Page 1

Quick Start

Quick Start

TIDALFLUX 4300 F

TIDALFLUX 4300 F

TIDALFLUX 4300 FTIDALFLUX 4300 F

Quick Start Quick Start

Electromagnetic flow sensor for partially filled pipes

The documentation is only complete when used in combination with the relevant

documentation for the converter.

© KROHNE 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 2

CONTENTS

TIDALFLUX 4300 F

1 Safety instructions 3

2 Installation 4

2.1 Scope of delivery............................................................................................................... 4

2.2 Transport .......................................................................................................................... 4

2.3 Installation conditions ...................................................................................................... 5

2.3.1 Inlet and outlet........................................................................................................................ 5

2.3.2 Mounting position.................................................................................................................... 5

2.3.3 Flange deviation...................................................................................................................... 6

2.3.4 Vibration .................................................................................................................................. 6

2.3.5 Magnetic field.......................................................................................................................... 6

2.3.6 Control valve ........................................................................................................................... 7

2.3.7 Slope........................................................................................................................................ 7

2.3.8 Mounting advice for difficult situations .................................................................................. 7

2.3.9 Cleaning of flow sensor .......................................................................................................... 8

2.3.10 Temperatures ....................................................................................................................... 8

2.4 Mounting........................................................................................................................... 9

2.4.1 Mounting grounding rings ...................................................................................................... 9

2.4.2 Torques and pressures........................................................................................................... 9

3 Electrical connections 11

3.1 Safety instructions.......................................................................................................... 11

3.2 Important notes on electrical connection...................................................................... 11

3.3 Connection of cables ...................................................................................................... 12

3.4 Cable lengths.................................................................................................................. 13

3.5 Signal cable A (type DS 300), construction .................................................................... 15

3.6 Preparing signal cable A, connection to measuring sensor ......................................... 16

3.7 Signal cable B (type BTS 300), construction .................................................................. 17

3.8 Preparing signal cable B, connection to measuring sensor ......................................... 17

3.9 Preparing field current cable C, connection to measuring sensor............................... 19

3.10 Interface cable.............................................................................................................. 21

3.11 Grounding ..................................................................................................................... 22

4 Start-up 23

4.1 Switching on the power .................................................................................................. 23

5 Technical data 24

5.1 Dimensions and weights ................................................................................................ 24

5.2 Vacuum load ................................................................................................................... 25

6 Notes 26

2

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 3

TIDALFLUX 4300 F

Warnings and symbols used

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

SAFETY INSTRUCTIONS 1

HANDLING

• This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

Safety instructions for the operator

CAUTION!

Installation, assembly, start-up and maintenance may only be performed by appropriately

trained personnel. The regional occupational health and safety directives must always be

observed.

LEGAL NOTICE!

The responsibility as to the suitability and intended use of this device rests solely with the user.

The supplier assumes no responsibility in the event of improper use by the customer. Improper

installation and operation may lead to loss of warranty. In addition, the "Terms and Conditions of

Sale" apply. They appear on the back of the invoice and form the basis of the purchase contract.

INFORMATION!

•

Further information can be found on the supplied CD-ROM in the manual, on the data sheet,

in special manuals, certificates and on the manufacturer's website.

•

If you need to return the device to the manufacturer or supplier, please fill out the form

contained on the CD-ROM and send it with the device. Unfortunately, the manufacturer

cannot repair or inspect the device without the completed form.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

3

Page 4

2 INSTALLATION

2.1 Scope of delivery

Figure 2-1: Scope of delivery

1 Ordered flowmeter

2 Product documentation

3 Factory calibration report

4 CD-ROM with product documentation

5 Grounding rings (optionally)

6 Cable

TIDALFLUX 4300 F

2.2 Transport

Figure 2-2: Transport

4

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 5

TIDALFLUX 4300 F

2.3 Installation conditions

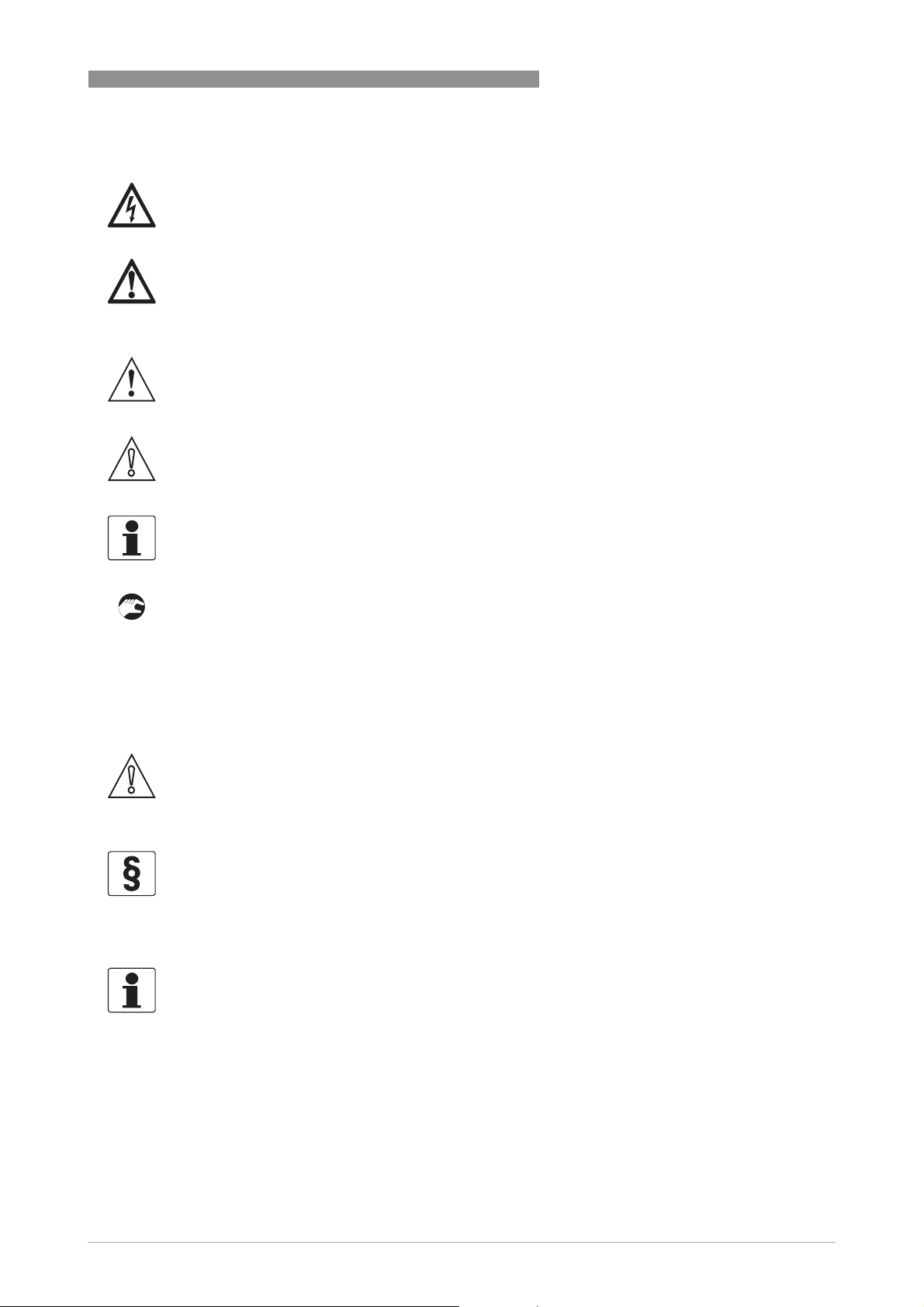

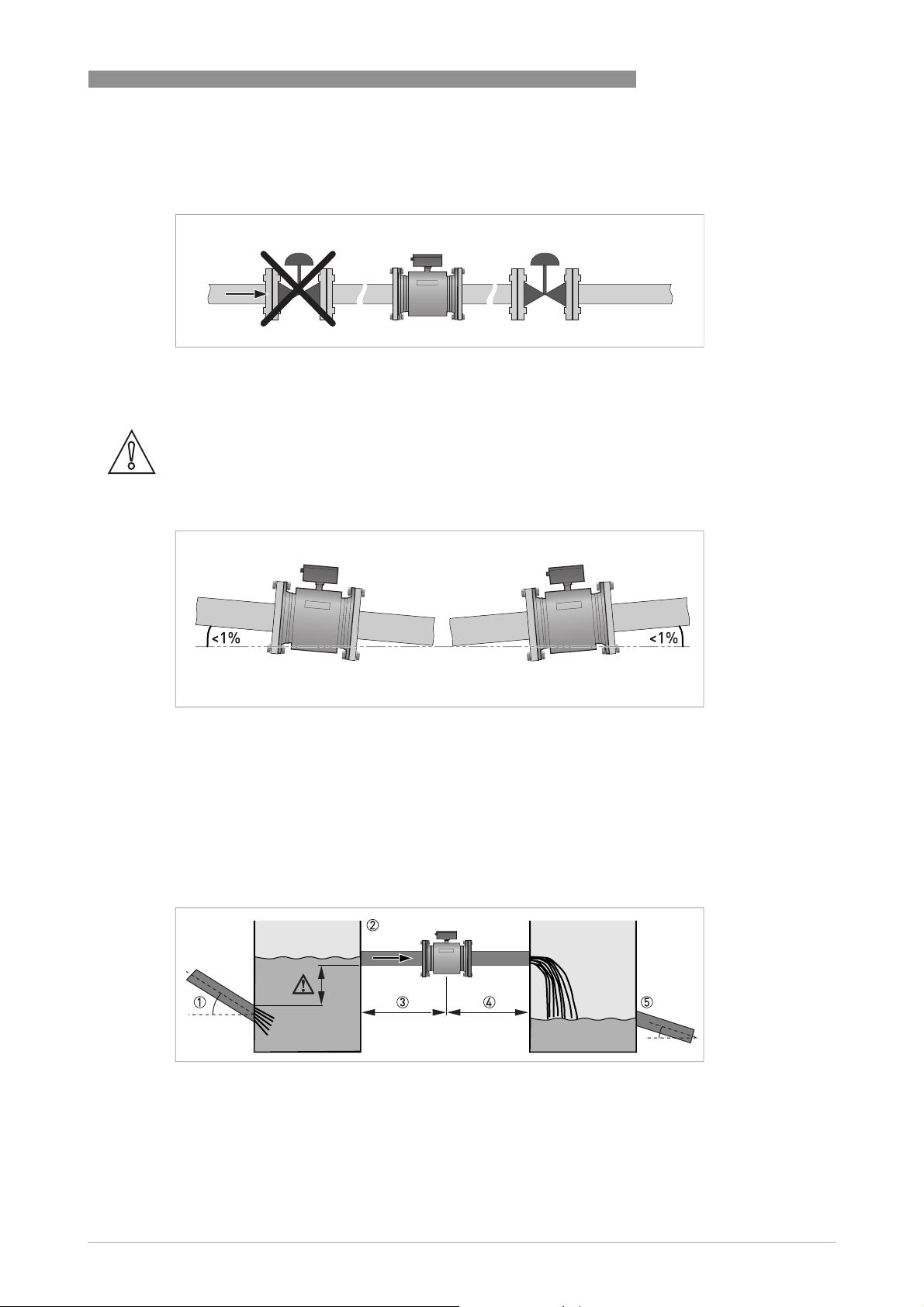

2.3.1 Inlet and outlet

Figure 2-3: Recommended inlet and outlet sections, top view

1 ≥ 5 DN

2 ≥ 3 DN

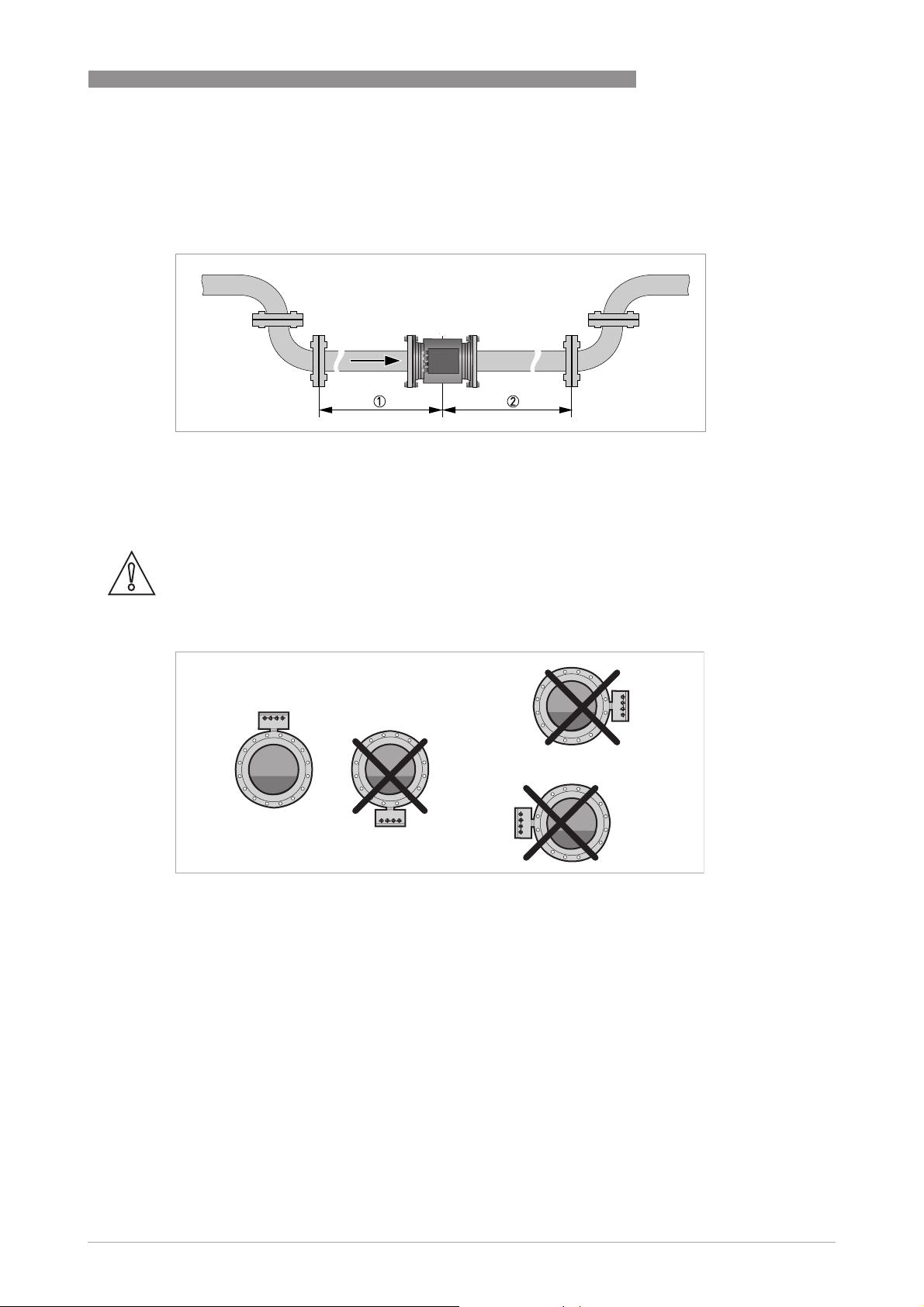

2.3.2 Mounting position

INSTALLATION 2

CAUTION!

Only install the flow sensor in the shown position to keep the electrodes under water. Limit the

±2°

rotation to

Figure 2-4: Mounting position

to maintain the accuracy.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

5

Page 6

2 INSTALLATION

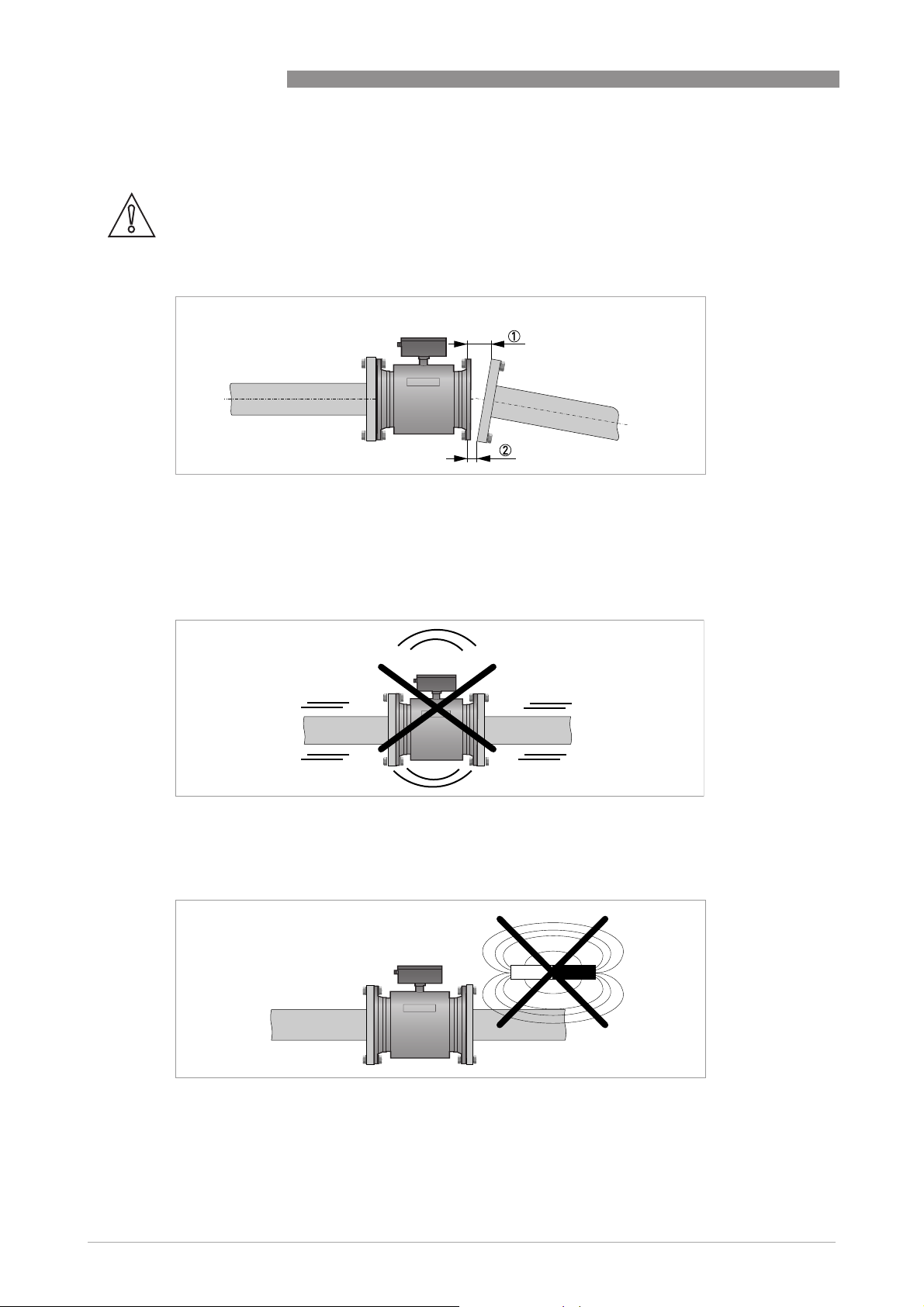

2.3.3 Flange deviation

CAUTION!

Max. permissible deviation of pipe flange faces:

- L

L

max

Figure 2-5: Flange deviation

1 L

max

2 L

min

≤ 0.5 mm / 0.02"

min

TIDALFLUX 4300 F

2.3.4 Vibration

Figure 2-6: Avoid vibrations

2.3.5 Magnetic field

Figure 2-7: Avoid magnetic fields

6

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 7

TIDALFLUX 4300 F

2.3.6 Control valve

Figure 2-8: Installation before control valve

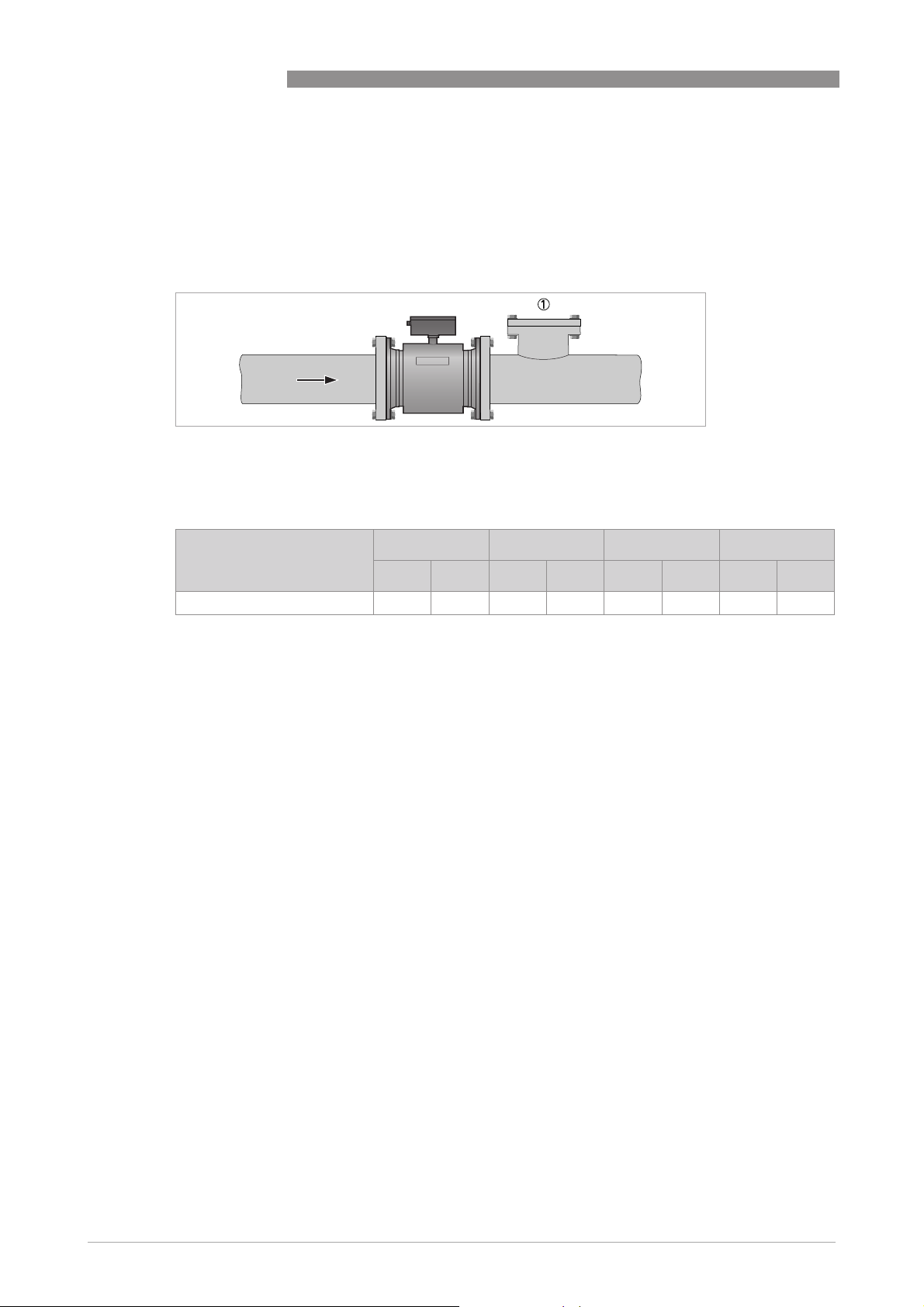

2.3.7 Slope

CAUTION!

The accuracy is influenced by the slope. Stay within

measurements!

INSTALLATION 2

±

1% to get the most accurate

Figure 2-9: Recommended slope

2.3.8 Mounting advice for difficult situations

If you can not meet the installation conditions install the flowmeter between two containers. The

inlet to the flowmeter must be higher than the outlet of the fluid. In this way you will have a calm

flow into the flowmeter, resulting in a highly accurate measurement. The sizes of the containers

must be proportional to the size of the flowmeter.

Figure 2-10: Installing in difficult situations

1 Use a container 2 if the Inlet pipe has a slope > 1%. Make sure that the outlet level of this pipe is below the inlet to the

flowmeter.

2 Inlet container

3 Inlet section of 10 DN

4 Outlet section of 5 DN

5 Outlet container advisable if outlet pipe has a slope > 1%.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

7

Page 8

2 INSTALLATION

2.3.9 Cleaning of flow sensor

The TIDALFLUX flow sensor is highly resistant against dirt and the measurement will rarely be

influenced by anything. However, it is advisable to create a possiblity for cleaning just before or

after the sensor.

Figure 2-11: Option for cleaning of flow sensor

1 Opening for cleaning

2.3.10 Temperatures

TIDALFLUX 4300 F

Temperature range Process [°C] Ambient [°C] Process [°F] Ambient [°F]

min. max. min. max. min. max. min. max.

All versions -5 60 -25 60 23 140 -13 140

8

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 9

TIDALFLUX 4300 F

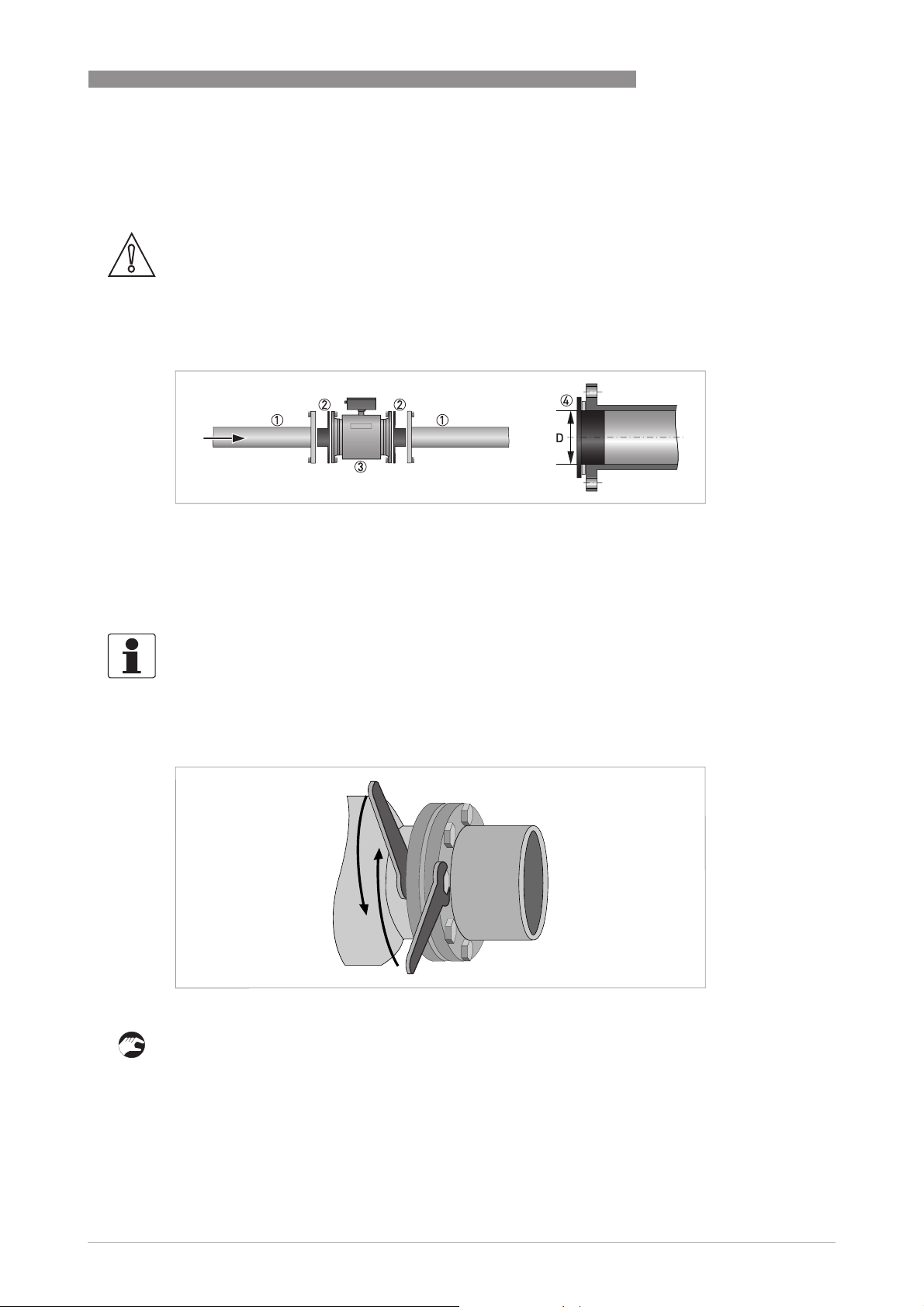

2.4 Mounting

2.4.1 Mounting grounding rings

CAUTION!

In order to get a reliable height measurement it is absolutely necessary

connecting pipeline is electrically conductive and connected to ground. If not, tailor-made

grounding rings with a cylindrical part can be delivered. Please contact your local agency in case

of doubt.

Figure 2-12: Grounding with grounding rings

1 Existing pipeline

2 Grounding rings, custom made to inner diameter of pipeline

3 TIDALFLUX

4 Insert the cylindrical part of the grounding ring into the pipeline. Use an appropiate gasket between the grounding ring

and the flange.

INSTALLATION 2

absolutely necessary that the inner side of the

absolutely necessaryabsolutely necessary

INFORMATION!

Sizes of the grounding rings are diameter dependent and available on request.

2.4.2 Torques and pressures

Figure 2-13: Tightening of bolts

Tightening of bolts

1 Step 1: Apply approx. 50% of max. torque given in table.

2 Step 2: Apply approx. 80% of max. torque given in table.

3 Step 3: Apply 100% of max. torque given in table.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

9

Page 10

2 INSTALLATION

INFORMATION!

Tighten the bolts uniformely in diagonally opposite sequence.

TIDALFLUX 4300 F

Nominal size

DN [mm]

Nominal size

[inch]

Pressure

Bolts Max. torque [Nm]

r a t i n g

200 PN 10 8 × M 20 68

250 PN 10 12 × M 20 65

300 PN 10 12 × M 20 76

350 PN 10 16 × M 20 75

400 PN 10 16 × M 24 104

500 PN 10 20 × M 24 107

600 PN 10 20 × M 27 138

700 PN 10 20 × M 27 163

800 PN 10 24 × M 30 219

900 PN 10 28 × M 30 205

1000 PN 10 28 × M 35 261

Flange class

Bolts Max. torque [Nm]

[lb]

8 150 8 × 3/4" 69

10 150 12 × 7/8" 79

12 150 12 × 7/8" 104

14 150 12 × 1" 93

16 150 16 × 1" 91

18 150 16 × 1 1/8" 143

20 150 20 × 1 1/8" 127

24 150 20 × 1 1/4" 180

28 150 28 × 1 1/4" 161

32 150 28 × 1 1/2" 259

36 150 32 × 1 1/2" 269

40 150 36 × 1 1/2" 269

10

INFORMATION!

Information for bigger sizes is available on request.

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 11

TIDALFLUX 4300 F

3.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

ELECTRICAL CONNECTIONS 3

3.2 Important notes on electrical connection

DANGER!

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

CAUTION!

•

Use suitable cable entries for the various electrical cables.

•

The sensor and converter are configured together in the factory. For this reason, please

connect the devices in pairs. Ensure that the sensor constant GK (see type plates) are

identically set

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

11

Page 12

3 ELECTRICAL CONNECTIONS

3.3 Connection of cables

Figure 3-1: Electrical connection

1 Unscrew the cover to reach the connectors

2 Unscrew the cover to reach the connectors

3 Field current cable

4 Interface cable

5 Signal cable (DS or BTS)

TIDALFLUX 4300 F

Connection diagram

Figure 3-2: Connection diagram

1 Protective Earth connection (PE)

2 Mains power neutral (N)

3 Mains power live (L)

4 Field current cable

5 Interface cable

6 Signal cable. Shown is the BTS cable. In case of DS cable, do not use connectors 20 and 30.

7 Connect housing to PE

12

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 13

TIDALFLUX 4300 F

Flow sensors with protection class IP 68 can not be opened anymore. The cables are factory

connected and labeled as follows.

Figure 3-3: Labeled cables for IP 68 versions

1 Mains power (10 = blank, 11 = blue, 12 = black)

2 Field current (7 = white, 8 = green)

3 Data interface (black wires, C = marked "1", D = marked "2", E = marked "3")

4 Electrodes (1 = blank, 2 = white, 3 = red)

ELECTRICAL CONNECTIONS 3

3.4 Cable lengths

CAUTION!

The maximum allowed distance between the flow sensor and the converter is determined by the

shortest cable length.

Interface cable

Interface cable: maximum length is 600 m / 1968 ft.

Interface cableInterface cable

Type B (BTS) signal cable

Type B (BTS) signal cable: maximum length is 600 m / 1968 ft.

Type B (BTS) signal cableType B (BTS) signal cable

Type A (DS) signal cable

Type A (DS) signal cable: maximum length depends on the conductivity of the fluid:

Type A (DS) signal cableType A (DS) signal cable

Electrical conductivity Maximum length

[µS/cm] [m] [ft]

50 120 394

100 200 656

200 400 1312

≥400 600 1968

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

13

Page 14

3 ELECTRICAL CONNECTIONS

Field current cable

Field current cable: The cross section of the cable determines the maximum length:

Field current cableField current cable

Cross section Maximum length

TIDALFLUX 4300 F

[mm2]

2 x 0.75 2 x 18 150 492

2 x 1.5 2 x 14 300 984

2 x 2.5 2 x 12 600 1968

[AWG] [m] [ft]

14

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 15

TIDALFLUX 4300 F

ELECTRICAL CONNECTIONS 3

3.5 Signal cable A (type DS 300), construction

• Signal cable A is a double-shielded cable for signal transmission between the measuring

sensor and signal converter.

• Bending radius: ≥ 50 mm / 2"

Figure 3-4: Construction of signal cable A

2

1 Stranded drain wire (1) for the inner shield (10), 1.0 mm

2 Insulated wire (2), 0.5 mm

3 Insulated wire (3), 0.5 mm

4 Outer sheath

5 Insulation layers

6 Stranded drain wire (6) for the outer shield (60)

2

Cu / AWG 20

2

Cu / AWG 20

Cu / AWG 17 (not insulated, bare)

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

15

Page 16

3 ELECTRICAL CONNECTIONS

3.6 Preparing signal cable A, connection to measuring sensor

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

• The outer shield (60) is connected in the terminal compartment of the measuring sensor

directly via the shield and a clip.

• Bending radius: ≥ 50 mm / 2"

Required materials

• PVC insulating tube, Ø2.0...2.5 mm / 0.08...0.1"

• Heat-shrinkable tubing

• Wire end ferrule to DIN 46 228: E 1.5-8 for the stranded drain wire (1)

• 2 wire end ferrules to DIN 46 228: E 0.5-8 for the insulated conductors (2, 3)

TIDALFLUX 4300 F

16

Figure 3-5: Preparing signal cable A, connection to measuring sensor

a = 50 mm / 2"

b = 10 mm / 0.39"

1 Strip the conductor to dimension a.

2 Trim the outer shield (60) to dimension b and pull it over the outer sheath.

3 Remove the stranded drain wire (6) of the outer shield and the inner shield (10). Make sure not

to damage the stranded drain wire (1) of the inner shield.

4 Slide an insulating tube over the stranded drain wire (1).

5 Crimp the wire end ferrules onto conductors 2 and 3 and the stranded drain wire (1).

6 Pull the heat-shrinkable tubing over the prepared signal cable.

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 17

TIDALFLUX 4300 F

ELECTRICAL CONNECTIONS 3

3.7 Signal cable B (type BTS 300), construction

• Signal cable B is a triple-shielded cable for signal transmission between the measuring

sensor and signal converter.

• Bending radius: ≥ 50 mm / 2"

Figure 3-6: Construction of signal cable B

2

1 Stranded drain wire for the inner shield (10), 1.0 mm

2 Insulated wire (2), 0.5 mm

3 Insulated wire (3), 0.5 mm

4 Outer sheath

5 Insulation layers

6 Stranded drain wire (6) for the outer shield (60), 0.5 mm

2

Cu / AWG 20 with stranded drain wire (20) of shield

2

Cu / AWG 20 with stranded drain wire (30) of shield

Cu / AWG 17 (not insulated, bare)

2

Cu / AWG 20 (not insulated, bare)

3.8 Preparing signal cable B, connection to measuring sensor

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

• The outer shield (60) is connected in the terminal compartment of the measuring sensor

directly via the shield and a clip.

• Bending radius: ≥ 50 mm / 2"

Required materials

• PVC insulation tubing, Ø2.0...2.5 mm / 0.08...0.1"

• Heat-shrinkable tubing

• Wire end ferrule to DIN 46 228: E 1.5-8 for the stranded drain wire (1)

• 2x wire end ferrules to DIN 46 228: E 0.5-8 for the insulated conductors (2, 3)

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

17

Page 18

3 ELECTRICAL CONNECTIONS

Figure 3-7: Preparing signal cable B, connection to measuring sensor

a = 50 mm / 2"

b = 10 mm / 0.39"

TIDALFLUX 4300 F

1 Strip the conductor to dimension a.

2 Trim the outer shield (60) to dimension b and pull it over the outer sheath.

3 Remove the stranded drain wire (6) of the outer shield and the shields and stranded drain

wires of the insulated conductors (2, 3). Remove the inner shield (10). Be sure not to damage

the stranded drain wire (1).

4 Slide an insulating tube over the stranded drain wire (1).

5 Crimp the wire end ferrules onto conductors 2 and 3 and the stranded drain wire (1).

6 Pull the heat-shrinkable tubing over the prepared signal cable.

18

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 19

TIDALFLUX 4300 F

ELECTRICAL CONNECTIONS 3

3.9 Preparing field current cable C, connection to measuring sensor

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

• The field current cable is not part of the scope of delivery.

• The shield is connected in the terminal compartment of the converter directly via the shield

and a clip.

• The shield is connected in the sensor via the special cable gland.

• Bending radius: ≥ 50 mm / 2"

Required materials

• Shielded 2-wire insulated copper cable

• Insulating tube, size according to the cable being used

• Heat-shrinkable tubing

• DIN 46 228 wire end ferrules: size according to the cable being used

Figure 3-8: Preparation of field current cable C

a = 125 mm / 5"

b = 10 mm / 0.4"

1 Strip the conductor to dimension a.

2 Trim the outer shield to dimension b and pull it over the outer sheath.

3 Crimp wire end ferrules onto both conductors.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

19

Page 20

3 ELECTRICAL CONNECTIONS

At flow converter side:

Connecting shielding under clamp in connection box of converter

Figure 3-9: Clamping of shields

1 Field current cable

2 Signal cable

At flow sensor side:

Connecting shielding via special cable gland

TIDALFLUX 4300 F

20

Figure 3-10: Connecting the shield within the cable gland

1 Wires

2 Isolation

3 Shielding

4 Isolation

5 Feed cable through dome nut and clamping insert and fold shielding over clamping insert. Make sure that the braided

shield overlaps the O-ring by 2 mm / 3/32".

6 Push clamping insert into body.

7 Tighten the dome nut.

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 21

TIDALFLUX 4300 F

3.10 Interface cable

The data interface cable is a shielded, 3 x 1.5 mm2 LIYCY cable. The standard length 10 m /

32.8 ft is included in the delivery.

Preparing the interface cable

Figure 3-11: Preparing the interface cable

a = 100 mm / 4"

b = 10 mm / 0.4"

ELECTRICAL CONNECTIONS 3

1 Strip the conductor to dimension a.

2 Trim the outer shield to dimension b and pull it over the outer sheath.

3 Crimp the wire end ferrules onto the conductors 1, 2 and 3.

Connect the shielding at both sides of the cable via the special cable gland.

Connecting shielding via special cable gland

Figure 3-12: Connecting the shield within the cable gland

1 Wires

2 Isolation

3 Shielding

4 Isolation

5 Feed cable through dome nut and clamping insert and fold shielding over clamping insert. Make sure that the braided

shield overlaps the O-ring by 2 mm / 3/32".

6 Push clamping insert into body.

7 Tighten the dome nut.

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

21

Page 22

3 ELECTRICAL CONNECTIONS

3.11 Grounding

DANGER!

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

CAUTION!

In order to get a reliable height measurement it is absolutely necessary

connecting pipeline is electrically conductive and connected to ground. If not, tailor-made

grounding rings with a cylindrical part can be delivered. Please contact your local agency in case

of doubt.

TIDALFLUX 4300 F

absolutely necessary that the inner side of the

absolutely necessaryabsolutely necessary

Figure 3-13: Grounding ring number 3

22

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 23

TIDALFLUX 4300 F

4.1 Switching on the power

Before connecting to power, please check that the system has been correctly installed.

This includes:

• The device must be mechanically mounted safely in compliance with the regulations.

• The power connections must be in compliance with the regulations.

• Make sure that all electrical connections are made and that the covers of the terminal

compartments are closed.

• Check that the electrical operating data of the power supply are correct.

• Switch on the power.

INFORMATION!

The sensor can not be programmed or changed in any way. All settable functions are included in

the converter. Please see the relevant documentation of the converter for more information.

START-UP 4

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

23

Page 24

5 TECHNICAL DATA

5.1 Dimensions and weights

The inner pipe diameter should match the inner diameter of the flowmeter. Since the inner

diameter is not a standard DN size, choose the inner pipe diameter to be just a little bit bigger

than the flow meter diameter. If a lot of sediment or fat is expected the optimal solution is to

produce a diameter compensation ring on both sides to have smooth transits.

TIDALFLUX 4300 F

IP 67 versions:

IP 67 versions:

IP 67 versions:IP 67 versions:

k = 232 mm / 9.1"

m = 110 mm / 4.3"

n = 202 mm / 7.95"

IP 68 versions:

IP 68 versions:

IP 68 versions:IP 68 versions:

k = 344 mm / 13.54"

m = 155 mm / 6.1"

n = 284 mm / 11.18"

EN 1092-1

Nominal size Dimensions [mm] Approx.

DN PN a b Øc d j ØD ØD

IP 67 IP 68

200 10 350 473 532 291 146 177 340 189 40

250 10 400 521 579 331 166 205 395 231 54

300 10 500 571 629 381 191 235 445 281 66

350 10 500 623 682 428 214 306 505 316 95

400 10 600 681 739 483 242 386 565 365 115

500 10 600 784 843 585 293 386 670 467 145

600 10 600 894 952 694 347 386 780 567 180

700 10 700 1010 1069 812 406 455 895 666 265

800 10 800 1125 1184 922 461 535 1015 768 350

900 10 900 1246 1305 1064 532 625 1115 863 425

1000 10 1000 1338 1396 1132 566 695 1230 965 520

1200 6 1200 1529 1588 1340 670 854 1405 1169 659

1400 6 1400 1732 1791 1521 761 1034 1630 1367 835

1600 6 1600 1932 1991 1721 861 1234 1830 1549 1659

weight

i

[kg]

24

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 25

TIDALFLUX 4300 F

150 lb flanges

Nominal size Dimensions [inches] Approx.

ASME 1PN

1 Nominal size ≤ 24": ASME; > 24": AWWA

TECHNICAL DATA 5

a b Øc d j ØD ØD

[psi]

IP 67 IP 68

8 284 13.78 19.02 20.9 11.46 5.75 6.97 13.39 7.44 90

10 284 15.75 21.06 22.8 13.03 6.54 8.07 15.55 9.09 120

12 284 19.69 23.54 24.8 15 7.52 9.25 17.52 11.06 145

14 284 27.56 25.43 26.8 16.85 9.8 12.05 19.88 12.44 210

16 284 31.5 27.72 29.1 19.02 9.53 15.2 22.24 14.37 255

20 284 31.5 31.73 33.2 23.03 11.54 15.2 26.38 18.39 320

24 284 31.5 36.14 37.5 27.32 13.66 15.2 30.71 22.32 400

28 Class D 35.43 40.4 42.7 31.97 15.98 17.87 36.50 26.22 692

32 Class D 39.37 45.2 47.5 36.3 18.15 21.06 41.75 30.24 1031

36 Class D 43.31 50.1 52.4 41.89 20.94 24.61 46.0 33.98 1267

40 Class D 47.24 53.8 56.1 44.57 22.28 27.36 50.75 37.99 1554

48 Class D 55.12 62.3 64.6 52.76 26.38 33.62 59.50 46.02 2242

i

weight

[lb]

5.2 Vacuum load

Diameter Vacuum load in mbar abs. at a process temperature of

[mm] 40°C 60°C

DN200...1600 500 600

Diameter Vacuum load in psia at a process temperature of

[inches] 104°F 140°F

8...64" 7.3 8.7

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

25

Page 26

6 NOTES

TIDALFLUX 4300 F

26

www.krohne.com 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

Page 27

TIDALFLUX 4300 F

NOTES 6

www.krohne.com09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en

27

Page 28

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 09/2010 - 7308302300 - QS TIDALFLUX 4000 R03 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...