KROHNE Tidalflux 4110 PF Specifications

TIDALFLUX

IFM 4110 PF and IFM 4210 PF

Electromagnetic Flowmeter

for partially filled pipelines

● Measurement in partially filled pipelines

● Patented, non-contact level measurement

up to DN 1800 / 72"

● Electromagnetic process flow measurement

system, proven in more than 40 years in the

water and wastewater sector

GR

©

KROHNE 09/2003 7.02354.23.00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

TIDALFLUX

flowmeters measure the volumetric flowrate

of electrically conductive liquids

in partially filled pipelines

Precision from KROHNE

● Developed for the water and waste water sector.

● In-depth testing in cooperation with leading companies in the waste

water sector.

● Steady display of measured values, even when product surface is

rough or the flow profile distorted.

● Precise factory calibration ensures a level of measurement accuracy

never possible before in partially filled pipes.

2

Innovative combination

of time-proven

measuring principles

The electromagnetic flowmeter and capacitive flow-level measuring system built into

the wall of the measuring tube provide

accurate flow measurements in partially

filled pipelines, with levels between 10 and

100 % of the pipe cross-section.

TIDALFLUX flowmeters measure the volumetric flowrate of electrically conductive liquids

in partially filled pipelines.

Fields of application

● Wastewater measurement in partially

filled pipelines

● Abrasion resistance: very high

● Chemical resistance:

alkaline solutions (e.g. NaOH)

up to 10% at 30°C / 86°F

acids (e.g. HNO

3

)

up to 5% at 20°C / 68°F

Calibrated on

EN 17 025

accredited

calibration rigs, accuracy of calibration

better than 99.97% of the measured value.

Determination of the flow

level and of the filled tube

cross-sectional area by

means of capacitive level

measurement and the

known inside tube diameter

without affecting the flow

profile

Determination of the flow

velocity by means of the

proven electromagnetic

measuring principle

Patented, capacitive

and non-contact flow

level measuring system,

integrated in the liner

Meter sizes

DN200-1800 / 8"-72"

Measuring error < 1% of the measured value

Exact measurements with a low time constant, even in cases of wave motion and

heavy contamination

Measurements

possible down to

10% filling of the

measuring tube

TIDALFLUX 3

TIDALFLUX

Measuring principle

The TIDALFLUX IFM 4110 PF is an electromagnetic flowmeter with an

integrated capacitive level measurement system.

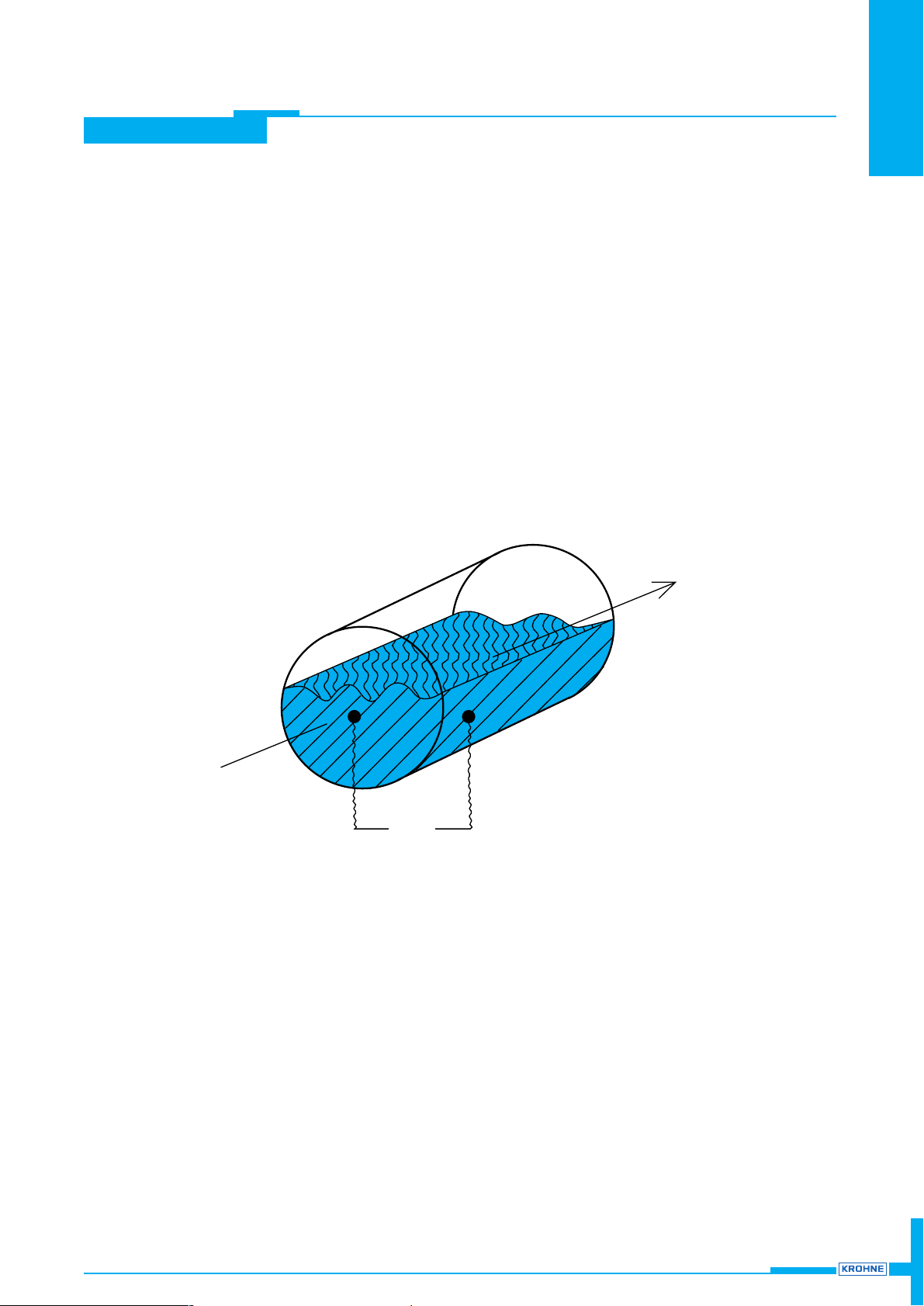

The flow rate Q(t) through the tube is: Q(t) = v × A

v = flow velocity of liquid product

A = wetted tube cross-section

Flow velocity v is determined on the basis of the known

electromagnetic measurement principle.

The two measuring electrodes are located in the lower part of the

measuring tube, on a level of approx. 10% of inside tube diameter.

Patented level measurement system

The wetted area A is computed from the known inside diameter of the

tube by the capacitive level measurement system that is built into the

measuring tube liner. The required electronics unit is accommodated in

a integral housing that is mounted direct on the primary head.

Communication with the remote signal converter is by way of an

RS 485 interface.

Capacitive flow level measurement

● Capacitive level measuring system

built into the measuring tube liner.

● Non-contact and accurate measurement of the flow level, with no

additional flow obstructions.

● Independent of flow profile influences, such as super-critical flow.

● Exact measurement of the flow level with low time constant, even

when waves are generated in the measuring tube.

● Reliable measurements, also when product is heavily

contaminated.

Electromagnetic flow measurement

● No constriction of the pipe cross-section.

● No additional pressure drop or backpressure.

● Linear and accurate flow measurements.

● Electromagnetic flowmeters from KROHNE are practice-proven for

over 40 years in the water and waste water sector

Q (t)

A

v

TIDALFLUX

TIDALFLUX

4

Measuring range and accuracies

Full-scale range Q

100%

in pipe running full between 34 m3/h or 160 US Gal/min (minimum for DN 200 / 8”)

and 100000m

3

/h or 500000US Gal/min (maximum for DN 1800 / 72”)

equivalent flow velocity 0,3 – 12 m/s or 1 – 40 ft/s

Units m3, litres or US gallons per second, minute or hour,

and 1 user-defined unit, e.g. litres per day or US million gallons per day

Error limits to reference conditions

Partially filled pipe for full-scale ranges v ≥ 1 m/s (≥ 3.3 ft/s): ≤ 1 % of full-scale range

Completely filled pipe for current measured values v ≥ 1 m/s (≥ 3.3 ft/s): ≤ 1 % of measured value

v < 1 m/s (≥ 3.3 ft/s): ≤ 0.5 % of measured value + 5 mm/s or

≤ 0.5 % of measured value + 0.20 inches/s

Reference conditions:

Product water at 10 – 30°C / 50 – 86°F

Electrical conductivity > 300 µS/cm

Power supply (line voltage) UN (± 2%)

Ambient temperature 20 – 22°C / 68 – 71.6°F

Warm-up time 60 min

Max. error of calibration system 10 x smaller than F

Inlet / outlet runs 10 x DN / 5 x DN (DN = meter size)

Primary head properly grounded and centered

TIDALFLUX 5

TIDALFLUX

Technical data

Meter sizes and versions

Meter sizes DN200 - 1600 / 8” - 64”,

Connecting flanges

DIN 2501 DN200 – 1800 / PN2.5 – PN 10

ANSI B16.5 8” – 72” / 150lb

AWWA and others on request

Protection category (IEC 529 / EN 60529) IP 67, equivalent to NEMA 6

Hazardous-duty version optionally Ex N, Zone 2

Process data

Liquid product water, waste water and chemical

Electrical conductivity ≥ 50µS/cm

Flow level in pipe min. 10 % of inside tube diameter

Process temperature –5 to + 60°C / + 23 to + 140°F

Ambient temperature – 25 to + 60°C / – 13 to + 140°F

Operating pressure max. 10bar / 150 psig

Integrated flow measuring system

Measuring principle electromagnetic flow measurement

Full-scale range Q

100%

in pipe running full between 34m3/h or 160US Gal/min (minimum for DN200 / 8”)

and 100 000 m

3

/h or 500 000 US Gal/min (maximum for DN1600 / 64”)

equivalent flow velocity 0.3 – 12m/s or 1 – 40 ft/s

Electrode design 1 pair of electrodes, solidly fitted, surface polished

Power for field coils from signal converter

Grounding rings available as an option

Integrated level measuring system

Measuring principle capacitive level measurement, built into the measuring tube liner

Pipe fill min. 10% of inside tube diameter,

outputs go to “zero” below 10% fill

Power for level measuring system

Voltage / frequency 230 / 115V AC, 50 – 60 Hz, others on request

Power consumption 14 VA

Communication with signal converter via RS 485 interface

Electronics housing integral, mounted directly on the primary head

Cable entries 3 x PG 16 and 1 x PG 9, optionally 1/2” NPT or 1/2”PF

Materials of construction

Measuring tube stainless steel 1.4301 (or higher materials number) / AISI 304

Liner Irathane®, 12 mm / 0.47”

Electrodes Hastelloy C4, others on request

Connecting flanges* steel 1.0038 (RST 37.2)

Converter housing* sheet steel

Electronics housing* cast aluminium

PG cable entries nickel-plated brass

Grounding rings (option) stainless steel 1.4571 / AISI 316 Ti

* with polyurethane finish 143 RAL 5015

The responsibility as to the suitability, intended use and corrosion-resistance of the materials used in

their construction rests solely with the purchaser.

Loading...

Loading...