Page 1

MYROAD 700i

unauthorized use without the written permission of

By KWANG YANG Motor Co., Ltd.

First Edition, FEB. 2011

All rights reserved. Any reproduction or

KWANG YANG Motor Co., Ltd.

is expressly prohibited.

4122-KKE5-S00

Page 2

ELECTRICAL

Q

MYROAD 700i

This Service Manual describes the

technical features and servicing

procedures for the KYMCO XCITING

700.

Section 1 contains the precautions for

all operations stated in this manual.

Read them carefully before any

operation is started.

Section 2 is the removal/installation

procedures for the frame covers which are

subject to higher removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules and

service information for each part, starting

from periodic maintenance.

Sections 8 through 14 give instructions

for disassembly, assembly and adjustment

of engine parts. Section 15 through 17 is

the removal/ installation of chassis.

Section 18 through 21 states the testing

and measuring methods of electrical

equipment.

Most sections start with an assembly or

system illustration and troubleshooting

for the section. The subsequent pages give

detailed procedures for the section.

KWANG YANG MOTOR CO., LTD.

PREFACE

The information and contents included in

this manual may be different from the

motorcycle in case specifications are

changed.

KYMCO reserves the right to make

changes at any time without notice and

without incurring any obligation.

OVERSEAS SALES DEPARTMENT

OVERSEAS SERVICE SECTION

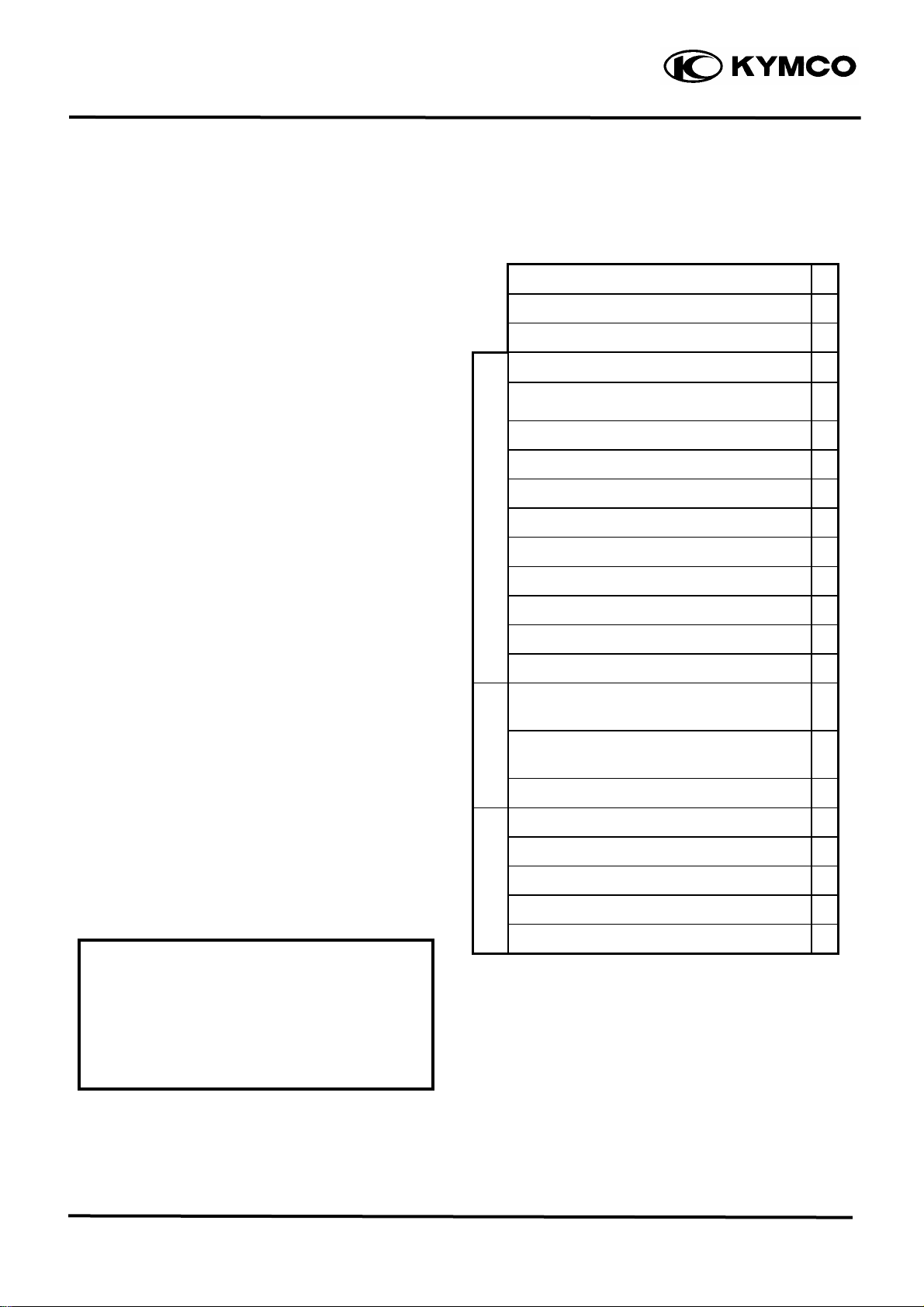

TABLE OF CONTENTS

GENERAL INFORMATION 1

FRAME COVERS /EXHAUST MUFFLER 2

INSPECTION/ADJUSTMENT 3

LUBRICATION SYSTEM 4

CABLE & HARNESS ROUTING

AFI (AUTOMATIC FUEL INJECTION) 6

COOLING SYSTEM 7

ENGINE

ENGINE REMOVAL/INSTALLATION 8

CYLINDER HEAD/VALVES 9

CYLINDER/PISTON 10

DRIVE AND DRIVEN PULLEY 11

FINAL REDUCTION 12

A.C. GENEARTOR/STARTER CLUTCH 13

CRANKCASE/CRANKSHAFT 14

STEERING HANDLEBAR/FRONT

CHASSIS

WHEEL/FRONT SHOCK ABSORBER

REAR FORK/REAR WHEEL/REAR

SHOCK ABSORBER`

BRAKE SYSTEM 17

BATTERY/CHARGING SYSTEM 18

E

UIPMENT

IGNITION SYSTEM 19

ELECTRIC STARTER 20

LIGHTS/METERS/SWITCHES 21

ANTI-LOCK BRAKE SYSTEM(ABS) 22

5

15

16

Page 3

1. GENERAL INFORMATION

MYROAD 700i

1

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

1

__________________________________________________________________________________

GENERAL INFORMATION

__________________________________________________________________________________

SERIAL NUMBER-----------------------------------------------------------1 - 1

SPECIFICATIONS ---------------------------------------------------------1 - 2

SERVICE PRECAUTIONS-------------------------------------------------1 - 3

TORQUE VALUES ----------------------------------------------------------1 - 7

SPECIAL TOOLS ------------------------------------------------------------1 - 9

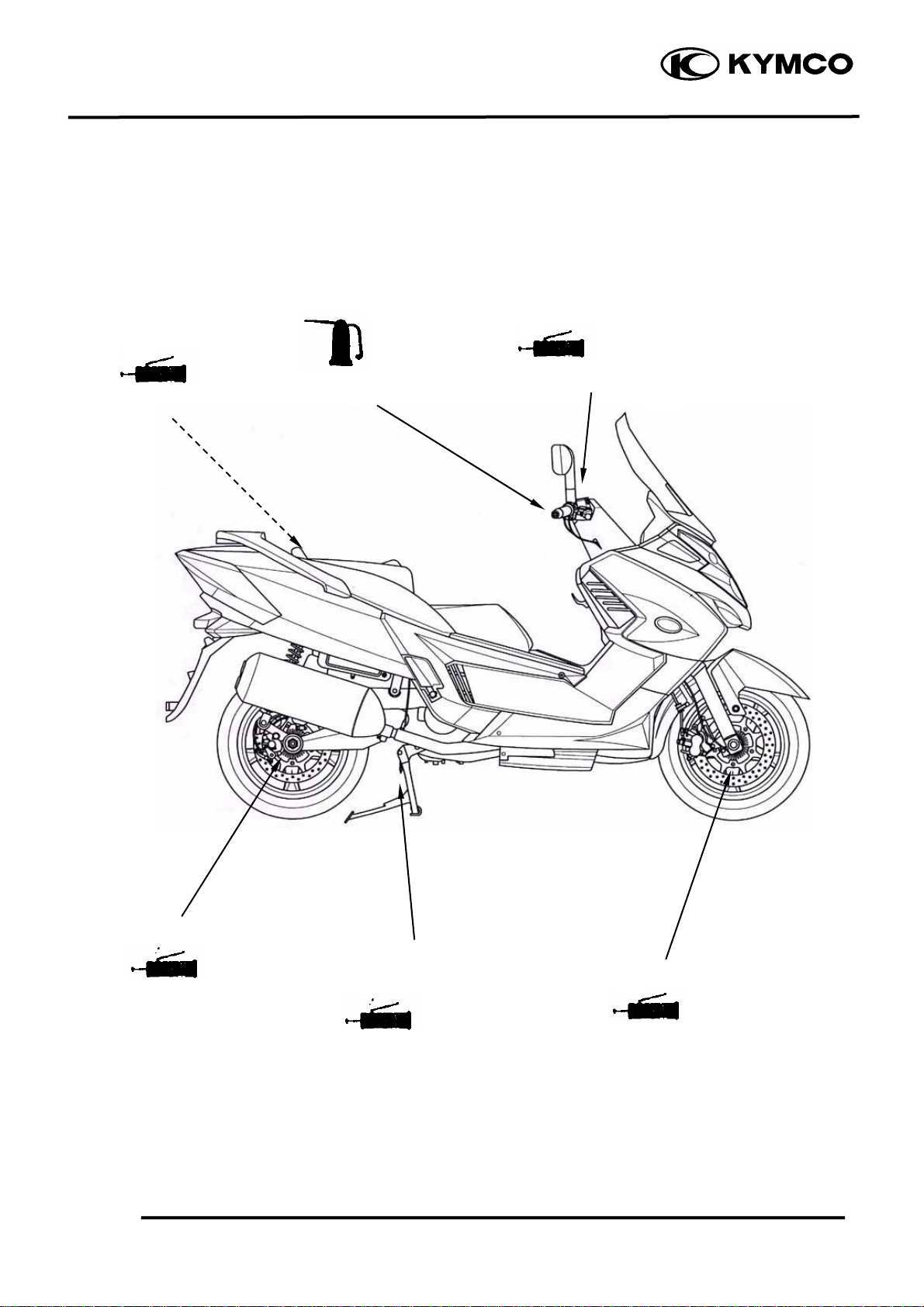

LUBRICATION POINTS ---------------------------------------------------1-10

TROUBLESHOOTING------------------------------------------------------1-12

1-0

Page 4

1. GENERAL INFORMATION

r

SERIAL NUMBER

VEHICLE IDENTIFICATION NUMBER(VIN):

FRAME NUMBER(VIN):

Location of Engine Serial Numbe

MYROAD 700i

1-1

Page 5

1. GENERAL INFORMATION

m

y

g

y

y

MYROAD 700i

SPECIFICATIONS

ITEM SPECIFICATIONS

Name MYROAD 700i

Overall length 2330 mm

Overall width 830 mm

Overall height 1510 mm

Wheel base 1615 mm

Engine type D.O.H.C.

Displacement

Fuel Used 92# nonleaded gasoline

Front wheel 108 kg

Dry weight Rear wheel 160 kg

Total 268 kg

Front wheel 116 kg

Curb weight Rear wheel 168 kg

Total 284 kg

Front wheel 120/70-R15

Tires

Rear wheel 160/60-R14

Ground clearance 135 mm

Min. turning radius 2700 mm

Starting system

Type Gasoline, 4-stroke

Cylinder arrangement Twin cylinder

Combustion chamber type ROOF

Valve arrangement O.H.C.

Bore x stroke

Compression ratio 10.5:1

Compression pressure

Engine

Intake valve

Exhaust valve

Valve clearance

(cold)

Idle speed Rpm

Oil pump type Trochoid

Oil filter type Full-flow filtration

Final reduction oil

Cooling Type Liquid cooled

Lubrication type

Lubrication

S

stem

Oil capacity

capacity

Open 7° BTDC

Close 40° ABDC

Open 40° BBDC

Close 10° ATDC

Intake 0.16 mm

Exhaust 0.22 mm

699.5 cc

Electric starter motor

76.9X75.3 mm

13 kgf/cm²

Forced pressure &

Wet sump

3 L

0.4 L

ITEM SPECIFICATIONS

Fuel S

Air cleaner type & No Wet paper type element

Fuel capacity

stem

Throttle Body Venturi

dia

Electrical Equipment

I

Spark plug DR8E

Spark plug gap 0.6~0.7 mm

Battery Capacity 12V12AH

Power Drive System

Preliminary

Final

Moving Device

Turning Left 40°

Brake syste

type

Damping

Device

Frame type Double cradle

Type

nition S

Ignition timing ECU

stem

Clutch Type

Transmis-

sion Gear

Type

Operation

Reduction

Ratio

Type CVT

FR/RR tire rolling

circumference

Tire pressure

(rider only/60

kg)

angle

Suspension

type

Front

Rear

Right 40°

Rear Disk brake

Front Disk brake

Front

Rear

14 L

φ 38 mm

Full transistor ignition

Dry, centrifugal

automatic

Helical gear/spur gear

Automatic centrifugal

Type

0.99

5.58

mm

2 kg/cm²

2.25 kg/cm²

Telescopic fork

Unit swing

1-2

Page 6

1. GENERAL INFORMATION

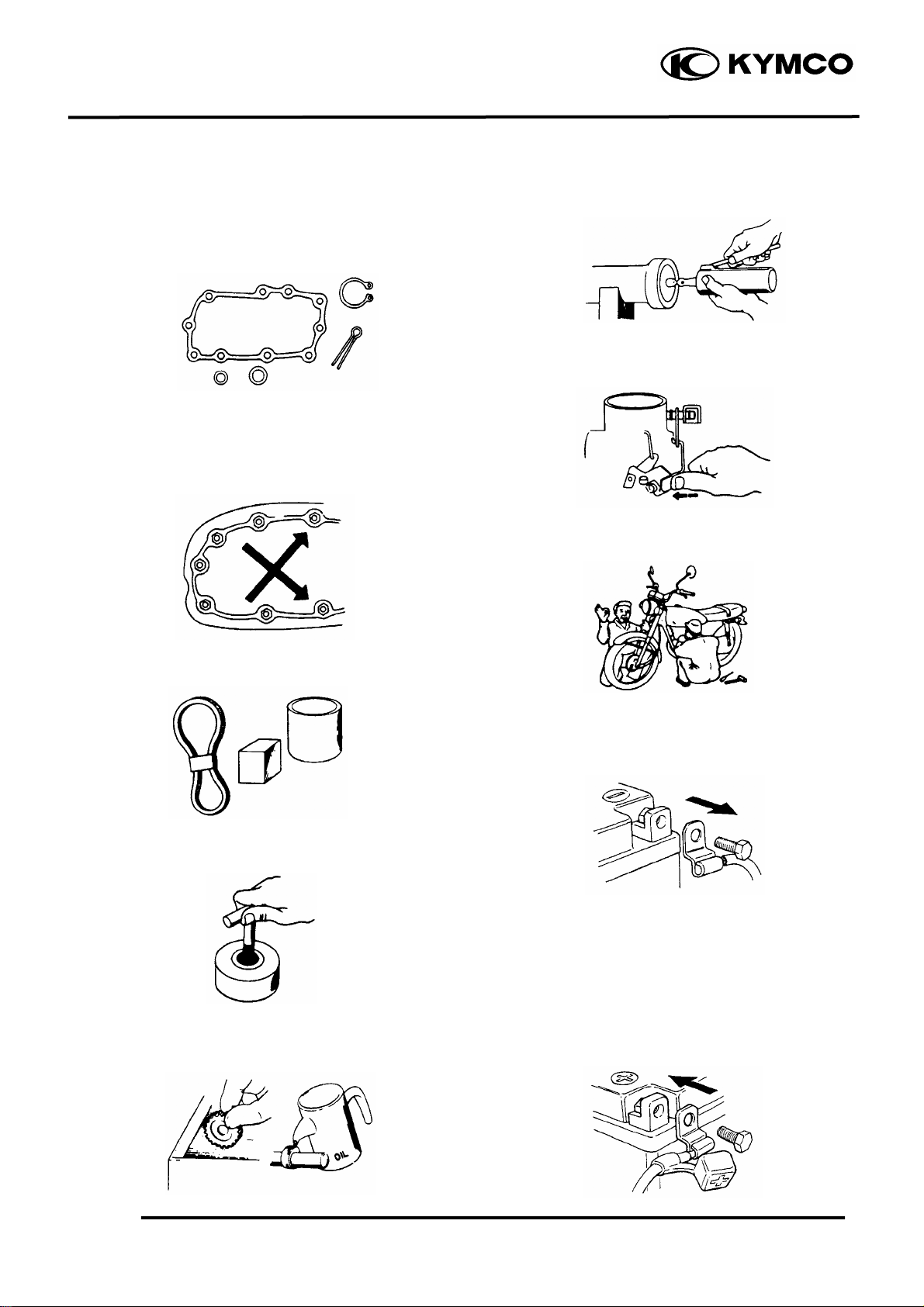

SERVICE PRECAUTIONS

Make sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when

reassembling.

When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

Use genuine parts and lubricants.

When servicing the motorcycle, be sure to

use special tools for removal and

installation.

After disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

MYROAD 700i

Apply or add designated greases and

lubricants to the specified lubrication

points.

After reassembly, check all parts for proper

tightening and operation.

When two persons work together, pay

attention to the mutual working safety.

Disconnect the battery negative (-) terminal

before operation.

When using a spanner or other tools, make

sure not to damage the motorcycle surface.

After operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

When connecting the battery, the positive

(+) terminal must be connected first.

After connection, apply grease to the

battery terminals.

Terminal caps shall be installed securely.

1-3

Page 7

1. GENERAL INFORMATION

MYROAD 700i

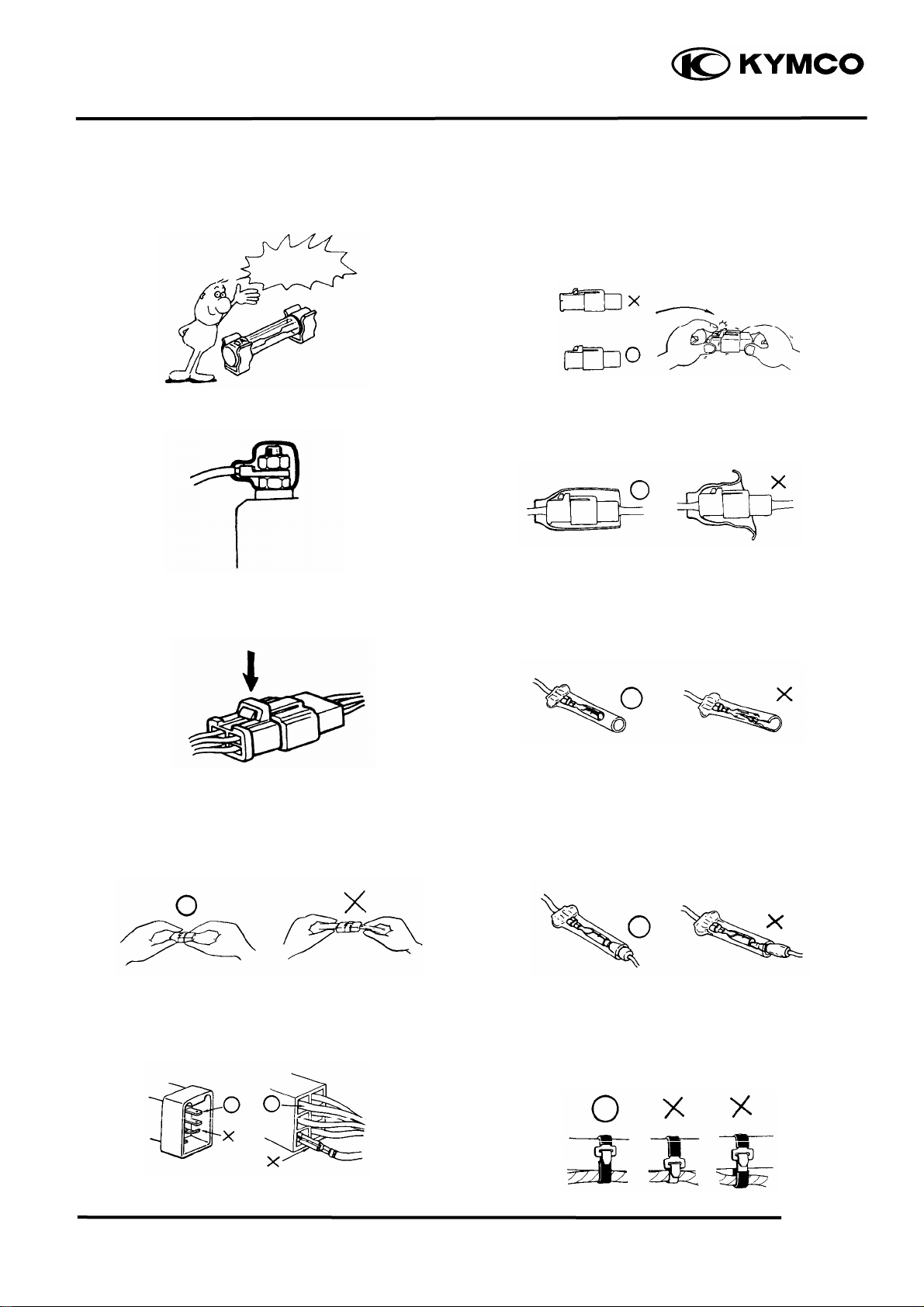

If the fuse is burned out, find the cause and

repair it. Replace it with a new one

according to the specified capacity.

After operation, terminal caps shall be

installed securely.

When taking out the connector, the lock on

the connector shall be released before

operation.

Hold the connector body when connecting

or disconnecting it.

Do not pull the connector wire.

Check if any connector terminal is bending,

protruding or loose.

Confirm

Capacity

The connector shall be inserted

completely.

If the double connector has a lock, lock

it at the correct position.

Check if there is any loose wire.

Before connecting a terminal, check for

damaged terminal cover or loose negative

terminal.

Check the double connector cover for

proper coverage and installation.

Insert the terminal completely.

Check the terminal cover for proper

coverage.

Do not make the terminal cover opening

face up.

Secure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the insulated

surfaces contact the wire harnesses.

1-4

Page 8

1. GENERAL INFORMATION

MYROAD 700i

After clamping, check each wire to make

sure it is secure.

Do not squeeze wires against the weld or

its clamp.

After clamping, check each harness to

make sure that it is not interfering with any

moving or sliding parts.

When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

Route wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.

Route harnesses so they are neither

pulled tight nor have excessive slack.

Do not pull

too tight!

Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner.

When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

Do not break the sheath of wire.

If a wire or harness is with a broken sheath,

repair by wrapping it with protective tape

or replace it.

When installing other parts, do not press or

squeeze the wires.

Do not press or

squeeze the

1-5

Page 9

1. GENERAL INFORMATION

MYROAD 700i

After routing, check that the wire harnesses

are not twisted or kinked.

Wire harnesses routed along with

handlebar should not be pulled tight, have

excessive slack or interfere with adjacent

or surrounding parts in all steering

positions.

When a testing device is used, make sure to

understand the operating methods

thoroughly and operate according to the

operating instructions.

Do you understand

the instrument?

Be careful not to drop any parts.

When rust is found on a terminal, remove

the rust with sand paper or equivalent

before connecting.

Remove Rust!

Symbols:

The following symbols represent the

servicing methods and cautions included in

this service manual.

Engine Oil

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for lubrication.

Grease

: Transmission Gear Oil (90#)

Gear Oil

*

: Note

1-6

Page 10

1. GENERAL INFORMATION

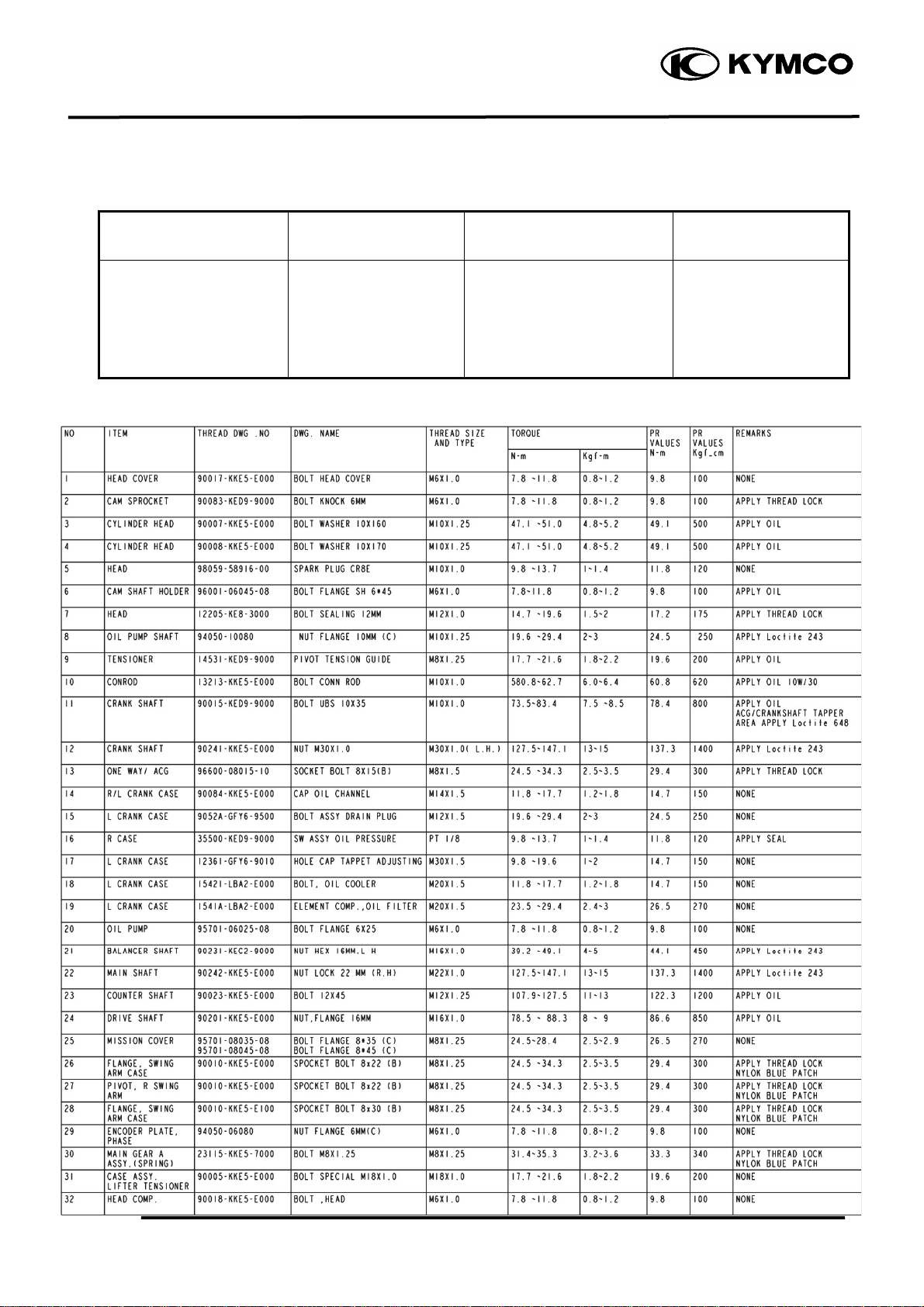

TORQUE VALUES

STANDARD TORQUE VALUES

5mm bolt and nut

6mm bolt and nut

8mm bolt and nut

10mm bolt and nut

12mm bolt and nut

Torque specifications listed below are for important fasteners.

ENGINE

Item

Torque

Kg-m

0.5

1.0

2.2

3.5

5.5

5mm screw

6mm screw, SH bolt

6mm flange bolt and nut

8mm flange bolt and nut

10mm flange bolt and nut

Item

MYROAD 700i

Torque

Kgf-m

0.4

0.9

1.2

2.7

4.0

1-7

Page 11

1. GENERAL INFORMATION

FRAME

MYROAD 700i

1-8

Page 12

1. GENERAL INFORMATION

SPECIAL TOOLS

Tool Name Tool No. Remarks

Lock nut socket wrench A120F00007 Steering stem removal or install

Oil seal & bearing installers A120E00014 Oil seal & bearing install

Universal holder A120E00017 Holding clutch for removal

MYROAD 700i

Flywheel holder A120E00021 A.C. generator flywheel holding

Bearing pullers A120E00030 Bearing removal

Tappet adjuster A120E00036 Tappet adjustment

Bearing pullers A120E00037 Bearing removal

Valve spring compressor A120E00040 Valve removal

Oil filter cartridge wrench A120E00052 Cartridge removal or install

Clutch spring compressor A120E00053 Clutch disassembly

Flywheel puller A120E00061 A.C. generator flywheel removal

Clutch fixed bolt A120E00038 Clutch

Balancer gear nut wrench A120F00080 Balancer gear

Connecting rod bolts wrench A120F00081 Connecting rod

1-9

Page 13

1. GENERAL INFORMATION

LUBRICATION POINTS

ENGINE

MYROAD 700i

Valve guide/valve stem movable part

Camshaft protruding surface

Valve rocker arm friction surface

Camshaft drive chain

Cylinder lock bolt and nut

Piston surroundings and piston ring grooves

Piston pin surroundings

Cylinder inside wall

Connecting rod/piston pin hole

Connecting rod big end

Crankshaft

Balancer shaft

Crankshaft one-way clutch movable part

Oil pump drive chain

Starter reduction gear engaging part

O-ring face

Oil seal lip

Lubrication Points Lubricant

•Genuine KYMCO Engine Oil (SAE 5W-50)

•API SJ Engine Oil

Drive gear shaft

Countershaft

Final gear

Final gear shaft

Transmission gearshaft bearing part

A.C. generator connector Adhesive

Transmission oil: SAE 90

1-10

Page 14

1. GENERAL INFORMATION

FRAME

The following is the lubrication points for the frame.

Use general purpose grease for parts not listed.

Apply clean engine oil or grease to cables and movable parts not specified. This will avoid

abnormal noise and rise the durability of the motorcycle.

Seat Lock

Rear Wheel Bearing

Grease

Grease

Throttle Cable

Center Stand/Side Stand Pivot

Engine Oil

Grease

Grease

Front/Rear Brake Lever Pivot

Front Wheel Bearing

MYROAD 700i

Grease

1-11

Page 15

1. GENERAL INFORMATION

g p

TROUBLESHOOTING

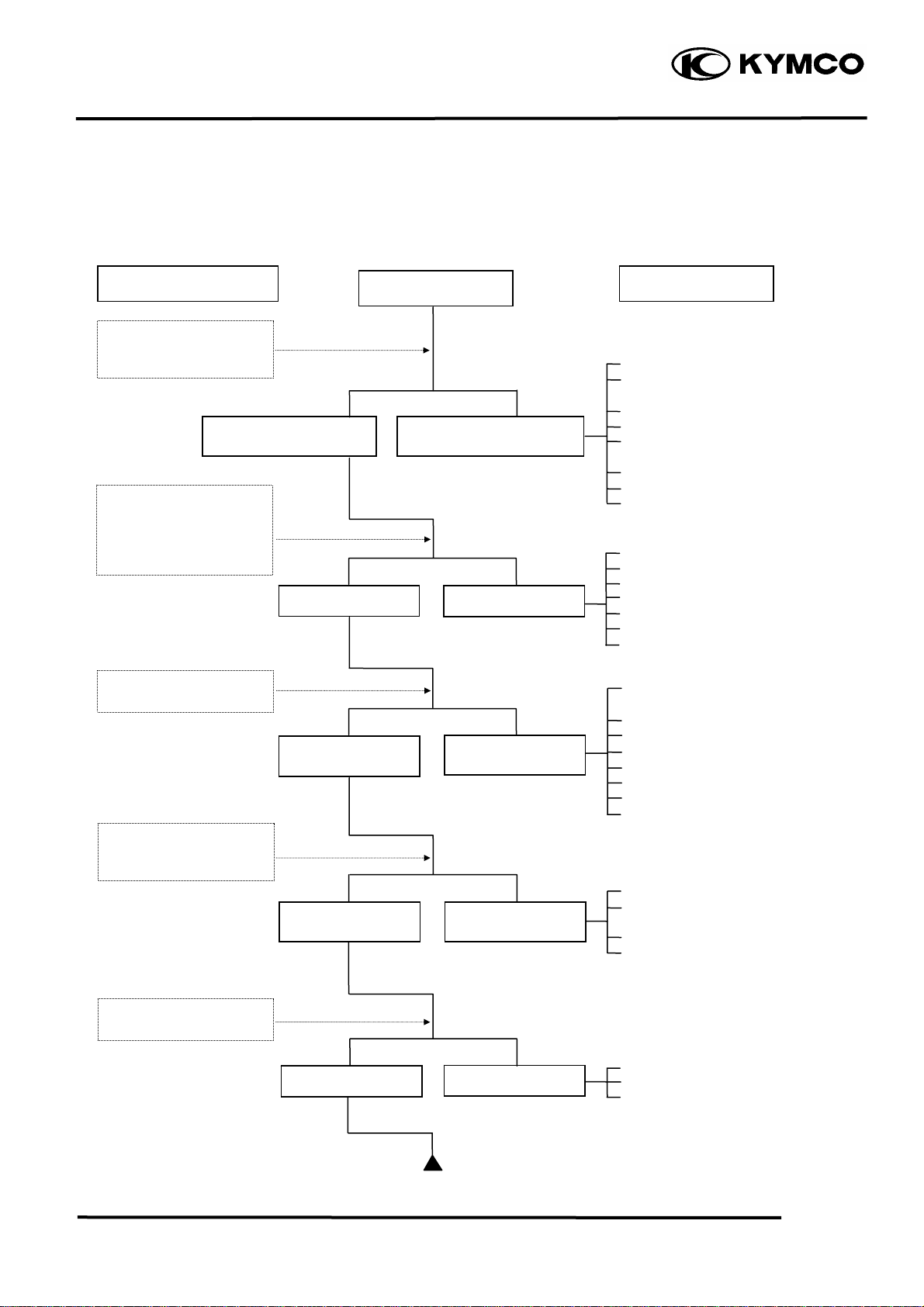

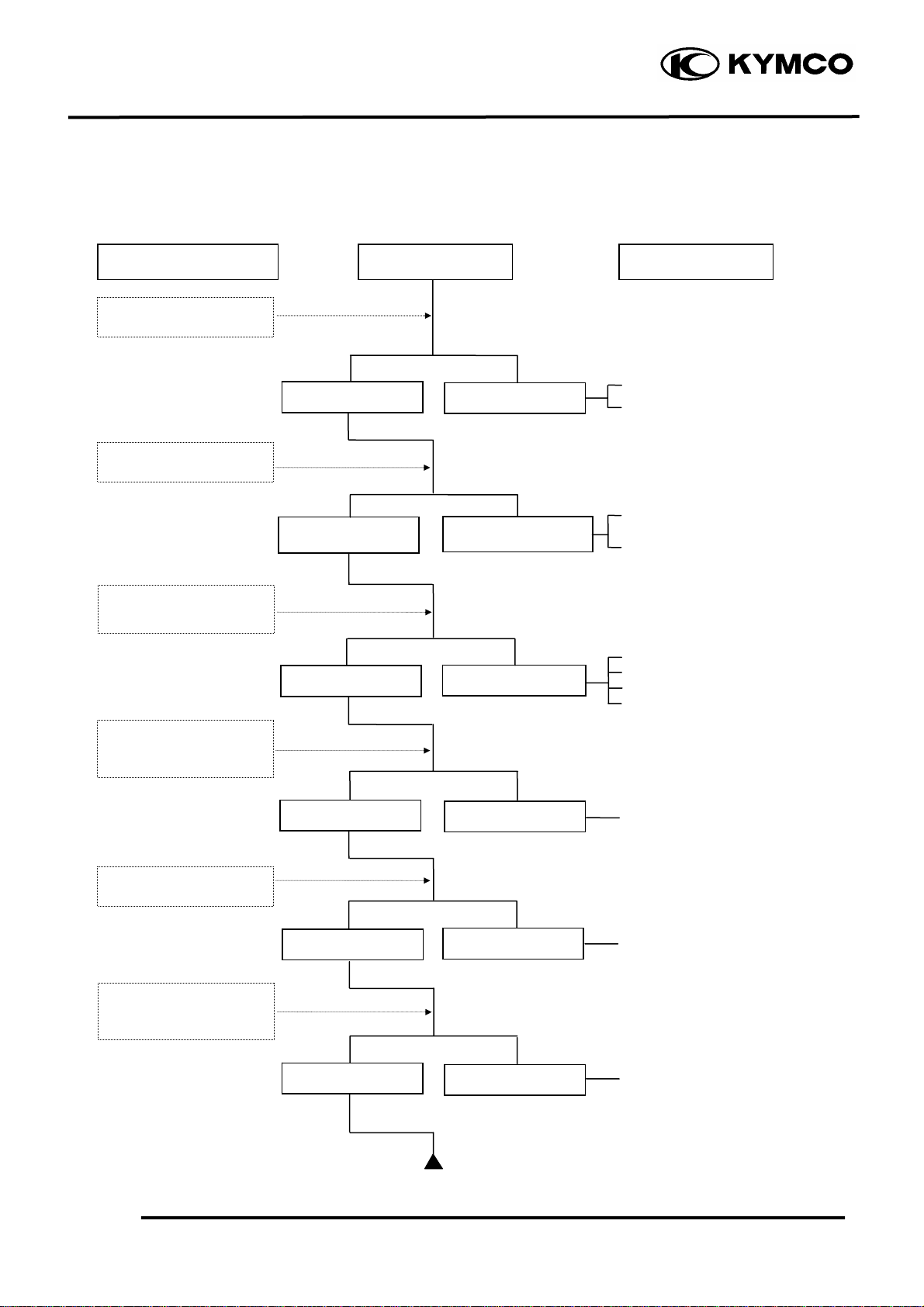

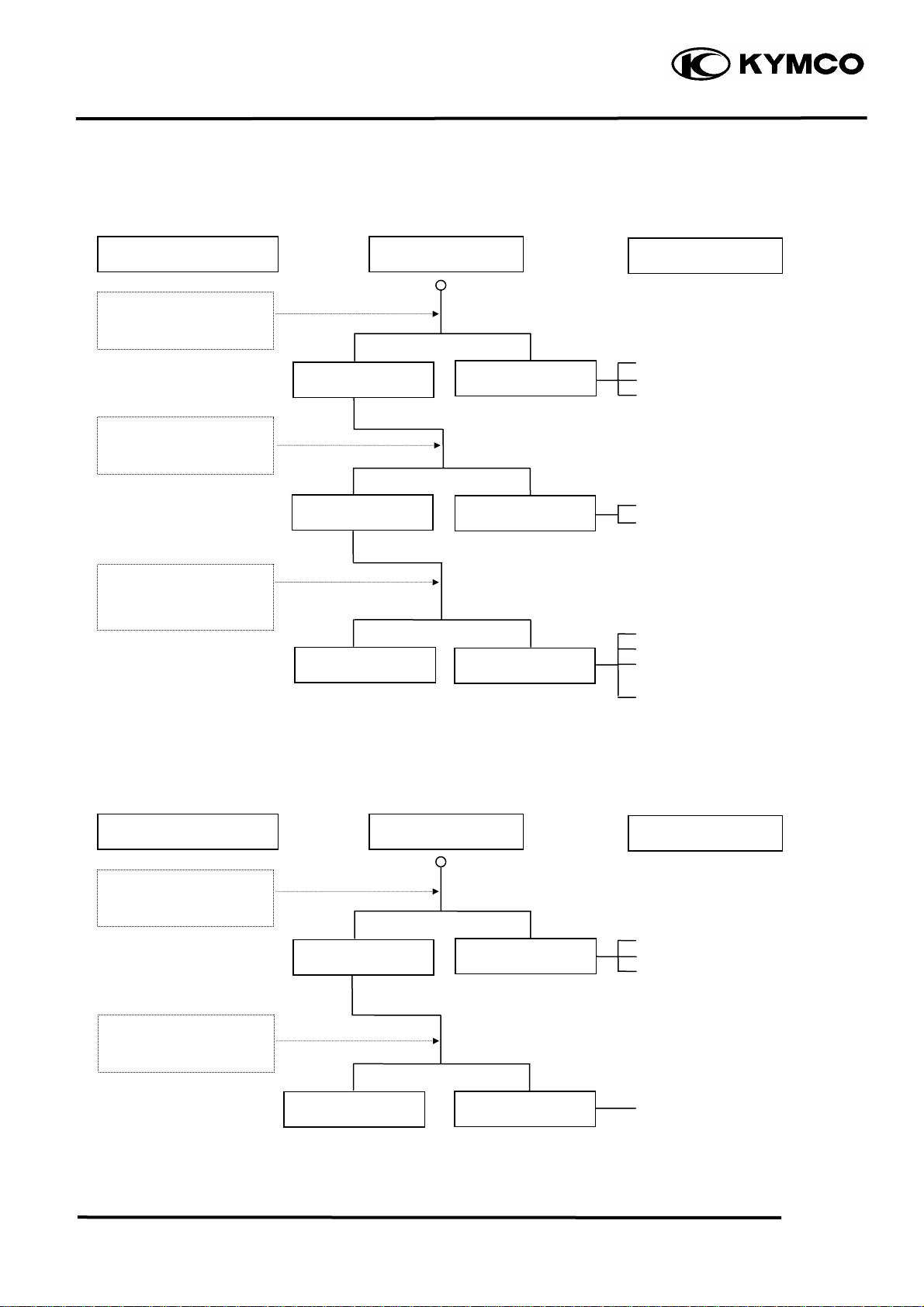

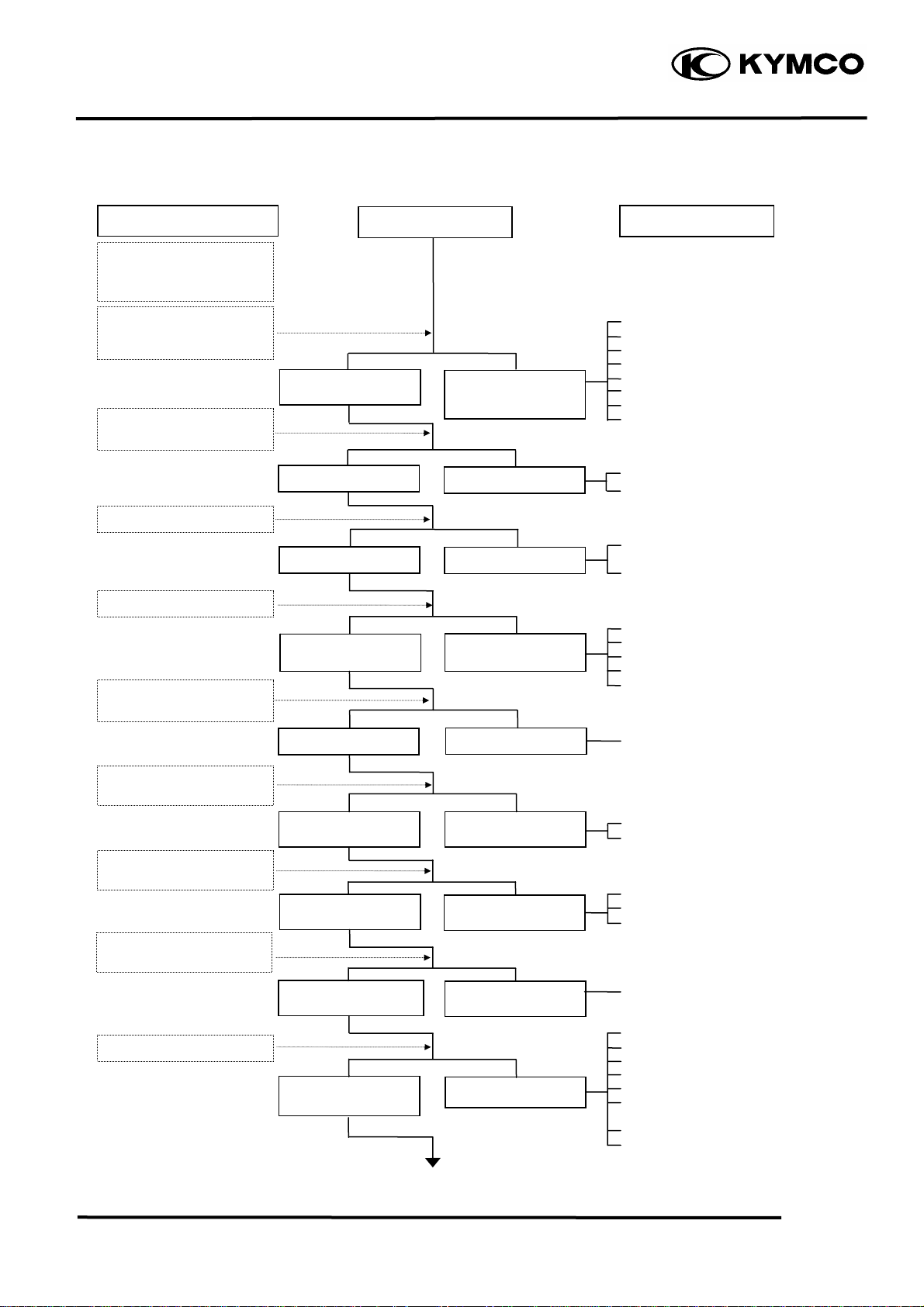

ENGINE WILL NOT START OR IS HARD TO START

Inspection/Adjustment

Check if fuel reaches

carburetor by loosening

drain screw

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

ground

Test cylinder

compression

Start engine by

follow-ing normal

startin

Remove spark plug and

inspect again

Fuel reaches

carburetor/fuel injector

rocedure

Spark jumps

Normal

compression

Engine does not

fire

Dry spark plug

Symptom

Fuel does not reach

carburetor/fuel injector

Weak or no spark

Low or no

compression

Engine fires but

does not start

Wet spark plug

MYROAD 700i

Probable Cause

cEmpty fuel tank

dClogged carburetor fuel inlet

tube, vacuum tube or fuel tube

eClogged auto fuel valve

fClogged float oil passage

gClogged fuel tank cap

breather hole

hClogged fuel strainer

iClogged fuel filter

jFaulty fuel pump

cFaulty spark plug

dFouled spark plug

eFaulty ignition unit

fFaulty A.C. generator

gBroken or shorted ignition coil

hBroken or shorted exciter coil

iFaulty ignition switch

cStarter motor idles but

crankshaft does not rotate

dValve clearance too small

eImproper valve and seat contact

fWorn cylinder and piston rings

gBlown cylinder head gasket

hFlaws in cylinder head

iSeized valve

jImproper valve timing

cFaulty auto bystarter

dAir leaking through intake

pipe

eIncorrect ignition timing

fIncorrectly adjusted pilot screw

cFlooded carburetor

dFaulty auto bystarter

eThrottle valve excessively

open

1-12

Page 16

1. GENERAL INFORMATION

g

y

g

g

t

N

N

b

t

r

t

r

prop

prop

y

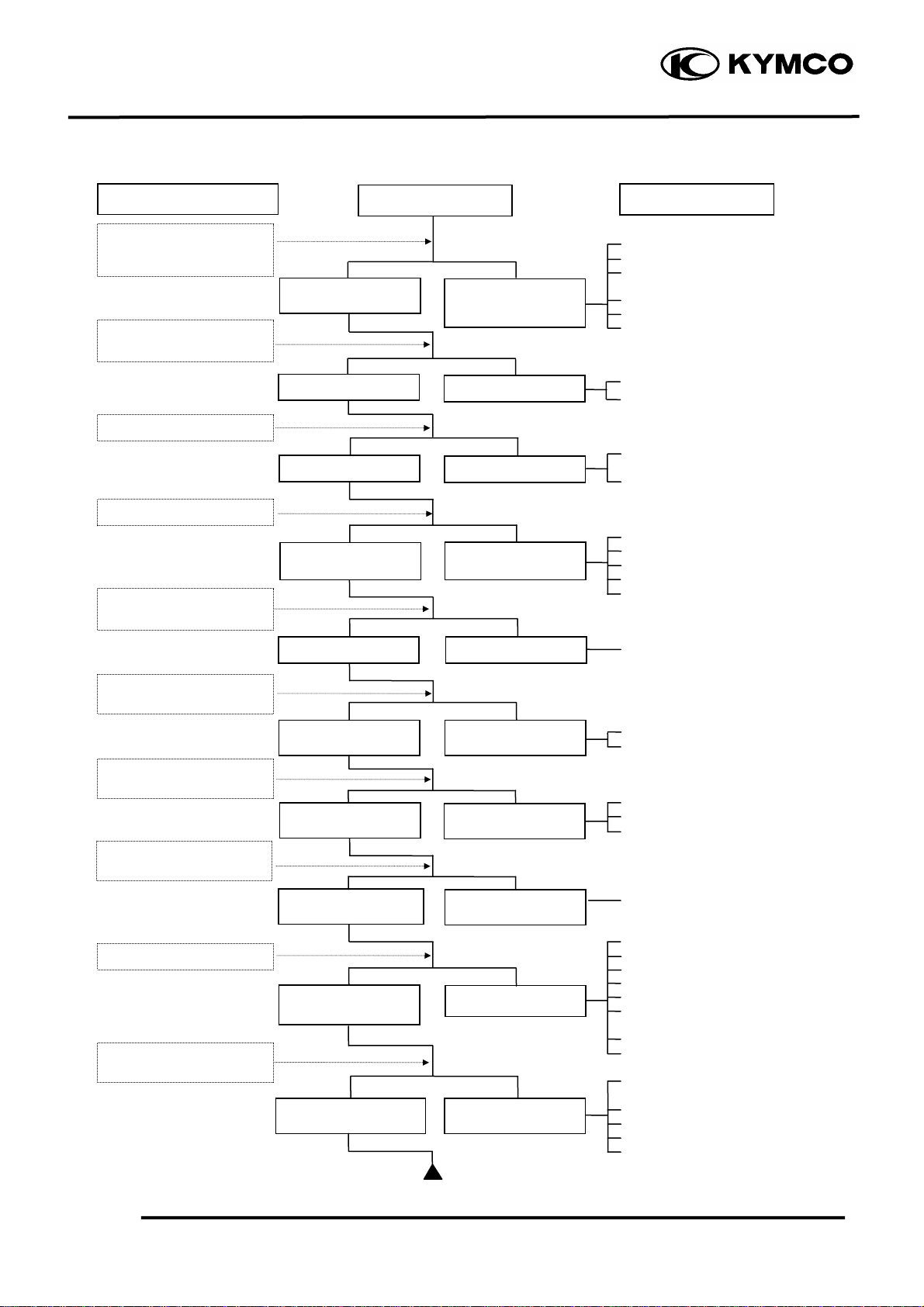

ENGINE LACKS POWER

Inspection/Adjustment

Start engine and

accelerate lightly for

Check ignition timing

(using a timing light)

Check valve clearance

Test cylinder compression

Check carburetor for

clogging

Remove spark plug and

inspect

Remove oil dipstick and

check oil level and condition

Remove cylinder head

olts and inspect

Check if engine overheats

Rapidly accelerate or run

at hi

h speed

Engine speed

Correct timin

Correct

ormal

compression

ot Clogged

Plug not fouled o

Correct and no

Valve train lubricated

erly

Engine does no

overheats

Engine does not knock

Symptom

Engine speed does

not increase

sufficientl

Valve train not

lubricated

Incorrect timin

Incorrec

Abnormal

compression

Clogged

Plug fouled or

Incorrect o

erl

Engine overheats

Engine knocks

MYROAD 700i

Probable Cause

cClogged air cleaner

dRestricted fuel flow

eClogged fuel line between fuel

tank and carburetor

fClogged exhaust muffler

gFaulty auto bystarter

hSplit carburetor vacuum piston

diaphragm

cFaulty

dFaulty A.C. generator

cImproper valve clearance

dWorn valve seat (valve stem too

cImproper valve and seat contact

dWorn cylinder and piston rings

eBlown cylinder head gasket

fFlaws in cylinder head

gImproper valve timing

cClogged carburetor jets

cFouled spark plug

dIncorrect heat range plug

cOil level too high

dOil level too low

eOil not changed

cFaulty oil pump

cInsufficient coolant

dFaulty thermostat

eWorn cylinder and piston rings

fMixture too lean

gPoor quality fuel

hExcessive carbon buildup in

iIgnition timing too early

jAir in cooling system

cExcessive carbon build-up in

dPoor quality fuel

eClutch slipping

fMixture too lean

g Ignition timing too early

ignition unit

adjustment

protruding

combustion chamber

combustion chamber

1-13

Page 17

1. GENERAL INFORMATION

g

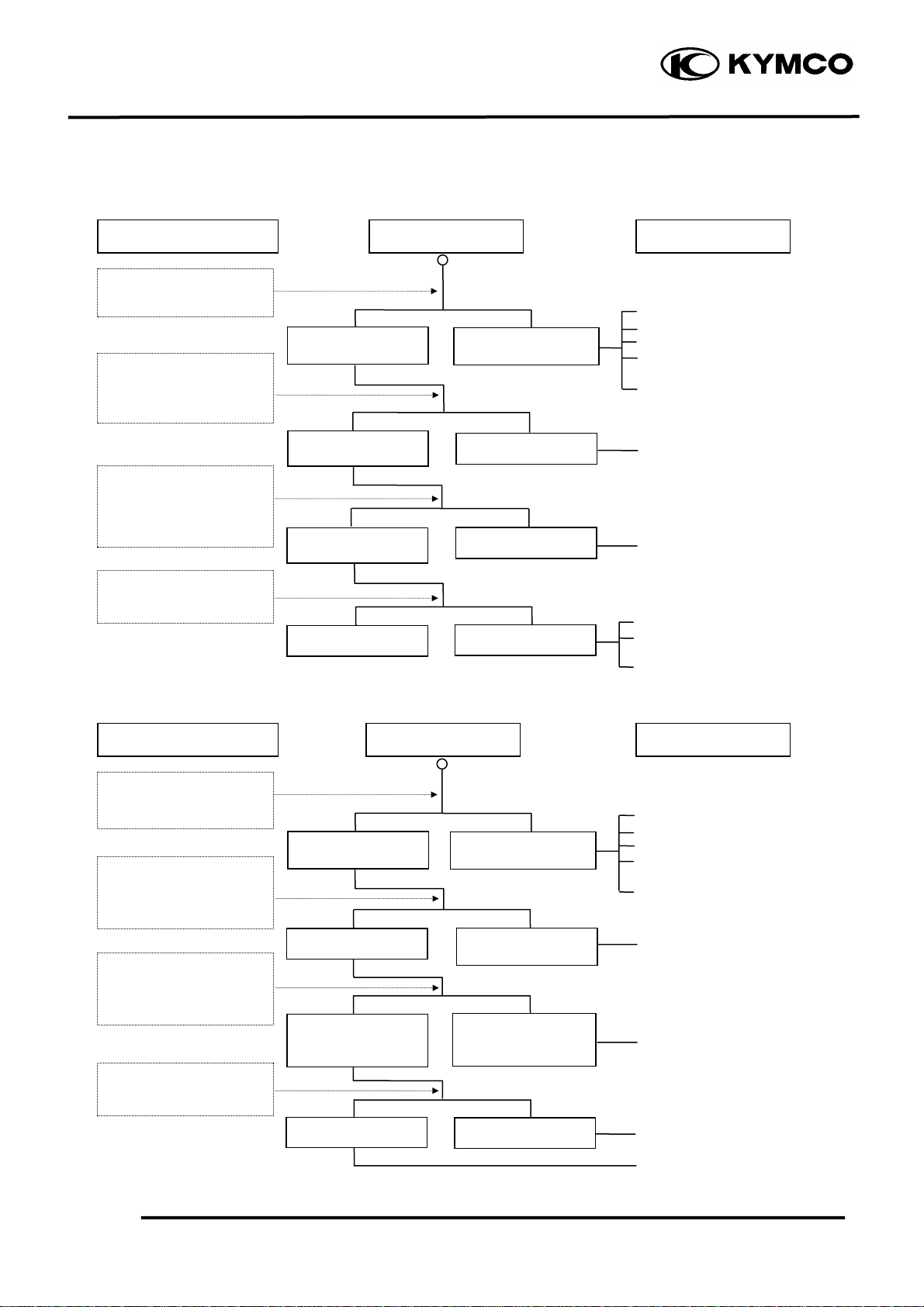

POOR PERFORMANCE (ESPECIALLY AT IDLE AND LOW SPEEDS)

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

cFaulty ignition unit

dFaulty A.C. generator

cMixture too rich (turn screw

out)

dMixture too lean (turn screw

in)

cDamaged insulator rubber

dCarburetor not securely

tightened

eFaulty intake manifold gasket

fDeformed carburetor O-ring

cFaulty or fouled spark plug

dFaulty ignition unit

eFaulty A.C. generator

fFaulty ignition coil

gBroken or shorted high

tension wire

hFaulty ignition switch

cDamaged air cut-off valve

diaphragm

dDamaged air cut-off valve

spring

Check carburetor pilot

screw adjustment

Check intake manifold

for air leaks

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

round

Check carburetor air

cut-off valve

Correct timing

Incorrect timing

Correctly adjusted

No air leak

Good spark

Good

Incorrectly adjusted

Air leaks

Weak or inter-

mittent spark

Faulty

MYROAD 700i

1-14

Page 18

1. GENERAL INFORMATION

t

t

POOR PERFORMANCE (AT HIGH SPEED)

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

cFaulty ignition unit

dFaulty A.C. generator

cImproperly adjusted valve

clearance

dWorn valve seat

cEmpty fuel tank

dClogged fuel tube or filter

eFaulty fuel pump

fCracked fuel

tube

cClean and unclog

cCam timing gear aligning

marks not aligned

cFaulty spring

Check valve clearance

Check fuel pump for

fuel supply

Check carburetor jets

for clogging

Check valve timing

Check valve spring

tension

Correct timing

Correctly adjusted

Fuel flows freely

Not clogged

Correc

Not weakened

Incorrect timing

Incorrectly adjusted

Fuel flow restricted

Clogged

Incorrec

Weak spring

MYROAD 700i

pump vacuum

1-15

Page 19

1. GENERAL INFORMATION

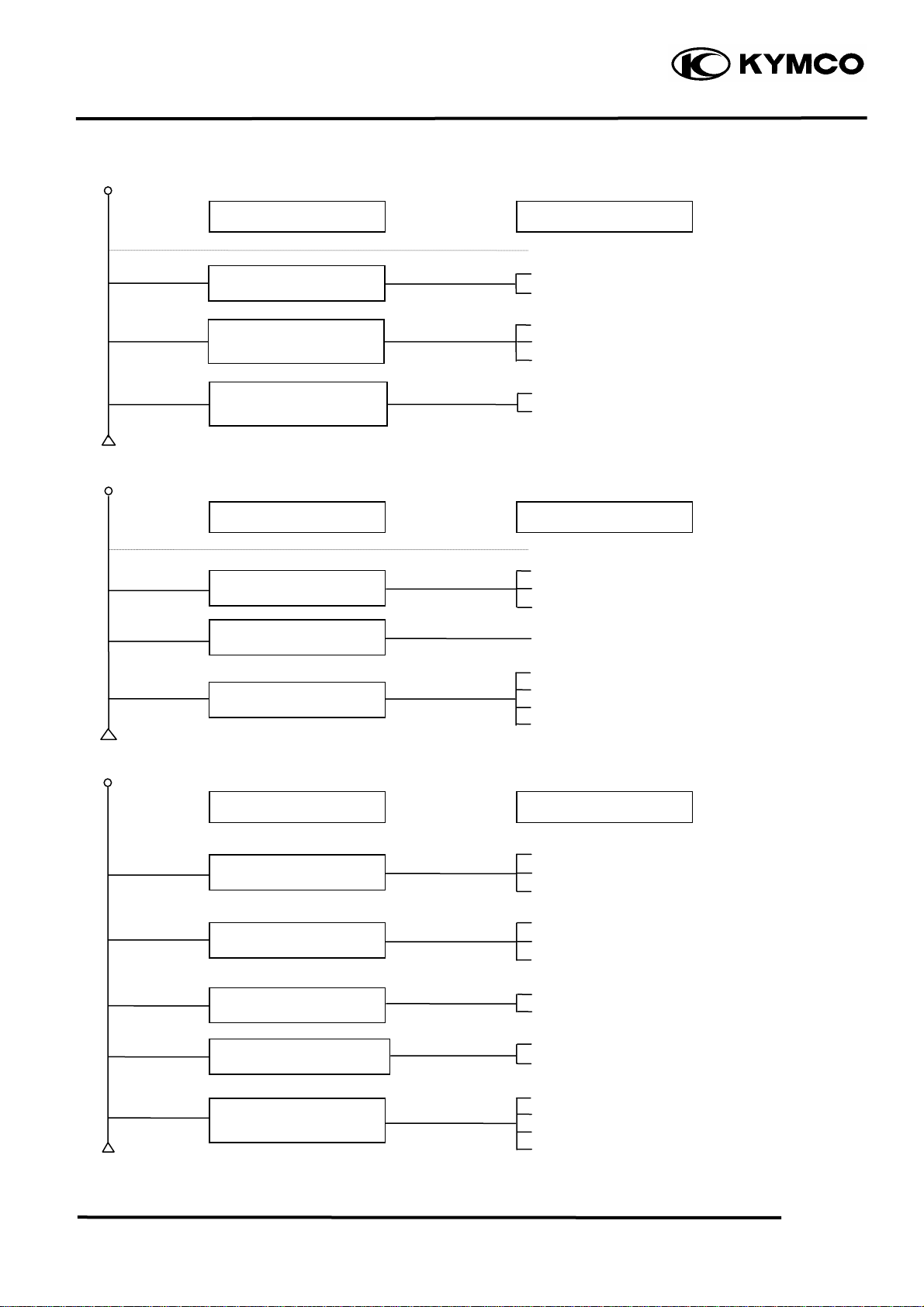

ENGINE NOISE

Symptom

Valve noise

Piston noise

Cam chain noise

Crankshaft noise

Gear noise

MYROAD 700i

Probable Cause

cValve clearance too large

dWorn camshaft lobe

cWorn piston rings

dWorn piston pin and connecting rod small

end

eExcessive carbon build-up in combustion

chamber

cDamaged cam chain tensioner

dWorn cam gear teeth

eWorn or damaged cam chain

fExtended cam chain

cFaulty crankshaft bearing

dWorn crank pin bearing

cWorn or damaged final reduction gears

dWorn final reduction gear shaft splines

1-16

Page 20

1. GENERAL INFORMATION

)

CLUTCH, DRIVE AND DRIVEN PULLEYS

Engine starts but

motor-cycle does not

Motorcycle creeps or

engine starts but soon

stops or seems to rush

out (Rear wheel rotates

when engine idles)

Engine lacks power at

start of a grade(poor

slope performance

Engine lacks power at

high speed

There is abnormal noise

or smell while running

Symptom

MYROAD 700i

Probable Cause

cWorn or slipping drive belt

dBroken ramp plate

eBroken drive face spring

fSeparated clutch lining

gDamaged driven pulley shaft splines

hDamaged final gear

iSeized final gear

cBroken shoe spring

dClutch outer and clutch weight stuck

eSeized pivot

cWorn or slipping drive belt

dWorn weight rollers

eSeized drive pulley bearings

fWeak driven face spring

gWorn or seized driven pulley bearings

cWorn or slipping drive belt

dWorn weight rollers

eWorn or seized driven pulley bearings

cOil or grease fouled drive belt

dWorn drive belt

eWeak driven face spring

fWorn or seized driven pulley bearings

1-17

Page 21

1. GENERAL INFORMATION

t

t

t

m

m

m

pplying

g

g

n

b

prop

n

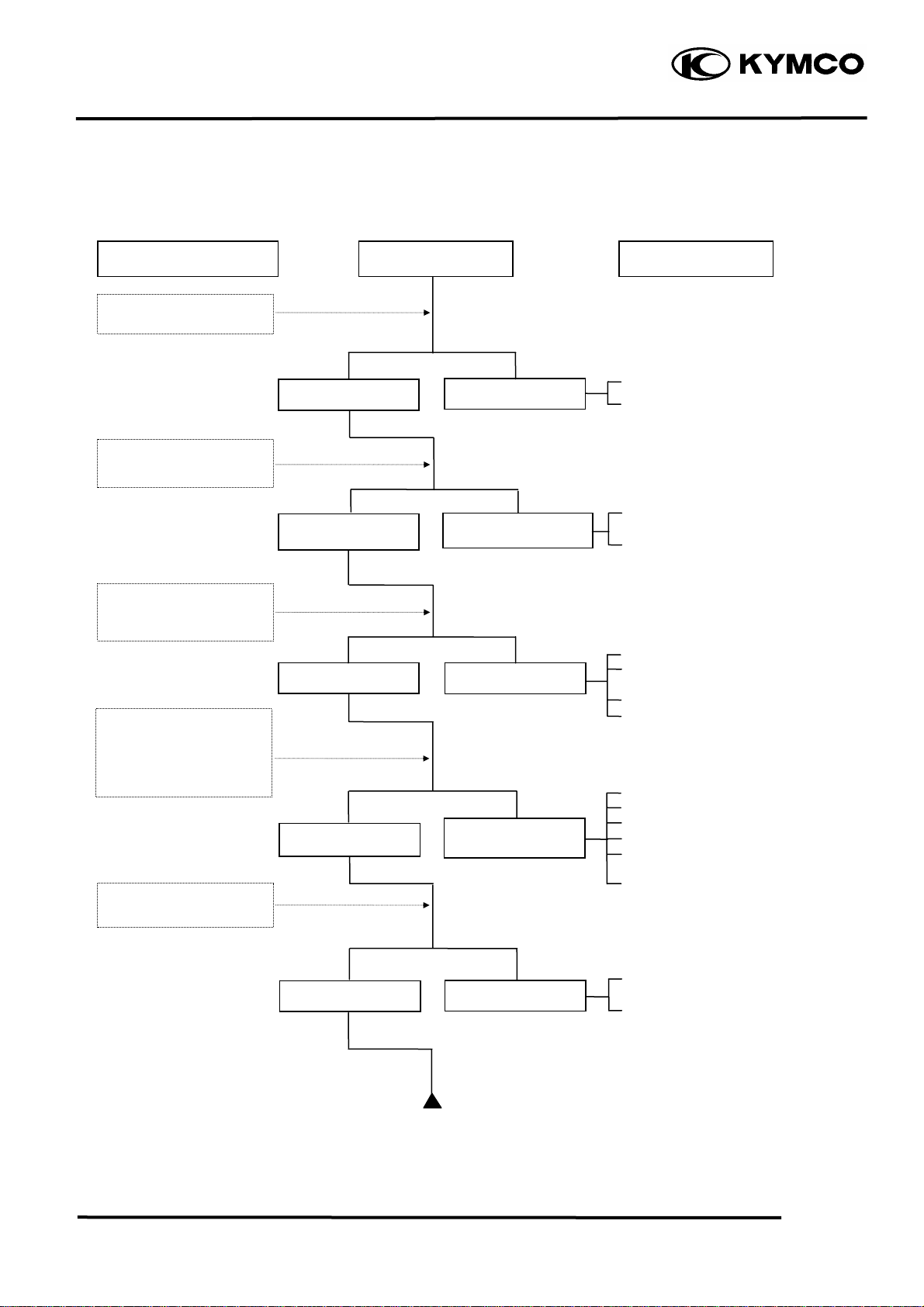

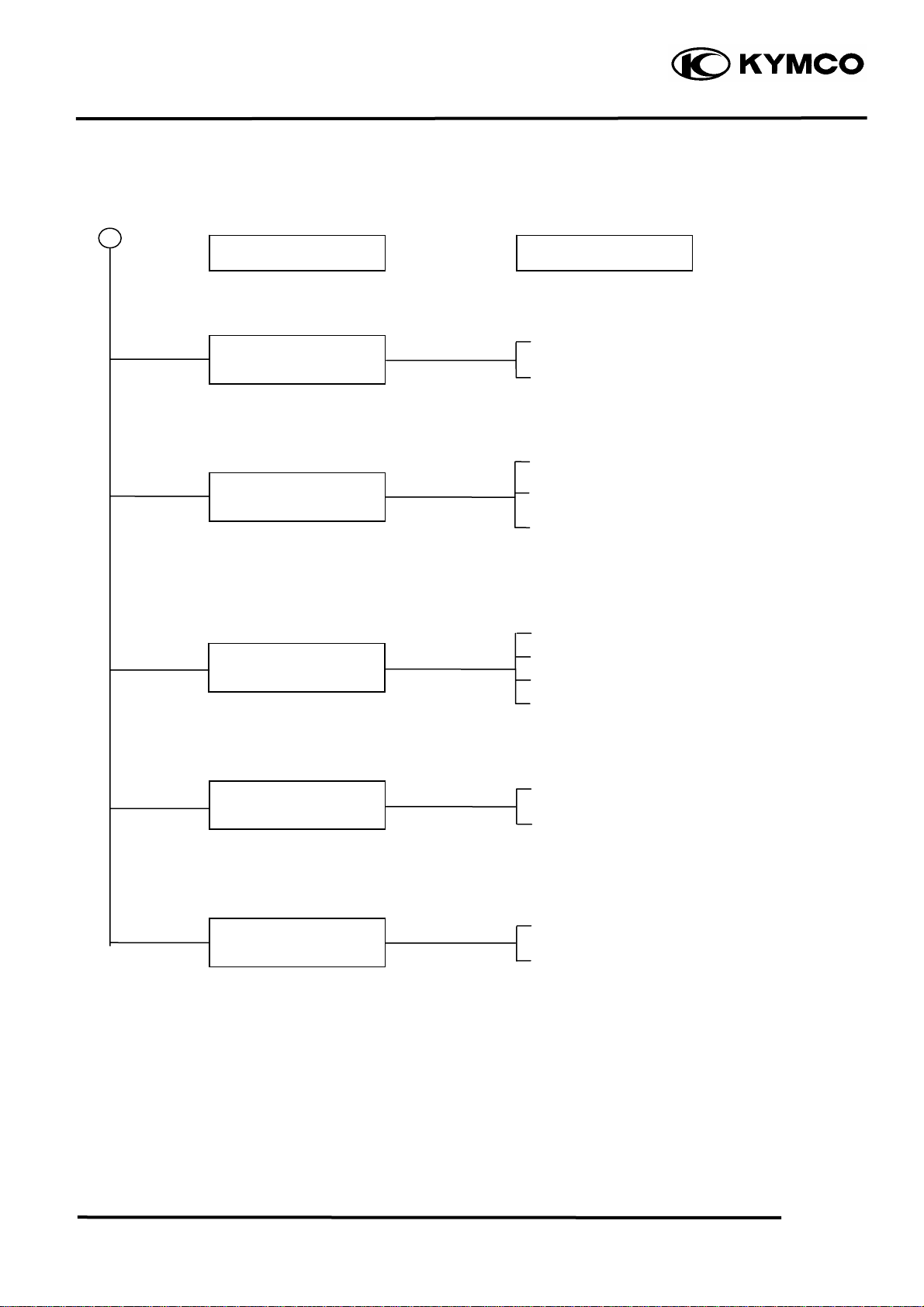

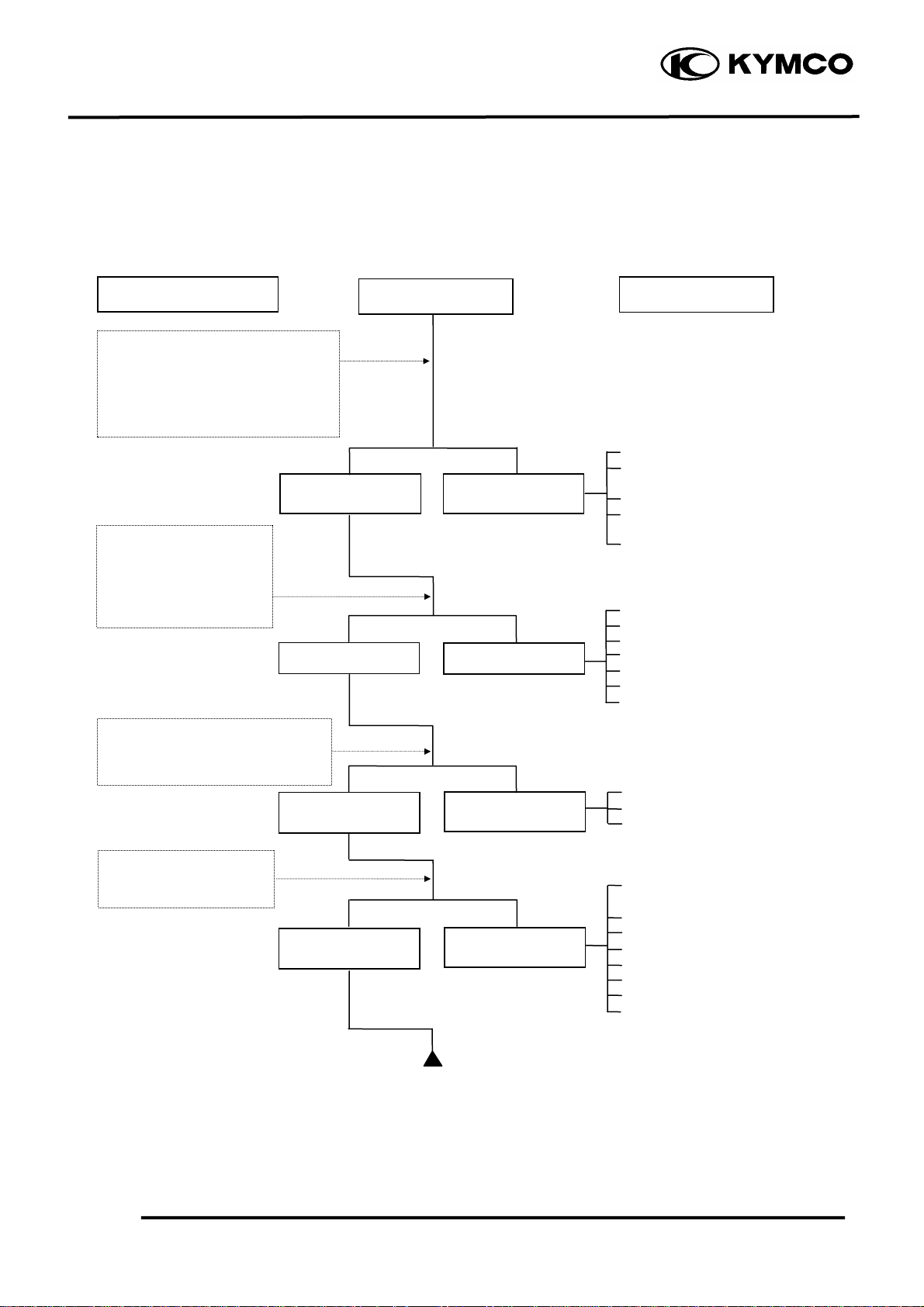

STARTER MOTOR

1. Starter motor won‘t turn

Inspection/Adjustmen

Check operation of

stop switch by

a

Check battery circuit

by operating turn

si

Check operation of

starter relay by

depressing starter

utton

Connect starter

motor directly to

battery

brake

Stoplight comes on

nals

Signals operate

properly

Relay operates

properly

Starter motor turns

2. Starter motor turns slowly or idles

Inspection/Adjustmen

Check battery circuit

by operating turn

nals

si

Signals operate

erly

Connect starter

motor directly to

battery

Rotate crankshaft

Starter motor

turns slowly

Turns easily

3. Starter motor does not stop turning

Inspection/Adjustmen

Turn ignition switch

OFF

Not stopped

Sympto

Sympto

Sympto

Stoplight does not

come on

Signals dim, remai

on or don‘t operate

Relay does not

operate

Starter does not turn

Signals dim, remai

on or don‘t operate

Starter motor

turns normally

Hard to turn

Stopped

MYROAD 700i

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty stop switch

fLoose or disconnected

connectors

gBroken or shorted ignition

switch wire

hFaulty side stand switch

cFaulty or weak battery

cPoor starter button connection

dOpen or shorted starter relay

eLoose or disconnected

connectors

cWorn brushes

dOpen or shorted wires or rotor

eOpen starter motor cable

fLoose connectors

cOpen wire harness

Probable Cause

cWeak or dead battery

cLoose connector or terminal

dPoor contact in starter relay

eFaulty starter clutch

cSeized cylinder

cBroken or shorted starter

motor cable

Probable Cause

cFaulty starter pinion

cStarter relay shorted or stuck

closed

1-18

Page 22

1. GENERAL INFORMATION

g

g

r

NO SPARK AT SPARK PLUG

Inspection/Adjustment Symptom

Replace with a new

spark plug and inspect

ain

a

Weak or no spark

Check spark plug cap

and high-tension wire

for looseness

Check ignition unit

coupler for looseness

Measure resistance

between terminals of

nition unit couple

i

Check related parts

Check ignition unit

Not loose

Good

Normal

Normal

Abnormal

Good spark

Loose

Good

Abnormal

Abnormal

MYROAD 700i

Probable Cause

cFaulty spark plug

cFaulty spark plug

cPoorly connected coupler

cFaulty ignition switch

dFaulty exciter coil

eFaulty pulser coil

fFaulty ignition coil

cBroken wire harness

dPoorly connected coupler

cFaulty ignition unit

1-19

Page 23

1. GENERAL INFORMATION

r

t

POOR CHARGING (BATTERY OVER DISCHARGING OR OVERCHARGING)

Undercharging

Inspection/Adjustment

Start engine and test

limit voltage of battery

terminals

Measure resistance

between AC generator

coil terminals

Test output voltage of

regulator/rectifier

coupler red wire

Overcharging

Inspection/Adjustment

Measure battery limit

voltage with an electric

teste

Check resistance

between regulator/

rectifier terminals

Normal voltage

Normal

Normal voltage

Normal

Normal

Symptom

Voltage does no

Resistance too low

Symptom

No voltage

Abnormal

Abnormal

Probable Cause

cFaulty AC generator

dFaulty regulator/rectifier

eFaulty battery

cShorted AC generator coil

dOpen circuit between AC

generator 3 yellow wires

cFaulty regulator/rectifier

dFaulty AC generator

eLoose regulator/rectifier

coupler

fLimit voltage too high

Probable Cause

cFaulty battery

dFaulty regulator/rectifier

eBroken or poorly connected

regulator/rectifier black wire

cLimit voltage too high

MYROAD 700i

1-20

Page 24

1. GENERAL INFORMATION

p

p

prop

n

prop

p

p

r

t

pty

FUEL GAUGE

1. Pointer does not register correctly (Ignition switch ON)

Inspection/Adjustment

Check battery circuit by

operating turn signals

Remove fuel unit and

check operation of

pointer by moving float

and down

u

Float up: Full

Float down: Em

Check operation of

pointer by opening and

shorting fuel unit

terminal on wire harness

Check connectors for

proper connection

Signals operate

erly

Pointer does not

Pointer does not

Good

2. Pointer fluctuates or swings (Ignition switch ON)

Inspection/Adjustment

Check battery circuit by

operating turn signals

and horn

Remove fuel unit and

check operation of

pointer by moving float

u

Move float up and

down rapidly (1 round

/sec.) to check the

o

Check connectors for

proper connection.

and down

eration of pointe

Signals operate

erly

Pointer moves

Pointer moves in

accordance with

floa

Good Faulty

Symptom

Signals dim, remai

on or don‘t operate

Pointer moves

Pointer moves

Symptom

Signals dim, remain

on or don‘t o

Pointer does not

move

Pointer does not

move in

accord-ance with

Faulty

erate

MYROAD 700i

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty ignition switch

fLoose or disconnected

connectors

gBroken wire harness

cFaulty float

cBroken or shorted fuel unit

wire

cDisconnected

dIncorrectly connected

connector

eBroken or shorted wire in

fuel gauge

connector

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty ignition switch

fLoose or disconnected

connector

gBroken wire harness

cPoor contact in fuel unit

cInsufficient damping oil in

fuel gauge

cLoose or disconnected

connector

cBroken or shorted wire in

fuel gauge

1-21

Page 25

1. GENERAL INFORMATION

g

STEERING HANDLEBAR DOES NOT TRACK STRAIGHT

Steering is heavy

Front or rear wheel is

wobblin

Steering handlebar pulls

to one side

POOR SUSPENSION PERFORMANCE

Suspension is too soft

Suspension is too hard

Suspension is noisy

POOR BRAKE PERFORMANCE

Soft brake lever

Hard brake lever

Hard to brake

Poor brake performance

Brake squeaks

Symptom

(Front and rear tire pressures are normal)

cSteering stem nut too tight

dBroken steering steel balls

cExcessive wheel bearing play

dBent rim

eLoose axle nut

cMisaligned front and rear wheels

dBent front fork

Symptom

(Front and rear tire pressures are normal)

cWeak shock spring

dExcessive load

eShock damper oil leaking

cBent fork tube or shock rod

cFork tube and slider binding

dFork spring and slider binding

eDamaged shock stopper rubber

fLoose steering stem nut

Symptom

cWorn brake linings

dForeign matter on brake linings

eRough brake drum contacting area

cWorn brake linings

dForeign matter on brake linings

eRough brake drum contacting area

cWorn brake linings

dWorn brake cam contacting area on

cWorn brake linings

dForeign matter on brake linings

cSluggish or elongated brake cables

dBrake shoes improperly contact

eWater and mud in brake system

fOil or grease on brake linings

MYROAD 700i

Probable Cause

Probable Cause

Probable Cause

1-22

Page 26

1. GENERAL INFORMATION

g

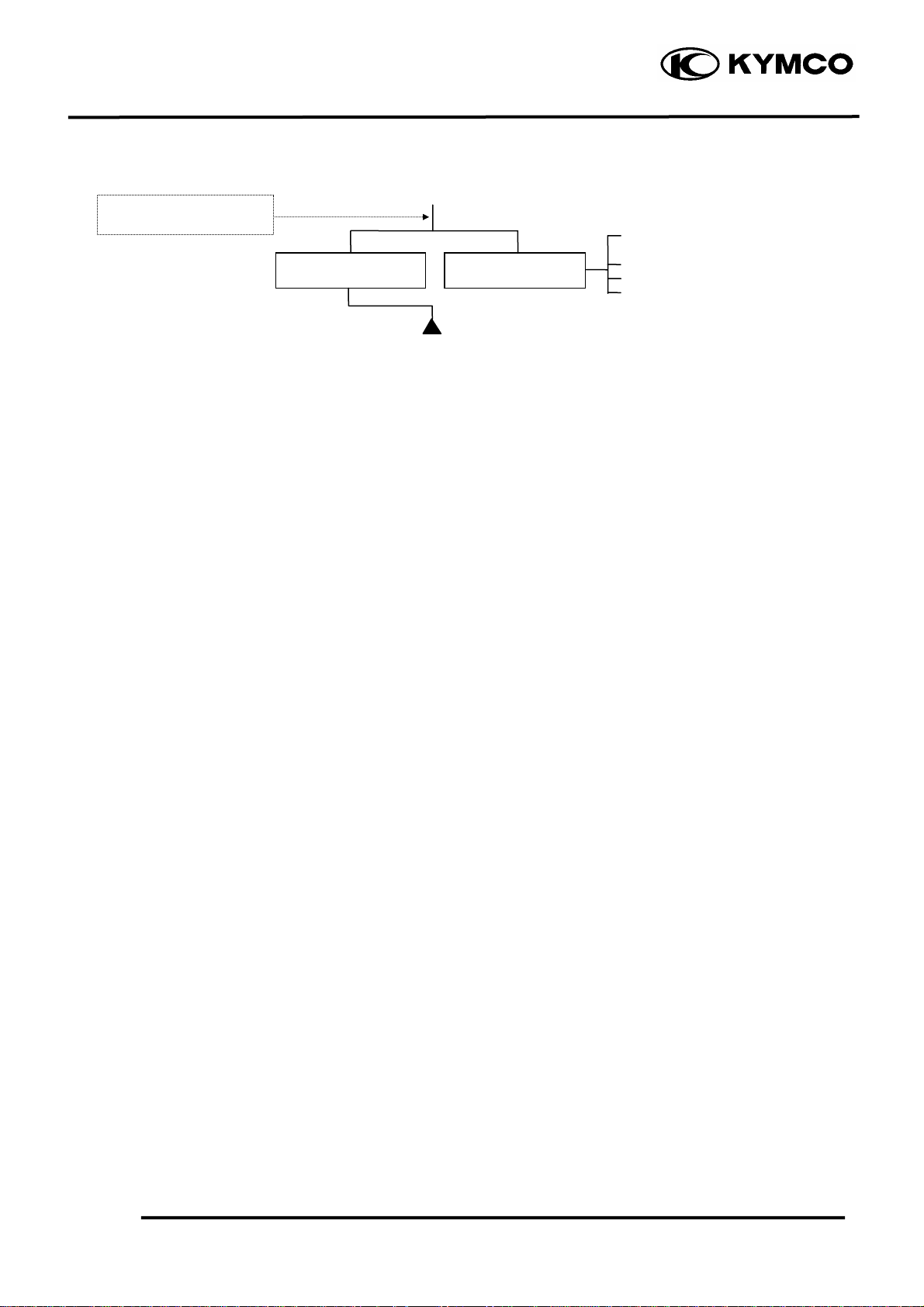

TROUBLESHOOTING (XCITING 250 AFI)

ENGINE WILL NOT START OR IS HARD TO START

Inspection/Adjustment

1. Make sure engine stop switch

is ON.

2. Put the side stand up.

3. Connect the diagnostic tool,

then check EMS and correct

problems.

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

round

Remove the fuel injector, start

the starter motor to check fuel

injector operation.

Test cylinder

compression

Fuel reaches fuel

injector

Fuel supply

compression

Spark jumps

Normal

Symptom

Fuel does not reach

fuel injector

Weak or no spark

No fuel supply

Low or no

compression

MYROAD 700i

Probable Cause

cEmpty fuel tank

dClogged fuel pump

filter

eFaulty fuel pump

fFaulty fuel cut-off

relay

gCracked fuel hose

cFaulty spark plug

dFouled spark plug

eFaulty ignition coil

fFaulty CPS

gBroken or shorted ignition coil

hBroken or shorted CPS

iFaulty ignition switch

cFaulty fuel injector

dClogged fuel injector

eFaulty ECU

cStarter motor idles but

crankshaft does not rotate

dValve clearance too small

eImproper valve and seat contact

fWorn cylinder and piston rings

gBlown cylinder head gasket

hFlaws in cylinder head

iSeized valve

jImproper valve timing

1-23

Page 27

1. GENERAL INFORMATION

g

y

g

pect

t

N

N

b

t

r

t

r

prop

prop

y

ENGINE LACKS POWER

Inspection/Adjustment

Connect the diagnostic

tool, then check EMS and

correct problems.

Start engine and

accelerate lightly for

Check ignition timing

Check valve clearance

Test cylinder compression

Check fuel injector for

clogging

Remove spark plug and

ins

Remove oil dipstick and

check oil level and condition

Remove cylinder head

olts and inspect

Check if engine overheats

Engine speed

Correct timin

Correct

ormal

compression

ot Clogged

Plug not fouled o

Correct and no

Valve train lubricated

erly

Engine does no

overheats

Symptom

Engine speed does

not increase

sufficientl

Abnormal

compression

Plug fouled or

Incorrect o

Valve train not

lubricated

Incorrect timin

Incorrec

Clogged

erl

Engine overheats

MYROAD 700i

Probable Cause

cClogged air cleaner

dClogged exhaust muffler

eFaulty spark plug

fFaulty throttle

gFaulty fuel pump

hFaulty fuel injector

iImproper valve timing

jLow or no compression

cFaulty

dFaulty CPS

cImproper valve clearance

dWorn valve seat (valve stem too

cImproper valve and seat contact

dWorn cylinder and piston rings

eBlown cylinder head gasket

fFlaws in cylinder head

gImproper valve timing

cFouled fuel injector

cFouled spark plug

dIncorrect heat range plug

cOil level too high

dOil level too low

eOil not changed

cFaulty oil pump

cInsufficient coolant

dFaulty thermostat

eWorn cylinder and piston rings

fMixture too lean

gPoor quality fuel

hExcessive carbon buildup in

iIgnition timing too early

jAir in cooling system

ECU

adjustment

protruding

combustion chamber

1-24

Page 28

1. GENERAL INFORMATION

Rapidly accelerate or run

at high speed

Engine does not knock

Engine knocks

MYROAD 700i

cExcessive carbon build-up in

combustion chamber

dPoor quality fuel

eClutch slipping

fIgnition timing too early

1-25

Page 29

1. GENERAL INFORMATION

g

POOR PERFORMANCE (ESPECIALLY AT IDLE AND LOW SPEEDS)

Inspection/Adjustment Symptom Probable Cause

Connect the diagnostic

tool, then check EMS and

correct problems.

Check ignition timing

cFaulty ignition coil

dFaulty CPS

eFaulty ECU

cFouled fuel injector

dFaulty fuel pump

cDamage insulator rubber

dThrottle body not securely

tighten

eFaulty intake manifold

O-ring

cFaulty CPS

dFaulty ignition coil

eBroken or shorted

high tension wire

fFaulty spark plug

cFouled throttle body

dFaulty TPI reset

Check fuel injector for

clogging

Check intake manifold

for air leaks

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

round

Check throttle body

Correct timing

Not Clogged

Incorrect timing

Clogged

No air leak

Good spark

Good

Air leaks

Weak or

intermittent spark

Faulty

MYROAD 700i

1-26

Page 30

1. GENERAL INFORMATION

t

t

POOR PERFORMANCE (AT HIGH SPEED)

Inspection/Adjustment Symptom Probable Cause

Connect the diagnostic

tool, then check EMS and

correct problems.

Check ignition timing

cFaulty spark plug

dFaulty ignition coil

eFaulty CPS

cImproperly adjusted valve

clearance

dWorn valve seat

cEmpty fuel tank

dClogged fuel hose or filter

eFaulty fuel pump

fClogged fuel injector

cClean and unclog

cCam timing gear aligning

marks not aligned

cFaulty spring

Check valve clearance

Check fuel pump for

fuel supply

Check throttle body or

air cleaner for clogging

Check valve timing

Check valve spring

tension

Correct timing

Correctly adjusted

Incorrect timing

Incorrectly adjusted

Fuel flows freely

Not clogged

Correc

Not weakened

Fuel flow restricted

Clogged

Incorrec

Weak spring

MYROAD 700i

1-27

Page 31

1. GENERAL INFORMATION

ENGINE NOISE

Symptom

Valve noise

Piston noise

Cam chain noise

Crankshaft noise

Gear noise

MYROAD 700i

Probable Cause

cValve clearance too large

dWorn camshaft lobe

cWorn piston rings

dWorn piston pin and connecting rod small

end

eExcessive carbon build-up in combustion

chamber

cDamaged cam chain tensioner

dWorn cam gear teeth

eWorn or damaged cam chain

fExtended cam chain

cFaulty crankshaft bearing

dWorn crank pin bearing

cWorn or damaged final reduction gears

dWorn final reduction gear shaft splines

1-28

Page 32

1. GENERAL INFORMATION

pe p

)

CLUTCH, DRIVE AND DRIVEN PULLEYS

Engine starts but

motor-cycle does not

Motorcycle creeps or

engine starts but soon

stops or seems to rush

out (Rear wheel rotates

when engine idles)

Engine lacks power at

start of a grade(poor

slo

Engine lacks power at

high speed

There is abnormal noise

or smell while running

Symptom

erformance

MYROAD 700i

Probable Cause

cWorn or slipping drive belt

dBroken ramp plate

eBroken drive face spring

fSeparated clutch lining

gDamaged driven pulley shaft splines

hDamaged final gear

iSeized final gear

cBroken shoe spring

dClutch outer and clutch weight stuck

eSeized pivot

cWorn or slipping drive belt

dWorn weight rollers

eSeized drive pulley bearings

fWeak driven face spring

gWorn or seized driven pulley bearings

cWorn or slipping drive belt

dWorn weight rollers

eWorn or seized driven pulley bearings

cOil or grease fouled drive belt

dWorn drive belt

eWeak driven face spring

fWorn or seized driven pulley bearings

1-29

Page 33

1. GENERAL INFORMATION

t

t

t

m

m

m

pplying

g

g

n

b

prop

n

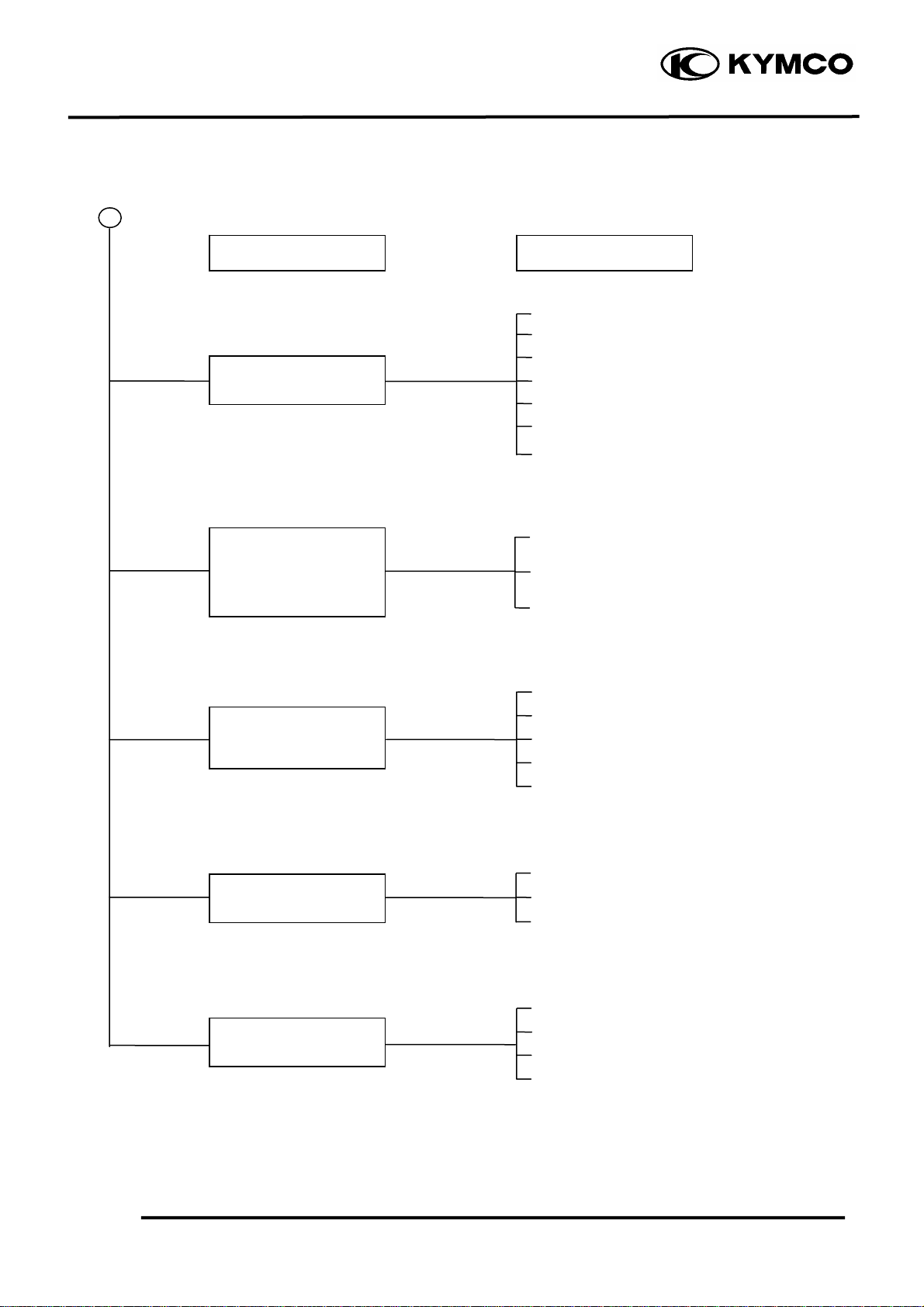

STARTER MOTOR

1. Starter motor won‘t turn

Inspection/Adjustmen

Check operation of

stop switch by

a

Check battery circuit

by operating turn

si

Check operation of

starter relay by

depressing starter

utton

Connect starter

motor directly to

battery

brake

Stoplight comes on

nals

Signals operate

properly

Relay operates

properly

Starter motor turns

2. Starter motor turns slowly or idles

Inspection/Adjustmen

Check battery circuit

by operating turn

nals

si

Signals operate

erly

Connect starter

motor directly to

battery

Rotate crankshaft

Starter motor

turns slowly

Turns easily

3. Starter motor does not stop turning

Inspection/Adjustmen

Turn ignition switch

OFF

Not stopped

Sympto

Sympto

Sympto

Stoplight does not

come on

Signals dim, remai

on or don‘t operate

Relay does not

operate

Starter does not turn

Signals dim, remai

on or don‘t operate

Starter motor

turns normally

Hard to turn

Stopped

MYROAD 700i

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty stop switch

fLoose or disconnected

connectors

gBroken or shorted ignition

switch wire

hFaulty side stand switch

cFaulty or weak battery

cPoor starter button connection

dOpen or shorted starter relay

eLoose or disconnected

connectors

cWorn brushes

dOpen or shorted wires or rotor

eOpen starter motor cable

fLoose connectors

cOpen wire harness

Probable Cause

cWeak or dead battery

cLoose connector or terminal

dPoor contact in starter relay

eFaulty starter clutch

cSeized cylinder

cBroken or shorted starter

motor cable

Probable Cause

cFaulty starter pinion

cStarter relay shorted or stuck

1-30

Page 34

1. GENERAL INFORMATION

g

g

r

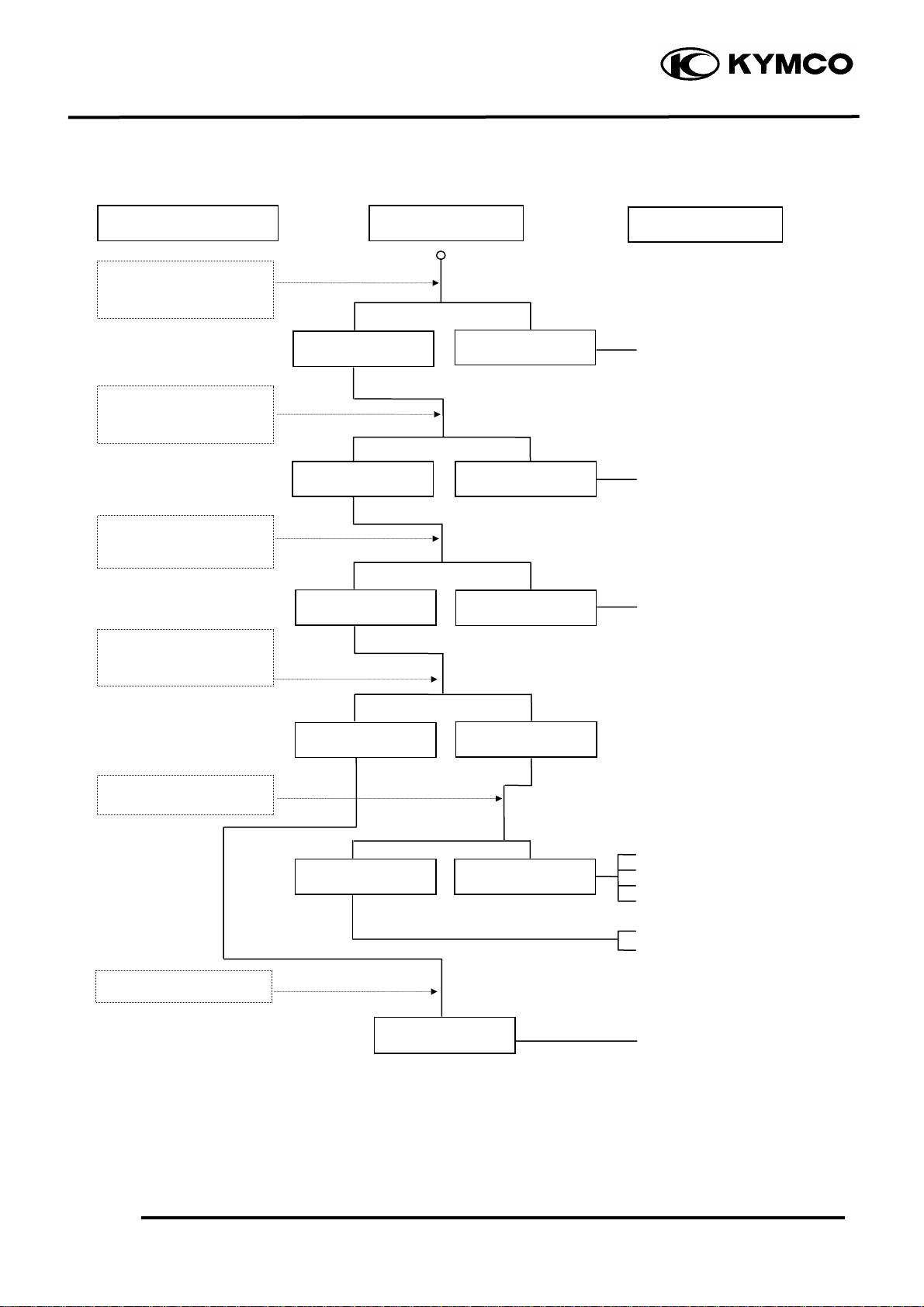

NO SPARK AT SPARK PLUG

Inspection/Adjustment Symptom

Connect the diagnostic

tool, then check EMS and

correct problems.

Replace with a new

spark plug and inspect

ain

a

Weak or no spark

Check spark plug cap

and high-tension wire

for looseness

Check ignition unit

coupler for looseness

Measure resistance

between terminals of

nition unit couple

i

Check related parts

Check ignition coil

Not loose

Good

Normal

Normal

Abnormal

Good spark

Loose

Good

Abnormal

Abnormal

MYROAD 700i

closed

Probable Cause

cFaulty spark plug

cFaulty spark plug

cPoorly connected coupler

cFaulty ignition switch

dFaulty CPS

eFaulty ignition coil

cBroken wire harness

dPoorly connected coupler

cFaulty ignition coil

1-31

Page 35

1. GENERAL INFORMATION

r

t

POOR CHARGING (BATTERY OVER DISCHARGING OR OVERCHARGING)

Undercharging

Inspection/Adjustment

Start engine and test

limit voltage of battery

terminals

Measure resistance

between AC generator

coil terminals

Test output voltage of

regulator/rectifier

coupler red wire

Overcharging

Inspection/Adjustment

Measure battery limit

voltage with an electric

teste

Check resistance

between regulator/

rectifier terminals

Normal voltage

Normal

Normal voltage

Normal

Normal

Symptom

Voltage does no

Resistance too low

Symptom

No voltage

Abnormal

Abnormal

Probable Cause

cFaulty AC generator

dFaulty regulator/rectifier

eFaulty battery

cShorted AC generator coil

dOpen circuit between AC

generator 3 yellow wires

cFaulty regulator/rectifier

dFaulty AC generator

eLoose regulator/rectifier

coupler

fLimit voltage too high

Probable Cause

cFaulty battery

dFaulty regulator/rectifier

eBroken or poorly connected

regulator/rectifier black wire

cLimit voltage too high

MYROAD 700i

1-32

Page 36

1. GENERAL INFORMATION

p

p

prop

n

prop

p

p

r

t

pty

FUEL GAUGE

1. Pointer does not register correctly (Ignition switch ON)

Inspection/Adjustment

Check battery circuit by

operating turn signals

Signals operate

erly

Remove fuel unit and

check operation of

pointer by moving float

and down

u

Float up: Full

Float down: Em

Check operation of

pointer by opening and

shorting fuel unit

terminal on wire harness

Check connectors for

proper connection

Pointer does not

Pointer does not

Good

2. Pointer fluctuates or swings (Ignition switch ON)

Inspection/Adjustment

Check battery circuit by

operating turn signals

and horn

Remove fuel unit and

check operation of

pointer by moving float

u

Move float up and

down rapidly (1 round

/sec.) to check the

o

Check connectors for

proper connection.

and down

eration of pointe

Signals operate

erly

Pointer moves

Pointer moves in

accordance with

floa

Good Faulty

Symptom

Signals dim, remai

on or don‘t operate

Pointer moves

Pointer moves

Symptom

Signals dim, remain

on or don‘t o

Pointer does not

move

Pointer does not

move in

accord-ance with

Faulty

erate

MYROAD 700i

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty ignition switch

fLoose or disconnected

connectors

gBroken wire harness

cFaulty float

cBroken or shorted fuel unit

wire

cDisconnected

dIncorrectly connected

connector

eBroken or shorted wire in

fuel gauge

connector

Probable Cause

cBurned out fuse

dWeak or dead battery

eFaulty ignition switch

fLoose or disconnected

connector

gBroken wire harness

cPoor contact in fuel unit

cInsufficient damping oil in

fuel gauge

cLoose or disconnected

connector

cBroken or shorted wire in

1-33

Page 37

1. GENERAL INFORMATION

g

STEERING HANDLEBAR DOES NOT TRACK STRAIGHT

Steering is heavy

Front or rear wheel is

wobblin

Steering handlebar pulls

to one side

POOR SUSPENSION PERFORMANCE

Suspension is too soft

Suspension is too hard

Suspension is noisy

POOR BRAKE PERFORMANCE

Soft brake lever

Hard brake lever

Hard to brake

Poor brake performance

Brake squeaks

Symptom

Symptom

Symptom

(Front and rear tire pressures are normal)

cSteering stem nut too tight

dBroken steering steel balls

cExcessive wheel bearing play

dBent rim

eLoose axle nut

cMisaligned front and rear wheels

dBent front fork

(Front and rear tire pressures are normal)

cWeak shock spring

dExcessive load

eShock damper oil leaking

cBent fork tube or shock rod

cFork tube and slider binding

dFork spring and slider binding

eDamaged shock stopper rubber

fLoose steering stem nut

cWorn brake linings

dForeign matter on brake linings

eRough brake drum contacting area

cWorn brake linings

dForeign matter on brake linings

eRough brake drum contacting area

cWorn brake linings

dWorn brake cam contacting area on

cWorn brake linings

dForeign matter on brake linings

cSluggish or elongated brake cables

dBrake shoes improperly contact

eWater and mud in brake system

fOil or grease on brake linings

MYROAD 700i

fuel gauge

Probable Cause

Probable Cause

Probable Cause

1-34

Page 38

1. GENERAL INFORMATION

MYROAD 700i

1-35

Page 39

2. FRAME COVERS/

MYROAD 700i

EXHAUST MUFFLER

2

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

2

__________________________________________________________________________________

FRAME COVERS/EXHAUST MUFFLER

__________________________________________________________________________________

SCHEMATIC DRAWING ------------------------------------------------- 2- 1

SERVICE INFORMATION------------------------------------------------ 2- 2

TROUBLESHOOTING----------------------------------------------------- 2- 2

FRAME COVERS REMOVAL ------------------------------------------- 2- 3

EXHAUST MUFFLER ----------------------------------------------------- 2-17

2-0

Page 40

2. FRAME COVERS/

EXHAUST MUFFLER

SCHEMATIC DRAWING

MYROAD 700i

2-1

Page 41

2. FRAME COVERS/

EXHAUST MUFFLER

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When removing frame covers, use care not to pull them by force because the cover joint claws

may be damaged.

• Make sure to route cables and harnesses according to the Cable & Harness Routing.

TORQUE VALUES

Muffler mount bolt 3.2~3.8 kg-m

Exhaust pipe joint nut 1.0~1.4 kg-m

Exhaust pipe band bolt 1.0~1.4 kg-m

TROUBLESHOOTING

MYROAD 700i

Noisy exhaust muffler

• Damaged exhaust muffler

• Exhaust muffler joint air leaks

Lack of power

• Caved exhaust muffler

• Clogged exhaust muffler

• Exhaust muffler air leaks

2-2

Page 42

2. FRAME COVERS/

t

r

t

N

r

EXHAUST MUFFLER

FRAME COVERS REMOVAL

SEAT

REMOVAL

Unlock the seat with the ignition key.

Open the seat.

Remove the two nuts and seat damper unit.

Remove the two nuts and the seat.

INSTALLATION

Installation is in the reverse order of the

removal.

After installation, check the seat installation

by moving the seat.

LUGGAGE BOX REMOVAL

After removal the seat, side cover, carrier,

body cover, then you can remove the luggage

box.

Remove the screws and bolts.

Raise the luggage box, disconnect the

luggage box light and accessory socket

connectors.

INSTALLATION

Installation is in the reverse order of removal.

Screws

Nuts

Damper Uni

Accessory Socket Connecto

Luggage box ligh

MYROAD 700i

Nuts

uts

Bolts

Connecto

2-3

Page 43

2. FRAME COVERS/

t

EXHAUST MUFFLER

FUEL PUMP LID

REMOVAL

Remove the bolt and lid.

INSTALLATION

Installation is in the reverse order of removal.

REAR SPOILER

REMOVAL

Unlock the seat with the ignition key.

Open the seat.

Remove the rubber cap.

Remove four bolts and rear spoiler.

INSTALLATION

Installation is in the reverse order of removal.

FRONT FENDER

RE MOVAL

Remove the six bolts and front fender.

INSTALLATION

Installation is in the reverse order of removal.

Bol

MYROAD 700i

Fuel pump Lid

Rubber Cap

Bolts

Bolts

2-4

Page 44

2. FRAME COVERS/

EXHAUST MUFFLER

UPPER HANDLEBAR COVER

REMOVAL

Remove four screws and upper handlebar

cover.

INSTALLATION

Installation is in the reverse order of removal.

RIGHT/LEFT SIDE COVERS

REMOVAL

After removing seat, the priority you

should remove would be side covers, there

are some screws and bolts hiding in these

parts.

Remove the two bolts and side covers

.

Remove the hex bolt and foot step.

MYROAD 700i

Screws

Bolts

Side Cover

Hex Bolt Foot step

2-5

Page 45

2. FRAME COVERS/

EXHAUST MUFFLER

Remove the side cover following the way of

picture showing.

Specially notice not to damage the tabs on the

side covers, especially the hook structures on

the end of side covers.

*

Be careful not to damage the tabs on the

side covers.

MYROAD 700i

2-6

Page 46

2. FRAME COVERS/

EXHAUST MUFFLER

RIGHT/LEFT FLOOR SKIRT

REMOVAL

Remove the floor mat.

Remove the right and left center body cover .

MYROAD 700i

Floor Mat

2-7

Page 47

2. FRAME COVERS/

EXHAUST MUFFLER

Remove the seven screws.

Remove two screws.

Remove the floor skirt.

*

Be careful not to damage the tabs on the

floor skirt.

INSTALLATION

Installation is in the reverse order of removal.

FLOORBOARD

REMOVAL

Remove right and left center body cover.

Remove the right and left floor skirt.

Remove the luggage box.

Remove six bolts, four screws and

floorboard.

INSTALLATION

Installation is in the reverse order of removal.

Screws

Screws

Bolts

MYROAD 700i

2-8

Page 48

2. FRAME COVERS/

r

EXHAUST MUFFLER

LICENCE LIGHT

REMOVAL

Remove two screws.

Disconnect the license light connector and

remove the license light.

INSTALLATION

Installation is in the reverse order of removal.

REAR FENDER

REMOVAL

Remove the licence light.

Remove two screws.

Remove two nuts and rear fender.

INSTALLATION

Installation is in the reverse order of removal.

Screws Connecto

Screws

Screws

Screws

MYROAD 700i

2-9

Page 49

2. FRAME COVERS/

r

EXHAUST MUFFLER

RIGHT/LEFT SIDE BODY COVER

REMOVAL

Remove the luggage box.

Remove the rear spoiler.

Remove two bolts.

Raise the side body cover, disconnect the

taillight/rear turn signal light connector and

remove the side body cover.

INSTALLATINON

Installation is in the reverse order of removal

REAR BODY COVER

REMOVAL

Remove the luggage box.

Remove the rear spoiler.

Remove two screws and rear body cover.

*

Be careful not to damage the tabs on the

rear body cover.

INSTALLATION

Installation is in the reverse order of removal.

Taillight/Rear Turn Signal Light Connecto

Screws

Body cover

MYROAD 700i

2-10

Page 50

2. FRAME COVERS/

EXHAUST MUFFLER

TAILIGHT/REAR TURN SIGNAL

LIGHT

REMOVAL

Remove the side and rear body cover.

Remove bolts and taillight/rear turn signal

light.

INSTALLATION

Installation is in the reverse order of removal.

REAR LOWER COVER

REMOVAL

Remove the side body cover.

Remove the rear lower cover.

REARVIEW MIRROR

REMOVAL

Remove bolts lid.

Remove three bolts and rearview mirror.

MYROAD 700i

Bolts

Screws

Rear Lower Cover

Bolts

2-11

Page 51

2. FRAME COVERS/

EXHAUST MUFFLER

Remove the two bolts, rearview mirror holder

and seat.

INSTALLATION

Installation is in the reverse order of removal

WINDSHIELD

REMOVAL

Remove four screws and windshield garnish.

Remove 6 bolts and windshield.

*

Be careful not to scratch or damage the

windshield surface.

INSTALLATION

Installation is in the reverse order of removal.

Bolts

Screws

Windshield Garnish

Windshield

MYROAD 700i

2-12

Page 52

2. FRAME COVERS/

EXHAUST MUFFLER

FRONT COVER REMOVAL

The priority to remove is front cover (with

head lights, then tunnel leg shield

(81141-KKE5), there are some bolts and

screws hide inside.

MYROAD 700i

2-13

Page 53

2. FRAME COVERS/

r

EXHAUST MUFFLER

Tunnel leg shield removal

Remove six screws.

Remove two screws.

Remove one screw.

Disconnect headlight and turn signal light

connectors.

INSTALLATION

Installation is in the reverse order of removal.

MYROAD 700i

Screws

Screws

Turn Signal Light Connectors

Screw Headlight Connecto

2-14

Page 54

2. FRAME COVERS/

r

EXHAUST MUFFLER

HEADLIGHT

REMOVAL

Remove the front cover.

Remove 8 screws and headlight.

INSTALLATION

Installation is in the reverse order of removal.

TURN SIGNAL LIGHT

REMOVAL

Remove the front cover.

Remove three screws and turn signal light.

INSTALLATION

Installation is in the reverse order of removal.

FRONT METER VISOR

REMOVAL

Remove the windshield.

Remove the front cover.

Remove four bolts and windshield holder.

MYROAD 700i

Windshield Holde

Bolts

2-15

Page 55

2. FRAME COVERS/

r

EXHAUST MUFFLER

Remove two screws and front meter visor.

INSTALLATION

Installation is in the reverse order of removal.

METER PANEL

REMOVAL

Remove the front cover.

Remove the front meter visor.

Remove the tunnel leg shield.

Remove screws from instrument.

Disconnect the speedometer connector and

remove meter panel.

INSTALLATION

Installation is in the reverse order of removal.

MYROAD 700i

Screw

Meter Panel

Speedometer Connecto

2-16

Page 56

2. FRAME COVERS/

EXHAUST MUFFLER

METER

REMOVAL

Remove the meter panel.

Remove two screws and meter.

INNER COVER

REMOVAL

Remove the front cover.

Remove the floorboard.

Remove the meter panel.

Remove the shutter screw and shutter.

Turn the fuel fill cap garnish

counterclockwise and remove it.

Remove three screws and disconnect the fuel

fill duct.

MYROAD 700i

Screws

Cap Garnish

Screws

2-17

Page 57

2. FRAME COVERS/

EXHAUST MUFFLER

Remove 2 bolts from front panel floor.

INSTALLATION

Installation is in the reverse order of removal.

FRONT LOWER COVER

REMOVAL

Remove the panel floor.

Remove the screws from lower cover.

Remove the lower cover.

Bolts

MYROAD 700i

2-18

Page 58

2. FRAME COVERS/

S

t

EXHAUST MUFFLER

EXHAUST MUFFLER

REMOVAL

Disconnect the connector with O2 heater/O2

sensor.

Remove screws from muffler protector.

Loosen the rear muffler cover screws.

Remove the exhaust pipe joint nuts and

exhaust pipe.

Remove the muffler.

INSTALLATION

Replace the gaskets with new ones.

Install the exhaust pipe and tighten the joint

nuts.

Torque: 1.0~1.4 kg-m

Install the muffler and tighten the mount

bolts.

Torque: 3.2~3.8 kg-m

Install and tighten the band bolts.

Torque: 2.1 kg-m

MYROAD 700i

Bolt Bol

Muffler protector

crews

2-19

Page 59

3. INSPECTION/ADJUSTMENT

3

__________________________________________________________________________________

__________________________________________________________________________________

MYROAD 700i

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION-------------------------------------------------- 3-1

MAINTENANCE SCHEDUL ----------------------------------------------- 3- 3

FUEL LINE--------------------------------------------------------------------- 3- 5

THROTTLE OPERATION--------------------------------------------------- 3- 5

AIR CLEANER ---------------------------------------------------------------- 3-7

CRANKCASE BREATHER ------------------------------------------------- 3- 8

SPARK PLUG------------------------------------------------------------------ 3- 8

VALVE CLEARANCE------------------------------------------------------- 3-10

ENGINE OIL------------------------------------------------------------------- 3-13

ENGINE OIL FILTER CARTRIDGE -------------------------------------- 3-15

RADIATOR COOLANT ----------------------------------------------------- 3-16

COOLING SYSTEM---------------------------------------------------------- 3-17

TRANSMISSION OIL-------------------------------------------------------- 3-18

BRAKE FLUED --------------------------------------------------------------- 3-19

BRAKE PAD WEAR --------------------------------------------------------- 3-20

BRAKE SYSTEM ------------------------------------------------------------- 3-20

BRAKE LOCK OPERATION -----------------------------------------------3-21

HEADLIGHT AIM-------------------------------------------------------------3-22

SIDE STAND---------- ---------------------------------------------------------3-23

SUSPENSION-------------------------------------------------------------------3-24

WHEELS/TIRES--------------------------------------------------------- ------3-24

STEERING HEAD BEARINGS----------------------------------------------3-25

3

3-0

Page 60

3. INSPECTION/ADJUSTMENT

MYROAD 700i

SERVICE INFORMATION

GENERAL

Place the scooter on al level ground before starting any work.

Gasoline is extremely flammable and is explosive under certain conditions.

Work in a well ventilated area. Smoking or allowing flames or sparks in the work area or where

the gasoline is stored can cause a fire or explosion.

If the engine must be running to do some work, make sure the area is well ventilated. Never run

the engine in an enclosed area.

The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and

may lead to death. Run the engine in an open area or with an exhaust evacuation sustem in and

enclosed area.

SPECIFICATIONS

ITEM SPECIFICATIONS

Throttle free play 2-6 mm (1/16 – 1/4 in)

Spark plug

Spark plug gap 0.6~0.7 mm

Engine oil capacity

Recommended engine oil

Engine idle speed 1250±100 rpm

Final reduction

oil capacity

Recommended final reduction oil SAE 90

Recommended brake fluid DOT 4

Tire size

Tire air pressure

Minimum tire tread depth

NGK DR8E

IN 0.16 mm Valve clearance

EX 0.22 mm)

At draining 2.75 liter

Total amount 3.0 liter

KYMCO 4-stroke oil or equivalent

motor oil API service classification: SJ

Viscosity: 5W50

At draining 0.36 liter

Total amount 0.4 liter

Front 120/70-R15

Rear 160/60-R14

Solo riding

Two up riding

Front 2 kgf/cm2

Rear 2.25 kgf/cm2

Front 2 kgf/cm2

Rear 2.5 kgf/cm2

Front 1.6 mm (0.06 in)

Rear 2.0 mm (0.08 in)

3-1

Page 61

3. INSPECTION/ADJUSTMENT

TORQURE VALUES

Engine oil drain plug 2.5 kgf•m

Oil strainer screen cap 1.2~1.8 kgf•m

Apply oil to the threads and seating surface.

Oil filter cartridge 1~2 kgf•m

Apply oil to the threads and seating surface.

Transmission oil drain bolt 2~3 kgf•m

Transmission oil filler bolt 1.2~1.8 kgf•m

SPECIAL TOOLS

Oil filter cartridge wrench A120E00061

MYROAD 700i

3-2

Page 62

3. INSPECTION/ADJUSTMENT

MYROAD 700i

MAINTENANCE SCHEDULE

Perform the pre-ride inspection in the owner’s manual at each scheduled maintenance period.

This interval should be judged by odometer reading or months, whichever comes first.

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY

C: CLEAN R: REPLACE A: ADJUST L: LUBRICATE

3-3

Page 63

3. INSPECTION/ADJUSTMENT

NOTE:

1 At higher odometer readings, repeat at the frequency interval established here.

2 Service more frequently if the scooter is ridden in unusually wet or dusty areas.

3 Service more frequently when riding in rain or at full throttle.

4 Inspect every 18000 km (12000 mi) after replacement.

5 Replace every 1 year, or every 10000km (6000mi), whichever comes first.

6 Replace every 2 year, or at indicated odometer interval, whichever comes first.

7 Replace every 2 years. Replacement requires mechanical skill.

MYROAD 700i

3-4

Page 64

3. INSPECTION/ADJUSTMENT

r

*

• Do not smoke or allow flames or

sparks in your working area.

FUEL FILTER

Visually check the fuel filter. If accumulation

of sediment or clogging is found, replace the

fuel filter with a new one.

THROTTLE OPERATION

Check for smooth throttle grip full opening

and automatic full closing in all steering

positions.

Check the throttle cables and replace them if

they are deteriorated, kinked or damaged.

Lubricate the throttle cables, if throttle

operation is not smooth.

Measure the throttle grip free play.

Free Play: 2~6 mm (1/16~1/4 in)

MYROAD 700i

Fuel Filte

3-5

Page 65

3. INSPECTION/ADJUSTMENT

MYROAD 700i

Throttle grip free play can be adjusted at

either end of the throttle cable.

Minor adjustment is made with the upper

adjuster.

Slide the rubber sleeve back to expose the

throttle cable adjuster.

Adjust the free play by loosening the lock nut

and turning the adjuster.

3-6

Page 66

3. INSPECTION/ADJUSTMENT

AIR CLEANER

The air cleaner should be serviced at regular

intervals. Service more frequently when

riding in unusually wet or dusty areas.

Install a new air cleaner element. Use the

KYMCO genuine air cleaner element or an

equivalent air cleaner element specified for

your model. Using the wrong. KYMCO air

cleaner element or a non-KYMCO air cleaner

which is not of equivalent quality may cause

premature engine wear or performance

problems.

Air cleaner element removal/installation

Remove the screws and air cleaner housing

cover

3-7

MYROAD 700i

Page 67

3. INSPECTION/ADJUSTMENT

t

Remove the air cleaner element.

Check the cleaner element.

Install the removed parts in the reverse order

of removal.

Air cleaner element removal/installation

Remove the luggage box.

Remove the six screws and air cleaner cover.

CRANKCASE BREATHER

Remove the crankcase breather tube plug

from the tube and drain deposits into a

suitable container.

Reinstall the crankcase breather tube plug.

Service more frequently when riding in rain,

at full throttle, or after the scooter is washed

or overturned. Service if the deposit level can

be seen in the transparent section of the drain

tube.

SPARK PLUG

REMOVAL

Remove the spark plug maintenance lid

Air Cleaner Elemen

Spark Plug Cap

Spark plug lid

MYROAD 700i

3-8

Page 68

3. INSPECTION/ADJUSTMENT

Remove the spark plug using a equipped

spark plug wrench or an equivalent tool.

Inspect or replace as described in the

maintenance schedule.

INSPECTION

Remove the carbon deposits from the spark

plug with a small wire brush or a spark plug

cleaning machine.

The spark plug should be replaced

periodically. Whenever removing the carbon

deposits, be sure to observe the operational

color of the spark plug's porcelain tip. This

color tells you whether or not the standard

spark plug is suitable for your type of usage.

A normal operating spark plug should be

light brown or tan color. If the spark plug is

very white or glazed appearing, then it has

been operating much too hot. This spark plug

should be replaced with the colder plug.

Recommended spark plug: DR8E

Measure the spark plug gap between the

center and side electrodes with the feeler

gauge.

If necessary, adjust the gap by bending the

side electrode carefully.

Spark plug gap:

0.6-0.7 mm (0.024-0.028 in)

Install the spark plug in the cylinder head and

hand tighten, then torque to the specification.

Torque: 1.0~1.4 kg•m

Install the spark plug cap.

Install the removed parts in the reverse order

of removal.

Spark Plug

MYROAD 700i

0.6~0.7 mm

3-9

Page 69

3. INSPECTION/ADJUSTMENT

VALVE CLEARANCE

*

Inspect and adjust the valve clearance

while the engine is cold (Below

35°C/95°F).

Inspection and adjust

Remove the cylinder head cover.

Remove the timing hole cap and O-ring.

Remove the crankshaft hole cap and O-ring.

Turn the crankshaft clockwise and align the

“T” mark on the flywheel with the index

mark on the right crankcase cover.

The punch marks “in” and “ex” on the

camshaft should be aligned with the boundary

of cylinder head as shown.

If the punch marks on the camshaft are facing

downward, turn the crankshaft clockwise one

full turn (360°) and the punch marks are

facing upward.

Timing Hole Cap/O-ring

Crankshaft Hole Cap/O-ring

“T” Mark

Index Mark

Mark “in”

Mark “ex”

MYROAD 700i

3-10

Page 70

3. INSPECTION/ADJUSTMENT

r

r

m

Insert the feeler gauge between the valve

lifter and the cam lobe.

Check the valve clearance for the valves

using a feeler gauge.

Valve Clearance

IN:0.16 mm(0.006 in)

EX:0.22 mm(0.009in)

Remove the camshaft.

Remove the valve lifters and shims.

The shims may stick to the inside of the valve

lifter. Don’t allow the shims to fall into the

crankcase.

Mark all of shims and valve lifters to ensure

correct reassembly in original locations.

The valve lifter can be easily removed with a

valve lapping tool or magnet.

The shims can be easily removed with

tweezers or magnet.

Clean the valve shim contact area in the valve

lifter with compressed air.

MYROAD 700i

Shi

Valve Lifte

Valve Lifte

3-11

Page 71

3. INSPECTION/ADJUSTMENT

Measure the shim thickness and record it.

Calculate the new shims thickness using the

equation below.

A+C=B+D

A: New shim thickness

B: Record valve clearance

C: Specified valve clearance

D: Old shim thickness

Grade number “T” Thickness Mark

01 1.80 180

02 1.85 185

03 1.90 190

04 1.95 195

05 2.00 200

06 2.05 205

07 2.10 210

08 2.15 215

09 2.20 220

10 2.25 225

11 2.30 230

12 2.35 235

13 2.40 240

14 2.45 245

15 2.50 250

16 2.55 255

17 2.60 260

18 2.65 265

19 2.70 270

20 2.75 275

21 2.80 280

22 2.85 285

23 2.90 290

24 2.95 295

25 3.00 300

Make sure the correct shim is selected by

measuring it with a micrometer.

Reface the valve seat if carbon deposits result

in a clearance of over 2.8mm

Install the removed parts in the reverse order

of removal.

MYROAD 700i

3-12

Page 72

3. INSPECTION/ADJUSTMENT

ENGINE OIL

OIL LEVEL INSPECTION

Start the engine and let it idle for 2-3

minutes.

Turn off the engine and support the scooter

level surface.

Check the engine oil level. The level must be

maintained between the upper H (1) and

lower level L (2) marks on the oil inspection

screen (3).

If the oil level is below or near the lower

level line, add the recommended engine oil

until the oil level is to the upper level.

Recommended engine oil:

KYMCO 4-stroke oil or equivalent motor

oil API service classification: SJ

Viscosity: SAE 5W50

*

Other viscosities shown in the chart may

be used when the average temperature in

your riding area is within the indicated

range.

ENGINE OIL & STARINER SCREEN

When running in very dusty conditions, oil

changes should be performed more frequently

than specified in the maintenance schedule.

Please dispose of used engine oil in a manner

that is compatible with the environment. We

suggest you take it in a sealed container to

your local recycling center or service station

for reclamation. Do not throw it in the trash

or pour it on the ground or down a drain.

Used engine oil may cause skin cancer if

repeatedly left in contact with the skin for

prolonged periods. Although this is unlikely

unless you handle used oil on a daily basis, it

is still advisable to thoroughly wash your

hands with soap and water as soon as possible

after handling used oil.

MYROAD 700i

Change the engine oil with the engine at

normal operating temperature and the scooter

on its center stand to assure complete and

rapid draining.

Remove the oil filler cap from the right

crankcase cover.

H

L

Engine oil capacity: 3.0 L

Engine oil exchanging capacity: 2.6 L

3-13

Page 73

3. INSPECTION/ADJUSTMENT

Place a drain pan under the crankcase and

remove the oil strainer cap.

The setting spring and oil strainer screen will

come out when the oil strainer cap is

removed.

Clean the oil strainer screen.

After draining the oil completely, install the

strainer screen and setting spring into the

engine.

Apply clean engine oil to the strainer cap

threads, flange surface and a new O-ring.

Install and tighten the strainer cap with a new

O-ring.

Torque: 1~2 kgf•m

Oil Strainer Screen

MYROAD 700i

Strainer Screen

Setting Spring

O-ring

Strainer Cap

Strainer Screen

Strainer Screen

Setting Spring

O-ring

Strainer Cap

3-14

Page 74

3. INSPECTION/ADJUSTMENT

Fill the crankcase with the recommended

engine oil.

Engine oil capacity: 3.0 L

Engine oil exchanging capacity: 2.6 L

Install the oil filler cap.

Check the engine oil level.

Make sure there are no oil leaks

.

ENGINE OIL FILTER

CARTRIDGE

REPLACEMENT

Drain the engine oil.

Remove and discard the oil filter cartridge

using the special tool.

Tool:

Oil filter wrench: A120 E00061

Apply clean engine oil to the new oil filter

cartridge threads, flange surface and a new

O-ring.

Install the new oil filter cartridge and tighten

it to the specified torque.

Torque: 2.4~3 kgf•m

Refill the engine oil

O-ring

MYROAD 700i

3-15

Page 75

3. INSPECTION/ADJUSTMENT

RADIATOR COOLANT

Place the scooter on its center stand.

The reserve tank is under left footboard.

Check the coolant level through the

inspection window (1) at the

left side skirt while the engine is at the

normal operating

temperature with the scooter in an upright

position. If the coolant

level is below the LOWER level mark (3),

remove the left floor

mat, remove the lid screw and reserve tank

lid and the

Reserve tank cap (4) and add coolant mixture

until it reaches the upper

level mark (2).

Remove the left floor mat and remove screw

and reserve tank lid.

Remove reserve tank cap.

Check to see if there are any coolant leaks

when the coolant level decrease very rapidly.

If reserve tank becomes completely empty,