Page 1

(Page.1/2)

Subject

Discharger Brushes Added to the TABLE PAPER

Model l:

PF-315, PF-315+

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures:

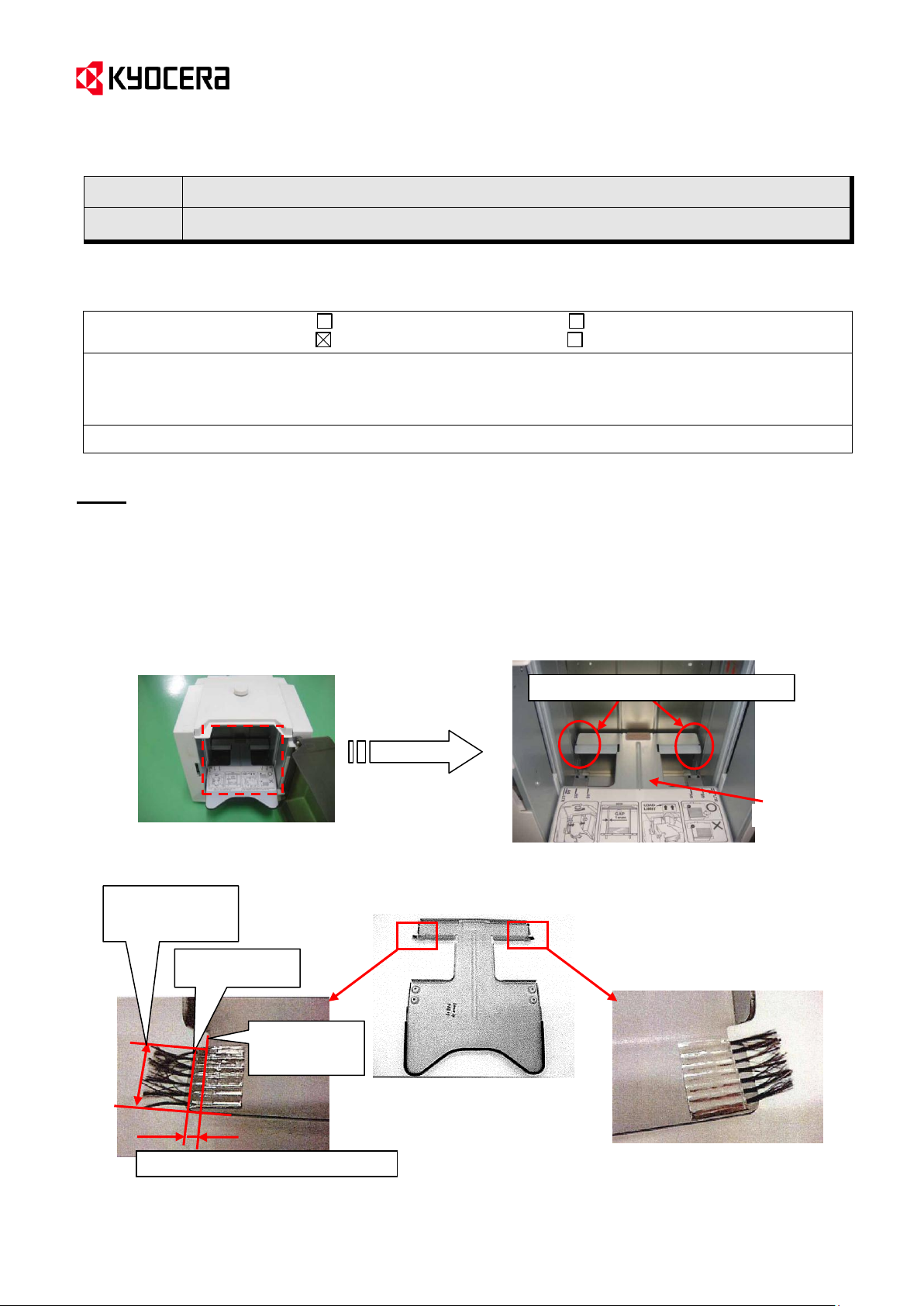

When the phenomenon described below occurs, please first replace the PF main PWB (303KF01020) with the

new one and then affix the DISCHRAGER TP (No.1) to the indicated positions on rear side of the TABLE

PAPER. (After cleaning the affixing part with alcohol, please affix No.1 according to the alignments.)

Serial Nos. of the Affected Machines: Please refer to the next page.

Rear side of the TABLE PAPER

Leading edge of

the brush base

Alignment to

the edge of the

metal plate

Allowable range of stick-out: +2/-0 mm

TABLE PAPER

(PF main

PWB side)

Positions of the discharger brushes

Brush shall not

stick out from the

metal plate width.

Service Bulletin Ref. No. 3KF-0003 (C313)

<Date> December 4, 2012

(Affected models)

PF-315: FS-3900DN, FS-4000DN, FS-3920DN, FS-4020DN

PF-315+: FS-2100D, FS-2100DN, FS-4100DN, FS-4200DN, FS-4300DN

Topic

In a very rare case, static electricity on the TABLE PAPER was short-circuited to the side plate attached the PF

main PWB after paper feeding which cause damage to the motor driver IC on the PF main PWB (303KF01020)(*).

Therefore, the discharger brushes (DISCHARGER TP: No1) were added to the rear side of the TABLE PAPER to

secure the antistatic function.

* If the motor driver IC is damaged, the TABLE PAPER cannot be lifted up, which causes no paper feed jam.

1. Two pcs. of the DISCHARGER TP (No.1) were added to the TABLE PAPER.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Page 2

(Page.2/2)

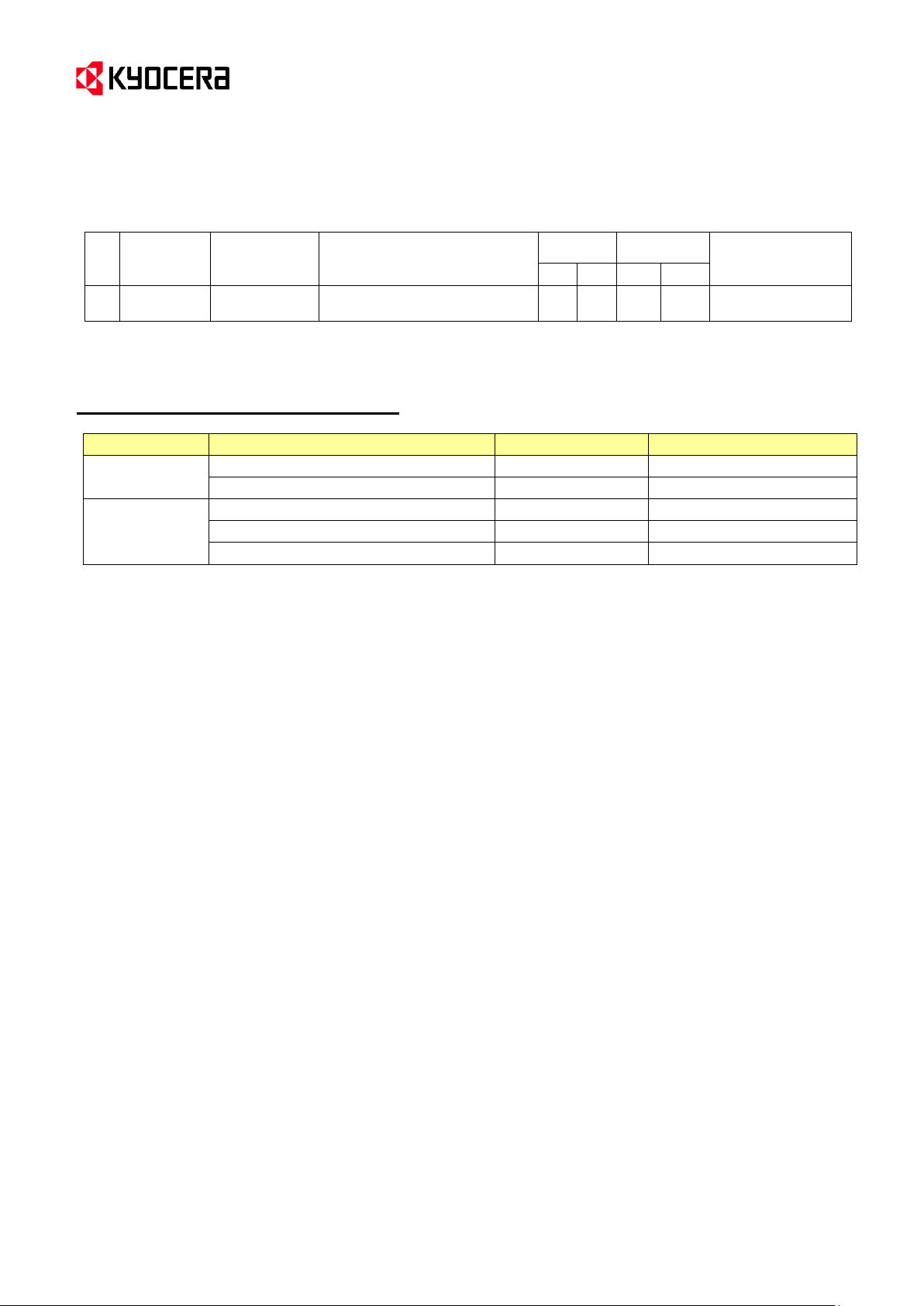

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

-----

303KF04120

3KF04120

DISCHARGER TP

- 2 -

O

Model

Destination

Item No.

Serial Number

PF-315

Other than KDCN

1203KF0KL0

Next production

KDCN

1203KF8KS0

Next production

PF-315+

Other than UTAX and Olivetti

1203KF0KL1

L4Y2Z00336 (Plan)

UTAX

1203KF8UT0

Next production

Olivetti

1203KF8LV0

L972Z00019 (Plan)

Service Bulletin Ref. No. 3KF-0003 (C313)

<Date> December 4, 2012

Serial Nos. of the Affected Machines

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...