Page 1

Service Bulletin

SB Number:

Subject:

SB COM-012

Fuser related error codes after replacing the fuser unit.

Creation Date: 28/10/2010

Model: All models

Phenomenon Fuser related error codes may occur after replacing the fuser unit.

Examples:

• C6000: Fuser heater 1 break

• C6020: Abnormally high fuser thermistor 1 temperature

• C6030: Fuser thermistor 1 break error

• C6120: Abnormally high fuser thermistor 2 temperature

• C6130: Fuser thermistor 2 break error

Solution Perform the following procedures:

1. Check the condition of the fuser interface connector.

2. Check the conductivity of the triac at the power source PWB.

The above mentioned instructions will be added to the next revision of the applicable service

manual.

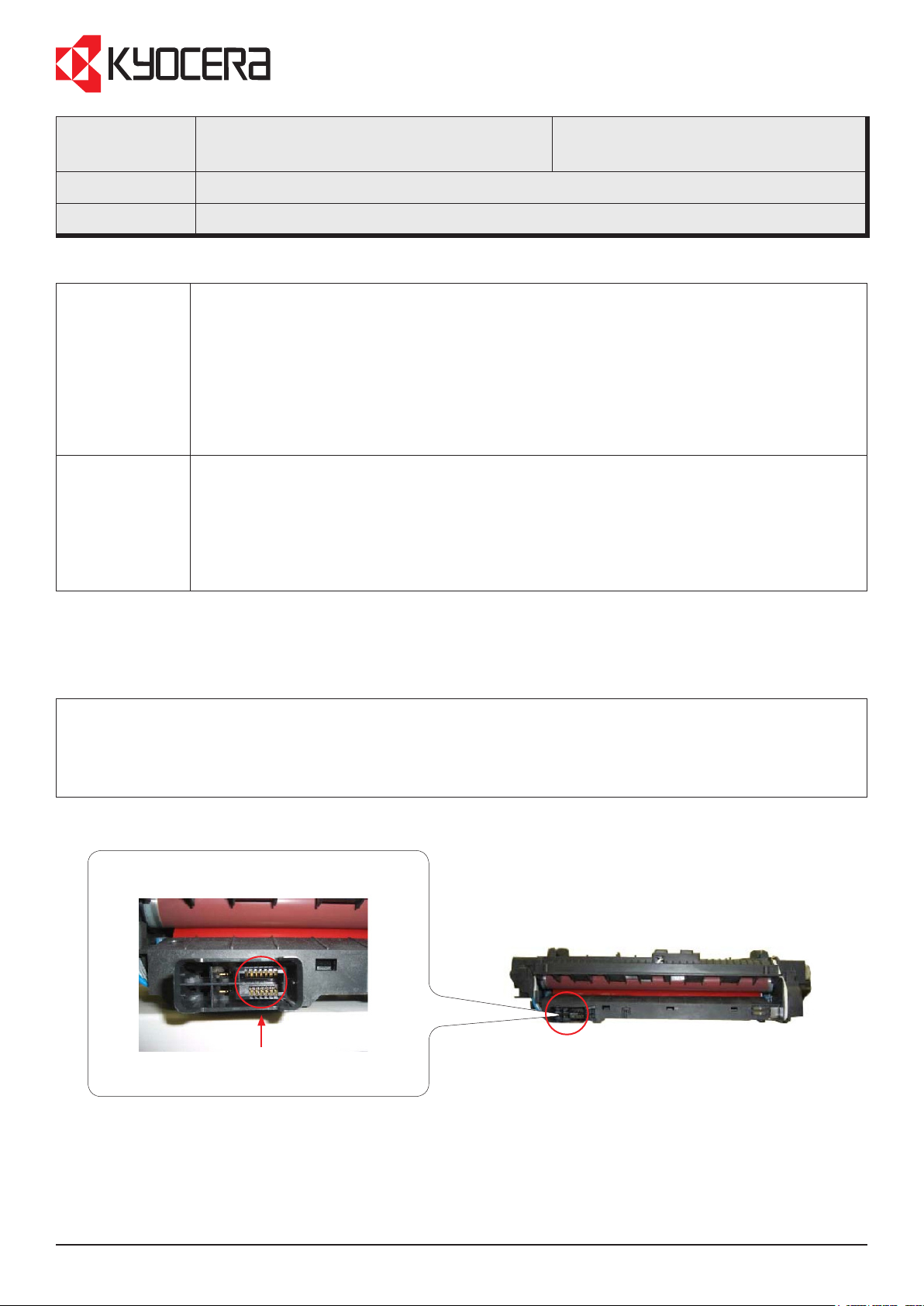

Procedure 1: Check the condition of the fuser interface connector.

If the pins in the fuser interface have been damaged, please replace the connector or the fuser unit including the

connector.

Please note that some models have another type of connector, therefore this procedure is not for all models.

Fuser interface connector

Check if the pins have been damaged.

Fuser unit

KMIS Service Department, Kyocera Mita Europe A275 / SB COM-012

Page 1 of 4

Page 2

Service Bulletin

Procedure 2: Check the conductivity of the triac at the power source PWB according to the A or B procedure.

Model name Procedure A (Without the relay

circuit/relay circuit PWB)

FS-C8500DN X O

FS-3040MFP/3140MFP X O

FS-C2026MFP/2126MFP X O

Models that are older than the above

mentioned models.

X=Not applicable / O=Applicable

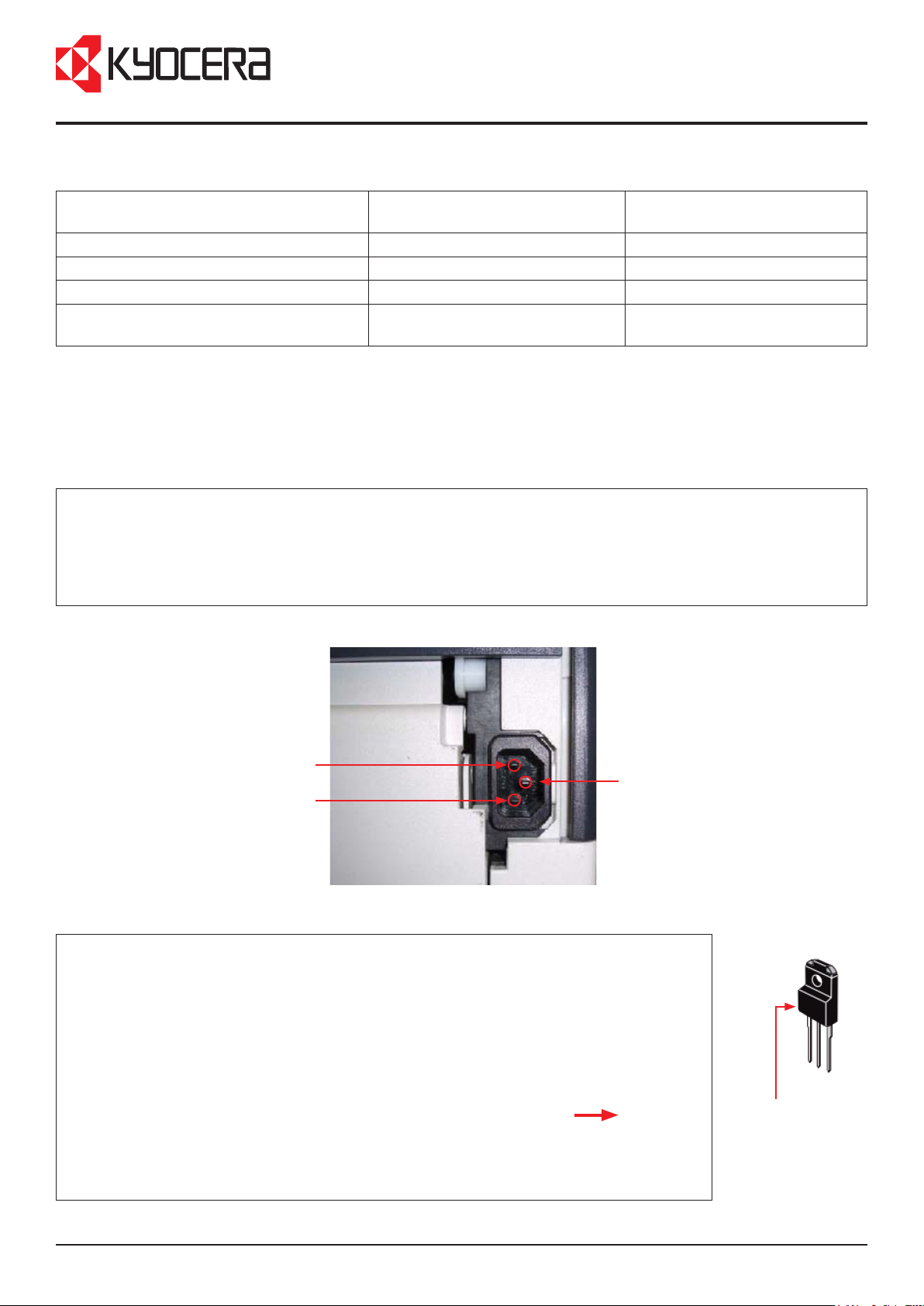

Procedure 2.(A): Check the conductivity in the power supply connector.

1. Remove the power cord while installing the fuser unit *2 and turn the main switch ON.

2. Check if the resistance between Live(L) and Netral(N) of the power supply connector (AC inlet) is the level of MΩ.

Check if there is no short-circuit.

3. Please replace the power source PWB, if there is no conductivity.

O X

Procedure B (With the relay

circuit/relay circuit PWB)

Live (L) side pin

Power supply connector

Netral (N) side pin

Procedure (B): Check the conductivity between T1 and T2 of the triac at the power source

PWB.

1. Remove the power cord and check if the resistance between T1 and T2 of the triac at the

power source PWB is the level of MΩ. Check if there is no short-circuit.

2. Please replace the power source PWB, if there is no conductivity.

Refer to the images on the following pages for the triac number, its postion etc. on the power

source PWB. The pins are the same on each triac. Viewed from the front the left pin is the T1

terminal and the middle pin is the T2 terminal. The direction of the arrows ( ) in each

image of the power source PWB, indicate the front view of the triac.

Do not use the gate terminal to check the conductivity instead of terminals T1 and T2 by

mistake. If the test can not be executed due to mounted parts around the applicable triac,

remove the power source PWB and perform the check from the soldering side at the back.

Triac

1

2

3

Front

1: T1 terminal

2: T2 terminal

3: Gate terminal

KMIS Service Department, Kyocera Mita Europe A275 / SB COM-012

Page 2 of 4

Page 3

Service Bulletin

FS-C8500DN

Check the conductivity between T1 and T2 of the CR201, CR202 and CR203 triacs.

Power source PWB: Parts unit low voltage (302H794351)

CR201

FS-C2026MFP/2126MFP

Check the conductivity between T1 and T2 of the TRA51 triac.

Power source PWB: Parts switching regulator 100V SP (302KW94040) ---120V

Parts switching regulator 230V SP (302KW94050) ---230/240V

CR202

CR202

TRA51

KMIS Service Department, Kyocera Mita Europe A275 / SB COM-012

Page 3 of 4

Page 4

Service Bulletin

FS-3040MFP/3140MFP

Check the conductivity between T1 and T2 of the TRA51 triac.

Power source PWB: PARTS SWITCHING REGULATOR (E) SP (302LW94050) --- 230/240V

TRA51

KMIS Service Department, Kyocera Mita Europe A275 / SB COM-012

Page 4 of 4

Loading...

Loading...