Page 1

E

ENVIROMAG 22000

Electromagnetic Flow Sensor

Engineered and manufactured for the North American water and wastewater industry

NSF Approved for potable water

Proven and unsurpassed lifetime performance

Long-term reliability and durability

Available IP68 rating

Available for direct burial installation

Technical Datasheet

Page 2

Solution ffor tthe wwater && wwastewater IIndustry

ENVIROMAG 22000

Highlights

Applications

The

and wastewater measurement applications. Its design and performance makes it

the choice for flow measurement throughout the process.

magmeter is the optimum solution for North American water

Short inlet and outlet runs

Unaffected by contamination, solids, fibers, slurries

No maintenance

Wet calibrated - includes calibration report

Suitable for potable, chlorinated, fluorinated water, etc.

Continuous self diagnostics

NSF approved (Hard Rubber Liner)

Available virtual reference eliminates grounding rings

Wastewater processes

1. Flanged design

2. PP. Polyurethane and

Hard Rubber liner

3. 3/8 to 80 diameter

4. ANSI or AWWA flanges

OPTIFLUX converters: All converters fit to all sensors

IFC 300 High-performance solution

Desalination processes

Irrigation networks

Clean water processes

Water distribution

Cooling stations - district heating

IFC 100 Economical solution

2

Page 3

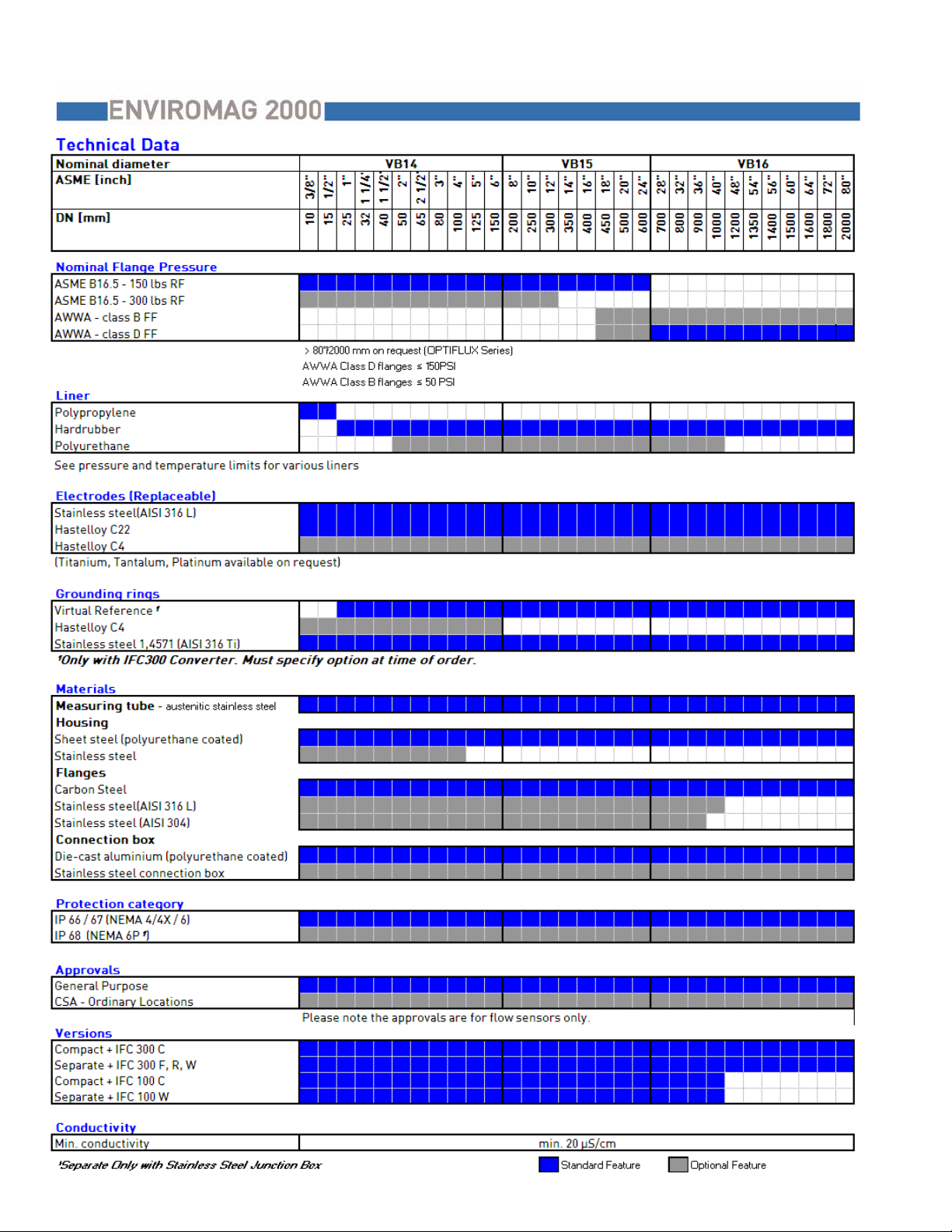

Technical Data

Nominal diameter

ASME [inch]

3/8"

1/2"

DN [mm]

10152532405065

Nominal Flange Pressure

ASME B16.5 - 150 lbs RF

ASME B16.5 - 300 lbs RF

sssssssssssssssssss

oooooooooooooo

AWWA - class B FF

AWWA - class D FF ooosssssssssss

> 80"/2000 mm on request (OPTIFLUX Series)

AWWA Class D flanges 150PSI

AWWA Class B flanges 50 PSI

Liner

Polypropylene

ss

Hardrubber (NSF approved)

Polyurethane ooooooooooooo

See pressure and temperature limits for various liners. Only products bearing the NSF Mark are Certified.

Electrodes (Replaceable)

Hastelloy C4

Stainless steel(AISI 316 L)

oooooooooooooooooooooooooooooo

ssssssssssssssssssssssssssssss

Hastelloy B2 oooooooooooooooooooooooooooooo

(Titanium, Tantalum, Platinum available on request)

Grounding rings

Virtual Reference

Hastelloy C4

¹

ssssssssssssssssssssssssssss

ooooooooooo

Stainless steel 1,4571 (AISI 316 Ti) ssssssssssssssssssssssssssssss

¹Only with IFC300 Converter. Must specify option at time of order.

VB14 VB15 VB16

1"

1 1/4"

1 1/2"2"2 1/2"

3"4"5"6"8"

80

100

125

150

200

10"

250

12"

300

14"

350

16"

400

18"

450

20"

500

24"

600

28"

700

oooooooooooooo

sssssssssssssssssssssss

32"

800

36"

900

40"

1000

48"

1200

54"

1350

56"

1400

60"

1500

64"

1600

72"

1800

80"

2000

Materials

Measuring tube - austenitic stainless steel

ssssssssssssssssssssssssssssss

Housing

Sheet steel (polyurethane coated)

ssssssssssssssssssssssssssssss

Stainless steel ooooooooo

Flanges

Carbon Steel

Stainless steel(AISI 316 L)

ssssssssssssssssssssssssssssss

ooooooooooooooooooooooo

Stainless steel (AISI 304) oooooooooooooooooooooo

Connection box

Die-cast aluminium (polyurethane coated)

ssssssssssssssssssssssssssssss

Stainless steel connection box oooooooooooooooooooooooooooooo

Protection category

IP 66 / 67 (NEMA 4/4X / 6)

IP 68 (NEMA 6P¹ )

ssssssssssssssssssssssssssssss

oooooooooooooooooooooooooooooo

Approvals

General Purpose

CSA - Ordinary Locations

ssssssssssssssssssssssssssssss

oooooooooooooooooooooooooooooo

Please note the approvals are for flow sensors only.

Versions

Compact + IFC 300 C

Separate + IFC 300 F, R, W

Compact + IFC 010 C

Separate + IFC 010 W

ssssssssssssssssssssssssssssss

ssssssssssssssssssssssssssssss

sssssssssssssssssssssss

sssssssssssssssssssssss

Conductivity

Min. conductivity

¹Separate Only with Stainless Steel Junction Box s Standard Feature o Optional Feature

min. 20 μS/cm

3

Page 4

Temperature Range

Temperature range [°C]

min. max. min. max.

Hardrubber

Polyurethane

Polypropylene

Tem

perature range [°F]

min. max. min. max.

Hardrubber

Polyurethane

Polypropylene

Process [°C] Ambient [°C]

Process [°F] Ambient [°F]

Separate flow sensor (OPTIFLUX 2000 F) -5 80 -40 65

Compact with IFC 300 (OPTIFLUX 2300 C) -5 80 -40 65

Compact with IFC 100 (OPTIFLUX 2010 C) -5 80 -25 60

* Hard Rubber available for sizes DN25 - 2000

Separate flow sensor (OPTIFLUX 2000 F) -5 69 -40 65

Compact with IFC 300 (OPTIFLUX 2300 C) -5 69 -40 65

Compact with IFC 100 (OPTIFLUX 2010 C) -5 69 -25 60

* Polyurethane available for DN 50-1000

Separate flow sensor (OPTIFLUX 2000 F) -5 90 -40 65

Compact with IFC 300 (OPTIFLUX 2300 C) -5 90 -40 65

Compact with IFC 100 (OPTIFLUX 2010 C) -5 90 -25 60

* Polypropylene available for DN 10-15

Separate flow sensor (OPTIFLUX 2000 F) 23 176 -40 149

Compact with IFC 300 (OPTIFLUX 2300 C) 23 176 -40 149

Compact with IFC 100 (OPTIFLUX 2010 C) 23 176 -13 140

* Hard Rubber available for sizes 1" - 80"

Separate flow sensor (OPTIFLUX 2000 F)

Compact with IFC 300 (OPTIFLUX 2300 C)

Compact with IFC 100 (OPTIFLUX 2010 C)

* Polyurethane available for sizes 2" - 40"

Separate flow sensor (OPTIFLUX 2000 F) 23 194 -40 149

Compact with IFC 300 (OPTIFLUX 2300 C) 23 194 -40 149

Compact with IFC 100 (OPTIFLUX 2010 C) 23 194 -13 140

* Polypropylene available for ASME 3/8" - 1/2"

23 156 -40 149

23 156 -40 149

23 156 -13 140

Page 5

Vacuum Load

Liner Diameter

[mm] 20ºC 40ºC 60ºC 80ºC

Polypropylene

Hardrubber

and

Polyurethane

Polypropylene

Hardrubber

and

Polyurethane

Minimum operating pressure absolute in

mbar (abs) at process temperature

Minimum operating pressure ab

solute in

psia at process temperature

DN 10 - 15 250 250 400 400

DN 25 - 300 250 250 400

DN 350 - 1000 500 500 600

DN 1200 - 2000 600 600 750

400¹

600¹

750¹

Liner Diameter

[inch] 68ºF 104ºF 140ºF 176ºF

¹Notes: Not applicable to Polyurethane liner, exceeds process temperature limt

3/8" - 1/2" 3.6 3.6 5.8 5.8

1"-12" 3.6 3.6 5.8

14" - 40" 7.3 7.3 8.7

48" -80" 8.7 8.7 10.9

5.8¹

8.7¹

10.9¹

Page 6

Dimensions and Weights

Refer to diagrams on page 7

Nominal

size

[inch-mm] Rating L¹ H W box 010 300 L¹ H W box 010 300

3/8"- 10

Flange

Type/

Dimensions [inch]Dimensions [mm]

TT

Approximate

weight

[kg] [lb]

ANSI 150 150 179 89 257 285 339 5.9 7.1 3.5 10.1 11.2 13.3 7 16.0

1/2"- 15 ANSI 150 150 179 89 257 285 339 5.9 7.1 3.5 10.1 11.2 13.3 7 16.0

1" - 25 ANSI 150 150 179 108 257 285 339 5.9 7.1 4.3 10.1 11.2 13.3 8 18.0

1½" -40

ANSI 150 150 203 127 281 309 363 5.9 8.0 5.0 11.1 12.2 14.3 10 22.0

2" -50 ANSI 150 200 191 152 269 297 351 7.9 7.5 6.0 10.6 11.7 13.8 13 29.0

3" - 80 ANSI 150 200 210 191 288 316 370 7.9 8.3 7.5 11.3 12.4 14.6 17 37.0

4" - 100 ANSI 150 250 256 229 334 362 416 9.8 10.1 9.0 13.2 14.3 16.4 23 51.0

5" - 125 ANSI 150 250 280 254 358 386 440 9.8 11.0 10.0 14.1 15.2 17.3 27 60.0

6" - 150

ANSI 150 300 304 279 382 410 464 11.8 12.0 11.0 15.0 16.1 18.3 34 75.0

8" - 200 ANSI 150 350 355 343 433 461 515 13.8 14.0 13.5 17.0 18.1 20.3 50 110.0

10" - 250 ANSI 150 400 433 406 511 539 593 15.8 17.1 16.0 20.1 21.2 23.3 73 160.0

12" - 300

ANSI 150 500 499 483 577 605 659 19.7 19.7 19.0 22.7 23.8 25.9 100 220.0

14" - 350 ANSI 150 500 552 533 630 658 712 19.7 21.7 21.0 24.8 25.9 28.0 114 250.0

16" - 400 ANSI 150 600 608 597 686 714 768 23.6 23.9 23.5 27.0 28.1 30.2 155 340.0

18" - 450 ANSI 150 600 672 635 750 778 832 23.6 26.5 25.0 29.5 30.6 32.8 170 375.0

20" - 500

AWWA Cl. D 600 739 699 817 845 899 23.6 29.1 27.5 32.2 33.3 35.4 191 420.0

24" - 600 AWWA Cl. D 600 852 813 930 958 1012 23.6 33.5 32.0 36.6 37.7 39.8 250 550.0

28" - 700 AWWA Cl. D 700 918 927 996 1024 1078 27.6 36.1 36.5 39.2 40.3 42.4 320 704.0

30" - 750 AWWA Cl. D 800 974 984 1052 1080 1134 31.5 38.3 38.8 41.4 42.5 44.6 358 787.6

32" - 800 AWWA Cl. D 800 1038 1060 1116 1144 1198 31.5 40.9 41.8 43.9 45.0 47.2 395 869.0

36" - 900

AWWA Cl. D 900 1144 1168 1222 1250 1304 35.4 45.0 46.0 48.1 49.2 51.3 450 990.0

40" - 1000 AWWA Cl. D 1000 1258 1289 1336 1364 1418 39.4 49.5 50.8 52.6 53.7 55.8 665 1463.0

42" - 1050 AWWA Cl. D 1300 1313 1350 1391 Not Applicable 1473 51.2 51.7 53.1 54.8 Not Applicable 58.0 683 1502.6

48" - 1200 AWWA Cl. D 1300 1483 1511 1561 Not Applicable 1643 51.2 58.4 59.5 61.5 Not Applicable 64.7 970 2134.0

54" - 1350

AWWA Cl. D 1600 1635 1682 1713 Not Applicable 1795 63.0 64.4 66.2 67.4 Not Applicable 70.7 TBA TBA

60" - 1500 AWWA Cl. D 1700 1782 1860 1860 Not Applicable 1942 66.9 70.2 73.2 73.2 Not Applicable 76.5 TBA TBA

70" - 1750 AWWA Cl. D 1800 2139 2197 2217 Not Applicable 2299 70.9 84.2 86.5 87.3 Not Applicable 90.5 TBA TBA

Nominal

size

Flange

Type/

Dimensions [mm]

TTweight

[inch-mm] Rating L¹ H W box 010 300 L¹ H W box 010 300

1" - 25

1½" -40

ANSI 300 150 145 124 223 251 305 5.9 5.7 4.9 8.8 9.9 12.0 8 18.0

ANSI 300 200 169 156 247 275 329 7.9 6.7 6.1 9.7 10.8 13.0 9 20.0

Dimensions [inch] Approximate

[kg] [lb]

2" -50 ANSI 300 250 186 165 264 292 346 9.8 7.3 6.5 10.4 11.5 13.6 13 29.0

3" - 80 ANSI 300 250 214 210 292 320 374 9.8 8.4 8.3 11.5 12.6 14.7 17 37.0

4" - 100 ANSI 300 300 275 254 353 381 435 11.8 10.8 10.0 13.9 15.0 17.1 23 51.0

6" - 150 ANSI 300 350 316 318 394 422 476 13.8 12.4 12.5 15.5 16.6 18.7 36 79.0

8" - 200

ANSI 300 400 382 381 460 488 542 15.8 15.0 15.0 18.1 19.2 21.3 71 157.0

10" - 250 ANSI 300 500 448 445 526 554 608 19.7 17.6 17.5 20.7 21.8 23.9 112 247.0

12" - 300 ANSI 300 600 519 521 597 625 679 23.6 20.4 20.5 23.5 24.6 26.7 170 375.0

14" - 350 ANSI 300 700 595 584 673 701 755 27.6 23.4 23.0 26.5 27.6 29.7 215 474.0

16" - 400 ANSI 300 800 646 648 724 752 806 31.5 25.4 25.5 28.5 29.6 31.7 290 639.0

18" - 450

ANSI 300 800 709 711 787 815 869 31.5 27.9 28.0 31.0 32.1 34.2 359 789.0

20" - 500 ANSI 300 800 777 775 855 883 937 31.5 30.6 30.5 33.7 34.8 36.9 426 937.0

24" - 600

ANSI 300 800 903 914 981 1009 1063 31.5 35.5 36.0 38.6 39.7 41.8 611 1345.0

Notes:

¹ If flowmeter is supplied with separate grounding rings, the totals fitting length "L" is computed as follows: "L" + 2 x 3 mm (1/8")+ 2

x gasket thickness

6

Page 7

Frontview ENVIROMAG 2000F Sideview ENVIROMAG 2000F

Frontview ENVIROMAG 2010C Sideview ENVIROMAG 2010C

Frontview ENVIROMAG 2300C Sideview ENVIROMAG 2300C

7

Page 8

KROHNE, Inc.

7 Dearborn Road

Peabody, MA, 01960 (USA)

1-800-FLOWING (978 535-6060)

www.krohne.com/northamerica

info@krohne.com

Version 2011-05

Loading...

Loading...