Page 1

Chapter 5 Troubleshooting

5-1 DU-25

Page 2

5.1. General

This section explains how to take the corrective action against a trouble. Since every

operating function of the duplexer is commanded through the communication with the

printer, most troubles could happen due to the communication error between the

duplexer and the printer.

Firstly, following the basic check flow on the next page can lead you check and solve the

errors involved with the communication circuit and the power supply.

5-2 DU-25

Page 3

5.1.1. Preparation and precaution

To operate the duplexer while it is separate from the printer, use an extension cable jig. It

should allow the duplexer to be fed power from the printer.

Before connecting an extension cable to the duplexer and to the printer, be

sure that the printer’s power switch is set to off.

To conduct troubleshooting on the duplexer, no other option equipment should be connected together with the duplexer and the printer.

5-3 DU-25

Page 4

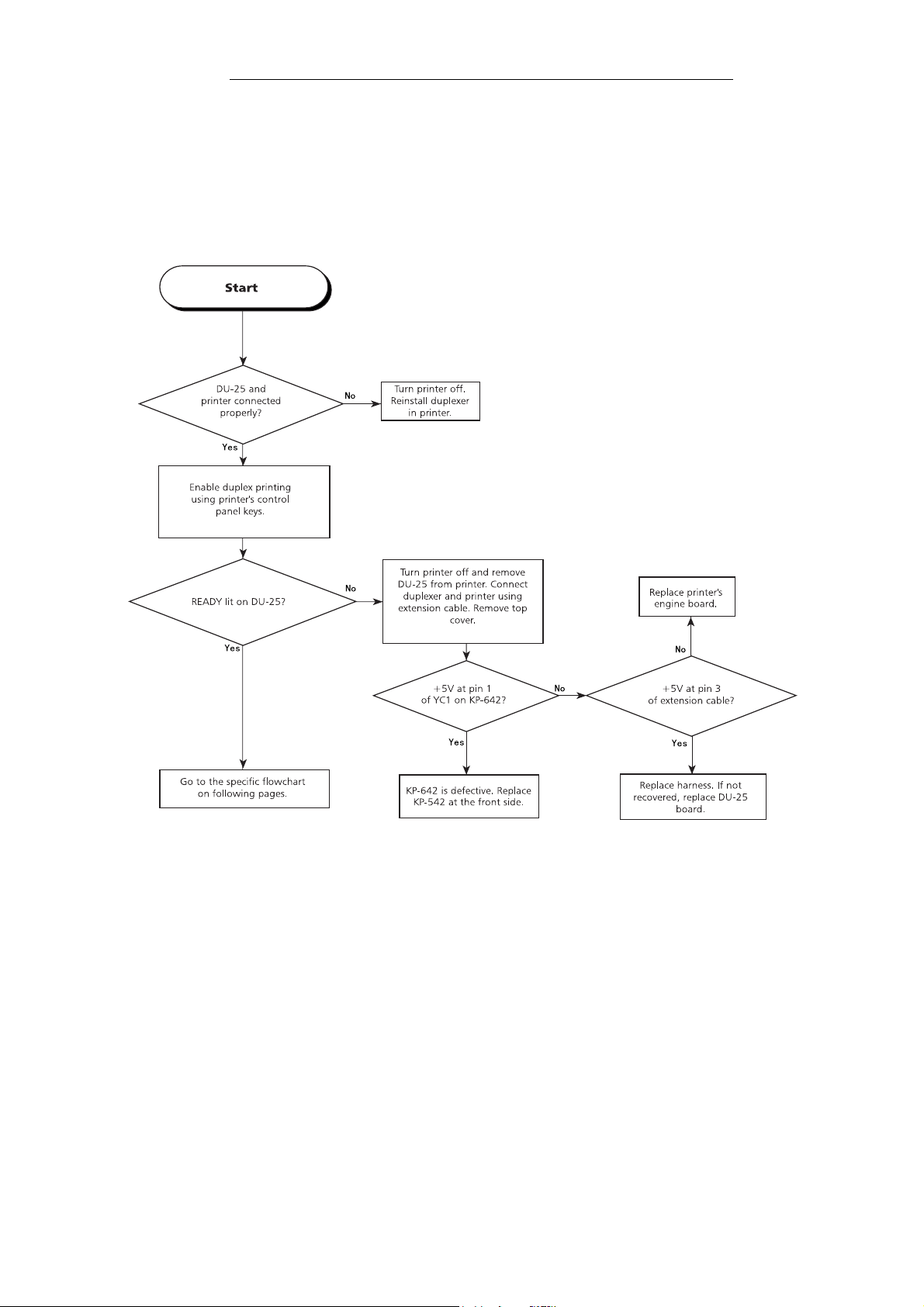

5.2. Electrical troubleshooting

The flow charts follow help isolate the defective parts in the duplexer. If the duplexer

needs to be dismantled in the procedures below, refer to

Chapter 2, Disassembly

.

5-4 DU-25

Page 5

5.2.1. Basic check

The flow chart below is used to check the power lines and communication lines in the

duplexer. This check must be conducted with the duplexer installed with the printer.

Basic check

5-5 DU-25

Page 6

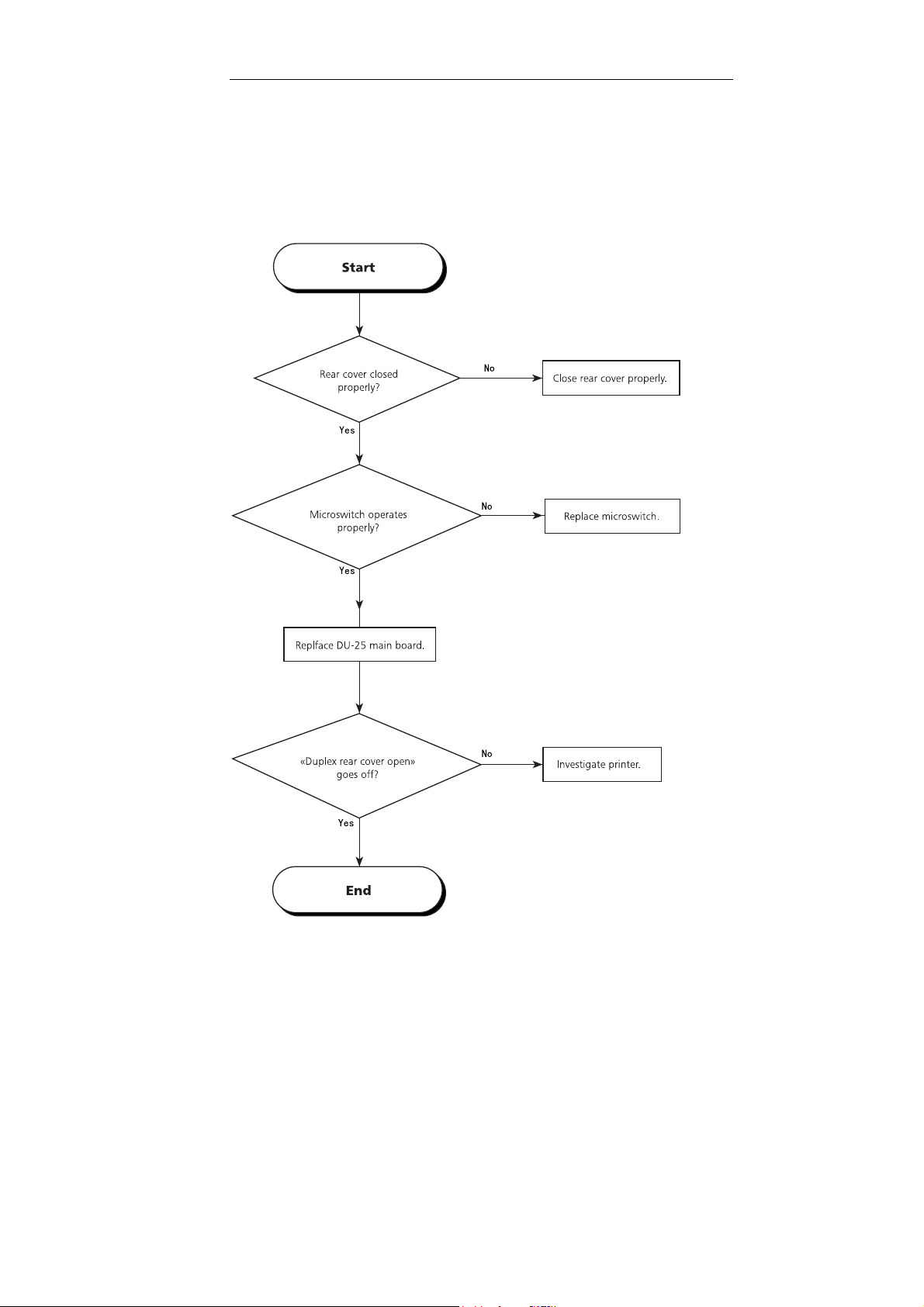

5.2.2. “Duplex unit rear cover open” does not go off

The rear cover status is monitored by a microswitch at the rear of the DU-25. Investigate

this microswitch following the procedures below.

Cover open message does not go off

5-6 DU-25

Page 7

5.2.3. Feed motor does not rotate

If the feed motor does not rotate, paper jam occurs. Investigate the motor power supply

using the following procedures.

Feed motor does not rotate

5-7 DU-25

Page 8

5.2.4. Paper detection sensor

The duplexer uses two sensors for detecting paper transportation. Failure of either sensor can cause paper jam. To investigate the failure of these sensors, start investigation on

sensor 1, then 2 using the same manner as for sensor 1.

Investigating failure on paper detection sensor 1

Using the same procedures above, investigate the operation of sensor 2 on the reversing

bay unit. In doing so, use pin 18 of CN2 for pin 2 of CN4 on KP-639; and use pin 20 of

CN2 on for pin 3 of CN4 on KP-639.

5-8 DU-25

Page 9

5.2.5. Reversing sensor

The reversing sensor (STSEN2) in the reversing bay detects presence of paper in the

reversing bay. If failure is suspected with this sensor, use the following procedures for

investigation.

Investigating failure on reversing bay sensor

5-9 DU-25

Page 10

5.2.6. Reversing bay paper sensor

Reversing bay paper sensor (STSEN1) detects paper entering the reversing bay. Failure

on this sensor can cause paper jam.

Reversing sensor

5-10 DU-25

Page 11

5.2.7. +24V line check

Following the procedures below allows investigation in the +24V power line in the

duplexer. For the +5V line, refer to Basic check.

+24V check

5-11 DU-25

Page 12

5.2.8. Duplexer error messages

The printer continuously monitors the status of the duplexer. In case of an error, it indicates an error code comprising a C and a number correponding to the location of the

error. The error code is succeeded by the message

Call service person

.

The error code(s) pertaining to the duplexer is as tabled below. Other error codes are

detailed in the printer’s service documentation.

Duplexer error(s)

Table 5.1. Duplexer error message

Error Meaning Suggested cause Corrective action

C1 The DU-25 cannot establish

communication with the

printer’s engine CPU.

The DU-25 main board or the

printer’s engine board is

defective. The option interface

connector is defective.

Follow procedure on Basic check

to isolate the location of failure.

5-12 DU-25

Page 13

5.3. Mechanical component

This section provides procedures for isolating paper jams or paper skew. These failures

can typically occur due to the faulty components.

5-13 DU-25

Page 14

5.3.1. Skew feed

If printer ejects paper in a skewed direction only when the duplexer is installed in it, follow the flowchart below. This will allow determine whether the paper is skewed because of

the duplexer or the printer.

Skew feed

5-14 DU-25

Page 15

5-15 DU-25

Page 16

5.3.2. Paper jam

The flowchart below should be used to determine the location of paper jam. For actual

actions to be taken for correction, refer to the sections that follow this diagram.

Paper jam

Hints on r em oving paper ja m

Bliking READYindicator on the DU-25 can mean one of the following possibilities:

Paper was not fed into the duplexer at all since printing has started.

•

Paper jam has occurred inside the duplexer.

•

The duplexer does not feed back the page into the printer.

•

Paper jam was detected at the moment the printer is powered up.

•

The following sections explain how to react these causes for the indication of paper jam.

In these, also refer to the for the location of sensors and motors.

5-16 DU-25

Page 17

Paper was not fed into the duplexer at all since printing has started.

Paper was not fed into the duplexer at all since printing has started.

Paper was not fed into the duplexer at all since printing has started.Paper was not fed into the duplexer at all since printing has started.

The duplexer recognizes that the paper is not present when the feed sensor does not find

paper See table below.

Table 5.1. Jam in the feed unit

Location of

paper jam

Feed unit (rear

end)

Printer and DU-25 are

not properly aligned with

Symptom Possible cause Corrective action

each other due to improper

installation.

Paper jam has occurred inside the duplexer.

Paper jam has occurred inside the duplexer.

Paper jam has occurred inside the duplexer.Paper jam has occurred inside the duplexer.

Paper jam is assumed when sensors SW1 and SW2 are not able to detect the presence of

paper.

Table 5.2. Jam in the duplexer

Location of

paper jam

Symptom Possible cause Corrective action

SW1, SW2 The leading edges of paper

are stuck at the entrance.

SW3 (Reversing

unit gate)

Paper hits the feed roller

(dia. 30 mm) at a perpendicular angle.

Printer is not installed

properly.

Rear feed guide is not

properly seated.

Remove the printer, then

install the printer properly.

Seat the rear feed guide

properly.

Feed unit is defective. Clean rollers; and invbesti-

gate guides.

Front feed guide is defec-

Replface front feed guide.

tive.

SW4 (Reversing

unitÅj

Location of

paper jam

Paper path adaptor

Feed roller (ɔ30) contaminated.

Motor revolves but does

not feed back paper.

Feed roller (ɔ30) is contaminated.

Reversing mylar piece is

defective.

The duplexer does not feed back the page into the printer.

The duplexer does not feed back the page into the printer.

The duplexer does not feed back the page into the printer.The duplexer does not feed back the page into the printer.

Table 5.3. Duplexer does not feed back the page

Symptom Possible cause Corrective action

Paper is stuck at the

duplex inlet.

Paper path adaptor is not

properly installed.

Clean feed roller using alcohol.

Clean feed roller using

alcohl.

Replace reversing mylar

piece.

Remove the paper path

adaptor; then install it again

properly.

5-17 DU-25

Loading...

Loading...