................................... 39

5.4.7 Setting the section thickness ......................................................................................................... 39

5.5 Daily operation of the instrument .................................................................................................. 40

5.5.1 Freezing specimens onto specimen .............................................................................................. 40

5.5.2 Freezing specimens onto specimen .............................................................................................. 41

5.5.3 Optional accessories for freezing .................................................................................................. 41

5.5.4 Inserting specimen discs into the .................................................................................................. 42

5.5.5 Specimen orientation ....................................................................................................................... 42

5.5.6 Trimming / sectioning ...................................................................................................................... 43

5.6 Finishing work ................................................................................................................................... 44

5.6.1 Daily routine steps............................................................................................................................ 44

5.6.2 Switching off the instrument for a ................................................................................................. 44

5.7 Defrosting .......................................................................................................................................... 45

5.7.1 Automatic chamber defrost cycle ................................................................................................. 45

5.7.2 Manual chamber defrost cycle ...................................................................................................... 46

5.7.3 Defrosting the specimen head ................................................................................................ 46

Leica CM3050 S – Cryostat

5

Page 6

Table of contents

6. Troubleshooting, applications tips ....................................................................................... 47

6.1 Displayed error messages .............................................................................................................. 47

6.1.1 Other error indications .................................................................................................................... 47

6.2 Potential problems - causes and remedies ................................................................................. 48

6.3 Reference chart for temperature settings (in minus °C) .................................................... 52

7. Disinfection, cleaning and maintenance ............................................................................ 53

7.1 Safety instructions ........................................................................................................................... 53

7.2 Spray disinfection with Leica Cryofect ......................................................................................... 53

7.3 Disinfection with conventional ....................................................................................................... 54

7.4 Cleaning ............................................................................................................................................. 54

7.5 Removing / reinstalling the microtome ......................................................................................... 55

7.5.1 Removing the microtome ................................................................................................................ 55

7.5.2 Disassembling the specimen head ................................................................................................ 55

7.5.3 Reinstalling the microtome ............................................................................................................. 56

7.6 Exchanging the fluorescent light lamp................................................................................... 57

8. Warranty and service .............................................................................................................. 58

9. Appendix .................................................................................................................................... 59

1. Electrohydraulic height adjustment .............................................................................................. 59

2. Ordering information - accessories ....................................................................................... 62

10. EC Declaration of Conformity ..................................................................................... 63

11. Decontamination Certificate (master) .................................................................................... 64

6

Instruction Manual V1.2 - 11/2006

Page 7

1. Important information

The chapters of the Leica CM3050 S cryostat

instruction manual:

Chapter 1 Structure of the manual:

• Table of contents

• Important information on this

manual

Chapter 2 Safety

• Read this chapter before

operating the instrument!

Chapter 3 Installation

• Unpacking and installation

• Standard delivery, information

on accessories

Chapter 4 Instrument properties

• Overview

• Technical data

Chapter 5 Operation

• Controls

• Setup, daily use and shut

down

Chapter 6 Trouble shooting

and applications tips

• Operating errors

• Display error messages

• Temperature reference chart

Chapter 7 Disinfection, cleaning

and maintenance

Chapter 8 Warranty and service

Chapter 9 Electrohydraulic height adjustment

Ordering information accessories

EC Declaration of Conformity

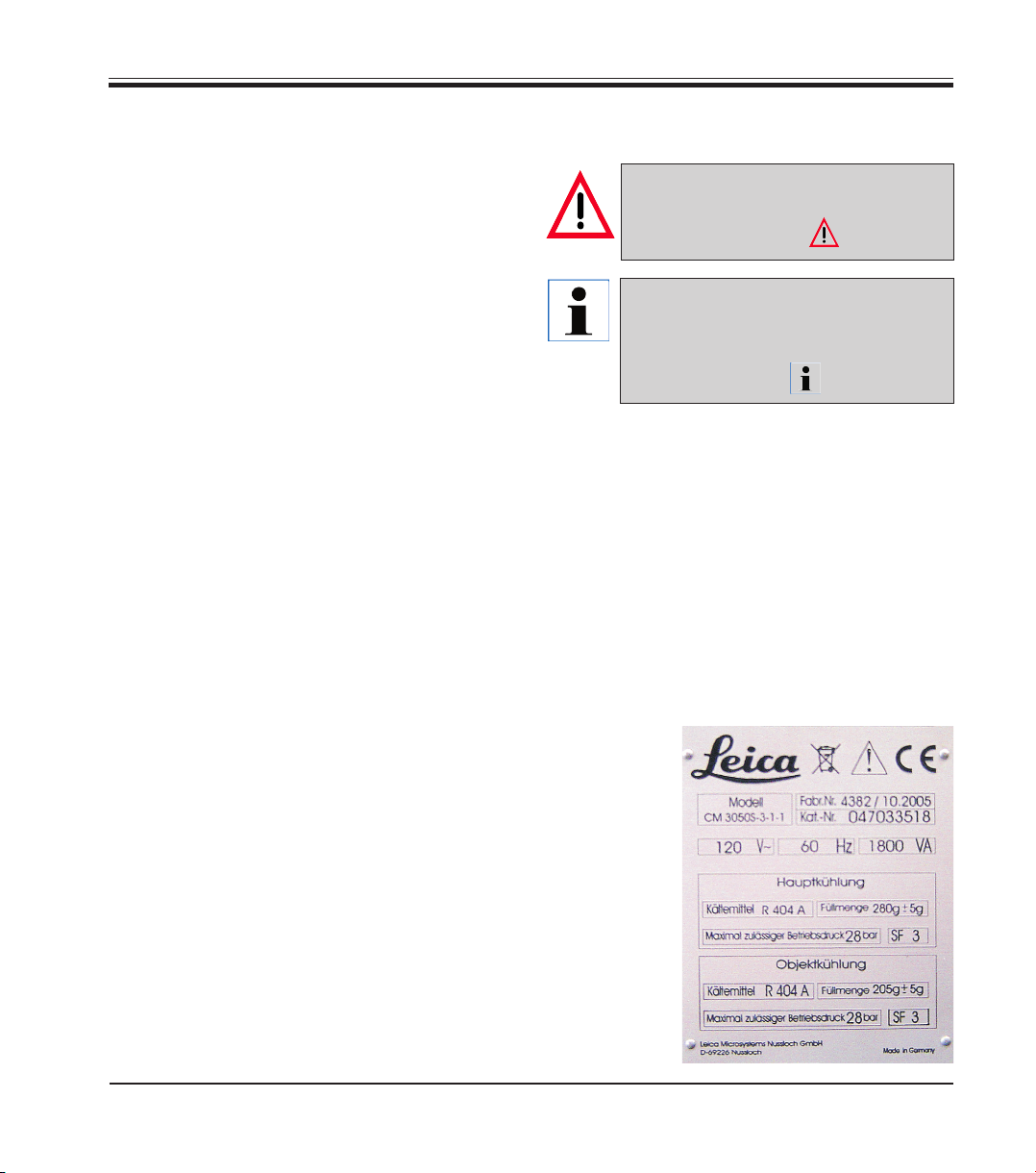

1.1 Symbols used in this manual and

their meaning

Warnings

appear in a grey box and are marked

by a warning triangle .

Notes

i.e. important user information

appears in a grey box and is marked

by an information symbol.

(5)

(Fig.5)

Instrument type:

All information given in this instruction manual

applies only to the instrument type indicated on

the title page.

A name plate, indicating the instrument serial

number, is attached to the back of the instrument.

Required information for

all inquiries:

For any inquiries please

specify:

• Instrument

type

• Serial-

number

Figures in brackets refer to item

numbers in drawings or to the

drawings themselves.

Leica CM 3050 S – Cryostat

7

Page 8

1. Important information

General

This instruction manual includes important

instructions and information related to the

operating safety and maintenance of the

instrument.

The instruction manual is an important part of the

product. It must be read carefully before using

the instrument for the first time and must always

be kept with the instrument.

If additional requirements, which exceed the

scope of this manual, are imposed by regula-tions

and/or laws on accident prevention and

environmental protection in the country of

operation, appropriate instructions for

compliance with such requirements must be

added to this manual.

Read this instruction manual carefully before

attempting to use or operate the instrument.

Please pay particular attention to

chapter 2 (safety features, safety

instructions). - Please read this

information, even if you are already

familiar with the operation and use of

other Leica products.

1.2 Designated use

The Leica CM3050S is a powerful cryostat for

routine as well as research applications in

biology, medicine and industry.

The instrument has been designed for rapid

freezing and sectioning of tissue samples.

The instrument has not been designed for unattended storage of tissue material.

The instrument may only be operated within the

scope of its designated use as described above

and as per the instructions given in this manual.

Any other use of the instrument is considered

improper.

1.3 Qualification of personnel

The Leica CM3050S may only be operated by

trained laboratory personnel.

All laboratory personnel designated to operate the

instrument must carefully read the present

instruction manual prior to starting work with the

instrument.

8

Instruction Manual V1.2 - 11/2006

Page 9

2. Sicherheit

2.1 General information on instrument

design and safe handling

This instrument has been built and tested in accordance with the following safety regulations

on electrical measuring, control, regulating and

laboratory devices:

• DIN EN 292

• DIN EN 61010-1

• EN 50082-1

• EN 55011

• IEC 1000-4

as well as according to the international quality

standard

• DIN ISO 9001

In order to maintain this condition and to ensure

safe operation, the operator must observe the

instructions and warnings contained in this instruction manual.

2.2 Integrated safety devices

The instrument is equipped with the following

safety devices:

• Handwheel lock

• Handwheel grip centering

• Emergency stop function

(instruments with sectioning motor only)

• Knife holder equipped with knife guard

The safety devices installed by the manufacturer of the instrument only constitute the basis of

accident prevention.

Mainly responsible for accident-free operation

is above all the institution which owns the instrument and, in addition, the designated personnel who operate, service or repair the

instrument.

Leica CM3050 S – Cryostat

9

Page 10

2. Safety

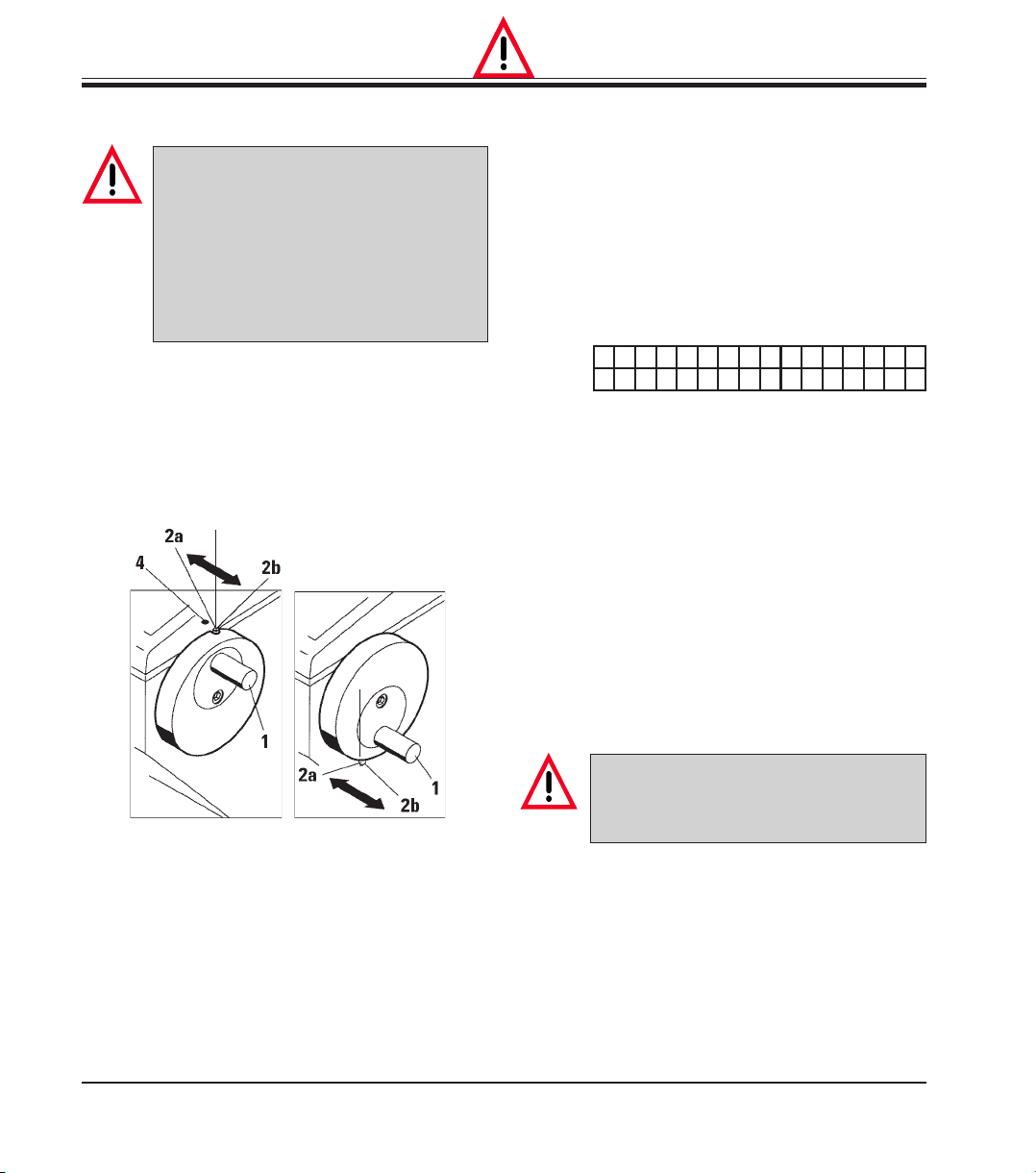

2.2.1 Locking the handwheel

Always cover the cutting edge with

the knife guard and lock the handwheel:

• Prior to doing any work on

knife and/or specimen.

• Prior to exchanging specimens.

• During work breaks.

The handwheel can be locked in 2 positions:

• with the grip in the uppermost position (left),

• with the grip in the lowest position (right).

2

Instruments with sectioning motor:

The sectioning motor is now blocked.

All instruments:

The message ‘LOCKED’ in the display of control

panel 1 indicates that the handwheel has been

locked:

CT-30°C OT-35°C

LOCK ED

Unlocking:

• To unlock, push locking pin (2) to the left into

position (2a).

• Display indication ‘LOCKED’ disappears.

Instruments with sectioning motor:

The sectioning motor can now be activated

again.

2

Locking:

• Rotate handwheel, until grip (1) is in upper or

lower position.

• To lock, press pin (2) to the right into position

(2b).

--> The upper locking position for pin (2) is

marked by a black dot (4).

10

2.2.2 Centering the handwheel grip

During motorized sectioning, for

safety reasons always center the

handwheel grip!

• To center grip (1), pull outwards and pivot

into center of handwheel.

• When released, the grip locks into position.

Instruction Manual V1.2 - 11/2006

Page 11

2. Safety

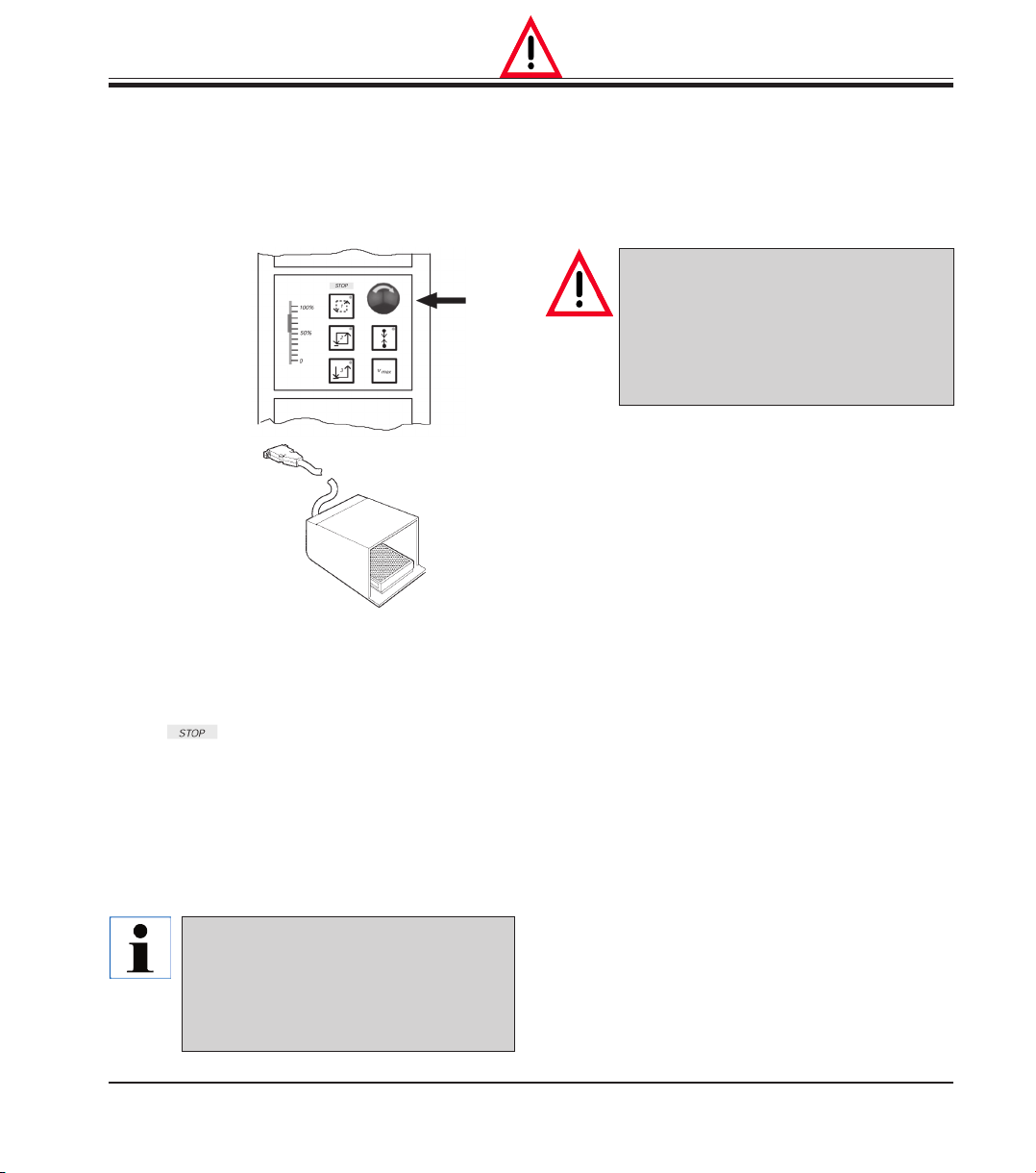

2.2.3 Emergency stop function

(instruments with sectioning

motor only)

The emergency stop is activated via the red

emergency stop button in control panel 2 or via

the footswitch

Control panel 2

Footswitch

Activating the emergency stop function

2.2.4 Knife guard

All knife holders are equipped with a knife

guard (--> see separate instruction manuals on

knife holders).

Always cover the cutting edge with

the knife guard:

• Prior to doing any work on knife

and/ or specimen.

• Prior to exchanging specimens.

• During work breaks.

• Press emergency stop button or step on

footswitch forcefully.

-->

STOP (red) lights up.

As soon as the emergency stop function is activated, the sectioning motor stops.

Deactivating the emergency stop

• To deactivate, rotate emergency stop button

in direction of arrow.

If the emergency stop function has

been activated by the footswitch,

unlocking is not necessary (func-tion

is unlocked as soon as the footswitch

is released).

Leica CM3050 S – Cryostat

11

Page 12

2. Safety

2.3 Safety instructions: handling and operation of the instrument

2.3.1 Transport

• To avoid severe damage to the instrument by

running it while the compressor oil is displaced from its regular position:

• Do not tilt the instrument,

only transport in an upright position.

• After transport, wait at least 4 hours be-

fore turning the instrument on.

-->The compressor oil may have been

displaced during transport and must

settle to its original position before switchingthe instrument on.

Otherwise, the instrument may be

severely damaged.

2.3.2 Site requirements

• Do not operate the instrument in rooms with

explosion hazard.

• To ensure proper instrument function maintain a minimum distance of 10 cm between

walls and/or furniture and all sides of the instrument!

2.3.3 Electrical connections

• Do not use extension cords for connecting

the instrument to mains.

--> Fire hazard!

--> Instrument malfunctions caused by

voltage drop.

• During the start-up phase of the compressor,

the nominal voltage must not drop below the

values specified in chapter 4.2 ‘Technical

data’!

--> The compressor needs a start-up current

at between 25 and 35 A (see chapter 4.2

‘Technical data’)

• Ensure uniform current supply according to

specifications.

--> Electrical power supply deviating from

specifications damages the instrument.

• Therefore, arrange for the electrical in-

stallations on site to be checked by a

trained professional and make sure any

necessary upgrades are installed!

• Have the circuit protected by a fuse of its

own!

• Do not connect any other consumers to

the same circuit.

• Prior to connecting the instrument to

mains, make sure the electrical power

supply in your laboratory corresponds to

the values indicated on the instrument

nameplate (located at the rear of the instrument)!

12

Instruction Manual V1.2 - 11/2006

Page 13

2. Safety

2.3.4 Handling microtome knives/blades

• Danger!

-->Microtome knives and disposable blades

have extremely sharp cutting edges and

can cause serious injuries. Therefore:

• Handle knives / blades with utmost care.

• Never leave any knives / blades in unprotected places!

• Never place a knife, no matter where,

with the cutting edge facing upwards.

• Never try to catch a falling knife.

• Always insert the specimen

inserting the knife.

before

2.3.5 Knife guard/handwheel lock

• Always cover the cutting edge with the knife

guard and lock the handwheel:

• Prior to doing any work on knife and / or

specimen.

• Prior to exchanging specimens.

• During work breaks.

2.3.6 Motorized sectioning

• Do not interrupt sectioning / trimming by setting the sliding potentiometer to zero speed!

-->This does not really switch the sectioning

function off - it only operates at ‘0’ speed.

If the sliding potentiometer is accidentally moved, the instrument will resume sectioning immediately (risk of injury)!

2.3.7 Defrosting/Handling frozen tissue

• Never leave specimens unattended in the

cryochamber over an extended period of

time!

-->In case of power failure or instrument

failure, or during the automatic defrost cycle, tissue material can be destroyed.

• During the defrost cycle the cryochamber is

partially warmed. - Therefore:

• Remove sensitive specimens from the

chamber prior to defrosting.

• If automatic defrosting is programmed to

take place during the night, remember to

remove all specimens from the cryochamber prior to leaving work.

2.3.8 Frozen parts of the instrument and

frozen accessories

• Prolonged contact of bare skin to frozen

surfaces of the instrument or to frozen

accessories (specimen discs, knife holder,

shelves etc.) can cause frostbite.

• Wear protective gloves.

• During motorized sectioning, always center

the handwheel grip!

Leica CM3050 S – Cryostat

13

Page 14

2. Safety

2.3.9 Infectious/radioactive material

• Danger!

Use caution when working with potentially

infectious specimens:

-->Risk of infection!

• When working with potentially infectious /

radioactive specimens:

• Wear protective clothes (gloves, protec-

tive boots, mask, lab coat), in compliance

with radiation safety regulations and/or

in-house regulations on handling infectious / radioactive material.

• When working with radioactive specimens:

• Comply with applicable radiation safety

regulations!

• Dispose of radioactive specimen waste ac-

cording to applicable regulations.

2.3.10 Disinfection and cleaning

• Prior to disinfection, switch the instrument

off and unplug it from mains.

• For removal of the microtome from the cryochamber see chapter 2.3.11 ‘ Removing the

microtome’.

• For disinfection, wear protective gear:

(gloves, mask, lab coat etc.)!

• For disinfection, only use alcohol-based disinfectants!

• Do not use solvents (xylene, acetone etc.)

for cleaning or disinfection!

• Do not spray disinfectants into the evaporator!

--> Risk of icing!

• Explosion hazard when working with alcohol:

Make sure the premises are appropriately

ventilated!

• When using disinfectants and detergents,

comply with all safety instructions supplied

by the manufacturer of the product!

14

• Dispose of waste liquids from disinfection/

cleaning as well as of sectioning waste according to applicable regulations on disposal

of special category waste!

• Disinfected accessories must be thoroughly

dry when reinserting them into the chamber!

--> Risk of icing!

• Make sure the chamber is completely dry

before switching the instrument back on:

--> Explosion hazard through alcohol vapors!

--> Risk of icing!

Instruction Manual V1.2 - 11/2006

Page 15

2. Safety

2.3.11 Removing/reinstalling the

microtome

• Before removing the microtome:

• Switch instrument off.

• Unplug from mains.

• Place handwheel grip in lowest position and

lock.

-->When removing the microtome, the

specimen head must always be lokked in the lowest position.

Otherwise the upper part of the slot

cover might be bent and consequently

damaged!

•

When removing the microtome:

• Wear gloves when removing the microtome while it is still frozen.

-->Risk of frost bite!

• On instruments with specimen cooling:

do not distort the refrigerating tube!

If distorted it might break, causing extremely cold refrigerant to escape. - > Risk of frost bite!

Before reinstalling the microtome:

•

• Microtome must be completely dry. ->Humidity in the interior of the microtome freezes and causes

microtome malfunctions and/or

damage to the microtome.

2.3.12 Display message ‘Dry microtome’

• If the error message ‘Dry Microtome’ is displayed in control panel 1, the following has

happened:

• Cryochamber refrigeration has been in-

terrupted for an extended period of time

(e.g. power failure), causing the chamber

temperature to rise into the positive

digits.

• If this message appears,

the instrument but remove the microtome

from the chamber, disinfect, if necessary,

and

dry thoroughly before reinstalling it

into the chamber (see chapter 7.1 to 7.5).

do not switch on

2.3.13 Maintenance

• Only technical service engineers authorized

by Leica may access the internal components of the instrument for service and repair.

• The fluorescent light lamp (chamber illumination), unless broken or splintered, can be

replaced by the user:

• Switch off mains switch!

• Unplug the instrument from mains!

• If the lamp is broken or splintered:

Have lamp replaced by Leica Technical

Service!

-->Risk of injury!

• All accessories/tools removed from the

cryochamber must be thoroughly dry before putting them back into the chamber!

-->Risk of icing!

Leica CM3050 S – Cryostat

• Use only those replacement lamps that correspond to technical specification (see

chapter 4.2 ‘Technical Data’).

15

Page 16

3. Installation

3.1 Site requirements

Make sure to read and follow all

safety instructions in chapter 2.3.2

‘Site requirements’!

3.1.1 General site requirements

• No direct sunlight.

• Electrical power supply within distance

(length of power cord = approx. 4 meters do not use extension cords!).

• No draft (caused by air conditioning etc.).

• Even floor surface.

• Practically vibration-free floor.

• Handwheel easily accessible.

• Room temperature constantly below +22 °C.

• Relative humidity of air maximum 60 %.

High ambient temperature and/or high

air humidity negatively affect

instrument cooling performance!

3.2 Unpacking and installation

Unpacking instructions are always located in a

transparent protective envelope on the outside

of the instrument shipping crate.

Make sure to read and follow all

safety instructions provided in

chapter 2.3.1 ‘Transport’ and on the

unpacking instructions!

3.2.1 Repacking

We recommend to keep the original shipping

crate and the unpacking instructions for the

Leica CM3050 S.

For repacking, proceed as per unpacking instructions, in reverse order.

Available models

• Basic instrument

- with sectioning motor

- without specimen cooling

3.1.2 Electrical connections

Make sure to read and follow all

safety instructions in chapter 2.3.3

‘Electrical connections’!

16

• Basic instrument

- without sectioning motor

- with specimen cooling

• Basic instrument

- with sectioning motor

- with specimen cooling

Instruction Manual V1.2 - 11/2006

Page 17

3.3 Standard delivery

3. Installation

1 Cryostat with microtome .............................................................................0460 32037

1 Handwheel with marking, antibacterial ...................................................0471 42558

1 Heat extractor, stationary ........................................................................... 0369 11197

1 Low-temperature stabilizer for heatextractor ........................................ 0452 27919

1 90° prism for direct specimen freezing on specimen head

with clamping screw to facilitate specimen trimming .......................... 0443 25949

1 Set of specimen discs ................................................................................. 0470 43550

- 4 Specimen discs, 25 mm ......................................................................... 0416 19275

- 4 Specimen discs, 30 mm ......................................................................... 0370 08587

1 Storage shelf, right ...................................................................................... 0443 25723

1 Storage shelf, left ......................................................................................... 0443 33549

1 Section waste tray .......................................................................................0400 26817

1 Foot switch with protective guard ............................................................ 0502 29977

1 Rubber mat .................................................................................................... 0443 25732

1 Freezing shelf cover .................................................................................... 0443 30783

1 Brush shelf .................................................................................................... 0398 13088

1 Tool set ........................................................................................................... 0436 43463

-1 Brush, fine .................................................................................................0183 28642

-1 Leica-brush ............................................................................................... 0183 30751

-1 Allen key, size 1.5 .....................................................................................0222 10050

-1 Allen key, size 2.5 .....................................................................................0222 04137

-1 Allen key, size 3.0 .....................................................................................0222 04138

-1 Allen key, size 4.0 .....................................................................................0222 04139

-1 Allen key with spherical head, size 4.0 ................................................ 0222 32131

-1 Allen key, size 5.0 .....................................................................................0222 04140

-1 Allen key with handle, size 5.0 ............................................................... 0194 04760

-1 Allen key, size 6.0 .....................................................................................0222 04141

-1 Single-head wrench, size 13.................................................................. 0330 33149

-1 Single-head wrench, size 16.................................................................. 0330 18595

1 Bottle of OCT-Compound, mounting medium

for cryosectioning, 125 ml ........................................................................... 0201 08926

1 Bottle of cryostat oil, type 407, 50 ml ........................................................ 0336 06098

1 Pair of cut resistant gloves, size S ............................................................ 0340 40859

1 Instruction manual Leica CM3050 S - G/E/F/S ........................................ 0708 37109

In addition to the above:

Instruments with specimen cooling:

1 90° Prism

for low temperature quick freezing

Leica CM 3050 S – Cryostat

Configured instruments:

1 Knife holder base

1 Knife holder with accessories

Instruments with sectioning motor:

1 Footswitch with

protective guard

17

Page 18

3. Installation

Further accessories:

In addition to the above:

• Instruments with specimen cooling:

1 90° Prism for low temperature quick freezing

• Configured instruments:

1 Knife holder base

1 Knife holder with accessories

• Instruments with sectioning motor:

1 Footswitch with protective guard

Further accessories which you ordered will be included in the box containing

the standard delivery items.

Knife holders are delivered with anti-roll guide, knife guard, and a

separate instruction manual.

In case of non-configured instruments, the knife holder is not a

part of standard delivery but must be ordered separately.

18

• Check all delivered parts against the packing list and against your order

to verify whether the delivery is complete!

If there is any difference, contact your local Leica office immediately.

Instruction Manual V1.2 - 11/2006

Page 19

3. Installation

3.4 Installing/inserting accessories

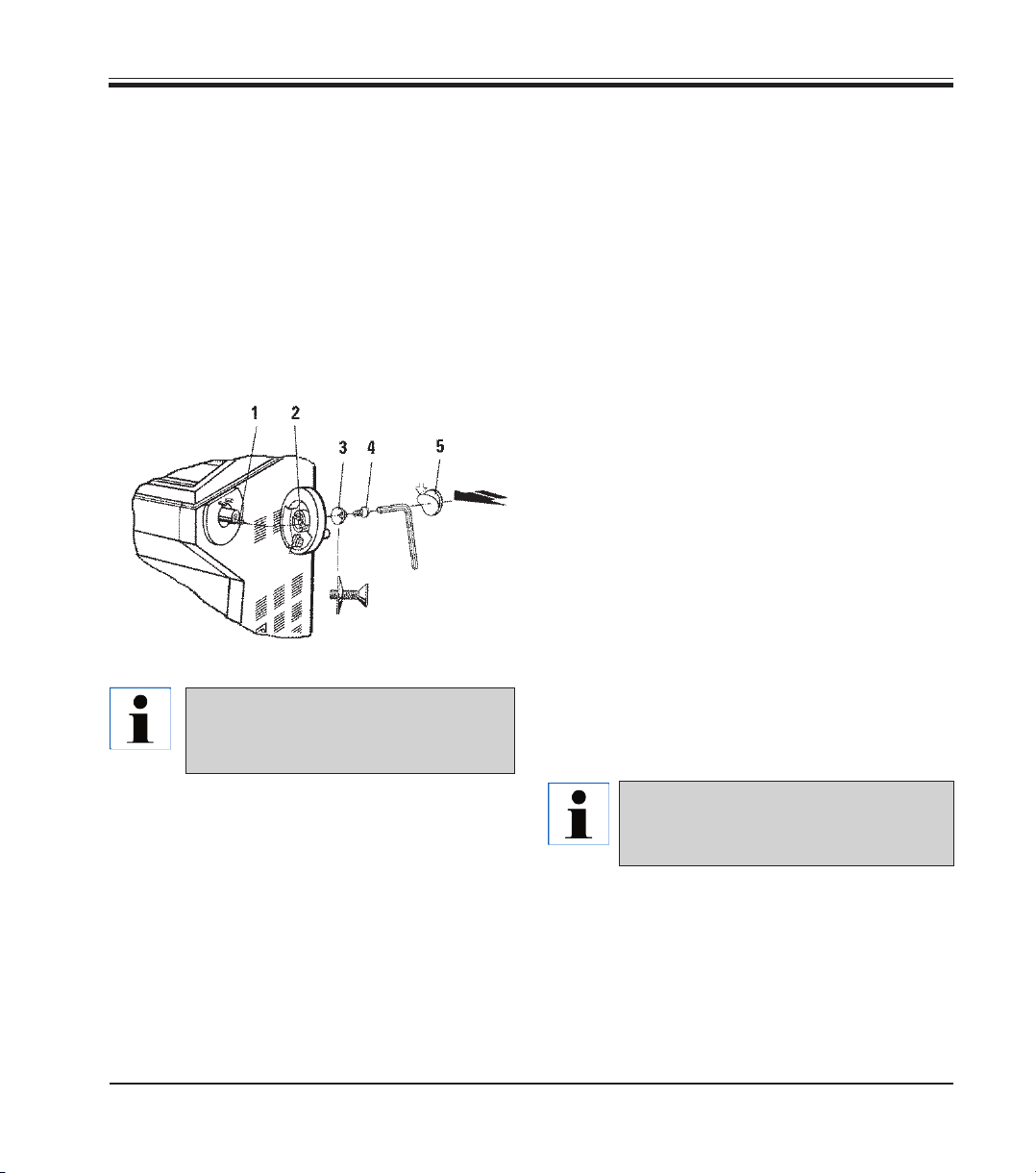

3.4.1 Installing the handwheel

• Insert pin (1) of the handwheel shaft into

hole (2).

• Place spring washer (3) onto screw (4) as

shown.

• Tighten screw (4) with an Allen key.

• Cover with selfadhesive disc (5).

For purposes of transport (e.g. narrow

doors), the handwheel can be

removed.

3.4.2 Inserting the accessories

• Place the rubber mat on top of the housing.

• Insert the storage shelves into the cryochamber.

• Install the stationary heat extractor into the

quick-freeze shelf (see also drawing in

chapter 5.5.1 ‘Freezing specimens onto

specimen discs’).

• Insert the low temperature stabilizer into the

quick freeze shelf (it must be located in the

pivoting range of the heat extractor - see

also drawing in chapter 5.5.1 ‘Freezing specimens onto specimen discs’).

• Insert section waste tray and brush shelf.

• Install knife holder base onto microtome

base plate and clamp.

• Install knife holder and clamp (see knife

holder instruction manual for details).

• Place knife case with knife into chamber to

precool.

• Place all tools needed for section preparation into the chamber.

• Close the sliding window.

• To remove the handwheel, proceed as described above but in reverse order.

Leica CM 3050 S – Cryostat

For a complete overview of all

individual parts:

--> see Chapter 4.1 ‘Overview’.

19

Page 20

3. Installation

3.4.3 The footswitch

Function

The footswitch performs the same task as the

RUN/STOP and RUN/ENABLE keys (activating/

deactivating motorized sectioning / trimming).

In addition, the footswitch can be used to activate the emergency stop function.

Models with footswitch:

All instruments with sectioning motor.

Important note:

In all instrument models that are

delivered with footswitch, the

footswitch must be installed! Otherwise the instruments are not

functional.

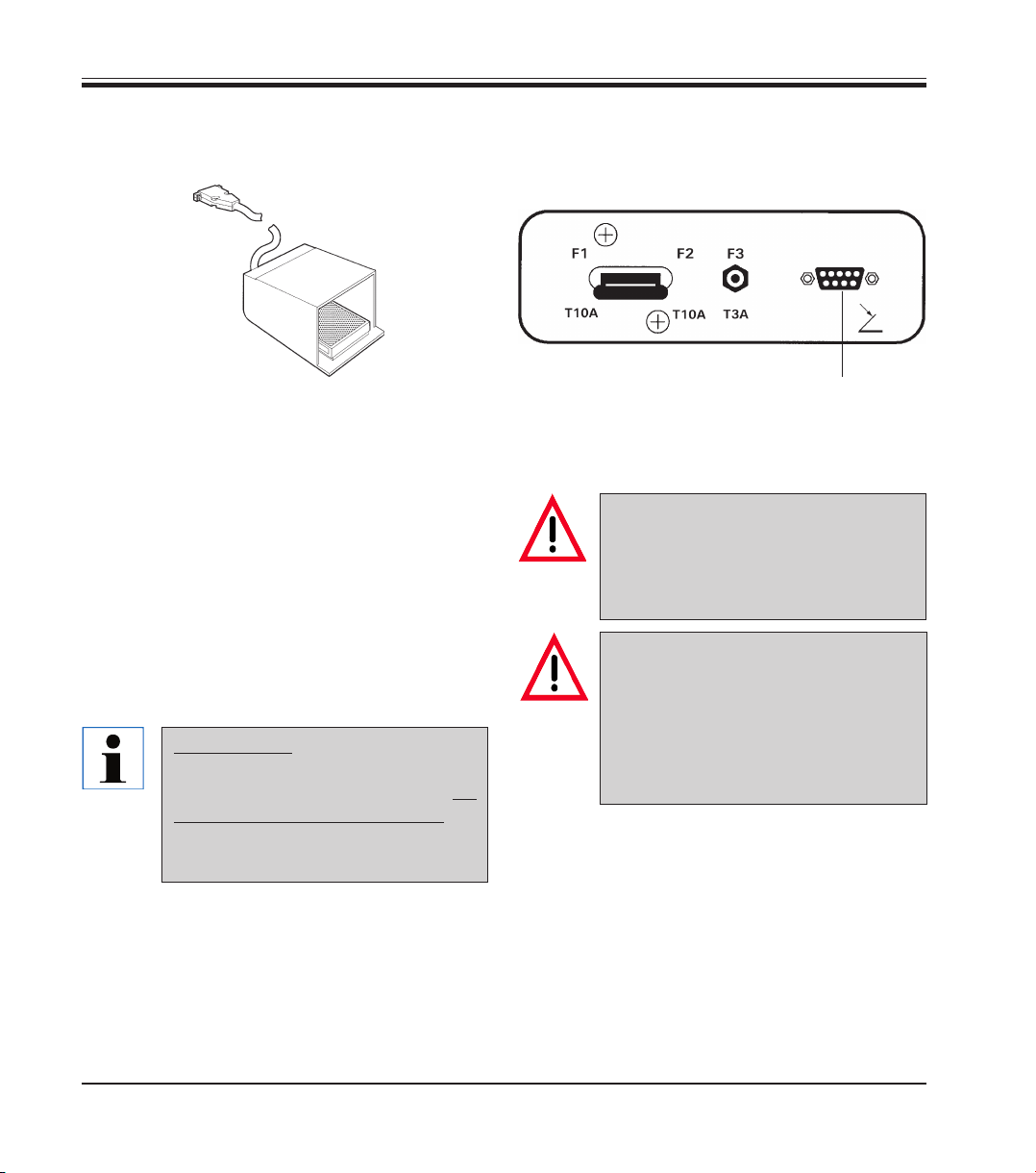

Connecting the footswitch

• Insert footswitch into port (1) and secure.

1

3.5 Prior to switching on the instrument

After transport, observe a waiting

period of at least 4 hours before

turning the instrument on! - See also

safety instructions in chapter 2.3.1

‘Transport’.

Have you observed all safety

instructions in chapters 2.3.2 ‘Site

requirements’ and 2.3.3 ‘Electrical

connections’?

If not:

--> Please read chapters 2.3.2 and

2.3.3!

• Insert mains plug into wall outlet.

• Continue with chapter 5.1 ‘Setting up the instrument’.

20

Instruction Manual V1.2 - 11/2006

Page 21

4. Instrument Properties

4.1 Overview

2

3

9

10

11

8

12

1 Cryostat CM3050 S

2 Control panel 1

3 Control panel 2

4

5

6

1

7

22

4 Storage shelf, left

5 Storage shelf, right

6 Rubber mat

7 Mains switch /

Automatic cutout

for instrument,

Automatic cutout

for sectioning motor,

Footswitch port

8 Quick-freeze shelf

9 Stationary

heat extractor

10 Mobile heat extractor

11 Specimen disc

12 Thermoblock (optional)

13 Section waste tray

14 Brush shelf

15 Specimen head w/o

specimen cooling

16 Specimen head with

specimen cooling

(Option)

17 90° Prism

(instruments with

specimen cooling

only)

18 Knife holder base

19 Knife holder CE

20 Knife holder CN

21 Knife holder CS

22 Footswitch with

protective guard

Leica CM3050 S – Cryostat

21

Page 22

4. Instrument Properties

15

17

16

11

11

13

14

21

20

22

19

18

Instruction Manual V1.2 - 11/2006

Page 23

4. Instrument properties

4.2 Technical Data

Operating temperature range (ambient temperature): + 18°C to + 40°C. All specifications related to temperature are valid only up to an ambient temperature of + 22°C and relative air humidity of less than 60 %!

Type CM3050S-10 CM3050S-1 CM3050S-8 CM3050S-9

Marks of conformity - - - Nominal voltage 100 V AC ±10% 230 V AC ±10% 240 V AC ±10% 100 V AC ±10%

Nominal frequency 50 Hz 50 Hz 50 Hz 60 Hz

Power draw 1800 VA 1800 VA 1800 VA 1800 VA

Max. start-up current for 5 sec 35 A eff. 25 A eff. 25 A eff. 30 A eff.

Protective fuse I I I I

Automatic cutout T15A M3 T10A T1 T10A T1 T15A M3

Pollution degree 2222

Overvoltage installation category II II II II

Heat emission (max.) 1800 J/s 1800 J/s 1800 J/s 1800 J/s

Refrigeration system 50 Hz 60 Hz

Cryochamber

Temperature selection range 0° C to -40°C (+ 2 K / - 0 K) 0° C to -40°C (+2 K / - 0 K)

Defrosting Automatic hot-gas defrost cycle, Automatic hot-gas defrost cycle,

Refrigeration capacity 690 W 690 W

Safety factor 3 3

Refrigerant 280 g ±5g refrigerant R 404A * 280 g ±5g refrigerant R 404A*

Compressor oil 0.6 l EMKARATE RL-22S, ICI * 0.6 l EMKARATE RL-22S, ICI *

programmable in 15-min increments; programmable in 15-min. increments;

1 automatic defrost cycle per 24 hours. 1 automatic defrost cycle per 24 hours.

Duration: 6 - 12 minutes Duration: 6 - 12 minutes

Manual defrost cycle Manual defrost cycle

Quick-freeze shelf

Maximum temperature - 43°C (+ 0 K / - 2 K) - 43°C (+ 0 K / - 2 K)

Number of quick-freeze stations 10 10

Specimen cooling (Option)

Temperature range -10° C to -50°C ±3K -10° C to -50°C ±3K

Defrosting Manual defrost cycle (electric) Manual defrost cycle (electric)

Refrigeration capacity 320 W 320 W

Safety factor 3 3

Refrigerant 185 g ±5g refrigerant R 404A * 185 g ±5g refrigerant R 404A *

Compressor oil 0.4 l alpha 22, Kyodo * 0.4 l alpha 22, Kyodo *

or RENISO E22, Fuchs * or RENISO E22, Fuchs *

Leica CM3050 S – Cryostat

23

Page 24

4. Instrument properties

*) Refrigerant and compressor oil to be replaced only by trained and authorized service

personnel!

CM3050S-3 CM3050S-6 CM3050S-7

c-UL - 120 V AC ±10% 208 V AC ±10% 230 V AC ±10%

60 Hz 60 Hz 60 Hz

1800 VA 1800 VA 1800 VA

35 A eff. 30 A eff. 25 A eff.

II I

T15A T1 T12A T1 T10A T1

22 2

II II II

1800 J/s 1800 J/s 1800 J/s

Fluorescent light lamp (cryochamber illumination):

50 Hz version: Osram Dulux S 11 W/21

Light color ‘LUMILUX hellweiß’

(brilliant white)

60 Hz version: Osram Dulux S 13 W/21

Light color ‘LUMILUX hellweiß’

(brilliant white)

Cryocabinet

Microtome

Rotary microtome

Section thickness setting 0.5 - 300 μm

Overall specimen feed 25 mm

Vertical stroke 59 mm

Specimen retraction 50 μm

Maximum specimen size 40 x 55 mm

Specimen orientation 8° (x-, y-, z-axis)

Trimming (6 thickness settings) 5 - 150 μm

Motorized coarse feed

- slow 500 μm/s

- fast 1,000 μm/s

Sectioning motor (Option):

Sectioning speed

- slow min. 0.1 mm/s

max. 100 mm/s

v

max

210 mm/s

- fast min. 0.1 mm/s

max. 170 mm/s

v

max

210 mm/s

Dimensions

Width (w/o handwheel) 800 mm

Width (including handwheel) 882 mm

Depth 766 mm

Height (arm rest level) 840 mm

Overall height 1040 mm

Weight

(incl. microtome, w/o specimen cooling) ca. 180 kg

24

according to IEC-1010, UL 3101

1

2

according to CECOMAF:

Liquid temperature 45°C

Evaporation temperature -25°C

Instruction Manual V1.2 - 11/2006

Page 25

5. Operation

5.1 Operating the instrument for the first time

Prior to setting up the instrument, make sure to read the instruction manual

carefully and in full.

When setting up the instrument, please follow the individual chapters in the

following order:

• First, study chapters 1, 2, and 3 - install the instrument as described in

chapter 3.

The overview in chapter 4.1 is helpful during the unpacking and installation procedure in order to identify individual parts and place them in

the correct location.

• Go on to chapter 5.

Read chapters 5.1, 5.2, 5.3 and 5.4 to learn all about the controls.

• Next, start to work with the instrument (chapter 5.5). Follow the instructions in chapter 5.5.

Chapter 5.5.2 applies to instruments with specimen cooling only.

The temperature chart in chapter 6.3 is useful when it comes to selecting appropriate sectioning temperatures for different types of specimens.

Leica CM3050 S – Cryostat

• When disinfecting / cleaning the instrument and/or removing / reinstalling the microtome, please follow the instructions in chapter 7.

• In case of problems and malfunctions, please refer to chapters 6.1 and

6.2. These chapters list the most common types of problems which

many times have simple causes that can be eliminated by the actual

user.

If you find ‘Call Technical Service’ in the ‘Remedy’ column, please do

so. Never try to solve these problems yourself!

25

Page 26

5. Operation

5.2 Switching on/fuses

2 (Automatic cutout

for sectioning

motor)

1 (Combination Mains switch /

automatic cutout for the

instrument)

Switching on

• To switch on the instrument, place switch (1)

in upper lock-in position.

Mains switch / automatic cutout for the

instrument:

Automatic cutout for sectioning motor:

The instrument is equipped with an automatic

cutout (2) for the sectioning motor.

If the sectioning motor is overloaded (e.g. when

sectioning extremely hard specimens etc.) the

automatic cutout (2) will be triggered.

To make the instrument functional again after

the automatic cutout (2) has been triggered:

• Push automatic cutout (2) inwards until it

locks into position.

In addition to its function as ON/OFF switch,

switch (1) is also the automatic cutout for the instrument.

If the automatic cutout has been triggered (e.g.

caused by overcurrent):

• Put switch (1) back in upper lock-in position.

26

Instruction Manual V1.2 - 11/2006

Page 27

5. Operation

5.3 Control panel 1

5.3.1 Key functions in control panel 1

ON/OFF key for cryochamber illumination.

To select the menu items for setting /

changing instrument parameters.

In the status indication, pressing the arrow keys displays the individual current

parameters.

In the menu, pressing the arrow keys

changes set values.

As soon as a value is displayed, it is automatically stored.

Activates the manual defrost cycle (cryochamber). This key is functional only

when one of the menu items ‘SET TEMP

CT ... °C’ or ‘SET TEMP OT ... °C’ (last

one only applies to instruments with

specimen cooling) has been selected

first.

Lock / unlock key:

- Locks the display to protect against

accidental changes of set parameters.

- Activates / deactivates a number of

functions.

5.3.2 Display functions in control panel 1

The display in control panel 1 combines several

different functions:

1. When switching the instrument on:

A series of standard indications is displayed,

during which two basic parameters can be selected (with the arrow keys):

Language (of display indications) and speed

level of sectioning motor.

See chapter 5.3.3 ‘Display indications when

switching on’.

2. Menu function (activated via menu key):

Via the menu key a number of parameters can

be selected, then be activated /deactivated via

the lock/unlock key and/or changed via the arrow keys.

See chapter 5.3.4 ’Menu functions: Setting param-

eters of refrigeration, time and preset counter’.

3. Status indication function:

The actual status of selected parameters is indicated in the display screen.

Some of those parameters are displayed automatically (e.g. sectioning stroke phase, coarse

feed position, handwheel locked).

Others can be displayed by pressing the arrow

keys; e.g. selected section thickness, preset

counter status etc.

See chapter 5.3.5 ‘Status indication’ and chapter 5.3.6 ‘Displaying state of refrigeration, section thickness and counters’.

Leica CM 3050 S – Cryostat

27

Page 28

5.3.3 Display indications when switching on

Meaning of indication:

Initialization phase 1

8 888 8 8888888 8888

8 888 8 8888888 8888

5. Operation

Operator activity:

---

Initialization phase 2

Software version

CM3 0 5 0S Vs . X X . XX

Selected display language

CUT T I NG MOTOR

Sectioning motor speed

level ‘slow’ / (fast)

yes

Temperature upon

switching on ≥ 0 °C

yes

no

CT . . ..°C OT . . . . ° C *)

DR Y MI CRO T OME

ENGL I S H

SLOW

Temperature prior to

switching off < 0 °C

---

---

Select language via

keys

Select speed level via

keys

no

CT....°C OT....° C *)

POWER FA I L URE

Acknowledge indication by

pressing

once briefly.

CT . . ..°C OT . . . . ° C *)

12 : 0 0

If this indication is displayed: Do not switch on

the instrument!

Prior to switching on, both microtome and

accessories must be completely dry!

Standard indication ‘locked’ is displayed:

(Display background dark)

To unlock: press

ground lights up:

until the display back-

Remove microtome/accessories, disinfect if

applicable, then dry thoroughly and reinstall.

(--> See chapters 7.1 - 7.5).

*) Indication in instruments with specimen cooling. Instruments without specimen cooling: only CT (centered) is displayed.

28

CT....°C OT....°C

HOME ❄❄

Instruction Manual V1.2 - 11/2006

Page 29

5. Operation

5.3.4 Menu functions: setting parameters of refrigeration, time and preset counter

Once the instrument has gone through the initial

sequence of indications, you can go on to the

menu functions to select and/or change instrument parameters.

If display is locked:

Press key until display background

lights up.

Next, press the menu key. With each key stroke

the following parameters will be displayed (display sequence as listed):

1. Specimen temperature

(in instruments with specimen cooling only)

(-10 - -50 °C)

2. Cryochamber temperature

(0 - -40 °C)

3. Selected number of sections - preset

counter

(ON/OFF and setting selection from 1 to 999)

4. Maximum specimen temperature

(ON/OFF)

5. Real time

(in 1-minute steps)

6. Defrost time (starting time of automatic

cryochamber defrosting)

(in 15-minute steps)

7. Duration of defrost cycle

(cryochamber defrosting)

(6 to 12 minutes duration)

1. Specimen temperature:

(instruments with specimen cooling only)

Press key until menu item ‘Set specimen

temperature’ is displayed:

SET TEMP OT - - - °C

--

Press key briefly.

The line in the specimen temperature

field is replaced by an asterisk.

SET TEMP OT- --°C

- ❄

From this point on the refrigeration system is activated and the desired set

temperature can be selected with one

of the arrow keys.

Press arrow key and release upon

reaching the desired value.

CT . . ..°C OT - 35 °C

HOME -❄

Note on the arrow key function:

Each time one of the arrow keys is pressed

briefly, the value displayed in the menu will be

changed one step up or down.

If an arrow key is pressed and held, the value

will change continually (auto-repeat function).

When holding the key, scrolling speed will increase after a while.

As soon as a value is displayed, it is at the same

time automatically stored.

Menu items 5 and 6 displayed on 24 hour clock.

Leica CM 3050 S – Cryostat

29

Page 30

5. Operation

2. Cryochamber temperature:

Press key until menu item ‘Set chamber

temperature’ is displayed:

--> Continue as described for

specimen temperature.

3. Preset counter

(instruments with sectioning motor only):

Press key until menu item ‘Preset

counter’ is displayed:

PRE S ET COUNTER

dn- --

= Preset counter activated

PRE S ET COUNTER

dn056

= Preset counter deactivated

Preset counter function:

The preset counter allows the user to carry out

a predefined number of sections in the ‘Continuous stroke’ sectioning mode.

Once the preselected number of sections has

been carried out (= section counter reading ‘0’),

the specimen head will stop automatically in the

lower limit position.

The reference value (i.e. the value from which

the preset counter counts downward) can be

selected in the corresponding menu item.

In order to be able to set a reference value, the

preset counter function must be active.

If the preset counter is deactivated (see diagrams

above), press

to activate.

Now there are two options:

1. Increase or decrease the actual reference

value by pressing

2. Press

reload the former reference value (‘0’ when

setting up the instrument) and then press either

the desired reference value. Depending on

where you start from and where you want to

go, method 1 or method 2 is quicker (see examples).

Example 1:

Actual preset counter reading = 50

Former reference value = 300

New reference value of 65 to be selected.

Method 1 is most convenient:

• Increase from 50 to 65 by pressing

Example 2:

Actual preset counter reading = 50

Former reference value = 300

New reference value of 320 to be selected.

Method 2 is most convenient:

• Press

reload old reference value (300):

• Increase from 300 to 320 by pressing

For further information on the preset counter,

please refer to chapter 5.3.6, Item 4 ‘Preset

counter’.

and simultaneously in order to

or individually in order to select

and simultaneously to

or .

.

.

30

Instruction Manual V1.2 - 11/2006

Page 31

5. Operation

4. Quick-freezing at maximum specimen

temperature* (instruments with specimen

cooling only)

Press key until menu item ‘Fast object

freezing’ is displayed:

FAST OBJ FREEZIN

OF F

or

FAST OBJ FREEZ IN

ON

Press lock/unlock key to activate or deactivate (ON/OFF).

5. Real time

Press key until menu item ‘Time’ is displayed:

TIME 10:23

• Use arrow keys (

or ) to set real time.

Setting minutes as well as hours in

1-minute steps. Holding arrow button increases scrolling speed!

6. Starting time of automatic defrost cycle:

Press key until menu item ‘Defrost time’ is

displayed:

DEFR T IME 4 : 30

(Time on display = start time of defrost

cycle)

• Use arrow keys ( or ) to select the desired defrost start time.

The automatic defrost cycle takes place once

every 24 hours at the selected defrost time.

7. Duration of defrost cycle:

Press key until menu item ‘Defrost period’

is displayed:

DEFROST PER I OD

CHAMBER : 0 8 MIN

• Use defrost keys (

frost time.

(Only if necessary - see below).

Important information for setting the

defrost parameters

Starting time of defrost cycle:

We recommend to program the

automatic defrost cycle for a time outside regular working hours as a

period of 4 hours should pass after the

defrost cycle before work with the

instrument is resumed (see also

chapter 5.7.1 ‘Automatic chamber

defrost cycle’).

Defrost cycle duration:

The duration of the chamber defrost

cycle is set to 8 minutes in factory.

This setting should only be

changed, if the evaporator is not

completely de-iced during the

8-minute cycle.

In such cases, increase the defrost

cycle duration gradually until the the

evaporator is ice-free after defrosting.

The selected defrost cycle duration is

valid for both automatic and

manual chamber defrost cycle.

or ) to adjust de-

*) with 90° prism - see also chapter 5.5.2.

Leica CM3050 S – Cryostat

31

Page 32

5. Operation

5.3.5 Status display

Each individual parameter is displayed in a certain area of the display screen.

Upper line:

In the menu (see chapter 5.3.4): indication of selected menu item.

Standard indication: Chamber temperature (instruments with specimen cooling: chamber and specimen temperature)

Standard indication upper line:

Instruments with chamber and specimen cooling

CT-30°C OT-35°C

HOME

Instruments with chamber cooling only

CT-30°C

HOME -

Upper line

Lower line

1 2 3 4 5 6 7 8 9 10111213141516

1 2 3 4 5 6 7 8 9 10111213141516

Digits 1 and 2

indicate sectioning stroke position:

• Sectioning stroke

(outside sectioning window)

: Retraction stroke

•

• [ ]: Sectioning stroke

(inside sectioning window)

Sectioning

○○○○○

○○

○○○○○○○○○○○○

stroke

Sectioning window [

○○

]

○○○○○

○○

Retraction stroke

Digits 3 - 6

indicate coarse feed position:

• Rear limit position: HOME

• Front limit position: STOP

Indication of ‘malfunction’ or

‘handwheel locked’:

• Microtome plug loose,

implausible values etc.: ????

• Handwheel is locked: LOCKED

Indication ‘LOCKED’ completely

overlays digits 3 through 16,

i.e. while ‘LOCKED’ is displayed, no

other parameters will be displayed

in digits 3 - 16 of the lower line.

• Further indications: see chapter 6.1

‘Error messages indicated in the

display screen’

Digits 7 - 16

indicate the following parameters:

• Refrigeration status:

Digit 15 = cryochamber

Digit 16 = specimen

Meaning of

refrigeration

symbols:

-

Refrigeration OFF

Refrigeration ON

Defrosting active

• Section thickness

(set value)

• Section counter

(actual value)

• Indication of total section thickness

(actual value)

• Preset counter

Digits 7 - 16:

Scroll via arrow buttons to display

individual parameters

32

Instruction Manual V1.2 - 11/2006

Page 33

5. Operation

5.3.6 Indication of refrigeration state, section thickness setting and counters

These parameters can be displayed via the arrow keys.

When pressing

, the parameters are displayed in the sequence listed on this page;

when pressing

, they are displayed in reverse order. The display can be scrolled continuously, i.e. after the last parameter the display

will automatically start again with the first.

1. Refrigeration state

CT- 3 0 °C OT- 35 °C

HOME

Meaning of the refrigeration symbols (asterisks):

--> see chapter 5.3.5 ‘Status indication’.

2. Section thickness

CT- 3 0 °C OT - 35°C

μ010.0

The sectioning thickness is set with the

or

key (see chapter 5.4.7 ‘Setting the section

thickness’).

3. Section counter

CT- 3 0 °C OT- 35 °C

∑∑

∑ n000

∑∑

Once displayed (via arrow keys), the section

counter can be set to ‘0’ at any time.

• To set to ‘0’ press

.

If the section counter is not set to ‘0’ by the user

at some point, sections are counted up to ‘999’

at which point the counter automatically

switches back to ‘0’.

4. Total section thickness counter

CT- 3 0 °C OT - 35°C

∑∑

∑ μ0000.0

∑∑

Can also be set to ‘0’ at any time (via

key).

If the total section thickness indication is not set to

‘0’ manually, the instrument counts up to maximum

9999.5 μm at which point the counter will automatically switch back to ‘0’.

This indication shows the total thickness of all

sections carried out since the counter was last

set to ‘0’. (

All sections, in sectioning and trim-

ming mode, are counted).

5. Preset counter

CT-30°C OT-35°C

dn056

Setting preset counter to ‘0’:

Press

key.

can also be pressed while the continuous

sectioning mode is in motion; in this case the

preset counter is set to ‘0’ and sectioning stops

upon reaching the lower limit position.

After it has been set to ‘0’, the preset counter is

inactive.

Reloading the former reference value:

Press

and simultaneously.

Reloading the former reference value is possible

also while the continuous sectioning mode is in

motion:

Upon pressing both arrow keys, the instrument

continues sectioning without interruption, starting to count down from the old reference value.

Leica CM 3050 S – Cryostat

33

Page 34

5. Operation

5.4 Control panel 2

Instruments without sectioning motor Instruments with sectioning motor

In instruments without sectioning motor, control panel

2 only consists of functional

area B (see below)

In instruments with sectioning motor, the control panel

is equipped with three functional areas: A, B and C (see

large diagram).

A

Functional area A:

• Sectioning modes

• Sectioning window

• Sectioning speed

• Emergency stop function

B

Functional area B:

• Coarse feed

• Trimming

• Section thickness selection

34

B

Functional area B:

• Coarse feed

• Trimming

• Section thickness selection

C

Functional area C:

• Start / Stop sectioning

Instruction Manual V1.2 - 11/2006

Page 35

5. Operation

Functional areas A and C - Instruments with sectioning motor only

5.4.1 Selecting a sectioning mode /

start and stop sectioning

Three different sectioning modes can be selected for motorized sectioning:

Sectioning mode 1 - Intermittent stroke:

The specimen head travels up and

down as long as the RUN/STOP and

RUN/ENABLE keys are pressed simultaneously or as long as the footswitch is

depressed.

Sectioning mode 2 - Continuous stroke:

The specimen head travels up and down

until it is stopped by pressing RUN/STOP

or RUN/ENABLE or by depressing the

footswitch.

Sectioning mode 3 - Single stroke:

The specimen head carries out one sectioning stroke and then stops in the lower limit position.

Activating a sectioning mode

Press one of the three sectioning mode keys described above. While a sectioning mode is active, the LED in the corresponding key will be illuminated.

Start / stop motorized sectioning

Sectioning mode 1 - Intermittent stroke:

• Simultaneously press and hold RUN/STOP and

RUN/ENABLE or depress and hold footswitch.

• To stop the sectioning stroke, release the

keys or the footswitch:

The specimen head stops immediately.

Sectioning mode 2 - Continuous stroke:

• Simultaneously press and release RUN/STOP

and RUN/ENABLE or depress and release

footswitch.

• To stop sectioning:

Press and release RUN/STOP or RUN/EN-

ABLE or depress and release the footswitch:

The specimen head stops upon reaching the

lower limit position.

Sectioning mode 3 - Single stroke:

• Simultaneously press and release RUN/STOP

and RUN/ENABLE or depress and release

footswitch.

• The instrument carries out one complete

section / retraction stroke and the specimen

head stops upon reaching the lower limit position.

While sectioning is in motion, LED ‘RUN’ is illuminated.

While the sectioning motor is deactivated, LED

‘STOP’ is illuminated.

Both LEDs are located in functional area C.

Leica CM 3050 S – Cryostat

35

Page 36

5. Operation

Functional areas A and C - Instruments with sectioning motor only

5.4.2 Setting the sectioning window

The term ‘Sectioning window’ stands for a different (slower) speed setting in that part of the

sectioning stroke where the specimen is actually cut, while the remaining sectioning stroke

(above and below the specimen) as well as the

retraction (return) stroke are carried out at a

higher speed level (time-saving feature).

If a sectioning window is set, speed inside the

window is as set on the control panel. Outside

the sectioning window the specimen head travels at a proportionately higher speed.

Always set the sectioning window

while in the sectioning stroke (specimen moves downward). Setting the

window in retraction stroke (specimen travels upward) is not possible.

• Position lower edge of specimen approx.

3 mm above the knife edge (rotate handwheel clockwise).

The value has been stored when the LED in the

sectioning window key lights up briefly.

If the LED flashes, the value has not yet been

stored, because the user has tried to set a window margin outside the possible window range

(the area in which the sectioning window can

be set is slightly smaller than the total section

stroke).

• In that case, repeat the step in question.

.

The sectioning window cannot be

deleted. If need be, it can be set to

maximum size (i.e. almost the entire sectioning stroke will be carried out at one and the same

speed).

Every time after the instrument is

disconnected from mains, the sectioning window is set to maximum

size upon switching back on. This

also applies when the instrument is

switched on for the first time.

Press sectioning window key.

• Position upper edge of specimen just below

the knife edge (continue to rotate the handwheel clockwise).

Press sectioning window key once

more.

36

Instruction Manual V1.2 - 11/2006

Page 37

5. Operation

Functional areas A and C - Instruments with sectioning motor only

5.4.3 Selecting sectioning speed

• Sectioning speed is selected via the sliding

potentiometer. Speed can be changed while

sectioning is in motion.

Caution when working in continuous mode:

If the slider is set to ‘0’, the sectioning motion

stops, however, the actual sectioning mode is

still active - just operating at ‘0’ speed.

If the slider is accidentally moved, sectioning

will be resumed! - Risk of injury!

Therefore:

Do not interrupt sectioning / trimming by setting the sliding potentiometer to zero speed!

See also safety instruction in Chapter 2.3.6 ‘Motorized sectioning’.

Vmax key

5.4.4 Emergency stop

• Activate by:

• either pressing the emergency stop

button forcefully (must lock in

position),

• or depressing the footswitch forcefully.

Either way, sectioning is interrupted at once.

In both cases, the red

area A lights up, indicating that the emergency

stop function has been activated. Simultaneously

all 3 sectioning modes are deactivated

(= all 3 LEDs off).

• To deactivate the emergency stop function,

rotate the button in the direction of the arrow until it unlocks and slips upward into its

original position.

As soon as the emergency stop button has been

unlocked, the red

• If the emergency stop function has been activated with the footswitch, unlocking is not

necessary.

LED in functional

LED is extinguished.

As long as the button is pressed, the

sectioning motion is carried out at maximum speed (210 mm/s).

While Vmax is active, the sectioning window is

inactive.

When the Vmax key is released, the sectioning

window becomes active again.

Leica CM 3050 S – Cryostat

As soon as the footswitch is released, the red

LED is extinguished.

• To continue work, select one of sectioning

modes 1 - 3 and restart the sectioning

motion.

See also chapter 2.2.3 ‘Safety - Emergency stop

function’ for further information on the emergency stop.

37

Page 38

Functional area B - all models

5. Operation

5.4.5 Coarse feed keys

The four coarse feed keys in functional area B

function as follows:

Coarse feed ‘fast backward’

- Travelling speed 1,000 μm/s

• Press

Specimen head travels backward

(= away from knife):

a. until it reaches the rear limit position,

b. until it is stopped by pressing one of the

coarse feed keys (to stop the function, any

of the four coarse feed keys can be

pressed).

• To start, press

Specimen head travels backward (= away

from knife) as long as the key is held.

key to activate.

Coarse feed ‘slow backward’

- Travelling speed 500 μm/s

and hold.

LED ‘HOME’ (located in key

‘Coarse feed fast backward’)

Coarse feed ‘fast forward’

- Travelling speed 1,000 μm/s

• To activate the function, press

and hold.

The specimen head travels forward (= towards the knife) as long as the key is held.

Coarse feed ‘slow forward’

- Travelling speed 500 μm/s

• To activate the function, press

and hold.

The specimen head travels forward

(= towards the knife) as long as the key is

held.

‘STOP’-LED (located in key

‘Coarse feed fast forward’)

As long as the forward coarse feed (both fast

and slow) is in motion, the ‘STOP’ LED is illuminated.

Upon reaching the front limit position, the

‘STOP’ LED starts flashing and the display in

control panel 1 reads ‘STOP’.

As long as the backward coarse feed (both fast

and slow) is in motion, the ‘HOME’ LED is

illuminated.

Upon reaching the rear limit position, the

‘HOME’ LED starts flashing and the display in

control panel 1 reads ‘HOME’.

38

Instruction Manual V1.2 - 11/2006

Page 39

5. Operation

Functional area B - all models

5.4.6 Trimming and sectioning functions

Switching between trimming

and sectioning

Press this key to alternate between the

two functions.

illuminated:

Trimming mode is active

off:

Sectioning mode is active.

Selecting trimming thickness

• Activate trimming mode

• Select trimming thickness (= sectioning

thickness at which trimming is carried out)

by pressing

The selected thickness is displayed in the corresponding LED

or .

:

Motorized trimming

5.4.7 Setting the section thickness

• Activate sectioning mode ( off).

CT....°C OT....°C

μ010.0

• Press

Pressing one of these keys once makes the

display in control panel 1 switch to section

thickness indication (thickness value not yet

being altered). Pressing

starts to change the actual section thickness setting.

Selectable section thickness settings:

0 - 2 μm in 0.5-μm steps,

2 - 10 μm in 1-μm steps,

10 - 20 μm in 2-μm steps,

20 - 60 μm in 5-μm steps,

60 - 100 μm in 10-μm steps,

100 - 300 μm in 50-μm steps.

or to select section thickness.

or further

• Select ‘Continuous stroke’ in functional area

A.

• Activate trimming by pressing RUN/STOP

and RUN/ENABLE (located in functional

area C) simultaneously or by depressing the

footswitch.

• To stop trimming press RUN/STOP or RUN/

ENABLE or depress the footswitch again.

Trimming thickness can be changed while trimming is in motion by pressing

Leica CM 3050 S – Cryostat

or .

39

Page 40

5. Operation

5.5 Daily operation of the instrument

• Select chamber temperature and, in instruments with specimen cooling, specimen

temperature according to the type of specimen to be sectioned (see also chapter 6.3

‘Reference chart for temperature settings’).

Do not continue with step 5.5.1 before the

•

actual chamber / (specimen) temperature

corresponds to the set value. This may take

several hours (e.g. when operating the instrument for the first time or when the instrument had been switched off).

Prior to operating the instrument ,

please read and observe the following safety instructions:

• ‘Integrated safety devices’

(Chapter 2.2) .

• ‘Handling microtome knives

/ blades’

(Chapter 2.3.4)

• ‘Knife guard /

Handwheel lock’

(Chapter 2.3.5)

5.5.1 Freezing specimens onto specimen

discs with quick-freeze shelf and

stationary heat extractor

• Size the specimen.

• Apply sufficient amount of embedding medi-

um onto ambient temperature specimen

disc.

• Inside the cryochamber, place the specimen

onto the disc and orient.

• Place specimen disc with specimen into one

of the 10 openings in the quick-freeze shelf

(see below) and freeze.

12

3

40

• ’Motorized sectioning’

(Chapter 2.3.6)

• ‘Defrosting

/ handling frozen tissue’

(Chapter 2.3.7)

• ‘Frozen instrument parts

and accessories’

(Chapter 2.3.8)

• ‘Infectious / radioactive material’

(Chapter 2.3.9)

The freezing process can be sped up further by

using the stationary heat extractor (1). Next to

the low temperature stabilizer (2) (‘Parking

station’), 3 specimen discs (3) can be placed

within its pivoting range.