Page 1

(Page.1/2)

Subject

Measures against the Noise and the KNOB SIZE Rotation Fault

Model l:

PF-315, PF-315+

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures:

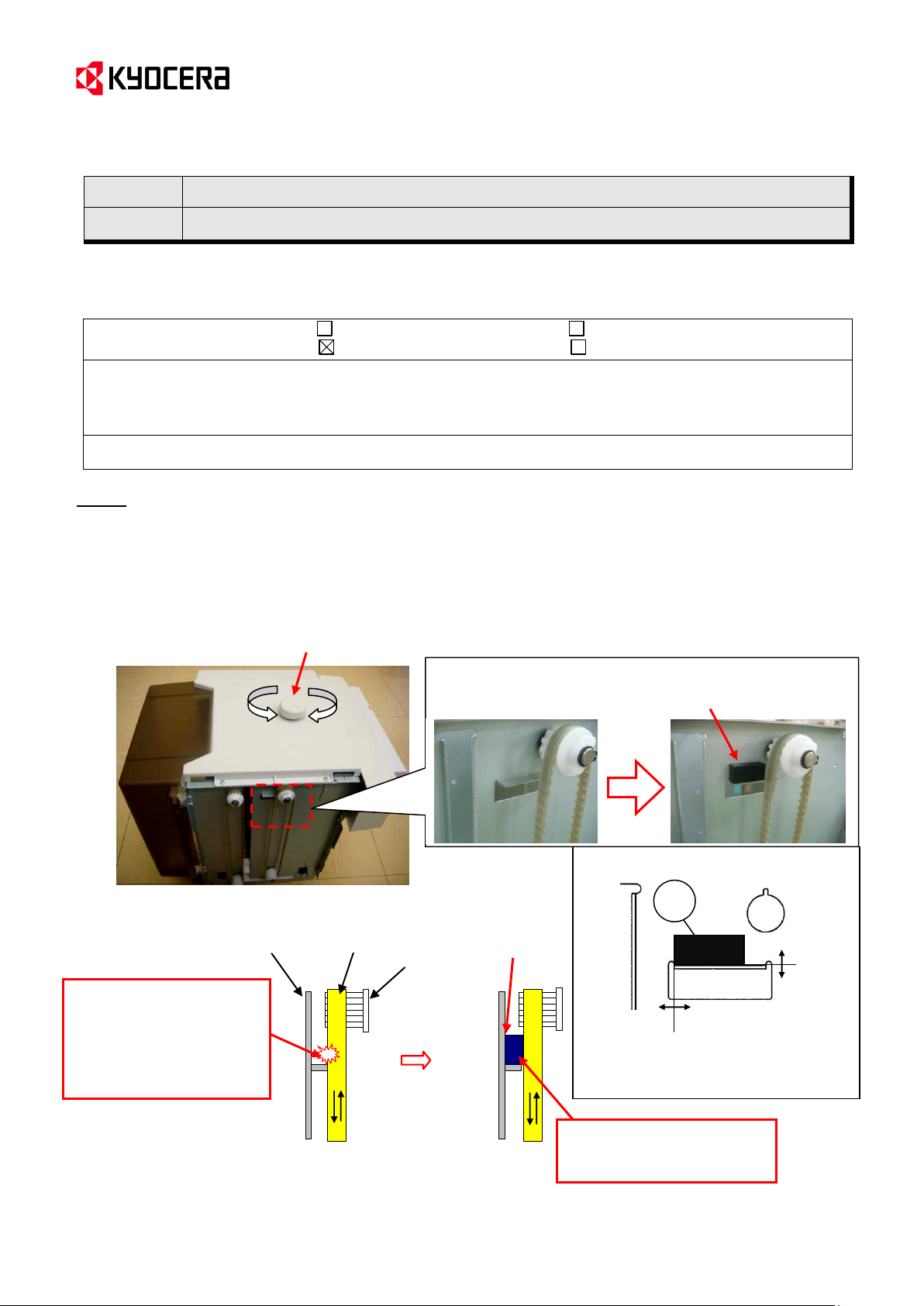

When the problems described below occur, please affix the SPACER (No1) to the upper side of the cutout of

FRAME L ASSY. (After cleaning the surface with alcohol, please affix it according to the criteria described on

the page 1. After affixing it, please confirm that the BELT is on the front side of the SPACER.)

Serial Nos. of the Affected Machines: Please refer to the table on the page 2.

FRAME L ASSY

PULLY

KNOB SIZE

Side with the

double-sided

tape

SPACER added

BELT

With the new SPACER, the

BELT surface will contact

with surface of the SPACER.

0.5mm

0.5mm

0.5mm

0mm

X

Y

No1

BELT skews and

the convex portion of

inside of the BELT contact

with the FRAME L which

causes noise or

heavy KNOB rotation.

X: Criteria for bent of cutout.

Y: Criteria for bent of the side part of cutout.

<Criteria to attach the SPACER >

Service Bulletin Ref. No. 3KF-0002 (C277)

<Date> Oct. 18, 2012

(Installation target models)

PF-315: FS-3900DN, FS-4000DN, FS-3920DN, FS-4020DN

PF-315+: FS-2100D, FS-2100DN, FS-4100DN, FS-4200DN, FS-4300DN

Topic

To adjust paper width, the KNOB SIZE is rotated. In a rare case, the BELT linked to KNOB skews and the convex of

the inside of the BELT contacts the FRAME L ASSY. Then, some noise is generated when driving or the rotation of

the KNOB will be heavy. Therefore, the SPACER (No.1) was added so that the edge of the BELT can contact the

SPACER when it skews.

1. New SPACER (No.1) (Material/color: ABS/black; Size: 10 mmX19 mm, t=6 mm)

<Cross section of affixing part of the SPACER>

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Page 2

(Page.2/2)

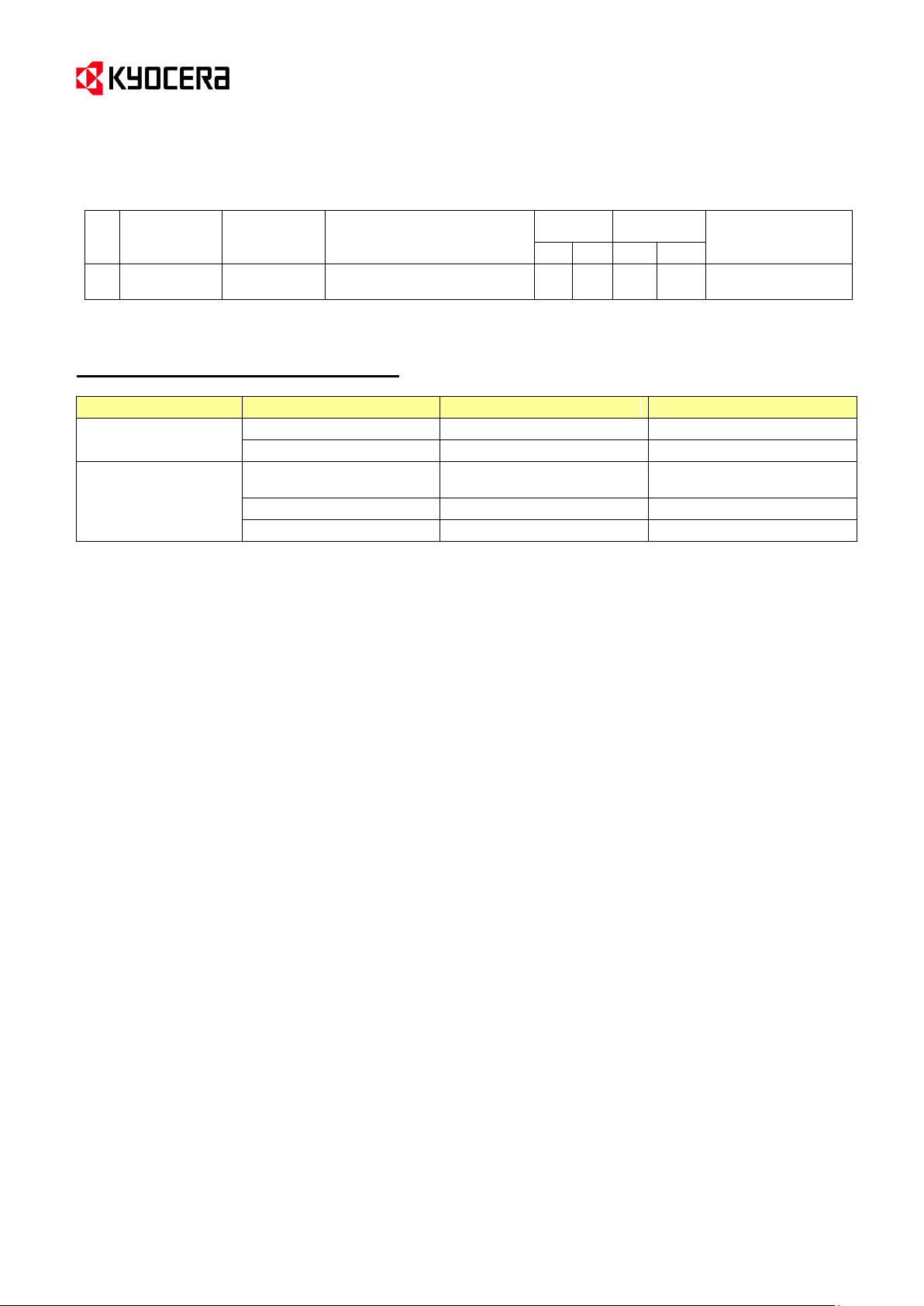

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

-----

303KF10140

3KF10140

SPACER

-

1

-

O

Model

Destination

Item Code

Affected Serial No.

PF-315

Other than KDCN specs.

1203KF0KL0

GPS2806129

KDCN

1203KF8KS0

From the next production

PF-315+

Other than UTAX and

Olivetti specs.

1203KF0KL1

L4Y2800004

UTAX

1203KF8UT0

L512800001

Olivetti

1203KF8LV0

L972900001

Service Bulletin Ref. No. 3KF-0002 (C277)

Serial Nos. of the Affected Machines

<Date> Oct. 18, 2012

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...