Page 1

KROHNE 06/20057.30935.32.00

©

GR

DIN A4: 7.10028.31.00

Service Handbook

Universal 3-Beam

ultrasonic flowmeter

UFM 3030 K/…EEx compact ultrasonic flowmeter

UFC 030 F/…EEx ultrasonic flow converter

UFS 3000 F/…EEx ultrasonic flow sensor

Subject to change without notice.

Electromagnetic flowmeters

Variable area flowmeters

Mass flowmeters

Ultrasonic flowmeters

Vortex flowmeters

Flow controllers

Level measuring instruments

Pressure and temperature

Heat metering

Communications technology

Switches, counters, displays and recorders

Engineering systems & solutions

Page 2

General advice on safety

• Do not instal l, operat e or maint ain this flow m eter wit h out reading, under standing and f ol lowing

the factor y-supplied in str uctions , other wi se inju ry or damage may r esu lt.

• Read these instructions carefully before starting installation and save them for future reference.

• Obs erve all war nings and instr u ctions marked on the pr oduct.

• Use only m a ins supply wi th protec tive ea rthi ng c onnected.

• Do not use the product with removed covers under wet conditions.

• Consider handling and lifting instructions to avoid da ma ge.

• Install the product securely and stable.

• Install and connect cabling proper to exclude damage or harmful situations.

• If the product does not operate normally, refer to the service instructions or refer to qualified

KROH N E servi ce en gi neers.

• There are no op erator-servi c eab le parts insi de the product.

The following symbols may appear in this manual or on the product

ATTENTIO N: r ef er to oper ating and installation instructi ons !

DANGER: ris k of elec tric shock!

PROTECTIVE conductor terminal!

These terms may appear in this manua l or on the product:

WARNING statement: identify conditi ons or practice that could result in injury or

loss of life.

CAUTI ON statemen t : identify c o nditions or practice that could result in dam a ge t o

th e pr oduct or othe r pr oper ty.

2 UFM 3030

Page 3

Disclaimer

• This do c ument contains impor t ant information on the product. KROHNE attempts t o be as

accurate and up-to-date as possible but assumes no responsibility for errors or omissions. Nor

does KROHNE make any com m it m ent to upda t e the inf ormation contained herein. T hi s m anual

an d all ot her documents are subject to change w it h out prior notic e.

• KROHNE will not b e lia ble for any damage of any kind by using its product , in cl u ding, but not

limited to direct, indirect, incidental, punitive and consequential damages.

• Th is disc laimer does not app ly i n ca se KROHNE ha s ac ted on purp os e o r with gr os s n egligence.

In the event any applica ble l aw does n ot allow such limita tions on implied wa rr a nt i es or the

exclusion of limitation of certain damages, you may, if such law applies to you, not be subject to

some or all of th e above di sclaimer, exclus ions or limit ations.

• Any product purchased from KROHNE is warranted in accordance with the relevant product

docum entation and our Terms and Condition s of Sal e.

• KROH N E reser ves the r ight to al ter the co ntent of its d o cuments, incl udi ng this di sclaimer in any

way, at any time, for any reason, without prior notification, and will not be liable in any way for

possib le consequences of such changes .

Product liability and warranty

• Responsi bility f or suitabilit y and int end ed us e of t his ultrasonic f l ow meter rests solel y with the

user. Improper inst allation and oper at i on of the flow meter (syst em ) ma y l ead to los s of warr a nt y.

• In addition, the Term s an d Conditions of Sale ar e applic a ble and are the basi s for the purchase

contract.

• If fl ow meter s need to be returned to KROHNE , pleas e note the informa tion given on the la st

pages of t he installati o n and oper at i ng instructi ons. KROHNE regret s that t hey cann ot repair or

check flow meter(s) unless accompanied by the completed form (see last pages of the

installation and operating instructions).

Items included with order

• UFM 3030 ult ras onic flow meter , com pr is ing of a flow sensor, UFS 3 000 and a sig nal converter,

UFC 030 either built tog ether as a compact system or supplied as two separat e pieces, in the

size as indicated on the packaging box

• Signal cable (only in case of a separate system)

• Special t ool for opening the converter housi ng

Documentation supplied

• Condensed installation and operat i ng manual

• For Ex- units: installation and opera ting instru ctions for use i n hazardous areas

• Instruction card : o v er vi ew of the co nfiguration menu and display ma rkers

• Product information CD

• Appro v al d oc uments, unless r epr oduced in the installatio n and oper a ting instructions

• Cert ific ate of sy st em calibration dat a

UFM 3030 3

Page 4

This instrument is develo ped a nd manufactur ed by:

KROHNE Altometer

Ker kep la at 12

3313 LC Dordr echt

The N et h erla n ds

For information, mai ntenance or servi c e pleas e co ntact your nearest local KROHNE repr esentative.

Notes on the ser vice handbook

This service handbook is divided into four parts for easy use. All ultrasonic flow meters are factoryset to your or der sp ecificati ons . Th erefore, no furt h er adjustments ar e necess ary prior to init ia l startup. Condens ed installation and operating instr uctions are available for installatio n and init i al start-u p.

Part A Chapter s 1, 2 and 3; System installati o n and star t - up. Install ati o n, con nec ting and

powering the flow meter.

Part B Chapter s 4 and 5; The sign al conv er ter. Operato r cont rol and function ing of the

signal converter.

Part C Chapters 6 and 7; Functional checks and service. Servicing the flow meter.

Part D Chapters 8, 9 and 10; Technical data. dimensi ons, block dia gram and ultrasonic

measuri ng principl e.

4 UFM 3030

Page 5

Table of contents

1

Introduction 6

1.1 Cautions 6

1.2 Unpacking and inspection 6

1.3 System description 6

1.4 Av ailable ver si ons 7

1.5 CE A pprovals 7

2 Mech a n ic a l in sta llatio n 8

2.1 Handli n g t he flowmeter 8

2.2 Installation location and position 8

2.3 Special installation requirem ents 9

2.4 Pipe fl anges 10

2.5 Pipes with cathodic pr otection 11

3 Connecting the signal converter 12

3.1 Safety instr ucti o ns 12

3.2 Converter terminal box 12

3.3 Power supply connection 12

3.4 Co n nec tion of s ens or cables ( UFM 303 0 F only) 13

3.5 Electrical connection of the sig nal i np ut s an d outputs 14

3.6 Connect i on diagram exam ples 16

4 Start-up 17

5 Operating the signal converter 18

5.1 Fron t panel a nd oper at ing keys 18

5.2 Menu structure and func tion of operati ng keys 19

6 Description of functions 28

6.1 Menu structure 28

7 Functional checks 40

7.1 Test functions of the signal converter Function 2.1 to 2.5 40

7.2 Measuri ng zero flow v alu e 41

8 Servi ce an d Repair 42

8.1 Replacement of elect r onic u nit of sign al convert er 42

8.2 Replacement of ultr as onic flow sensor in separ ate systems 42

8.3 Change of po wer s upp ly fu s e 43

8.4 Cleaning 44

8.5 Turning the display circuit board 44

8.6 Turn ing the signal c onv er ter hous ing 44

9 Returning the flow meter for service or repair 45

10 Dimensions 46

11 Block diagram 46

12 Ultrasonic measurement principle 47

12.1 Transit time differential method 47

12.2 Three beam ultr asonic measurement 47

UFM 3030 5

Page 6

Part A System Installati on and Start-up

1 Introduction

1.1 Cautions

Only for flow meters supplied with a voltage over 5 0 VAC.

Refer all maintenance or servi c e to tra i ned KROHNE service eng ineers.

Mains power s hall be disconnected from the product before performing any

maintenance.

This product is prepared for and can only function with the rated AC mains voltage

as indicated on the nameplate.

This product is a Class 1 device (earthed) and requ ir es a c orrect connecti on to

prot ective earth. The protective ear th conductor of the m ain power s h all be properl y

connected to the marked protective earth terminal to ensure safety from electric

shock for the operator and its environment. For detail refer to this s er vi ce handbook.

1.2 Unpacking and inspection

• This pro du ct has been thorou ghly inspected and t ested before shi pment and is ready for

operation.

• After carefully unpacking, inspect for shipping damage before attempting to operate. If any

indi c ation of mechanic al damage is found contact immediately the r esp on sible trans por t s ervi c e

and your local KROHNE representative.

• A simpl e oper at i ng check of the electr oni c s after unpacki n g and bef ore permanent installation is

advisable to ascertain whether it has suffered damage during shipment. Confirm for the correct

mains voltage printed on the namepla te. I f it diff ers f rom th e ordered produc t pleas e co n tact y our

local KROHNE representative.

• Afte r connectin g to t he m ain s , ch eck i f th ere is any i n dica tion on the dis p lay an d if the b acklight

of the display is lighted. If not, contact your local KROHNE representative for advice.

1.3 System description

The UFM 3030 ultra sonic flow meter is a precis ion instr ument designed for li n ear, bi/directional flow

measur ement of liquids. Flow measurem ent val ues c a n be outp ut vi a t he standard anal og and- or

pulse/f requency out puts. Via a user friendly operat or int er f ac e (HMI) the unit can be set up for a

wide range of applications. Next to actual volumetric flow measurement the unit can be configured

to perform flow totalization (pl us, mi nus and sum ). Also measurement and output of t he liqu id so nic

velocity can be configu r ed. Op tionally the unit c an b e set to perfo rm one of the followi n g additional

functions:

• Ca lc ulate a nd ou tput corrected stan dar d volumetri c or mas s f low usin g the extern a l pres sure

and temperature inputs

• Batch function

• Heat function, combining T1, T2 and volume

6 UFM 3030

Page 7

1.4 Available versions

The UFM 3030 consists of a flow sensor ( UFS 30 00) and a signal conv ert er ( UFC 030), which can

be built i nt o a comp act flo w m eter, UF M 30 30 K or a separate fl o w m eter, UF M 3030 F.

Both flow sensor and signal converter are available with an approval for use in hazardous areas.

Special c od es and regulati ons apply i n thes e ar eas and are refer r ed to in the instructions for

hazardous area versions, supplied as a separate manual.

UFS 3000 UFC 030 UFM 3030 K

1.5 CE Approvals

EMC, Electr oma gn e tic Compatibility Directive

The produ ct complies wit h the requi r em ent s of t he harm o nis ed standards u nd er

the EMC directive 89/336/EEC.

Low Voltage Directive

The produ ct compl ies with the requir em ent s of t he Lo w Voltage Directi v e

73/23/EEC and is designed in accordance with EN IEC 61010-1 first and second

edit ion . (s afety req uirements for elec tr ica l equipment for measurement , control

and laboratory use part 1)

Lo cal saf e ty regul a t io ns shall b e obs erved in c ombination with t he measu res

special to this product to avoid dangerous situations.

Pressure Equipment Directive

The KROHNE organisation com plies with the requirements of Modu le H of the

Pr ess u re Equipment Di rective 97/23 /EC ( full quali t y assurance).

Please refer to the CE declaration for more detailed information.

UFM 3030 7

Page 8

2 Mechanical installation

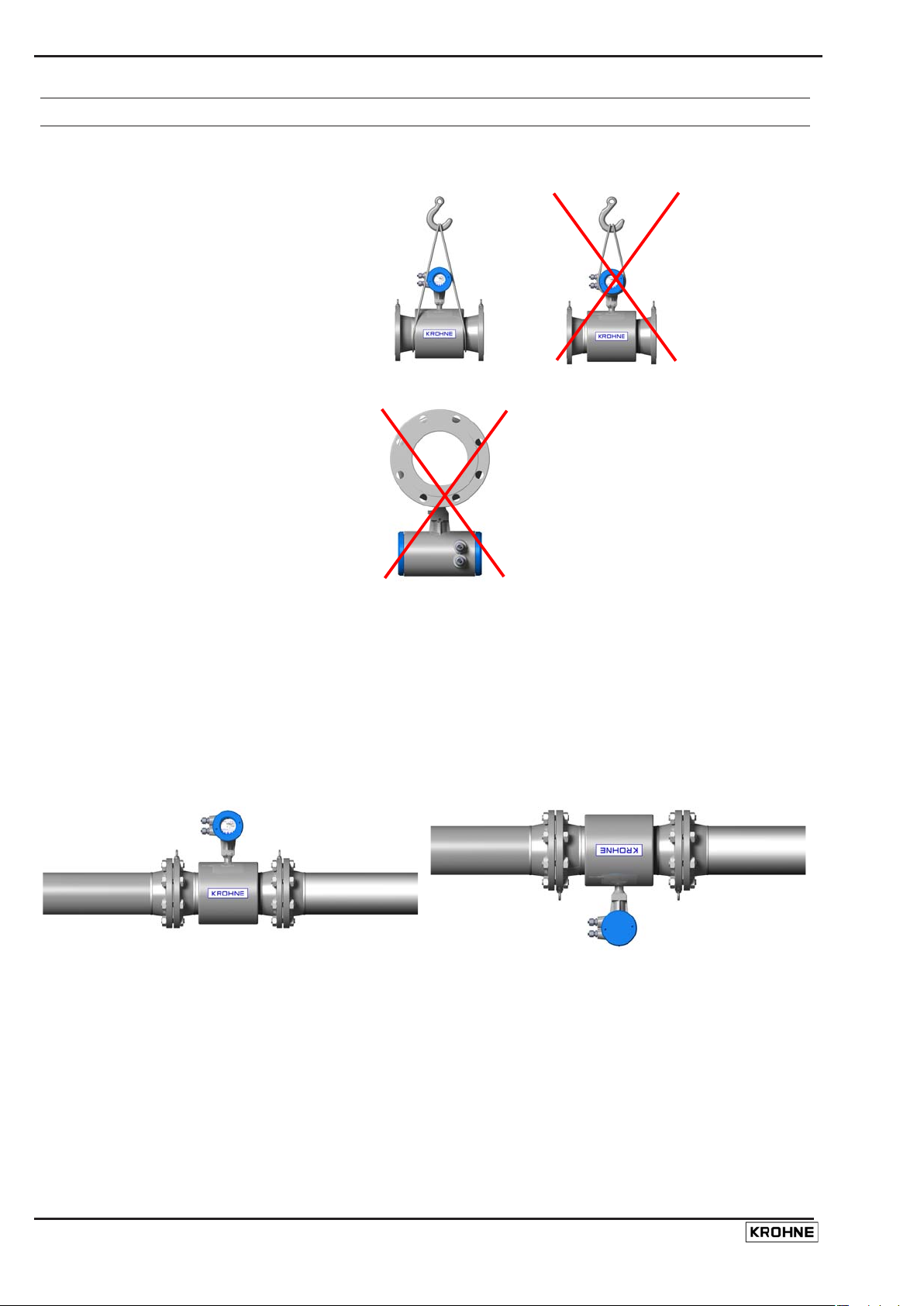

2.1 Handling the flowmeter

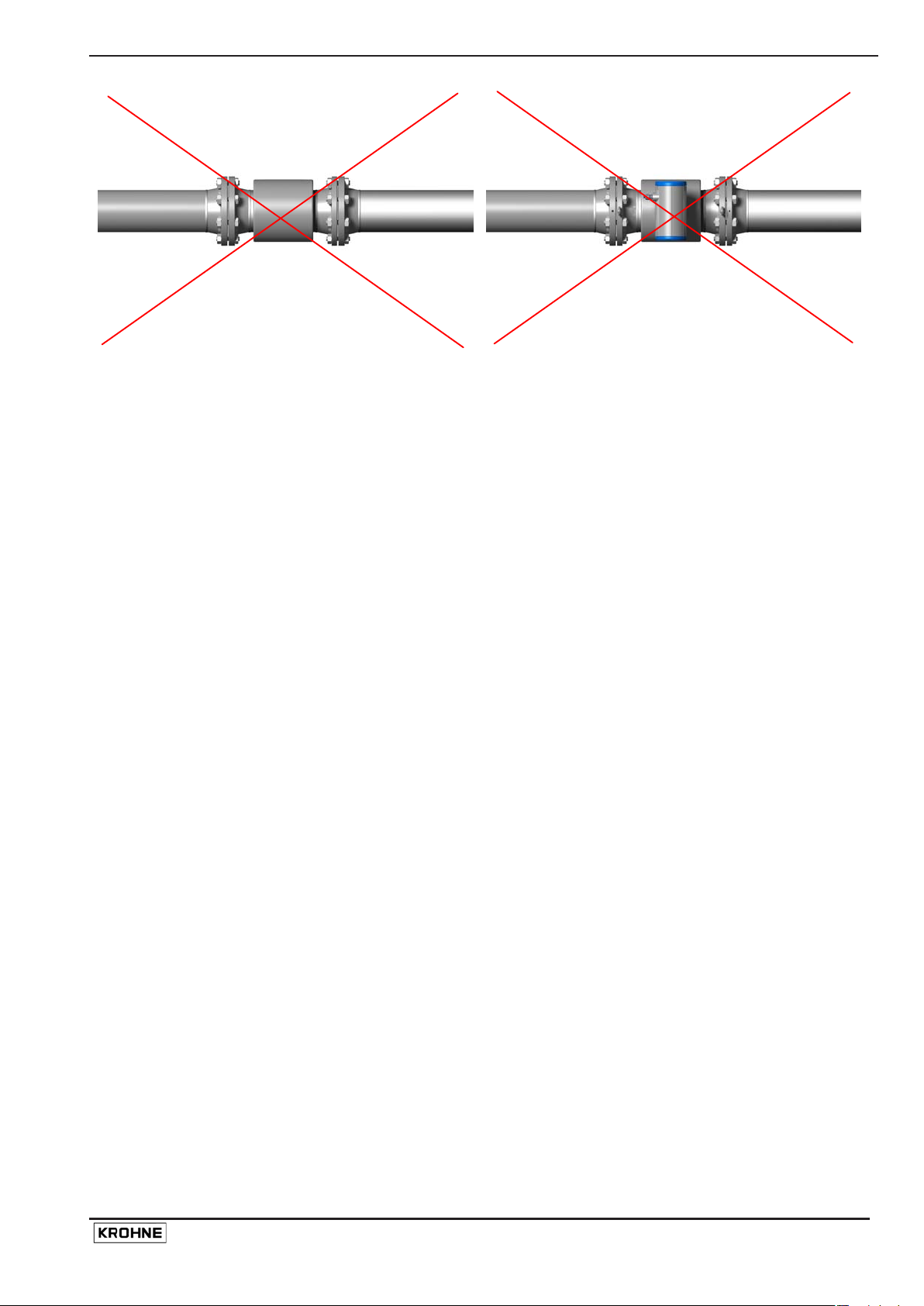

Important: Do not lift the compact

flowmeter by the signal converter

housing or the terminal box. Check the

weight of the flowmeter as indicated on

the type plate before handling the unit.

When handli ng the flowm eter avo i d hard

blows, jolts or impacts.

Do not plac e the fl owmeter on the sign al

conver ter housing.

2.2 Installation location and position

The UFM 3030 flow meter can be instal l ed in hori zo ntal, sli ghtly ascendin g or vertical pipelines.

If insta lled i n a horizontal or s lightly asc e ndin g pip elin e, a lways i ns tall the c onv ert er or terminal

box in vertical positi o n opposite th e flow sens or ei ther with the conver ter up or down, but never in

horizontal position.

8 UFM 3030

Page 9

If requi red the po sit io n of the signal con verter ca n be m odifi ed b y turning th e dis p lay circ u it b oard

thr ough 90° or 18 0° t o achi eve a hor izontal posit ion of the display. In additi on the signal converter

housing may be turned through 90° opposite the flow sensor.

For an exact description of this procedure, refer to chapter 8.6.

The measuring tube must be completely filled at all times for proper flow measurement, as the

sensor s bec ome non-wetted, a los s of si gnal message will be disp layed. There is no damage

when thi s occ u rs.

Flow dir ect ion. The UFM 3030 is a bi-dir ec tional flo w meter . Note the indicati ng arrow for the

positive direction on the flow meter.

It is recommended to protec t t h e signal converter fr om direct sunlight to prol ong the life. Alth ough

no direct damage will occur, installation of a sunshield is advised.

Do not expose the signal converter to excessive vibration. To protect the flow meter from

excessi v e vibrati on su pport t he pip eline on either si de of th e flow meter.

Make sure there is sufficient room next to the pipe flanges to fit the bolts and nuts.

To achieve t he spec ified accur acy of the flow meter , a straig ht inlet s ection of 10 × DN (D N =

met er size) an d an outlet section of 5 × DN should be applied.

Norm all y zero s ett i ng is not necessary , but if r equired the zero p oin t can b e checked and the

meter can be re-zeroed under stationary flow conditions (see Function 1.01.03 of the converter

menu). To f orc e zero flow , a shut - off valve should be p ro v ided u pstr eam a nd/ or do wnstream of

the flow sens or.

Mixi ng different fluid products. Install the fl ow meter upstream of mix ing point or at minim um

dist an c e of 30× D N (DN = meter size) do wnstream of the mixing point, otherwise the flow

meas urem ent may be unstable.

Ambient temperature all flow meters: -40 to +65°C/ -40 to +149°F

Product temperature compact flow meter: -25 to +140°C/ -13 F to +284°F

Prod u ct tempera ture separate flow meter: -25 to +1 8 0 °C/ -13 to +356°F

Special v er s ions are availa ble for higher proces s temperatur es.

In case of a pipel ine running alo ng a wall: pl eas e obs er v e a minim um distance between pipe

centreline and the wall of at least 0.5 m (1.6 ft).

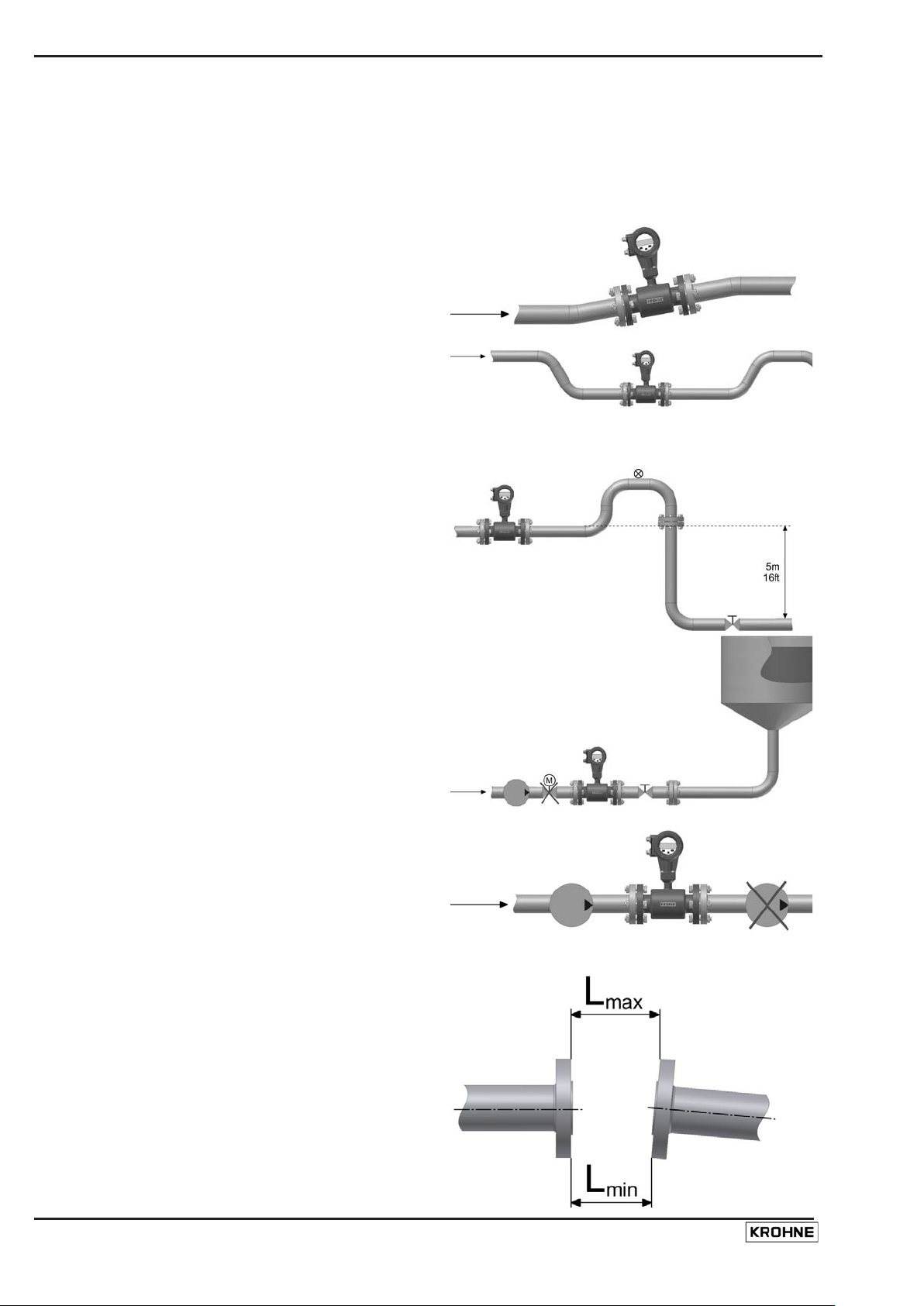

2.3 Speci al installation requirem ents

To avoi d meas ur ing er rors and malfunctioning of the flow meter due to gas or air inclusions or an

empt y pipe, please observe t he following precau t io ns:

UFM 3030 9

Page 10

Sinc e gas will collect at the highest point of a pipe, in s tallati on of the flow meter at that locati o n

should be avoided at all times. Also installation in a down going pipe should be avoided since a

compl et ely fi lled pipe may not be guaranteed due to casca di ng aff ects. Additionally flow profile

distortion is possi ble.

Long h orizontal pip es: ins tall in slightly ascending

pipe section. If not possi ble, ensur e adequate

velocity to prevent air, gas or vapour from

collecting in upper part of flow tube As a partial ly

filled meter will report higher than actual flow

rat es, or n ot meas ure (as transduc er pair s becom e

non-wetted).

Open feed or dis c h arge: Install m eter in a lower ed

section of the pipe to ensur e a full pipe condition

thro ug h th e meter .

Down goin g pipel ine over 5 m (16 ft) lengt h: install

air vent downstr eam of th e flow meter. To prevent

vacuum . While thi s wil l n ot harm t he m eter, it may

cause gas es to com e out of s olution (cavit ate) and

int erfere with proper m easurements.

Always install control valves downstream of flow

meter in order to avoid cavitation or distortion of

flow profile.

Never i nstall flow meter on a pump suct i on side in

order to avoid cavitation or flas hing in the flow

meter.

2.4 Pipe flanges

Refer to dimensional dra wings for flange s pacing

and in addition allow for thickness of gaskets.

Insta ll flow meter in line with pipe axis. Pip e fl an ge

faces must be parall el to each other, max.

Per missible deviation: Lmax - Lmi n ≤ 0.5 mm

(0.02").

10 UFM 3030

Page 11

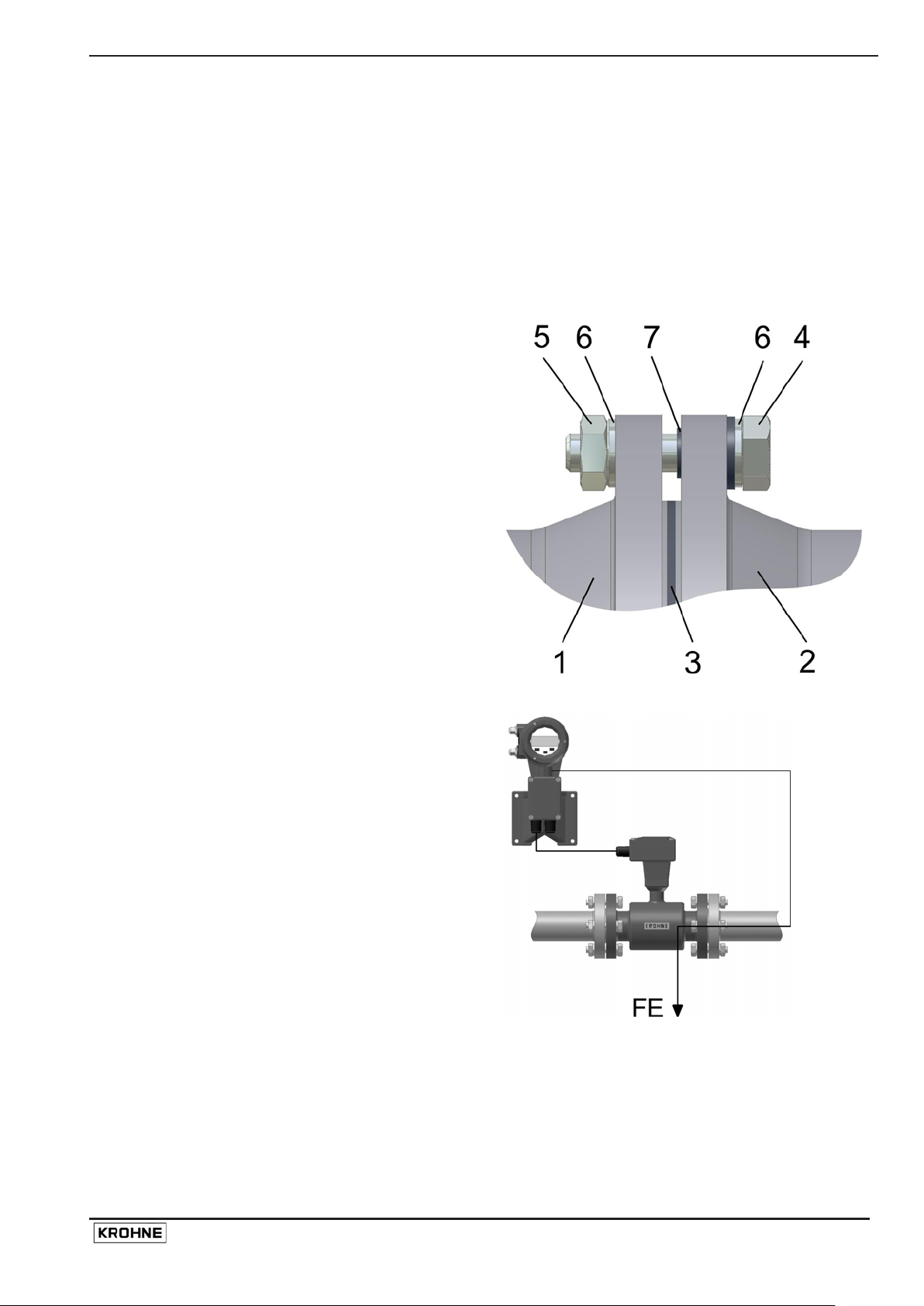

2.5 Pip es with cathodic protection

Pipes with electric corrosion protection are generall y insulated inside and outside so that t he fluid

has no conductive connection to ground. The flow meter must be insulated from the pipe. Note

the foll owing when in stallin g th e flo w m eter:

The pipe fl a nges must be connected to each other usin g a copper cable (L), but must not be

connected to the flow meter.

The bolts for the flange connections and the gaskets must be insulated. Use sleeves and washers

that are m ad e of ins ula ting material (these must be provided by customer).

1. Flange of flow sensor

2. Gas ke t

3. Pipe flange

4. Bol t

5. Nut

6. Washer

7. Insula t ing sle e ve

Follow grounding instructions.

Use ≥ 4 mm2 (≥ AWG 10 ca ble).

No te: No earthing c ables are sup plied b y

KROHNE.

UFM 3030 11

Page 12

3 Connecting the signal converter

3.1 Safety instructions

This product is designed for use in accordance with EN IEC 61010-1 for Installation Category 2

and Pollut i on Degr ee 2. Haza r dous voltag es are pr esent within thi s pro du ct during normal

operation. The product is designed for Pr otection Class I and should never be operated without

prot ective earthi ng. T he pr odu ct sha ll al s o never b e oper ated with covers rem ov ed unl ess

equivalent prot ecti on of the operator and its environment fr om accidental contact with hazar dous

inter n al voltages is provided. Always fol l ow basic and local safet y pr ecau t i ons when using thi s

product t o r educ e ri s k of injury from electrical shock , spr ead of fir e or other dangerou s sit uat io ns.

3.2 Converter terminal box

• The converter termi nal box is accessible after removi n g t he rear (blind) cover of the

el ect ro n ics sec tion using t he s pecial wr enc h s upplied with th e flow meter.

• Do not damage the screw thread and the gasket, never allow dirt to accumulate, and make

sure tha t the sc rew t hr ead i s w ell grea sed, using Tef lo n gr e ase a t all t i mes. A damaged

gaske t must be replaced imme d iately!

• Do not cross or loop the cables in the terminal box of the signal converter. Use separate cable

entries for power supply and signal cables.

• Special regulations apply to in stallation in hazardous areas (see installation instruction s for

hazardous areas).

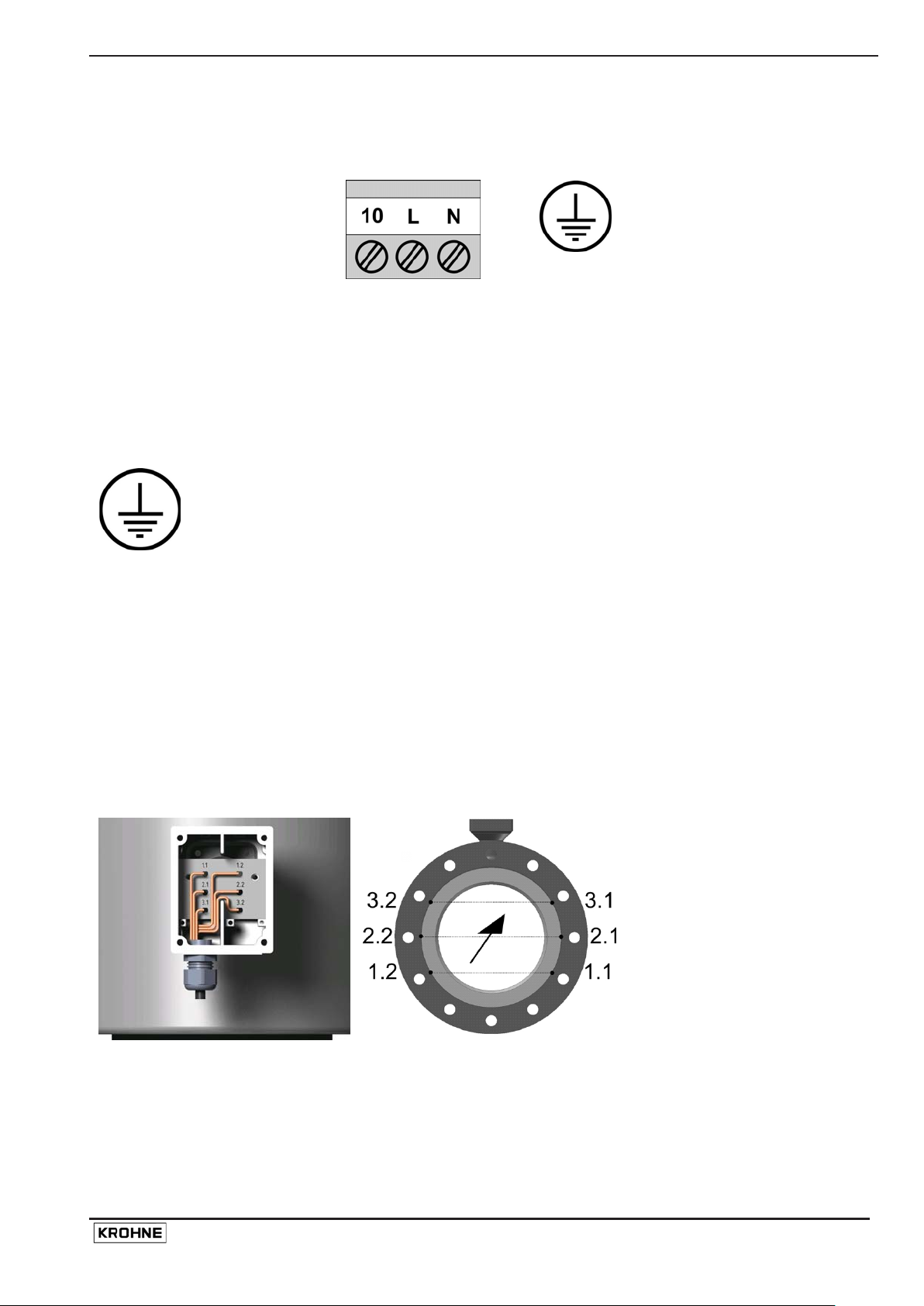

3.3 Power supp ly connection

In case of con nection to the mains supply voltage:

Environmenta l co nditions

• The UFM3030 is desi gned to operate safe under the follo wi ng c onditi ons :

• Suita ble for indoor and outdoor use, the instrument is usable up to protecti on cat egory IP67

(IEC 60529)

• Use up to an altitu d e of 2000 m ab ov e see level

• Suita ble for an operati on ambient tempera ture range -40°C to +65° C

• Suitable for an storage temperature range -40°C to + 80°C

• Suitable for use in atmo s pheres wit h a relative humidity up to 80%

• Over voltages up to category II on the mai n sup ply voltage ( IEC 603 64- 4-4 43 )

• Connected to protective earth conductor ( Protection Class I)

• Rated pollution degr ee 2

• This in s trument is intend ed f or permanent connection to the mains. It is requir ed

(f or example for servic e) t o mount a n external switch or circuit br eaker near the

product for disconnection from the mains. It must be easily reachable by the

operator and marked as the dis c onnecting dev ic e f or this product.

The swi tch or circuit break er ha s to be suitable for the ap plic ation and shall als o

be in accor dance with to loc al (safety) requirements and of the building

installa t ion . (IEC 60947 -1 /-3 ).

• The pro tec tive conducto r cl am p t erminal size M5, pres s- fitted in the t erminal

compart ment (near the ma in c onnection termin als), shall alwa ys t o be c onnected

to the protective ear th conductor of the mai ns supply. Con ducto rs up to 4 mm²

(11 AWG) b e connect ed to this termin al. The diameter of t he cond uct ors of the

mains supply, in c ludi ng the protective earth c o nduct or s h all be i n accor danc e

wit h the general and local requir ements.

12 UFM 3030

Page 13

• It is not allowed to use the protective conductor terminal for any other connection

than the pro tectiv e ea rth co nduct o r.

• IP 67 i s only warranted when using suitable cabling with the cable glands and

covers mounted as specified.

The power supply terminals

has thre e conne c tions

Th ere is a sep ar ate earthing

that must be connected:

:

Terminal Function Specification

10 Reserved G round connection Not for pro tective earthing

L / L1 Live power sup ply Mains vol t age AC supply:

100 V AC < U < 240 V AC: -15%, +10%

SELV AC/D C suppl y:

DC: 18-32 V dc

AC: 24 V AC: -10% +15%

N / N1

Neutra l po wer suppl y

PE: Prot ect i v e gro und connecti on

FE: Functional ground connection

Pr ot ective co nduc to r cl amp terminal.

Conductors up to 4 mm² (11 AW G) need

to be connected to this terminal.

3.4 Connection of sensor cables (UFM 3030 F only)

For the UF M 303 0 F the sens or s must be con nected using the factory supplied M R06 ca b le

between the flow sensor terminal box and t he converter housing terminal box. For the UFM

3030C this is connected at the factory.

Both the flow sensor terminal s and t he c onver ter sensor termi na ls should be connected using the

appropr i a t e num ber s i ndi cated on the sensor cabl e. )

Cable diameter: 11 mm (0,433 inch), minimum bending radius: 8 x cable diameter.

UFM 3030 13

Page 14

3.5 Electrical connection of the signal inputs and outputs

The termin al to connect the electr ical sig nal i nputs and outputs consis t o f 6 connections.

For standard instrumen ts

For instr uments with a communi c at i on module

For wiring of the signal inputs and outputs it is advised to use unshielded twisted pairs.

Inter nal ci r c uit of t he signal inputs a nd out p ut s

of the converter

Terminal

⊥

A1 Analog input 1, for temperature

A2 Analog input 2, for temperature or

I/C Combined Current outp ut (I) and

Function Specification

Common ground -

0(4) to 20 mA

measur em ent. Configuration via menu

option 3.2.2. and 3.2.3.

Ri = 58,2 Ω,

fuse: 50 mA

0(4) to 20 mA

pressure measurement. Configuration

via m enu option 3.2 .4. and 3.2. 5.

Ri = 58,2 Ω,

fuse: 50 mA

Current output (I): I ≤ 22 mA, Rload ≤ 680

Digital input (C).

Current output (I) Incl . Har t

communication

Function can be set via m enu option

Ω. Umax = 15Vdc.

Digital input (C): low = 0-5 VDC, high = 15-

32 VDC. Will be switc hed off when current

output activated.

3.4.0. and 3.6.0.

P Pulse/frequency output. Function can

be set via menu option 3.5.0.

I max: 150 mA

Umax: 32Vdc, 24Vac

Max frequency: 2 kHz

V+ DC po wer s upply f r om con v erter for

active wir ing of inputs a nd outputs

14 UFM 3030

22 VDC at full loa d, 24 VDC maximum. I ≤

100 mA.

Page 15

D+ Communication connection+ For fieldbus communication

D- Communication connection - For fieldbus communication

P/I/C Combined c urrent output (I) digit al

ou tput ( C) and p uls e out put (P). See

See individual I/C terminal and P terminal

specifications.

indi v id ual I/C t erm in al an d P ter minal

functions

The electr ical input and output signals can be connected eit her in active or in passiv e m od e. I n

active mod e DC supply voltag e is provi ded from the V+ terminal. In passiv e mode supply voltage

is provi ded from an external source. Please obs er v e ins t r ument polarit y: cur rent (I) is always

flowing towards I, C, P, A1, A2 terminals (current sink).

Note! Never use the active and passive mode at the same terminal simultaneously.

If HART communication is used, do not connect the pulse/frequency output P in active mode.

UFM 3030 15

Page 16

3.6 Connection diagram examples

In the foll owi ng, some examples of how t o con nec t t h e electr ical input and output signals.

Current output

Active

Ri <= 680 Ω

Pulse output

Active Passive

Passive

For supply: U = 15 – 24Vdc, I >= 22mA

Digital input

Active

Analog input

R1>= 470 Ω, R2 =

U*R1/(V+ - U)

For supply: U<= 32Vdc, <= 24Vac

Passive

For supply: U = 15 – 30Vdc, I >= 1,5 mA

16 UFM 3030

Page 17

4 Start-up

• Ch e ck that t h e fl ow meter ha s been corr ectly installed.

• Wi th separate systems , check before initi al start-u p t hat t he correct converter (UFC 030 F) is

used with the correct flow sensor (UFS 3000).

• O rd er No. , see in strument nameplates

• Meter size (DN) , Function 3.1.5

• Primary cons ta nt GK, Function 3.1.6

• Flow direction, Function 3.1.7

• When powered, the signal converter operates in the measuring mode. TEST, NO ERROR and

IDENT NO. _ _ _ _ _ _ _ of the signal converter appear in succession on the display. This is

foll owed by di s play of the actual flow r ate and/or the int er nal count on a continuous or

alternating basis (depending on setting, see Function 3.03 Display or Function 1.02 Display).

•

UFM 3030 17

Page 18

Part B The signal converter

5 Operating the signal conve rter

5.1 Front panel and operating keys

The front panel and its oper ating keys are a cce ssible aft er removin g th e front (glass) c ove r o f th e

elect ronics s ection us ing the special wren ch sup plied wit h th e flo wmeter.

When removing the cover, d o not damage the screw thread and th e gas k et, never

allow di rt to accumulat e, and mak e sure that they are well greas ed us ing Teflon

grease at all times. A damaged ga sket must be repl ac ed imm edi ately!

1. Display 1st (top) li ne, m easu r ed valu e

2. Display 2nd (middle) li ne, uni ts of measured val ue

3. Display 3rd (bot tom ) line with ma rke rs ▼ to identify

actual displayed value, from left to right:

Flow rate

Velocity Of Sound VOS

Total + Totalizer (forward flow)

Total - Totalizer (re verse flow )

Total Σ Totalizer sum (+ and -)

4. Compass field for error indication

5. Operating keys for programming the signal converter

6. Magnetic sensors to program the signal converter by

means of a hand-held bar magnet (option al) without

having to open the housi ng.

The function of the sensors is as follows: the left most

sensor is equivalent to left key, the right most, the right

key, and the top, the center key.

The converter is capable of displayi ng sev era l ty pes of measured val ues (dependi ng on the

programming under Submenu 1.02 or 3.03.0 0 DI SPLAY), indicat ed by the m arker s at the di s pl ay

bottom li ne. Depending o n the pro gram m i ng of Funct ion 3.03.07 CYCL DISP, they c a n be

selected manually at any time by pressing the ↑ key or they ar e automatical ly cycled at 5 second

intervals.

Dependin g on the programming of Funct ion 3.03.0 8 ERROR MSG, err or s are ind ic ated by

flashing display lines and/or by the compass field. For a description of the errors and what to do,

see m ain menu Er ror/Totalizer.

18 UFM 3030

Page 19

5.2 Menu structure and function of operating keys

The menu str uct ur e co nsi sts of 5 user accessible blocks.

• Function block 0 Error/Totali zer reset can be accessed from the measuri ng mode and

provi des detailed inf o rm at ion on errors occur r ed du ri ng operation. It all ows for fast and easy

resetting of the errors and Totalizers.

• Function block 1 Operati on contains a subset of options from funct io n block 3, Installation.

The options in function block 1 are selected so that the most commonly used functions can be

selected quickly from this menu. In most cases only function block 1 needs to be accessed in

order to perform the required setting or programming task.

• Fu nction block 2 Test con t ai ns al l av aila ble tes t fu n c tions. This blo ck can be acces sed to

check prop er fu ncti oning off all converte r ha rd- and s oftware.

• Fu nction block 3 Installa tion c ontains all oth er set- up par ameters for the co n ver ter. In general

the con v erter is fa ct ory -preset. Experi enc ed users can make modi f i cations here.

• Functi on block 4 Param eter Error becomes act iv e automatically when non-pla usi bl e values

ha ve b een progr a m me d, e.g. a too high a flow rate in too small a di ameter. If this i s th e case

menu 4 will indicate that either FULL SCALE or METER SIZE needs to be changed.

The figur e bel o w sho ws the main operatio n str ucture of the conver ter. The curs or or fl as hi ng par t

of the displ ay is sho wn as und erlined text. Fo r a complete overvi ew of the menu and detailed

descri pt i on of all functi ons see paragrap h 4.2 and chapter 5 of thi s handbook.

Measuring

Measuring

mode

mode

Error/

Error/

Totalizer reset

Totalizer reset

mode

mode

Parameter

Parameter

setting

setting

mode

mode

Parameter

Parameter

error

error

mode

mode

Data acceptance

Data acceptance

Main menu level

Main menu level

Submenu level

level

level

(only appears

(only appears

after change

after change

of data)

of data)

START

START

Submenu level

Function level

Function level

100.0

m3/hr

Parameter

check

CODE 1

---------

CODE 2

--

Fct. 0.00.01

VIEW ERR

9 x

Fct. 1.00.00

STORE YES

Fct. 1.00.00

STOR E NO

Fct. 1.00.00

RETURN

Fct. 1.00.00

OPERATION

Fct. 1.01.00

FLOW

Fct. 1.01.01

FULL SCALE

Fct. 4.00.00

STOR E Y ES

Fct. 4.00.00

STORE NO

Fct. 4.00.00

RETURN

Fct. 4.00.00

PARAM ERR

Fct. 4.0 1.00

FLOW VELOC

Fct. 4.01.01

FU LL SCALE

Data level

Data level

Error

messages

1.0000E+2

m3/hr

1.0000E+2

m3/hr

UFM 3030 19

Page 20

Use up arrow to advance. Displayed value direct

ly present a t

Key Measuring mode Menu mode Data level

→

Go to the parameter setting mode,

function 1.00.00 OPERATION. If acc ess

CODE 1 is activated, CODE 1 must be

entered first. Using function 3.07.02

Go to the next, lower

menu level.

Go to the next

character or change

li n e (only when 2 lines

are displayed)

access CODE 1 can be activated or

deactivated.

↵

Go to the error/Totalizer reset mode (via

"COD E 2")

Re tur n to th e pre vious

(higher) menu lev el or

Accept entered value

leave the menu mode.

↑

Cycle th ro ugh measured val ues, see

Function 3.03.07 CYCL DISP

Cycle through menu

option s within actual

menu level.

Cycl e active digit up to

new values

Function Text Description and settings

0.00.00 ERROR/ TOT Main m enu 0.00. 00 Error/Total izer

0.00.0 1 VIE W ERR View error messa ge s list

0.00.02 RST ERR Reset err or messages

NO RES ET (keep error mes sages list)

RESET (reset err or messages list)

0.00.03 RST TOTAL Reset Totali zer ( opti on avail abl e depending on setti ng in

3.7.8) RE SET ALL (reset all Total i zer values)

NO RES ET (keep Totaliz er values )

1.00.00 OPERAT IO N Main m enu 1.00. 00 Opera tion

1. 01.00 FL OW Submenu 1.0 1.00 Flow

1.01.01 FULL SCALE Full-scale value for 100% volume flow rate, see Function

3.01.01

1.01.02 ZERO VALUE Zero value, s ee Fun c tion 3.01.02

1.01.03 ZERO CAL Zero calibr ation, see Function 3.01.03

1.01.04 MASTER TC Master t ime constant, s ee Function 3.01.0 4

1.01.05 LF CUTOFF Low-flow cut- off, see Functio n 3. 01.05

1.01.06 CUTOFF ON Cut-off active, see Function 3.01.06

1.01.07 CUTOFF OFF Cut-of f de- active, see Func tion 3.01.07

1.02.00 DISPLAY Submenu 1.02.00 Display

1.02.01 DISP FLOW Display of flow, see Function 3.03.01

1.02.02 DISP TOTAL Function of Totalizer, see Function 3.03.02

1.02.03 TOTAL VOL Display of Totalizer, see Function 3.03.04

1. 03.00 PULSE OUTP Submenu 1.03.00 Pu l se o utput

1.03.01 PULSE RATE Pulse fr equency value f or 100 % scale, See Func t i on 3. 05.08

1.03.02 PULSE/UNIT Pulse value per volume flow unit, see Func tion 3.05.0 9

1.03.03 PULSE/UNIT Pulse value per energy unit, see fun ction 3.05.1 0

2.00.00 TEST Main menu 2.00.00 Test functions

2.01.00 DISPLAY Submenu 2.01.00 Display

2.01.01 DISPLAY

Test display, lights all pixels. End with ↵ key

2. 02.00 OU TPUTS Submenu 2.0 2.00 Ou tpu ts

2.02.01 CURRENT Test current output

0 mA 4 mA

12 mA 20 mA

22 mA

curr ent output. Actual value present at output after pressing ↵

20 UFM 3030

Page 21

Zero cal i br at i on (s ee Function 1. 01.03)

key.

2.02.02 PULSE Test pulse/frequency output

1 Hz 10 Hz

100 Hz 1000 Hz

2000 Hz

Use the up arrow to adv ance. Display ed v al ue dir ec tly

present at pulse output. Actual valu e present a t o utput after

pressing ↵ ke y

2.03.00 INPUTS Submenu 2.03.00 Inputs

2.03.01 AN INP 1 Test analog input 1

Measure cu r r ent at an alog input 1.

End wit h ↵ key.

2.03.02 AN INP 2 Test analog input 2

Measure cu r r ent at an alog input 2.

End wit h ↵ key.

2.03.03 DIG INPUT Test digital input

Measure level at digital input.

End wit h ↵ key.

2.03.04 SENSOR

Sensor st atus, per sensor (6 statuses in total) : g oo d, op en,

short

Sensor coding:

X.X = path.sensor

Path 1 = lower path, path 2 = middle path, path 3 = upper

path.

X.1: up stream sensor

X.2: do wn str eam s ens or

2.04.00 DEV INFO Submenu 2.04.00 Device information

2.04.01 MANUFACT Display manufacturer

2.04.02 MODEL NO Display model number

2.04.03 SERIAL NO Displa y ser i al num ber

2.04.04 UP2 HW NO Dis play µP2 hardware number

2.04.05 UP2 SW NO Display µP2 soft war e numb er

2.04.06 FRNT HW NO Di s play front end hard war e numb er

2.04.07 DSP HW NO Display D.S. P. har dware number

2.04.08 DSP SW NO Di s play D.S.P. software number

2.04.09 TIME COUNT Display time counter

3.00.00 INSTALL Main menu 3.00.00 Installation

3.01.00 FLOW Submenu 3.01.00 Volume flow parameters

3.01.01 FULL SCALE Full-scale value for 100% volume and flow rate unit s (see

Fu nction 1.01 .01). The sel ection of uni ts m ay be lim ited to SI

units only.

m3/s, m3/min, m3/hr, L/s, L/min, L/hr,

US.Gal/s, US.Gal/min, US.Gal/hr, bbls/hr, bbls/day,

********** (free user configurable unit).

3.01.02 ZERO VALUE Zero value (see Functi on 1.01.02)

FIXED (fact ory zero set ting)

MEASURED (zero c a libration possible, see Funct i on 3.01.03)

3.01.03 ZERO CAL

Carry out only at “zero” flow and with complet ely filled

UFM 3030 21

Page 22

meas uri ng tub e. Du rat io n appro x i ma tely 15s w i th dis pla y

indi cati ng "B USY " . STORE NO (preserve old ze ro val ue)

STORE YES (st o r e n ew zero va lue)

3.01.04 MASTER TC Master t ime constant of dis pl ay an d cur r ent out put (see

Function 1.01.04)

Range: 0.02 through 99. 99 s

3.01.05 LF CUTOFF Low-flow cut- off for display an d out puts (s ee 1.01.05)

NO ( fi x ed tr ip ping points : ON = 0.1%, OFF = 0.2%)

YES (see Function 3.01.06 and 3.01.07)

3.01.06 CUTOFF ON Cut off “active” value

Range: 1 thro ugh 19% of Q100%

3.01.07 CUTOFF OFF Cut off “de-active” value

Range: 2 thro ugh 20% of Q100%

Value "o ff " m ust be gr e ater than val ue "on"

3.01.08 METER SIZE Meter size

Se l ection of size from meter size table :

25-3000 mm equivalent t o 1-12 0 inc h

3.01.09 GK VALUE Flow se nsor constant (GK)

Must equal flow sensor nam eplat e v alu e

Range: 0.02 through 20

3.01.10 FLOW DIR Definition of forward flow direction

POSITIVE

NEGATI V E

Setting in accordance with direction of arrow on flow sensor

3.01.11 MIN VOS Minimum veloci ty of sound (VOS)

Value used for I0% or P0% when function "VOS" selected in

Function 3.04.01 or 3.05. 01

Unit: m/s or feet/s

Range: 0 thr ough 4999 m/ s (0 through 15000 feet/s)

3.01.12 MAX VOS Maximum v eloc ity of sound

Value us ed for I100% or P100% when functi on " VOS"

selec ted in Function 3.04.01 or 3.0 5.01

Unit: m/s or feet/s

Range:1 through 4999 m/s (0 through 15000 feet/ s)

Maximum value must be greater than minimum value

3. 02.00 VER SION Su bmenu 3.0 2.00 Versio n

3.02.01 FUNCTIO N Function of convert er

This is factory pre-set and can only be changed to standard

from any setting. MODIS setting can not be altered.

STANDARD

CORR T (t emperature cor rection via input 1, see also

Function 3.02.08 throu gh 3. 02 .11)

CORR T+ P (temperature correction via input 1, pressure

corr ec tion via input 2, s ee also Func tion 3.02.08 through

3.02.11)

HEAT (heat measurement, see function 3.02.12)

BATCH (batch volume, see Function 3.02.13)

MODIS

3.02.02 INP1 4 mA 4 mA Reference for analog input 1

4 mA Temperature reference

Unit: Celsius or Fahrenheit

Range: - 5 0° through 150°C

3.02.03 INP1 20 mA 20 mA Reference fo r analog input 1

20 mA Temperature reference

22 UFM 3030

Page 23

Unit: Celsius or Fahrenheit

Range: - 5 0° through 150°C

3.02.04 INP2 4 mA 4 mA Reference for ana log input 2

4 mA Temperature reference

Unit: Celsius or Fahrenheit

Range: - 5 0° through 150°C

3.0205 INP2 20 mA 20 mA Reference for analog input 2

20 mA Temperature reference

Unit: Celsius or Fahrenheit

Range: - 5 0° through 150°C

3.02.06 INP2 4 mA 4 mA Reference for ana log input 2

4 mA Pressur e r eferenc e

Unit: bar(a) or psi(a)

Ra n ge: 0 t hro u gh 1 00 Bar(a)

3.02.07 INP2 20 mA 20 mA Reference for analog input 2

20 mA Pressure referen ce

Unit: bar(a) or psi(a)

Ra n ge: 0 t hro u gh 1 00 Bar(a)

3.02.08 K0 Product constant K0

Range: 10-9 through 109

3.02.09 K1 Product constant K1

Range: : 10-9 through 109

3.02.10 K2 Product constant K2

Range: : 10-9 through 109

3.02.11 DENSITY 15

Produ ct density at T = 15°C

Range: 500 through 2000 kg/m3

3.02.12 FULL SCALE Heat measurement

Full scale setting and unit f or Heat power.

GJ/s, GJ/hr, MJ/s, MJ/hr, GCal/s, GCal/hr, MCal/s, M Cal/hr

3.02.13 BATCH VOL Batch volum e Total size and units.

m3, Lit er , US . Gall on, B arrel or user definable unit

Range: 0.025 through 100000 m3

3.03.00 DISPLAY Submenu 3.03.00 Displ ay (s ee Func tion 1.02. 01)

3.03.01 DISP FLOW Display of flow

RATE (f ull-scale units)

Percent ( percenta ge of ful l- s c ale, 0% - 100%)

NO DISPLAY (n o flow display)

3.03.02 FUNCT TOT Functi on of Totalizer

ACT FLOW (actual flow units)

CORR FLOW (corrected flow unit s )

POS BOTH (bot h, onl y forwa r d)

3.03.03 DISP TOTAL Display of Totalizer (see Function 1.02.02)

A Totali zer c an be sel ect ed her e f o r dis pl aying. Avail a ble options

are TOTAL OFF, FORW ARD, REVERSE, BOTH, SUM, BOTH +

SUM, NO DISPLAY

3.03.04 TOTAL VOL Unit for volum e Totalizer

X10 m3, US.Gallon, m3, Barrel, liter

3.03.05 TOTAL ENER Unit for energy Totali zer

X 10 GJ, GJ, MJ, GCal, MCal

3.03.06 VOS Unit for Velocity Of Sound

NO DISPLAY, m/s, feet/s

3.03.07 CYCL DISP Cyclic display of measured values

NO, YES

UFM 3030 23

Page 24

3.03.08 ERROR MSG Displ ay er r o r m es sages

NO, YES

3.03.09 DATE Display date

NO, YES

3.03.10 AN INPUT Display analog inputs

NO, YES

3.03.11 SIGN LEVEL Display signal level

NO, YES

3.04.00 CURR OUTP Submenu 3.04.0 0 Current output

3.04.01 FUNCTION Function of current output

OFF (switched off)

ACT FLOW (actual flow)

CORR FLOW (corrected flow), see Function 3.0 2.02 and 3.02.08

throu gh 3.02.11

F/R IND (for war d/rev erse indi ca tion of actua l flow)

VOS (vel ocity of sound, rang e is defined in Function 3.01.11 and

3.01.12)

GAIN (sensor signal gain, range is 0 dBV through 100 dBV)

AN INP 1 (analog input 1)

AN INP 2 (analog input 2)

3.04.02 DIRECTIO N Directi on of current output

FORWARD (forward flow measurement)

BOTH (forward and reverse flow measurement indicating both in

the same range)

F/R SPEC (forward and reverse flow measur ement indicated in

different range see Func tion 3.04. 04)

3.04.03 RANGE Range of current output

OTHER (user def ined, see Functi on 3.04.04 thr ough 3.04.06)

0-20/2 2 mA (0 pct - 100 pct / limit )

4-20/2 2 mA(0 pct - 100 pct / lim it )

3.04.04 0 pct Current v al u e f or 0% scale

Range: 0 through 16 mA

3.04.05 100 pct Current value for 100% scale

Range: 4 through 20 mA

Value must be at least 4 mA greater than current value for 0%

scale

3.04.06 LIMIT Limitation of current value

Range: 20 thr ough 22 mA

3.04.07 ERR INDIC IERR = 3.6 MA

IERR = 21.5 MA

(only available for NAMUR devices)

3.05.00 PULSE OUTP Submenu 3.05.00 Pulse output

3.05.01 FUNCTION F un c t i on of pul s e out put

OFF (switched off)

ACT FLOW (actual flow)

CORR FLOW (corrected flow), see Function 3.0 2.01 and 3.02.08

throu gh 3.02.11

F/R IND (f orward/reverse flow indication)

VOS (vel ocity of sound, rang e defined in Functio n 3.01.11 and

3.01.12)

DIG OUTPUT (digital outpu t, see Func tion 3.05.03)

BATCH OUTP (batch output indication, see Function 3.02.01)

GAIN (sensor signal gain, range is 0 dBV through 100 dBV)

AN INP 1 (analog input 1)

AN INP 2 (analog input 2)

24 UFM 3030

Page 25

3.05.02 DIRECTIO N Directi on of pulse output

FORWARD (forward flow measurement)

BOTH (forward and reverse flow measurement indicating both in

the same range)

3.05.03 DIG OUTPUT Function of digit al output

PATH E RR (measu r in g path er ror in dicat i on)

TOTAL ERR (Totali ze r error i n dicat ion)

ALL ER R (indication of all er ro rs)

AN INP ERR (analog input error indication

OVERRANGE (overrange indication)

TRIP POINT ( tr ips when ac tu al fl ow (Q) goes over a set limit)

3.05.04 TRIP PNT 1 First trip point

Range: 0 thro ugh 120% of Q100%

3.05.05 TRIP PNT 2 Second trip point

Ra n ge: 0 t hro u gh 1 20 % of Q10 0%

3.05.06 TIME CONST Time const ant of pulse output

25 ms

MASTER TC (see Function 3.01.04)

3.05.07 OUTPUT Un i t of pulse output (see Func tion 1.03.00)

PULSE FREQUENCY, pulses per unit time, see Function

3.05.08)

PULSE/UNIT, Totali zer pulse output, pulses per unit volume, see

Function 3.05.09

3.05.08 PULSE RATE Pulse rate (frequency) value for 100 % scale

pulse/s, pulse/h r, pulse/min

Range: 1 puls e/hr throug h 2000 pulse/s

3.05.09 PULSE/UNIT Pu lse valu e per volume unit for totali s at ion

pulse/m3, pulse/l , pulse/US.G al , pul s e/ bbl,

free user def inabl e unit

3.05.10 PULSE/UNIT Pu lse valu e per h eat energy uni t fo r t ot alis a t i on

Puls e/M J, pulse/Gc al, puls e/Mcal, p ulse/G J

3.05.11 PULS WIDTH

Pulse width for frequencies ≤ 10 Hz

25 ms, 50 ms, 100 ms, 200 ms, 500 ms

3. 06.00 DIG IN P UT Submenu 3.0 6.00 Digital in put

3.06.01 FUNCTION Functio n of digi tal input

OFF (swit c hed off )

RST TOTAL (r eset display Tot alizer )

RST ERROR ( reset error mess ages)

FORCE ZERO (set outputs to minimum values)

BATCH (start batch)

3. 07.00 USER DA TA Submenu 3.07.00 Us er d ata

3.07.01 LANGUAGE Language for display texts

GB/USA ( English)

D (German)

F (French )

3.07.02 ENTRY CODE Entry code for sett ing mode

NO (entry with key only)

YES (entry with key and code 1, fact ory set on 9 x key, see

Function 3.07.03)

3.07.03 CODE 1 Code 1

Press any 9-keystroke combination and then press the same

combination again. Ea c h keyst r o k e is acknowledged by "Ж" in

the disp lay. If both combinat ions are equal, "CODE OK" appears

and the new cod e can be stored, else "WRO NG CODE" app ear s

and the desi r ed c ode has to be entered again.

UFM 3030 25

Page 26

3.07.04 LOCATION Tag name setting

Free settable tag for identifi cation, maximum 10 characters.

Characters assign able to each place: A.. Z / bla nk char acter / 0..9

Factor y set ting: KROHNE

3.07.05 UNIT TEXT Text for user-defined unit

Definition: volume/time

Characters assign able to each place: A.. Z / bla nk char acter / 0..9

Fraction bar "/" in 5th place is unalterable

Factory set ting: XXXX/YYY

3. 07.06 UNIT VOL User- defined uni t volume

Quantity of user-d efined v olume per m3.

Range: 10-5 through 107

Factor y s etting: 1

3.07.07 UNIT TIME User-defined unit time

Amount of user-defin ed time in seconds

Range: 10-5 through 107

Factor y s etting: 1

3.07.08 RST ENABLE Enable Totalizer reset

NO (Totalizer reset disabled)

YES (Totalizer reset enabled)

3.07.09 ERR LIMIT Error limit in % of measured value for plausibility filter on the

sensor paths.

3.07.10 CNT DECR Counter decrement setting for plausibility filter

3.07.11 CNT LIMIT Counter limit f or pla usi bility fi lter

W hen "0" is set, t he pl au sibility fi lter will bec ome inac ti ve

Range: 0 through 1000

Factor y s etting: 0

3. 09.00 COMMU N IC Su bmenu 3.09. 00 Comm uni c ation

3.09.01 PROTOCOL Communication protocol

OFF (no communicatio n)

HART (HART)

PROFIB PA (PRO FIBUS P A)

3.09.02 HART ADDR HART address

Range: 00 thr ough 16

3.09.03 PP/FF ADDR PROF IBUS PA/FOUNDATION Fi el dbus address

Range: 00 0 t hro ugh 1 26

4.00.00 PARAM ERR Mai n menu 4.00.00 Parameter error

4. 01.00 FLOW VELOC Volume flow vel ocit y ( v) v alue in co r rect. The flo w sp eed i s

calculated from the full scale volume flow and the meter size.

Ensure condition 0.5 m/s ≤ v ≤ 20 m/s (1,5 to 66 feet/s) is met!

4.01.01 FULL SCALE Full-scale value for 100% volume flow rate, see Function 3.01.01

4.01.02 METER SIZE Meter size, see Functi on 3.01.08

4.02.00 CURR OUTP Cur r ent output range i nco rrect. Setti n g for 100% is c om par ed

with setting for 0%. Ensure condition 100 pct-0 pct ≥ 4 mA is met!

4.02.01 RANGE Range of curr ent output, see Function 3.04.03

4.02.02 0 pct Current value for 0% scale, see Function 3.04.04

4.02.03 100 pct Current value for 100% scale, see Function 3.04.05

4.03.00 LF CU TOFF Low-flow cut-off range incorrect: If low flow cut-off is set to on ,

the value for CUTOFF-OFF is compared with the value of

CUTOFF-ON on.

Ensure condition CUTOFF-OFF – CUTOFF-ON ≥ 1% is met!

4.03.01 LF CUTOFF Low-flow cut-off, see Function 3.01.05

4.03.02 CUTOFF ON Cutoff “on” value, see Function 3.01.06

26 UFM 3030

Page 27

4.03.03 CUTOFF OFF Cutoff “ off” value, see Function 3.01.07

4.04.00 ENERGY Full scal e value for heat energy rate (E) incorrect. The fullscale

value is compared with the maximum value that can be

meas ured and should meet th e condition: Emax < E f ullscale <

Emax/1 000

The maximum value that can be measured is at maximum flow

and 200 ° C temperat u r e dif ference.

4.04.01 HEAT FS Full-scale value for 10 0 % heat energy rate, see Function 3.02.1 2

4.05.00 PULSE/VOS Unit of pulse out put f or vel oc ity of sound function incorr ect

Ensure "PULSE RATE" is selected for "VOS"!

4.05.01 PULS FUNCT Function of pulse output, see Function 3.05.01

4.05.02 PULSE OUTP Unit of pulse output, see Function 3. 05.07

4. 06.00 VO S Veloc ity of s ound rang e incorrect:

Ensure co n di t ion MAX VOS − MIN VOS ≥ 1 m/ s (3.3 feet/se c ) is

met!

4.06.01 MIN VOS Minimum velocit y of sound, see Function 3.01.11

4.06.02 MAX VOS Maximum velocity of sound, see Function 3.01.12

4.07.00 PULSE OUTP Pulse output frequency value (f) incorrect. The max frequency is

calcul a ted fro m th e pulse /unit setting and the ma x value of th e

measur ed v alue.

Ensu re condition 1 pulse/ hr ≤ f ≤ 2000 pu ls e/s is met.

4.07.01 PULSE/UNIT Pu lse valu e for vol ume flow rate unit, see Fun c tion 3.05.09

4.07.02 PULSE/UNI T Pulse value for heat power rate unit, see Function 3.05.10

4.08.00 PULS WIDTH Puls e out p ut pul s e widt h in c orrect

Ensu re condition pulse width ≤ 0.5 x pulse period time is met.

4.08.01 PULS WIDTH

Pulse width for frequencies ≤ 10 Hz, see Function 3.05.11

4.09.00 HART Current output ra nge for HART incorr ect. If Hart is activated the

minimum possible current should be 4 mA.

Ensur e co ndition CURR 0 pct ≥ 4 mA is met.

4.09.01 CURR

Range of current output, see Function 3.04.03

RANGE

4.09.02 CURR 0 pct Current v alue for 0% scale, see Funct io n 3.04.04

4.10.00 INP/O UT P The di gital input ( C) and current output (I) are not allowed to be

switched on simultan eous ly . If t he Pro fibus option is a ctiv at ed

only one of the following input/output functions can be used:

digit al input (C), cur r ent output (I), puls e out put (P ). The current

output is deactiv ated by s etting the function of current output to

of f en set ting the range of c urrent output t o 0-20mA.

4.10.01 INP FUNCT Func tion of digit al input, see Functi on 3. 06.01

4.10.02 CURR FUNCT Funct i on of current output, see Functi on 3.04.01

4.10.03 CURR

Ra n ge of cu rr ent output, s e e Function 3.04.03

RANGE

4.10.04 PULS FUNCT Range of pulse output, see Funct ion 3.05.01

4.13.00 EPROM EPROM checksum error, reset device.

UFM 3030 27

Page 28

Measuri ng t u be not completely

filled,

6 Description of functions

6.1 Menu structure

In thi s chapt er the differ ent functions of the m enu st ru c tur e are descr ibed In mo re d epth. Since t he

UFC 030 co n verter can be e q uipp ed with dif feren t options , t he availabil ity of certain opt ion s

depends on the function of the converter (see 3.02.01).

Main menu 0.00.00 Error/Totalizer

This m enu is accessible from the m easur ing mode by pressing the ↵ key and entering "CODE 2"

(↑→).

Dependin g on the programming of Funct ion 3.03.08 ERRO R MSG, err or s occ ur ri n g duri ng process

flow measurement are represented with flashing display lines and/or a compass field. Depending

on the pro g ramming of Fu ncti on 3. 03. 07 CYCL DIS P , th e error mess a ges alter nate with th e display

of the measur ed v alu e( s ) every 5 seconds, or they c an be manua lly selected b y pres si ng the ↑ key.

1. Flash ing line with number o f err or s that have occurred.

2. Flash ing line with d escri ption of error message(s).

3. Flashi ng bar, i ndicati ng "new" erro r s, n ot yet

acknowledged.

4. Compass field , indicat ing mea s urin g p ath er r or(s) :

Indication of measuring path er r ors:

1, 2, 3: for m eas ur ing path 1,2 and 3, open or short ed sensor no measured val ue from

path.

4. Noi s e err or , to much noise on measurin g path ( s). Flow meter functi ons outside

specification

The following list giv es an alphabetical ov er vi ew o f err or m essages t h at can occur during pro c ess

flow m easur em ent and what to do. The error mes s ages onl y appear when Functio n 3.03.08

ERROR MSG is YES.

Error

message

ADC AN INP Analog input internal error, A1 or A2 Switch off and on the flow meter. If the

COMMUNIC Communication device internal error Reset the error, wait for one minute. If

CURR > MAX Cur r ent outp ut ov erflow (> 22 mA) Check flow velocity

DSP Dig ital signal processor (DSP) intern al

EE MENU Menu parameters corrupted Contact KROHNE representative

EE SERVICE Service parameters internal error Contact KROHNE repr esentative

EMPTY PIPE

Descri pti on of erro r m essage What to do

error stil l exis ts, contac t KROH NE

representative

th e error re-a p pea r s, c ontact K ROHNE

representative

Only checked at power-up. Switch off

error

and on the flow m eter. If the err or still

ex ists, contact KR OHNE re p rese n tative

Fill mea suring tub e com pletel y

28 UFM 3030

Page 29

flowreading to 0, erro r o n all 3 pa ths.

FLOW > MAX Measuring ra nge overflow (flo w > 2 x

Check flow velocity

Qmax)

FRONT END Front end internal error Only checked at power-up. Switch off

and on the flow meter. If the err or sti ll

exists, contact KROHNE representative

INP1 < MIN Anal og input 1 too low (< 3.6 mA) Check analog input 1 connec tion

INP1 > MAX Analog input 1 too high (> 22 mA) Reduc e analog input 1 current

INP2 < MIN Anal og input 2 too low (< 3.6 mA) Check analog input 2 connec tion

INP2 > MAX Analog input 2 too high (> 22 mA) Reduc e analog input 2 current

RE S T A R T F lo w meter restart ed R eset errors

UNRELIABLE Flow data disturbed, same as right

Check flow conditions

comp ass f ield ( 4 )

OPEN CIRC Sensor X.X not conn ect ed or defect

(combin ed with "SENSOR X.X"

message).

Check con nec tion sensor X.X.

For sensor numbering: see description

test function 2.03 .04.

PATH 1 Measuring path 1 error Check flow conditions

PATH 2 Measuring path 2 error Check flow conditions

PATH 3 Measuring path 3 error Check flow conditions

PULS > M AX Pu ls e output ov erflo w (> 120 %) Check flow velocit y

SENSO R X.X Sensor X. X er ror

(combin ed with "OPEN CIRC" or

Check con nec tion sensor X.X.

"SHORT CIRC" mes s ag e)

SHORT CI R C Sensor X.X short -circuited

Check con nec tion sensor X.X

(combin ed with "SENSOR X.X"

message)

TIME/DATE Real time clock internal error Not available, reserved for future use.

TOT > DISP Totalizer out of display r ange

Reset Totalizer or cha nge Tot ali zer unit

(maximum 8 characters)

TOT CHKSUM Totalizer corrupted Reset Totalizer

UP2 µP2 int ern al error Contact KRO HNE serv ic e

Function 0.00.01 through 0.00.02 View error messages list/Reset error messages

All occurred error m essages are stored in an err or messages list an d can be viewed usi ng Function

0. 00.01 VIEW ER R. T he mes sa ges a re kept in this list u nti l the ca u se o f the errors h as b een

removed and the er r or messages have been reset using Functio n 0.00.02 RST ER R. Er r or s tha t

have been reset, but whose caus e has no t been rem ov ed, are kept in the list but a r e dis played

wi thout bar . This allow s i dentification of previousl y ackn owl edged and una cknowled ged errors.

Function 0.00.03 Reset Totalizer

Reset display Totalizer(s). Only available when Function 3.07.08 RST ENABLE is YES. Note that

all Totalizer values are r eset.

Main menu 1.00.00 Operation

The functions in this m enu are a subset of Mai n menu 3.00.00 Inst allati on, and ar e sel ected in this

menu as most commonly used functions for a quick installation. Note that parameters set in these

functions are automatically set in both menus.

Main menu 2.00.00 Test functions

This menu is for tes ting the disp lay, the i n- an d ou tputs and for i nformat ion on hard- and so ft w ar e

numbers. See chapter 7.1 on functional checks.

UFM 3030 29

Page 30

Main menu 3.00.00 Installat io n

Subm enu 3.01.00 Volume flow parameters

Function 3.01.01 Full-scale value for 100% volume flow rate

The following unit s can be applied:

m3/s - cubic metre per second

m3/min- cubic metre per minute

m3/hr- cubic metre per hour

L/s - lit er per second

L/mi n -liter per minut e

L/hr -liter per hour

US.Gal/s - US gallons per second

US.Gal/min - US gallons per minute

US.Gal/hr - US gallons per hour

bbls/hr - barrels per hour

bbls/day - barrels per day

free unit, a user-definable unit, which can be

defined usi ng Function 3. 0 7. 05 to 3.07. 0 7.

Range depends on diameter (DN) and volume flow velocity (v):

Qmin) [m3/ h] = 0,9 x DN² (vmin = 0.5 m/s)

Qmax [m3/h ] = 31,25 x DN² (vma x = 20 m/s)

Qmin [US GPM]= 3,9 x DN² (vmin = 1.5 feet /s)

Qmax [US GPM] = 138 x DN² (vmax = 20 m/s)

Function 3.01.02 through 3.01.03 Zero value / Zero calibration

Althou gh zero calibra ted at t he fa cto ry the flow sensor might still give an offset fl ow readi ng, at

"zero" flow in the pipeline (measuring tube completely filled with medium. Function 3.01.02 ZERO

VALUE can be used for zero c alibration. It can be set to either FI XED, whic h will give a factory zero

setting, or MEASURED, which wil l allow to compensate for the small signal using Function 3.01.03

ZERO CAL.

Function 3.01.04 Master time constant of display and outputs

This is the time that it takes for th e disp la y and th e curr ent and pulse outputs to reach 66% of the

end value, a ft er a chang e in th e flow ra te. The time consta nt does n ot ap ply for totalisat i on. The

time constant does not apply for the current output in F/R setting.

If r equired , a diff eren t time constant va lue can be set f o r the pu ls e / fr equency output under Function

3.05.0 6 TIME CONS T .

Function 3.01.05 through 3.01.07 Low-flow cut off for display and outputs / Cut off "on"

value/ Cut off "off" value

Due to the extrem e low flow sensitivi ty of the UFM 3030, it will d et ect the slightest mo v em ent o f

fluid, even at zero flow. To avoid these measurements causing outputs and Totalizer changes, the

lo w flow c ut- off can b e us ed to fo r ce read ing to z ero . Th ese a re se t a s a p ercenta ge of Full Sc a le,

as configured in Fct.1. 01.01 or 3.01.01.

When the fl ow rate decreases belo w the "on " v alue, the display an d out puts are set to their "zero"

values. Wh en th e f lo w increas es a b ove h e "off" value, mea surem ents ar e res umed. The " o ff " value

must be larger than the "on" value by at least 1%. With Function 3.01.05 LF CUTOFF set t o NO,

factory settings ar e used for the "on" and "off" v alu es.

Function 3.01.08 Meter size

The nominal diameter of the meas urin g tube. See the flow sens or nameplate. Thi s valu e can be

entered In mm or in inches.

Function 3.01.09 Flow sensor c onstant GK

At the factory, each flow sensor is calibrated and supplied with a cal ibration constant. This constant

can be found on th e flow sens or nameplate.

30 UFM 3030

Page 31

Function 3.01.10 Definition of for wa r d flow direction

The forward flow direction is indicated with an arrow on the flow sensor. If the actual flow is in the

direction of the arrow t hen the fl o w is in the positive direction and the conv erter will have a positive

flow reading. By setting this function to NEGATIVE, the converter's reading can be reversed. This

can be useful when the process flo w di r ection is chang ed so the flow sens o r will not need to be

reversed.

Function 3.01.11 through 3.01.12 Minimum/Maximum velocity of sound

In media of v arying composit ion , the ultrasonic wave sp eed will var y , lik e in oil-water mixtures. This

is identi f i able by means of measuri n g t he v eloc ity of sound. The curr ent output and the puls e output

can be program med to indicat e t he vel ocit y of s ound, see Functi on 3.04.01 and 3.05.01. Their

"zero " va lues (0% scale) will then correspond w it h th e velocity of sound set i n Fun c ti on 3.0 1.11 MIN

VOS, wher e their "full-scale" va lu es (100% scale) will correspond with the velocity of sou nd set in

Function 3.01.12 MAX VO S. See also F unc tion 3.03.06 VO S for the di splay of the velo city of

sound. NOTE: Only necessary for setting span for outputting VOS, is not needed to measure flow!

Submenu 3.02.00 Version

Function 3.02.01 Function of converter

This function is factory pre-set, and can be changed between STANDARD and the appropriate

versi on that is defi n ed in t he c onverter's har dwar e. The followin g versi ons are possibl e:

STANDARD, standard functi o nality

CORR T version wit h tem per ature correction of the measured fl o w, usi n g analog input 1

CORR T+P versi on with temperature- and pressure co rr ec tion of the measured flow, usin g analog

inputs 1 and 2

HEAT version, reserved f or m easurement of heat power and heat energy totalis ation.

BATCH versi on for batch volumes.

The batch function can be used for repetitive dosing of a fixed volume. It provides sim ple single

stag e batchi ng. A batch volum e can be set using FUNCTION 3.2.13. The digital input is used to

start a batch, see FUNTION 3.6.1. T he digi tal output i s used to in dic ate th at the se t batch vo lume

has been reach ed, see Function 3.5.1. The forw ard flo w Tot ali zer counts th e actual batch volum e

and is reset at th e start of every new bat c h. The r everse flow Totali zer c ounts the total of all

batches.

The following tabl e giv es an over vi ew of the ad dit i onal featu r es of each vers ion, in compari s on with

th e stand ard version.

Remark: with every change from a con v erter f un ction to STANDARD, the Tot alizer is switched off .

See function 3.03.03 to set the Totalizer

UFM 3030 31

Page 32

Converter

Menu Function

Function

Flow dis pla y (Fun c t ion

3.03.01)

CORR T CORR T+P BATCH

Additional corr ec ted volum e flow indica tion

Totalizer display ( see

Function 3.03.02 through

3.03.05)

Correc ted volum e

flow totalizer

indication

Autom ati c v olume fl o w

Totalizer and batch

Totalizer indication

Selectable

Current output function (see

Function 3.04.01)

Pulse output function (s ee

Output s pro por t i onal with corrected volum e

Used as digi tal input

flow

Selectable Indicate end batch

Function 3.05.01)

Analog input 1 (see Function

Temp e rat ur e corre ction

3.02.02 through 3.02.03)

Analog input 2 (see Function

Pressure correction

3.02.02 through 3.02.07)

Di gital in put (s ee Funct ion

Start/Stop batch

3.06.01)

Note: Depending on the progr amm i ng of Fun ction 3.03.0 7 CYCL DIS P, th e addi tional or select a ble

indicat ions can be manuall y s elected by pressi ng the ↑ key, or th ey a re al ternating w ith the displa y

of the measured value(s). The corrected volume flow indication or volume flow Totalizer indication is

mark ed wi th the l e tt e r "C" at th e lef t of th e dis play 2 n d (middle) line. The batch Tot a lizer indica tio n is

marked with the letter "B".

Function 3.02.02 through 3.02.07 4/20 mA Reference for analog input 1/2

These func tions are available depending on the version (see Funct ion 3.02.0 1). The an alog inputs

are su ppl ied wi t h the 4-20 m A cur ren t ra ng e sig nal coming fr om th e t emperatur e - and p ressure

tran sducers. The ir 4 m A a nd 2 0 mA values rep res ent a cer tai n t emp erature- or pres sure v alu e,

which must be defined in these functions.

Function 3.02.08 through 3.02.11 Product constant K0/K1/K2 /Product density at T = 15 °C

Calcula tion of the corrected volume.

Only available for the CORR T or CORR T + P version (see Funct i on 3.02.01).

One of the features of the 3-beam ultr asonic fl ow meter is the capabil ity of calcul ating t h e cor r ec t ed

volume. Cor rect ed v olume calcu lation can be car r ied out either b ase d on temperat u re

comp ens ation or ba sed on temperat u re and pres su re compensat io n .

The corrected volume is calculat ed to stan da rd co ndi tions defin ed as 15 ° C and, if a ppli c able,

1. 01325 Bara. For this pu r pose t he a nalog i nputs a re set to co n nec t a temperat ur e transm it ter and a

pressure tra n smi tt er. F or accura te c alculat i ons it is ad v is ed to cal ibrate t he indivi d ual P and T

instruments.

The corrected volume i s calcu la ted from the following formu la:

Vcor rected = Vact ual * VCF

Vcorrected = calculat ed c or r ect ed v olume at standard c on dit io ns i.e. 15°C and 1.01 325 bara

Vactual = actual volume measured by the 3-beam flow meter

VCF = Volum e Correction Factor and is calc ulated from [Ctl x Cpl]

32 UFM 3030

Page 33

The calculation of the Vol ume Correction F act or is based o n the st a ndards of the Americ an

Petroleum Institu te (API), and consi sts of two individual correction factors : chapter 11.1 standard

2540 for calculating the temperat ure correction (Ctl ) a nd chapter 11.2.1 M for calcul at i ng the

pressure correction (Cpl).

The correction for the influence of temperature on liquid (Ctl) is calculated from:

Ctl = EXP [-αt (Tactual - 15) * ( 1 + 0.8 αt (Tactual – 15))]

Tactu al = act ual liquid temperature [°C]

αt = th er mal expan sion coeff i ci ent

The therm al expans i on coeffic ient αt is calculated from the standard d ensity at 15° C a nd thr ee

constant s of the m eas ured pr od uct (K0, K1 and K2).

αt = K0/ρ152 + K1/ρ15 +K2

Product

Density range (kg/m3)

ρ15 at 15 °C

K0 K1 K2

Crude 610.5 1075.0 613.9723 0 0

Gasoline 653.0 770.0 346.4228 0.4388 0

Transition

770.5 787.5 2680.3206 0 -0.00336312

area

Jet group 788.0 838.5 594.5418 0 0

Fuel oil 839.0 1075. 0 186 .9696 0.4862 0

Free fill 500.0 2000.0 0 0 0

As a rule of thumb t he vol ume correctio n factor can be estimated a s 0.1% per degr ee Cels i us .

(0, 055% per degr ee Fah r enh eit)

Cor rection for the in f luence of pres sure on liq uid ( C pl)

When the featu r e has been selected fo r the com pens at i on of the measur ed volume for the influence

of temperature and pressure, no extra parameters have to be programmed for the pressure

corr ection. The calculation of this pr ess u r e correction is only depending on the giv en standard

densit y at 15 ° C. Based on t he dens ity the compress ibility factor is c alc ul at ed fr om the following

mathematical mode l:

F = EXP [-1.62080 + 0.00021592 * tactual + 0.87096/ρ15 *10-6 + 0.0042092 * tactual/ρ15 * 10-6]

Tactu al = act ual liquid temperature [°C]

ρ15 = density at sta ndar d c ondition i. e. at 15 °C [kg/m3]

By using this calculated c ompr ess ibility factor the Correc tion for press ure is calculat ed f r om :

1 Cpl = 1/ 1-F * Pactual*10-4

F = compr essibility factor

Pactual = absolute actual pressure [bar]

As a r ule of thumb the volume correction factor can be estimated as 0.01% per bar (0,00068% per

PSI)

With the fl uid d ens i ty entered and t he c o r rect ed v olume calculate d , t h e corr ected v o lume flow ca n

be displayed as mass f l ow. This can be done as follows:

3.1.1. Set the unit to free user definable unit (**********)

3.7.5. Set the required unit text e.g. kg/hr.

3.7.6. Set the amount of mass per m3 in the unit as displayed e.g. kg.

3. 7.7. Set t he time unit relati ve to s eco n ds e.g. for hour en ter 36 00

UFM 3030 33

Page 34

Function 3.03.01 Display of flow

To displa y the flow, three opti ons are available

Rate; flow is shown with the unit as set in function 3.01.01

Percentage; flow is shown as a percentage of the full scale as set in 3.01.01

No display; no flow is shown.

Function 3.03.02 Function of Totalizer

Two Tot alizers ( count ers) are avai lable . T he Totaliz er val ues are in c remented and s tored once a

sec ond. T he follo wing settin gs for th e function of th e Totalize rs ar e ava i lable .

ACTUAL FLOW; the actual flow is used for counting the total volume in the Totalizer. Two

Totalizers are available, one for each dir ec tion. The sum of the two can als o be dis pl a y ed.

CORRECTED FLOW ; the corrected flow is used for counting the total volume in the Totalizers.

BOTH; Both the actual and the corrected flow are used for counting the total volume in the

Totalizers. Both are only counted in the positive direction

Function 3.03.03 Display of Totalizer

A Totalizer can be selected here for displaying.

FORWARD (forward volume units)

REVERSE (reverse volume units)

BOTH (both, alternating)

SUM ( sum of both)

BOTH + SUM (both and sum)

NO DISPLAY (Totalizers not d is pla y ed, howev er

Totalizers continue counting)

TOTAL OFF (Totalizer switched off, counting is

halted)

Function 3.03.04 Total volum e

Unit for volume Totalizer can b e set in this fun c tion.

Availa ble units: x10 m3, m3, lit er , US.Gallon, Barrel

The max. value of t he T otalizer is 99999999 x10 m3 and will roll ov er to 0 at overr un.

Function 3.03.04 Total energy

Unit for the total heat energy counter.

Availa bl e un its: x10GJ, GJ, MJ, Gcal , Mc al.

The ma x i mum valu e of t he Totalizer is 999999 99 x1 0 GJ and wil l roll over to 0 at overrun.

Function 3.03.06 Unit for velocity of sound

The display of the velocity of sound, as described in Function 3.01.11 through 3.02.12.

The following unit s can be applied:

NO DISPLAY no display of velocity of sound

m/s metre per second

feet/s feet per second m3

Function 3.03.07 Cyclic display of measured values

Whenever more than one measur ed valu e is to be dis played (e.g. Fl ow rate an d Tot alizer), eac h

value can be selected manually by pressing the ↑ key, or the values can be alternately di splayed

each 5 seconds by turni ng the cyclic display function on.. This also includes the display of various

readings as described in Func tion 3.03.08 t hro ug h 3.0 3.11.

Function 3.03.08 Display error m e ssages

Enable/ disable th e dis play of error mess ag es as descr i bed in section 5.1. Wh en ena bl ed, the

converter display will FLASH when an error occurs, and the error code will be di splayed. It will

continue to flash until the alarm is acknowledged or cleared. An unacknowledged alarm will be

displayed with 3 horizo ntal lines in front of the error m essage. Ack n owledging the al arm wil l remove

th e lines . If th e alarm is ackn o wledged but t he caus e is n ot r emo ved the error will stay in the error

list. To remov e t h e error from t he list the cause must be rem oved an d t he error must be reset.

When it is turned off, th e co mp a ss disp la y ind ic ates errors ar e pr esen t, but the di splay w ill no t flas h.

34 UFM 3030

Page 35

Function 3.03.09 Display date

Not available, reserv ed for fu ture use.

Function 3.03.10 Display analog input

Enable/disable the display of the analog inputs.

Only available for conv ert er f un ctions CORR T and CORR T + P (see Function 3.02.01). The

displa y o f the values represented by t he c urr ent signal coming from th e tem perat ur e- and pr essure

transducers. See Function 3.02.02 through 3.02.07.

Function 3.03.11 Display gain

Enable/disable the display of the signal l evel from the sensors. For each measuring path this level is

displayed as a gain value 0 dBV thr ough 80 dBV at the input amplifi er.

Submenu 3.04.00 Curr ent output

Function 3.04.01 Function of current output

The current output can b e programmed for the following functi on s:

• OFF swit c hed off , current output st eady at curr ent value for 0 % scale, see Func tion 3.04.03

ACT FLOW propor tional with the actual volume fl ow, see Funct i on 3.01.0.1 FUL L S CA LE

• CO RR F L OW proporti onal wi th the corrected volume flow, only avai la ble i f t he converter

function is set to CORR T or CORR T + P (see Function 3.02.01)

• F/R IND forward/reverse flow indication, see Function 3.01.10, 100 pct mA value for forward

flow, 0 pct mA value for reverse flow, see Function 3.04.03 through 3.04.05

• VOS proportional with the velocity of sound, see Function 3.01.11 thr ough 3.01.12

• SIGN LEVEL proportional with the signal level, see Function 3.03.11

• AN INP 1 proportional with th e si g nal on analog input 1, see Func tion 3.02.01 , On ly avai l able if

the converter function is set to CORR T or CORR T + P (see Function 3.02.01)

• AN INP 2 proportional with th e si g nal on analog input 2, see Func tion 3.02.0 1. On ly avai l able if

the converter function is set to the CORR T or CORR T + P (see Functi on 3.02.01)

Function 3.04.02 Direction of current output

Only available when ACT FLOW or CORR FLOW is sel ect ed in Fu nct ion 3.04.01. When

FORWARD is select ed, the current output will onl y be active when the flow is in the for war d f lo w

direction as defined in Function 3. 01.10 F LOW DIR, whi le when BOTH is selected, the current

output will be active forward and reverse flow direction. Use F/R SPEC to indicate the reverse flow

in the range from 0 mA through 0 pct m A (see Function 3.04.04 0 pct). I.e. when the flow goes from

th e forwa rd direction to the negativ e direction, the cu rr ent output will pas s th e "0 pct" mA v alu e

down to 0 mA, where it st ops .

UFM 3030 35

Page 36

Abbreviations used:

I Current out put

I0 %Current outp ut at 0 % sc a le

EF F orw ard ener gy flow rate

I100% Current output at 100 % scale

Imax Current output maximum

ER Reverse energy flow rate

When VOS or Signal gain is set, only the f orward

characteristic applies

QR Reverse volume flow rate

Function 3.04.03 Range of current output

The range of the cur r ent output can be set to standard 0-20mA or 4-20 mA or to “other” for other

user specified spans. Max reading is 22 mA. The rang e for “other” is set using functions 3.04. 0 4 t o

3.04.06.

Function 3.04.04 0 pct

mA setting for 0 percent of the range. It can be set between 0 and 16 mA. Default is 4 mA

Function 3.04.05 100pct

mA setting for 100 percent of the range. It can be set between 4 and 20 m A. Default is 20 mA

Function 3.04.06 Limit

Limit of current output. Max setting and default setting: 22 mA. Limit it to 20mA when safety

systems reserve higher curr ents as Fault Codes.

Function 3.04.07 Error indication

Only available for NAMUR version. Allow to predefine the current (3.6 or 21.5 mA) i n case of failure.