Page 1

Handbook

Handbook

OPTITEMP TRA/TCA PLUS

OPTITEMP TRA/TCA PLUS

OPTITEMP TRA/TCA PLUSOPTITEMP TRA/TCA PLUS

Industrial thermometers for advanced requirements

with replaceable measuring inserts.

HandbookHandbook

© KROHNE 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

OPTITEMP TRA/TCA PLUS

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2011 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 3

OPTITEMP TRA/TCA PLUS

CONTENTS

1 Safety instructions 6

1.1 Intended use ..................................................................................................................... 6

1.2 Approvals and certifications............................................................................................. 6

1.2.1 CE ............................................................................................................................................ 6

1.2.2 ATEX ........................................................................................................................................6

1.3 Safety instructions from the manufacturer ..................................................................... 7

1.3.1 Copyright and data protection ................................................................................................ 7

1.3.2 Disclaimer ............................................................................................................................... 7

1.3.3 Product liability and warranty ................................................................................................ 8

1.3.4 Information concerning the documentation........................................................................... 8

1.3.5 Warnings and symbols used................................................................................................... 9

1.4 Safety instructions for the operator................................................................................. 9

2 Device description 10

2.1 Scope of delivery............................................................................................................. 10

2.2 Device description .......................................................................................................... 11

2.2.1 Design of industrial thermometers for advanced requirements......................................... 11

2.2.2 Types of connection heads.................................................................................................... 12

2.2.3 Measuring insert designs and measuring insert length...................................................... 14

2.2.4 Types of temperature transmitters ...................................................................................... 15

2.2.5 Neck tubes ............................................................................................................................ 17

2.2.6 Thermowells and thermowell tips........................................................................................ 18

2.3 Process connections and areas of application .............................................................. 19

2.3.1 Weld-in thermometer ........................................................................................................... 19

2.3.2 Threaded thermometer ........................................................................................................ 19

2.3.3 Flange thermometer............................................................................................................. 20

2.4 Overview of available versions ....................................................................................... 21

2.5 Nameplate ...................................................................................................................... 25

3 Installation 26

3.1 General notes on installation ......................................................................................... 26

3.2 Storage ........................................................................................................................... 26

3.3 Transport ........................................................................................................................ 26

3.4 Proper installation.......................................................................................................... 27

3.4.1 Possible installations............................................................................................................ 27

3.4.2 Other installation requirements........................................................................................... 28

3.5 Load limits ...................................................................................................................... 29

3.5.1 Typical load types.................................................................................................................. 29

3.5.2 Vibration load ........................................................................................................................ 32

3.5.3 Temperature load ................................................................................................................. 32

3.6 Installation notes on the individual device classes........................................................ 34

3.6.1 Weld-in thermometer ........................................................................................................... 34

3.6.2 Threaded thermometer ........................................................................................................ 35

3.6.3 Flange thermometer............................................................................................................. 36

en

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

3

Page 4

CONTENTS

OPTITEMP TRA/TCA PLUS

4 Electrical connections 37

4.1 Safety instructions.......................................................................................................... 37

4.2 Grounding ....................................................................................................................... 37

4.3 Protection category ........................................................................................................37

4.4 Power supply .................................................................................................................. 37

5 Operation 38

5.1 Start-up........................................................................................................................... 38

5.2 Normal operation ...........................................................................................................38

5.3 Faults and damage: reason and remedies .................................................................... 38

6 Service 40

6.1 Replacing the electronics............................................................................................... 40

6.2 Cleaning and maintenance............................................................................................. 40

6.3 Spare parts availability...................................................................................................40

6.4 Availability of services .................................................................................................... 40

6.5 Returning the device to the manufacturer..................................................................... 40

6.5.1 General information.............................................................................................................. 40

6.5.2 Form (for copying) to accompany a returned device............................................................ 42

6.6 Disposal .......................................................................................................................... 42

7 Technical data 43

7.1 Measuring principle........................................................................................................43

7.1.1 Resistance thermometer...................................................................................................... 43

7.1.2 Thermocouples ..................................................................................................................... 44

7.2 Technical data tables ..................................................................................................... 45

7.3 Dimensions ..................................................................................................................... 49

7.3.1 Cable gland ........................................................................................................................... 49

7.3.2 Neck tubes ............................................................................................................................ 50

7.3.3 Lengths of thermowells........................................................................................................ 51

7.3.4 Thermowells: Diameter, wall thickness, tips....................................................................... 60

7.3.5 Sleeves .................................................................................................................................. 61

7.3.6 Flanges.................................................................................................................................. 62

7.4 Measuring accuracy ....................................................................................................... 64

7.5 Process connections ...................................................................................................... 65

7.6 Measuring range and permitted load ............................................................................ 66

7.6.1 Operating limits for multipart, welded thermowells ........................................................... 66

7.6.2 Operating limits for one-piece, straight bar stock thermowells ......................................... 67

7.6.3 Operating limits for one-piece, conical bar stock thermowells .......................................... 68

7.6.4 Operating limits for one-piece, reduced bar stock thermowells ........................................ 69

7.6.5 Operating limits for conical weld-in bar stock thermowells ............................................... 71

7.6.6 Operating limits for straight, bar stock weld-in thermowells ............................................. 71

7.7 Permissible temperatures ............................................................................................. 72

7.7.1 Connection head ................................................................................................................... 72

7.7.2 Unloaded thermowell and immersion tubes........................................................................ 72

7.8 Sensor response times .................................................................................................. 73

4

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 5

OPTITEMP TRA/TCA PLUS

CONTENTS

8 Appendix 74

8.1 Technical legislation in effect ........................................................................................ 74

9 Notes 75

en

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

5

Page 6

1 SAFETY INSTRUCTIONS

1.1 Intended use

DANGER!

ATEX approval is pending. Until such approval has been granted, do not install or operate the

industrial thermometer for advanced requirements in potentially hazardous areas. Otherwise

you could cause an explosion that could have fatal consequences.

CAUTION!

Responsibility for the use of the measurement devices with regard to suitability, intended use

and corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

The thermometer for advanced requirements is used to measure the temperature of gases,

liquids, vapour and solids in industrial applications. The devices are particularly suited to the

measurement of

OPTITEMP TRA/TCA PLUS

• liquids with low viscosity,

• water and chemicals with low corrosiveness,

• saturated steam and superheated steam.

1.2 Approvals and certifications

1.2.1 CE

Article 1, section 2.1.4 of the Pressure Equipment Directive 97/23/EC does not apply to

thermometers for advanced requirements. For this reason, neither a conformity assessment nor

a CE marking is possible. The EC directives applicable to temperature transmitters are

contained in the corresponding transmitter documentation.

1.2.2 ATEX

ATEX approval is pending. As soon as this is available, you have the option of ordering Exapproval according to ATEX. The relevant Ex handbook contains more detailed information.

6

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 7

OPTITEMP TRA/TCA PLUS

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SAFETY INSTRUCTIONS 1

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

7

Page 8

1 SAFETY INSTRUCTIONS

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

OPTITEMP TRA/TCA PLUS

8

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 9

OPTITEMP TRA/TCA PLUS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS 1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

9

Page 10

2 DEVICE DESCRIPTION

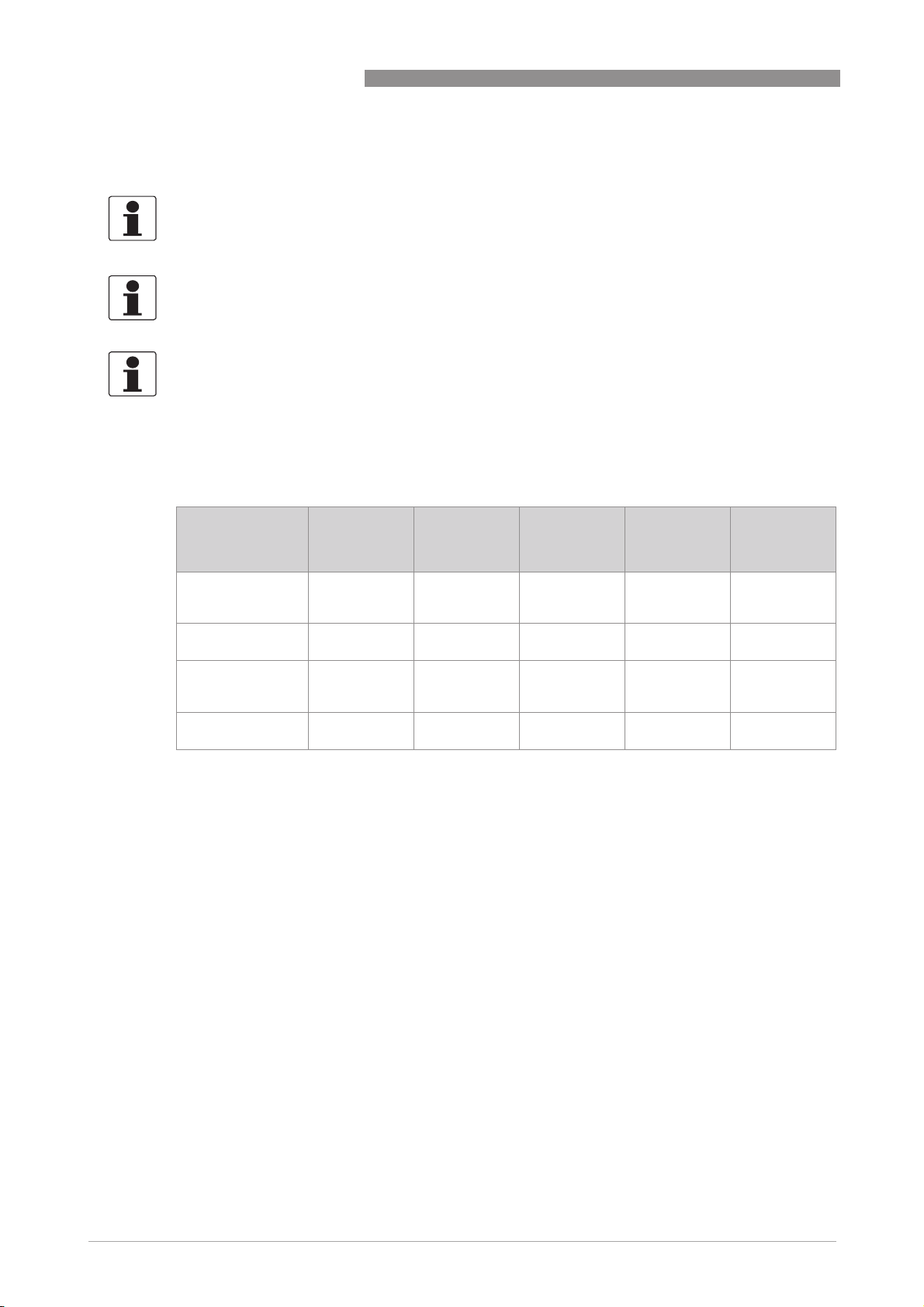

2.1 Scope of delivery

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

The manufacturer delivers all industrial thermometersfor advanced requirements with the

relevant technical documentation. The following table illustrates which thermometer for

advanced requirements is delivered with which documentation (HB = Handbook):

OPTITEMP TRA/TCA PLUS

Scope of order Hb. for

thermometer

s

Thermometer

without

transmitter

Thermometer with

transmitter

Ex-thermometer

without

transmitter

Ex-thermometer

with transmitter

Ex-hb. for

thermometer

s

X - X - -

X - X - X

X X X X -

X X X X X

Hb. for

measuring

inserts

Ex-hb. for

measuring

inserts

Hb. for

transmitters

10

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 11

OPTITEMP TRA/TCA PLUS

DEVICE DESCRIPTION 2

2.2 Device description

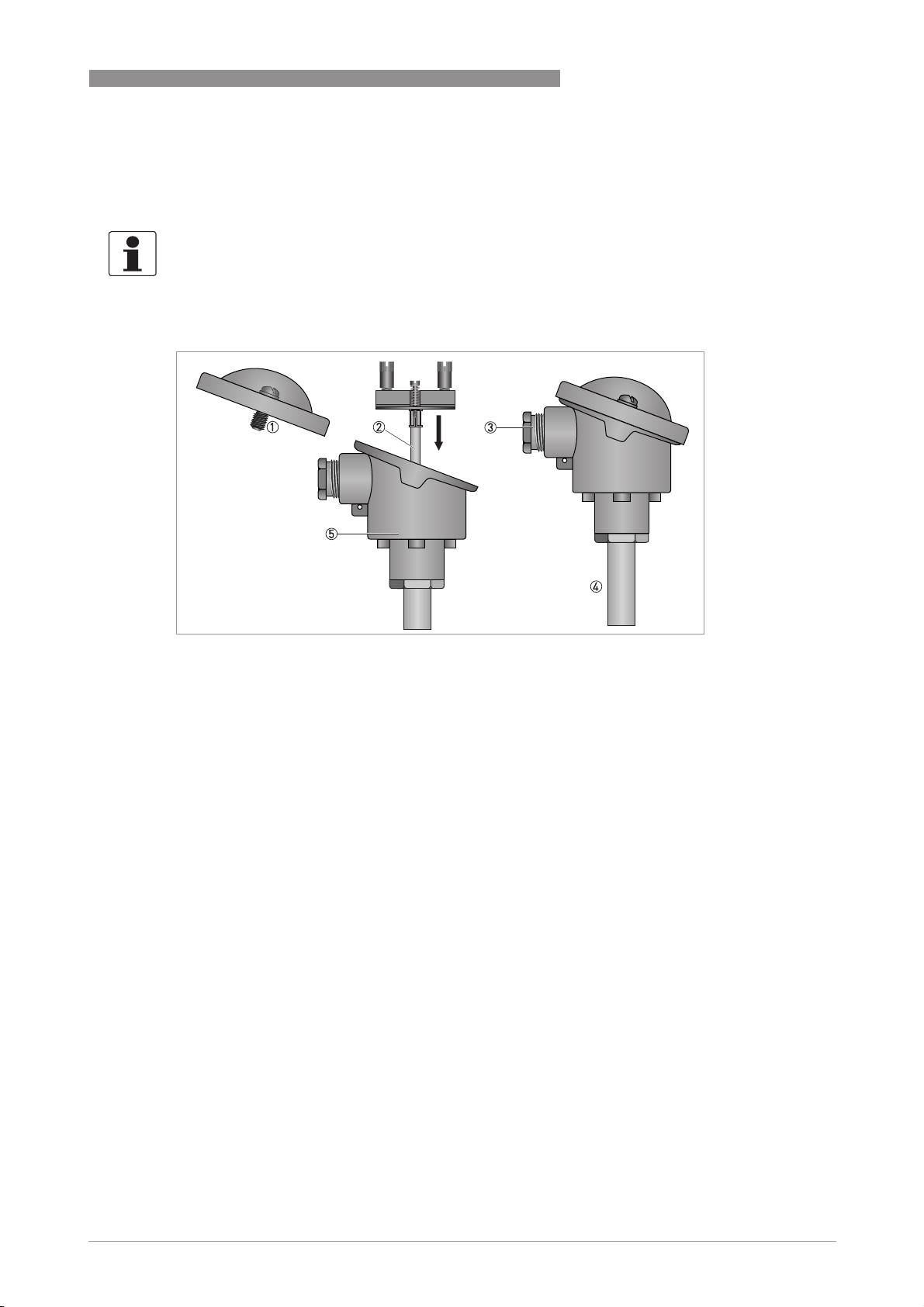

2.2.1 Design of industrial thermometers for advanced requirements

INFORMATION!

In this documentation, the name "Industrial thermometer for advanced requirements" refers to

thermometer assemblies with multipart, welded thermowells as well as those with one-piece

bar stock thermowells.

Figure 2-1: Design of an industrial thermometer for advanced requirements

1 Connection head cover

2 Measuring insert

3 Cable gland M20 x 1.5 (only available if the process connection has the dimensions M24 x 1.5, otherwise there is a blind

plug here instead)

4 Neck tube

5 Connection head

All thermometers for advanced requirements consist of a thermowell with process connection, a

neck tube and a connection head. The connection head and the thermowell are largely thermally

decoupled by way of the neck tube. The neck tubes for thermometers with advanced

requirements are available with two different thread types:

• As per DIN: M24 x 1.5 mm

• As per ASME/ANSI: ½"NPT

The connection head is screwed onto the neck tube using the thread. The M24 x 1.5 thread

makes it possible to align the connection head so that the cable gland always faces in the desired

direction (during assembly, the connection head is aligned first before screwing in the thread

using hex nut). In contrast, the alignment of the connection head with ½" NPT threads is only

possible to a limited extent, depending on the type of neck tube.

You can insert either a measuring insert with RTD (OPTITEMP TR 100) or with thermocouple

(OPTITEMP TC 100) into the thermometer assembly. Both measuring inserts are available in

three different versions (for more information see refer to

measuring insert length

(for more information see refer to

on page 14), the manufacturer also offers a variety of thermowell tips

Thermowells and thermowell tips

Measuring insert designs and

on page 18).

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

11

Page 12

2 DEVICE DESCRIPTION

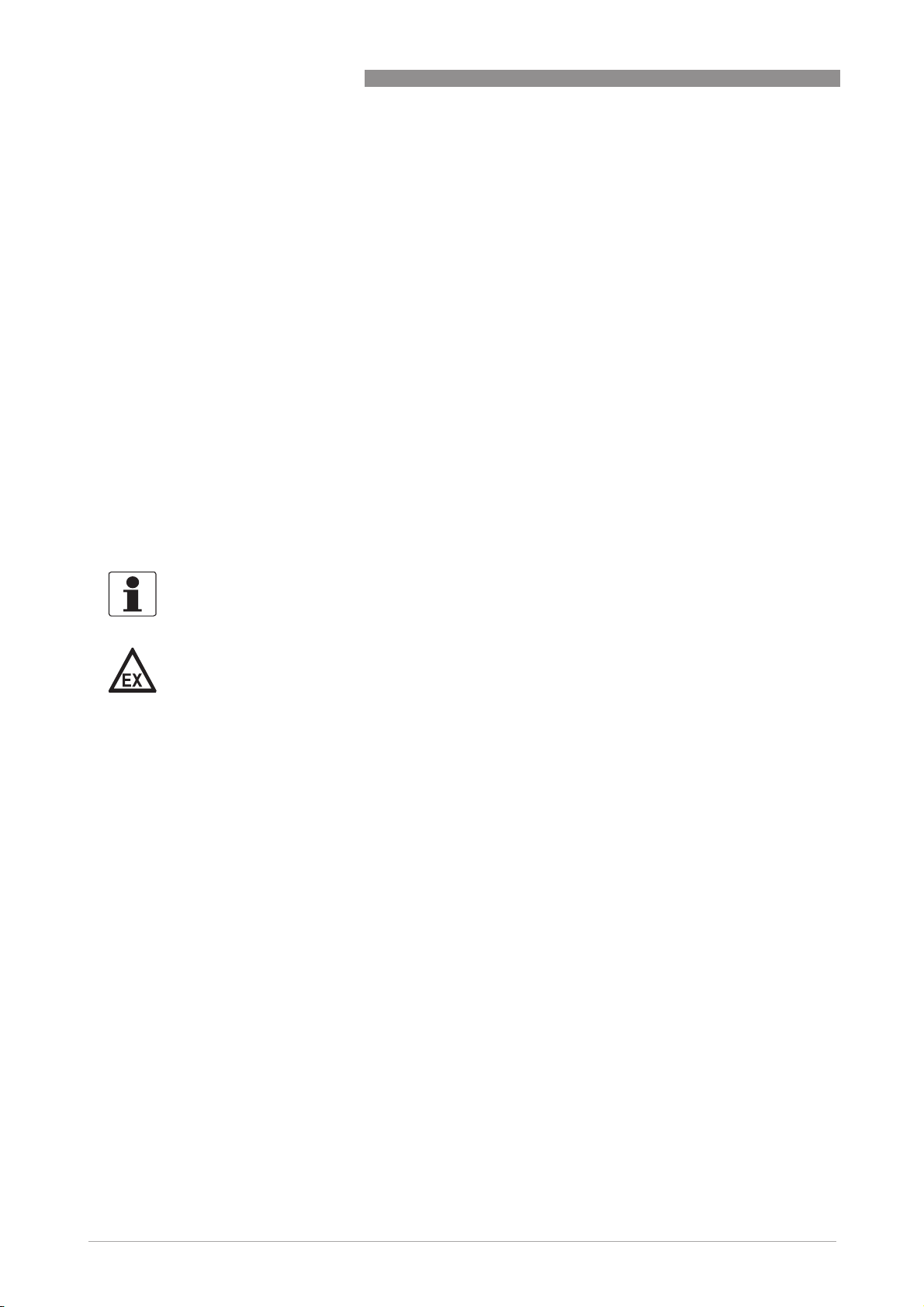

2.2.2 Types of connection heads

A connection head protects the terminals and the temperature transmitter from environmental

effects (e. g. dirt or dust). The cable gland for the connection head on the industrial thermometer

for advanced requirements depends on the process connection for the connection head

(M20 x 1.5 for process connections with the dimensions M24 x 1.5 and ½" NPT for all process

connections with ½" NPT threads, for more information see refer to

There are oil-resistant rubber seals on the covers of all connection heads (can be used up to

100°C / 212°F ambient temperature). The connection heads are available in the following

materials:

• Die-cast aluminium for standard applications (Types: BA, BUZ-T/S/H/HW, BGK and AXD). The

surface of these connection heads features a 70µm thick powder coating made of polyester.

• Stainless steel (type BVA), especially for the pharmaceutical and food and beverage

industries

• Plastic (type BBK)

The type "BUZ-HW" is the only connection head with an integrated, head-mounted display fed by

the 4...20 mA current loop.

OPTITEMP TRA/TCA PLUS

Cable gland

on page 49).

INFORMATION!

The inside dimensions of the connection heads depicted here comply with DIN 43735.

DANGER!

ATEX approval is pending. Until such approval has been granted, do not install or operate the

industrial thermometer for advanced requirements in potentially hazardous areas. Otherwise

you could cause an explosion that could have fatal consequences.

12

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 13

OPTITEMP TRA/TCA PLUS

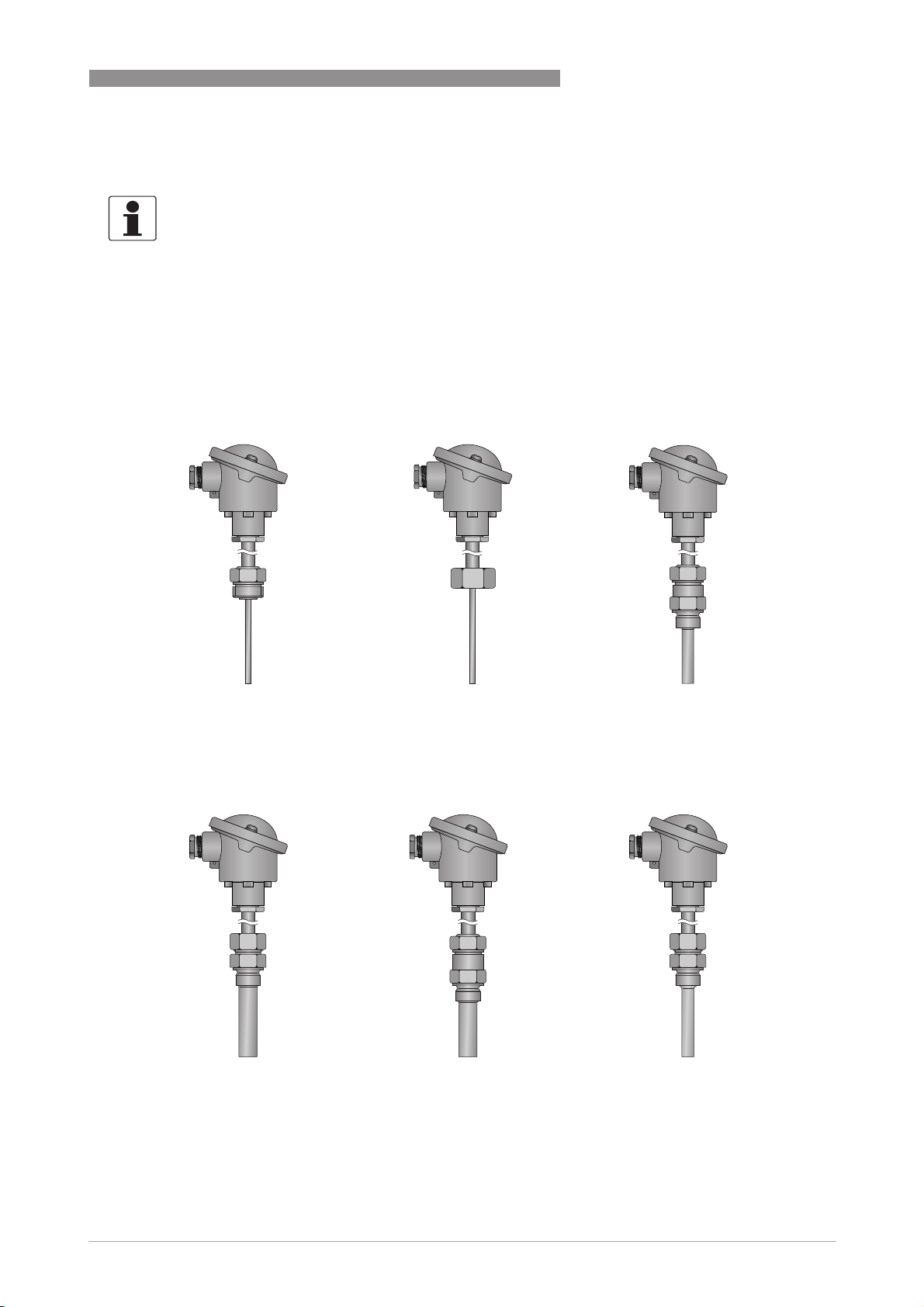

Connection heads available

BA (aluminium, IP65)

BA (aluminium, IP65) BUZ-T (aluminium, IP65)

BA (aluminium, IP65)BA (aluminium, IP65)

BUZ-H (aluminium IP65)

BUZ-H (aluminium IP65) BUZ-HW (aluminium, IP65)

BUZ-H (aluminium IP65)BUZ-H (aluminium IP65)

DEVICE DESCRIPTION 2

BUZ-T (aluminium, IP65) BUZ-S (aluminium, IP65)

BUZ-T (aluminium, IP65)BUZ-T (aluminium, IP65)

BUZ-HW (aluminium, IP65) BGK (aluminium, IP67)

BUZ-HW (aluminium, IP65)BUZ-HW (aluminium, IP65)

BUZ-S (aluminium, IP65)

BUZ-S (aluminium, IP65)BUZ-S (aluminium, IP65)

BGK (aluminium, IP67)

BGK (aluminium, IP67)BGK (aluminium, IP67)

BBK (PA, IP54)

BBK (PA, IP54) BVA (VA, IP65)

BBK (PA, IP54)BBK (PA, IP54)

BVA (VA, IP65) AXD (aluminium, IP68)

BVA (VA, IP65)BVA (VA, IP65)

AXD (aluminium, IP68)

AXD (aluminium, IP68)AXD (aluminium, IP68)

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

13

Page 14

2 DEVICE DESCRIPTION

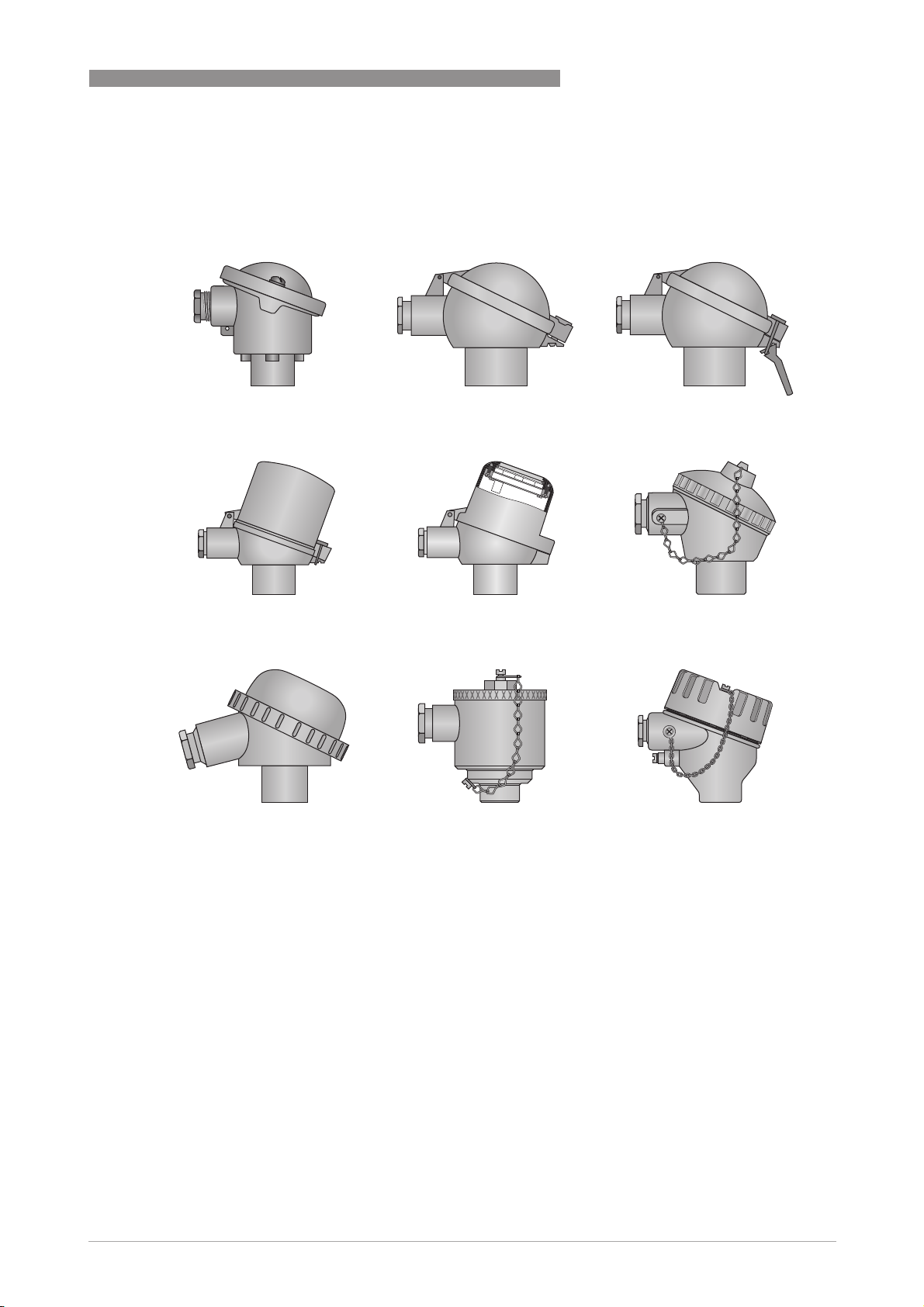

2.2.3 Measuring insert designs and measuring insert length

INFORMATION!

The versions, dimensions and other construction features of the measuring inserts are

standardised in DIN 43735.

The replaceable measuring insert contains the temperature sensor, which may be either a Pt100

RTD or a thermocouple. The measuring insert is pushed through the open connection head into

the thermometer assembly and attached using two spring loaded M4 screws (this guarantees

that the tip of the measuring insert is in constant contact with the bottom of the thermowell). The

following versions of measuring insert are available:

OPTITEMP TRA/TCA PLUS

Figure 2-2: Available measuring insert versions

1 Measuring insert with flying wires

2 Measuring insert with ceramic terminal block

3 Measuring insert with head-mounted transmitter

14

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 15

OPTITEMP TRA/TCA PLUS

One distinguishing dimension of the measuring insert is its length. The length is measured from

the bottom edge of the base to the tip of the immersion tube ("a" in the drawing below):

Figure 2-3: Measuring insert length

The selection of the right measuring insert depends on the conditions of use:

• A measuring insert with a thermocouple is better suited to heavy thermal or mechanical

loads.

• When increased accuracy is required, a measuring insert with a resistance thermometer is

better suited for temperatures up to +500°C / +932°F and in exceptional cases up to +600°C/

+1112°F.

DEVICE DESCRIPTION 2

INFORMATION!

Consult the handbook "OPTITEMP TR/TC 100" for more detailed information on the measuring

inserts.

2.2.4 Types of temperature transmitters

Electrical thermometers have just one, weak, interference-prone output signal. If this signal has

to travel a great distance or if a standard signal of 4...20 mA is required, use of a temperature

transmitter is recommended:

INFORMATION!

The manufacturer cannot make any general statement as to the distance from which the use of a

temperature transmitter is necessary as it depends on the specific interference associated with

the installation site. The operator alone is responsible for this decision.

There are two types of temperature transmitters:

• Head-mounted transmitter: Located on the measuring insert and thus in the connection head

of the thermometer during operation, recognisable by the "C" in the product name

(e.g.TT10C)

• Rail-mounted transmitter: Located in the control cabinet or field housing, recognisable by

the "R" in the product name (e. g. TT 11 R); they are usually used when the temperature in the

connection head does not allow for the use of a head-mounted transmitter

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

15

Page 16

2 DEVICE DESCRIPTION

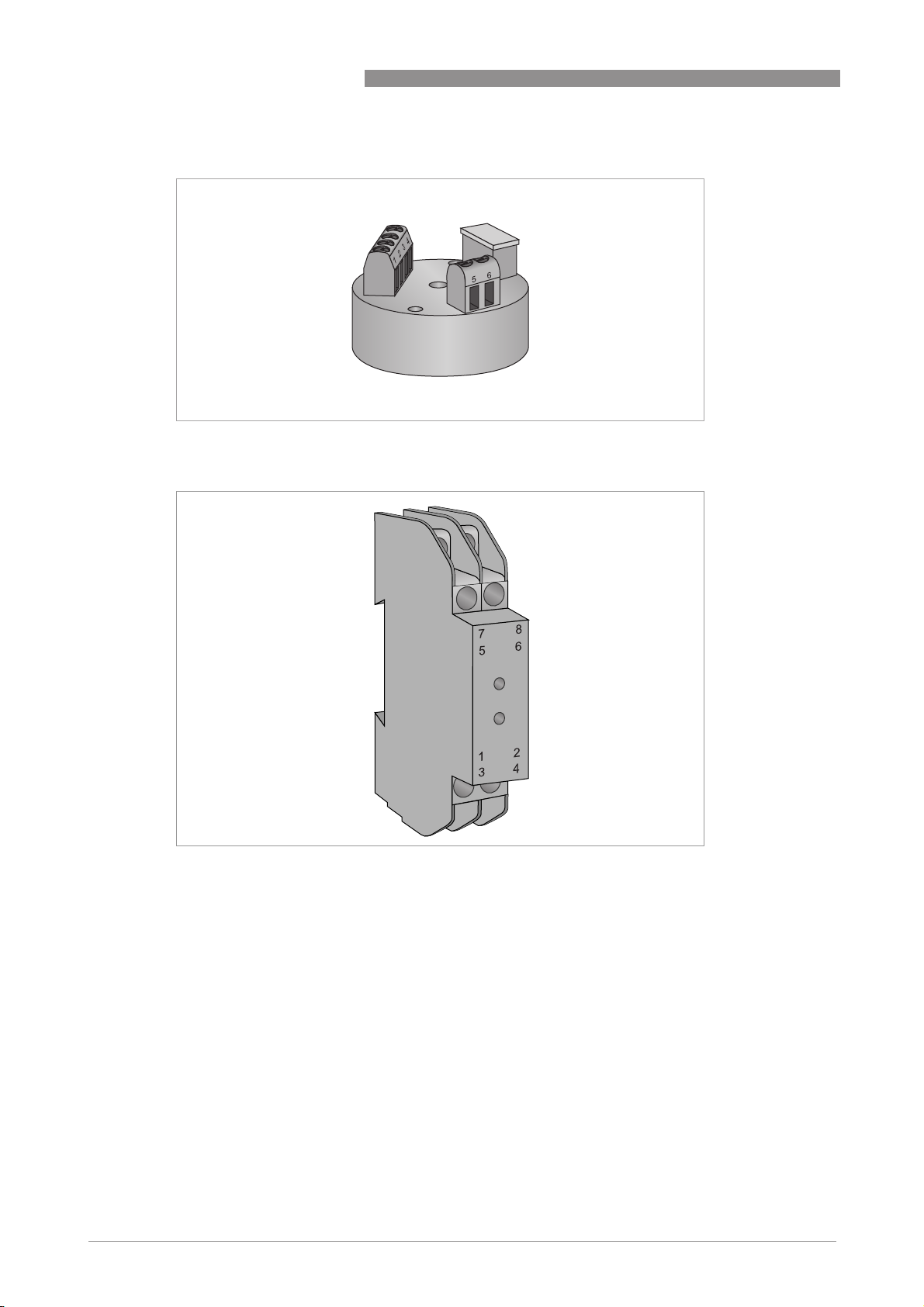

Figure 2-4: Example of a head-mounted transmitter

OPTITEMP TRA/TCA PLUS

16

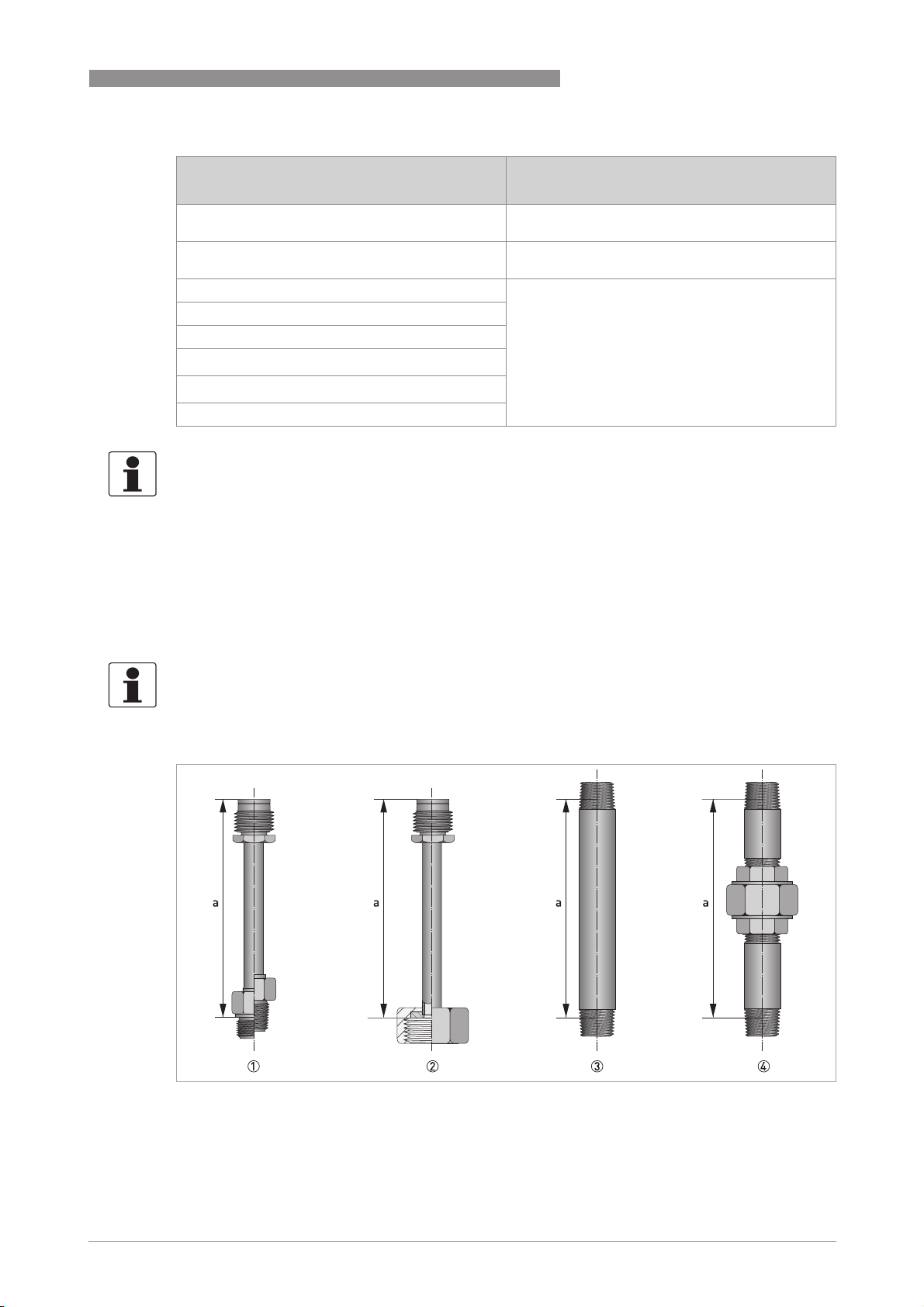

Figure 2-5: Example of a rail-mounted transmitter

Head-mounted and rail-mounted transmitters both convert the temperature sensor's small

signal into a standardised output signal of 4...20 mA, not susceptible to interference, or into a

digital signal. The output signal depends on the type of temperature transmitter. The following

three 2-wire technology options are currently available:

• 4...20 mA

• 4...20 mA with HART

®

• Profibus-PA

You can parameterise almost any temperature transmitter using a PC and a computer program.

The only exceptions are the TT 10 C/R and TT 11 C/R versions, whose measuring ranges must be

set using solder bridges. The following temperature transmitters are currently available:

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 17

OPTITEMP TRA/TCA PLUS

DEVICE DESCRIPTION 2

Available in both head-mounted and railmounted version

TT 10 C/R (analogue, standard, 4...20 mA) TT 31 R (3-wire circuit, 0/4...20 mA, outputs:

TT 11 C/R (analogue, 3- or 4-wire circuit, output:

0...10 VDC)

TT 20 C/R (analogue, 4...20 mA)

TT 30 C/R (digital, 4...20 mA, standard)

TT 40 C/R (digital, 4...20 mA, precise)

TT 50 C/R (digital, 4...20 mA, HART®)

TT 51 C/R (digital, 4...20 mA, HART®, SIL2)

TT 60 C/R (digital, Profibus-PA)

INFORMATION!

Consult the relevant transmitter handbook for more detailed information on the temperature

transmitters.

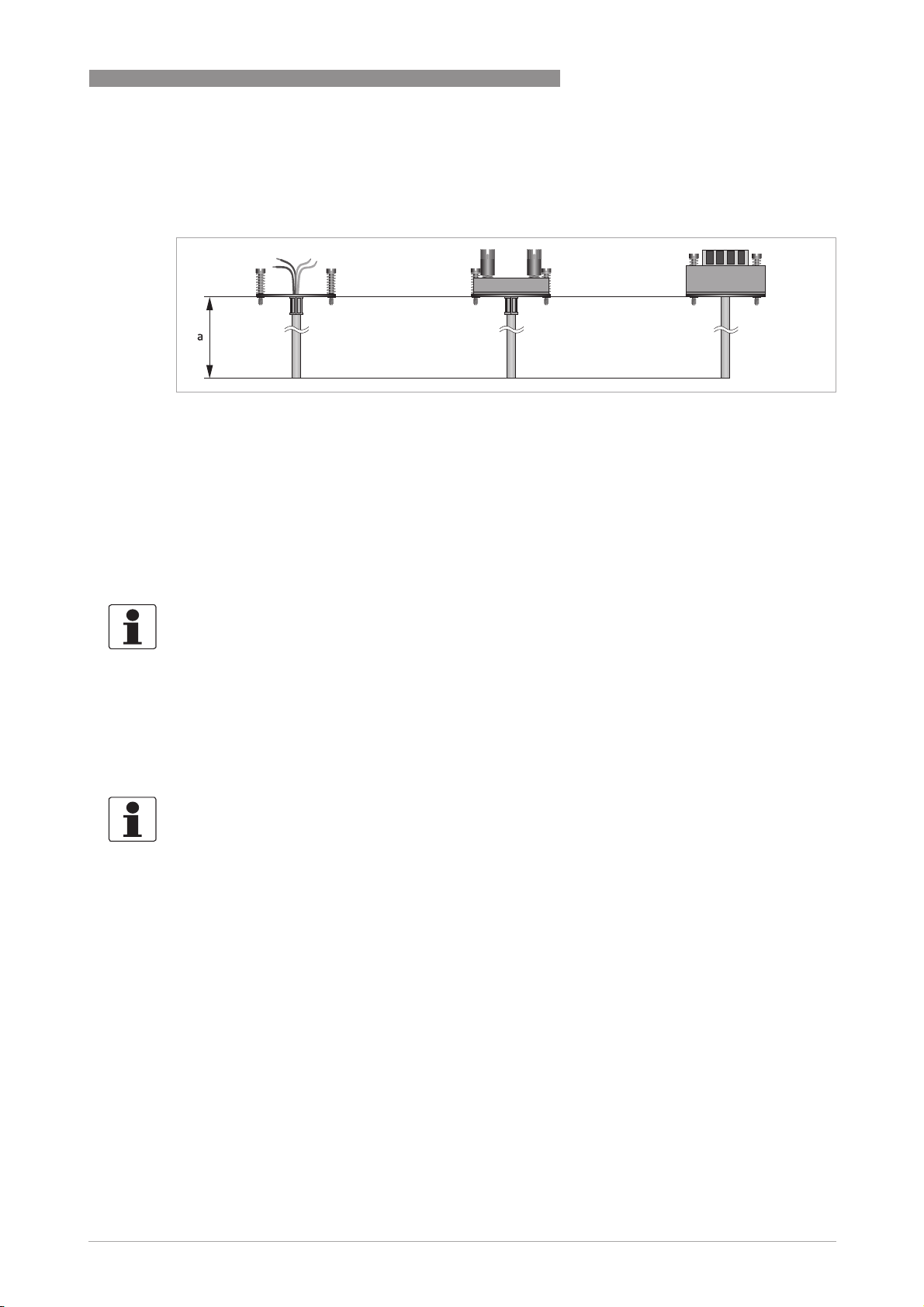

2.2.5 Neck tubes

The neck tube connects the process connection (i.e. screw socket or flange) to the connection

head. Its function is to largely thermally decouple the connection head so that it and any existing

temperature transmitter do not heat up too much. Depending on both the standard and the

version of the thermowell, there are different threads:

Only available in rail-mounted version

0/1...5 VDC, 0/2...10 VDC)

TT 32 R (4-wire circuit, 0/4...20 mA, outputs:

0/1...5 VDC, 0/2...10 VDC)

INFORMATION!

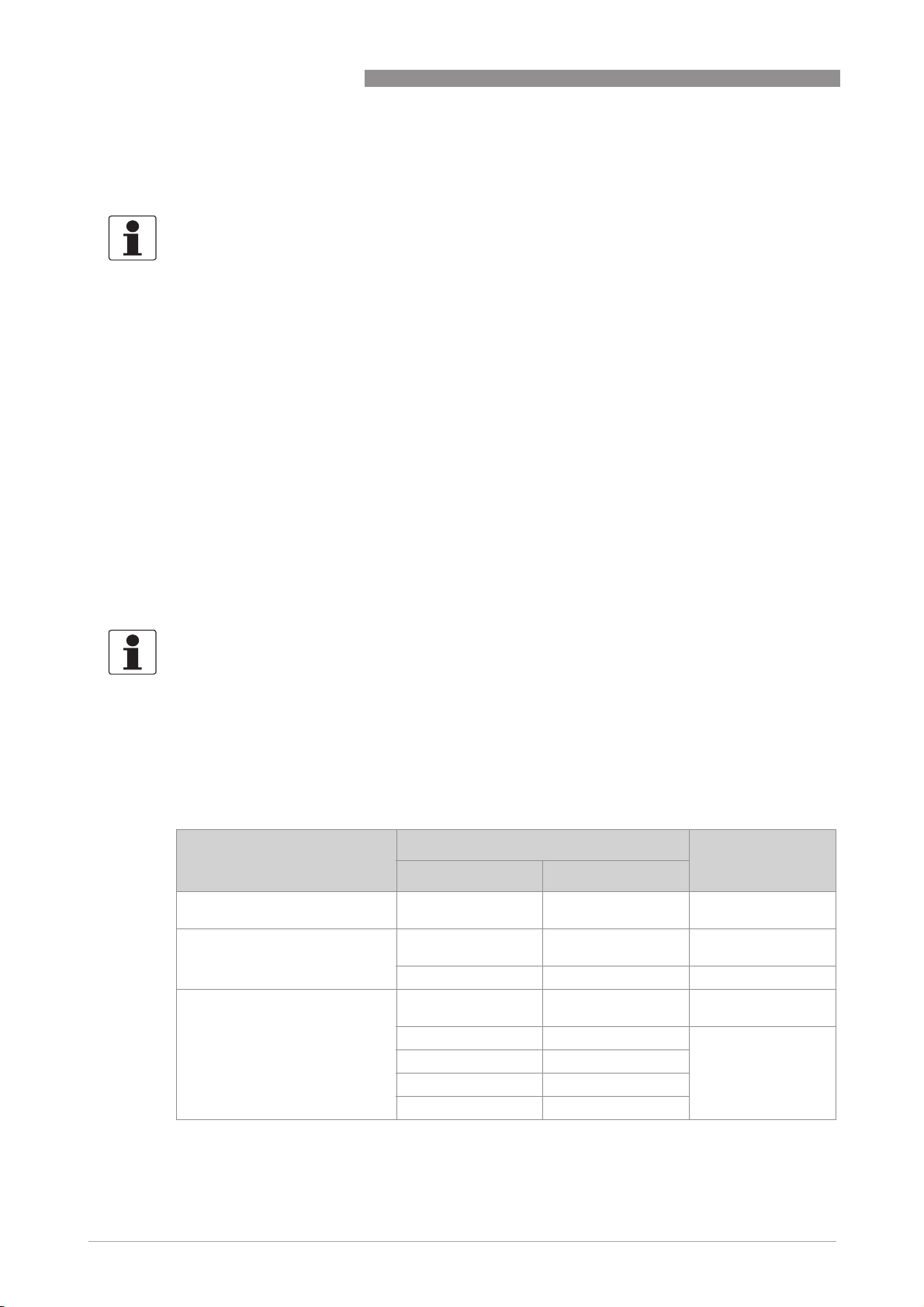

The thread for the connection head is the top thread in the following drawing. The dimension "a"

denotes the length of the neck tube.

Figure 2-6: Thread types on neck tubes

1 DIN neck tube, process connection with metric thread (left) and NPT thread (right)

2 DIN neck tube, process connection with union nut

3 ASME neck tube with Nipple-Nipple (NN) connection

4 ASME neck tube with Nipple-Union-Nipple (NUN) connection

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

17

Page 18

2 DEVICE DESCRIPTION

The neck tubes for industrial thermometers for advanced requirements are made of stainless

steel.

INFORMATION!

The neck tube material may differ from the thermowell material.

The standard neck tube length of a DIN neck tube is 165 mm / 6.5", that of a NUN connection

with ½" NPT thread is 152 mm / 6". Other neck tube lengths are available on request.

2.2.6 Thermowells and thermowell tips

The thermowell is designed to prevent external loads (e. g. static pressure, flowing and

aggressive media) from damaging the measuring insert. As a rule, thermowells are made of the

same material as the system in which the measuring is done. In terms of the material and

design, we can distinguish between two types of thermowells:

• Multipart, welded thermowells

• One-piece bar stock thermowells

OPTITEMP TRA/TCA PLUS

This handbook covers thermometers for advanced requirements such as high pressure and high

flow velocities. For this reason, one-piece thermowells manufactured using bar stock are used

in addition to multipart welded thermowells.

INFORMATION!

The manufacturer checks all of the thermowells for leaks. An optional certified pressure test is

available for a fee.

Thermowells and thermowell tips in different versions are manufactured for the industrial

thermometers for advanced requirements. For more information refer to

Diameter, wall thickness, tips

on page 60.

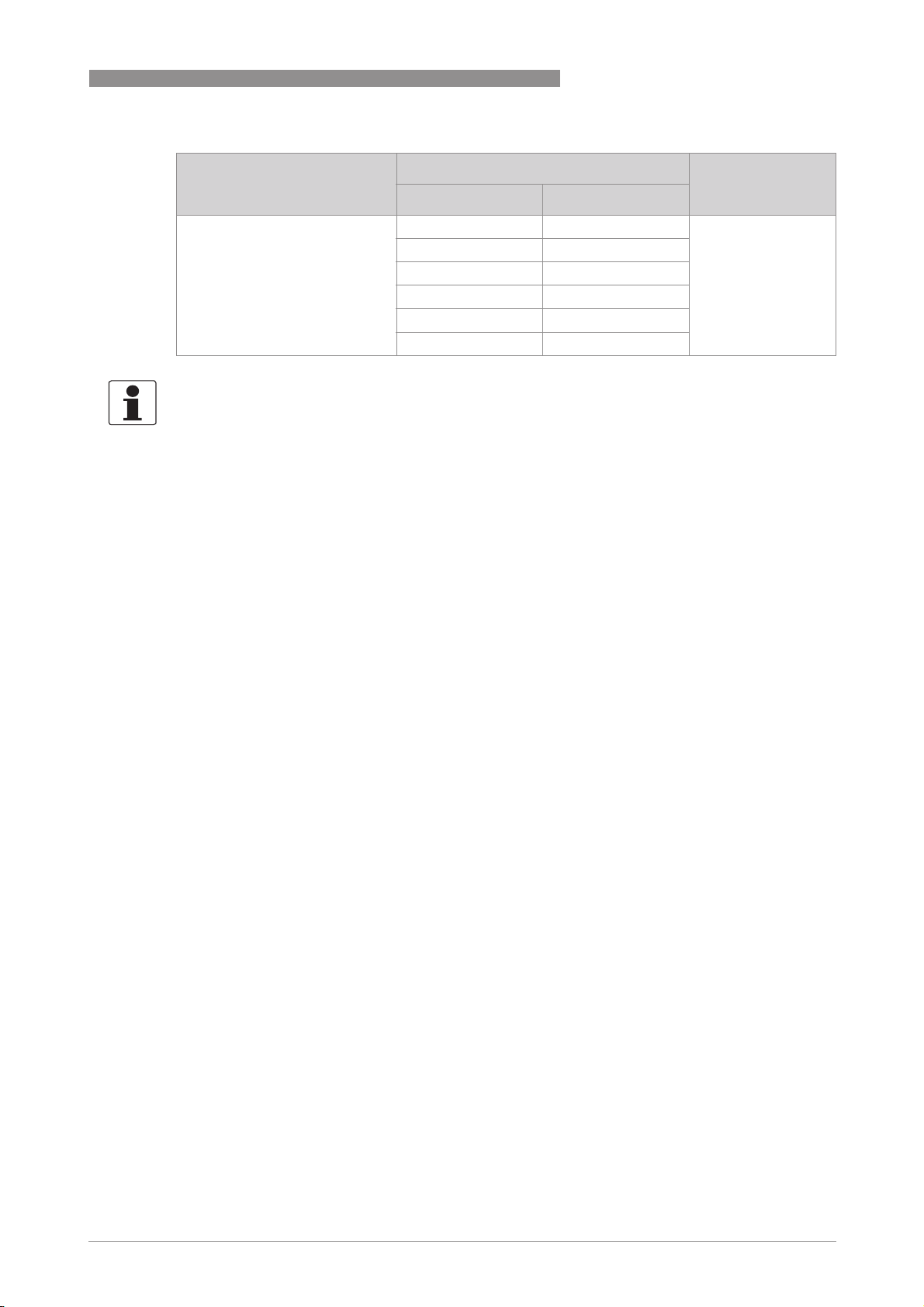

Thermowells:

All thermowells require a measuring insert with a diameter of 6 mm / 0.24".

Thermowell/thermowell tip Ø Similarity to

standard

[mm] ["]

Straight, multipart, welded 9 / 10 / 11 /12 0.35 / 0.39 / 0.43 /

0.47

Straight, one-piece 17 / 23 0.67 / 0.91 DIN 43772, Form 6, 7

16 / 19 0.63 / 0.75 ASME

Conical, one-piece 24 to 12.5

0.94 to 0.49

16 to 13 0.63 to 0.51 ASME

19 to 16 0.75 to 0.63

22 to 16 0.87 to 0.63

25 to 19 0.98 to 0.75

DIN 43772, Form 5

and 8

and 9

DIN 43772, Form 4

and 4F

18

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 19

OPTITEMP TRA/TCA PLUS

Thermowell/thermowell tip Ø Similarity to

[mm] ["]

Reduced tip, one-piece 12 to 9 0.47 to 0.35 ASME

16 to 13 0.63 to 0.51

19 to 13 0.75 to 0.51

19 to 16 0.75 to 0.63

22 to 13 0.87 to 0.51

23 to 13 0.91 to 0.51

INFORMATION!

Both the reduced and the conical tip feature a shorter response time than a straight thermowell.

However, compared to the reduced tip, the conical tip withstands higher pressures.

2.3 Process connections and areas of application

2.3.1 Weld-in thermometer

DEVICE DESCRIPTION 2

standard

Weld-in thermometers for advanced requirements are always the first choice when you want to

measure temperatures in quickly flowing product under high pressure. Compared to threaded

thermometers for advanced requirements, weld-in thermometers are more resilient as they are

not weakened by the notch effect of a thread on the joint.

A typical area of application for weld-in thermometers with advanced requirements is the

measurement of temperature in process vapour lines and cooling water lines, especially in

power plants.

2.3.2 Threaded thermometer

Threaded thermometers with separate neck tubes are particularly well suited to measuring

tasks in process technology or machine building and plant engineering. In this case, screwing

into the pipelines and tanks is the most common process adaption.

The neck tube increases the distance between the process connection and the connection head

so that the latter does not overheat. It also makes it possible to install connection heads outside

of the insulation of pipelines and tanks.

The threaded thermometers for advanced requirements are offered with three different

thermowell shapes forms which are similar to or comply with DIN and ASME standards. These

include a straight thermowell, a conical thermowell and a reduced thermowell. G or NPT thread

variants are available.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

19

Page 20

2 DEVICE DESCRIPTION

2.3.3 Flange thermometer

All of the flange thermometers for advanced requirements available from the manufacturer

feature a separate neck tube to thermally decouple the process connection and connection head.

They are typically used in the mid and upper temperature range in industrial applications (up

to +600°C / +1112°F).

Flange thermometers for advanced requirements are predominantly suited to measuring the

temperature in the chemical and petrochemical industries (particularly for pipelines, tanks and

reactors). This area of application opens up because optional coating of the surface is possible.

According to the requirements for chemical resistance, the manufacturer can coat the flange

thermometer with Teflon, PTFE or a customer-specific material.

When it comes to flanges, you can choose between DIN and ASME flanges. The surface

roughness of the flange raised face is R

R

= 3.2...6.3 μm (ASME flanges).

a

As with the threaded thermometers for advanced requirements, the flange thermometers for

advanced requirements also give you the choice between different thermowell forms which are

similar to or comply with valid DIN and ASME standards. Also included are a straight

thermowell, a conical thermowell and a reduced thermowell.

OPTITEMP TRA/TCA PLUS

= 12.5...50 μm (DIN EN flanges) or

z

20

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 21

OPTITEMP TRA/TCA PLUS

2.4 Overview of available versions

INFORMATION!

The beginning of the product name refers to the type of sensor in the measuring insert:

•

TRA: Thermometer with Pt100 RTD

•

TCA: Thermometer with thermocouple

Thermometer with separate neck tube according to DIN 43722

Thermometer with separate neck tube according to DIN 43722

Thermometer with separate neck tube according to DIN 43722Thermometer with separate neck tube according to DIN 43722

Threaded thermometer

TRA / TCA-S34

TRA / TCA-S34 TRA / TCA-S34

TRA / TCA-S34TRA / TCA-S34

TRA / TCA-S34 TRA / TCA-TS32

TRA / TCA-S34TRA / TCA-S34

DEVICE DESCRIPTION 2

TRA / TCA-TS32

TRA / TCA-TS32TRA / TCA-TS32

Connection head with DIN neck

tube, no thermowell

TRA / TCA-TS35

TRA / TCA-TS35 TRA / TCA-TS36

TRA / TCA-TS35TRA / TCA-TS35

Multipart thermowell, neck tube

with union nut, similar to Form 8

Connection head with DIN neck

tube and union nut, no thermowell

TRA / TCA-TS36 TRA / TCA-TS37

TRA / TCA-TS36TRA / TCA-TS36

One-piece thermowell, neck tube

with external thread, similar to

Form 7

Multipart thermowell, neck tube

with external thread, similar to

Form 5

TRA / TCA-TS37

TRA / TCA-TS37TRA / TCA-TS37

One-piece thermowell, neck tube

with union nut, similar to Form 9

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

21

Page 22

2 DEVICE DESCRIPTION

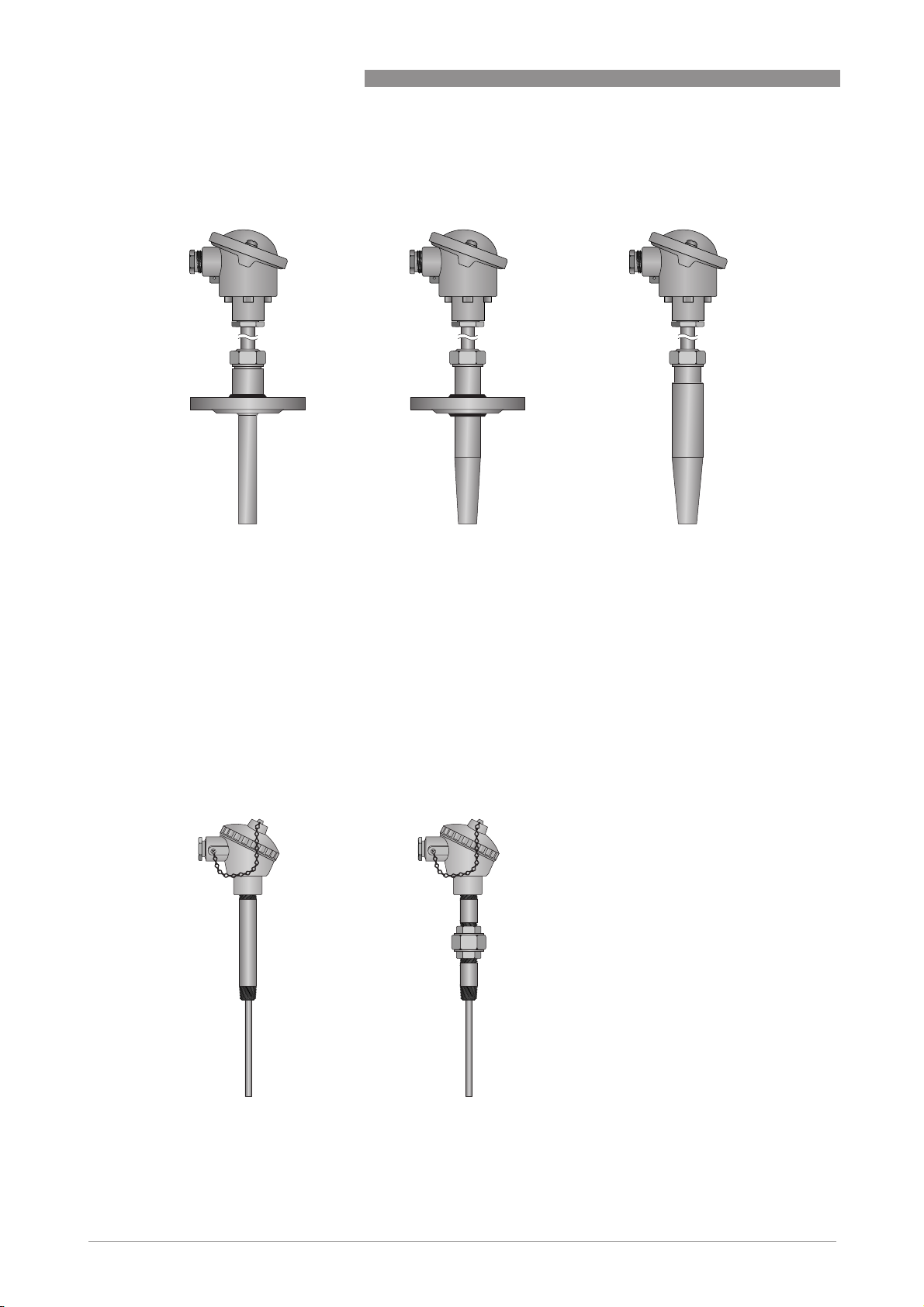

Flange and weld-in thermometers

TRA / TCA-TF33

TRA / TCA-TF33 TRA / TCA-TF31

TRA / TCA-TF33TRA / TCA-TF33

OPTITEMP TRA/TCA PLUS

TRA / TCA-TF31 TRA / TCA-T30

TRA / TCA-TF31TRA / TCA-TF31

TRA / TCA-T30

TRA / TCA-T30TRA / TCA-T30

Multipart thermowell, neck tube

with external thread

Thermometer with separate neck tube according to ASME standard

Thermometer with separate neck tube according to ASME standard

Thermometer with separate neck tube according to ASME standardThermometer with separate neck tube according to ASME standard

One-piece thermowell, neck tube

with external thread, similar to

Form 4F

One-piece thermowell, neck tube

with external thread, similar to

Form 4

Threaded thermometer

TRA / TCA-S50 (NN neck tube)

TRA / TCA-S50 (NN neck tube) TRA / TCA-S50 (NUN neck tube)

TRA / TCA-S50 (NN neck tube)TRA / TCA-S50 (NN neck tube)

TRA / TCA-S50 (NUN neck tube)

TRA / TCA-S50 (NUN neck tube)TRA / TCA-S50 (NUN neck tube)

22

Head with NN neck tube, no

thermowell

Head with NUN neck tube, no

thermowell

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 23

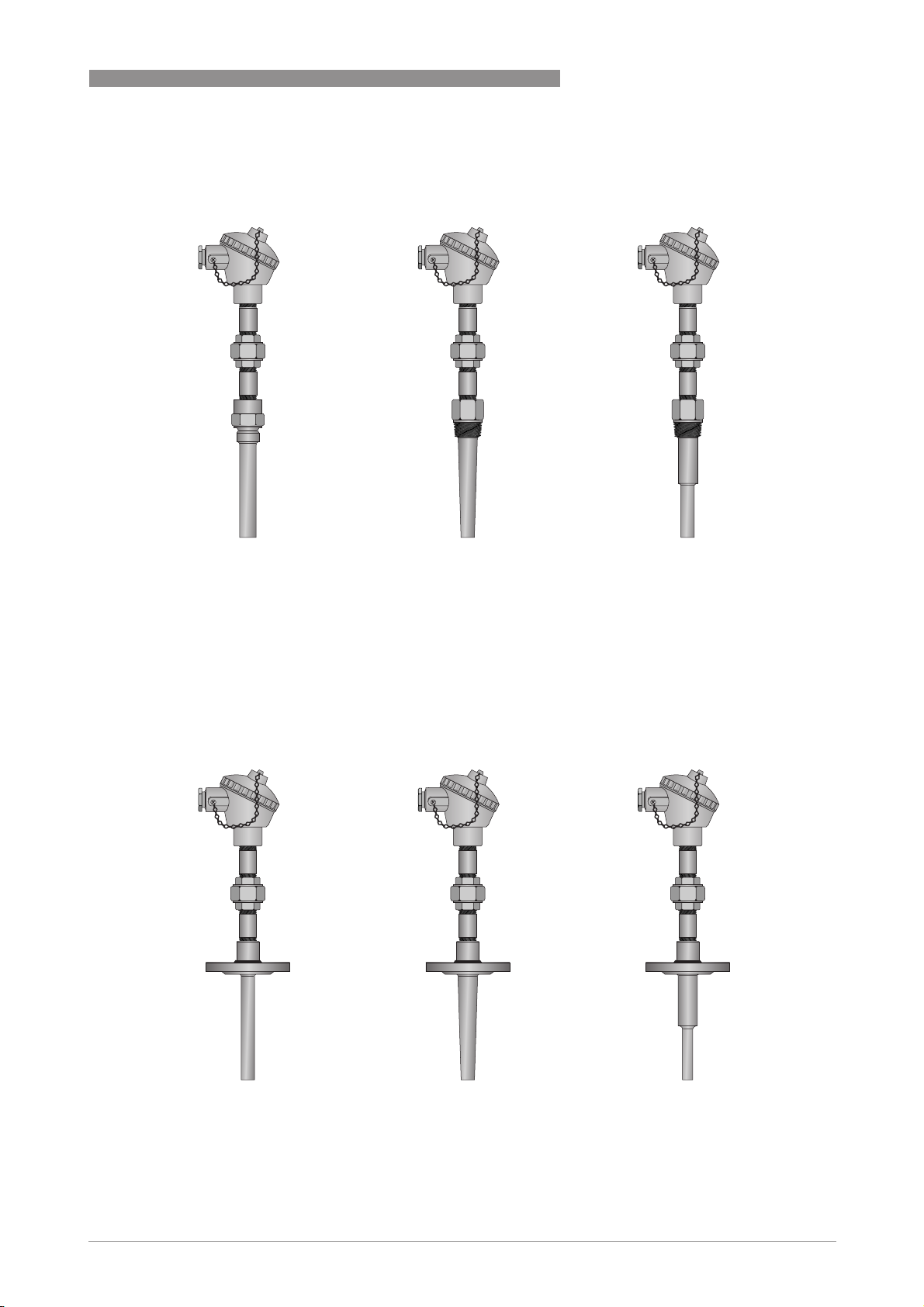

OPTITEMP TRA/TCA PLUS

Threaded thermometer

TRA / TCA-TS52

TRA / TCA-TS52 TRA / TCA-TS53

TRA / TCA-TS52TRA / TCA-TS52

DEVICE DESCRIPTION 2

TRA / TCA-TS53 TRA / TCA-TS54

TRA / TCA-TS53TRA / TCA-TS53

TRA / TCA-TS54

TRA / TCA-TS54TRA / TCA-TS54

Screw-in thermowell, one-piece,

straight

Screw-in thermowell, one-piece,

conical

Flange thermometer

TRA / TCA-TF55

TRA / TCA-TF55 TRA / TCA-TF56

TRA / TCA-TF55TRA / TCA-TF55

TRA / TCA-TF56 TRA / TCA-TF57

TRA / TCA-TF56TRA / TCA-TF56

Screw-in thermowell, one-piece,

reduced

TRA / TCA-TF57

TRA / TCA-TF57TRA / TCA-TF57

Flange thermowell, one-piece,

straight

Flange thermowell, one-piece,

conical

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Flange thermowell, one-piece,

reduced

23

Page 24

2 DEVICE DESCRIPTION

Weld-in thermometer

TRA / TCA-TW58

TRA / TCA-TW58 TRA / TCA-TW59

TRA / TCA-TW58TRA / TCA-TW58

TRA / TCA-TW59

TRA / TCA-TW59TRA / TCA-TW59

OPTITEMP TRA/TCA PLUS

Weld-in thermowell, one-piece,

straight

Weld-in thermowell, one-piece,

conical

24

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 25

OPTITEMP TRA/TCA PLUS

2.5 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

The nameplate is located on the connection head, it measures 70 mm x 18 mm / 2.76 x 0.71":

Figure 2-7: Sample nameplate (measuring insert with Pt100 RTD)

1 Manufacturer

2 Production site

3 Manufacturing year

4 Type of thermometer

5 Measuring insert specification

6 Type of temperature transmitter

7 Allowable voltage range of power supply

8 Manufacturer's website

9 Note that the handbook is available for download from the manufacturer's website.

10 Type code

11 Individual serial number

12 VK number

13 Production order number

DEVICE DESCRIPTION 2

INFORMATION!

For a customer-specific TAG No., the manufacturer can print out a separate label if required.

If the thermometer has a transmitter or an Ex approval, this information is found on the right

side of the nameplate.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

25

Page 26

3 INSTALLATION

3.1 General notes on installation

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

INFORMATION!

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

OPTITEMP TRA/TCA PLUS

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.2 Storage

CAUTION!

Always store industrial thermometers for advanced requirements in a dry place protected from

dust. The permissible range for storage temperatures is -40...+70

3.3 Transport

CAUTION!

Always transport industrial thermometers for advanced requirements in their original

packaging. Do not expose the devices to moisture or vibration during transport. The information

that applies to storage also applies to transport.

°

C / -40...+176°F.

26

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 27

OPTITEMP TRA/TCA PLUS

3.4 Proper installation

CAUTION!

Take the following points into consideration prior to installing the thermometer:

•

The dimensions of the thermowell (length, diameter, wall thickness, type of tip) comply with

the requirements of the measuring point. The mechanical load as a result of flowing media,

vibration and resonances is the focus here. In addition, incorrect dimensions can lead to

measurement errors.

•

The thermowell is sufficiently resistant to chemically aggressive media (refer to the generally

accessible corrosion tables). Otherwise, corrosion may occur or the medium may penetrate

into the thermowell. When in doubt, select a thermowell made from the same material as

your system.

3.4.1 Possible installations

Installations include the parameters "installation site", "installation angle" and "insertion

length". Depending on the space available and the diameter of the pipe, three installations are

recommended for pipes with flowing product:

INSTALLATION 3

• Small pipe diameter: Installation directly against the direction of flow in a bend in the

pipe (1).

• Small pipe diameter: Installation diagonally against the direction of flow, if a bend in the pipe

is available (2).

• Large pipe diameter: Vertical installation, if flow-induced periodic vortex shedding does not

cause the thermometer to vibrate in its resonance frequency (3).

Figure 3-1: Recommended installations

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insert

Permitted insertion length of the thermowell or measuring insertPermitted insertion length of the thermowell or measuring insert

The "insertion length" of the thermowell or measuring insert refers to the distance from the seal

of the process connection (for G threads), two-thirds of the thread height (for NPT threads) or the

bottom of the flange (for flange thermometers) to the tip of the thermowell or sheath. This

length determines how far the sensor projects into the measured medium.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

27

Page 28

3 INSTALLATION

To avoid measurement errors, ensure that the insertion length ("b" in the drawing below) meets

the following requirements:

• Insertion length = 10...15 x thermowell diameter, but at least 100 mm / 3.94" (shorter

insertion lengths are possible but they impair measuring accuracy).

• Tubes with Ø < 300 mm / 11.8": thermowell tip should project past the middle of the pipe is

possible, if the flow velocity of the product allows it.

OPTITEMP TRA/TCA PLUS

Figure 3-2: Permitted insertion length

INFORMATION!

For more information on the maximum insertion length, please refer to the subsection "Typical

load types".

3.4.2 Other installation requirements

DANGER!

When a seal is damaged or incorrect, the medium may leak out, causing material damage or

bodily harm! It is the sole responsibility of the operator to select the right seal.

• A well-insulated pipeline or tank around the measuring point reduces the heat transfer and

the distorting influence of the ambient temperature.

• To avoid measurement errors caused by poor heat transfer, the measuring insert must

always be in contact with the bottom of the thermowell (this is normally guaranteed by the

spring-loaded version of the measuring insert).

• Choosing the right gasket for the process connection depends on the process conditions; the

manufacturer can thus only give the general recommendation that the gasket must comply

with the individual requirements of the measuring point (e.g. pressure, temperature,

chemically aggressive media).

28

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 29

OPTITEMP TRA/TCA PLUS

3.5 Load limits

The load limits of industrial thermometers depend on several factors:

• Dimensions and design of the thermowell (especially the insertion length and diameter)

• Thermowell material

• Mechanical conditions the thermowell is subject to due to the measured medium (pressure,

temperature, flow velocity, viscosity, density)

• Sealable pressure of the process connection

• Vibration load

INFORMATION!

The "sealable pressure" is the maximum pressure the process connection can seal against.

The sheer number of factors at play illustrates the difficulty in making universally valid

statements about the load limits. The diagrams in the next subsection serve as an initial

assessment.

INSTALLATION 3

3.5.1 Typical load types

DANGER!

To prevent destruction or damage, never operate the thermometer outside of its permissible

mechanical, thermal or chemical limits. For further information refer to the rest of this section

and the "Technical data" section.

DANGER!

The information in this subsection is informative only and does not reflect the vibration load

caused by flow-induced eddy shedding and the resulting vibration. If necessary, prior to

purchasing and installing an industrial thermometerfor advanced requirements, have a specific

strength calculation performed (e. g. as per DITTRICH or MURDOCK, ASME PTC 19,3TW-2010).

For further information contact the manufacturer.

INFORMATION!

The manufacturer can provide an optional strength calculation for a fee.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

29

Page 30

3 INSTALLATION

The first diagram applies to thermometer(s):

• TRA/TCA-T30 (Form 4)

• Ø 24 x 8.5 mm / 0.94 x 0.33"

• Material 1.4571 / 316 Ti

OPTITEMP TRA/TCA PLUS

Figure 3-3: Load diagram for TRA/TCA-T30

1 Pressure of the measured medium

2 Steam pressure curve

3 Steam

4 Water

5 Insertion length 125 mm or 4.92"; water with 5 m/s or 16.4 ft/s

6 Insertion length 125 mm or 4.92"; steam with 60 m/s or 196.9 ft/s

7 Insertion length 125 mm or 4.92"; air with 60 m/s or 196.9 ft/s

8 Temperature of the measured medium

30

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 31

OPTITEMP TRA/TCA PLUS

The second diagram applies to thermometer(s):

• TRA/TCA-TS36 (Form 6 and 7)

• Ø 17 x 5 mm / 0.67 x 0.20"

• Material 1.4571 / 316 Ti

400

360

320

280

240

INSTALLATION 3

200

160

120

80

40

Figure 3-4: Load diagram for TRA/TCA-TS36

1 Pressure of the measured medium

2 Steam pressure curve

3 Steam

4 Water

5 Insertion length 230 mm or 9.06"; water with 3 m/s or 9.8 ft/s

6 Insertion length 230 mm or 9.06"; steam with 40 m/s or 131.2 ft/s

7 Insertion length 230 mm or 9.06"; air with 40 m/s or 131.2 ft/s

8 Temperature of the measured medium

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

31

Page 32

3 INSTALLATION

3.5.2 Vibration load

CAUTION!

Permanently operating the thermowell in its natural resonance can quickly damage or destroy

the thermometer! So, prior to installation, ensure that this does not happen and select a

thermowell with a different length, a different diameter or another material if necessary.

All thermometers that feature a thermowell and neck tube and are attached to the process

connection have two components that can vibrate: the thermowell and the connection head with

the neck tube. That is why the terms "thermowell resonance" and "head resonance" are

commonly heard.

A thermowell surrounded by the measured medium is a body behind which vortices periodically

are released ("Kármán vortex street"). If the frequency of the vortex detachment is equal to the

resonance frequency of the thermowell, it starts to vibrate. If this happens for a short period of

time, such as when starting up the system and the frequency of the vortex detachment passes

through the resonance range of the thermowell, there is generally no damage is caused. The

opposite is true, however, if the vibrations remain permanently in the resonance range.

3.5.3 Temperature load

OPTITEMP TRA/TCA PLUS

For this reason, all of the industrial thermometers for advanced requirements feature a neck

tube. It causes extensive thermal decoupling and can prevent the connection head and the

temperature transmitter from overheating at high process temperatures.

CAUTION!

When the temperature is too high, the connection head and the components found in it

(e. g. temperature transmitter or display) can be damaged or destroyed! It is your responsibility

as the operator to ensure that the connection head does not get too hot. If this does happen,

select another installation site or lengthen the neck tube or, with insertion-type thermometers,

increase the distance between the connection head and the process connection.

CAUTION!

Sometimes even a neck tube cannot prevent the maximum permissible temperature in the

connection head from being exceeded! It does cause extensive thermal decoupling of the

connection head but you still have to always take into consideration the installation situation as

well as the ambient and process temperatures!

32

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 33

OPTITEMP TRA/TCA PLUS

The following diagram will aid in the selection of the right neck tube length and shows how the

process temperature and the neck tube length impact the temperature of the connection head:

CAUTION!

The diagram only shows the amount by which the temperature of the connection head increases.

To determine the actual temperature of the connection head you must add the ambient

temperature to it in a second step!

INSTALLATION 3

Figure 3-5: Heating of the connection head

1 Process temperature +220°C / +428°F

2 Process temperature +400°C / +752°F

3 Process temperature +570°C / +1058°F

4 Temperature of the connection head

5 Neck tube length

INFORMATION!

For more information regarding the maximum allowable temperatures, please refer to the

"Technical data" section.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

33

Page 34

3 INSTALLATION

3.6 Installation notes on the individual device classes

3.6.1 Weld-in thermometer

Compared to other types of fastening, welding in thermometers allows for higher process

pressures and flow velocities. Weld-in thermometers can be installed in two different ways:

• Welded in directly: possible in pipes and tanks with a wall thickness ≥20 mm / 0.79"

• Welded in using a welded sleeve: pipes and tanks with a wall thickness < 20 mm / 0.79"

require welding of a sleeve, into which the thermowell is then welded.

The following drawing shows a weld-in sleeve suitable for the TRA/TCA-T30 version:

OPTITEMP TRA/TCA PLUS

Figure 3-6: Welded sleeve for thermometer thermowells according to DIN 43772, Form 4

1 Neck tube

2 Welded sleeve

3 Thermowell

CAUTION!

When installing welded sleeves, always make sure that the transition point between the conical

and straight part of the thermowell is flush with the inner wall of the pipe or tank. You, the user,

are responsible for proper welding, not the manufacturer!

CAUTION!

Sometimes even a neck tube cannot prevent the maximum permissible temperature in the

connection head from being exceeded! It does cause extensive thermal decoupling of the

connection head but you still have to always take into consideration the installation situation as

well as the ambient and process temperatures!

INFORMATION!

For more information on the dimensions of the welded sleeve, please see the

subsection "Dimensions" in the section "Technical Data". Note that the welded sleeve is not

included in the scope of standard delivery but is an optional accessory.

34

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 35

OPTITEMP TRA/TCA PLUS

3.6.2 Threaded thermometer

A threaded thermometer can be installed two different ways:

• Screwed in directly: Pipes with a wall thickness ≥ 20 mm / 0.79" make it possible to drill a

hole and cut a thread.

• Screw into threaded sleeves: Pipes with a wall thickness < 20 mm / 0.79" require a sleeve to

be welded in; these are not included in delivery but make up part of the accessories range.

The following drawing shows a threaded jacket suitable for process connections with G½"

threads:

INSTALLATION 3

Figure 3-7: Welded sleeve for threaded thermometer

1 Neck tube with connection head

2 Permanently welded on threaded sleeve

3 Thermowell

CAUTION!

You, the user, are responsible for selecting a suitable sealing material for the process

connection, not the manufacturer! When installing the seals to the process connection, always

ensure a good fit!

CAUTION!

Sometimes even a neck tube cannot prevent the maximum permissible temperature in the

connection head from being exceeded! It does cause extensive thermal decoupling of the

connection head but you still have to always take into consideration the installation situation as

well as the ambient and process temperatures!

INFORMATION!

For more information on the dimensions of the threaded sleeve please see the

subsection "Dimensions" in the section "Technical Data". Note that the threaded sleeve is not

included in the scope of standard delivery but is an optional accessory.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

35

Page 36

3 INSTALLATION

3.6.3 Flange thermometer

The flange thermometer can be installed using a weld neck flange, for example, as shown in the

following drawing:

OPTITEMP TRA/TCA PLUS

Figure 3-8: Installing a flange thermometer with a weld neck flange

1 Thermowell with flange as process connection

2 Weld neck flange

3 Pipeline or container wall

CAUTION!

When attaching the flange, tighten the screws evenly and crosswise to avoid leaks at the process

connection.

CAUTION!

You, the user, are responsible for selecting a suitable sealing material for the process

connection, not the manufacturer! When installing the seals to the process connection, always

ensure a good fit!

36

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 37

OPTITEMP TRA/TCA PLUS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

4.2 Grounding

DANGER!

The thermowells on the industrial thermometer for advanced requirements are grounded via the

process connection. No additional grounding is required. One exception is the coated flange

thermowells, which must be grounded separately.

4.3 Protection category

The IP protection category of an industrial thermometer depends on the type of connection and

the cable gland used. Connection heads with ½" NPT threads are supplied without cable glands.

The following protection categories are available: IP54 (BKK), IP65 (BA, BUZ-T/S/H/HW, BVA),

IP67 (BGK), IP68 (AXD).

4.4 Power supply

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

The only components of an industrial thermometer for advanced requirements that require a

power supply are the measuring insert and any temperature transmitter used. For more

detailed information on supplying these components with power, consult the product-specific

manuals.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

37

Page 38

5 OPERATION

5.1 Start-up

CAUTION!

Double check the following things prior to starting up an industrial thermometer in order to

avoid measuring errors as well as damage to or the destruction of the thermometer:

•

Ensure that the thermowells have been properly installed according to the manufacturer's

instructions.

•

Ensure that the process connection has been successfully tested for leaks.

•

Ensure that the measuring insert sits firmly on the bottom of the thermowell.

•

Ensure that the measuring insert has been properly electrically connected according to the

manufacturer's instructions (refer to measuring insert handbook).

CAUTION!

When operating the transmitters and the display in the BUZ-HW connection head, always refer to

the technical documentation of these devices.

5.2 Normal operation

OPTITEMP TRA/TCA PLUS

During the course of normal operation, it is not necessary to make any adjustments to the

thermometer, measuring insert, temperature transmitter or temperature indicator.

WARNING!

Never touch the thermowell, neck tube or connection head in operation without protective

gloves! These components can become very hot during operation and cause burns.

5.3 Faults and damage: reason and remedies

INFORMATION!

The most probable cause of a fault is the measuring insert itself and its electronic components

(see the handbook for measuring inserts, subsection "Faults: Reasons and Remedies"). The

following issues come into question here:

•

Short circuit or open circuit

•

Insulation resistance too low

•

Ageing

•

Wrong thermocouple wire or compensating line

In addition, the following faults and damage may occur:

Liquid on the process connection

A damaged or incorrect seal can lead to a leak at the process connection. Should this occur,

replace the seal and ensure that the new one meets the individual requirements of the

measuring point (pressure, temperature, chemically aggressive media). It is the sole

responsibility of the operator of the device to select the right seal.

38

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 39

OPTITEMP TRA/TCA PLUS

Temperature indication too high or too low

When reference measurements result in an incorrect temperature indication, three causes

come into question:

• Severe heat transfer caused by too short insertion length of thermowell or measuring insert:

the thermometer indicates a temperature that is too low when it is above the ambient

temperature and one that is too high when it is below the ambient temperature.

• Severe heat transfer via the process connection, the pipeline or the tank wall due to a lack of

insulation.

• Incorrect thermowell dimensions (diameter, wall thickness).

To keep the heat transfer to a minimum, either increase the insertion length of the thermometer

or improve the insulation of the measuring point.

Slow response to changes in temperature

If the measuring insert is not resting firmly on the bottom of the thermowell, the response to any

changes in temperature may be slowed. So, ensure that the measuring insert touches the

bottom of the thermowell using the spring-loaded mounting. If the thermometer is to react to

changes in temperature as quickly as possible, thermowells with a tapered or reduced tip are

recommended.

OPERATION 5

Damage to the thermowell and penetrating liquid

If the thermowell is not sufficiently resistant to chemically aggressive media, corrosion may

occur and the measured medium may penetrate. In case of doubt, choose a thermowell made of

the same material as the pipe or tank in which the medium is located.

Breaks or tears

It is possible for breaks or tears to occur due to the force of the media flowing against the

thermowell. It is also possible for vibrations in the resonance range to damage or destroy the

thermowell. Superimposition of the two causes or a combination of insufficient mechanical and

chemical resistance is also possible. The following are starting points for troubleshooting:

• Selection of a thermowell with different dimensions

• Change in neck tube length at critical head resonances

• Selection of a different installation site

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

39

Page 40

6 SERVICE

6.1 Replacing the electronics

When it comes to industrial thermometers for advanced requirements, it is only possible to

replace an electronic component if there is a temperature transmitter or, if applicable, a headmounted display. Consult the handbook for the temperature transmitter or, if applicable, the

head-mounted display to learn what you need to take into consideration when replacing the

electronics.

6.2 Cleaning and maintenance

As a rule, the industrial thermometers for advanced requirements require no cleaning or

maintenance. However, depending on the conditions of use and the thermal and mechanical

load, they can age. This is true of both measuring inserts with Pt100 RTDs and measuring inserts

with thermocouples.

As a result of the ageing process, the characteristics ("characteristic curve") can change. That

means that the relationship between the electrical resistance (measuring insert with Pt100 RTD)

or the thermovoltage (measuring insert with thermocouple) and the temperature changes. In

this case, calibration shows whether any deviations in measurement values are still within

permissible tolerances.

OPTITEMP TRA/TCA PLUS

6.3 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

40

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 41

OPTITEMP TRA/TCA PLUS

6.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local representative.

6.5 Returning the device to the manufacturer

6.5.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

SERVICE 6

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

41

Page 42

6 SERVICE

6.5.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

OPTITEMP TRA/TCA PLUS

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.6 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

42

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 43

OPTITEMP TRA/TCA PLUS

7.1 Measuring principle

All of the thermometers described here belong to the class known as "contact thermometers".

Unlike "radiation thermometers", these thermometers come into direct contact with the

medium whose temperature they are to measure.

The type of measuring principle depends on the measuring insert sensor that you combine with

the transmitter. Two different sensor types are available. Their respective measuring principles

are described in the following subsections.

7.1.1 Resistance thermometer

The measuring insert with a resistance thermometer features a temperature-sensitive sensor

made from a platinum RTD, whose value at 0°C / +32°F is 100 Ω. That is where the name "Pt100"

comes from.

It is generally valid that the electric resistance of metals increases according to a mathematical

function as the temperature rises. This effect is taken advantage of by resistance thermometers

to measure temperature. The "Pt100" thermometer features a measuring resistance with

defined characteristics, standardised in IEC 60751. The same is true for the tolerances. The

average temperature coefficient of a Pt100 is 3.85 x 10

+32...+212°F.

TECHNICAL DATA 7

-3K-1

in the range from 0...+100°C/

During operation, a constant current I (≤ 1 mA) flows through the Pt100 RTD, which brings about

a voltage drop U. The resistance R is calculated using Ohm's Law (R=U/I). As the voltage drop U

at 0°C / +32°F is 100 mV, the resulting resistance of the Pt100 thermometer is 100 Ω (100 mV /

1 mA = 100 Ω).

Figure 7-1: Pt100 resistance thermometer in 4-wire connection at 0°C / +32°F, schematic.

1 Pt100 RTD

2 Voltage meter

3 Current source

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

43

Page 44

7 TECHNICAL DATA

7.1.2 Thermocouples

The thermocouple features two electric conductors made from different metals, connected at

one end. Each free end is connected to a compensation cable which is then connected to a

millivolt meter. This circuitry forms a "thermal circuit". The point at which the two electric

conductors connect is called the measuring point and the point at which the compensation

cables connect to the conductors of the millivolt meter is called the cold junction.

If the measuring point of this thermal circuit is heated up, a small electrical voltage (thermal

voltage) can be measured. If, however, the measuring point and the cold junction are at the same

temperature, no thermoelectric voltage is generated. The degree of thermoelectric voltage, also

known as electromotive force (EMF), depends on the thermocouple material and the extent of

the temperature difference between the measuring point and the cold junction. It can be

measured using the millivolt meter with no auxiliary power.

Simply put, the thermocouple behaves like a battery, the voltage of which also increases as the

temperature rises.

INFORMATION!

The characteristic curves and tolerances of commercially available thermocouples are

standardised in IEC 60584.

OPTITEMP TRA/TCA PLUS

44

Figure 7-2: Thermocouple measuring circuit, schematic.

1 Measuring point t

2 Thermocouple

3 Transition junction t

4 Compensation cable / extension cable

5 Reference junction t

6 Copper conductor

7 Voltage meter U

(hot junction)

1

2

(cold junction)

3

th

www.krohne.com 01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

Page 45

OPTITEMP TRA/TCA PLUS

7.2 Technical data tables

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Application range Measuring the temperature of gases, liquids, vapours and solid

Measuring principle Contact thermometer

Measured value Temperature

Design

Modular design Industrial thermometers for advanced requirements consist of

TECHNICAL DATA 7

bodies in industrial processes with advanced requirements (e.g. high

pressure and high flow velocities).

several components which, together, form a thermometer assembly:

• Measuring insert with temperature sensor

• Transmitter (either inside on the measuring insert or outside)

• Connection head

• Separate neck tube

• Thermowell

Signal converter Analogue or digital temperature transmitter in the TT family as head-

Sensor Pt100 RTD as thin layer variant (TF) or as wire wound variant (WW)

Measuring range Refer to "Operating conditions".

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Display Only in connection head "BUZ-HW": 4...20 mA, non-illuminated, LCD,

Operation Only in connection head "BUZ-HW": interior keys.

Display functions

mount or rail-mount transmitter.

with a characteristic according to DIN EN 60751.

Type "J" or "K" thermocouple with a characteristic according to

DIN EN 60584.

loop powered indicator.

Temperature, either as output signal (HART® penetrable) in mA or

scaled to °C/°F.

www.krohne.com01/2012 - 4000630301 - MA OPTITEMP TRA/TCA Plus R01

45

Page 46

7 TECHNICAL DATA

Measuring accuracy

Reference conditions Ambient temperature: +23°C / +73.4°F (fluctuations due to air

Maximum measuring error More detailed information in the subsection "Measurement Error"

Operating conditions

Load limits The load limits depend on several factors (e.g. dimensions, design

Temperature

Temperature

TemperatureTemperature

Process temperature -200...+600°C / -328...+1112°F, depending on measuring insert,

Ambient temperature -40...+100°C / -40...+212°F, depending on connection head and

Storage temperature -40...+70°C / -40...+158°F at 40...60% relative humidity.

Other conditions

Other conditions

Other conditionsOther conditions

Protection categories Depends on the connection head and the cable gland used: IP 54

OPTITEMP TRA/TCA PLUS

pressure and density have no impact on measuring accuracy.)

(also in the "Technical Data" section). The maximum measurement

error also depends on the type of sensor:

• Measuring insert with Pt100 RTD: measurement error in

accordance with tolerance classes A, B, 1/3 B and 1/10 B according

to DIN EN 60751.

• Thermocouple: measurement error in accordance with tolerance

class 1 acc. to DIN EN 60584.

and material of thermowell). Other information can be found in the

"Installation" section or in separate subsections of section "Technical

data".

Thermometer without thermowell: 0.8...1.2 bara / 11.6...17.4 psia.