Kuppersbusch USA IKD 12250.0 User Manual

Instructions Booklet

GB

FR

Mode d’emploi

IKD 12250.0

READ AND SAVE THESE INSTRUCTIONS

The Installer must leave these instructions with the homeowner.

The homeowner must keep these instructions for future reference and for local electrical

inspectors’ use.

READ THESE INSTRUCTIONS BEFORE YOU START INSTALLING THIS RANGEHOOD

WARNING: - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE: Never leave

surface units unattended at high settings. Boilovers cause smoking and greasy spillovers

that may ignite. Heat oils slowly on low or medium setting. Always turn hood ON when

cooking at high heat or when flambeing foods (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambè). Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter. Use proper pan size. Always use cookware appropriate for the

size of the surface element.

WARNING: - TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING: SMOTHER FLAMES with a

close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately EVACUATE AND CALL THE FIRE

DEPARTMENT. NEVER PICK UP A FLAMING PAN - You may be burned. DO NOT USE

WATER, including wet dishcloths or towels - a violent steam explosion will result. Use an

extinguisher ONLY if: 1. You know you have a Class ABC extinguisher, and you already know

how to operate it. 2. The fire is small and contained in the area where it started. 3. The fire

department is being called. 4. You can fight the fire with your back to an exit.

ALL WALL AND FLOOR OPENINGS WHERE THE RANGEHOOD IS INSTALLED MUST BE

SEALED.

This rangehood requires at least 24" of clearance between the bottom of the rangehood and

the cooking surface or countertop. This minimum clearance may be higher depending on

local building code. For example, for gas ranges, a minimum of 30" may be required. The

maximum depth of overhead cabinets is 13". Overhead cabinets on both sides of this unit

must be a minimum of 18" above the cooking surface or countertop. Consult the cooktop or

range installation instructions given by the manufacturer before making any cutouts. MOBILE

HOME INSTALLATION. The installation of this rangehood must conform to the Manufactured

Home Construction and Safety Standards, Title 24 CFR, Part 3280 (formerly Federal Standard for Mobile Home Construction and Safety, Title 24, HUD, Part 280). Four wire power

supply must be used and the appliance wiring must be revised. See Electrical Requirements.

VENTING REQUIREMENTS

Determine which venting method is best for your application. Ductwork can extend either

through the wall or the roof. The length of the ductwork and the number of elbows should

be kept to a minimum to provide efficient performance. The size of the ductwork should be

uniform. Do not install two elbows together. Use duct tape to seal all joints in the ductwork

system. Use caulking to seal exterior wall or floor opening around the cap.

Flexible ductwork is not recommended. Flexible ductwork creates back pressure

and air turbulence that greatly reduces performance.

Make sure there is proper clearance within the wall or floor for exhaust duct before making

cutouts. Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut,

then a supporting frame must be constructed

WARNING - To Reduce The Risk Of Fire, Use Only Metal Ductwork.

3GB

WARNING

• Venting system MUST terminate outside the home.

• DO NOT terminate the ductwork in an attic or other enclosed space.

• DO NOT use 4" laundry-type wall caps.

• Flexible-type ductwork is not recommended.

• DO NOT obstruct the flow of combustion and ventilation air.

• Failure to follow venting requirements may result in a fire.

ELECTRICAL REQUIREMENTS

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp fused circuit.

A time-delay fuse or circuit breaker is recommended. The fuse must be sized per local codes

in accordance with the electrical rating of this unit as specified on the serial/rating plate

located inside the unit near the field wiring compartment. THIS UNIT MUST BE CONNECTED

WITH COPPER WIRE

ONLY. Wire sizes must conform to the requirements of the National Electrical Code, ANSI/

NFPA 70 - latest edition, and all local codes and ordinances. Wire size and connections must

conform with the rating of the appliance. Copies of the standard listed above may be

obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fused disconnect (or circuit breaker)

through flexible, armored or nonmetallic sheathed copper cable. Allow some slack in the

cable so the appliance can be moved if servicing is ever necessary. A UL Listed, 1/2" conduit

connector must be provided at each end of the power supply cable (at the appliance and

at the junction box).

When making the electrical connection, cut a 1 1/4" hole in the wall. A hole cut through wood

must be sanded until smooth. A hole through metal must have a grommet.

WARNING - TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, do not use this fan

with any solid-state speed control device.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING: Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the manufacturer.

Before servicing or cleaning unit, switch power off at service panel and lock the service

disconnecting means to prevent power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a prominent warning device, such

as a tag, to the service panel.

CAUTION: For General Ventilating Use Only. Do Not Use To Exhaust Hazardous or Explosive

Materials and Vapors.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING: Installation Work And Electrical Wiring Must Be

4GB

Done By Qualified Person(s) In Accordance With All Applicable Codes And Standards, Including

Fire-Rated Construction.

Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those published by the National Fire

Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden

utilities.

Ducted fans must always be vented to the outdoors.

WARNING

• Electrical ground is required on this rangehood.

• If cold water pipe is interrupted by plastic, nonmetallic gaskets or other materials, DO

NOT use for grounding.

• DO NOT ground to a gas pipe.

• DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral or

grounding circuit could result in electrical shock.

• Check with a qualified electrician if you are in doubt as to whether the rangehood is

properly grounded.

• Failure to follow electrical requirements may result in a fire.

5GB

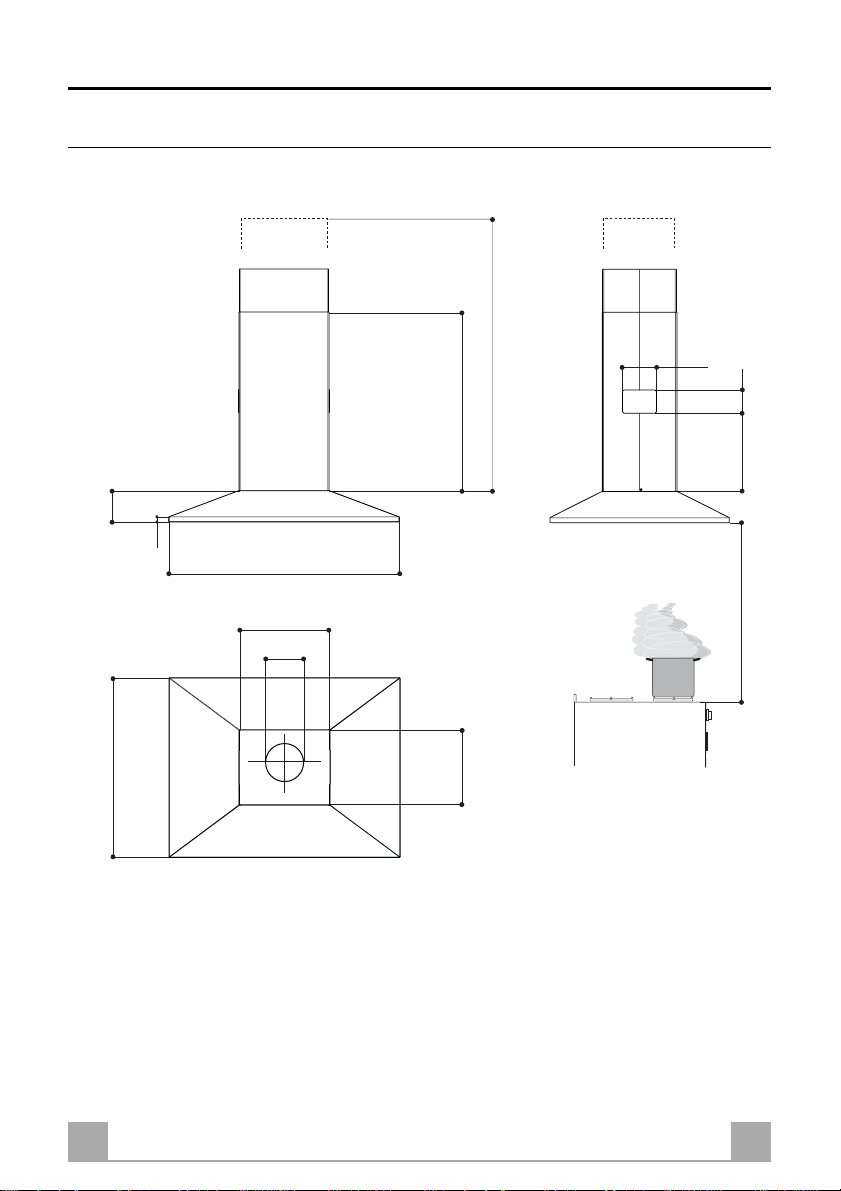

CHARACTERISTICS

120

20

898

Dimensions

696

130

90

min.861 -max.1146

306

698

350

ø

150

650 min.

290

6GB

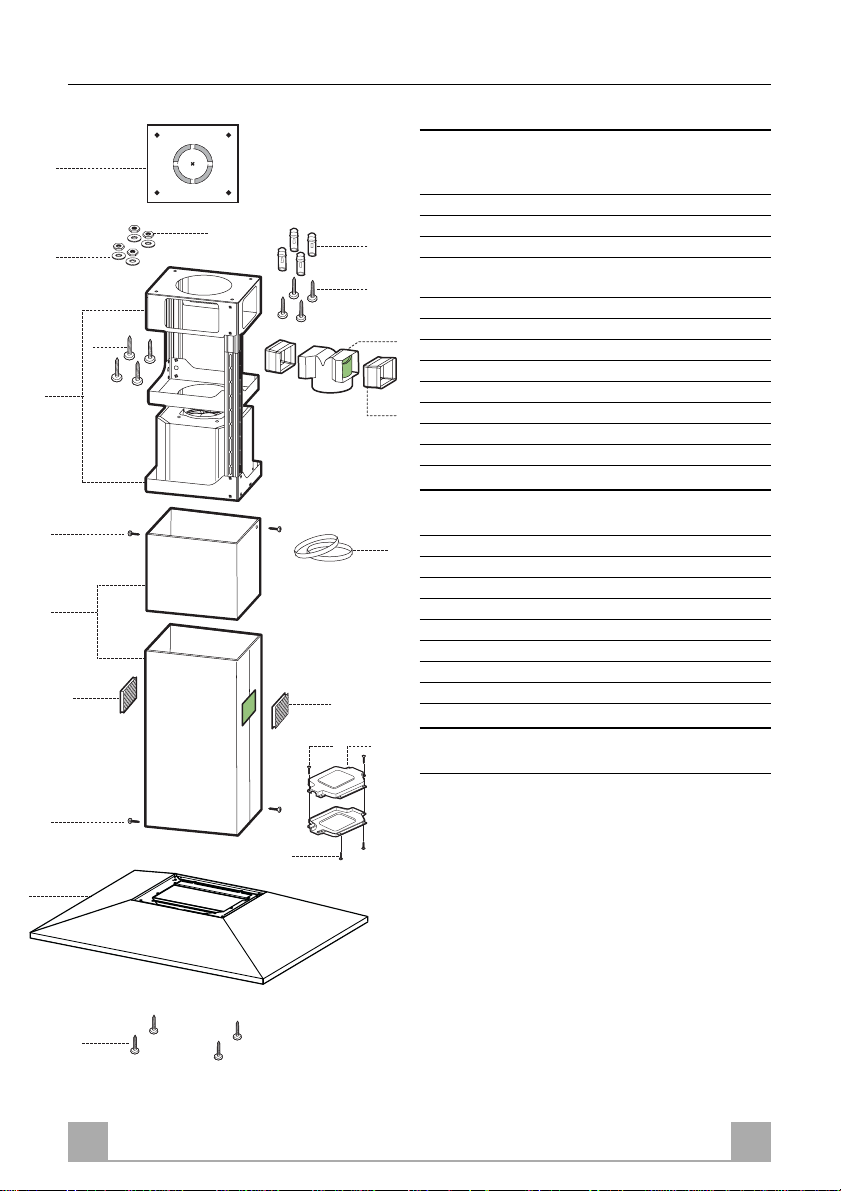

Components

7.1

12c

2

21

22

8b

7.1a

12g

7.1b

2.1

2.2

23

8a

11

12h

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light,

2 1 T elescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

7.1 1 T elescopic frame complete with extractor,

7.1a 1 Upper frame

7.1b 1 Lower frame

15

8a 1 Right Air Outlet Grill

8b 1 Left Air Outlet Grill

14.1 1 Air Outlet Connection Extension

14.1

15 1 Air Outlet Connection

24 1 Junction box

14

25 2 Pipe clamps

9

Ref. Q.ty Installation Components

11 4 Wall Plugs ø 10

25

12c 6 Screws 2,9 x 9,5

12e 2 Screws 2,9 x 6,5

12f 4 Screws M6 x 10

12g 4 Screws M6 x 80

12h 4 Screws 5,2 x 70

21 1 Drilling template

22 4 6.4 mm int. dia washers

23 4 M6 nuts

Blower, Filters

consisting of:

12e

24

12c

12c

1

12f

Q.ty Documentation

1 Instruction Manual

7GB

INSTALLATION

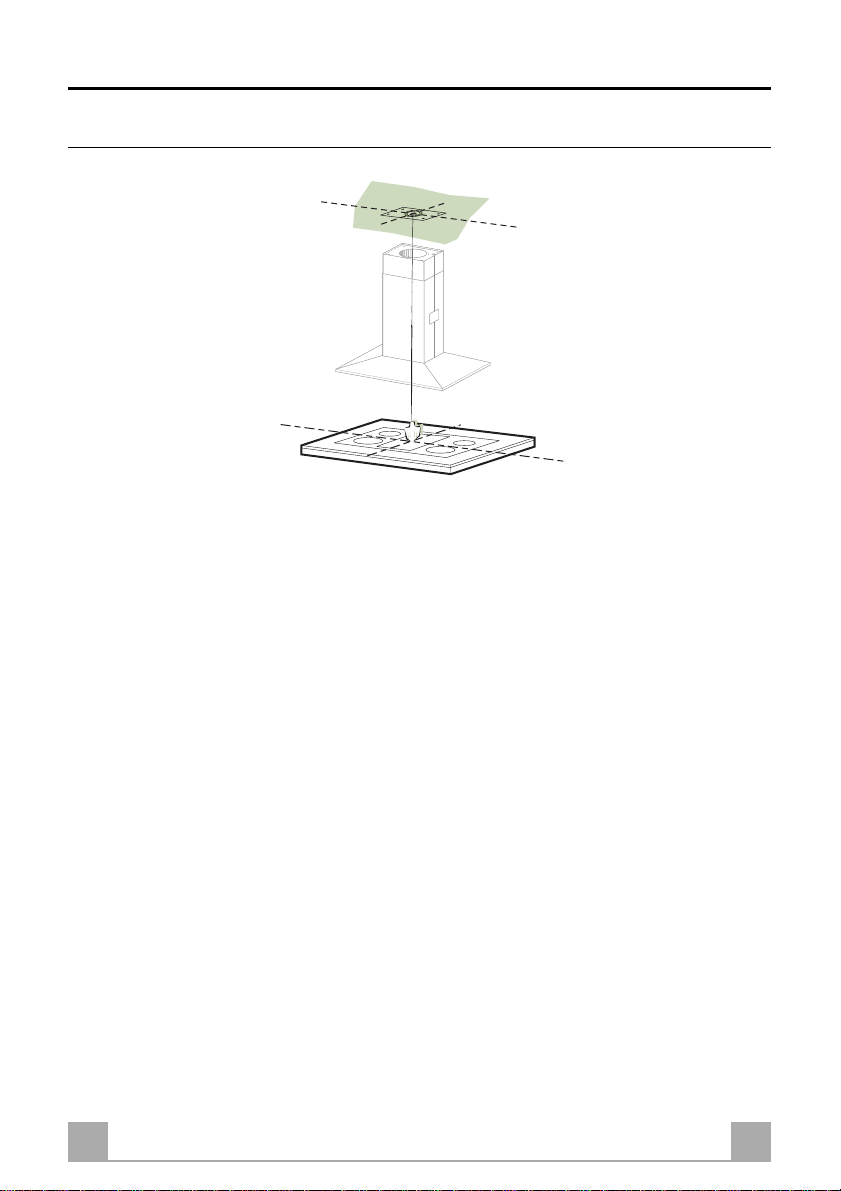

Drilling the Ceiling/shelf and fixing the frame

DRILLING THE CEILING/SHELF

• Use a plumb line to mark the centre of the hob on the ceiling/support shelf.

• Place the drilling template 21 provided on the ceiling/support shelf, making sure that the template is

in the correct position by lining up the axes of the template with those of the hob.

• Mark the centres of the holes in the template.

• Drill the holes at the points marked:

• For concrete ceilings, drill for plugs appropriate to the screw size.

• For hollow brick ceilings with wall thickness of 20 mm: drill ø 10 mm (immediately insert the

Dowels 11 supplied).

• For wooden beam ceilings, drill according to the wood screws used.

• For wooden shelf, drill ø 7 mm.

• For the power supply cable feed, drill ø 10 mm.

• For the air outlet (Ducted V ersion), drill according to the diameter of the external air exhaust duct

connection.

• Insert two screws of the following type, crossing them and leaving 4-5 mm from the ceiling:

• For concrete ceilings, use the appropriate plugs for the screw size (not provided).

• For Cavity ceiling with inner space, with wall thickness of approx. 20 mm, Screws 12h, supplied.

• For wooden beam ceilings, use 4 wood screws (not provided).

• For wooden shelf, use 4 screws 12g with washers 22 and nuts 23, provided.

8GB

Loading...

Loading...